Patents

Literature

5344results about "Fluid actuated clutches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

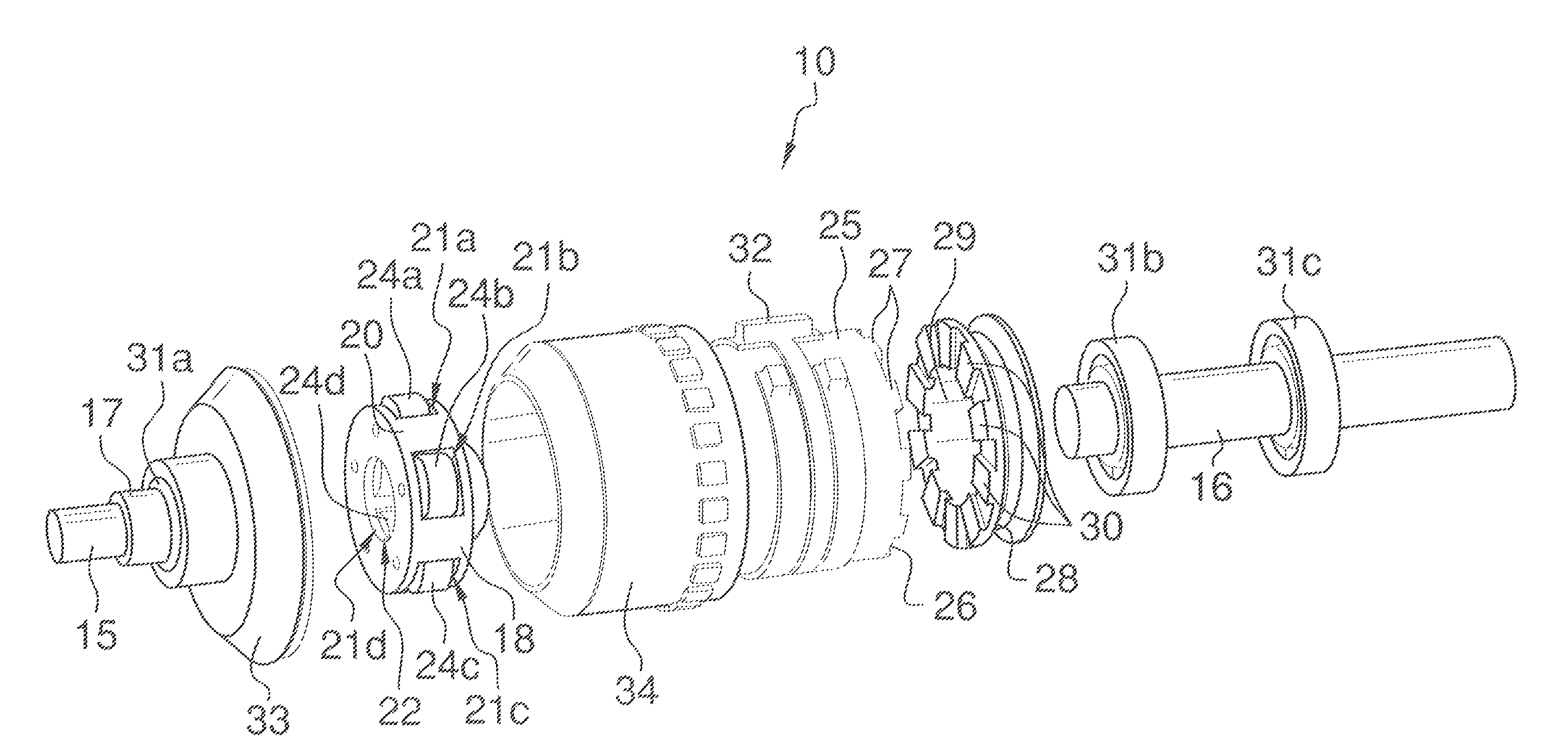

Force transmission device in particular for power transmission between a drive engine and an output

ActiveUS8161739B2Reduce variationEliminate variationRotating vibration suppressionYielding couplingTuned mass damperSelf adaptive

A force transmission device, in particular or power transmission between a drive engine and an output, comprising a damper assembly with at least two dampers, which can be connected in series, and a rotational speed adaptive absorber, wherein the rotational speed adaptive tuned mass damper is disposed between the dampers at least in one force flow direction through the force transmission device.

Owner:SCHAEFFLER TECH AG & CO KG

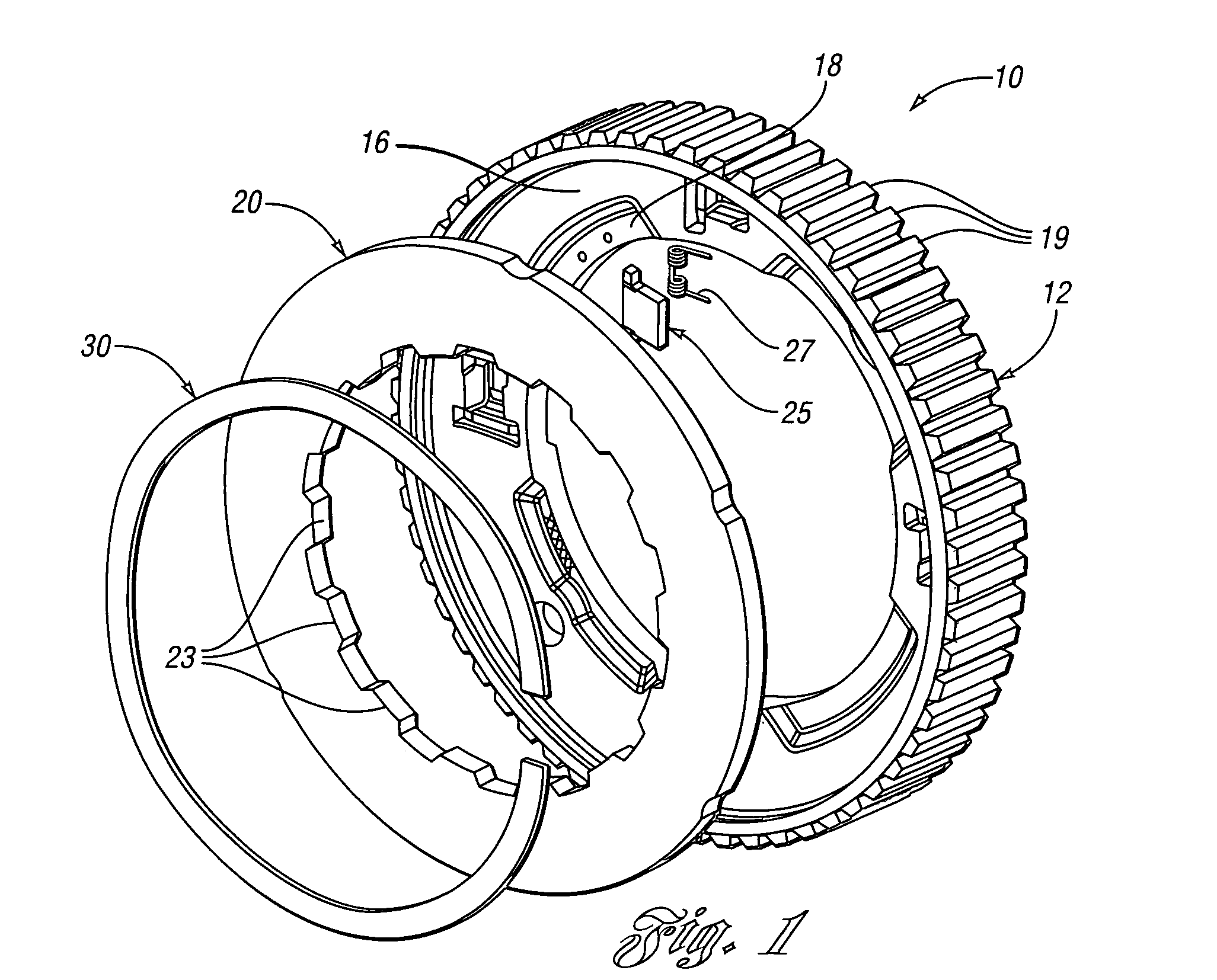

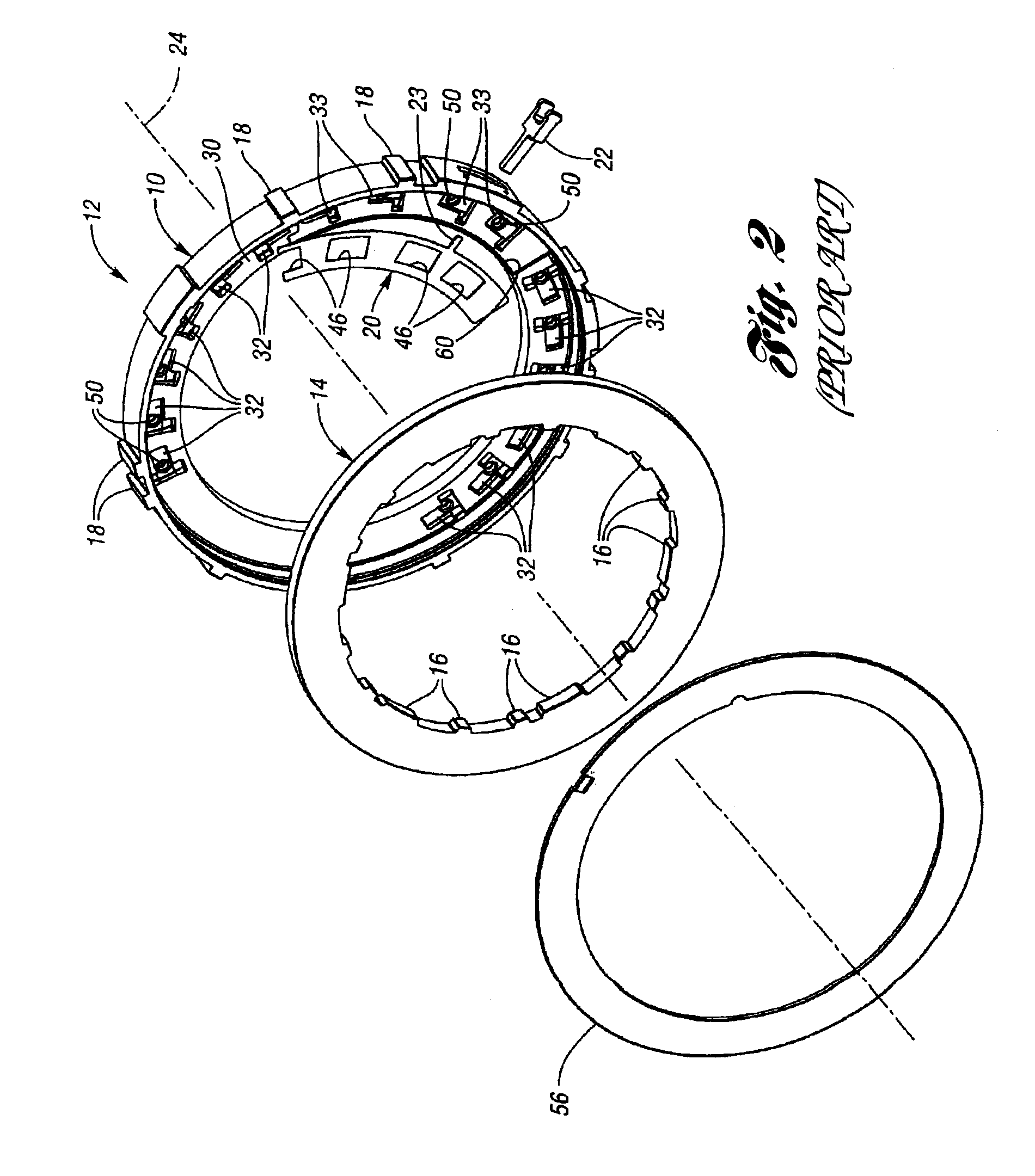

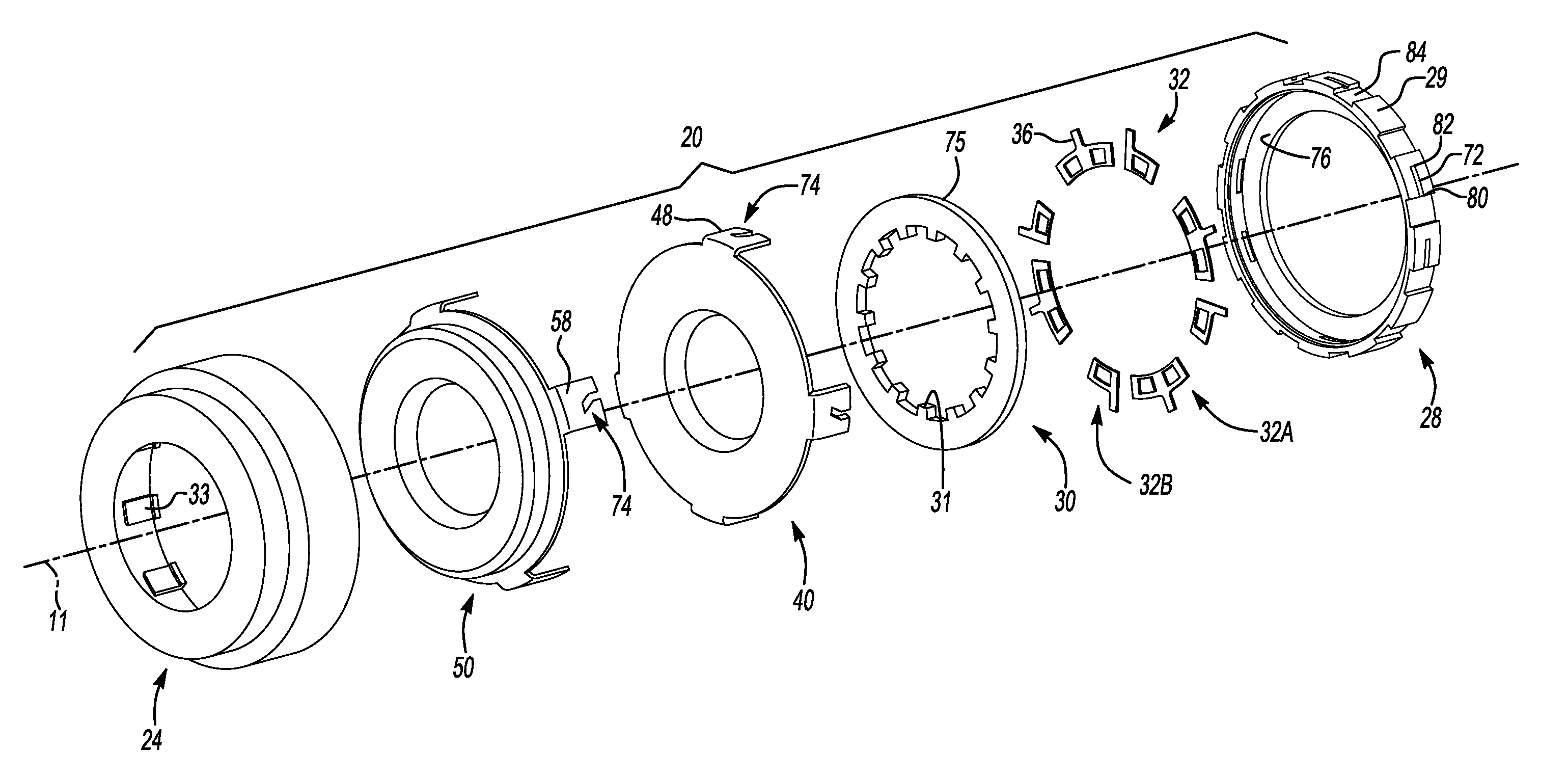

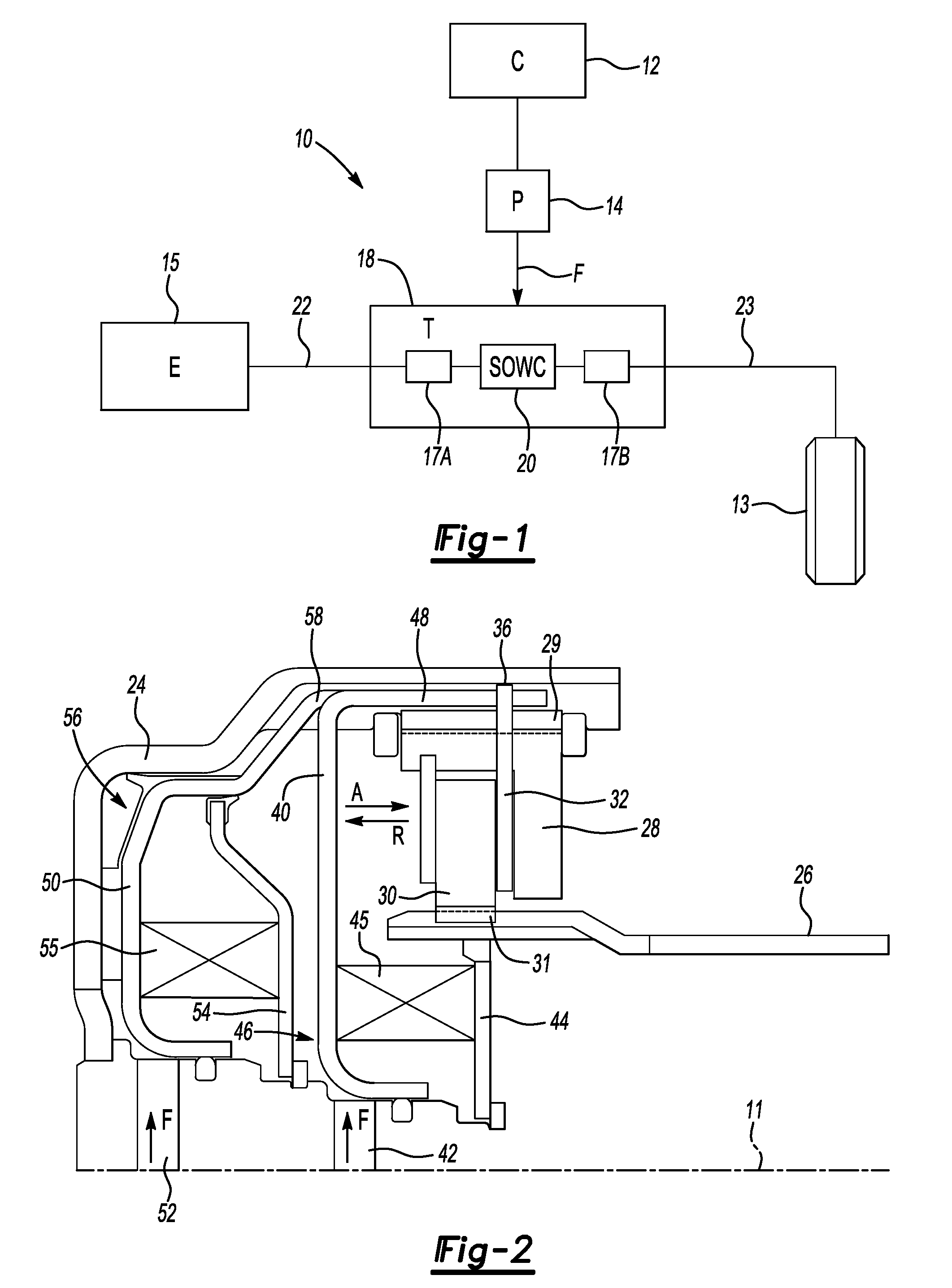

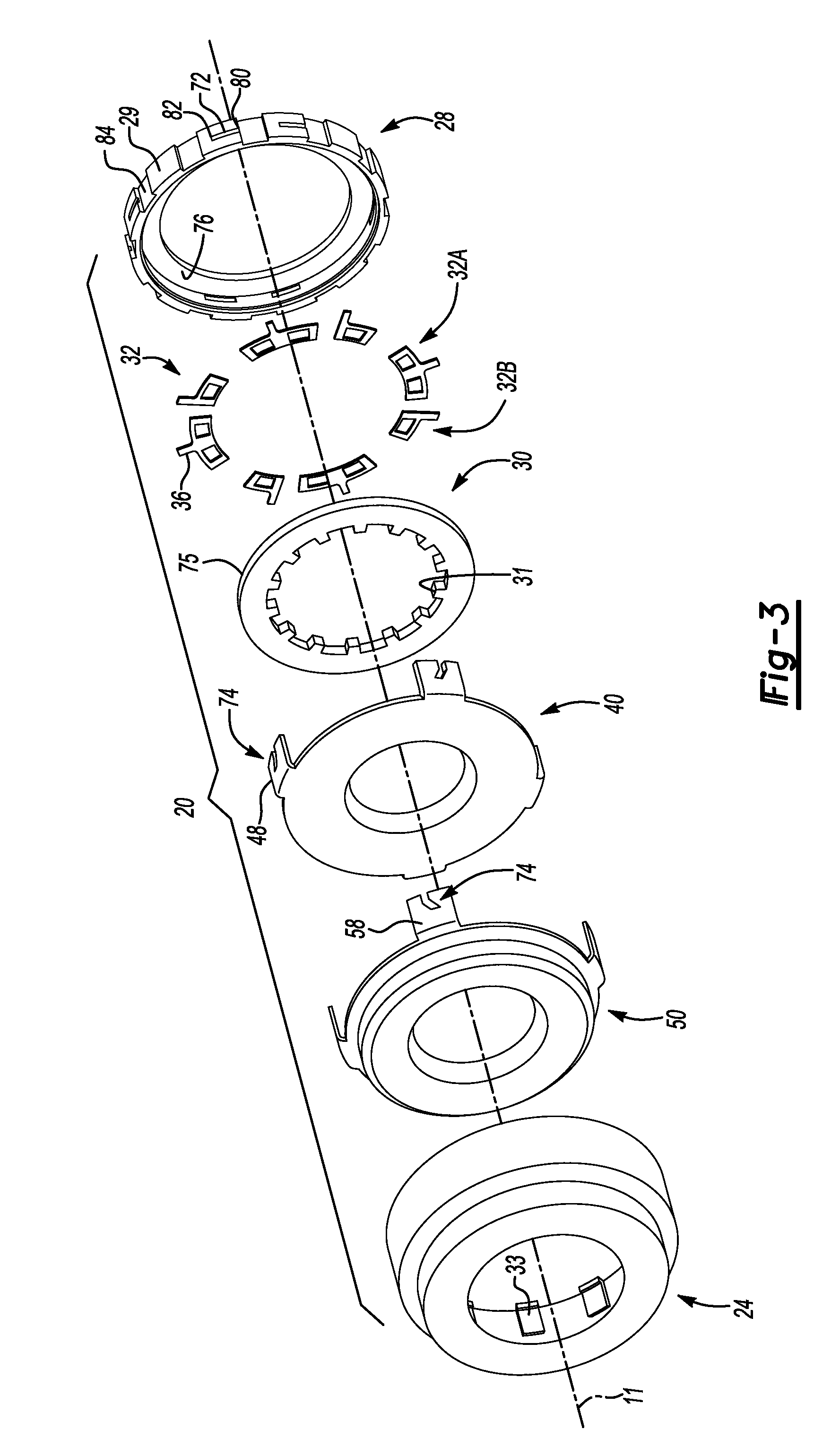

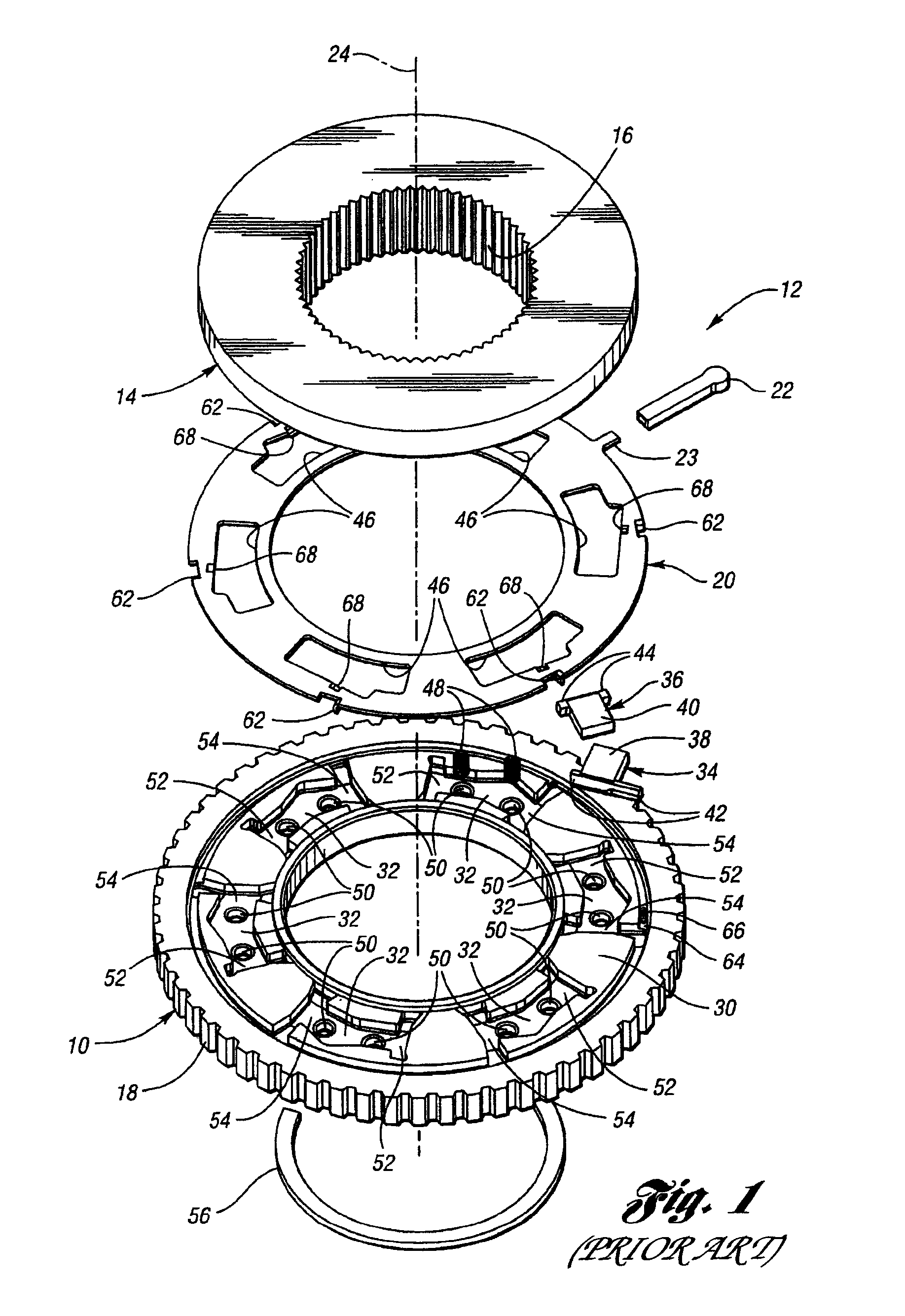

Dual-mode one-way torque transmitting device

InactiveUS20060185957A1Low costReduce hoop stressFluid actuated clutchesFriction clutchesDual modeEngineering

A dual mode one-way torque transmitting device includes an inner race having a first plurality of notches spaced about an axis. An intermediate race includes a second plurality of notches spaced about the axis, a first plurality of pockets spaced about the axis, and a first plurality of rockers, each rocker being located in a pocket of the intermediate race. A spring urges each rocker toward engagement with a notch on the inner race. An outer race includes a second plurality of pockets spaced about the axis, a second plurality of rockers, each rocker being located in a pocket on the outer race, and a plurality of actuators, each actuator alternately engages and disengages a rocker on the outer race and a notch on the intermediate race.

Owner:FORD GLOBAL TECH LLC

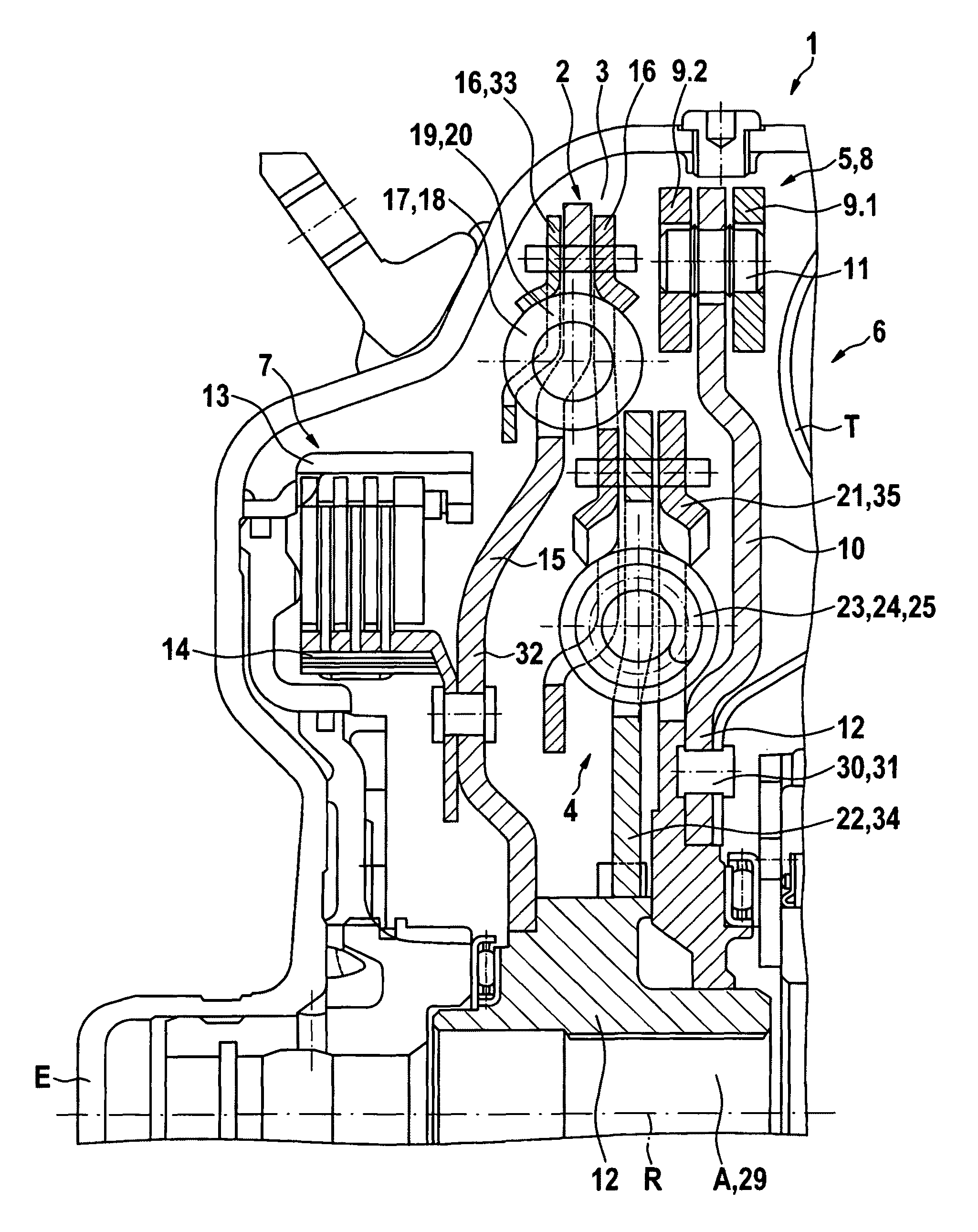

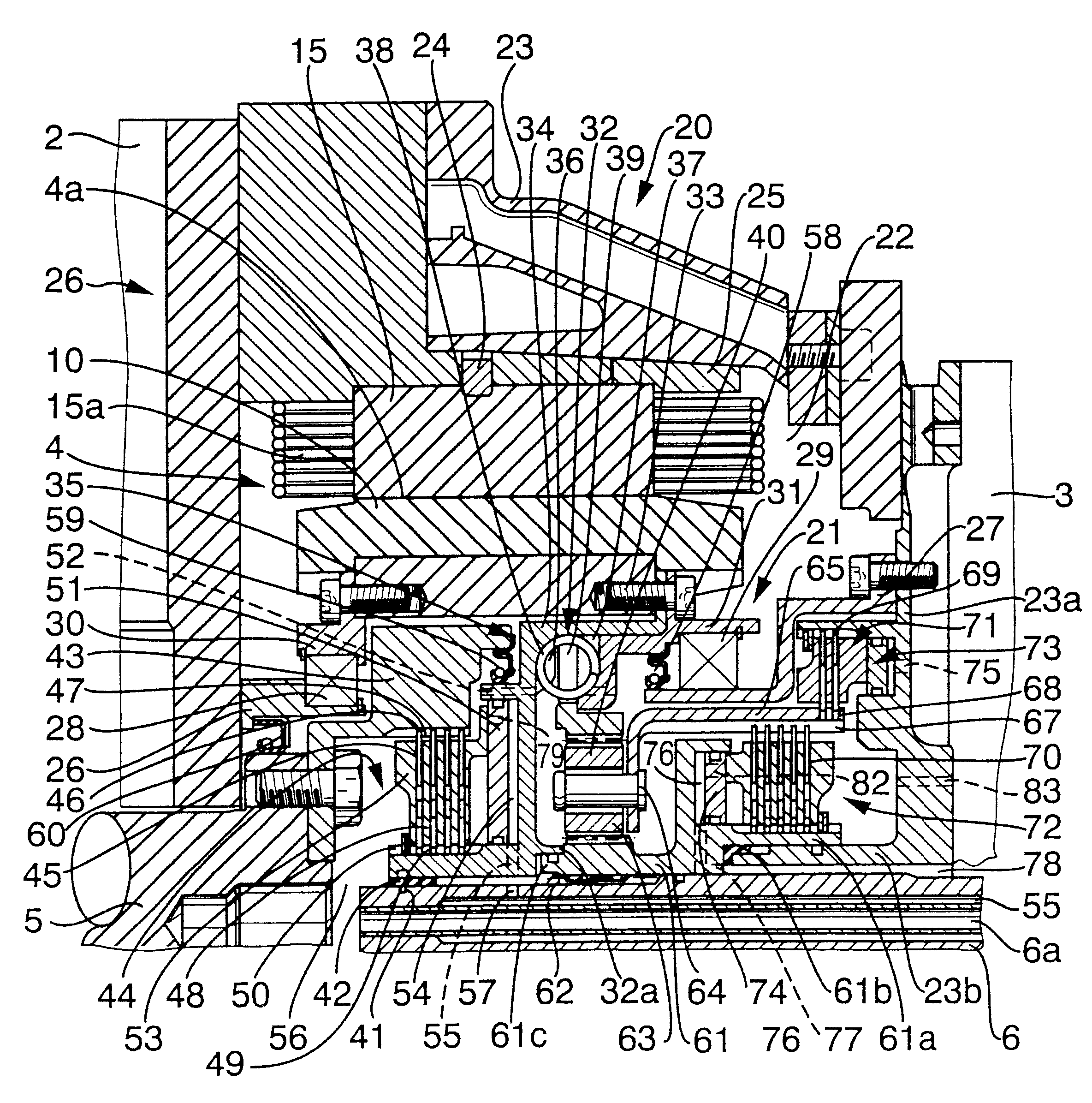

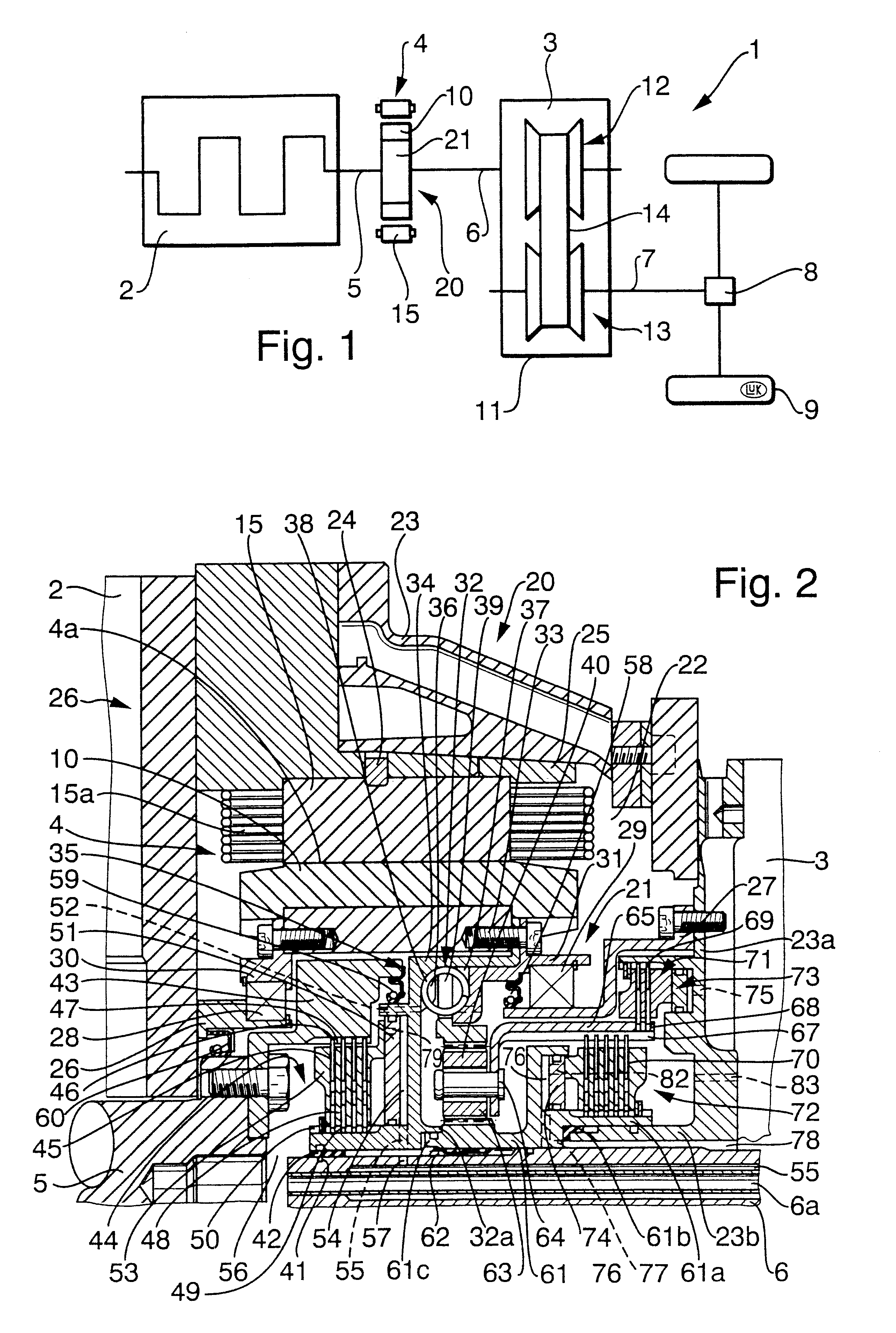

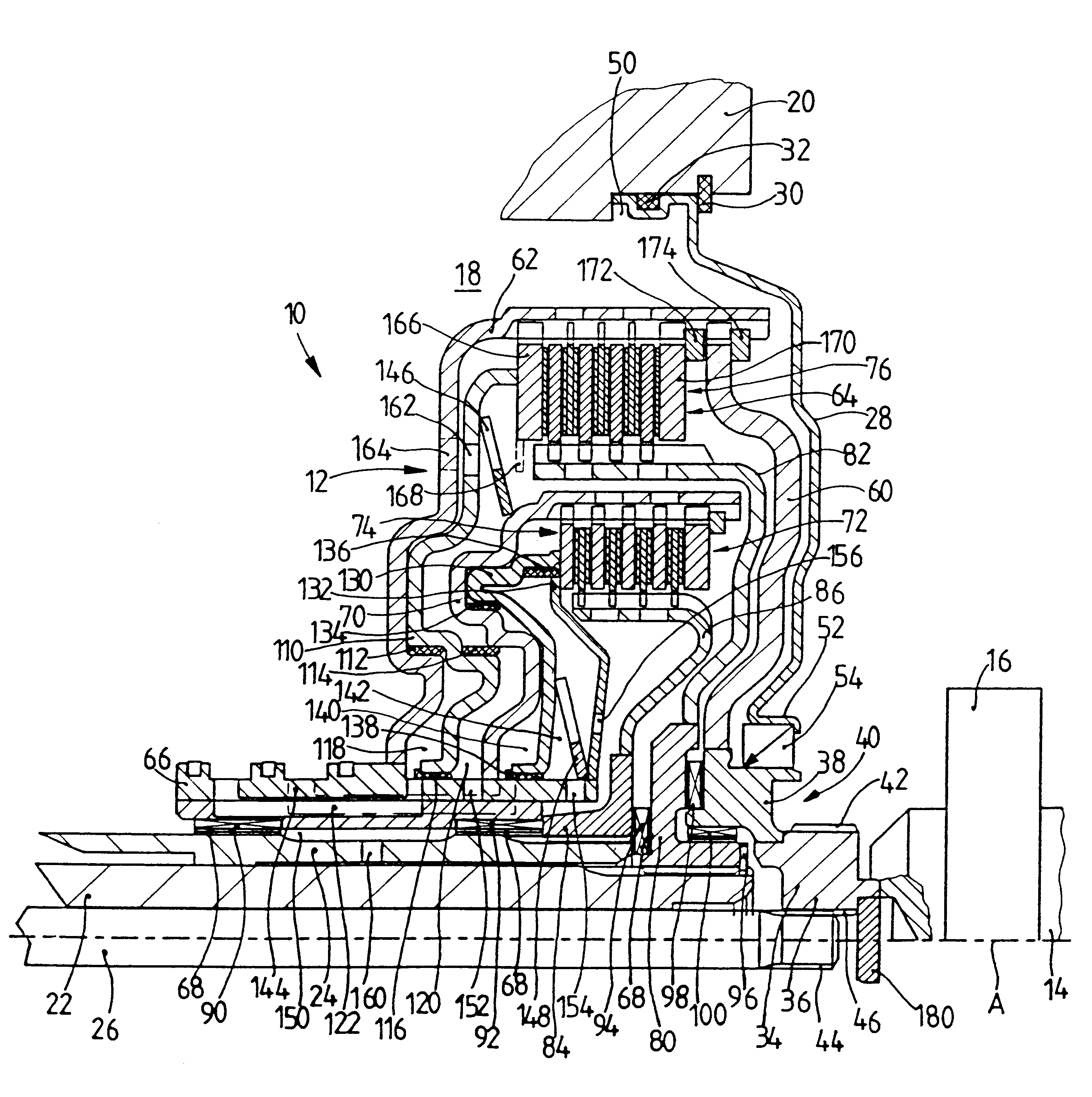

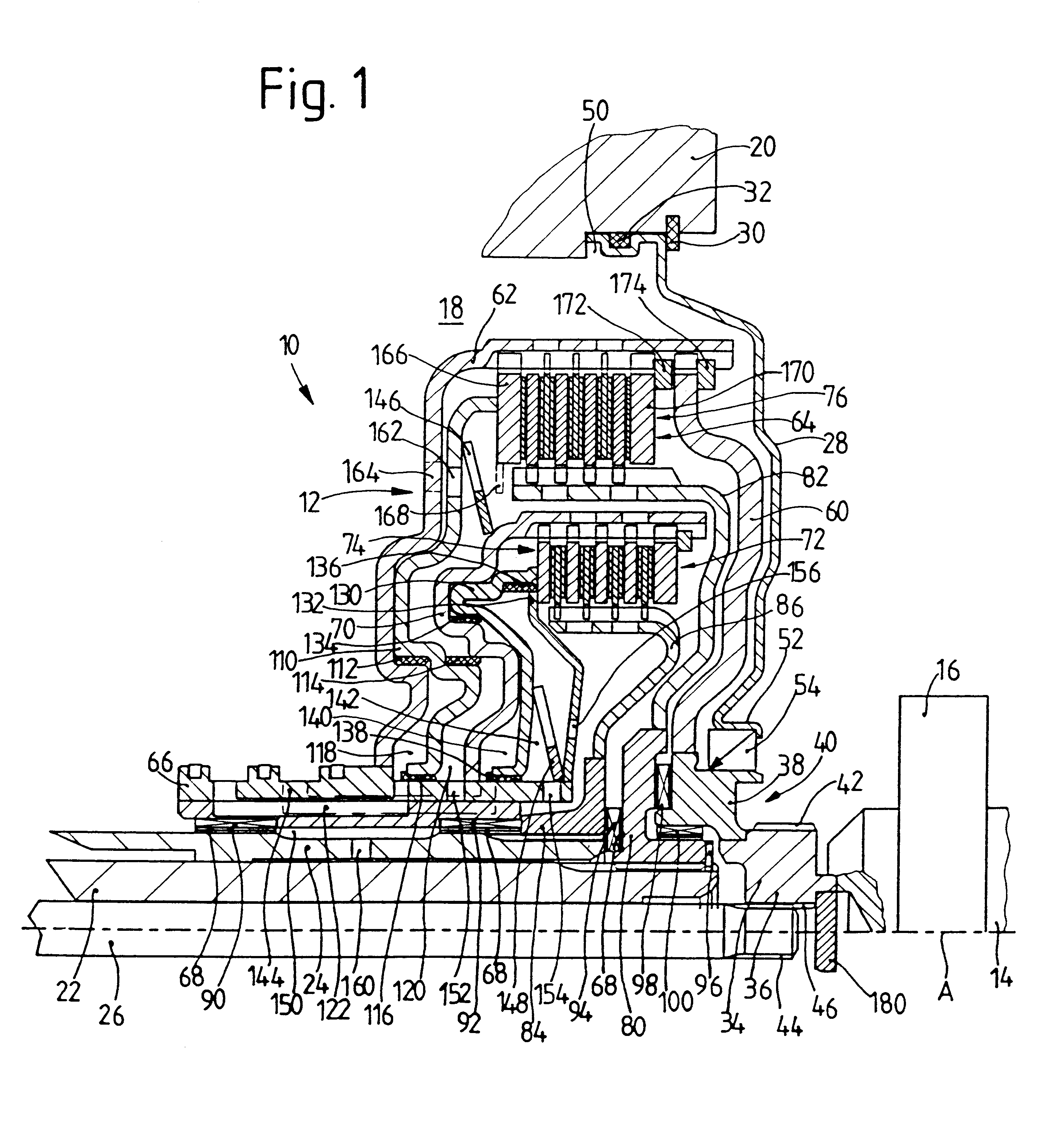

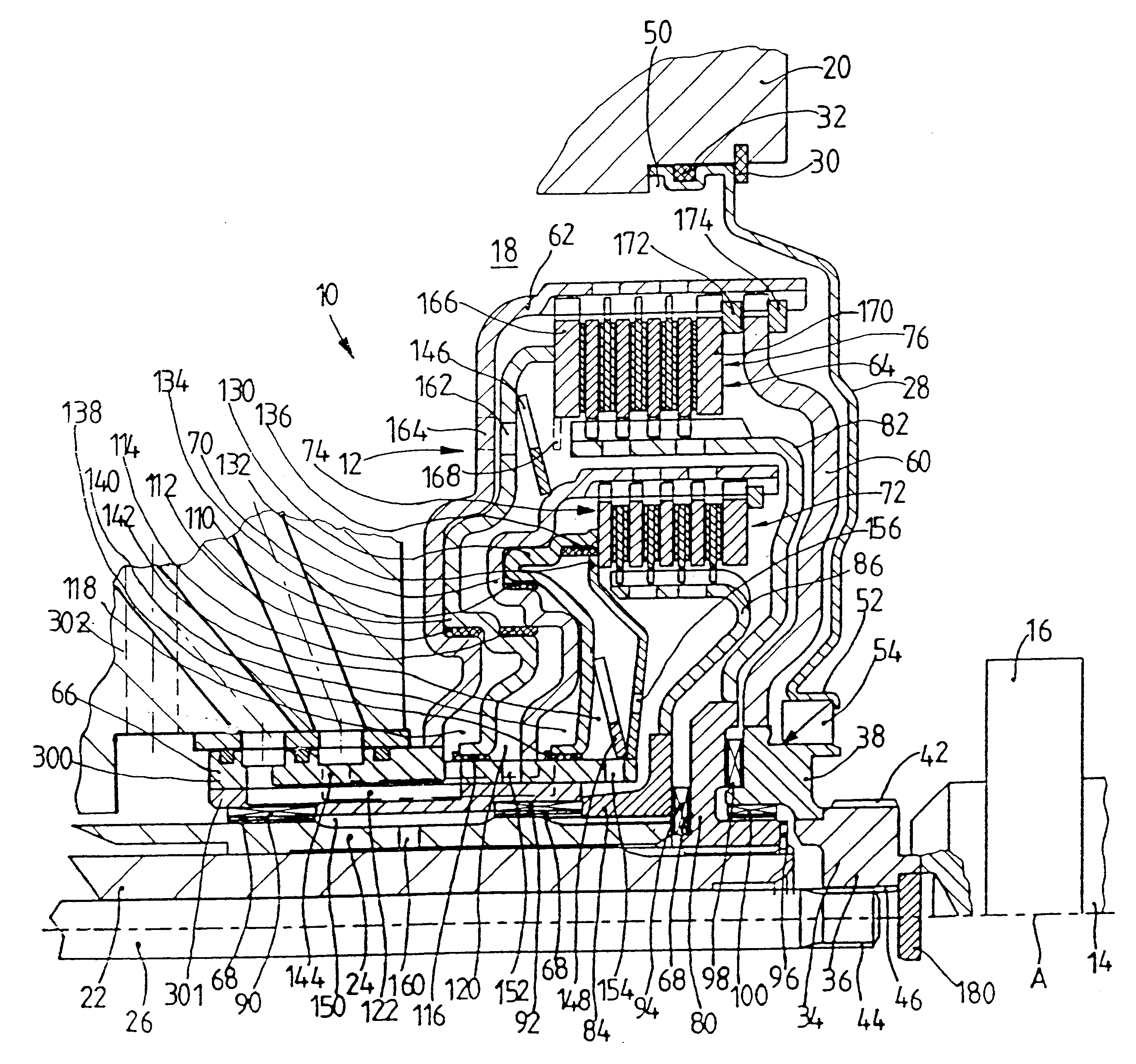

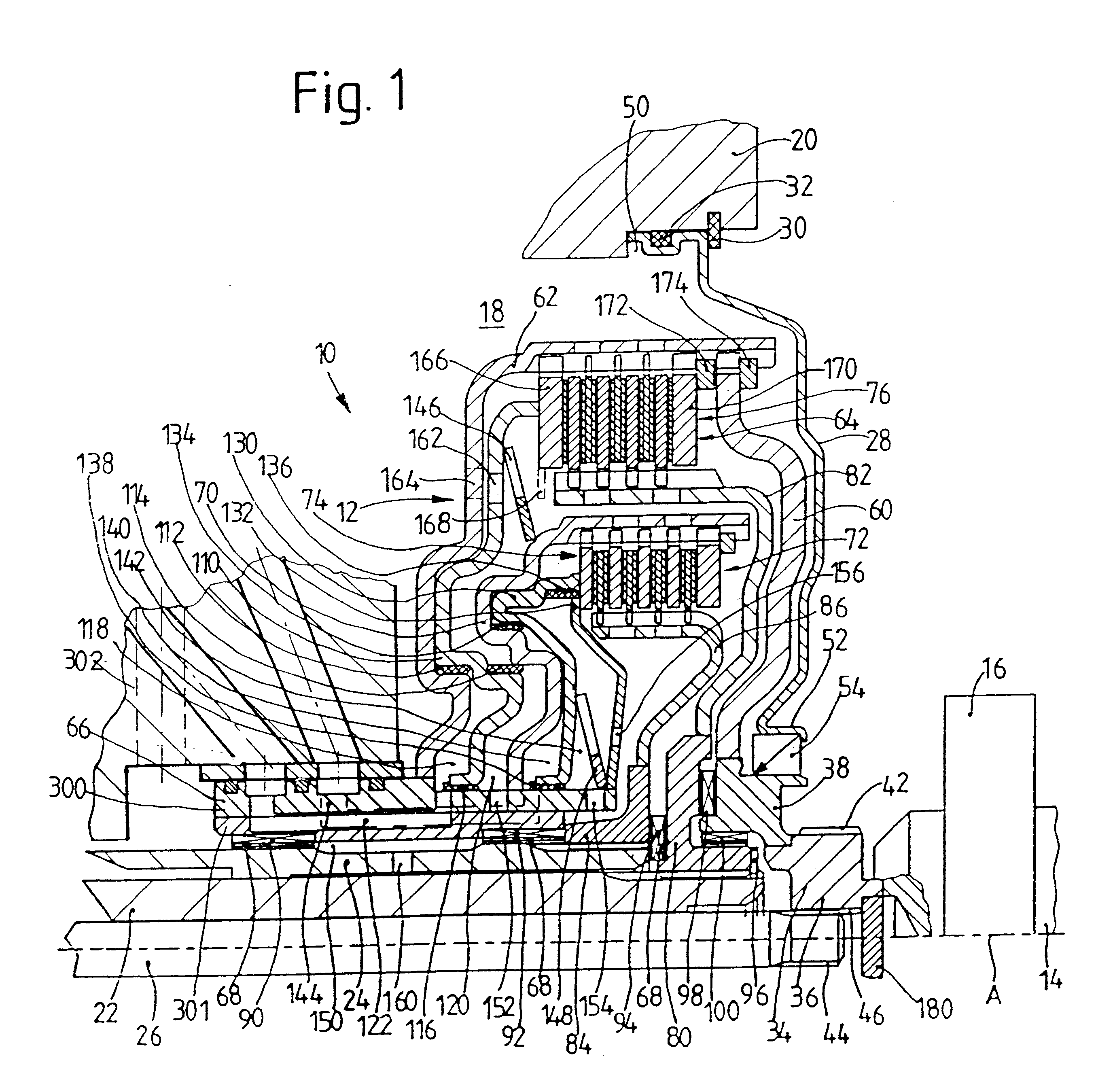

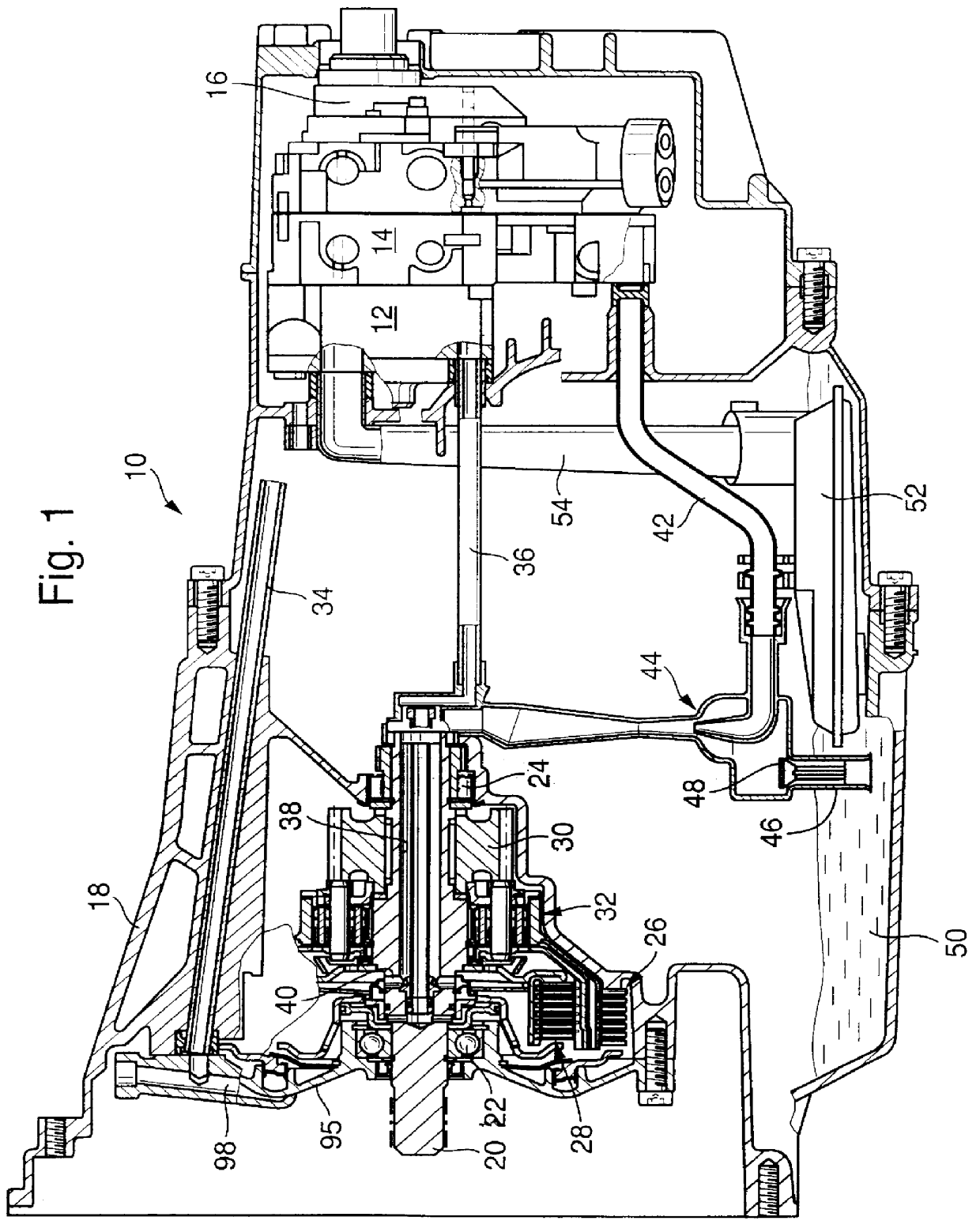

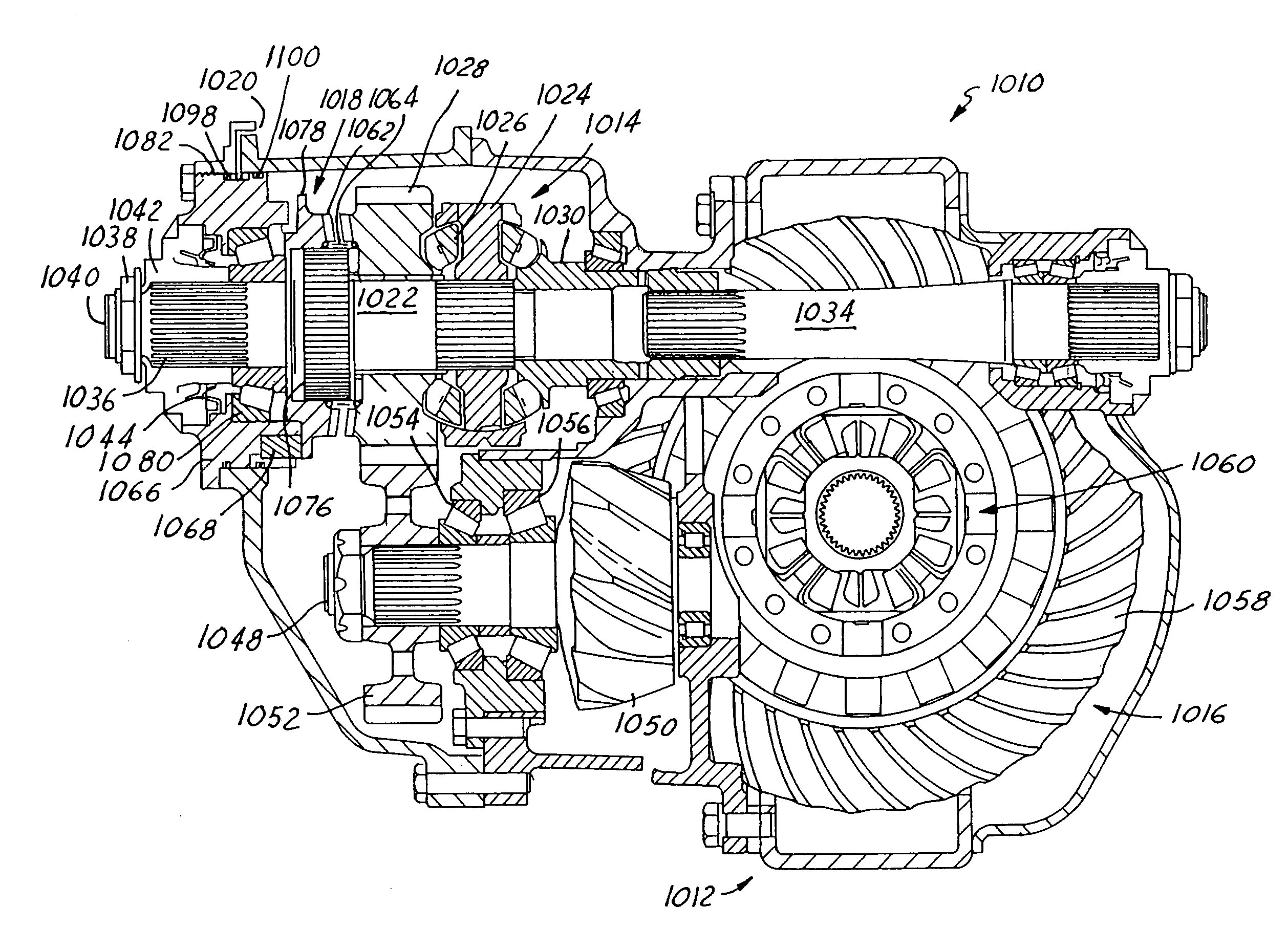

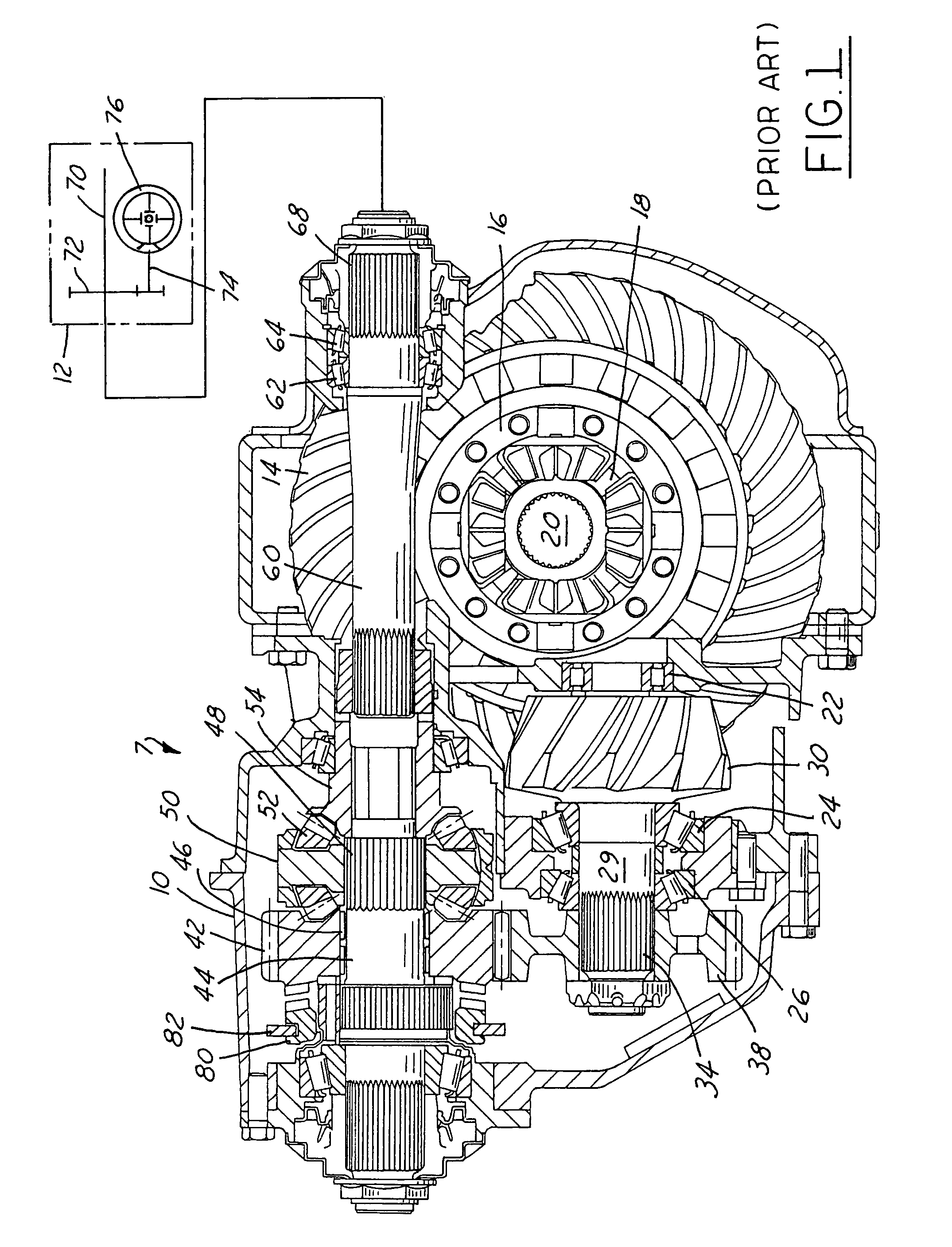

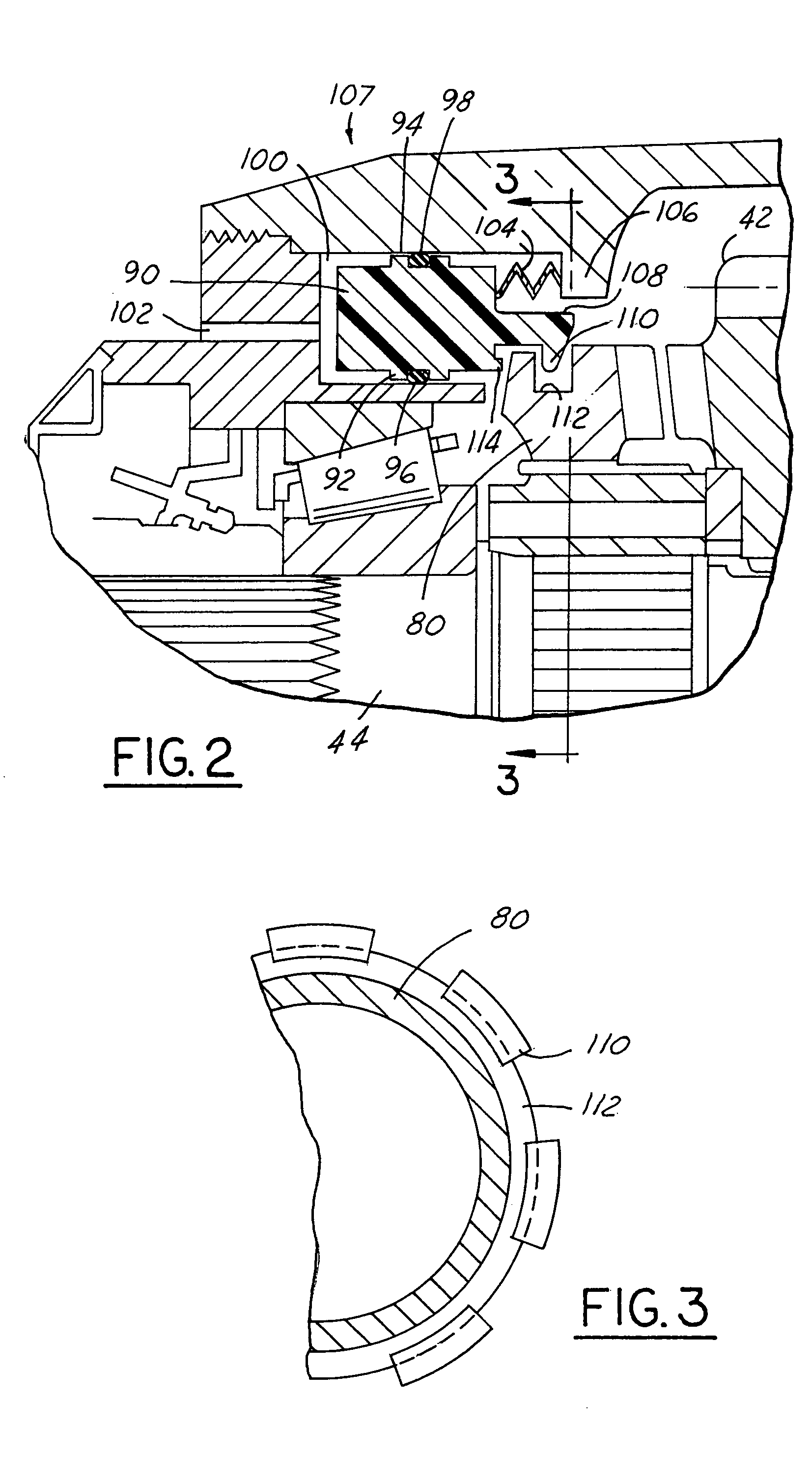

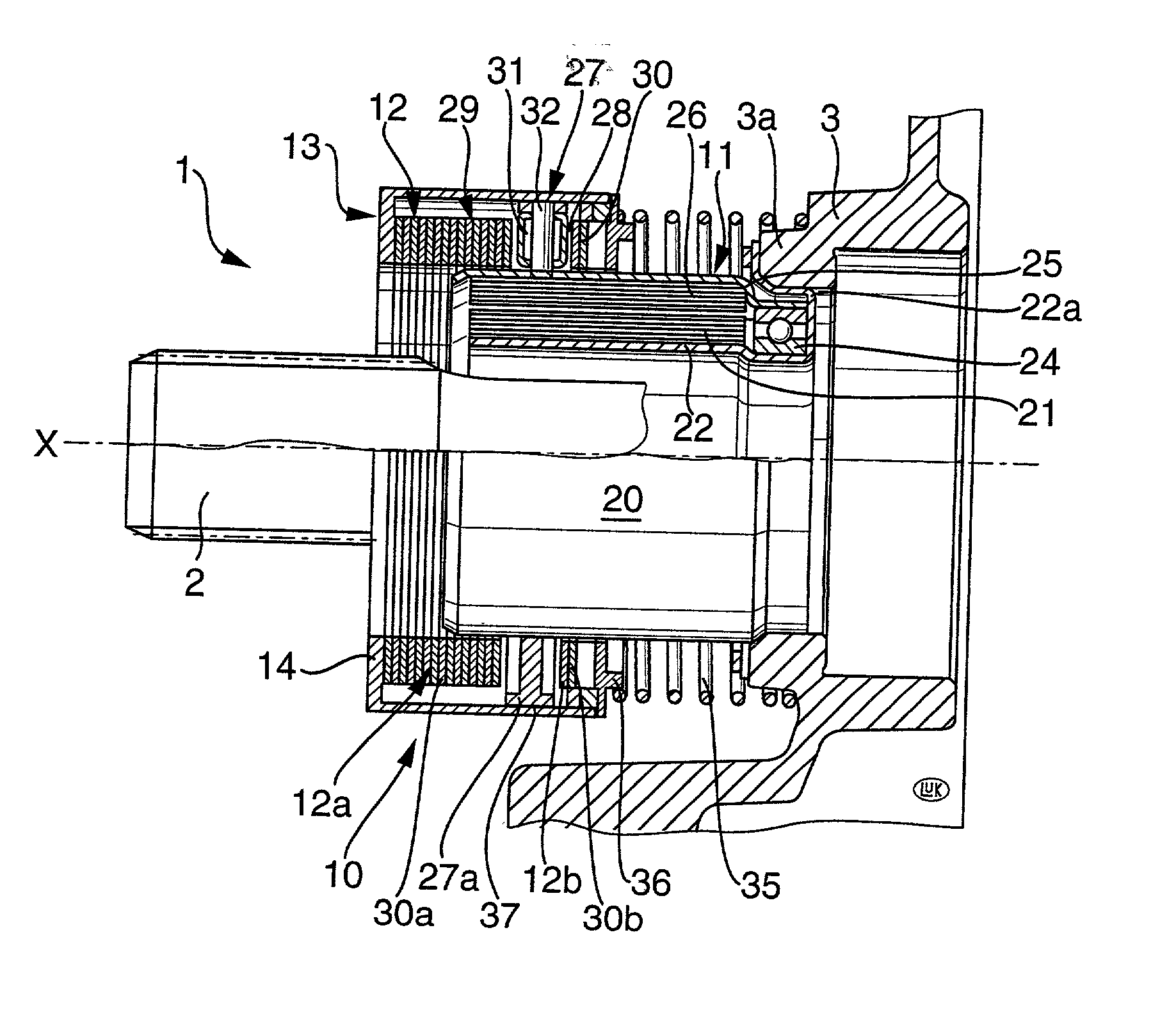

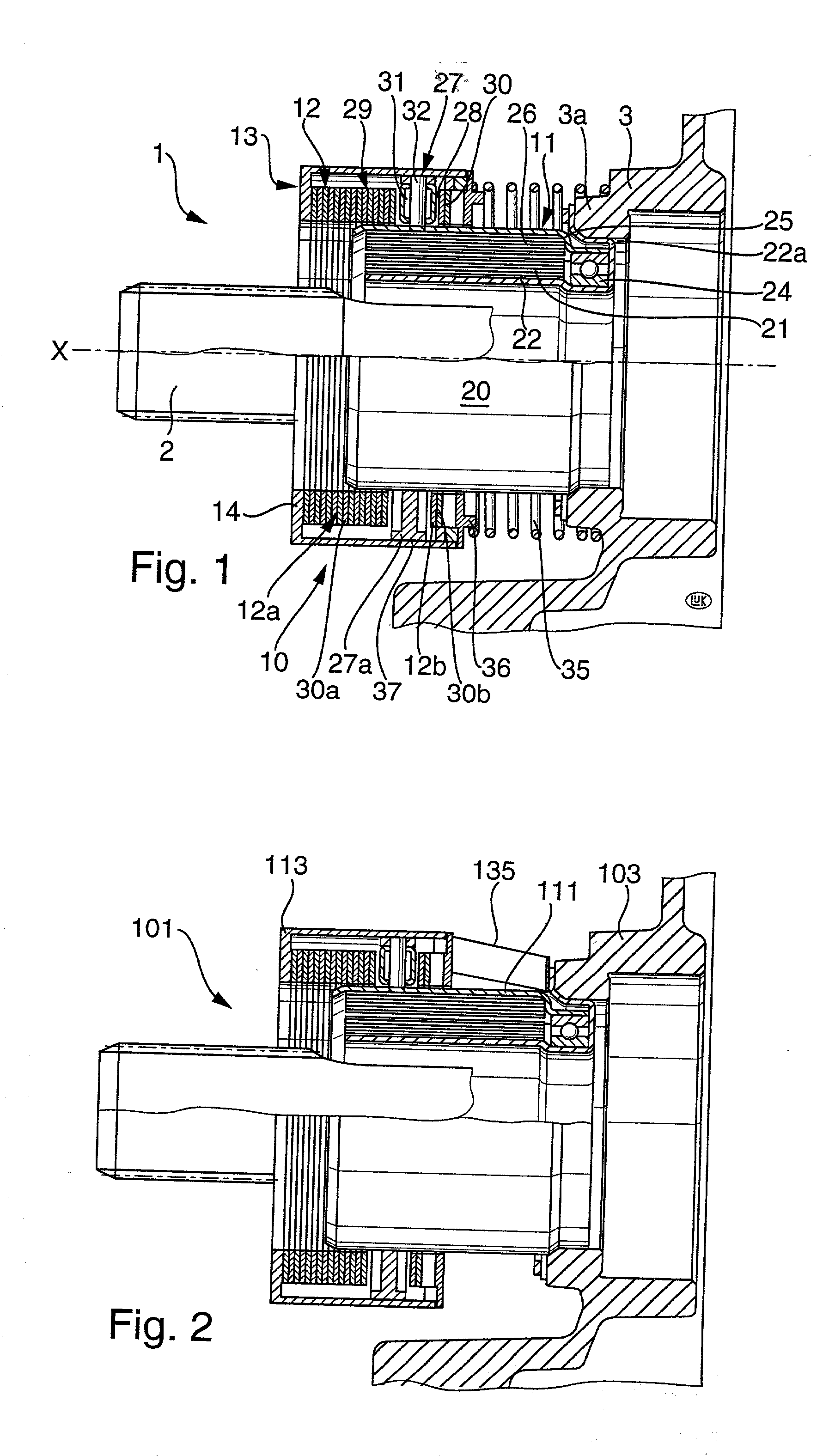

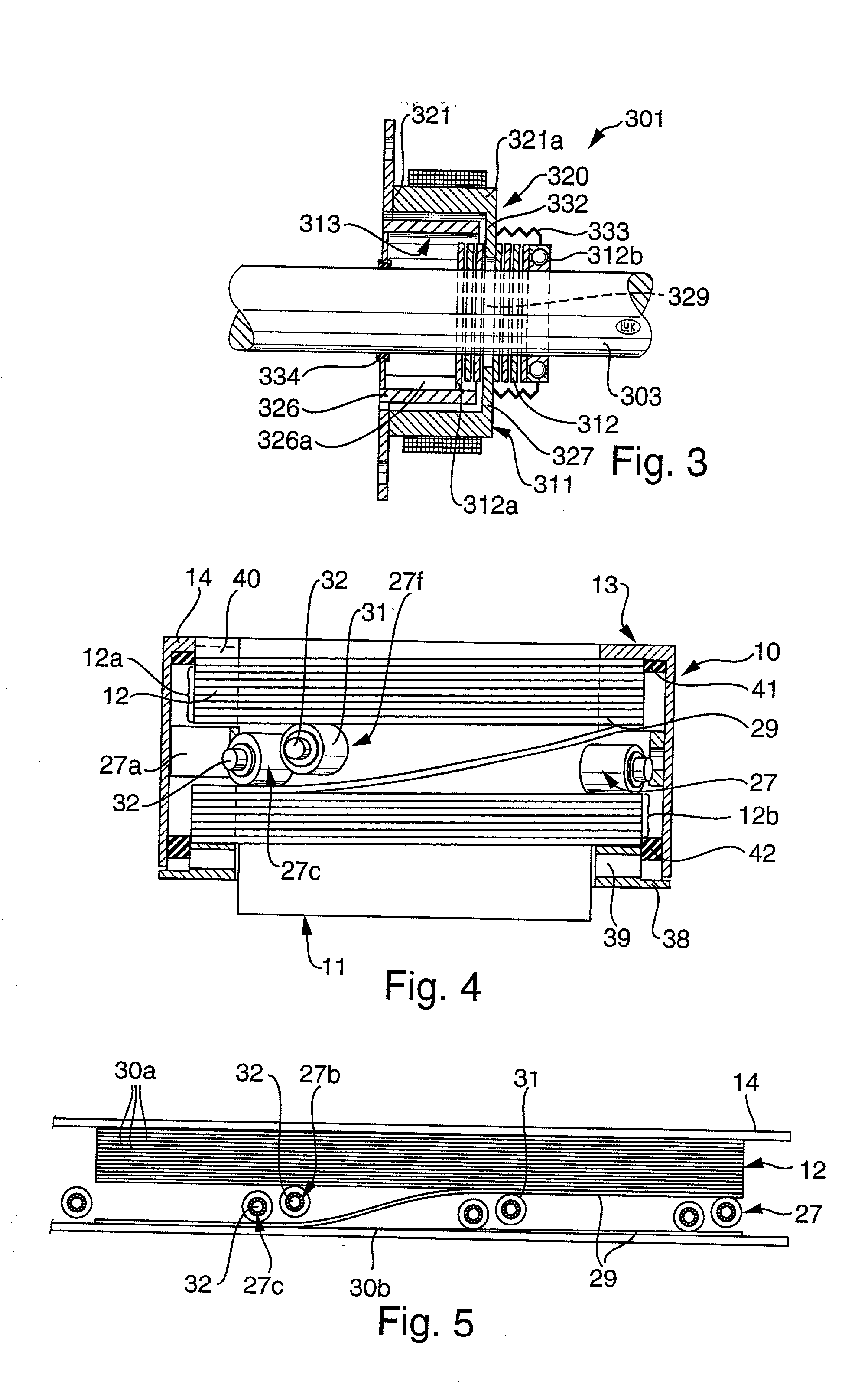

Power train for use in motor vehicles and the like

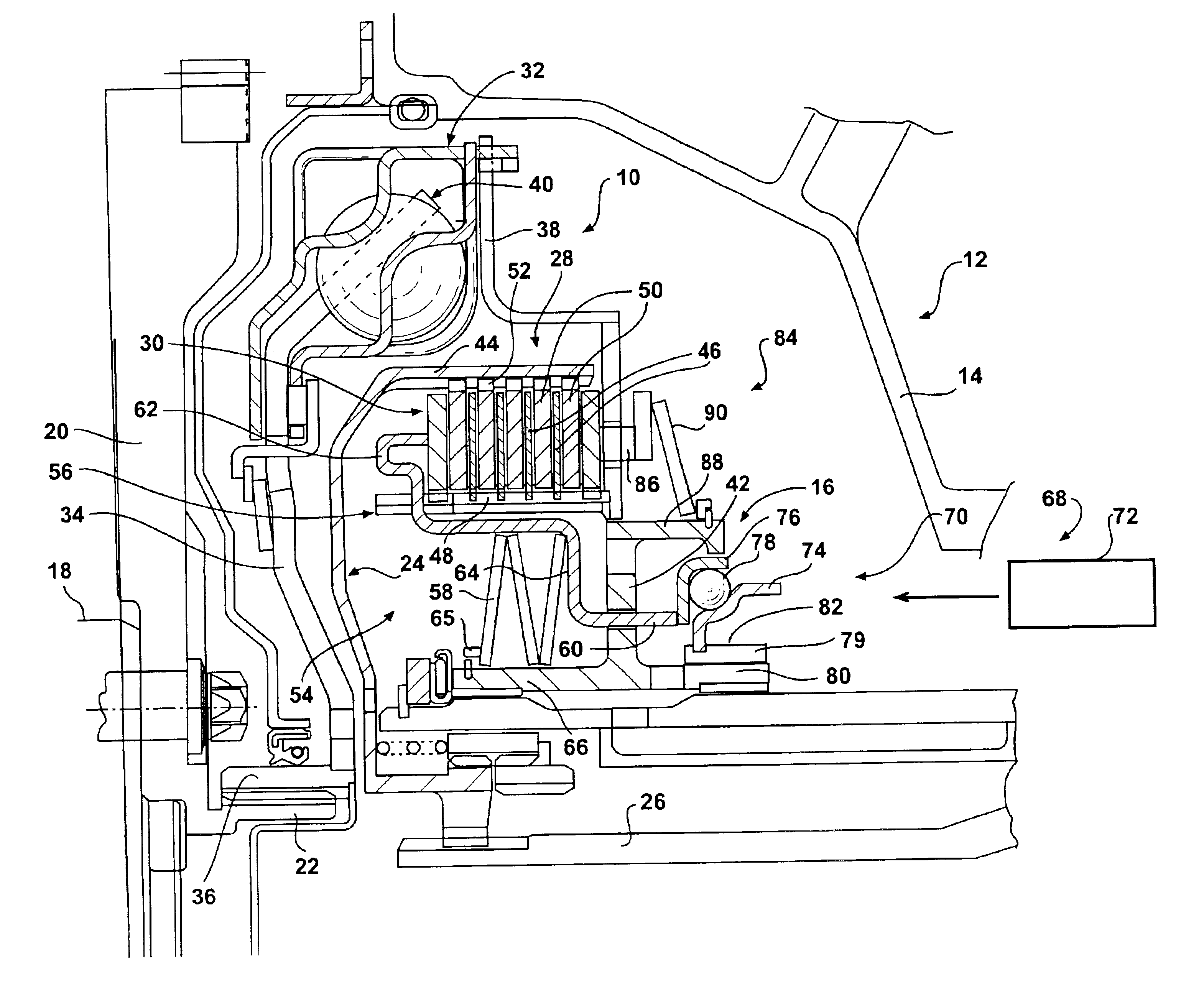

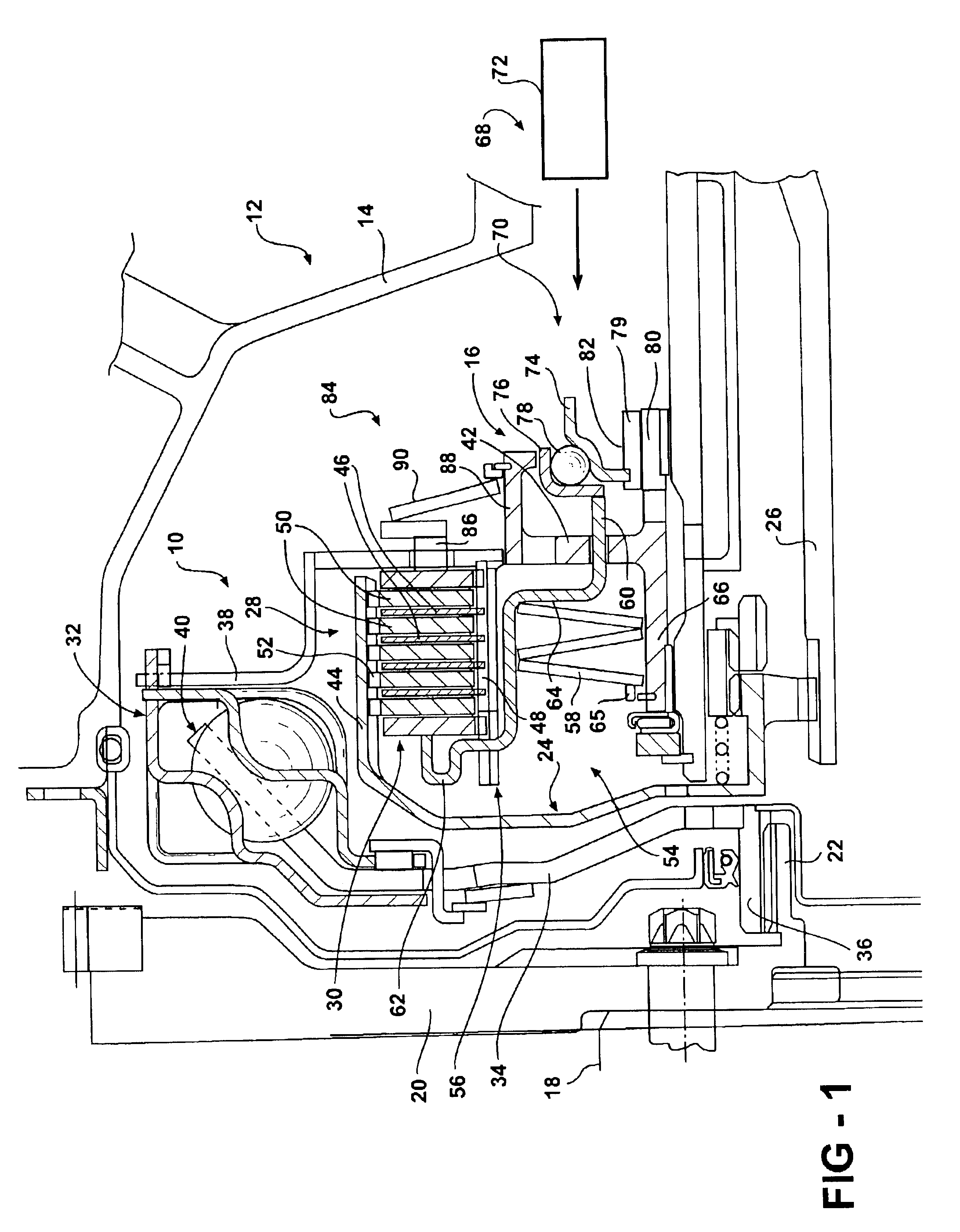

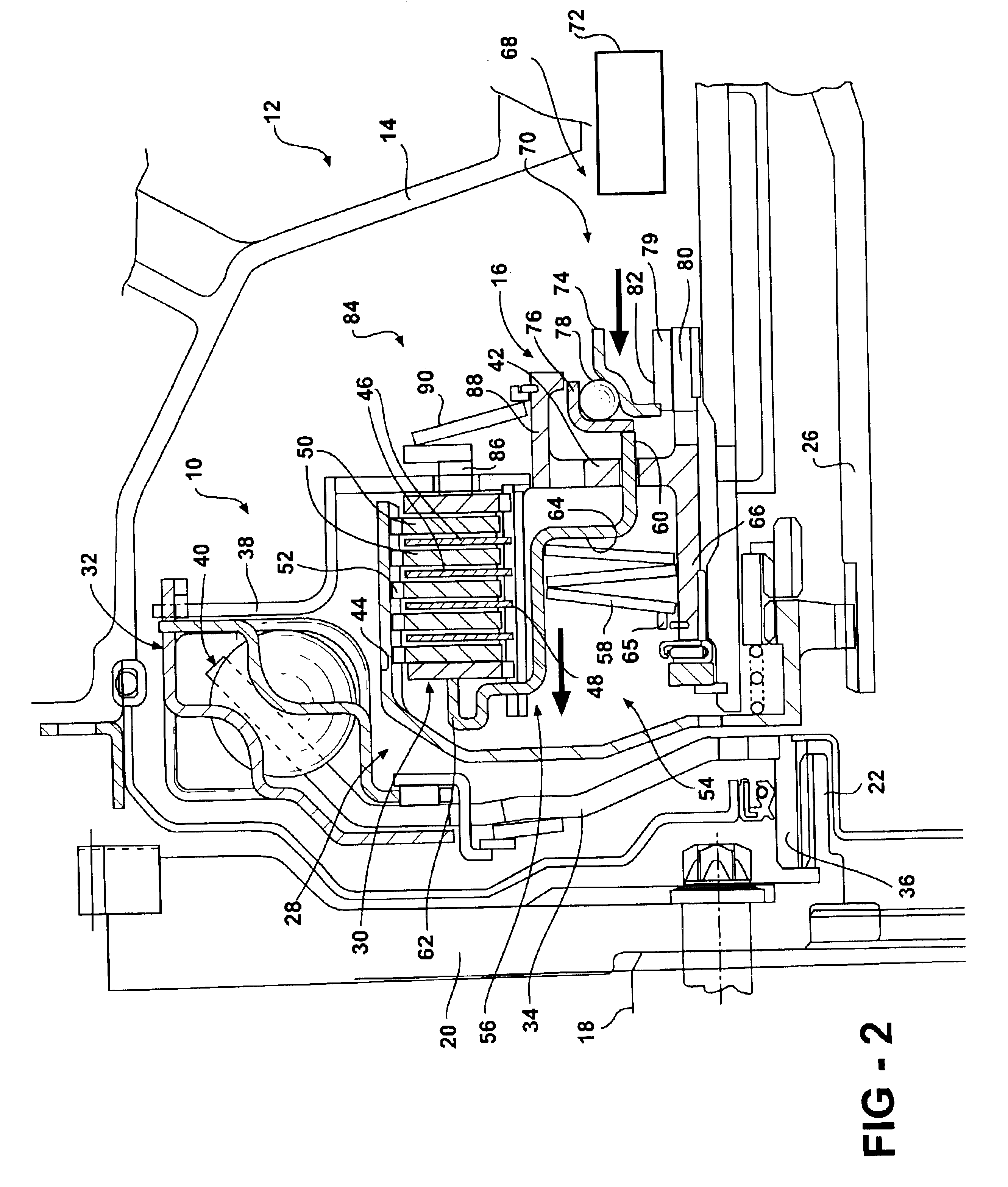

InactiveUS6354974B1Improve compactnessSimple and compactFluid actuated clutchesPropulsion using engine-driven generatorsMobile vehicleCombustion

The output shaft of a combustion engine and / or the input shaft of a transmission in the power train of a motor vehicle is directly or indirectly connected to or connectable with the rotor of an electric machine. The stator of the electric machine surrounds the rotor and the latter surrounds, at least in part, a gearing and / or a clutch for and / or another constituent of the transmission. Such design contributes to compactness of the power train.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

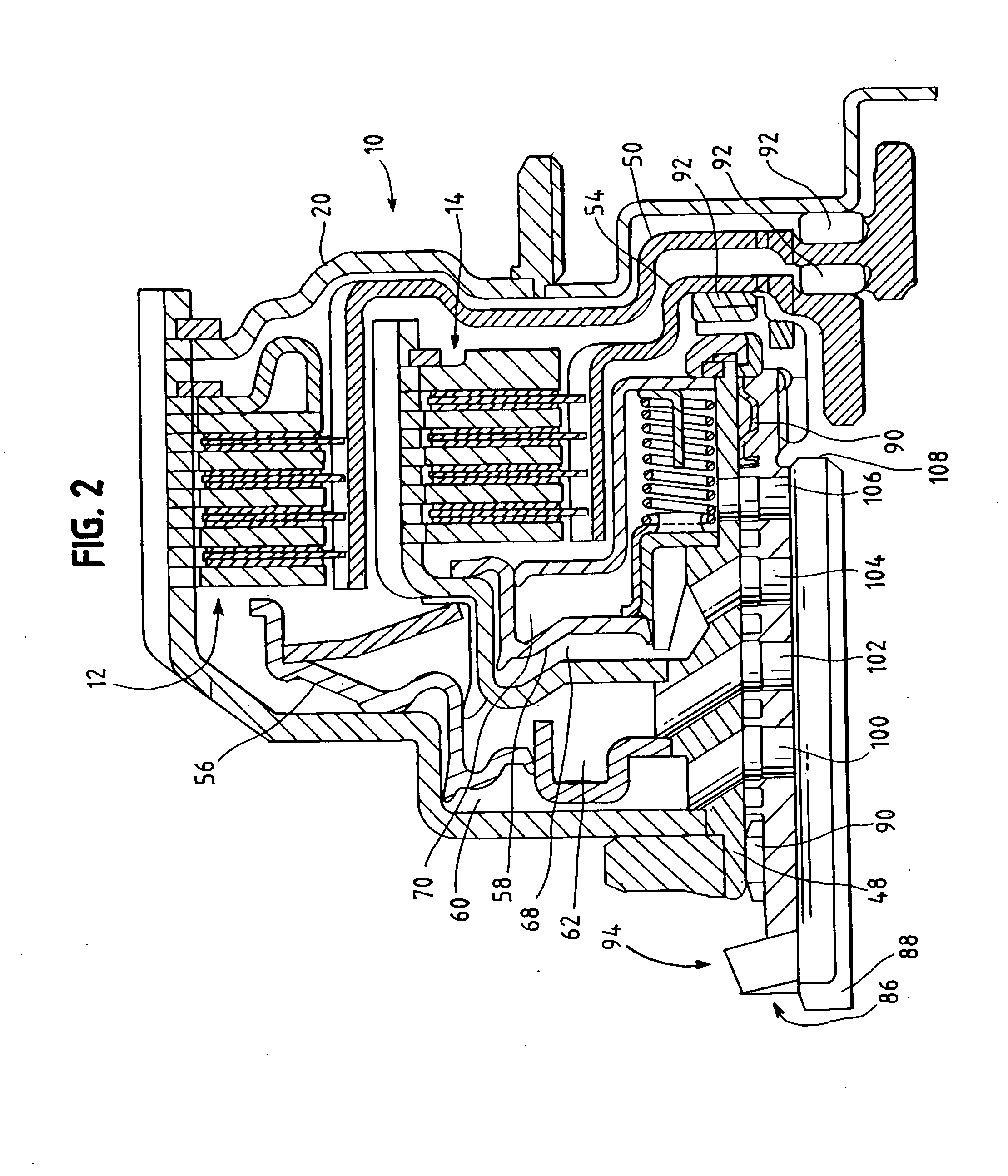

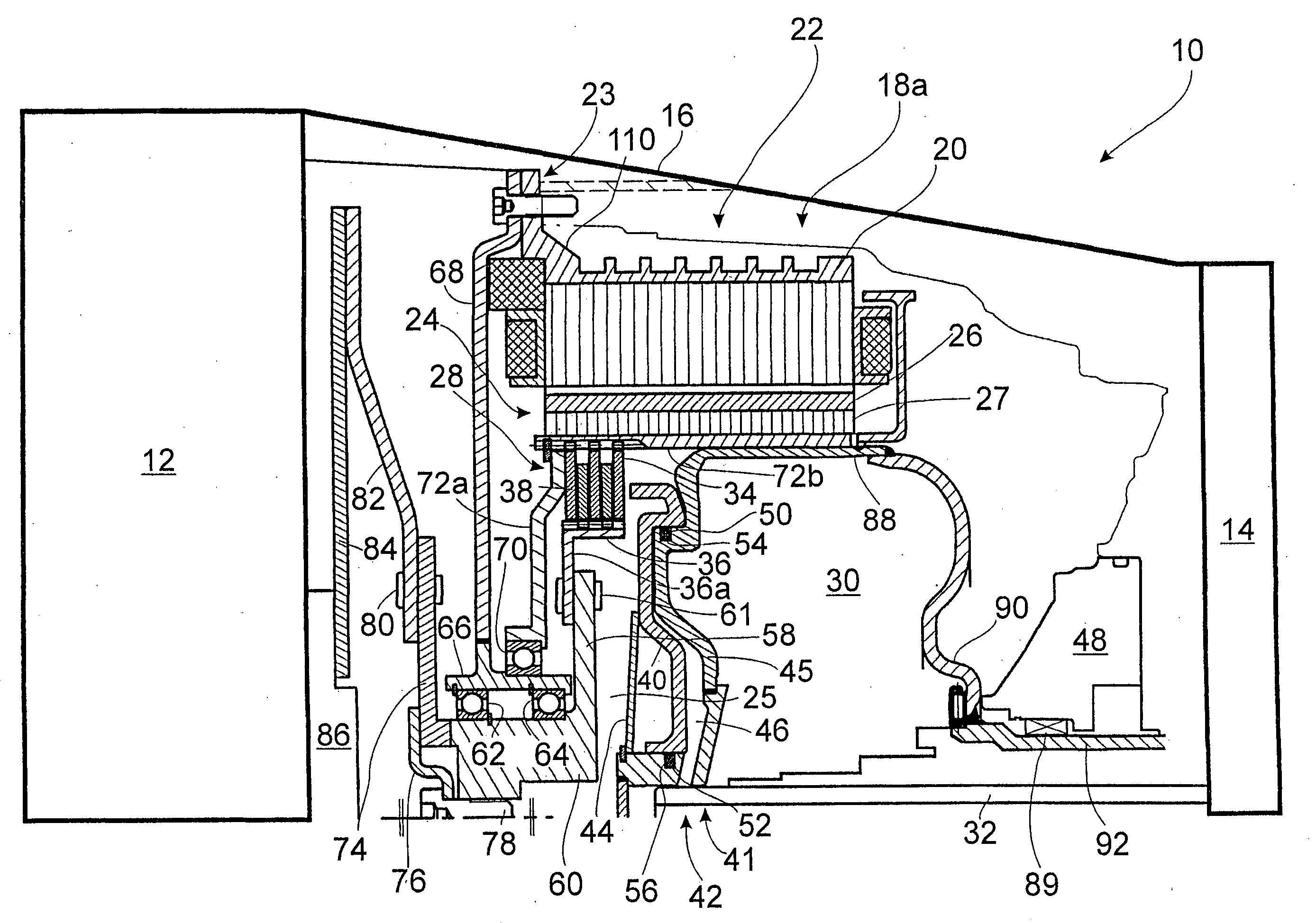

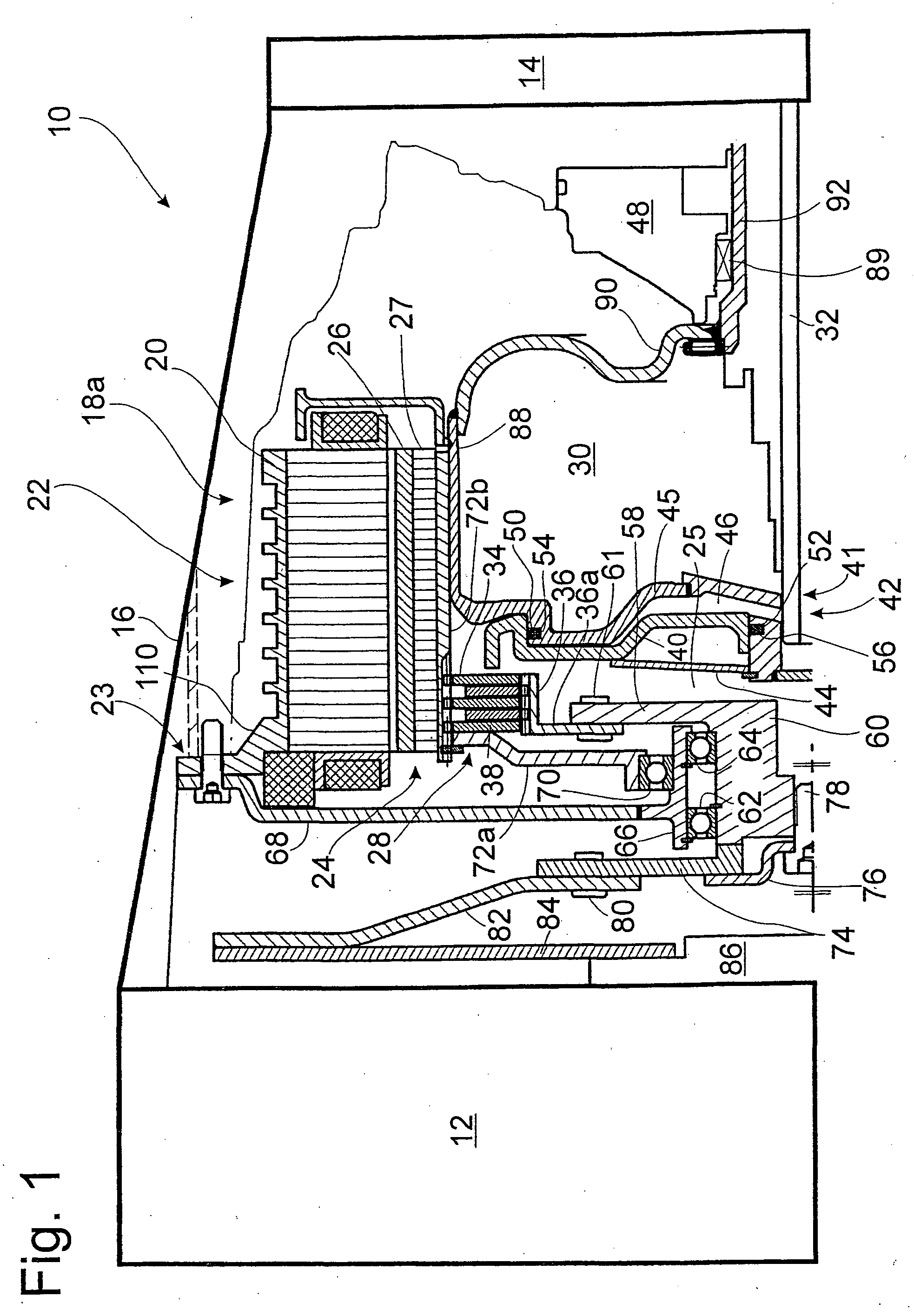

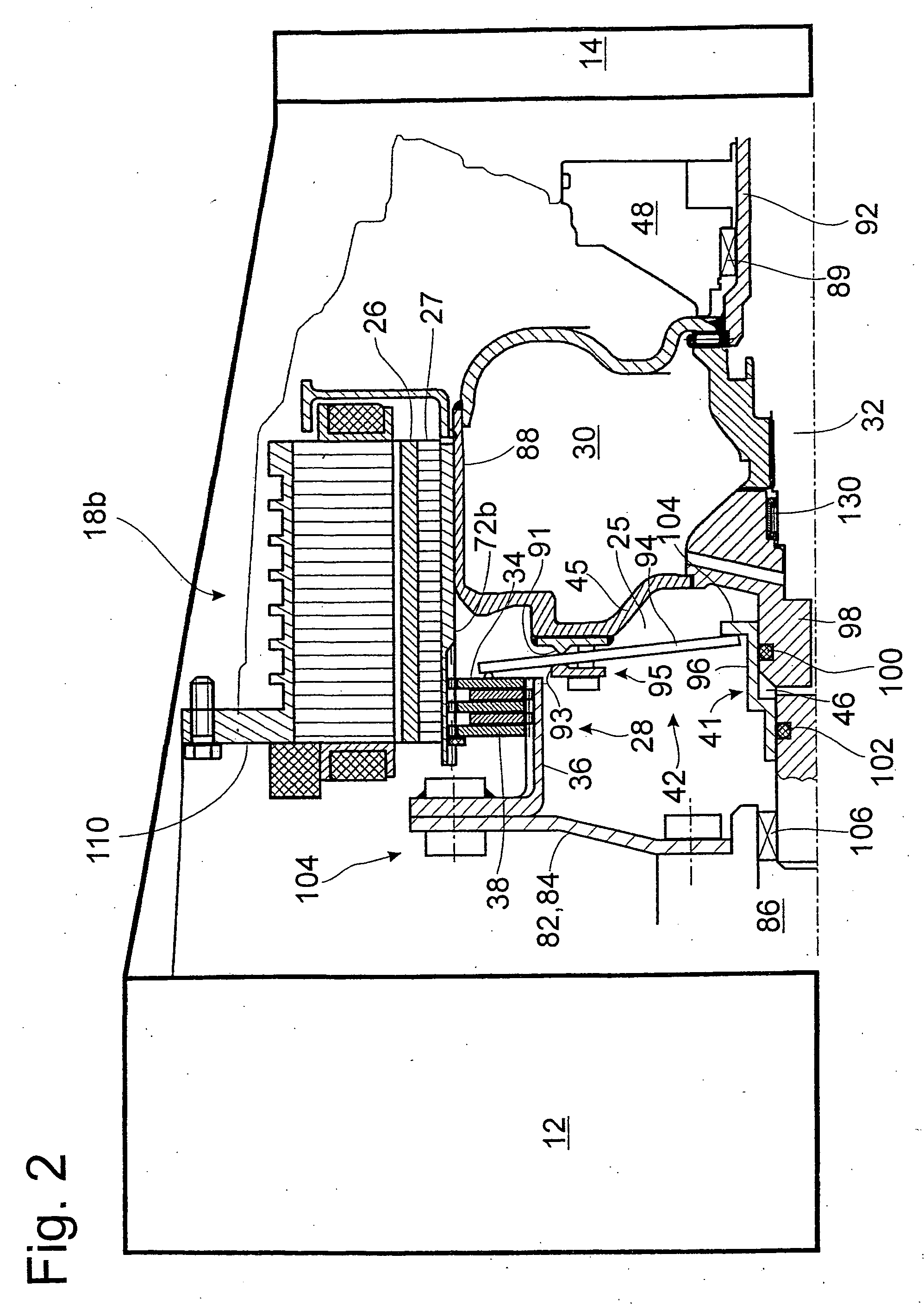

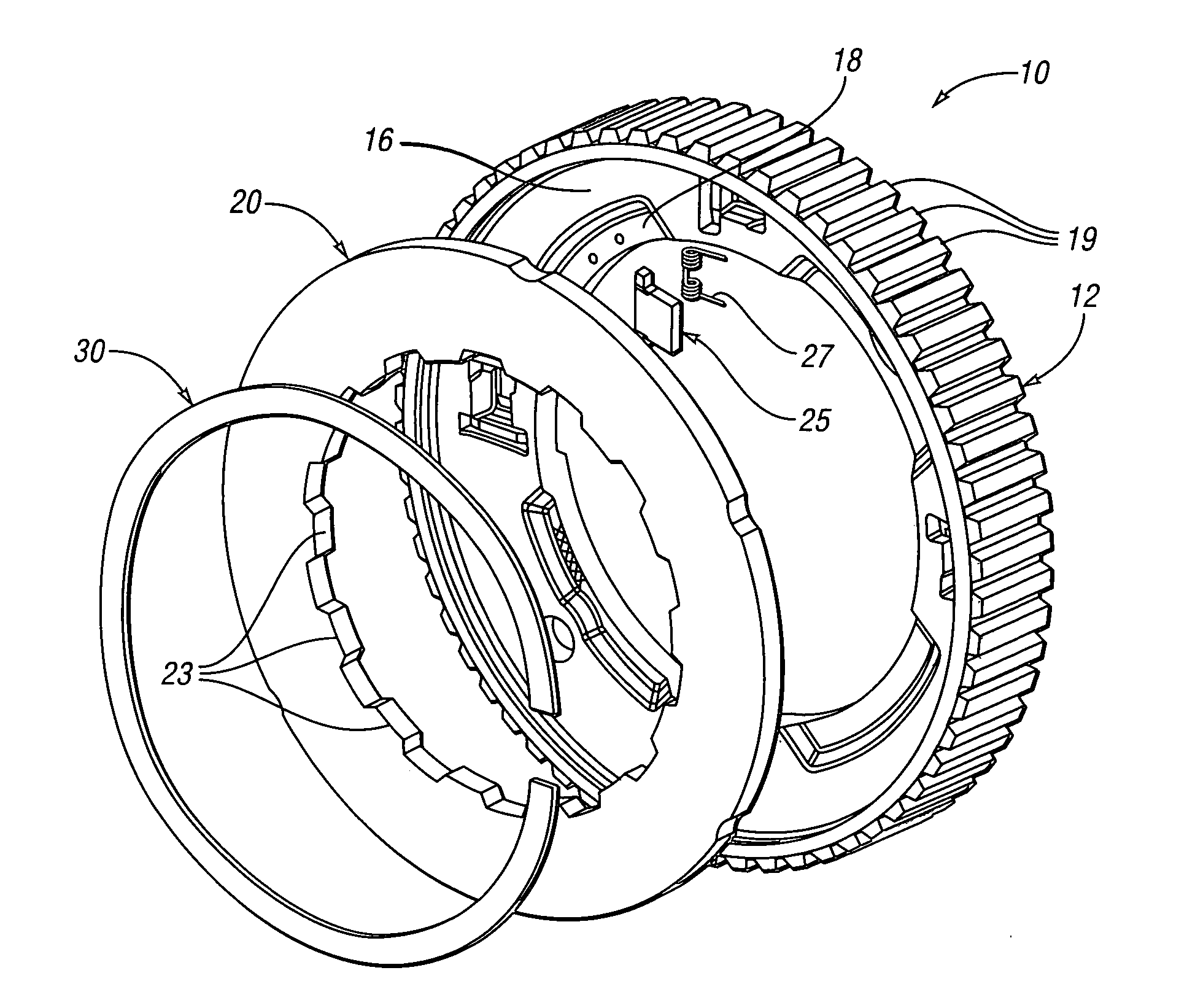

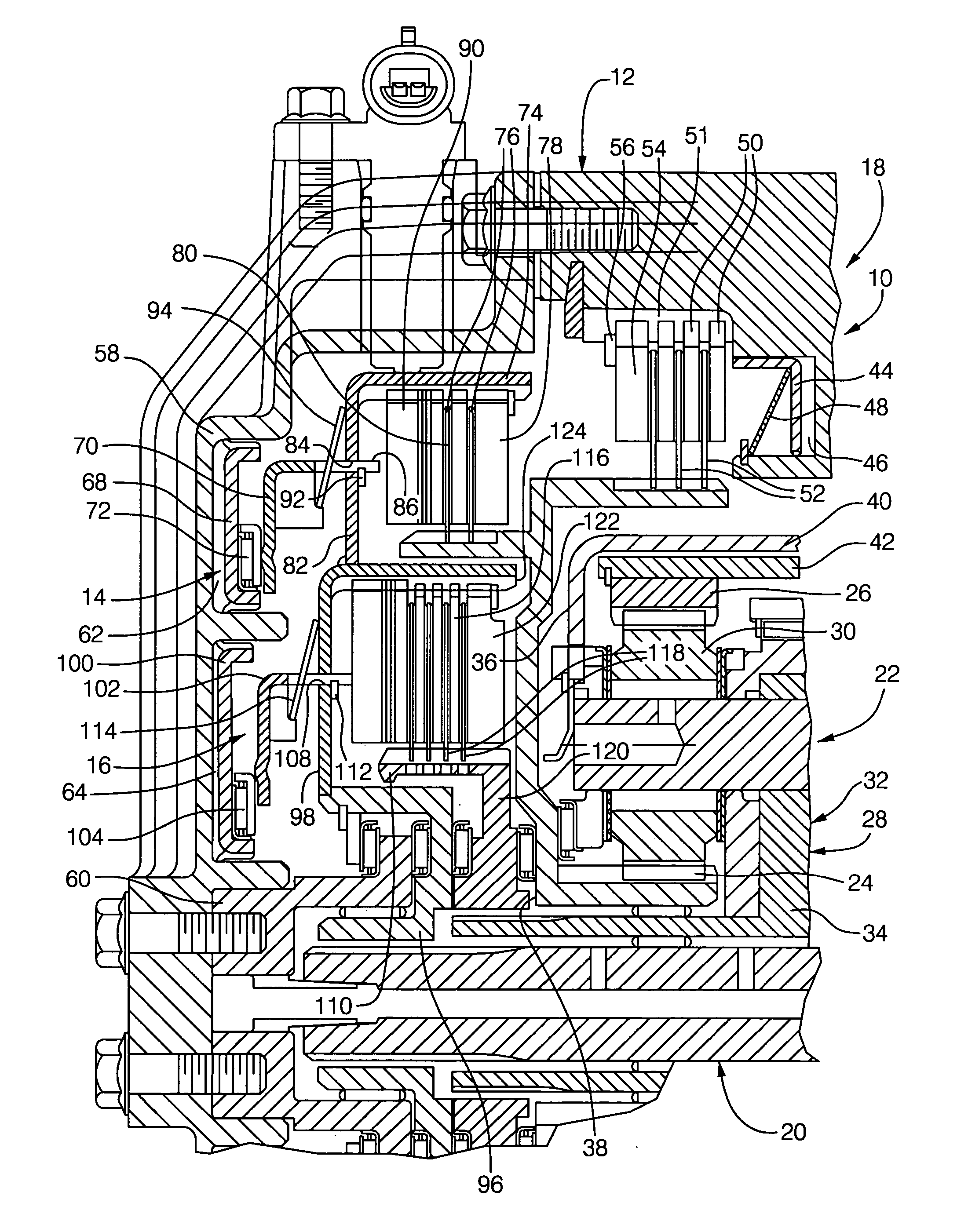

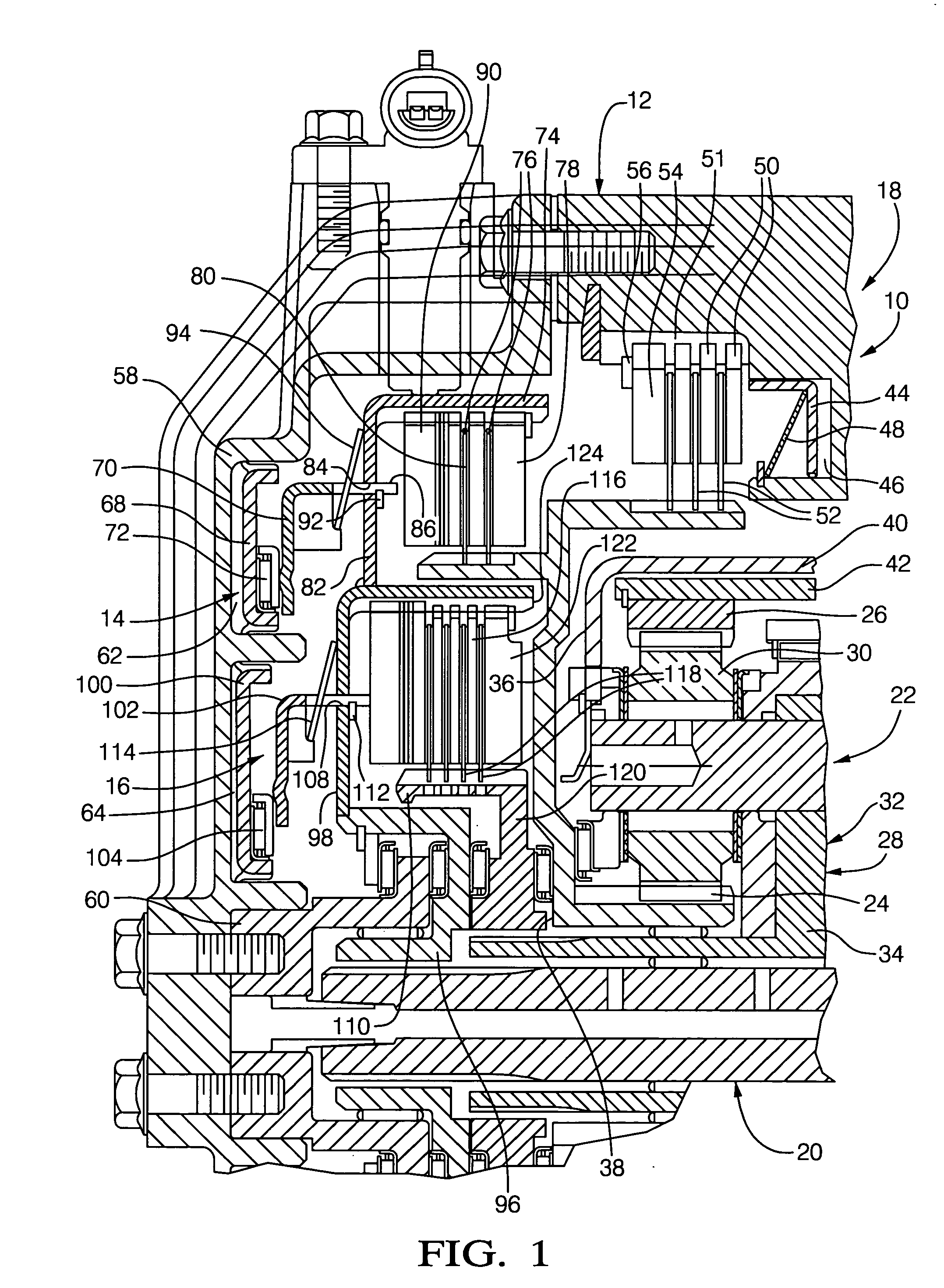

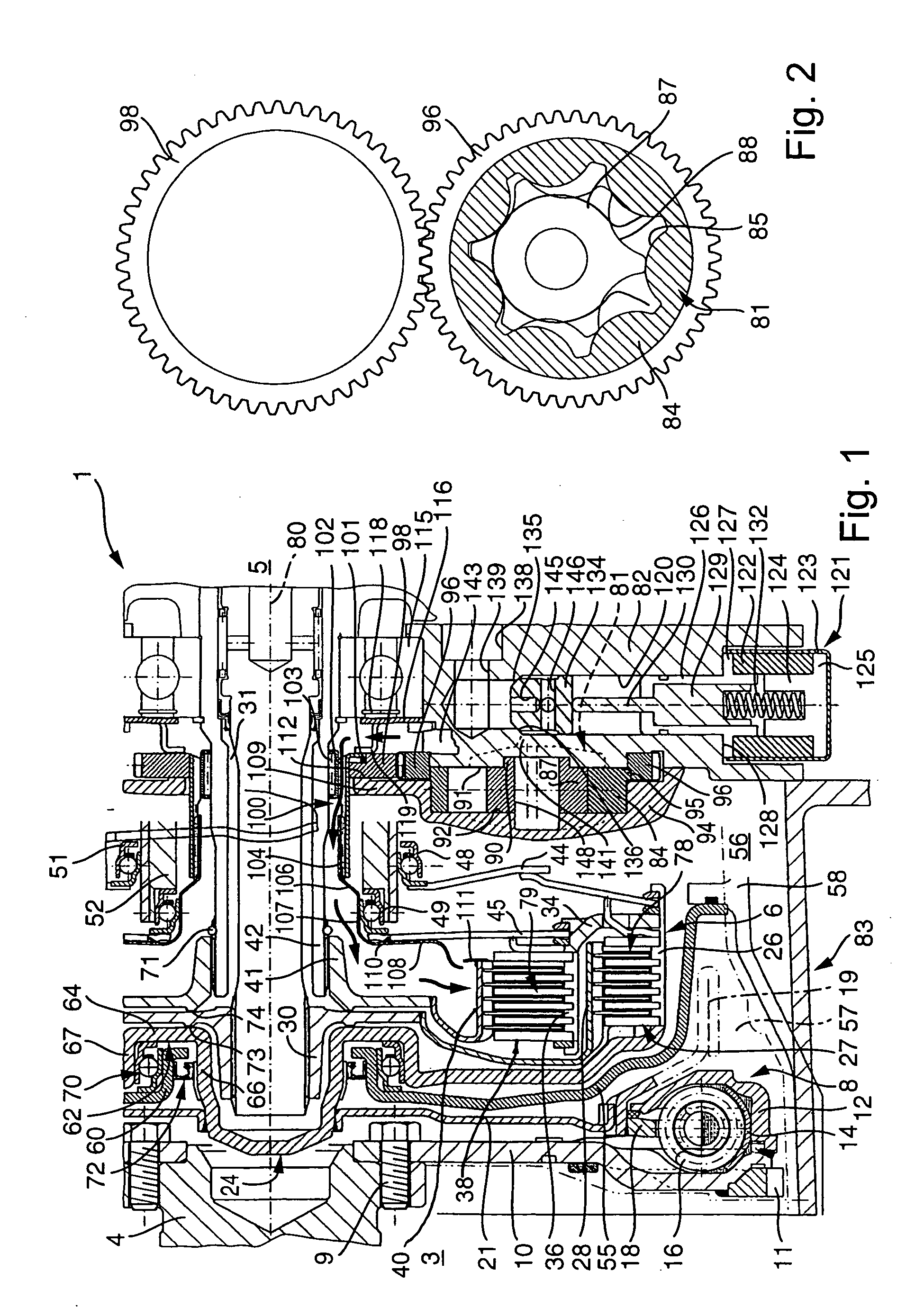

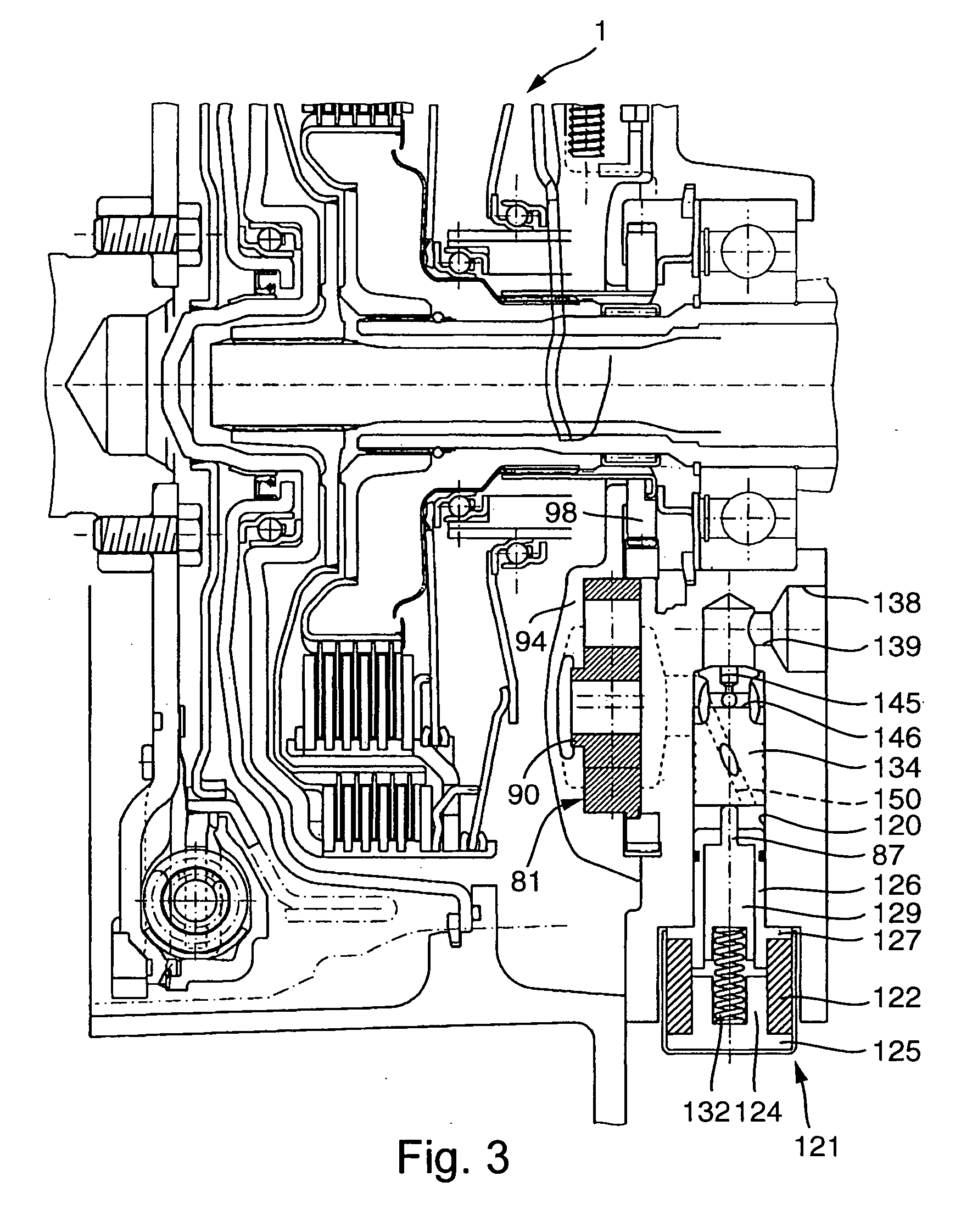

Oil management system for dual clutch transmissions

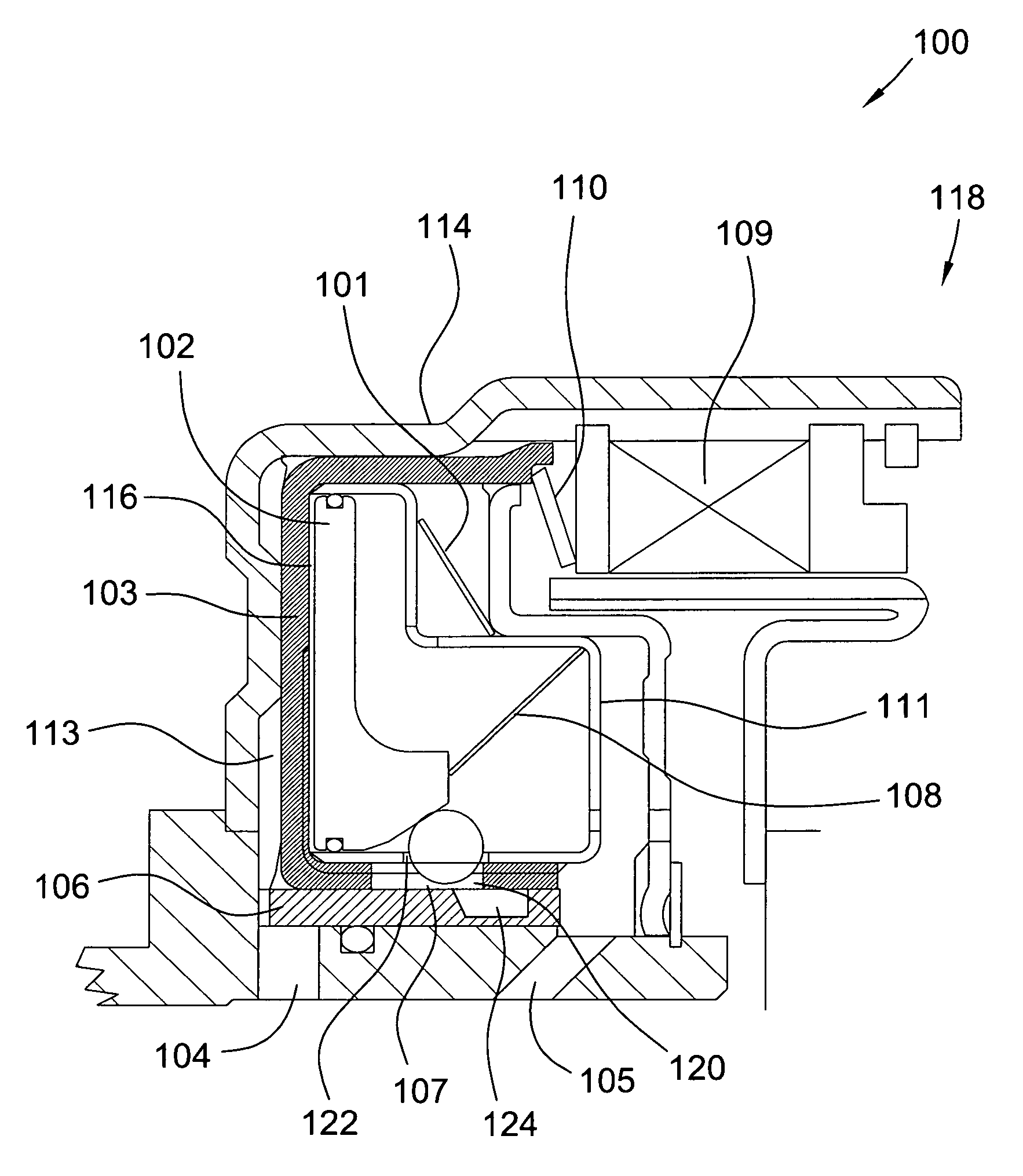

InactiveUS20050067251A1Solve the lack of balanceReduce flow of fluidFluid actuated clutchesGear lubrication/coolingEngineeringCentrifugal force

The present invention provides an improved fluid management system for dual and other multiple clutch assemblies having fluid-operated pistons and fluid operated balance chambers offsetting the undesired pressures exerted by fluids within the piston chamber induced by centrifugal forces. Among other improvements, the system provides an effective and cost efficient arrangement of fluid supply channels and supply openings capable of maintaining desired fluid levels in the balance chambers under low, otherwise insufficient, flow rate conditions. In another aspect, the system provides a reservoir for the balance chambers under conditions where the fluid flow is stopped or interrupted.

Owner:BORGWARNER INC

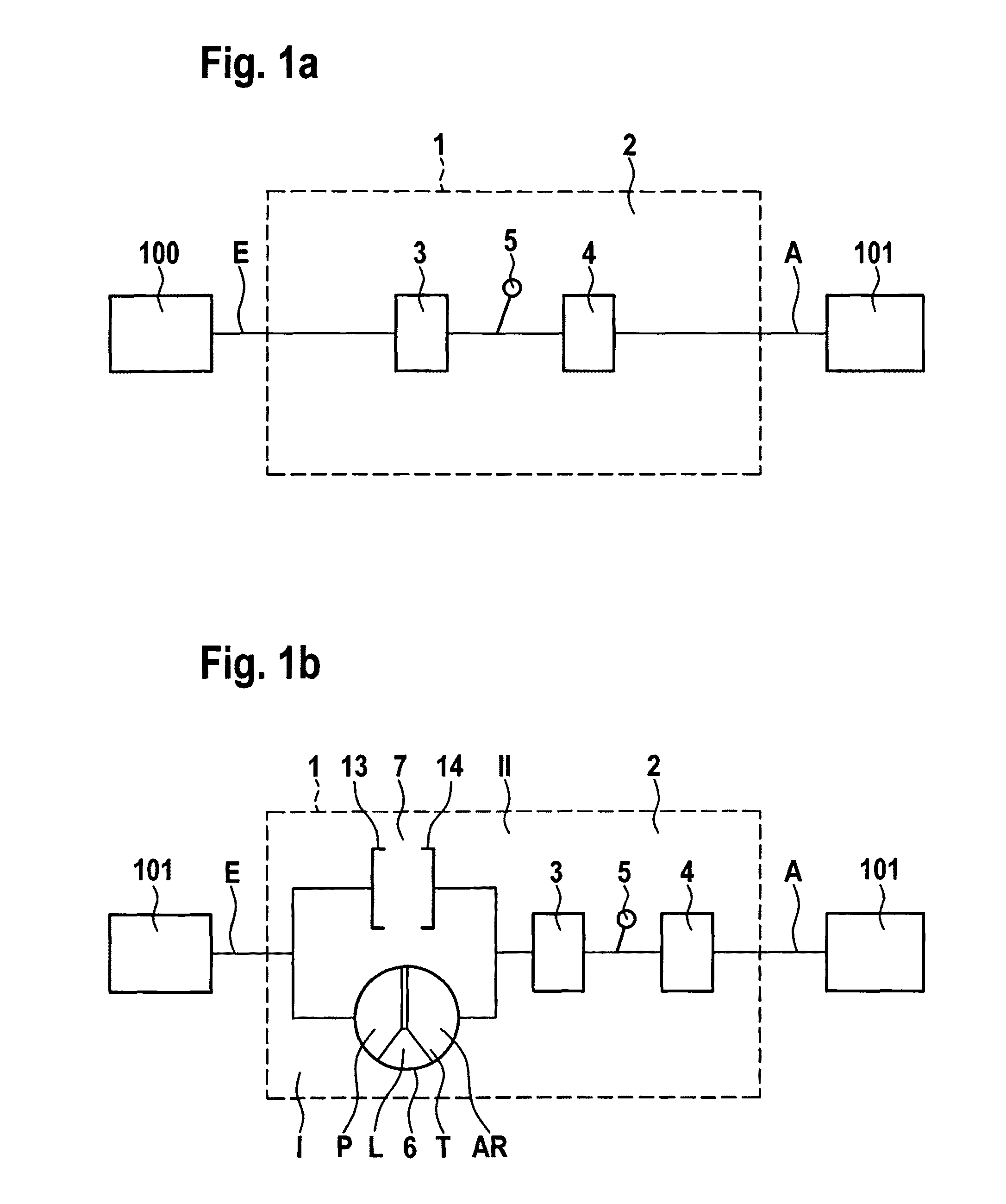

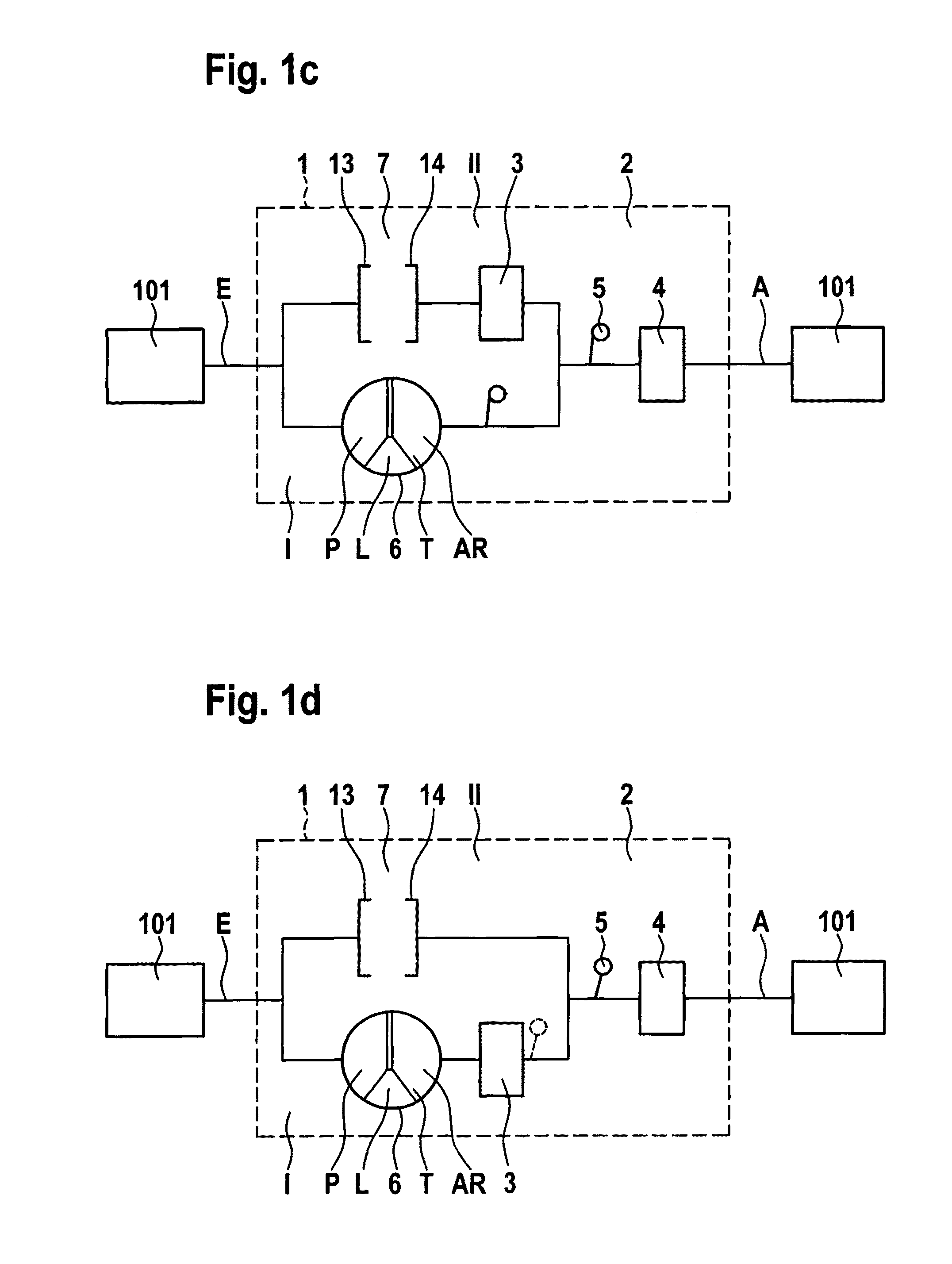

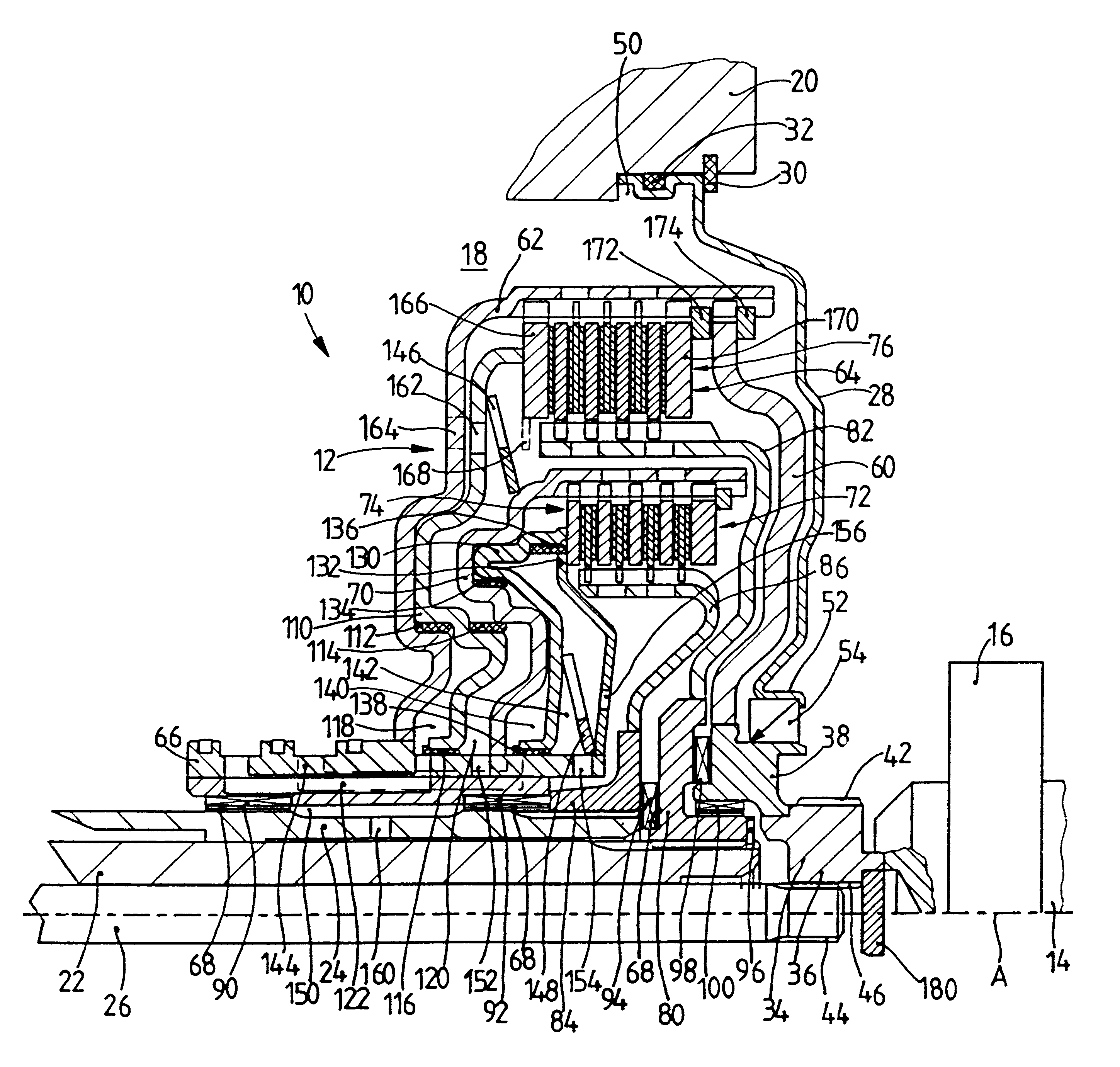

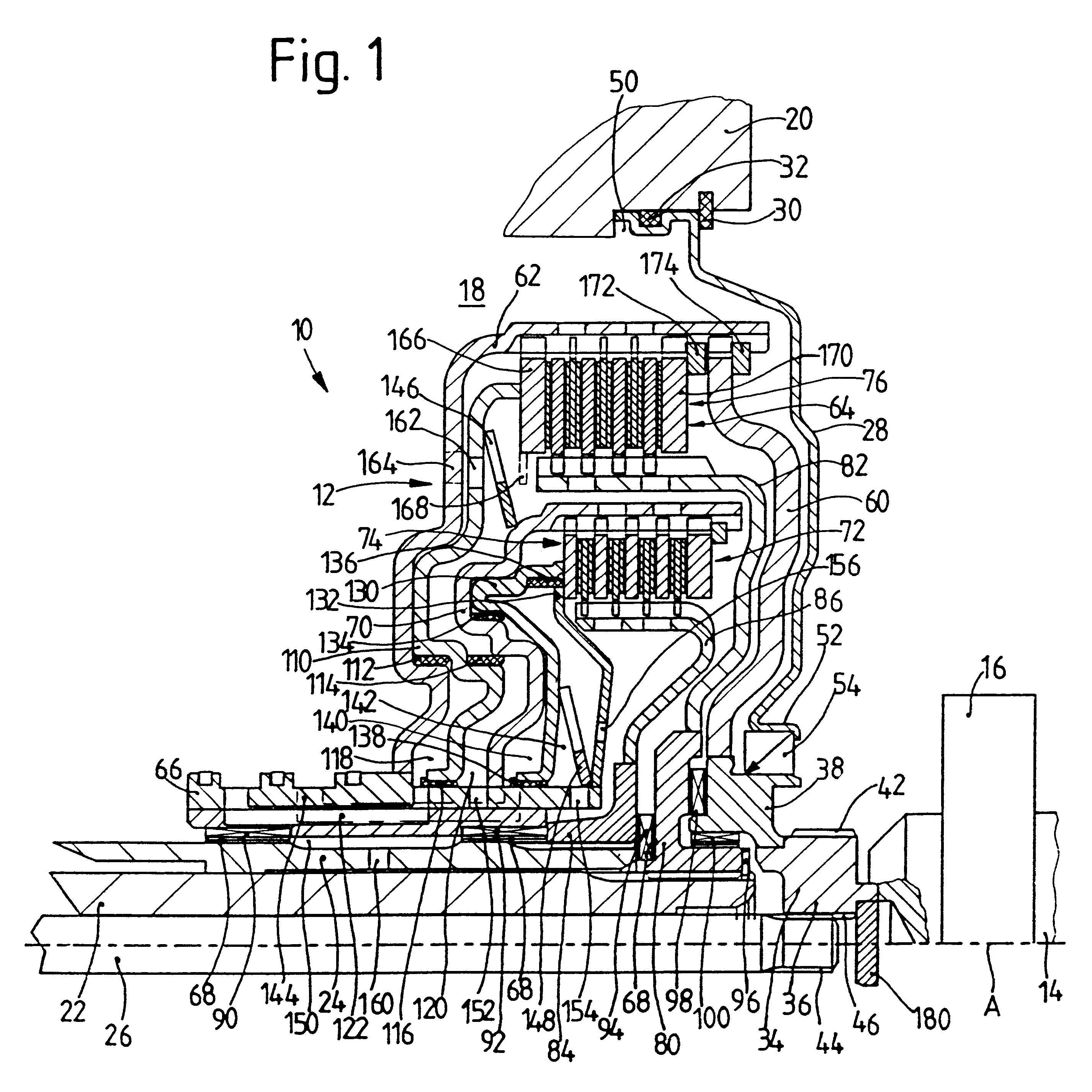

Electromotive drive module

InactiveUS20060289209A1Low costSave considerable assembly timeFluid actuated clutchesGas pressure propulsion mountingElectric machineExternal combustion engine

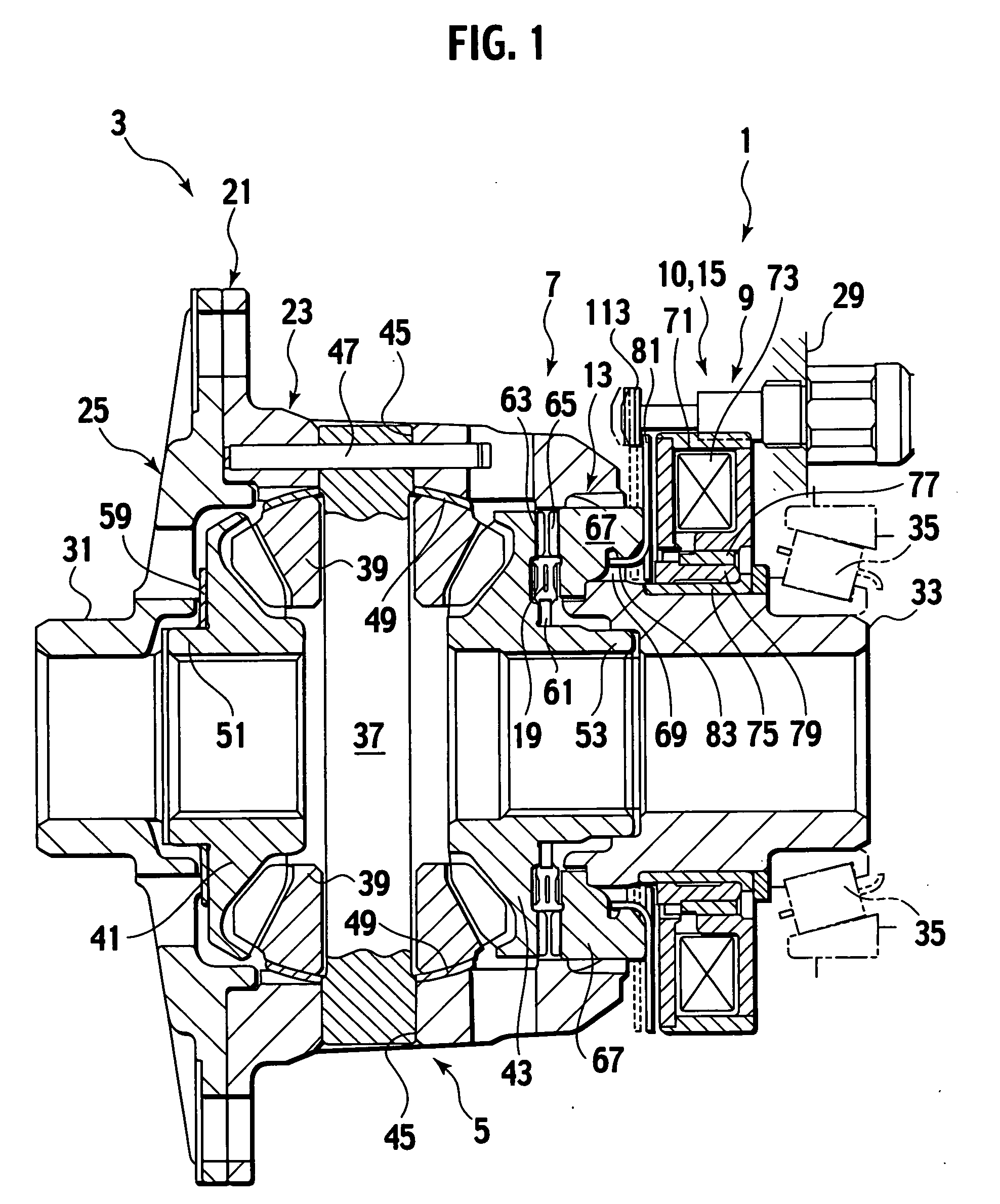

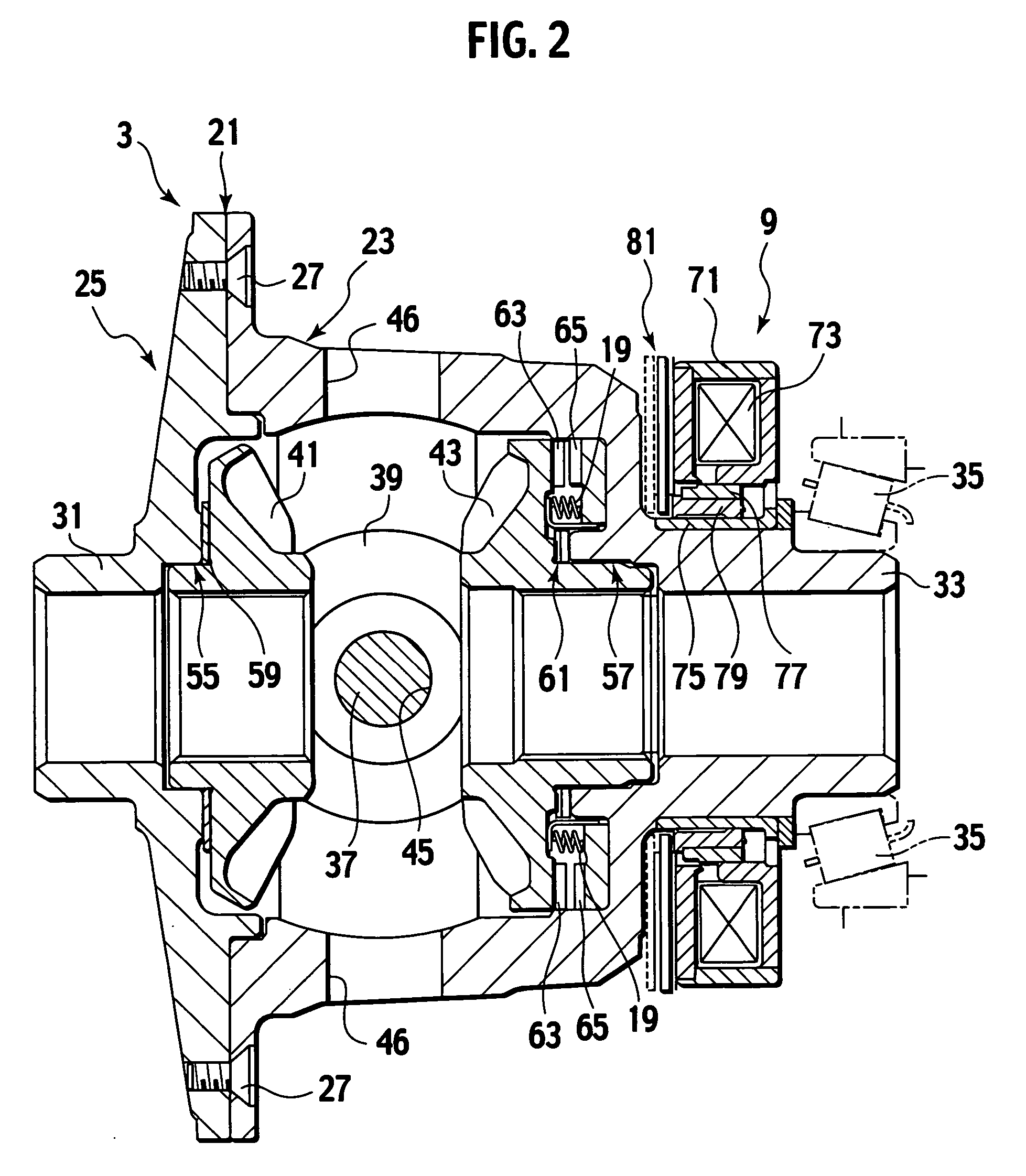

An electromotive drive module for installation in a housing between an internal combustion engine and a transmission of a motor vehicle power train. The drive module includes an electric machine with a stator and a rotor and first and second clutch devices, by means of which the rotor can be connected when desired to the internal combustion engine and / or to the transmission for the transmission of torque.

Owner:ZF FRIEDRICHSHAFEN AG

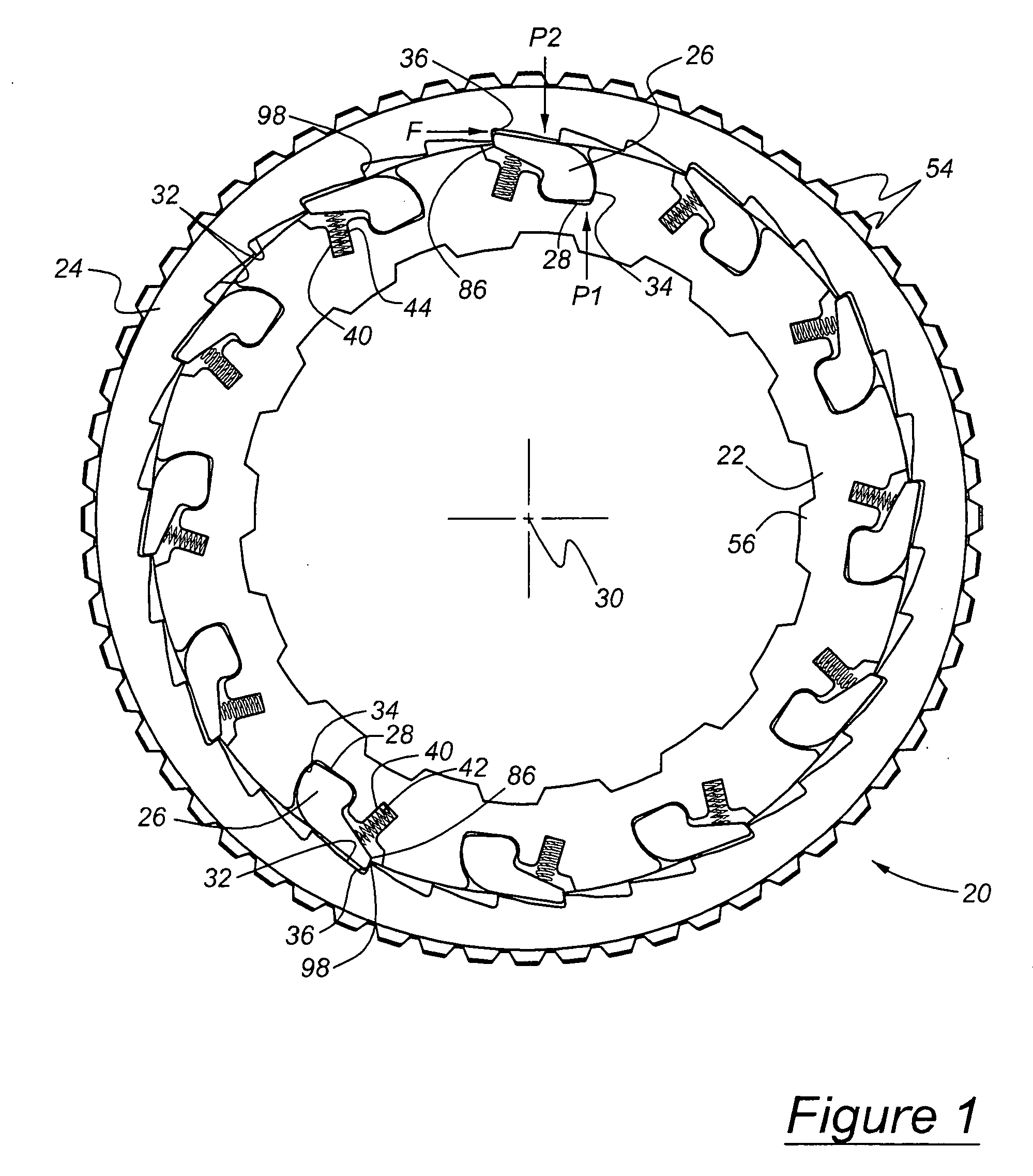

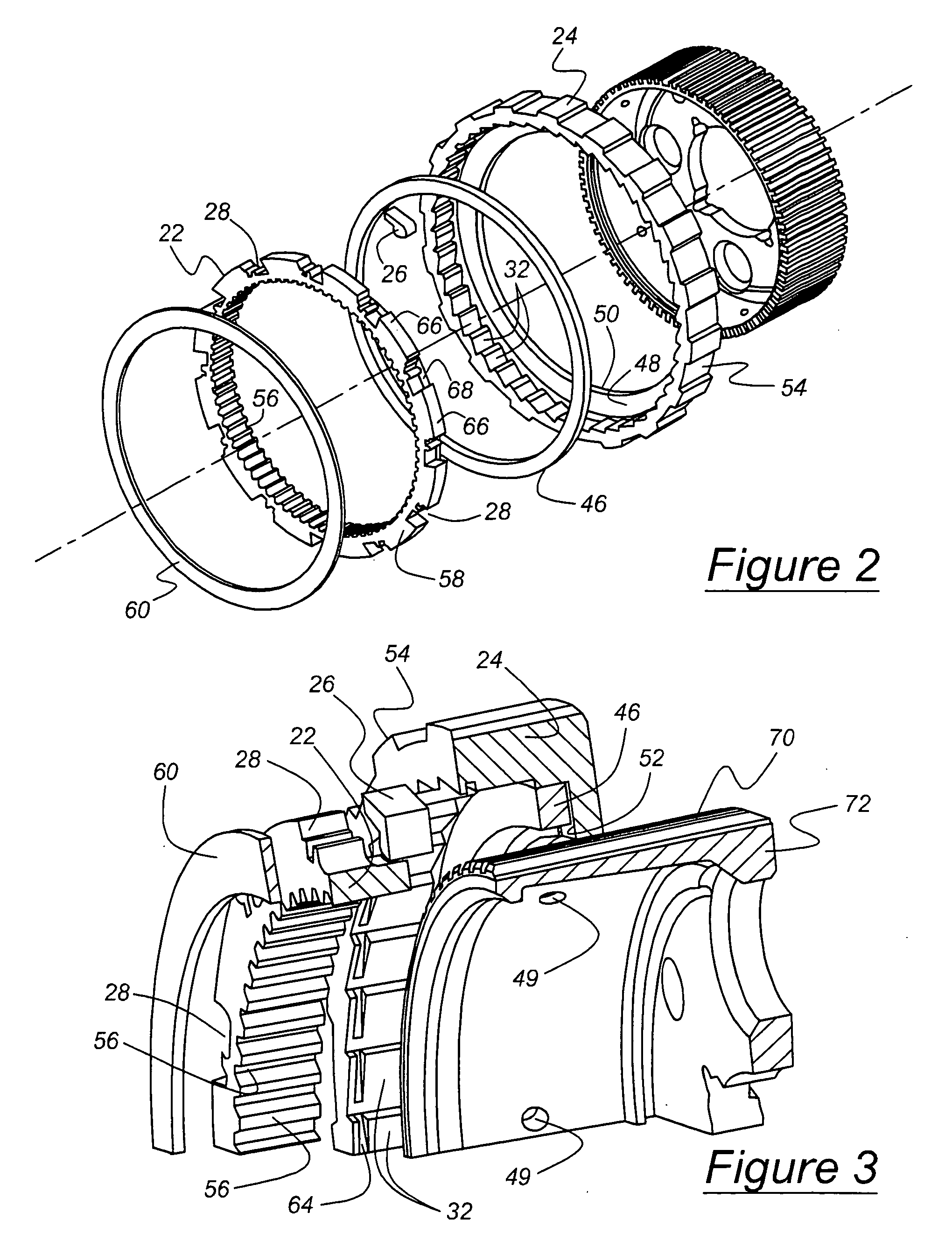

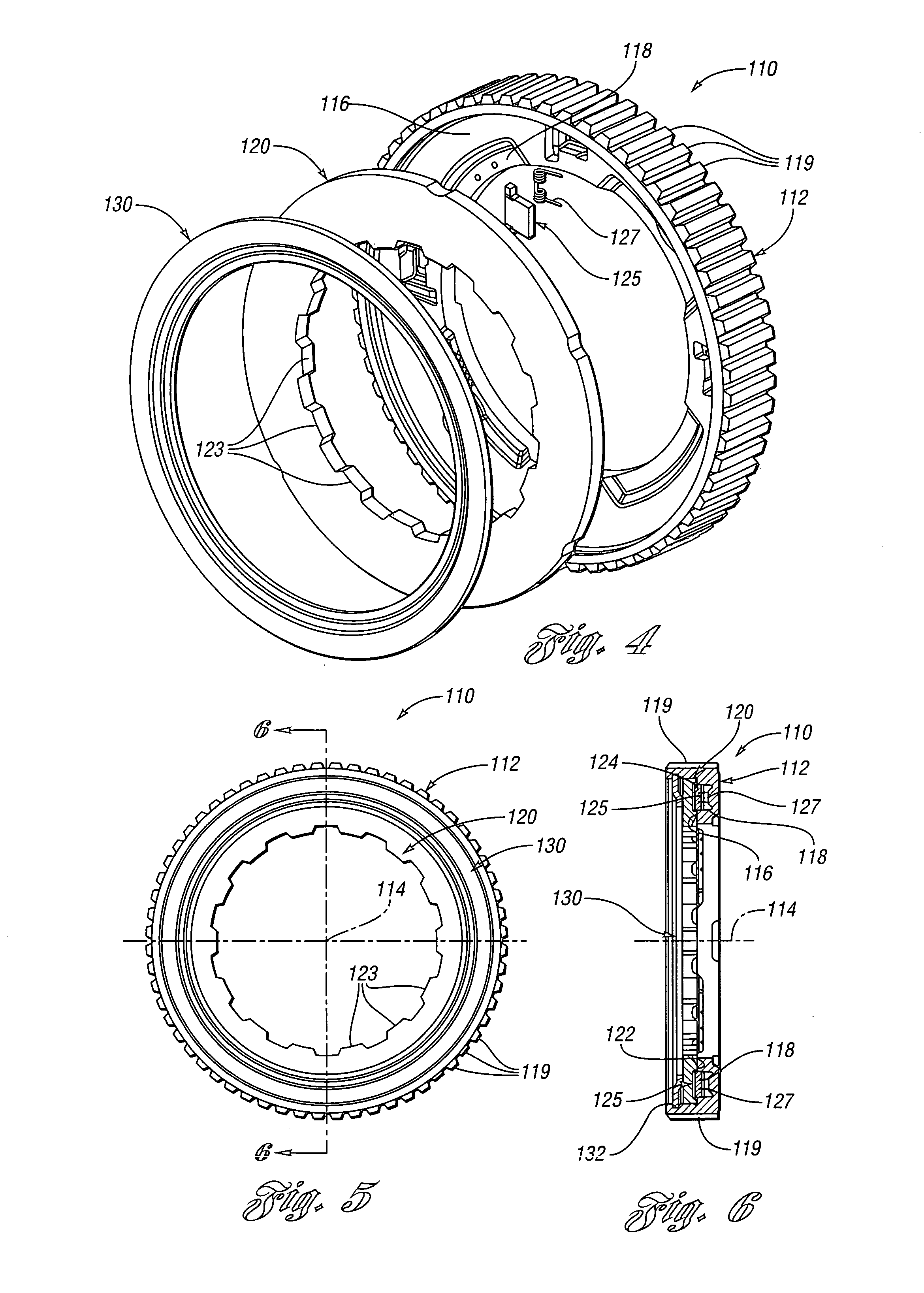

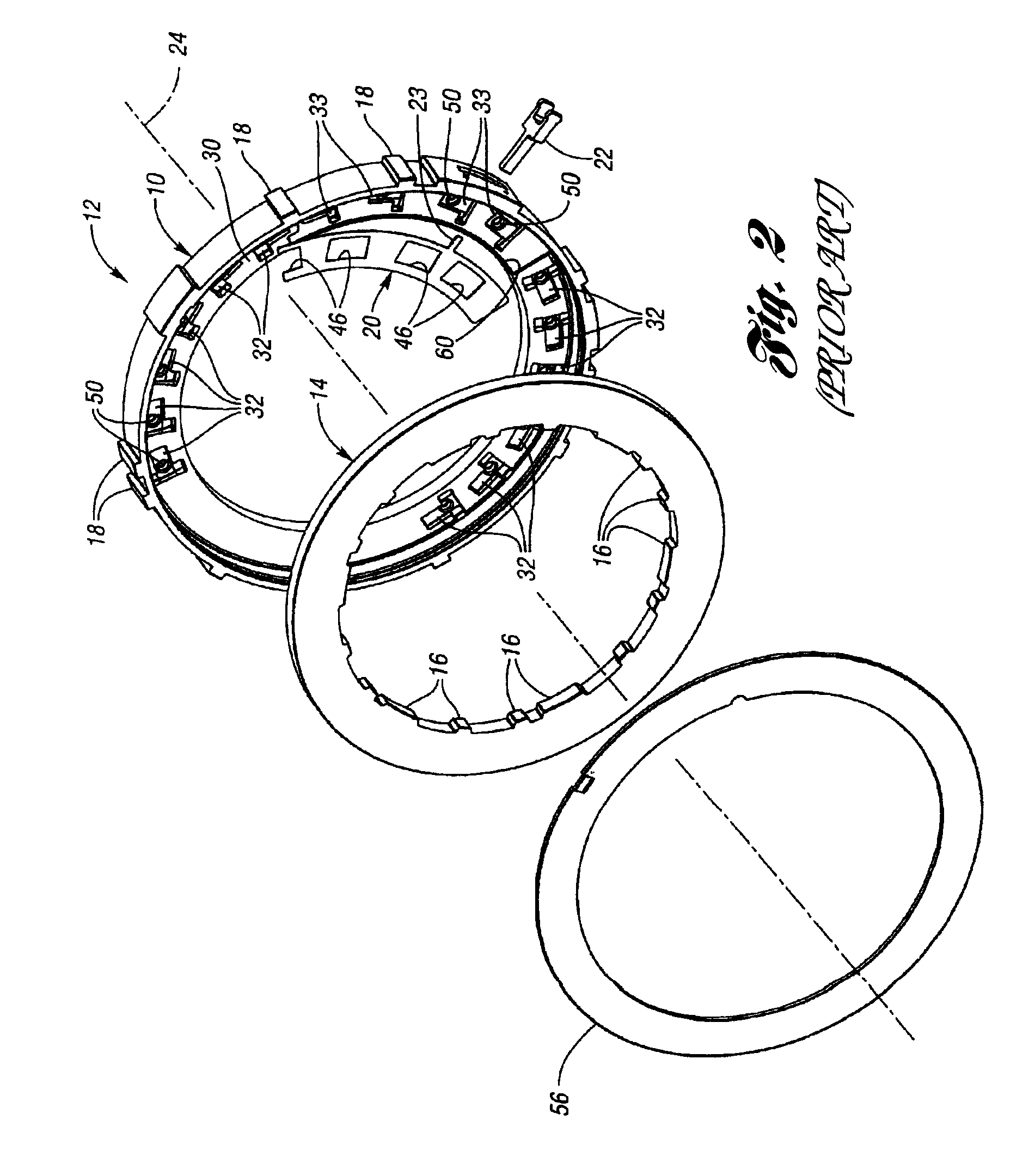

Overrunning coupling assembly having improved shift feel and/or noise reduction

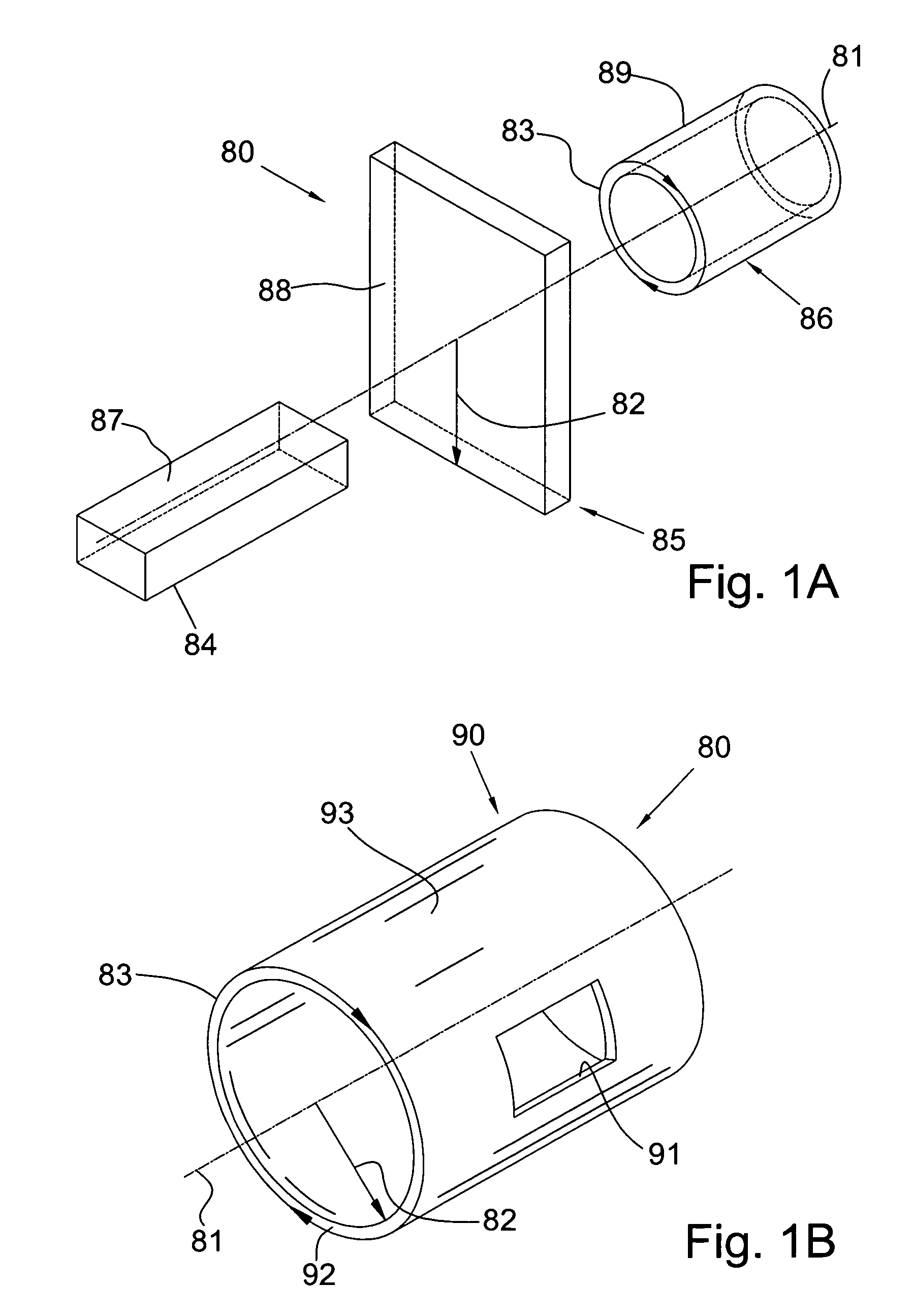

ActiveUS7275628B2Improved shift feel and noise reductionReduce axial forceRotating vibration suppressionFluid actuated clutchesWave shapeCoupling

An overrunning coupling assembly having improved shift feel and / or noise reduction is provided. The assembly includes planar first and second members rotatable about a first axis. In a locked position, torque transfer is permitted between the first and second members in a first direction about the first axis. In a disengaged position, the first and second members are permitted to free-wheel relative to each other in a second direction opposite the first direction. A compliant retaining device retains the first and second members together and absorbs axial impact loads. The retaining device is less compliant in the locked position than in the disengaged position to decrease axial force at time of axial impact and improve shift feel and / or noise reduction. In a first embodiment, the retaining device includes a wave spring. In a second embodiment, the retaining device includes a stepped weir plate.

Owner:MEANS IND INC

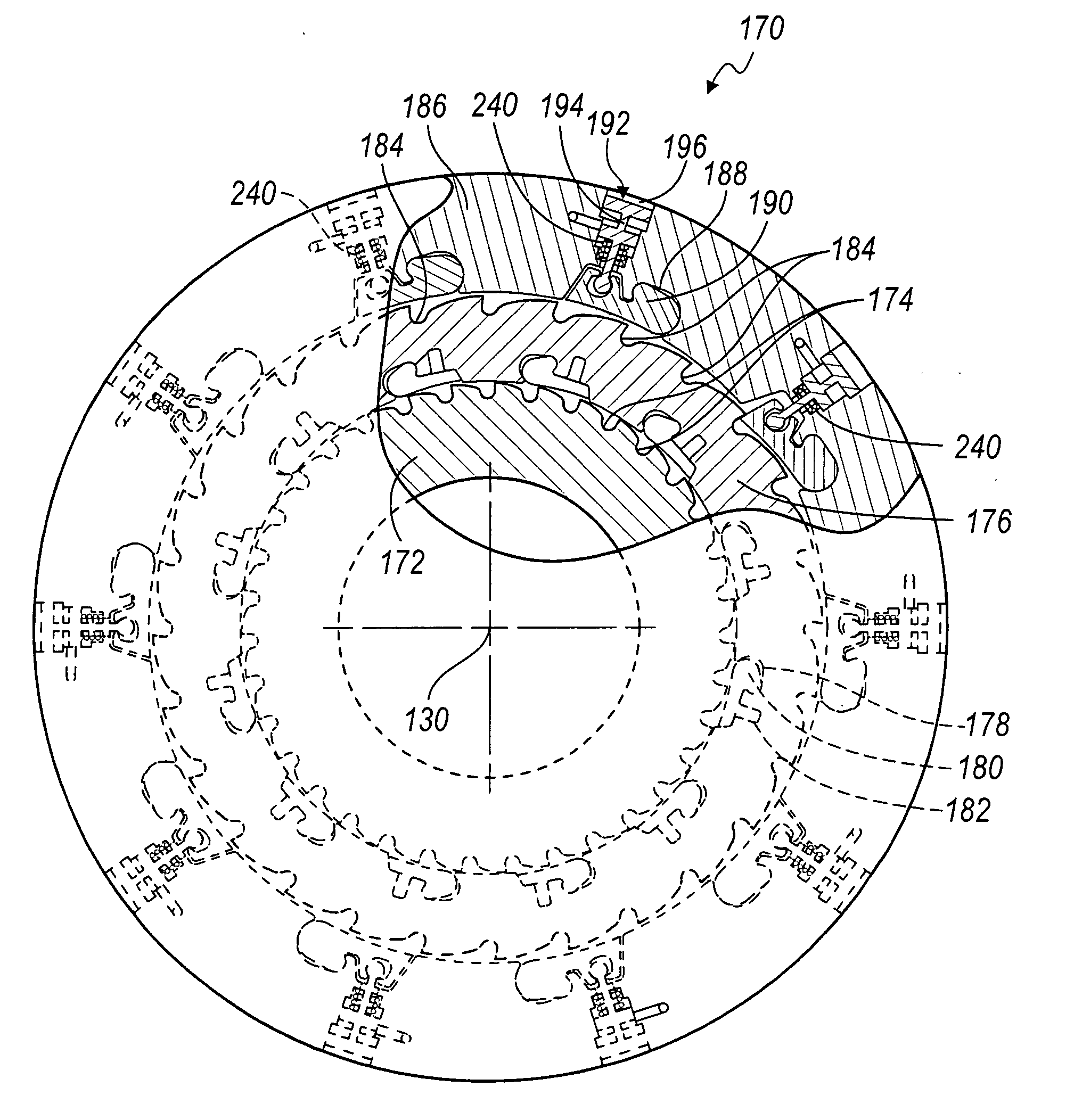

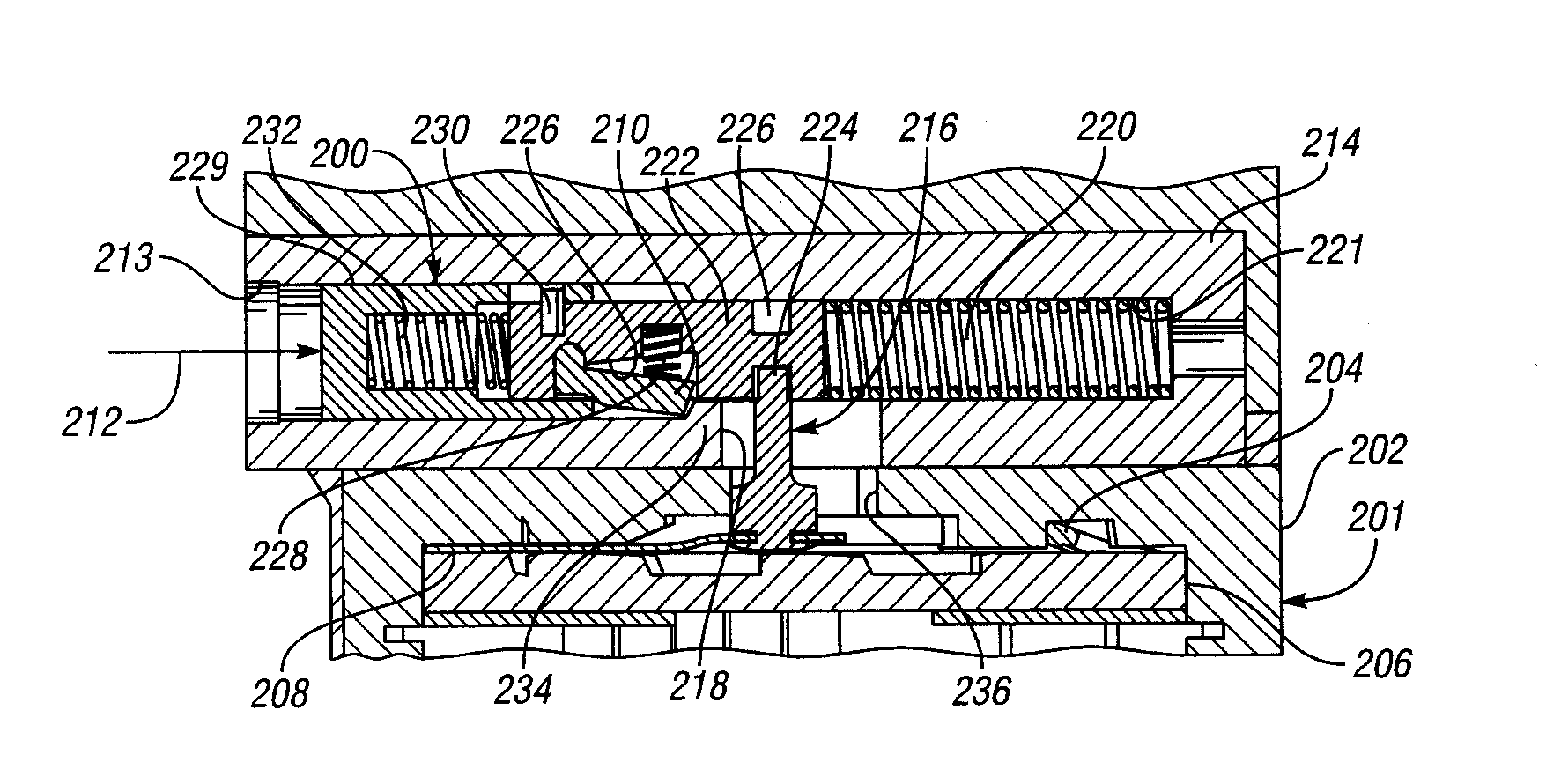

Overrunning coupling and control assembly including apparatus having a latching mechanism

ActiveUS20100200358A1Improved overrunning couplingLimitations is associated with assembliesFluid actuated clutchesFreewheel clutchesCouplingActuator

Overrunning coupling and control assemblies, each of which includes control apparatus having a latching mechanism are provided. Each latching mechanism prevents an actuator arm of an overrunning coupling assembly from moving in a first direction substantially parallel to a shift direction of a control plate of the coupling assembly within a housing slot in a locked condition of the mechanism in a first position of the control plate. A control pressure signal within a bore of the housing changes the condition of the latching mechanism from locked to unlocked to unlock the actuator arm and causes the unlocked actuator arm to move along the first direction within the slot and the control element to move along the shift direction to a second position. The control pressure signal also causes a piston which has a groove formed in its outer surface to receive and retain a free end portion of the actuator arm to slide within the bore in the housing against the biasing force of the at least one biasing member. In the absence of a control pressure signal, the at least one biasing member moves the piston and thereby the unlocked actuator arm in a second direction opposite the first direction within the slot and the control element along the shift direction from the second position back to the first position and changes the condition of the latching mechanism from unlocked to locked to lock the actuator arm.

Owner:MEANS IND INC

Multiple-clutch device

InactiveUS6523657B1Large massLarge heat capacityRoad transportFluid actuated clutchesMobile vehicleDrivetrain

The invention is directed to a multiple-clutch device, such as a double-clutch device, for arranging in a drivetrain of a motor vehicle between a drive unit and a transmission, wherein the clutch device has a first clutch arrangement associated with a first transmission input shaft of the transmission and a second clutch arrangement associated with a second transmission input shaft of the transmission for transmitting torque between the drive unit and the transmission. According to one aspect of the invention, it is suggested that plates in a plate stack of a clutch arrangement constructed as a plate clutch arrangement which have at least one friction facing can be brought into frictional engagement with plates having no friction facing, wherein at least one of the plates not having a friction facing is thicker in axial direction than friction facing carrying elements of adjacent plates having at least one friction facing. Alternatively or in addition, it is suggested that at least one plate which has at least one friction facing of sintered material and at least one plate which has at least one friction facing made of another friction facing material are provided in the plate stack, wherein the other friction facing material has a progressive frictional coefficient curve (dlambd / dDELTAN) in relation to a slip speed (DELTAN).

Owner:ZF FRIEDRICHSHAFEN AG +1

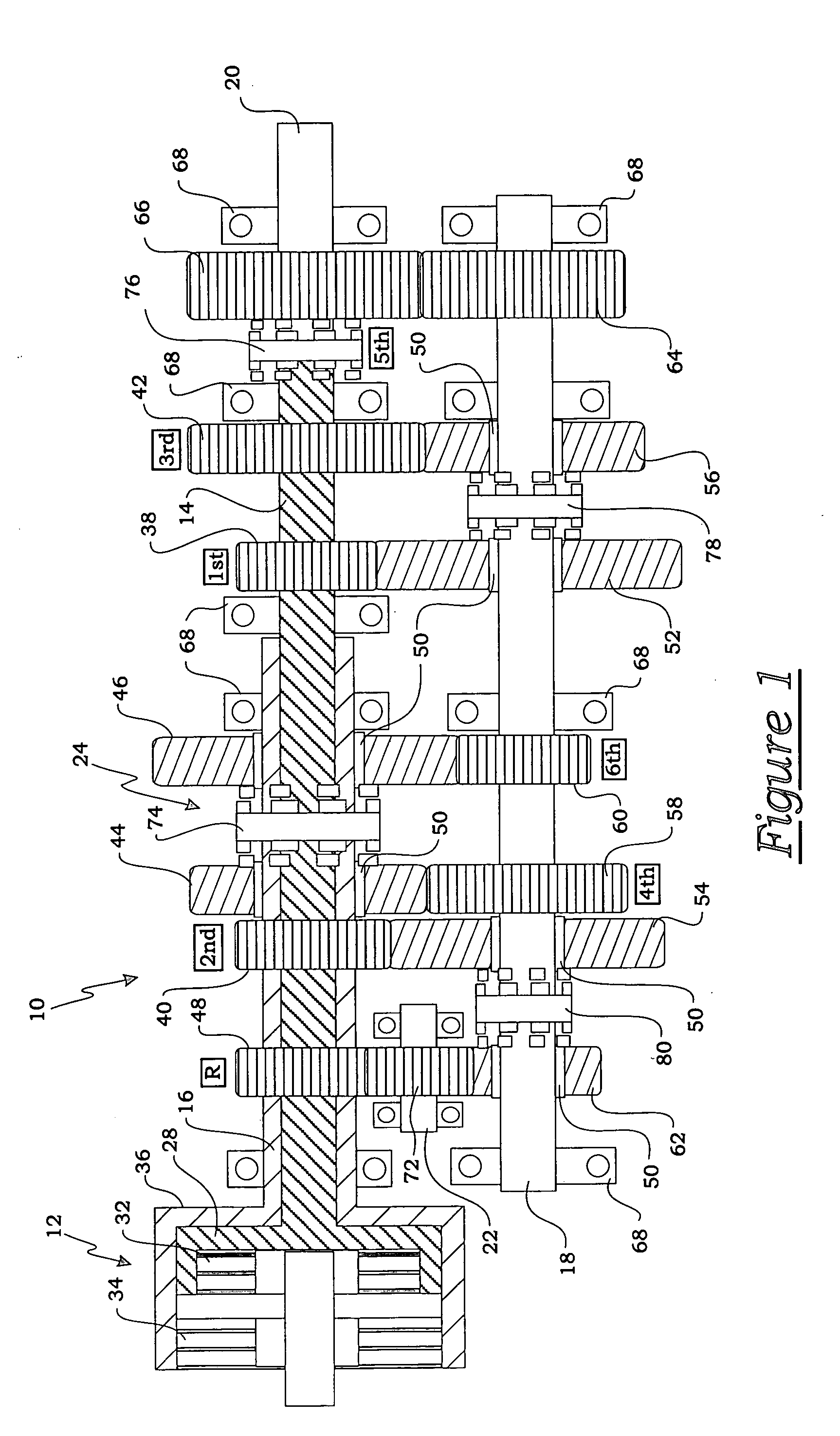

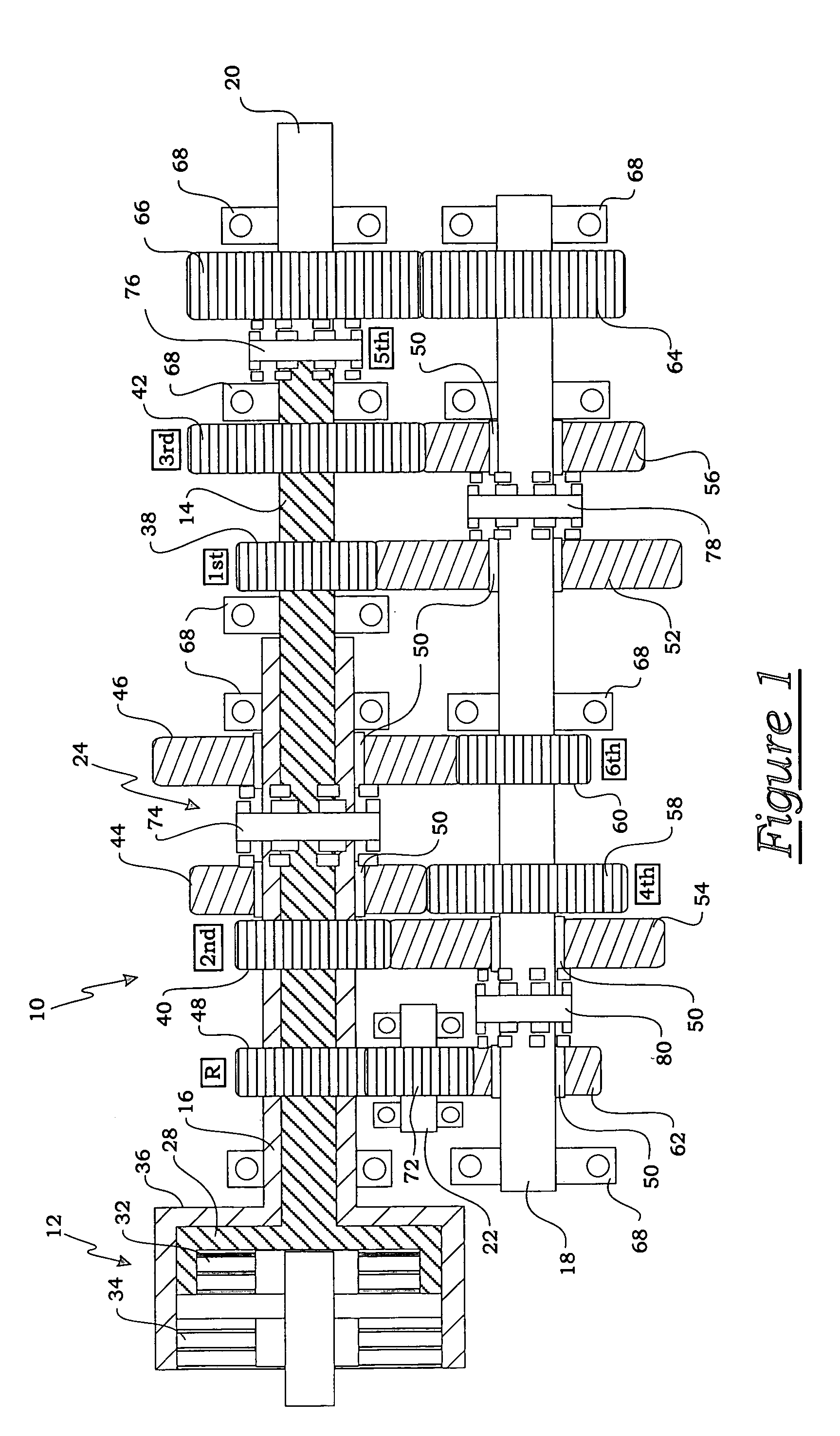

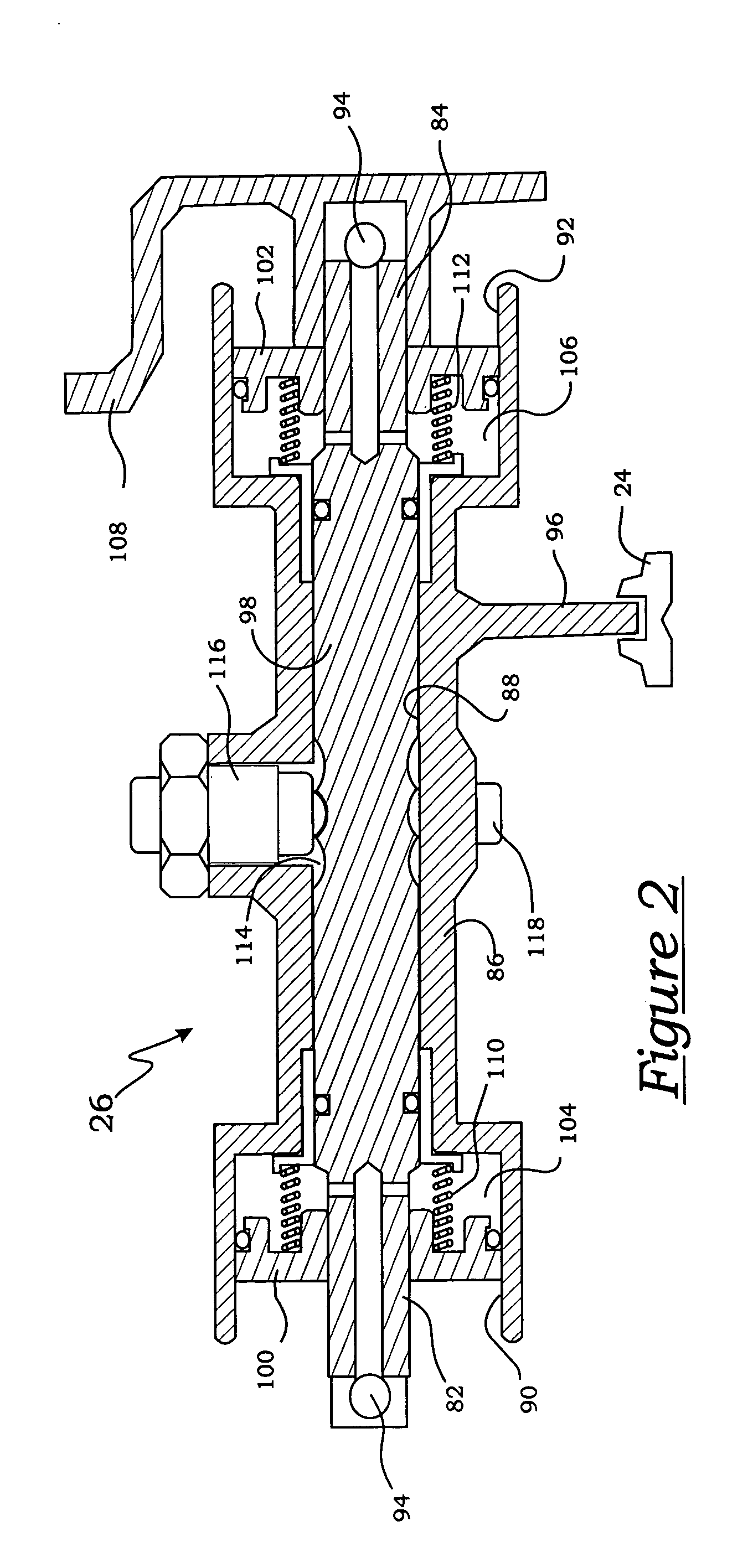

Method for controlling the positioning of the synchronizers of a dual clutch transmission

InactiveUS6883394B2Avoid adjustmentAccurate and consistent over operationMechanical actuated clutchesFluid actuated clutchesHysteresisActuator

A method of controlling the positioning of the synchronizers of a dual clutch transmission having a plurality of synchronizers to selectively engage and disengage various gears sets, and a plurality of shift actuators adapted to move the synchronizers. The method includes the steps of initiating a control routine to move a synchronizer to a full engagement position with a gear set and monitoring the positions of all engaged synchronizers. The method also includes reinitiating the control routine to move a synchronizer back into the full engagement position when any engaged synchronizer slips out to a minimum engagement position. Further, the method includes initiating a control routine to move a synchronizer to a neutral position and monitoring the position of all disengaged synchronizers. Also, reinitiating the control routine to move a synchronizer back to the neutral position when any disengaged synchronizer drifts beyond a pre-determined neutral hysteresis position.

Owner:BORGWARNER INC

Electromagnetic actuator, and electromagnetic clutch and differential using the same

ActiveUS20050279607A1Inhibit heat generationSuppress power consumptionMechanical actuated clutchesFluid actuated clutchesElectromagnetic clutchEngineering

The electromagnetic actuator includes an electromagnetic coil configured to provide actuation force in accordance with a solenoid current to be supplied, to a clutch and configured to actuate the clutch to control relative rotation between first and second members. The electromagnetic actuator includes a detector configured to detect the clutch actuated to produce a detection signal. The electromagnetic actuator includes a controller configured to respond to the detection signal from the detector to control the solenoid current.

Owner:TOCHIGI FUJI IND CO LTD

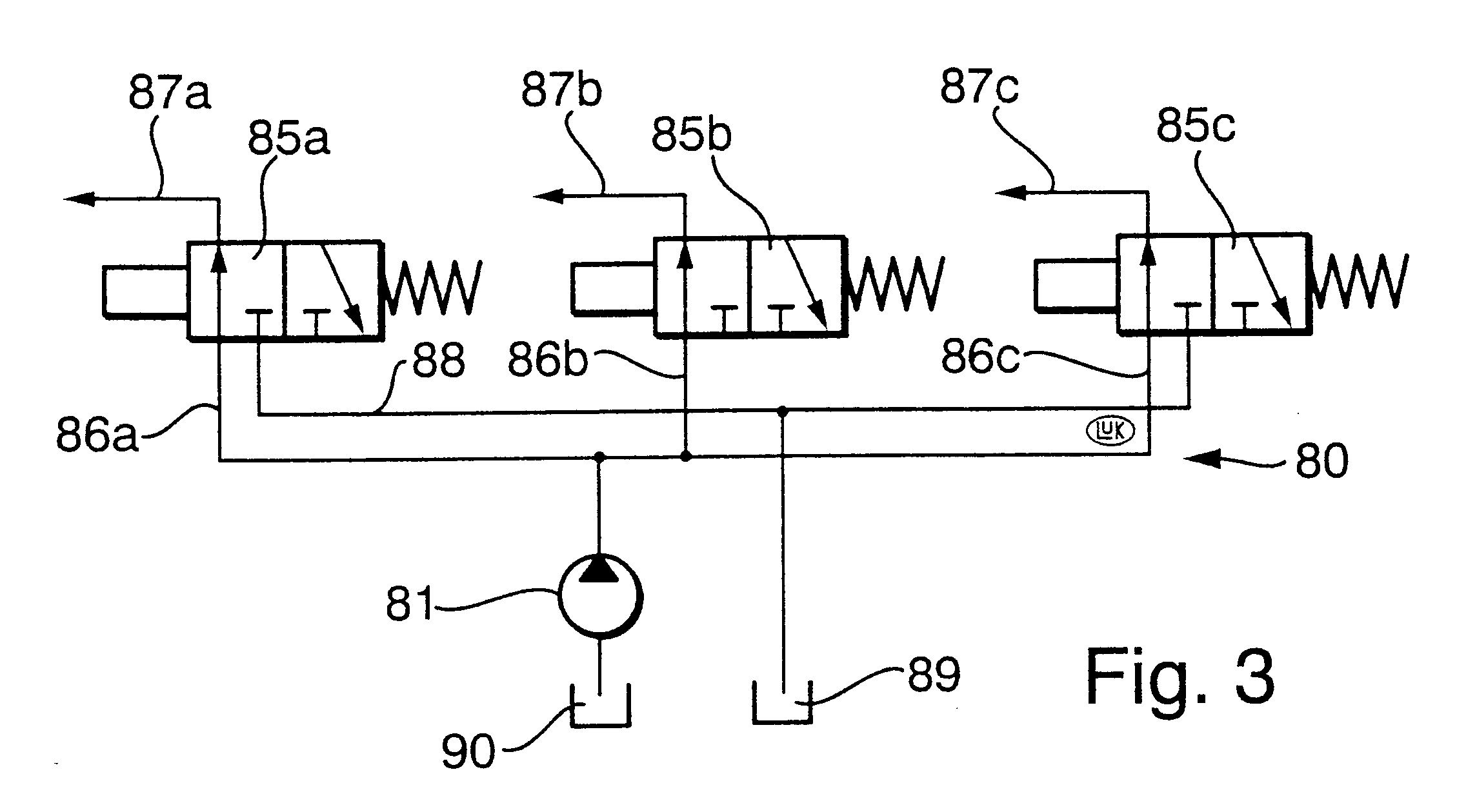

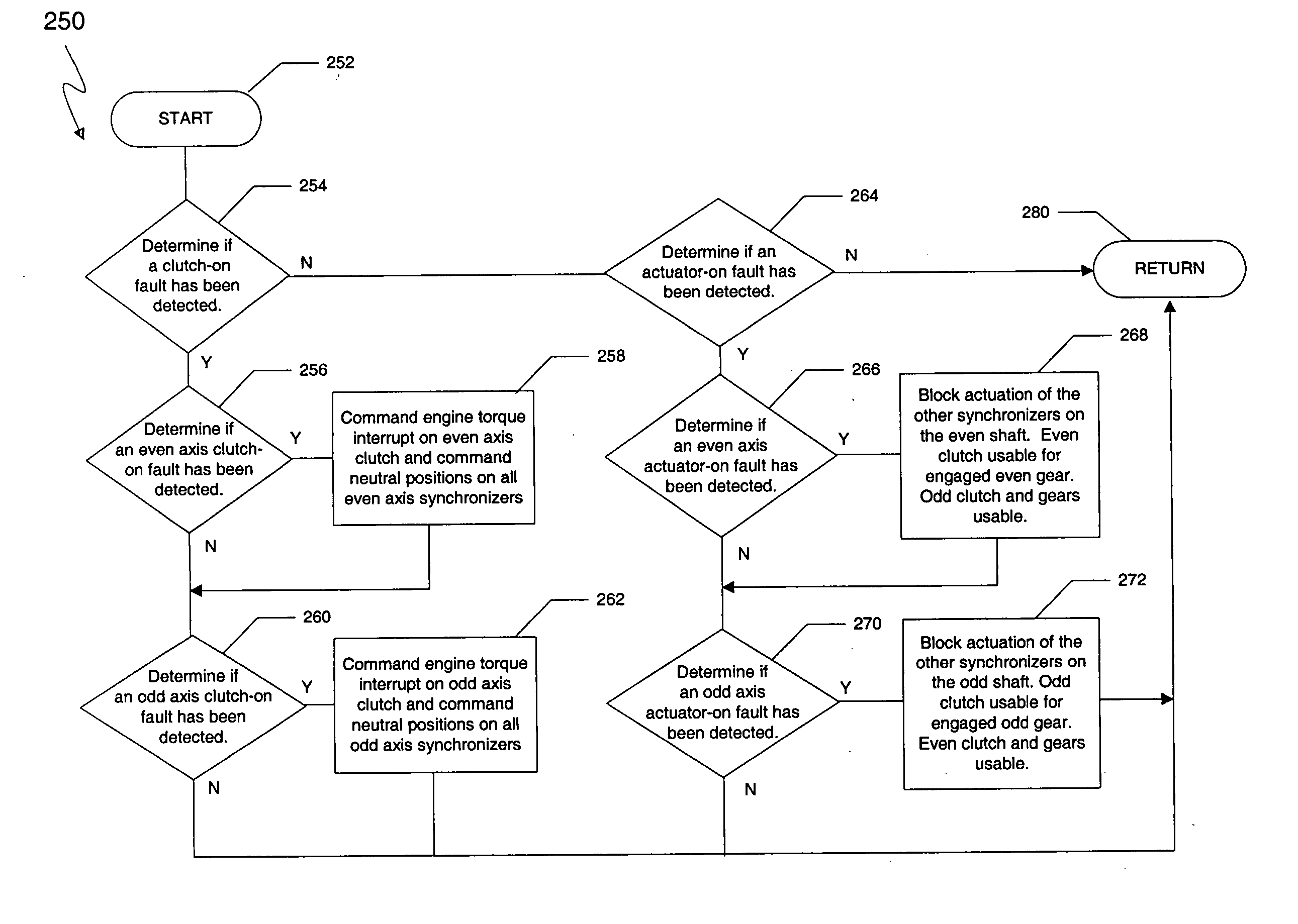

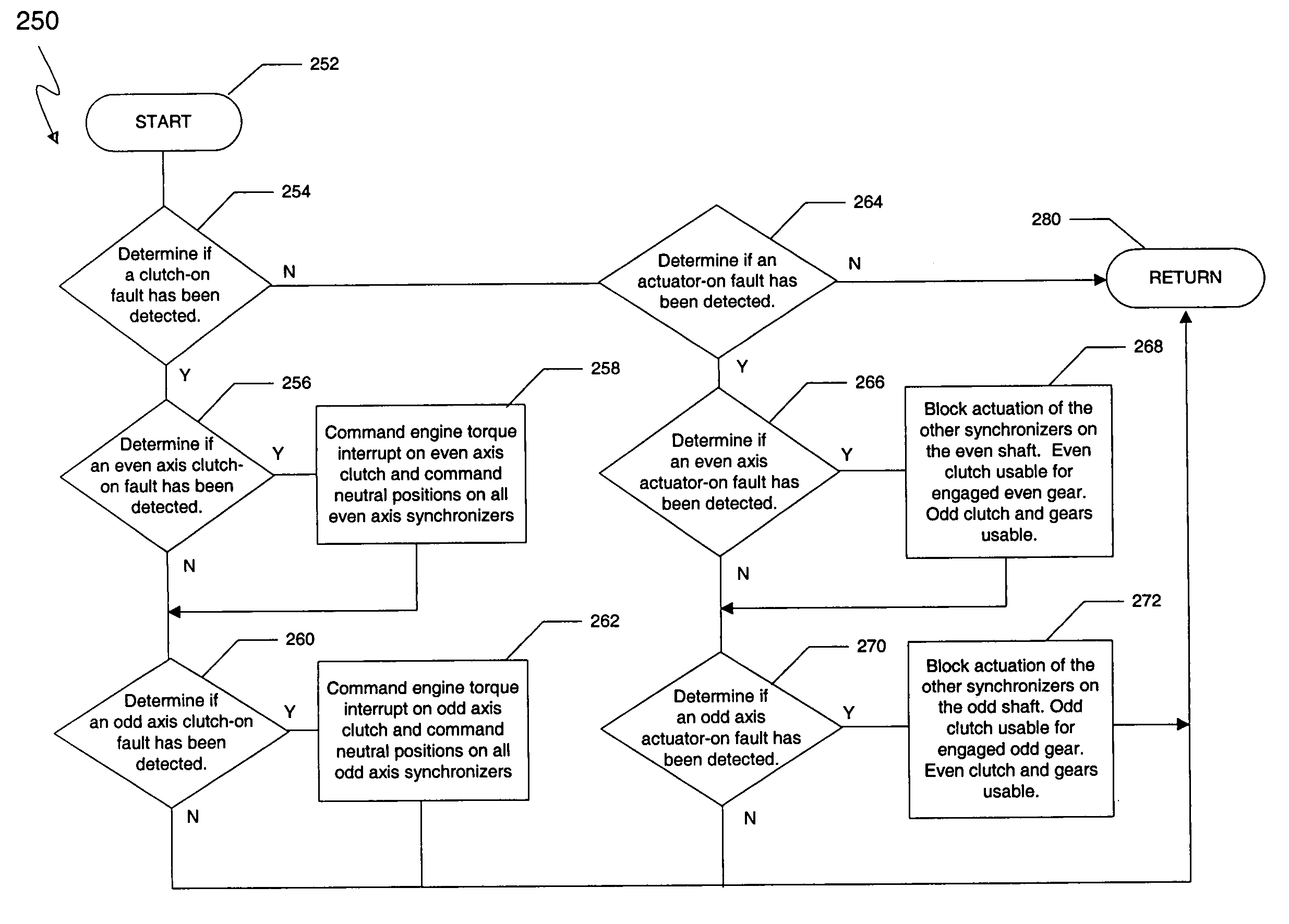

Method for controlling a dual clutch transmission

ActiveUS20050107214A1Reduce complexityReduce in quantityFluid actuated clutchesToothed gearingsEngineeringActuator

A method of controlling the hydraulic actuation of the clutches and the synchronizers in a dual clutch transmission in the event of a clutch or synchronizer fault. The method includes the steps of determining which clutch is faulted when a clutch-on fault is detected, then commanding an interruption of engine torque to the faulted clutch and a neutralization of all synchronizers of the same axis shaft as the faulted clutch. The method further senses if a synchronizer actuator-on fault has occurred, then determines which synchronizer is faulted if an actuator-on fault has is detected. The method steps further include preventing the further actuation of the other synchronizers on the same axis shaft as the faulted actuator.

Owner:BORGWARNER INC

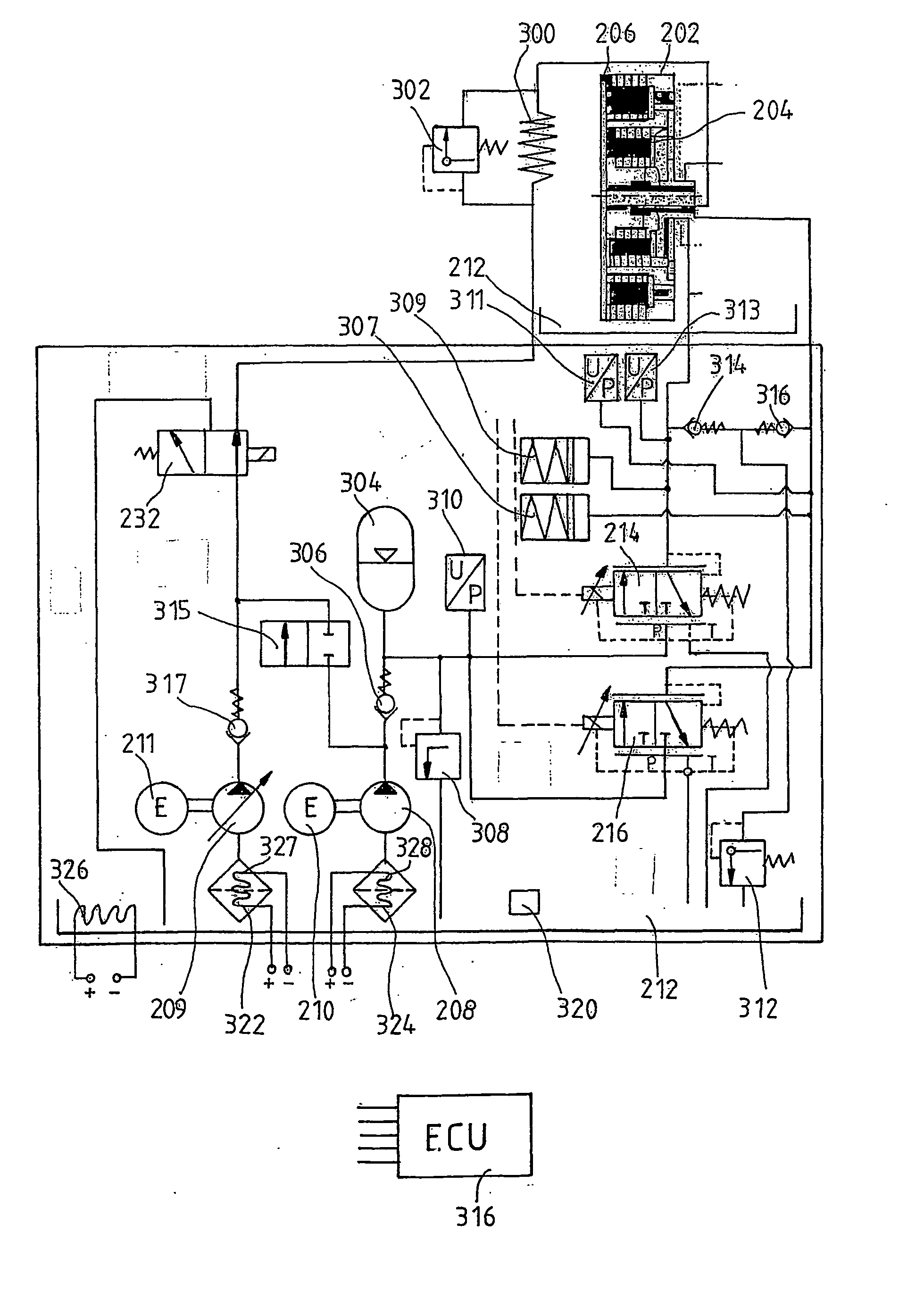

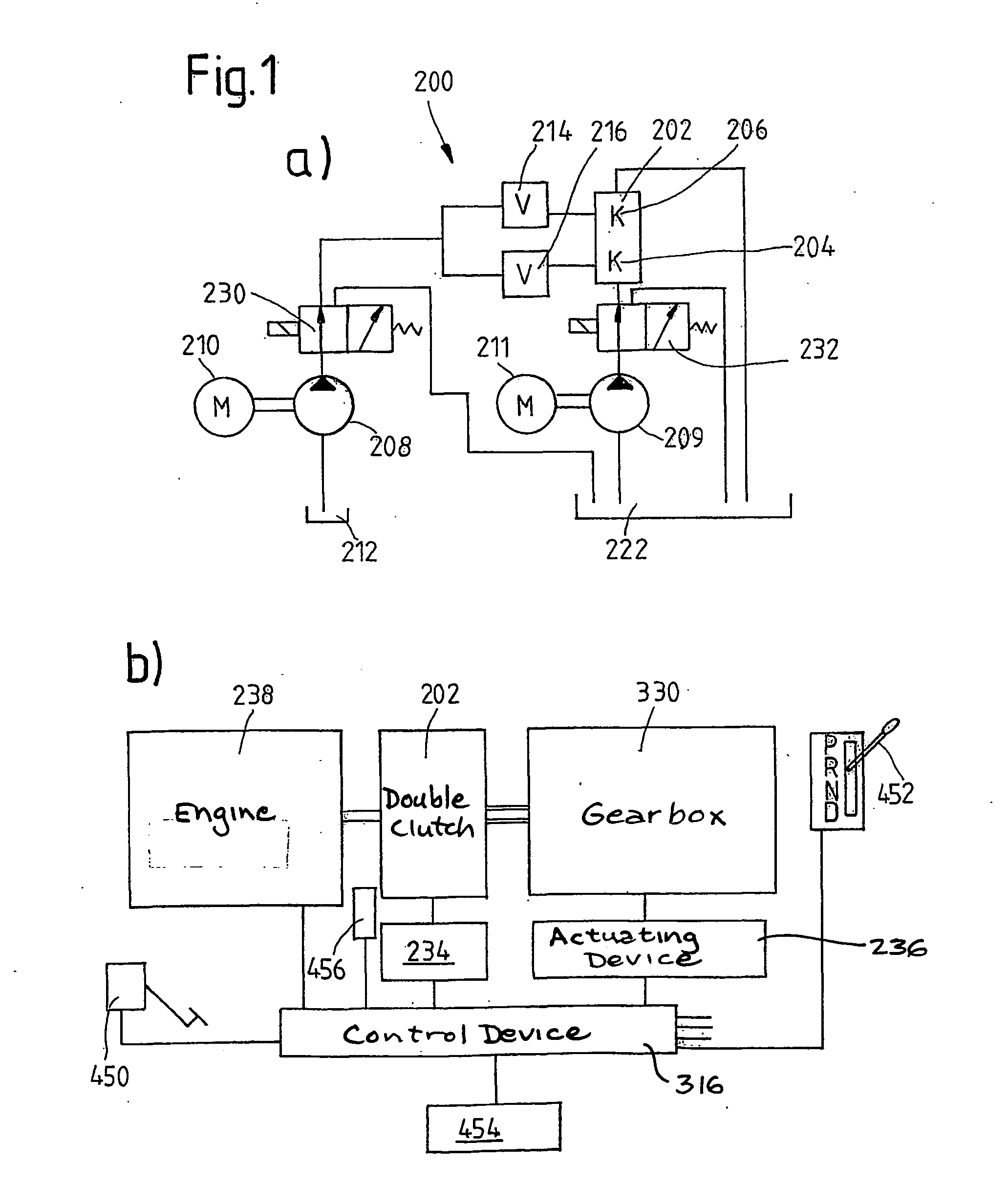

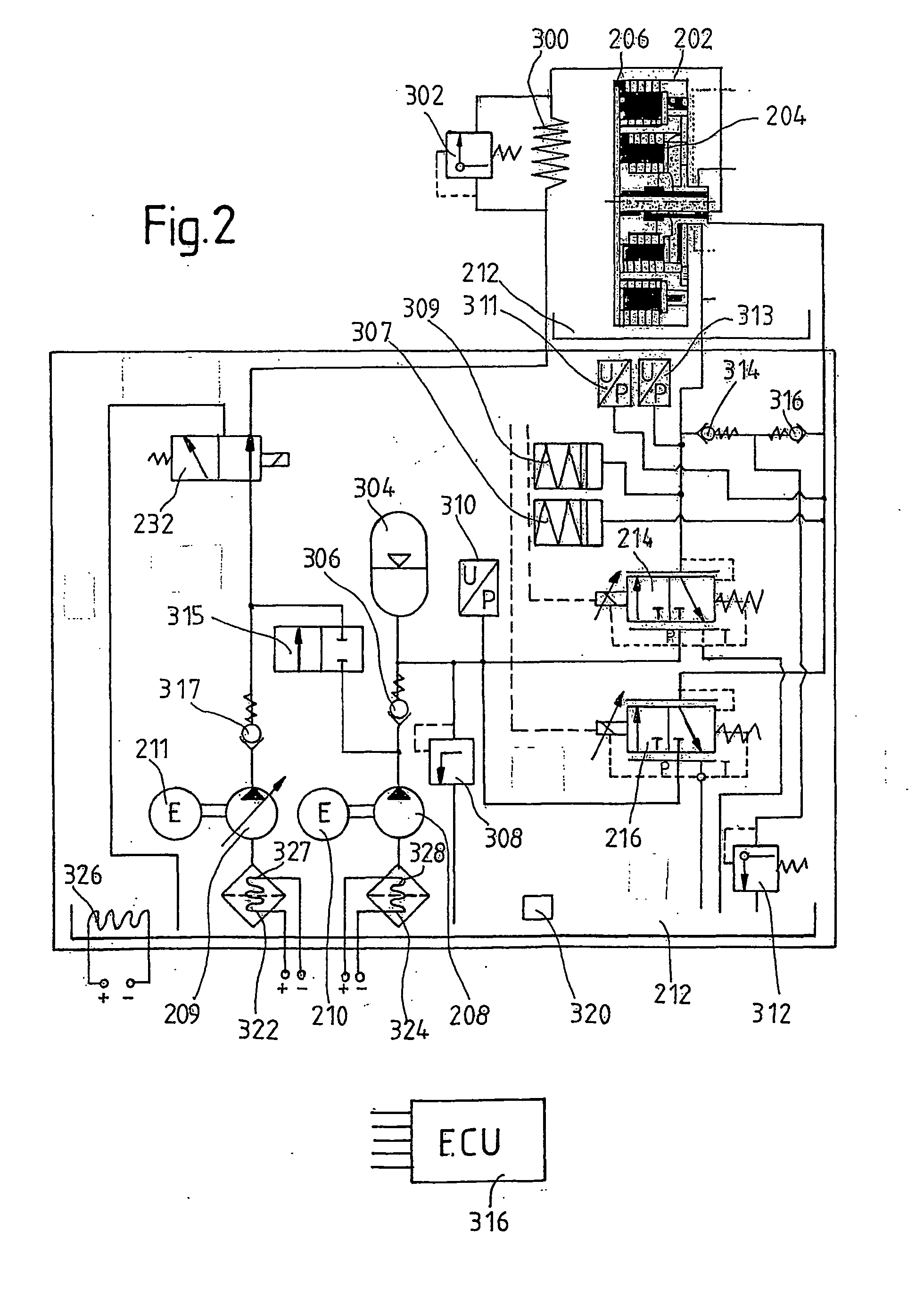

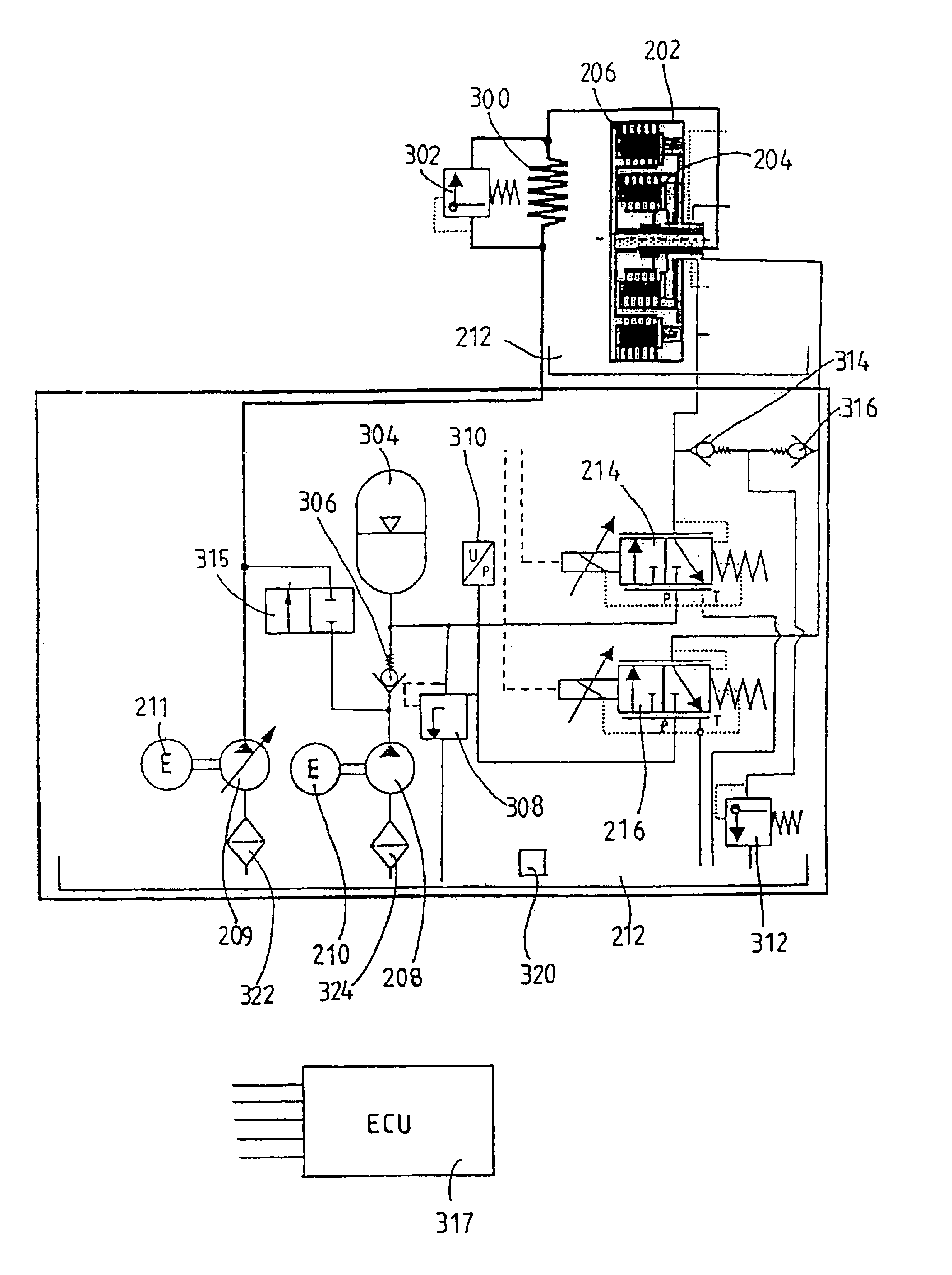

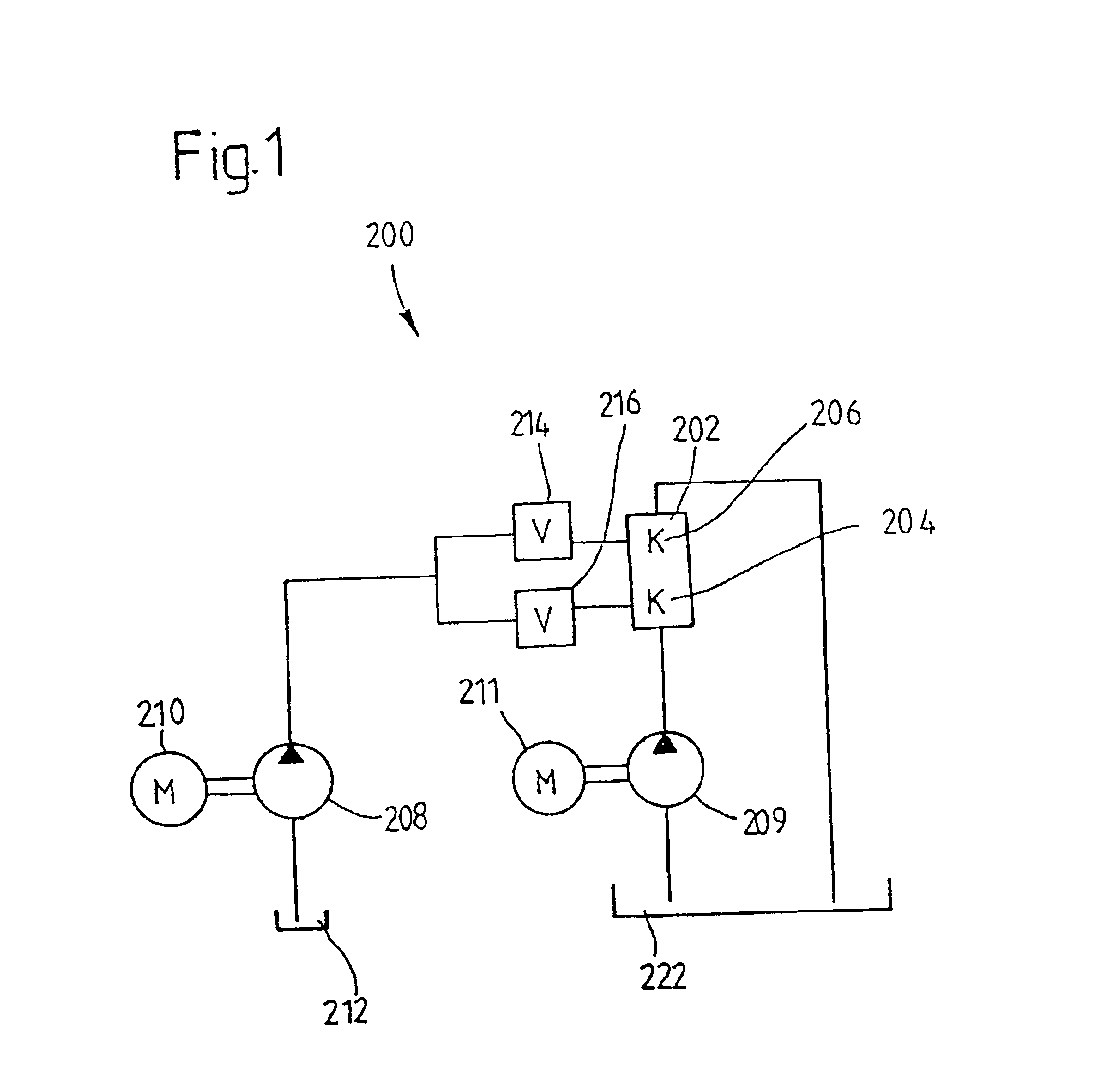

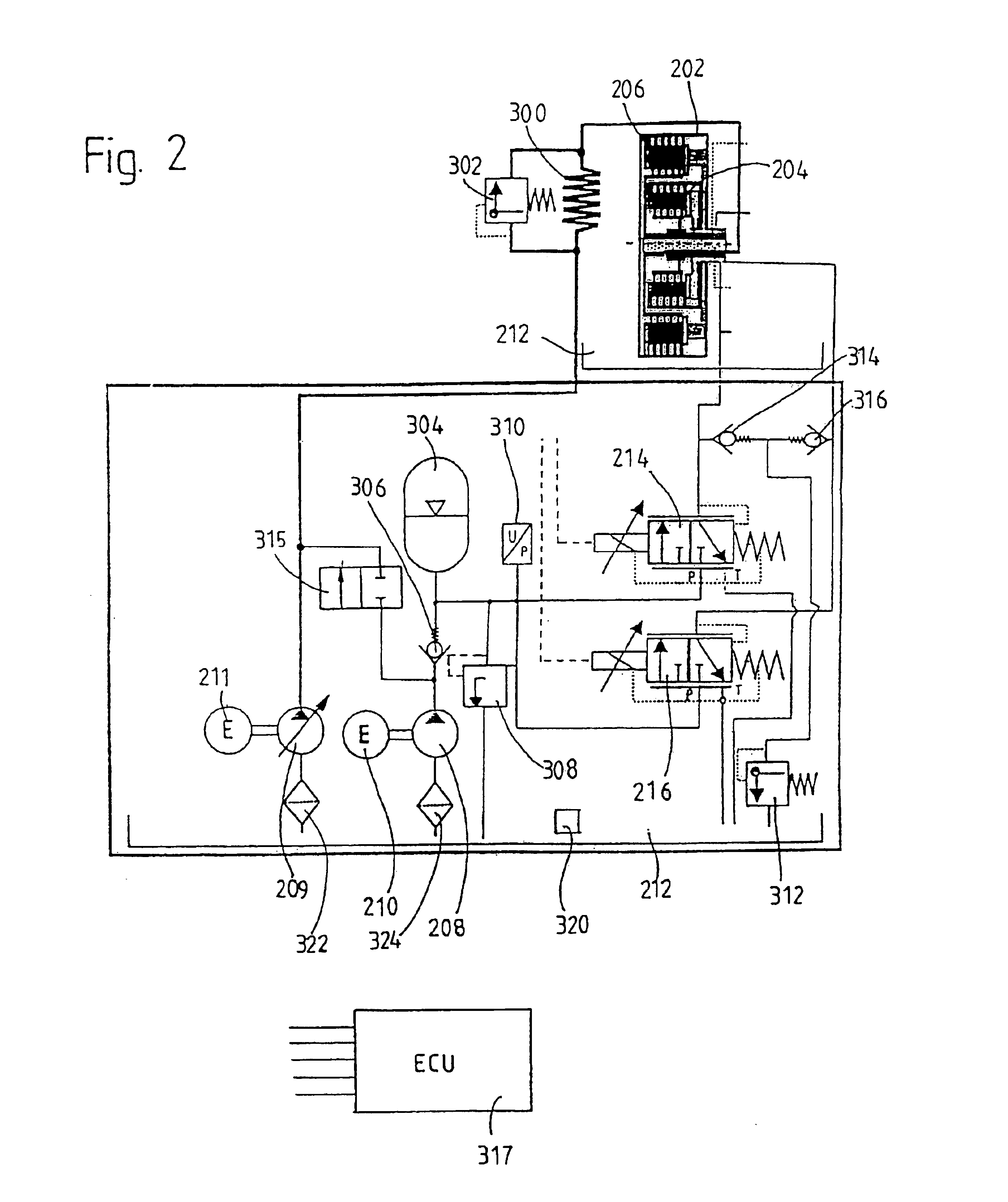

Motor vehicle comprising a drive train having a multiple clutch drive

InactiveUS20040112171A1Easy to participateIncrease engine speedGear lubrication/coolingVehicle sub-unit featuresWorking fluidGear wheel

The invention relates to measures for controlling or reducing drag torque occurring in a multi-plate clutch device (202) due to temperature-related increased viscosity of an operating fluid which is supplied to the plates in operation. The aim of the invention is to enable a motor vehicle to be started or operated even at low temperatures. According to one aspect of the invention, a motor vehicle comprising a drive train is especially provided. Said drive train comprises a drive unit (238), gearbox (330) having a first gearbox input shaft and a second gearbox input shaft, and a clutch (202) having a first clutch device which is associated with the first gearbox input shaft, and a second clutch device which is associated with the second gearbox input shaft, for transferring torque between the drive unit and the gearbox. Said clutch devices are embodied in the form of plate clutches to which an operating fluid can be supplied, especially a cooling oil in order to operate the same. Said gearbox (330) is associated with an actuator device and a control device (316) for controlling the actuator device, the arrangement of which enables the gears associated with the first and second gearbox input shafts to be engaged and disengaged. According to the invention, the control device (316) is designed in such a way that at least one gear is automatically engaged by means of the actuator device (236), as a result of the clutch release of the vehicle.

Owner:VOLKSWAGEN AG +1

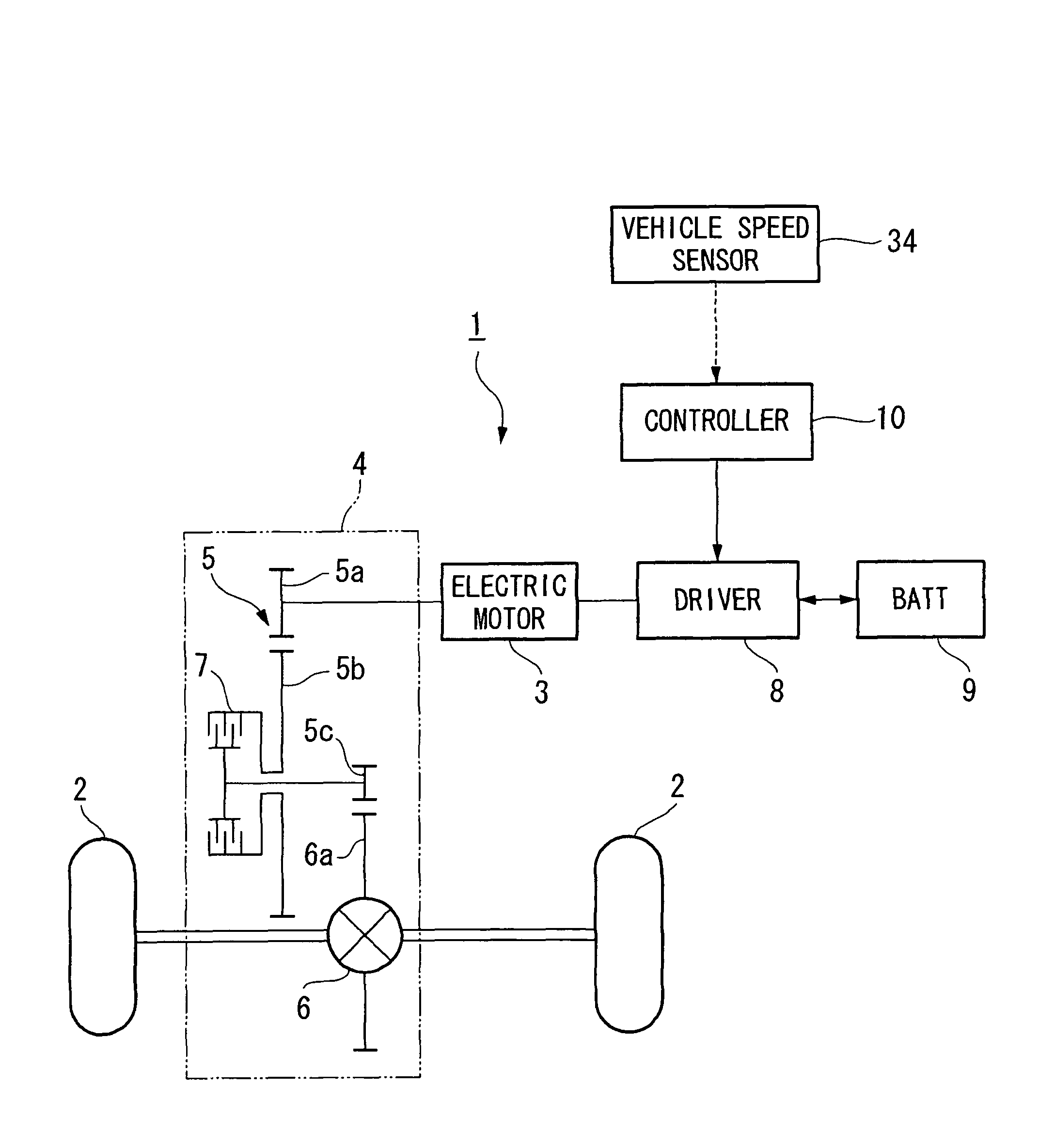

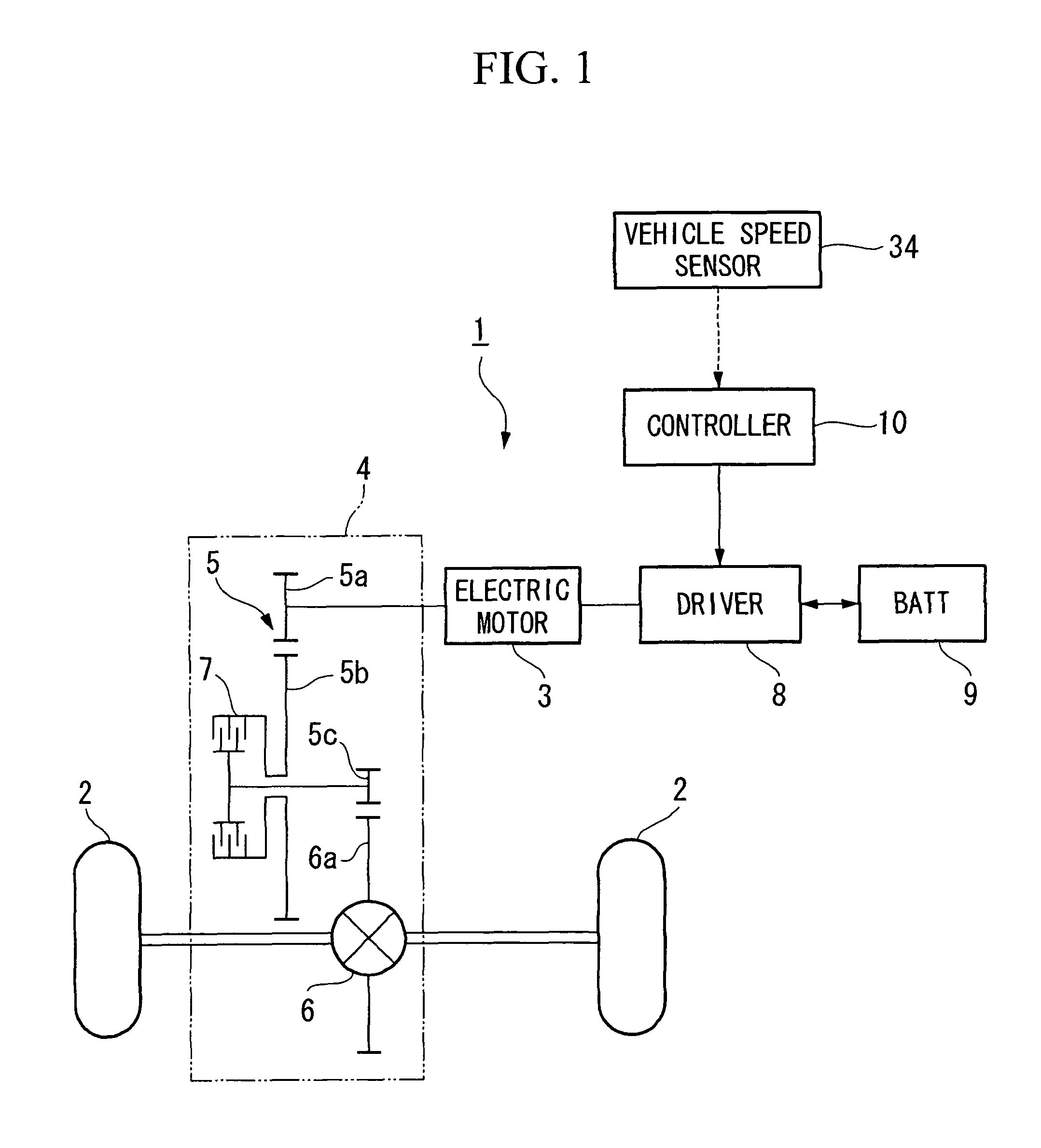

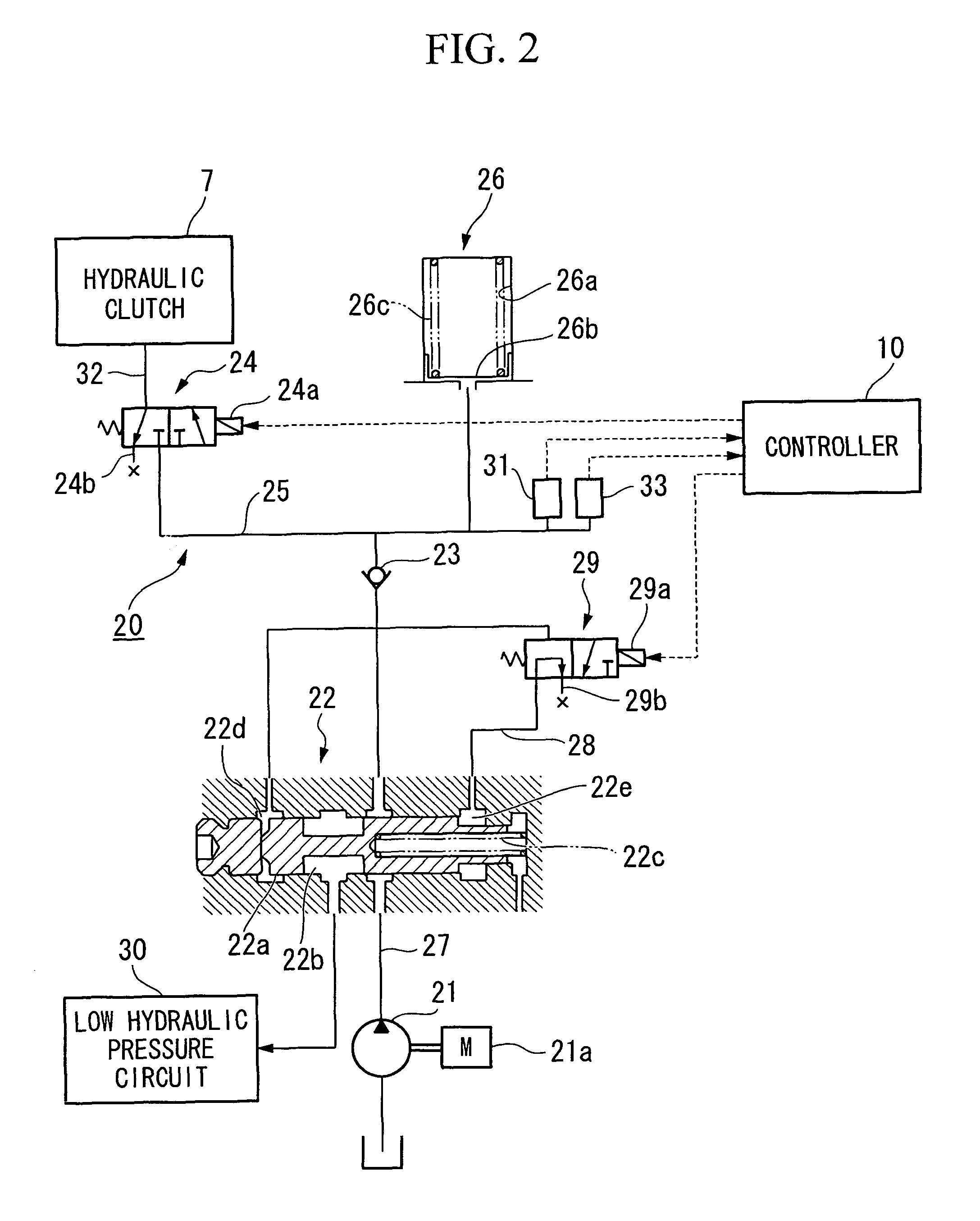

Control unit for an electric oil pump

InactiveUS7909729B2Reduce power consumptionReduce operating frequencyGearingFluid actuated clutchesFluid supplyControl unit

A control unit for an electric oil pump of the present invention includes: a one-way valve that permits circulation of operating fluid from the electric oil pump to the friction engagement device and blocks circulation in the opposite direction; an accumulator that is connected to a fluid supply path joining the one-way valve to the friction engagement device and accumulates hydraulic pressure required for operating the friction engagement device; a hydraulic pressure measuring device that measures hydraulic pressure inside the fluid supply path; a vehicle speed measuring device that measures a vehicle speed of the vehicle; and a pressure setting device that sets a first predetermined pressure based on the vehicle speed measured by the vehicle speed measuring device.

Owner:HONDA MOTOR CO LTD

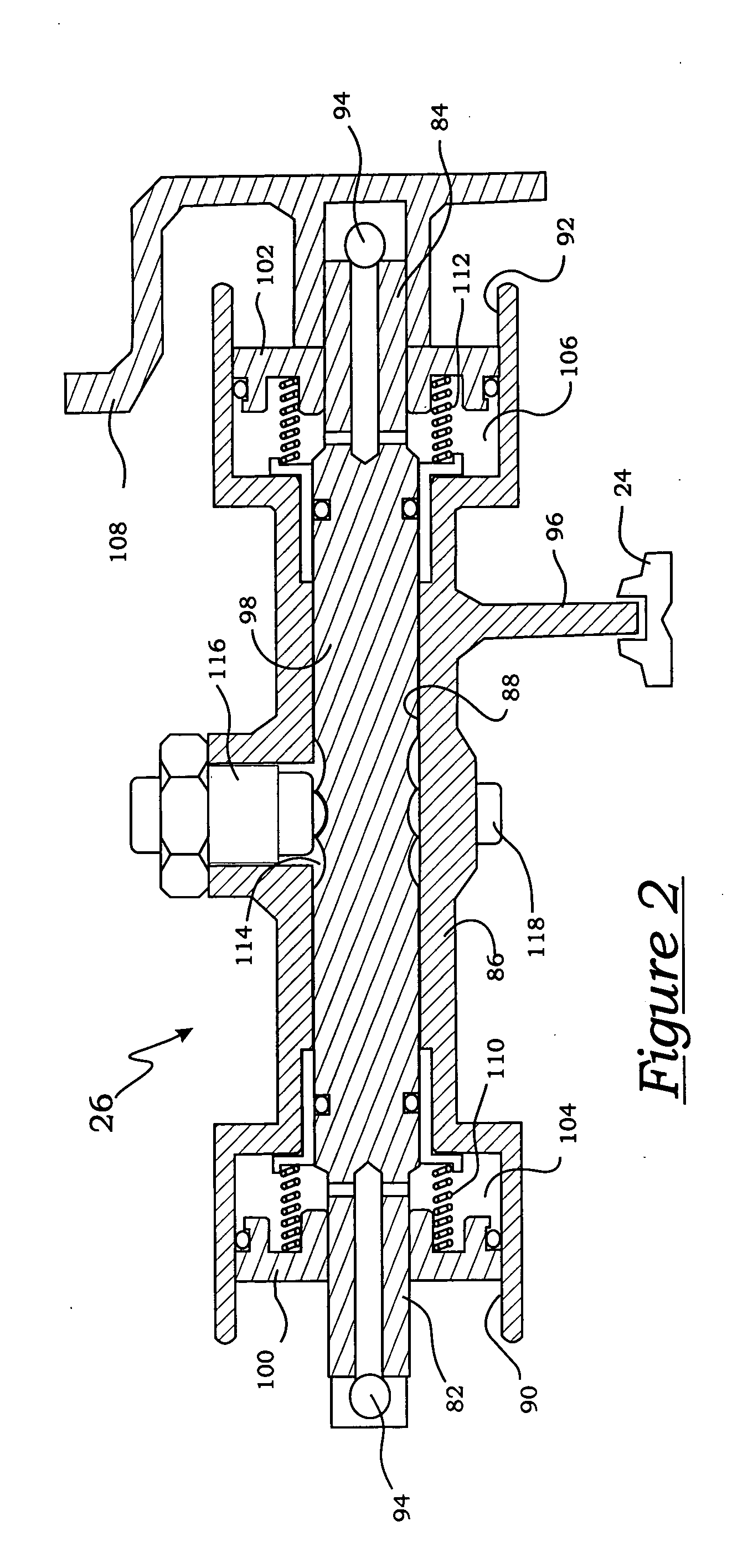

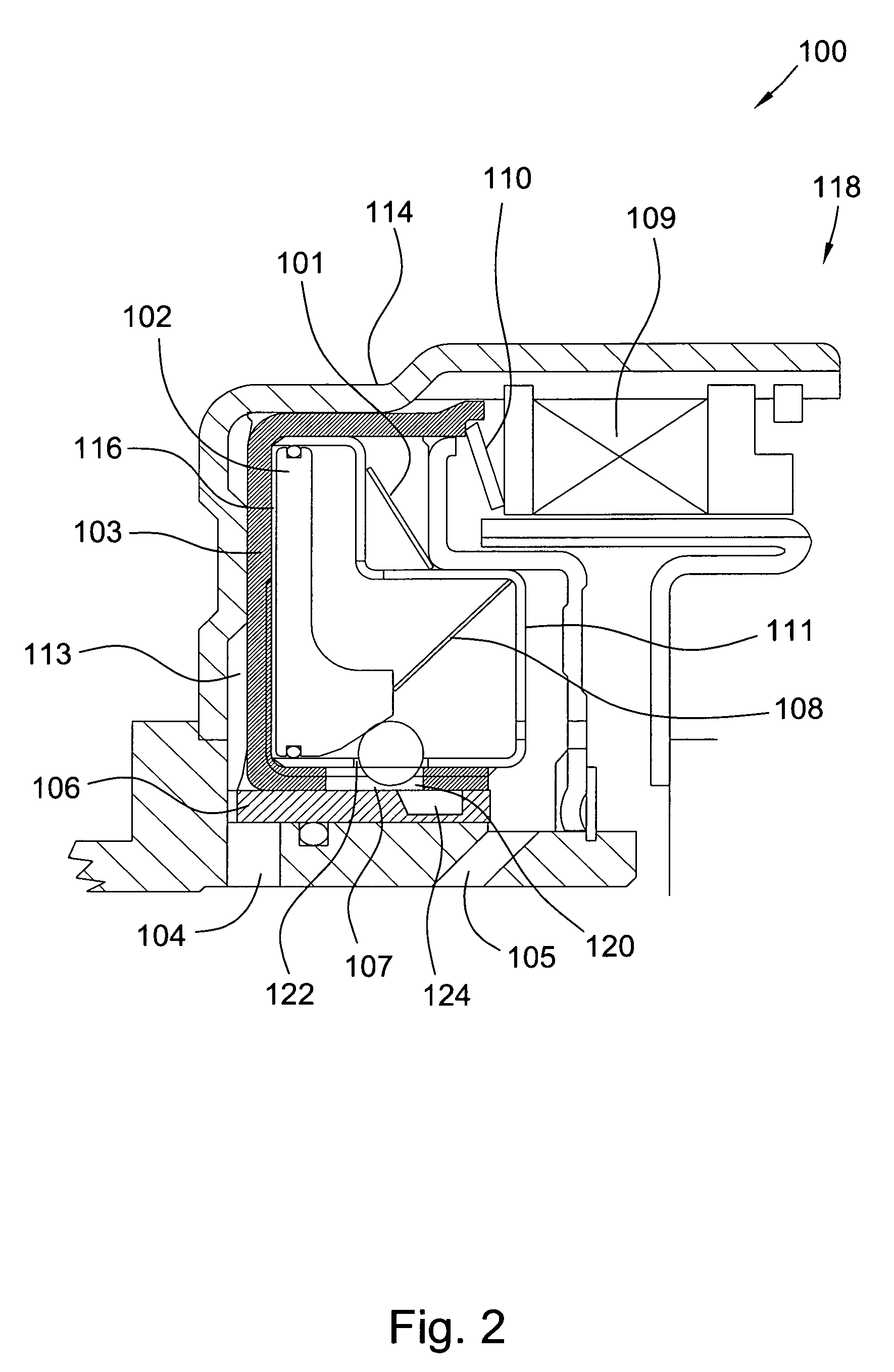

Clutch and brake latch mechanism

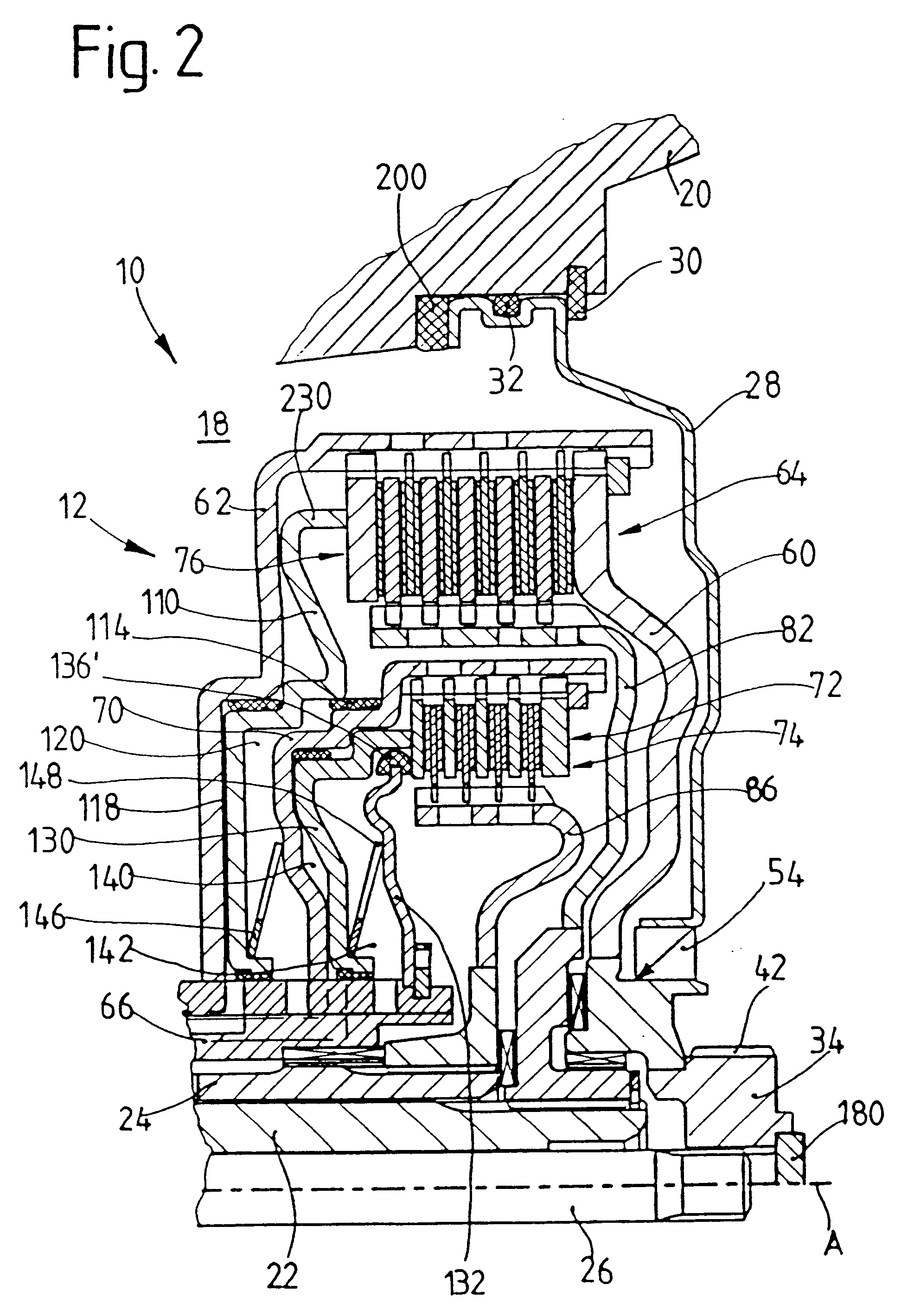

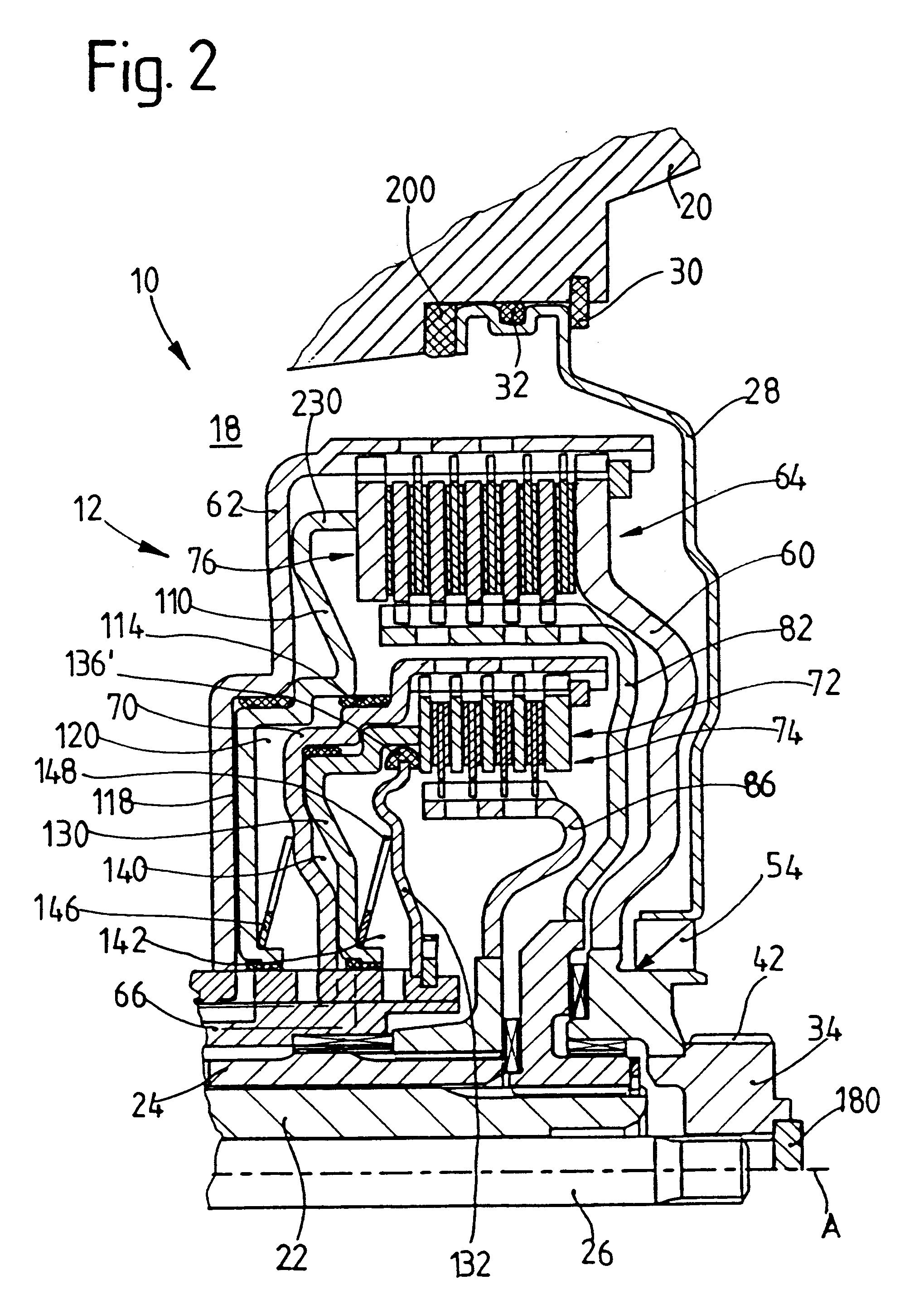

A clutch including: a first piston displaceable to operate a clutch pack; a second piston; a first fluid chamber partially formed by the pistons, wherein the second piston is displaceable by fluid pressure in the first fluid chamber; and a locking means fixable by the second piston to hold the pack closed. In a preferred embodiment, the locking means includes at least one displaceable ball. In another preferred embodiment, in response to a loss of fluid pressure in the first chamber, the second piston is displaceable to enable displacement of the locking means to open the pack. In a further preferred embodiment, the clutch includes a second chamber, separate from the first chamber and partially formed by the first piston. The first piston is displaceable in response to fluid pressure in the second chamber. The pack remains closed after a loss or reduction of fluid pressure in the second chamber.

Owner:SCHAEFFLER TECH AG & CO KG

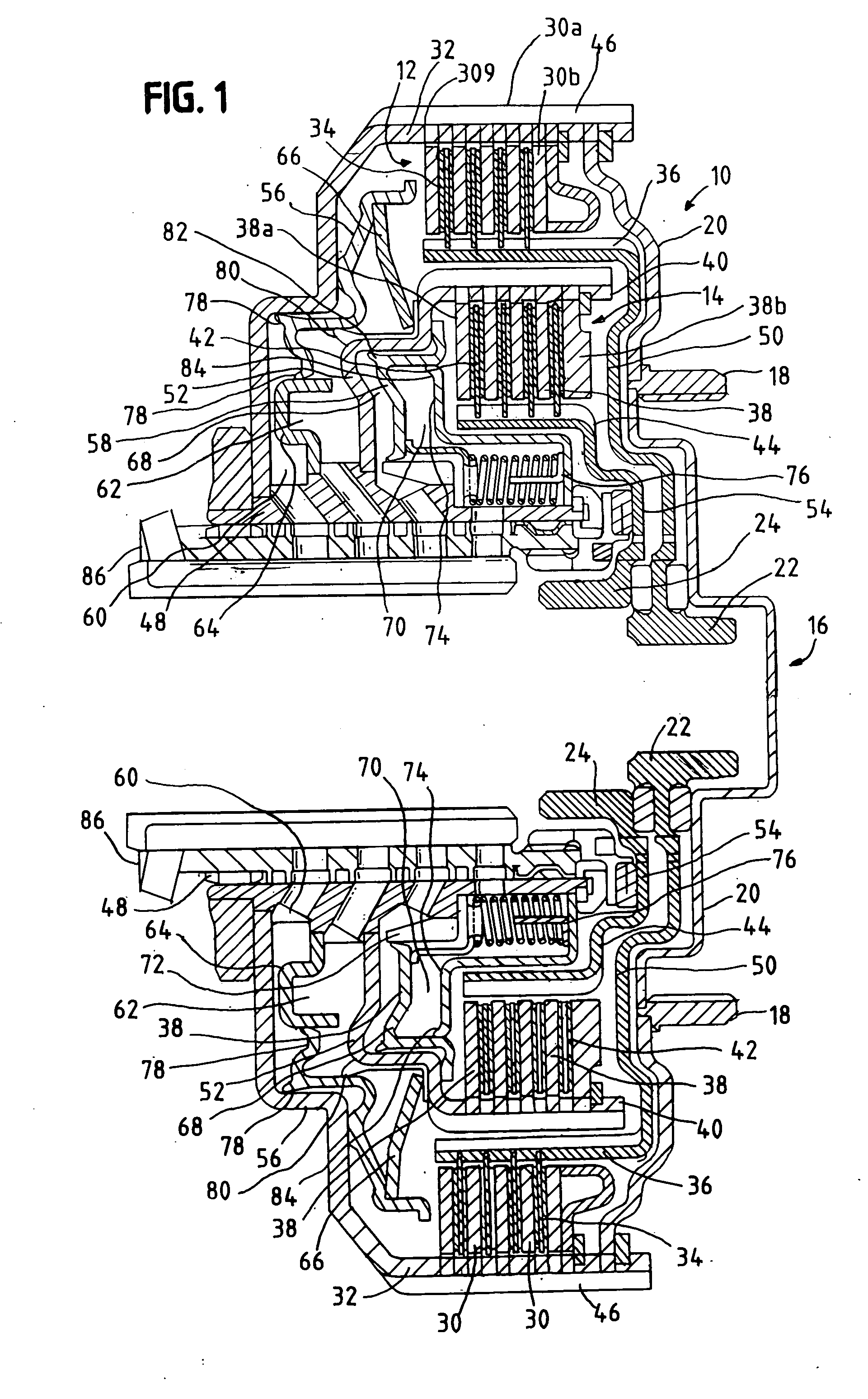

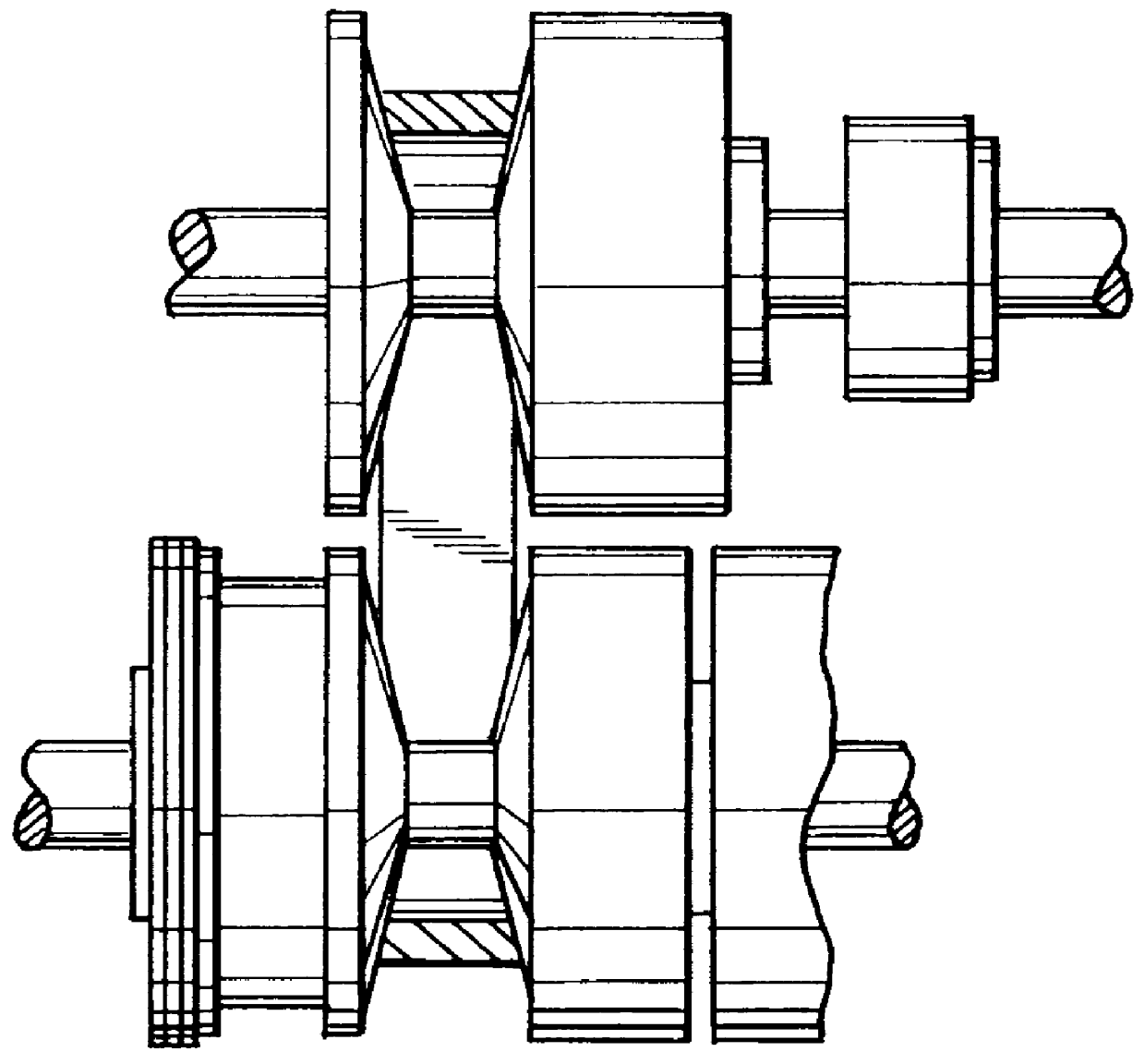

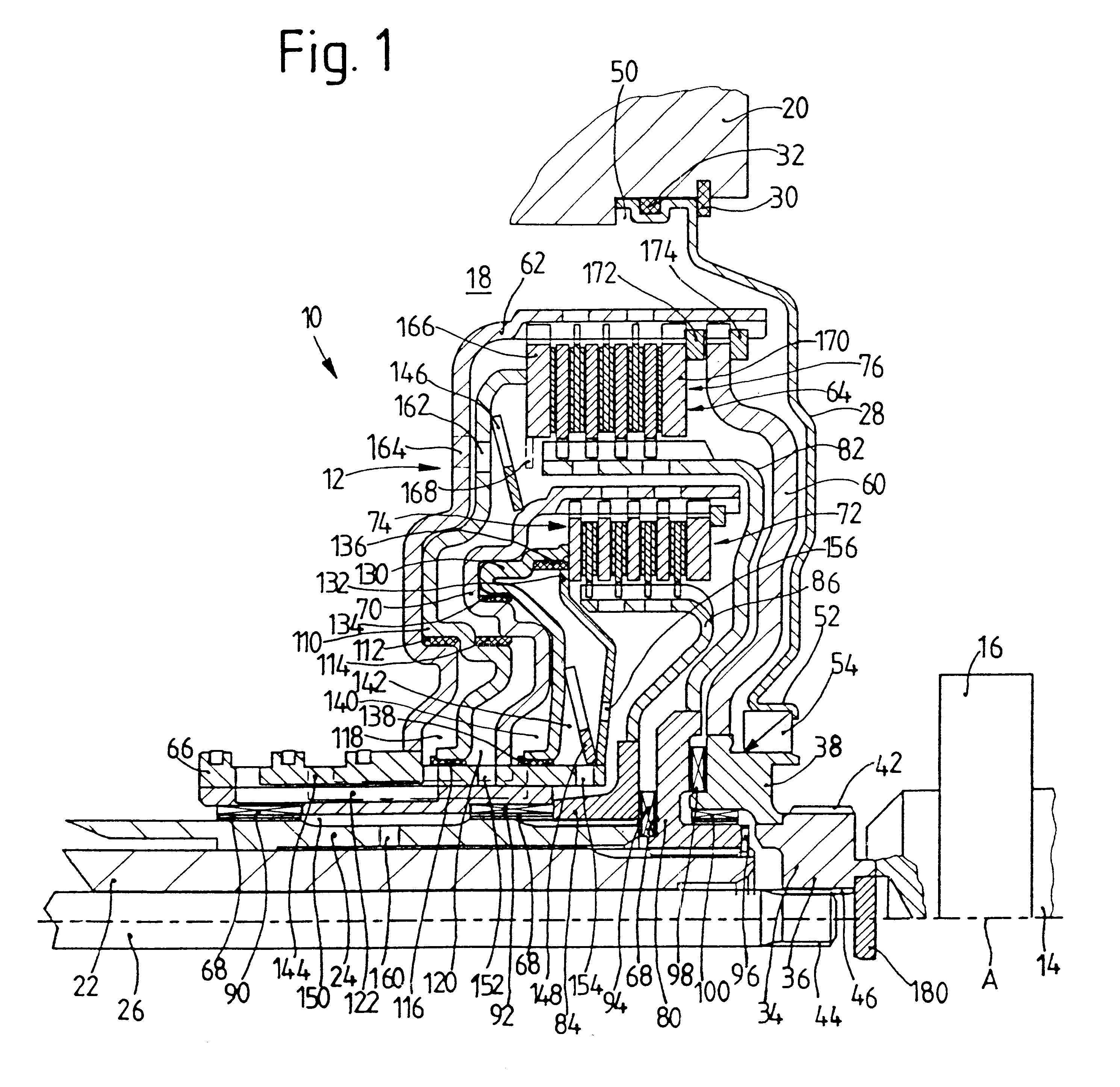

Multiple-clutch device

InactiveUS6464059B1Reduced Tolerance RequirementsReduce dependenceRotary clutchesFluid actuated clutchesMobile vehicleDrivetrain

The invention is directed to a multiple-clutch device, such as a double-clutch device, for arranging in a drivetrain of a motor vehicle between a drive unit and a transmission, wherein the clutch device has a first clutch arrangement associated with a first transmission input shaft of the transmission and a second clutch arrangement associated with a second transmission input shaft of the transmission for transmitting torque between the drive unit and the transmission. It is suggested that a bearing arrangement is associated with at least one of the clutch arrangements, wherein the latter is supported or can be supported so as to be relatively rotatable by means of the bearing arrangement on at least one of the transmission input shafts, at least one of which is constructed as a hollow shaft and a shaft constructed as a hollow shaft encloses the other shaft, preferably at least at the radial outer transmission input shaft which is constructed as a hollow shaft.

Owner:VOLKSWAGEN AG +1

Start-up clutch assembly

InactiveUS6868949B2Reduce and eliminate undesirable vibrationReduce and eliminate and torque spikeFluid actuated clutchesFriction clutchesActuatorControl theory

Owner:BORGWARNER INC

Clutch system

InactiveUS6789658B2Lower the volumeShort switching timeMechanical actuated clutchesFluid actuated clutchesMobile vehicleMotorized vehicle

Owner:ZF FRIEDRICHSHAFEN AG

Apparatus for cooling clutches on a transmission shaft

InactiveUS6059682AExtended service lifeSimple and inexpensive and compactFluid actuated clutchesGear lubrication/coolingMobile vehicleDrive shaft

A change-speed transmission in the power train of a motor vehicle has a planetary gearing and coaxial radially inner and outer disc clutches, namely a direct clutch and a reverse clutch. At least that clutch which is engaged (i.e., in use) is cooled by a lubricant for the planetary gearing, and the flow of coolant to the clutches is regulated by the axially movable pressure plate of one of the clutches. A jet pump conveys lubricant from the sump in the transmission case into an axially extending channel of the input shaft of the transmission, and such channel forms part of a system of passages which supply coolant at least to that clutch which is then in use to transmit torque from the input shaft to an output element of the transmission.

Owner:LUK GETRIEBE SYST +1

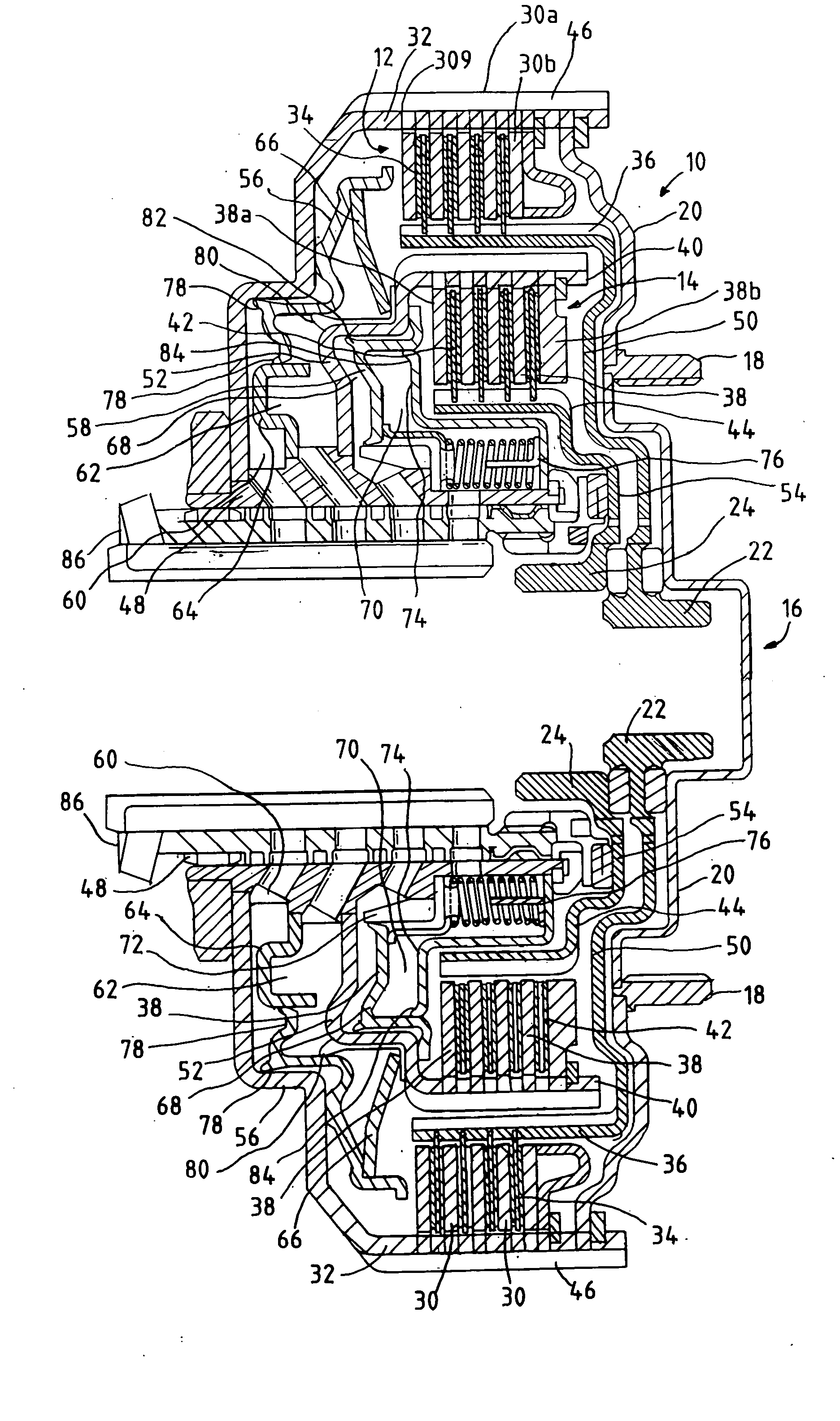

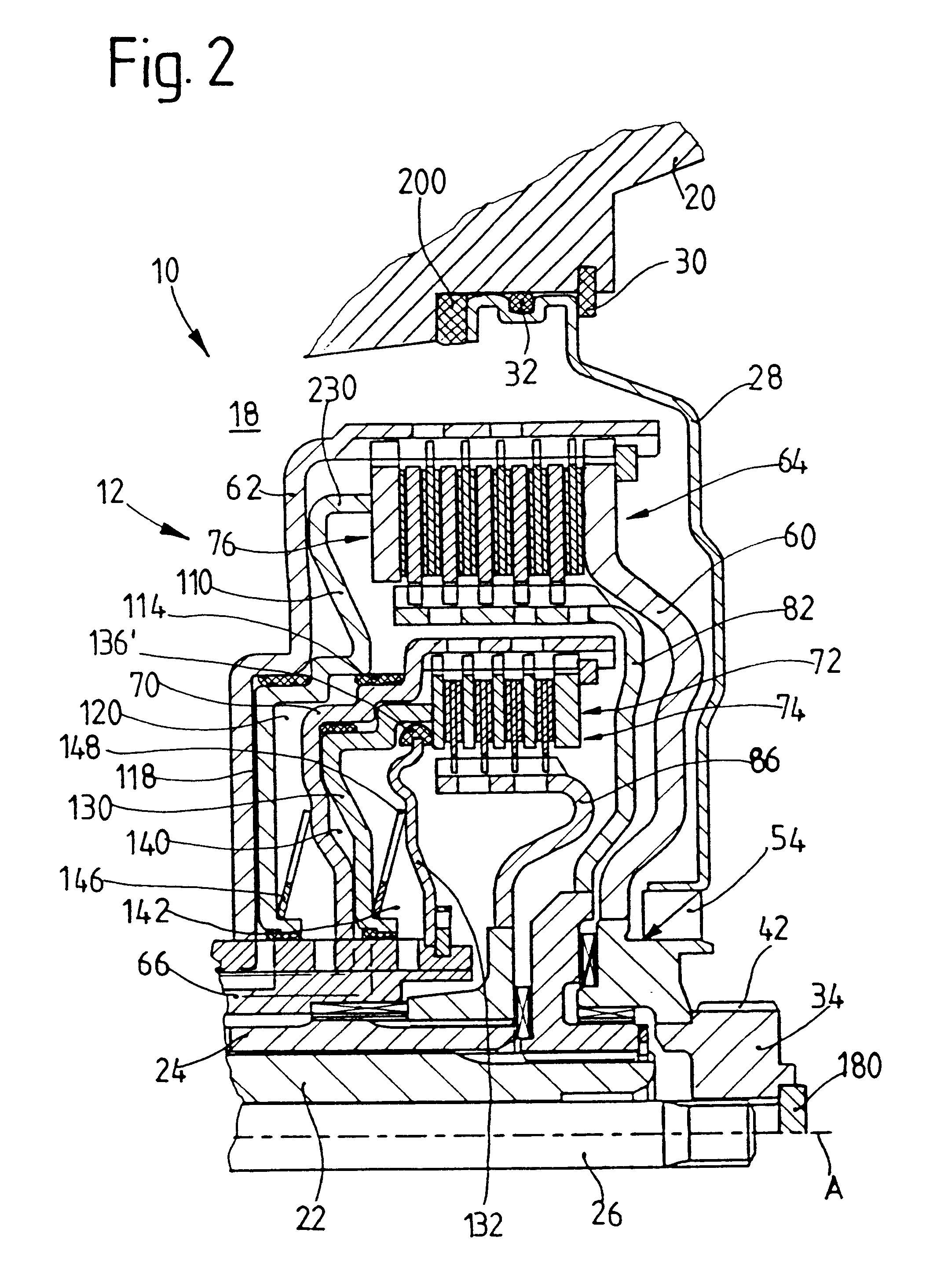

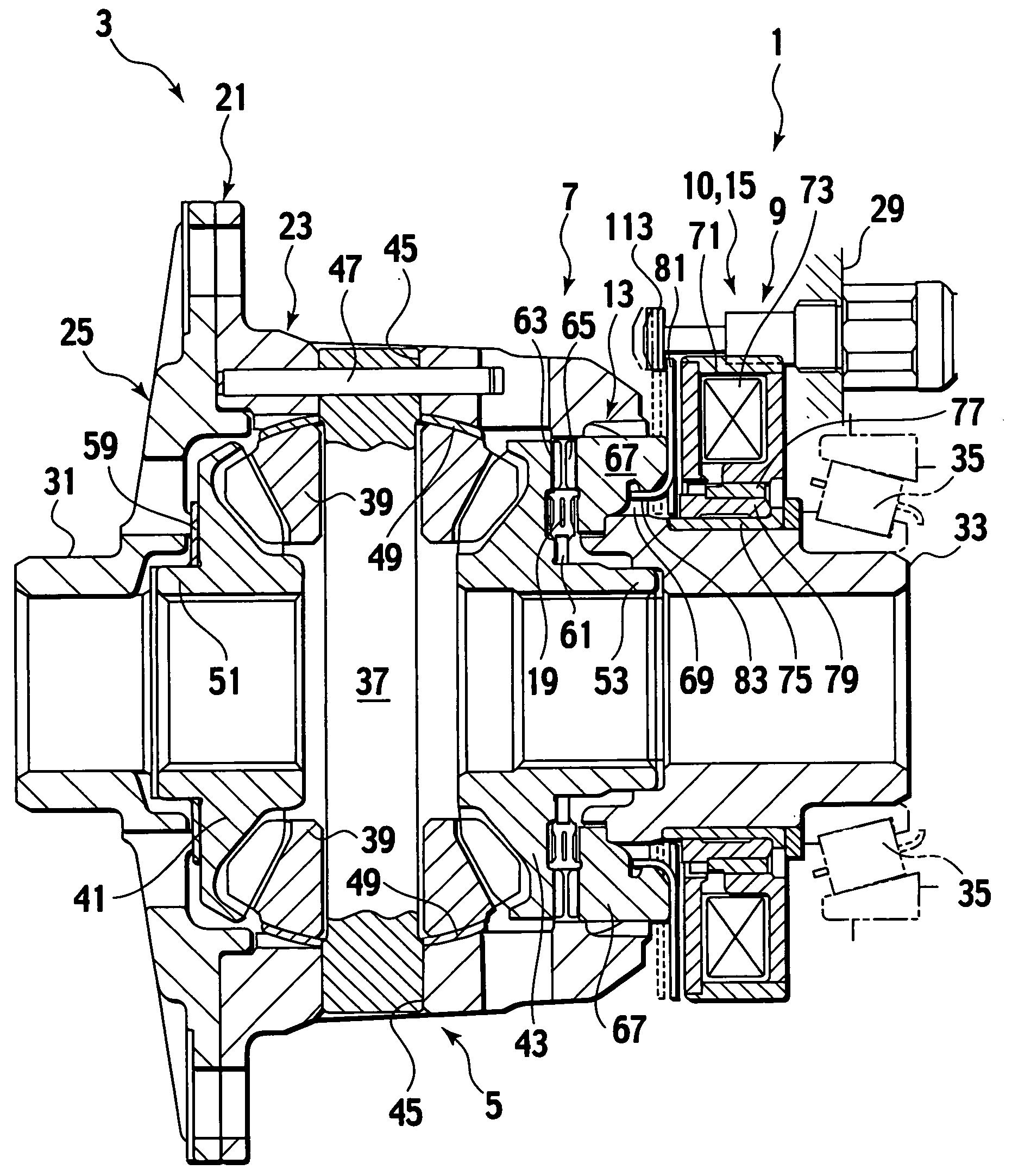

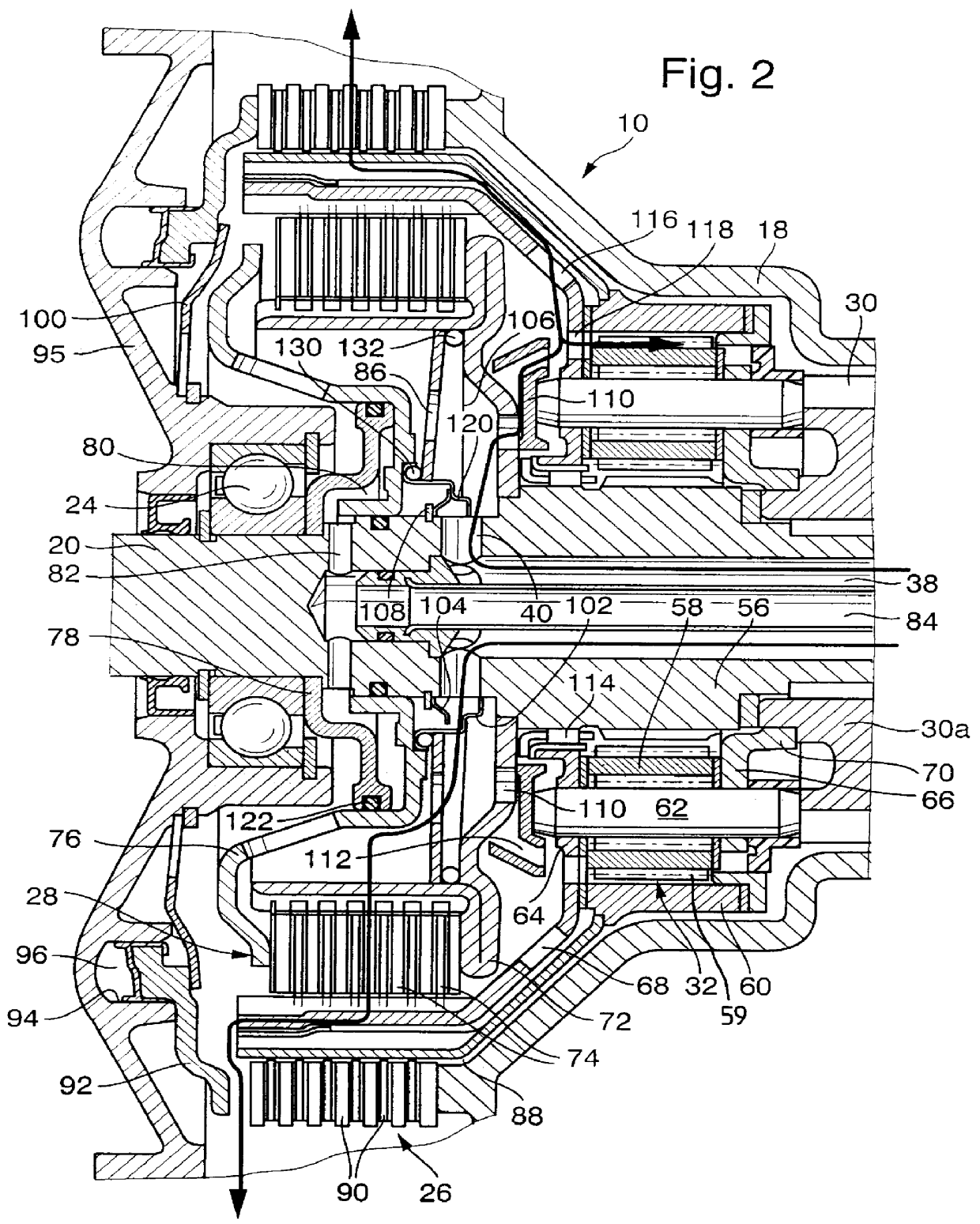

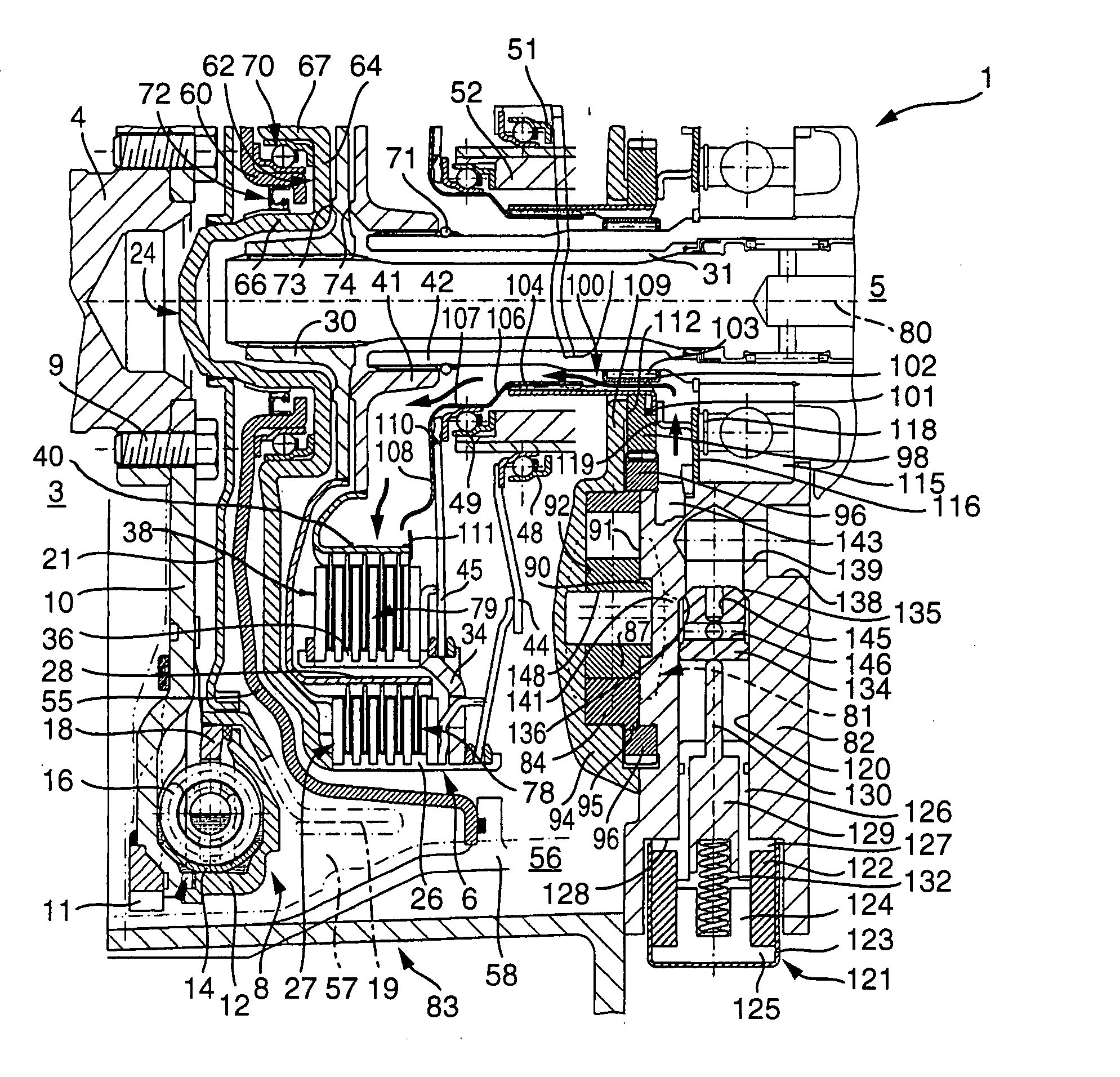

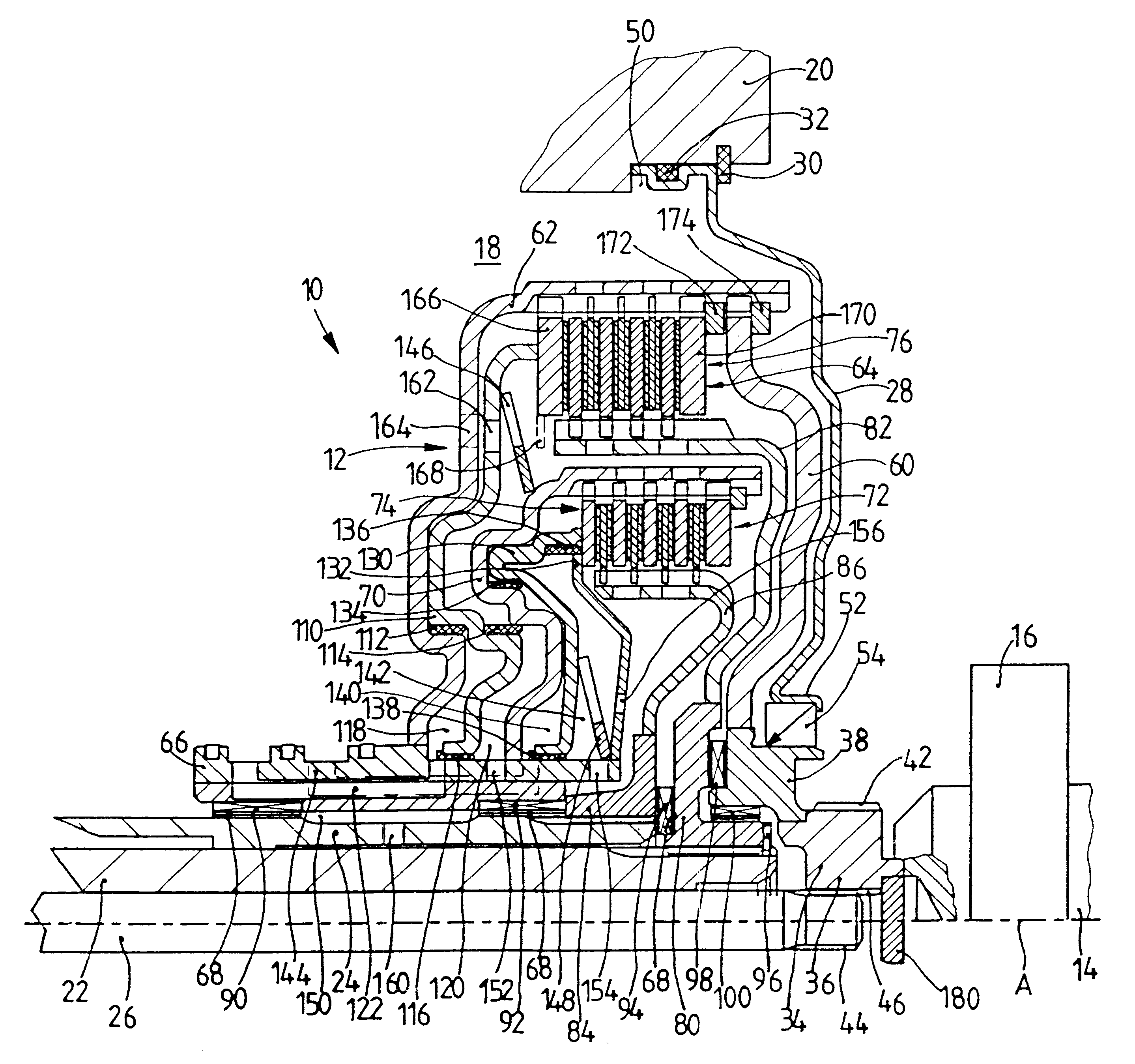

Multiple-clutch device

InactiveUS6454074B1Guaranteed uptimeEasy to assembleMechanical actuated clutchesFluid actuated clutchesMobile vehicleDrivetrain

The invention is directed to a multiple-clutch device, such as a double-clutch device, for arranging in a drivetrain of a motor vehicle between a drive unit and a transmission, wherein the clutch device has a first clutch arrangement associated with a first transmission input shaft of the transmission and a second clutch arrangement associated with a second transmission input shaft of the transmission for transmitting torque between the drive unit and the transmission. According to one aspect of the invention, it is suggested that at least one of the clutch arrangements has an actuating piston defining a pressure chamber for actuation, preferably for engagement of the clutch arrangement by means of a pressure medium, preferably a hydraulic medium, wherein the actuating piston divides the pressure chamber from an associated centrifugal force pressure compensation chamber which receives a pressure compensation medium.

Owner:VOLKSWAGEN AG +1

Rotating torque-transmitting apparatus

InactiveUS20050279605A1Reduce loadRotary clutchesFluid actuated clutchesTorque transmissionEngineering

A rotatable torque-transmitting apparatus includes a stationary piston and a rotatable apply plate. The rotatable apply plate is disposed adjacent a rotatable housing and separated therefrom by a return spring assembly which in a preload condition is trapped between the apply plate and the rotatable housing to limit the disengaged force which is transmitted between the rotatable housing and the stationary piston.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for controlling a dual clutch transmission

ActiveUS6953417B2Reduce complexityReduce in quantityFluid actuated clutchesToothed gearingsActuatorControl theory

A method of controlling the hydraulic actuation of the clutches and the synchronizers in a dual clutch transmission in the event of a clutch or synchronizer fault. The method includes the steps of determining which clutch is faulted when a clutch-on fault is detected, then commanding an interruption of engine torque to the faulted clutch and a neutralization of all synchronizers of the same axis shaft as the faulted clutch. The method further senses if a synchronizer actuator-on fault has occurred, then determines which synchronizer is faulted if an actuator-on fault has is detected. The method steps further include preventing the further actuation of the other synchronizers on the same axis shaft as the faulted actuator.

Owner:BORGWARNER INC

Torque transmitting unit and power train having a torque transmitting unit

InactiveUS20060000684A1Simple to fillCooling becomes necessaryFluid actuated clutchesFriction clutchesCircular discTorque transmission

A torque transmitting unit in the power train of a motor vehicle for transmitting torque between an engine crankshaft, and a transmission having at least one input shaft with at least one friction clutch. The transmission input shaft is coupled with the crankshaft by the friction clutch, which includes friction disks on the power input and / or output sides, and that are pressed together axially along an axis of rotation of the transmission input shaft to form a frictional engagement through a plurality of disks arranged in alternating layers in the axial direction. The disks are pressed against a stop by an actuator and with an actuating bearing interposed, wherein the actuator is connected to a fixed part of the transmission housing in a rotationally fixed connection. The friction clutch is a wet clutch.

Owner:SCHAEFFLER TECH AG & CO KG

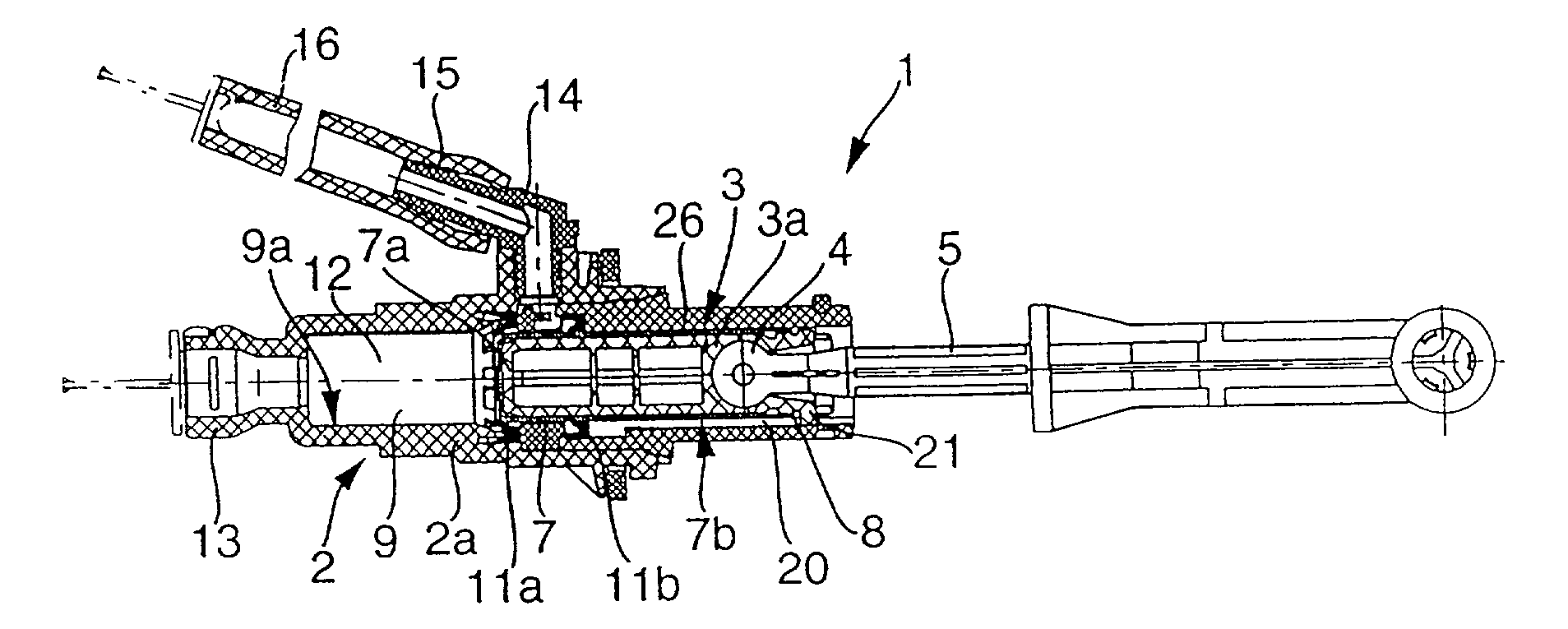

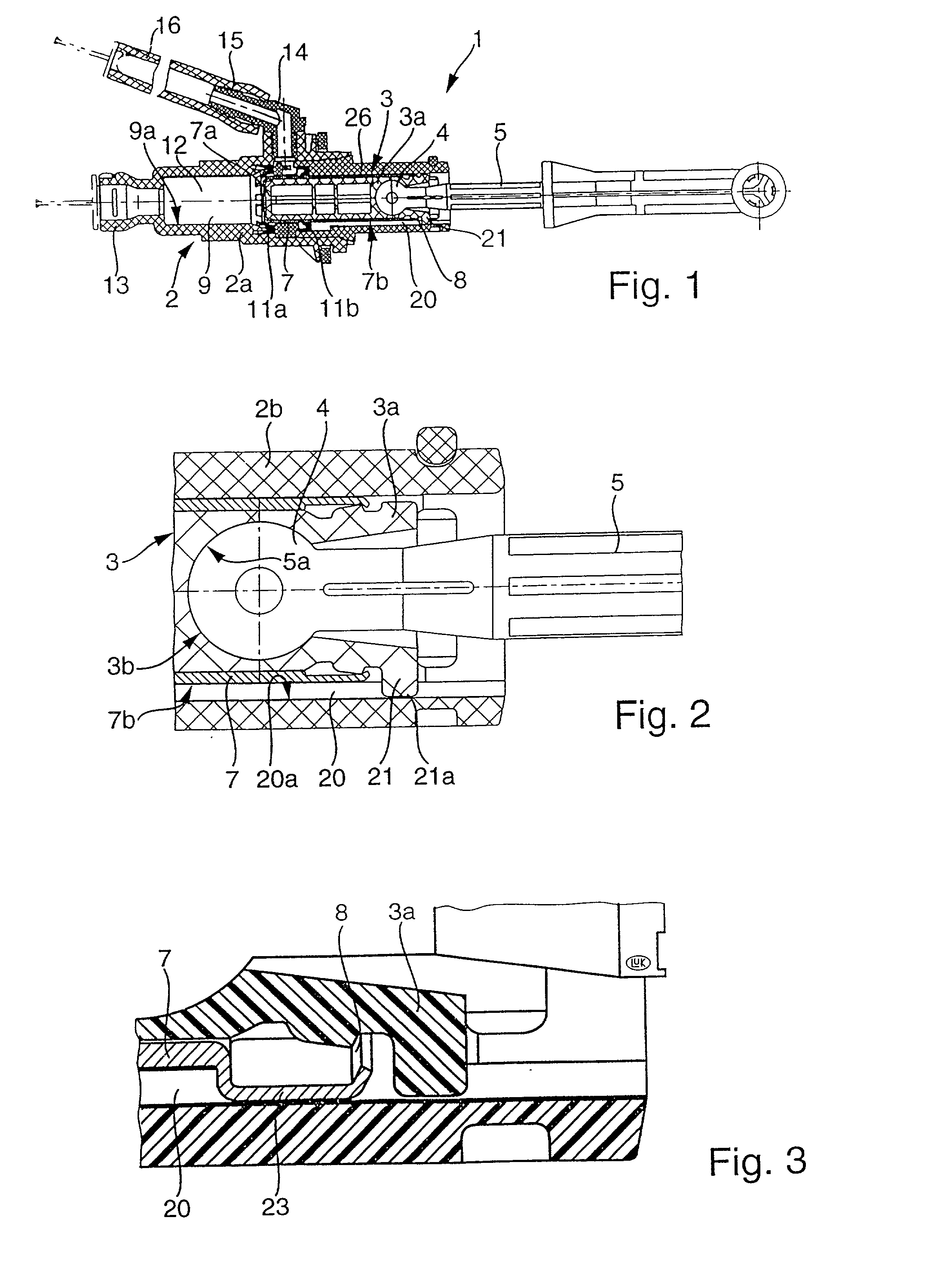

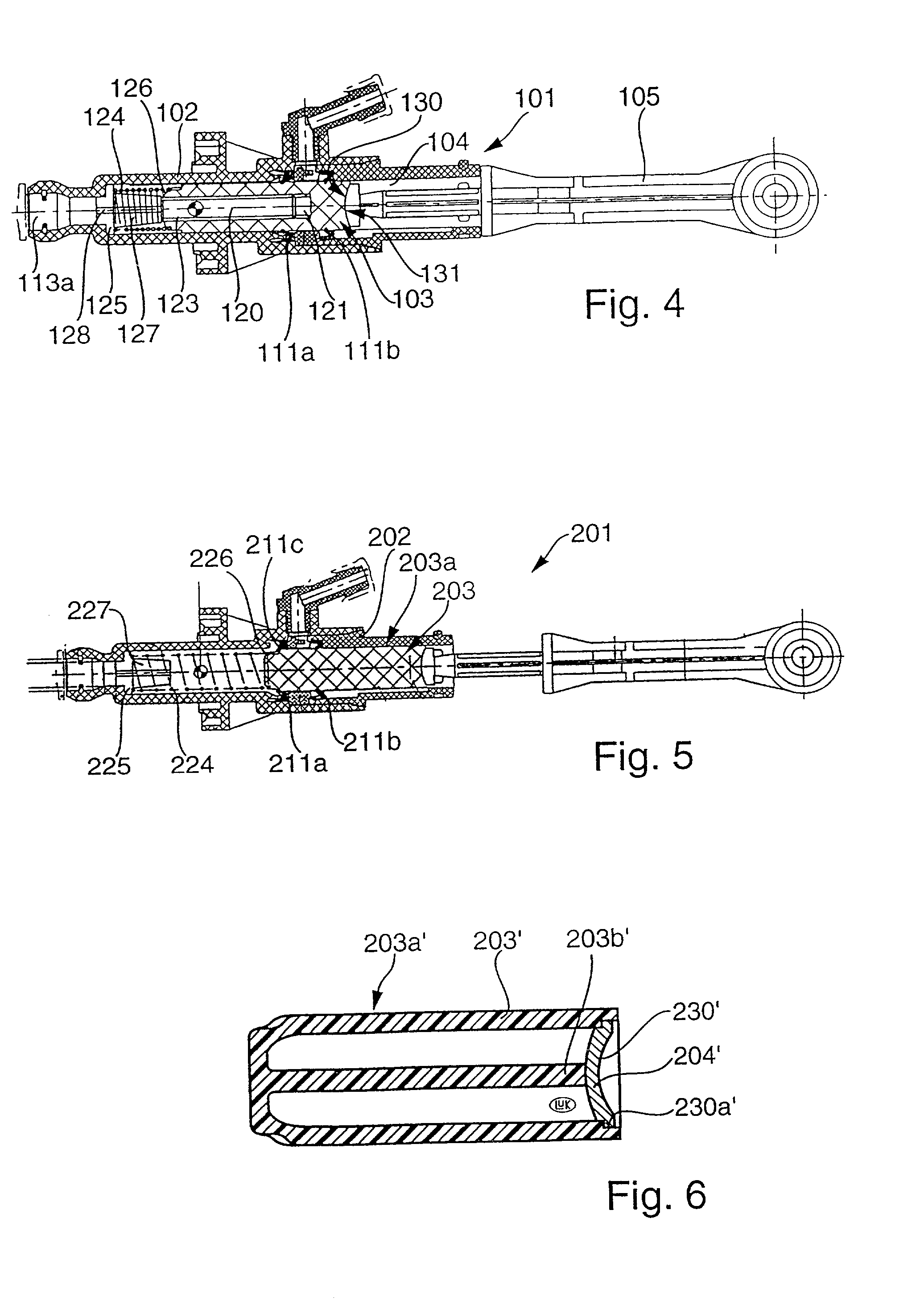

Master cylinder for use in power trains of motor vehicles

InactiveUS20020116924A1Satisfactory operationAvoid spreadingPiston ringsRotary clutchesMaster cylinderControl theory

A master cylinder for use in the power train of a motor vehicle to actuate the brakes or the friction clutch is designed to avoid the generation of screeching noise and / or the transmission of stray movements to the piston rod in response to shifting of the piston relative to the housing and relative to the sealing element(s) between the piston and the housing. This can be accomplished by causing the piston to turn relative to the housing and the sealing element(s) during axial movement in the housing and / or by installing one or more dampers between the piston and the housing and / or between the piston and the piston rod. The dampers can constitute separately produced parts and / or specially configured and / or finished surfaces provided on the piston and contacting the housing and / or the sealing element(s). The invention also relates to improvements in the configuration and / or the material(s) of the piston.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

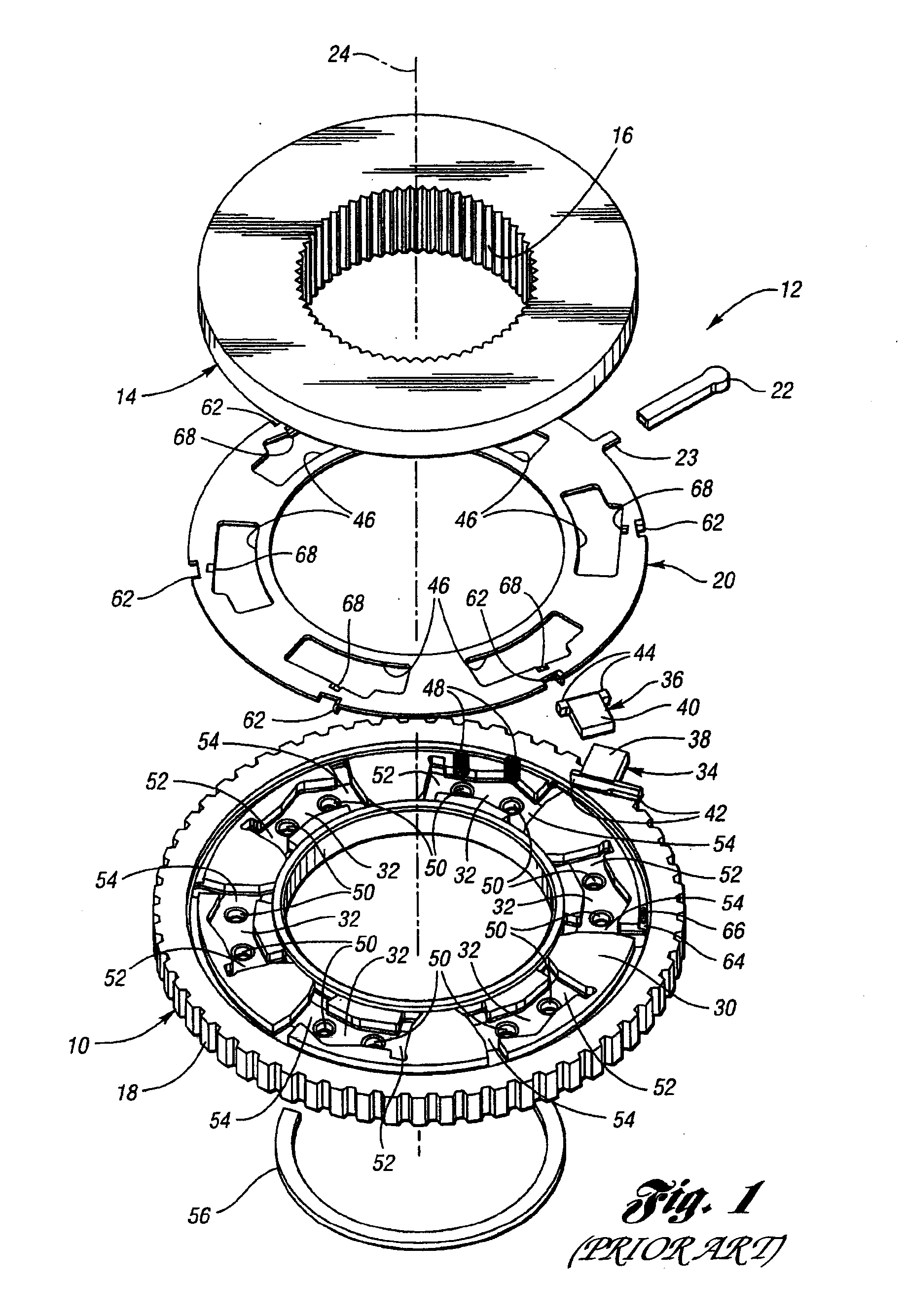

Inter-axle differential lock shift mechanism

InactiveUS7211017B2Reducing space and material requirementLow production costFluid actuated clutchesGear lubrication/coolingGear driveEngineering

An improved inter-axle differential locking clutch is provided that aligns the actuator and the clutch member thereby reducing space and material requirements in the axle assembly housing. The clutch also eliminates the need for a pushrod and shift fork thereby reducing tooling and production costs, as well as eliminating issues associated with misalignment of the piston and pushrod, relative rotation of the shift fork and clutch member, and tipping of the shift fork. The clutch includes one or more pistons disposed within either the axle housing or a carrier supporting the input shaft bearing. Fluid pressure actuates the pistons against a clutch member causing selective engagement between the clutch member and either a side gear driven by the inter-axle differential or a differential case housing the differential gears of the inter-axle differential.

Owner:DANA HEAVY VEHICLE SYSTEMS GROUP LLC

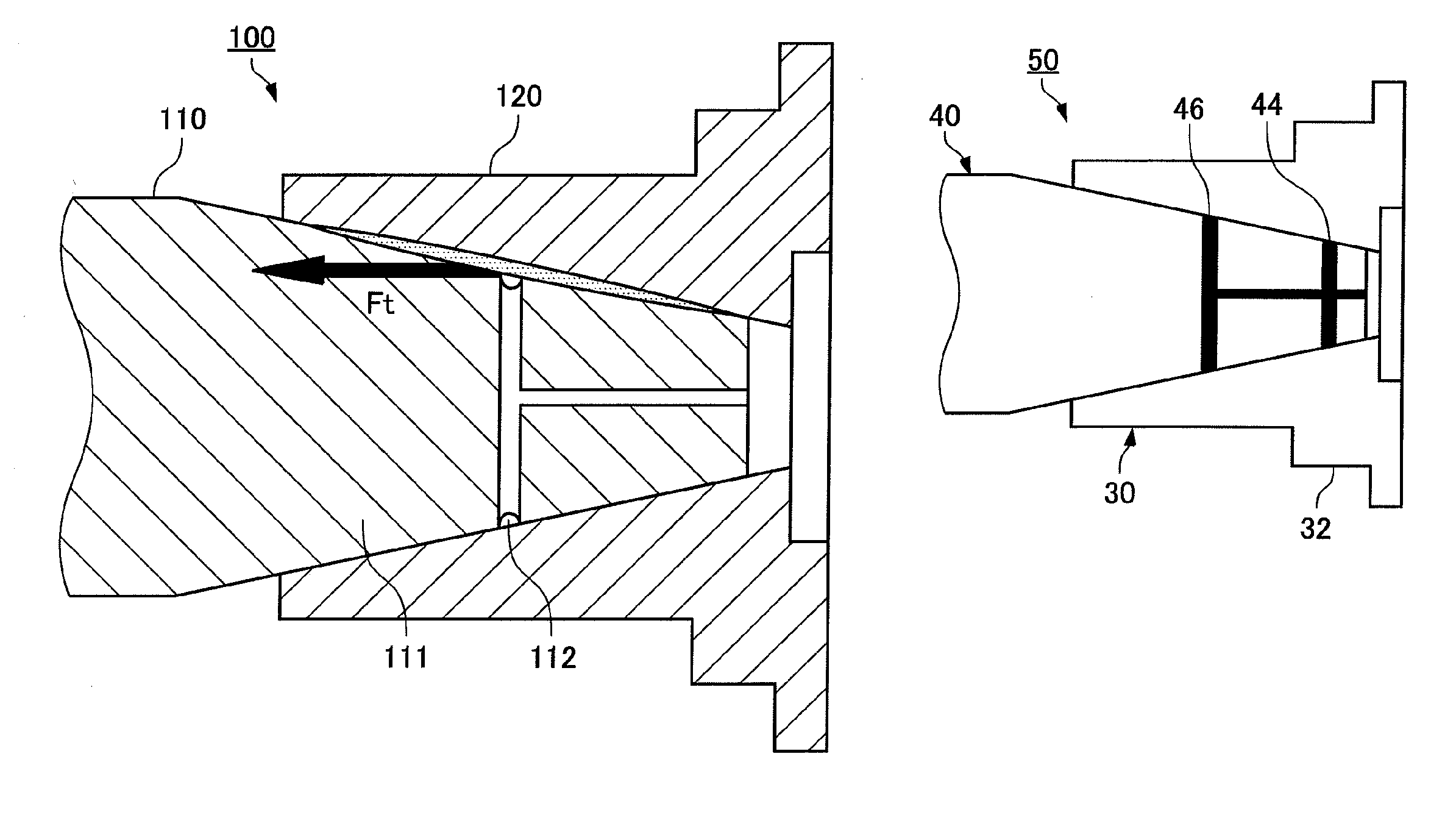

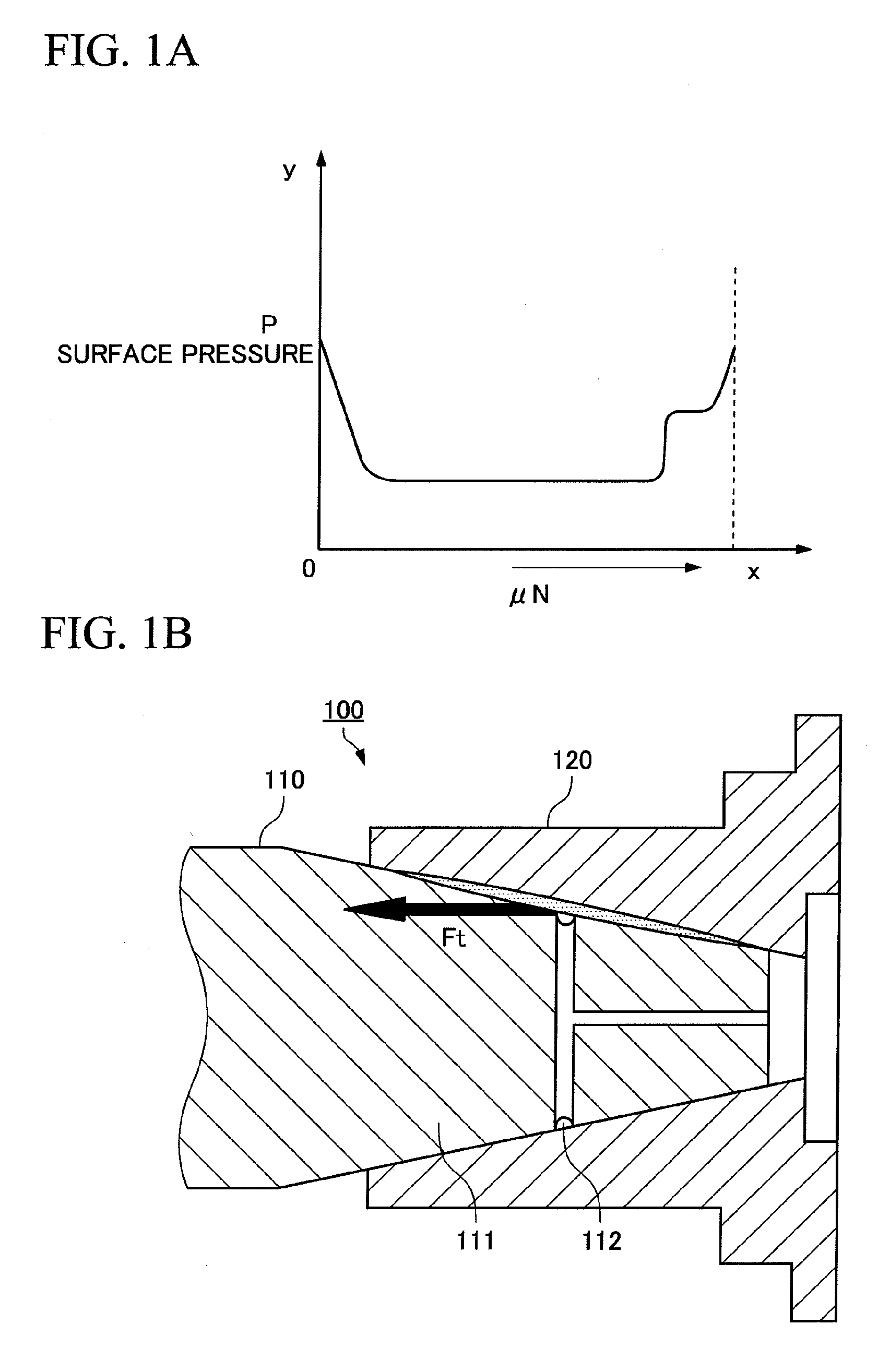

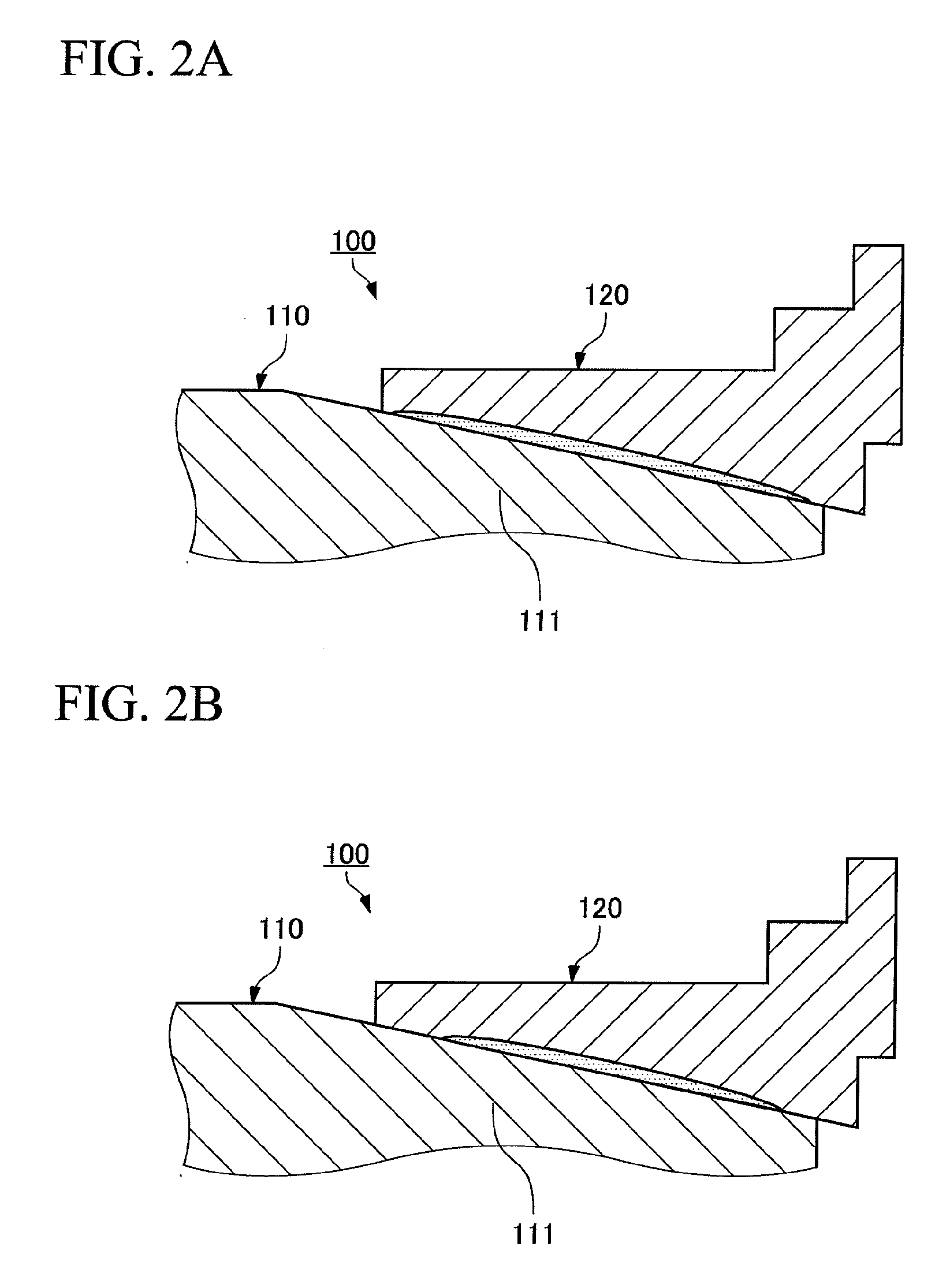

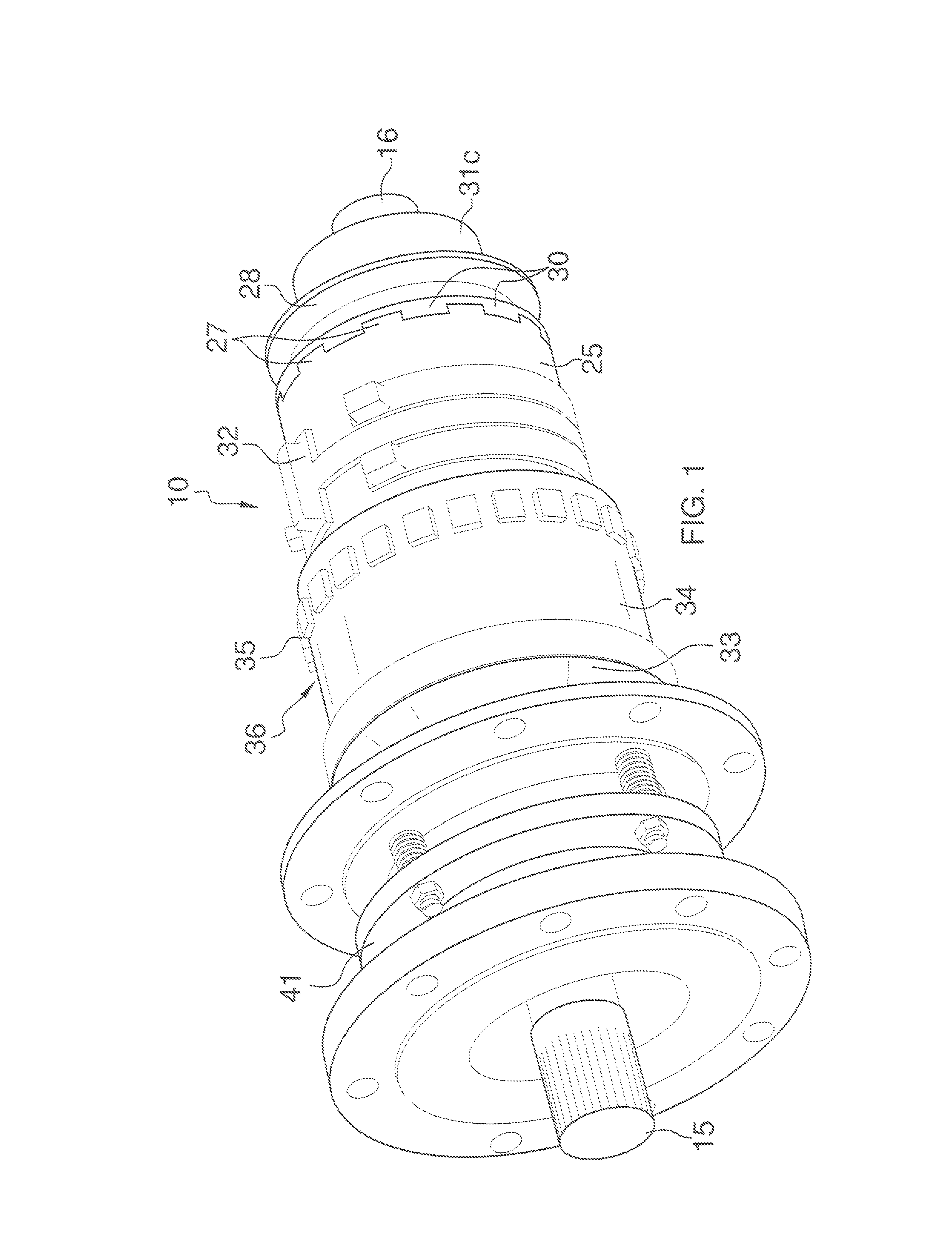

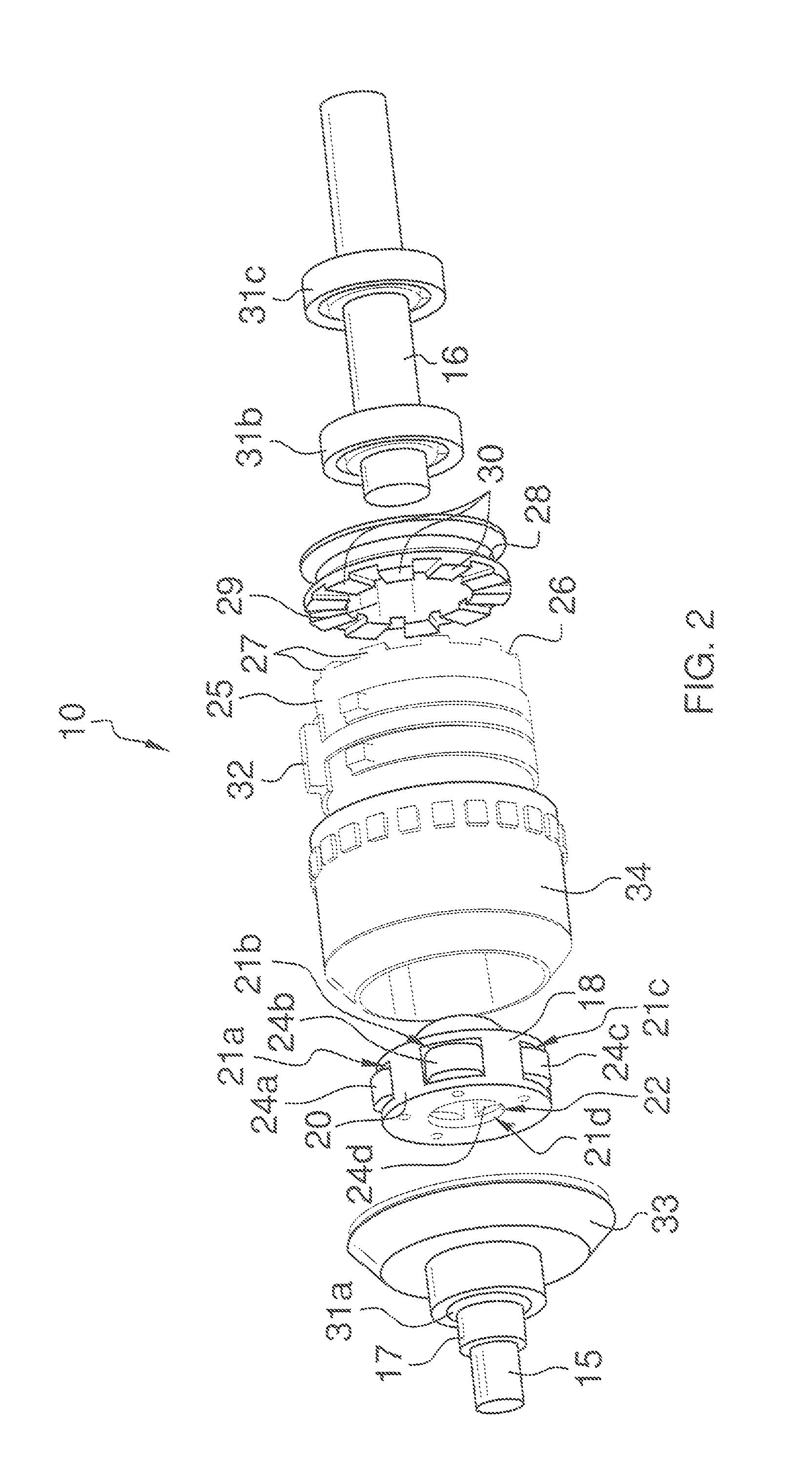

Tapered coupling structure and rotating machine

ActiveUS20100200354A1Increase surface pressureWithout usingFluid pressure sealed jointsFluid actuated clutchesCouplingEngineering

There is provided a tapered coupling structure in which a tapered shaft can be coupled to and decoupled from a hub without the use of an O-ring. In a tapered coupling structure 10 in which a tapered shaft 20 and a hub 30 are coupled to each other, the tapered shaft 20 is provided with a taper part 21 on the side of being coupled to the hub 30, and the hub 30 is provided with a high-rigidity part 32 having a thickness in the radial direction larger than that of other regions and having a high rigidity in the radial direction. An oil groove 24 formed in the outer peripheral surface of the taper part 21 to feed oil to the coupling surfaces of the taper part 21 and the hub 3 is provided in a region corresponding to the high-rigidity part 32 in the axial direction.

Owner:MITSUBISHI HEAVY INDUSTIES COMPRESSOR CORP

Rotary-type selectable one-way clutch

Owner:GM GLOBAL TECH OPERATIONS LLC

Motion transmitting apparatus

InactiveUS20020065171A1More versatileLess expensiveFluid actuated clutchesMagnetically actuated clutchesMobile vehicleCoil spring

A motion transmitting apparatus wherein an electric motor, an engine or another prime mover rotates an axially fixed first part relative to a coaxial axially movable non-rotatable second part. The structure which serves to move the second part axially in response to clockwise or counterclockwise rotation of the first part includes a follower borne by the first part and a helical spring having end convolutions affixed to the first part. The follower extends between two intermediate convolutions of the helical spring. If the apparatus is utilized in the power train of a motor vehicle, the axially movable part can serve to engage or disengage or change the extent of engagement of the friction clutch between the output element of the engine and the input element of the change-speed transmission.

Owner:SCHAEFFLER TECH AG & CO KG

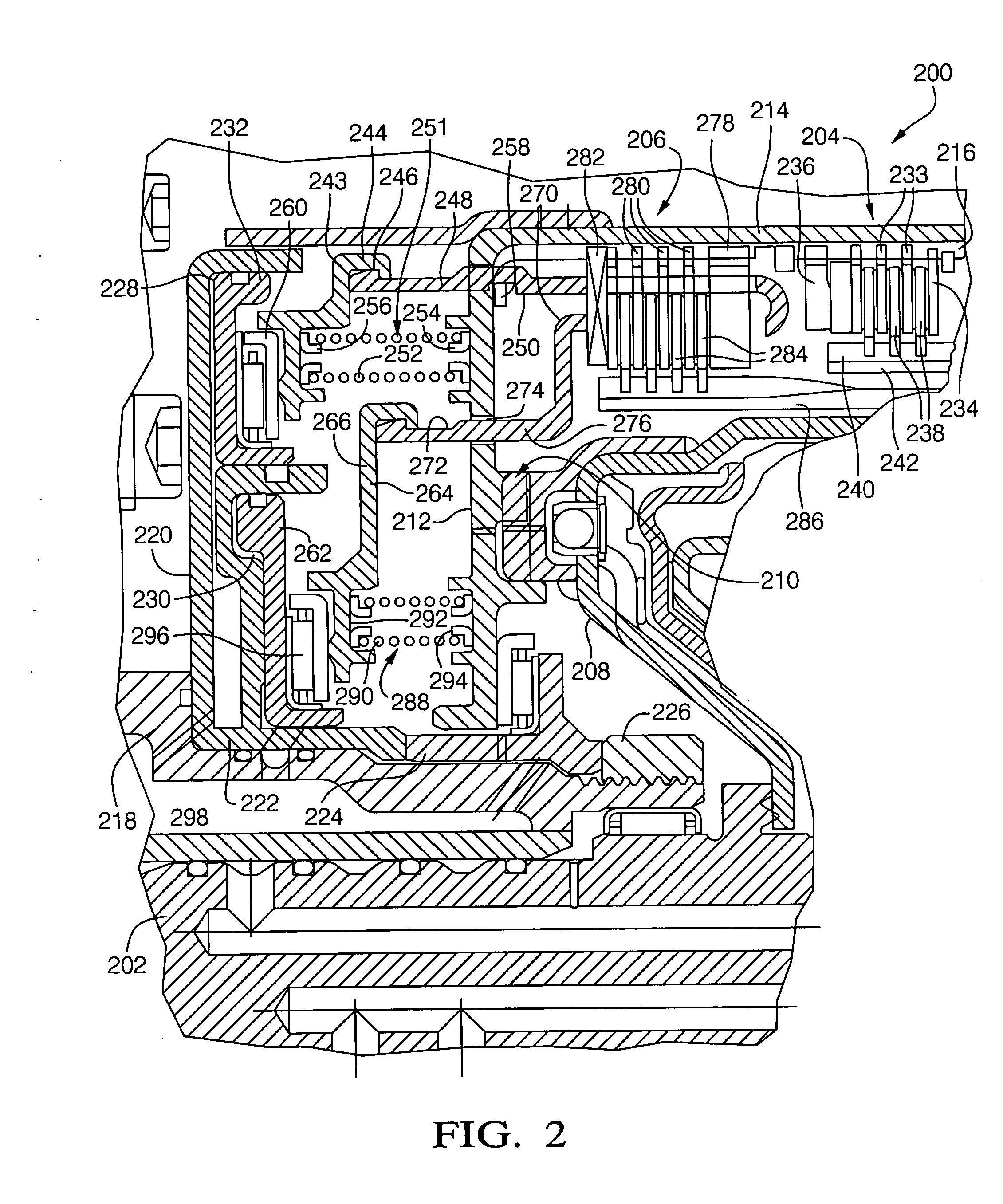

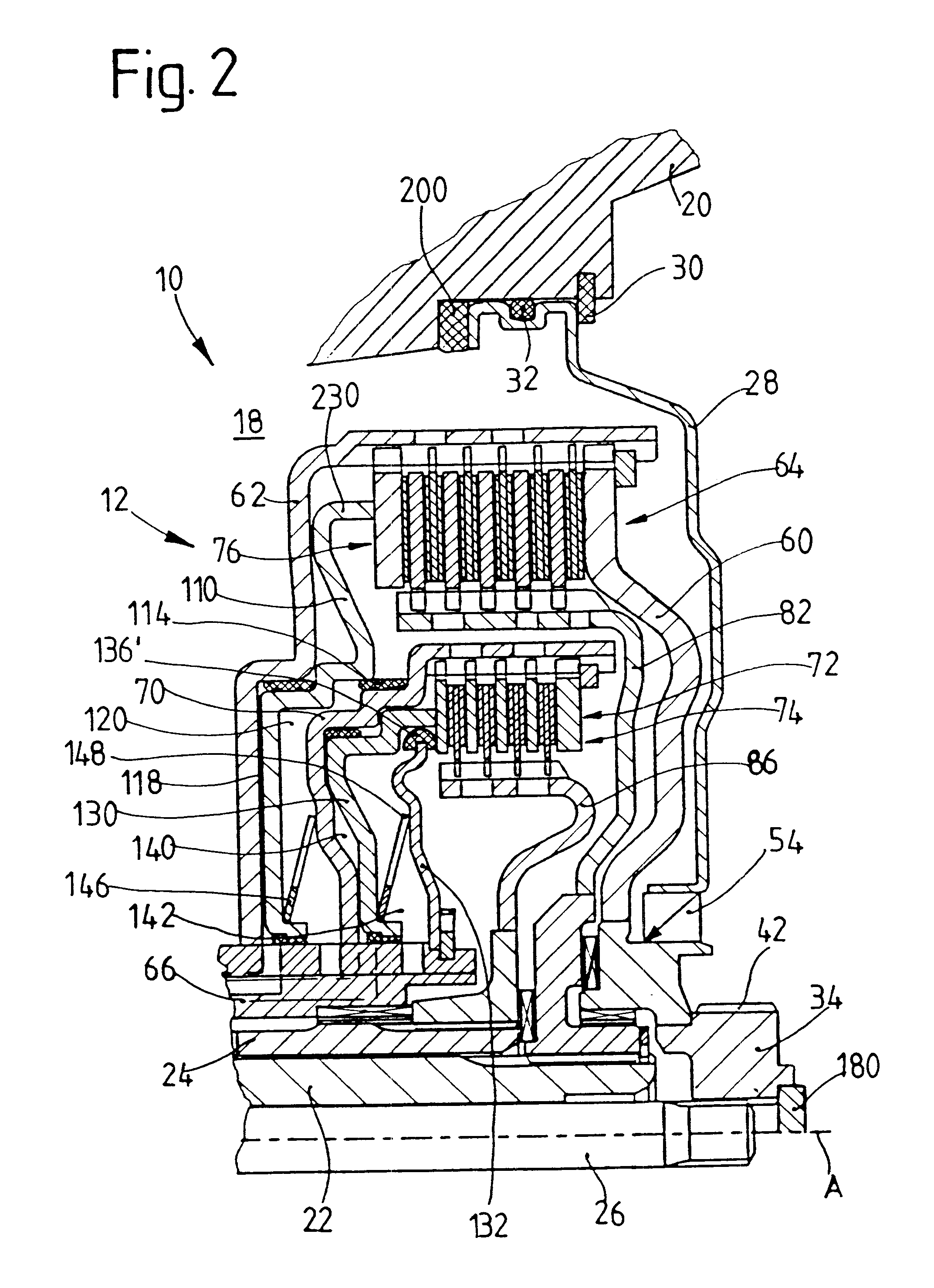

Multiple-clutch device

The invention is directed to a multiple-clutch device, such as a double-clutch device, for arranging in a drivetrain of a motor vehicle between a drive unit and a transmission, wherein the clutch device has a first clutch arrangement associated with a first transmission input shaft of the transmission and a second clutch arrangement associated with a second transmission input shaft of the transmission for transmitting torque between the drive unit and the transmission. According to one aspect of the invention, it is suggested that at least one of the clutch arrangements is constructed as a plate clutch arrangement and has an actuating piston defining a pressure chamber for actuation, preferably for engagement, of the plate clutch arrangement by means of a pressure medium, preferably hydraulic medium, wherein cooling fluid, possibly cooling oil, can be supplied to the plate clutch arrangement from a cooling fluid supply, possibly a cooling oil supply, wherein the actuating piston, and also, if desired, a plate carrier, possibly an outer plate carrier, has at least one pressure compensation opening and / or cooling fluid outlet opening in a radial outer and / or central area.

Owner:ZF FRIEDRICHSHAFEN AG +1

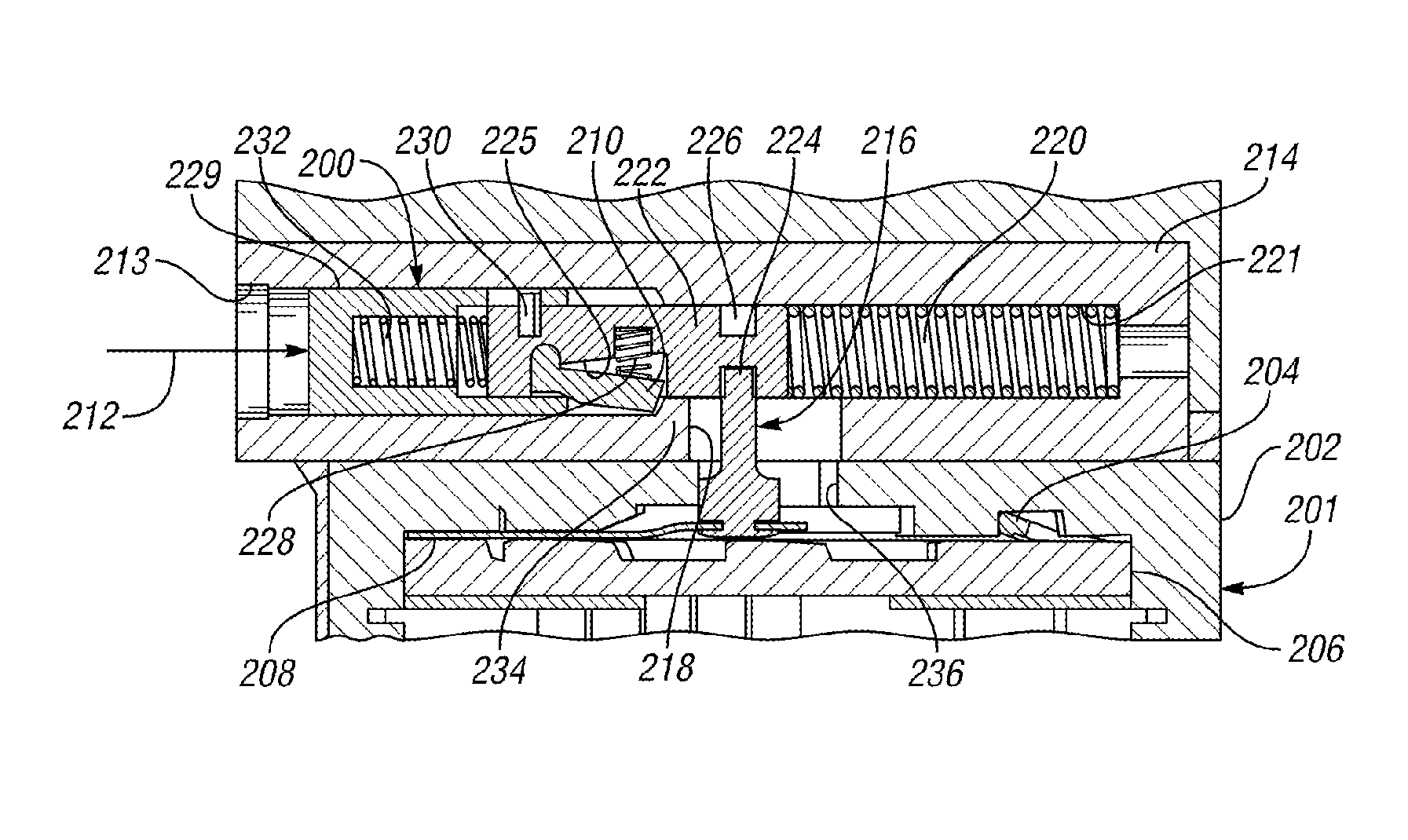

Overrunning coupling and control assembly including apparatus having a latching mechanism

ActiveUS8272488B2Limitations is associated with assembliesPrevent movementFluid actuated clutchesLimiting/preventing/returning movement of partsCouplingEngineering

Overrunning coupling and control assemblies, each of which includes control apparatus having a latching mechanism are provided. Each latching mechanism prevents an actuator arm of an overrunning coupling assembly from moving in a first direction substantially parallel to a shift direction of a control plate of the coupling assembly within a housing slot in a locked condition of the mechanism in a first position of the control plate. A control pressure signal within a bore of the housing changes the condition of the latching mechanism from locked to unlocked to unlock the actuator arm and causes the unlocked actuator arm to move along the first direction within the slot and the control element to move along the shift direction to a second position. The control pressure signal also causes a piston which has a groove formed in its outer surface to receive and retain a free end portion of the actuator arm to slide within the bore in the housing against the biasing force of the at least one biasing member. In the absence of a control pressure signal, the at least one biasing member moves the piston and thereby the unlocked actuator arm in a second direction opposite the first direction within the slot and the control element along the shift direction from the second position back to the first position and changes the condition of the latching mechanism from unlocked to locked to lock the actuator arm.

Owner:MEANS IND INC

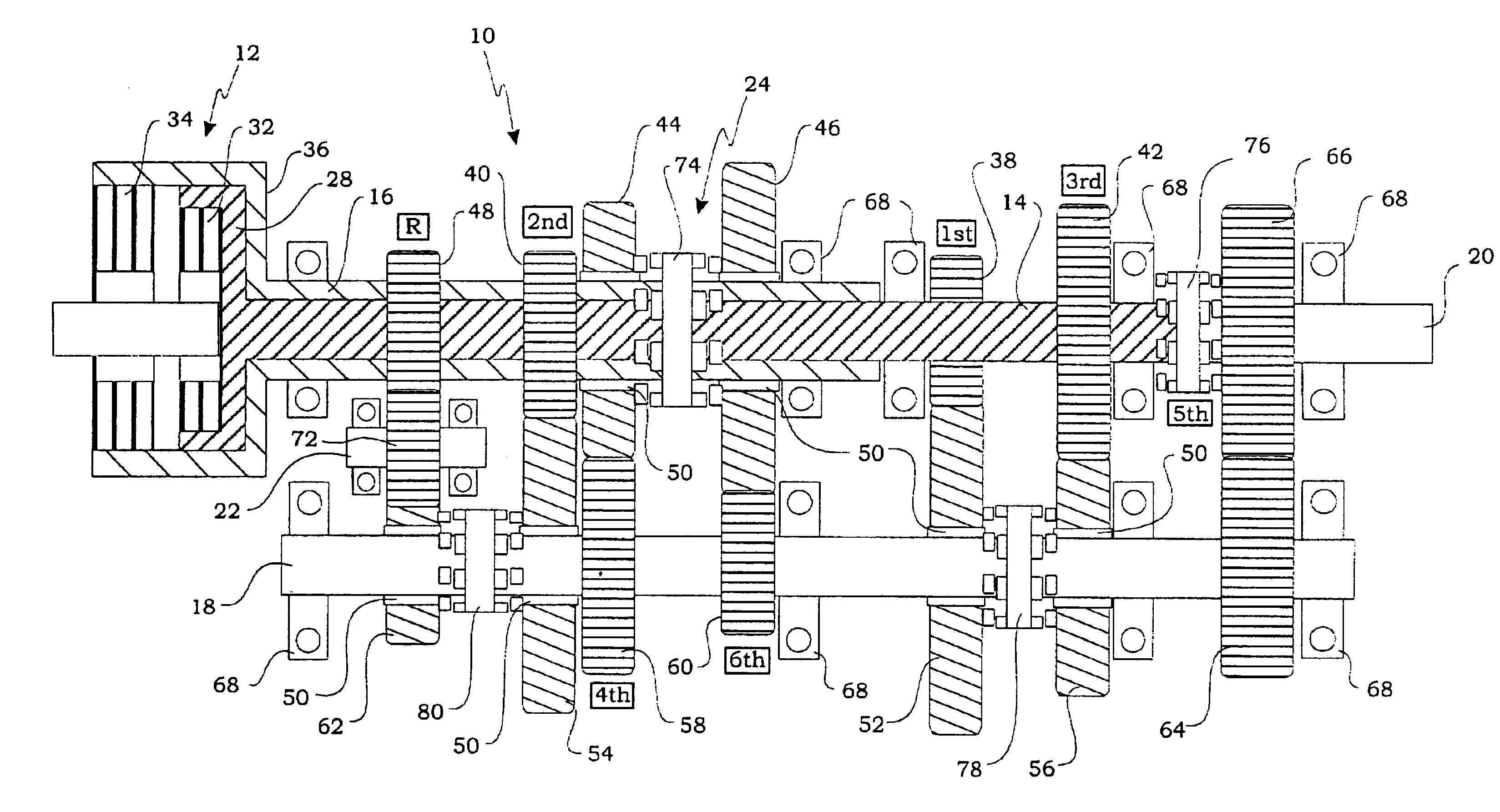

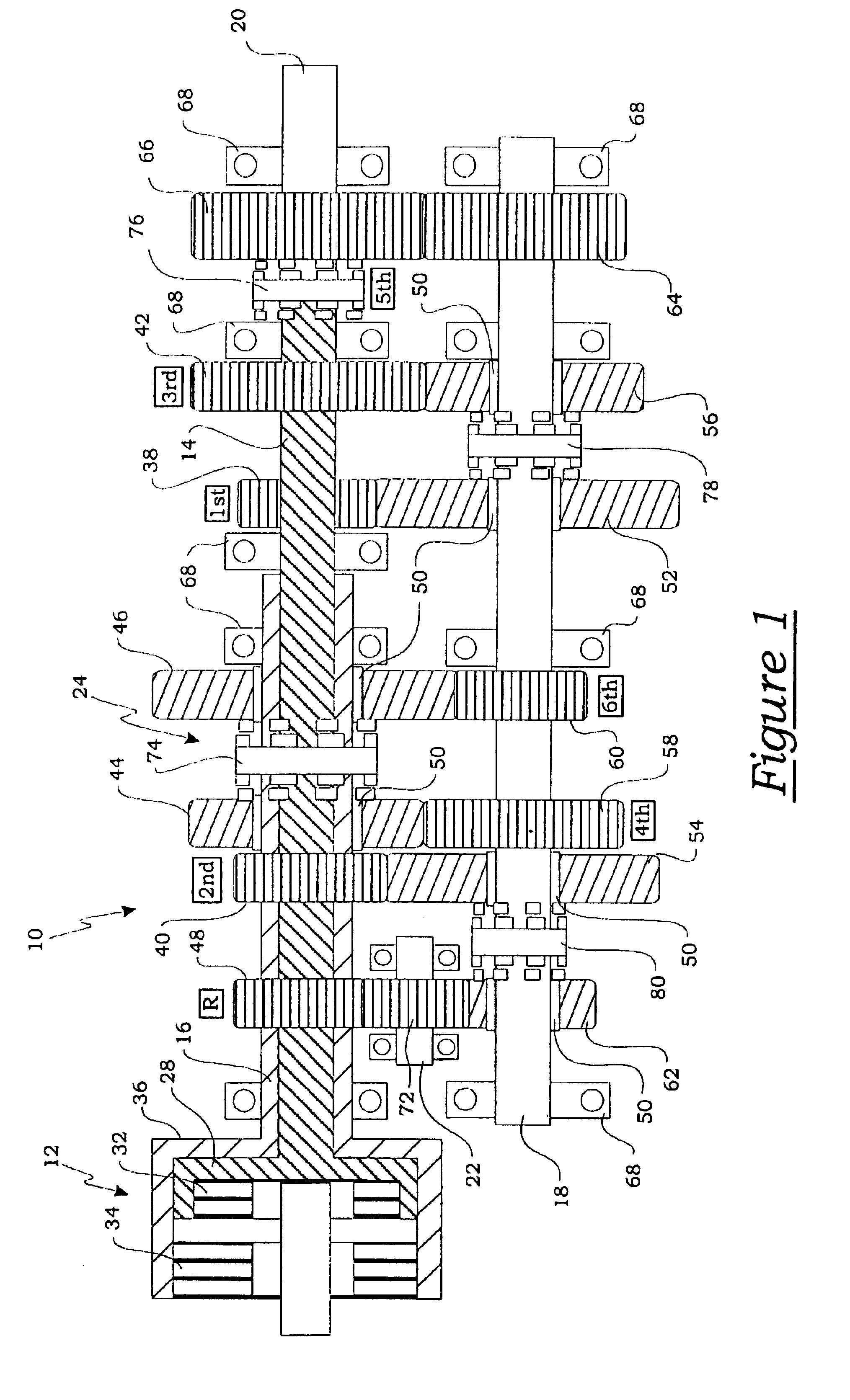

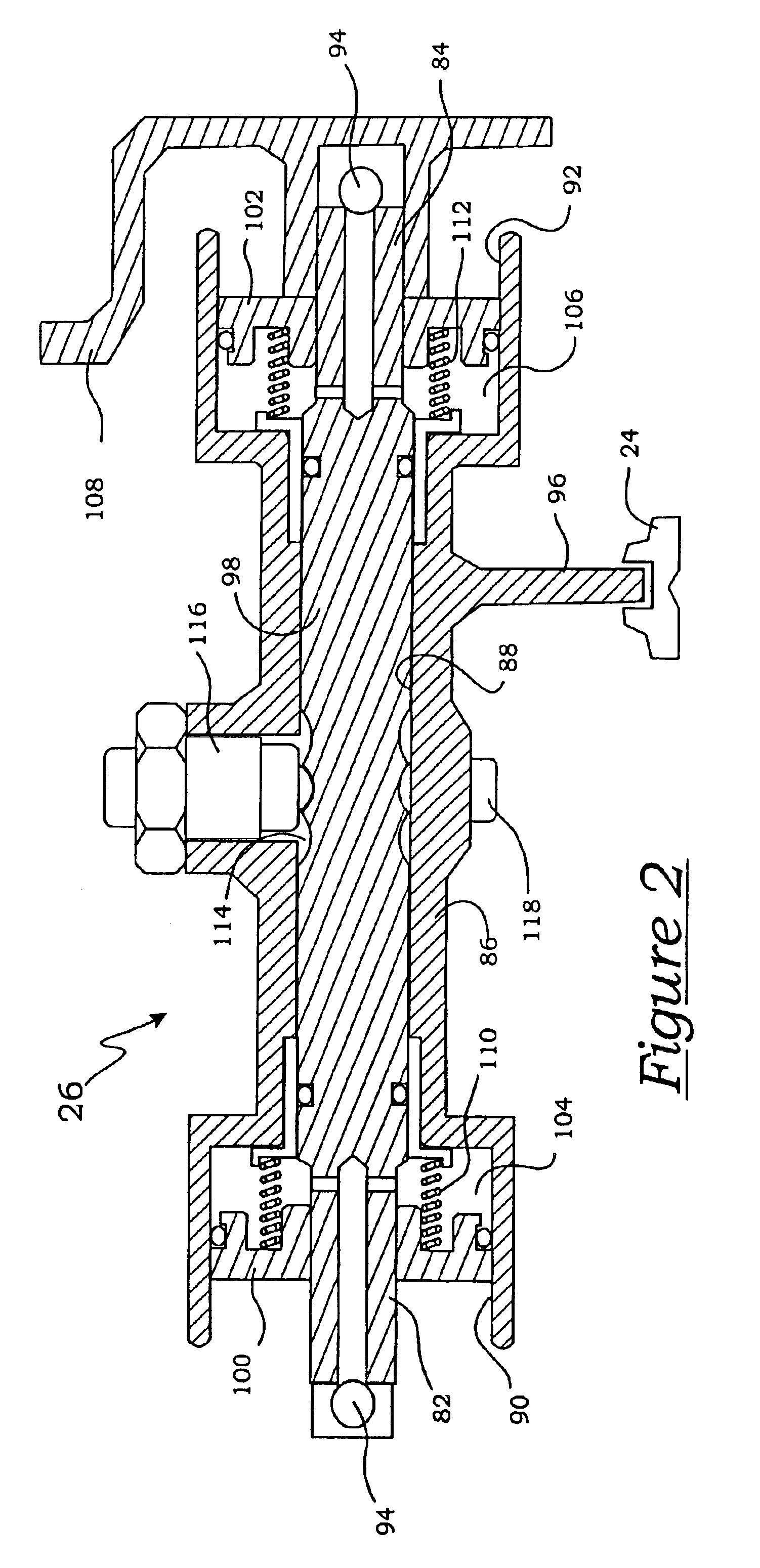

Mechanical power transmission system and method

InactiveUS8517888B1Effectively change speedImprove fuel efficiencyFluid actuated clutchesToothed gearingsElectric power transmissionMechanical power transmission

A mechanical power transmission system for transforming and delivering power effectively and efficiently using external pressure to propel a vehicle. The mechanical power transmission system includes a case; rotational members; a gear set being in operable communication to at least one of the rotational members; and a clutch system being in operable communication to the gear set and using external fluid pressure from a fluid source to effectively change speeds.

Owner:BROOKINS ERNIE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com