Patents

Literature

83 results about "Bulky waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bulky waste or bulky refuse is a technical term taken from waste management to describe waste types that are too large to be accepted by the regular waste collection. It is usually picked up regularly in many countries from the streets or pavements of the area. This service is provided free of charge in many places, but often a fee has to be paid.

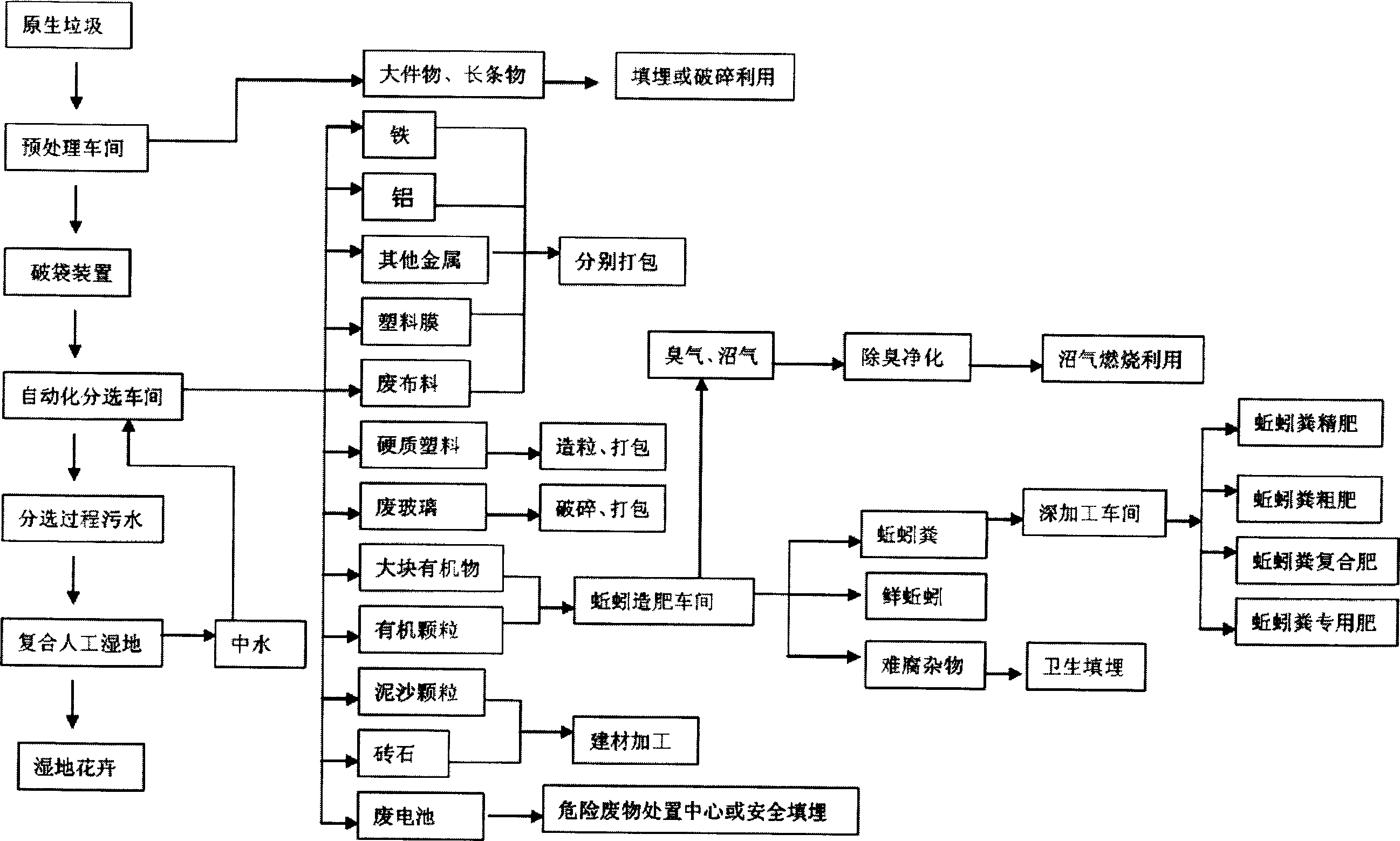

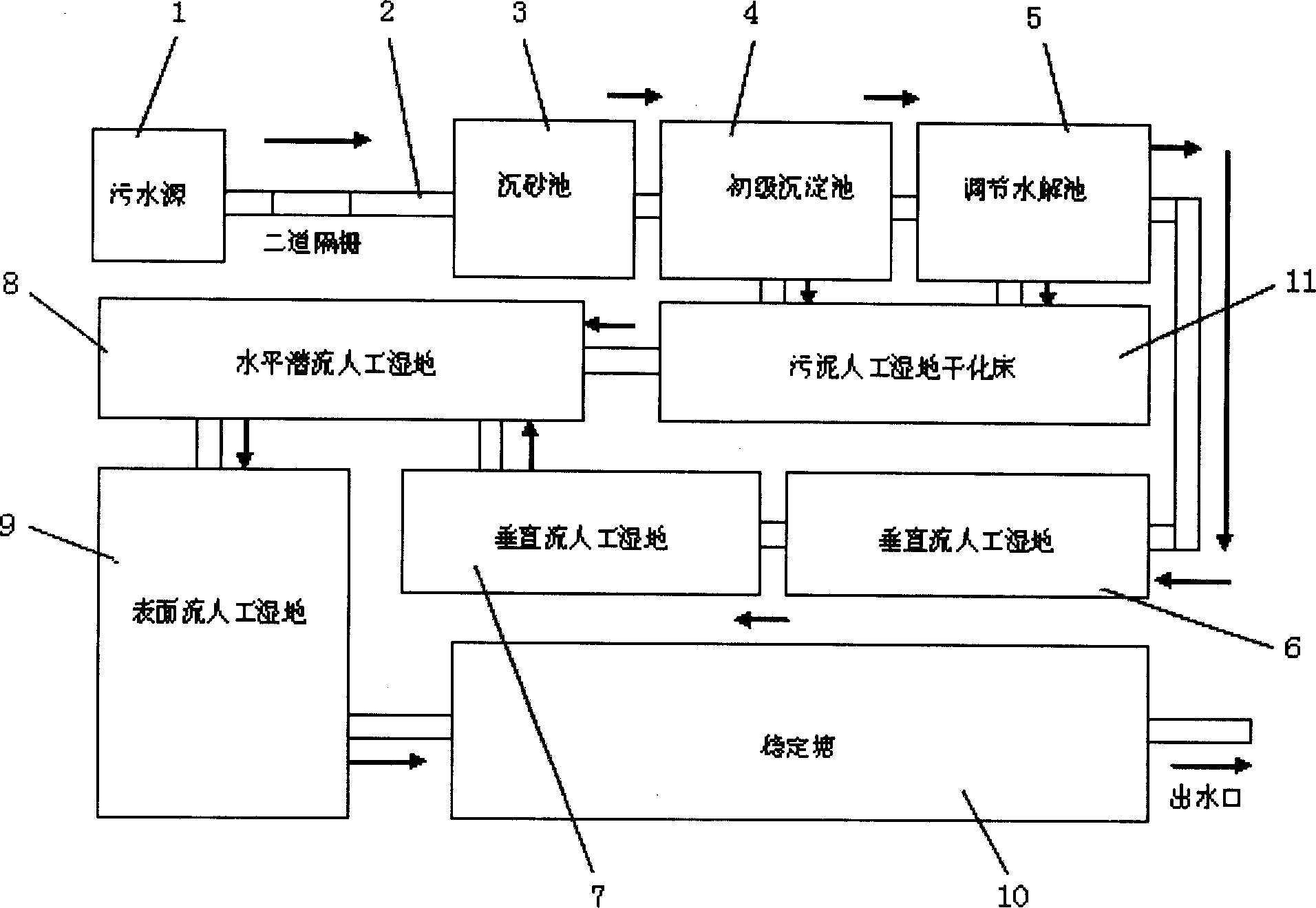

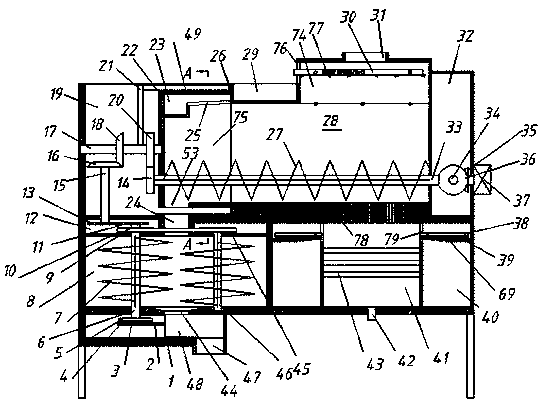

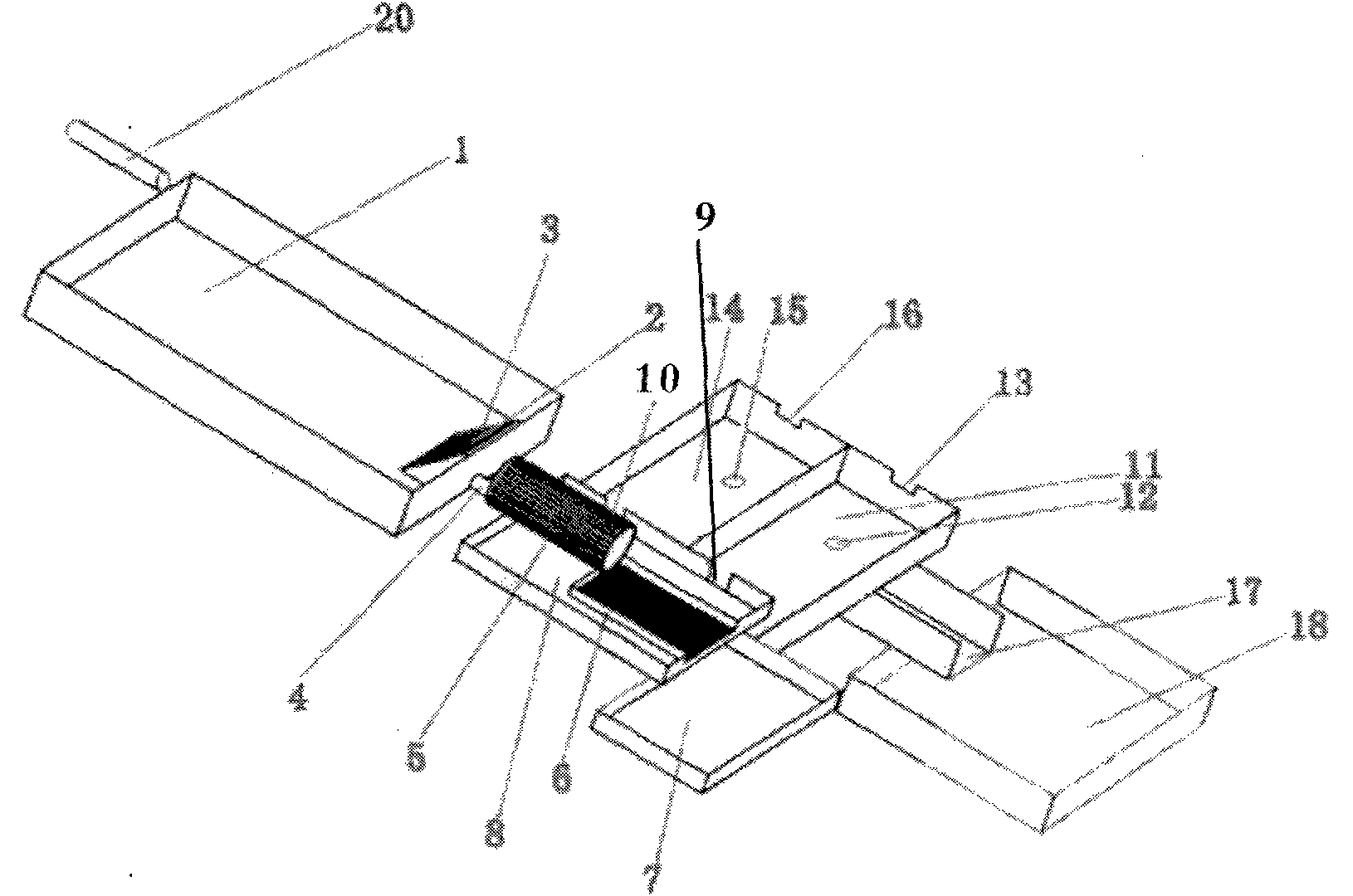

Garbage comprehensive treatment method and apparatus

InactiveCN1850365ABio-organic fraction processingSolid waste disposalConstructed wetlandChemical solution

The present invention relates to a comprehensive treatment method of refuse. Said method includes the following several steps: spraying biological chemical solution, deodorizing by using ozone, UV ray sterilization, separation, including biological solution separation, magnetic separation, pneumatic separation, vortex flow separation, drum sieve separation and vibration sieve separation, so that the refuse can be separated into 10-odd substances of iron, aluminium, other metal, plastic film, hard plastics, waste fabric, waste glass, organics, broken brick and waste battery, etc. The above-mentioned wastes can be used for making fertilizer, can be recovered and can be made into other useful resources.

Owner:广州德润环保科技发展有限公司

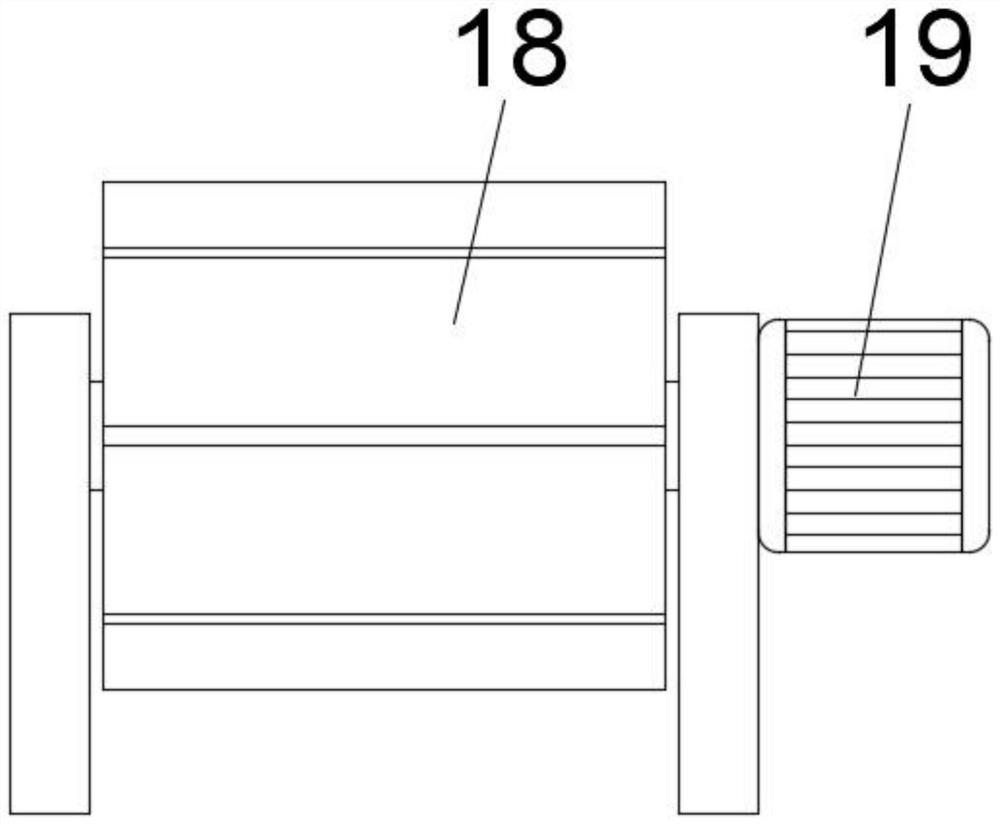

Sintered neodymium iron boron waste remoulding method

ActiveCN102719725ANo abnormal coarse crystal phenomenonEasy to operateInductances/transformers/magnets manufactureMagnetic materialsMetallurgyBulky waste

The invention discloses a sintered neodymium iron boron waste remoulding method. The sintered neodymium iron boron waste remoulding method comprises the steps of: a), crushing neodymium iron boron bulky waste into powder smaller than 40 meshes, putting the powder into a jet mill, and pulverizing, wherein the rotation speed of the jet mill speed is set at 800-1000rpm, the interior of the jet mill is protected by nitrogen gas, and the oxygen content is controlled at 2ppm; b), filling the powder finely ground by the jet mill into a material barrel protected by the nitrogen gas, adding 1-2ml of gasoline and 0.2-1ml of an oxidation preventer into each kilogram of the powder, and putting the material barrel into a mixer for stirring and mixing; and c) moulding the mixed powder, and sintering into a neodymium iron boron magnet. The neodymium iron boron magnet prepared by the method has normal cross-section crystallization; abnormal coarse-grained phenomenon does not appear; the performance of the neodymium iron boron magnet is consistent with that before the neodymium iron boron magnet is processed; and a normal material flow can be adopted. The sintered neodymium iron boron waste remoulding method is easy and convenient to operate and convenient and direct to process; and by the sintered neodymium iron boron waste remoulding method, waste of resources can be reduced and cost can be saved.

Owner:NINGBO KETIAN MAGNET +1

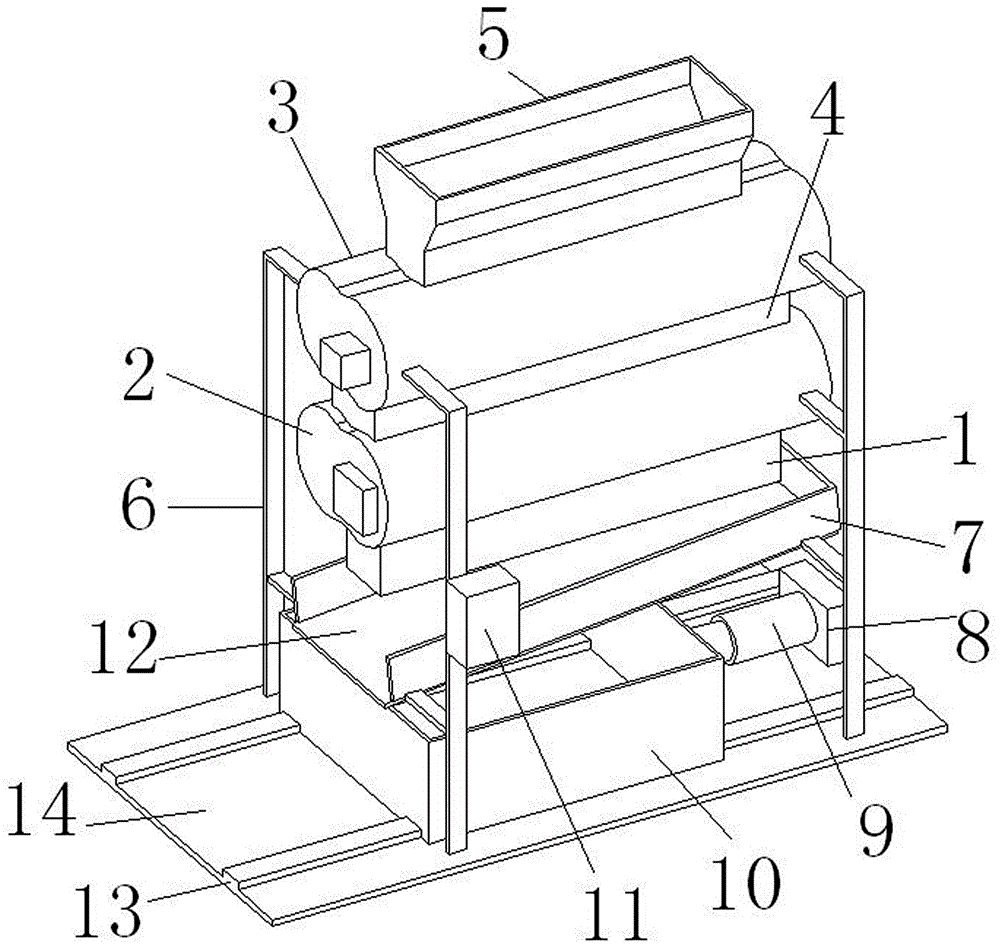

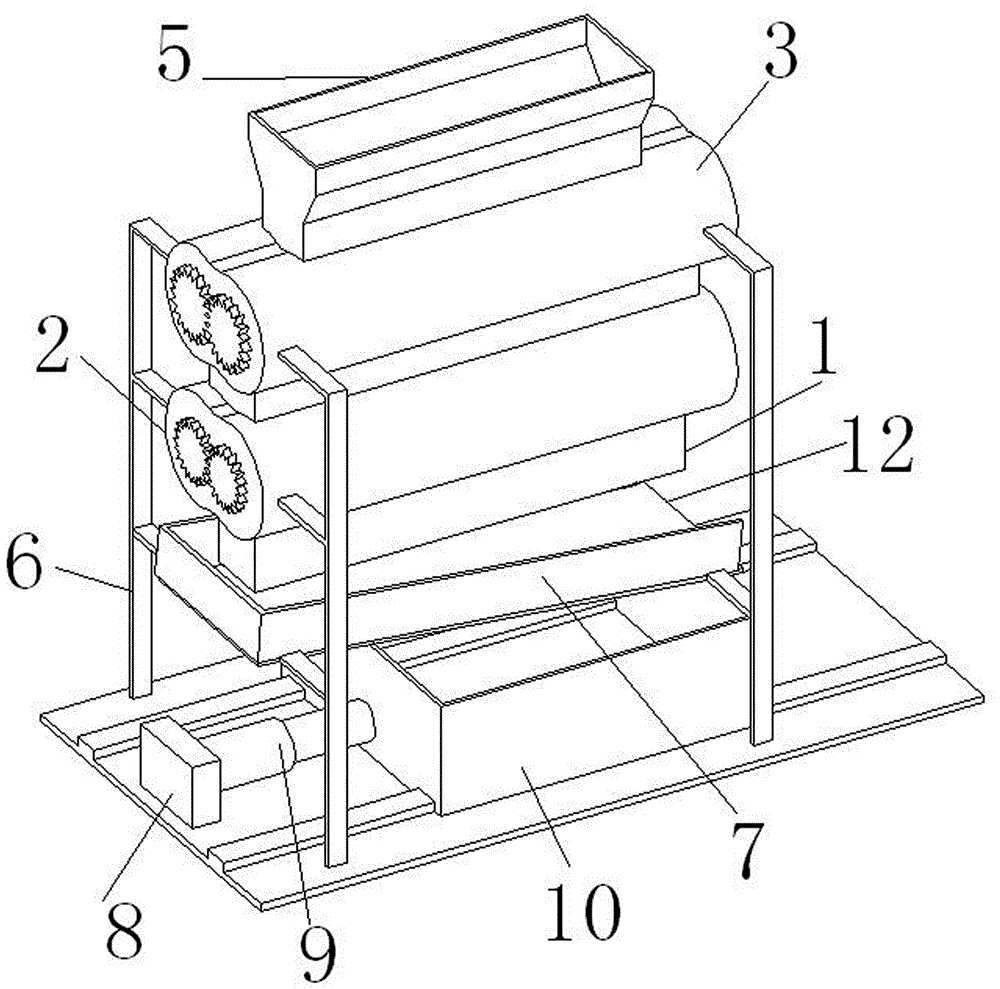

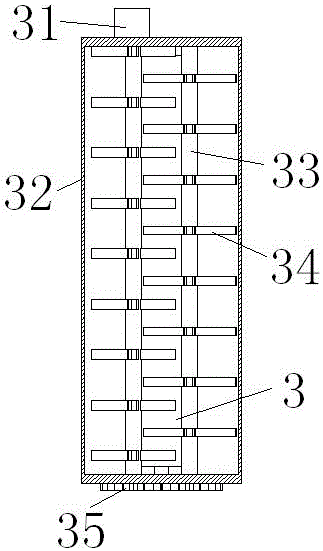

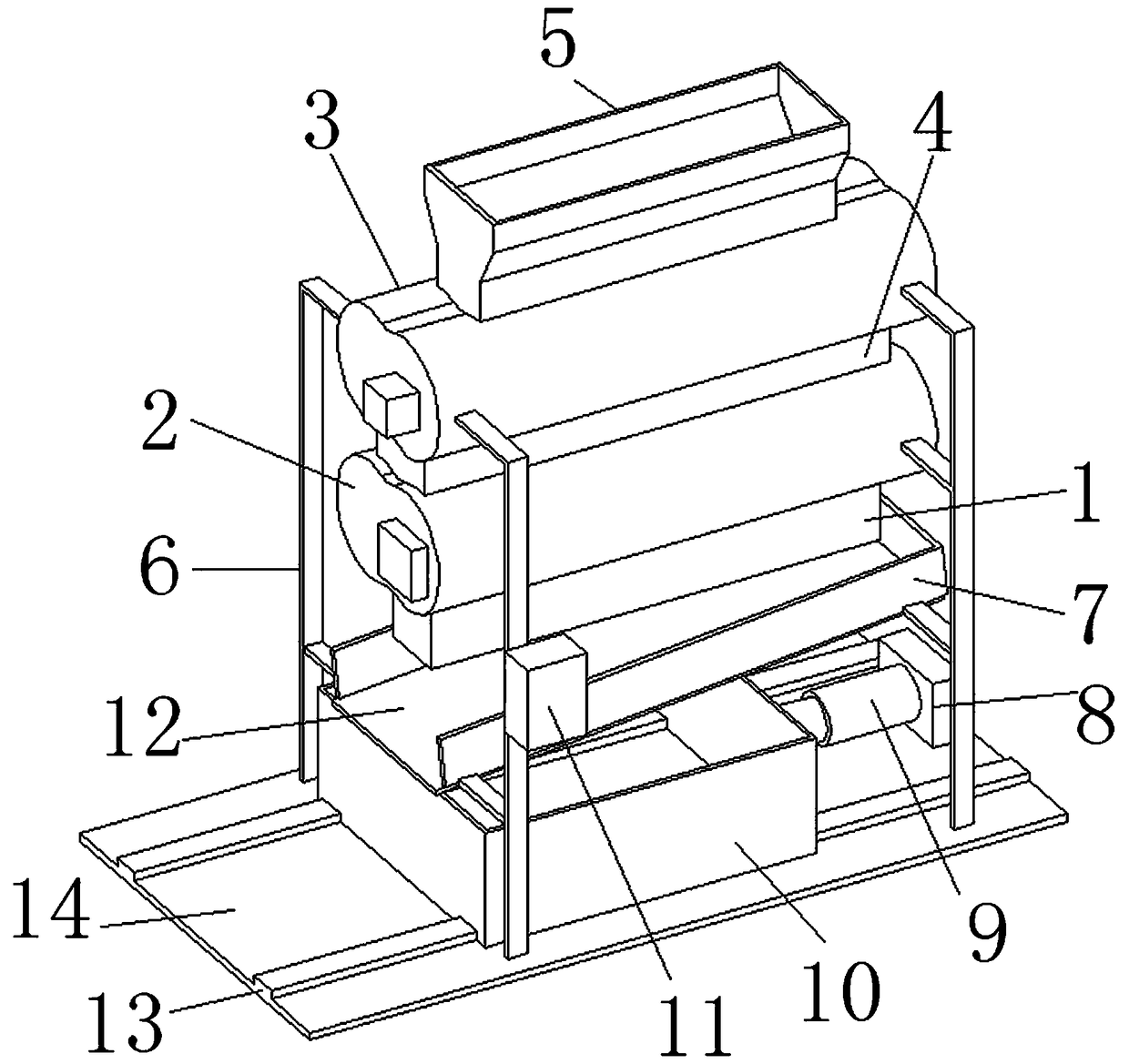

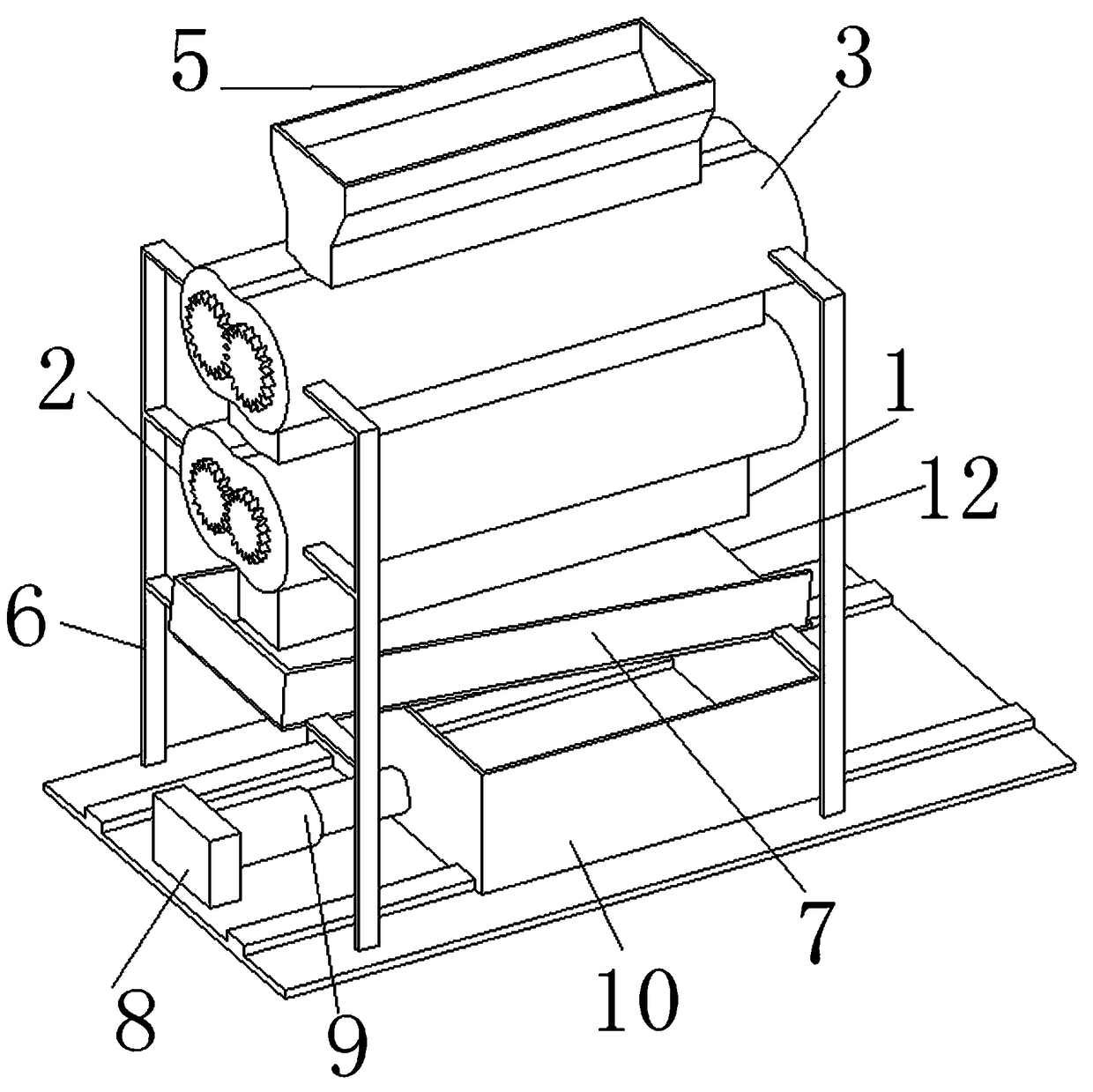

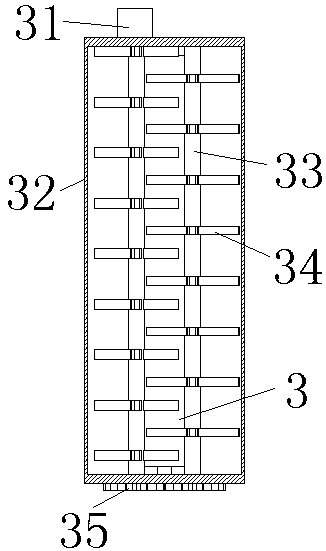

Building waste crushing apparatus

ActiveCN106622473ASimple enoughSimple and fast operationMagnetic separationGrain treatmentsBulky wasteMetal

The invention discloses a building waste crushing apparatus, comprising a bottom plate; four supports are arranged on the upper surface of the bottom plate; a primary crushing unit is arranged among the upper ends of the four supports, the upper end of the primary crushing unit is provided with a feed port, the upper end of the feed port is provided with a feed trough, a first motor is arranged on one side of the primary crushing unit, and the lower end of the primary crushing unit is provided with a discharge port; it is possible to crush bulky waste through the primary crushing unit so that crushing is more convenient; a secondary crushing unit is arranged below the primary crushing unit; it is possible to crush the waste thoroughly through the secondary crushing unit so that crushing is more thorough; it is possible to attract metals in the crushed waste through an electromagnetic plate so that the metals can be recycled; the building waste crushing apparatus is simple in structure and simple to operate, and is capable of crushing waste thoroughly and sorting the metals in the waste in order to collect and reuse the metals.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

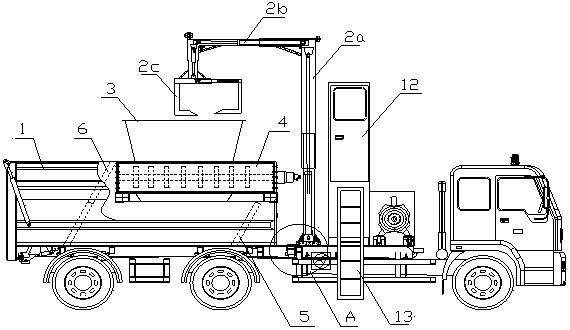

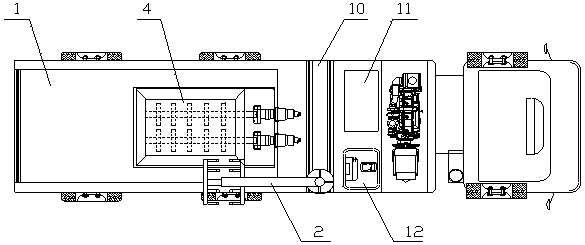

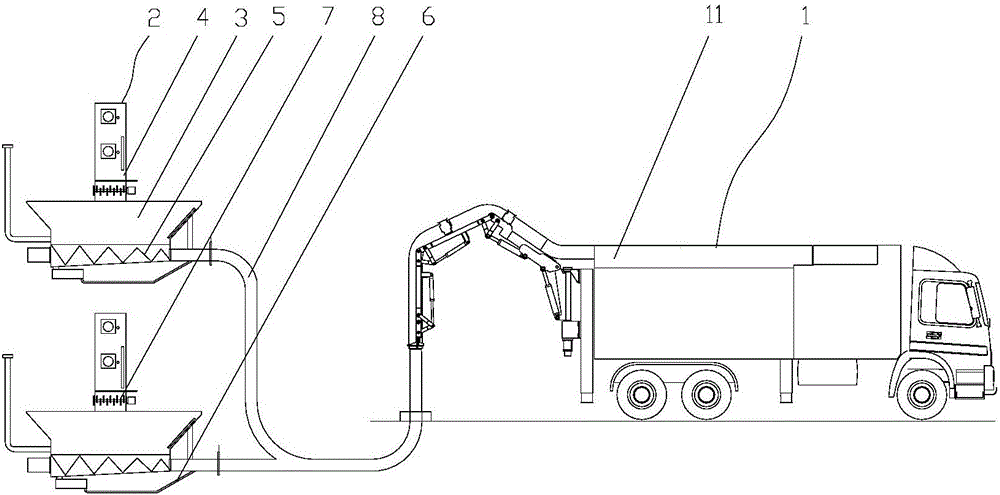

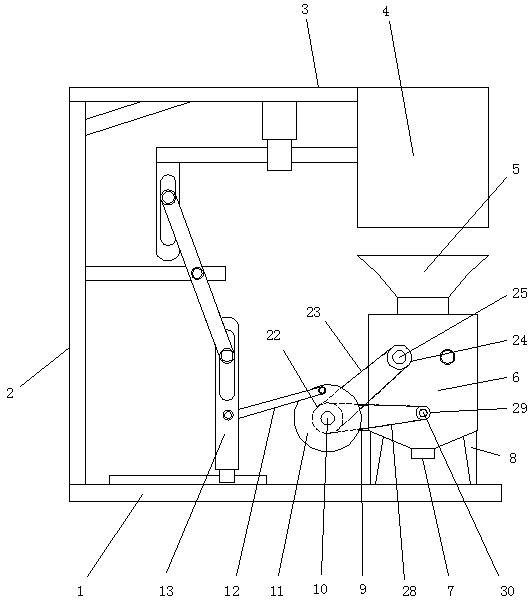

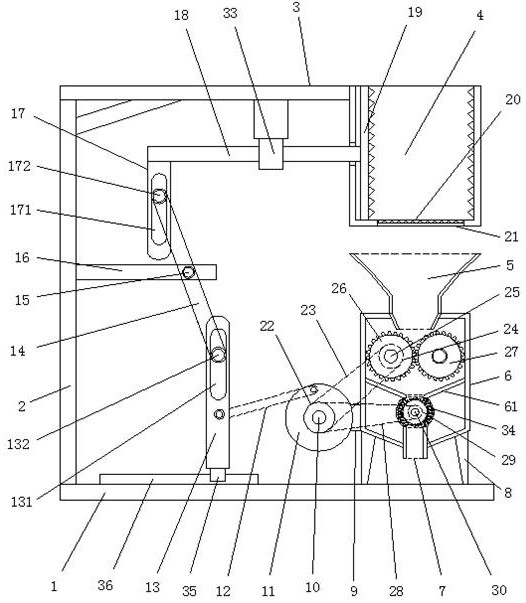

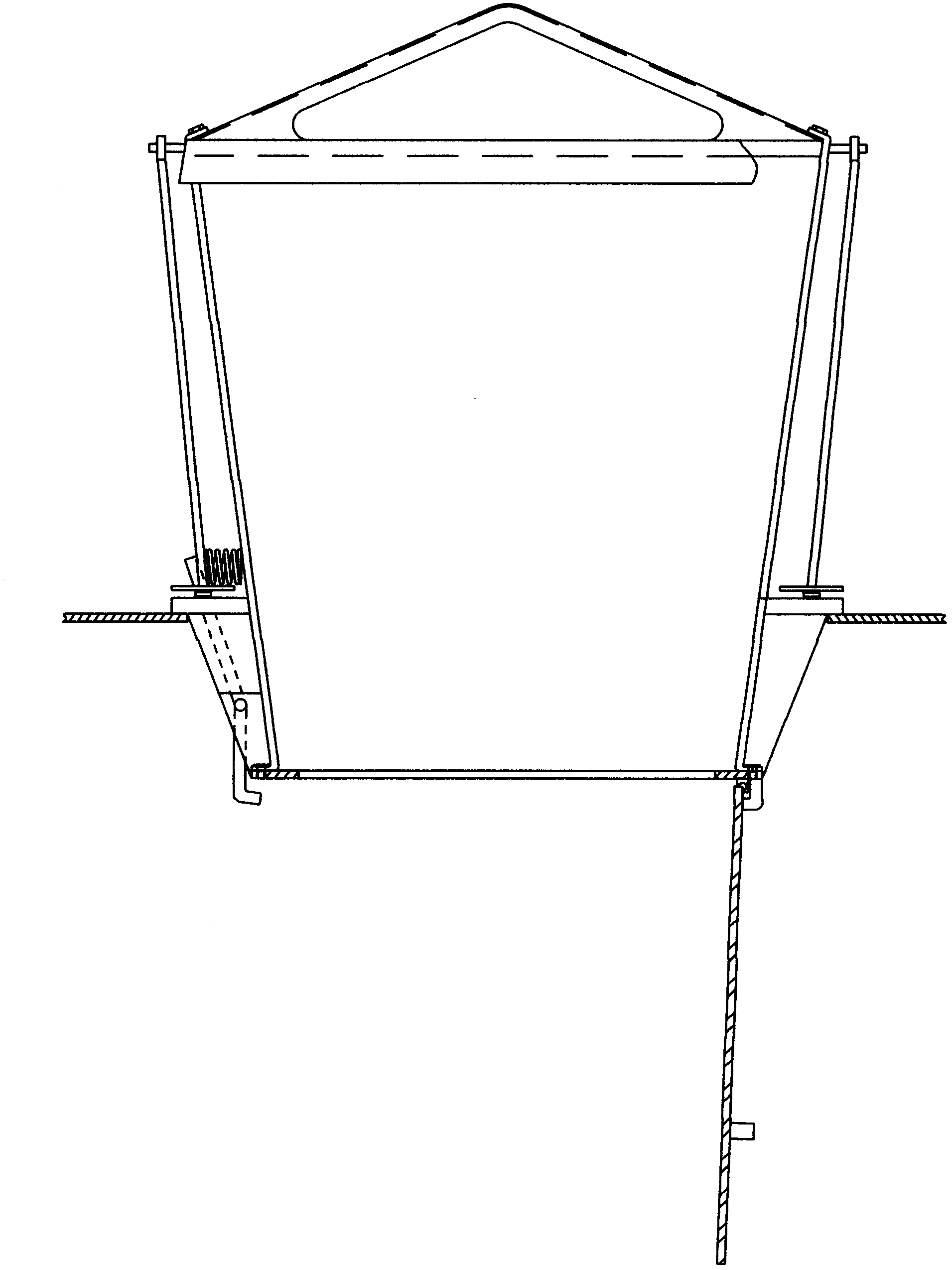

Bulky household garbage crushing and compressing truck

ActiveCN104340570AImprove space utilizationReduce labor intensityRefuse vehiclesElectric machineBulky waste

The invention discloses a bulky household garbage crushing and compressing truck, which comprises a compartment arranged on an automotive chassis, a manipulator for grasping bulky garbage arranged on an automobile, a manipulator rotating motor for driving the manipulator to rotate arranged on the automobile, a feed hopper arranged on the compartment, a garbage crushing device arranged in the compartment and used for crushing the grasped bulky household garbage, and a garbage compressing device arranged in the compartment and used for compressing the crushed bulky household garbage. The bulky household garbage crushing and compressing truck provided by the invention integrates mechanical feeding, crushing and compression into a whole, so that the problems that the bulky household garbage is inconvenient to transport and backfill are solved; meanwhile, the garbage is automatically grasped by the manipulator without sanitation workers for feeding, and the labor intensity of sanitation workers is reduced; in addition, the garbage grasped by the manipulator is crushed and compressed, so that the space utilization rate of the compartment is improved, and the actual load capacity of the garbage truck is ensured.

Owner:CHONGQING TIEMA TENGFEI AUTO

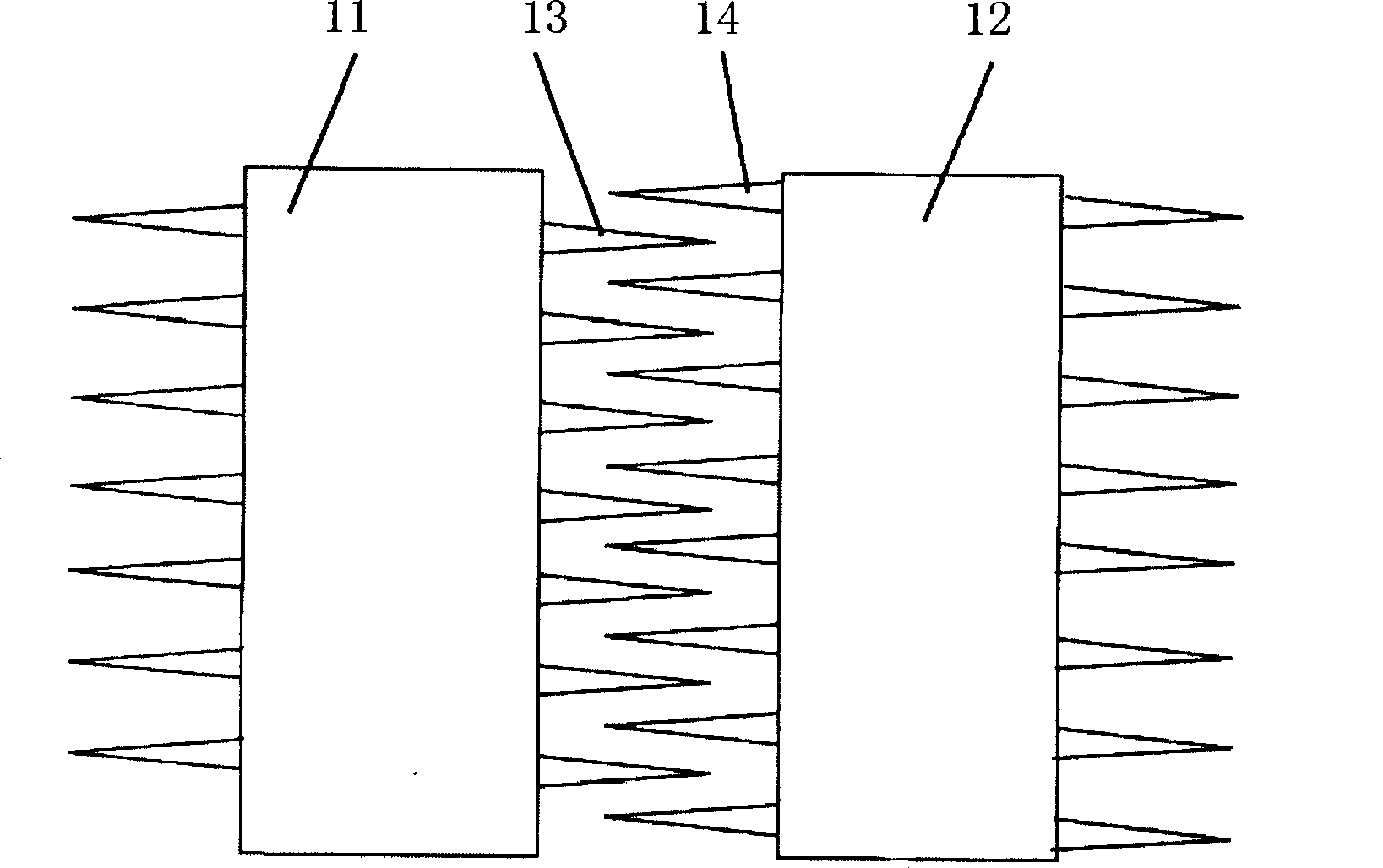

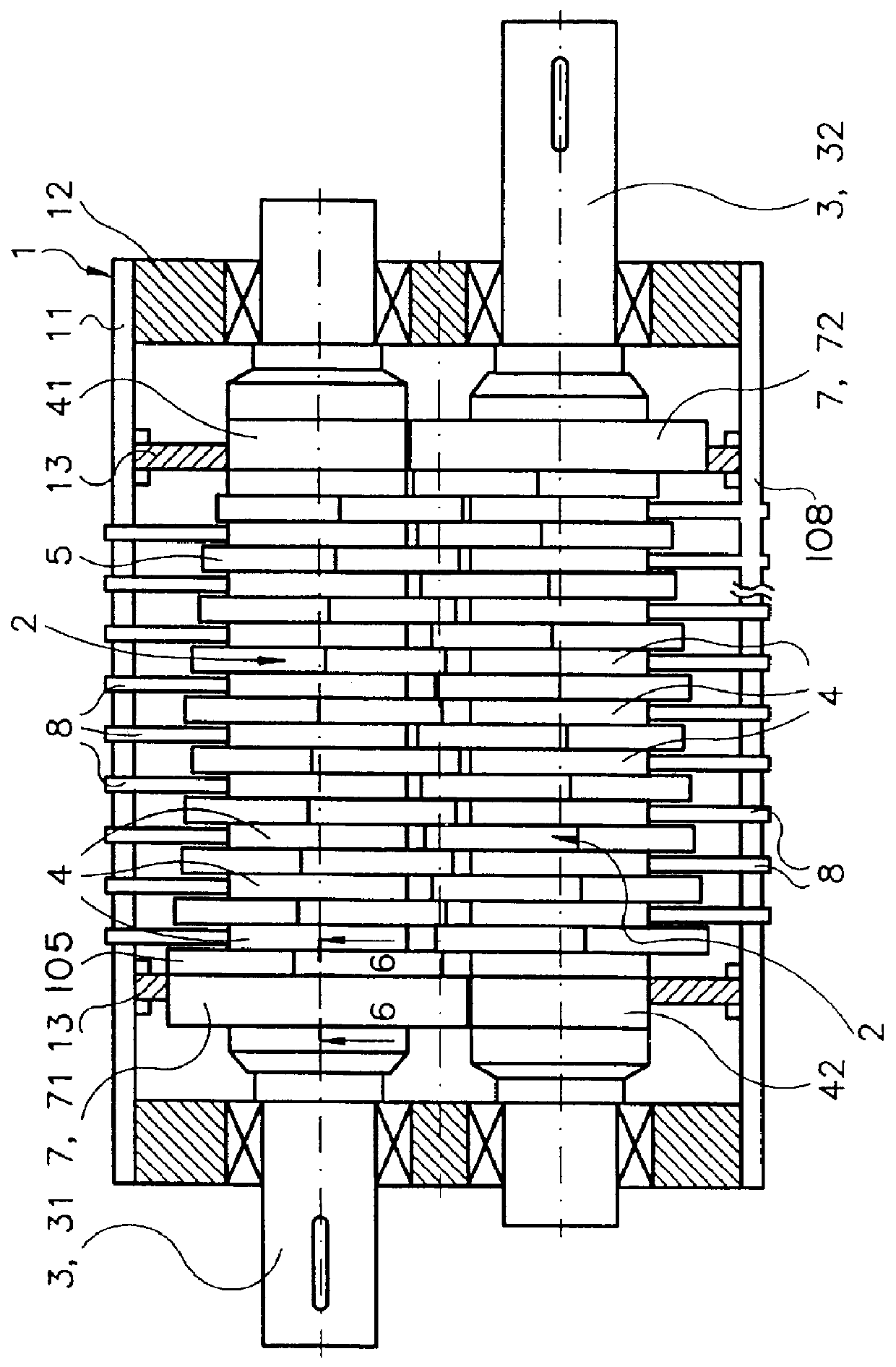

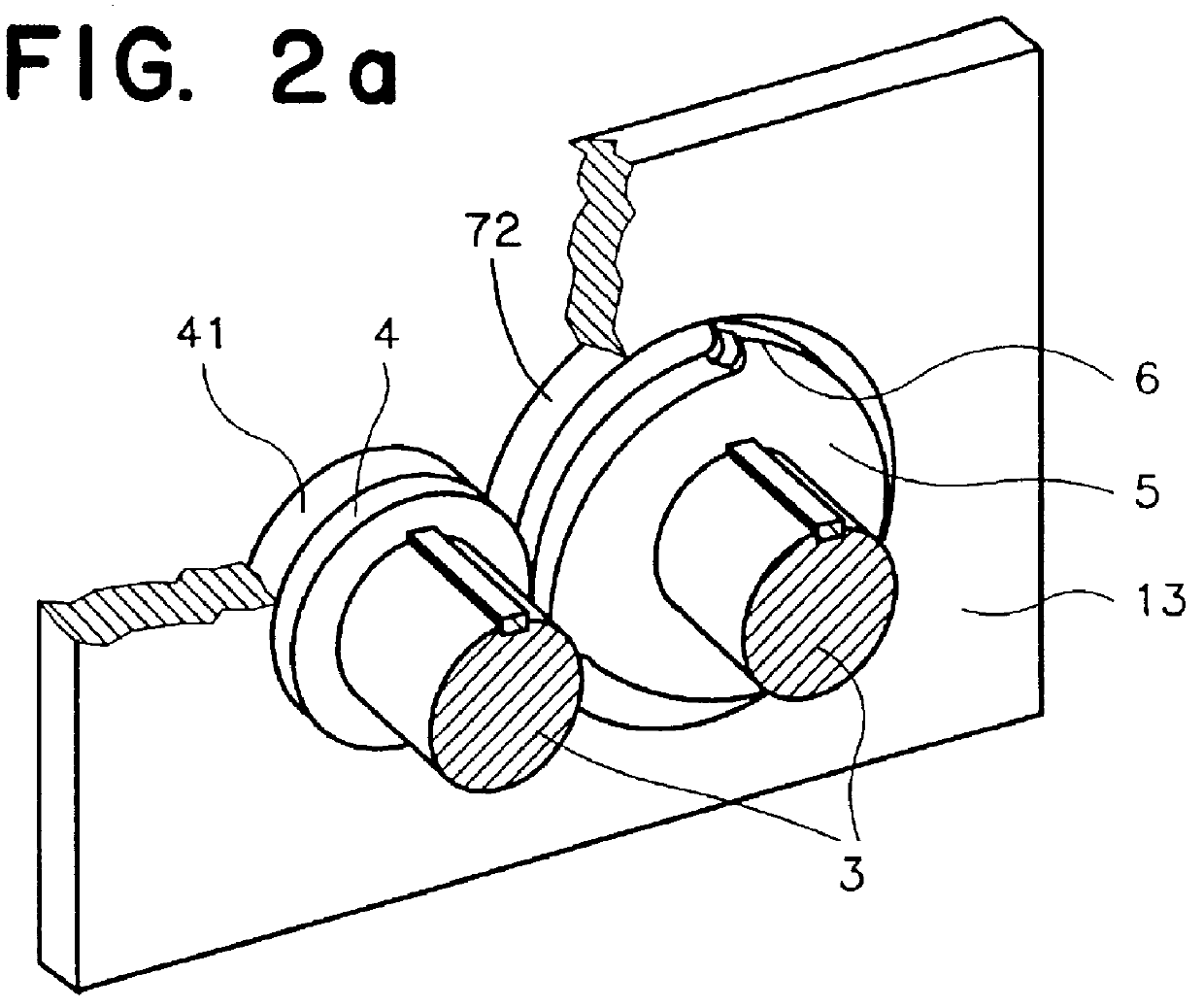

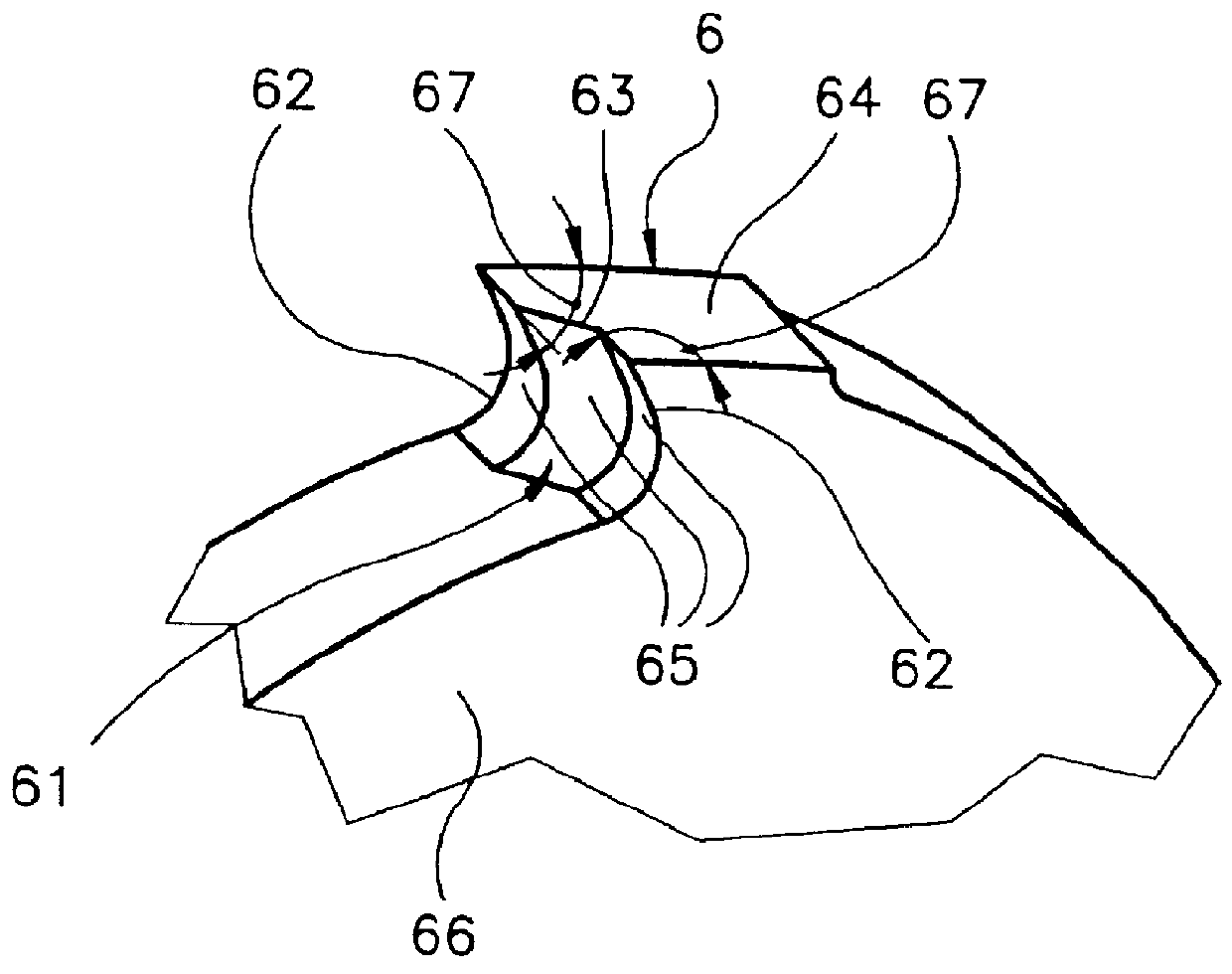

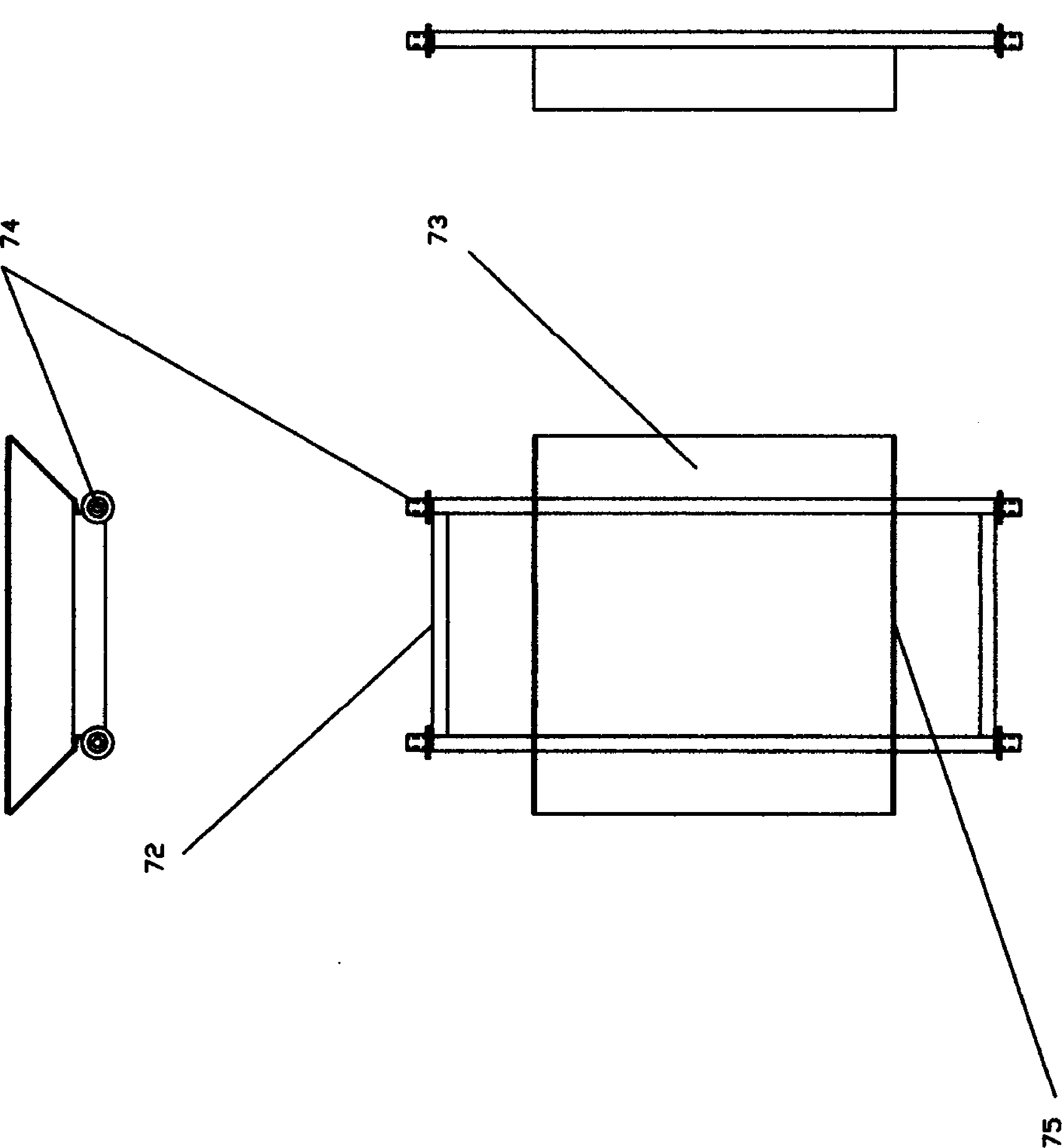

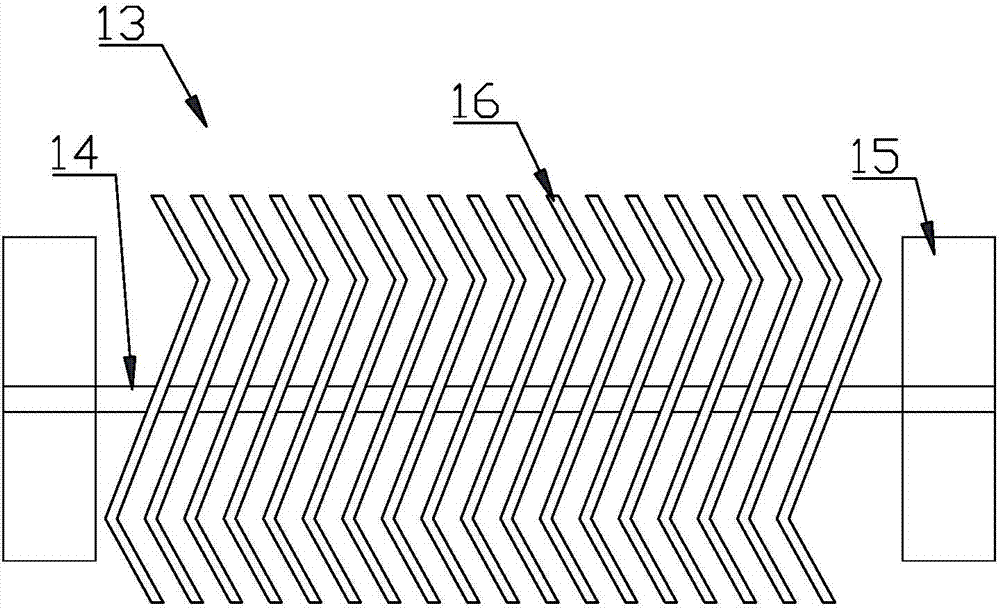

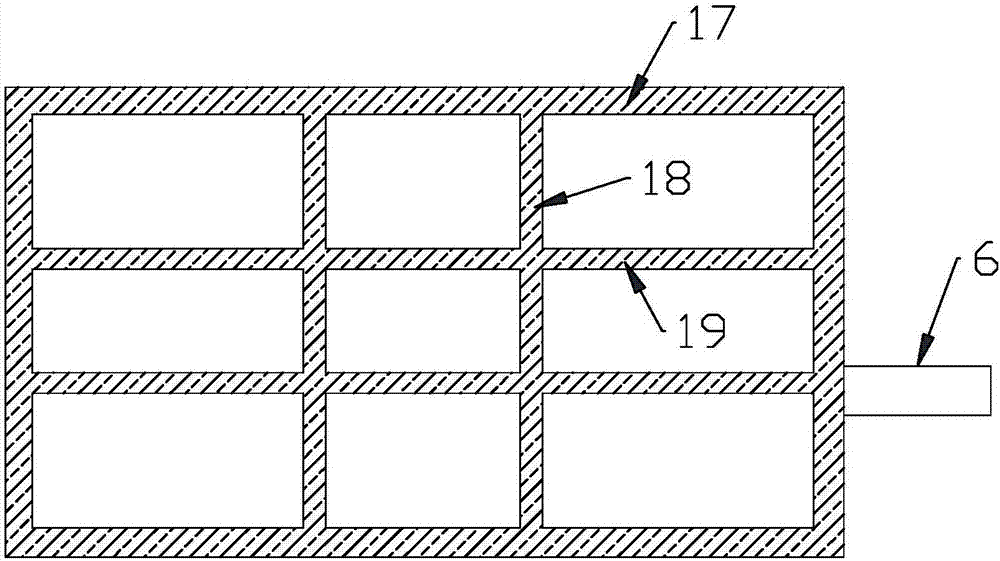

Rotor shear for comminuting particularly bulky waste material

InactiveUS6024312AReduce wearEnhancing comminuting processCocoaGrain treatmentsBulky wasteEngineering

A rotor shear for comminuting particularly bulky waste materials is formed by two cutting rotors (2) combing each other, disposed parallel to each other, supported in a housing (1), and each driven in an opposite direction. Each cutting rotor (2) comprises spacer rings (4) and rotor disks (5) furnished with cutting teeth (6). A face of a front flank (61) of at least one cutting tooth (6) is furnished with geometrically staggered and / or angled partial faces (65). The spacer rings (4) and the rotor disks (5) are disposed on shafts (3). Wear disks (7) are coordinated to outer rotor disks (5) with corresponding circumferences and are connected to the shaft (3). The cutting teeth (6) operate against the circumference of the spacer rings (4) disposed between the rotor disks (5). At least one support device / stripper device (8) is coordinated with at least one shaft (3), where support parts (81) and stripper parts (82) of the support device / stripper device (8) are functionally separated.

Owner:METABO LINDEMANN GMBH

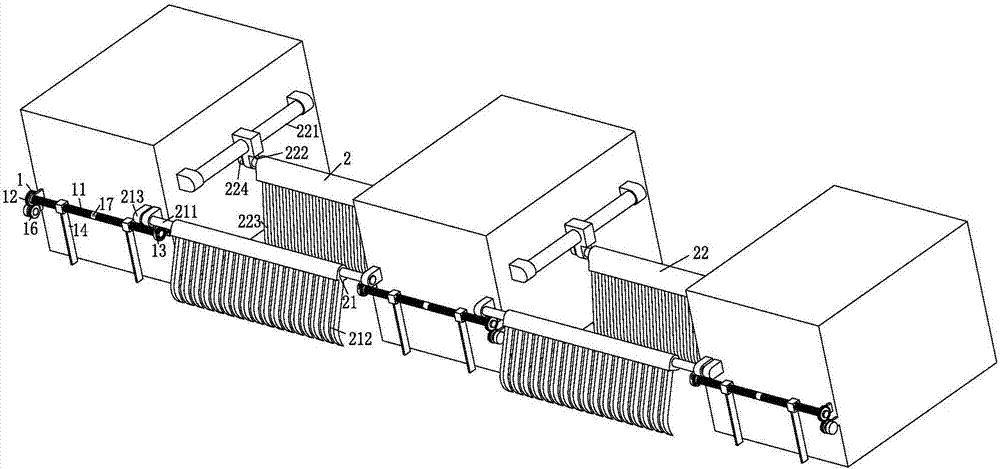

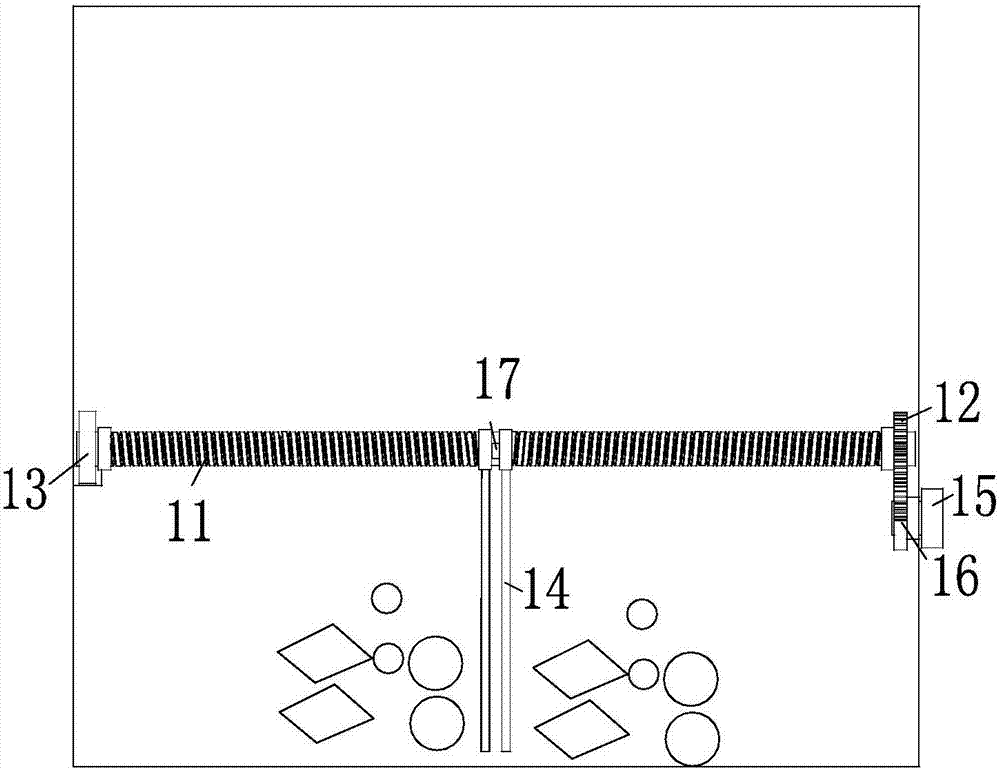

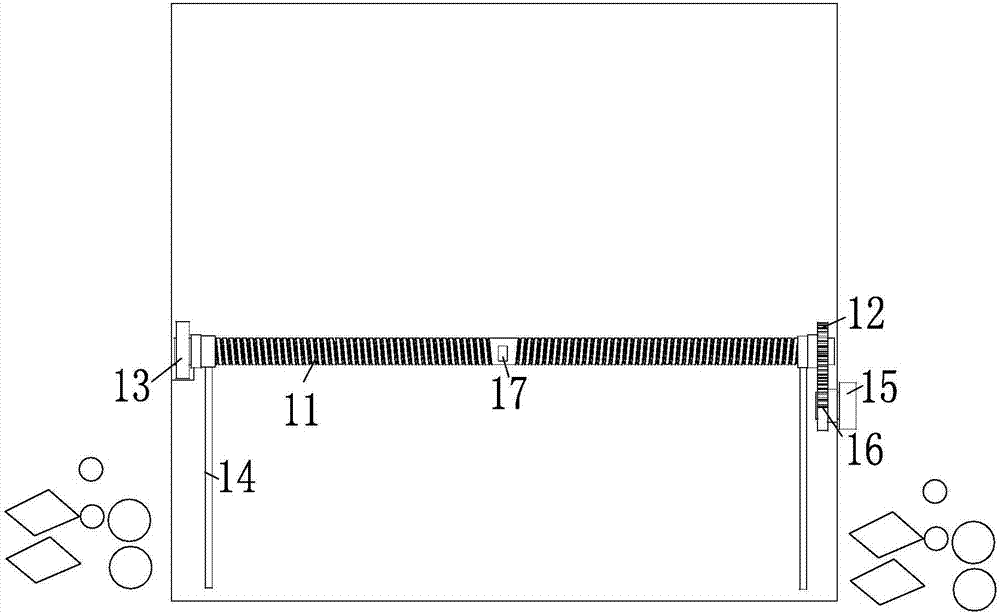

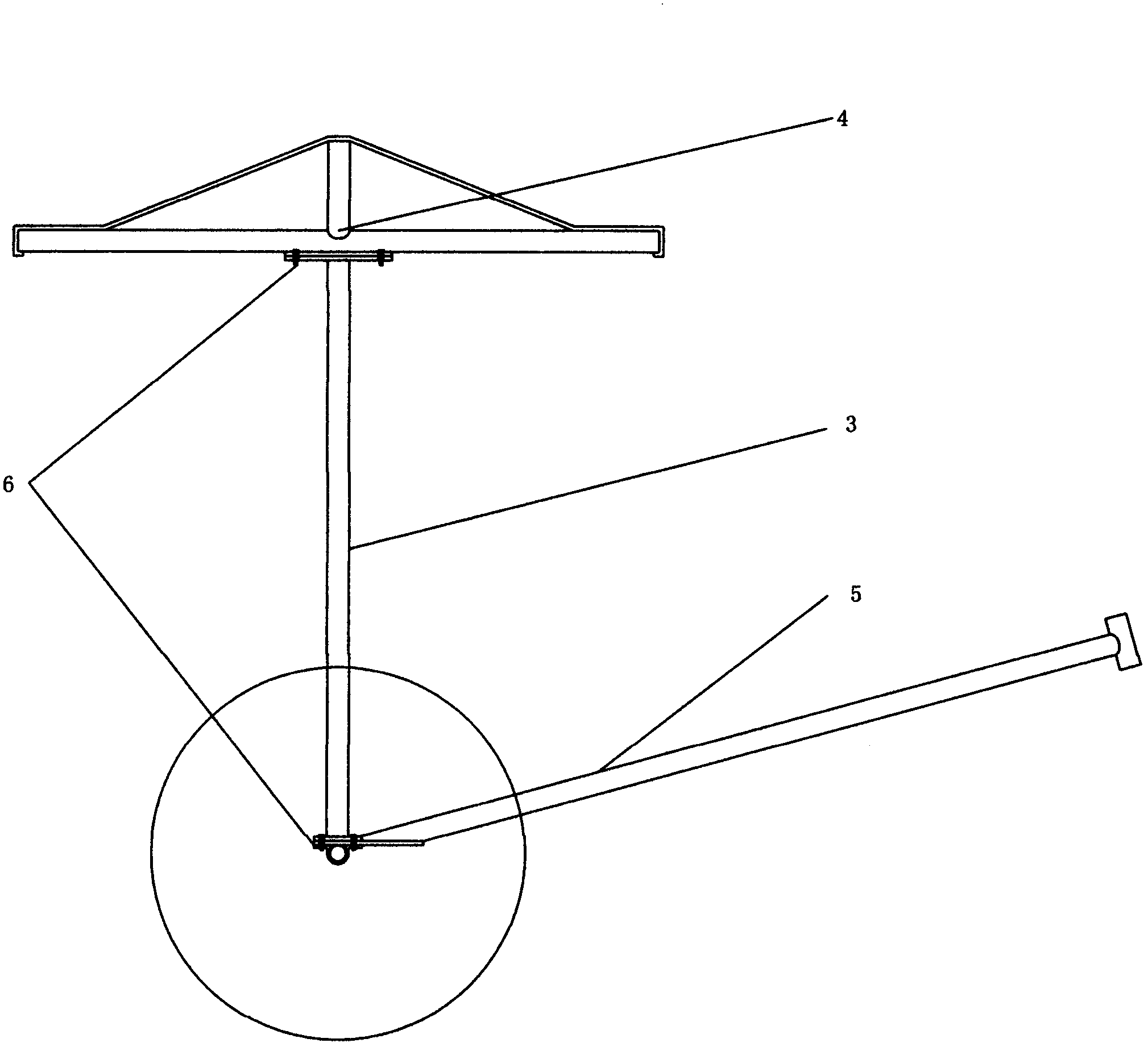

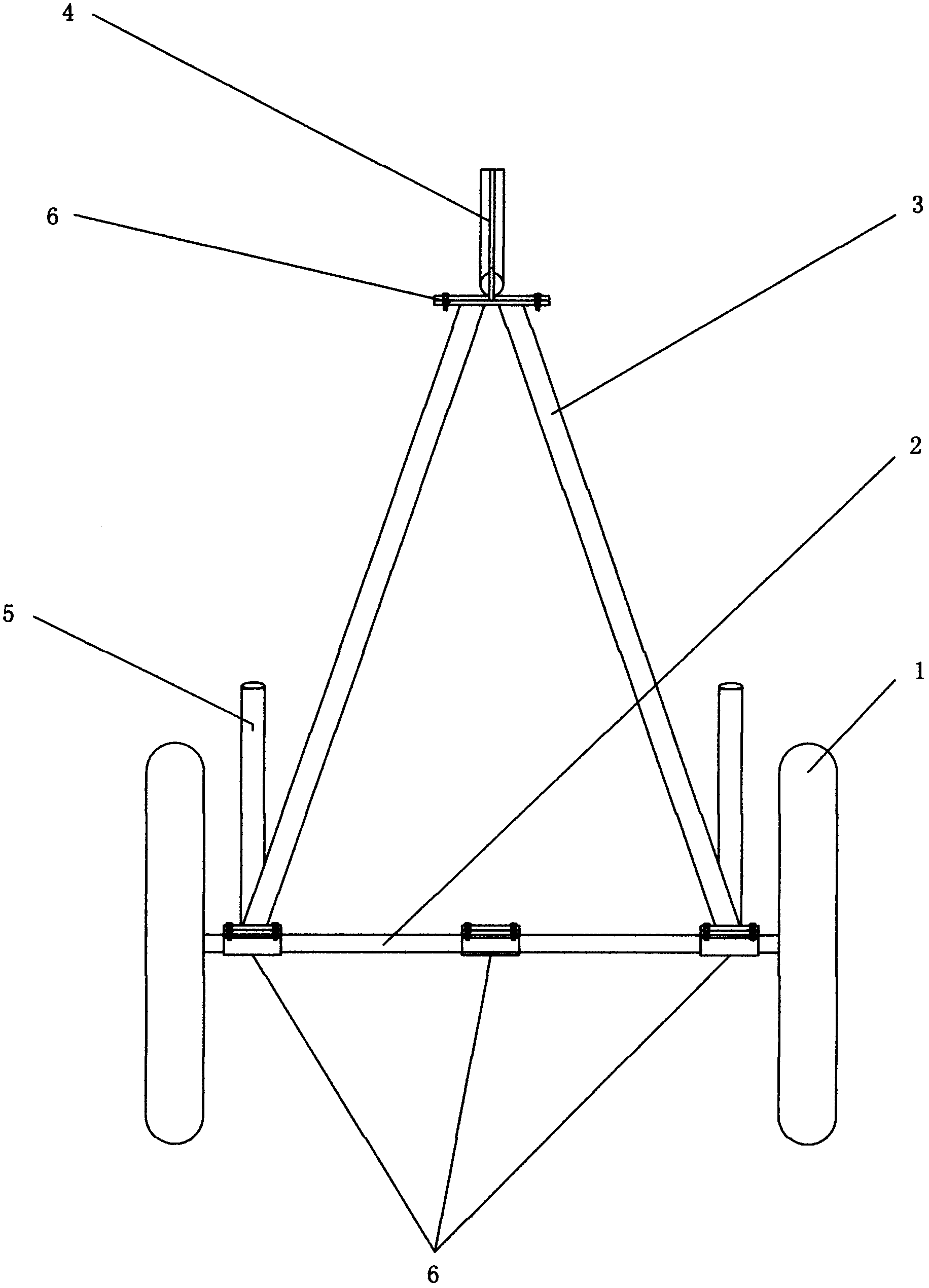

Broad-sense garbage collection and transportation method and device

InactiveCN103832756ASolve collection and transportation proceduresReduce collection and transportation proceduresRefuse receptaclesRefuse vehiclesBulky wasteEngineering

The invention provides a broad-sense garbage collection and transportation method and device, and belongs to the technical field of urban environmental sanitation equipment. Broad-sense garbage is a general item of household garbage, construction waste and bulky waste. At present, urban environmental sanitation equipment can only realize collection and transportation of the household garbage and can not realize collection and transportation of the construction waste and the bulky waste. To solve the technical problem, the technical schemes of a tipping bucket with a bi-directional open / close cover, an uncovered tipping bucket, a crane trolley, a dump truck provided with a lifting device and a compacting device, a dump truck provided with a lifting device and an open cover and other devices are provided, and therefore not only the household garbage by also the construction waste and the bulky waste can be collected and transported by the urban environmental sanitation department.

Owner:浙江长大建设技术有限公司

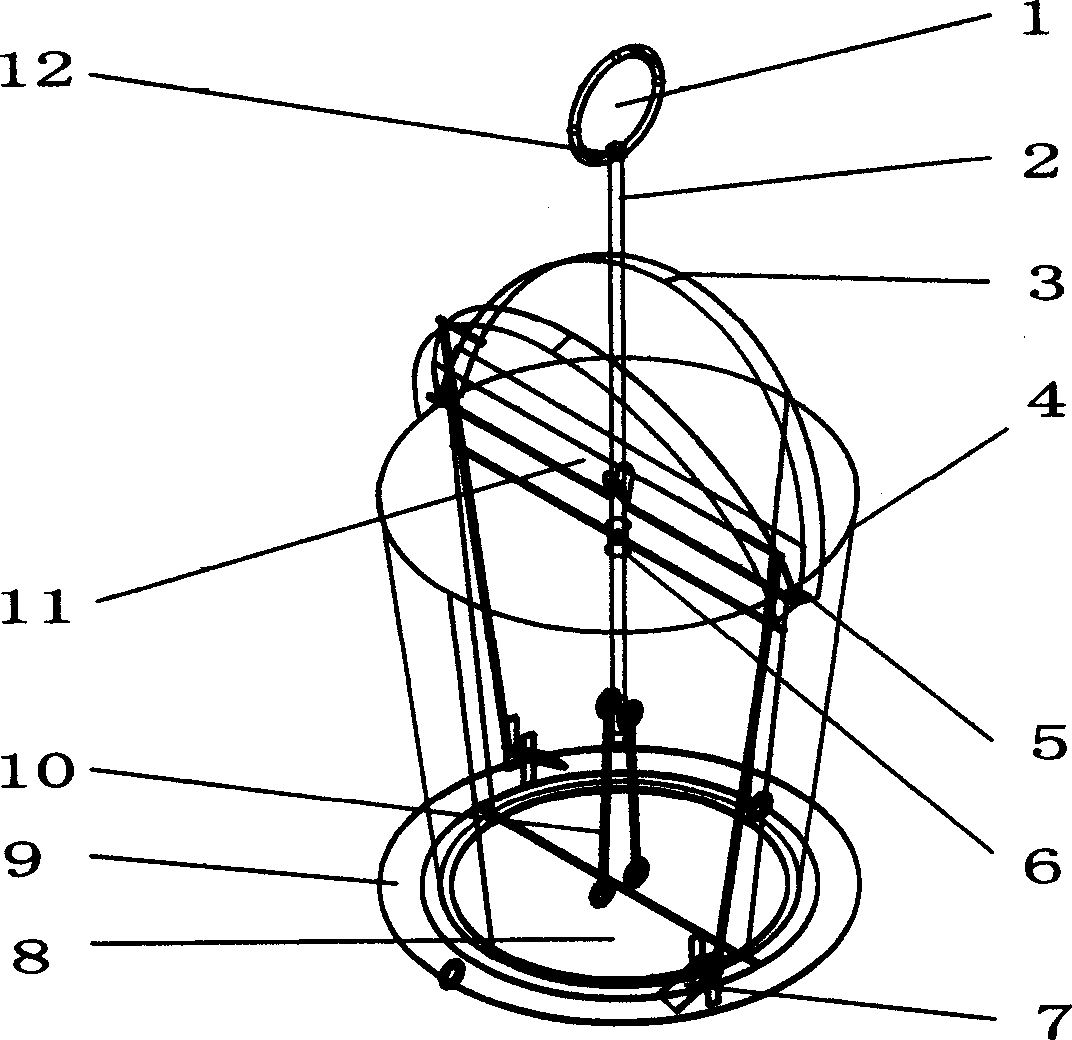

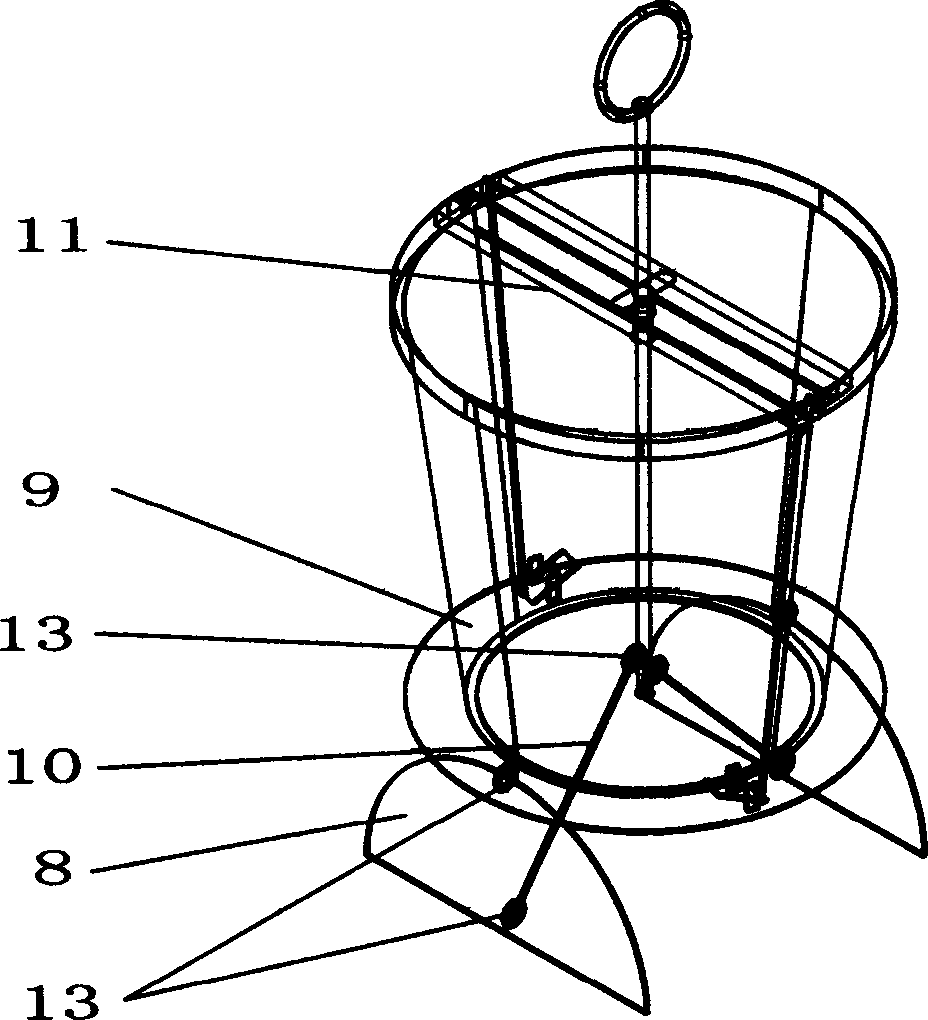

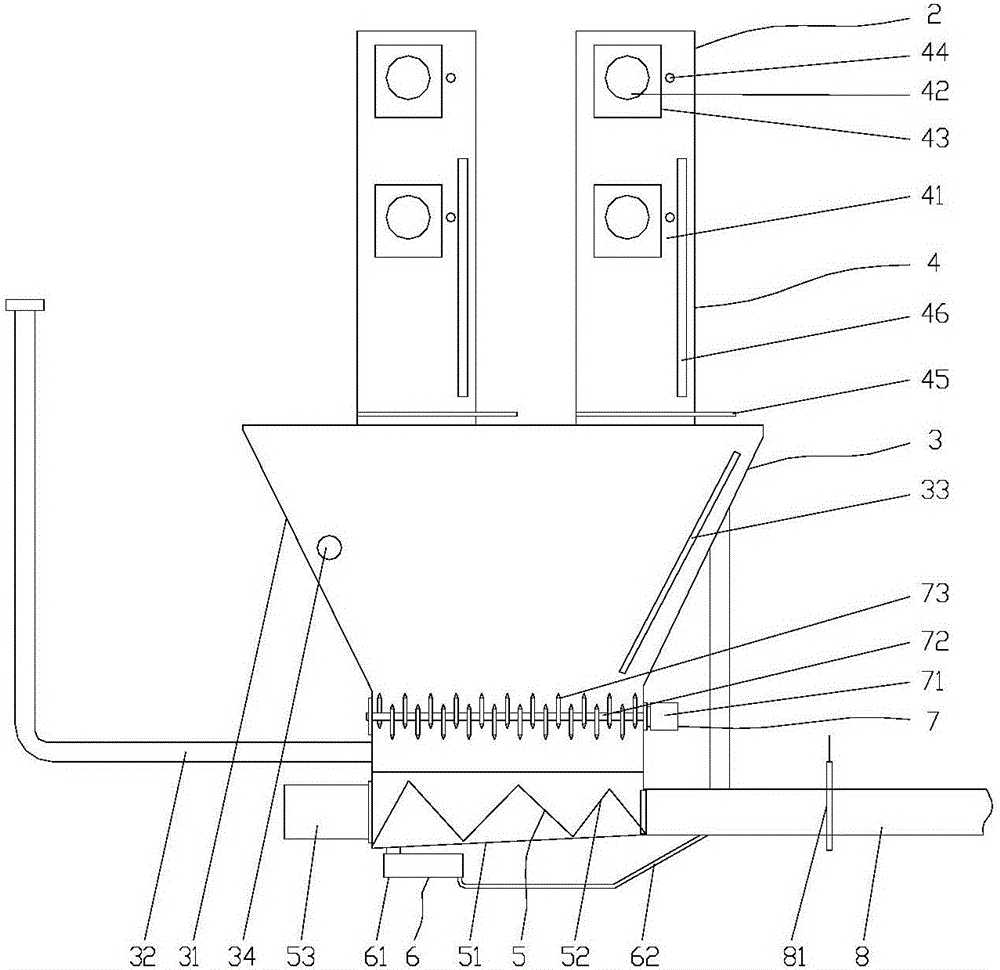

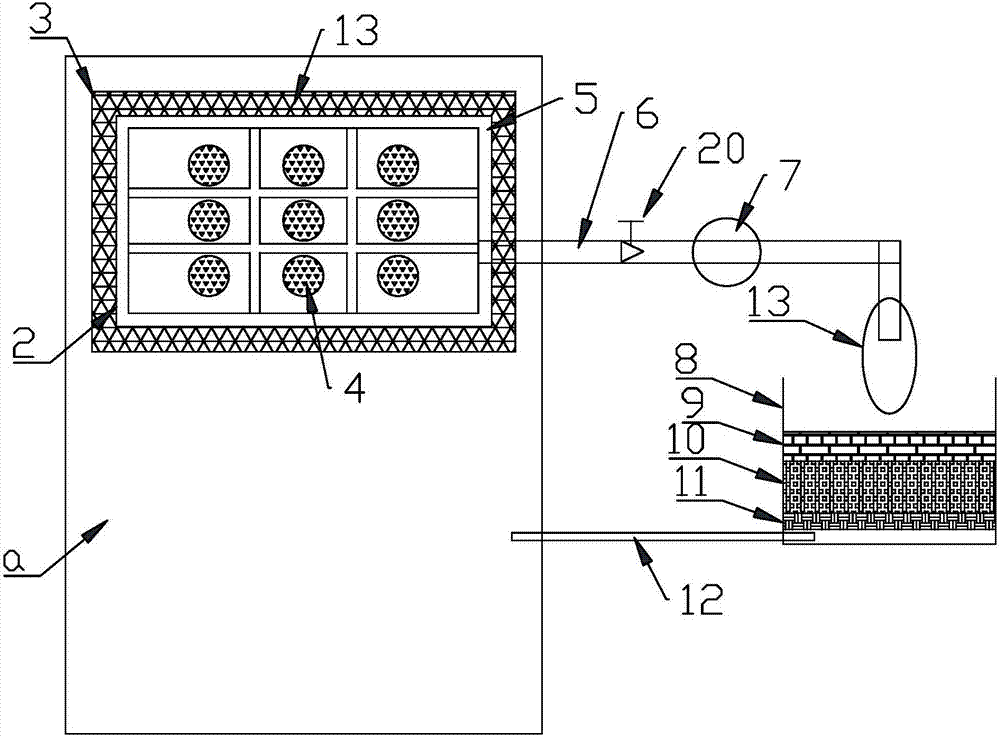

Closed automated garbage collection system

InactiveCN106429127AMake sure the suction speedReduce frictional resistanceRefuse receptaclesRefuse transferringRefuse collectionCollection system

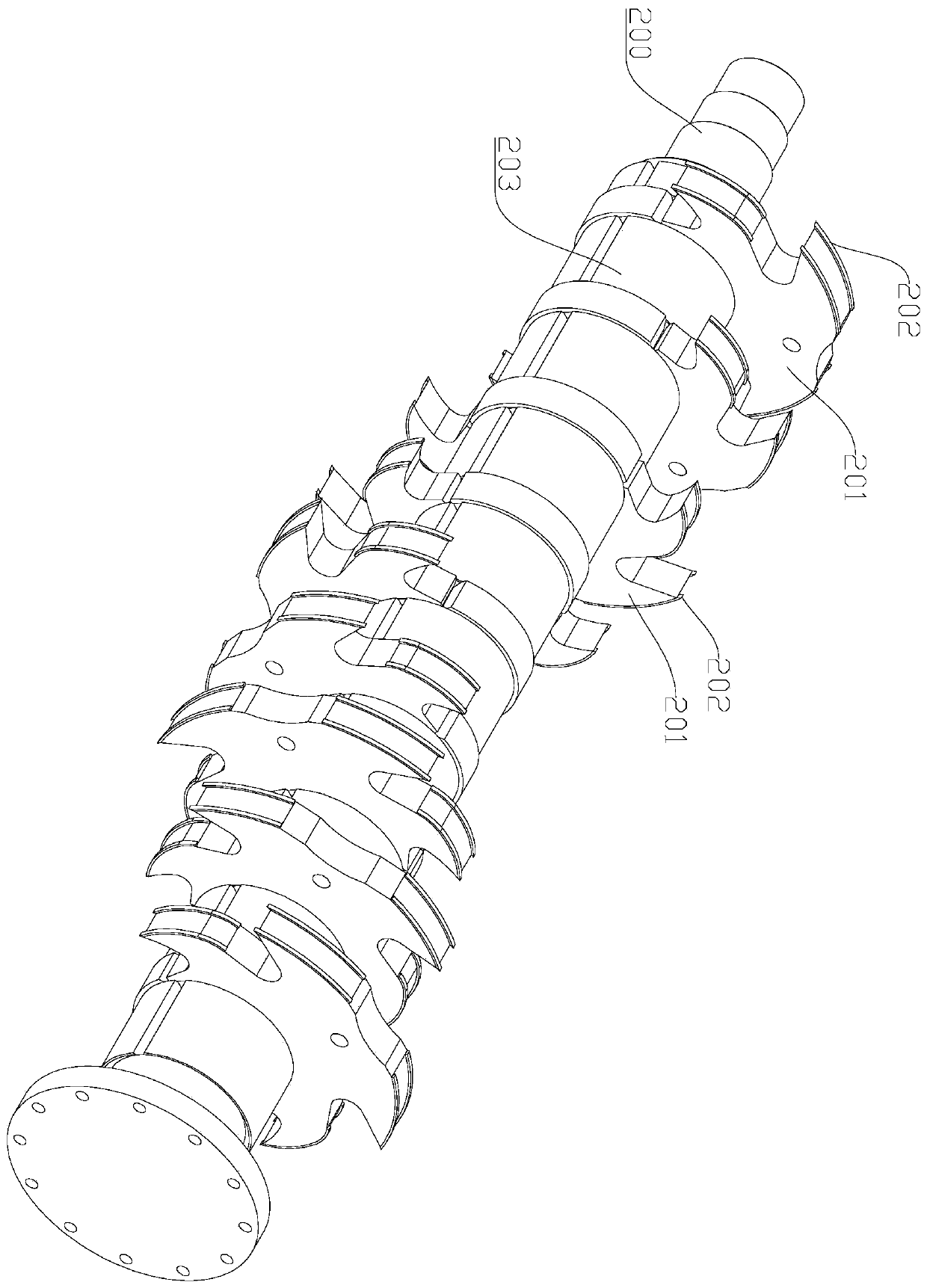

The invention relates to a closed automated refuse collection system, comprising a control center, a suction transit equipment and one or more garbage collection devices. The control center is respectively connected with the suction transit equipment and the garbage collection devices through communication. The garbage collection devices comprise a garbage storage mechanism utilized to store garbage. A garbage disposal mechanism utilized to put and transport garbage into the garbage storage mechanism is arranged on the upper part of the garbage storage mechanism. A screw driving mechanism utilized to stir, drive and transport the garbage in the garbage storage mechanism is arranged at the lower part of the garbage storage mechanism. A pollution discharge mechanism utilized to collect and discharge waste residual liquid is arranged at the lower part of the screw driving mechanism. A plurality of bag breaking mechanisms utilized to crush bulky waste and garbage bags is arranged between the screw driving mechanism and the garbage disposal mechanism. A discharge port of the screw driving mechanism is connected with the suction transit equipment through suction tubes. The suction transit equipment pumps and transfers the garbage stored in the screw driving mechanism into the suction transit equipment through negative pressure formed in the suction tubes.

Owner:福建海山机械股份有限公司

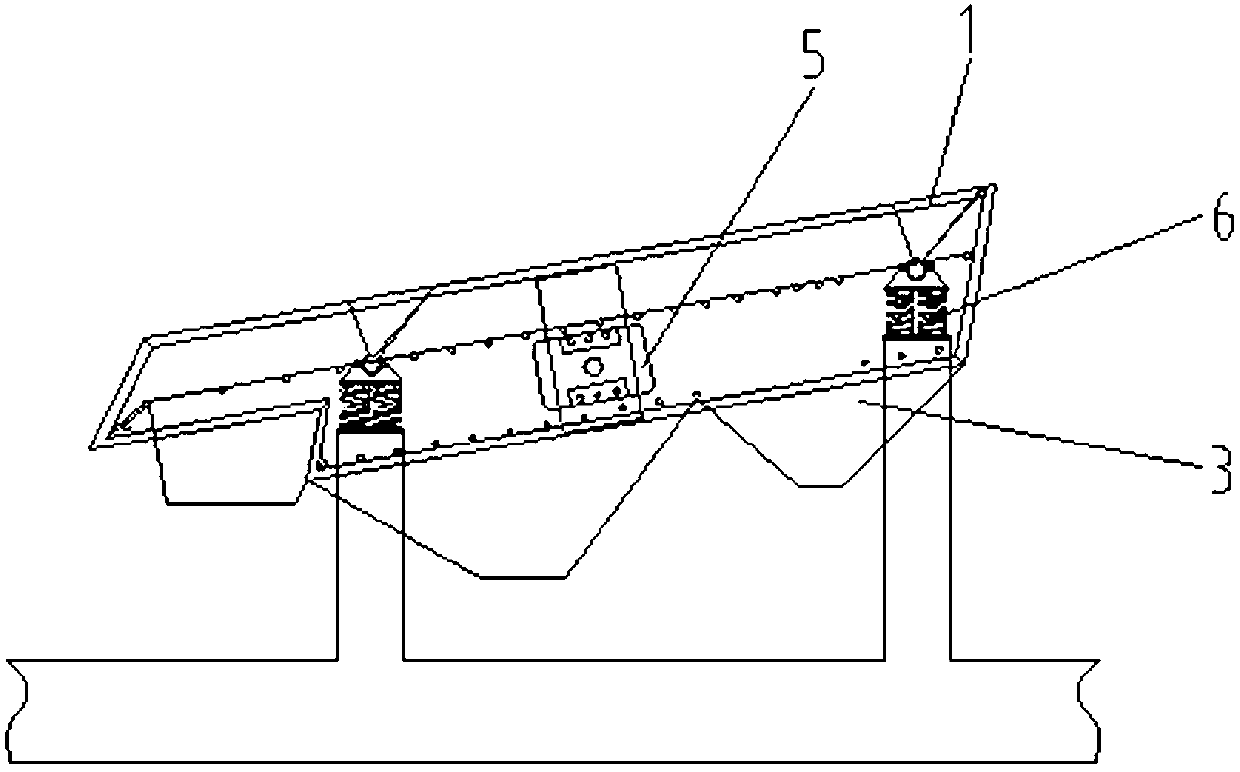

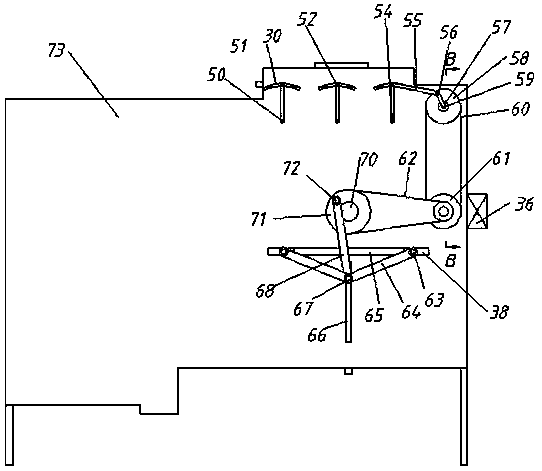

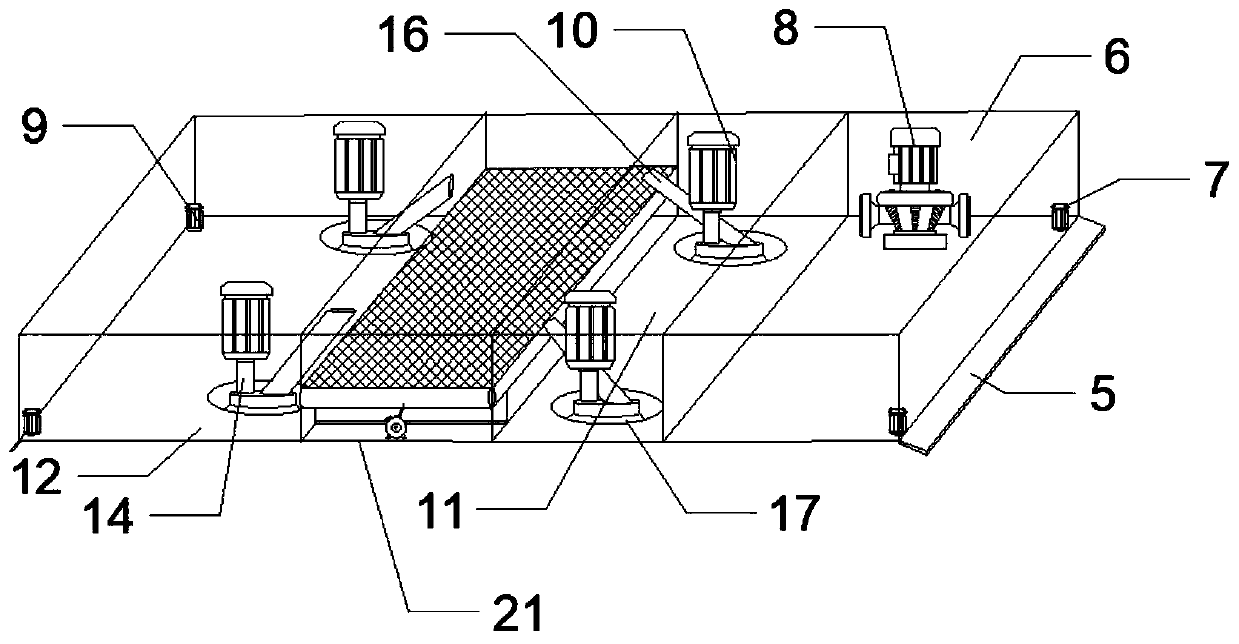

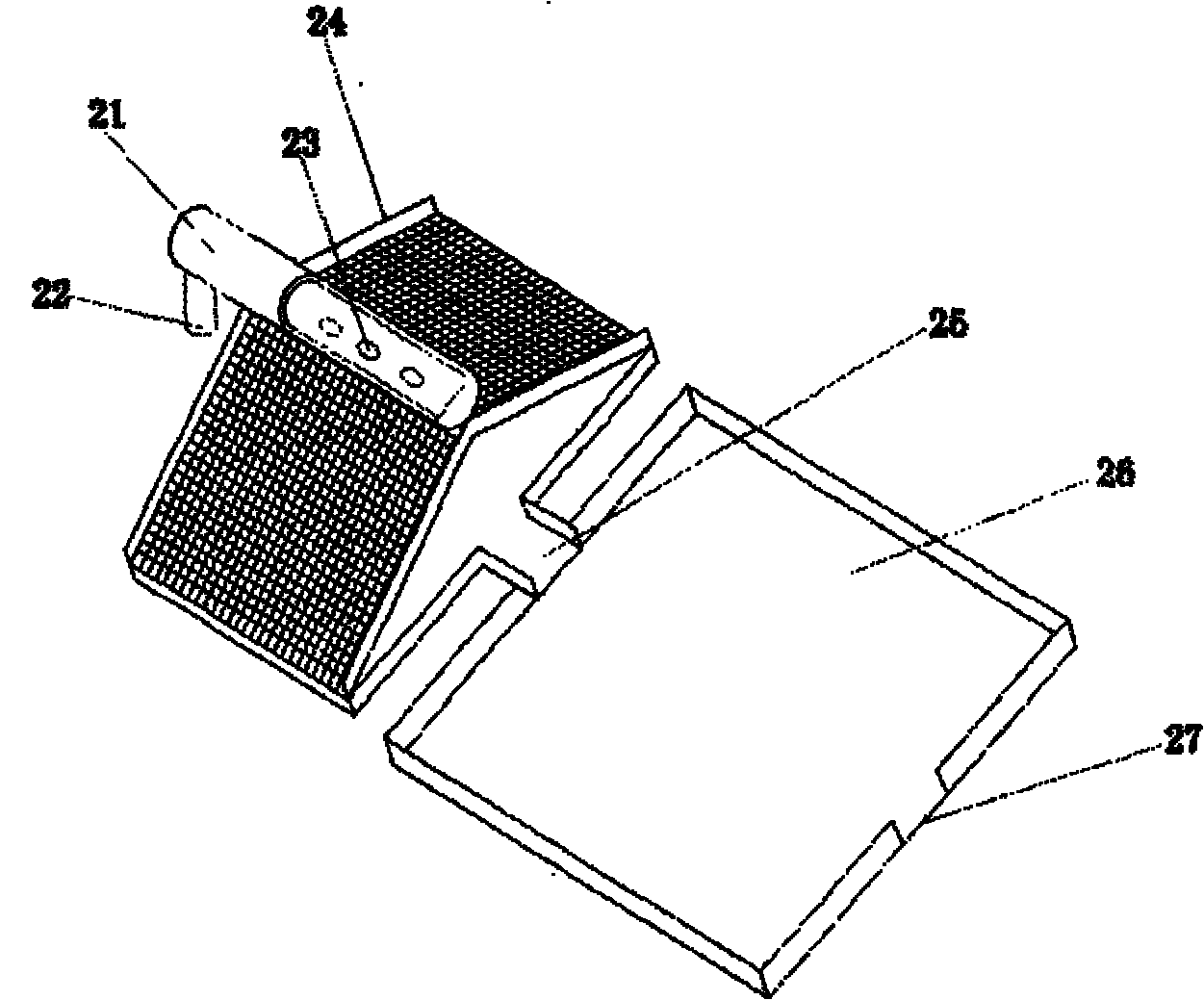

Vibration screening machine

InactiveCN103121009ABroaden your optionsGood removal effectSievingScreeningElectric machineryBulky waste

The invention relates to a vibration screening machine which comprises an oblique screening plate. The vibration screening machine is characterized in that three sections of screening grooves, namely a front section screening groove, a middle section screening groove and a rear section screening groove, are formed in an object carrying face of the screening plate, wherein screening holes are formed in each section of screening groove, and the screening holes in the three sections of screening grooves are different in size and are used for screening materials with different specifications. A vibrating motor is arranged on a side plate on the left side of the screening plate, another vibrating motor is arranged on a side plate on the right side of the screening plate, a group of spring device used for buffering and continuing vibration is arranged on the front side below the screening plate, and another group of spring device used for buffering and continuing the vibration is arranged on the rear side below the screening plate. Due to the fact that the three sections of screening grooves are formed, the selection range of the materials is effectively expanded, construction waste can be respectively recovered according to different granule sizes, large waste impurities can be conveniently removed and crushed in a classified mode, repeated crushing procedures are reduced, power consumption is lowered, the crushing efficiency is improved, and the vibration screening machine has the advantages of being novel in design, simple in structure, convenient to operate and maintain, large in processing quantity, high in efficiency, low in power consumption and wide in material processing range.

Owner:SHAOGUAN HELI HEAVY IND MACHINERY

Riverway sewage disposal device for environmental protection

The invention relates to a riverway sewage disposal device, in particular to a riverway sewage disposal device for environmental protection. The riverway sewage disposal device comprises transverse shifting devices and vertical shifting devices. The transverse shifting devices are mounted on the front side of stone blocks. Each vertical shifting device is mounted between the corresponding adjacent stone blocks. Each transverse shifting device comprises a two-way screw, a gear, a coil spring, sliding rods, a half-gear, a first motor and a collision sensor. Each vertical shifting device comprises a front shifting device body and a rear shifting device body. Each of the front shifting device body and the rear shifting device body comprises a cross rod, a rotary rake and a second motor. The rear shifting device further comprises two rodless air cylinders and an infrared sensor. Waste blocked by the stone blocks is shifted to a gap between the two stone blocks, in combination with the effect of the vertical shifting devices, bulky waste can be conveyed to the slope position automatically, the waste is extremely easily washed down the slope by river water, no manual cleaning is needed, and the convenience is brought to the life of residents.

Owner:NANTONG UNITED HEAVY MACHINERY

Riverway oil slick automatic collecting and treating device

PendingCN107215999AFix landscaping effectsRealize automatic cleaningFatty/oily/floating substances removal devicesTreatment involving filtrationActivated carbonGrating

The invention relates to the field of ecological floating island sewage treatment and in particular to a riverway oil slick automatic collecting and treating device. The biological floating island of the device comprises an island main frame, large size garbage grating barrier layers arranged around the island main frame and an aquatic plant basket arranged in the island main frame. The island main frame is formed by connecting pipelines provided with water absorption holes in surfaces; the island main frame is connected to a high housepower water suction pump through a water suction pipeline, and a water outlet of the water suction pipeline communicates to a microbial automatic consumption pond which is successively provided with a fine sand filter layer, an activated carbon filter layer and a macadam filter layer from top to bottom; the filtered clean water is returned to a water body of the ecological island in the bottom of the microbiological consumption pond through a drain pipe. The device provided by the invention is capable of automatically cleaning oil slick and foam on the surfaces of water bodies such as riverways and lakes and preventing the oil slick and foam from drifting downward to keep clean water surface, so that the human labor is lowered and the utilization ratio of water resources is increased, and the device also has an environment-beautifying effect of repairing the riverway.

Owner:FOSHAN YUHUANG ECOLOGICAL ENVIRONMENT TECH

Construction waste treatment device

ActiveCN111921674ASolve the problem that it is difficult to perform normal crushing processingThe processing is progressing smoothlyGrain treatmentsArchitectural engineeringBulky waste

The invention discloses a construction waste treatment device. The construction waste treatment device comprises a base plate, a left end of a top part of the base plate is fixedly connected with a vertical plate, the top part of the vertical plate is fixedly connected with a top plate, a right side of the top plate is fixedly connected with a bulky waste treatment box, and a collection hopper isarranged under the bulky waste treatment box. The construction waste treatment device not only can crush smaller construction waste, but also can perform primary crushing for bigger construction wasteand then performs further crushing, thus, a problem of failure in normal crushing treatment for some bigger construction waste accumulated and blocked in a crushing box in the prior art is solved, aprocess of continuous treatment for the construction waste is guaranteed, construction waste treatment progress is guaranteed to be carried out smoothly, moreover, an aim of crushing the whole waste is realized just by one motor taken as a power source, and the construction waste treatment device is not only novel in structure, but also guarantees continuity of construction waste treatment, and satisfies usage requirements of people.

Owner:饶孟树

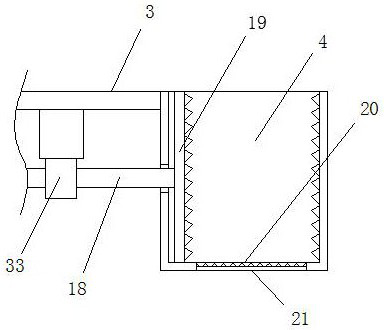

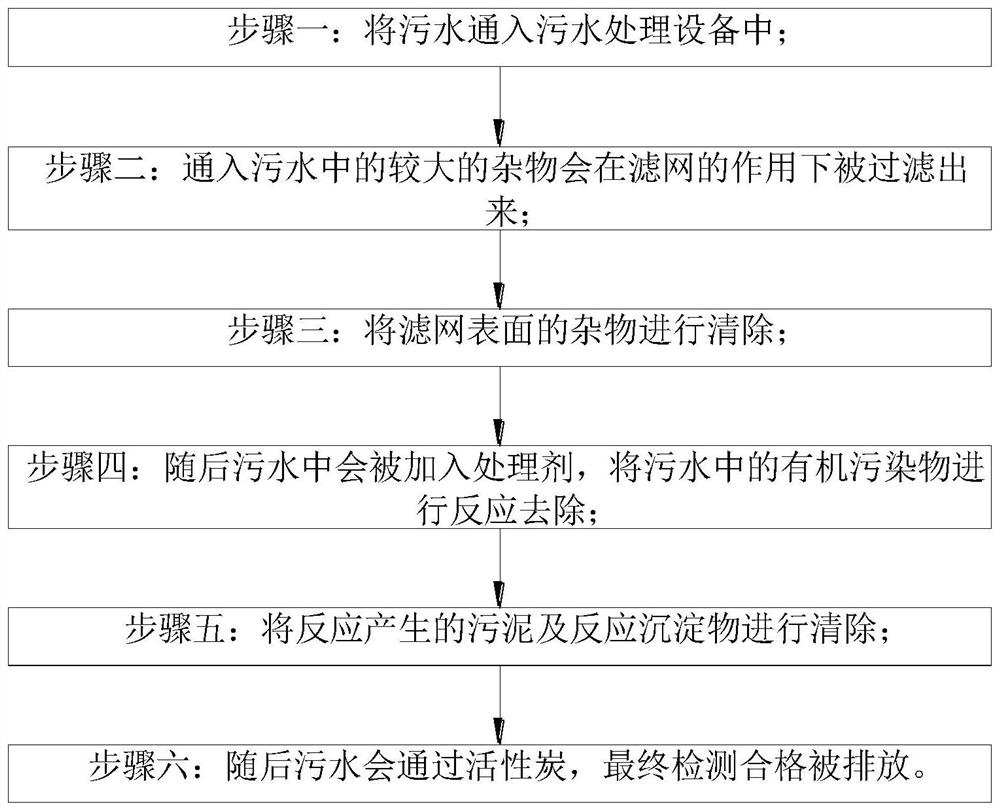

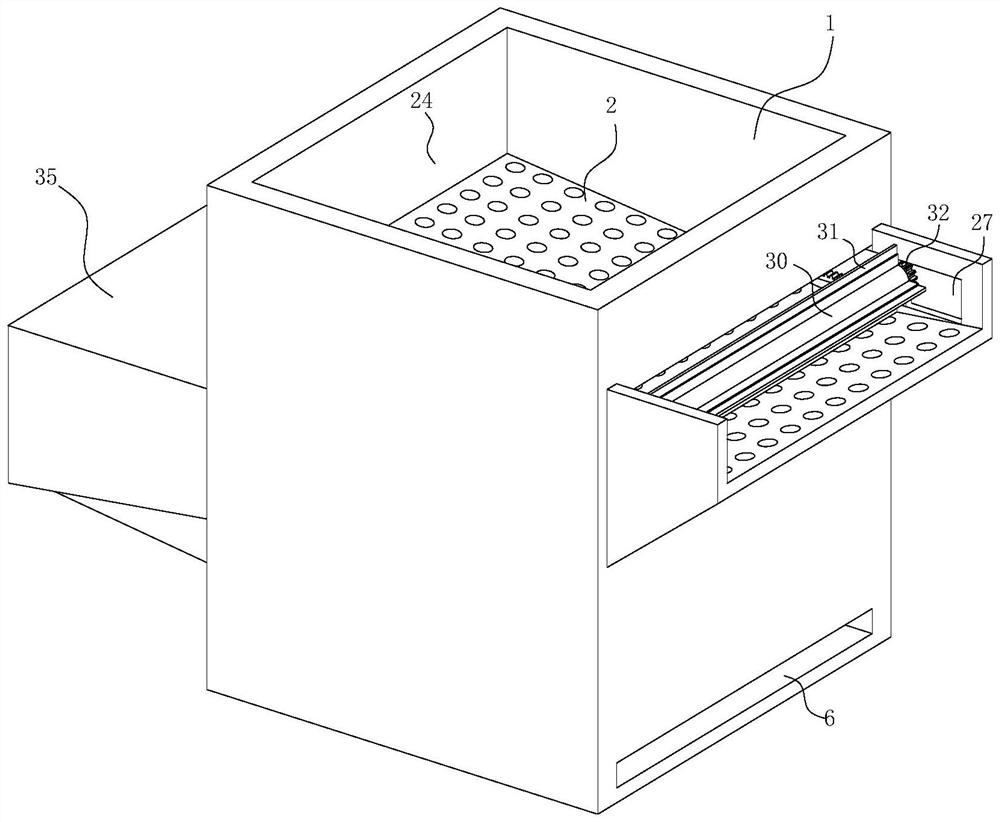

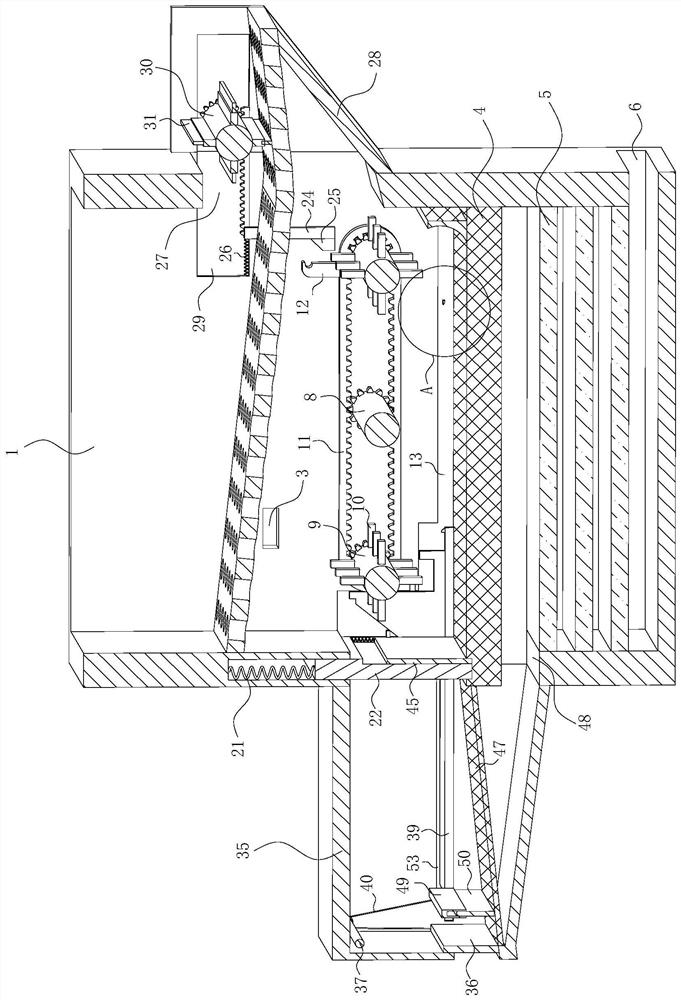

Multi-stage sewage treatment equipment and treatment method for hydraulic engineering

InactiveCN113023936AWon't clogImprove filtering effectSpecific water treatment objectivesTreatment involving filtrationSludgeBulky waste

The invention discloses multi-stage sewage treatment equipment and treatment method for water conservancy projects in the technical field of sewage treatment. The multi-stage sewage treatment equipment comprises a shell, an opening is formed in the top of the shell, and a large garbage filter screen used for filtering large impurities in sewage is fixedly connected to the upper portion of the inner wall of the shell. An adding opening is formed in the position, located below the large garbage filter screen, of the inner wall of the shell, and the adding opening is used for adding a sewage treatment agent into sewage. The middle part of the inner wall of the shell is fixedly connected with a biological sludge filter screen used for filtering biological sludge generated by reaction. The large garbage filter screen and the biological mud filter screen divide the shell into three parts. While sewage is filtered, a conveyor belt is used to drive an arc-shaped scraping plate to intermittently clean sludge and reaction precipitates on the surface of the biological sludge filter screen, so that meshes on the surface of the filter screen cannot be blocked, and the filter screen can keep an optimal filtering effect in the whole sewage filtering process.

Owner:王敏妮

A construction waste crushing device

ActiveCN106622473BSimple enoughSimple and fast operationMagnetic separationGrain treatmentsBulky wasteMetal

The invention discloses a building waste crushing apparatus, comprising a bottom plate; four supports are arranged on the upper surface of the bottom plate; a primary crushing unit is arranged among the upper ends of the four supports, the upper end of the primary crushing unit is provided with a feed port, the upper end of the feed port is provided with a feed trough, a first motor is arranged on one side of the primary crushing unit, and the lower end of the primary crushing unit is provided with a discharge port; it is possible to crush bulky waste through the primary crushing unit so that crushing is more convenient; a secondary crushing unit is arranged below the primary crushing unit; it is possible to crush the waste thoroughly through the secondary crushing unit so that crushing is more thorough; it is possible to attract metals in the crushed waste through an electromagnetic plate so that the metals can be recycled; the building waste crushing apparatus is simple in structure and simple to operate, and is capable of crushing waste thoroughly and sorting the metals in the waste in order to collect and reuse the metals.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

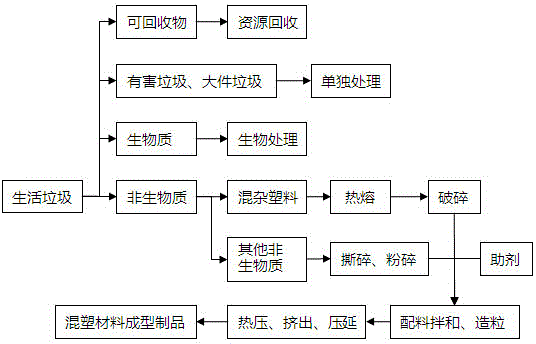

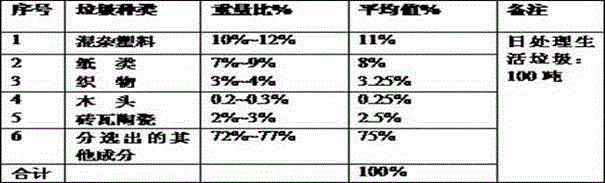

Method for manufacturing novel composite material through non-biomass substances in household refuse

After recyclable materials in household refuse are recycled, harmful refuse and large refuse in the household refuse are independently treated and biomass substances in the household refuse are biologically treated, a novel composite material, namely the mixed plastic material is produced with mixed plastic in non-biomass substances in the residual household refuse as matrix resin and other non-biomass substances as padding. Firstly, the mixed plastic in the non-biomass substances in the household refuse is directly hot-melted to form blocky materials, and after being cooled, the blocky materials are crushed into particles smaller than 10 mm; the other non-biomass substances in the non-biomass substances in the household refuse are torn up and crushed into sheets smaller than 20 mm or particles smaller than 2 mm; secondly, the mixed plastic and the other non-biomass substances which are treated are blended according to a specific proportion, and whether pelleting is carried out or not and whether assistants with compatibility and / or a coupling property are added or not are determined according to the subsequent production requirement for the mixed plastic material; and finally, molded mixed plastic material products are produced through hot pressing or extrusion or the rolling process, and therefore the maximum recycling of household refuse treatment is achieved.

Owner:中国科学院生态环境研究中心鄂尔多斯固体废弃物资源化工程技术研究所

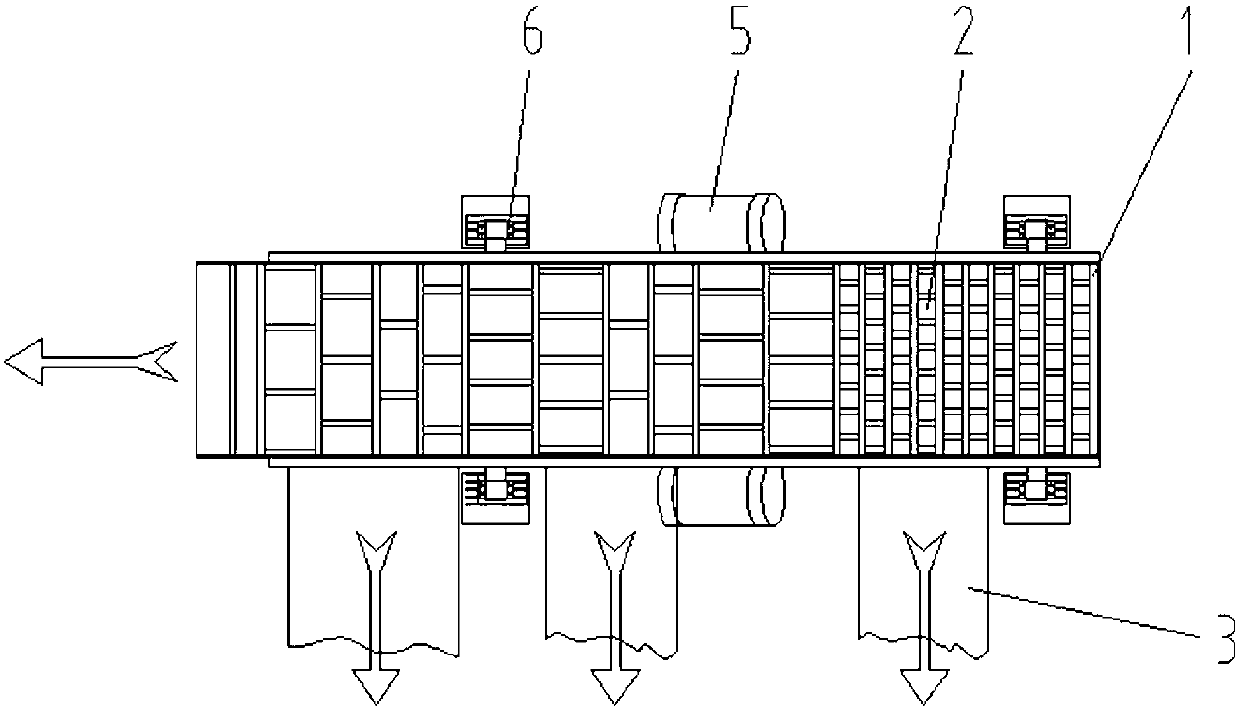

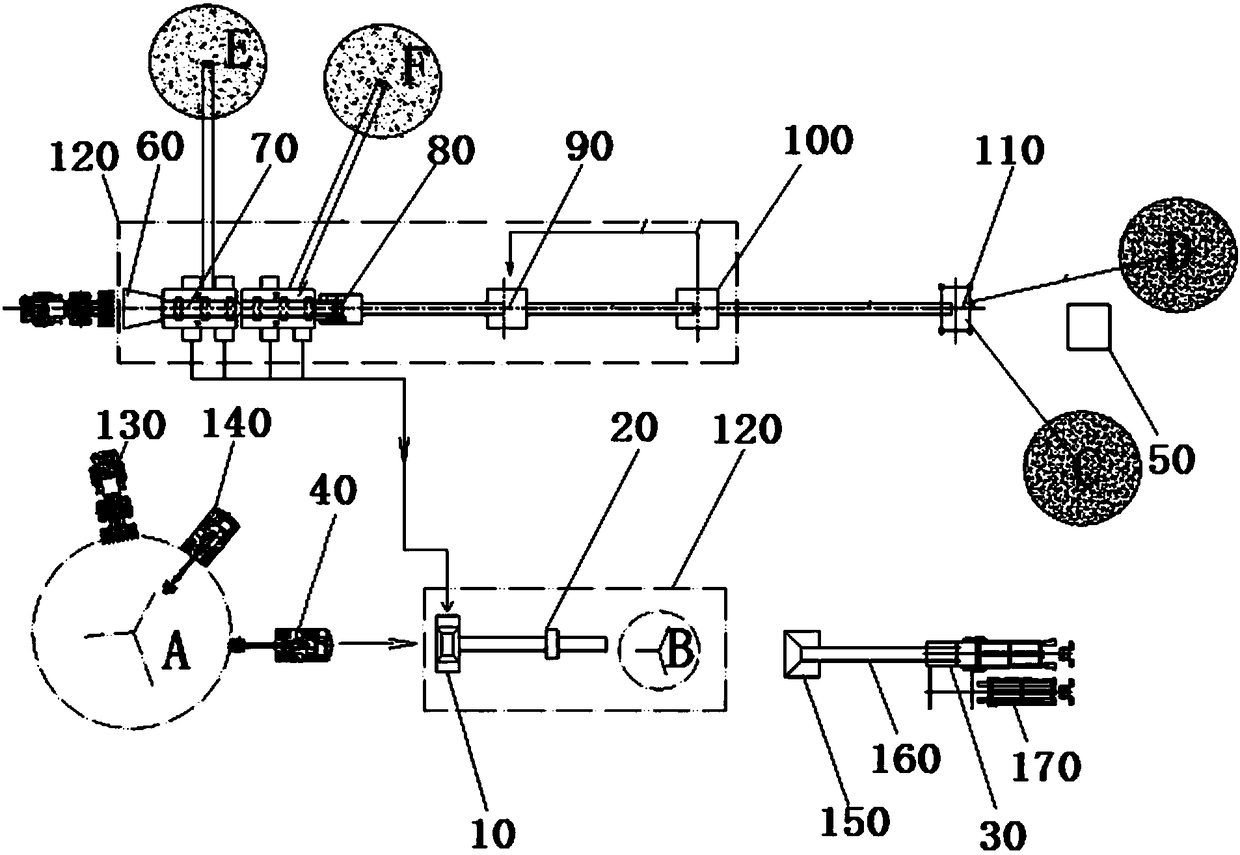

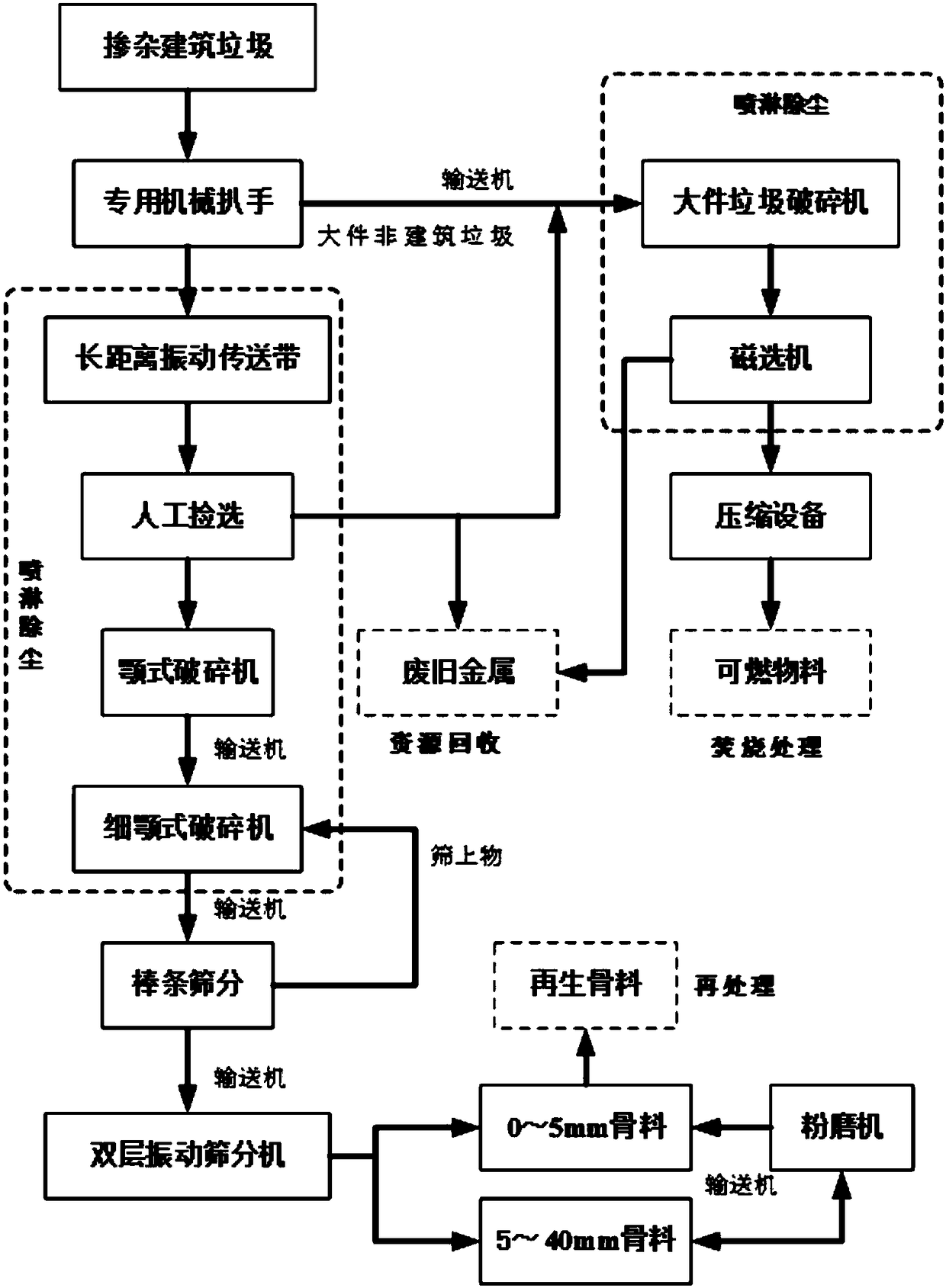

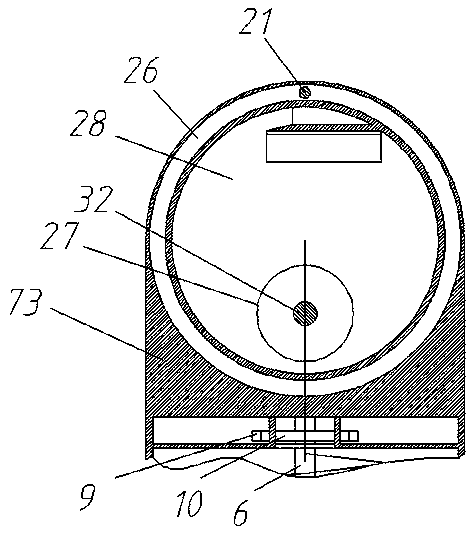

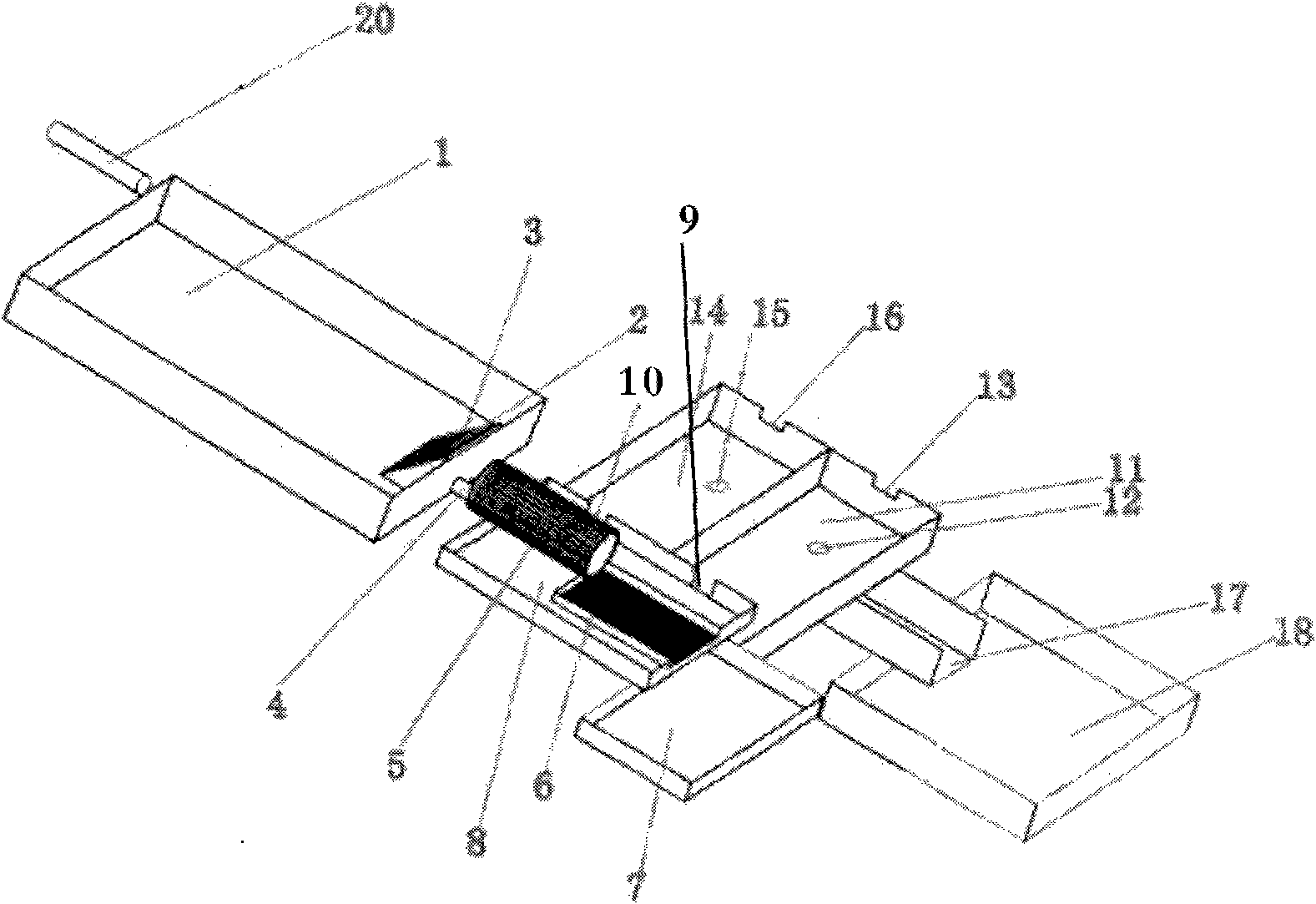

Separation device for mixed construction waste and separation method thereof

InactiveCN108080397AImprove separation efficiencyConducive to resource processingConstruction waste recoverySolid waste disposalMagnetic separatorBulky waste

The invention provides a separation device for mixed construction waste and a separation method thereof. The separation device comprises a bulky waste crusher, a magnetic separator arranged behind thebulky waste crusher, compression equipment arranged behind the magnetic separator, a vibratory feeding platform, first-stage crushing equipment arranged behind the vibratory feeding platform, second-stage crushing equipment arranged behind the first-stage crushing equipment, first-stage screening equipment arranged behind the second-stage crushing equipment, second-stage screening equipment arranged behind the first-stage screening equipment, and a pulverizer arranged behind the second-stage screening equipment; the vibratory feeding platform comprises a feeding chute and a vibratory feeder,and is used for receiving other waste separated by a mechanical claw and carrying out secondary manual picking of bulky non-construction waste from the waste. The separation device has the advantagesof being efficient, environmentally friendly, capable of saving energy and high in production efficiency and is beneficial to obtaining concrete material with high purity, and then the concrete material which is separated out can be used as aggregate of recycled concrete to increase the utilization rate of resources.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

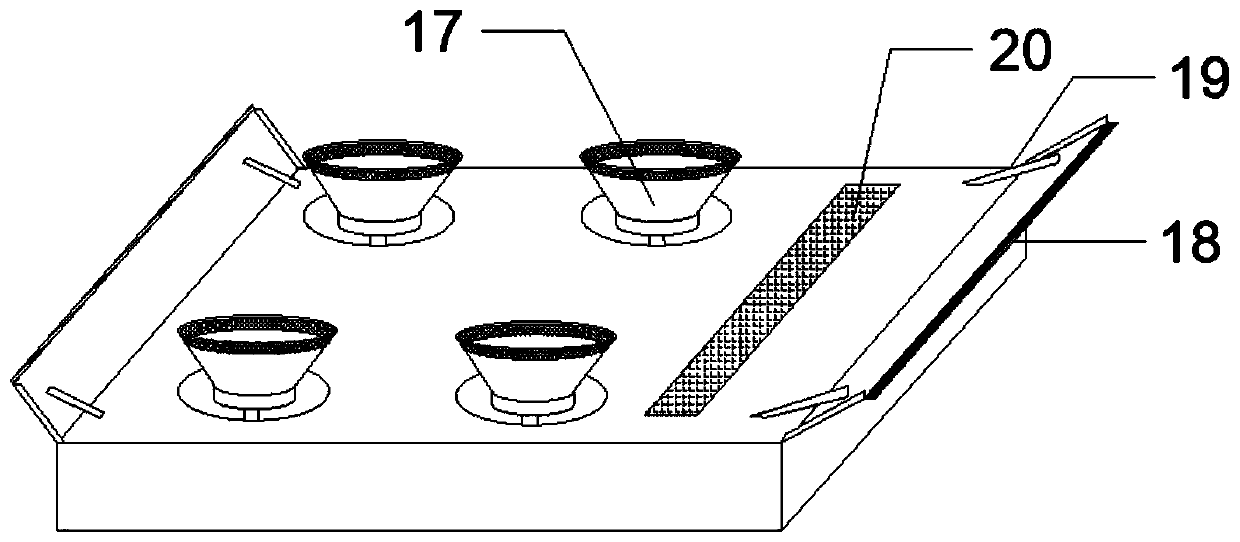

Kitchen garbage classifying treatment equipment

ActiveCN110743681AImprove processing efficiencySimple organizationGrain treatmentsWater storageBulky waste

The invention discloses kitchen garbage classifying treatment equipment. The kitchen garbage classifying treatment equipment comprises a main machine body and a garbage conveying cavity arranged in the main machine body, and a large garbage cavity is arranged in the garbage conveying cavity; a vibration classifying device is arranged in the main machine body; an iron product garbage cavity is arranged in the main machine body; a water storing cavity is arranged in the main machine body, a water leaking hole cooperating with the water storing cavity is formed in the garbage conveying cavity, and the two sides of the water storing cavity are provided with waste oil cavities; a transmission cavity is arranged in the main machine body; and a mincing cavity is arranged in the main machine body,and a garbage extruding cavity is arranged in the mincing cavity. According to the kitchen garbage classifying treatment equipment, the mechanisms are simple, use is easy and convenient, large and small garbage classification, iron product garbage separation, bone mincing and water and oil classification are achieved, multiple kinds of garbage are simultaneously treated, and the garbage treatmentefficiency is greatly improved; and the cost is low, the kitchen garbage classifying treatment equipment can be popularized in various large and small garbage treatment stations, and the garbage treatment efficiency is improved for the treatment stations.

Owner:浙江爱源环境工程有限公司

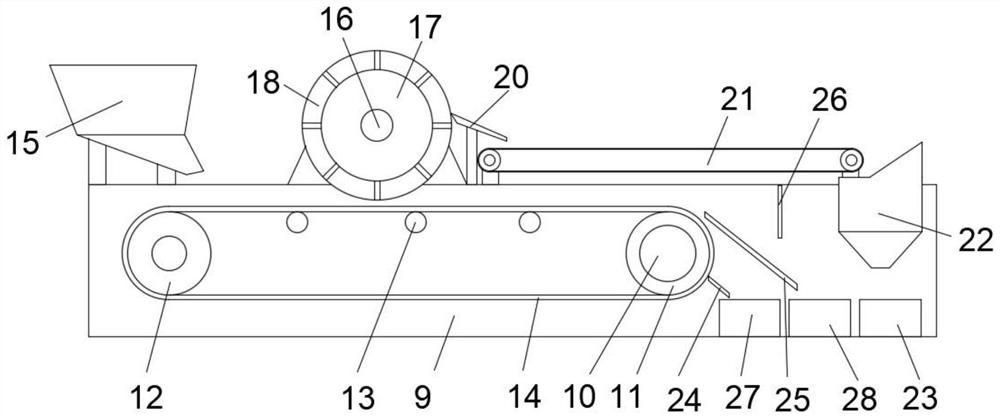

Household garbage sorting system

InactiveCN111804432APrevent infiltrationExtended service lifeSolid waste disposalMagnetic separationBulky wasteElectric machinery

The invention discloses a household garbage sorting system, which comprises a uniform feeder, a large garbage sorting machine, a large garbage crusher, a bag breaking crusher, a comprehensive winnowing machine, a winnowing device, a grain separation device and a magnetic separation device, wherein the magnetic separation device comprises a rack, the inner wall of the rack is rotationally connectedwith an eccentric magnetic cylinder and a driving roller, the eccentric magnetic cylinder and the driving roller are both driven by a motor, the rotating direction of the eccentric magnetic cylinderis the same as that of the driving roller, the outer wall of the eccentric magnetic cylinder is rotationally sleeved with an outer cylinder, and the outer wall of the outer cylinder and the outer wallof the driving roller are jointly sleeved with a conveying belt. By arranging the gear motor, an arc-shaped electromagnet, a rotating shaft and the sleeve, ferromagnetic metal can be preferentially collected before metal objects and non-metal objects are separated, so that iron particles are effectively prevented from seeping between the conveying belt and the eccentric magnetic cylinder, the service life of the conveying belt and the service life of the eccentric magnetic cylinder are prolonged, and then the working stability of the magnetic separation device is guaranteed.

Owner:成都市爱七面品牌管理有限公司

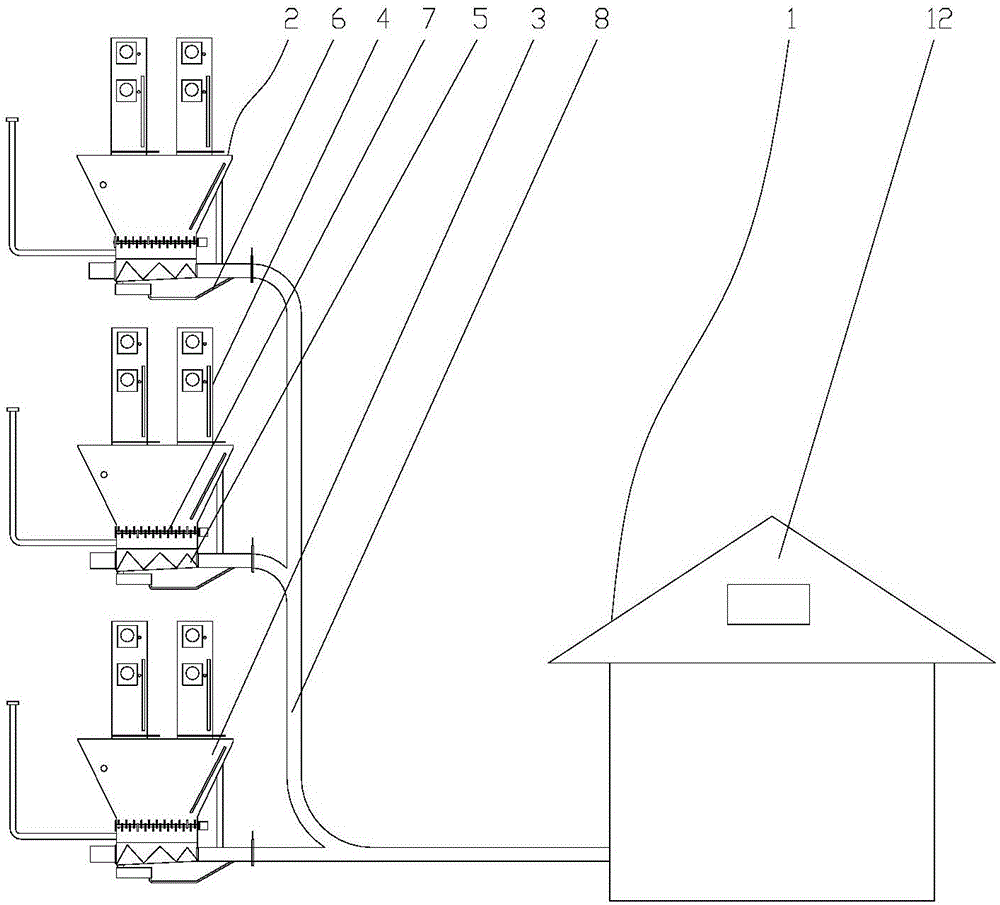

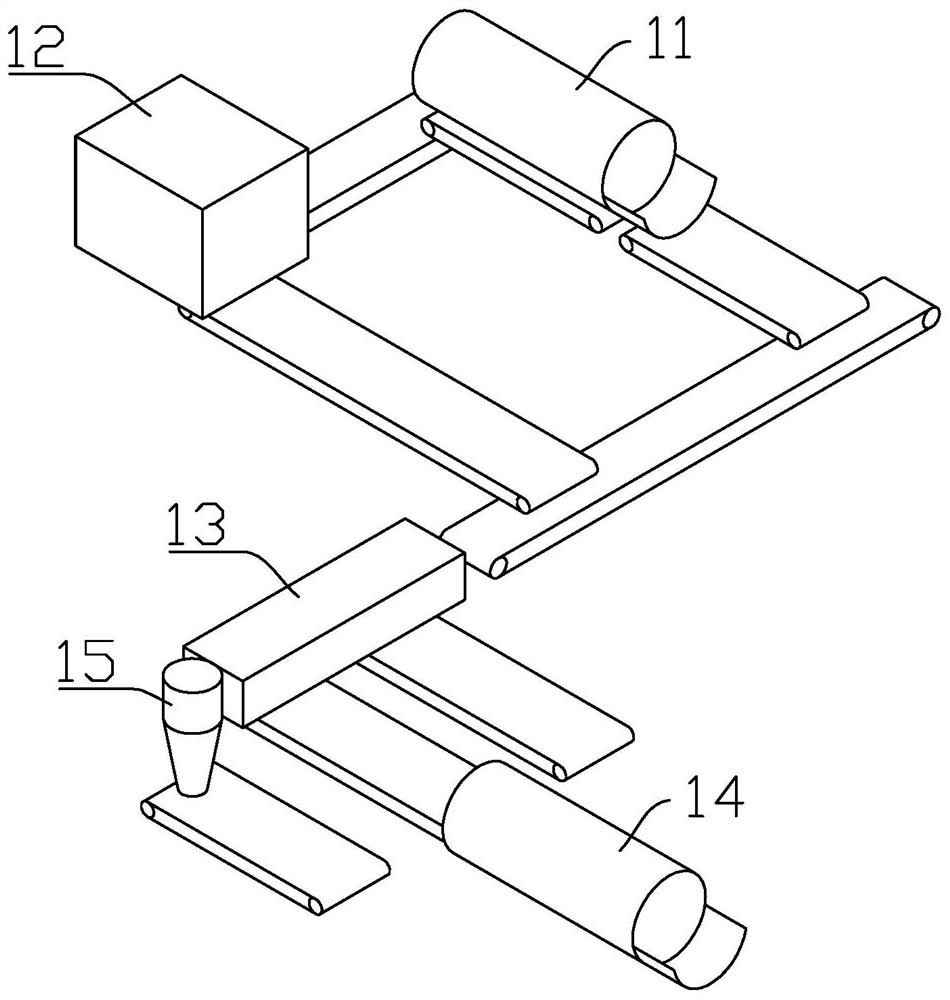

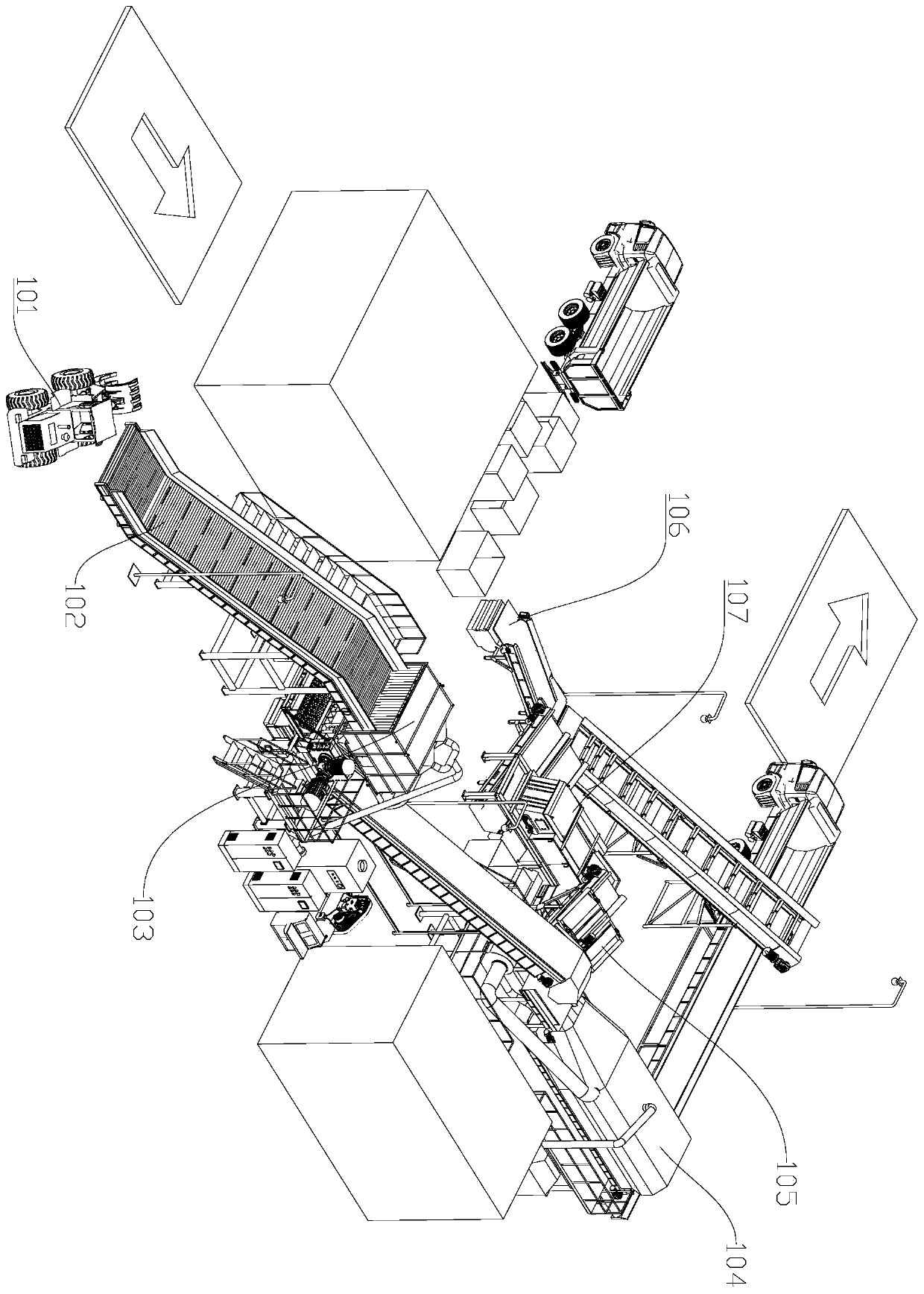

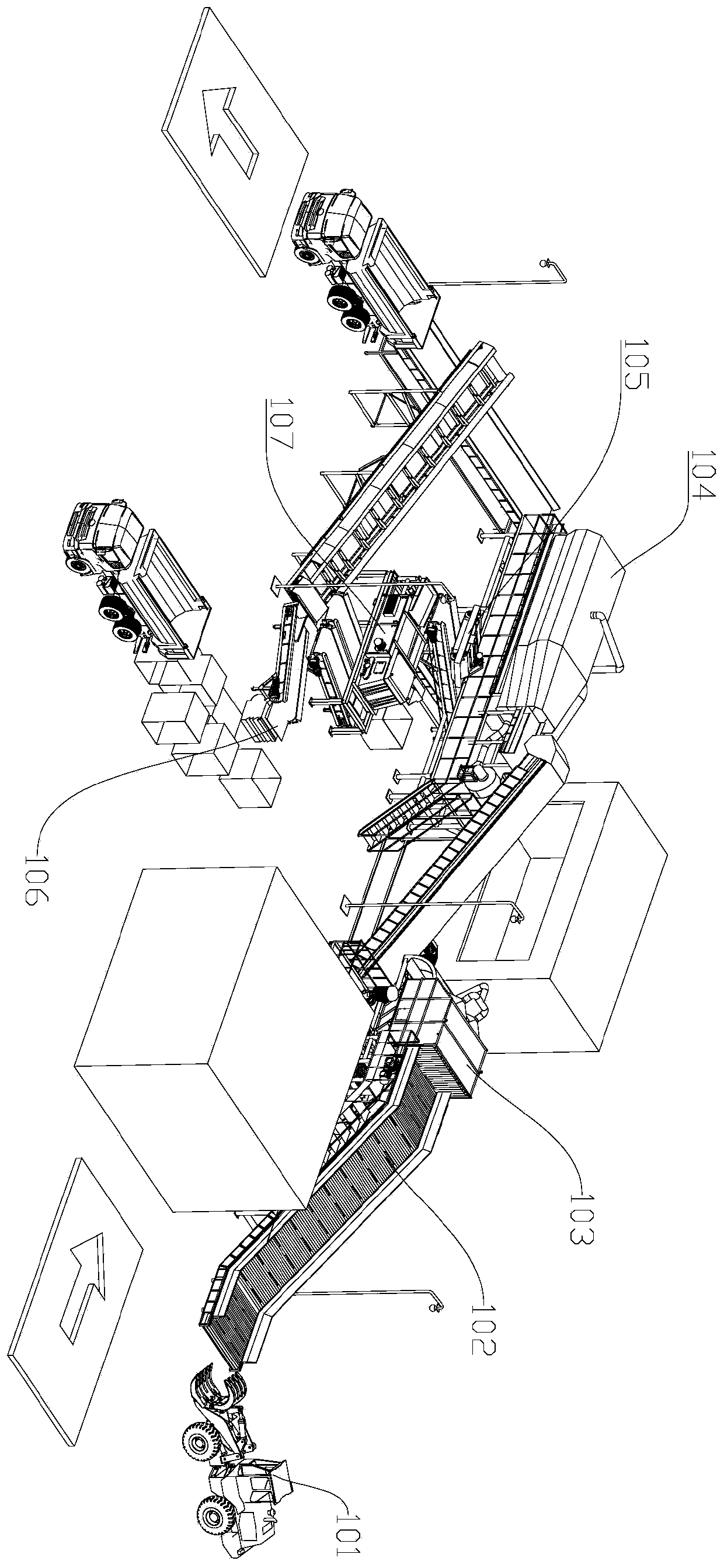

Garbage collecting and conveying equipment

ActiveCN104309971AReduce volumeIncrease in sizeRefuse vehiclesRefuse collectionManufacturing technology

The invention discloses garbage collecting and conveying equipment, belongs to the technical field of environmental sanitation production and expands and improves the conventional garbage collecting, hoisting, compressing and conveying methods and equipment. The conventional environmental sanitation can only collect and convey household garbage through waster transfer stations and fails to solve small-scale construction garbage, made during house decoration and reconstruction and the like, and large-piece garbage including abandoned large old furniture which are required to be conveyed by owners themselves. According to the arrangement, the conventional garbage collecting and conveying process is simplified, the waste transfer stations are omitted, fewer sanitation workers are required, and household garbage, construction garbage and large-piece garbage are collected and conveyed in the rapid manner.

Owner:江苏乐尔环境科技股份有限公司

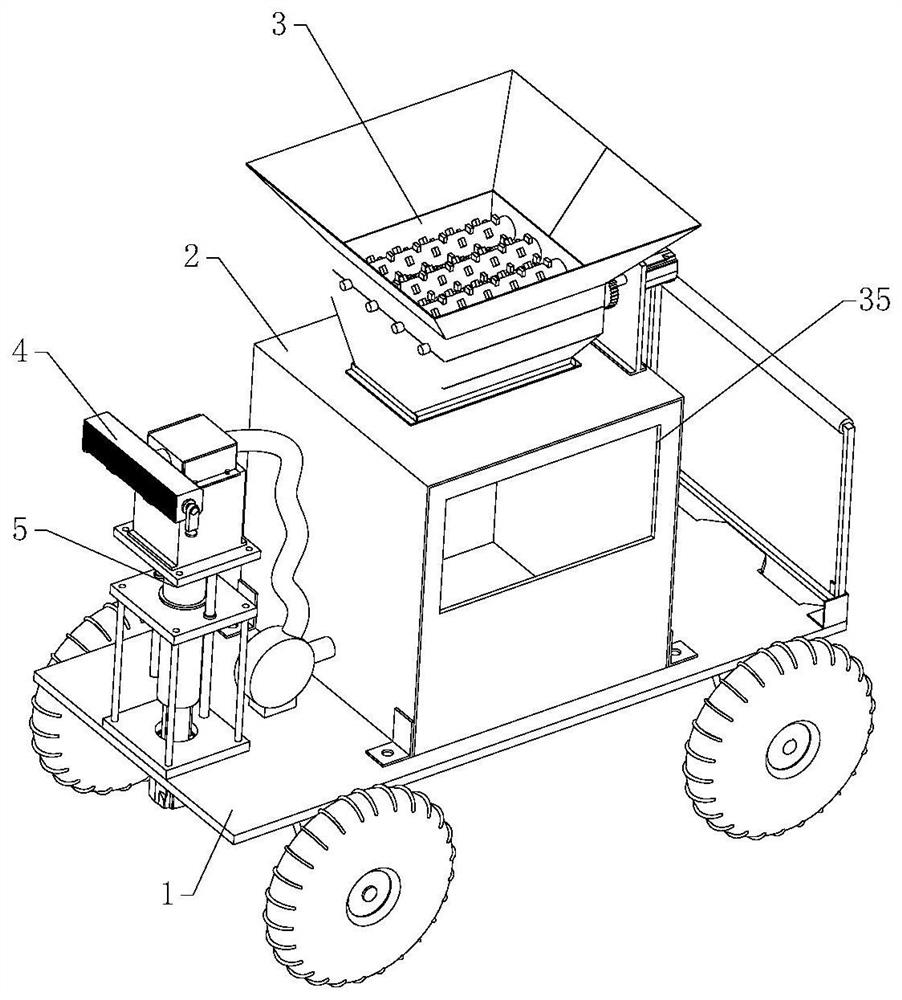

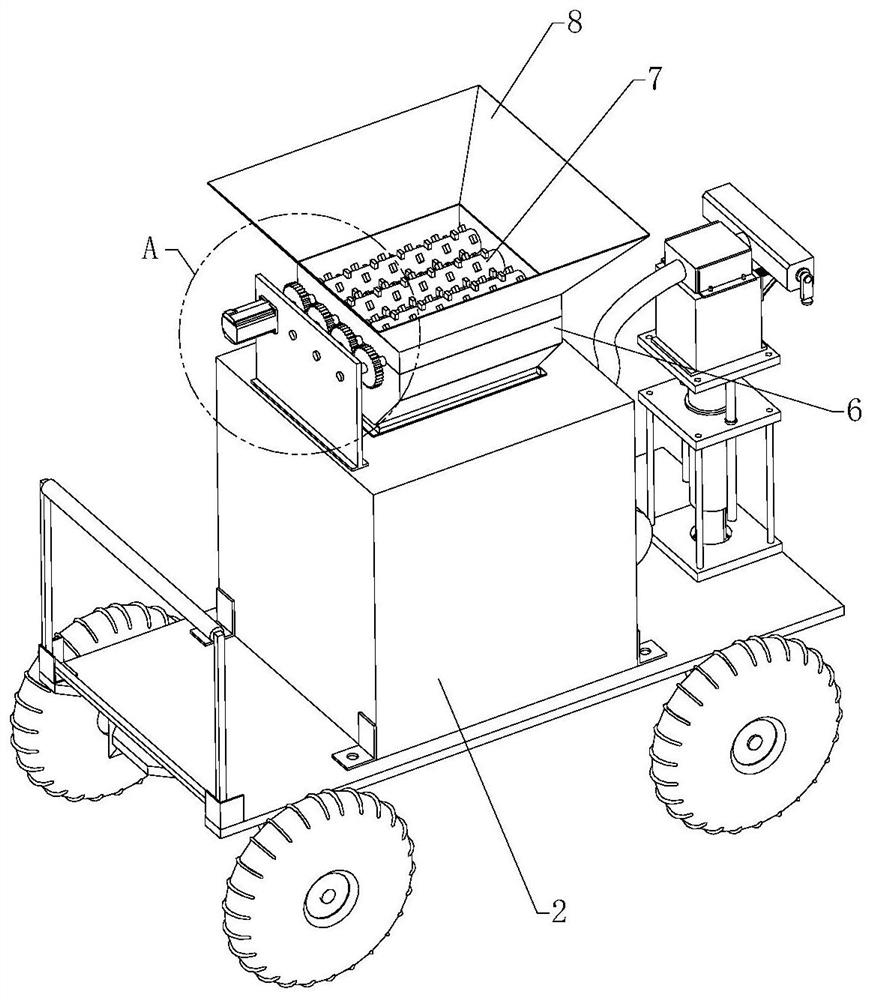

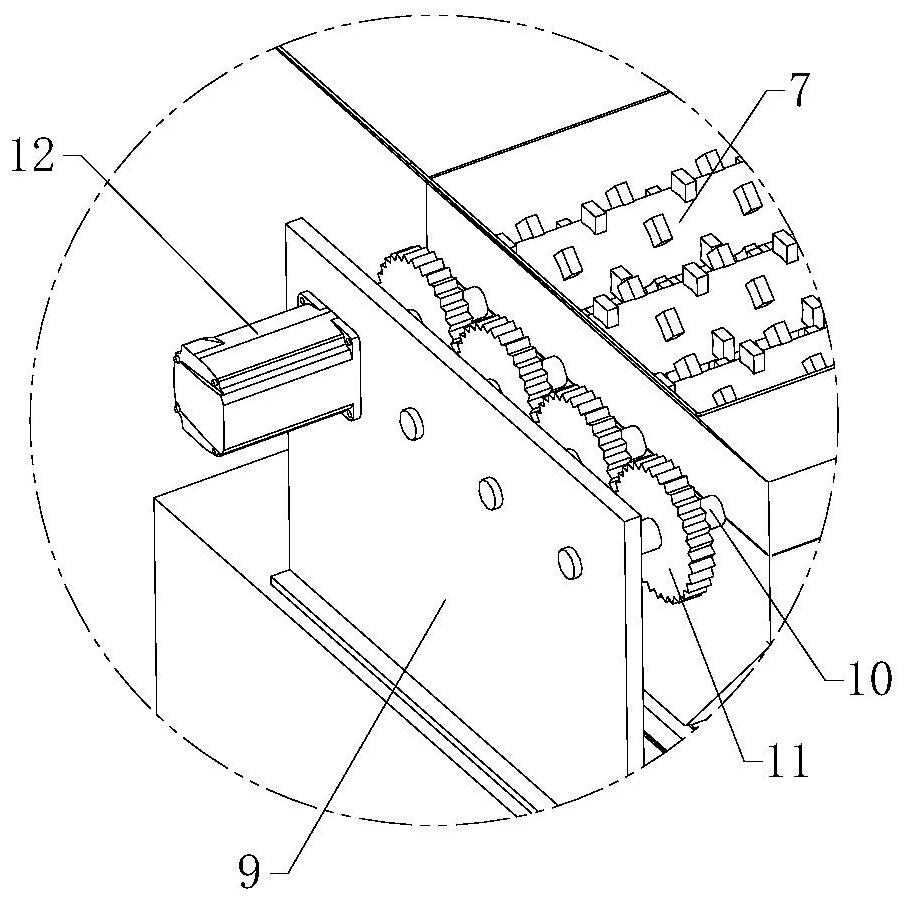

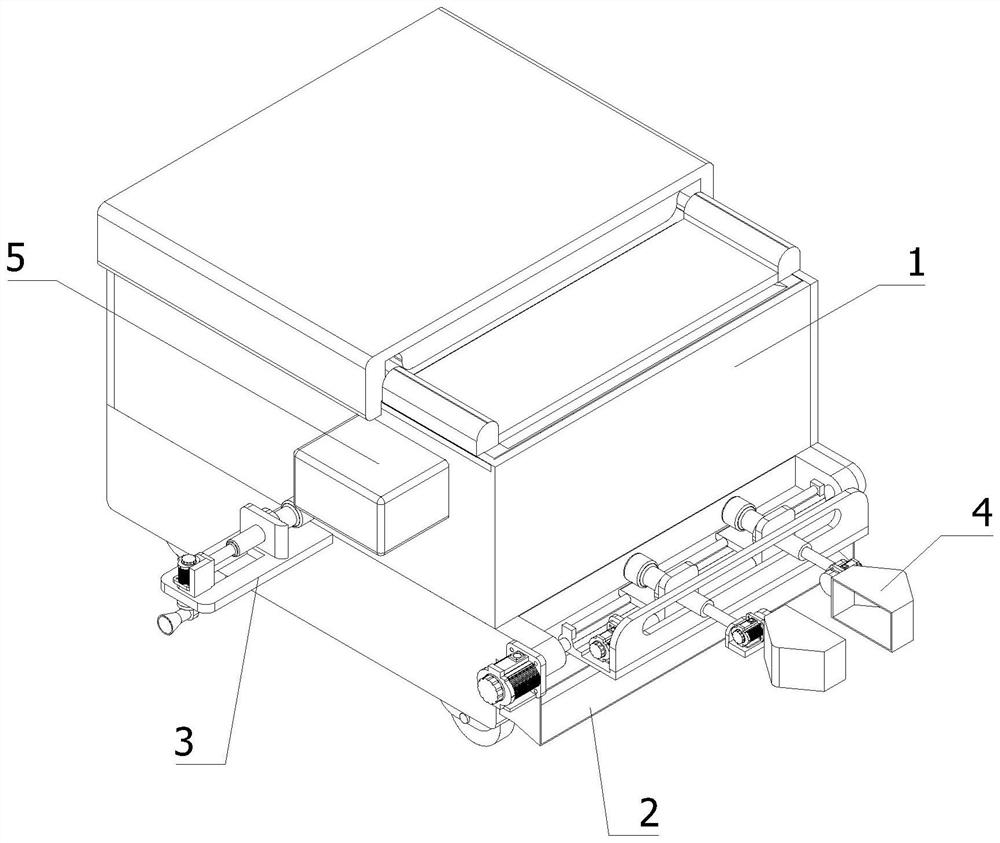

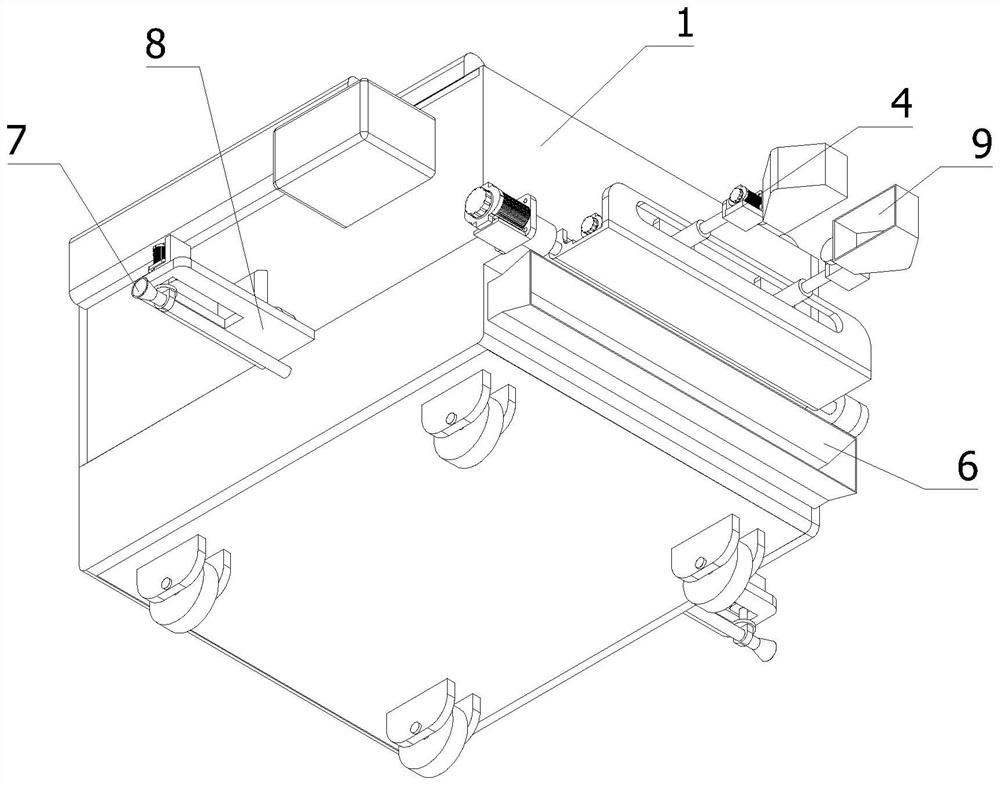

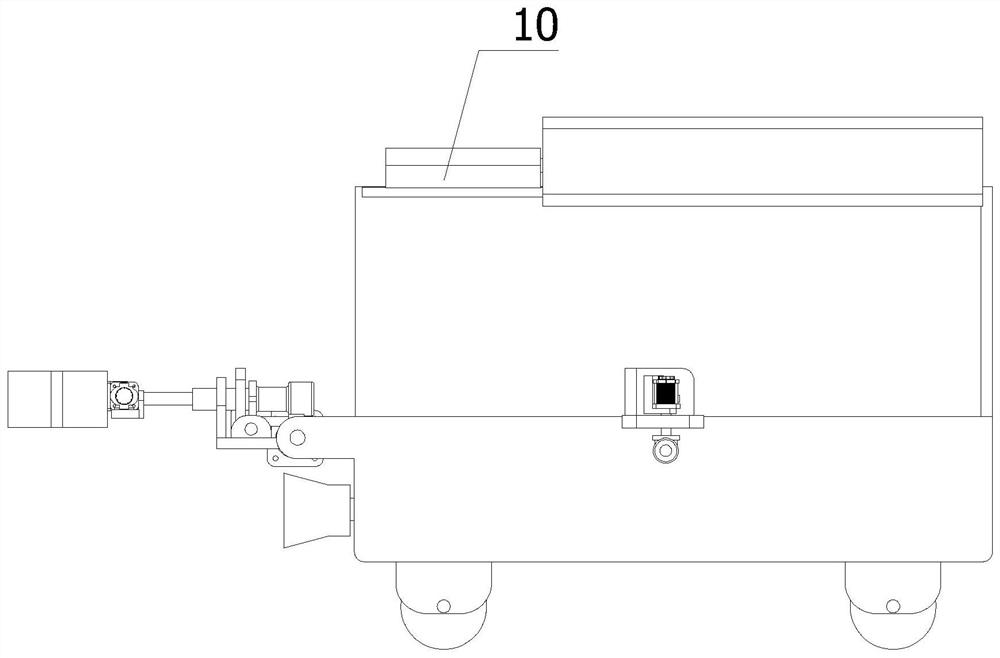

Waste collecting device for intelligent manufacturing workshop

InactiveCN112844581AEasy to adjustSolve incomplete cleaningCleaning using gasesGrain treatmentsBulky wasteProcess engineering

The invention relates to the technical field of waste collection, in particular to a waste collecting device for an intelligent manufacturing workshop. The waste collecting device comprises a flat car, a collecting box, a large-piece collecting mechanism, a small-piece collecting mechanism and a lifting positioning mechanism; the collecting box is arranged in the center of the top of the flat car and used for collecting workshop waste; the large-piece collecting mechanism is arranged at the top of the collecting box and used for crushing large-piece garbage to be put into the collecting box and then putting the crushed large-piece garbage into the collecting box; the small-piece collecting mechanism is arranged at one side of the lower end of the collecting box and used for throwing small-piece garbage in the workshop into the collecting box; and the lifting positioning mechanism is arranged at one end of the top of the flat car, the working end of the lifting positioning mechanism is detachably connected with the working end of the small-piece collecting mechanism, and the lifting positioning mechanism can drive the small-piece collecting mechanism to do the lifting procedure. According to the technical scheme, the problem that cleaning is not thorough due to manual cleaning is solved; and by means of the waste collecting device, waste materials of different sizes can be collected, collection at the designated position is automatically achieved, and the collection efficiency is improved.

Owner:周哓霞

Lifting side-tipping trash bin

The invention provides a lifting side-tipping trash bin. The lifting side-tipping trash bin is characterized in that a bin cover is openable, allowing large trash to be conveniently thrown in; a bin body is connected through a central post; a slide way allows lifting of the bin body; side tipping allows all trash to be conveniently poured out; a small door in the bin body allows sanitation workers to conveniently choose cleaning modes according to the quantity of trash.

Owner:江朝霞

Pavement vacuum sweeper and dust collection method thereof

InactiveCN111270636AAvoid damageReduce workloadDirt cleaningRoad cleaningRefuse collectionBulky waste

The invention discloses a pavement vacuum sweeper and a dust collection method thereof. The invention belongs to the technical field of pavement cleaning equipment. The pavement vacuum sweeper comprises a base and a storage box mounted at the top of the telescopic base, a cab is arranged on one side of the storage box, a plurality of wheels are arranged at the bottom of the base, a garbage collection and treatment box is arranged in the storage box, a large garbage storage box is arranged on one side of the garbage collection and treatment box, a garbage collection chamber is arranged in the garbage collection and treatment box, a first dust collection chamber is arranged on one side of the garbage collection chamber, and a second dust collection chamber is arranged on the other side of the garbage collection chamber. By arranging the electromagnet, iron waste sucked into dust in the dust collector can be completely adsorbed, secondary sorting can be reduced, the iron waste can be collected in a centralized mode, and the dust collector is prevented from being damaged.

Owner:宿州海翔环保科技有限公司

Method for treating urban domestic garbage by soaking and screening and treatment equipment

InactiveCN101811130AImprove recycling ratesA large amount of processing in a single daySolid waste disposalWet separationLitterScreening method

The invention discloses a method for treating urban domestic garbage by soaking and screening and treatment equipment. The method comprises the following steps: a, pouring the urban garbage into a large-scale garbage pool through a truck till the garbage pool is filled to two thirds, and leveling the garbage by using mechanical equipment; b, filling water into the pool to just soak the garbage into the water; c, after the garbage is soaked into the water for certain time, dissolving most soluble garbage, making the insoluble garbage sink to the bottom of the pool or float in the water, separating the large garbage and the dissolved garbage in a multiplex screening mode, separating out the large garbage and the garbage with large density, and recycling the garbage. The garbage is decomposed by using the soaking and screening method; and the garbage treatment mode has large single-day treatment amount and simple operation, does not need to use expensive treatment equipment, and greatly reduces the treatment cost.

Owner:李永旺

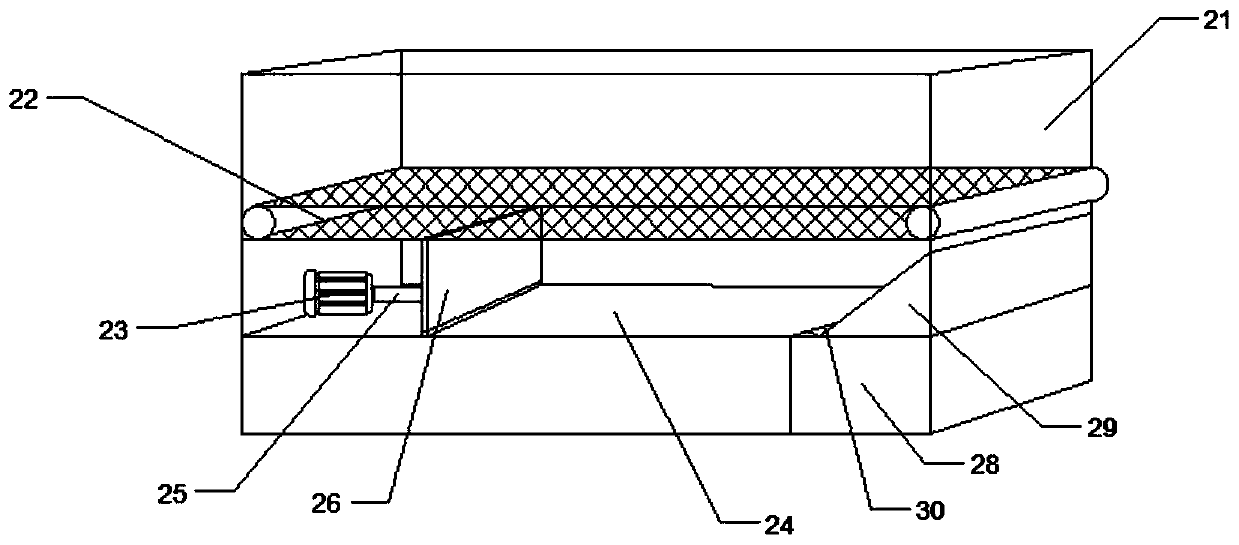

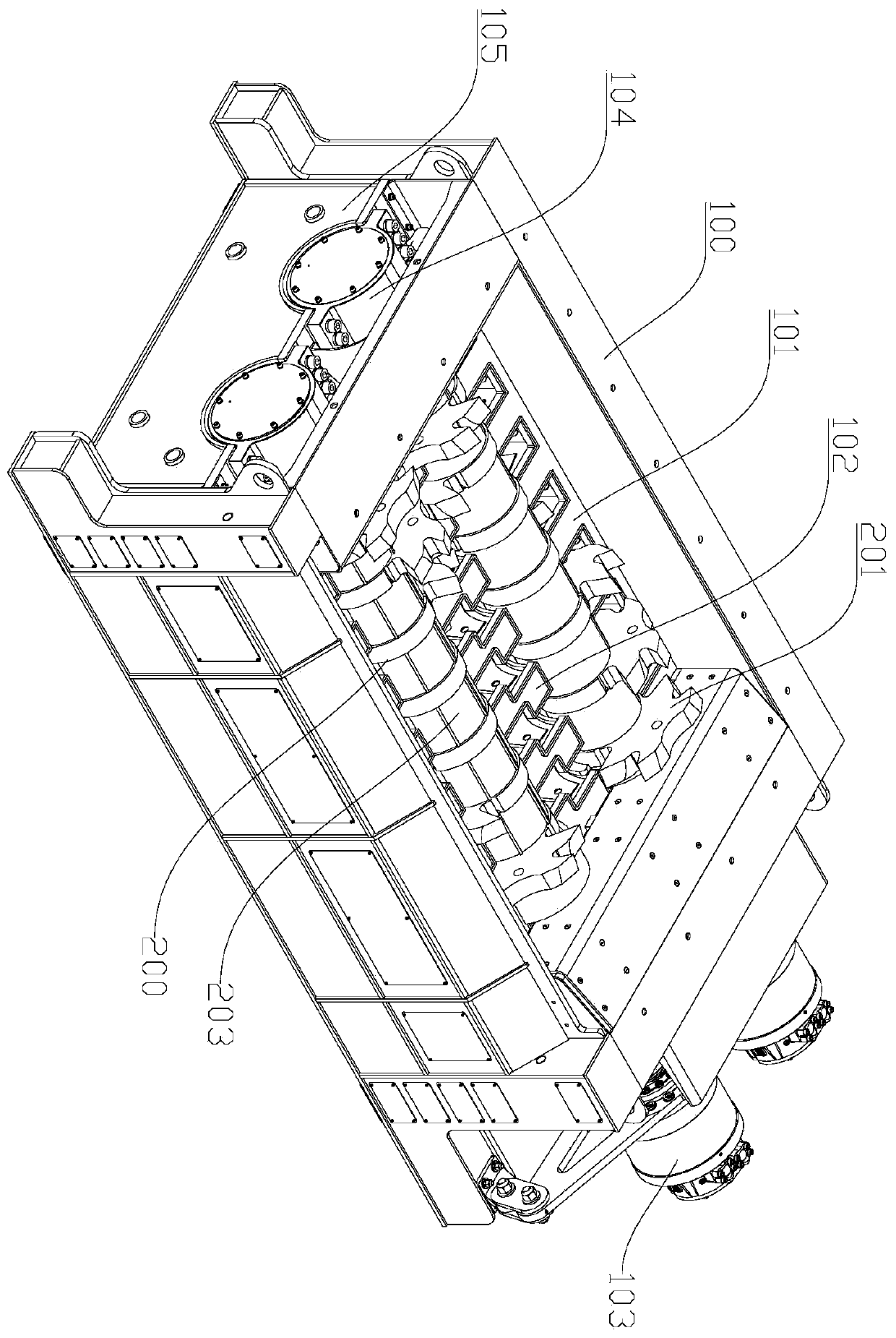

Coarse crushing device for large garbage

PendingCN110694762AAvoid scrolling unexpected situationsImprove crushing efficiencyMagnetic separationGrain treatmentsButt jointMagnetic separator

The invention provides a coarse crushing device for large garbage. The coarse crushing device comprises a crusher and a magnetic separator in butt joint with the crusher, and is used for sequentiallycompleting crushing and sorting of the large garbage, wherein the crusher is provided with a plurality of cutter shafts; a plurality of blades are arranged on the cutter shafts; and the blades have atleast two size specifications with different diameters or different shapes or different diameters and shapes. Due to the fact that the cutter shafts of the crusher are provided with the blades with different size specifications or shapes, the situation that the large garbage cannot eat materials when rolling on the cutter shafts can be avoided, and the crushing efficiency is improved; and sortingis carried out after crushing, reasonable recycling is carried out, and the resource utilization rate is high.

Owner:HARDEN SHREDDER TECH

Garbage can with two can bodies

The invention provides a garbage can with two can bodies. The garbage can is reasonable in structure and convenient to use. The garbage can comprises the two can bodies, one can body is used for containing liquid garbage, and the other can body is used for containing solid garbage, so that garbage classification is facilitated. The solid garbage contained inside the can body is smashed, large garbage is made to be smaller, and the space of the garbage can is sufficiently utilized; the using frequency of garbage bags made of polymeric materials is reduced, and environment pollution is reduced; a broom and a dustpan in the garbage can are movably fixed to the garbage can to be placed in a concentrated mode, so that the environment appears to be clean.

Owner:陈伟群

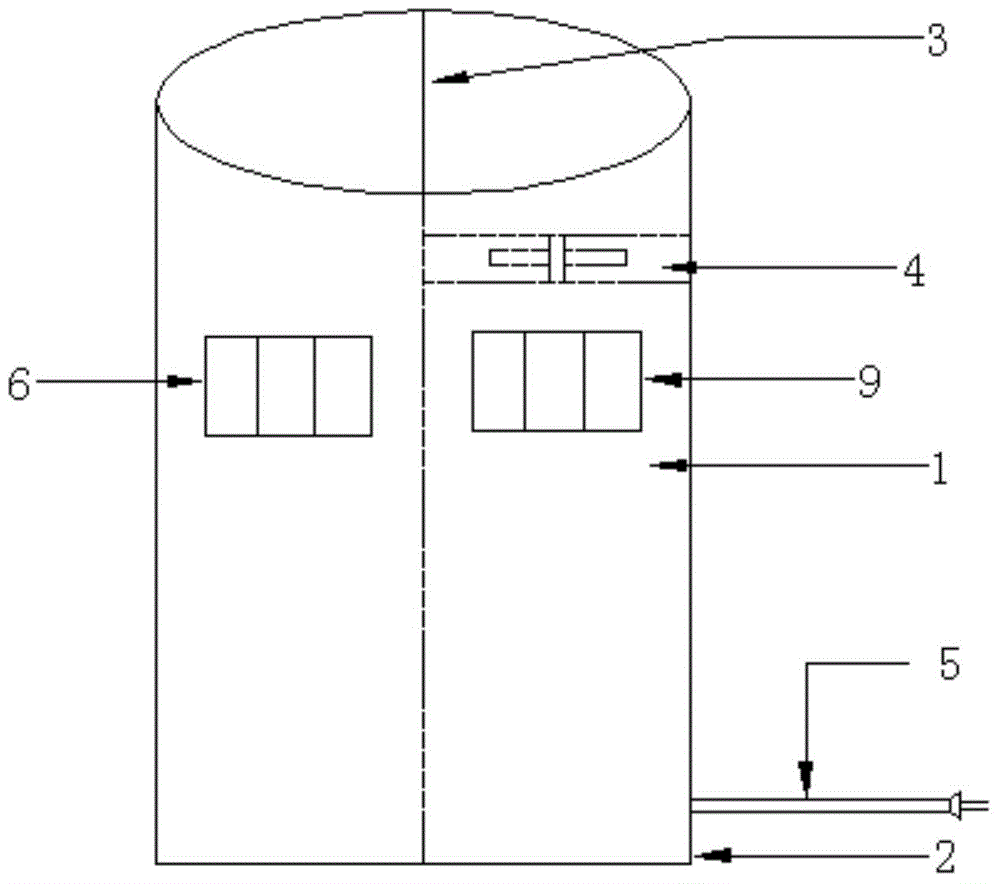

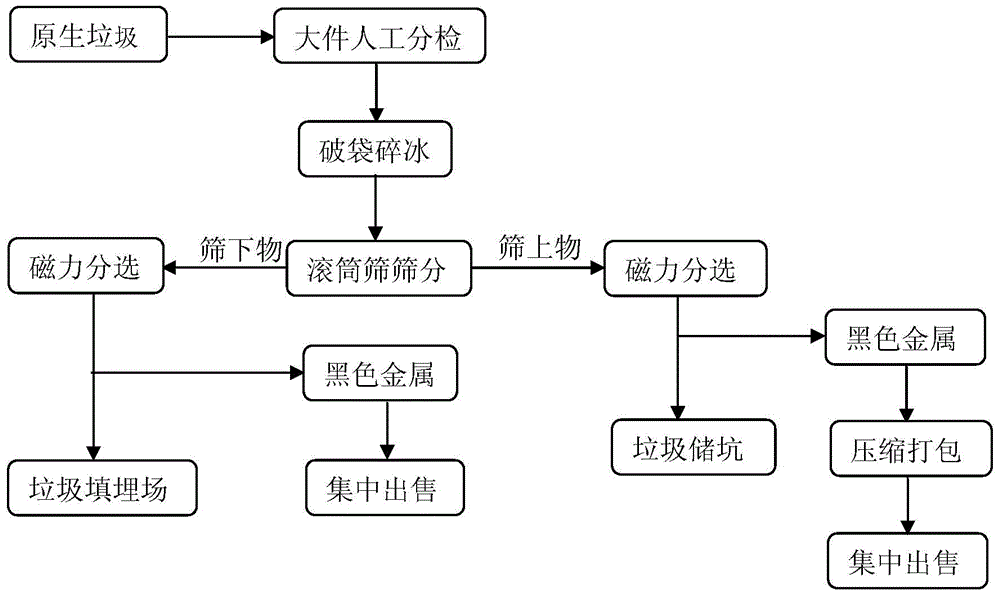

Waste incineration pre-treatment technological method for alpine underdeveloped areas

A waste incineration pre-treatment technological method for alpine underdeveloped areas comprises the steps of manual sorting of bulky crude waste, bag tearing and ice breaking, screening, magnetic separation and water seepage in a waste storage pit. In the step of manual sorting, the bulky waste is manually separated from waste; in the step of bag tearing and ice breaking, waste bags are torn, and ice blocks and ice lumps in the waste are broken up by beating; in the step of screening, the waste is screened into oversize products and undersize products; the undersize products are mainly composed of dust and are subjected to landfill treatment after magnetic separation, and the oversize products are fed into the waste storage pit for water seepage after magnetic separation; the ferrous metal obtained through magnetic separation is collected in a centralized mode for sale. The waste incineration pre-treatment technological method has the advantages that the ice blocks and the ice lumps can be fully melted after being broken by beating, so the water content of the waste put into a furnace is lowered; as the dust in the waste is screened out, the incineration heat value is increased remarkably; the fault rate of equipment can be lowered after the ferrous metal is removed from the waste put into the furnace; accordingly, the economic benefits of a waste incineration power plant are improved remarkably.

Owner:CHINA FIRST HEAVY IND +1

Sintered neodymium iron boron waste remoulding method

ActiveCN102719725BNo abnormal coarse crystal phenomenonEasy to operateInductances/transformers/magnets manufactureMagnetic materialsMetallurgyBulky waste

The invention discloses a sintered neodymium iron boron waste remoulding method. The sintered neodymium iron boron waste remoulding method comprises the steps of: a), crushing neodymium iron boron bulky waste into powder smaller than 40 meshes, putting the powder into a jet mill, and pulverizing, wherein the rotation speed of the jet mill speed is set at 800-1000rpm, the interior of the jet mill is protected by nitrogen gas, and the oxygen content is controlled at 2ppm; b), filling the powder finely ground by the jet mill into a material barrel protected by the nitrogen gas, adding 1-2ml of gasoline and 0.2-1ml of an oxidation preventer into each kilogram of the powder, and putting the material barrel into a mixer for stirring and mixing; and c) moulding the mixed powder, and sintering into a neodymium iron boron magnet. The neodymium iron boron magnet prepared by the method has normal cross-section crystallization; abnormal coarse-grained phenomenon does not appear; the performance of the neodymium iron boron magnet is consistent with that before the neodymium iron boron magnet is processed; and a normal material flow can be adopted. The sintered neodymium iron boron waste remoulding method is easy and convenient to operate and convenient and direct to process; and by the sintered neodymium iron boron waste remoulding method, waste of resources can be reduced and cost can be saved.

Owner:NINGBO KETIAN MAGNET CO LTD +1

Automatic urban garbage sorting and collecting vehicle

ActiveCN111794155AImprove aestheticsEasy to handle workRoad cleaningAgricultural engineeringBulky waste

The invention relates to the field of urban street garbage treatment, and particularly relates to an automatic urban garbage sorting and collecting vehicle. The vehicle comprises a vehicle body, a road surface dust collection assembly, a green belt dust collection assembly, a large garbage pickup assembly and a garbage treatment assembly, wherein the road surface dust collection assembly comprisesa first dust collection head capable of collecting road surface dust; the first dust collection head is horizontally hinged to the lower portion of the front end of the vehicle body; the green belt dust collection assembly comprises a second dust collection head capable of sweeping a green belt; first mounting frames are arranged on two sides of the vehicle body; the garbage pickup assembly comprises a clamping jaw capable of clamping and carrying large garbage; the garbage treatment assembly is arranged in the vehicle body and comprises a crushing mechanism and a compacting mechanism. The automatic urban garbage sorting and collecting vehicle can automatically and intelligently sweep urban streets, the sweeping range is large, the labor intensity of workers is greatly reduced, garbage issorted and collected, and the automatic urban garbage sorting and collecting vehicle is environmentally friendly and efficient.

Owner:益阳瀚鑫机械制造有限公司

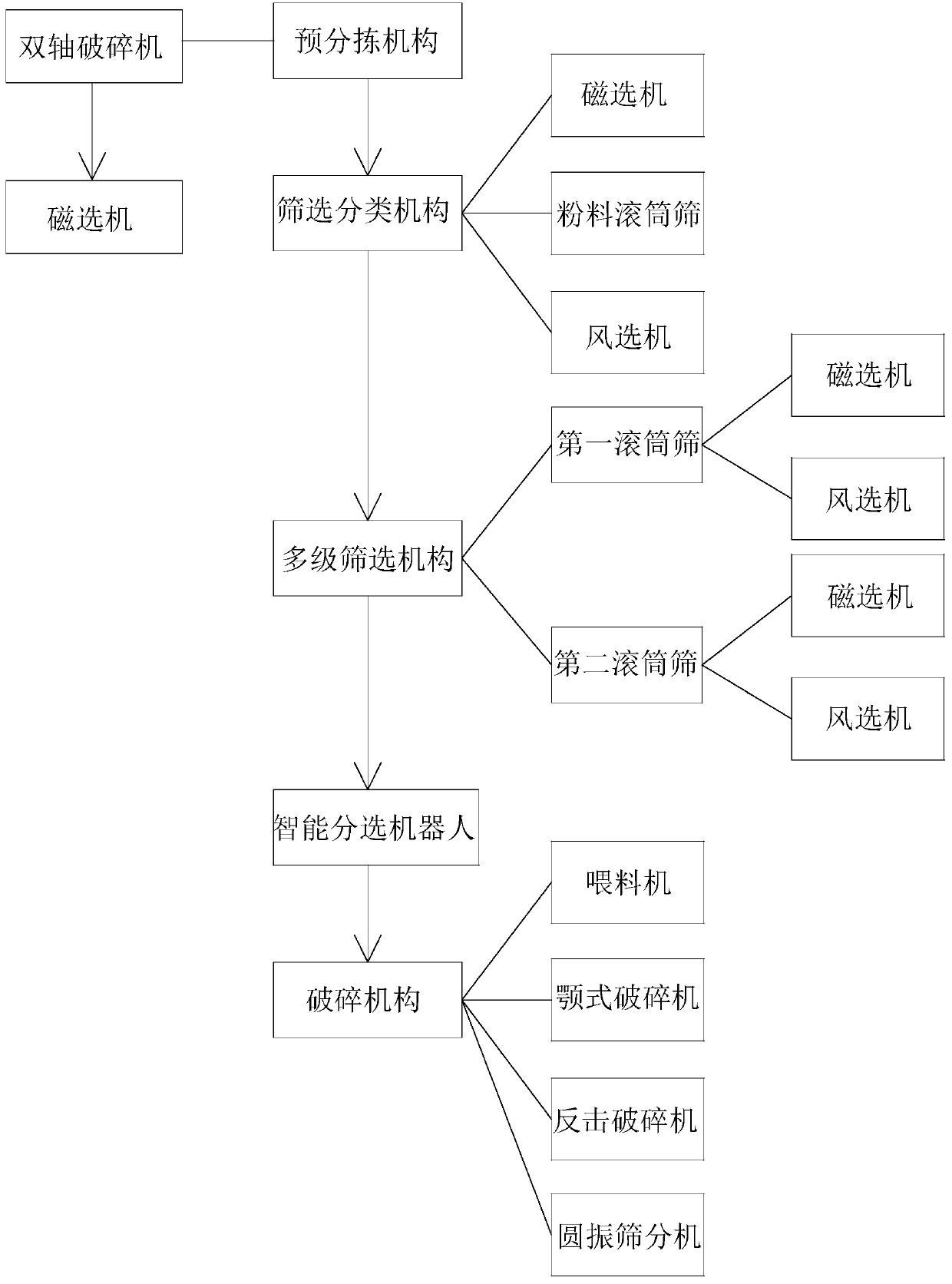

Building decoration waste recycling treatment system and process

PendingCN111360042AImprove sorting efficiencyHigh purityConstruction waste recoverySolid waste disposalConstruction engineeringBulky waste

The invention belongs to the technical field of building decoration waste sorting, and particularly relates to a building decoration waste recycling treatment system and process. The building decoration waste recycling treatment system comprises a screening and classifying mechanism, a crushing mechanism and an intelligent sorting robot, wherein the screening and classifying mechanism and the intelligent sorting robot are suitable for classifying building decoration waste; and the crushing mechanism is suitable for crushing large waste and classified high-cleanliness aggregate. According to the building decoration waste recycling treatment system, the building decoration waste is classified through the screening and classifying mechanism, and finally the classified high-cleanliness aggregate is crushed through the crushing mechanism, so that the sorting efficiency of the building decoration waste is improved, the purity of sorted finished products is high, and the effects of turning waste into wealth and saving resources are achieved.

Owner:SHANGHAI INST FOR DESIGN & RES ON ENVIRONMENTAL ENG

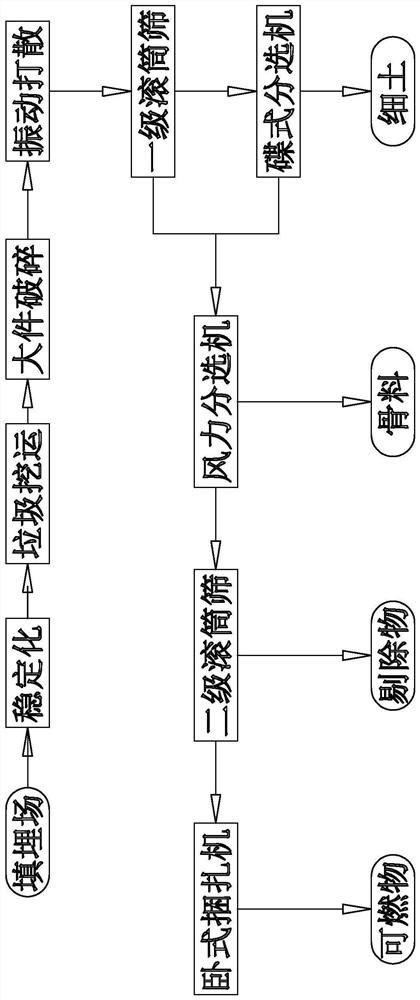

In-situ screening method for landfill stock garbage

PendingCN111922029AAvoid accumulationHarmlessSievingGas current separationBulky wasteEnvironmental engineering

The invention discloses an in-situ screening method for landfill stock garbage. The method comprises the following specific steps of stably treating garbage heaps, excavating and transporting garbage,crushing large garbage, vibrating and scattering the garbage, screening fine soil garbage by using a primary drum screen and a disc separator, screening aggregate garbage by using a wind separator, screening rejected garbage by using a secondary drum screen, and packing combustible materials. Stock garbage is screened into four substances including fine soil, aggregate, rejected materials and combustible materials, the four substances are recycled and treated separately, the garbage is prevented from being accumulated in a landfill, and the harmless, recycling and reduction renovation purposeis achieved. The method can be widely applied to the technical field of garbage treatment.

Owner:广东亨益环保集团有限公司

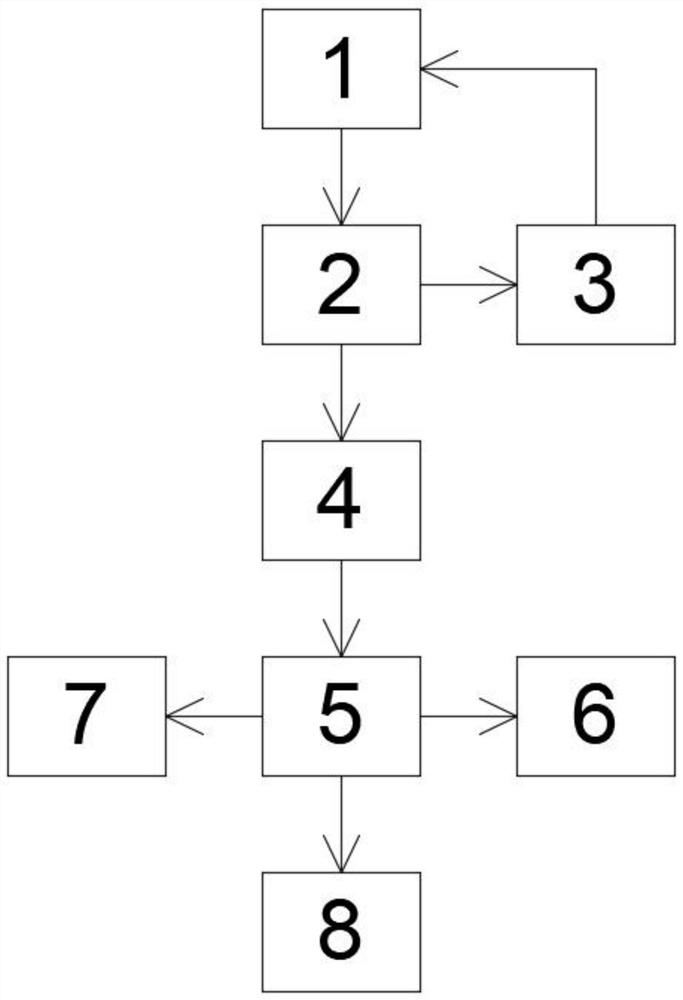

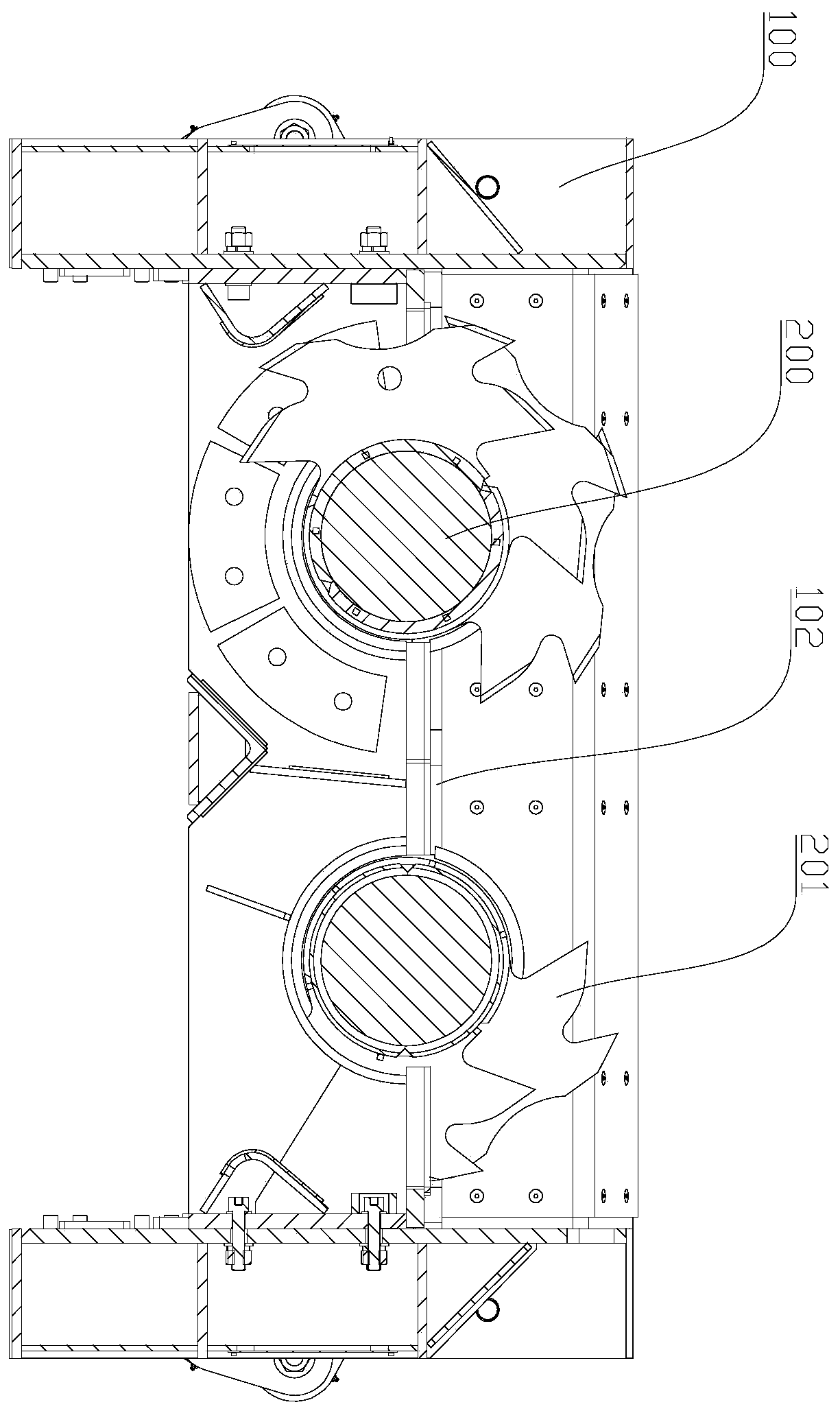

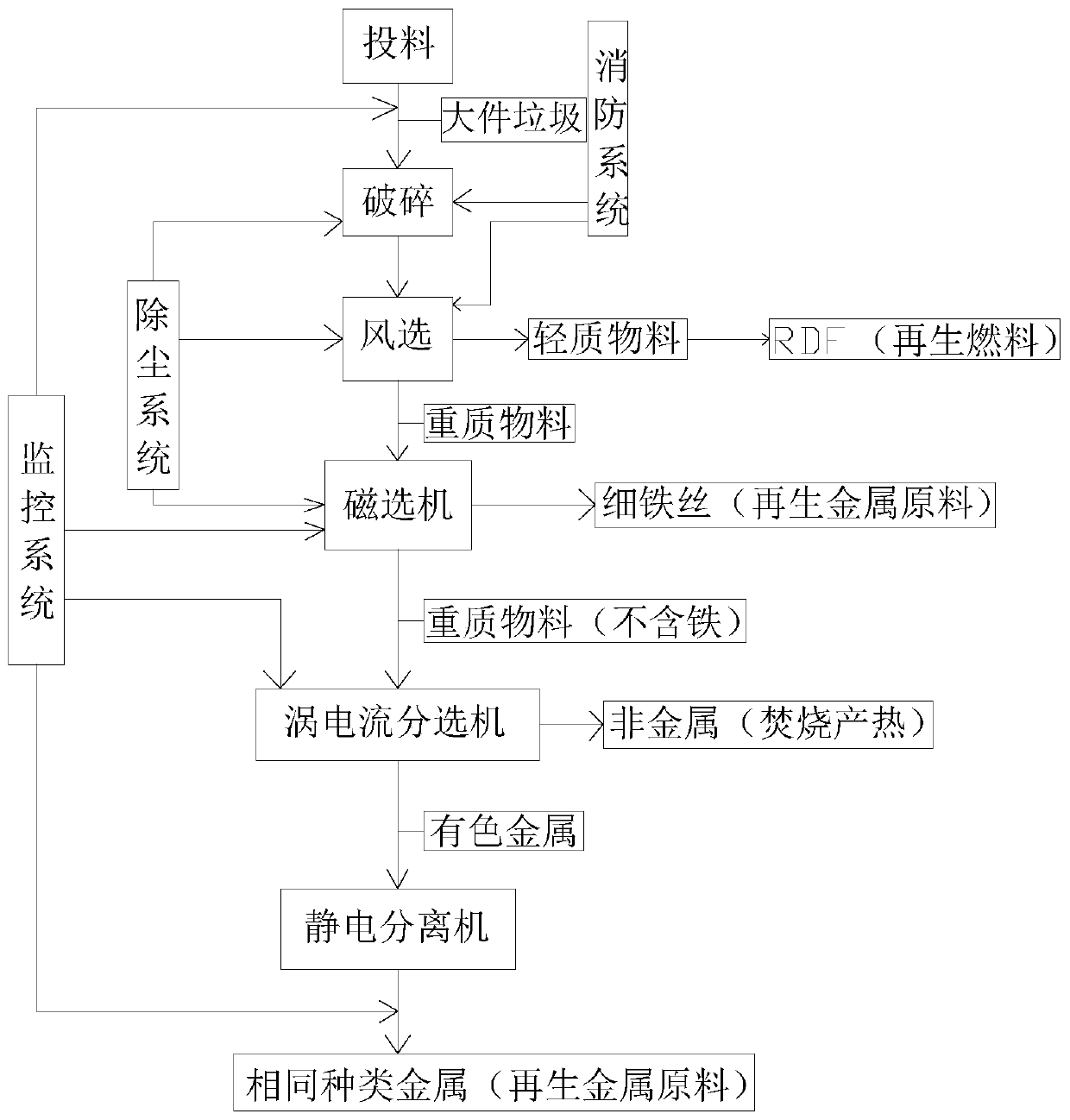

Large garbage treatment process and system

PendingCN110711759AEfficient separationSeparation is effectively doneSolid waste disposalTransportation and packagingElectrostatic separationEddy current separator

The invention provides a large garbage treatment process and system. The process comprises the following steps: step 1, crushing large garbage; step 2, separating light materials from heavy materials;and step 3, sequentially separating iron metals, nonferrous metals and nonmetals from the heavy materials. The system is provided with a four-axis crusher, a winnowing machine, a magnetic separator,an eddy current separator and an electrostatic separator which are sequentially butted. According to the treatment process and system, the large garbage can be firstly crushed, the size of the large garbage is controlled to be a proper size, then the light materials and the heavy materials are separated, and then the iron metals, the nonferrous metals and the nonmetals are separated, so that separation of corresponding components can be effectively completed, and resource reutilization is realized.

Owner:HARDEN SHREDDER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com