Patents

Literature

141 results about "Pre cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

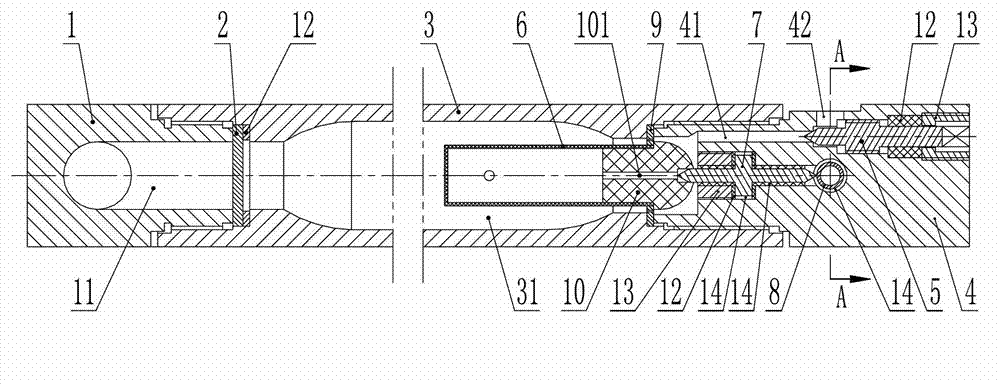

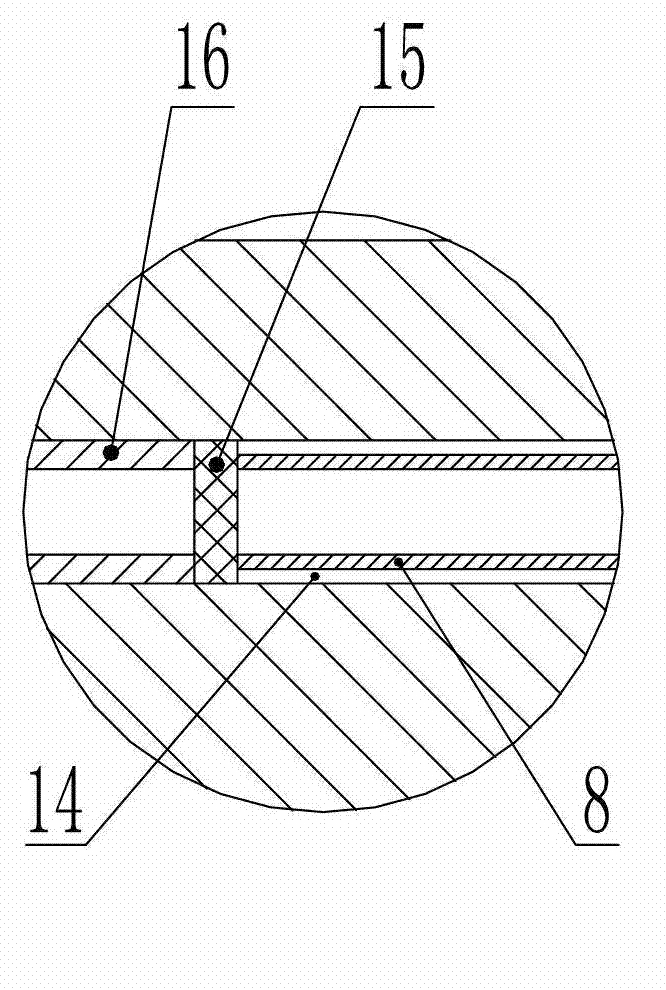

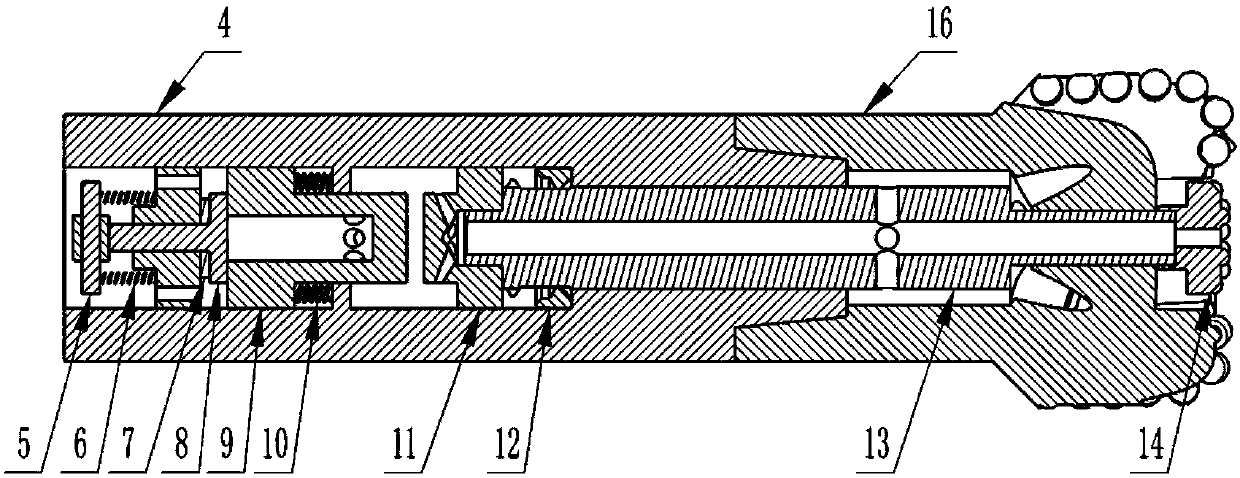

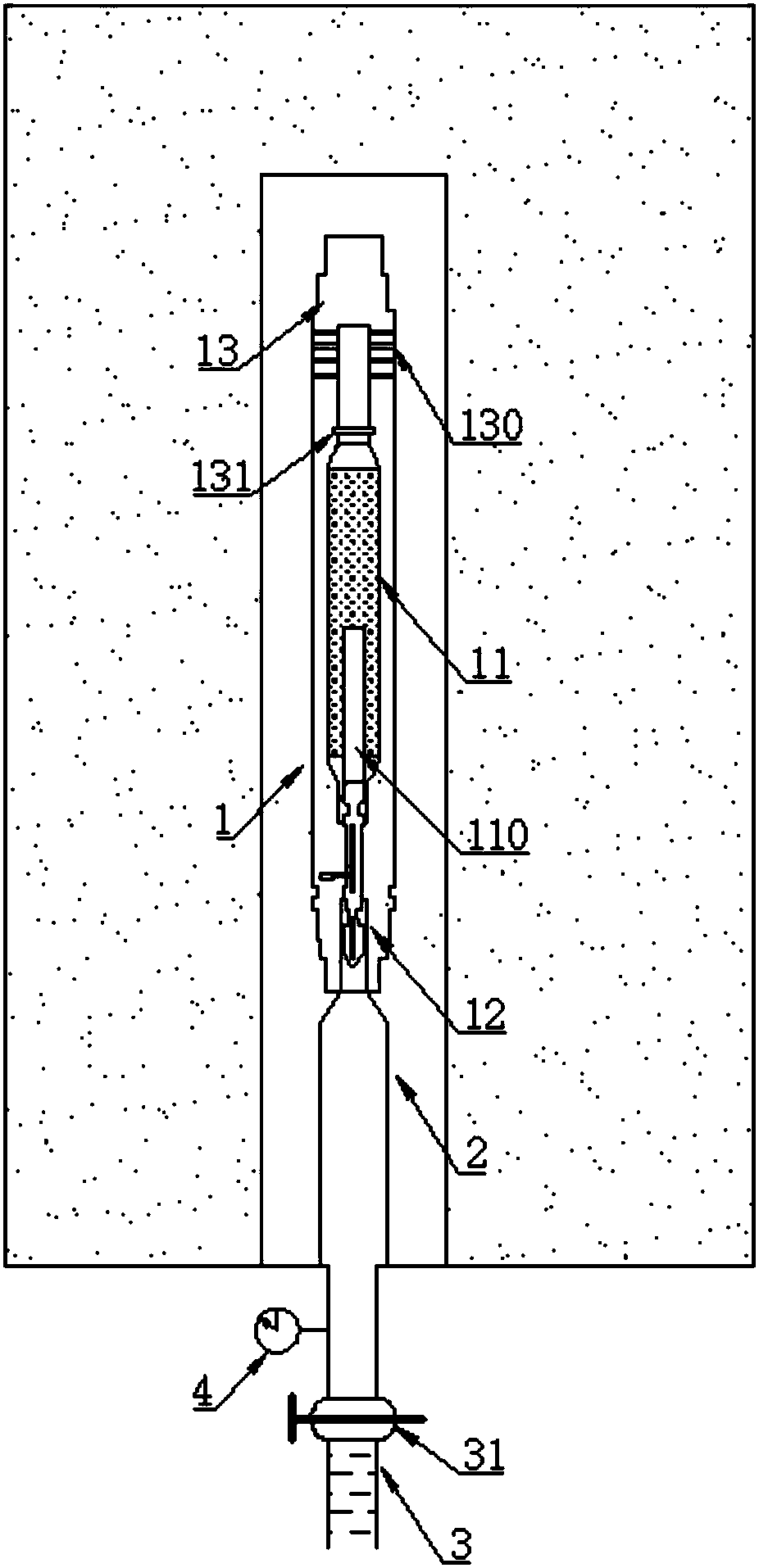

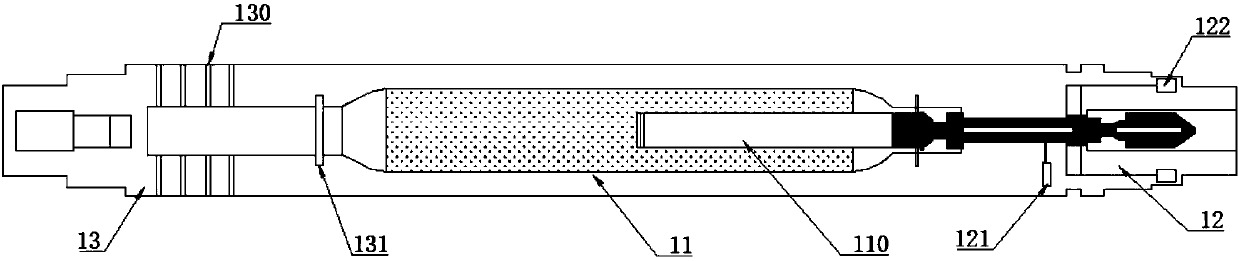

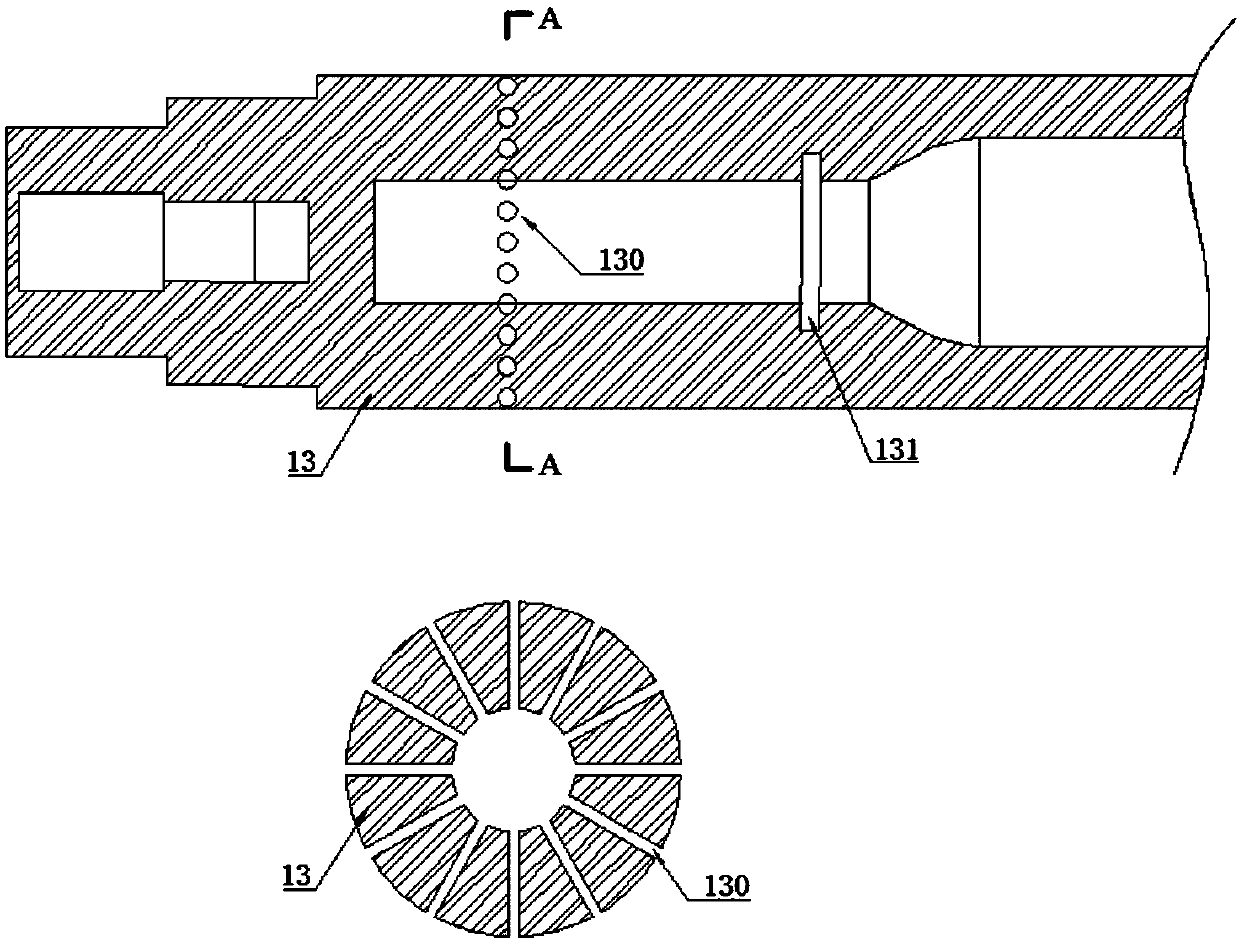

Carbon dioxide mining device

The invention discloses a carbon dioxide mining device. The carbon dioxide mining device comprises an energy release head, a fixed pressure energy release sheet, a main pipe and a filling head, wherein the energy release head and the filling head are respectively fastened at the two ends of the main pipe; a filling passage and an ejector pin are arranged on the filling head; the filling passage is led to a main pipe filling chamber, and the ejector pin is used for opening and closing the filling passage; an energy release passage is formed in the energy release head; one end of the energy release passage is led to the main pipe filling chamber; the other end of the energy release passage is led outside the carbon dioxide mining device; the fixed pressure energy release sheet is arranged between the energy release passage of the energy release head and the main pipe filling chamber in a sealed way; a heating device is arranged in the main pipe filling chamber; and the fixed pressure energy release sheet is fractured when liquid carbon dioxide filled into the main pipe filling chamber is heated, gasified and expanded to a certain pressure by the heating device. The carbon dioxide mining device disclosed by the invention can be used instead of common detonators and explosives in mine mining; gas explosion caused by fire explosion is avoided and safety production of the mine is also achieved; and a coal body can be also pre-cracked in the gas mining process, so that the air permeability of a coal layer is effectively improved, and the gas mining efficiency of the coal layer is increased.

Owner:CCTEG CHINA COAL RES INST

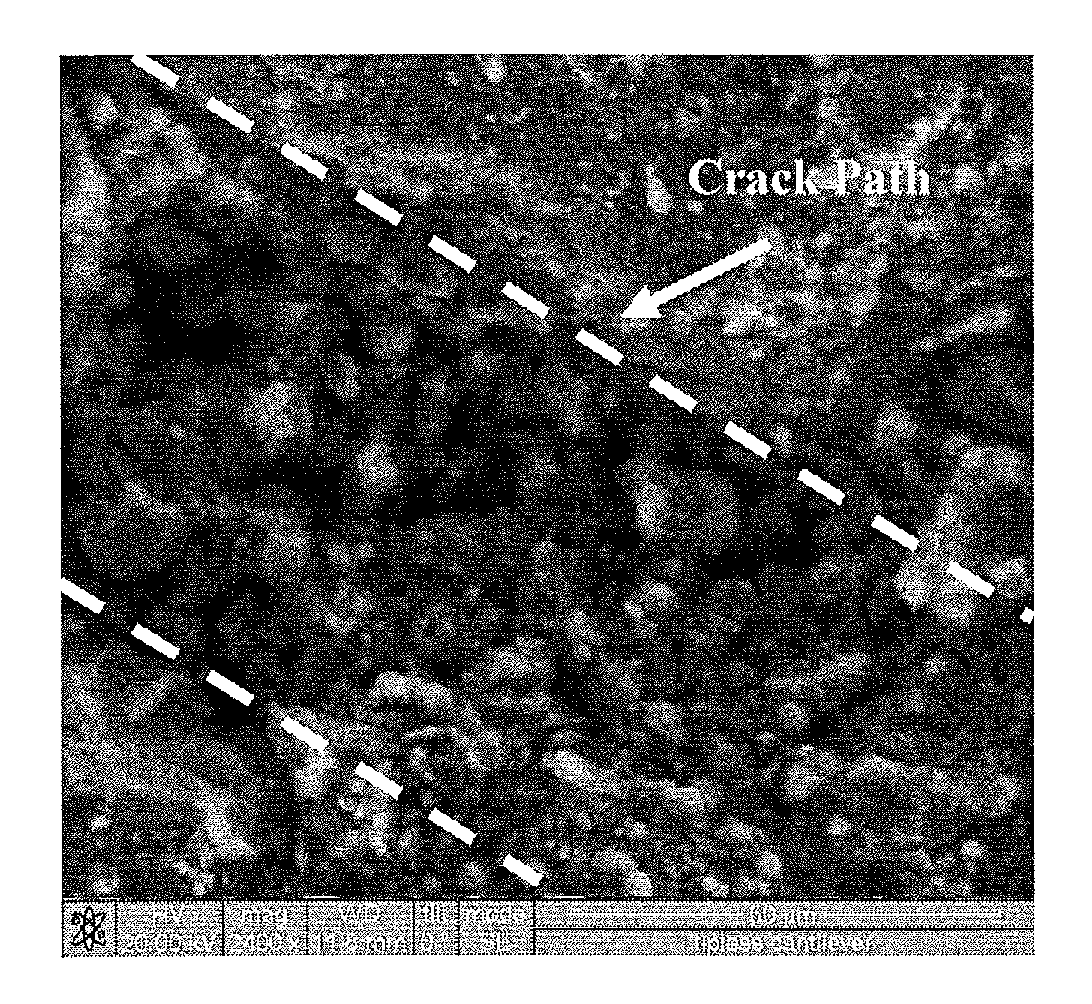

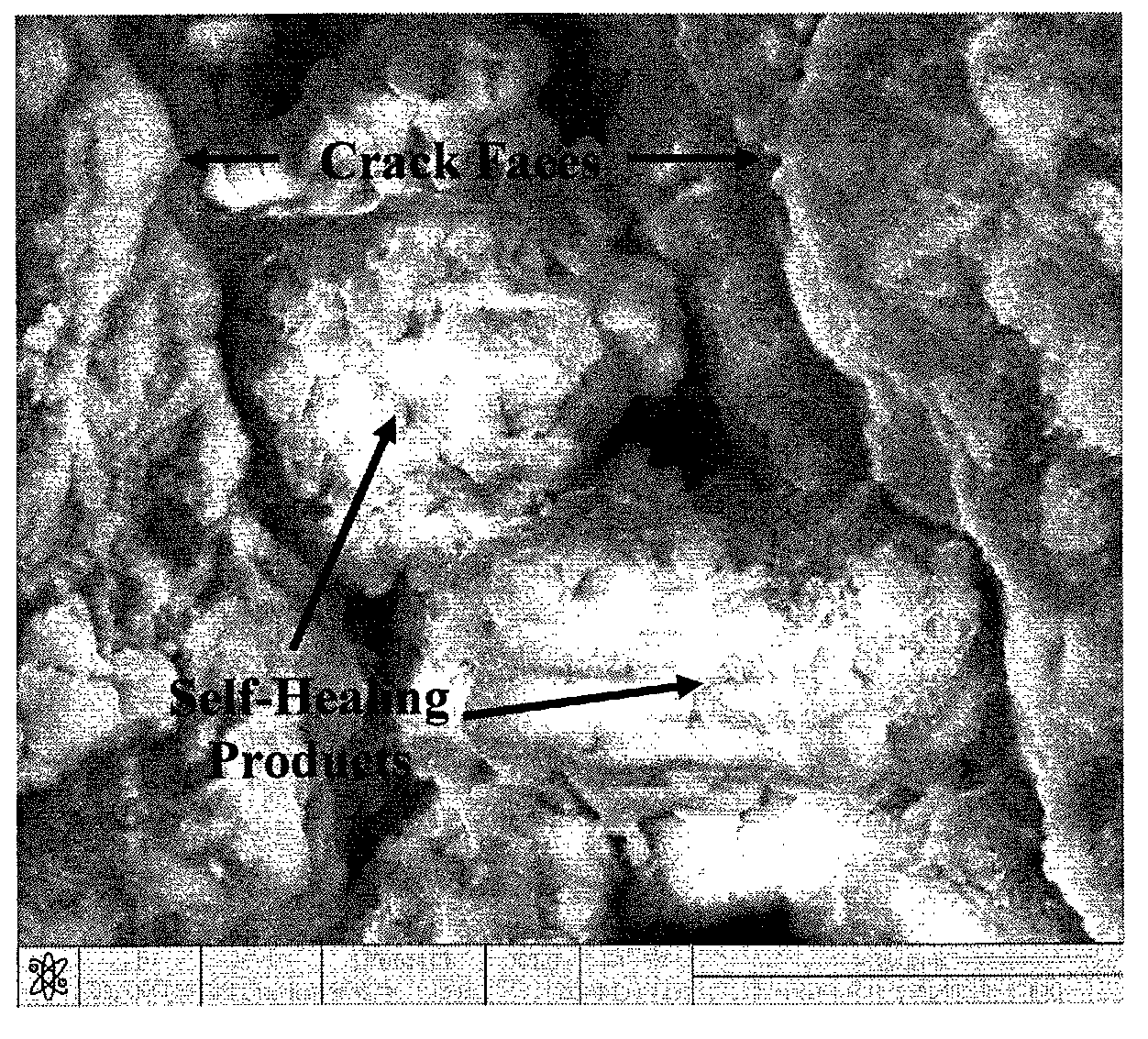

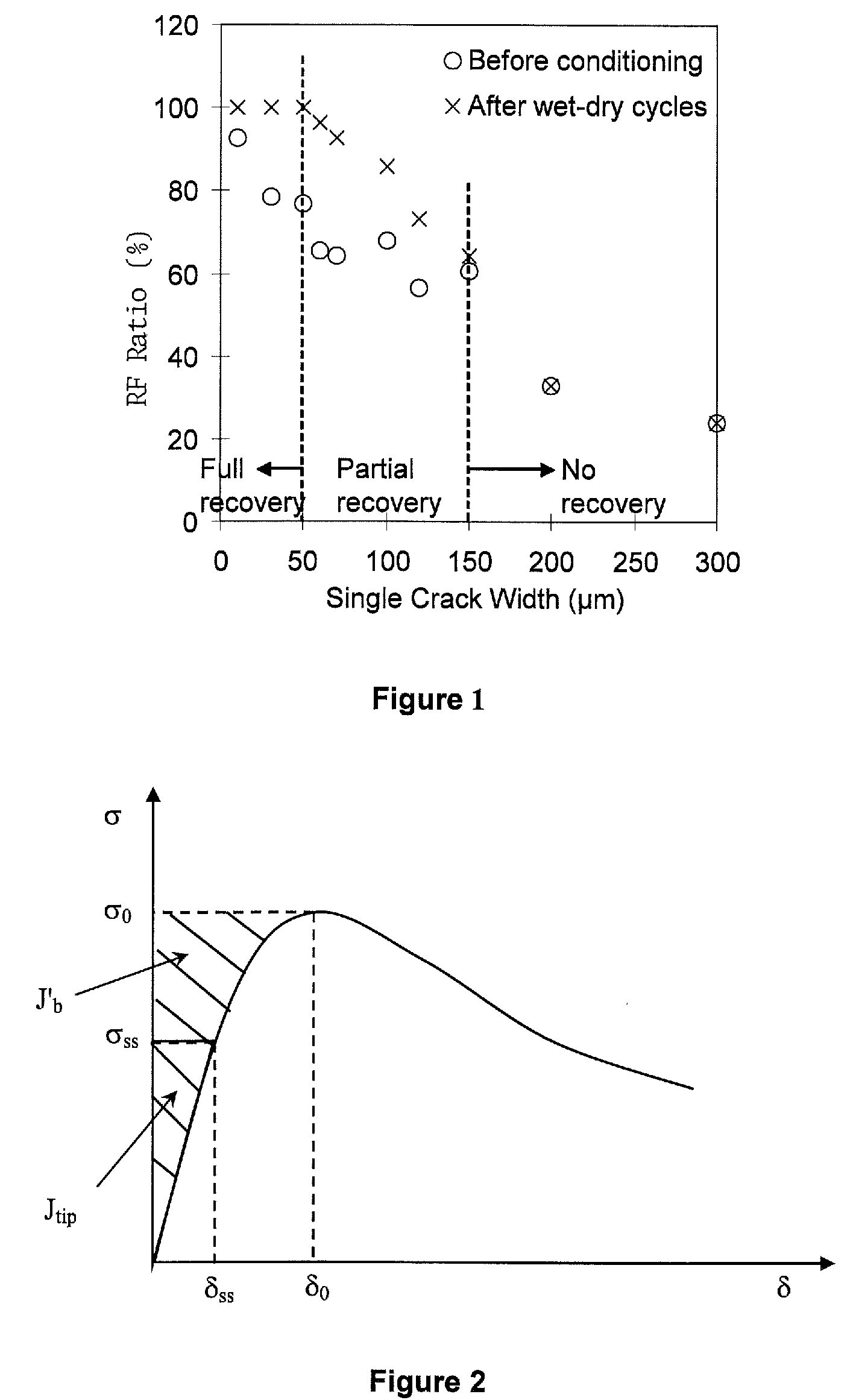

Engineered self healing cementitious composites

ActiveUS20080261027A1Highly controlled crack widthPreferable flowabilitySolid waste managementSynthetic resin layered productsSelf-healingCement composites

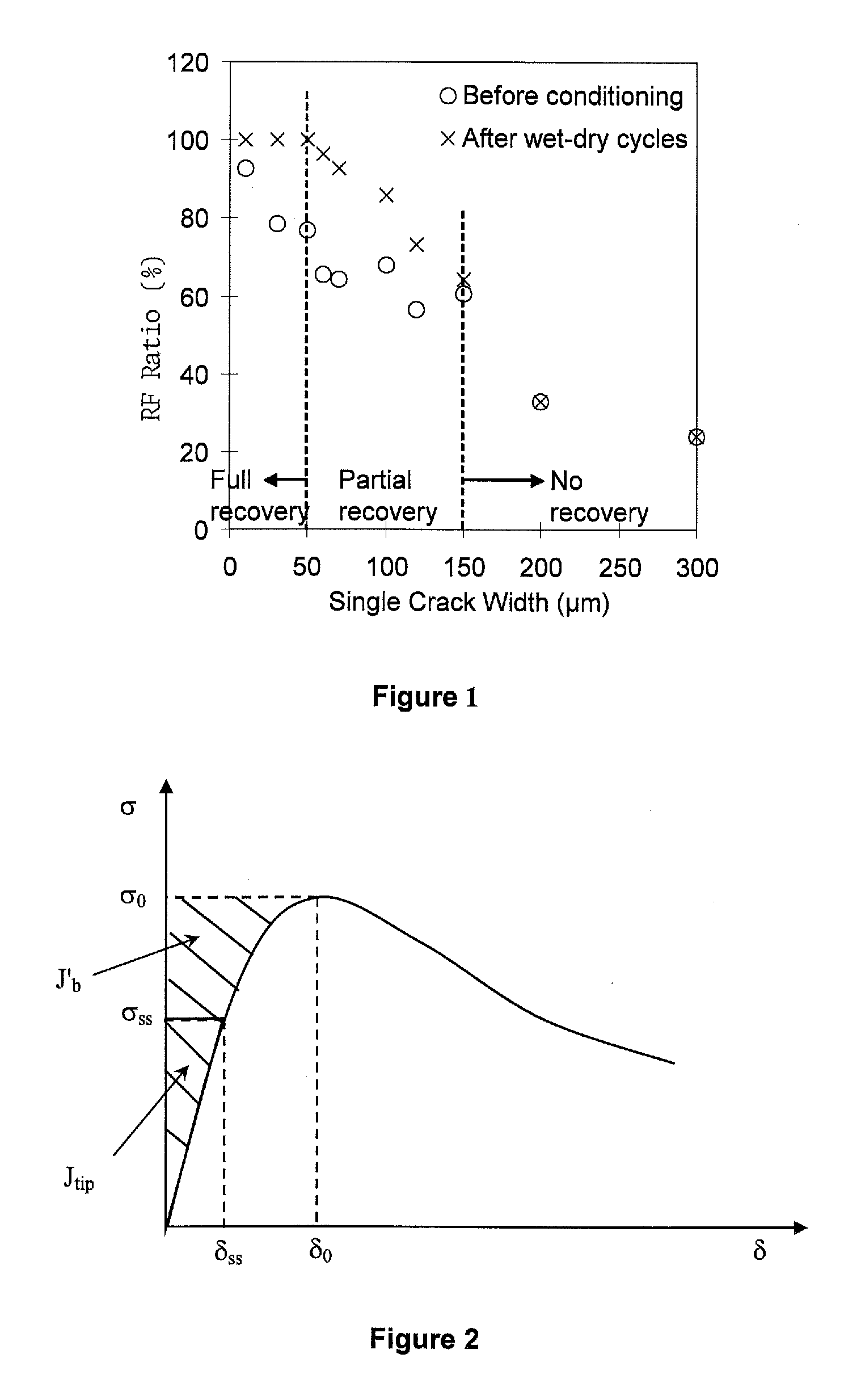

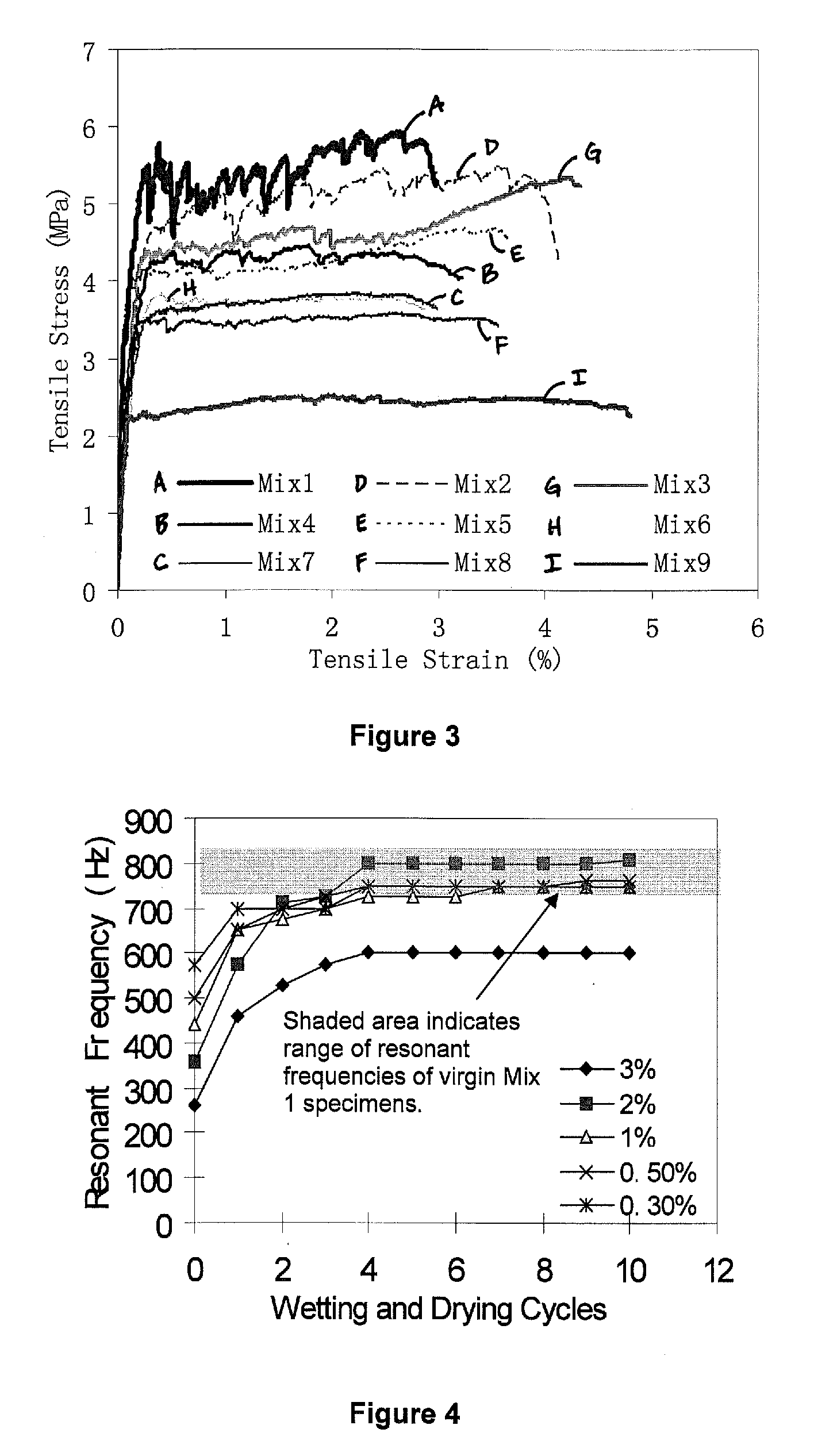

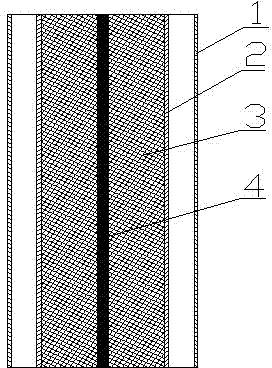

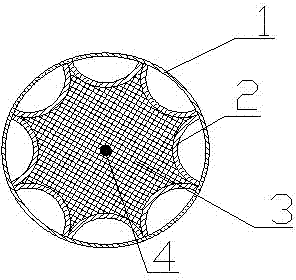

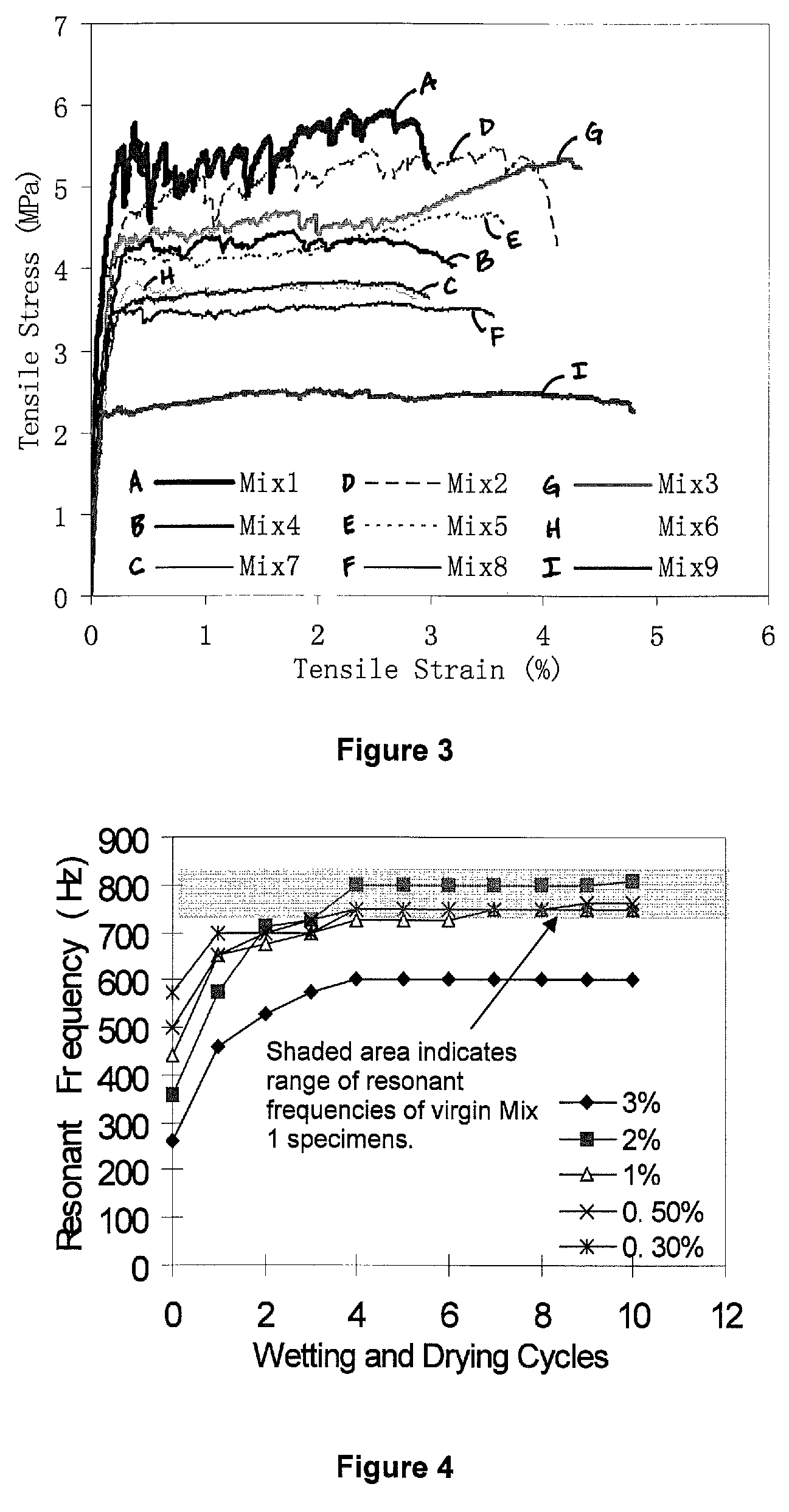

Cementitious composites engineered for self-healing, combining self-controlled tight crack width and extreme tensile ductility. Self-healing takes place automatically at cracked locations without external intervention. In the exemplary embodiment, fiber-reinforced cementitious composites with self-controlled tight crack width less than 50 μm and tensile ductility more than 2% are prepared. Self-healing in terms of mechanical and transport properties recovery of pre-damaged (by pre-cracking) composite is revealed in a variety of environmental exposures, include wetting and drying cycles, water permeation, and chloride submersion.

Owner:RGT UNIV OF MICHIGAN

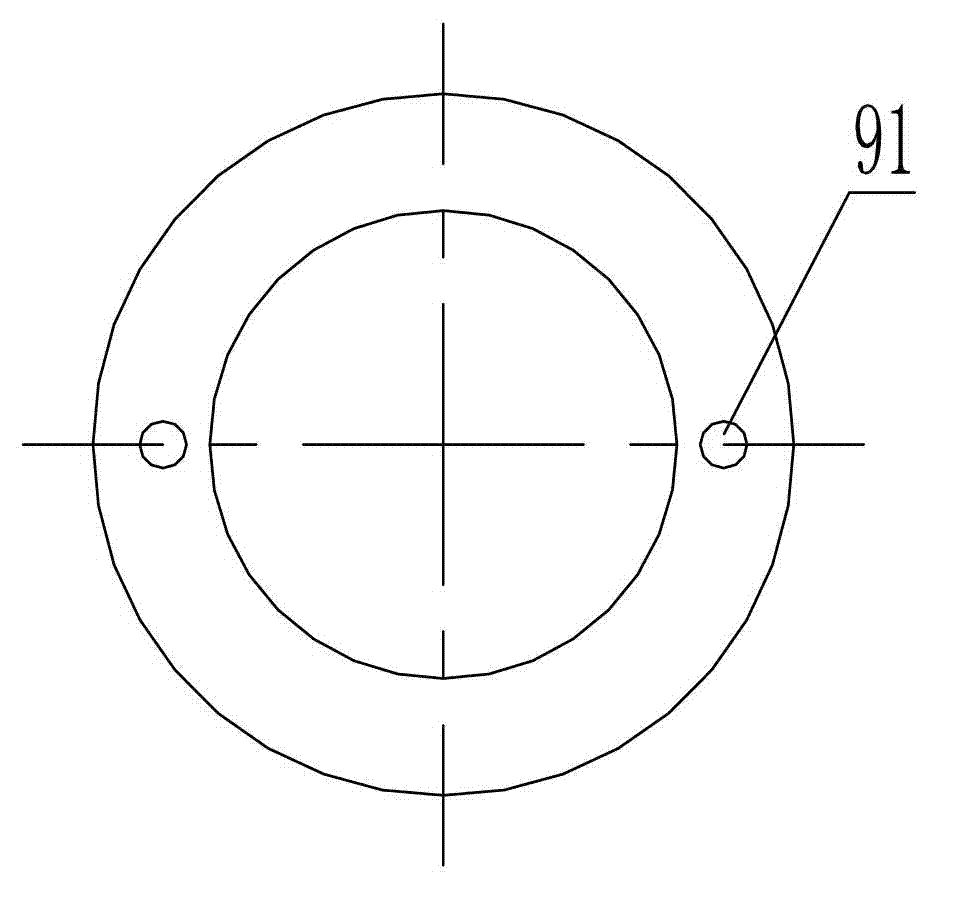

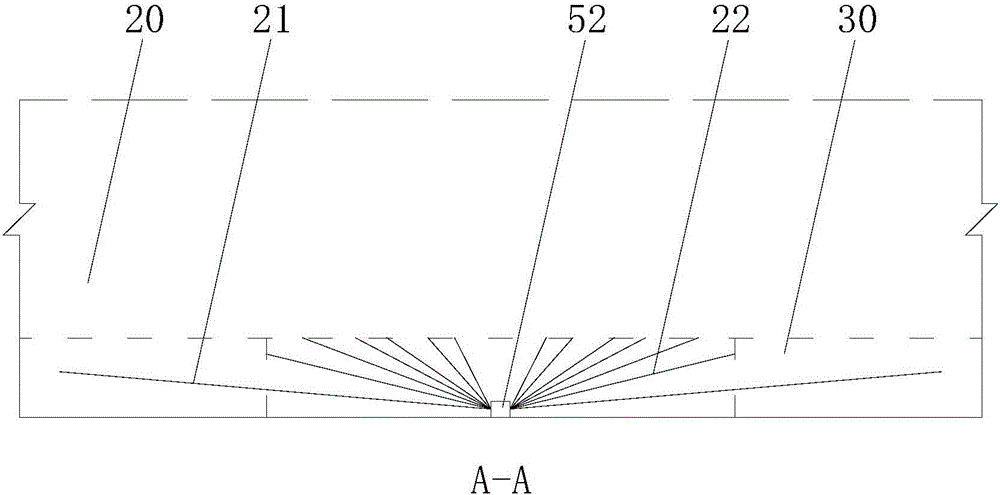

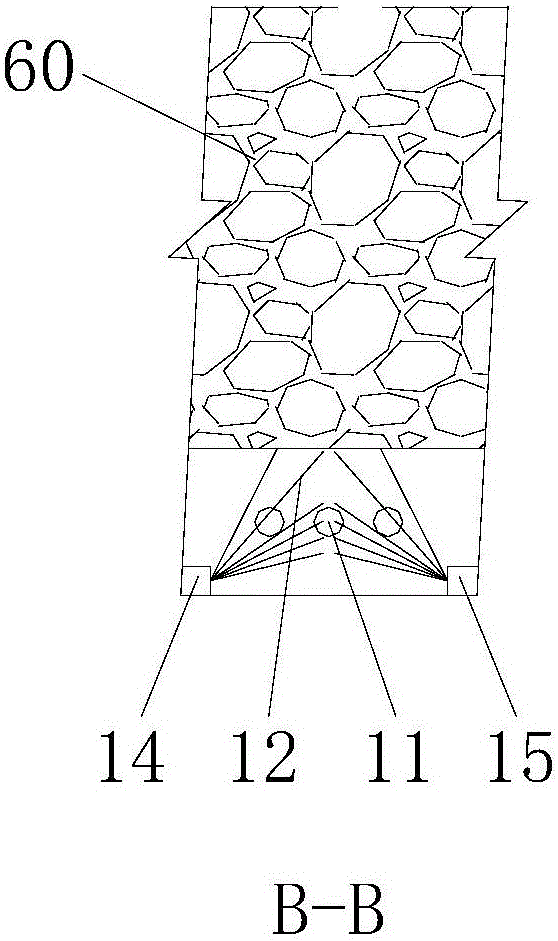

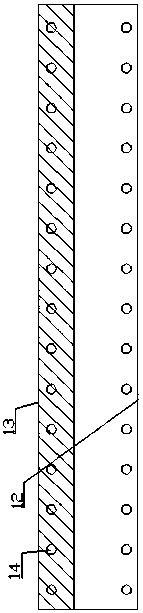

Annular linear energy-accumulation cutter

The invention belongs to the technical field of engineering blasting and discloses an annular linear energy-accumulation cutter. The annular linear energy-accumulation cutter comprises a restraining shell, explosives, liners and a detonation device, wherein the restraining shell is a columnar pipe; a plurality of semi-circular tubular linear liners are arranged inside the shell; notches of the pipes all face towards and are in contact with the inner wall surface of the shell; the outer walls of each two adjacent semi-circular tubes are in tangent mutually; the length of each tube is the same as the length of the restraining shell, and the axes of each tube and the restraining shell are in parallel; a middle space surrounded by the liners is filled with the explosives and is provided with a detonating fuse; the axis of the middle space is coincided with the axis of the restraining shell; the restraining shell and the liners are made of metal materials or plastic materials; and the explosives are common industrial explosives. The annular linear energy-accumulation cutter reasonably utilizes the energy of the explosives and can be used in excavating operation in coals or rocks and generate a plurality of cracks in the coals or the rocks; and the annular linear energy-accumulation cutter is particularly applicable to middle and deep hole pre-cracking blasting of coal seams and can effectively reduce or eliminate the danger of gas burst in the coal seams and prevent or reduce severe mining safety accidents such as gas burst or fire hazard.

Owner:UNIV OF SCI & TECH OF CHINA

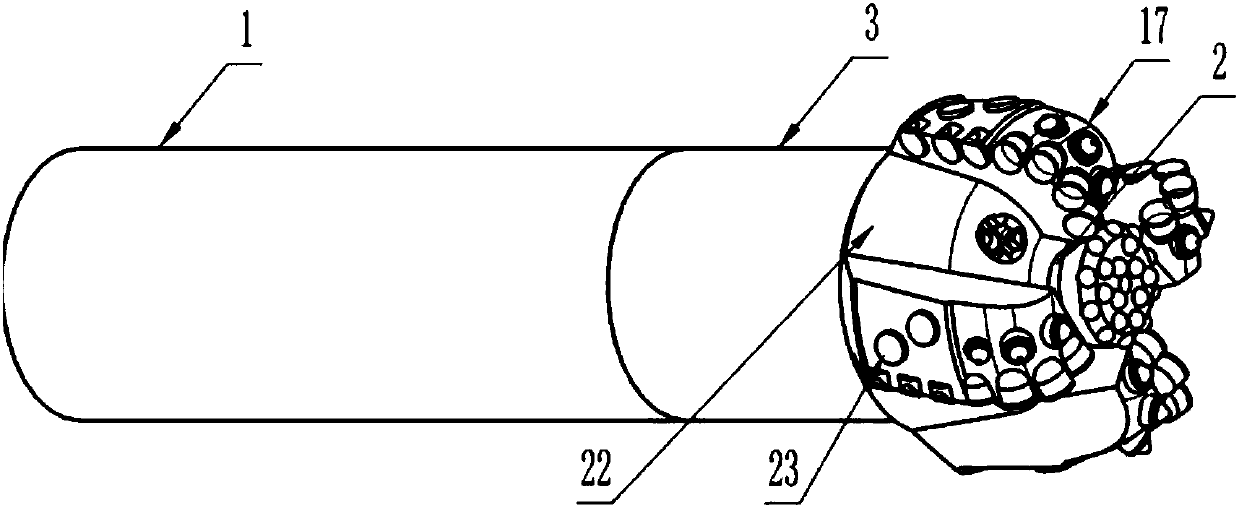

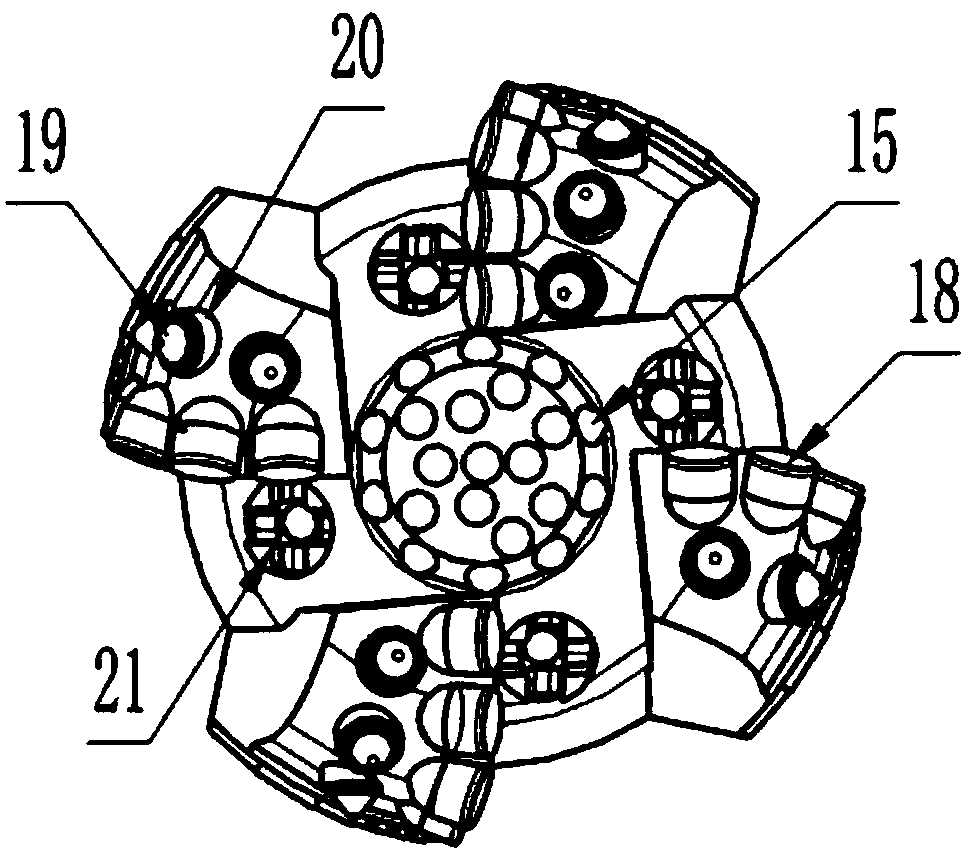

Punching-shear composite drill bit for hard rock drilling

ActiveCN107842317AReduced compressive strengthLow shear strengthDrill bitsTectonic stressPre cracking

The invention discloses a punching-shear composite drill bit for hard rock drilling. The punching-shear composite drill bit comprises three parts of an impactor, an internal punching bore bit and an external cutting drill bit, a lower joint of the impactor can be in threaded connection with the external cutting drill bit, and the upper part of the internal punching bore bit is connected with the impactor in a spline mode; and the lower end face of the internal punching bore bit extends out of the surface of the external cutting drill bit, the central axis of the internal punching bore bit is parallel to or coincident with the central axis of the external cutting drill bit, distributed teeth on the internal punching bore bit and distributed teeth on the external cutting drill bit are combined and can completely cover a downhole, and distributed teeth on the internal punching bore bit and the distributed teeth on the external cutting drill bit are independent of each other. In this way,rock crushing through shearing and rock crushing through impact are creatively combined together, a rock stratum at the hole bottom is pre-cracked first through the internal punching bore bit, the whole tectonic stress of the rock stratum is destroyed, the strength of compression resistance and shearing resistance of rock is reduced so that PDC column teeth and PDC cone teeth can more easily cut / plough-cut the rock, and the rock-breaking efficiency of the super hard rock stratum is greatly improved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Impacting-shaping composite spherical energy dissipation structure for vertical hole blasting

ActiveCN106949797ASleek appearanceLittle effect of hole wall roughnessBlastingDetonationNuclear power

The invention provides an impacting-shaping composite spherical energy dissipation structure for vertical hole blasting. The energy dissipation structure comprises a composite spherical energy dissipation base and a buffer layer located below the composite spherical energy dissipation base, wherein the composite spherical energy dissipation base is of a double-layer structure which is soft externally and hard internally or hard externally and soft internally from outside to inside. According to the energy dissipation structure, under the action of an initial impact load after explosive detonation in a blast hole, the composite spherical energy dissipation base generates secondary plasticity, finally an ellipsoidal or a concave-shaped rigid cushion block reflects most of the explosion energy which is propagated in the rock mass below the hole bottom, meanwhile, the composite spherical energy dissipation base and the buffer layer absorb partial explosion energy in the deformation process, and therefore the rock on the foundation surface can be broken, the rock on the hole bottom can be protected, and the existing horizontal pre-cracking or smooth blasting technology can be partially replaced. The energy dissipation structure is simple and convenient to install, can partially replace the existing horizontal pre-cracking or smooth blasting technology and is suitable for protecting layer rock mass blasting excavation in the fields of water conservancy and hydropower, nuclear power, traffic and the like.

Owner:WUHAN UNIV

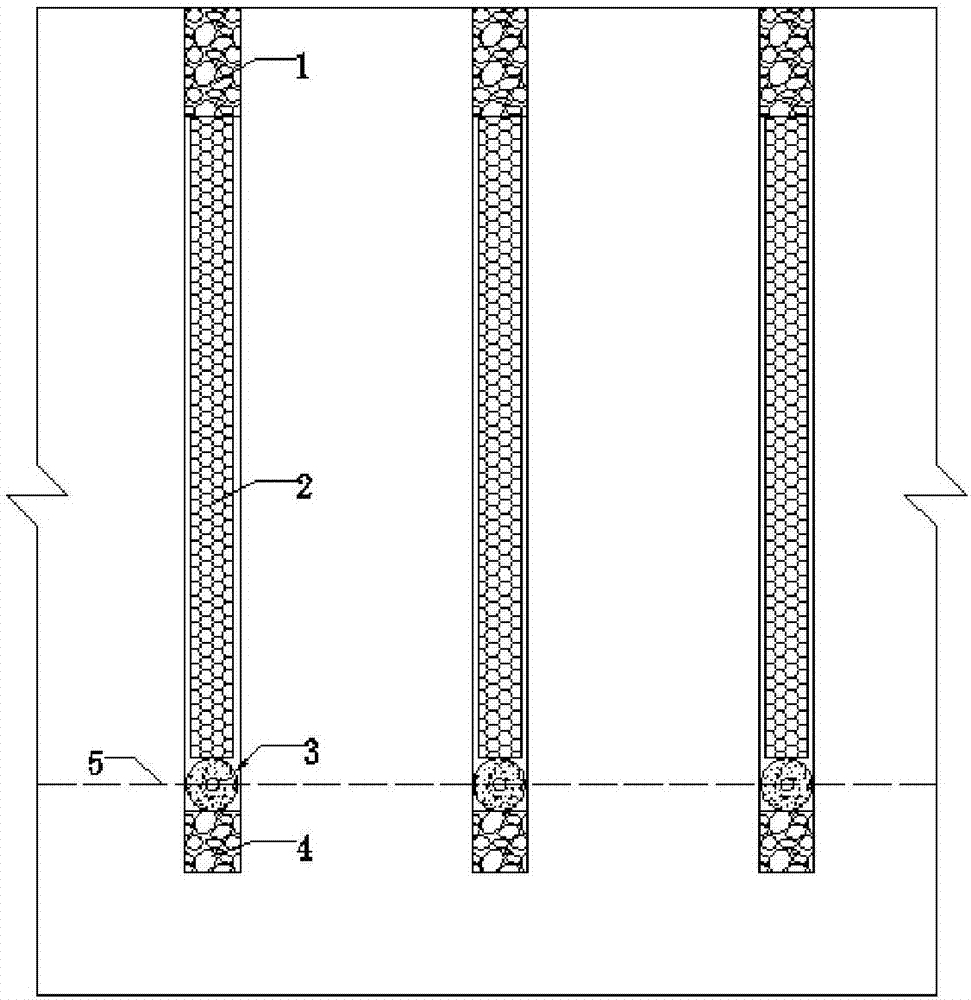

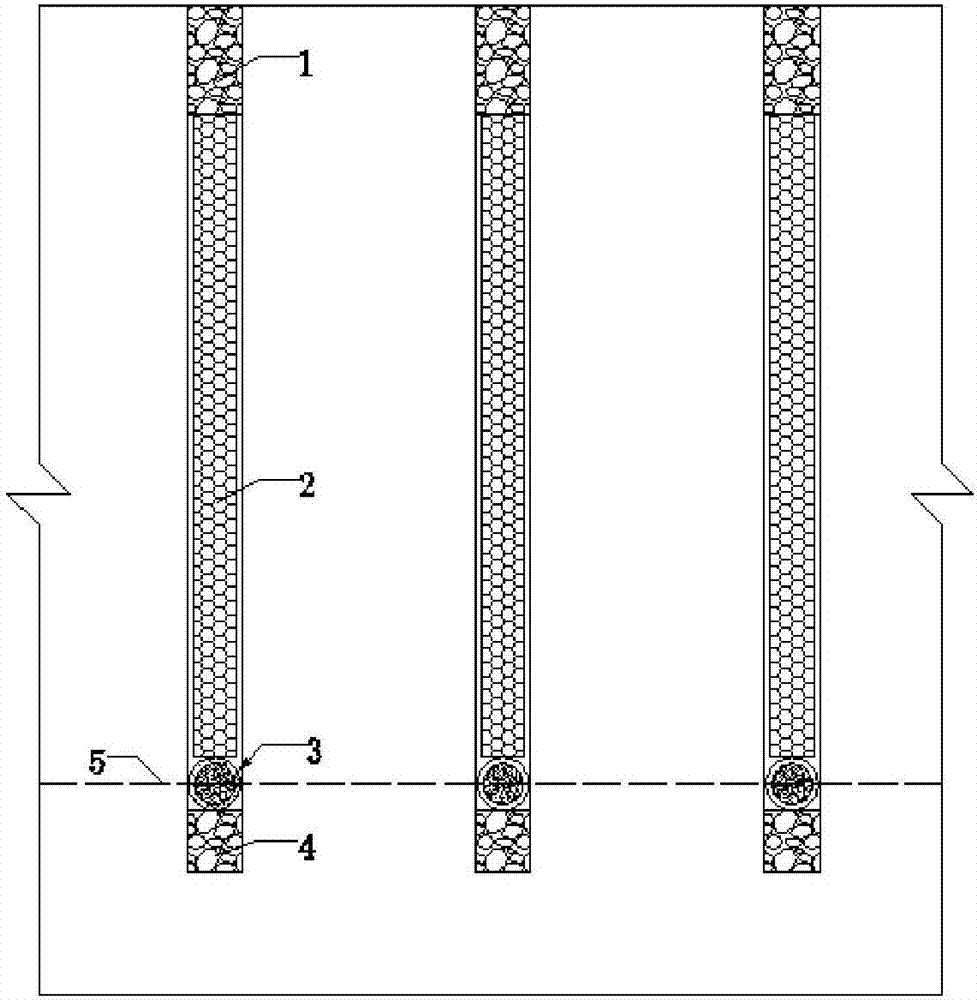

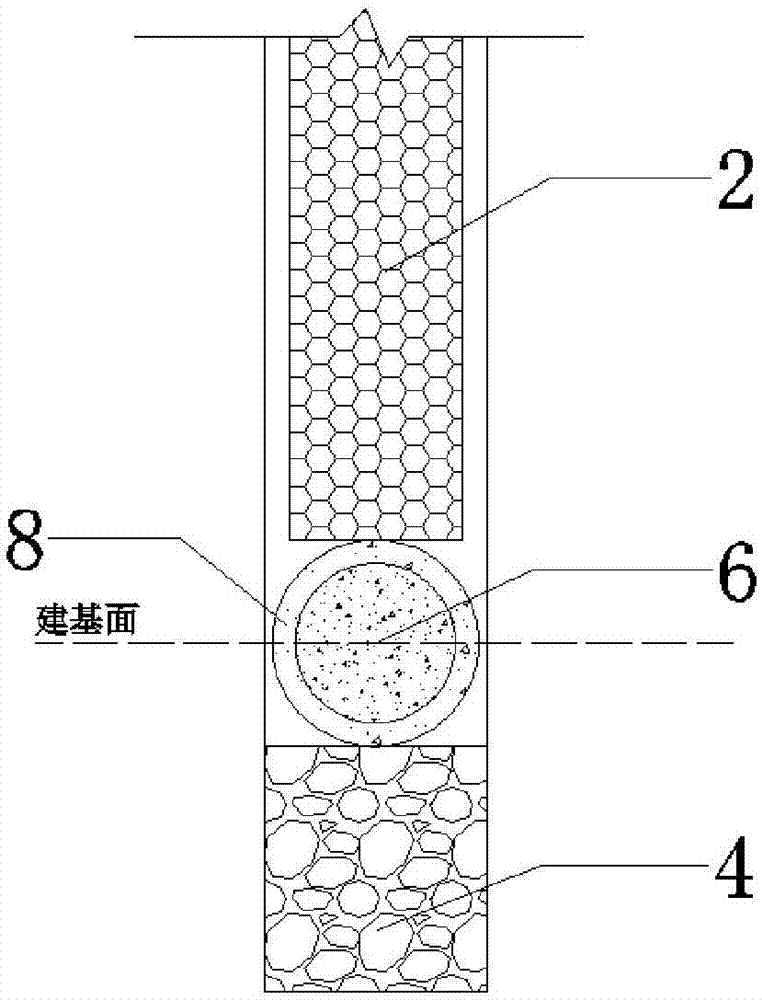

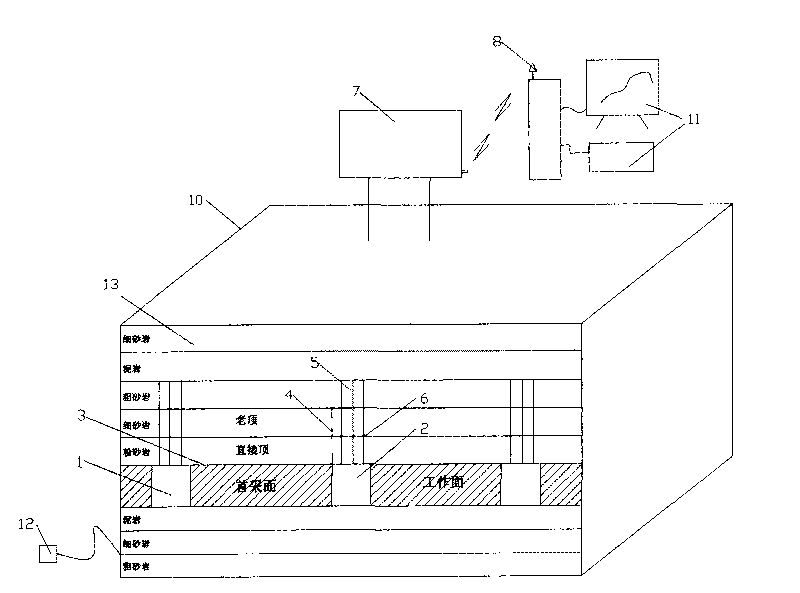

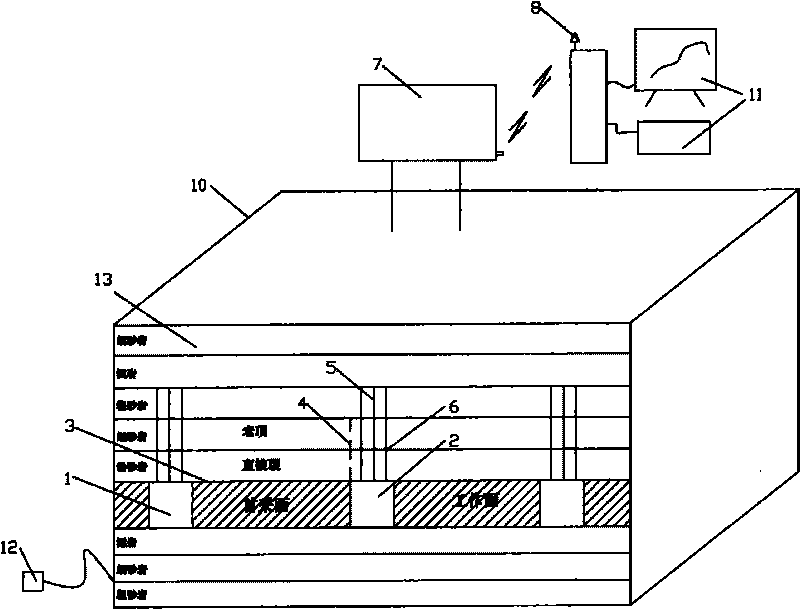

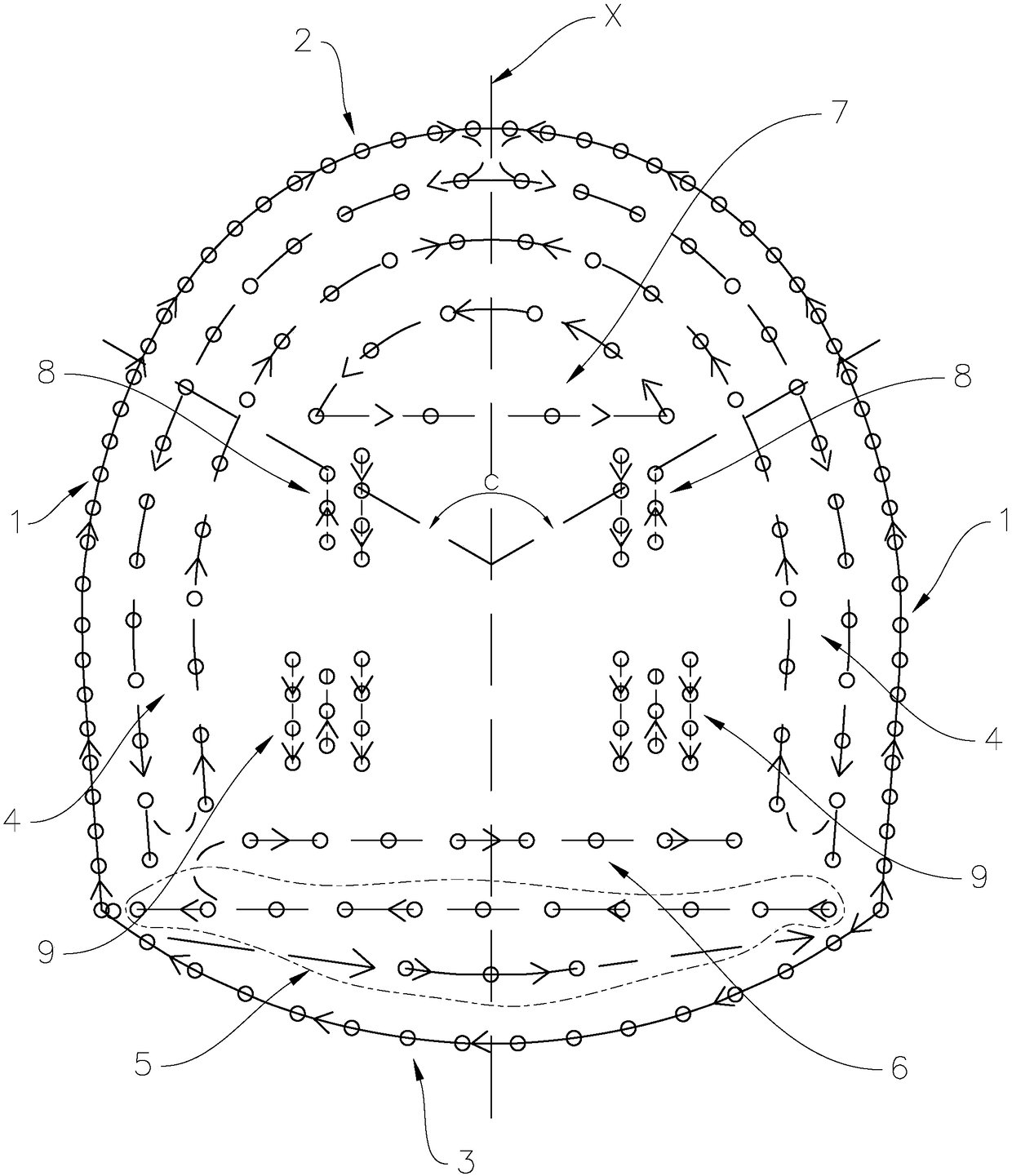

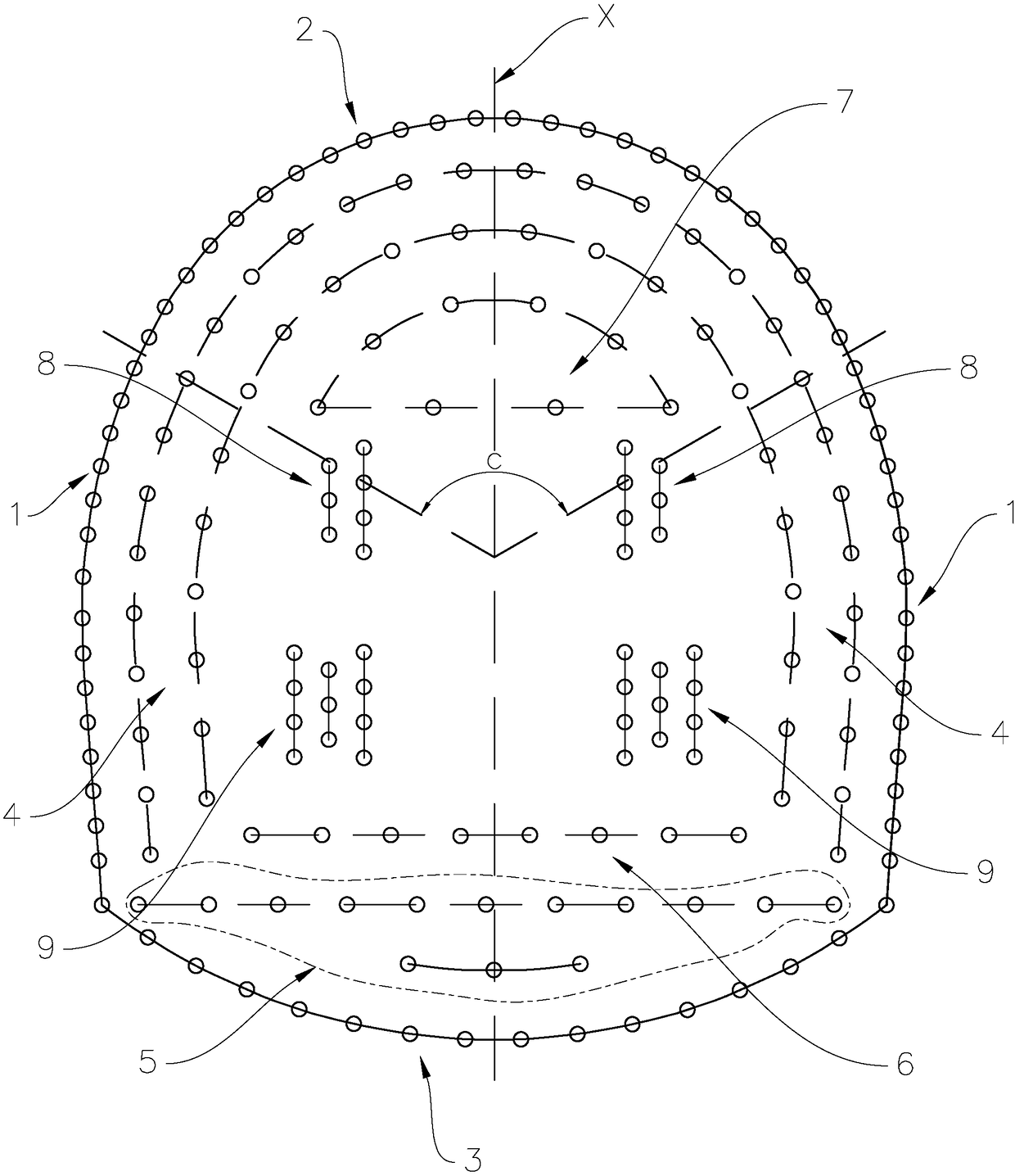

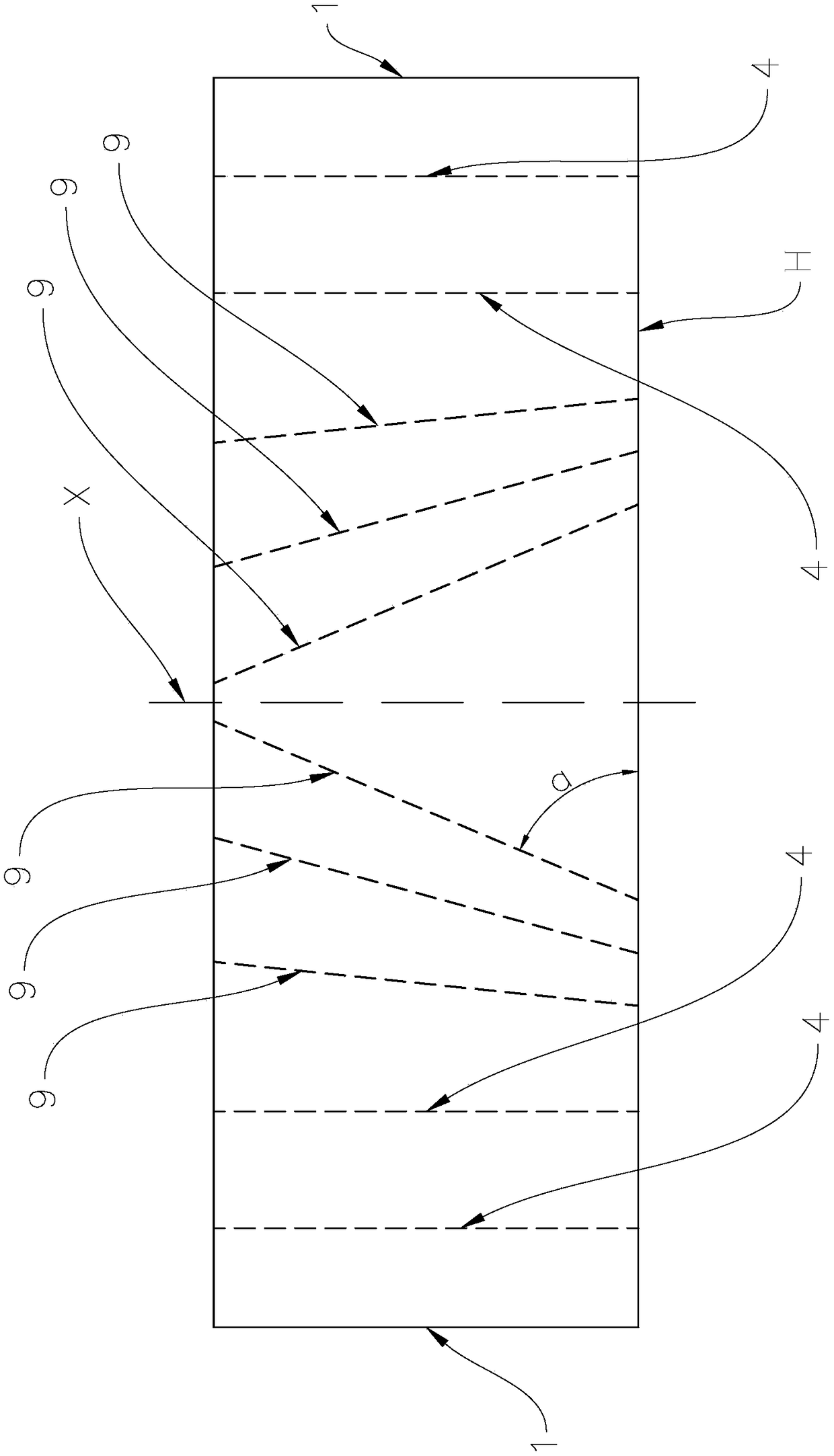

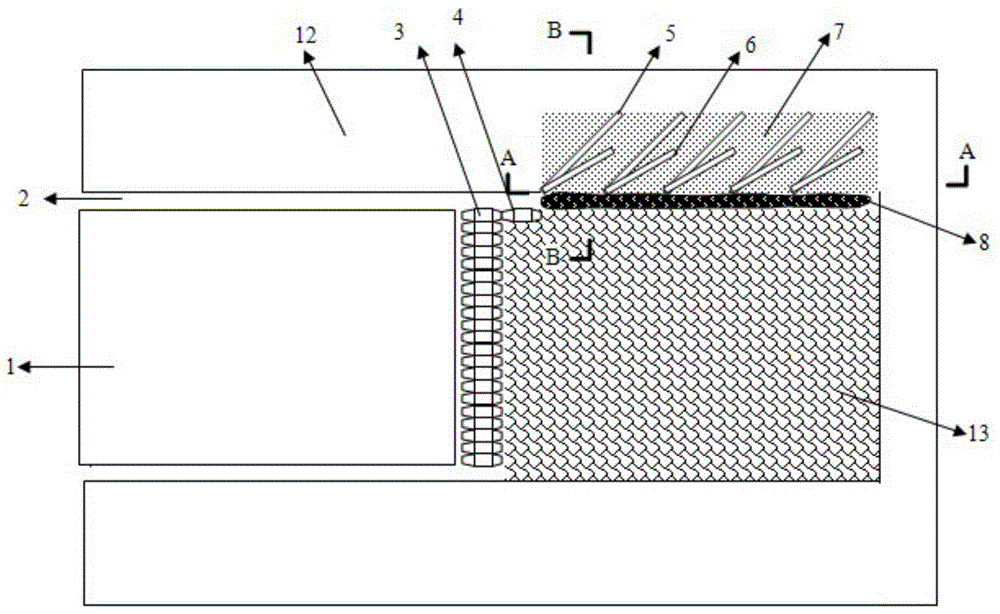

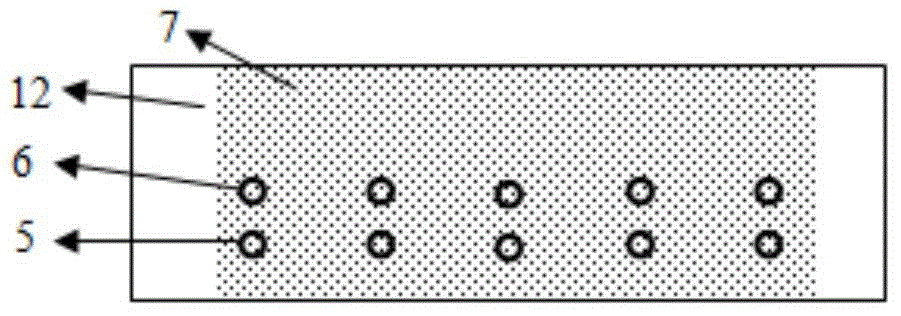

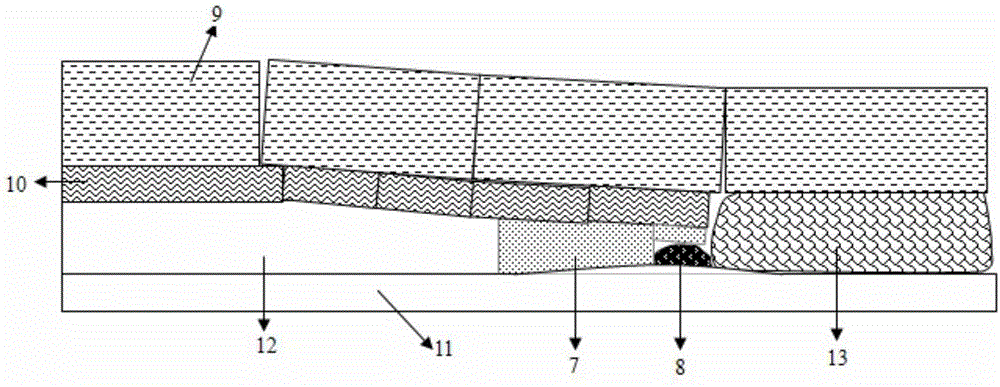

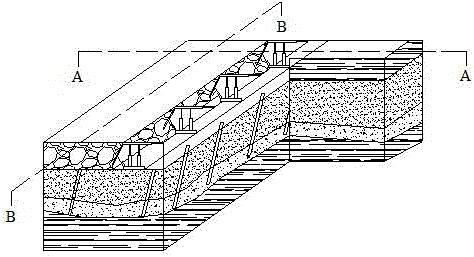

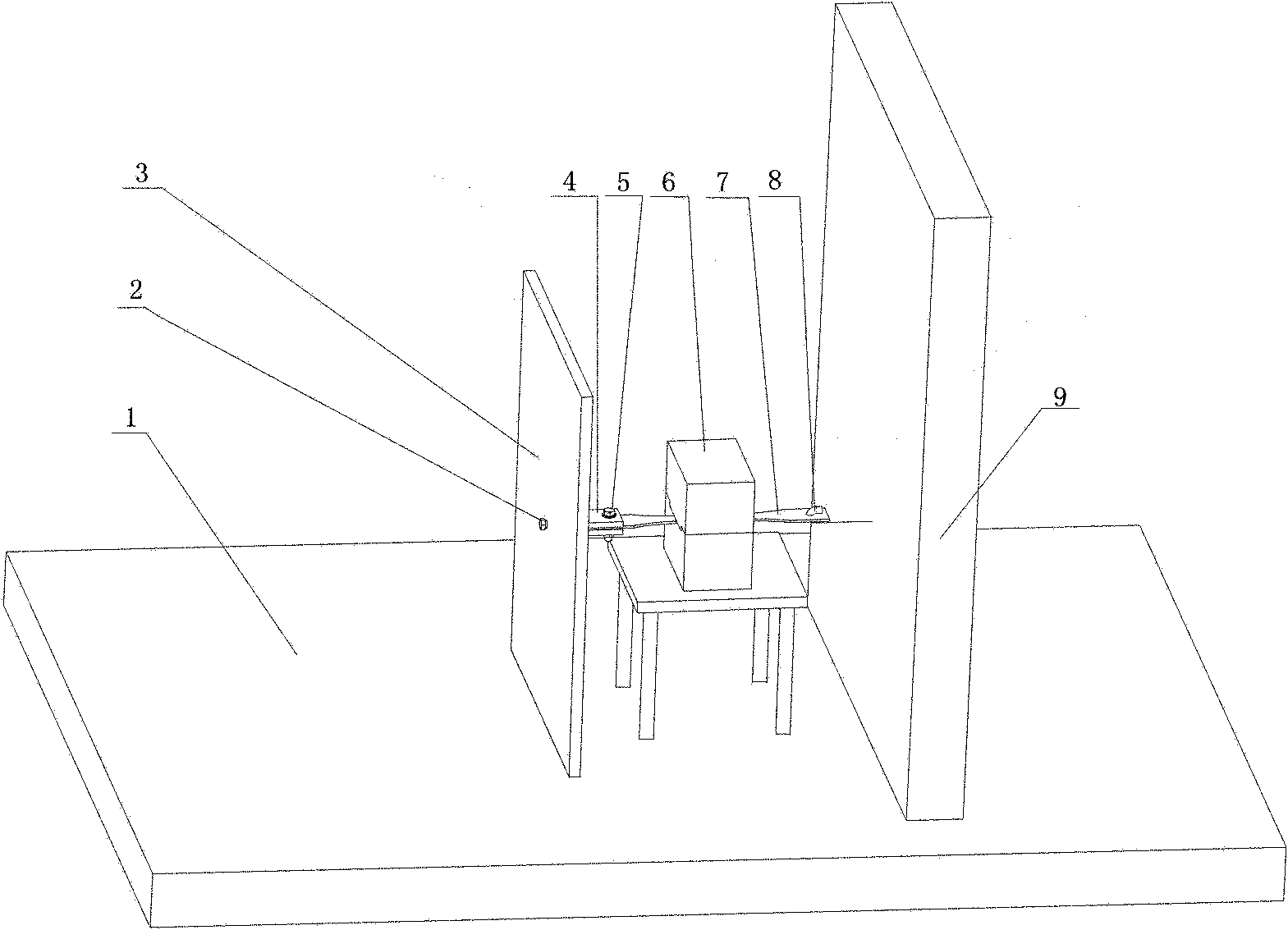

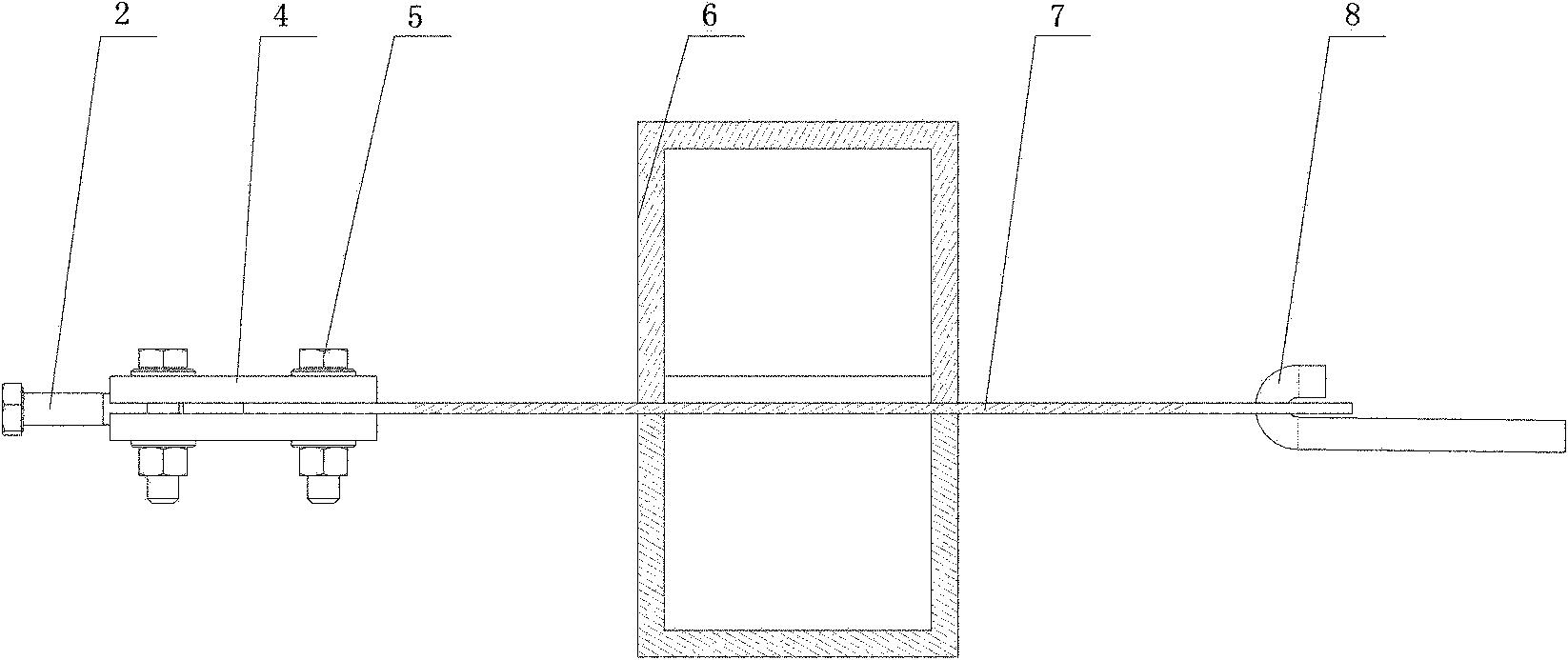

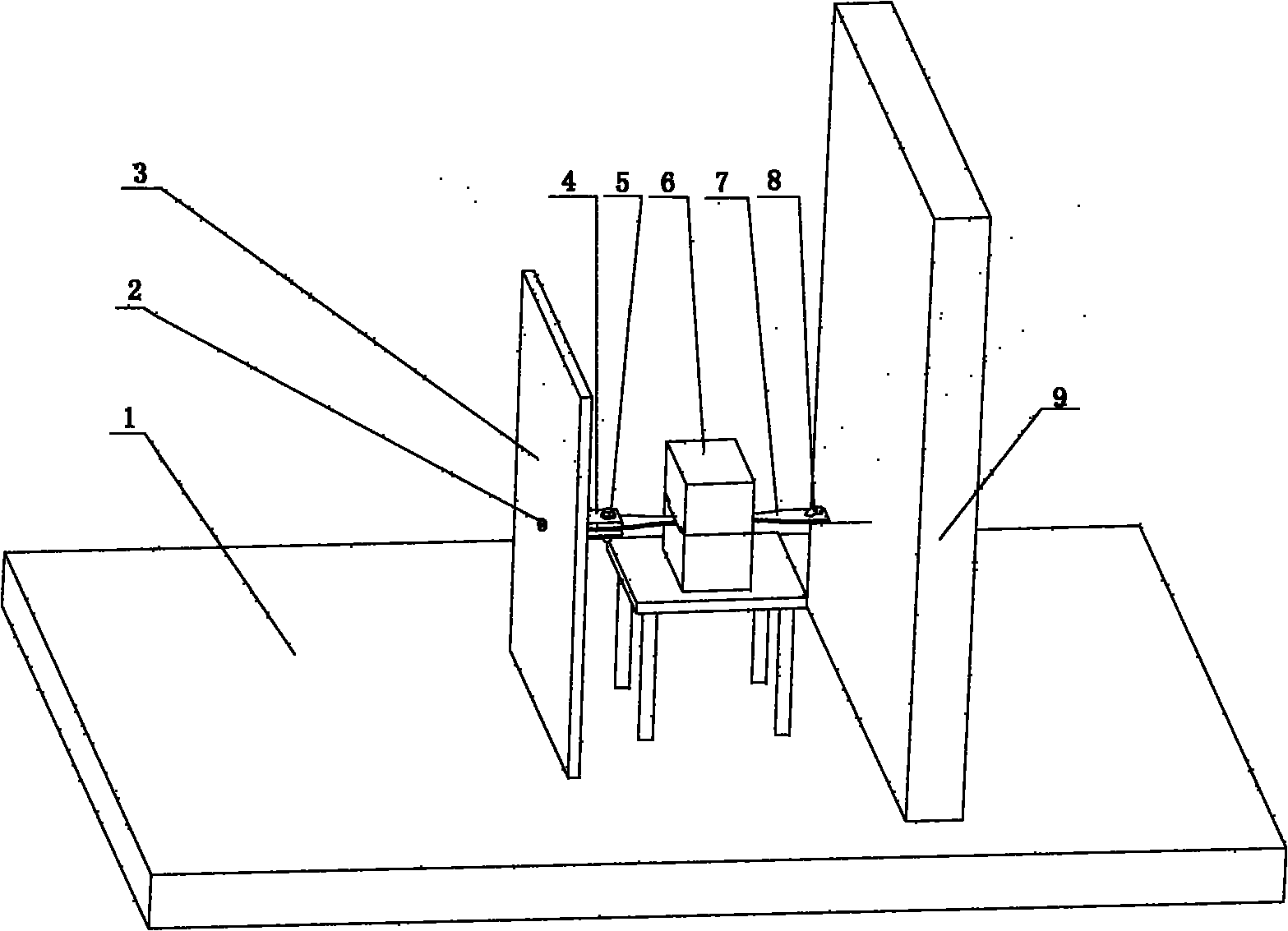

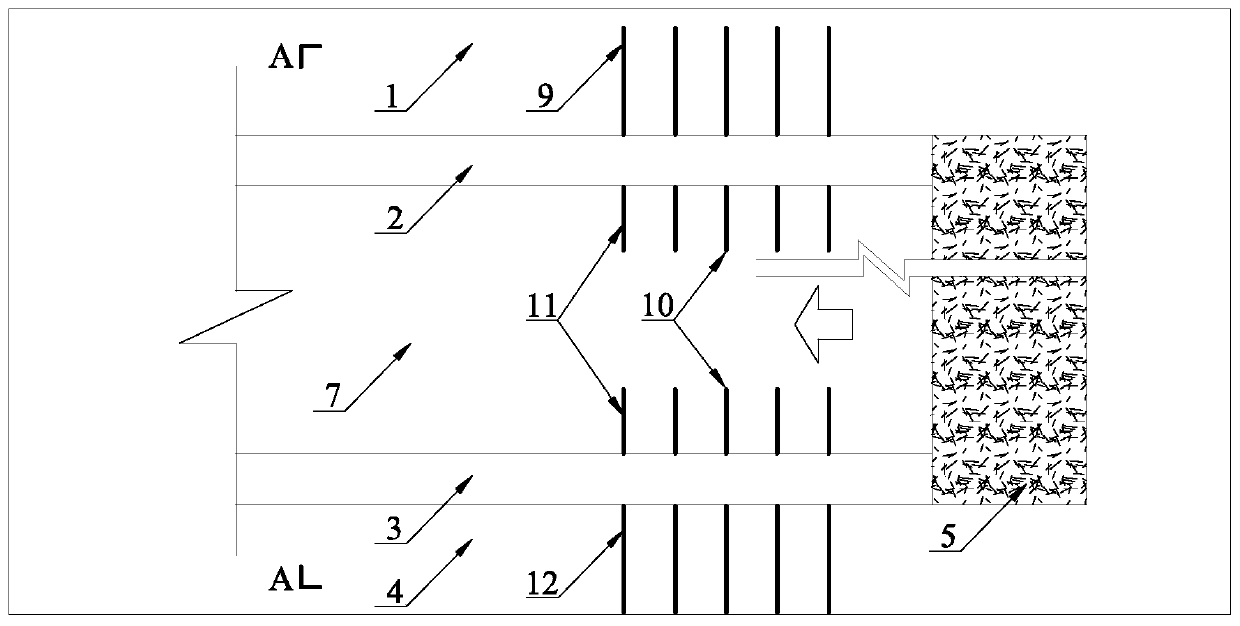

Deep stope automatic lane forming physical simulation test method and device

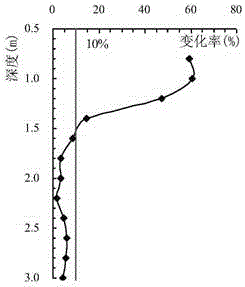

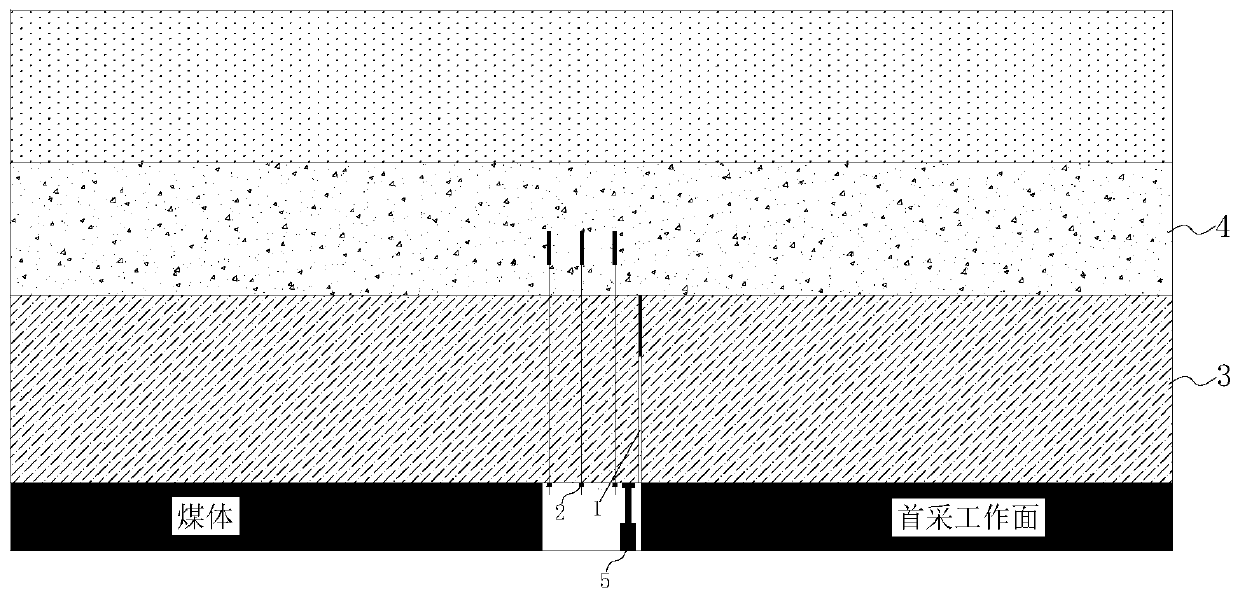

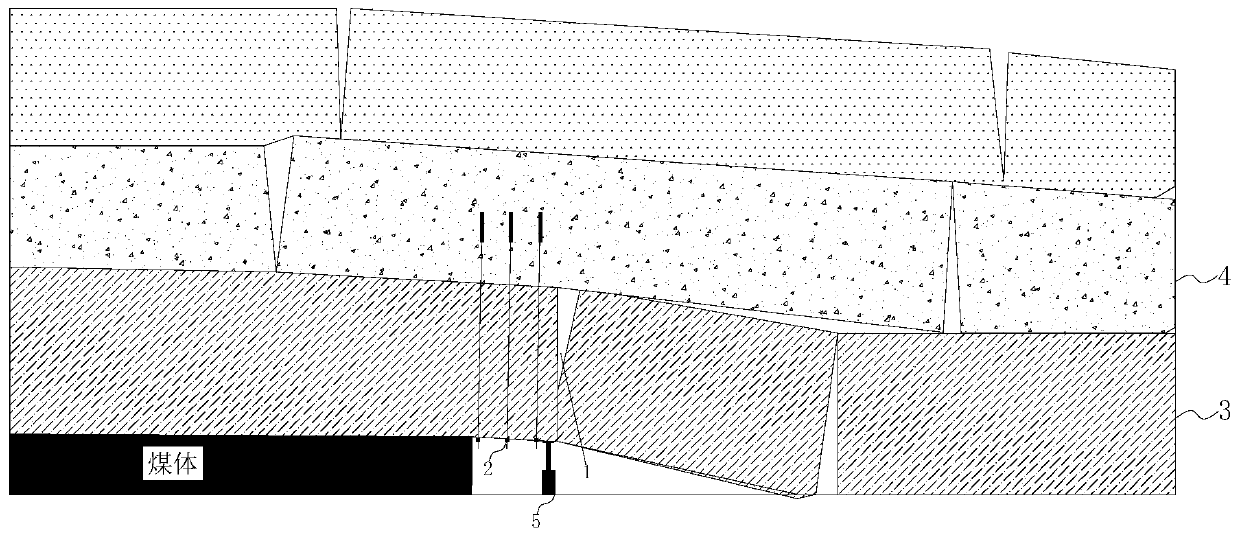

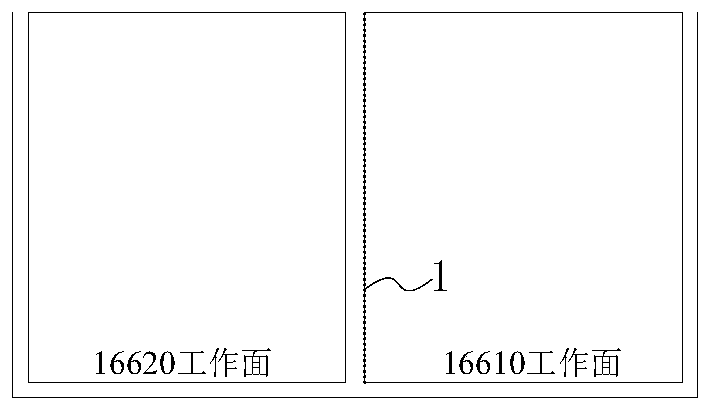

ActiveCN101737056AReduce stress concentrationReduce wasteForce measurementTunnelsStress concentrationLongwall mining

The invention discloses a novel lane forming method for mining a long wall, namely a deep stope automatic lane forming physical simulation test method which changes the traditional mode of mining the long wall through a single face and double lanes. An oriented pre-cracking top-cutting lane-reserving technique is adopted; and a return mining lane of a gate road under a primary work face is reserved and serves as one of return mining lanes of the next new work face so as to mine through a single face and a single lane. The method has the advantages of removing concentrated stress above the coal on adjacent working faces, reducing the mining ratio, improving the production efficiency and reducing the resource waste, and belongs to a novel, safe, efficient, economic and scientific mining technique. At the same time, the invention designs a deep stope automatic lane forming physical simulation test device based on the principle so as to prove the reliability of the method and ensure the authenticity and the availability of the test process.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

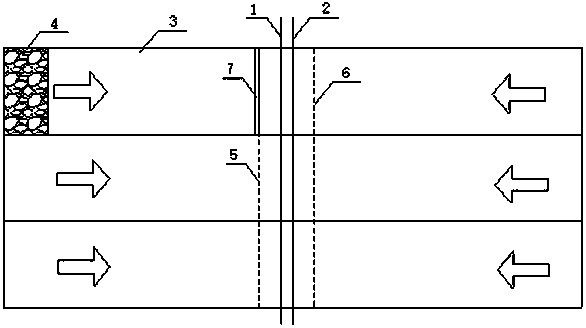

Non-coal-pillar auto-roadway-forming mining method suitable for thick-seam fully mechanized top coal caving

ActiveCN110206542AConducive to collapseIncrease stressDisloding machinesUnderground miningPre crackingCoal pillar

The invention relates to the technical field of coal mine mining, in particular to a non-coal-pillar auto-roadway-forming mining method suitable for thick-seam fully mechanized top coal caving. The method includes the following steps that reinforcing and supporting are carried out on a roof and two walls of a roadway; roof cutting explosion is carried out to form a pre-cracking seam; a temporary supporting device in the roadway and a gangue blocking device are erected along a retained entry; coal caving is not performed within a preset distance to the working face end close to the entry retaining side; after the roadway is stabilized, the temporary supporting device in the roadway is removed, a goaf is closed, and the entry retaining is completed. The roof cutting explosion better facilitates collapsing of the rock stratum in the goaf, the stoping space can be well filled after the rock stratum in the seam is collapsed, a short arm beam structure is formed in the lateral direction of the entry-retaining roof, a long suspended roof formed in the goaf is avoided, and the surrounding rock stress of the gob-side entry is improved; coal caving is not performed within a certain range ofthe working face end of the entry retaining side, the filling effect of the empty area of the entry retaining side is further guaranteed, rotary sinking of basic top block bodies is effectively limited, and the influence on the entry retaining stability is greatly reduced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

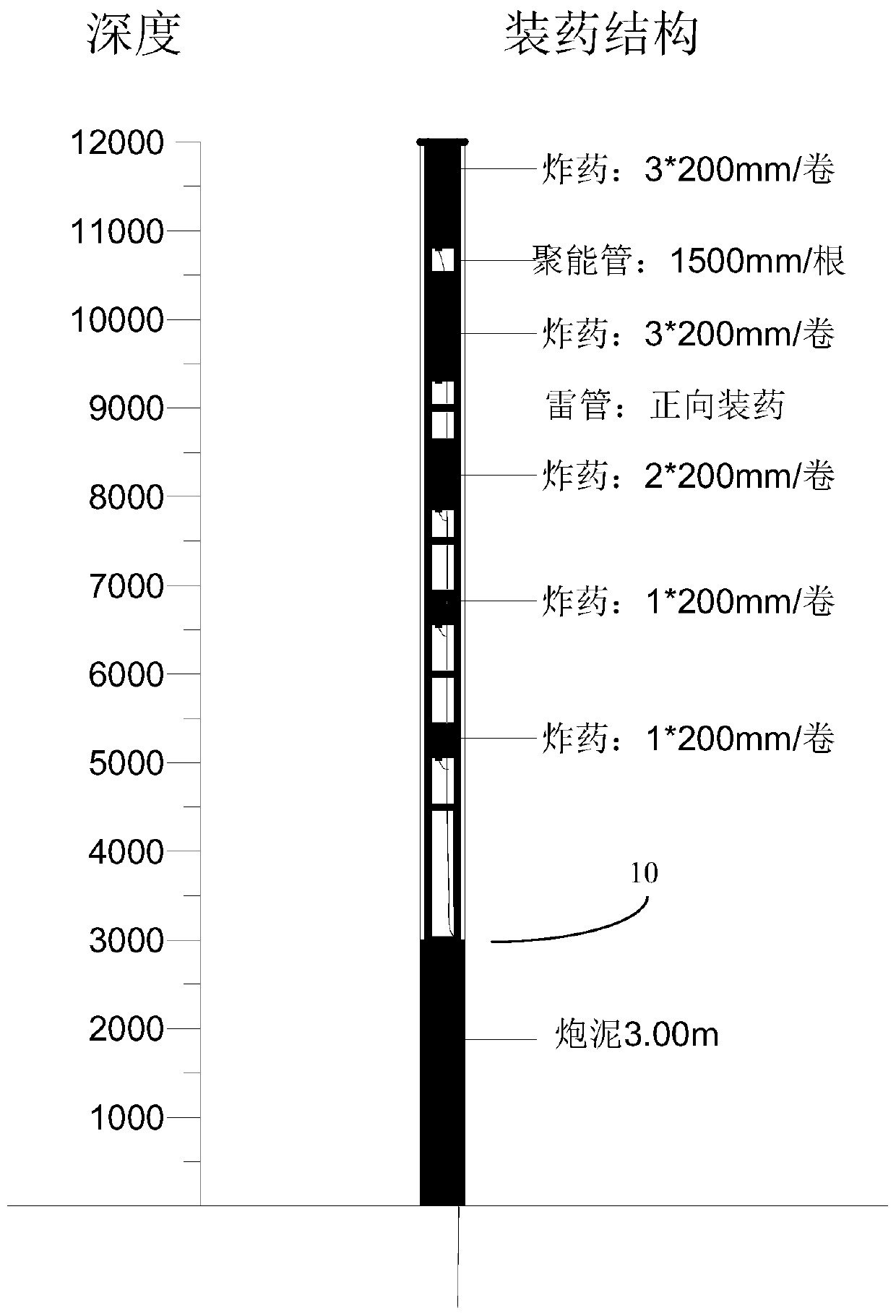

Tunnel hole distributing explosion method

The invention provides a tunnel hole distributing explosion method. The method comprises the steps that a shot hole is formed, charging is performed at a hole site, and shot hole explosion is performed; during hole site charging, charging is performed on side wall peripheral holes and tunnel bottom peripheral holes according to pre-cracking explosion, charging is performed on tunnel arch peripheral holes according to polished explosion, and the side wall peripheral holes, the tunnel bottom peripheral holes and the tunnel arch peripheral holes are each of a non-coupled charging structure; during shot hole explosion, the side wall peripheral holes, the tunnel bottom peripheral holes, the lower middle breaking-in holes, the tunnel bottom auxiliary holes, the tunnel bottom lifting cannons, theupper middle breaking-in holes and the tunnel arch peripheral holes are subjected to explosion according to the sequence. According to the tunnel hole distributing explosion method, in the explosionprocess, the partition explosion sequence is controlled so as to effectively control the back-break range value obtained after tunnel explosion, meanwhile, it is ensured that the whole wheel contour is smooth and flat after tunnel peripheral hole explosion to the maximum extent, disturbance to peripheral breaking surrounding rock during explosion is greatly lowered, and the whole explosion effectis safe and stable.

Owner:NO 5 ENG OF CHINA RAILWAY 19 BUREAU GRP +1

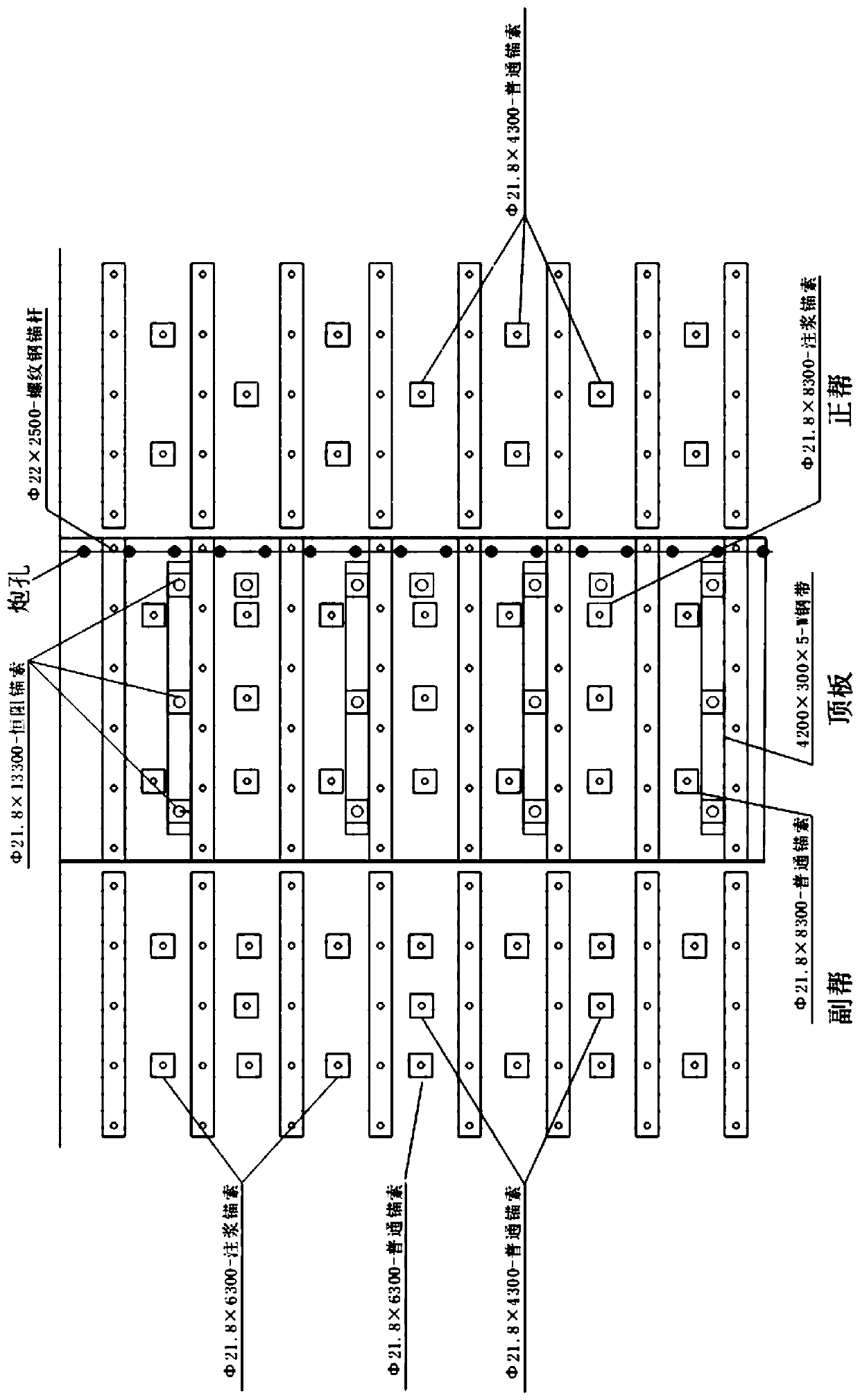

Roof-cutting and pressure relief roadway-protecting method for end-mining equipment remove gateway of coal face

ActiveCN108661643AReduce mining impactEnsure safety and stabilityUnderground miningSurface miningEngineeringPre cracking

The invention discloses a roof-cutting and pressure relief roadway-protecting method for an end-mining equipment remove gateway of a coal face, and belongs to the technical field of mining engineeringmine pressure control and roadway maintenance. The problem that the mining rate of a mining area is low due to the large size of a protection coal pillar between an existing working face stop line and a mining area main roadway is solved. According to the roof-cutting and pressure relief roadway-protecting method for the end-mining equipment remove gateway of the coal face, the working face support equipment remove gateway is excavated in advance along the stop line position and a propagation path of the working face mining advanced supporting pressure is cut off through deep hole pre-cracking of a coal seam roof. The mining area main roadway is protected from the mining action of the mining face on both sides and the width of the protection coal pillar between the working face stop lineand the mining area main roadway is reduced, so that the mining rate of the mining area is improved. The mining rate of the mining area of non-renewable coal resources is improved under the premise ofensuring the safety and stability of the mining area main roadway.

Owner:TAIYUAN UNIV OF TECH

Engineered self healing cementitious composites

ActiveUS7572501B2Reduce capacityReduce stiffnessSolid waste managementSynthetic resin layered productsSelf-healingCement composites

Owner:RGT UNIV OF MICHIGAN

Method for preventing hard top plate type rock burst on basis of carbon dioxide blasting

ActiveCN105735993AAchieve stabilizationTo achieve the effect of pre-crackingDisloding machinesEngineeringPre cracking

The invention belongs to the technical field of mine safety and particularly relates to a method for preventing hard top plate type rock burst on the basis of carbon dioxide blasting.Firstly, a plurality of sets of drilled holes are formed in the portions, close to the top corner of a work face, of a transport roadway and an air return roadway which are located on the two sides of the work face in the direction of a top plate rock stratum on the inner side of the work face, and carbon dioxide fracturing devices are installed in the drilled holes and used for sequential grouping pre-cracking blasting.Meanwhile, a plurality of parallel drilled holes are formed in the top of the air return roadway of the work face close to a replaced work face in the direction of the work face, the drilled holes point to the inside of the top plate rock stratum, certain inclined angles are formed between the drilled holes and the air return roadway, pre-cracking blasting is conducted, and roof-cutting blasting of top plate rock stratums on the front side and the side face of the work face.The method can effectively control rock burst appearance under the hosting conditions of the hard top plate rock stratum, plays an important role in prevention of rock burst caused by the hard top plate, and is simple, good in safety, easy to operate, convenient to use and wide in applicability.

Owner:LIAONING TECHNICAL UNIVERSITY

Method for preventing gob-side entry rock burst through side-drawing filling

InactiveCN103557000ADoes not affect recoveryReduce retentionUnderground miningSurface miningTechnological systemPre cracking

The invention discloses a method for preventing gob-side entry rock burst through side-drawing filling. The method comprises the following steps: additionally arranging a bracket for supporting behind a stope face bracket; constructing, exploding and drilling holes in entry sides behind the support bracket at certain intervals, wherein shallow holes are pre-cracking holes for loosening coal, and deep holes are throwing holes for throwing loosened coal into the entry; filling a part of the entry to form a pressure relief protection zone, and forming a wedged clamping anti-burst structure through top plates and bottom plates; tunneling in a previous mining surface filling entry following the mining surface gob-side entry, supporting by using a shed, carrying out guniting on the surface of the entry behind a tunneling head, and reinforcing and preventing and extinguishing fire in partial areas by taking backfill grouting measures. A novel anti-burst technical system for performing explosion, filling, in-situ tunneling and supporting behind the mining surface is established.

Owner:UNIV OF SCI & TECH BEIJING

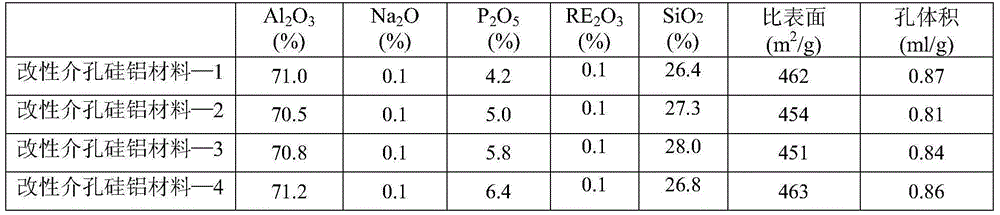

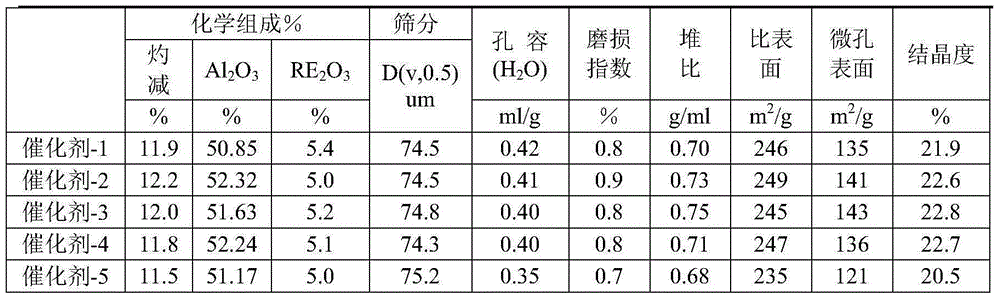

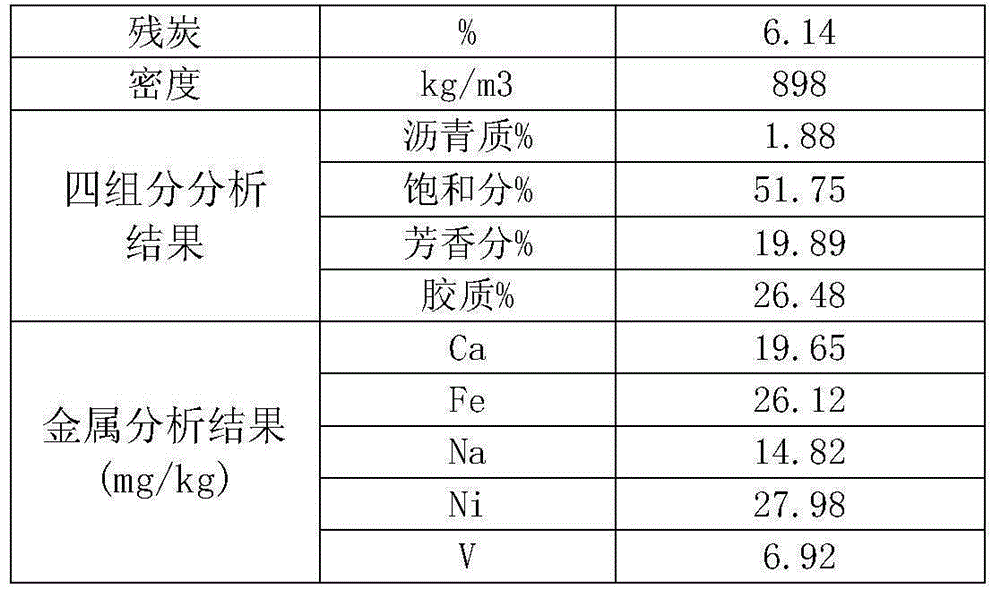

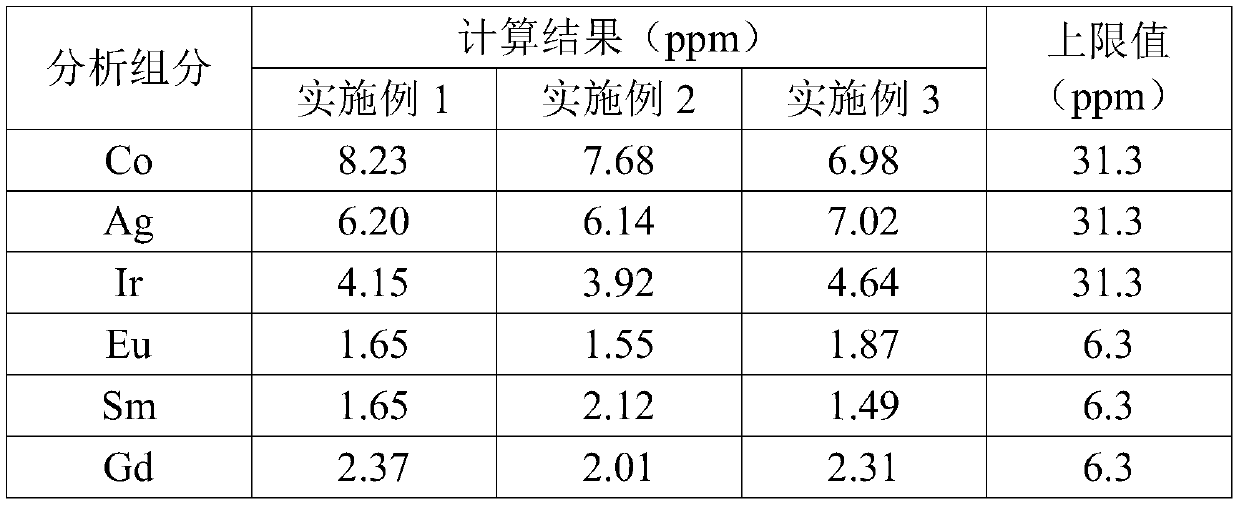

Preparation method of modified mesoporous silicon-aluminum material

ActiveCN105126928AImprove cracking capacityHigh hydrothermal stabilityCatalyst carriersHigh concentrationRare earth

The invention discloses a preparation method of a modified mesoporous silicon-aluminum material. The modified mesoporous silicon-aluminum material has a pseudo-boehmite physical structure. The anhydrous chemical formula of the material by the weight of oxides is (0-8)P2O5(0-0.1)Na2O*(20-30)SiO2*(70-80)Al2O3(0-1.0)RE2O3. The specific area is 200 to 500 m2 / g, and the pore volume is 0.5 to 1.5 mL / g. The preparation method comprises the following steps: step one, adding a low-concentration aluminum source into a silicon source solution, controlling the pH in a range of 10.3 to 10.8, and carrying out stationary aging for 0.5 to 3 hours; step two, adding phosphor-aluminum gel and a high-concentration aluminum source into the previous solution according to a certain ratio, and controlling the pH in a range of 3.4 to 3.8; step three, adding a rare earth solution according to a certain ratio; step four, adjusting the pH of the previous slurry to 8.0-9.0 by an alkaline solution; step five, filtering the slurry, and washing the solids by deionized water and ammonium salt. The provided modified mesoporous silicon-aluminum material can be used as the carrier of FCC catalyst, has a proper pore volume and acidic property, and is capable of performing pre-cracking on macromolecular raw oil. RE2O3 exists in a deposited state of oxides and can prevent the metal pollution, so the provided material can improve the heavy oil cracking performance of FCC catalyst, moreover, the hydrothermal stability of FCC catalyst is good, and the coke selectivity is excellent.

Owner:QINGDAO HUICHENG PETROCHEM TECH

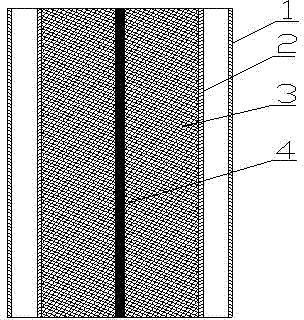

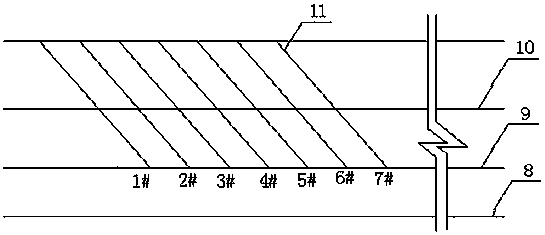

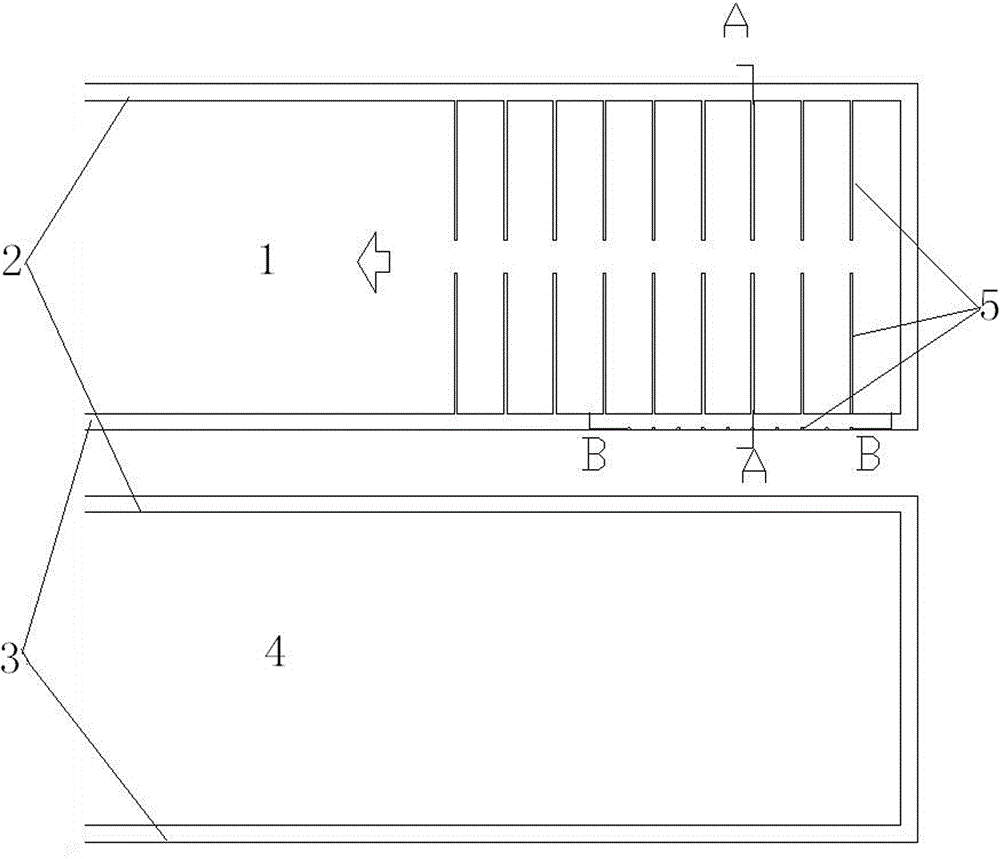

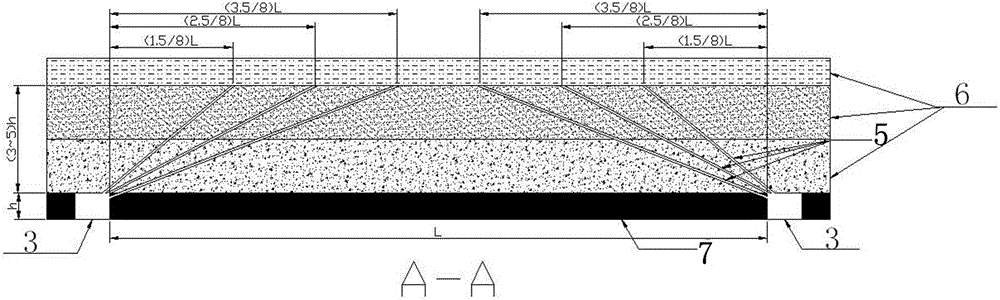

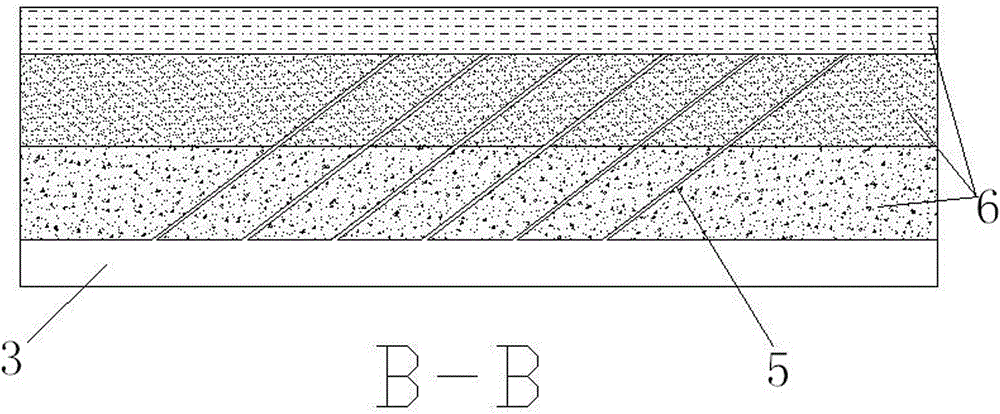

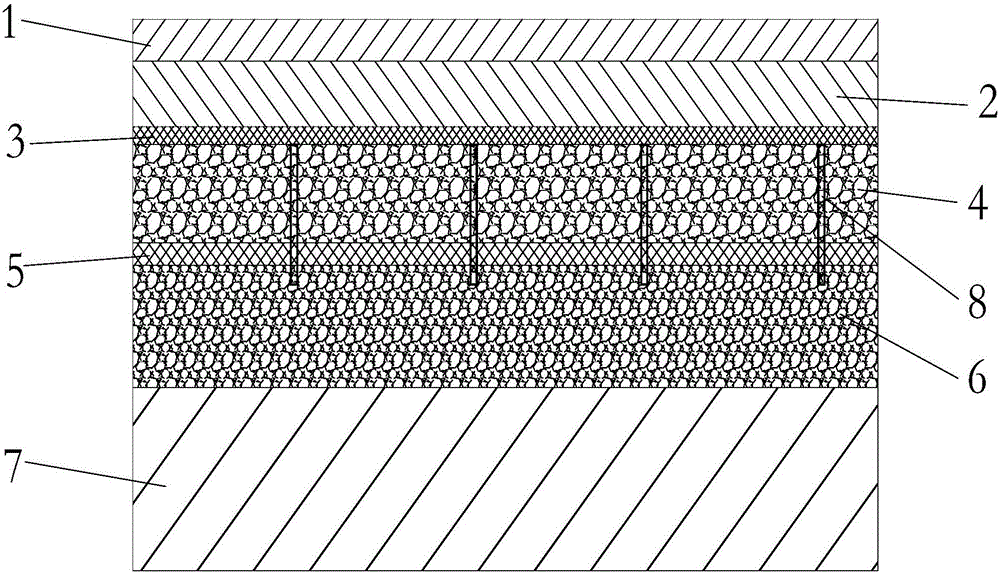

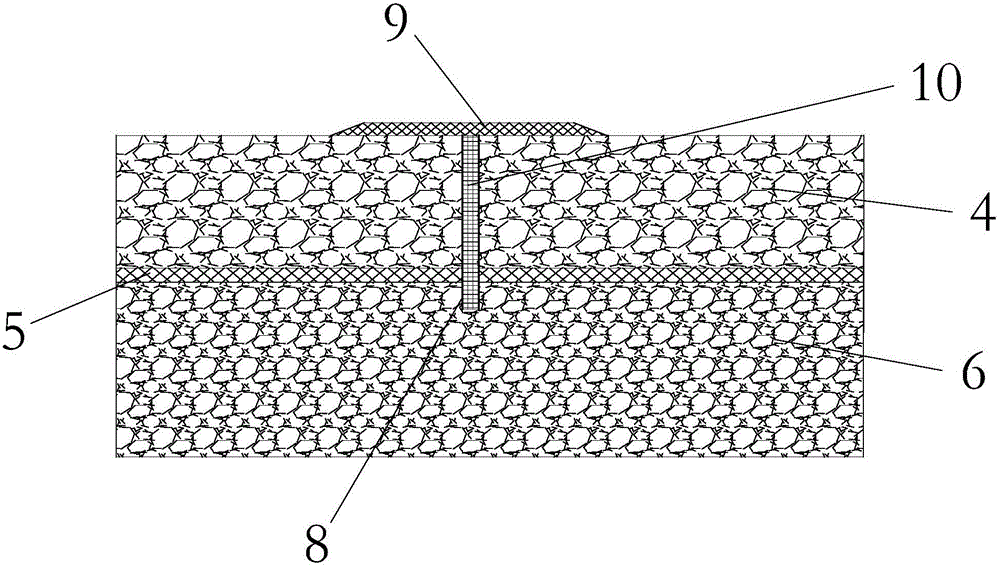

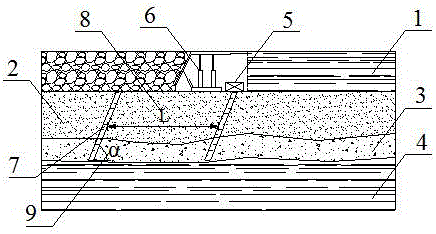

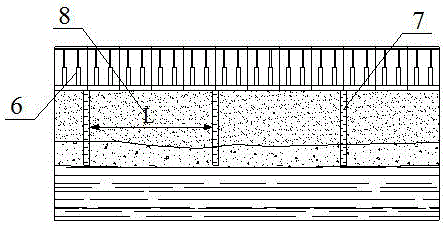

Semi-rigid base layer anti-cracking pavement structure and construction method suitable for high-temperature-difference area

ActiveCN106012743AFast constructionAverage distributionIn situ pavingsStructure of the EarthRoad surface

The invention discloses a semi-rigid base layer anti-cracking pavement structure and construction method suitable for a high-temperature-difference area. The pavement structure comprises face layers, base layers and pre-cracking cracks. The base layers and the face layer are arranged from bottom to top in sequence, the base layers comprise a lower base layer and an upper base layer, the face layers comprise a lower face layer and an upper face layer, and the lower face layer is arranged above the upper base layer; the base layers are internally provided with a plurality of the pre-cracking cracks, each pre-cracking crack comprises a pre-cut crack, a crack pouring material and a crack attaching material, the crack opening at the upper end of each pre-cut crack of each pre-cracking crack is flush with the upper end face of the upper base layer, the lower end of each pre-cut crack of each pre-cracking crack penetrates through the upper base layer and is arranged in the lower base layer, the crack pouring materials are poured into the pre-cut cracks of the pre-cracking cracks, and the upper end face of the upper base layer is provided with the crack attaching materials tightly attached to the crack openings at the upper end of the pre-cut cracks correspondingly. According to the semi-rigid base layer anti-cracking pavement structure and the construction method suitable for the high-temperature-difference area, cracks generated in the construction and maintenance period and the operation period of the semi-rigid base layers are actively controlled, the expansion rule in the pavement structure is changed, and damage, caused by crack reflection, to pitch pavement can be effectively lowered.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Method for pre-cracking and softening of igneous rock hard roof

ActiveCN106285679AReduce construction difficultyEasy to operateDisloding machinesUnderground miningChemical reactionHigh pressure

The invention discloses a method for pre-cracking and softening of an igneous rock hard roof. While an upper coal seam is exploited, on the premises that the distance between upper and lower coal seams, rock stratum characteristics between the coal seams and the invasion condition of an igneous rock hard rock stratum are mastered, during exploitation of the upper coal seam, by reasonably forming drilling holes in a bottom plate of an upper working face and injecting a high-pressure acid solution, a fracture acidizing unit is used for controlling the pressure of injected acid solution, on one hand, the hard igneous rock stratum are cracked through pressure, and on the other hand, the igneous rock stratum is furthered softened through the chemical reaction function of the acid solution, so that the effect of safely and efficiently cracking and softening the hard igneous rock roof of the lower coal seam is achieved finally. According to the method, acid is injected while the upper coal seam is exploited, the structure of the hard roof of the lower coal seam is broken, and the strength of the hard roof is lowered; and possible hazards of the igneous rock hard roof to normal exploitation of the working face, staff and equipment can be reduced or even avoided during exploitation of the lower coal seam.

Owner:TAIYUAN UNIV OF TECH

Prevention method for pressure bump of approximately-vertical super-thick coal seams

InactiveCN105804750AReduce riskSlow down energy buildupUnderground miningSurface miningHorizontal stressPre cracking

The invention discloses a prevention method for pressure bump of approximately-vertical super-thick coal seams. The prevention method comprises the following steps that S1, before a horizontal coal seam in each stage is exploited, rock pillars, a coal seam roof and a coal seam floor on the corresponding exploitation level are subjected to water injection and softening; S2, the rock pillars, the coal seam roof and the coal seam floor on the corresponding exploitation level are subjected to pre-cracking and bursting; and S3, the horizontal coal seam in the corresponding stage is subjected to water injection, softening, pressure relief and bursting. The rock pillars, the coal seam roof and the coal seam floor are all rock mass. By the adoption of the prevention method for pressure bump of the approximately-vertical super-thick coal seams, regional structure horizontal stress can be prevented from being transferred to the coal rock mass, the energy accumulation degree of the coal rock mass is reduced, the risk of pressure bump of the approximately-vertical super-thick coal seams is effectively lowered, and technical support and safety insurance are provided for safe and efficient production of mines under the similar conditions.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

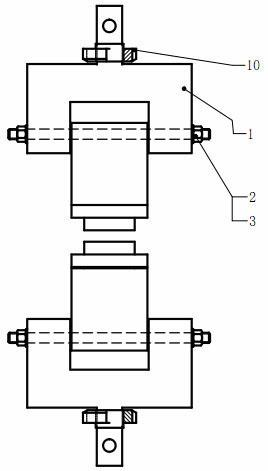

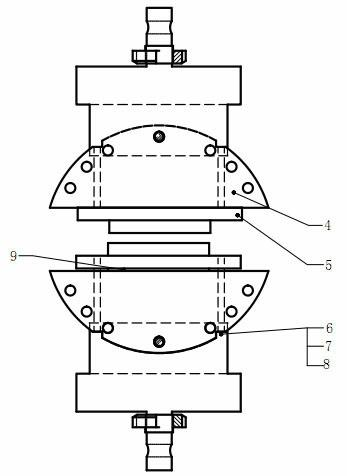

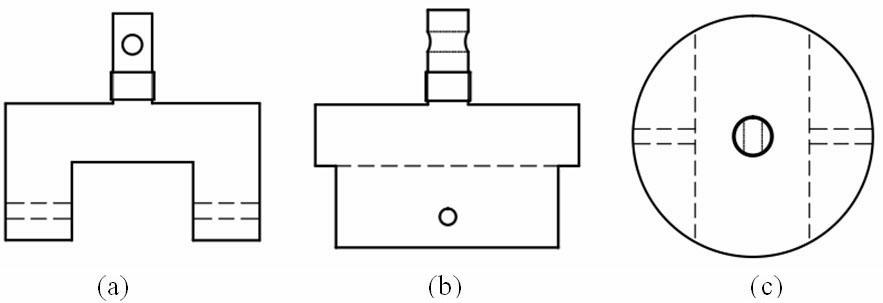

Clamp for mixed fracture test of dual-phase material interface

The invention belongs to the technical field of a material detection, and particularly relates to a clamp for mixed fracture test of a dual-phase material interface. The clamp is divided into an upper part and a lower part that are symmetric to each other; each of the upper part and the lower part consists of a pulling rod, a semiround plate and a sample table; the sample table is connected with the semiround plate by bolts; the semiround plate is connected with the pulling rod by a bolt; a plurality of round holes are symmetrically arranged at the edge of the semiround plate; and the upper pulling rod and the lower pulling rod are fixedly connected with an upper force-applying system and a lower force-applying system of a pulling machine respectively. The clamp can be used together with a universal mechanic tensile testing machine; a sample with a pre-crack is fixed on the clamp; subsequently the clamp can be rotated so as to apply the pull forces of different angles to the sample; the critical fracture strength of the interface crack can be calculated according to a force-displacement curve. The clamp can be used for conveniently determining the situations of the I-type mixed fracture mode and the II-type mixed fracture mode under different tensile loading angles, and is also applicable to determinine the I-type fracture situation of the dual-phase material interface.

Owner:FUDAN UNIV

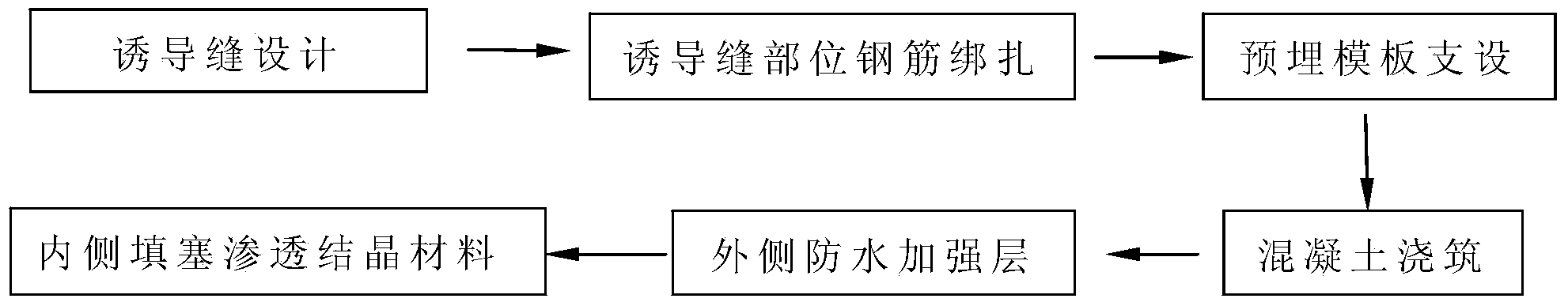

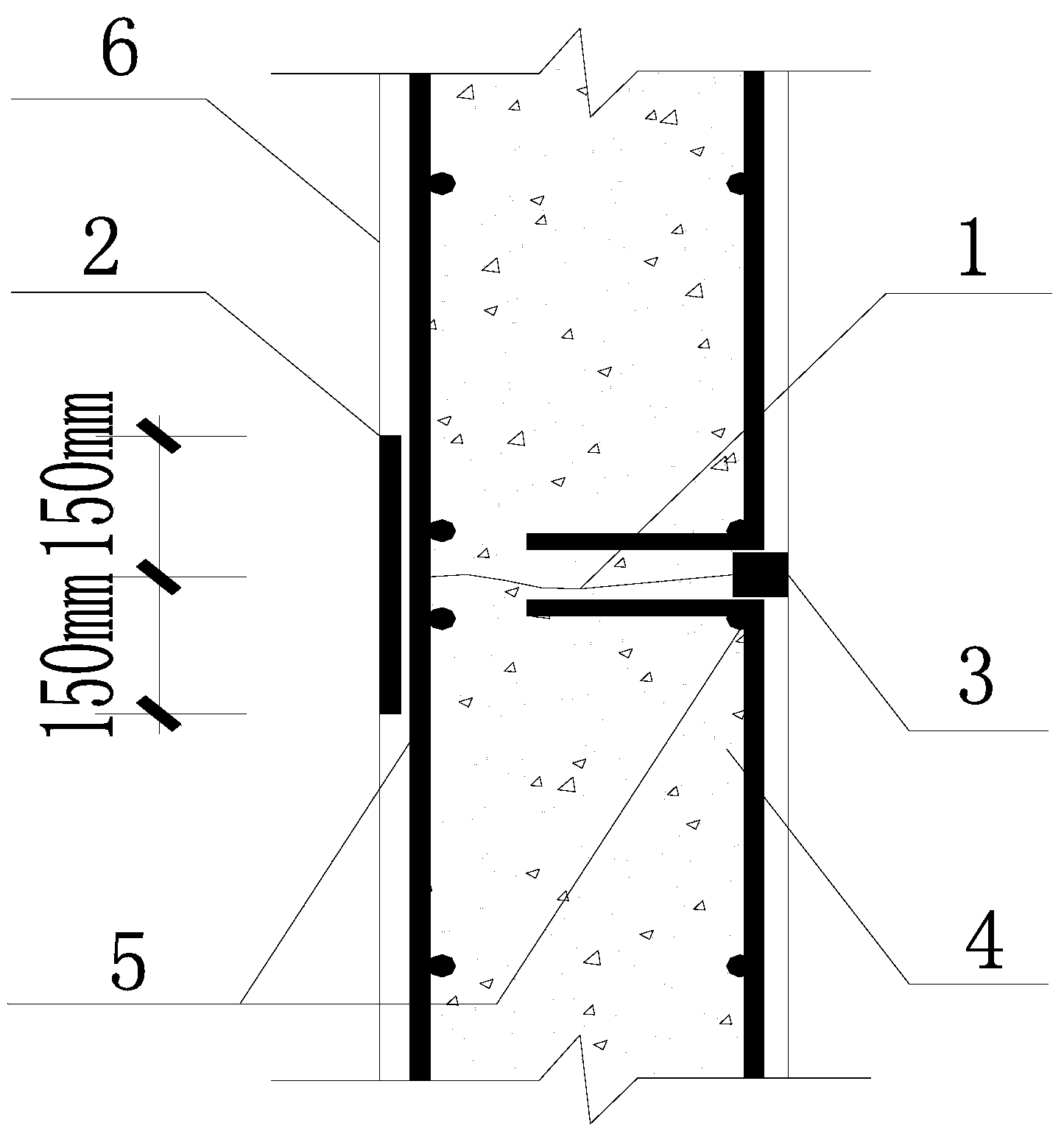

Underground structure crack control construction method by adding inducing joints

ActiveCN104032771ASimple and fast operationReduce and control developmentArtificial islandsProtective foundationBasementStress concentration

The invention discloses an underground structure crack control construction method by adding inducing joints. The method includes inducing joint design, inducing joint part steel bar binding, embedded formwork setting up, concrete pouring, outer waterproof reinforcing layer construction and inner permeable crystalline waterproof material filling. The inducing joints are arranged on a concrete structure to form pre-cracking parts, stress concentration is reduced in a releasing manner, stress is relieved, further wall crack expansion is reduced and controlled, and range of cracking and deformation is limited. Water proofing is enhanced on pre-cracking parts, waterproof effect is guaranteed, and project quality is improved. The method can be widely applied to exterior wall construction of basement concrete structures in the fields of industrial and civil buildings.

Owner:中建五局第三建设有限公司

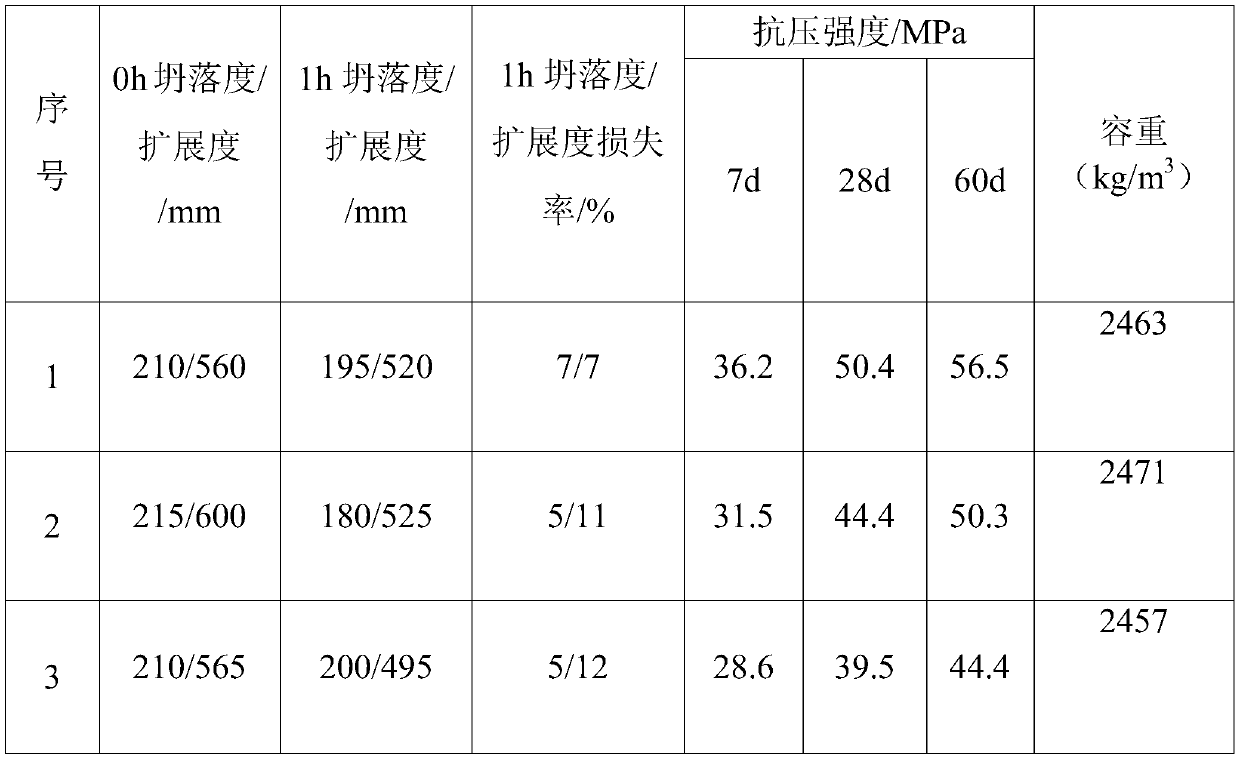

Anti-radiation C40 concrete used for prefabricated part and preparation method of anti-radiation C40 concrete

The invention discloses anti-radiation C40 concrete used for a prefabricated part. The concrete is prepared by mixing the following ingredients in parts by weight: 200-300 parts of cement, 120-210 parts of coal ash, 700-750 parts of river sand, 1,100-1,200 parts of gravels, 7-10 parts of an additive, 20-40 parts of an expanding agent and 140-160 parts of water. Compared with the prior art, the anti-radiation C40 concrete has the following advantages: 1, basalt is taken as an aggregate, and the performance density of the concrete is ensured to be 2,350kg / m<3> through optimization of a match ratio, so that the anti-radiation C40 concrete has the performance of shielding proton rays and neutron rays, and the strength of the concrete reaches the C40 grade; 2, the quantity of induced radioactivity of a concrete shield wall is controlled by strictly controlling the content of harmful elements in raw materials of the concrete; 3, by mixing a large amount of admixtures, solid wastes are utilized, the cost is lowered, and the hydration heat and pre-cracking of the concrete can be greatly reduced; 4, by adding the high-performance expanding agent, the shrinkage of the concrete is compensated, the cracking caused by shrinkage is prevented, and the radiation shield effect is intensified.

Owner:安徽海龙建筑工业有限公司

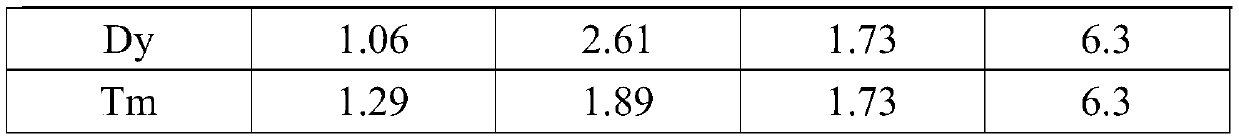

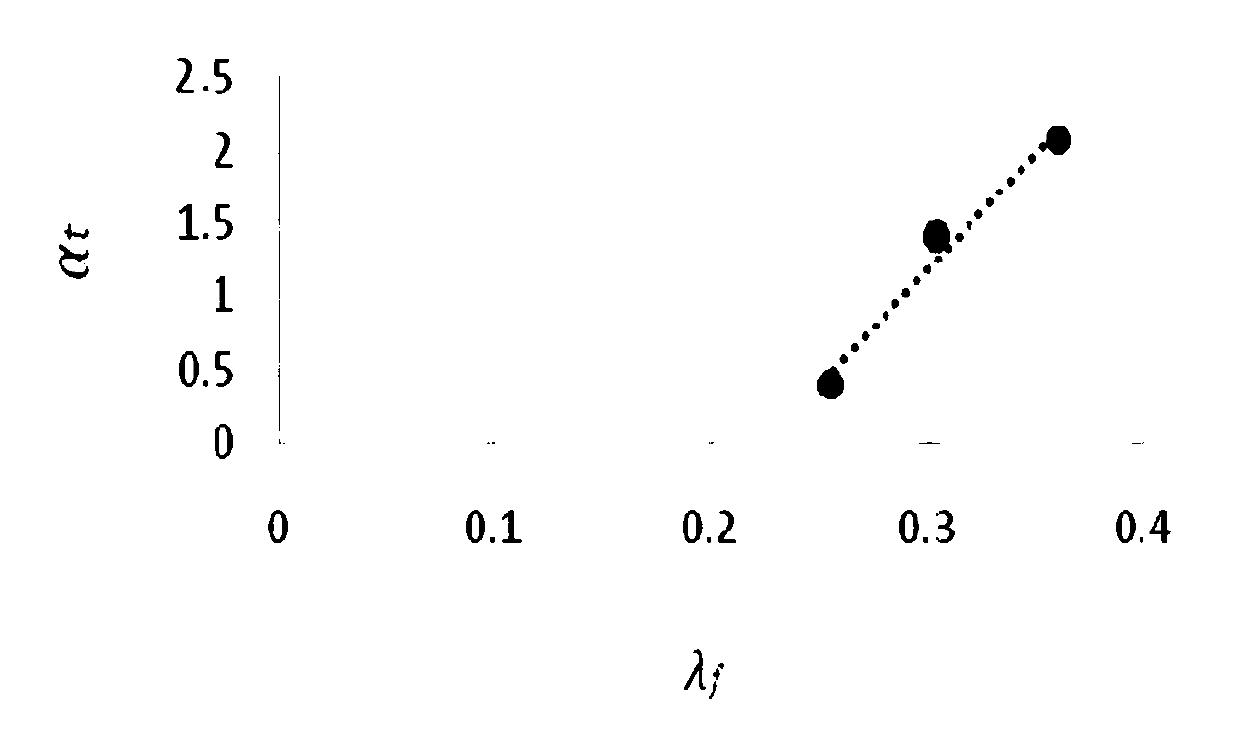

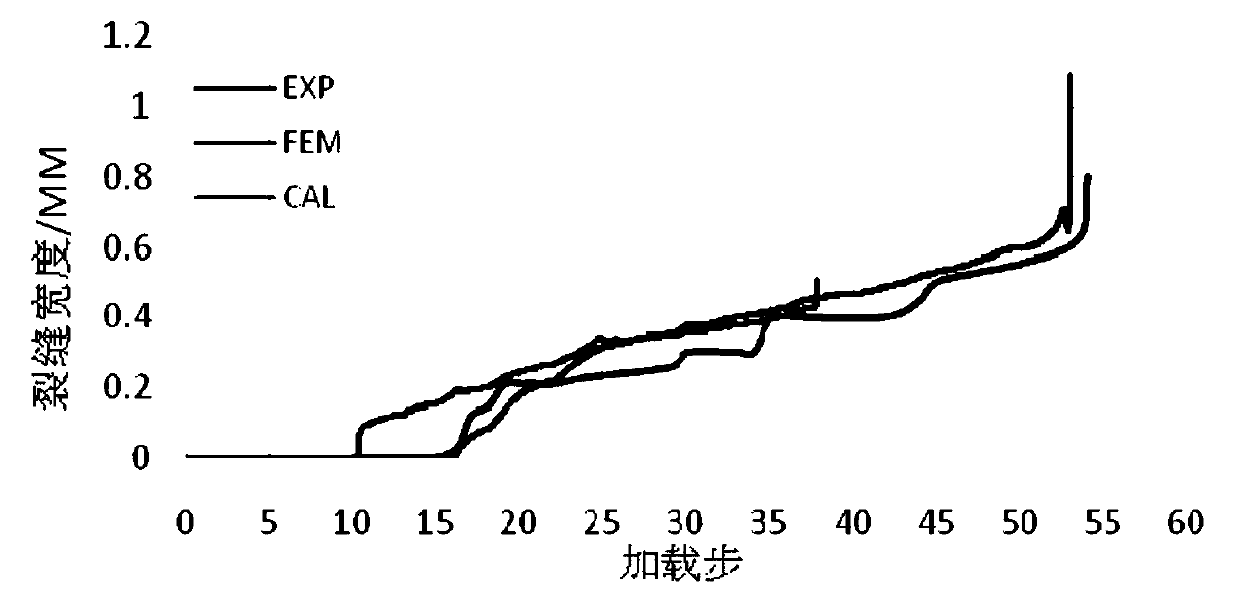

Method for calculating crack width of reinforcing steel bar-steel fiber concrete shield duct piece

InactiveCN109781501AThe calculation result is accurateClose to the measured resultsStrength propertiesFiberConcrete beams

The invention discloses a method for calculating the crack width of a reinforcing steel bar-steel fiber concrete shield duct piece. The method comprises: S1, carrying out loading testing on a reinforcing steel bar-steel fiber concrete beam; S2, carrying out calculation based on loading test data to obtain a crack width influence coefficient; S3, determining a corresponding pre-crack width according to the crack width influence coefficient; S4, carrying out calculation based on loading test data to obtain a tensile strength influence coefficient; S5, determining a corresponding crack bending moment based on the tensile strength influence coefficient; and S6, carrying out correction based on the calculation formula of the pre-crack width and acquiring a corresponding crack width according tothe corrected calculation formula. The calculation result is more accurate and close to the actually measured result. The method is easy to apply directly in the engineering practice and the reference is provided for the tunnel duct piece design. The method has the important engineering application value. An assessment basis is provided for evaluating the durability of the high-strength reinforcing steel bar-steel fiber concrete shield duct piece.

Owner:SOUTHWEST JIAOTONG UNIV

Blasting method for benches in open mining area

InactiveCN108412495AReduce the amount of strippingEasy constructionDisloding machinesUnderground miningRational useSlope angle

The present invention relates to a blasting method for benches in an open mining area. At least three groups of holes, namely, pre-splitting holes, main blast holes and blast holes, are drilled vertically downward on a bench flat plate. Interval charging is carried out in the blast holes, and the explosive load is increased from top to bottom according to the need; interval charging is further carried in the pre-splitting holes, and the explosive load is decreased from top to bottom; and the main blast holes are fully charged. The pre-splitting holes are initiated first, the main blast holes and the blast holes are initiated after the pre-splitting holes are initiated for 50-120ms, and the interval time between the main blast holes and the blast holes is [delta]t in sequence. The effect that an idea bench slope is directly blasted out is achieved. According to the blasting method for the benches in the open mining area, vertical drilling is adopted, the construction is relatively simple, and the requirements on a drilling rig are not high; the charging procedure adopts interval charging, the blasting effect in each section can be effectively used to form an ideal bench slope angle,and the amount of rock stripping is reduced; and in terms of blasting time, the pre-cracking holes are initiated first to form a pre-splitting surface, differential blasting is used for remaining blast hole rows and between holes, and the best blasting effect is achieved by rational use of explosive energy rationally.

Owner:XIAN UNIV OF SCI & TECH

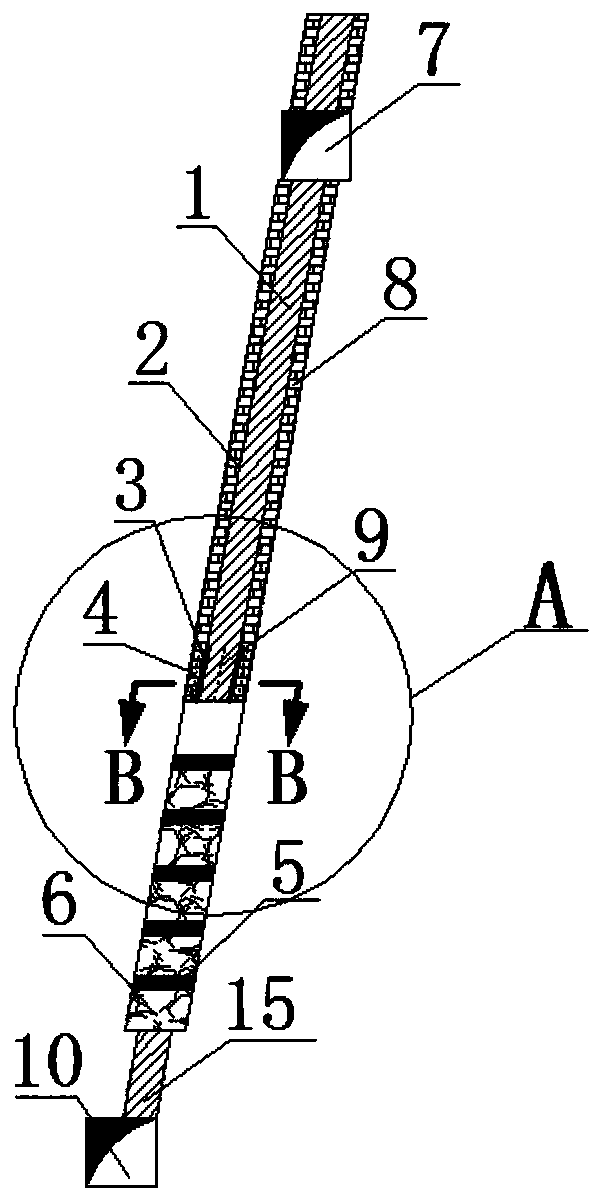

Stress corrosion test method and device for metal sheet pre-cracked sample

InactiveCN102103063ALower requirementSave materialWeather/light/corrosion resistanceCrazingMetallic materials

The invention discloses a stress corrosion test method and a stress corrosion test device for a metal sheet pre-cracked sample. The method comprises the following steps of: fixing one end of the sample on a bearing wall, clamping the other end of the sample by using an upper clamping plate and a lower clamping plate and fixing; clamping a test section of the sample by using a corrosion environment test box; pre-estimating the initially applied stress field intensity factor according to the threshold stress field intensity factor of crack propagation of similar metal materials, wherein the pre-estimated value is greater than the threshold stress field intensity factor of the crack propagation of the metal materials; loading stress to the metal sheet sample, measuring the crack length of the sheet sample to obtain a crack stress field intensity factor, and stopping loading the stress when the crack stress field intensity factor is equal to the pre-estimated value; filling a corrosion medium in the corrosion environment test box; measuring the length of a crack at the tip of the pre-cracked sample at intervals of certain time; and measuring the crack length and the loaded stress after the crack stress field intensity factor is stabilized to obtain the threshold stress field intensity factor of stress corrosion crack propagation. The method is convenient to operate and high in measuring accuracy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

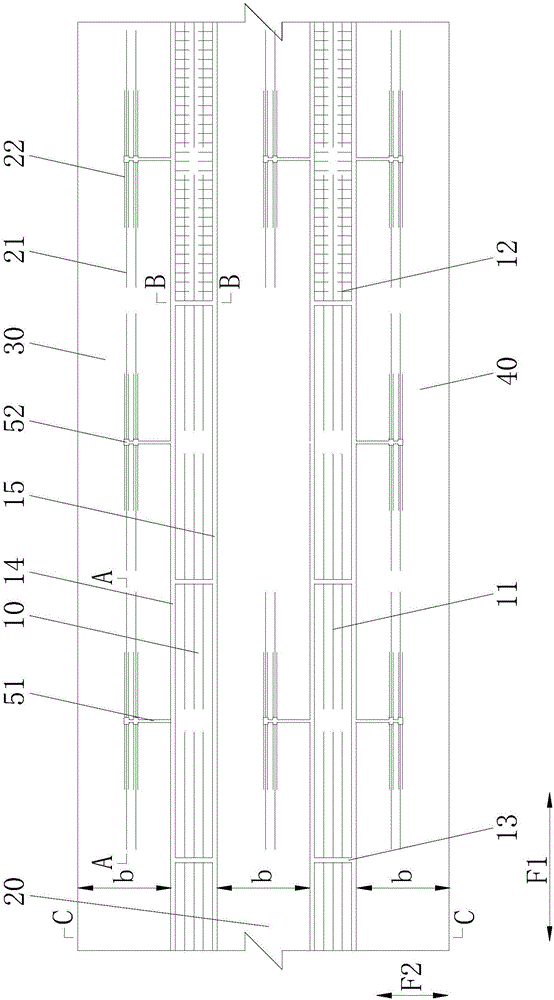

Stope structure arrangement manner through fast-tilting extremely-thin vein cliff filling stoping method

ActiveCN110617065AHigh strengthControl deformationUnderground miningSurface miningMining engineeringPre cracking

The invention discloses a stope structure arrangement manner through a fast-tilting extremely-thin vein cliff filling stoping method. An undercutting space is evacuated from human-working ventilatingraises on the two sides to the interior of an ore block along the upper boundary of a bottom column (15), a plurality of upward passes are evacuated upwards on the side, close to an upper disc of an ore body, of a middle-section transporting roadway (10) and used as ore chutes, cliff holes (4) are drilled in an upper and lower disc cliff surrounding rock (8), ore blanking holes (9) are drilled inan extremely-thin vein (1), and pre-cracking holes (3) are drilled in the contact surface of the rock; and a waste stone filling body (6) is formed by collapsed upper and lower disc cliff surroundingrock (8), a tailing cementing filling body (5) is formed by using tailing cementing filling, and finally, a mixed filling body of the tailing cementing filling body (5)-waste stone filling body (6)-tailing cementing filling body (5) is formed. By means of the stope structure arrangement manner, the strength of the mixed filling body is improved, the purpose of controlling the deformation of the surrounding rock is achieved, and the tailing cementing filling body (5) is used as an ore blanking platform to avoid the secondary depletion of the ore.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

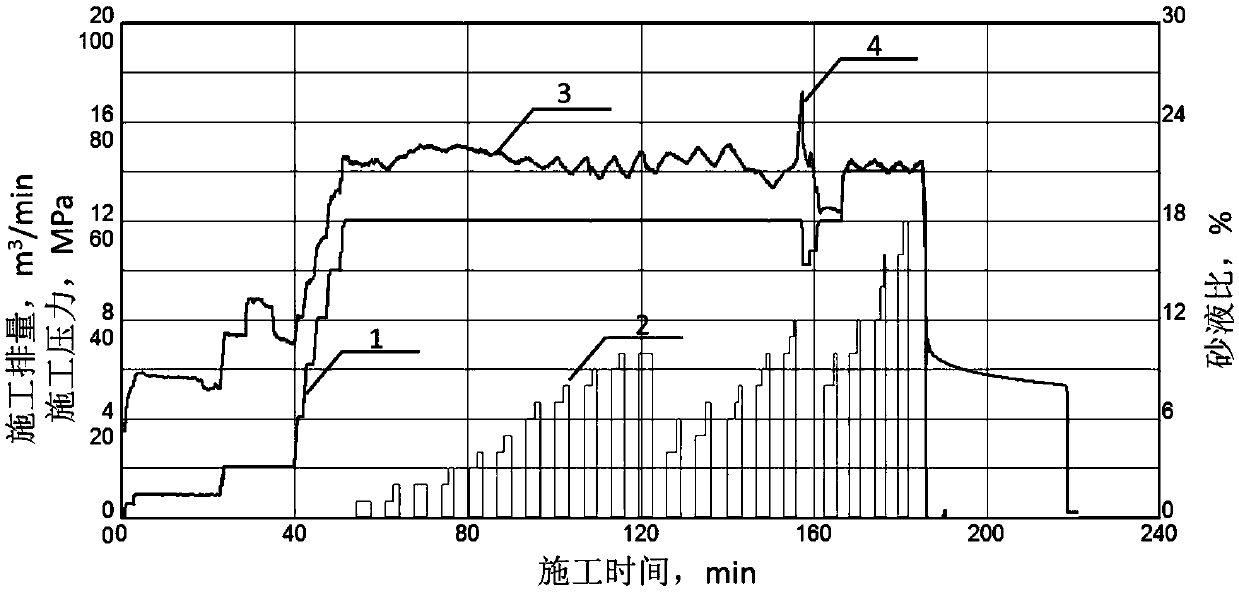

Critical sand plug fracturing method for improving crack complexity

ActiveCN110344799AIncrease net pressureImprove steering performanceFluid removalHorizontal stressCalcium in biology

The invention discloses a critical sand plug fracturing method for improving crack complexity. The method includes the following steps: (1) formation evaluation before fracturing; (2) preferable selection of viscosity of pre-crack generation fracturing fluid; (3) application of different viscosity fracturing fluid to generate cracks of different sizes at different stages; (4) preferable selectionof dosage proportion and particle size of a proppant matching the different crack sizes; (5) design of a bench type slug sanding mode; (6) implementation of a critical sand plug fracturing process; and (7) other construction steps and a flowback and production process. The method realizes the effective promotion of net pressure and an induced stress field in the whole process of one-time sand fracturing, thereby reducing a horizontal stress difference of two directions of a formation at different positions of a main crack to make the opening of natural cracks or micro cracks filled with calcium easier. The main crack turns and then communicates and intersects with the natural cracks or the micro cracks, thereby maximizing the complexity of the whole crack system and further improving the crack reconstruction volume and single well production.

Owner:CHINA PETROLEUM & CHEM CORP +1

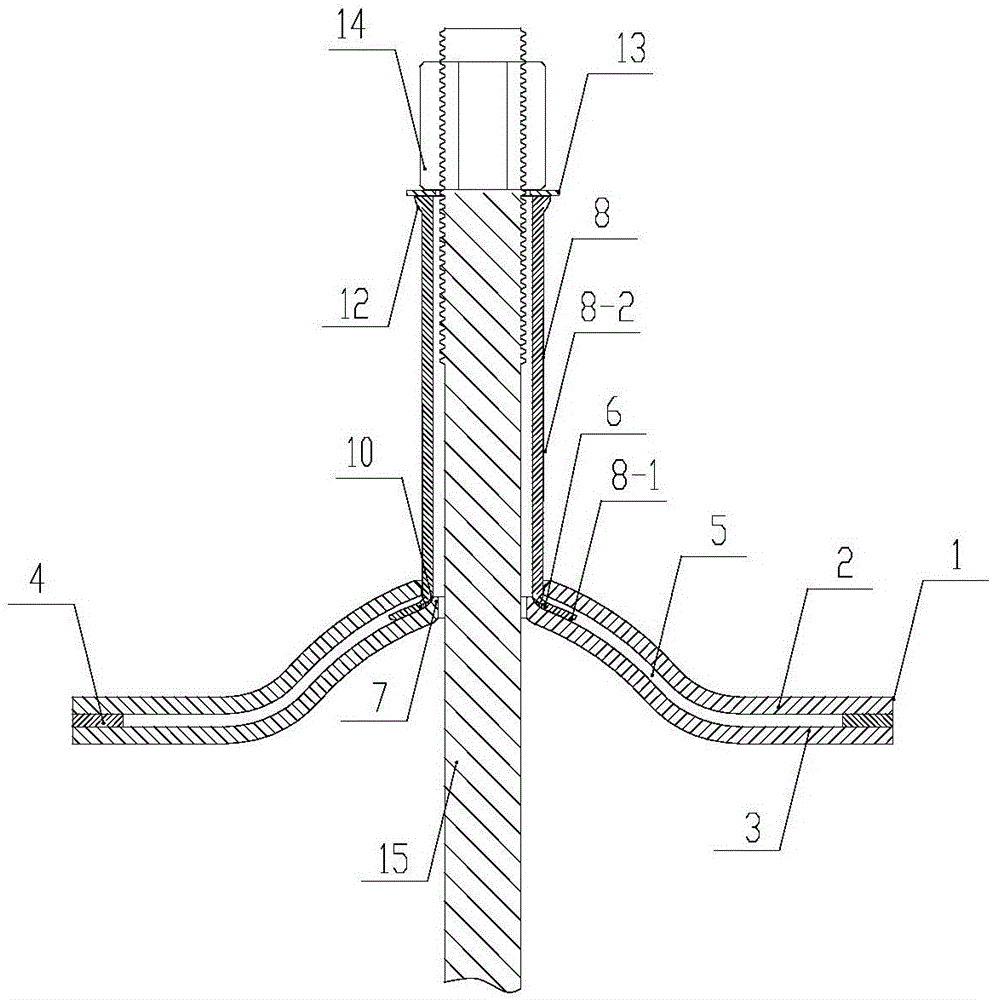

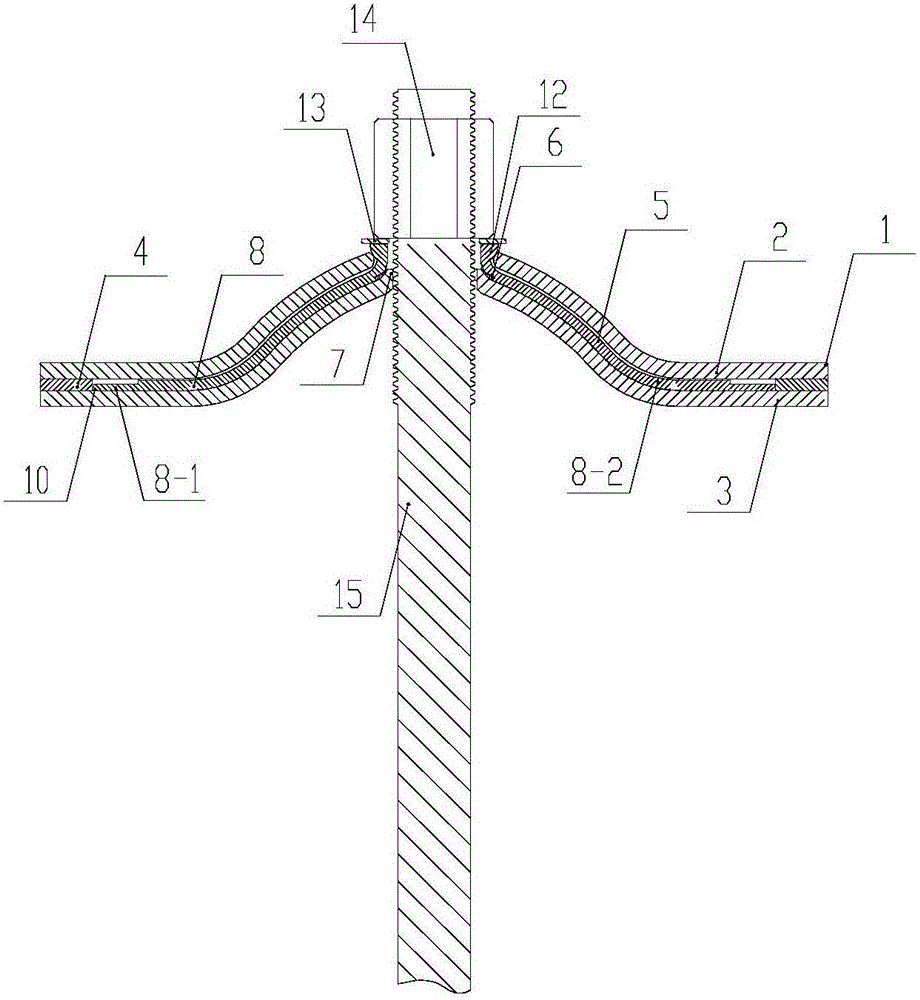

Energy absorption anchor rod tray

ActiveCN105781599AAvoid shockPrevent sudden deformation failureAnchoring boltsEnergy absorptionEngineering

The invention discloses an energy absorption anchor rod tray which comprises a double-layer disk-type tray body capable of moving along an anchor rod and a pre-tightening nut which is in threaded connection to the exposed end of the anchor rod, wherein a hollow disk-type guide slot is formed between an upper-layer disk-type tray and a lower-layer disk-type tray of the double-layer disk-type tray body through an interlayer gasket; an energy absorption pipe sleeving the anchor rod is arranged between the pre-tightening nut and the double-layer disk-type tray body and consists of a tear energy absorption section and a tear pre-tightening section; the lower part of the tear pre-tightening section penetrates through a central hole of the upper-layer disk-type tray and then presses an energy absorption pipe alignment table around a central hole of the lower-layer disk-type tray through a chamfer; pre-cracked line slots are formed in the chamfer in a spacing manner; cracking supporting knives corresponding to the pre-cracked line slots are arranged at the outer edge of the energy absorption pipe alignment table. Under an impact load, the energy absorption tray can realize continuous and stable yielding energy absorption through shaft cracking yielding of the energy absorption pipe; when matched with the high-strength anchor rod, the energy absorption tray can effectively support and protect surrounding rock with high impact trend.

Owner:LIAONING TECHNICAL UNIVERSITY

Method for preventing and treating impact mine pressure through high-dipping super-high-seam mining roadway combined pressure relief

InactiveCN110067558AReduce stress concentrationEliminate strong vibration disturbanceMining devicesDisloding machinesStress concentrationEngineering

The invention discloses a method for preventing and treating impact mine pressure through high-dipping super-high-seam mining roadway combined pressure relief. By implementing blasting pressure reliefon a roadway side and bottom corners, the stress concentration degree of a coal body around a roadway is decreased; and by implementing deep-hole blasting pre-cracking on a roof and floor rock stratum, a roof and floor can be collapsed in time along with working face coal caving, thus large-area roof and floor rock stratum suspension is prevented from being formed, the stress concentration degreeof roadway surrounding rock is decreased, meanwhile, strong vibration disturbance generated by sudden breaking of the roof and floor rock stratum is eliminated, and the risk that vibration induces the high-stress coal body around the roadway to generate the impact mine pressure dynamic disaster is reduced.

Owner:CHINA UNIV OF MINING & TECH +2

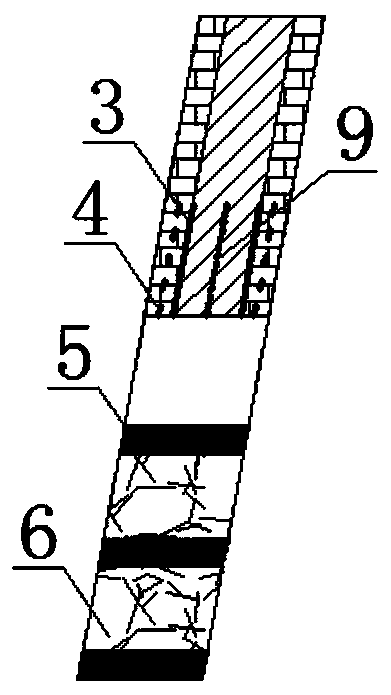

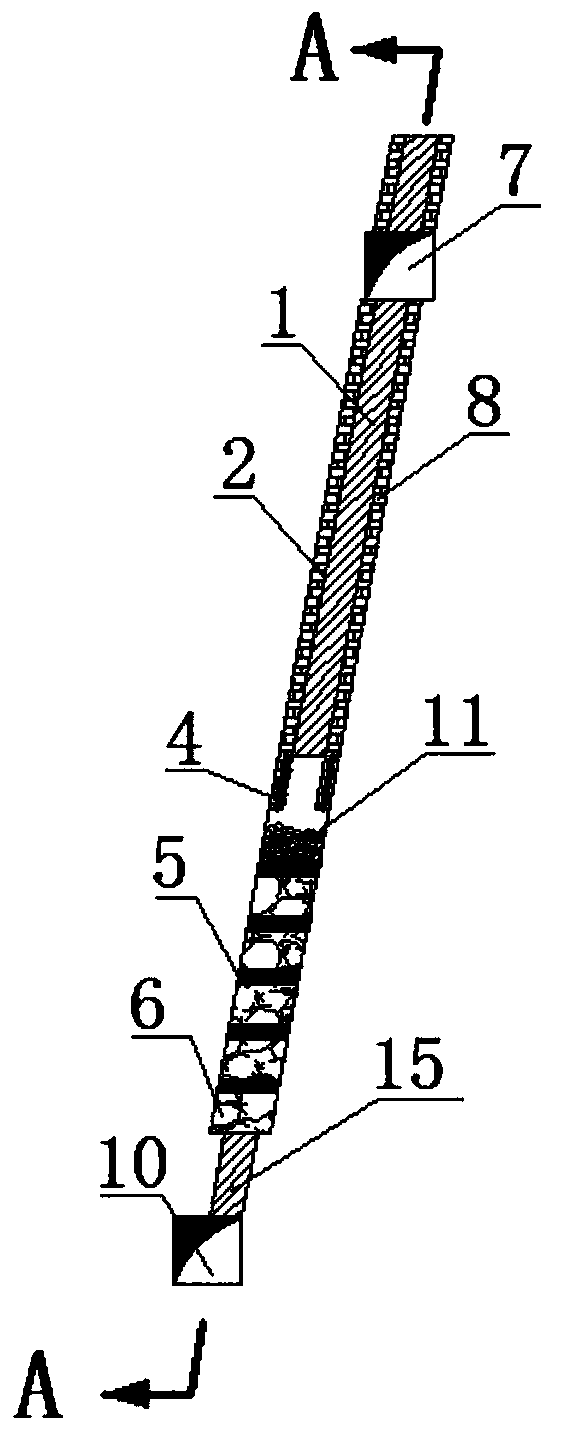

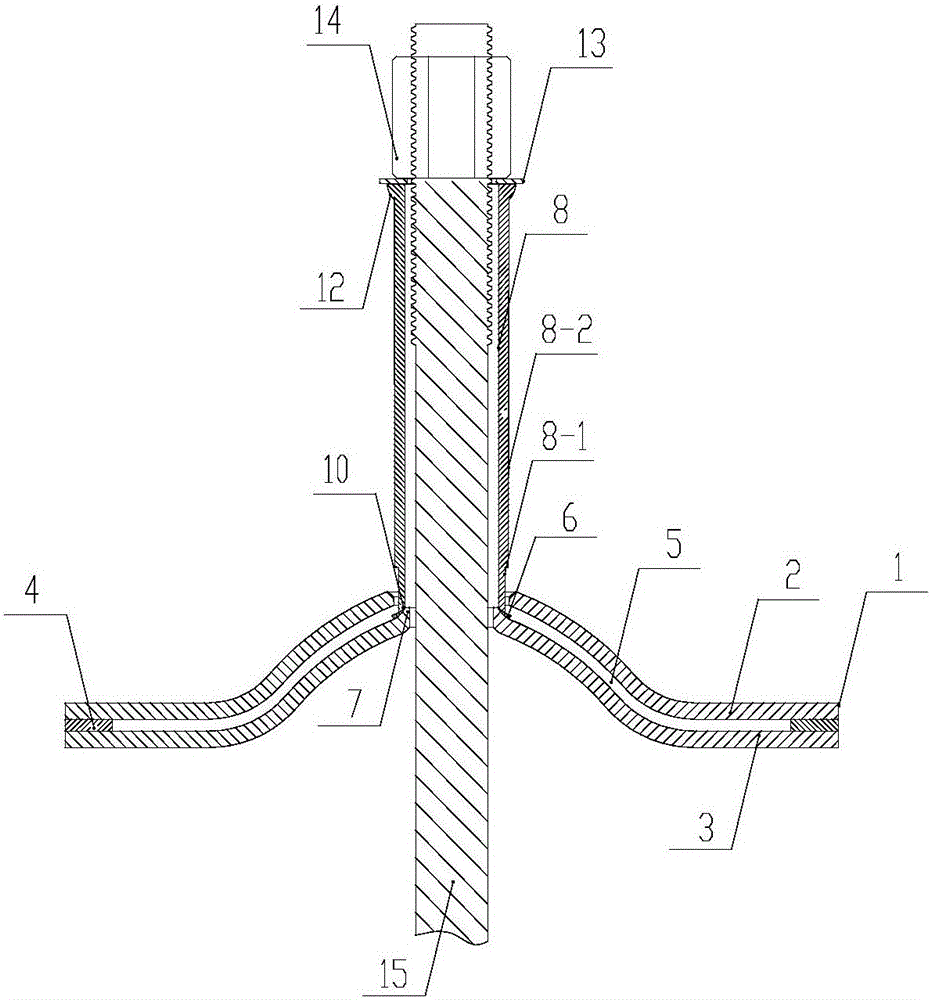

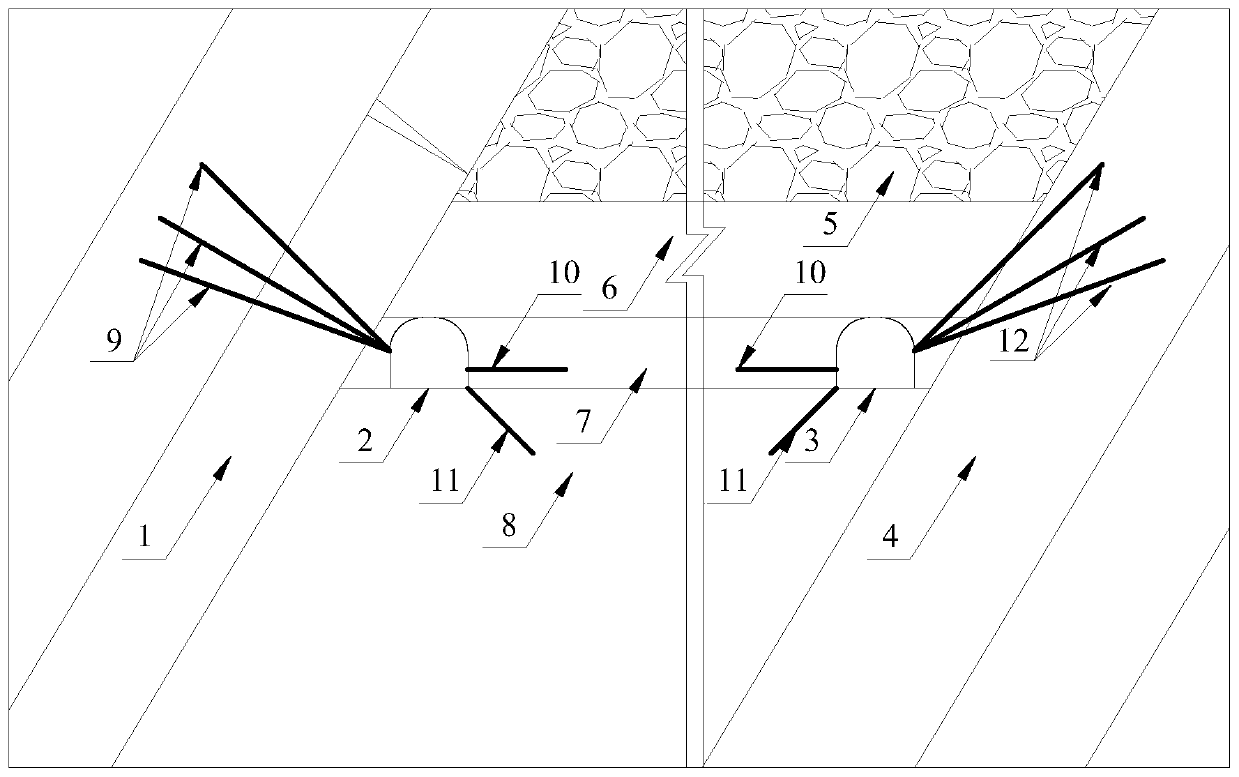

Gas-liquid combination directional cracking device and method

InactiveCN109931060ARetrofit BreathabilityImplement extensionsDisloding machinesEngineeringHigh pressure water

The invention provides a gas-liquid combination directional cracking device and a method thereof. The gas-liquid combination directional cracking device is arranged in a borehole, comprising a CO2 phase change generator and a hole packer, wherein the CO2 phase change generator is of a cylinder structure, and with liquid CO2 stored inside, a first end of the generator is provided with a plurality of nozzles, and a second end is connected with the hole packer; the hole packer is of an elastic capsule structure, arranged in the back end of the CO2 phase change generator and connected with a high-pressure water pipe; the hole packer expands with water injection and is used to pack the borehole. At first, the gas-liquid combination directional cracking device arranged in the borehole performs CO2 phase change cracking in the borehole, in order to instantly release the gas in the CO2 phase change generator into the borehole to directionally pre-crack the inner wall of the borehole, and thenperforms hydraulic cracking to the borehole to allow the hydraulic crack to continuously expand, thereby forming a wide range of hydraulic crack zone in the coal and rock mass, and achieving governance of the hard roof, top coal and percussive ground pressure in a coal mine; at the same time, the permeability of a coal seam is improved, which is beneficial to coal seam permeability improvement andoutburst elimination.

Owner:CHINA UNIV OF MINING & TECH

Construction method for breaking end socket tunnel portal retaining structure of shield section

ActiveCN108868784AMinimize origination riskShort construction periodTunnelsReinforced concreteSlurry

The invention discloses a construction method for breaking an end socket tunnel portal retaining structure of a shield section. The method comprises the following steps of 1, drilling holes in a circular tunnel portal of the retaining structure; 2, stirring expansion slurry; 3, injecting the stirred expansion slurry into vertical holes and longitudinal holes, sealing the holes, and pre-cracking concrete; 4, chiseling a launching surface of the circular tunnel portal; 5, dividing the circular tunnel portal into a first area, a second area, ... and an nth area; 6, sequentially carrying out concrete peeling and reinforced concrete breaking on the launching surface of the circular tunnel portal in the first area, the second area, ... and the nth area; 7, chiseling a soil surface of the circular tunnel portal; 8, carrying out shield launching / reception tunneling construction. According to the method, through reasonable drilling arrangement and precise drilling depth, it is ensured that theconcrete breaking range of the tunnel portal can meet clearance requirements of design and construction; the whole process has high safety, collapse does not easily occur, the construction is fast, and meanwhile, the safety of construction personnel is ensured.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG

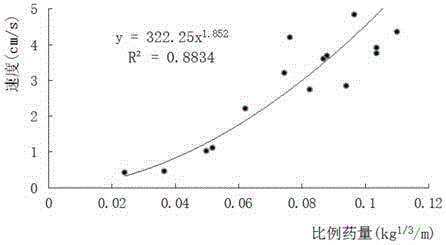

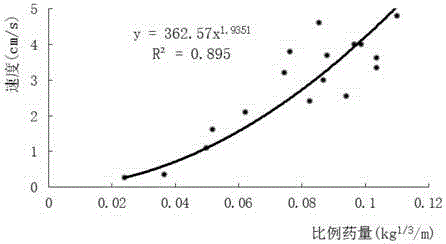

Blasting excavation layered control method for nuclear power engineering foundation

ActiveCN106382867AIncrease workloadReduce the number of field trialsAnalysing solids using sonic/ultrasonic/infrasonic wavesBlastingUltrasound attenuationNuclear power

The invention relates to a blasting excavation layered control method for a nuclear power engineering foundation. The blasting excavation layered control method comprises the following steps of: determining an excavation layer number and excavation depth according to foundation negative excavation depth H; determining the site attenuation rule by carrying out blasting vibration test; preliminarily determining rock mass damage depth by carrying out acoustic wave test; calculating rock mass point vibration speed and rock blasting damage depth by carrying out finite element numerical simulation; separately establishing the changing rule of mass-point peak vibration speed along with the rock blasting damage depth at positions with difference distances from a blasting source under a step blasting way and a pre-cracking blasting way; determining layered blasting excavation control standards of three distances under different blasting ways according to blasting excavation allowable damage depth of each layer; and guiding blasting design by combining the site attenuation rule to invert maximum-section dose. The blasting excavation layered control method effectively solves the problem that a three-layer excavation way of an existing method is difficult in effectively controlling damage depth and the defects that existing control standards are single, are inconvenient to use, are not suitable for the pre-cracking blasting way, and the like, so that construction progress is quickened, and relatively good economic benefits are generated.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

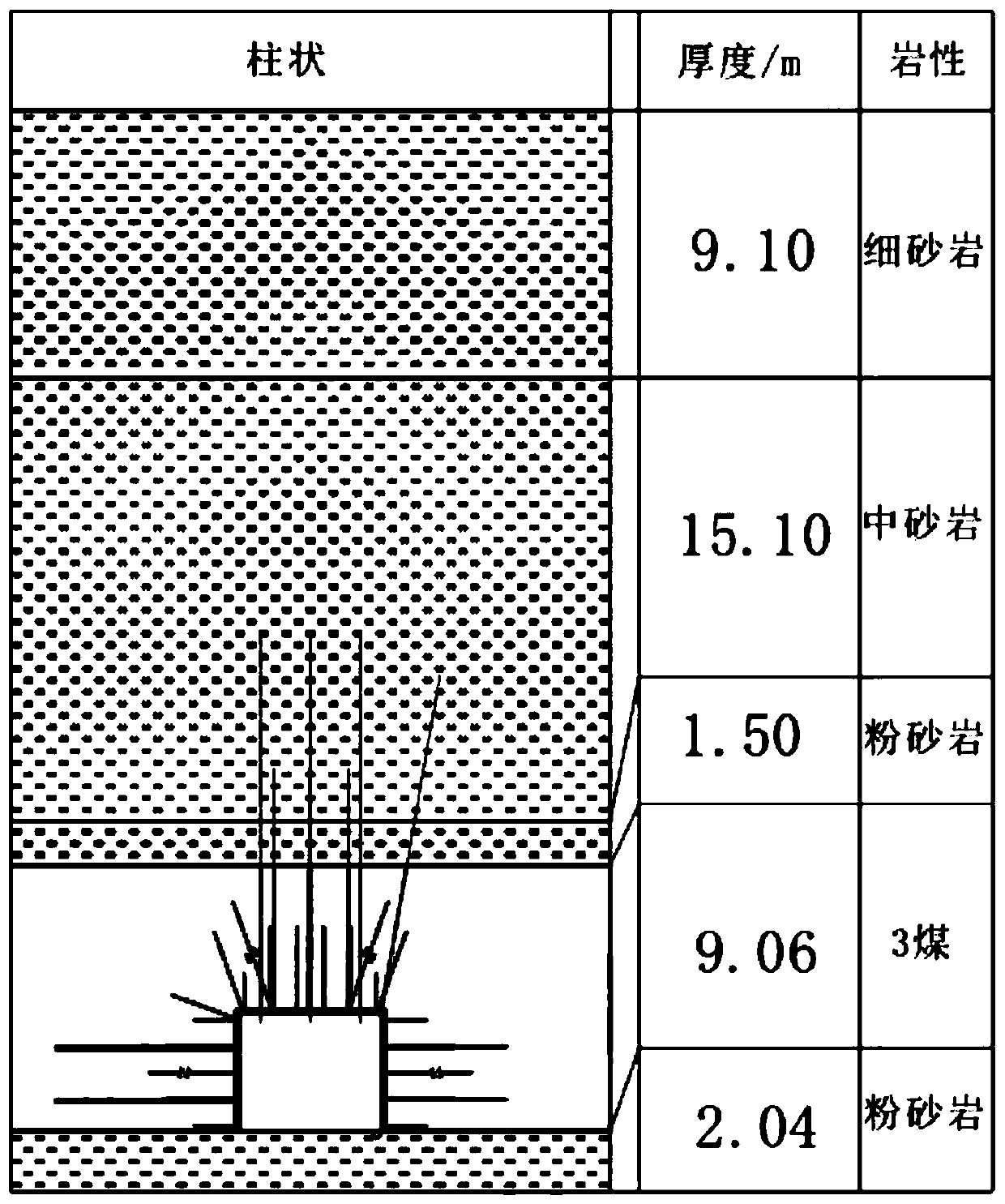

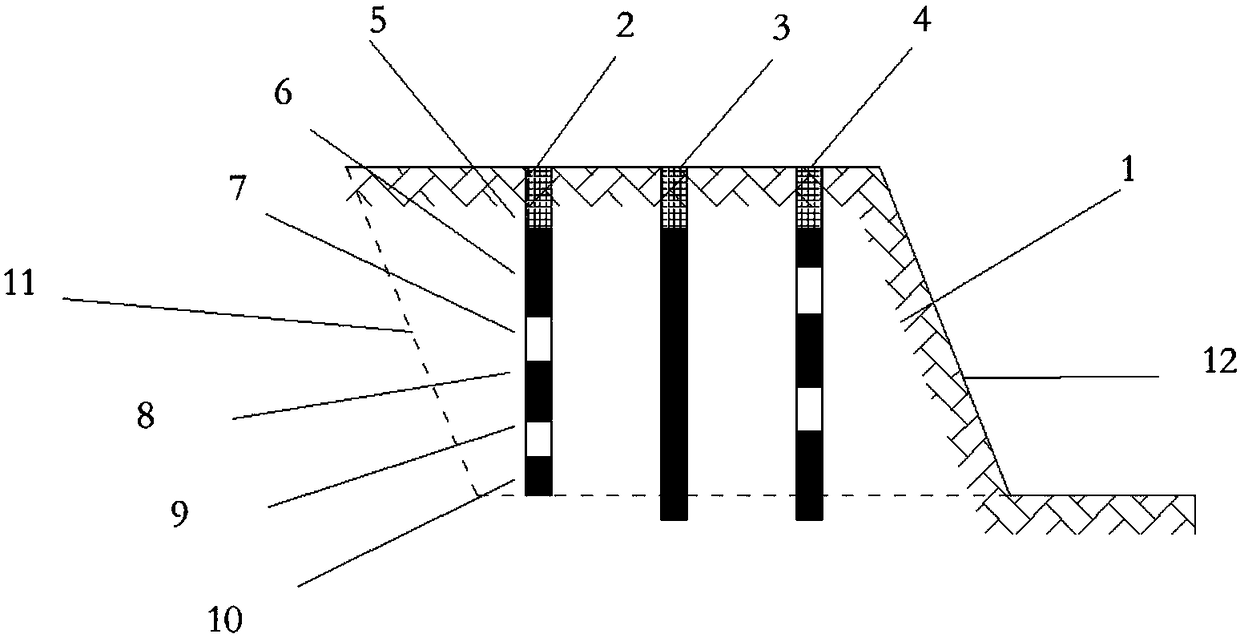

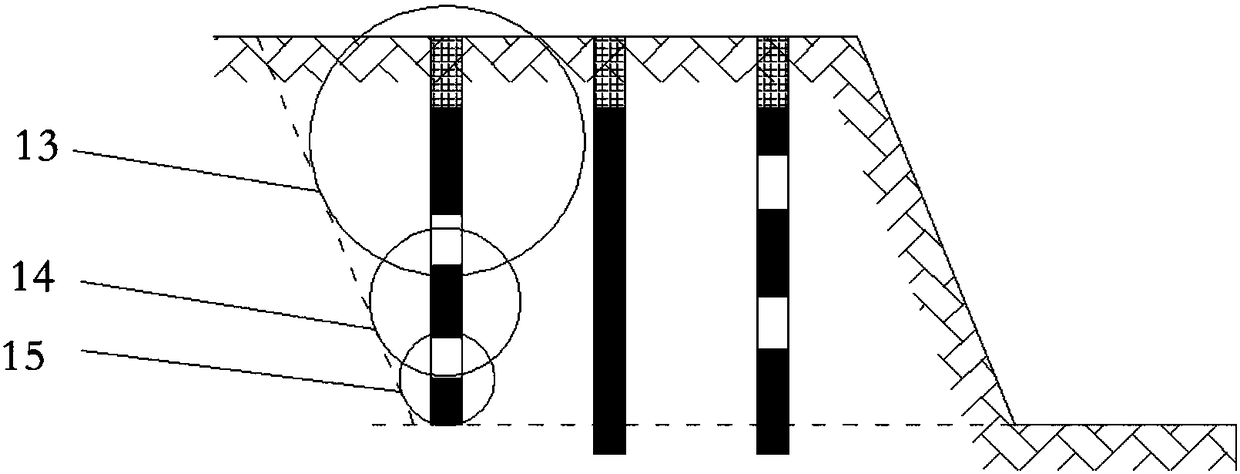

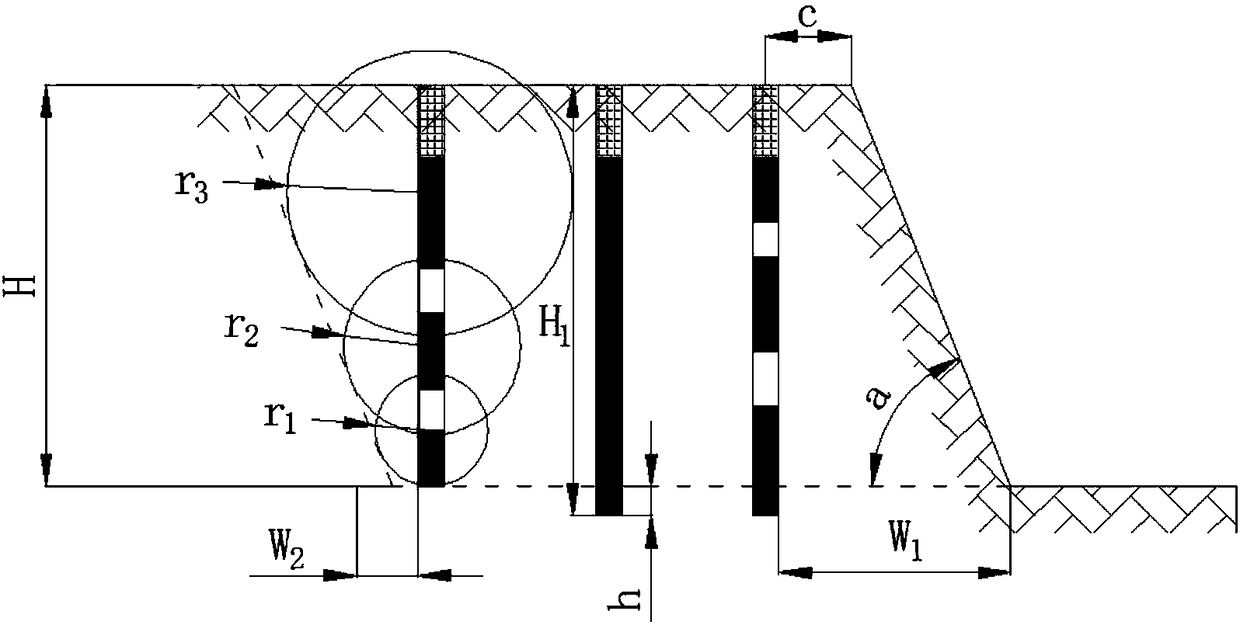

Coal-pillar-free mining method for pre-cracking arching under hard roof condition

ActiveCN109826628AImprove stress environmentReduce distortionUnderground chambersUnderground miningEngineeringCoal pillar

The invention provides a coal-pillar-free mining method for pre-cracking arching under a hard roof condition, and relates to the technical field of underground mining methods. The method comprises thesteps that A, a mining roadway of a first mining working face is excavated, and anchor rods and anchor cables are used for supporting the mining roadway; B, pre-cracking holes are formed in a roof inthe mining roadway along the coal wall of the working face, wherein the pre-cracking holes are perpendicular to the roof, and the length of the pre-cracking holes is equal to the thickness of the immediate roof; C, hydraulic supports are arranged at one side of the coal wall of the first mining working face; D, the pre-cracking holes within the range of 50-70 m on an advanced working face are loaded with explosive for blasting to crack the immediate roof; E, push mining is conducted on the working face, and the immediate roof of a pre-cracking section at the rear portion of the working face is subjected to sinking arching; F, after the sinking amount of the roof is stabilized, the height of the roadway is adjusted; G, a mining roadway of an adjacent working face is excavated, steps A to Fare repeated, and the hydraulic supports in the mining roadway of the last working face are recovered along with pushing of the adjacent working face. The method solves the problem that roofs are broken and easily leak wind, and has the advantages that the deformation amount of the roadways is small, and construction is convenient.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com