Support layer for perovskite base thin film solar cell and production method of support layer

A thin-film solar cell and support layer technology, applied in the field of solar cells, can solve the problems of complicated cell preparation process and increased cost, and achieve the effect of easy control of the thickness of the support layer and expansion of the selection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

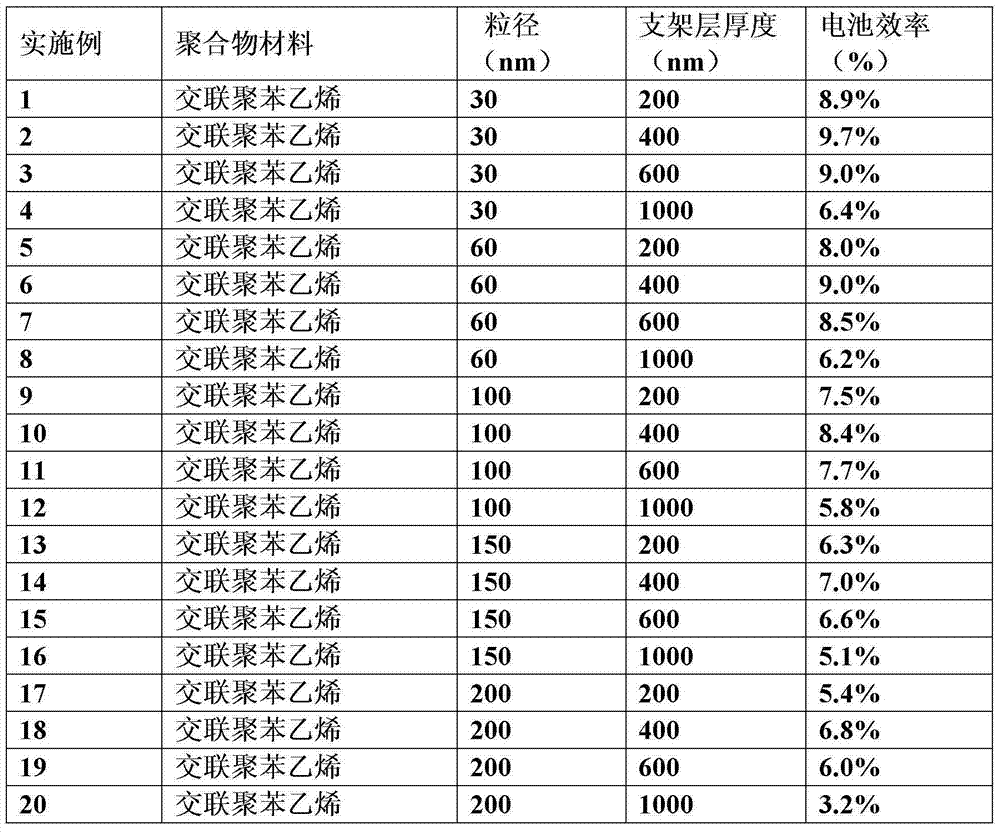

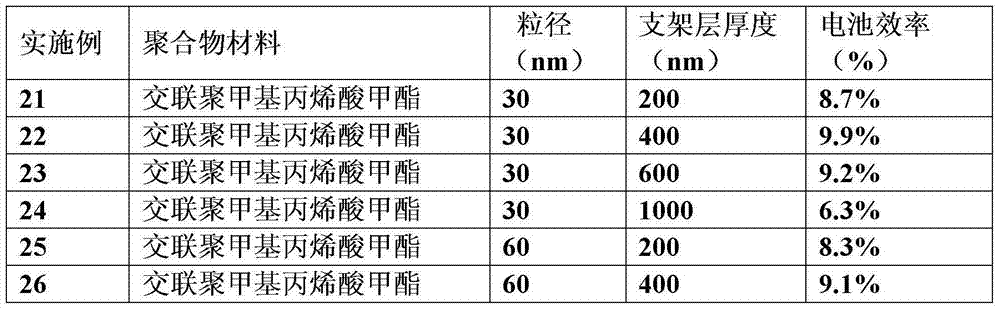

Examples

Embodiment Construction

[0039] Before describing the embodiments of the present invention in detail, the battery efficiency measurement method used in the present invention will be introduced first. The photoelectric performance of the battery was measured by a computer-controlled constant potential / galvanostat (Princeton Applied Research, Model 263A). Connect the photoanode and photocathode of the prepared solar cell device to the working electrode and the counter electrode terminal of the constant potential / galvanostat, respectively. The light source uses a 500W xenon lamp, and the incident light intensity is 100mW / cm 2 , the illuminated area is 0.1cm 2 . Unless otherwise specified, the photoelectric performance measurements in the following examples are all carried out at room temperature.

[0040] Terms used in the present invention, unless otherwise indicated, are to be understood according to their conventional meanings in the technical field.

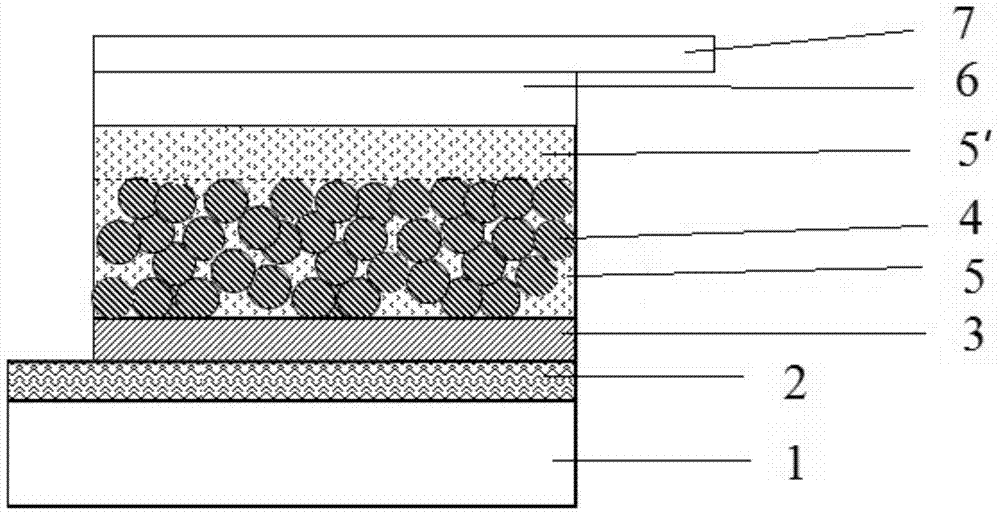

[0041] figure 1 is a schematic structural vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com