Preparation method for titanium silicalite molecular sieve and applications

A technology of titanium-silicon molecular sieve and silicon source, applied in the direction of molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problems of increasing catalyst costs, wasting gold, and catalyst deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

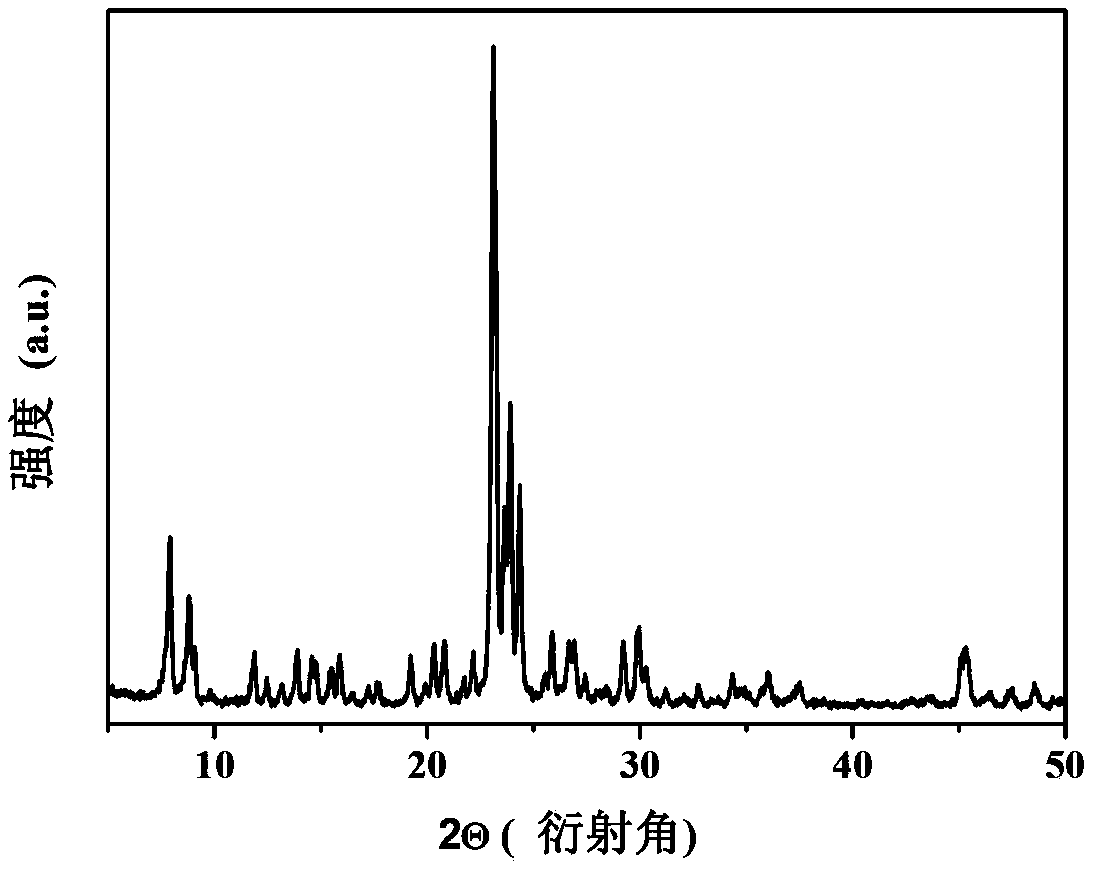

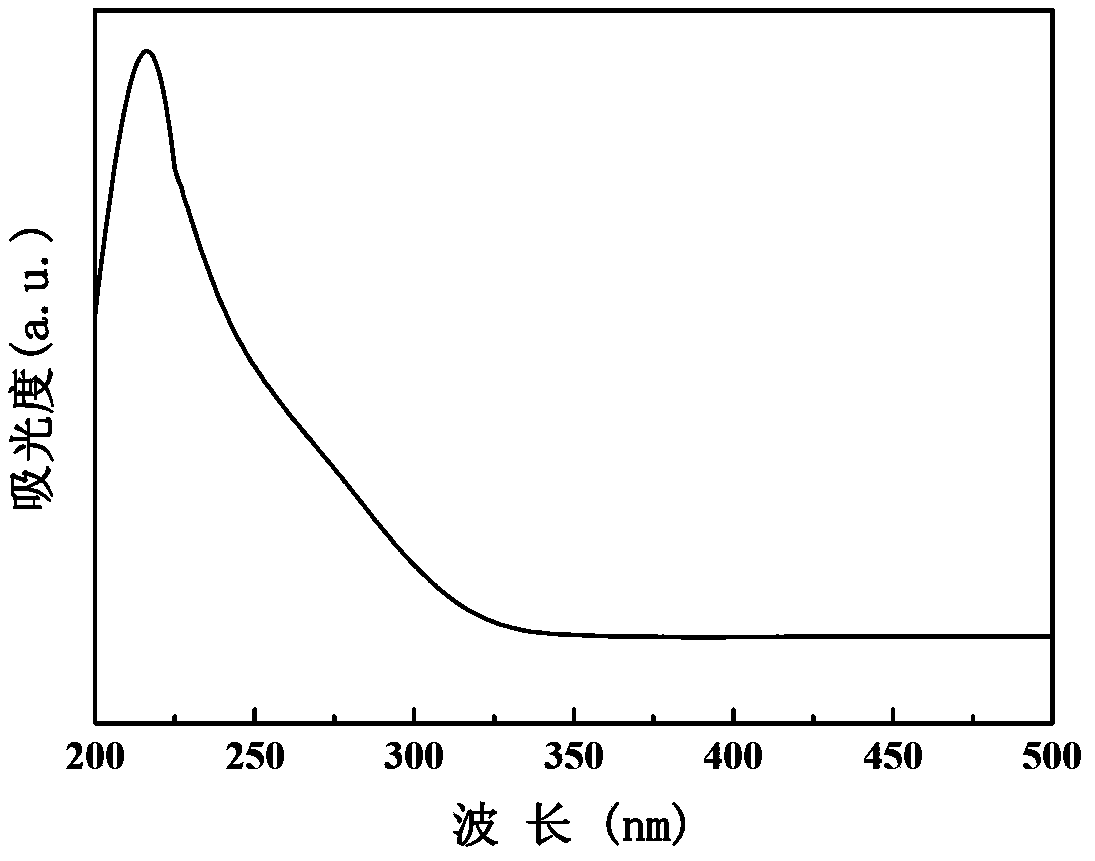

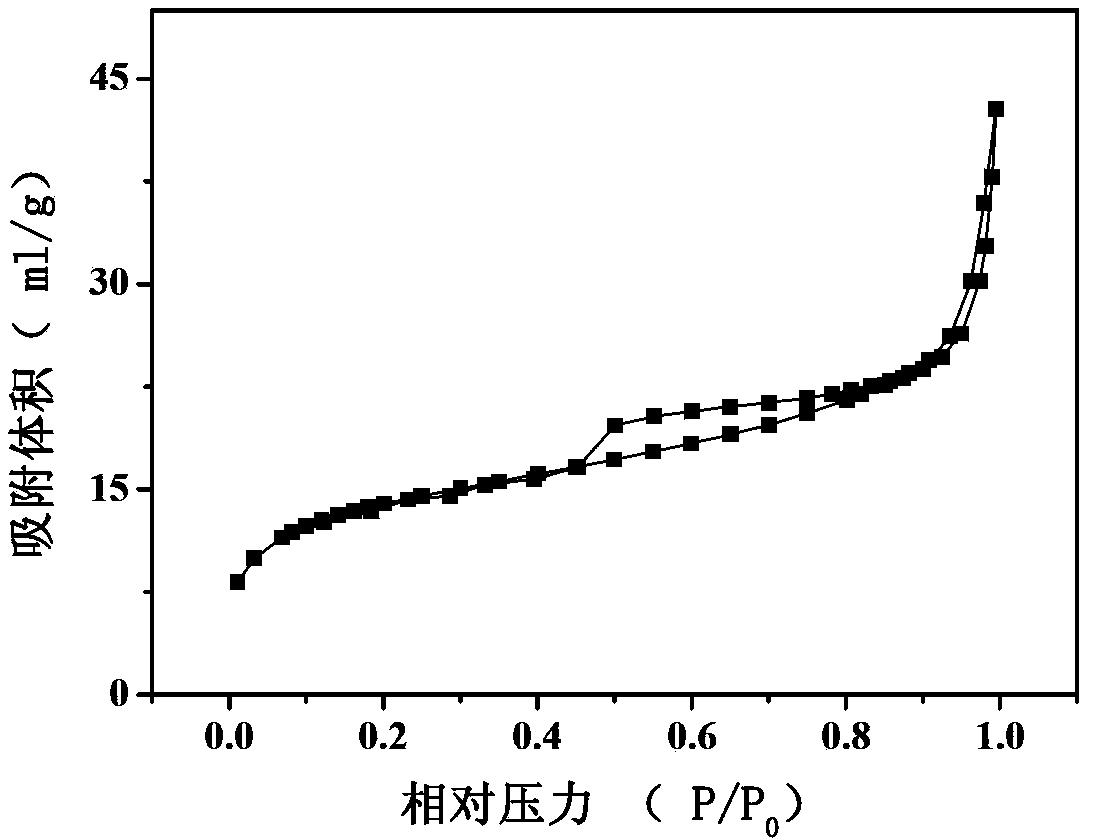

[0063] Preparation of Ti-Si Molecular Sieve TS-1 with Micropores Blocked by Template Agent

[0064] Take 1.5g of Tween-20 and 25g of deionized water in a beaker and mix and stir to obtain a mixed solution 1. Take 66g of ethyl orthosilicate and 26g of tetrapropylammonium hydroxide into solution 1 and stir for 30 minutes to obtain mixed solution 2. 20 mL of isopropanol and 0.22 g of n-butyl titanate were mixed and stirred for 1 hour to obtain a mixed solution 3. Solution 3 was added to solution 2 at a rate of 0.5 ml / min and stirred for 1 hour to obtain solution A. The mixed solution A was dealcoholized at 80°C for 2 hours. The solution after alcohol removal was placed in an autoclave, crystallized at 160°C for 18 hours, taken out, washed and dried.

Embodiment 2

[0066] Preparation of Ti-Si Molecular Sieve TS-1 with Micropores Blocked by Template Agent

[0067] Take 10g of Tween-20 and 100g of deionized water in a beaker and mix and stir to obtain a mixed solution 1. Take 66g of ethyl orthosilicate and 52g of tetrapropylammonium hydroxide into solution 1 and stir for 30 minutes to obtain mixed solution 2. 20 mL of isopropanol and 3.08 g of n-butyl titanate were mixed and stirred for 1 hour to obtain a mixed solution 3 . Solution 3 was added to solution 2 at a rate of 0.1 ml / min and stirred for 1 hour to obtain solution A. The mixed solution A was dealcoholized at 80°C for 6 hours. The solution after alcohol removal was placed in an autoclave, crystallized at 180 degrees for 48 hours, taken out, washed and dried.

Embodiment 3

[0069] Get 0.5g of the carrier in Example 1 and place it in a 250mL beaker, add 10mL concentration of chloroauric acid solution of 0.001mol / L to it, stir for 30 minutes, adjust the pH to 7 with 1mol / L sodium hydroxide, and age for 6 hours; after centrifugation and washing, the catalyst was vacuum-dried overnight at 30°C to obtain a catalyst with a low loading of 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com