Patents

Literature

113results about How to "Reduce coking rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

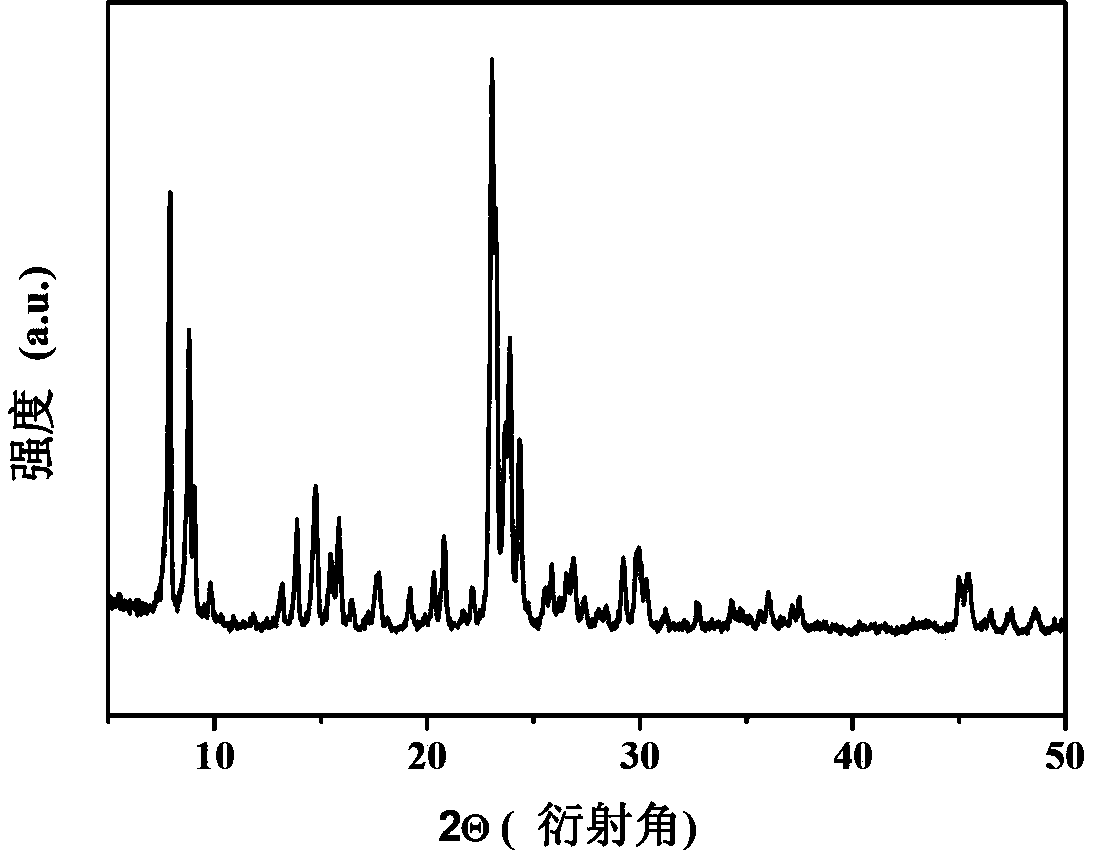

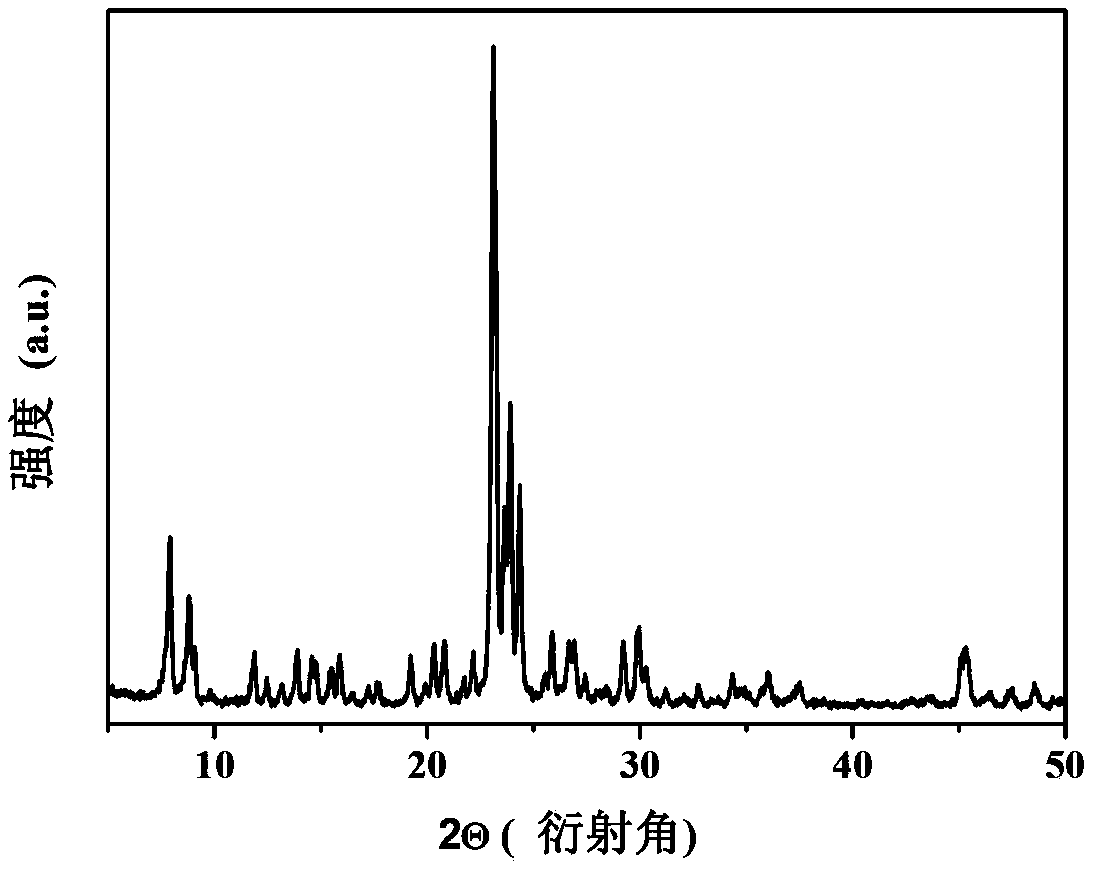

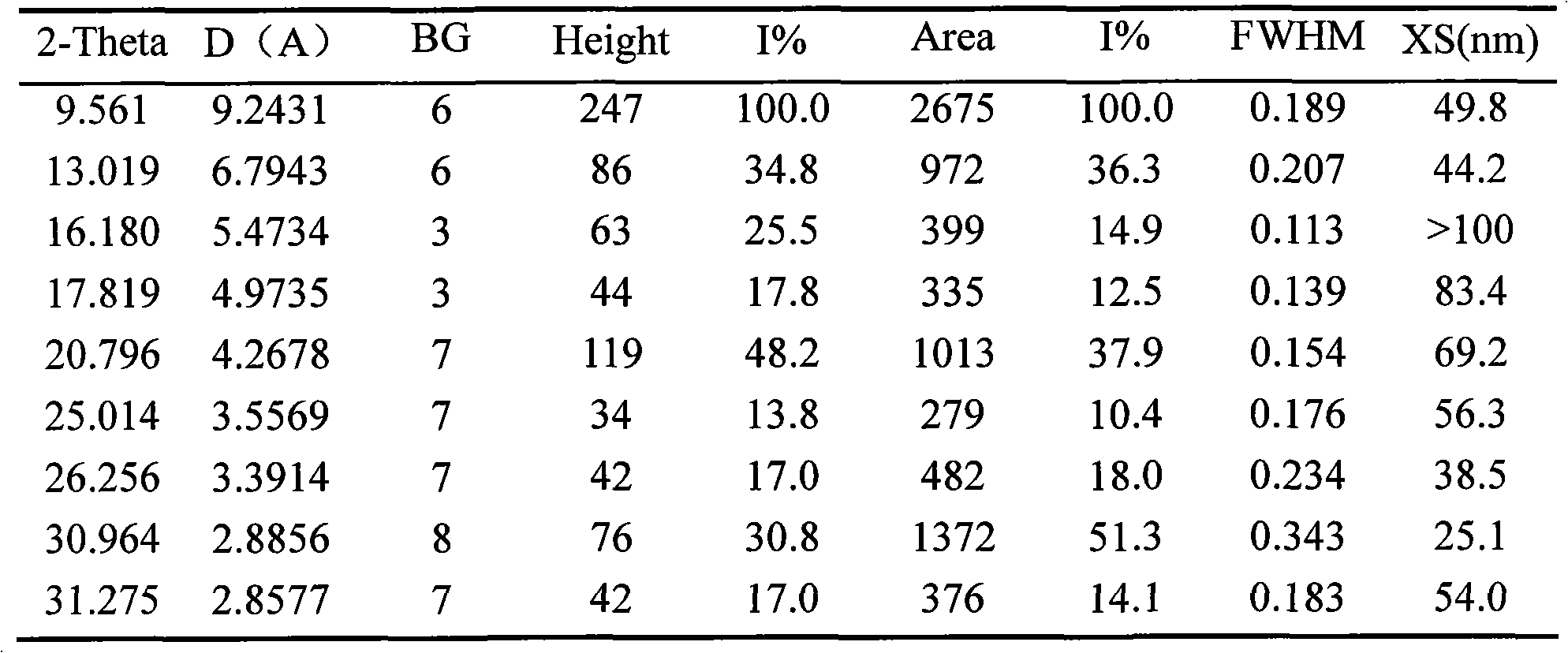

Nano ZSM-5 molecular sieve based catalyst and preparation and use methods

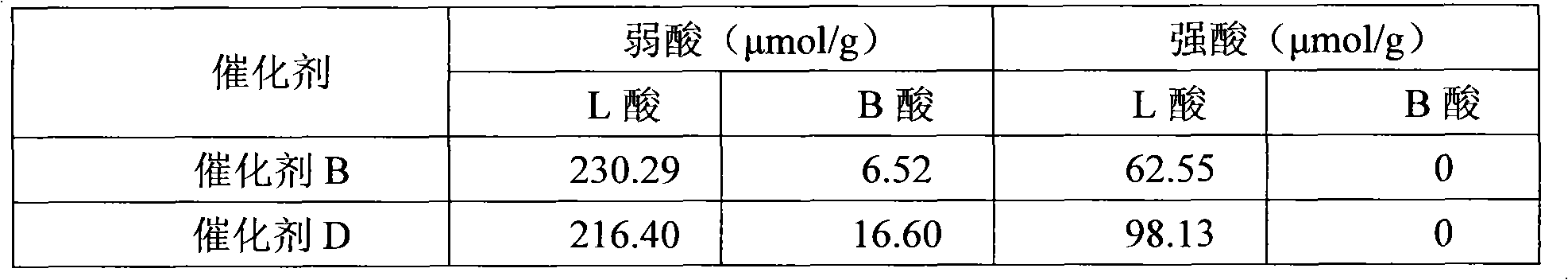

ActiveCN104941695AShorten the diffusion pathEasy to spreadMolecular sieve catalystsHydrocarbon from oxygen organic compoundsStrong acidsZSM-5

The invention discloses a nano ZSM-5 molecular sieve based catalyst and preparation and use methods. The molecular sieve catalyst consists of molecular sieves and metal components, wherein the molecular sieves are nano ZSM-5 molecular sieves with a short b-axis, a medium high silica-alumina ratio, less strong acid, high Lewis acid content, and resistance to hydrothermal deactivation. The preparation method is as follows: mixing a silicon source, an aluminum source, a template agent, a structure promoter, an additive and alkali with water, and stirring to prepare a precursor solution, then crystallizing, separating solid from liquid, and calcinating to obtain molecular sieve raw powder; mixing the molecular sieve raw powder with an ammonium salt solution, stirring, filtering, mixing with the ammonium salt solution for several times, stirring, filtering, and calcinating to obtain hydrogen-type ZSM-5 molecular sieves; mixing with the metal precursor solution, drying and calcinating to obtain the aromatization catalyst. The use method is as follows: transforming oxy-compound raw materials to aromatic hydrocarbon through the catalyst under the reaction conditions. The nano ZSM-5 molecular sieve based catalyst has the characteristics of being high in aromatics yield (reaching up to 99%) and long in service life (the catalyst is alive after 300 hours, and the aromatics selectivity reaches up to 70% after the catalyst is subjected to hydrothermal aging at 760 DEG C for 4 hours).

Owner:TSINGHUA UNIV

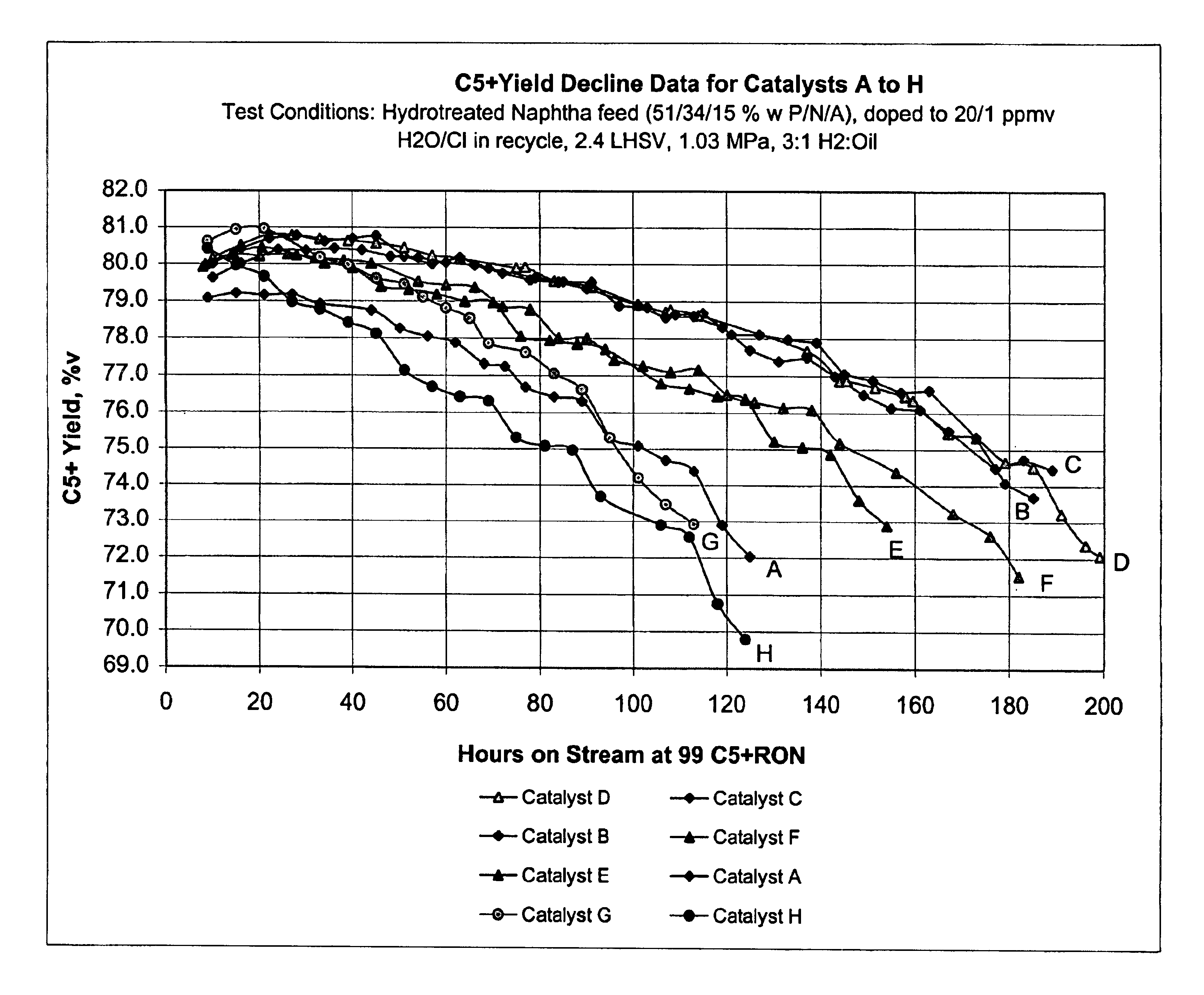

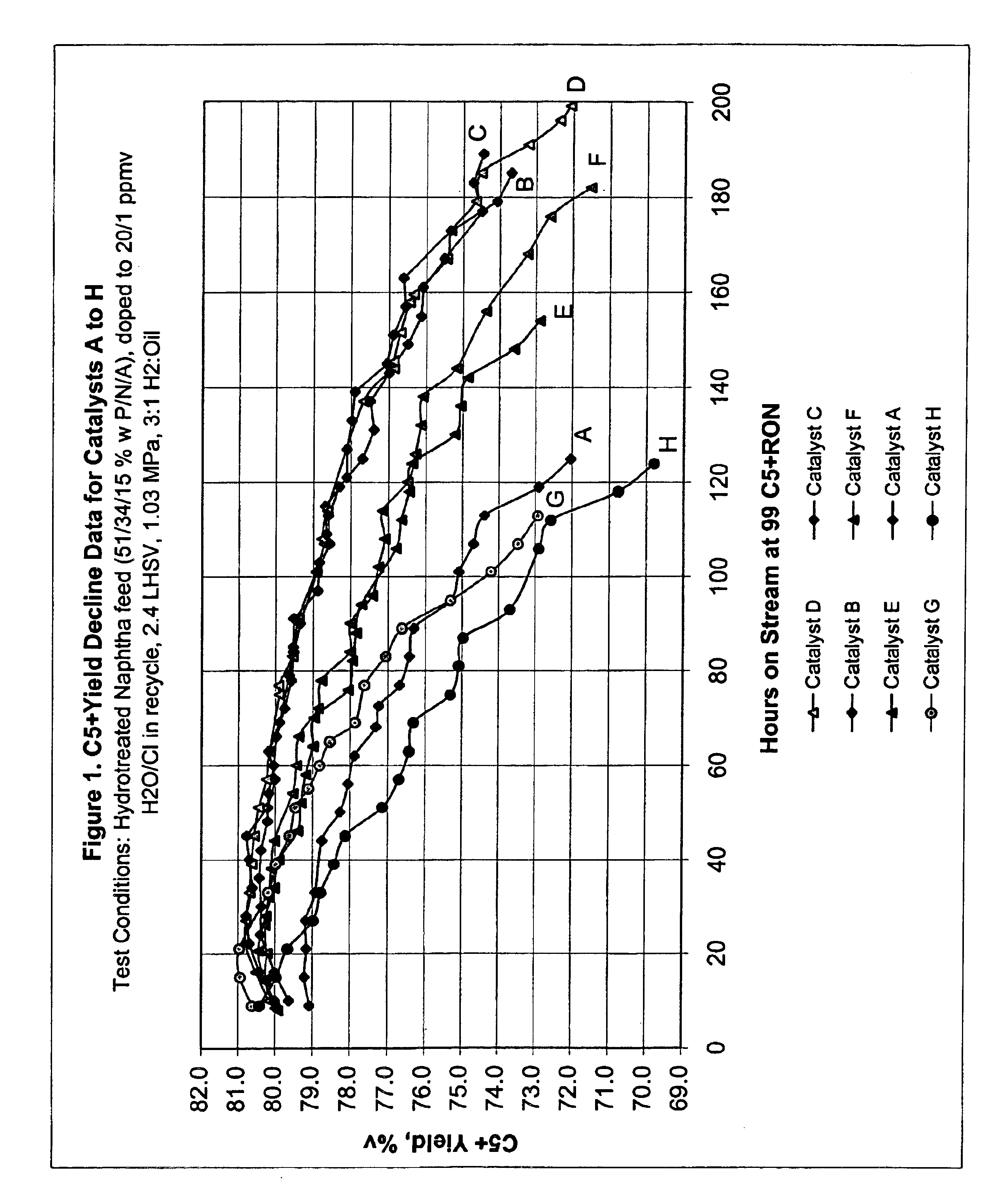

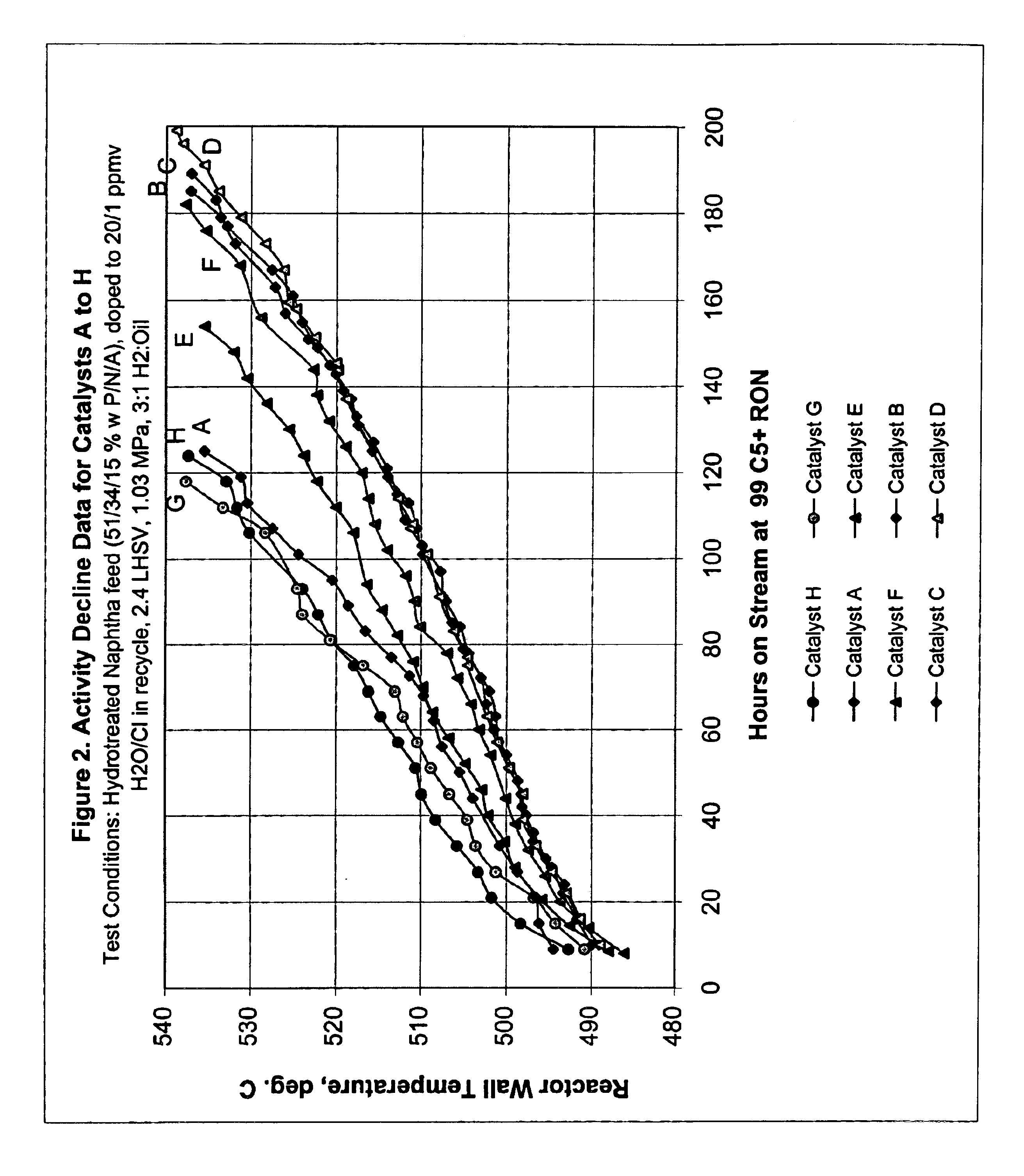

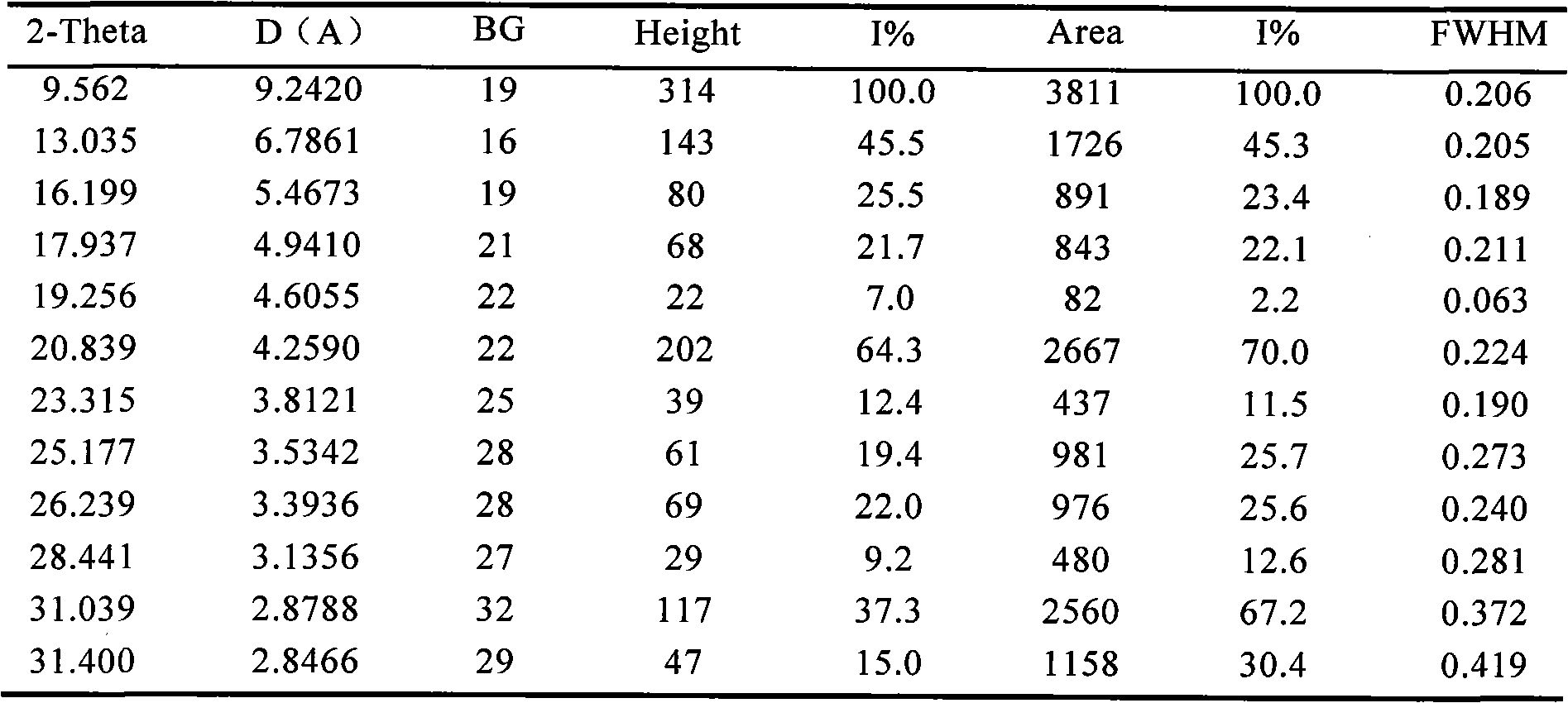

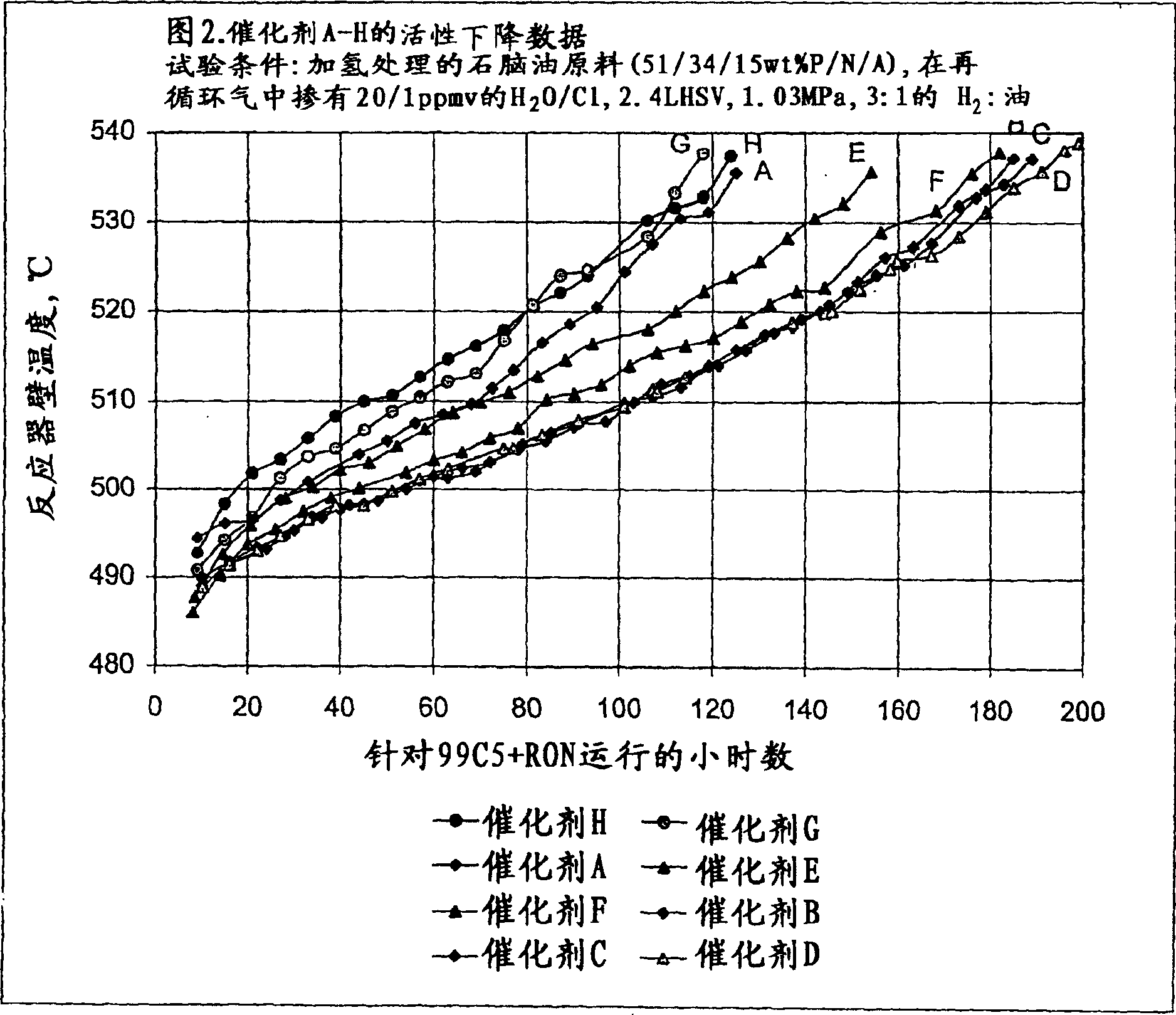

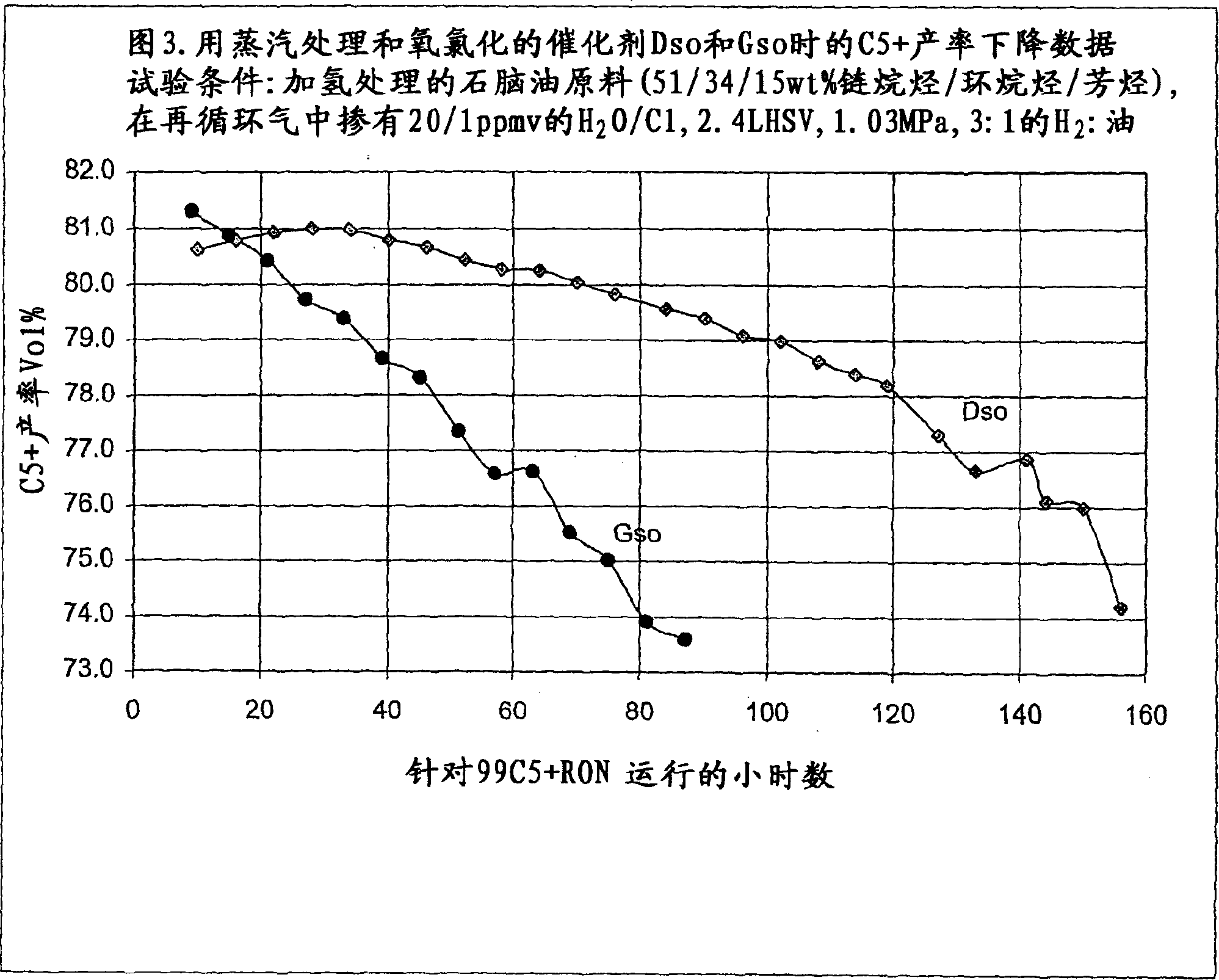

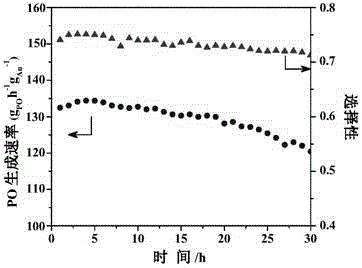

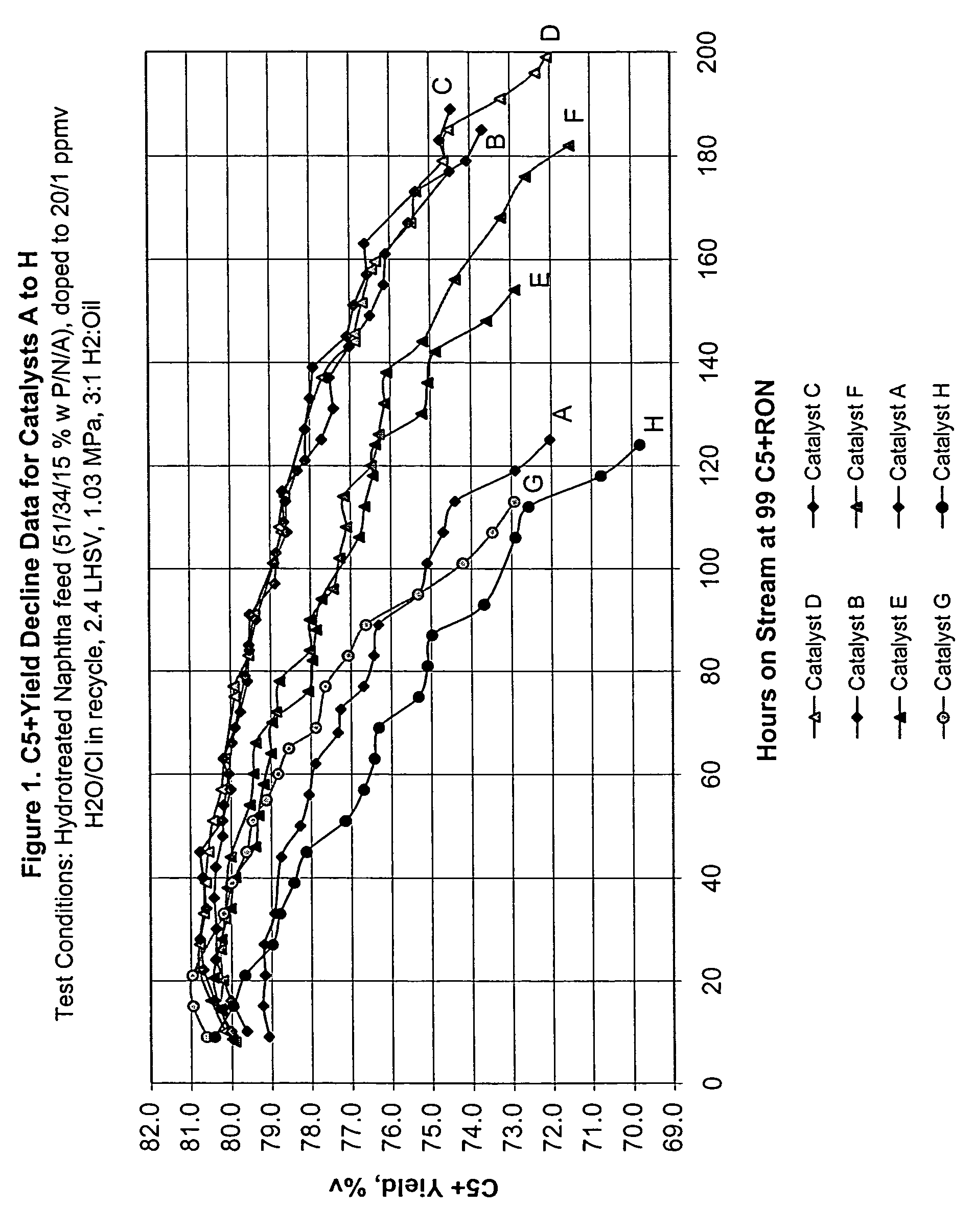

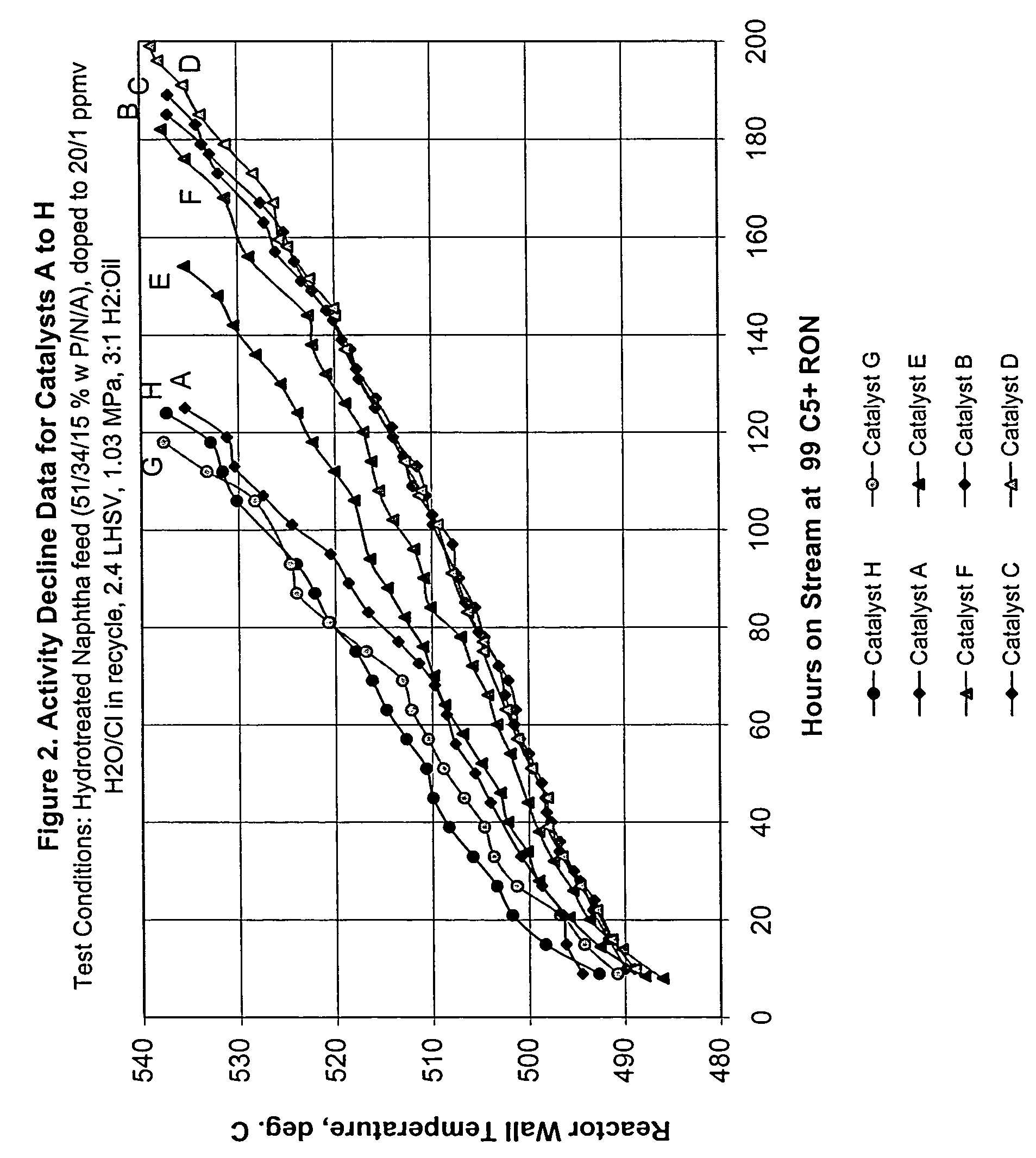

Bismuth- and phosphorus-containing reforming catalysts, method of making and naphtha reforming process

InactiveUS6864212B2Improve octaneReduce coking rateCatalyst carriersOther chemical processesNaphthaEngineering

Bismuth- and phosphorus-containing naphtha reforming catalysts, methods of making such catalysts, and a naphtha reforming process using such catalysts.

Owner:INST FR DU PETROLE

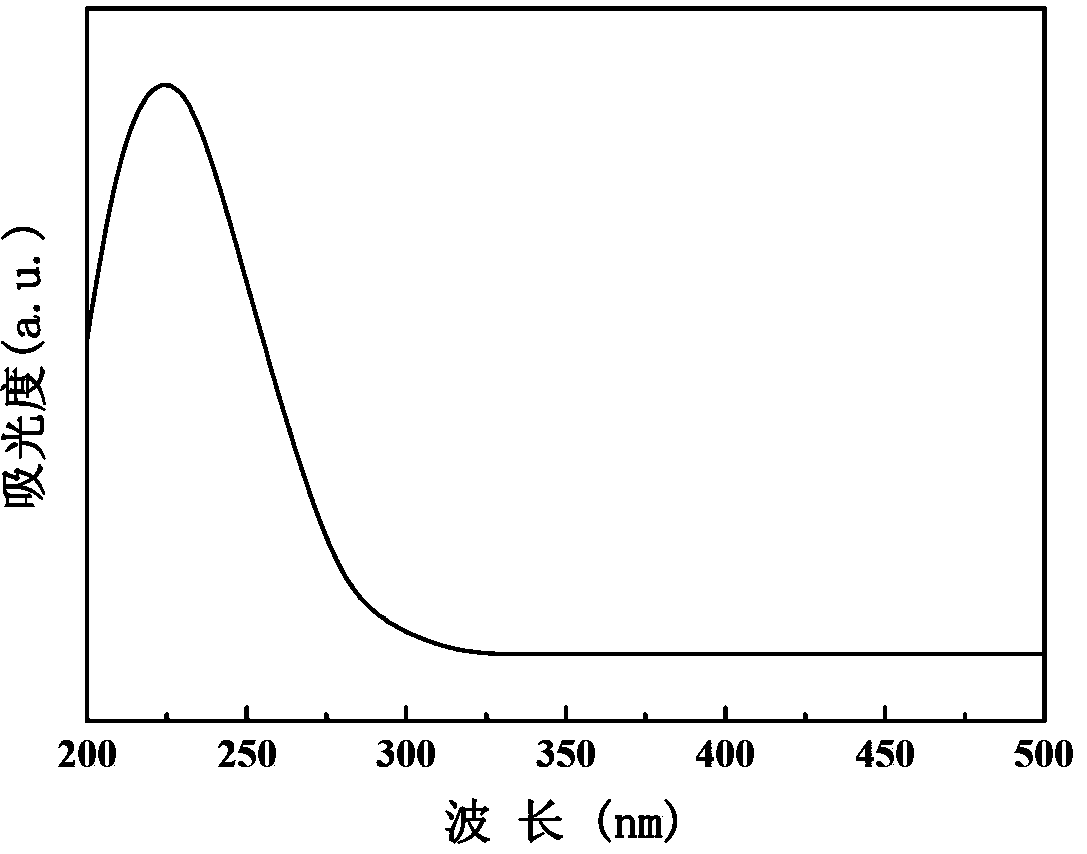

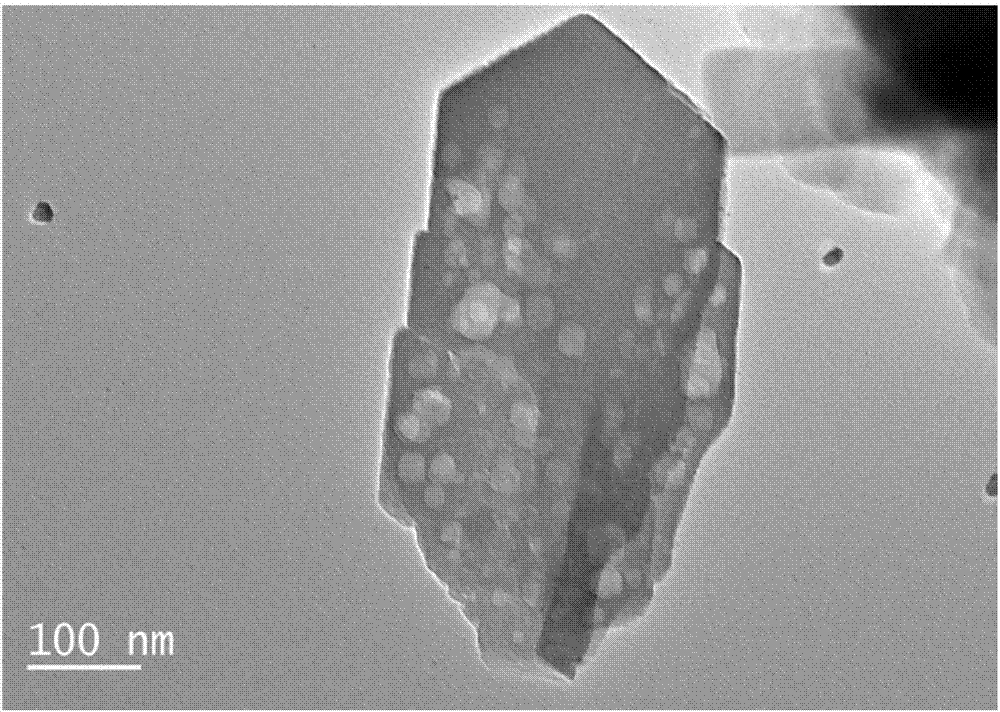

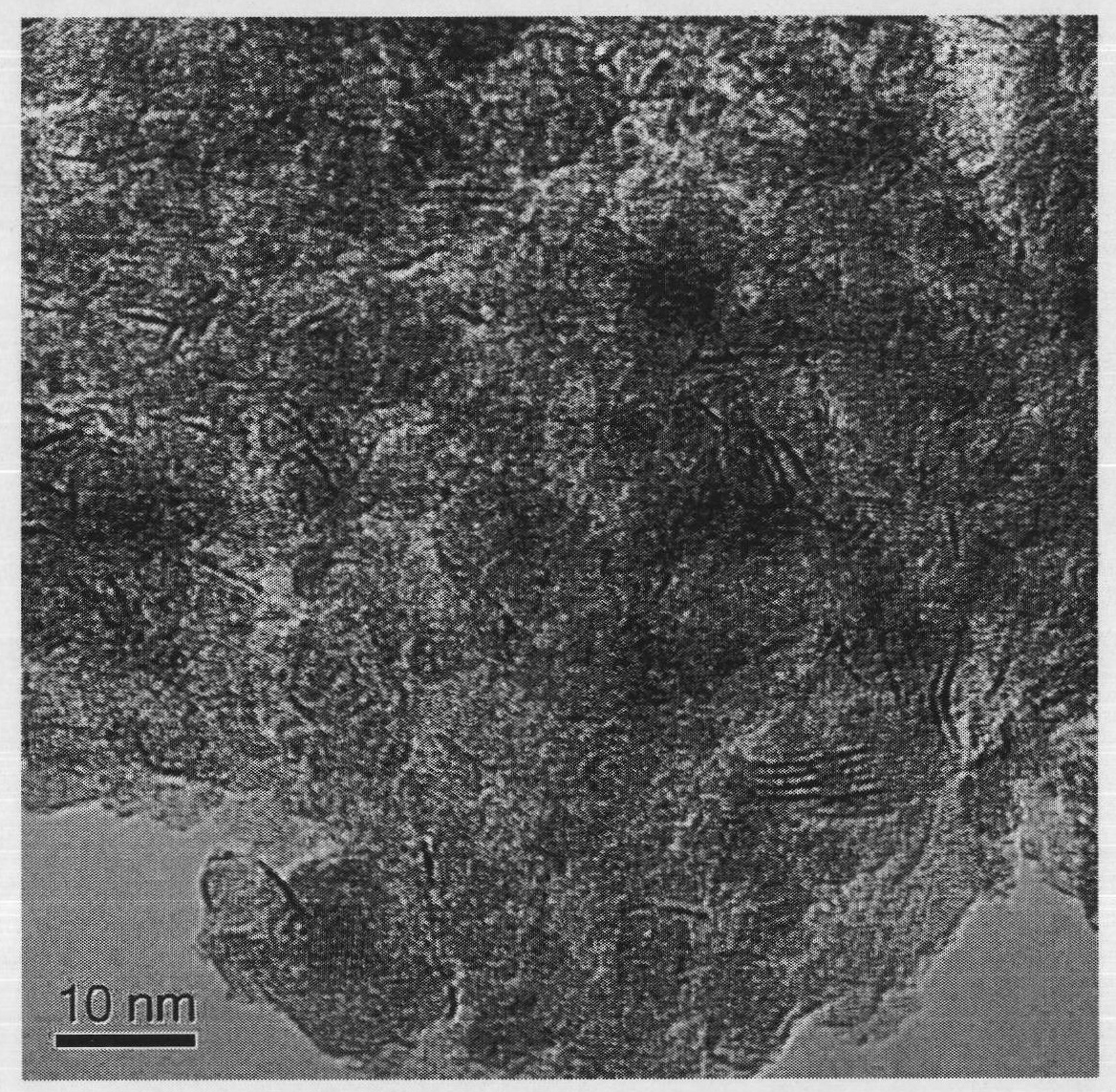

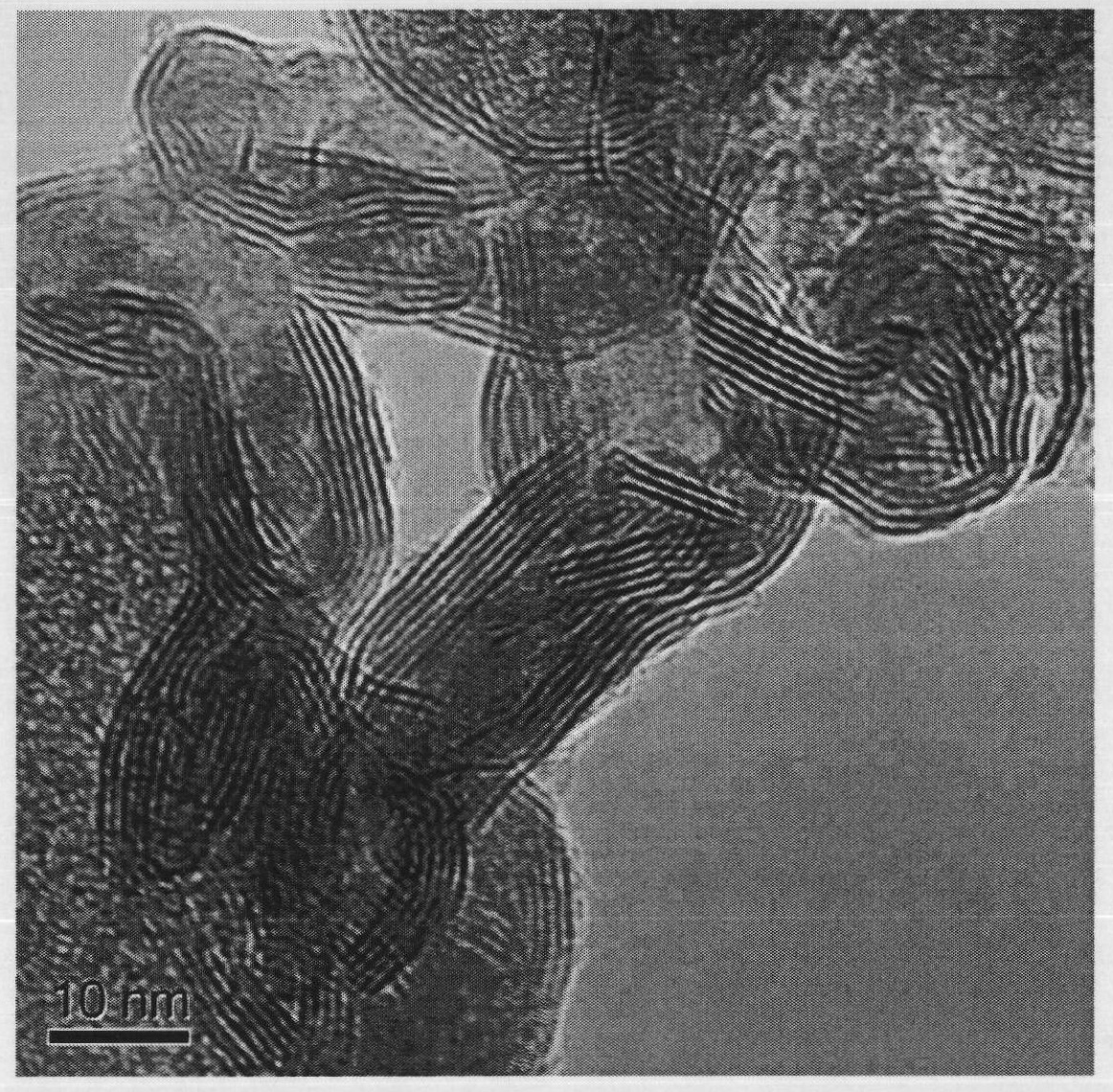

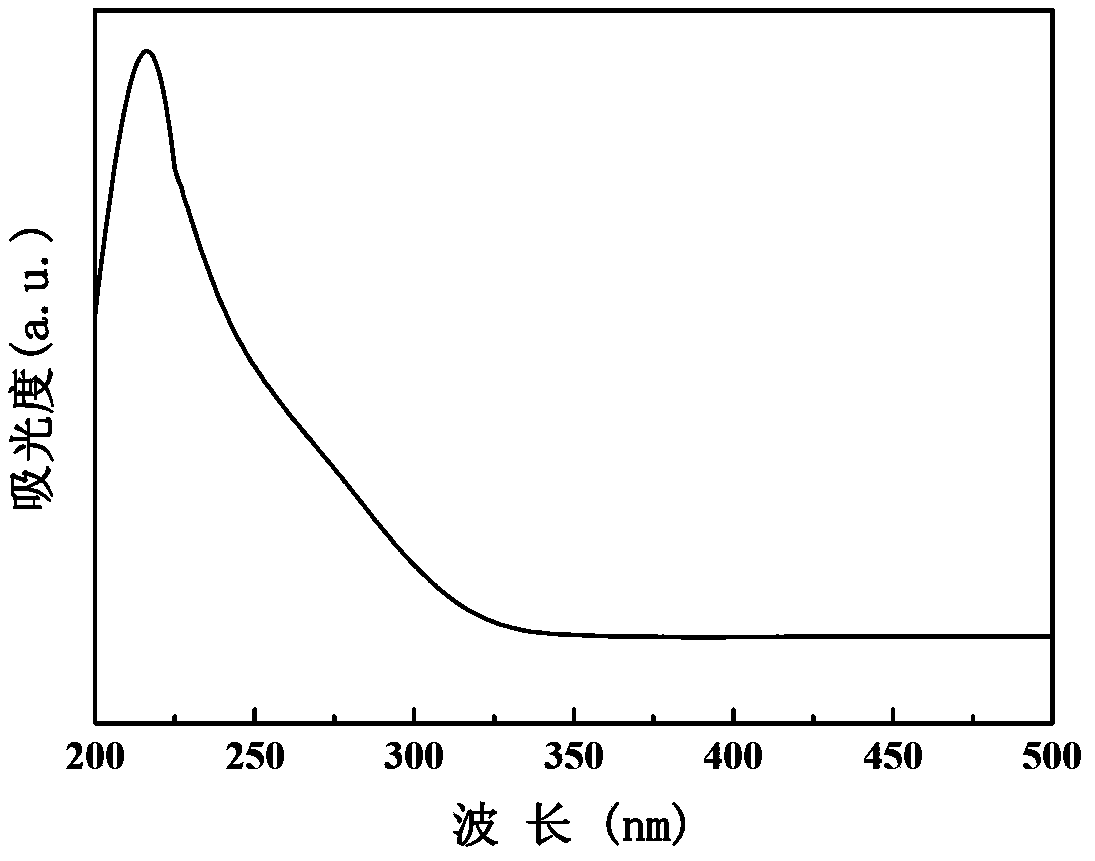

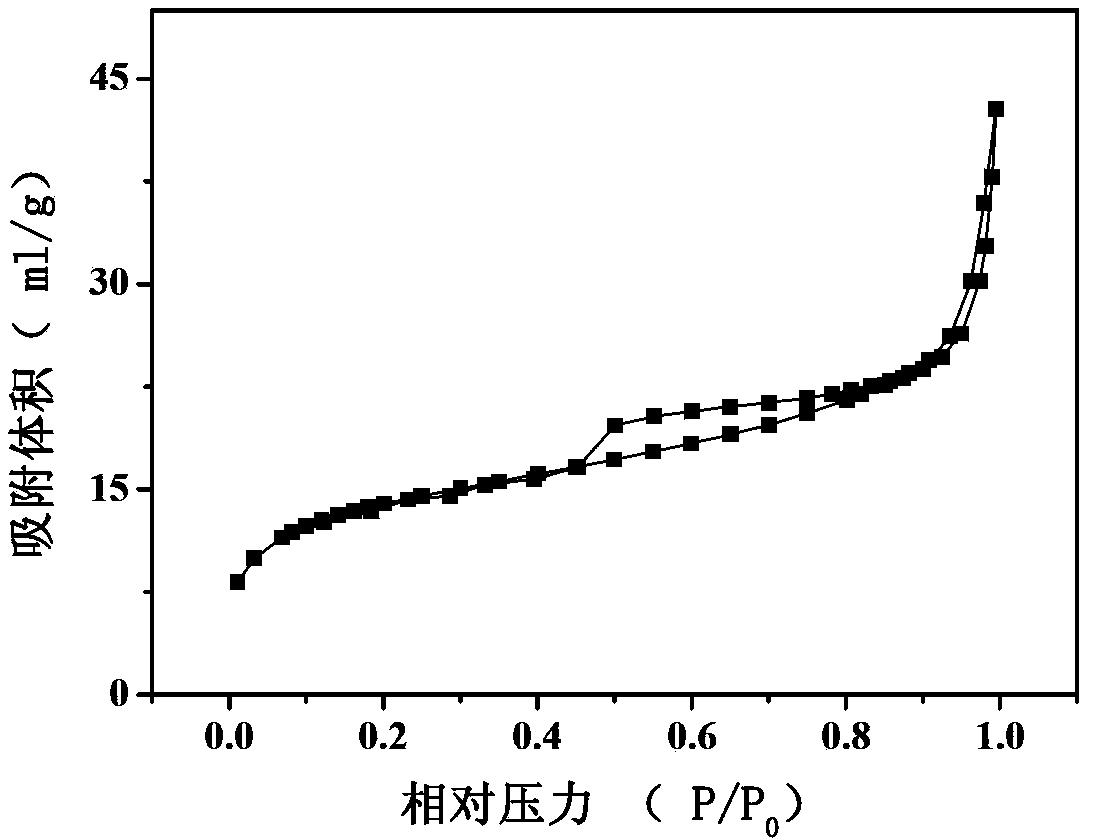

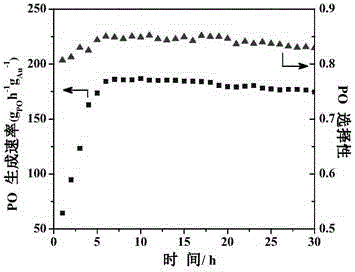

Mesoporous titanium-silicon molecular sieve, and preparation method and application thereof

ActiveCN103357432AReduced Diffusion ResistanceFacilitated DiffusionOrganic chemistryMolecular sieve catalystsMolecular sieveGas phase

The invention discloses a mesoporous titanium-silicon molecular sieve, and a preparation method and application thereof. The titanium-silicon molecular sieve is a mesoporous nano titanium-silicon molecular sieve TS-1. The invention also discloses a novel catalyst for preparing an epoxy propane system through direct gas-phase epoxidation of propylene. Metal particles are loaded on the catalyst by taking the mesoporous nano titanium-silicon molecular sieve TS-1 provided by the invention as a supporter.

Owner:EAST CHINA UNIV OF SCI & TECH

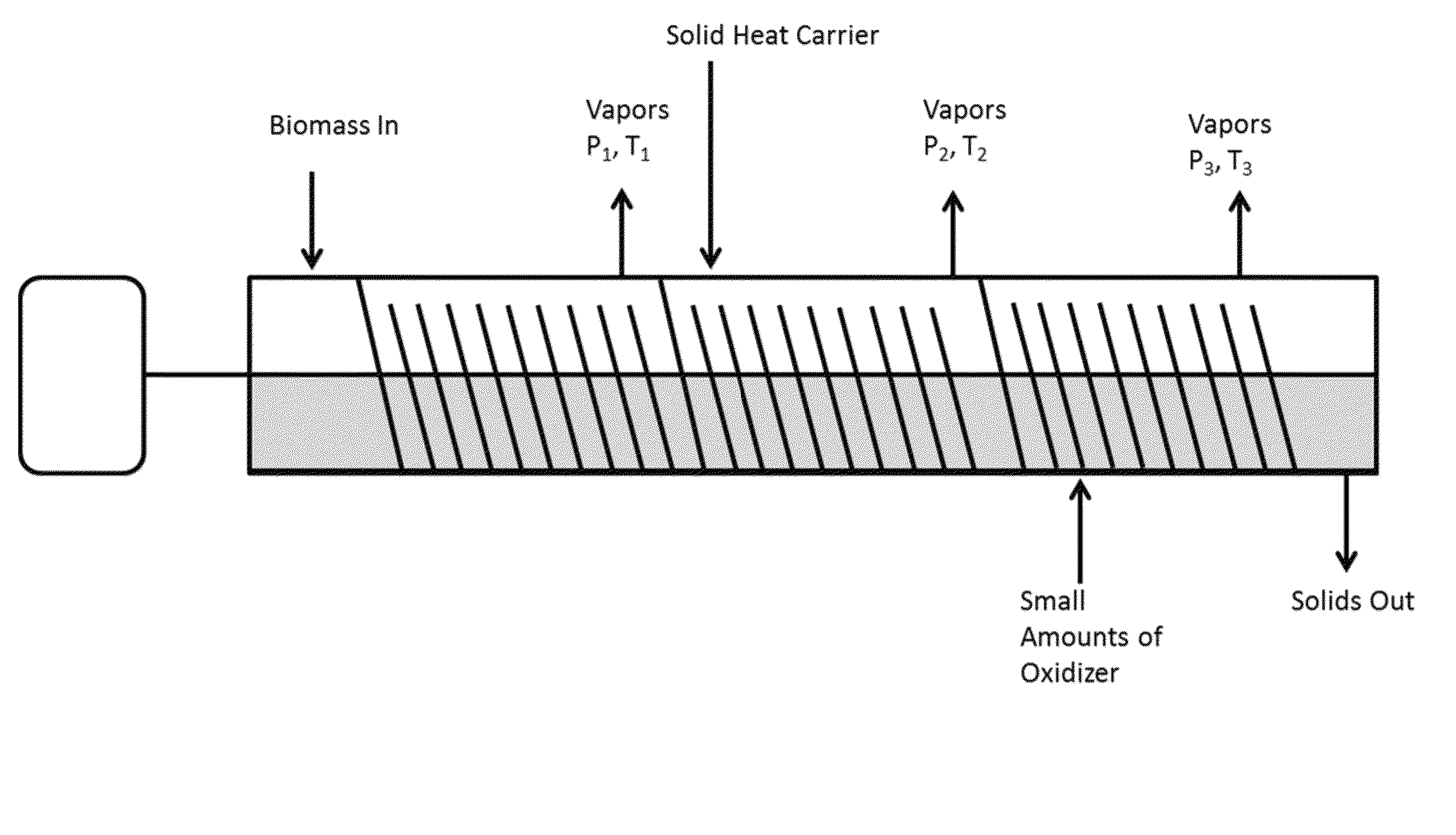

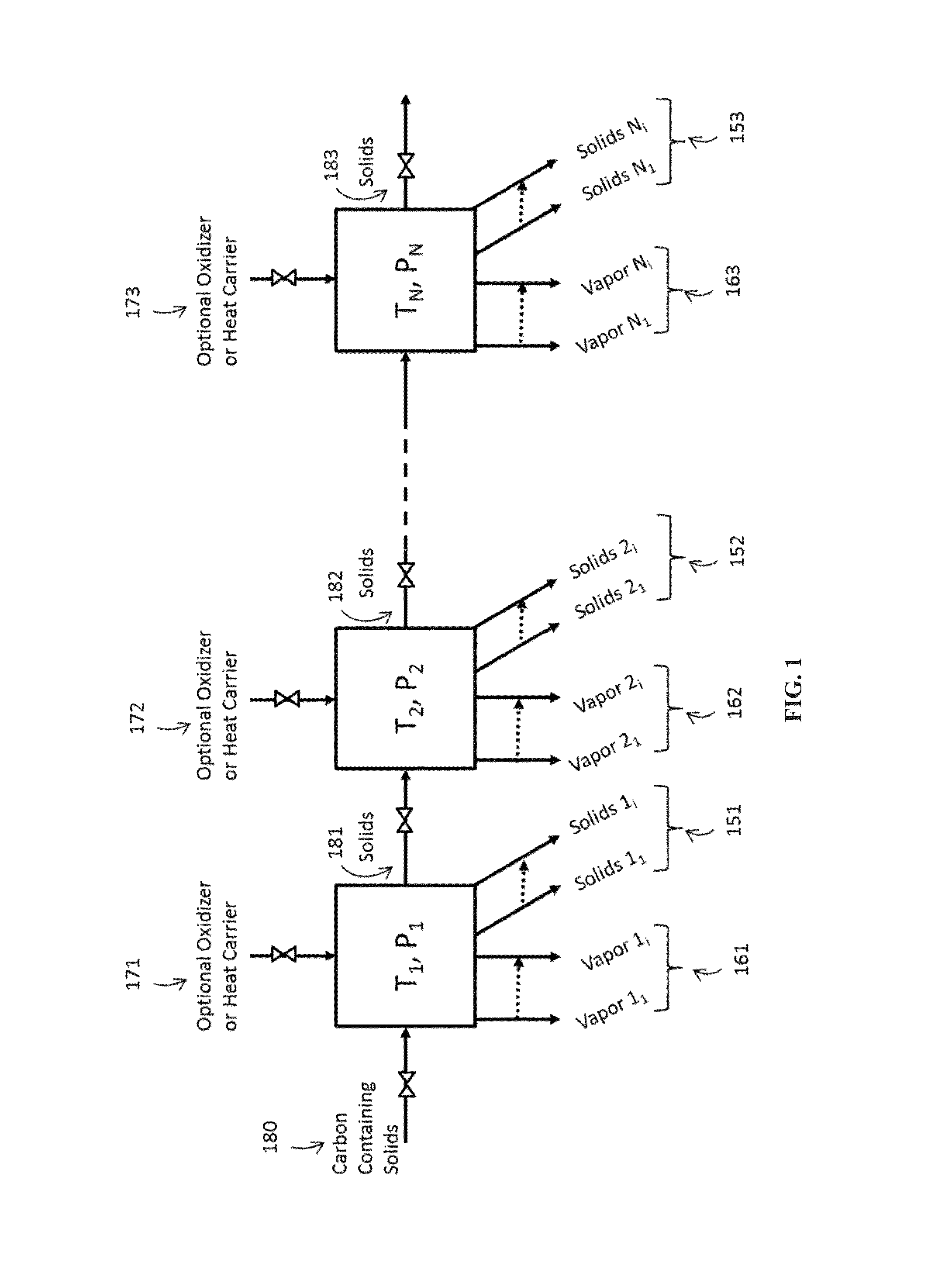

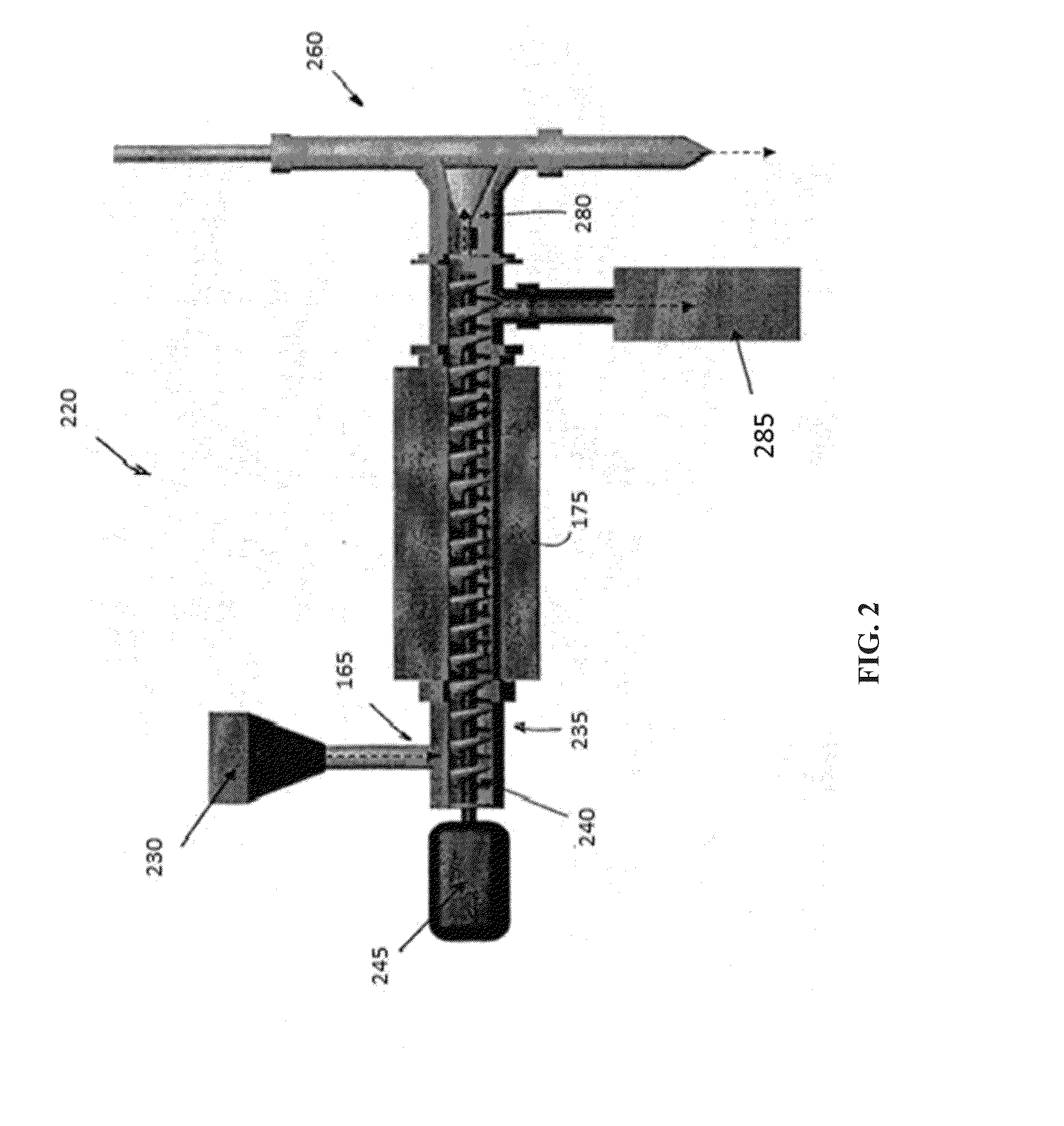

Staged biomass fractionator

InactiveUS20140183022A1Low coking rateReduce coking rateDrying solid materials with heatCharging-discharging device combinationsBiomassProcess engineering

Various biomass reactors systems and methods of pyrolyzing biomass are disclosed. One type of biomass reactor system comprises a plurality of biomass processing stations configured in series, each station comprising an auger reactor including an auger inlet for receiving biomass and a transfer screw for conveying the biomass through the auger reactor.

Owner:COOL PLANET ENERGY SYST

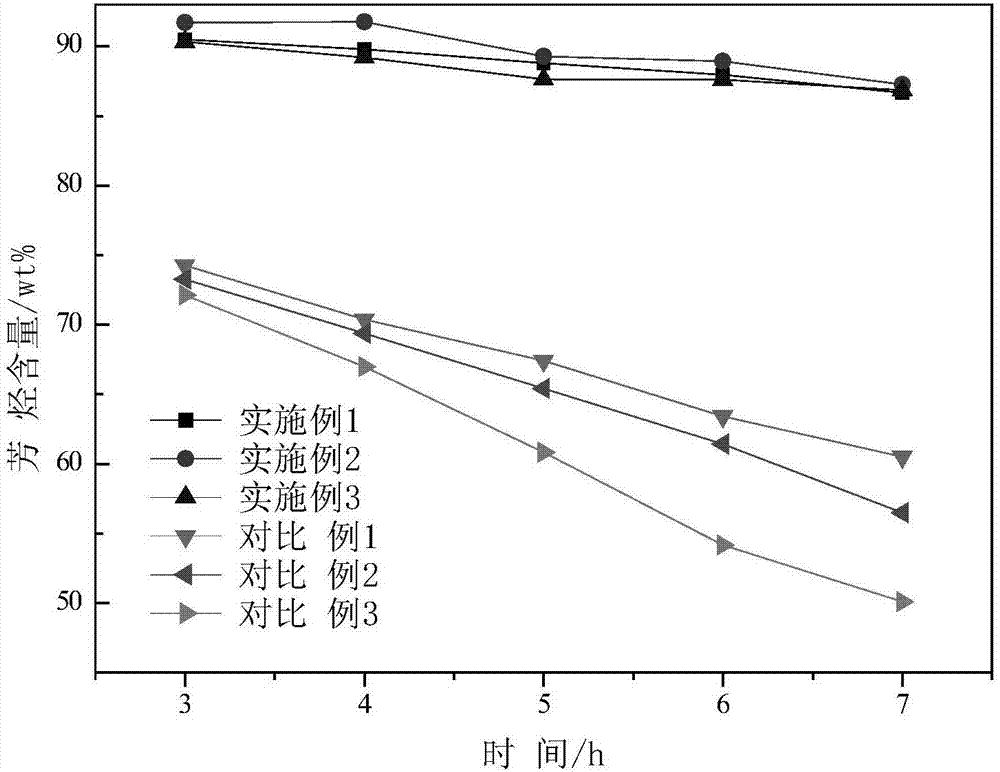

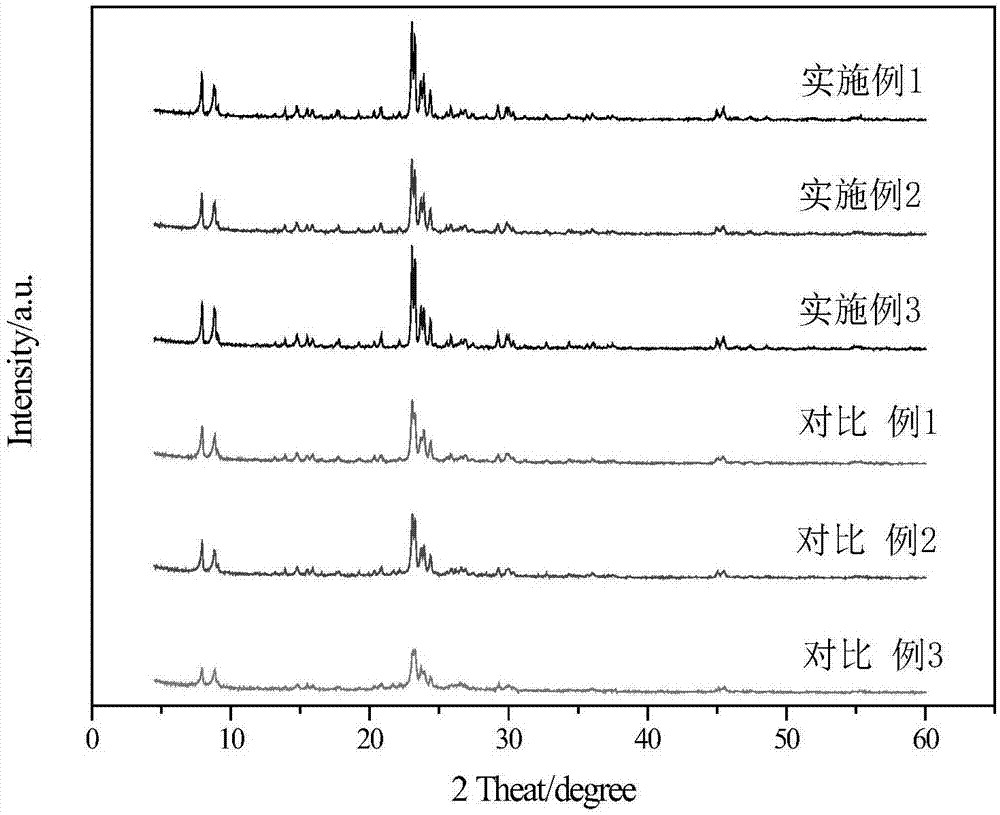

Alkali-modified ZSM-5 molecular sieve, preparation method and application thereof

InactiveCN107876082AReduced Diffusion ResistanceExtend your lifeMolecular sieve catalystsHydrocarbonsAromatizationOrganic chemistry

The invention relates to a preparation method of an alkali-modified ZSM-5 molecular sieve, which includes the steps of: mixing ZSM-5 molecular sieve with an alkali solution, performing a reaction andperforming post-treatment, wherein the reaction is carried out at 150-200 DEG C. The invention also relates to an application of the alkali-modified ZSM-5 molecular sieve in an aromatization reactionof hexene. The alkali-modified ZSM-5 molecular sieve is low in micropore ratio, wherein the micropores are enlarged into the range of mesopores and macropores (5-110 nm); the molecular sieve also is higher in crystalline degree, can effectively delay deactivation due to coking, thus increasing service life of a catalyst; without damage on the appearance of the ZSM-5 molecular sieve, grain size canbe controlled and acidity of the ZSM-5 molecular sieve can be regulated; in addition, pore structure in the molecular sieve is regulated, so that catalytic performance and service life of the catalyst are improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

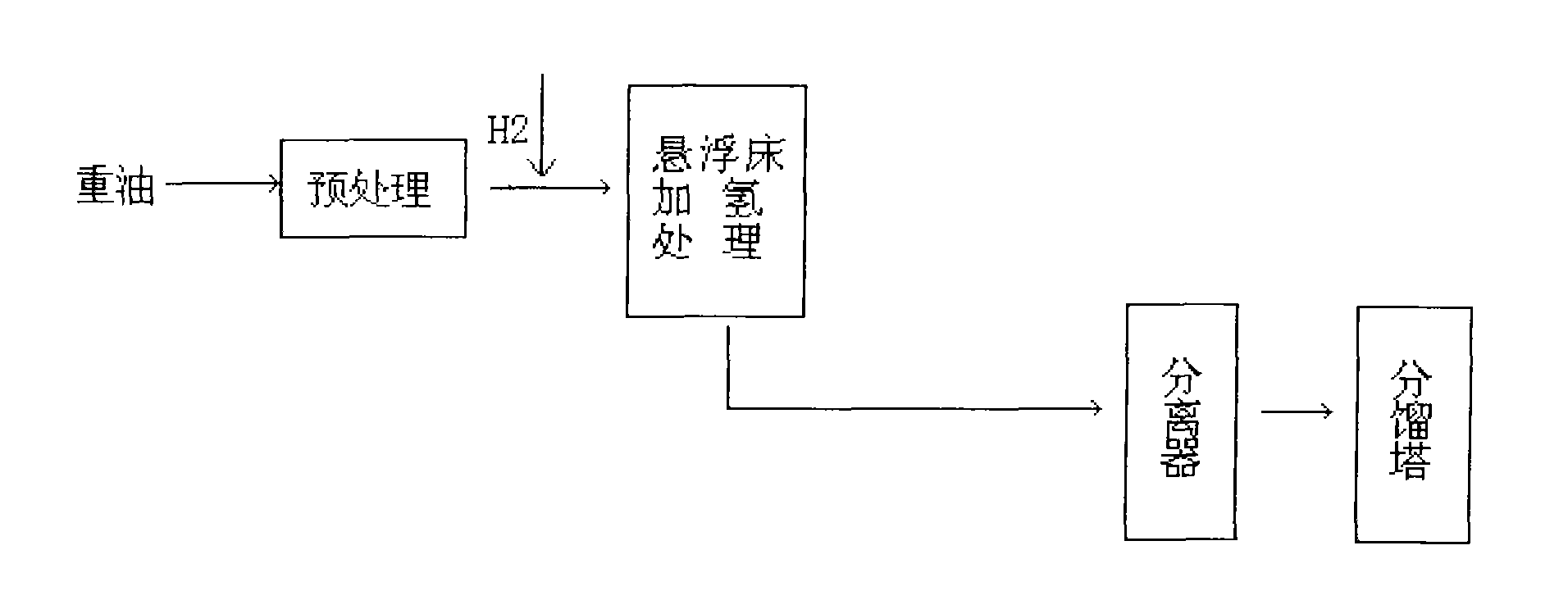

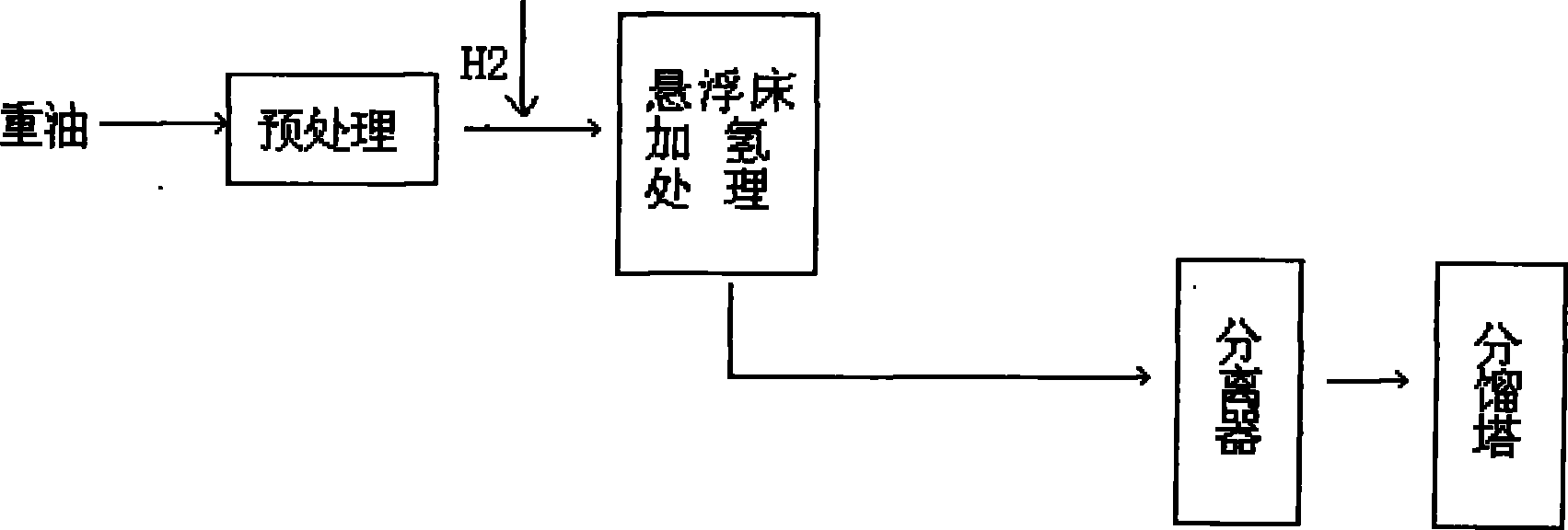

Heavy oil hydrogenation modifying method

The invention discloses a heavy oil modifying method which comprises the following steps: mixing a heavy oil raw material with a homogeneous catalyst, and mixing with a supercritical hydrogen supply solvent, wherein the content of the hydrogen supply solvent in the heavy oil raw material is 50 mug / g-5wt%; and in the presence of hydrogen, carrying out heavy oil hydrocracking reaction on the mixture of the heavy oil raw material, the catalyst and the hydrogen supply solvent under certain reaction conditions. In the heavy oil modifying method, suspension bed hydrocracking and supercritical treatment are organically combined, and the respective advantages are given full play to achieve the effect of synergic cooperation, thereby reducing the coking tendency, enhancing the impurity removal capacity and also enhancing the operational stability of the suspension bed hydrocracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

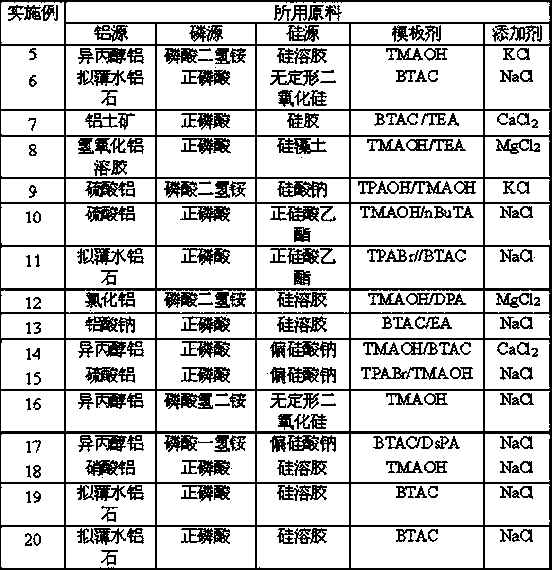

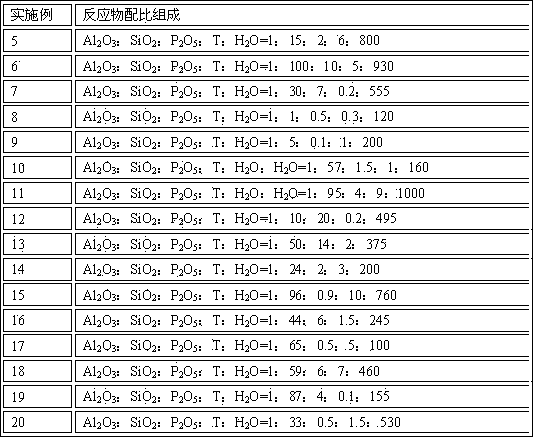

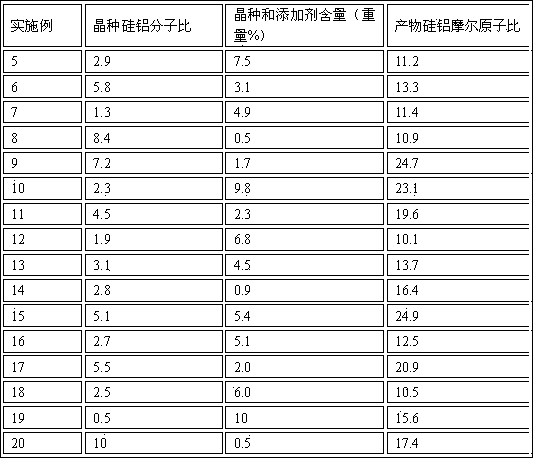

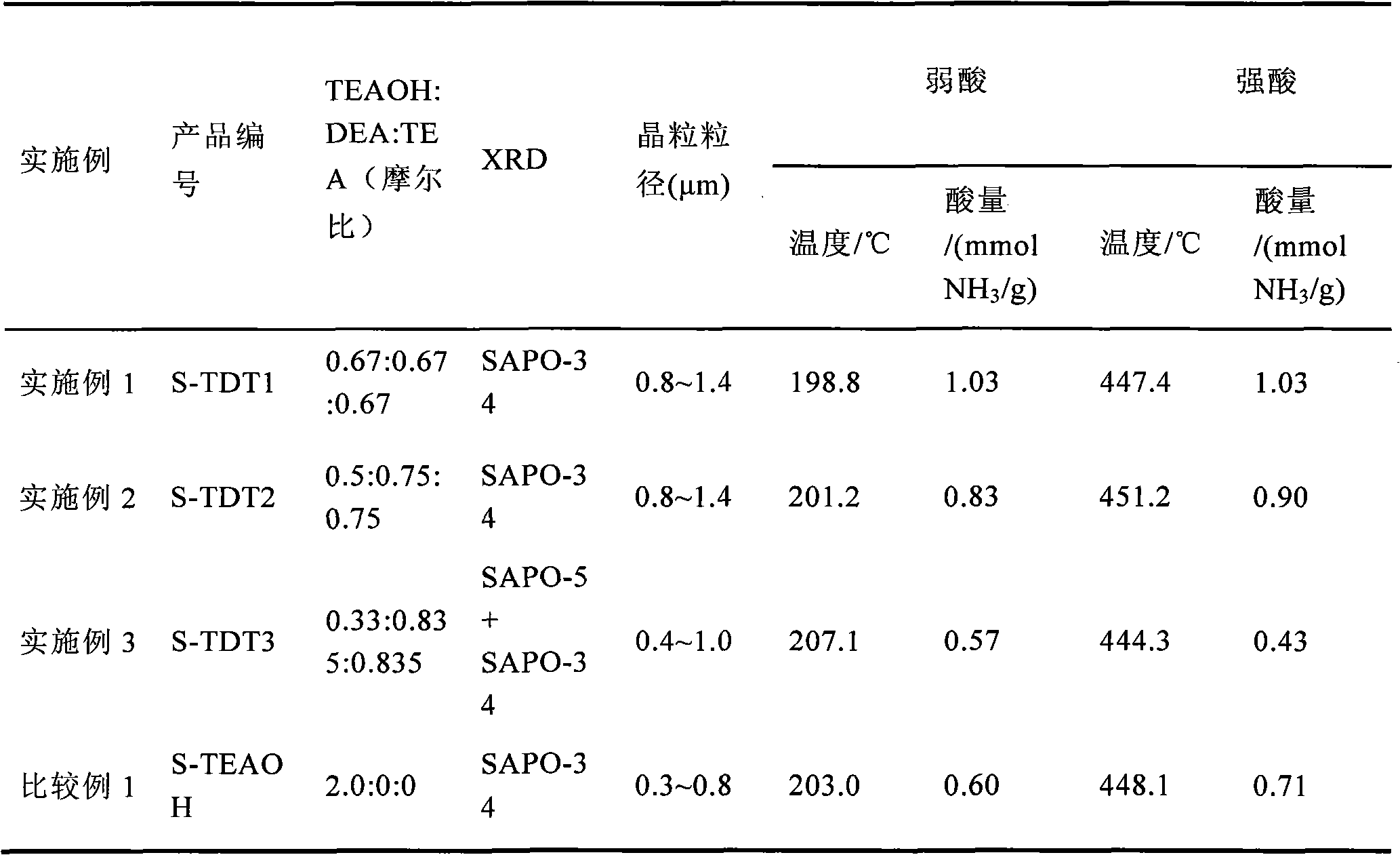

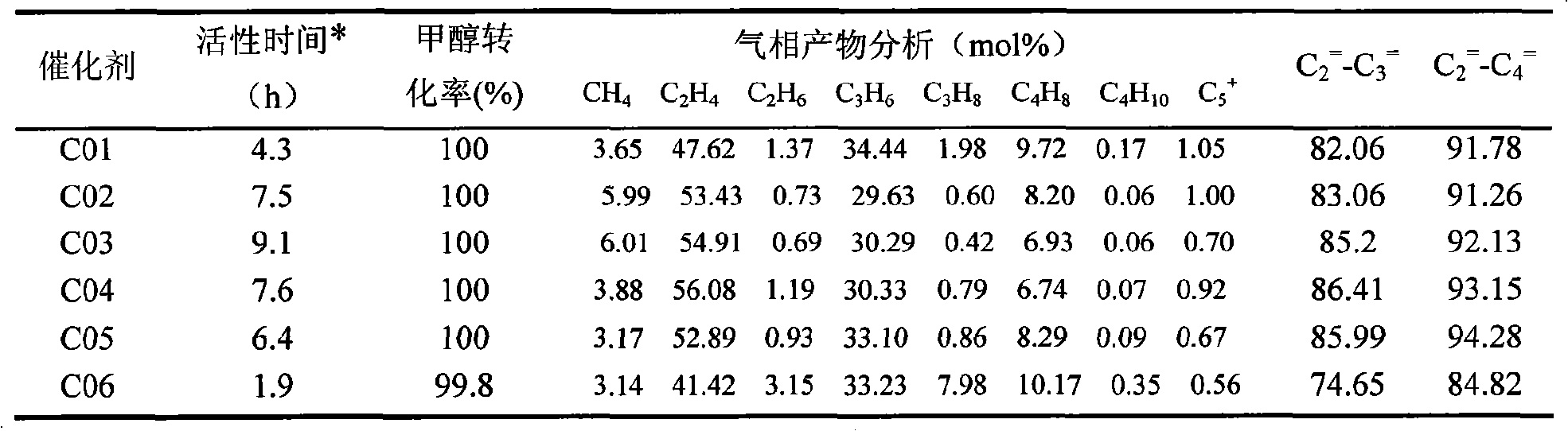

Silicoaluminophosphate molecular sieve with high silica-alumina ratio and CHA structure, and synthetic method thereof

ActiveCN104108726AHigh catalytic activityReduce coking rateMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveAluminium

The invention discloses a silicoaluminophosphate molecular sieve with a high silica-alumina ratio and a CHA structure, and a synthetic method thereof. The problems of low silica-alumina ratio, poor activity on a methanol-to-low carbon olefin reaction, and fast coking rate of silicoaluminophosphate molecular sieve with the CHA structure are mainly solved. The atom ratio of silicon / aluminum of the silicoaluminophosphate molecular sieve with a high silica-alumina ratio and a CHA structure is 10-25. The silicoaluminophosphate molecular sieve with a high silica-alumina ratio and a CHA structure well solves the problems, and can be used in the methanol-to-low carbon olefin industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing pentafluoroethane

ActiveCN101157595AReduce contentReduce coking ratePreparation by halogen replacementHydrogen fluorideDistillation

The invention discloses a method of preparing the pentafluoroethane (HFC-125), which adopts the hydrogen fluoride (HF) and the perchlorethylene (PCE) as the material, and takes two reactors and two steps of gas phase catalysis fluorination reaction. A first reactor fluorinates the PCE and synthesizes 2,2-dichlor-1,1,1-trifluoroethane(HCFC-123) and 2-chlorin-1,1,1,2-tetrafluorothane(HCFC-124), and the second reactor fluorinates HCFC-123 and HCFC-124 and synthesizes HFC-125. The unreacted PCE in the resultant flow of the first reactor is separated by a first distillation tower and then circulates to the first reactor; the HF, HCFC-126, HCFC-124, HFC-125 and HCL in the resultant flow of the first reactor and the second reactor are separated by a second distillation tower and a third distillation tower, and then the separated HF circulates to the first reactor and the second reactor, while the HCFC-123, the HCFC-124 and the HFC-134a circulate to the second reactor. The invention can prolong the service life of the catalyst and improve the one-way conversion of PCE as well as remarkably reduce the content of chloropentafluoroethane(CFC-115) in the desired product HFC-125.

Owner:XIAN MODERN CHEM RES INST +1

Hydrofining catalyst

ActiveCN102166520AImprove hydrogenation activityHigh selectivityOrganic reductionCatalyst activation/preparationHydrodesulfurizationAlkali metal oxide

The invention relates to a hydrofining catalyst which is obtained by adding a carrier into a dipping liquid for aging and drying after dipping, and then activating. The catalyst, containing the carrier, molybdenum and cobalt, is characterized by containing molybdenum oxide 5-25%, cobalt oxide 1-6%, tungstic oxide 0-15%, nickel oxide 0-4%, and alkali metal oxides 0-4.5%, by the catalyst weight of 100%. Besides, the catalyst pore volume is 0.30-0.85ml / g, and the specific surface area is 110-380 m <2> / g. Compound solvent in the catalyst preparation contains ammonia water and polyamine complexingagent at the same time. The catalyst of the invention while undergoing hydrodesulfurization, saturates monoolefine to the maximum through hydrogenation, to be able to meet the requirements of an oil product with changeable sulfur and diene contents and high air speed running. Catalyst has good hydrogenation activity, high selectivity, long running time and superior anti coking performance.

Owner:PETROCHINA CO LTD

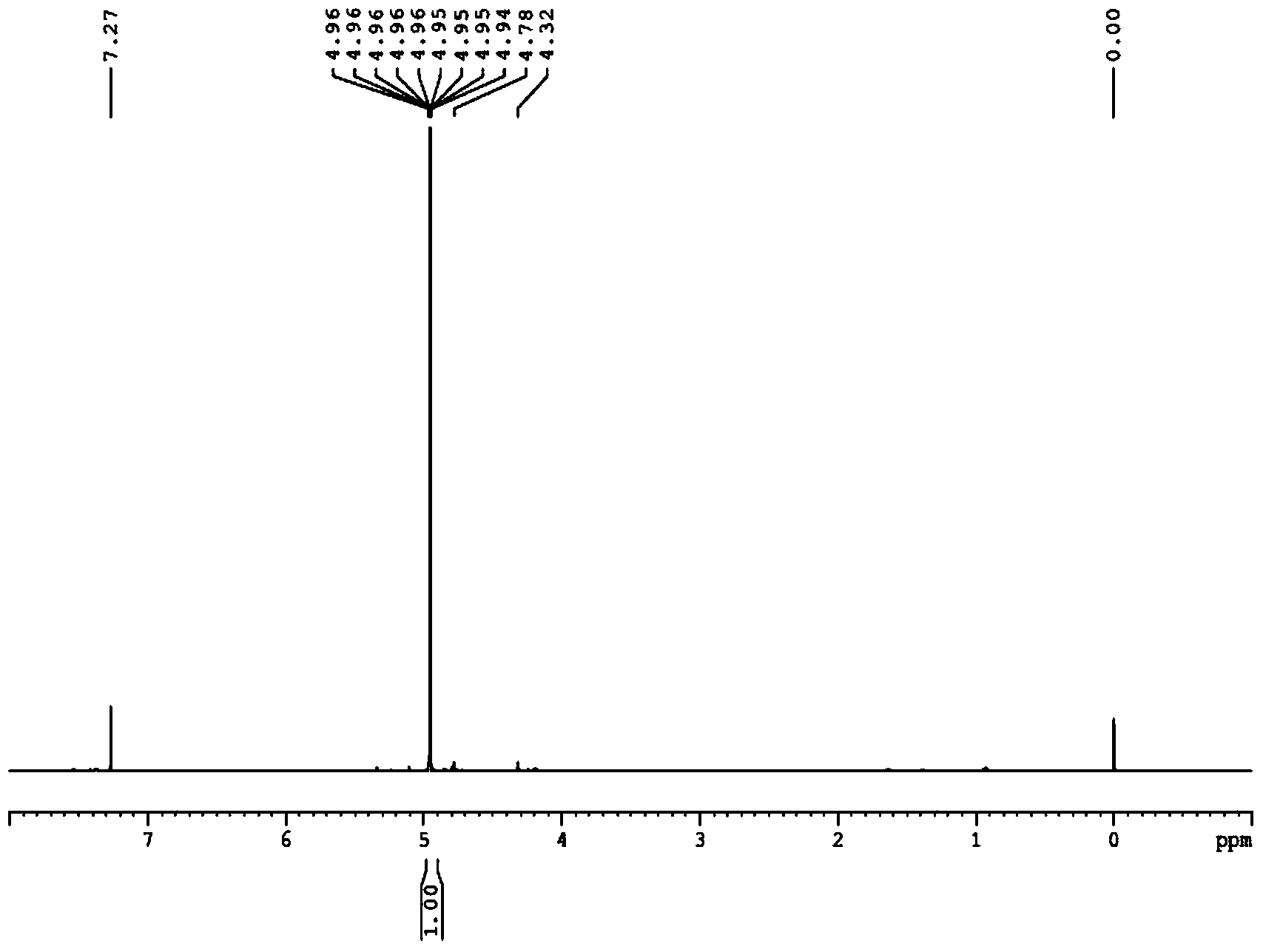

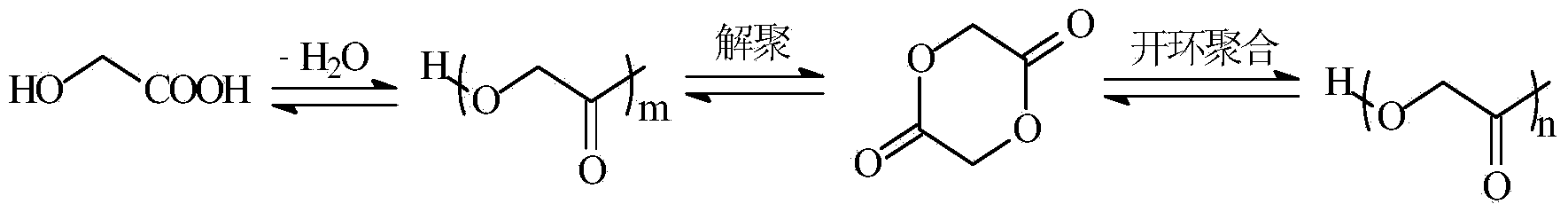

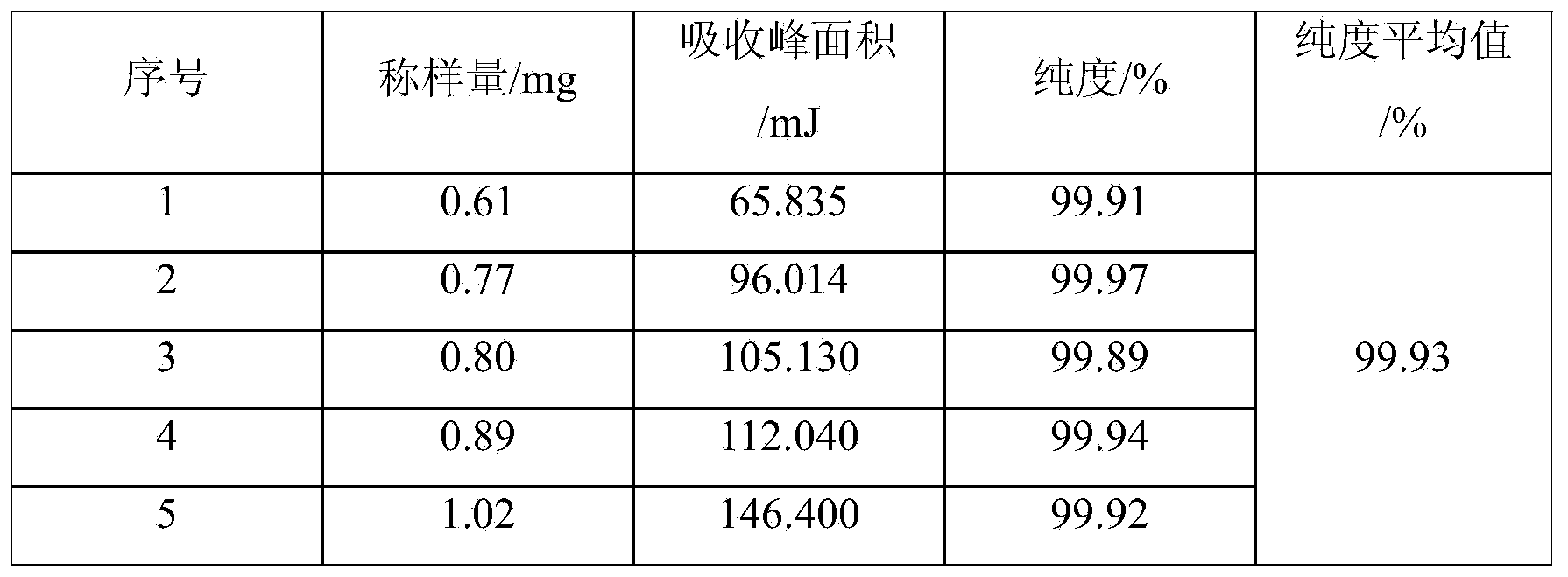

Low-temperature high-efficiency glycolide preparation method based on catalytic depolymerization

ActiveCN104163810AAvoid thermal degradation problemsDepolymerization temperature decreasedOrganic chemistryDepolymerizationCoke rate

The invention belongs to the field of preparation of glycolide monomers, and particularly relates to a low-temperature high-efficiency preparation process which is beneficial to increase the glycolide yield. The process can obviously reduce the depolymerization temperature of PGA oligomers, increase the glycolide yield and reduce the coking rate of a reaction system. The technical scheme is as follows: under the catalytic action of metal acetoacetonate, polyglycolic acid oligomers, or a mixture of polyglycolic acid and azeotropic solvent, or a mixture of polyglycolic acid, azeotropic solvent and cosolvent is depolymerized to prepare the glycolide monomer; and the reaction temperature of the glycolide monomer preparation based on depolymerization can be reduced to 160-210 DEG C.

Owner:CHANGZHOU UNIV

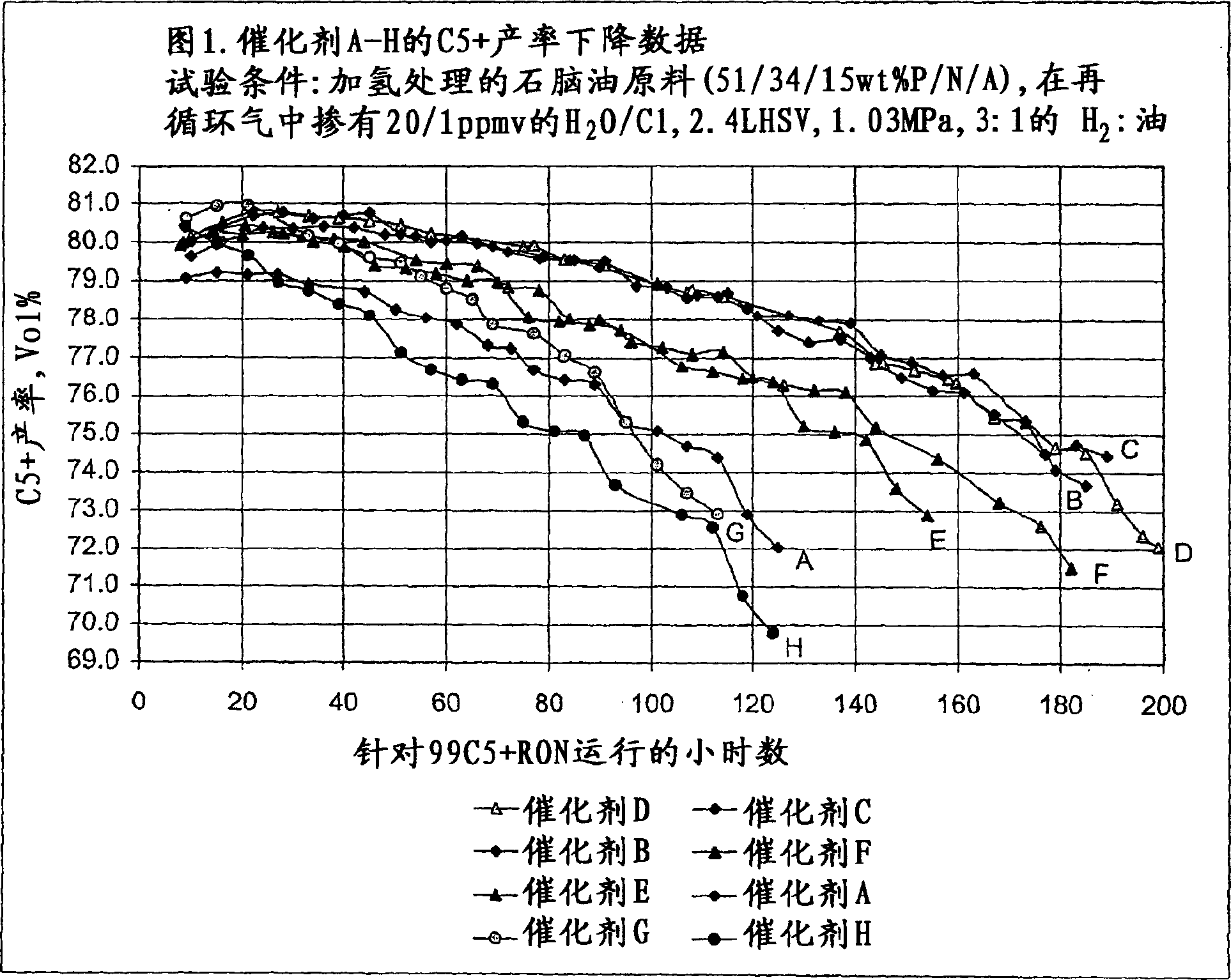

Silicoaluminophosphate molecular sieve and preparation method and application thereof

ActiveCN101857244ASolution to short lifeExtend your lifeMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveCoke rate

The invention relates to a silicoaluminophosphate molecular sieve and a preparation method and application thereof. The structure formula of the molecular sieve is (0.2-3.0) R: (Si0.01-0.3Al0.01-1P0.01-0.9 ):(10-400) H2O, and three templates, a silicon source, an aluminum source and a phosphorus source are mixed with water to form gel, and then the silicoaluminophosphate molecular sieve can be obtained by the steps of crystallization and drying. Compared with the preparation methods of the molecular sieve with single template and double templates in the prior art, the invention is taken as a catalyst and is applied to the reaction of light olefins from methanol, can improve the conversion rate of raw materials, delay coking rate, prolong reaction activity time, and improve the selectivities of ethylene and propylene, and simultaneously solve the problem that the synthesis cost of the silicoaluminophosphate molecular sieve is high in the prior art.

Owner:YANKUANG ENERGY R&D CO LTD

Bismuth- and phosphorus-containing catalysts support, reforming catalysts made from same, method of making and naphtha reforming process

InactiveCN1655868AReduce coking rateImprove octaneCatalyst carriersCatalytic naphtha reformingPolymer scienceNaphtha

Bismuth- and phosphorus-containing catalyst supports, naphtha reforming catalysts made from such supports, methods of making both support and catalyst, and a naphtha reforming process using such catalysts.

Owner:INST FR DU PETROLE

Preparation method for titanium silicalite molecular sieve and applications

ActiveCN103395799AFacilitated DiffusionExtend your lifeOrganic chemistryMolecular sieve catalystsMolecular sieveGas phase

The invention discloses a titanium silicalite molecular sieve, a preparation method therefor and applications. The titanium silicalite molecular sieve is uncalcined titanium silicalite molecular sieve TS-1. The invention also discloses a new catalyst applied to systems of direct preparation of epoxypropane from propylene through gas-phase epoxidation. The catalyst employs the uncalcined titanium silicalite molecular sieve TS-1 as a carrier and loads the carrier with metal particles.

Owner:EAST CHINA UNIV OF SCI & TECH

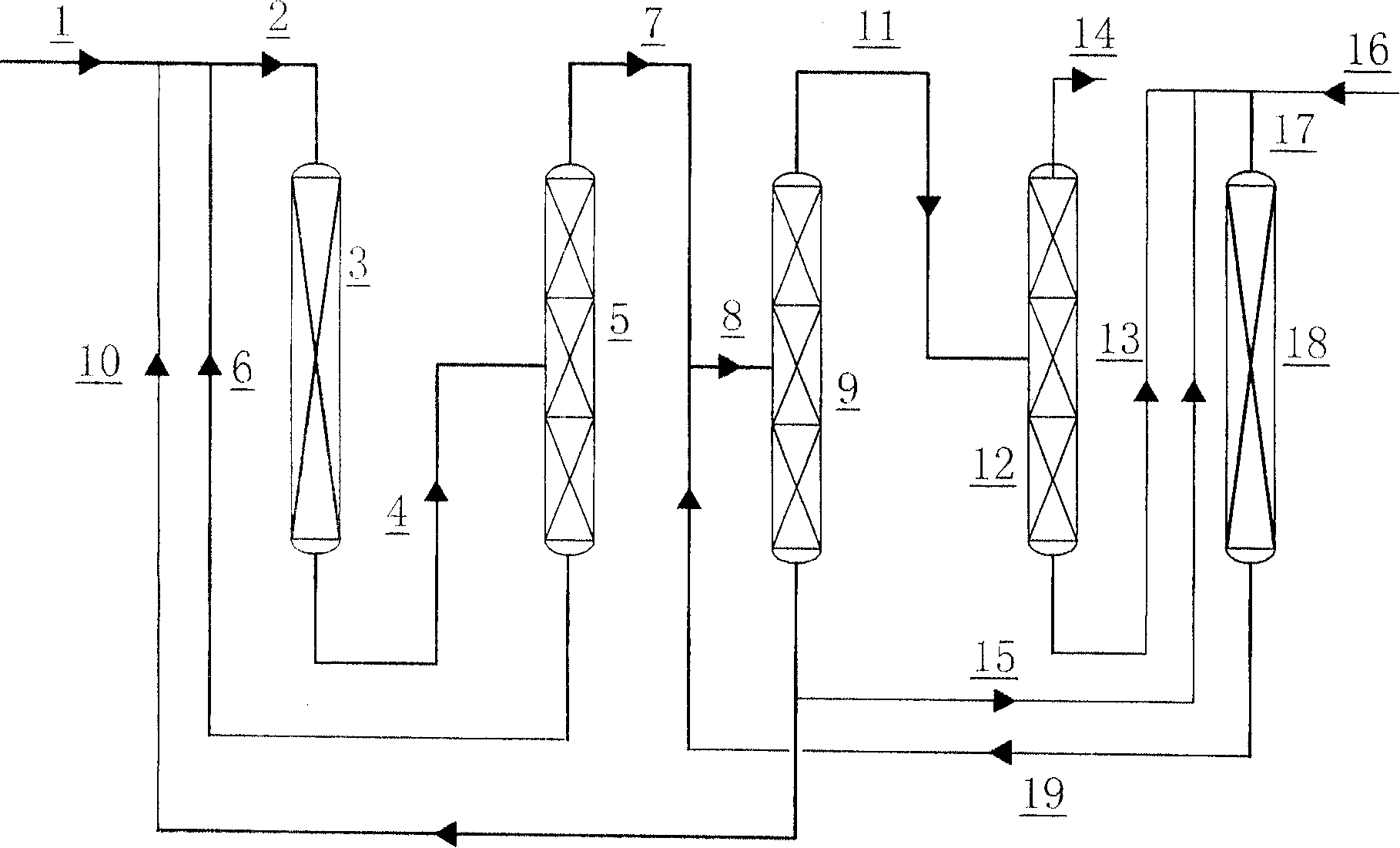

Suspension bed residual oil hydrogenation-catalytic cracking combined technological process

ActiveCN101434867AAppropriate mode of operationLower conversion rateTreatment with hydrotreatment processesHydrogenation reactionResidual oil

The invention discloses a combination process of hydrogenation-catalytic cracking used for suspension bed residual oil. The method comprises the steps as follows: residual oil and catalytic cracking decanted oil enter a suspension bed hydrogenation reaction device and carry out hydrogenation reaction with the presence of hydrogen and a catalyst; the vacuum distillate oil gained during the hydrogenation reaction enters a catalytic cracking device, the vacuum residual oil is circulated back to the suspension bed hydrogenation device, and the catalytic cracking decanted oil and heavy circular oil can wholly or partly enter the suspension bed hydrogenation device which adopts a relatively moderate operation condition. The method organically combines the suspension bed hydrogenation device with the catalytic cracking device, and therefore not only ensures the stable running of the suspension bed hydrogenation device, but also improves the impurity removal capability of the suspension bed hydrogenation device, improves the raw material quality of the catalytic cracking device, and increases the yield of the light oil products.

Owner:CHINA PETROLEUM & CHEM CORP +1

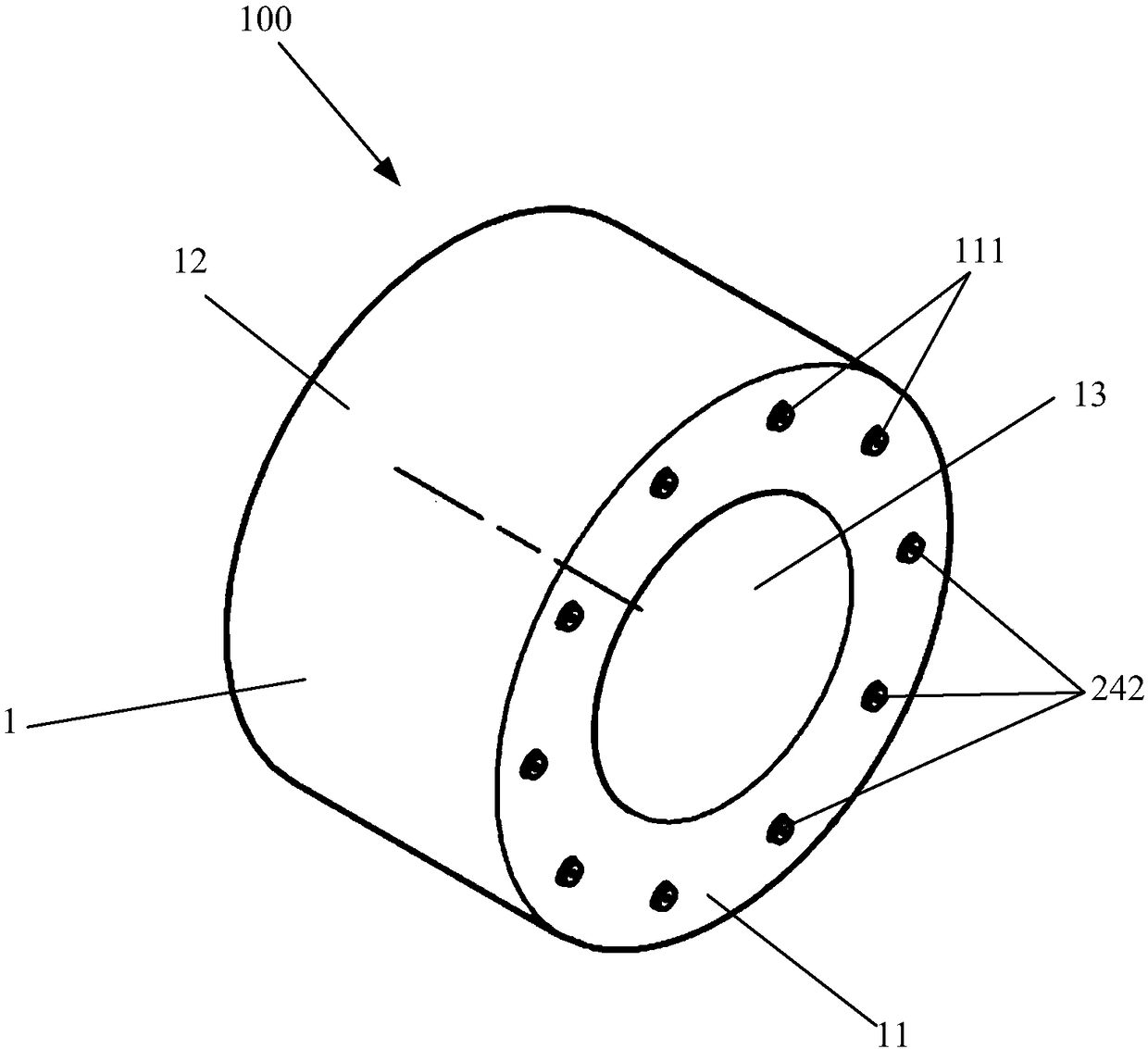

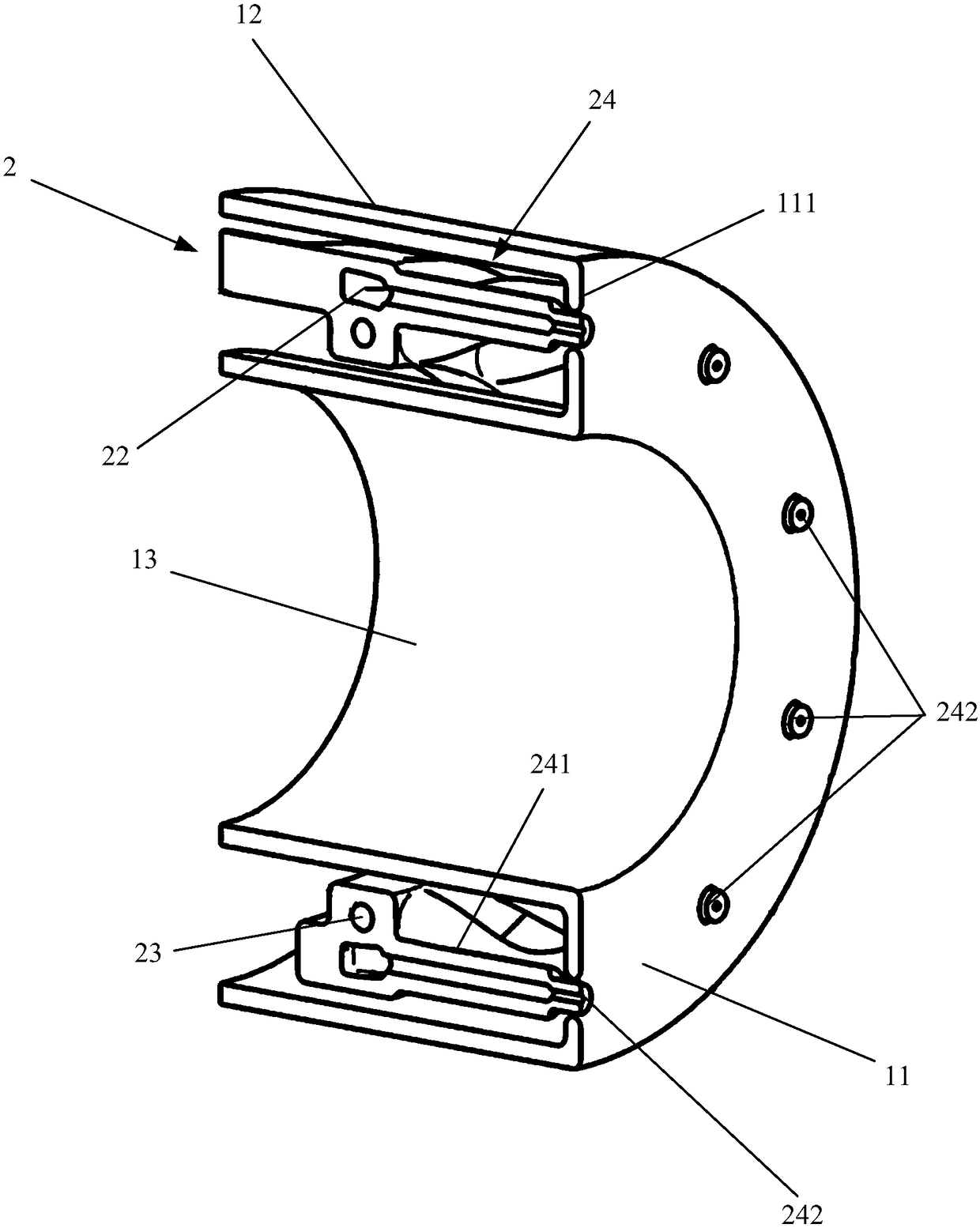

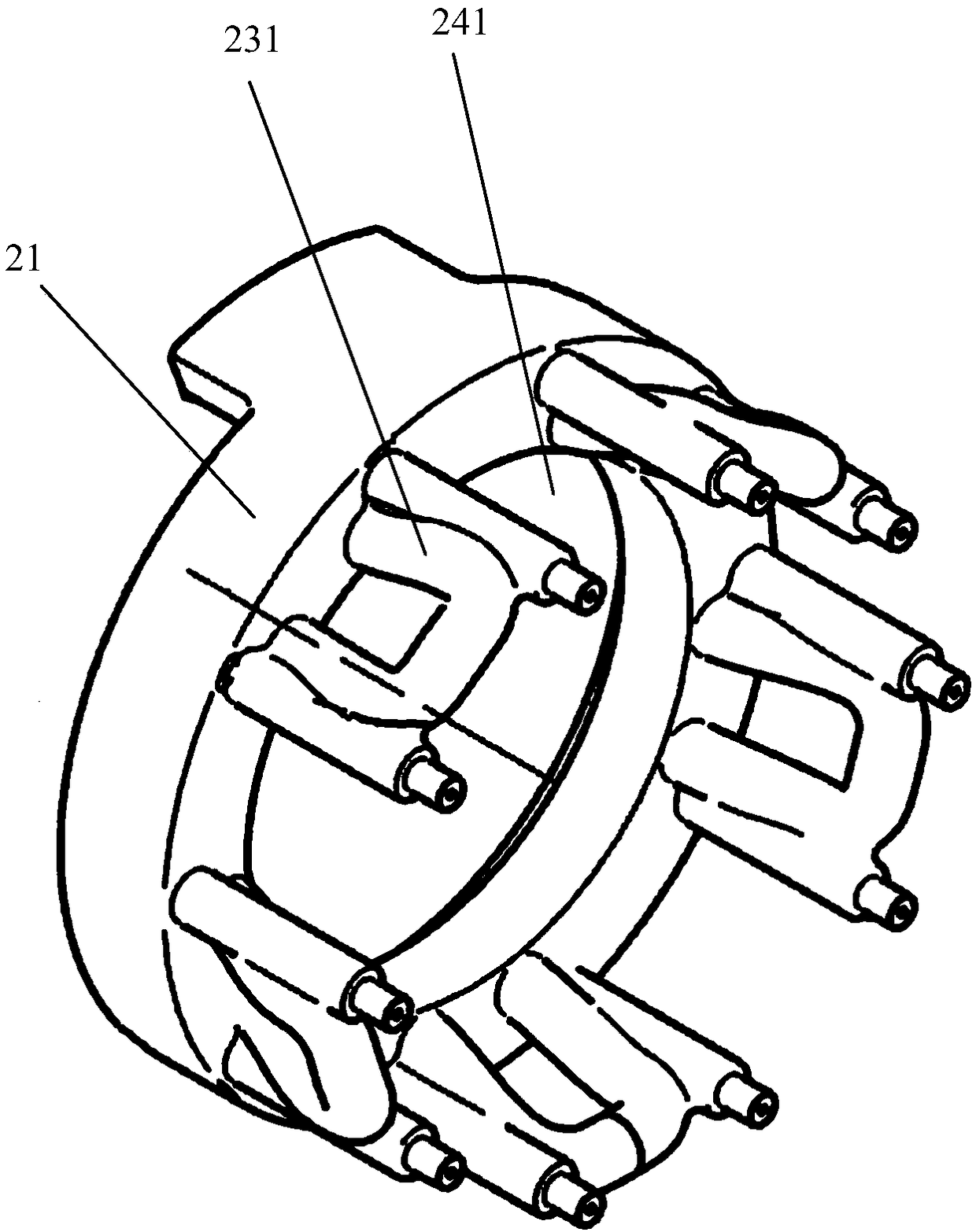

Engine, fuel nozzle and collector ring

ActiveCN108266274AImprove cooling effectReduce coking rateTurbine/propulsion fuel supply systemsTurbine/propulsion engine coolingCooling effectFuel line

The invention provides a collector ring, comprising a shell and a fuel circuit component. The shell has a circular bottom, an outer wall and an inner wall; the circular bottom has at least one spout hole. The fuel circuit component is arranged between the outer wall and the inner wall and includes a first fuel line, a second fuel line and at least one injector rod component. Each injector rod component includes a rod communicated with the first fuel line and extended to the circular bottom, and a spout positioned in the end of the rod and extended out of the corresponding spout hole. The second fuel line includes a second fuel line body and at least one bent portion extended to the circular bottom; at least part of each bent portion is abutted to the rod. Compared with existing fuel nozzles, the collector ring using the above technical scheme has the advantages of good cooling effect and low chances for fuel deposition and coking.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Alkyne selective hydrogenation catalyst and preparation method and applications thereof

ActiveCN108927173ASolve the mismatch problem of high activity and poor selectivity or high selectivity and poor activityHigh hydrogenation stabilityHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsPetrochemicalPetroleum

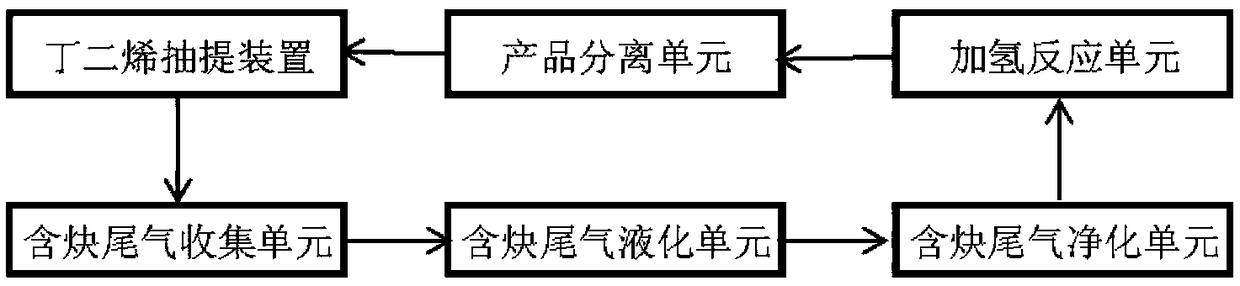

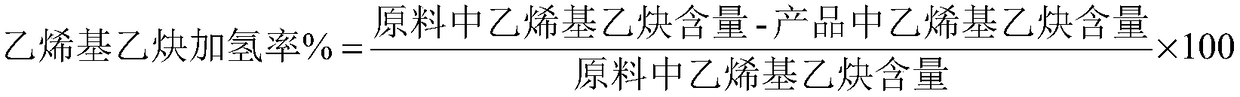

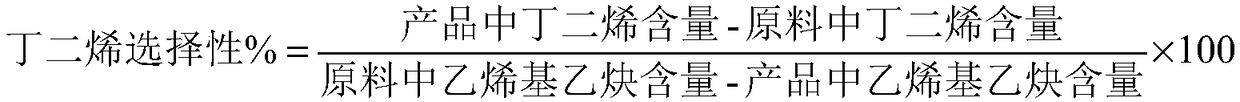

The invention belongs to the technical field of petrochemical engineering, and specifically relates to an alkyne selective hydrogenation catalyst and a preparation method and applications thereof. Thecatalyst is composed of an active component, a co-catalyst component, and a carrier. The active component is palladium. The co-catalyst component is added into the catalyst in different modes so as to enhance the hydrogenation stability and selectivity, reasonably adjust the acidity of the catalyst surface, promote the dispersion of active component (palladium), and create more active sites. Thecatalyst is applied to the selective hydrogenation of alkyne containing materials, in particular, C4 materials, which have a high alkyne content and are discharged from a butadiene extraction device.Vinyl acetylene and ethyl acetylene are converted into butadiene and butylene. The hydrogenation products are returned to a raw material storage tank or a butadiene extraction device to recover butadiene and butylene. The catalyst has the advantages that the hydrogenation conditions are mild, the activity and selectivity are high, the stability is good, and the operation period is long, and the catalyst is suitable for hydrogenation of materials with a high alkyne content.

Owner:沈阳沈科姆科技有限公司

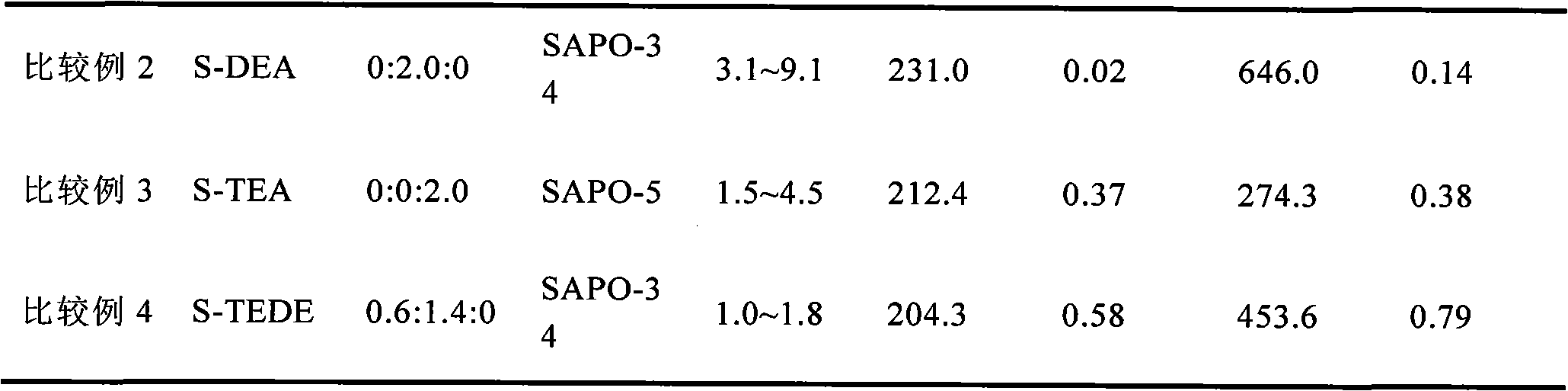

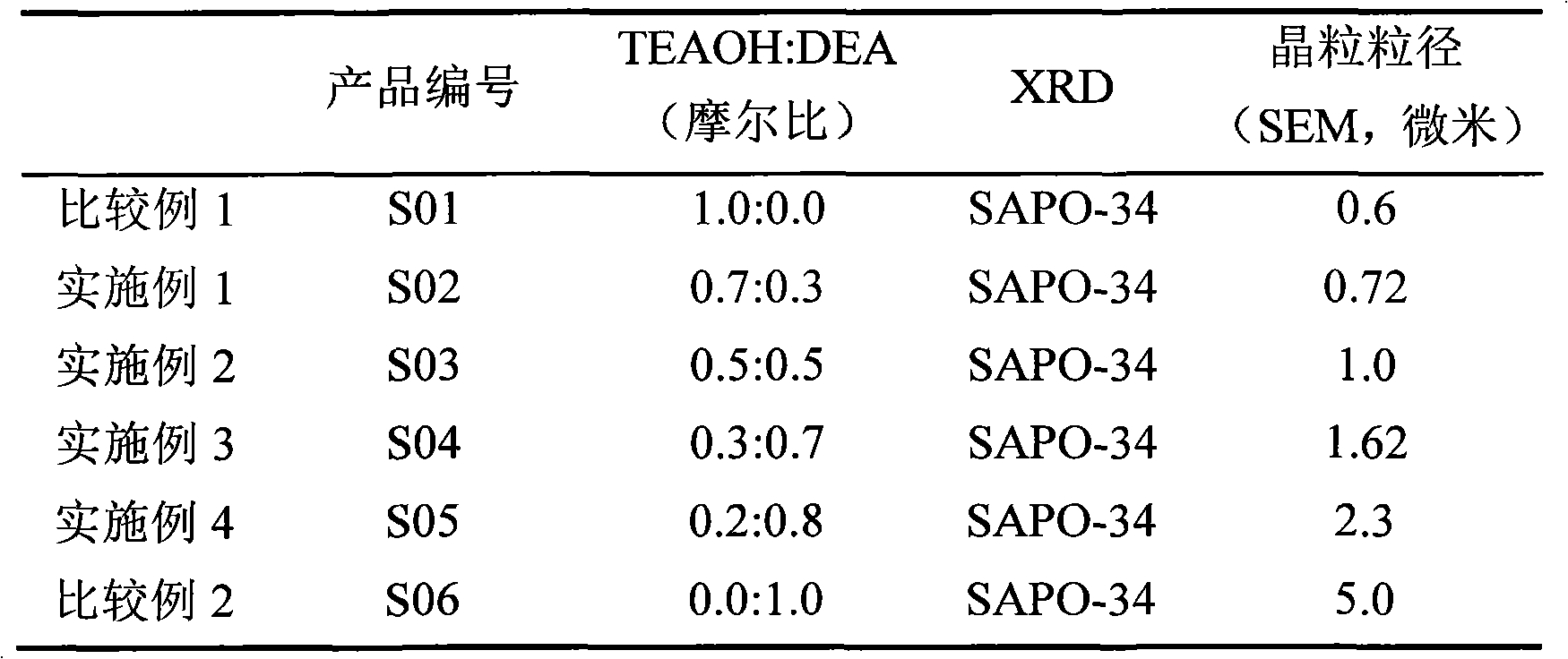

Composite mould plate agent synthesized silicon-aluminum phosphate molecular sieve, production and uses thereof

ActiveCN101492169AExcellent catalytic performanceSlow down the coking rateMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveAmmonium hydroxide

The invention relates to a silicon-aluminium phosphate molecular sieve synthesized by a composite template agent, and a preparation method and application thereof. The structural formula of the molecular sieve is (0.2-3.0)R: (Si0.1-0.3Al0.1-1P0.01-0.9): (10-400)H2O, wherein R is a tetraethyl ammonium hydroxide / diethylamine composite template agent, and the composite template agent is x tetraethyl ammonium hydroxide+(1-x) diethylamine, wherein x is equal to between 0 and 1. Compared with the prior art, the composite template agent (tetraethyl ammonium hydroxide / diethylamine) has low synthesis cost for synthesizing the silicon-aluminium phosphate molecular sieve and is easy for industrial production, and when used as a catalyst in the preparation of low-carbon olefin from methanol, the template agent has slow reaction cocking rate and deactivation rate, and long activity time and service life, and has the advantages of high feed stock conversion, high selectivity for low-carbon alkene such as ethylene, propylene, and the like.

Owner:YANKUANG ENERGY R&D CO LTD

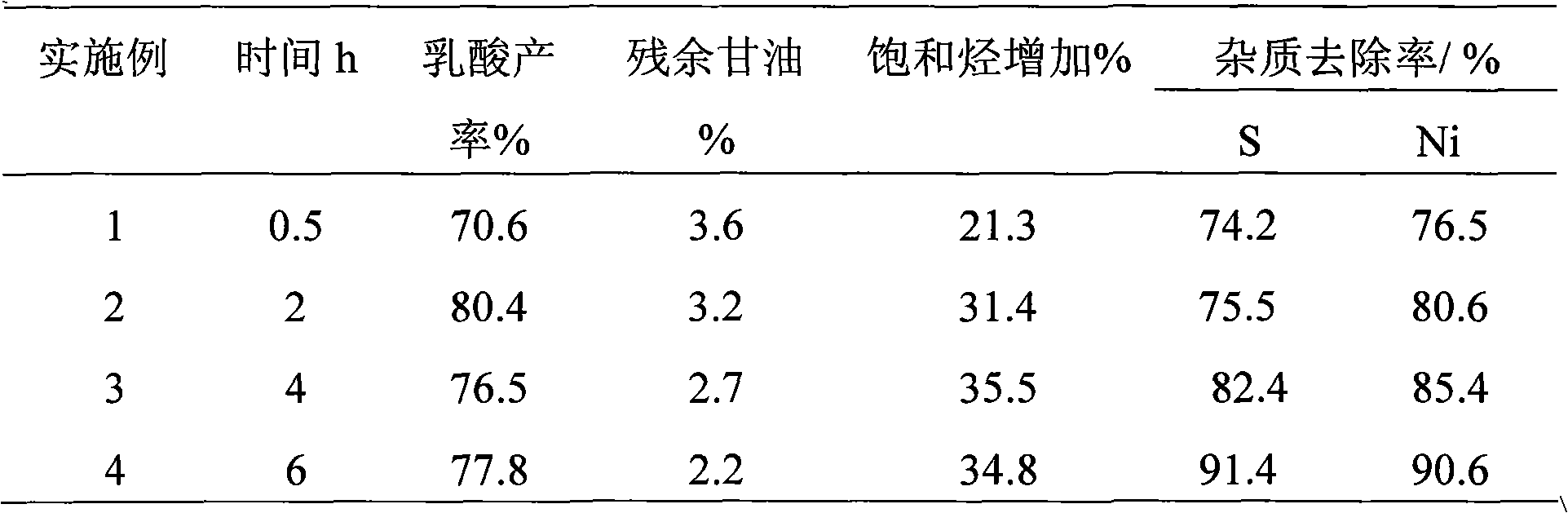

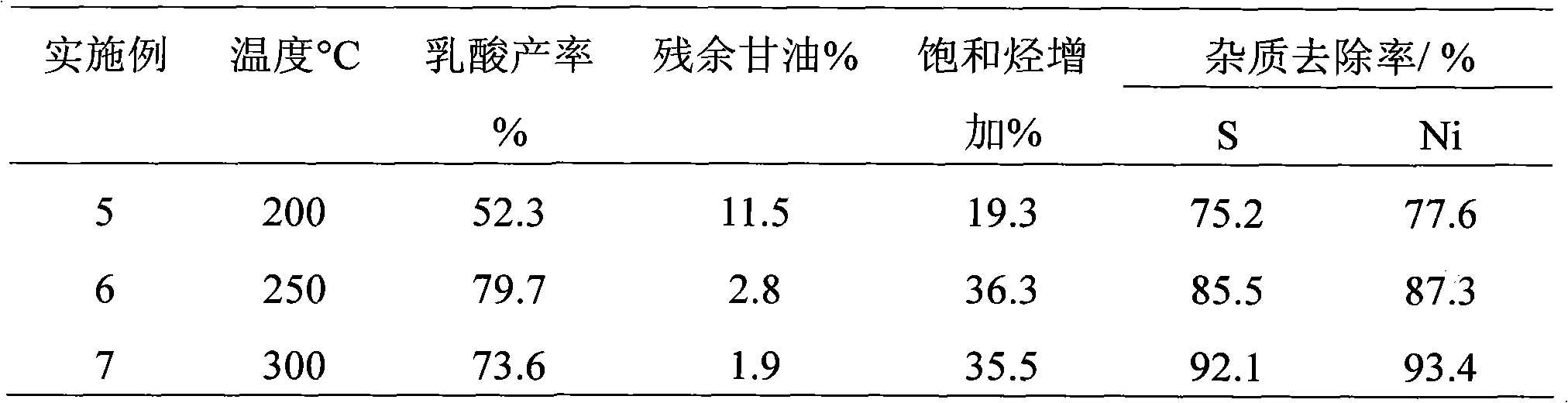

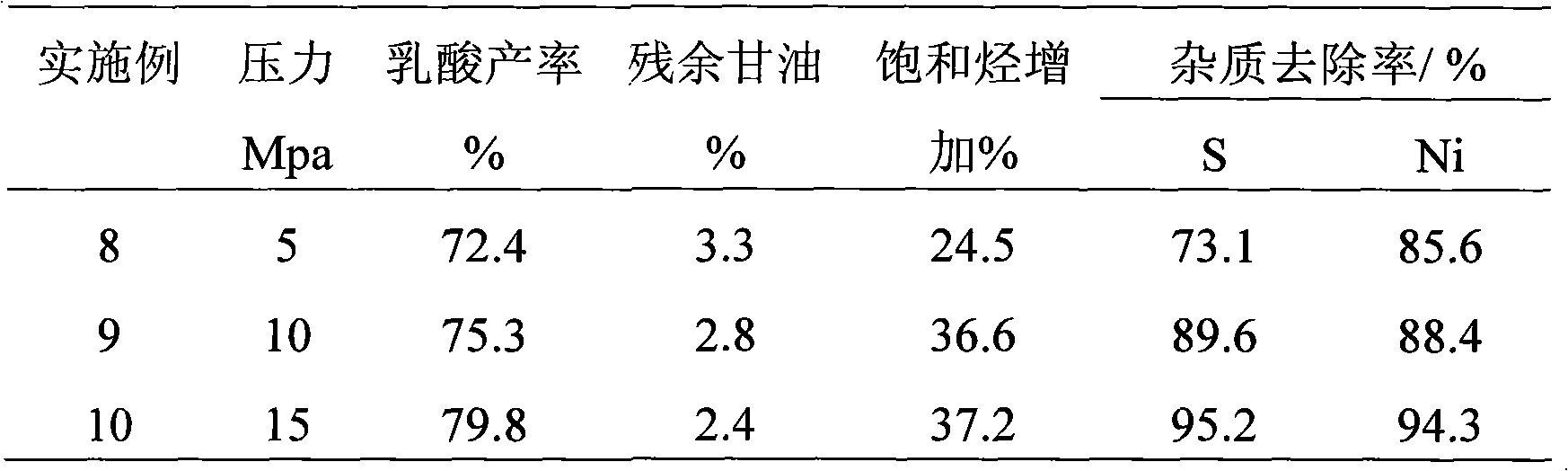

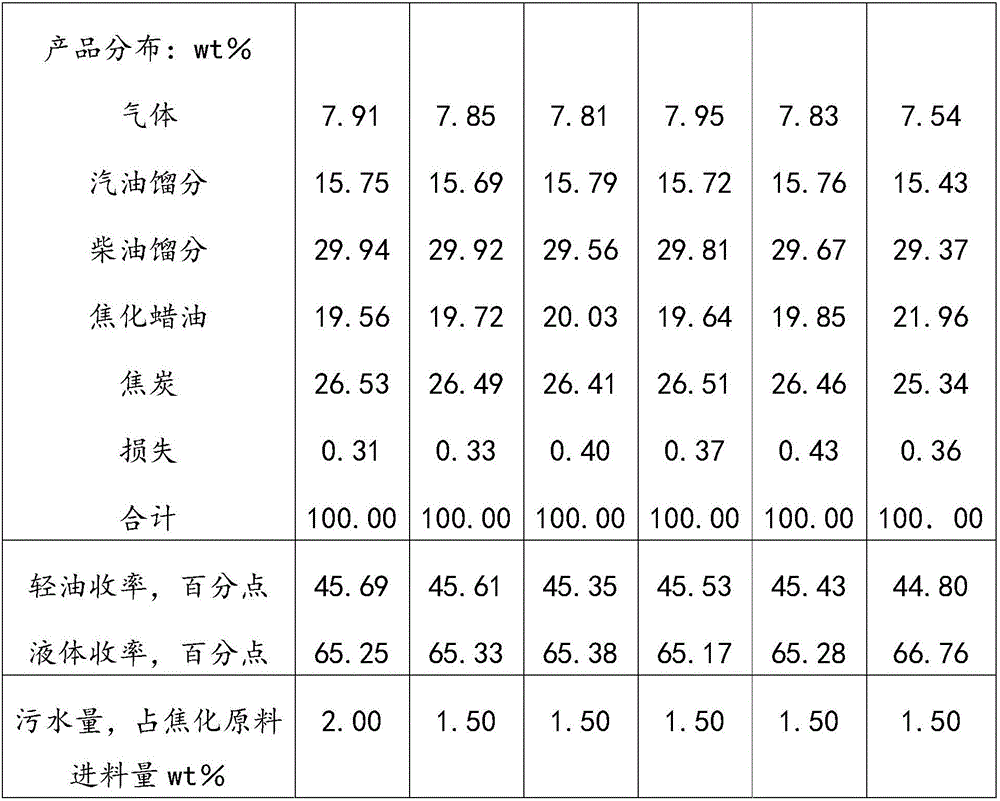

Method for coprocessing glycerol and heavy oil in hydrothermal mode to simultaneously obtain lactic acid and light oil

InactiveCN102093913ALightweightReduce coking rateChemical industryLiquid hydrocarbon mixture productionGas phaseGlycerol

The invention relates to a method for coprocessing glycerol and heavy oil in a hydrothermal mode to simultaneously obtain lactic acid and light oil, which comprises the following steps: dissolving a certain amount of glycerol in an alkaline water solution, preheating the water solution and heavy oil through a heat exchanger, sending into a reactor to carry out reaction, cooling the reaction products through the heat exchanger, and separating out a gas phase component, a liquid phase component and an oil phase component, wherein the gas phase component mainly comprises hydrogen, and can be used for catalytic hydroprocessing of heavy oil after being purified; the liquid phase component mainly comprises lactates which can be purified and acidified to obtain lactic acid; and the oil phase component can be heated through the heat exchanger and then be treated in a fractionating tower to obtain light products of the heavy oil, such as gasoline, diesel oil, fuel oil and the like. Compared with the prior art, the invention converts glycerol into lactic acid in a hydrothermal mode, converts heavy oil into light oil while generating hydrogen from glycerol by hydrothermal reaction, and also has the functions of saving the energy, protecting the environment and removing sulfur, nitrogen and metallic impurities.

Owner:TONGJI UNIV

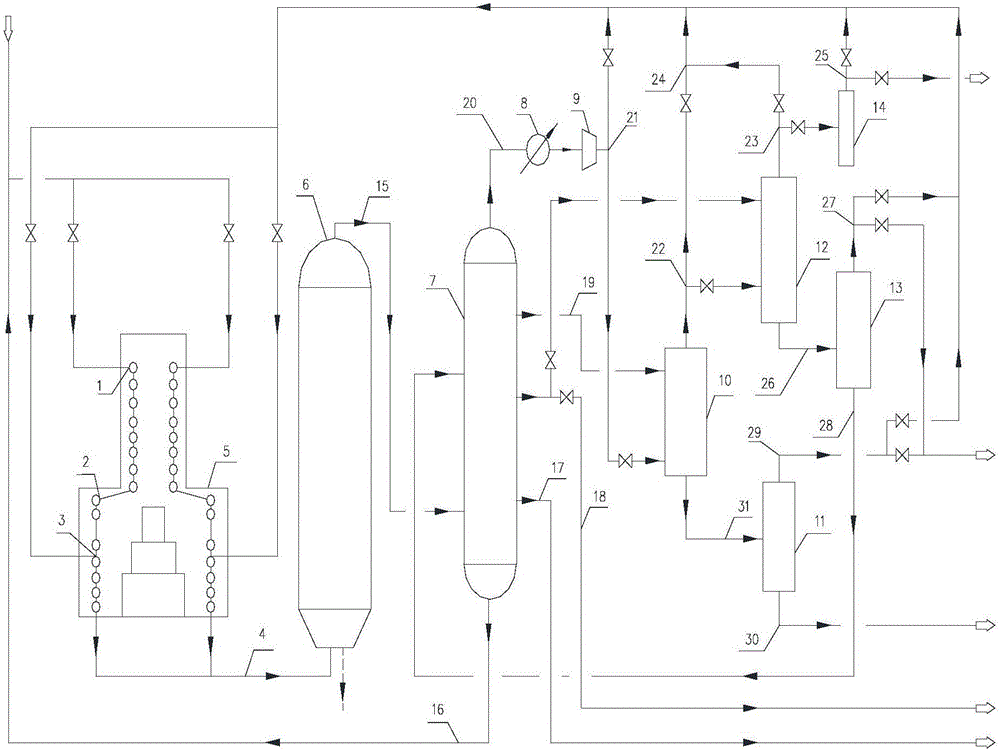

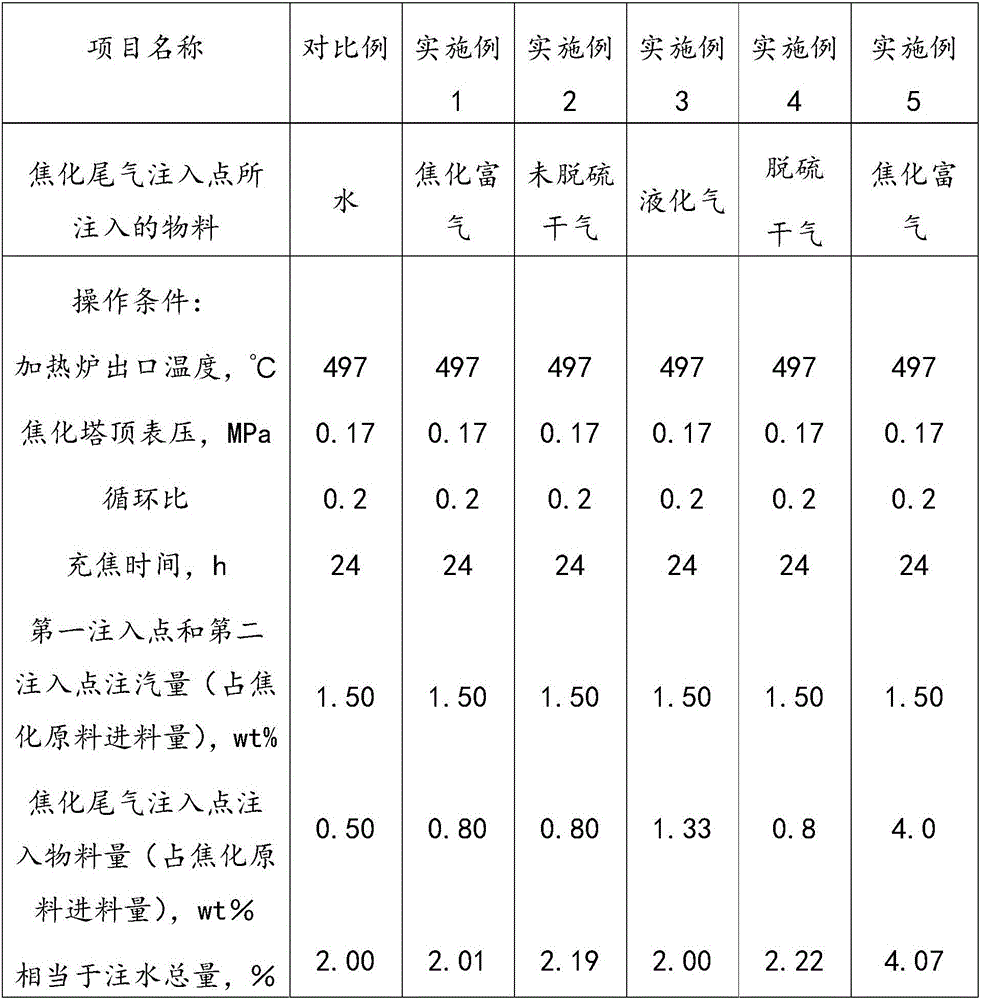

Delayed coking method and apparatus for heavy oil

InactiveCN106433740AIncrease liquid yieldReduce dosageThermal non-catalytic crackingTreatment with plural serial stages onlyWater vaporProcess engineering

The invention provides a delayed coking method and apparatus for heavy oil; according to the method, coking tail gas is injected into a heating furnace radiating segment tube under delayed coking operational process conditions, operating is simple, the required apparatus is simple in structure, the coking tail gas, instead of steam, is injected into the heating furnace radiating segment tube, usage of steam is effectively reduced, the defect that existing coking heating furnace is injected with much water is overcome, processing energy consumption of the apparatus is reduced, sewage emission is decreased, liquid yield of the coking apparatus can be increased through circulation of partial coking tail gas, and especially the yield of coker gas oil is evidently increased.

Owner:SINOPEC ENG GRP CO LTD

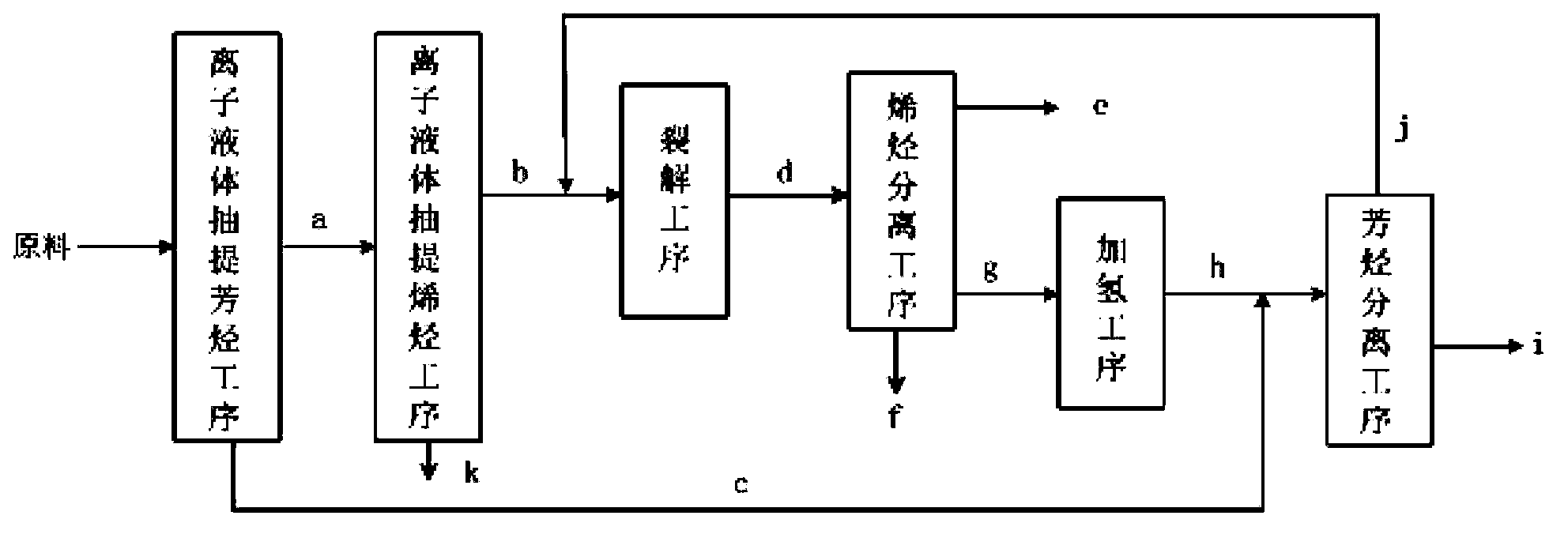

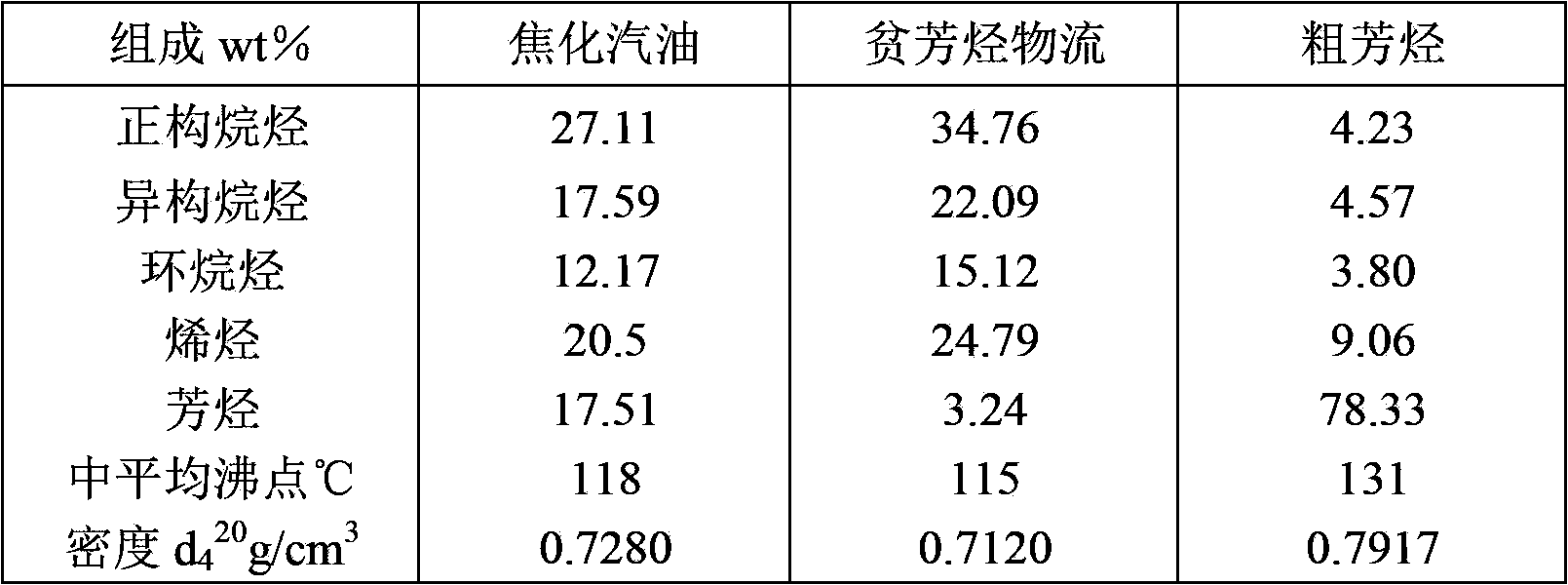

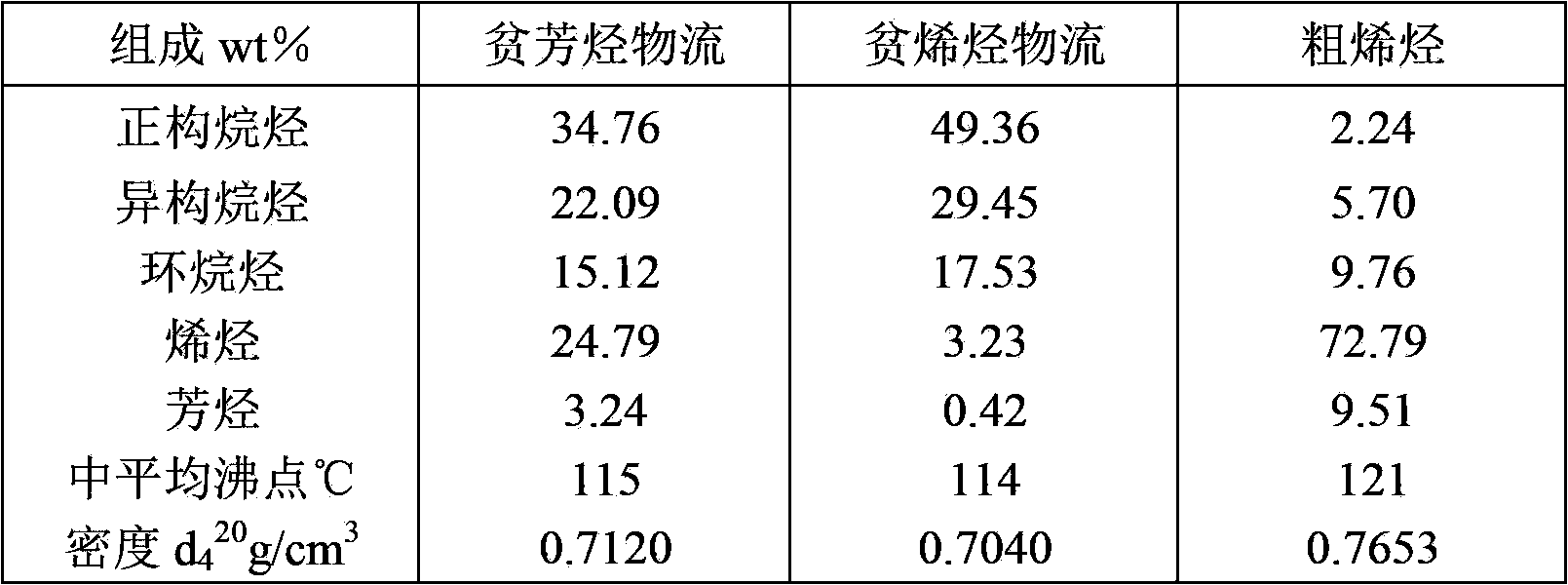

Method for increasing yields of low-carbon olefins and aromatics by coker gasoline steam cracking

ActiveCN103666550AExpand sourceEffective way to useHydrocarbon purification/separationTreatment with plural serial stages onlyGasolineSolvent

The invention relates to a method for increasing yields of low-carbon olefins and aromatics by coker gasoline steam cracking, which comprises the following steps: aromatic extraction by an ionic liquid solvent and olefin extraction by an ionic liquid solvent are respectively performed to pretreat raw oil so as to remove aromatics and olefins, thereby obtaining a hydrocarbon stream in which the aromatic content is lower than 2 wt% and the olefin content is lower than 4 wt%; the hydrocarbon stream enters a steam cracking procedure to be subjected to cracking and separation; the crude aromatic stream is sent into a hydrocracking gasoline aromatic extraction unit to separate the aromatic product; and the obtained stream containing rich saturated hydrocarbons is returned and introduced into the cracking procedure together with a petroleum hydrocarbon stream containing less aromatics to react and produce the low-carbon olefins. The method provides a proper application way for coker gasoline, widens the cracking raw material sources, recycles the non-aromatic components by using the original cracking hydrogasoline aromatic extraction system, and increases the yields of the low-carbon olefins and aromatics in the cracking process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of composite rose flower tea

The invention belongs to the technical field of food processing and particularly discloses a preparation method of composite rose flower tea. The preparation method includes the steps of: 1) weighingraw materials including: 18-30 parts of rose flowers, 5-10 parts of lily, 3-6 parts of radices lithospermi, 3-6 parts of chrysanthemum indicum and 1-5 parts of red dates; 2) processing of rose flowers: successively performing microwave, fumigation and drying treatment to the rose flowers; 3) treatment of other raw materials: mixing and extracting other raw materials to prepare an extract powder; 4) spray coating treatment: spray-coating the rose flowers with the extract powder. The composite rose flower tea has abundant nutrients and is high in sensing quality, and has strong functions of beautifying and nourishing face, quieting heart to nourish spirit and tonifying and activating blood.

Owner:柳州市汉象教育咨询有限责任公司

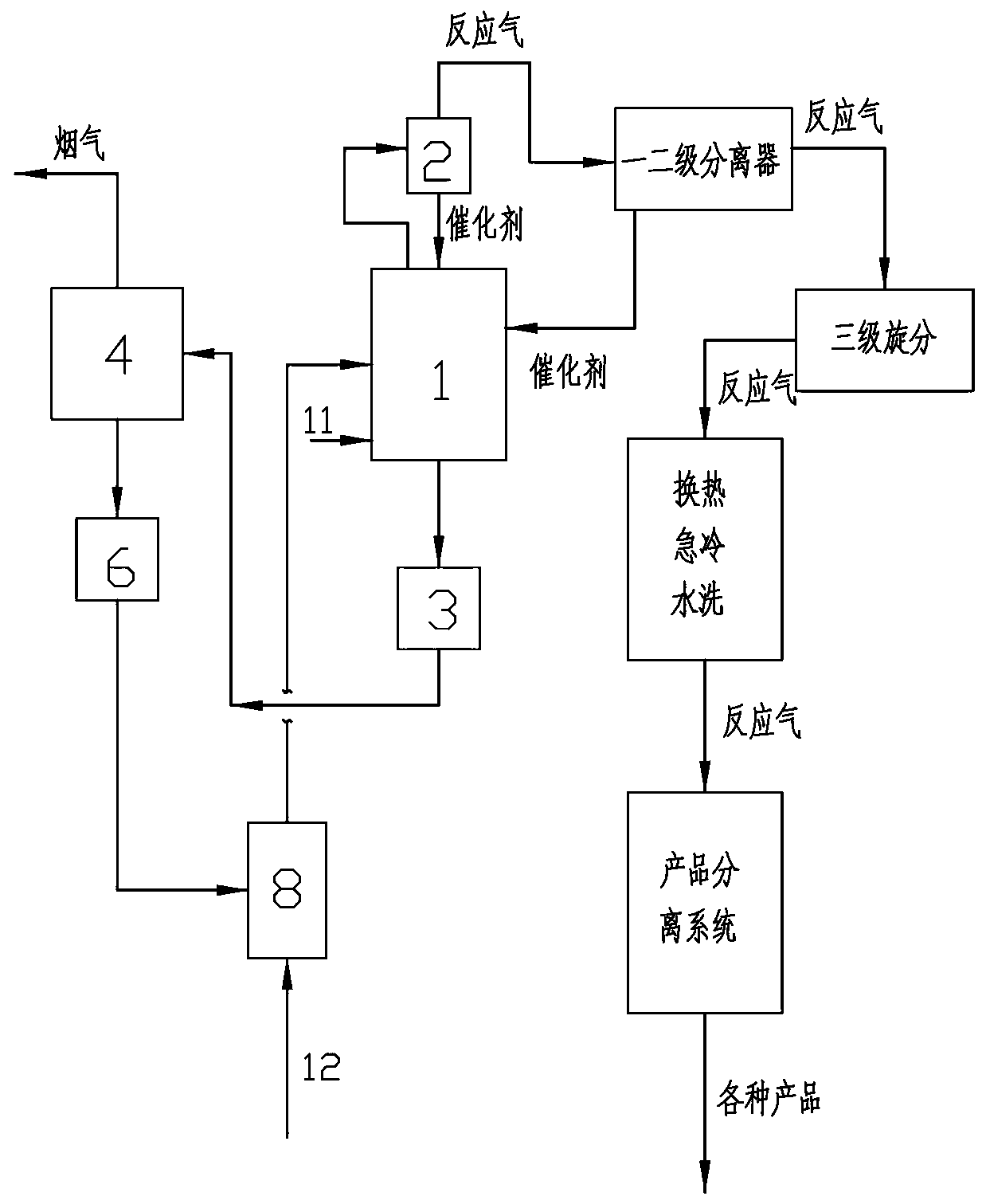

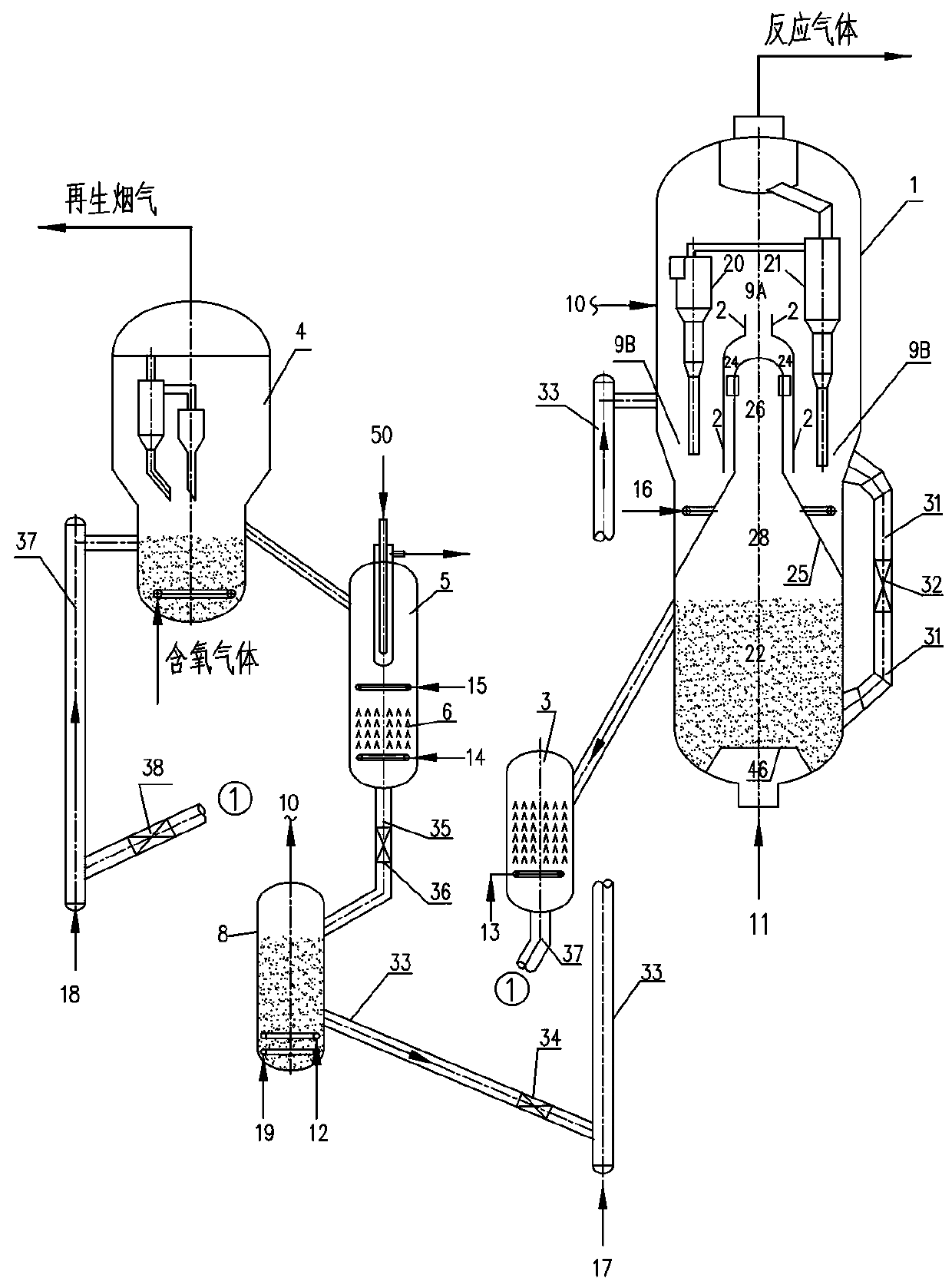

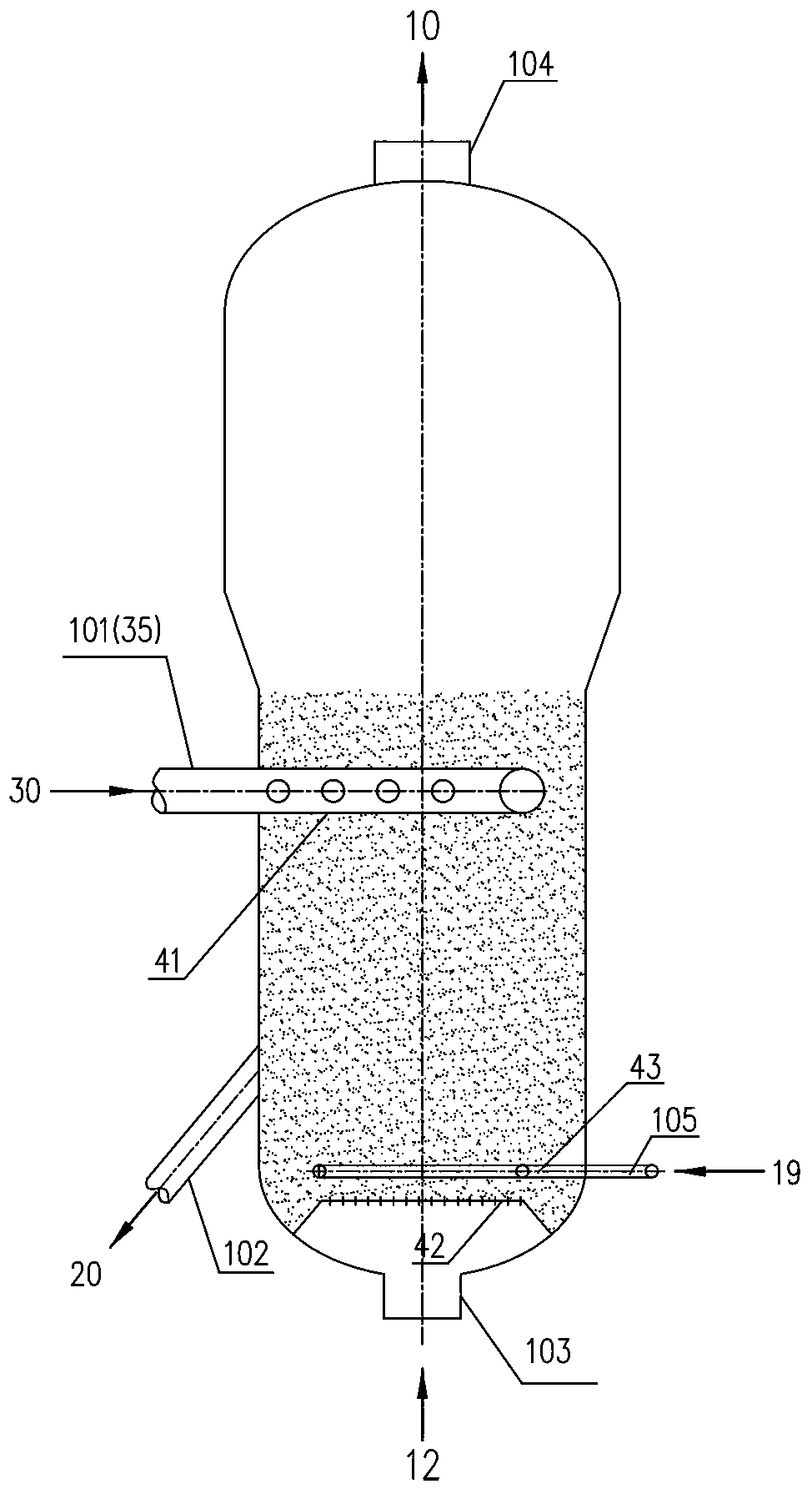

Method and device for improving selectivity of low-carbon olefin preparation using oxygen-containing compound converting

PendingCN111018646AImprove distributionHigh selectivityMolecular sieve catalystCatalyst regeneration/reactivationPtru catalystProcess engineering

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD +1

Ethene cracking furnace of one-way radiant section furnace tube and application in chemical field

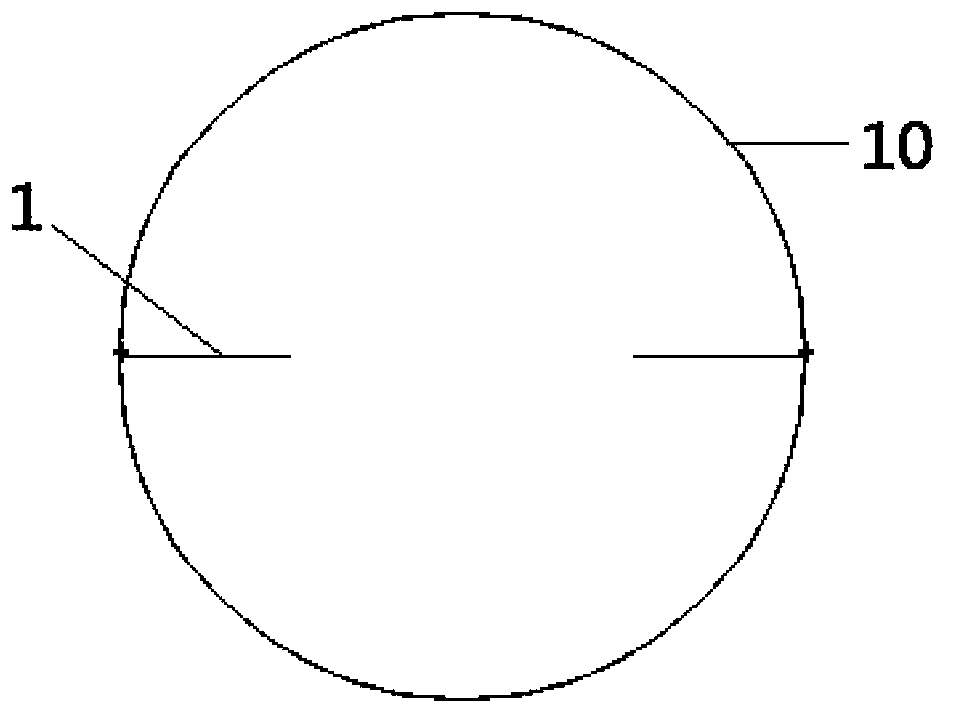

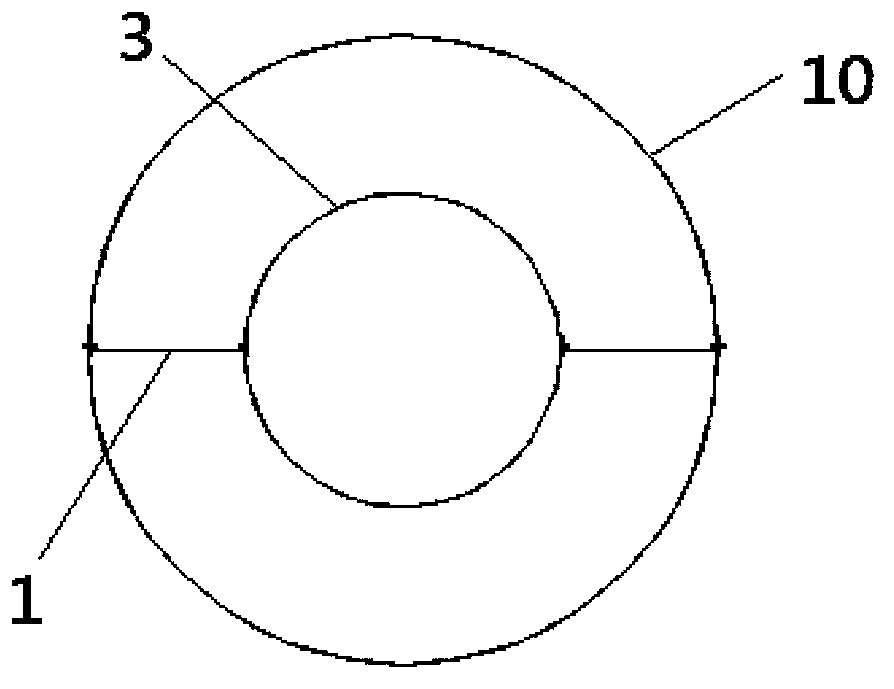

ActiveCN103788981AExtended cleaning cycleReduce coking rateThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingDistortionAlkene

The invention discloses an ethene cracking furnace of a one-way radiant section furnace tube, the ethene cracking furnace comprises a radiant section, the radiant section has a heat exchange tube (10), wherein, a reinforcement heat transfer element is arranged in the heat exchange tube (10), the reinforcement heat transfer element comprises a distortion sheet, and holes are provided on the distortion sheet. The invention also provides an application of the ethene cracking furnace of the one-way radiant section furnace tube in the chemical field. According to the above technical scheme, the reinforcement heat transfer element is arranged on the heat exchange tube of the radiant section of the one-way radiant section furnace tube ethene cracking furnace, good heat transfer effect is realized, the coking rate of the ethene cracking furnace is reduced, cleaning period of the furnace tube is prolonged, the decoking operation is convenient, the integral performance of the ethene cracking furnace is increased, pressure drop in the furnace tube is effectively reduced, the yield of products alkene is increased, and the ethene cracking furnace has good industrial application and prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

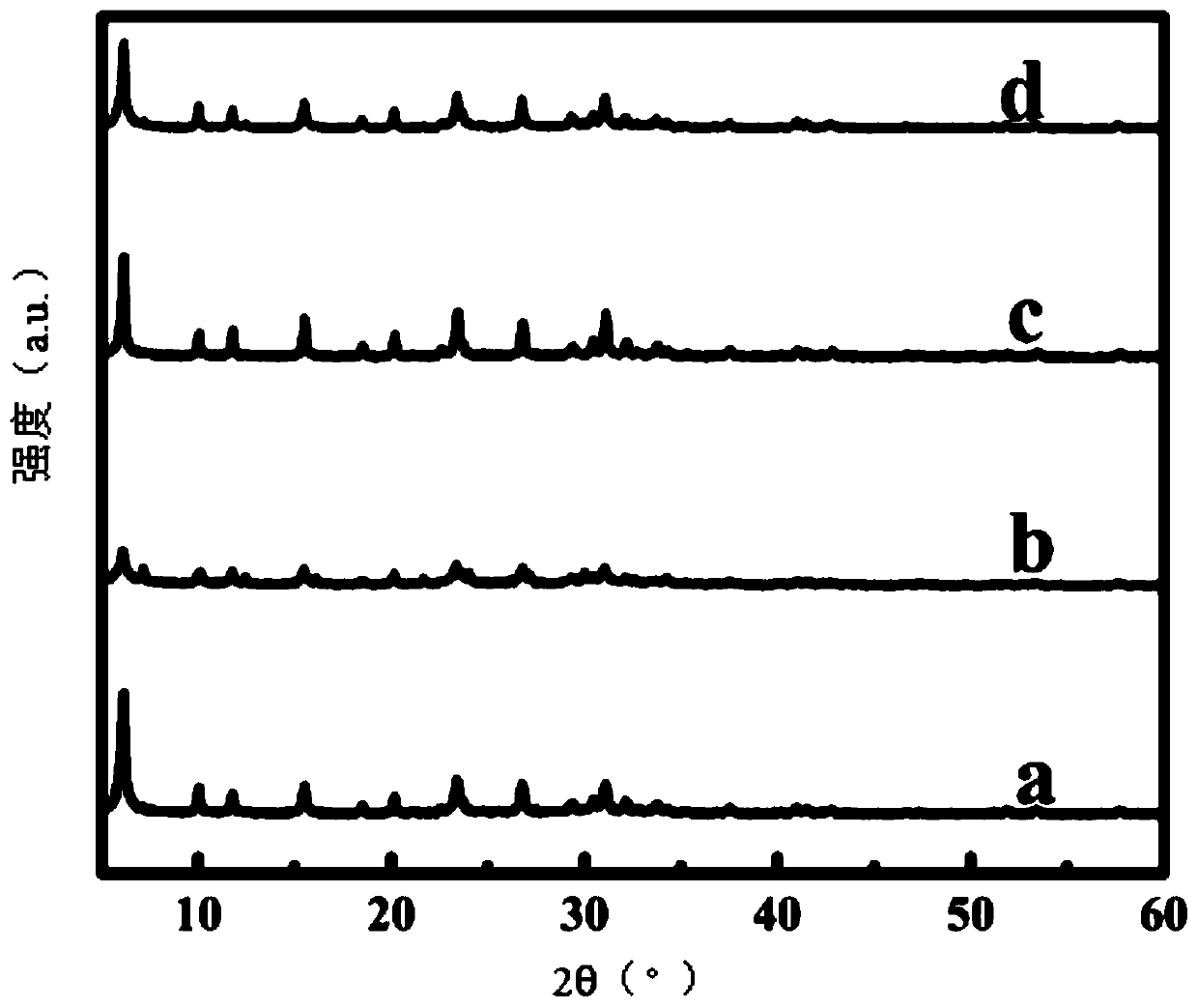

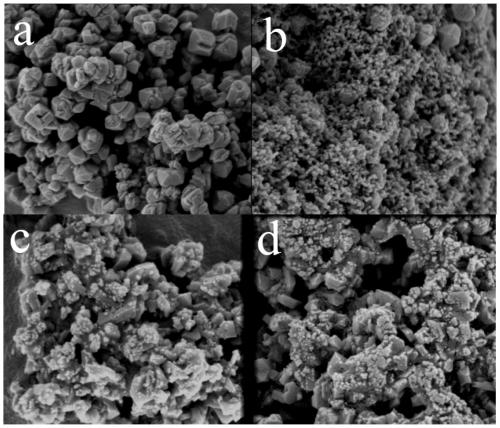

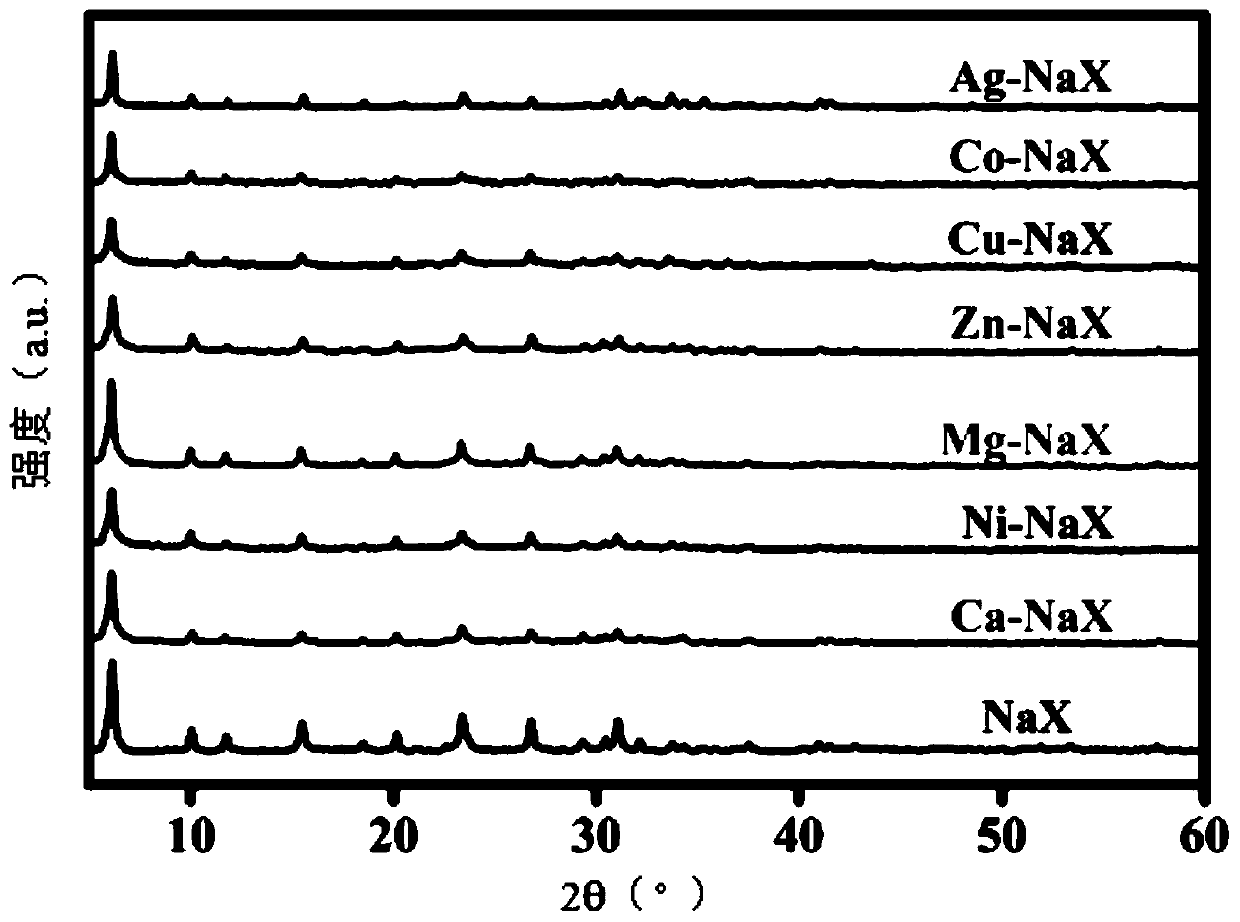

Binder-free FAU type molecular sieve particles and preparation method and application thereof

ActiveCN111302358ARaw materials are cheap and easy to getThe experimental method is simpleMolecular-sieve and base-exchange compoundsMolecular sieveSilicone Gels

The invention provides binder-free FAU type molecular sieve particles and a preparation method and application thereof. The method comprises the following steps that 1, an alkaline solution with an aluminum source dissolved serves as a water phase, and a surfactant aqueous solution and an oil phase are sequentially added to the upper portion of the water phase; (2) a silica gel mixture obtained byuniformly mixing a gelatinizing agent and silica sol is added, and the silica gel mixture penetrates through the oil phase and the surfactant phase to reach the water phase so as to obtain a silica gel precursor; and 3) the oil phase and the surfactant phase are removed, the silica gel precursor and the water phase are aged, and crystallized to obtain the binder-free FAU type molecular sieve particles. The experiment steps are effectively simplified, the experiment process is shortened, the environmental pollution problem caused by the high temperature hot oil is avoided, and the prepared binder-free FAU molecular sieve particles have characteristics of large specific surface area, large hexene adsorption capacity, high adsorption / desorption rate and excellent anti-coking performance in comparison with the particles in the prior art.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for improving stability and activity of catalyst for gas-phase epoxidation of propylene

InactiveCN105013480AHigh activityImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsAlloy catalystGas phase

The invention discloses a method for improving the stability and the activity of a gold catalyst for preparing propylene oxide through propylene epoxidation. Silver metals are added to the gold catalyst to form nanometer gold silver alloy particles of which the particle sizes are small, and the alloy is used for changing oxygen adsorption, so that the content and the nature of coke are further improved, and the catalyst activity and the stability of a gold-silver alloy catalyst are greatly improved.

Owner:EAST CHINA UNIV OF SCI & TECH

Bismuth- and phosphorus-containing reforming catalysts, method of making and naphtha reforming process

InactiveUS7538063B2Reduce coking rateImprove octaneOther chemical processesCatalytic naphtha reformingNaphthaProcess engineering

Owner:INST FR DU PETROLE

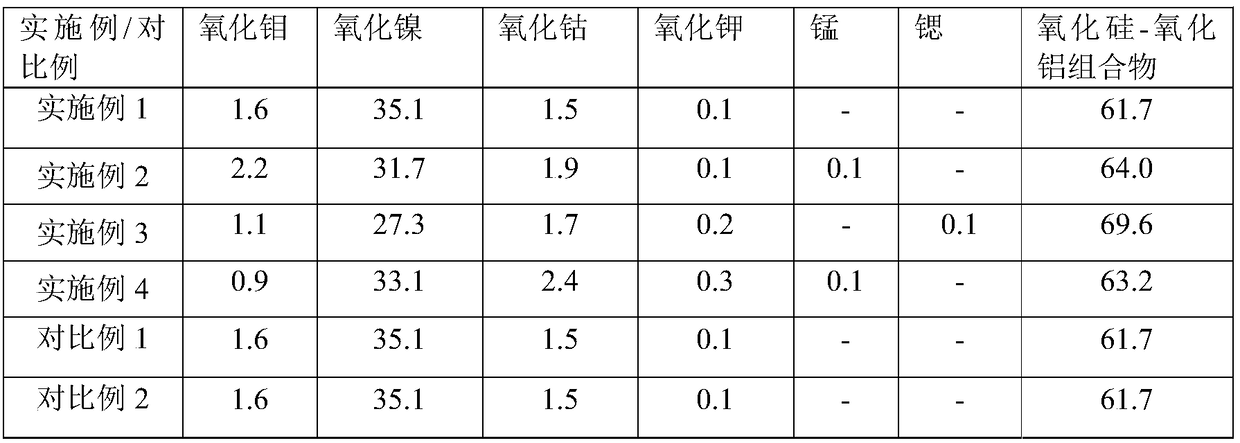

Unsaturated C5 fraction and hydrogenation method

ActiveCN109439364AHigh hydrogenation selectivityReduce reactivityHeterogenous catalyst chemical elementsRefining by selective hydrogenationPotassiumFixed bed

The invention relates to an unsaturated C5 fraction and hydrogenation method. According to the method, by the aid of a fixed bed reactor, a used catalyst is a nickel hydrogenation catalyst, and the catalyst is reduced by the aid of hydrogen or hydrogen-containing gas at the temperature of 350-500 DEG C. The catalyst comprises main active components and a silicon oxide-aluminum oxide composition, and the main active components include molybdenum, nickel, cobalt and potassium. Hydrogenation process conditions include that a reactor inlet temperature is 30-660 DEG C, reaction pressure is 1.5-6.0MPa, liquid volume per hour is 1.0-6.0h<-1>, and the volume ratio of hydrogen to oil is 100:400. According to the unsaturated C5 fraction and hydrogenation method, the used nickel-based saturated hydrogenation catalyst has high hydrogenation activity and the advantages that the catalyst is resistant to sulfur, water and colloid, and hydrogenation reaction can be performed at low temperature.

Owner:兰州金润宏成新材料科技有限公司

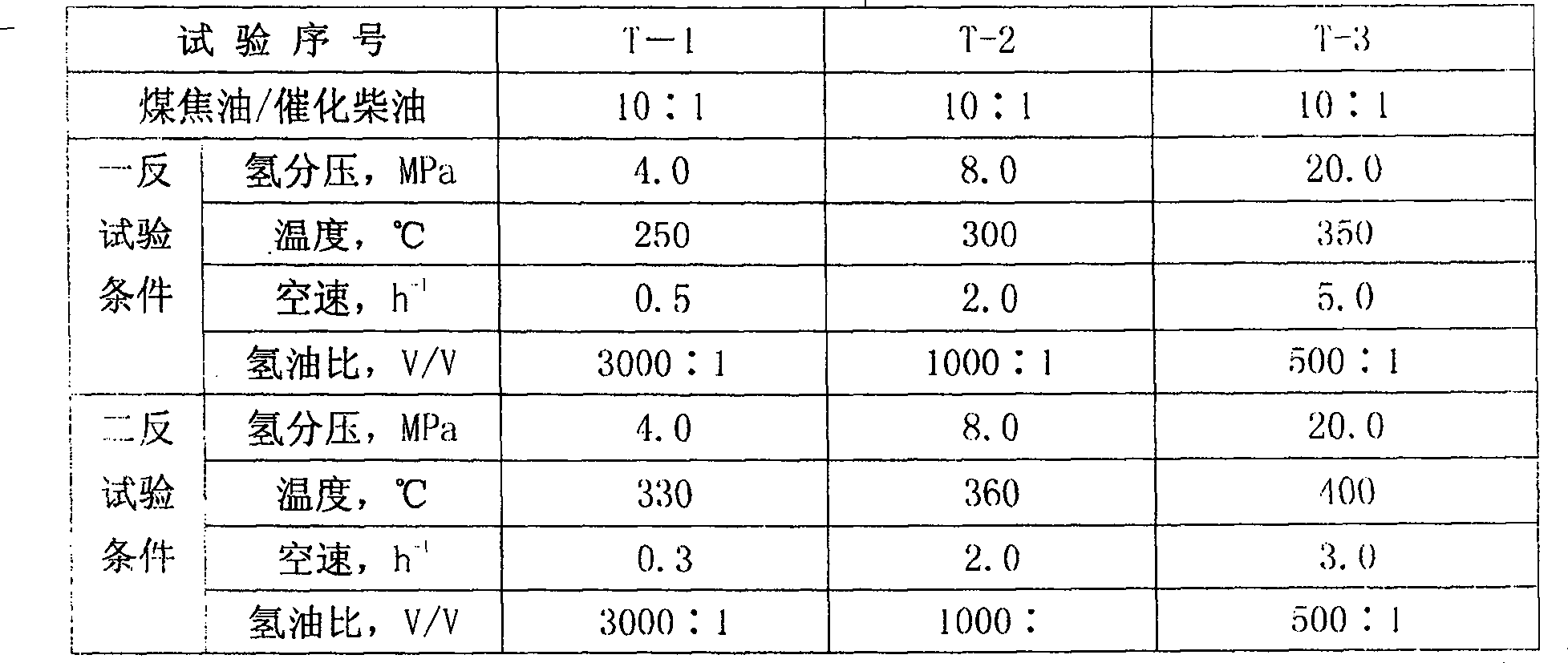

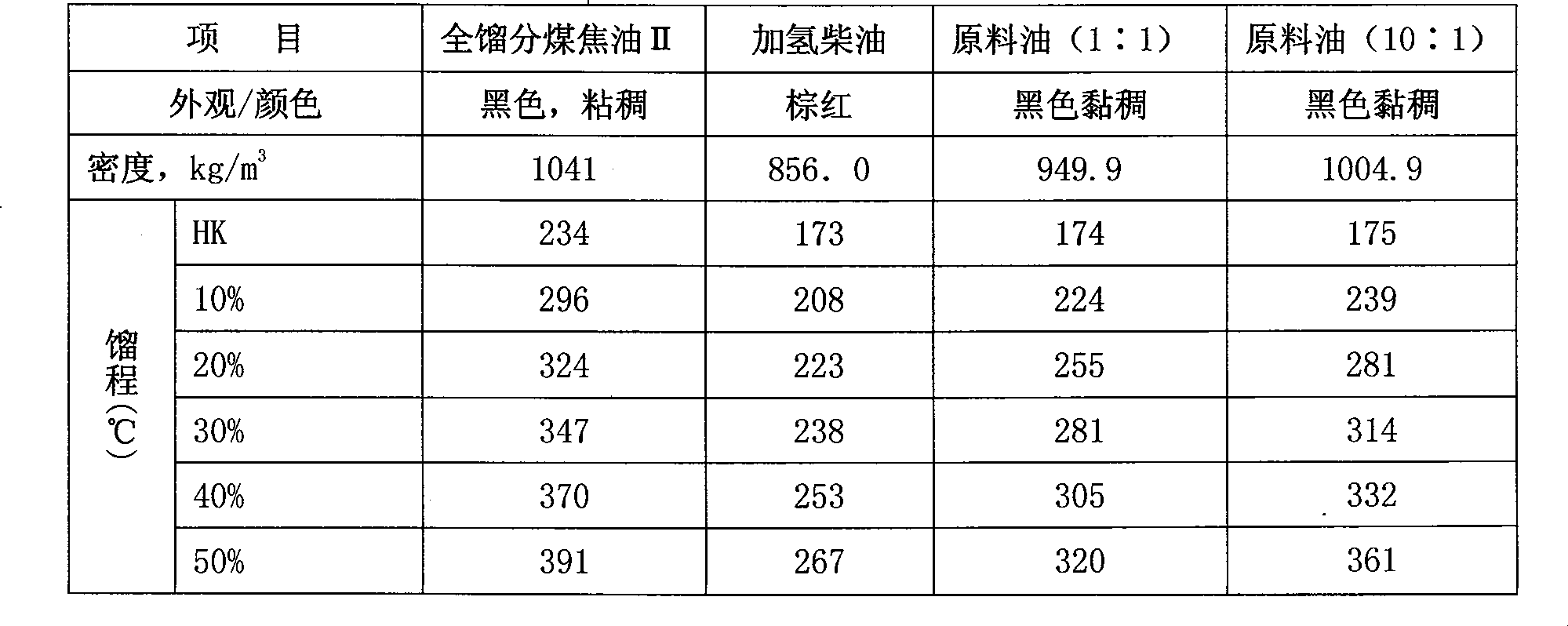

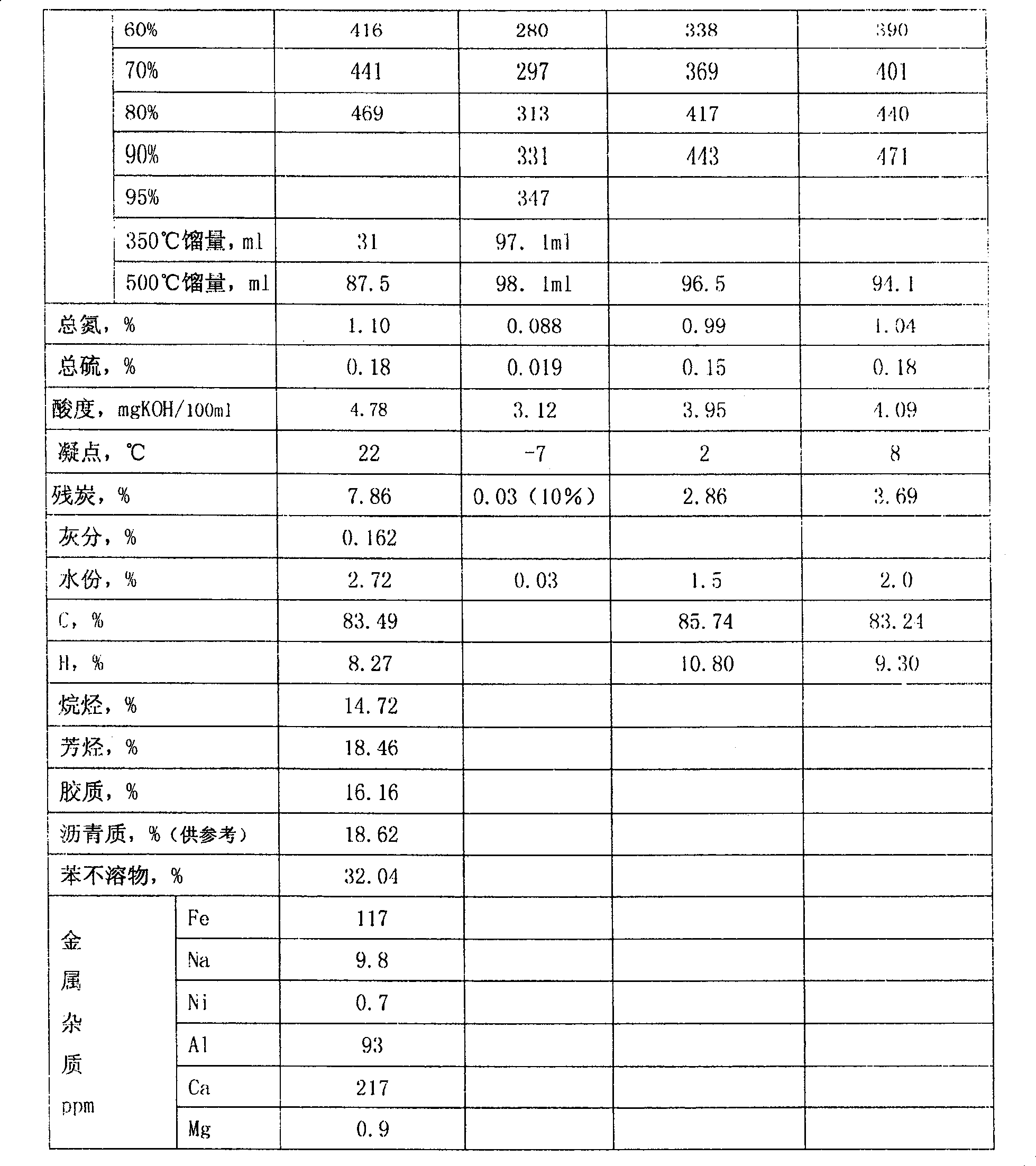

Method of producing fuel oil by coal tar hydrogenation modifying

ActiveCN100532509CReduce temperature riseReduce coking rateTreatment with hydrotreatment processesGasoline stabilisationLow nitrogenSulfur

The present invention relates to a method for producing fuel oil by utilizing coal tar. It is characterized by that said method includes the following steps: after the whole coal tar in which the moisture and ash are removed and diluting oil are mixed according to a certain mixing ratio, making the obtained mixture be successively passed through a shallow hydrogenation unit with hydrogenation protecting agent and prehydrogenation catalyst and a deep hydrogenation unit with main hydrogenation catalyst, then making the product obtained after deep hydrogenation undergo the processes of high-pressure separation, low-pressure separation and fractionation so as to obtain light-oil fraction, medium-oil fraction and tail-oil fraction, namely obtain low-sulfur low-nitrogen fuel oil and light oil product.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

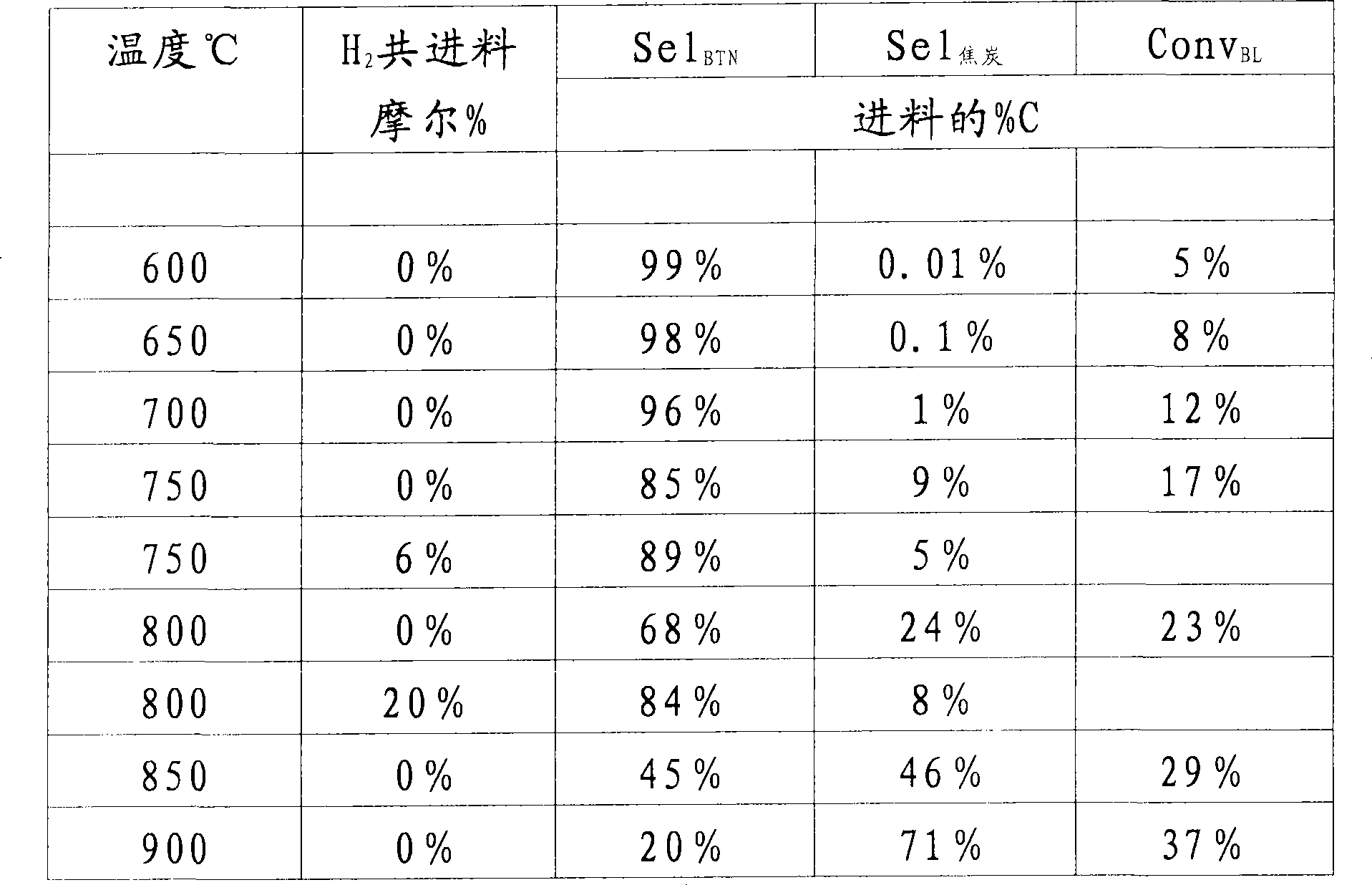

Process for methane conversion

InactiveCN101460429AReduce exposureExtend your lifeLiquid hydrocarbon mixtures productionHydrocarbon by hydrocarbon condensationReaction zoneAromatic hydrocarbon

A process for converting methane to higher hydrocarbon(s) including aromatic hydrocarbon(s) in a reaction zone comprises providing to a hydrocarbon feedstock containing methane and a catalytic particulate material to the reaction zone and contacting the catalytic particulate material and the hydrocarbon feedstock in a substantially countercurrent fashion in the reaction zone, while operating the reaction zone under reaction conditions sufficient to convert at least a portion of said methane to a first effluent having said higher hydrocarbon(s).

Owner:EXXONMOBIL CHEM PAT INC

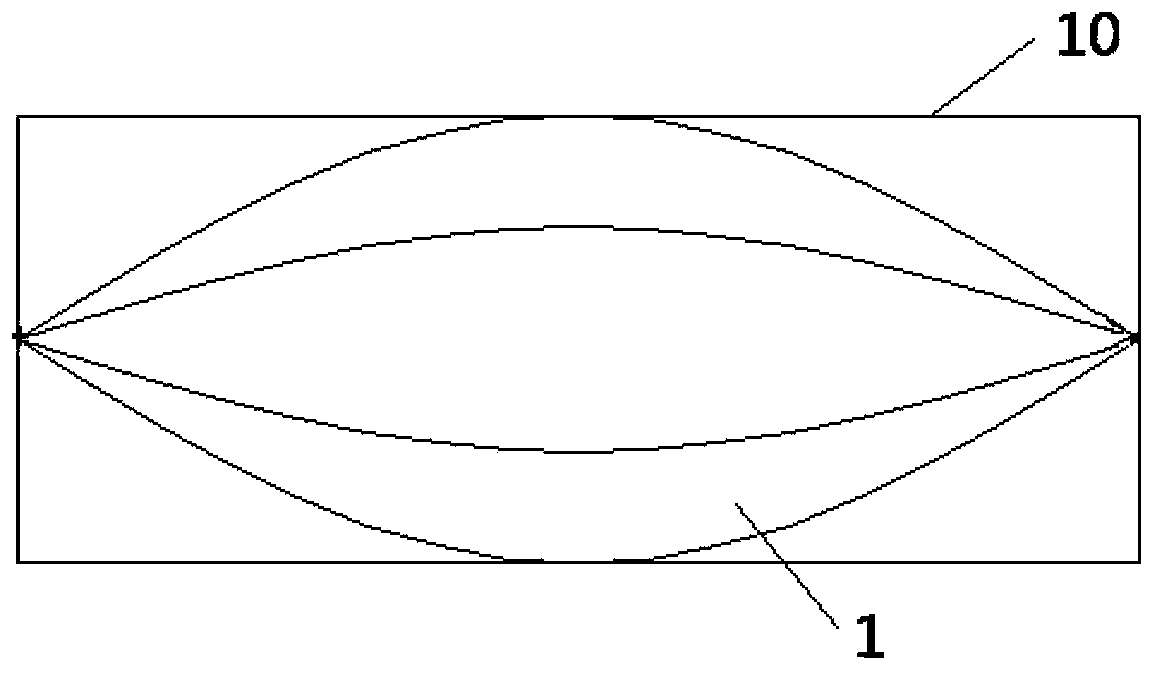

Two-range radiant section boiler tube ethene cracking furnace and application of ethene cracking furnace in chemical field

ActiveCN103788982AExtended cleaning cycleReduce coking rateThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingEngineeringAlkene

The invention discloses a two-range radiant section boiler tube ethene cracking furnace, which comprises a radiant section, the radiant section comprises a heat exchange tube (10), wherein, a reinforcement heat transfer element is arranged in the heat exchange tube (10), the reinforcement heat transfer element comprises a distortion sheet, and the distortion sheet comprises apertures. The invention also provides an application of the ethene cracking furnace in a chemical field. According to the technical scheme, the reinforcement heat transfer element is arranged in the heat exchange tube of the radiant section of the two-range radiant section boiler tube ethene cracking furnace, good heat transfer effect is realized, the coking rate of the ethene cracking furnace is reduced, the cleaning period of the furnace tube is prolonged, the decoking operation is convenient, the integral performance of the ethene cracking furnace is increased, pressure drop in the furnace tube is effectively reduced, the products alkene yield is increased, and the two-range radiant section boiler tube ethene cracking furnace has good industrial application and prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com