Patents

Literature

425results about How to "Improve remanence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of Rare Earth Permanent Magnet Material

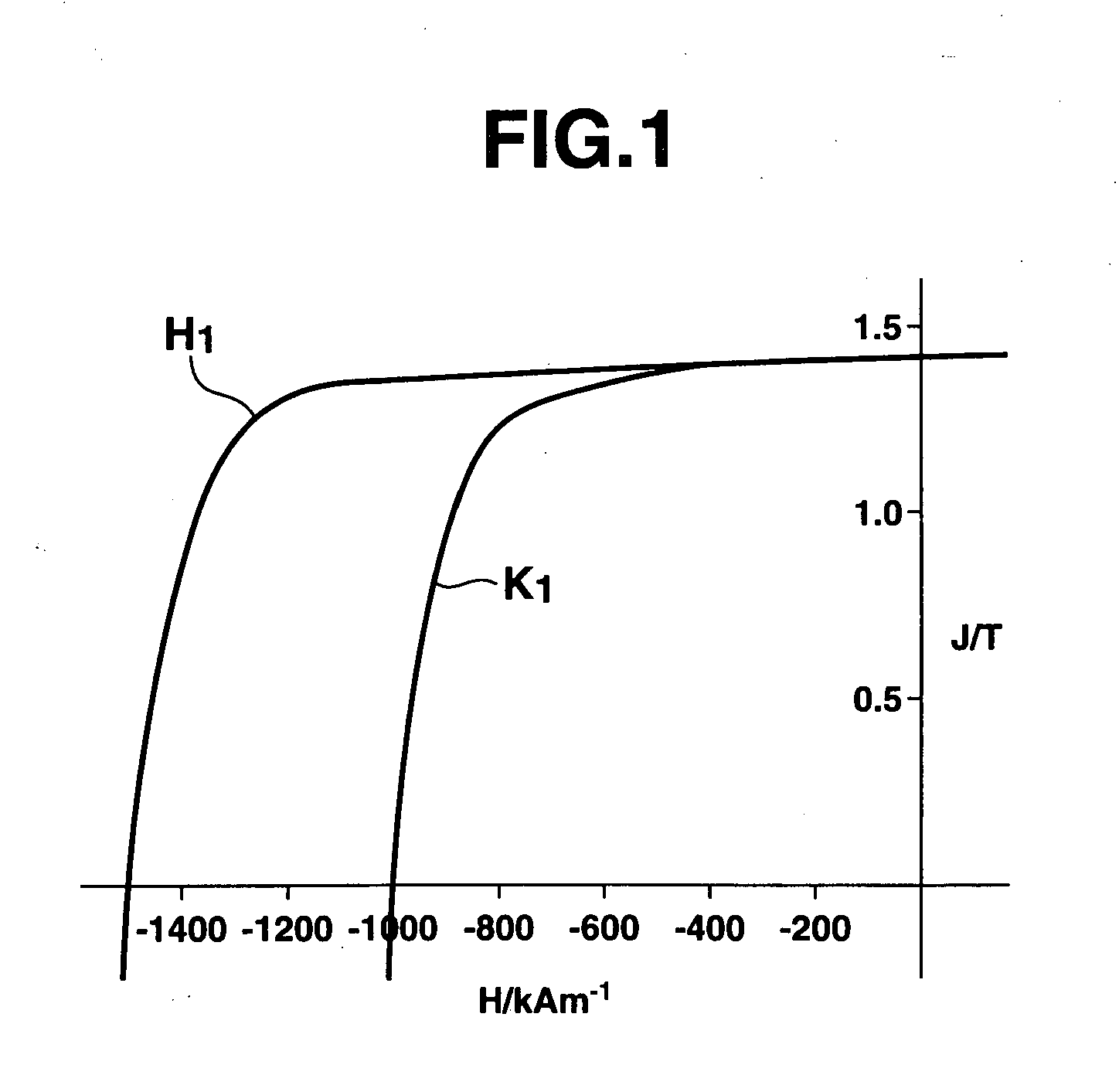

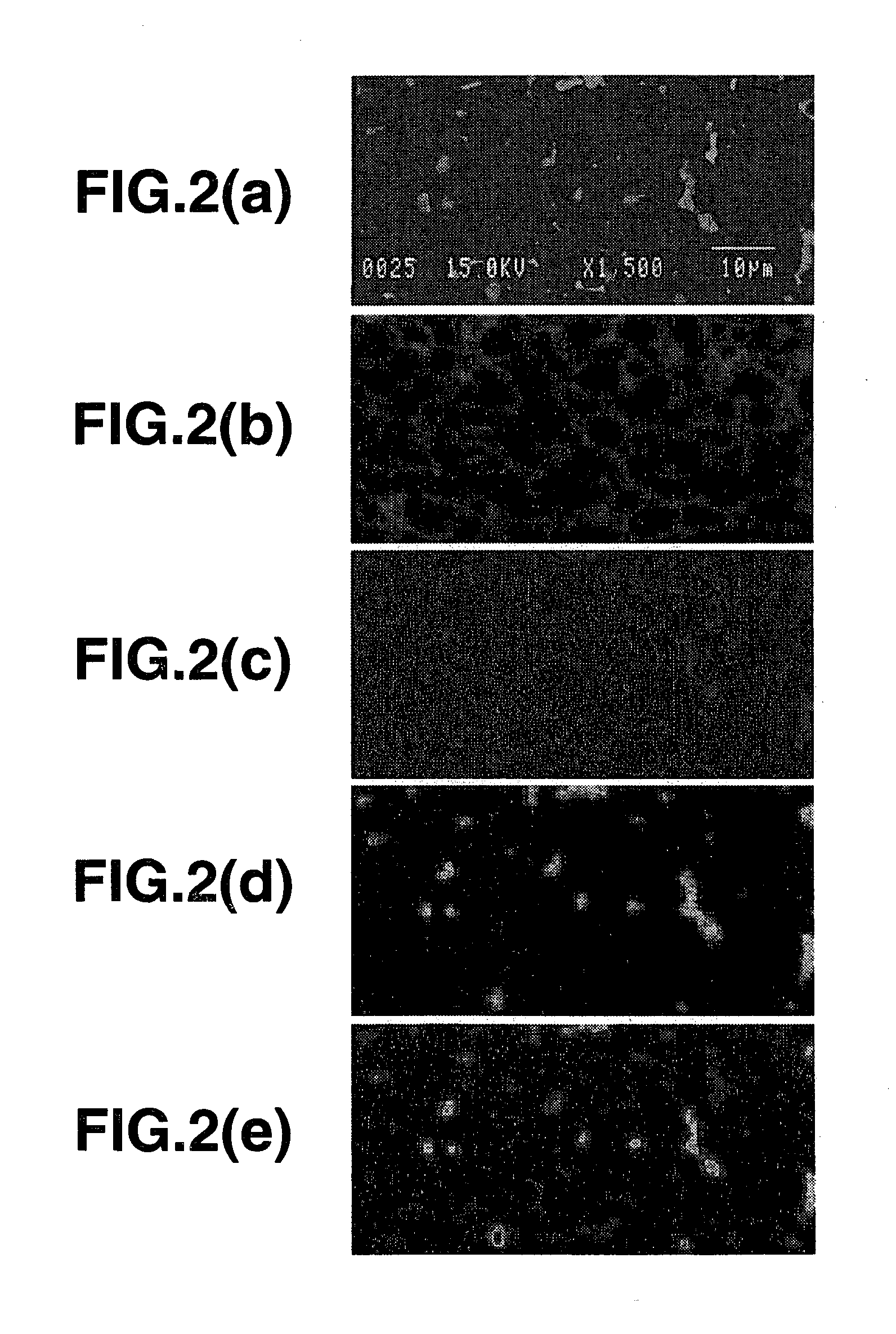

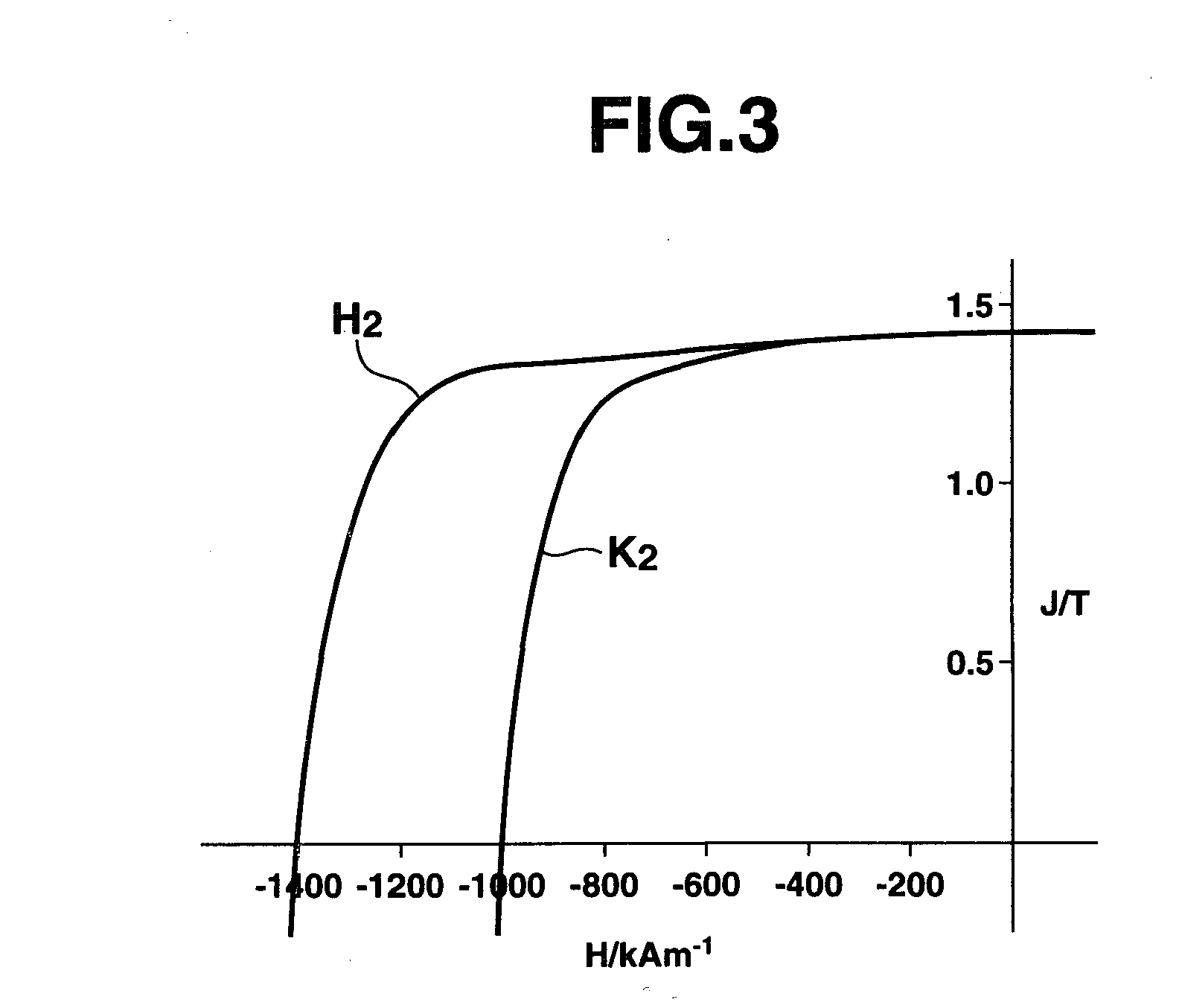

ActiveUS20080245442A1Improve remanenceImprove coercive forceElectric discharge tubesPermanent magnetsRare-earth elementRemanence

A method for preparing a rare earth permanent magnet material comprising the steps of:disposing a powder comprising one or more members selected from an oxide of R2, a fluoride of R3, and an oxyfluoride of R4 wherein R2, R3 and R4 each are one or more elements selected from among rare earth elements inclusive of Y and Sc on a sintered magnet form of a R1—Fe—B composition wherein R1 is one or more elements selected from among rare earth elements inclusive of Y and Sc, andheat treating the magnet form and the powder at a temperature equal to or below the sintering temperature of the magnet in vacuum or in an inert gas.The invention offers a high performance, compact or thin permanent magnet having a high remanence and coercivity at a high productivity.

Owner:SHIN ETSU CHEM IND CO LTD

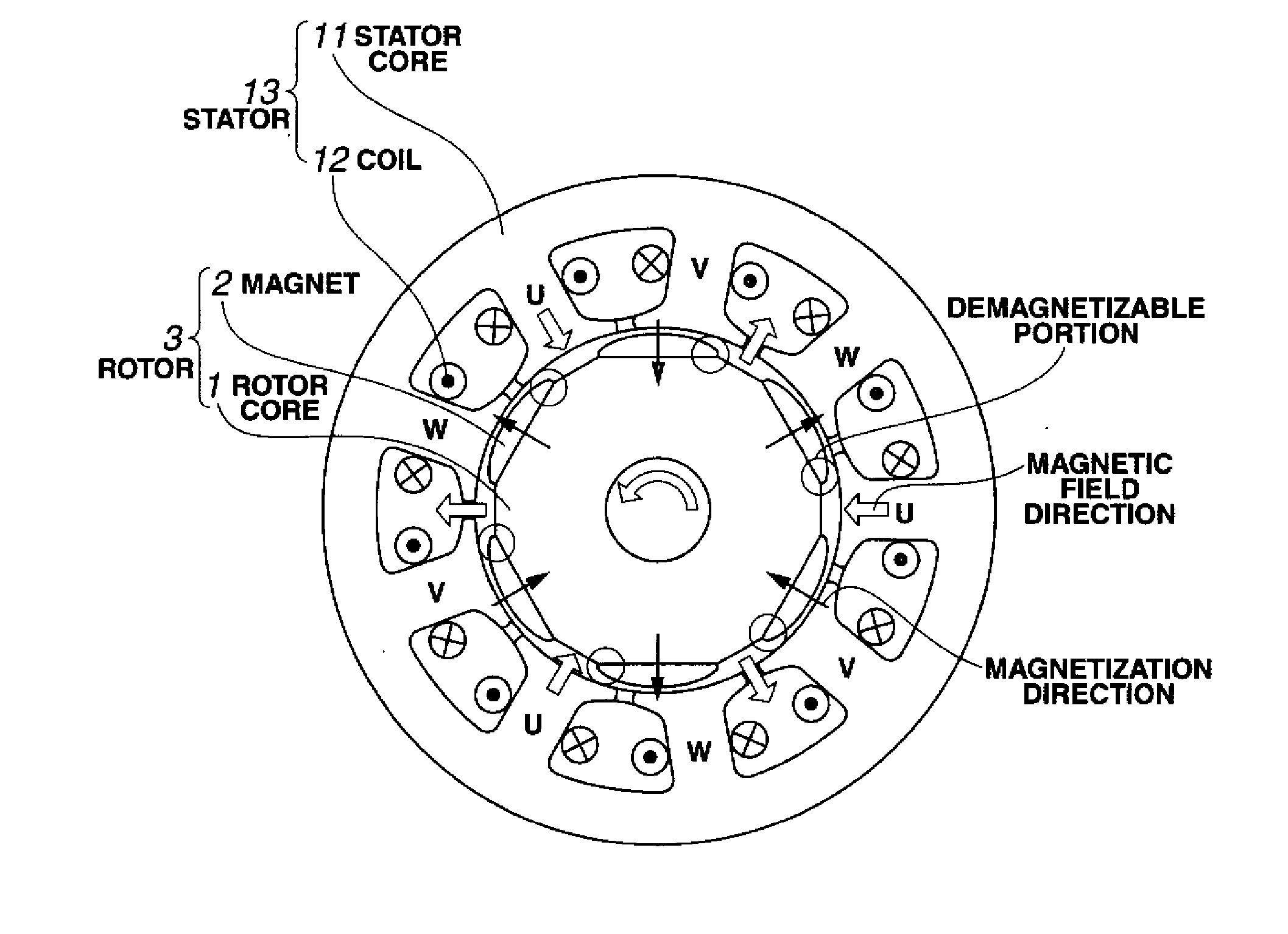

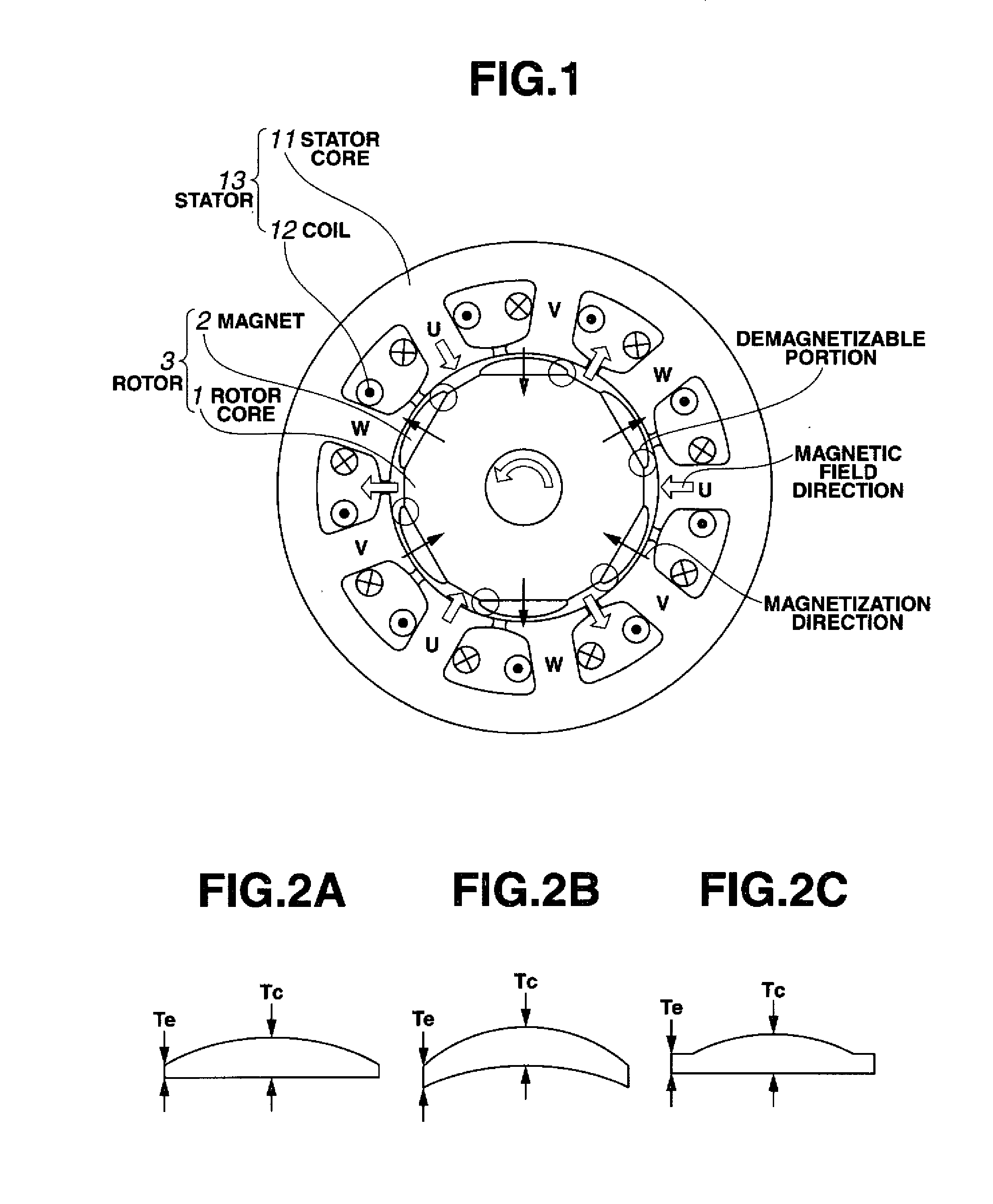

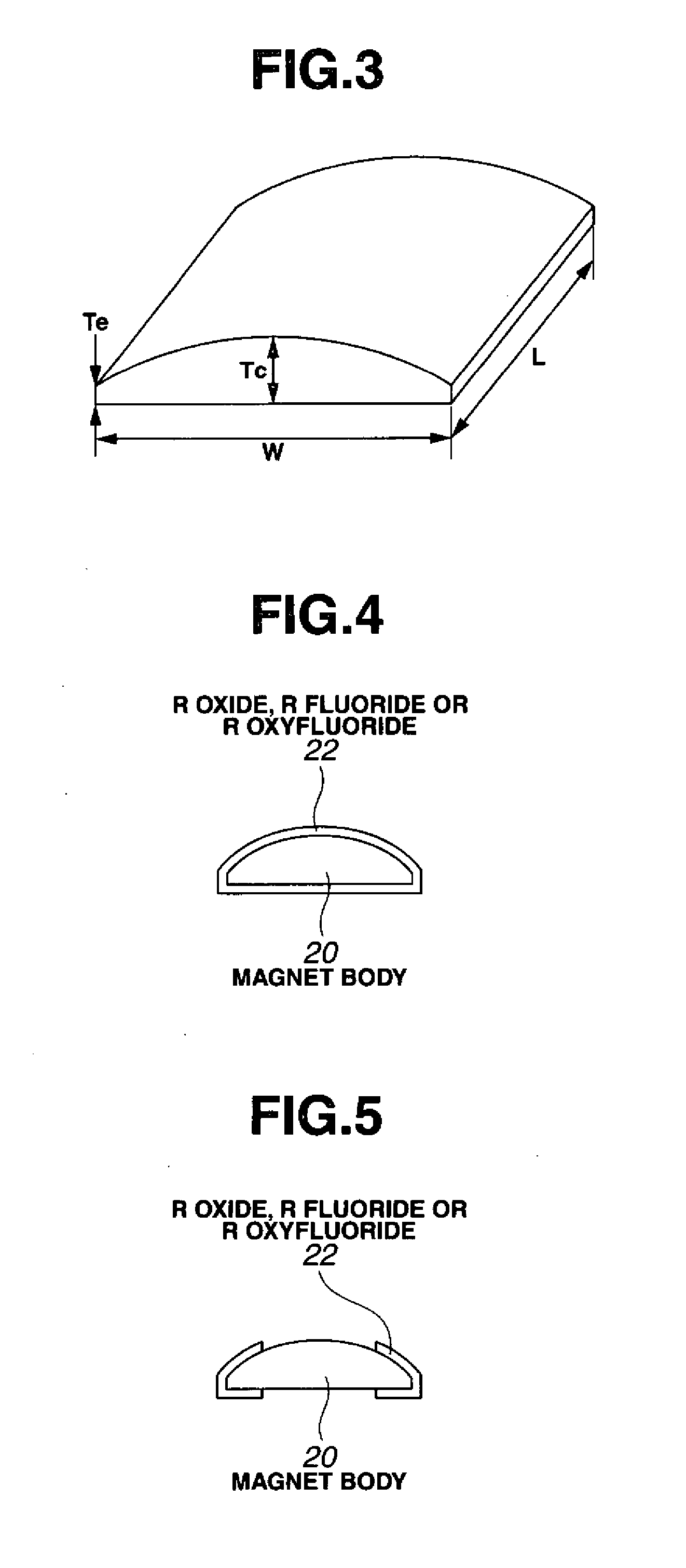

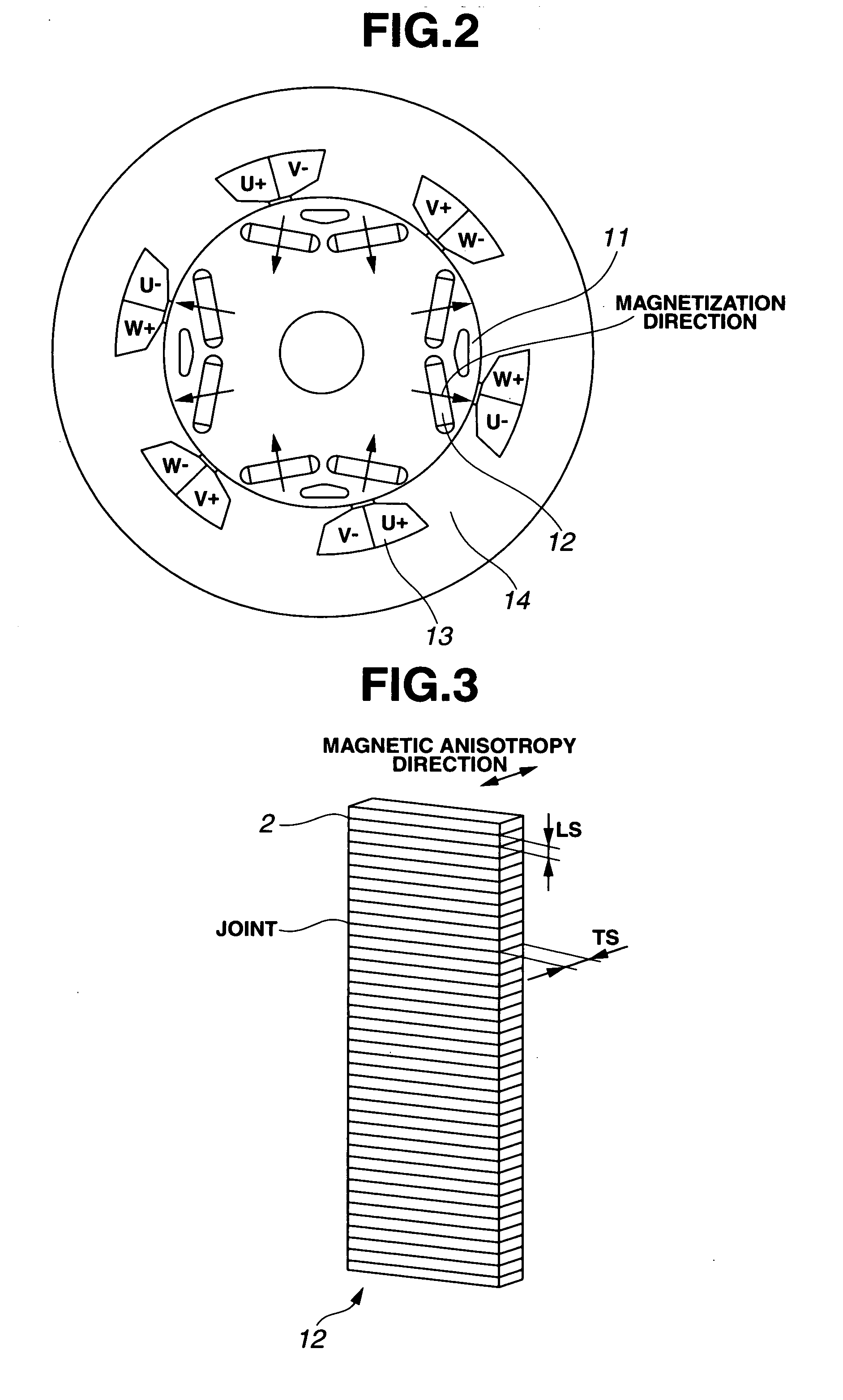

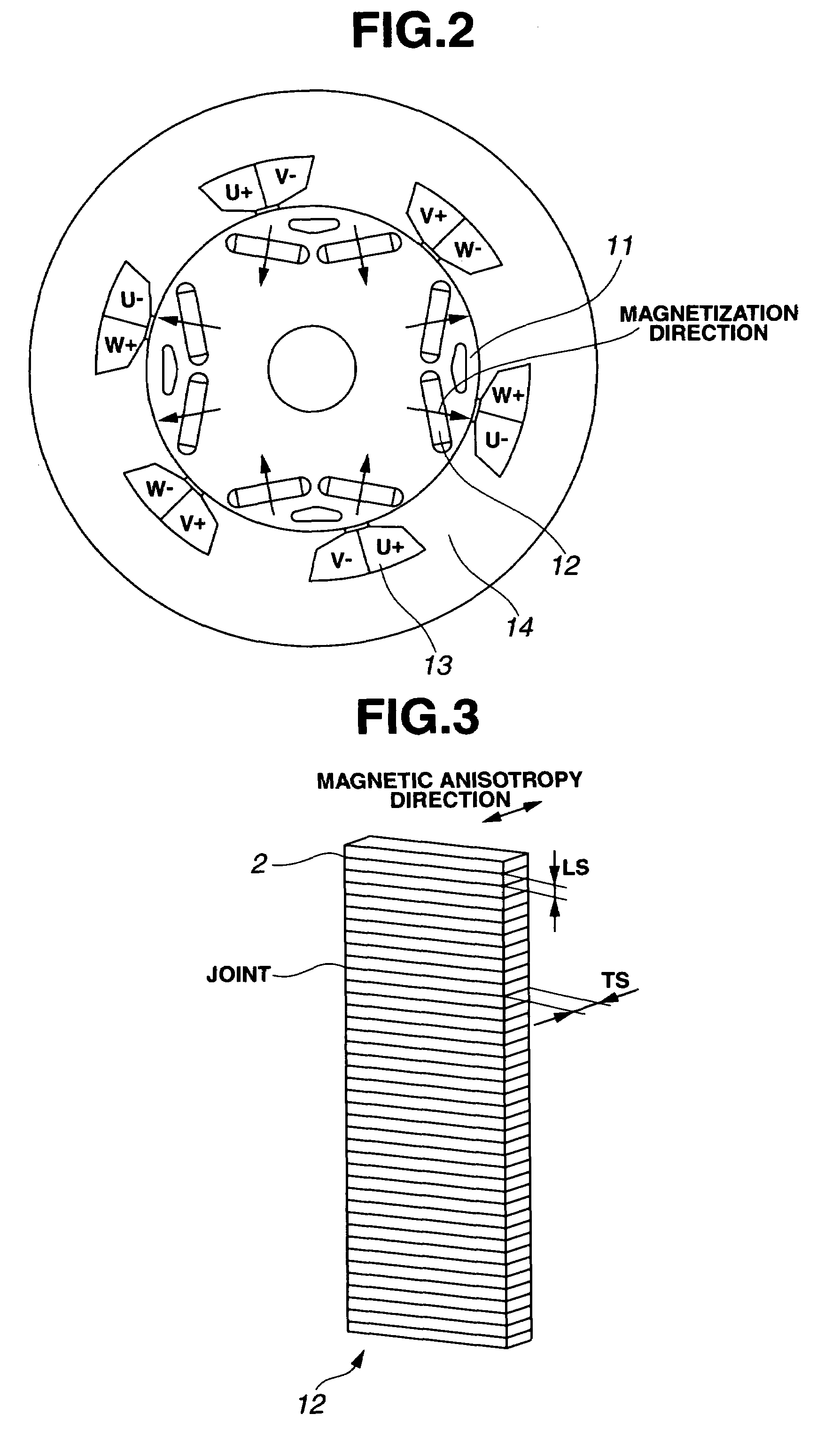

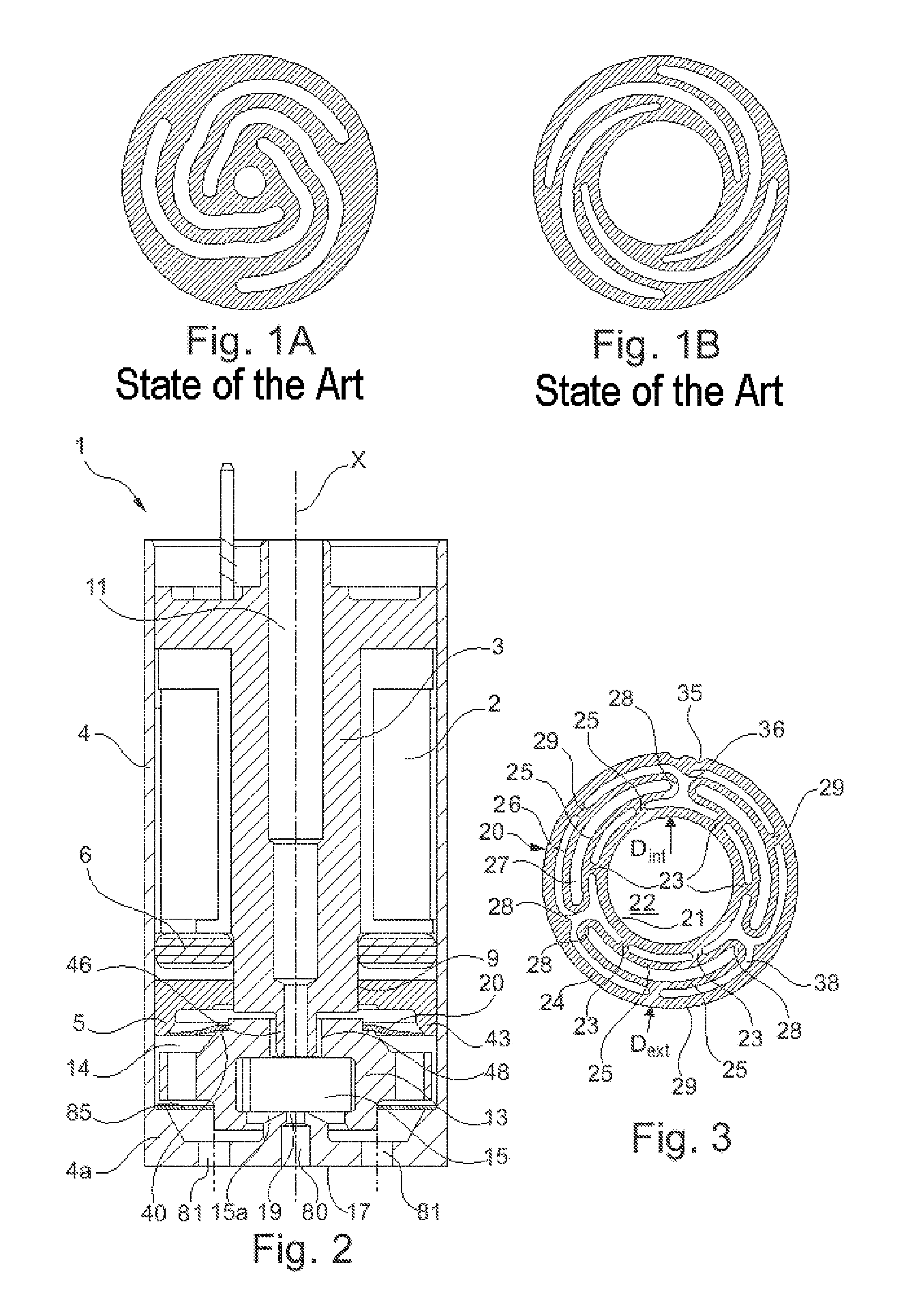

Permenent magnet rotating machine

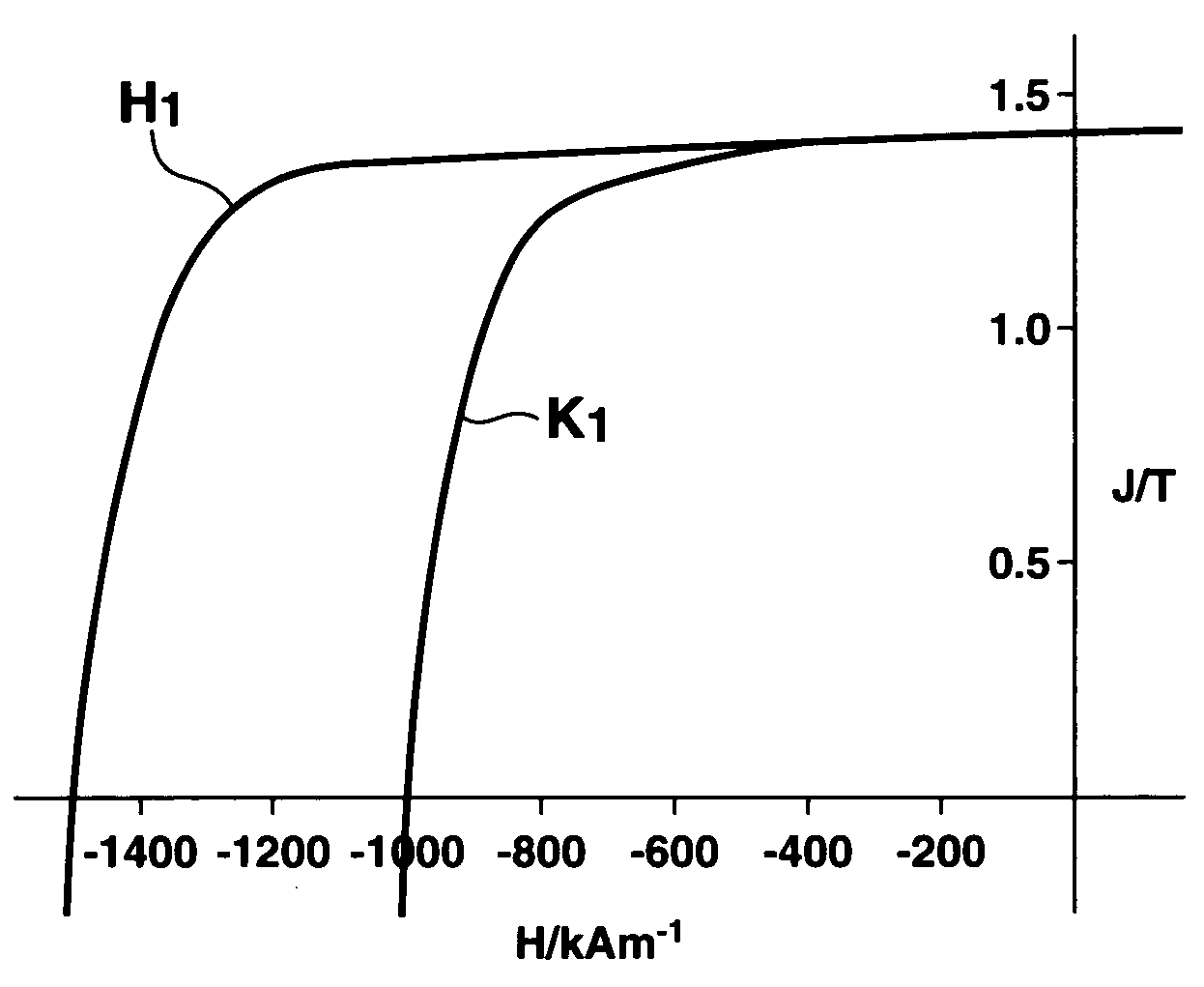

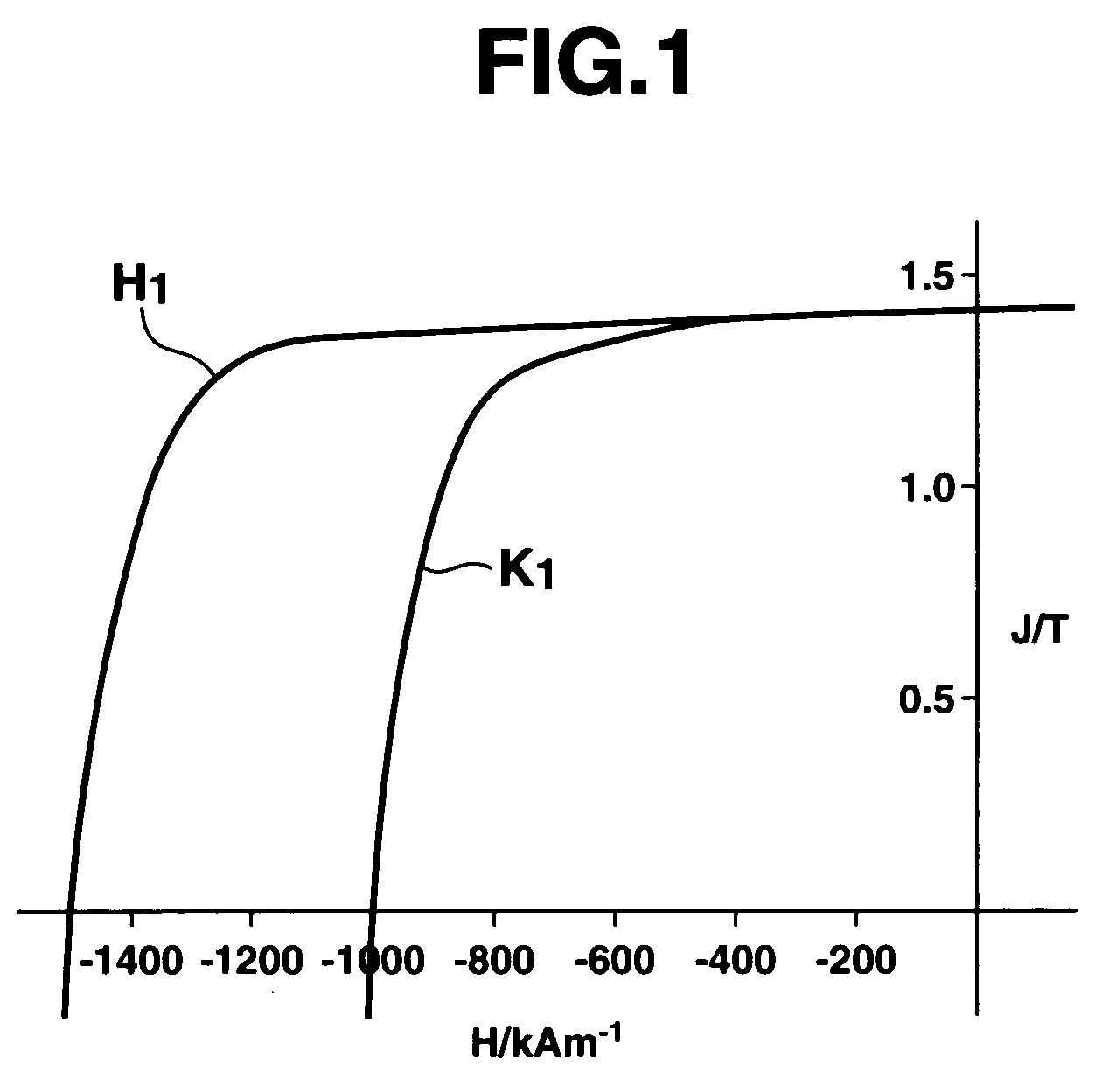

ActiveUS20080054736A1Improve remanenceImprove coercive forceMagnetic circuit rotating partsManufacturing dynamo-electric machinesRare-earth elementSintered magnets

In a rotating machine comprising a rotor including a rotor core and a plurality of permanent magnet segments, and a stator including a stator core and windings, the permanent magnet segment is obtained by disposing a powder comprising an R2 oxide, R3 fluoride or R4 oxyfluoride on a sintered magnet body of R1—Fe—B composition, wherein R1 to R4 are rare earth elements, and heat treating the powder-covered magnet body. The permanent magnet segment of a cross-sectional shape which is tapered from the center toward opposed ends has a higher coercive force at the ends than at the center.

Owner:SHIN ETSU CHEM IND CO LTD

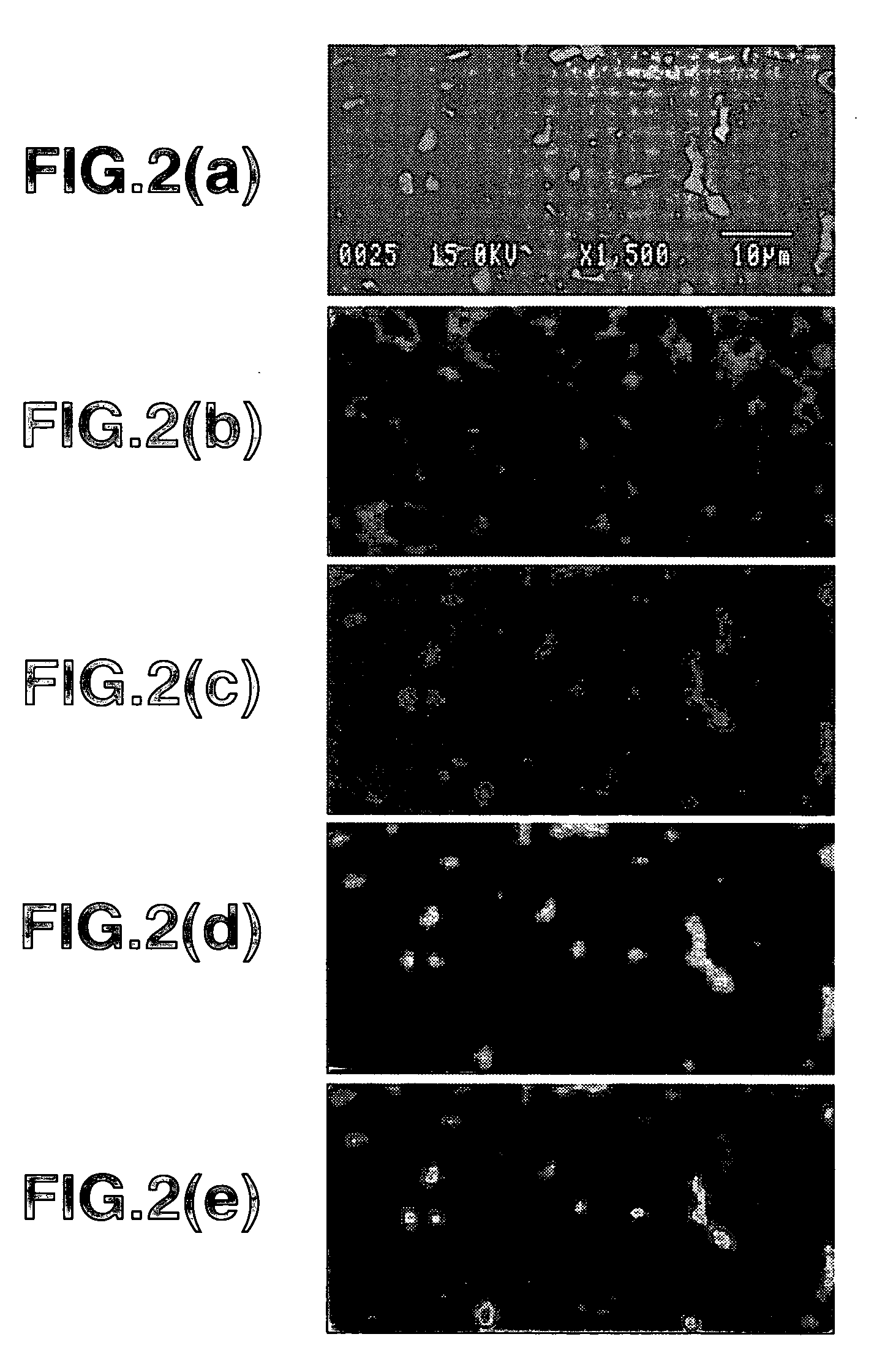

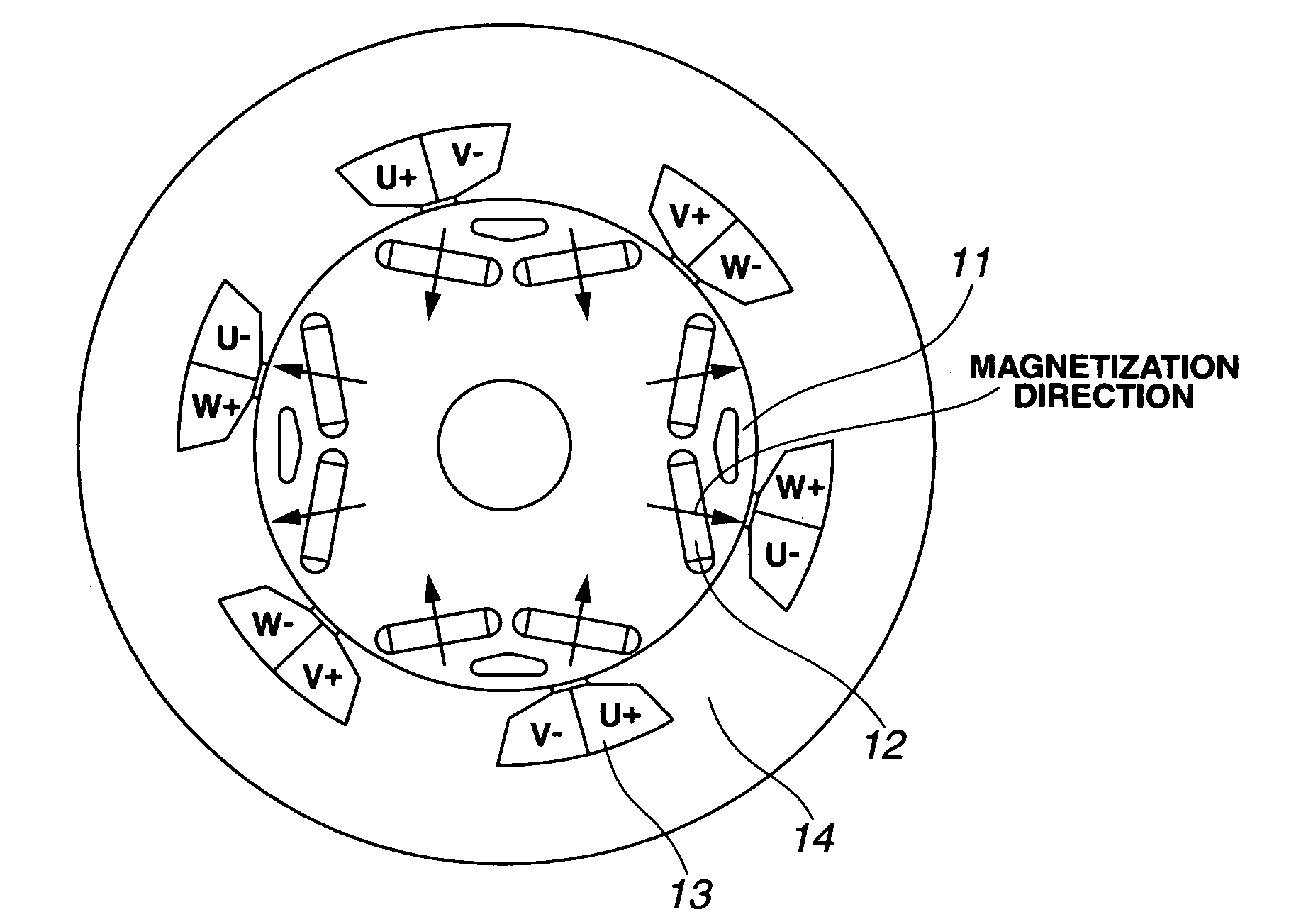

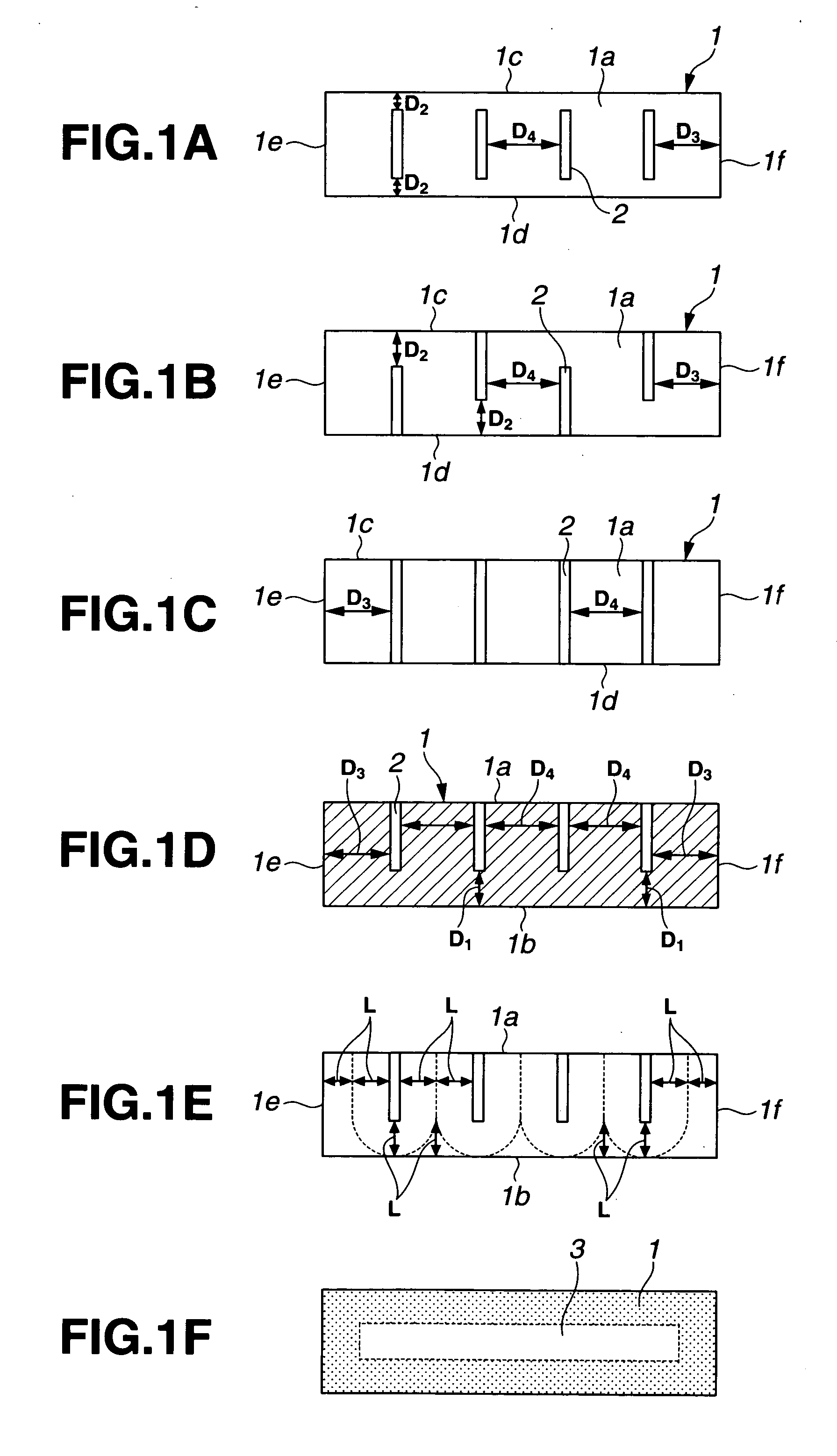

Rare earth permanent magnet, making method, and permanent magnet rotary machine

ActiveUS20070017601A1Minimized eddy currentImprove remanenceMagnetic circuitInorganic material magnetismRare-earth elementSintered magnets

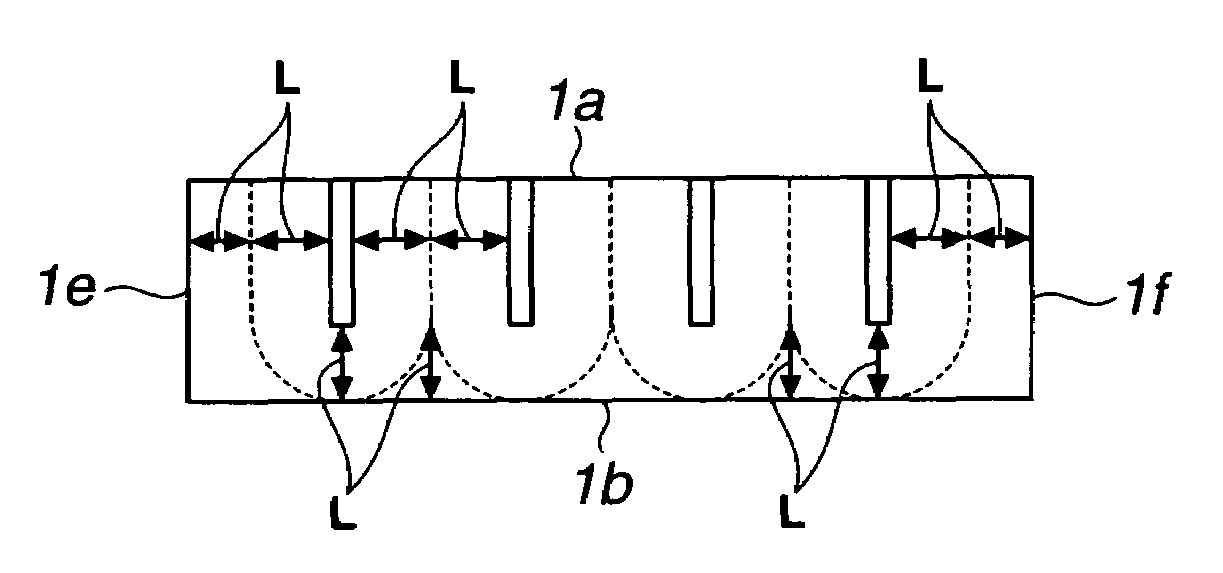

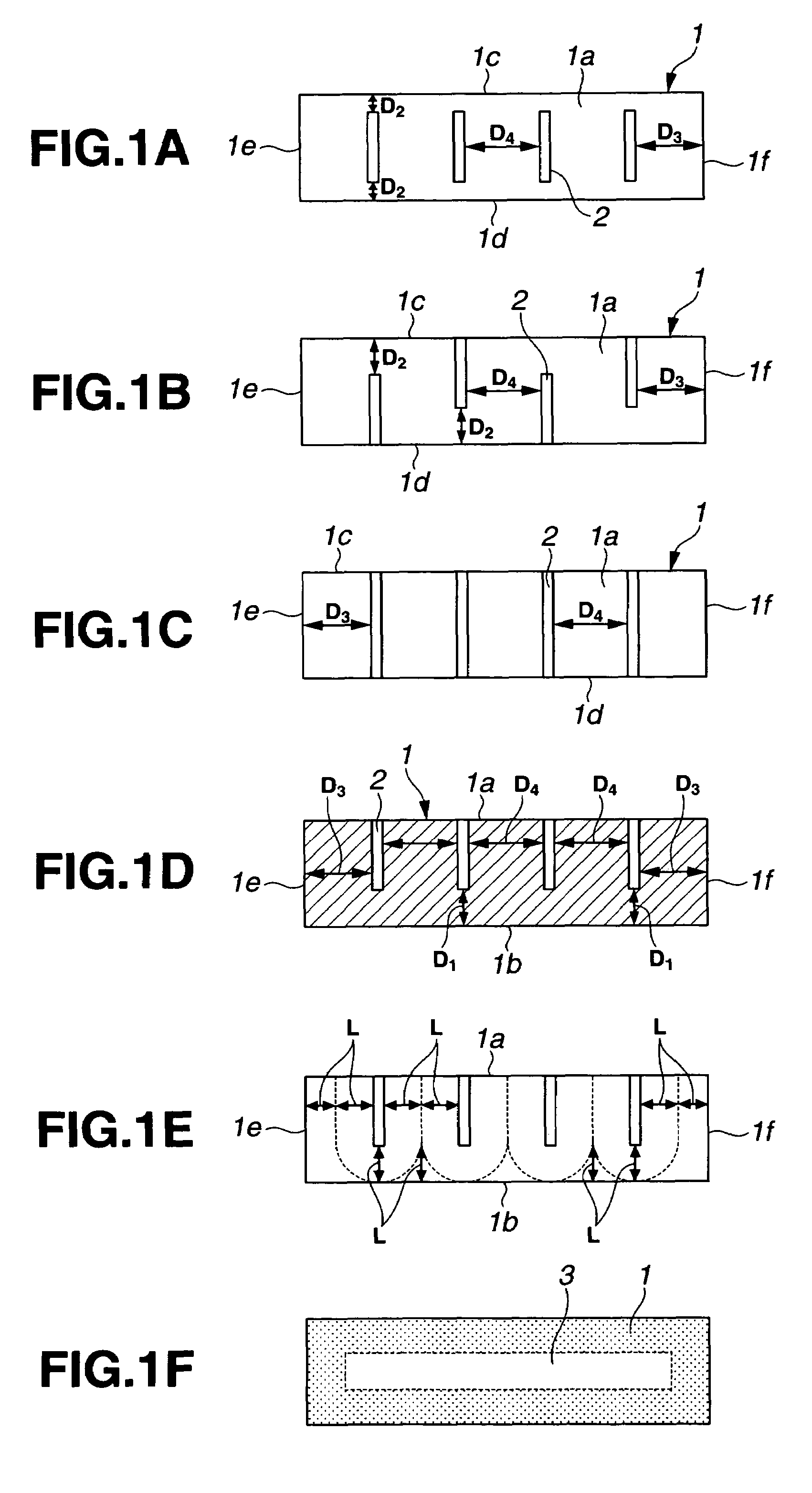

A rare earth permanent magnet is prepared from a sintered magnet body of a R1—Fe—B composition wherein R1 is a rare earth element inclusive of Y and Sc, by forming a plurality of slits in a surface of the magnet body, disposing a powder on the magnet body surface, the powder comprising an oxide of R2, a fluoride of R3, or an oxyfluoride of R4 wherein each of R2, R3, and R4 is a rare earth element, and heat treating the magnet body and the powder below the sintering temperature in vacuum or in an inert gas.

Owner:SHIN ETSU CHEM IND CO LTD

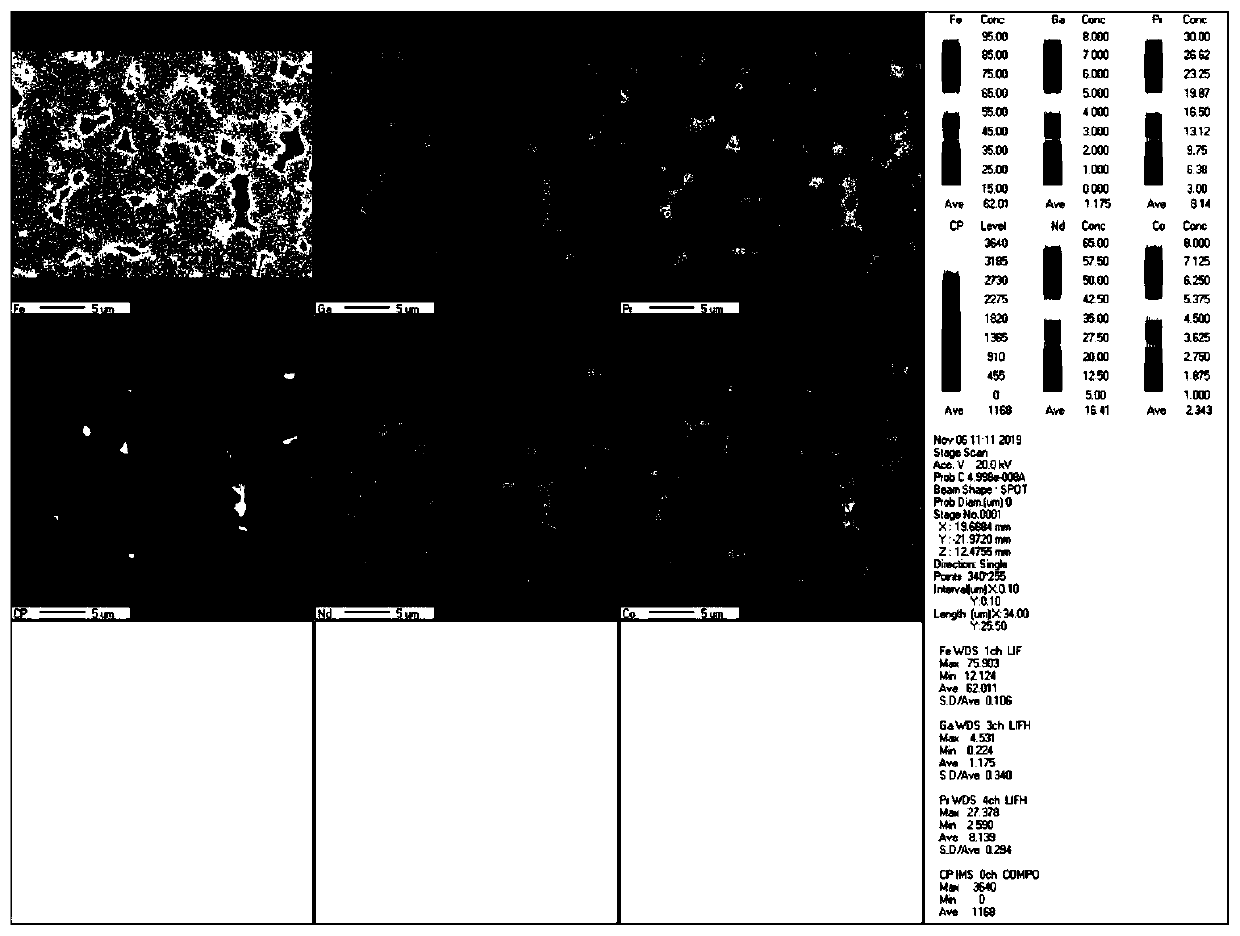

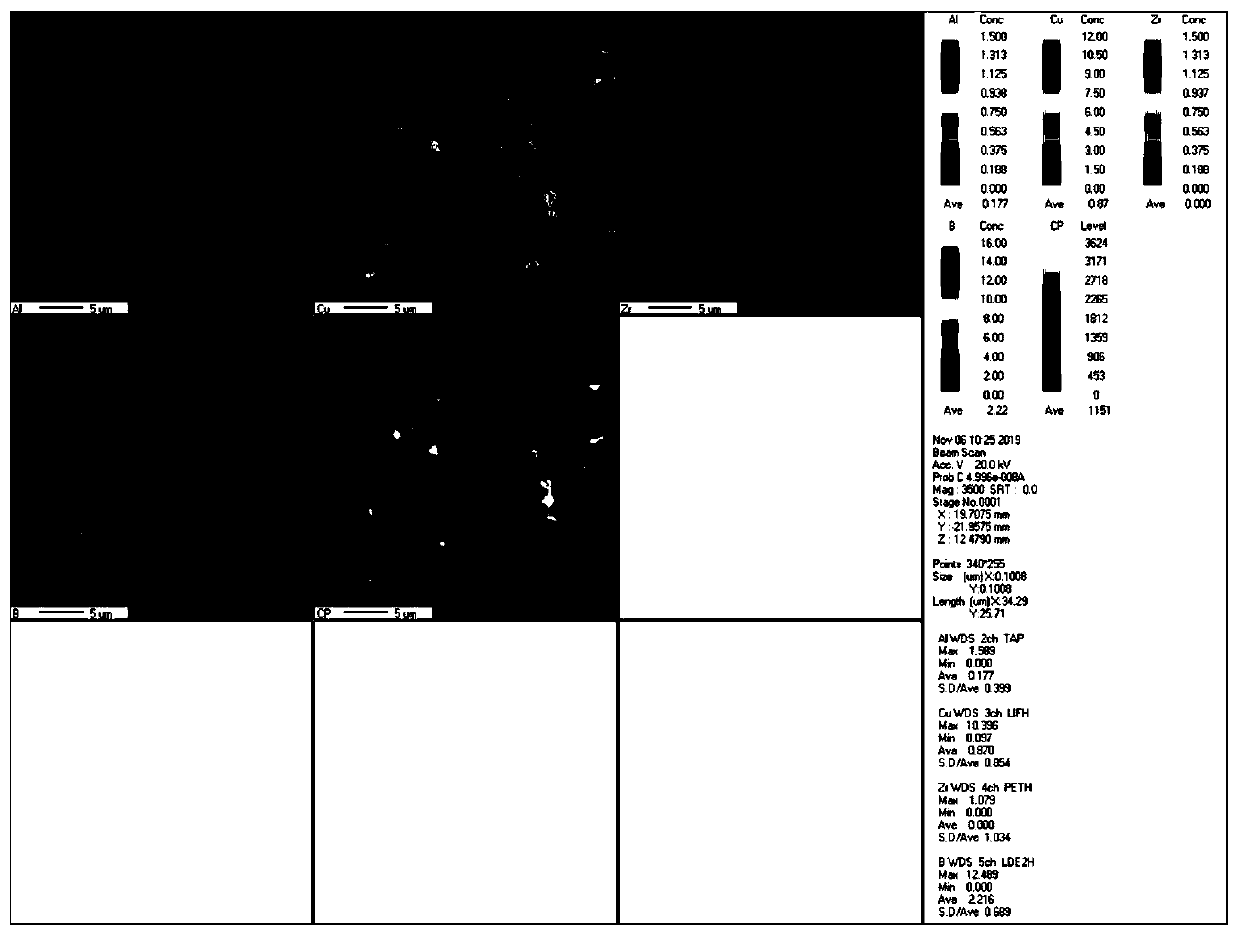

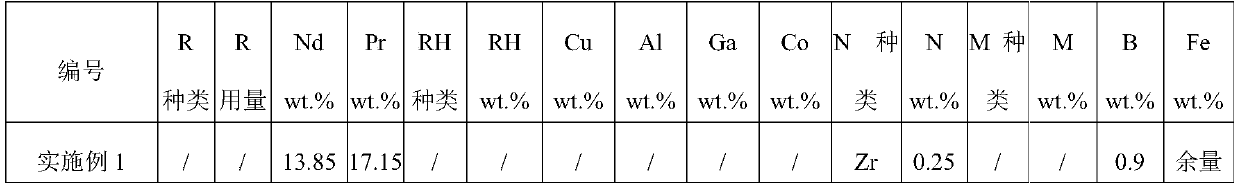

R-T-B series permanent magnet material and preparation method and application thereof

ActiveCN110853855AImprove coercive forceImprove remanenceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementComposite material

The invention discloses an R-T-B series permanent magnet material and a preparation method and application thereof. The R-T-B series permanent magnet material comprises components of 29.5-33.0 wt.% ofR', N, B and Te, wherein the R' comprises R, Pr, Nd, the R is a rare earth element except Pr and Nd, the content of Pr is greater than or equal to 8.85 wt.%, a mass ratio of Nd to R' is less than 0.5, the N is greater than 0.05 wt.% and is not greater than 4.1 wt.%, the N is Ti, Zr or Nb, the B is 0.90-1.2wt.%, and the Fe is 62.0-68.0wt.%. The R-T-B series permanent magnet material is advantagedin that a sintered permanent magnet product with high coercive force and a stable temperature coefficient is prepared by adopting a formula with high Pr content, advantages of Pr can be exerted to themaximum extent by adopting the formula disclosed by the invention, and production cost is effectively reduced.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

Preparation method of neodymium iron boron magnet

ActiveCN102103916AReduce usageUniformity controllableInductances/transformers/magnets manufactureMagnetic materialsRare earthImpurity

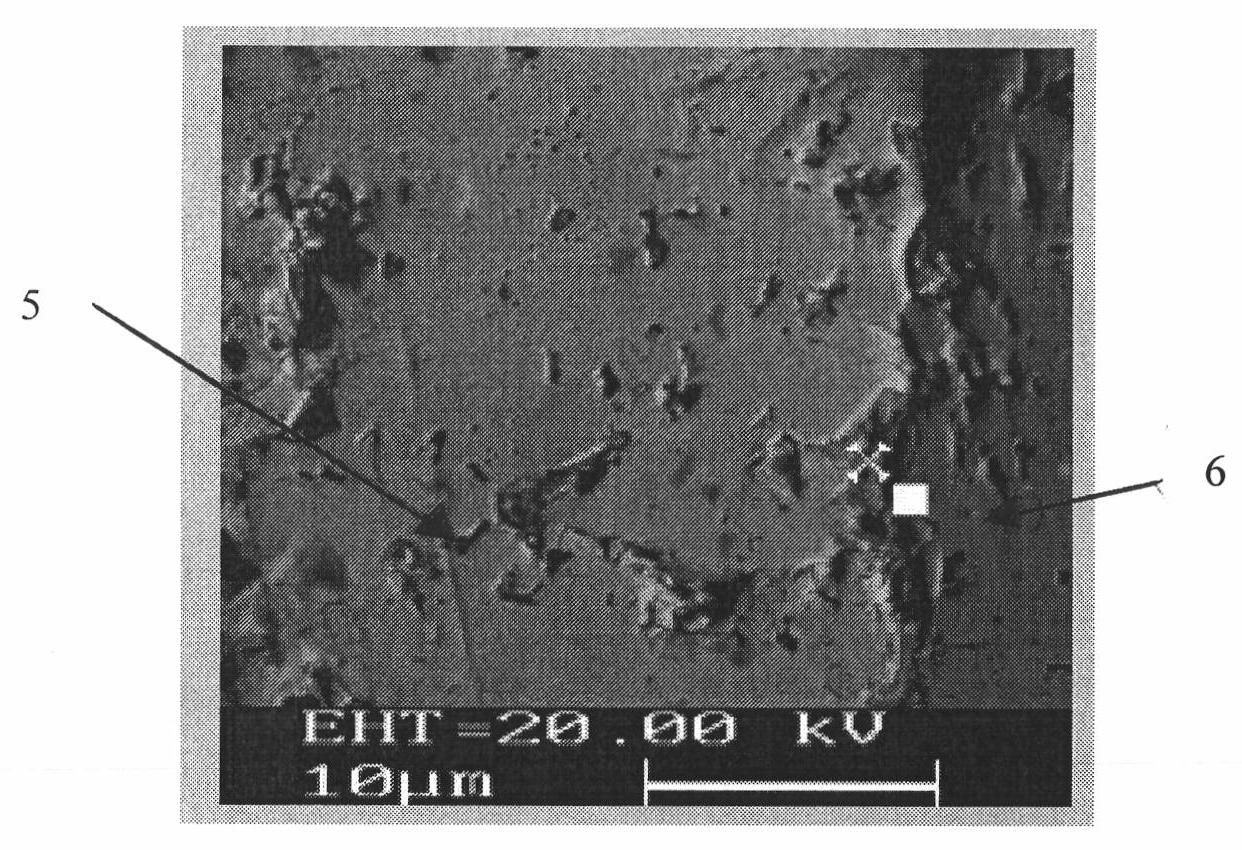

A preparation method of neodymium iron boron magnet is disclosed. The composition general formula of the magnet provided by the invention is R1R2FeMB, wherein R1 is at least one element selected from the group consisting of Nd, Pr, La, Ce, Sm, Sc, Y and Eu, having a content of 23 to 35 wt%; R2 is at least one element selected from the group consisting of Tb, Dy, Gd, and Ho, having a content of 0.1 to 5 wt%; M represents transition group metal with the exception of Fe, having the content of 0.01 to 5 wt%; B represents simple substance boron, having the content of 0.8 to 1.2 wt%; the balance isFe and the other inevitable impurities. The preparation method of neodymium iron boron magnet provided by the invention works in such a manner that: one or more elements in the R2 are plated to the surface of the magnet, the metal R2 is diffused into the interior of the magnet by primary high temperature heat treatment, and imbalance organization and internal stress brought by the high temperature treatment are eliminated through secondary low temperature tempering. Low temperature molten salt electrodeposition method is employed to plate films. The present invention is advantageous in greatly improving the production efficiency, reducing the dosage of the heavy rare earth during preparation process of magnet, saving rare earth resource, and obtaining high coercivity without reducing remanent magnetism and magnetic energy product of a magnet.

Owner:GRIREM ADVANCED MATERIALS CO LTD

R-t-b-type sintered magnet and method for production thereof

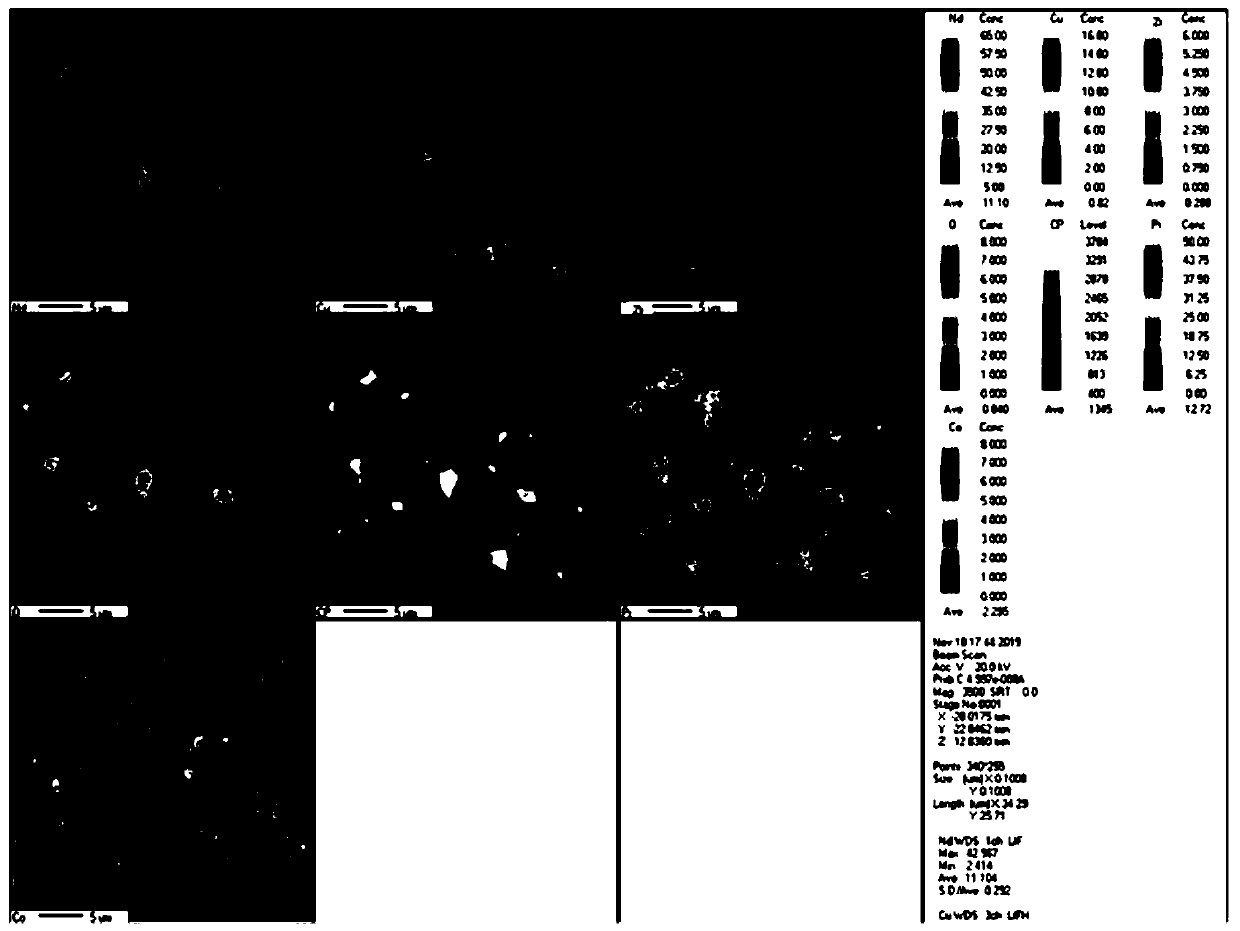

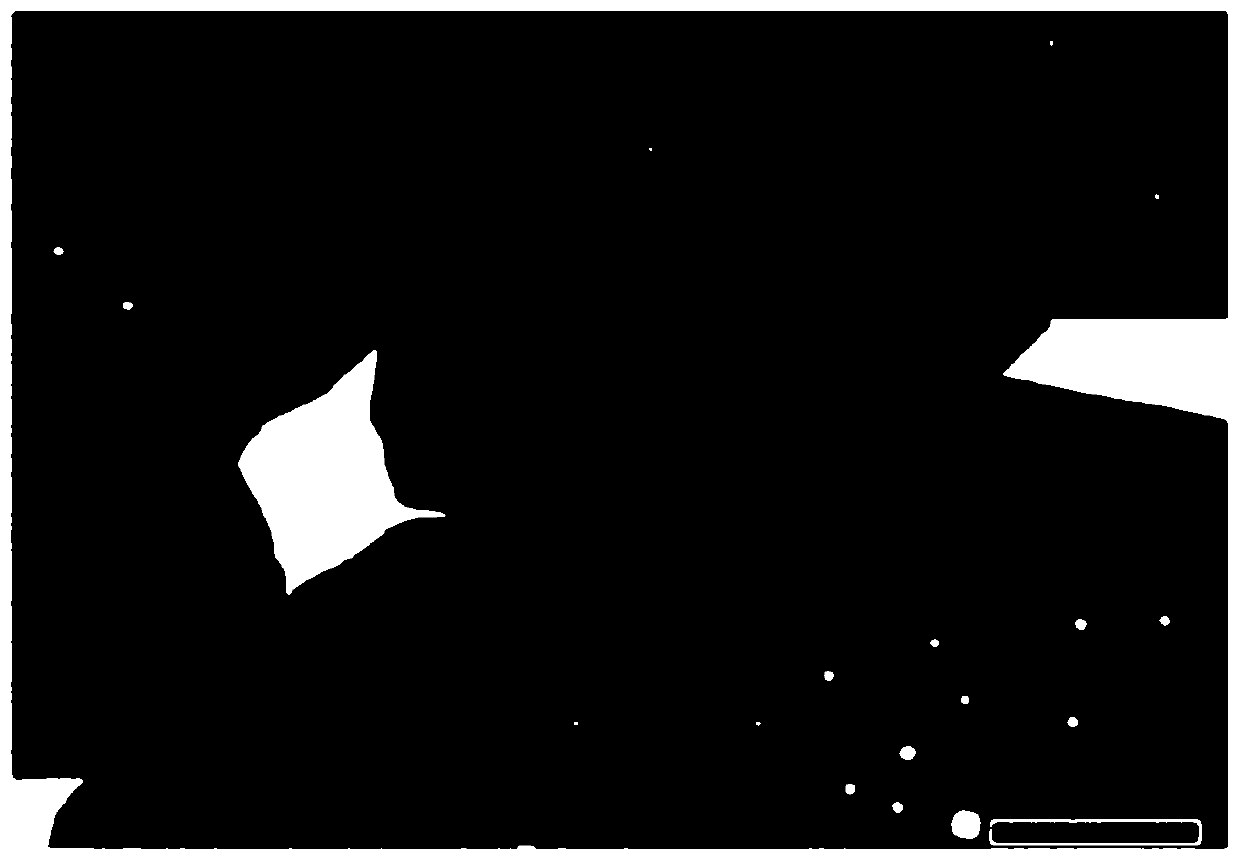

ActiveUS20110025440A1Increase in coercivityImprove remanencePermanent magnetsInductances/transformers/magnets manufactureSintered magnetsOxygen content

An R-T-B based sintered magnet according to the present invention has a composition including: 27.3 mass % to 29.5 mass % of R; 0.92 mass % to 1 mass % of B; 0.05 mass % to 0.3 mass % of Cu; 0.02 mass % to 0.5 mass % of M; and T as the balance, and has an oxygen content of 0.02 mass % to 0.2 mass %. The main phase of the sintered magnet is an R2T14B type compound. The crystal grain size of the main phase is represented by an equivalent circle diameter of 8 μm or less. And crystal grains with equivalent circle diameters of 4 μm or less account for at least 80% of the overall area of the main phase.

Owner:HITACHI METALS LTD

Neodymium-iron-boron magnet material and raw material composition thereof, and preparation method and application of neodymium-iron-boron magnet material

ActiveCN110828089AImprove remanenceImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementMetallurgy

The invention discloses a neodymium-iron-boron magnet material and a raw material composition thereof, and a preparation method and application of a neodymium-iron-boron magnet material. The raw material composition of the neodymium-iron-boron magnet material is prepared from the following components in percentage by mass: 29.5-32% of R' which is a rare earth element and comprises Pr and Nd, wherein Pr>=17.15%; Cu being not less than 0.35%; 0.9-1.2% of B; and Fe: 64-69.2%, wherein the percentage refers to the mass percentage of the total mass of the raw material composition of the neodymium-iron-boron magnet material. According to the neodymium-iron-boron magnet material disclosed by the invention, the residual magnetism and the coercive force of the obtained neodymium-iron-boron magnet material are still relatively high under the condition that heavy rare earth elements are not added.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

Preparation of rare earth permanent magnet material

ActiveUS20110150691A1Improve remanenceImprove coercive forceElectric discharge tubesPermanent magnetsRare-earth elementRemanence

A method for preparing a rare earth permanent magnet material comprises the steps of: disposing a powder comprising one or more members selected from an oxide of R2, a fluoride of R3, and an oxyfluoride of R4 wherein R2, R3 and R4 each are one or more elements selected from among rare earth elements inclusive of Y and Sc on a sintered magnet form of a R1—Fe—B composition wherein R1 is one or more elements selected from among rare earth elements inclusive of Y and Sc, and then heat treating the magnet form and the powder at a temperature equal to or below the sintering temperature of the magnet in vacuum or in an inert gas. The result high performance, compact or thin permanent magnet has a high remanence and coercivity at a high productivity.

Owner:SHIN ETSU CHEM CO LTD

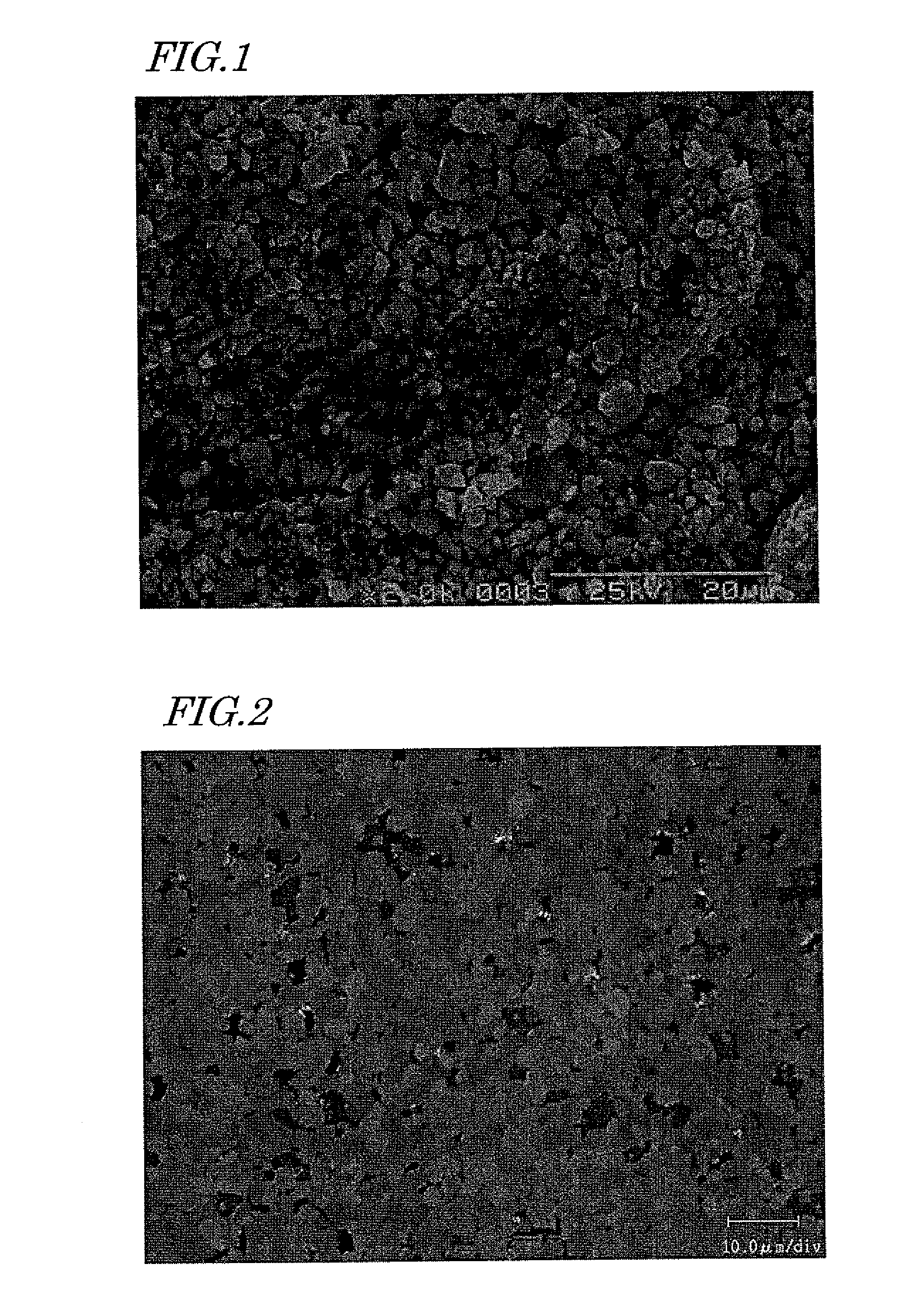

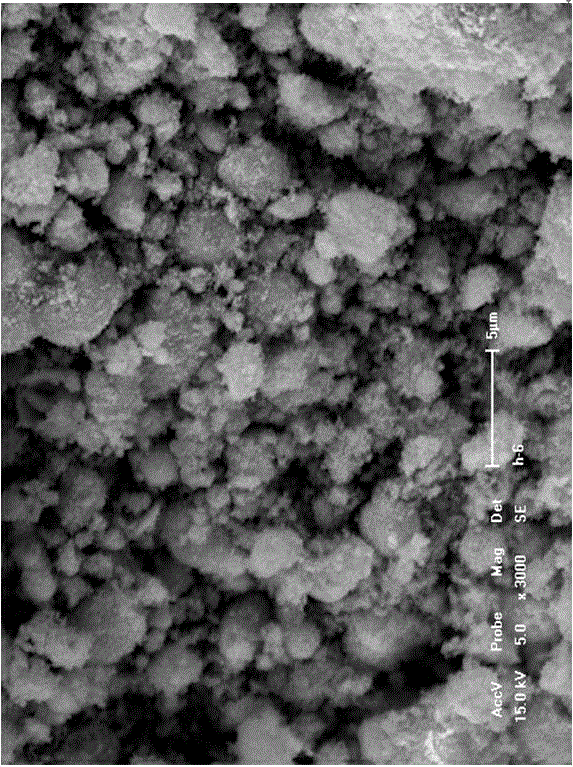

Method for preparing high coercive force sintering rare-earth-iron-p permanent magnetic material

ActiveCN1905088AImprove remanenceHigh energy productInorganic material magnetismTerbiumWorking environment

The invention relates to the method used to make rare earth-iron-boron permanent magnetic material with high coercive force which belongs to magnetic material field. The excellent magnetism of the NdFeB permanent magnetism will be obviously reduced while the working environment temperature rises. The invention includes the following steps: using rapid hardening slice technology to make NdFeB rapid hardening slice; smashing to powder with 3-5 micron; making terbium and dysprosium powder with 10-50nm; mixing them with 1-3% weight ratio; orientating at 2.5T magnetic field; processing secondary heat treatment after 2-4 hours sintering at 1050-1120 centigrade degree; the first order heat treatment is at 900-1000 degree centigrade for 1-3h; the secondary is at 550-700 degree centigrade for 1-3h. The invention has better coercive force and lower terbium and dysprosium content compared with the traditional NdFeB permanent magnetic material.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

Ultrahigh-coercivity sintered neodymium-iron-boron magnet and preparation method thereof

ActiveCN103794322AImprove coercive forceAchieve magnetic hardeningPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementHigh volume manufacturing

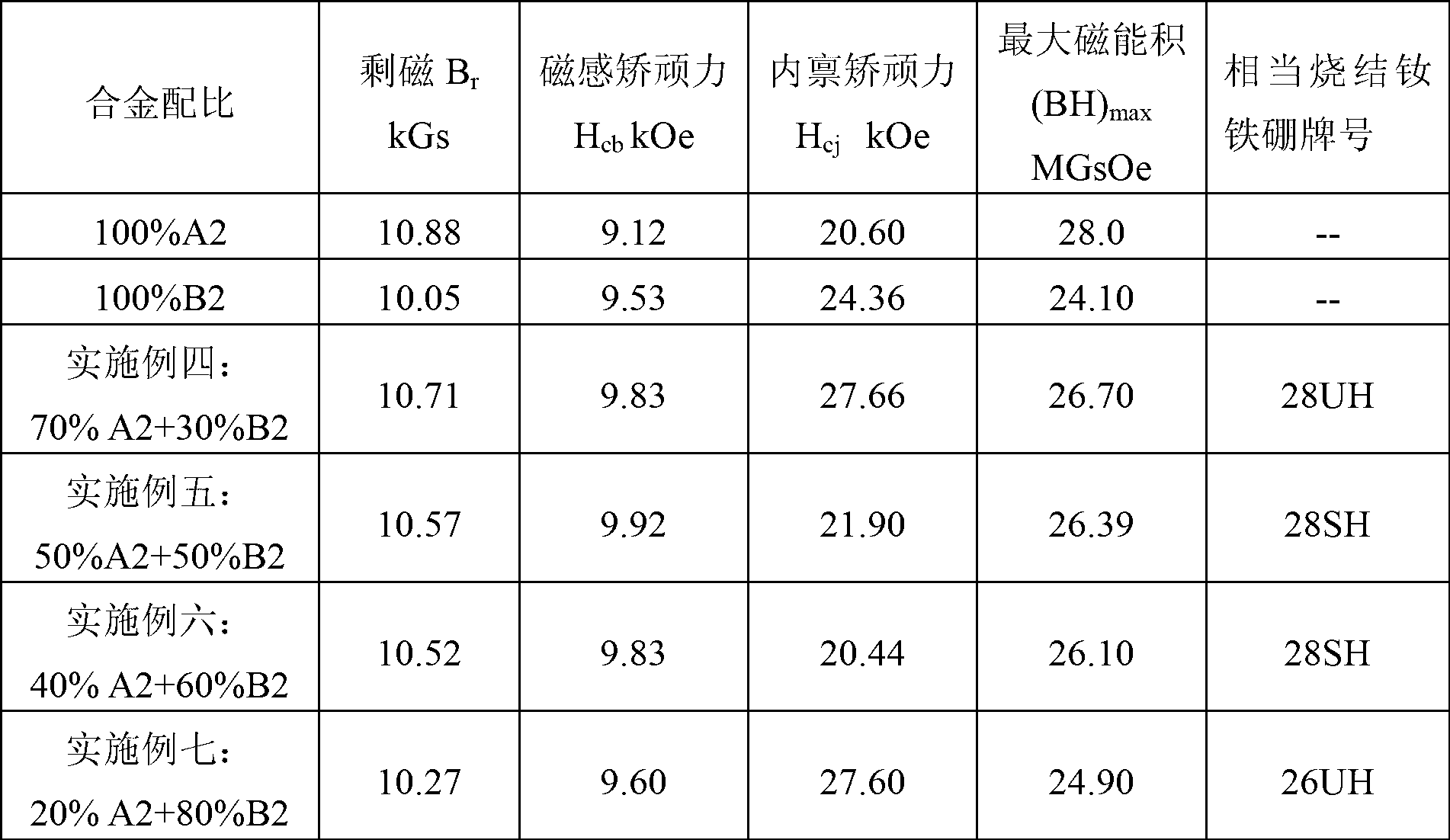

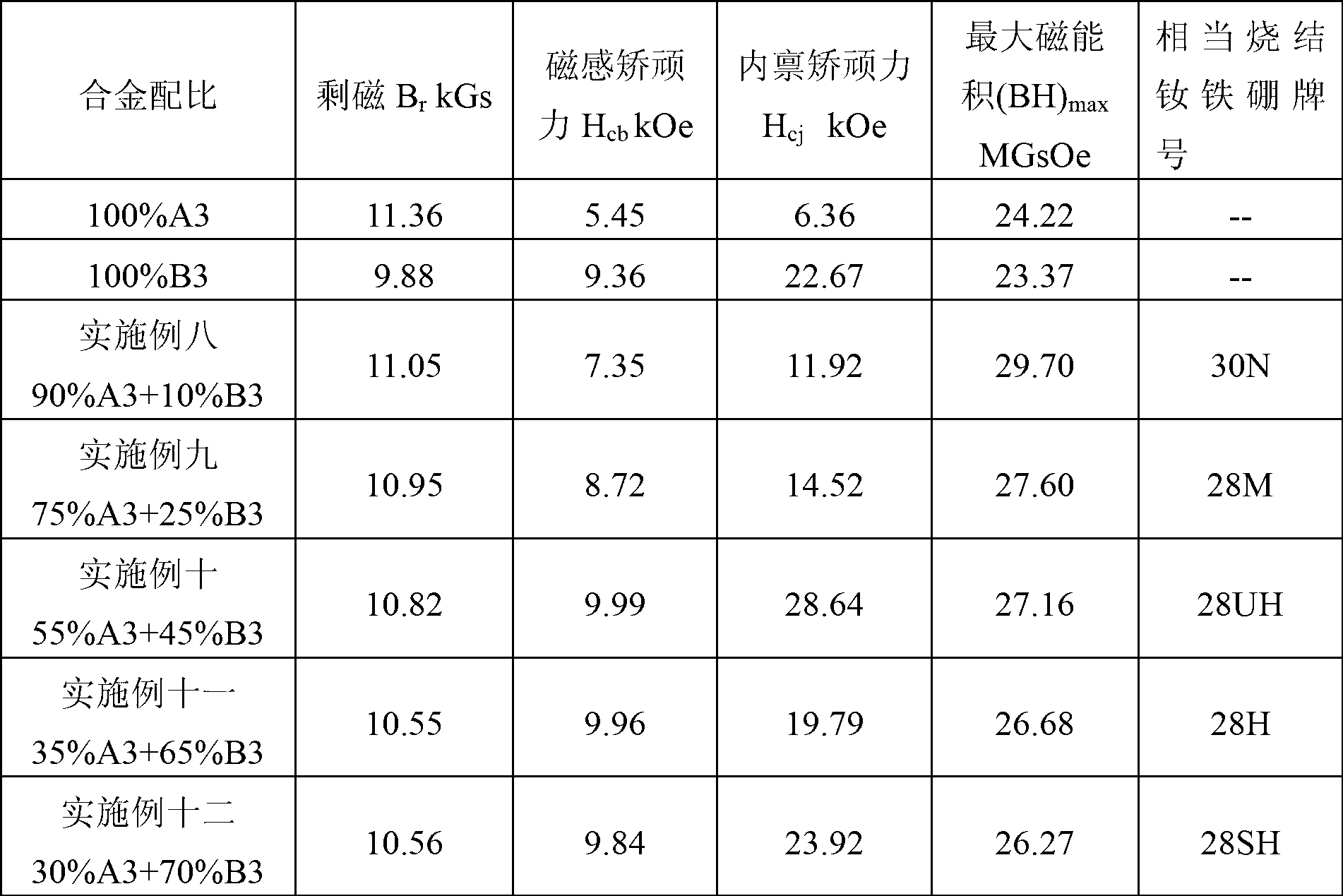

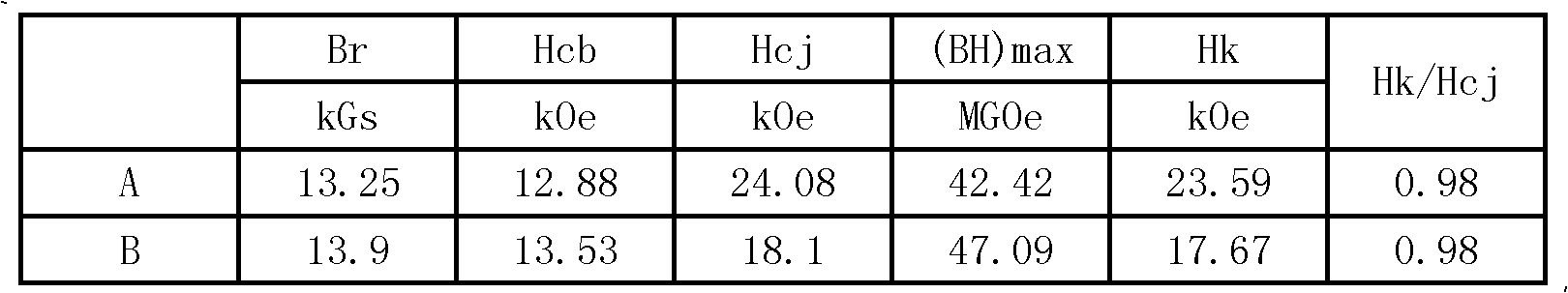

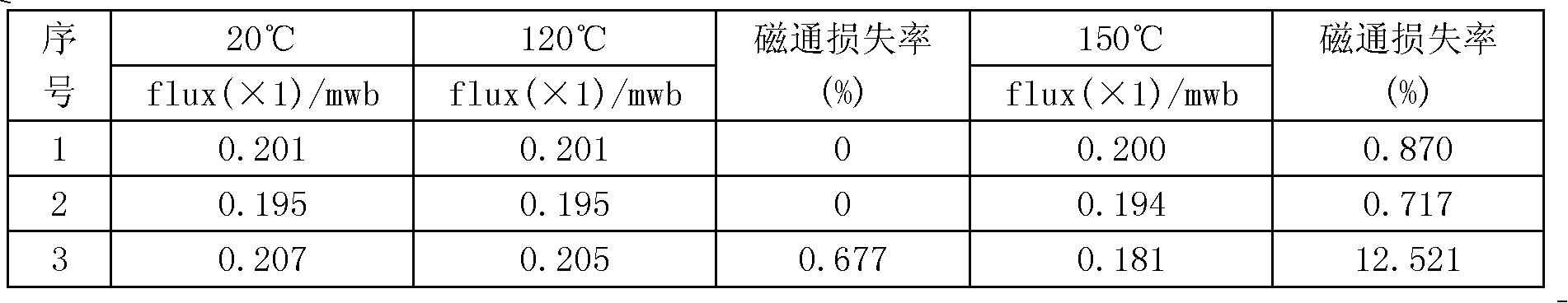

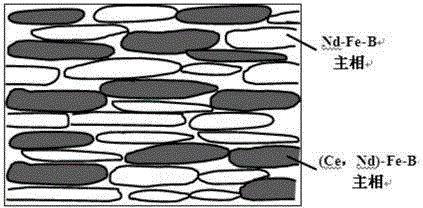

The invention discloses an ultrahigh-coercivity sintered neodymium-iron-boron magnet and a preparation method thereof. The ultrahigh-coercivity sintered neodymium-iron-boron magnet comprises a main phase and a crystal boundary adding phase. The main phase comprises low-HA main alloy and high-HA main alloy. The high magnetocrystalline anisotropy field HA main alloy and the low-HA main alloy are used as the main phase, so that the heavy rare earth element diffuses from the high-HA phase to the low-HA phase in the sintering and heat treatment process to initially improve the coercivity; in addition, alloy components and the preparation technology can be controlled at the same time, the content of Nd2Fe14B in the magnet is improved, and it is ensured that the magnet has the high magnetic energy product. The crystal boundary adding phase can further achieve crystalline grain surface magnetic hardening and improve the coercivity, the microscopic structure is optimized, and the coercivity is further improved. The preparation method of the ultrahigh-coercivity sintered neodymium-iron-boron magnet has the advantages of both a traditional dual alloy method and a single alloy crystal boundary adding method, and is easy to operate and suitable for mass production of ultrahigh-coercivity high-residual-magnetism sintered neodymium-iron-boron magnets.

Owner:ZHEJIANG UNIV +1

Rare earth permanent magnet, making method, and permanent magnet rotary machine

ActiveUS7559996B2Improve remanenceEffective absorptionMagnetic circuitPermanent magnetsRare-earth elementSintered magnets

Owner:SHIN ETSU CHEM IND CO LTD

Sintered neodymium-iron-boron magnet and preparation method thereof

ActiveCN102903472AImprove remanenceImprove coercive forcePermanent magnetsInorganic material magnetismMetallurgyMagnetic energy

The invention discloses a sintered neodymium-iron-boron magnet, comprising the following components in percent by weight: 29.5%-32.5% of R, 62.85%-67.54% of Fe, 0.96%-1.15% of B and 2.0%-3.5% of TM, wherein R consists of Nd, Pr and Gd or consists of Nd, Pr and Ho; B represents boron, Fe represents iron, and Tm is one or more in Al, Nb, Cu, Co, Ga and Zr. In addition, the invention also discloses a preparation method of the sintered neodymium-iron-boron magnet, and the sintered neodymium-iron-boron magnet is prepared by adopting a quick-curing piece technology and a forming and pre-pressing process. The invention has the advantages that the largest magnetic energy product and intrinsic coercive force of the sintered neodymium-iron-boron magnet can be furthest improved, and the produced sintered neodymium-iron-boron magnet has high residual magnetism and high coercive force and is lower in cost.

Owner:NINGBO YUNSHENG +4

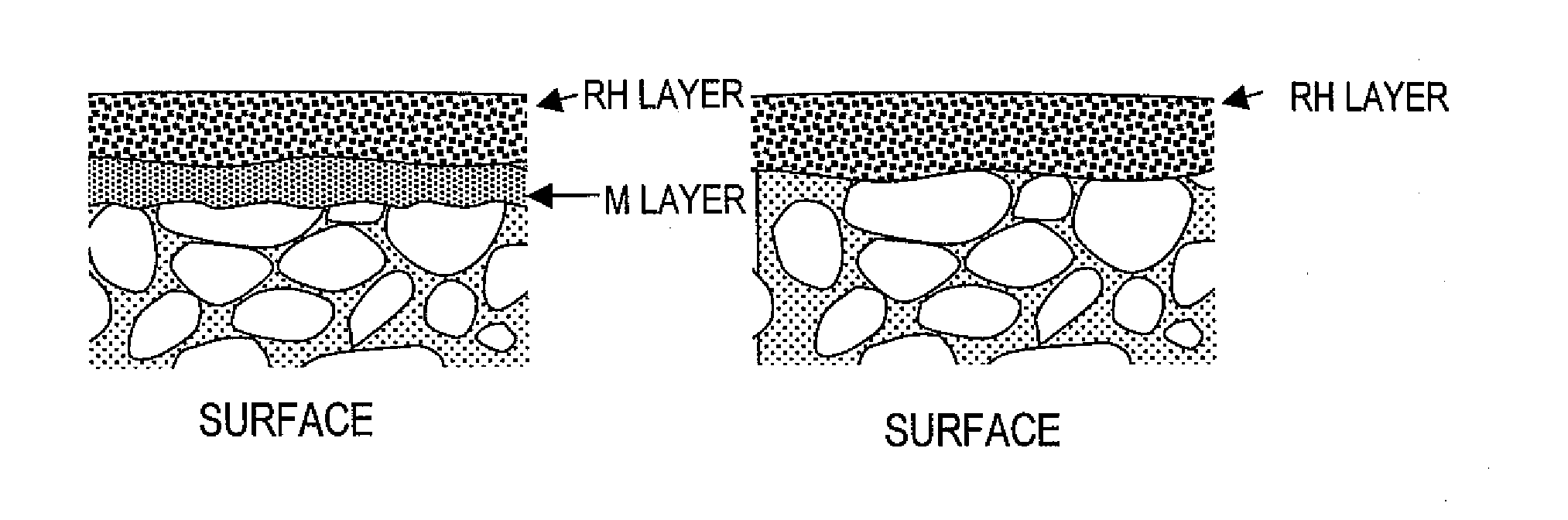

R-Fe-B RARE-EARTH SINTERED MAGNET AND PROCESS FOR PRODUCING THE SAME

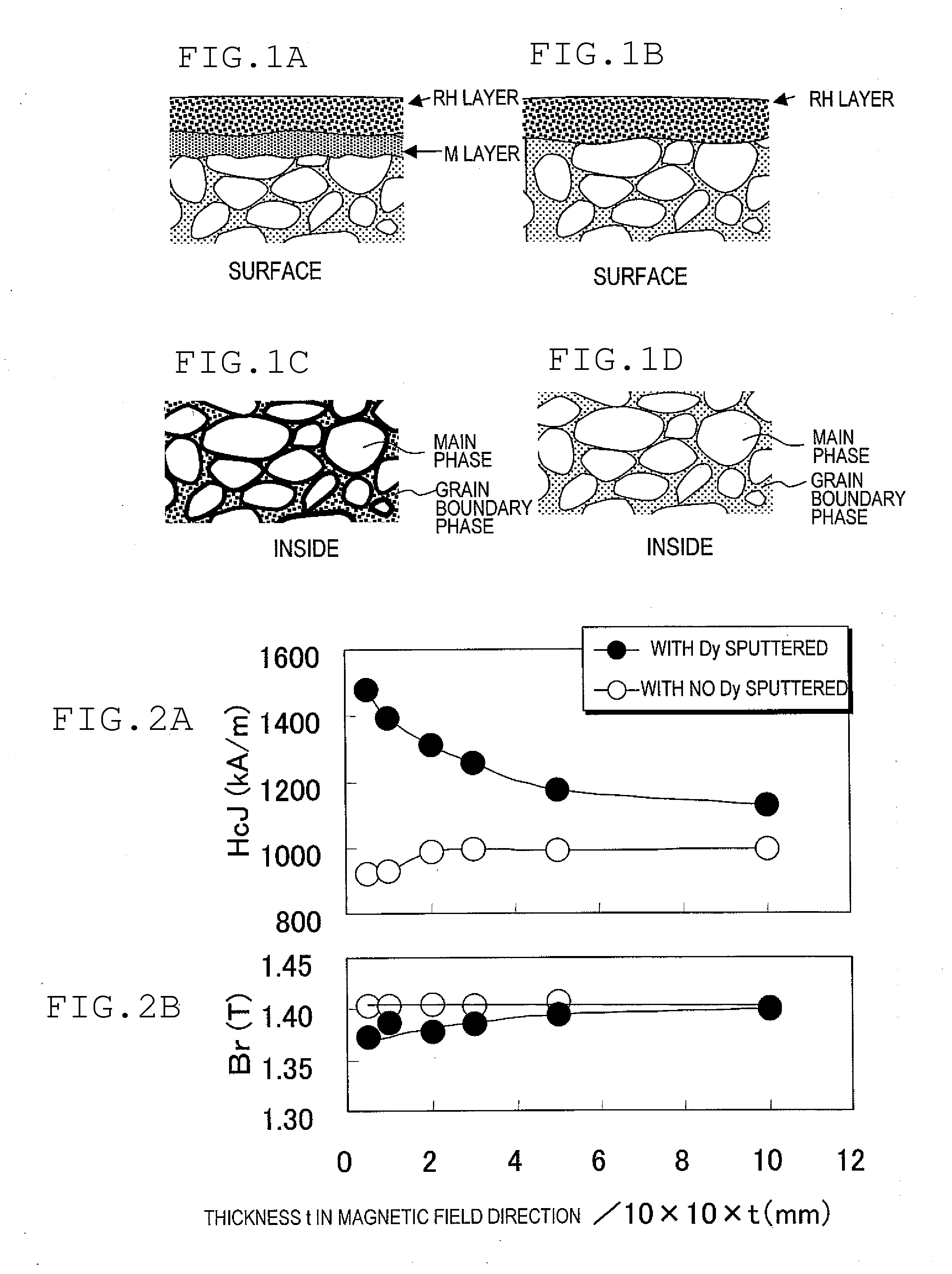

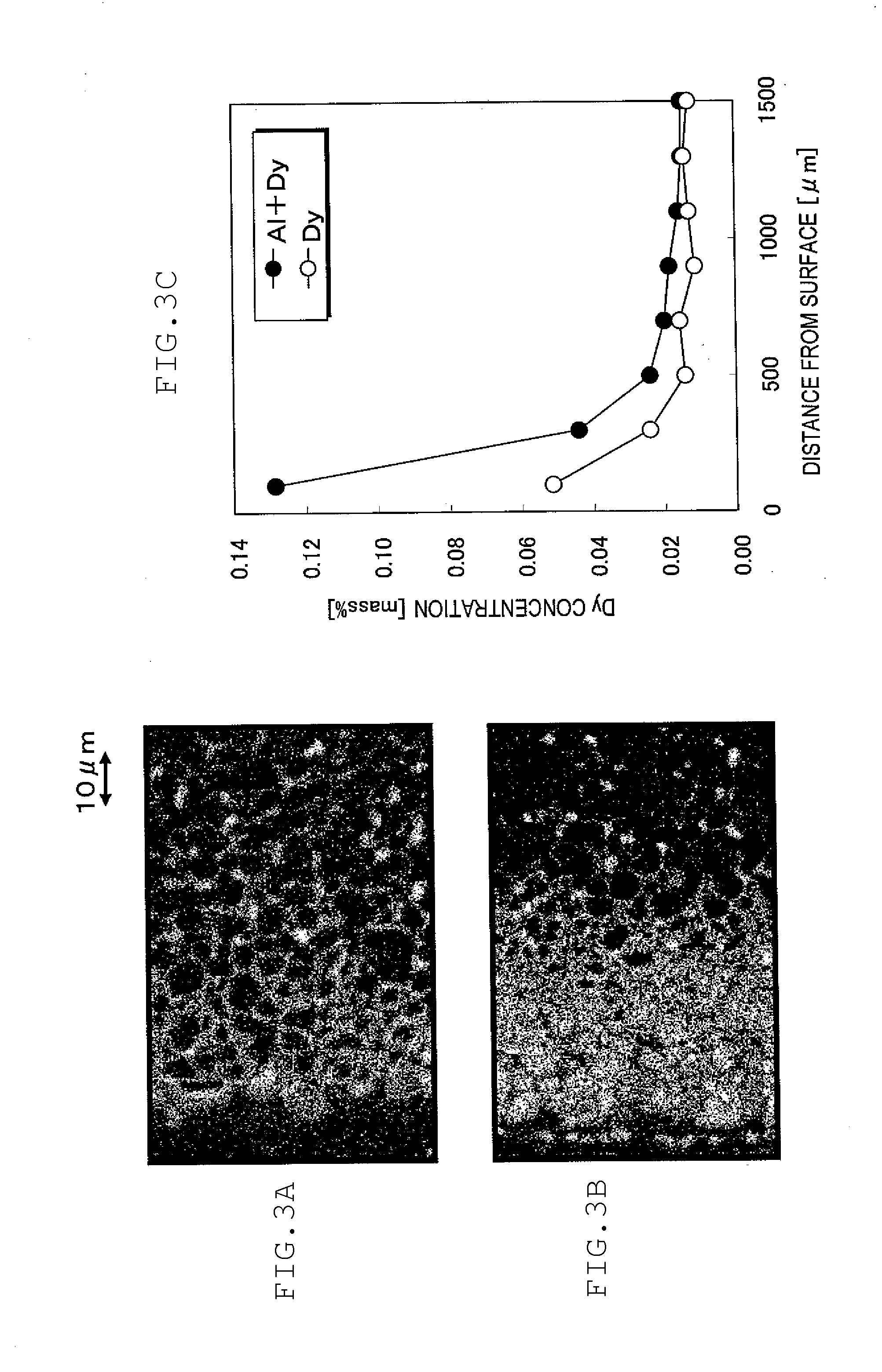

ActiveUS20100231338A1Easy to useImprove remanenceVacuum evaporation coatingSputtering coatingRare-earth elementSintered magnets

First, an R—Fe—B based rare-earth sintered magnet body including, as a main phase, crystal grains of an R2Fe14B type compound that includes a light rare-earth element RL, which is at least one of Nd and Pr, as a major rare-earth element R is provided. Next, an M layer, including a metallic element M that is at least one element selected from the group consisting of Al, Ga, In, Sn, Pb, Bi, Zn and Ag, is deposited on the surface of the sintered magnet body and then an RH layer, including a heavy rare-earth element RH that is at least one element selected from the group consisting of Dy, Ho and Tb, is deposited on the M layer. Thereafter, the sintered magnet body is heated, thereby diffusing the metallic element M and the heavy rare-earth element RH from the surface of the magnet body deeper inside the magnet.

Owner:HITACHI METALS LTD

Aqueous dispersion of colloidal particles of mineral filler and fibres

InactiveUS20070141095A1Good effectImprove mechanical propertiesCosmetic preparationsHair cosmeticsFiberWrinkle skin

The invention relates to a composition containing an aqueous dispersion of colloidal particles of at least one mineral filler, and fibres. The invention also relates to a process for treating the skin, especially wrinkled skin, via the application of the described composition to the skin.

Owner:LOREAL SA

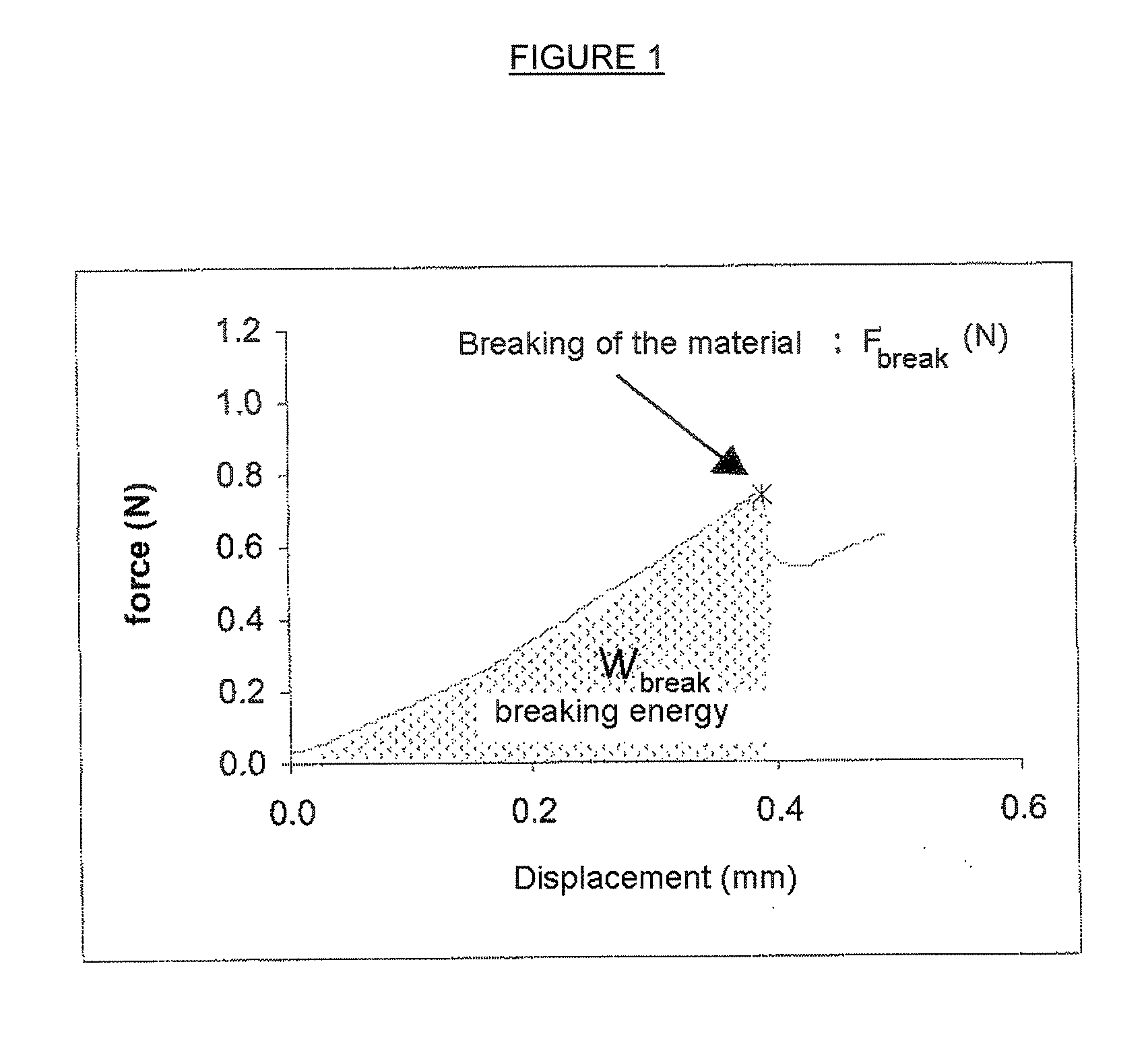

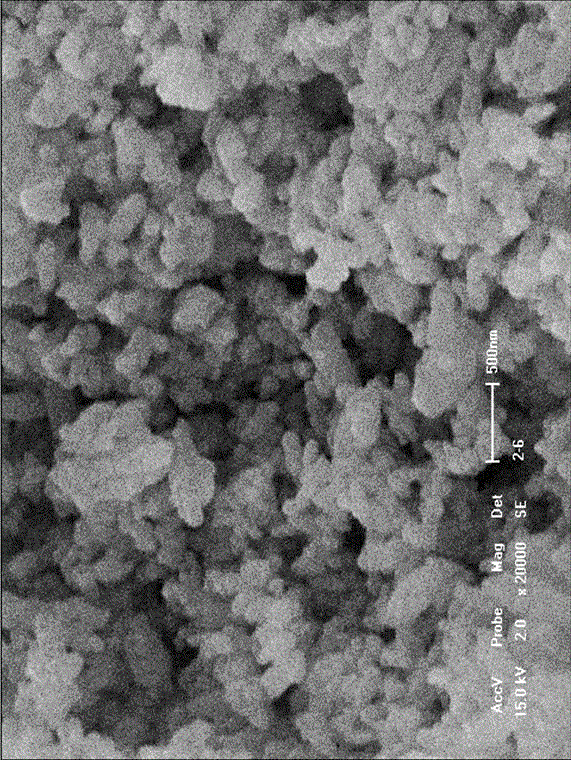

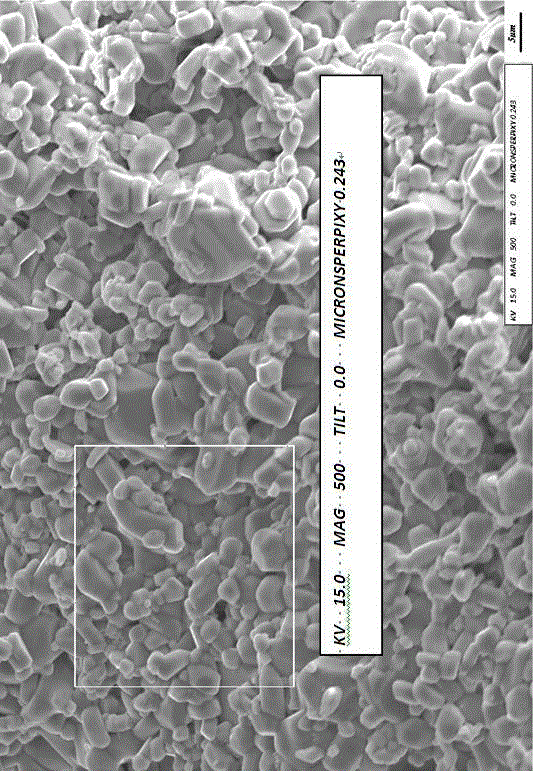

Nano toughening NdFeB magnetic material and preparation method thereof

InactiveCN102751064AEasy to processImprove coercive forceInorganic material magnetismRare-earth elementGrain boundary

The invention discloses a nano toughening NdFeB magnetic material and a preparation method of the nano toughening NdFeB magnetic material. The main mechanism is that a nano composite crystal boundary phase is formed on an NdFeB main phase crystal boundary, an H-grade rare earth permanent magnetic material with high coercive force M is prepared without doping any heavy rare earth, and then, a SH-grade rare earth permanent magnetic material is prepared by adding a little heavy rare earth. The nano material is prepared by a plasma arc method, has a grain size of 5-80nm and mainly contains metallic elements, such as Al, Cu, Cr, Co, Fe, Zn and the like, and all kinds of rare earth elements. A NdFeB main phase having a rare earth content of Pr-Nd is prepared by a SC-HD process; after smelting and hydrogen breaking, the product grain size is milled to be about 3.5 microns by an air-current mill, and in the argon protection atmosphere, a nano additive is added in a manner of jetting composite, so the nano additive is uniformly attached to the NdFeB main phase. In the sintering process, the nano powder and the main phase form the crystal boundary, the coercive force of NdFeB is greatly increased, and since the product has uniform crystal components, the machining property is also elevated well, the NdFeB magnetic material can be applied to the wider field. At the same time, the technical process is simple, low-cost and suitable for the batch production.

Owner:辽宁恒德磁业有限公司

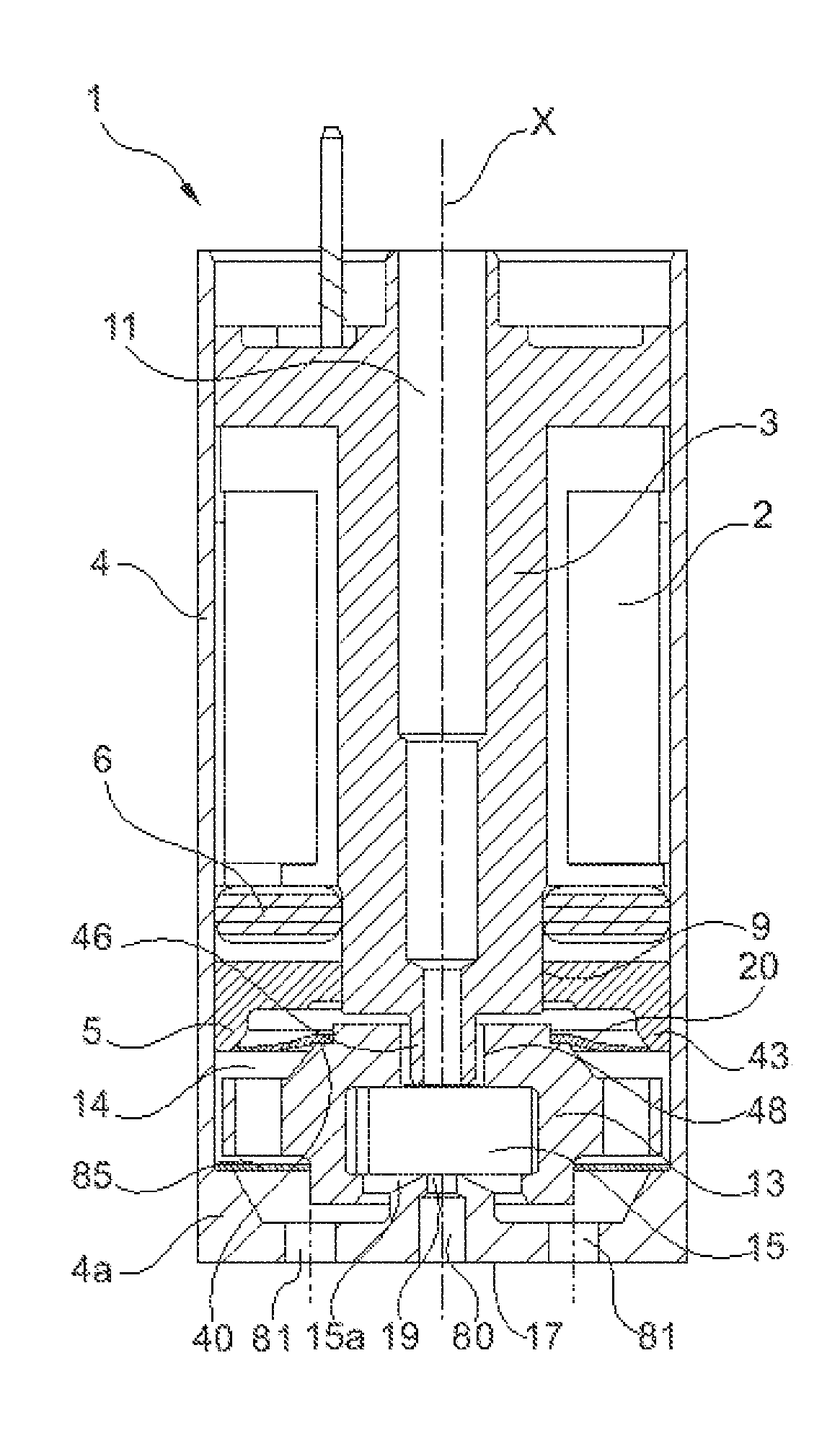

Solenoid valve with flat core and flat spring

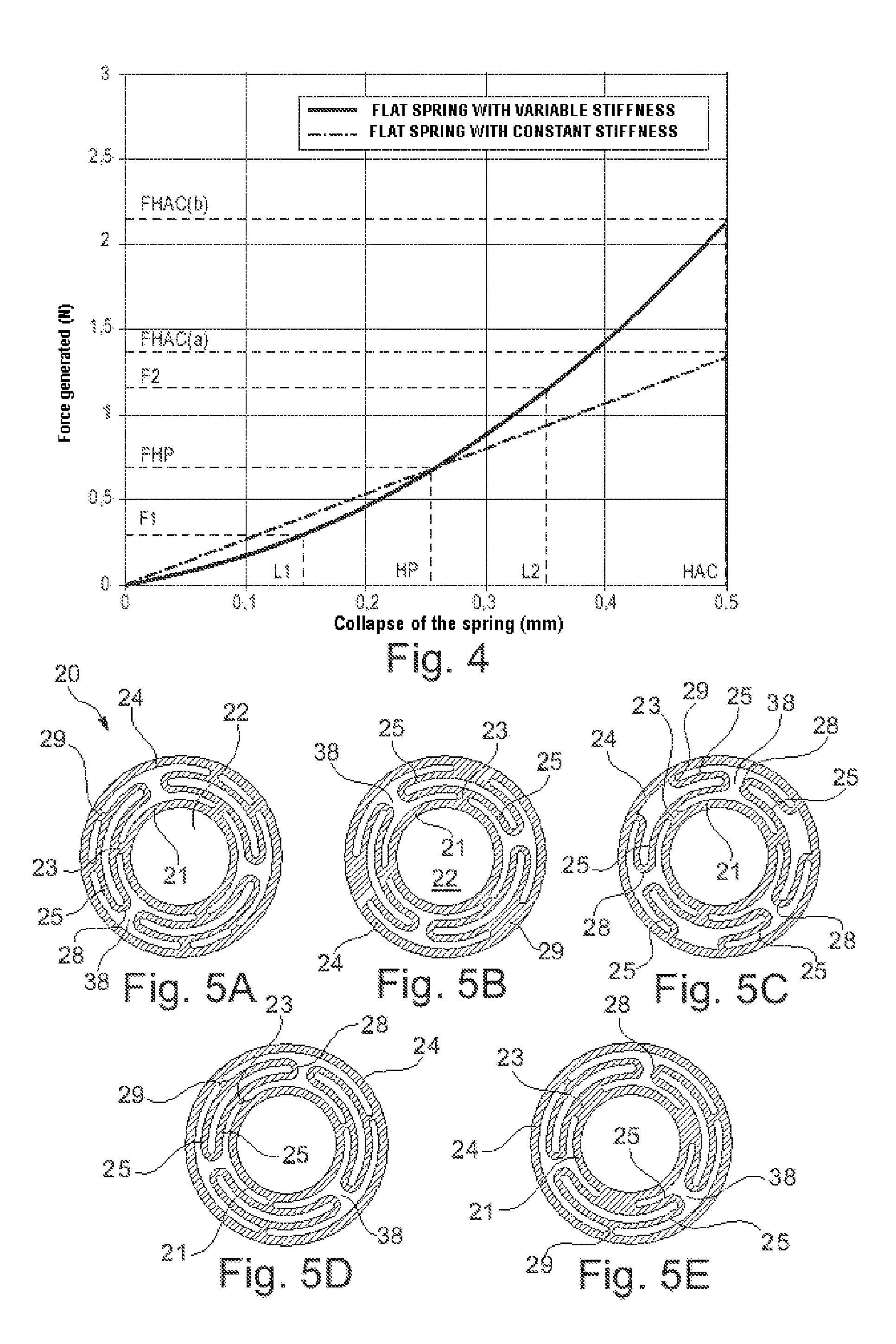

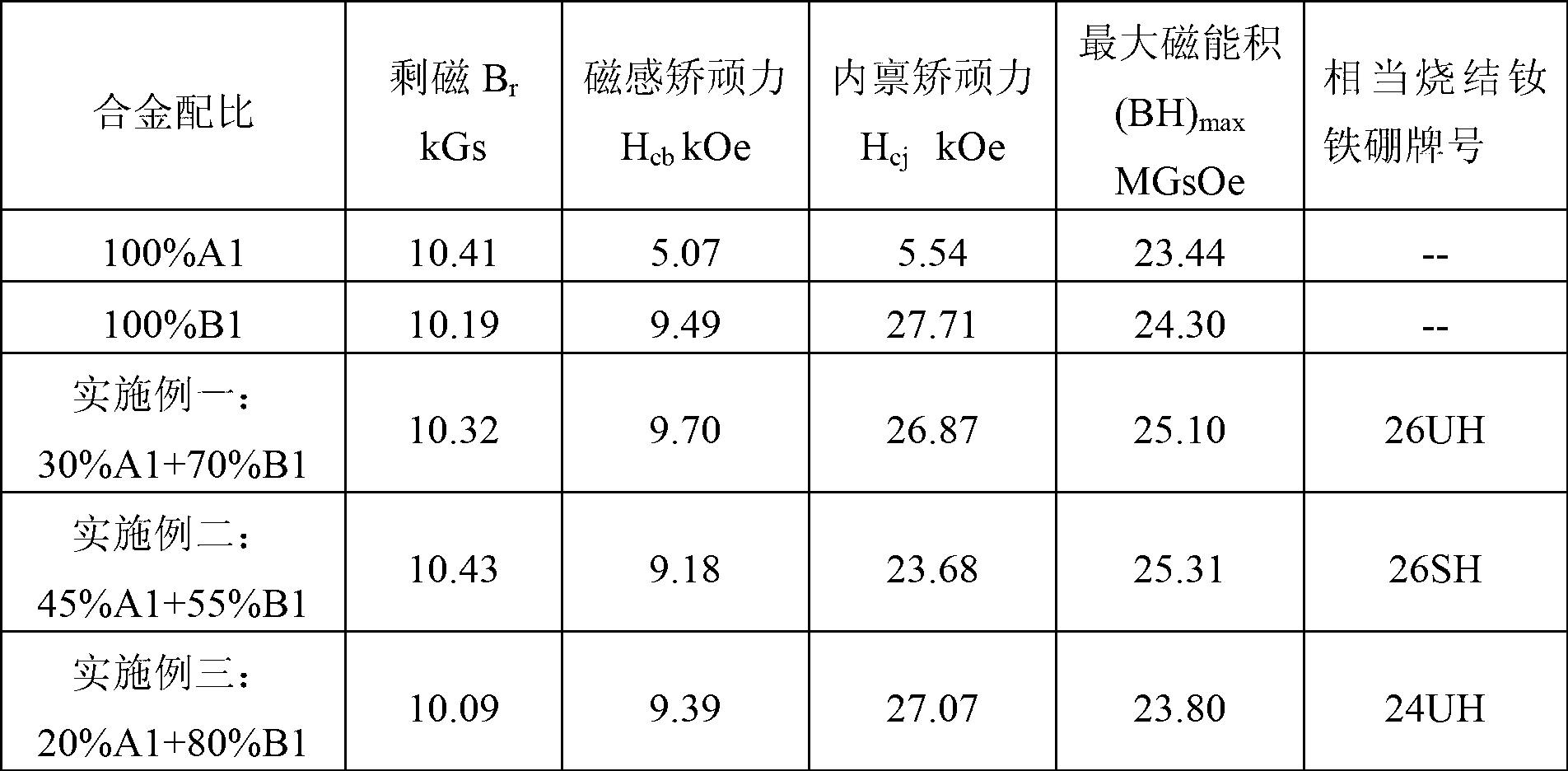

InactiveUS20140008557A1Improve deformationIncrease the spring rateOperating means/releasing devices for valvesLeaf springsVariable stiffnessRest position

A solenoid valve of the type with a flat core and a flat spring. The present invention related to a solenoid valve comprising a coil, a fixed core arranged inside the coil, a movable core arranged outside the coil, bearing a valve gasket, and a flat return spring to stress the movable core into a rest position, the solenoid valve being characterized in that the flat spring has variable stiffness, preferably bearing without embedding on corresponding surfaces of the solenoid valve.

Owner:ASCO JOUCOMATIC

Method for preparing sintered samarium-cobalt magnet

ActiveCN103065788AGet over the actual ingredientsTo overcome the large deviation of design componentsInorganic material magnetismInductances/transformers/magnets manufactureRemanenceSamarium–cobalt magnet

The invention discloses a method for preparing a sintered samarium-cobalt magnet. The method comprises the following steps of: preparing a first samarium-cobalt alloy and a second samarium-cobalt alloy; performing primary crushing on the first samarium-cobalt alloy and the second samarium-cobalt alloy; mixing first samarium-cobalt alloy primarily crushed magnetic powder and second samarium-cobalt alloy primarily crushed magnetic powder, and performing fine crushing, so that primarily crushed mixed magnetic powder is refined, and components are homogenized; and performing magnetic field orientation forming, cold isostatic pressing, sintering, solid solution treatment and ageing treatment on samarium-cobalt magnetic powder obtained by fine crushing in sequence. The method has the advantages that the first samarium-cobalt alloy has high remanence component characteristic, the second samarium-cobalt alloy has high coercivity component characteristic, the sintered samarium-cobalt magnets with various magnetic properties can be obtained by adjusting the mixing ratio of the first samarium-cobalt alloy primarily crushed magnetic powder to the second samarium-cobalt alloy primarily crushed magnetic powder, and the process is stable and low in cost.

Owner:NINGBO YUNSHENG +3

Method for preparing NdFeB (neodymium-iron-boron) magnet by waste materials

InactiveCN104576019AImprove coercive forceImprove remanenceInductances/transformers/magnets manufactureRecycling and recovery technologiesAntioxidantRare earth

The invention relates to an NdFeB (neodymium-iron-boron) magnet, in particular to a method for preparing the NdFeB magnet by waste materials, and belongs to the technical field of magnetic materials. The preparing method of the NdFeB magnet comprises the following steps that firstly, NdFeB magnet waste materials are cleaned and are dried through being blown, the NdFeB magnet waste materials are crushed into particles being 10 to 15mm by a crushing machine, rare earth metal is added into the particles, then, hydrogen crushing treatment is carried out to obtain crushed powder, and next, antioxidants are added for airflow grinding to obtain fine powder with the average particle diameter being 3.0 to 4.0 mu. m; next, lubricating agents are added, orientation is carried out under the protection atmosphere of nitrogen gas, in addition, pressing forming is carried out, and finally, NdFeB magnet finished products are obtained through discharging plasma sintering, secondary tempering heat treatment and surface treatment. The method has the advantages that waste materials are used as major raw materials, the simple and feasible preparing method is adopted, the recovery and utilization rate of the waste materials is effectively improved, in addition, Tb, Dy, Nd and Ce are added and compounded in the preparing process, and the obtained NdFeB magnet has better coercive force, residual magnetism and magnetic energy product.

Owner:NINGBO GERONGLI MAGNETIC IND

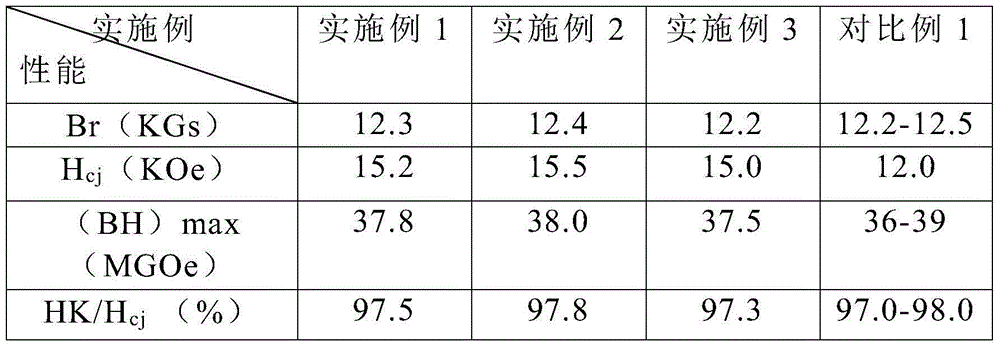

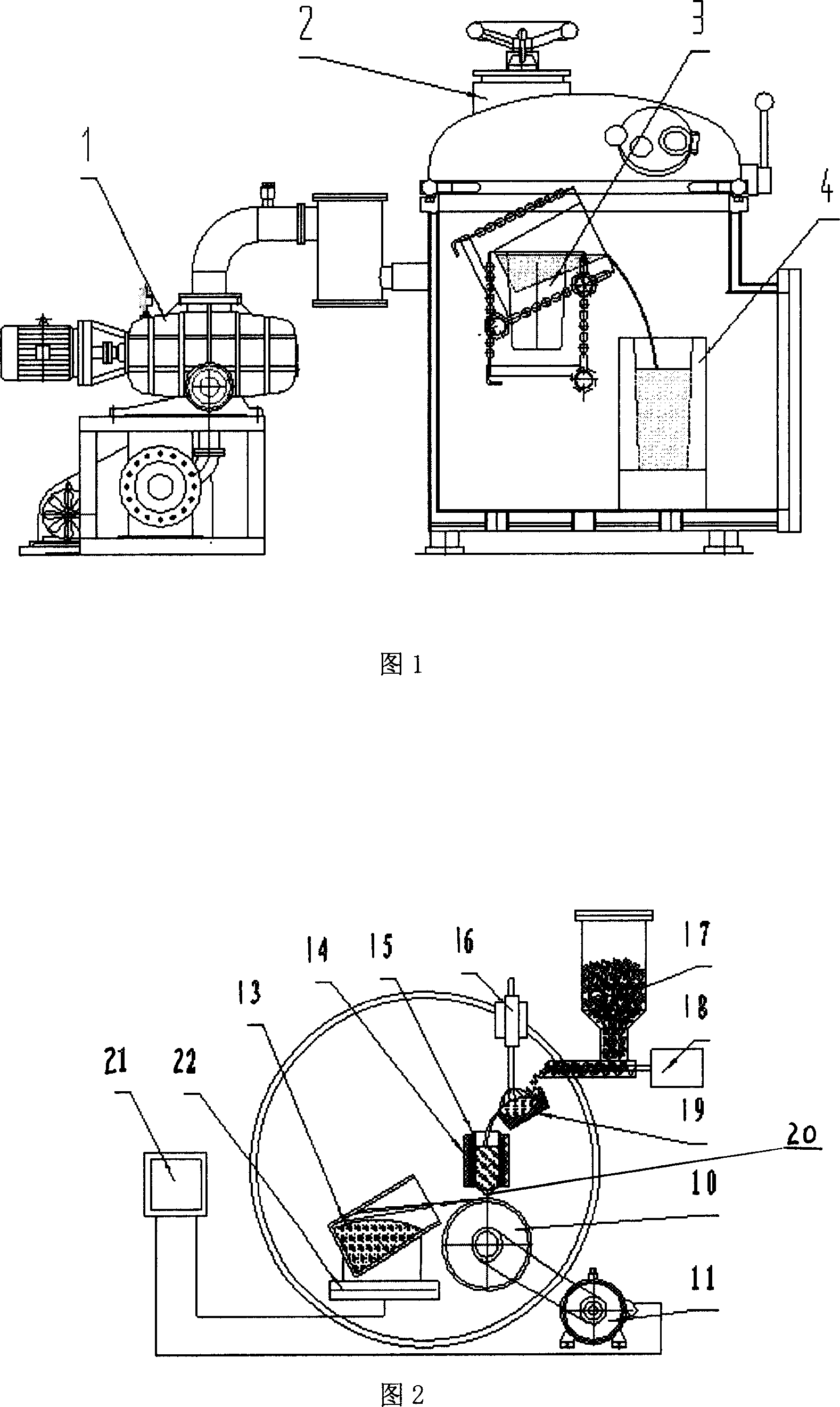

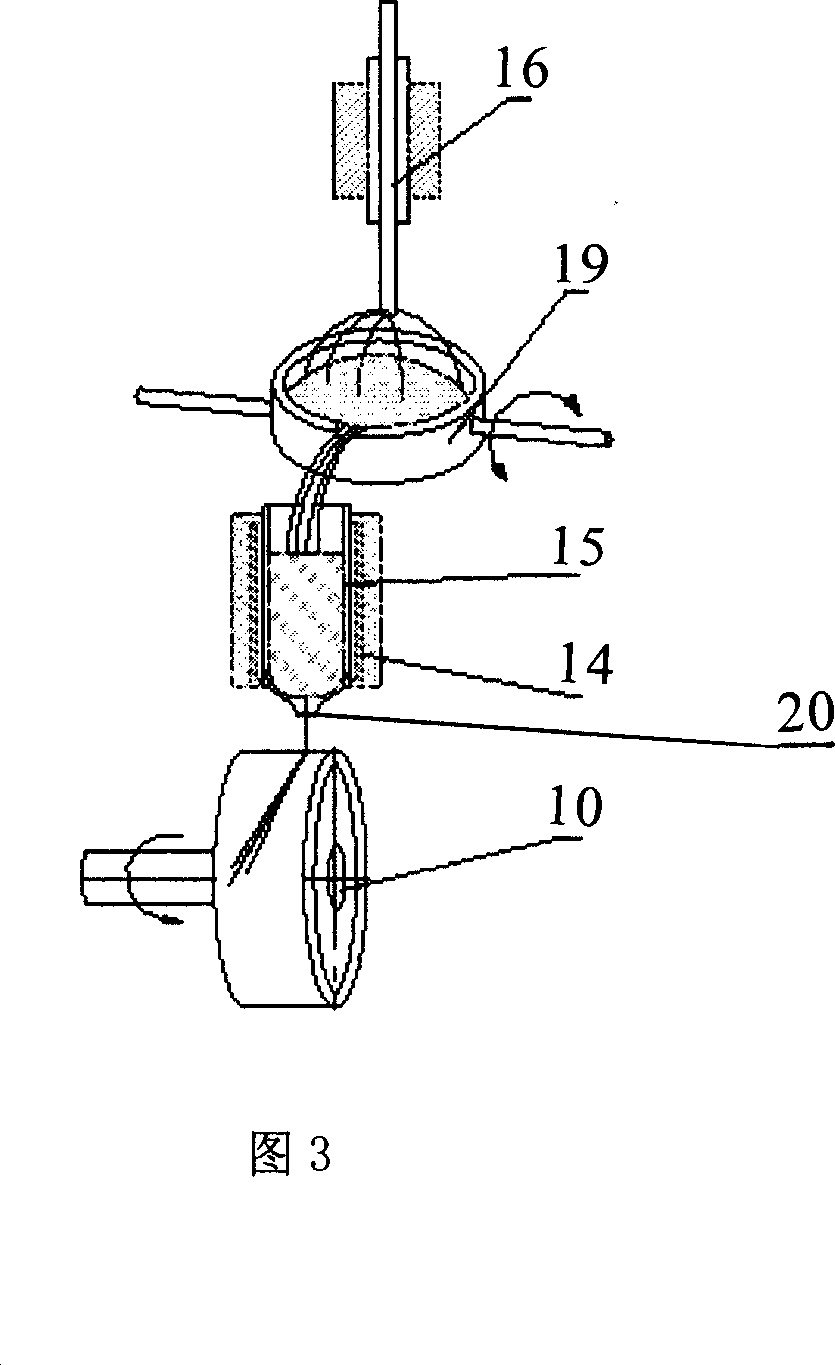

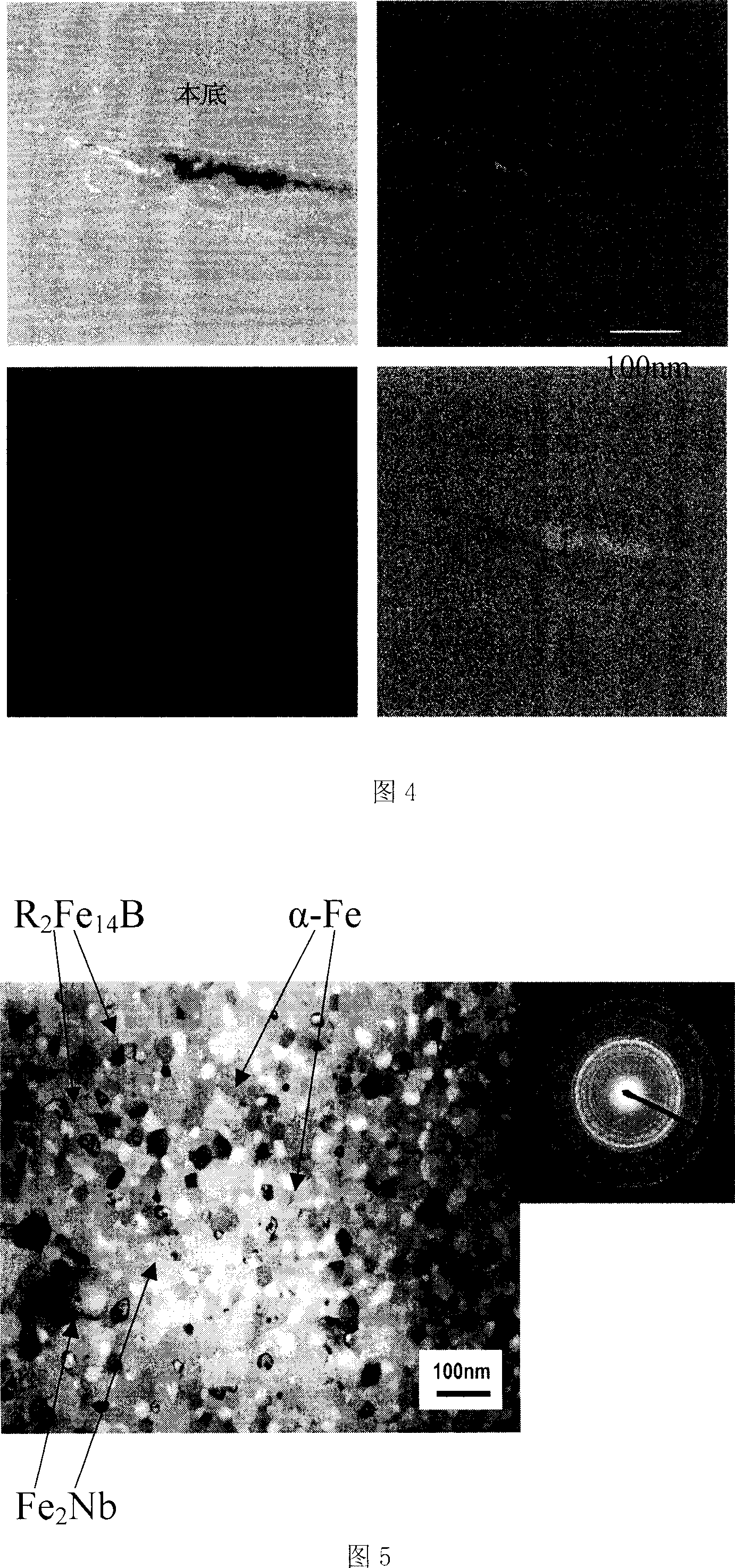

High stability and high magnetism quenched R-Fe-B base permanent magnetic alloy powder

The high stability and high magnetism quenched R-Fe-B base permanent magnetic alloy powder has the basic expression of RxFe100-x-y-z-vMzCovBy, where R is light RE element(s) Nd, Pr and La, and M is element(s) of Nb, Zr, Ti, etc; and consists of main R2Fe14B phase and small amount of superfine auxiliary Fe-alpha-M-beta phase. Adding Nb and other transition elements to form small amount of superfine auxiliary Fe-alpha-M-beta phase during fast solidification can inhibit over nucleation and growth of Nd2Fe14B crystal grain, improve the performance of the quenched material, fine the Nd2Fe14B crystal grain and raise the temperature stability and antioxidant process of the material. In addition, the permanent magnetic alloy powder has obviously raised intrinsic coercive force, high saturated magnetization, high residual magnetism and other advantages.

Owner:DONGFANG MICRON & NANOMETER SCI TECH

Gradient coercive-force neodymium-ferrum-boron magnet and production method thereof

ActiveCN101847487AReduced eddy current lossReduce thermal demagnetizationPermanent magnetsInorganic material magnetismSurface layerMagnetic characteristic

The invention discloses a gradient coercive-force neodymium-ferrum-boron magnet and a production method thereof, and relates to a neodymium-ferrum-boron permanent-magnet material with the gradient coercive-force. The invention aims to provide the gradient coercive-force neodymium-ferrum-boron magnet with high magnetic characteristics and high demagnetization resistance and the production method thereof. The gradient coercive-force neodymium-ferrum-boron magnet comprises at least two neodymium-ferrum-boron magnetic material layers with different coercive forces, including a high coercive force surface layer and at least one low coercive force middle layer, wherein the high coercive force surface layer is connected with the low coercive force middle layer in the orientating direction through a sintered layer.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

Methods for manufacturing cerium-rich anisotropy nano-crystalline rare-earth permanent magnets

ActiveCN104576028AShort thermal deformation timeShorten the production cycleInorganic material magnetismInductances/transformers/magnets manufactureCeriumIngot

The invention discloses a method for manufacturing cerium-rich anisotropy nano-crystalline rare-earth permanent magnets. The method includes (1), proportioning materials according to a chemical formula of (Ce<x>, RE<1-x>)Fe<100-a-b-c>BTM<c>; (2), melting the materials to obtain alloy ingots; (3), crushing the alloy ingots, and then rapidly quenching melt to obtain rapidly quenched magnetic powder; (4), carrying out hot-pressing on the rapidly quenched magnetic powder for 1-10 minutes at the temperatures ranging from 500 DEG C to 800 DEG C under the pressures ranging from 100MPa to 300MPa, and then enabling the rapidly quenched powder to thermally deform for 3-10 minutes at the temperatures ranging from 600 DEG C to 900 DEG C under the pressures ranging from 50MPa to 200MPa. The invention further provides a method for manufacturing the cerium-rich anisotropy nano-crystalline rare-earth permanent magnets according to chemical formulas of (Ce<x>, RE<1-x>)Fe<100-a-b-c>BTM<c> and NdFe<100-a-b-c>BTM<c>. The methods have the advantages that processes can be simplified, the cost can be reduced, and the obtained cerium-rich anisotropy nano-crystalline rare-earth permanent magnets are excellent in magnetic performance.

Owner:SICHUAN UNIV

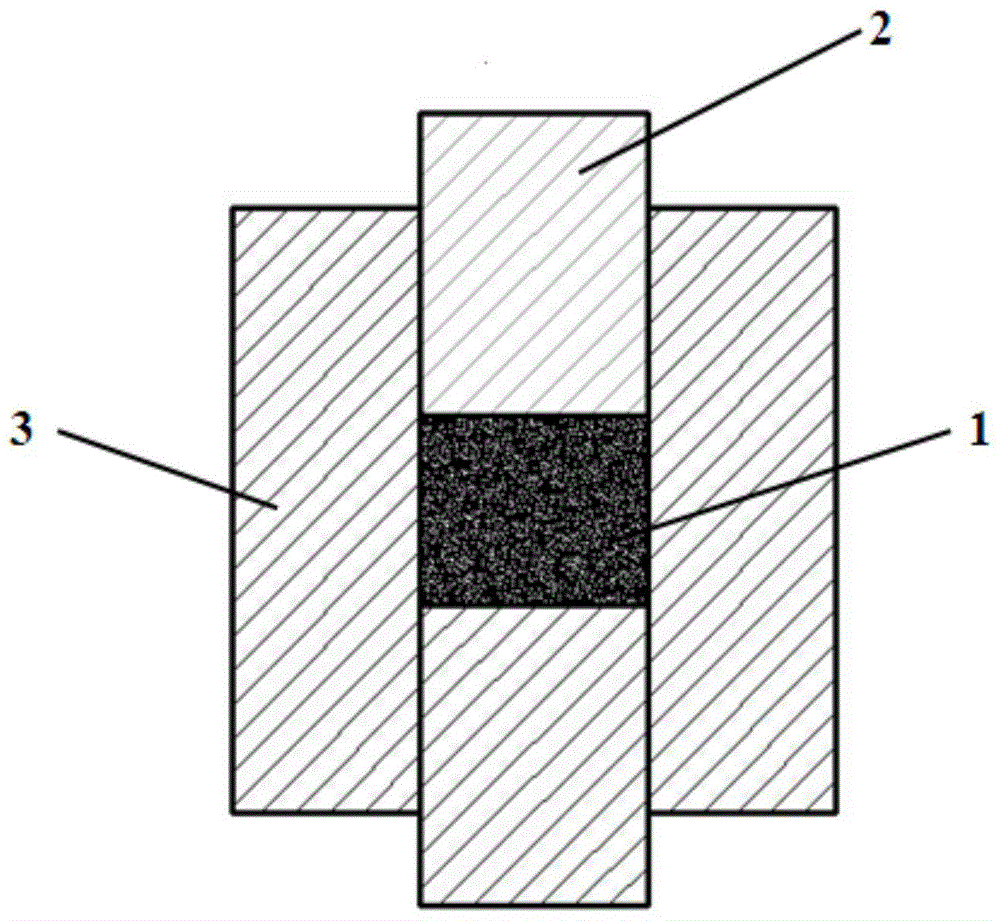

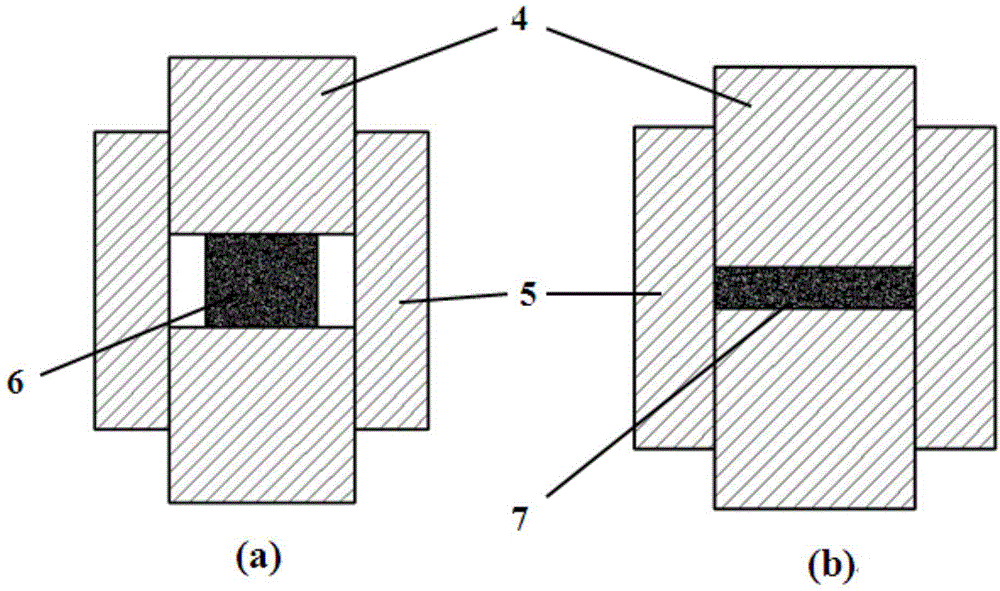

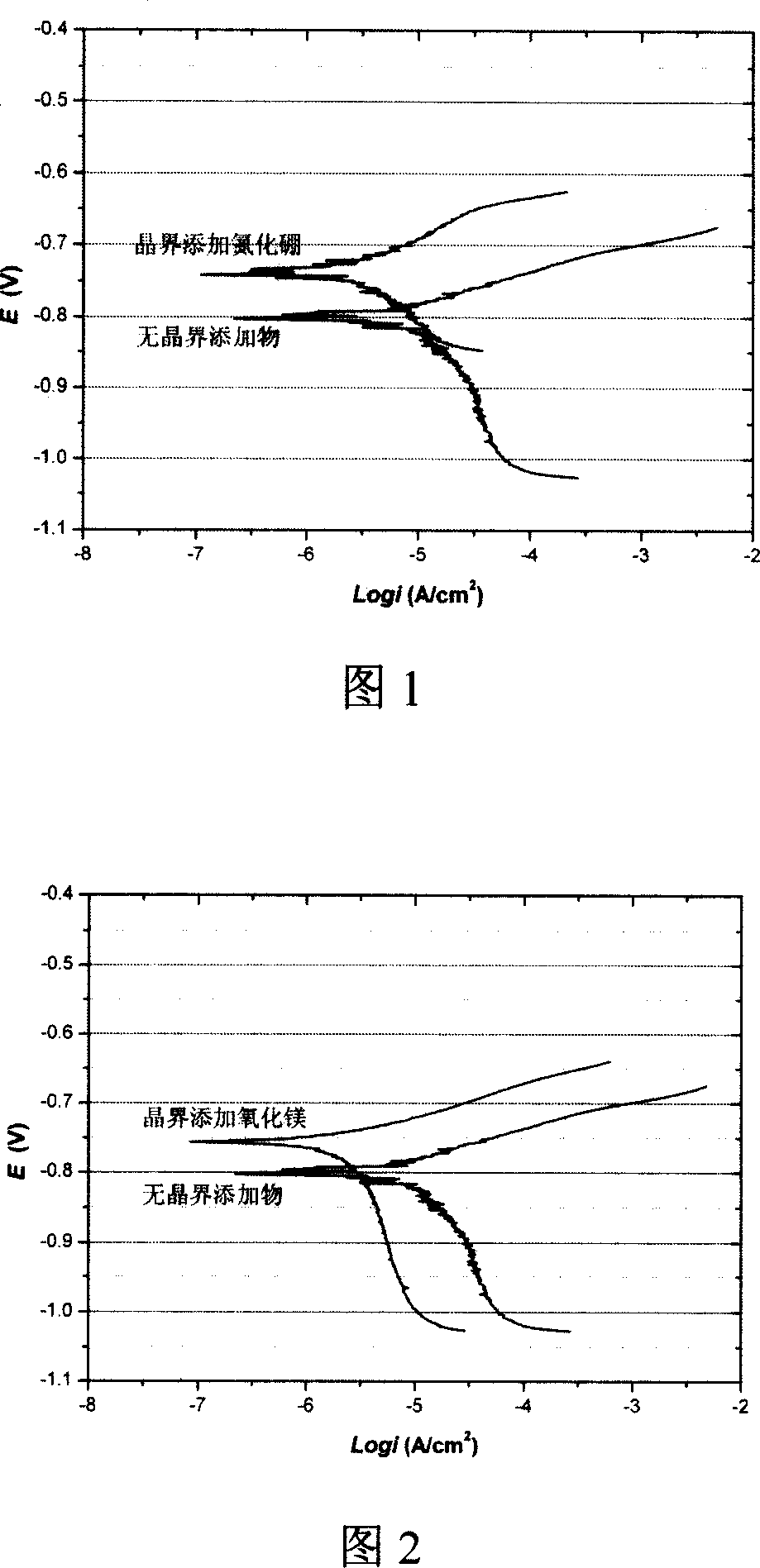

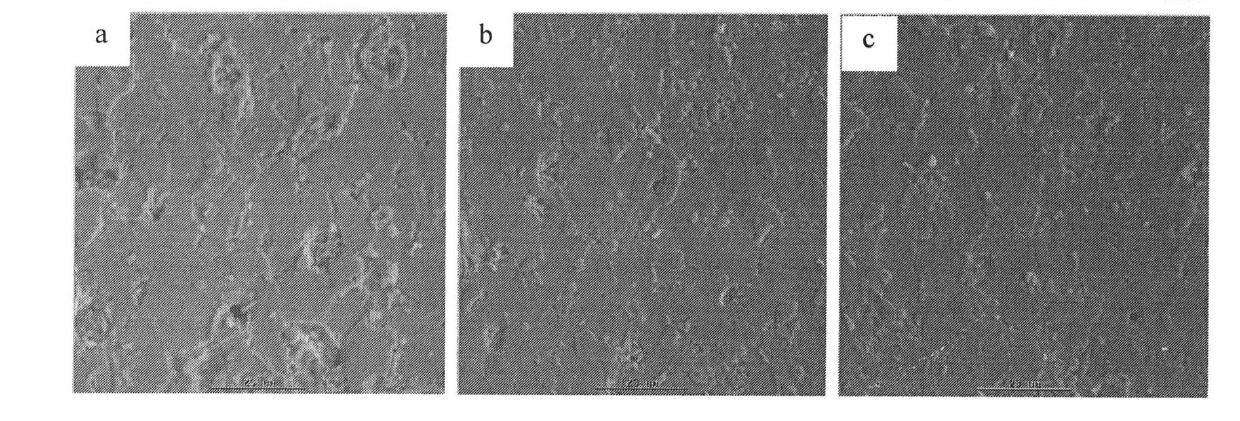

Method for increasing neodymium-iron-boron permanent magnetic performance and corrosion-resisting performance

The method includes steps: (1) using ingot-casting technique to manufacture Nd-Fe-B ingot-casting alloy, or using technique of rapid hardening sheet to produce rapid hardening sheet of Nd-Fe-B alloy; (2) first carrying out coarse crushing for alloy, then producing powder through airflow grinding; (3) adding powder of boron nitride or magnesia, and mixing them evenly; (4) pressure molding oriented mixed powders under magnetic field, and then carrying out cold isopressing process for blanks; (5) sintering and tempering blanks in high vacuum sintering furnace. Nd-Fe-B magnet produced according to the invention possesses better magnetic performance and corrosion resistance than magnetic performance and corrosion resistance of magnet without adding powder of boron nitride or magnesia.

Owner:SHANGHAI JIAO TONG UNIV

Neodymium iron boron magnet, preparation method and device applying same

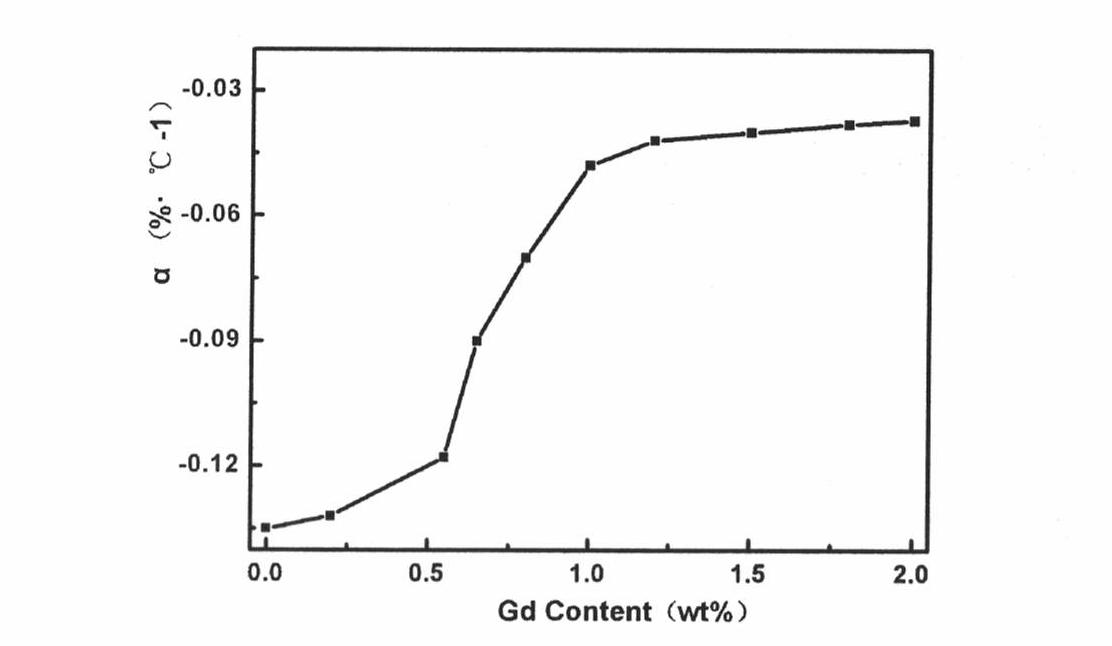

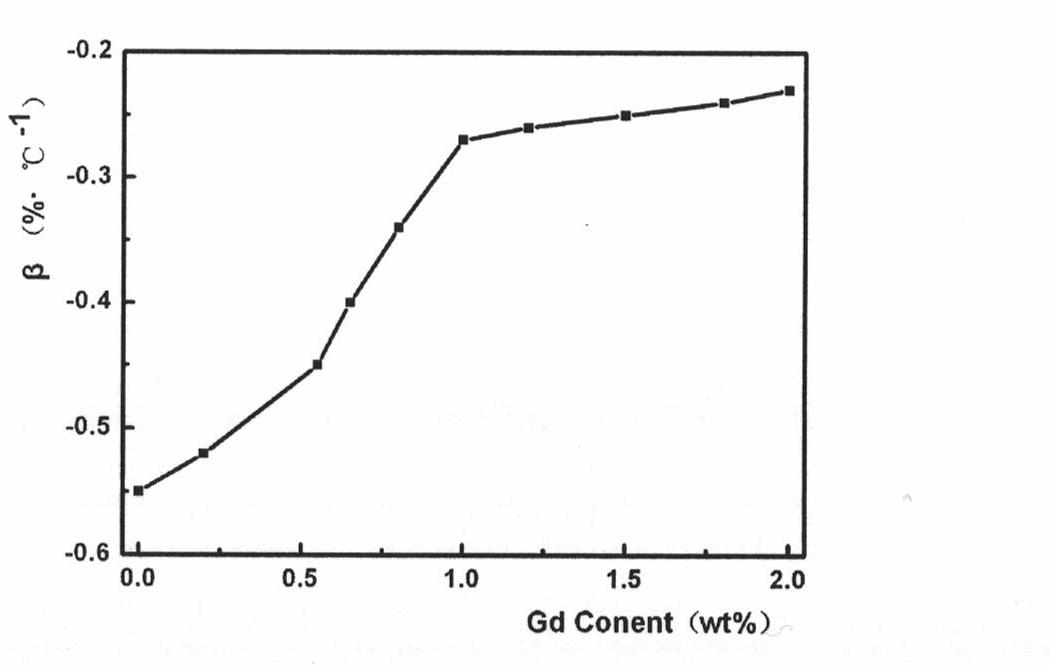

ActiveCN102103917ASmall temperature coefficientImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementMetallurgy

The invention discloses a neodymium iron boron magnet, a preparation method and a device applying the same, belonging to the field of magnetic materials. The magnet comprises the following components in percentage by weight according to the general formula: 27 to 35 percent of R representing one or two rare-earth elements except Gd, 0.55 to 2 percent of Gd, 0.5 to 3.5 percent of Co, 0.05 to 0.5 percent of M1 representing one transition metal element such as Cu, Al or Ge, 0 to 0.5 percent of M2 being one or two transition metal elements except Co and M1, 0.9 to 1.2 percent of B (namely boron) and the balance of Fe and unavoidable impurities. The neodymium iron boron magnet disclosed by the invention is compounded with Gd, Co, M1 and M2, thus the reversible magnetic induction temperature coefficient alpha and the coercive force temperature coefficient beta are better improved, the coercive force of the magnet is greatly improved while the magnetic energy product and residual magnetism are guaranteed not to reduce, the heavy rare earth element Gd is effectively utilized, and the performance is improved while the manufacturing cost is well saved.

Owner:GRIREM ADVANCED MATERIALS CO LTD

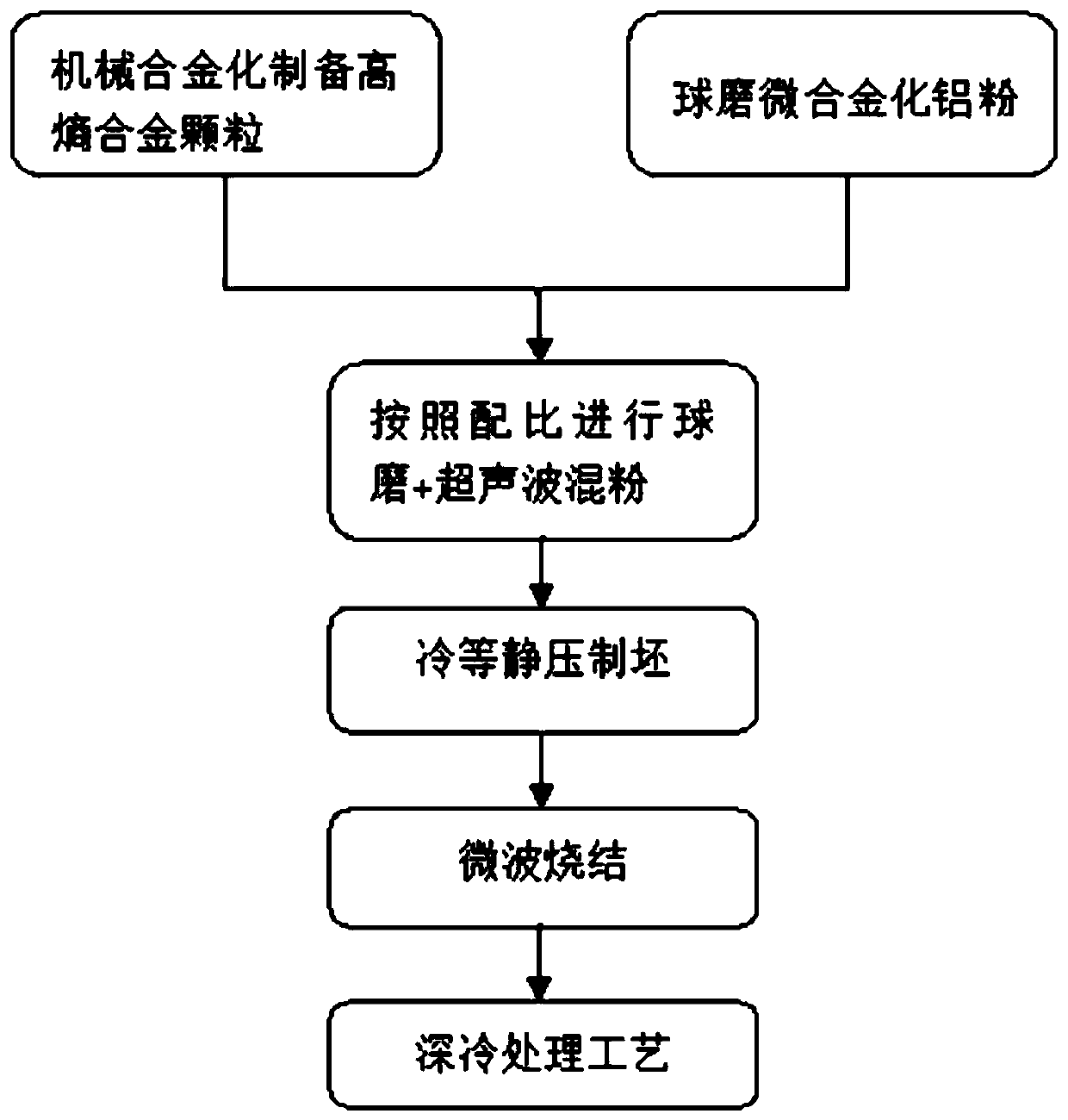

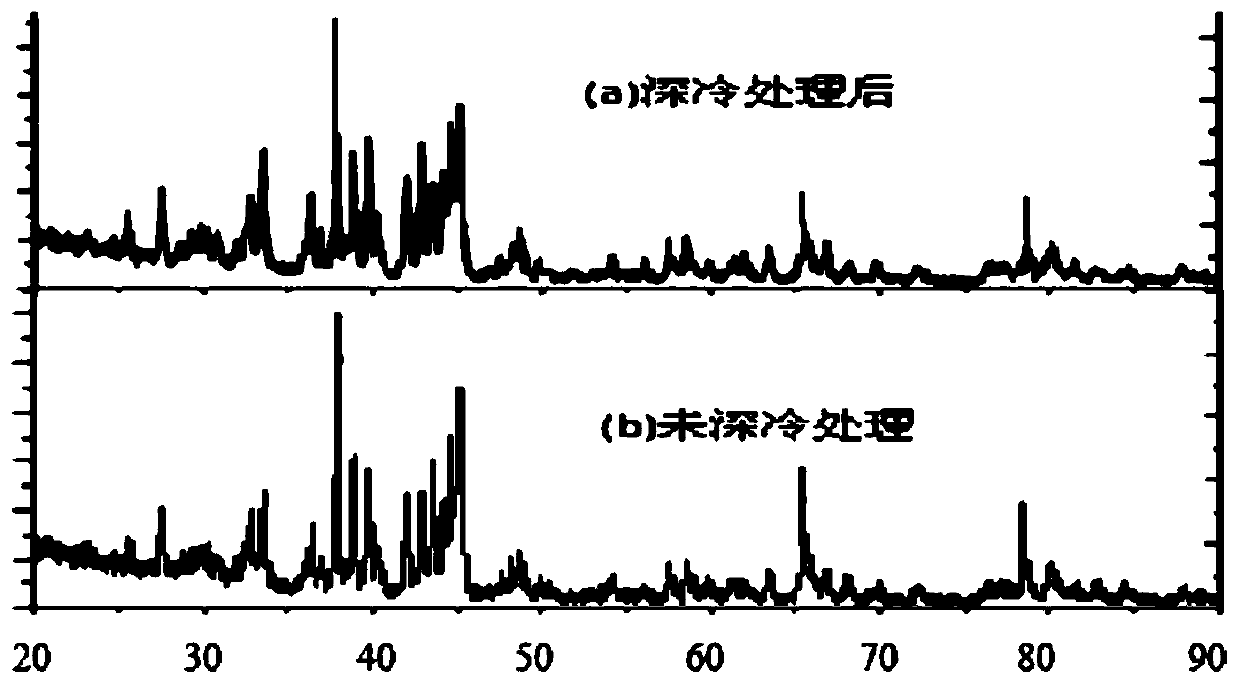

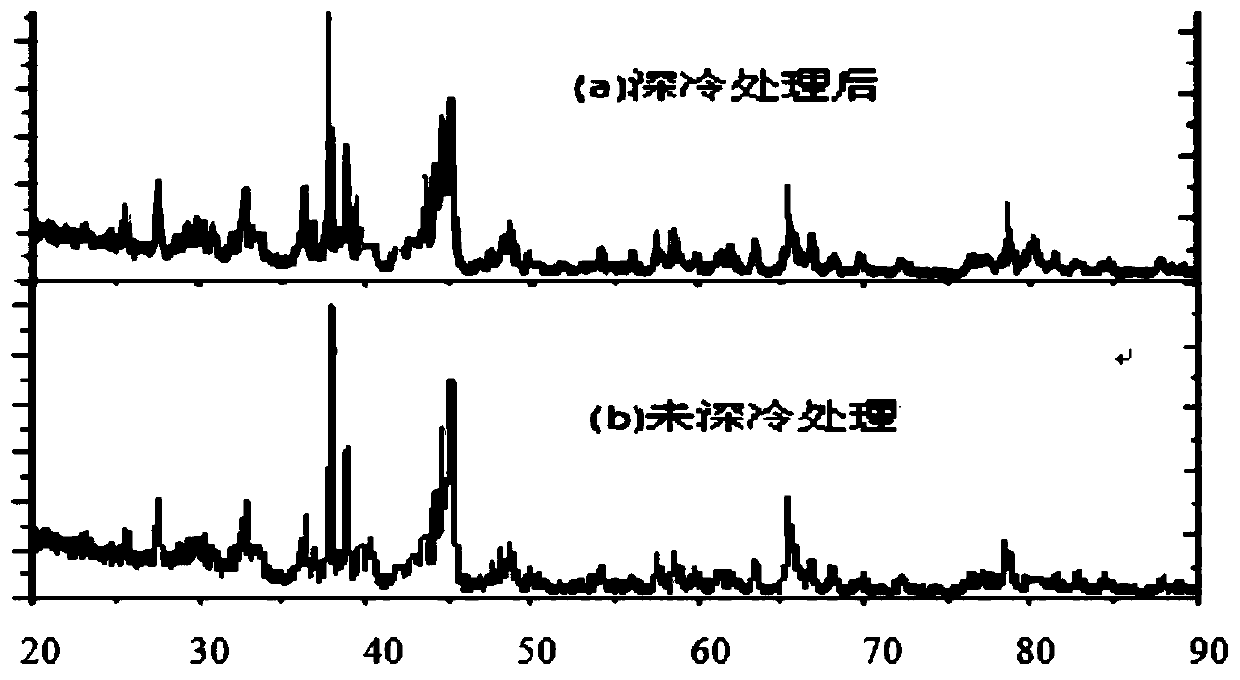

High-entropy alloy particle reinforced cryogenic treatment aluminum-based composite material and preparation method thereof

ActiveCN110523997AHigh strengthEvenly distributedTransportation and packagingMetal-working apparatusCompression moldingMaterials preparation

The invention belongs to the technical field of composite material preparation, and particularly relates to a high-entropy alloy particle reinforced cryogenic treatment aluminum-based composite material and a preparation method thereof. High-entropy alloy components are optimally designed, then vacuum ball milling is conducted to prepare high-entropy alloy, and high-entropy alloy powder and microalloyed aluminum matrix powder are evenly mixed in proportion and dried to obtain mixed powder; compression molding is performed by utilizing isostatic cool pressing to obtain a composite billet; a microwave sintering process is adopted to obtain a high-entropy alloy particle reinforced aluminum-based composite material; and finally, cryogenic treatment is performed on the aluminum-based compositematerial. According to the high-entropy alloy particle reinforced aluminum-based composite material, the strength and plasticity of the aluminum-based composite material are improved, and meanwhile the aluminum-based composite material can have good magnetic performance.

Owner:JIANGSU UNIV

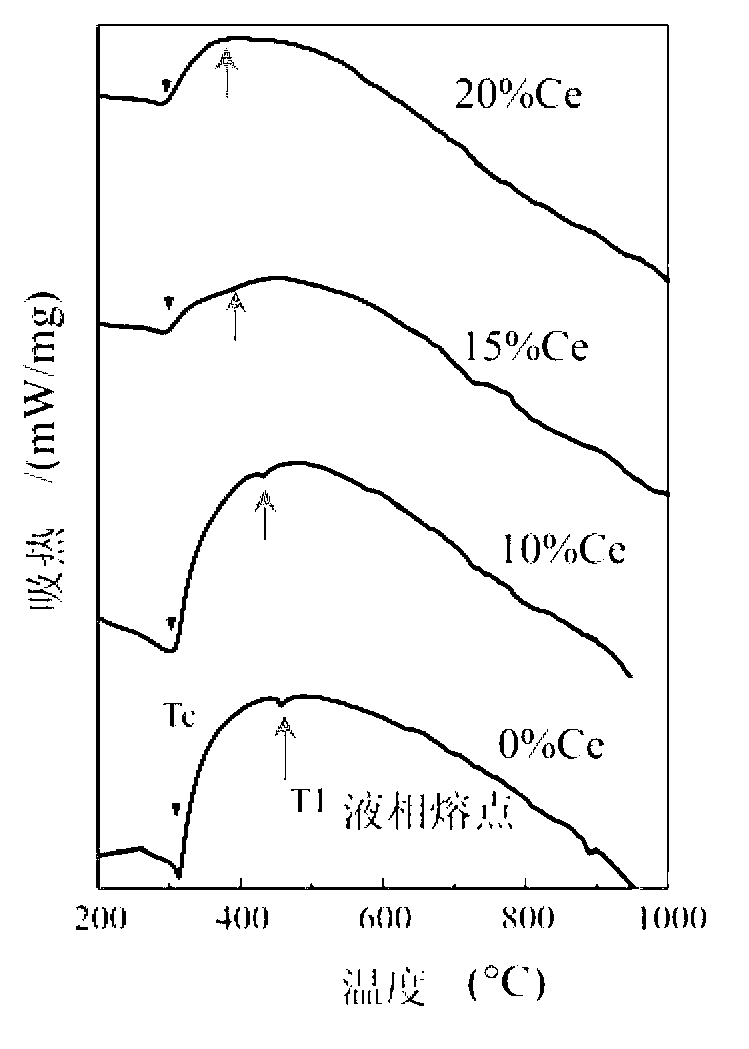

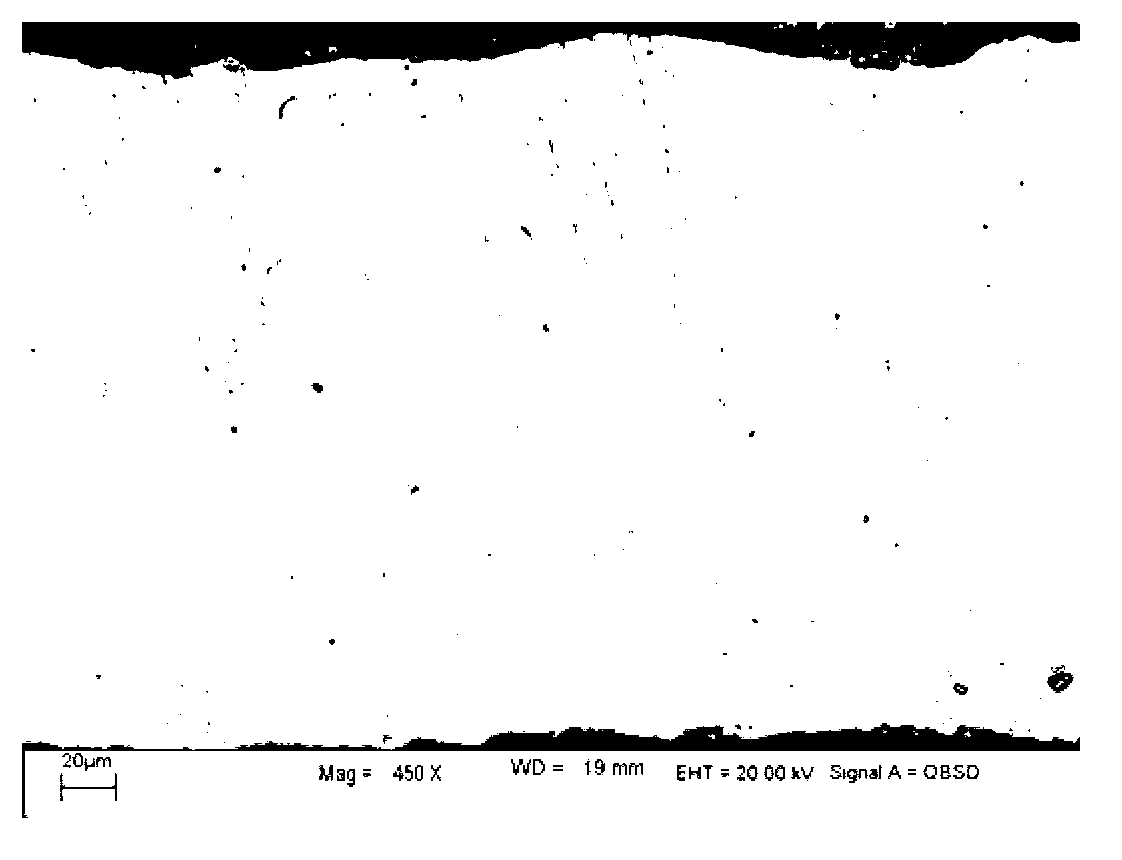

Cerium-containing low-melting-point rare-earth permanent magnet liquid phase alloy and production method of permanent magnet comprising same

ActiveCN103280290AReduce entryImprove remanenceMagnetic liquidsInductances/transformers/magnets manufactureCeriumRare earth

The invention relates to the technical field of rare-earth permanent magnet materials, in particular to cerium-containing low-melting-point rare-earth permanent magnet liquid phase alloy, a permanent magnet comprising the liquid phase alloy and a production method of the permanent magnet. According to mass percent, the chemical formula of the liquid phase alloy is that (Cex,Nd1-x)y-Mz-Fe100-y-z, wherein 0.1<=x<=1.0, 0.04<=y<=0.9, 0<=z<=5, M is one or several of Co, Al, Cu, Ga, Nb, Mo, Ti, Zr and V. The liquid phase alloy is added in an alloy or rapid hardening mode, cerium elements entering the principal phase can be reduced and the residual magnetism can be improved by aid of scientific and reasonable composition design, the sintering temperature of the neodymium iron boron magnet can be reduced through the low-melting-point liquid phase, and therefore low-temperature sintering is achieved, and reducing of the crystal grain dimension of the magnet is benefited. The microstructure of the liquid phase is controlled through the oxygen content so that the liquid phase is ensured to be of a cerium-containing face-centered cubic structure with high coercivity, further the coercivity of the magnet is improved, and good combination property can be obtained.

Owner:CENT IRON & STEEL RES INST

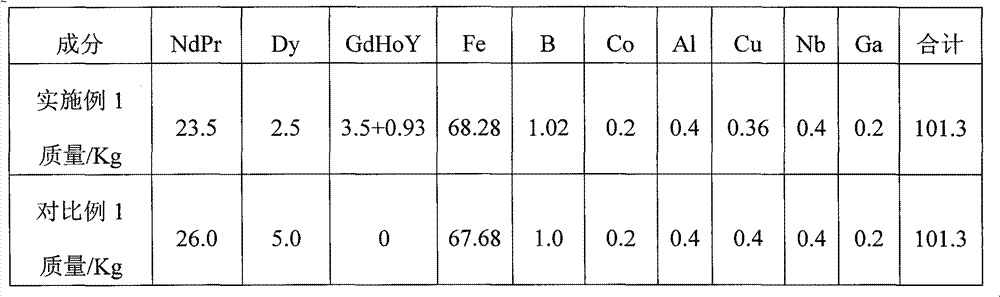

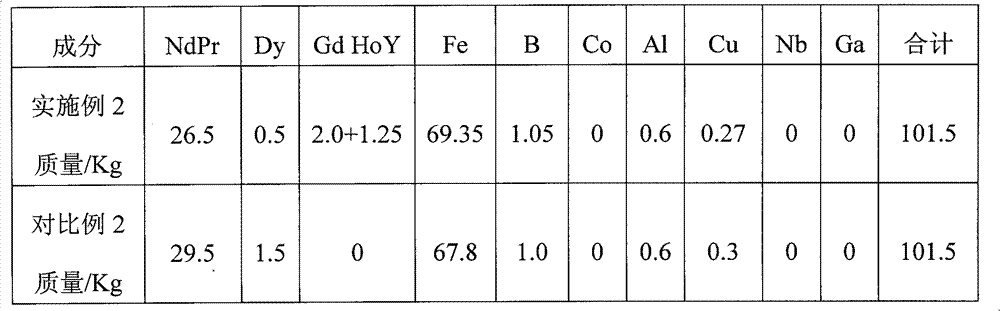

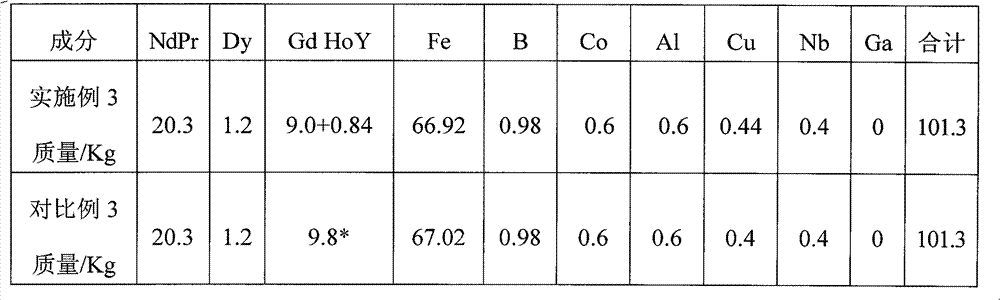

Method for preparing composite sintered neodymium-iron-boron permanent magnet material added with gadolinium, holmium and yttrium

ActiveCN102956336AImprove remanenceIncrease the maximum energy productInorganic material magnetismRare-earth elementCurie temperature

The invention provides a method for preparing a composite sintered neodymium-iron-boron permanent magnet material added with gadolinium, holmium and yttrium. The method includes the steps of primary batching, fusion casting, milling, secondary batching, powder mixing, forming, sintering and heat treatment, wherein in the primary batching step, iron alloy added with three rare earth elements of the gadolinium, the holmium and the yttrium is composited, and in the secondary batching step, oxide added with the three rare earth elements of ultrafine gadolinium, holmium and yttrium and cuprous oxide powder are composited. By the method, the relative surplus and cheap gadolinium, holmium and yttrium can be used for partially substituting for rare earth elements of neodymium, praseodymium or dysprosium, and accordingly neodymium, praseodymium or dysprosium consumption can be decreased by 10-30wt.%. Besides, Curie temperature and coercivity force of the prepared neodymium-iron-boron permanent magnet material are increased, corrosion resistance is enhanced, operating temperature and toughness are increased, and processability is improved.

Owner:GANZHOU JIATON ADVANCED MATERIALS

Method of raising permanent magnetic ferrite residual magnetization by adding additive

InactiveCN1414575AImprove remanenceHigh energy productInorganic material magnetismStrontiumSilicon dioxide

An additive to be used for raising the residual magnetism of ferrite in permanent magnetism adds an additive of raising the residual magnetism with the molecular formula of MxSiyO2, where X=1=4, y=0-2, Z=2-6 in addition to add calcium carbonate and 1-4 additives of kaolin silica, aluminium oxide and boracic acid to increase its coercive force in the secondary process during production course of strontium ferrite or barium ferrite, where X, Y and Z can be decimal and M is one or more kinds of mixtures of Fe, Pr, Nd, Mn, Sr and C. With the same raw material, by use of the additive of MxSiyO2 ofthe present invention, the residual magnetism can be raised by 50-150 Gs based on 3600-4100 Gs.

Owner:BGRIMM TECH CO LTD +2

Production method for rare earth permanent magnet

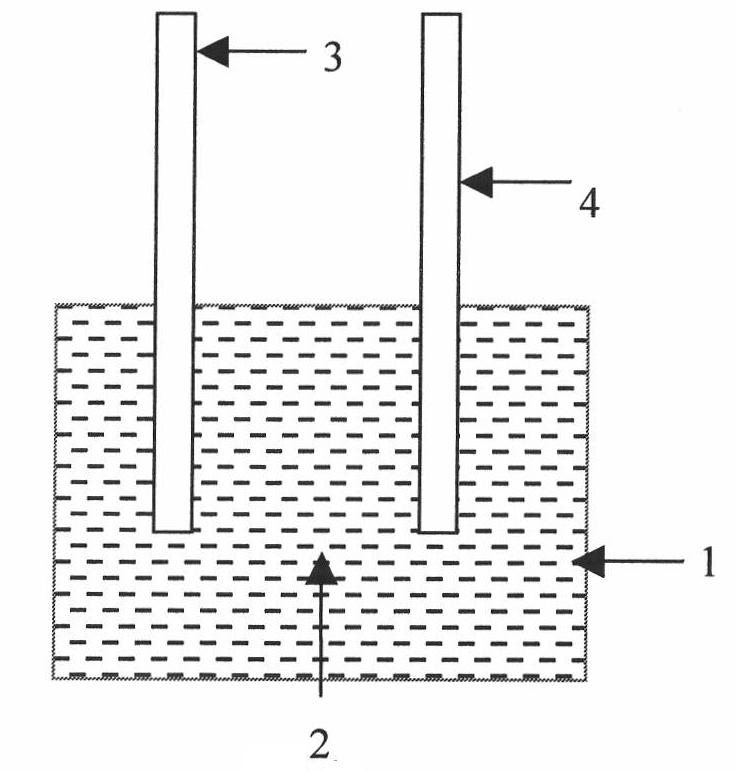

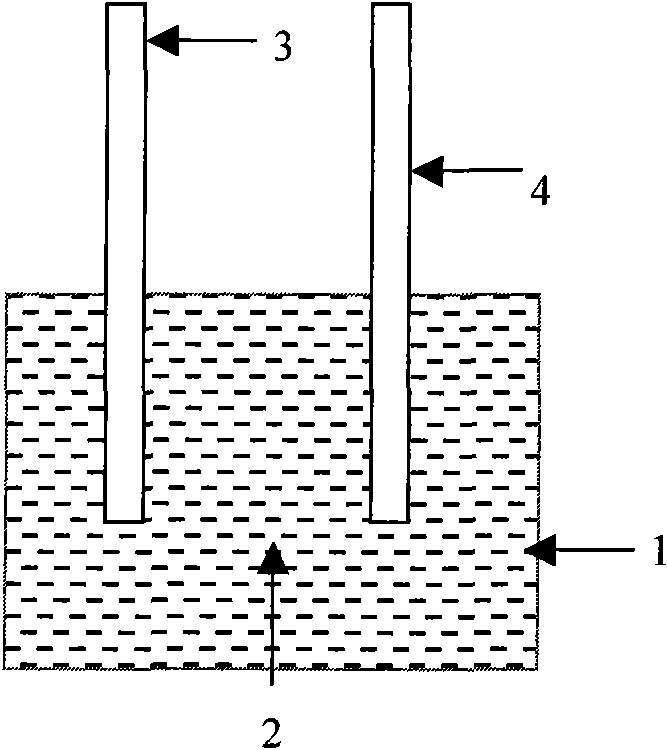

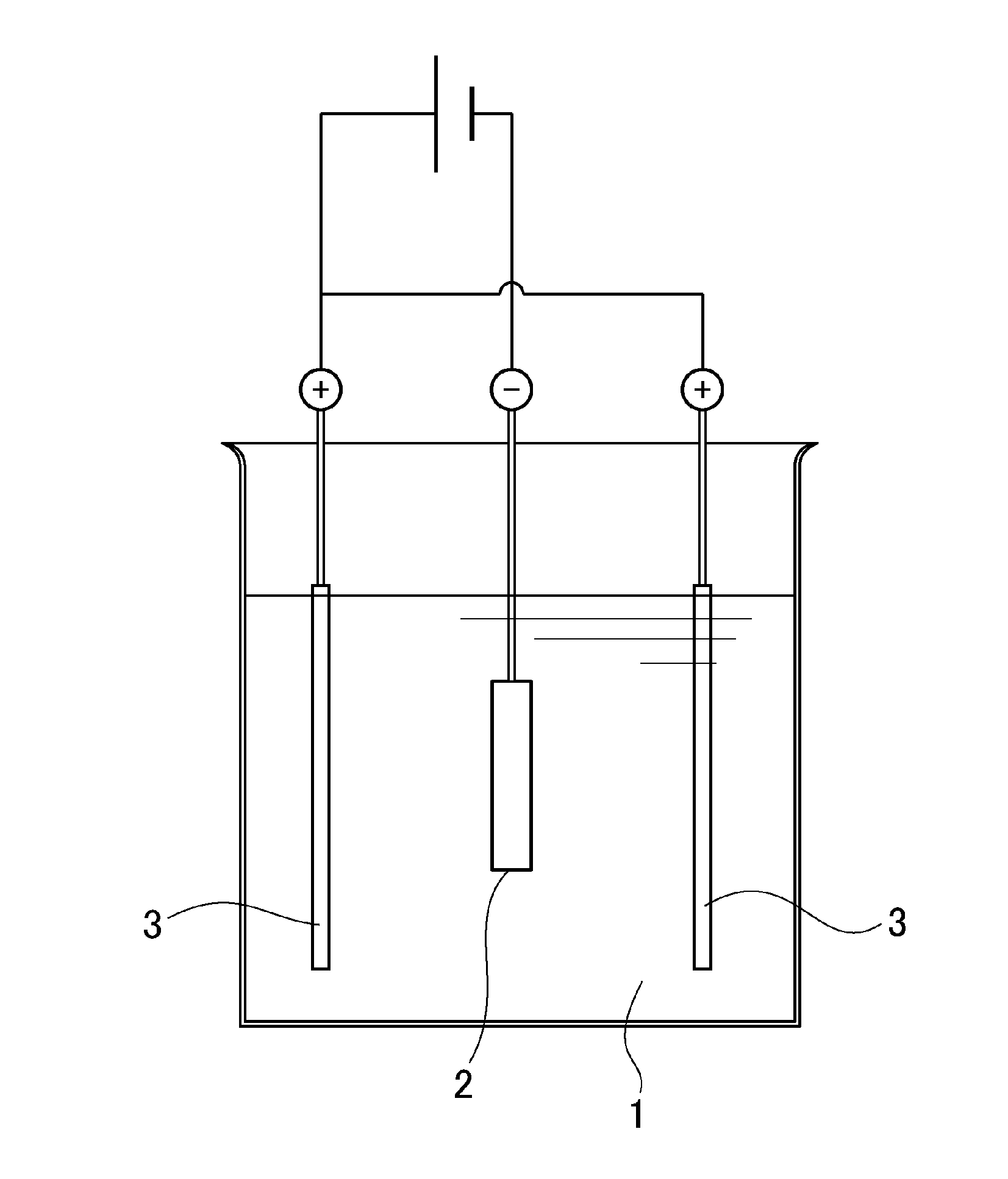

ActiveUS20150211139A1Improve remanenceEfficient preparationInorganic material magnetismElectrophoretic coatingsRare-earth elementSintered magnets

A production method for a rare earth permanent magnet, wherein: a sintered magnet body comprising an R1—Fe—B composition (R1 represents one or more elements selected from among rare earth elements, including Y and Sc) is immersed in an electrodeposition liquid comprising a slurry obtained by dispersing a powder containing an R2 fluoride (R2 represents one or more elements selected from among rare earth elements, including Y and Sc) in water; an electrodeposition process is used to coat the powder onto the surface of the sintered magnet body; and, in the state in which the powder is present on the surface of the magnet body, the magnet body and the powder are subjected to a heat treatment in a vacuum or an inert gas at a temperature equal to or less than the sintering temperature of the magnet.

Owner:SHIN ETSU CHEM IND CO LTD

Commercial rare earth permanent magnet produced from high-abundance rare earth and preparing method thereof

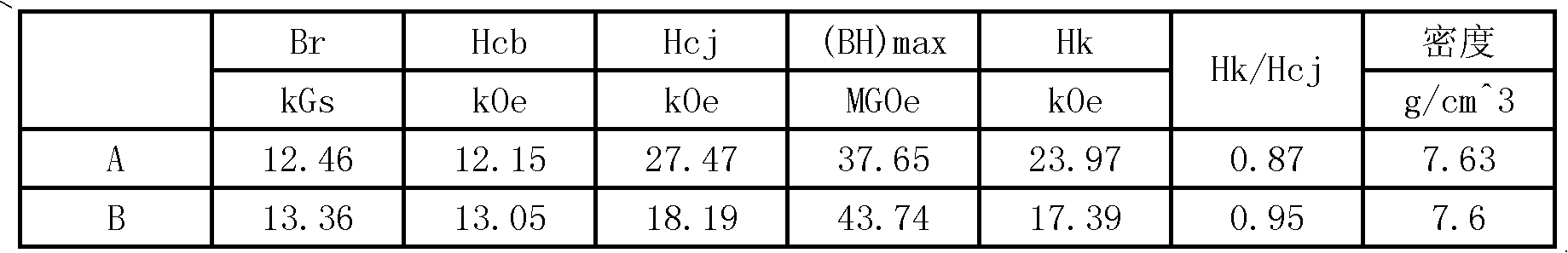

ActiveCN103794323AImprove remanenceHigh energy productPermanent magnetsInductances/transformers/magnets manufactureElectrode potentialRemanence

The invention discloses a commercial rare earth permanent magnet produced from high-abundance rare earth and a preparing method of the commercial rare earth permanent magnet. The commercial rare earth permanent magnet comprises a main phase and a grain boundary modification phase, wherein the main phase comprises low H (RE100-aMMa)-Fe-B alloy and high H Nd-Fe-B alloy. According to the commercial rare earth permanent magnet, two kinds of main alloy is adopted, the ingredients of the magnet are controlled, a stable 2:14:1 phase is formed by the high-abundance rare earth, and decomposing will not happen in the sintering process; the Cu element high in electrode potential is added into the grain boundary modification phase, the corrosion resistance of the magnet is improved, and meanwhile the microstructure of the magnet can be optimized by the grain boundary modification phase. According to the method, the two main alloy method is combined with the grain boundary modification technology, the advantages of both the two main alloy method and the grain boundary modification technology are achieved simultaneously, the problems that because of addition of the high-abundance rare earth, the corrosion resistance, the residual magnetism and the magnetic energy product of the magnet are reduced are solved, and the prepared rare earth permanent magnet meets the application requirements of commercial magnets.

Owner:ZHEJIANG UNIV +1

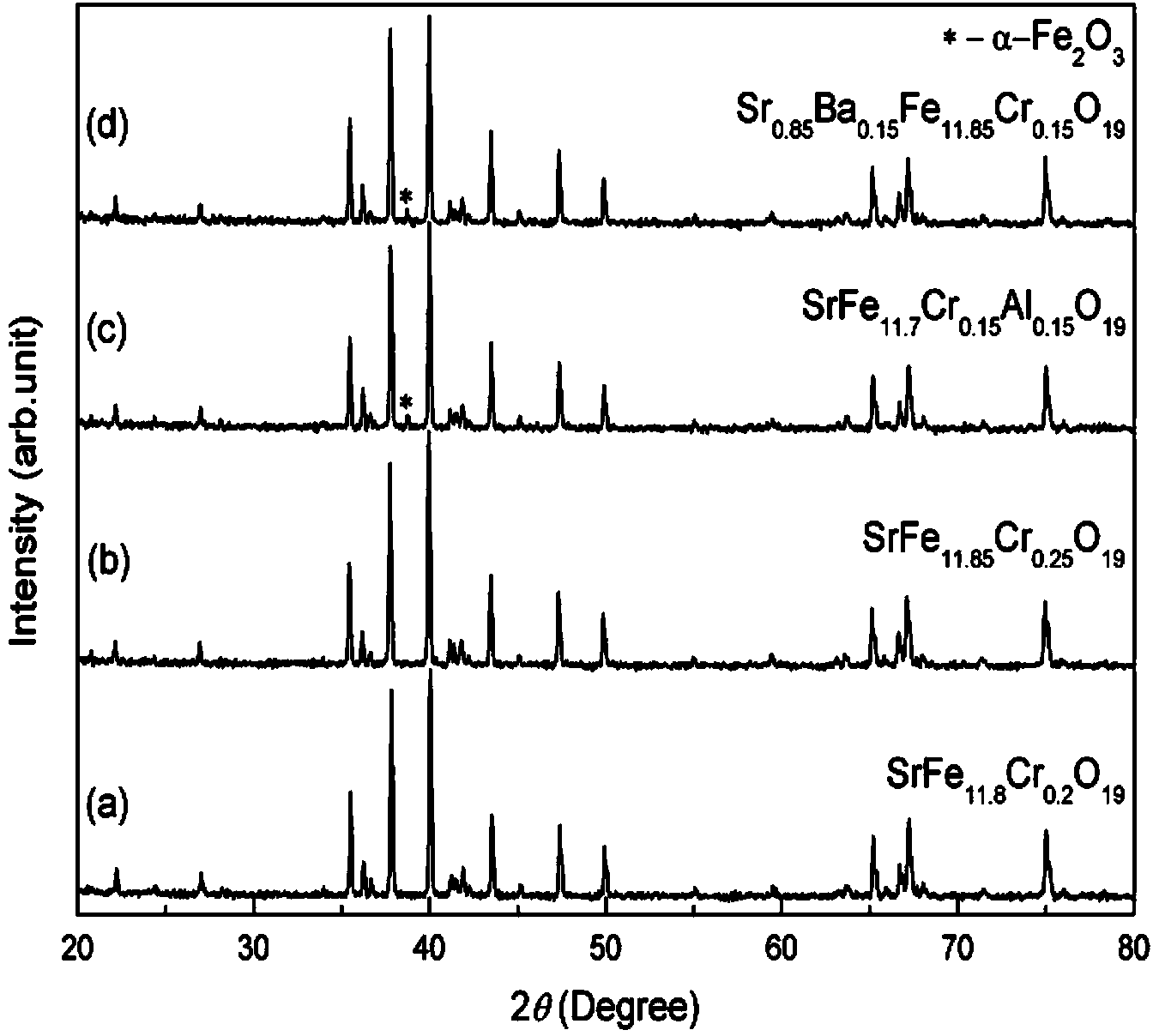

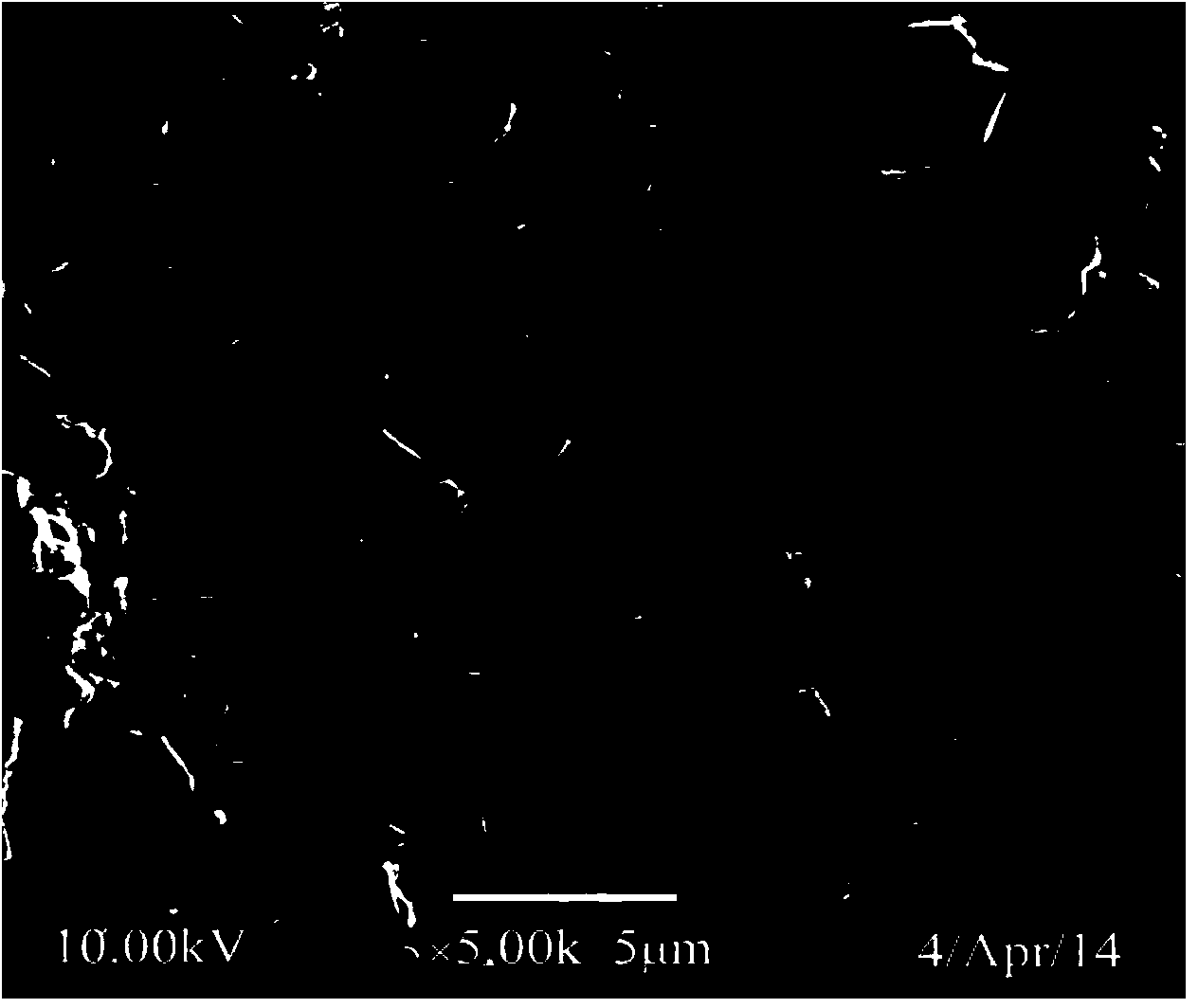

High-performance permanent magnet ferrite material and preparing method thereof

The invention relates to a high-performance permanent magnet ferrite material and a preparing method thereof and belongs to the technical field of magnetic function material preparation. The invention adopts the technical scheme as follows: carrying out preparation according to a main phase molecular formula Sr1-xBaxO.nFe(12-y) / nRy / nO3, wherein x is not smaller than 0 and not bigger than 0.998, n is not smaller than 5.75 and not bigger than 6.15, y is bigger than 0 and not bigger than 0.6, R refers to Cr or Cr and Al, and the content of Cr and Al is smaller than or equal to 0.6 when R refers to Cr and Al; secondarily adding one or more than two of industrial-purity CeO2, Ga2O3 and MoO3. The rest magnetism Br value of the high-performance permanent magnet ferrite prepared by the method is larger than or equal to 390mT, the intrinsic coercivity Hcj value is larger than or equal to 346.1kA / m, and the magnetic energy product (BH)max value is larger than or equal to 28.7kJ / m<3>. The method has the advantages that the high-performance permanent magnet ferrite material with a high performance-to-cost ratio is prepared through the relatively cheap chromium or chromium and aluminum substituted combination additive without adding expensive rare earth and rare metal oxide.

Owner:合肥领远新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com