Patents

Literature

532 results about "Transalkylation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

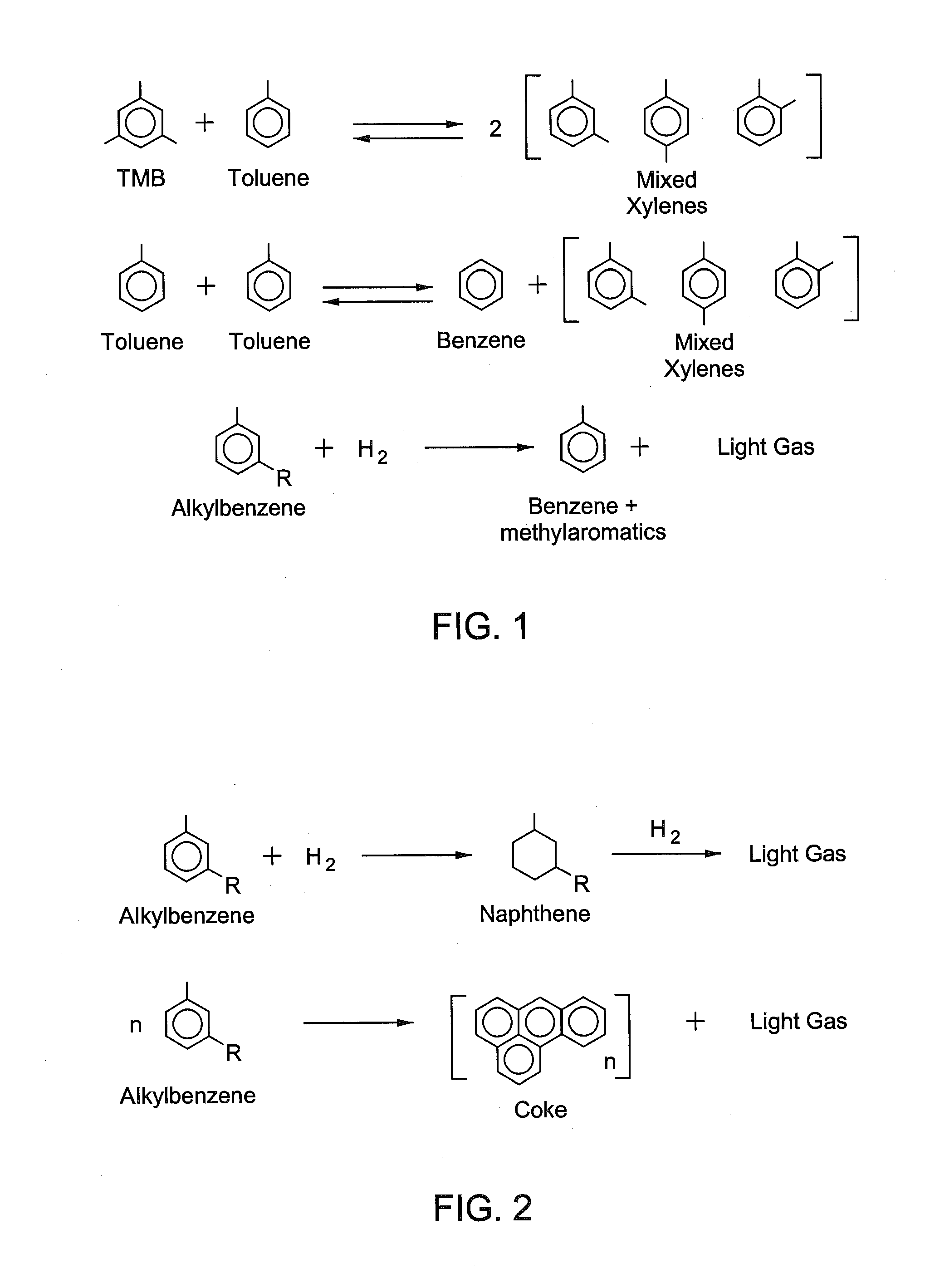

Transalkylation is a chemical reaction involving the transfer of an alkyl group from one organic compound to another. The reaction is used for the transfer of methyl and ethyl groups between benzene rings. This is of particular value in the petrochemical industry to manufacture p-xylene, styrene, and other aromatic compounds. Motivation for using transalkylation reactions is based on a difference in production and demand for benzene, toluene, and xylenes. Transalkylation can convert toluene, which is overproduced, into benzene and xylene, which are under-produced. Zeolites are often used as catalysts in transalkylation reactions.

Alkylaromatics production

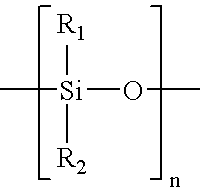

The present invention provides a process for producing a monoalkylated aromatic compound, particularly cumene, comprising the step of contacting a polyalkylated aromatic compound with an alkylatable aromatic compound under at least partial liquid phase conditions and in the presence of a transalkylation catalyst to produce the monoalkylated aromatic compound, wherein the transalkylation catalyst comprises a mixture of at least two different crystalline molecular sieves, wherein each of said molecular sieves is selected from zeolite beta, zeolite Y, mordenite and a material having an X-ray diffraction pattern including d-spacing maxima at 12.4±0.25, 6.9±0.15, 3.57±0.07 and 3.42±0.07 Angstrom.

Owner:EXXONMOBIL CHEM PAT INC

Alkylaromatics production

The present invention provides a process for producing a monoalkylated aromatic compound, particularly ethylbenzene or cumene, in which a polyalkylated aromatic compound is contacted with an alkylatable aromatic compound in the liquid phase and in the presence of a transalkylation catalyst comprising TEA-mordenite having an average crystal size of less than 0.5 micron.

Owner:EXXONMOBIL CORP (US)

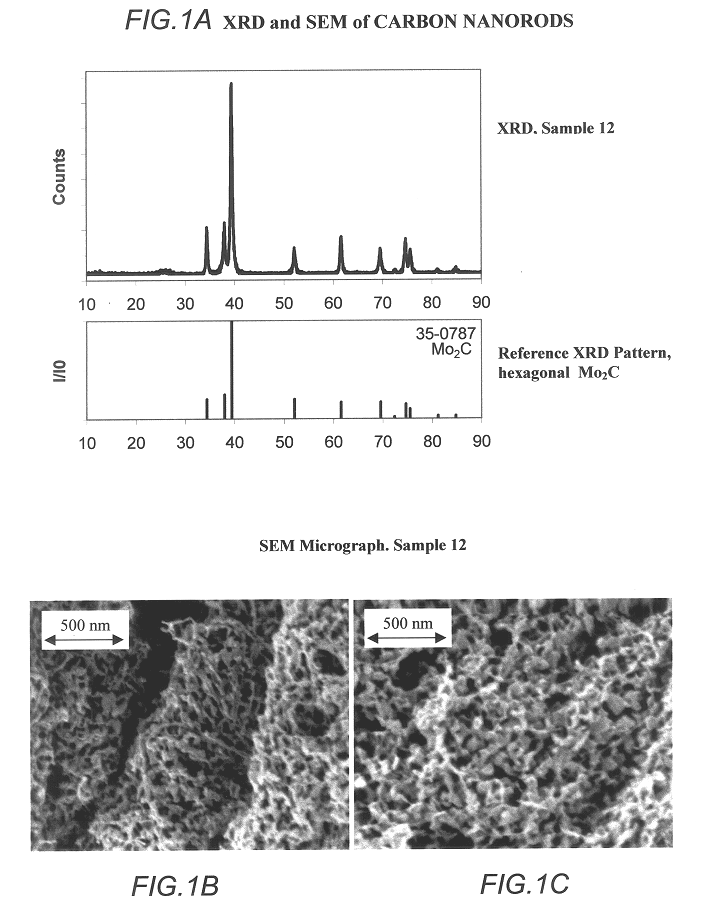

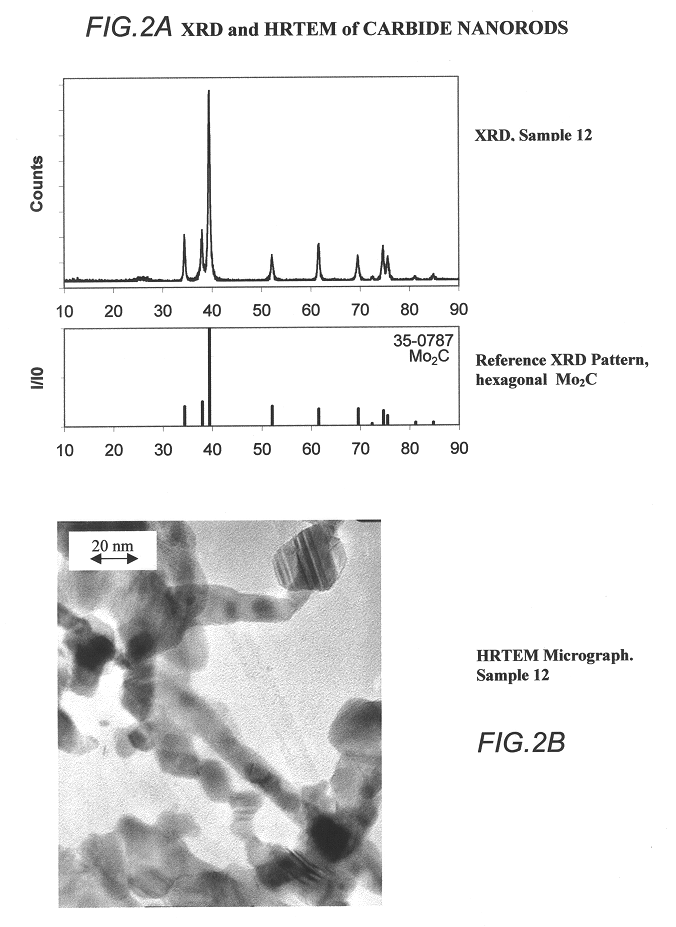

Carbide and oxycarbide based compositions, rigid porous structures including the same, methods of making and using the same

InactiveUS6514897B1Easy to diffuseSpeed up the flowMaterial nanotechnologyHydrocarbon by isomerisationIsomerizationChemical reaction

The present invention relates to compositions and rigid porous structures that contain nanorods having carbides and / or oxycarbides and methods of making and using such compositions and such rigid porous structures. The compositions and rigid porous structures can be used either as catalysts and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided. The fluid phase catalytic reactions catalyzed include hydrogenation hydrodesulfuriaation, hydrodenitrogenation, hydrodemetallization, hydrodeoxygenation, hydrodearomatization, dehydrogenation, hydrogenolyis, isomerization, alkylation, dealkylation, oxidation and transalkylation.

Owner:HYPERION CATALYSIS INT

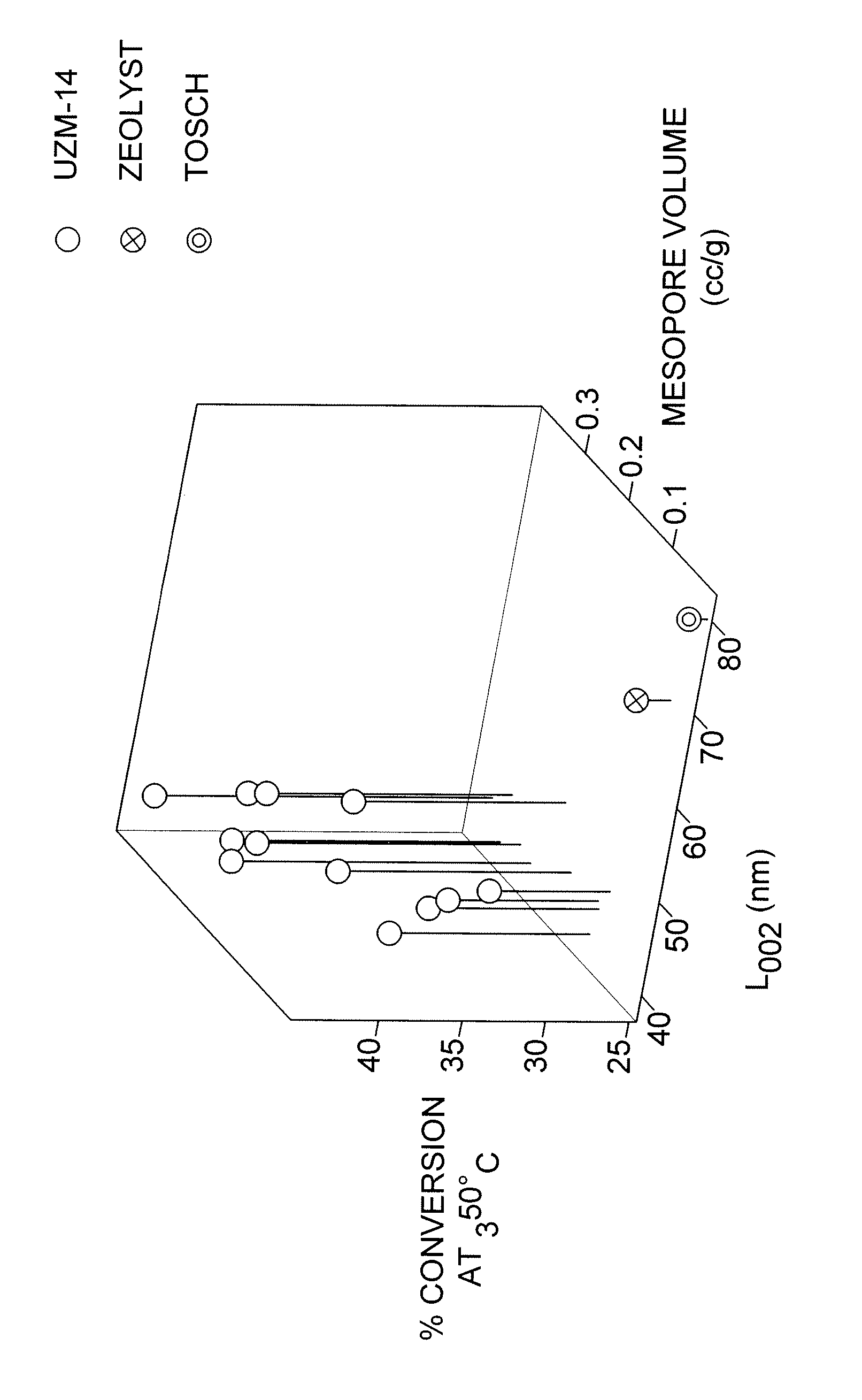

Selective catalyst for aromatics conversion

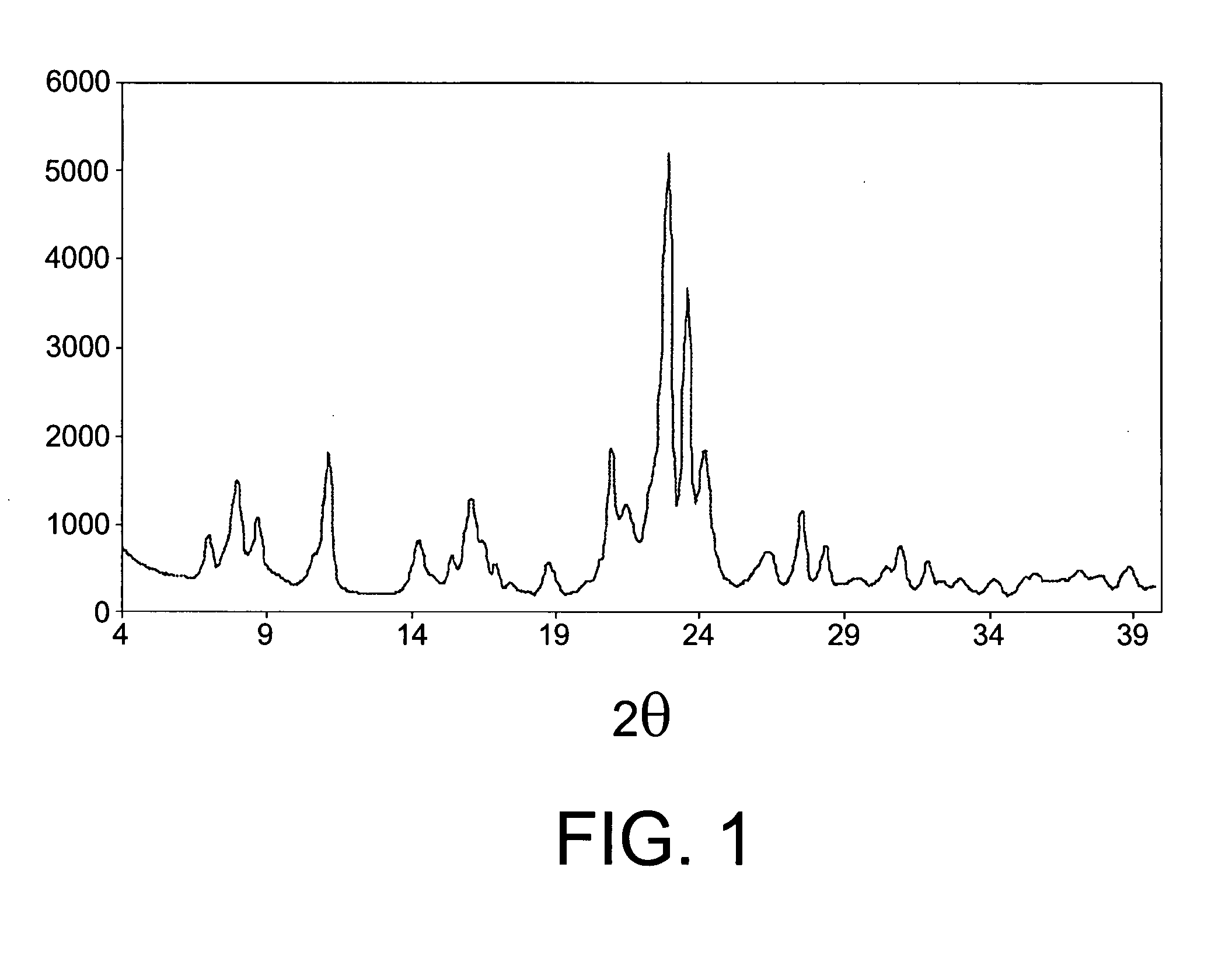

The subject invention comprises a novel UZM-14 catalytic material comprising globular aggregates of crystallites having a MOR framework type with a mean crystallite length parallel to the direction of 12-ring channels of about 60 nm or less and a mesopore volume of at least about 0.10 cc / gram. Catalysts formed from the novel material are particularly effective for the transalkylation of aromatics.

Owner:UOP LLC

Production of monocycloalkyl aromatic compounds

There is described a process for the transalkylation of a polycycloalkyl aromatic compound, particularly the transalkylation of dicyclohexylbenzene to produce monocyclohexylbenzene. The process comprises contacting the polycycloalkyl aromatic compound with benzene in the presence of a catalyst selected from the group consisting of an acidic solid comprising a Group IVB metal oxide modified with an oxyanion of a Group VIBA metal oxide, TEA-mordenite, zeolite beta and a porous crystalline material having an X-ray diffraction pattern including d-spacing maxima at 12.4±0.25, 6.9±0.15, 3.57±0.07 and 3.42±0.07 Angstrom. Preferably the catalyst is a WOx / ZrO2 material.

Owner:EXXONMOBIL CORP (US)

Catalyst for aromatics alkyl transferring and dealkylation to synthesis benzene and xylene

ActiveCN101121144AAdjust acid strengthIncreased transalkylationMolecular sieve catalystsHydrocarbonsCeriumMordenite

The present invention relates to a benzene and xylene catalyst, which is synthesized by aromatics transalkylation and dealkylation. The present invention mainly solves the problem in the prior art that a high by-product content in a benzene product of the reaction products causes bad quality of the benzene product. The present invention solves the problem well by a technical proposal that a catalyst consists of 40 to 130 portions of a mixture of a beta zeolite, SiO2 / Al2O3, Beta zeolite, the molar ratio of which is 10 to 100 and at least one zeolite which is selected from a mordenite, a Y zeolite, ZSM-12 or ZSM-5, 10 to 60 portions of binder, and 0.1 to 20 portions of at least one oxide of which is selected from molybdenum, palladium, fe, bismuth, cerium, lanthanum, nickel, tin or platinum, and all components are accounted by weight portions. The catalyst can be used for the technologies of a transfer of a heavy aromatic hydrocarbon of carbon-nine or above with toluene alkyl and the dealkylation and used for the industrial production of the xylene products.

Owner:CHINA PETROLEUM & CHEM CORP +1

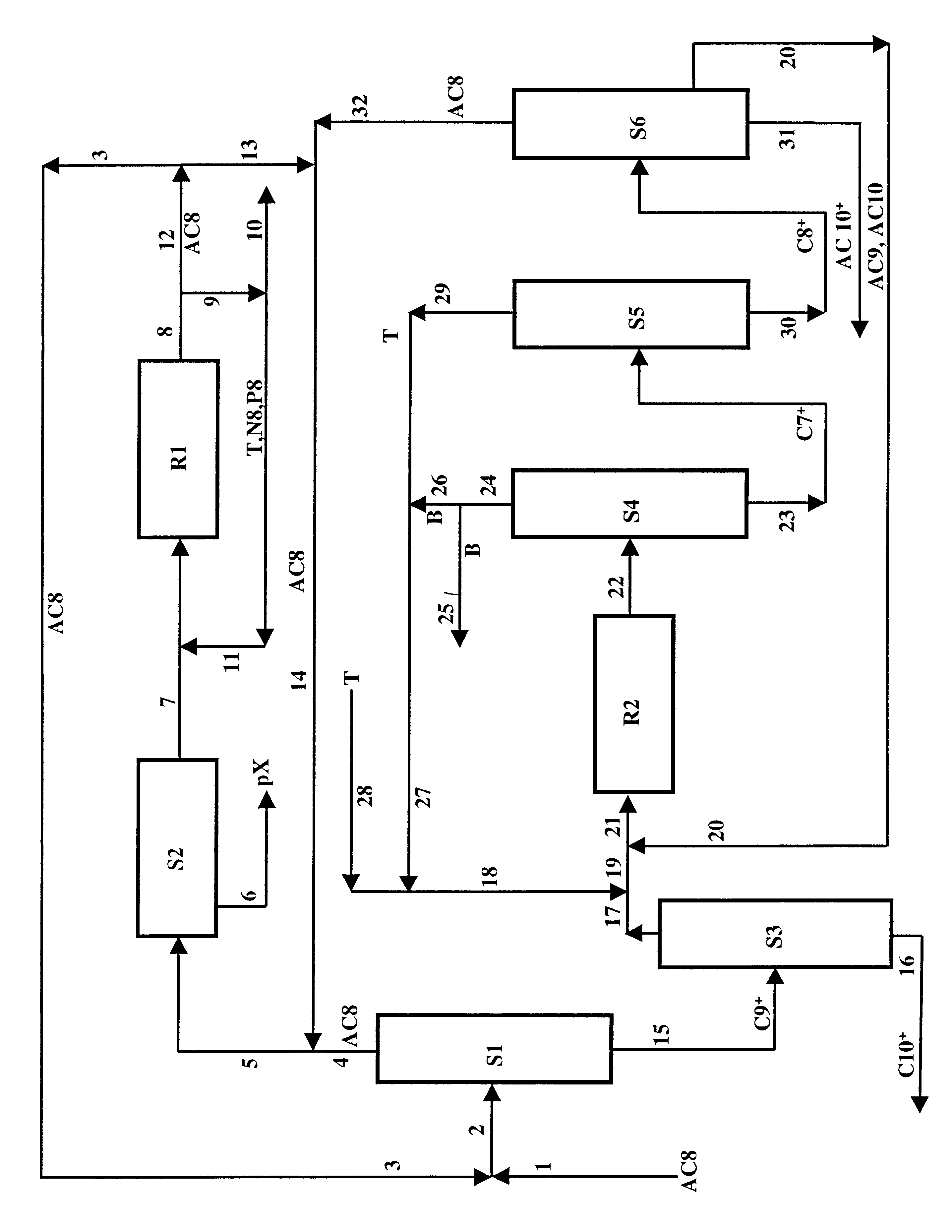

Production of a xylene isomer in three stages: separation, isomerization with a catalyst with an EUO zeolite base and transalkylation with recycling of C10-aromatic compounds

A process for the production of at least one xylene isomer, paraxylene, metaxylene or orthoxylene from an aromatic feedstock that has 7 to 10 carbon atoms per molecule. The process comprises a stage for transalkylation of C7- and C9-aromatic compounds, a stage for separation of xylenes and a stage for isomerization of xylenes. The isomerization catalyst used in the process comprises at least one EUO zeolite composition whose crystals are grouped in aggregates that have a grain size with a value of Dv,90 less than or equal to 500 microns and at least one element of group VIII.

Owner:INST FR DU PETROLE

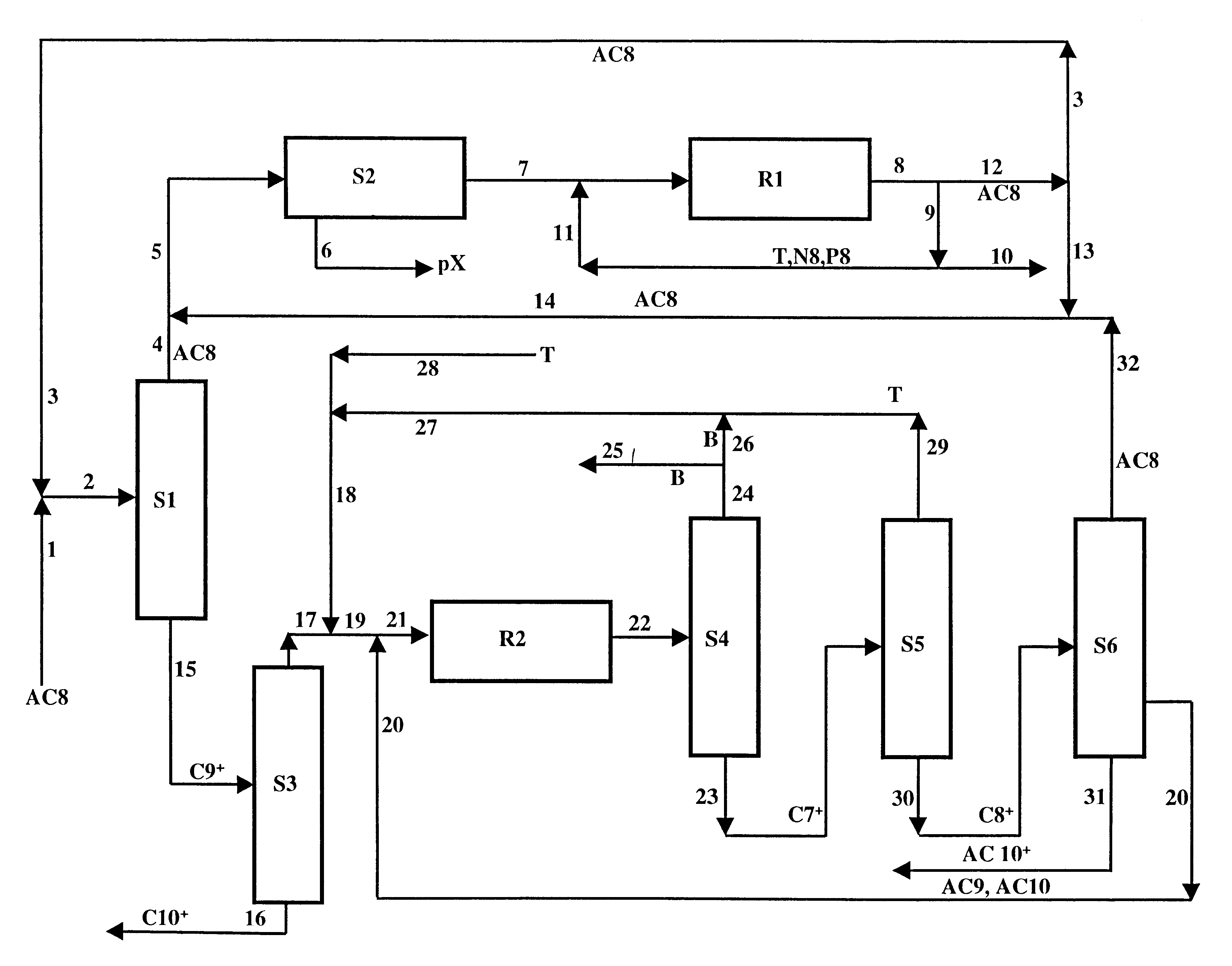

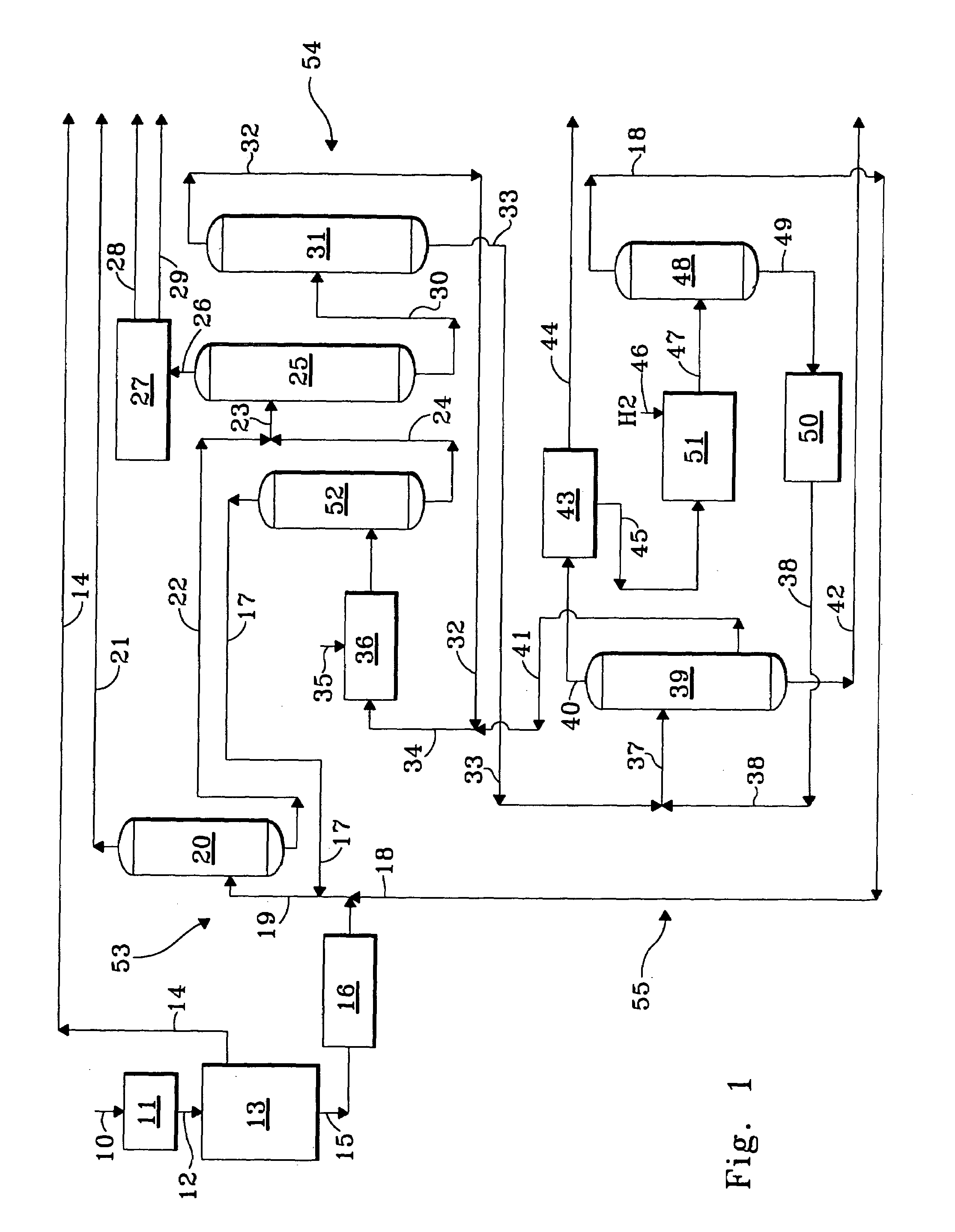

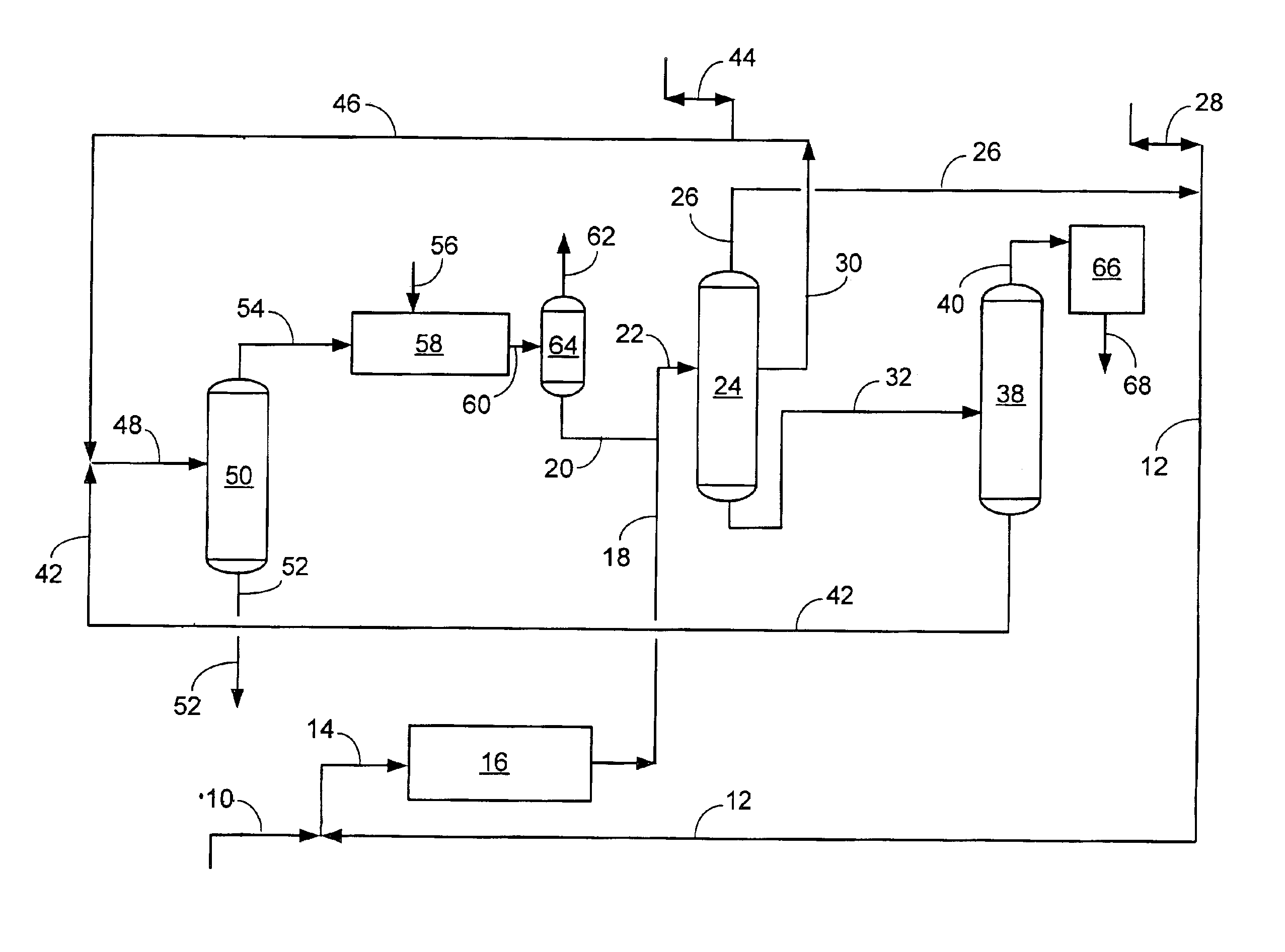

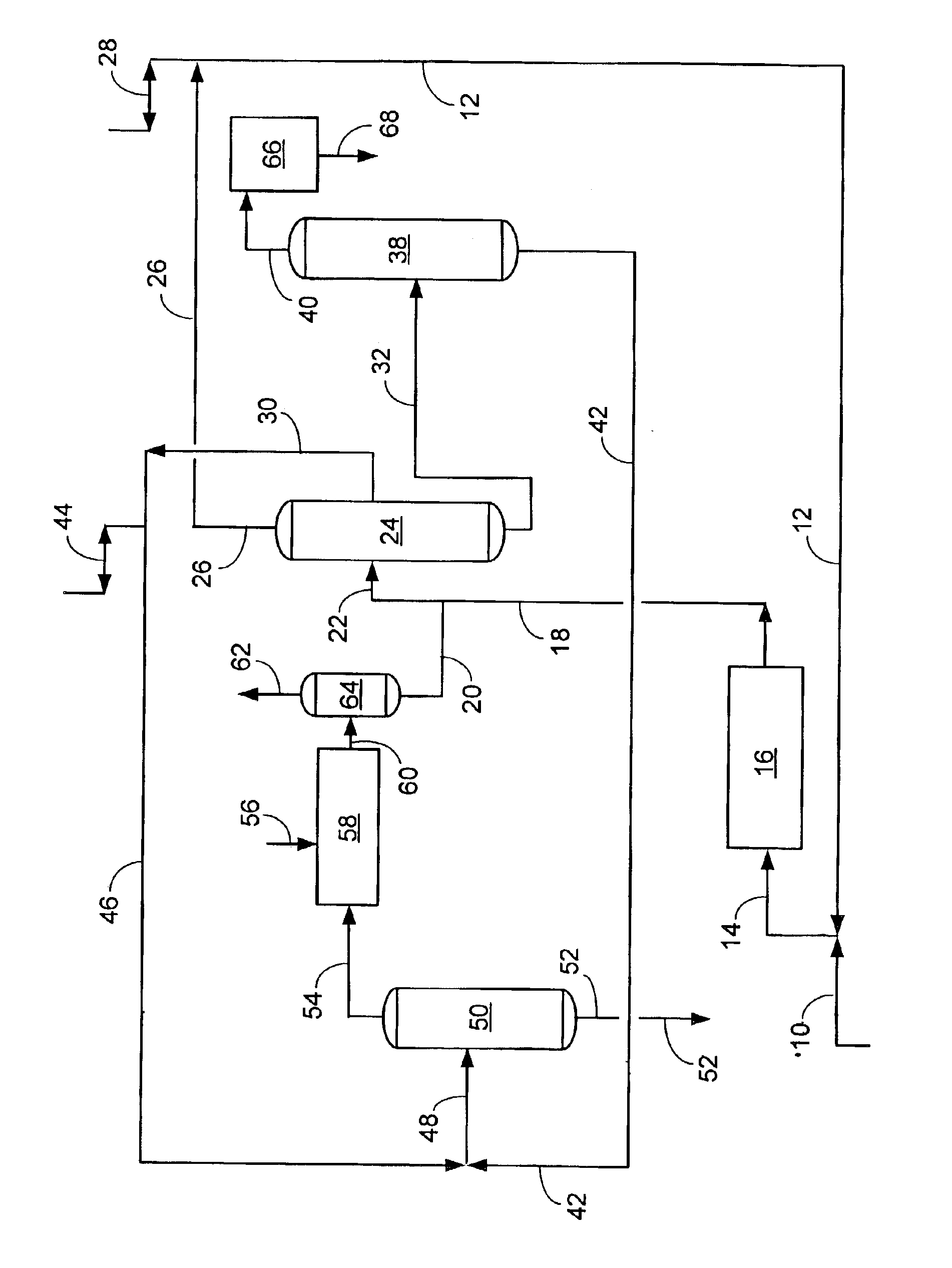

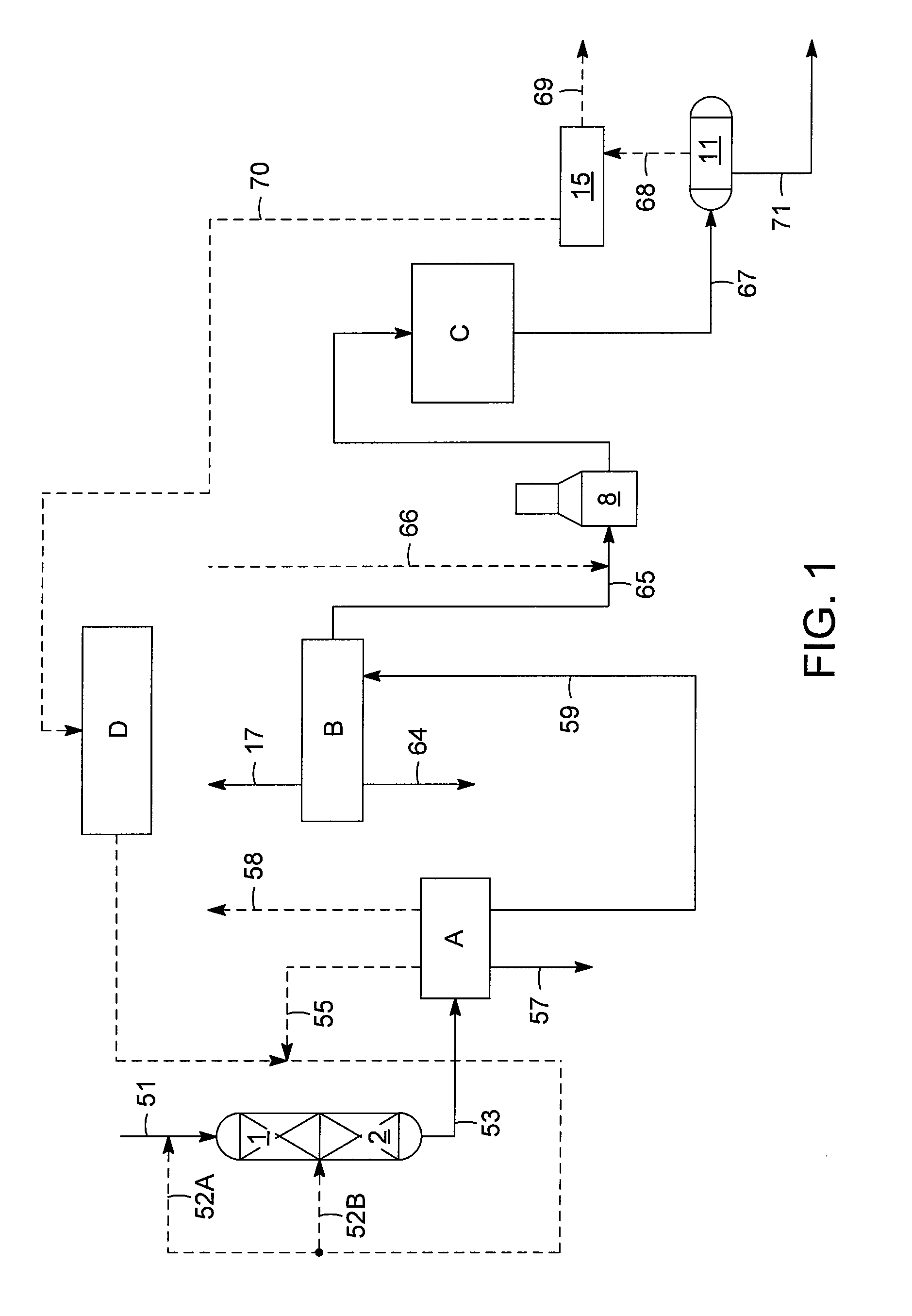

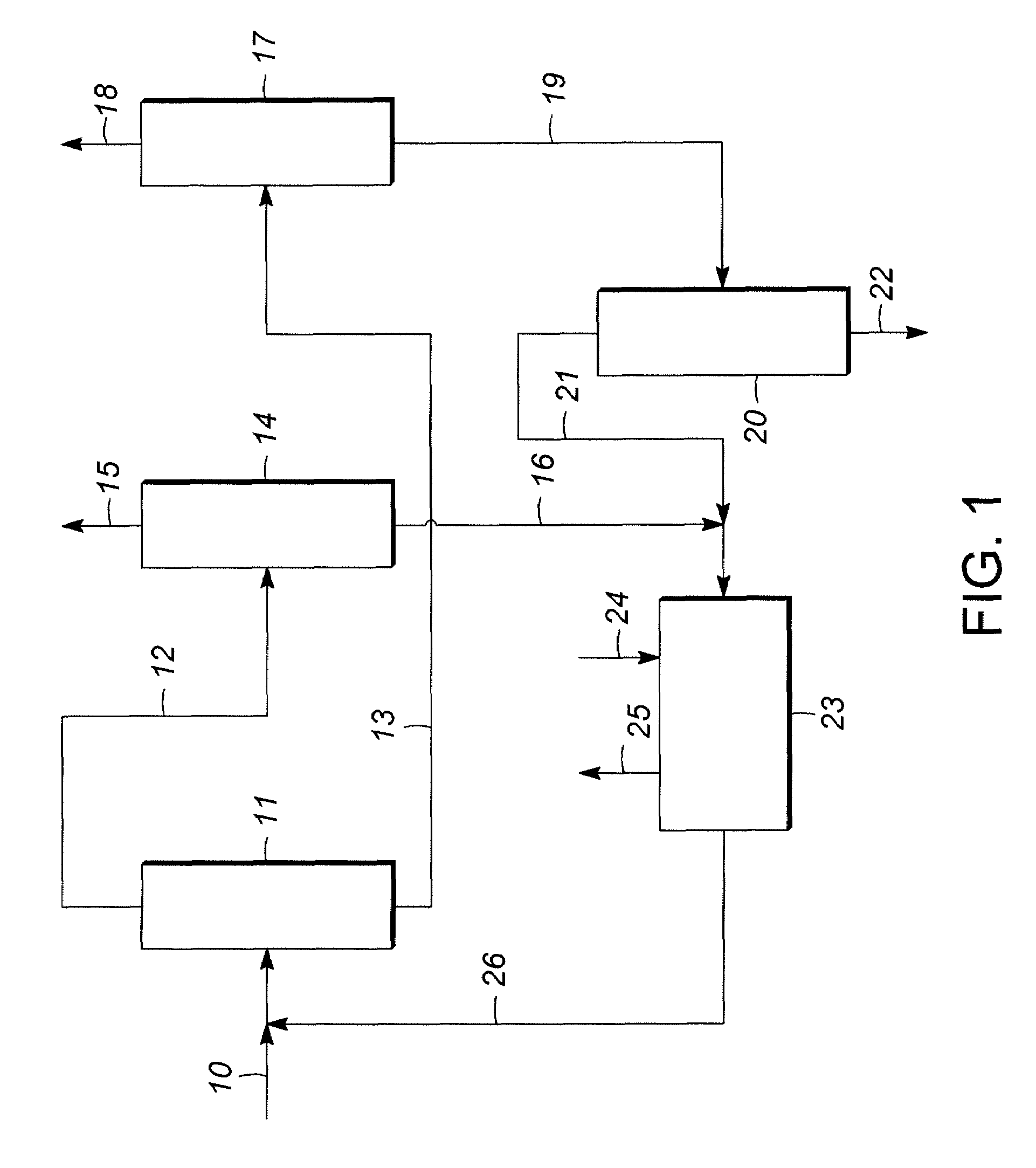

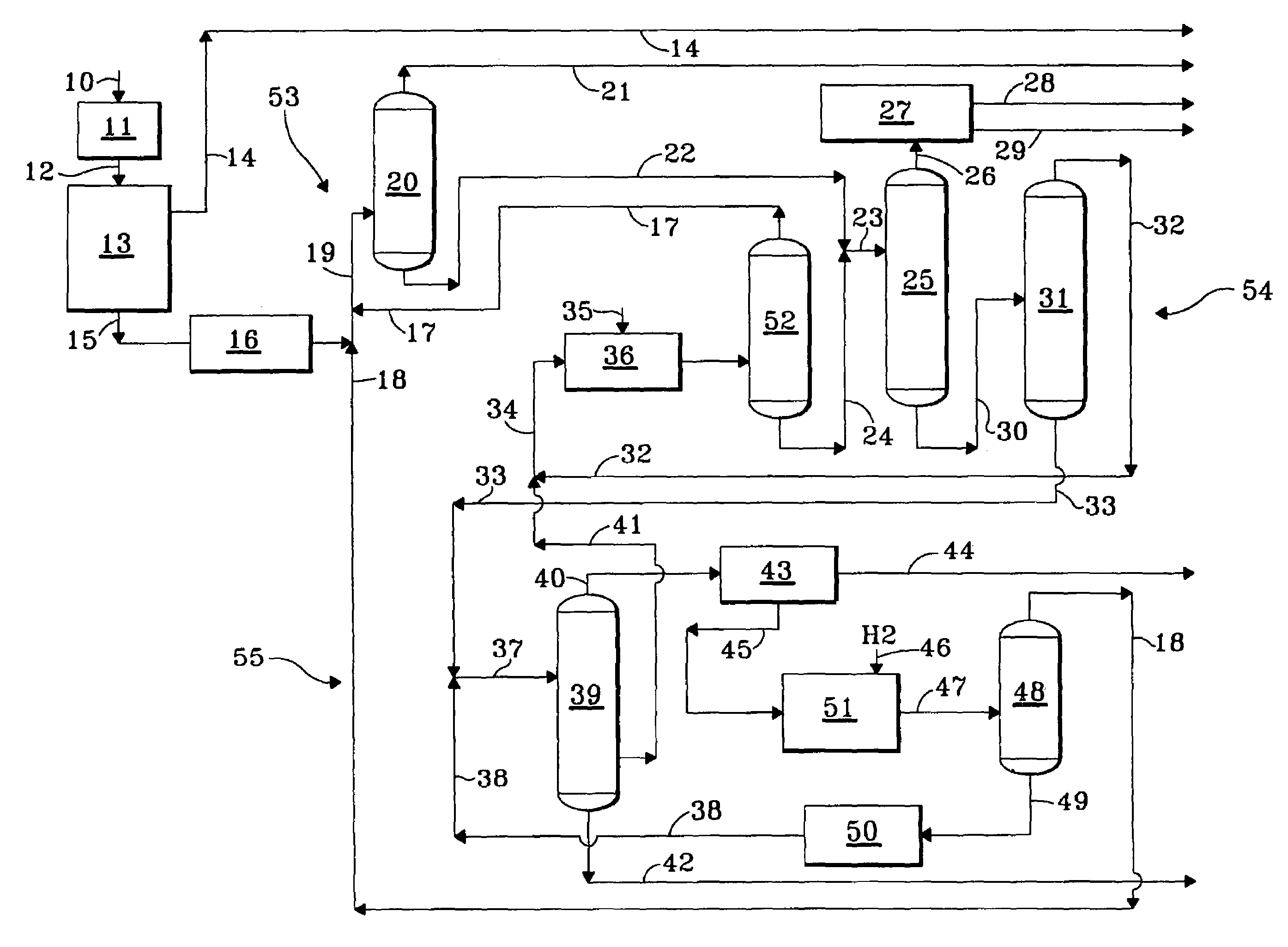

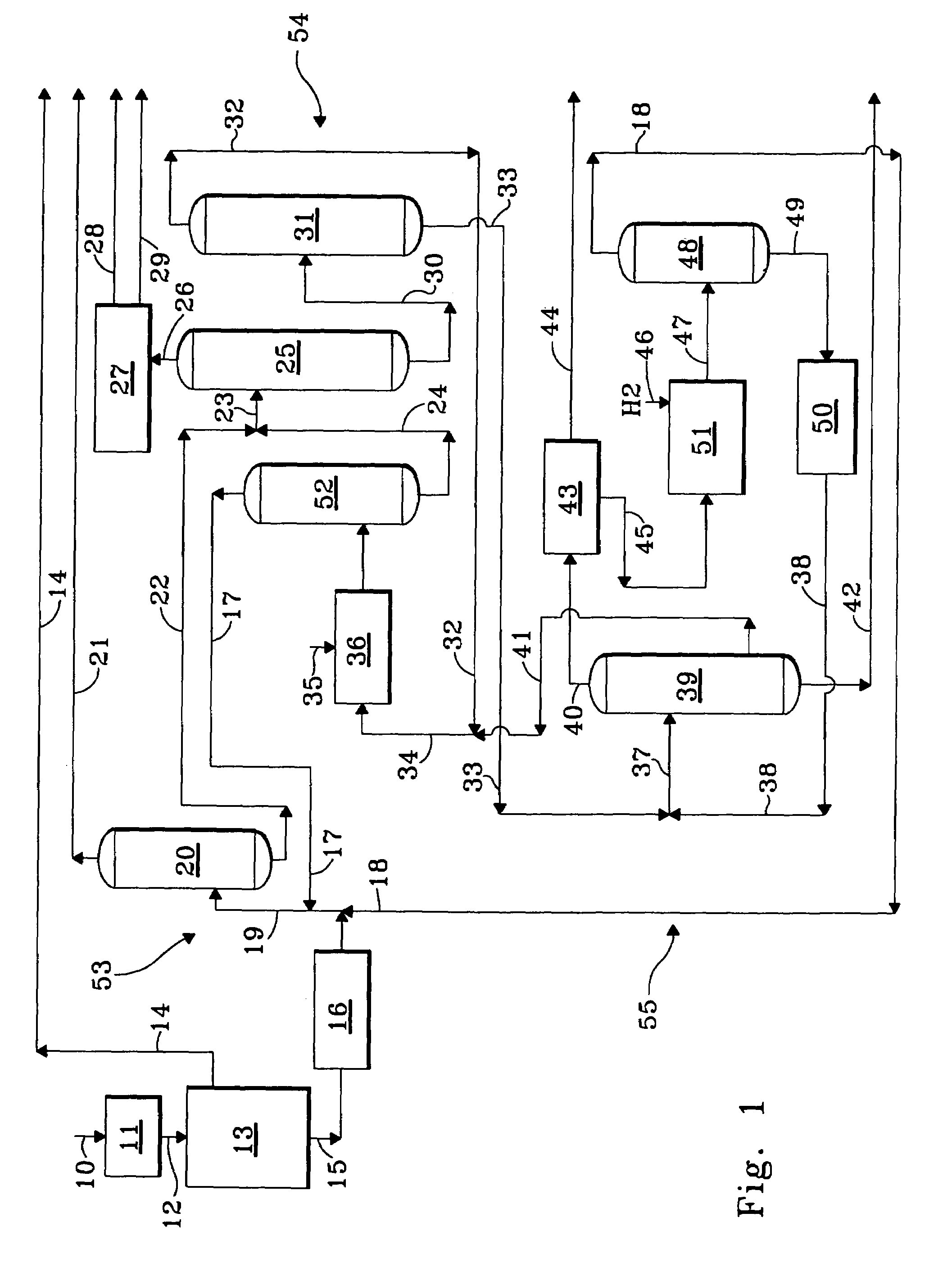

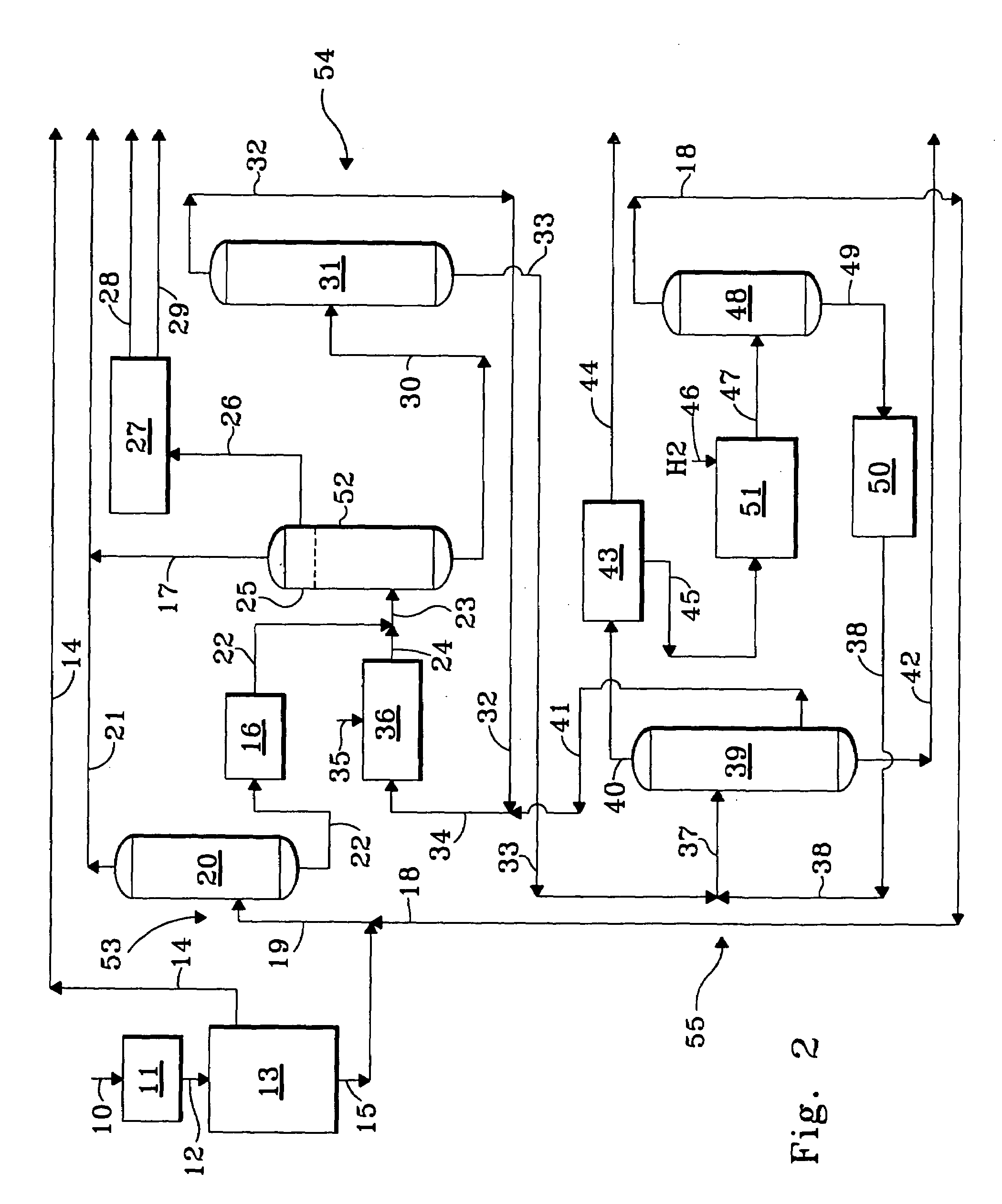

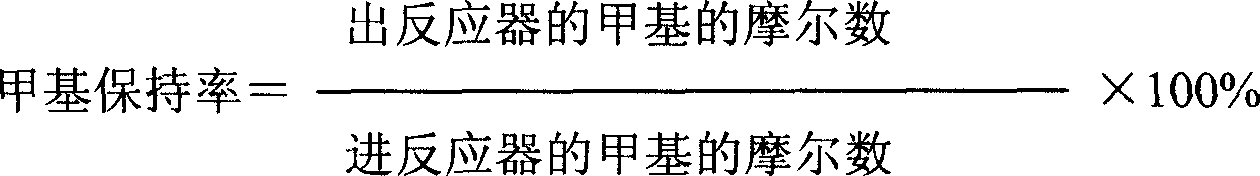

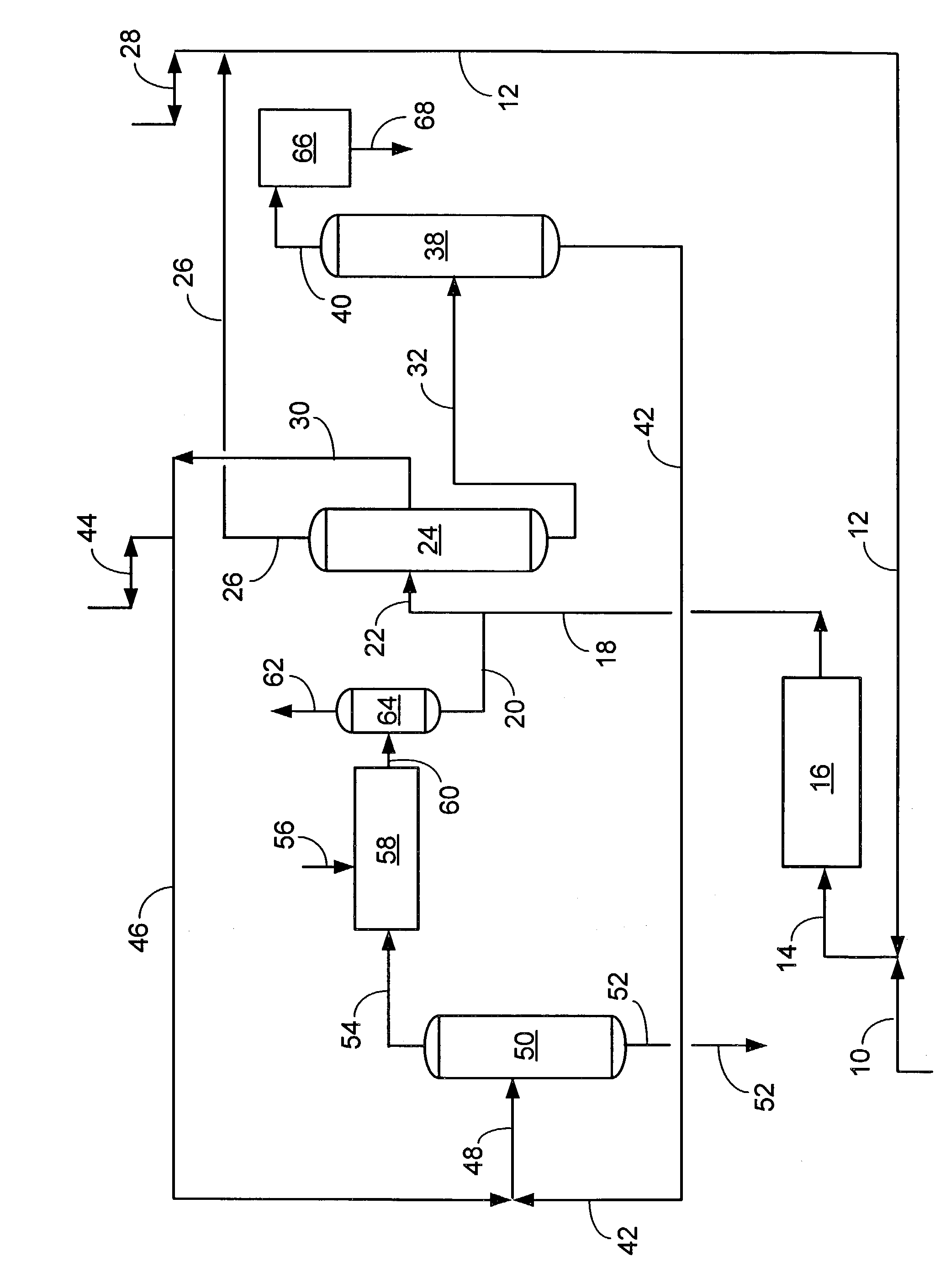

Integrated apparatus for aromatics production

Enabling a transalkylation process to handle both C10 alkylaromatics and unextracted toluene permits the following improvements to be realized. No longer extracting toluene allows a reformate-splitter column to be eliminated. The extraction unit can be moved to the overhead of a benzene column and integrated together with the transalkylation unit to reduce costs. No longer requiring a rigorous split between C9 and C10 alkylaromatics allows a heavy aromatics column to be eliminated. Such an enabled transalkylation process requires stabilization of a transalkylation catalyst through the introduction of a metal function. These improvements result in an aromatics complex apparatus with savings on inside battery limits curve costs and an improvement on the return on investment in such a complex.

Owner:UOP LLC

Preparation of group IVA and group VIA compounds

Methods of preparing Group IVA and Group VIA organometallic compounds, particularly Group IVA organometallic compounds, are provided. Such manufacturing methods employ an amine and / or phosphine catalyst in a transalkylation step and may be performed in a batch, semi-continuous or continuous manner.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Processes for Transalkylating Aromatic Hydrocarbons

InactiveUS20120083635A1Reduce productionHigh purityHydrocarbon by isomerisationMolecular sieve catalystsWater sourceAromatic hydrocarbon

A process for transalkylating aromatic hydrocarbon compounds, the process comprising introducing an aromatic hydrocarbon feed stream and a water source to a transalkylation zone. The feed stream contacts a catalyst in the transalkylation zone in the presence of water, and produces a reaction product stream comprising benzene and xylene. The invention includes methods to control the transalkylation process.

Owner:UOP LLC

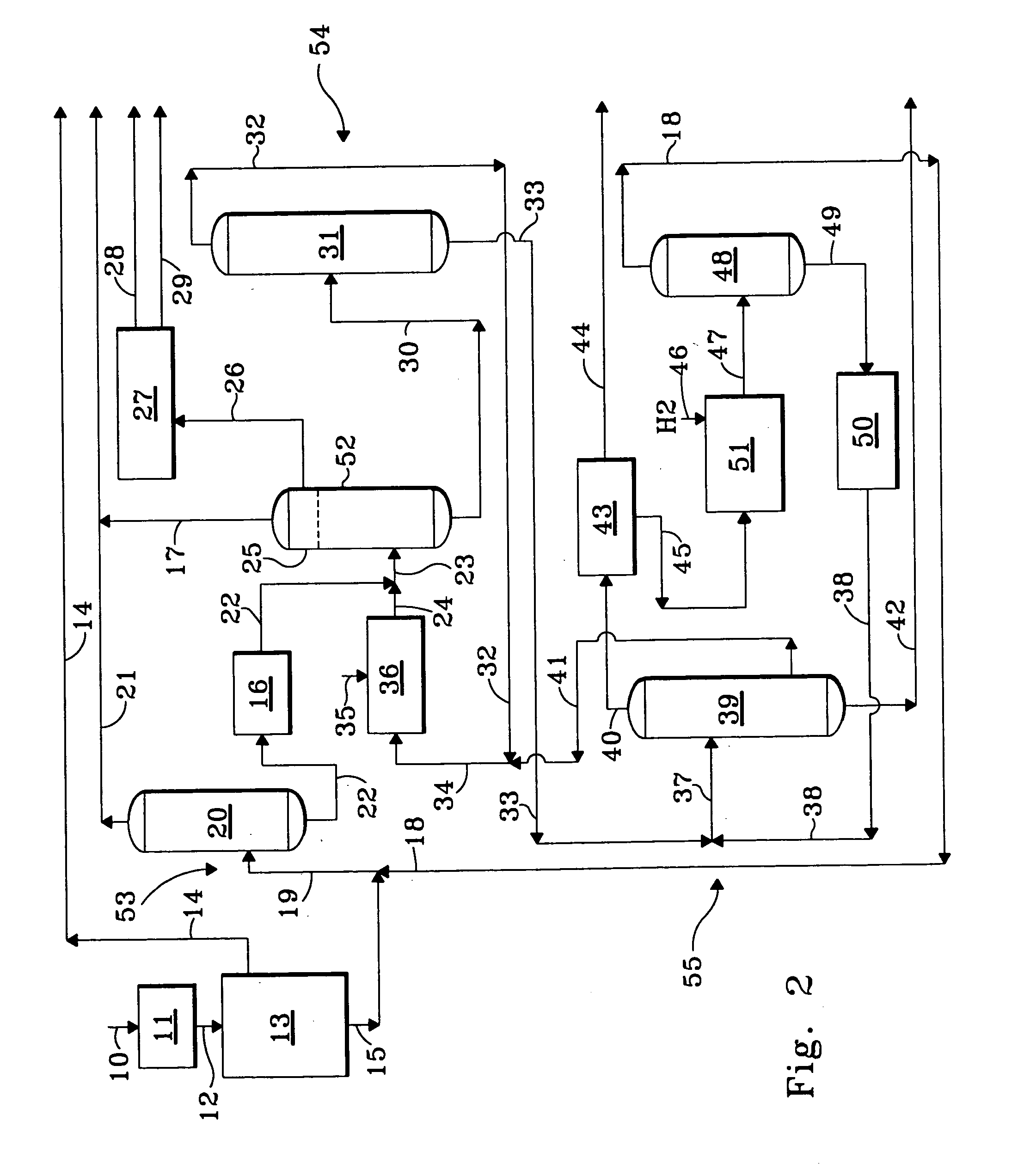

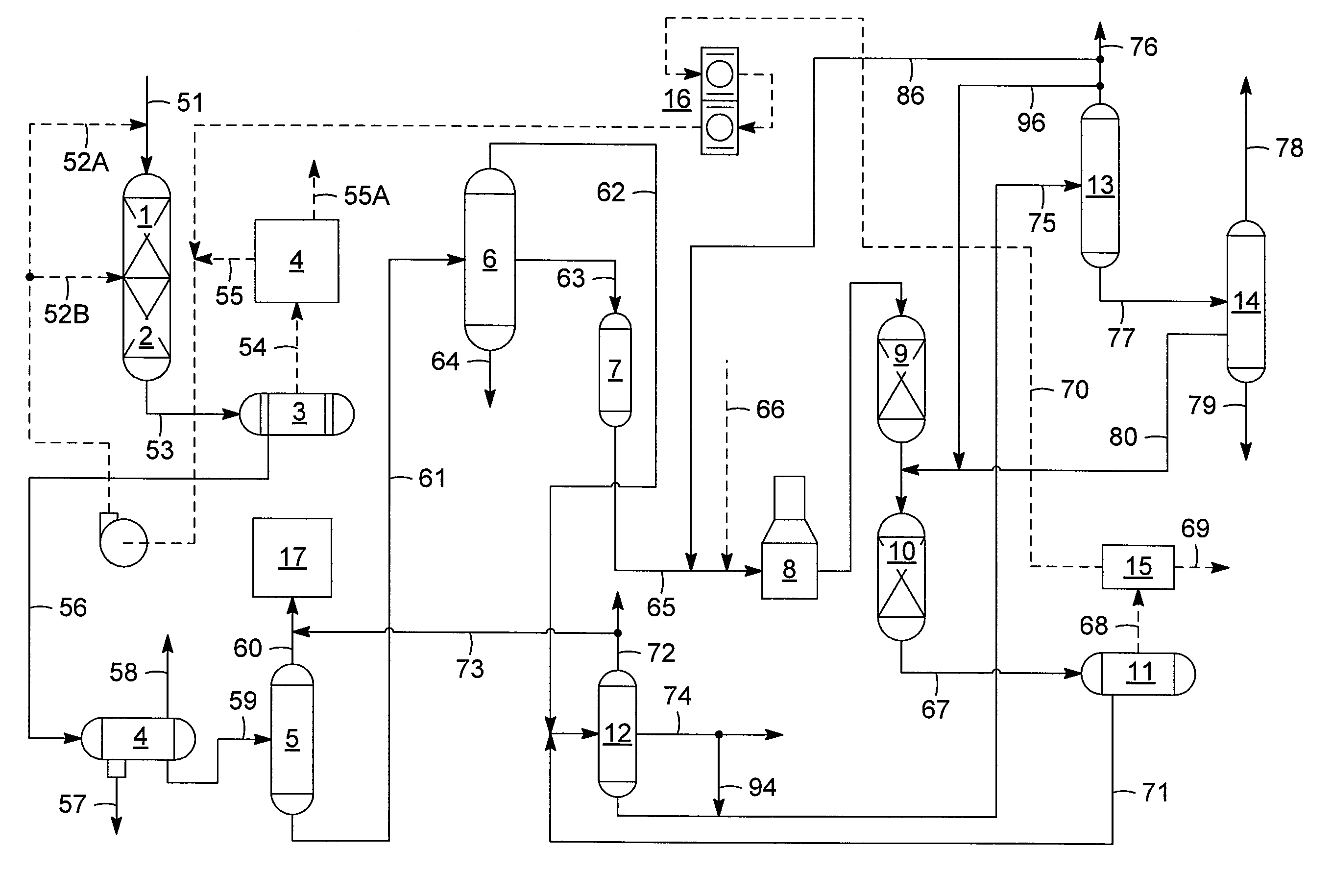

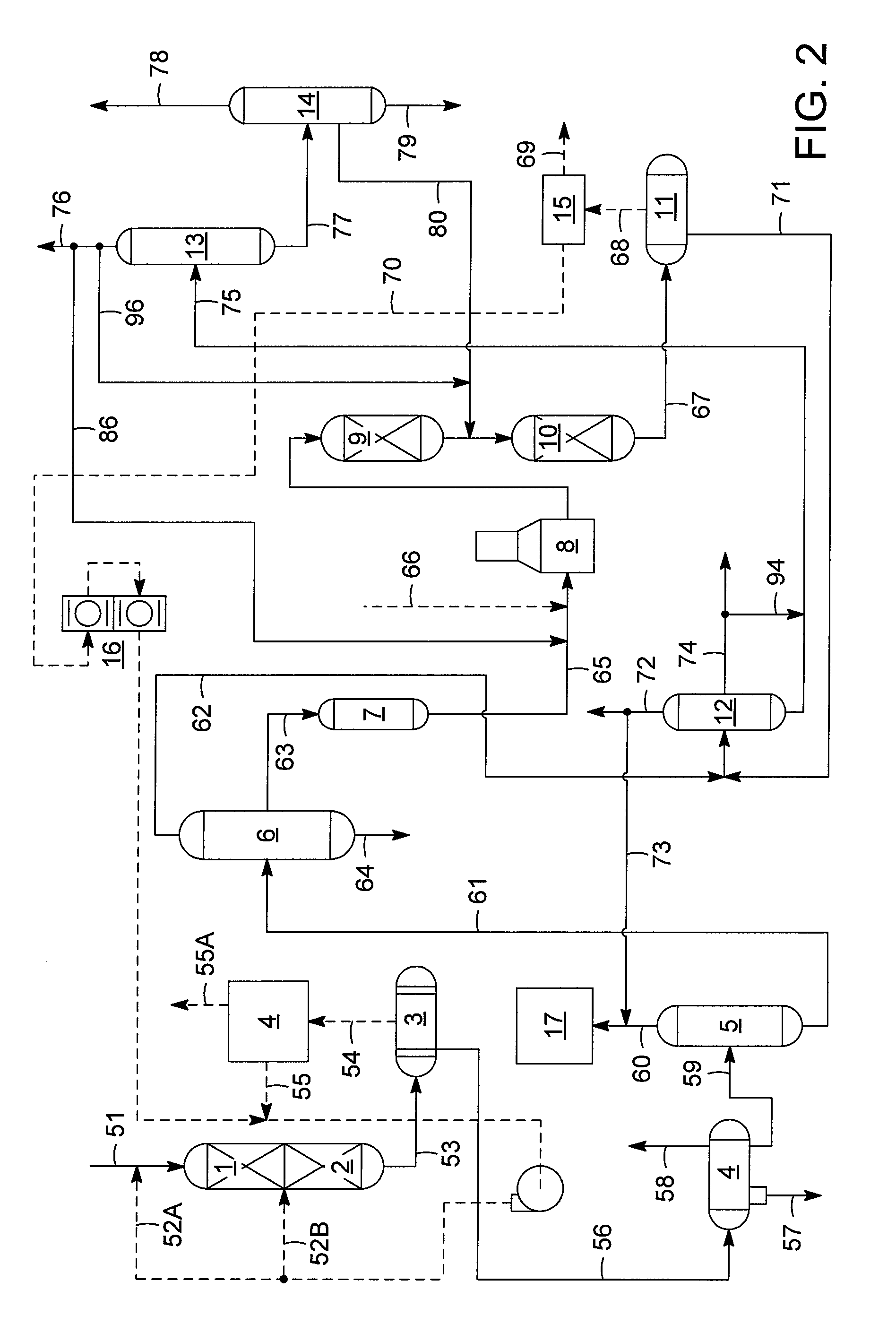

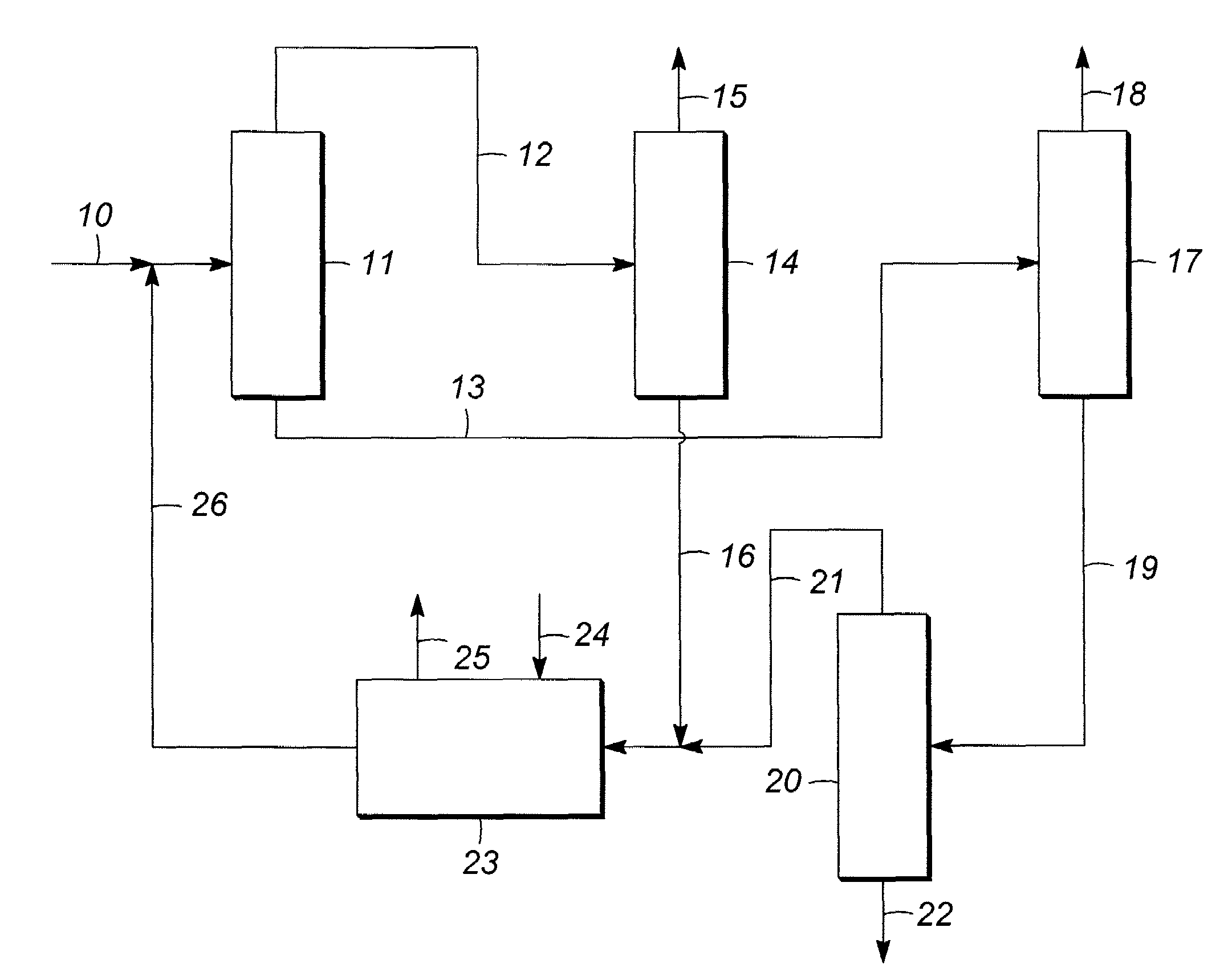

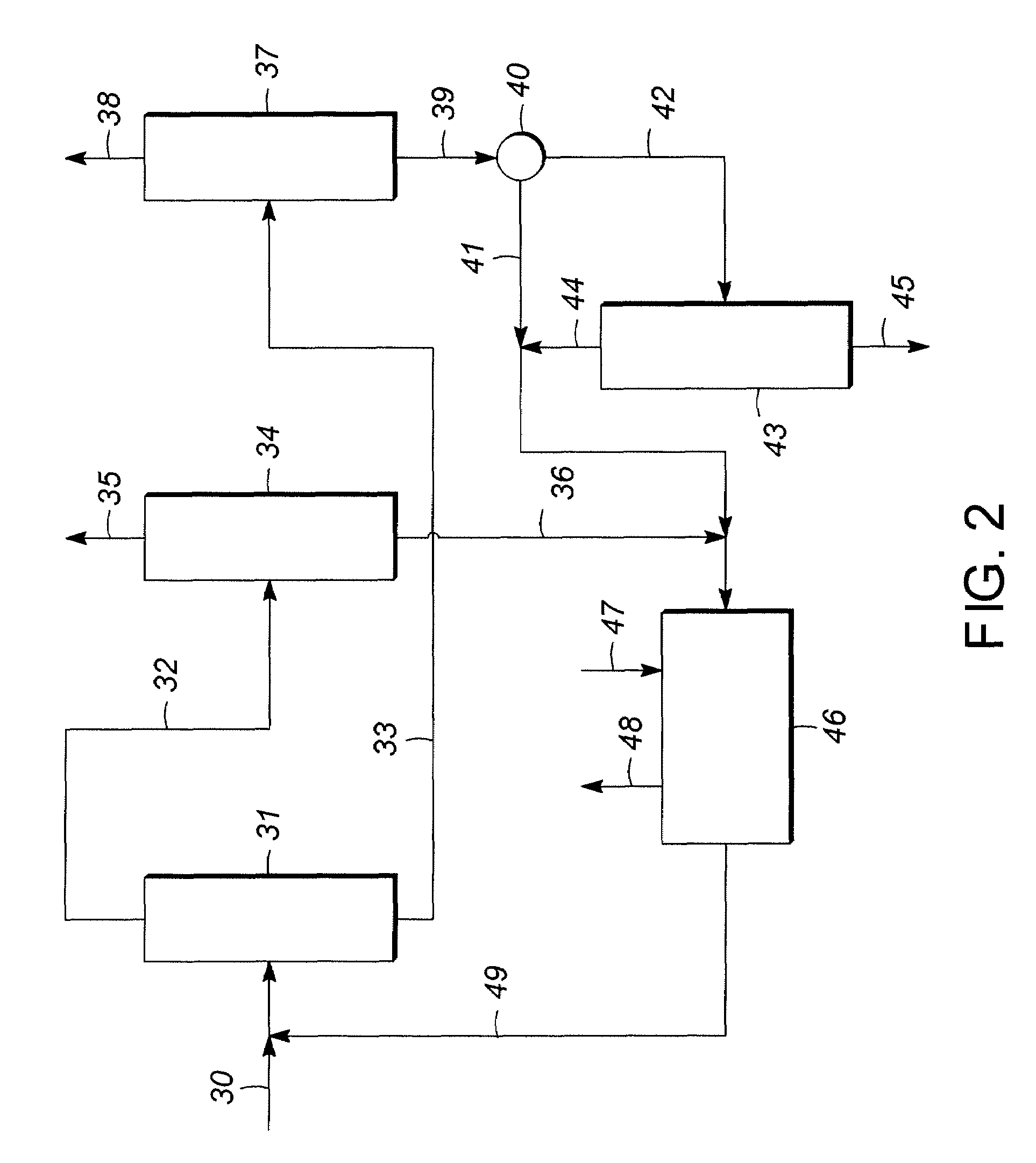

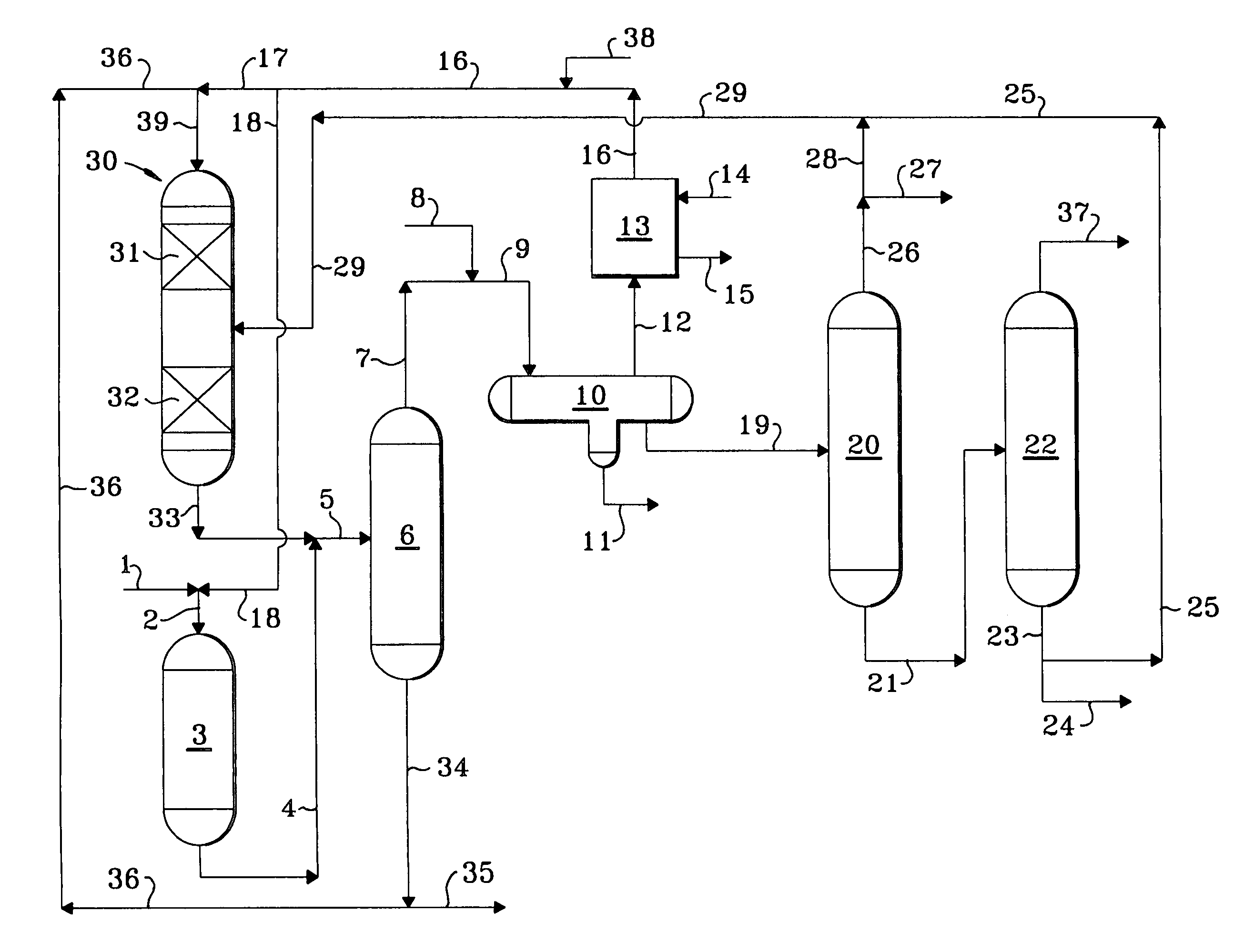

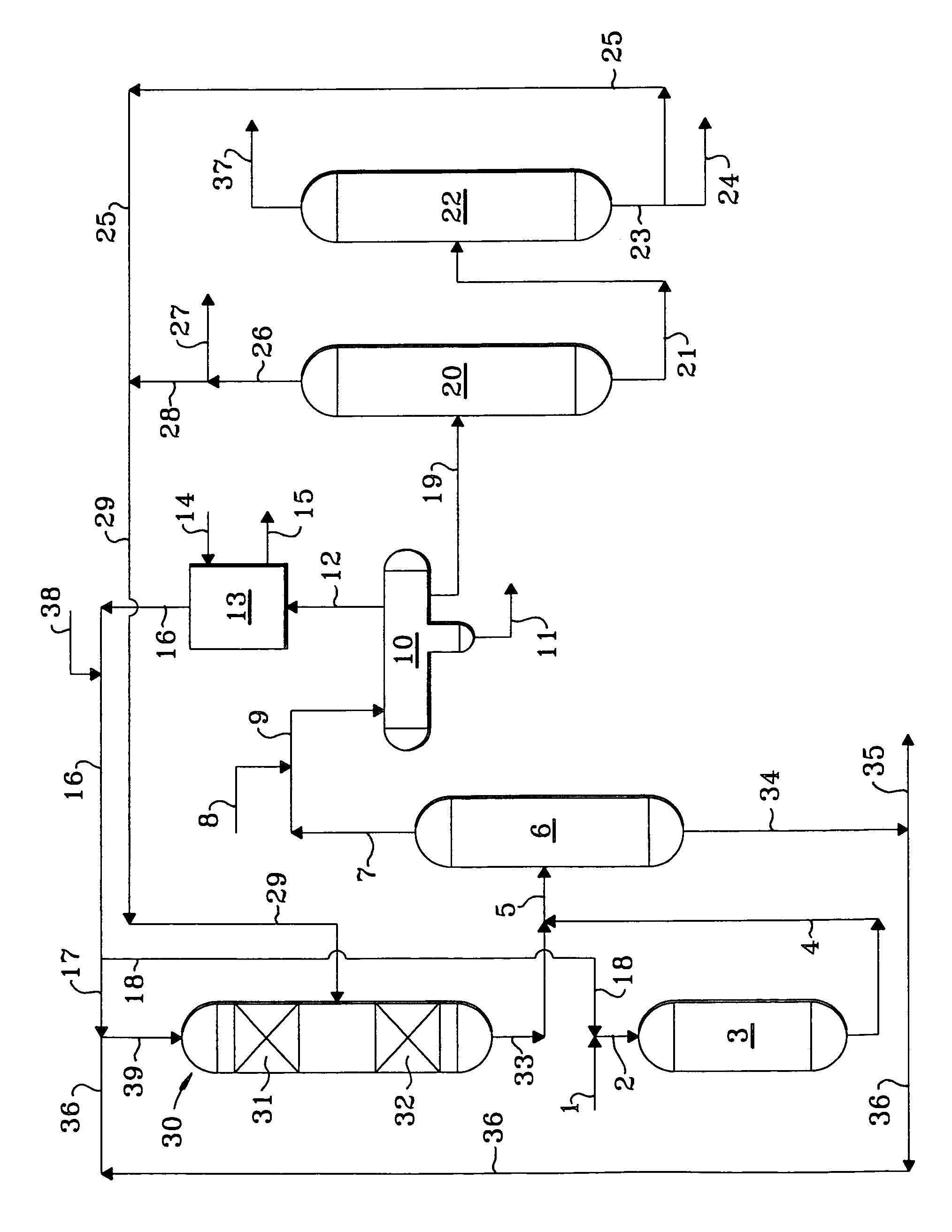

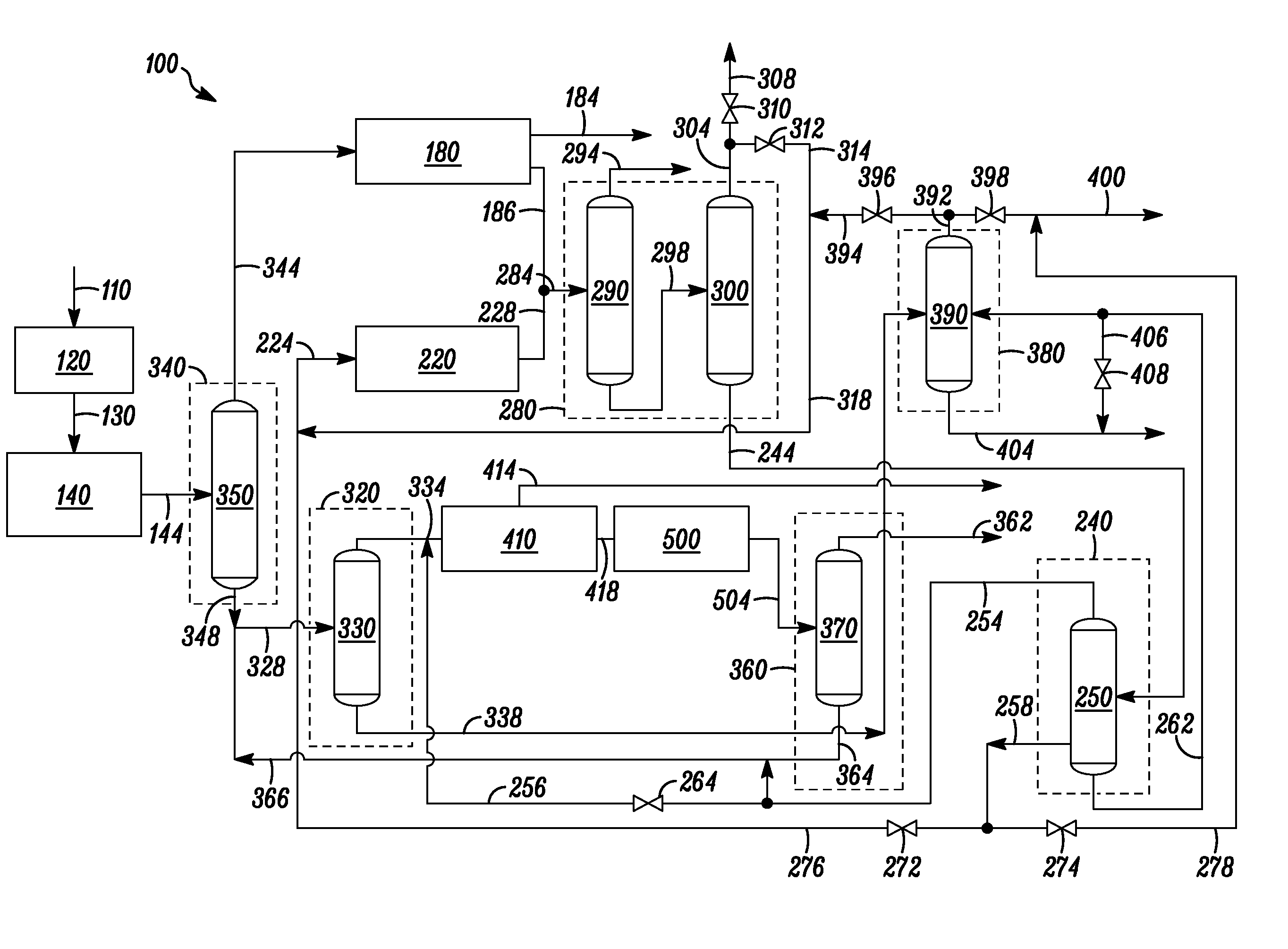

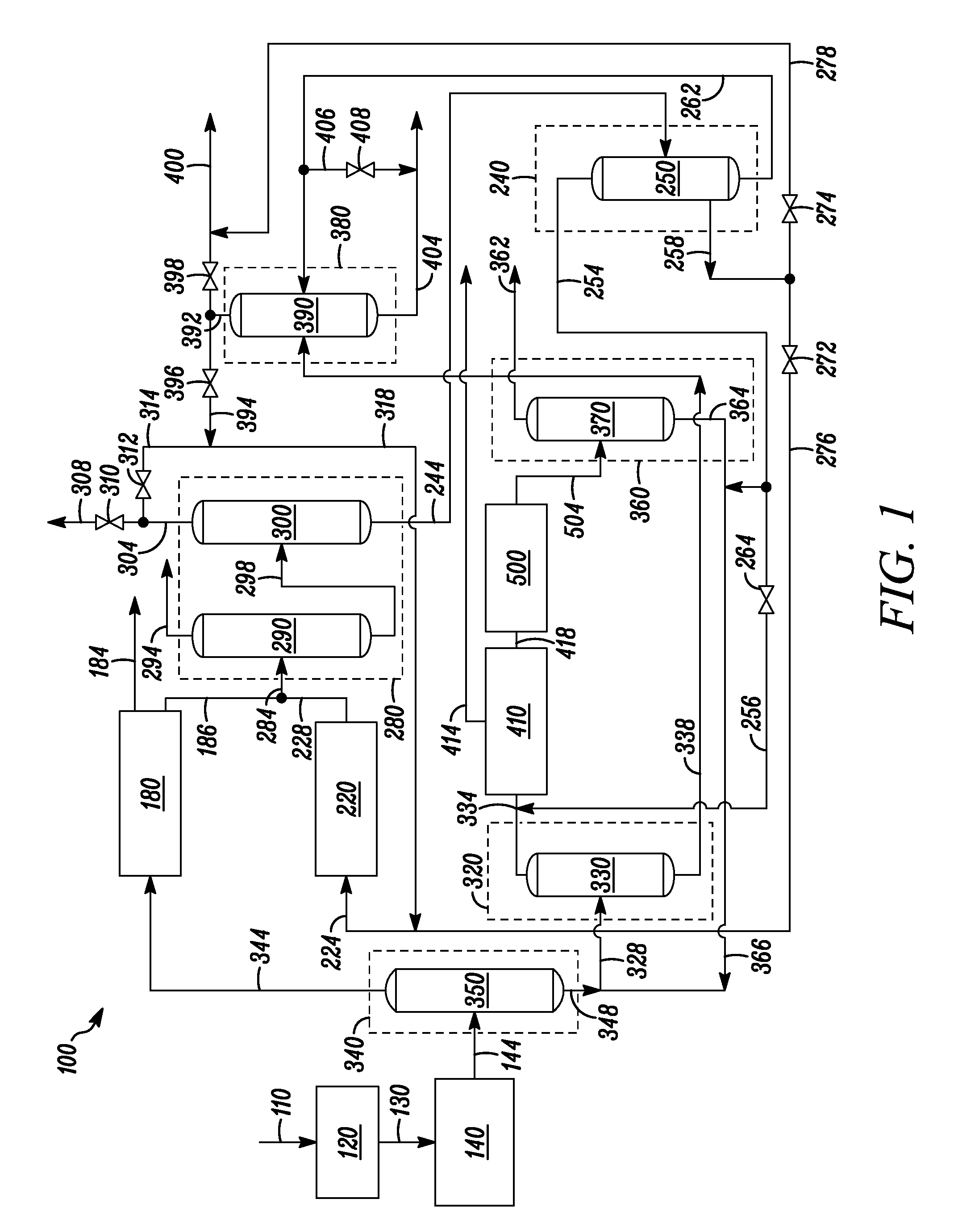

Process and apparatus for ethylbenzene production and transalkylation to xylene

InactiveUS6855854B1High selectivityHigh yieldHydrocarbon by isomerisationMolecular sieve catalystCarbon numberGas phase

The use of two transalkylation catalysts to react aromatic compounds of carbon number nine (and heavier carbon numbers) with benzene to form carbon number eight aromatics is disclosed. The two catalyst system preserves ethyl-group species on the heavier aromatics that would otherwise de-ethylate over most gas-phase transalkylation catalysts to form undesired ethane gas with benzene or toluene. Thus, by using a transalkylation step to save ethylbenzene, a greater yield of para-xylene or other carbon number eight aromatics may be achieved within an integrated complex. An apparatus and process for the two transalkylation catalyst system is disclosed with a liquid-phase unit and a gas-phase unit.

Owner:UOP LLC

Xylene Production Processes With Integrated Feedstock Treatment

ActiveUS20090036724A1Reduction in capitalReduce operating costsHydrocarbon by isomerisationHydrocarbonsMolecular sievePre treatment

A process for aromatic transalkylation and olefin reduction of a feed stream is disclosed. Transalkylation conditions provide a product having increased xylene concentration and reduced olefin concentration relative to the feed. The process may be used in a xylene production facility to minimize or avoid the necessity of feedstock pretreatment such as hydrotreating, hydrogenation, or treating with clay and / or molecular sieves.

Owner:UOP LLC

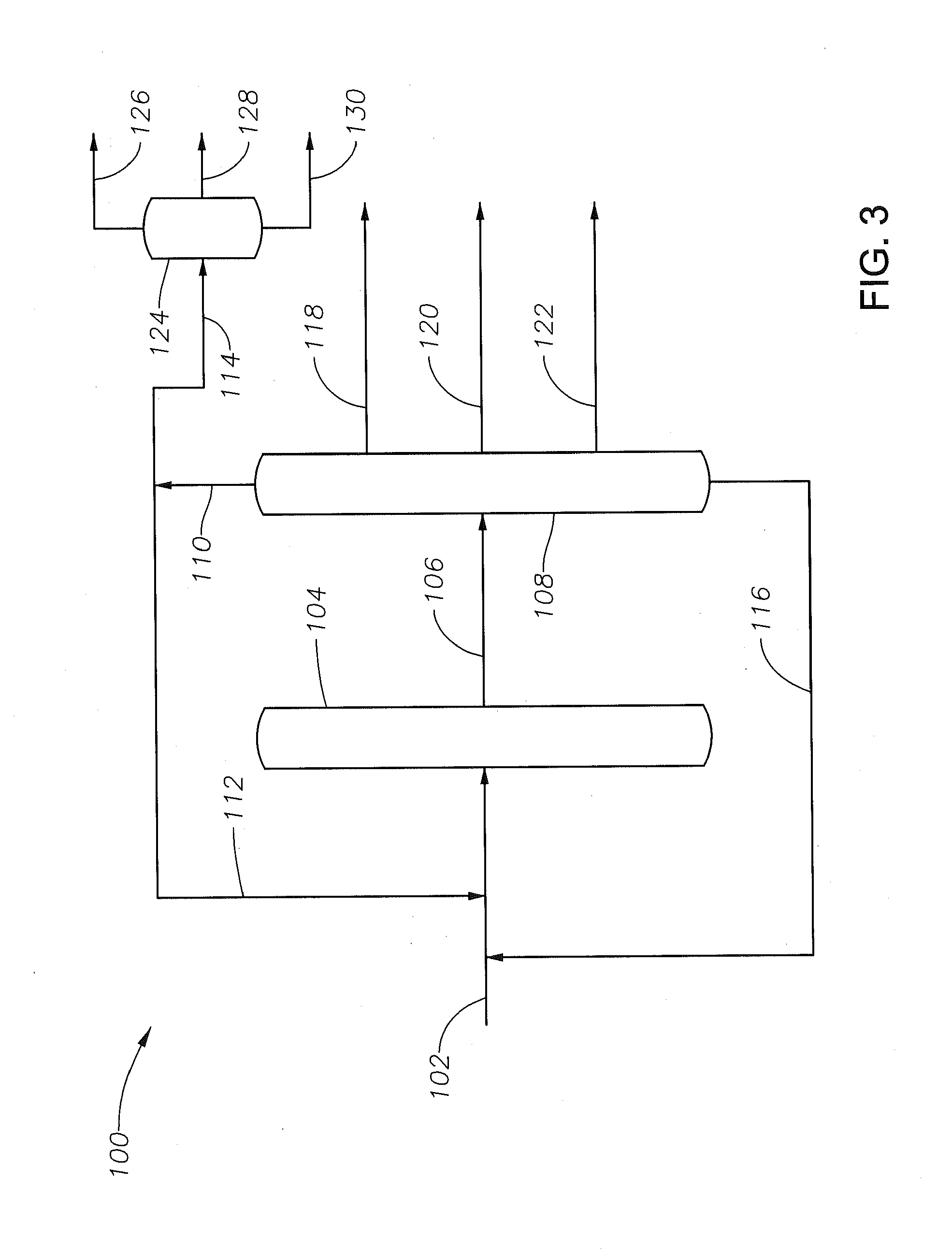

Method for efficient use of hydrogen in aromatics production from heavy aromatics

InactiveUS20100160699A1Reduce needEasy to useOrganic reductionHydrocarbon by hydrogenationLiquid productBoiling point

A method for efficient use of hydrogen in aromatics production from heavy aromatic oil. A hydrocarbonaceous stream comprising C9+ hydrocarbons and an essentially pure hydrogen stream are hydrotreated and hydrocracked to produce a hydrocracking zone effluent comprising aromatics. The hydrocracking zone effluent is fractionated to separately recover C4 and lighter hydrocarbons, hydrocarbons boiling between about 180° F. and about 380° F., and diesel. The heavier hydrocarbons are combined with a low purity hydrogen-containing stream and heated, then dehydrogenated or transalkylated to form hydrogen, volatile compounds, and aromatics. The hydrogen and volatile components are separated from the aromatics and treated by pressure swing adsorption to provide an essentially pure hydrogen-containing stream, which is compressed and provided to the hydrotreating and hydrocracking steps. Liquid products are recovered from the aromatics-containing stream.

Owner:UOP LLC

Method for converting heavy aromatics to light aromatics and transferring alkyl radical

The invention relates to a method for converting heavy aromatics to light aromatics and transferring an alkyl radical, which mainly solves the problem of low activity during the reaction of converting the heavy aromatics to the light aromatics and transferring the alkyl radical in the presence of a conventional catalyst. In the invention, a new method for converting the heavy aromatics to the light aromatics and transferring the alkyl radical is adopted, wherein the catalyst comprises the following components in part by weight: a) 5 to 95 parts of nuclear-shell molecular sieve material and b)95 to 5 parts of adhesive; the nuclear phase of the nuclear-shell molecular sieve is ZSM-5; and the shell layer is beta zeolite grains with coverage of between 50 and 100 percent. The technical scheme solves the problem better and the method can be used in the industrial production of converting the heavy aromatics to the light aromatics and transferring the alkyl radical.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for hydrogenation pyrolysis of prolific benzene and xylene by using pyrolysis gasoline

InactiveCN101734986AModerate hydrogenation performanceIncrease added valueHydrocarbon by hydrocarbon crackingNaphtha reformingAlkaneIsomerization

The invention relates to a method for hydrogenation pyrolysis of prolific benzene and xylene by using pyrolysis gasoline. The method mainly solves the problems that only BTX (B is benzene, T is toluene and X is xylene) arene is separated in the traditional process of the pyrolysis gasoline, and the light arene output contains a great amount of toluene with lower utilization value with the separated heavy arene. In the invention, alkyl transfer reaction is carried out among the pyrolysis gasoline material of C7+, the heavy arene hydrogenation and the light arene are in the presence of catalyst, and isomerization reaction is carried out on the light arene into the component rick in BTX light arene; and the liquid-phase is separated into benzene, toluene, xylene and C9+ distillate according to different boiling points, wherein the toluene and the C9+ distillate can be returned for further processing as the feedstock and the light alkane can be separated from gas-phase output, thereby favorably solving the technical problem. The method can be used for the industrial production of light arene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coated zeolite catalysts and use for hydrocarbon conversion

InactiveUS20060011514A1Improve performanceHydrocarbon by isomerisationCatalytic crackingIsomerizationToluene

There is provided a coated zeolite catalyst in which the accessibility of the acid sites on the external surfaces of the zeolite is controlled and a process for converting hydrocarbons utilizing the coated zeolite catalyst. The zeolite catalyst comprises core crystals of a first zeolite and a discontinuous layer of smaller size second crystals of a second zeolite which cover at least a portion of the external surface of the first crystals The coated zeolite catalyst finds particular application in hydrocarbon conversion processes where catalyst activity in combination with zeolite structure are important for reaction selectivity, e.g., catalytic cracking, alkylation, disproportional of toluene, isomerization, and transalkylation reactions.

Owner:EXXONMOBIL CHEM PAT INC

Alkylaromatics production

ActiveUS20070179329A1Hydrocarbon by isomerisationPhysical/chemical process catalystsWater contentAlkyl transfer

A process for alkylation of an alkylatable aromatic compound to produce a monoalkylated aromatic compound, comprising the steps of: (a) providing at least one reaction zone having a water content with at least one catalyst; (b) supplying the reaction zone with at least one alkylatable aromatic compound and at least one alkylating agent; (c) operating the reaction zone under suitable alkylation or transalkylation conditions, to produce at least one effluent which comprises a monoalkylated aromatic compound and a polyalkylated aromatic compound(s); (d) monitoring the amount of the monoalkylated aromatic compound or the amount of the polyalkylated aromatic compound(s) in the effluent; (e) adjusting the water content in the reaction zone to secure a desired amount of the monalkylated aromatic compound or the polyalkylated aromatic compound(s) in the effluent, the water content in the reaction zone being in a range from about 1 wppm to about 900 wppm; and wherein the polyalkylated aromatic compound(s) produced is reduced as compared to the reaction zone having a water content of about 0 wppm when the reaction zone is operated under equivalent conditions.

Owner:EXXONMOBIL CHEM PAT INC

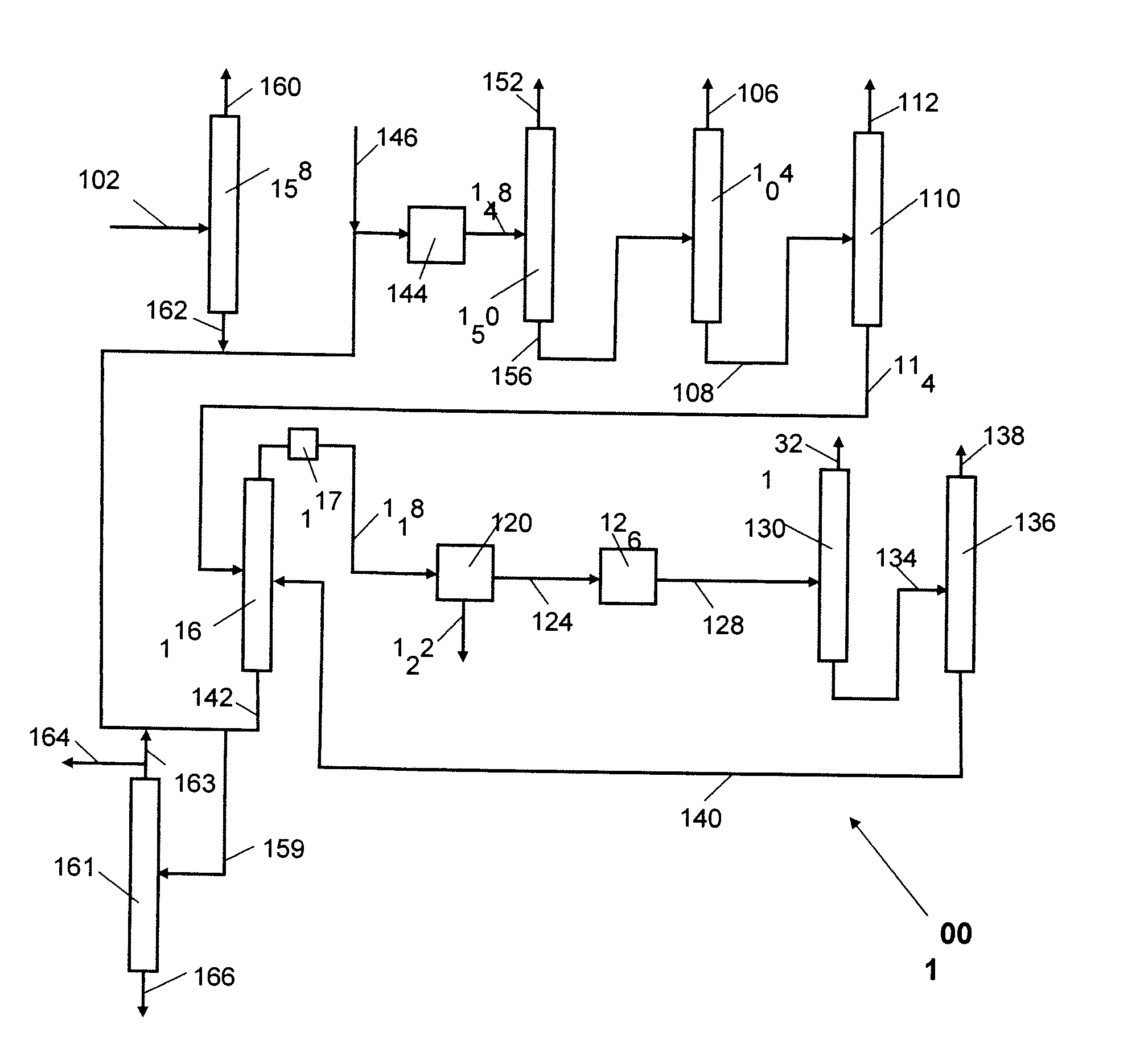

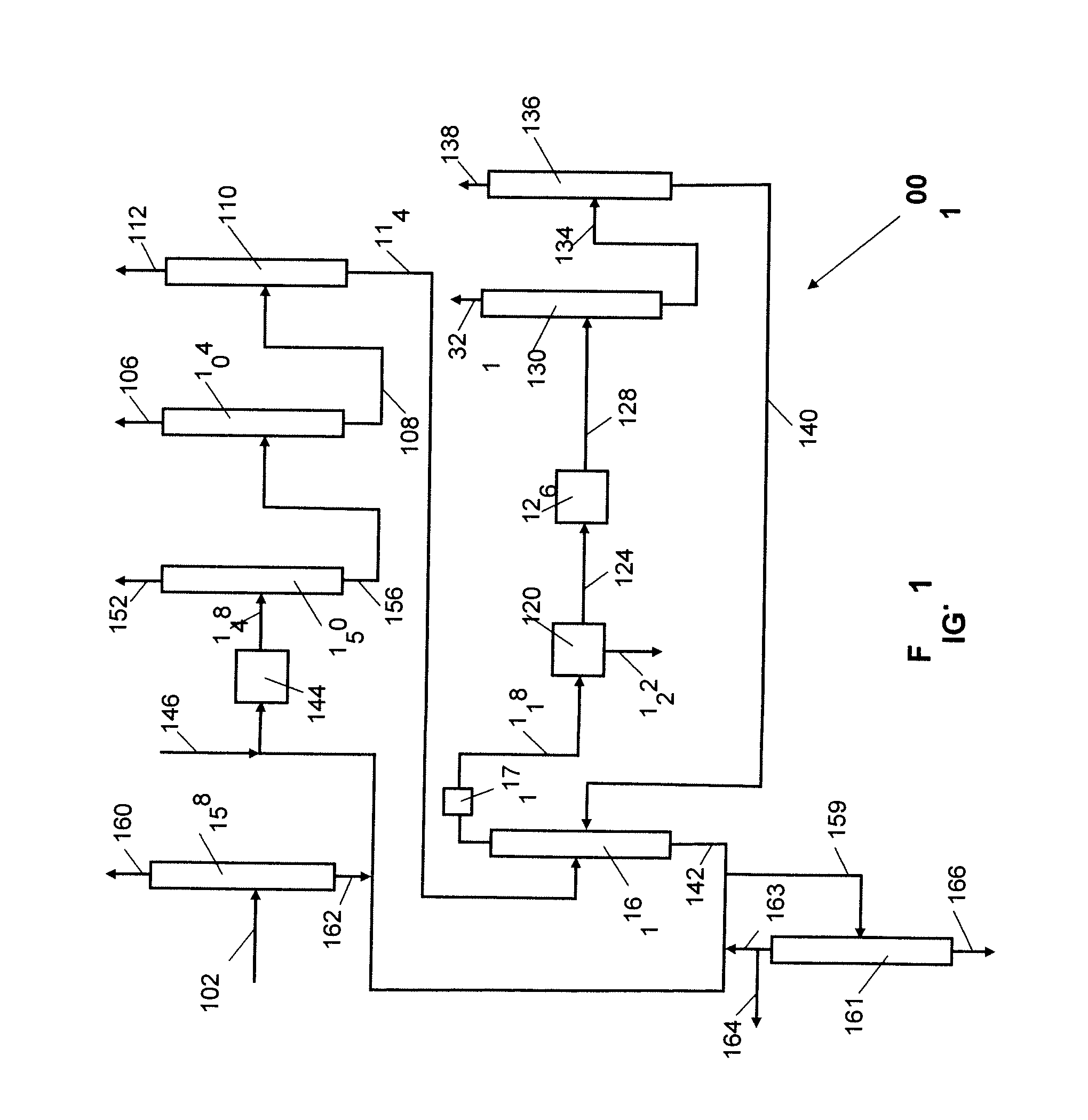

Integrated process yielding xylenes from mixed aromatics

ActiveUS7605295B1Improve concentrationHydrocarbon by isomerisationMolecular sieve catalystHigh activityCoordination complex

The subject invention comprises an aromatics complex to improve yields from a mixed aromatics feed. Through the use of a novel catalyst having higher activity and stability in a transalkylation unit in the complex, a higher xylene yield is obtained.

Owner:UOP LLC

Zeolite catalyst and use for hydrocarbon conversion

InactiveUS6958305B2Improve performanceHydrocarbon by isomerisationCatalytic crackingIsomerizationToluene

There is provided a zeolite bound zeolite catalyst which can be tailored to optimize its performance and a process for converting hydrocarbons utilizing the zeolite bound zeolite catalyst. The zeolite bound zeolite catalyst comprises a first zeolite and a binder comprising a second zeolite. The structure type of the second zeolite is different from the structure type of the first zeolite. The zeolite bound zeolite finds particular application in hydrocarbon conversion process, e.g., catalytic cracking, alkylation, disproportional of toluene, isomerization, and transalkylation reactions.

Owner:EXXONMOBIL CHEM PAT INC

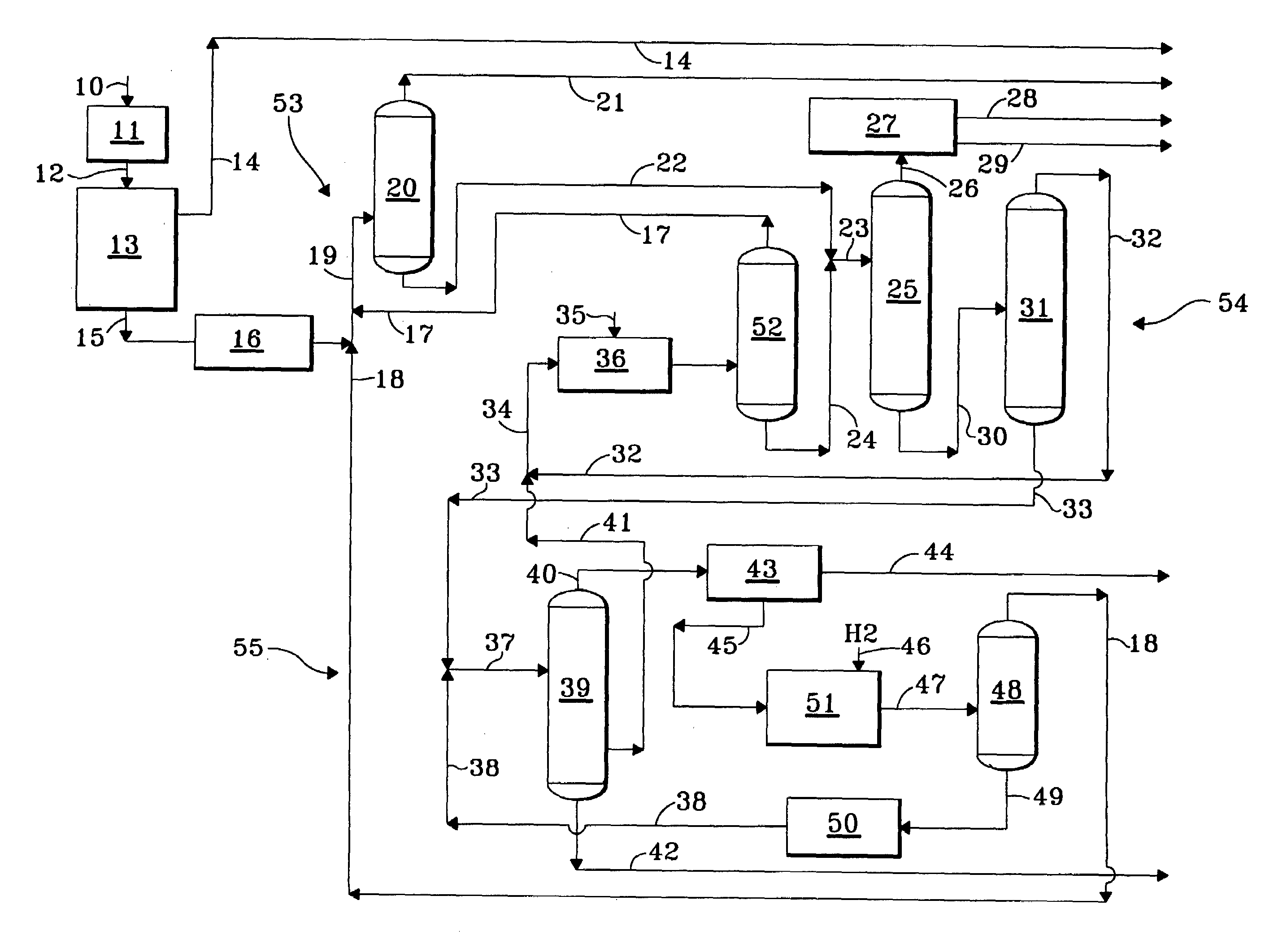

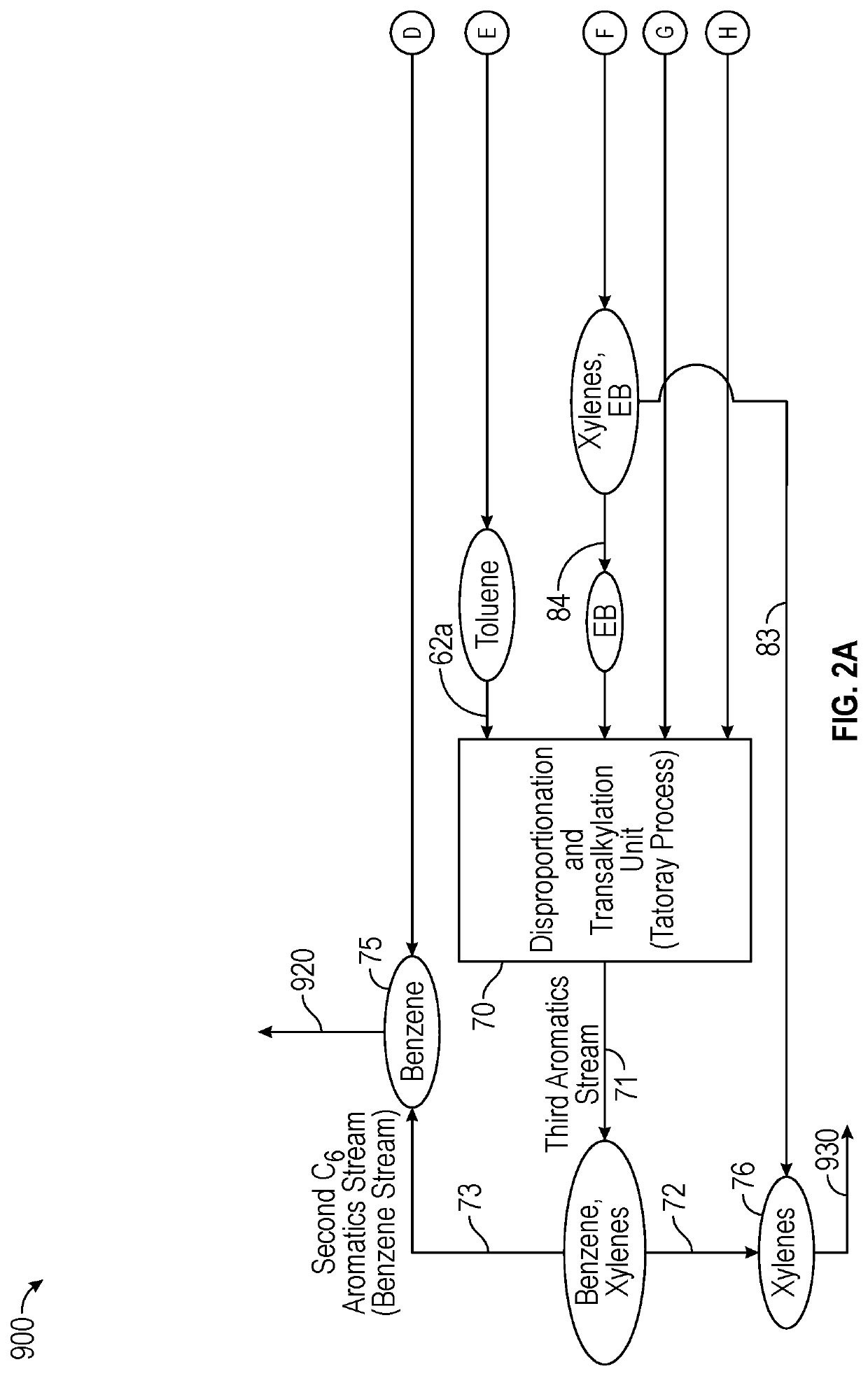

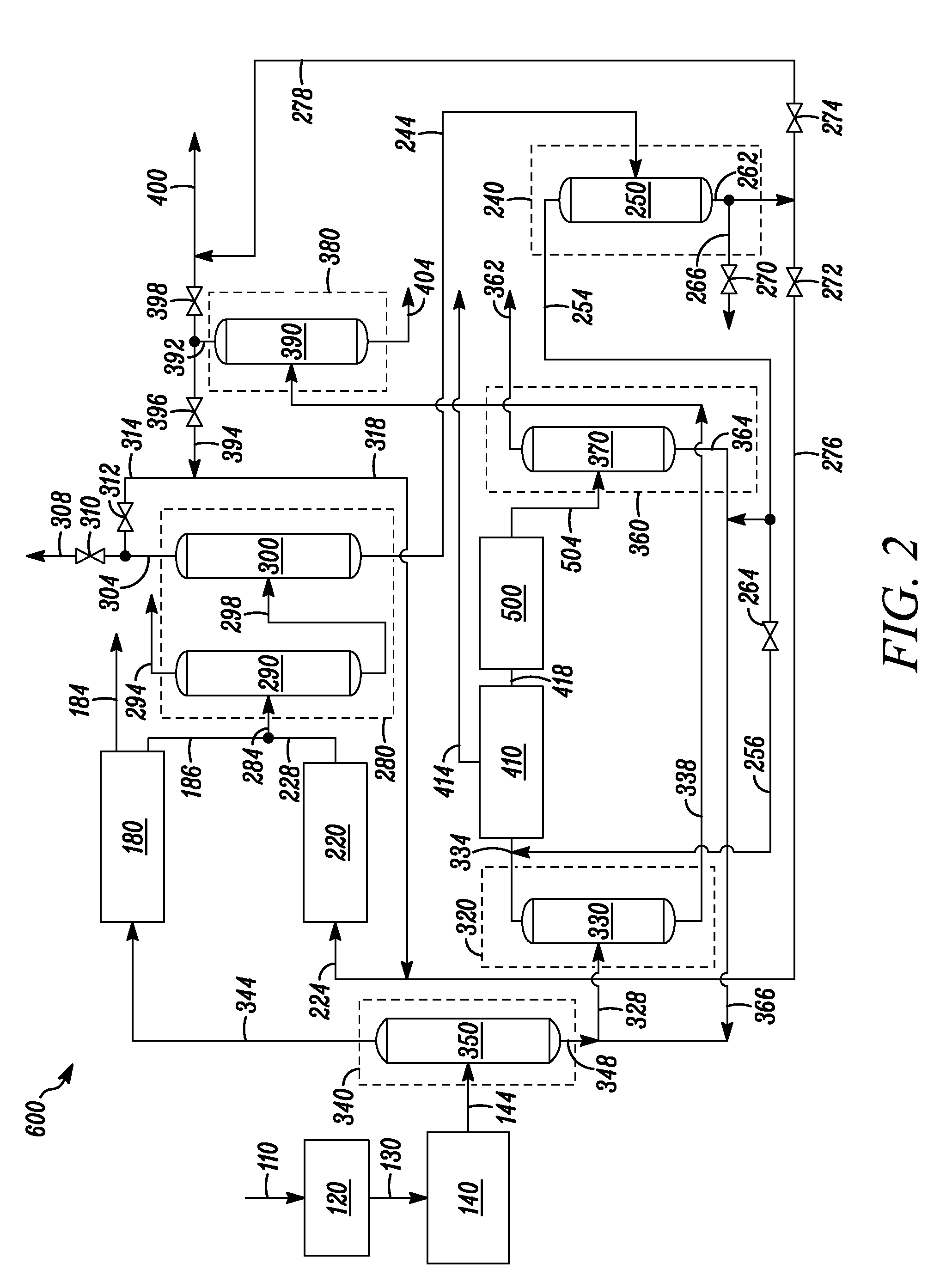

Integrated apparatus for aromatics production

Enabling a transalkylation process to handle both C10 alkylaromatics and unextracted toluene permits the following improvements to be realized. No longer extracting toluene allows a reformate-splitter column to be eliminated. The extraction unit can be moved to the overhead of a benzene column that is also closely integrated with the transalkylation unit. No longer requiring a rigorous split between C9 and C10 alkylaromatics allows a heavy aromatics column to be eliminated. Such an enabled transalkylation process requires stabilization of a transalkylation catalyst through the introduction of a metal function. These improvements result in an aromatics complex apparatus with savings on inside battery limits curve costs and an improvement on the return on investment in such a complex.

Owner:UOP LLC

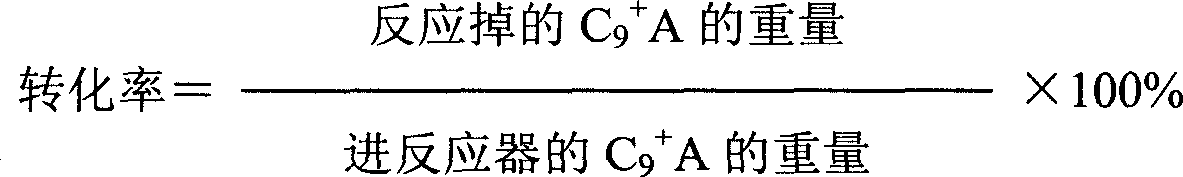

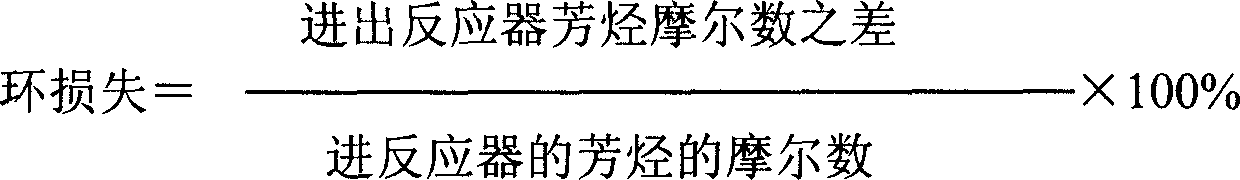

Dealkylation and alkyl-transfering catalyst for C9 or more heavy aromatic hydrocarbons

ActiveCN101045208AImprove conversion rateHigh yieldMolecular sieve catalystsHydrocarbonsHydrogenAromatic hydrocarbon

Owner:CHINA PETROLEUM & CHEM CORP +1

Aromatics transalkylation to ethylbenzene and xylenes

InactiveUS6958425B1Promotes methyl-group species transalkylationObvious advantagesHydrocarbon by isomerisationHydrocarbonsCarbon numberGas phase

The use of transalkylation catalysts to react heavy aromatic compounds of carbon number nine (and heavier carbon numbers) with benzene to form carbon number eight aromatics is disclosed. The catalyst system preserves ethyl-group species on the heavier aromatics that are otherwise de-ethylated over most gas-phase transalkylation catalysts to form undesired ethane gas with benzene or toluene. The catalyst system also promotes methyl-group species transalkylation at selected conditions. Thus, by using the transalkylation system, a greater yield of para-xylene or other carbon number eight aromatics may be achieved overall within an integrated aromatics complex.

Owner:UOP LLC

Process for the Production of Xylenes and Light Olefins from Heavy Aromatics

A method for the transalkylation of a heavy reformate is provided. The heavy reformate is contacted with a transalkylation catalyst and hydrogen gas in a transalkylation reactor to selectively convert the heavy reformate to a xylenes-rich product stream. Light alkanes produced during the reaction can be supplied to a steam cracker where they are converted to light olefins.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS +1

Process for xylene production

A process for the conversion of a hydrocarbon feedstock to produce xylene compounds. The feedstock is selectively hydrocracked and introduced into a transalkylation zone with a hydrocarbonaceous stream rich in benzene, toluene and C9+ hydrocarbons.

Owner:UOP LLC

Production of alkyl aromatic compounds with catalyst reactivation

Improved processes are provided for the production of alkyl aromatic compounds using zeolite catalyst(s) and for periodic reactivation in situ of zeolite catalyst(s) that have at least in part become deactivated. Processes according to this invention are typically carried out in a reaction section loaded with catalyst(s) wherein a desired alkyl aromatic compound is produced from feed aromatic and olefin compounds followed by a separation section in which the desired product is isolated and recovered. Alkylation, transalkylation, and / or isomerization reactions that occur in the reaction section are carried out in liquid phase or partial liquid phase over the said zeolite catalyst(s). At least a portion of the zeolite catalyst(s) employed in the reaction section is (are) reactivated in situ, periodically or when deemed necessary, by contacting the deactivated catalyst(s), at elevated temperature and in the substantial absence of olefin feedstock, with an aromatic stripping stream comprising the feed aromatic compound, the desired alkyl aromatic product, byproducts formed in the process, or mixtures thereof, to restore its (their) activity.

Owner:STONE & WEBSTER PROCESS TECH

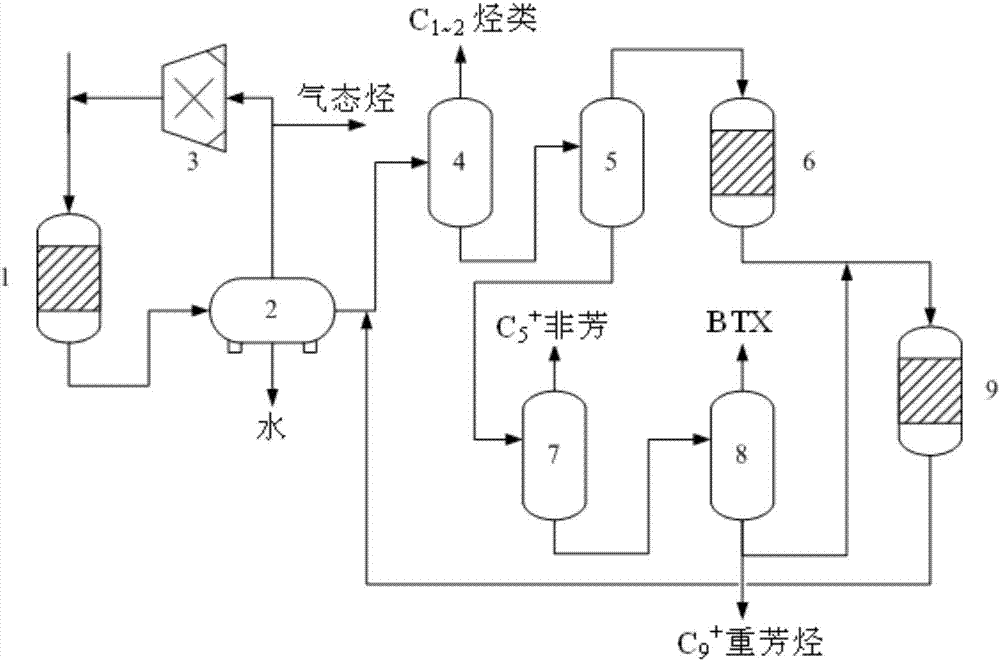

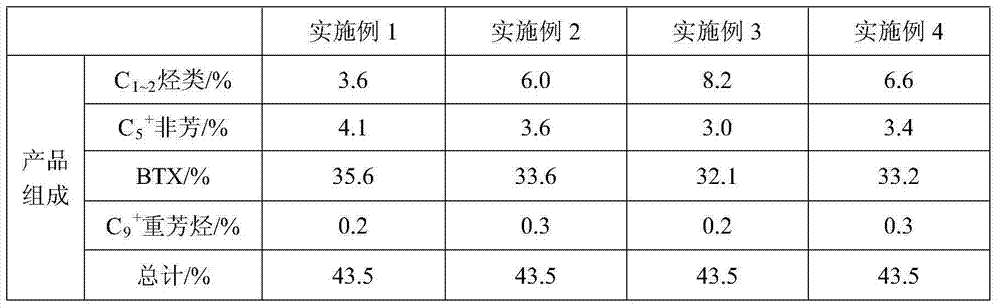

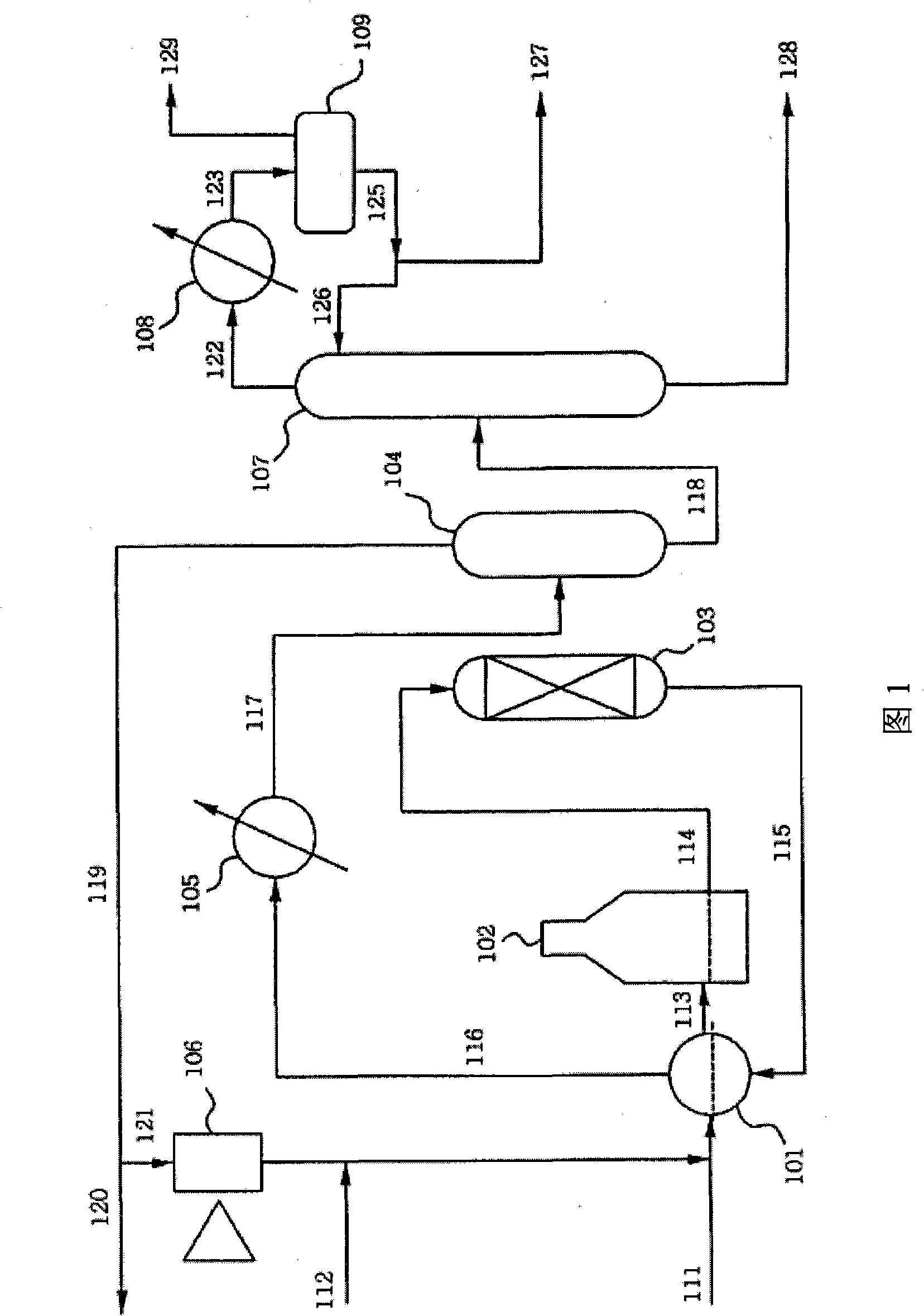

Integrated system and method used for preparing aromatic hydrocarbons from methyl alcohol

ActiveCN103936541AAchieve reuseReduce coking rateHydrocarbon from oxygen organic compoundsHydrocarbonsAlcoholAromatization

The invention belongs to the technical field of aromatic hydrocarbon production, and specifically relates to an integrated system and a method used for preparing aromatic hydrocarbons by taking methyl alcohol as a raw material. The method comprises following steps: methyl alcohol is delivered through an aromatization reactor so as to obtain mixed hydrocarbons rich in aromatic hydrocarbons; the mixed hydrocarbons are separated so as to obtain C1-2 hydrocarbons, C3-4 hydrocarbons, C5+ non-aromatic hydrocarbons, BTX, and C9+ heavy aromatic hydrocarbons; C1-2 hydrocarbons, C5+ non-aromatic hydrocarbons and BTX are discharged as products, C3-4 hydrocarbons are subjected to aromatization for a second time, an obtained material is directly mixed with C9+ heavy aromatic hydrocarbons, and an obtained mixture is taken as a raw material and is delivered into an alkyl transfer reactor; an obtained reaction product is delivered back to a separation tower, and a less amount of C9+ heavy aromatic hydrocarbons is discharged via rectifying tower bottom pipelines. The invention also discloses the integrated system used for preparing aromatic hydrocarbons by taking methyl alcohol as the raw material. According to the method, methyl alcohol aromatization, liquefied gas aromatization, and heavy aromatic hydrocarbon lightening are combined, so that recycle of liquefied gas and recycle of heavy aromatic hydrocarbons are realized, cost and energy consumption are saved, catalyst service cycle is prolonged, and BTX yield is increased greatly.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method and Catalyst for the Transalkylation/Dealkylation of Organic Compounds

InactiveUS20080021253A1Improve catalytic selectivityMaximize productionHydrocarbon by isomerisationMolecular sieve catalystsCatalytic methodCrystal structure

The invention relates to a catalytic method for the transalkylation / dealkylation of organic compounds, consisting in bringing a supply comprising organic compounds into contact with a catalyst containing a first zeolitic component that is selected from among: a) one or more zeolites having crystalline structure ITQ-13; b) one or more zeolites having crystalline structure ITQ-13, which are modified either by means of selectivation or with the incorporation of one or more metals, or both; and c) a mixture of a) and b). The invention also relates to a catalyst comprising one or more modified zeolites having crystalline structure ITQ-13.

Owner:CORMA CANOS AVELINO +3

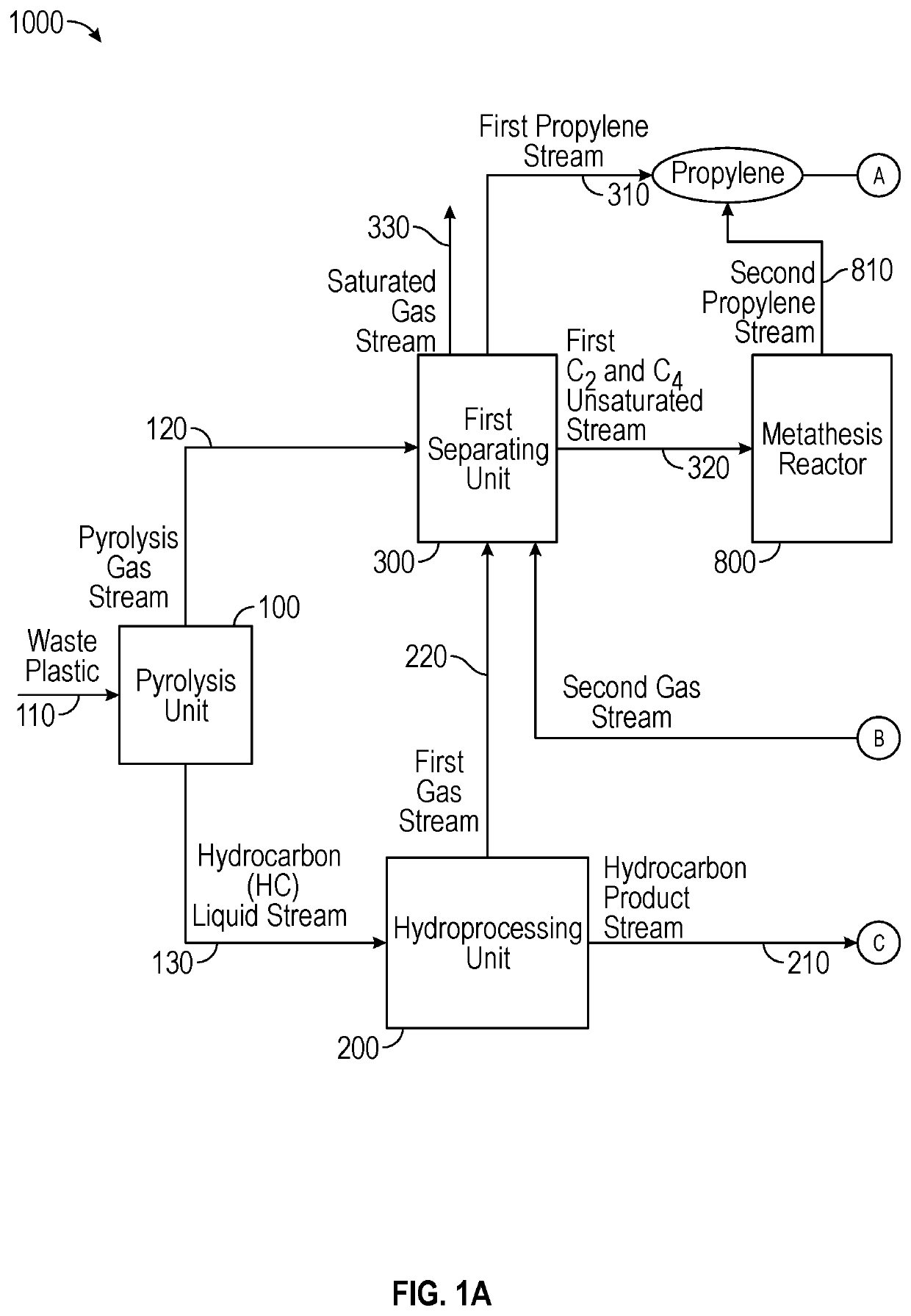

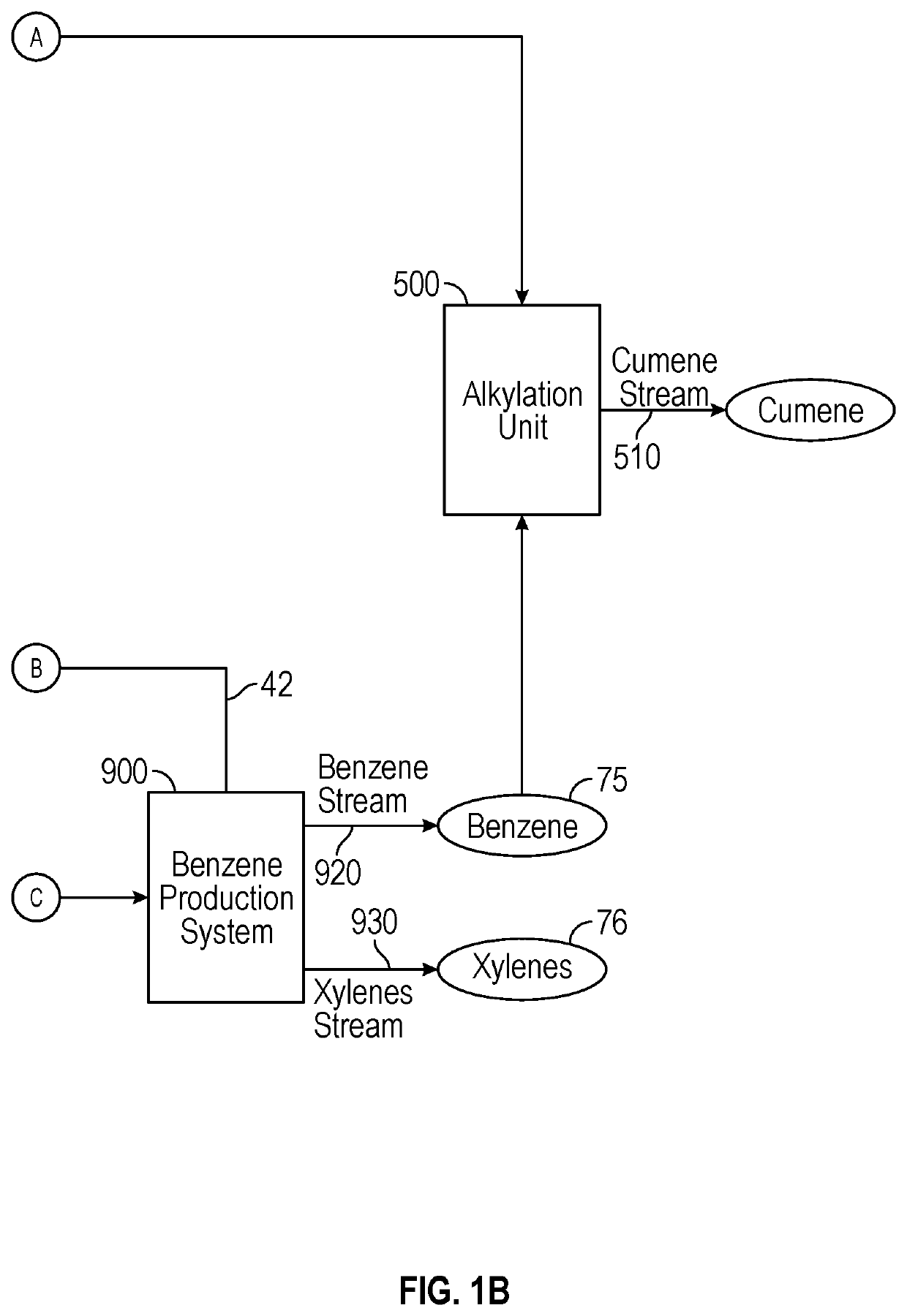

Conversion of waste plastic to propylene and cumene

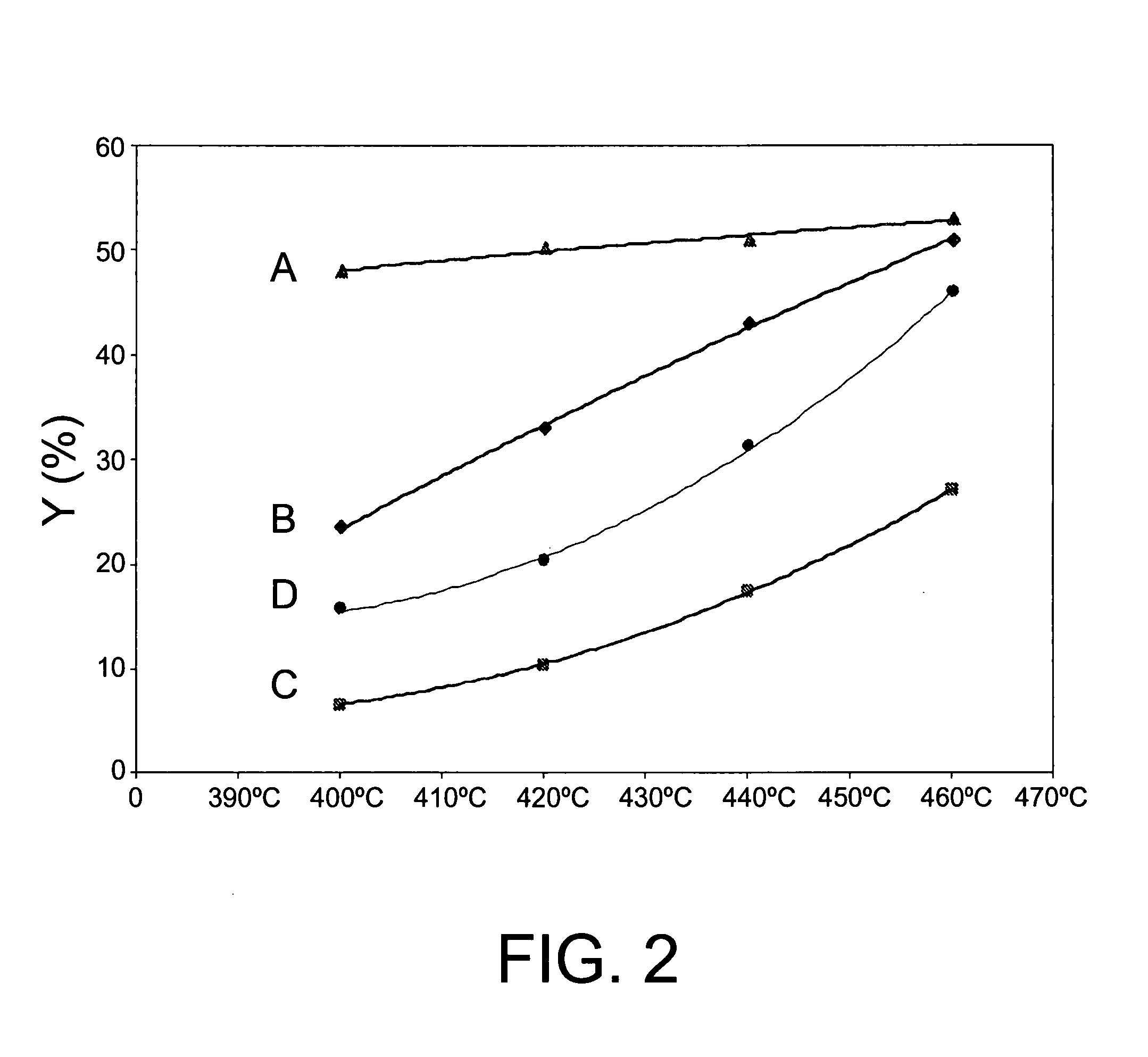

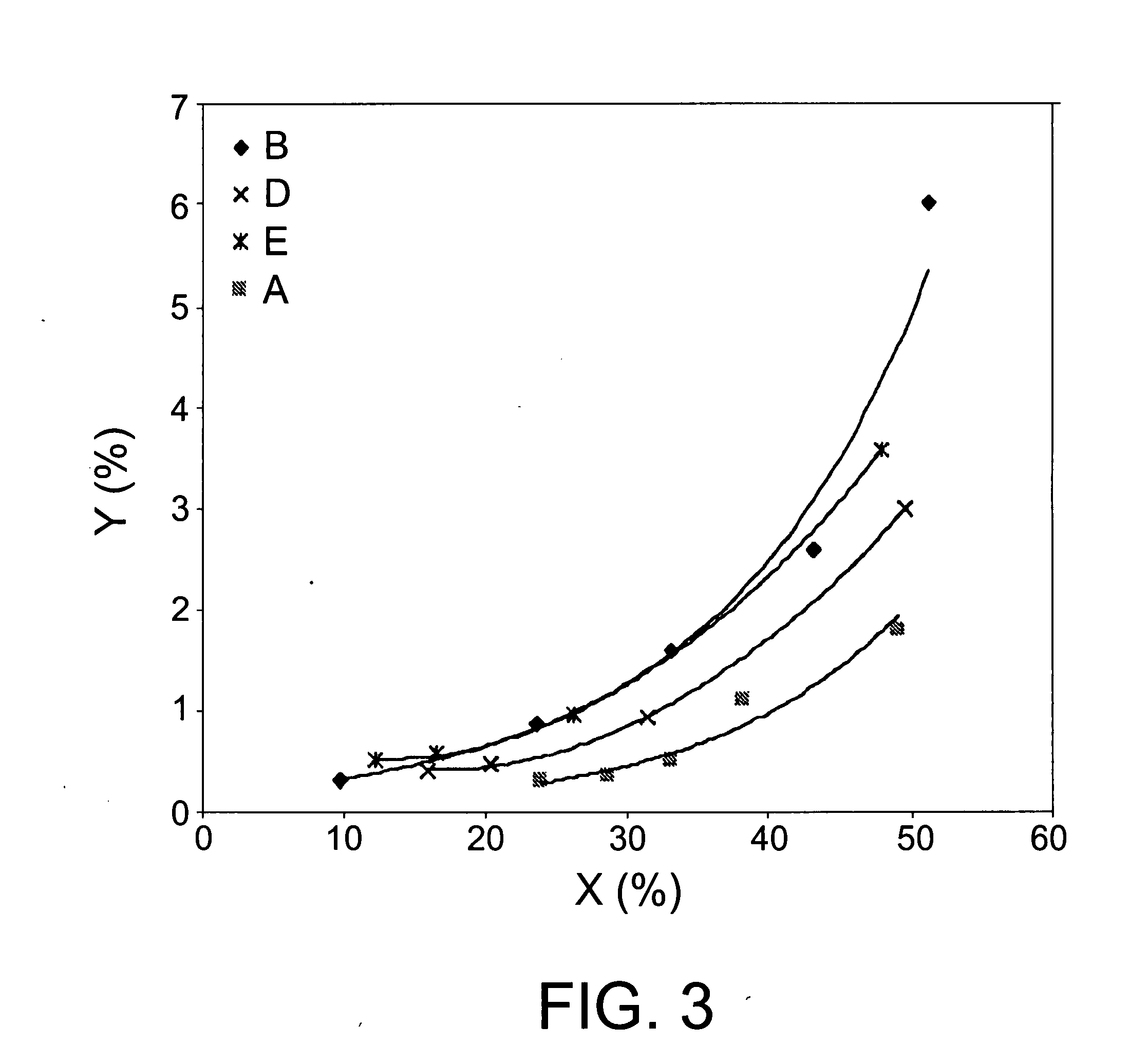

A process for producing cumene comprising converting plastics to hydrocarbon liquid and pyrolysis gas; feeding hydrocarbon liquid to hydroprocessor to yield hydrocarbon product and first gas stream; feeding hydrocarbon product to reforming unit to produce reforming product, second gas stream, and hydrogen; separating reforming product into non-aromatics recycle stream and second aromatics stream (C6+ aromatics); recycling non-aromatics recycle stream to reforming unit; separating second aromatics stream into benzene, C7, C8, C9, C10, and C11+ aromatics; contacting C7, C9, and / or C10 aromatics with a disproportionation&transalkylation catalyst / H2 to yield benzene&xylenes; conveying C11+ aromatics to hydroprocessor; introducing pyrolysis gas, first and / or second gas stream to first separator to produce first propylene stream, first C2&C4 unsaturated stream, and saturated gas (H2 and C1-4 saturated hydrocarbons); introducing first C2&C4 unsaturated stream to metathesis reactor to produce second propylene stream; and feeding benzene, and first and / or second propylene stream to alkylation unit to produce cumene.

Owner:SABIC GLOBAL TECH BV

Aromatic production apparatus

InactiveUS7727490B2Provide in manufacturingIncrease productionHydrocarbon by isomerisationHydrocarbon from carbon oxidesFractionationXylene

Owner:UOP LLC

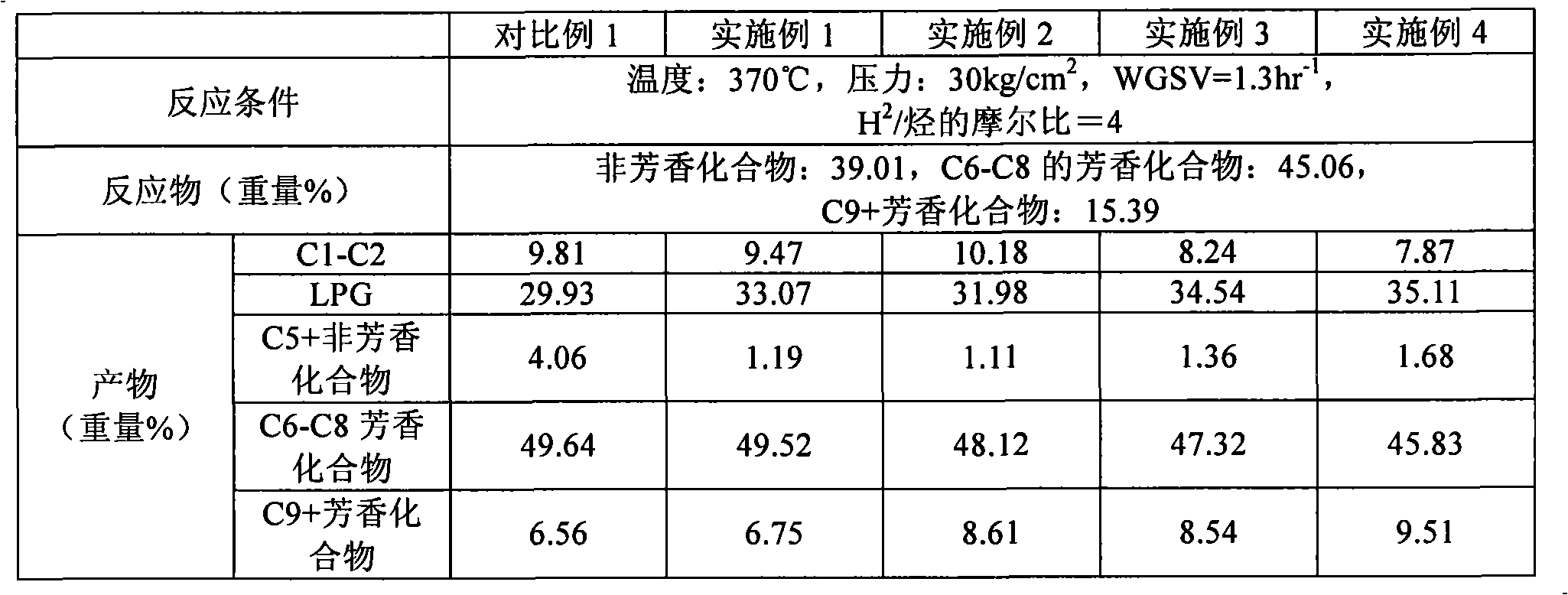

Process of preparing aromatic hydrocarbons and liquefied petroleum gas from hydrocarbon mixture

InactiveCN101305078AHigh purityPromote value-addedCatalytic naphtha reformingHydrocarbon oil crackingLiquid productHydrocarbon mixtures

Disclosed is a process of preparing aromatic hydrocarbons and liquefied petroleum gas (LPG) from a hydrocarbon mixture, in which a non-aromatic compound in the hydrocarbon feedstock mixture is converted into a gaseous material having a large amount of LPG through hydrocracking, and an aromatic compound therein is converted into an oil component having large amounts of benzene, toluene, and xylene (BTX) through dealkylation and transalkylation, in the presence of a catalyst obtained by supporting platinum / bismuth onto a mixture support having zeolite and an inorganic binder. The gaseous product is separated into LPG and a mixture of methane and ethane depending on differences in boiling point through distillation, while the liquid product is separated into benzene, toluene, xylene, and C9+ aromatic compounds depending on differences in boiling point through distillation.

Owner:SK ENERGY CO LTD (KR)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com