Vibration screening machine

A technology of vibrating screening machine and vibrating motor, which is applied in screen, solid separation, grid and other directions, can solve the problems of frequent equipment failures, high production cost, low processing efficiency, etc., and achieves large processing capacity, convenient operation and maintenance, The effect of improving crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

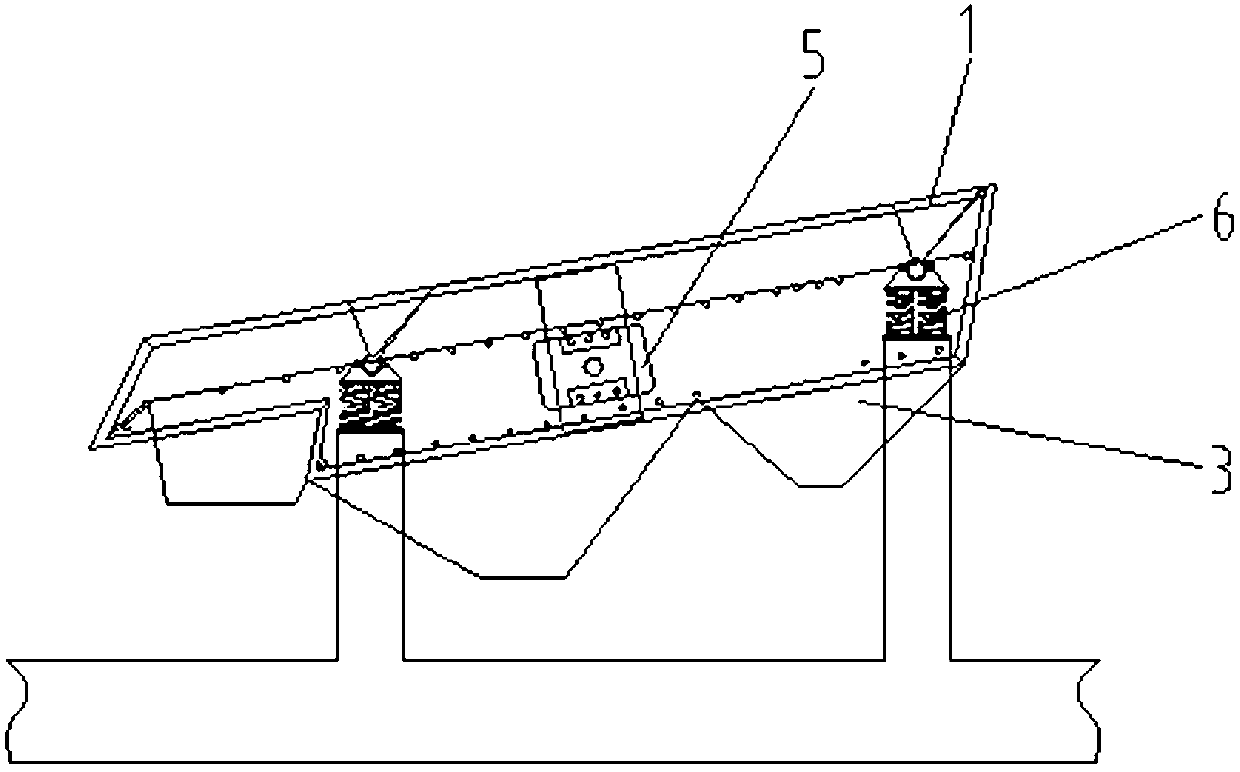

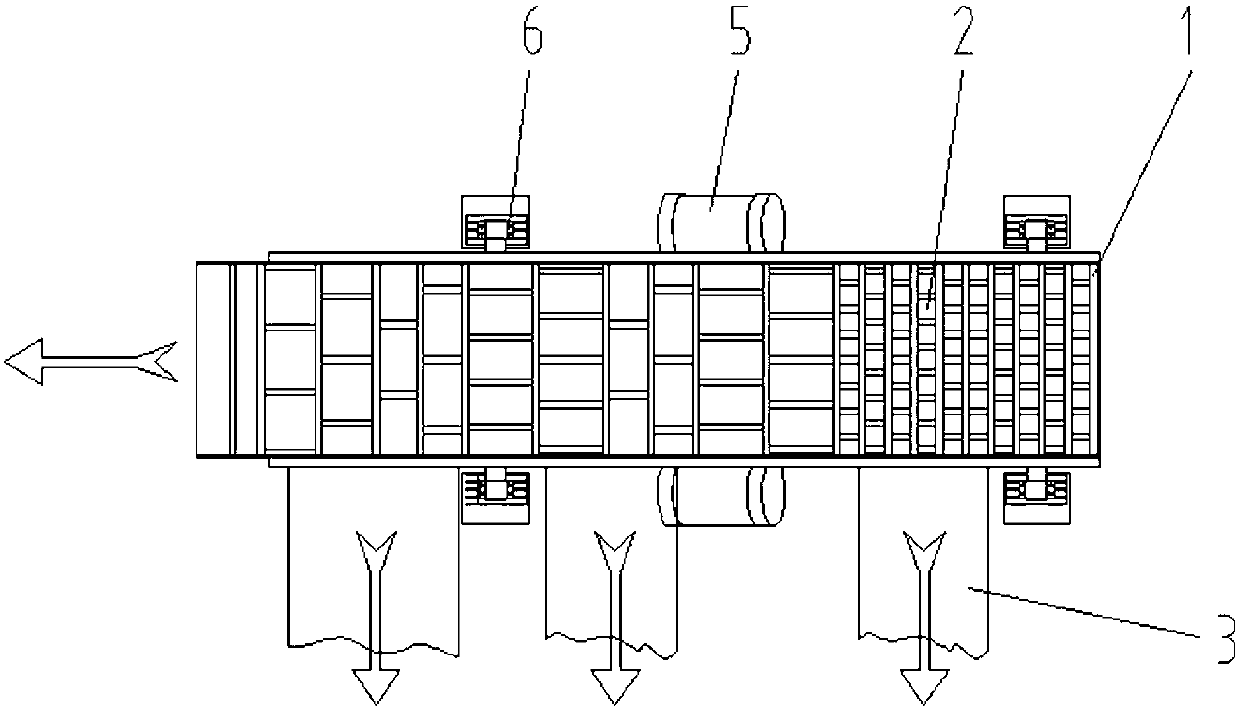

[0012] see figure 1 and figure 2 , a vibrating screening machine, comprising an inclined screening plate 1, on the loading surface of the screening plate 1 are provided with three sections of screening slots, front, middle and back, each section of screening slots are respectively provided with different sizes for screening different specifications The screening hole 2 for the material, the lower end of the screening tank are respectively provided with three receiving hoppers 3 for recovering the screened materials, and a vibrating motor 5 is respectively provided on the side plates on the left and right sides of the screening plate 1. A group of spring devices 6 for buffering and continuous vibration are respectively provided on the front and rear sides, and a support column is provided at the lower end of the spring device 6 .

[0013] The inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com