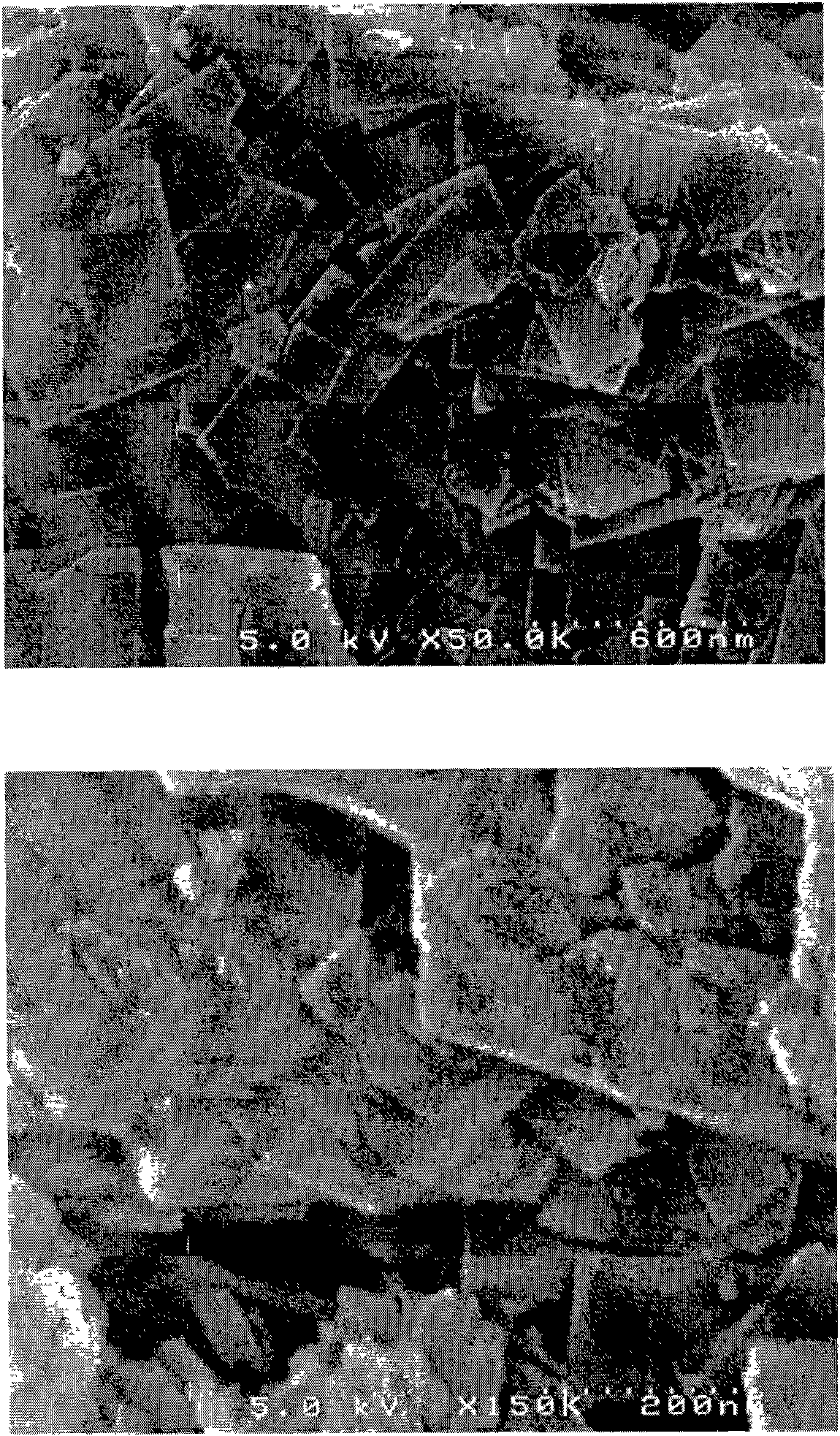

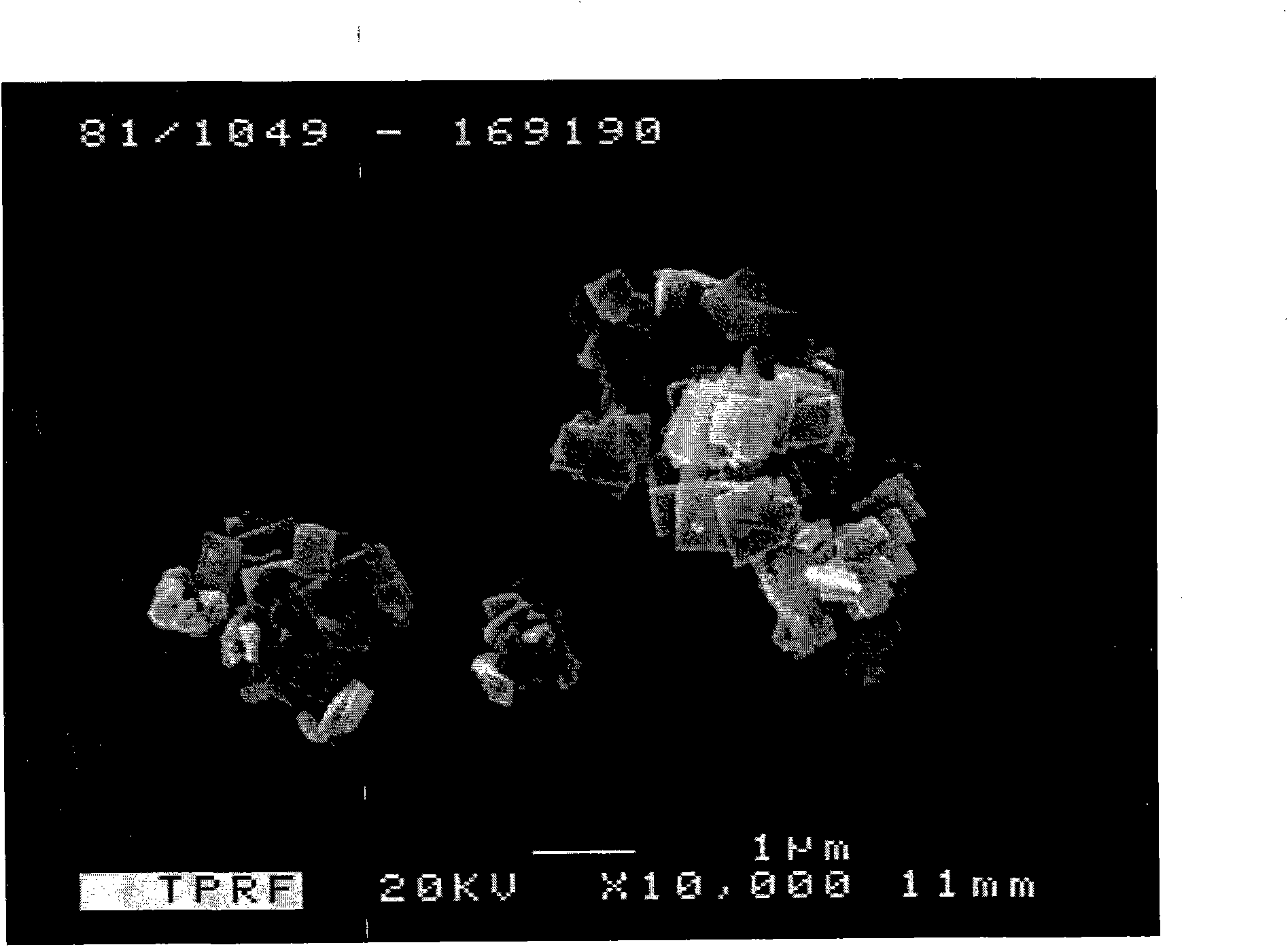

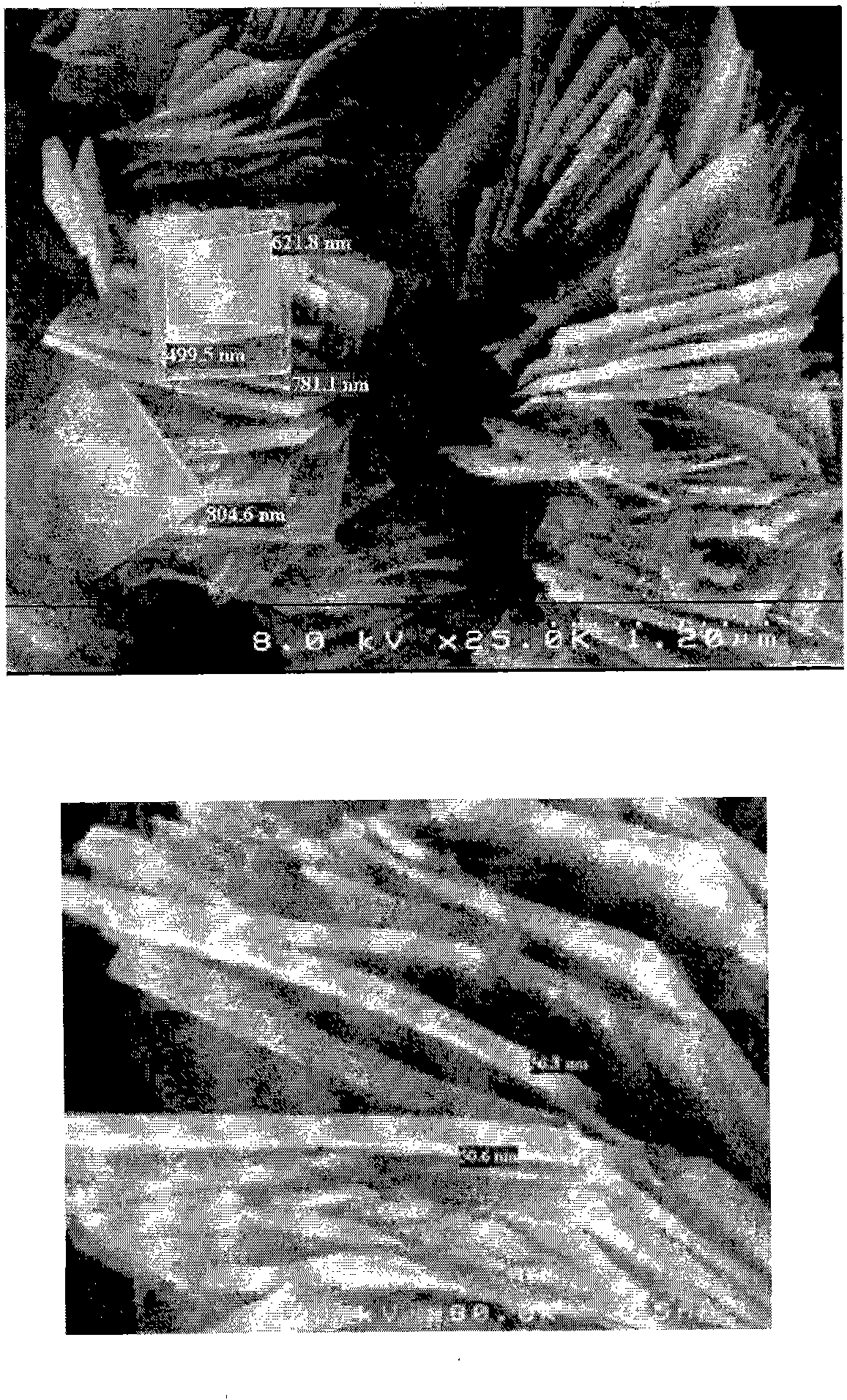

Metalloaluminophosphate molecular sieves with lamellar crystal morphology and their preparation

A metalloaluminophosphate and layered crystal technology, which is applied in the direction of molecular sieve catalysts, molecular sieve-specific aluminum phosphates, and catalysts containing molecular sieves, can solve problems affecting the crystal structure of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0090] A reaction mixture of TIA, phosphoric acid (85% in water) and TEAOH solution (40% in water) was prepared in a polytetrafluoroethylene container. The corresponding amounts of Al source and Si source were added to the solution. The slurry was mixed at room temperature for about 30 minutes until homogeneous. Then, the polytetrafluoroethylene container was put into a stainless steel autoclave. The autoclave was closed and kept at an elevated temperature with stirring. After cooling to room temperature, the sample was taken out, washed and dried. The separation of the solid and liquid phase after synthesis is performed by centrifugation. The separated solid was dried overnight at 110°C and calcined in a stream of air at 600°C for 10 hours. The ratios and operating conditions are in the table below. This procedure is applied to all examples.

[0091]

[0092] Example

Embodiment 4~6

[0095]

[0096]

Embodiment 7~8

[0098] Example

[0099] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com