Patents

Literature

555results about How to "Reduce axial force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

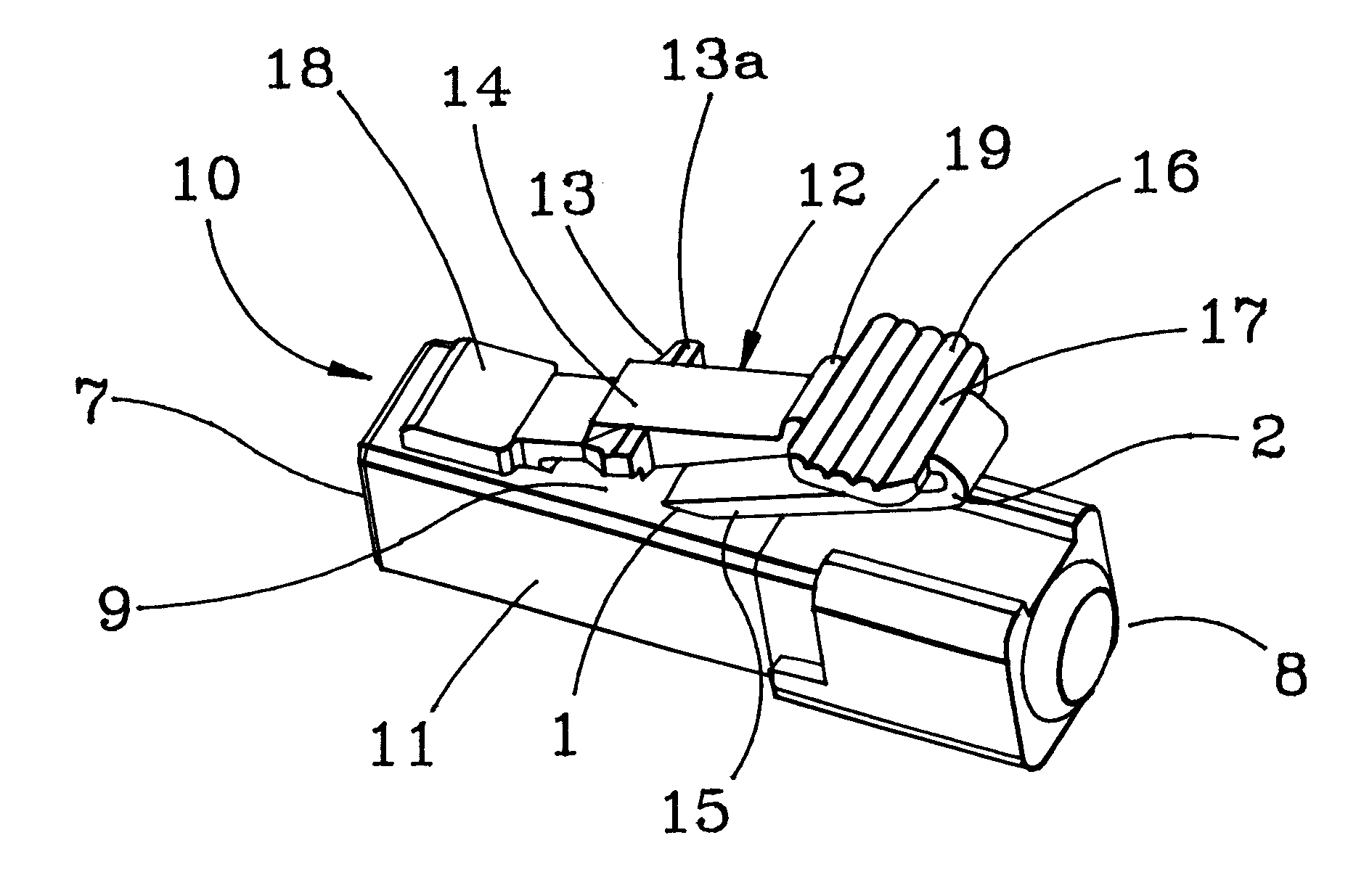

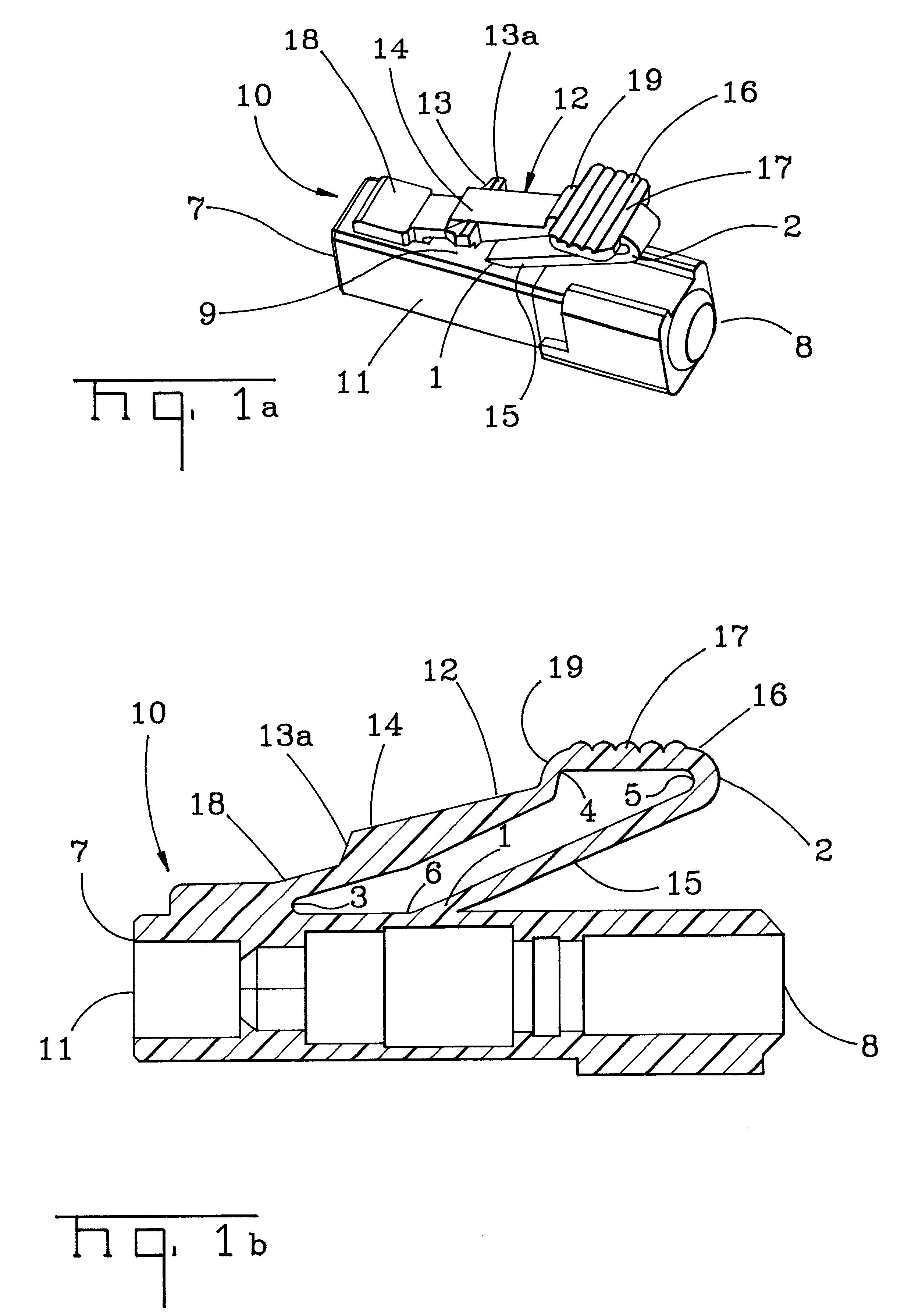

Connector with articulated latch

InactiveUS6364685B1Reduce axial forceMinimize rotationCoupling device detailsCoupling light guidesMating connectionEngineering

A connector for engaging a mating connector comprising: (a) a housing having a longitudinal axis and a front and back orientation and being adapted for receiving a signal carrying medium; and (b) an articulated latch connected to the housing at one or more primary joints and having a plurality of sections, wherein at least one of the sections has an engagement structure which is adapted to engage a corresponding structure on the mating connector such that the connector and the mating connector cannot be separated without actuating the latch, and wherein at least two sections are connected at a secondary joint, the primary and secondary joints being configured such that, when an actuating force is applied to the articulated latch, a moment on one side of the actuation point is reduced by an opposing moment on the opposite side of the actuation point, thereby reducing the axial force on the connector.

Owner:COMMSCOPE TECH LLC

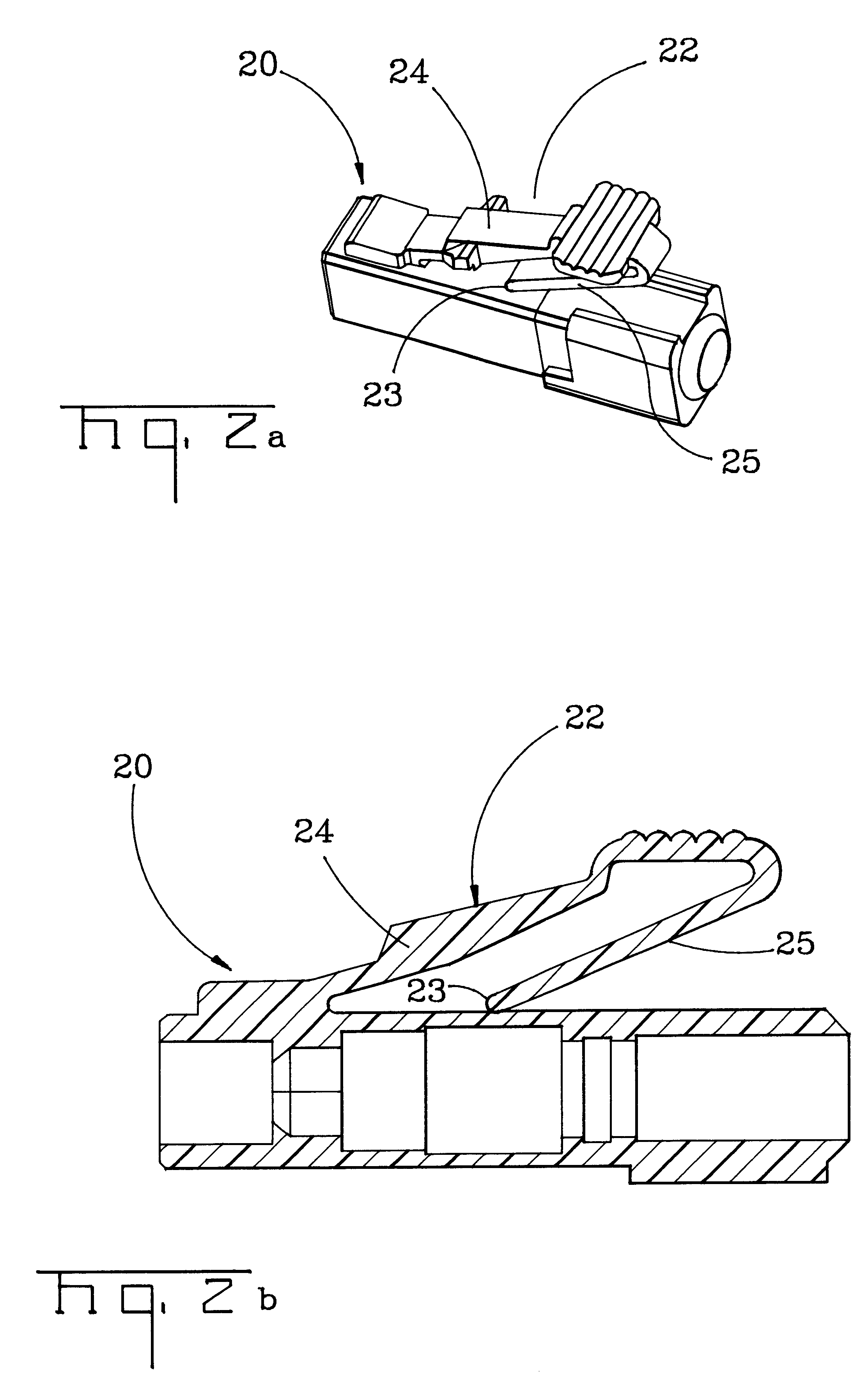

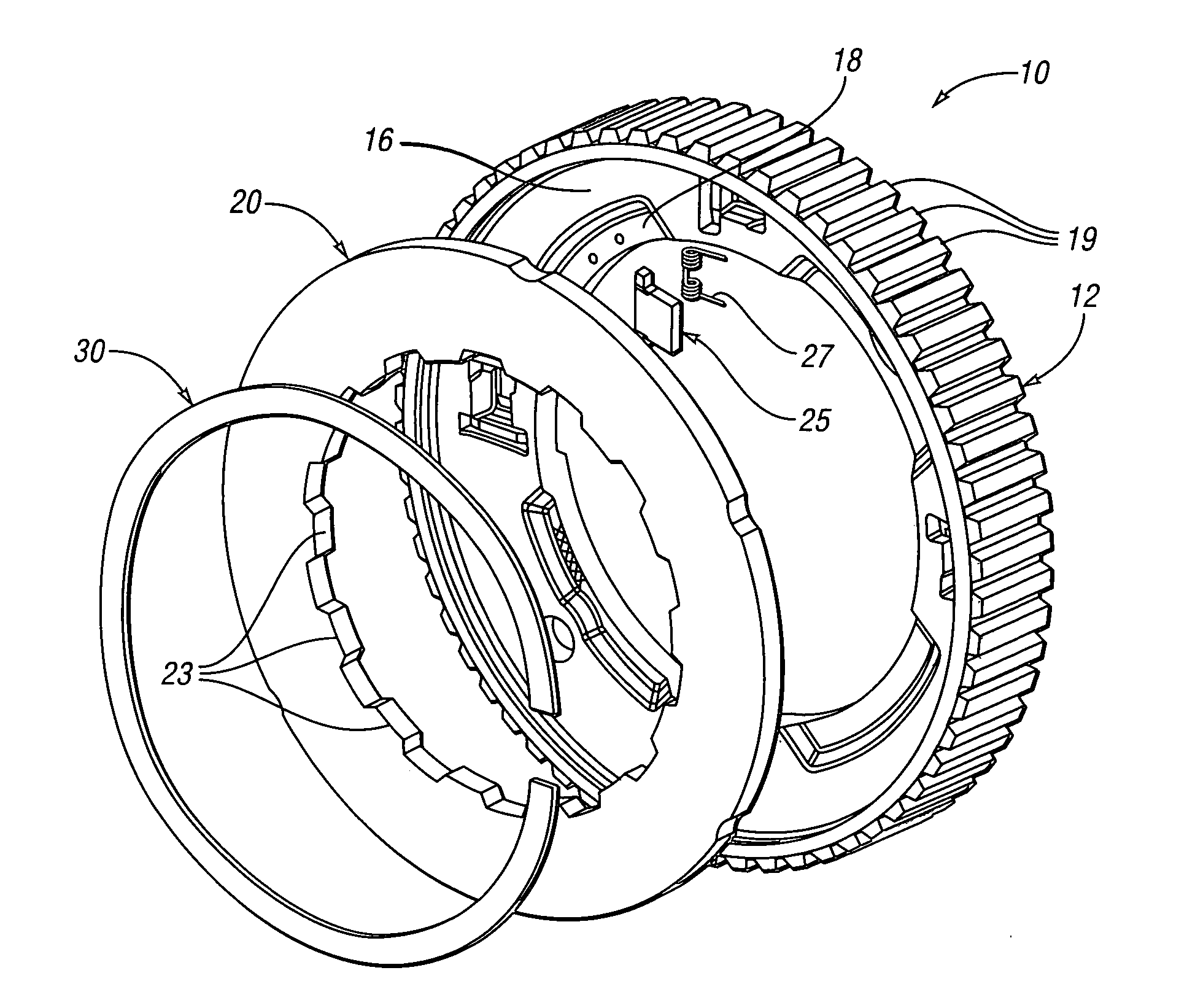

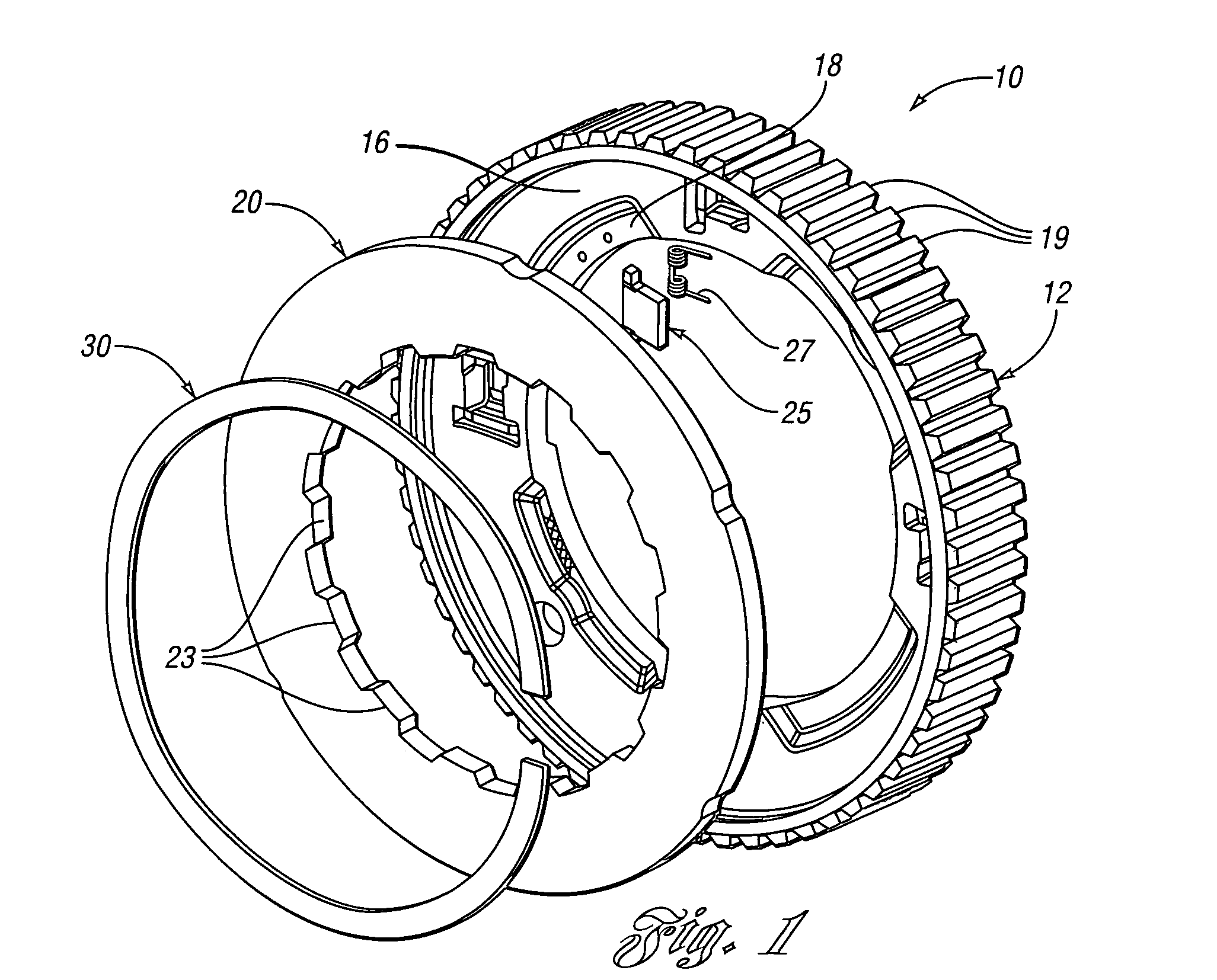

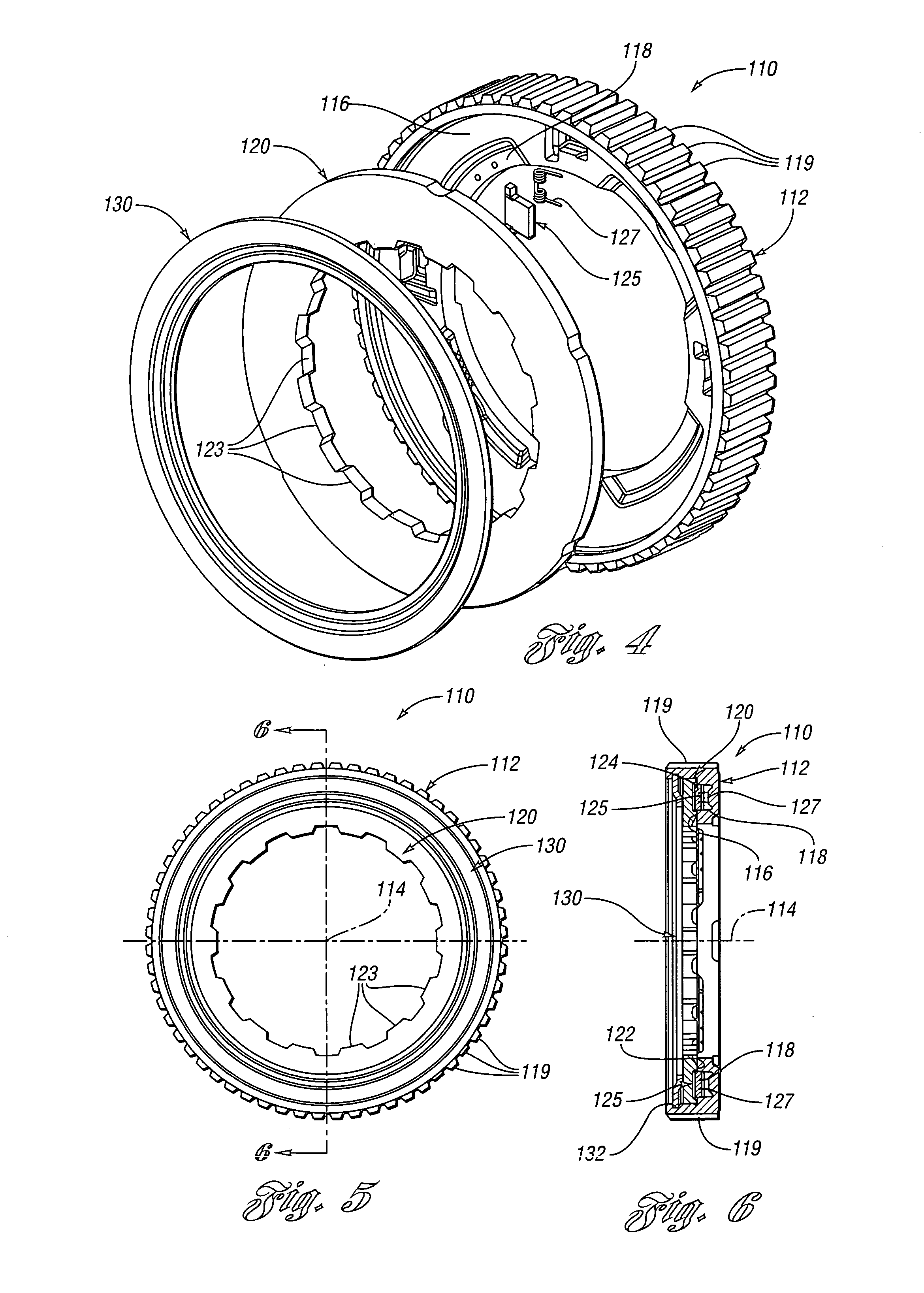

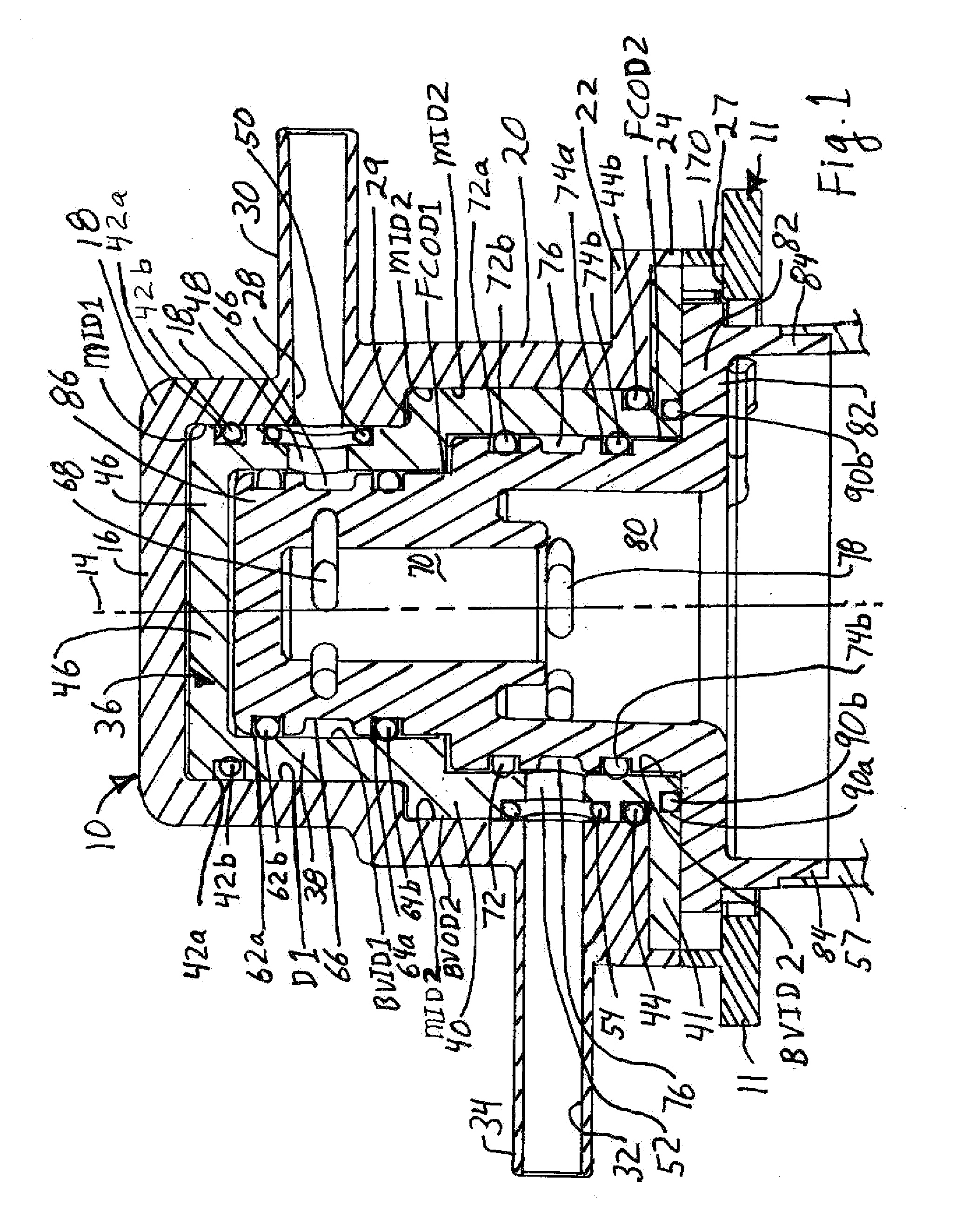

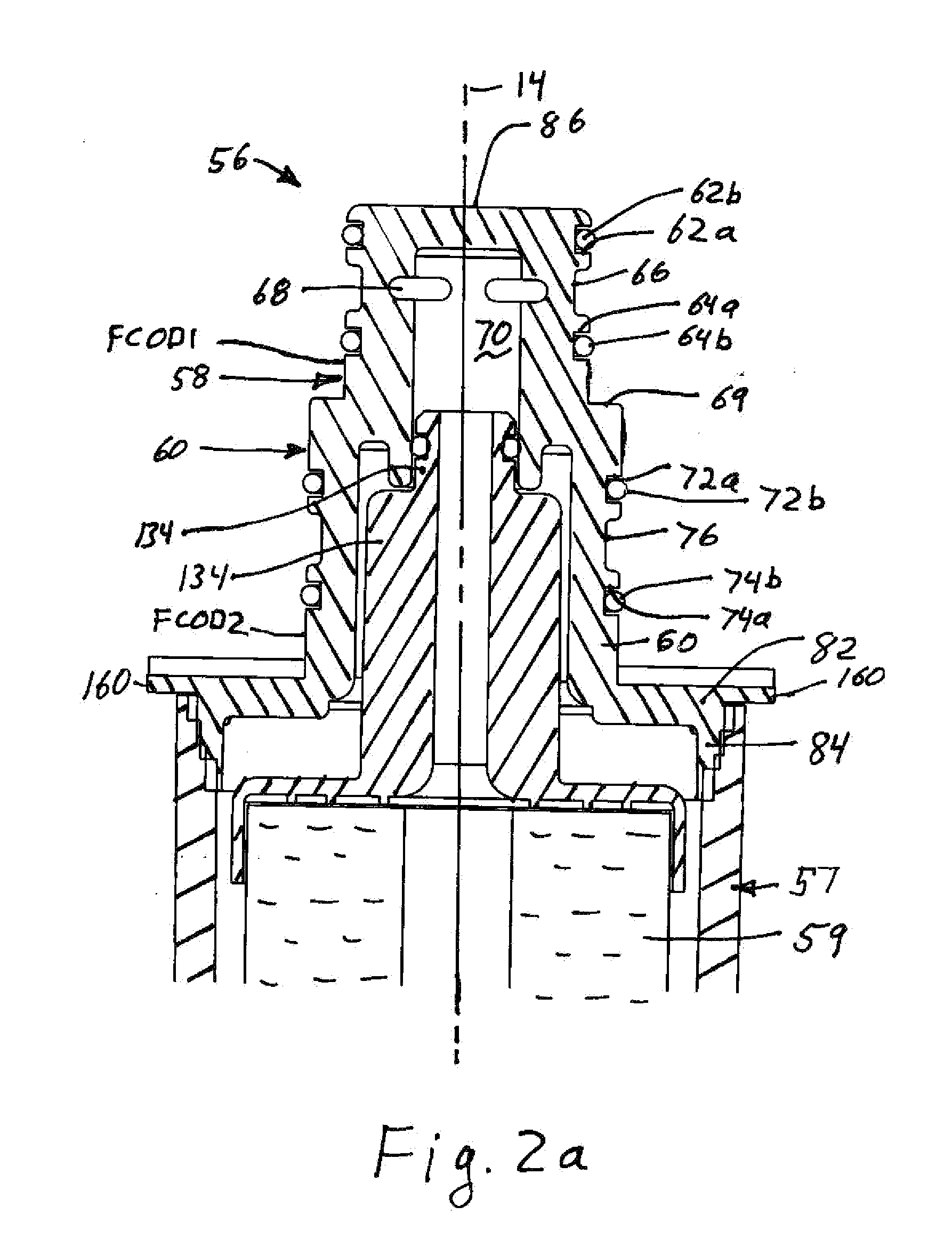

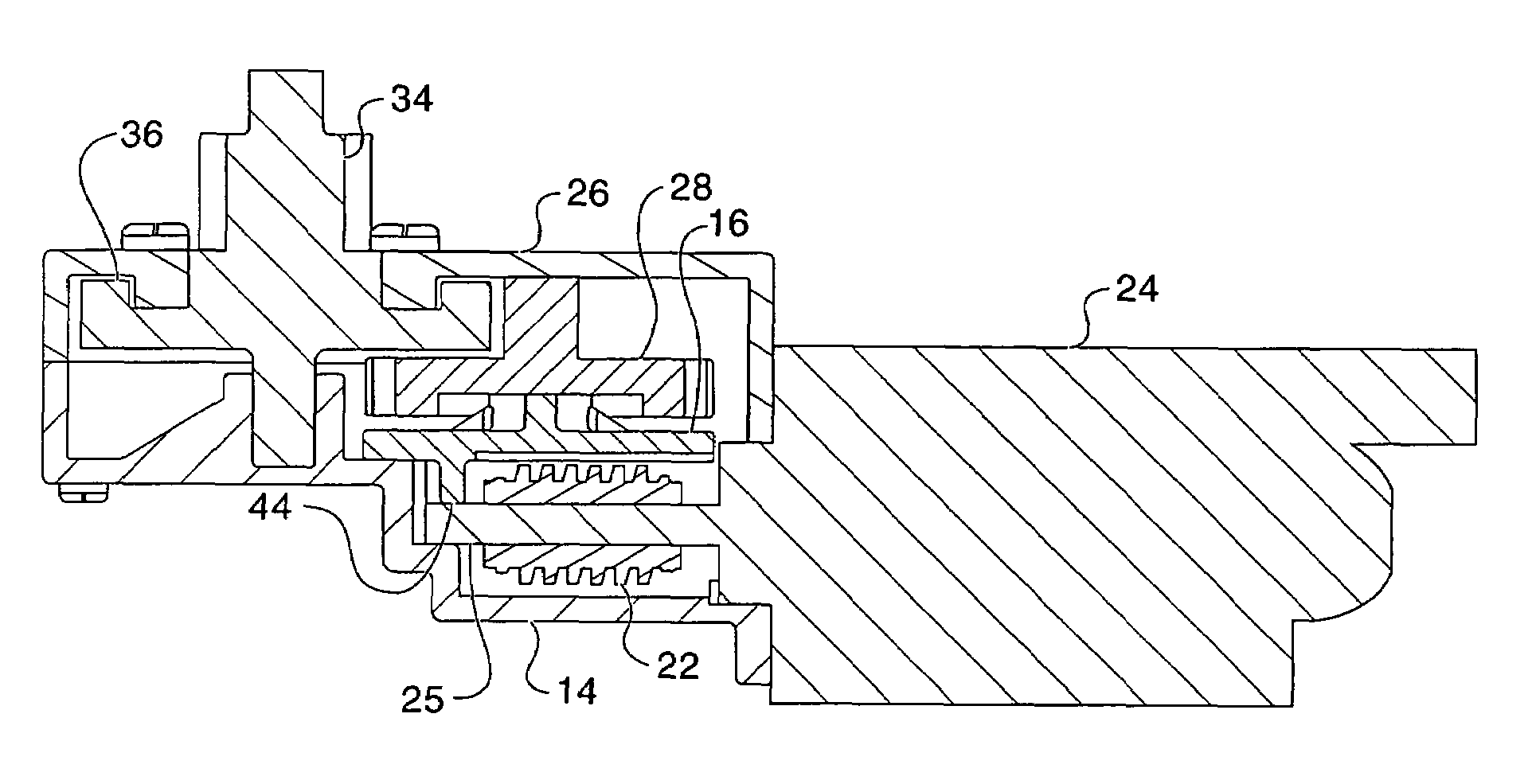

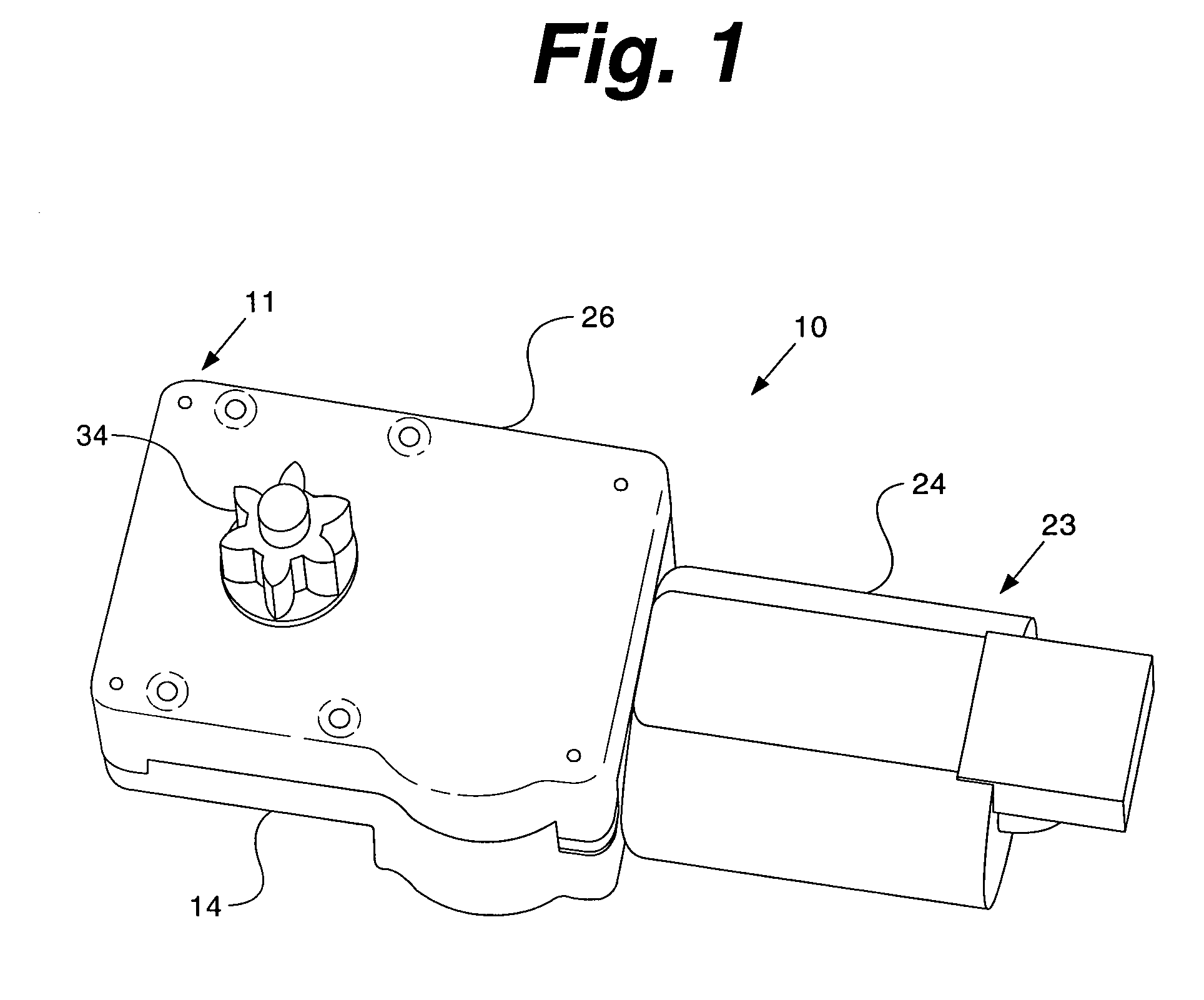

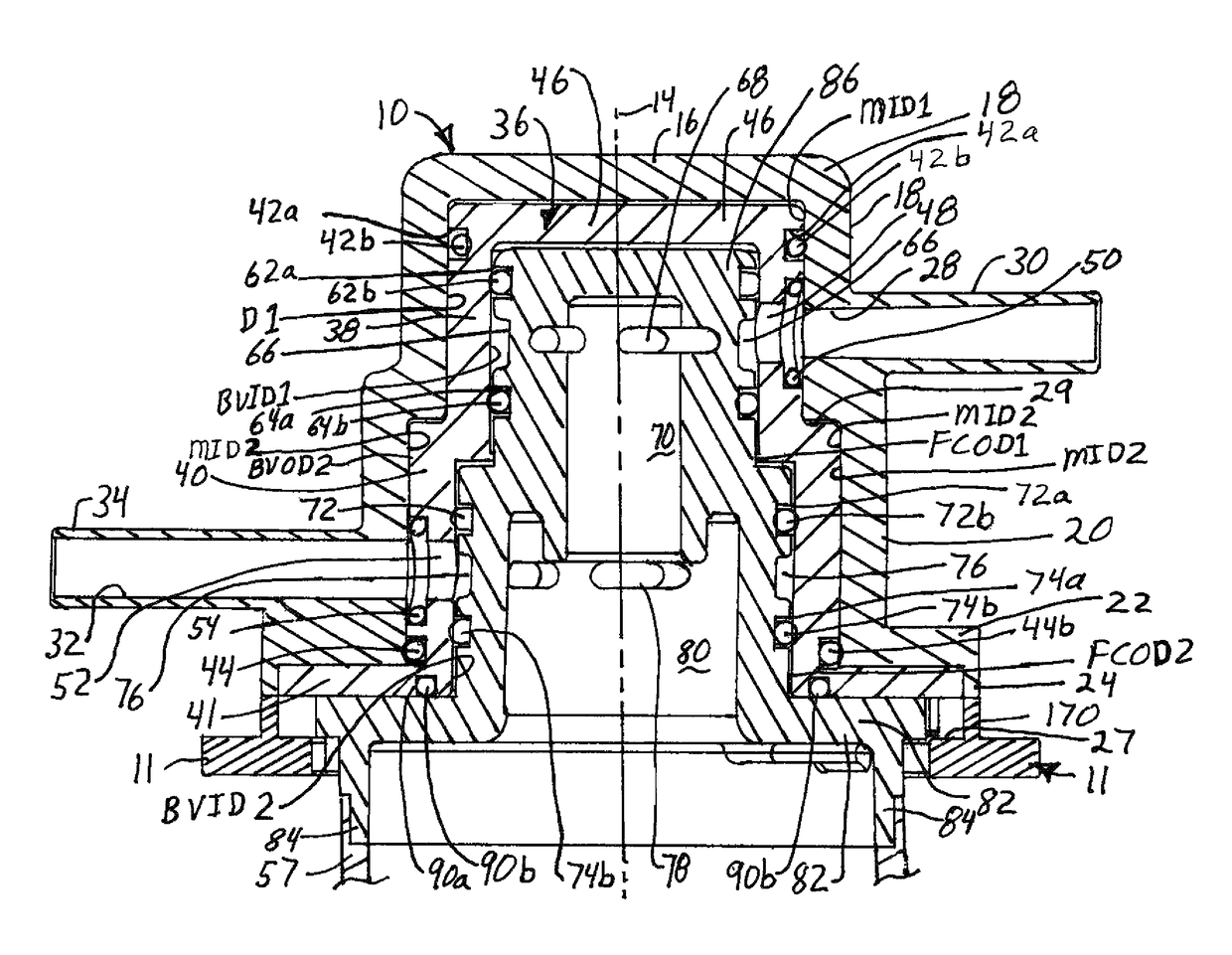

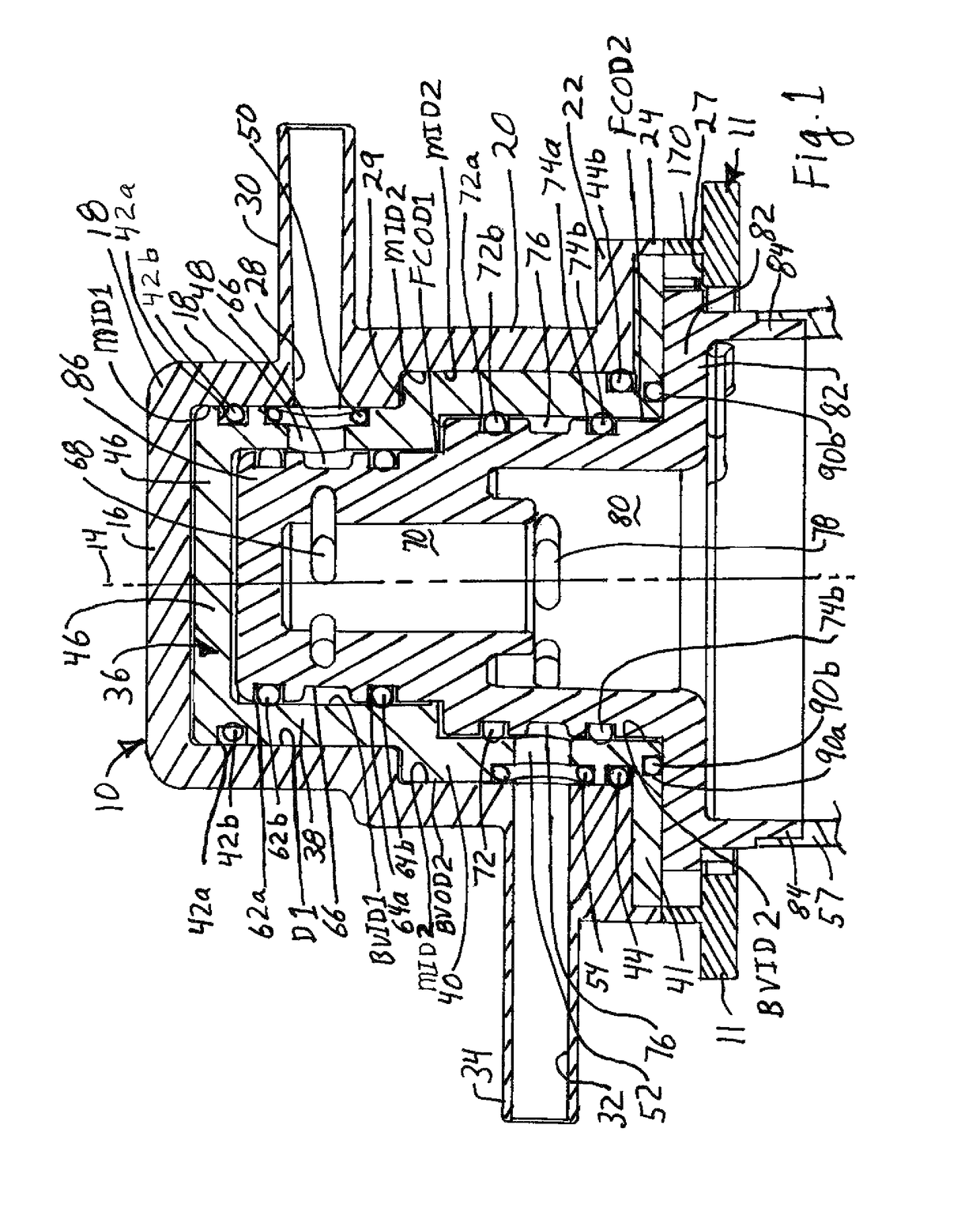

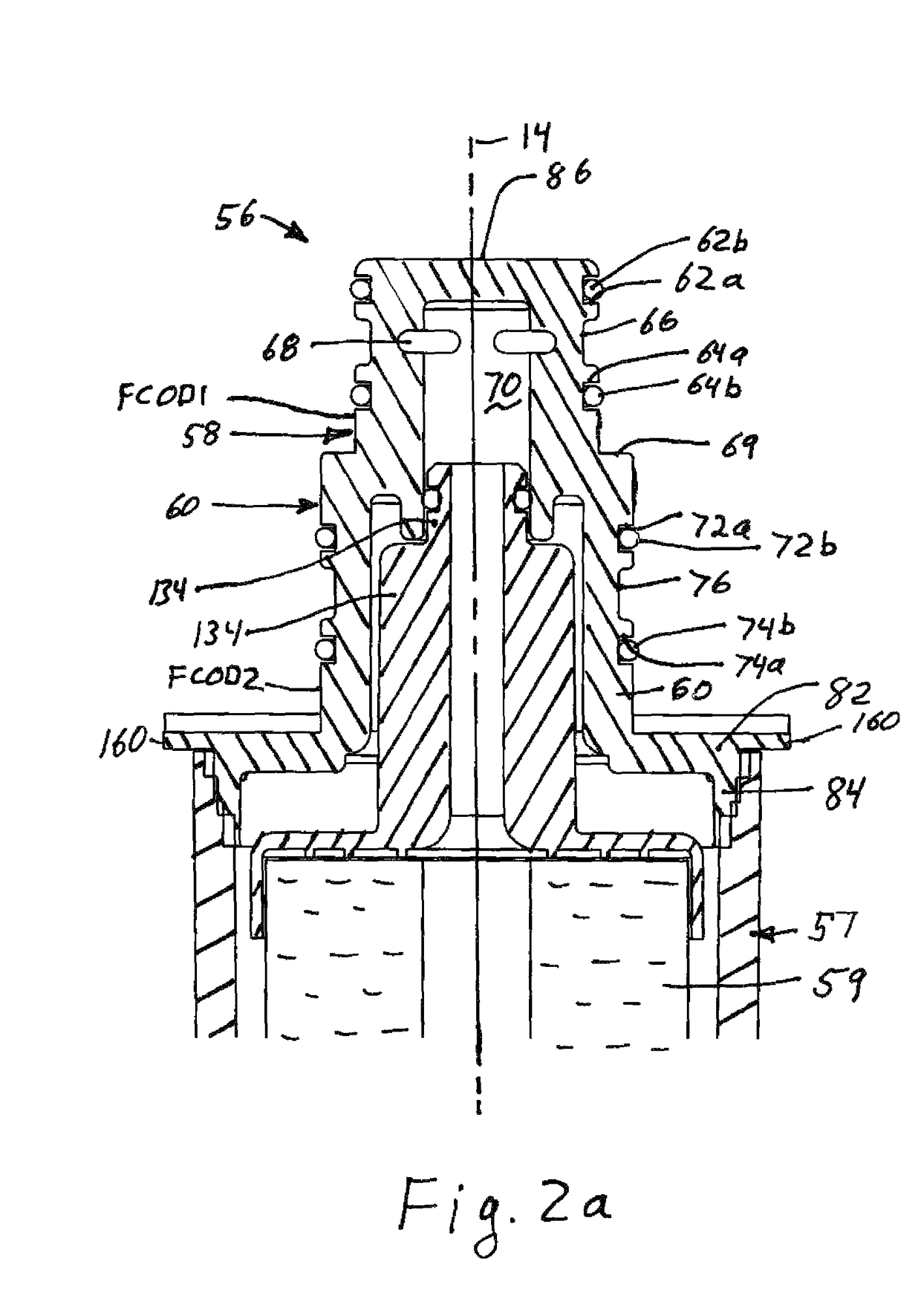

Overrunning coupling assembly having improved shift feel and/or noise reduction

ActiveUS7275628B2Improved shift feel and noise reductionReduce axial forceRotating vibration suppressionFluid actuated clutchesWave shapeCoupling

An overrunning coupling assembly having improved shift feel and / or noise reduction is provided. The assembly includes planar first and second members rotatable about a first axis. In a locked position, torque transfer is permitted between the first and second members in a first direction about the first axis. In a disengaged position, the first and second members are permitted to free-wheel relative to each other in a second direction opposite the first direction. A compliant retaining device retains the first and second members together and absorbs axial impact loads. The retaining device is less compliant in the locked position than in the disengaged position to decrease axial force at time of axial impact and improve shift feel and / or noise reduction. In a first embodiment, the retaining device includes a wave spring. In a second embodiment, the retaining device includes a stepped weir plate.

Owner:MEANS IND INC

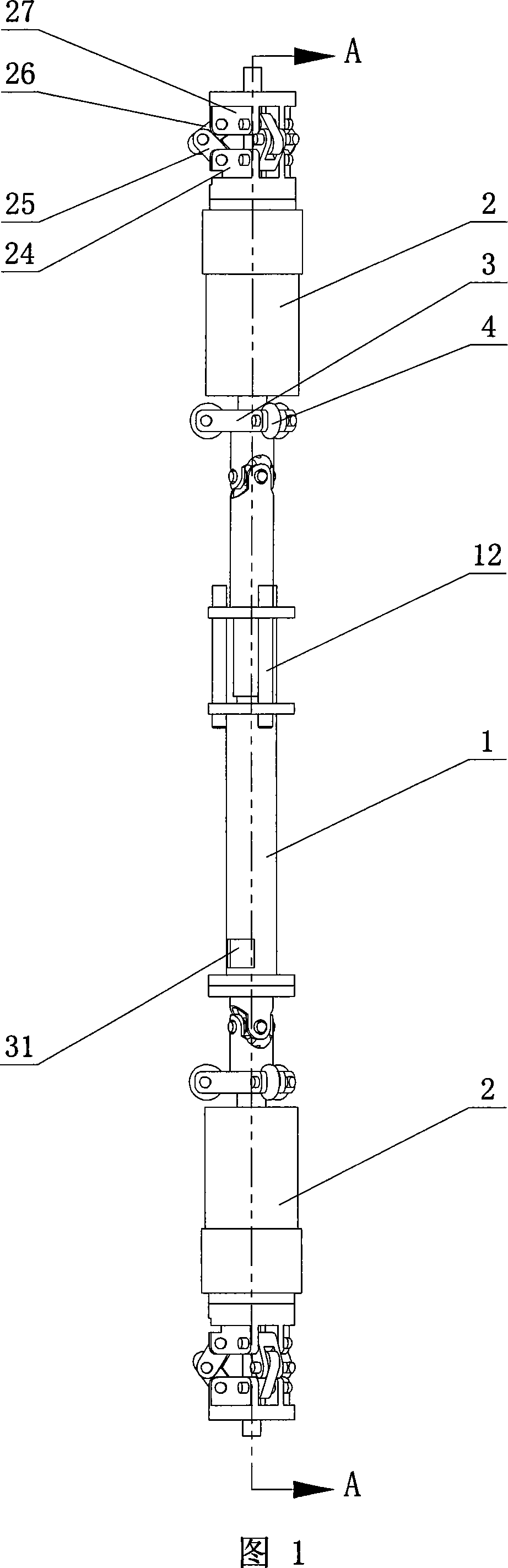

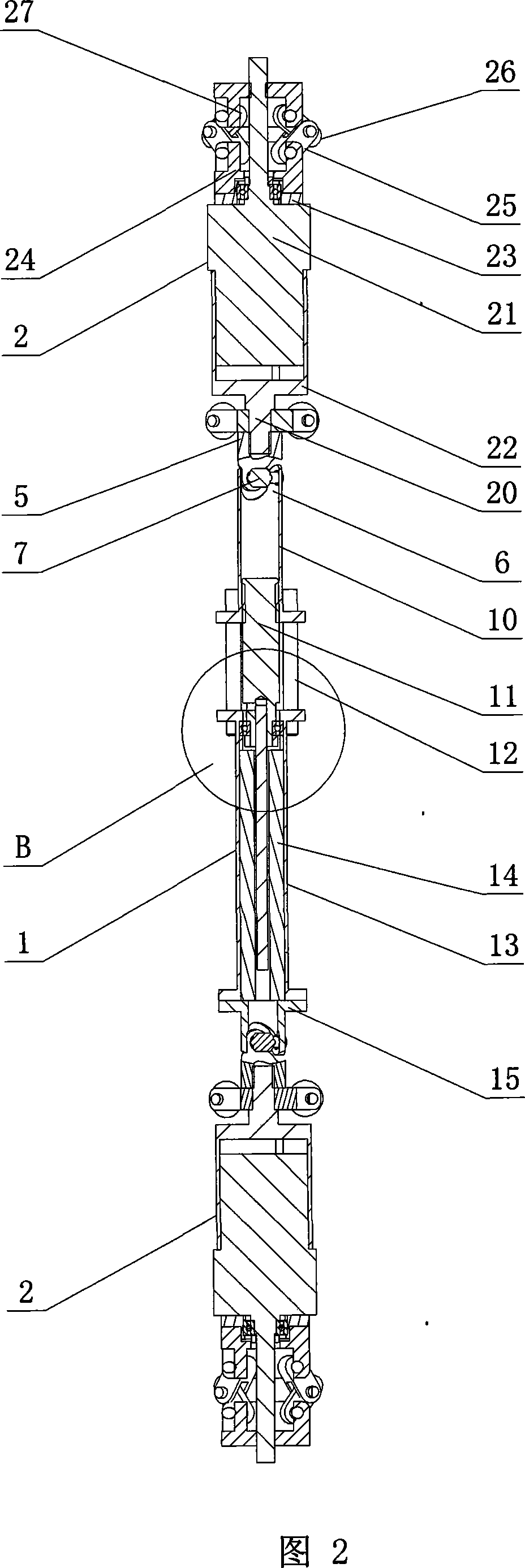

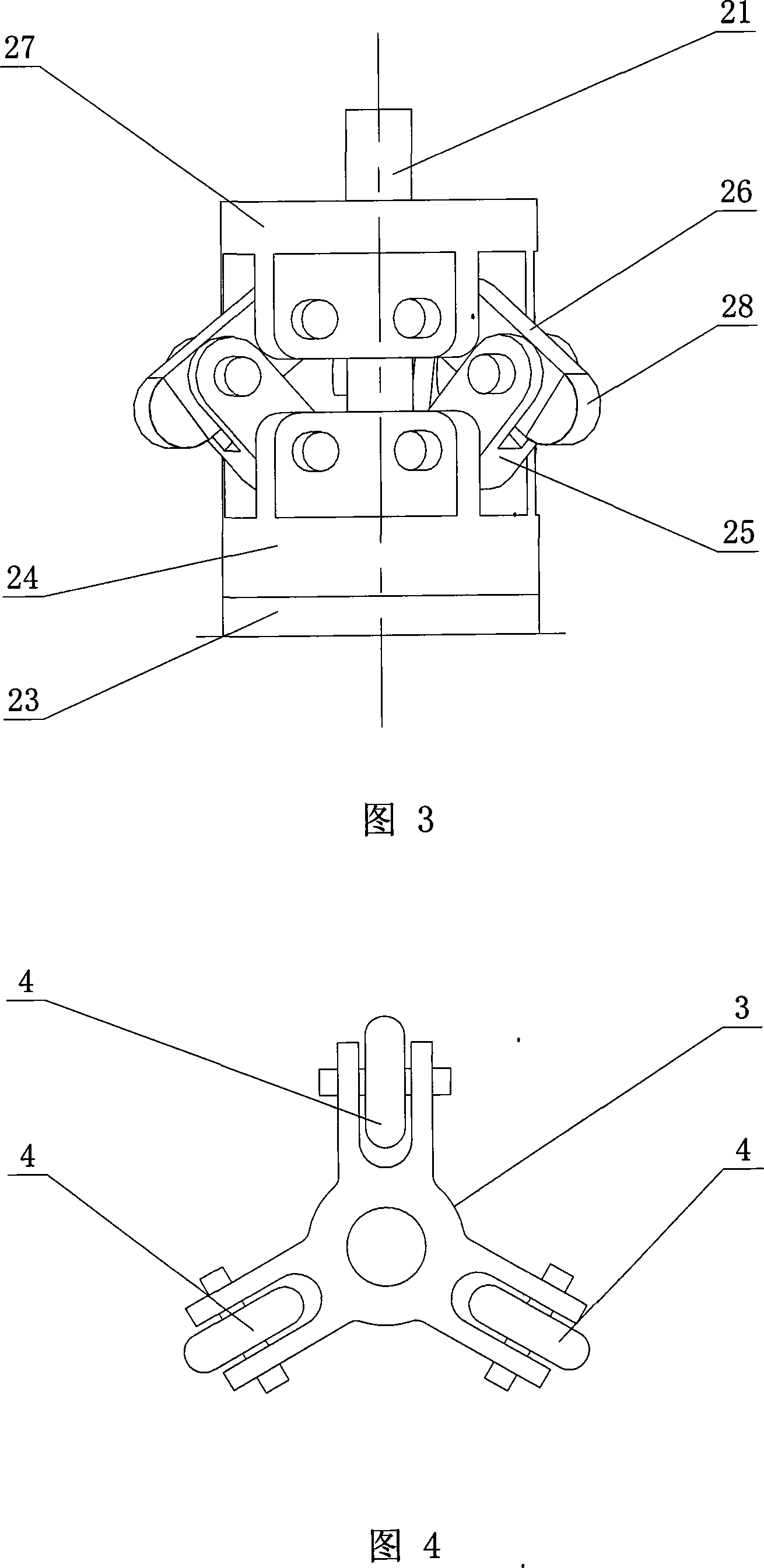

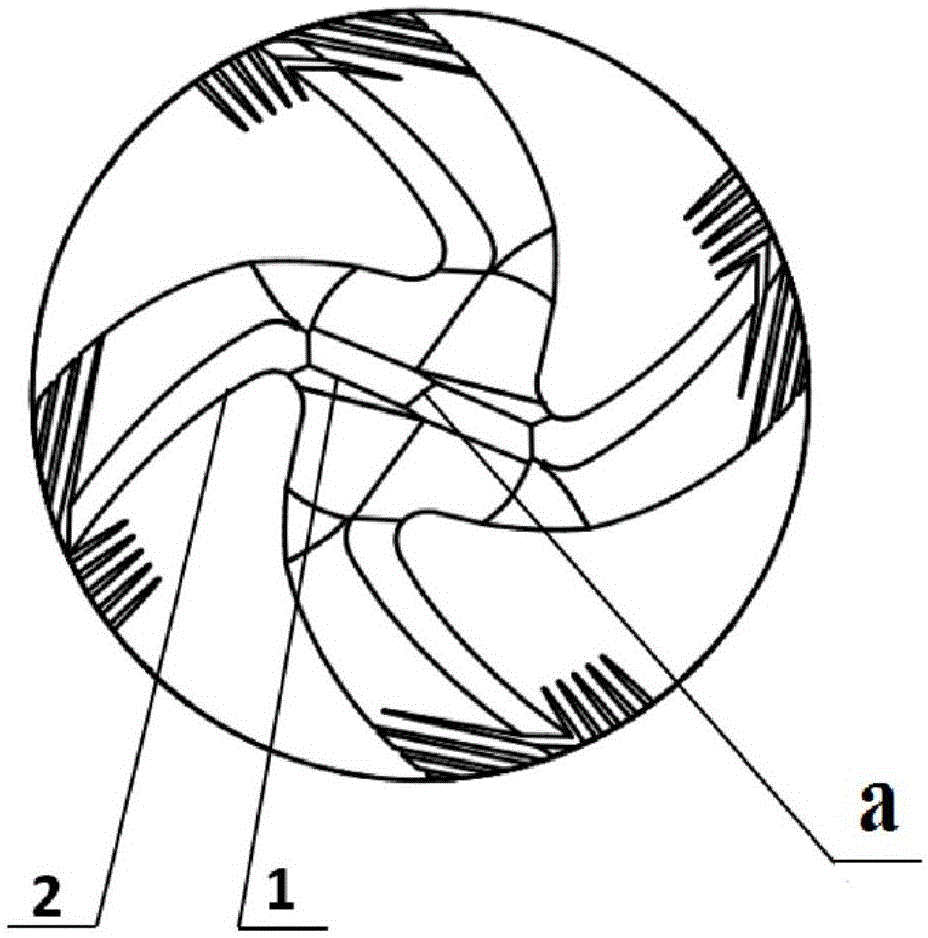

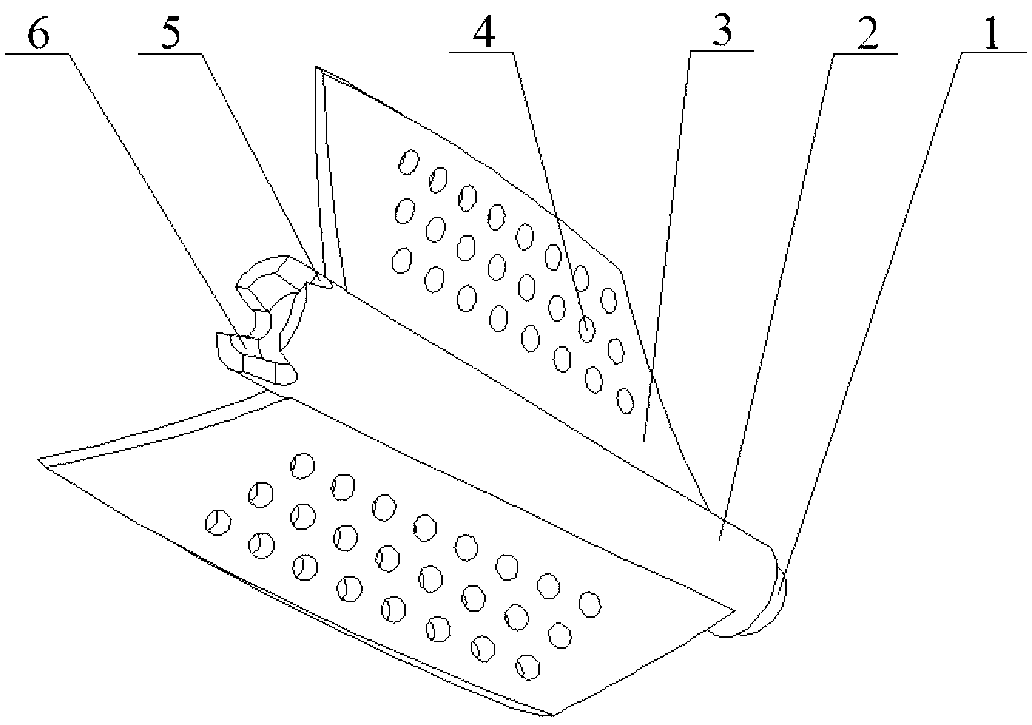

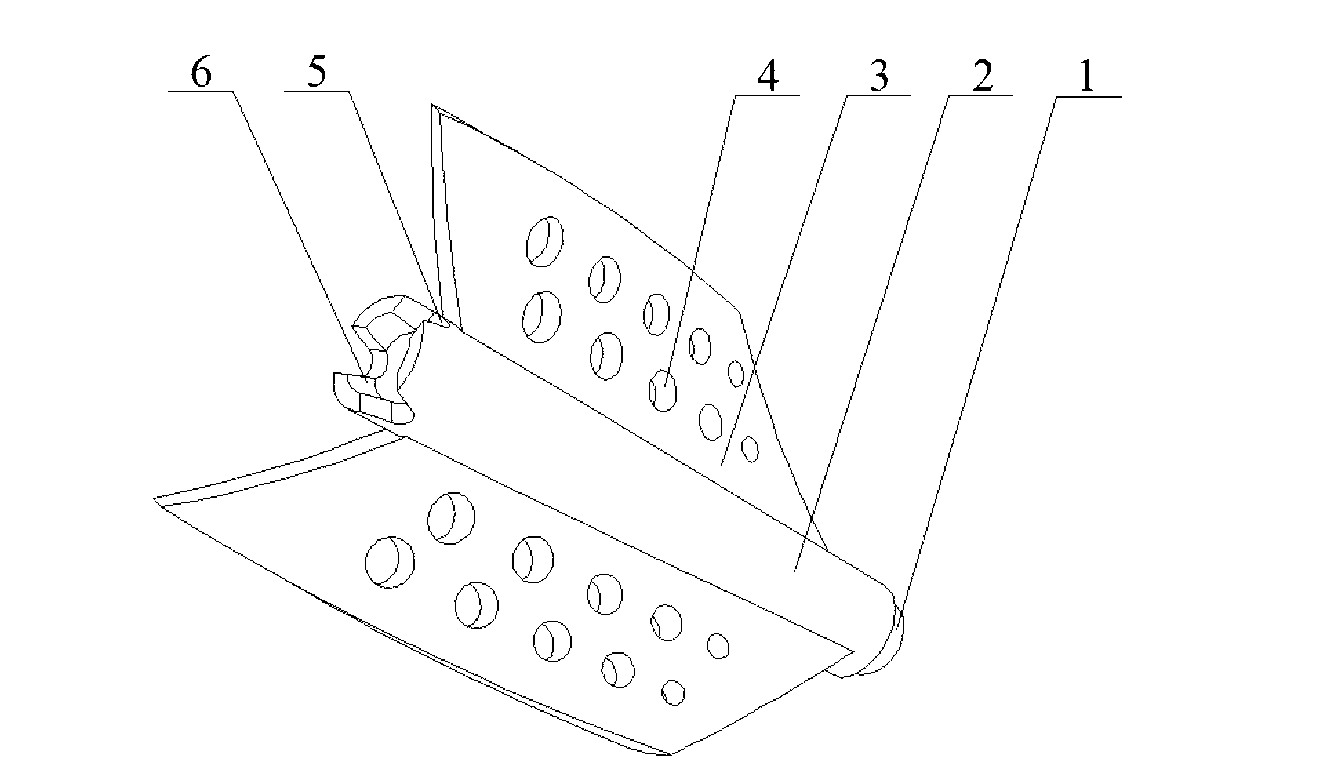

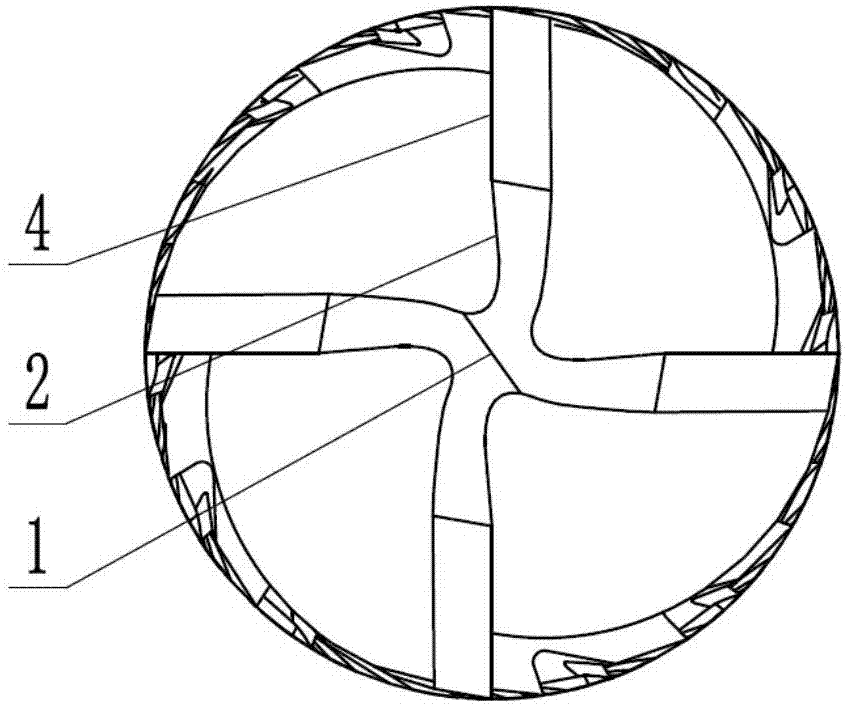

Crawling type micro pipeline robot

The invention discloses a creeping motion type mini pipeline robot, which comprises a middle stretching part and two supporting parts being able to be supported in the mini pipeline. The two supporting parts are respectively connected with the both ends of the middle stretching part, the supporting parts comprise nut supporting frames and driving devices driving the nut supporting frames to move backward and forward, rear supporting legs are hinged on the driving devices, front supporting legs are hinged on the nut supporting frames, and the rear supporting legs are hinged with the front supporting legs. The creeping motion type mini pipeline robot with enough driving traction force can freely move frontward and rearward in the mini pipeline with an arbitrary slope angle, can also creep in an upright pipeline, and can be embarked an extended function module, to realize the examining, the detecting and the maintenance of the condition in the mini pipeline.

Owner:NAT UNIV OF DEFENSE TECH

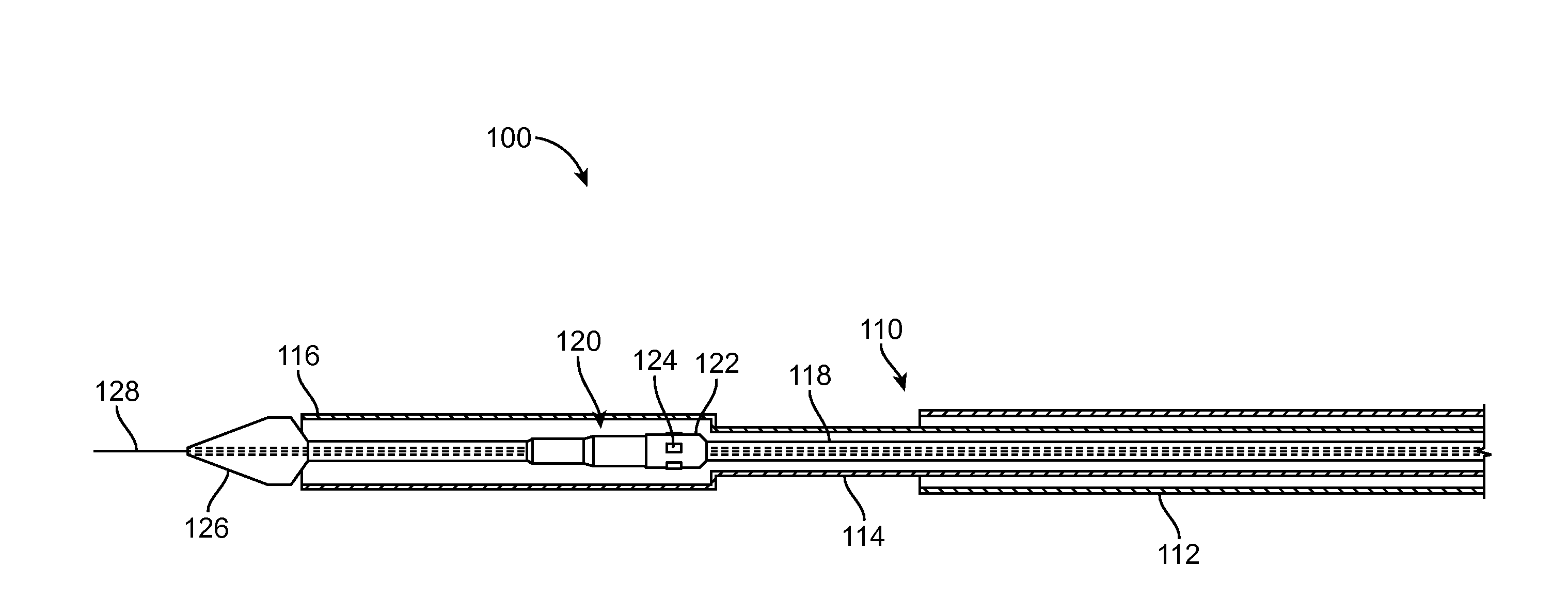

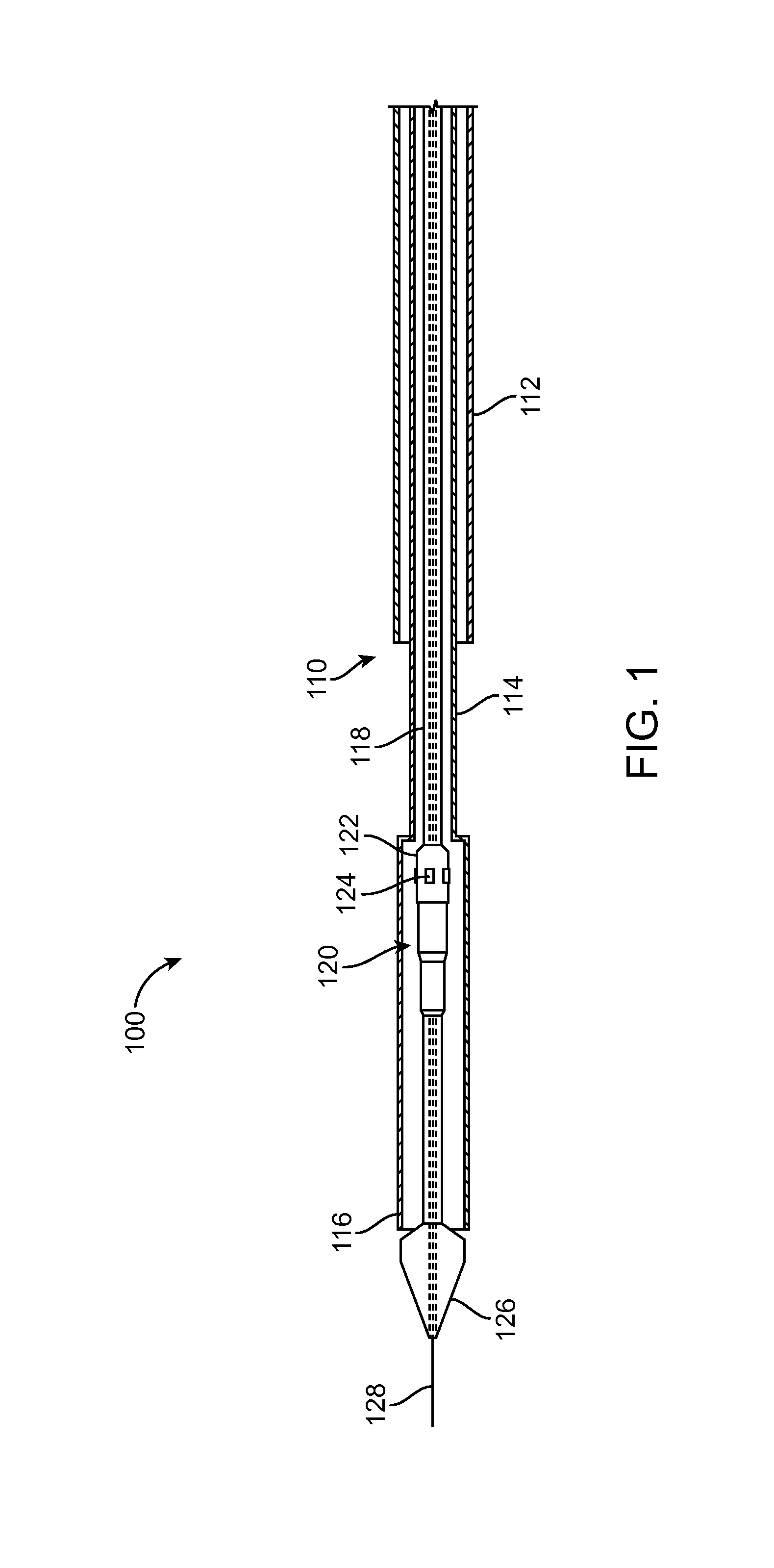

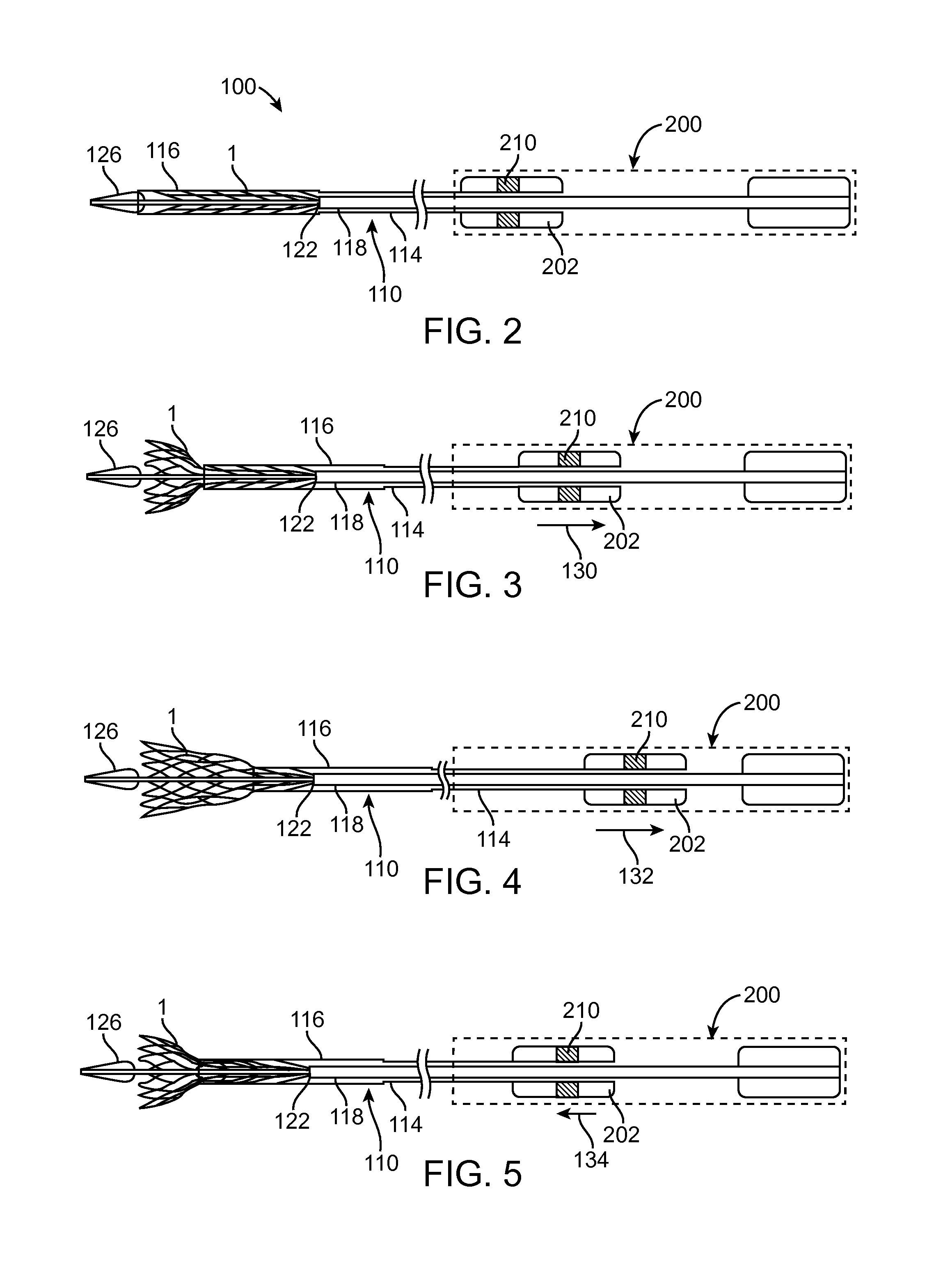

Transcatheter Valve Prosthesis Delivery System With Recapturing Feature and Method

ActiveUS20140128963A1Reduce coefficient of frictionReduce axial forceStentsHeart valvesCatheterDelivery system

A delivery system for percutaneously deploying a valve prosthesis. The system includes a catheter assembly including a delivery sheath capsule and a handle having an oscillating device. The capsule is configured to compressively retain the valve prosthesis during implantation. After the valve prosthesis is partially exposed during implantation, the oscillating device can create a vibratory motion to reduce the friction between the valve prosthesis and the delivery sheath capsule in order to recapture the valve prosthesis.

Owner:MEDTRONIC INC

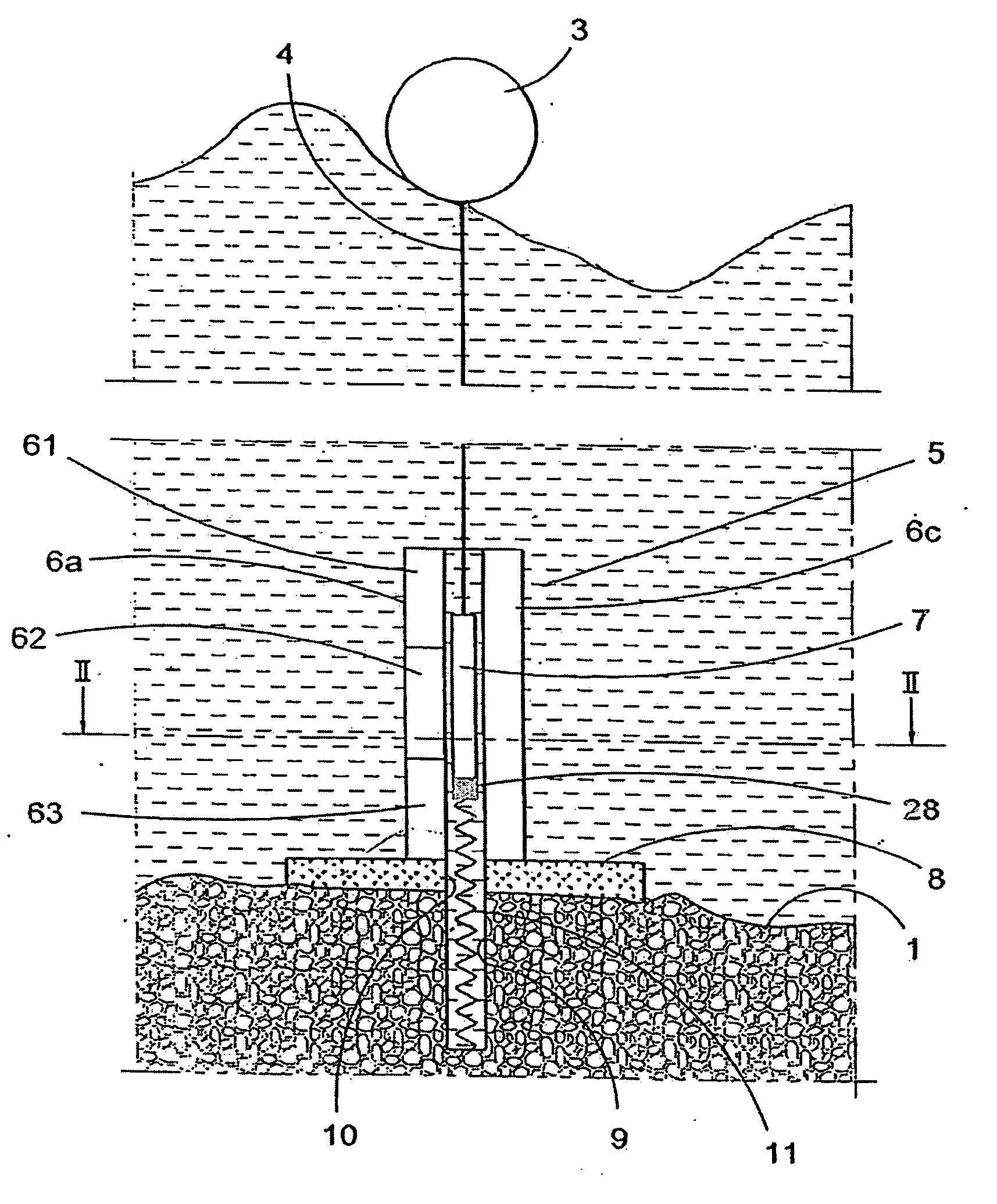

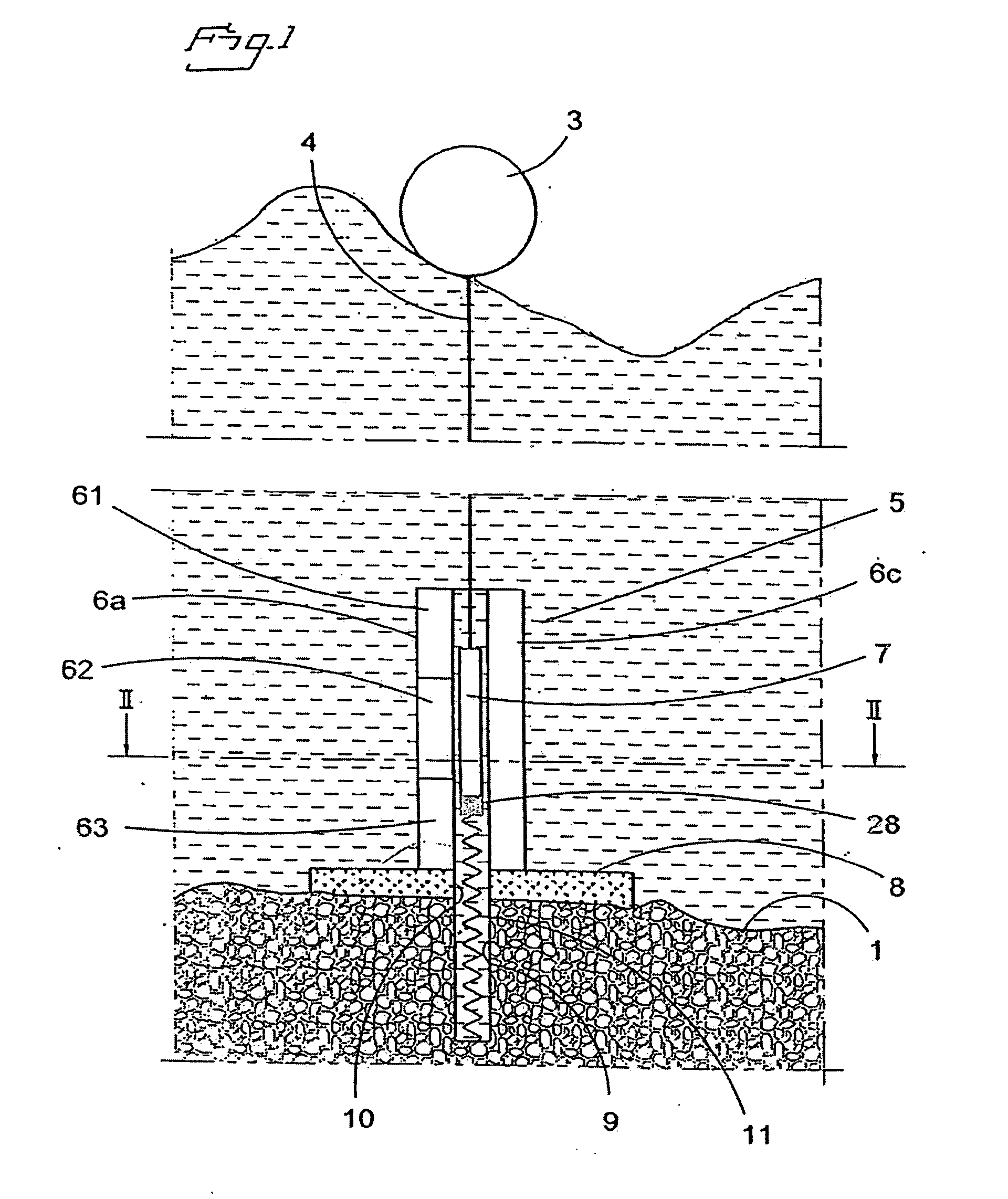

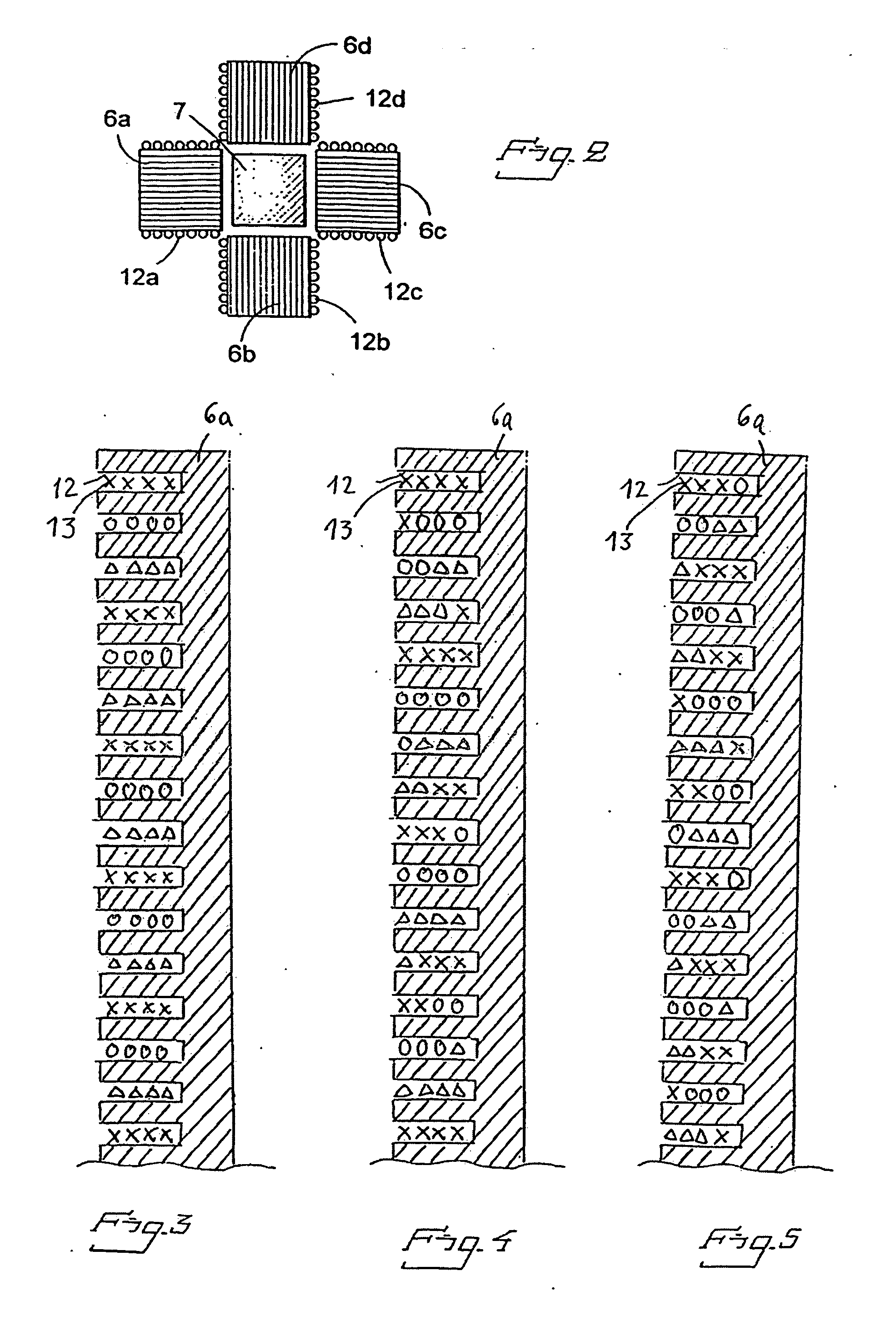

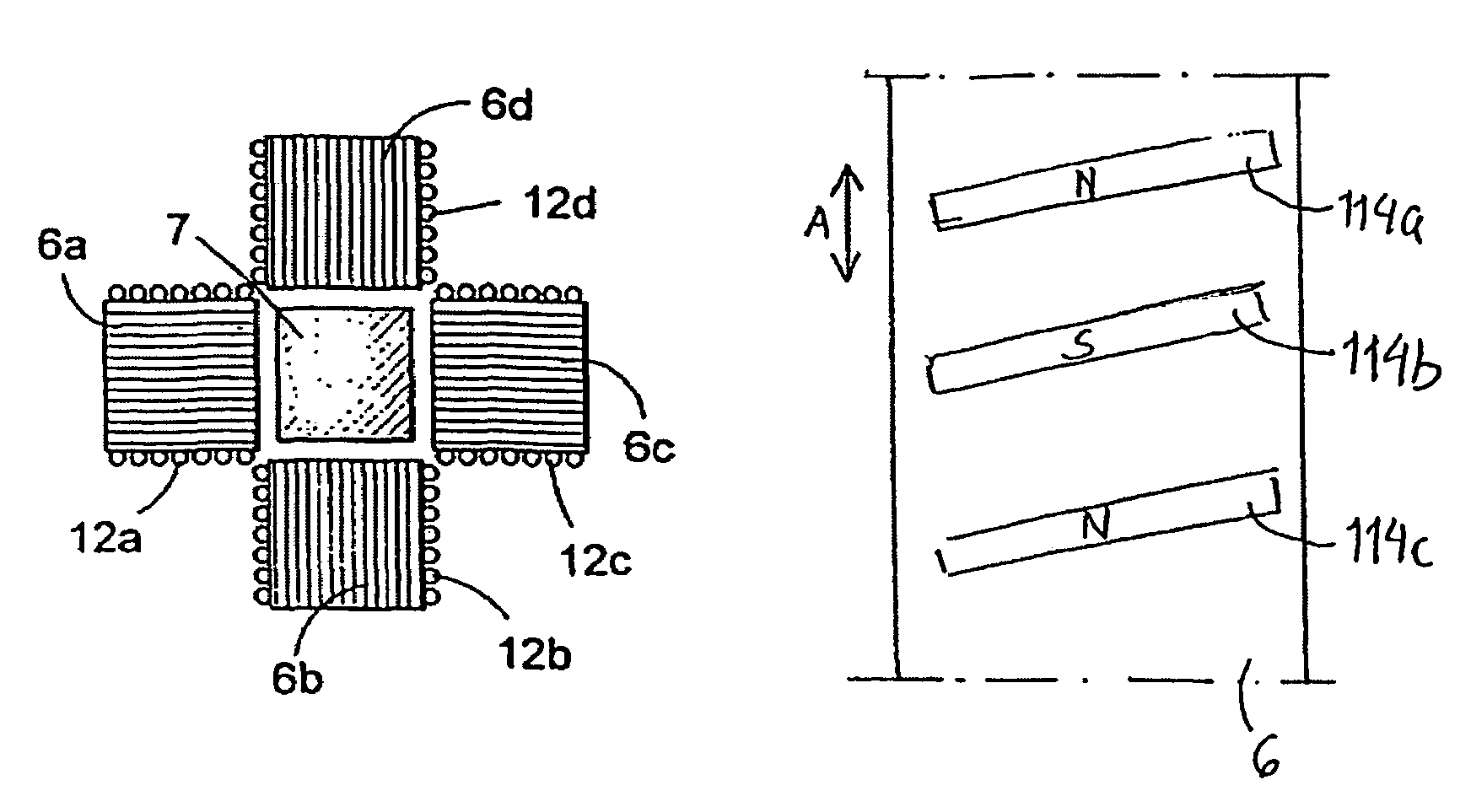

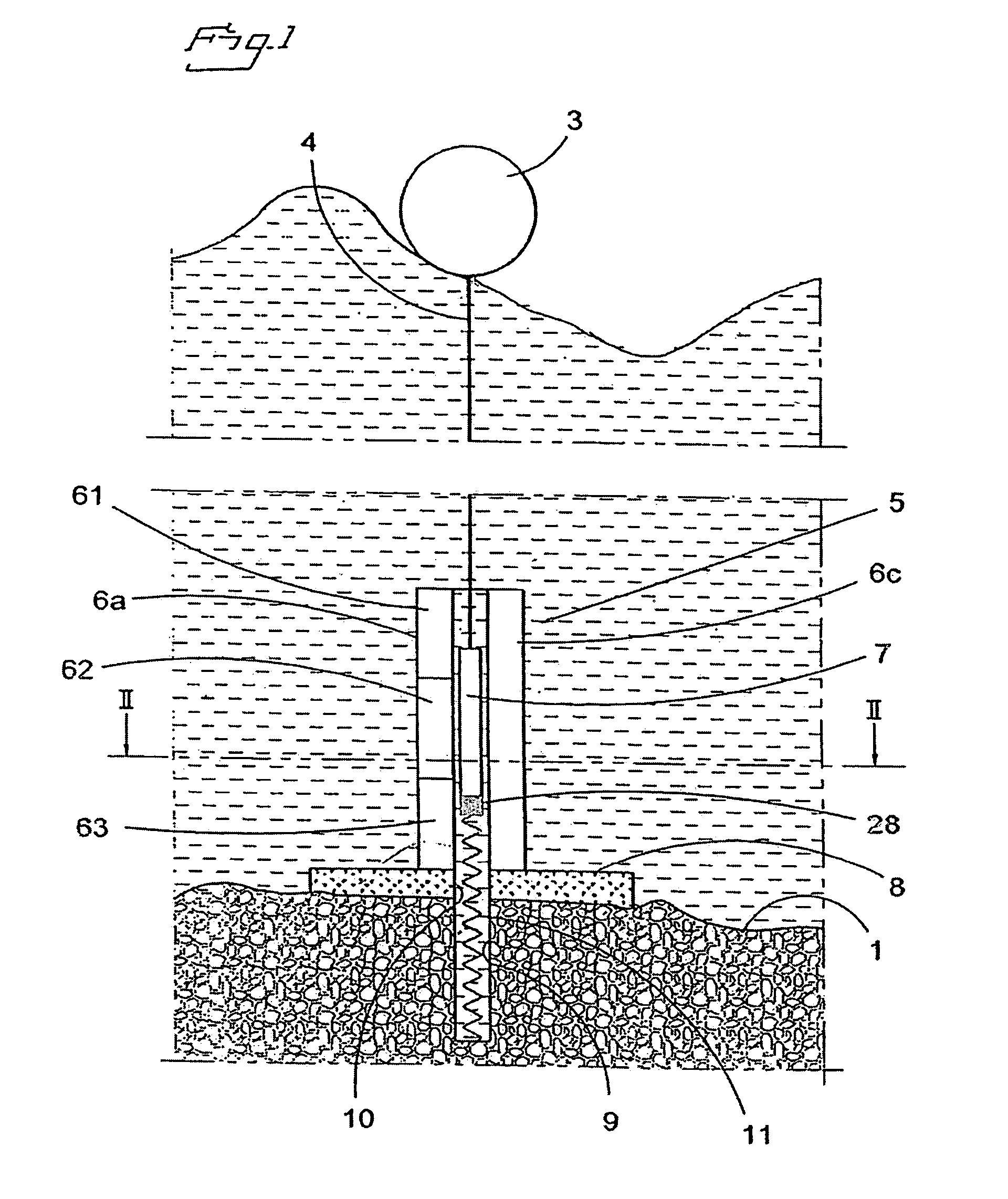

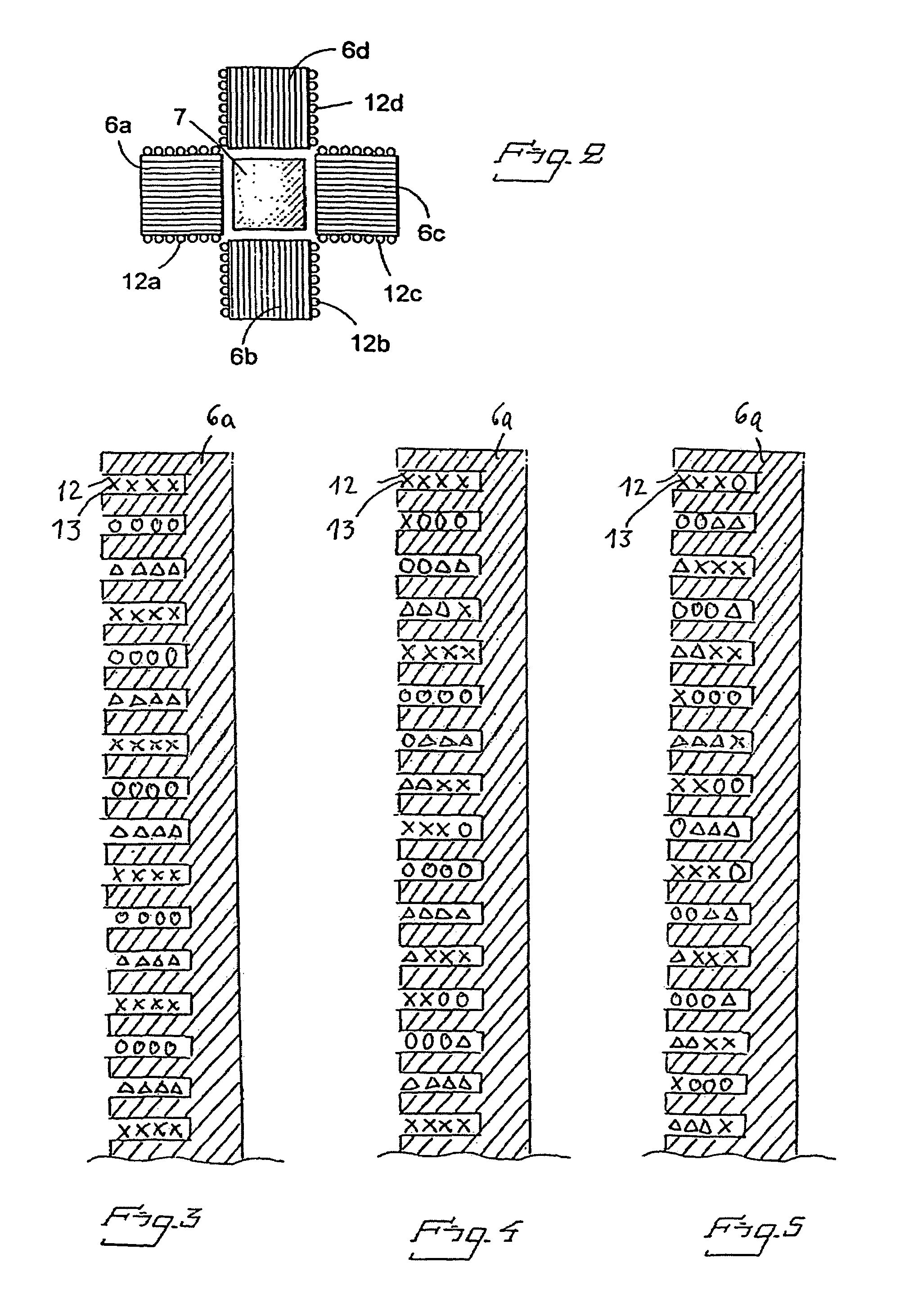

Wave power assembly with an electromagnetic dampning means

InactiveUS20070040384A1Improve efficiencyReduce riskMachines/enginesEngine componentsRotor magnetsEngineering

A wave power assembly comprising a hull and a linear electric generator. The rotor is connected to the hull and the stator is arranged to be anchored at a sea / lake bottom. The generator is provided with an electromagnetic damping means in order to keep the pulsations of the axial force exerted by the stator on the rotor at a relatively low level, which damping means comprises geometric arrangement adapted herefor of at least some one of the stator winding, the stator slots and the rotor magnets. The invention also relates to a wave power plant built up from wave power assemblies according to the invention. Furthermore, the invention relates to a use of the wave power assembly and a method for generation of electric energy.

Owner:SEABASED AB

Hydraulic shaping device of stainless steel lined compound pipe and its shaping method

InactiveCN1651163AUniform expansion forceManufacturing quality is easy to guaranteeHydroformingCopper

A hydraulic apparatus for forming a composite pipe with stainless steel liner is composed of core rod, left and right expanding ehads fixed respectively to both ends of said core rod, two self-fastened sealing rings for left and right expanding heads, and the fixers at the ends of said expanding heads. Its forming technology is also disclosed.

Owner:EAST CHINA UNIV OF SCI & TECH

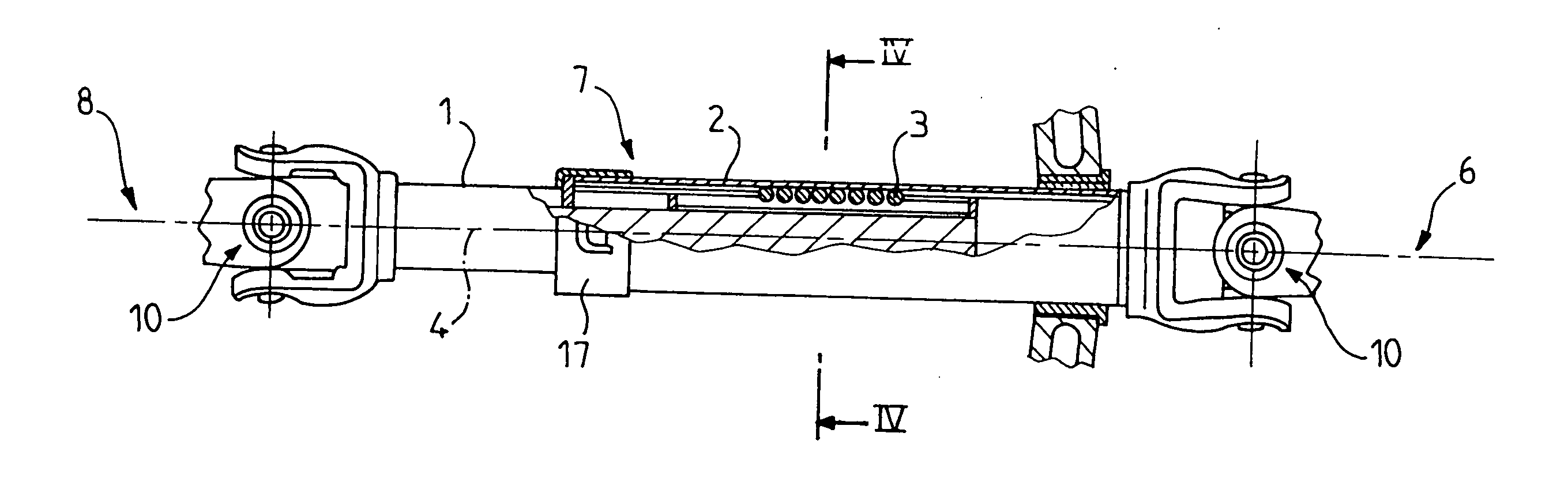

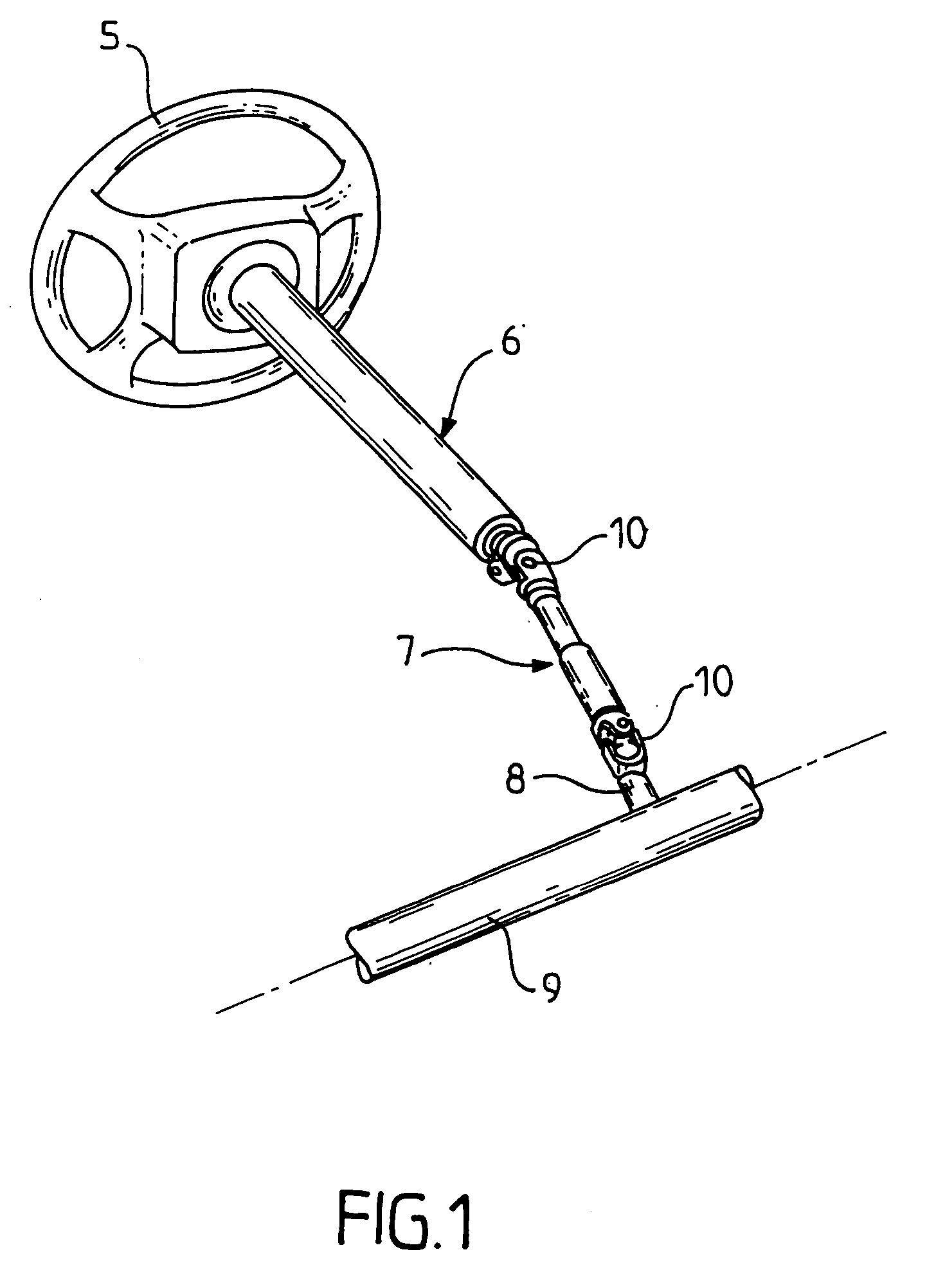

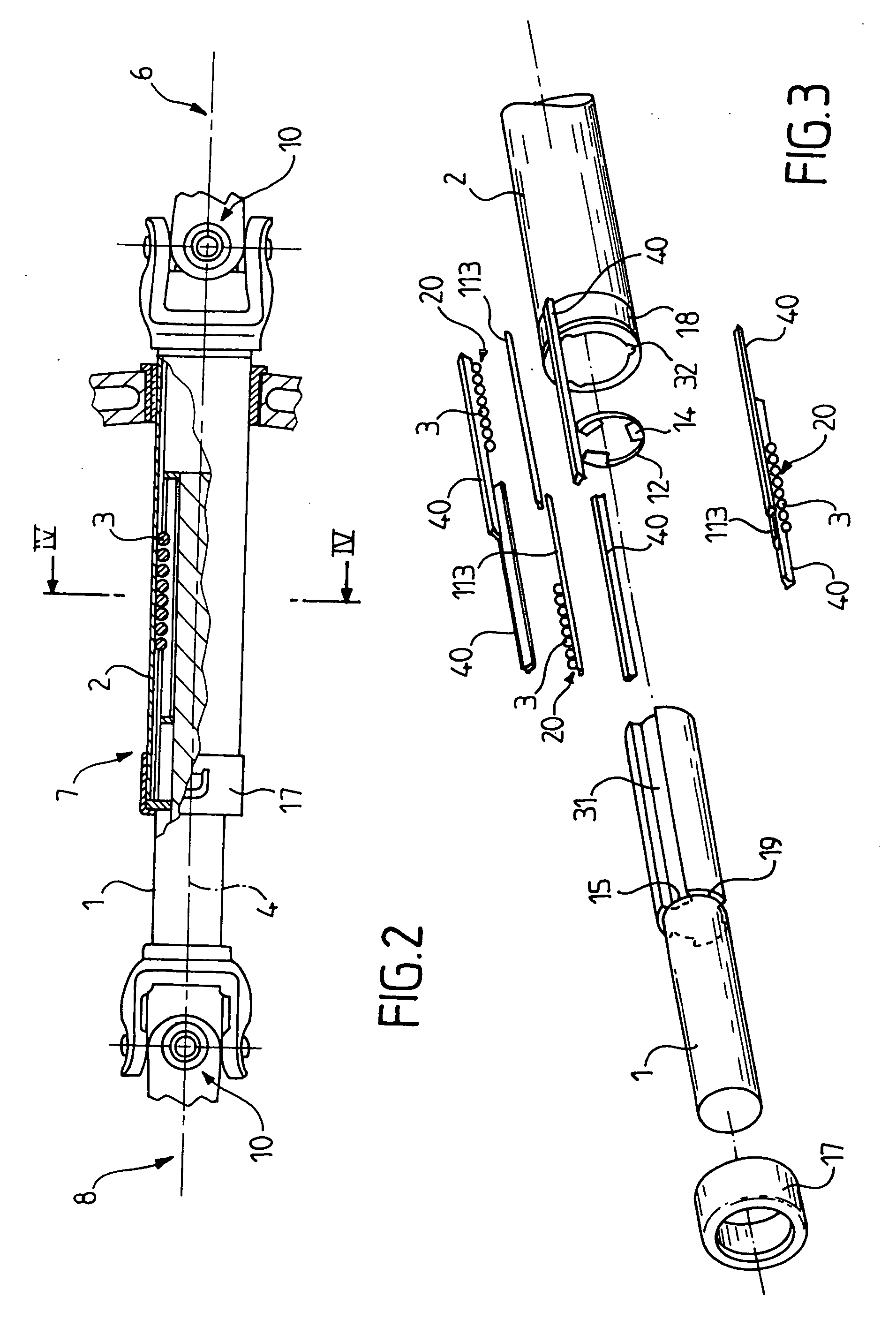

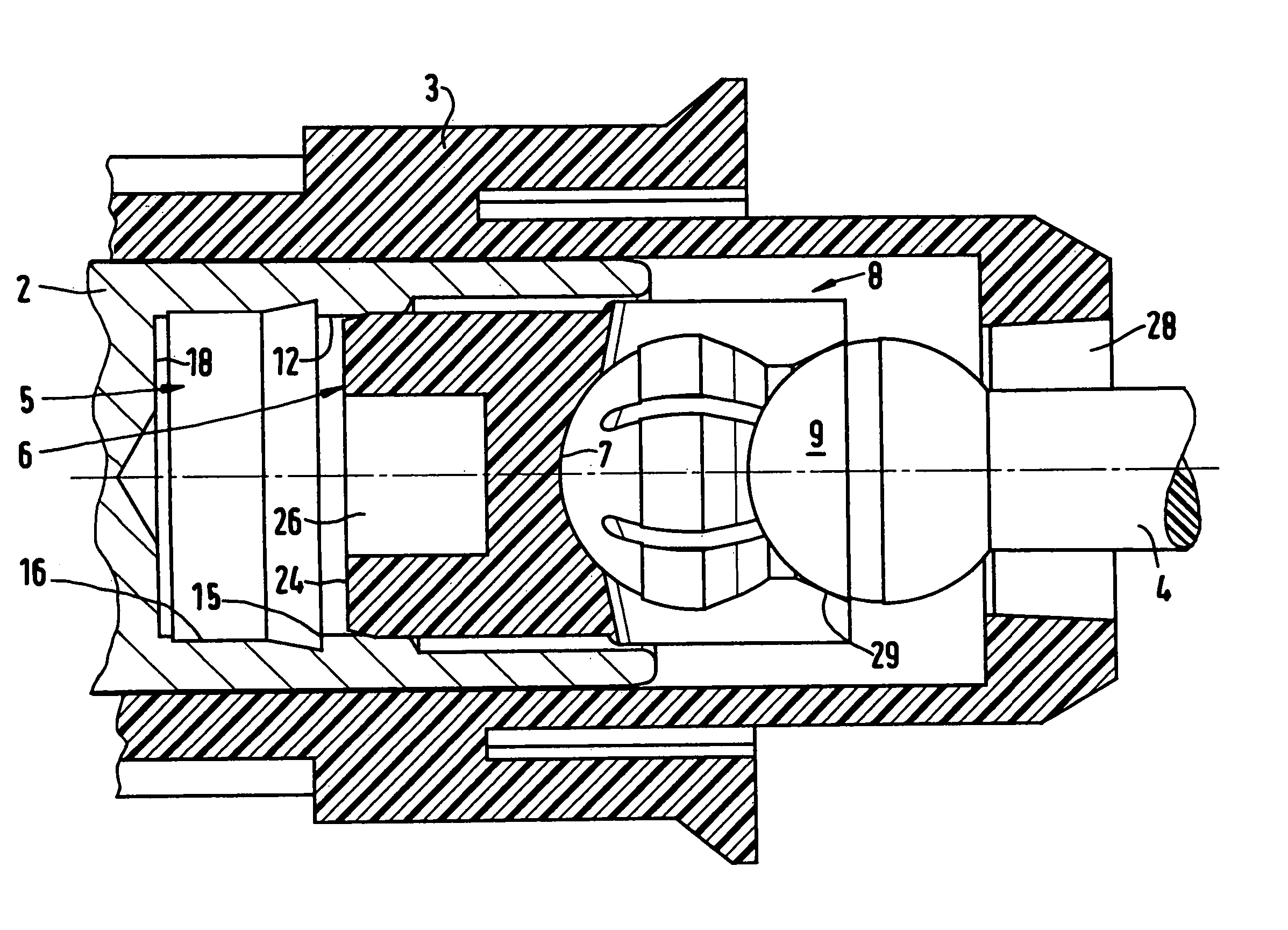

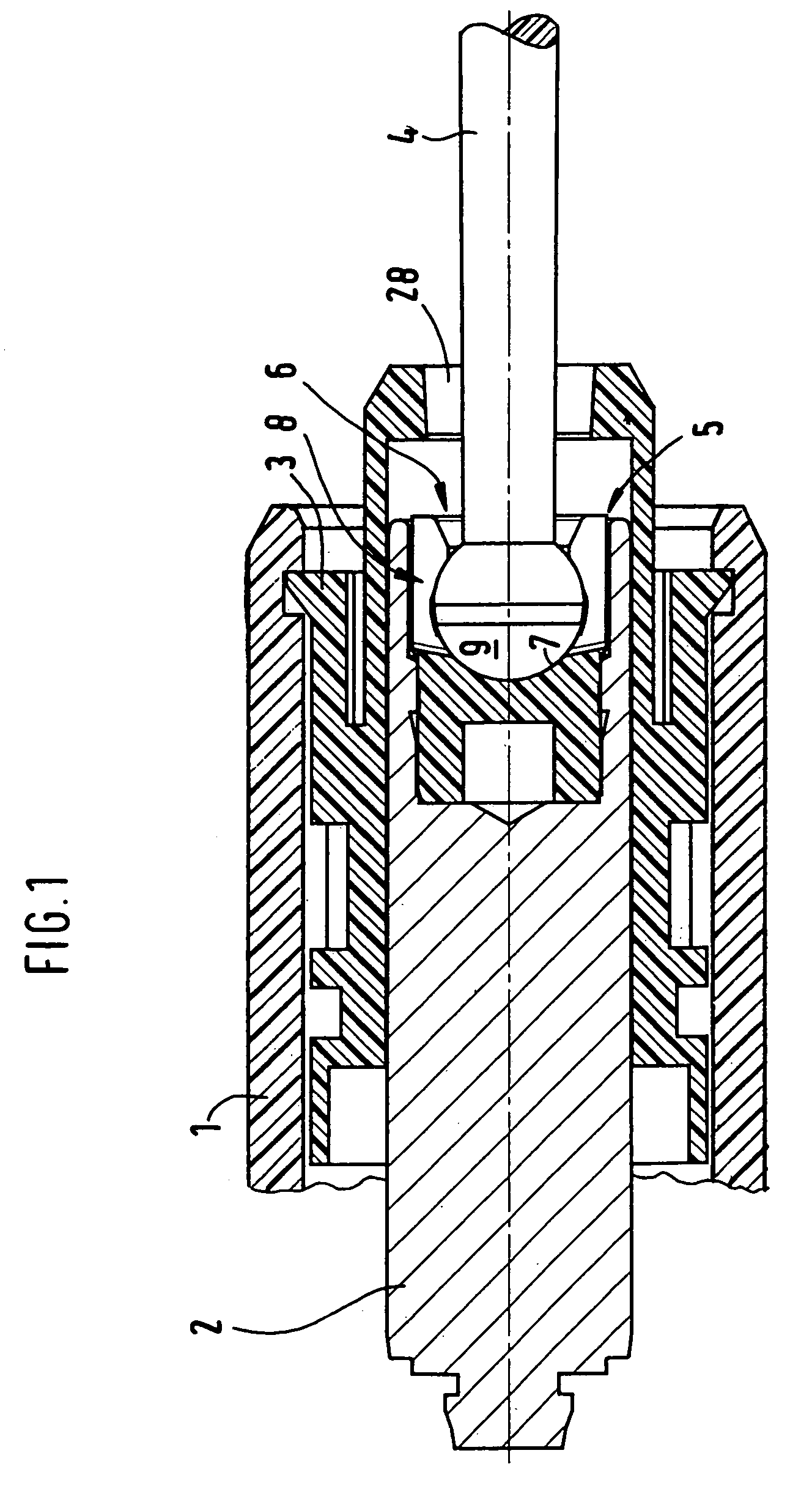

Ball coupling device for keeping two sliding shafts articulated

ActiveUS20060053934A1Reduce axial forceAvoids axial jerkYielding couplingLinear bearingsMechanical engineering

Device for coupling an inner shaft and an outer shaft that slide in the direction of a common axis with balls disposed between the two shafts. The balls are disposed in axial grooves of the inner shaft and in axial grooves of the outer shaft. Each row of balls is held by a double spring member that bears on the groove and which pushes on two rolling tracks for the balls, which come into contact with the groove. The two rolling tracks are articulated at the junction of the groove and the inner shaft.

Owner:ROBERT BOSCH AUTOMOTIVE STEERING VENDOME SAS

Wave power assembly with an electromagnetic dampning means

InactiveUS7355293B2Improve efficiencyReduce riskMachines/enginesEngine componentsRotor magnetsEngineering

Owner:SEABASED AB

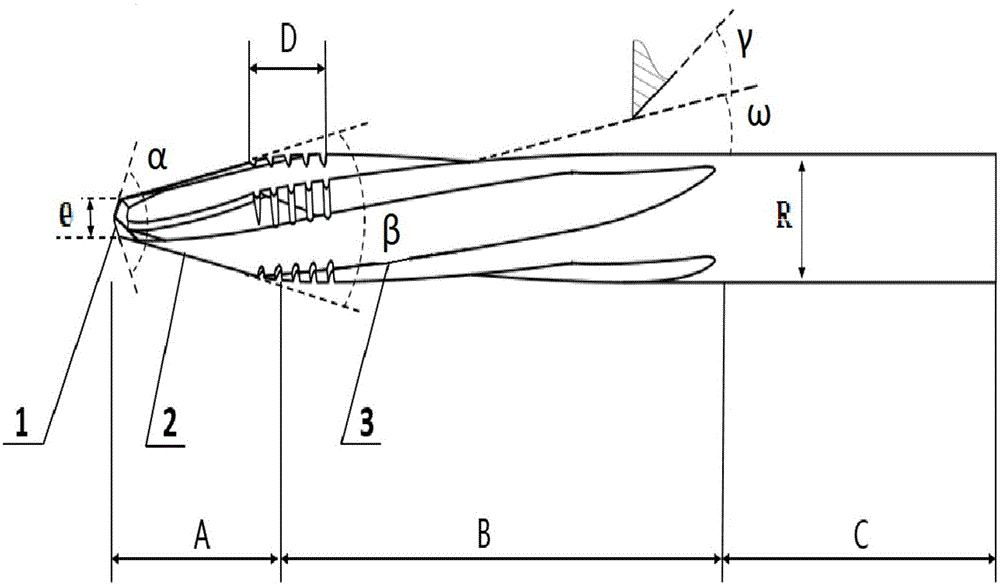

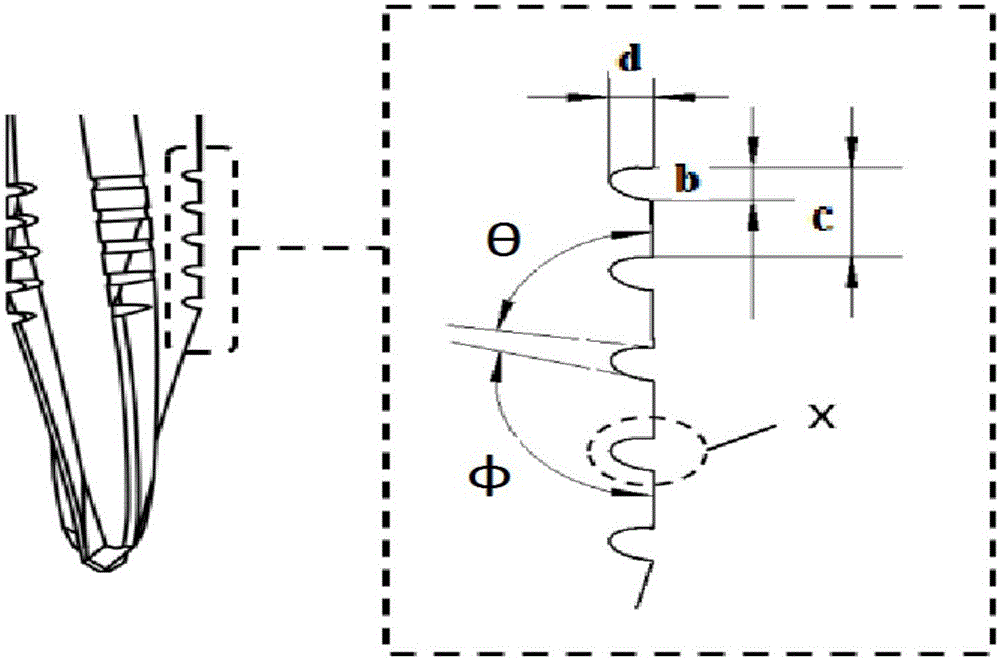

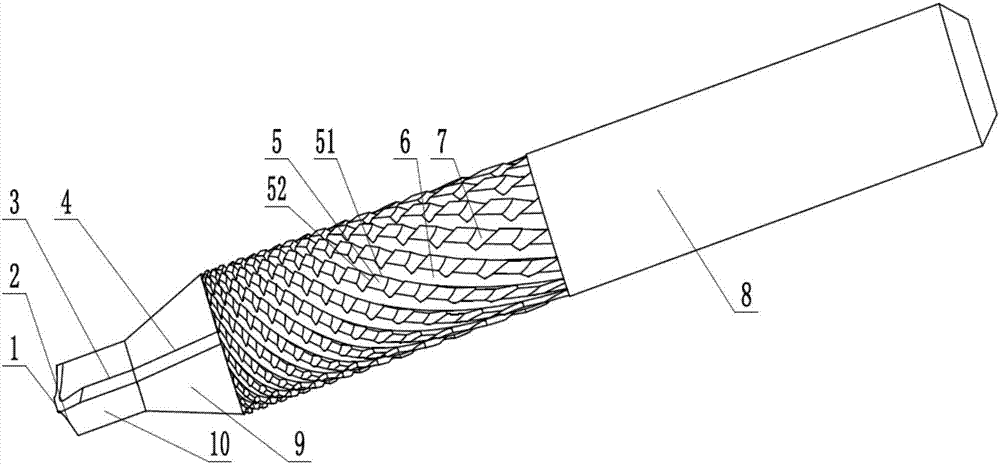

High-efficiency special drilling head for drilling holes in carbon fiber composite material

ActiveCN104999118AHigh dimensional accuracyReduce axial forceTransportation and packagingWorkpiecesCarbon fiber reinforced compositeIntegrated processing

The invention belongs to the technical field of drilling and cutting tools in mechanical processing, and relates to a high-efficiency special drilling head for drilling holes in a carbon fiber composite material. A cutter is the multiple-cutting-edge cutter with double vertex angles and a micro tooth structure and particularly suitable for the one-time high-quality high-efficiency processing of the high-performance carbon fiber reinforced composite material. The drilling head consists of a main cutting region, an assistant cutting region and a cutter handle, wherein a micro tooth cutting region is arranged at a connecting position of the main cutting region and the assistant cutting region; the main cutting region consists of a first main cutting edge and a second main cutting edge; in the assistant cutting region, a left-hand thread is formed in an assistant cutting edge; the micro tooth cutting region consists of a plurality of micro teeth. According to the high-efficiency special drilling head disclosed by the invention, the double vertex angles and the micro tooth structure are utilized, so that a function of integrated processing of drilling-expanding-reaming is realized, the axial force of the drilling and the cutting is reduced, layered defects are overcome, the holes with high size accuracy are obtained, the service life of the drilling head is prolonged, the situation that the cutter is frequently replaced is avoided, and the processing efficiency is improved.

Owner:DALIAN UNIV OF TECH

Water filter cartridge and manifold head seal

ActiveUS20150307365A1Avoid creatingEasy to engageDetection of fluid at leakage pointMeasurement of fluid loss/gain rateWater filterEngineering

A water filter cartridge has a cap with radially oriented first and second (either inlet or outlet) flow channels on first and second generally cylindrical portions. First and second seals encircle the first flow channel on the first portion and third and fourth seals encircle the second flow channel on the second portion. The second and third seals form a void volume during use which may be accessed by a vent path to eliminate moisture or to test for or indicate leaks. The radial flow paths reduce axial, push out forces on the filter cartridge and allow smaller locking tabs to be used. The first seal forms a top void volume during use which may be accessed by a vent path to eliminate moisture or to test for or indicate leaks.

Owner:BAIRD MICAHEL T

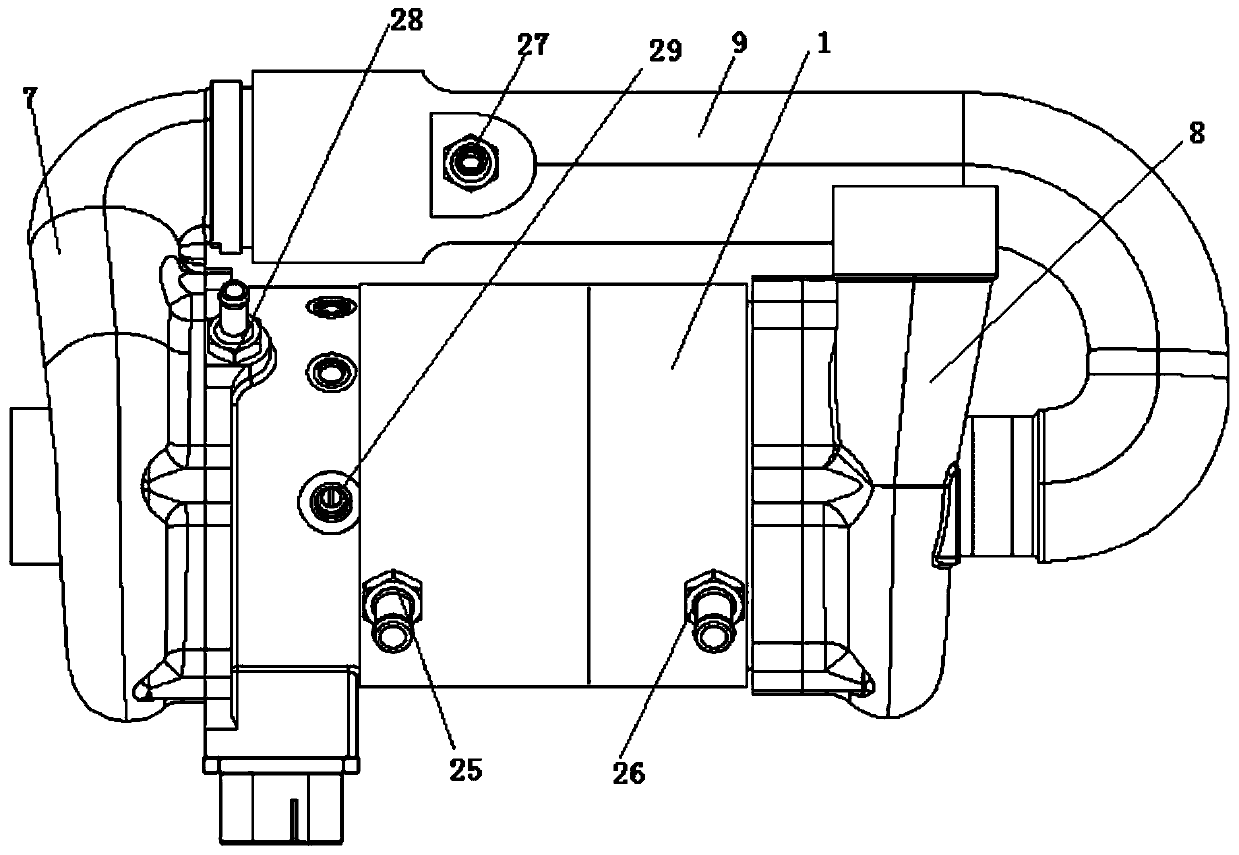

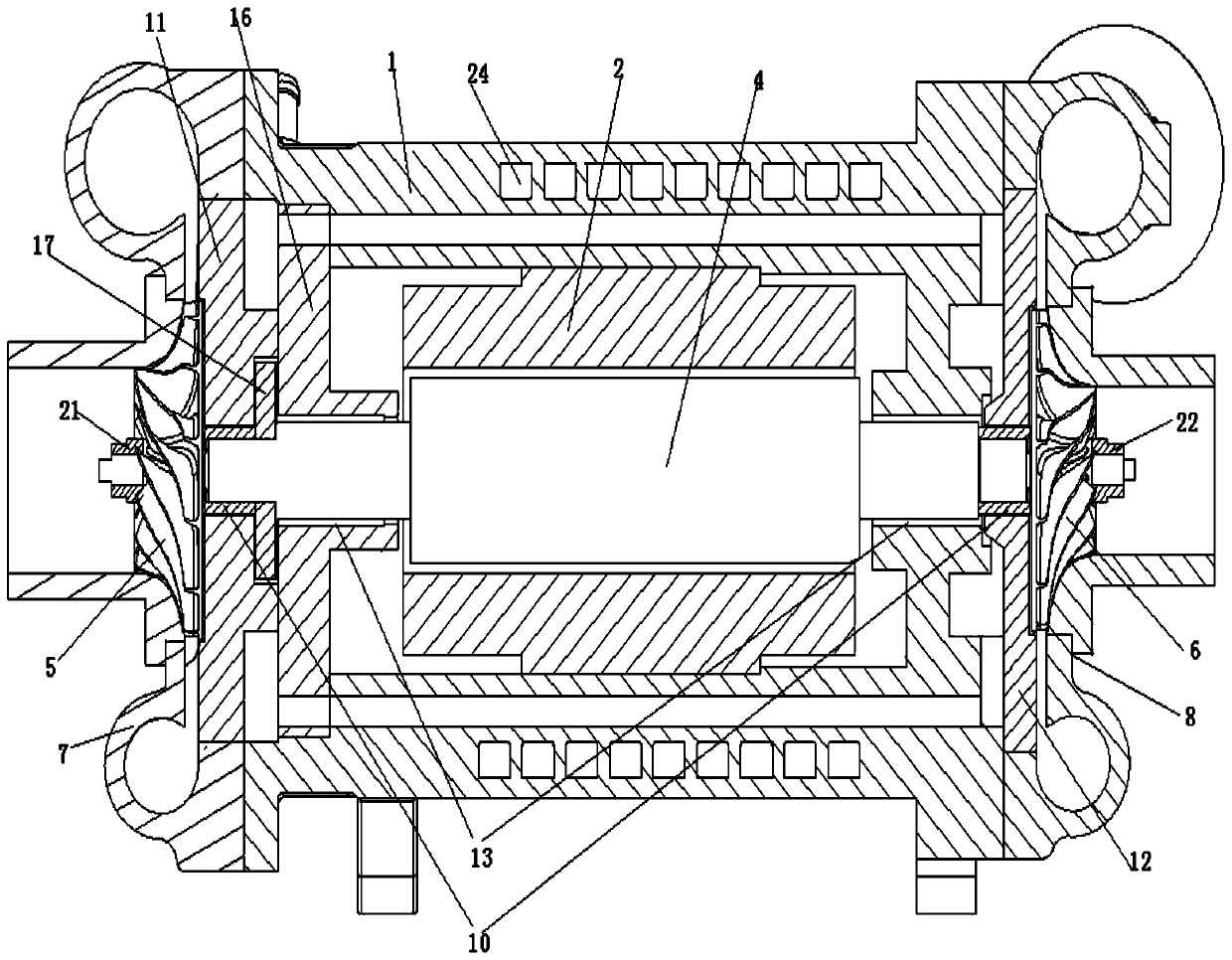

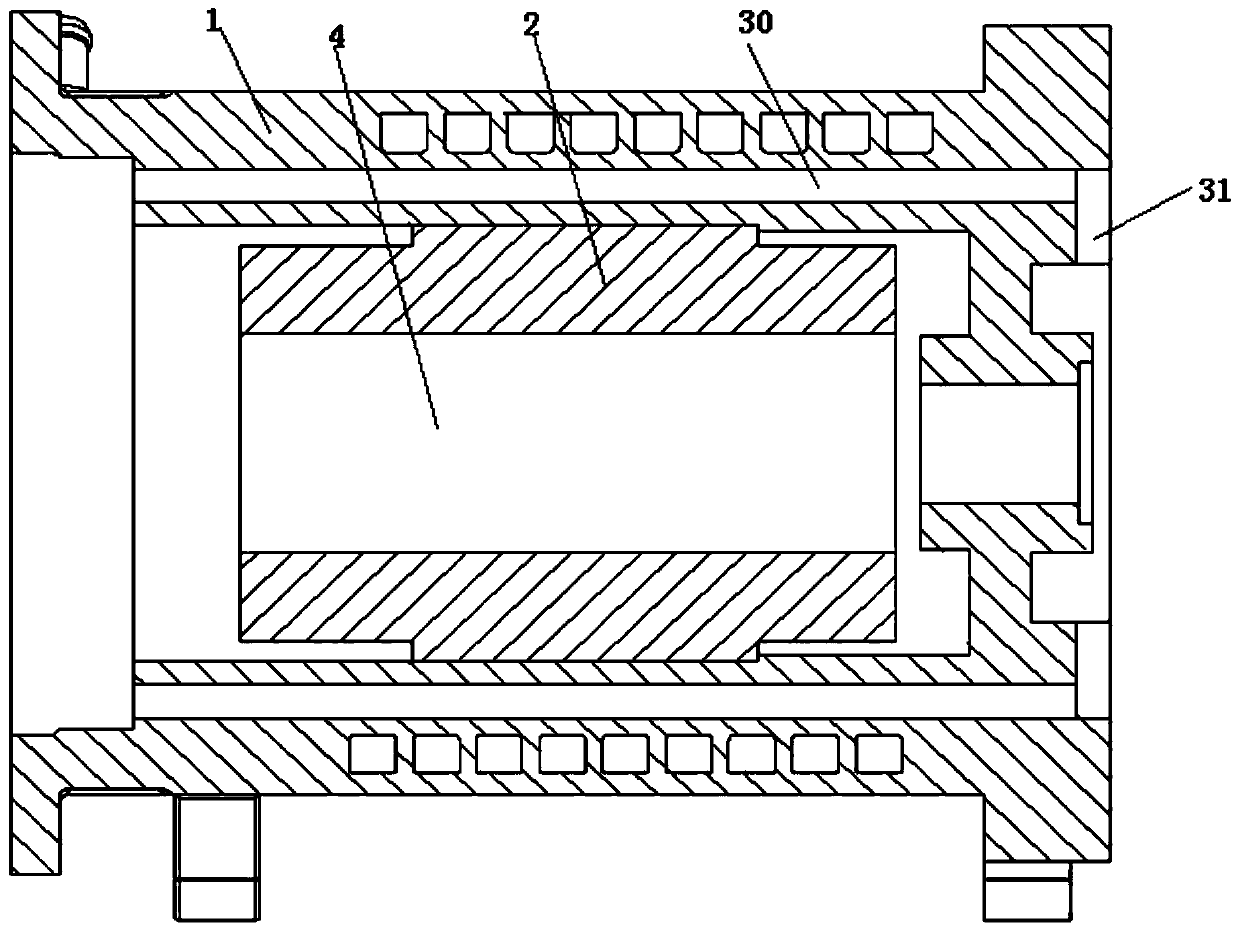

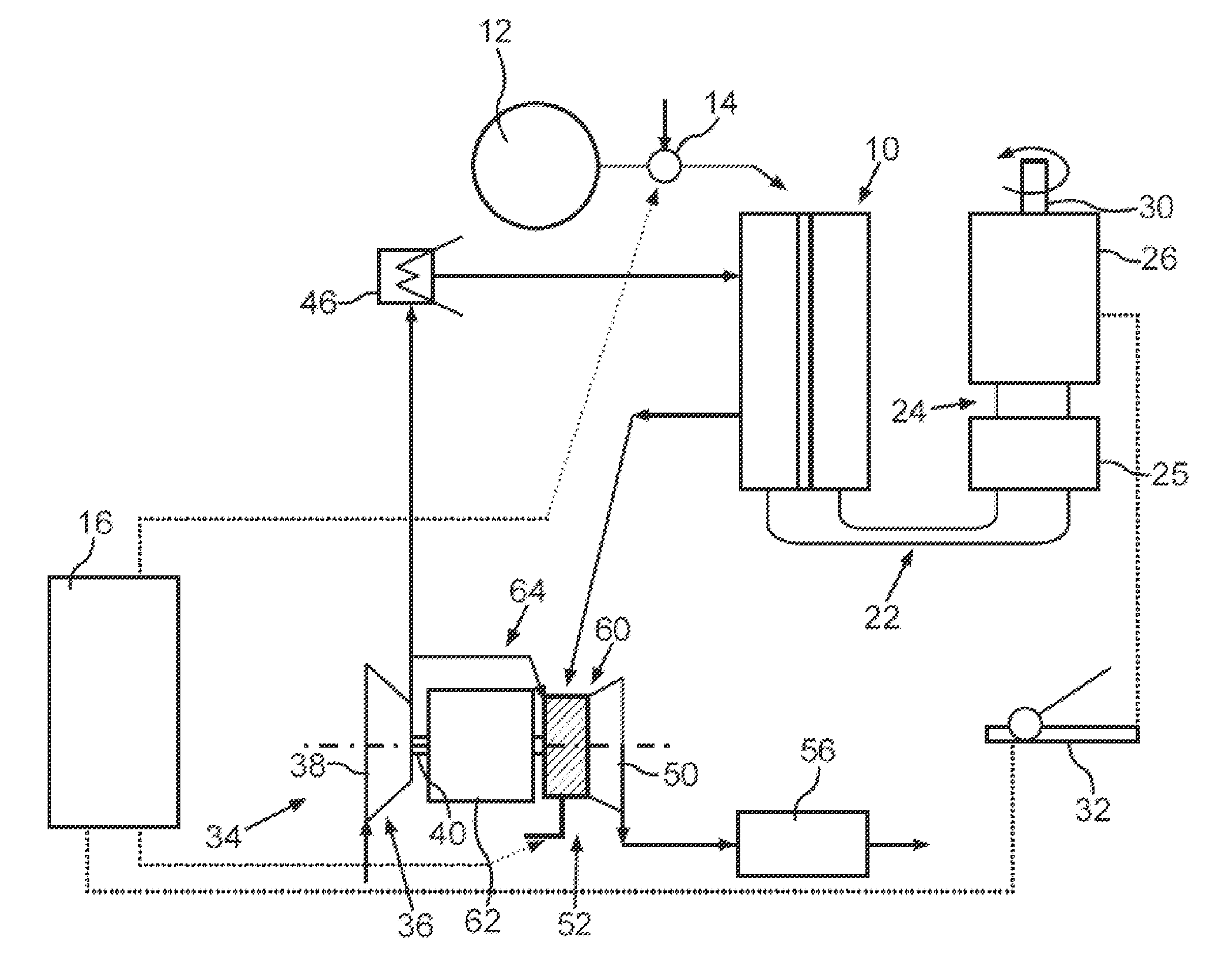

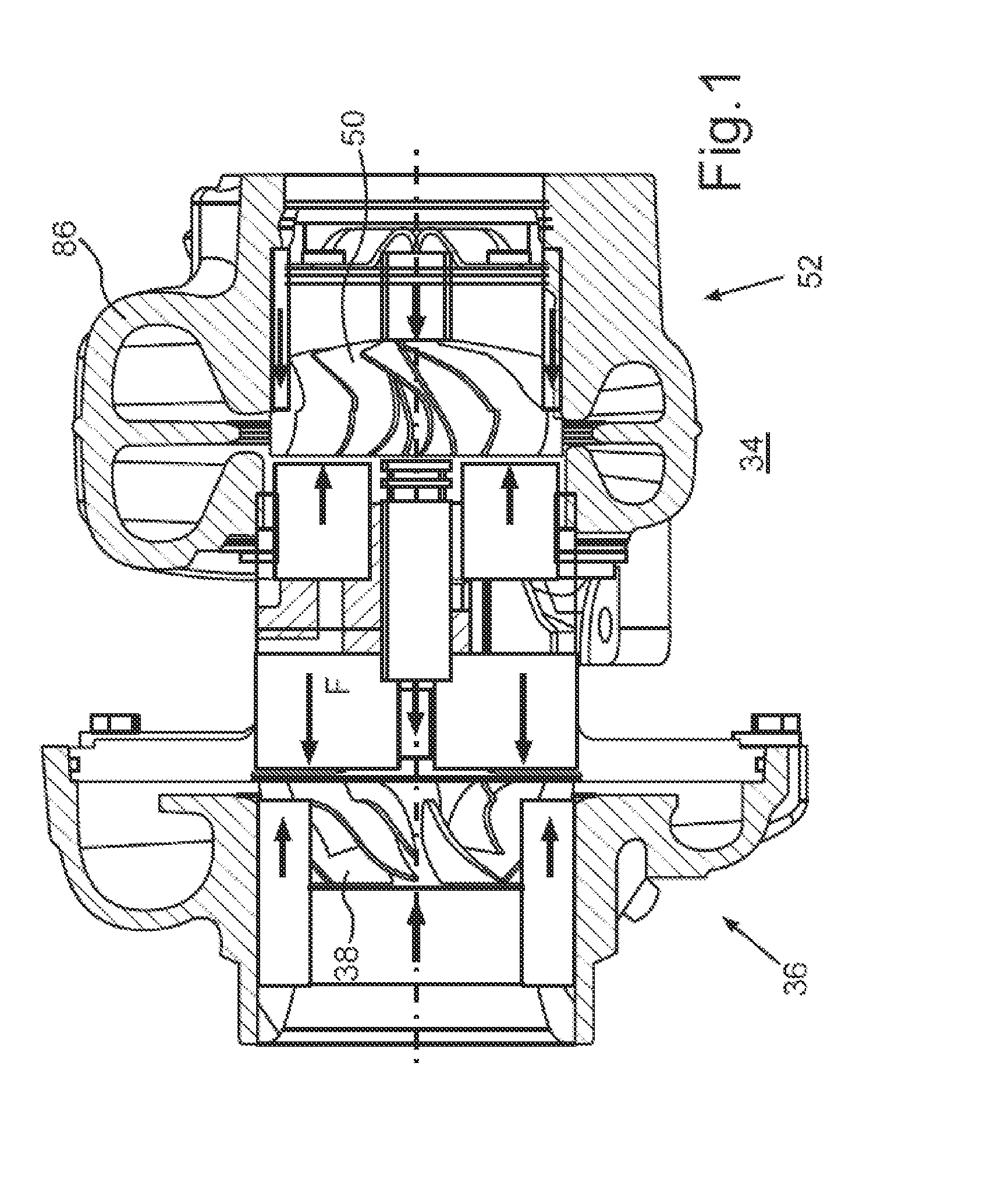

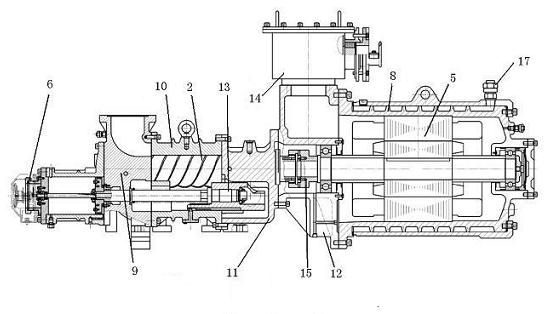

Two-stage air-suspending centrifugal electric direct drive air compressor

The invention discloses a two-stage air-suspending centrifugal electric direct drive air compressor. The two-stage air-suspending centrifugal electric direct drive air compressor comprises a shell, amotor stator, a spindle, impellers, lock nuts, volutes and a cooling system, wherein the shell, the motor stator and the spindle are sequentially arranged from outside to inside, the impellers, the lock nuts and the volutes are arranged on the two sides of the spindle, and the cooling system is arranged on the shell. The two-stage air-suspending centrifugal electric direct drive air compressor hasthe beneficial effects that the shell, the motor stator, the spindle, the impellers and the volutes are integrally designed, and the size and the weight of the whole machine are reduced. The two stages of impellers are connected in series through a middle pipeline, and small flow and the high-pressure ratio are achieved. Axial thrust of the two stages of impellers can be mutually offset, and axial force applied by thrust bearings is reduced. Radial and axial air bearings are adopted, gas films are formed through high-pressure gas generated by the bearings, friction between the bearings and arotor is reduced, air-suspending motor high-speed direct drive is formed, and mechanical losses are reduced. Part of compressed gas is introduced into a machine shell assembly through the middle pipeline, the motor stator, the spindle, the radial bearings and the thrust bearings are cooled, and the service life of the air compressor is prolonged.

Owner:势加透博洁净动力如皋有限公司

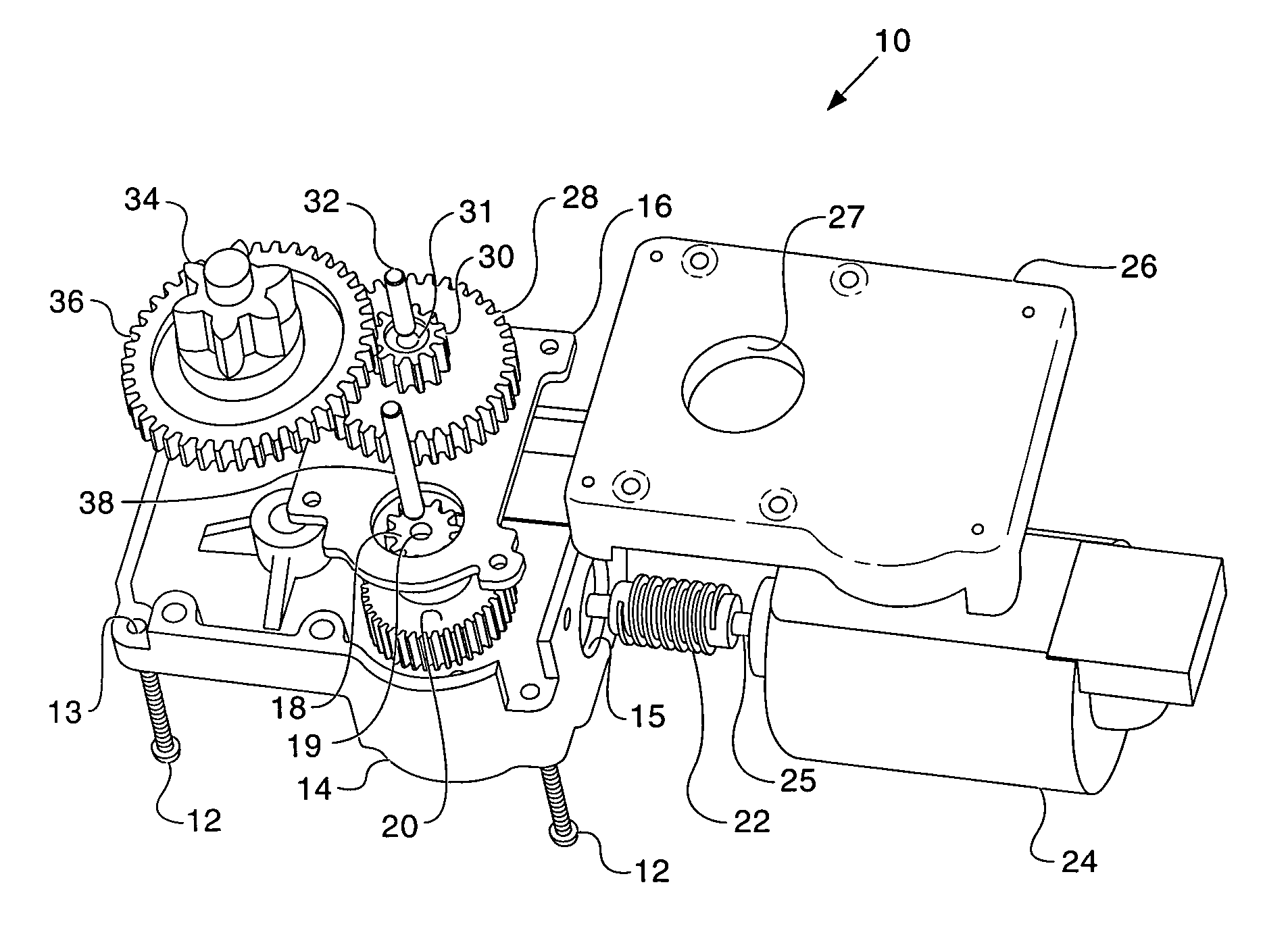

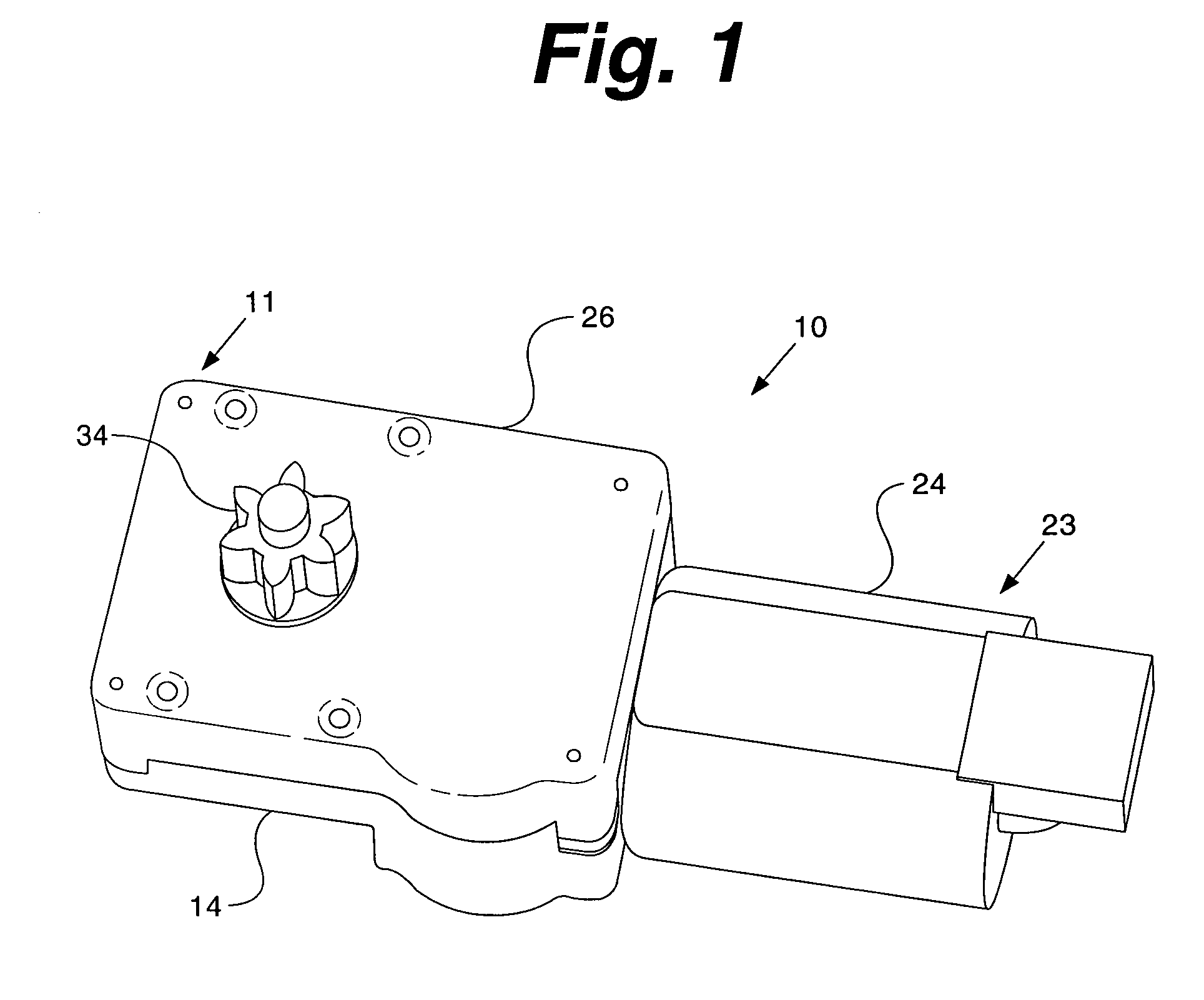

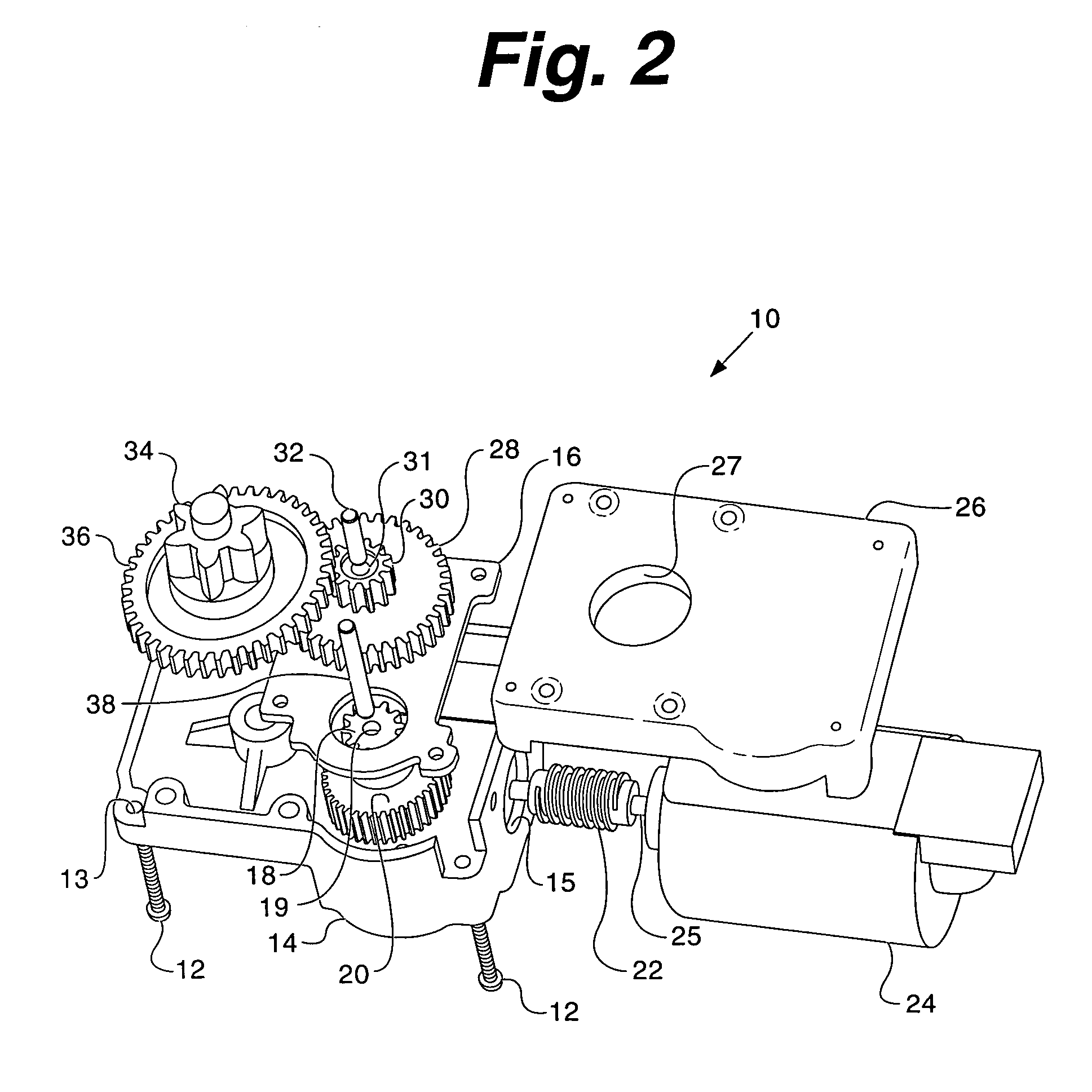

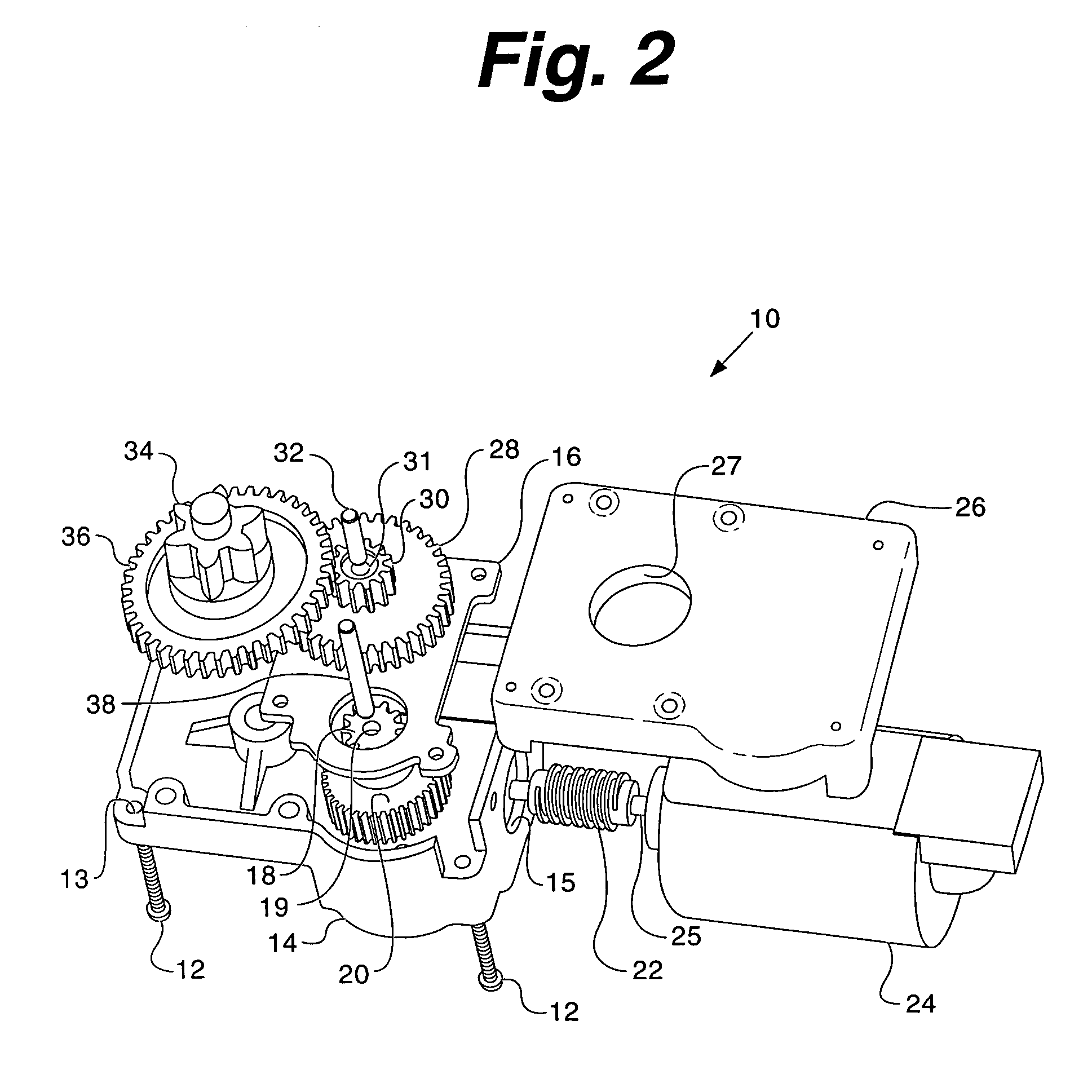

Actuator

InactiveUS20060117890A1Simple internal structureEliminate breaksVehicle seatsToothed gearingsGear wheelActuator

An actuator is disclosed. The actuator includes two main assemblies: (1) a motor assembly; and (2) a gearbox assembly. The gearbox assembly includes multiple stages of gear reduction and a dividing plate. In some embodiments, the gearbox assembly has a single-lead worm, a worm gear with a right-hand helix tooth direction, and a worm gear with a left-hand helix tooth direction. The worm gears are driven by the single-lead worm. The single-lead worm has two ends, one end has a right-hand tooth helix direction, and the other end has a left hand helix direction.

Owner:SCHUKRA OF NORTH AMERICA

Method for machining slotted holes on carbon fiber laminated boards

The invention discloses a method for machining slotted holes on carbon fiber laminated boards, which belongs to a machining method for nonmetallic materials, solves the problem that by the existing milling and drilling methods, carbon fiber laminated boards are easy to laminate, split and burn, and aims at improving the machining precision of carbon fiber composite products and reducing the surface roughness of carbon fiber composite products. The method disclosed by the invention comprises a clamping step, a machining step and a post-processing step, wherein the machining step is one or two of a milling machining step and a drilling machining step. According to the invention, in the machining process, a non-deformed clamping mode is used, and through selecting reasonable cutting tool materials, geometric parameters of cutting tools, and milling and drilling machining parameters, the appearance allowances in machining are reasonably arranged, thereby solving the quality problems of laminating, splitting and burning and the like existing in the process of opening or drilling carbon fiber thin-wall revolution bodies and carbon fiber laminated boards by using the traditional methods, so that the qualified rate of carbon fiber parts is increased from 50% to more than 99%.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

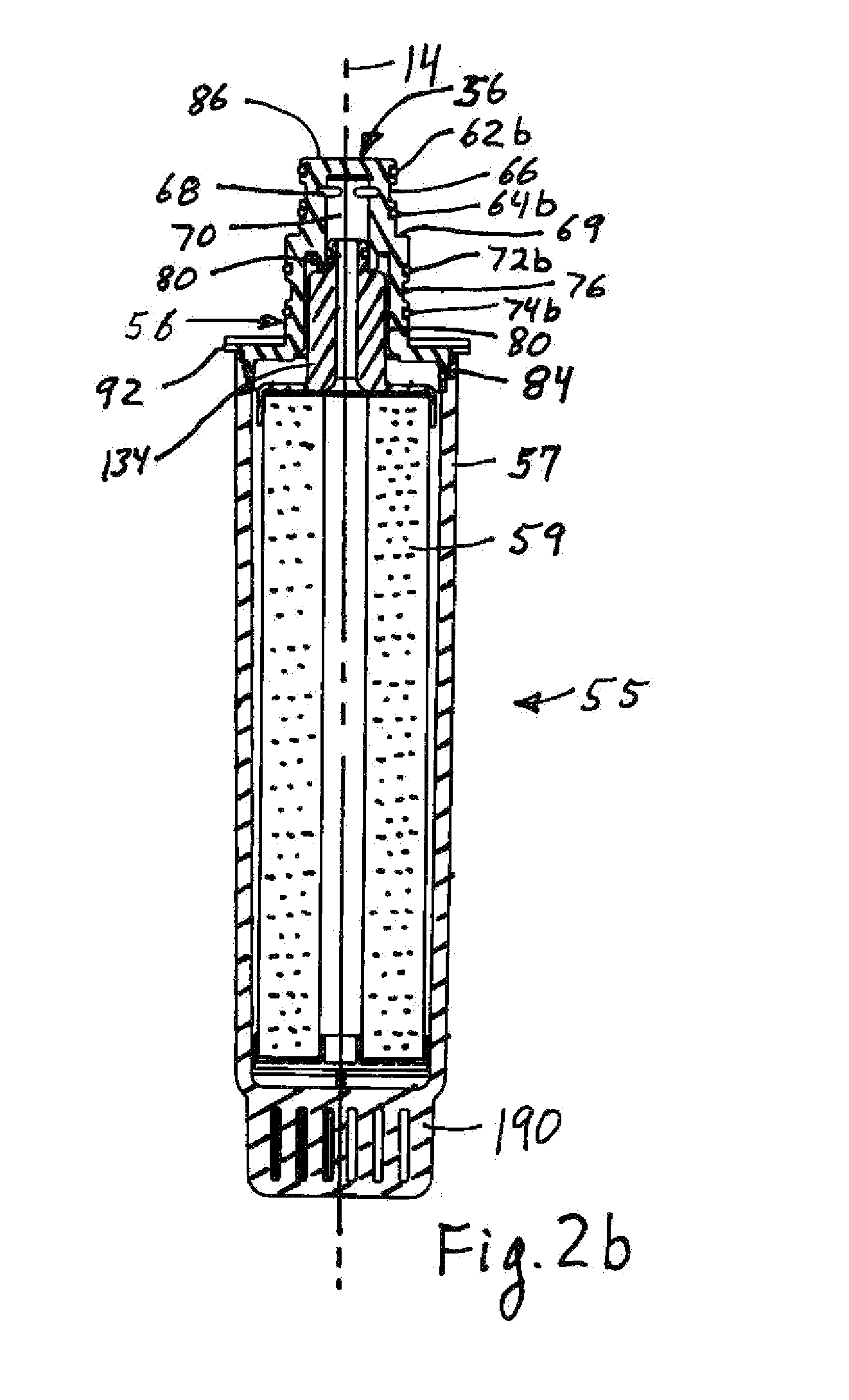

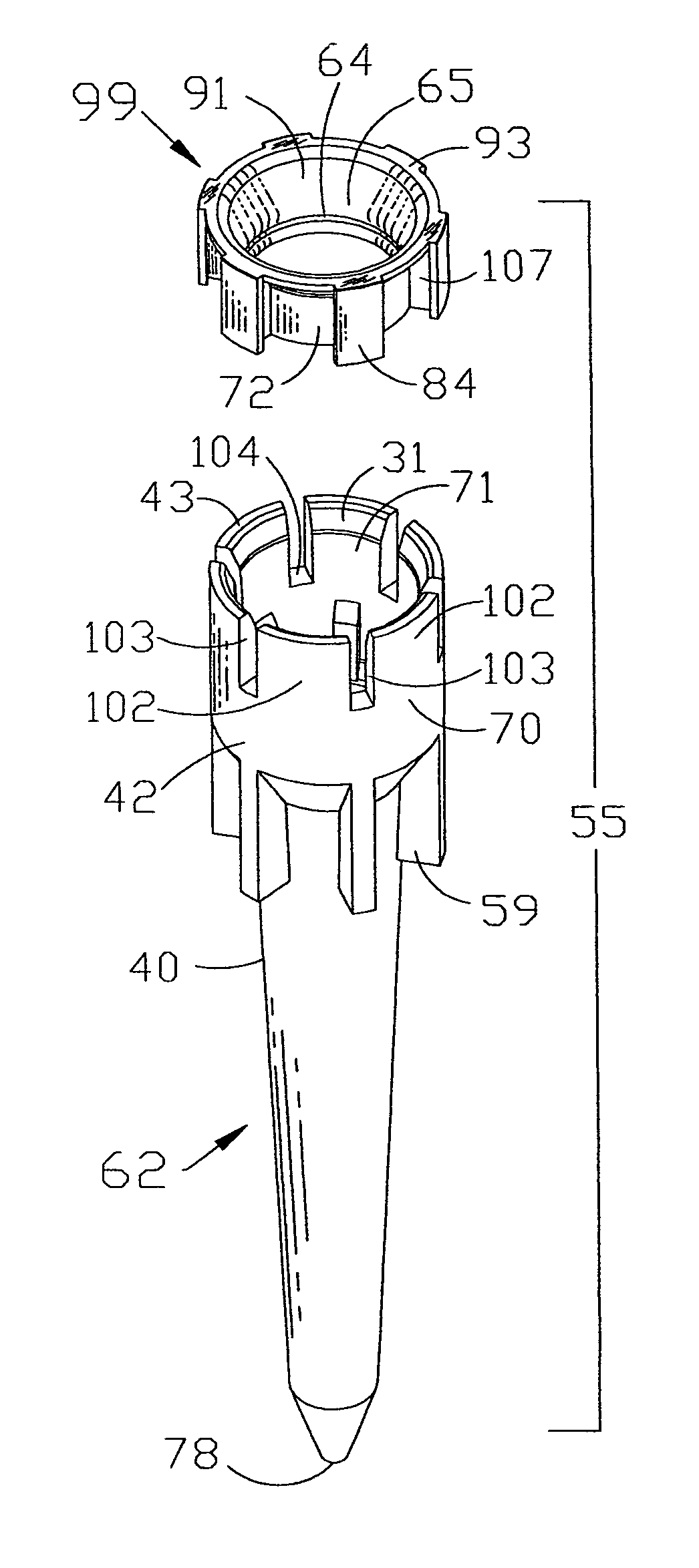

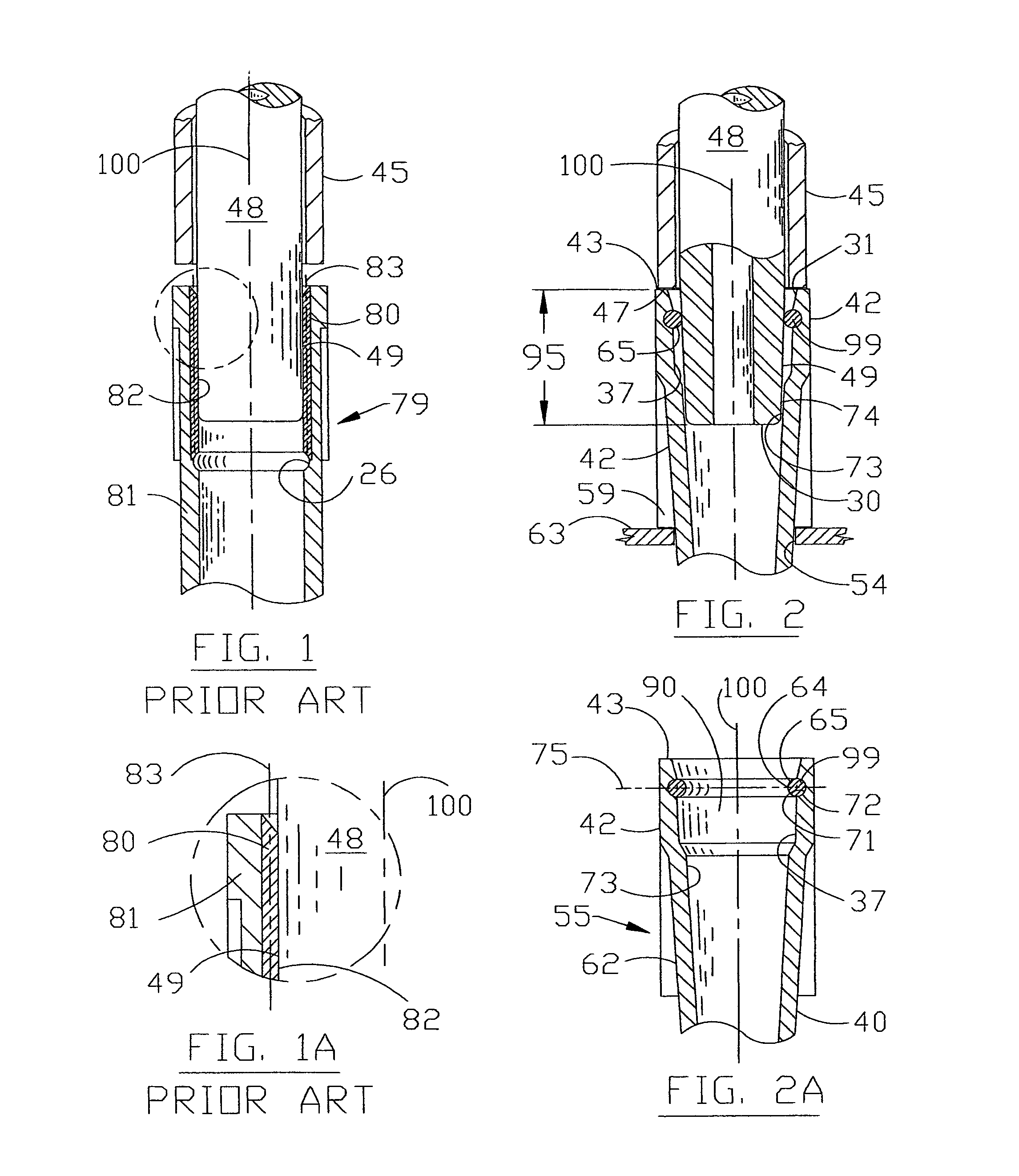

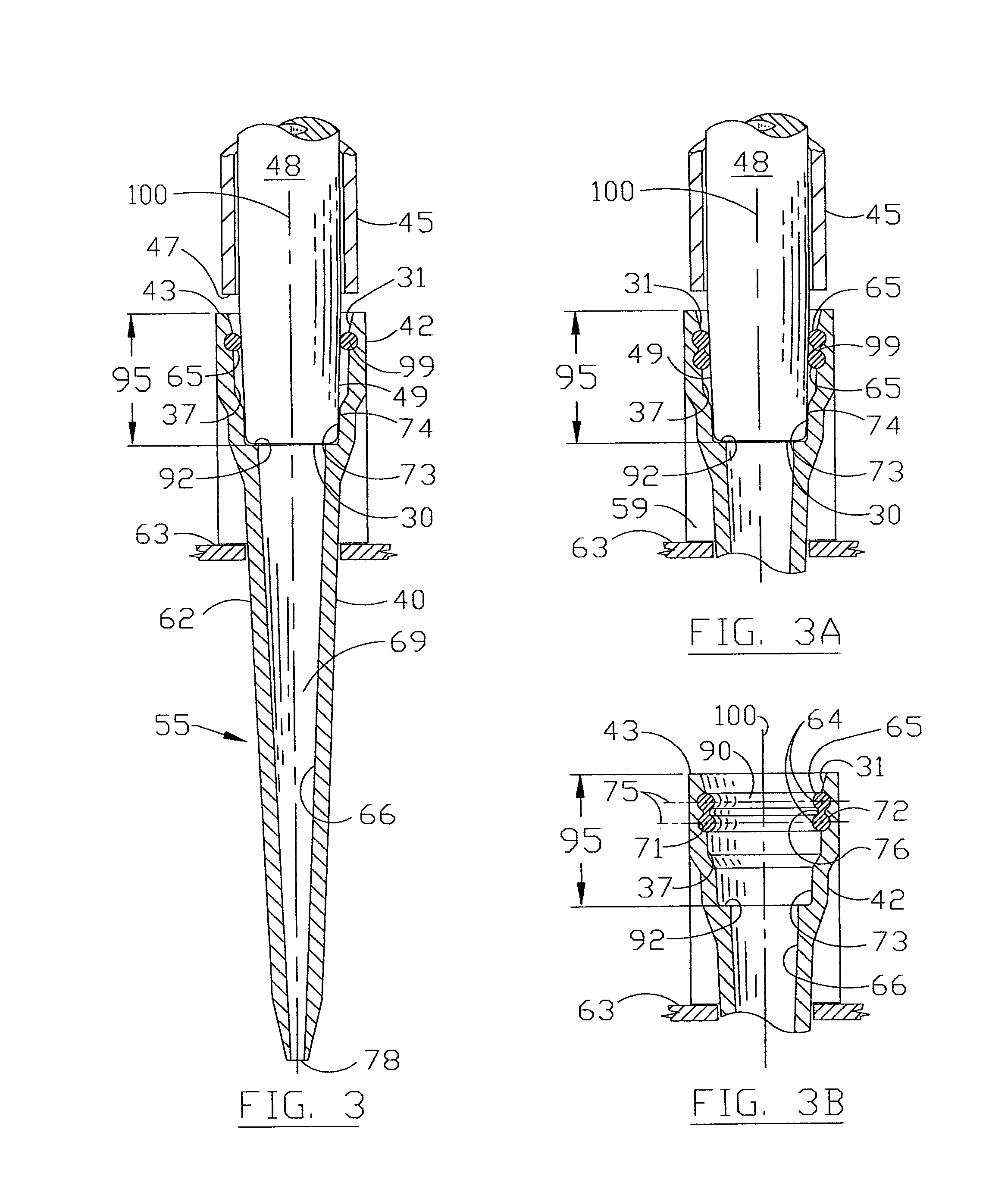

Ergonomic pipette tip

ActiveUS8557200B1Reduce axial forceImprove sealingWithdrawing sample devicesBurettes/pipettesElastomerPipette

An ergonomically designed pipette tip that can be securely mounted to a barrel of a pipetter yet is designed to substantially reduce the axial force necessary to install and eject the pipette tip from the pipetter thus reducing the injuries resulting in repetitive stress injury to the thumb and hand. The new ergonomic pipette tip incorporates a separate sealing member constructed from an elastomer that is coupled to the more rigid and chemically inert elongated tubular member that becomes the receptacle for transferring the fluid sample aspirated by the pipetter. The new elastomeric sealing member allows for greater sealing capability or squeeze between the pipetter barrel and the new pipette tip while lowering the coefficient of friction between the mating parts, thus decreasing the axial ejection forces require to overcome the breakaway friction between the new ergonomic pipette tip and the pipetter.

Owner:SMITH JAMES C

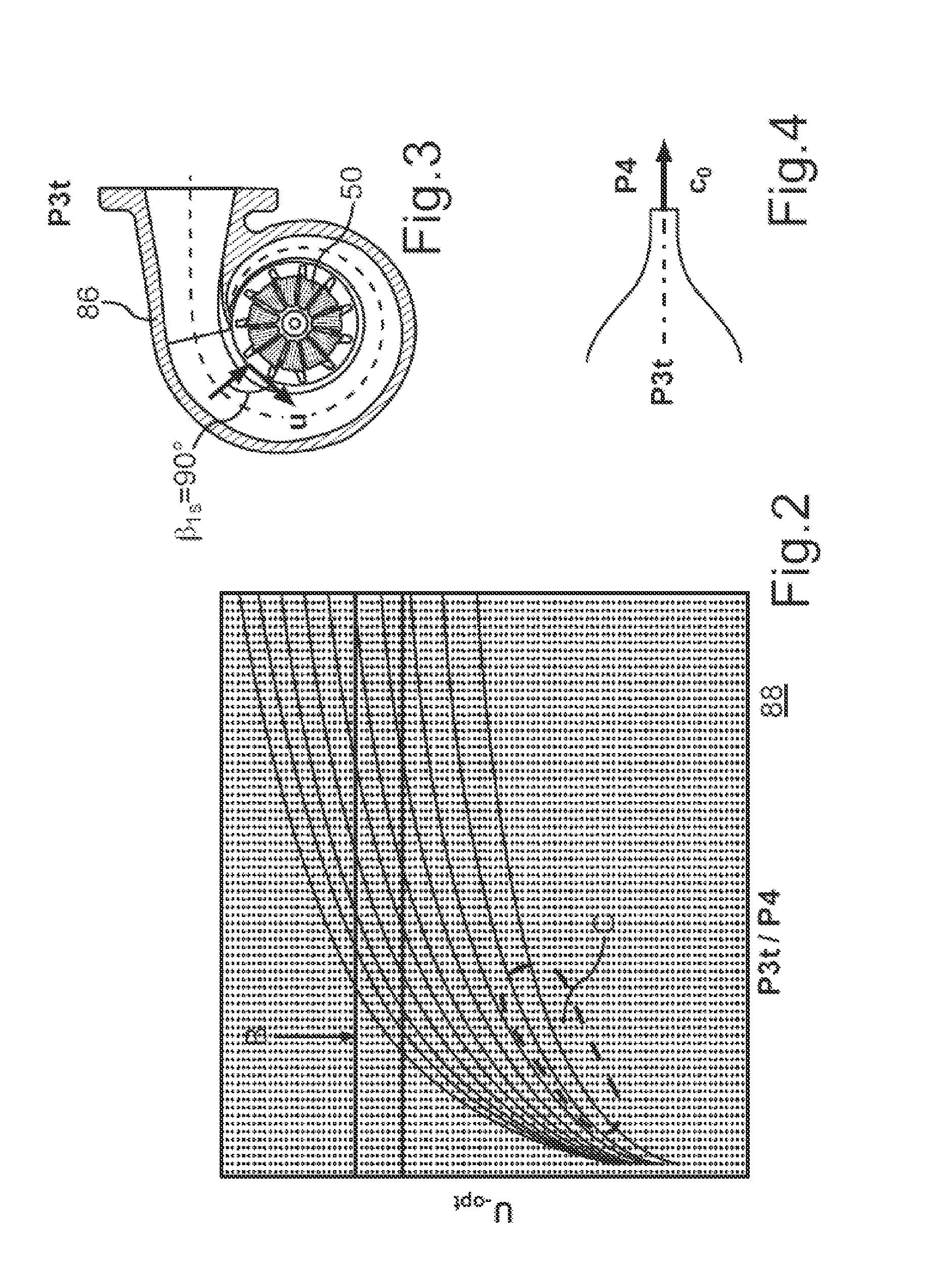

Charging Device for a Fuel Cell, in Particular of a Motor Vehicle

InactiveUS20140370412A1Reduce axial forceEasy to operateFuel cell auxillariesGas turbine plantsImpellerTurbine wheel

A charging device for a fuel cell includes a turbine having a housing part with a receiving chamber in which a turbine wheel of the turbine is received so as to be rotatable relative to the housing part about an axis of rotation. The turbine wheel includes impeller vanes via which a medium, in particular a gaseous waste gas of the fuel cell, can flow against the turbine wheel in an inlet region, and which are curved forwards at least in the inlet region.

Owner:DAIMLER AG

Porous screw blade rotor in heat exchange tube

InactiveCN103217054AAvoid depositionSave materialHeat transfer modificationRotary device cleaningWater flowEngineering

The invention relates to a porous screw blade rotor in a heat exchange tube. The porous screw blade rotor is formed by a hollow shaft and porous screw blades. The porous screw blades are evenly distributed on the surface of the hollow shaft. The external diameter of the porous blades is smaller than the internal diameter of the heat exchange tube. The blades are in a spiral shape around the hollow shaft, and micropore structures are arranged on the surfaces of the blades along the axial direction and the radial direction of the hollow shaft. Micropores keep a certain distance from the hollow shaft. Edges, being firstly contacted with water flow, of micropore blades form slant chamfers or round chamfers. Holes communicated with inner holes of the hollow shaft are evenly formed in the hollow shaft far from a water inlet end along the circumferential direction. The rotary torque of fluid to the rotor and a combination fixing mode of the porous blades on the hollow shaft can be changed through changing of spiral angles of the porous screw blades along the axial direction of the hollow shaft, the axial length of the hollow shaft, the height along the radial direction of the hollow shaft, the distance between the micropores and root portions of the blades, sizes of the micropores, spaces between the micropores, the arrangement mode of the micropores and the number of the micropores along the axial direction and the radial direction of the hollow shaft so as to facilitate installation of the rotor in the heat exchange tube.

Owner:BEIJING UNIV OF CHEM TECH

Actuator

InactiveUS7464620B2Simple internal structureEliminate breaksVehicle seatsToothed gearingsGear wheelReduction drive

An actuator for an automotive seat that includes two main assemblies: (1) a motor assembly; and (2) a gearbox assembly. The gearbox assembly includes multiple stages of gear reduction and a dividing plate. In some embodiments, the gearbox assembly has a single-lead worm, a worm gear with a right-hand helix tooth direction, and a worm gear with a left-hand helix tooth direction. The worm gears are driven by the single-lead worm. The single-lead worm has two ends, one end has a right-hand tooth helix direction, and the other end has a left hand helix direction.

Owner:SCHUKRA OF NORTH AMERICA

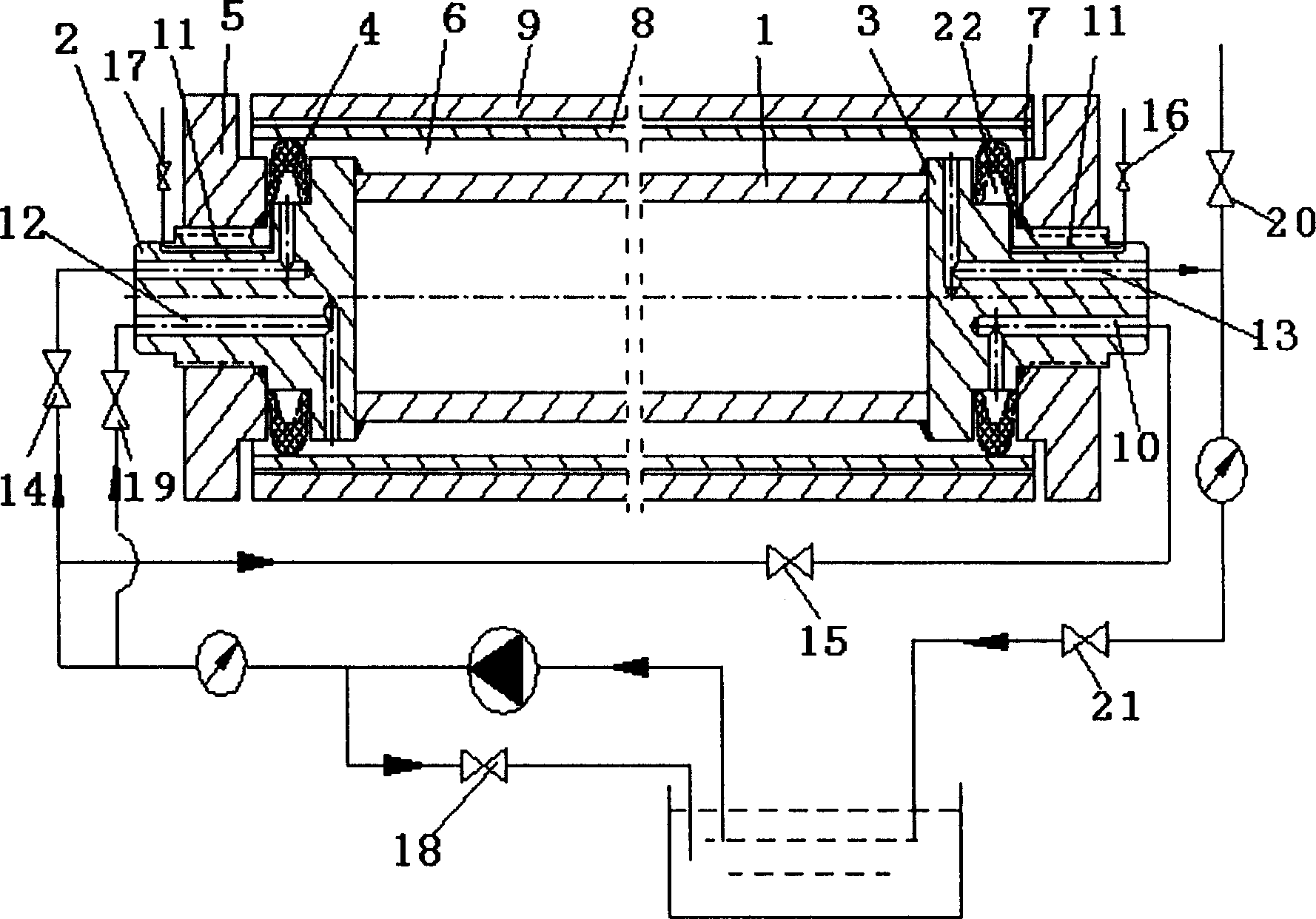

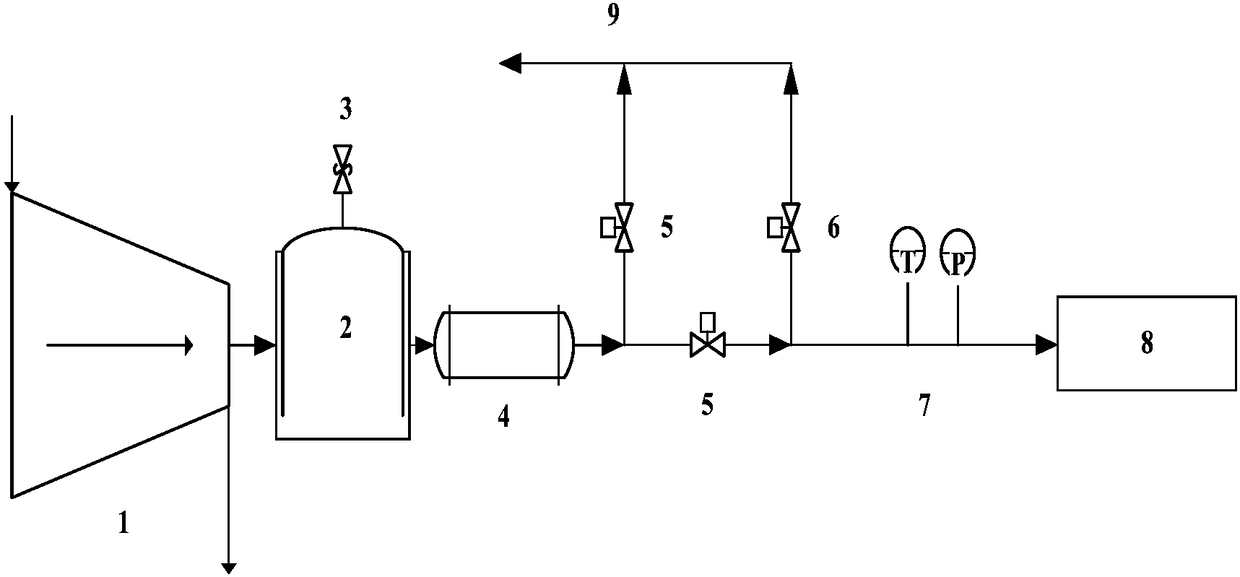

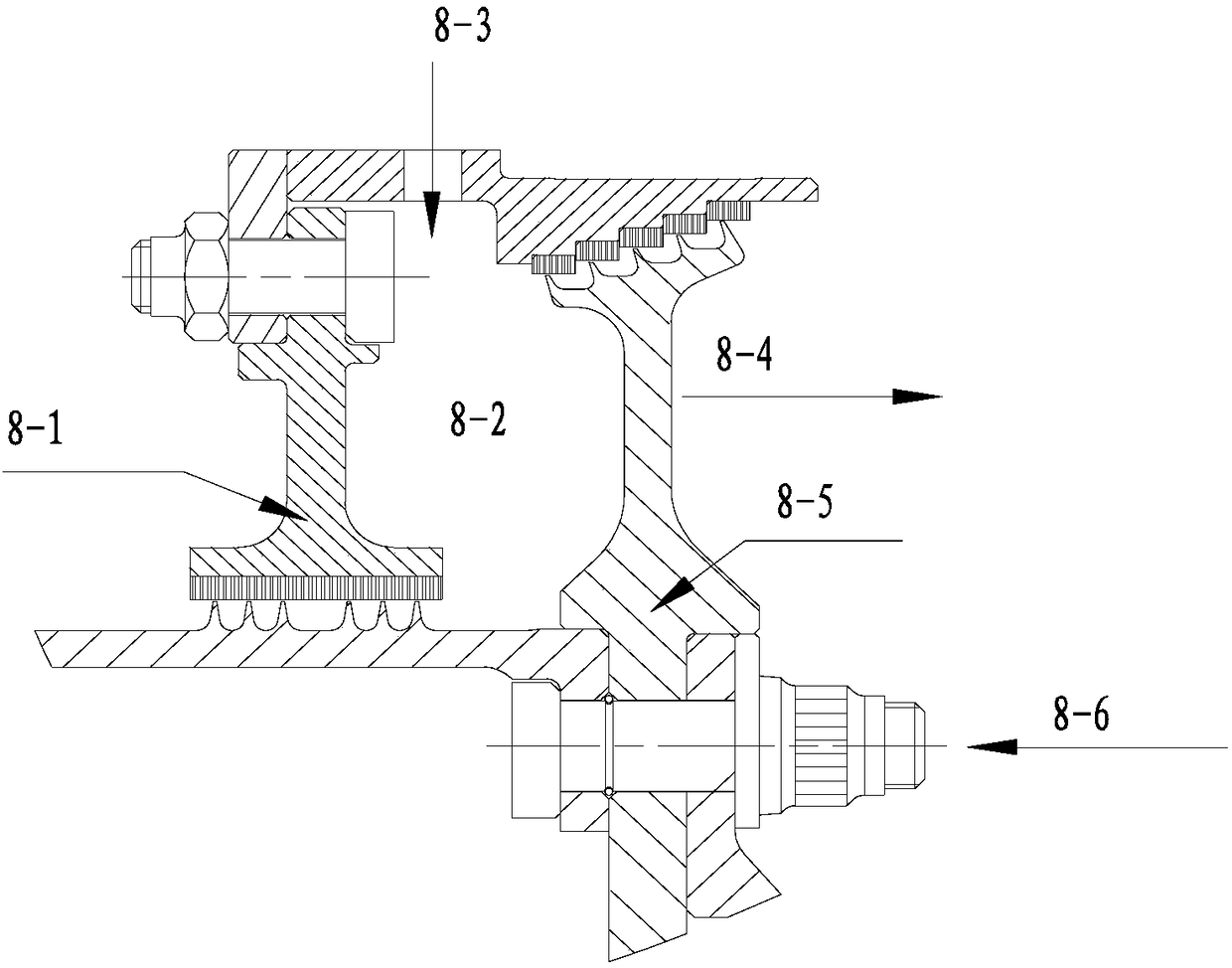

Axial force balance device used for performance testing of axial-flow gas compressor

InactiveCN108252961AImprove running stabilityGuaranteed uptimePump componentsPump controlGas compressorSolenoid valve

The invention relates to an axial force balance regulation and control device used for performance testing of an axial-flow gas compressor. The axial force balance regulation and control device is designed for regulating and controlling the axial force of a test part rotor during test running of an aero-engine gas compressor component. The axial force balance regulation and control device comprises the compressor 1, a gas storage tank 2, a dryer 4, a pressure regulating valve 5, a solenoid valve 6, a testing unit 7, a test part balance chamber 8 and relevant pipes. The axial force balance regulation and control device is designed into an independent system. The device pipes can be flexibly arranged according to the actual working conditions. In the design process, the axial force balance regulation and control device is required to achieve continuous adjustability of variable working conditions, output stable and clean dry compressed gas and have the functions of rapidly and accuratelyadjusting and rapidly relieving pressure. After the design is completed, during the testing process of the gas compressor component, the axial force of the gas compressor component rotor is effectively balanced, the running state of the rotor is greatly improved during the running process of the test part, the testing risk is lowered, and the testing working efficiency is improved.

Owner:AECC SICHUAN GAS TURBINE RES INST

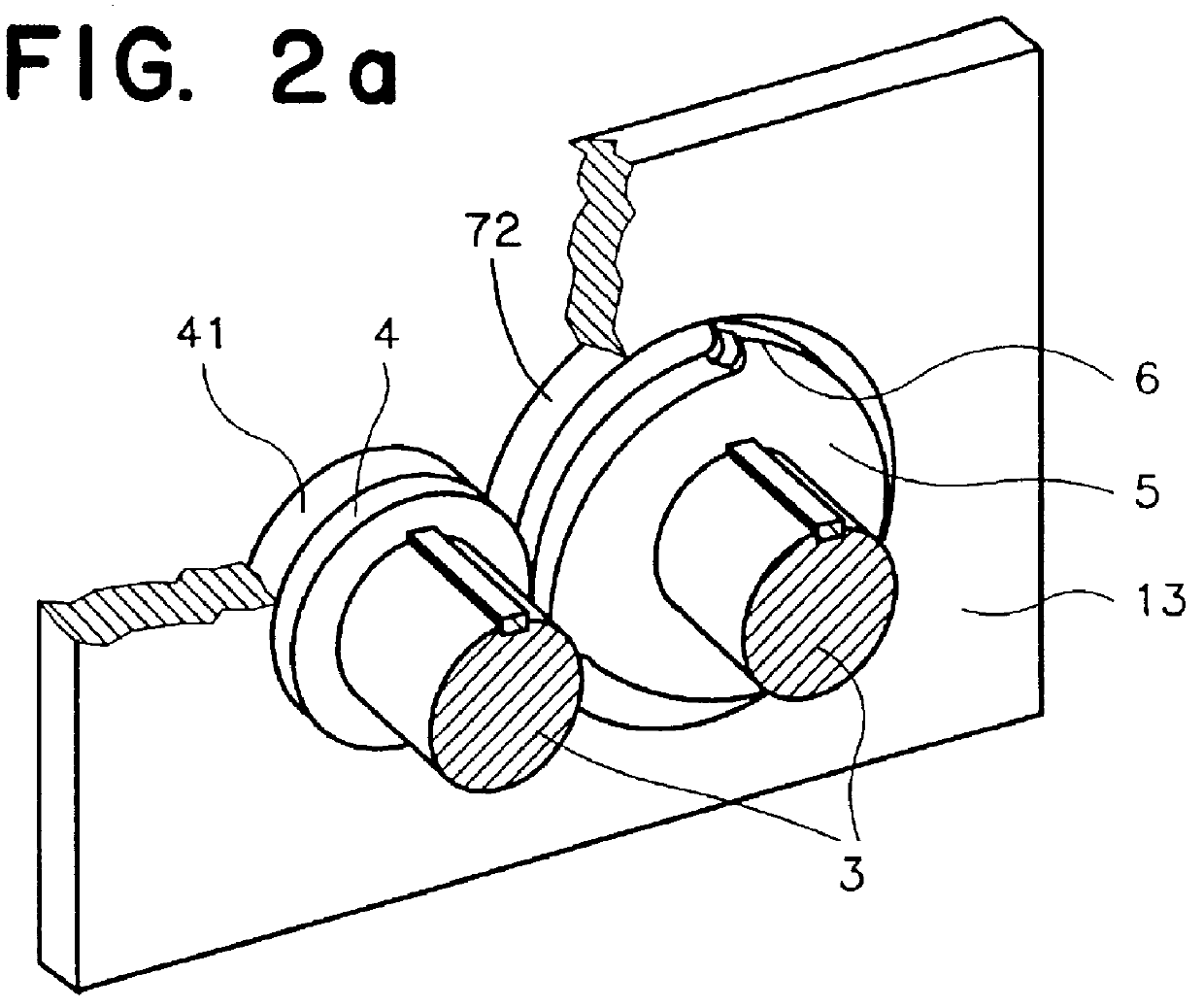

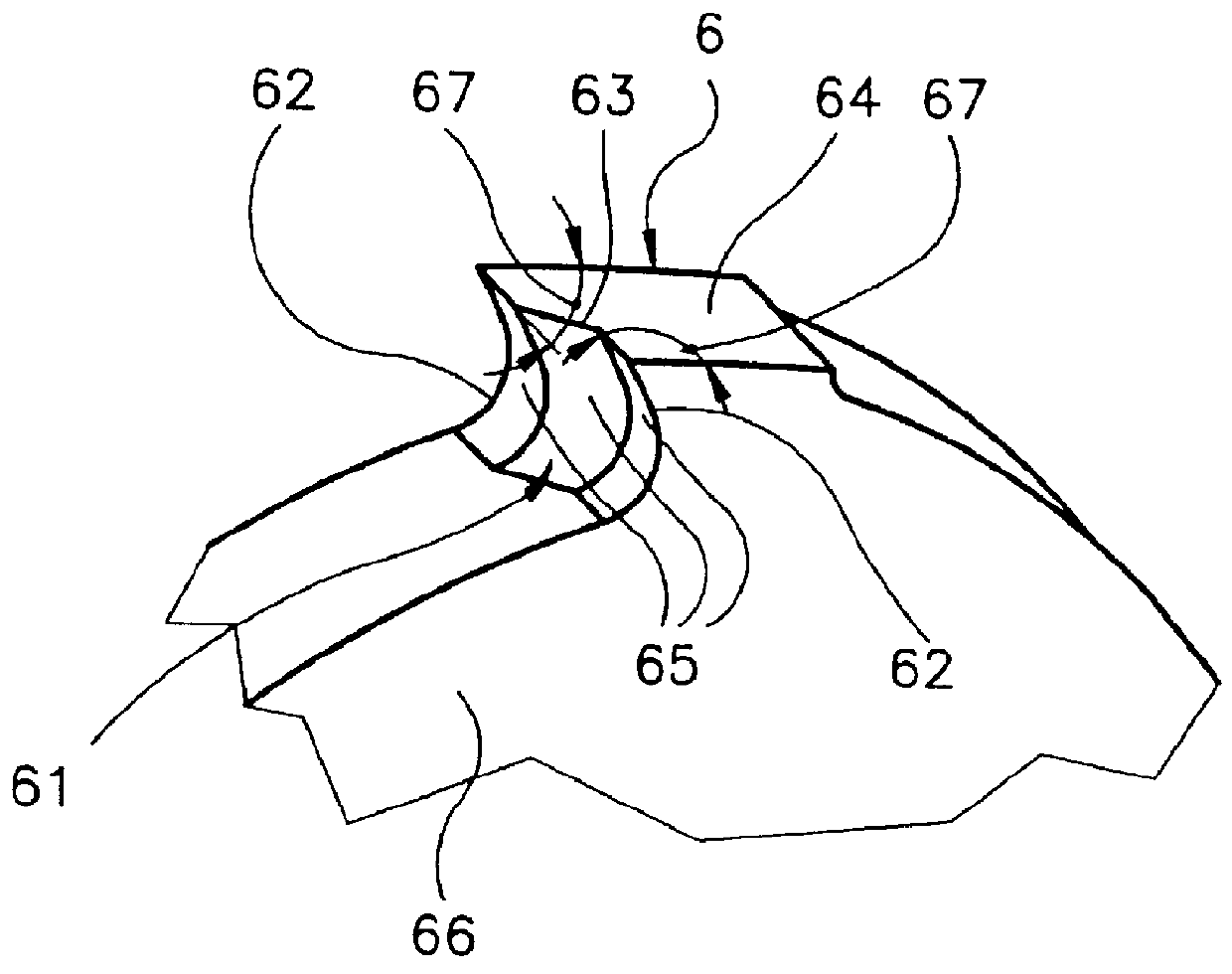

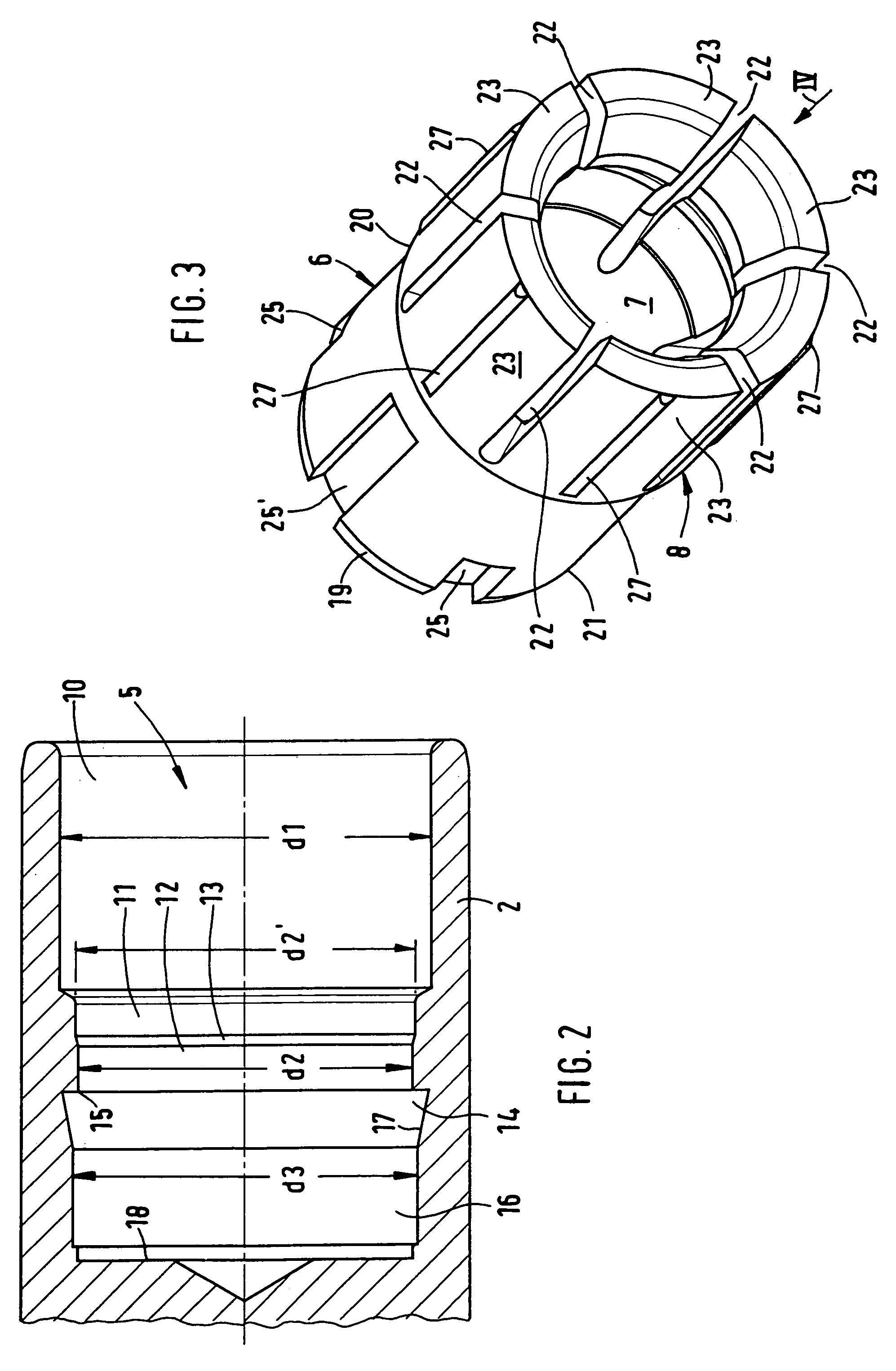

Rotor shear for comminuting particularly bulky waste material

InactiveUS6024312AReduce wearEnhancing comminuting processCocoaGrain treatmentsBulky wasteEngineering

A rotor shear for comminuting particularly bulky waste materials is formed by two cutting rotors (2) combing each other, disposed parallel to each other, supported in a housing (1), and each driven in an opposite direction. Each cutting rotor (2) comprises spacer rings (4) and rotor disks (5) furnished with cutting teeth (6). A face of a front flank (61) of at least one cutting tooth (6) is furnished with geometrically staggered and / or angled partial faces (65). The spacer rings (4) and the rotor disks (5) are disposed on shafts (3). Wear disks (7) are coordinated to outer rotor disks (5) with corresponding circumferences and are connected to the shaft (3). The cutting teeth (6) operate against the circumference of the spacer rings (4) disposed between the rotor disks (5). At least one support device / stripper device (8) is coordinated with at least one shaft (3), where support parts (81) and stripper parts (82) of the support device / stripper device (8) are functionally separated.

Owner:METABO LINDEMANN GMBH

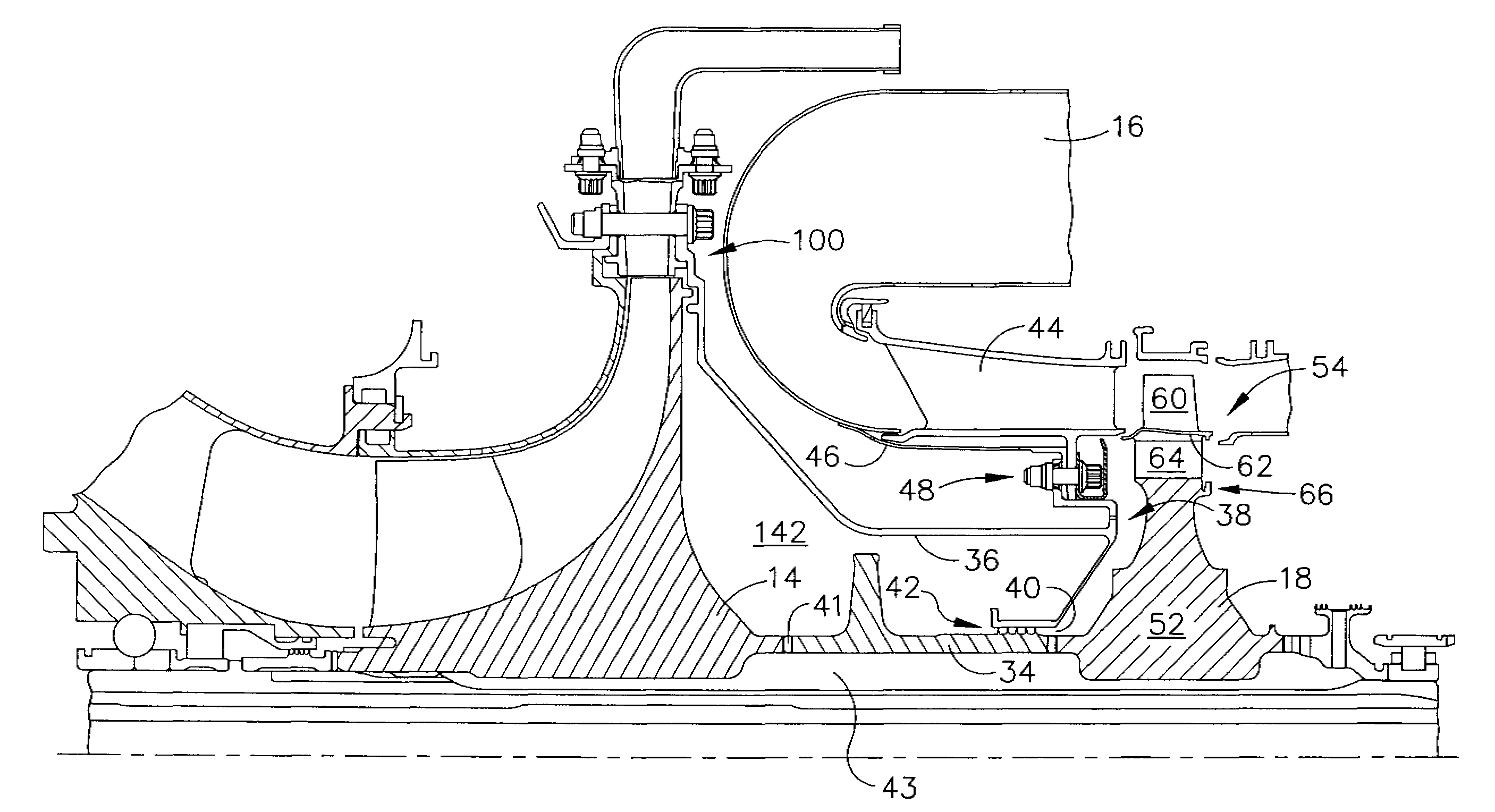

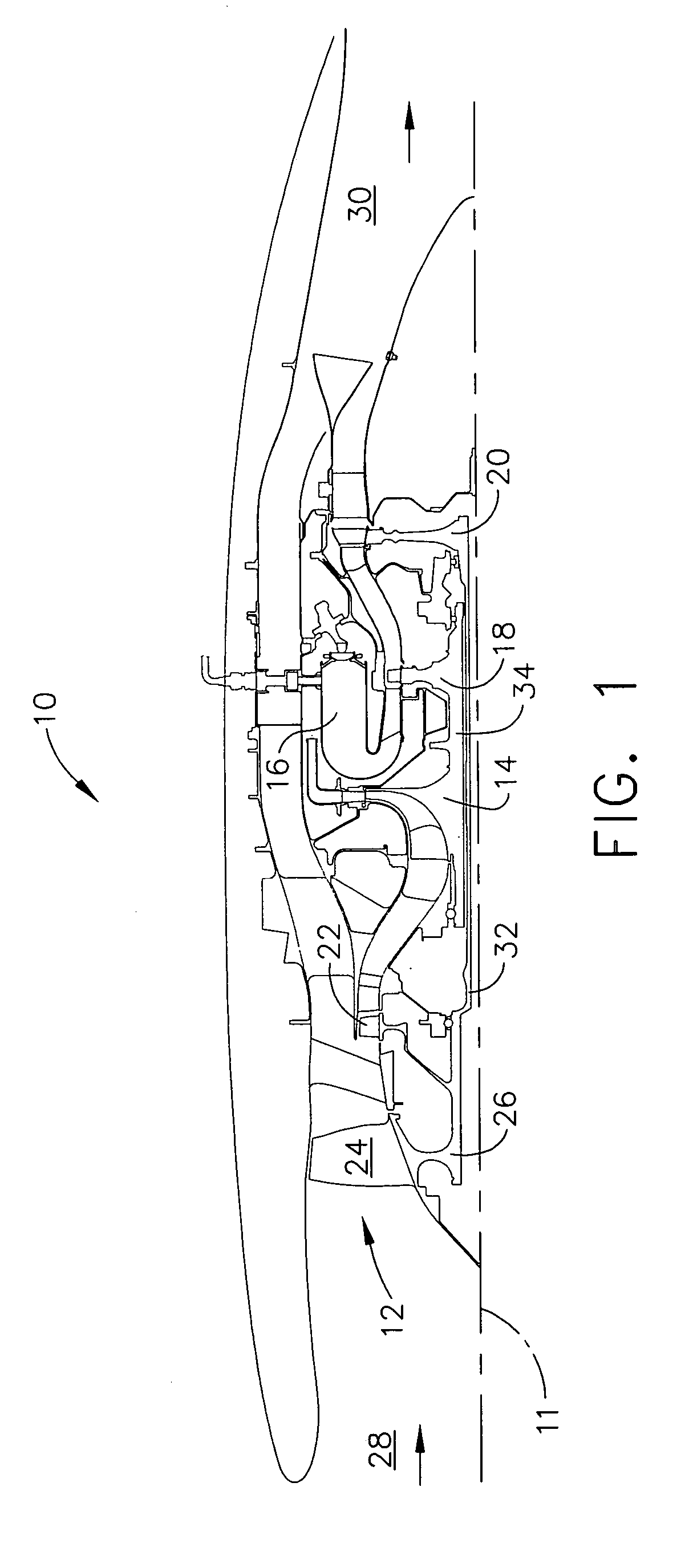

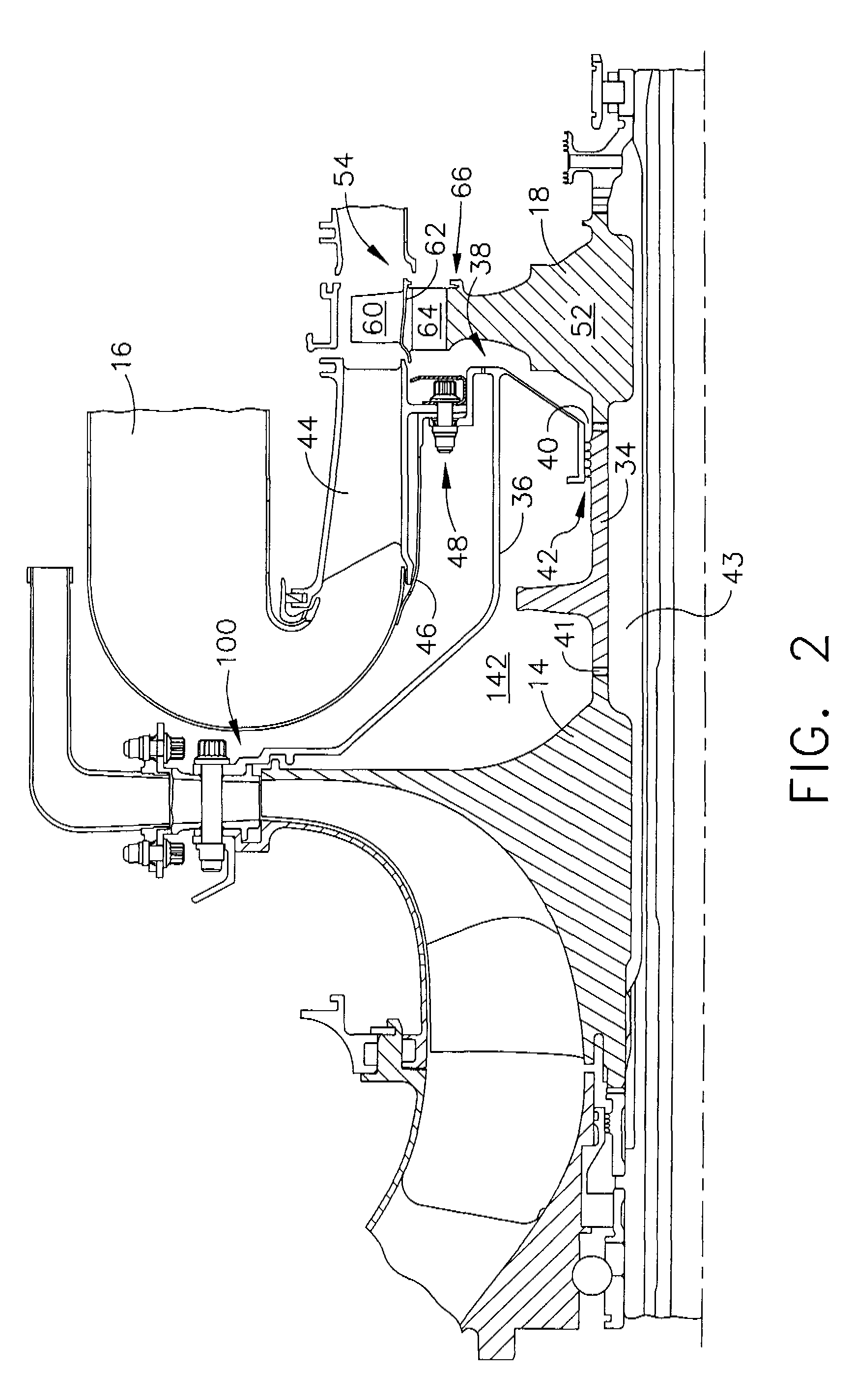

Gas turbine engines seal assembly and methods of assembling the same

ActiveUS7363762B2Reduce pressureReduce axial forcePump componentsGas turbine plantsCombustorCavity pressure

A method of assembling a gas turbine engine includes providing a gas turbine engine including a compressor, a combustor downstream from the compressor, and a turbine coupled to the compressor, and coupling a seal assembly aft of the compressor such that air discharged through the seal assembly facilitates reducing the cavity pressure, and therefore reducing the axial forces induced to an aft side of the compressor.

Owner:GENRERAL ELECTRIC CO

Piston arrangement of a hydraulic actuating device on motor vehicles

InactiveUS7188563B2Easy to assembleGood deformabilityPlungersFluid actuated clutchesMobile vehicleMaster cylinder

A piston arrangement for master and / or slave cylinders of a hydraulic actuating device for clutch and / or brake systems on motor vehicles is disclosed. An insert is inserted into a recess of the piston up to a first stop, the insert having a ball seat and an expandable insertion sleeve which is undercut with respect to the ball seat and protrudes with its expandable region. A ram is pushed into the sleeve with its ball end until it snaps into the ball seat. As the ram is further pressed axially, the insert slides over the first stop, is firmly pressed into a narrow hole section of the recess and strikes a second stop at the inner end of the recess. The insertion sleeve is then tightly enclosed by the piston wall and can no longer expand even in the event of very high pull-out forces, i.e. cannot release the ball end of the ram.

Owner:FTE AUTOMOTIVE GMBH & CO KG

Water filter cartridge and manifold head seal

ActiveUS10087085B2Avoid creatingEasy to engageDetection of fluid at leakage pointMeasurement of fluid loss/gain rateWater filterMoisture

A water filter cartridge has a cap with radially oriented first and second (either inlet or outlet) flow channels on first and second generally cylindrical portions. First and second seals encircle the first flow channel on the first portion and third and fourth seals encircle the second flow channel on the second portion. The second and third seals form a void volume during use which may be accessed by a vent path to eliminate moisture or to test for or indicate leaks. The radial flow paths reduce axial, push out forces on the filter cartridge and allow smaller locking tabs to be used. The first seal forms a top void volume during use which may be accessed by a vent path to eliminate moisture or to test for or indicate leaks.

Owner:BAIRD MICAHEL T

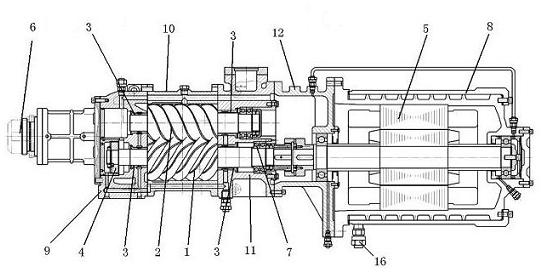

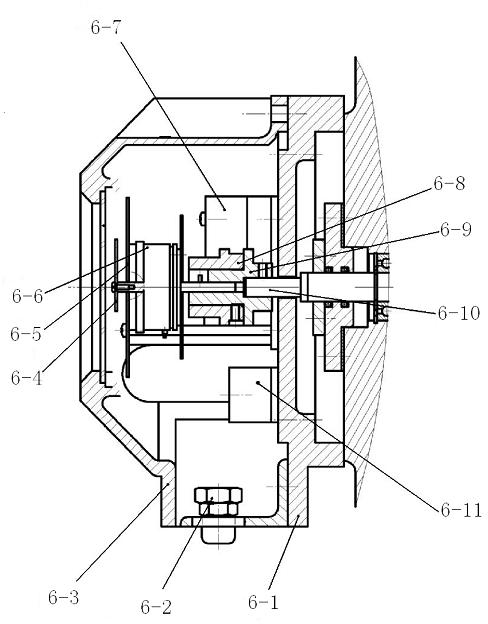

Novel water-cooling semi-sealed helical-lobe compressor

InactiveCN102352842AExtend your lifeImprove reliabilityRotary piston pumpsRotary piston liquid enginesCurrent loadCoupling

The invention discloses a novel water-cooling semi-sealed helical-lobe compressor. A machine body (10) is internally provided with a male rotor (1) and a female rotor (2) which are mutually engaged with each other; and two ends of the machine body are connected with an air suction end seat (9) and an air exhaust end seat (11). The novel water-cooling semi-sealed helical-lobe compressor is characterized in that two sides of the male rotor (1) and the female rotor (2) are respectively connected with sliding bearings (3); one side, which is adjacent to an air suction end, of the male rotor (1) is connected with a balance piston (4); one side, which is adjacent to an air exhaust end, of the male rotor (1) and one side, which is adjacent to the air exhaust end, of the female rotor (2) are respectively connected with thrust bearings (7); compressor slide valves (13) are arranged below the male rotor (1) and the female rotor (2) in the machine body (10) and the compressor slide valves (13) are connected with an energy indicator (6); the machine body (10) is connected with a water sleeve (8) through a middle body (12) and the water sleeve (8) is internally provided with a motor (5); the water sleeve (8) is provided with a water inlet (16) and a water outlet (17), the male rotor (1) is connected with the motor (5) through a shaft coupler (15) and the middle body (12) is provided with a junction box (14). The novel water-cooling semi-sealed helical-lobe compressor has the advantages that the service life of the bearings is longer and the reliability is higher; and the current load position of the compressor can be really indicated, and the efficiency is very high.

Owner:YANTAI MOON

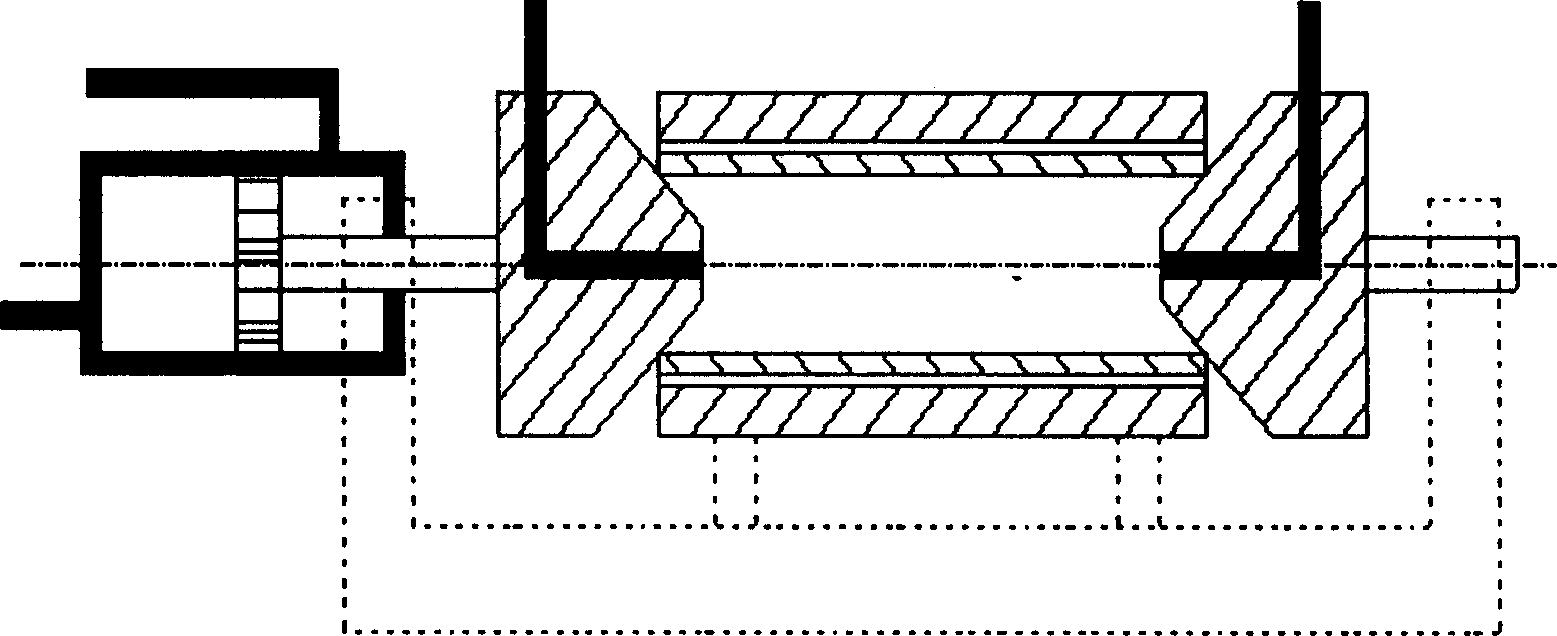

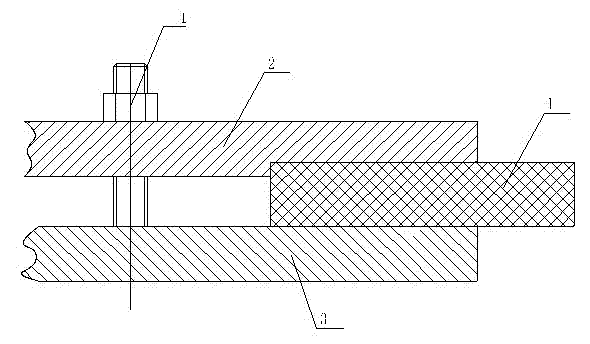

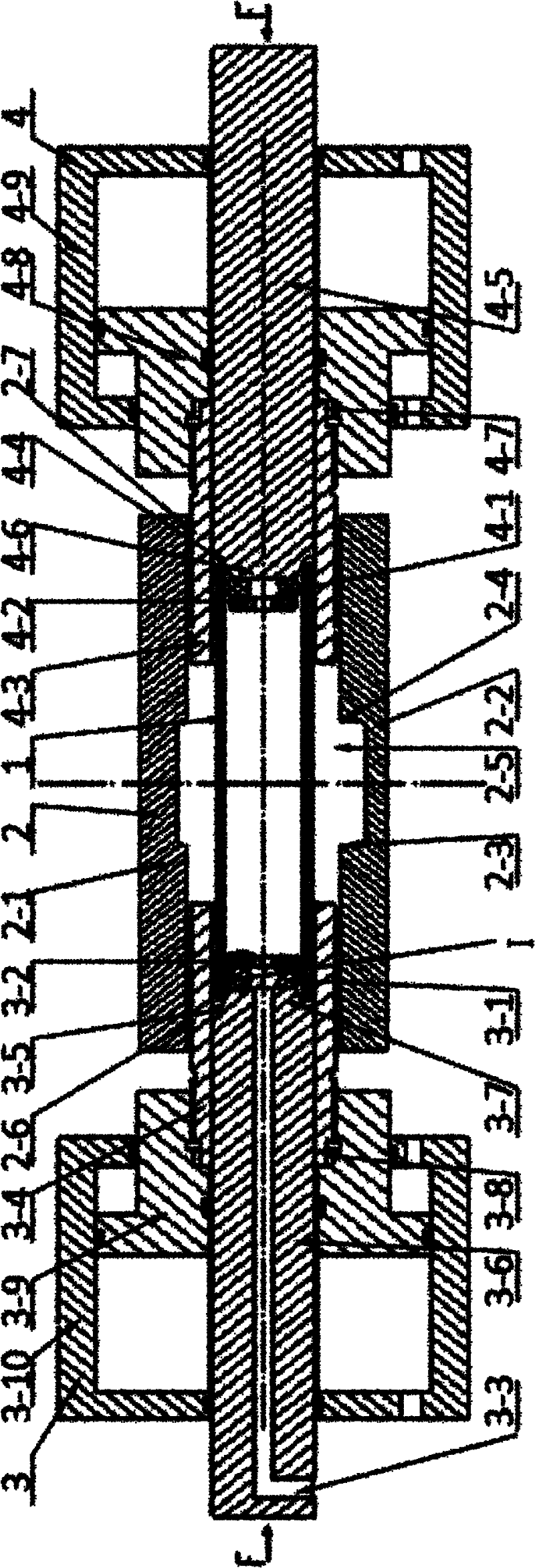

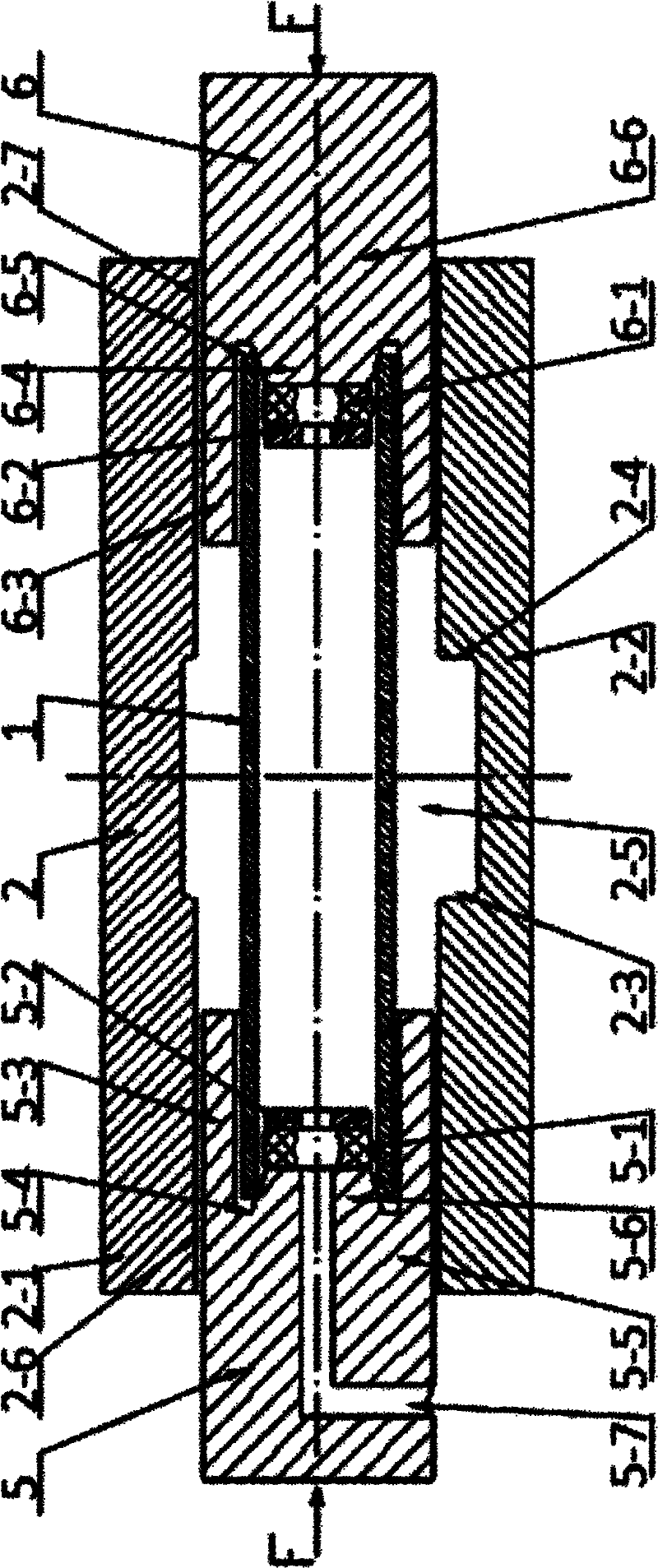

Thick-wall pipe hydroforming device

The invention discloses a thick-wall pipe hydroforming device. The thick-wall pipe hydroforming device comprises a main body module and a left feed device and a right feed device which are arranged at two ends of the main body module respectively; the main body module consists of an upper main body module and a lower main body module, and after the upper main body module and the lower main body module are closed, the main body module has a cylindrical structure with two open ends, and a cavity is formed in the main body module; the left end of the main body module is provided with a left guide hole which is communicated with the cavity, and the right end of the main body module is provided with a right guide hole which is communicated with the cavity; the right end of a left movable module is arranged in the left guide hole; the outer cylinder side wall of a left punch is in clearance fit with the left movable module; the left end of a right movable module is arranged in the right guide hole; and the outer circular side wall of a right punch is in clearance fit with the right movable module. By giving a certain initial gap to the movable module and the main body module, the high contact pressure area acting on the main body module by the movable module is reduced, the frictional resistance applied to the guide area is reduced, the axial feeding of a pipe is facilitated, and the quality of the hydroformed workpiece of a thick-wall pipe is improved. Meanwhile, due to the adoption of a self-sealing structure of a pipe end, the high pressure sealing problem can be solved.

Owner:XI AN JIAOTONG UNIV

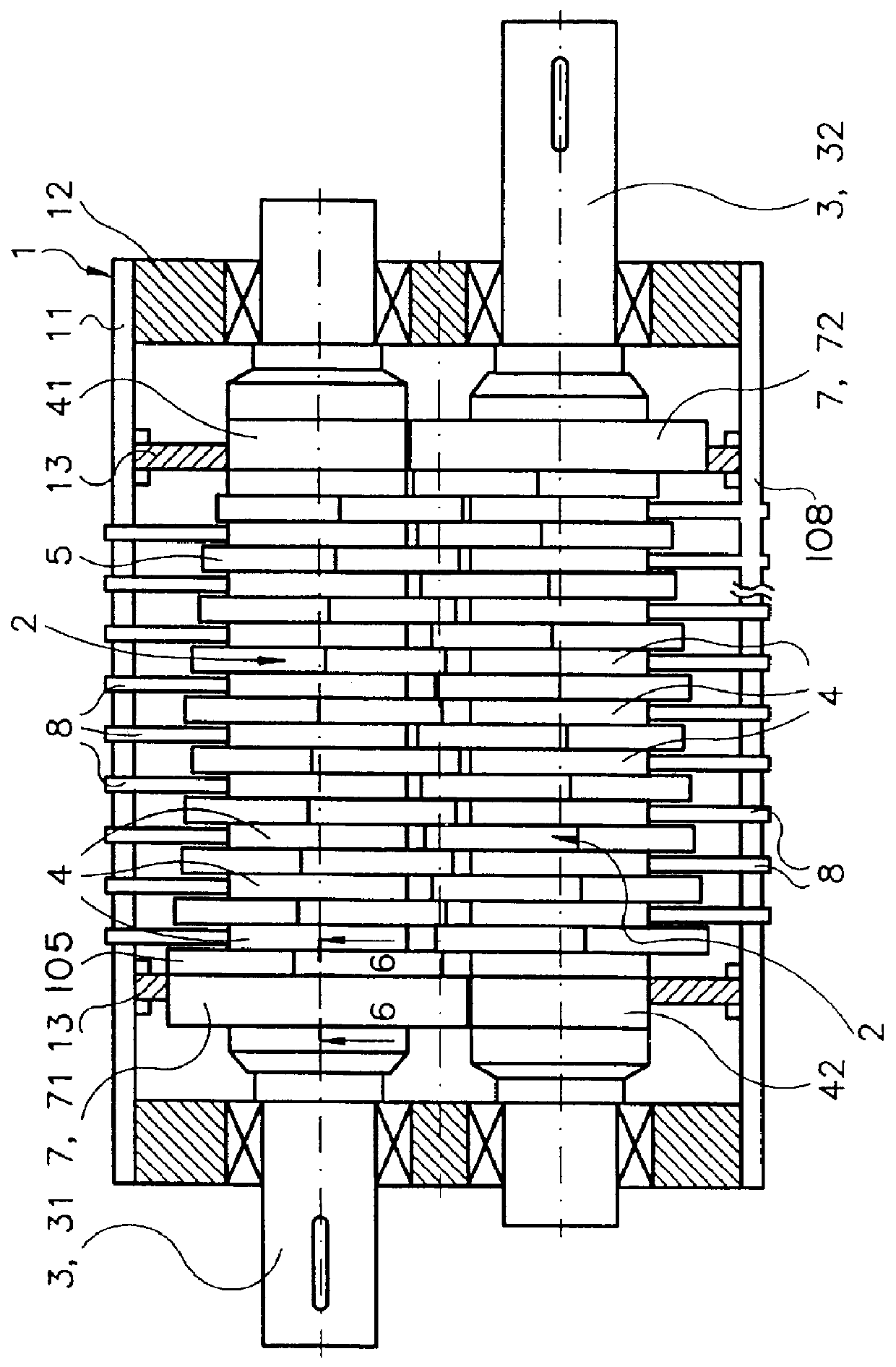

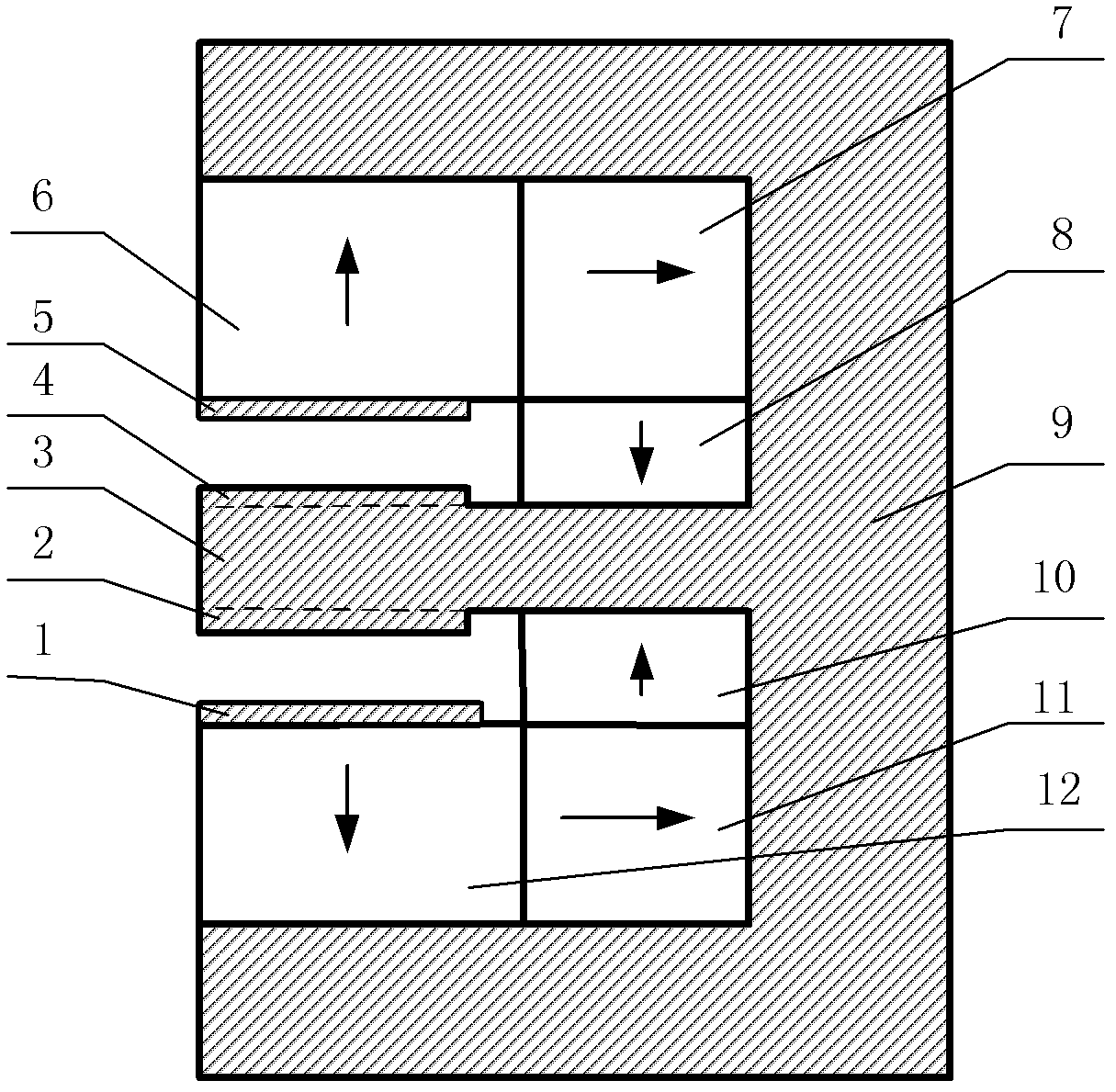

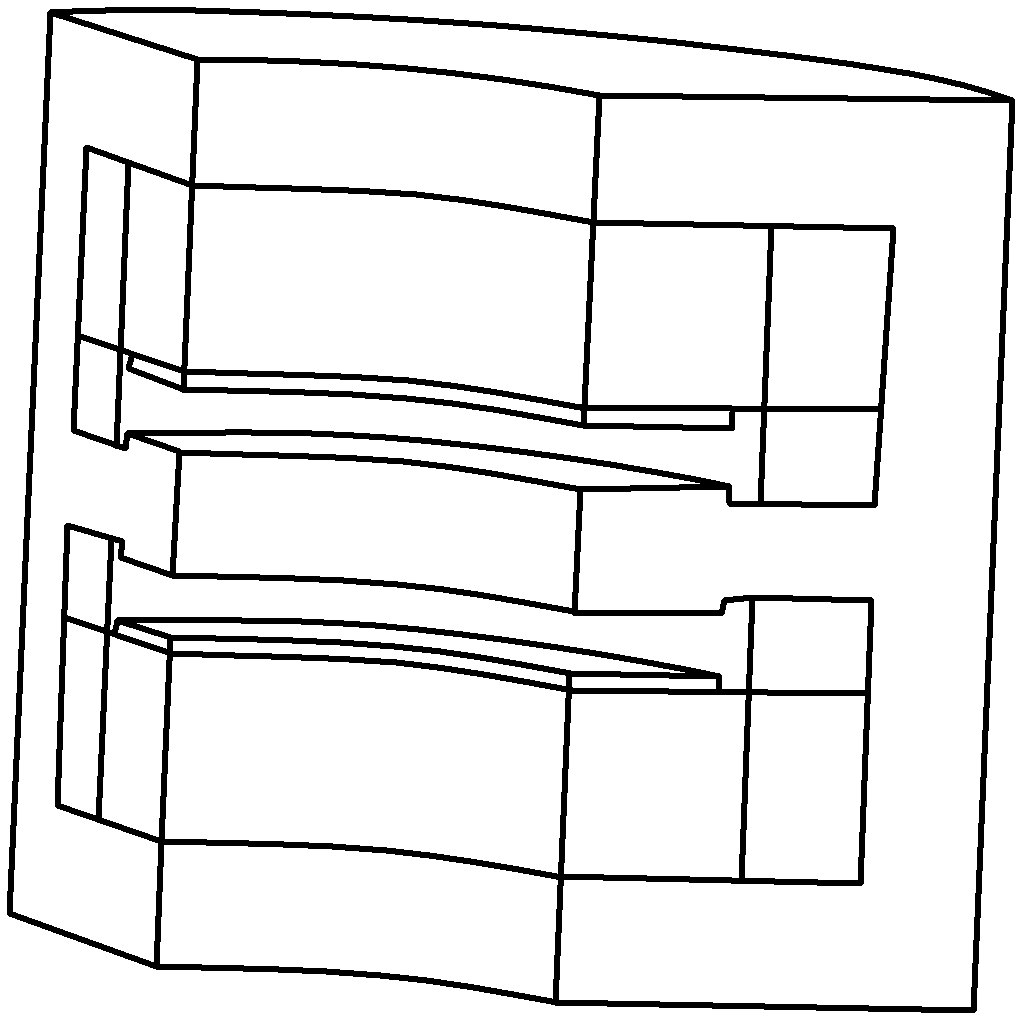

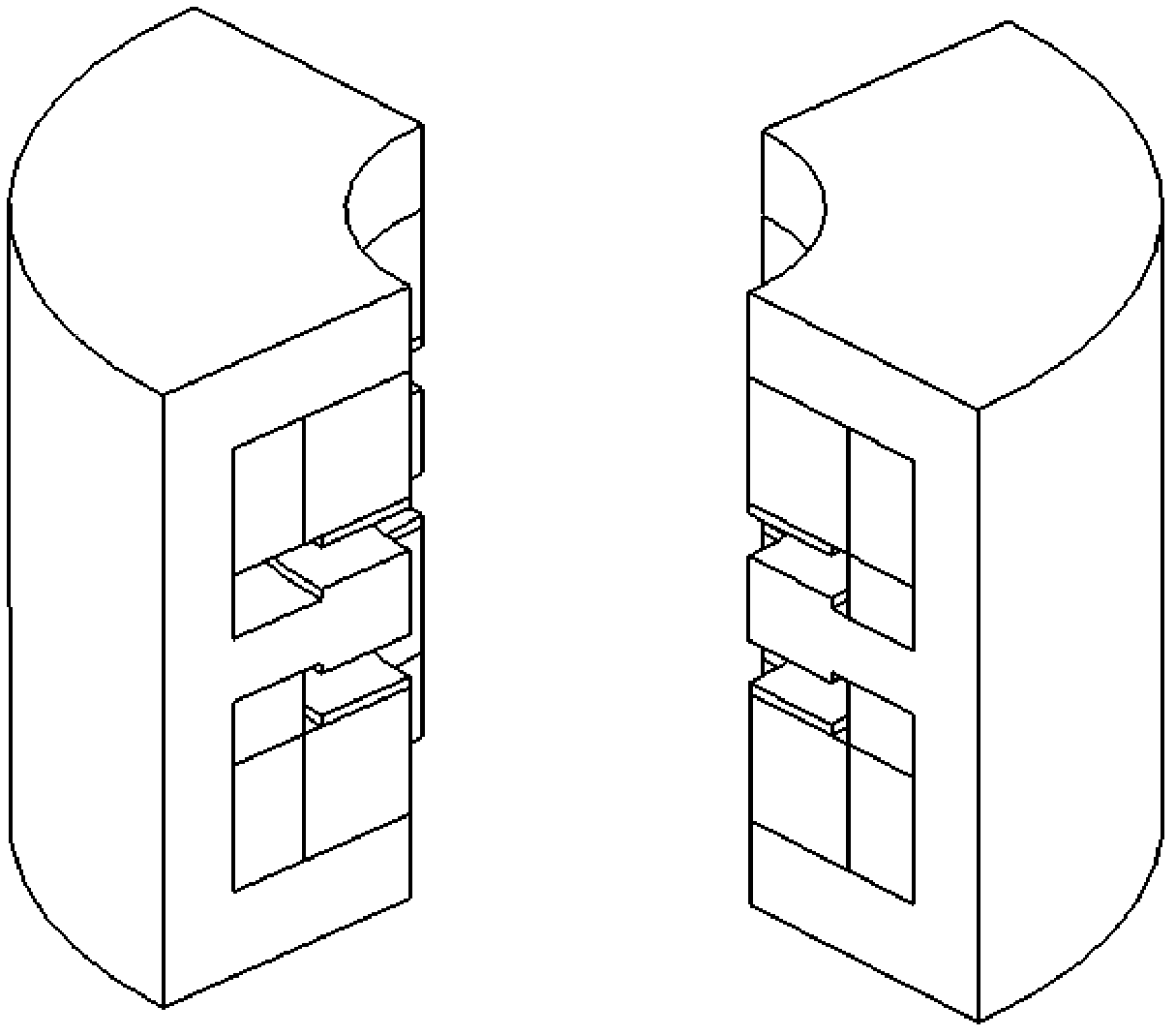

Dynamo-electric machine

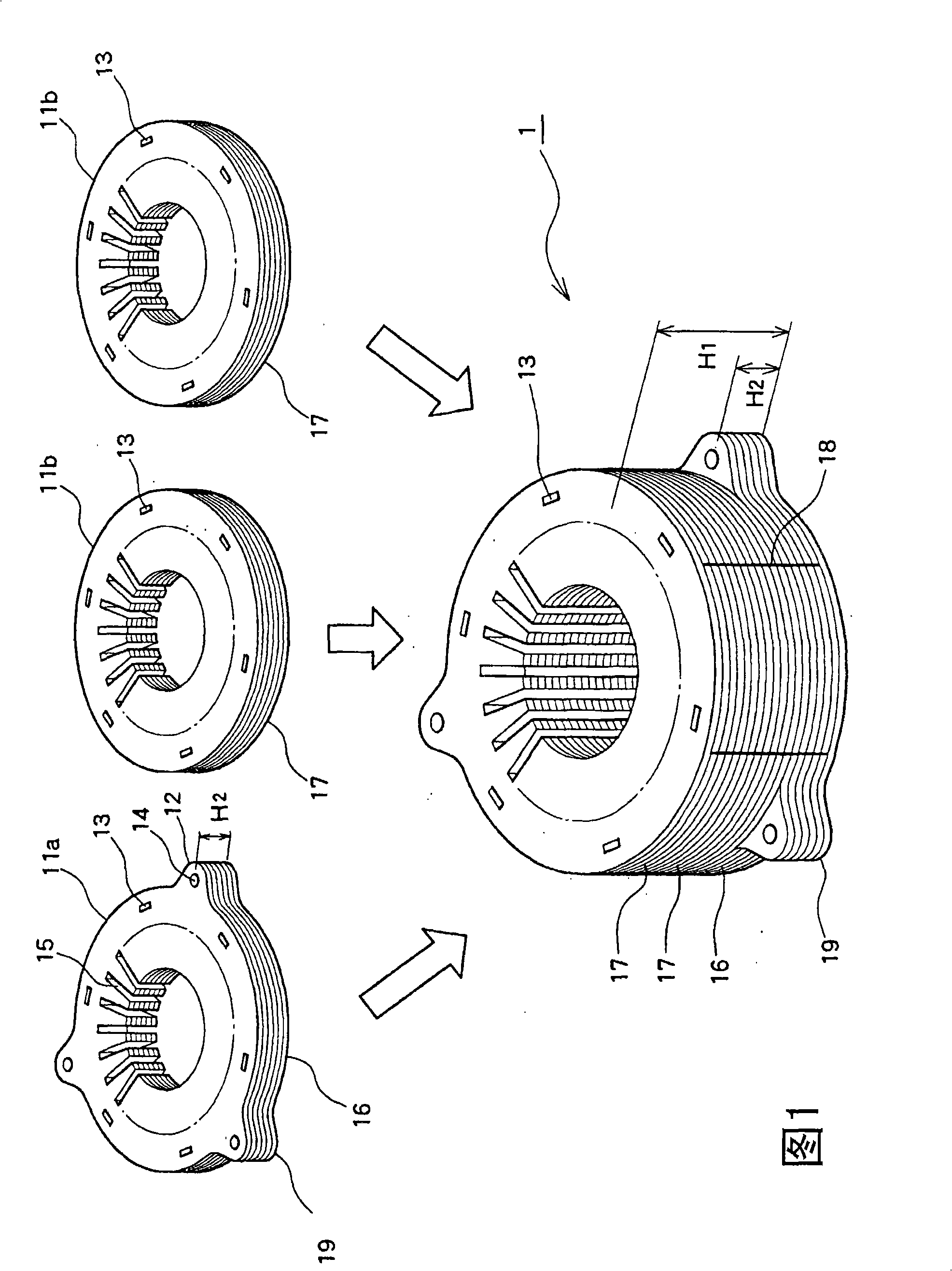

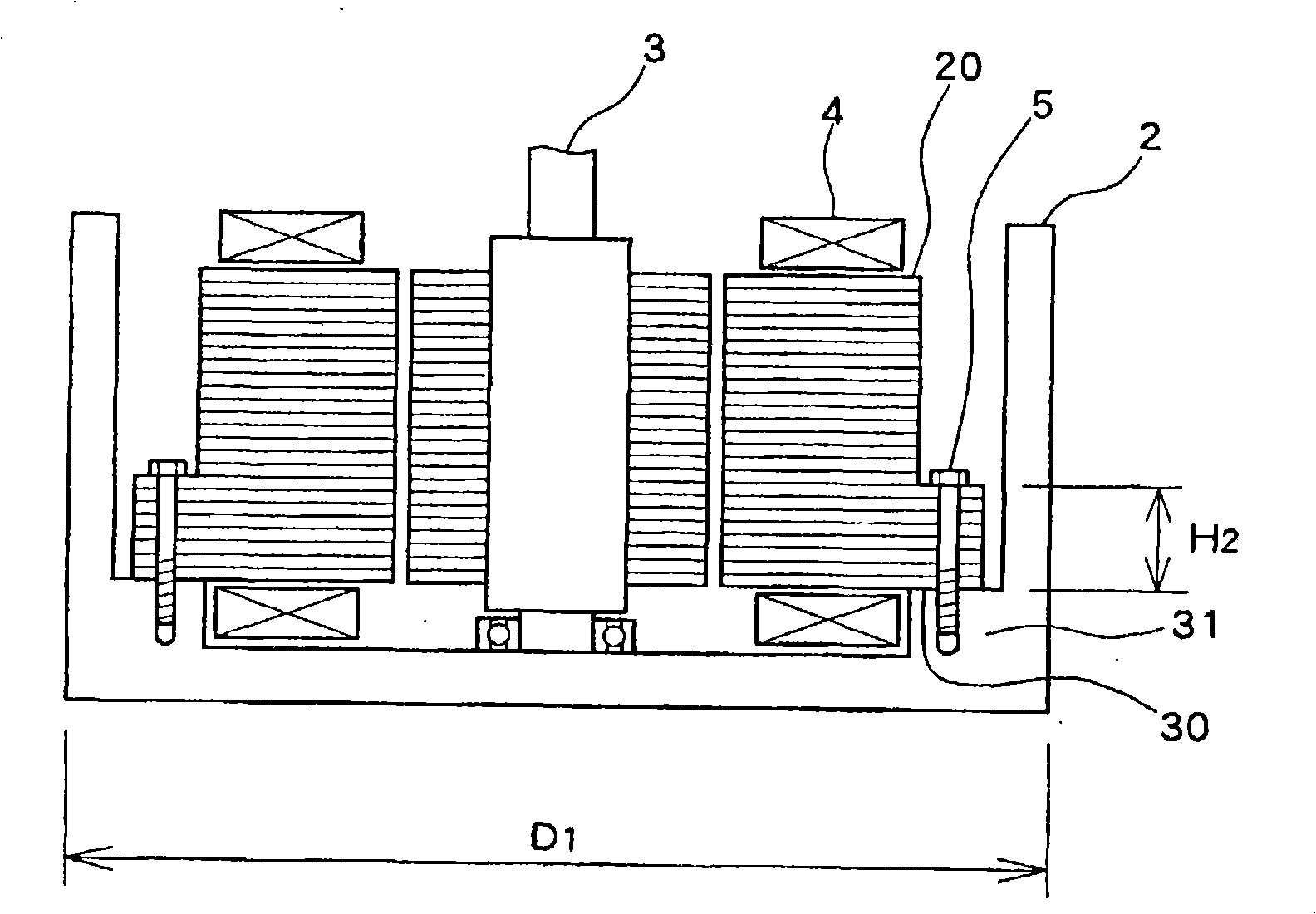

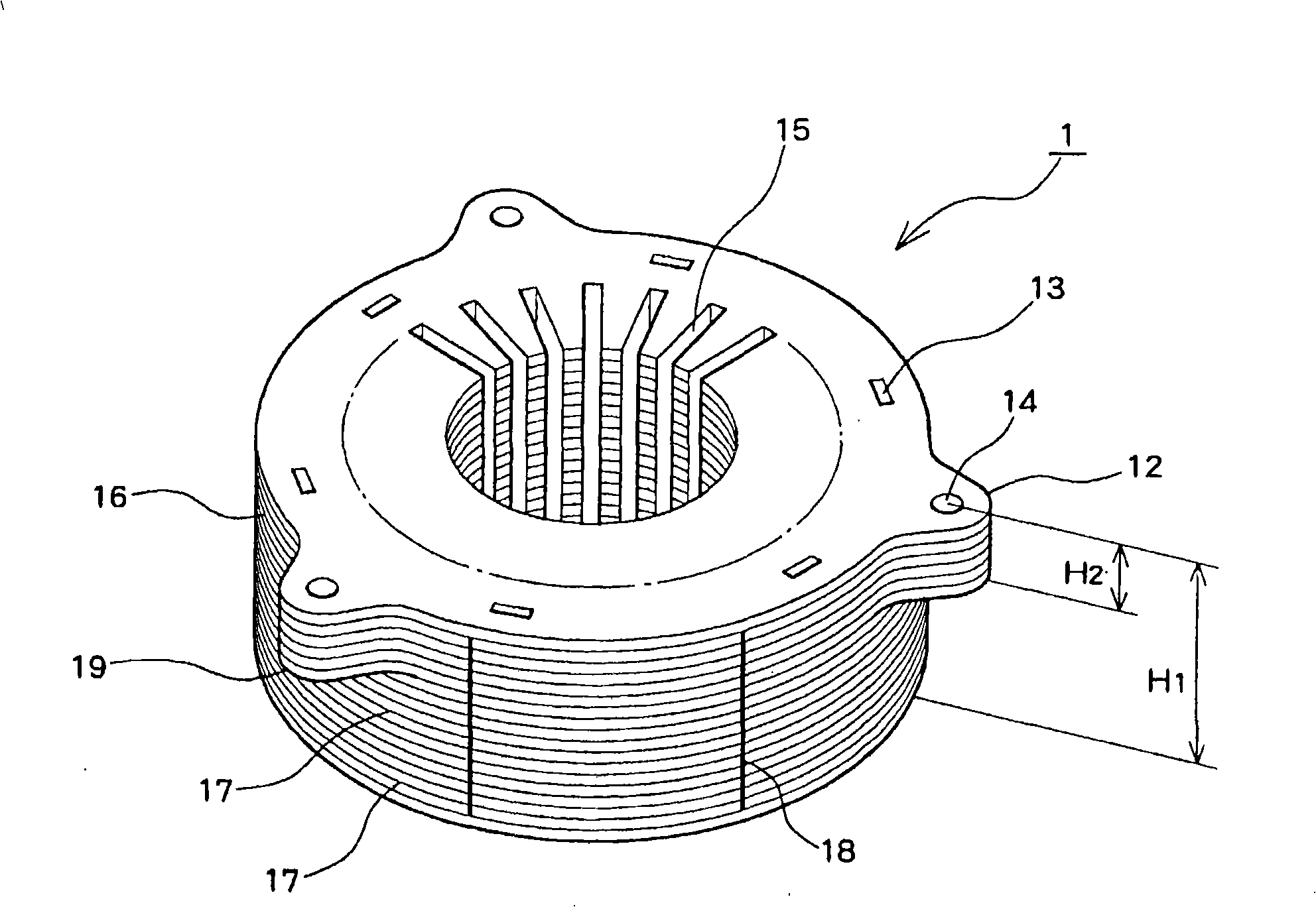

InactiveCN101326698AReduce axial forceIncrease the degree of fixationMagnetic circuit stationary partsElectric machineAxial force

A first laminate layer block having a bolt fixing unit laminated / fixed by caulking a plurality of steel plates having lug metals protruding diametrically and a second laminate layer block laminated / fixed by caulking a plurality of steel plates not having lug metals are rolled and laminate on part of a steel plate, and are welded on the surfaces of their side surface in a laminate direction to be laminated and integrated. Accordingly, it is possible to prevent the axial force of the fixed bolt from being lowered due to thermal shock of a stator to decrease the occurrence of vibration or noise, and reduce vibration or noise by increasing the fixing levels of the stator and a case.

Owner:TOYOTA JIDOSHA KK

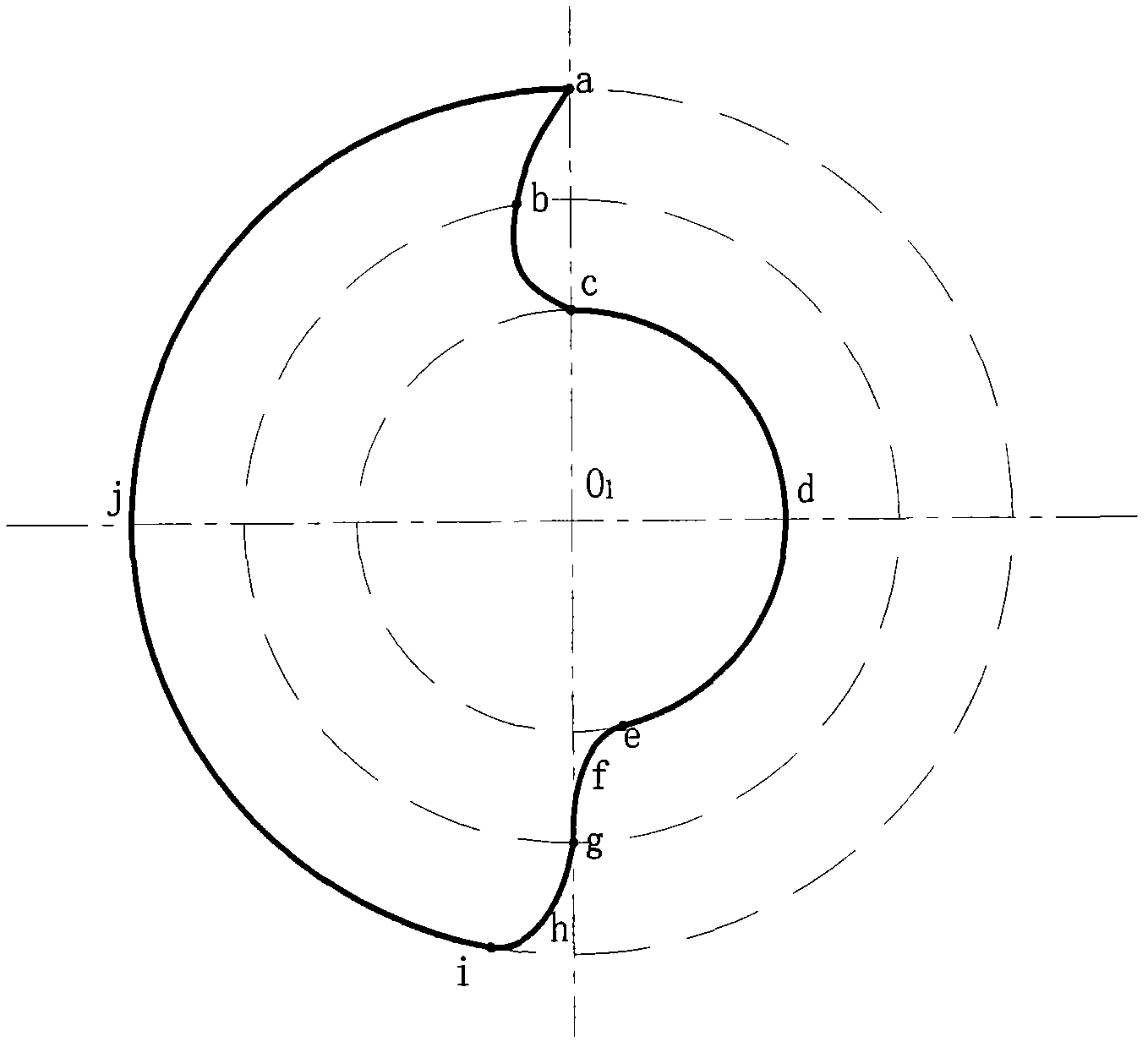

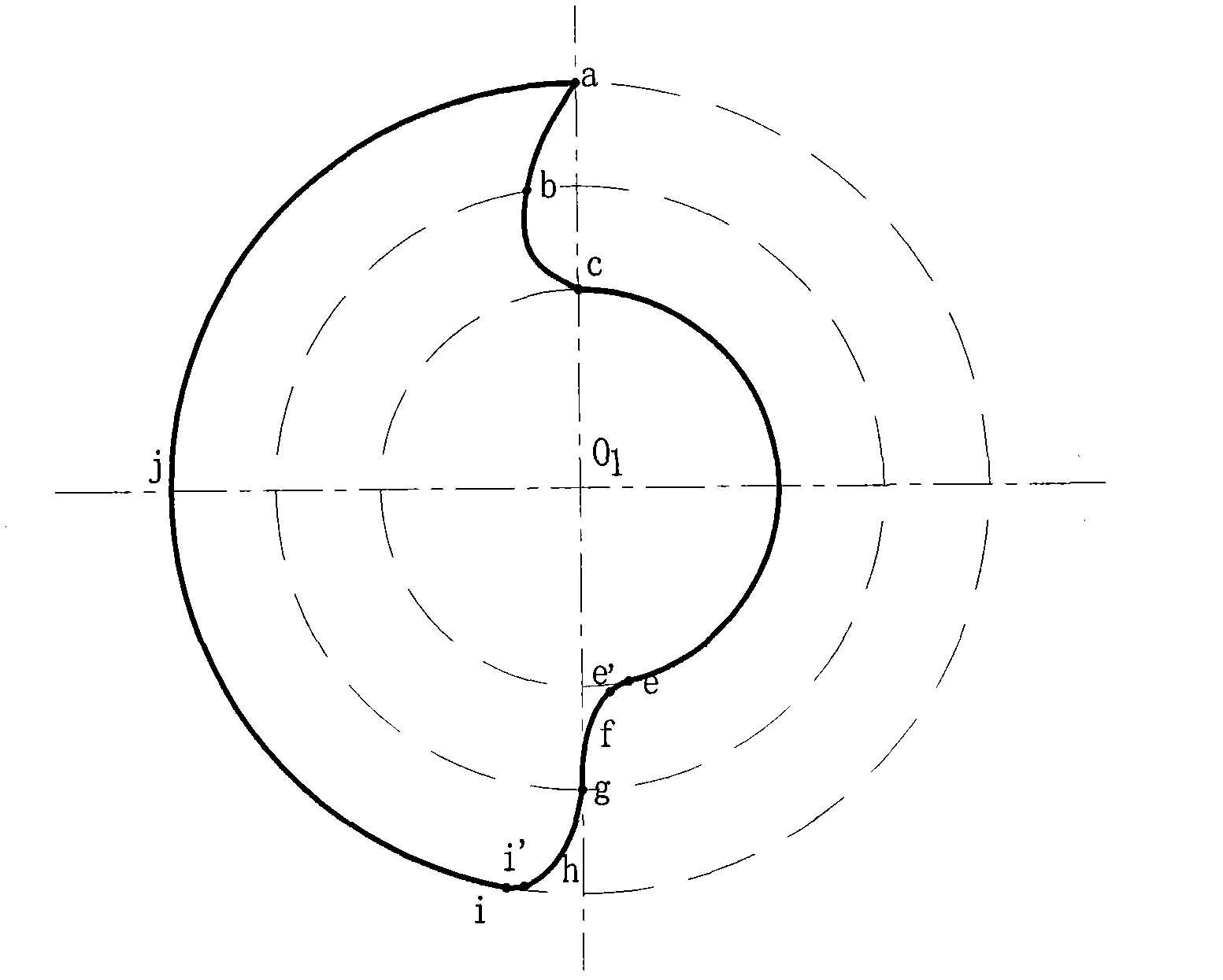

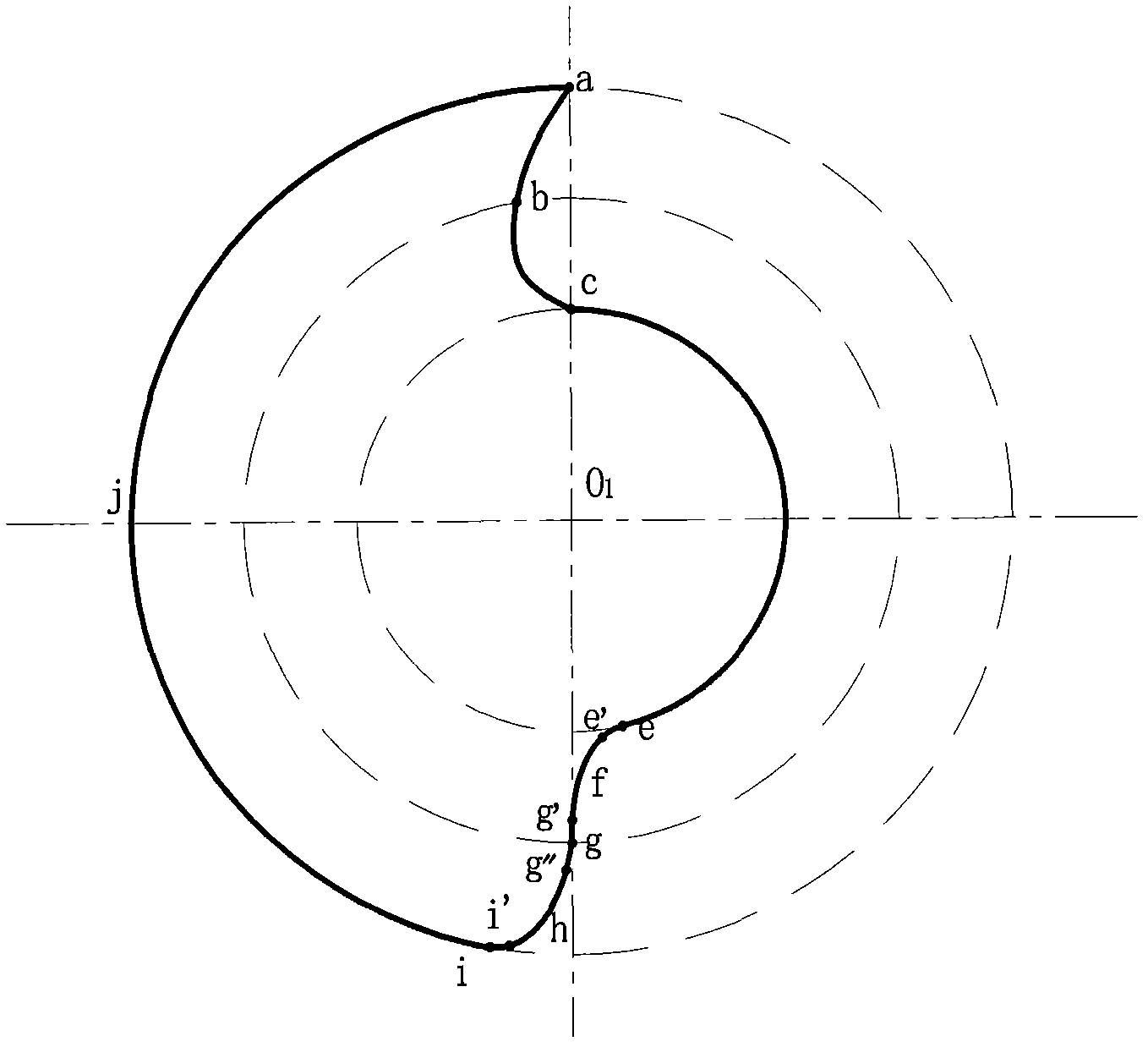

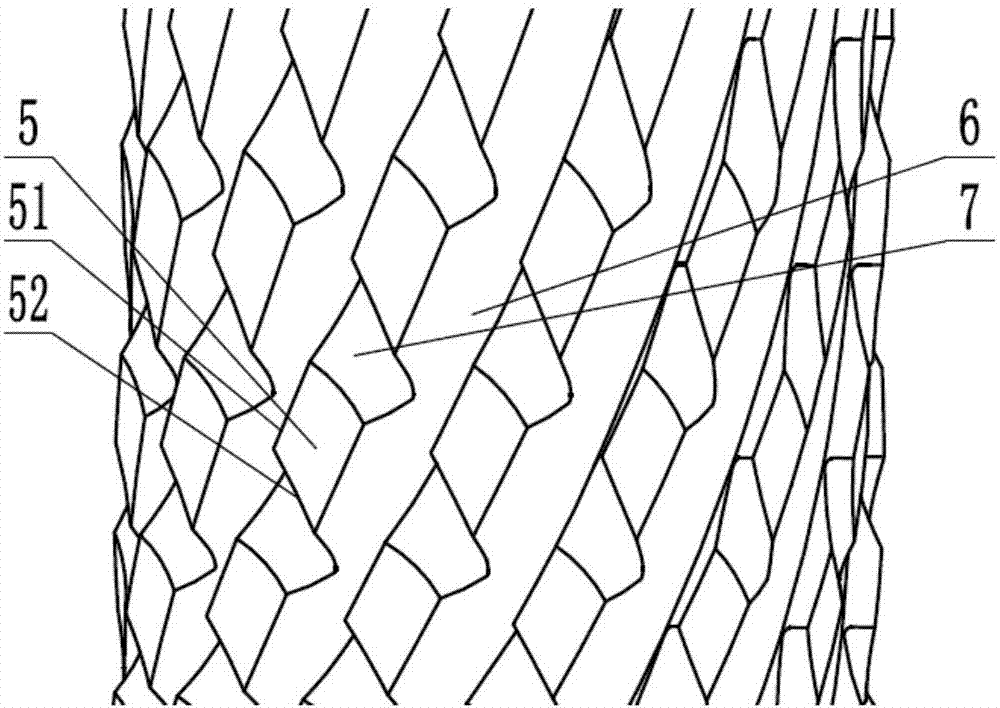

Screw rotor end face tooth type

InactiveCN102465871AImprove volumetric efficiencyRun smoothlyRotary piston pumpsRotary piston liquid enginesEllipseEngineering

The invention relates to a screw rotor end face tooth type for a double-screw pump and a twin screw compressor. The screw rotor end face tooth type is formed by multiple miscellaneous tooth curves, wherein each tooth curve comprises a cycloid curve, a circular arc, a circular arc envelope curve, an ellipse arc, an ellipse arc envelope curve and the like. The screw rotor end face tooth type has the technical characteristics that: the tooth curve on a screw rotor end face is formed by five sections of tooth curves which comprise a cycloid curve tooth curve abc, a circular arc tooth curve cde located on a dedendum circle, a circular arc tooth curve ija located on an addendum circle, an ellipse arc tooth curve efg, and an ellipse arc envelope curve tooth curve ghi by taking the ellipse arc tooth curve efg as a baseline; and a section of circular arc or two sections of circular arcs can be simultaneously added on the two sides of the ellipse arc respectively to form four different combination schemes. The screw rotor end face tooth type provided by the invention can realize strict (complete) seal, and a contact line generated through meshing is shorter; and the double-screw pump or the twin screw compressor produced by applying the invention has the advantages of high volumetric efficiency, high medium pressure capable of being delivered, and the like.

Owner:上海格什特螺杆科技有限公司

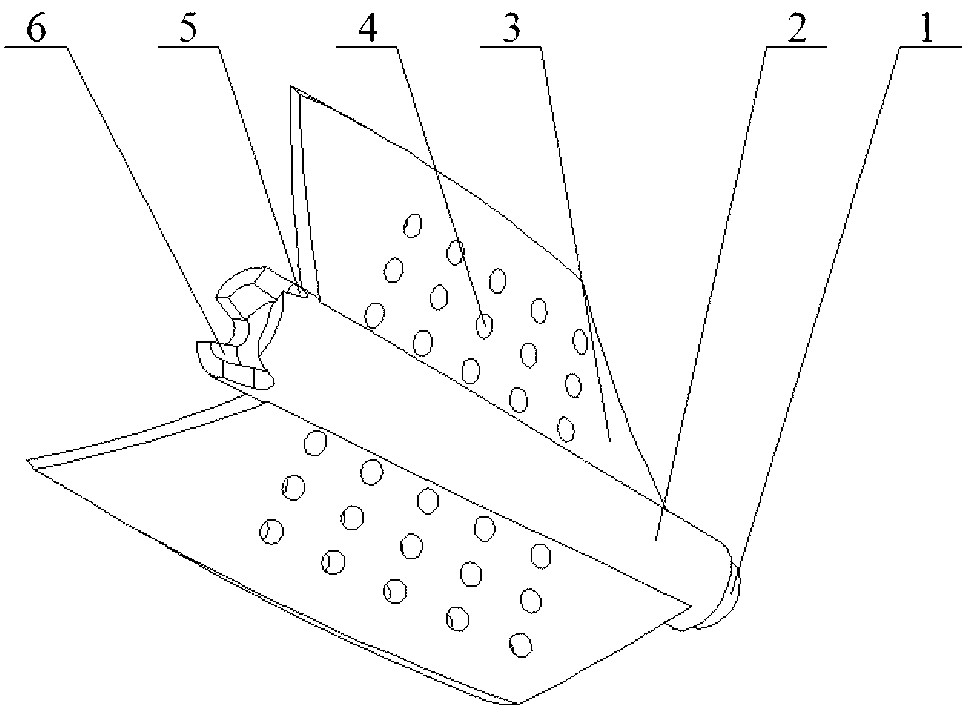

Multi-step multi-edge gradient micro toothed cutter for drilling carbon fiber reinforced plastics

The invention provides a multi-step multi-edge gradient micro toothed cutter for drilling carbon fiber reinforced plastics, which belongs to the technical field of composite material machining. The multi-step multi-edge gradient micro toothed cutter is composed of a straight-edge drilling area, a reaming area, a trimming area and a cutter handle, wherein the straight-edge drilling area is provided with a cross edge, main cutting edges, secondary cutting edges and drilling chip grooves, the reaming area is provided with reaming cutting edges and reaming chip grooves, the trimming area is provided with rhombic micro cutting units, right-handed rotating chip grooves and left-handed rotating chip grooves, the rhombic micro cutting units are structurally divided into micro toothed main cutting edges and micro toothed secondary cutting edges, and the sizes of the rhombic micro cutting units are gradually increased in the direction of the right-handed rotating spiral line. The multi-step multi-edge gradient micro toothed cutter is a complete tool and has sufficient strength and rigidity, the drilling axial force is reduced, and additionally, the sizes of the rhombic micro cutting units are gradually increased, so that the deburring efficiency is greatly improved, the trimming quality of a processed hole wall is guaranteed, the transition of the machining process is smooth, and the machining efficiency is improved.

Owner:DALIAN UNIV OF TECH

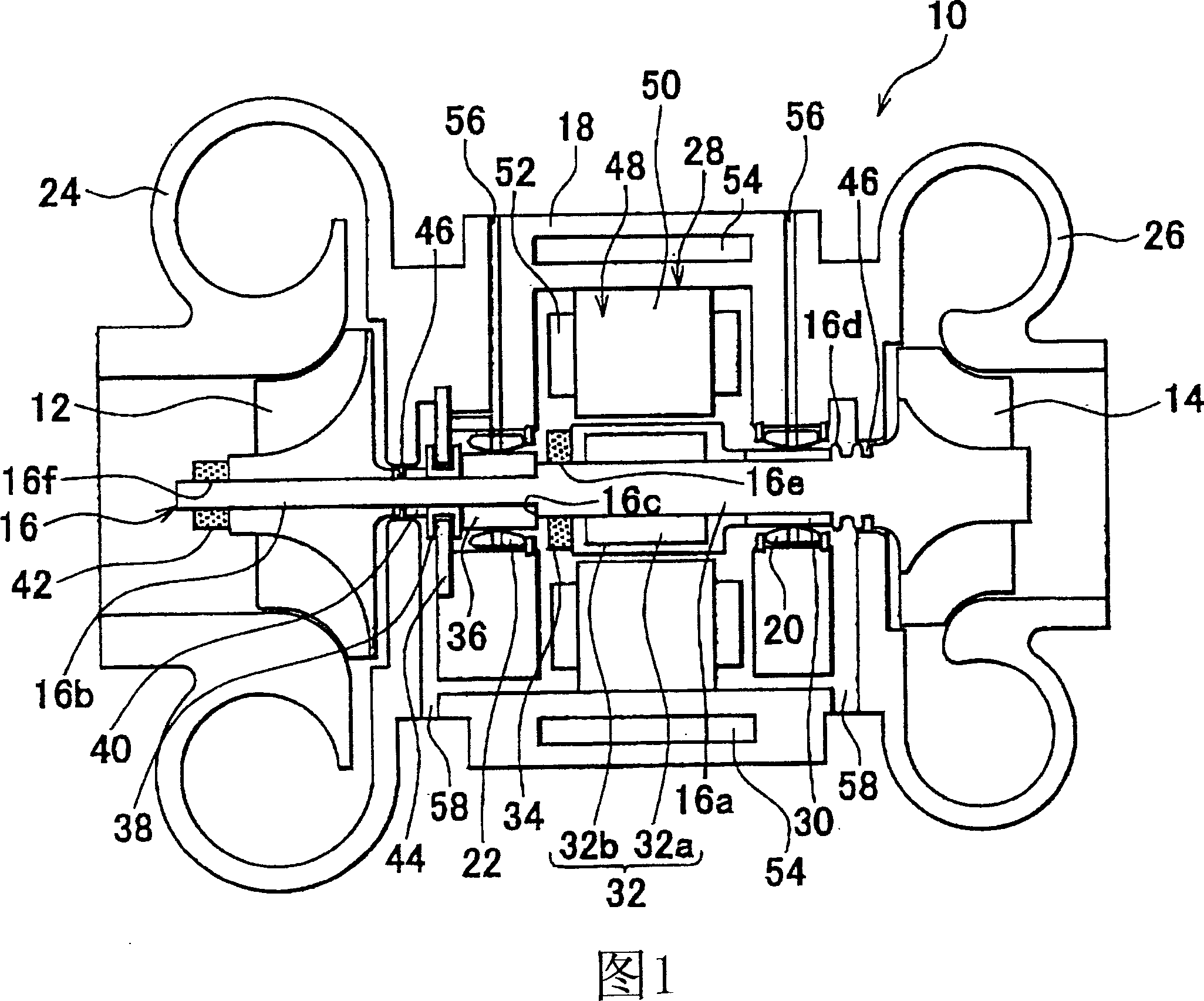

Turbocharger

InactiveCN1928334AReduce axial forceMagnetic circuit rotating partsInternal combustion piston enginesImpellerTurbine wheel

The turbocharger has a connecting shaft (16) connecting a compressor wheel (12) and a turbine wheel (14). The shaft has a section of larger diameter and a section of smaller diameter, and intermediate units are provided between the compressor wheel and the turbine wheel. The compressor wheel is fixed to the section of smaller diameter by using a smaller screw (42) nut with respect to a flat section. A rotor (32) of an electric motor (28) is fixed to the section of the larger diameter by using a larger screw nut (34) with respect to an end section of the shaft.

Owner:TOYOTA JIDOSHA KK

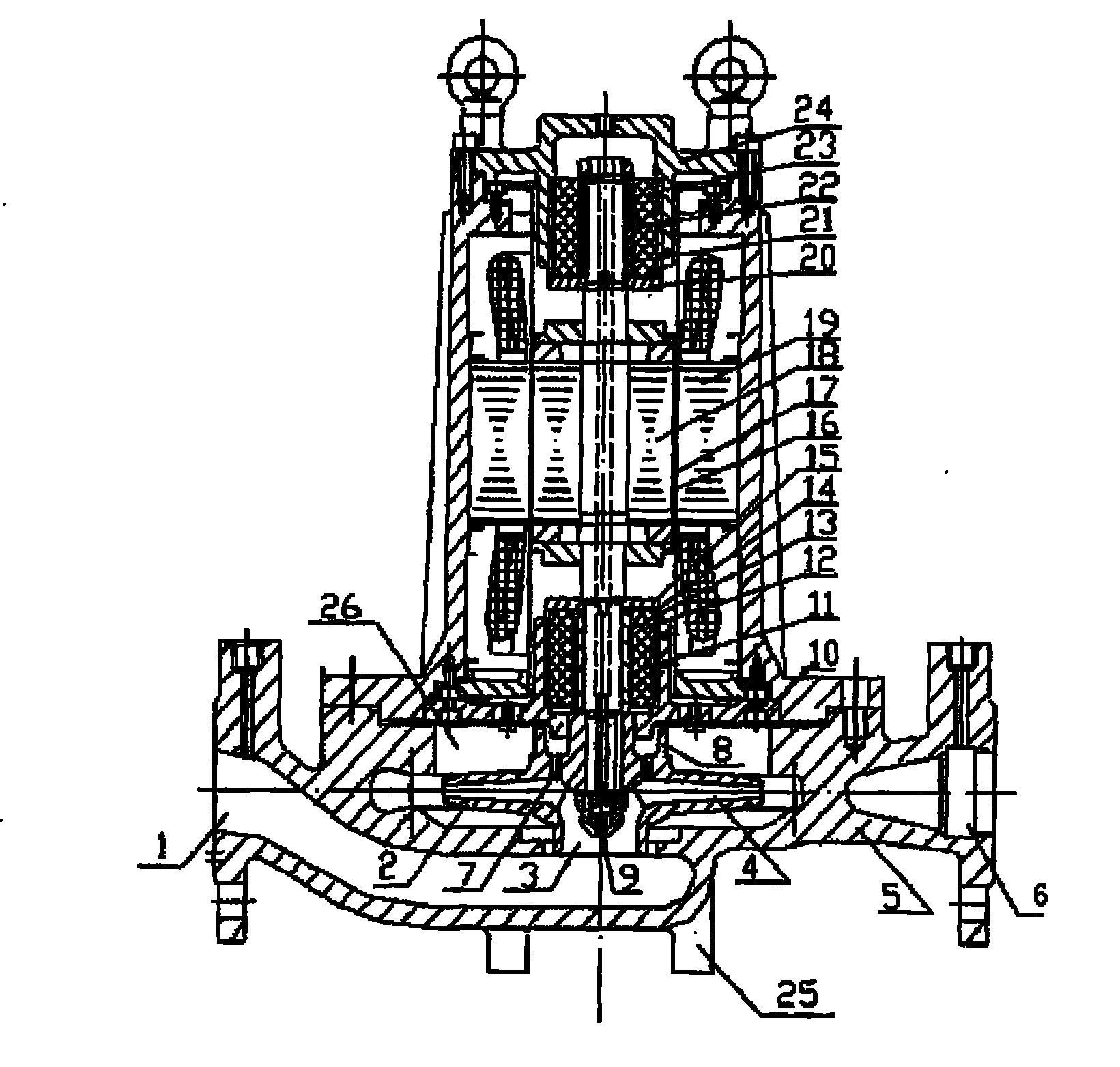

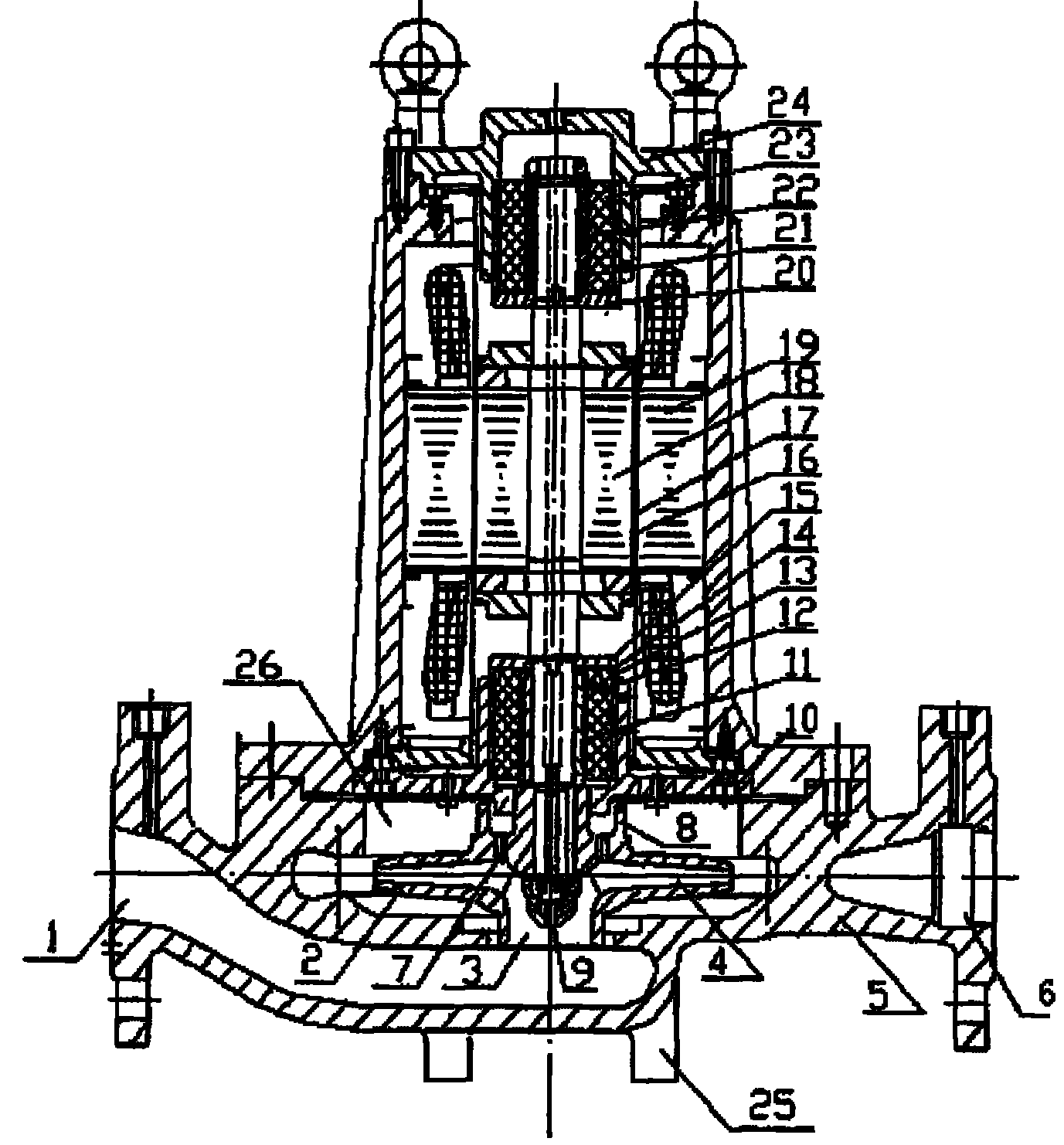

Pipeline shielding structural electric pump working in manner of internal circulation

The invention discloses a pipeline shielding structural electric pump working in a manner of internal circulation. The pipeline shielding structural electric pump comprises a pump body and a shielding motor connected to the pump body and is characterized in that a circulation through hole is arranged in a rotor shaft, one end of the circulation through hole is communicated with an impeller inlet,and the other end thereof is communicated with an inner cavity of an upper bearing seat; and grooves are respectively arranged on an upper graphite bearing and a lower graphite bearing, a gap betweena rotor shielding sleeve and a stator shielding sleeve is connected with the inner cavity of the upper bearing seat and a cavity body between an impeller back ring and a lower bearing seat through the grooves arranged on the upper graphite bearing and the lower graphite bearing, and the cavity body between the impeller back ring and the lower bearing seat is connected with an impeller chamber through an impeller balanced hole. Through decreasing total weight of a rotor and reducing pressure of the rotor acting on the lower bearing seat synchronously, the invention improves the axial force adjustment capacity of the shielding electric pump per se and prolongs the service life of the graphite bearings and the shielding electric pump; and the electric pump in an internal circulation structure can effectively prevent from leakage of the electric pump.

Owner:HEFEI XINHU CANNED MOTOR PUMP

Swing type room temperature magnetic refrigeration machine

ActiveCN102305491ASimple structureImprove efficiencyEnergy efficient heating/coolingMachines using electric/magnetic effectsHeat transmissionControl system

The invention discloses a swing type room temperature magnetic refrigeration machine, which comprises a permanent magnet magnetic field source system, a magnetic working medium turntable system, a fluid heat exchange system and a motion control system, wherein the motion control system controls a turntable box of the magnetic working medium turntable system to rotate so as to drive a magnetic working medium to get in or get out a magnetic field space; the magnetic working medium positioned in the magnetic field space is magnetized to release heat; heat transmission fluid flows towards a hot-end heat exchanger so as to transmit the heat produced by the magnetic working medium to the hot-end heat exchanger; the hot-end heat exchanger transmits the heat to a high temperature space; the magnetic working medium which is not positioned in the magnetic field space is demagnetized to absorb heat; the heat transmission fluid flows towards a cold-end heat exchanger; and the magnetic working medium absorbs the heat from a low temperature closed space through the fluid and the cold-end heat exchanger, so that a refrigeration effect at room temperature can be achieved and the structure of the magnetic refrigeration machine is simplified. The swing type room temperature magnetic refrigeration machine has the advantage of simple structure of a reciprocating room temperature magnetic refrigeration machine and the advantage of high efficiency of a rotary room temperature magnetic refrigeration machine.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com