Boiler wet slag removal system

A boiler and wet technology, applied in the field of boiler wet slag removal system, can solve the problems of endangering the safety of conveying equipment and operating personnel, poor adaptability to changes in boiler slag volume, and difficult control of operating parameters, etc., to achieve enhanced cracking effect and fuel saving Effects of reduction in consumption and floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

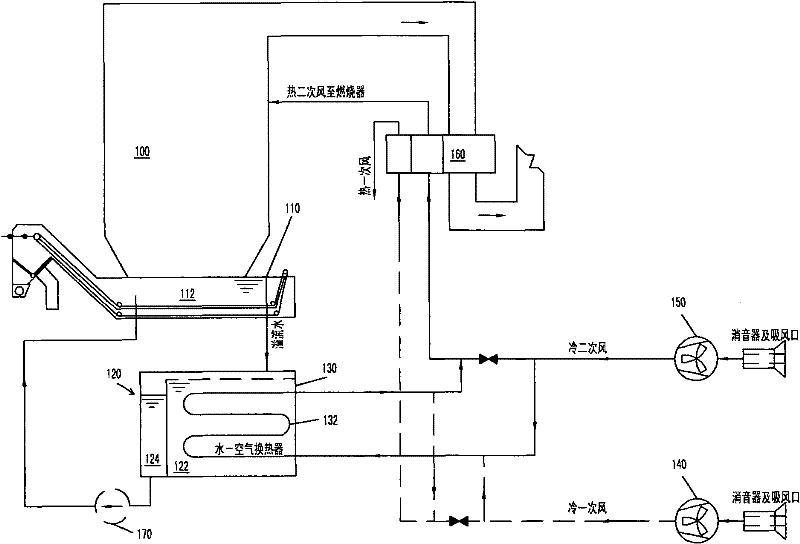

[0028] figure 1 The slag removal system of the first embodiment of the present invention is shown. refer to figure 1 As shown, in this embodiment, each boiler 100 is equipped with a water-immersed scraper slag extractor 110, an overflow water tank 120, a water-air heat exchanger 130, and a slag bin (not shown). The slag falls from the bottom of the boiler 100 through the slag well into the water-immersed scraper slag extractor 110, is cooled and cracked in the water tank 112 in the water-immersed scraper slag extractor 110, and then transported by the water-immersed scraper scraper extractor Enter the slag bin. During this process, the water in the tank of the water-immersed scraper scraper machine is heated by the slag.

[0029] An overflow port is arranged on the upper part of the water tank 112 of the water-immersed scraper scraper 110 , and the water in the water tank 112 passes through the overflow port, and the overflow water flows into the overflow water tank 120 . ...

no. 2 example

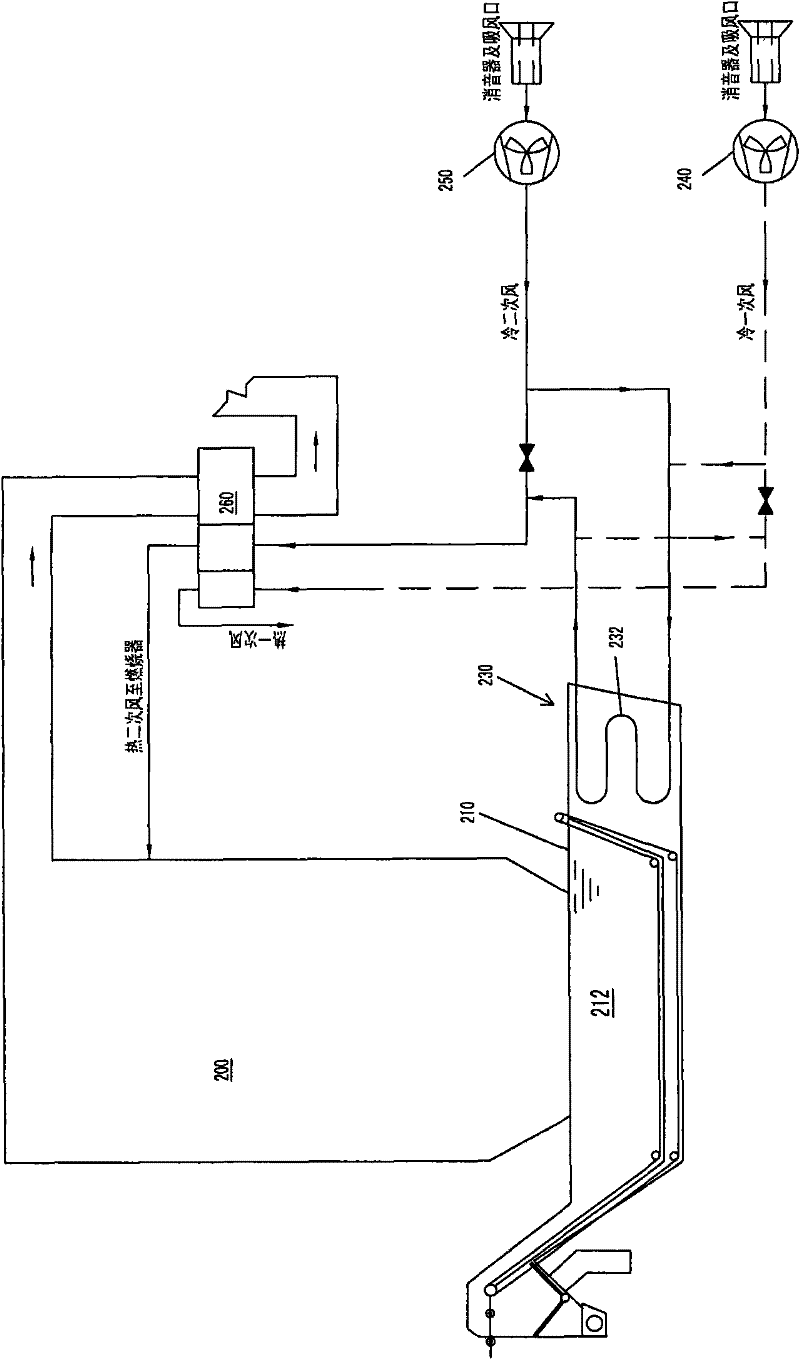

[0034] figure 2 The slag removal system of the first embodiment of the present invention is shown. refer to figure 2 As shown, in this embodiment, each boiler 200 is equipped with a water-immersed scraper slag extractor 210, a water-air heat exchanger 230, and a slag bin (not shown). The slag falls from the bottom of the boiler 200 through the slag well into the water-immersed scraper slag extractor 210, cools and cracks in the water tank 212 in the water-immersed scraper slag extractor 210, and then passes through the water-immersed scraper scraper extractor 210 Conveying into the slag bin. During this process, the water in the water tank 212 of the water-immersed scraper slag extractor is heated by the slag.

[0035]A water-air heat exchanger 230 is arranged on one side, or both sides, or the lower part, or other positions of the water tank 212 of the water-immersed scraper scraper machine, so that the heat exchanger and the water tank are integrated. The water side of...

no. 3 example

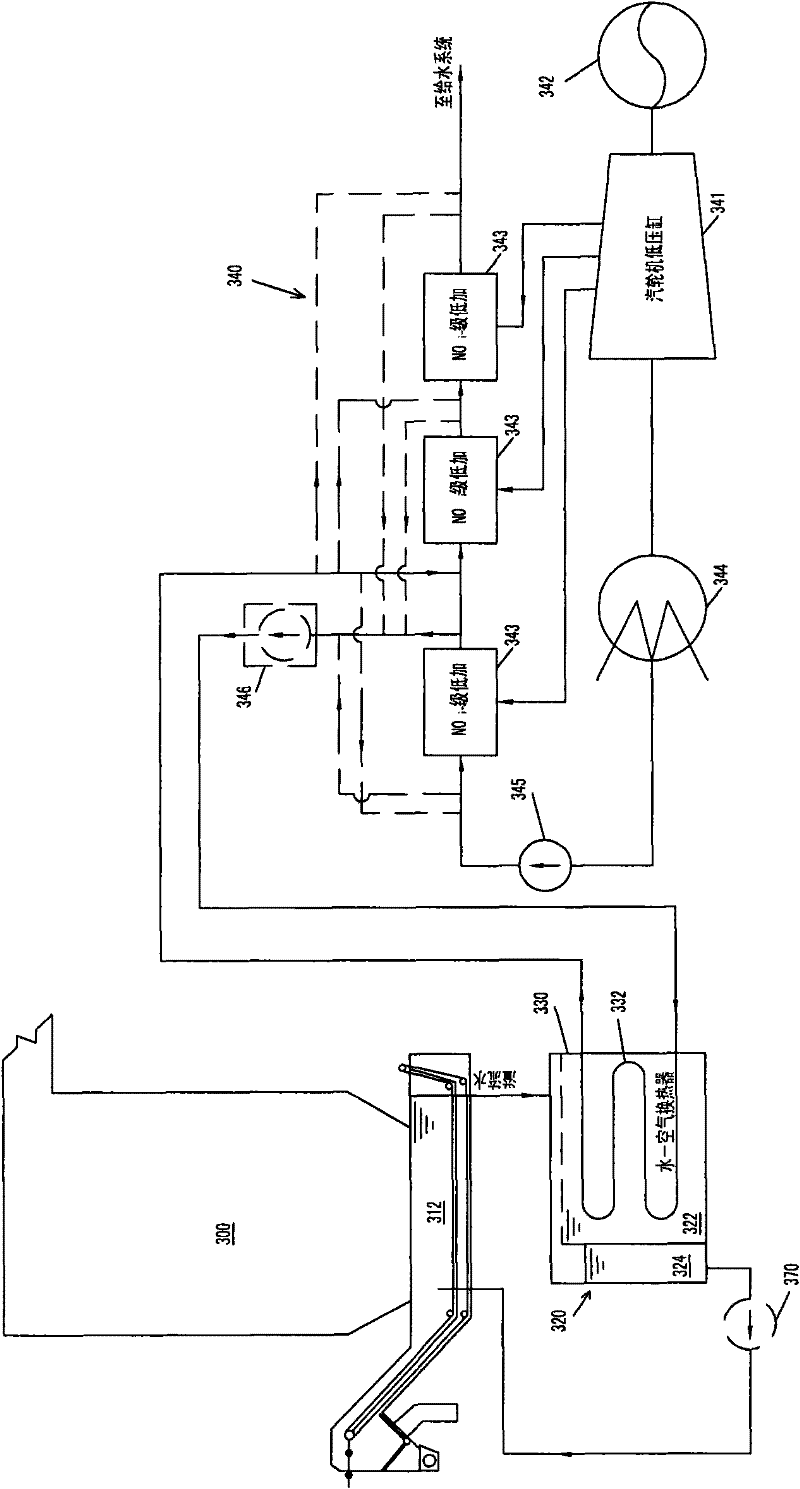

[0038] image 3 A slag removal system according to a third embodiment of the present invention is shown. refer to image 3 As shown, in this embodiment, each boiler 300 is provided with a water-immersed scraper slag extractor 310, an overflow water tank 320, a water-water heat exchanger 330, and a slag bin (not shown). The slag falls from the bottom of the boiler 300 through the slag well into the water-immersed scraper slag extractor 310, is cooled and cracked in the upper water tank 312 of the water-immersed scraper slag extractor, and then transported through the water-immersed scraper slag extractor 310 Enter the slag bin. During this process, the water in the water tank 312 of the water-immersed scraper slag extractor is heated by the slag.

[0039] The upper water tank 312 of the water-immersed scraper scraper 310 is provided with an overflow port, and the water in the water tank passes through the overflow port, and the overflow water flows into the overflow water ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com