Method for preparing NdFeB (neodymium-iron-boron) magnet by waste materials

A neodymium-iron-boron and magnet technology, applied in the field of magnetic materials, can solve the problems of complex processing process, insufficient magnetic properties of neodymium-iron-boron magnets, low recycling rate, etc., and achieves good comprehensive performance, simple and feasible method, and recycling rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

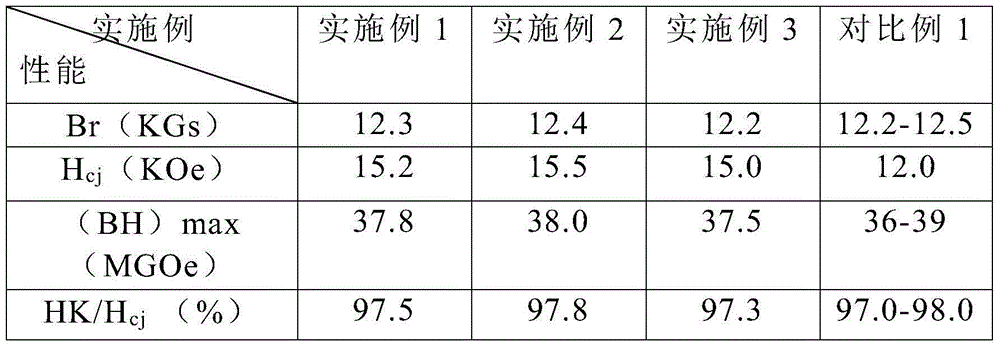

Examples

Embodiment 1

[0022] Waste pre-treatment: put the waste generated during the production of N38 NdFeB magnets in Na with a mass fraction of 35% and a temperature of 40 °C 2 CO 3 Soak in the solution for 5 minutes to clean and dry, and then crush it into 10mm particles with a crusher under the protection of inert gas.

[0023] Powder making: adding rare earth metals with a content of 3.0%-5.0% of the total mass of the NdFeB magnet to the above waste particles and hydrogen crushing treatment to obtain crushed powder with an average particle size of 10.0 μm, and then adding 0.01% triethanolamine boron Ester, after mixing evenly, perform jet milling to obtain a fine powder with an average particle size of 3.0 μm, and stir it with a mixer for 1.5 hours; the rare earth metals are specifically 0.5% Tb, 0.5% Dy, 1.0% Nd, 0.8% Ce;

[0024] Among them, the hydrogen crushing treatment includes two processes of hydrogen absorption and dehydrogenation, that is, after the particles crushed by the crushe...

Embodiment 2

[0028] Waste pre-treatment: put the leftovers produced during the post-processing of N38 NdFeB magnets in Na with a mass fraction of 45% and a temperature of 50 °C 2 CO 3 Soak in the solution for 6 minutes to clean and dry, and then crush it into 12mm particles with a crusher under the protection of inert gas.

[0029] Powder making: add rare earth metals with a content of 3.0%-5.0% of the total mass of the NdFeB magnet to the above waste particles and undergo hydrogen crushing to obtain crushed powder with an average particle size of 12.0 μm, and then add 0.02% N-deca Dialkyl bis-quaternary ammonium salt, after mixing evenly, carry out jet milling to obtain a fine powder with an average particle size of 4.0 μm, and stir with a mixer for 2.0 h; wherein the rare earth metal is specifically 0.8% Tb, 0.8% Dy, 1.5% Nd, 0.9% Ce;

[0030] Among them, the hydrogen crushing treatment includes two processes of hydrogen absorption and dehydrogenation, that is, after the particles crus...

Embodiment 3

[0034] Waste pretreatment: put N38 waste NdFeB magnets in Na with a mass fraction of 55% and a temperature of 60 °C 2 CO 3 Soak in the solution for 7 minutes to clean and dry, and then crush it into 14mm particles with a crusher under the protection of inert gas.

[0035] Powder making: add rare earth metals with a content of 3.0%-5.0% of the total mass of the NdFeB magnet to the above waste particles and undergo hydrogen crushing to obtain crushed powder with an average particle size of 13.0 μm, and then add 0.01% triethanolamine boron Ester and 0.01% glyceryl stearate, after mixing evenly, carry out jet milling to obtain a fine powder with an average particle size of 4.0 μm, and stir with a mixer for 2.5 hours; wherein the rare earth metals are specifically 1.0% Tb and 1.0% Dy , 1.5% Nd, 1.0% Ce;

[0036] Among them, the hydrogen crushing treatment includes two processes of hydrogen absorption and dehydrogenation, that is, after the particles crushed by the crusher are add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com