High stability and high magnetism quenched R-Fe-B base permanent magnetic alloy powder

A permanent magnetic alloy powder, high stability technology, applied in the chemical industry, can solve the problem of narrow parameter window, difficult to grasp, etc., to achieve the effect of improving performance and quality, improving microscopic grain structure, and enhancing temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

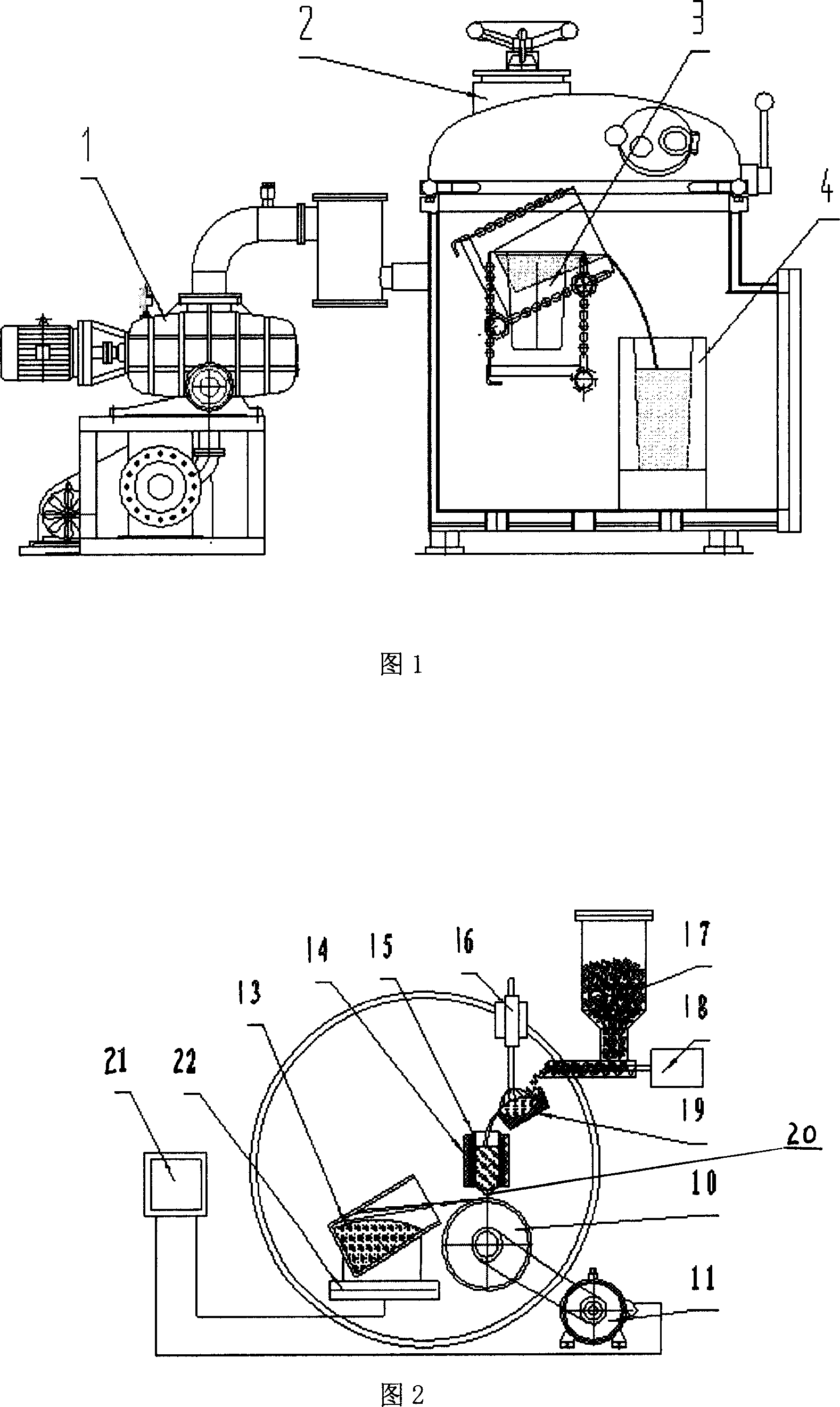

Method used

Image

Examples

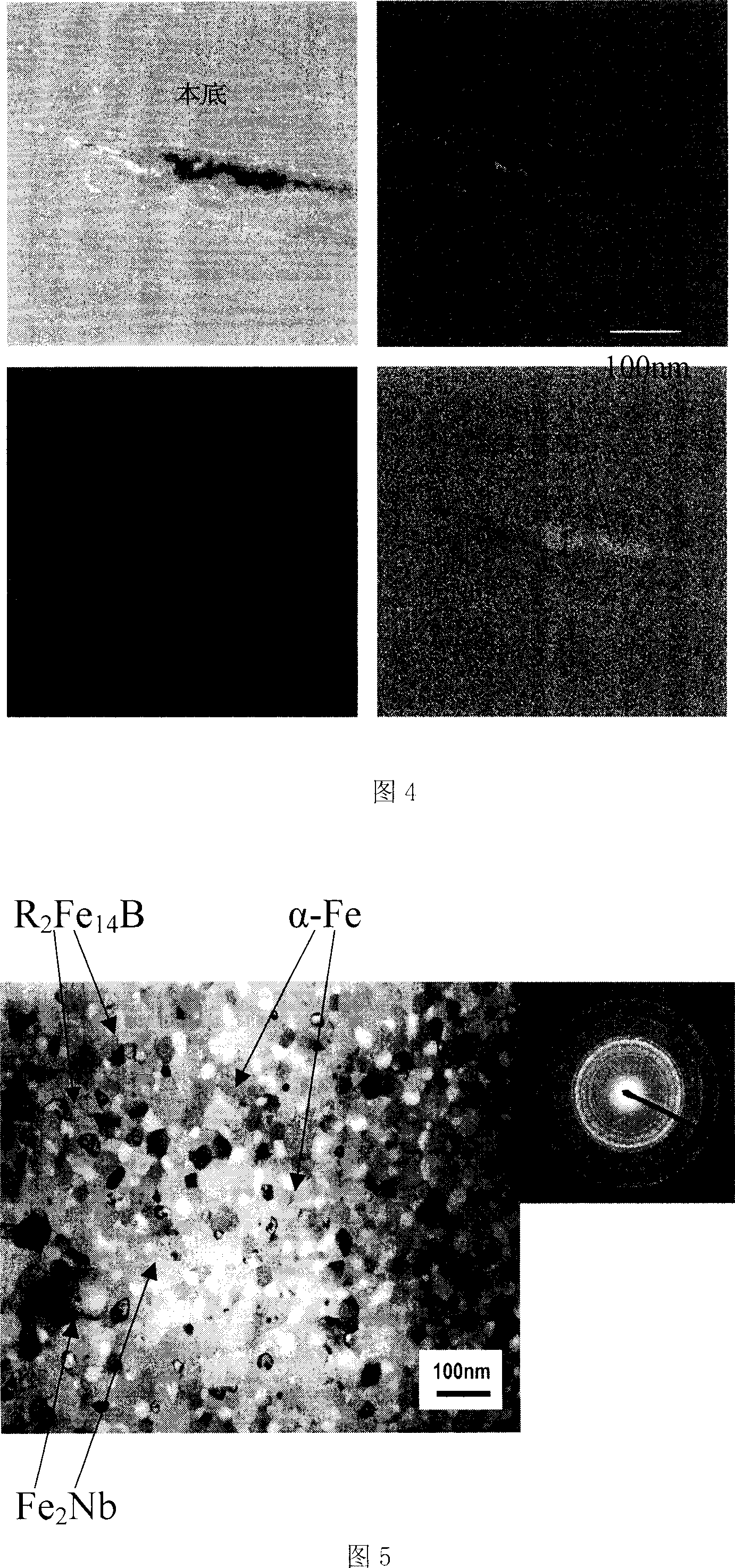

Embodiment 1

[0069] According to the following ingredient formula, the purity is 99.9% Nd metal, and the atomic percentage is 8.1%; Fe-B alloy (wherein the content of B is 19%), and the atomic percentage of B is 5.9%; Fe-Nb alloy (Nb's The content is 67%), the atomic percentage of Nb is 4.0%; the atomic percentage of iron is 82.0%. According to the alloy process (1) described herein, 40 kilograms of alloy ingots are made, and the composition of the retested alloy is correct. With the quick quenching powder making process (2) described in this article, make quick quenching magnetic powder, keep the temperature of the quartz nozzle cavity at 1375 ° C, the spray speed is 0.5-0.7 kg / min, and the wheel speed is 27 m / s about. The crystallization temperature was kept at 650° C., and the crystallization time was 10 minutes. The prepared magnetic powder is measured with a vibrating sample magnetic phase meter (VSM), and the magnetic properties of the magnetic powder are as follows: Br=0.892T, Hcj...

Embodiment 2

[0071] According to the following ingredient formula, the purity is 99.9% Nd metal, and the atomic percentage is 9.5%; Fe-B alloy (wherein the content of B is 19%), and the atomic percentage of B is 5.9%; Fe-Nb alloy (Nb's The content is 67%), the atomic percentage of Nb is 2.6%; the atomic percentage of iron is 82.0%. According to the alloy process (1) described herein, 40 kilograms of alloy ingots are made, and the composition of the retested alloy is correct. With the quick quenching powder making process (2) described in this article, make quick quenching magnetic powder, keep the temperature of the quartz nozzle cavity at 1375 ° C, the spray speed is 0.5-0.7 kg / min, and the wheel speed is 27 m / s about. The crystallization temperature was kept at 680° C., and the crystallization time was 10 minutes. The prepared magnetic powder is measured with a vibrating sample magnetic phase meter (VSM), and the magnetic properties of the magnetic powder are as follows: Br=0.895T, Hcj...

Embodiment 3

[0073] According to the following ingredient formula, (A) the Nd metal with a purity of 99.9%, the atomic percentage is 12.1%; the Fe-B alloy (wherein the content of B is 19%), the atomic percentage of B is 5.5%; the metal Co, The atomic percentage is 5.5%; the atomic percentage of iron is 76.9%. (B) Nd metal with a purity of 99.9%, 11.1% atomic number; Fe-B alloy (wherein B content is 19%), B 5.5 atomic%; metal Co, 5.5 atomic% ; Fe-Nb alloy (Nb content is 67%), the atomic percentage of Nb is 1.0%; the atomic percentage of iron is 76.9%. According to the alloy process (1) described herein, 40 kilograms of alloy ingots are made, and the composition of the retested alloy is correct. With the quick quenching powder making process (2) described in this article, make quick quenching magnetic powder, keep the temperature of the quartz nozzle cavity at 1375 ° C, the spray speed is 0.5-0.7 kg / min, and the wheel speed is 27 m / s about. The crystallization temperature is controlled at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com