SAPO-34 molecular sieve and synthesis method thereof

A technology of SAPO-34 and molecular sieve, which is applied in the direction of molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, etc., which can solve the problems of expensive templating agent and unfavorable industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Raw material is the same as comparative example 1, and raw material is according to: Al 2 o 3 :yP 2 o 5 : zSiO 2 :H 2 The ratio of O:DEA:TEA=1:0.8:0.6:50:0.4:0.6 is fully stirred and mixed evenly. The reaction mixture was packed into a stainless steel crystallization kettle, stirred and crystallized at 180°C and autogenous pressure for 10 hours, then lowered to room temperature, and the remaining diethylamine was added to make the composition of the reaction material into Al 2 o 3 :yP 2 o 5 : zSiO 2 :H 2 O: DEA: TEA = 1: 0.8: 0.6: 50: 1: 0.6, and the temperature was raised to 180° C. to continue crystallization for 38 hours. Then filter, wash, and dry the crystallized product at 100-110°C to obtain the original molecular sieve powder product. Part of the crystallized product was taken for X-ray powder diffraction measurement, and the result showed that the synthesized molecular sieve was SAPO-34 molecular sieve.

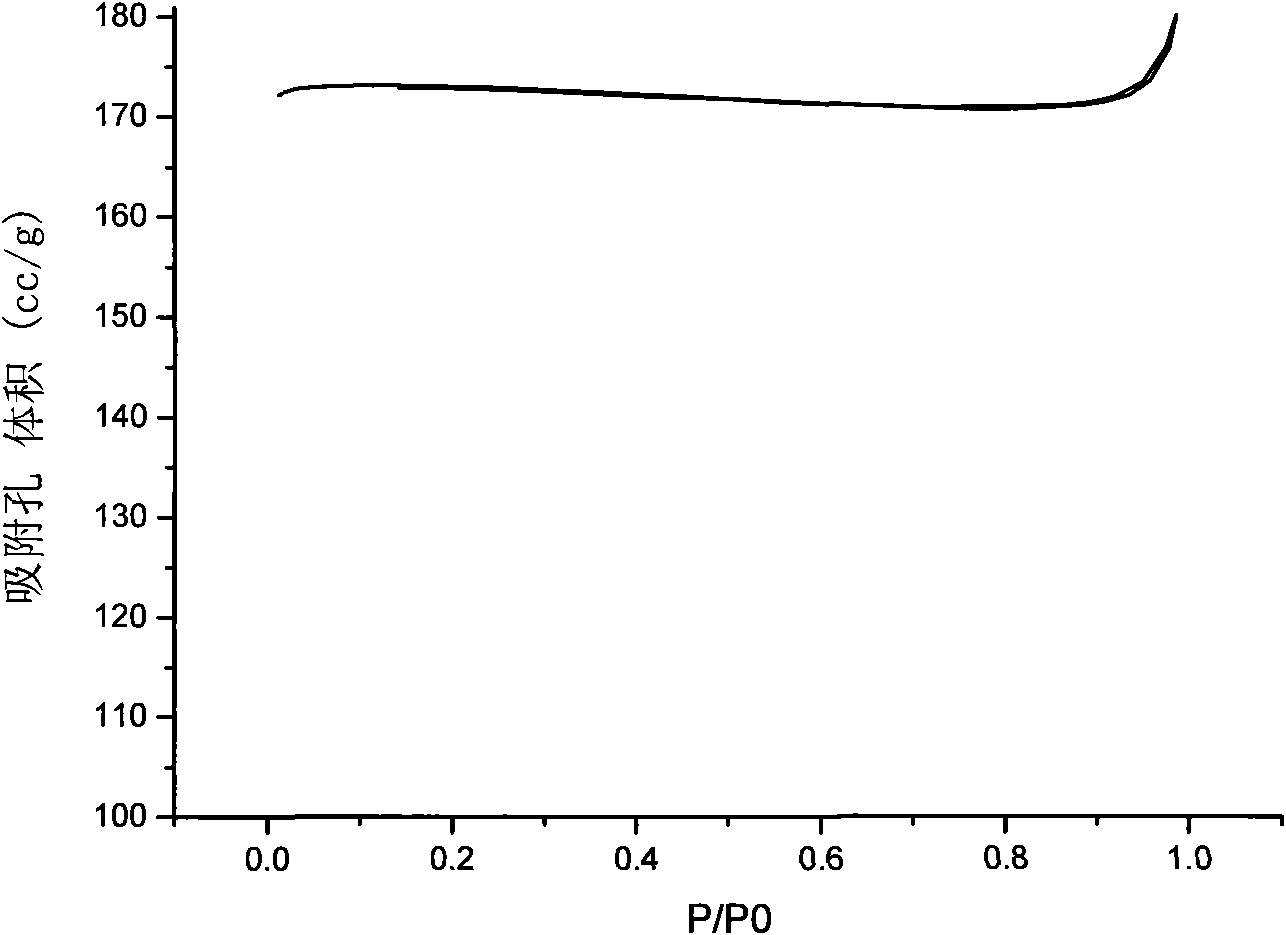

[0034] Take part of the above-mentioned mole...

Embodiment 2

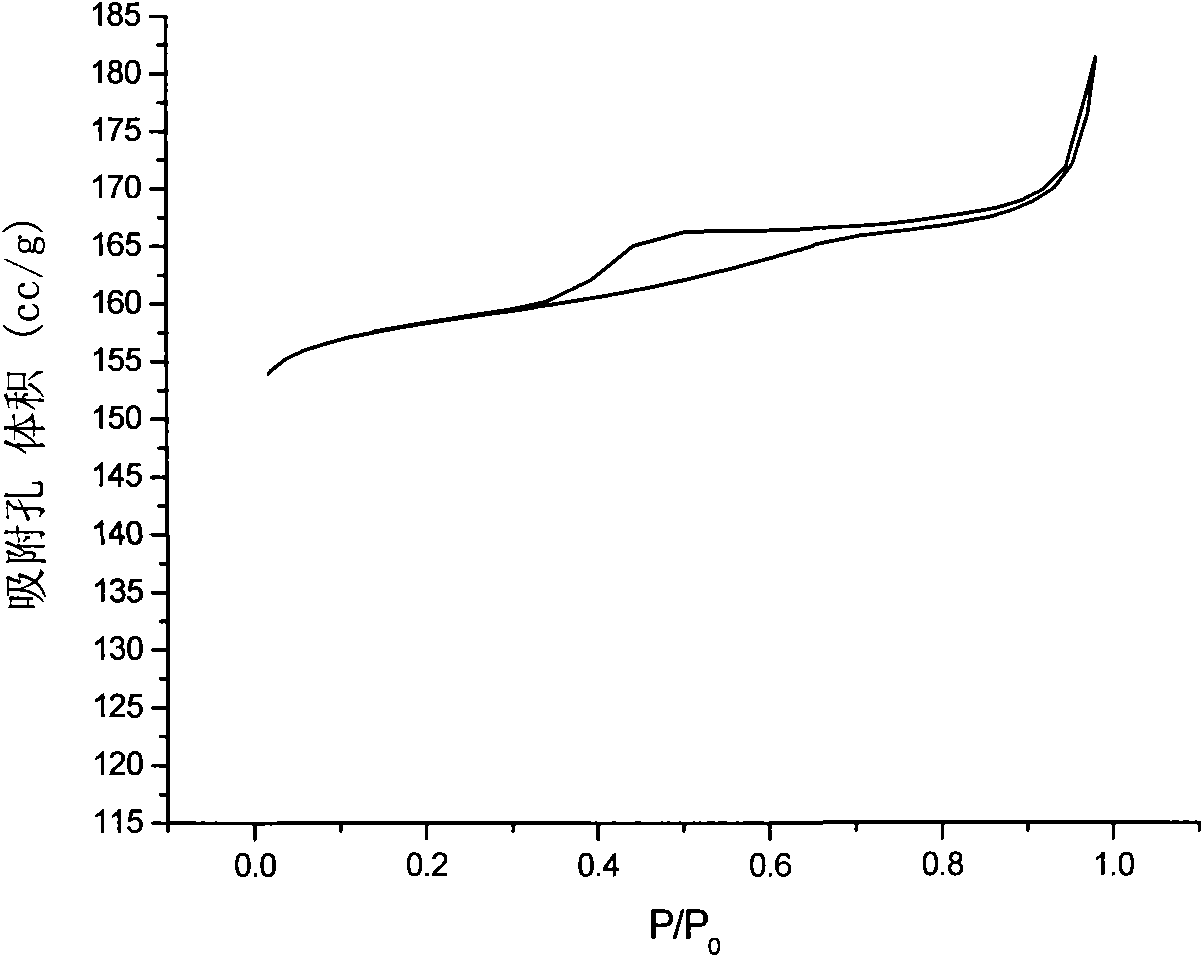

[0036] The raw materials are the same as in Comparative Example 1 except the template agent, the template agent is changed to DEA, and the raw materials are changed to: Al 2 o 3 :yP 2 o 5 : zSiO 2 :H 2 The ratio of O:DEA=1:1.0:0.3:40:1 was fully stirred and mixed evenly. The reaction mixture was packed into a stainless steel crystallization kettle, stirred and crystallized at 150°C and autogenous pressure for 15 hours, then lowered to room temperature, and the remaining diethylamine was added to make the composition of the reaction material into Al 2 o 3 :yP 2 o 5 : zSiO 2 :H 2 O: DEA = 1: 1: 0.3: 40: 1.8, and the temperature was raised to 175° C. to continue crystallization for 10 hours. Then filter, wash, and dry the crystallized product at 100-110°C to obtain the original molecular sieve powder product. Part of the crystallized product was taken for X-ray powder diffraction measurement, and the result showed that the synthesized molecular sieve was SAPO-34 molecu...

Embodiment 3

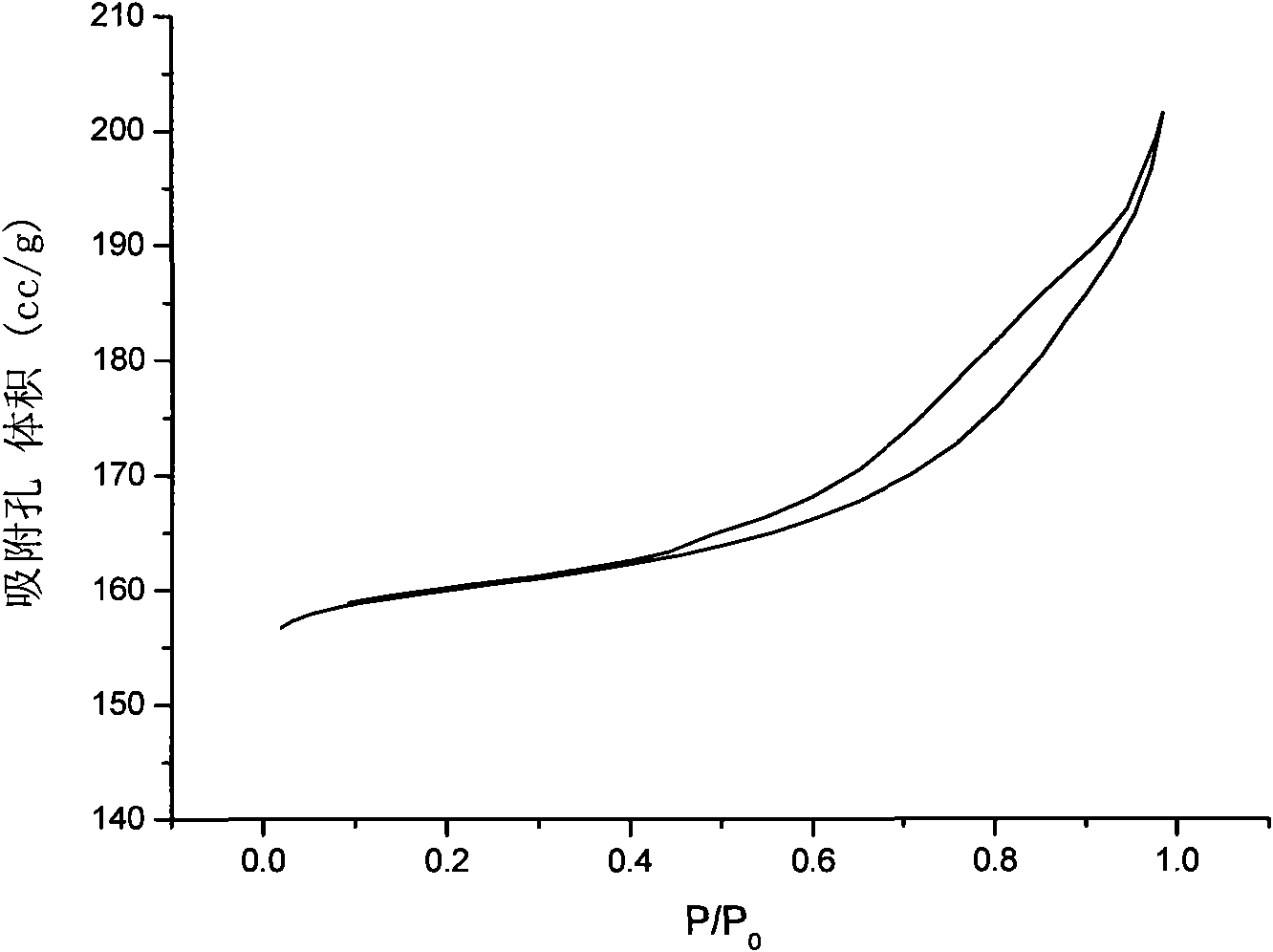

[0039] Raw material is the same as comparative example 1 except template agent, and template agent is changed into TEA and tetraethylammonium hydroxide (TEAOH, 28%), and raw material is pressed: Al 2 o 3 :yP 2 o 5 : zSiO 2 :H 2 The ratio of O:TEA:TEAOH=1:1.1:0.1:50:0.8:0.2 is fully stirred and mixed evenly. The reaction mixture was packed into a stainless steel crystallization kettle, stirred and crystallized at 120°C and autogenous pressure for 5 hours, then lowered to room temperature, and the remaining triethylamine was added to make the composition of the reaction material into Al 2 o 3 :yP 2 o 5 : zSiO 2 :H 2 O: TEA: TEAOH = 1: 1.1: 0.1: 50: 1.4: 0.2, and the temperature was raised to 190° C. to continue crystallization for 8 hours. Then filter, wash, and dry the crystallized product at 100-110°C to obtain the original molecular sieve powder product. Part of the crystallized product was taken for X-ray powder diffraction measurement, and the result showed that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com