Horizontal solid-liquid mixing device and application thereof

A solid-liquid mixing, horizontal technology, applied in the direction of mixers, mixing methods, mixers with rotating stirring devices, etc., can solve the problems of blocking the feed inlet, the mixing device cannot continue, and it is difficult to disperse and mix, so as to achieve the goal of mixing High efficiency, good continuous operation effect and good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

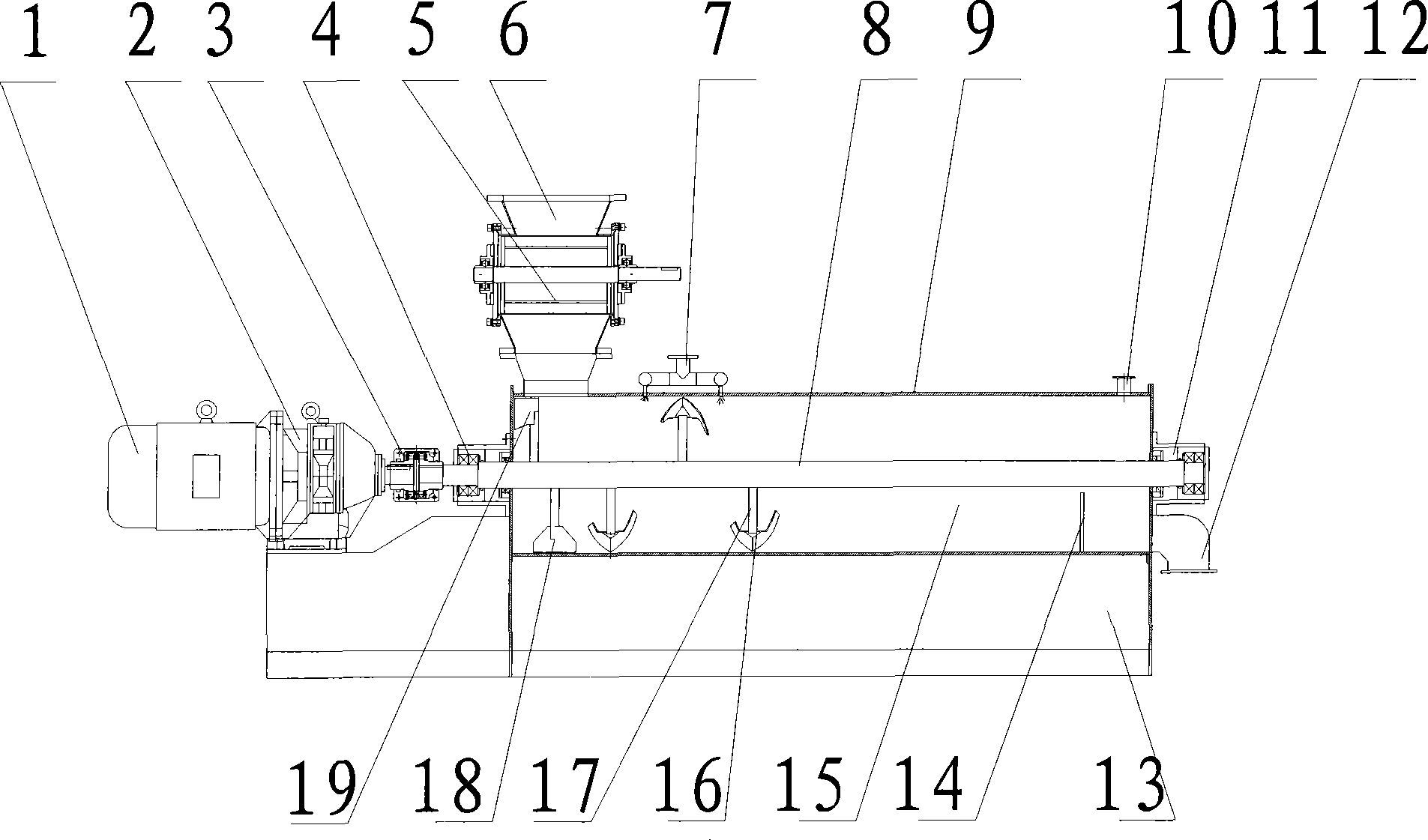

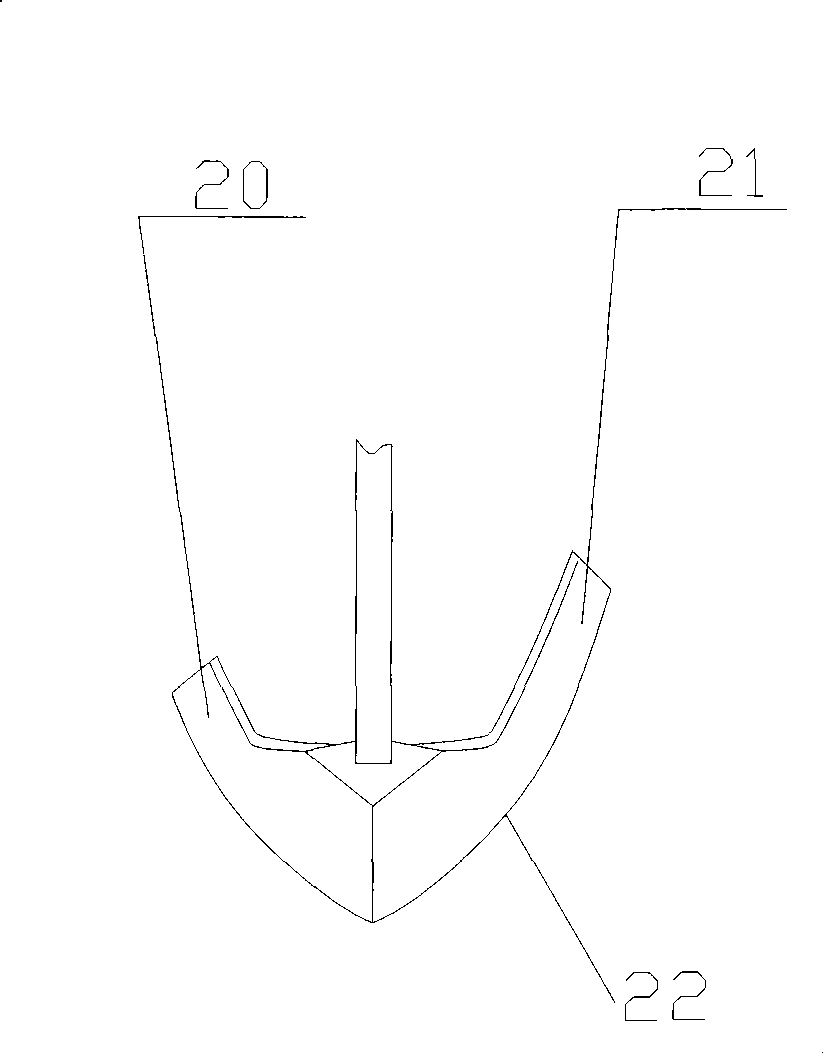

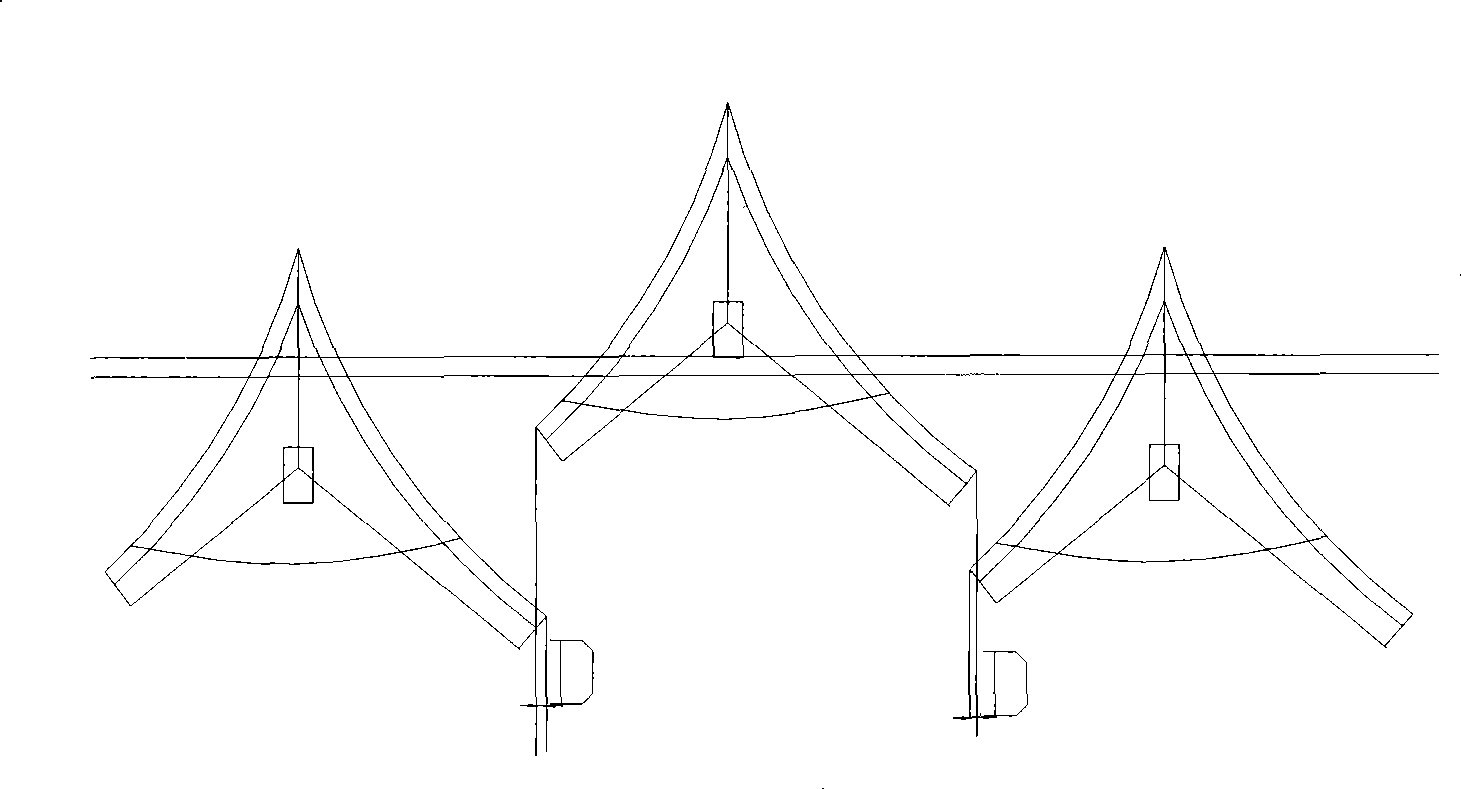

[0035] Such as figure 1 As shown, a horizontal solid-liquid mixing device mainly includes a motor 1, a reduction box 2, a coupling 3, a front bearing end 4, a rotary valve 5, a solid feed port 6, a liquid feed port 7, and a stirring shaft 8 , mixing cylinder 9, exhaust port 10, rear bearing end 11, discharge port 12, bracket 13, baffle plate 14, solid-liquid mixing chamber 15, coulter 16, coulter fixing rod 17, second scraper 18, The first scraper 19.

[0036] The motor 1 drives the reduction box 2. After deceleration, the stirring shaft is driven to rotate through the coupling 3. The front bearing end 4 and the rear bearing end 5 support and maintain the installation of the stirring shaft 8 and the mixing cylinder 9. Concentricity, the front bearing end 4 and the rear bearing end 5 are fixed on the mixing cylinder 9 by bolts, the rotary valve 5 is connected with the solid feed port 6 to control the amount of solid feed, the solid feed The feed port 6 is arranged at the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com