Patents

Literature

963results about "Molecular-sieve silicoaluminophosphates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicoaluminophosphate molecular sieve

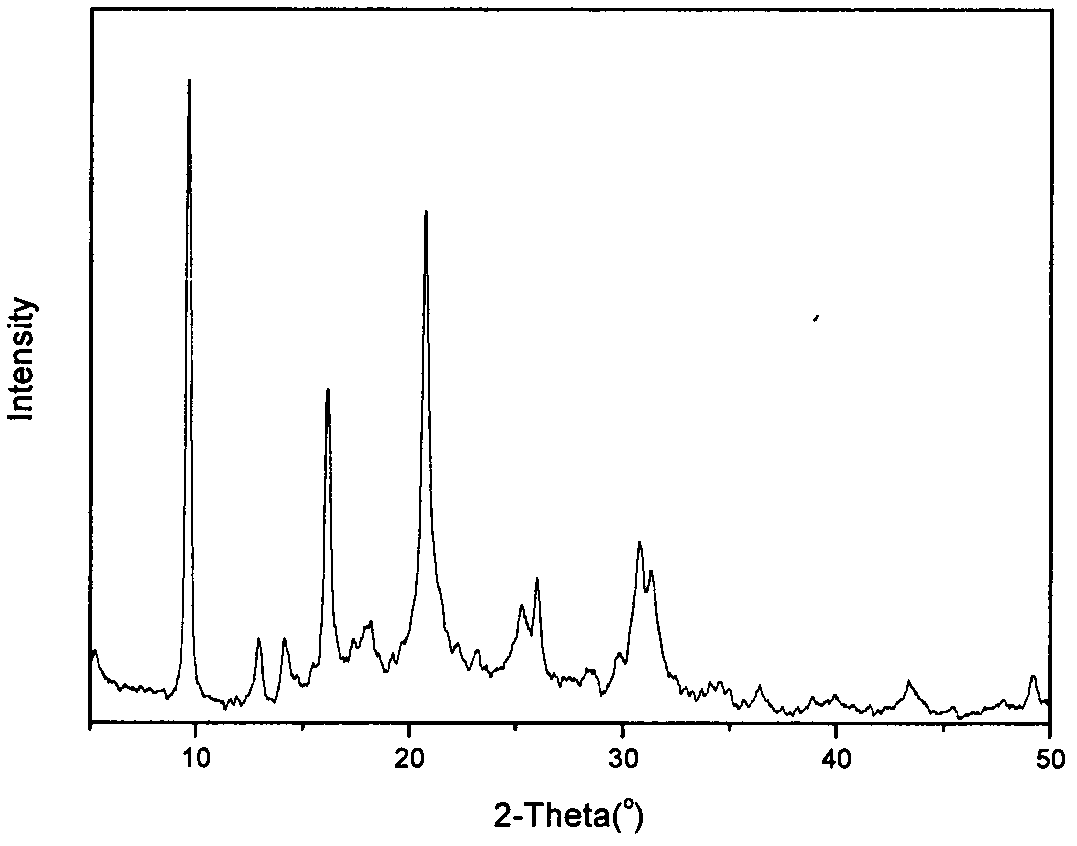

InactiveUS20050096214A1Improve catalytic performanceMolecular sieve catalystsCatalyst activation/preparationMolecular sieveX-ray

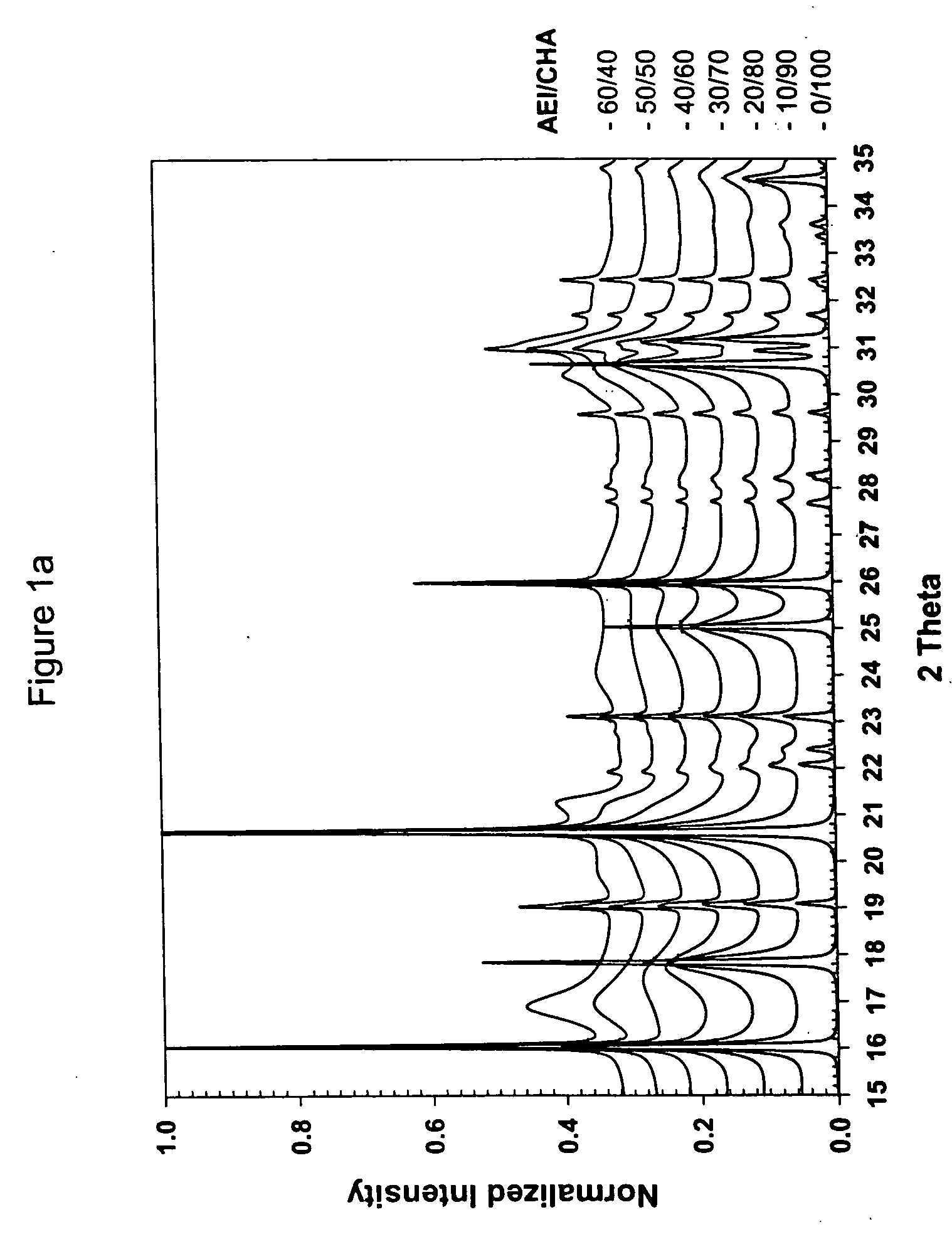

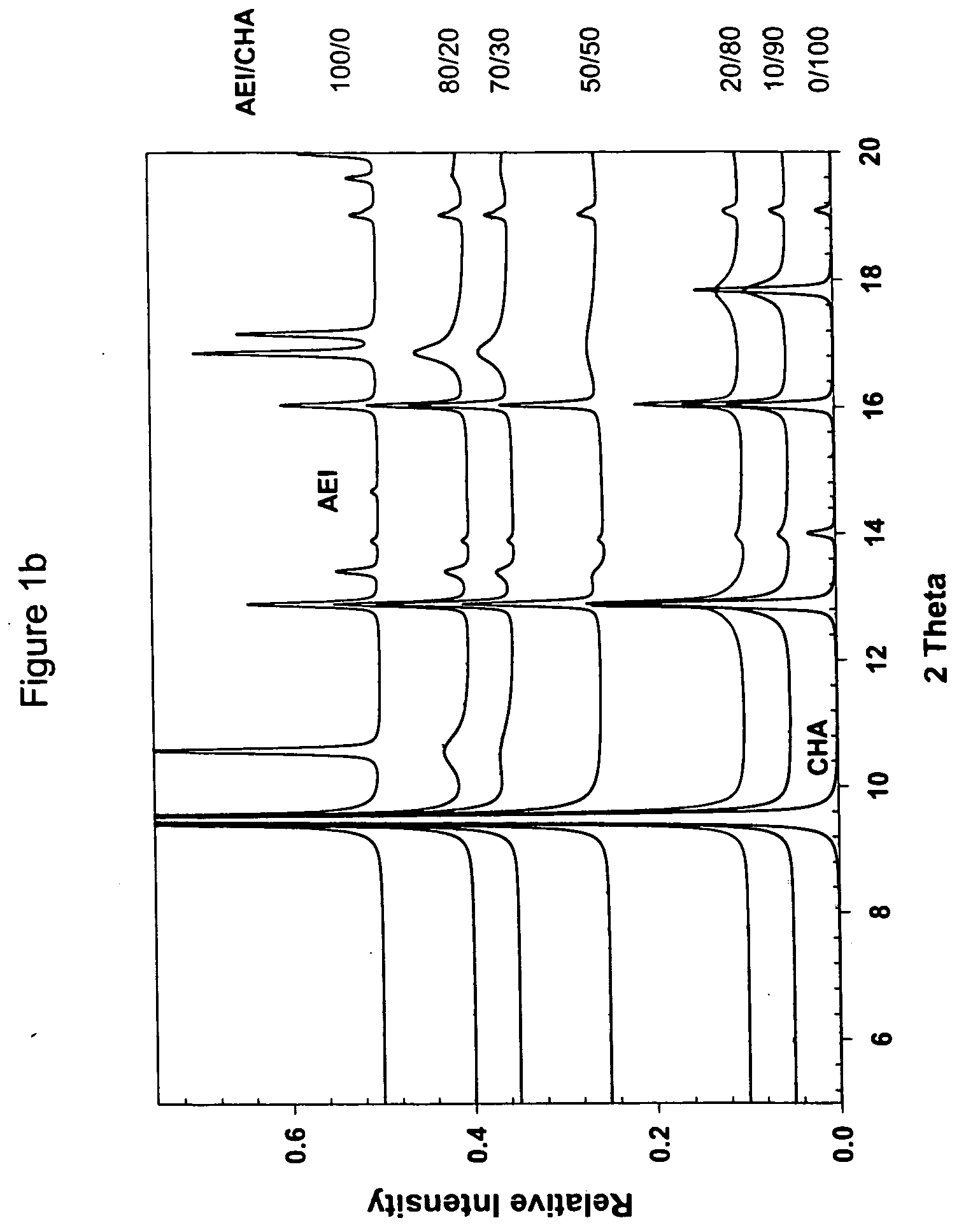

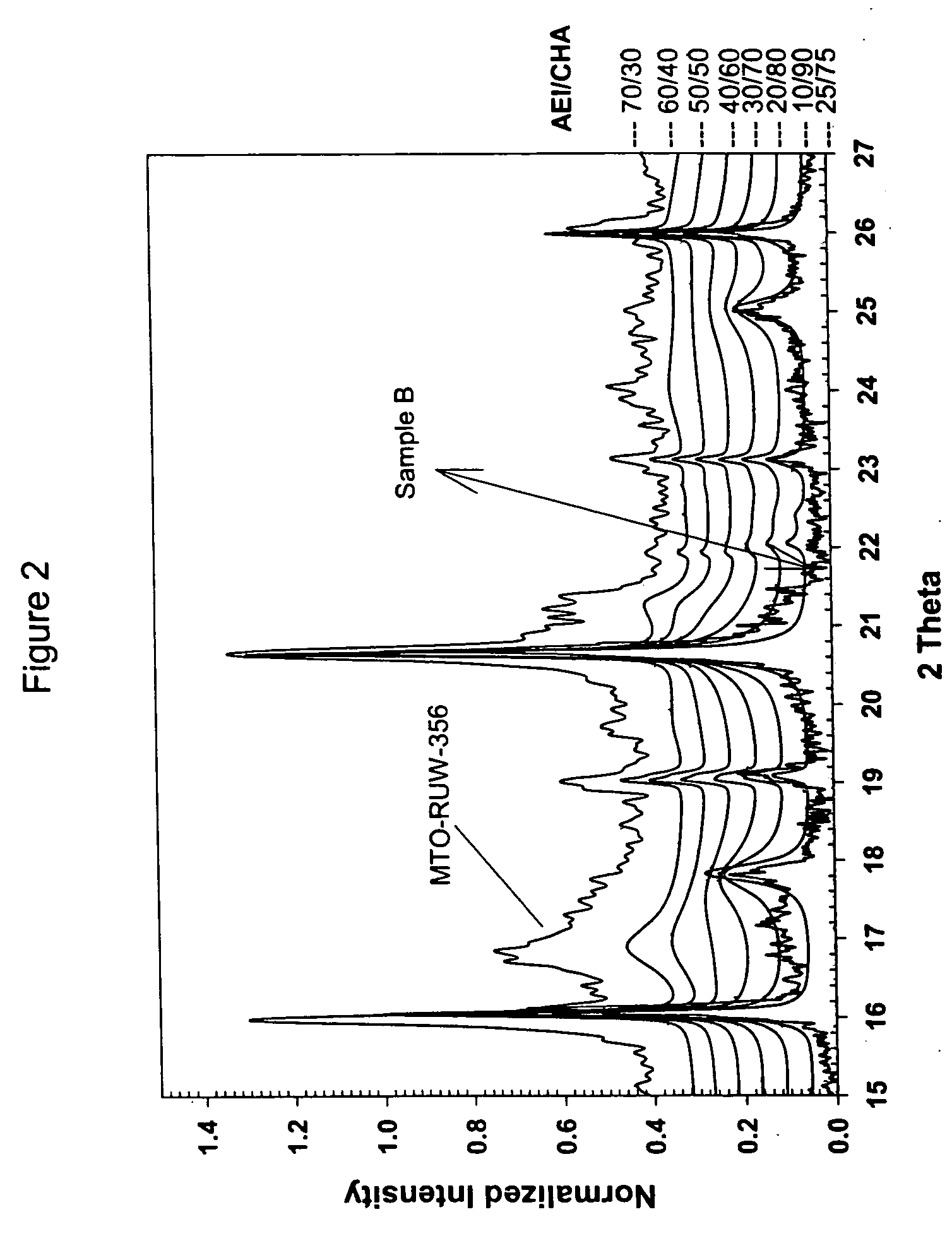

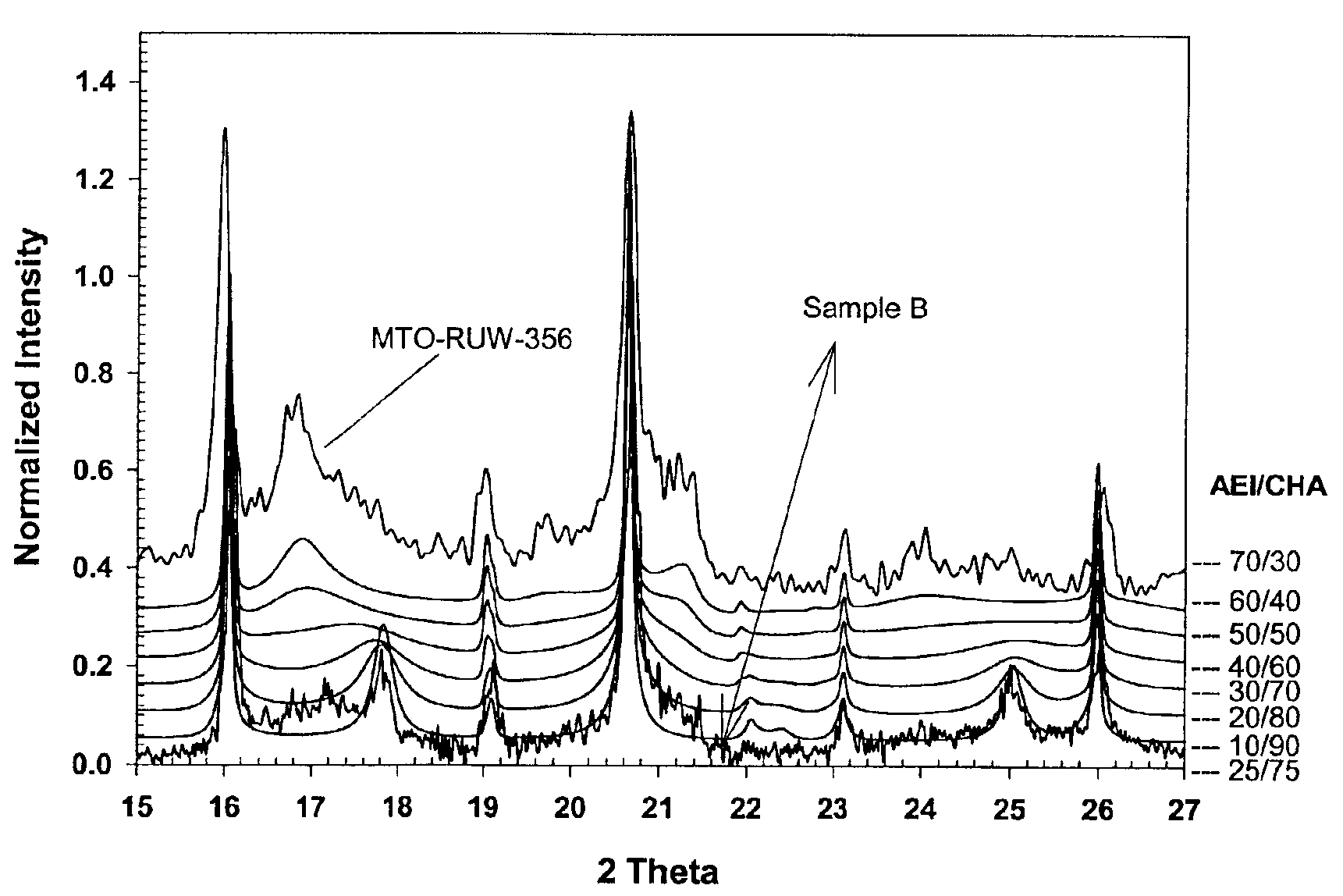

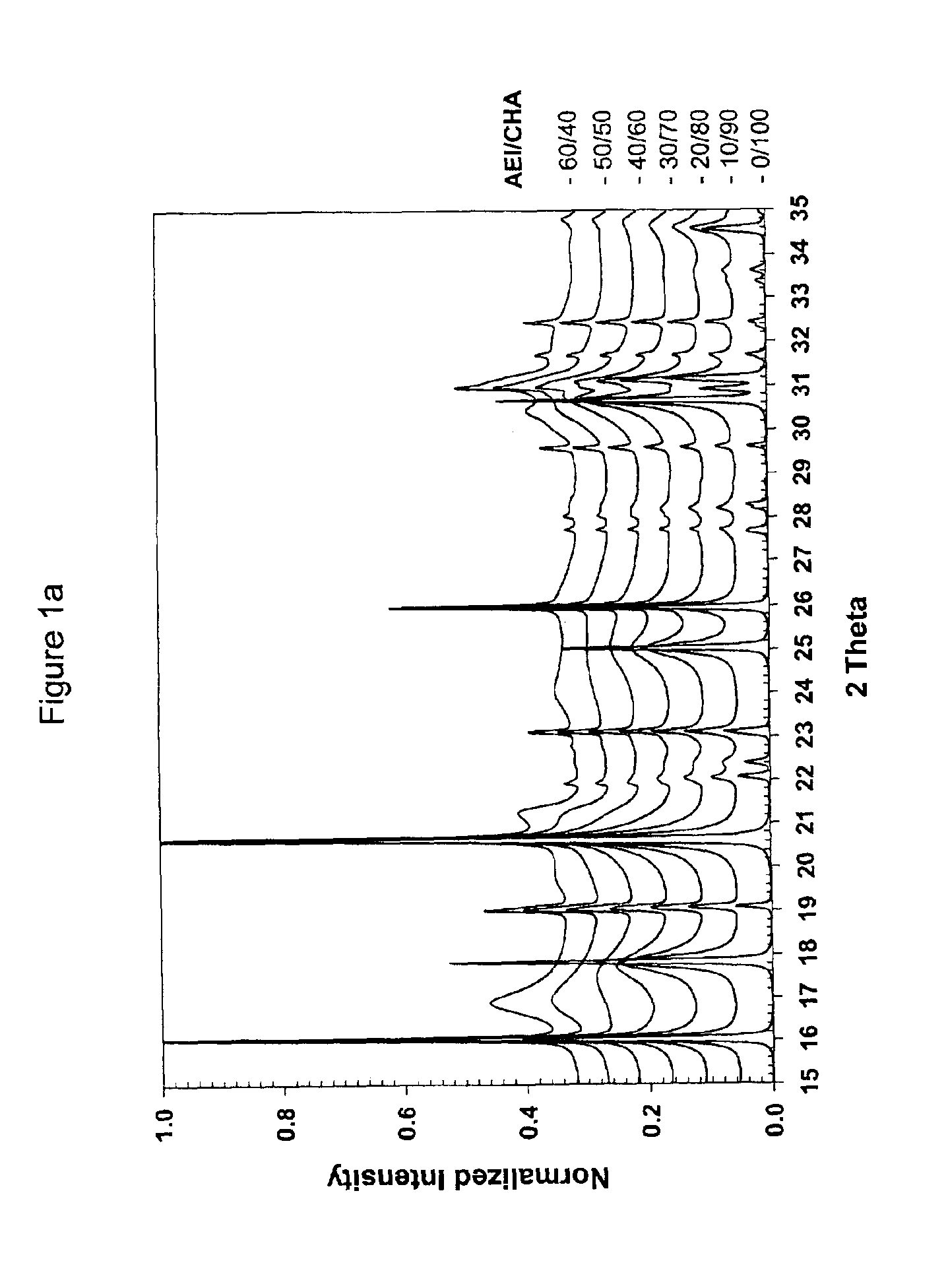

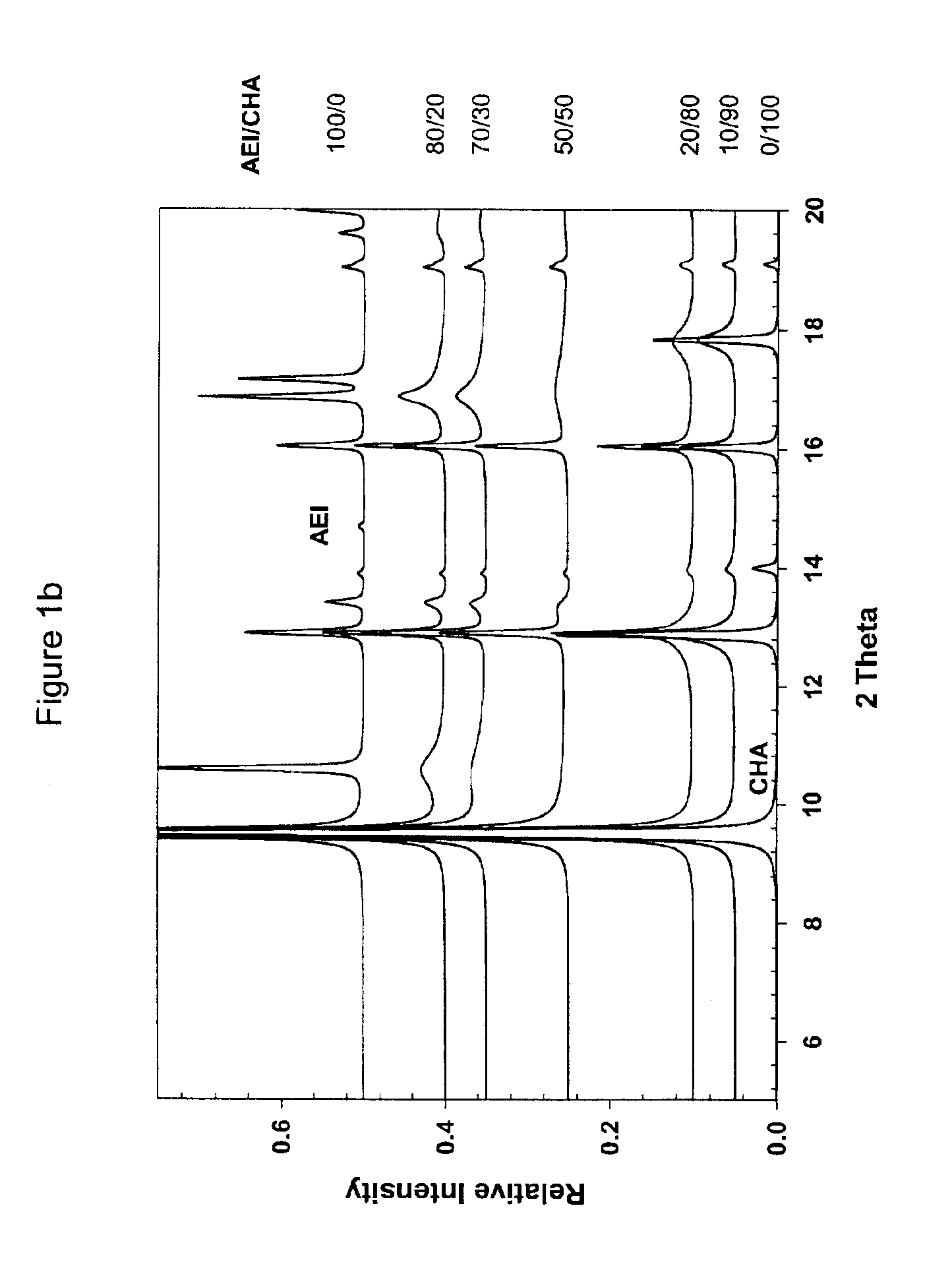

The present invention relates to a silicoaluminophosphate molecular sieve comprising at least one intergrown phase of molecular sieves having AEI and CHA framework types, wherein said intergrown phase has an AEI / CHA ratio of from about 5 / 95 to 40 / 60 as determined by DIFFaX analysis, using the powder X-ray diffraction pattern of a calcined sample of said silicoaluminophosphate molecular sieve. It also relates to methods for its preparation and to its use in the catalytic conversion of methanol to olefins.

Owner:JANSSEN MARCEL J G +4

Silicoaluminophosphate molecular sieve

InactiveUS6953767B2Improve catalytic performanceMolecular sieve catalystsAluminium silicatesMolecular sieveX-ray

The present invention relates to a silicoaluminophosphate molecular sieve comprising at least one intergrown phase of molecular sieves having AEI and CHA framework types, wherein said intergrown phase has an AEI / CHA ratio of from about 5 / 95 to 40 / 60 as determined by DIFFaX analysis, using the powder X-ray diffraction pattern of a calcined sample of said silicoaluminophosphate molecular sieve. It also relates to methods for its preparation and to its use in the catalytic conversion of methanol to olefins.

Owner:EXXONMOBIL CHEM PAT INC

Synthesis of molecular sieves having the chabazite framework type and their use in the conversion of oxygenates to olefins

The synthesis of a crystalline aluminophosphate or silicoaluminophosphate molecular sieve having a chabazite-type framework type is conducted in the presence of an organic directing agent having the formula (I) [R1R2R3N—R4]+X− (I) wherein R1, R2 and R3 are independently selected from the group consisting of alkyl groups having from 1 to 3 carbon atoms and hydroxyalkyl groups having from 1 to 3 carbon atoms; R4 is selected from the group consisting of 4- to 8-membered cycloalkyl groups, optionally substituted by 1 to 3 alkyl groups having from 1 to 3 carbon atoms; 4- to 8-membered heterocyclic groups having from 1 to 3 heteroatoms, said heterocyclic groups being optionally substituted by 1 to 3 alkyl groups having from 1 to 3 carbon atoms and the heteroatoms in said heterocyclic groups being selected from the group consisting of O, N, and S; and aromatic groups optionally substituted by 1 to 3 alkyl groups, said alkyl groups having from 1 to 3 carbon atoms; and X− is an anion.

Owner:EXXONMOBIL CHEM PAT INC

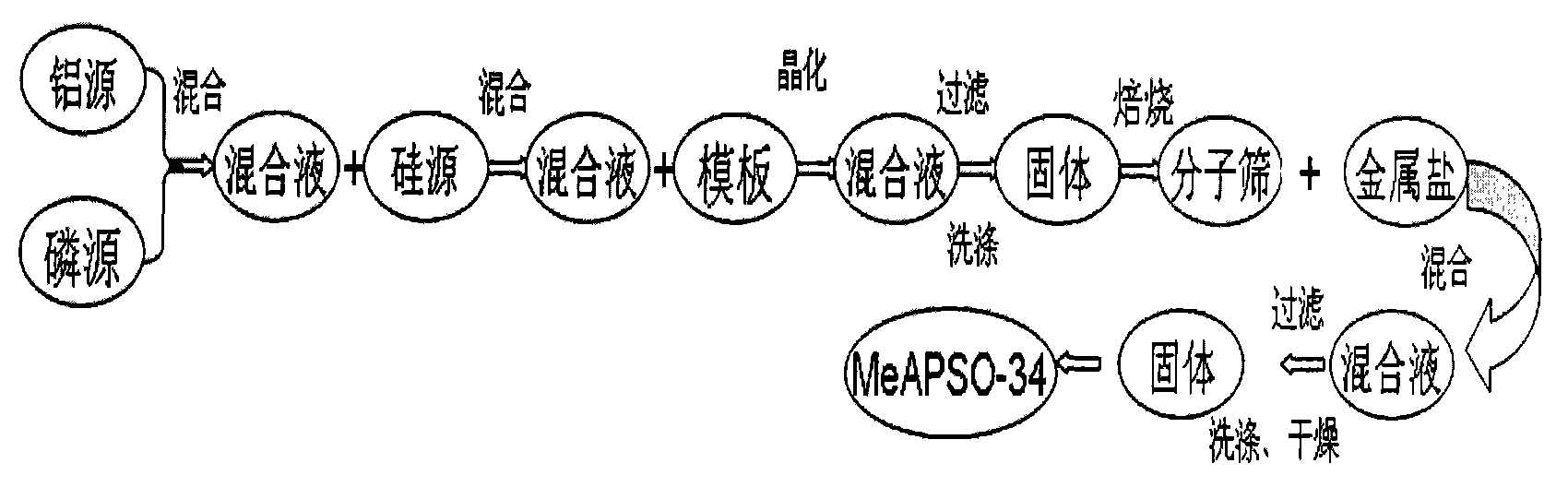

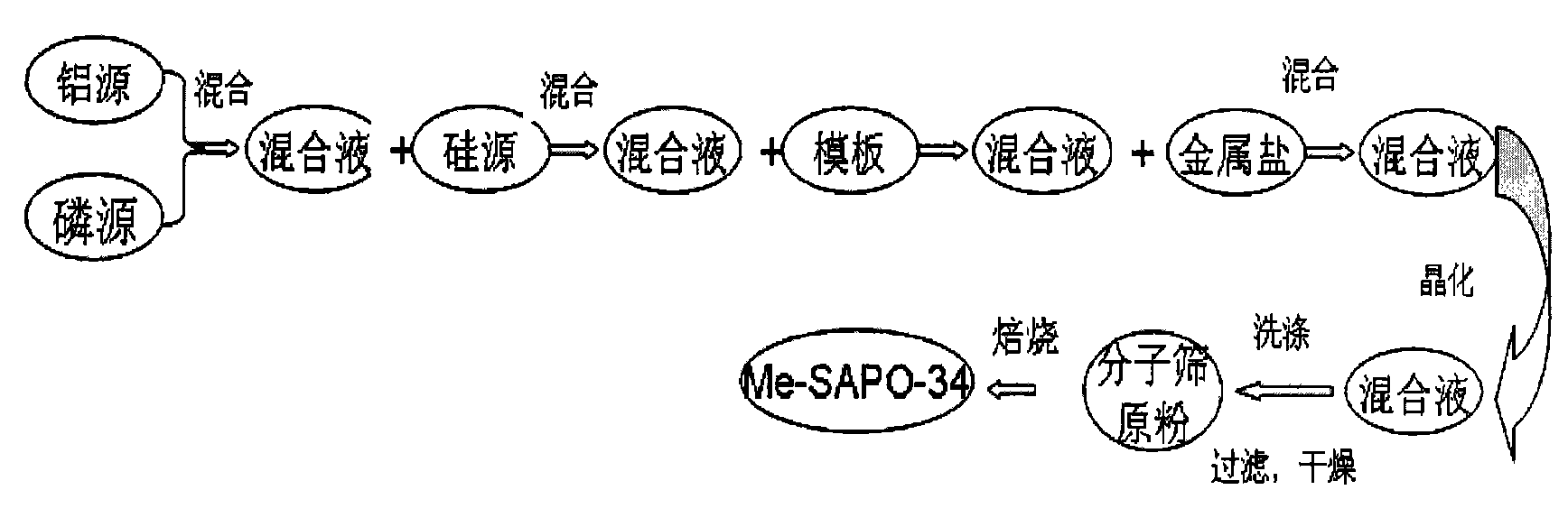

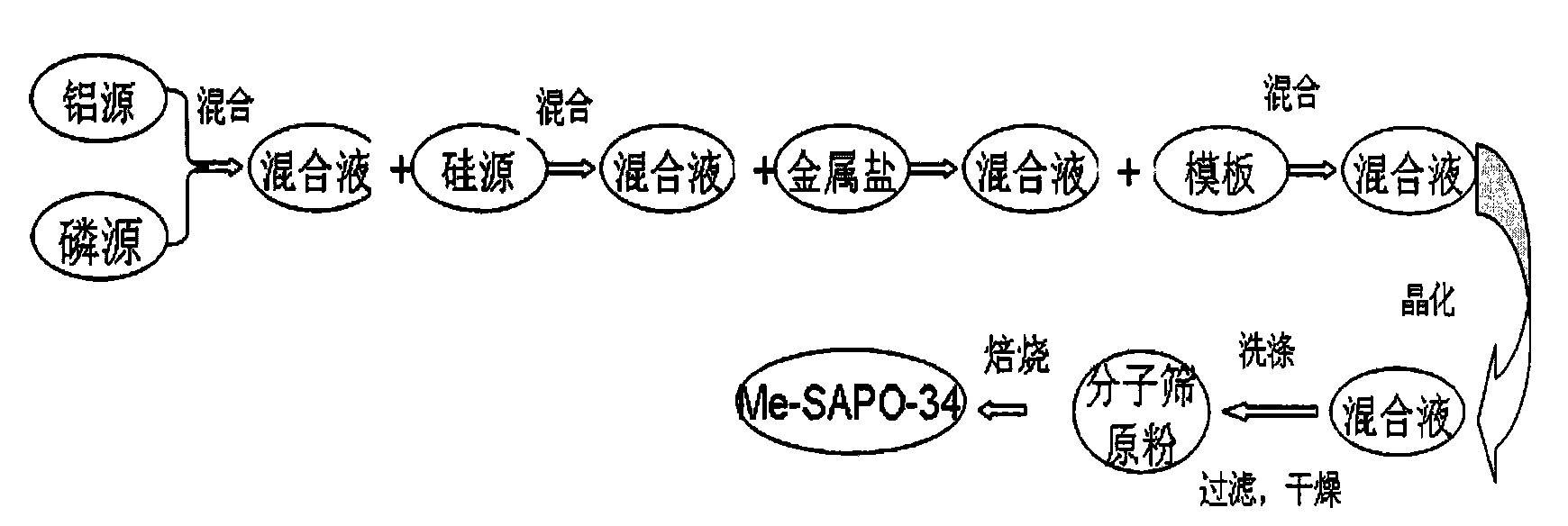

Preparation method of metal-modified SAPO-34 molecular sieve and catalyst containing the molecular sieve

ActiveCN101555022AHigh crystallinityHigh selectivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveCrystallinity

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

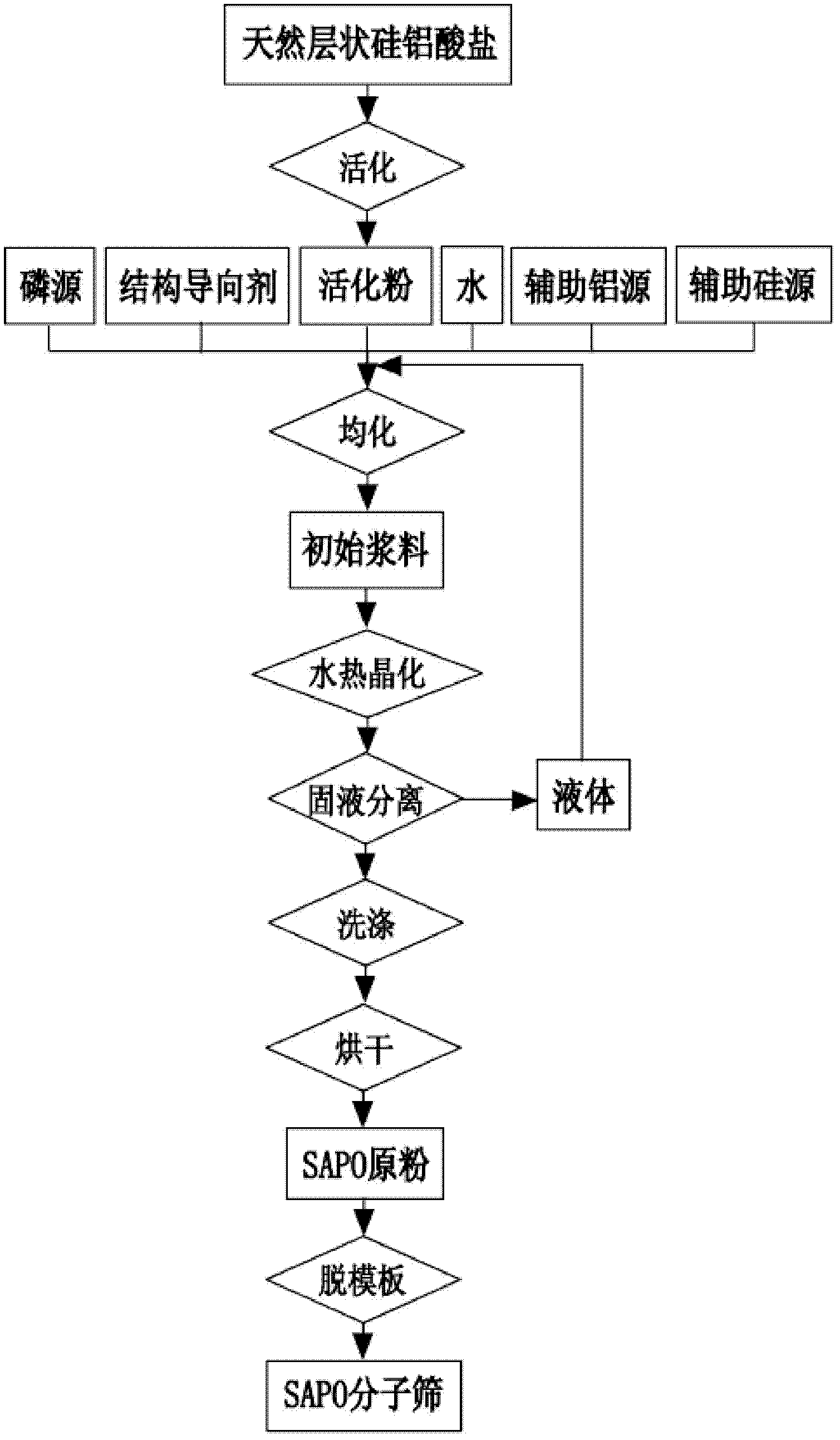

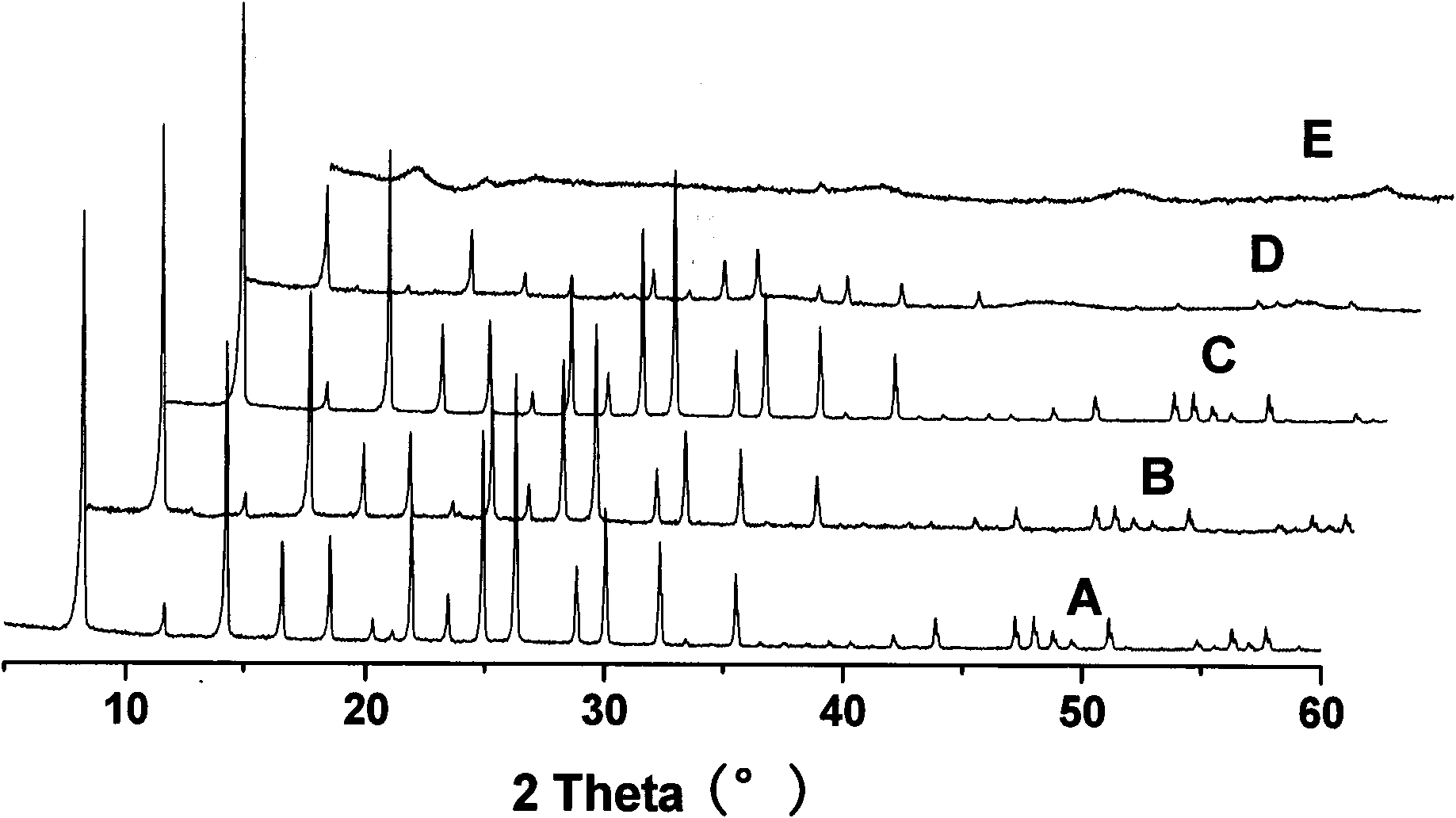

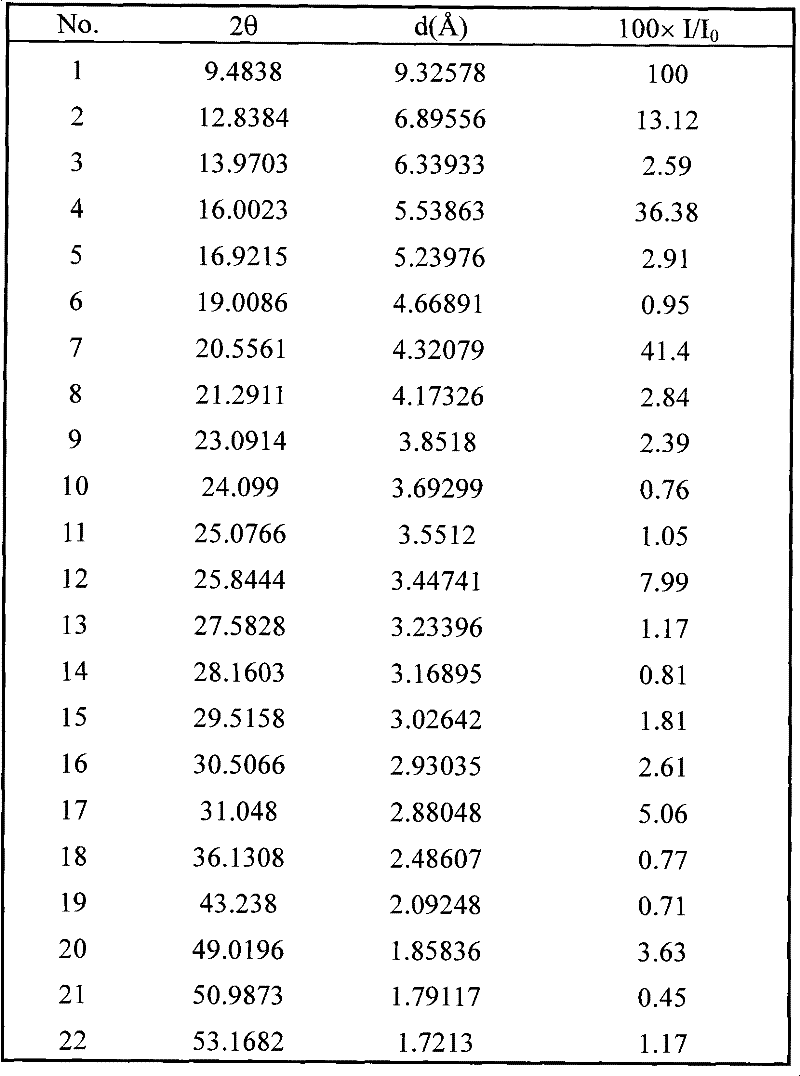

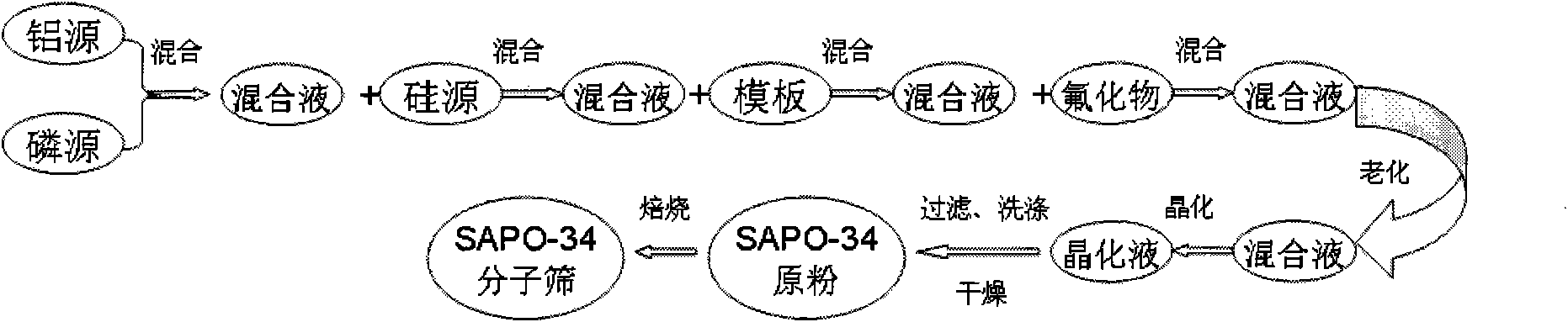

Preparation process for aluminosilicophosphate molecular sieve

ActiveCN102424399ALower synthesis costVariable structureMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveIon exchange

The invention discloses a universal preparation process for aluminosilicophosphate (SAPO) molecular sieve materials from natural lamellar aluminosilicate minerals. According to the invention, on the basis of the cheap natural lamellar aluminosilicate minerals, the SAPO molecular sieve materials are prepared by carrying out activation, slurrying of ingredients, hydrothermal crystallization and removal of structure directing agents; the natural lamellar aluminosilicate minerals can be fully used as a composite silicon aluminum source, are enabled to completely dissolve by utilizing the reaction activity of an alumina layer with phosphorous species and structure directing agent species under a hydrothermal condition and utilizing dissolving and coordination capacity of a silica layer in a medium, and can assemble anew to form a variety of SAPO molecular sieve materials under the action of the structure directing agents. The process provided in the invention substantially reduces synthesis cost for SAPO molecular sieves; the prepared molecular sieves have variable structure and composition, controllable silicon content and silicon distribution and adjustable acidic site intensity and acidic site distribution; the prepared SAPO molecular sieve materials have a wide application prospect in the fields of catalysis, adsorption, ion exchange, functional materials, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

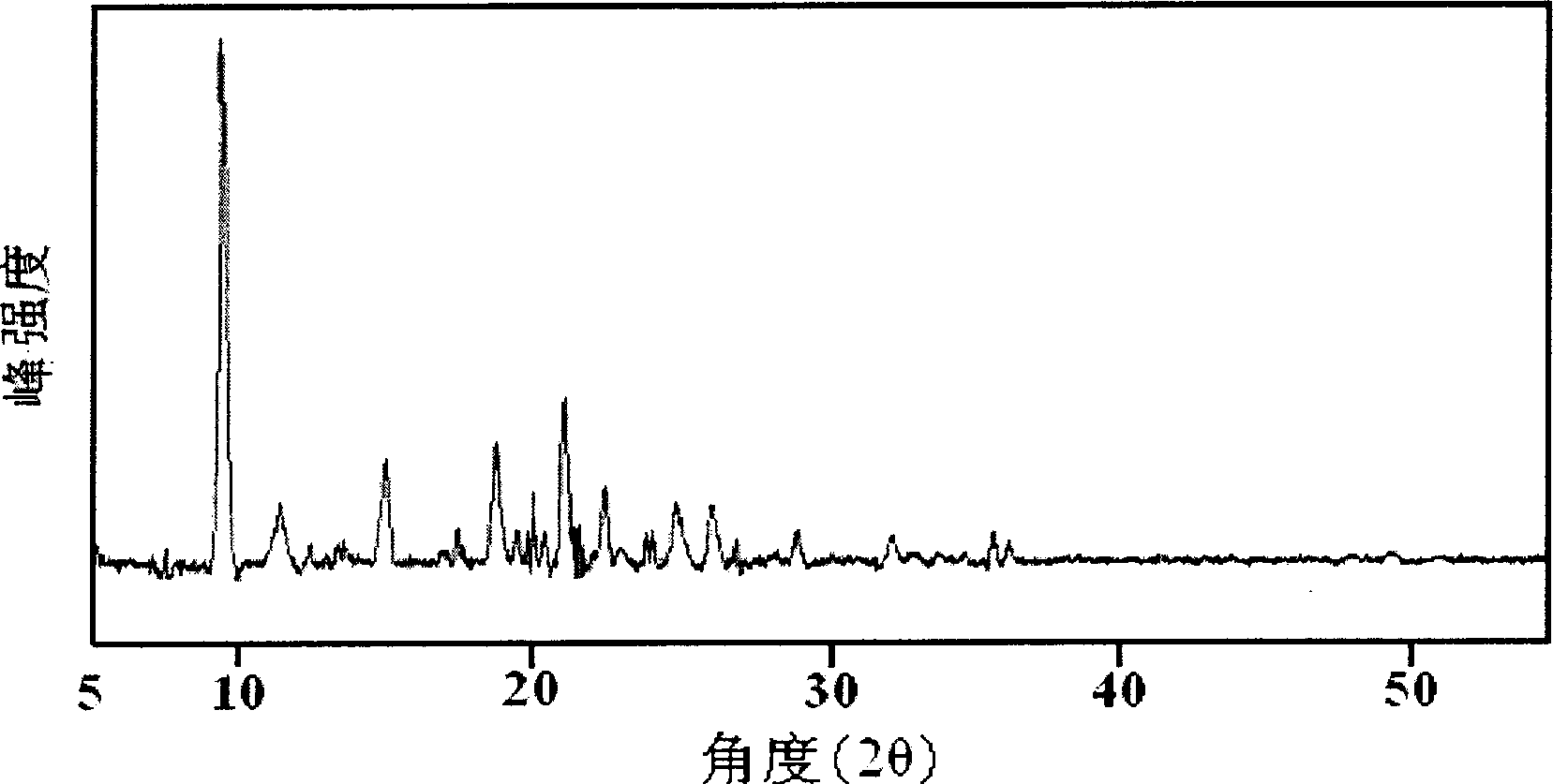

SAPO (silicoaluminophosphate) molecular sieve with RHO skeleton structure and preparation method thereof

ActiveCN101993093AMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveChemical composition

The invention relates to an SAPO (silicoaluminophosphate) molecular sieve with an RHO skeleton structure. The molecular sieve is formed by a PO2+, AlO2- and SiO2 tetrahedron and has a three-dimensional skeleton structure, the anhydrous chemical composition can be shown as mR.(SixAly Pz)O2. The preparation process comprises the following steps of: mixing a silicon source, an aluminum source, a phosphorous source, a surfactant, a template with deionized water to obtain an initial gel mixture; moving the prepared initial gel mixture material to a synthesis reactor for airtight temperature rise and crystallization; and washing and drying a solid crystallized product to obtain SAPO molecular sieve raw powder with the RHO structure; or the preparation process comprises the following steps of: mixing a silicon source, an aluminum source, a phosphorous source with the deionized water to obtain a gel mixture; evaporating the moisture content of the gel mixture to prepare a dry gel; moving the dry gel mixture, the template and the deionized water to the synthesis reactor for airtight rotation and crystallization; and washing and drying the solid crystallized product to obtain the SAPO molecular sieve raw powder with the RHO structure.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Solvent thermal synthesis method of SAPO (silicoaluminophosphate) molecular sieve and catalyst prepared by SAPO molecular sieve

InactiveCN102530987AHigh synthetic yieldEasy to separateMolecular sieve catalystsMolecular sieve catalystMolecular sieveSynthesis methods

The invention relates to a solvent thermal synthesis method of an SAPO (silicoaluminophosphate) molecular sieve and a catalyst prepared by the SAPO molecular sieve. The solvent thermal synthesis method provided by the invention is characterized in that organic amine is directly used as a solvent and a template agent of a synthesis system, and the SAPO molecular sieve is prepared through solvent thermal synthesis.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

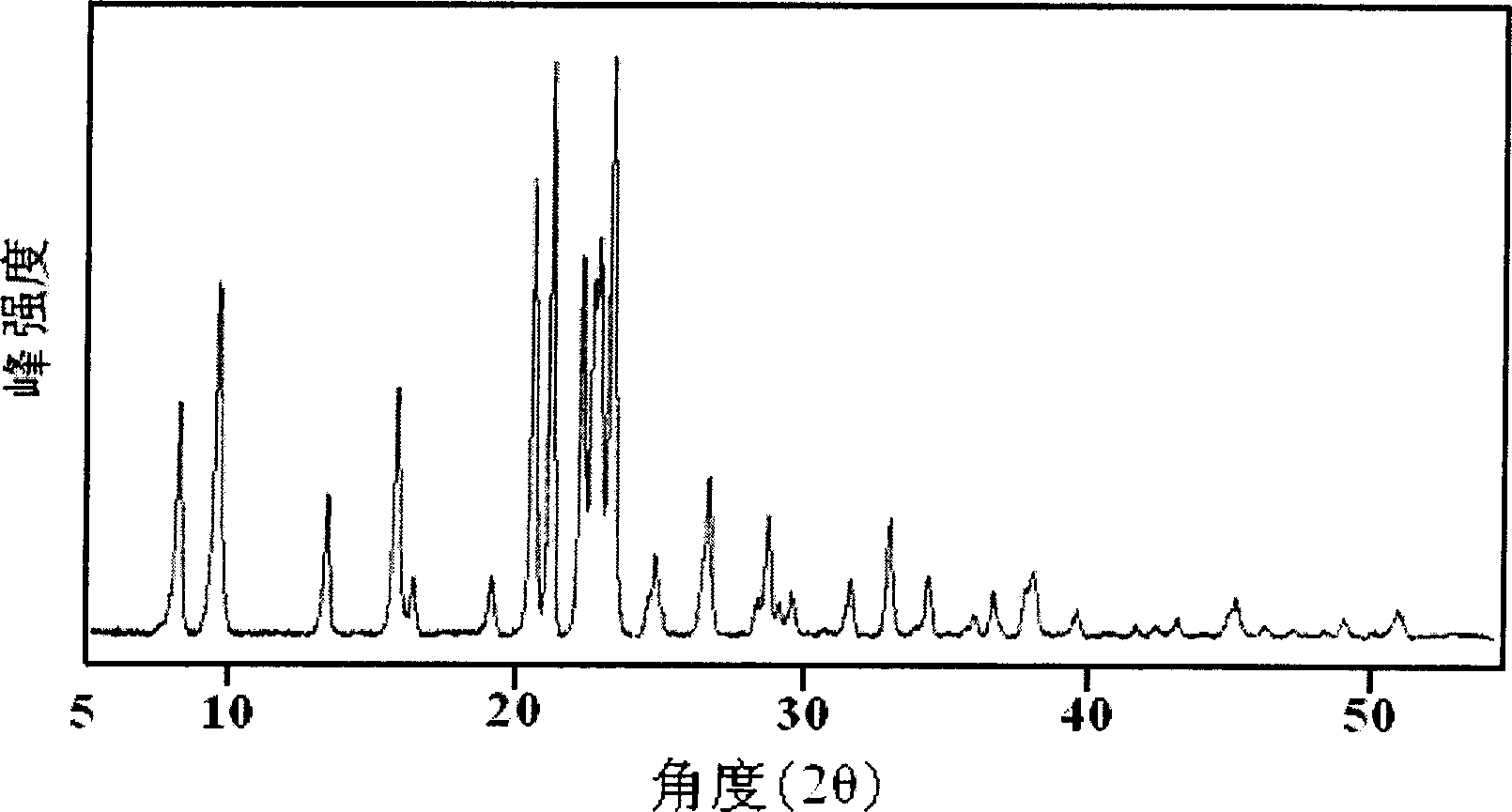

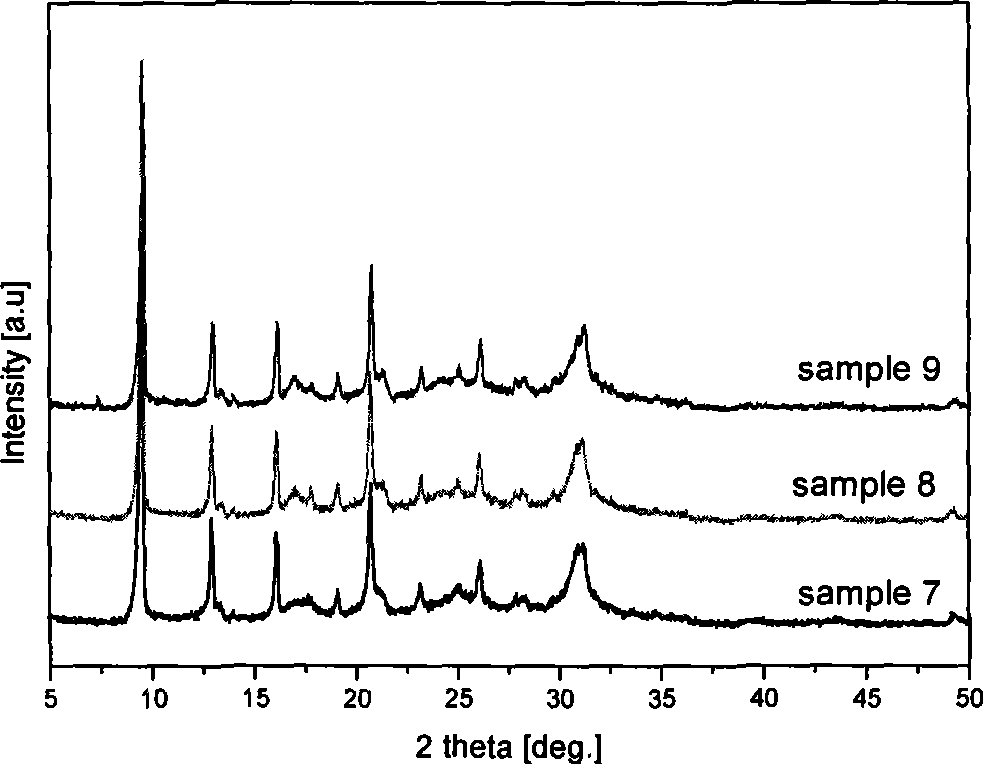

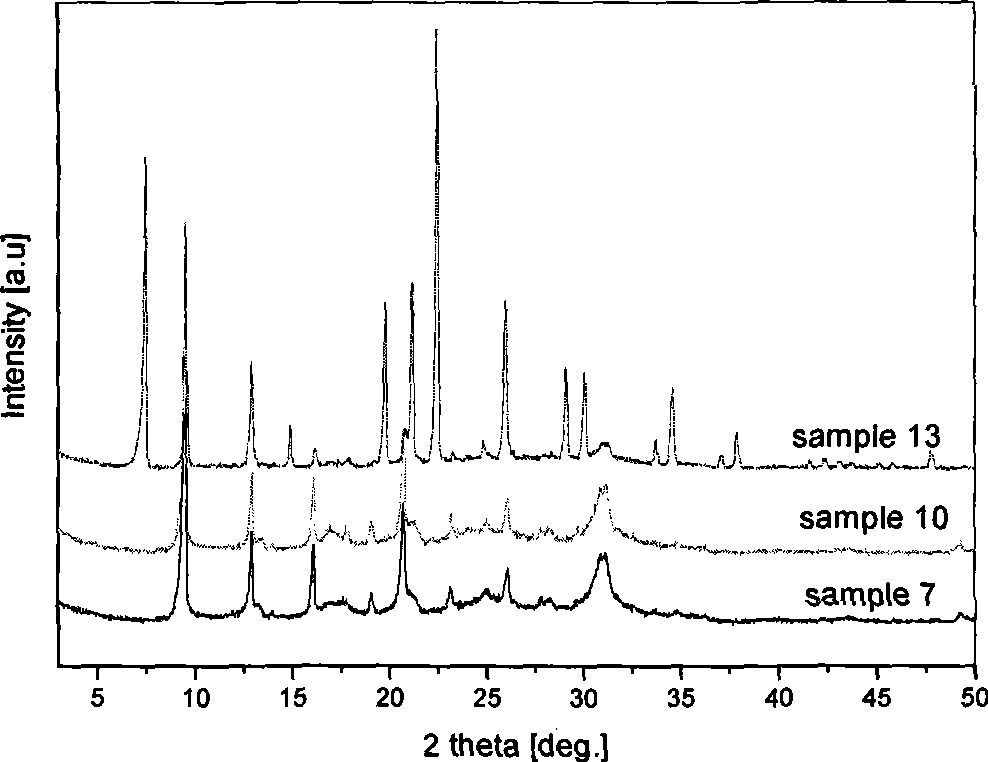

AEI/CHA eutectic molecular sieve containing triethylamine and synthetic method thereof

InactiveCN101450806AMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveChemical composition

The invention discloses an AEI / CHA eutectic molecule sieve containing triethylamine. An anhydrous chemical composition of the AEI / CHA eutectic molecule sieve is expressed as mR.(Six.Aly.Pz)O2, wherein x, y and z are molar fractions of Si, Al and P respectively; the x is between 0.001 and 0.98; the y is between 0.01 and 0.6; the z is between 0.01 and 0.6, x+y+z is equal to 1; the R is a template agent, and the m is a mole number of the R; and the value of the m is between 0.02 and 0.6. A preparation method for the AEI / CHA eutectic molecule sieve comprises the following steps: a) according to the mol ratio of oxides of various components, stirring and mixing evenly a silicon source, an aluminum resource, a phosphorus source, the template agent, and water are to obtain an initial gel mixture; and b) transferring the initial gel mixture into a stainless steel synthesis kettle to be sealed, then heating the kettle to a crystallization temperature of between 160 and 250 DEG C, and performing crystallization at constant temperature for 1 to 120 hours under the self-generated pressure, and separating a solid product, washing the solid product to be neutral, and drying the solid product to obtain the AEI / CHA eutectic molecule sieve. The molecule sieve can be used as a catalyst for an acid catalytic reaction after the template agent is removed through the baking.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

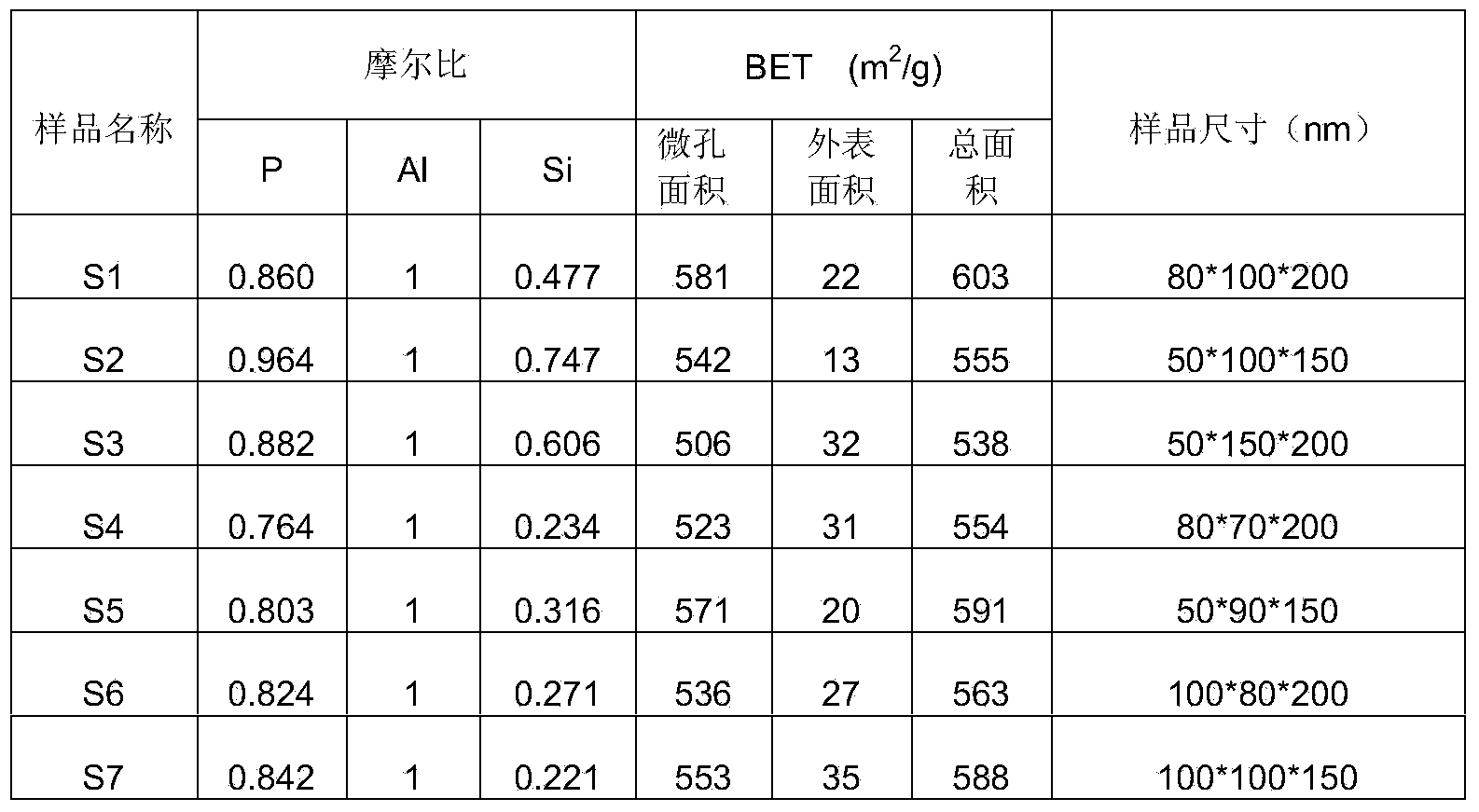

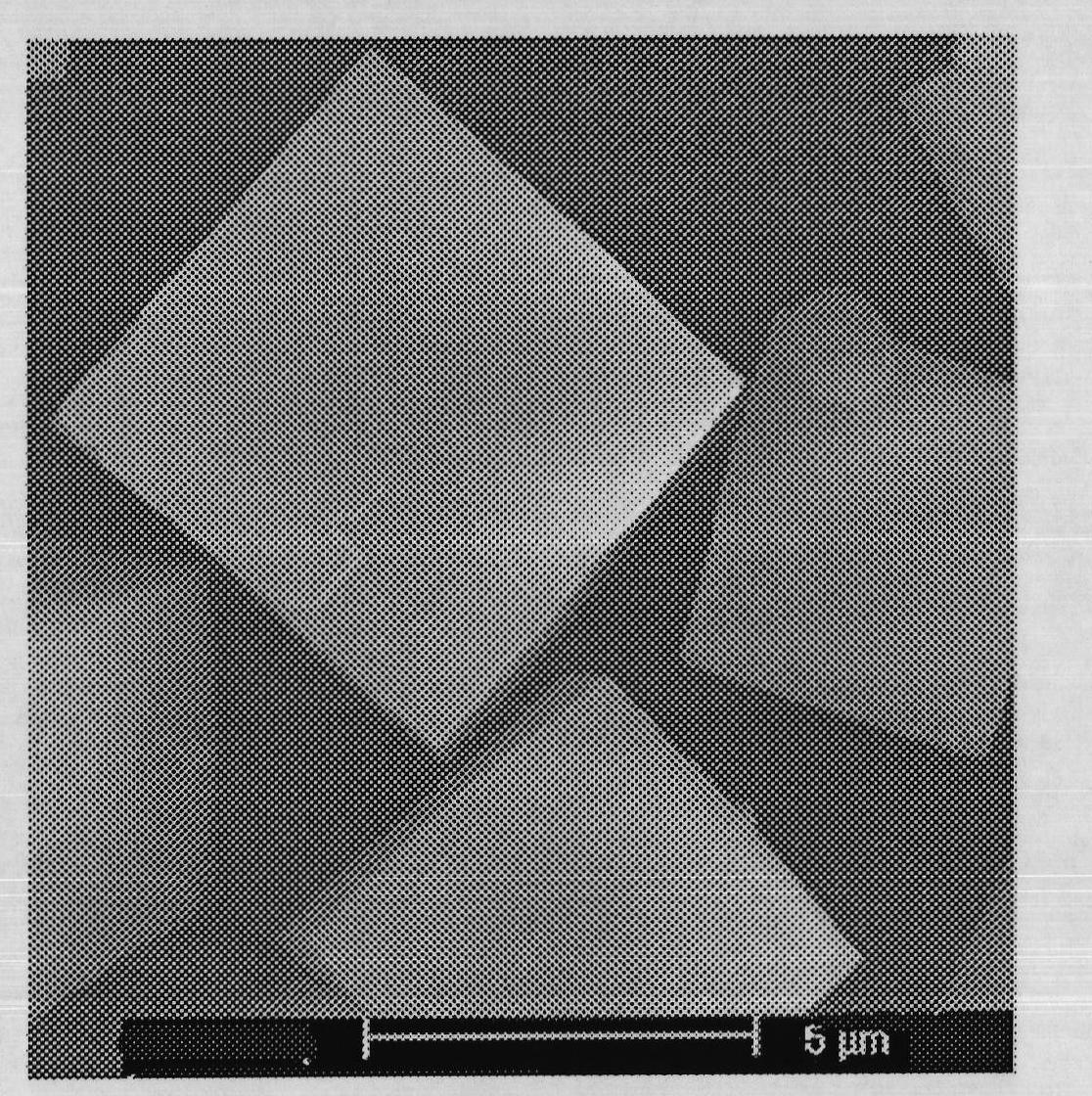

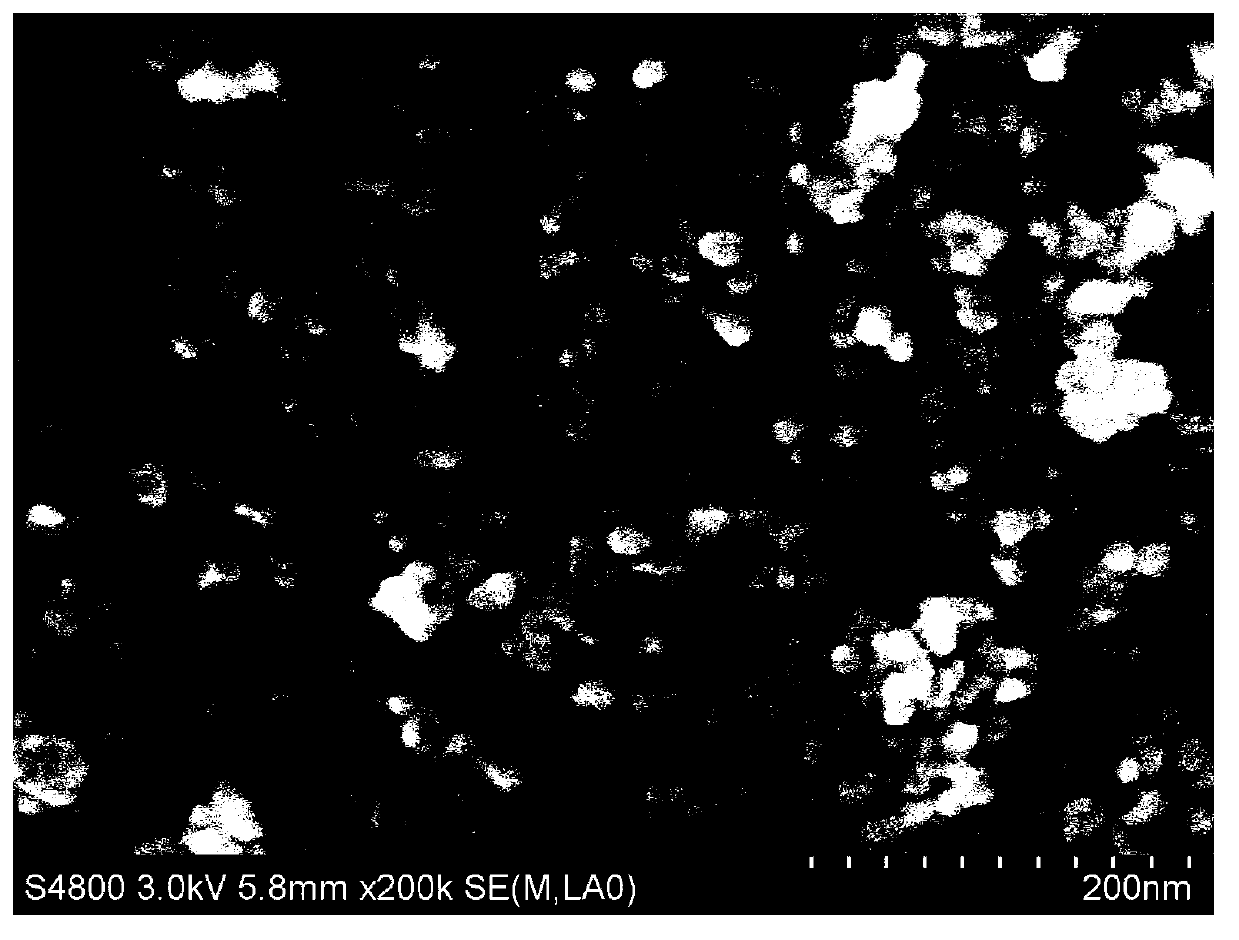

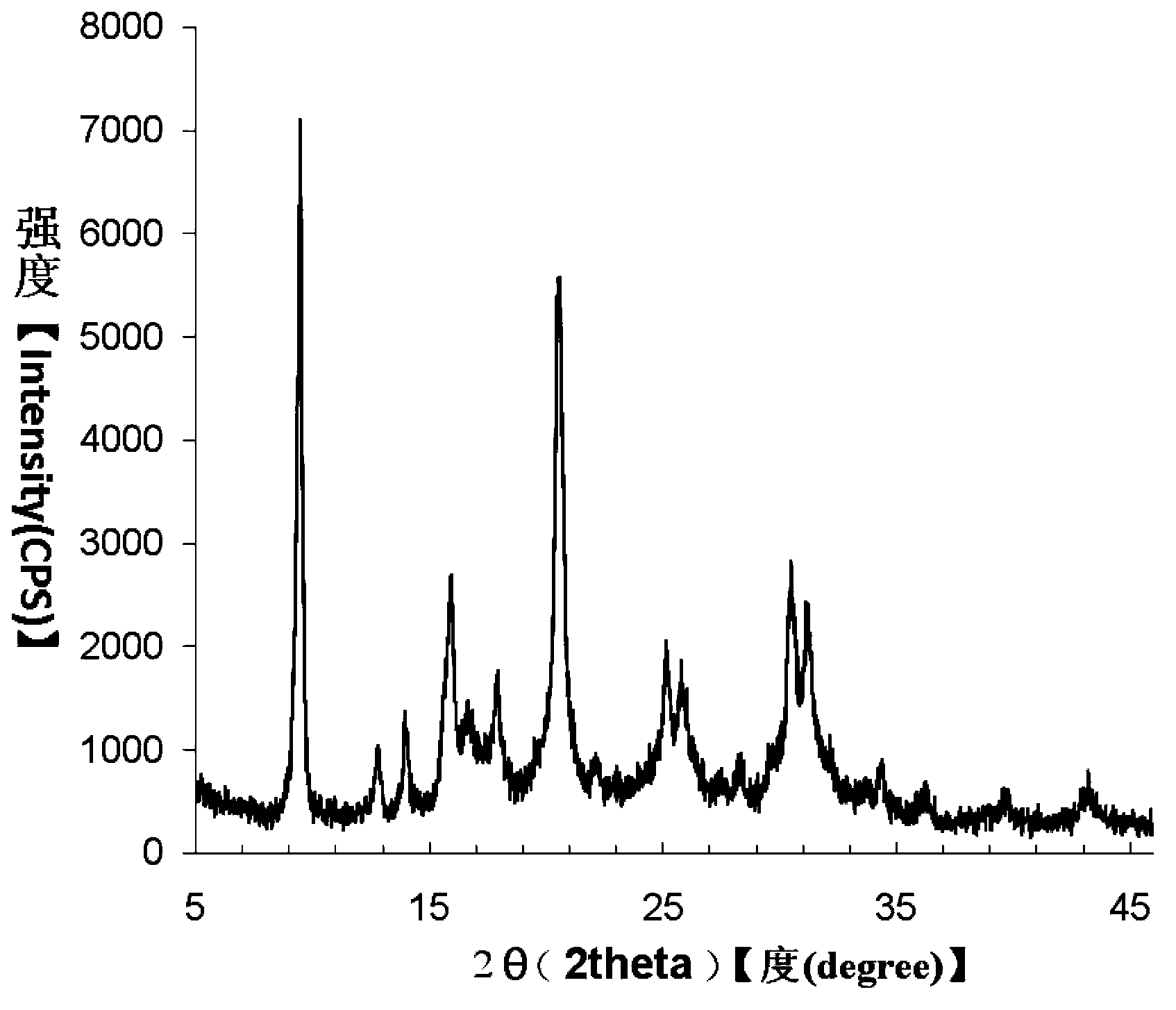

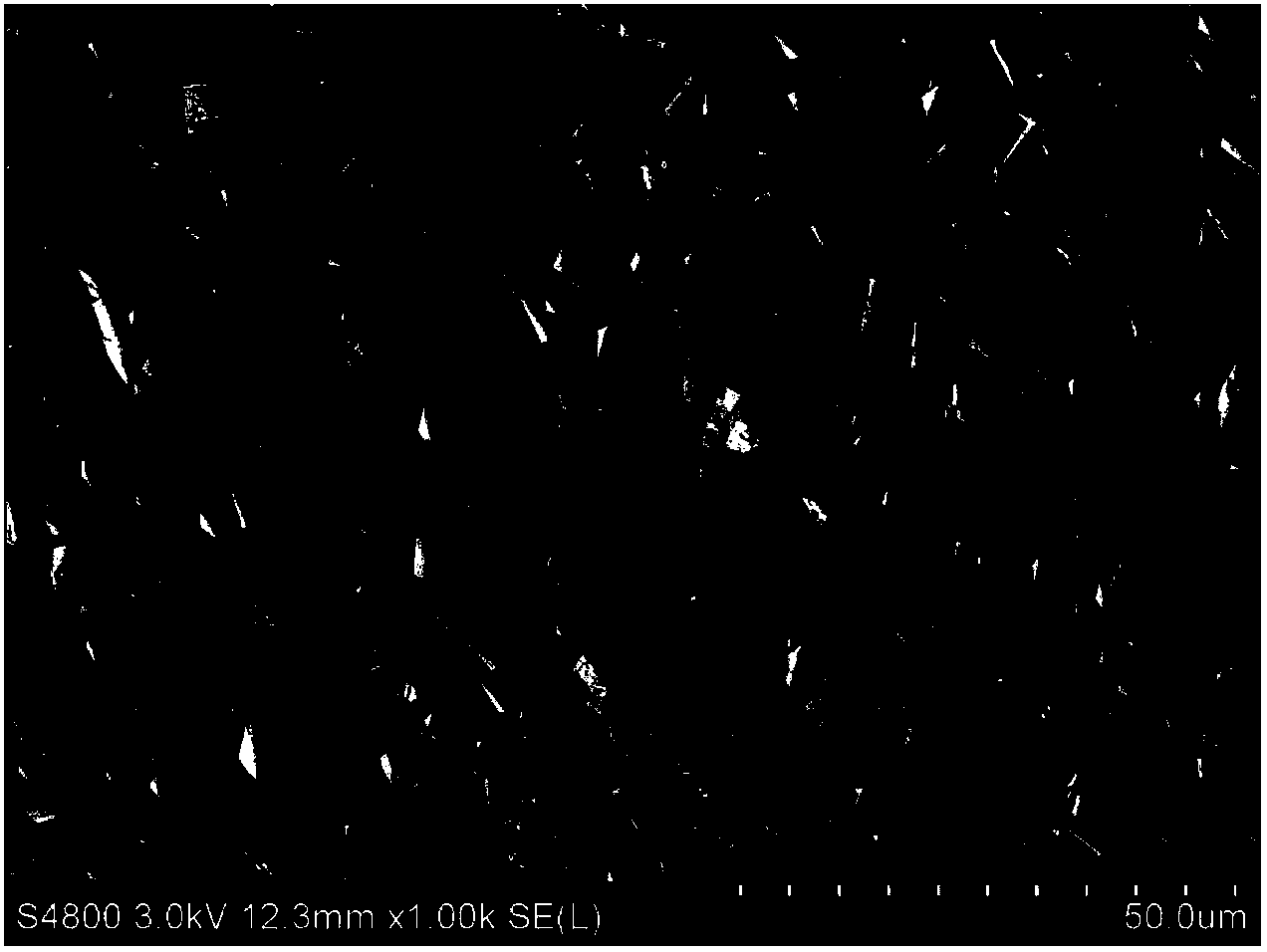

Slice-shaped nanometer SAPO-34 molecular sieve with relatively low silicon content, preparation method and application thereof

ActiveCN103641131ALong catalyst lifeIncreased diffusion rateMaterial nanotechnologyMolecular sieve catalystsGranularitySolvent

The invention discloses a slice-shaped nanometer SAPO-34 molecular sieve with relatively low silicon content, a preparation method and an application thereof, and belongs to the technical field of molecular sieves. Tetraethylammonium hydroxide is used as a template, the slice-shaped nanometer SAPO-34 molecular sieve with relatively low silicon content is synthesized by using the traditional hydrothermal method or a solvothermal synthesis method. The synthesized nanometer SAPO-34 sample is a slice-shaped feature, of which the average crystal granularity size is 50-250nm and the thickness is 50-100nm. The synthetic method is simple and efficient; the solvent consumption is low; the yield of the synthesized nanometer SAPO-34 sample is extremely high and can be up to 85-90 percent; the synthesized nanometer SAPO-34 sample is high in low carbon olefin selectivity during reaction of methanol to olefin (MTO), particularly, the total yield of ethylene and propylene can be up to more than 83 percent, and the molecular sieve is very suitable for industrial amplification application.

Owner:JILIN UNIV

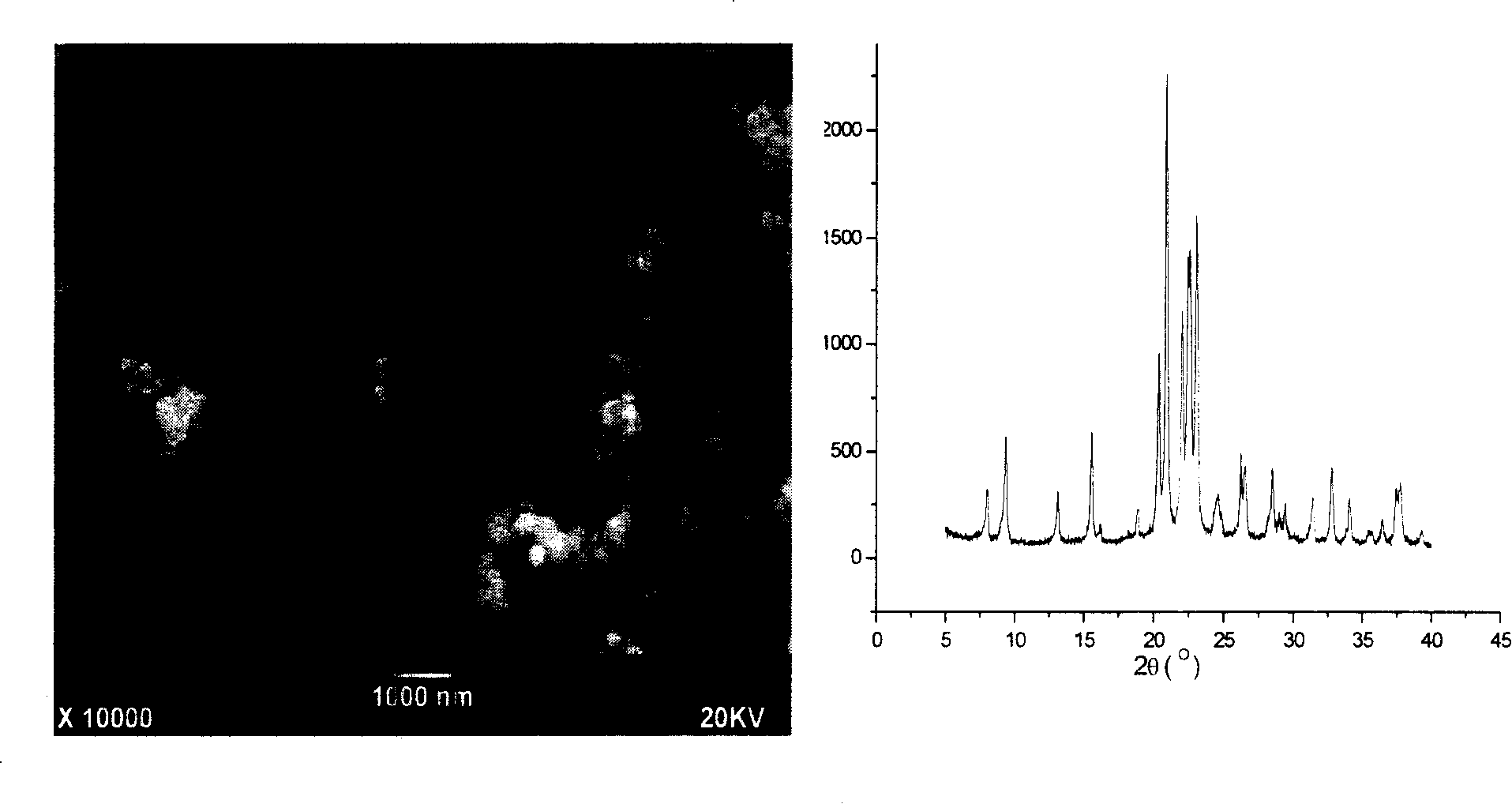

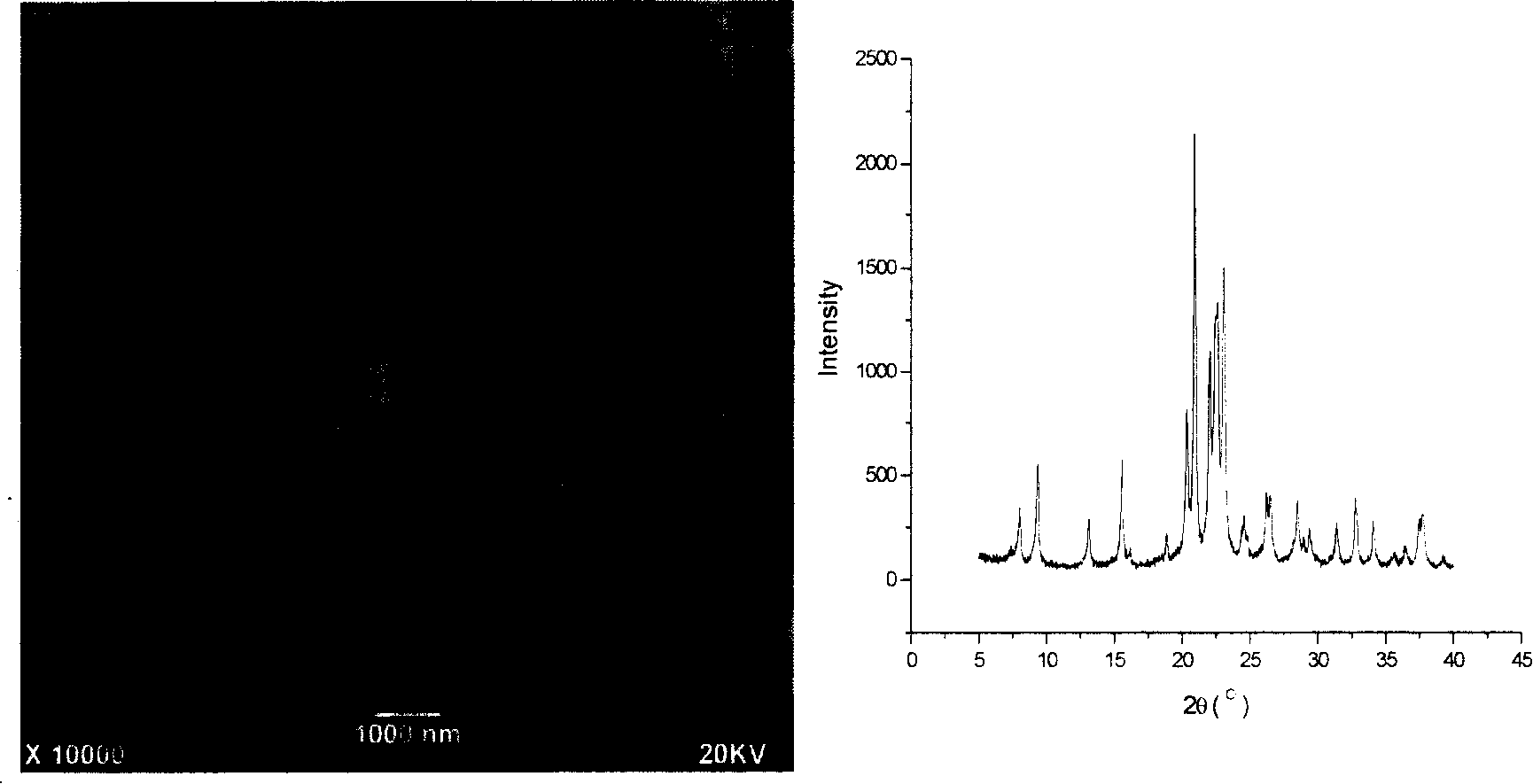

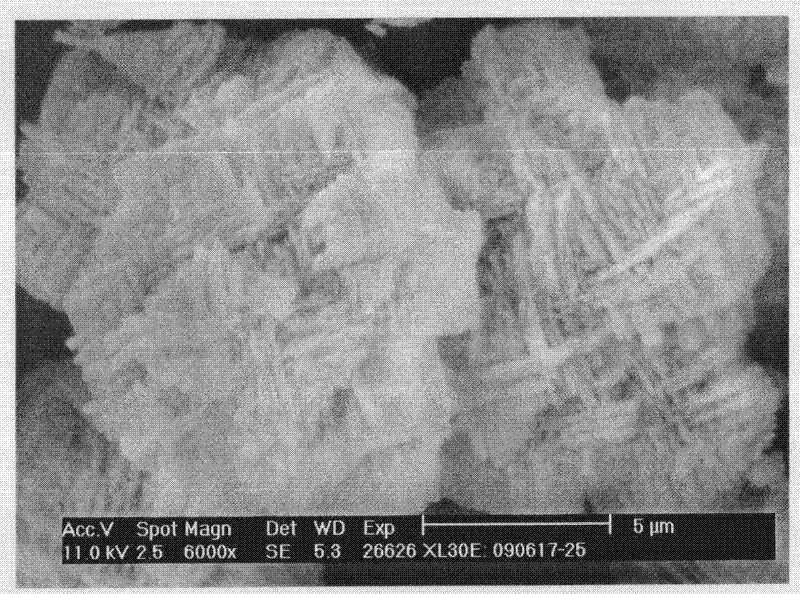

SAPO-11 molecualr sieve and its preparing method

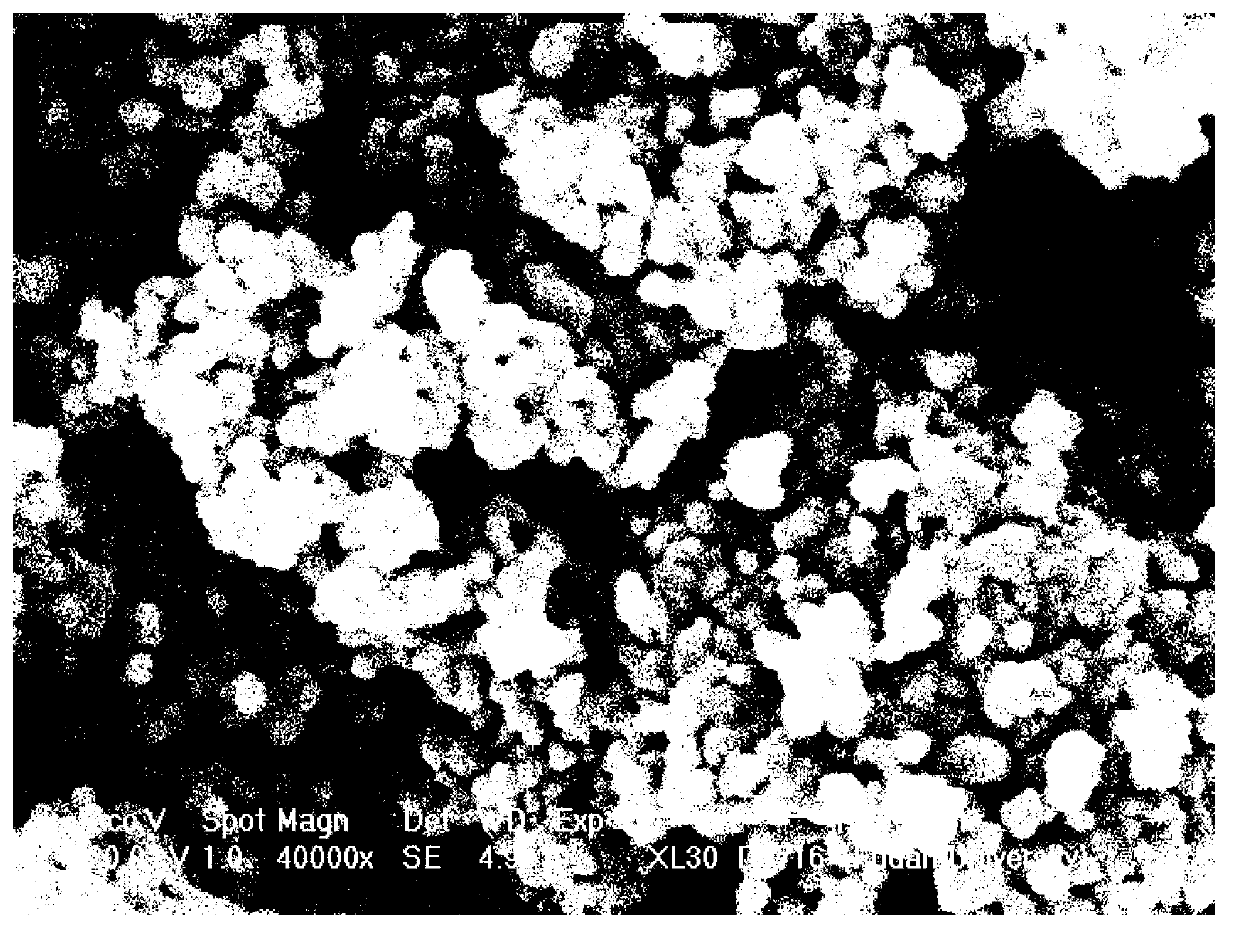

InactiveCN1392099AReduce sizeControl distributionMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMolecular sieveAlkane

The present invention provides a synthesis process of SAPO-11 molecular sieve. Available technology adopts conventional hydrothermal method, which is non-repeatable and easy to produce many Si areas to degrade catalytic performance. The present invention is that in a water-surfactant-organic alcohol system, nano level SAPO-11 molecular sieve with high repeatability, less Si areas and more strong B acid is synthesized. After carrying noble metal, the molecular sieve has high selectivity, yield and repeatability while being used in hydrogensing isomerization reaction of long-chain alkane.

Owner:FUDAN UNIV

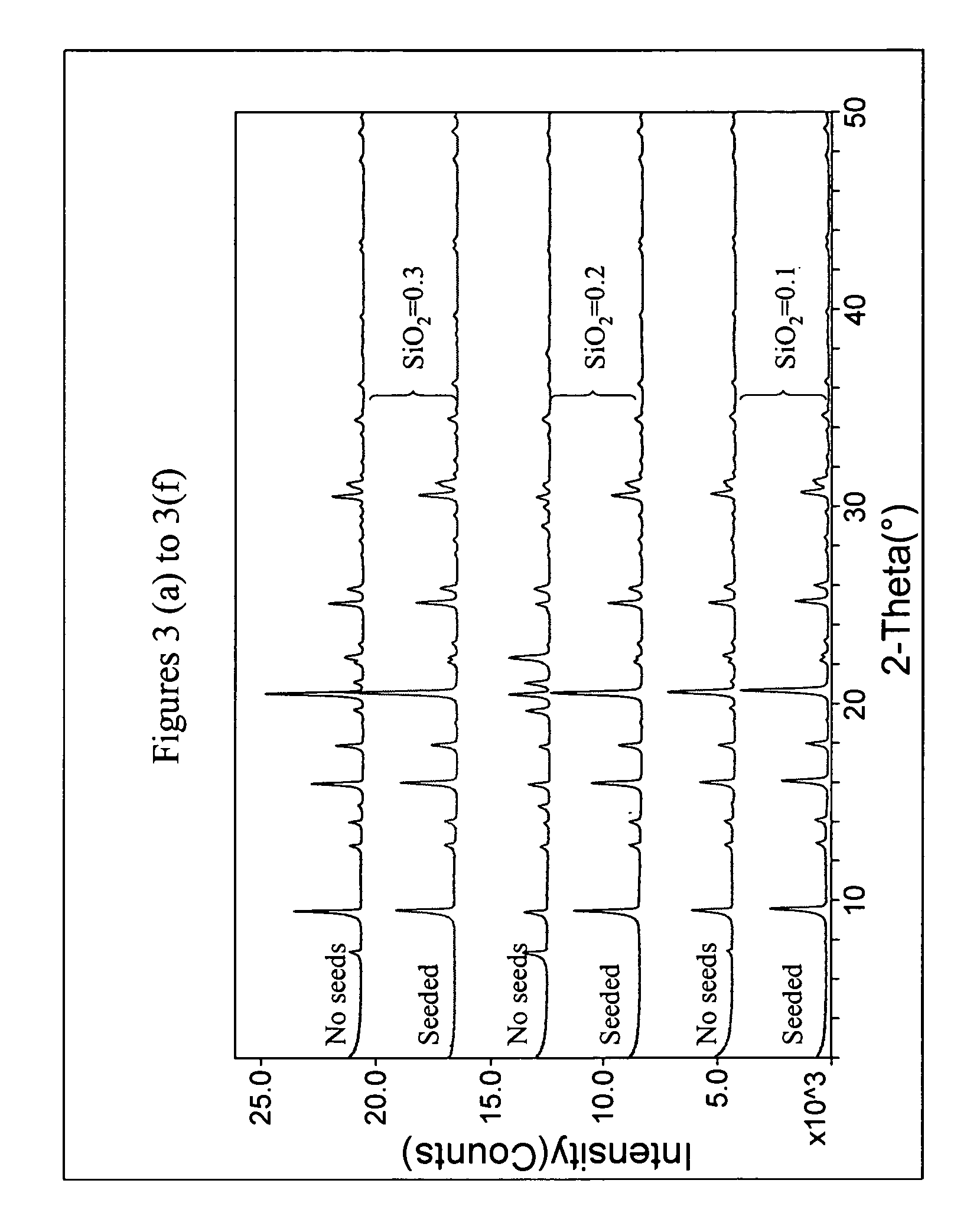

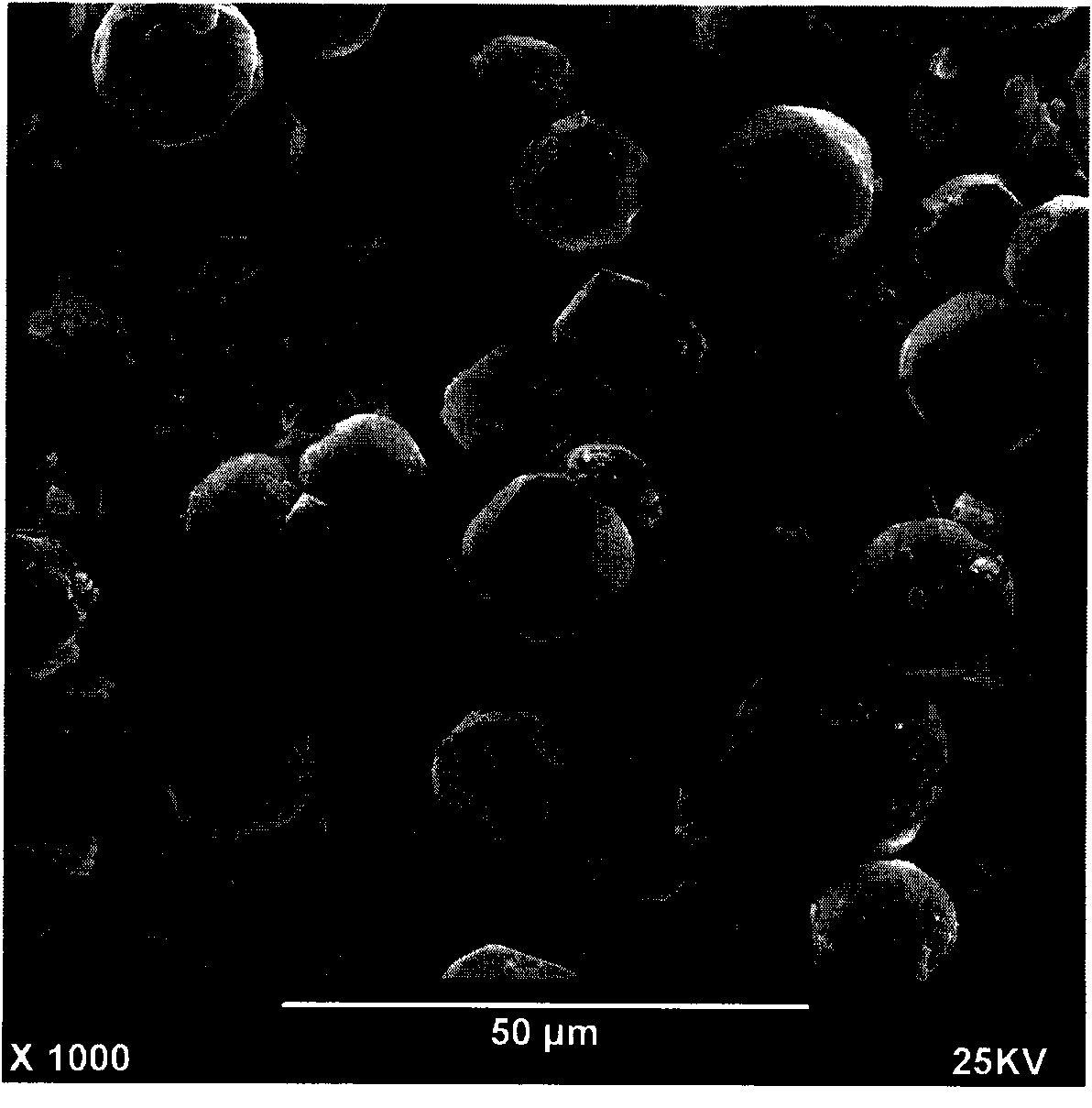

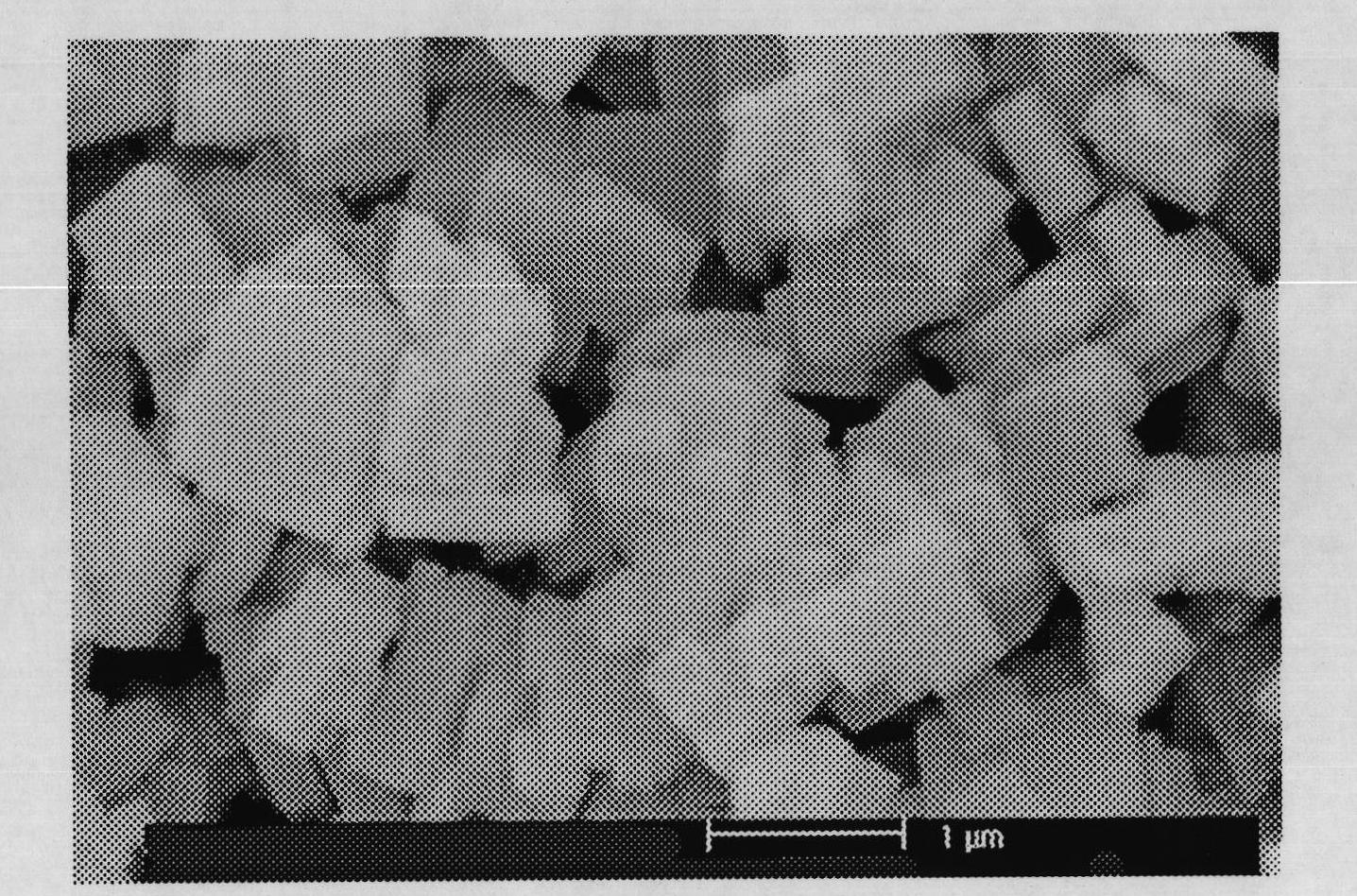

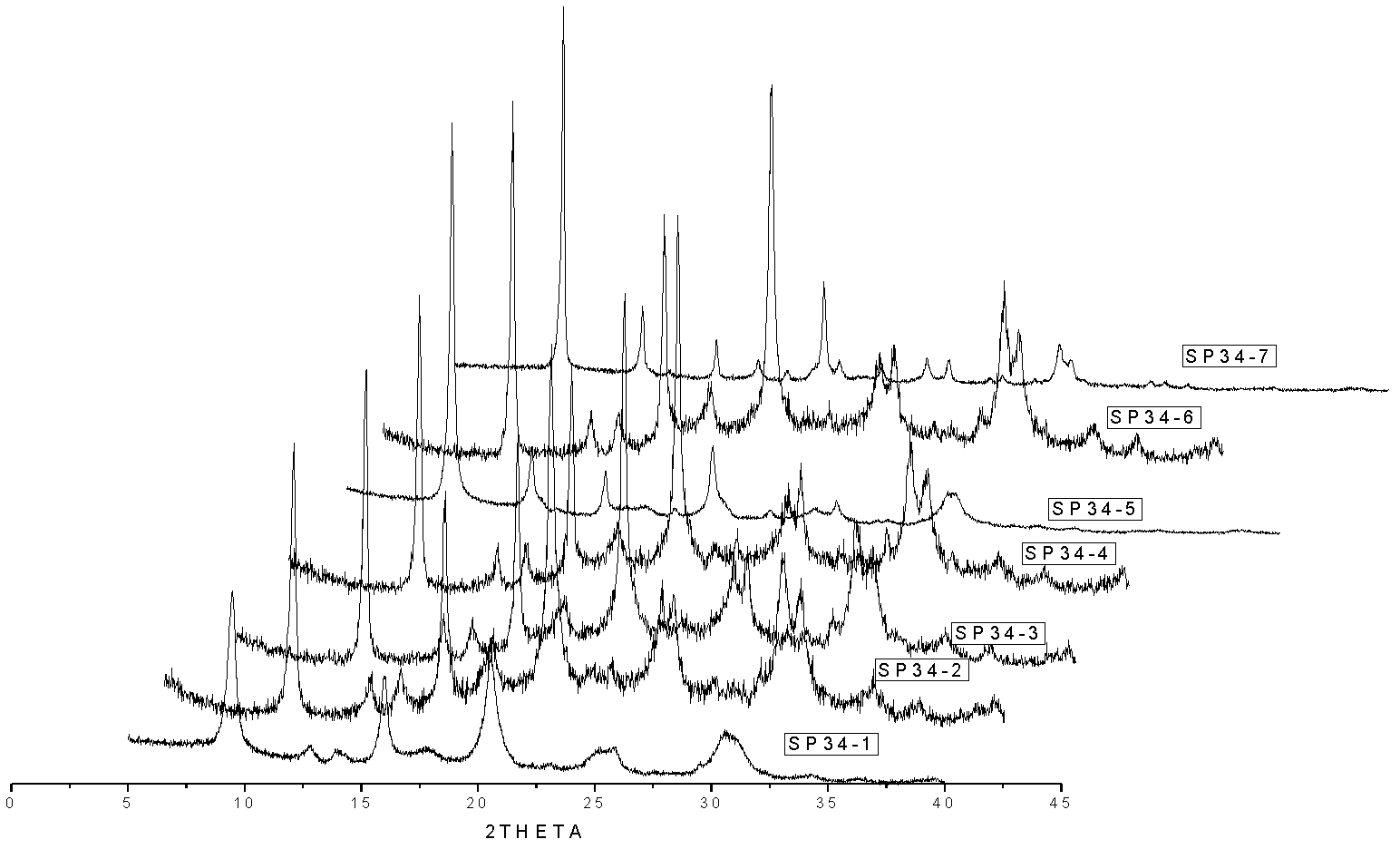

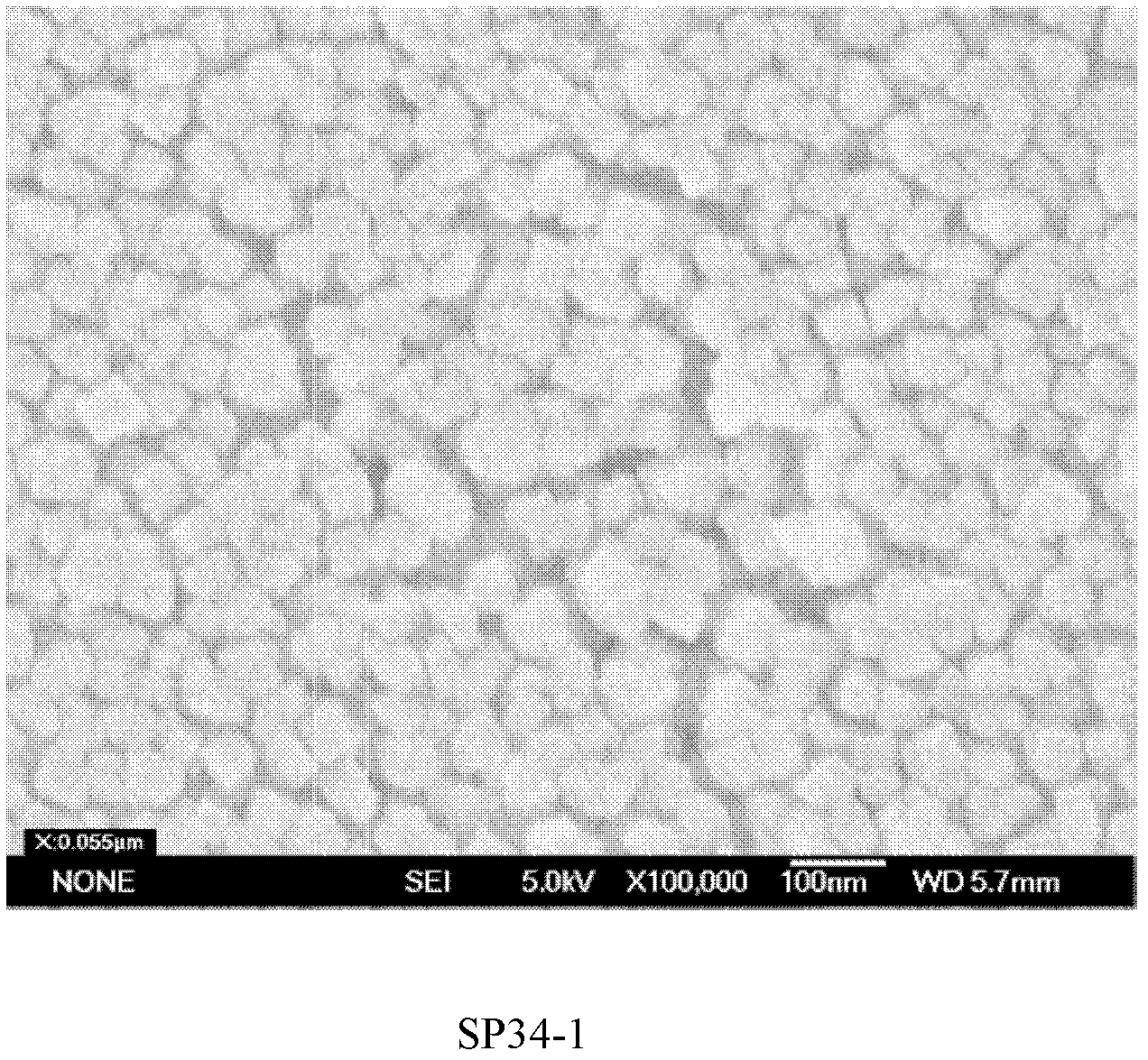

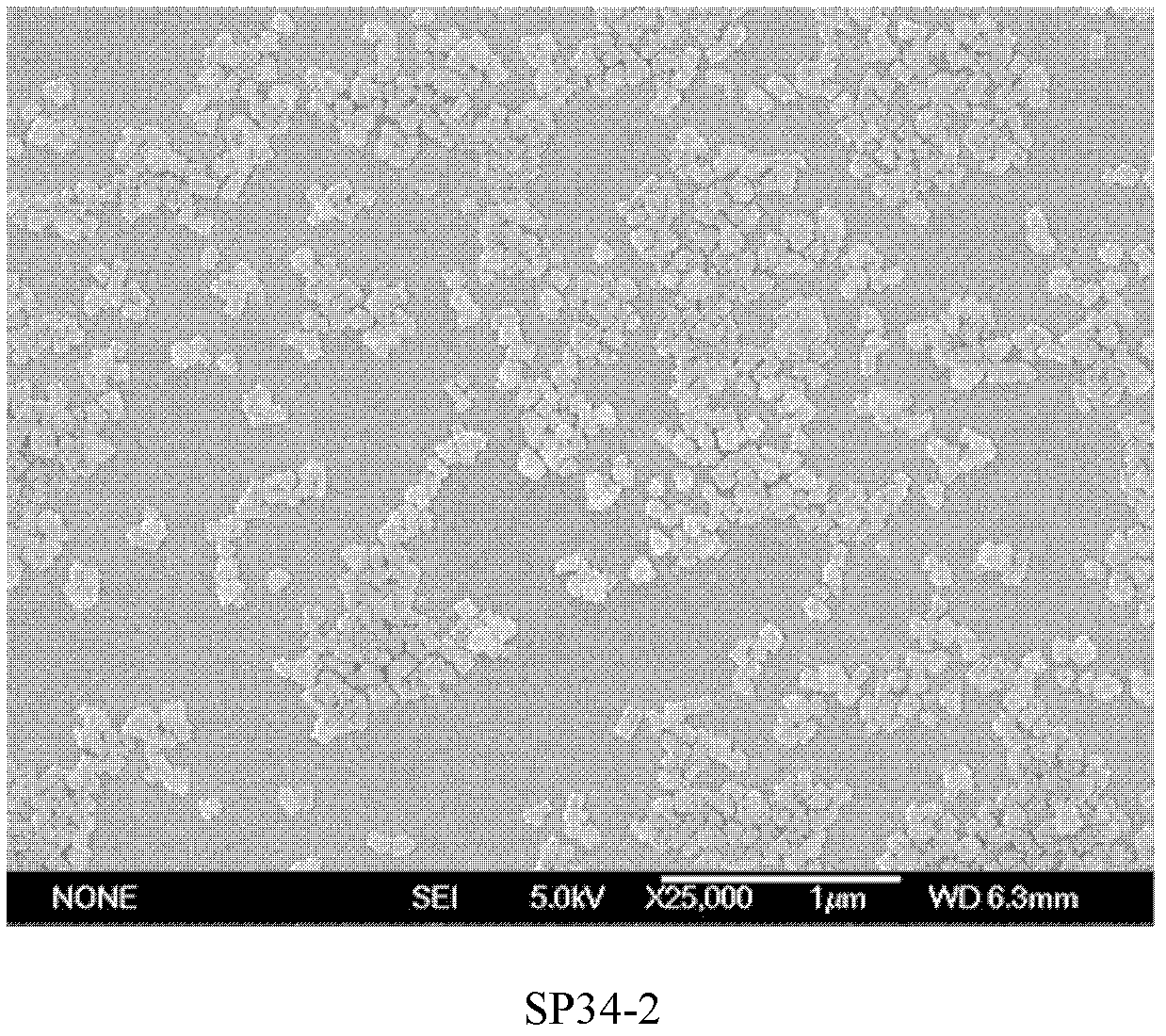

Preparation method for silicoaluminophosphate (SAPO)-34 molecular sieve with small crystal particle

ActiveCN102464338AImprove catalytic performanceMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveHydrogen fluoride

The invention relates to a preparation method for a silicoaluminophosphate (SAPO)-34 molecular sieve with a small crystal particle, which mainly solves the problem of larger product particle diameter in the SAPO-34 synthesis process in the prior art. The preparation method comprises the following steps: a) preparing an initial gel mixture at the following molar ratio: 0.5-10 moles of SiO2, 0.05-10 moles of Al2O3, 0.2-3 moles of P2O5, 0.001-0.02 moles of hydrogen fluoride (HF) and 20-200 moles of H2O, and stirring and ageing at the room temperature for 1-24h; b) adding the aged mixed solution into a crystallization kettle, carrying out hydrothermal crystallization at the temperature of 170-220DEG C for 0.1-20h, taking out, and quenching to obtain crystallization directing agent; c) according to the step a), preparing the gel mixture again, adding the crystallization directing agent obtained in the step b) to be evenly mixed, loading into the crystallization kettle, and carrying out hydrothermal crystallization at the temperature of 150-260DEG C for 5-48h; and d) recovering a molecular sieve product. According to the technical scheme, the problem is better solved, and the preparation method can be used for the industrial preparation of the SAPO-34 molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

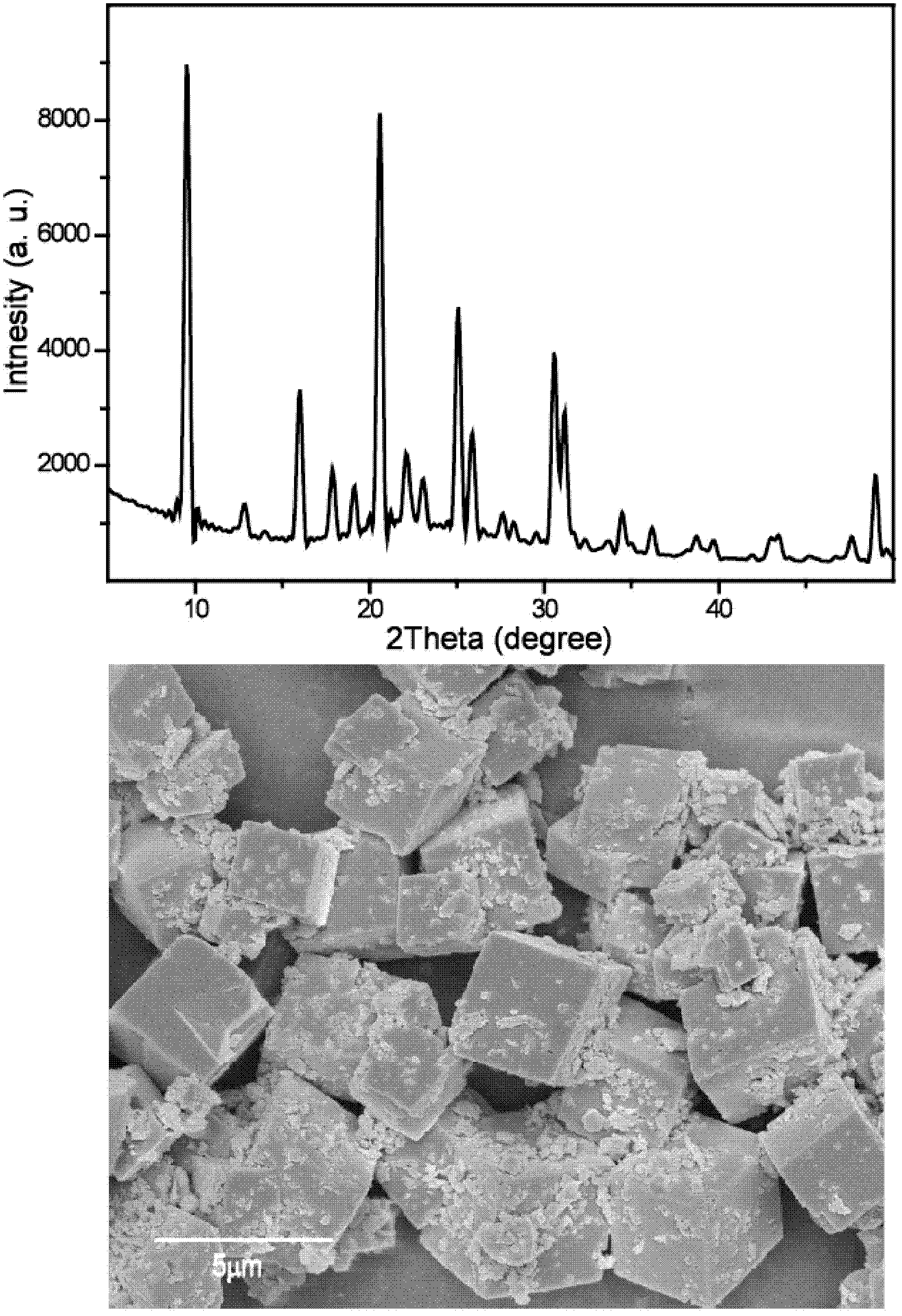

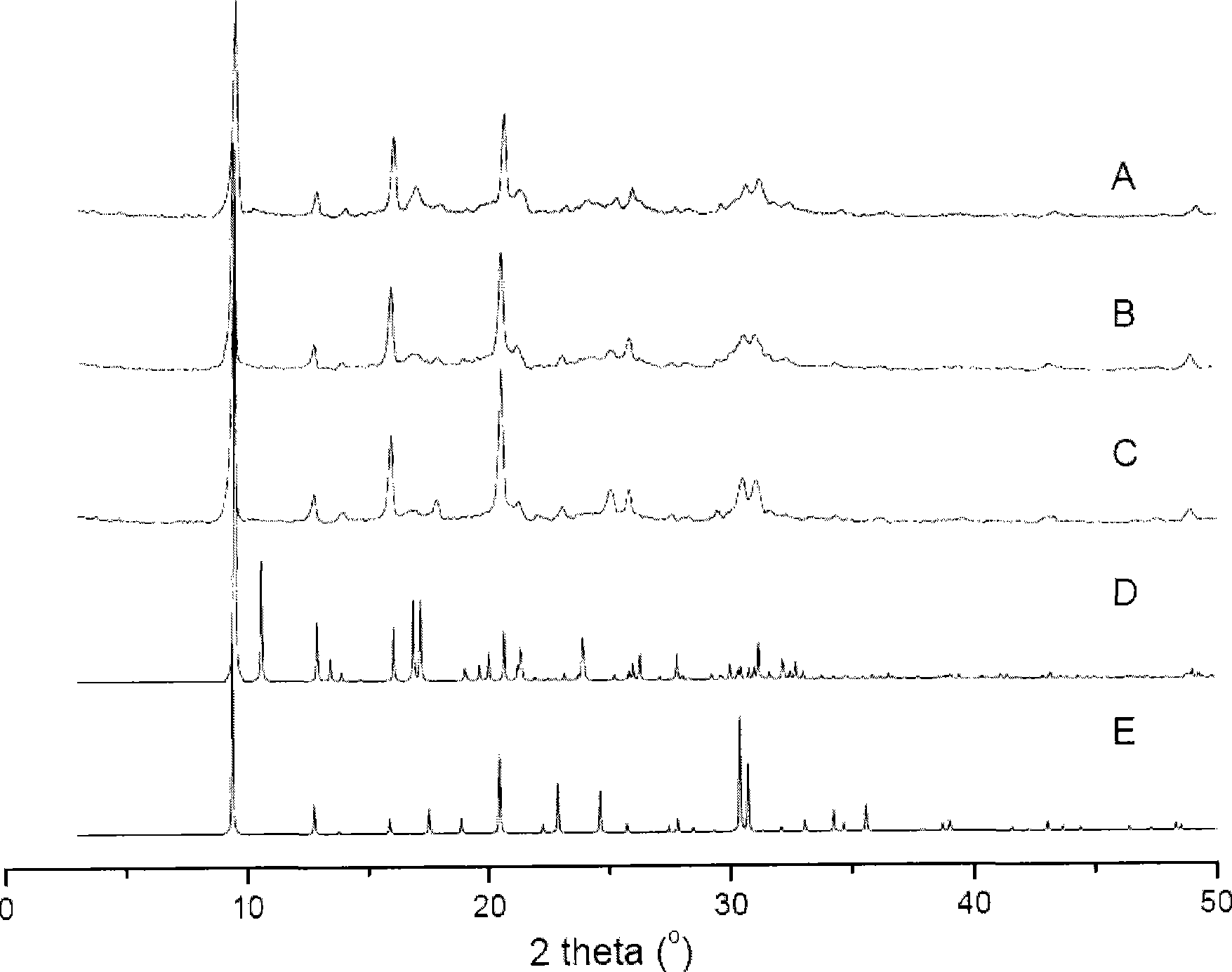

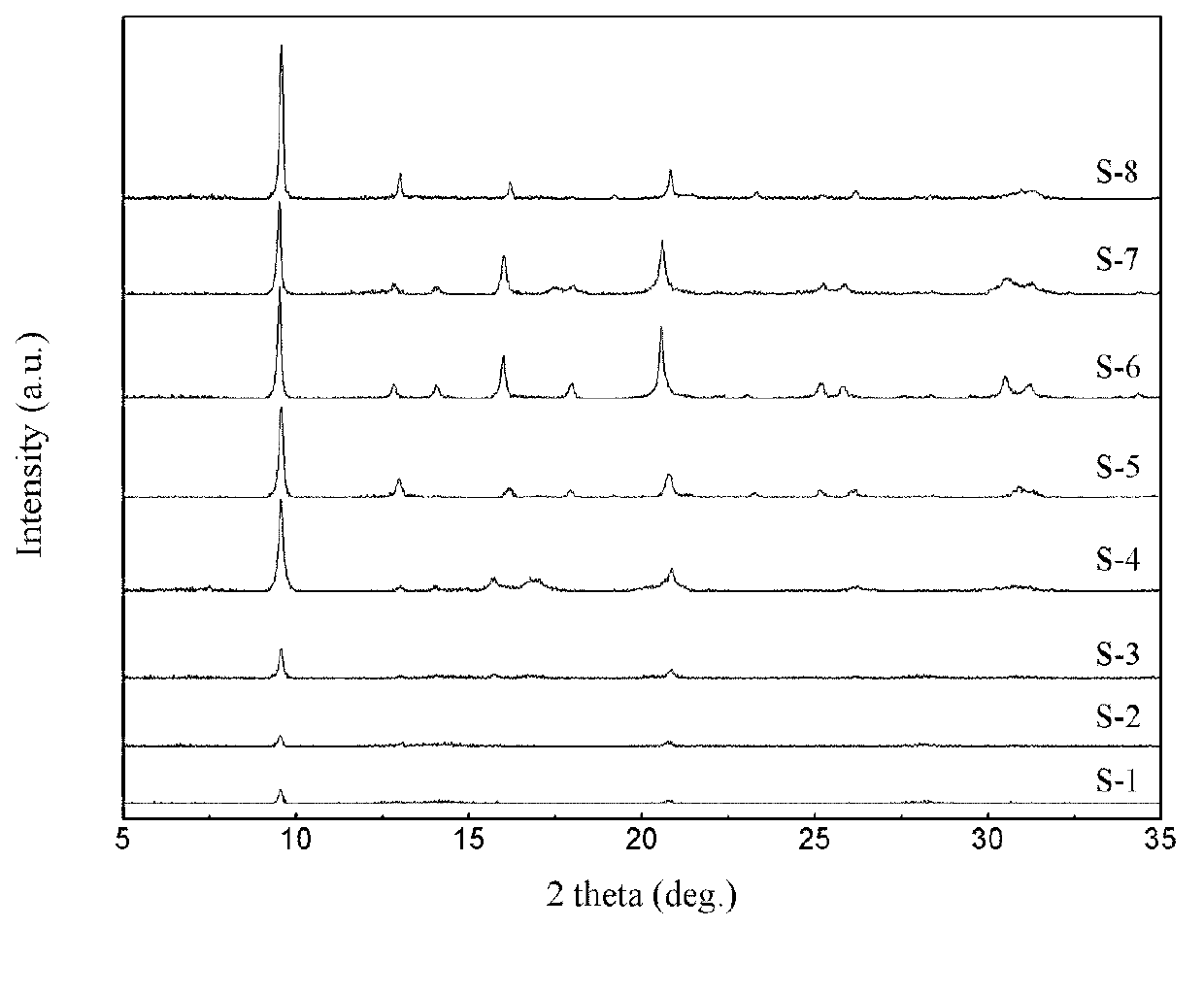

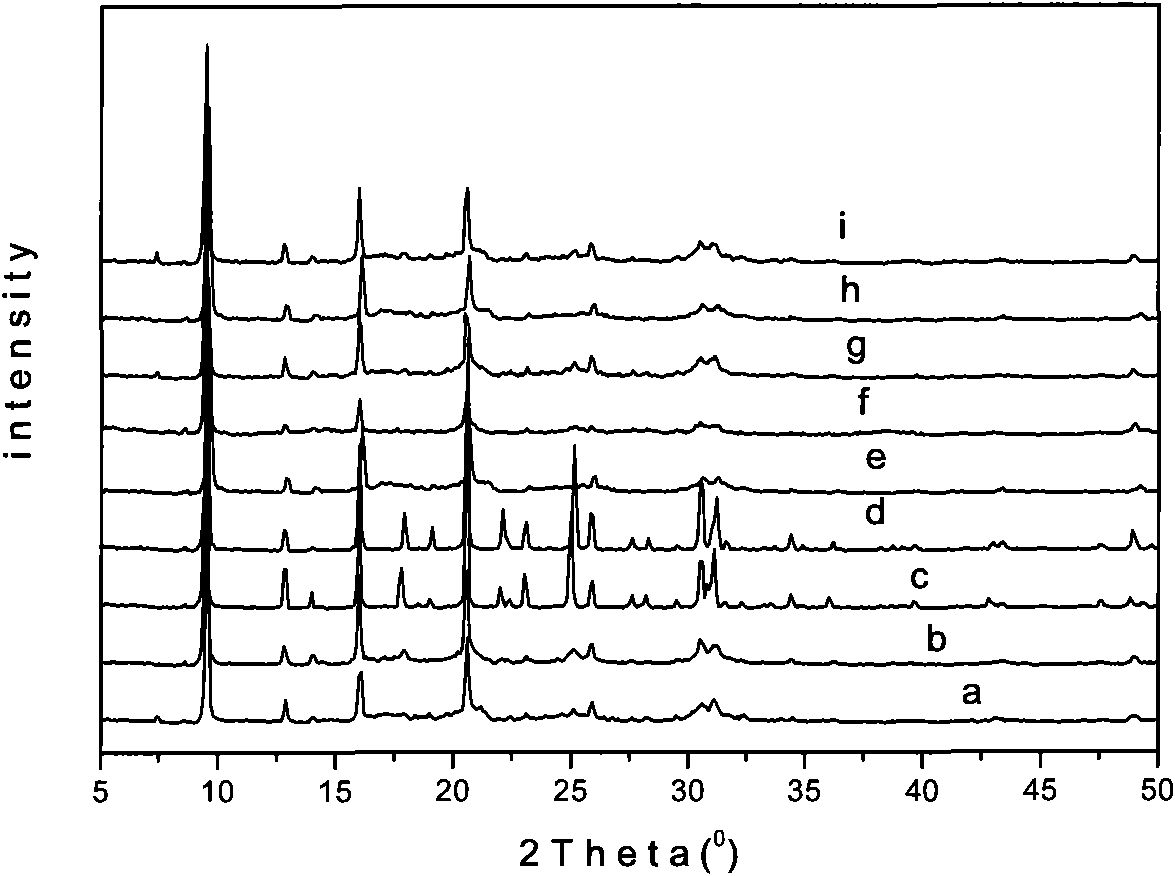

Synthetic method of SAPO-5 and SAPO-34 symbiotic molecular sieves

InactiveCN102372290AImprove catalytic performanceMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesState of artMolecular sieve

The invention relates to a synthetic method of SAPO-5 and SAPO-34 symbiotic molecular sieves and mainly solves the problems of single aperture and low activity of a porous material synthesized by the prior art. The synthetic method provided by the invention comprises the following steps of: using a phosphor source, an aluminium source, a silicon source and an organic template as raw materials, mixing the raw materials according to a certain proportion to form a mixed solution, and carrying out hydrothermal crystallization to obtain a series of SAPO-5 and SAPO-34 symbiotic molecular sieves. The synthesized symbiotic molecular sieves have the following molar ratio: AlO3: P2O5: SiO2: R: H2O=1: 0.2-1-2: 0.1-2.0: 0.5-2.5: 20-100, wherein R is the organic template. The technical scheme provided by the invention greatly solves the problems, and can be used in the industrial production of low carbon olefin prepared by methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for prepareing SAPO-34 molecular siever

InactiveCN1693202AHigh crystallinityHigh catalytic activityMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveGas phase

A process for preparing molecular sieve SAPO-34 includes such steps as adding deionized water to the container with stirrer, proportionally and sequentially adding the compounds of Al, P and Si and organic amine while stirring, evaporating water in baker to obtain dried substance, putting it on the upper position of a gas-phase reactor, filling the mixture of organic amine and water into its bottom, reaction, cooling, washing, drying and calcining.

Owner:NANJING UNIV OF TECH

Synthesis of silicoaluminophosphates

Disclosed is a method for the manufacture of silicoaluminophosphate (SAPO) and / or aluminophosphate (ALPO) molecular sieves. The method includes maintaining the slurry of the as crystallized molecular sieve under substantially static conditions when stored after substantially complete crystallization and prior to recovery of the product.

Owner:EXXONMOBIL CHEM PAT INC

Method for preparing small-grain SAPO-11 molecular sieve

ActiveCN101205076ALower synthesis costThe process steps are simpleMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveDistilled water

The invention relates to a method for preparing a molecular sieve with small crystal of SAPO-11, which does not use any other organics additives except template. The method prepares the molecular sieve with small crystal of SAPO-11 which has a size ranging from 300mm to 800mm and has an AEL structure comprising water, phosphorus source, aluminum source, template, and silica source. The preparation method includes the following steps: (1) the preparation of colloid slurry: according to the total material mole ration of P2O5: (0.5 to 1.5)AL2O3: (0.4 to 2.0) R: (0 to 1.0)SiO2:(17 to 60) H2O, the water, the phosphorus source, the aluminum source, the template and the silica source are added under the condition of temperature of 5 to 80 DEG C, fast mixing and the PH value controlled between 3.5 to 7.0, wherein, R is the template; (2) the aging of slurry: the reaction mixture acquired from step (1) is gel static aged under the temperature of 80 to 190 DEG C for 0.5 to 24 hours then is cooled to the room temperature; (3) the crystallization of the slurry: under the stirring condition, 0 to 200 percent of distilled water of the total mixture is put into the aging solution, then the solution is heated up to 100 to 220 DEG C for continuous crystallization for 4 to 72 hours to get the product by filtering, washing and drying after the crystallization.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

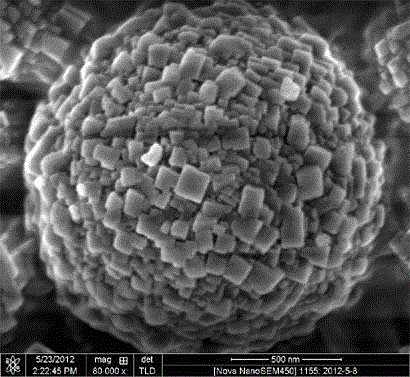

Nano SAPO (silicoaluminophosphate)-34 molecular sieve with spherical or flaky appearance, synthetic method thereof, catalyst prepared by same and application thereof

InactiveCN103011188AVarious shapesLong catalyst lifeMaterial nanotechnologyMolecular sieve catalystsMolecular sieveMicrowave

The invention discloses a nano SAPO (silicoaluminophosphate)-34 molecular sieve with a spherical or flaky appearance, a synthetic method of the nano SAPO-34 molecular sieve and a methanol to olefin catalyst prepared by the molecular sieve. The SAPO-34 molecular sieve is prepared in a microwave heating manner. The nano spherical or flaky SAPO-34 molecular sieve can be obtained by controlling microwave synthesis conditions, is a sphere having a crystal grain size less than 30nm or a sheet having a thickness less than 70nm, and the has the characteristics of short synthetic time, controllable crystal grain appearance and the like. A molecular sieve catalyst prepared by the molecular sieve is used for reactions of methanol to olefin, such as methanol to ethylene, methanol to propylene and the like, wherein a methanol conversion rate can reach 100%, the selectivity of C2 to C4 can reach 89.85%, the single pass life of the catalyst can reach 350 minutes.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

Method for preparing AlPO4 or SAPO molecular sieve

InactiveCN1850606AHigh selectivityControls are responsiveMolecular-sieve aluminophosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveHydrofluoric acid

The invention is a method for preparing AlPO4 or SAPO molecular sieve, using ionic liquid as reaction medium, adding in amine as auxiliary template. And it can be used to synthesize molecular sieves of various structures, comprising the steps of: A) using halogen 1-alkyl-3- methylimidazole ionic liquid as reaction medium and amine as auxiliary template, blending at 70-100 deg.C for 1-30 min; B) adding in precursor compounds of P, Al and Si and hydrofluoric acid to prepare precursor mixture of molecular sieve, crystallizing at 150-300 deg.C for 0.5-3 h, where the molar ratio of Al2O3 to P2O5 to SiO2 to HF to amine to halogen 1-alkyl -3-methylimidazole ionic liquid = 1:(1.7-3.8):(0-1):(0.05-0.2):(0.5-3):(10-40); and C) cooling to room temperature, filtering, washing and drying, so as to obtain a solid-AlPO4 or SAPO molecular sieve.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for synthesising porous crystalline aluminophosphate molecular sieves

InactiveUS20060147364A1Easy to handlePhosphatesMolecular sieve catalystsMolecular sieveOrganic chemistry

Owner:COUNCIL OF SCI & IND RES

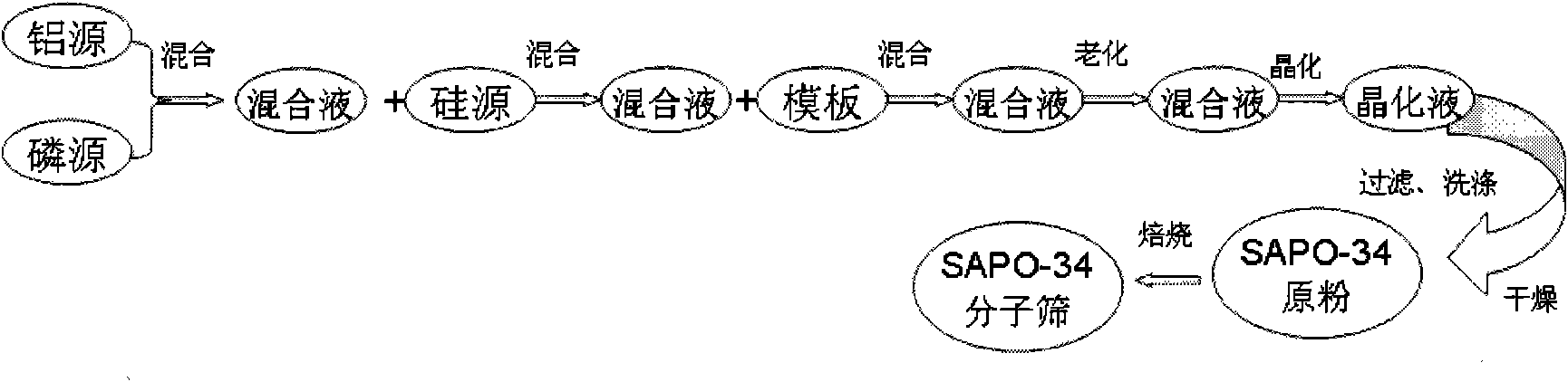

Method for preparing SAPO-34 molecular sieve

InactiveCN101525141AShort crystallization timeHigh crystallinityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sievePre treatment

The invention discloses a method for preparing SAPO-34 molecular sieve, which is characterized in that Al2O3, P2O5, SiO2, R and H2O which have the mol ratio of 1:0.5-1.02:0.1-0.8:0.32-3:50-200 are mixed together into crystallization liquid and processed by aging treatment at the temperature of 2-110 DEG C for 10-24hr; or the crystallization liquid is processed by ultrasonic treatment at the temperature of 20-90 DEG C for 0.5-1hr, the ultrasonic frequency is 40-60 Hz, and the power is 200-400W. After being pretreated by the technique, the crystallization liquid is crystallized at the temperature of 180-200 DEG C for 18-48hr, and the solid product is washed in a centrifugal way and dried at the temperature of 105-115 DEG C; then, the obtained solid product is calcined at the temperature of 530-560 DEG C for 5-6hr, so that the SAPO-34 molecular sieve is obtained.

Owner:CHENGDU HUIEN FINE CHEM +1

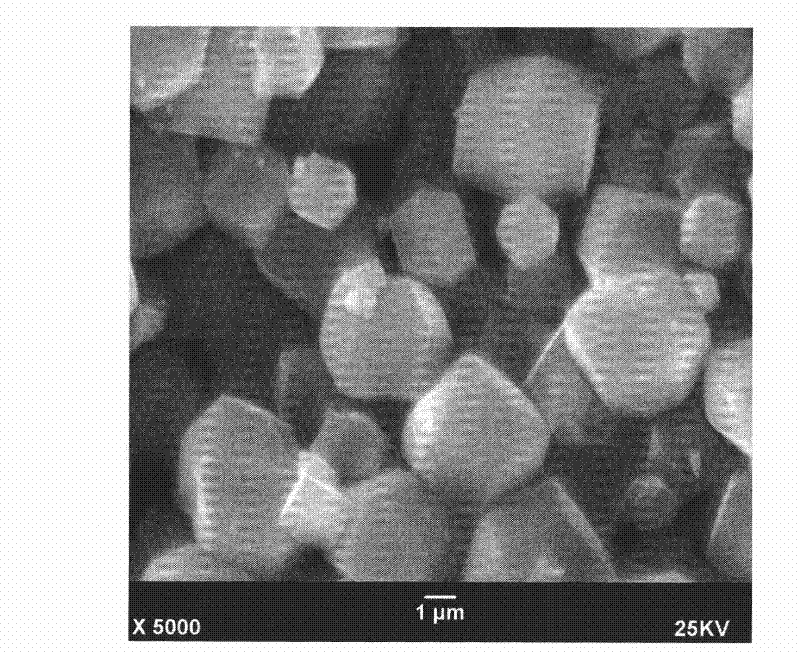

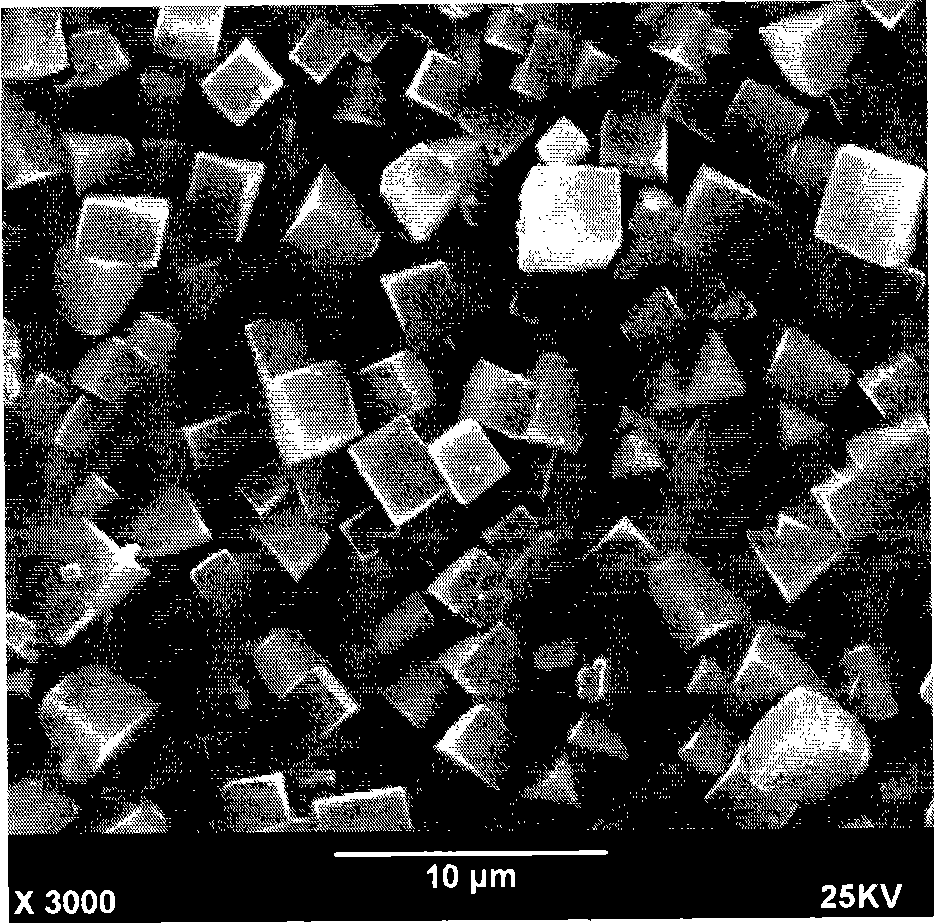

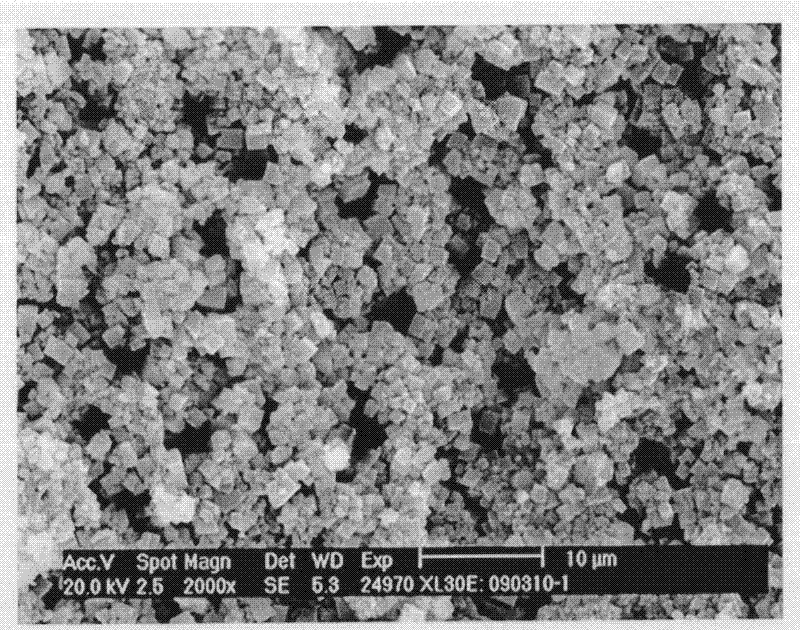

Cubic or sheet-shaped nano SAPO-34 molecular sieve and application thereof

ActiveCN102616810AReduce grain sizeHigh yieldMolecular sieve catalystsNanotechnologyMolecular sieveMicrowave

The invention belongs to the technical field of molecular sieves and particularly relates to a cubic or sheet-shaped nano SAPO-34 molecular sieve and application thereof in conversion, separation and absorption of all kinds of hydrocarbons. The dimension range of the molecular sieve is within 20-300nm and is rapidly prepared by using tetraethyl ammonium hydroxide as template agent, mixing the tetraethyl ammonium hydroxide with an aluminum source, a silicon source and a phosphorus source and adding specific solvent to control gel concentration through the traditional hydrothermal or microwave heating method. The nano-scale SAPO-34 molecular sieve synthesized by adopting the method has the characteristics that the cost of raw materials for gel is low, the production speed of the molecular sieve is rapid, the preparation time of crystallized start materials is short, the reaction energy consumption is low, the yield of the molecular sieve is high, the catalytic application life is long and the catalytic effect of the molecular sieve in catalytic reaction can be obviously improved.

Owner:JILIN UNIV

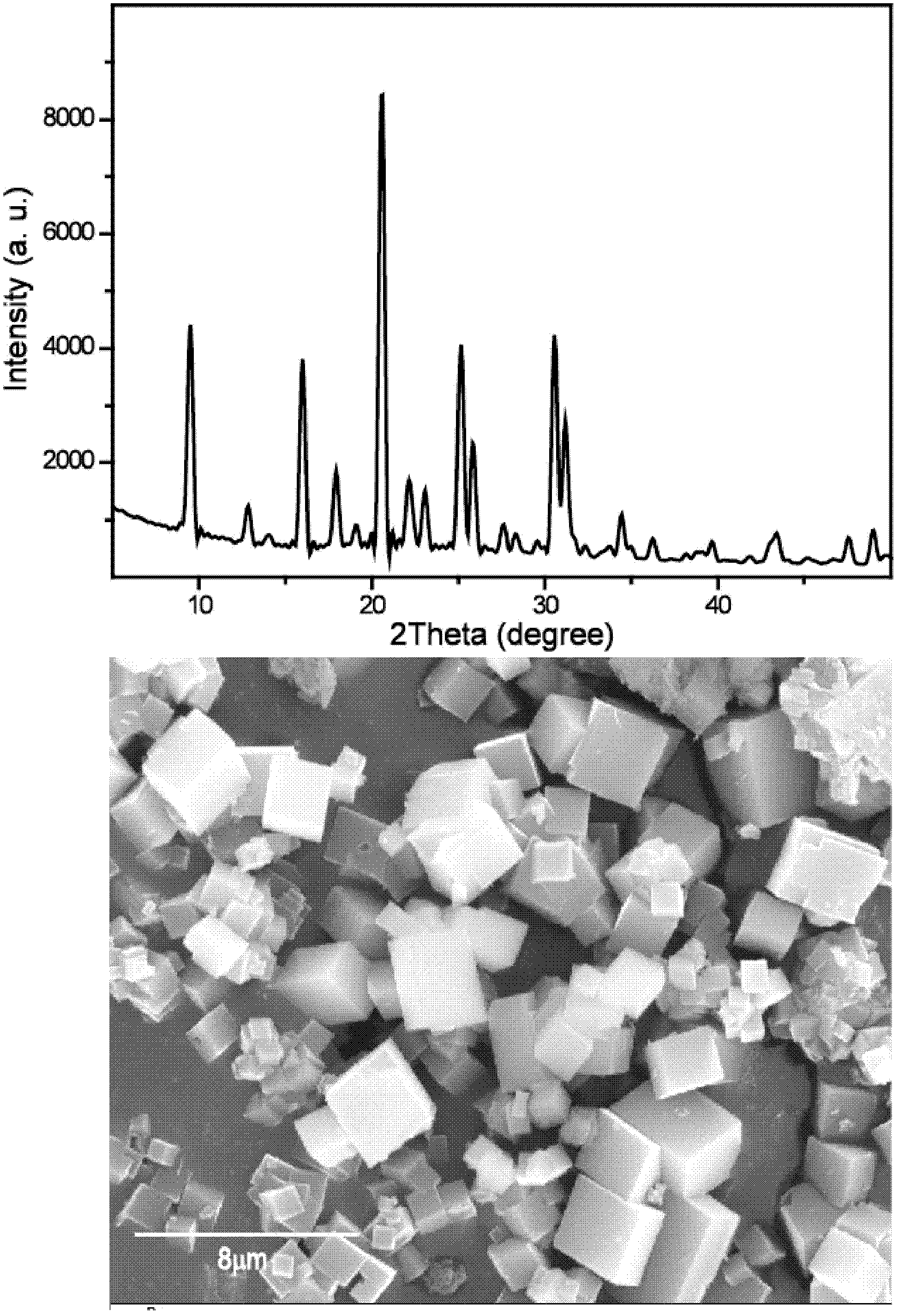

Method for preparing SAPO-34 molecular sieve

ActiveCN101767800AIncrease profitChange shapeMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveCrystallization temperature

The invention provides a method for preparing a SAPO-34 molecular sieve. The method comprises the following steps of: 1, uniformly mixing a proper amount of phosphorus source, aluminum source, silicon source, template, auxiliary template and water at a proper temperature and under a stirring condition to obtain mixed solution, of which a molar ratio of all components, namely, the molar ratio of R to F- to SiO2 to Al2O3 to P2O5 to H2O, is a:b:c:1:d:e, wherein R represents the template, a is 0.2 to 5.0, b is 0 to 1.0, c is 0.2 to 1.5, d is 0.2 to 2.0 and e is 20 to 200; 2, ageing the mixed solution; and putting the aged mixed solution in a crystallization kettle, sealing the crystallization kettle, heating the mixed solution to a crystallization temperature, and crystallizing the mixed solution at the constant crystallization temperature; 3, performing centrifugal separation of the crystallized mixed solution, filtering, washing the mixed solution until a pH value of the mixed solution is 7 to 8, and drying a solid sample to obtain the SAPO-34 raw powder; and 4, baking the SAPO-34 raw powder at the temperature of between 450 and 650 DEG C for 4 to 8 hours to obtain the SAPO-34 molecular sieve. The SAPO-34 molecular sieve prepared by the method is characterized by high crystallinity and can show better low carbon olefin selectivity in an MTO reaction.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

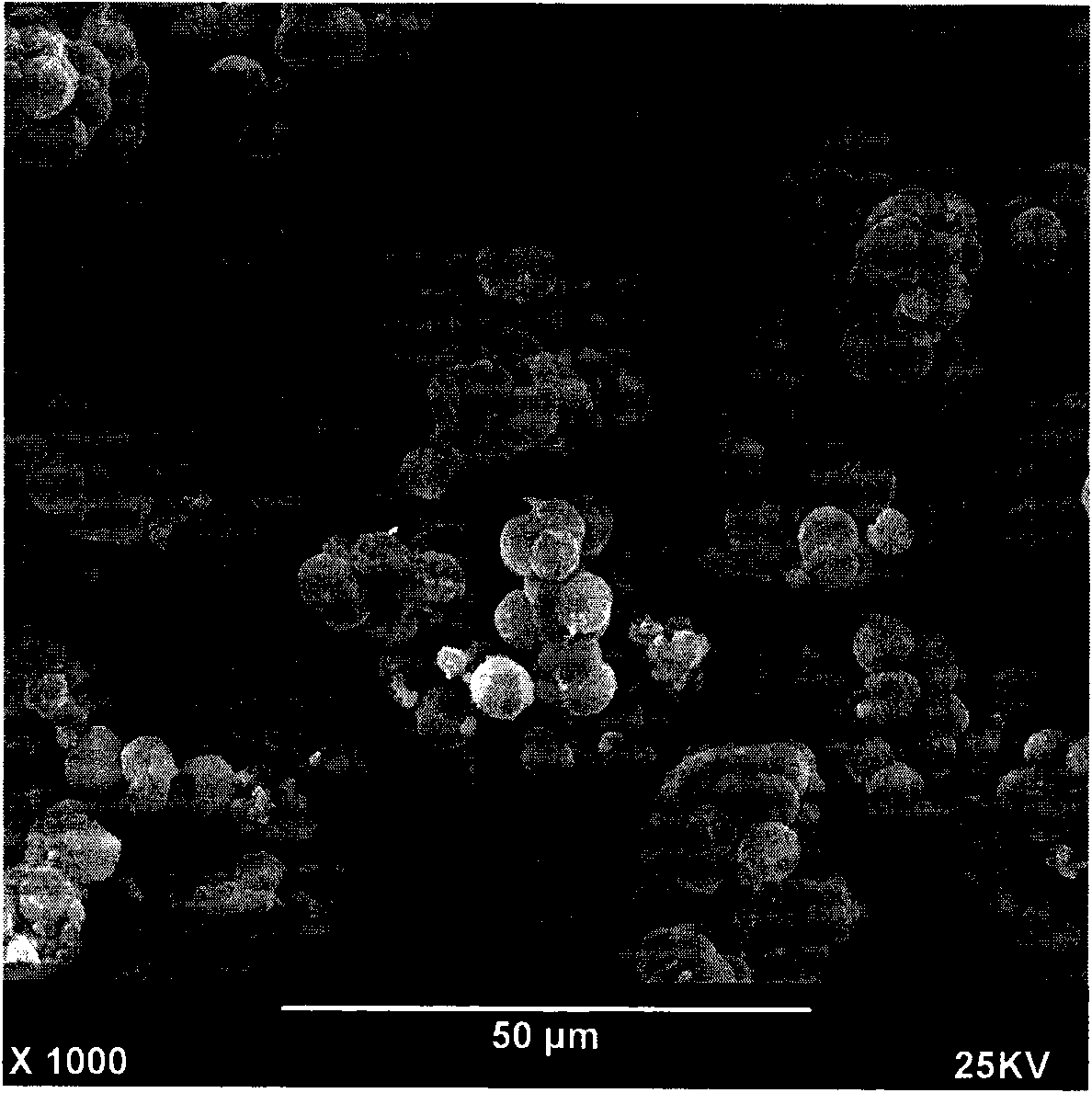

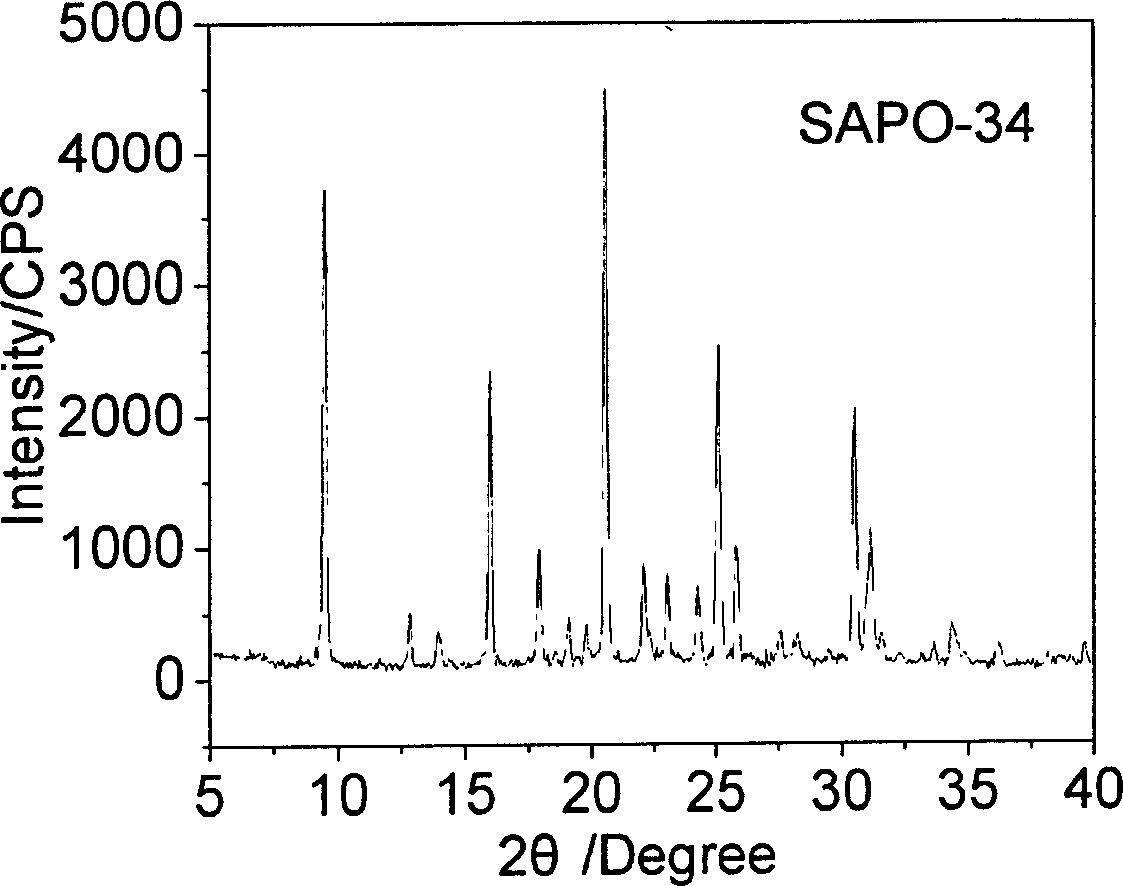

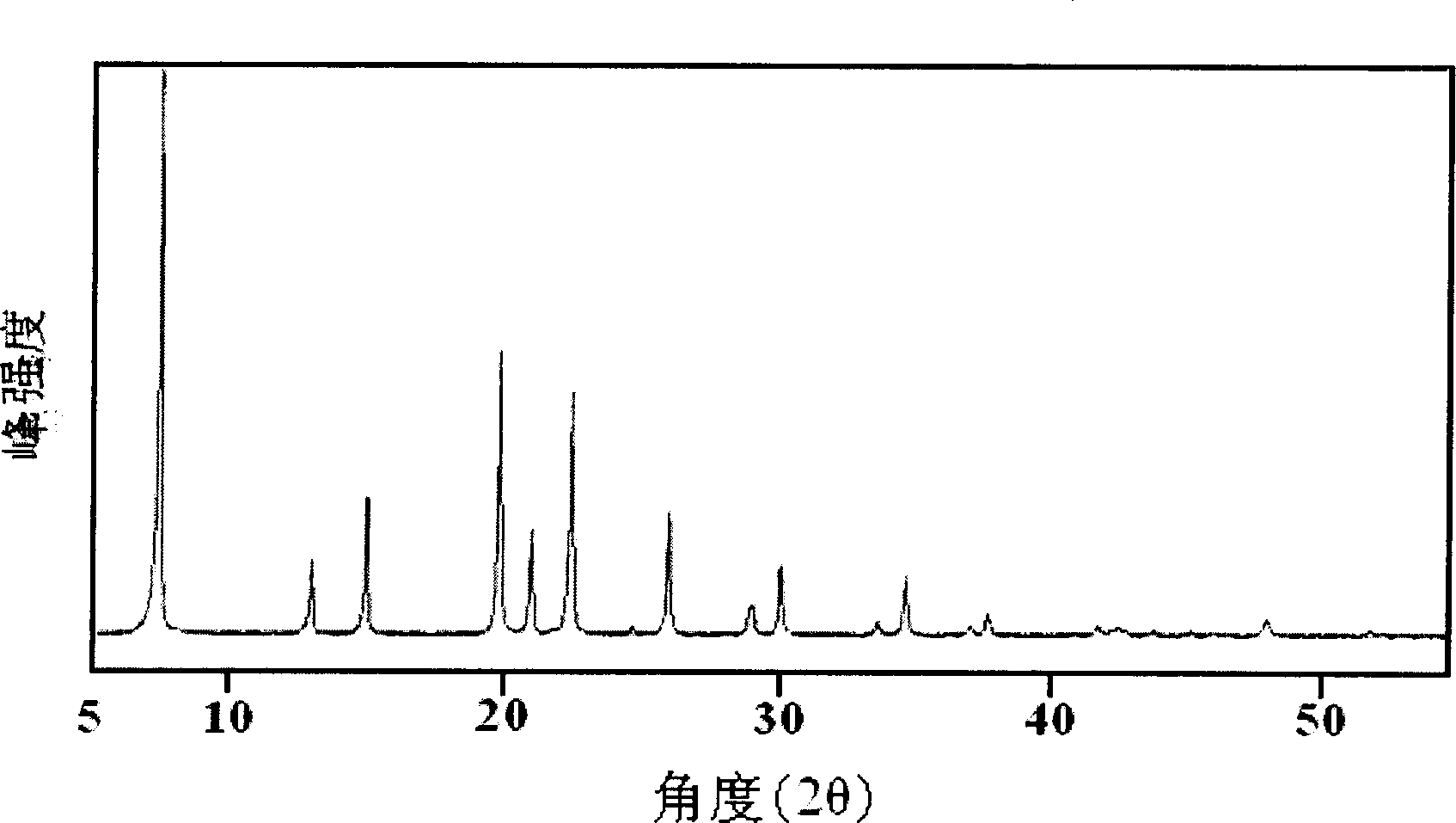

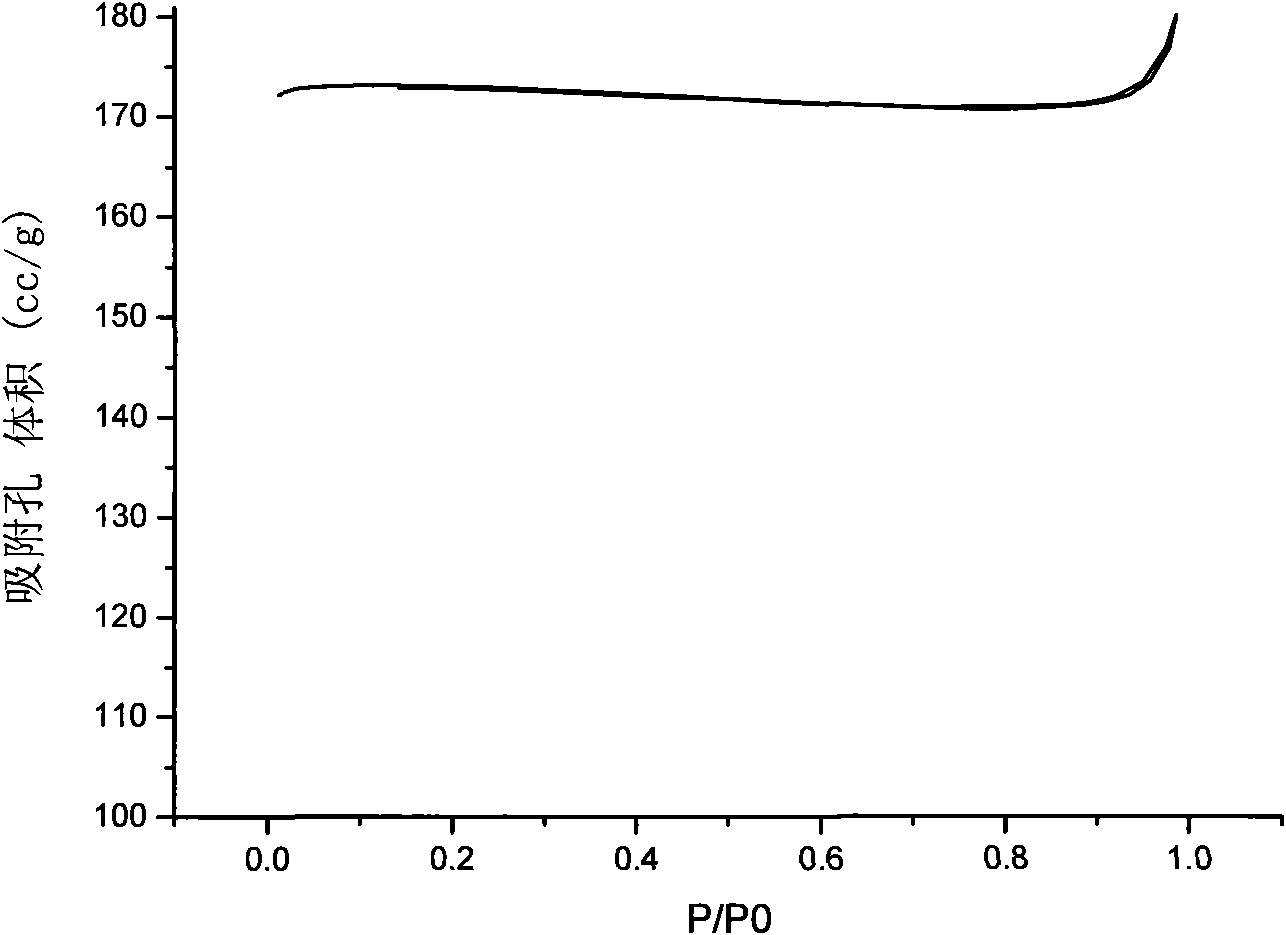

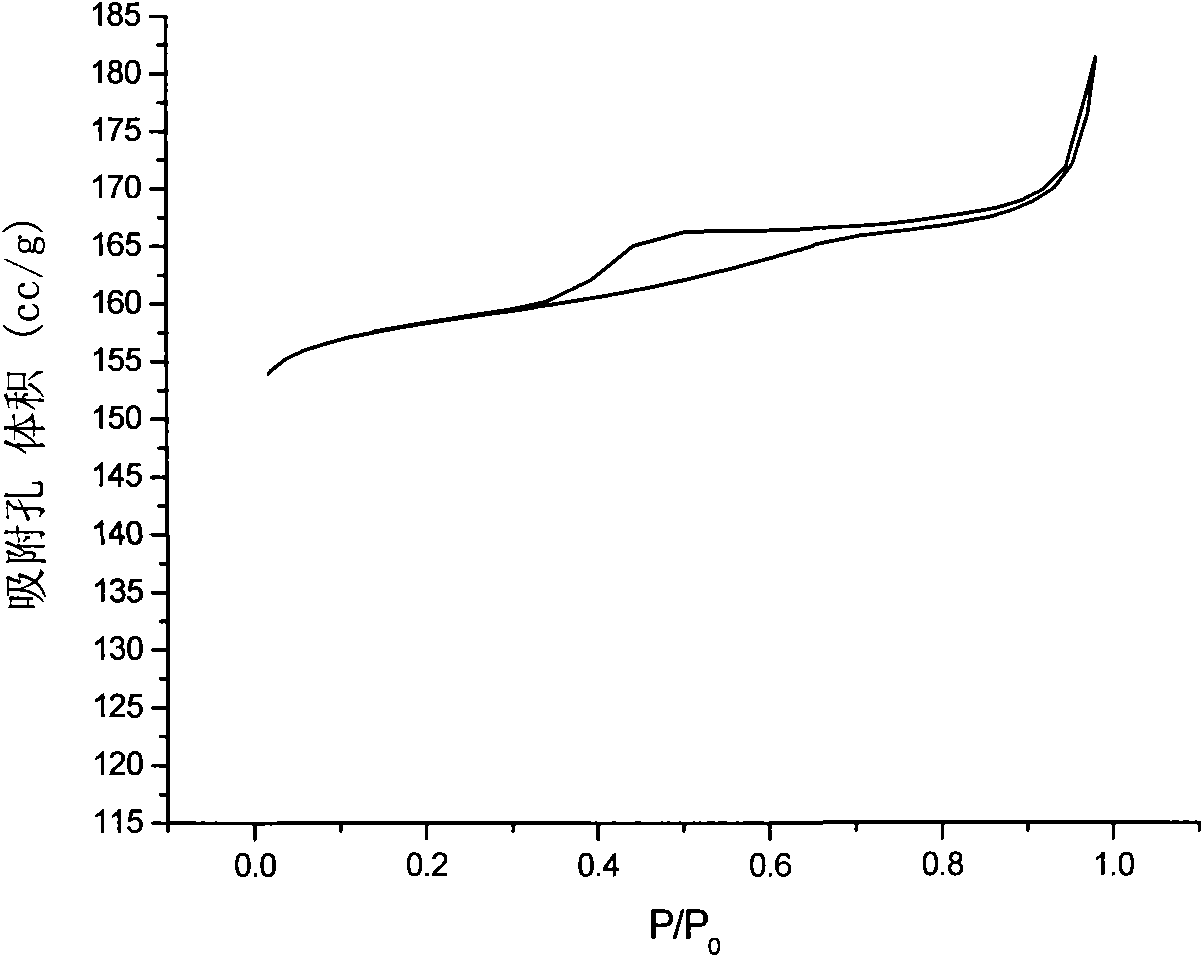

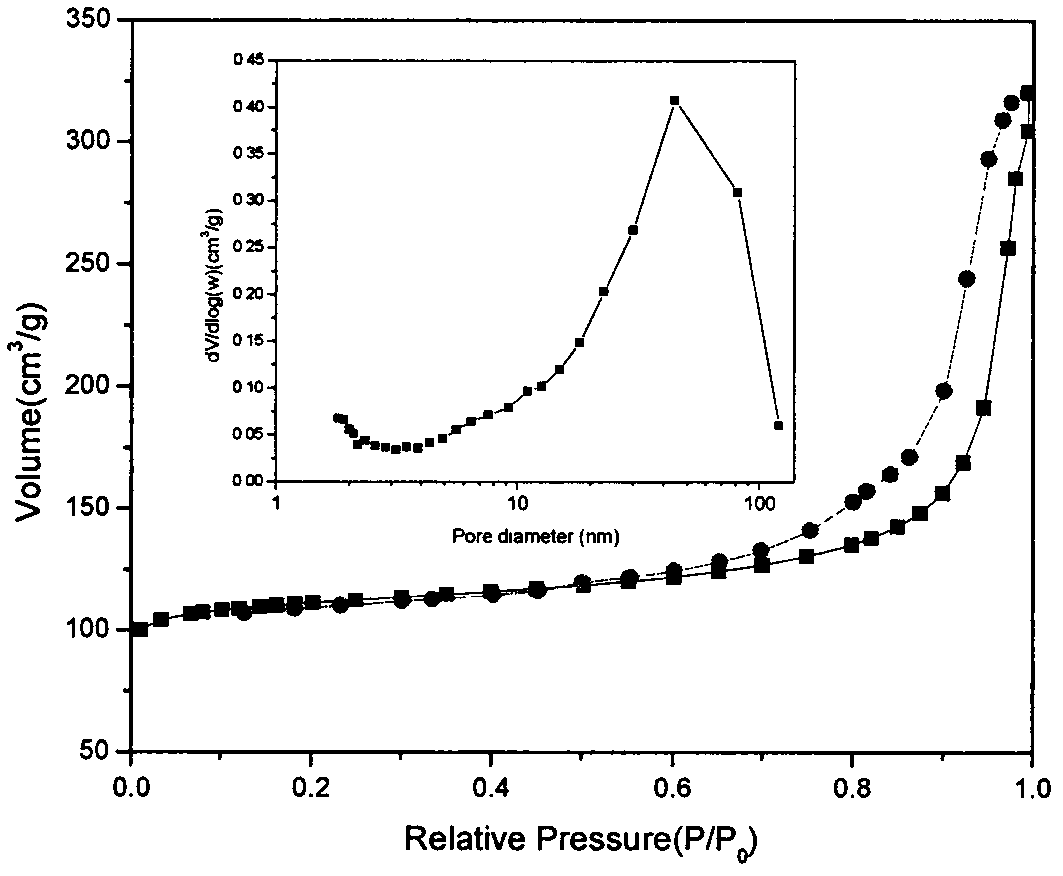

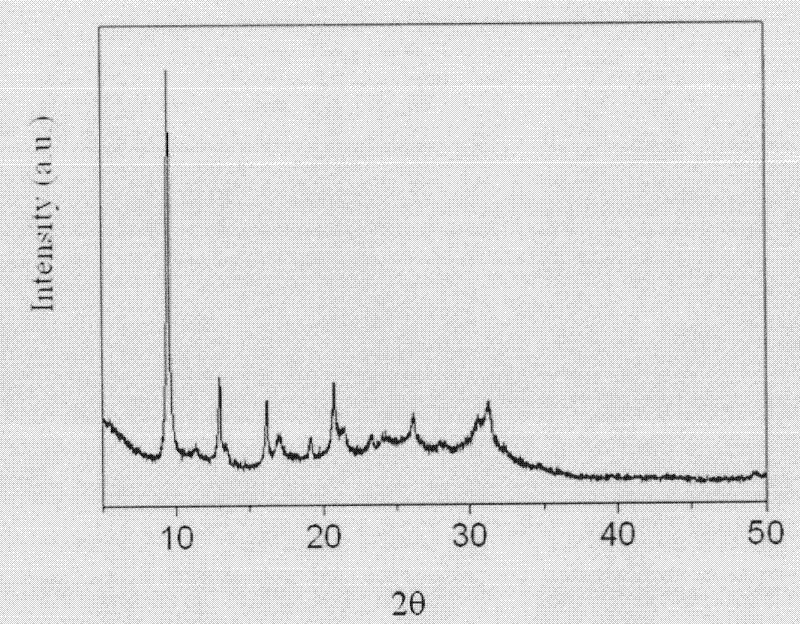

SAPO-34 molecular sieve and synthesis method thereof

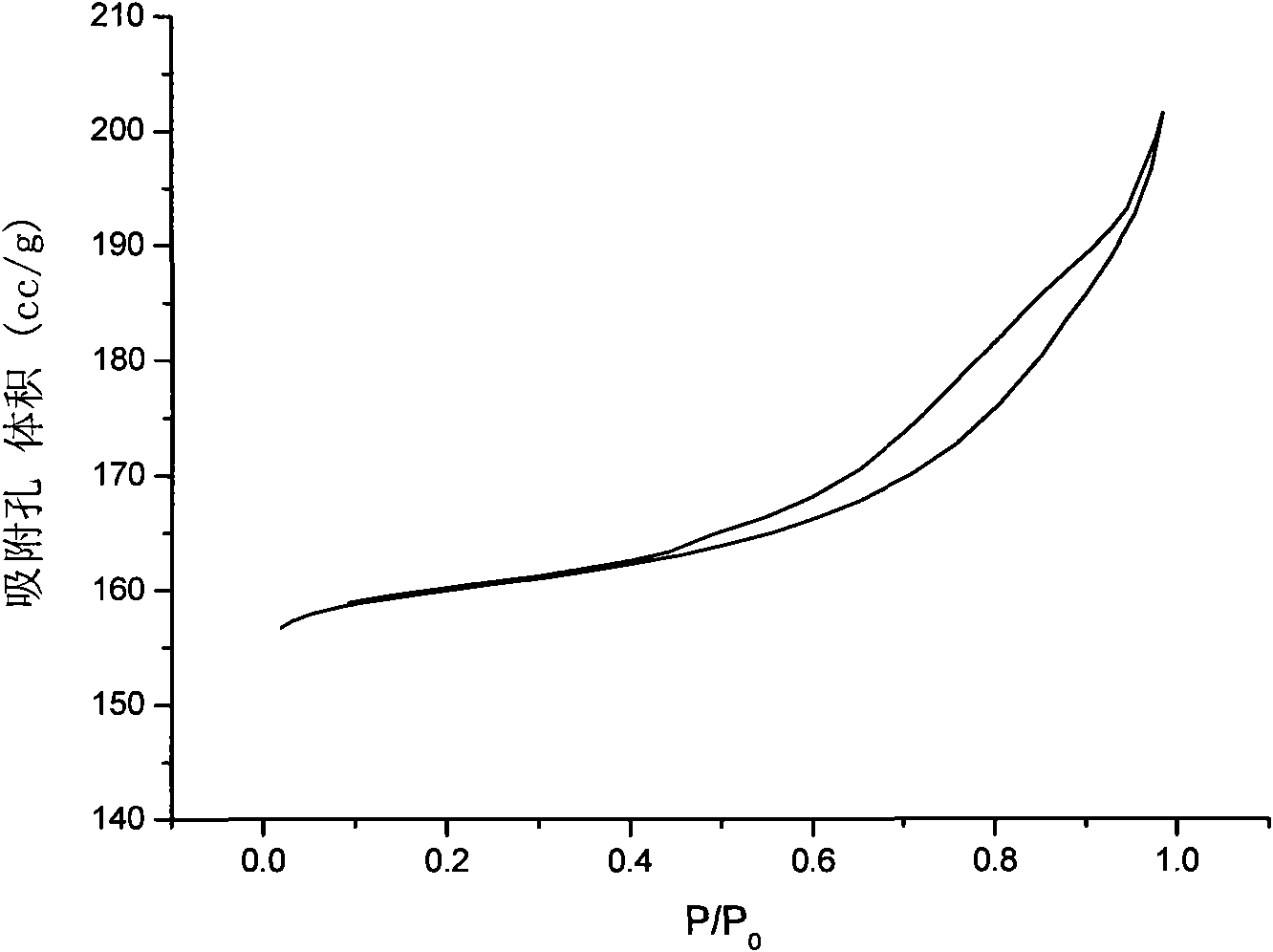

ActiveCN101633508AMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesHysteresisSynthesis methods

The invention provides an SAPO-34 molecular sieve and a synthesis method thereof. A hysteresis loop is arranged between nitrogen adsorption isotherm and desorption isotherm of the molecular sieve; and a molecular sieve crystal comprises topographies such as hollow shells, holes, concave-convex, cracks, nuclear shells and the like. The molecular sieve is obtained by mixing an aluminum source, a phosphorous source, a silicon source and an organic template agent to form gel and hydrothermally crystallizing the gel for 4 to 500 hours at the temperature of between 100 and 250 DEG C, wherein the organic template agent is added in two steps, one part is added during forming the gel, and the rest is added during hydrothermal crystallization. The molecular sieve is a catalyst of active components, can be used for conversion reaction of oxygenated organic compounds, and also can be used for conversion reaction of hydrocarbons, or used as a hydrogen conversion catalyst of hydrocarbons after supporting metals.

Owner:CHINA PETROLEUM & CHEM CORP +1

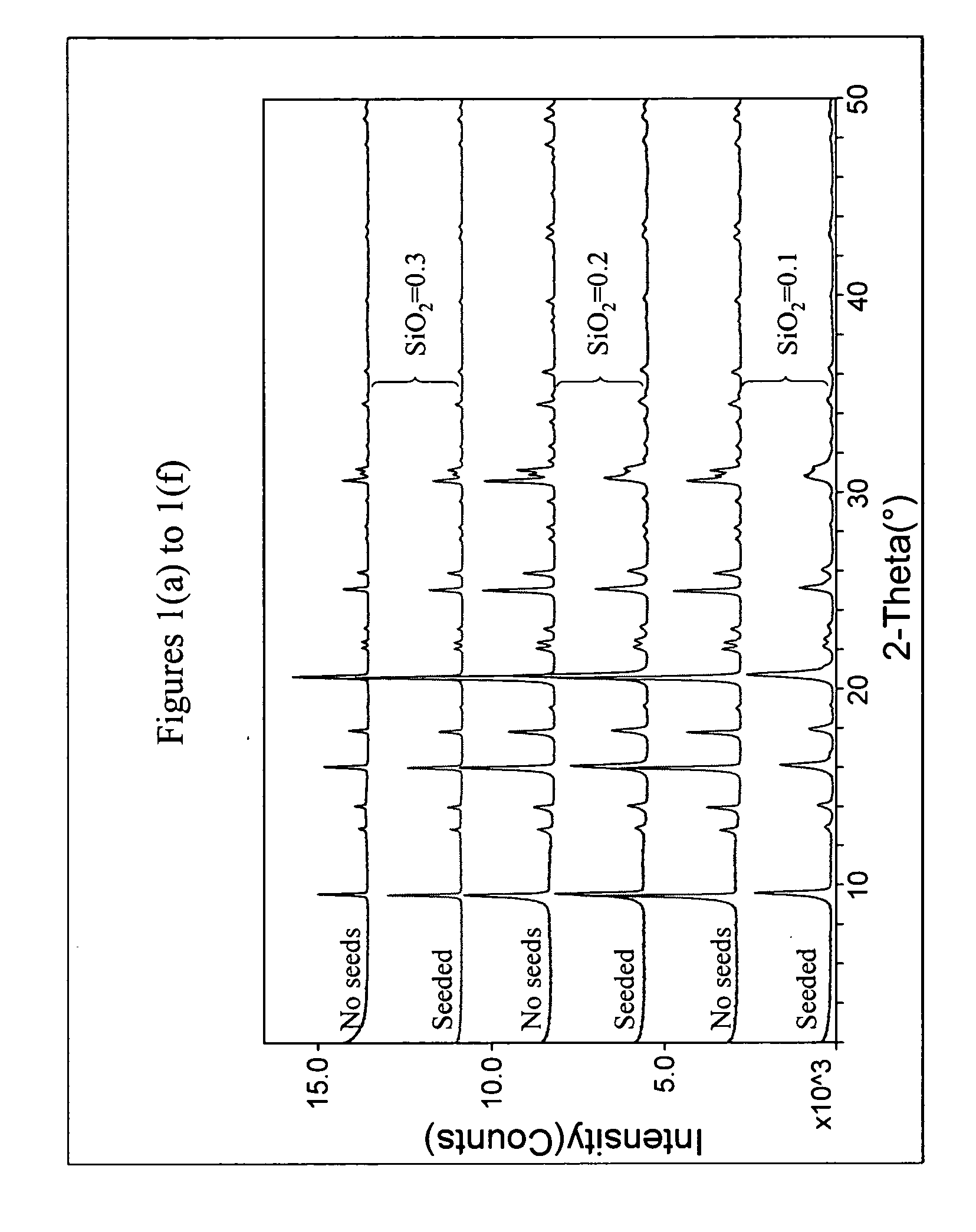

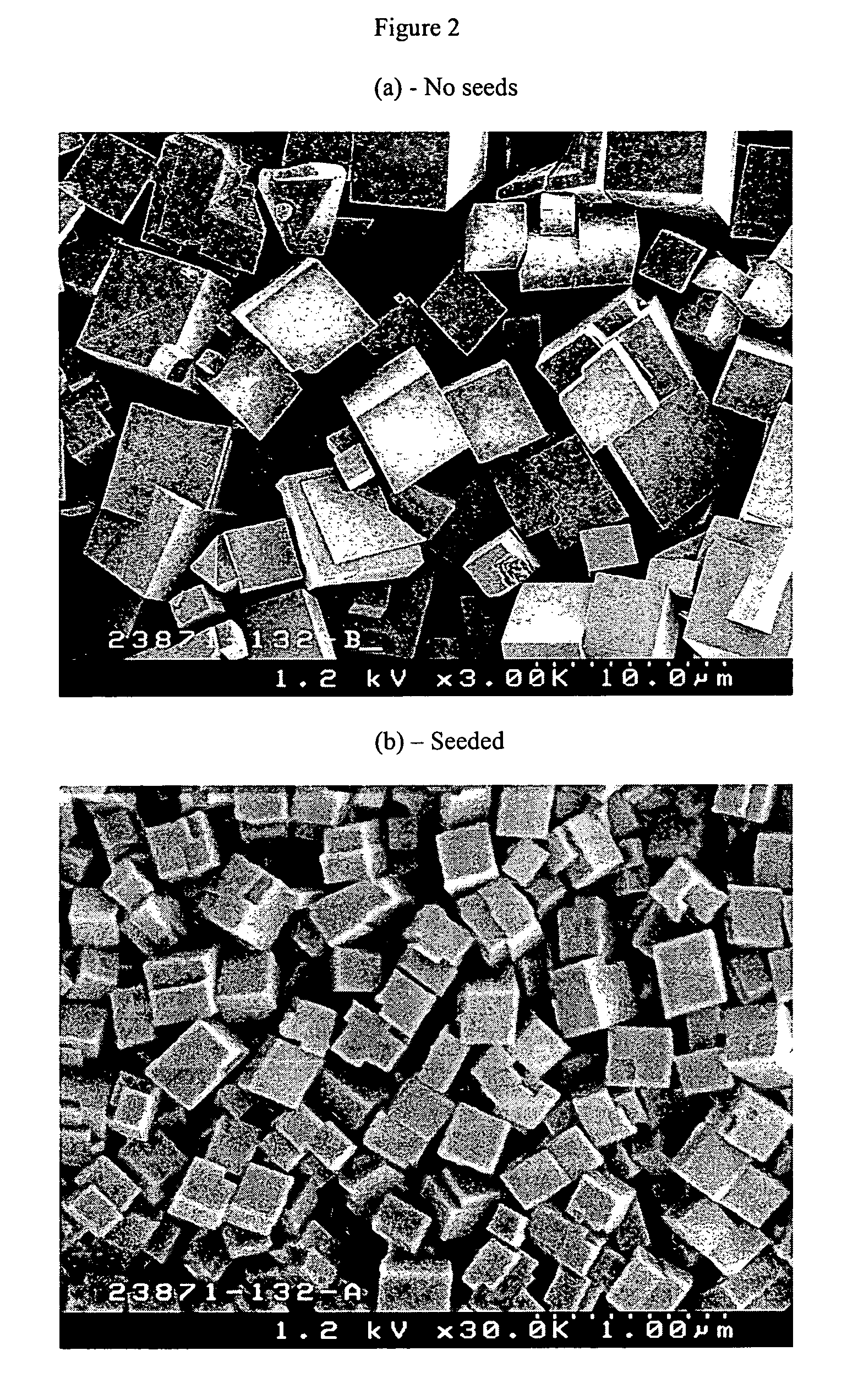

Preparation method of high-performance SAPO (silicoaluminophosphate)-34 molecular sieve membrane

InactiveCN103896300AImprove synthesis reproducibilityImprove gas permeabilityProductsMethane captureMolecular sieveRepeatability

The invention discloses a preparation method of a high-performance SAPO (silicoaluminophosphate)-34 molecular sieve membrane. The preparation method comprises the following steps: (1) obtaining an SAPO-34 molecular sieve crystal seed; (2) coating the SAPO-34 molecular sieve crystal seed on the inner surface of a porous carrier; (3) putting the prepared porous carrier coated with the SAPO-34 molecular sieve crystal seed into synthesizing mother liquor of the molecular sieve membrane and synthesizing an SAPO-34 molecular sieve membrane tube; (4) roasting to remove a template agent, thereby obtaining the SAPO-34 molecular sieve membrane without the template agent. The preparation method disclosed by the invention has the advantages that the uniformity and stability of the synthesizing mother liquid are greatly improved, the synthesis repeatability of the SAPO-34 molecular sieve membrane is improved, and the synthesized SAPO-34 molecular sieve membrane has higher gas permeability and CO2 / CH4 selectivity. Furthermore, the SAPO-34 molecular sieve membrane prepared by the preparation method can be applied to gas separation of CO2-CH4, CO2-H2 and CO2 / N2 and the like.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

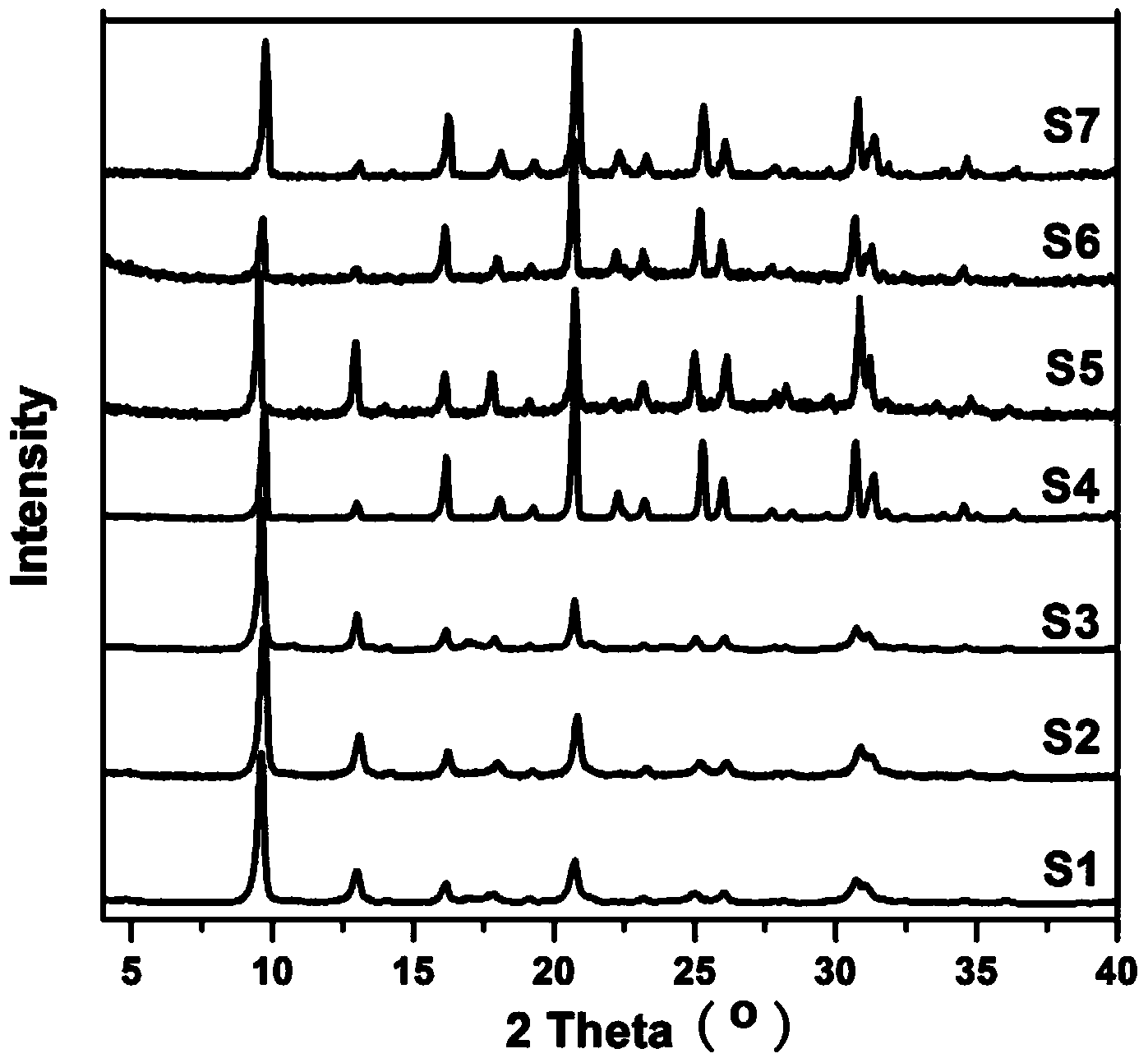

Solvent volatilization self-assembly method used for preparing multistage-channel SAPO-34 and SAPO-18 molecular sieves

InactiveCN102992339AMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveWater vapor

The invention discloses a method for preparing multistage-channel SAPO-n (n=34, 18) through solvent volatilization. According to the invention, a zeolite template agent is added into a mixed solution of an aluminum source, a silicon source, and a phosphorus source; stirring and a reaction are sufficiently carried out; the solution is completely delivered into a culture dish, and is air-dried into gel; under the effect of steam formed by water added into an autoclave, the gel is subjected to hydrothermal synthesis; powder converted from the gel is subjected to a heat treatment under high temperature, such that the multistage-channel SAPO-n zeolite is formed. The method provided by the invention has the advantages of simple process, easy control, easy realization, low cost, and environment friendliness.

Owner:EAST CHINA UNIV OF SCI & TECH

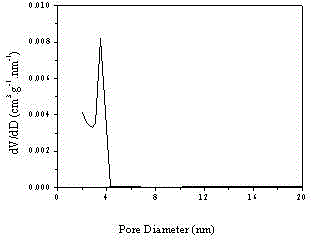

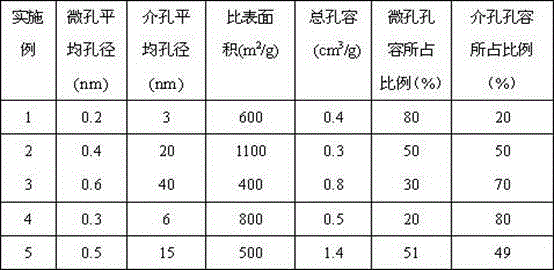

Hierarchical porous structure SAPO molecular sieve material and preparation method thereof

ActiveCN104556092AMolecular sieve catalystsHeterogenous catalyst chemical elementsMolecular sieveHierarchical porous

The invention relates to a preparation method of a hierarchical porous structure silicon-phosphorus-aluminum SAPO molecular sieve. The technical scheme adopted by the invention for mainly solving the problem that the hierarchical porous structure SAPO molecular sieve is hard to prepare in the prior art is as follows: the preparation method of the hierarchical porous structure silicon-phosphorus-aluminum SAPO molecular sieve comprises the following steps: hydrolyzing a mixture prepared by a high-molecular polymer R1, water, an organic template agent R2, a phosphorus source, an aluminum source and an alkali-treated silicon source at -20 DEG C to 100 DEG C to prepare sol, then putting the sol in a reaction kettle for crystallizing; and washing, drying and roasting a sample after crystallizing to prepare the hierarchical porous structure SAPO molecular sieve. The preparation method of the hierarchical porous structure silicon-phosphorus-aluminum SAPO molecular sieve can be applied to industrial production of the hierarchical porous structure molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

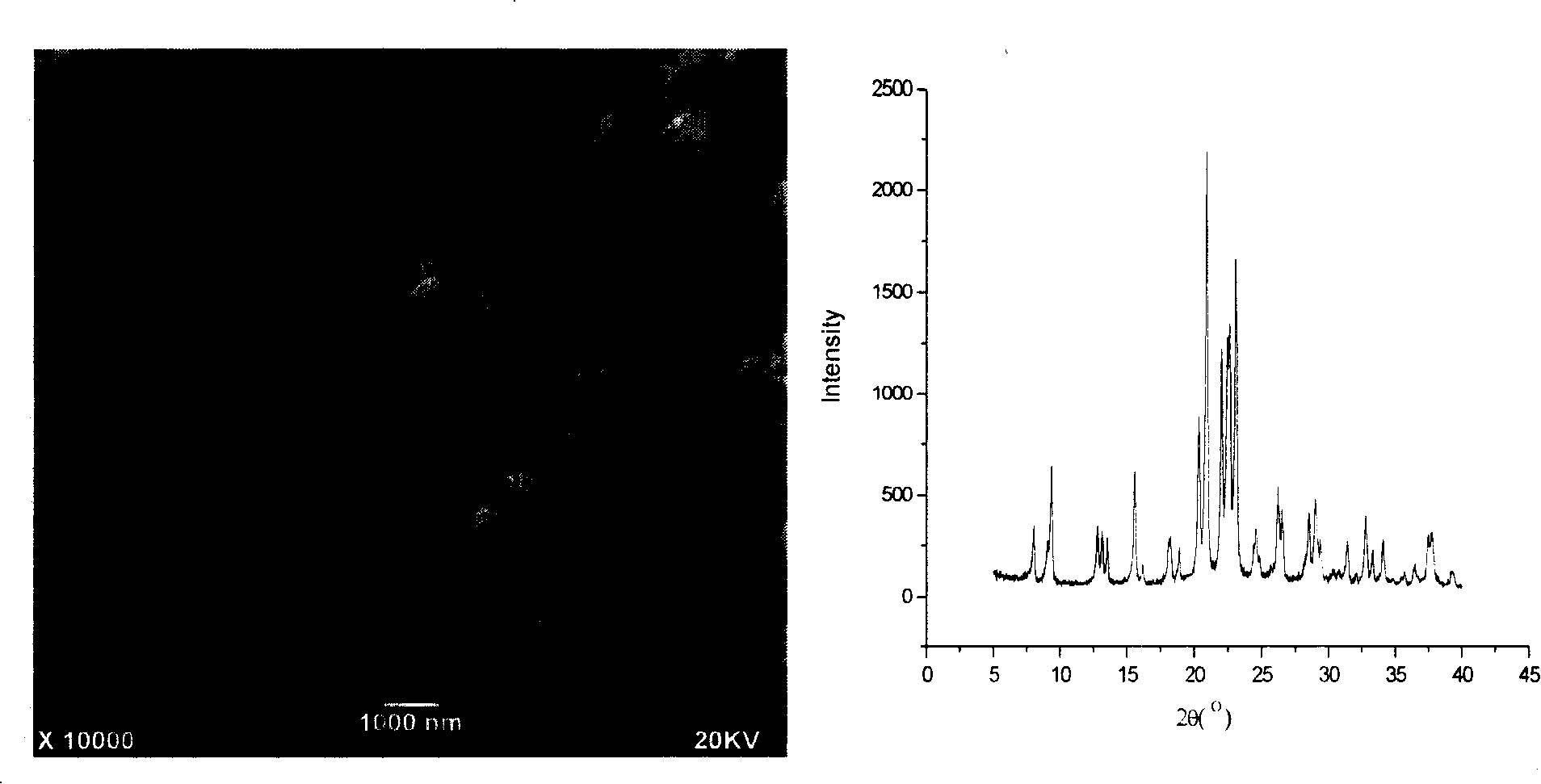

Method of synthesizing silicon phosphorus aluminium molecular sieve

ActiveCN1590295ALow costHigh crystallinityMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMolecular sieveMorpholine

A process for synthesizing SiPAl molecular sieve used for preparing low-carbon olefin from methanol features that tetra-ethyl ammonium hydroxide and morpholine are used as composite template to prepare SAPO-34 molecular sieve with low cost and high crystallinity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing SAPO (Silico-Aluminophosphate) molecular sieve material with multi-level-hole structure

InactiveCN102219237AEasy to prepareEasy to controlMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveOrganic solvent

The invention relates to a method for preparing SAPO (SIlico-Aluminophosphate) molecular sieve material with a multi-level-hole structure, mainly solving the problem that the whole SAPO molecular sieve material with the multi-level-hole structure is difficult to obtain in the prior art. The method adopts the following technical scheme for better solving the problem: adopting and hydrolyzing a mixture of phase-separation inducer R1, a gel accelerator R2, an organic solvent R3, water, a phosphorus source, a silicon source and an aluminum source to obtain a precursor I of silicon-phosphorus-aluminum oxide material; carrying out gel aging on the precursor I, thus obtaining a precursor II of the silicon-phosphorus-aluminum oxide material; drying and roasting the precursor II of the silicon-phosphorus-aluminum oxide material, thus obtaining silicon-phosphorus-aluminum oxide material III with a double-continuous-large-hole structure; dipping the silicon-phosphorus-aluminum oxide material III into solution containing a template agent, drying the silicon-phosphorus-aluminum oxide material III, then arranging the silicon-phosphorus-aluminum oxide material III at the upper part of a reaction kettle, adding organic amine solution at the bottom of the reaction kettle, and then crystallizing; and after the crystallization, washing, drying and roasting a sample, thus obtaining the whole SAPO molecular sieve material with the multi-level-hole structure. The method can be used for industrial production of the molecular sieve with multi-level-hole structure.

Owner:CHINA PETROLEUM & CHEM CORP +1

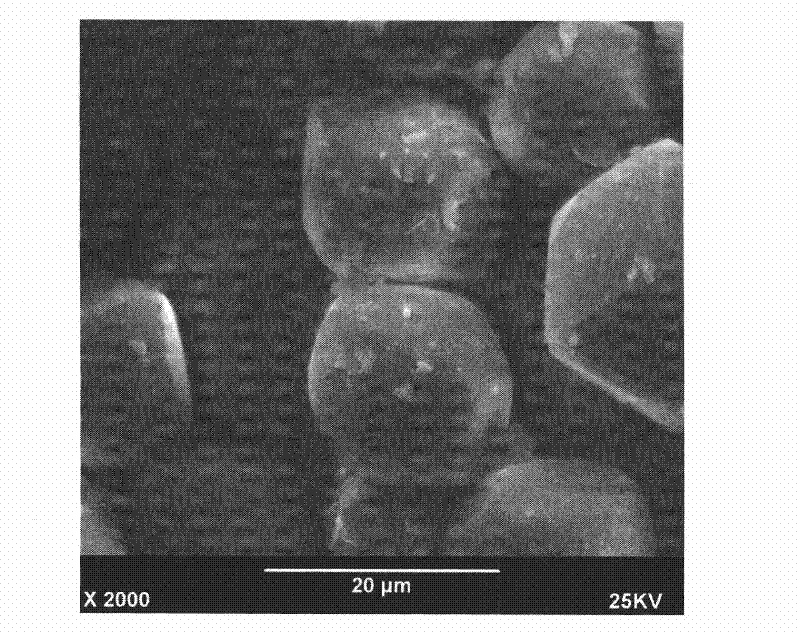

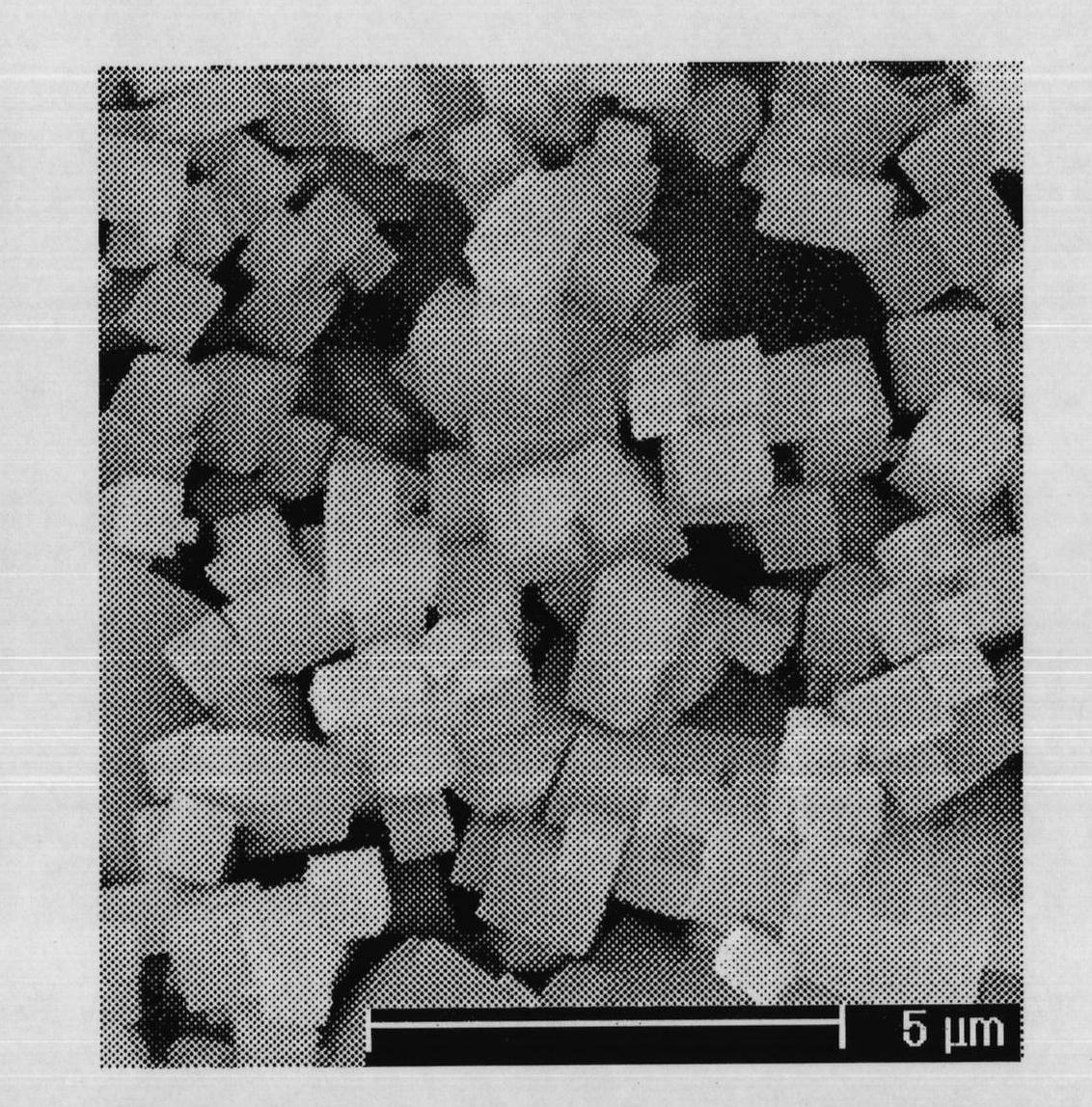

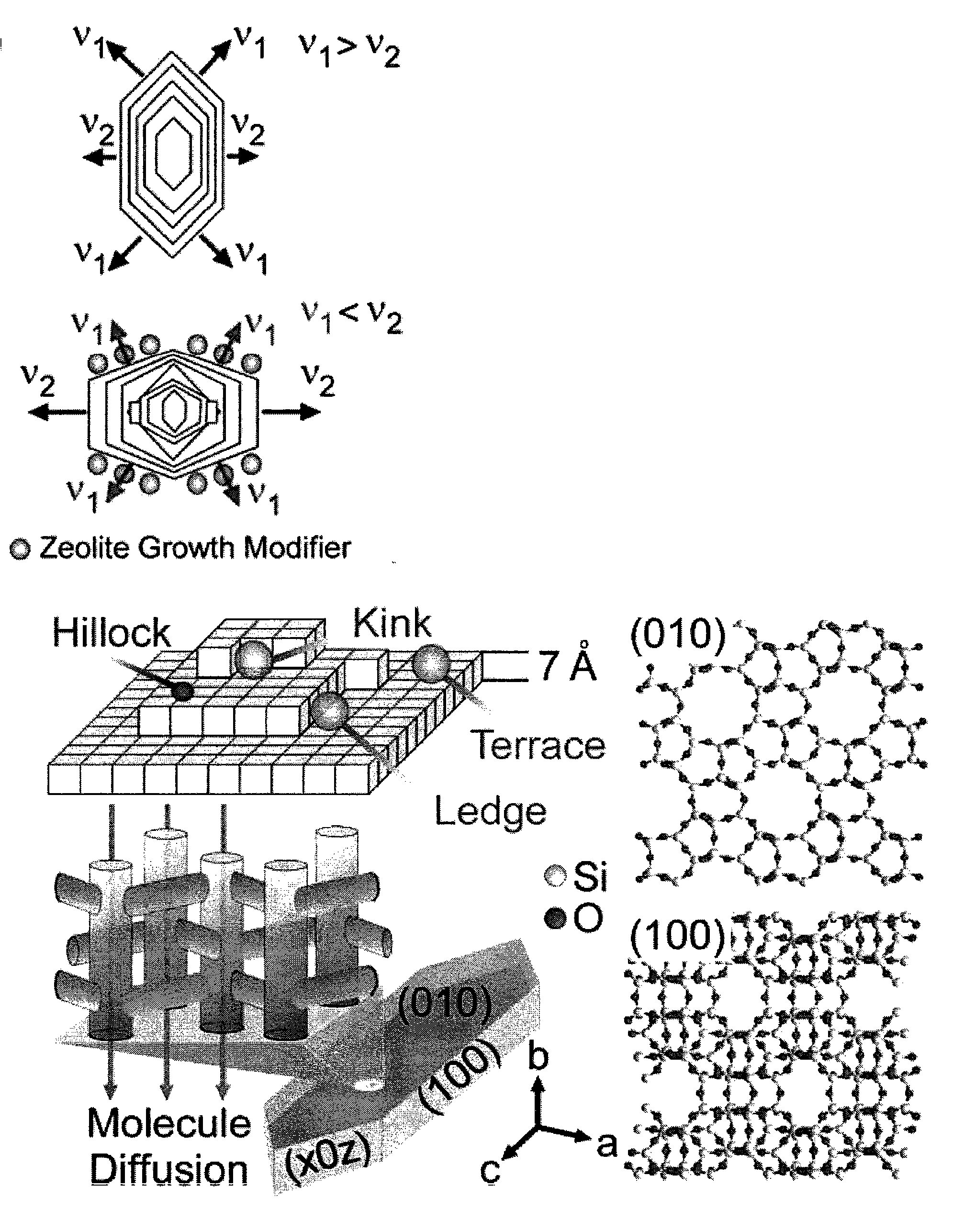

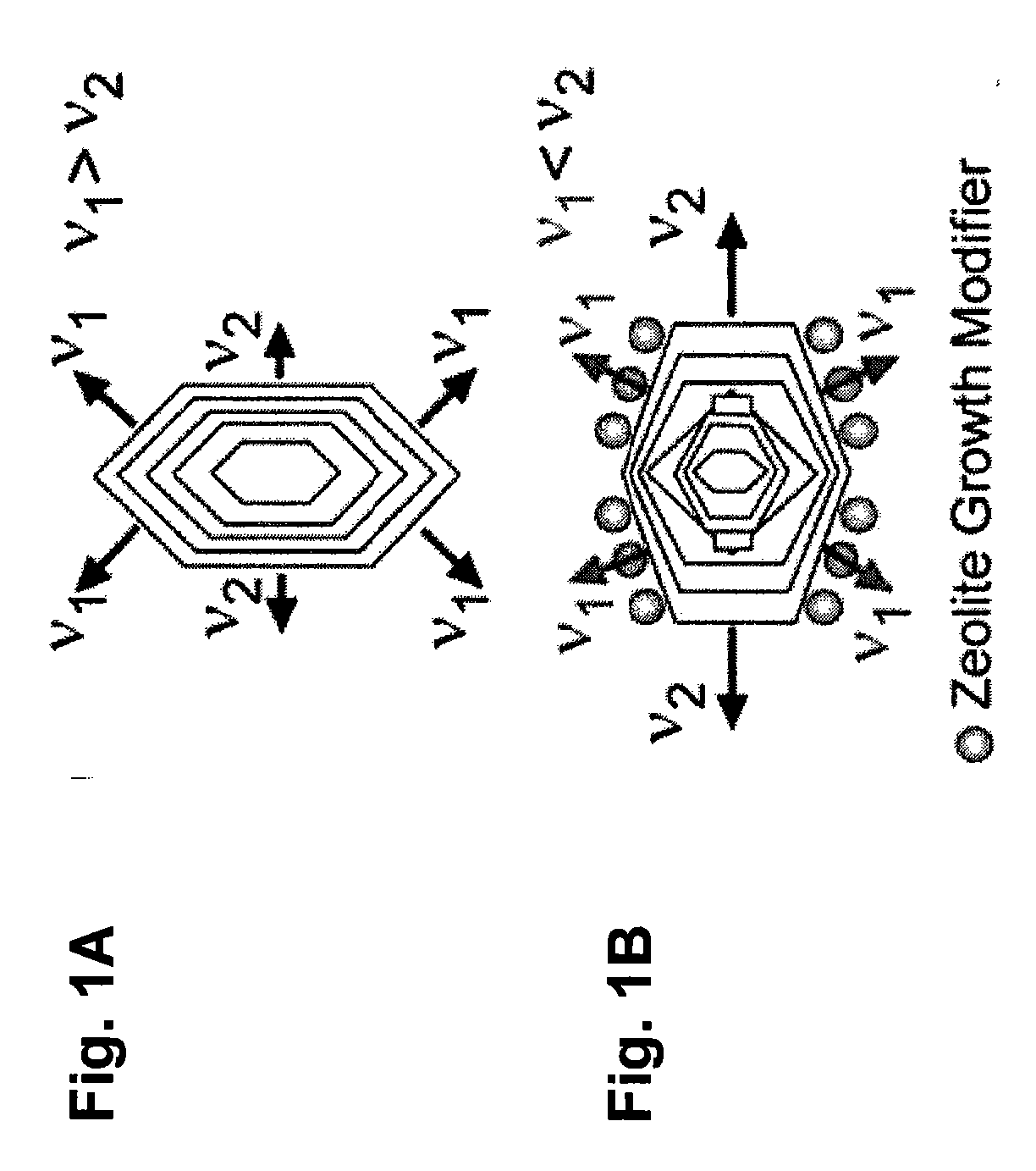

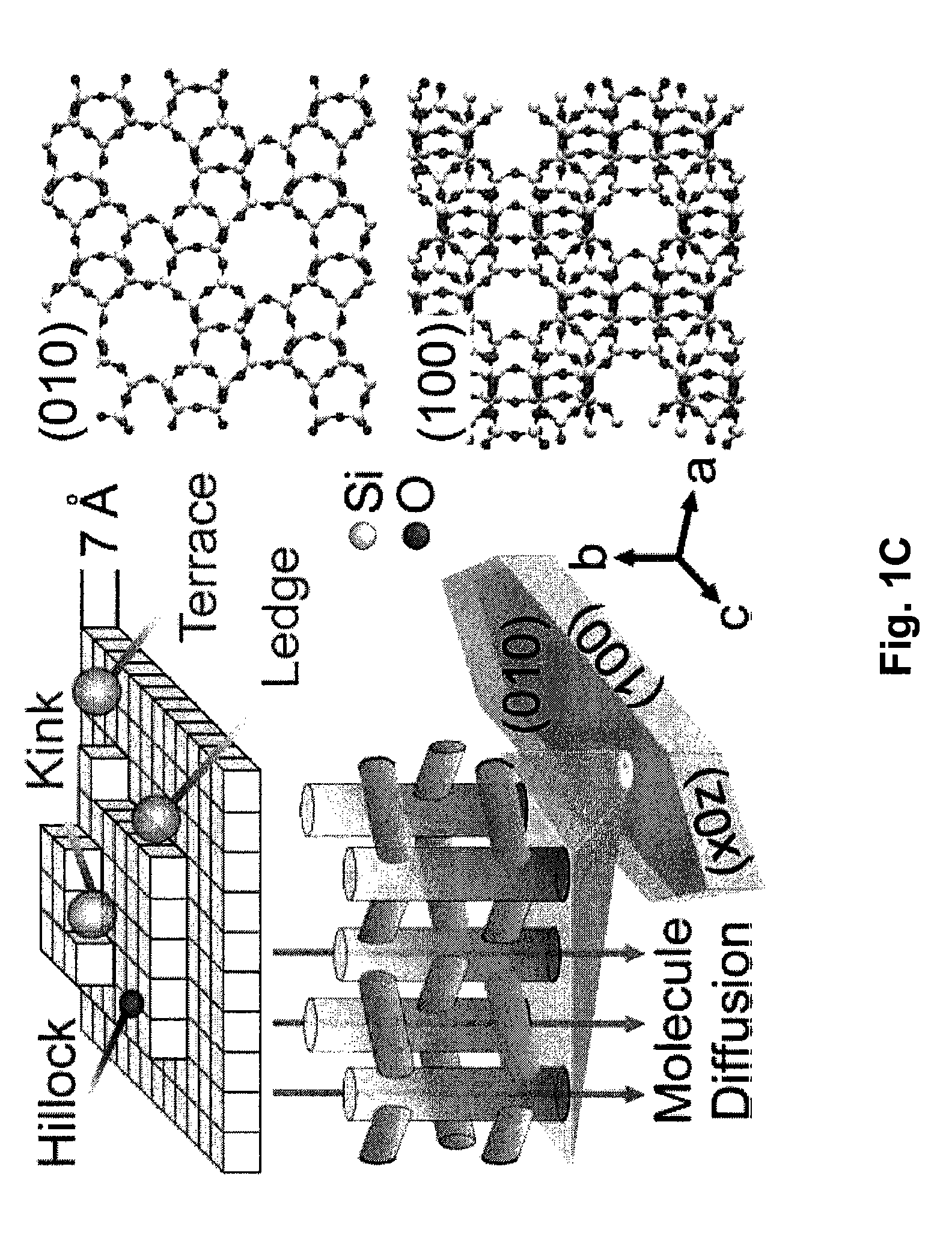

Zeolite compositions and methods for tailoring zeolite crystal habits with growth modifiers

InactiveUS20120202006A1Minimized crystal thicknessShortened internal diffusion pathlengthPolycrystalline material growthFrom normal temperature solutionsCrystal habitCrystal growth rate

Embodiments of the invention generally provide compositions of crystalline zeolite materials with tailored crystal habits and the methods for forming such crystalline zeolite materials. The methods for forming the crystalline zeolite materials include binding one or more zeolite growth modifiers (ZGMs) to the surface of a zeolite crystal, which results in the modification of crystal growth rates along different crystallographic directions, leading to the formation of zeolites having a tailored crystal habit. The improved properties enabled by the tailored crystal habit include a minimized crystal thickness, a shortened internal diffusion pathlength, and a greater step density as compared to a zeolite having the native crystal habit prepared by traditional processes. The tailored crystal habit provides the crystalline zeolite materials with an aspect ratio of about 4 or greater and crystal surfaces having a step density of about 25 steps / μm2 or greater.

Owner:UNIV HOUSTON SYST

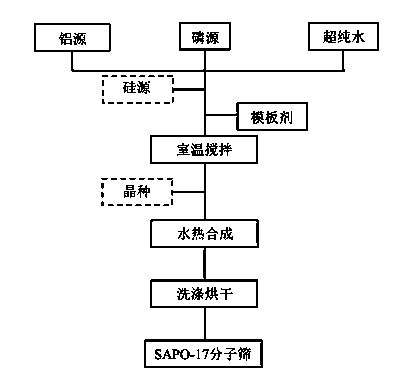

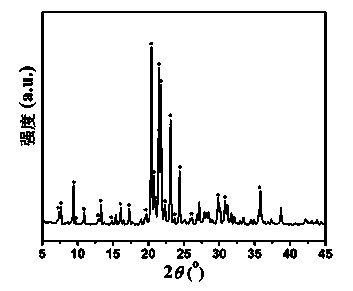

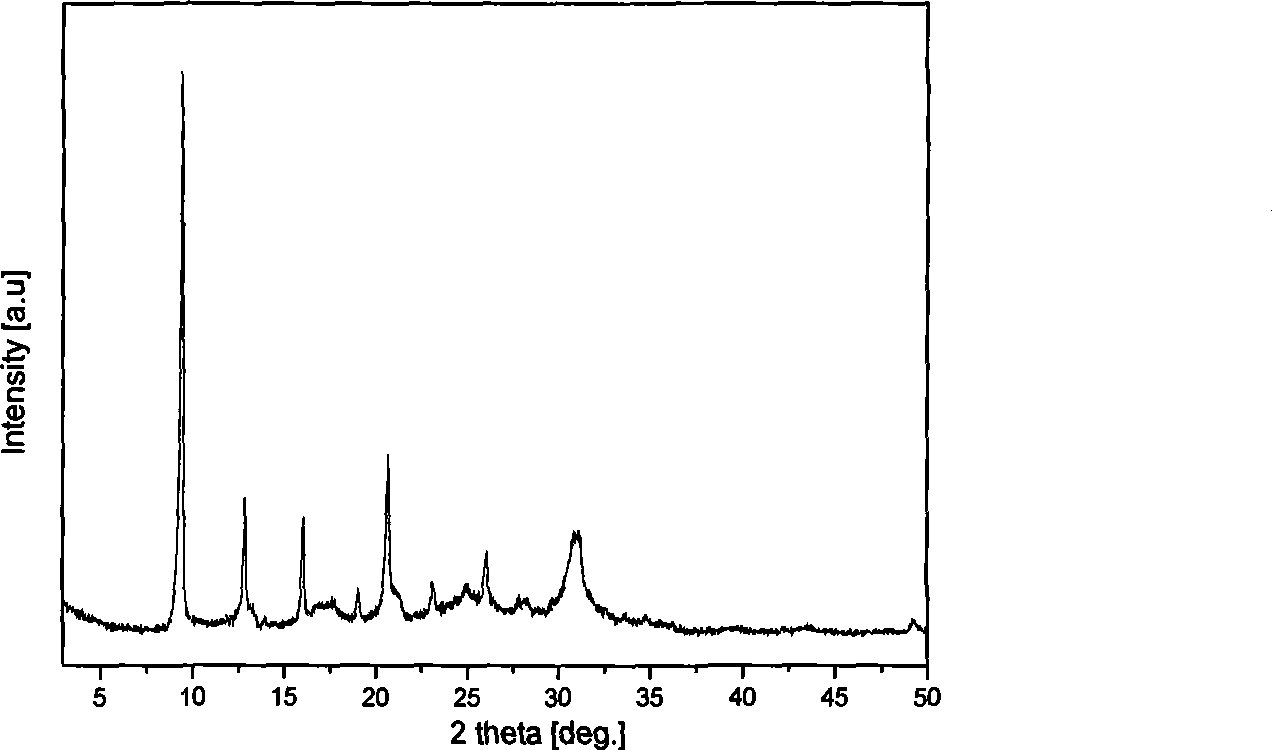

Preparation method of SAPO-17 molecular sieves

InactiveCN103922361AMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesIsomerizationSynthesis methods

The invention provides a method for synthesizing SAPO-17 molecular sieve crystals. The method is characterized in that high-crystallinity and pure-phase SAPO-17 molecule sieves are quickly synthesized by adopting zeolite molecular sieves (crystalline silicon source) as a silicon source. Compared with a synthesis method adopting amorphous silicon sources such as silica sol and silicon powder, the method is capable of increasing the content of skeleton silicon and greatly increasing the crystallization rate of the molecular sieves; the synthesis time is shortened by 3-10 times. The SAPO-17 molecular sieves synthesized by the method have a weakly acidic activity center and can be used as a catalyst for conversion from methanol into olefins and isomerization of low-carbon hydrocarbon.

Owner:JIANGXI NORMAL UNIV

Preparation of fine grain SAPO-34 molecular sieve

InactiveCN101462742AUniform particle sizeImprove performanceMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sievePolymer science

The invention relates to a method for preparing a small crystal grain SAPO-34 molecular sieve with high crystallinity and large specific surface area. The method for preparing the molecular sieve is mainly characterized in that a structure guide agent containing triethylamine and fluoride is added in the forming process of a colloid mixture; and at the same time, after an ageing process, the colloid mixture is crystallized. The SAPO-34 molecular sieve prepared by the method has the advantages of small grain diameter, large specific surface area and high crystallinity.

Owner:NANKAI UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com