High-efficiency special drilling head for drilling holes in carbon fiber composite material

A composite material and carbon fiber technology, applied in the field of high-efficiency special drills and multi-blade tools, can solve problems such as delamination and burr defects, and achieve the effect of reducing delamination defects, improving processing efficiency and reducing use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

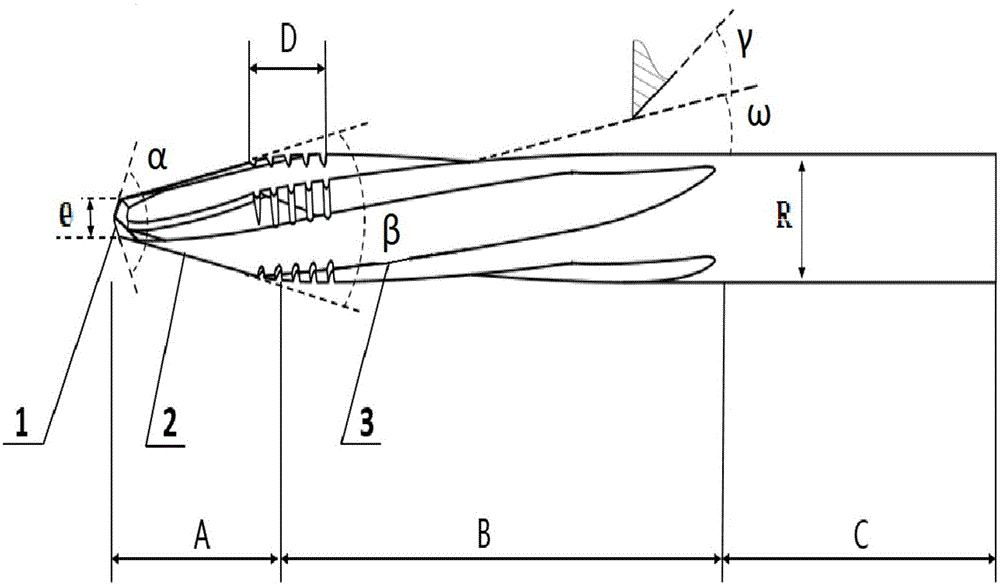

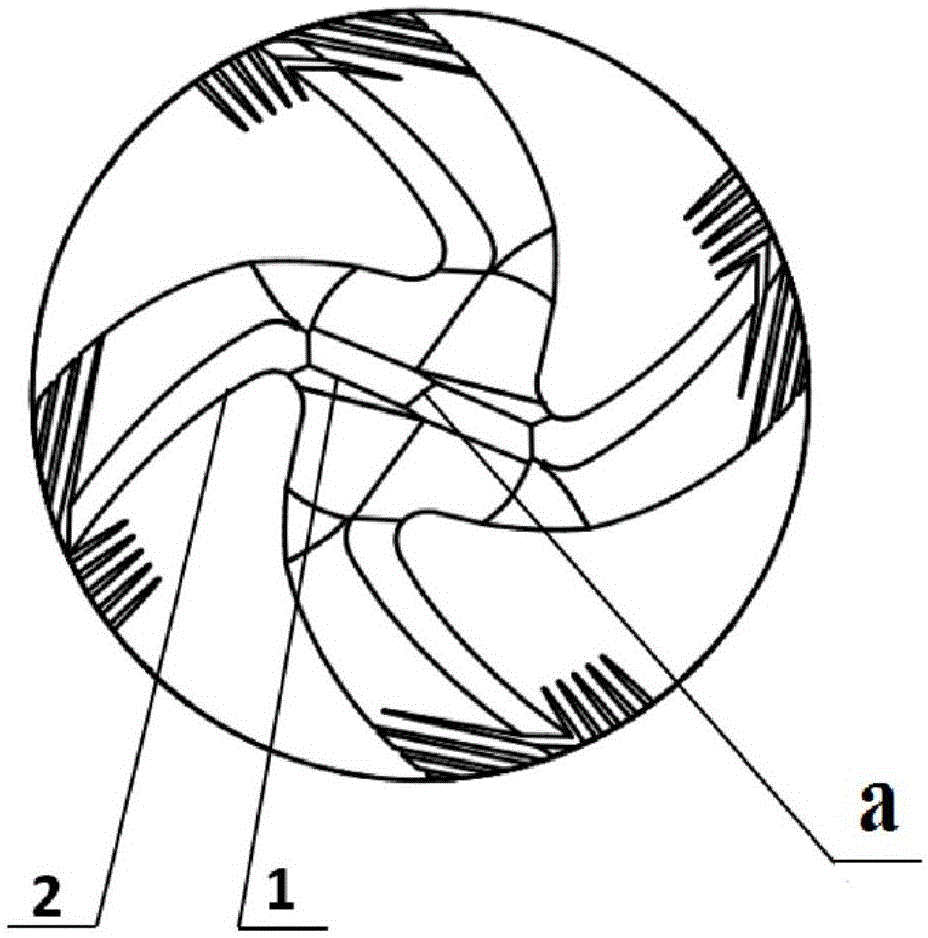

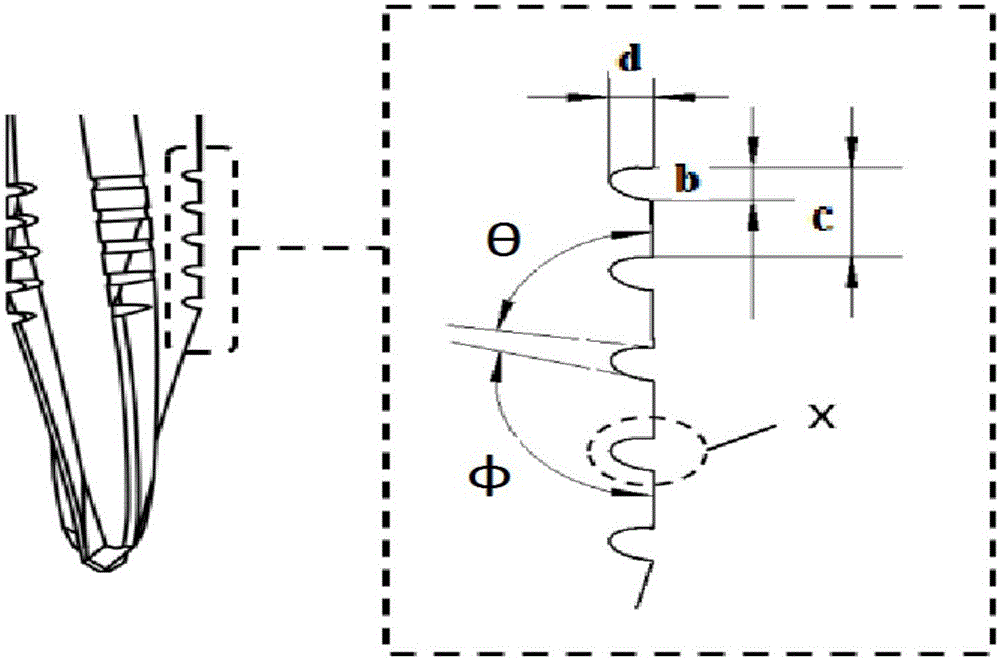

[0014] like figure 1 , figure 2 , image 3 The high-efficiency special drill shown is divided into three parts: the main cutting area A, the auxiliary cutting area B and the tool holder C. There is also a micro-tooth cutting area composed of several micro-tooths X at the junction of the main cutting area A and the auxiliary cutting area B. d. The drill bit can be divided into five stages during the drilling process. The first stage is extrusion. The chisel edge a contacts and squeezes the workpiece. Due to the extrusion effect of the chisel edge, the axial thrust increases rapidly; the second stage is extrusion. Pressing and drilling, at this time the first main cutting edge 1 enters the material, begins to remove material, and the thrust increases in a small range; the third stage is drilling, at this time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com