Patents

Literature

1359 results about "Design values" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A design value is a statistic that describes the air quality status of a given location relative to the level of the National Ambient Air Quality Standards (NAAQS). Design values are typically used to designate and classify nonattainment areas, as well as to assess progress towards meeting the NAAQS.

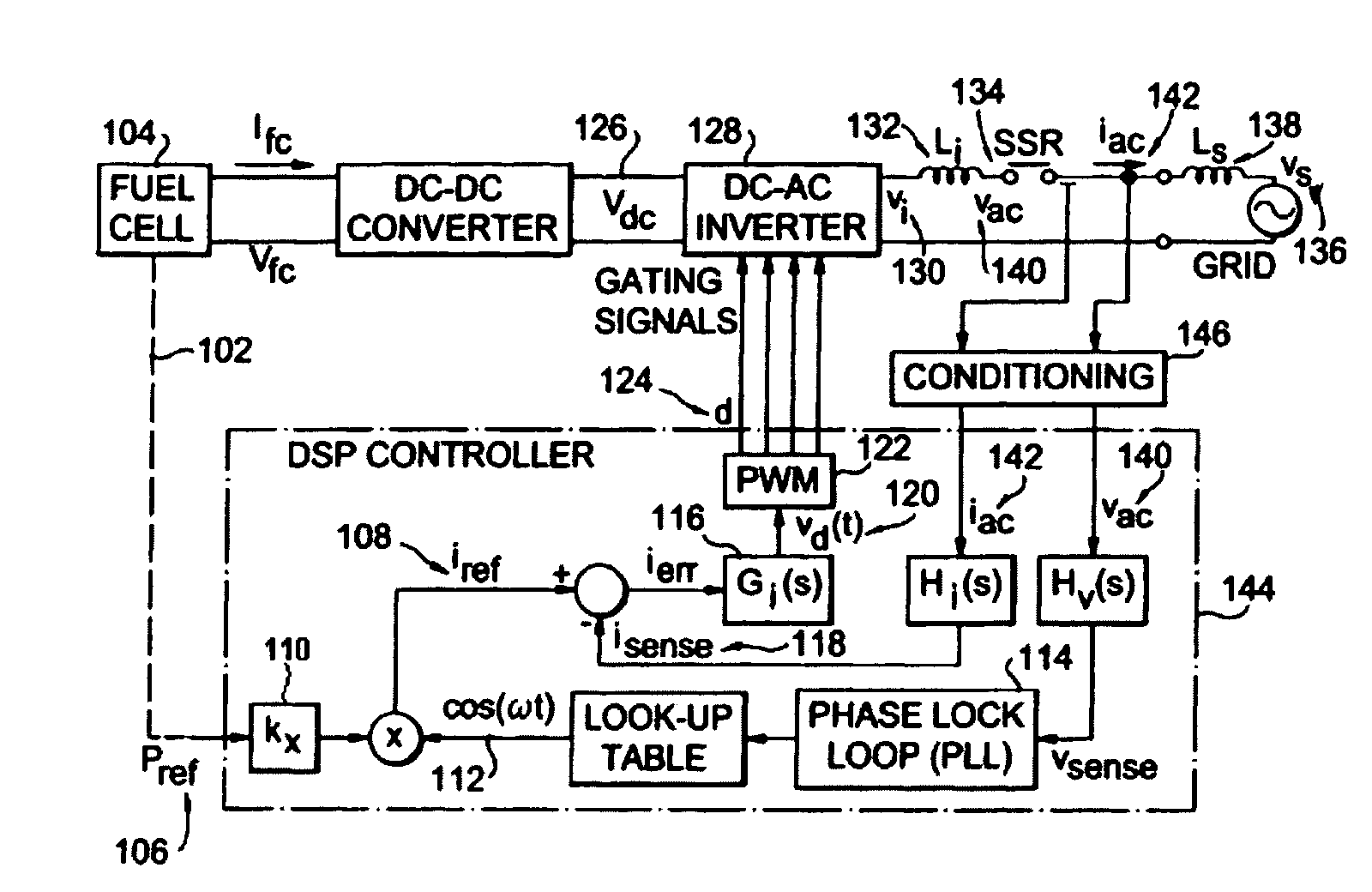

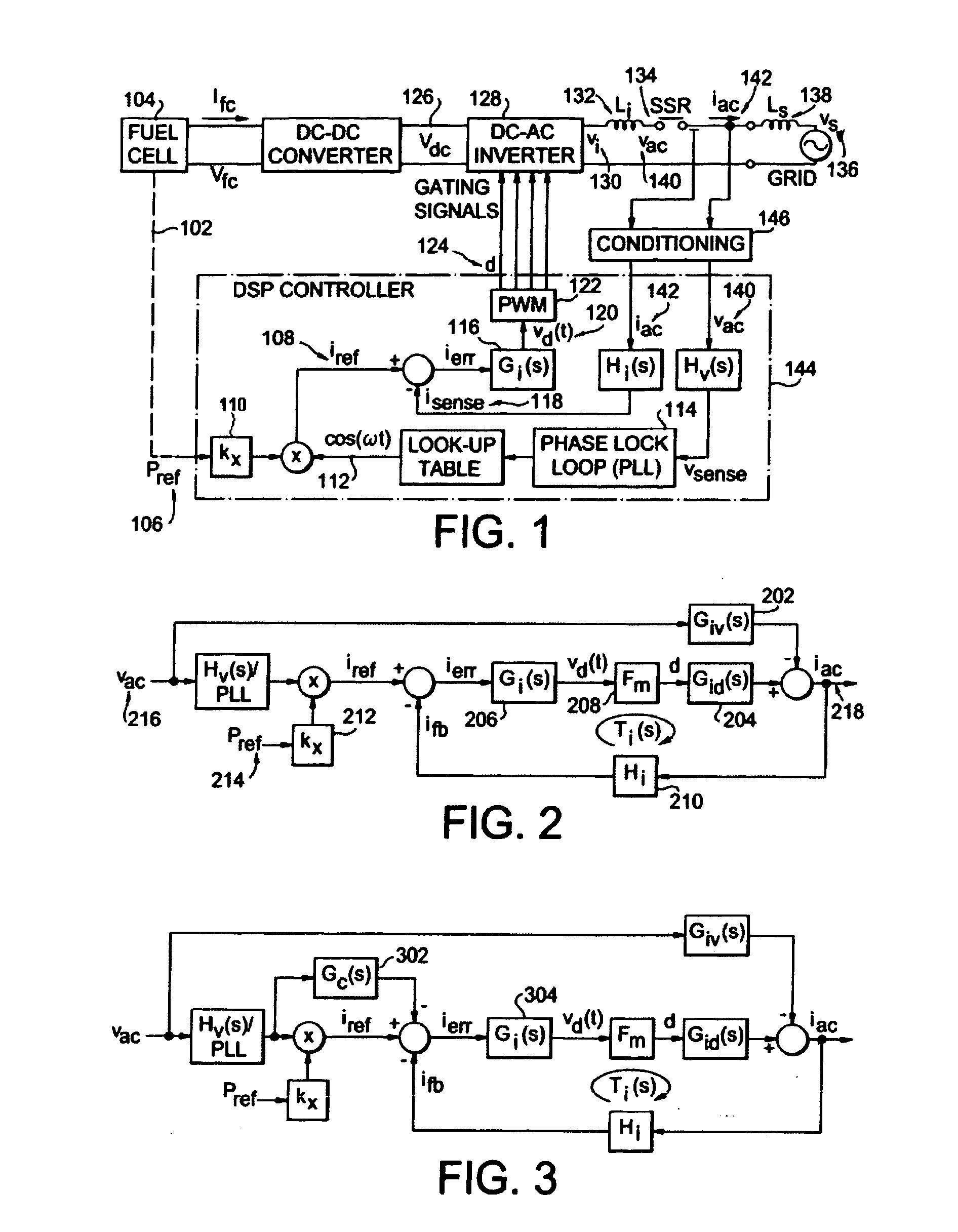

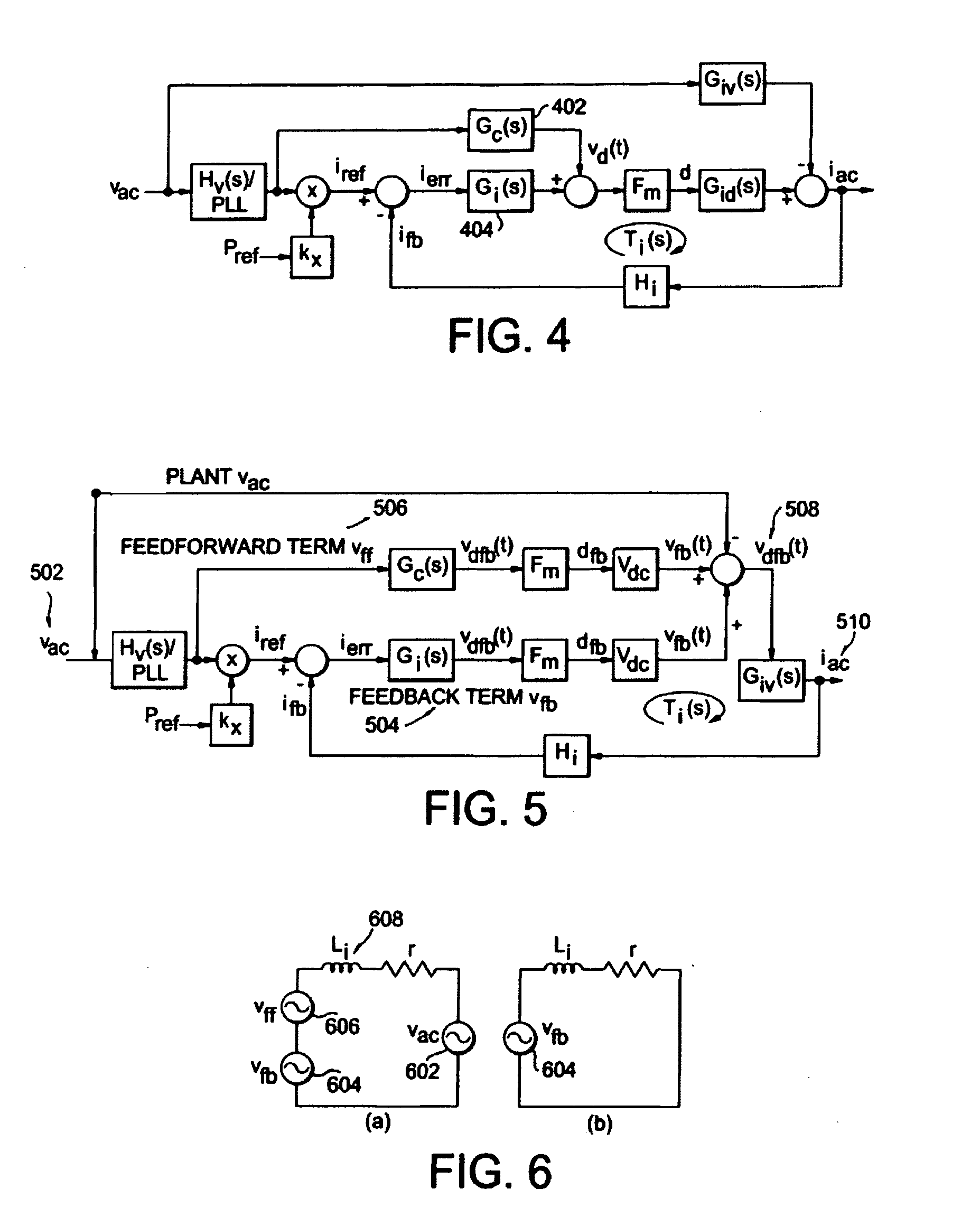

Control system and method for a universal power conditioning system

ActiveUS20080205096A1Avoid precision problemsSolve the stability is not highEfficient power electronics conversionAc-dc conversionFundamental frequencyCatastrophic failure

A new current loop control system method is proposed for a single-phase grid-tie power conditioning system that can be used under a standalone or a grid-tie mode. This type of inverter utilizes an inductor-capacitor-inductor (LCL) filter as the interface in between inverter and the utility grid. The first set of inductor-capacitor (LC) can be used in the standalone mode, and the complete LCL can be used for the grid-tie mode. A new admittance compensation technique is proposed for the controller design to avoid low stability margin while maintaining sufficient gain at the fundamental frequency. The proposed current loop controller system and admittance compensation technique have been simulated and tested. Simulation results indicate that without the admittance path compensation, the current loop controller output duty cycle is largely offset by an undesired admittance path. At the initial simulation cycle, the power flow may be erratically fed back to the inverter causing catastrophic failure. With admittance path compensation, the output power shows a steady-state offset that matches the design value. Experimental results show that the inverter is capable of both a standalone and a grid-tie connection mode using the LCL filter configuration.

Owner:VIRGINIA TECH INTPROP INC

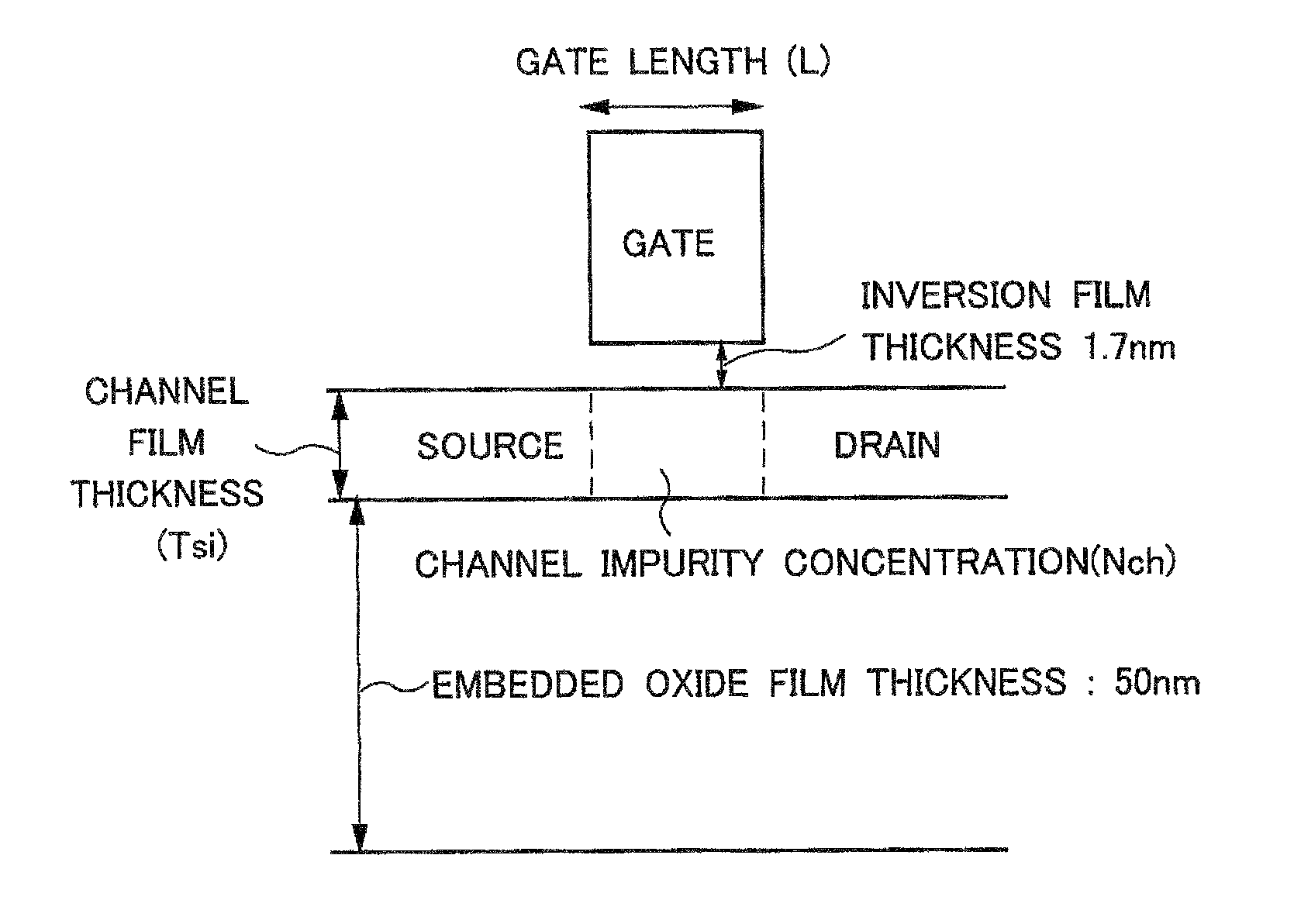

Semiconductor device, integrated circuit, and semiconductor manufacturing method

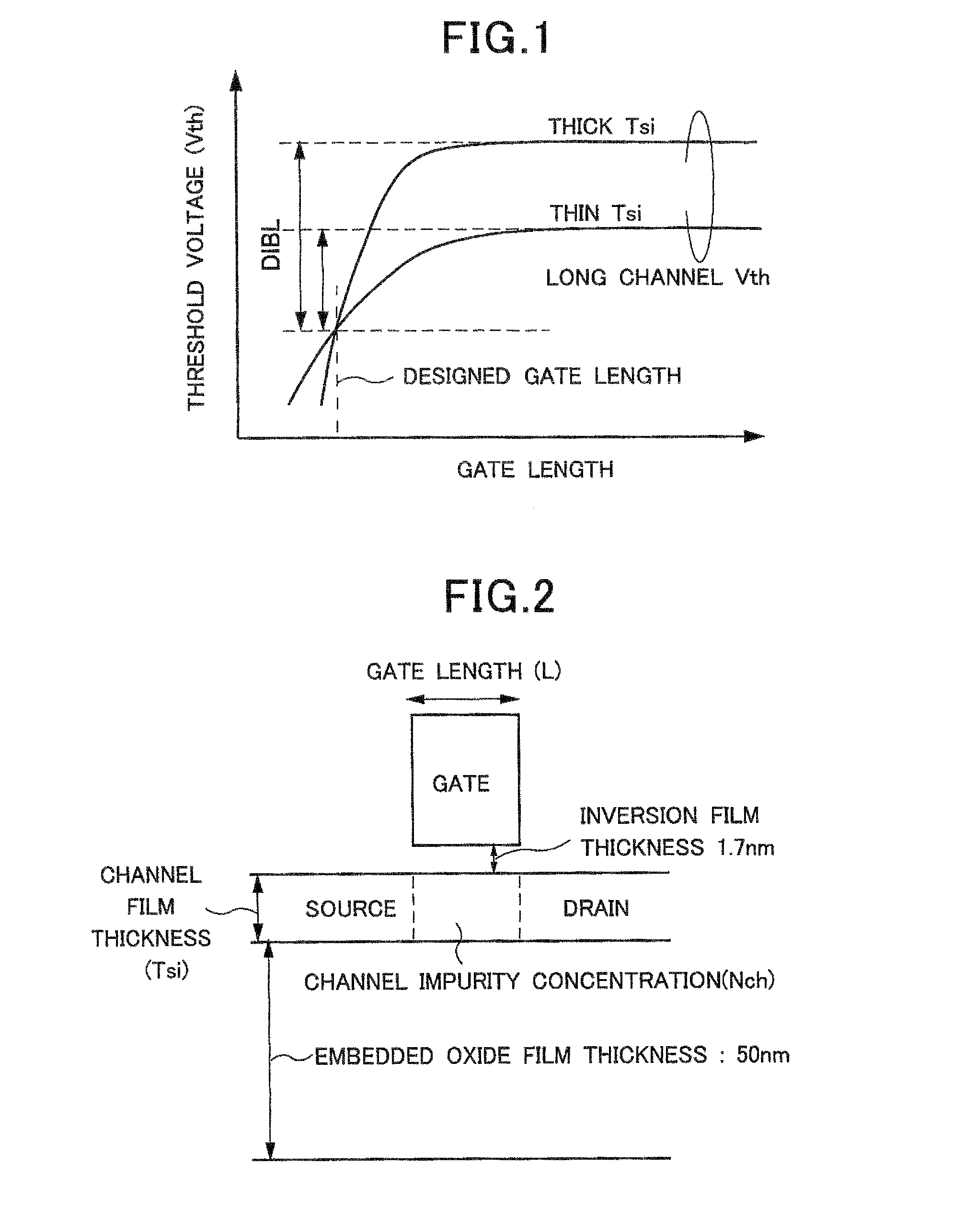

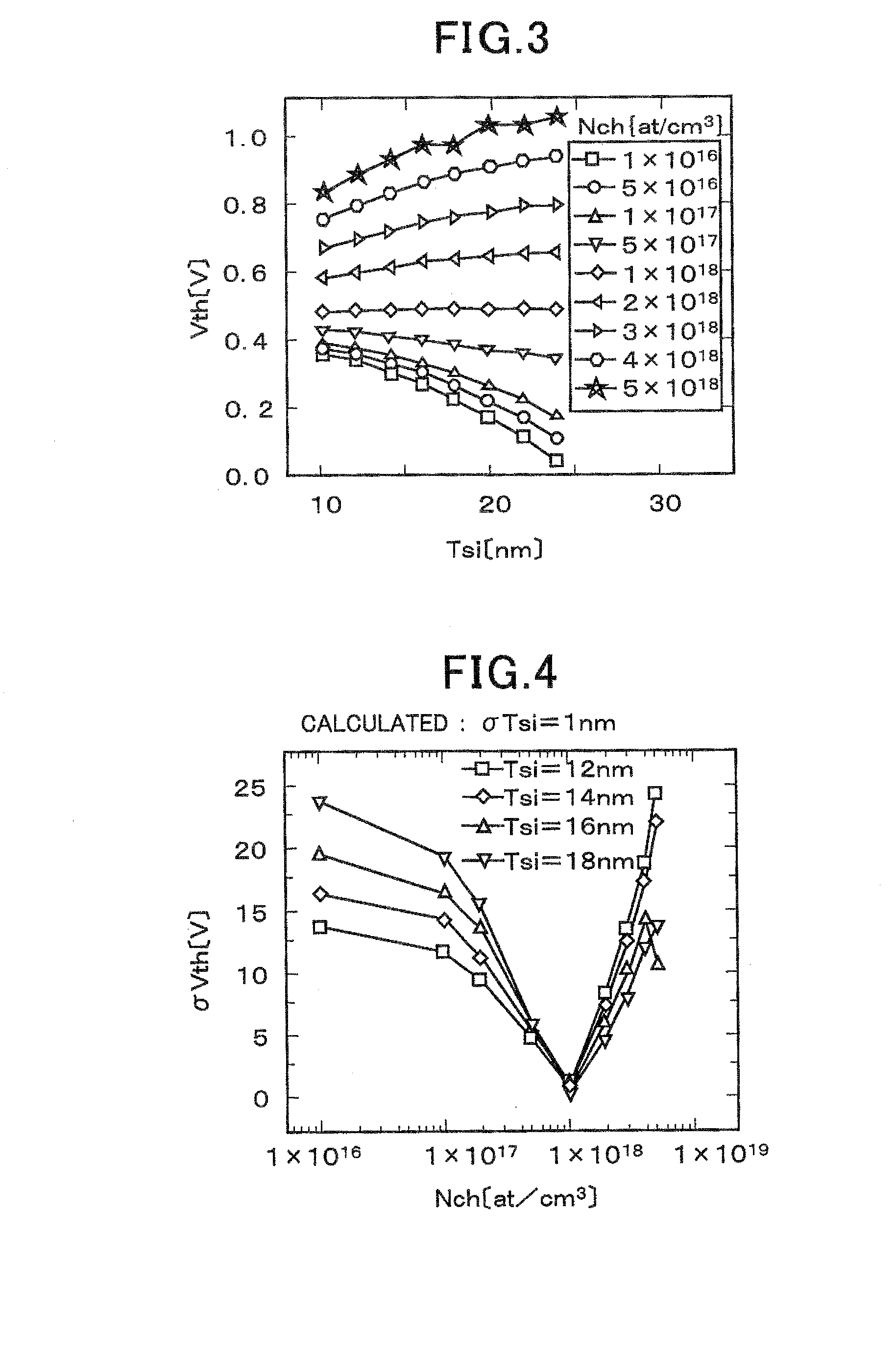

A semiconductor circuit has a plurality of MISFETs formed with channel films comprised of semiconductor layers on an insulation film. Channel film thicknesses of each MISFET are different. A correlation relationship is fulfilled where concentration per unit area of impurity contained in the channel films becomes larger for MISFETs of a thicker channel film thickness. As a result, it is possible to suppress deviation of threshold voltage caused by changes in channel film thickness. In this event, designed values for the channel film thicknesses of the plurality of MISFETs are preferably the same, and the difference in channel film thickness of each MISFET may depend on statistical variation from the designed values. The concentration of the impurity per unit area is proportional to the channel film thickness, or is a function that is convex downwards with respect to the channel film thickness.

Owner:RENESAS ELECTRONICS CORP

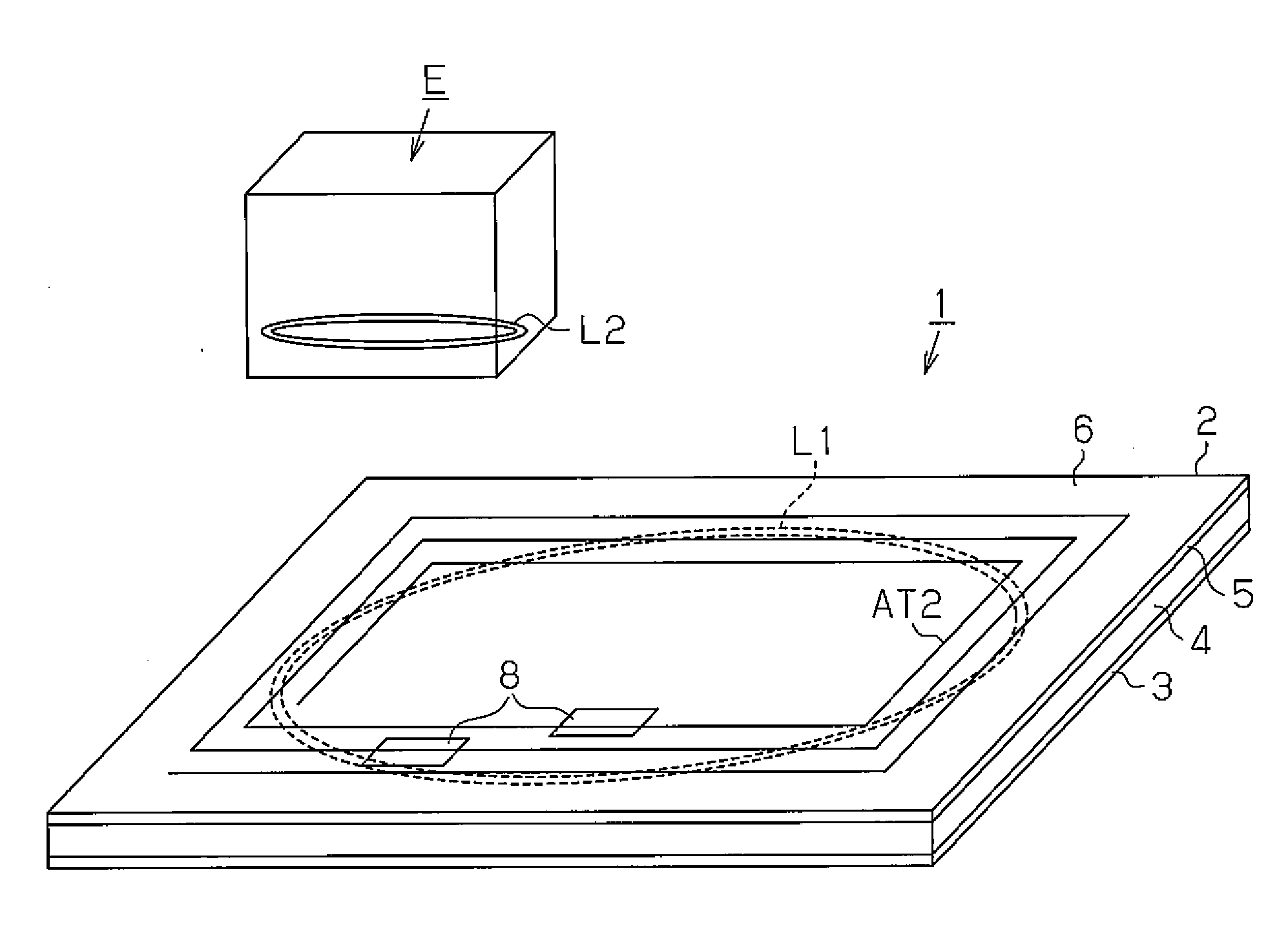

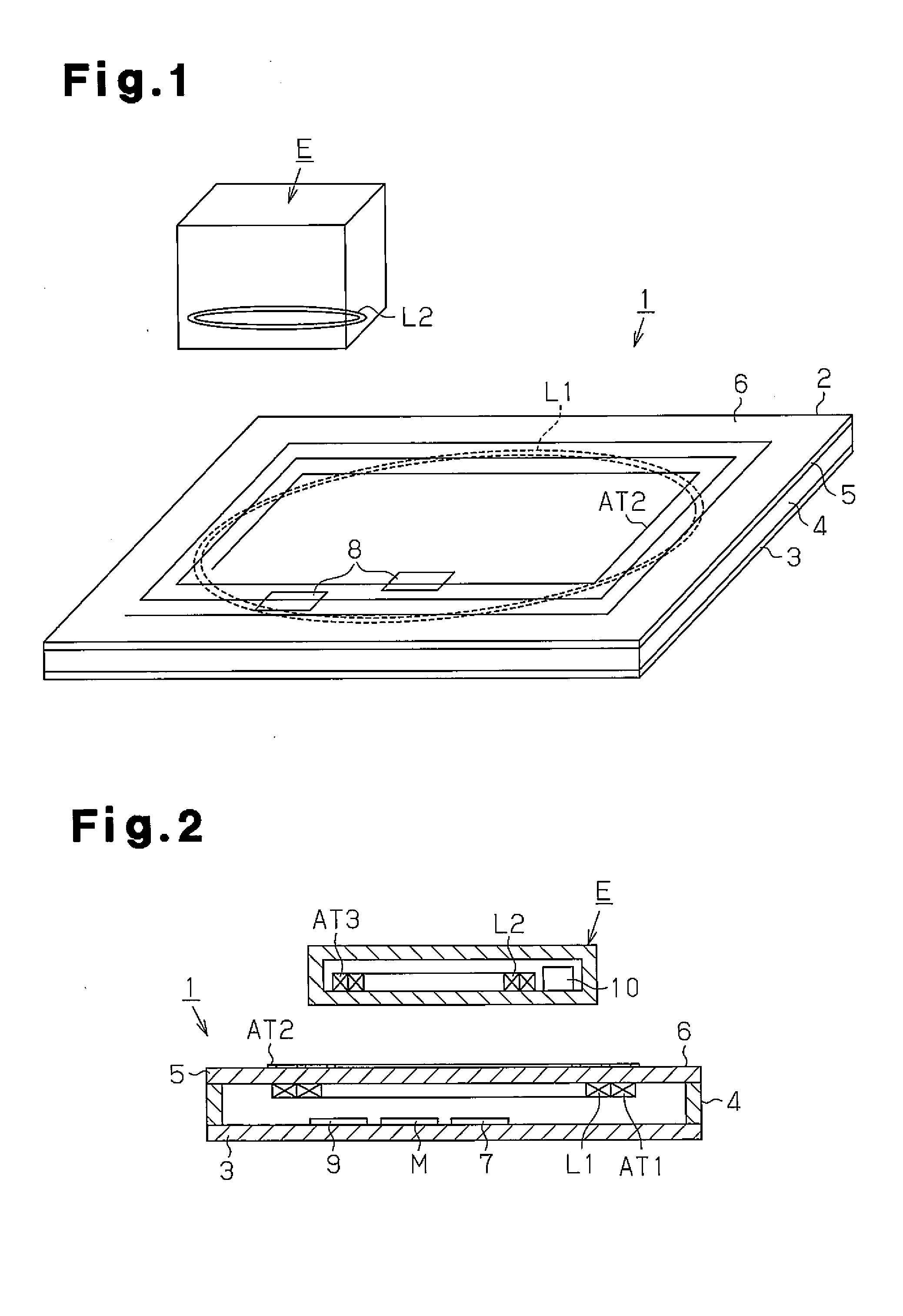

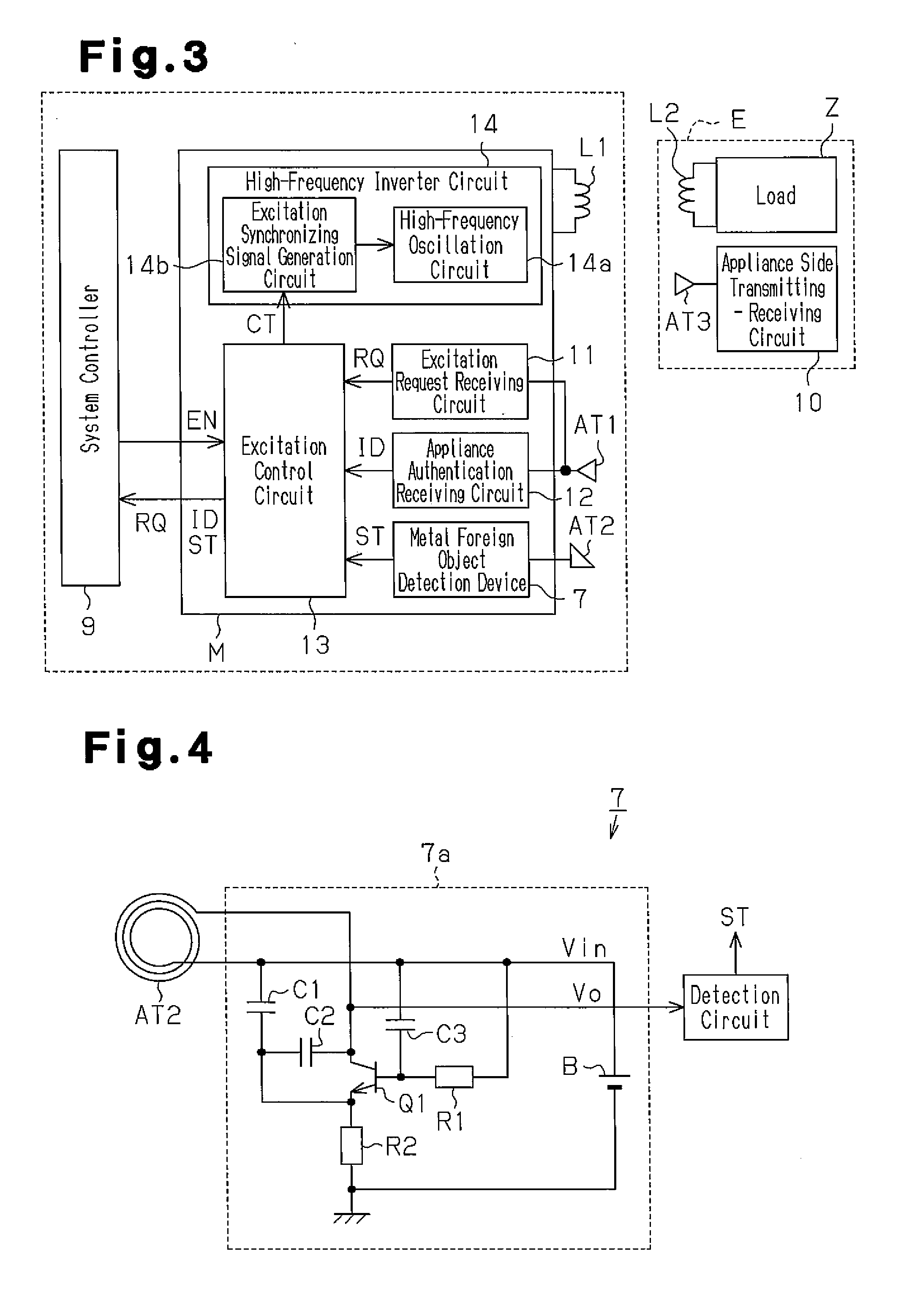

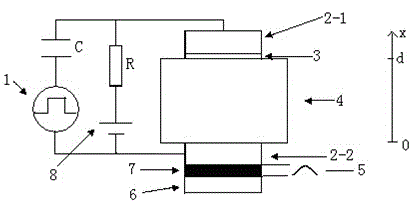

Contactless power supplying system and metal foreign object detection device of contactless power supplying system

ActiveUS20130099592A1High sensitivityImprove accuracyCircuit authenticationElectromagnetic wave systemUltrasound attenuationForeign object

A contactless power supplying system, which excites a primary coil of a power supplying device to generate an induced electromotive force at a secondary coil of an appliance arranged on the device and supply the induced electromotive force to a load of the appliance, includes a metal foreign object detection device. The metal foreign object detection device includes an antenna coil, an oscillation circuit, and a detection circuit. The oscillation circuit includes a component having a design value that generates oscillation in a range of oscillation conditions from immediately after the oscillation circuit starts to generate oscillation to just before a stable and continuous oscillation condition. The detection circuit detects a suspension of the oscillation or an attenuation in amplitude of the oscillation based on a change in an electric characteristic of the antenna coil caused by a metal foreign object on the power supplying device.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

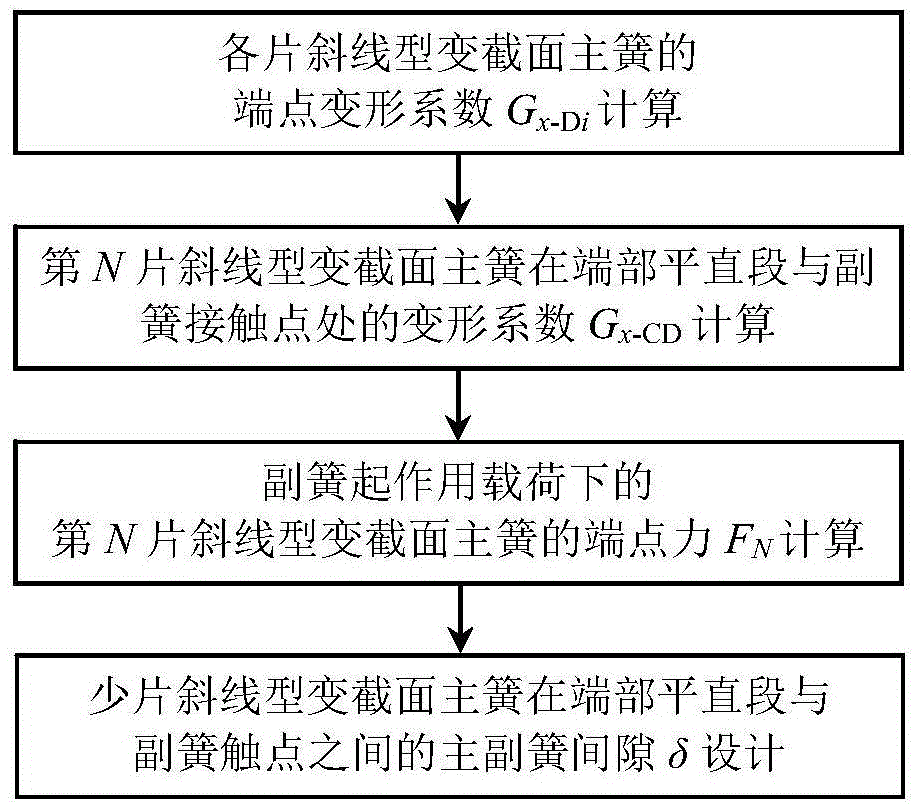

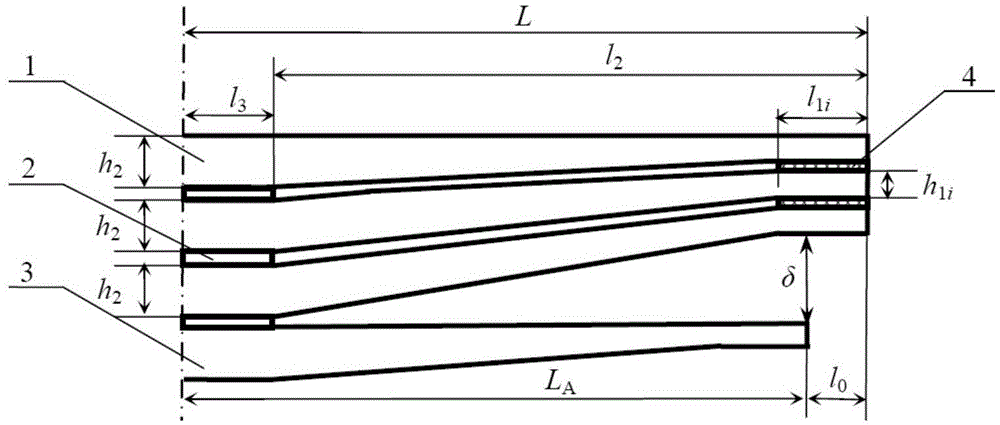

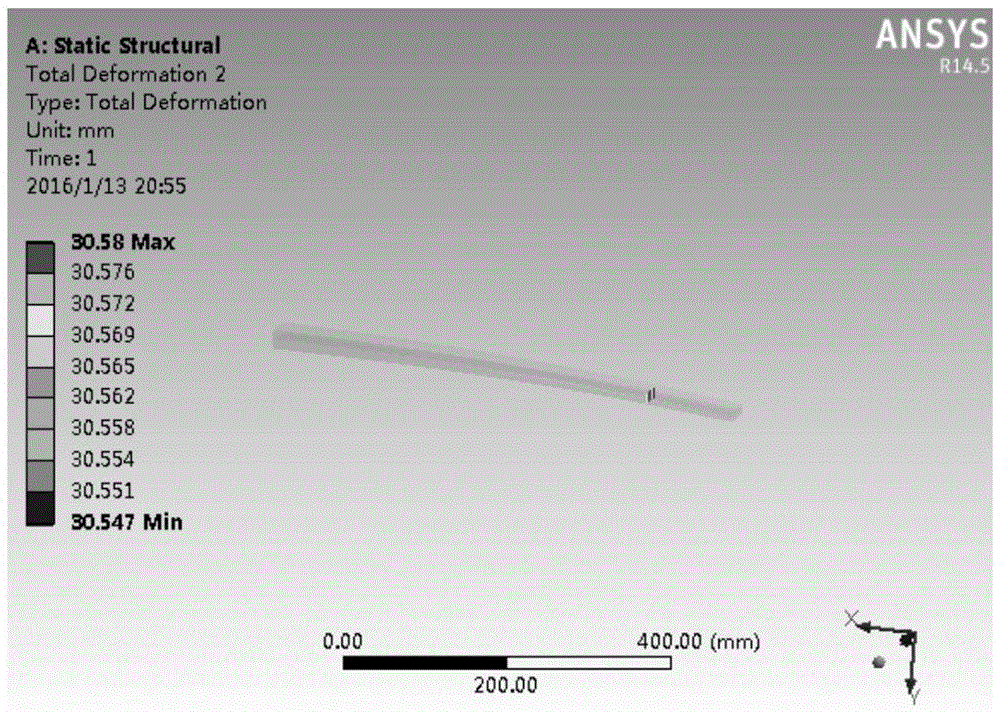

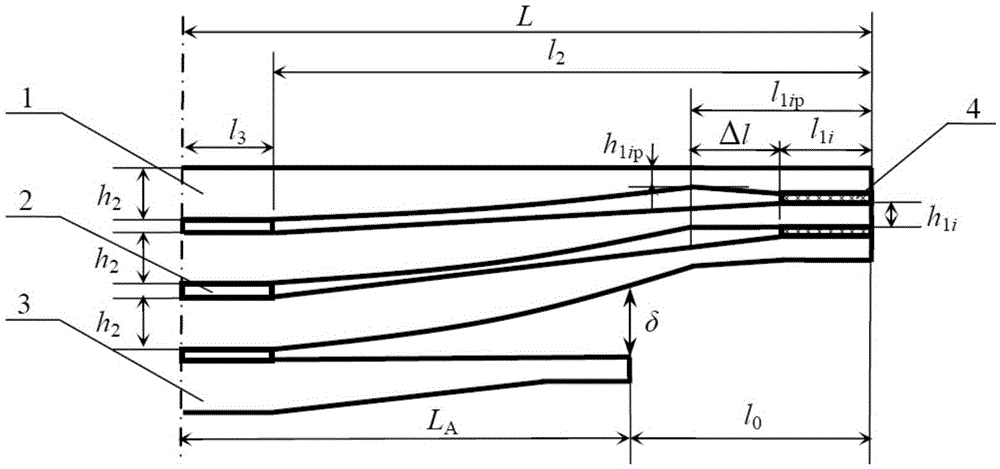

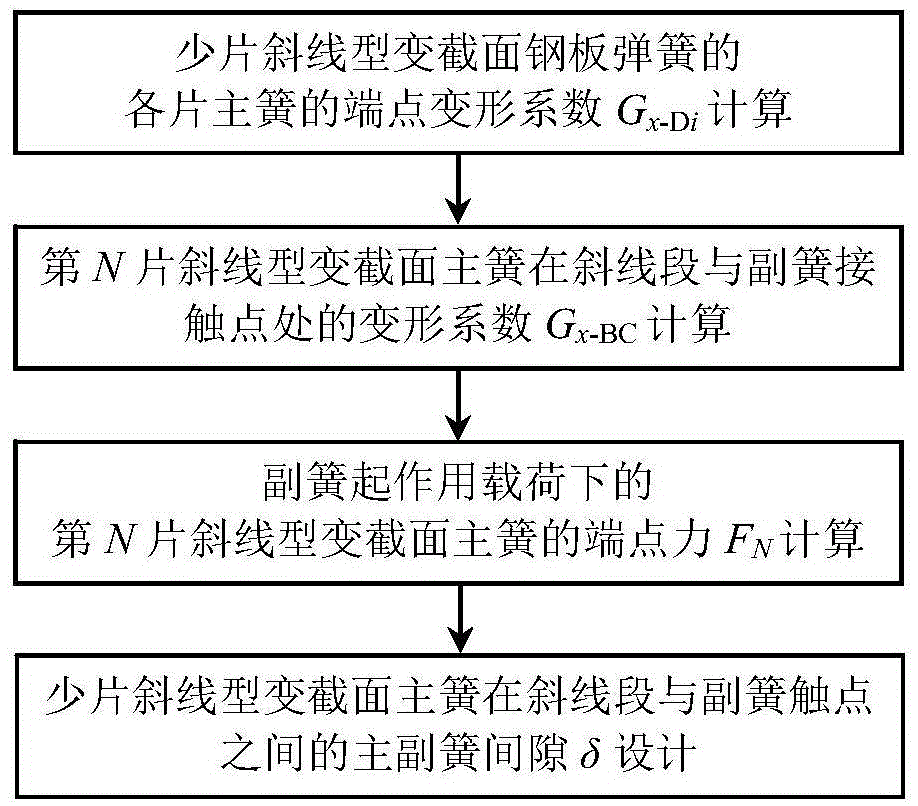

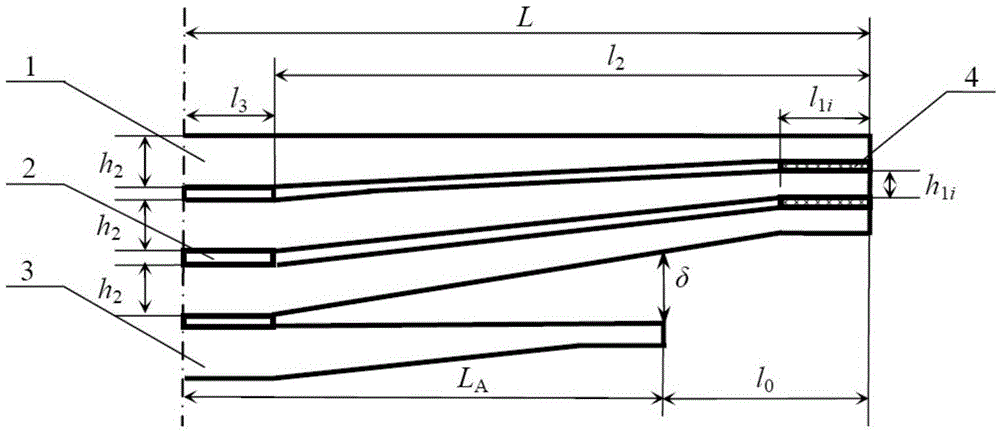

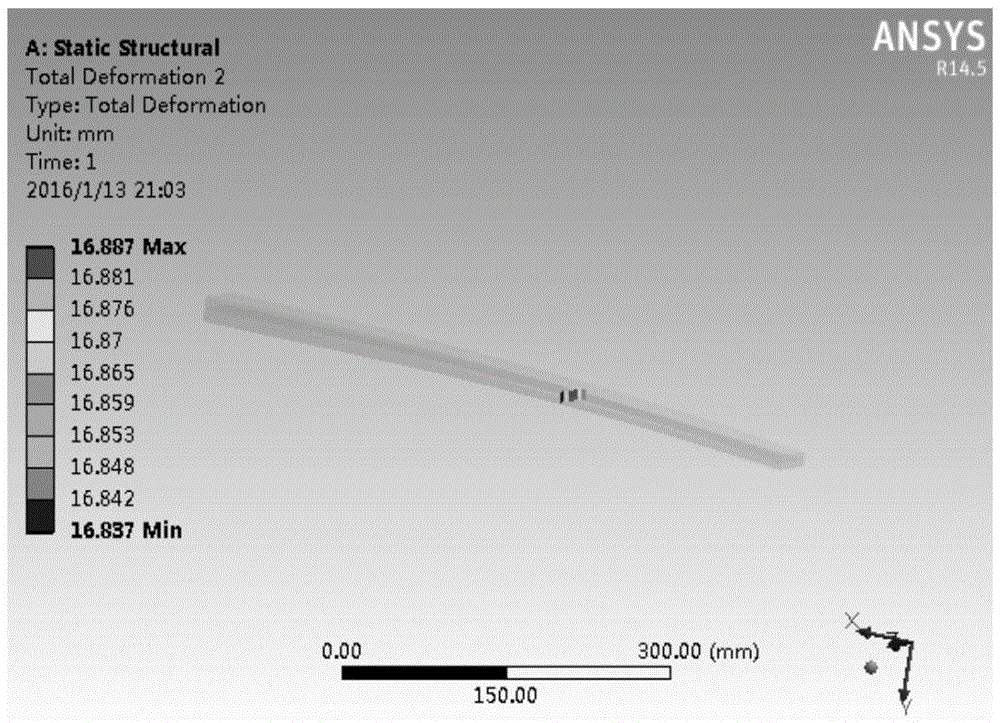

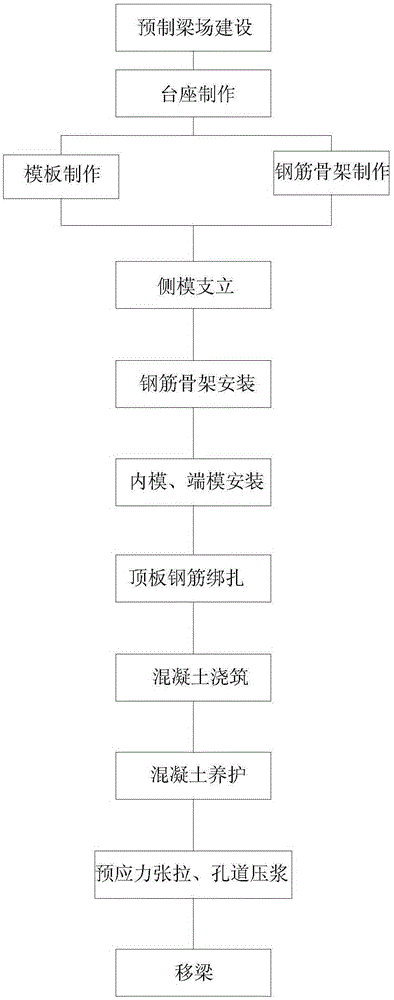

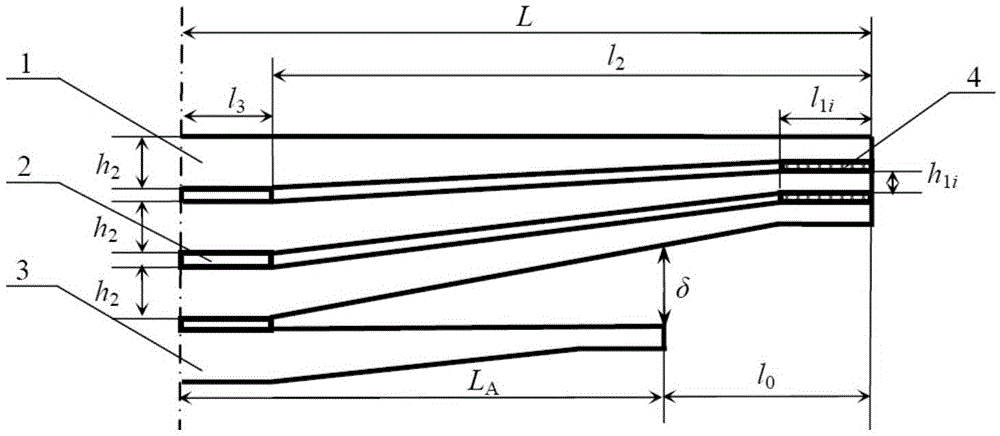

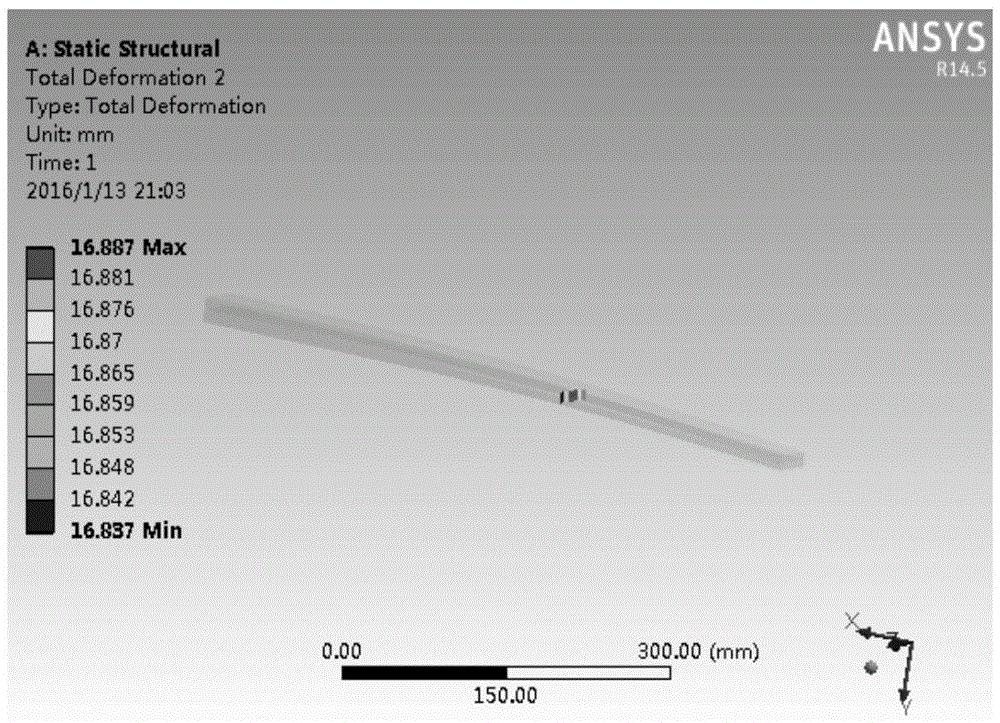

Method for designing gaps of end straight sections of diagonal few-leaf main springs and auxiliary springs

ActiveCN105526290AExact design valueReliable design valueGeometric CADLeaf springsEngineeringDesign values

The invention relates to a method for designing gaps of end straight sections of diagonal few-leaf main springs and auxiliary springs, and belongs to the technical field of suspension steel plate springs. The method includes determining endpoint deformation coefficients of the various main springs and deformation coefficients G<x-CD> of contact points of the end straight sections of the N main springs and the auxiliary springs according to structure sizes and elastic modulus of the various diagonal variable-section main springs; acquiring endpoint force F<N> of the N main springs according to acting load of the auxiliary springs and the endpoint deformation coefficients of the various main springs; designing the main and auxiliary spring gaps between contact points of the end straight sections of the main springs and the auxiliary springs according to the thicknesses h<2> of roots of the N main springs, the endpoint force F<N> and the deformation coefficients G<x-CD>. The method has the advantages that as known from simulation verification, design values of the gaps of the end straight sections of the diagonal few-leaf variable-section main springs and the auxiliary springs can be accurately and reliably obtained by the aid of the method, and accordingly the product design level and performance and the vehicle ride comfort can be improved; the design and experiment costs can be reduced, and the product development speeds can be increased.

Owner:山东恒日悬架弹簧股份有限公司

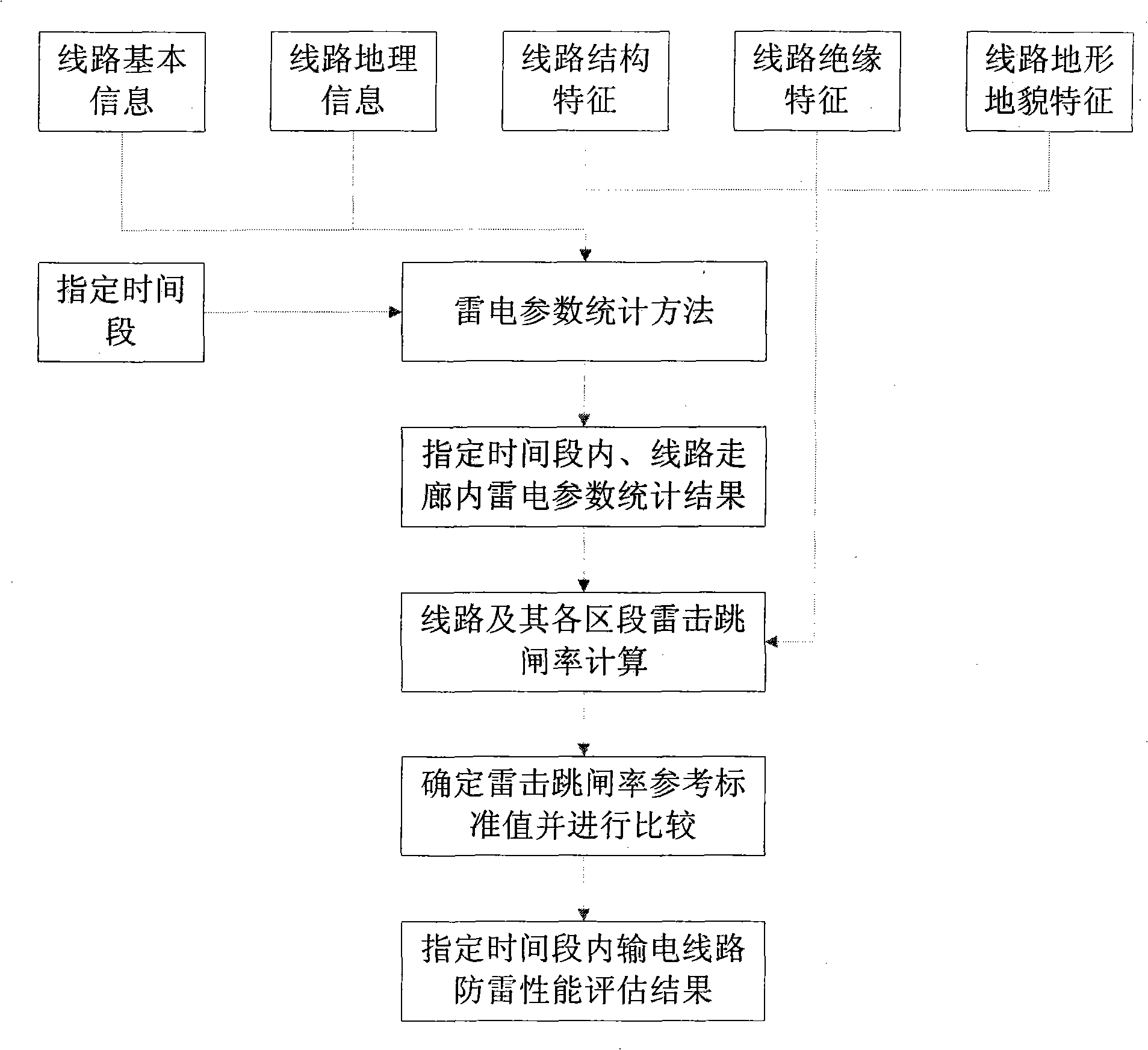

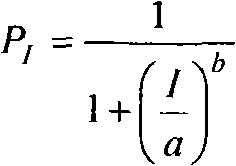

Electric power line lightning protection performance estimation method based on thunder and lightning parametric statistics

ActiveCN101315400AEvaluation results are reliableImprove ground lightning protection performanceElectrical testingLightning strokesEngineering

The invention relates to a method for evaluating the lightning protection performance of transmission lines based on the parametric statistics of lightning. The method comprises the following basic steps: firstly, the information of the transmission lines which require the lightning protection performance evaluation is given; secondly, the ground flash density and the probability distribution statistics of the lightning current magnitude within a specified period are performed to the given transmission lines; thirdly, the lightning-stroke trip-out rate in each section of the transmission lines segmented according to a pole tower within the specified period is calculated; fourthly, a reference value is set according to a design value, a specified value or an operation experience value of the lightning-stroke trip-out rate, and the time difference and the space difference of the lightning protection performance of the transmission lines are evaluated according to the lightning-stroke trip-out rate of each section of the transmission lines and a whole line within the specified period, wherein the lightning-stroke trip-out rate is obtained through the calculation in the step three. The method has the advantages that the evaluation to the lightning protection performance of the transmission lines is performed on the basis of the parametric statistics of lightning with time and space differences; the evaluation result of the method to the lightning protection performance of the transmission lines is more reliable, and has more pertinence; and the evaluation to the lightning protection performance of the transmission lines on different times and different spaces is realized.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST

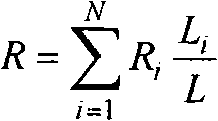

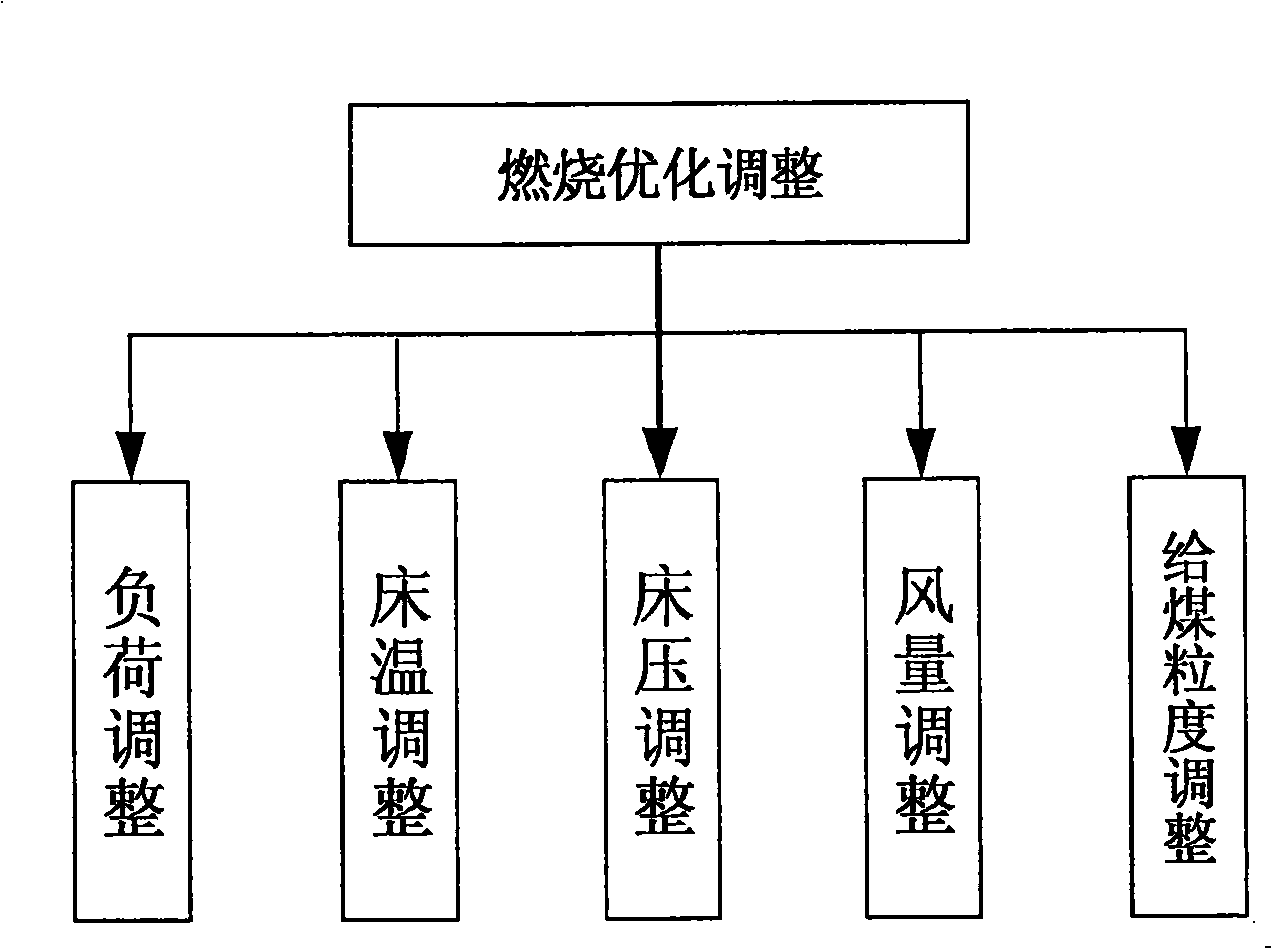

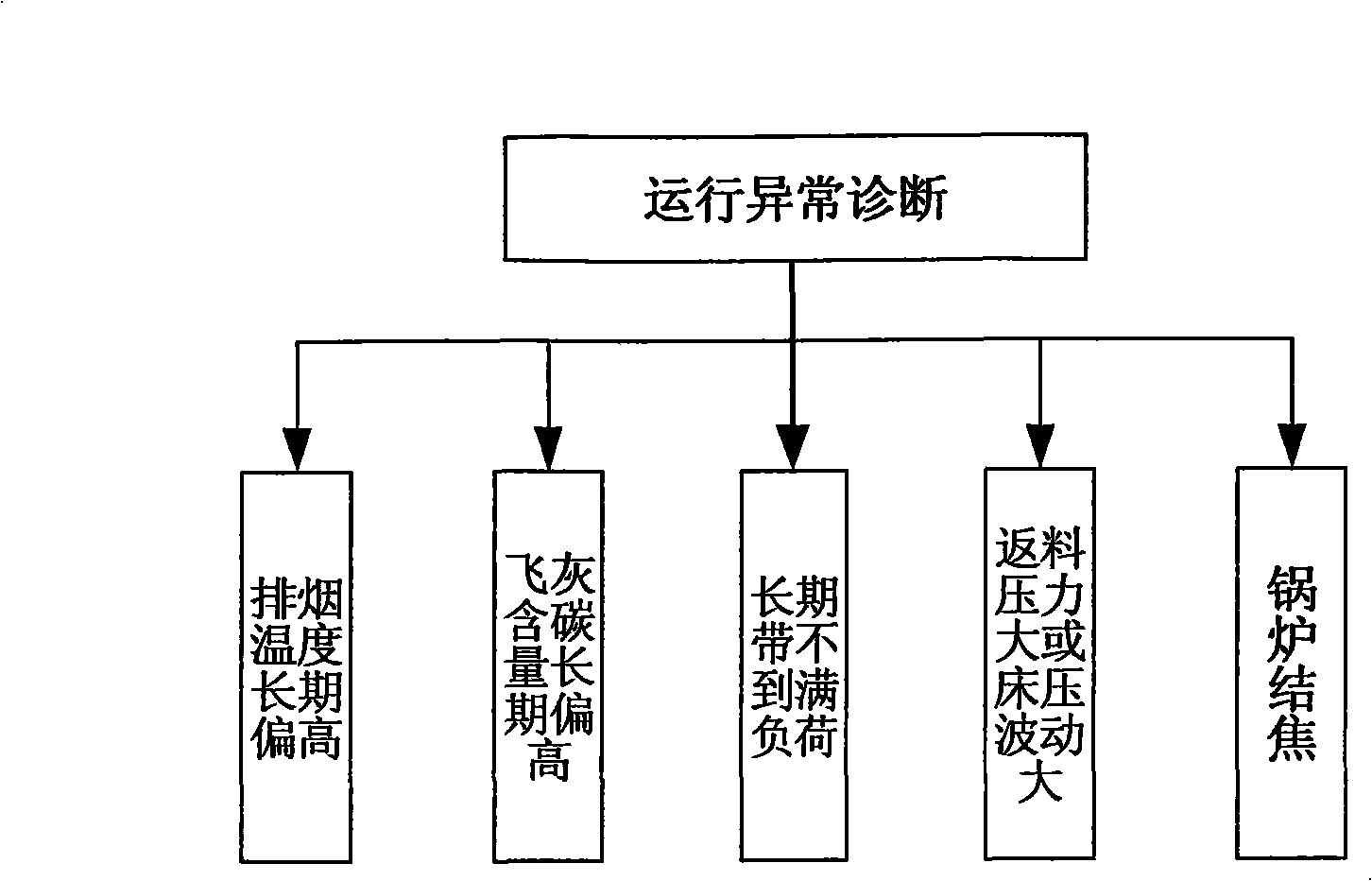

Method for optimizing and diagnosing circulating fluid bed boiler combustion

InactiveCN101329582AImprove economyFix security issuesElectric testing/monitoringAdaptive controlAir volumeEngineering

The invention relates to a circulating fluidized bed boiler combustion optimization and diagnosis method for acquiring and sorting out operation data such as bed temperature, bed pressure, load, efficiency, coal supply amount, limestone supply amount, primary air volume, primary wind pressure, upper secondary air volume and wind pressure, lower secondary air volume and wind pressure, oxygen content, induced air volume, slagging amount, NOx, Sox, etc., to build a neural network model as the basis for optimization adjustment and diagnosis. Field data of design value, measured value during operation, fuel chemistry assay value and etc. of the circulating fluidized bed boiler are utilized as the basis for optimization adjustment and diagnosis to calculate boiler efficiency as the basis for optimization adjustment and diagnosis; a judgment criterion for the optimization adjustment of combustion work condition is established and a corresponding solution is proposed, and therefore, optimization adjustment can be carried out when the circulating fluidized bed boiler deviates from the optimum combustion work condition; a judgment criterion for abnormal operation is established and a solution thereof is proposed; and therefore, problems which can not be solved after optimization adjustment can be diagnosed and analyzed. Common accident phenomena are summarized and processing strategies can be proposed, and therefore, guidance can be provided to accident handling.

Owner:SOUTHEAST UNIV

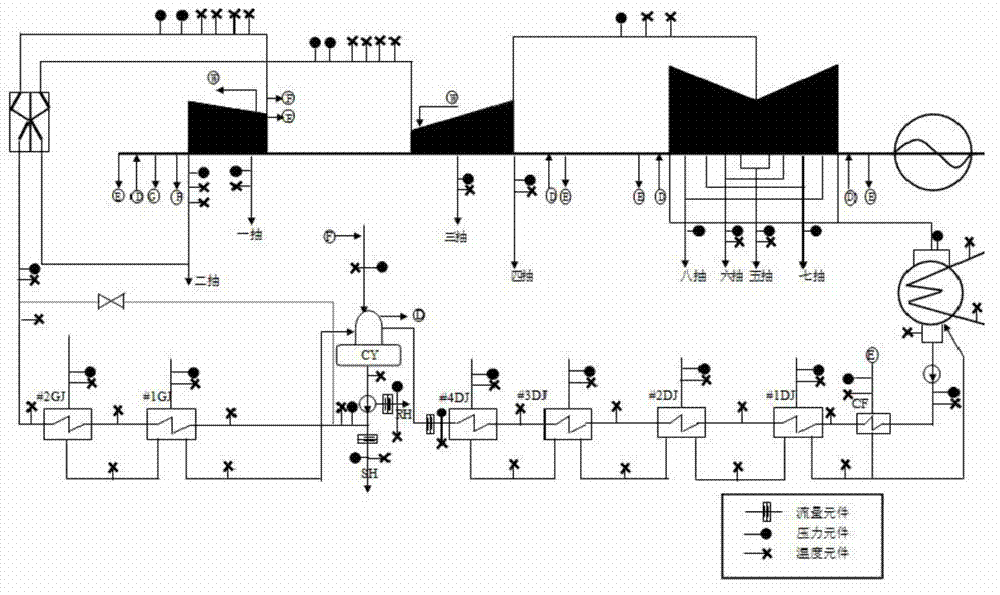

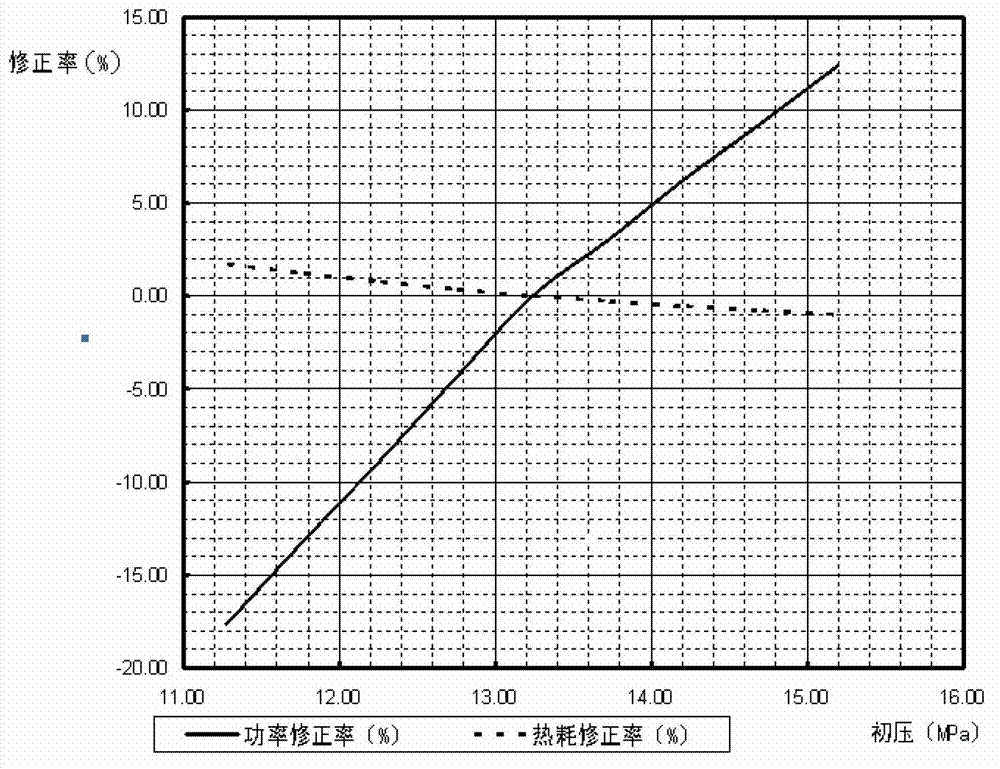

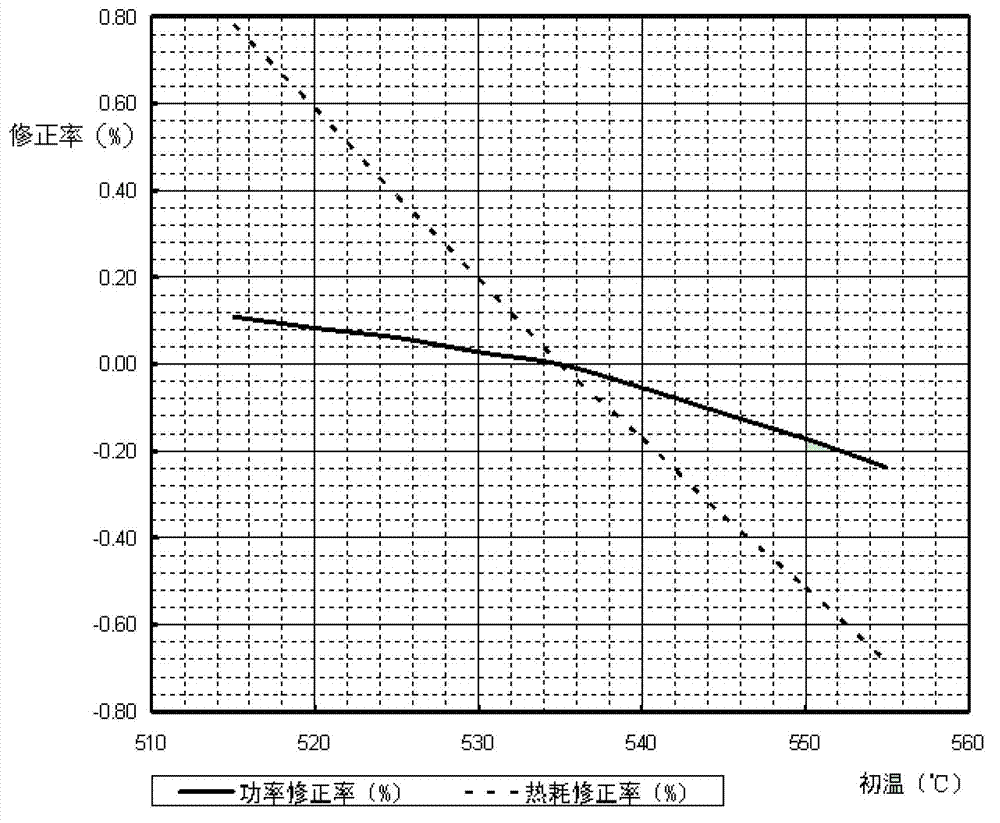

Method for evaluating performances of condensing steam turbine after high back pressure improvement

The invention discloses a method for evaluating performances of a condensing steam turbine after high back pressure improvement. The method comprises the following steps: distributing sufficient pressure, temperature, flow and electric power test points on a thermodynamic system of a turbine unit; stopping heating steam extraction on a low pressure cylinder gap bridge pipe; calculating the main steam flow, the cold reheat steam flow and the reheat steam flow; calculating the low pressure cylinder efficiency of a unit; taking a high back pressure heat supply unit as a pure condensing unit running under a high back pressure working condition, calculating the heat loss efficiency of the unit, and performing the second-type correction on the heat rate; and comparing the heat rate and the lower pressure cylinder efficiency with design values of a manufacture plant, and evaluating the lower pressure cylinder improvement technology and the unit improvement effect. The method disclosed by the invention is easy and feasible.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

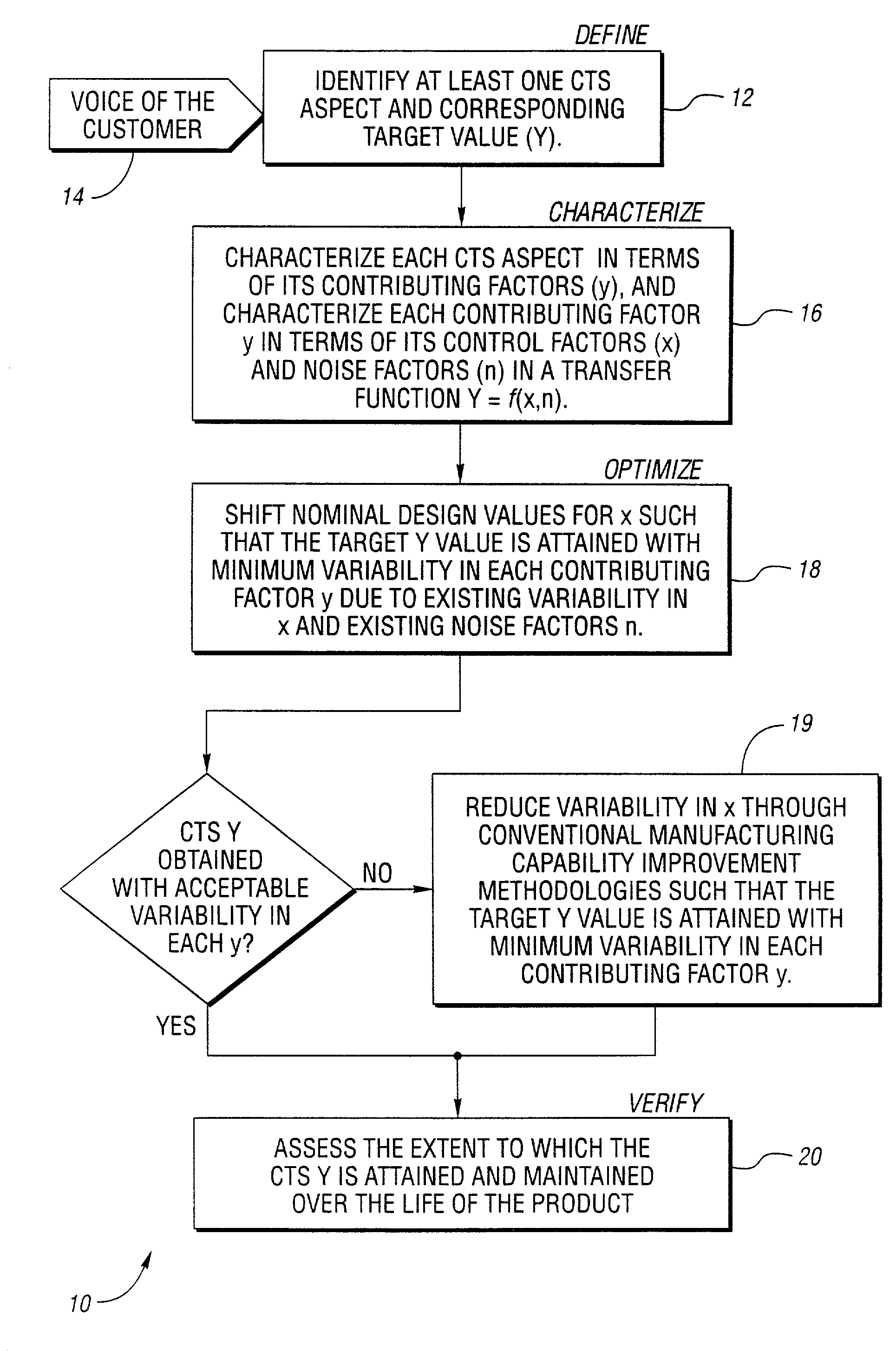

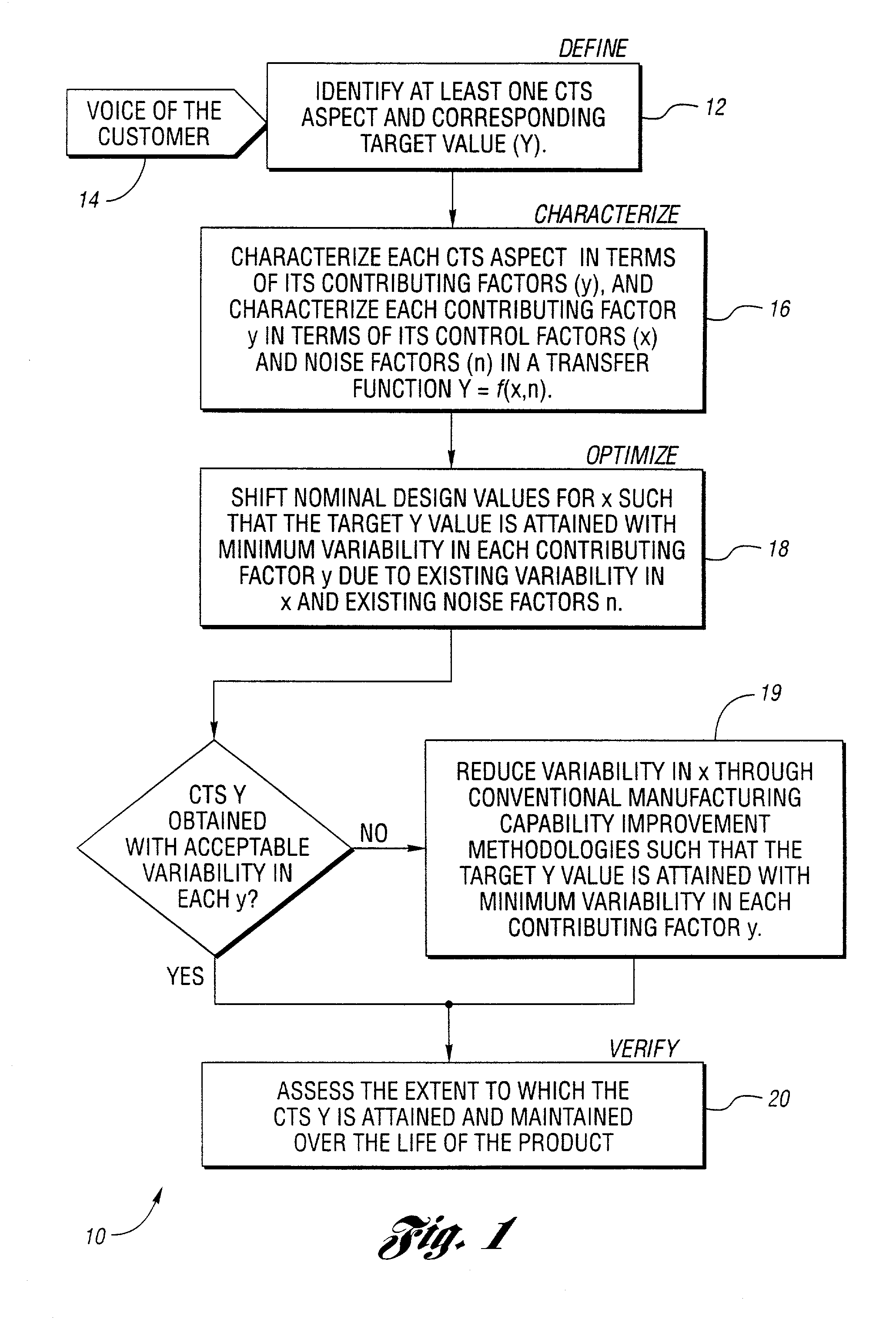

Method and system for product optimization

ActiveUS7219068B2Improve the level ofFacilitate the processForecastingSpecial data processing applicationsProduct optimizationLife time

A method and computer-implemented system for optimizing a product. Based on the “voice of the customer”, aspects of the product that are critical to the customer satisfaction, and target values, therefore, are identified. Aspects are characterized in terms of their contributing factors. Each contributing factor is characterized in a transfer function in terms of control and noise factors impacting the contributing factors. Contributing factors are optimized during product design by shifting nominal design values for control factors with respect to the transfer function such that target contributing factors are attained with minimum variability due to existing noises and variability in control. Where target values cannot be obtained through design optimization, conventional methods of manufacturing optimization are implemented. The extent to which the target values are attained and maintained over the life of the product are assessed.

Owner:FORD MOTOR CO

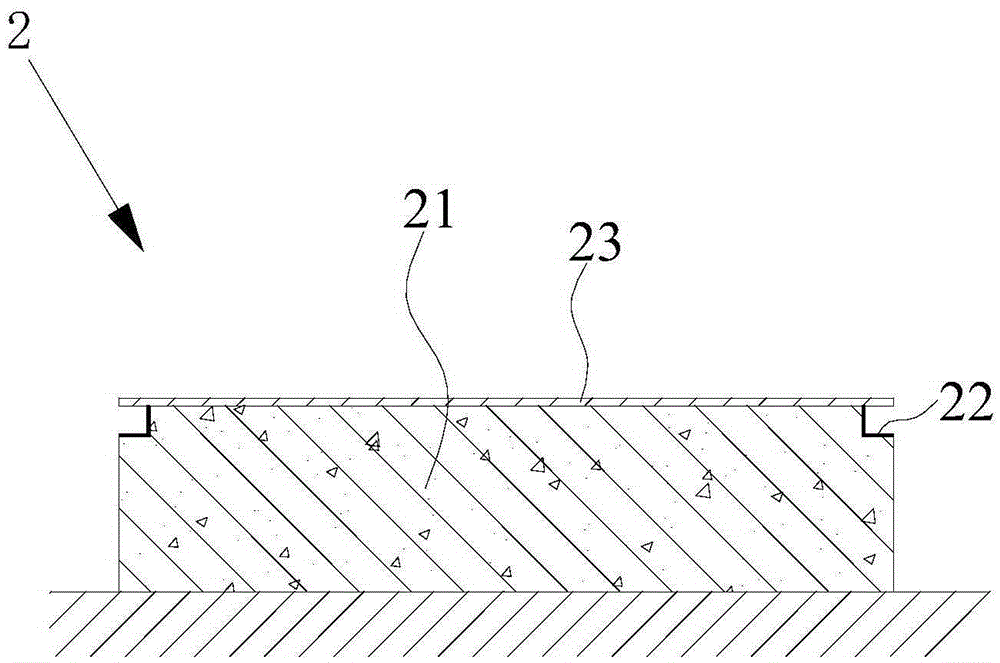

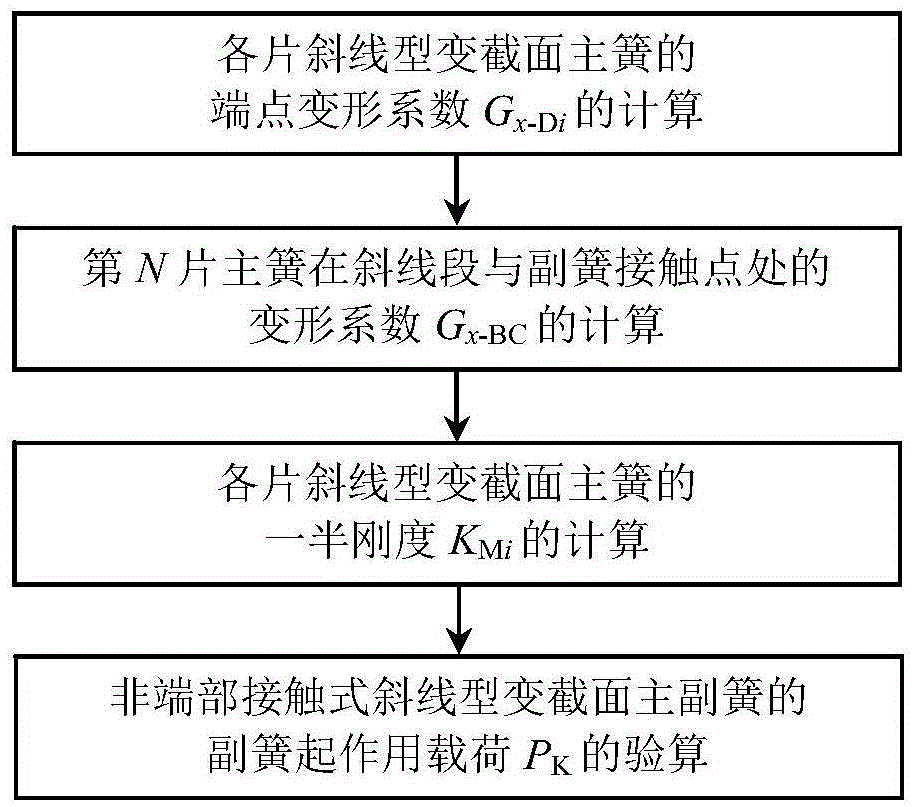

Auxiliary spring work load checking method of non end part contact type end part strengthened few-leaf main and auxiliary springs

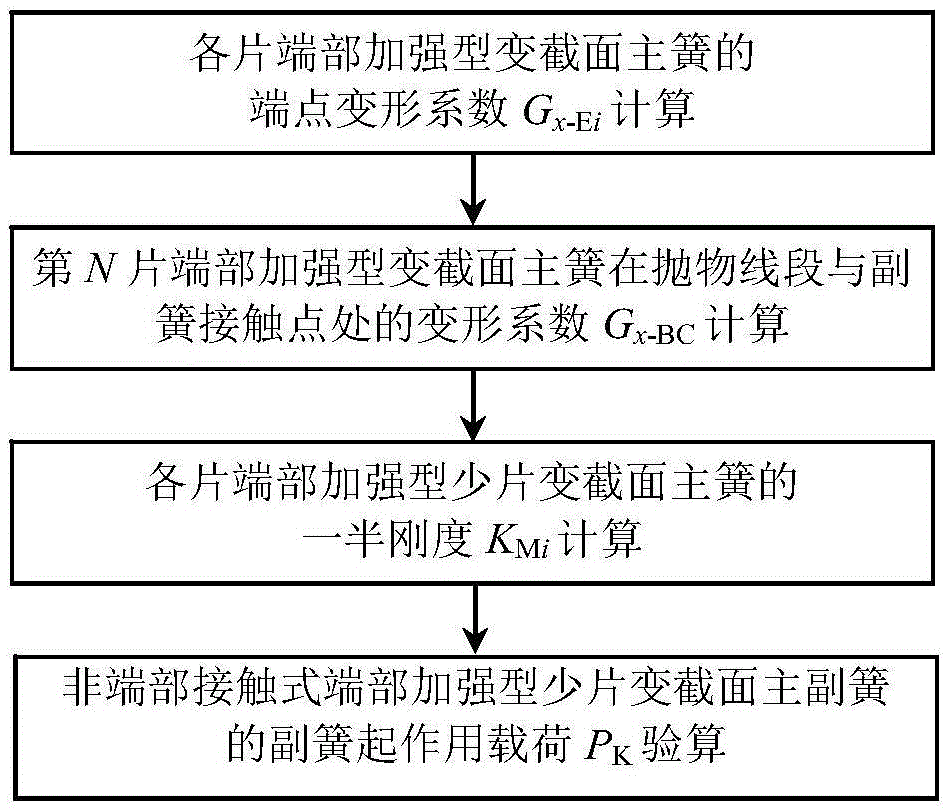

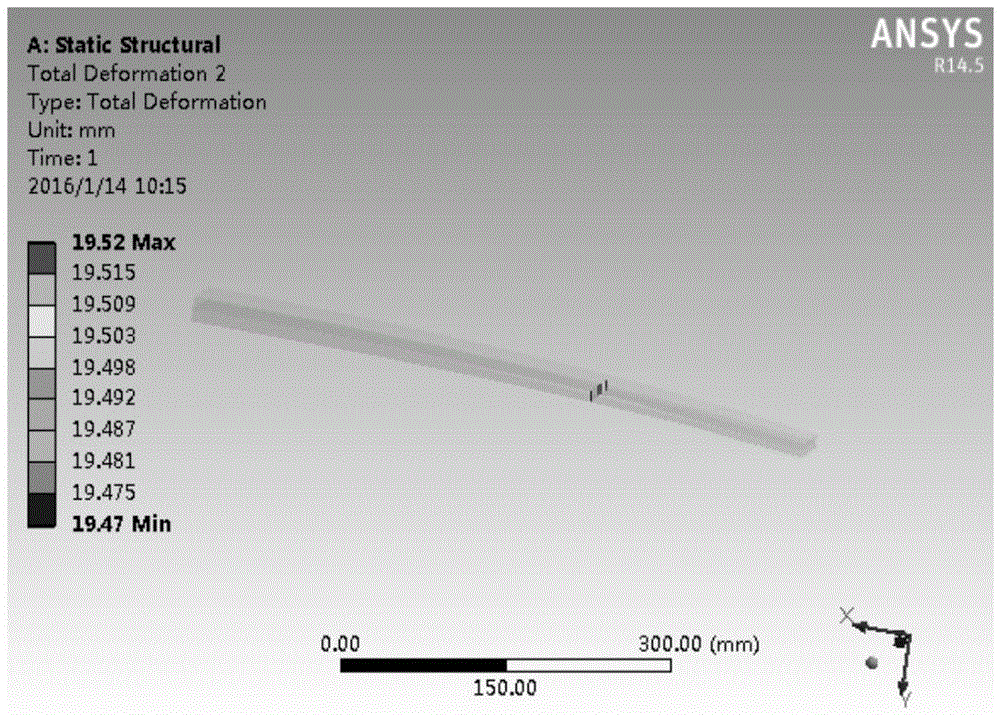

ActiveCN105590009AImprove the design levelThe checking method is reliableDesign optimisation/simulationSpecial data processing applicationsContact typeEngineering

The invention relates to an auxiliary spring work load checking method of a non end part contact type end part strengthened few-leaf main and auxiliary springs belonging to the suspension steel plate spring technical field. According to the method of the invention, firstly, according to the structure size and the elastic modulus of each end part strengthened few-leaf cross-section variable main spring, the end point deformation coefficient Gx-Ei and the half rigidity KMi of each main spring, and the deformation coefficient Gx-BC at the contact point of the Nth main spring and an auxiliary spring on a parabolic segment can be determined; then, according to the half rigidity KMi of each main spring, the thickness h2 of a root straight section, the Gx-BC of the Nth main spring and a main and auxiliary spring interval Delta design value, the auxiliary spring work load of the non end part contact type end part strengthened few-leaf cross-section variable main and auxiliary springs is checked. Through the emulation proof, in adoption of the method of the invention, the accurate and reliable auxiliary spring work load checking value can be obtained; therefore, the design levels and performances of the few-leaf cross-section variable main and auxiliary springs and the smoothness of a vehicle are improved; moreover, the design and test cost is saved; and the product development speed is accelerated.

Owner:SHANDONG AUTOMOBILE SPRING FACTORY ZIBO CO LTD

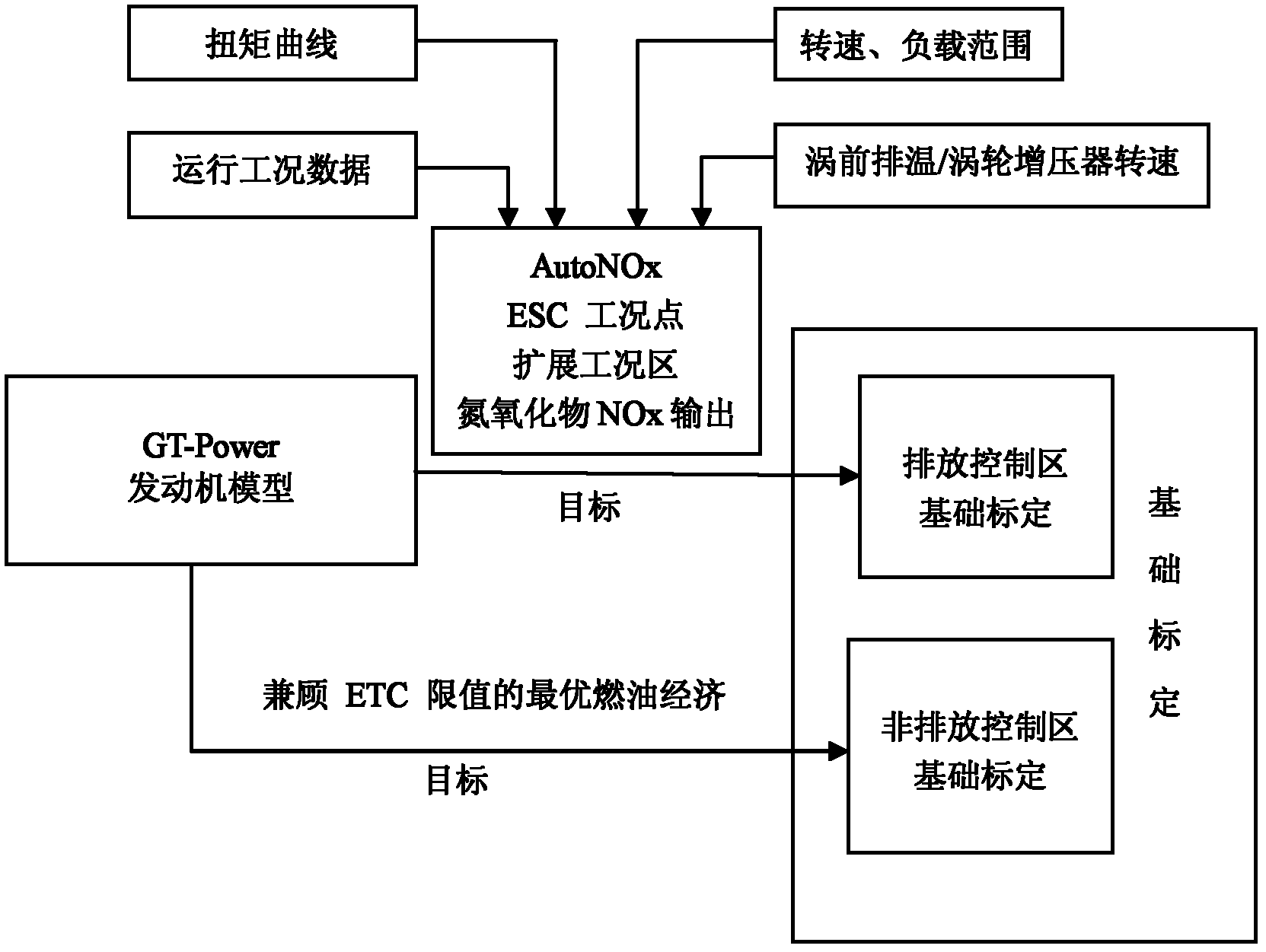

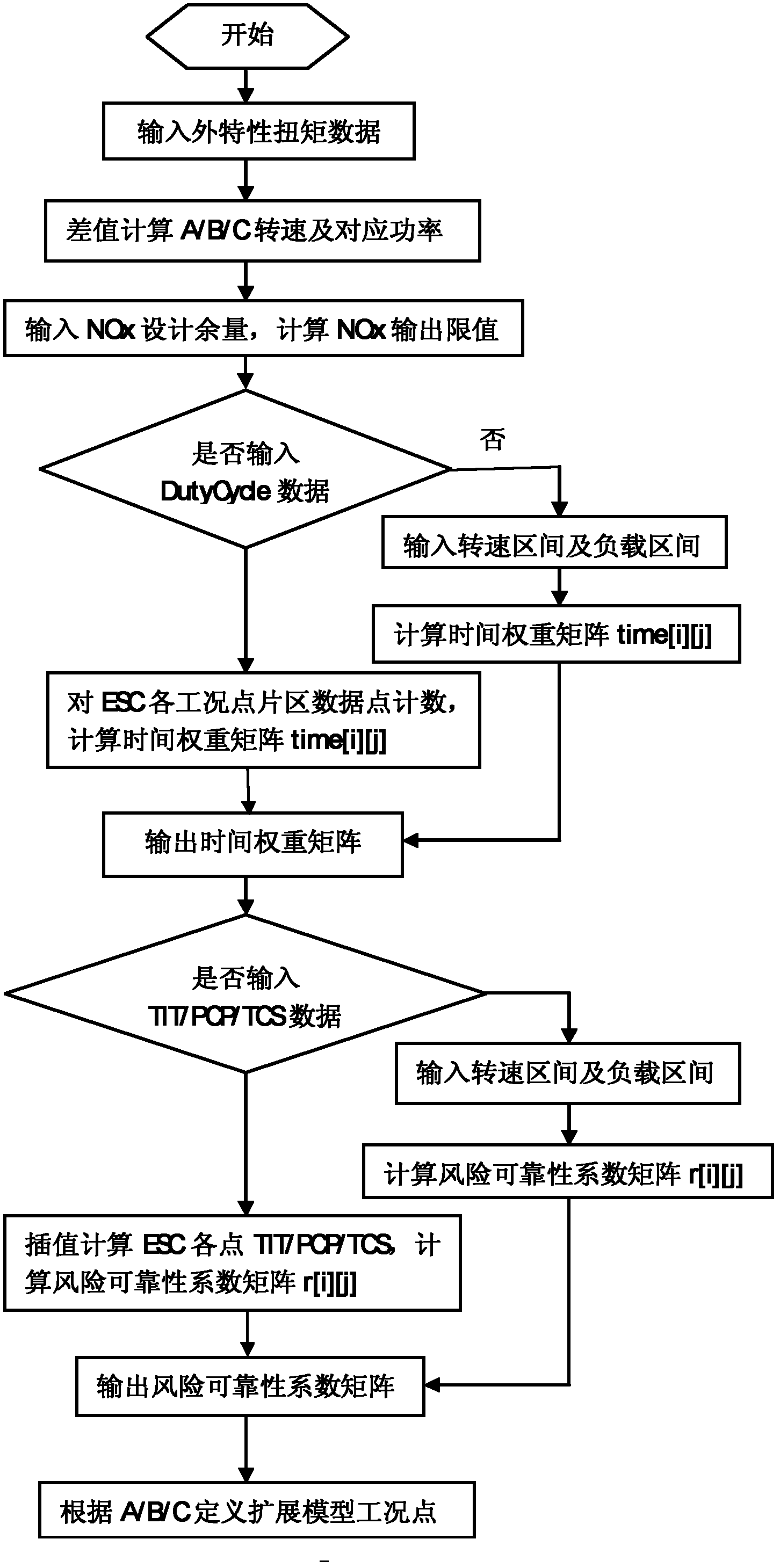

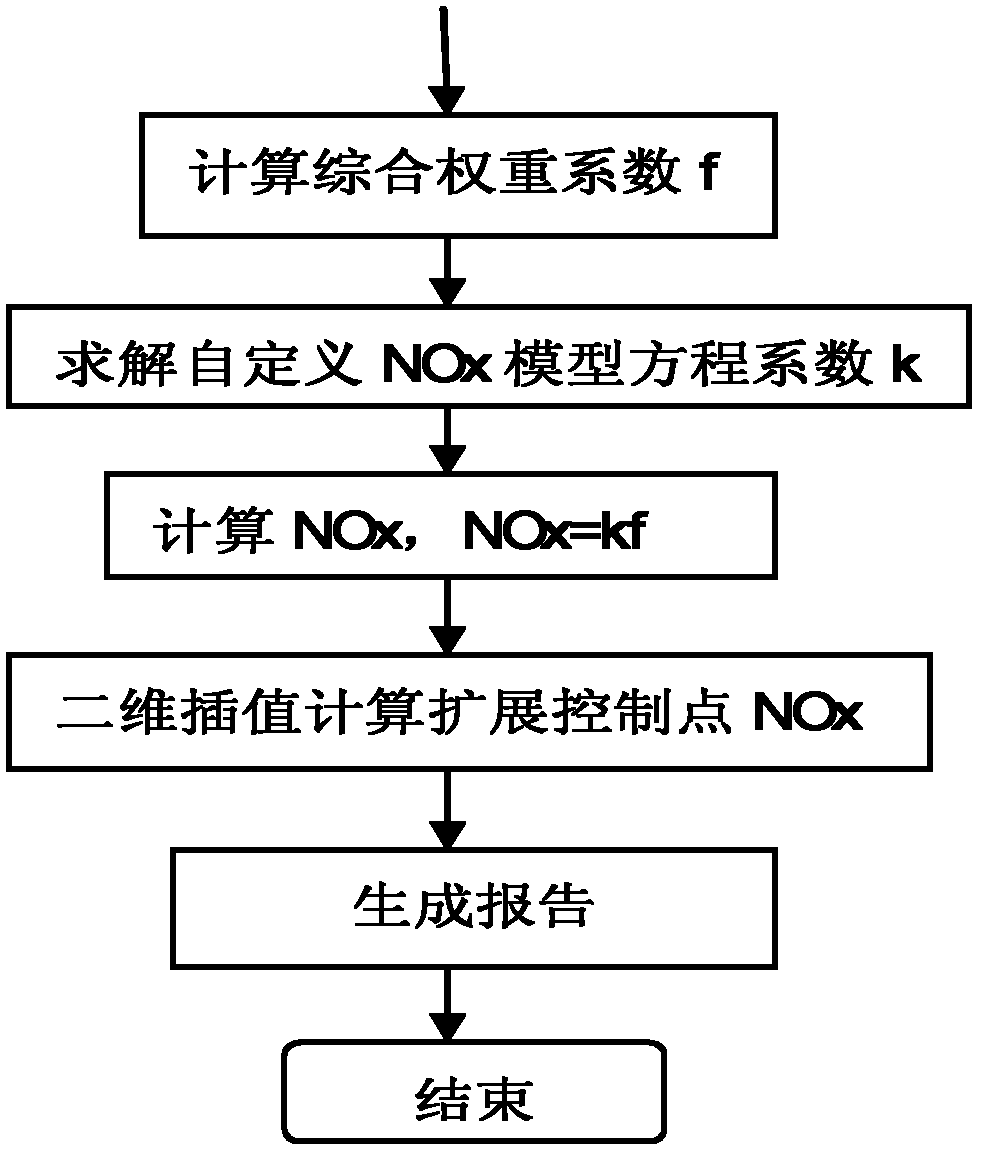

Method for calibrating electrically controlled diesel engine

InactiveCN102331350AImprove performanceImprove efficiencyEngine testingSpecial data processing applicationsNitrogen oxidesDiesel engine

The invention relates to a method for calibrating an electrically controlled diesel engine. The software AutoNOx inputs the emission values of nitrogen oxides at each working condition point in an automatically allocated emission region of the electrically controlled diesel engine according to the complete vehicle running features and the like, the AutoNOx software automatically completes the calculation of the emission design values of nitrogen oxides at each working condition point in an engine emission control region according to the factors of engine operating cycle working condition, thetarget torque curve, the complete engine reliability and the like, the calculation result is used as the emission target of one-dimensional thermodynamics GT-Power engine model, and the GT-Power software obtains the main calibration parameters of the engine through internal computations to form basic calibration in the emission control region of the electrically controlled diesel engine. The method is applicable to the development of performance and emission of various electrically controlled diesel engines, and optimal balance between emission and fuel economy in actual working condition is realized.

Owner:DONGFENG CUMMINS ENGINE

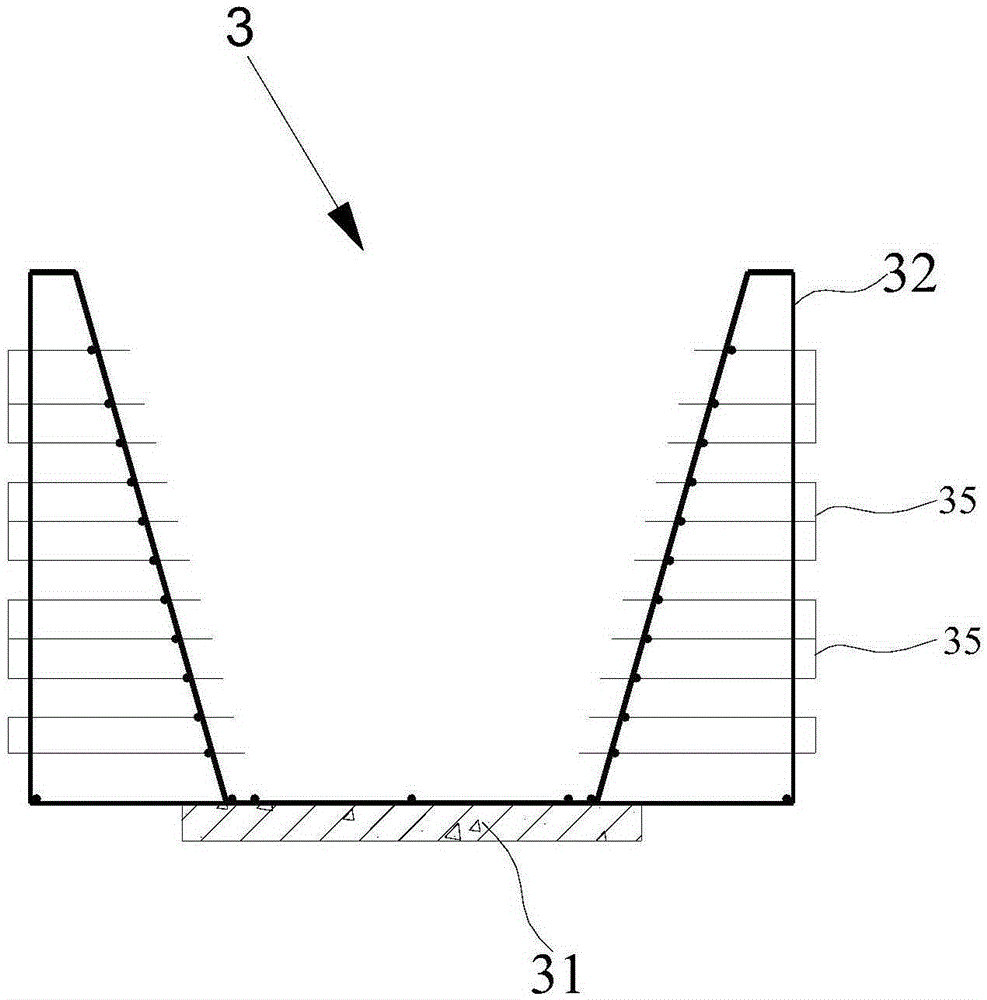

Method for designing few-leaf oblique line type variable-section main springs in gaps between oblique line segments and auxiliary spring

ActiveCN105550487AImprove the design levelQuality improvementGeometric CADDesign optimisation/simulationLine segmentOblique line

The invention relates to a method for designing few-leaf oblique line type variable-section main springs in the gaps between oblique line segments and an auxiliary spring, and belongs to the technical field of suspension steel plate springs. According to the structural sizes and the elasticity moduli of the oblique line type variable-section main springs, the endpoint deformation coefficient Gx-Di of each main spring and the deformation coefficient Gx-BC of the Nth main spring at the contact point of the corresponding oblique line segment and the auxiliary spring are determined first; then, according to the required auxiliary spring acting load design value and the endpoint deformation coefficient Gx-Di of each main spring, endpoint force FN of the Nth main spring is obtained; then, according to the thickness h of the root straight section of the Nth main spring, the Gx-BC and the FN, main spring and auxiliary spring gaps between the oblique line segment of the main springs and the contact point of the auxiliary spring are designed. Through simulation verification, it can be known that the main and auxiliary spring gap design value meeting the auxiliary spring acting load requirement can be obtained by means of the method, and the product design level, product performance and vehicle smoothness are improved. Meanwhile, design and testing cost is reduced, and product development speed is increased.

Owner:JIANGSU HAIHONG MACHINERY MFG

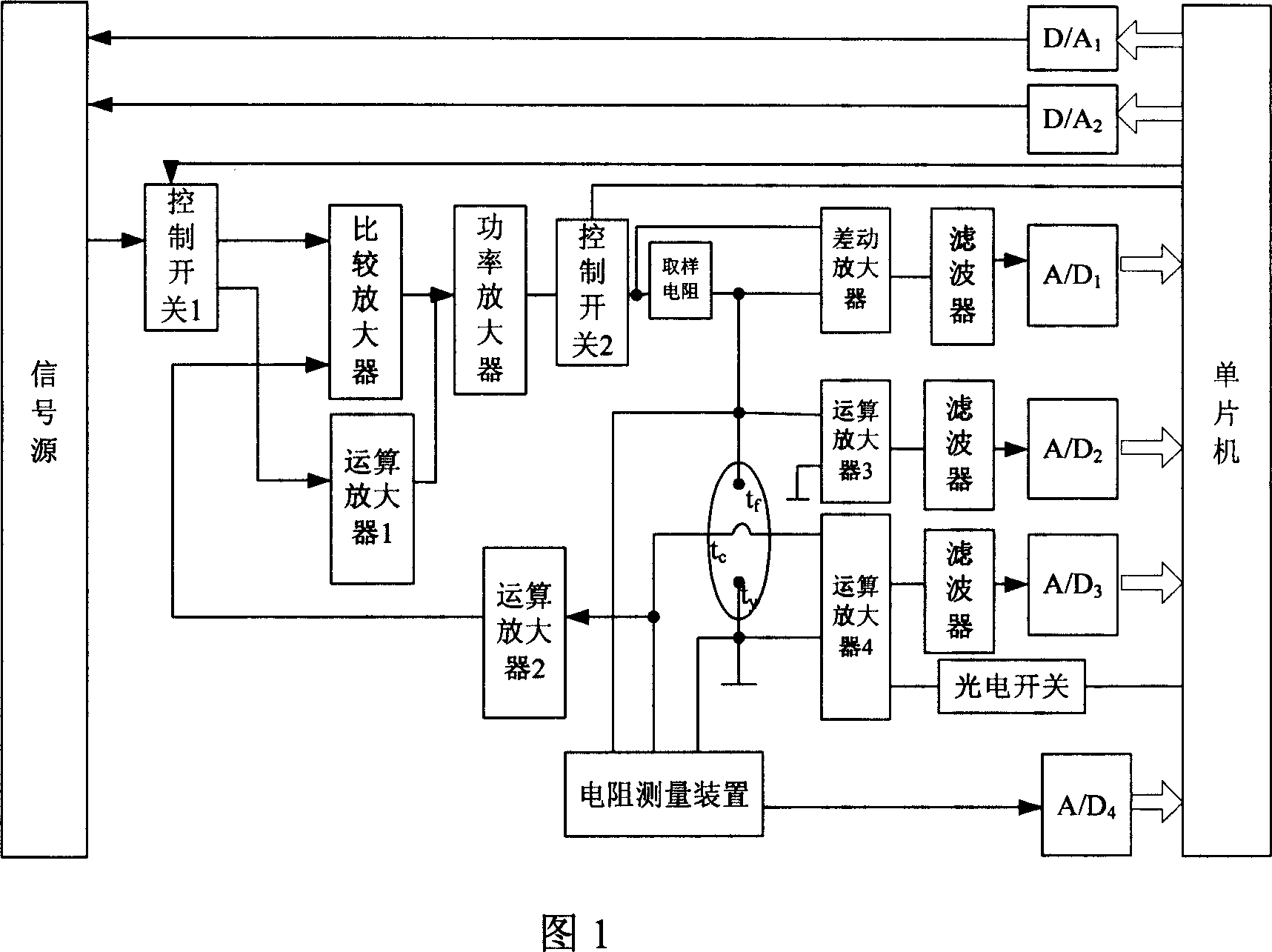

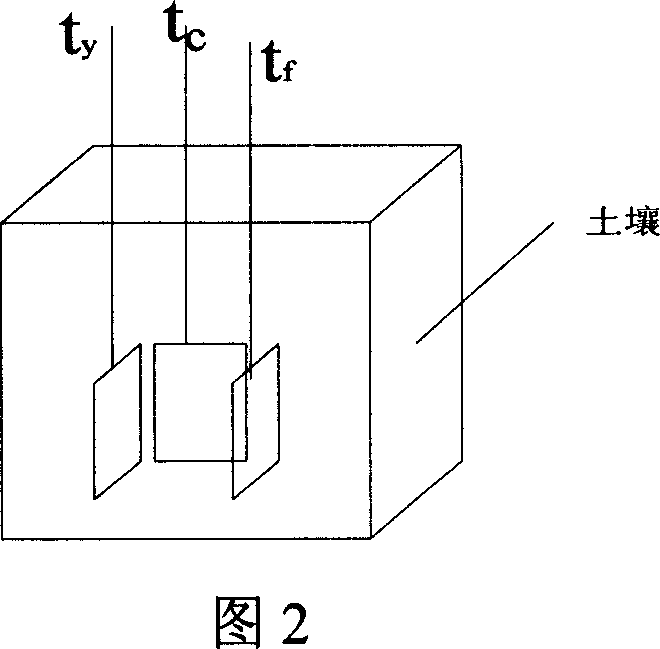

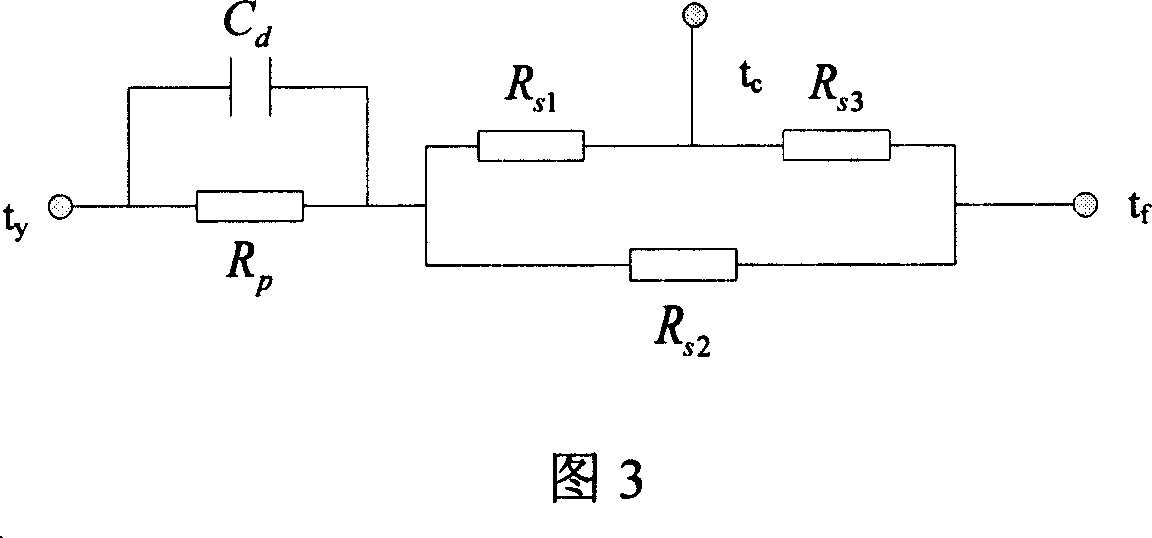

Method and device for online monitoring power station and substation grounding grid

InactiveCN101034129AAccurate assessmentAccurate detectionEarth resistance measurementsFault locationEngineeringTransmitter

This invention discloses an on-line monitoring method of grounding net of power station and its device. The method includes following steps: bury state transmitter in soil where have station earthing net; survey electric resistance of transmitter electrode and self corrosion electric potential; add square wave signal to electrode of state transmitter, survey electric current; after smoothing surveyed data, deliver to microprocessor to compute corrosion rate of electrode, take it as corrosion rate of grounding electrode in corresponding area; use corrosion rate to compute corrosion deep and actual geometry size of grounding electrode of grounding net, and use computing method of grounding net numerus to compute electricity performance parameter of grounding net; compare computed electricity performance parameter and design value, judge safe performance of grounding net. This invention can do online monitoring to corrosion deep and electricity performance parameter of grounding net of power station. The invention provides a overall, effective, economic, real time solving method to survey and evaluate grounding net of power station.

Owner:HUNAN UNIV

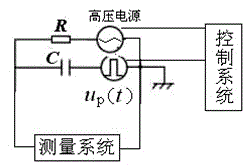

Method for measuring and judging insulation aging based on PEA space charges

ActiveCN103558531AAchieve statisticsImplement aging assessmentTesting dielectric strengthElectrical field strengthHigh pressure

The invention relates to a method for measuring and judging insulation aging based on PEA space charges. The method includes the steps that a pulsed electro-acoustic space charge measurement system is built, a space charge test is conducted on an insulating layer of a power cable, statistics is conducted on the absolute charge quantity of the space charges, the currently measured quantity and a threshold value are compared with historical data, and insulation is evaluated by utilizing the total quantity and the charge increased speed to analyze parameters; according to an externally applied high voltage power supply electric field and an insulation internal space charge distribution curve, an electric field intensity method is utilized to analyze insulation of the power cable, when calculated field intensity is higher than a design value, the insulation can be damaged, and the aging degree of insulation can be judged according to the increased speed of the electric field intensity. According to the method, the insulation internal space charges of the power cable are online monitored, and insulation aging of the power cable is evaluated according to data.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

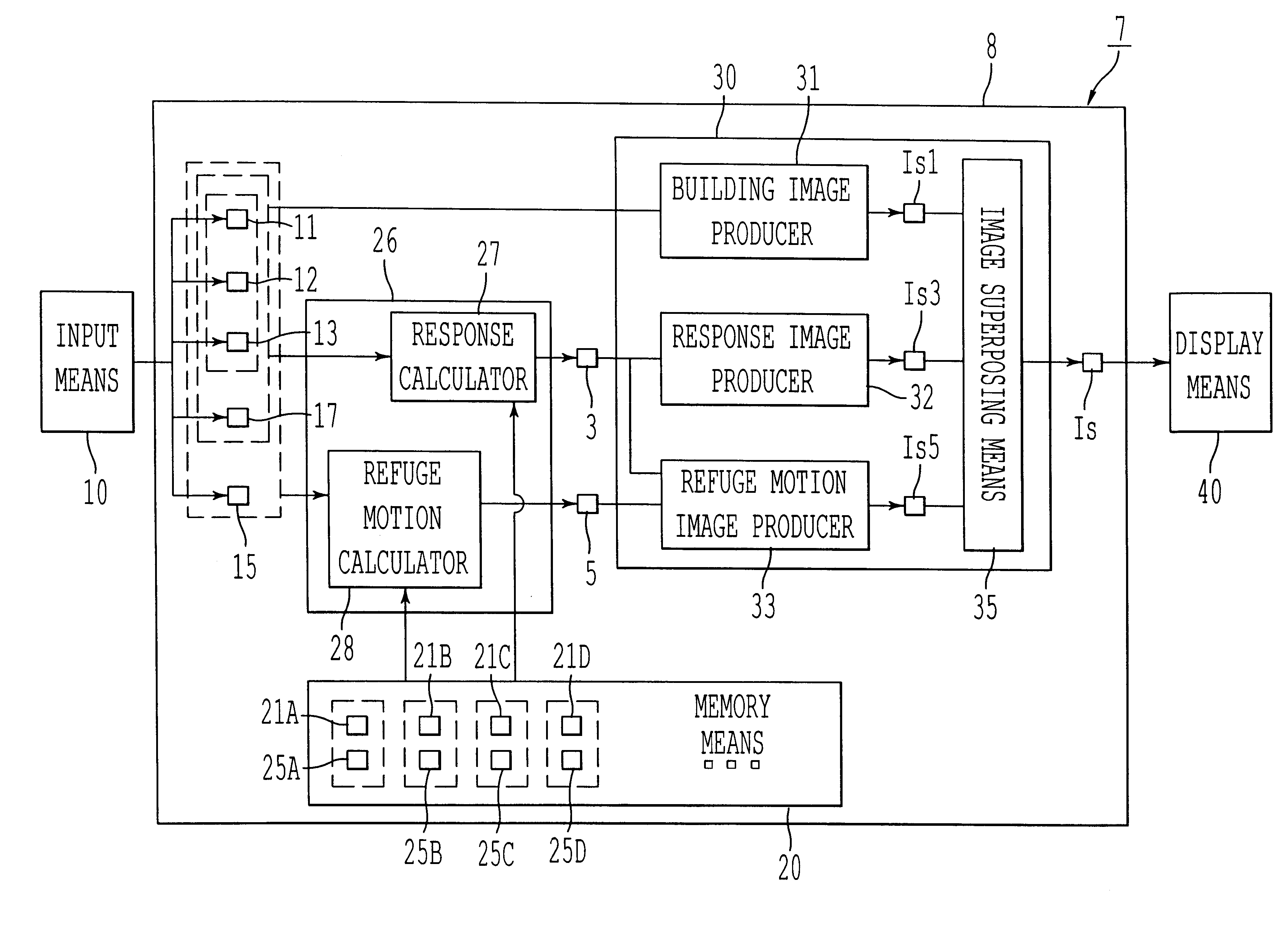

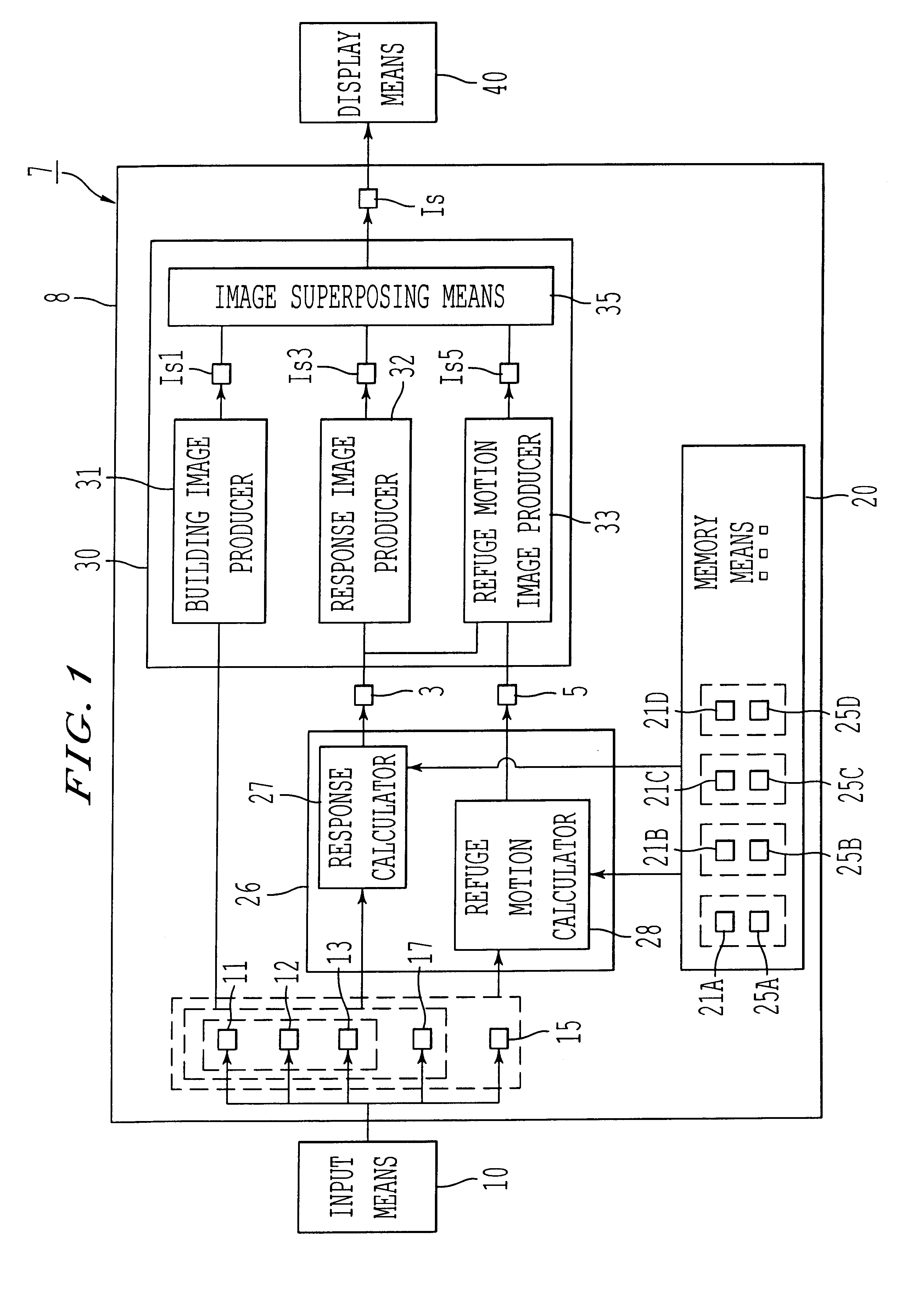

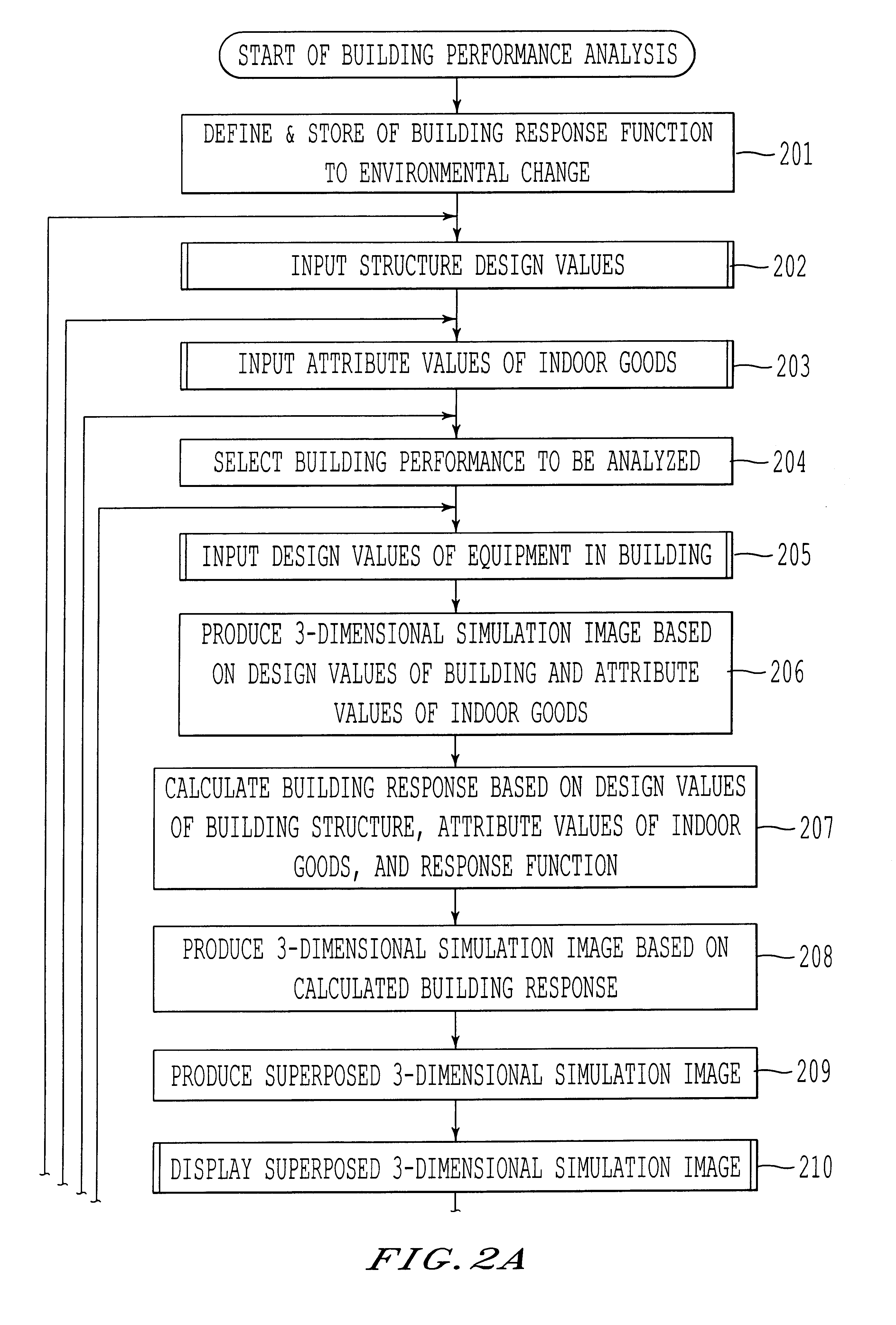

Method and apparatus for analyzing building performance

InactiveUS6701281B2Easy assessment processSmooth formation of consensusGeometric CADBuilding constructionsThree dimensional simulationComputer graphics (images)

A building response function defining a response of a building to specific environmental change, e.g., occurrence of a fire, in terms of the building structure, is stored in a computer. Also stored is a refuge motion function defining the refuge motion of individuals in terms of attributes of the individuals and the building response. The building response is computed by substituting design values of the building structure into the response function. Attributes of persons are inputted to the computer, and individuals' refuge motion is computed by using both inputted attributes and the computed building response. With the inputted and computed values, three-dimensional (3D) simulation images of the building structure, of the building response, and of individuals' refuge motion are computed. Then, a superposed 3D simulation image of the three images is displayed to facilitate analysis of the building performance.

Owner:KAJIMA CORP

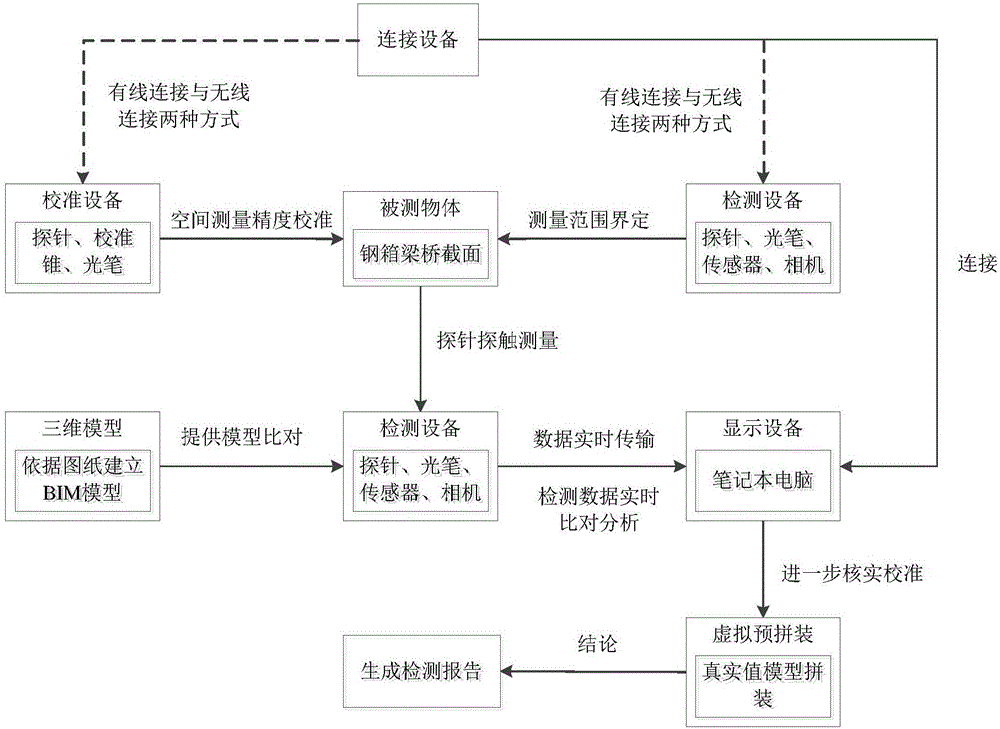

Steel structure pre-splicing method and system

ActiveCN106354950ARealize virtual assembly inspectionSave spaceGeometric CADImage data processingThree dimensional measurementDesign values

The invention discloses a steel structure pre-splicing method and system. When steel structures are pre-spliced, workpiece actual values are measured through a three-dimensional measurement technology and then compared with design models in real time, the design value models are modified to obtain actual value models, the actual value models are pre-spliced, and the factory on-site splicing process is omitted. Sensors are erected on the sections of the steel structures, calibration devices are arranged, probes are used for detecting and touching the sections of steel box girders, the actual value models are compared with the design models, and manufacturing error values are obtained. Virtual splicing can be achieved in software, the measured actual value models are spliced in the software in real time, and the result whether splicing can be conducted or not is visually obtained. By means of the technology, the steel structures are virtually spliced and detected, more reliable guarantees are provided for construction detection, and the site, labor cost and time are saved.

Owner:HUAZHONG UNIV OF SCI & TECH

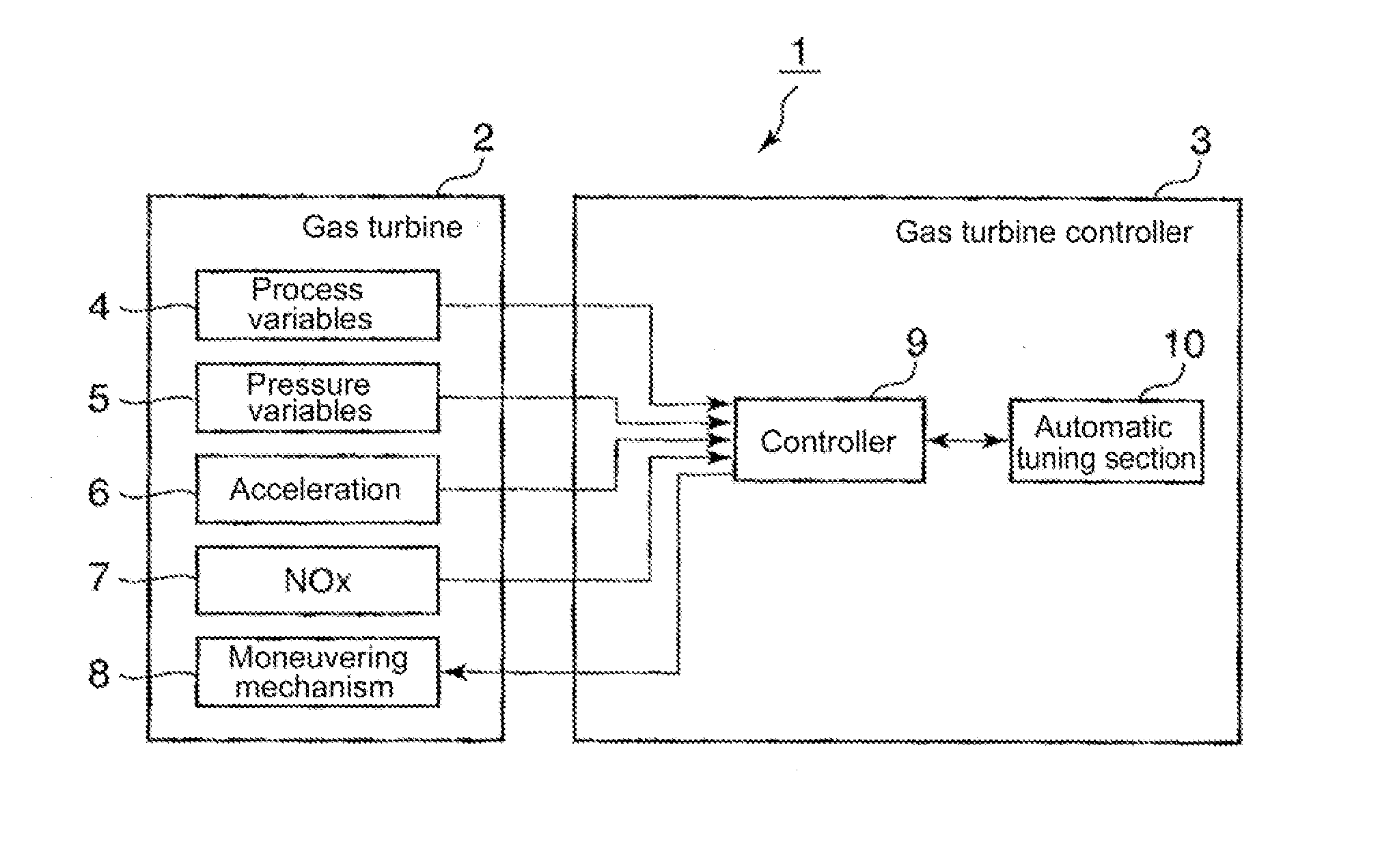

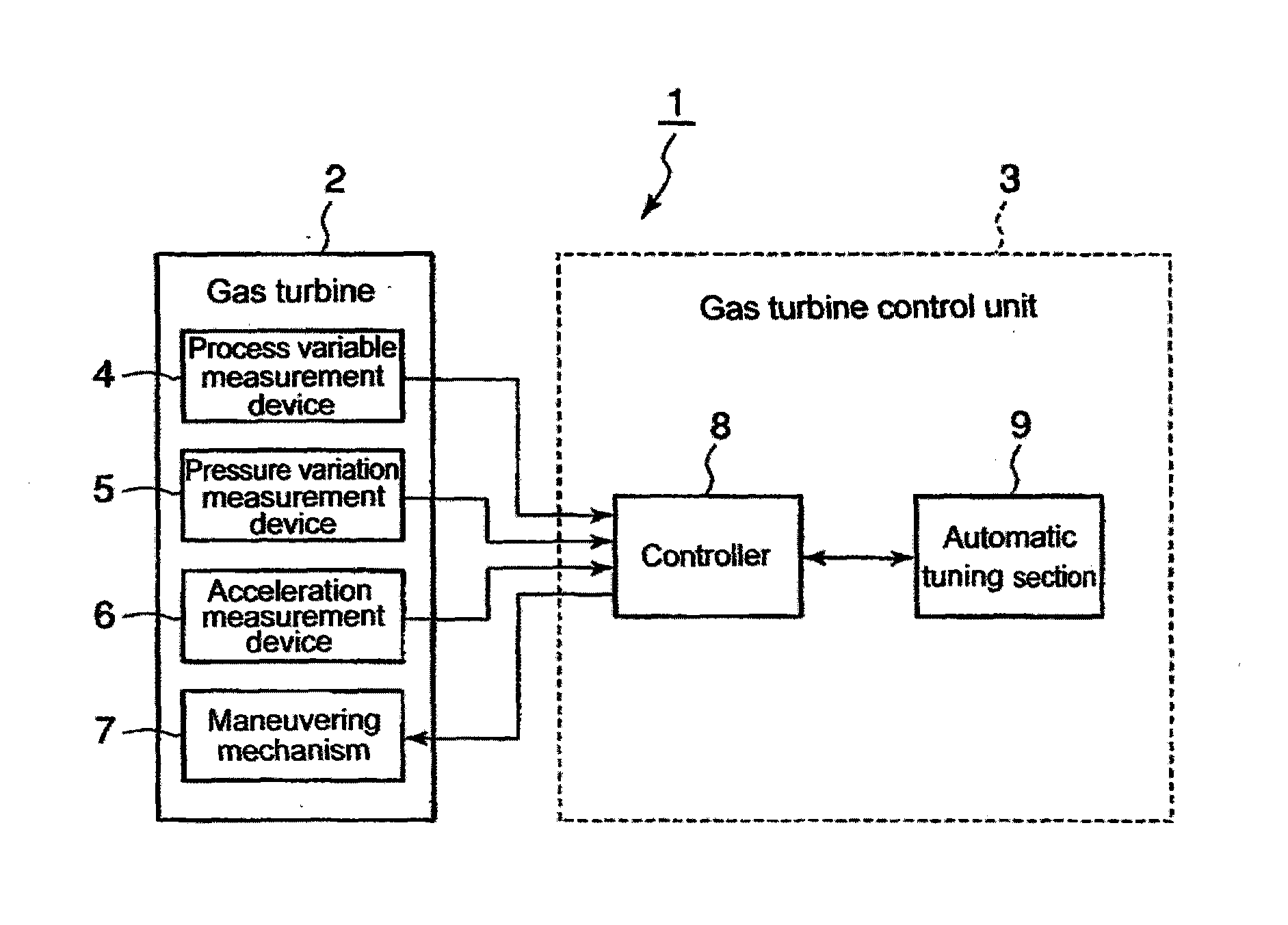

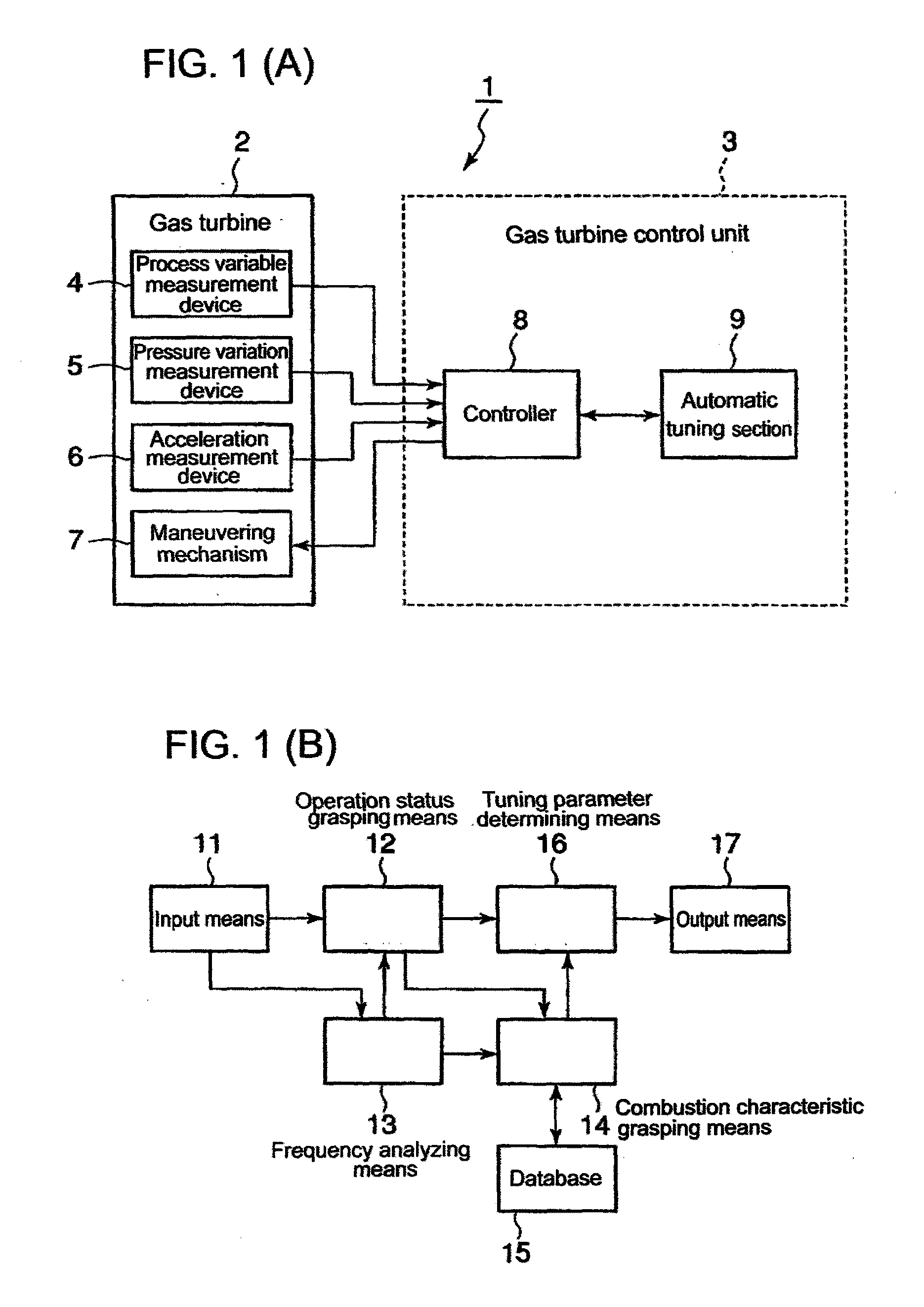

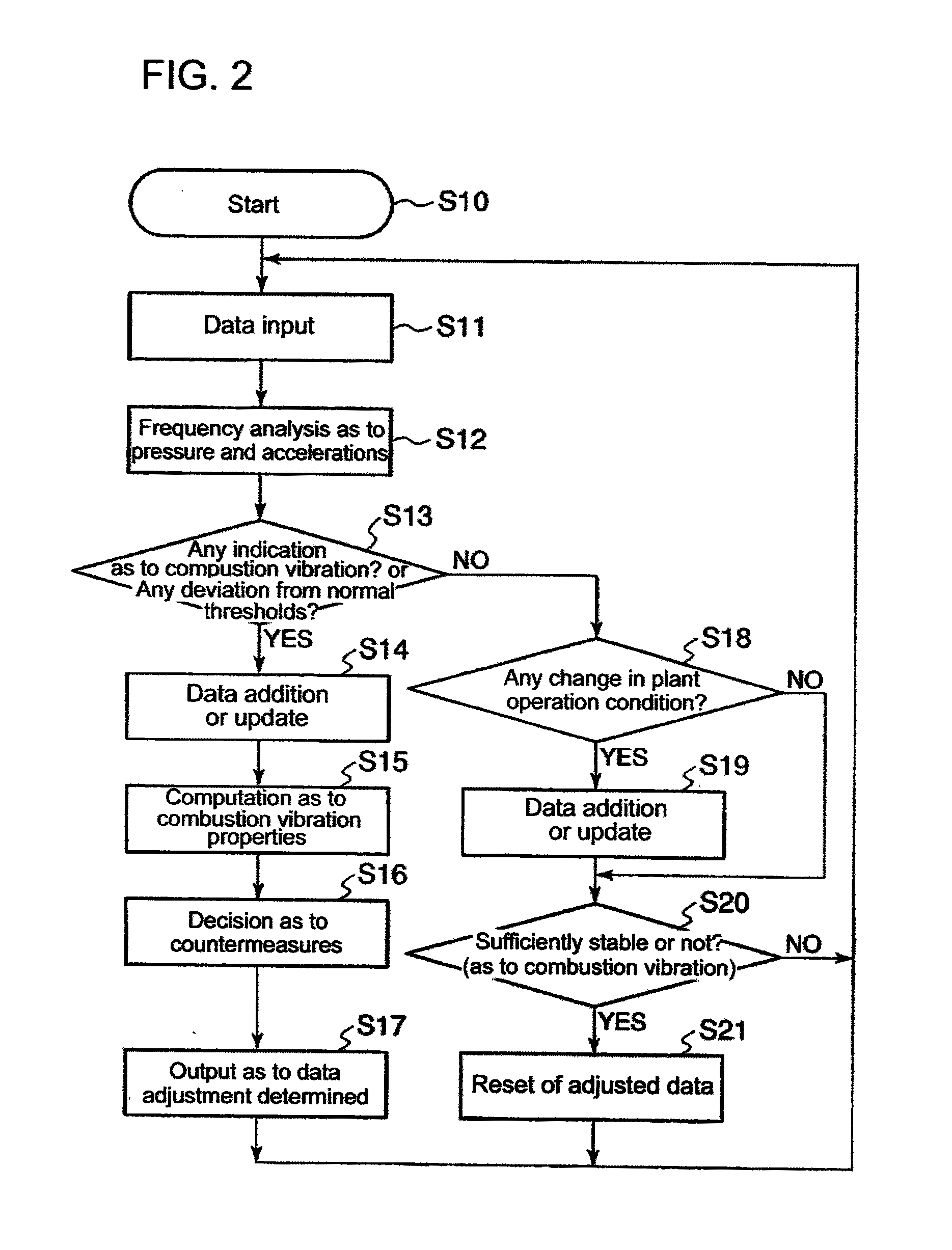

Gas turbine control method and device

ActiveUS20110004390A1Improve combustion stabilityAnalogue computers for vehiclesGas turbine plantsCombustorOperant conditioning

Provided is a gas turbine control method and control device whereby a design performance and an operating state based on ideal fuel flow rate and air flow rate simulated at the time of designing can be maintained by preventing an operation deviated from an operating condition that is based on ideal fuel flow rate and air flow rate simulated by initial design values, in a gas turbine control method designed to search optimal operating conditions automatically using control inputs such as a pilot ratio. The gas turbine controller comprises a second database that stores load sensitivity, i.e. the correlation between the load amount of a gas turbine and control inputs such as a fuel flow rate, air flow rate, pilot fuel ratio, and top hat fuel ratio in the gas turbine, wherein the amount of load variation for at least one of control inputs, a fuel flow rate or an air flow rate supplied to a combustor is predicted according to operational conditions obtained by searching using the load sensitivity, regulation is made according to the prediction results, and the regulation results are stored in the second database.

Owner:MITSUBISHI POWER LTD

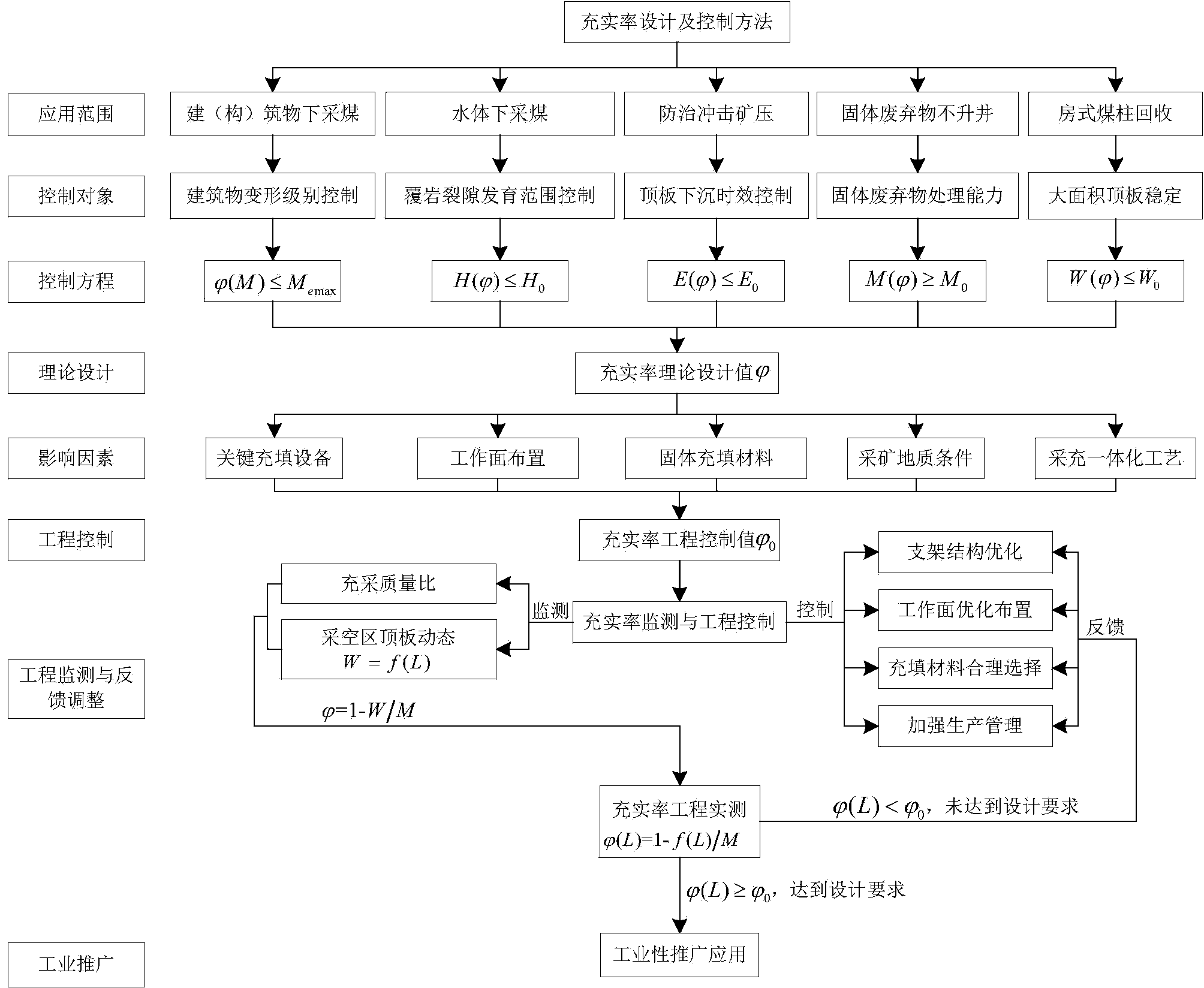

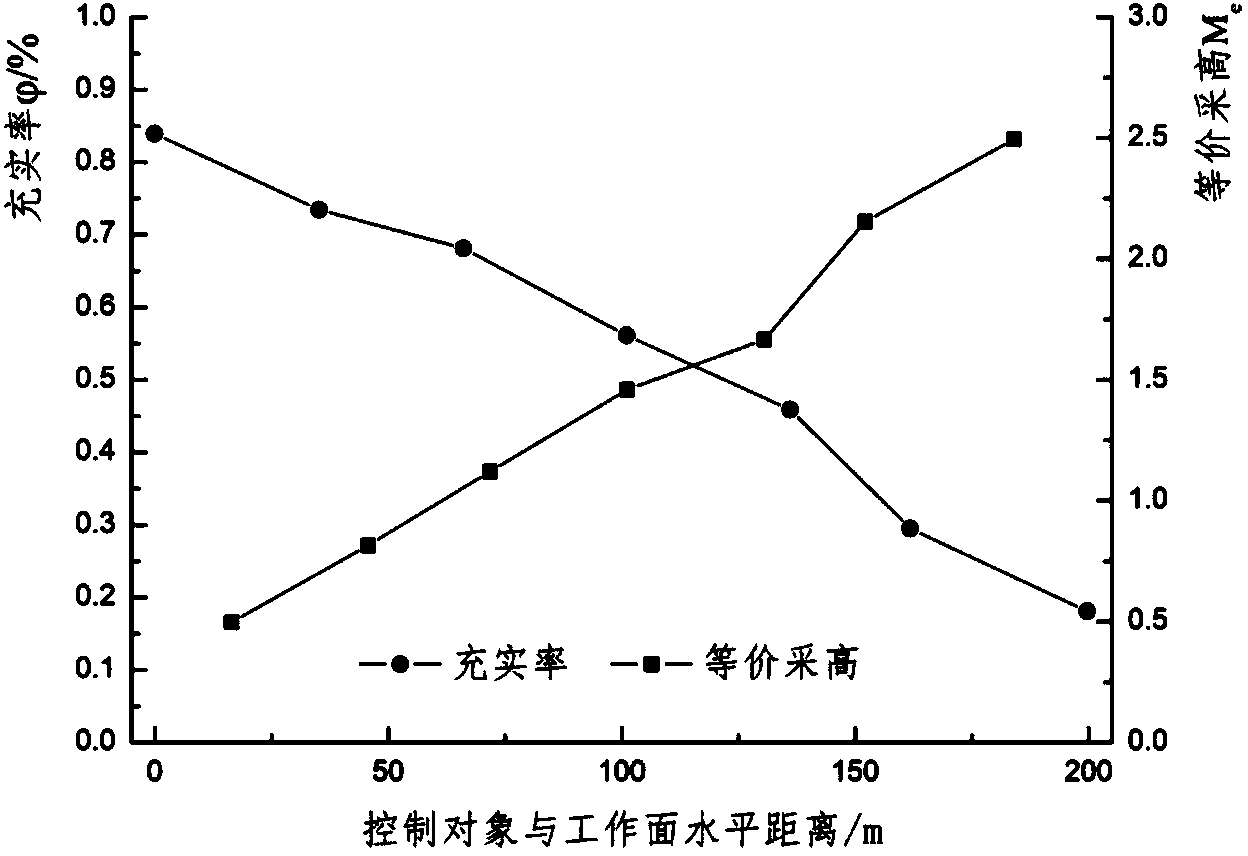

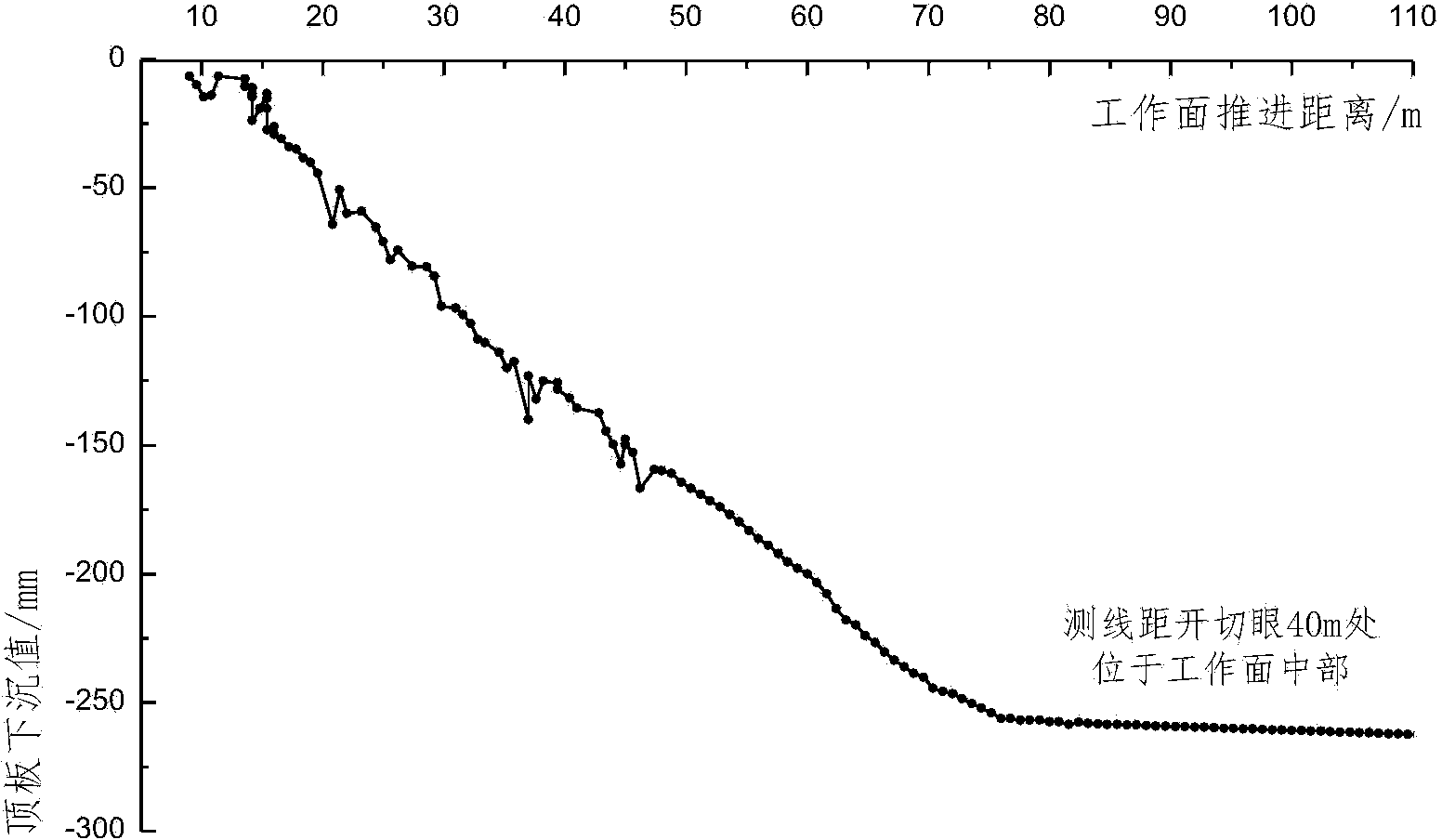

Filling rate design and control method for solid filing in coal mining

The invention discloses a filling rate design and control method for solid filing in coal mining, and belongs to filling rate design and control methods in cut and fill. The filling rate design and control method includes firstly, acquiring a theoretical design value phi of a solid filling coal mining filling rate according to cut and fill objectives and control objects; comprehensively analyzing influences of main controlling factors including key filling equipment, working face arrangement, solid filling materials, mining geological conditions and cut and fill integrated technologies on the filling rate to design an engineering control value of the filling rate phi0; during engineering practice, mounting a roof dynamic monitoring device in a gob to acquire measured filing rate curves phi(L) of different advancing positions of an on-site working face through actual measurement; comparing the engineering control value phi0, and adjusting the technology and the management method to ensure a measured filling value to meet engineering design requirements and guarantee filling effect. The method provides reference for design and control of the solid filling coal mining filling rate, and provides theoretical support for on-site popularization and application of the solid cut and fill technology.

Owner:CHINA UNIV OF MINING & TECH

Method for checking useful load of auxiliary springs of non-end contact diagonal main and auxiliary spring

ActiveCN105653883AImprove transportation efficiencyImprove securityInformaticsSpecial data processing applicationsEngineeringOblique line

The invention relates to a method for checking a useful load of auxiliary springs of a non-end contact diagonal primary and auxiliary spring, and belongs to the technical field of suspension steel plate springs. The method comprises the following steps: firstly, determining an endpoint deformation coefficient and the half rigidity of each main spring, as well as a deformation coefficient Gx-CB of the contact point between an Nth main spring and the auxiliary spring at an oblique line segment according to a structural dimension and an elastic modulus of the diagonal variable cross-section main spring with non-isostructural end parts; then, checking the useful load of the auxiliary springs of the non-end contact few-leaf diagonal variable cross-section main and auxiliary spring according to the thicknesses of root straight sections of the main springs, Gx-CB of the Nth main spring, the half rigidity of each main spring and a design value of the clearance Delta between the main springs and the auxiliary springs. The simulated verification shows that an accurate checking value of the useful load of the auxiliary springs of the non-end contact diagonal main and auxiliary spring can be obtained by using the method, the design level and performance of products are improved, the vehicle running smoothness is improved, meanwhile, the design, manufacturing and test costs are reduced, and the product development speed is increased.

Owner:平邑经济开发区投资发展有限公司

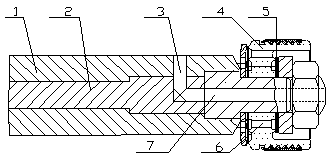

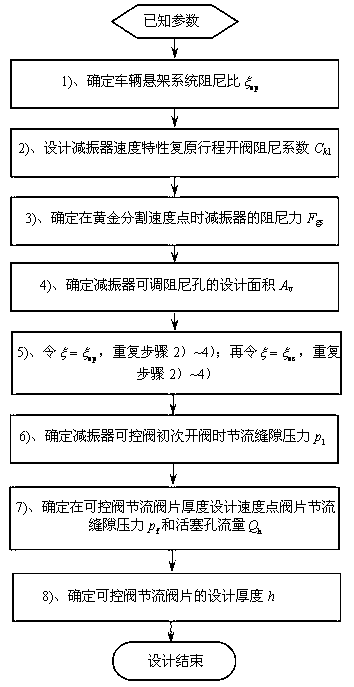

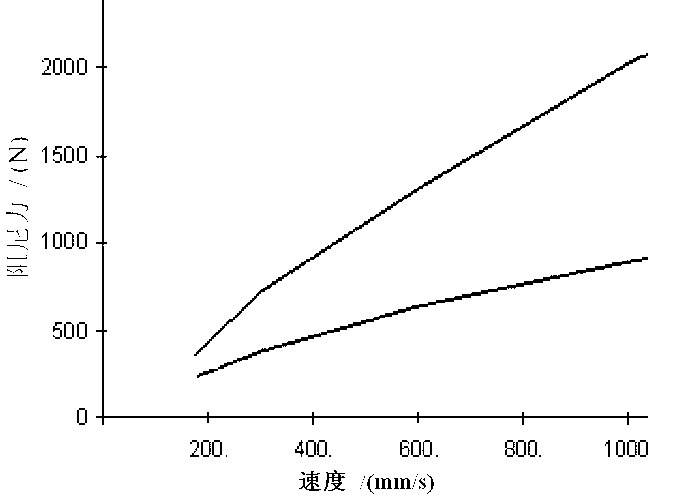

Optimal design method for parameter of controllable cylinder type hydraulic buffer of semi-active suspension

InactiveCN102840265AReduce design costShorten the development cycleSpringsShock absorbersSemi activeDamping ratio

The invention relates to an optimal design method for a parameter of a controllable cylinder type hydraulic buffer of a semi-active suspension. The optimal design method is characterized by adopting the following steps: 1), determining the damping ratio of a vehicular suspension system; 2), designing an open valve damping coefficient of a buffer speed property recover route; 3), determining the damping force of the reducer at a golden cutting speed point; 4), determining the design area of an adjustable damping hole of the reducer; 5), repeating the steps 2) to 4), calculating the adjustable damping hole area required by the thickness of the design valve block is calculated; repeating the steps 2) to 4) again, and calculating the minimum area of the adjustable damping hole; 6), determining the throttle seam pressure when a controllable valve of the buffer is opened at the first time; 7), determining the throttle seam pressure and the piston hole flow rate at the thickness designed speed point of the controllable valve throttle valve block; 8), determining the design thickness of the controllable valve throttle valve block. By adopting the design method, the design value of the valve parameter is exact and reliable; the repeatedly test and modification are avoided; the design cost of the controllable buffer is reduced; and the development cycle of the buffer is shortened.

Owner:SHANDONG UNIV OF TECH

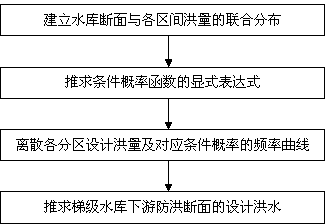

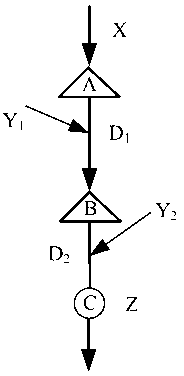

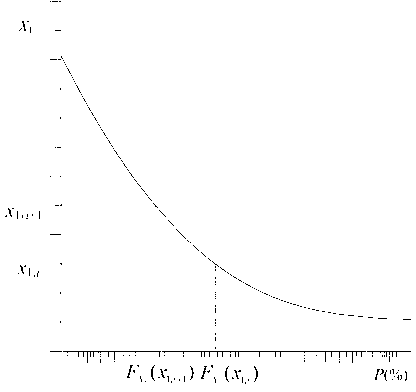

Method of determining downstream design flood of cascade reservoirs

ActiveCN103276686AReflect flood control effectClimate change adaptationHydraulic engineering apparatusDesign floodMulti dimensional

The invention belongs to the field of flood control safety design of reservoirs, and relates to a method of determining downstream design flood of cascade reservoirs. The method comprises the following steps that by the adoption of the Copula function, multi-dimensional simultaneous distribution of the section flood volume and the regional flood volume of the reservoirs is constructed, the explicit expression of a conditional probability function is deduced, the frequency curve of the conditional probability is dispersed, and according to the principle of probability combination discrete summation, the design value and the corresponding probability of the annular maximum peak discharge of downstream sections are determined after flood regulation is conducted through the cascade reservoirs. The method can overcome the defects of traditional determination technologies of the design flood of the cascade reservoirs, and provides more comprehensive reference information for cascade planning and development of drainage basins.

Owner:WUHAN UNIV

Limestone-plaster wet method flue gas desulfurization composite synergistic agent

The invention relates to a limestone-plaster wet method flue gas desulfurization composite synergistic agent, which comprises the following ingredients in percentage by mass: 40 percent to 50 percent of organic acid synergistic agents, 25 percent to 35 percent of organic salt synergistic agents, 15 percent to 20 percent of efficient activating agents, 5 to 10 percent of oxidation catalysts and 1 percent of tracers. The half dissolving time of limestone is shortened by more than 40 percent, and the dissolving speed of the limestone is greatly accelerated, so the activity of the limestone is greatly improved. Under the work condition of the designed surfur content, the circulation intensity of serous fluid can be reduced by one third to one half, the liquid-gas ratio of a system is reduced, the system resistance is reduced, the energy consumption of a desulphurization system is obviously reduced, the utilization rate of limestone and oxidation air is improved, and the scale formation and blockage effects on back-stage equipment are reduced. Under the condition that the coal-fired sulfur exceeds the design value, the utilization rate of the oxidation air can be improved by 50 percent to 60 percent, on the basis without transforming the original oxidative system, the oxidation effect that when the fired-coal surfur content exceeds 20 to 30 percent can be met, and the requirements of the desulfurization efficiency and the clean flue gas SO2 discharge concentration are met.

Owner:XIAN THERMAL POWER RES INST CO LTD

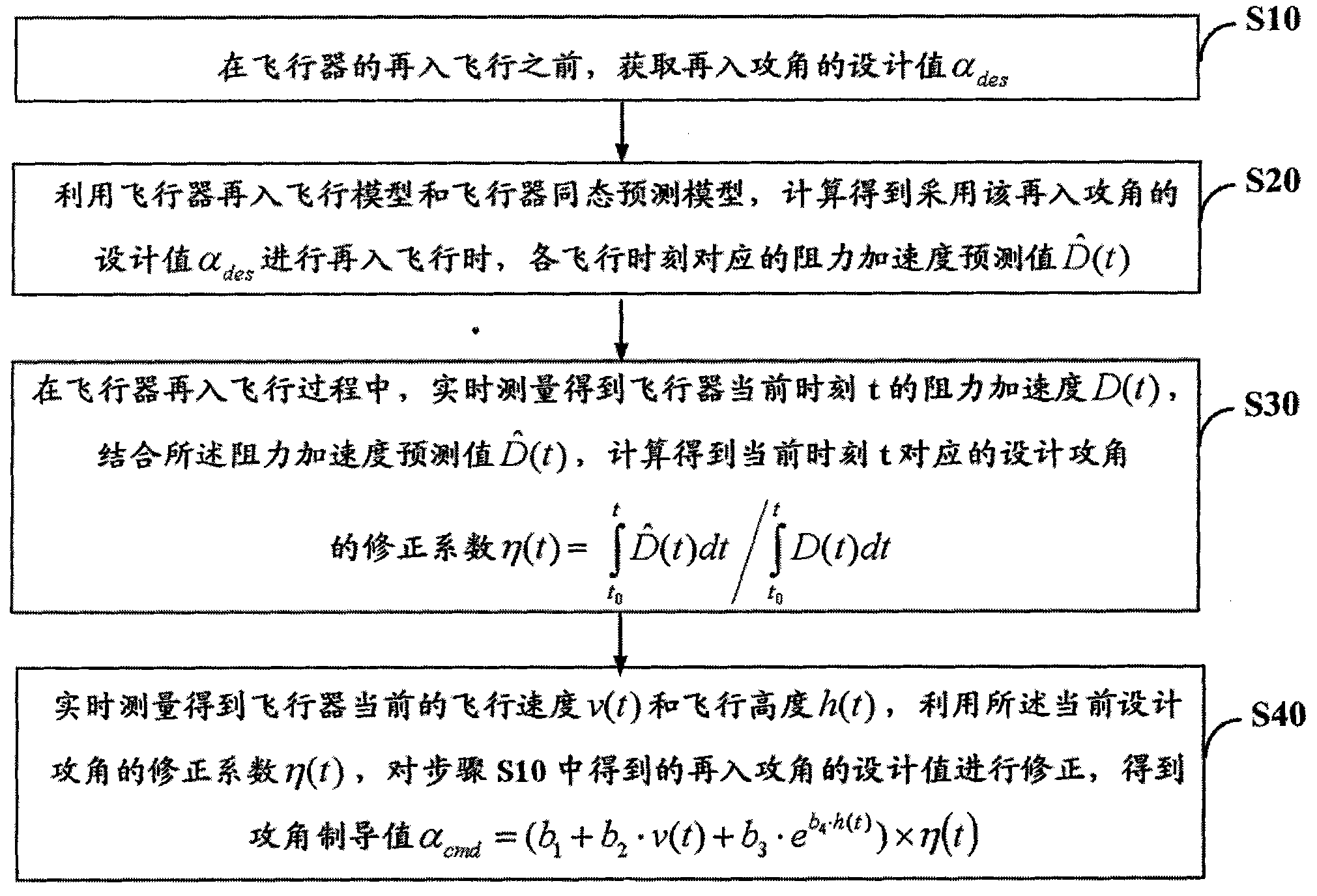

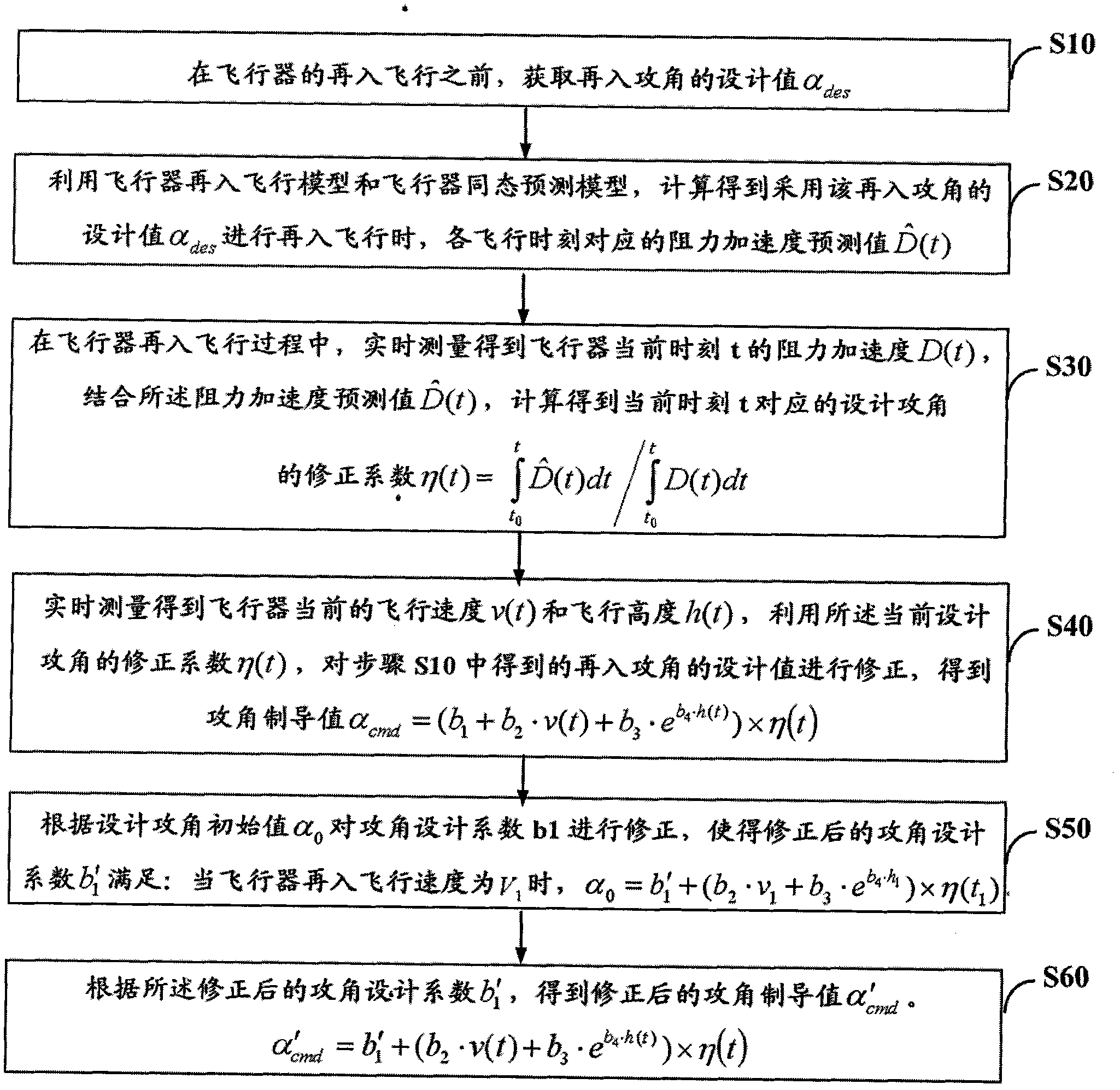

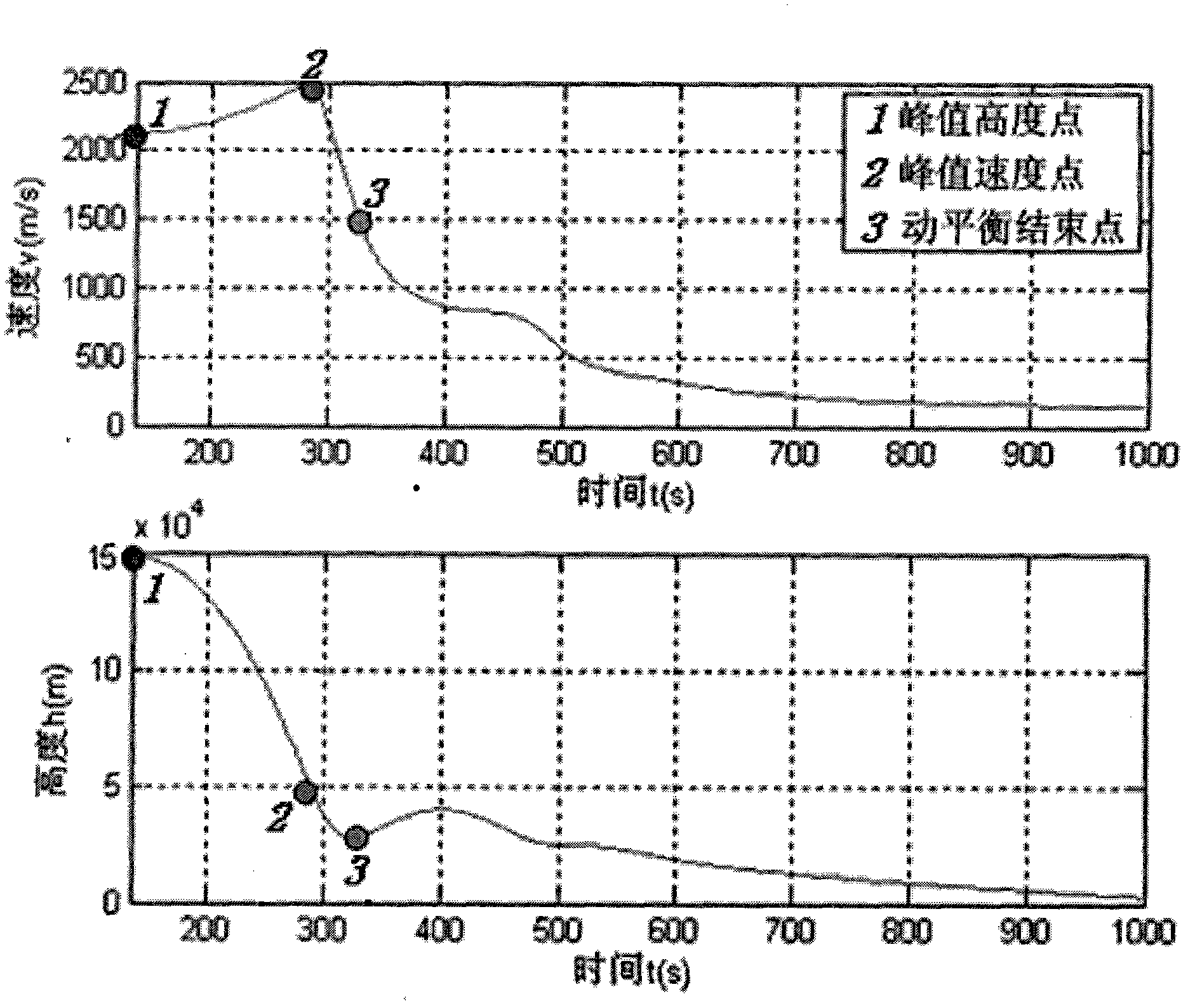

Reentry flight attack angle guiding method of sub-orbital vehicle

ActiveCN102139768AAchieve dynamic balanceTo achieve the purpose of guidanceSpacecraft guiding apparatusFlight vehicleDynamic balance

The invention discloses a reentry flight attack angle guiding method of a sub-orbital vehicle. The method comprises the following steps of: acquiring an attack angle design predicted value through analogue simulation at time intervals; finding the attack angle design predicted value, which keeps a normal overload value of the vehicle always in a fluctuation region of expected normal overload dynamic balance, by using a vehicle homomorphic prediction model in each time interval, so as to realize normal overload dynamic balance at the time interval; acquiring a practical reentry flight attack angle design parameter of the vehicle through the attack angle design predicted value by a fitting method, and determining a reentry flight attack angle design value of the vehicle; and introducing resistance acceleration integration ratio correction at each flight time to make a practical reentry flight resistance acceleration integral value tend to be the same as a predicted resistance acceleration integral value under the attack angle design value, so the reentry flight normal overload of the sub-orbital vehicle is kept to fluctuate in a predetermined region in a dynamic balance section consisting of each time interval and then the aim of reducing the reentry flight normal overload peak value of the sub-orbital vehicle is fulfilled.

Owner:广东空天科技研究院

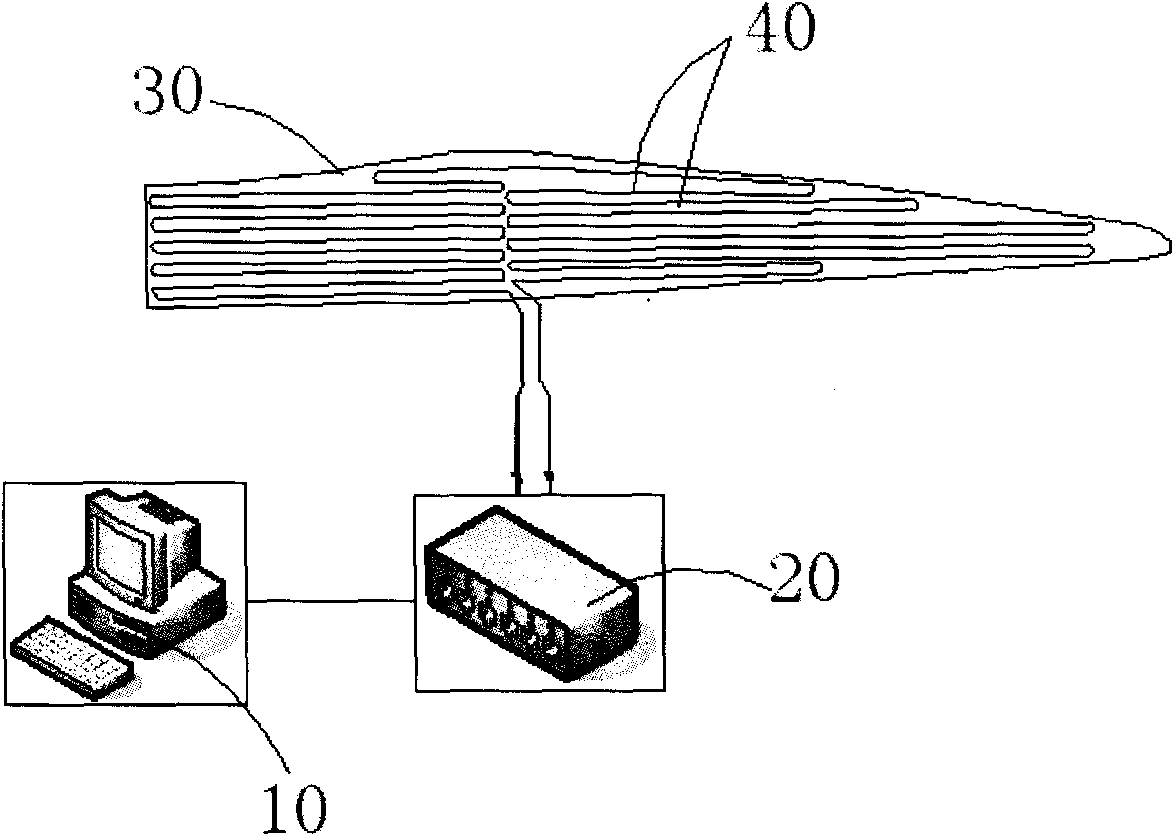

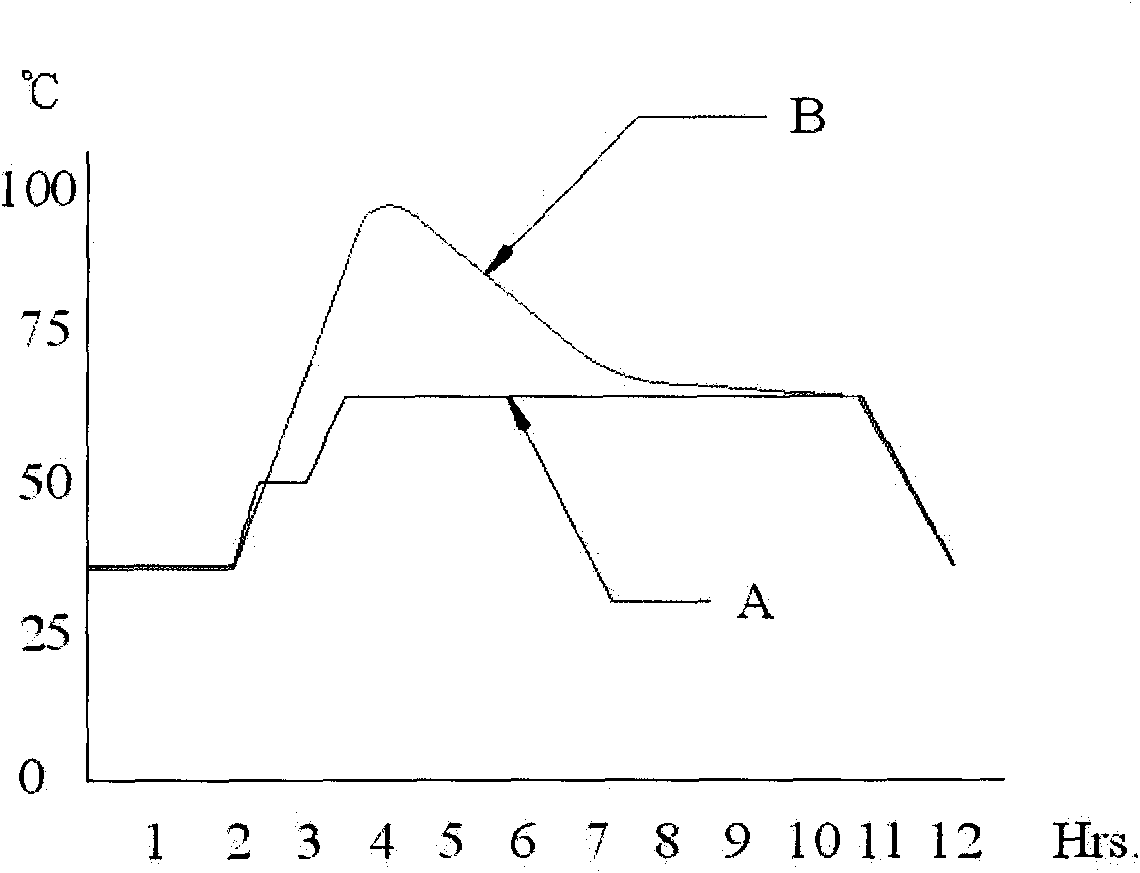

Intelligent segmental temperature control system of wind power blade die

The invention relates to an intelligent segmental temperature control system of a wind power blade die, which is provided based on the technical theory that segmental temperature control is bound to be carried out based on the differences on the formed region thickness of a designed blade structure and the energy-saving purpose can be achieved by lowering the dependence on external heating in a curing manufacturing procedure by utilizing the reaction exothermic character of a matrix material. To achieve the purpose, the invention adopts the technical measures of the construction of a die segmental temperature control pipeline, which ensures that each temperature segment can be heated or cooled independently based on requirements on thermal energy in the curing manufacturing procedure; the establishment of an intelligent temperature control system, wherein temperature and hardness data of the die and a blade shell can be captured to judge whether heating setting, exothermic peak initiating temperature and the states of completion degree, gel curing degree and the like are completed or conform to design values; and antecedent technical measures, wherein energy consumption is saved by utilizing the reaction heat of materials per se to heat and reaction and temperature control are combined to match the design of a temperature curve, which are helpful for obtaining the blades with uniform curing and excellent quality and can improve the production efficiency as a characteristic.

Owner:上海力仓实业有限公司

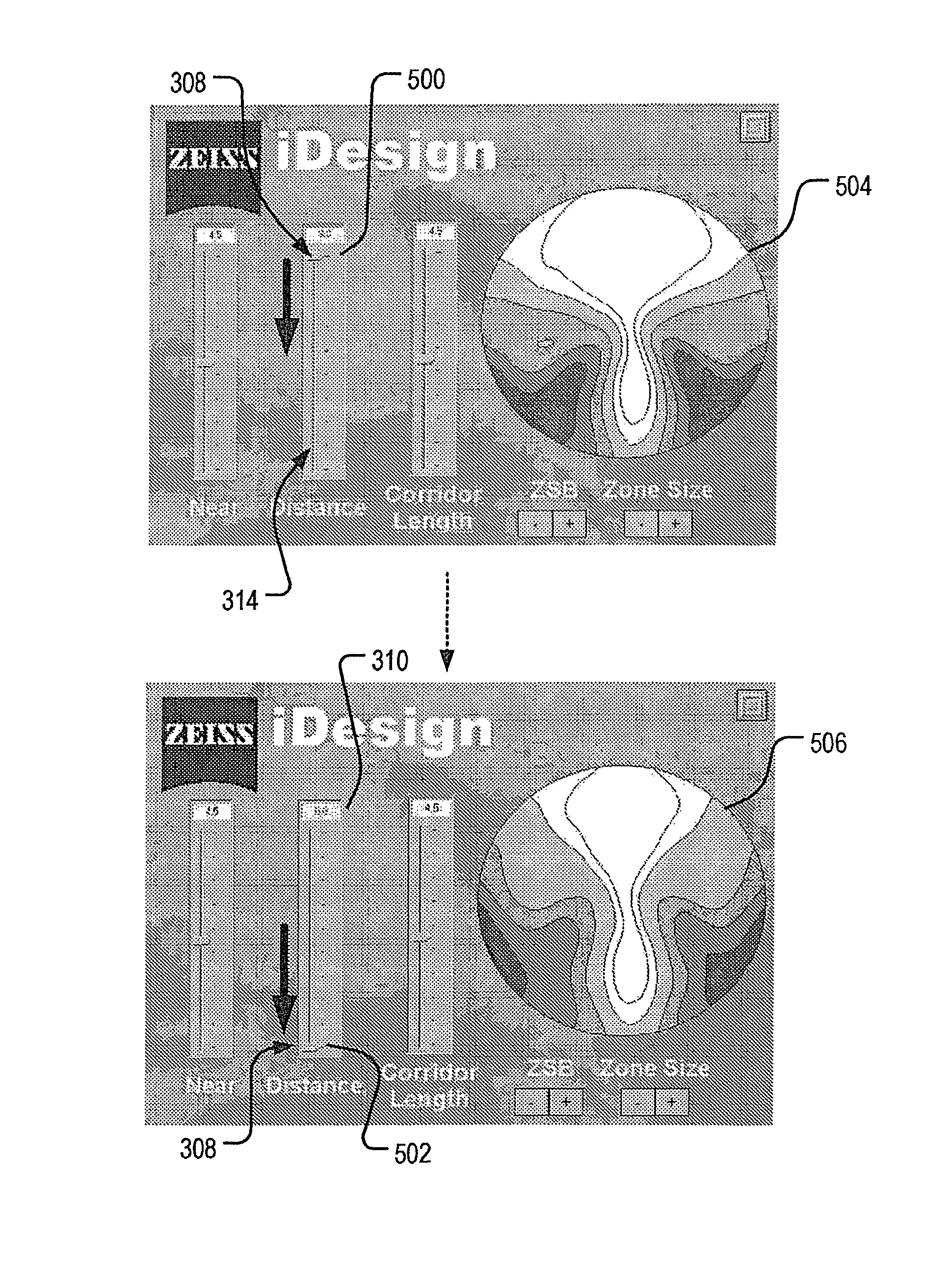

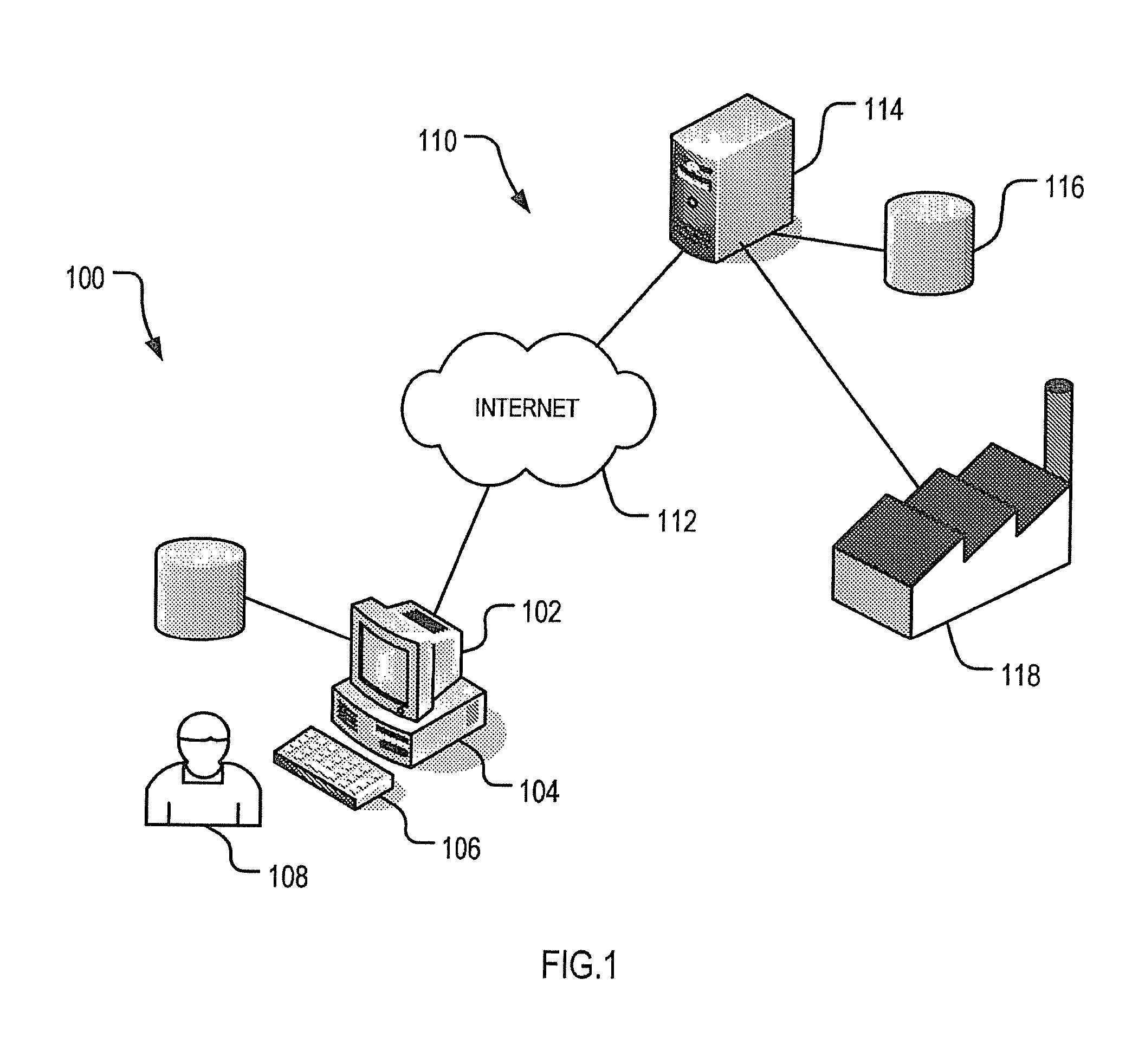

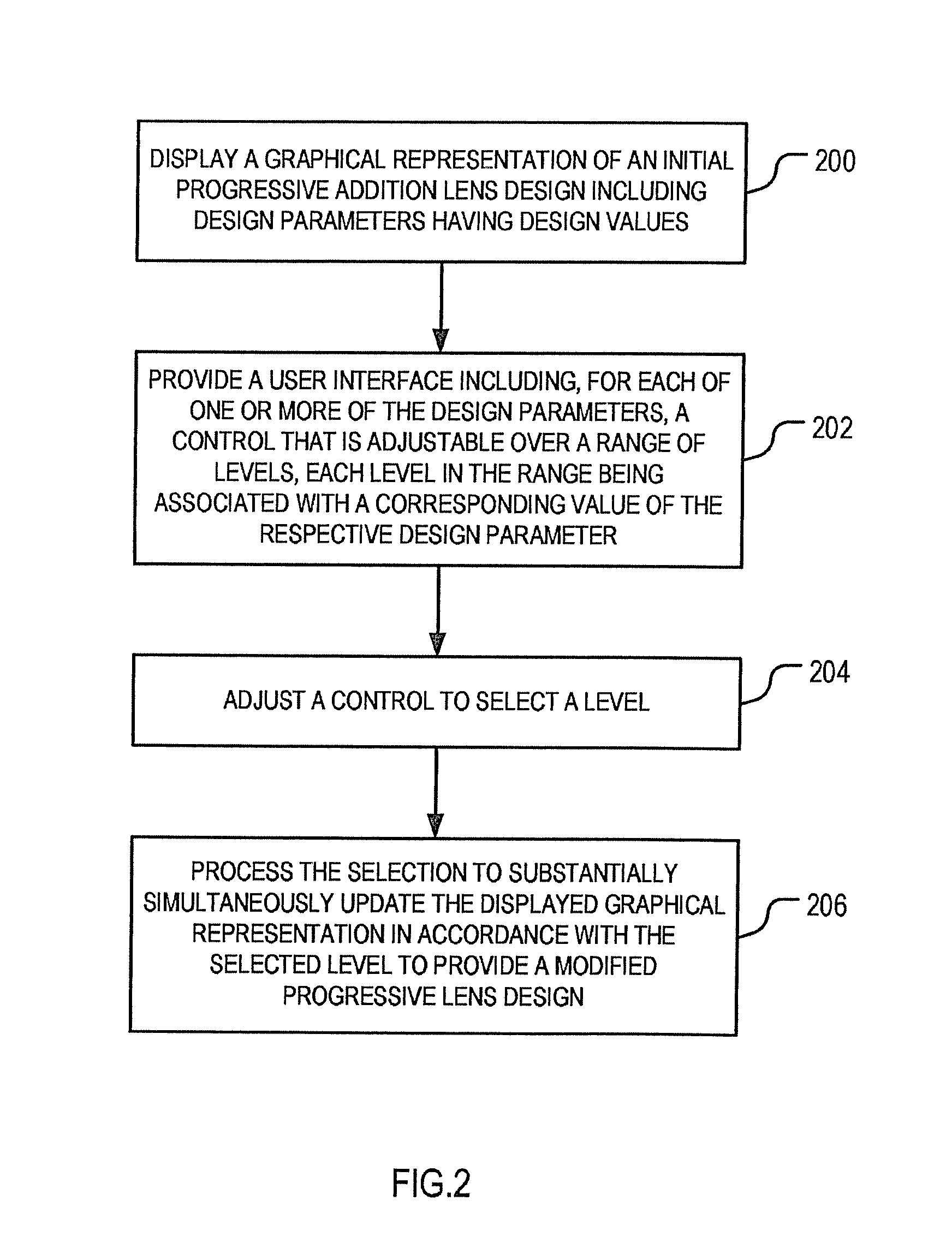

Ophthalmic lens design and/or dispensing

ActiveUS8434025B2Restrict levelObserved effectSpectales/gogglesEye diagnosticsGraphicsMultifocal lenses

A method of designing and / or selecting a progressive addition lens design for a wearer is disclosed. In an embodiment, the method includes displaying a graphical representation of an initial progressive addition lens design including design parameters having design values. A user interface is provided including, for each of one or more of the design parameters, a control that is adjustable over a range of levels, each level in the range being associated with a corresponding value of the respective design parameter. A control is adjusted to select a level and the selection is processed so as to substantially simultaneously update the displayed graphical representation in accordance with the selected level to provide a modified progressive lens design. A system for designing and / or selecting a progressive addition lens design for a wearer is also disclosed.

Owner:CARL ZEISS VISION AUSTRALIA HO +1

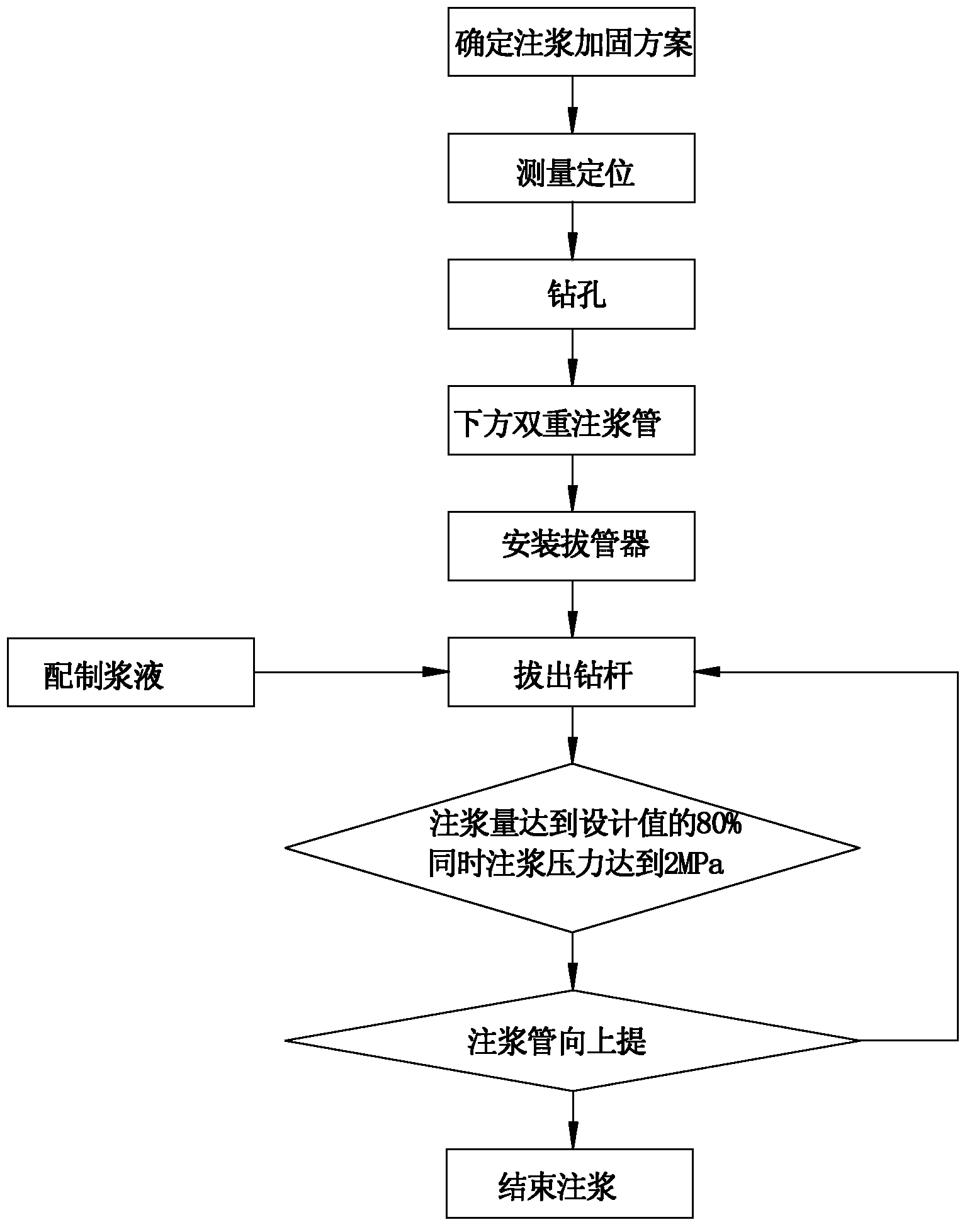

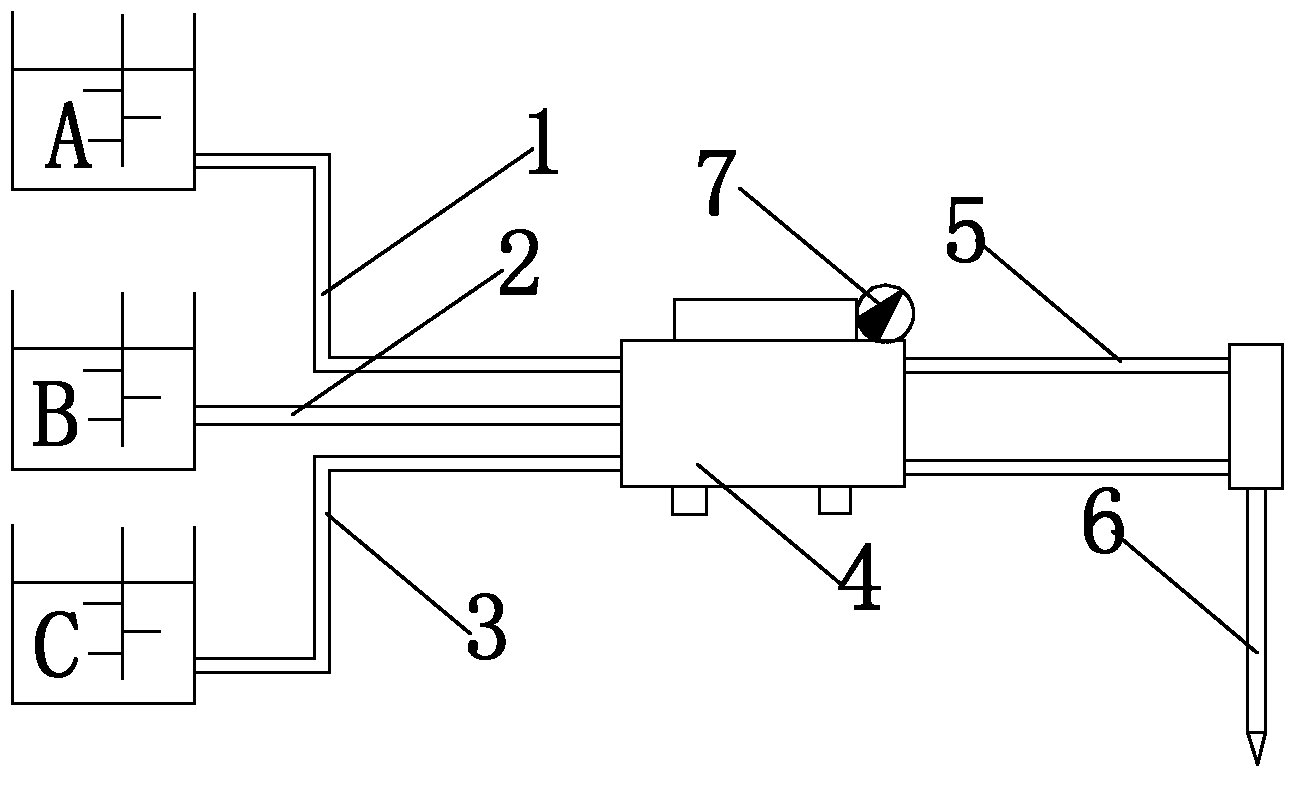

Sublevel retreating type two-fluid composite grouting construction method for deep foundation pit of sandy gravel stratum

ActiveCN103266614AWith hydraulic fully automatic operationLarge operating torqueExcavationsSlurryPermeability coefficient

The invention discloses a sublevel retreating type two-fluid composite grouting construction method for a deep foundation pit of a sandy gravel stratum. The method comprises the steps of determining a grouting reinforcement scheme; conducting field measuring and setting-out; drilling holes, placing double grouting pipes downwards after the holes are formed, then installing pipe pulling devices, and pulling out drill pipes; preparing grouting fluids; conducting grouting in every other hole, conducting two-fluid composite grouting of the cement-water glass grouting fluid and the modified water glass grouting fluid, and comprehensively considering conversion of the grouting fluids according to changes of the grouting pressure, the flow and grouting positions, wherein the grouting pressure reaches 2MPa or exceeds 3MPa at the same time when the grouting quantity exceeds 80% of the designed value; and after the double pipes are lifted, repeating the grouting process till grouting is finished. The method has the advantages that the phenomenon that the grouting pipes can not be installed due to hole collapse can be avoided; advantages of the two grouting fluids are integrated by composite grouting of the two grouting fluids, waterproof curtains are achieved, meanwhile, the permeability coefficient is low, and the setting strength is high; and the problem that the pipes are pulled difficultly due to grouting fluid backflow is solved.

Owner:BEIJING MUNICIPAL CONSTR +2

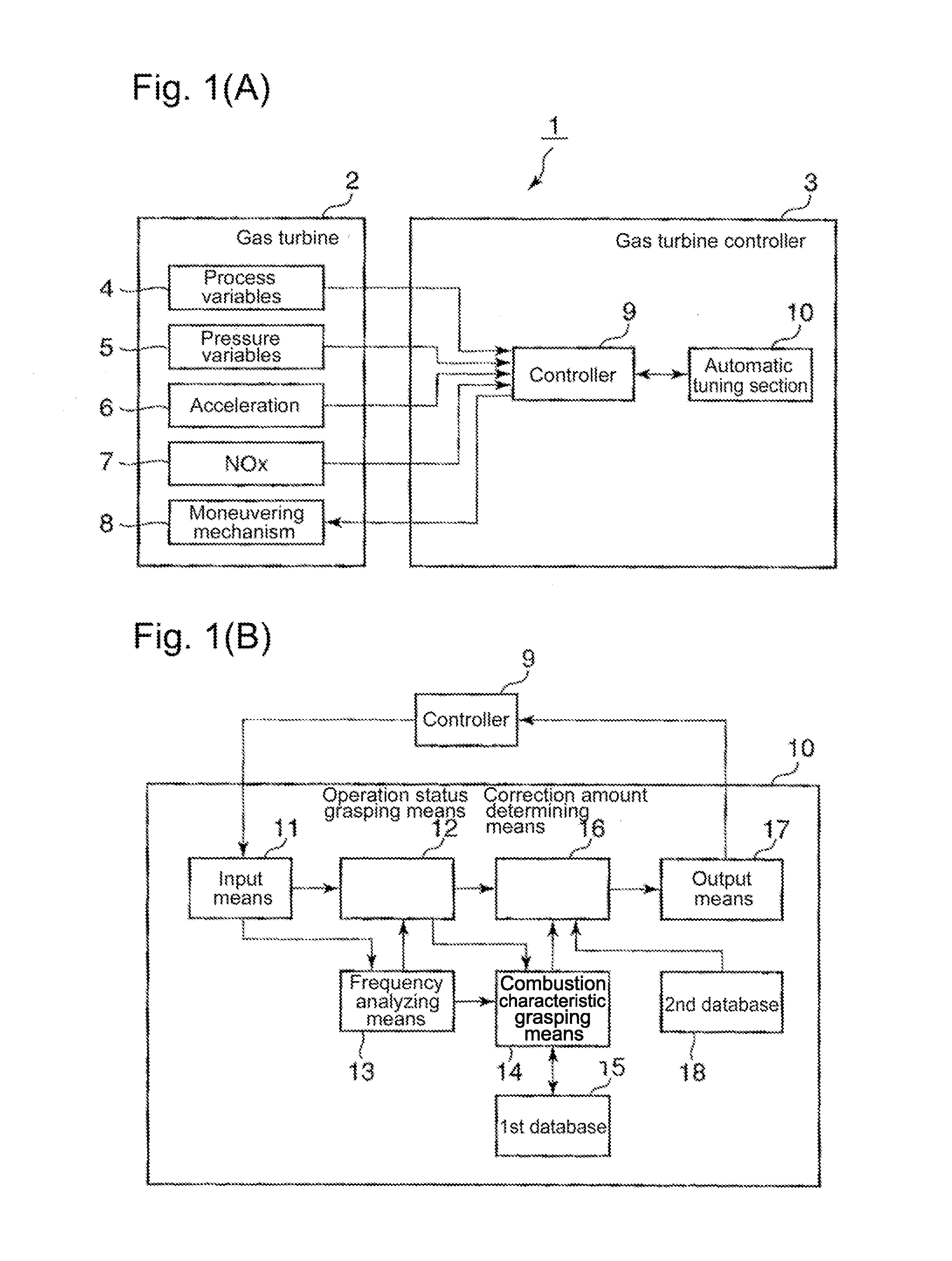

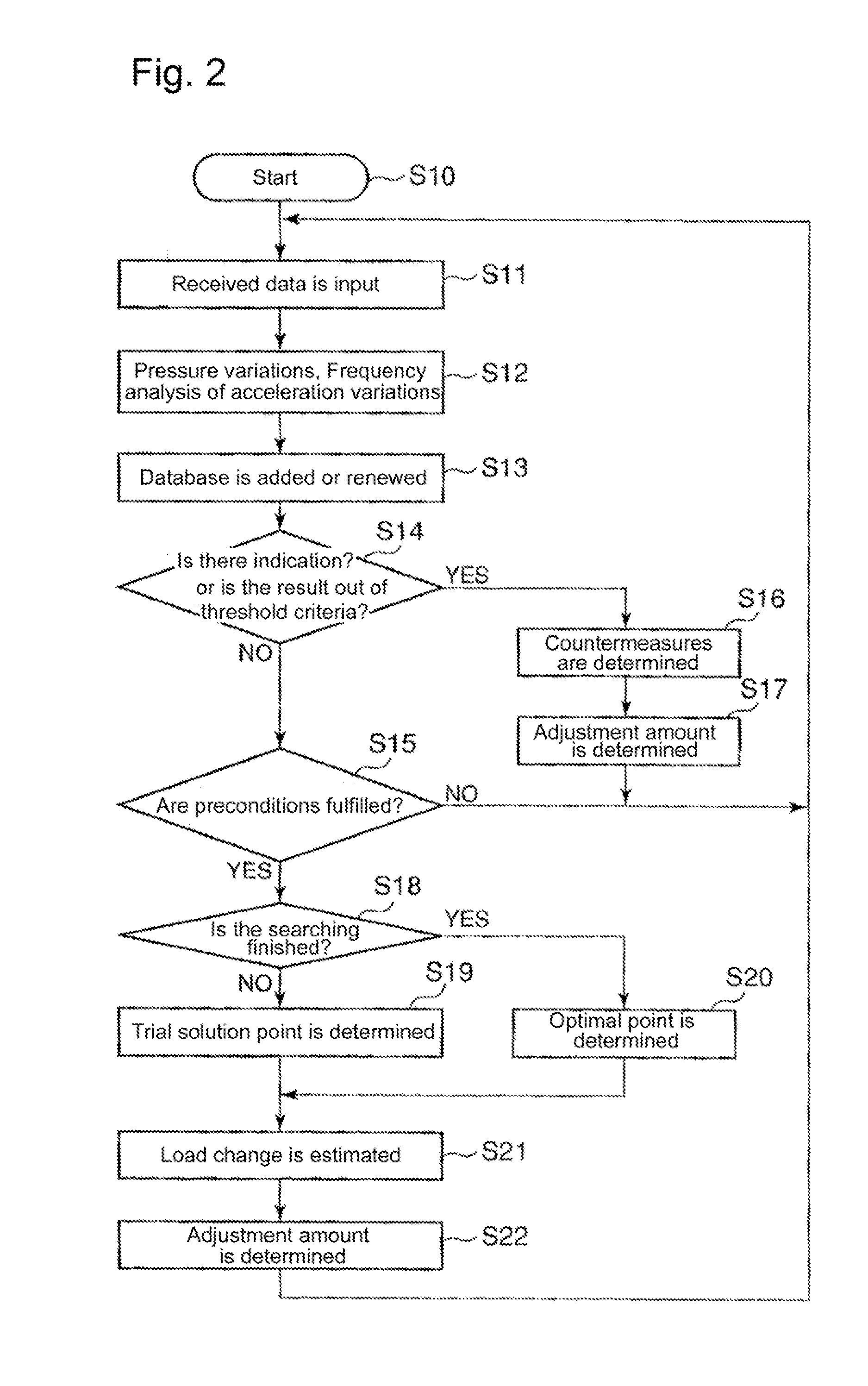

Gas turbine control method and device

A gas turbine control method for preventing then operation from deviating from the operating state at the ideal fuel and air flow-rates expected when the gas turbine is designed and maintaining an efficient operating state. A gas turbine control device comprises a frequency analyzing means for analyzing the frequencies inside the combustor of a gas turbine, a state grasping means for grasping the combustion state in the gas turbine on the basis of a state signal representing the result of the analysis by frequency band, the amount of operation process including a ratio between the air flow rate and pilot fuel in the gas turbine, the atmosphere state, and the load amount, a combustion characteristic grasping means for grasping the characteristic of the combustion vibration, and a control section for calculating a correction value of at least either the air flow rate supplied to the combustor or the pilot ratio from the grasped combustion vibration characteristic and the grasped combustion state each time the degree of the combustion vibration exceeds a predetermined control value, correcting the initial design values of the air flow rate and the pilot ratio predetermined correspondingly to the amount of operation process and the state signal, and thereby driving the gas turbine. The control section resets the correction of the initial design values when the degree of combustion vibration of the gas turbine is below the predetermined control value for a given period of time and operates the gas turbine using the initial design values.

Owner:MITSUBISHI POWER LTD

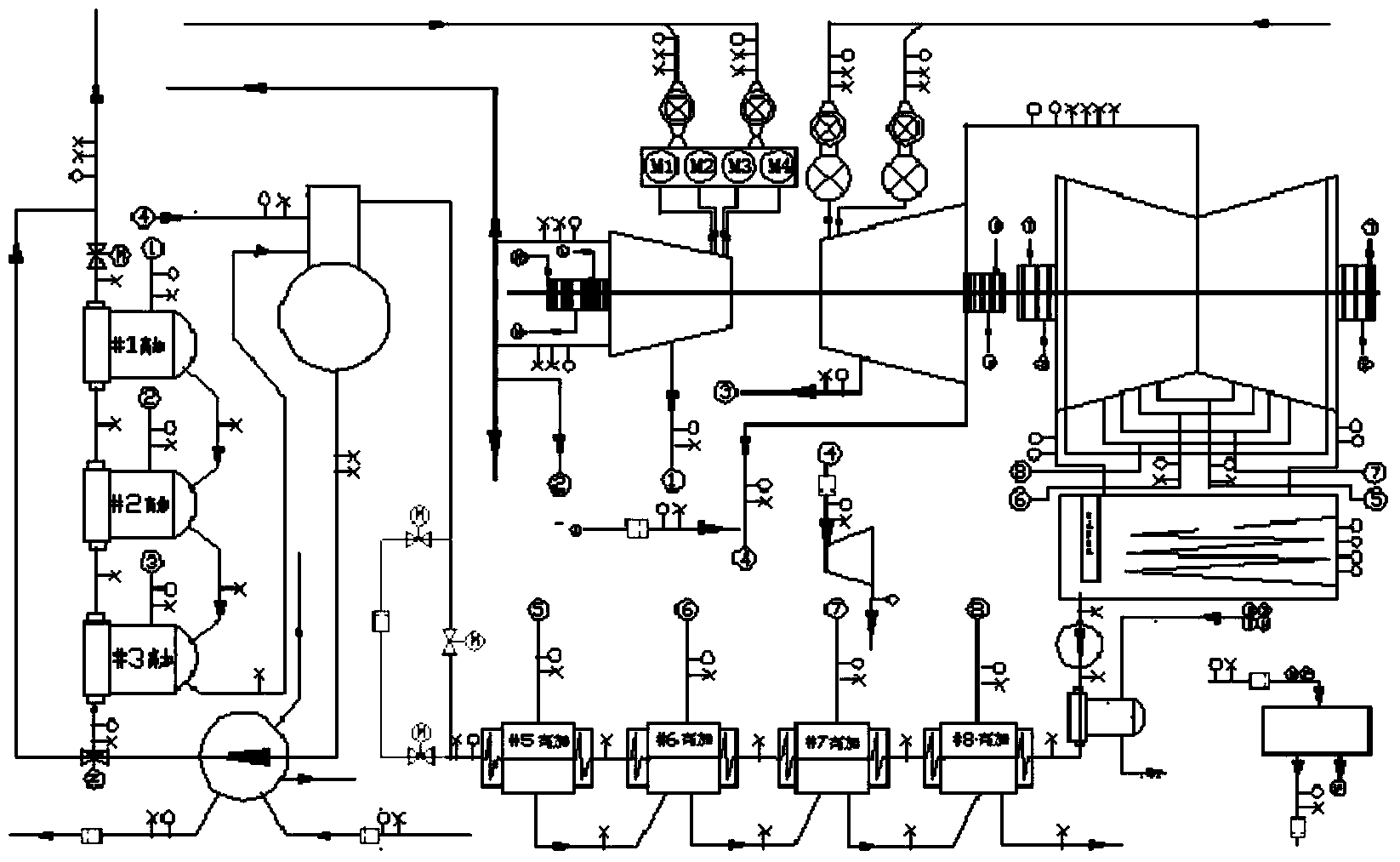

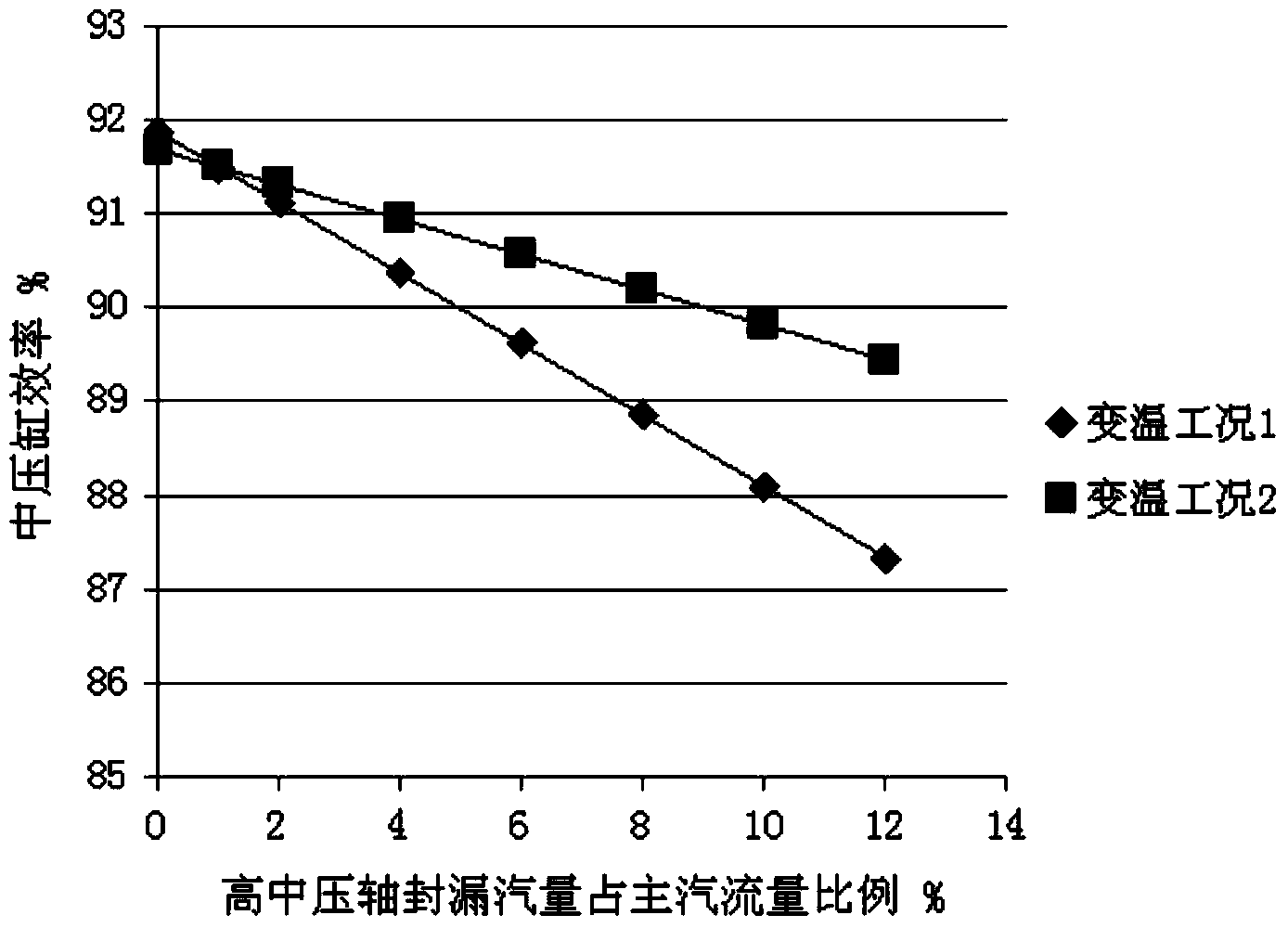

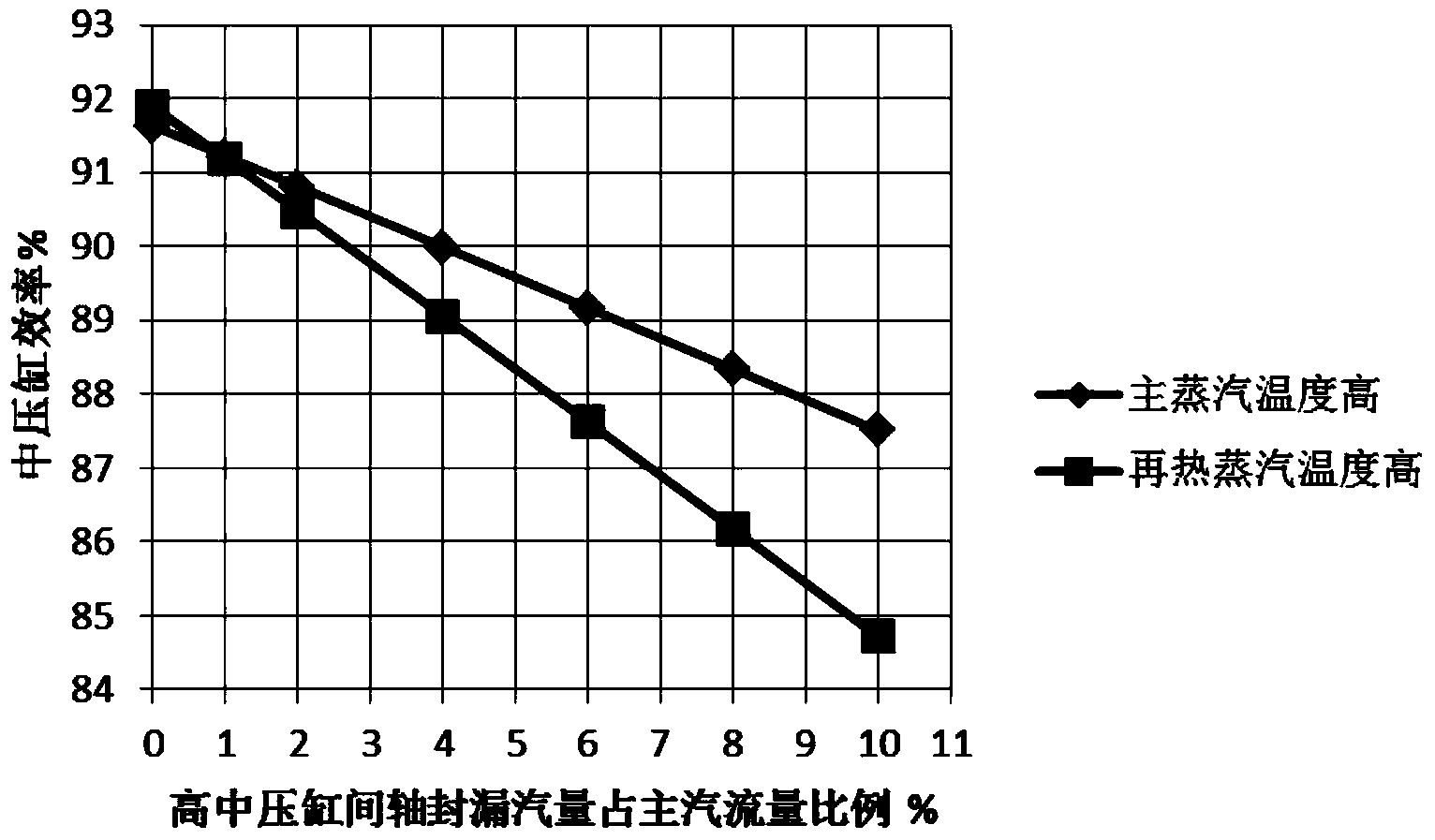

Comprehensive calculation method for energy-saving effect after steam turbine steam seal modification

ActiveCN103646176AThe effect of high steam seal modificationLower main steam temperatureEngine testingSpecial data processing applicationsEngineeringElectric power

The invention discloses a comprehensive calculation method for an energy-saving effect after a steam turbine steam seal modification. In detail, the comprehensive calculation method includes the steps that pressure, temperature, flow and electric power test points are arranged on a steam turbine set thermal system; fed water flows, main steam flows, cold reheat steam flows and reheat steam flows are calculated; steam leakage amount of high pressure cylinder and intermediate pressure cylinder balance disc shaft seals of a set is calculated; the steam leakage amount of the high pressure cylinder and intermediate pressure cylinder shaft seals, the steam inlet amount of a low pressure cylinder shaft seal, pressure of the low pressure cylinder shaft seal and temperature rise of condensation water passing through a shaft seal heater are measured; the test heat rate of the set and a heat rate after a parameter modification are calculated; all parameters of a steam turbine are compared with design values prior to the steam shaft modification, so that the energy-saving effect of the steam turbine steam seal modification is evaluated. Through thermal performance testing performed on the steam turbine, the parameters of the thermal system are tested, and the evaluation and analyzing method for the energy-saving effect after the steam turbine steam seal modification are provided. The method is simple and reasonable, and the calculated result is more accurate.

Owner:STATE GRID CORP OF CHINA +1

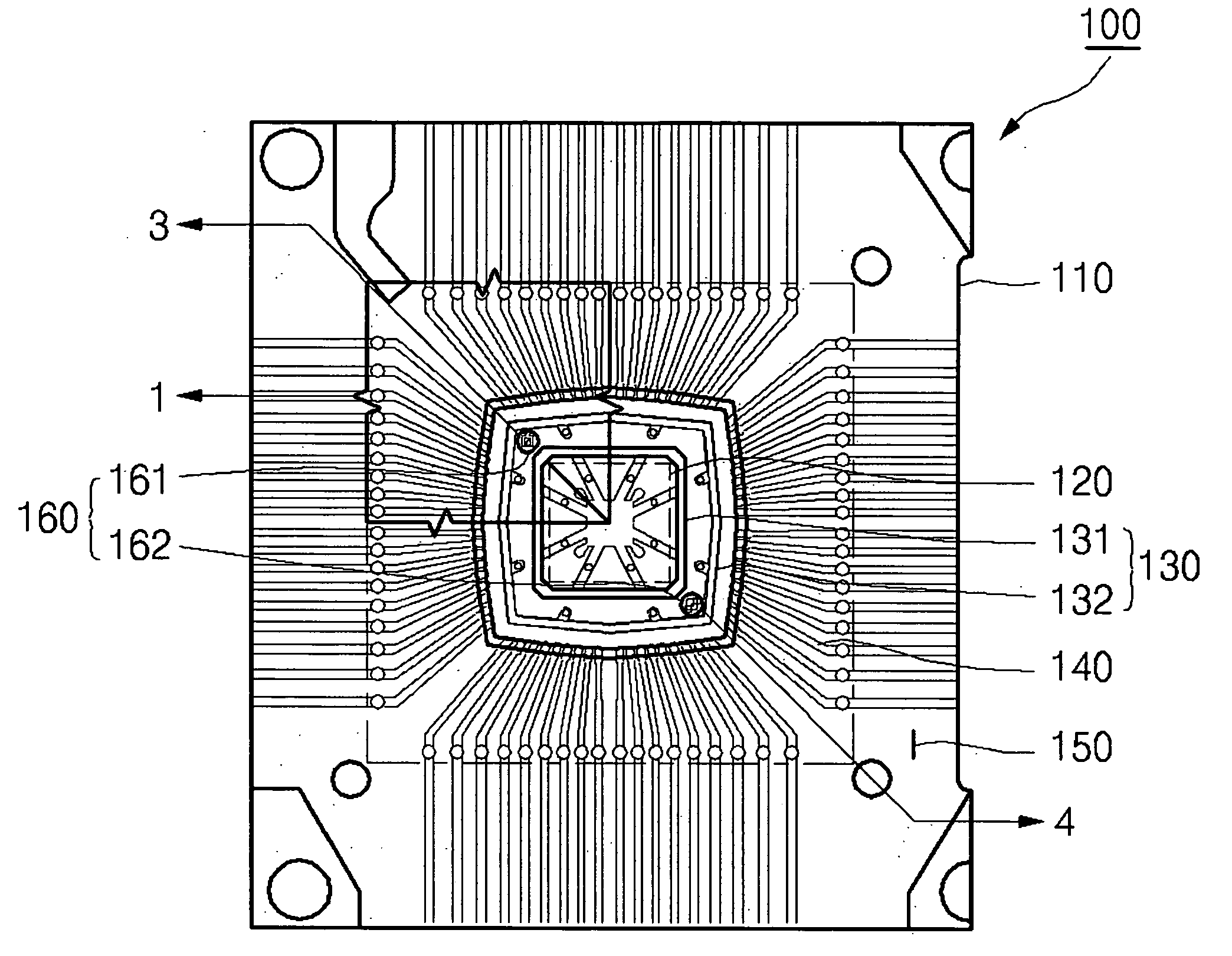

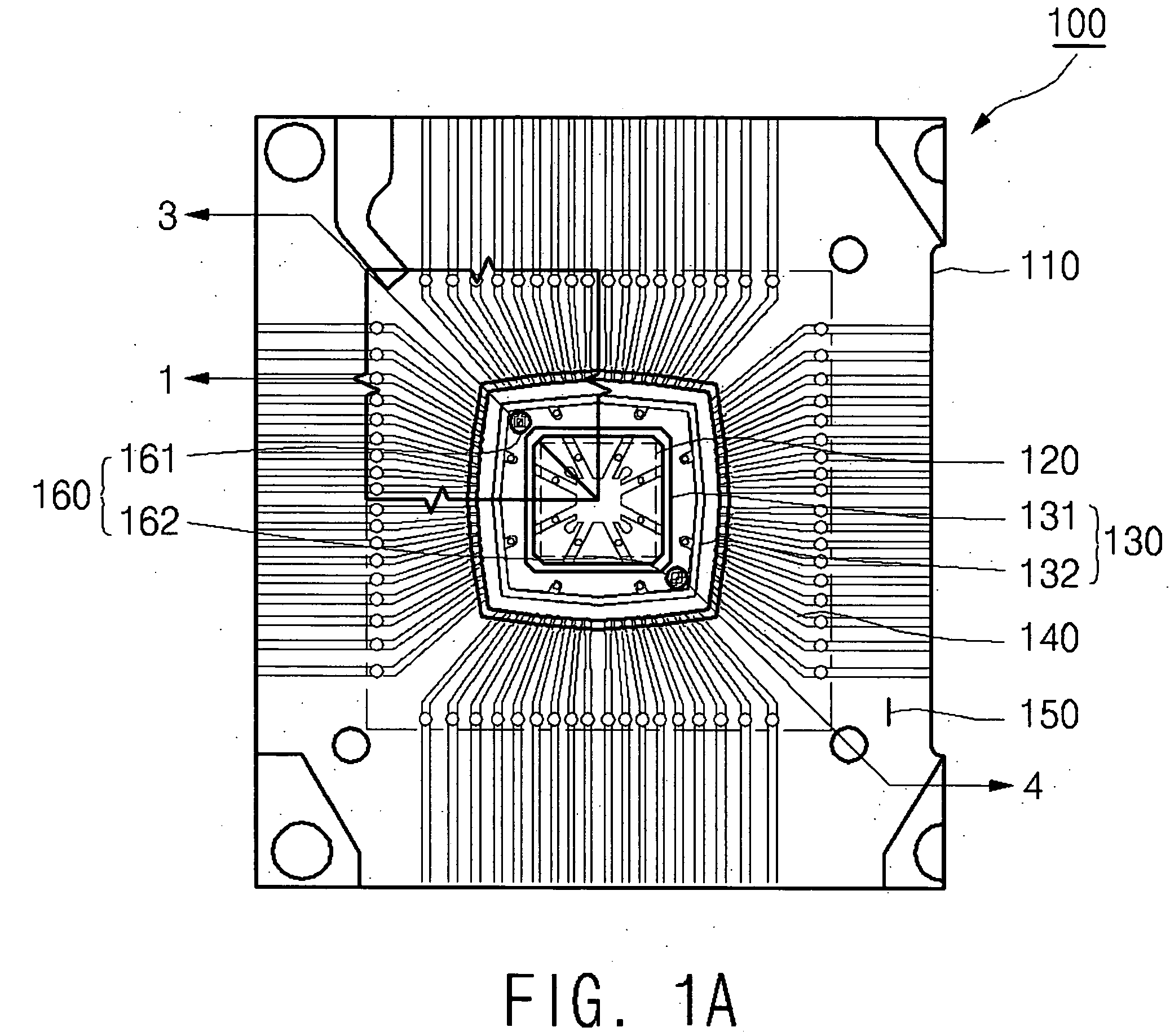

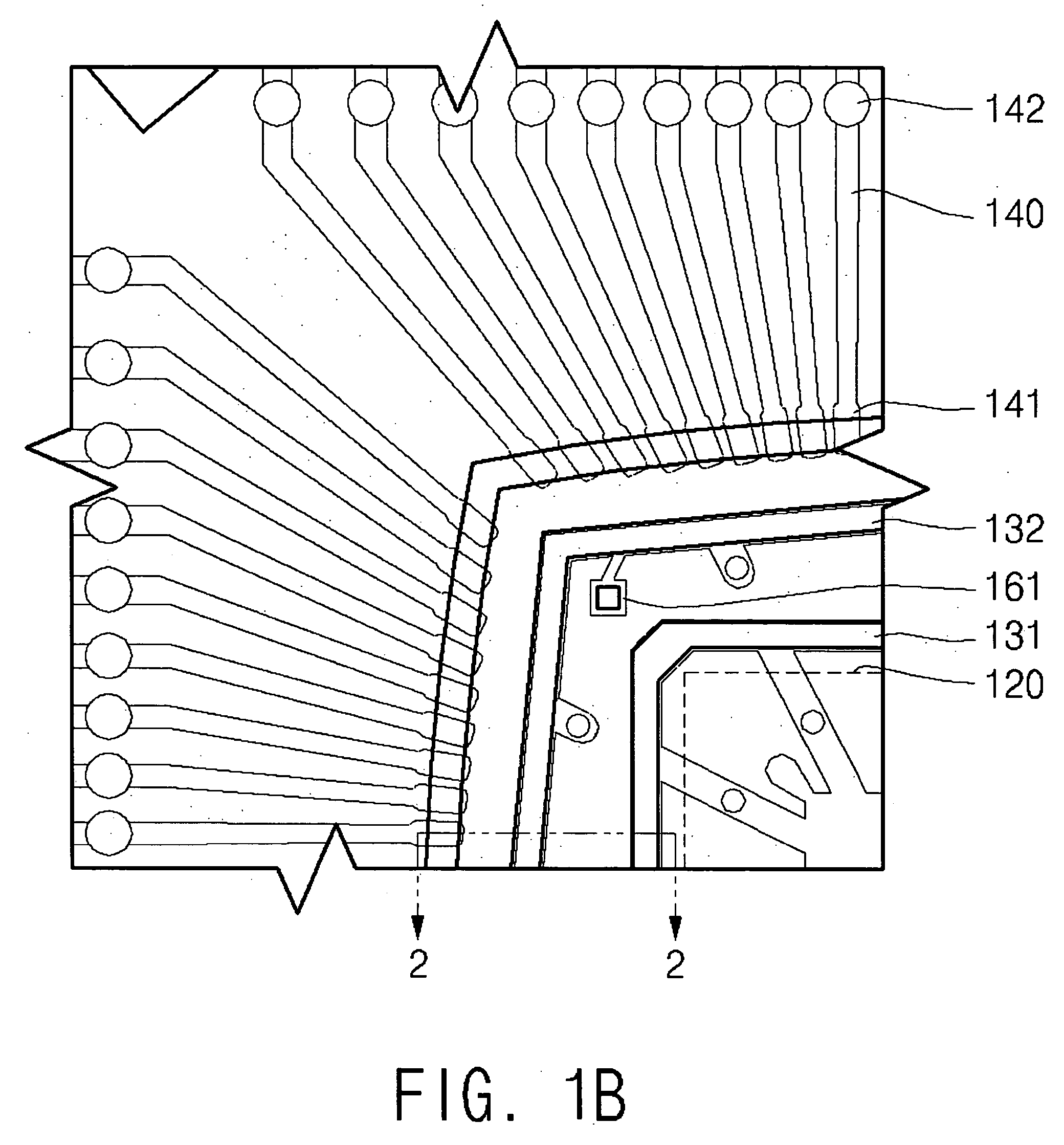

Substrate for semiconductor package wire bonding method using thereof

ActiveUS20050001299A1Semiconductor/solid-state device detailsPrinted circuit aspectsSolder maskLead bonding

Disclosed is a substrate for semiconductor package and a wire bonding method using thereof. The substrate is provided with at least one reference mark on its surface to check a loading position and a shift state of a solder mask. The reference mark is composed of a combination of a reference pattern and a solder mask opening and is positioned in any location on an outer peripheral edge of a die attachment region. The reference mark may take various shapes. A method for checking a solder mask shift using the reference mark includes comparing a design value of the reference pattern and the solder mask opening with the reference pattern and the solder mask opening, which are formed in an actual material. After the solder mask shift is calculated, a wire bonding coordinate is newly constructed in consideration of the solder mask shift. This minimizes the wire bonding error.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

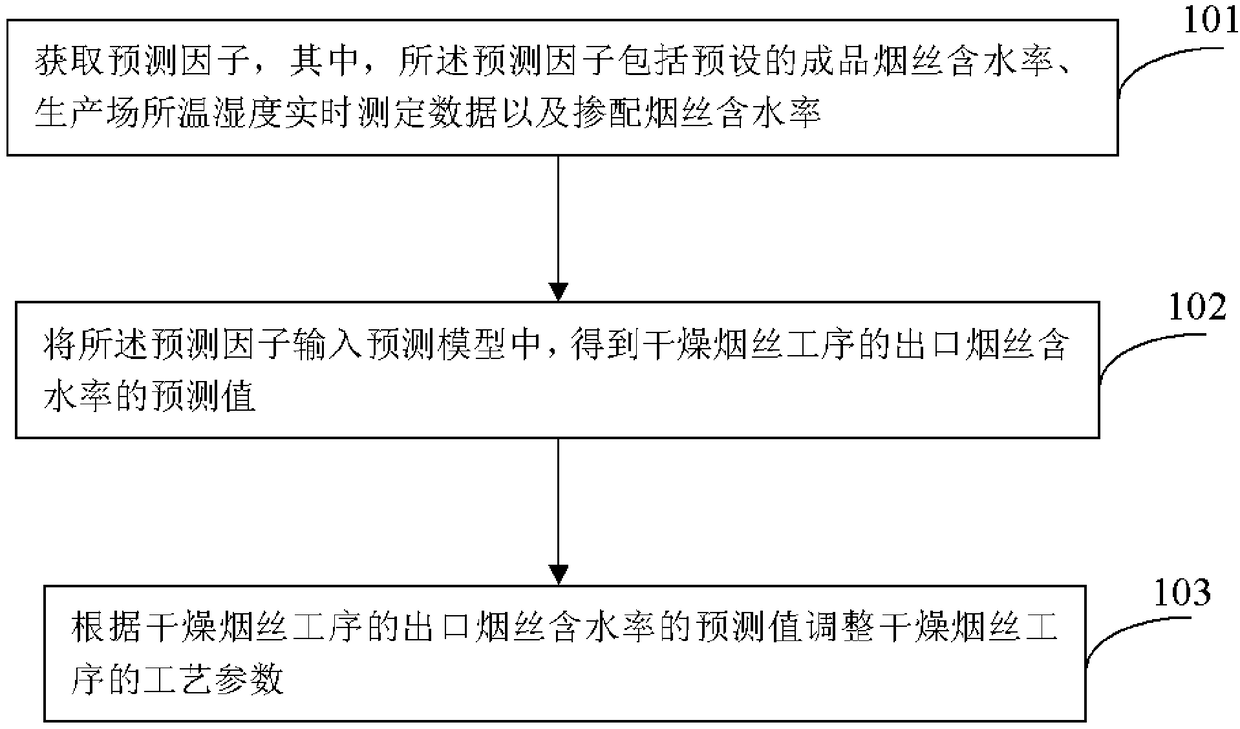

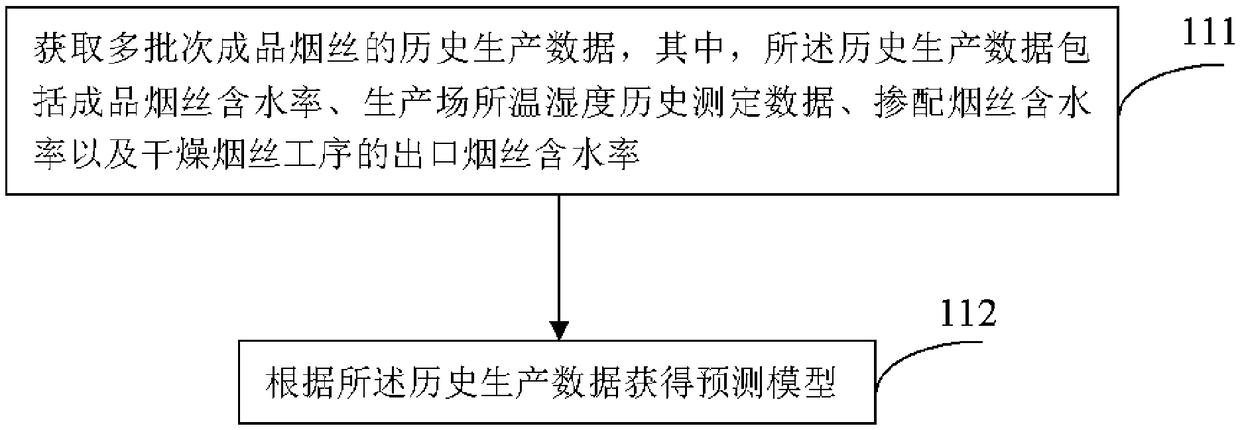

Method for drying cut tobacco and device for predicting moisture content of outlet cut tobacco

The invention belongs to the field of tobacco manufacturing and relates to a method for drying cut tobacco. The method comprises the following steps: acquiring predictive factors, wherein the predictive factors comprise preset moisture content of finished cut tobacco, real-time determined data of temperature and humidity in production places and moisture content of blended cut tobacco; inputting the predictive factors into a prediction model so as to obtain a predicted value of the moisture content of the outlet cut tobacco in a cut tobacco drying process; and adjusting process parameters of the cut tobacco drying process according to the predicted value of the moisture content of the outlet cut tobacco in the cut tobacco drying process, wherein the prediction model is established according to historical production data of the finished cut tobacco of multiple batches, and the historical production data comprises the moisture content of the finished cut tobacco, historical determined data of the temperature and humidity in production places, the moisture content of the blended cut tobacco and moisture content of the outlet cut tobacco in the cut tobacco drying process. The inventionfurther relates to a device for predicting moisture content of outlet cut tobacco in the cut tobacco drying process. According to the method disclosed by the invention, the moisture content of the outlet cut tobacco in the cut tobacco drying process is controlled, so that the moisture content of the finished cut tobacco reaches a design value and is kept stable, and the stable cigarette quality is further ensured.

Owner:CHINA TOBACCO FUJIAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com