Patents

Literature

2514 results about "Plough" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A plough (UK) or plow (US; both /plaʊ/) is a tool or farm implement used for initial cultivation to loosen or turn the soil in preparation for sowing seed or planting. Ploughs were traditionally drawn by working animals such as oxen and horses, but in modern farms are drawn by tractors. A plough may be made of wood, iron, or steel frame with an attached blade or stick used to cut and loosen the soil. It has been a basic instrument for most of history, and is one of the most significant inventions. The earliest ploughs were wheelless, with the Romans using a wheelless plough called the aratrum, but Celtic peoples began using wheeled ploughs during the Roman era.

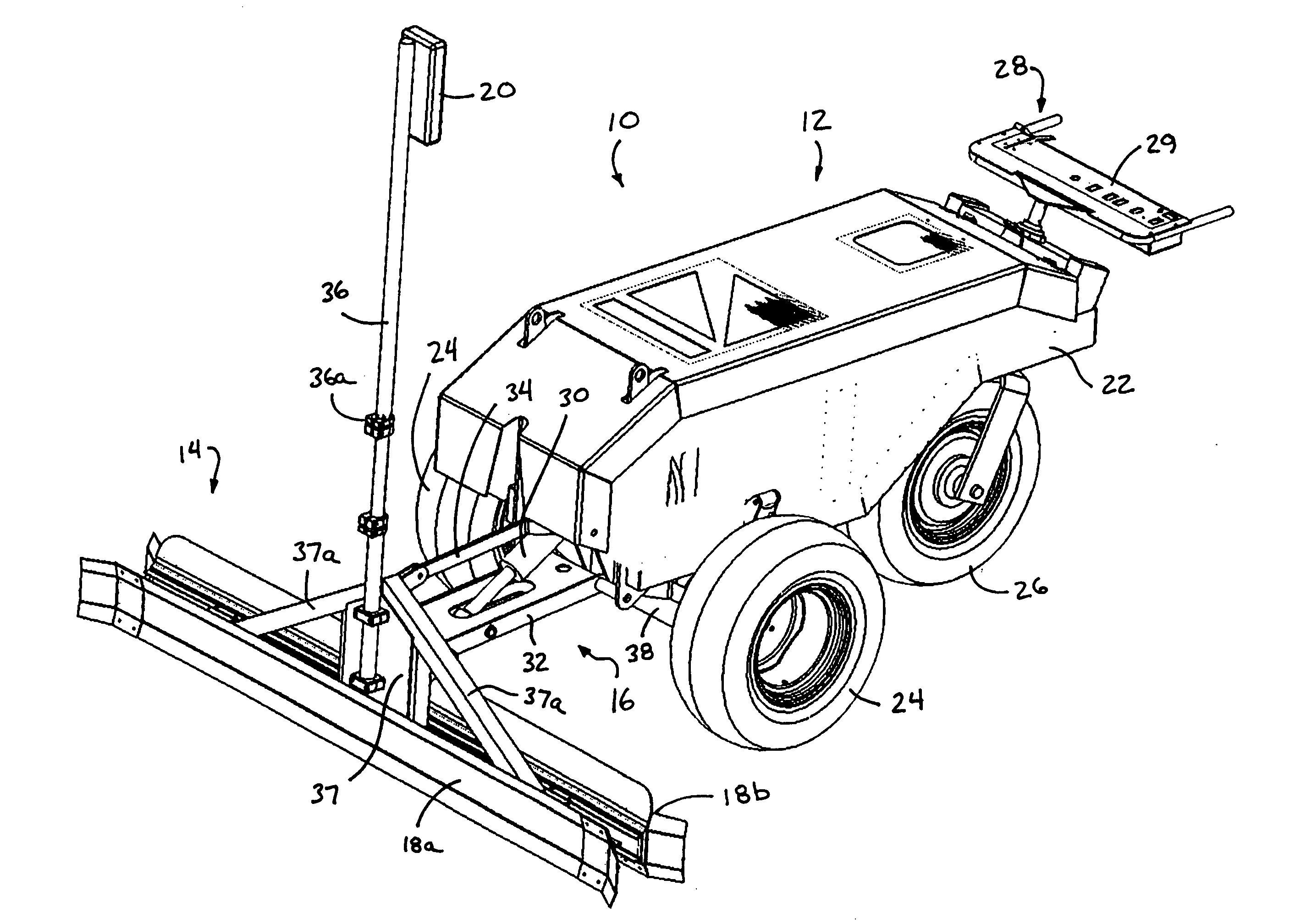

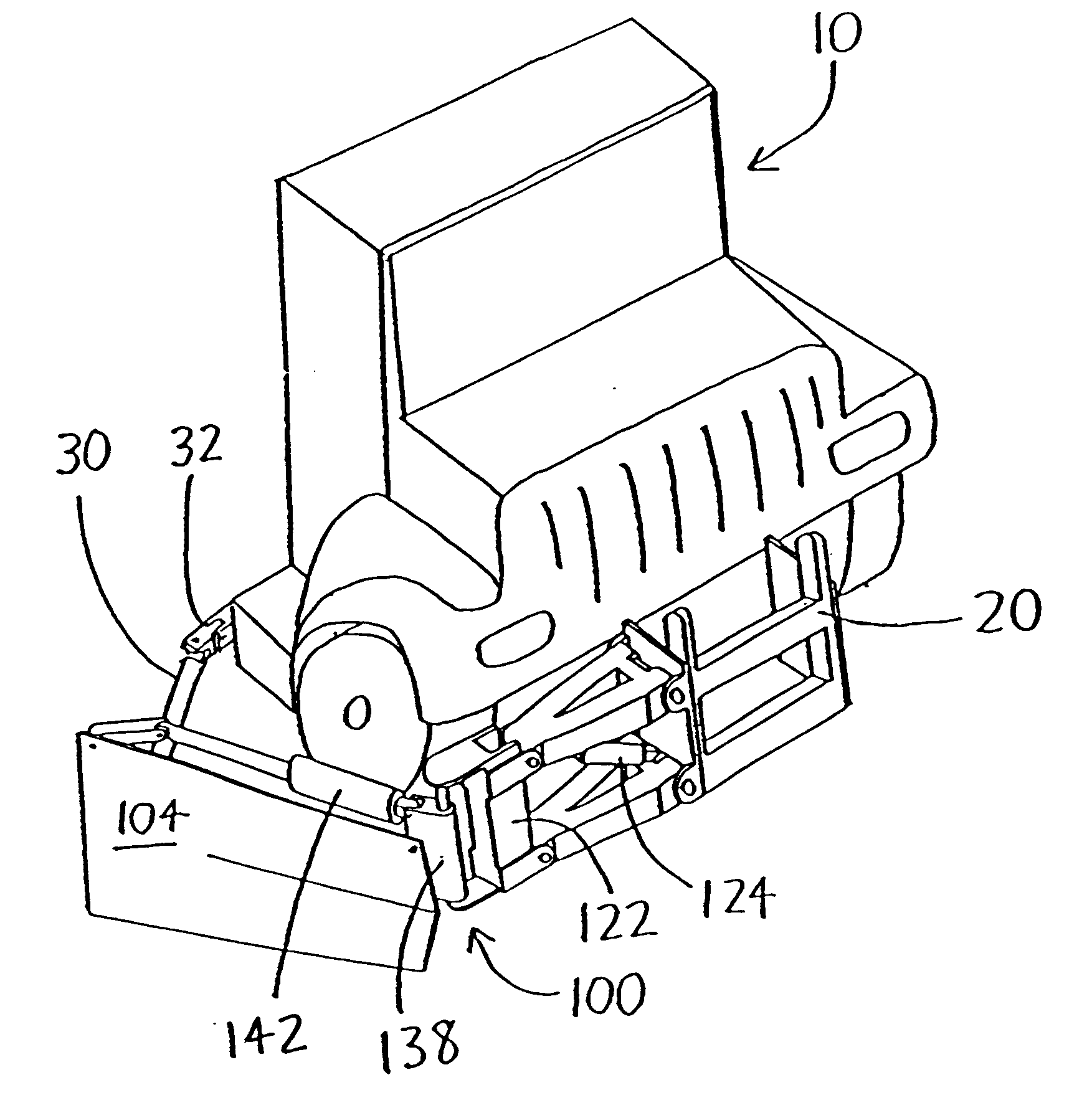

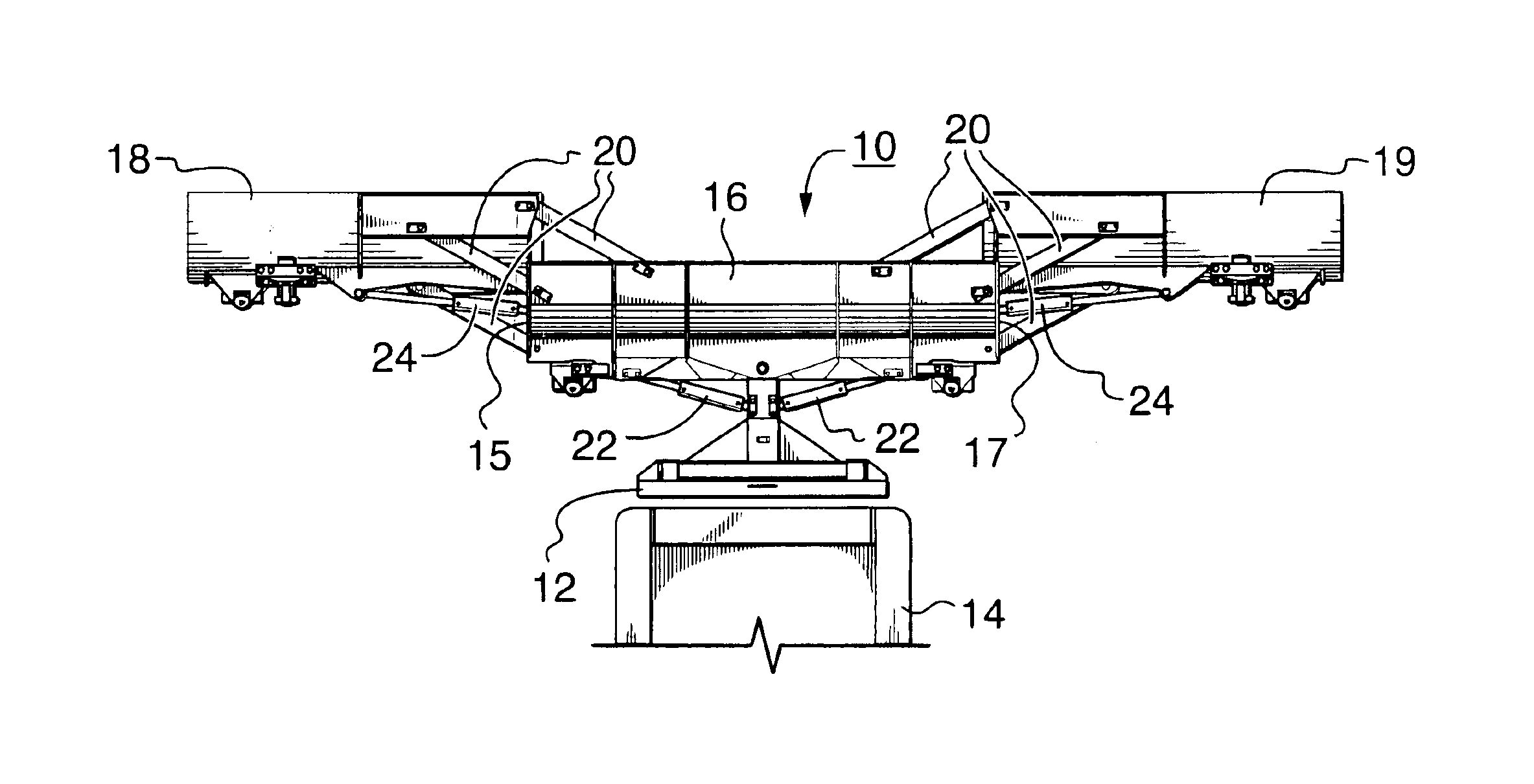

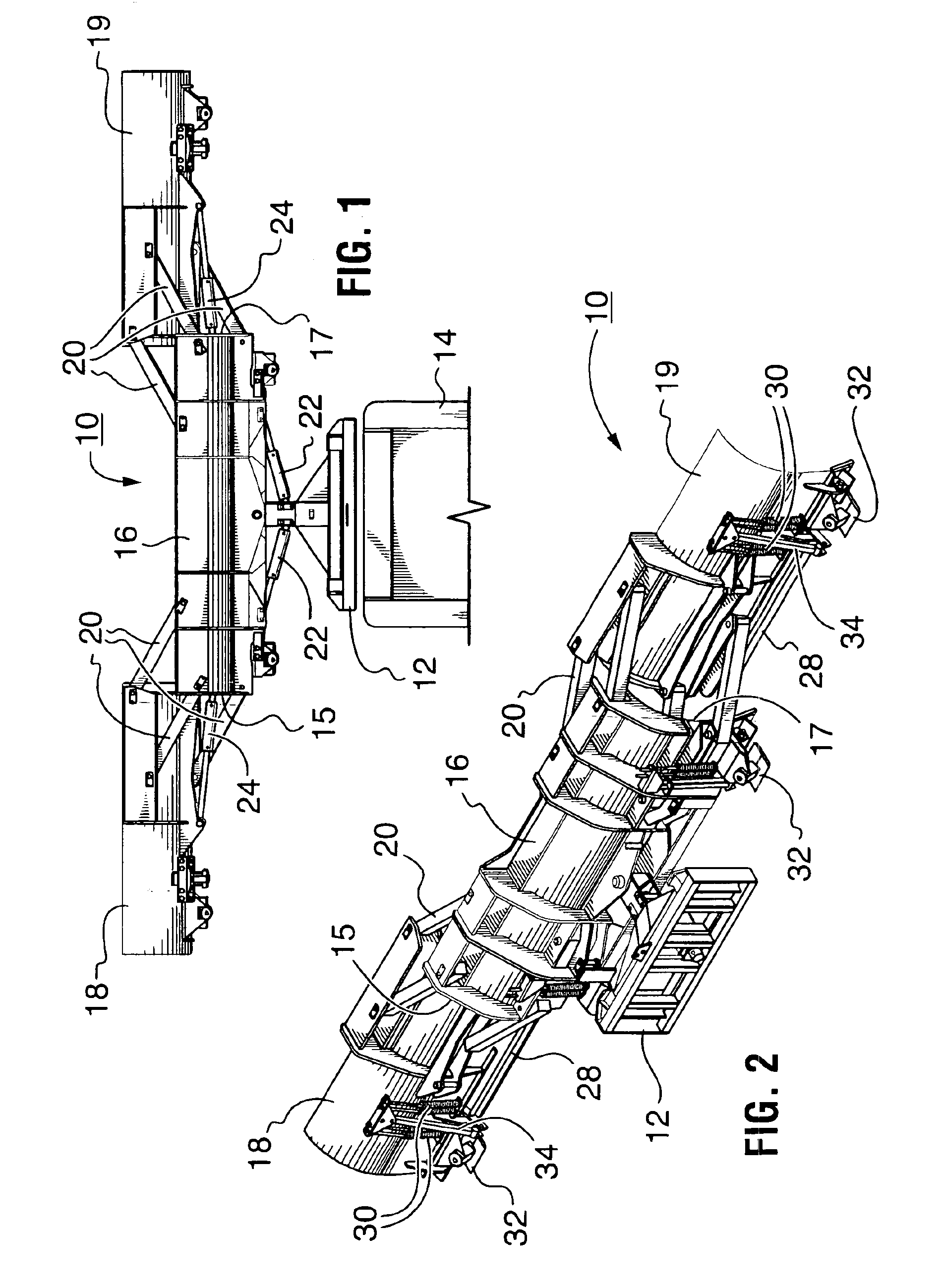

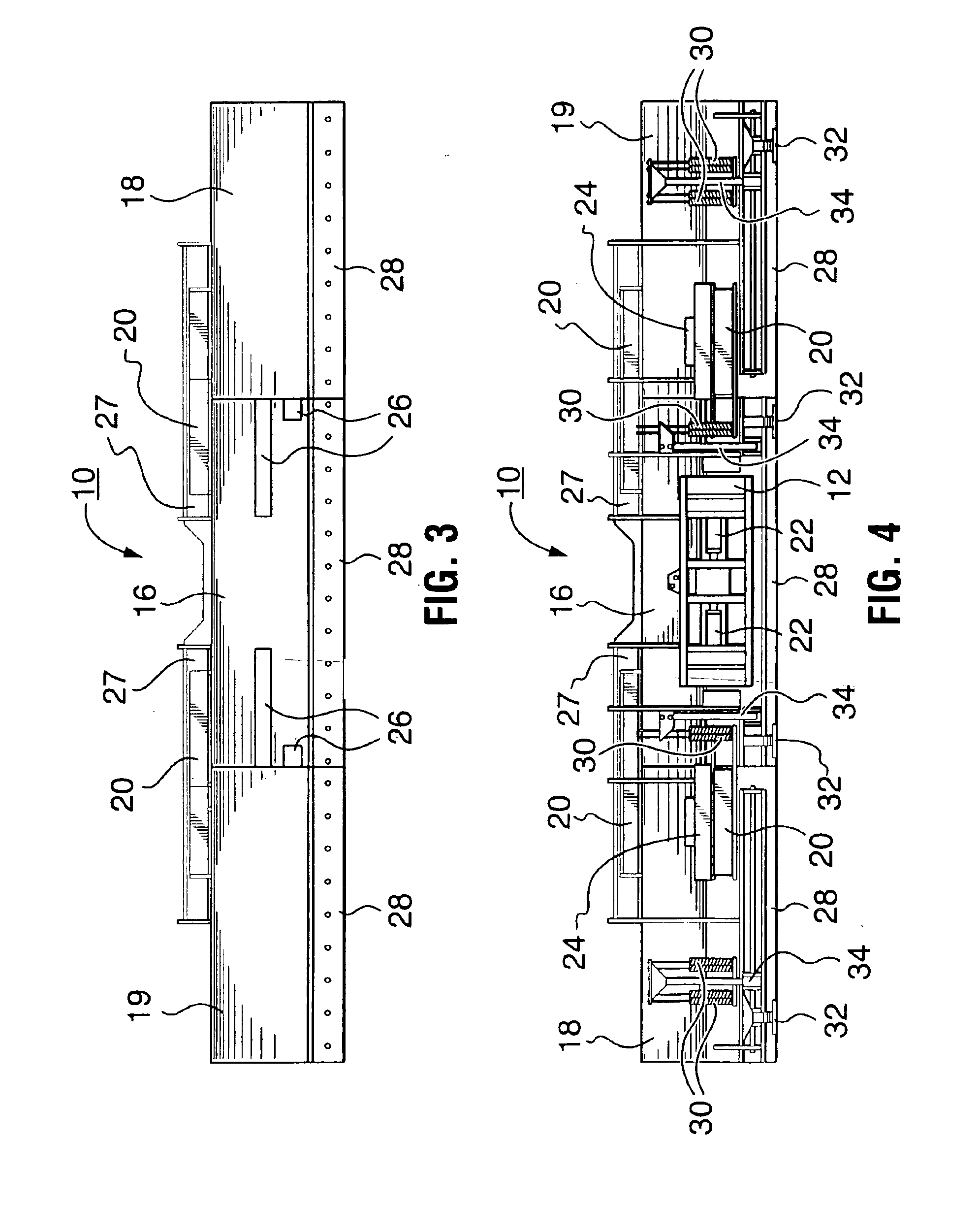

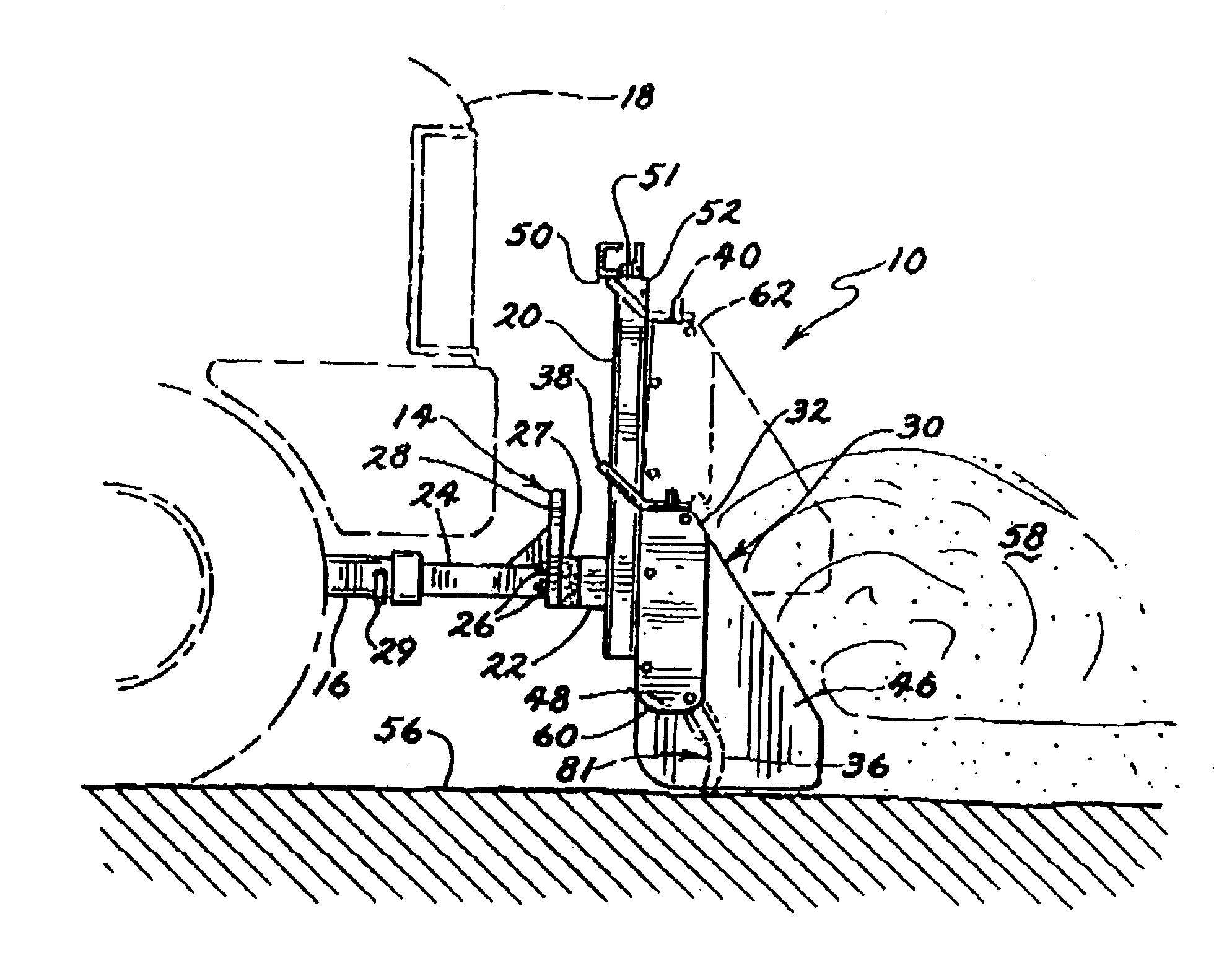

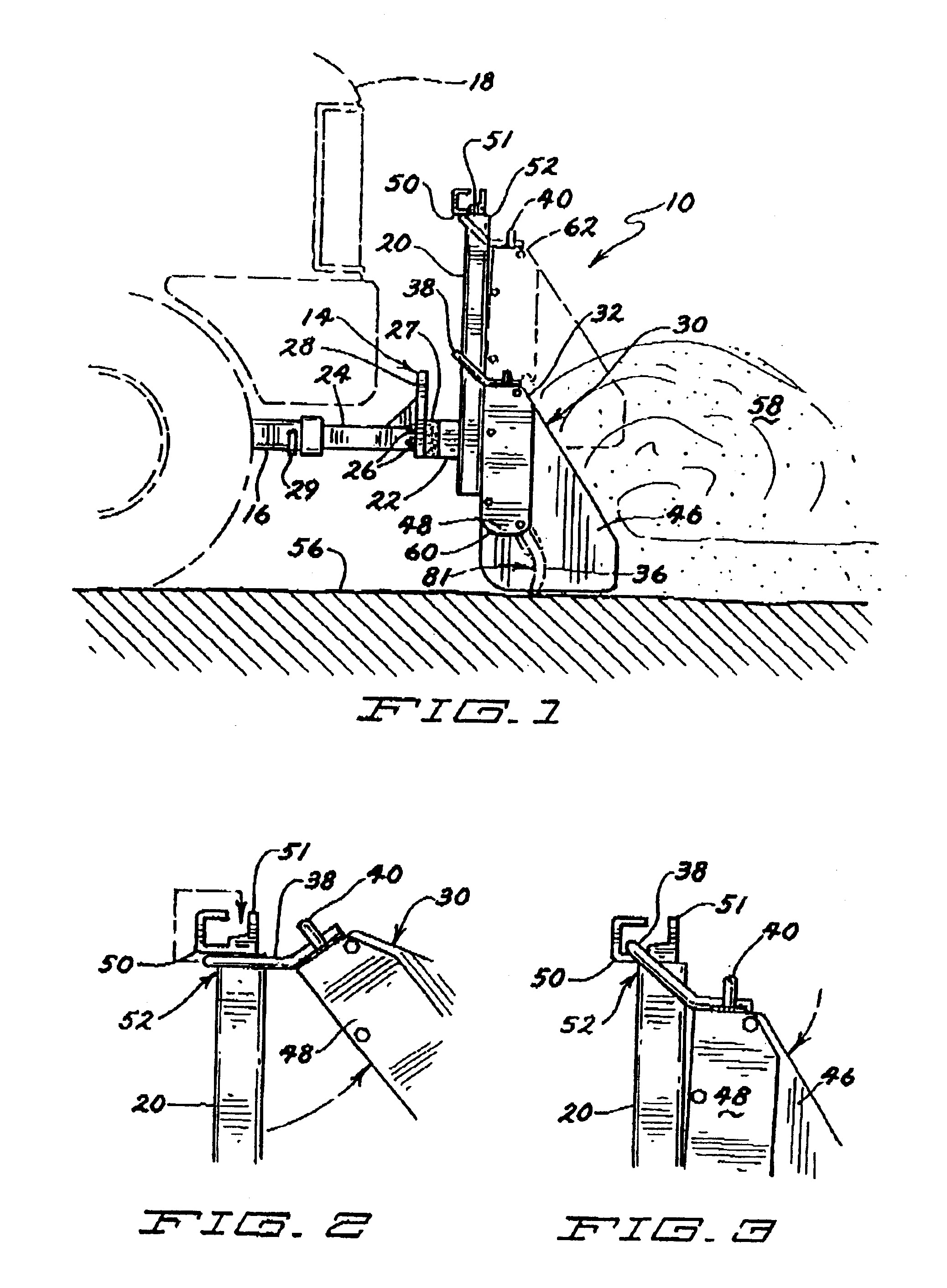

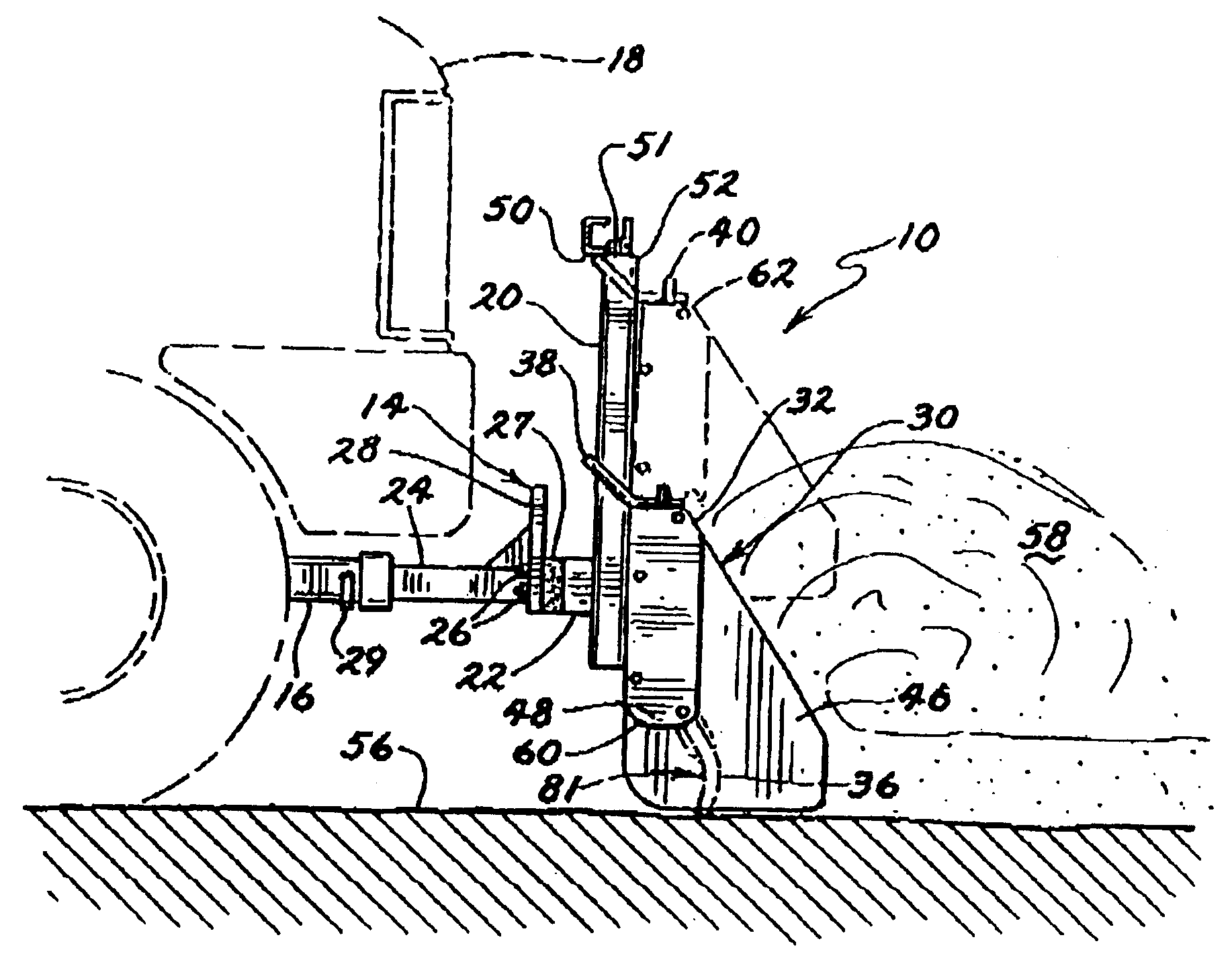

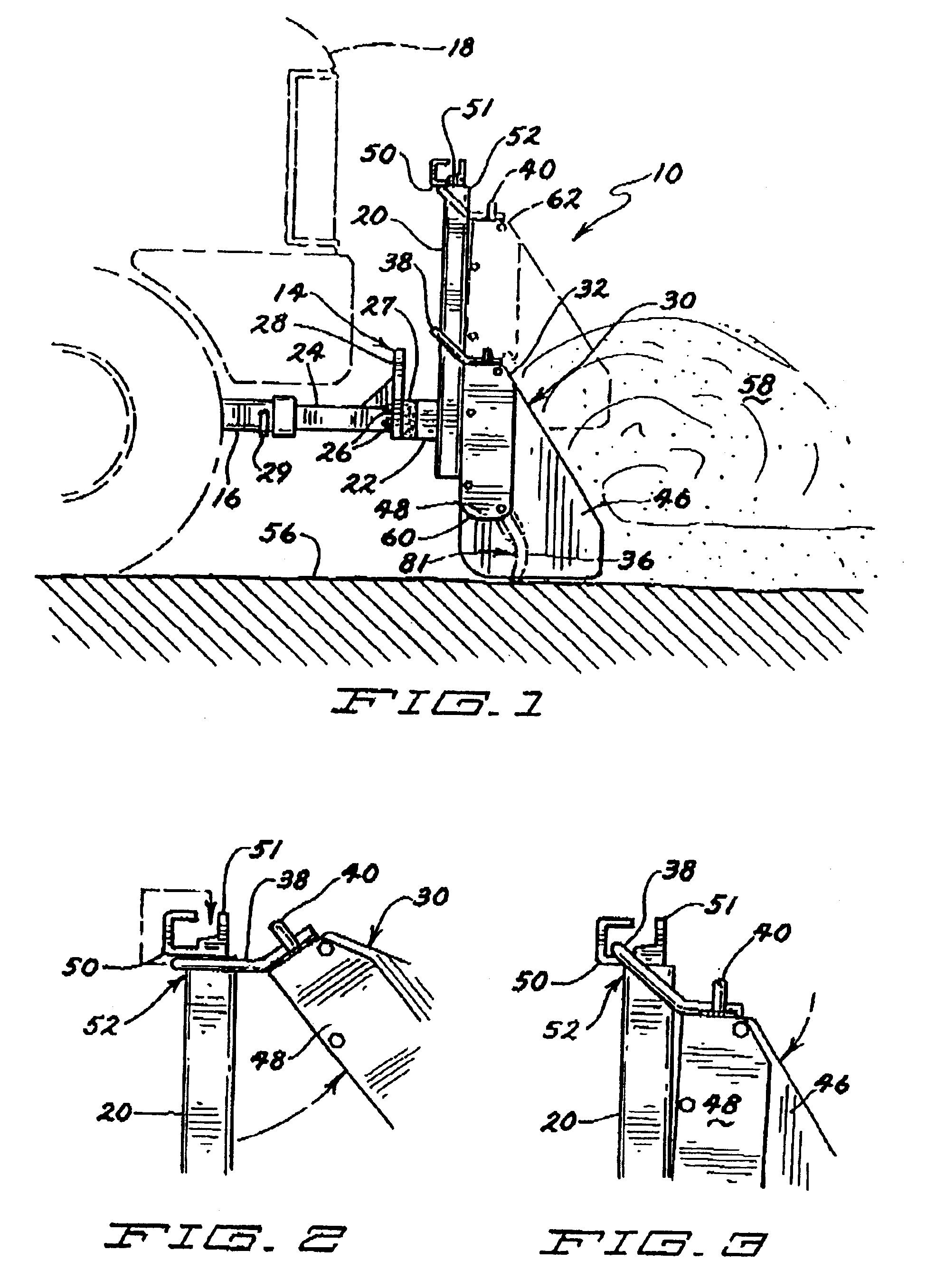

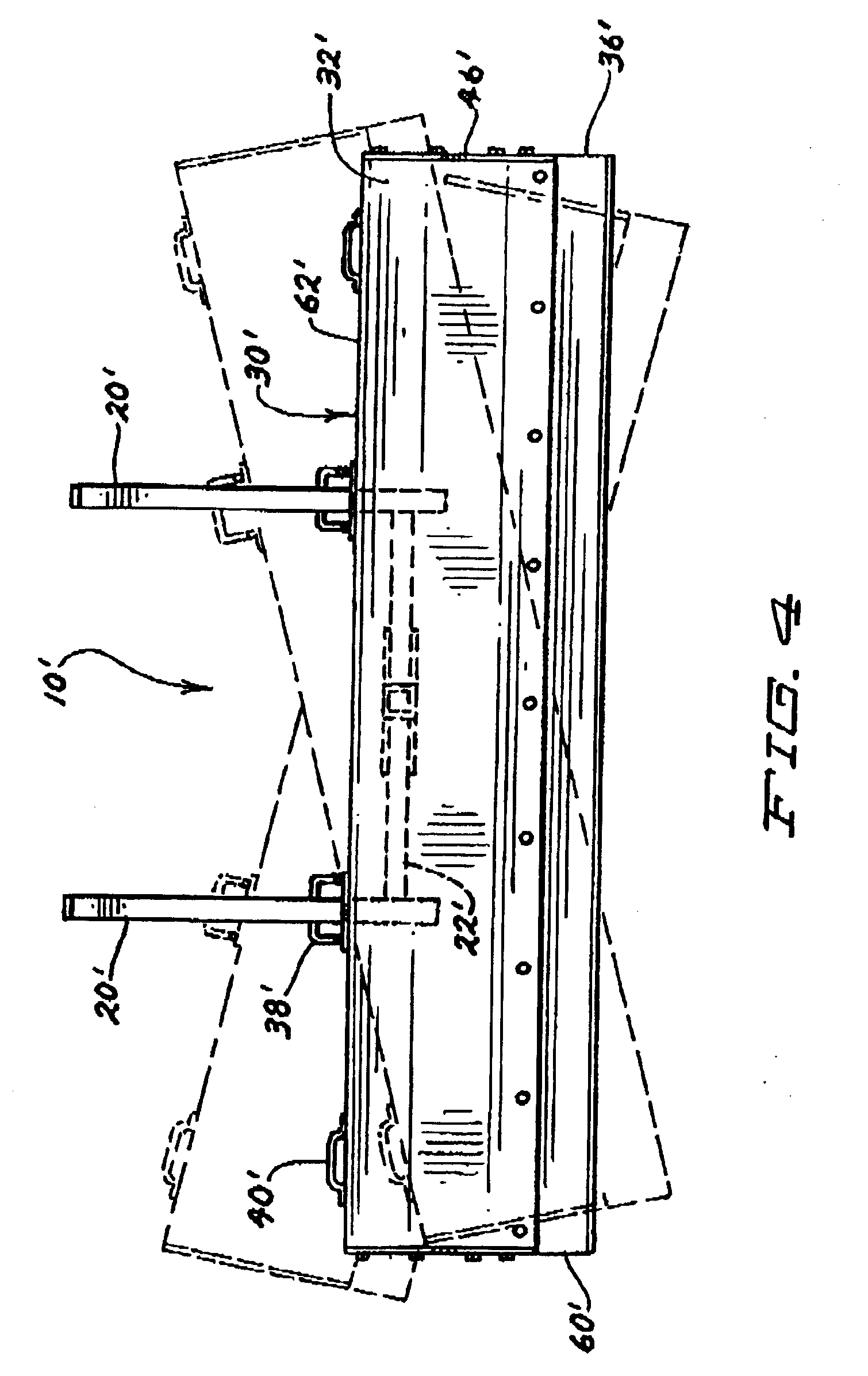

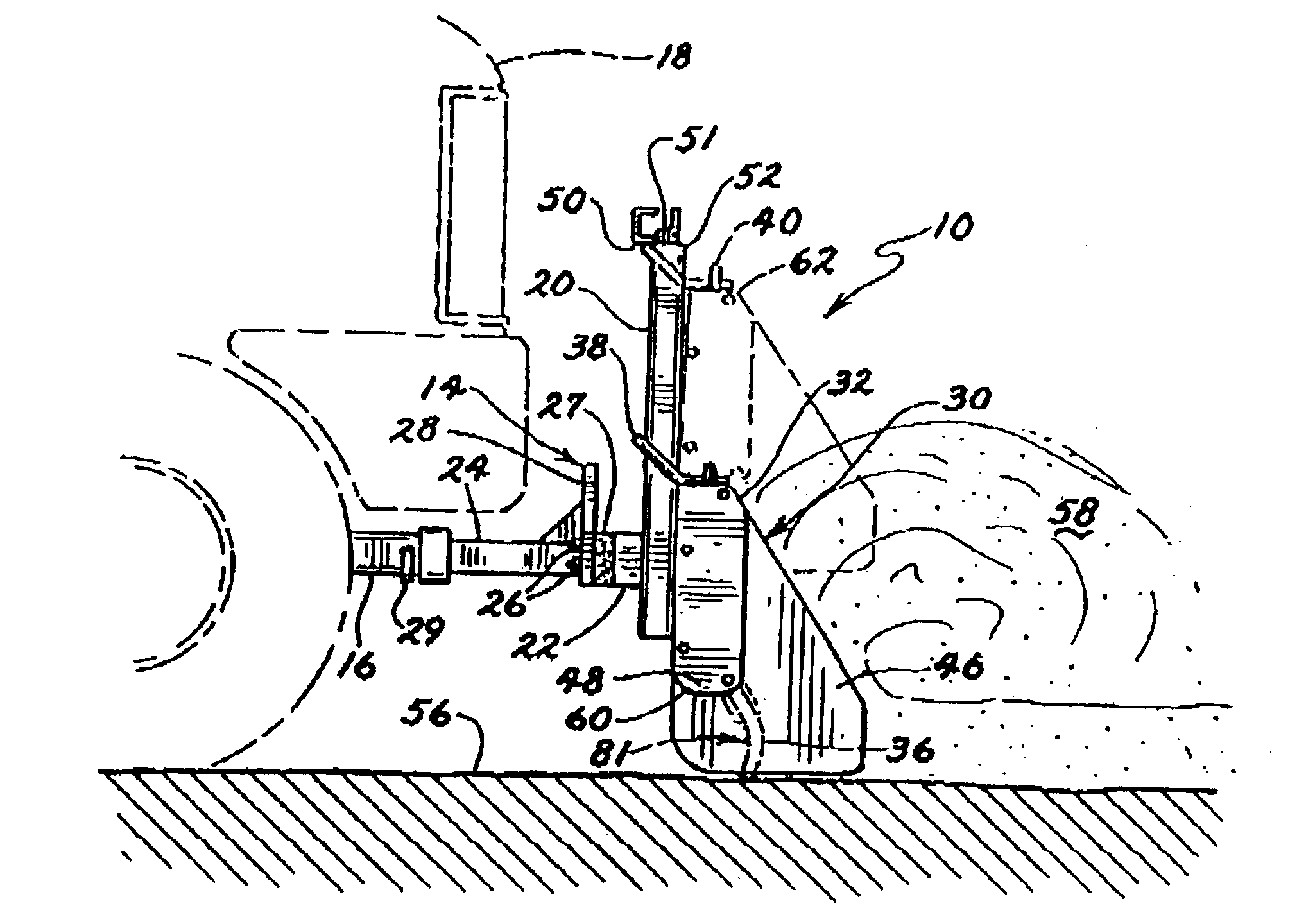

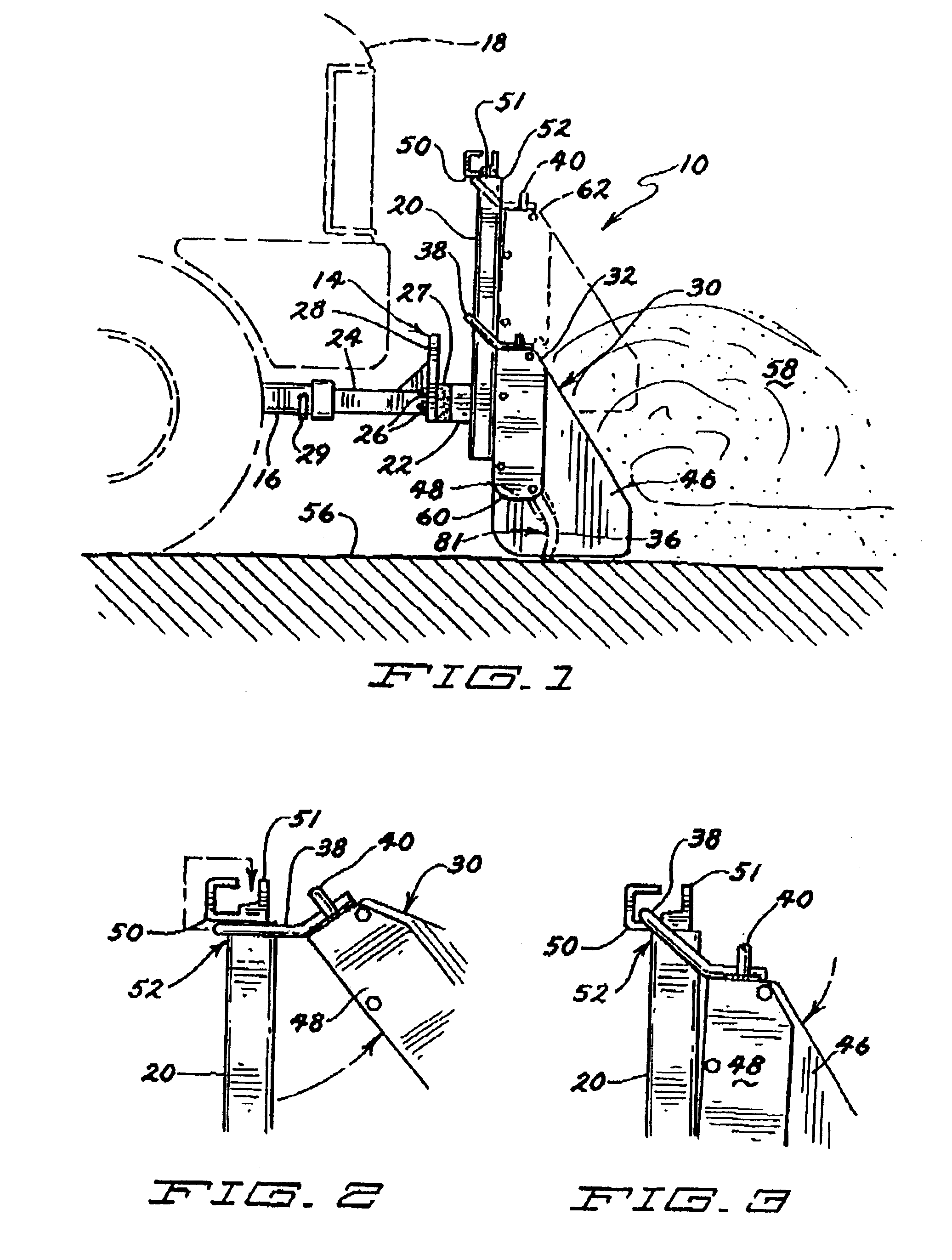

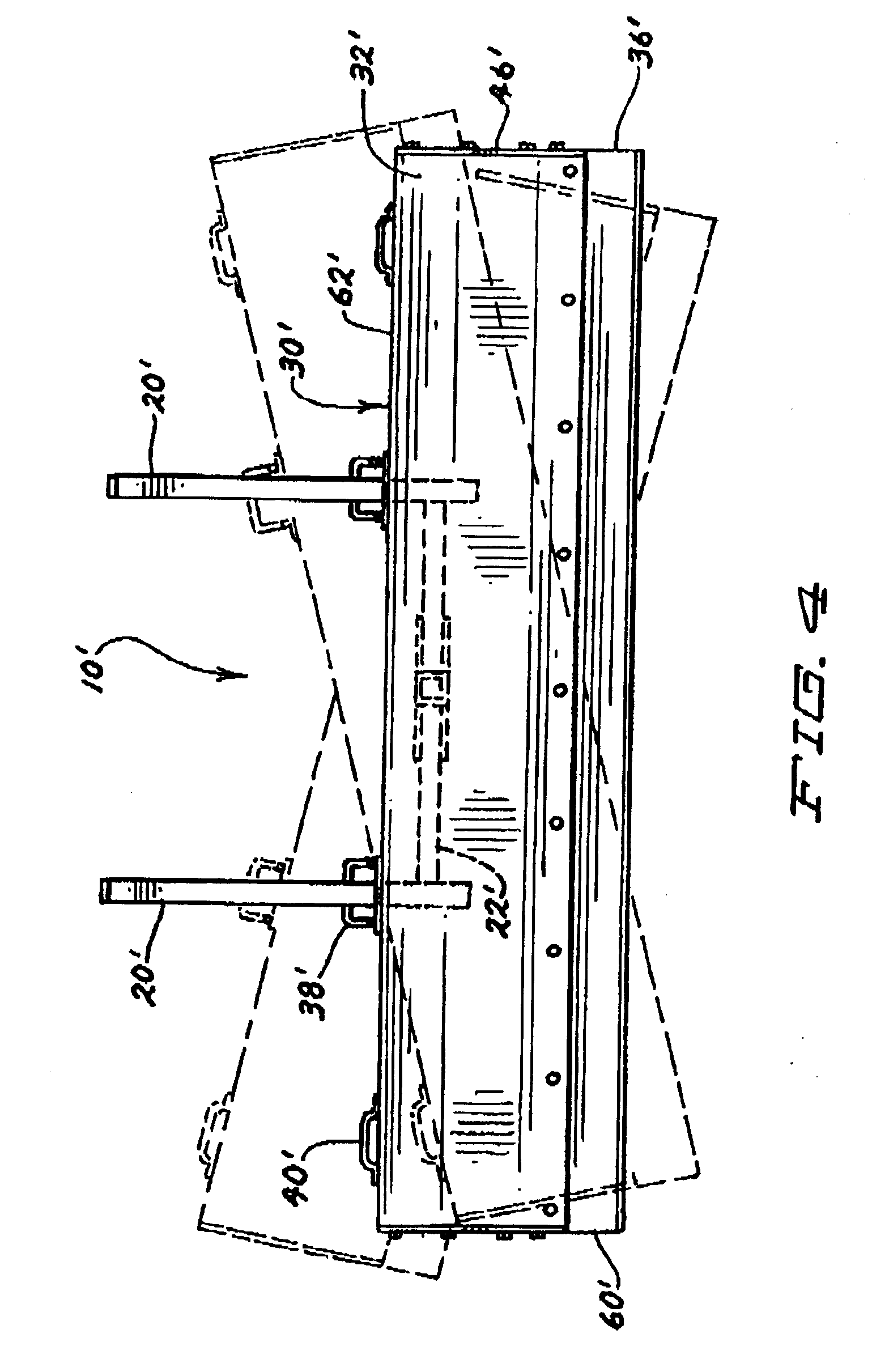

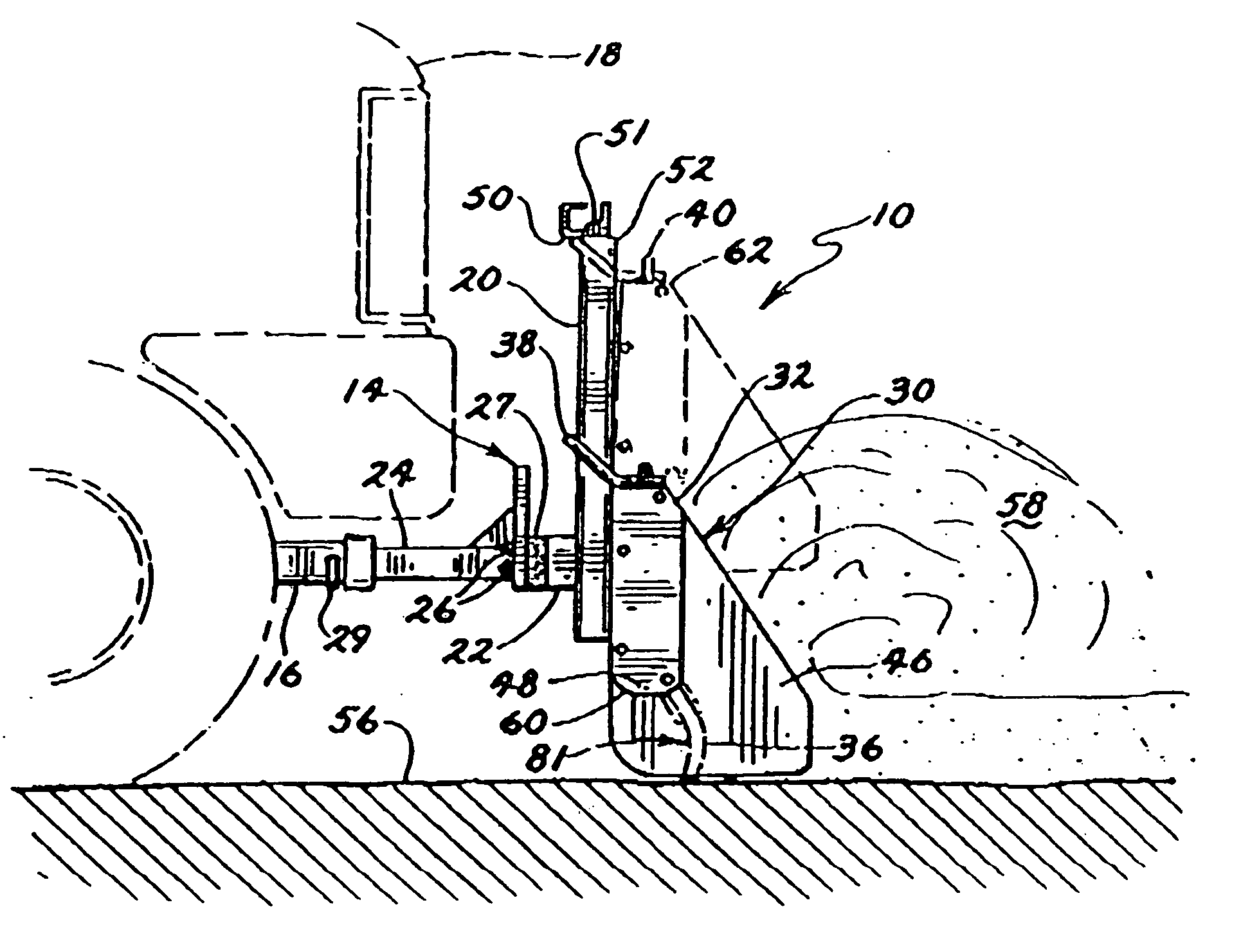

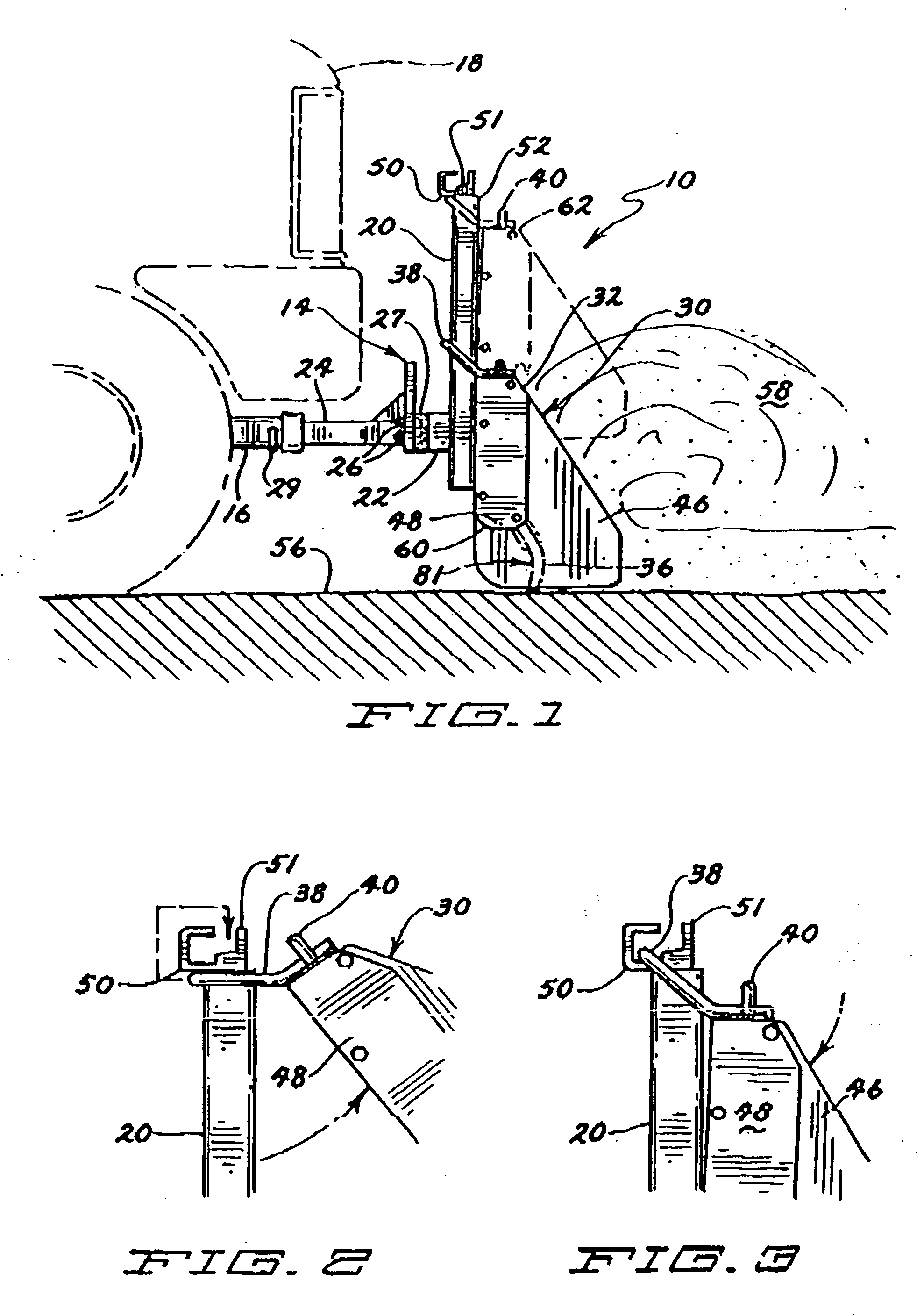

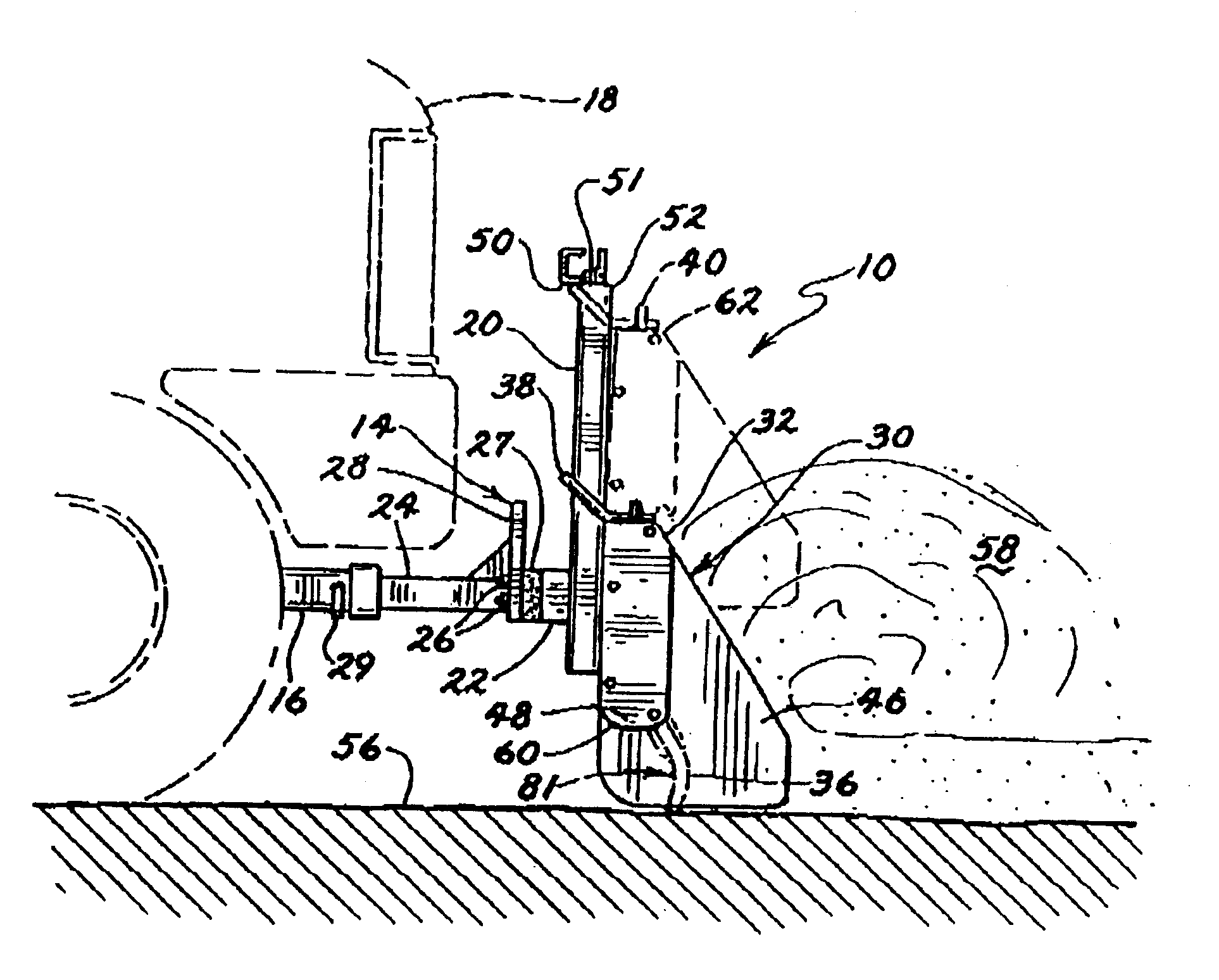

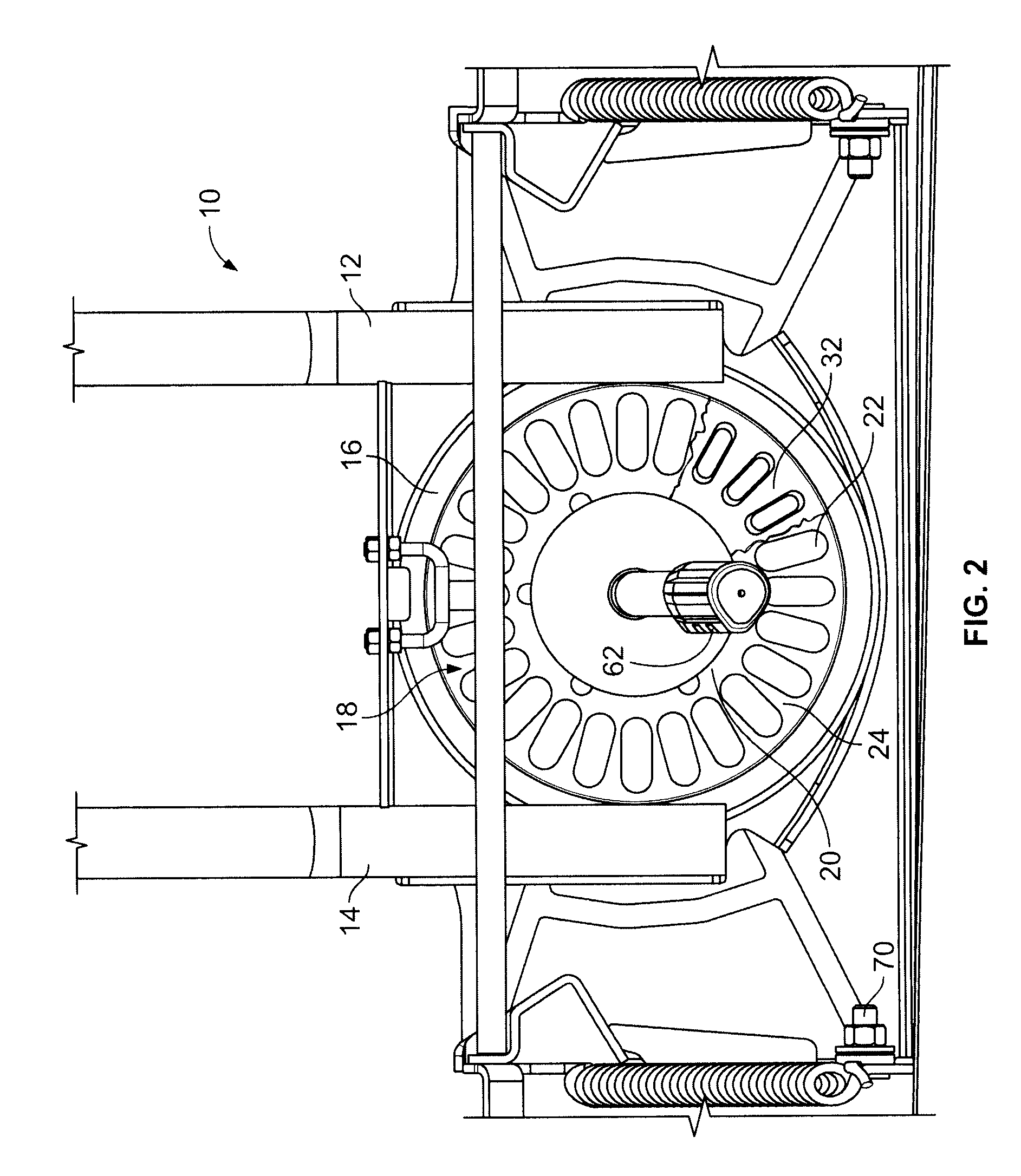

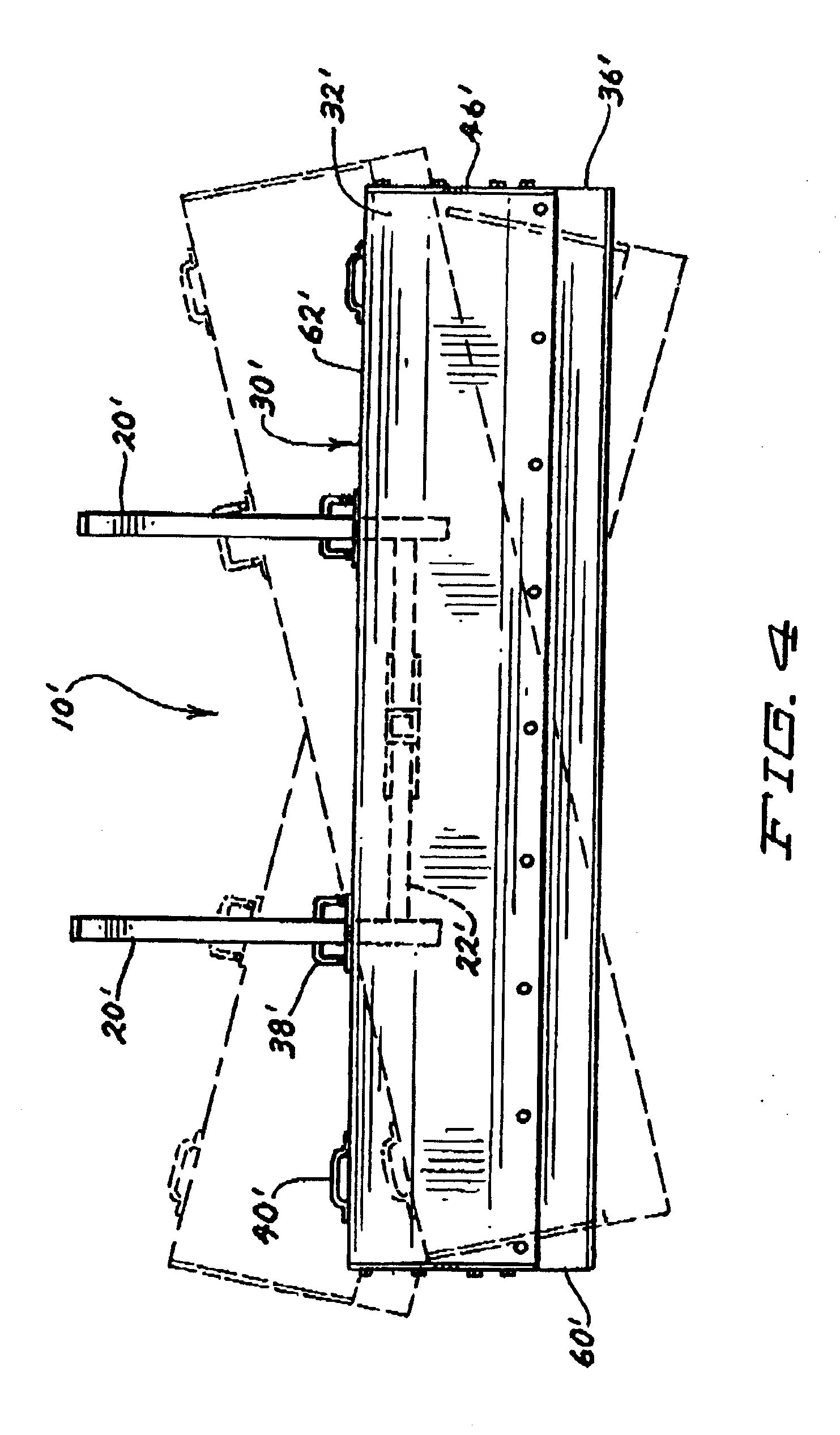

Powered strike-off plow

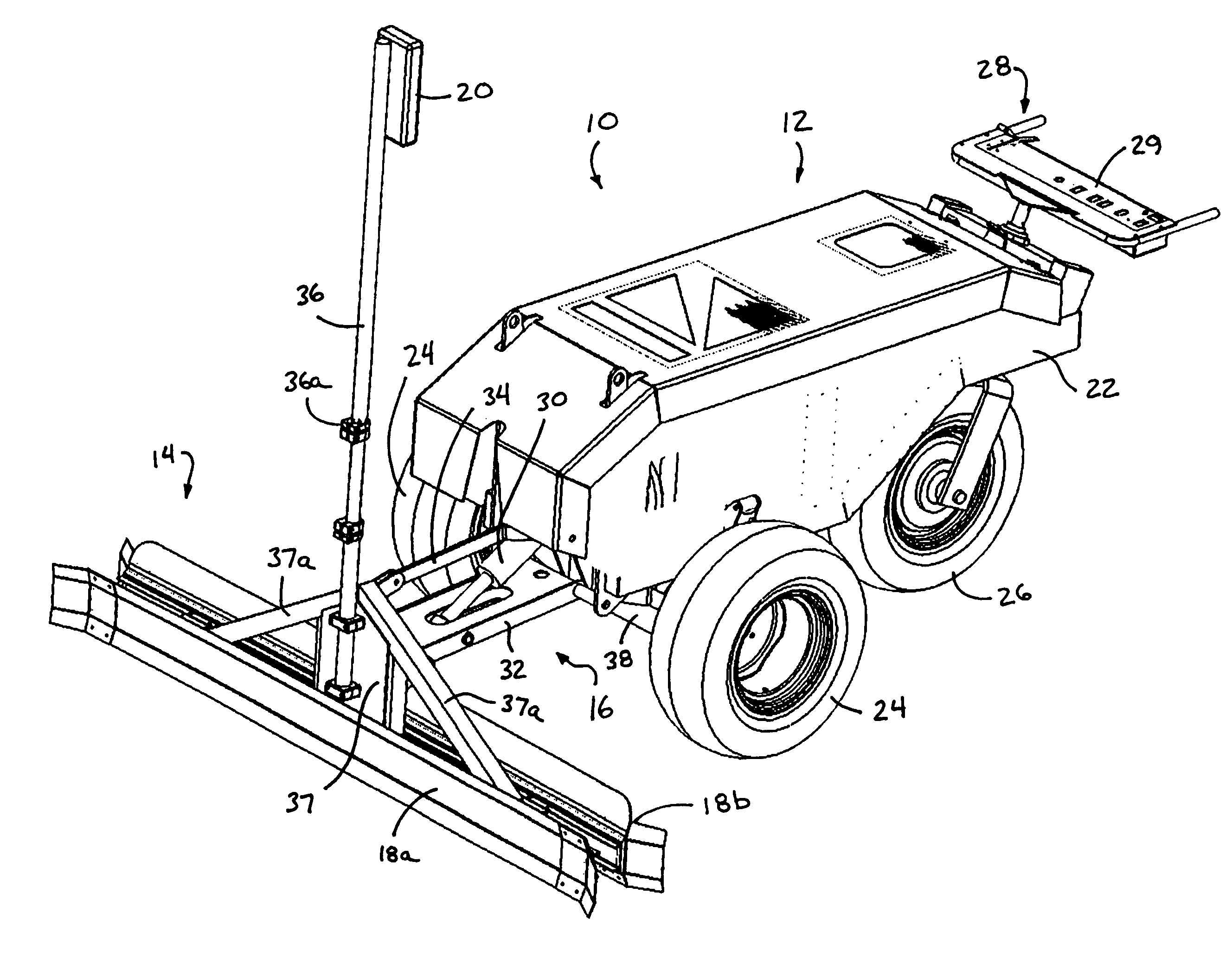

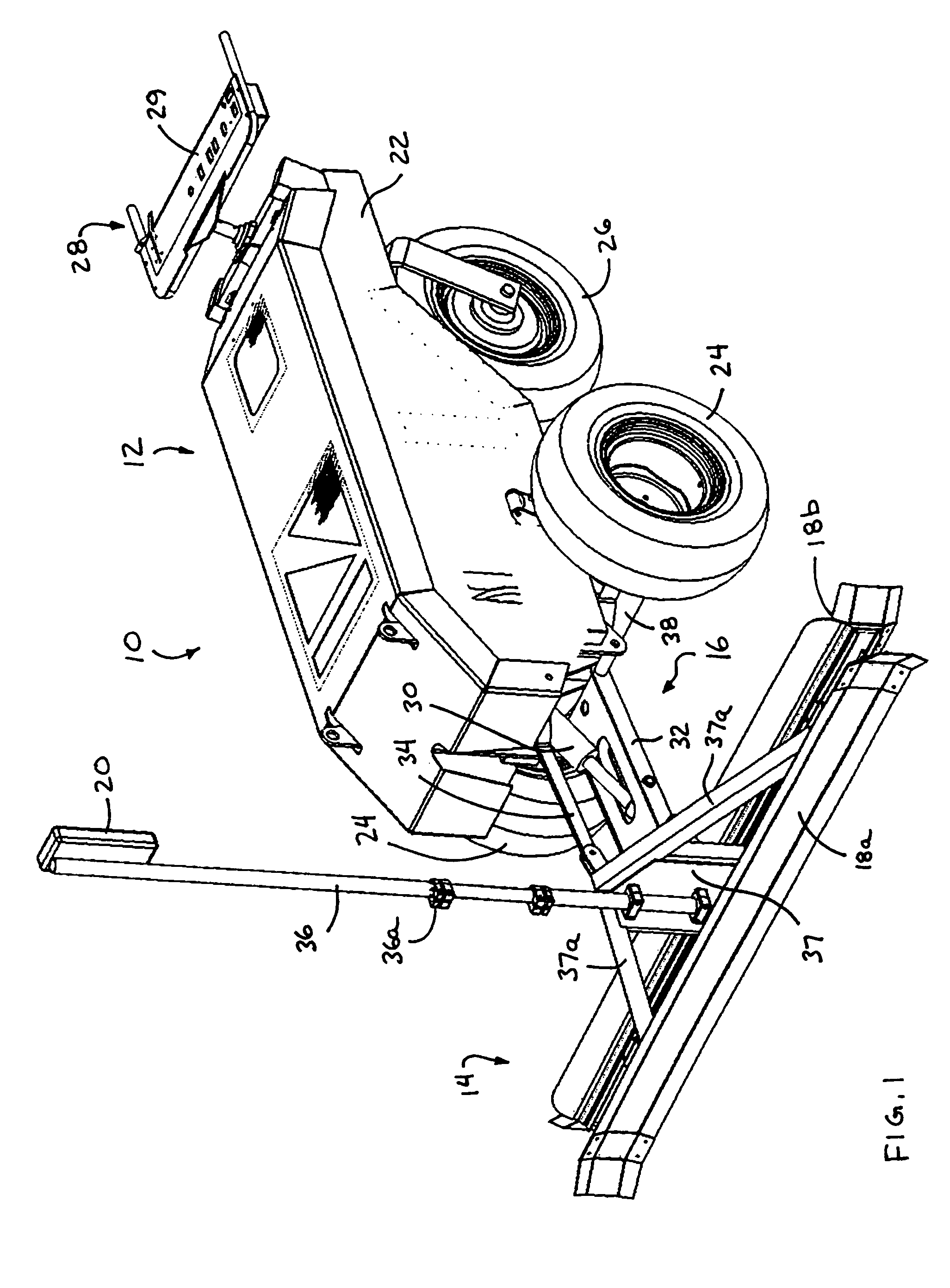

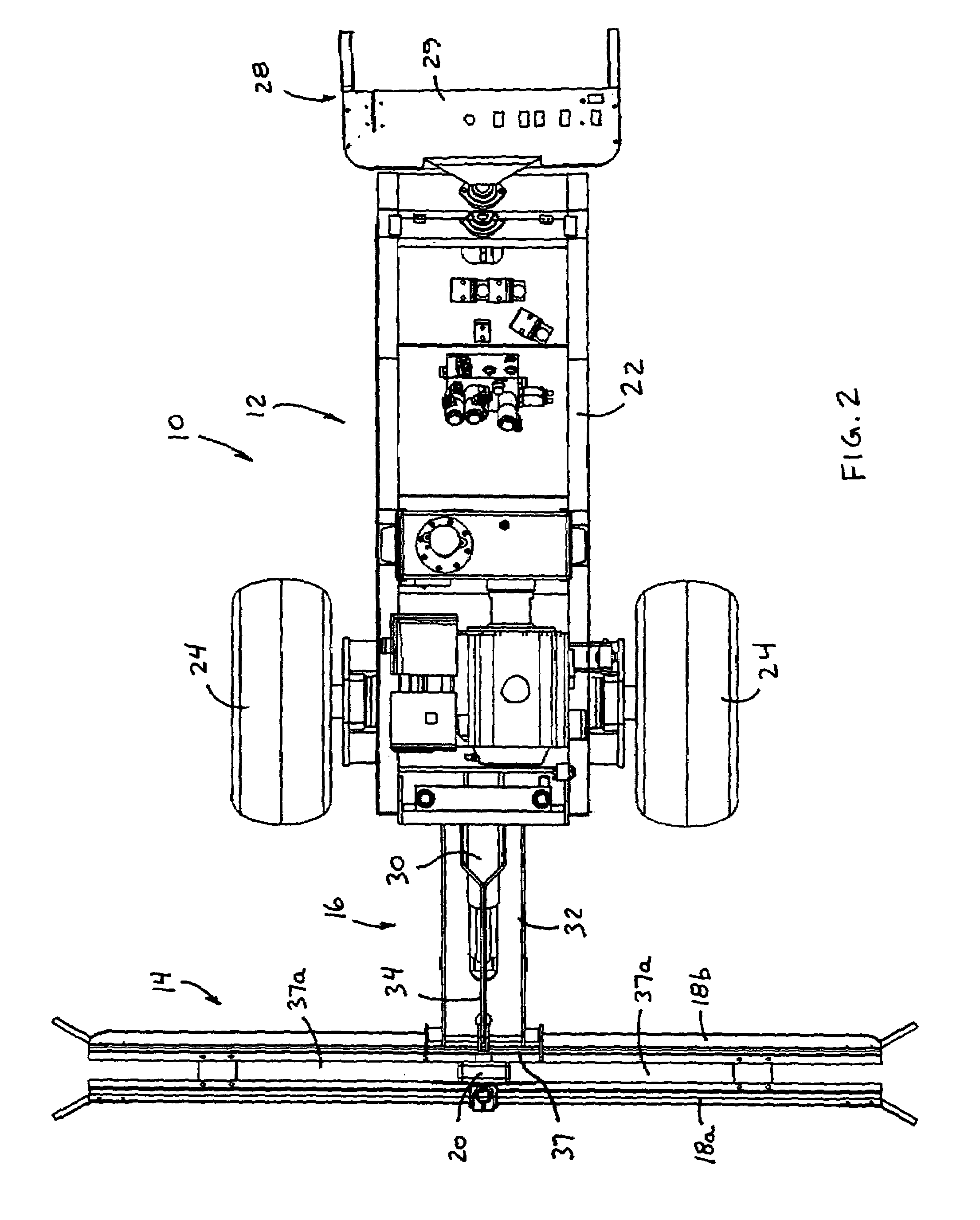

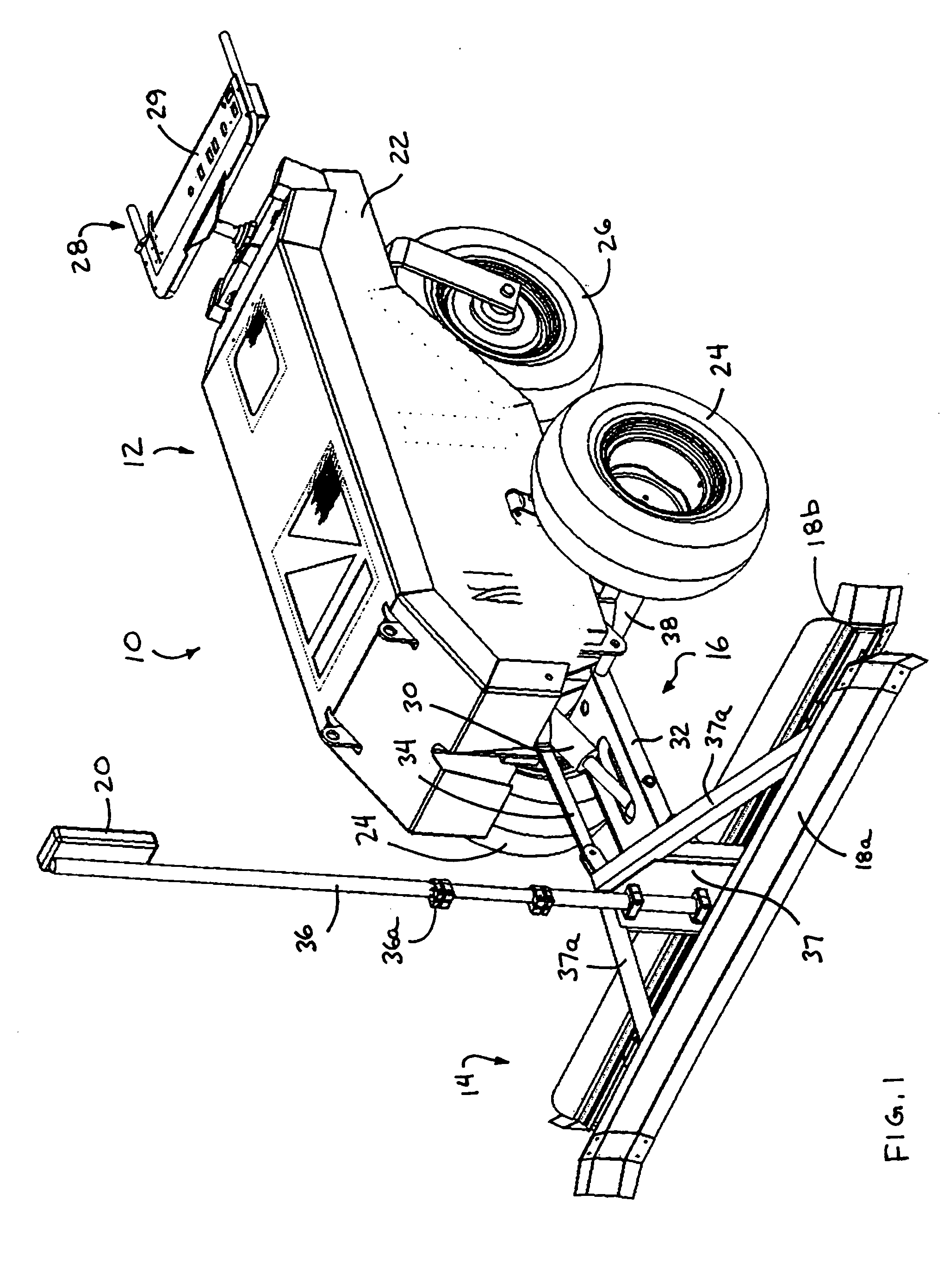

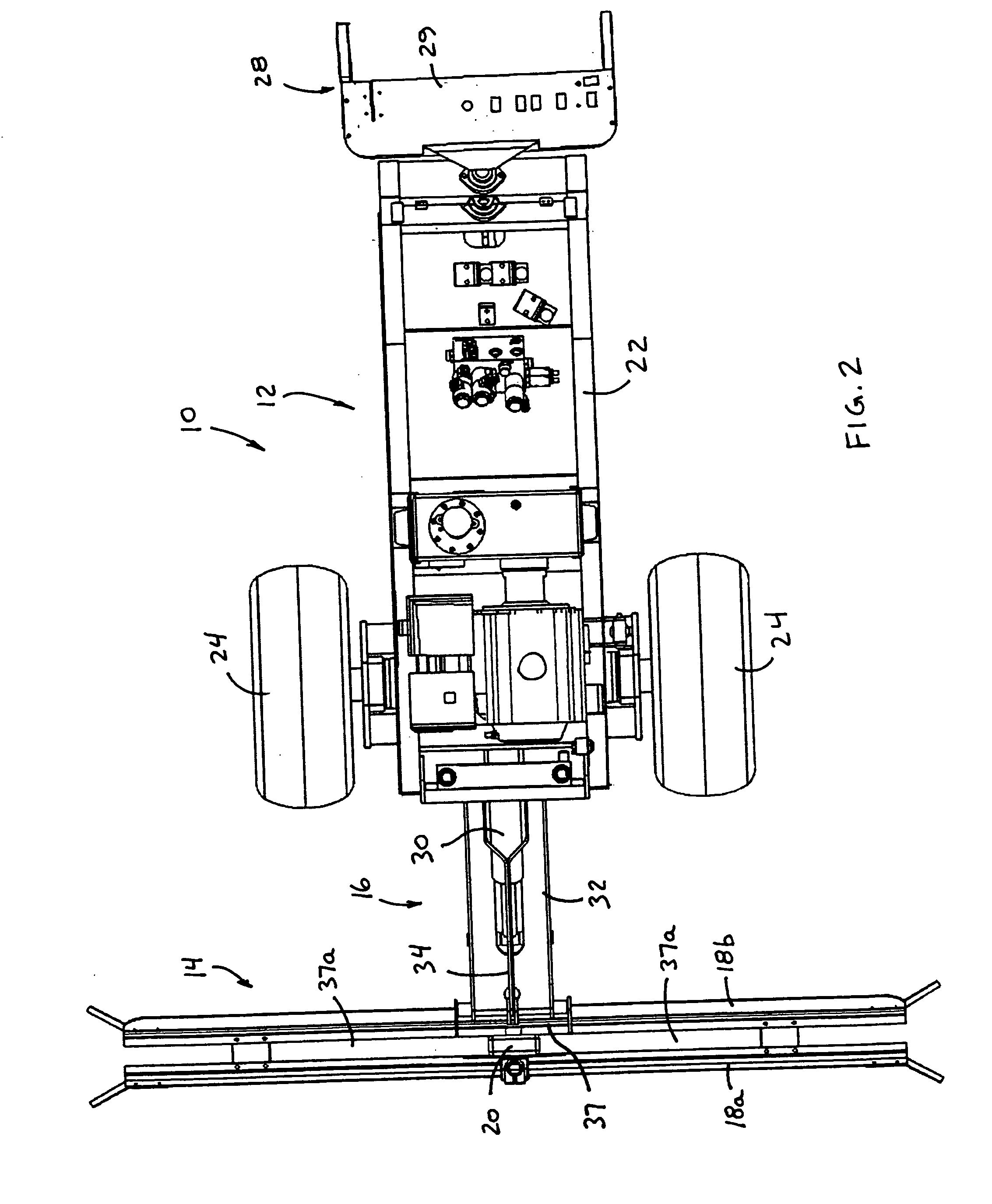

A wheeled strike-off apparatus is movable over a surface of uncured concrete or subgrade materials and is operable to establish a desired grade of the uncured concrete surface or subgrade surface. The apparatus includes a wheeled support and a plow assembly. The wheeled support may have a front frame portion and a pair of front wheels rotatably mounted at the front frame portion, and may have a rear frame portion and a pair of rear wheels rotatably mounted at the rear frame portion. The plow assembly may be adjustably mounted to the front frame portion and may be vertically adjustable relative to the frame portion via an actuator. The plow assembly includes at least one plow member for engaging and establishing the desired grade.

Owner:SOMERO ENTERPRISES INC

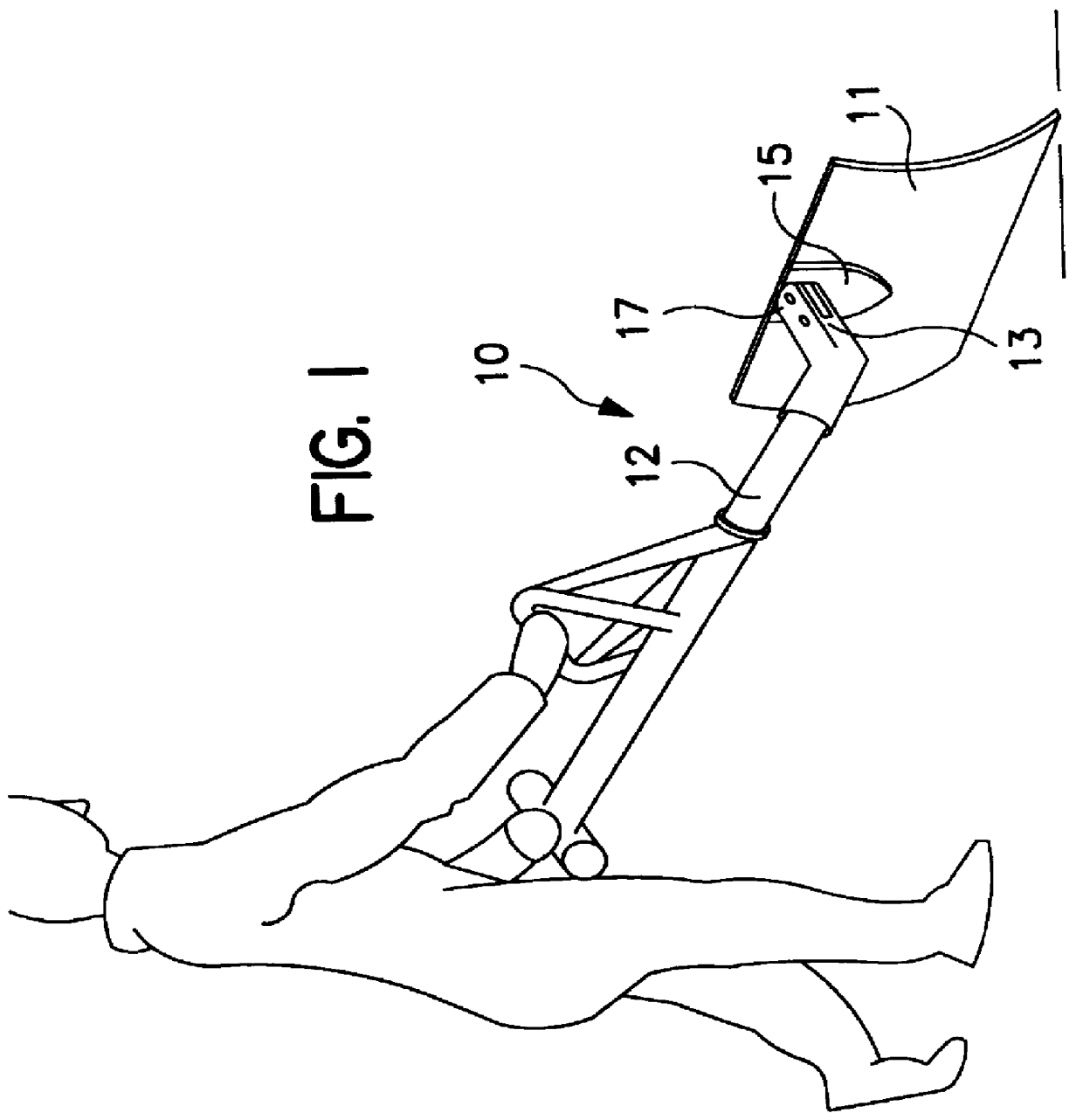

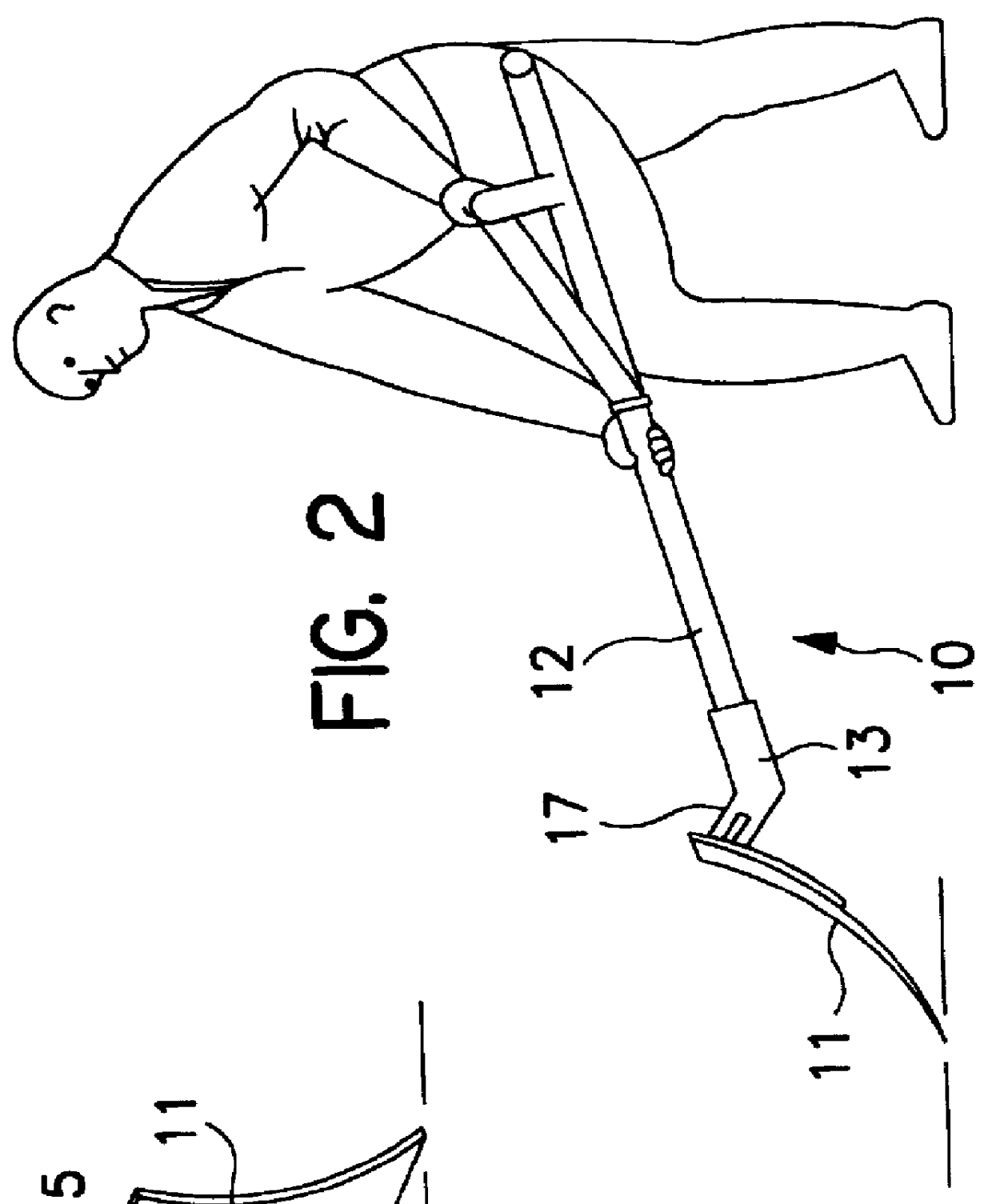

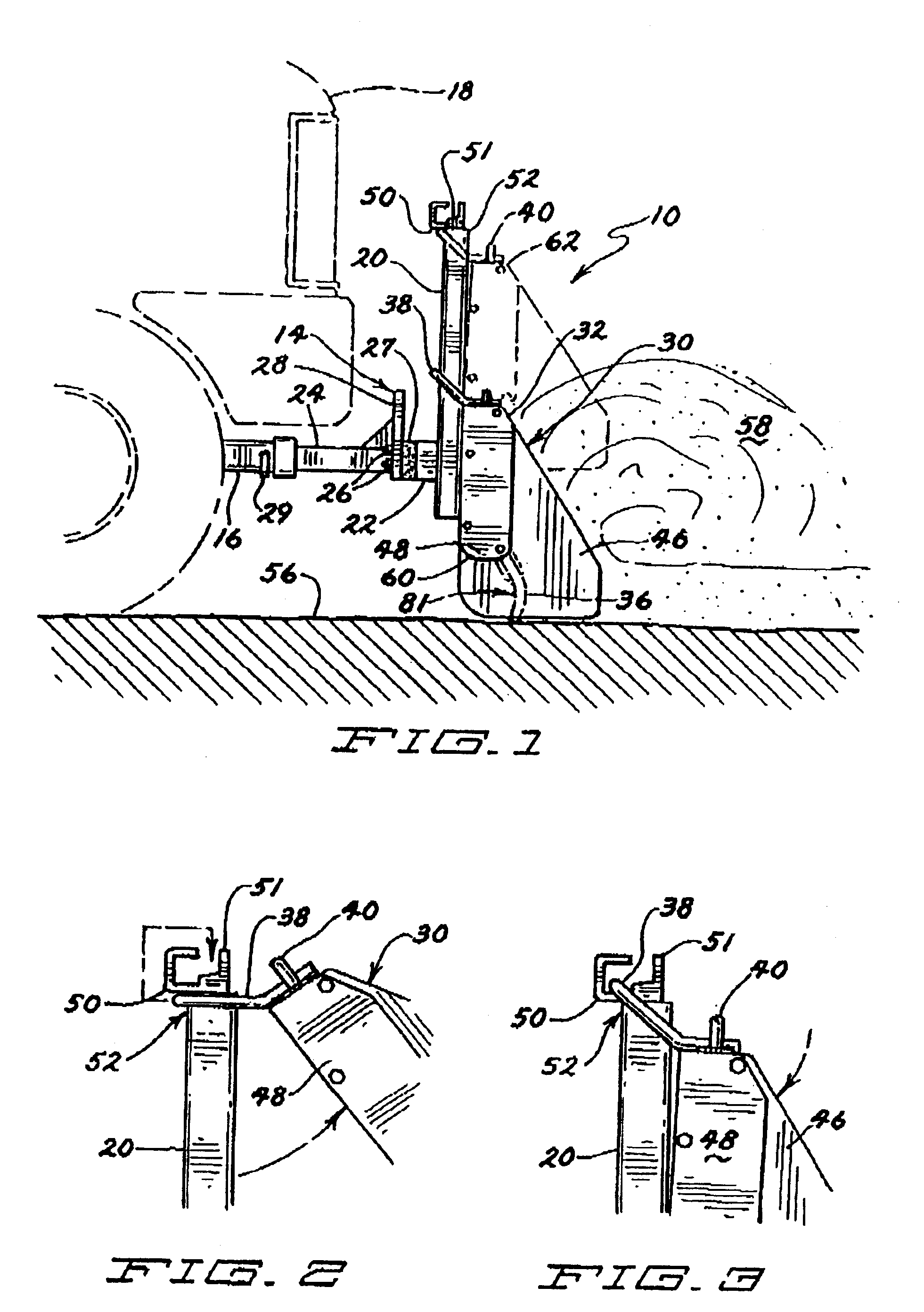

Manually-operable combination shovel and plow for snow and other material

A manually-operable shovel for efficiently moving material, including a shovel blade, a shovel handle, a joint for attaching the shovel blade to the shovel handle, and an articulation device cooperating with the joint for permitting the operator to position the blade to a predetermined fixed angle in relation to the direction of blade movement for moving the material in a predetermined desired relation to the direction of blade movement. The articulation device is moveable between an unlocked position wherein the angle of the blade in relation to the direction of blade movement is variable and a locked position wherein the angle of the blade is locked into a fixed angle in relation to the direction of blade movement. The articulation device automatically assumes the locked position during a forward, material engaging movement of the shovel and automatically assumes the unlocked position during a rearward material disengaging, movement of the shovel.

Owner:BOWLES JR LOUIS G

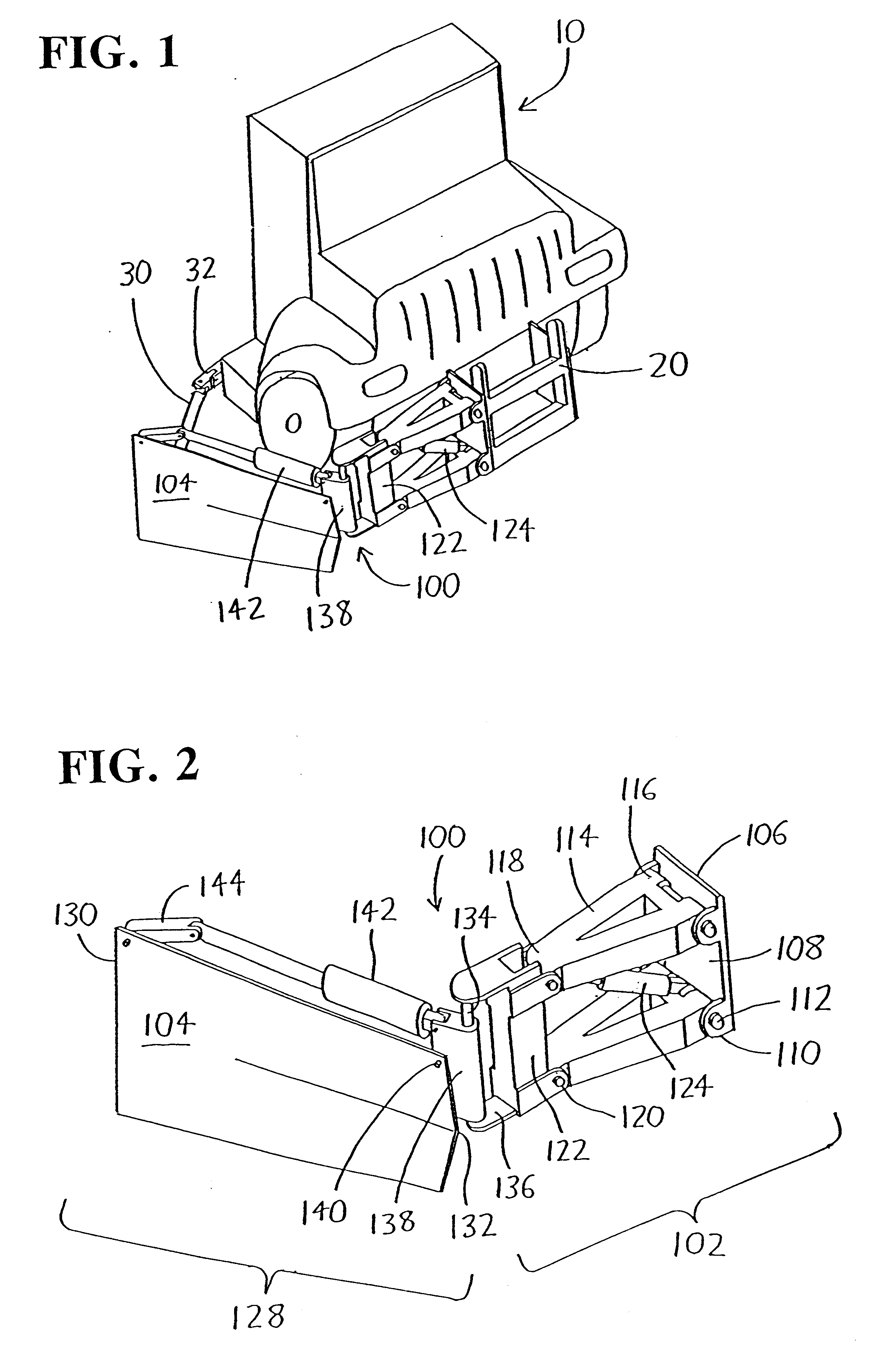

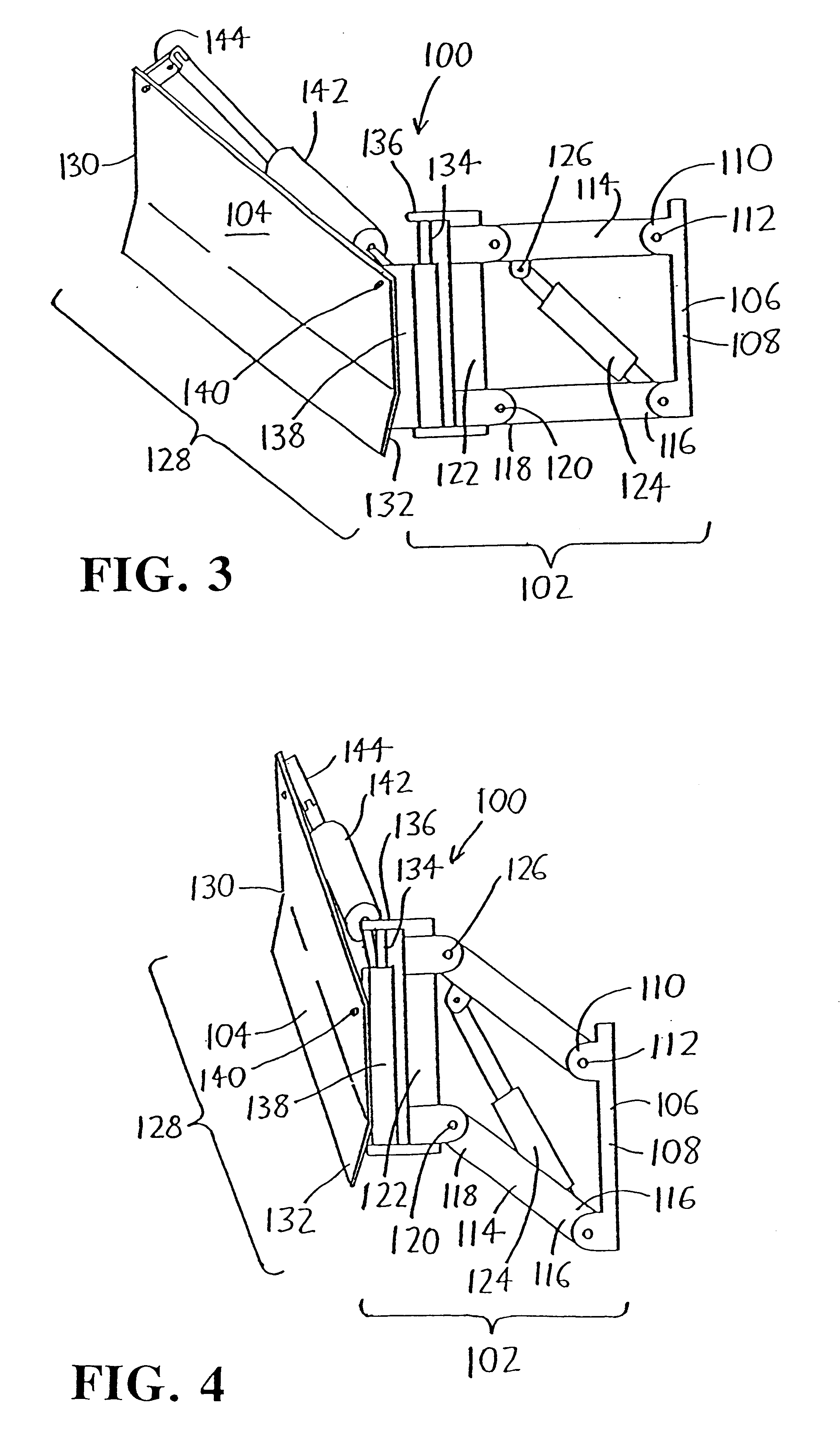

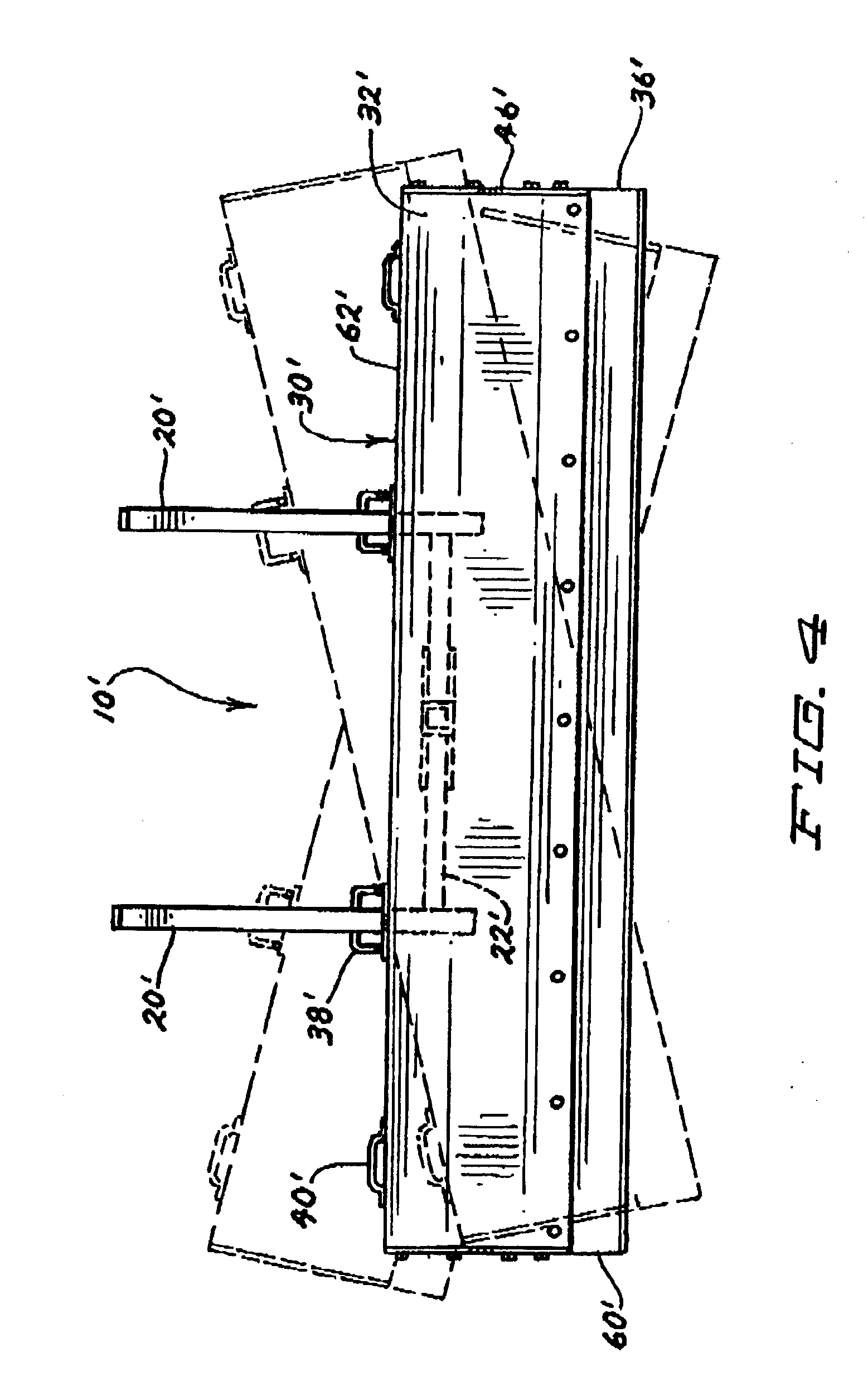

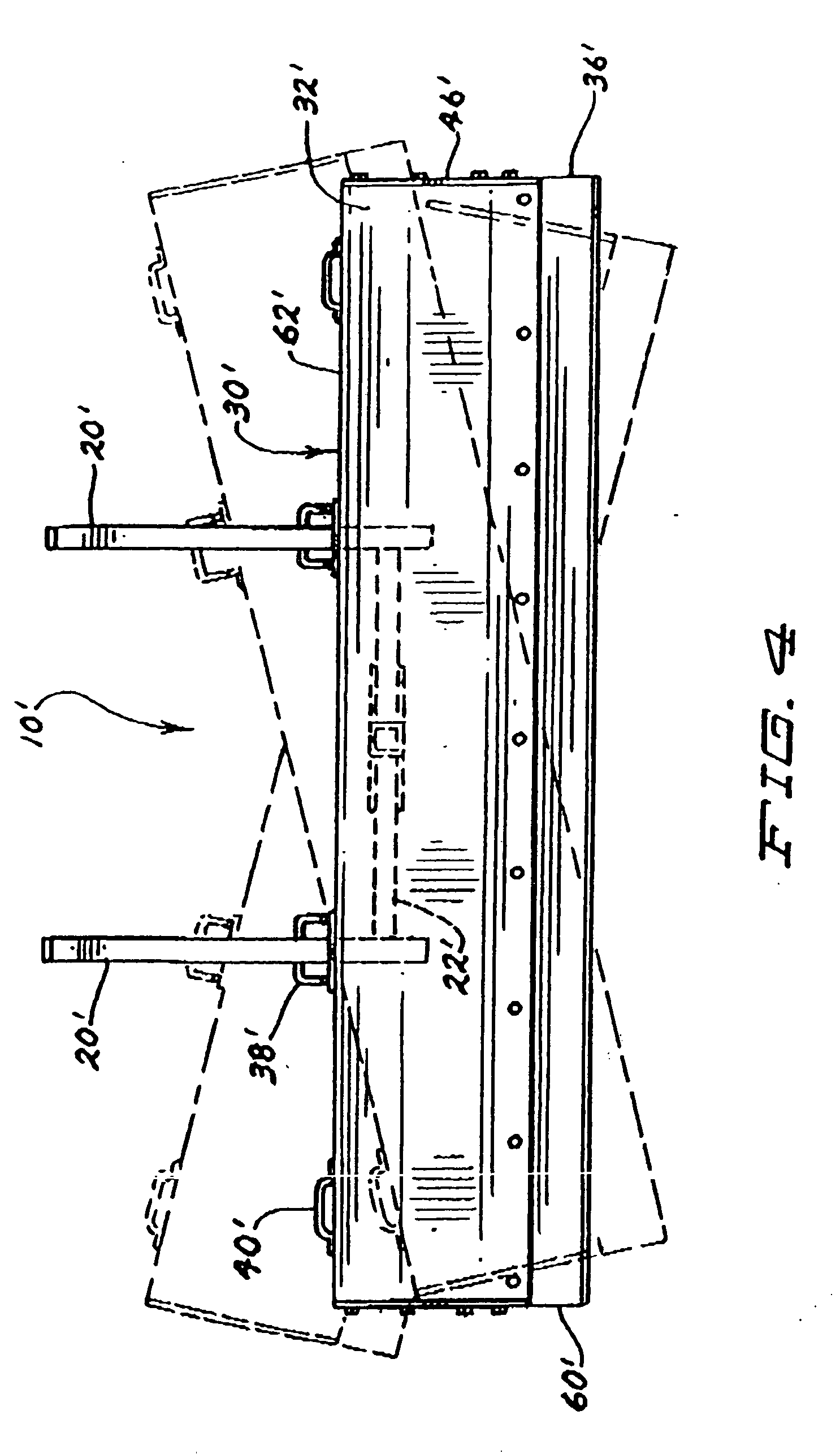

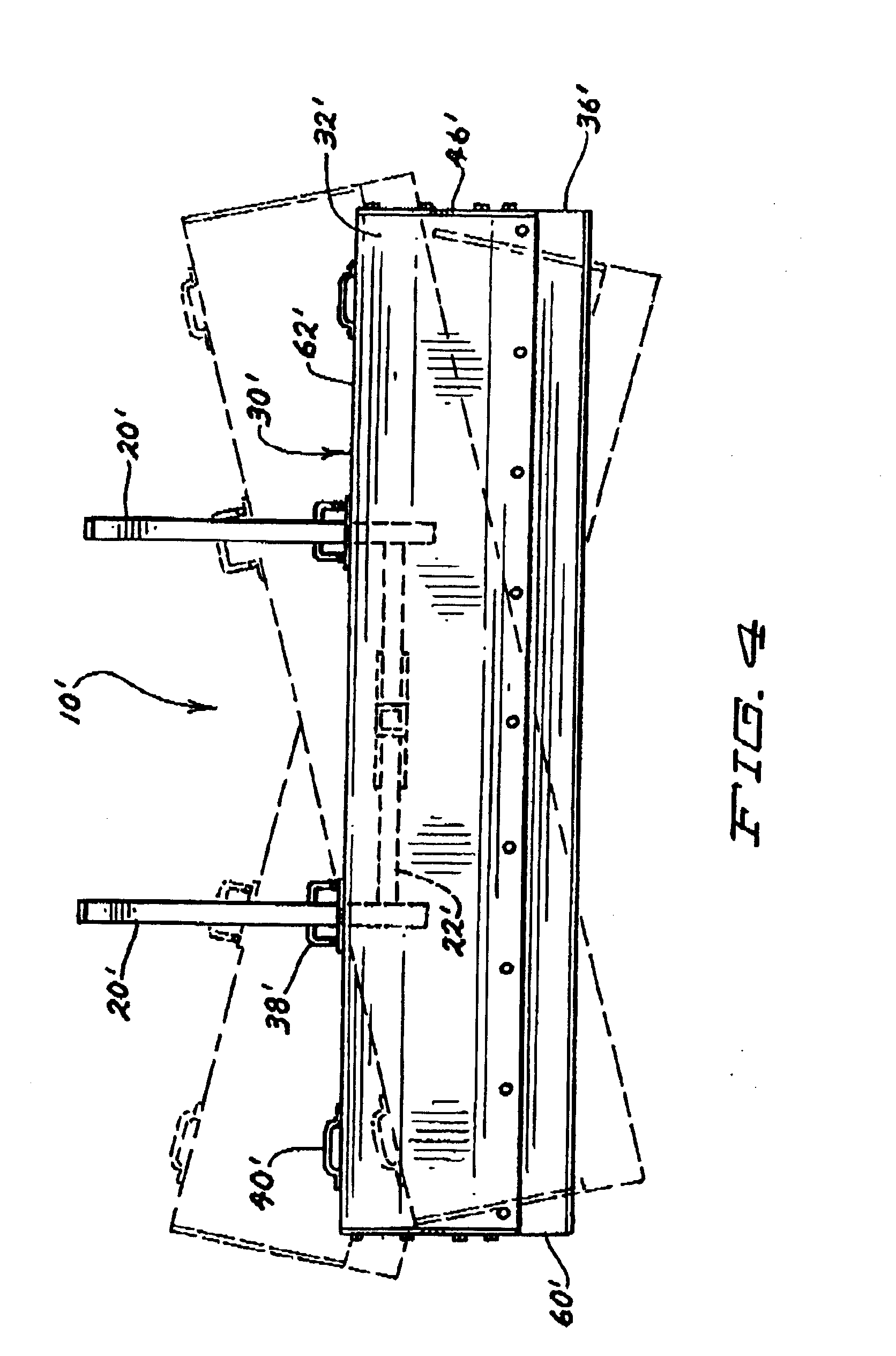

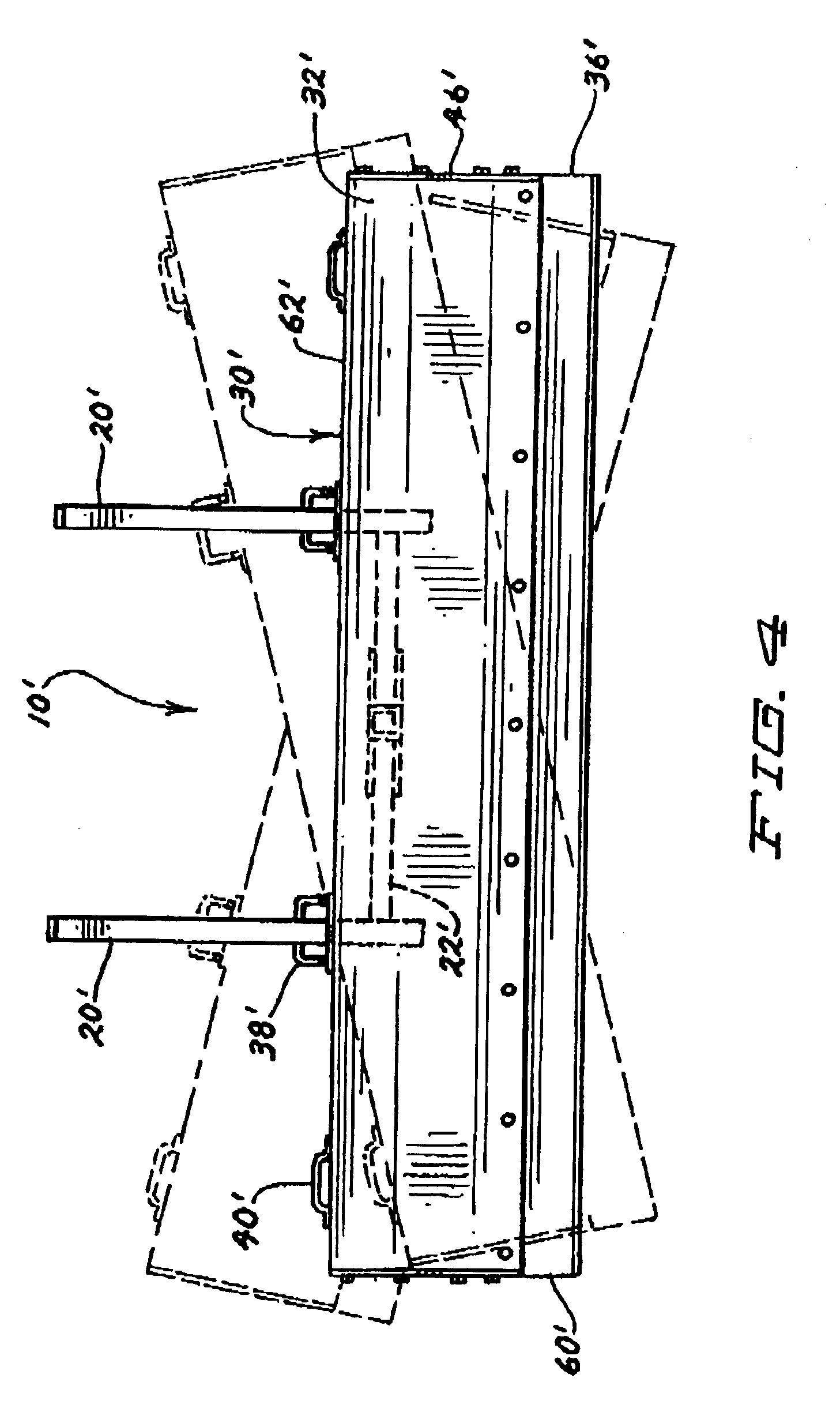

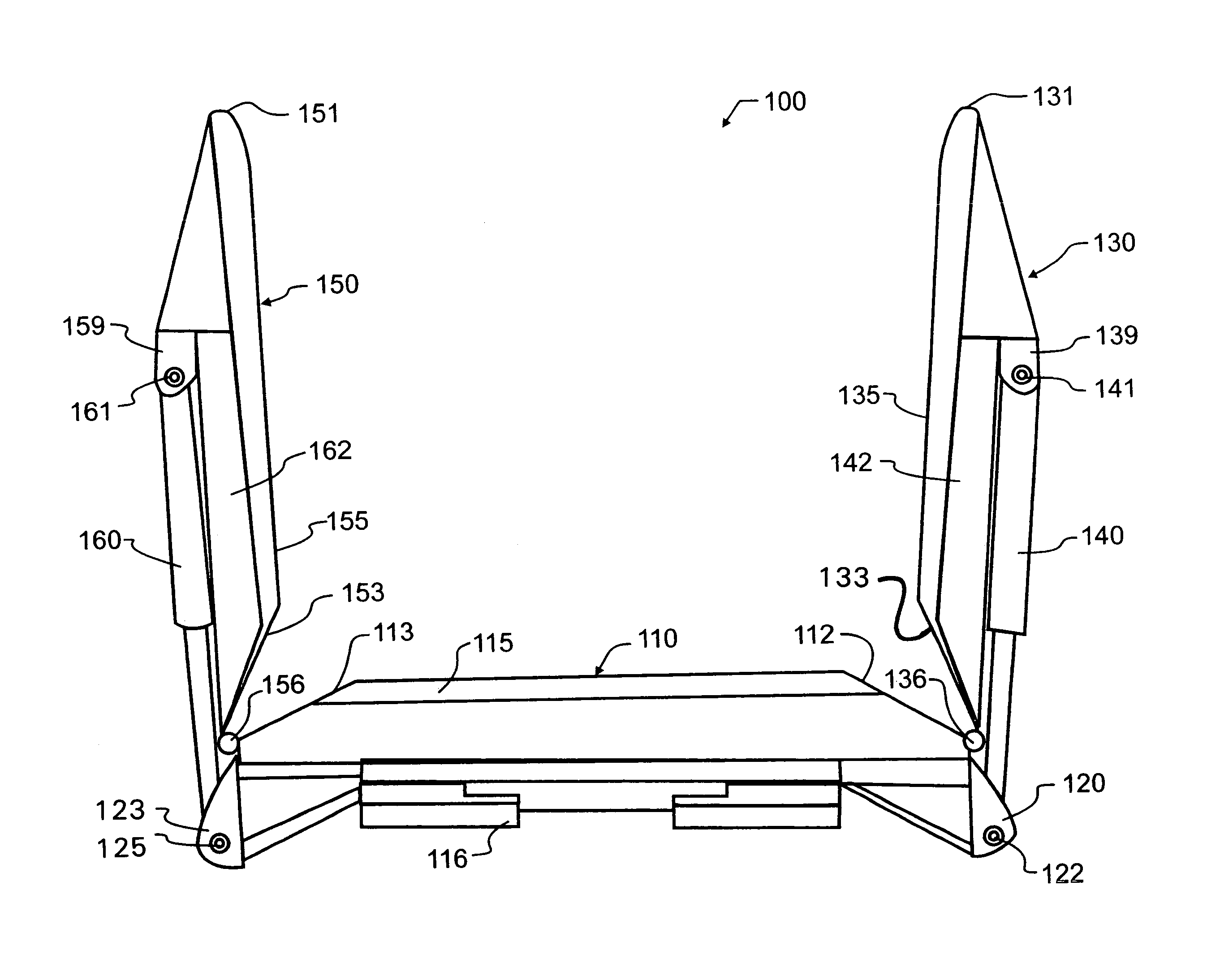

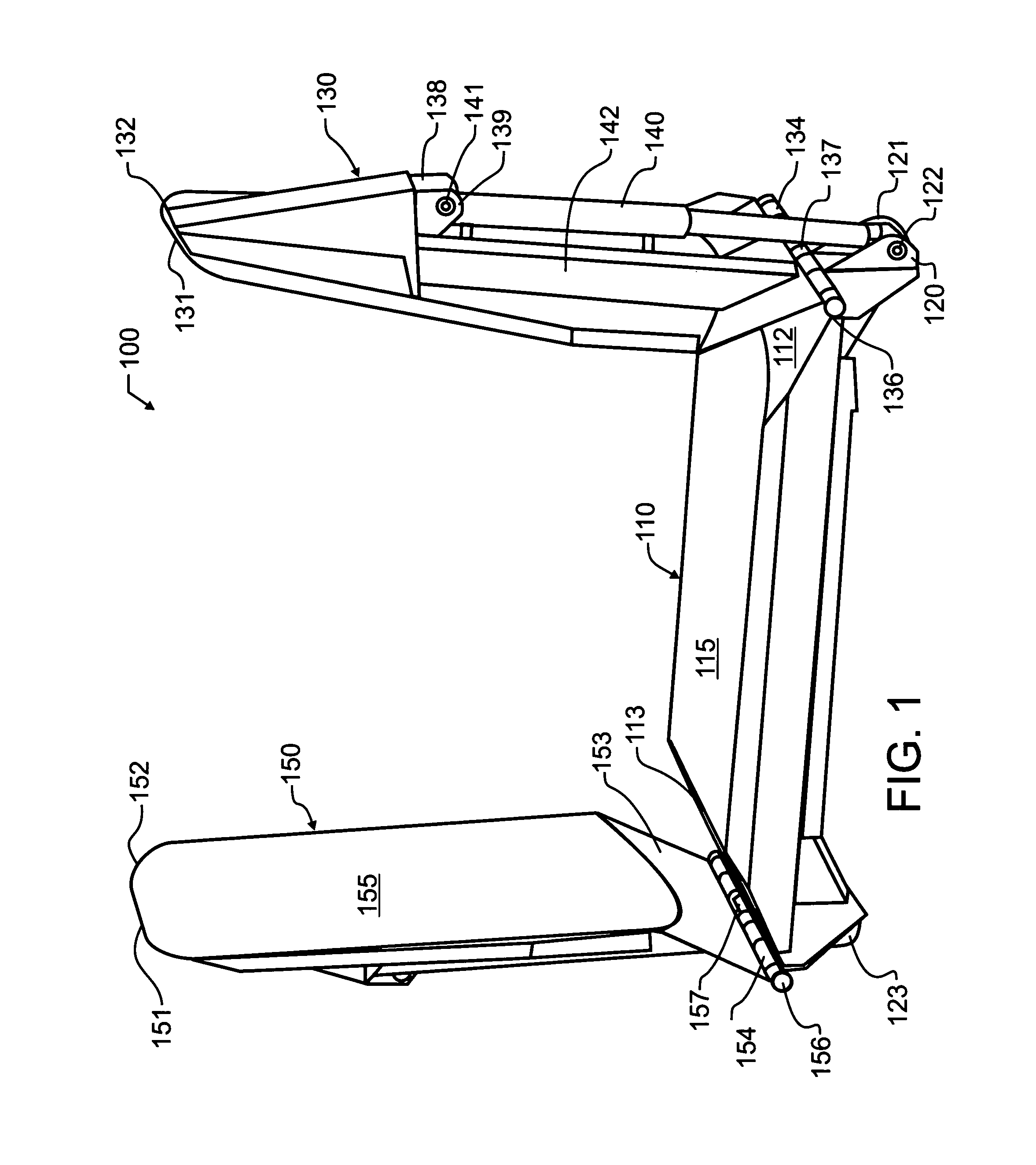

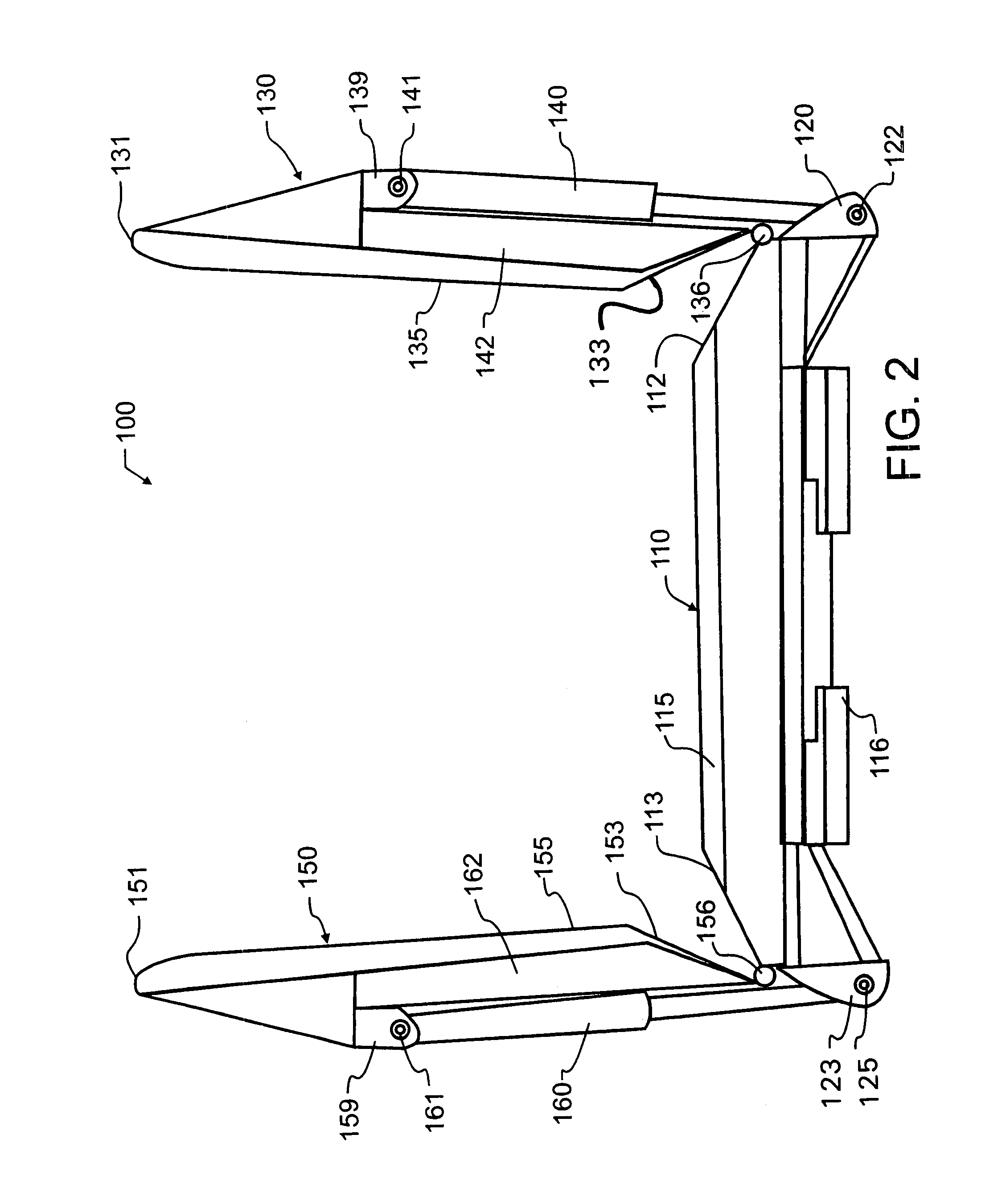

Plow with blade wing

A plow assembly comprises a blade, structure attached to the blade and adapted to be attached to a vehicle for mounting the blade to and supporting the blade from the vehicle, and a wing attached to an end of the blade. The wing has a first portion mounted to the blade for translational movement relative thereto, and a second portion mounted to the first portion for rotational movement relative thereto. An actuator has a cylinder and first and second oppositely movable piston rods. The first piston rod and the cylinder operable to move the first portion of the wing relative to the blade, and the second piston rod and the cylinder are operable to move the second portion of the wing relative to the fist portion of the wing.

Owner:DOUGLAS DYNAMICS

Self-adjusting snow plow

InactiveUS7131221B2Easy to mountEasy to removeMechanical machines/dredgersSnow cleaningPickup truckEngineering

Owner:AGRI COVER

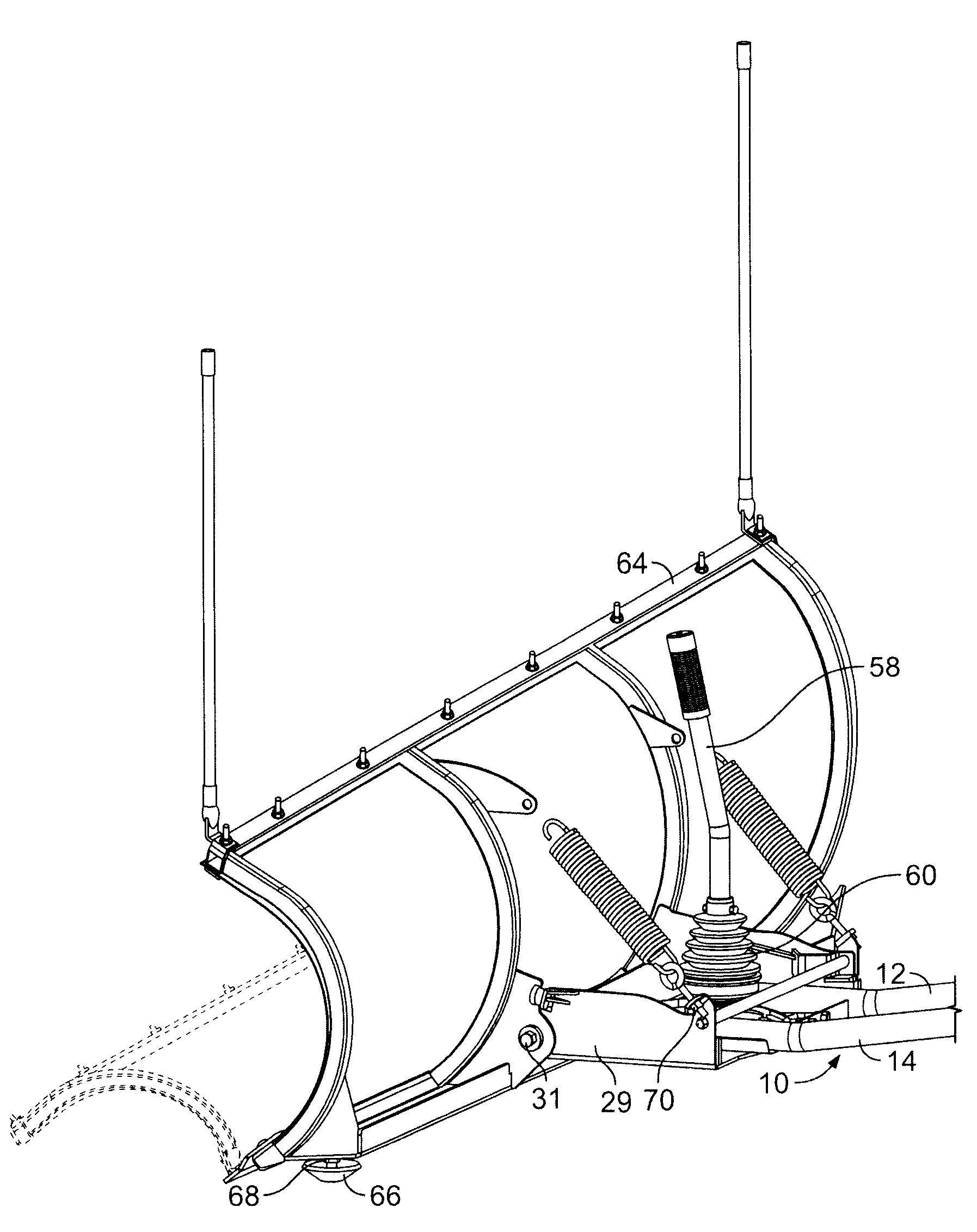

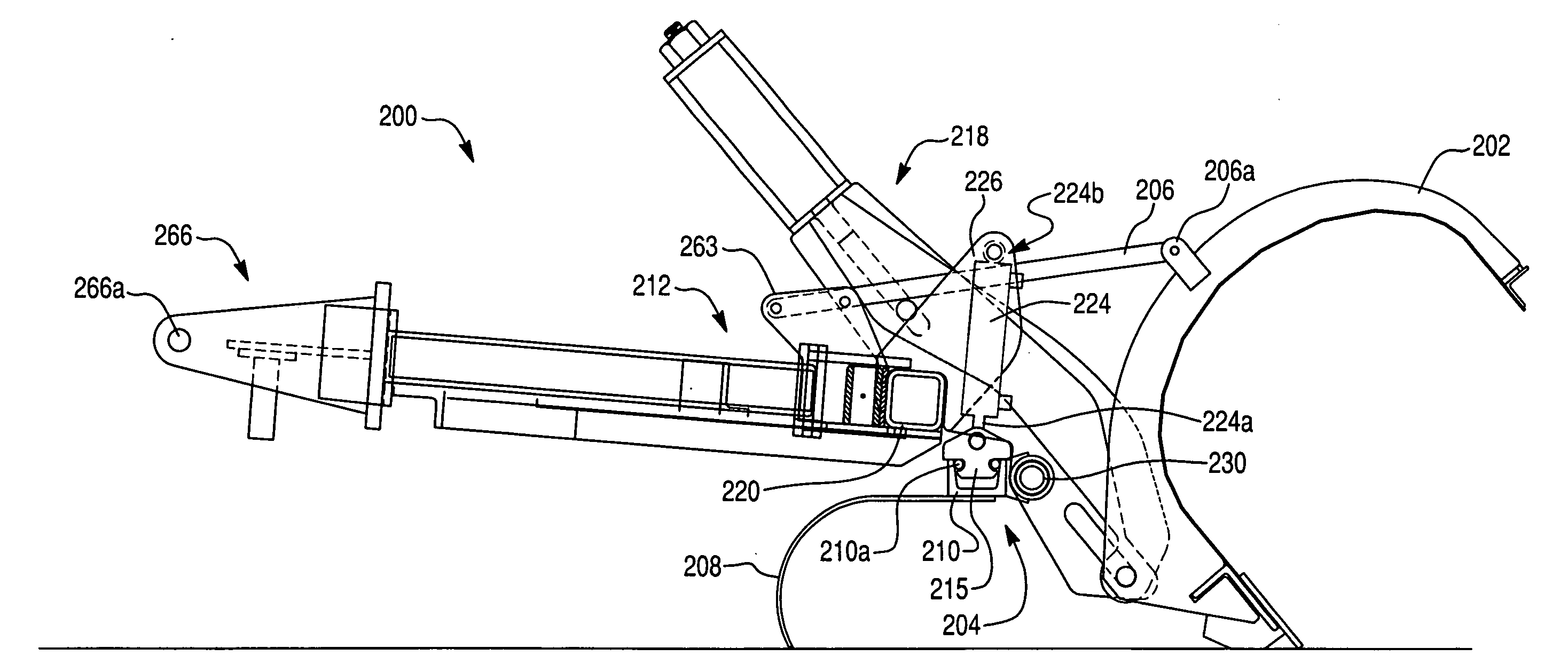

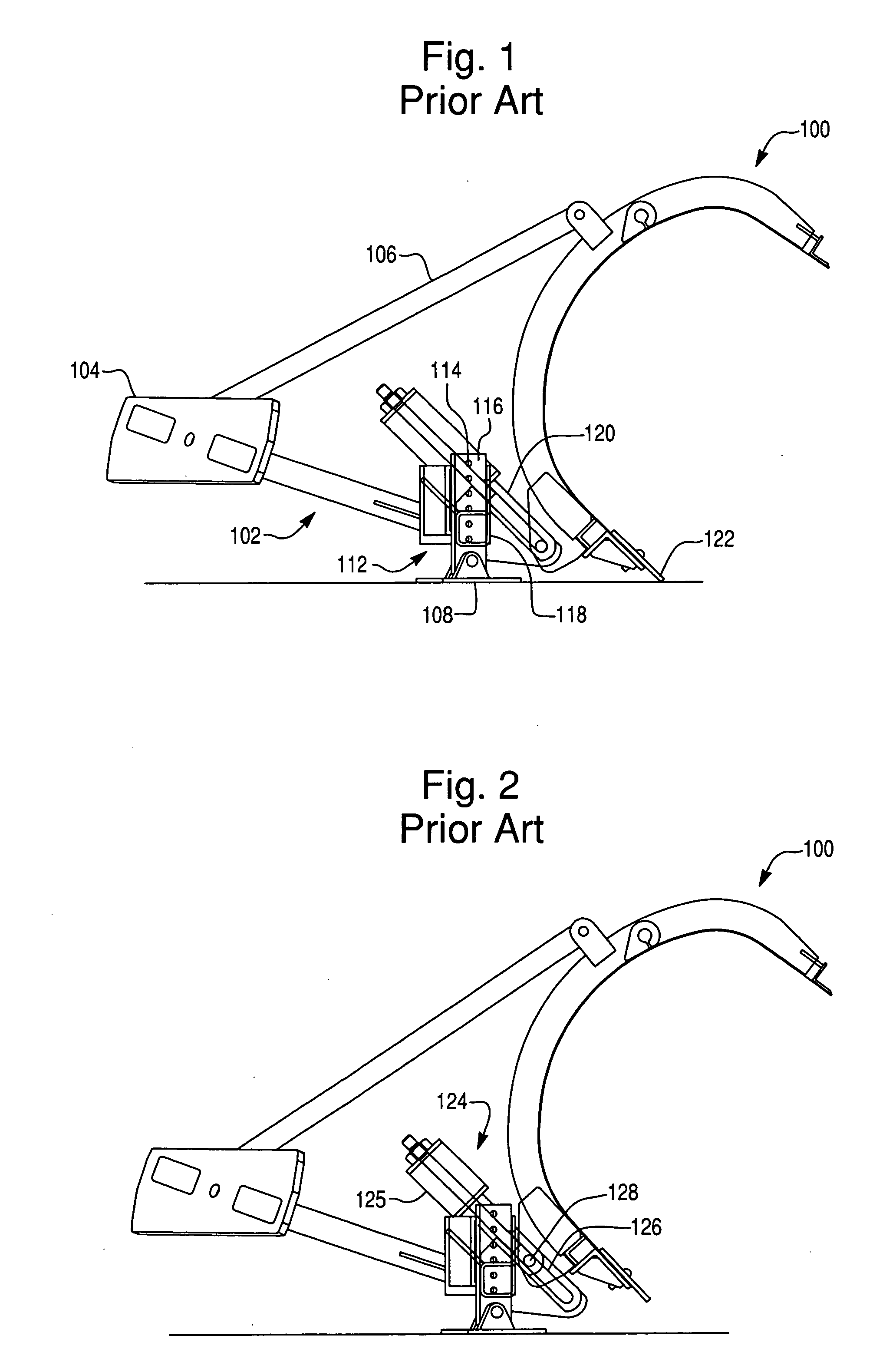

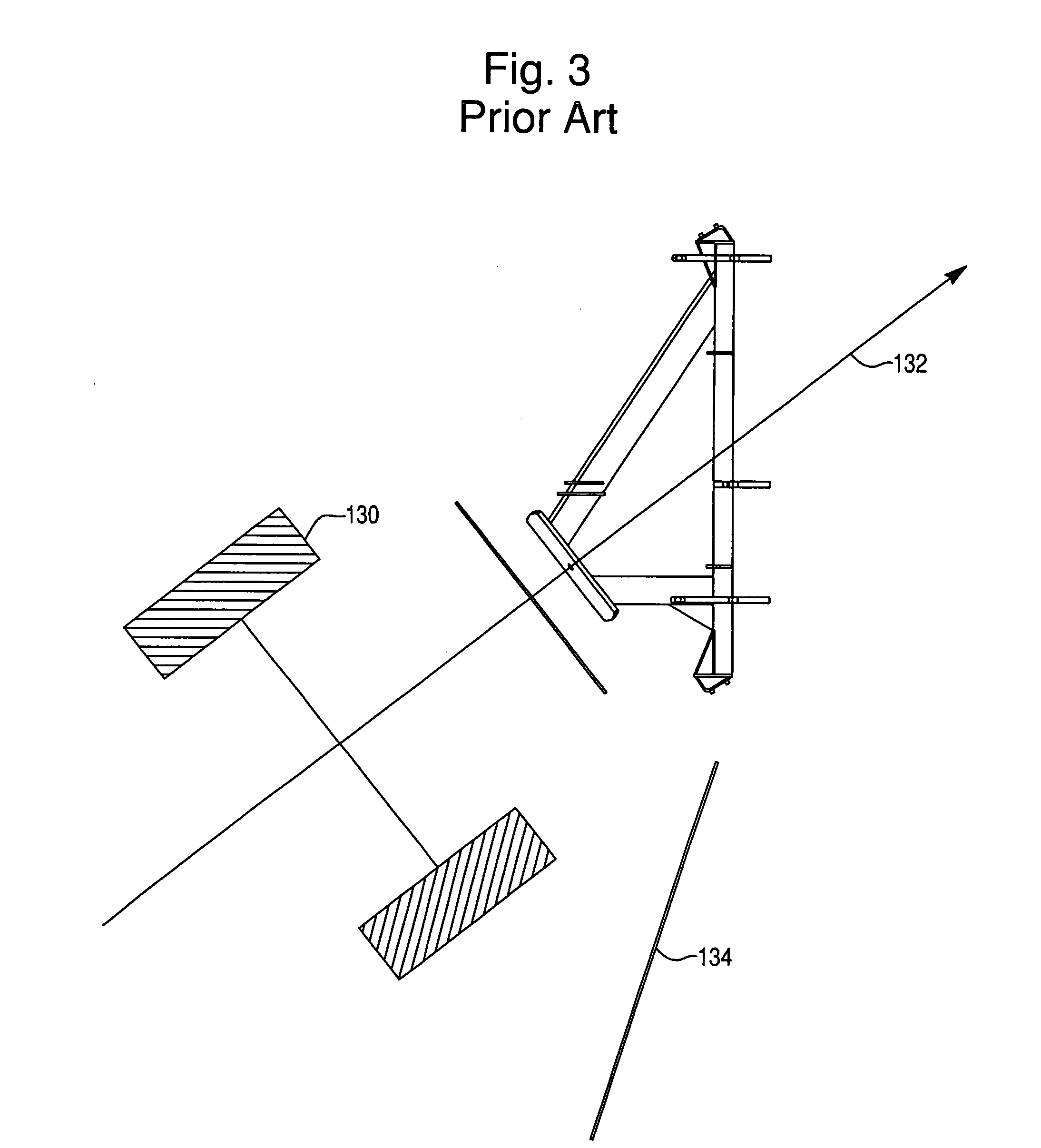

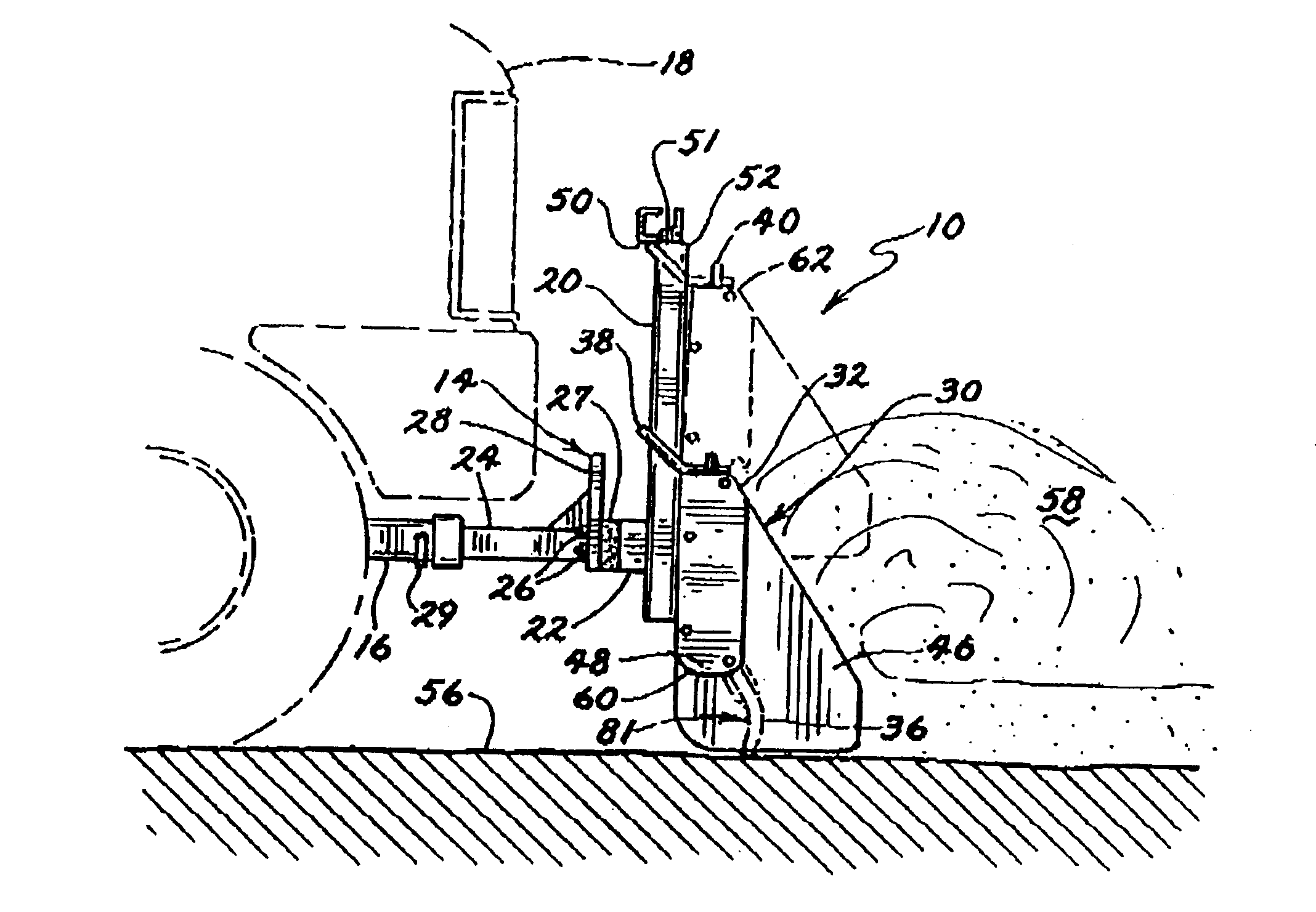

Homeowner's method of snow removal with a motor vehicle

This method provides various high-power-ratio snow removal devices which clear paths narrower than the motor vehicles. We use small, light, low-priced, yet also safe, durable devices to clear the narrow swaths. High power ratios result from applying motor vehicle horsepower to small snow removal devices similar to those found on lawn tractors. Such devices may comprise moldboard plows (FIGS. 3, 9, 10, 11, 15, 16), snow throwers (FIGS. 7 and 13), or combinations of both types (FIG. 12 and 17). Quick-connect and quick-release fittings (FIGS. 3A, 3B, 6, 8, 9A, 9B, 14) position each device for temporary propulsion by a vehicle. The connectors allow quick conversion of the family car to a plowing machine, and when plowing is done, quick re-conversion. A moldboard plow of about half the car's width (FIG. 3) is our preferred embodiment. The mini-moldboard (FIG. 10) is least expensive. Deepest snow can be handled by our tall, narrow moldboard (FIG. 15). We protect homeowners, their cars and their plows from injury when plows strike hidden objects. Protection devices comprise safety springs (60) and pivots (63, 67 and 69) of FIG. 3B, the tension-release mechanism mentioned but not detailed in FIG. 15, annor shields (396, 398) of FIG. 16 and various others mentioned or provided for in our drawings but not detailed. We prefer cars' chassis tie-down ears (72) in FIG. 3A, as connector points for our plow or thrower arms. For cars lacking such ears, we propose add-on ears. For example, tie-down ear (126) in FIG. 6.

Owner:NUGENT GORDON W

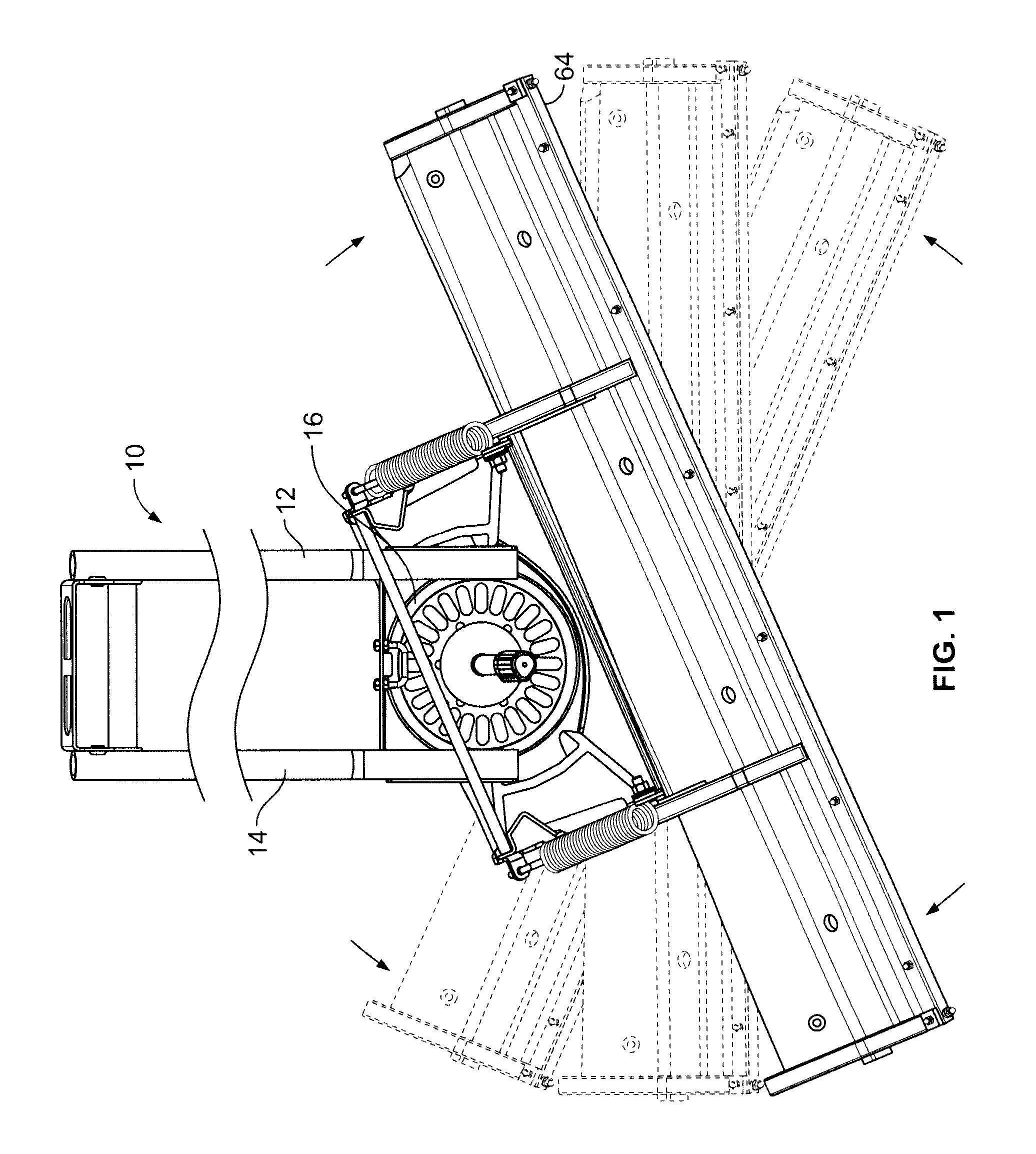

Powered strike-off plow

A wheeled strike-off apparatus is movable over a surface of uncured concrete or subgrade materials and is operable to establish a desired grade of the uncured concrete surface or subgrade surface. The apparatus includes a wheeled support and a plow assembly. The wheeled support may have a front frame portion and a pair of front wheels rotatably mounted at the front frame portion, and may have a rear frame portion and a pair of rear wheels rotatably mounted at the rear frame portion. The plow assembly may be adjustably mounted to the front frame portion and may be vertically adjustable relative to the frame portion via an actuator. The plow assembly includes at least one plow member for engaging and establishing the desired grade.

Owner:SOMERO ENTERPRISES INC

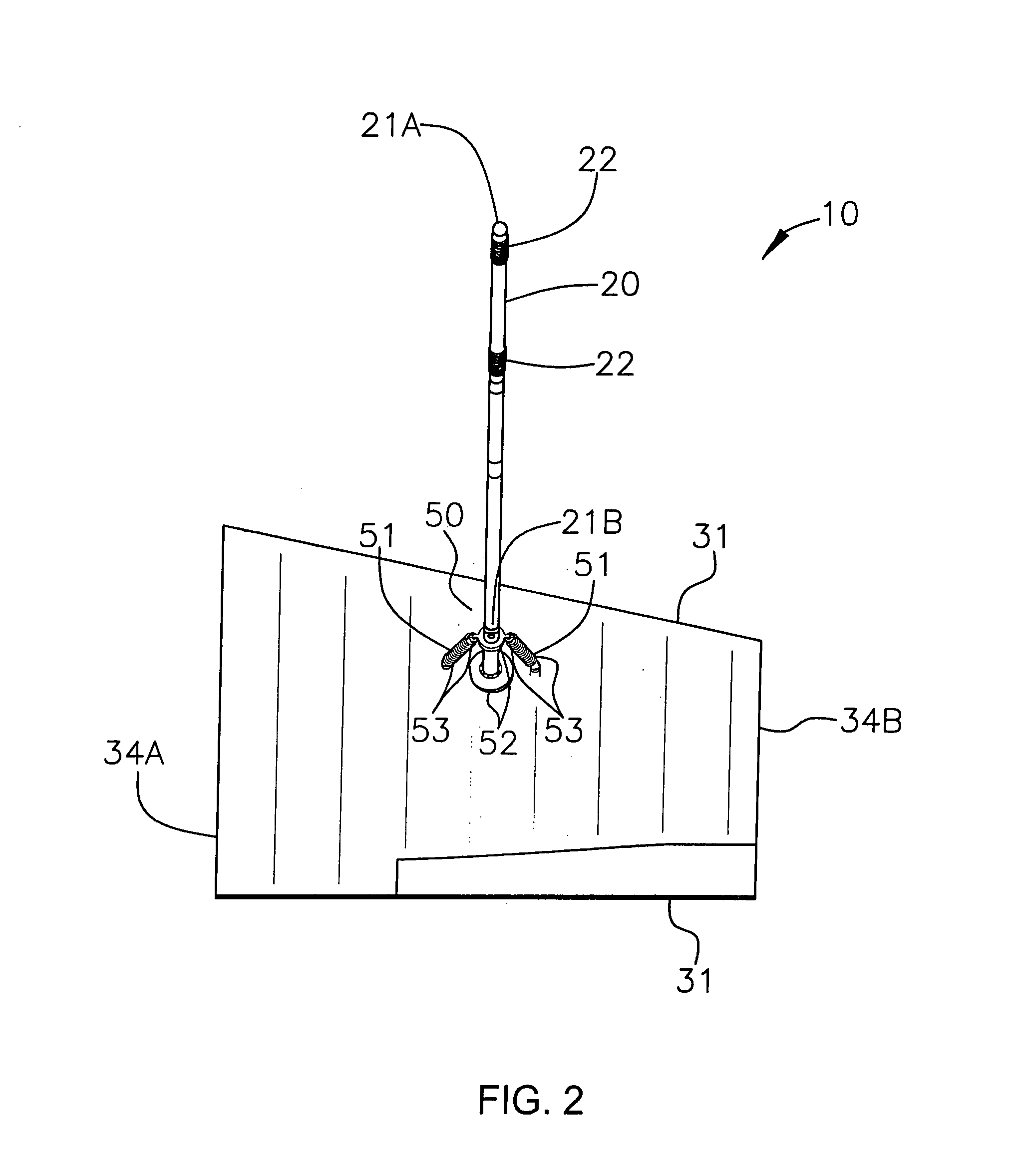

Snow-shoveling apparatus

An apparatus includes a shaft that has proximal and distal end portions. The shaft includes spaced grip covers conjoined about an outer surface thereof and is provided with a centrally registered sleeve formed therein. An arcuately shaped plow section is affixed to the distal end portion and includes a heel support that has an arcuately shaped top surface for assisting to maintain the plow section registered along a horizontal plane. The plow section further includes fastening members spaced along the bottom edge for removing the bottom edge to be sharpened or replaced. The apparatus further includes a mechanism for pivoting the plow section between alternate radial paths during operating conditions. A mechanism is included for automatically biasing the plow section to an equilibrium position after the plow section is biased to a pivoted position.

Owner:PURVIS RICHARD A

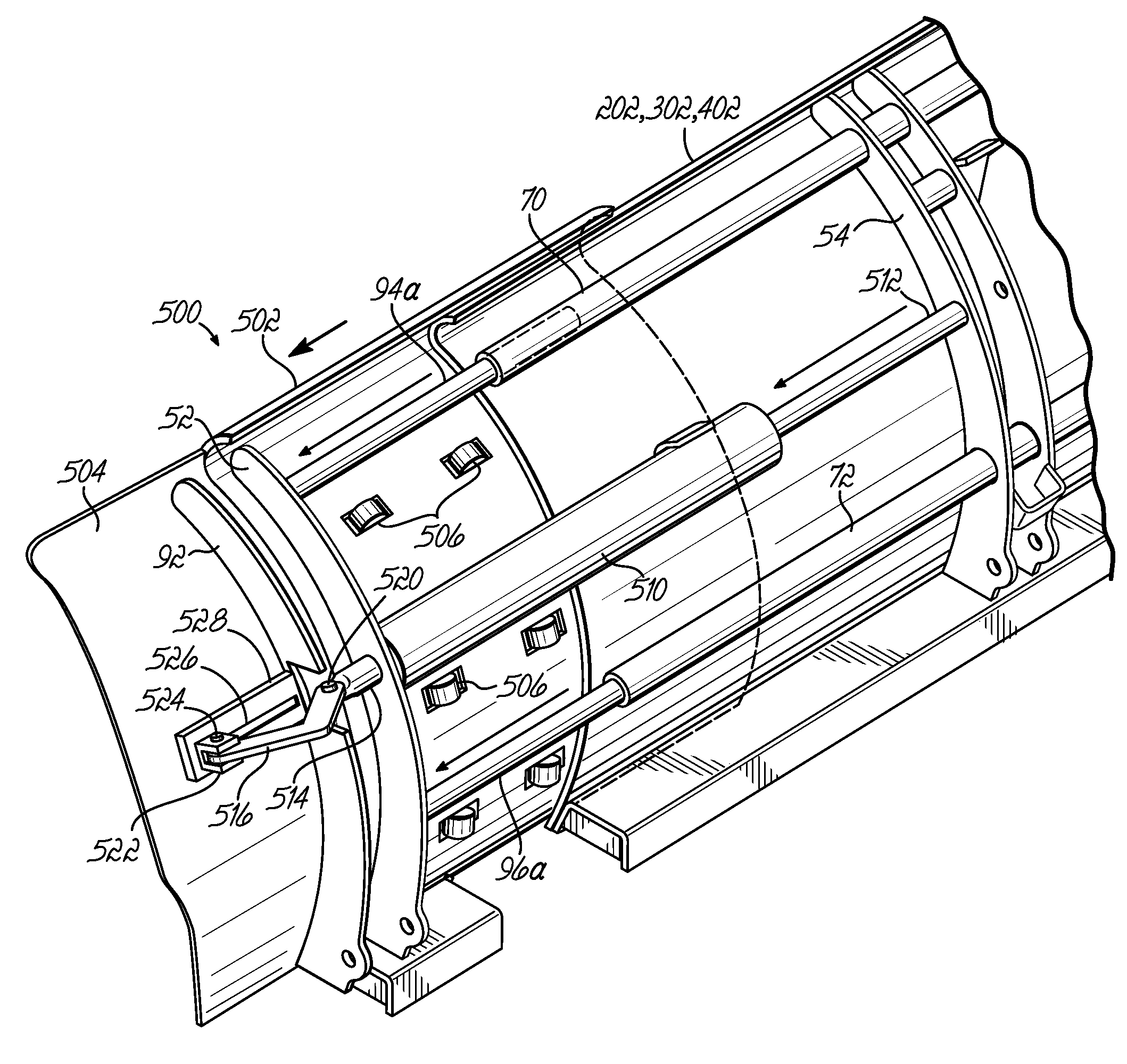

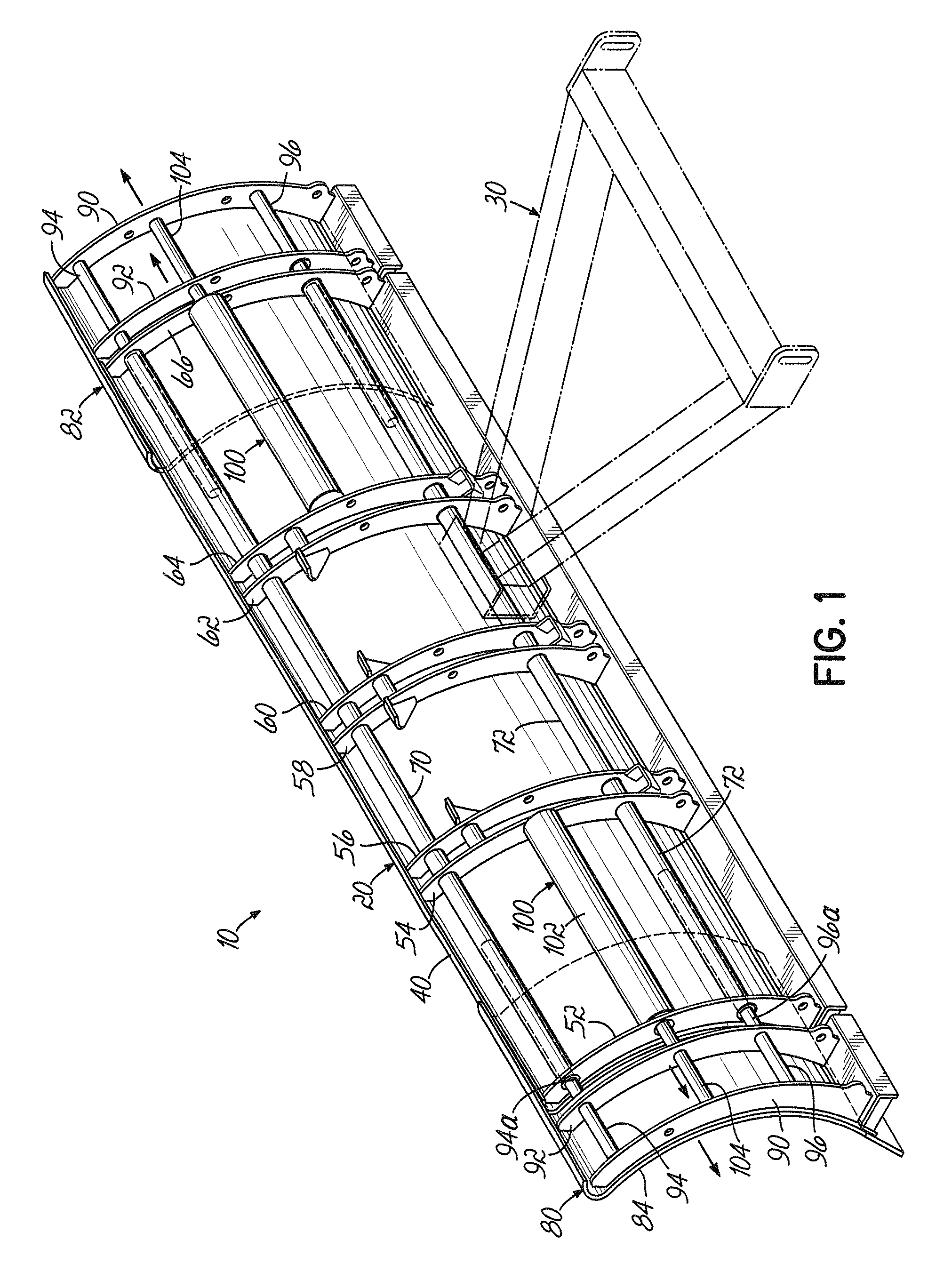

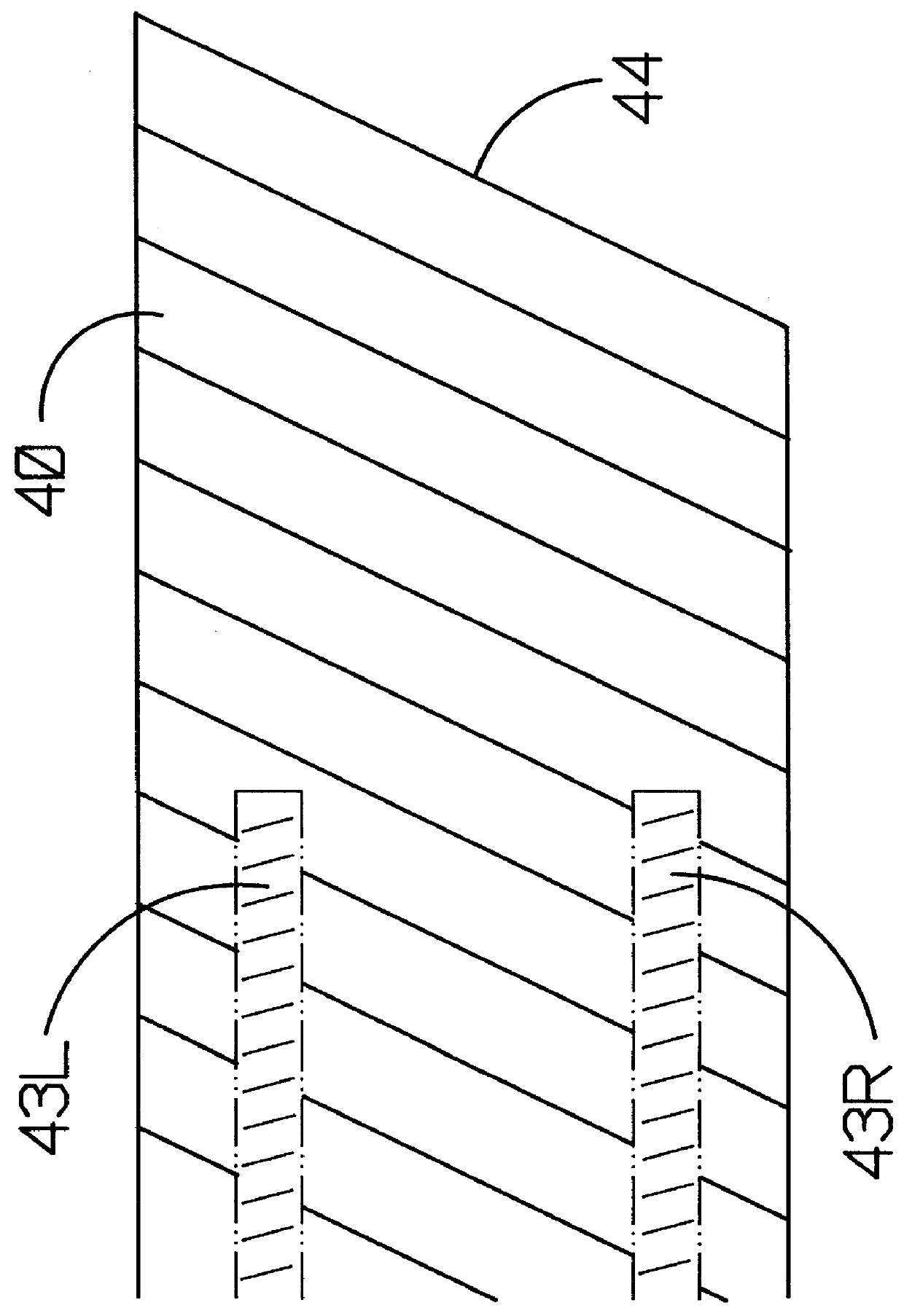

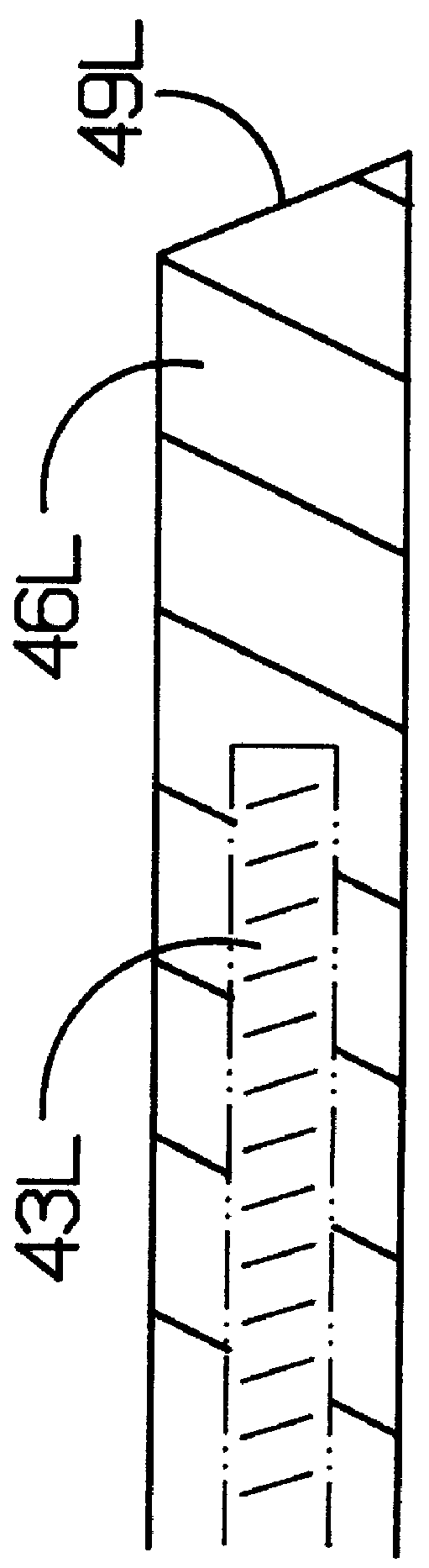

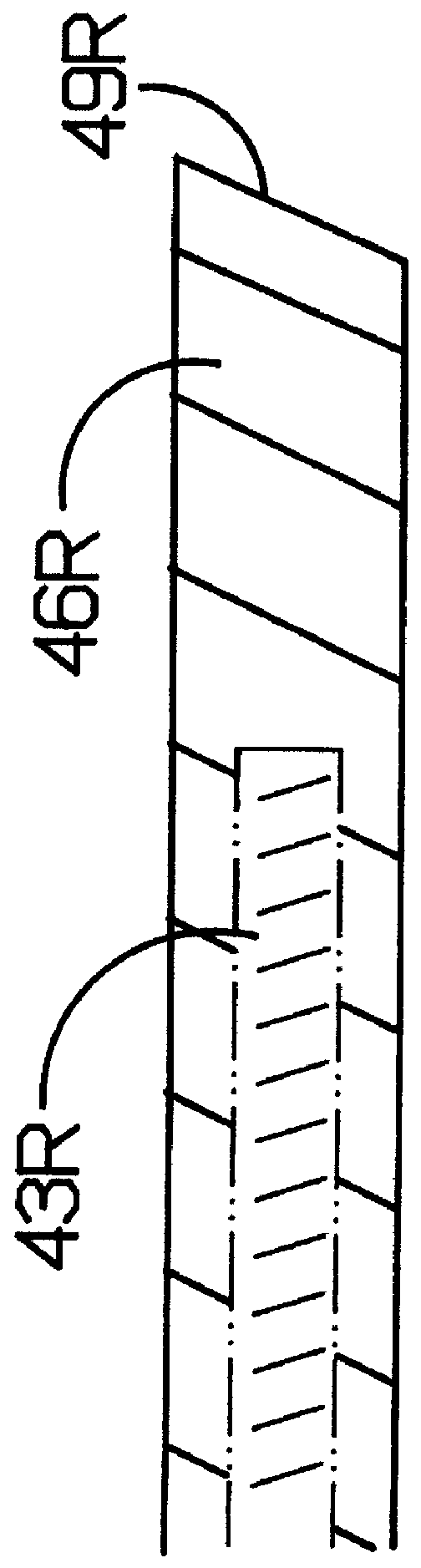

Snow plow having two-piece mold board

InactiveUS20070062072A1Improve practicalityEasy to liftMechanical machines/dredgersSoil-working equipmentsAgricultural engineeringAluminum extrusion

A snow plow for attachment to a vehicle, the snow plow including a mounting apparatus having a mounting frame, the mounting frame including at least one mounting upright. The snow plow further including a plow blade including a retention apparatus constructed and arranged to slidlingly and disengageably secure the plow blade to the mounting upright(s) when the plow blade is in a working orientation. The plow blade includes a two piece mold board, the mold board preferably being an aluminum extrusion.

Owner:AGRI COVER

Wing plow assembly

A wing plow assembly includes a base member for mounting to a plowing vehicle (or to structures connected to a plowing vehicle, such as on a plow frame for a front moldboard). Upper and lower height adjustment arms each have a base end pivotally anchored to the base member, and an opposing plow end pivotally linked to a plow positioning leg. The base member, height adjustment arms, and plow positioning leg form a parallelogram linkage wherein the plow positioning leg may vertically swing on the height adjustment arms about the base member. A wing plow having a length extending between a inner end and a outer end has its inner end affixed to the plow positioning leg so that the wing plow may also vertically swing about the base member, thereby allowing the wing plow to be raised and lowered with respect to the base member (and thus with respect to the plowing vehicle). Additionally, the wing plow inner end is preferably affixed to the plow positioning leg so that it may swing horizontally thereon, thereby allowing the wing plow outer end to be folded toward or away from the plowing vehicle. The wing plow inner end is affixed to the plow positioning leg (or associated structure), and a wing fold linear actuator then extends from the outer end of the wing plow to affix to the plow positioning leg (or associated structure). The wing fold linear actuator is extendible and contractible to horizontally swing the wing plow about the plow positioning leg, and thus fold the wing plow with respect to the plowing vehicle.

Owner:BURKE TRUCK & EQUIP

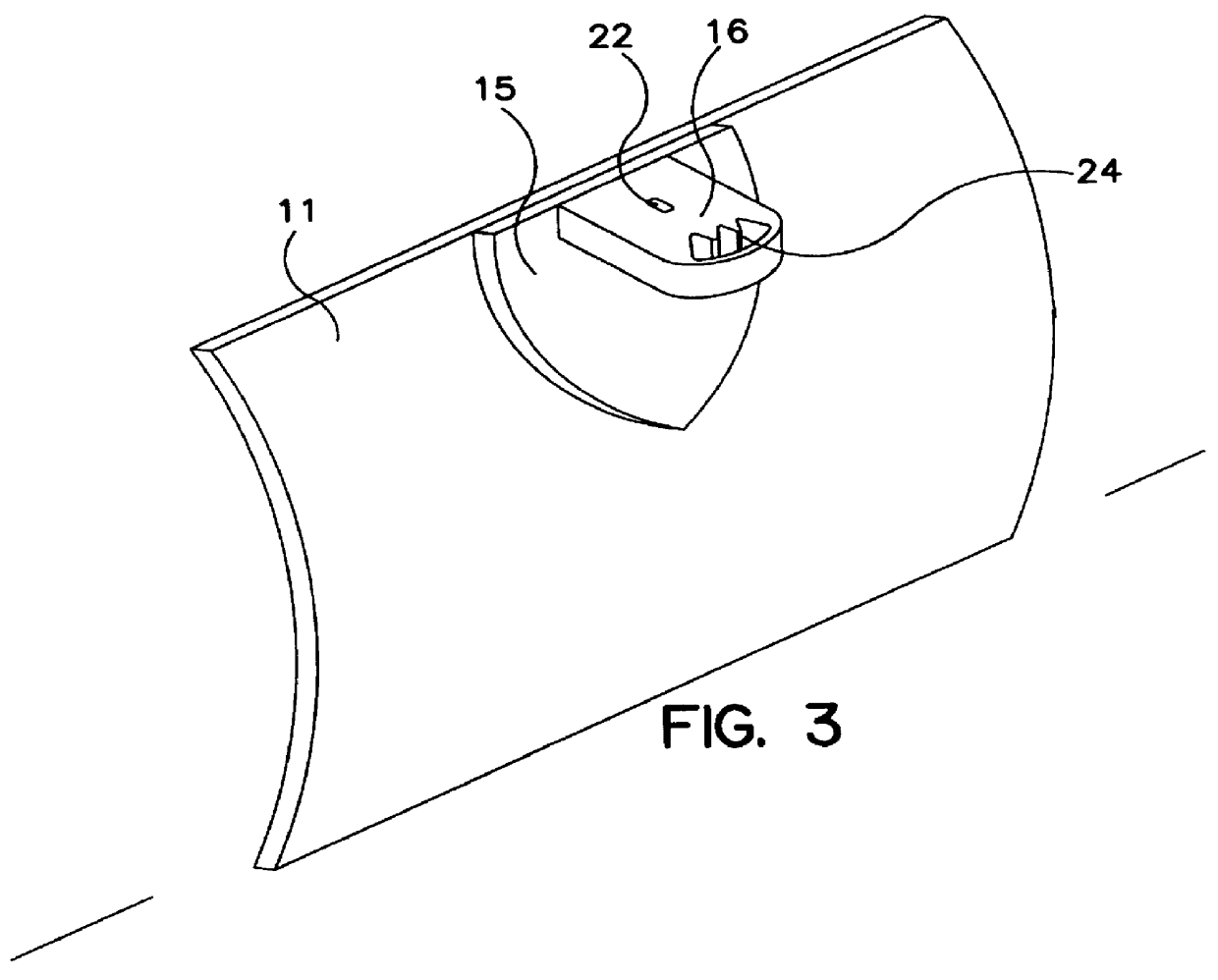

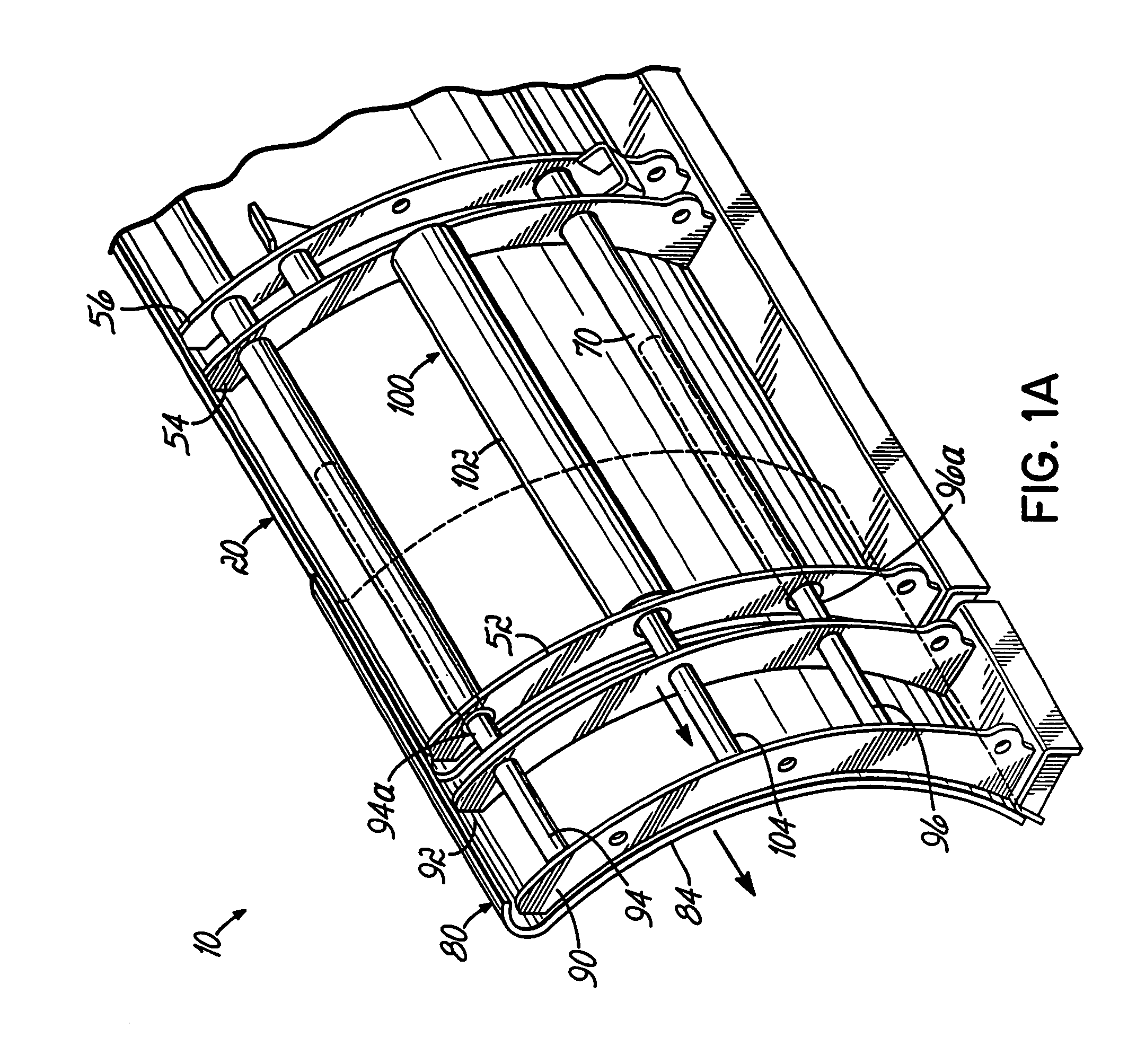

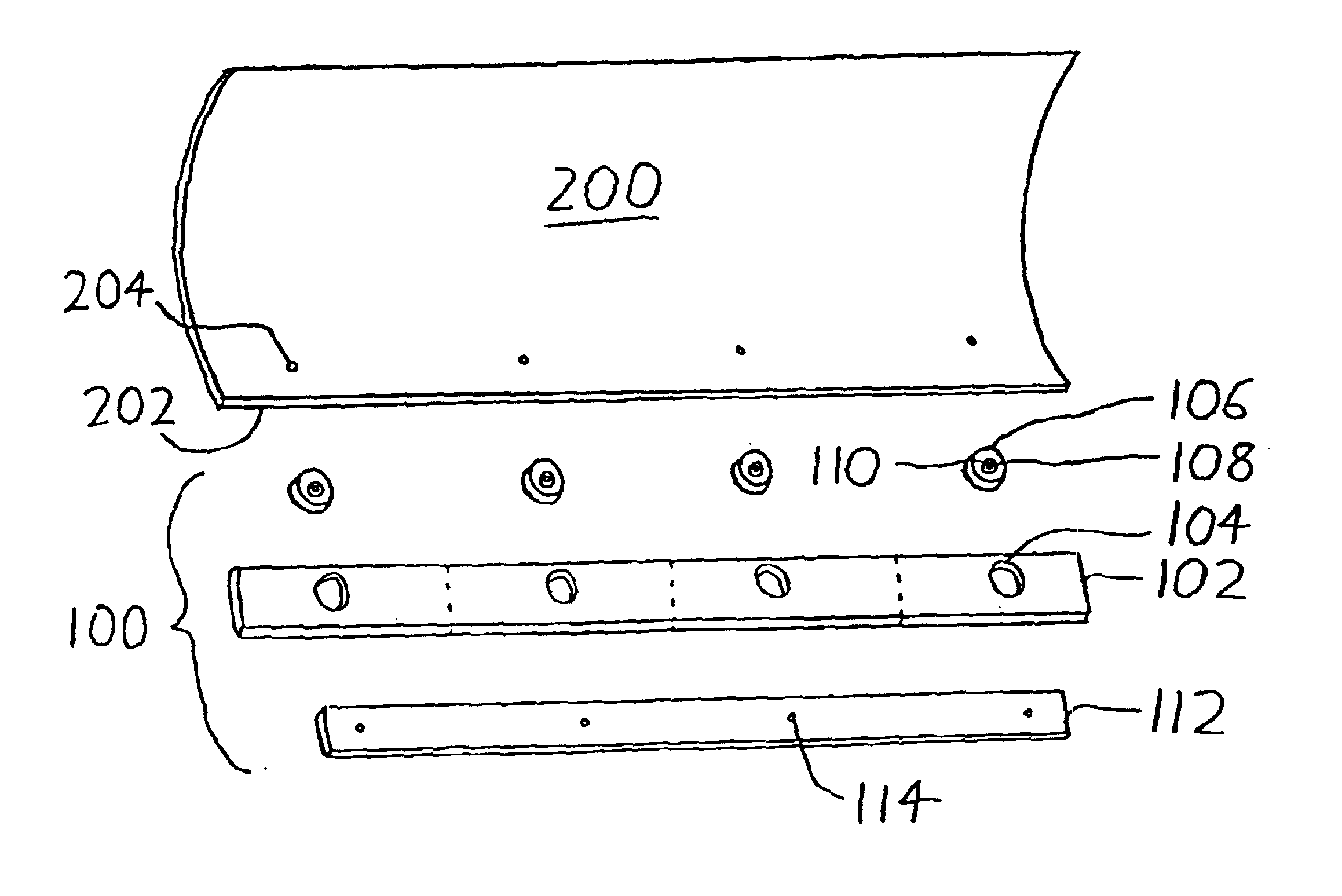

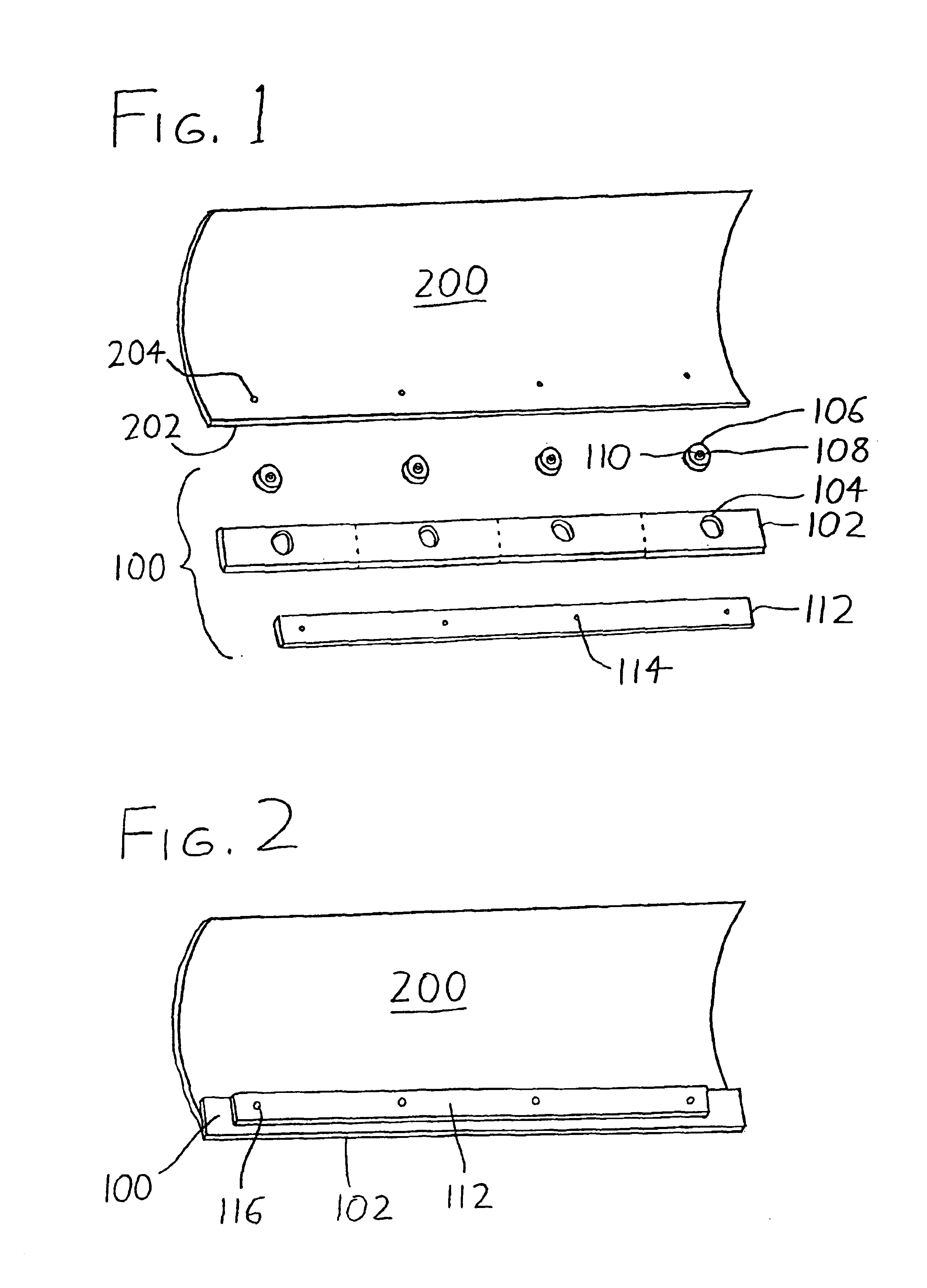

Plow cutting edge

ActiveUS6922924B2Avoid shock transmissionReduce wearSoil-working equipmentsMechanical machines/dredgersEngineeringKnife blades

A plow moldboard cutting edge includes a cutting edge blade having a front (leading) face and a rear (trailing) face, with one or more receiving apertures defined therebetween. An elastic bushing is then provided in each of the receiving apertures of the cutting edge blade, with each bushing having a through hole defined therein. The cutting edge blade is then fastened to the lower edge of a plow moldboard by extending fasteners through cutting edge mounting holes defined in the plow moldboard adjacent its lower edge, and then into the through holes of the bushings. The fasteners secure the bushings to the plow moldboard, and thereby mount the cutting edge blade (which is situated about the elastic bushings) to the plow moldboard as well, with the elastic bushings elastically spacing the cutting edge blade from the fasteners. As a result, when the cutting edge blade is driven along a roadway or other surface to be plowed, the elastic bushings elastically suspend the cutting edge blade from the moldboard so that the cutting edge blade rides along the plowing surface and better conforms to the plowing surface's contour. The elastic bushings additionally help to avoid shock transmission between the cutting edge blade and moldboard, and assist in reducing wear on the cutting edge blade.

Owner:BURKE TRUCK & EQUIP

Front retracting plow

The plow includes a vehicle mount for mounting the plow to a host vehicle, and a main blade mounted to the vehicle mount The plow further includes a pair of wing blades pivotally mounted to the main blade for travel in an arcuate path relative to the main blade, and four bar parallel arm linkages and actuators connected between opposing ends of the main blade and each of the wing blades for supporting and swinging the at least one wing blade in said arcuate travel path throughout the full distance between a retracted position in front of the main blade such that at least a substantial portion of the at least one wing blade is disposed in overlapping relation with the main blade, and an extended position in substantial longitudinal alignment with the main blade whereby a plurality of plowing widths is provided. It should be noted that the blade is advantageously used for the plowing of snow, however the plowing of other materials is envisioned such as sand or gravel.

Owner:AGWAY MFG

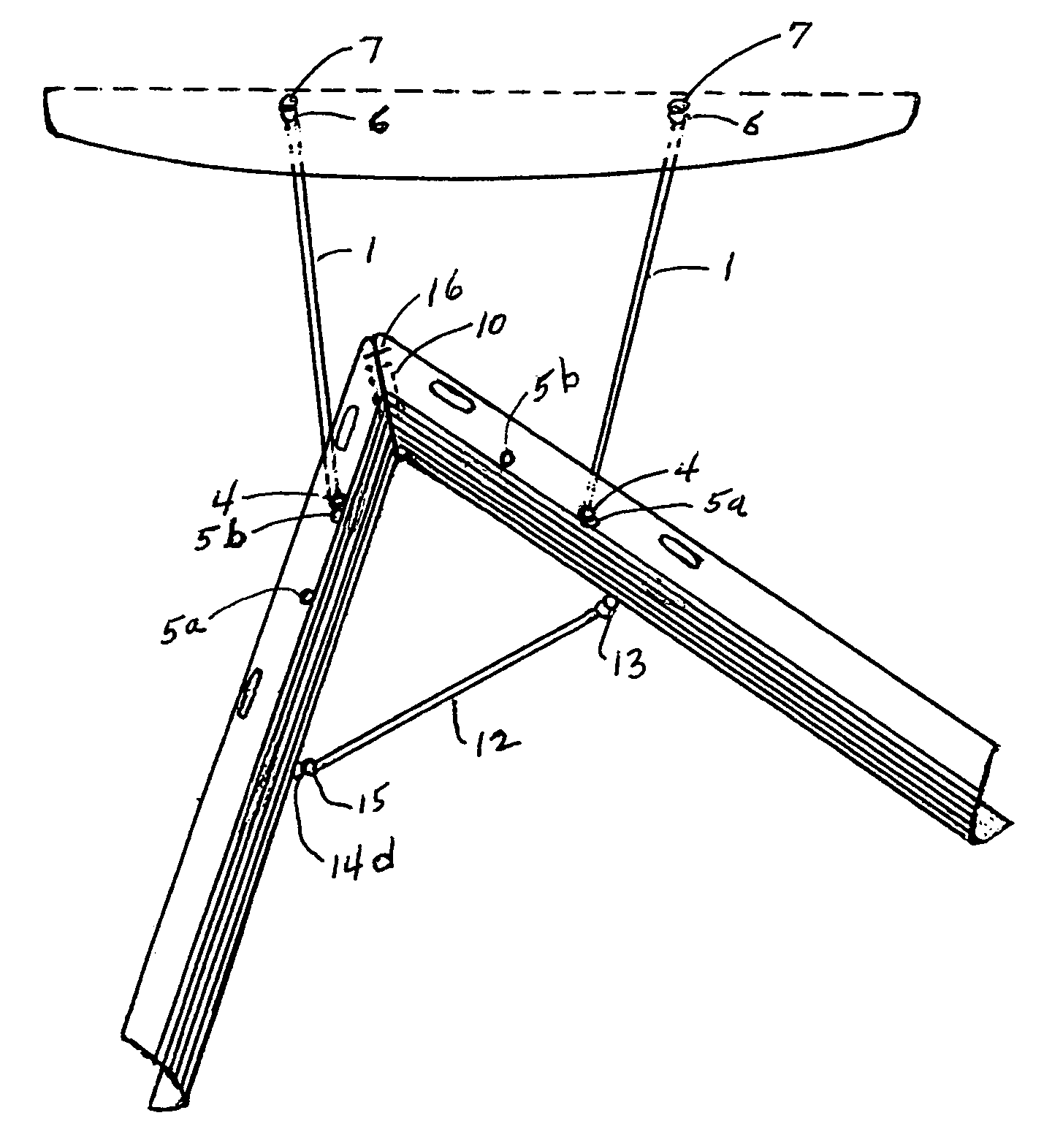

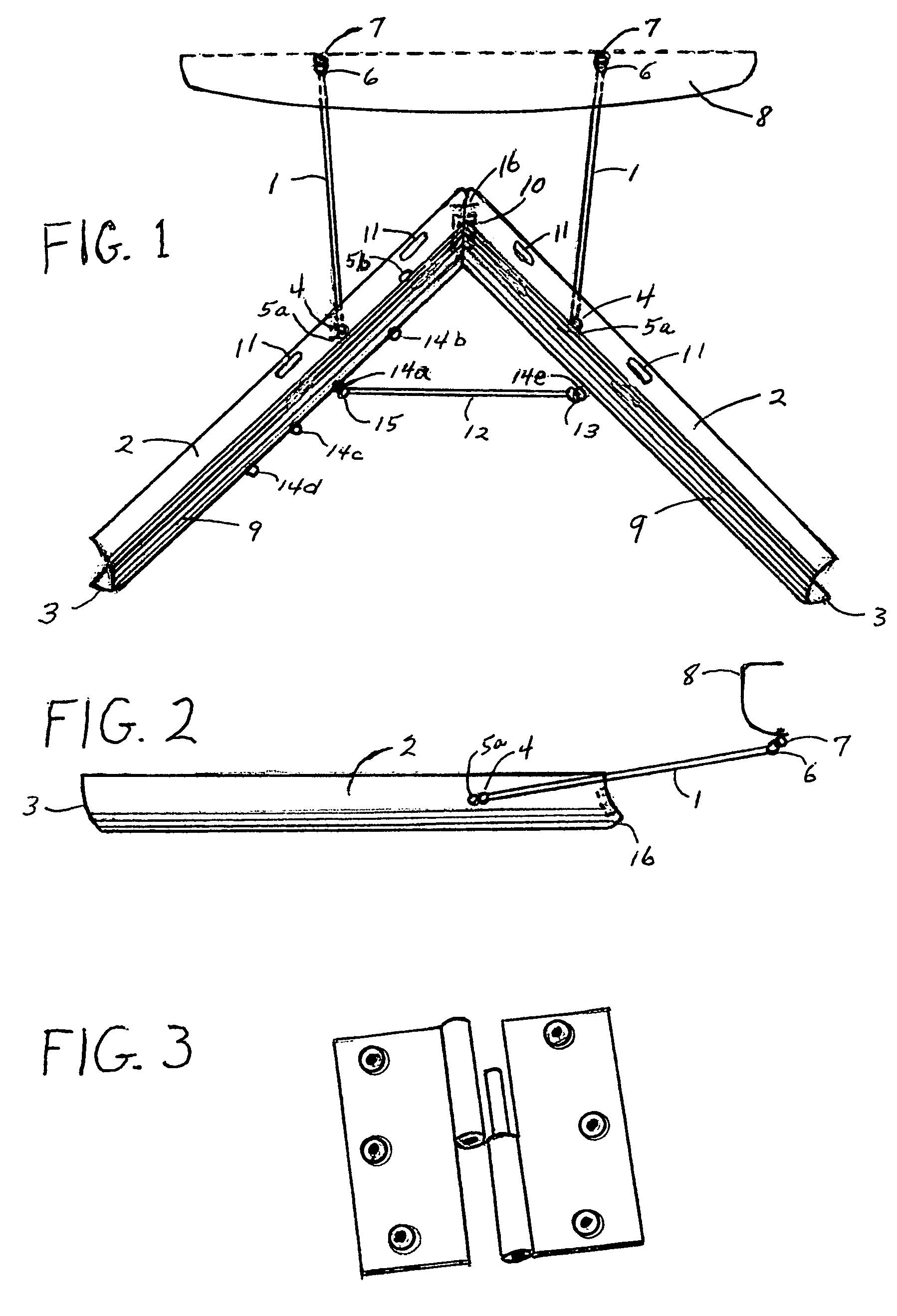

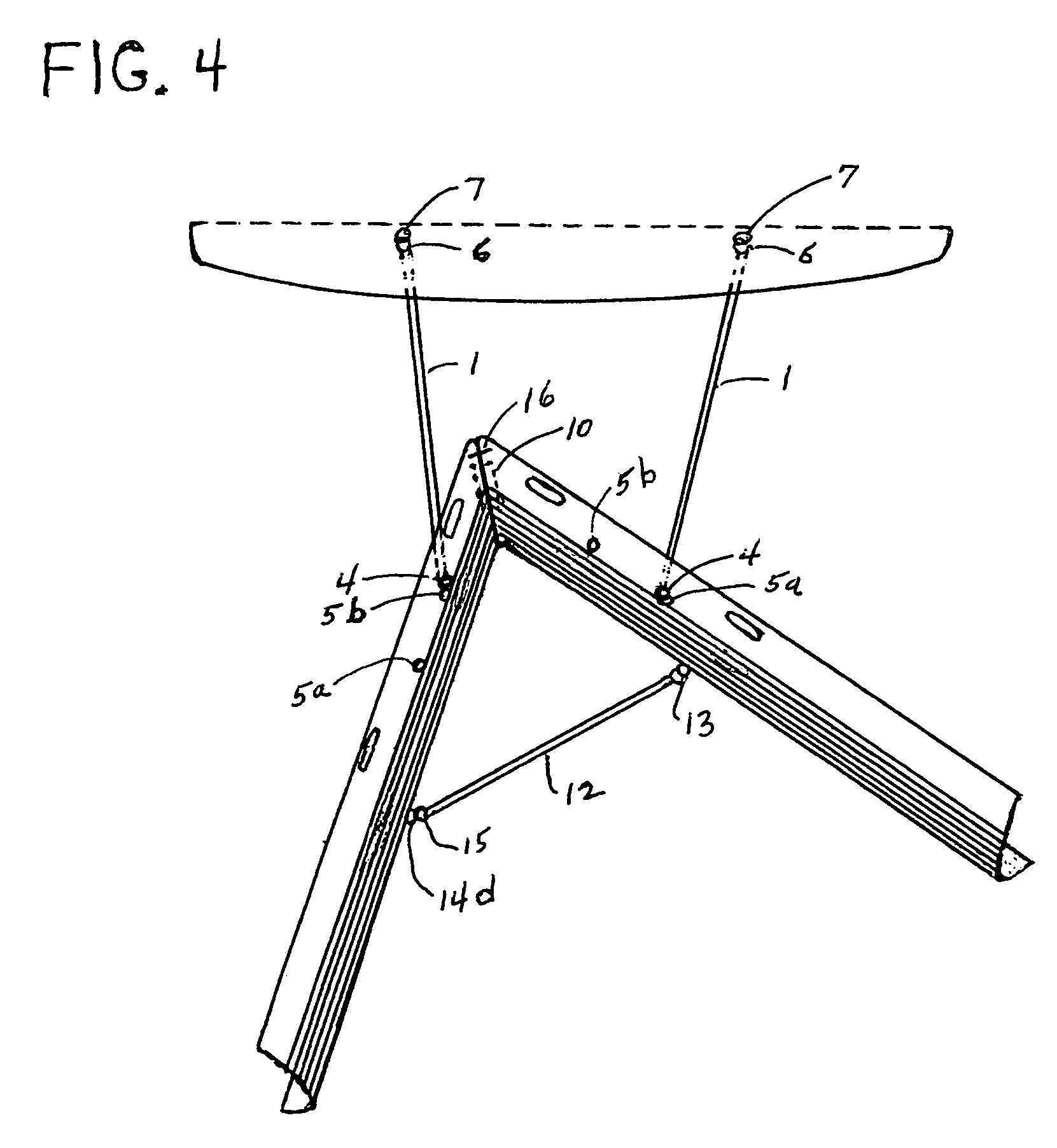

Inexpensive snowplow

InactiveUS6983558B2Easy and fast assemblyQuickly and easily attachedSnow cleaningEngineeringUltimate tensile strength

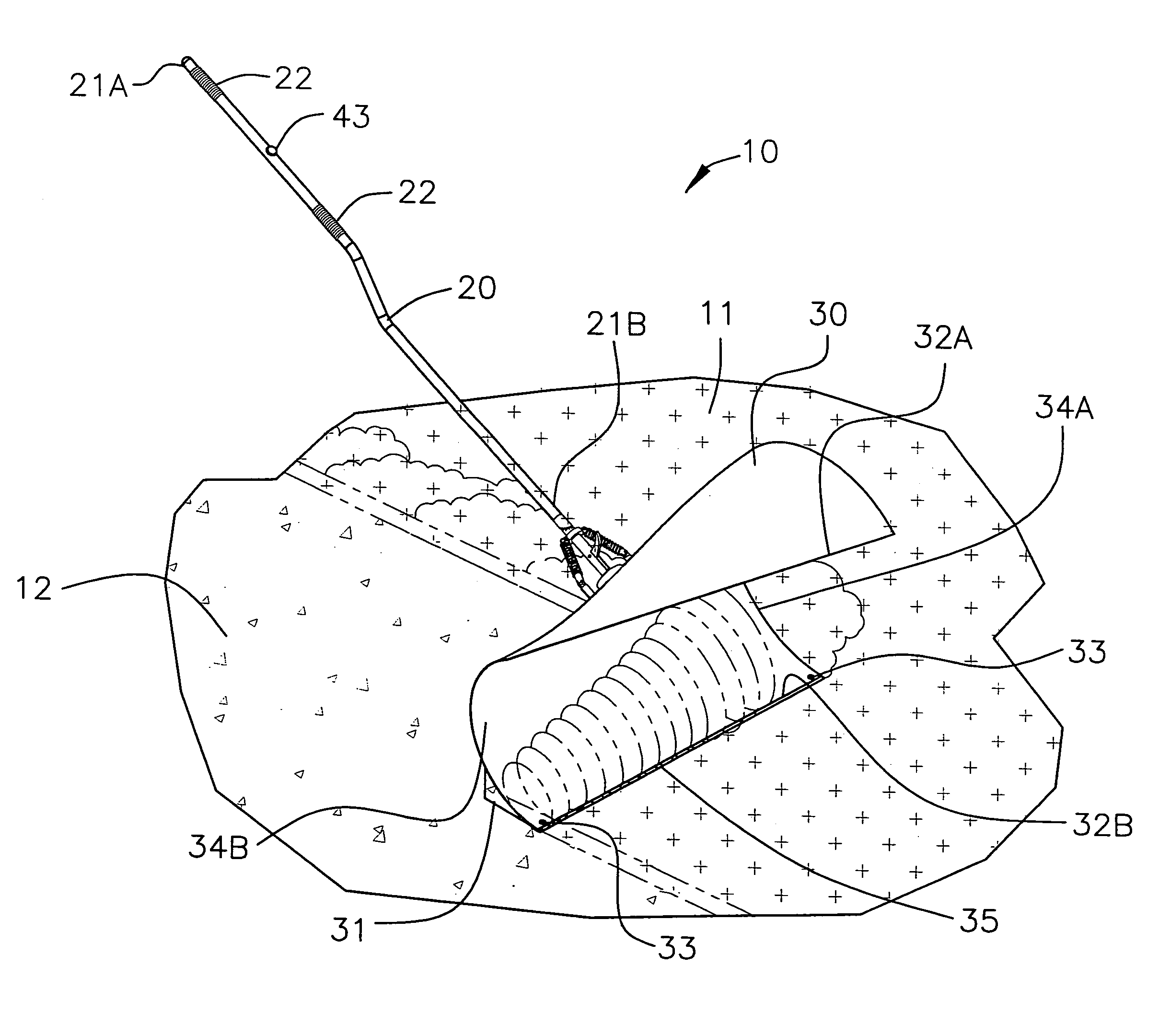

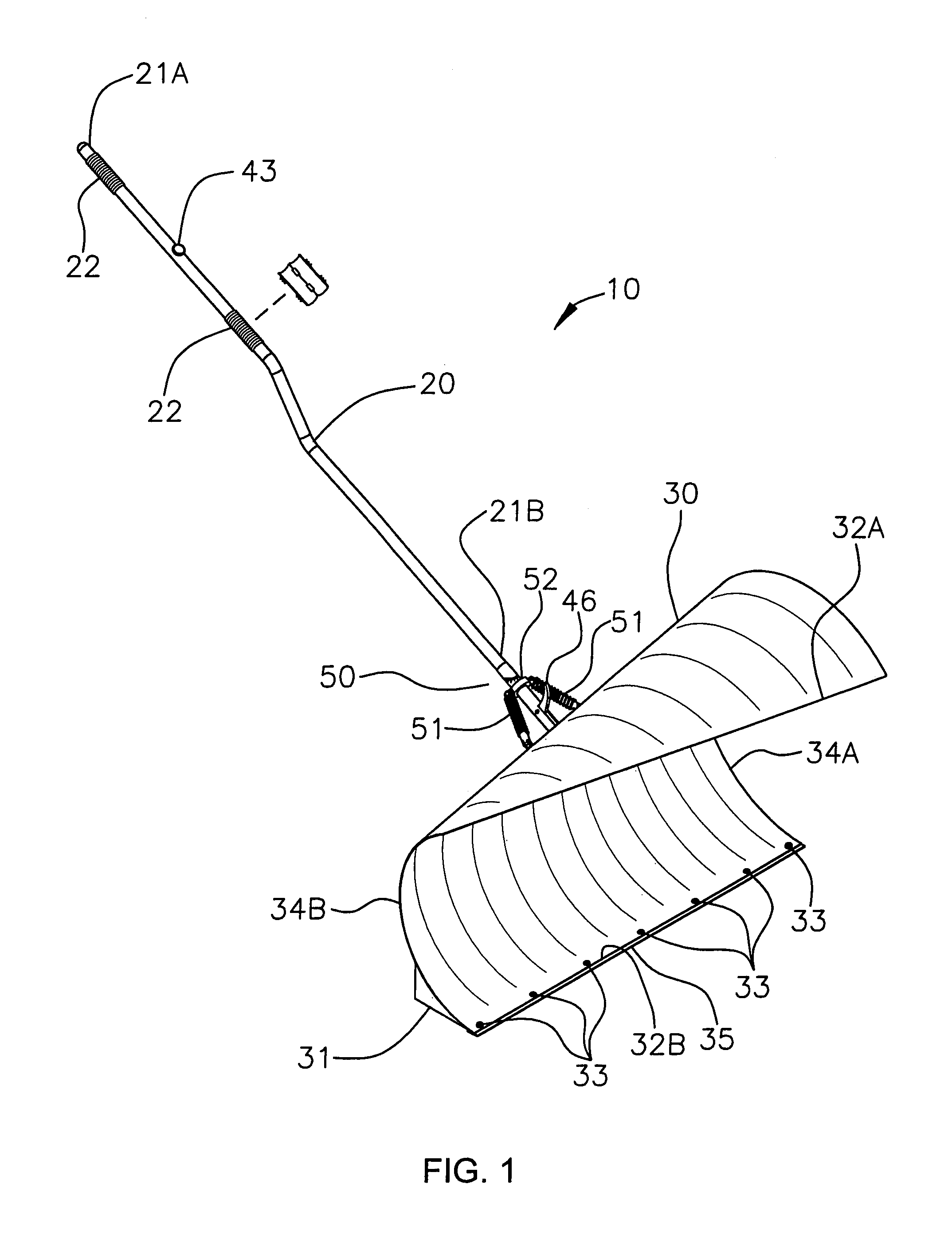

A lightweight, adjustable snowplow, able to be lifted, carried, and manipulated by one person (adult or teenager) of normal strength, designed to remove new-fallen or otherwise soft snow or slush. It has a minimum number of parts. A plurality of struts attaches the plow to any kind of towing vehicle, providing horizontal stability. No brackets, hitches, or lifting devices are needed on the towing vehicle.

Owner:HAAS THEODORE OTTO

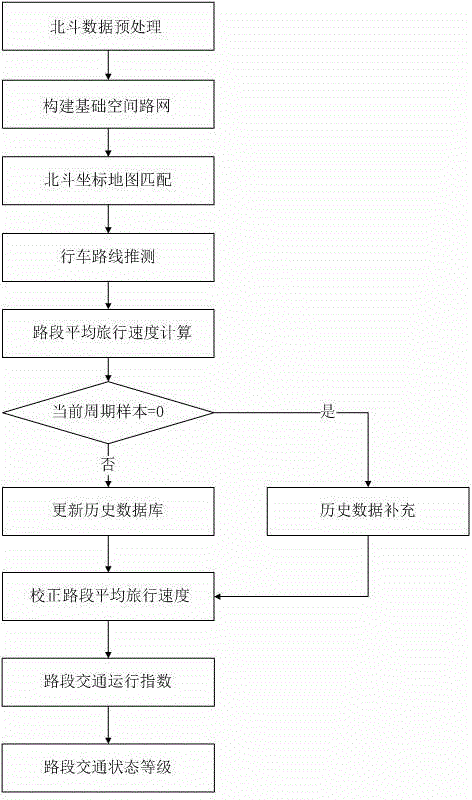

City large-area road network traffic sensing method based on plough satellite

ActiveCN104574967ARealize traffic status awarenessReduce the deviation of Beidou positioningDetection of traffic movementSatellite dataRoad networks

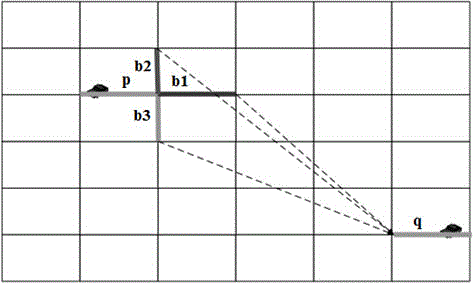

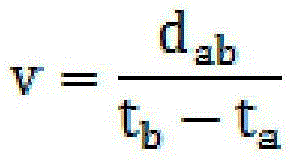

The invention provides a city large-area road network traffic sensing method based on the plough satellite. The city large-area road network traffic sensing method comprises the steps of preprocessing plough satellite data; structuring a basic space road network; matching a plough satellite coordinate map; speculating driving routes; calculating the road segment average travel speed; supplementing historical data; correcting the road segment average travel speed; calculating road segment traffic operation indexes; judging road segment traffic state levels. According to the city large-area road network traffic sensing method, the traffic states within a large-area range of the road network are sensed by structuring a plough satellite data preprocessing model, a vehicle coordinate matching index model, a vehicle route planning module and a road segment traffic operation index model, the deviation of city road network plough satellite positioning is lowered under the high-rise building traffic environment, the collection and distribution accurate of city road traffic states are improved, and the traffic operation efficiency and the service level of the city road network are increased.

Owner:HEFEI GELYU INFORMATION TECH

Snow plow having wear minimizing apparatus

InactiveUS20070056193A1Improve practicalityEasy to liftMechanical machines/dredgersSnow cleaningMechanical engineeringSnow

A snow plow for attachment to a vehicle, the snow plow including a mounting apparatus having a mounting frame, the mounting frame including at least one mounting upright. The snow plow further including a plow blade including a retention apparatus constructed and arranged to slidlingly and disengageably secure the plow blade to the mounting upright(s) when the plow blade is in a working orientation. The plow blade includes a mold board, the plow blade including a rubber scraper connected to the mold board and at least one wear minimizing apparatus positioned to minimize contact between the rubber scraper and the ground surface when the vehicle is moving in a direction rearward of the plow blade and the plow blade is in a working orientation.

Owner:AGRI COVER

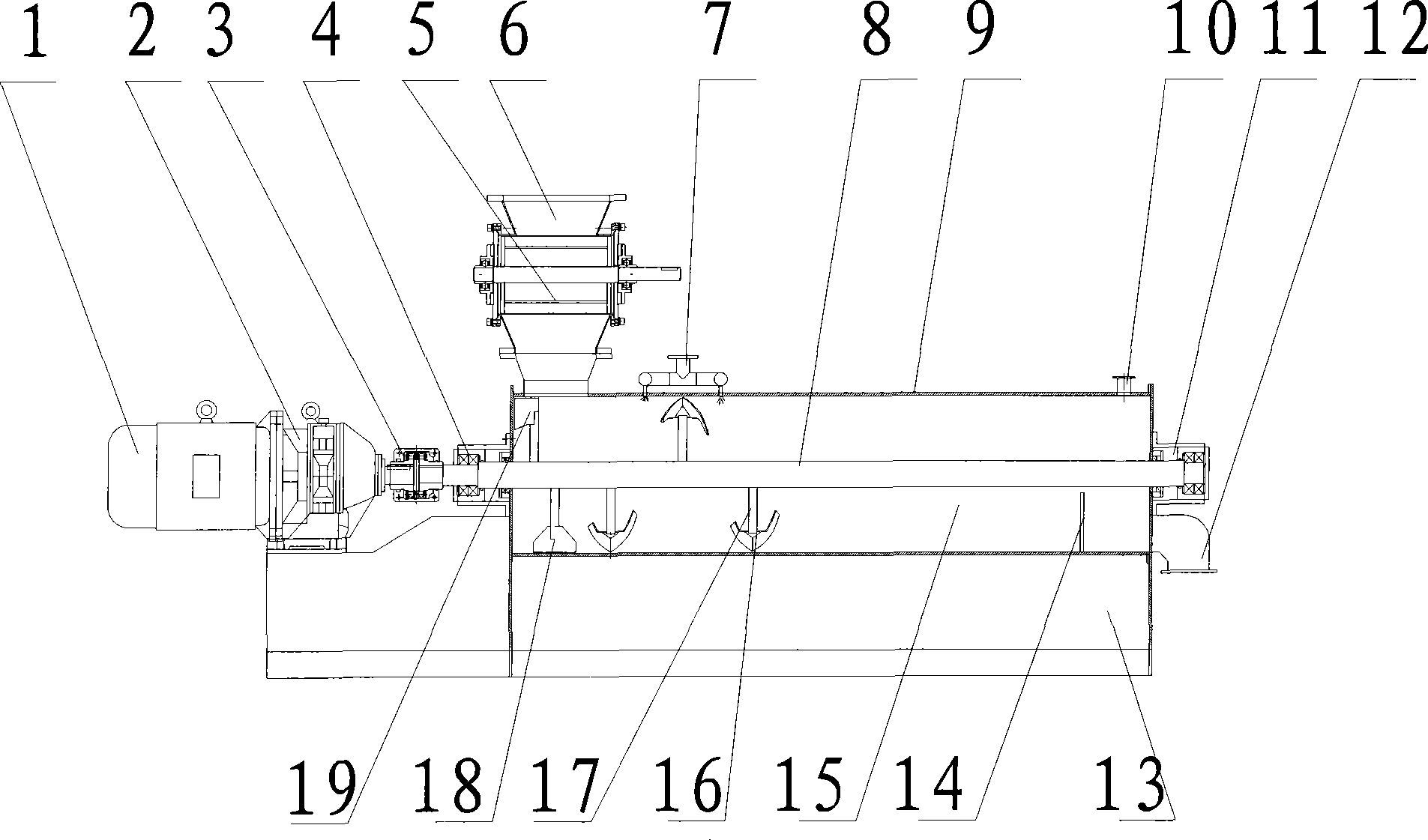

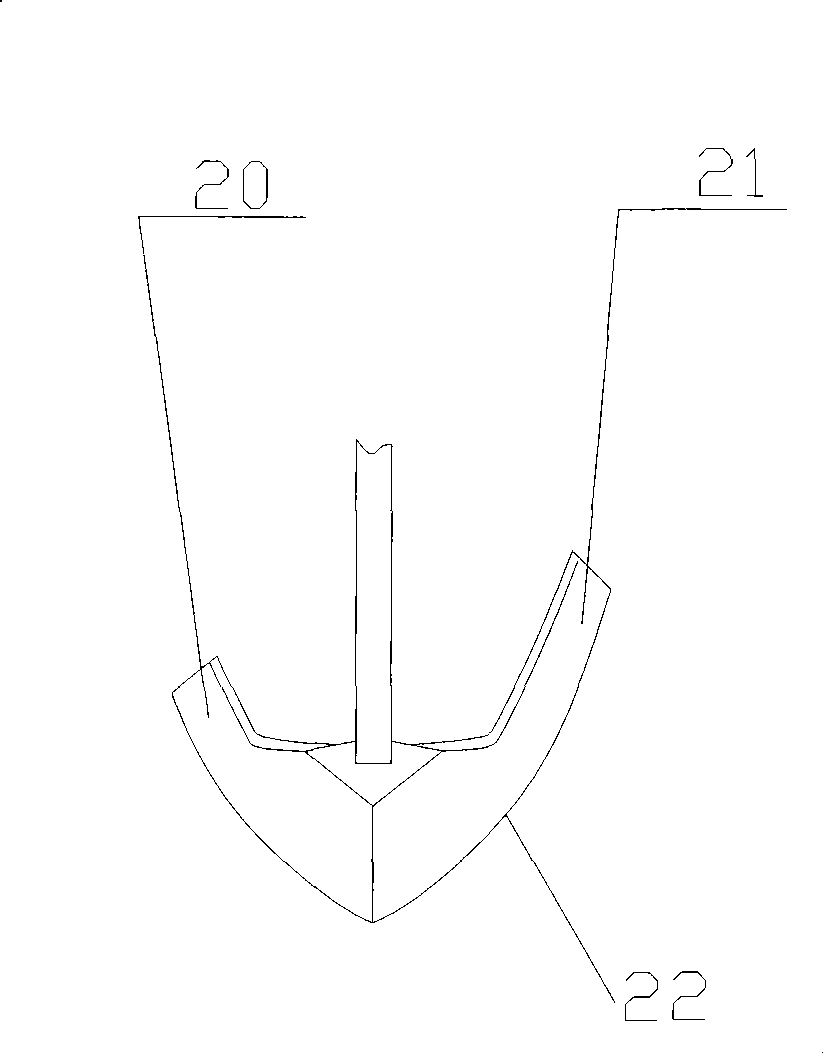

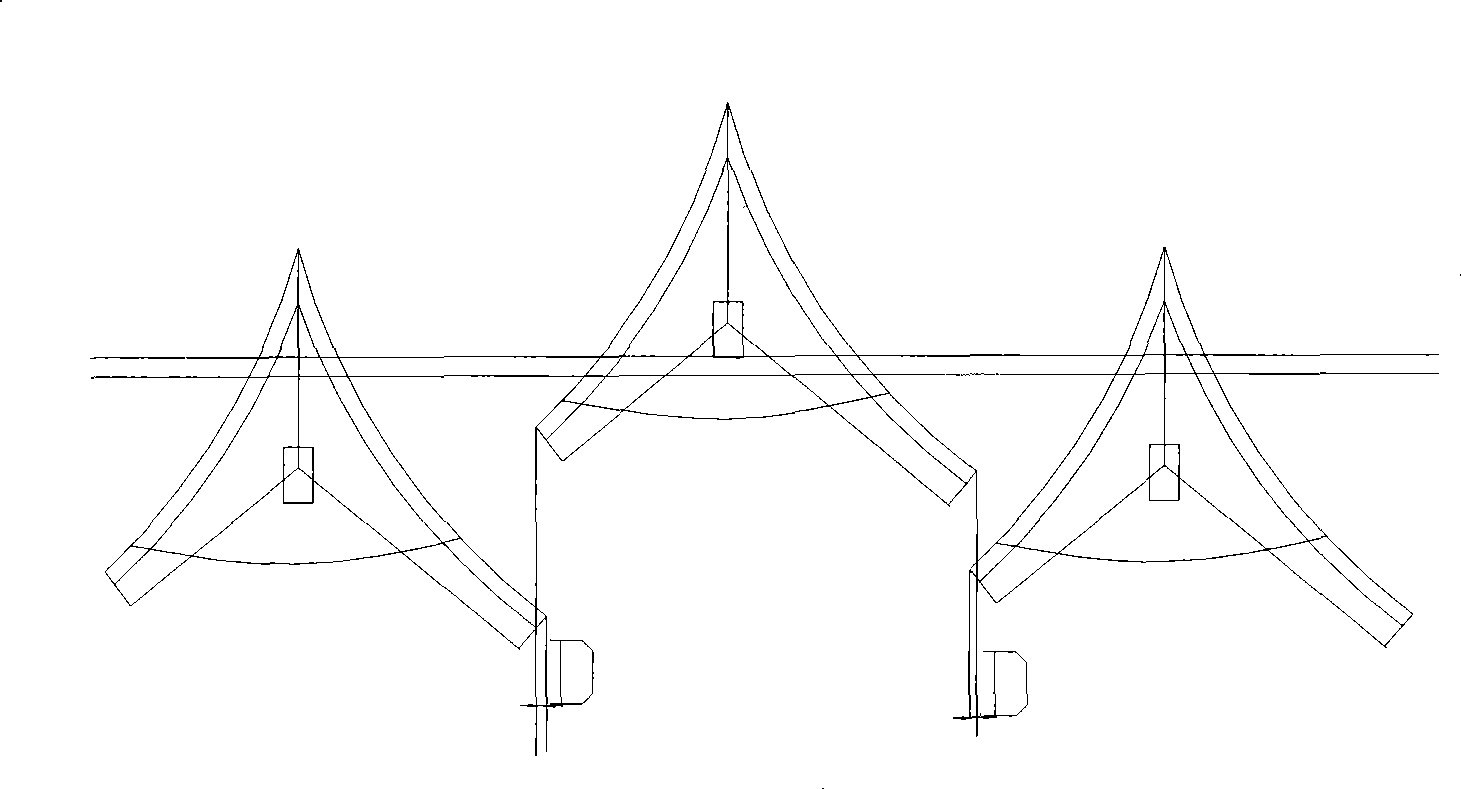

Horizontal solid-liquid mixing device and application thereof

InactiveCN101444705AWell mixedQuality improvementRotary stirring mixersMixing methodsChemical industryRotary valve

The invention relates to a horizontal solid-liquid mixing device and the application thereof. The mixing device comprises a motor, a reduction gearbox, a ratcheting, a front bearing end, a rotary valve, a solid feeding hole, a liquid feeding hole, a mixer shaft, a mixing cylinder, an exhaust hole, a rear bearing end, a discharge hole, a solid-liquid mixing room, a drawing template, a plough coulter, a fixed link of the plough coulter and a baffle; wherein, the drawing template is fixed on the mixer shaft and arranged under the solid feeding hole, the plough coulter is fixed on the mixer shaft by the fixed link of the plough coulter, a plowshare of the plough coulter forms an angle with the mixer shaft, the baffle is arranged inside the mixing cylinder, and a gap is arranged at the position of a contact surface between the baffle and the cylinder in front of the discharge hole. Compared with the prior art, the horizontal solid-liquid mixing device can fully mix two phases of solid and liquid within a short time, has high mixing efficiency, low energy consumption and even material mixing, does not produce 'powder balls' generated by mixing the powder and the liquid, is good in continuous operation effect and can be widely applied to industries such as petroleum, chemical industry, coal chemical industry, food, medicine, etc.

Owner:SHANGHAI RES INST OF CHEM IND +1

Plow blade having integrally formed attachment channel

A snow plow for attachment to a vehicle, the snow plow including a mounting apparatus having a mounting frame, the mounting frame including at least one mounting upright. The snow plow further including a plow blade including a retention apparatus constructed and arranged to slidlingly and disengageably secure the plow blade to the mounting upright(s) when the plow blade is in a working orientation. The plow blade includes a mold board, the mold board preferably being an aluminum extrusion. The aluminum extrusion will preferably include at least one attachment channel, more preferably a plurality of attachment channels, in which parts of the snow blade can be secured or anchored. The plow blade preferably includes first and second attachment channels and the retention apparatus preferably includes at least one retention member anchored in at least one of the attachment channels.

Owner:AGRI COVER

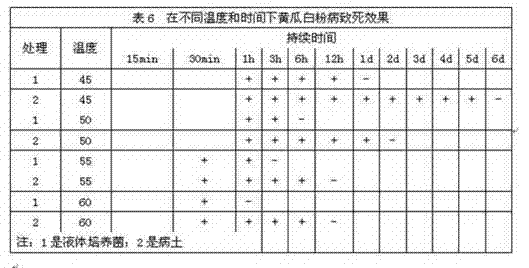

Compound microbes for reducing and disinfecting greenhouse soil and soil disinfection method

InactiveCN102776124AImprove the microfloraImprove biological activitySoil lifting machinesFungiChemical structureGreenhouse crops

The invention relates to the greenhouse crop planting field, in particular to compound microbes for reducing and disinfecting greenhouse soil and a soil disinfection method, and solves the problem of multiple defects in the prior art. The compound microbes comprise bacteria, actinomycetes, saccharomycetes and moulds. The soil disinfection method includes the steps of selecting June to September as a disinfection period to apply crop straws, organic fertilizer and the compound microbes on the soil after the crops are harvested; deeply plowing soil layers to form small ridges; covering ridge surfaces with plastic film, filling enough water under the film till the soil humidity achieves 100%, and sealing the mulching film and covering the greenhouse plastic film for 20 to 25 days; and uncovering the greenhouse plastic film and removing the mulching film for planting. According to the compound microbes for reducing and disinfecting greenhouse soil and the soil disinfection method, the method is non-toxic, harmless, pollution-free and residue-free, pathogenic bacteria, ova and the like in soil plough layers are killed, soil organics are increased, the soil physical and chemical structure is improved, soil fertility is improved, and good foundation is laid for improving product qualities.

Owner:AGRI BIOTECH RES CENT OF SHANXI PROVINCE +1

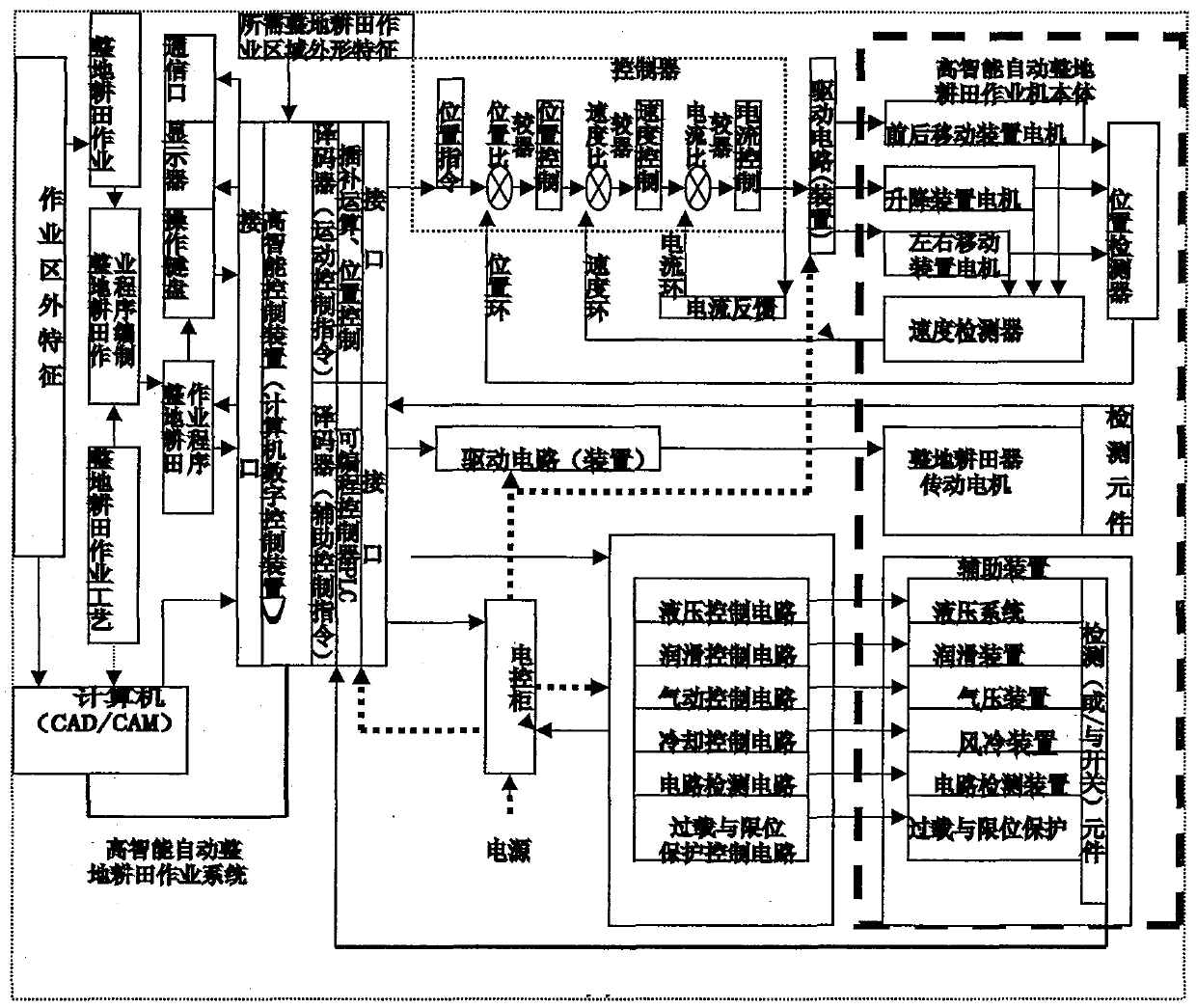

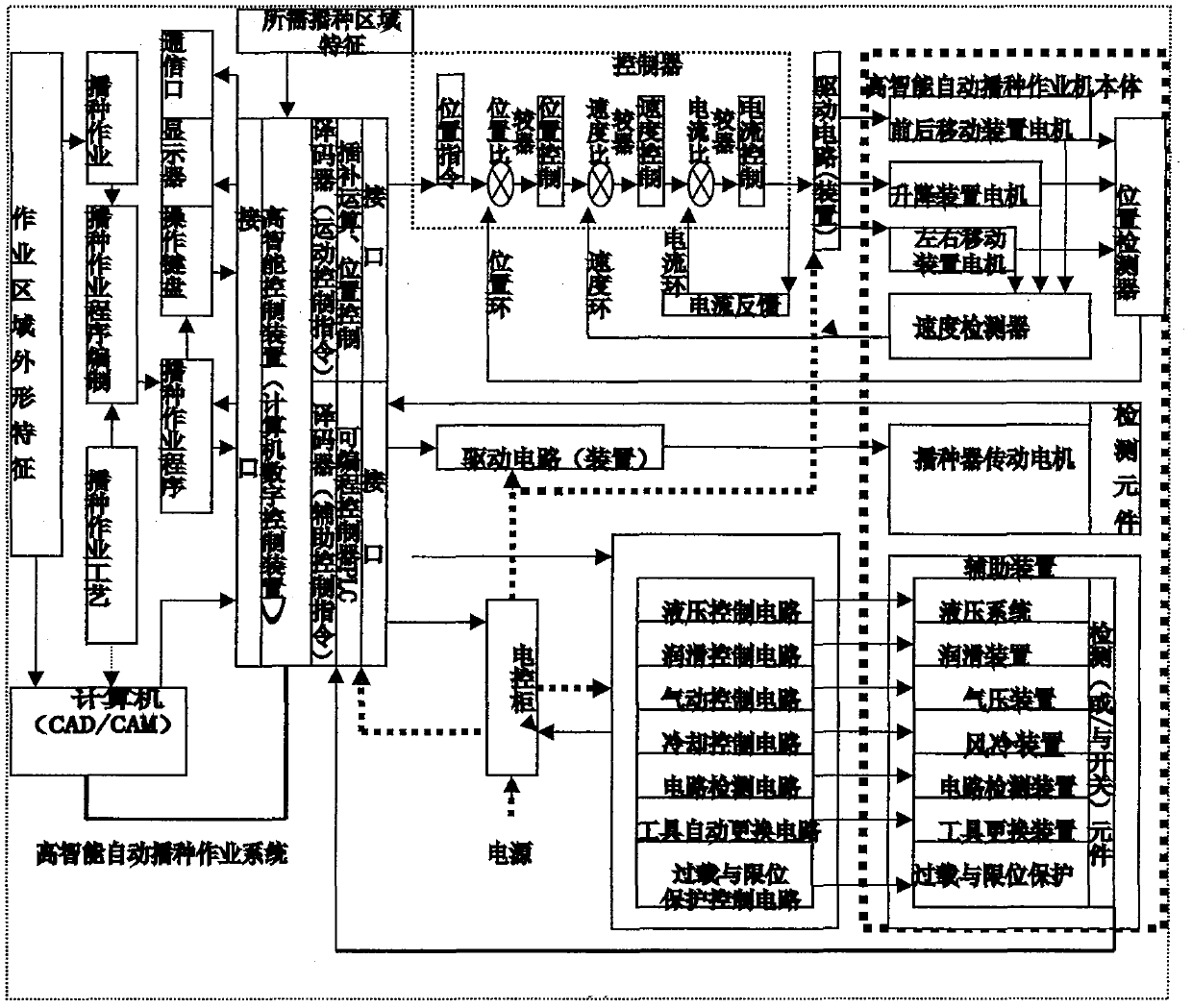

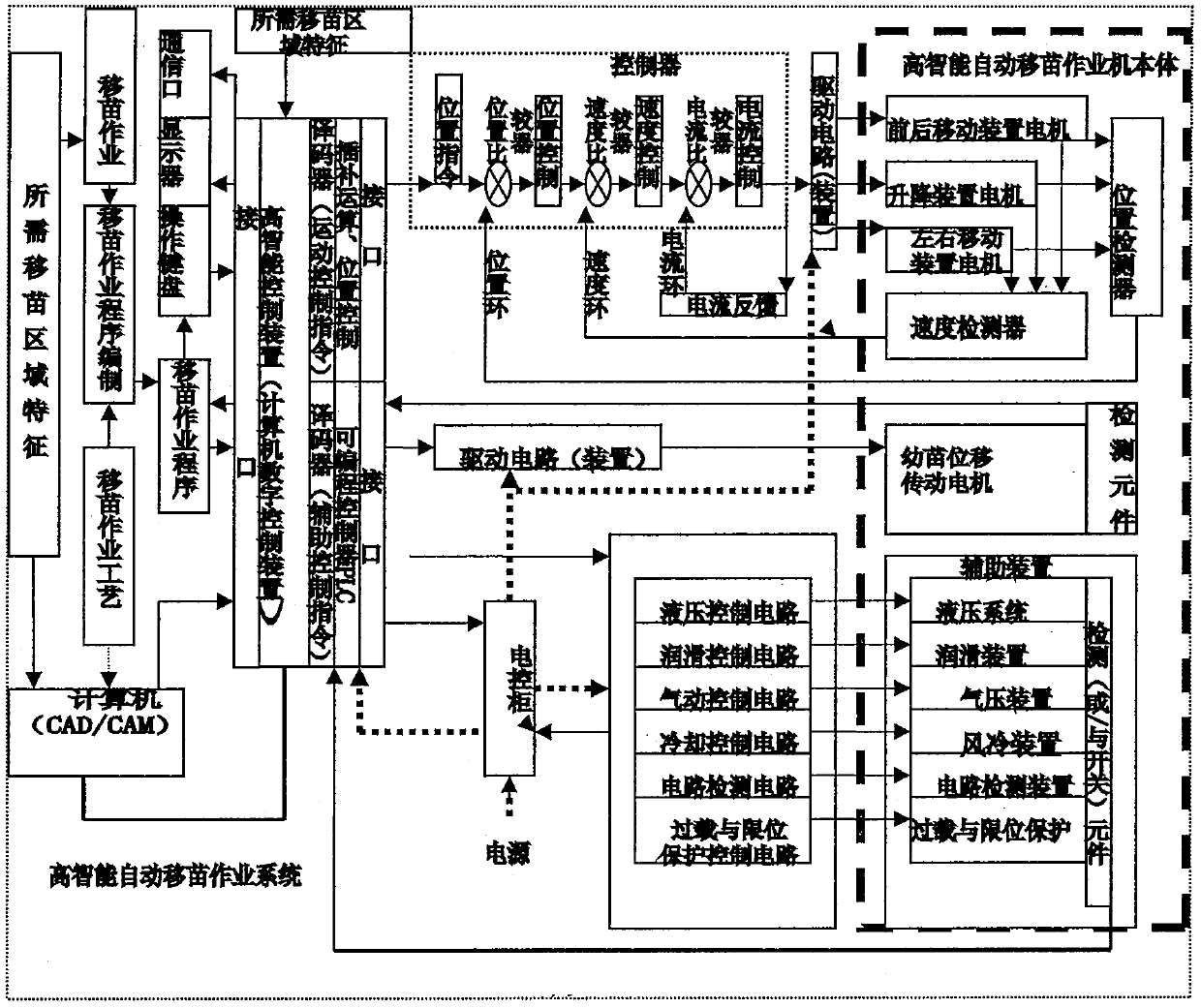

High-intelligence agricultural mechanical apparatus and system

InactiveCN108170104ARealize automated productionRealize zero emission at workAgricultural undercarriagesProgramme total factory controlElectric machineryAgricultural engineering

The invention belongs to the agricultural machinery field and relates to an agricultural mechanical apparatus and system. With the agricultural mechanical apparatus and system adopted, the problem that agricultural machinery cannot perform automatic operation can be solved. According to the agricultural mechanical apparatus and system, electric energy, motors and tracks are adopted to perform automatic operation; operation and work which are required by an operation area can be automatically and orderly completed according to the shape feature of the operation area or / and the crops of the operation area and an operation mode required by the operation area or / and the crops of the operation area; one such agricultural mechanical apparatus can be driven and controlled to complete various operation of the full-process management of plough, farming and harvest of the crops; and one or more agricultural mechanical apparatuses can be driven and controlled to complete various operation of thefull-process management of plough, farming and harvest of the crops.

Owner:杨新高

Snow plow having catch structure

InactiveUS20070056195A1Improve practicalityEasy to liftMechanical machines/dredgersSnow cleaningEngineeringKnife blades

A snow plow for attachment to a vehicle, the snow plow including a mounting apparatus having a mounting frame, the mounting frame including at least one mounting upright. The snow plow further including a plow blade having a retention apparatus constructed and arranged to slidlingly and disengageably secure the plow blade to the mounting upright(s) when the plow blade is in a working orientation. The mounting upright includes a limiting member that limits upward movement of the retention member when the plow blade is in a working orientation such that the retention member is secured on the mounting upright. The preferred snow plow may also include an attachment member located on the mounting apparatus, wherein the plow blade retention member may be removably secured within the attachment member when the plow blade is in a non-working orientation.

Owner:AGRI COVER

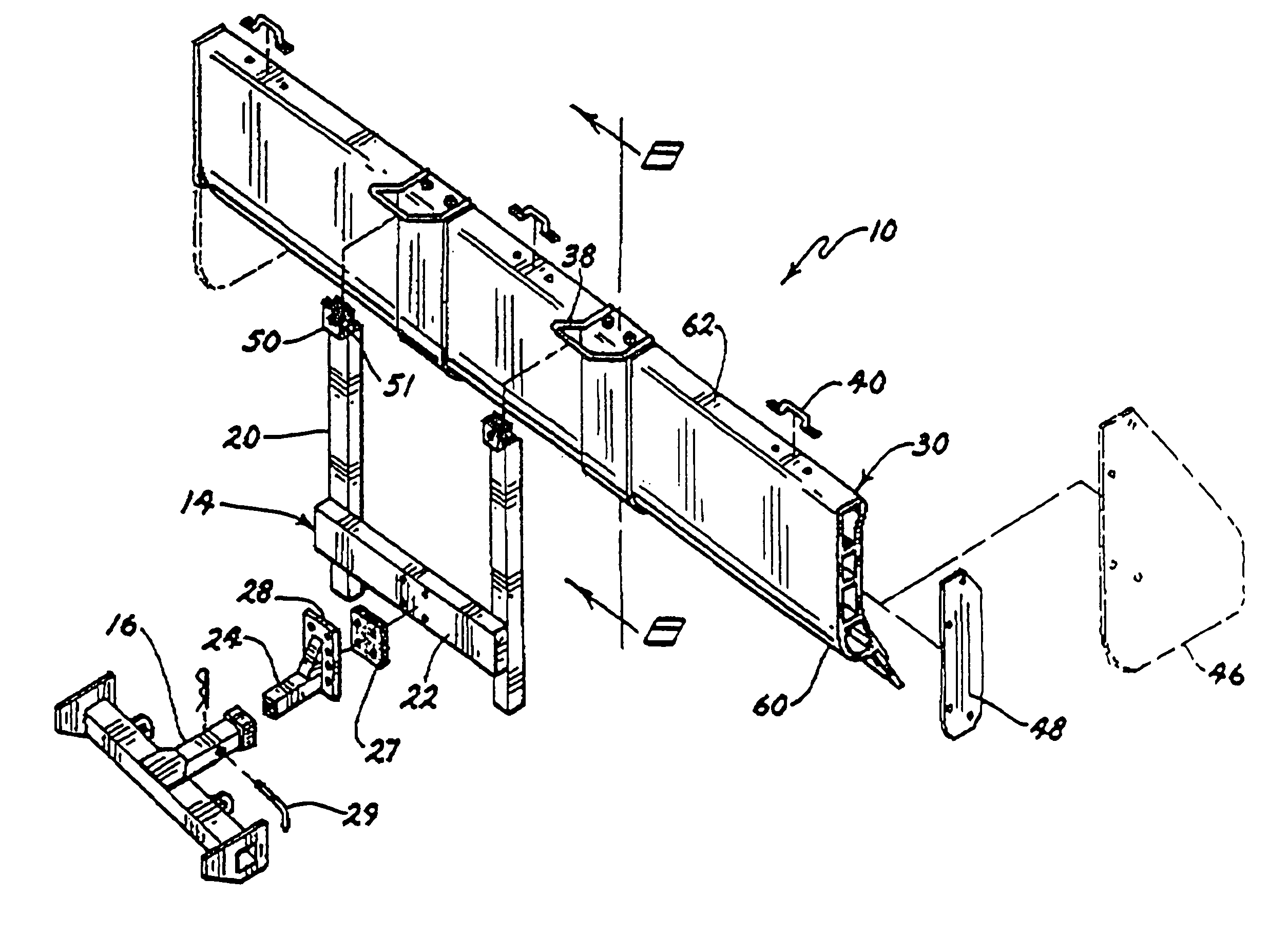

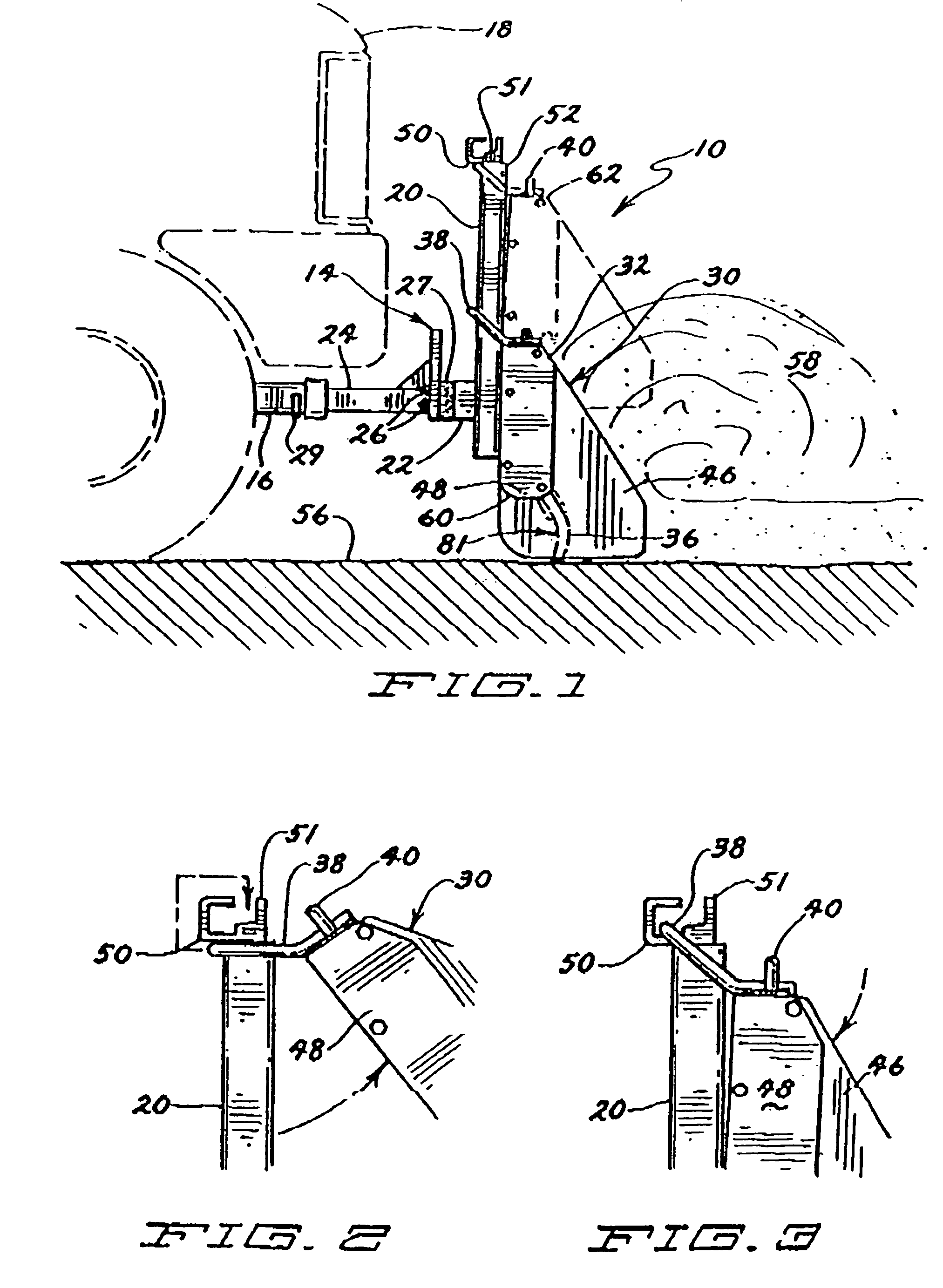

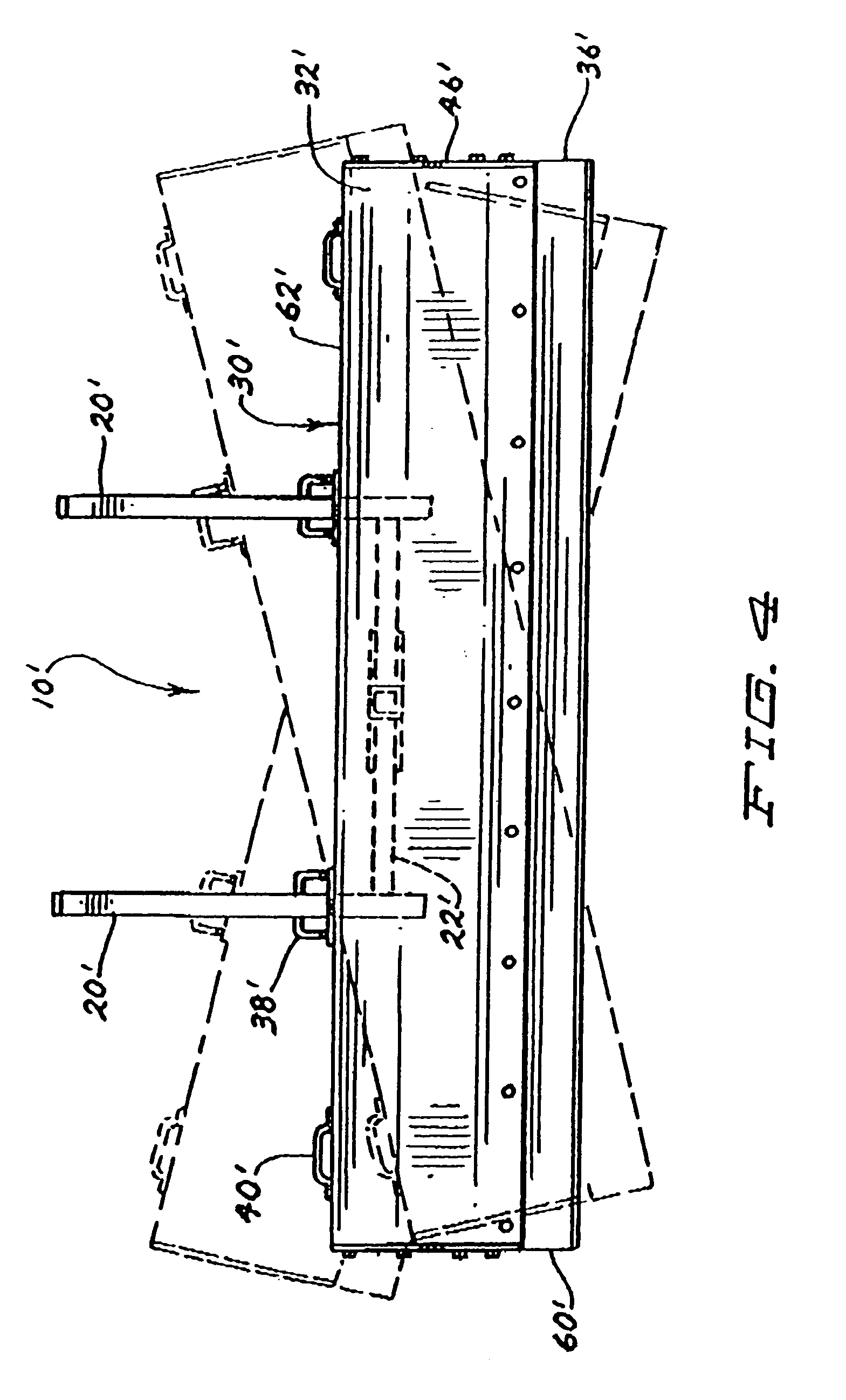

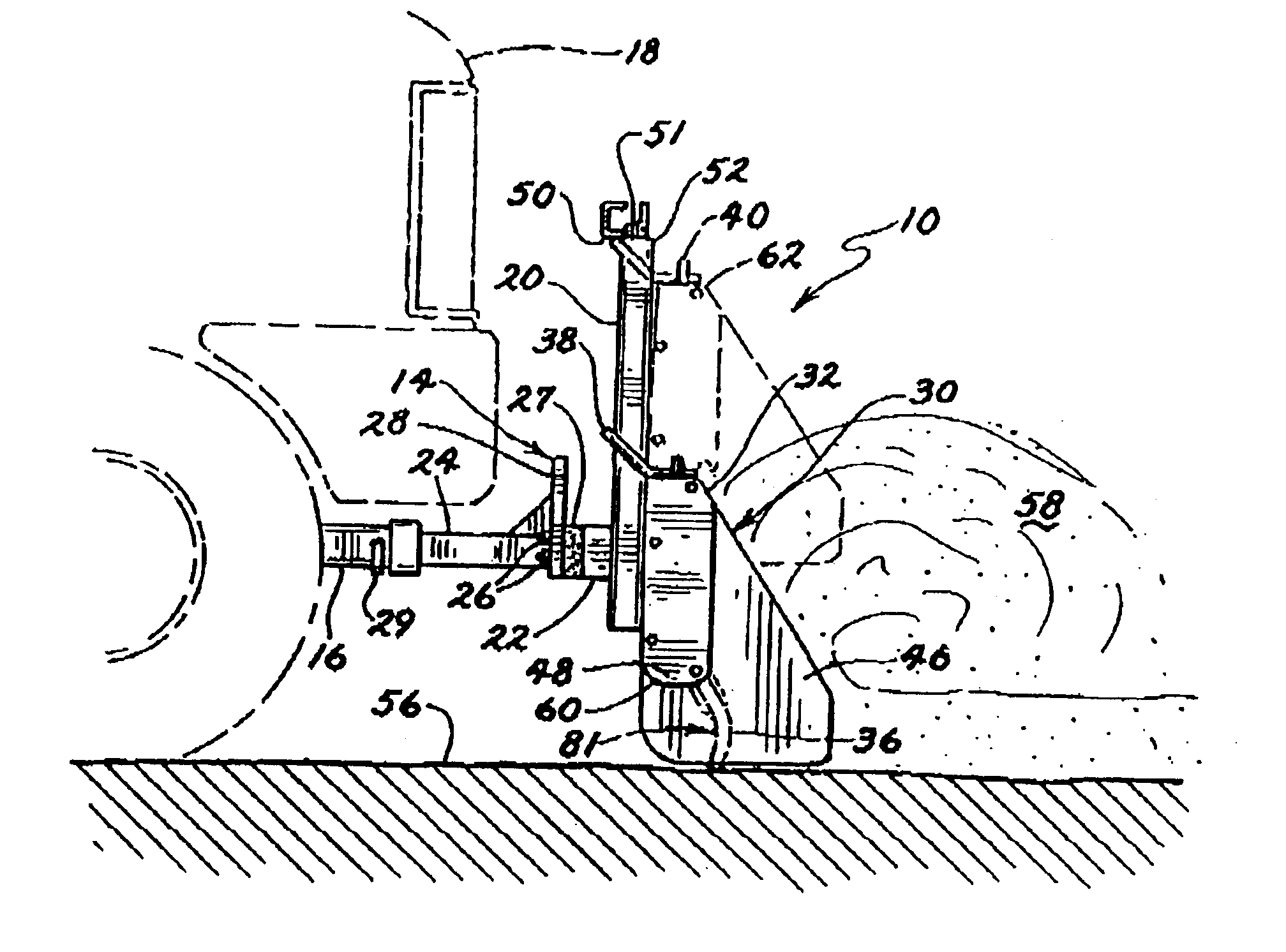

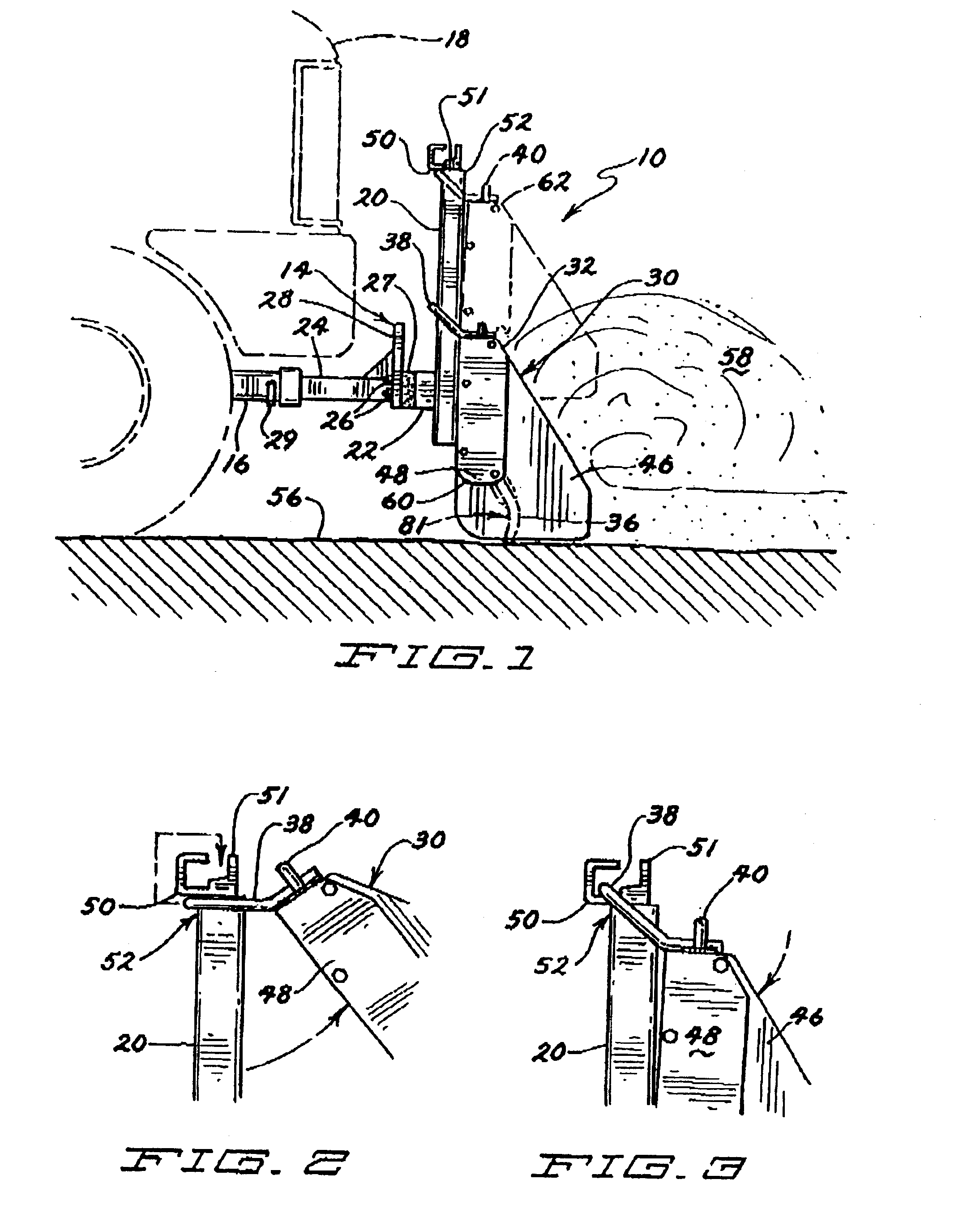

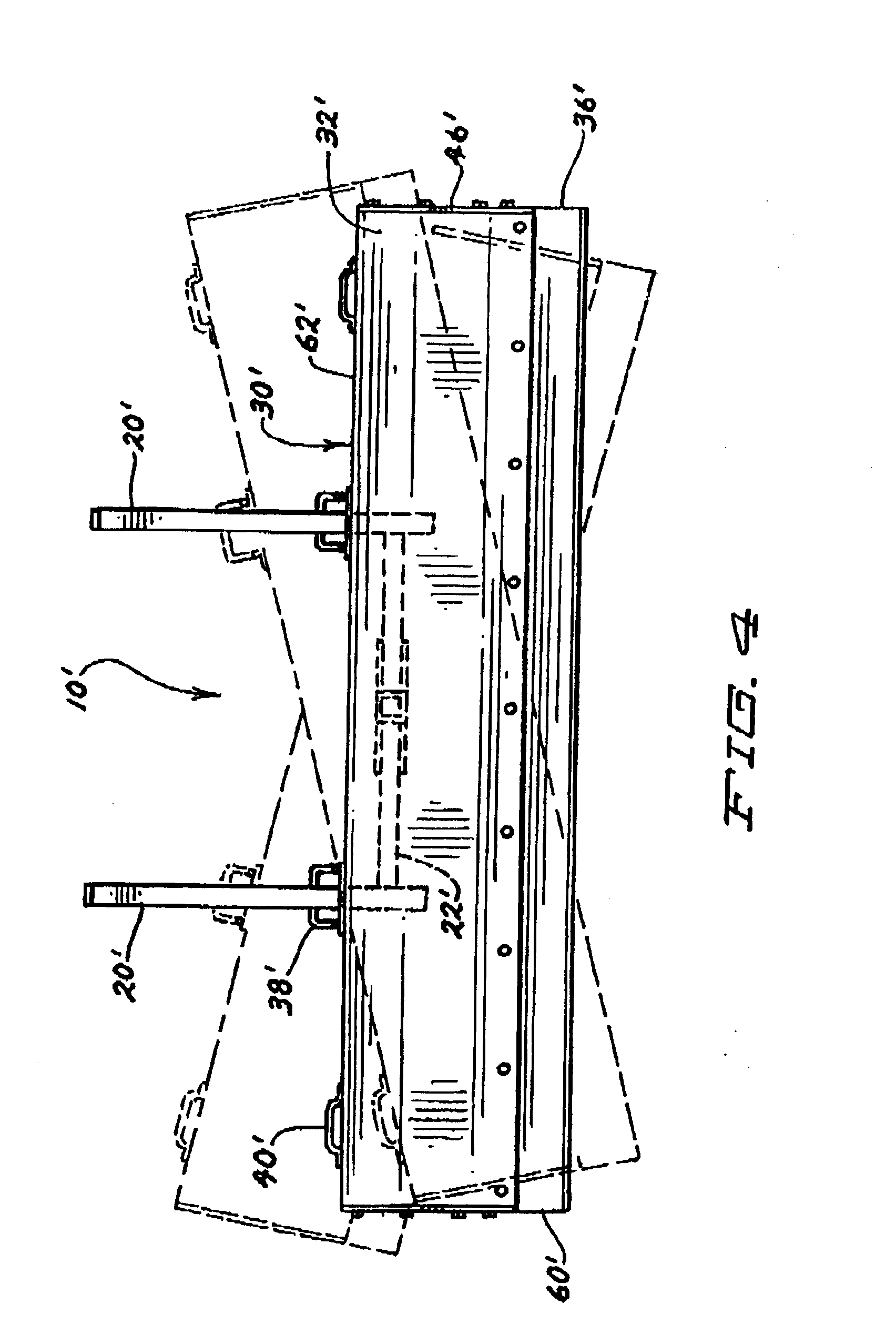

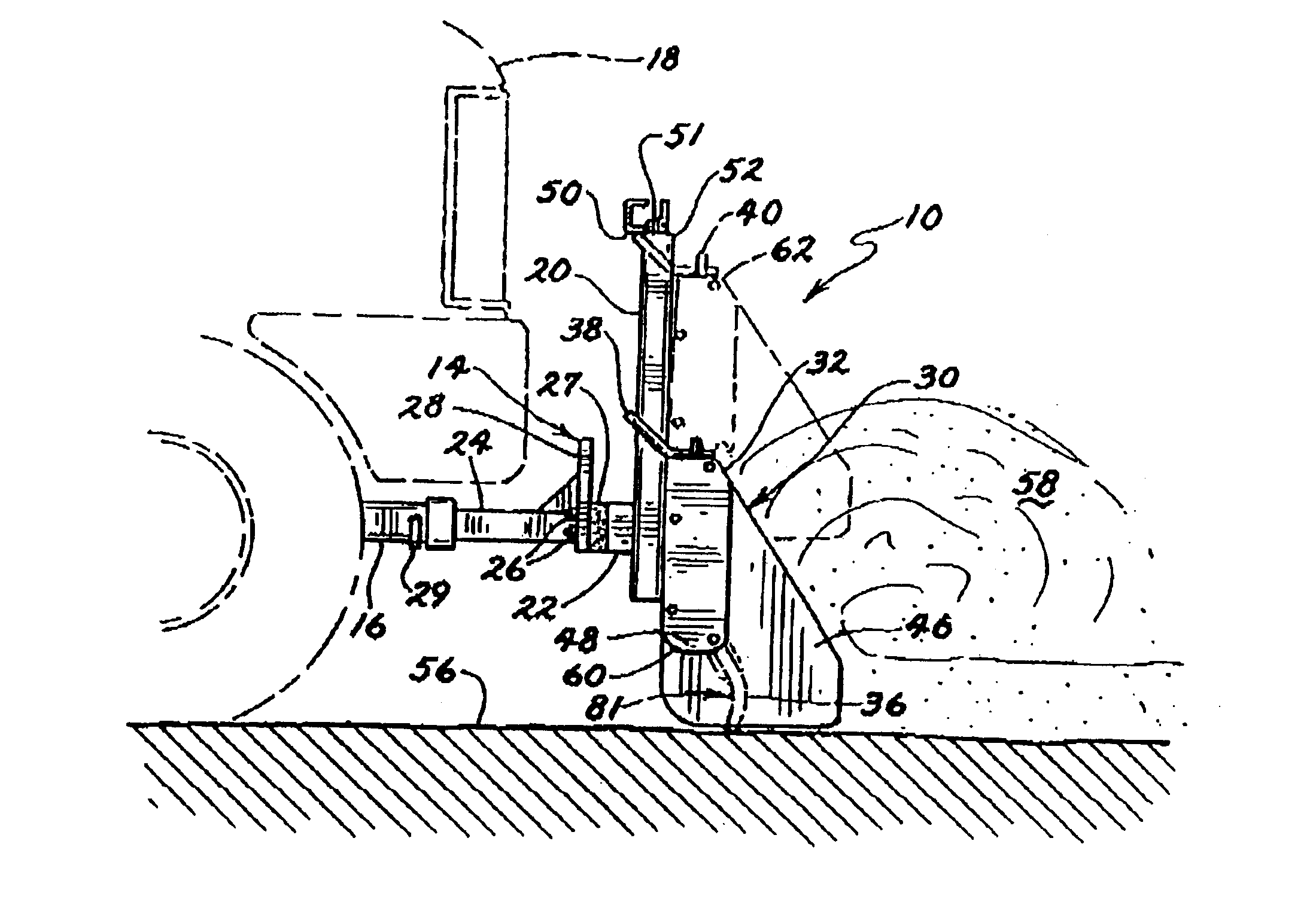

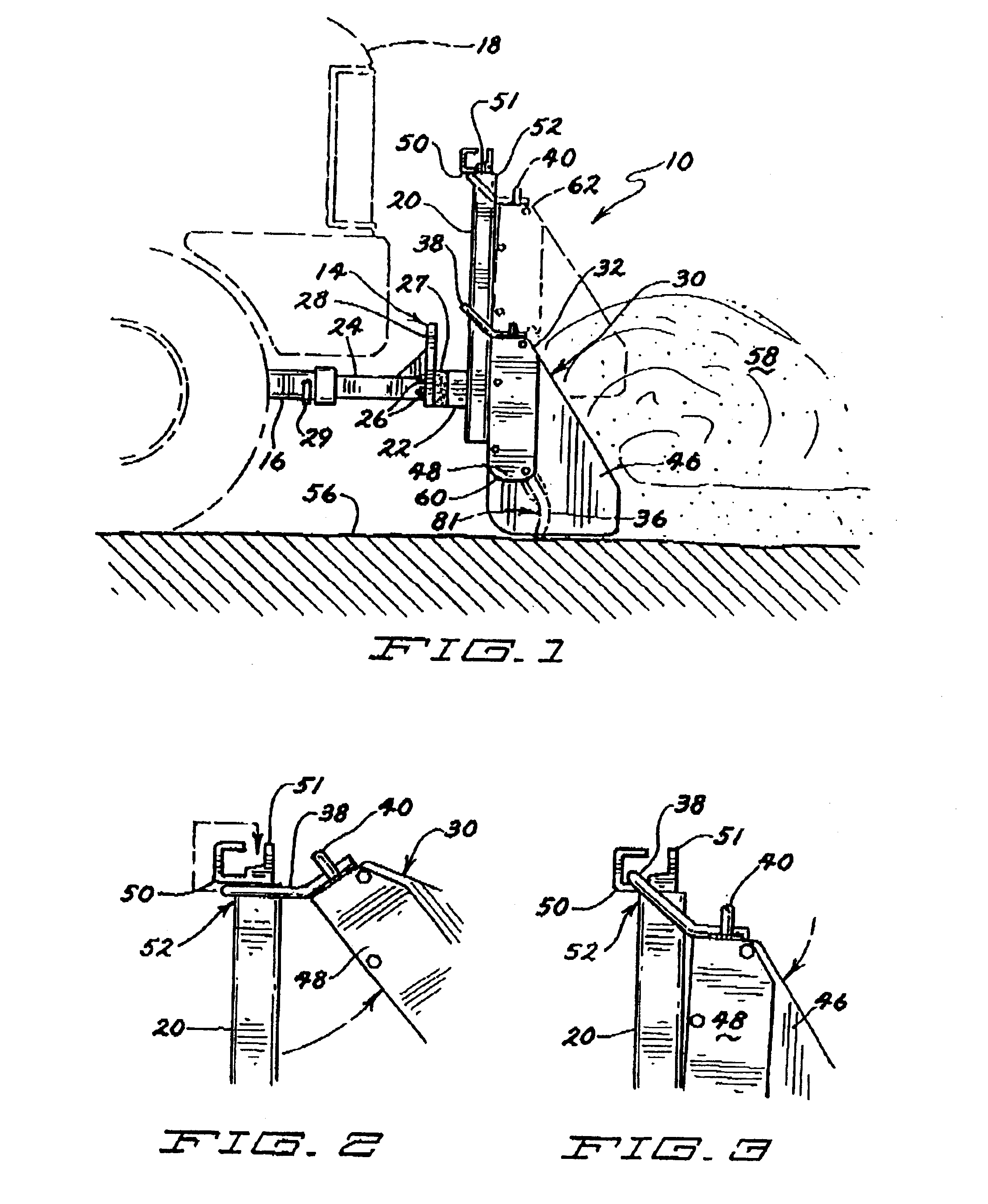

Self-adjusting snow plow

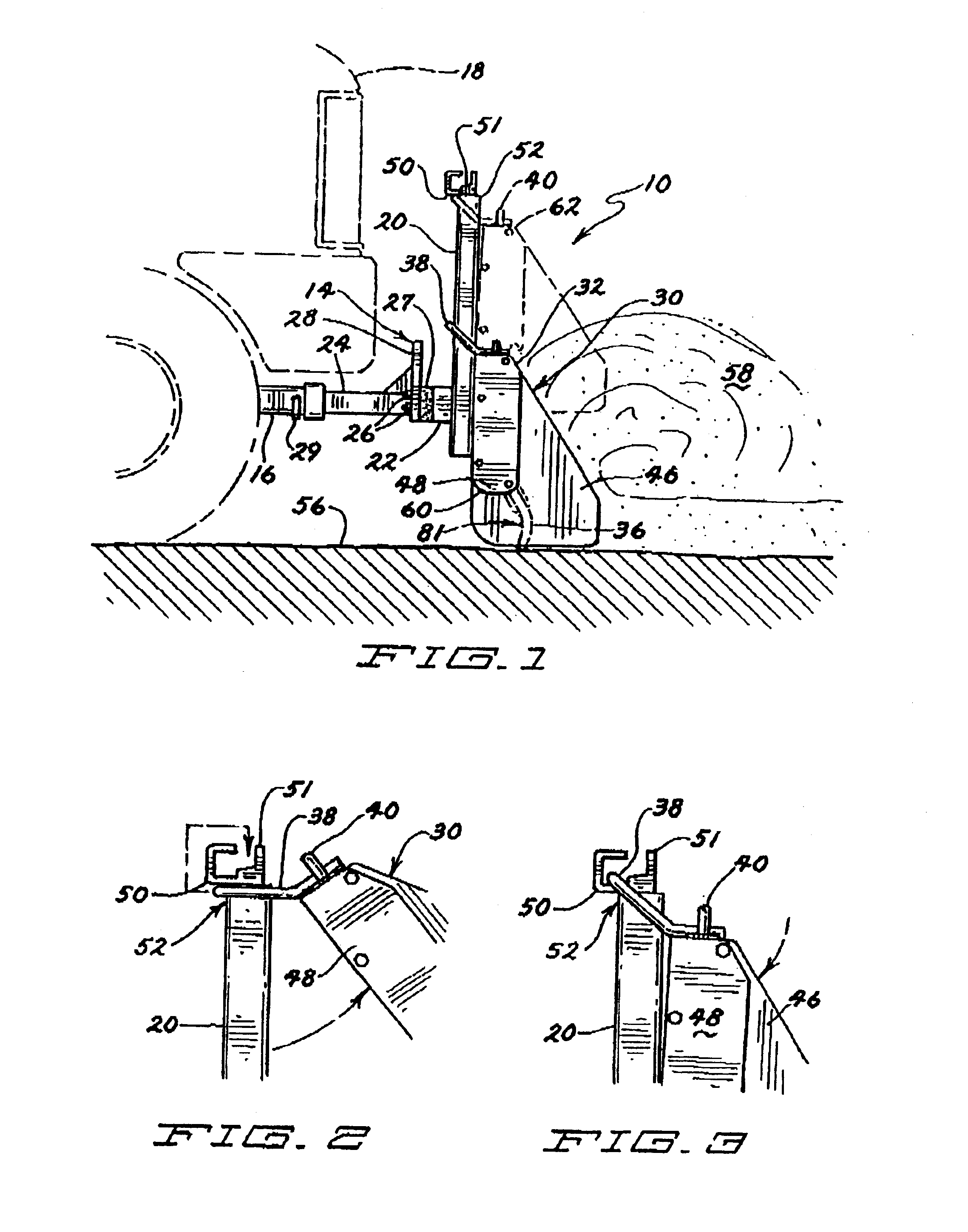

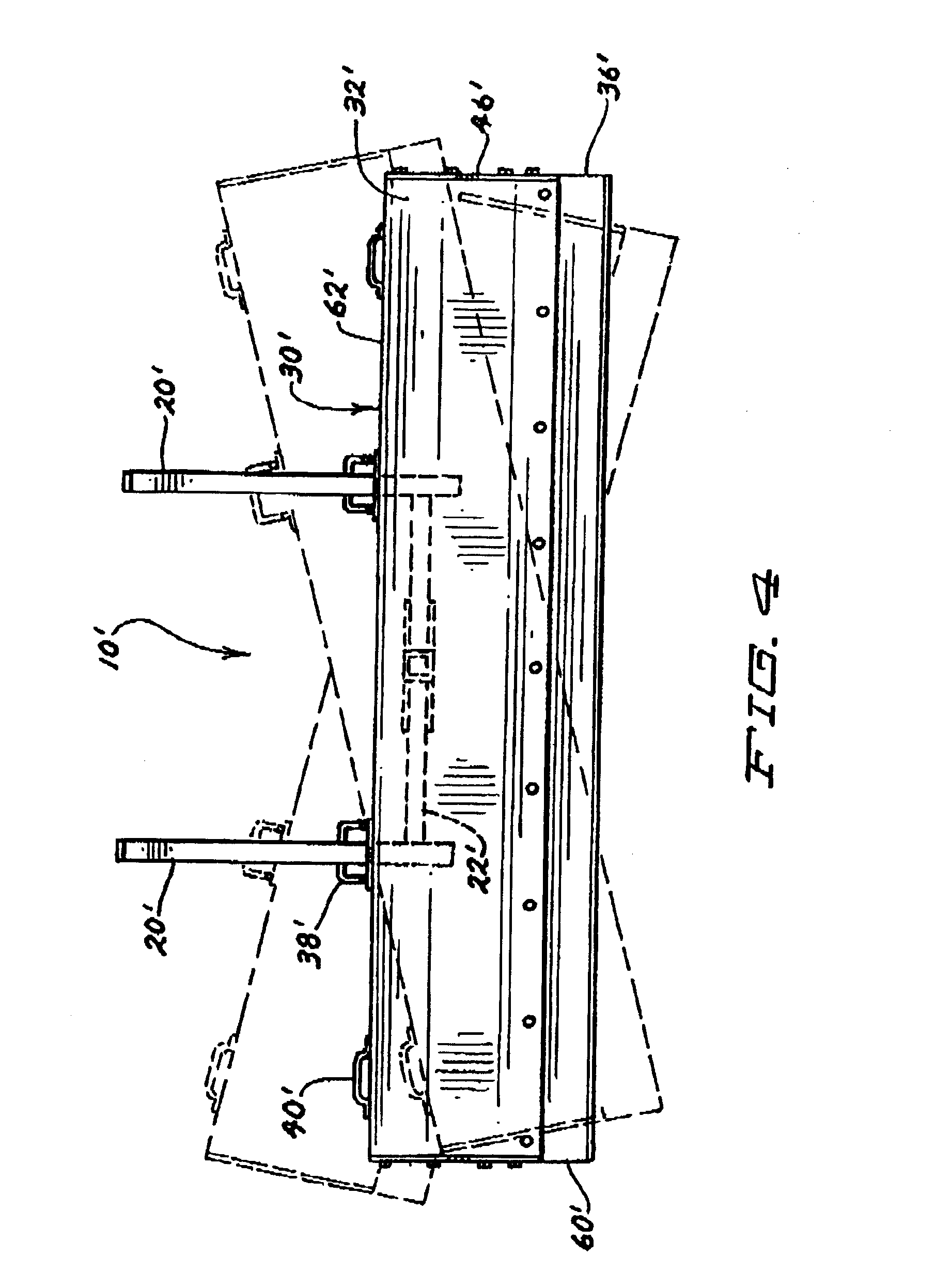

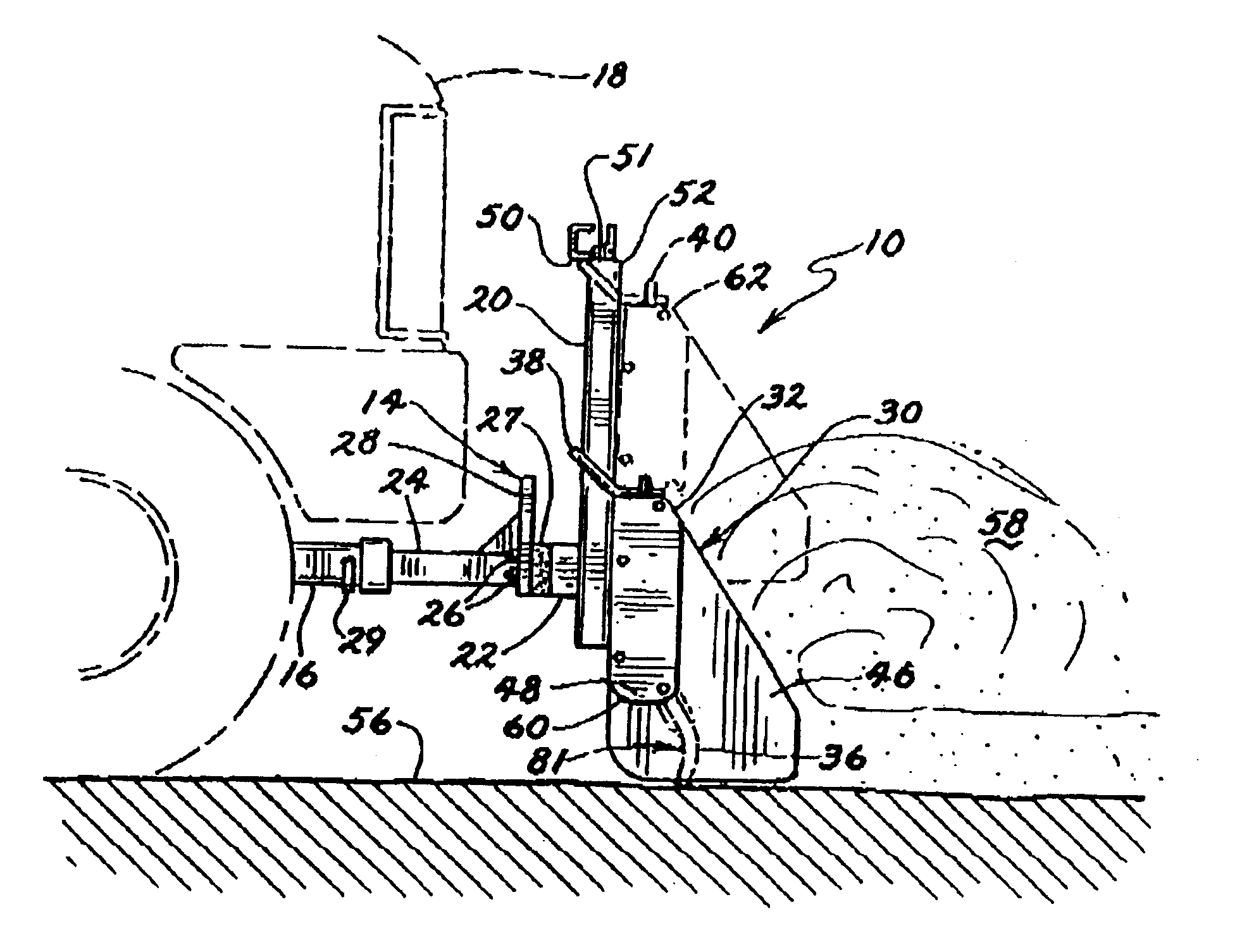

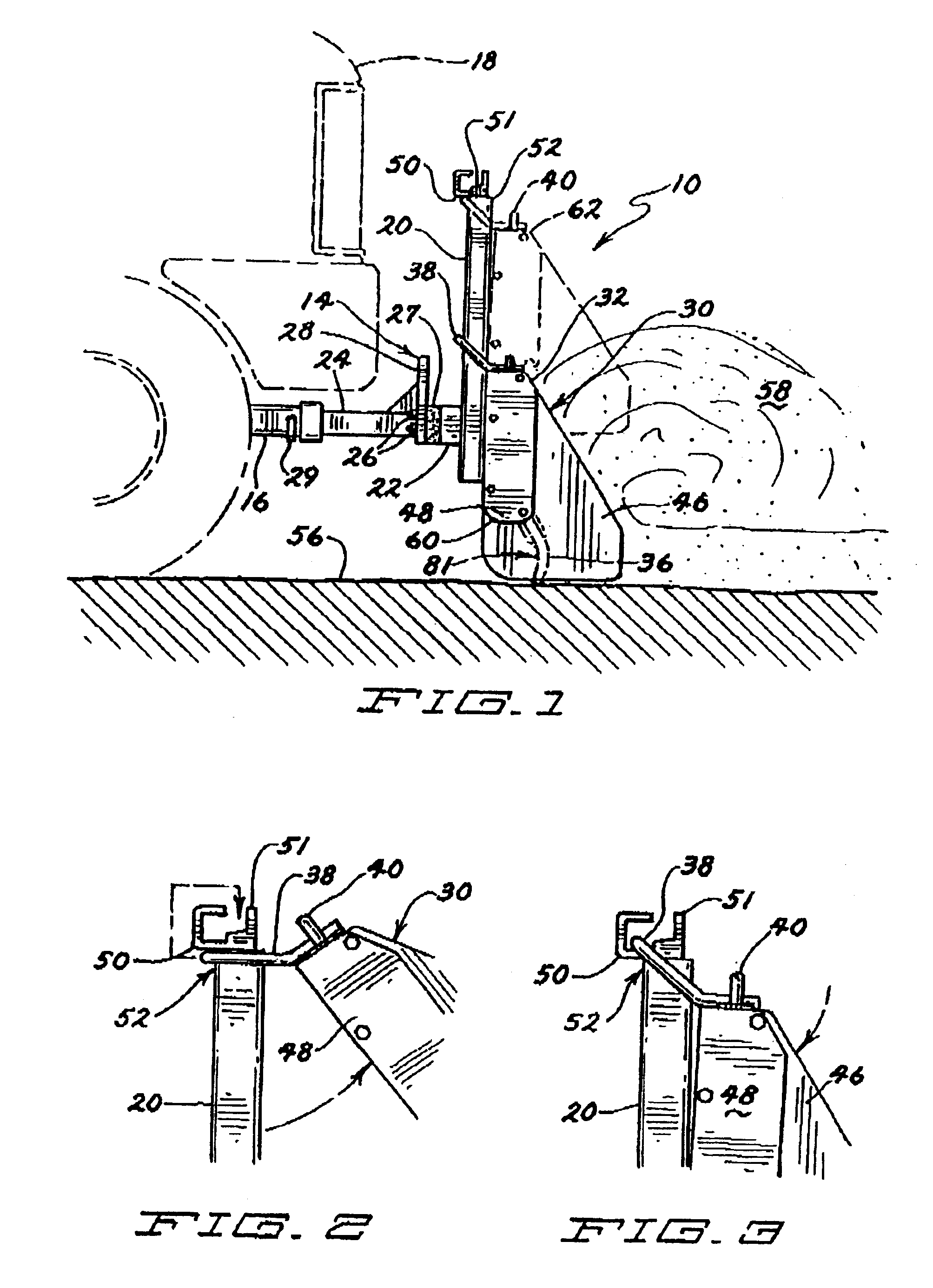

InactiveUS20050066554A1Easy to installSimple to useMechanical machines/dredgersSnow cleaningPickup truckSport utility vehicle

A self-adjusting snow plow for use with pickup trucks and sport utility vehicles is disclosed. The snow plow includes a mounting apparatus for attachment to a vehicle and a plow blade having first and second ends, a top, a bottom, a plurality of retention members and a rubber scraper. The mounting apparatus includes a pair of mounting uprights and a hitch tongue which is easily mounted in a hitch receiver which is secured to the front of a vehicle. The retention members are constructed and arranged to at least partially encircle and slideably engage one of the respective mounting uprights and the retention members allow the respective ends of the plow blade to slide upward relative to the mounting upright most proximate to that end of the plow while the other end of the plow remains generally in the same position relative to the mounting upright proximate that end of the plow blade. The retention members also permit the bottom of the plow blade to pivot away from the respective mounting uprights when the plow blade is engaged with the mounting apparatus in a working orientation and the vehicle is in motion in a direction rearward of the plow blade.

Owner:AGRI COVER

Multifunctional plow blade positioning apparatus and method

InactiveUS20070062073A1Improve practicalityEasy to liftMechanical machines/dredgersSnow cleaningPickup truckAgricultural engineering

A self-adjusting snow plow for use with pickup trucks, SUVs, all-terrain vehicles or other land vehicles. The snow plow includes a mounting apparatus for attachment to a vehicle and a plow blade, preferably including a mold board and a retention apparatus assembly. The retention apparatus assembly disengageably secures the plow blade to the mounting apparatus when the plow blade is in a snow displacement position. The snow plow further includes an elongated strap selectively connectable between the plow blade and the mounting apparatus in at least one position, wherein the position is a constrained orientation wherein the elongated strap resists upward movement of the plow blade when the plow blade is disengageably secured to the mounting apparatus or an elevated orientation, wherein the elongated strap suspends the plow blade a desired distance from the ground to prevent the plow blade from contacting the ground and / or snow on the ground.

Owner:AGRI COVER

Straw returning biological agent for greenhouse crops and biological fermentation method

InactiveCN107022512AImprove organic matterImprove fertilityFungiBio-organic fraction processingMicrobial agentGreenhouse crops

The invention discloses a straw returning biological agent for greenhouse crops and a biological fermentation method. The biological fermentation method comprises the steps: applying a compound microbial agent into a greenhouse, uniformly mixing the compound microbial agent with soil, smashed straws and manure, irrigating the greenhouse with enough water, and sealing the greenhouse for fermentation. The microbial agent enables organic matters and organic fertilizer in the soil and the straws to be quickly fermented, rotted and decomposed, and can quickly kill pests and diseases in the straws and the soil plough layer and quickly increase the content of organic matters and the fertility of the soil; heat generated by rotting fermentation of the organic manure and the straws and heat energy supplied by sunlight under a condition that the greenhouse is sealed can quickly heat the soil to create a high-temperature wet soil environment and enable the temperature in the greenhouse to reach 70 to 80 DEG C; the high temperature in the greenhouse is conducted into the soil to enable the soil temperature in the greenhouse to reach 45 to 60 DEG C; and the high temperature in the greenhouse can kill the pests and the diseases which float in the air and are attached to a wall and a material such as a plastic thin film.

Owner:寿光市固本培园农业科技有限公司

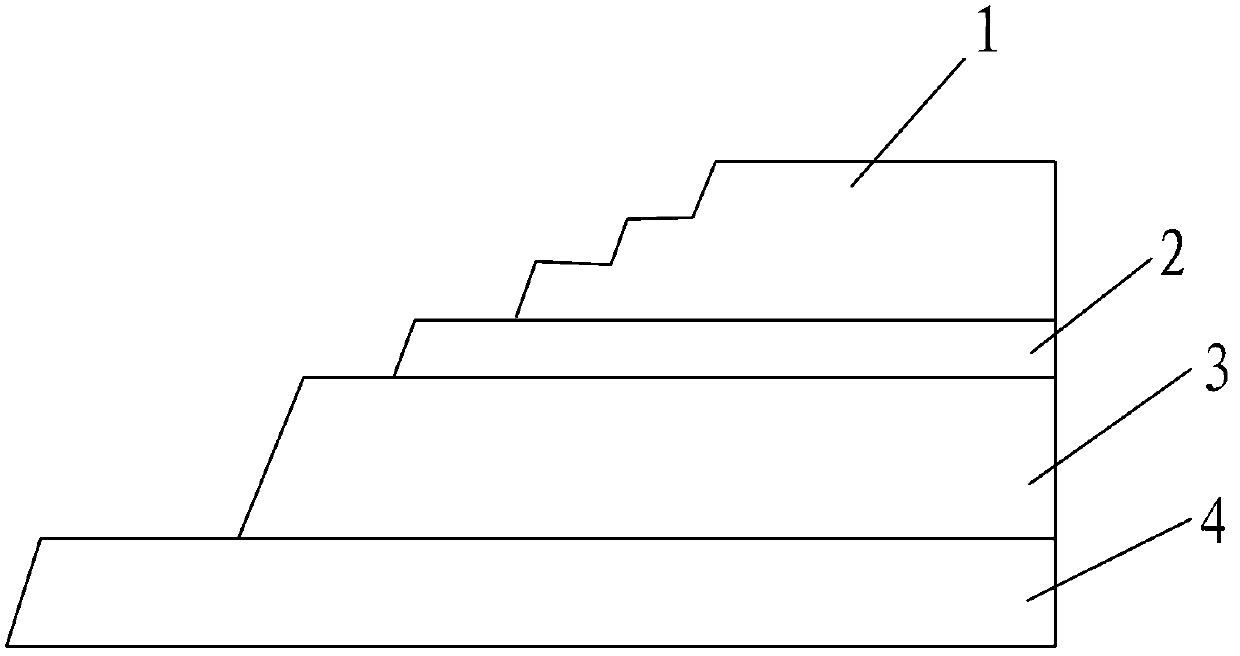

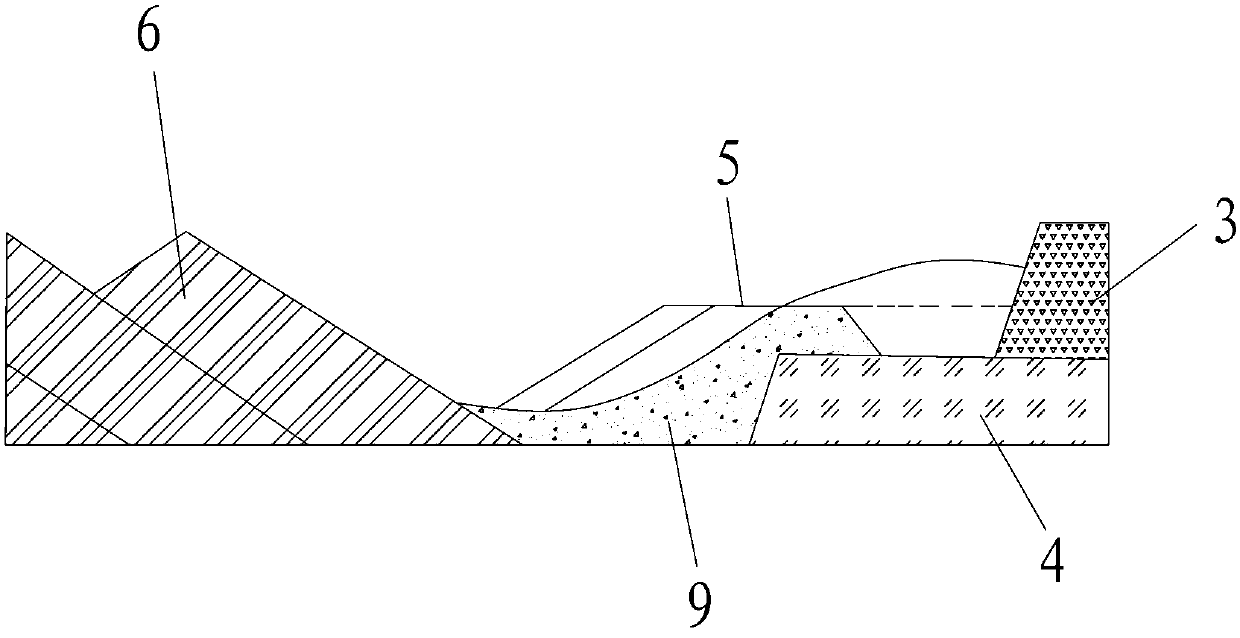

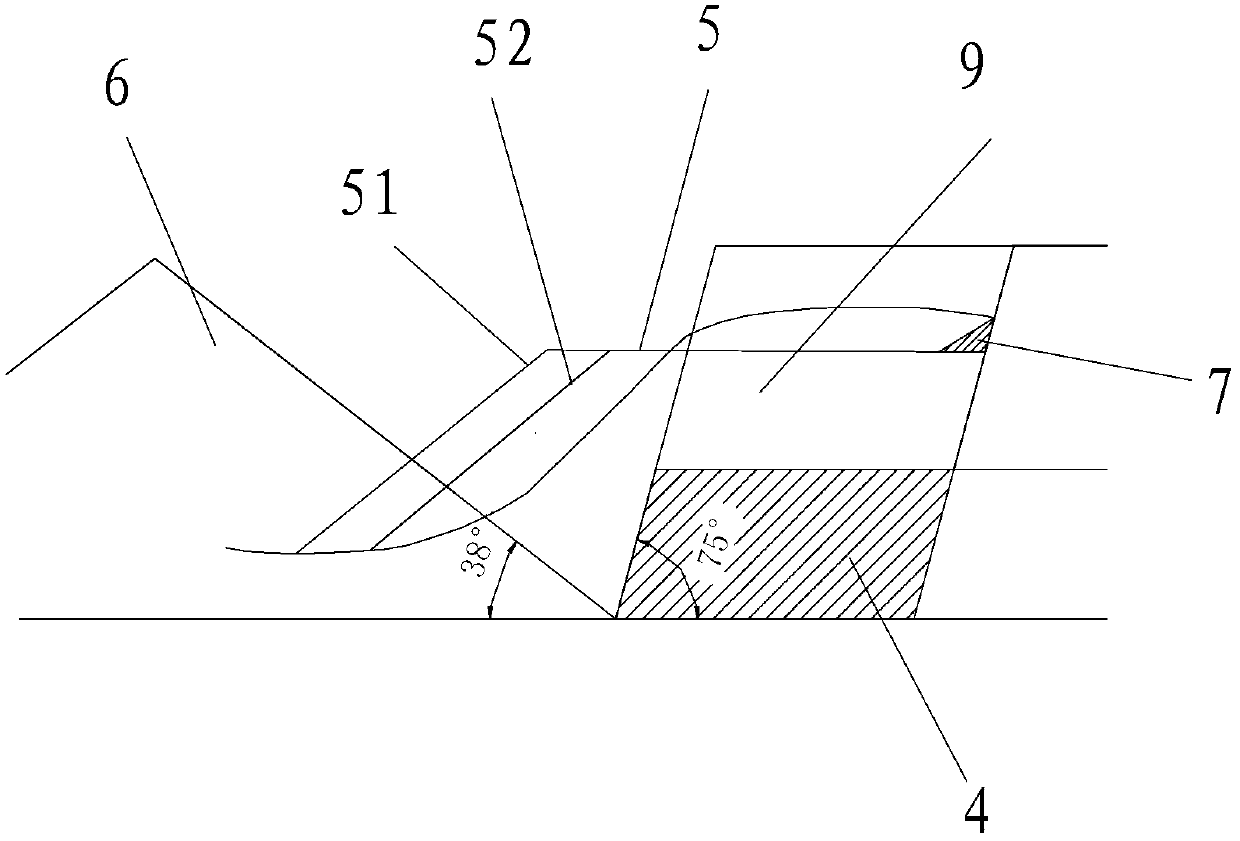

Open pit coal mine mining process

ActiveCN103216238AReduce the amount of secondary dumpingGuaranteed continuity of fitUnderground miningSurface miningMining engineeringExcavator

The present invention provides an open pit coal mine mining process, which comprises the following operation steps: 1, adopting a bucket wheel excavator to dig a loess layer on the upper portion, and adopting a dumping plough to dump the loess on a conveying belt into a dump; 2, adopting a loosening blasting method to blast a rock layer on the upper portion, and then adopting a single bucket truck to convey rocks to the dump until a rock layer on the lower portion is exposed; 3, adopting a casting-blasting method to blast the rock layer on the lower portion, adopting a bulldozer to form a combination extension platform, and adopting match of the single bucket truck and a dragline to directly dump the blasting amount into the dump on the combination extension platform until a coal layer is exposed; and 4, adopting the loosening blasting method to blast the coal layer with a thickness of 30 m in one time, carrying out tracking type mining along a dragline work line direction in two coal mining benches, adopting the single bucket truck to convey the mined coal to a crushing plant, and then conveying the crushed coal to a designated location with a belt conveyor.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Snow plow for all terrain vehicle

InactiveUS20070084090A1Improve practicalityEasy to liftAgricultural machinesMechanical machines/dredgersEngineeringLandform

A snow plow for attachment to a vehicle, preferably an all terrain vehicle, the snow plow including a mounting apparatus having a mounting frame, the mounting frame including at least one mounting upright. The snow plow further including a plow blade. The plow blade has a mold board including a main surface, a rubber scraper proximate the main surface and a retention apparatus constructed and arranged to disengageably secure the plow blade with the mounting upright; wherein the retention apparatus allows the plow blade to pivot with respect to the mounting upright such that the rubber scraper can pivot away from the mounting upright when the plow blade is in a working orientation and the vehicle moves in a direction rearward from the plow blade.

Owner:AGRI COVER

Snow plow

A snow plow with a clutch mechanism for allowing the plow blade to deflect when an off-center portion the blade strikes an obstacle.The clutch comprises two plates in axial alignment, with one plate being attached to brackets for the plow support and the other plate being attached to brackets supporting the blade. One plate has a number of small protuberances and the other plate a corresponding number of shallow pockets. The plates are releasably held in nested relation by an axially adjustable mechanism.

Owner:WILLEY BARRY A

Two-stage snow plow

A snow plow includes a primary moldboard and auxiliary plow positioned behind the primary moldboard. The snow plow may be a one-way or reversible snow plow. In the later case, the primary moldboard and auxiliary plow are attached to a drive frame that is rotatable about a frame. The frame is secured to the front of a vehicle by a frame and bracket, and controlled by hydraulic mechanisms. The auxiliary plow is operated independently of the moldboard by a pair of hydraulic cylinders and includes tines or a resilient blade for clearing snow and ice that is not taken up by the primary moldboard. The device also includes a mechanism whereby the scraping edge of the secondary plow follows the same path as the scraping edge of moldboard by sliding movement of the secondary plow relative to the drive frame, and the blade of the auxiliary plow may be formed by tines or a resilient blade.

Owner:CIVES

Snow plowing system

A detachable snow plow blade is driven by a skid-steer or other suitable vehicle. The detachable plow blade has hydraulically adjustable wing blades that each pivot under separate control about a main blade. Pins that support power cylinders between braces are arranged to enable each wing to extend through a range of motion from essentially perpendicular to and ahead of the main blade to essentially perpendicular to and behind the main blade. In a further alternative embodiment, the entire blade, including wing blades, may additionally be pivoted with respect to the vehicle, resulting in a very adjustable blade which is well adapted to emulate prior art box plow / pushers, conventional plows, pull back / drag plows, V-plows and fold-out plows.

Owner:DEGELMAN IND LP

Snow Plow Having Slidleable Retention Apparatus

InactiveUS20070151127A1Improve practicalityEasy to liftSnow cleaningEngineeringMechanical engineering

A snow plow for attachment to a vehicle, the snow plow including a mounting apparatus having a mounting frame, the mounting frame including at least one mounting upright. The snow plow further including a plow blade. The plow blade has a mold board including a main surface, a rubber scraper proximate the main surface and a retention apparatus constructed and arranged to disengaeably secure the plow blade with the mounting upright; wherein the retention apparatus allows the plow blade to pivot with respect to the mounting upright such that the rubber scraper can pivot away from the mounting upright when the plow blade is in a working orientation and the vehicle moves in a direction rearward from the plow blade.

Owner:AGRI COVER

Snow plow having internally reinforced mold board

InactiveUS20070256334A1Efficient productionMechanical machines/dredgersSnow cleaningEngineeringAluminum extrusion

A snow plow for attachment to a vehicle, the snow plow including a mounting apparatus having a mounting frame, the mounting frame including at least one mounting upright. The snow plow further including a plow blade including a retention apparatus constructed and arranged to slidlingly and disengageably secure the plow blade to the mounting upright(s) when the plow blade is in a working orientation. The plow blade includes a mold board, preferably, a two piece mold board being an aluminum extrusion. The mold board will preferably include a front and a back and cells or compartments partially formed by support structures that extend between the front and the back of the mold board and along the width of the plow blade.

Owner:AGRI COVER

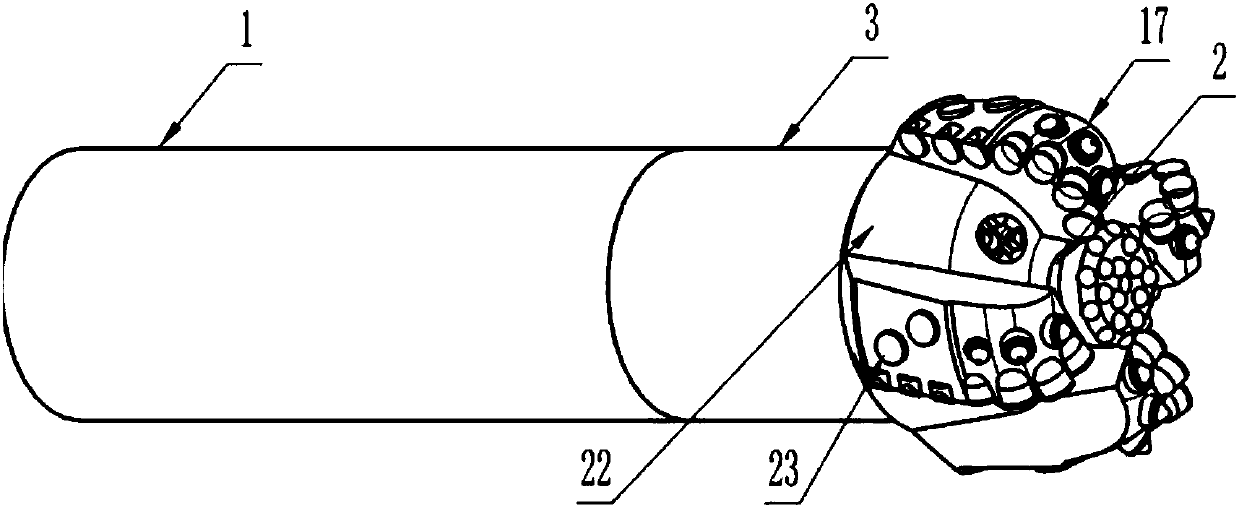

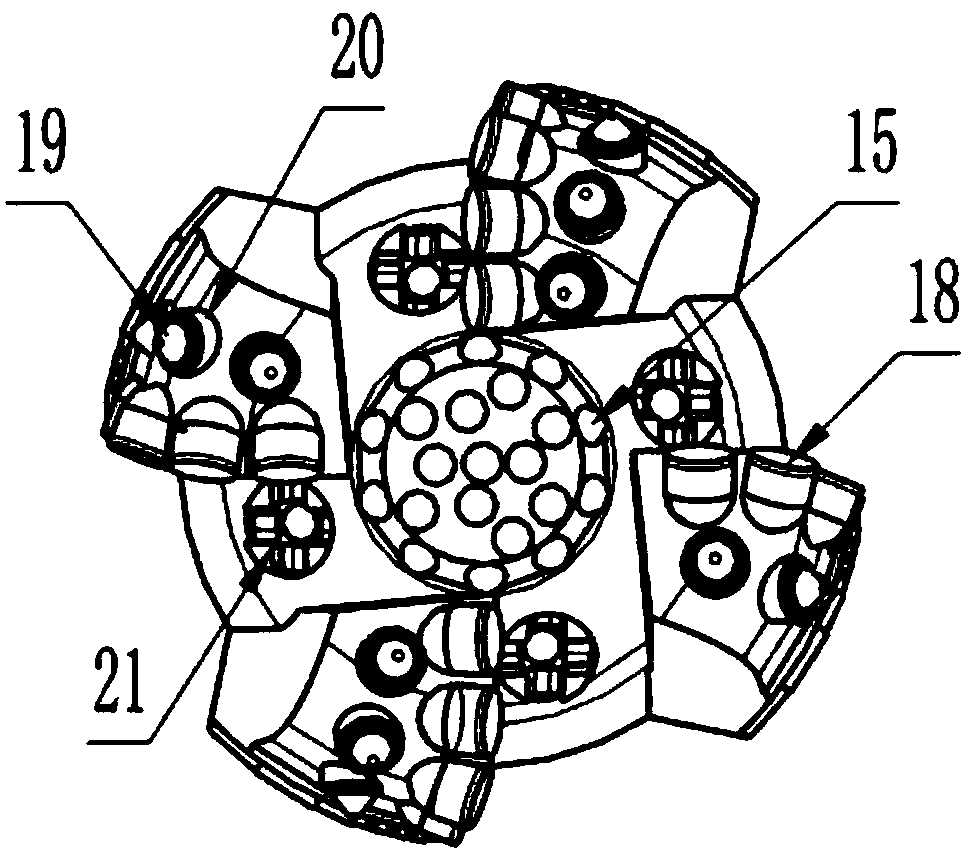

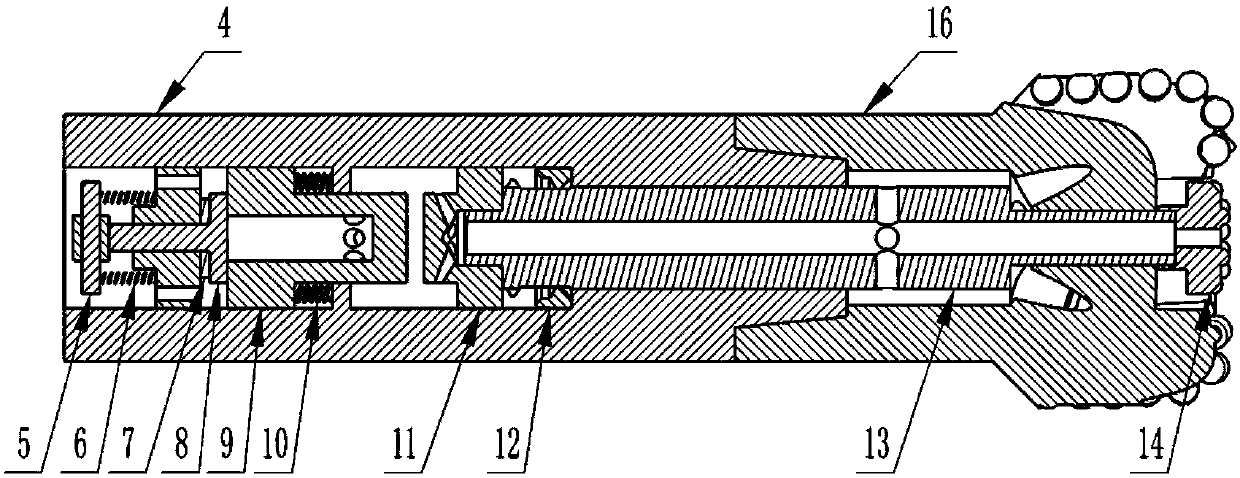

Punching-shear composite drill bit for hard rock drilling

ActiveCN107842317AReduced compressive strengthLow shear strengthDrill bitsTectonic stressPre cracking

The invention discloses a punching-shear composite drill bit for hard rock drilling. The punching-shear composite drill bit comprises three parts of an impactor, an internal punching bore bit and an external cutting drill bit, a lower joint of the impactor can be in threaded connection with the external cutting drill bit, and the upper part of the internal punching bore bit is connected with the impactor in a spline mode; and the lower end face of the internal punching bore bit extends out of the surface of the external cutting drill bit, the central axis of the internal punching bore bit is parallel to or coincident with the central axis of the external cutting drill bit, distributed teeth on the internal punching bore bit and distributed teeth on the external cutting drill bit are combined and can completely cover a downhole, and distributed teeth on the internal punching bore bit and the distributed teeth on the external cutting drill bit are independent of each other. In this way,rock crushing through shearing and rock crushing through impact are creatively combined together, a rock stratum at the hole bottom is pre-cracked first through the internal punching bore bit, the whole tectonic stress of the rock stratum is destroyed, the strength of compression resistance and shearing resistance of rock is reduced so that PDC column teeth and PDC cone teeth can more easily cut / plough-cut the rock, and the rock-breaking efficiency of the super hard rock stratum is greatly improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com