Silicoaluminophosphate molecular sieve and preparation method and application thereof

A silicoaluminophosphate and molecular sieve technology, applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of low carbon olefin selectivity, low raw material conversion rate, large molecular sieve grain size, etc. Achieve high selectivity, easy industrial production, and long catalyst life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

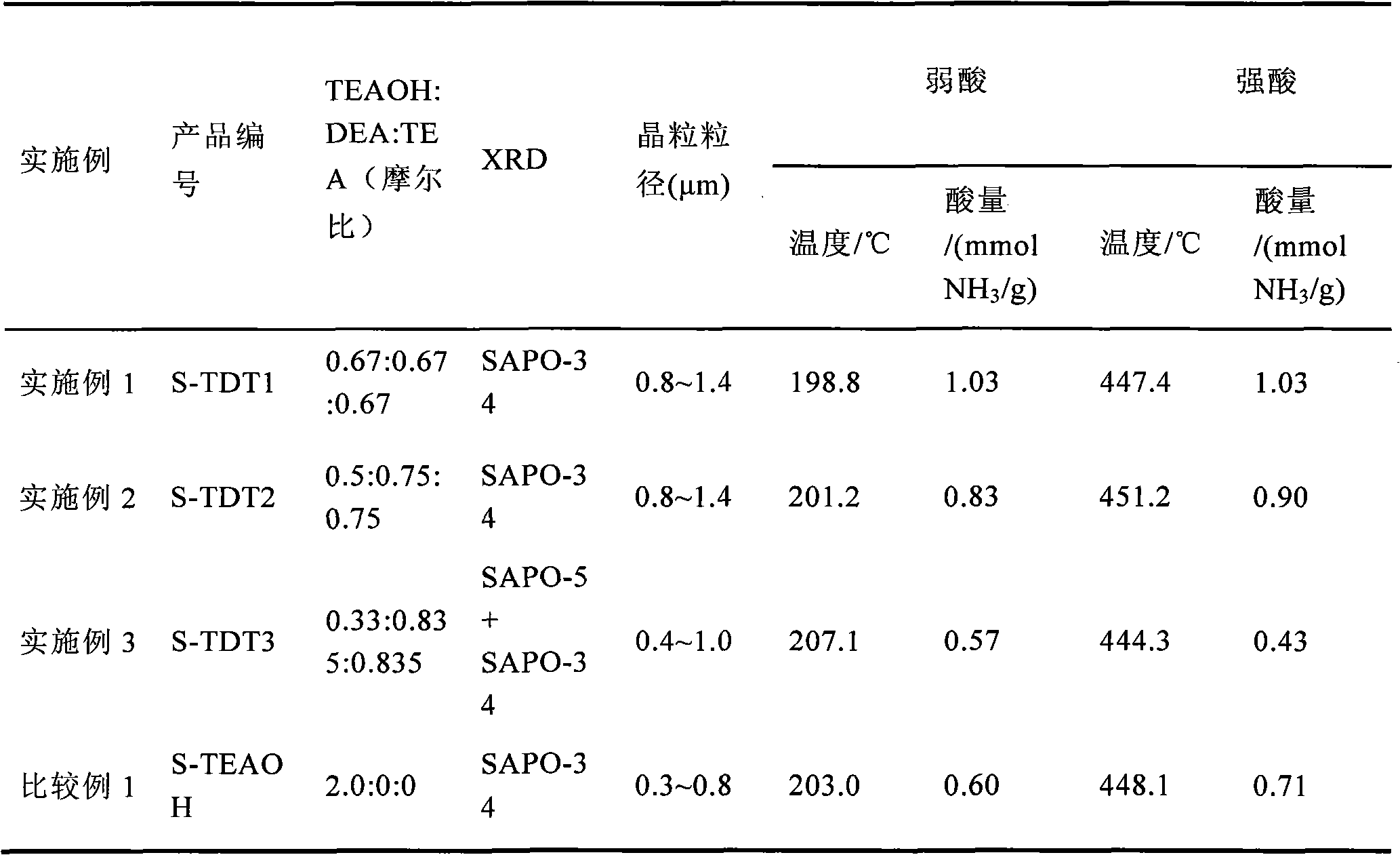

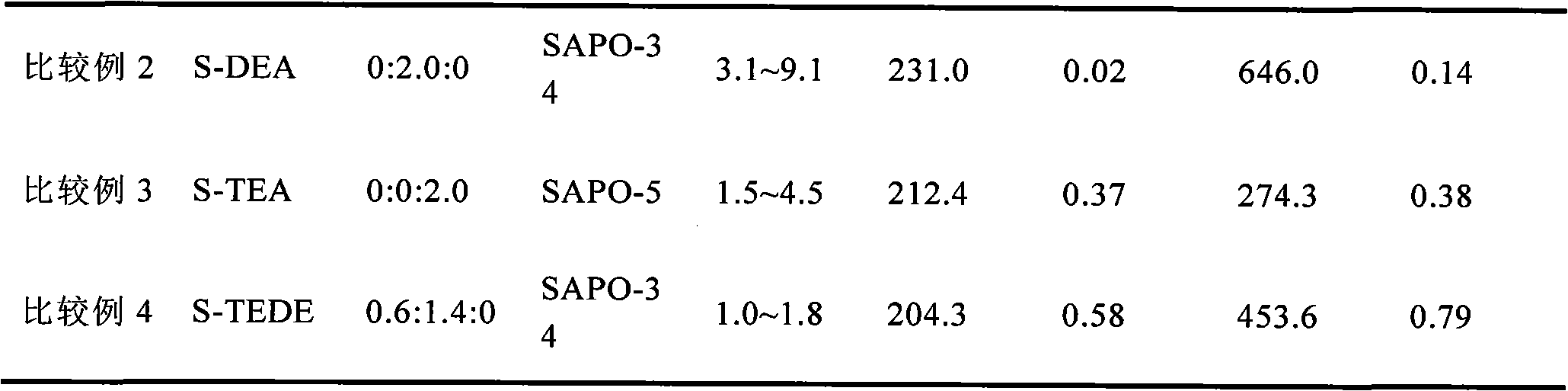

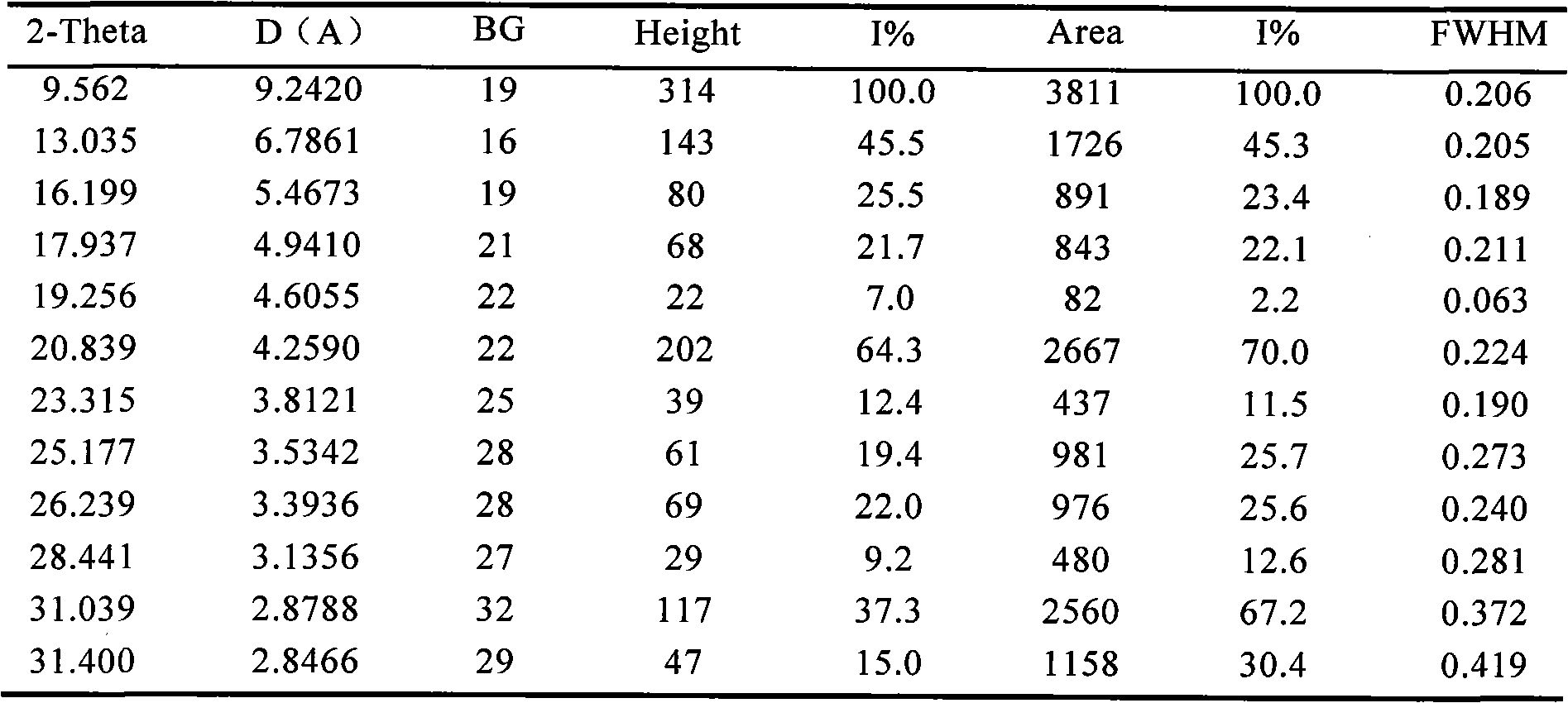

[0026] Synthesis of SAPO-34 Molecular Sieve

[0027] According to the ratio: Al 2 o 3 :P 2 o 5 : 0.6SiO2 2 :xTEAOH:yDEA:(2-x-y)TEA:53H 2 O Weigh the raw materials, and the values of x and y are shown in Table 1.

[0028] Mix a certain amount of pseudo-boehmite, phosphoric acid, and deionized water in a certain order, and stir thoroughly for a certain period of time until uniform, then add 30% silica sol, and after fully stirring, slowly mix the three template agents TEAOH, DEA, and TEA successively Add it to the mixture, and then stir it for a certain period of time to form a gel. The prepared gel was transferred into a high-pressure titanium alloy reactor, sealed, kept stirring under its own pressure, and crystallized by temperature programming, crystallization at 110°C for 24 hours, and crystallization at 200°C for 72 hours. Take out the solid product, wash it repeatedly with deionized water until it becomes neutral, and place it in a drying oven at 110°C to dry ove...

Embodiment 4

[0040] Preparation of SAPO-34 Molecular Sieve Catalyst

[0041] The original powders of silicoaluminophosphate molecular sieves synthesized in Examples 1-3 and Comparative Examples 1-4 were S-TDT1, S-TDT2, S-TDT3, S-TEAOH, S-DEA, S-TEA, S-TEDE Calcined at 550°C for 4.0 hours to remove the template agent, cooled to room temperature, and after tableting and crushing, sieve molecular sieve particles with a particle size of 80-100 mesh, which are sequentially numbered as C-TDT1, C-TDT2, C-TDT3, C-TEAOH, C-DEA, C-TEA, C-TEDE catalysts, pending evaluation.

Embodiment 5

[0043] SAPO-34 Molecular Sieve Catalyst Evaluation Reaction 1

[0044] Using a fixed bed catalytic reaction device, the reactor is a stainless steel tube, and the catalysts C-TDT1, C-TDT2, C-TDT3, C-TEAOH, C-DEA, C-TEA, and C-TEDE prepared in Example 4 are respectively subjected to MTO The reaction activity evaluation, the technological conditions used in the evaluation are: the loading amount of catalyst is 1.5 grams, the reaction temperature is 425°C, the reaction pressure is normal pressure, the raw material is 99.50mol% methanol, and the mass space velocity is 1.0 hour -1 , the nitrogen flow rate is 60 ml / min. After gas-liquid separation of the product, the gas phase product was analyzed online by gas chromatograph GC6890N, and the liquid phase product was analyzed by gas chromatograph GC6820. The evaluation results are shown in Table 3.

[0045] Table 3 Results of Methanol Conversion to Light Olefins

[0046]

[0047] * The activity time is defined as the time at wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com