Preparation method of modified mesoporous silicon-aluminum material

A mesoporous silica-alumina, modified technology, applied in chemical instruments and methods, catalyst carriers, catalysts for physical/chemical processes, etc., can solve the problem of poor hydrothermal stability, weak acidity of mesoporous molecular sieves, catalyst production stability and life. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

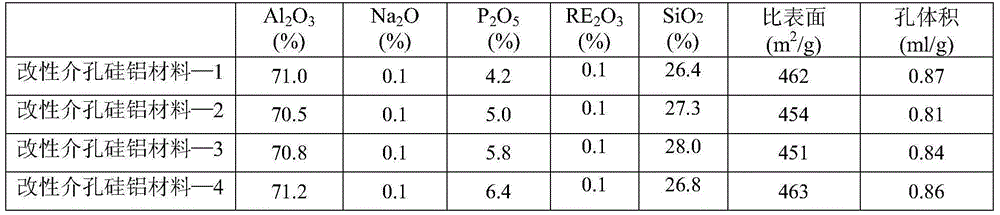

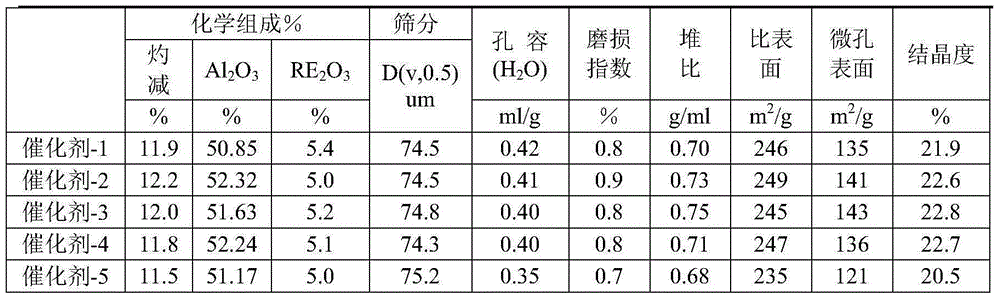

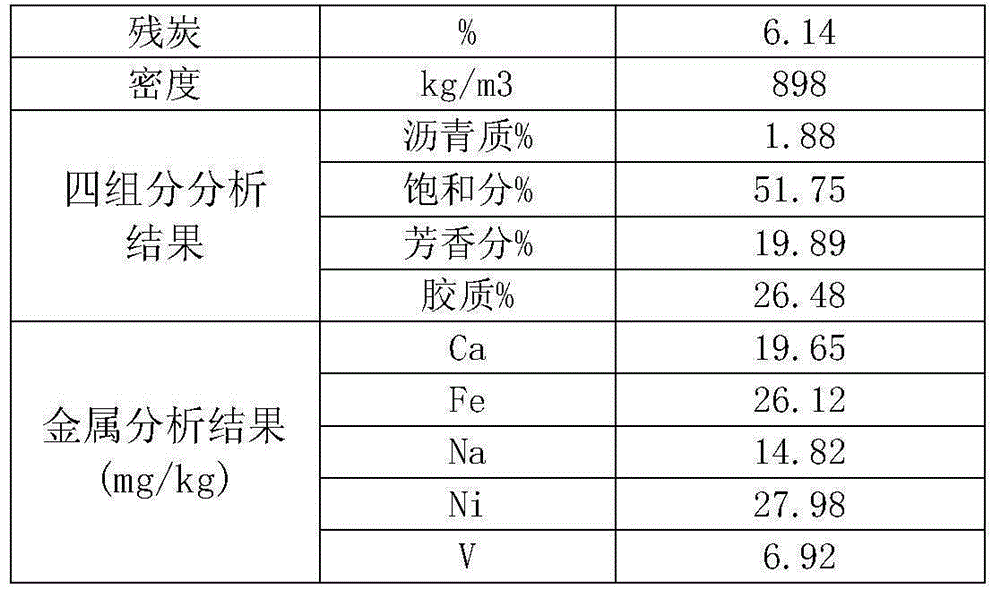

Examples

Embodiment 1

[0027] (1) Add (calculated as alumina) 10% pseudo-boehmite slurry into 50% phosphoric acid solution, control the reaction temperature at 50°C, and react for 10 hours, wherein P 2 o 5 / Al 2 o 3 =2.0 (this ratio is relatively low, need to increase the reaction temperature), recorded as solution A.

[0028] (2) The concentration is 45g / l (as Al 2 o 3 meter) aluminum chloride solution with a concentration of 55g / l (as SiO 2 In the water glass solution, control the pH=10.3, the temperature is 10 ℃, static aging for 1 hour, record it as solution B.

[0029] (3) Mix solution A with a concentration of 85g / l (with Al 2 o 3 In terms of) aluminum chloride as P 2 o 5 :Al 2 o 3 =0.06 was added into solution B, the pH was controlled to be 3.4, and the temperature was 10°C, which was recorded as solution C.

[0030] (4) Add the lanthanum chloride solution in solution C in a certain proportion, control lanthanum:aluminum=0.02, record it as solution D.

[0031] (5) Add 5% ammonia ...

Embodiment 2

[0035] (1) Add (calculated as alumina) 20% pseudoboehmite slurry into 60% phosphoric acid solution, control the reaction temperature at 60°C, and react for 15 hours, wherein P 2 o 5 / Al 2 o 3 =3.0, recorded as solution A.

[0036] (2) The concentration is 50g / l (as Al 2 o 3 meter) of aluminum sulfate solution with a concentration of 60g / l (as SiO 2 In the alkaline silica sol solution, the pH is controlled at 10.4, the temperature is 20° C., and the static aging is 1.5 hours, which is recorded as solution B.

[0037] (3) Mix solution A with a concentration of 90g / l (with Al 2 o 3 In terms of aluminum sulfate in P 2 o 5 :Al 2 o 3 =0.08 into solution B, control pH=3.5, temperature 20°C, record as solution C.

[0038] (4) Add the lanthanum chloride solution in solution C in a certain proportion, control lanthanum:aluminum=0.03, record it as solution D.

[0039] (5) Add 5% sodium hydroxide to solution D to control pH=8.2.

[0040] (6) Wash and filter with chemical wat...

Embodiment 3

[0043] (1) Add (calculated as alumina) 30% pseudo-boehmite slurry into 70% phosphoric acid solution, control the reaction temperature at 70°C, and react for 20 hours, wherein P 2 o 5 / Al 2 o 3 =4.0, recorded as solution A.

[0044] (2) The concentration is 50g / l (as Al 2 o 3 The concentration of sodium metaaluminate solution added is 60g / l (as SiO 2 In the water glass solution, control the pH=10.5, the temperature is 30 ℃, static aging for 2 hours, record it as solution B.

[0045] (3) Mix solution A with a concentration of 90g / l (with Al 2 o 3 In terms of) sodium metaaluminate dissolved in P 2 o 5 :Al 2 o 3 =0.10 was added to solution B, the pH was controlled to be 3.6, the temperature was 30°C, and it was recorded as solution C.

[0046] (4) Add the lanthanum chloride solution in solution C in a certain proportion, control lanthanum:aluminum=0.04, record it as solution D.

[0047] (5) Add 5% ammonia water to the solution D to control the pH=8.4.

[0048](6) Was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com