Method for treating urban domestic garbage by soaking and screening and treatment equipment

A technology for municipal solid waste and treatment equipment, applied in the field of municipal solid waste treatment, can solve the problems of polluting the surrounding environment, increasing greenhouse gas emissions, polluting groundwater resources, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

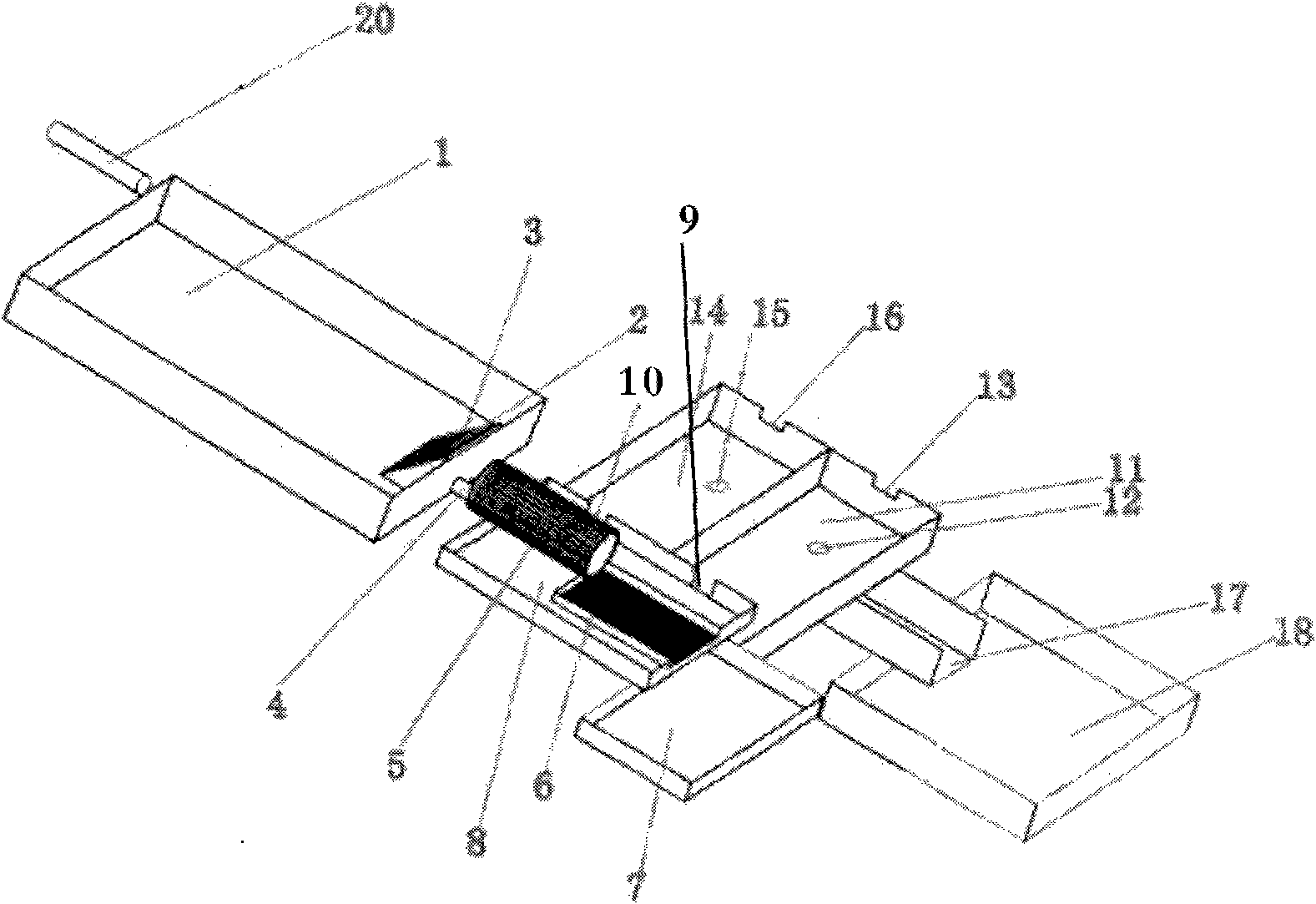

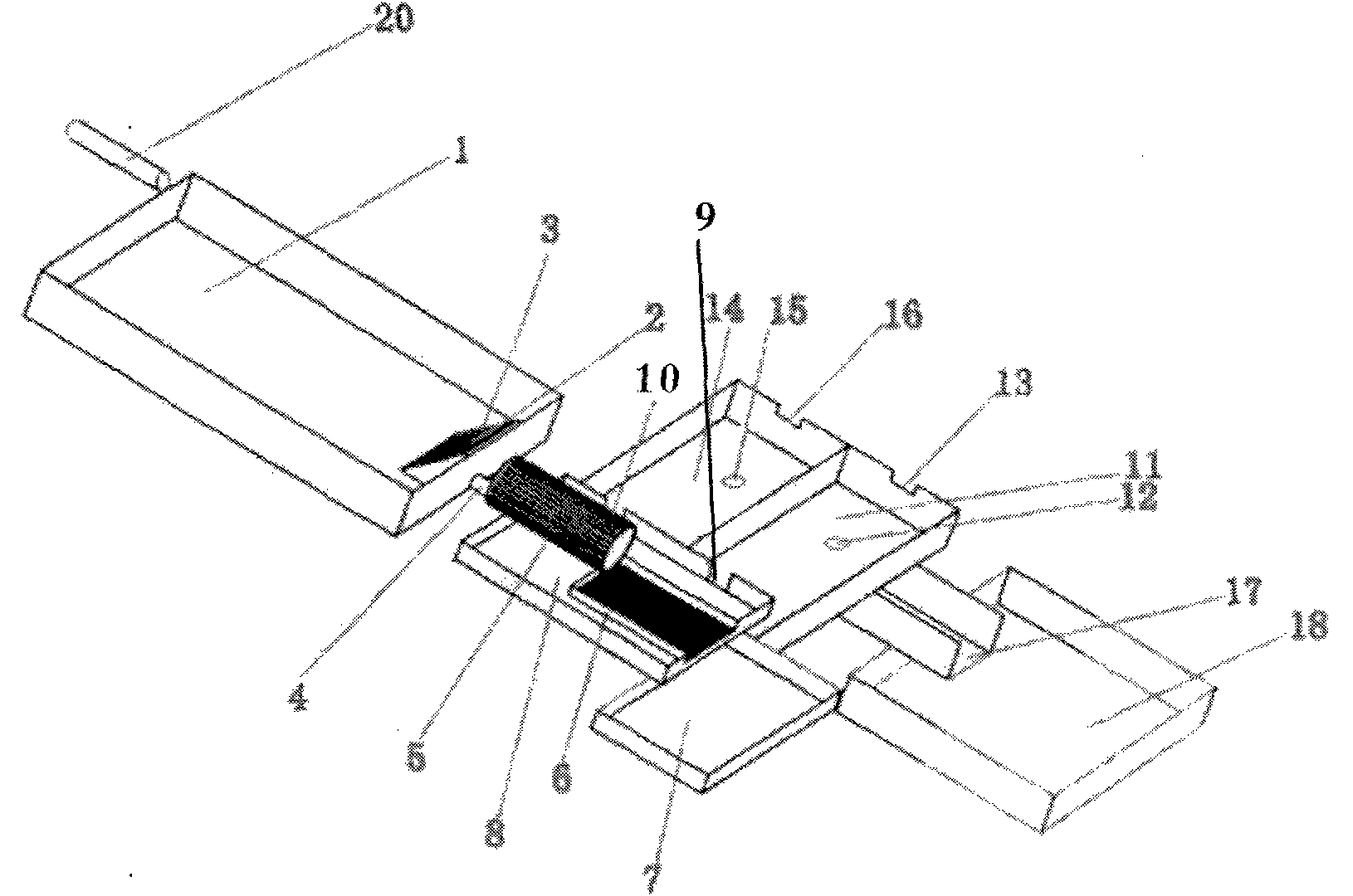

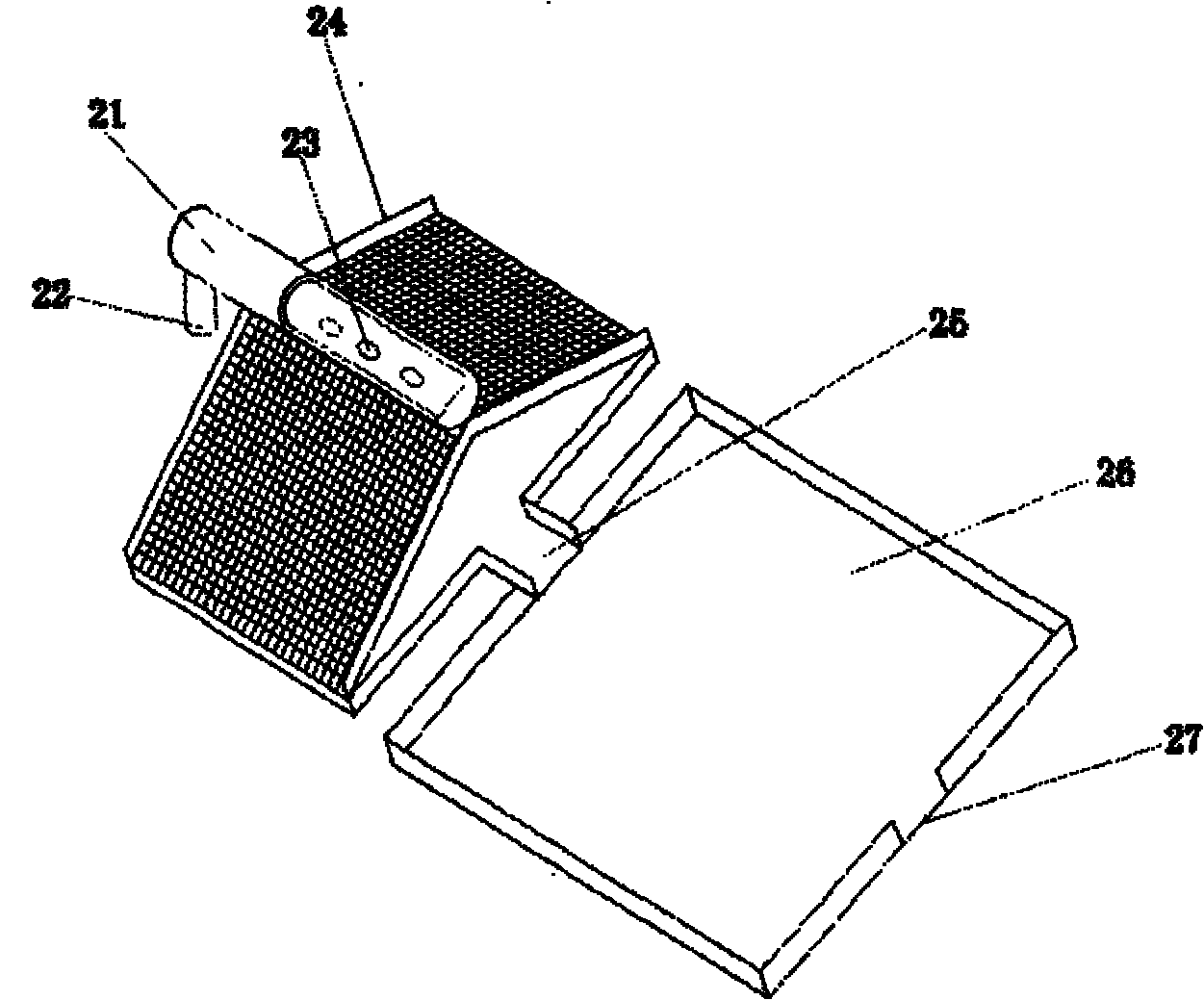

[0033] Embodiment one, as shown in Figure 1, it comprises large-scale garbage pond 1, and garbage transport vehicle pours rubbish into large-scale garbage pond 1, until large-scale garbage pond 1 is filled to two-thirds, and level with mechanical equipment, in garbage A movable water pipe 20 on the top of the pool is filled with water until the garbage is just soaked in the water. At the same time, during the operation, when the garbage in the pool is treated to a certain extent, water can be injected into the pool through the movable water pipe 20, and the garbage can be collected by the flow of water. There are 3 water outlet gates to move, there is a water outlet gate 3 on one side of the garbage pool 1, there is a first-class iron bar screen 2 above the water outlet gate 3, there is a water outlet pipe 4 at the bottom of the water outlet gate 3, and there is a large net at the outlet of the water outlet pipe 4. Shape drum 5, secondary iron screen cloth 6 and tank 8 are arra...

example 2

[0037] Build three large garbage pools (each pool is: length 80 meters * width 50 meters * height 10 meters = 40,000 cubic meters, one of which is operated first, and the other two are used as backup, and the three pools can be recycled quickly and in large quantities. Municipal solid waste, the daily processing capacity can reach more than 1000 tons). First pour the municipal solid waste transport vehicle into the garbage pool 1 until the garbage pool is filled to two-thirds, and leveled with mechanical equipment.

[0038] Live water injection in the pool by a movable water pipe 20 above the garbage pool so that the garbage just soaks in the water.

[0039] After the garbage is soaked for 15 days, most of the soluble garbage is dissolved, and the insoluble garbage sinks to the bottom of the pool or floats in the water, and then the outlet gate 3 in the large garbage pool is properly opened, and the organic solution and smaller solid garbage pass through a Grade iron bar scre...

Embodiment 3

[0048] Construction of the garbage disposal site: 1. The site has a hillside, and the garbage disposal is a flow-through operation. There must be a height difference from the beginning to the end, and a certain high slope is required. 2. The site has a water source, and the daily water used for garbage disposal exceeds 1,000 tons, and there are low-lying lands or near water sources. 3. There are barren mountains and wastelands for bamboo forests. Bamboo is a water-resistant and fertilizer-tolerant plant. The sewage treated by the three-stage septic tank can be used to irrigate the bamboo forests to kill two birds with one stone. 4. Near the highway. 5. Closer to the city, the garbage is under the action of water, and the odor is reduced. If it is too far away from the city, the transportation cost will be increased.

[0049] It can be built next to the landfill, and this method can also be used to dispose of the landfilled waste and dig up the landfilled waste for disposal. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com