Patents

Literature

230results about How to "Improve cracking capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

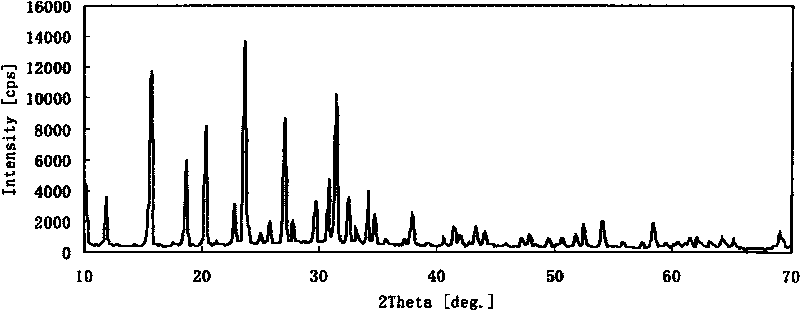

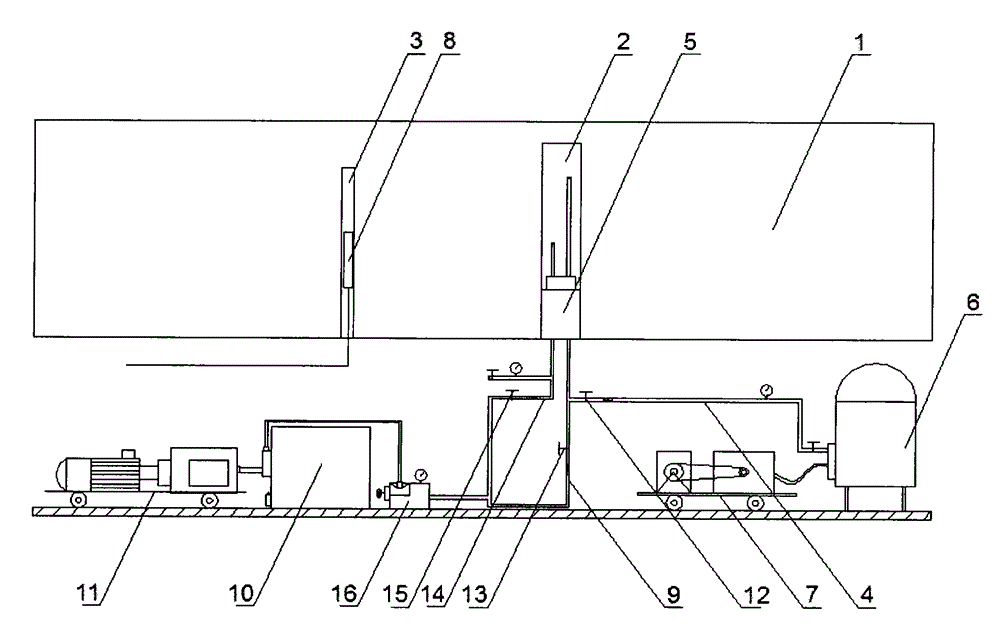

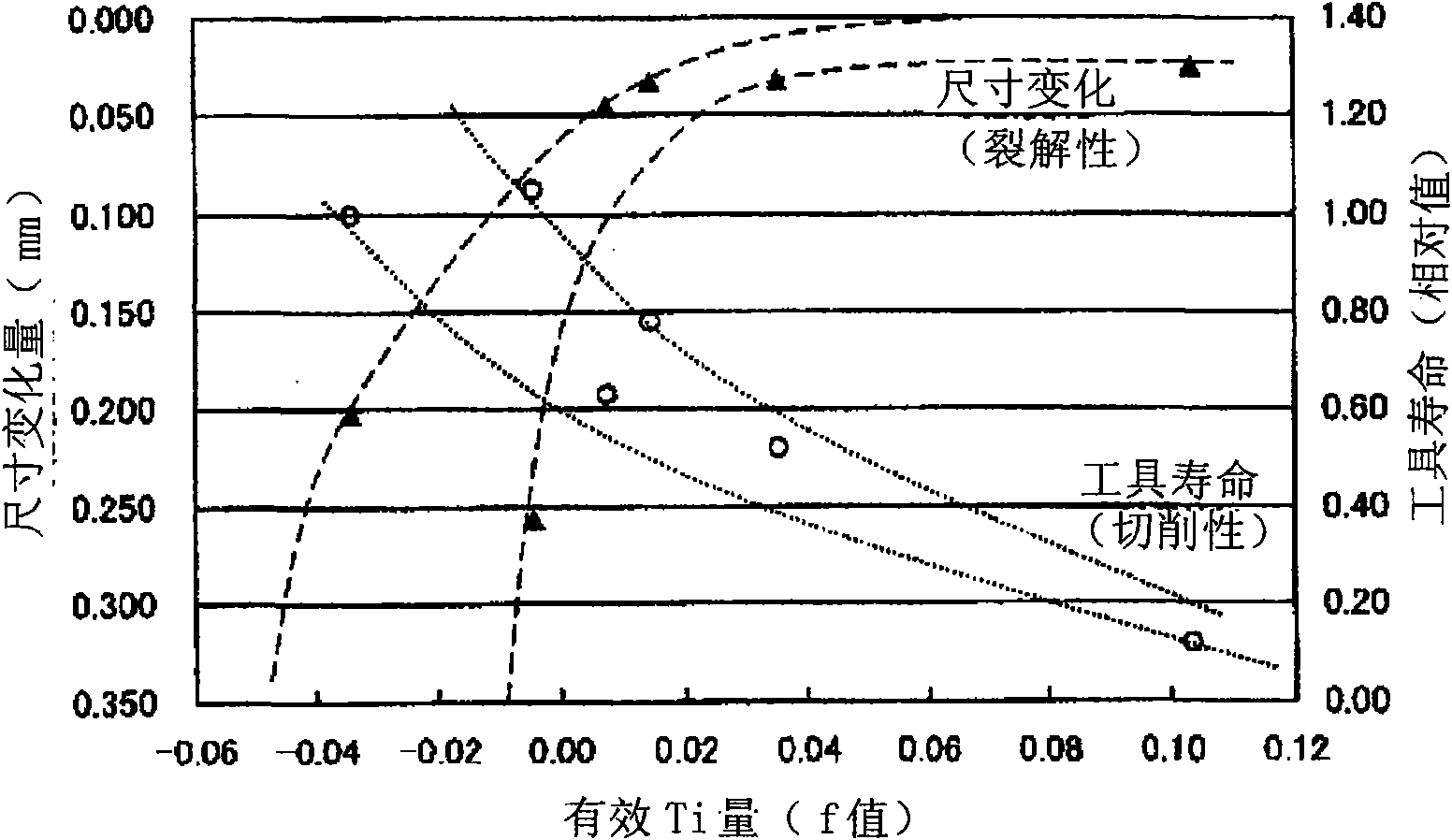

NaY-type molecular sieves and preparation method thereof

ActiveCN101722023AOrderly formationOrderly and stableMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveThermal stability

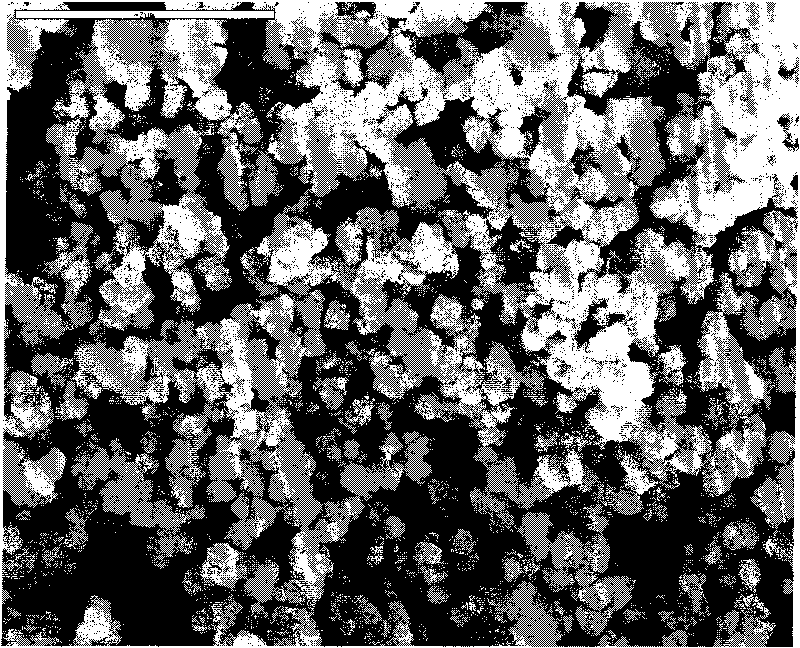

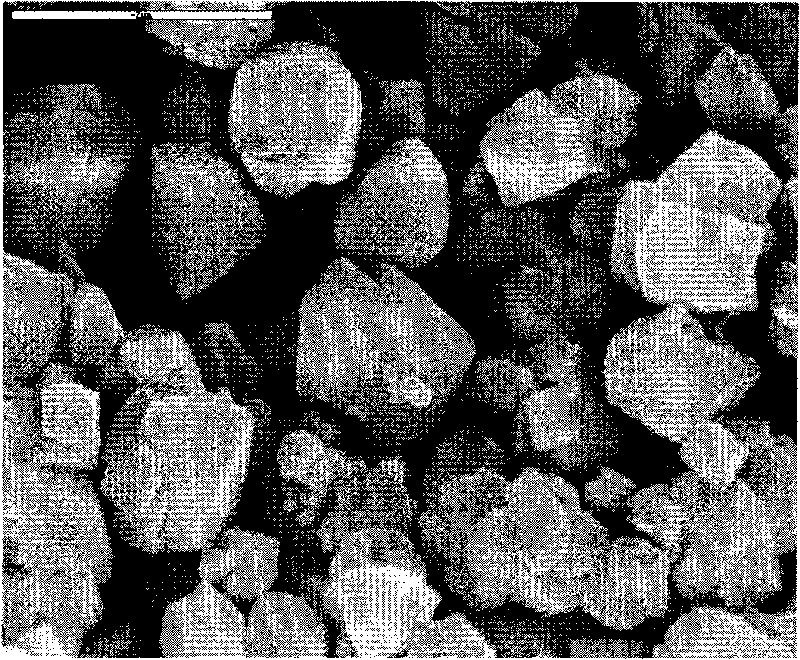

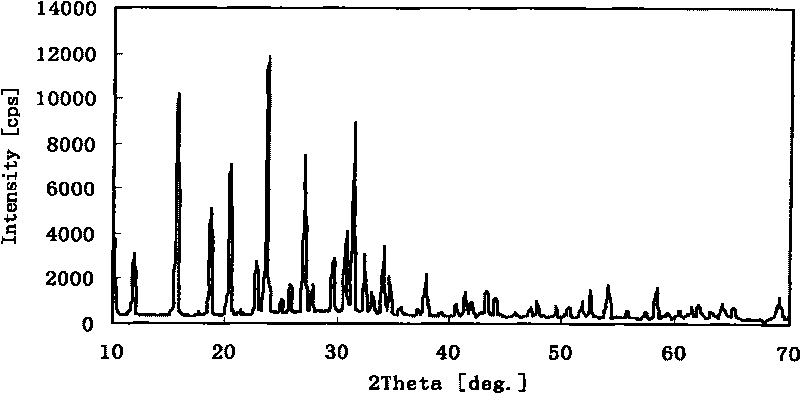

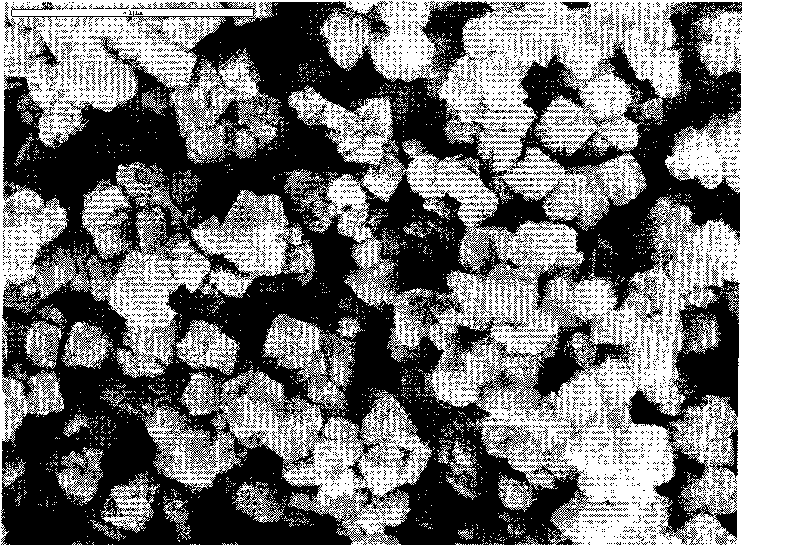

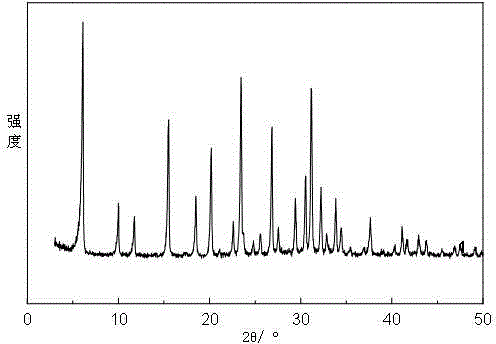

The invention discloses microcrystal NaY-type molecular sieves and a preparation method thereof. In the microcrystal NaY-type molecular sieves, the molar ratio of SiO2 to Al2O3 is 4.0 to 6.0, and the average particle size is 100 to 700 nanometers. The microcrystal NaY-type molecular sieves are prepared by a method combining low-temperature synthesis directing agent, low-temperature synthesis gel and two-stage variable-temperature dynamic crystallization. The NaY-type molecular sieves have a relative crystallinity of over 80 percent after being roasted in the air at 600 DEG C for 3 hours or after undergoing hydrothermal treatment with vapor at 650 DEG C for 1 hour, as well as high thermostability and hydrothermal stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing low carbon olefin by petroleum hydrocarbon cracking

InactiveCN1504540AImprove cracking capacityHigh reaction conversion rateCatalytic crackingCarbon numberDecomposition

The invention discloses a catalyst for preparing lower carbon number hydrocarbon olefin through petroleum hydrocarbon decomposition, which comprises (catalyst weight as benchmark) 0-70% clay, 5-99% inorganic oxide compound and 1-50% zeolite, wherein the zeolite is 25-100 wt% MFI structure zeolite and 0-75 wt% Y-type zeolite, characterized by that, the MFI structure zeolite contains phosphor and transient metal M. the catalyst can improve the cracking capability for heavy oil macromolecule and conversion rate of reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

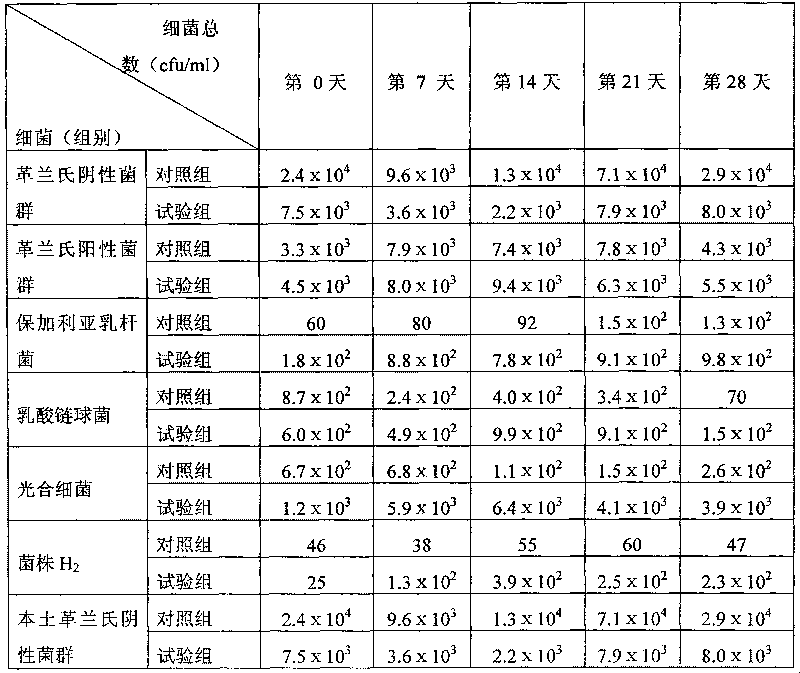

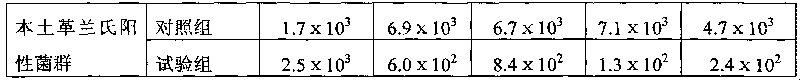

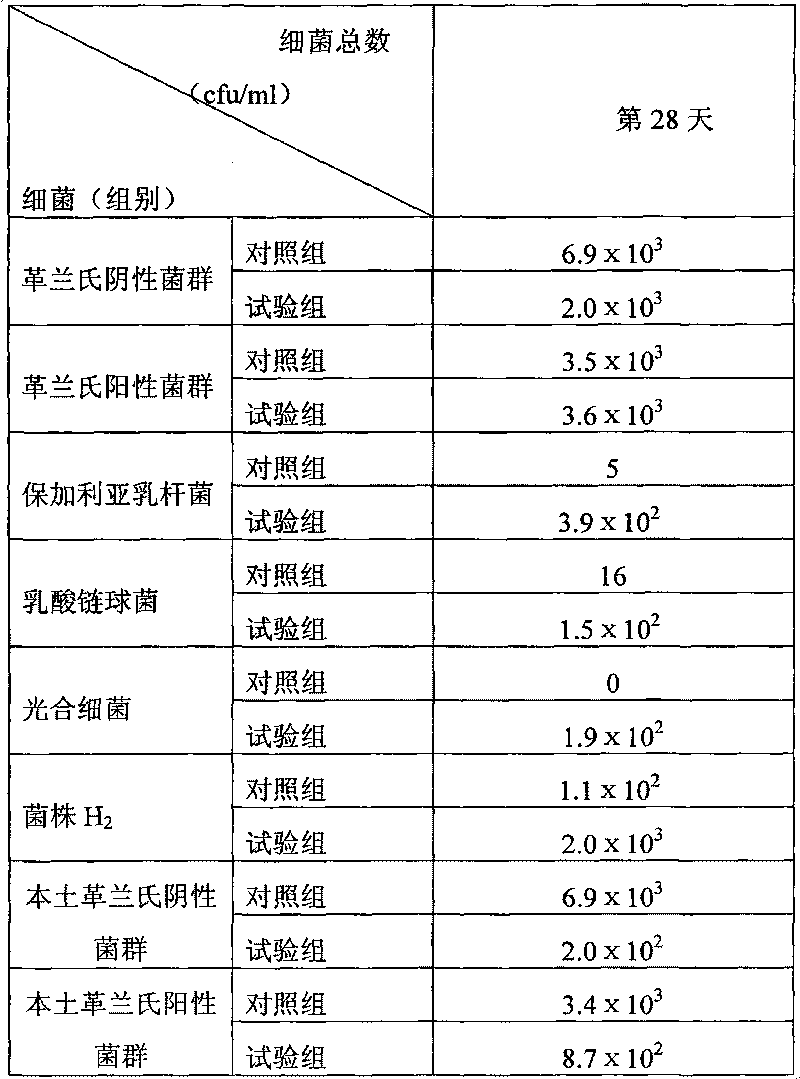

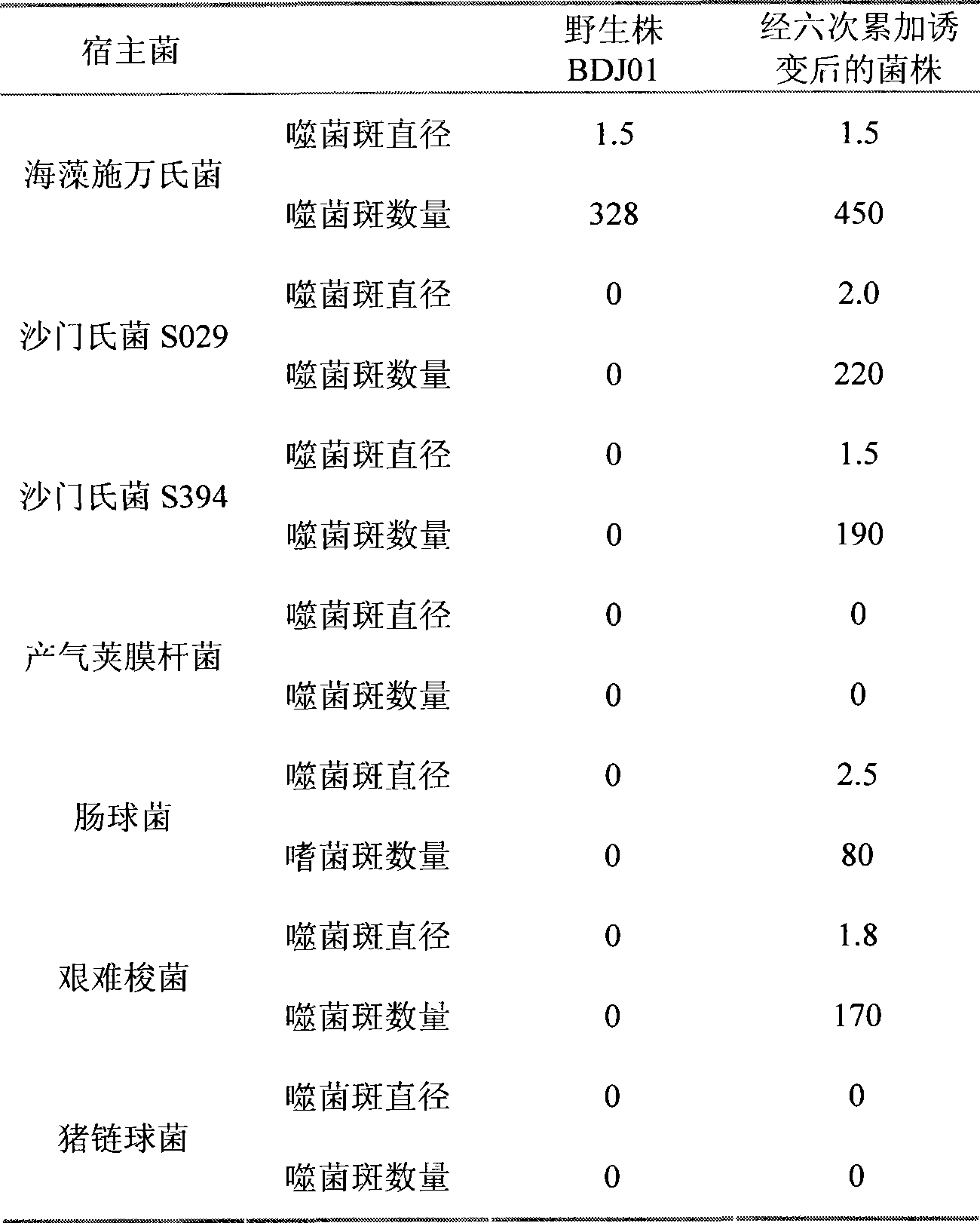

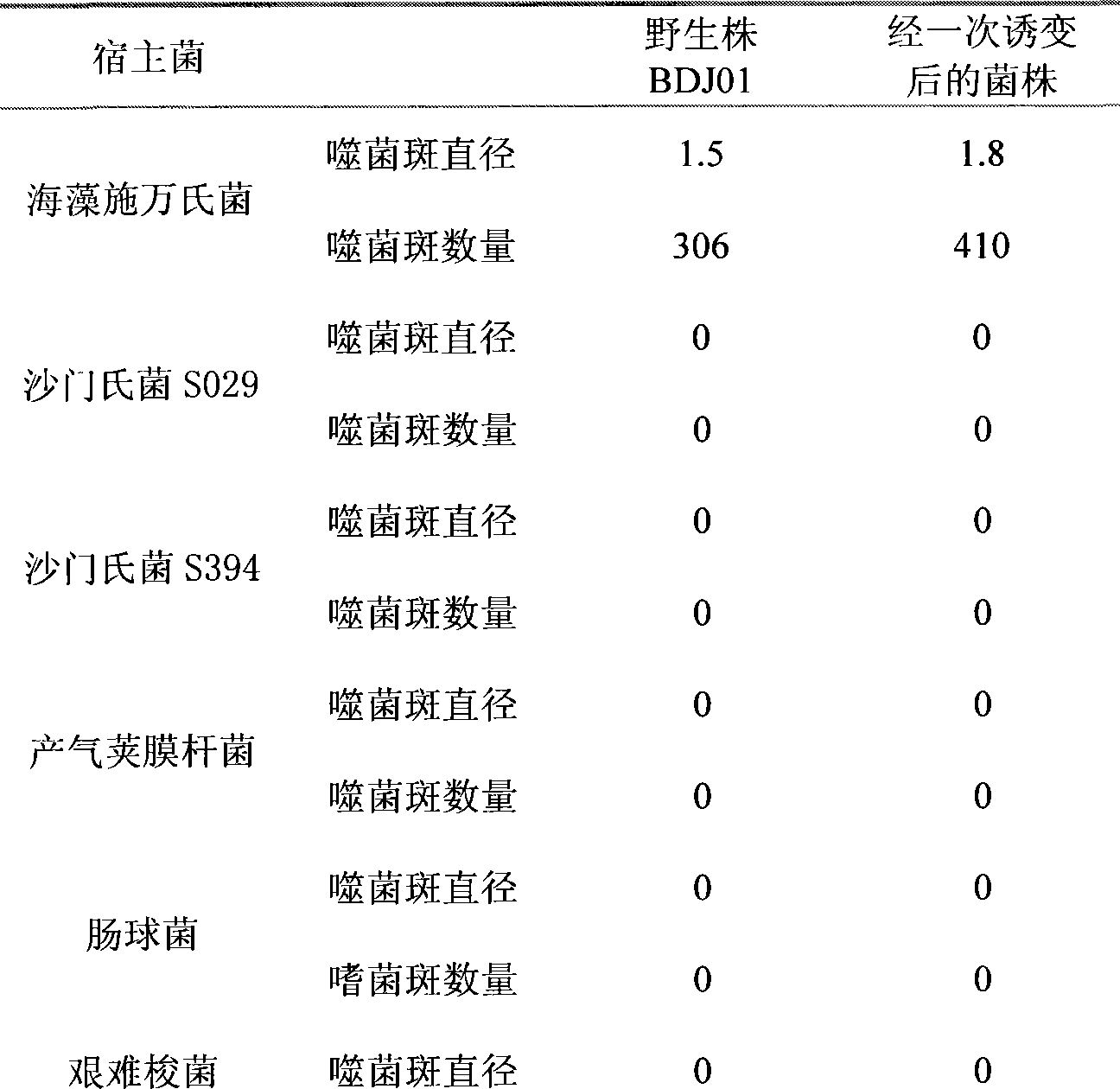

High-density bdellovibrio swim body fermenting and culturing technique

InactiveCN101173231AGuaranteed lytic activityIncreased cracking capacityBacteriaHigh densityWater source

The invention relates to fermentation culturing technology of high density Bdellovibrio telotroch, comprising the steps as following: firstly, culturing the host-germ shaking table and adding DNB liquid after centrifugating to obtain host-germ suspension; secondly; adding the host-germ suspension into the DNB liquid and then adding the Bdellovibrio to culture, at last adding DNB liquid after centrifugating to obtain Bdellovibrio concentrated solution; thirdly; adding sodium glutamate into DNB liquid and then adding the host-germ suspension, at last adding the Bdellovibrio concentrated solution to make the concentration 1 to 10<3>PFU / mL. The fermentation liquid of the Bdellovibrio with density of 10<8> to 10<14>PFU / mL can be obtained by culturing in a fermentation cylinder for four to six days and the concentrated solution of Bdellovibrio telotroch can be obtained through concentration by centrifuging. The invention has the advantages of low cost, high final concentration of Bdellovibrio and wide application range, and can be used not only in the control of water source pathogen and food pathogen, but also in fields of medical science, environmental pollution, agriculture, industry and military matters.

Owner:SOUTH CHINA UNIV OF TECH

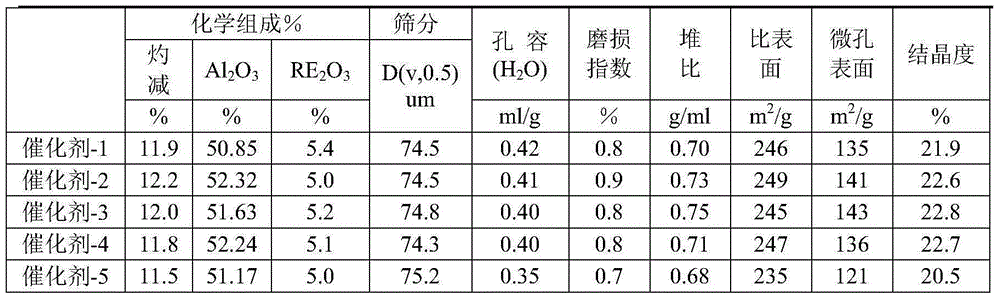

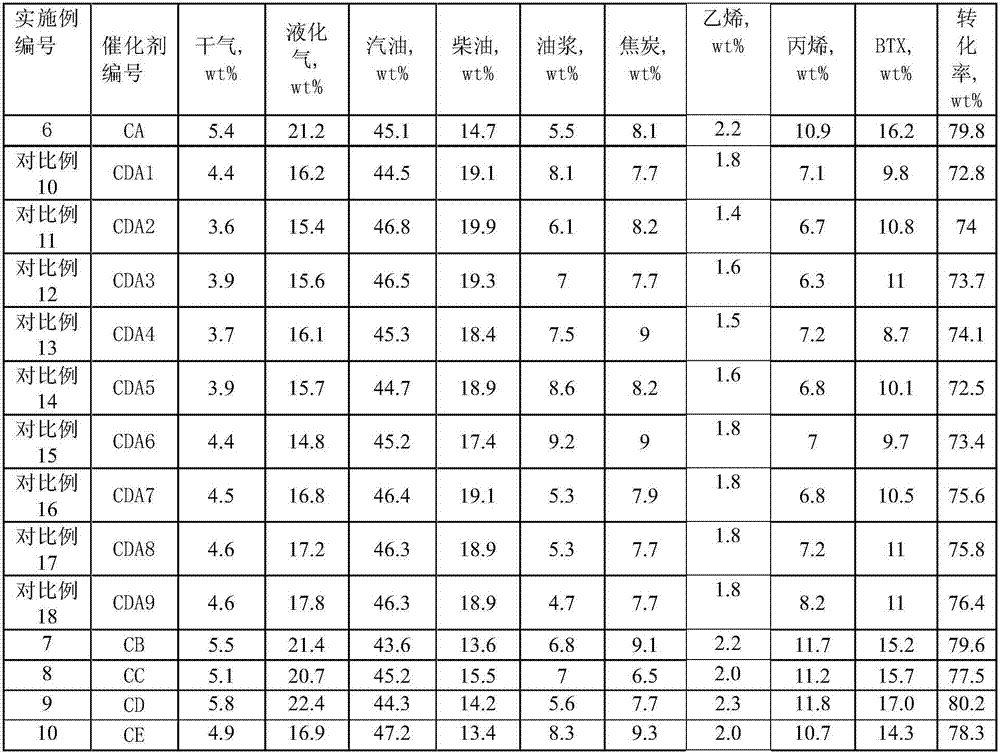

Cracking Catalyst and a Process for Preparing the Same

ActiveUS20080293561A1Increase lytic activityQuality improvementCatalytic crackingMolecular sieve catalystsMolecular sieveGasoline

A cracking catalyst, which contains alumina, phosphorus and molecular sieve, with or without clay, wherein said alumina is η-alumina or a mixture of η-alumina and χ-alumina and / or γ-alumina, and wherein the catalyst contains, on the basis of the total amount of the catalyst, 0.5-50 wt % of η-alumina, 0-50 wt % of χ-alumina and / or γ-alumina, 10-70 wt % of molecular sieve, 0-75 wt % of clay, and 0.1-8 wt % of phosphorus, measured as P2O5. The catalyst not only has higher cracking activity and higher cracking ability for cracking heavy oil, but also improves significantly quality and yield of gasoline, LCO and LPG in cracking products.

Owner:CHINA PETROCHEMICAL CORP +1

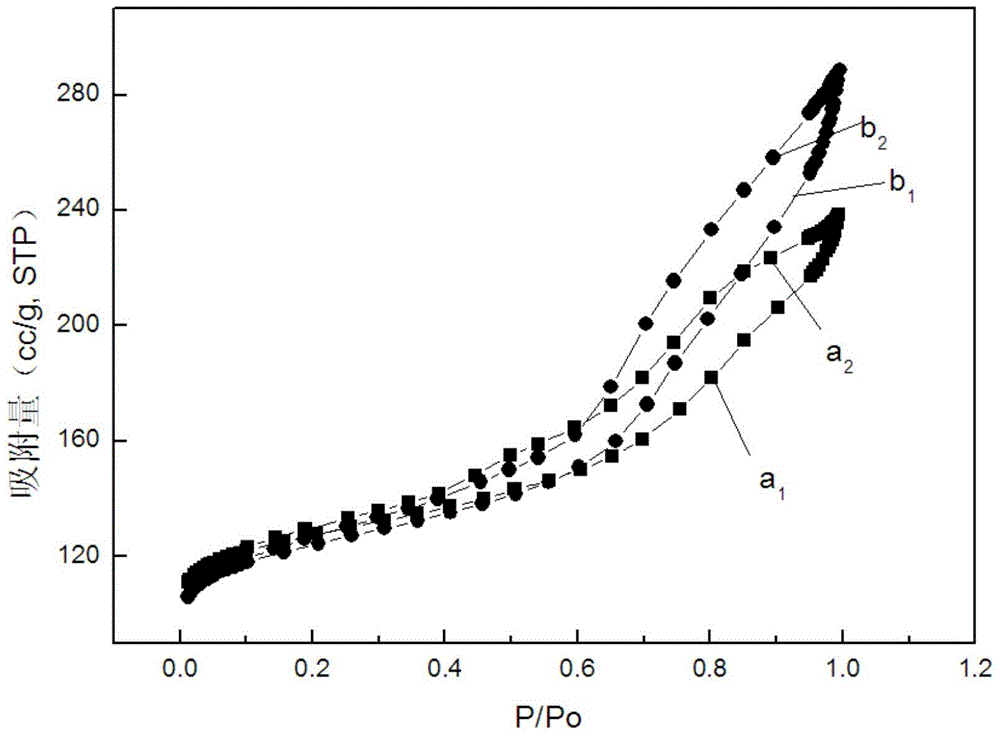

Small crystal grain Y-shaped molecular sieve and preparation method thereof

ActiveCN101723400AGuaranteed skeleton continuityReduce collapseFaujasite aluminosilicate zeoliteOxygenFluosilicates

The invention discloses a small crystal grain Y-shaped molecular sieve and a preparation method thereof. The small crystal grain Y-shaped molecular sieve has the following properties that: the molar ratio of SiO2 / Al2O3 is 5.0-20.0; the average diameter of crystal grains is 100 to 700nm; the crystallization reservation degree is over 95 percent; and the weight percentage of sodium oxide is less than or equal to 0.1 percent. The small crystal grain Y-shaped molecular sieve takes a small crystal grain NaY molecular sieve with good thermal stability and hydrothermal stability as a raw material, has a high silicon-aluminum ratio, good stability and a uniform framework, namely a silicon-aluminum structure, can uniformly remove aluminum and supplement silica in an ammonium exchanging and ammonium fluosilicate dealuminizing and silica-supplementing process, guarantees the framework continuity of the molecular sieve product, decreases the probability of framework structure collapse, and furthest reserves the integrity of the product, namely the silicon-aluminum-oxygen structure so that the product has very high crystallization reservation degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

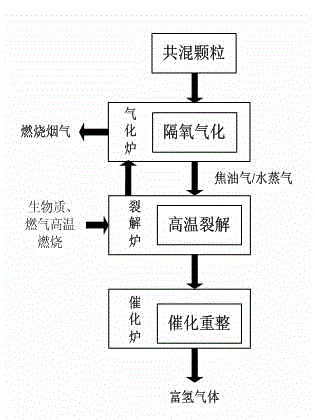

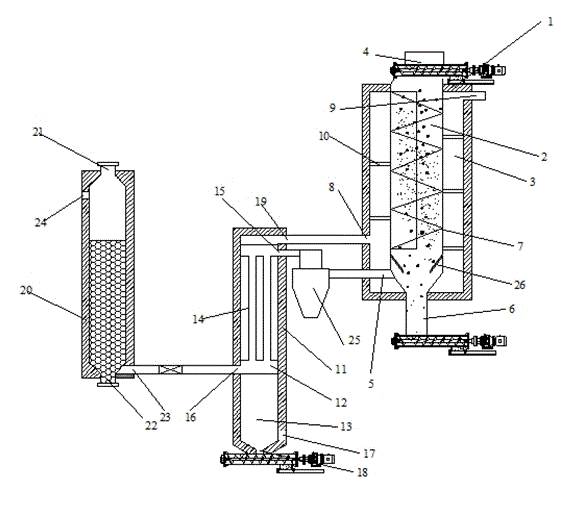

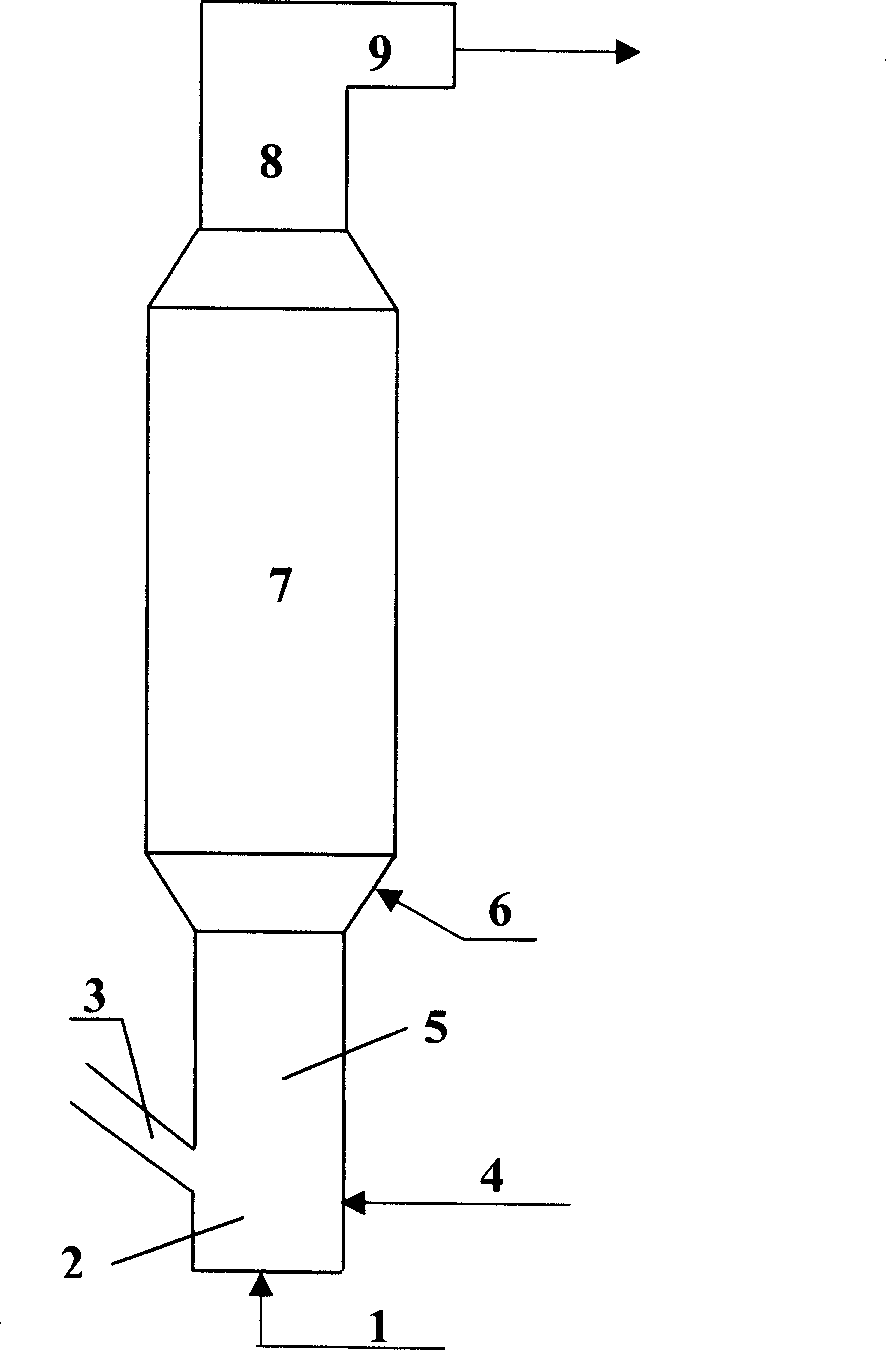

Method and device for producing hydrogen through blending and gasifying of sludge and biomass

ActiveCN103979491AReduce loadReduce catalyst carbon depositionHydrogenBulk chemical productionProcess engineeringHydrogen production

The invention provides a method and a device for producing hydrogen through blending and gasifying of sludge and biomass. The device comprises a gasification furnace, a cracking furnace and a catalytic reforming furnace. Highly humid sludge and biomass are firstly blended by the device so as to prepare into particles for gasifying, then thermal cracking is carried out on tar gas and vapor produced by gasification in the high-temperature cracking furnace, most heavy tar is converted into light tar, and the tar gas and vapor which are not cracked completely enter the catalytic reforming furnace for further catalytic reforming. According to the invention, municipal sludge, municipal organic household garbage, forestry and agricultural waste and plastic are blended and gasified to produce hydrogen. Low-cost and renewable biomass or gasified fuel gas thereof is used as a heat source for gasification of the sludge and splitting and catalytic reforming of the tar gas, so that the economic value of the biomass energy and sludge resource can be fully used; moisture in the sludge is heated and evaporated in gasification, and the generated vapor is taken as a gasification agent and hydrogen source for gasification and catalytic reforming, so that organic matters in the sludge are recycled and are converted into high-grade and high-value hydrogen energy.

Owner:深圳市远卓科技有限公司

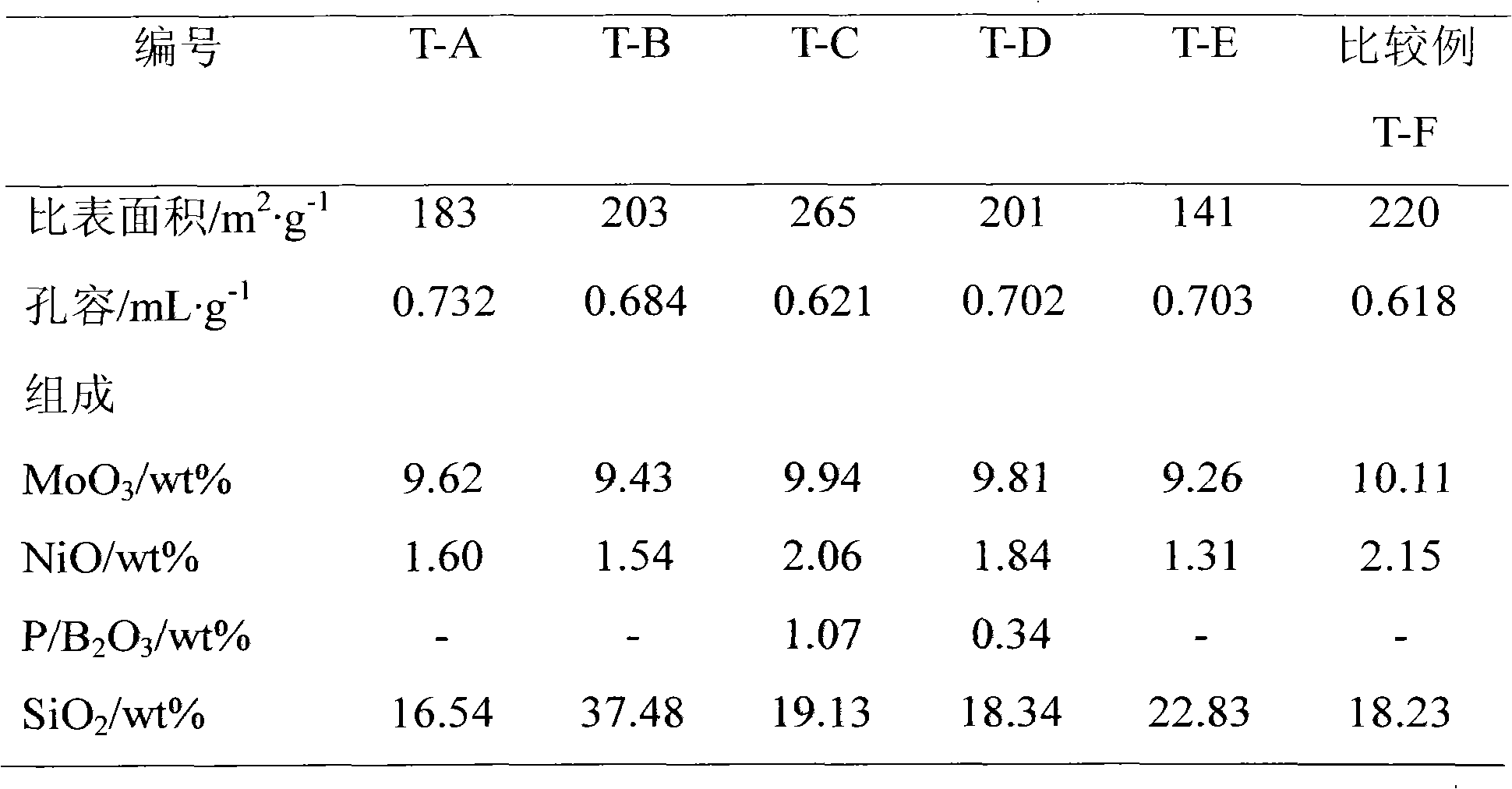

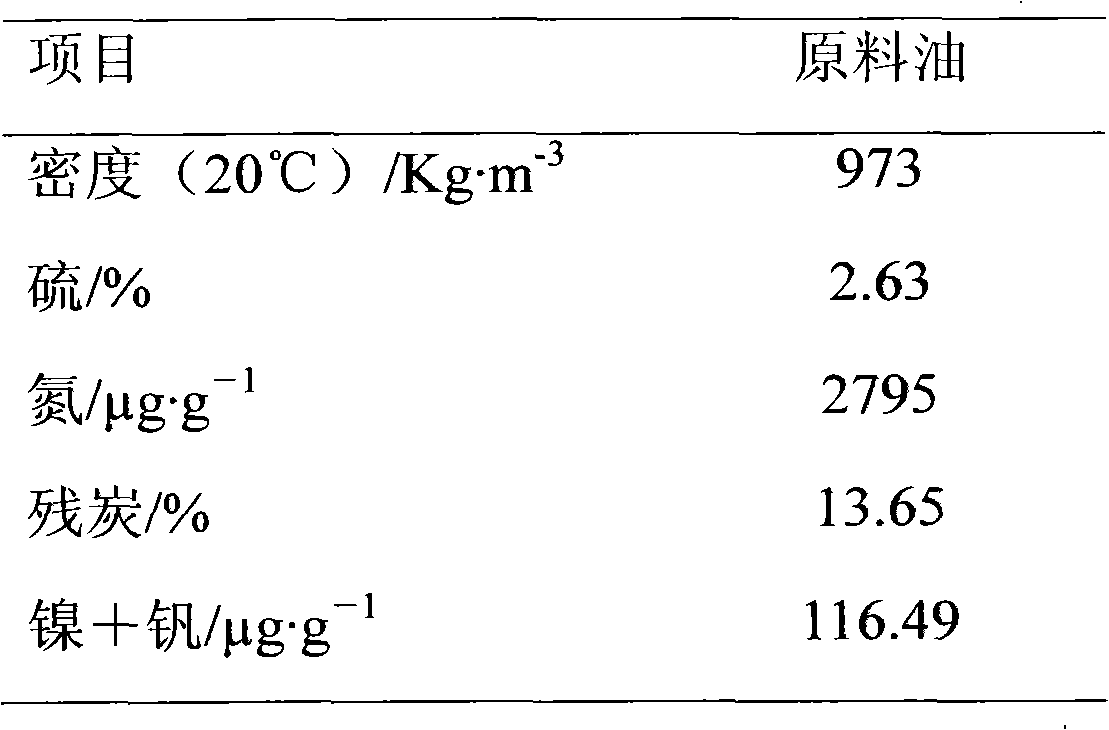

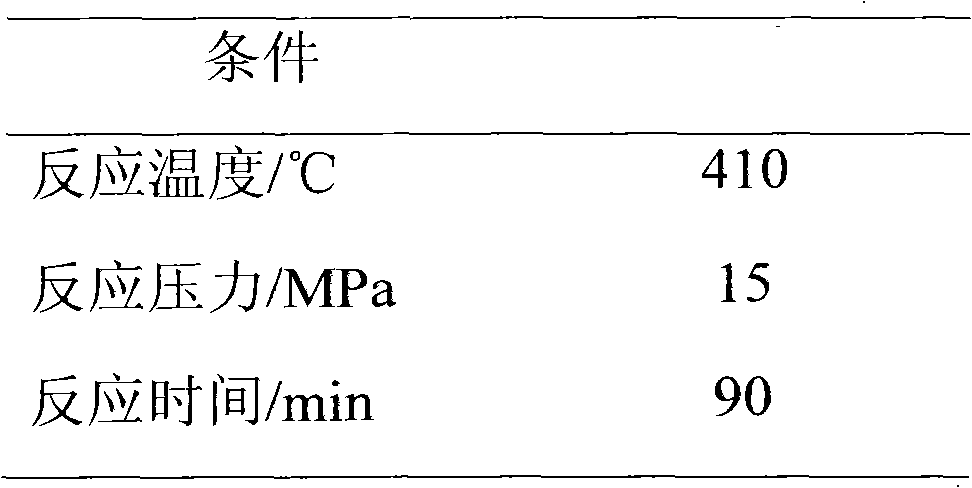

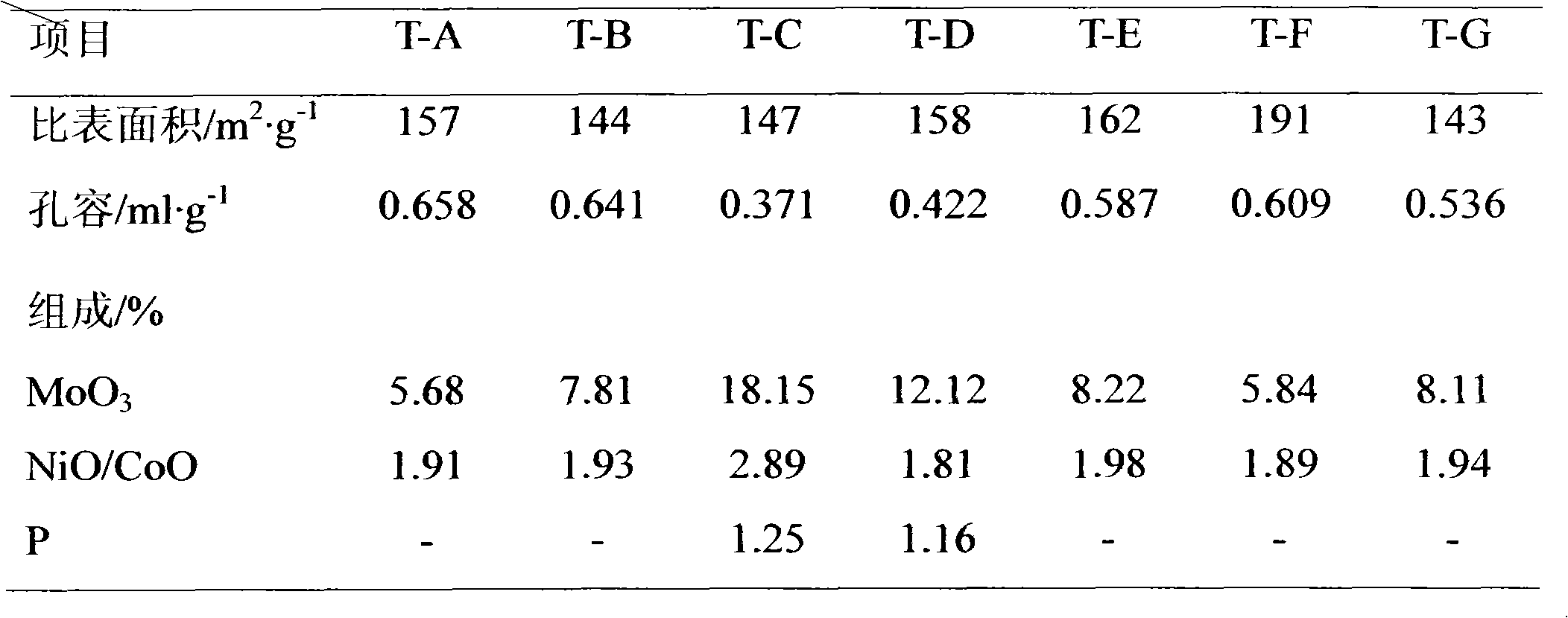

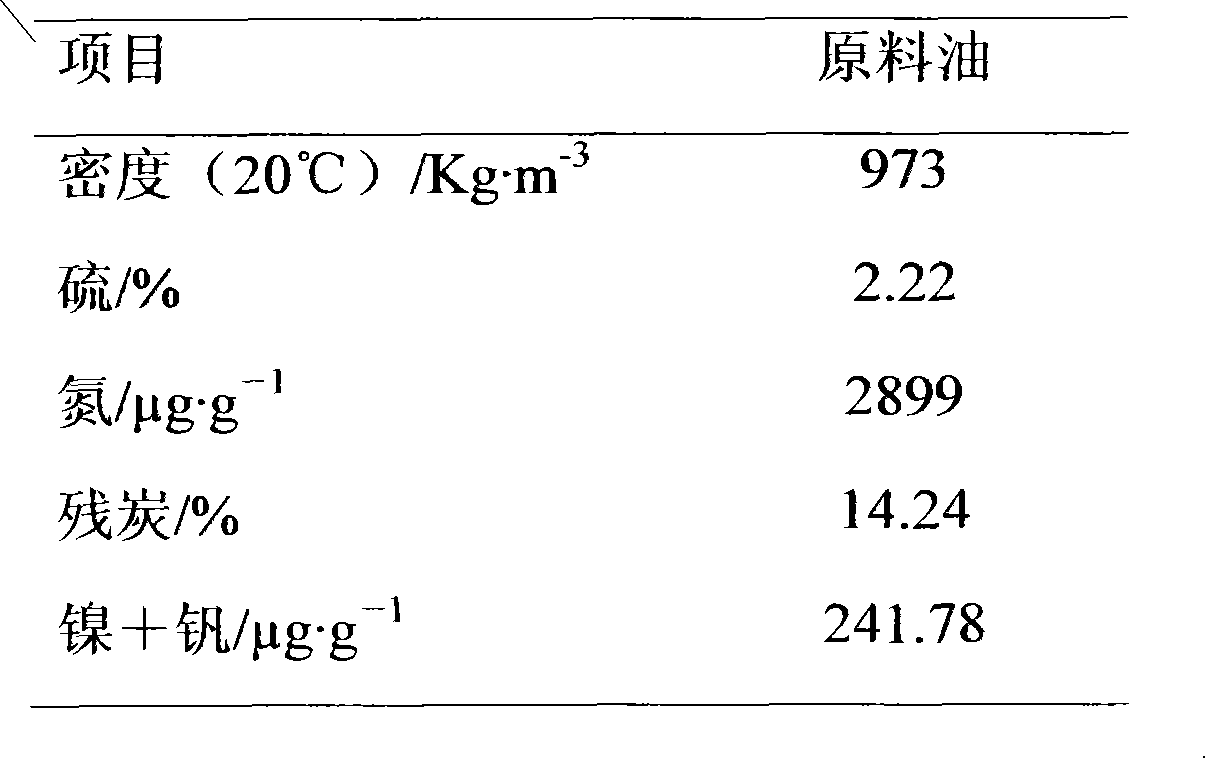

Heavy oil or residual oil hydrogenation catalyst and preparation method thereof

ActiveCN102039138AIncrease acidityImprove cracking capacityCatalyst carriersCatalyst activation/preparationFuel oilSolvent

The invention discloses a heavy oil or residual oil hydrogenation catalyst and a preparation method thereof. The catalyst carrier is prepared from silicon-containing aluminum hydroxide prepared by using a clay modified raw material as a crystal seed, active metal ingredients comprise VIII and VIB metals, and the silicon dioxide content of the catalyst is 0.1 to 45 weight percent. The preparation method for the catalyst comprises the following processes of: preparing the silicon-containing aluminum hydroxide, then adding proper glue solvent and additive for molding, performing drying and roasting to obtain the heavy oil or residual oil hydrogenation catalyst carrier, soaking the residual oil hydrogenation catalyst carrier into the active hydrogenation metal ingredients, and then performingdrying and roasting to obtain the heavy oil or residual oil hydrogenation catalyst. The physical and chemical properties and the use performance of the catalyst, particularly the use performance in the heavy oil or residual oil hydrogenation process, can be obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Residual oil hydrogenation catalyst and preparation method and use thereof

ActiveCN101491764AIncrease acidityImprove cracking capacityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationStrong acids

The invention relates to a residual oil hydrogenation catalyst, a preparation method and application thereof. The residual oil hydrogenation catalyst contains modified kaolin; the process for modifying the kaolin mainly comprises the steps of roasting and treating raw kaolin, and then treating the raw kaolin with mixed acid of strong acid and weak acid; and the modified kaolin has larger aperture and proper surface property, and is properly used as a carrier material of the residual oil hydrogenation catalyst. The residual oil hydrogenation catalyst adopts an impregnation method to load active metal components of VIB and VIII families; and the prepared catalyst can be applied in the field of hydrogenation demetallization, hydrogenation desulfurization, hydrogenation conversion, and the like of heavy oil or residual oil, and has good using performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

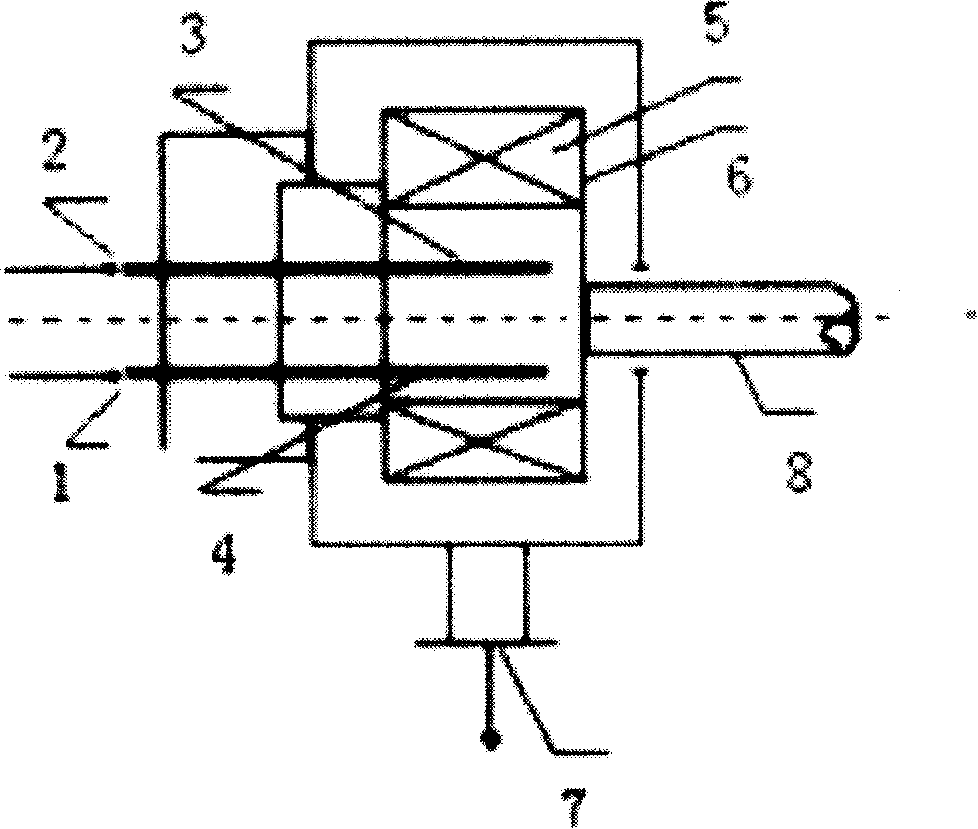

Method for catalytic cracking petroleum hydrocarbons

This invention discloses a method for catalytically pyrolyzing petroleum hydrocarbons. The method comprises: (1) introducing preheated petroleum hydrocarbons into a pyrolysis reactor containing two reaction zones; (2) catalytically pyrolyzing in the presence of water vapor and a hot catalytically pyrolyzing in the presence of water vapor and a hot catalyst in the first and the second reaction zones sequentially. The reaction temperature and time in the first reaction zones are 495-550 deg.C and 0.5-20 s, and those in the second reaction zone are 460-495 deg.C and 2-30 s. The catalyst comprises: Y-type zeolite modified with Zn and rare earth metals 25-50 wt.%, clay 20-50 wt.%, and inorganic oxides 20-50 wt.%. The contents of the Y-type zeolite are 0.5-10 wt. %, respectively. The method can lower the olefin content, and increase the lightweight oil yield in the products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Microbial inoculum for improving water body and structure of biological intestinal colony, and preparation method and application thereof

Owner:SOUTH CHINA UNIV OF TECH

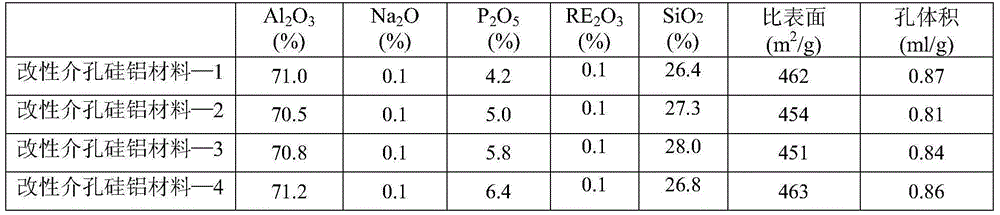

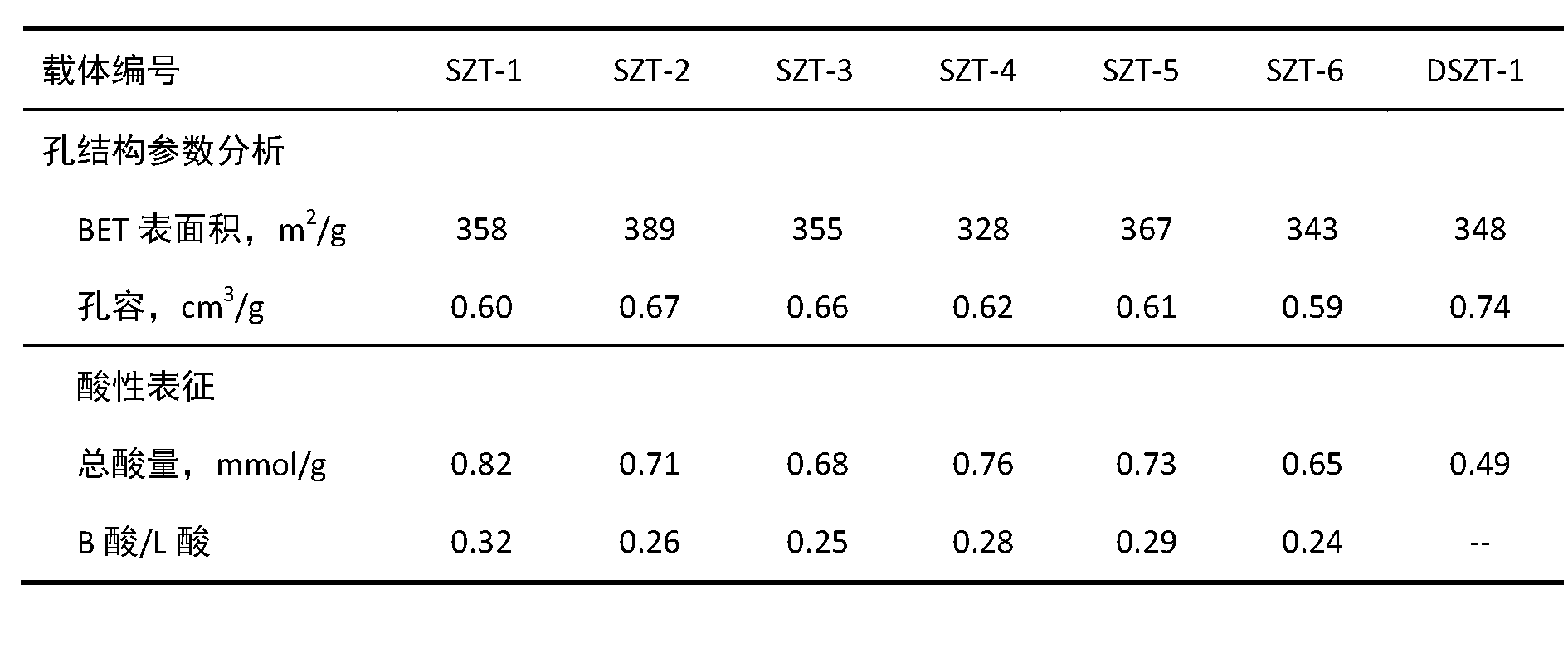

Preparation method of modified mesoporous silicon-aluminum material

ActiveCN105126928AImprove cracking capacityHigh hydrothermal stabilityCatalyst carriersHigh concentrationRare earth

The invention discloses a preparation method of a modified mesoporous silicon-aluminum material. The modified mesoporous silicon-aluminum material has a pseudo-boehmite physical structure. The anhydrous chemical formula of the material by the weight of oxides is (0-8)P2O5(0-0.1)Na2O*(20-30)SiO2*(70-80)Al2O3(0-1.0)RE2O3. The specific area is 200 to 500 m2 / g, and the pore volume is 0.5 to 1.5 mL / g. The preparation method comprises the following steps: step one, adding a low-concentration aluminum source into a silicon source solution, controlling the pH in a range of 10.3 to 10.8, and carrying out stationary aging for 0.5 to 3 hours; step two, adding phosphor-aluminum gel and a high-concentration aluminum source into the previous solution according to a certain ratio, and controlling the pH in a range of 3.4 to 3.8; step three, adding a rare earth solution according to a certain ratio; step four, adjusting the pH of the previous slurry to 8.0-9.0 by an alkaline solution; step five, filtering the slurry, and washing the solids by deionized water and ammonium salt. The provided modified mesoporous silicon-aluminum material can be used as the carrier of FCC catalyst, has a proper pore volume and acidic property, and is capable of performing pre-cracking on macromolecular raw oil. RE2O3 exists in a deposited state of oxides and can prevent the metal pollution, so the provided material can improve the heavy oil cracking performance of FCC catalyst, moreover, the hydrothermal stability of FCC catalyst is good, and the coke selectivity is excellent.

Owner:QINGDAO HUICHENG PETROCHEM TECH

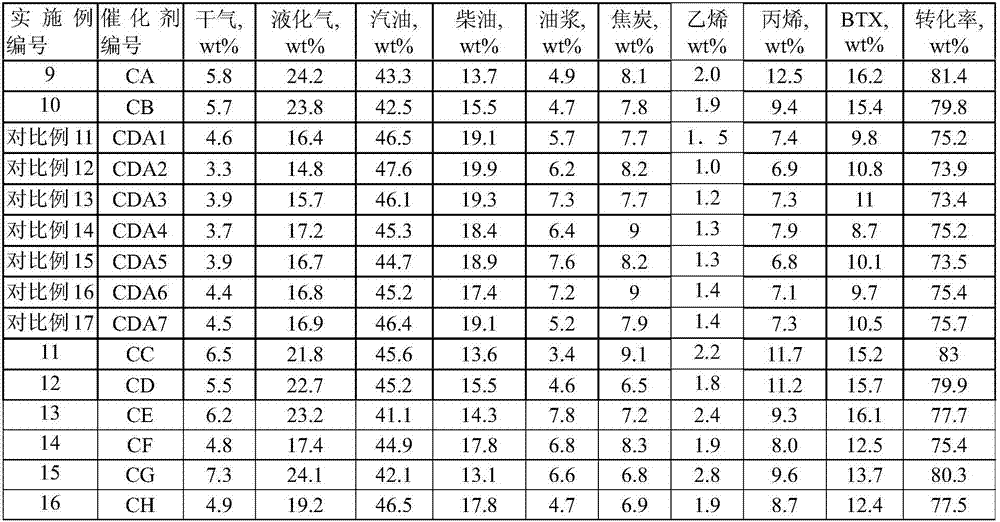

Catalytic cracking catalyst and preparation method thereof

ActiveCN107971015AMesopore richPromote generationCatalytic crackingMolecular sieve catalystsMolecular sieveStrong acids

The invention provides a catalytic cracking catalyst and a preparation method thereof, wherein the catalyst comprises 15-65% of natural minerals, 10-60% of an oxide, and 25-75% of a Y type molecular sieve and a phosphorus-containing and supported-metal-containing MFI-structure molecular sieve, wherein the n(SiO2) / n(Al2O3) of the phosphorus-containing and supported-metal-containing MFI-structure molecular sieve is more than 18 and less than 70, the Al distribution parameter D is more than or equal to 0.6 and is less than or equal to 0.85, the volume of the mesopores accounts for 50-80% of the total pore volume, the volume of the mesopores with the pore size of 2-20 nm accounts for more than 85% of the total mesopore volume, the amount of the strong acid accounts for 50-80% of the total acidamount, a ratio of the acid B to the acid L is 7-30, the phosphorus content is 1-15 wt%, and the supported metal content is 0.1-5 wt%. The preparation method comprises: carrying out mixing beating onthe phosphorus-containing and supported-metal-containing MFI-structure molecular sieve, the Y type molecular sieve, the natural minerals and an inorganic oxide binder, and carrying out spray drying.According to the present invention, the catalytic cracking catalyst has the high low-carbon olefin yield in the catalytic cracking of petroleum hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Boiler wet slag removal system

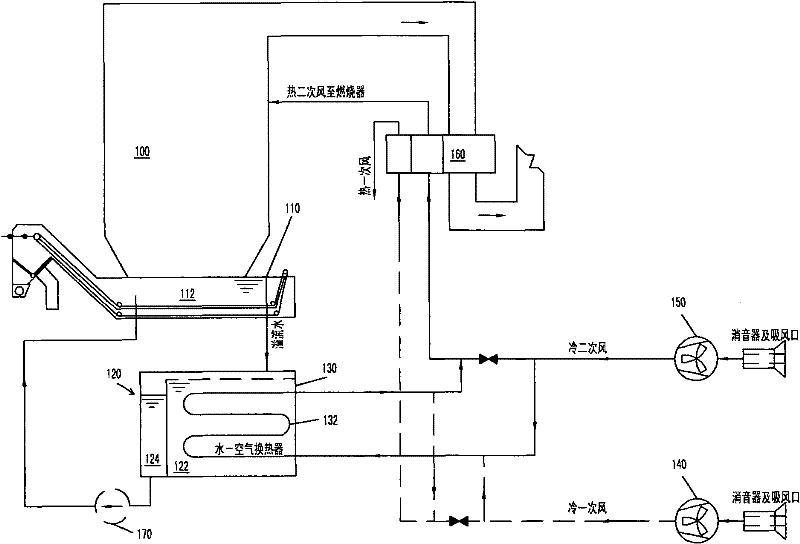

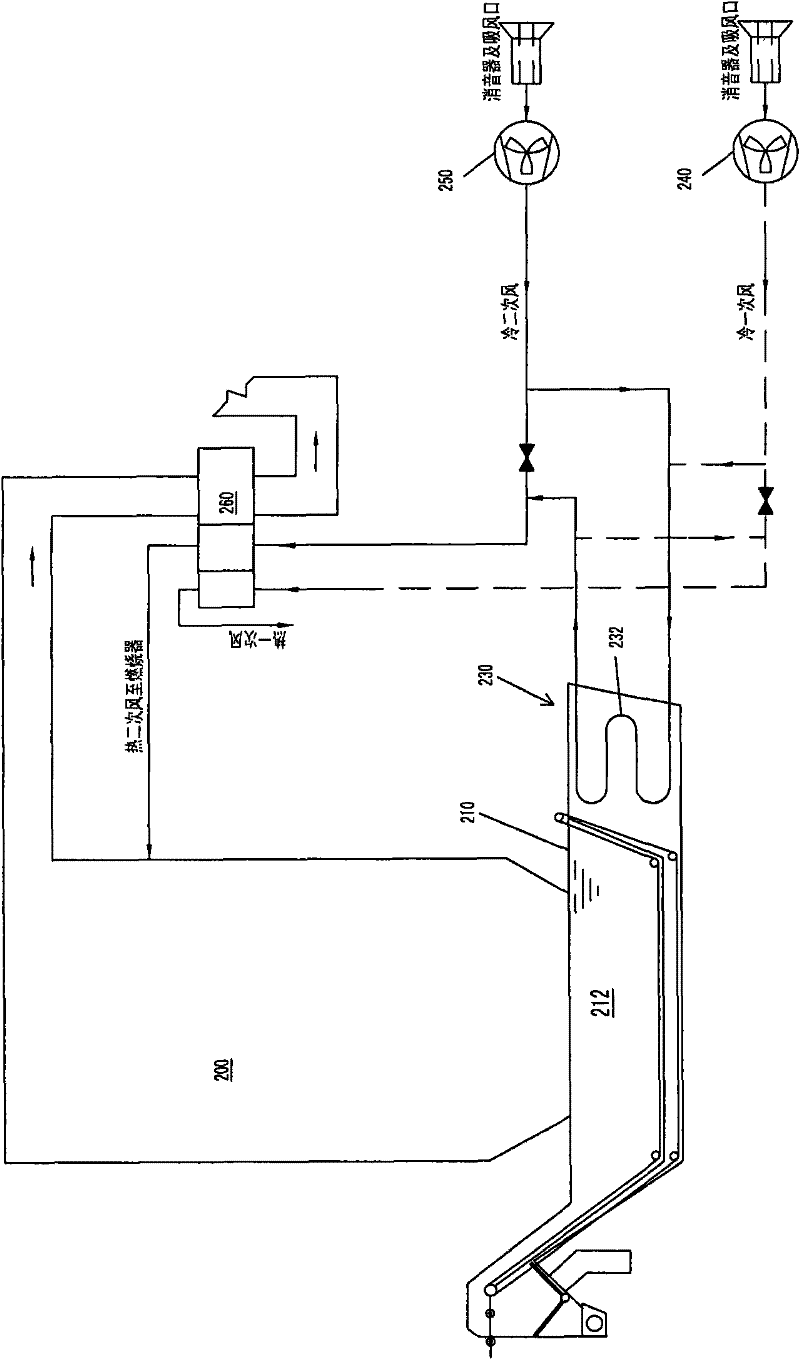

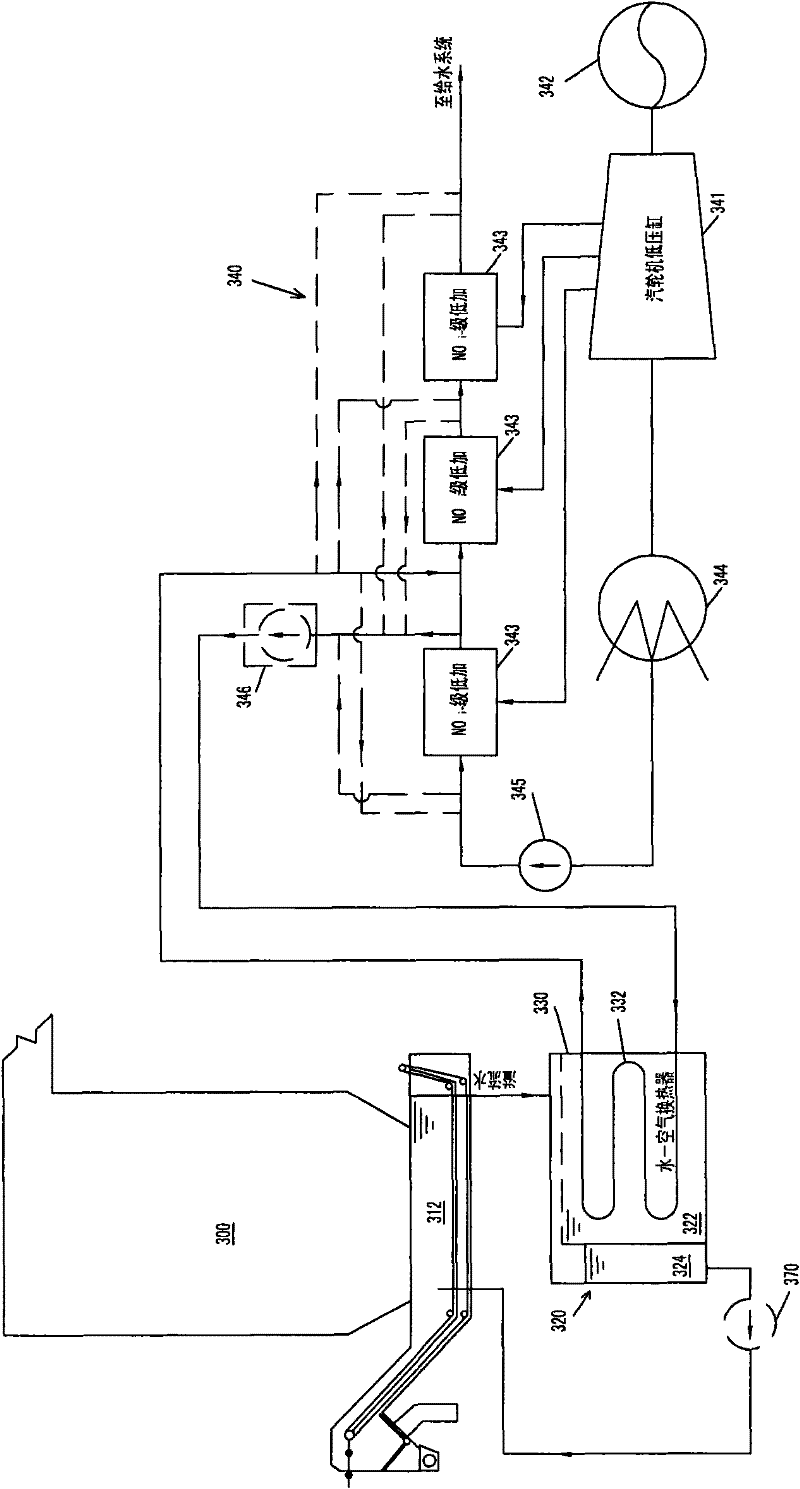

InactiveCN102287835AIncrease power generationReduce fuel consumptionCombustion processMachines/enginesAir preheaterBottom ash

The invention relates to a boiler wet slag removal system, which comprises a slag extractor and a heat exchanger. The slag extractor is located under the boiler and has a water tank for receiving boiler bottom slag. The heat exchanger includes a heat exchange surface, one side of the heat exchange surface introduces the water in the water tank as the first heat exchange medium, and the other side of the heat exchange surface is the flowing second heat exchange medium to absorb the water in the water tank energy. In one solution of the present invention, the second heat exchange medium can be air, which is provided by the blower or the primary blower of the boiler, and is sent to the air preheater for the boiler together with the cold air of the blower or the primary blower after being heated . In another solution of the present invention, the second heat exchange medium can be condensed water, which is provided by one or more low-pressure heaters of the steam turbine condensate system, and is heated and delivered to one or more low-pressure heaters . In this way, the waste heat of the slag can be recovered, which simplifies the structure of the wet slag removal system and reduces the water consumption.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

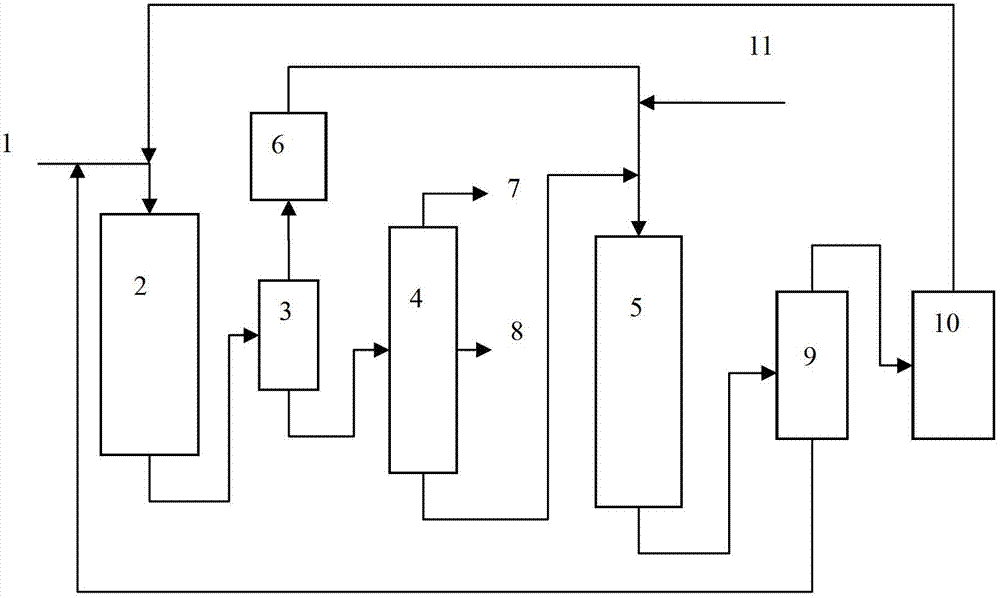

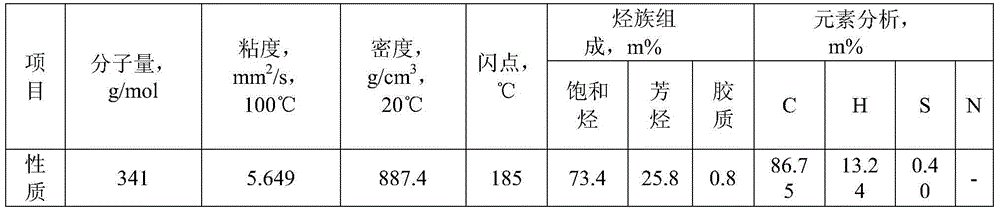

Two-stage hydrogenation process of coal tar

ActiveCN102851071AHigh yieldOvercome expensiveTreatment with hydrotreatment processesPtru catalystThermodynamics

The invention discloses a two-stage hydrogenation process of coal tar. The process comprises the steps of: (a) sending a coal tar raw material into a hydrotreating reaction section, and carrying out a hydrotreating reaction on the coal tar by contacting with a hydrotreating catalyst in the presence of hydrogen and under hydrogenation conditions; (b) carrying out gas-liquid separation on an effluent from the hydrogenating reaction section, and sending a separated liquid phase into the a fractionation device, in order to distillate out a light fraction and a heavy fraction; (c) sending at least part of the heavy fraction from the step (b) into a hydrocracking reaction section, and carrying out a hydrocracking reaction on the heavy fraction by contacting with a hydrocracking catalyst in the presence of hydrogen and under hydrogenation cracking conditions; and (d) sending an effluent from the hydrocracking reaction section into a hot high pressure separator, in order to separate out a gas phase and a liquid phase, and sending at least part of the liquid phase to the hydrotreating reaction section in the step (a). Compared with the prior art, the method provided by the invention improves the yield of light fuel production from coal tar, prolongs the service life of a catalyst, and increases operation cycle of the device.

Owner:上海竣铭化工工程设计有限公司

ZSM-5 molecular sieve limited rhodium monatomic catalyst and preparation method thereof

ActiveCN107890881AImprove stabilityExtended service lifeChemical analysis using catalysisMolecular sieve catalystsCalcinationZSM-5

The invention relates to a preparation method of a ZSM-5 molecular sieve limited rhodium monatomic catalyst. The technical problems that in the prior art, the precious metal catalyst preparation costis high, the atom utilization rate is low, and the high-temperature reaction stability is poor are solved. The ZSM-5 molecular sieve limited rhodium monatomic catalyst is obtained through the steps that a rhodium-containing radical group is dispersed in a ZSM-5 molecular sieve through one-step crystallization, calcination is conducted in a fixed atmosphere in a high temperature furnace, the rhodium radical group can be promoted to be decomposed into rhodium atoms, and single atoms in the molecular sieve are dispersed. Accordingly, the catalyst preparation method is simple, the utilization rateof the precious metal rhodium is increased, the preparation cost of the rhodium-based catalyst is lowered, the stability of the rhodium atoms is improved, and the service life of the catalyst is prolonged. The catalyst has the channel confinement effect and the size effect simultaneously, the pyrolysis capacity of methane in the active site can be improved, and a methane synthesis gas reaction can be greatly promoted.

Owner:TAIYUAN UNIV OF TECH

Catalyst for preparing low carbon olefin by petroleum hydrocarbon cracking

InactiveCN1205306CImprove cracking capacityHigh reaction conversion rateCatalytic crackingFuel oilPetroleum

Owner:CHINA PETROLEUM & CHEM CORP +1

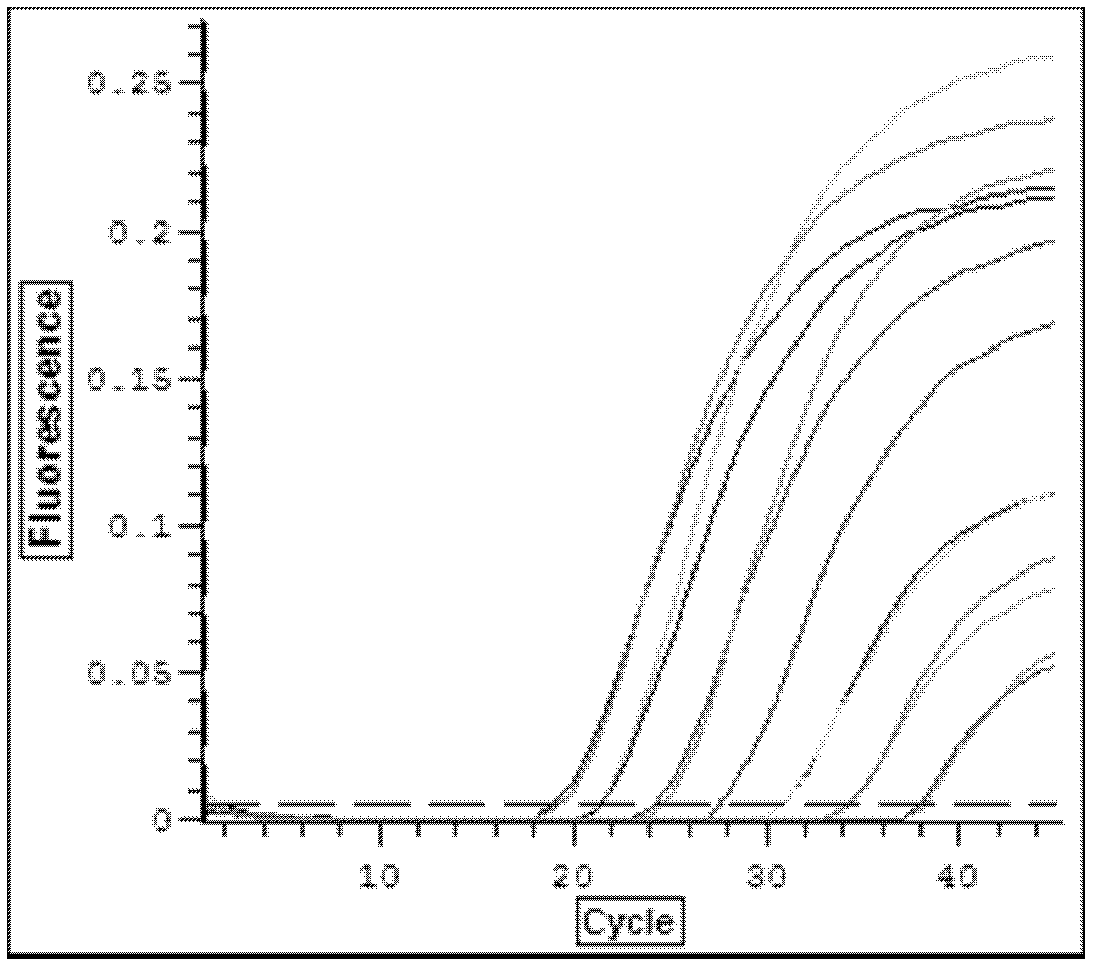

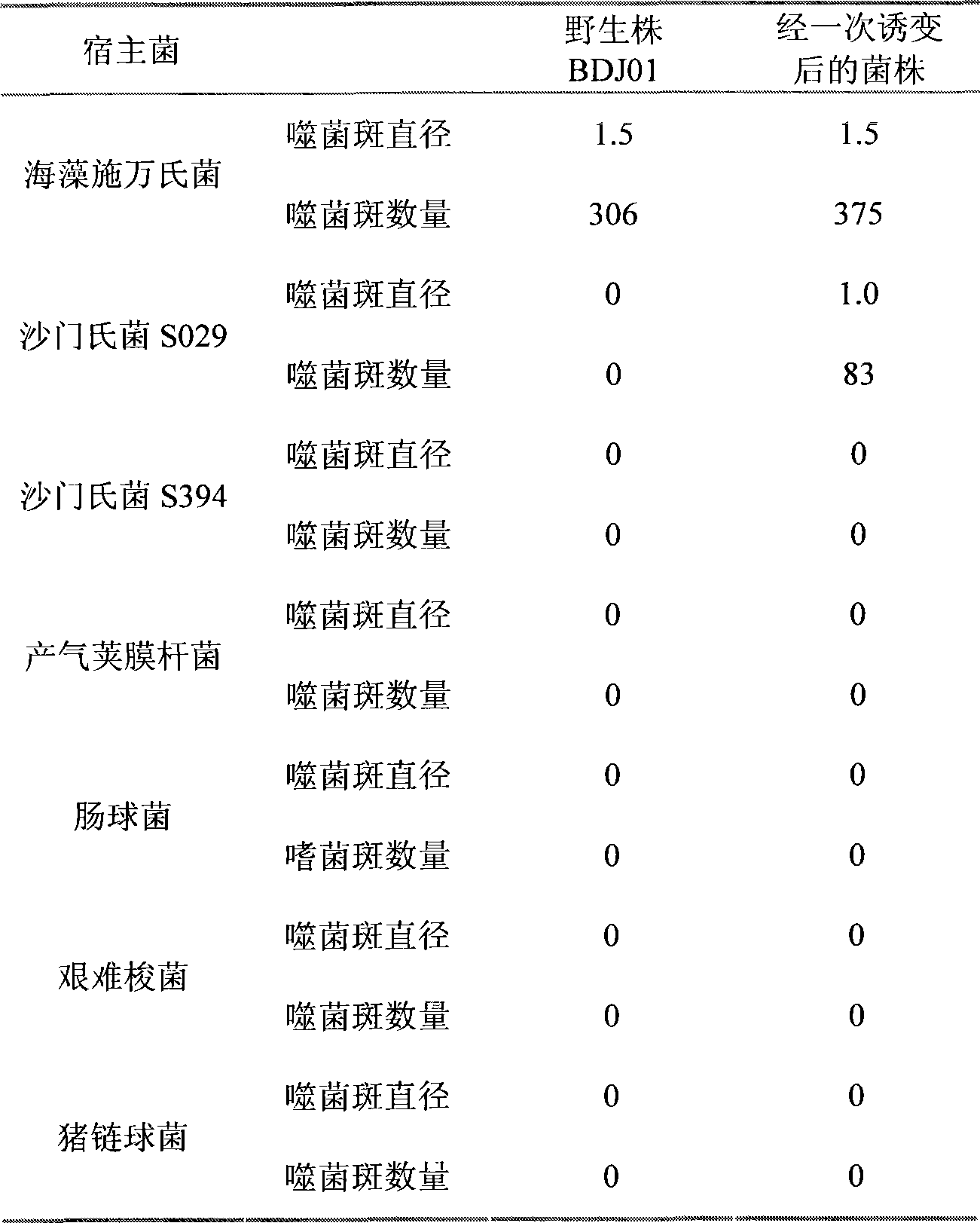

One-tube magnetic bead method for extraction of virus nucleic acid for fluorescent quantitative detection

InactiveCN102605102AImprove cracking capacityThorough and fast lysisMicrobiological testing/measurementMicroorganism based processesFluorescenceMagnetic bead

The invention relates to a one-tube magnetic bead method for extraction of virus nucleic acid for fluorescent quantitative detection, which belongs to the technical field of biological nucleic acid application and includes: firstly, preparing lysis solution, adding the lysis solution and magnetic beads into a tube strip, adding a sample of virus nucleic acid into the tube strip, and mixing well to lead the magnetic beads to fully absorb the virus nucleic acid; secondly, placing magnetic bead mixed liquor on a magnetic carrier, and allowing the liquor to stand for seconds to separate the magnetic beads and solution; and thirdly, rinsing for protein removal and desalination, and drying in air at room temperature. The method is simple and quick, less apt to cause pollution and high in flexibility. By the method, extracting efficiency is high, nucleic acid purity is high, testing repeatability is good, compatibility to amplification reagents is high, production cost is reduced, operation accuracy is improved, and works such as clinical diagnosis, medicolegal identification and the like are facilitated greatly.

Owner:TIANGEN BIOTECH BEIJING

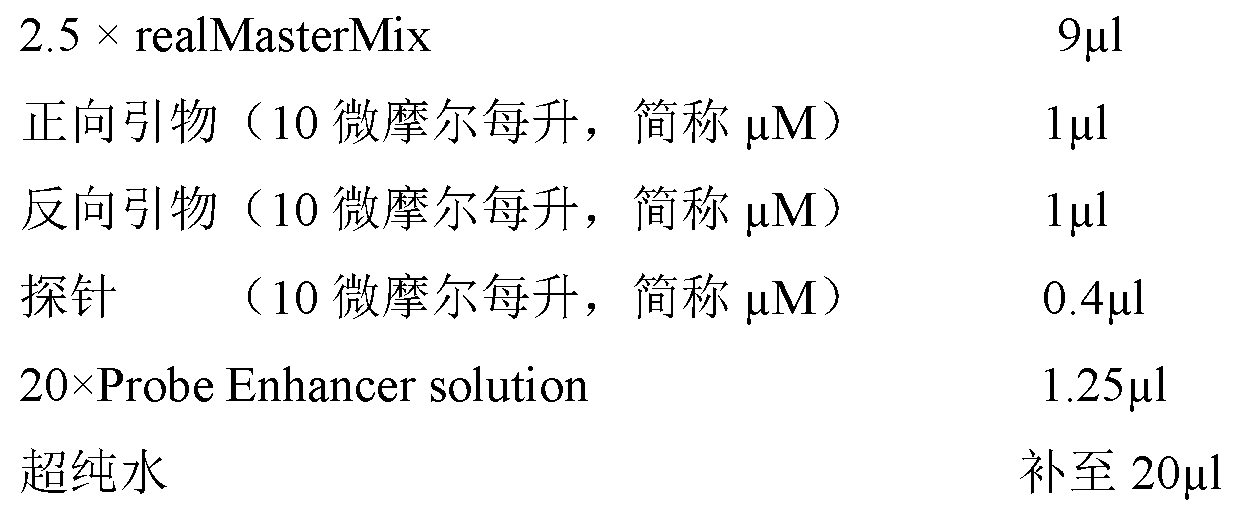

Use of UV induction mutation for reinforcing cracking performance of Bdellovibrio

InactiveCN101440362AIncreased cracking capacityExpand the scope of applicationMutant preparationElectrical/wave energy microorganism treatmentClostridium difficile (bacteria)Mutagenic Process

The invention belongs to the technical field of mutation breeding of microorganisms, and particularly relates to application of ultraviolet-induced mutation in the strengthening pyrolysis performance of bdellovibrio bacteria. The application takes the ultraviolet-induced mutation as a main way and is assisted with an infrared light source and LiCl enhanced mutagenesis to perform induced mutation under the slow stirring, the time is between 2 and 8 minutes, and the radiation distance is between 5 and 20 centimeters; and the bdellovibrio bacteria is preserved under dark light and ice bath conditions and is accumulatively mutagenized until the requirement is achieved. The application has a simple method and convenient operation, has remarkable effect on strengthening the pyrolysis performance of the bdellovibrio bacteria, can pyrolyze two salmonella strains which fail to be pyrolyzed originally and a plurality of Gram-positive bacteria (including bacillus aerogenes capsulatus, clostridium difficile, streptococcus suis and enterococcus) proven by the experiment, solve the problems that usually the bdellovibrio bacteria can not pyrolyze the Gram-positive bacteria and the pyrolysis ability is extremely weak even if the bdellovibrio bacteria can pyrolyze the Gram-positive bacteria, and widen the application range of the bdellovibrio bacteria.

Owner:SOUTH CHINA UNIV OF TECH

Catalytic cracking catalyst and preparation method thereof

ActiveCN107971028AMesopore richPromote cracking reactionCatalytic crackingMolecular sieve catalystsMolecular sieveStrong acids

The invention provides a catalytic cracking catalyst and a preparation method thereof, wherein the catalyst comprises 15-65% of natural minerals, 10-60% of an oxide, and 25-75% of a Y type molecular sieve and a phosphorus-containing IMF-structure molecular sieve, wherein the n(SiO2) / n(Al2O3) of the phosphorus-containing IMF-structure molecular sieve is more than 18 and less than 70, the phosphoruscontent is 1-15 wt%, the Al distribution parameter D is more than or equal to 0.6 and is less than or equal to 0.85, the volume of the mesopores accounts for 40-70% of the total pore volume, the volume of the mesopores with the pore size of 2-20 nm accounts for more than 85% of the total mesopore volume, the amount of the strong acid accounts for 45-75% of the total acid amount, and a ratio of the acid B to the acid L is 8-30. According to the present invention, the catalytic cracking catalyst has high low-carbon olefin yield and high BTX yield in the catalytic cracking of petroleum hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

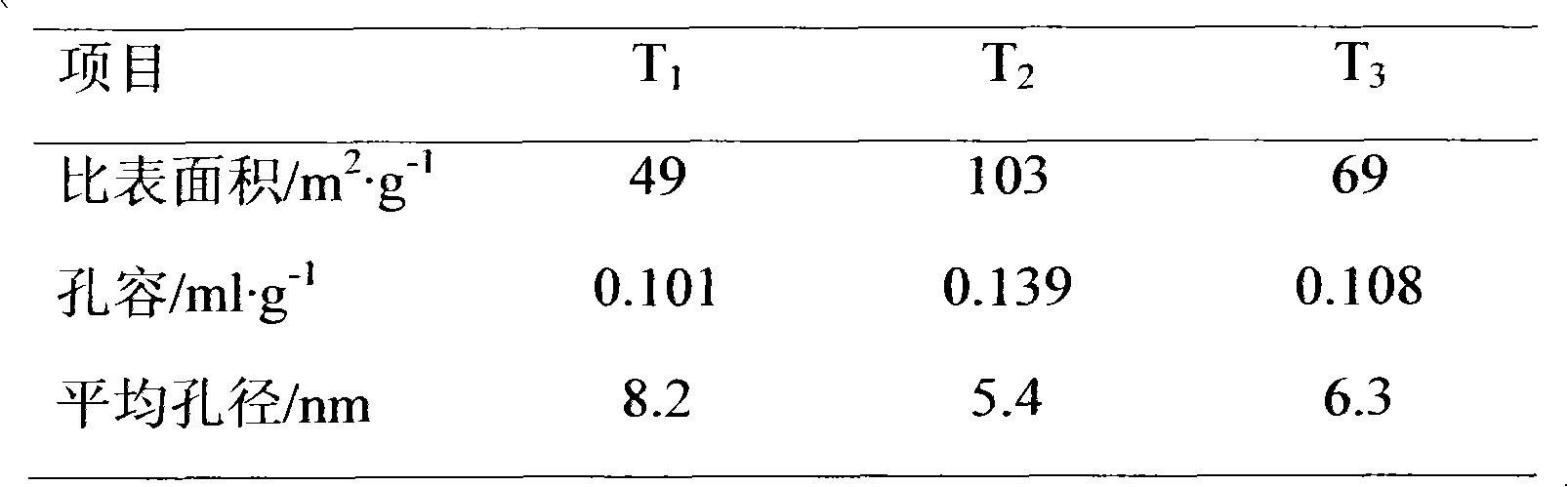

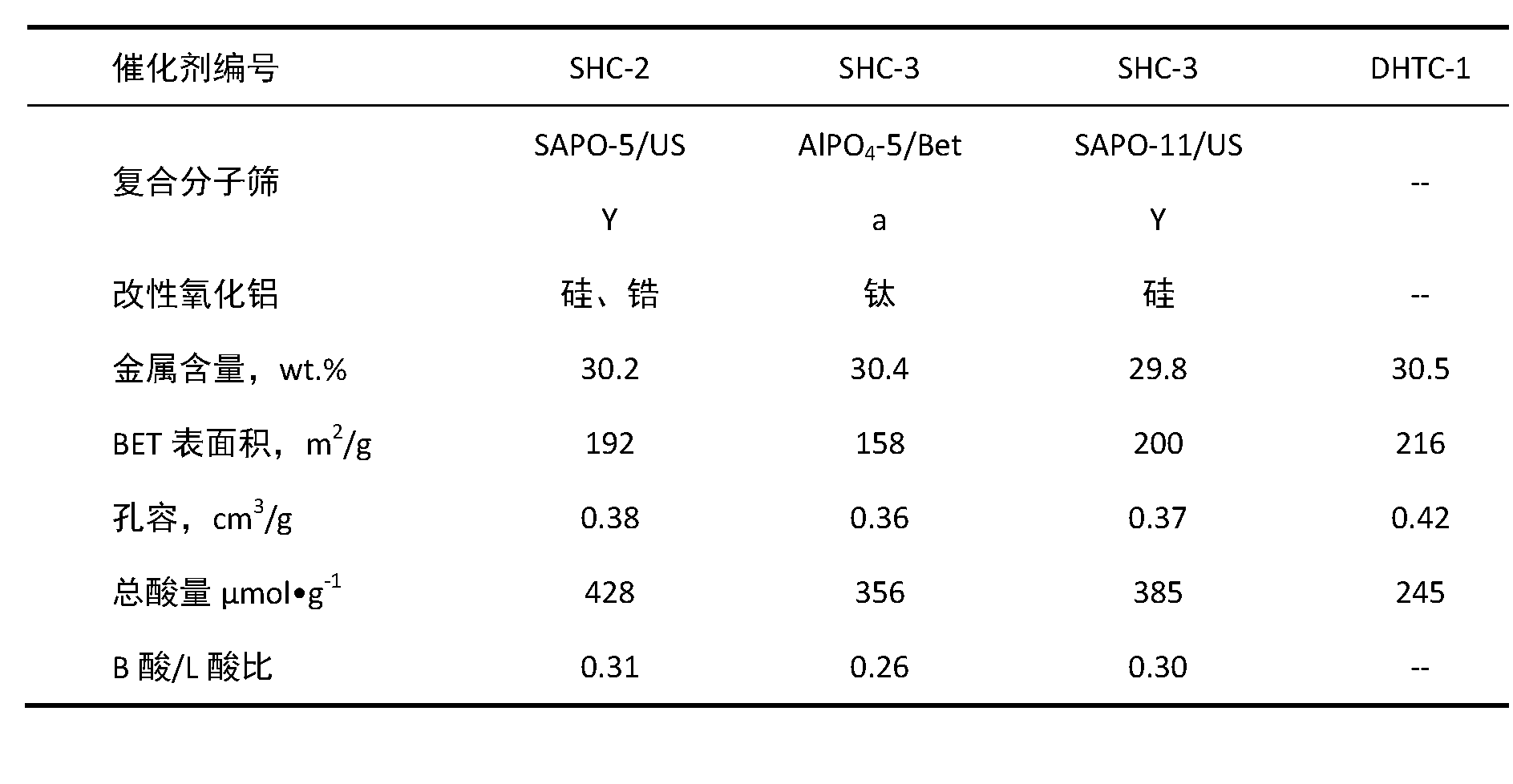

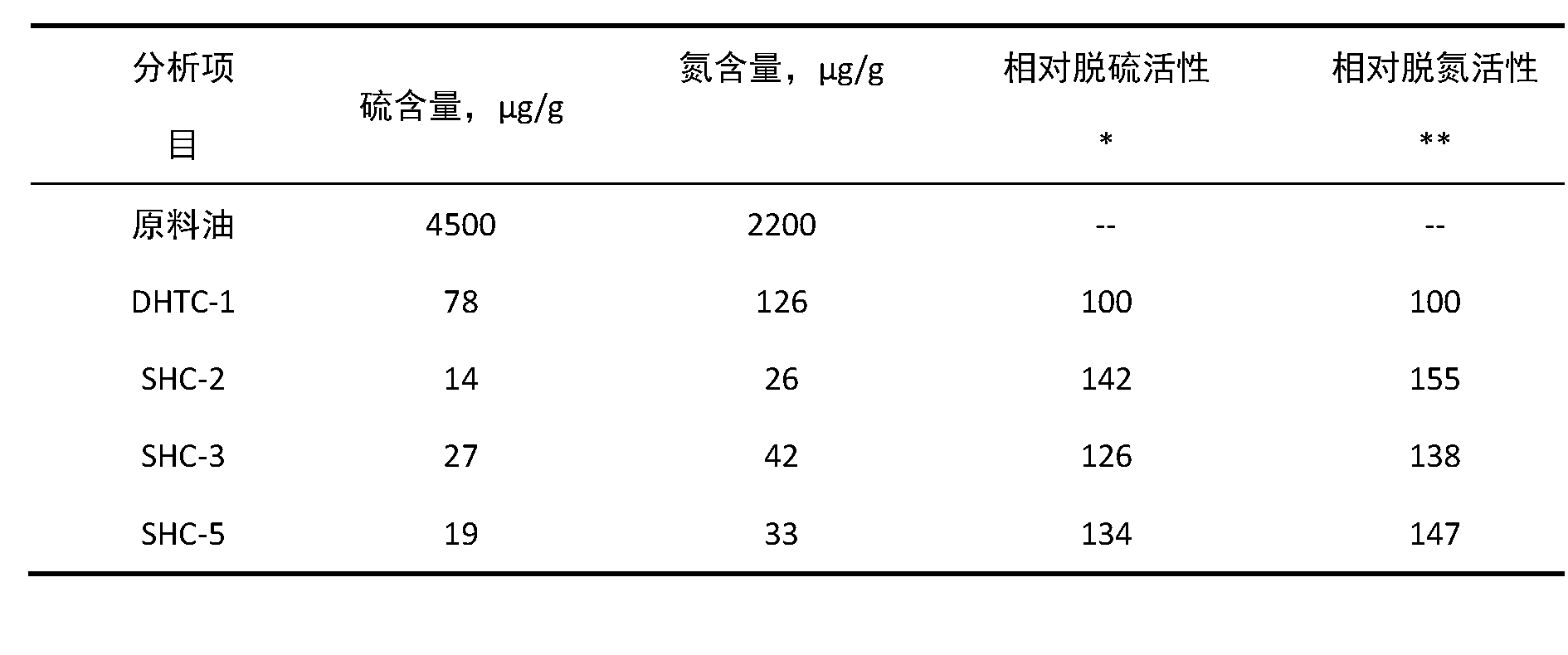

Preparation method of catalyst carrier for hydrotreating pretreatment of wax oil

ActiveCN103301888AHigh densityGood dispersionCatalyst carriersMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a preparation method of a catalyst carrier for hydrotreating pretreatment of wax oil. The carrier prepared by the method comprises the main components and contents based on the carrier by weight percent: 25 to 45wt% of a silicon aluminum-phosphorus aluminum composite molecular sieve, 30 to 60wt% of macroporous alumina, and 15 to 45% of modified alumina, wherein the silicon aluminum-phosphorus aluminum composite molecular sieve is a composite molecular sieve with silicon aluminum or modified aluminosilicate zeolites serving as a core and a phosphorus aluminum or modified phosphorus aluminum molecular sieve serving as a housing, and has the specific surface area of 250 to 400m<2> / g and pore volume of 0.50 to 0.80cm<3> / g. The carrier is characterized in that the silicon aluminum-phosphorus aluminum composite molecular sieve is introduced to improve the acidity of the carrier and adjust the distribution of hydroxide radicals on the aluminum oxide surface in order to disperse active metal components easily. The carrier is loaded with metallic oxides of VIB group and VIII group for preparing a catalyst, shows outstanding aromatic ring hydrogenation saturation capacity and cracking capacity respecting to C-S and C-N bonds in the hydrotreating process of the wax oil, and is applicable to the catalytic cracking and hydrocracking of raw materials.

Owner:CHINA NAT OFFSHORE OIL CORP +2

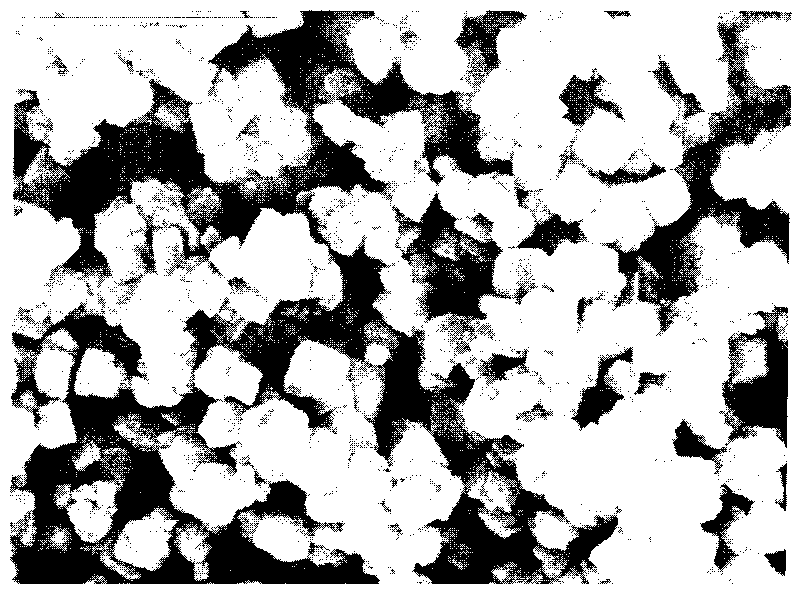

Method for preparing nano NaY molecular sieve

InactiveCN101177281AHigh product purityWell dispersedFaujasite aluminosilicate zeoliteSodalitesChemistryMolecular sieve

The invention relates to a preparation method of nanometer NaY molecular sieve, which is as follow: under the hypergravity condition of the revolving bed, performing guiding agent preparation, mother solution preparation, and mixing of guiding agent and mother solution, and the sequent crystallization of the reaction product. The invention enables to shorten the crystallization reaction time, simplify the technological process and prepare the high-quality nanometer NaY molecular sieves. The nanometer NaY molecular sieve catalyst prepared through the method can be used for the catalytic cracking of the heavy oil. Compared with the normal industrial molecular sieve, the nanometer NaY molecular sieve has the advantages of great increase of gasoline productivity, diesel fuel productivity, clean oil yield and total-liquid yield, improvement of the product selectivity, and obvious improvement of the product distribution.

Owner:BEIJING UNIV OF CHEM TECH

Medium and low temperature combination processing method of coal tar

ActiveCN102851073AHigh yieldLow yieldTreatment with hydrotreatment processesTar working-up by distillationLighter fuelHigh pressure

The invention comprises a combination processing method of coal tar. The method comprises the steps of: (a) subjecting a coal tar raw material to atmospheric distillation to obtain light distillate oil, phenol oil and bottom oil; dephenolizing the phenol oil to obtain the dephenolized oil; sending the bottom oil and a liquid phase from a hot high pressure separator in a step (d) into a vacuum distillation tower to obtain a heavy distillate with asphaltene removed; and conducting a hydrotreating reaction on the light distillate, dephenolized oil and the heavy distillate; (b) fractionating a liquid phase from the hydrotreating reaction into a light fraction and a heavy fraction; (c) subjecting the heavy fraction from the step (b) to a hydrocracking reaction; and (d) sending an effluent from the hydrocracking reaction into the hot high pressure separator, and sending the separated liquid phase to the vacuum distillation tower in the step (a). Compared with prior art, the method provided by the invention increases yield of light fuel production from coal tar, prolongs the service life of catalyst, and improves operation cycle of the device.

Owner:吉林省弘泰新能源有限公司

Catalytic cracking catalyst and preparation method thereof

ActiveCN107971011AHigh hydrocarbon oil cracking cracking activityHigh selectivityMolecular sieve catalystsBulk chemical productionMolecular sieveStrong acids

The invention relates to a catalytic cracking catalyst and a preparation method thereof, wherein the catalyst comprises 15-65% of natural minerals, 10-30% of an oxide, and 25-75% of a Y-type molecularsieve and a phosphorus-containing and supported metal-containing IMF structural molecular sieve, the Al distribution parameter D of the phosphorus-containing and supported metal-containing IMF structural molecular sieve is more than or equal to 0.6 and is less than or equal to 0.85, the volume of mesopores accounts for 50-80% of the total volume of pores, the volume of pores with a pore size of 2-20 nm accounts for more than 85% of the total volume of mesopores, the strong acid accounts for 50-80%, a ratio of an acid B to an acid L is 7-30, the phosphorus content is 0.1-15 wt%, and the supported metal content is 0.1-5 wt%. The preparation method comprises: carrying out mixing beating on the phosphorus-containing and supported metal-containing IMF structural molecular sieve, the Y-type molecular sieve, the natural minerals and an inorganic oxide binder, and carrying out spray drying. According to the present invention, with the application of the catalytic cracking catalyst in catalytic cracking of petroleum hydrocarbons, the yield of low-carbon olefins is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

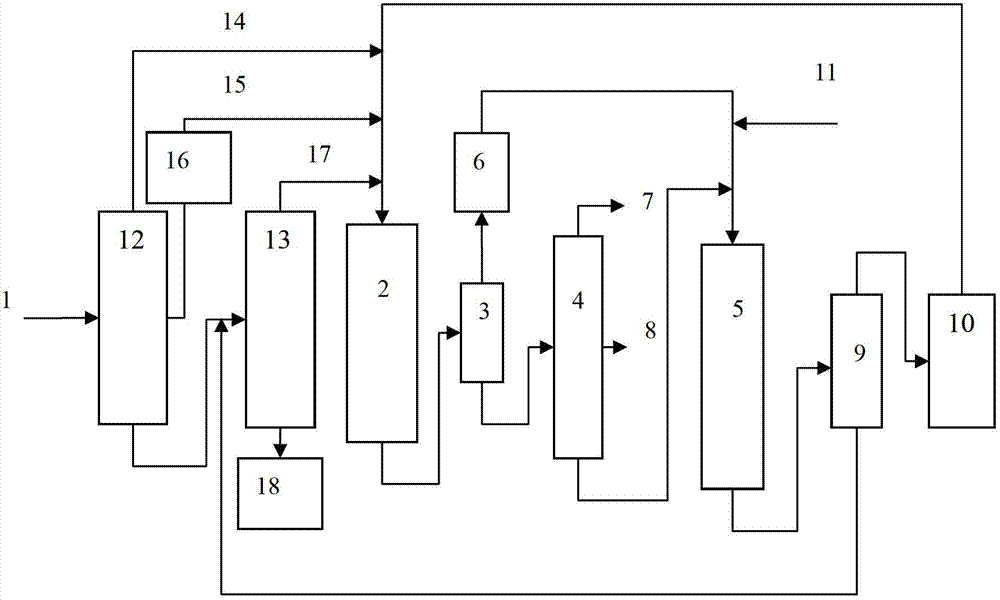

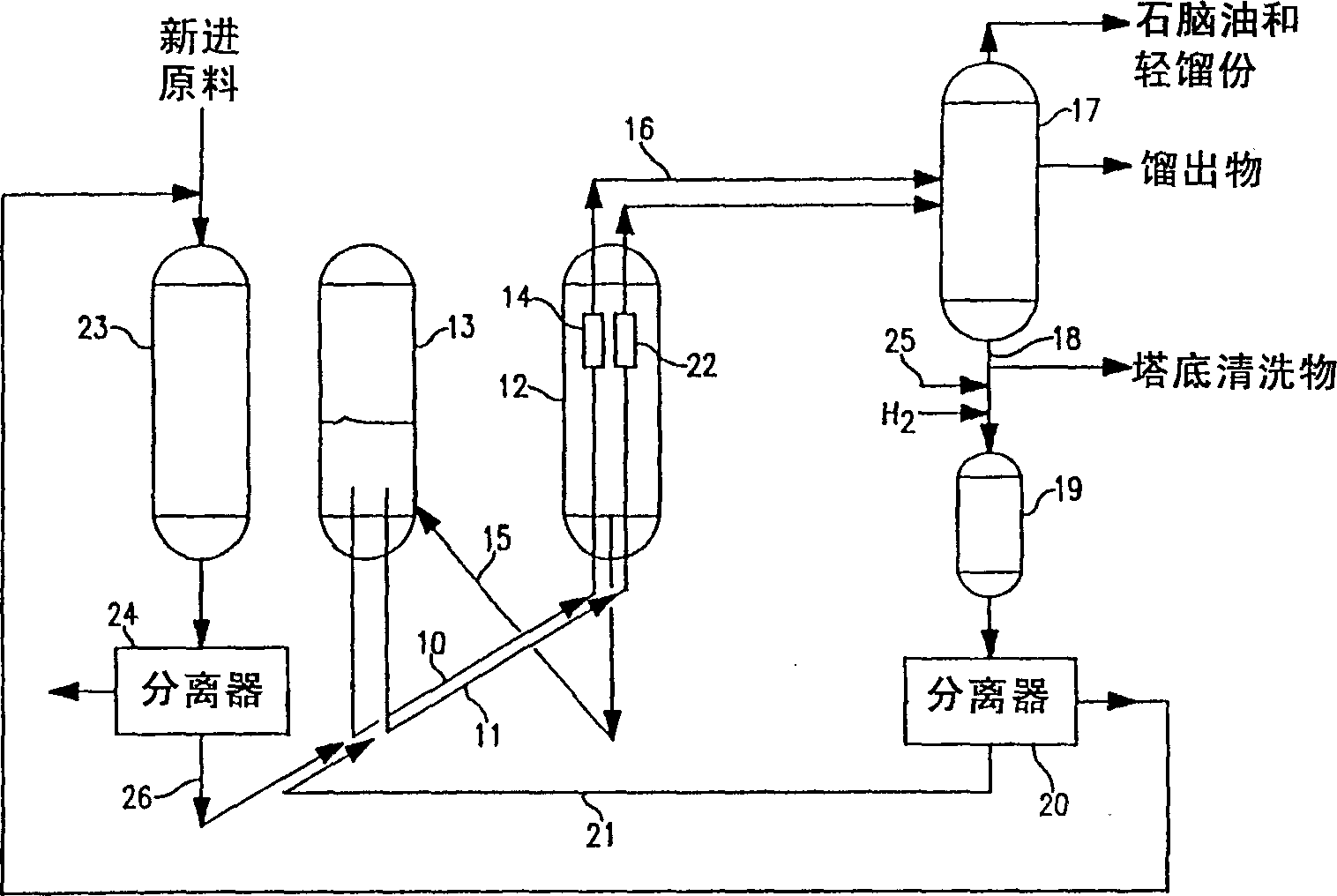

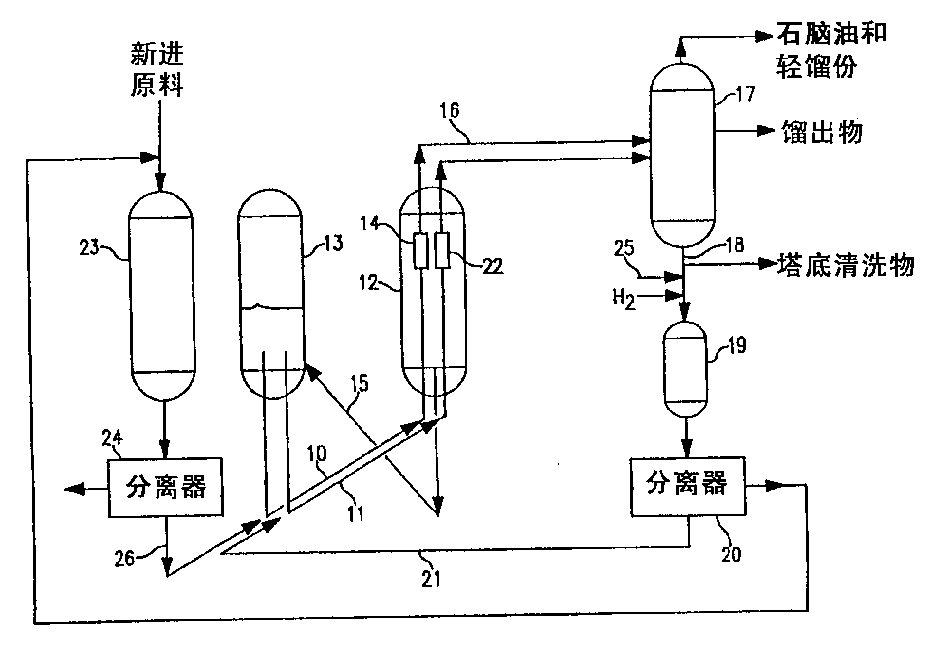

Integrated staged catalytic cracking and staged hydroprocessing process

InactiveCN1332783AHigh selectivityReduce in quantityTreatment with hydrotreatment processesHydrogenAlkene

A catalytic cracking process includes more than one catalytic cracking step and integrates catalytic cracking steps with hydroprocessing in order to maximize olefins production, distillate quality and octane level of the cracked product. In the process, a hydrocarbon feed is hydroprocessed in a hydroprocessor (23) with thishydroprocessed hydrocarbon being passed to a first catalytic cracking zone (10) to form a first cracked product. This first cracked product is passed to a separator (17) in which hydrocarbon fractions including a gas oil-containing bottoms fraction are separated. This bottoms fraction is then passed to a second hydroprocessor (19) to form a second hydroprocessed hydrocarbon. This second hydroprocessed hydrocarbon is then passed to a second separator (20) to separate a hydroprocessed bottoms fraction and an unspent hydrogen fraction. The unspent hydrogen fraction is combined with the feed and the hydroprocessed bottoms fraction is passed to a second catalytic cracker (11) to form a second cracked product.

Owner:EXXON RES & ENG CO

Preparation method of catalytic cracking catalyst

ActiveCN105728014ALarge pore volumeImprove wear indexCatalytic crackingMolecular sieve catalystsMolecular sieveSlurry

A preparation method of a catalytic cracking catalyst includes the following steps: 1) moulding of a catalyst: mixing and pulping water, a binding agent, clay and a molecular sieve and spray-drying and roasting the mixture to mould catalyst solid granules; 2) acidic modification: adding water to the catalyst solid granules, adding an acidic substance until the pH value is 2.5-5.5, and stirring the mixture for 30-180 min; 3) modification with a modifier; adding a weak-alkaline medium modifier to the catalyst slurry to enable the pH value to be 6.0-9.0; and 4) filtering and drying the modified catalyst slurry, and roasting a product at 300-800 DEG C for 10-180 min. The catalyst has high pore volume and reaction performance, is improved in strength and is prolonged in service life.

Owner:PETROCHINA CO LTD

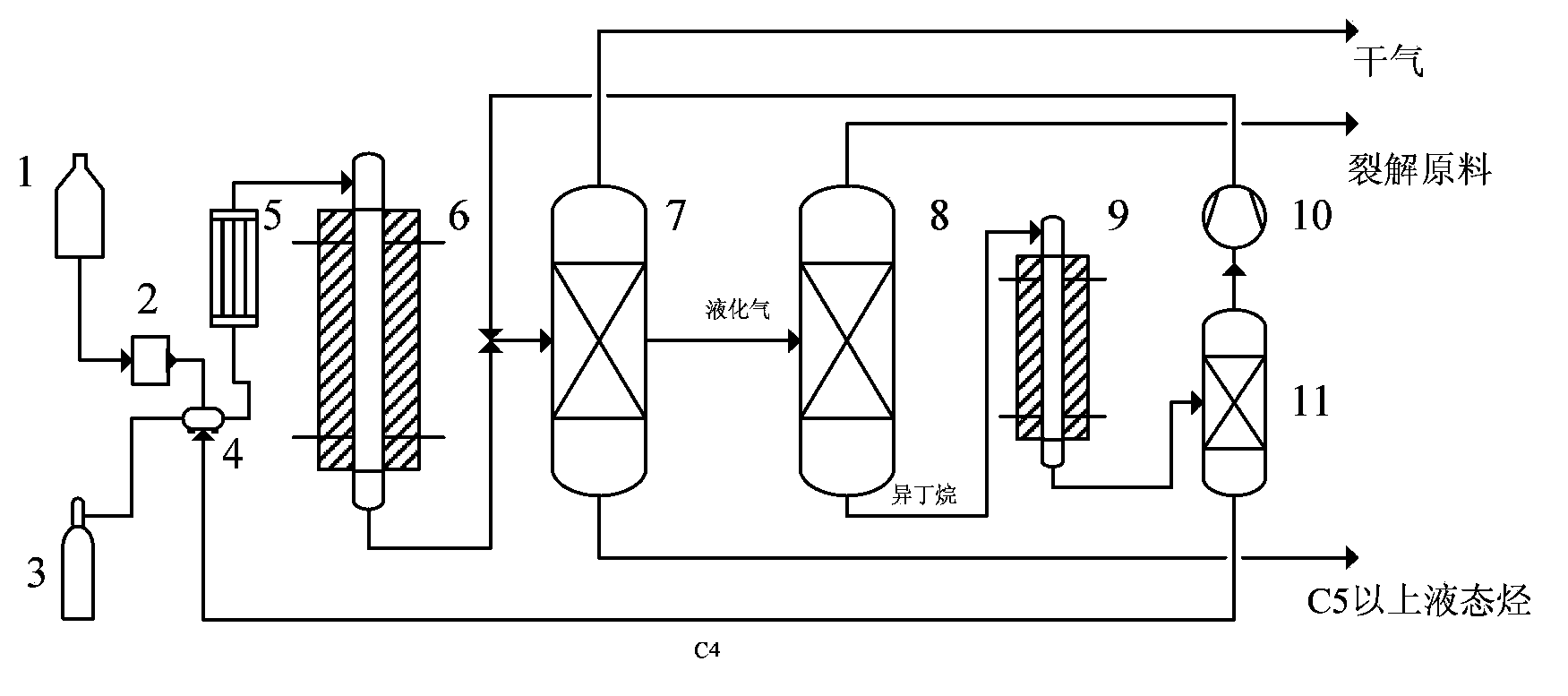

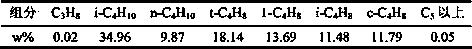

Method for producing high octane number gasoline blending component through mixing C4 hydrocarbon aromatization

ActiveCN103509600AHigh yieldImprove cracking capacityLiquid hydrocarbon mixtures productionTreatment with hydrotreatment processesEconomic benefitsDehydrogenation

The invention relates to a method for producing a high octane number gasoline blending component and concurrently co-producing an ethylene cracking raw material by using C4 hydrocarbons. The method is characterized in that an aromatization and isobutane dehydrogenation combination manner is adopted, such that isobutane doing not participating in the aromatization reaction is subjected to dehydrogenation to produce isobutene, and the isobutene circularly enters the aromatization reactor to participate in the reaction. According to the present invention, isobutane circularly participates in the reaction, and the cracking raw materials are propane and n-butane, such that the cracking performance is good; and the gasoline blending component yield is high, the octane number of the gasoline blending component is high, and economic benefits of the equipment is good.

Owner:PETROCHINA CO LTD

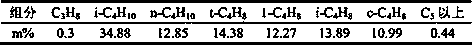

Low permeability coal bed liquid nitrogen freeze thawing cracking permeability increasing method

ActiveCN104963674AIncreased wet rangeExpand the range of freeze-thaw crackingFluid removalGas removalCoalDrill hole

The invention provides a low permeability coal bed liquid nitrogen freeze thawing cracking permeability increasing method. The low permeability coal bed liquid nitrogen freeze thawing cracking permeability increasing method comprises the following steps that a, a freeze thawing drill hole and a monitoring drill hole are drilled; b, a first pipeline is arranged, one end of the first pipeline extends into the freeze thawing drill hole, the other end of the first pipeline is connected with a nitrogen generation separating device, and the nitrogen generation separating device is connected with a liquid nitrogen injection pump; c, a temperature monitoring device is installed in the monitoring drill hole, after the temperature monitored by the temperature monitoring device is stable, the temperature at the moment is determined to service as the initial temperature T0; d, the liquid nitrogen injection pump is started, the nitrogen generation separating device is driven to inject liquid nitrogen into the freeze thawing drill hole, and the temperature of the freeze thawing drill hole is monitored in real time; e, when the temperature T in the monitored drill hole is reduced by 50%-80% compared with the T0, the liquid nitrogen is stopped from being injected, and the temperature in the drill hole is monitored continuously; f, when the temperature T in the monitored drill hole is increased to the condition when |T-T0| / T0<5%, the step d and the step e are repeated; g, the step f is repeated for 3-5 times. By means of the low permeability coal bed liquid nitrogen freeze thawing cracking permeability increasing method, the pore structure of an original coal body is modified, the problem that the permeability effect of a low permeability coal bed is poor, and the permeability increasing efficiency of the low permeability coal bed is effectively improved.

Owner:CCTEG CHINA COAL RES INST

Small-grain NaY-type molecular sieve and preparation method thereof

ActiveCN104591207AImprove stabilityHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteAluminosilicate zeolite type-AMolecular sieveWater vapor

The invention discloses a small-grain NaY-type molecular sieve and a preparation method thereof. The small-grain aY-type molecular sieve has the following properties: the SiO2 / Al2O3 molar ratio is higher than 6.0 and no higher than 9.0; the grain average diameter is 200-700nm; the specific surface area is 800-1000m<2> / g; the pore volume is 0.30-0.45mL / g; the relative crystallinity degree is 90-130%; the lattice parameter is 2.460-2.470nm; the relative crystallinity degree after roasting for 3h under a temperature of 650 DEG C in air is higher than 90%; and the relative crystallinity degree after a water vapor hydrothermal treatment for 2h under a temperature of 700 DEG C is higher than 90%. The preparation method comprises the following steps: an amorphous silica-alumina precursor prepared with a specific carbonization method, a directing agent synthesized under low temperature, part of a silicon source, and the like are mixed under a low temperature, such that silica-alumina gel is prepared; and crystallization is carried out, such that the small-grain NaY-type molecular sieve is obtained. The small-grain NaY-type molecular sieve can be applied in a hydrocracking reaction, has has good cracking activity and product selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

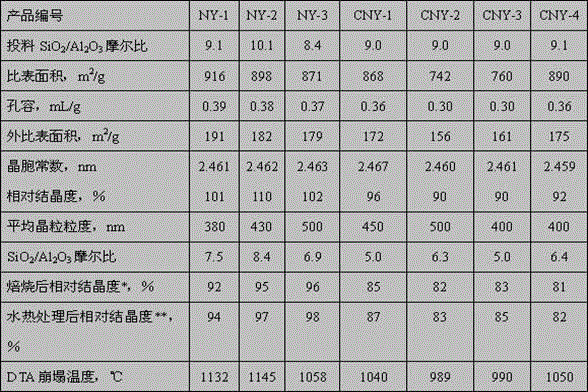

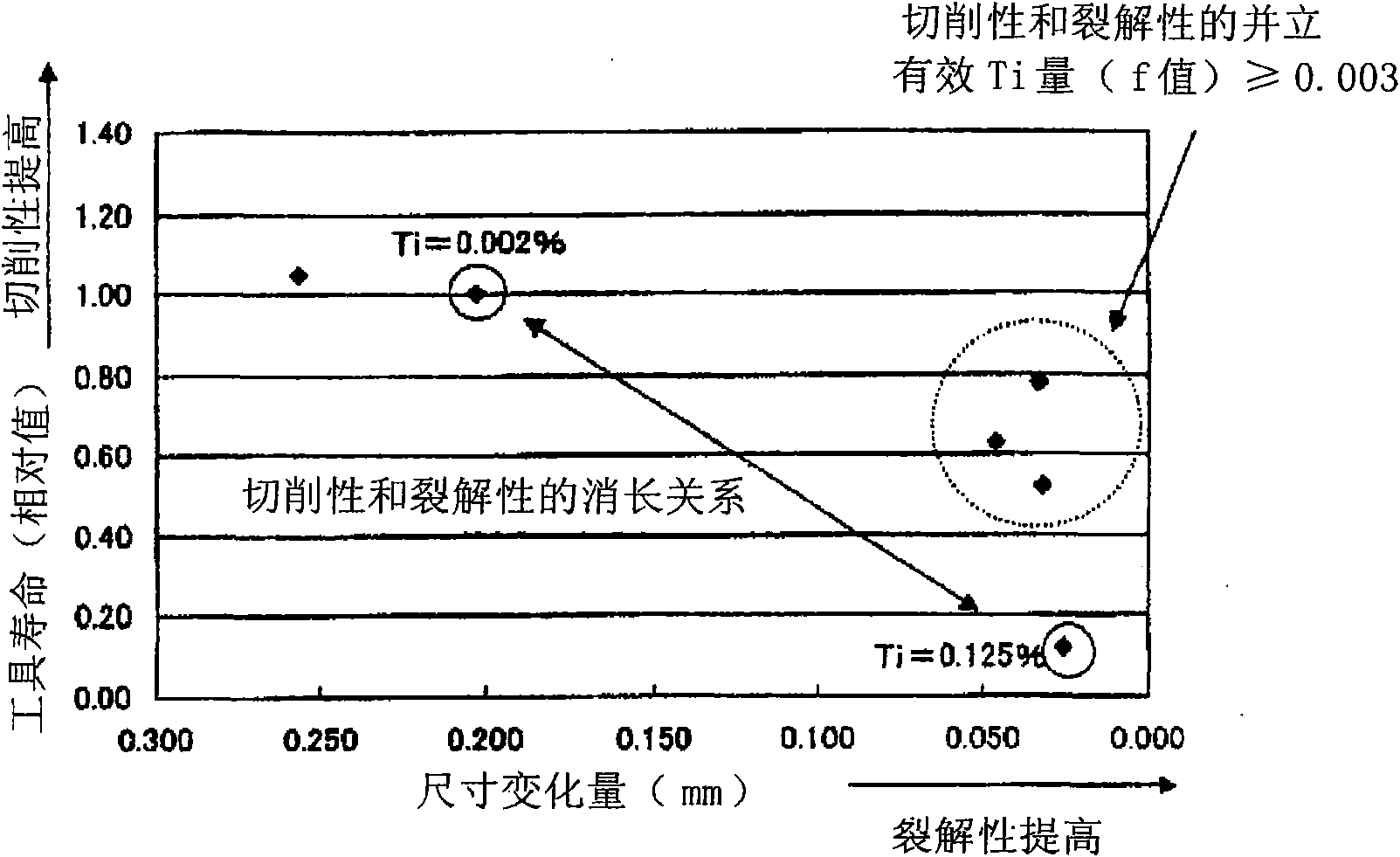

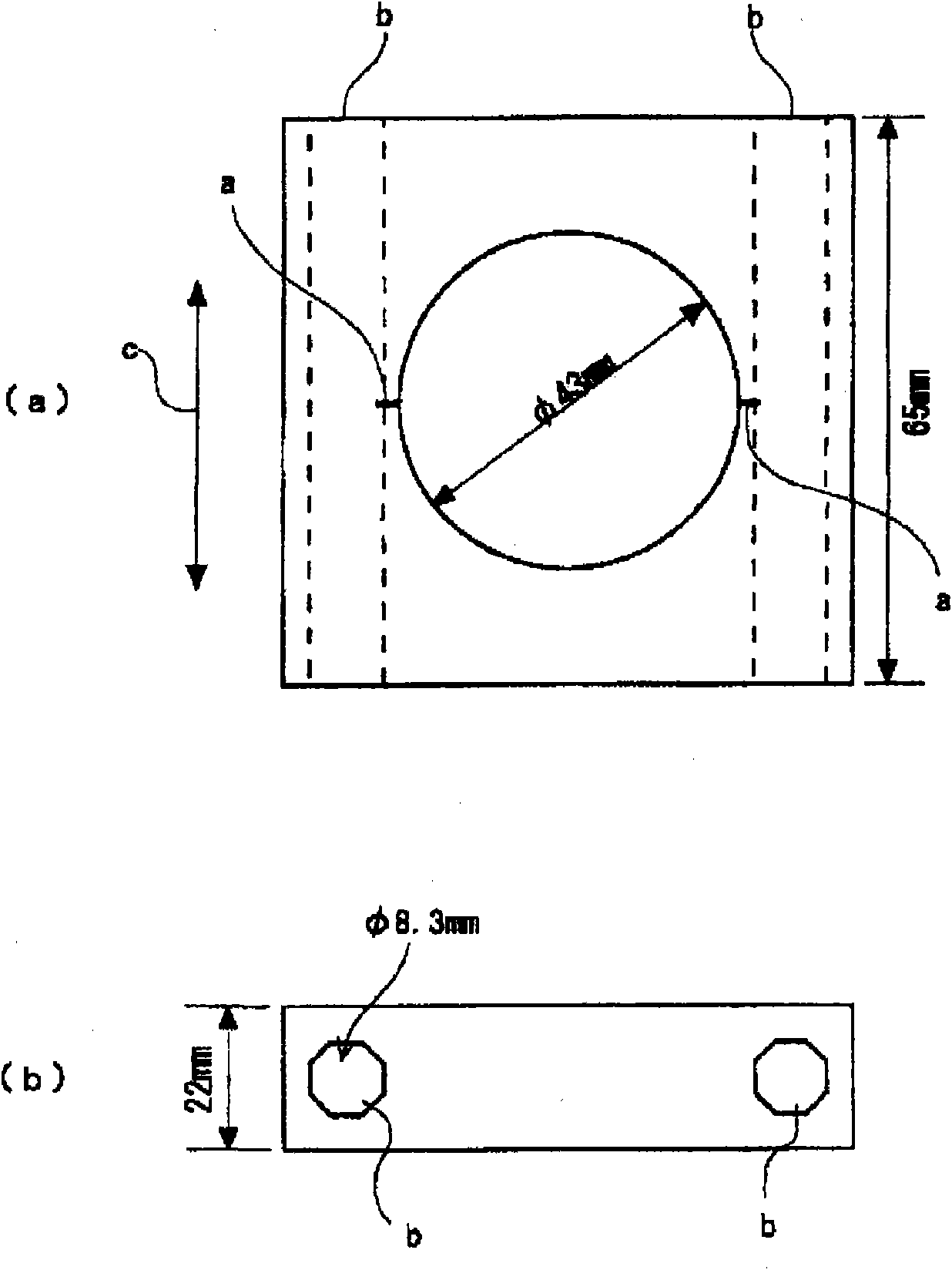

Steel for fracture split connecting rods

InactiveCN101883873AImprove cracking capacityImprove cutting performanceMetallurgyPhysical chemistry

A steel for fracture split connecting rods, characterized by containing by mass C: 0.25 to 0.5%, Si: 0.01 to 2.0%, Mn: 0.50 to 2.0%, P: 0.015 to 0.080, S: 0.01 to 0.2%, V: 0.02 to 0.20%, Cr: 0.05 to 1.0%, Ti: 0.01 to 0.10% and N: 0.01% or below and having an f value of 0.003 to 0.04 as defined by the following formula and an average aspect ratio of sulfide inclusions of 15 or below: f = [Ti]-[N]x48 / 14 wherein [Ti] and [N] are contents (mass%) in steel of Ti and N respectively.

Owner:KOBE STEEL LTD

Preparation method for hydrocracking catalyst

ActiveCN104826645AImprove cracking capacityHigh activityCatalyst carriersMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a preparation method for a hydrocracking catalyst. The method comprises the following steps: subjecting a small-grain Y type molecular sieve, amorphous silicon-aluminum and a binder prepared from alumina to mechanical mixing and molding and then carrying out drying and roasting so as to prepare a catalyst carrier; and loading a hydrogenation active metal component on the catalyst carrier and then carrying out drying and roasting so as to prepare the catalyst. According to the method, a NaY type molecular sieve raw material with a high silica-alumina ratio, a high degree of crystallization and good stability is employed and successively undergoes ammonium exchange, primary hydro-thermal treatment, treatment with an alkali-containing solution, secondary hydro-thermal treatment and treatment with a mixed solution of acid and an ammonium salt; and the obtained small-grain Y type molecular sieve has a high SiO2 / Al2O3 mol ratio and a high proportion of secondary pores, retains the stability of the molecular sieve and has a high specific surface area and a high degree of crystallization. The hydrocracking catalyst provided by the invention is applicable as a hydrocracking catalyst for high and medium oil and has good activity, medium oil selectivity and product properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com