Patents

Literature

93 results about "Product optimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Product optimization Production optimization is the practice of making changes or adjustments to a product to make it more desirable. ... Multivariate optimization is one of the most common methods for product optimization. In this method, multiple product attributes are specified and then tested with consumers.

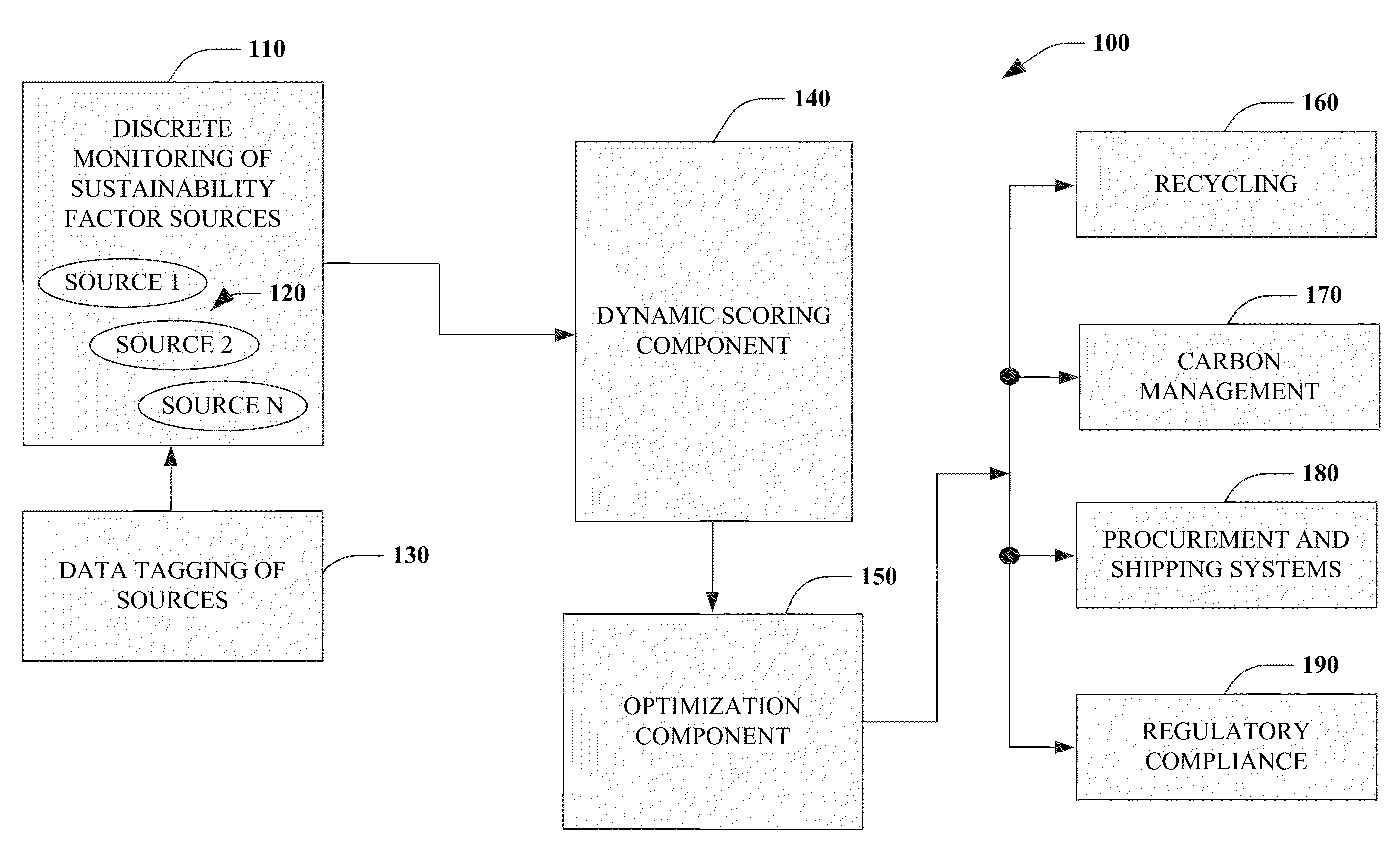

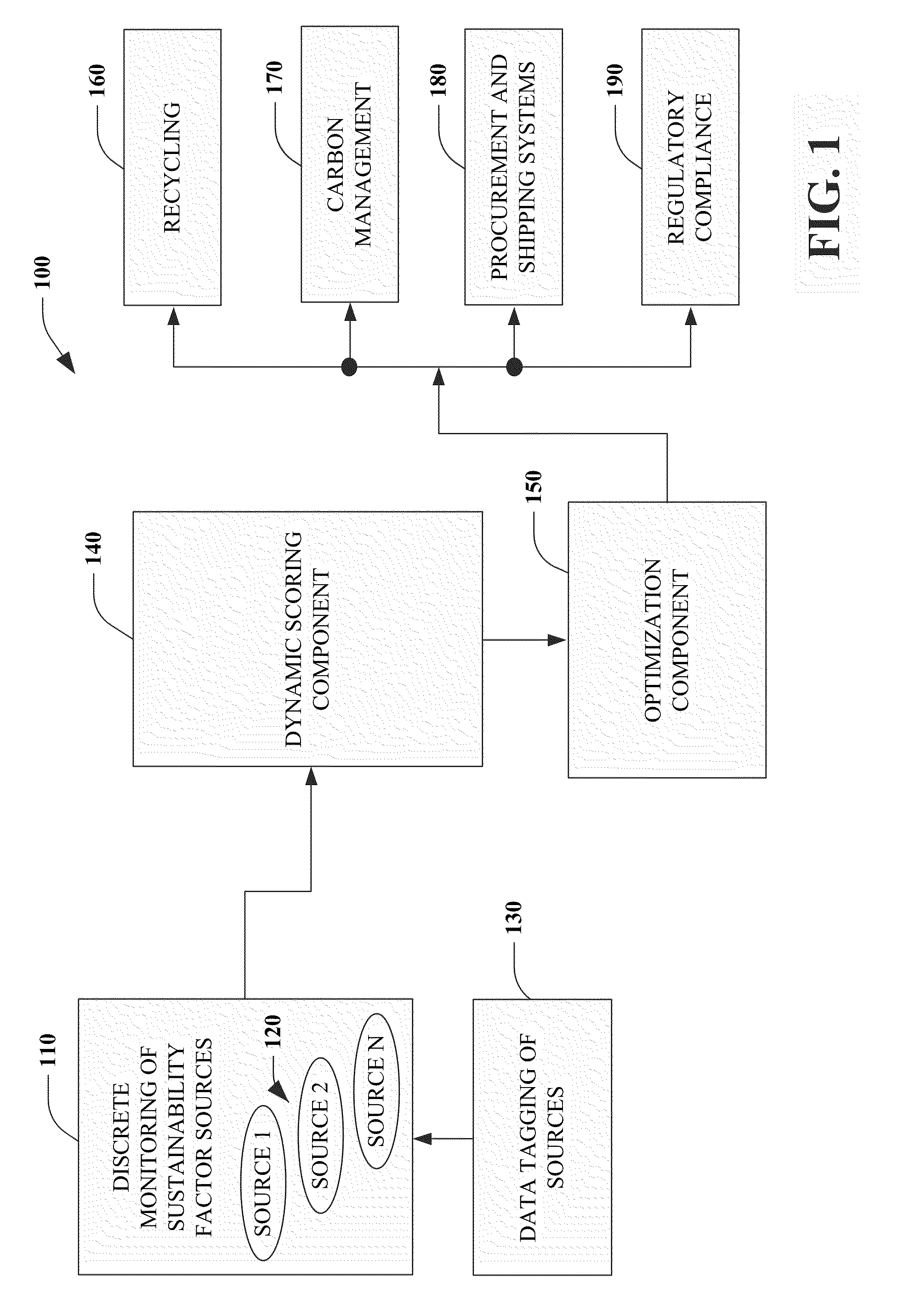

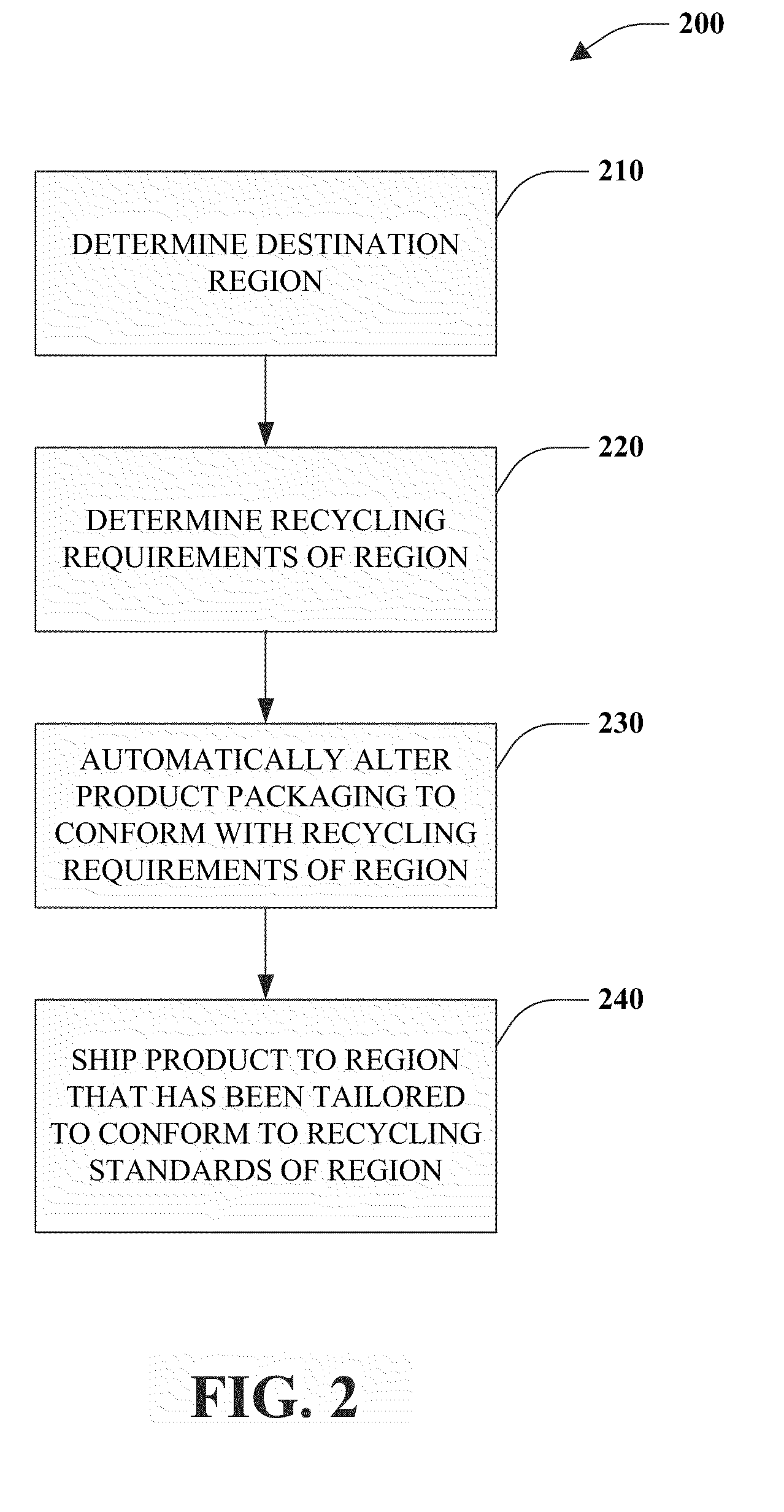

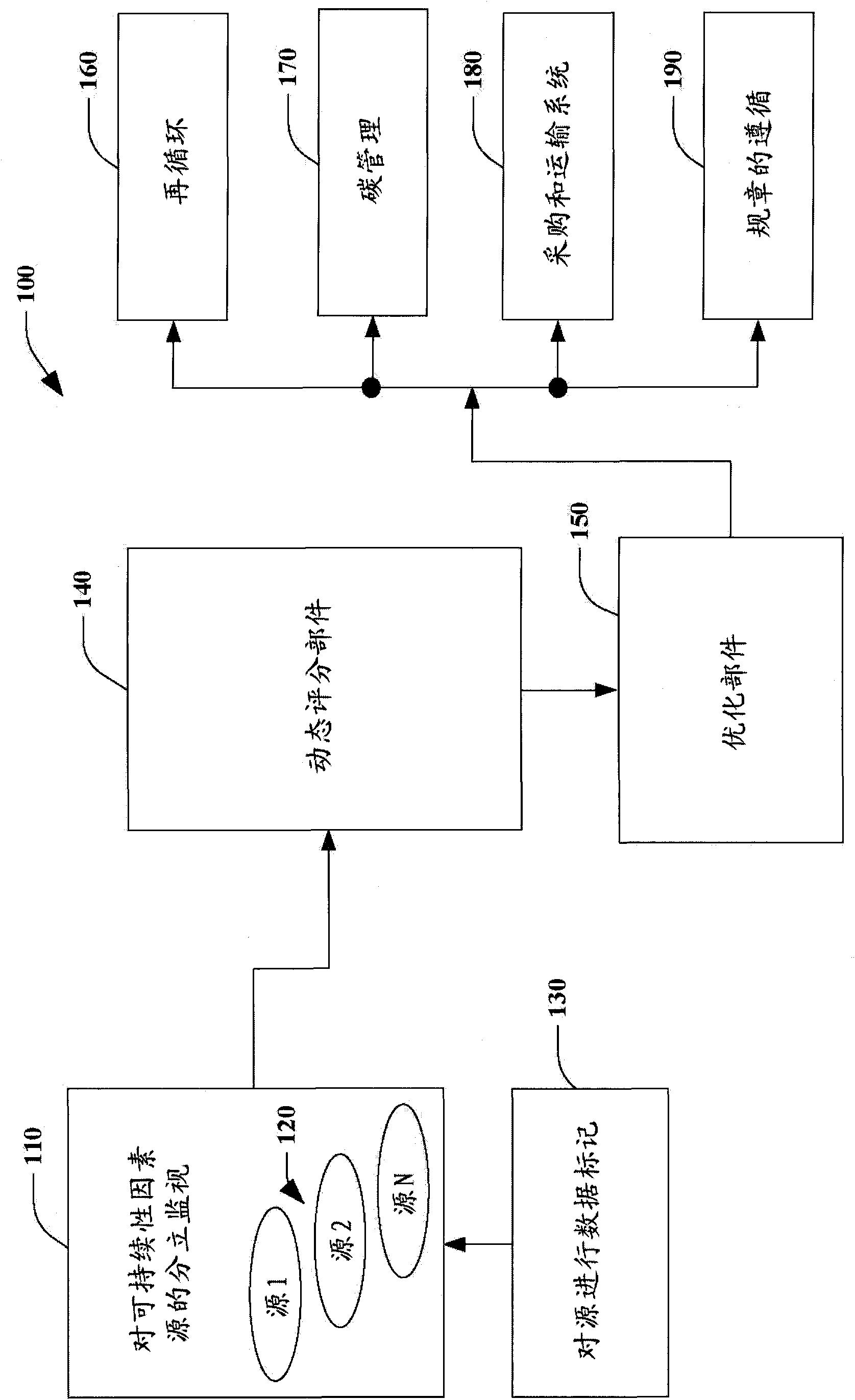

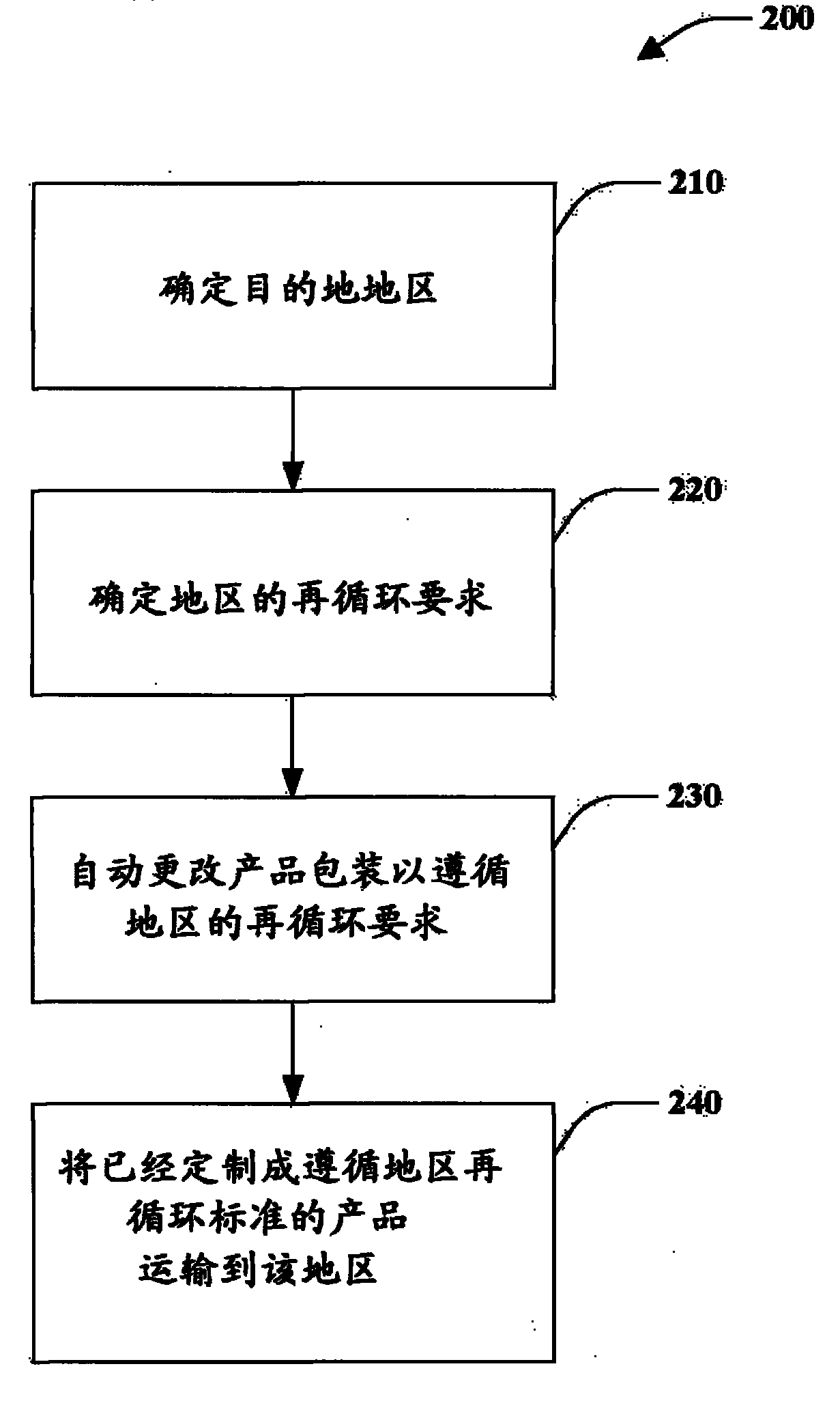

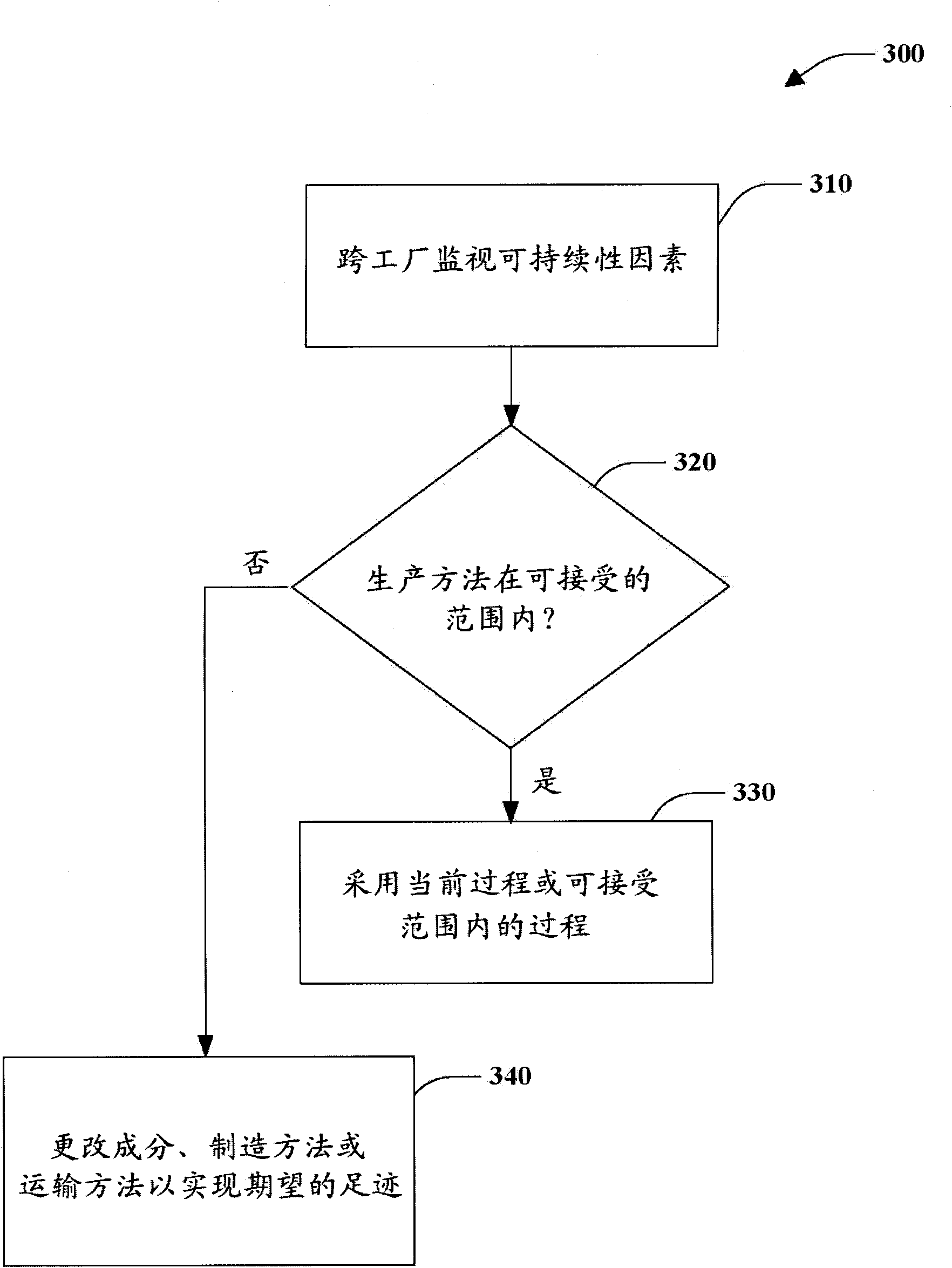

Utilizing sustainability factors for product optimization

InactiveUS20100274612A1Improve sustainabilityEasy to operateProgramme controlMechanical power/torque controlProcess optimizationCarbon footprint

An industrial control system is provided. The system includes a processor to analyze one or more sustainability factors and a scoring component to assign a weight to the sustainability factors. An optimizer automatically adjusts a production process in view of the sustainability factors, the weight, and at least one of a recycling requirement, a carbon footprint, a procurement process, a shipping process, or a regulatory requirement.

Owner:ROCKWELL AUTOMATION TECH

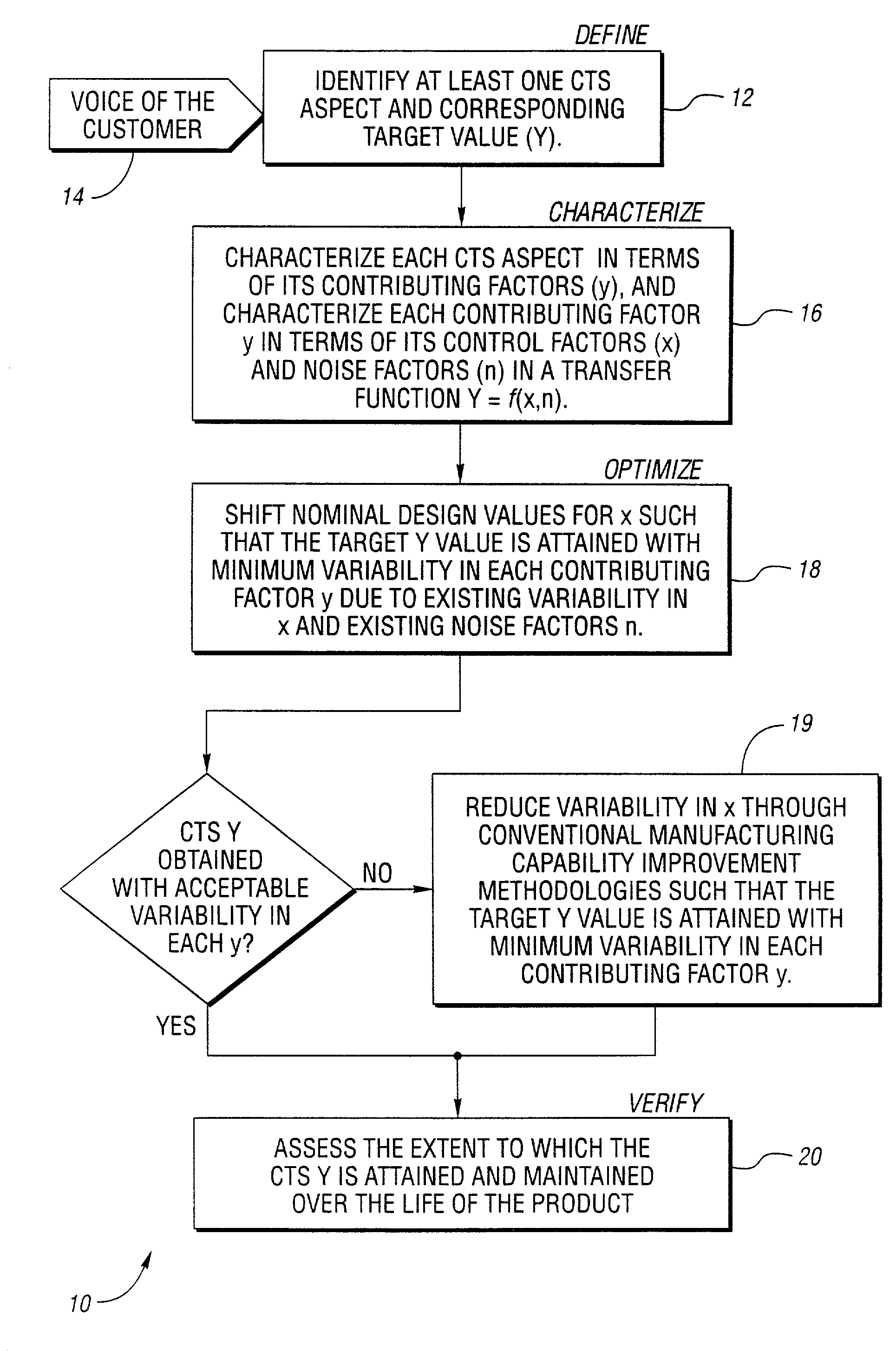

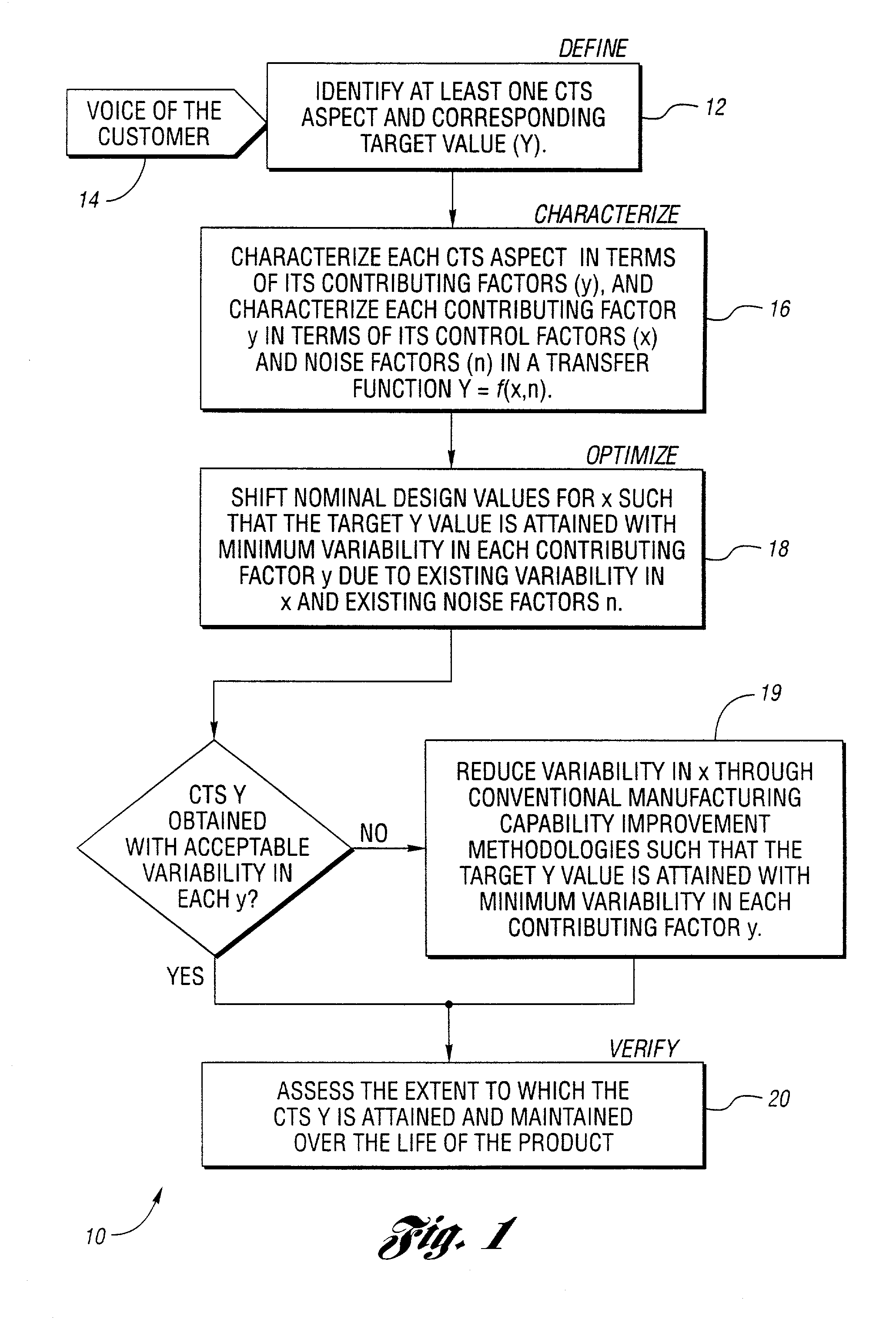

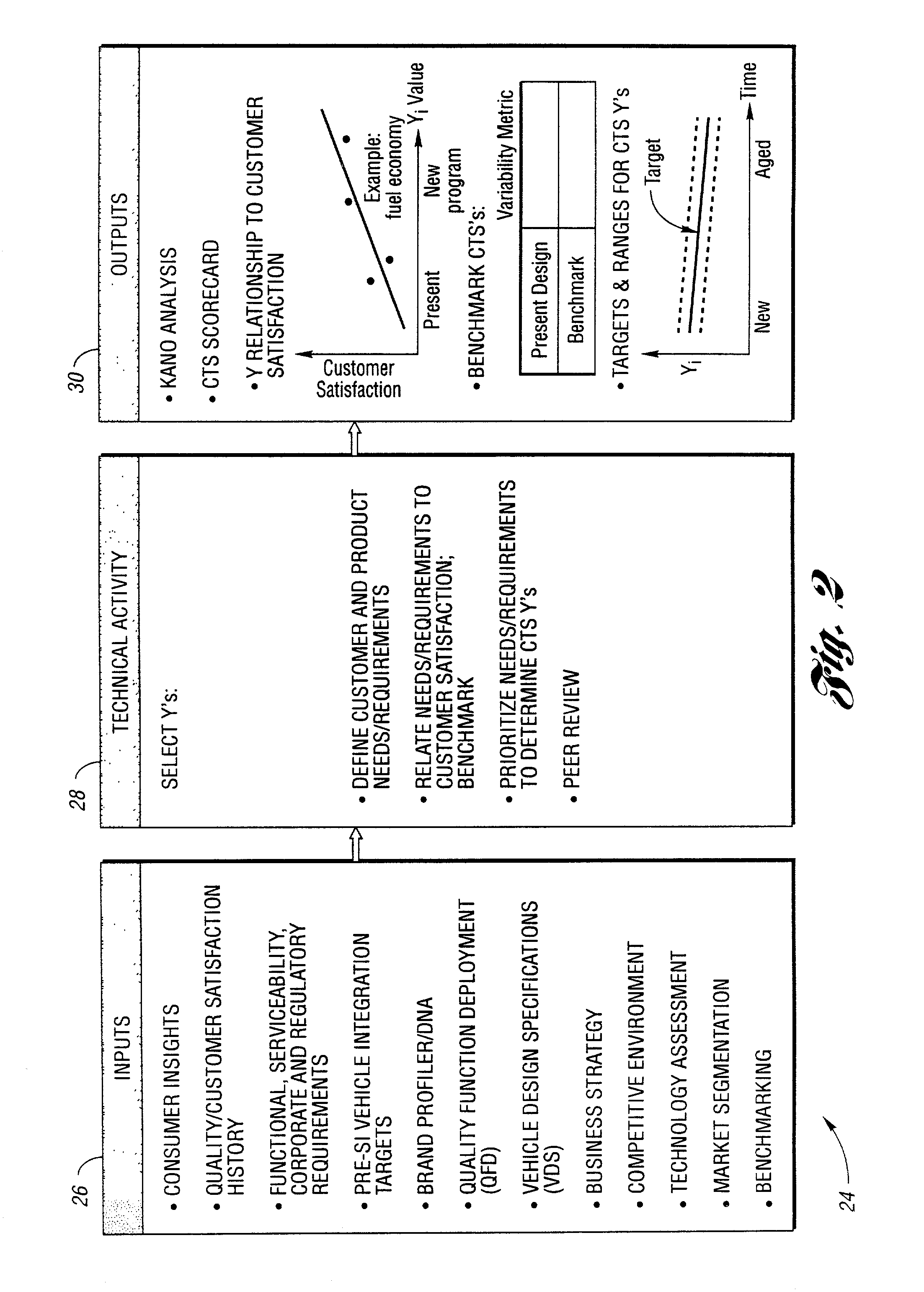

Method and system for product optimization

ActiveUS7219068B2Improve the level ofFacilitate the processForecastingSpecial data processing applicationsProduct optimizationLife time

A method and computer-implemented system for optimizing a product. Based on the “voice of the customer”, aspects of the product that are critical to the customer satisfaction, and target values, therefore, are identified. Aspects are characterized in terms of their contributing factors. Each contributing factor is characterized in a transfer function in terms of control and noise factors impacting the contributing factors. Contributing factors are optimized during product design by shifting nominal design values for control factors with respect to the transfer function such that target contributing factors are attained with minimum variability due to existing noises and variability in control. Where target values cannot be obtained through design optimization, conventional methods of manufacturing optimization are implemented. The extent to which the target values are attained and maintained over the life of the product are assessed.

Owner:FORD MOTOR CO

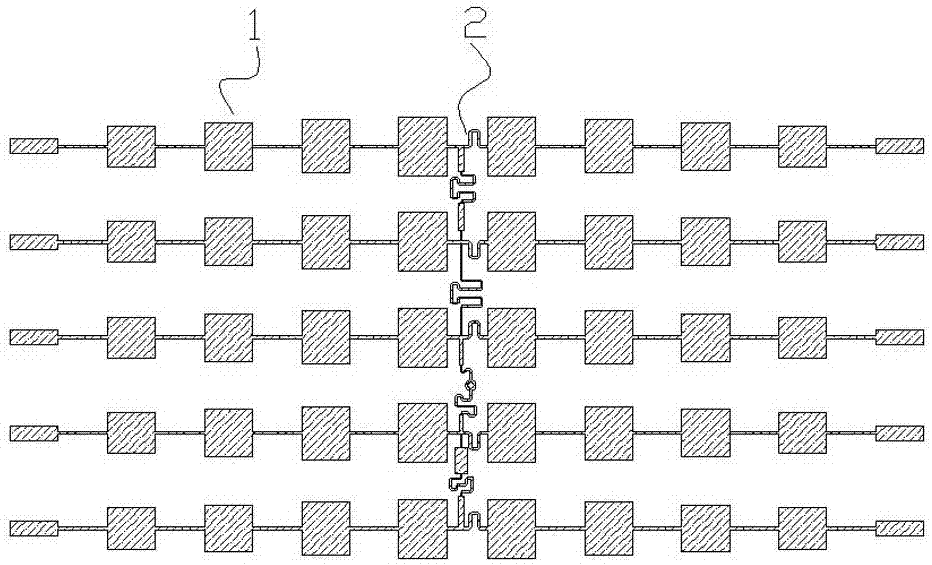

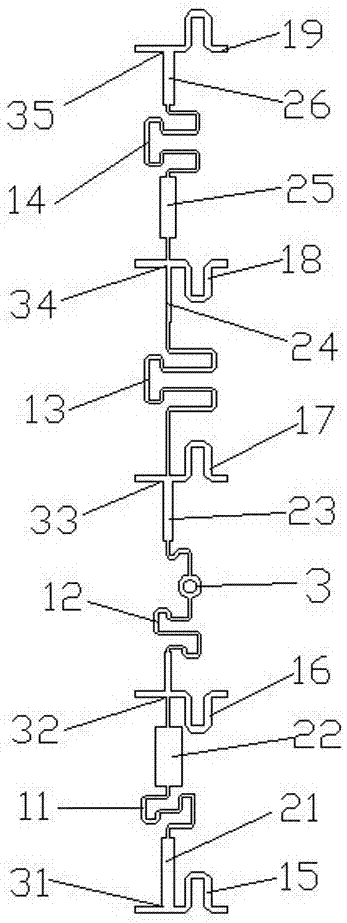

Vehicular radar array antenna

ActiveCN106972244AMeet needsReduce distractionsAntenna adaptation in movable bodiesRadiating elements structural formsImpedance matchingProduct optimization

The invention provides a vehicular radar array antenna. The vehicular radar array antenna comprises a radiation fin array and an impedance matching network arranged on the same plane, and the radiation fin array is configured in a bilateral symmetry manner by taking the impedance matching network as the center axis. According to the invention, a novel feed network is employed, based on the microstrip line impedance match and phase shift principle, relevant parameter demands of the antenna radiation array are achieved by means of a simple implementation form, and furthermore product optimization is achieved. The simulation of the vehicular anticollision radar array antenna and the debugging of the antenna sample are convenient and fast, by arranging the impedance matching network and the array antenna in the same plane, the whole radar antenna profile is reduced, and the duty ratio of the antenna feed part in the whole vehicular radar is effectively reduced. By employing the novel design concept and design method, a conventional feed power splitting network structure with a complicated back side is broken through, electromagnetic interference on other radio frequency devices is effectively reduced, and the vehicular radar array antenna has a deep business application value in the actual engineering.

Owner:HUIZHOU SPEED WIRELESS TECH CO LTD

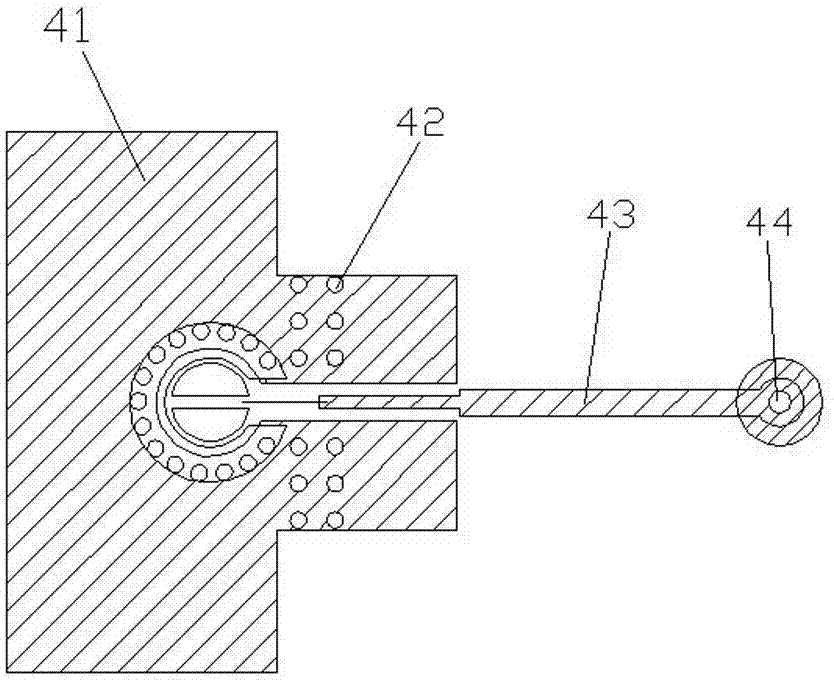

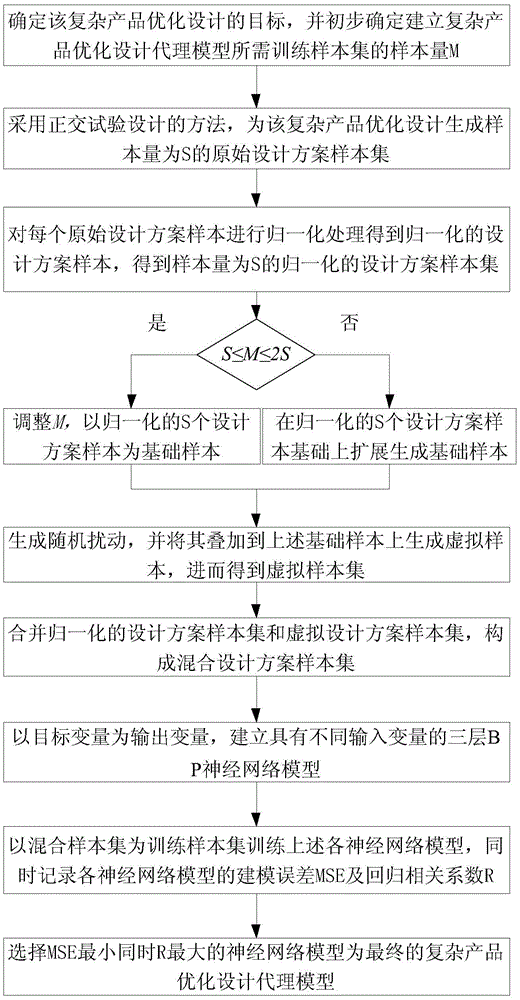

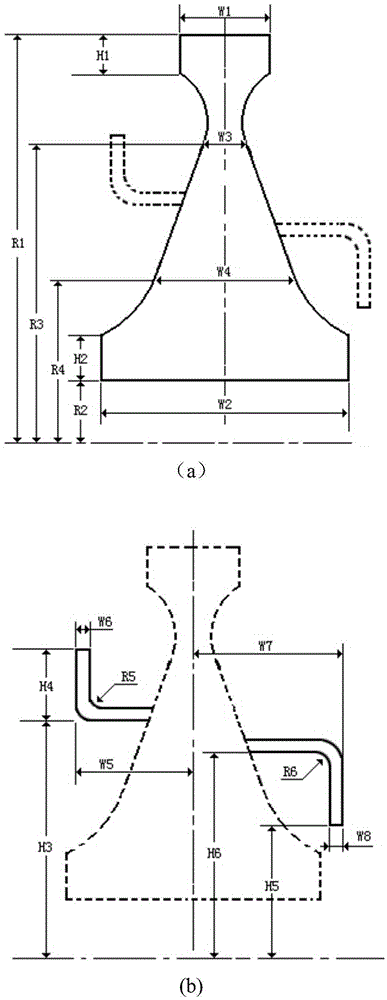

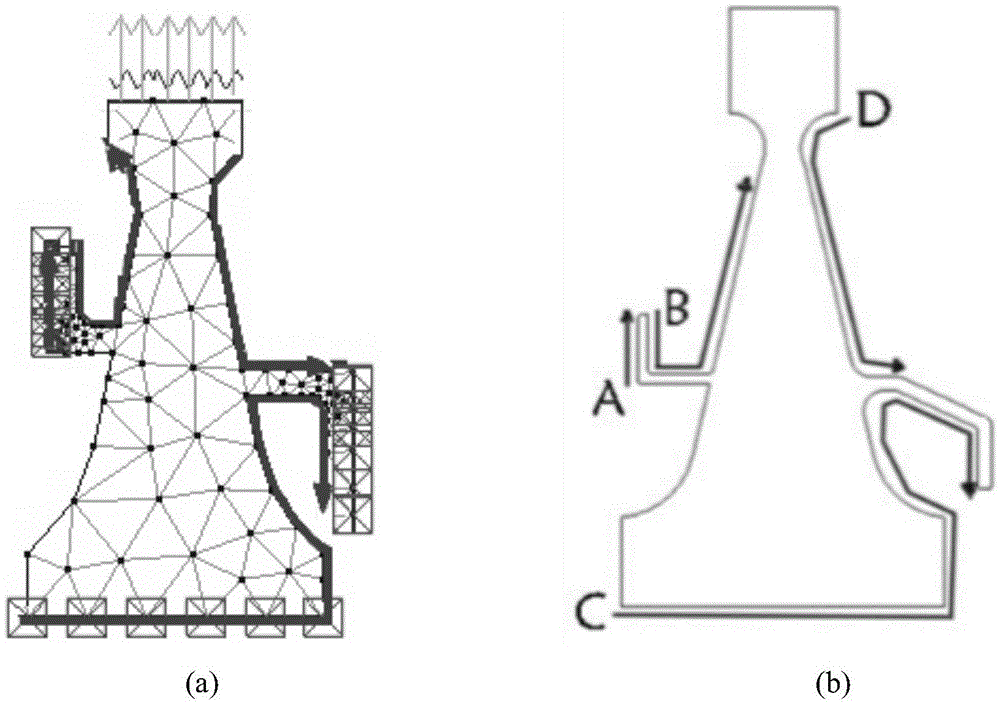

Method for establishing complex product optimization design agent model based on small sample

ActiveCN105488297ASatisfy sample size requirementsGuaranteed accuracyGeometric CADSpecial data processing applicationsSmall sampleAlgorithm

The invention relates to a method for establishing a complex product optimization design agent model based on a small sample, belonging to the technical field of complex product optimization design. The method comprises the following steps: setting a goal of the complex product optimization design; generating an original design scheme sample set, the sample capacity of which is S, for the complex product optimization design; generating a virtual design scheme sample set for the complex product optimization design; combining the original design scheme sample set with the virtual design scheme sample set so as to form a mixed design scheme sample set; determining the sensitivities of the target of the complex product optimization design corresponding to various decision variables, and sorting the sensitivities; establishing a three-layer BP neural network model having different input variables by taking the target variable as the output variable; and training various neural network models by taking the mixed sample set as the training sample set; and selecting the neural network model having the optimal performance as the final complex product optimization design agent model. By means of the method, the sample generation workload is reduced; and the precision of the complex product optimization design agent model is ensured.

Owner:NORTHEASTERN UNIV

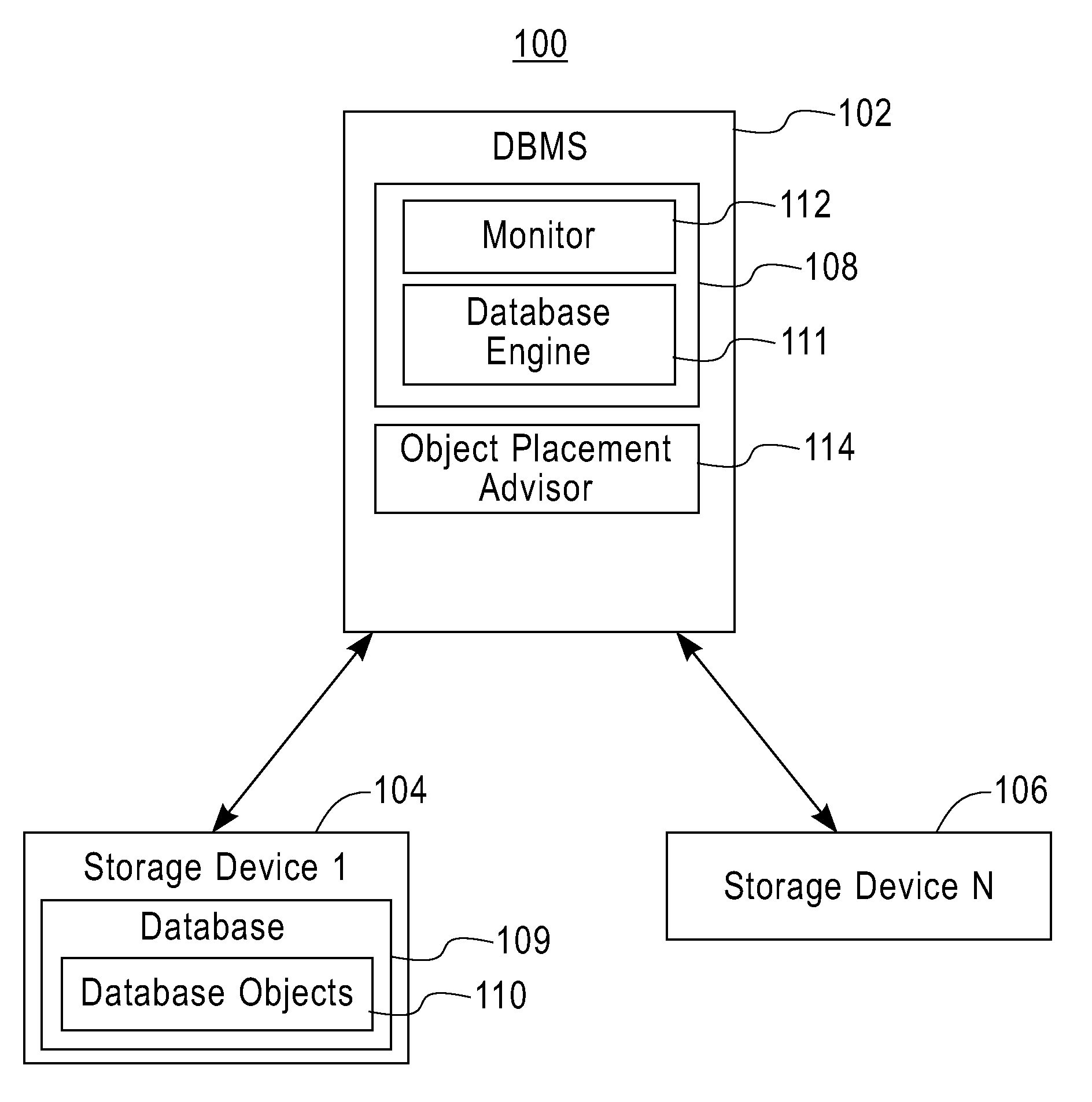

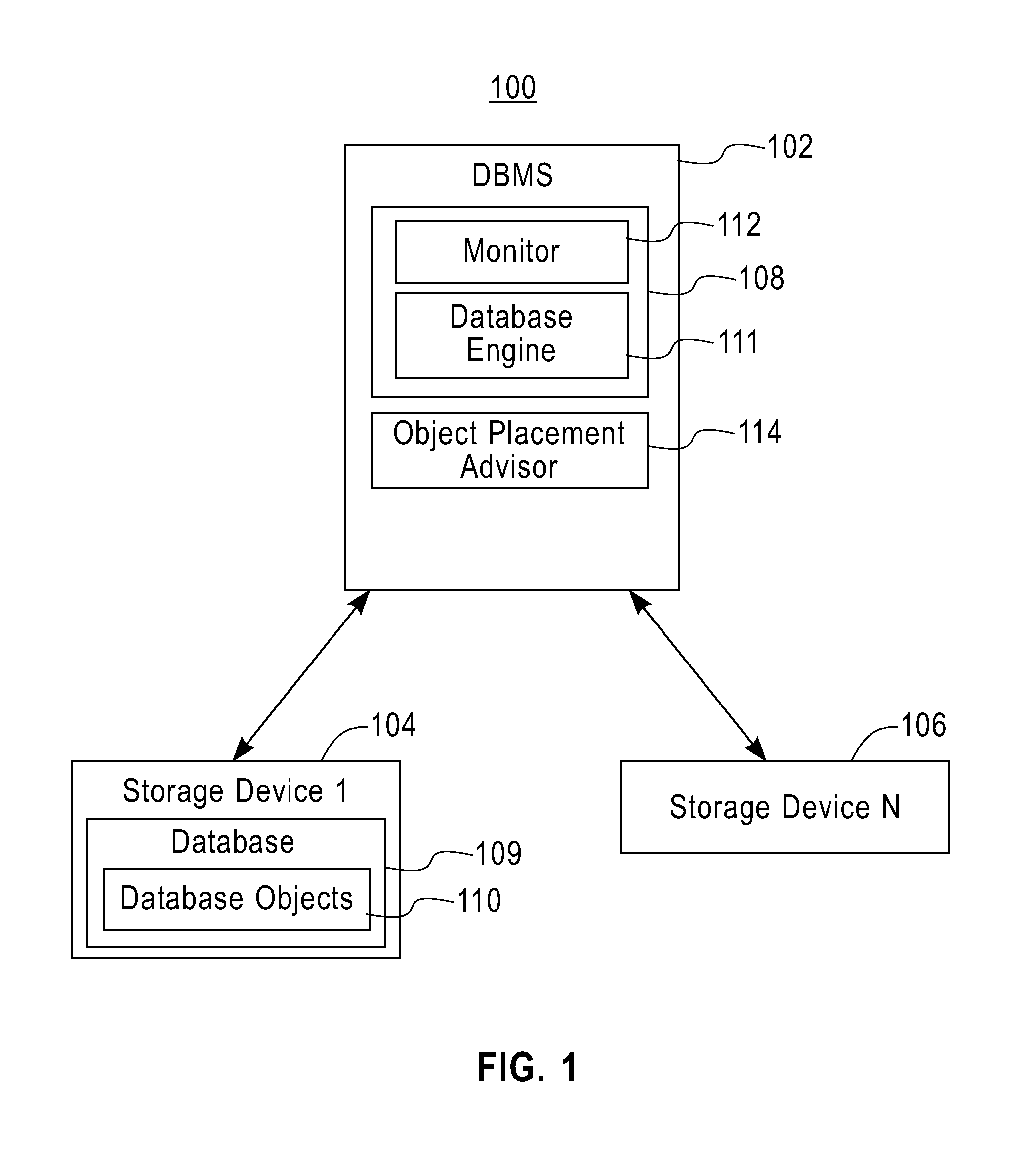

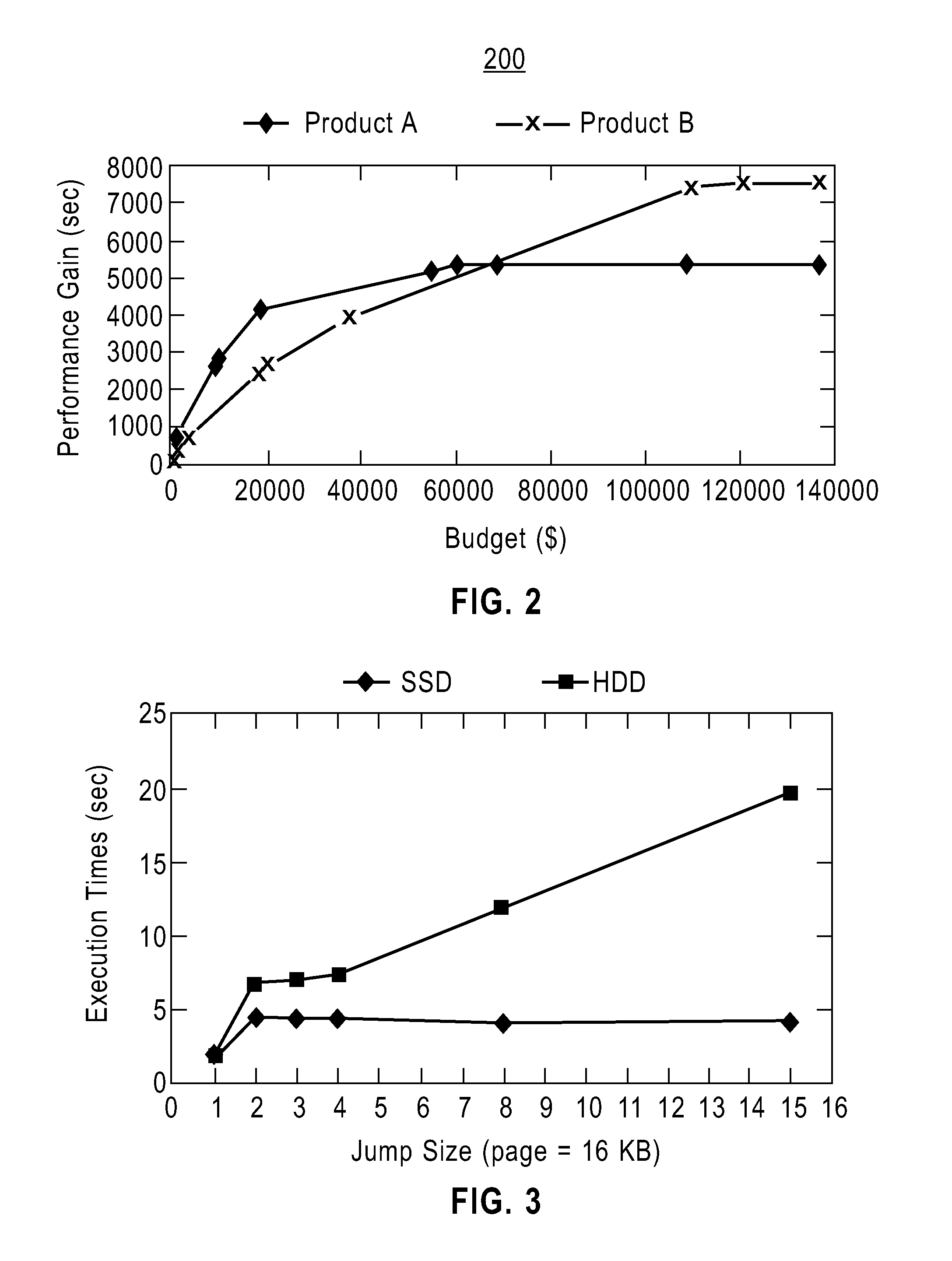

Managing database object placement on multiple storage devices

InactiveUS9165021B2Web data indexingDigital data processing detailsInformation processingProduct optimization

A method, information processing system, and computer program storage product optimize the placement of database objects on a multiplicity of storage devices. A set of database objects are placed on a first storage device in a multiplicity of storage devices. Each storage device comprises differing characteristics. A query workload is run on the set of database objects that have been placed on the first storage device. Profiling information associated with the query workload that is running is collected. A subset of database objects is selected from the set of the database objects to be stored on a second storage device. The second storage device is a separate physical device from, and performs faster than, the first storage device. The subset of database objects is stored on the second storage device and all remaining database objects in the set of database objects on the first storage device.

Owner:INT BUSINESS MASCH CORP

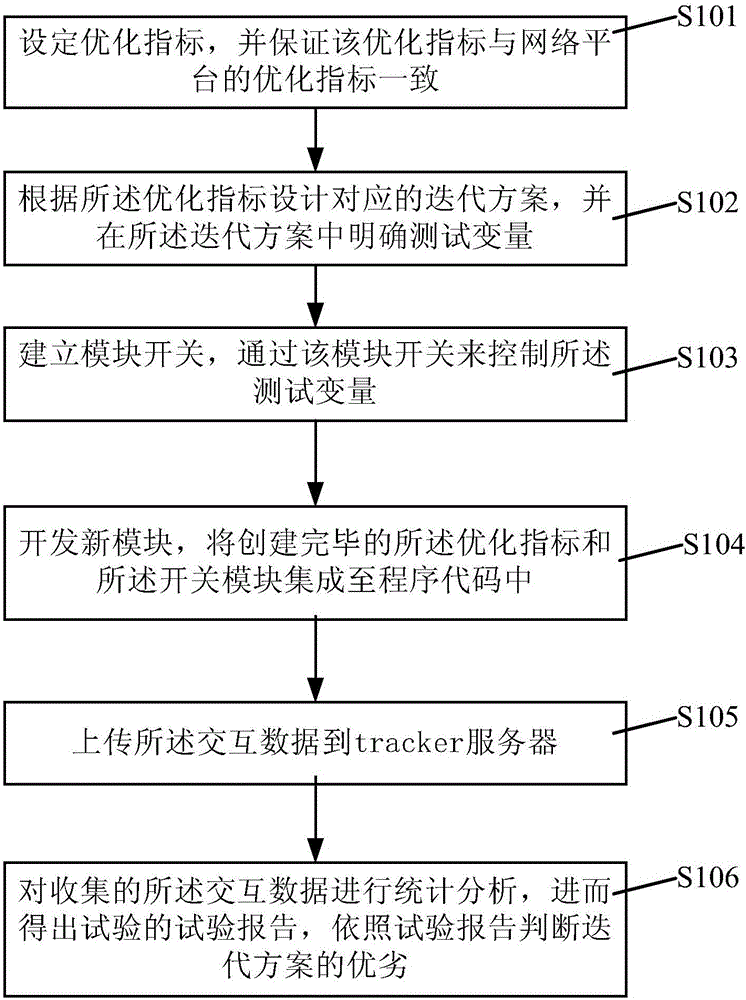

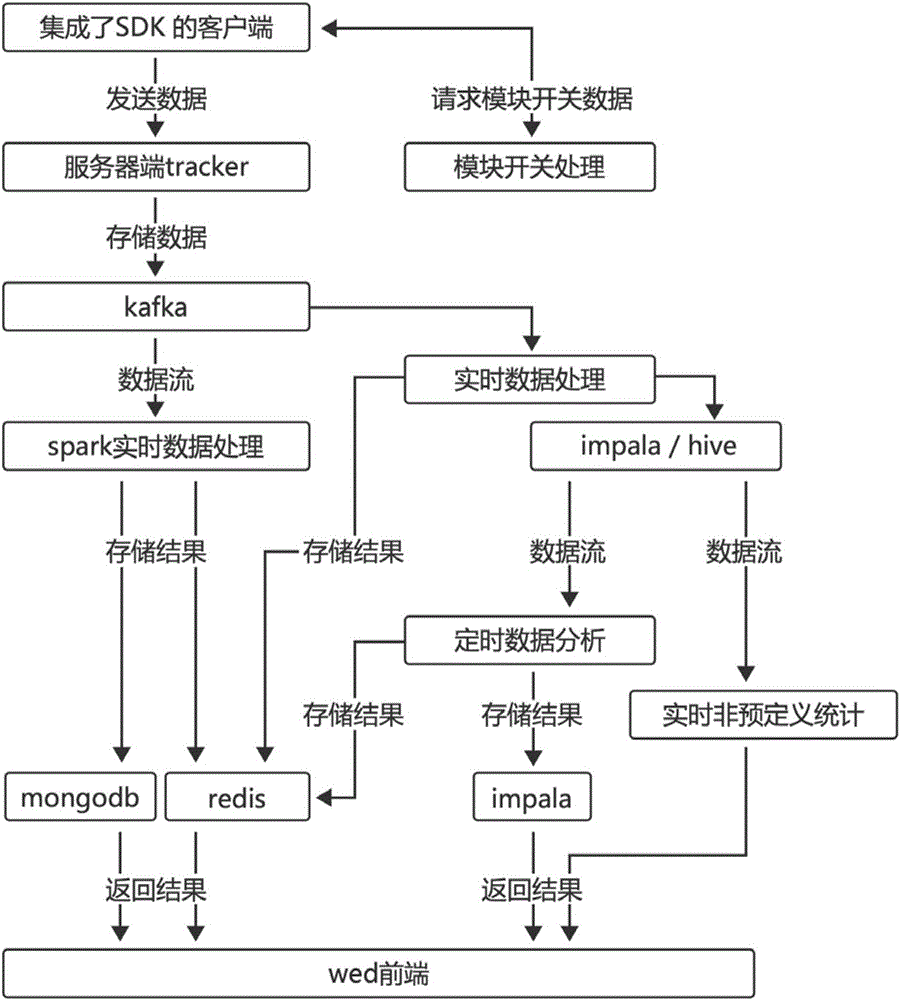

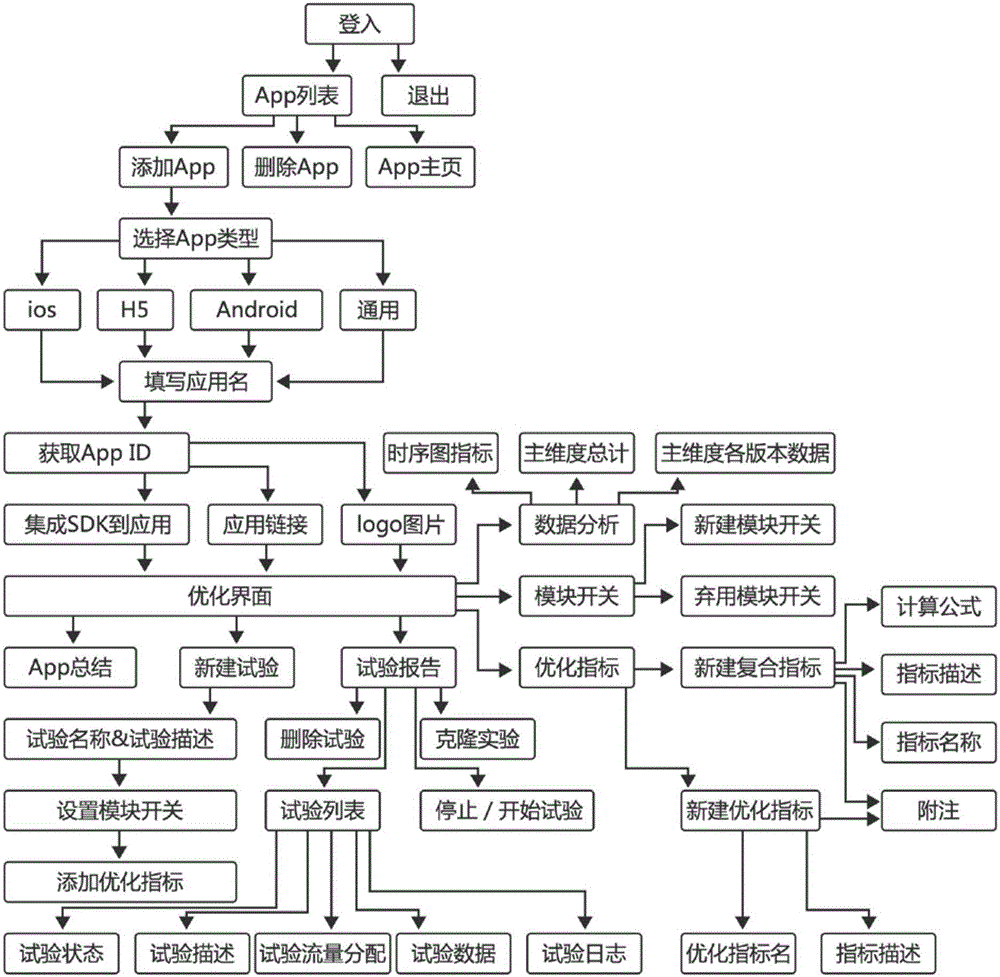

Data driving-based AB test method

InactiveCN105913145ABreak through dependenceGet feedback quicklyForecastingResourcesStatistical analysisComputer module

The invention discloses a data driving-based AB test method which comprises the following steps: an optimizing index consistent with a network platform is set, an iteration solution corresponding to the optimizing index is set, a module switch is built to control test variables in a the iteration solution, interaction data of a user is collected and is subjected to statistical analysis operation, and whether the iteration solution is good or not is determined according to a data analysis result. The beneficial effects of the data driving-based AB test method are that dependence over personal experience is eliminated via the data driving-based AB test method, feedback can be quickly obtained via data mining, and fast iterative optimization of products can be fulfilled; the method is suitable for Internet industry product optimization, advertising industry product optimization and product optimization in other industries that can be conducted via user feedback data collecting and analyzing operation.

Owner:BEIJING APPADHOC CO LTD

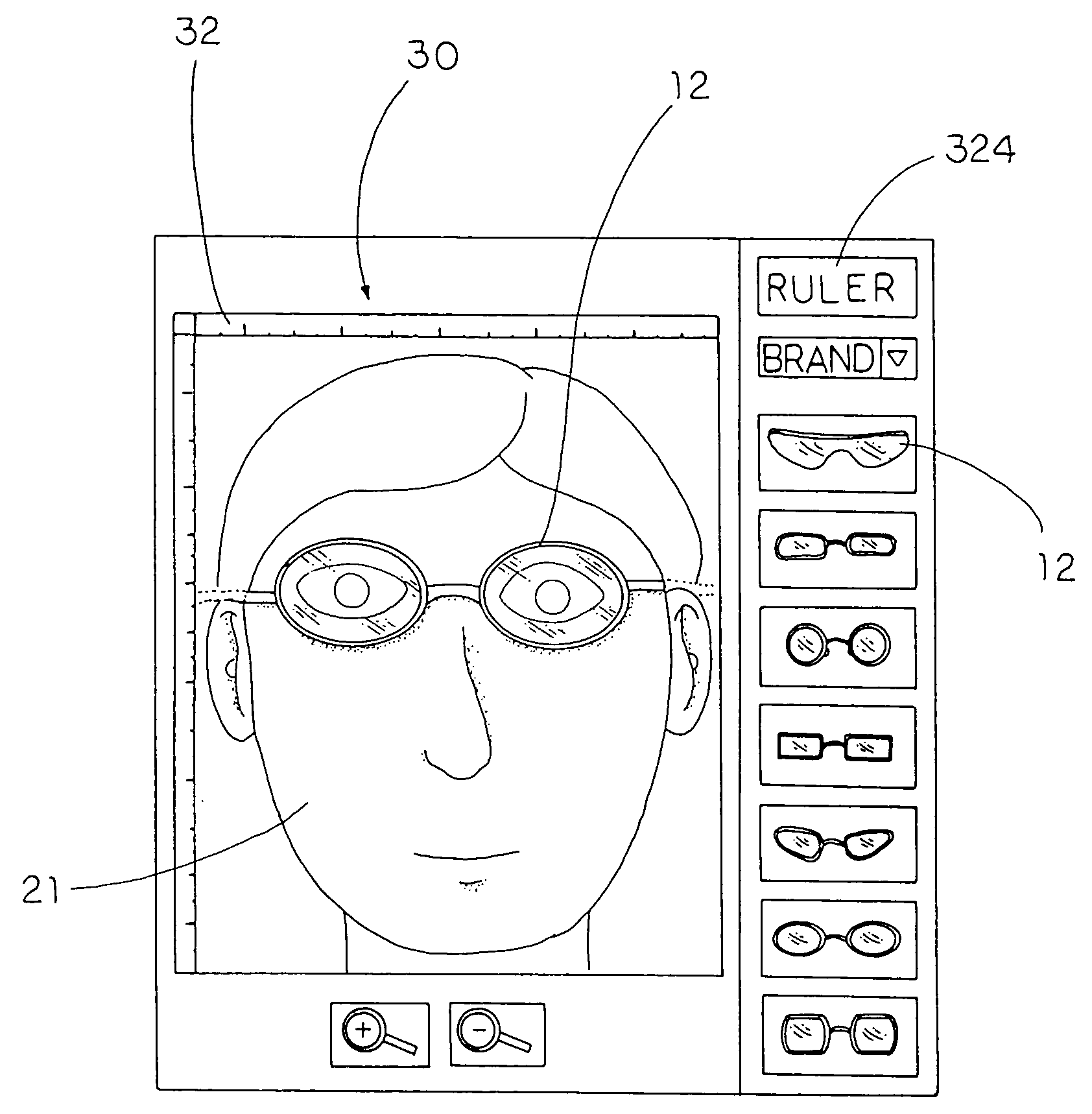

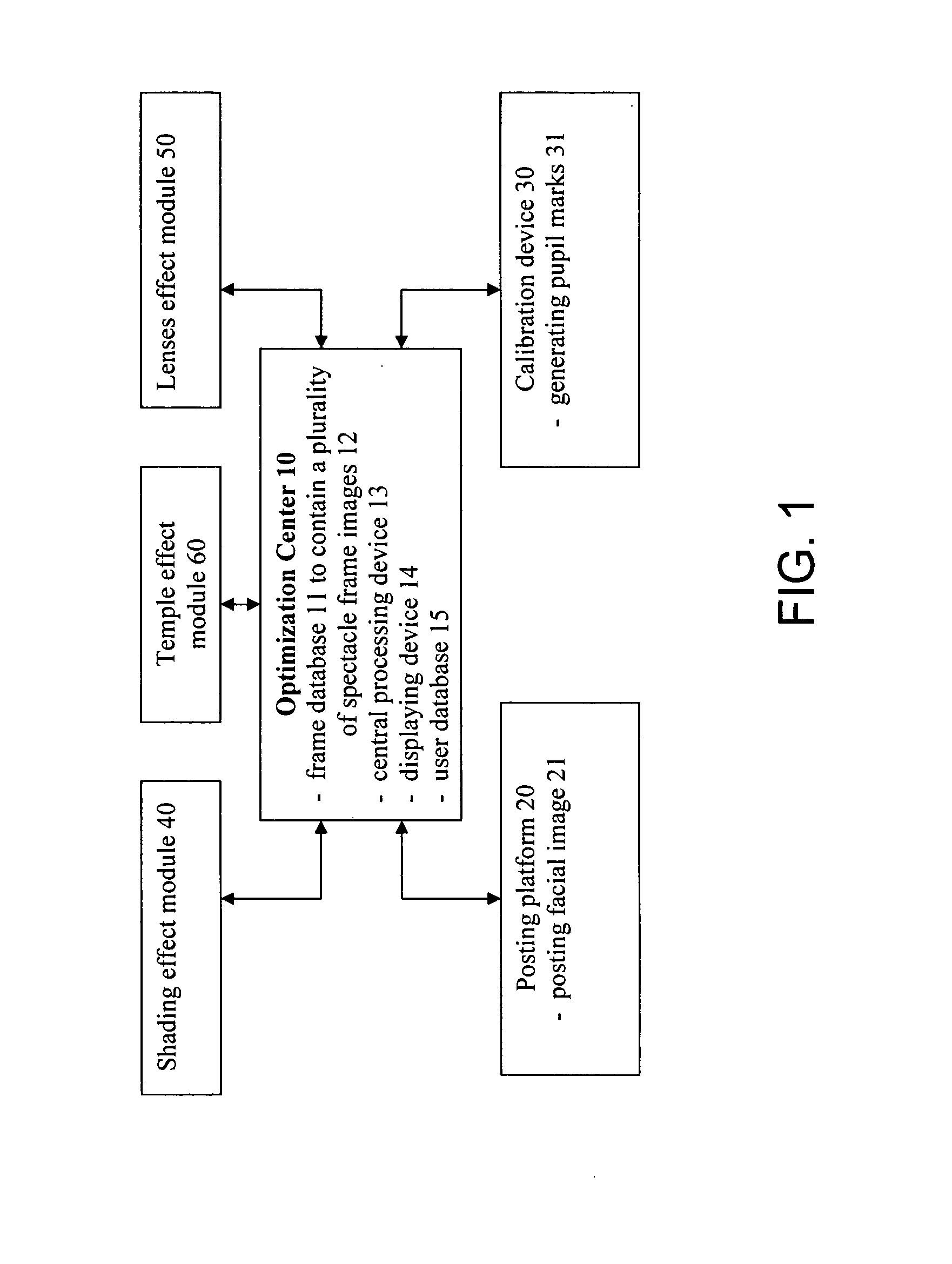

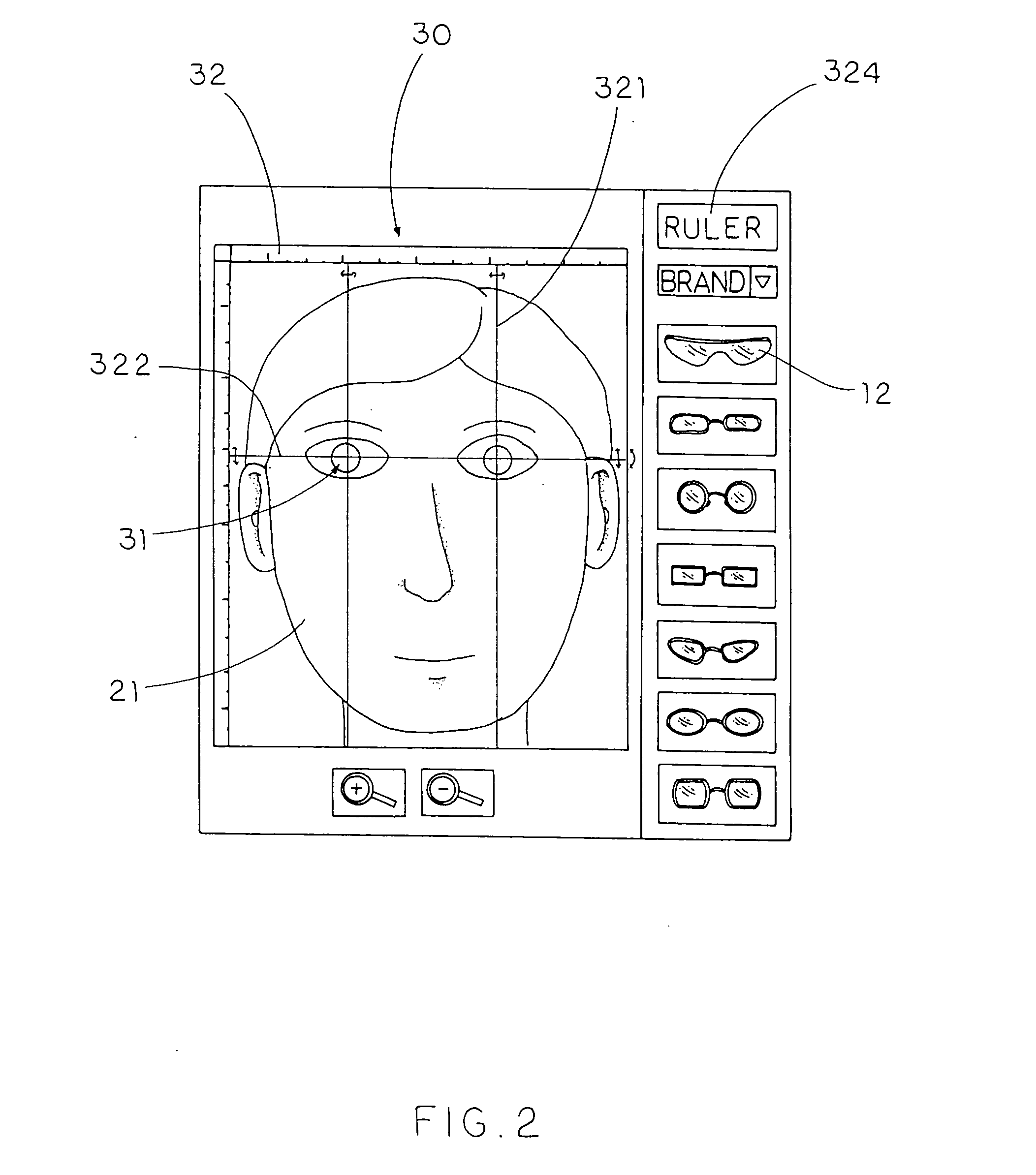

System and method of optimizing optical products through public communication network

InactiveUS20080074440A1Process can be speededSimplify the calibration stepsSpectales/gogglesCathode-ray tube indicatorsEyewearPupil

An optical products optimization system for use with a public communication network includes an optimization center, a posting platform, and a calibration device. The optimization center has a database which contains a plurality of digital spectacle frame images of a plurality of spectacle frames for the user to select. The posting platform is communicatively linked to the database for the user posting a facial image thereof on the posting platform through the public communication network. The calibration device calibrates the frame scale with two pupil marks located at two pupils of the user on the facial image respectively to fittingly overlap the spectacle frame image selected by the user on the facial image for simulating a virtual appearance of the user wearing the respective spectacle frame.

Owner:XIE YILING

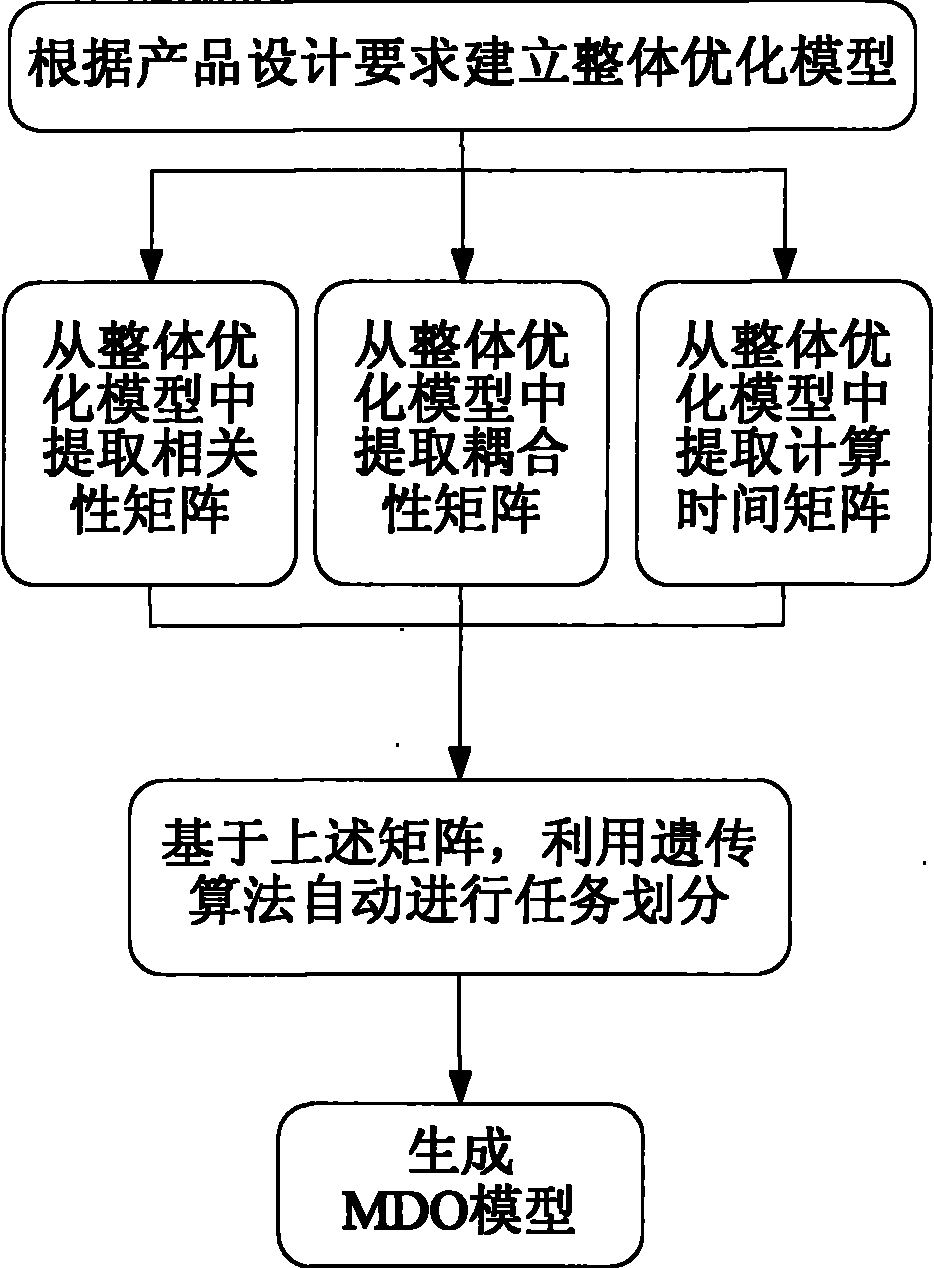

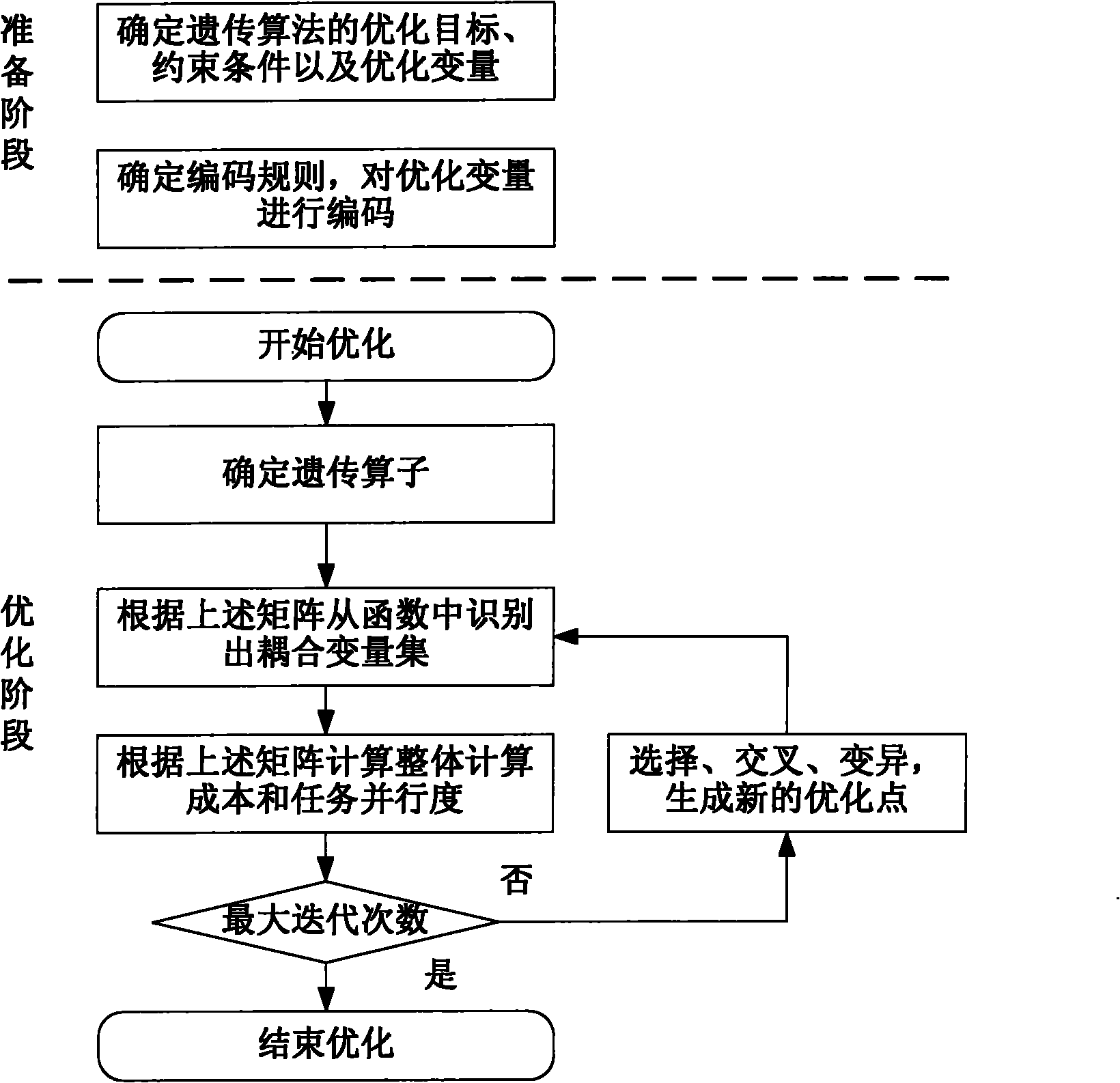

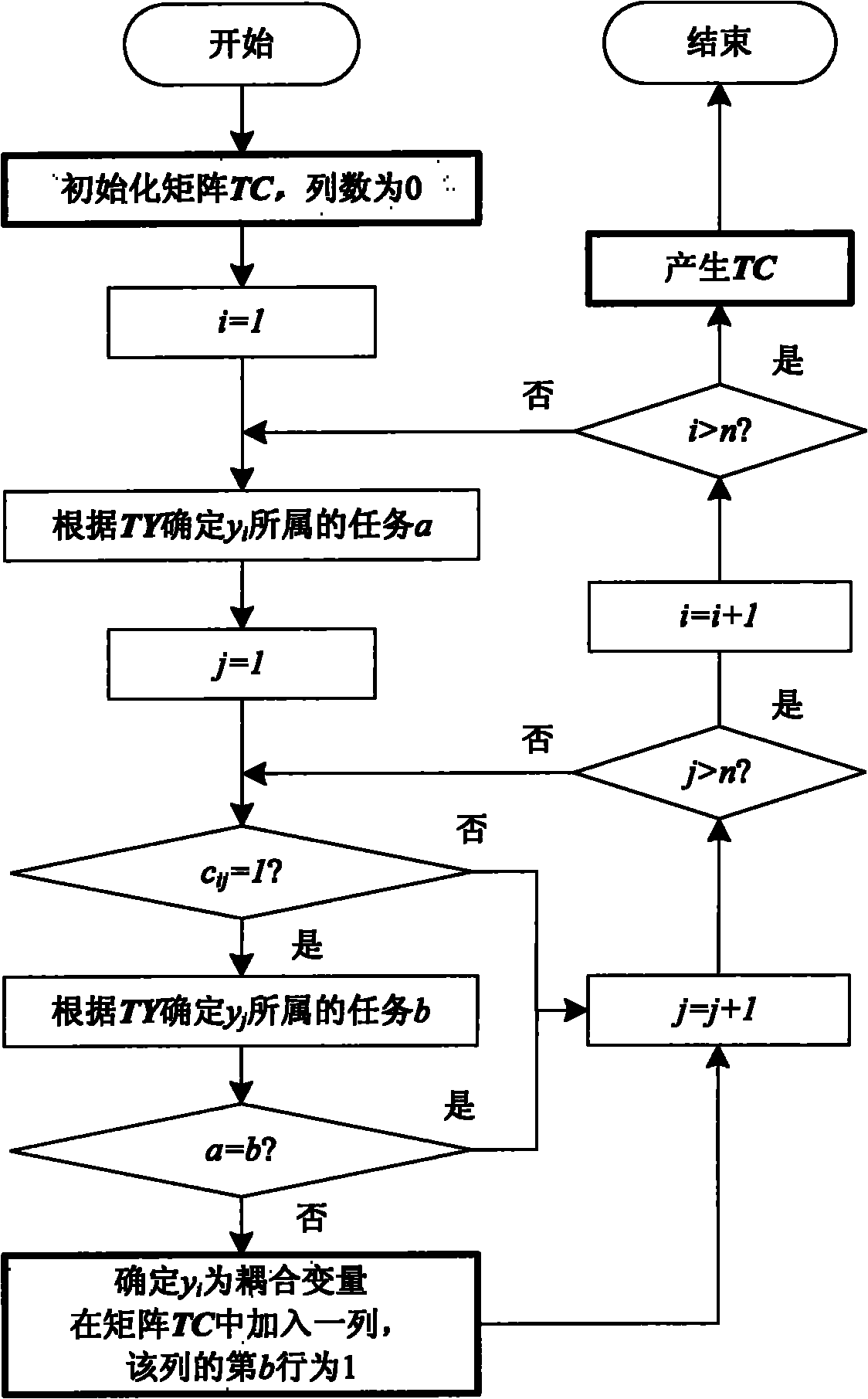

Method for generating practical multidisciplinary design optimization model automatically

InactiveCN102063525AAvoid overdependenceThe generation method is simpleSpecial data processing applicationsInclusion relationApplicability domain

The invention relates to a method for generating a practical multidisciplinary design optimization model automatically, which comprises the following steps of: first, establishing an integrated product optimization model according to design requirements; second, filling in a 'correlation' matrix D according to the inclusion relation between functions and optimization variables in the integrated product optimization model; third, filling in a 'coupling' matrix C according to the inclusion relation among functions in the integrated product optimization model; fourth, filling in a 'time' matrix T according to time taken for calculating functions in the integrated product optimization model; fifth, carrying out automatic task division by a genetic algorithm according to the matrixes to obtain one main task and a plurality of subtasks; sixth, generating an MDO (Multidisciplinary Design Optimization) model according to the task division scheme. The method supports the computer based automatic generation of the MDO model, avoids the excessive independence on experience of designers, can obtain the most reasonable MDO model, and has the characteristics of good simplicity and practicality, wide application and the like.

Owner:BEIHANG UNIV

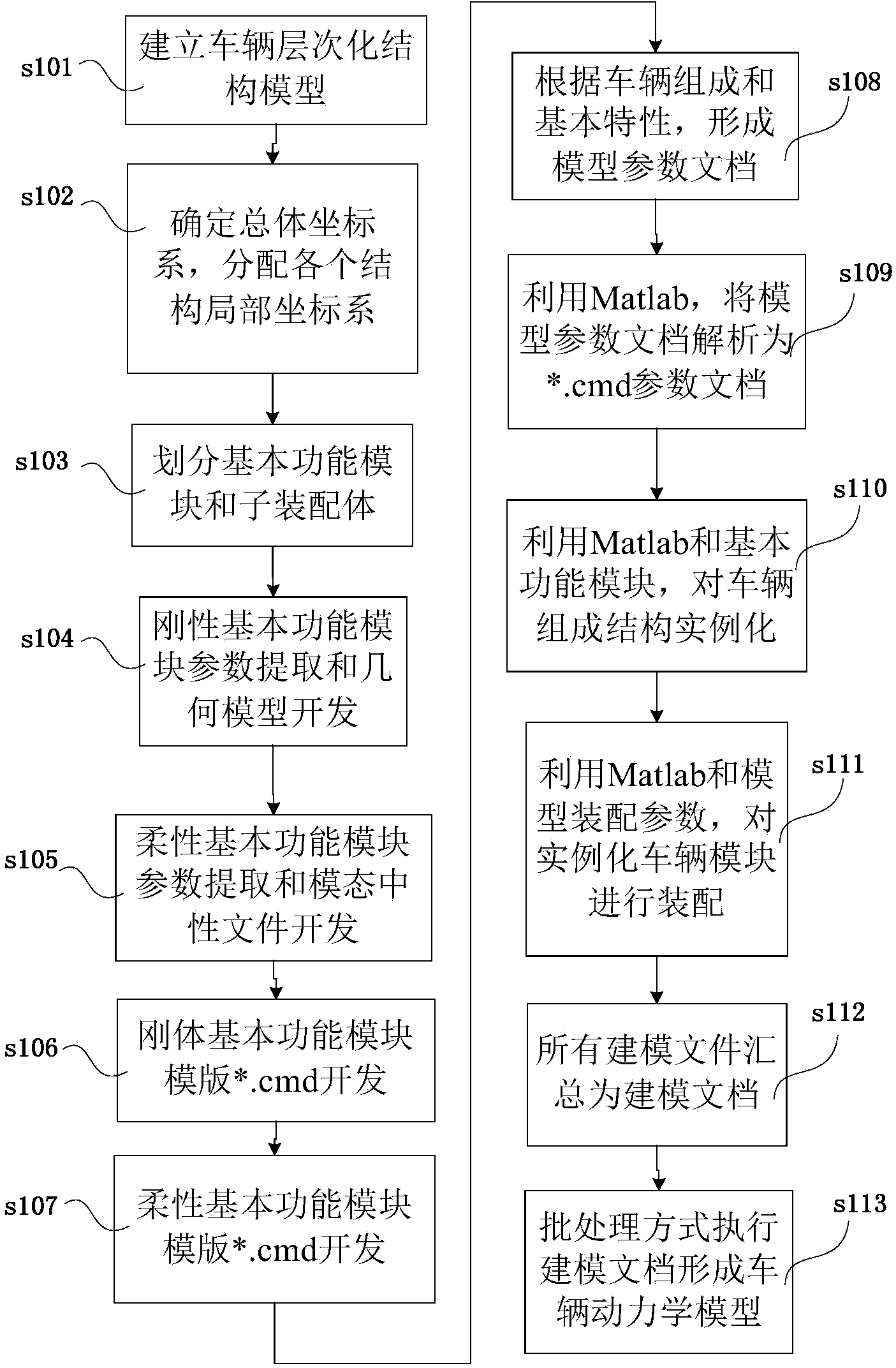

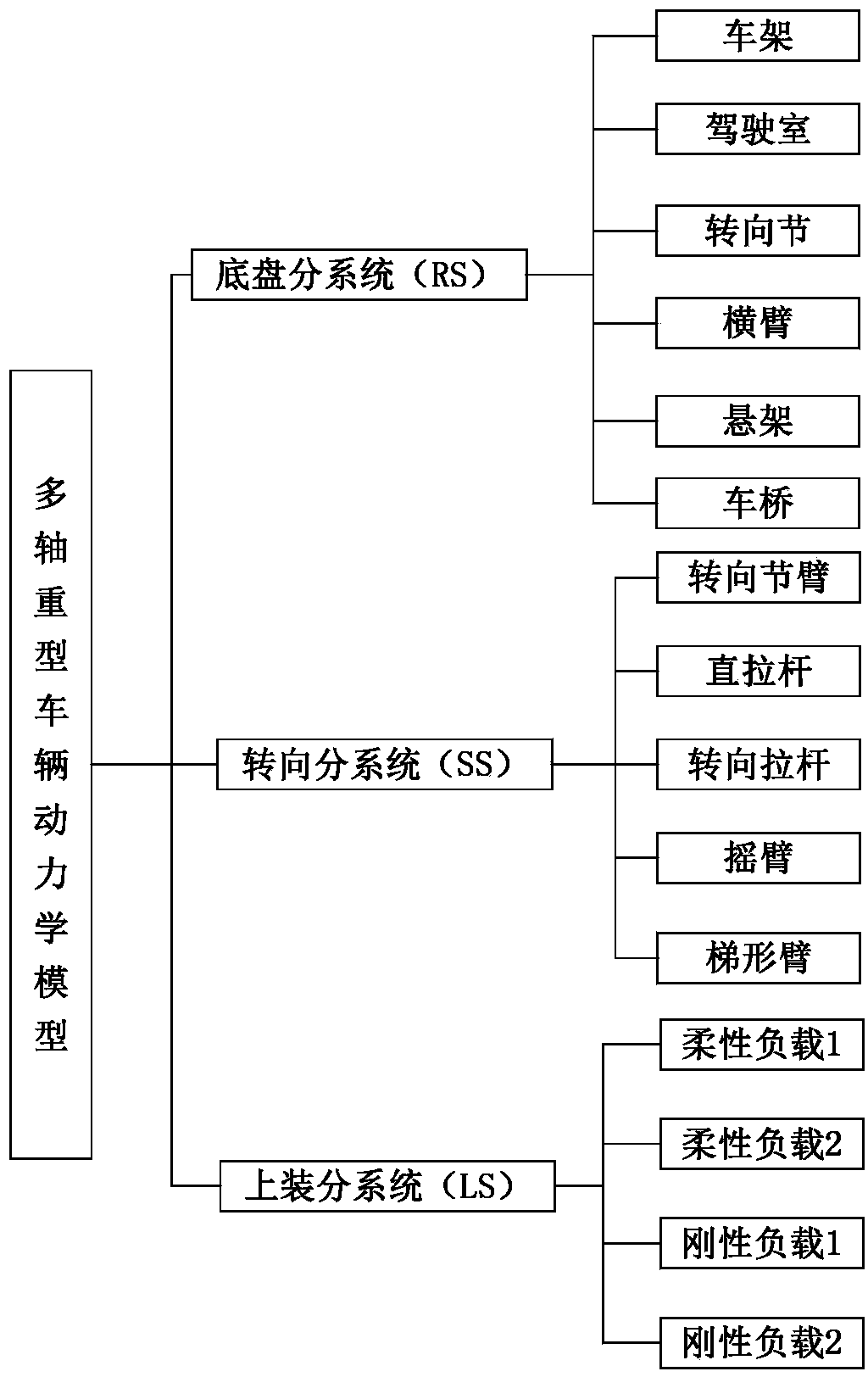

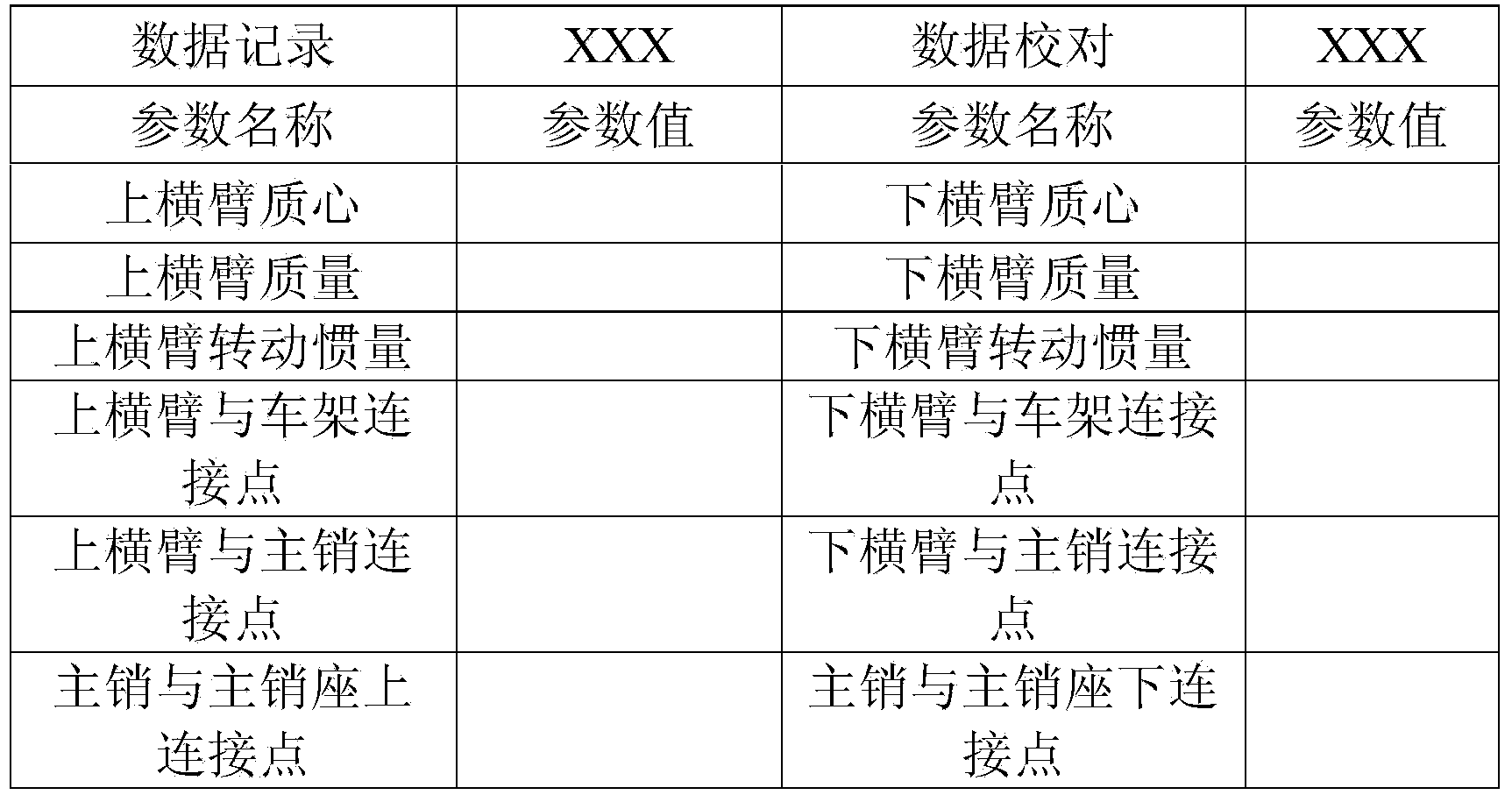

Method for building virtual prototype of multi-shaft heavy vehicle

ActiveCN104361149AImprove adaptabilityReduced modeling effortSpecial data processing applicationsBatch processingProduct optimization

The invention discloses a method for building a virtual prototype of a multi-shaft heavy vehicle. An ADAMS serves as an application software platform, a Matlab serves as an application implementation tool, a cmd scripting language and an m language serve as development languages, four templates such as a parameterized and modularized model template, a parameter template, a functional module template and a model binding template and two application services such as parameter analysis and model binding are formed by development, and a kinetic model can be quickly built by file packaging and batch processing operation. The method for building the virtual prototype of the multi-shaft heavy vehicle has the advantages that the parameterization and the modularization of main functional modules of the multi-shaft heavy vehicle are realized; the kinetic model of the vehicle is built by using the templates and parameters as the core, the domination and the streamlining of tacit enterprise knowledge are realized, and the working efficiency and the repeatability of the working process are improved; the modeling efficiency is remarkably improved, and meanwhile, parameter-based product optimization and sensitivity analysis are supported.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

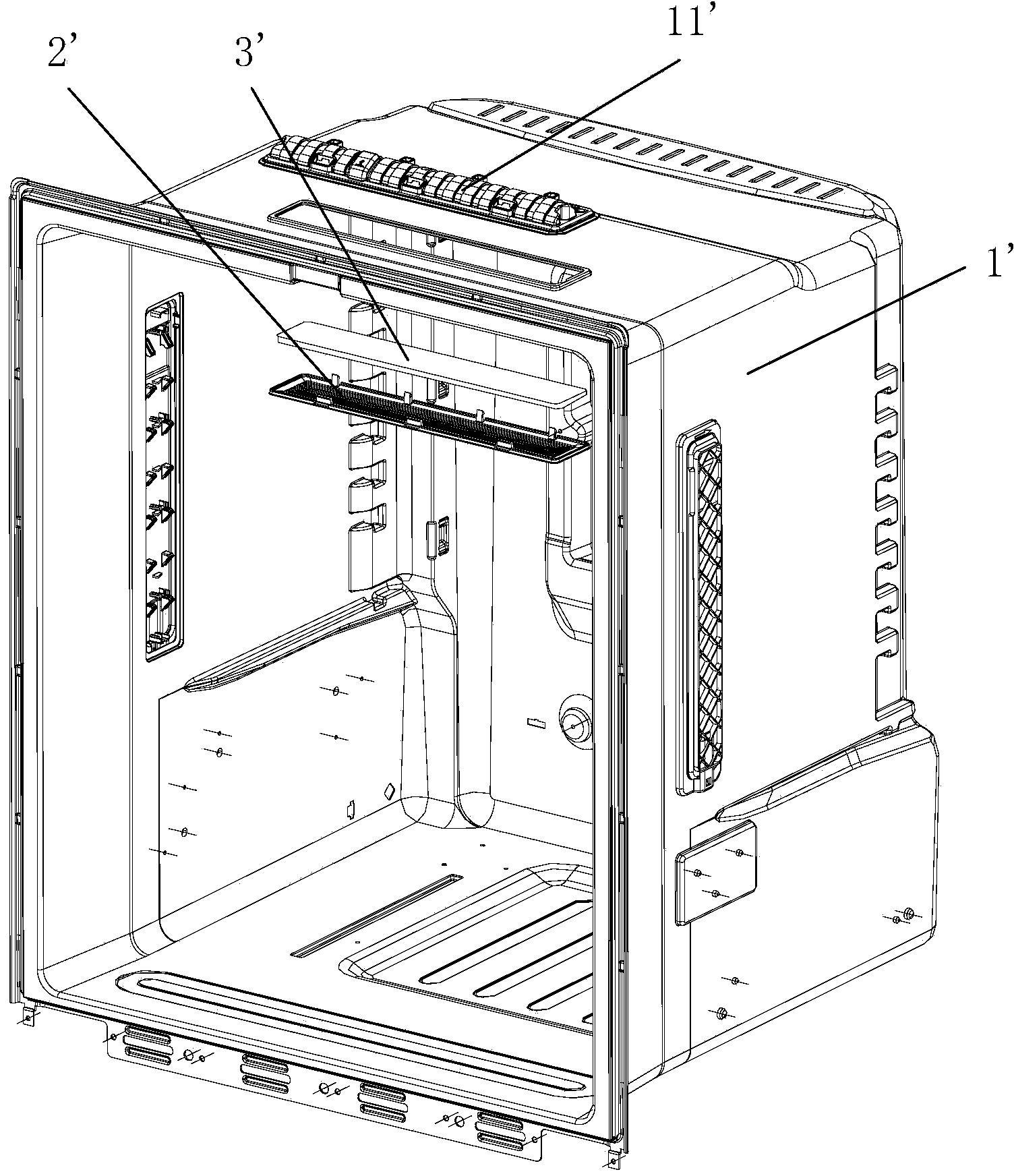

Refrigerator body and refrigerator

InactiveCN104019607ASimple structureEasy to assembleLighting and heating apparatusLighting arrangementRefrigerator carProduct optimization

The invention provides a refrigerator body and a refrigerator. The refrigerator body comprises a hollow refrigerator container with one end open, a lampshade fixed to the wall of the refrigerator container, and a light emitting piece fixed in the lampshade and used for lighting the interior of the refrigerator container. The refrigerator body is simple in structure and convenient to assemble, the lampshade and the light emitting body are directly fixed to the wall of the refrigerator container in a combined mode, a pre-buried box structure in the related technology is removed, the installing technology of the refrigerator body is effectively simplified, manufacturing cost of the refrigerator body is reduced, and the purpose of enterprise product optimization is achieved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

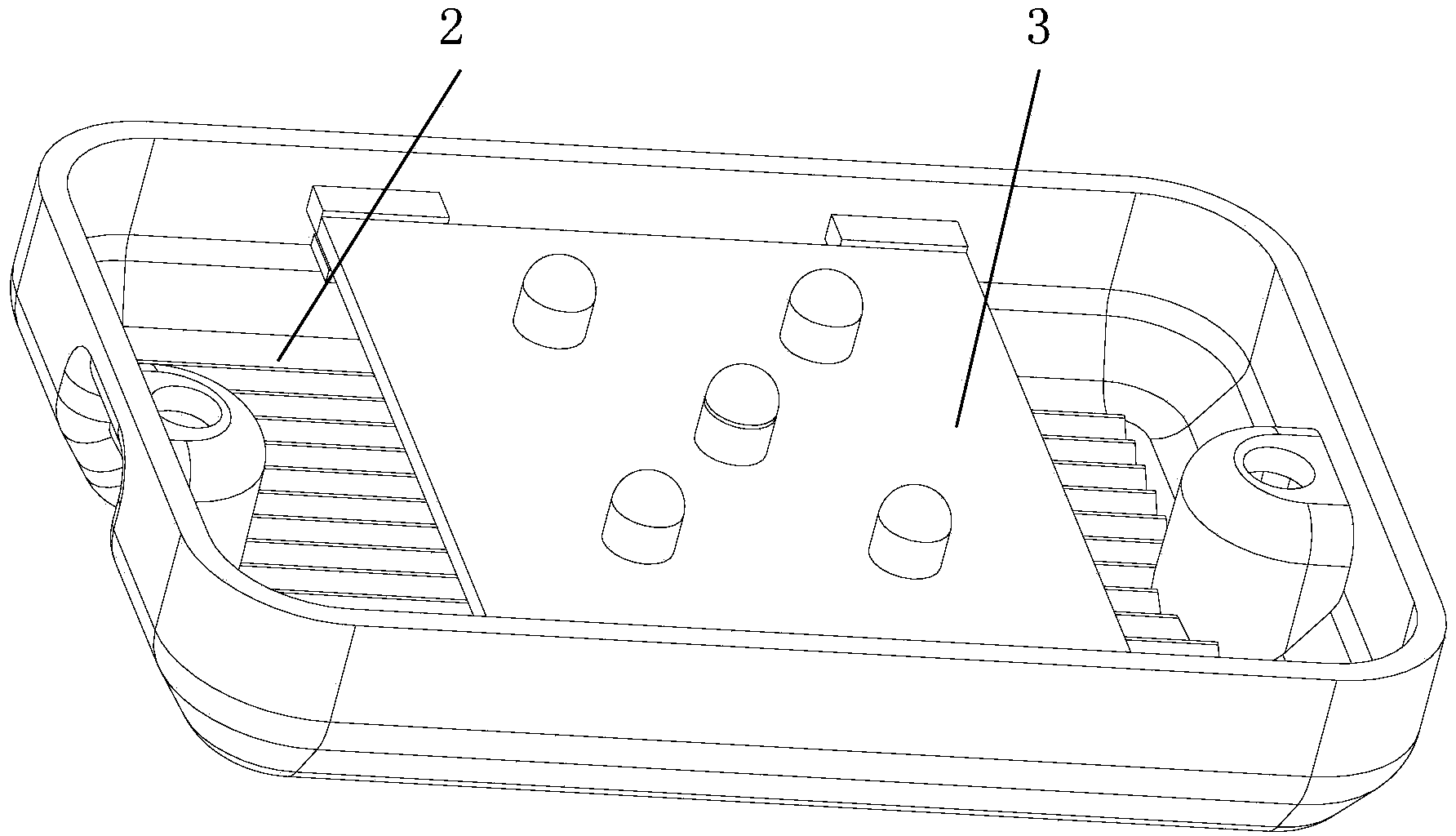

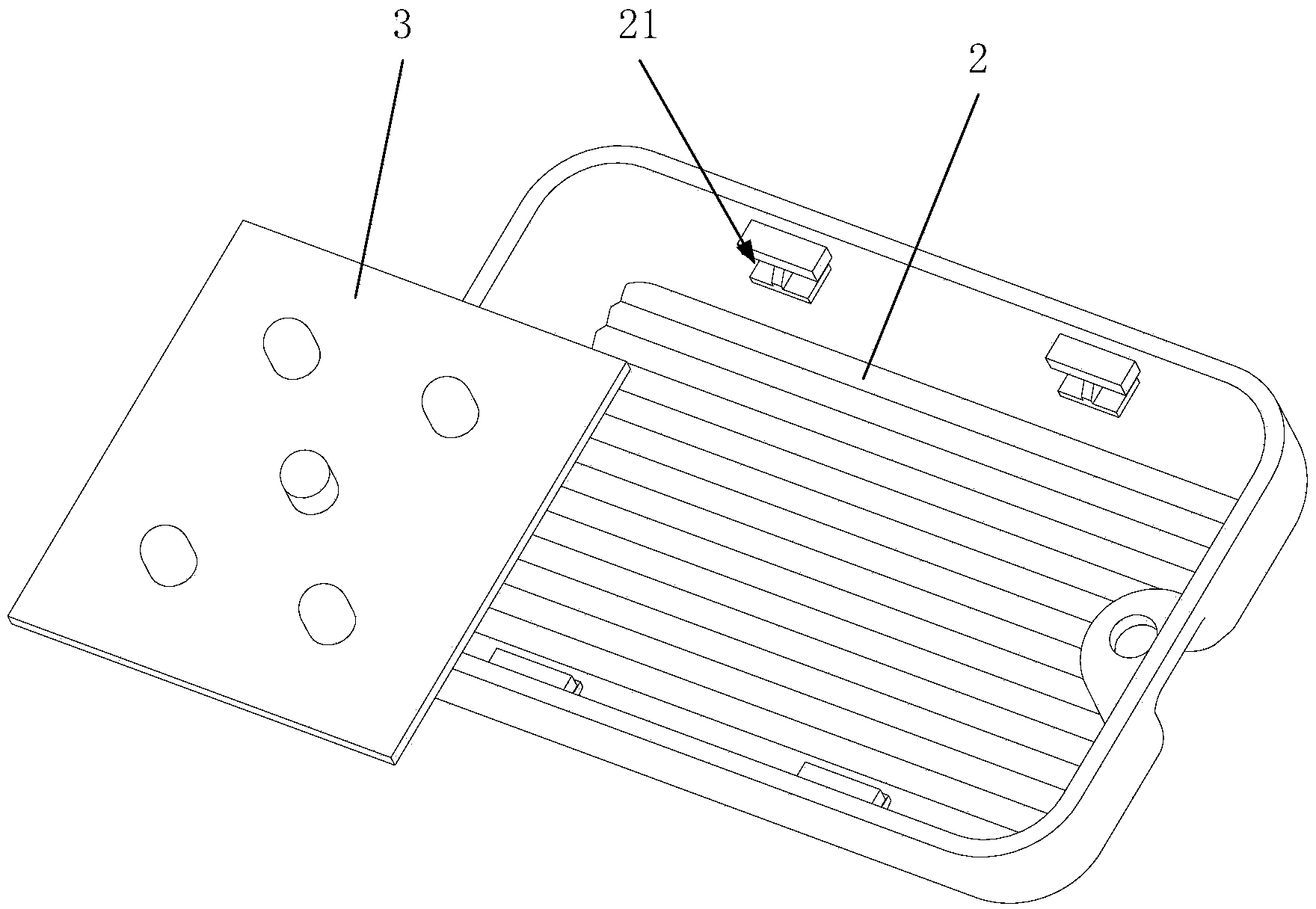

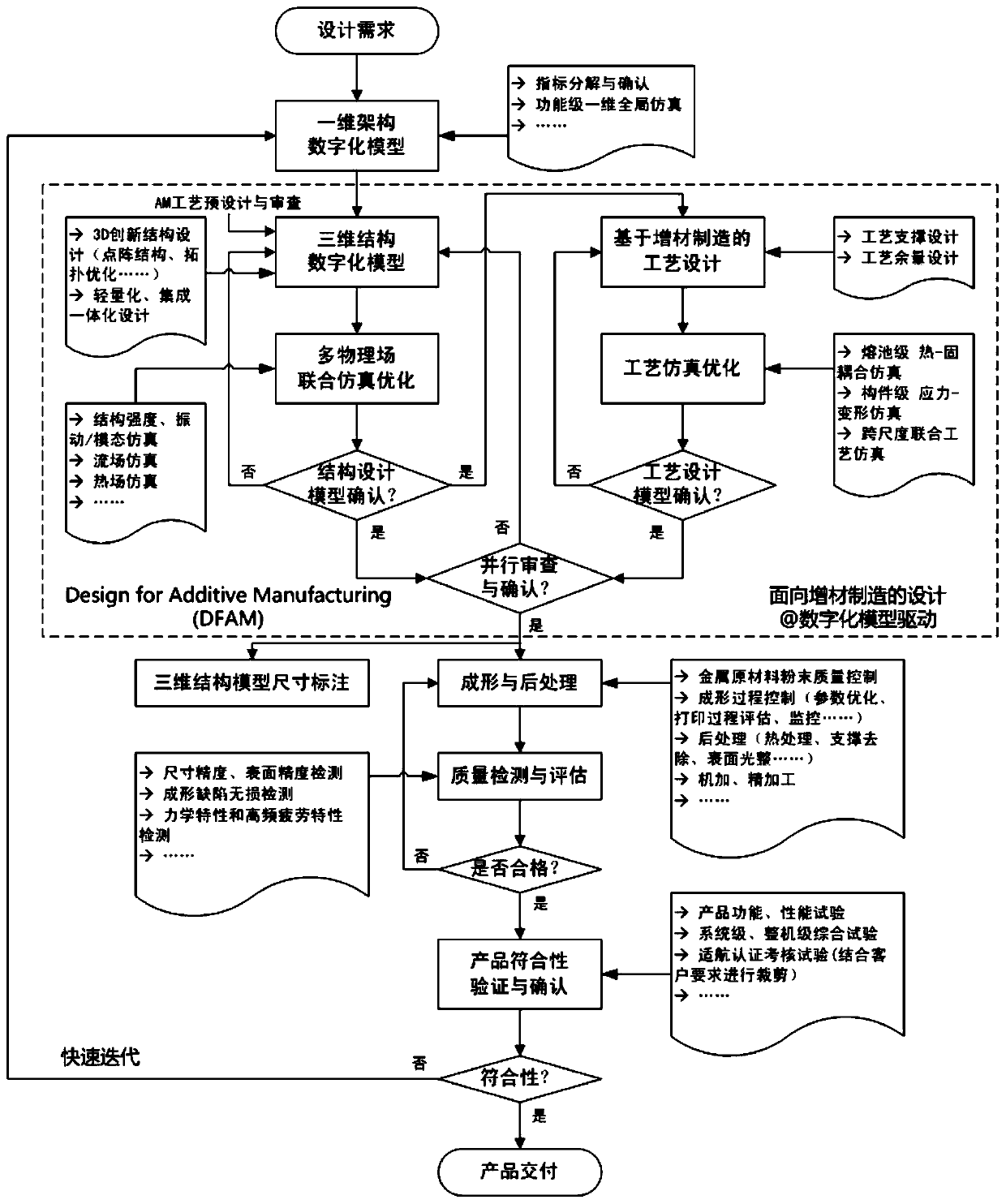

Rapid development method for aero-engine control system product

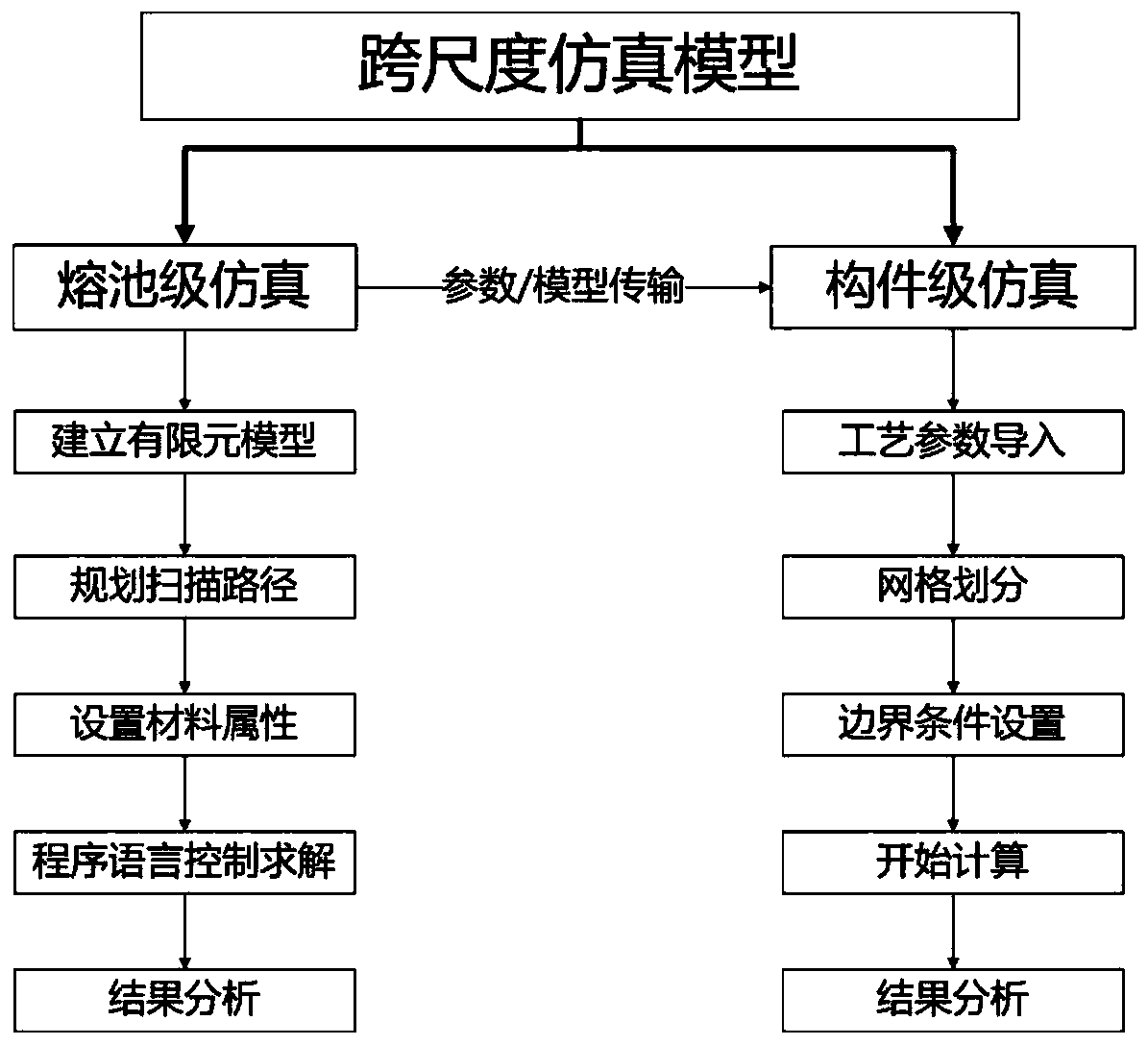

InactiveCN110874503ASolve efficient and seamless deliverySolve the "last mile" technical problems of rapid trial productionGeometric CADAdditive manufacturing apparatusManufacturing technologyControl system

The invention relates to a rapid development method for an aero-engine control system product. In the rapid research and development iterative technology method based on combination of digital model driving and an SLM additive manufacturing technology, by establishing an efficient forward research and development mode of additive manufacturing enabling, an design-simulation-manufacturing-verification-authentication integrated iterative process and a technical path are broken through, and optimal development and implementation of functions and performance of aero-engine control system productsare achieved. The development period and cost of the product are greatly reduced, efficient seamless transmission of a digital model of a complex product can be achieved through model driving, the product optimization design iteration efficiency is greatly improved, and the development period is shortened by one time or above; the design and implementation of the additive manufacturing enable canachieve the effect that the comprehensive weight of the product is reduced by more than 30%, and also solve the technical problem of last kilometer achieved by rapid trial production of a physical prototype of a complex product.

Owner:中国航发控制系统研究所

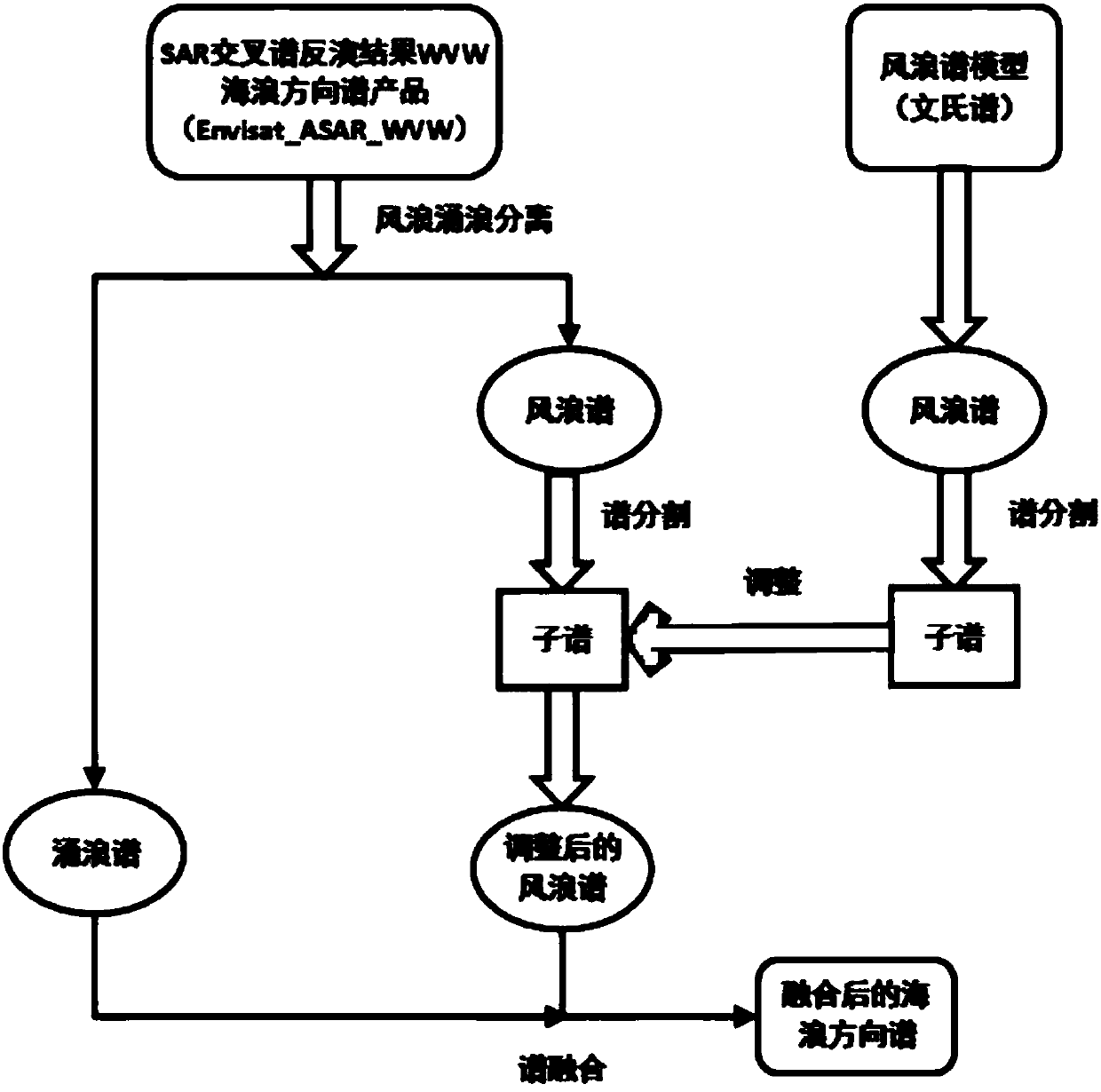

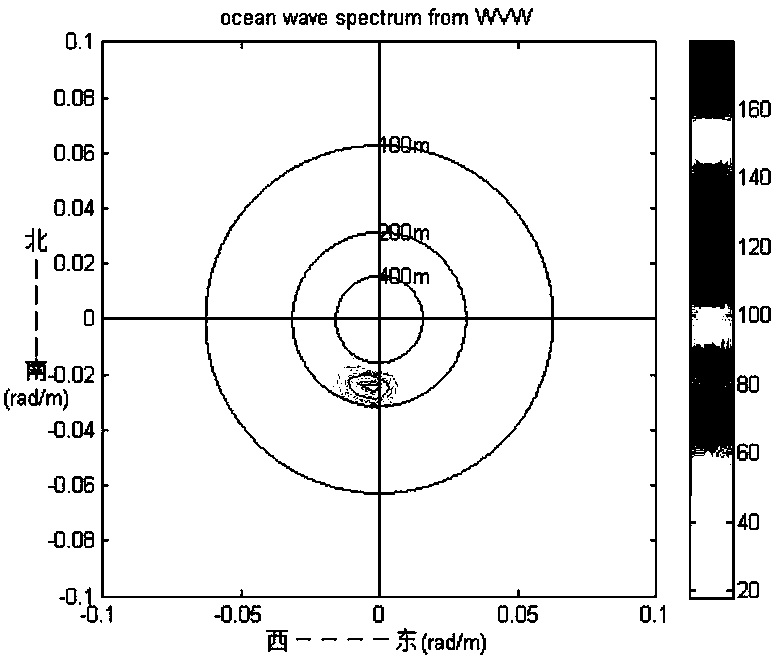

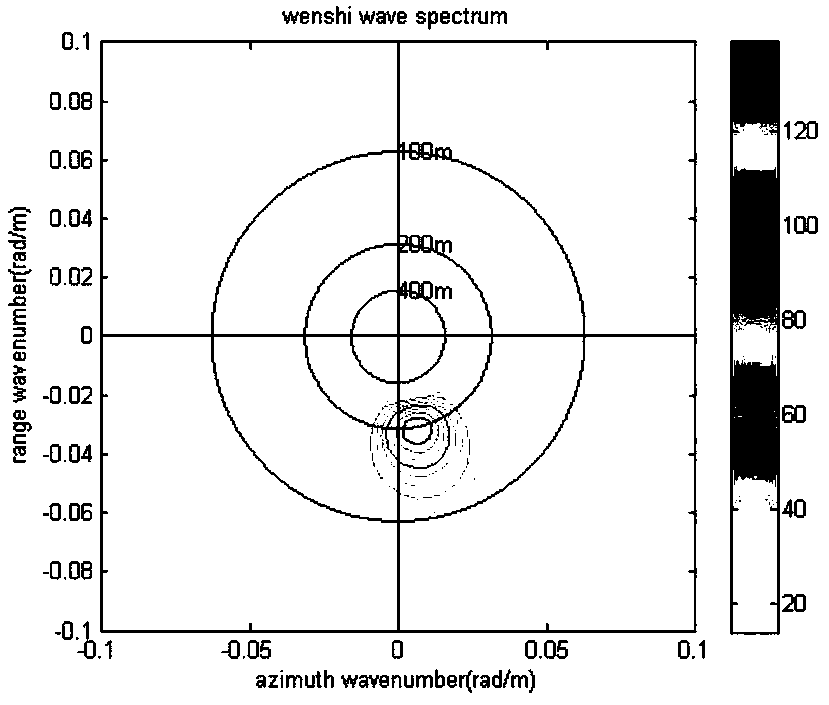

SAR wave pattern directional ocean wave spectrum product optimization algorithm

ActiveCN107064934AEfficient integrationImprove inversion accuracyRadio wave reradiation/reflectionWind waveProduct optimization

The invention discloses an SAR wave pattern directional ocean wave spectrum product optimization algorithm, which comprises the following steps: (1) a wind wave spectrum and a swell spectrum of the WVW directional ocean wave spectrum are separated; (2) a wind wave spectrum model is introduced; (3) spectrum segmentation and cross adjustment on the wind wave spectrum are carried out; and (4) the swell spectrum separated from the WVW directional ocean wave spectrum is effectively fused with a wind wave spectrum through Wen's spectrum adjustment to acquire a new directional ocean wave spectrum. The algorithm does not use a quasi-real time first guess spectrum which is hard to acquire but adopts an already-verified cross spectrum inversion result WVW product with a high inversion precision in the swell part, with the widely-applied wind wave spectrum (Wen's spectrum) model, the two are effectively fused, and a directional ocean wave spectrum with the swell information and the wind wave information is obtained.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

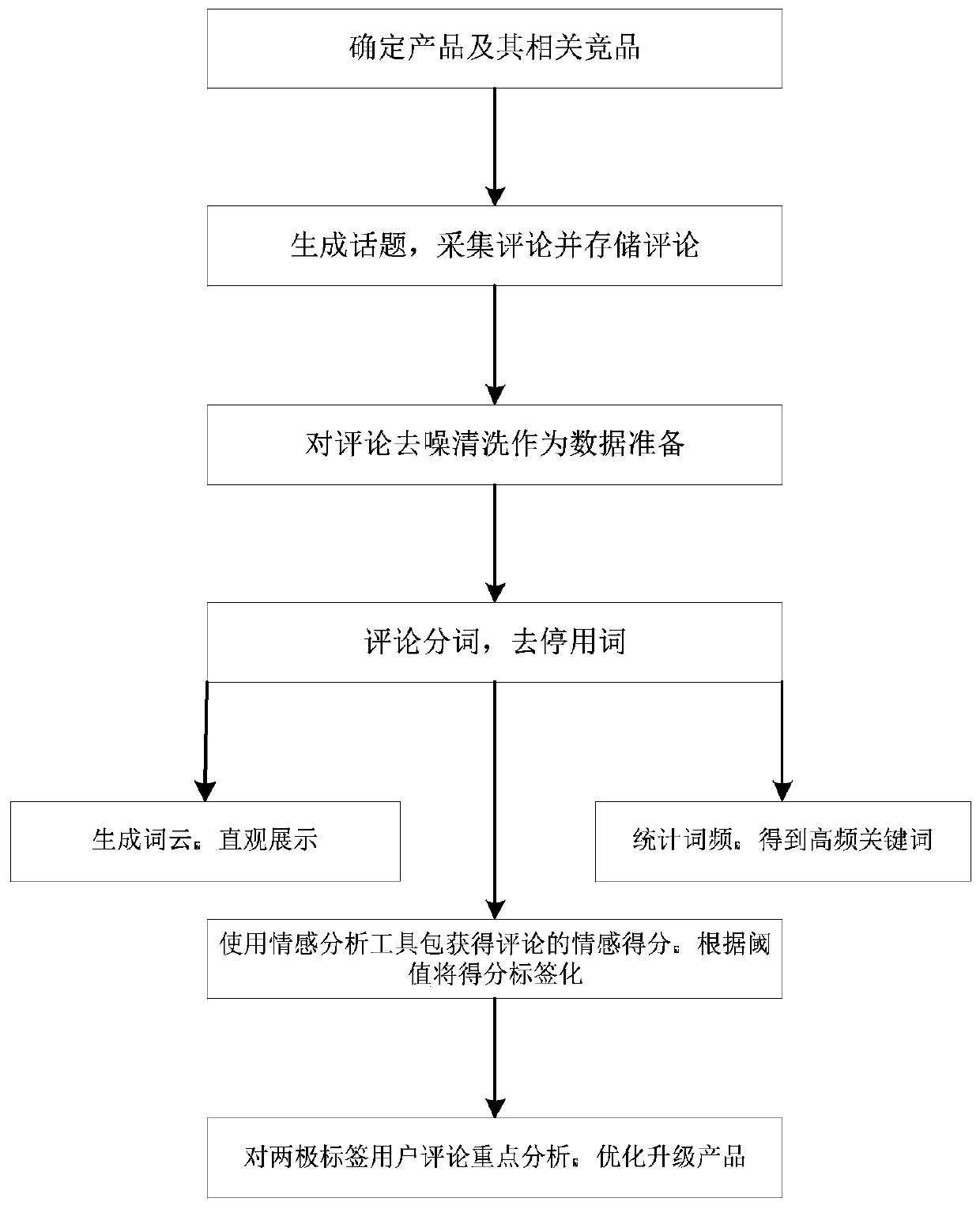

Big data-based competitive product analysis method and system, storage medium and electronic equipment

PendingCN111292167AReduce the impactScale upWeb data indexingBuying/selling/leasing transactionsProduct optimizationNetizen

The invention discloses a competitive product analysis method and system based on big data, a storage medium and electronic equipment. The method belongs to the technical field of big data and competitive product analysis. The technical problem to be solved by the invention is how to analyze and mine emotional trends of netizens on specified products and competitive products thereof by using big data to realize competitive product analysis. The adopted technical scheme is as follows: ;according to the method, relying on completely public social network platform comment data, the emotion trendsof netizens to specified products and related competitive products are mined from network comments by analyzing massive comments, and the attitude opinions of the netizens to the products are obtained by performing multiple analysis modes including emotion analysis on the comments, so that the purpose of competitive product analysis is achieved. The system comprises a product and related competitive product determination unit, a topic generation and comment acquisition and storage unit, a comment denoising and cleaning unit, a comment word segmentation and stop word removal unit, a comment emotion score acquisition and tagging unit and a comment analysis and product optimization and upgrading unit.

Owner:山东爱城市网信息技术有限公司

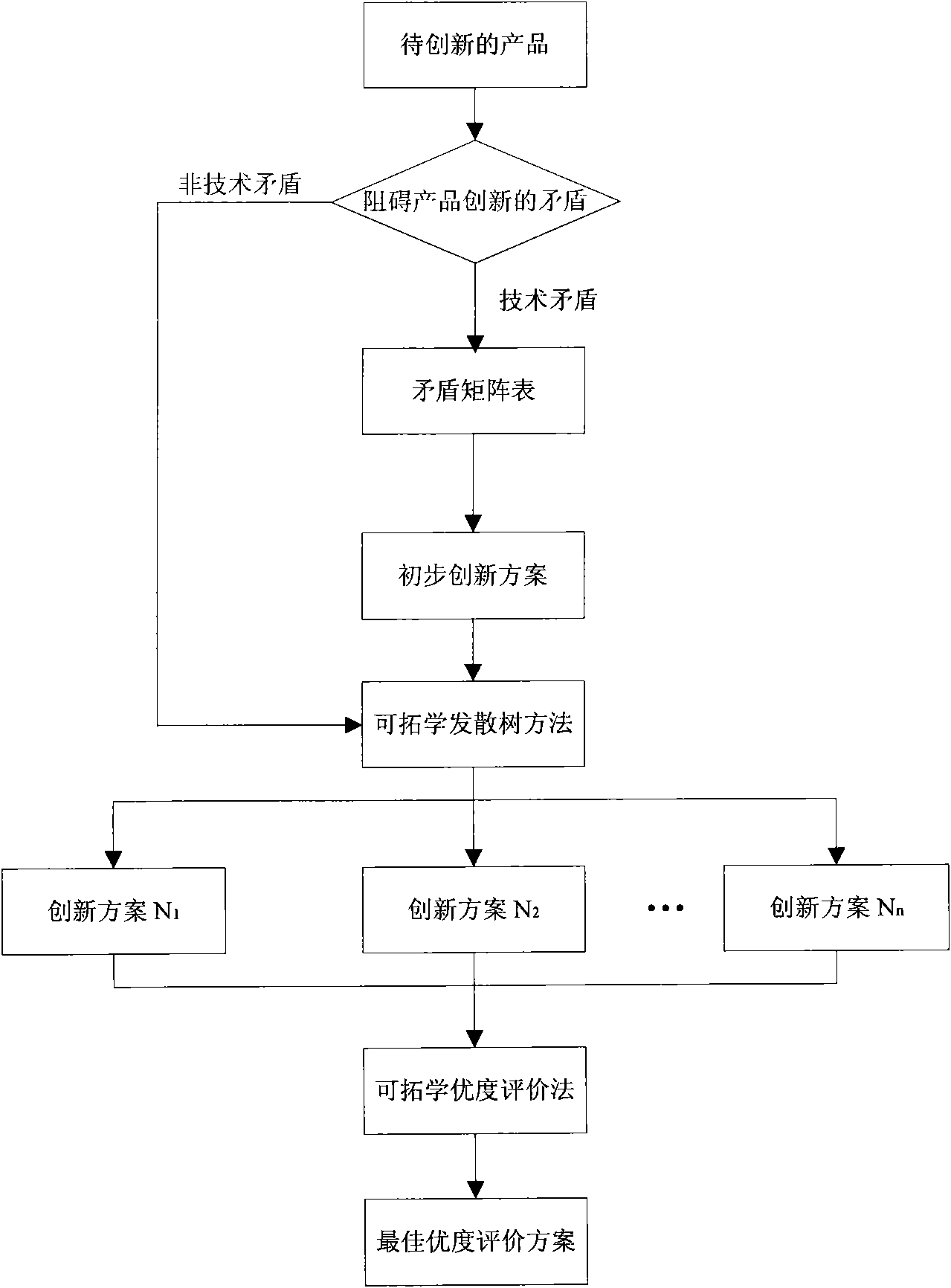

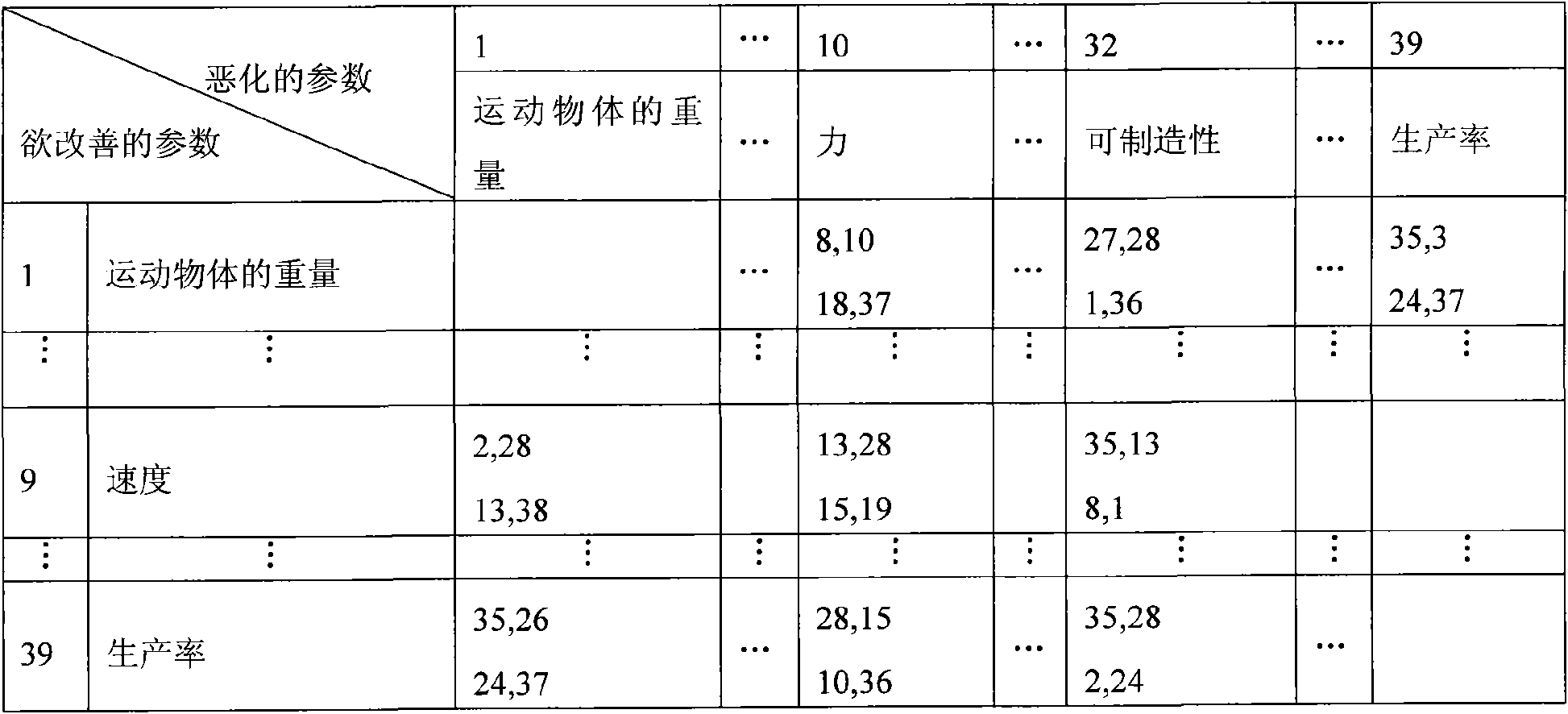

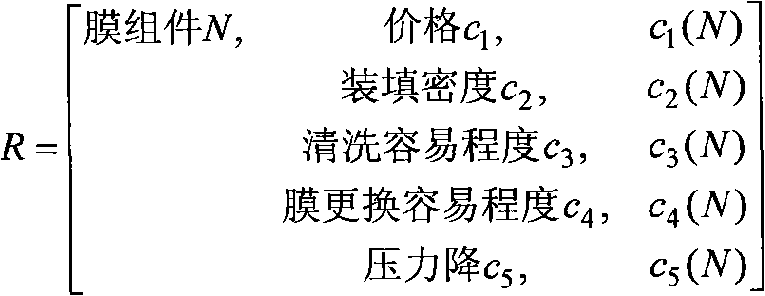

Product optimization design method combined with extenics based on TRIZ

InactiveCN101551897AHigh feasibilityPerfect innovationData processing applicationsProduct optimizationComputer science

A product optimization and design method combined with extenics based on TRIZ comprises: A) analyzing product to find out the technical conflict or un-technical conflict which obstacles the product technical performance; B) if the conflict which obstacles the product technical performance is a technical conflict, using the TRIZ conflict matrix to obtain a preliminary scheme to solve the technical conflict; C) entering an extenics diverging tree process, using the diverging tree method to obtain a diverged schemes set (shown on right); D) entering the diverged schemes converging process, that is, performing extenics goodness estimation to the diverging schemes set obtained in the step C) by the goodness grading method to obtain a goodness sequence about the diverged schemes, selecting the scheme with the highest goodness value as the optimal preferred scheme, and entering into policy making and implementing step; B) if the conflict which obstacles the product technical performance is an un-technical conflict, entering the step C) directly, and finally entering the step D). The invention can be widely used in the development and design of various industrial products.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Aluminum alloy for manufacturing automobile security castings and preparation method thereof

The invention relates to an aluminum alloy for manufacturing automobile security castings and a preparation method thereof. The aluminum alloy is characterized by consisting of 0.95 to 1.05 percent of Si, 0.55 to 0.6 percent of Mg, 0.42 to 0.52 percent of Mn, 0.02 to 0.05 percent of Sc, 0.08 to 0.20 percent of Cr, 0.03 to 0.05 percent of Ti, 0.005 to 0.01 percent of B and the balance of industrial pure aluminum. The preparation method comprises the following steps of: smelting, performing heat treatment, extruding at high temperature, performing online hydrocooling, introducing into a quenching device, heating sections, reducing temperature, discharging from a furnace and cooling. The aluminum alloy has the advantages that: the aluminum alloy has a product optimization formula, the tensile strength of 330-360MPa, the stipulated non-proportional extension strength of 280-310MPa and the elongation of above 12-14 percent, and ensures that products prepared from the aluminum alloy have good strength and impact toughness.

Owner:JILIN LIYUAN REFINED

Utilizing sustainability factors for product optimization

ActiveCN101872160AAchieve recyclingLow environmental impactProgramme controlTechnology managementCarbon footprintProduct optimization

An industrial control system is provided. The system includes a processor to analyze one or more sustainability factors and a scoring component to assign a weight to the sustainability factors. An optimizer automatically adjusts a production process in view of the sustainability factors, the weight, and at least one of a recycling requirement, a carbon footprint, a procurement process, a shipping process, or a regulatory requirement.

Owner:ROCKWELL AUTOMATION TECH

Numerical weather forecast and lattice point objective forecast product optimization method

ActiveCN111352174AQuality improvementImproving the Application Ability of Numerical Weather PredictionWeather condition predictionProduct optimizationAtmospheric sciences

The invention belongs to the technical field of weather forecast, and relates to a numerical weather forecast and lattice point objective forecast product optimization method. The method comprises thefollowing steps: setting an optimal prediction intensity threshold and an optimal time period, processing data, identifying a target object, matching and scoring the target object, carrying out regional prediction overall evaluation, and carrying out prediction optimization. According to the method, the optimal numerical weather forecast product can be better selected, a high-quality objective product is provided for a pre-announcer, and the numerical weather forecast application capability is improved. The optimal product can also be directly applied as a lattice point objective forecastingproduct, and the weather forecasting accuracy is effectively improved.

Owner:山东省气象科学研究所

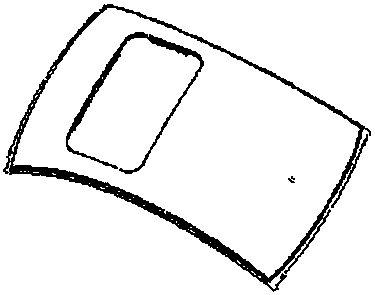

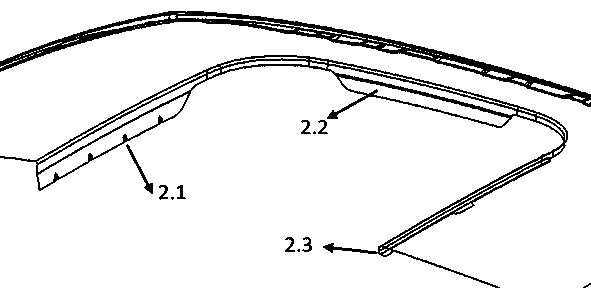

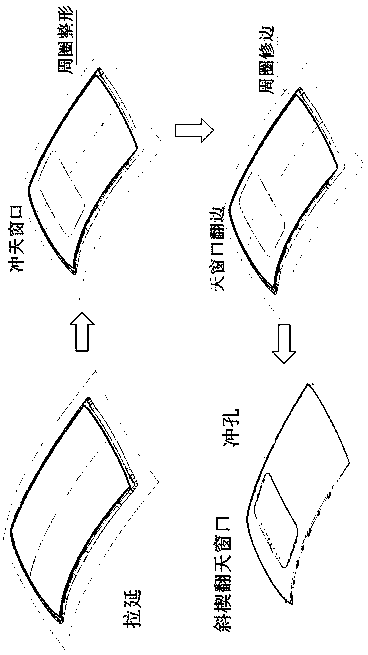

Top cover collinear manufacturing process of common and panoramic sunroofs

InactiveCN110142333AReduce maintenance costsReduced conversion timeVehicle componentsProcess efficiency improvementProduction linePunching

The invention discloses a top cover collinear manufacturing process of common and panoramic sunroofs. The process is characterized in that top covers of a common sunroof and a panoramic sunroof sharea mold, and collinear production is carried out; the sunroof part adopts a design structure of a trimming and turning one-body mold, so that trimming and shaping are carried out in one sequence; the adopted measures are as follows that the product is optimized, the strength of an insert is increased, and the thickness of a convex-concave mold insert is not less than 8 mm through product optimization. The material quality of the mold is improved, and the quenching process is Cr12MoV integral quenching. A turning convex-concave mold and the trimming concave mold are opposite to each other, and internal stress is eliminated. The process comprises the following steps of drawing, trimming and turning the sunroof, shaping the periphery, side turning and whole punching the sunroof or trim turningand punching the sunroof, and mold sharing during drawing. According to the process, the top covers of the common sunroof and the panoramic sunroof share the mold, and collinear production is carriedout; and the mold is reduced to four-procedure, the cost of mold developing and maintenance is low, moreover, due to the fact that the mold is shared by the top covers of the two sunroofs, the mold switching time is shortened, and the productivity of an automatic production line is improved.

Owner:FAW CAR CO LTD

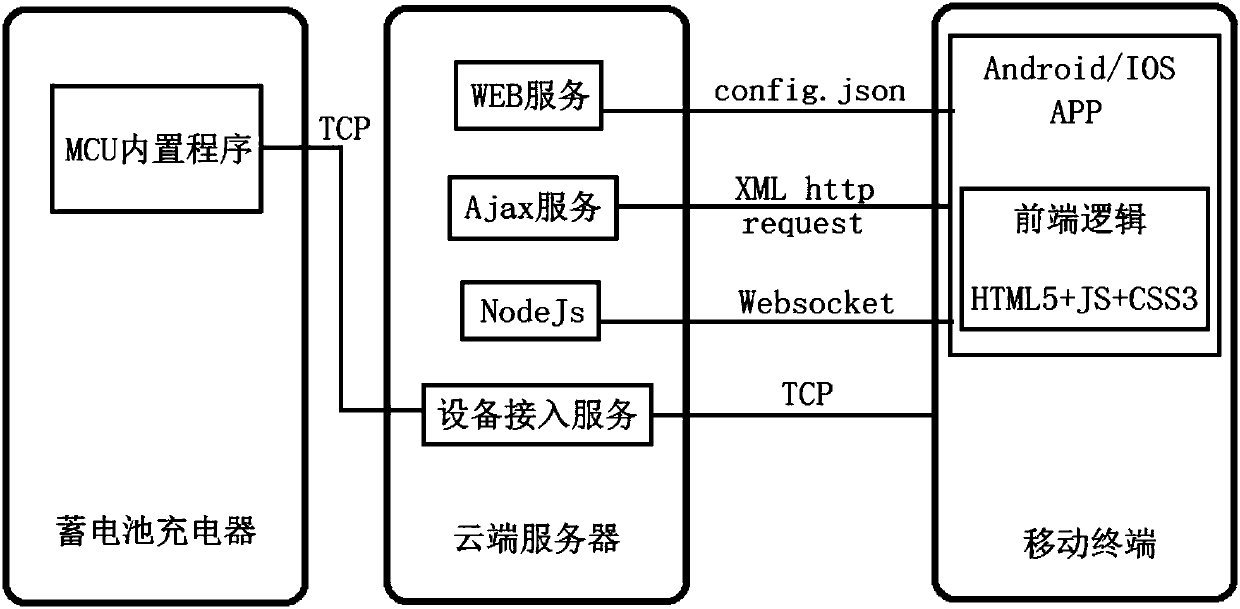

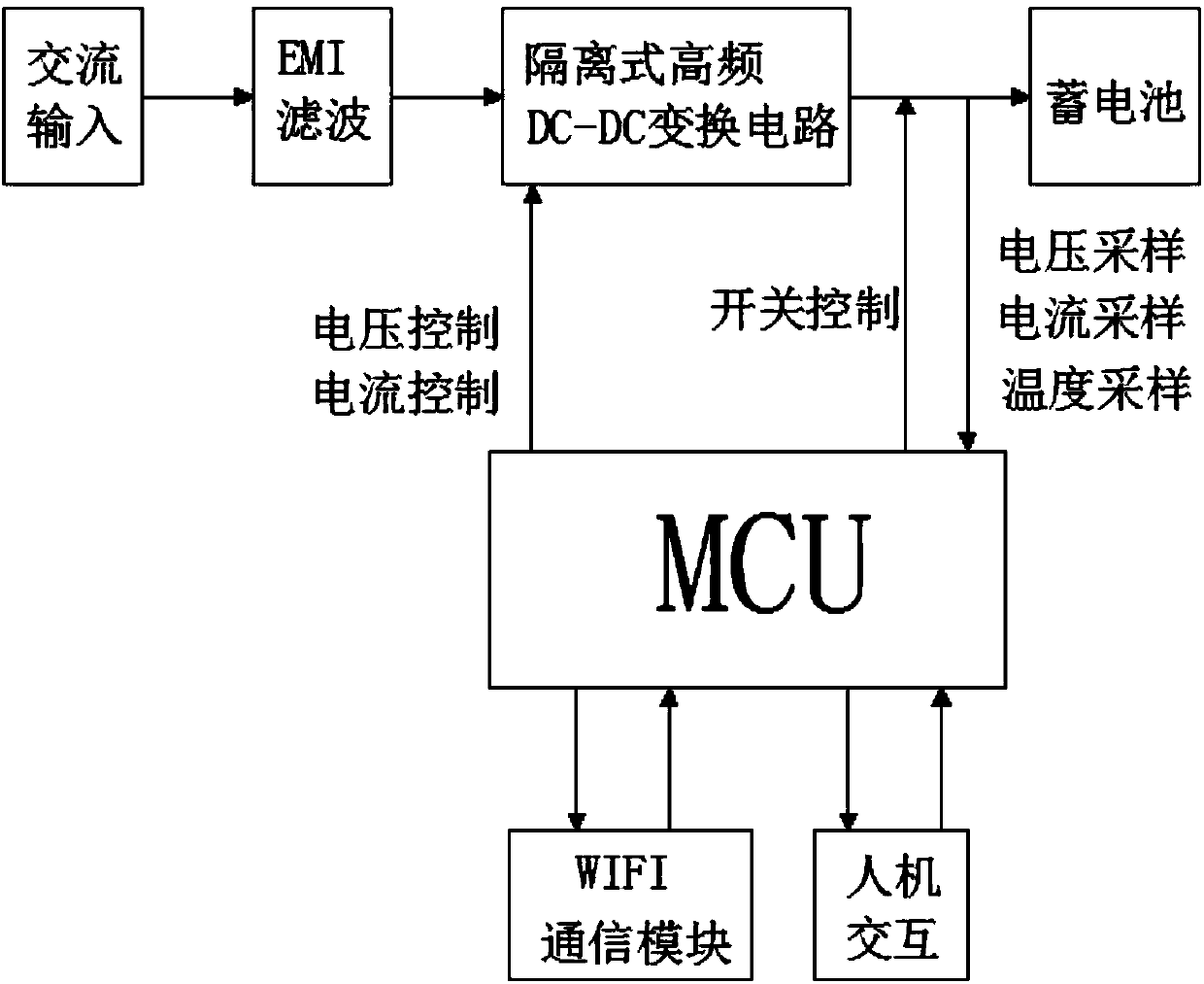

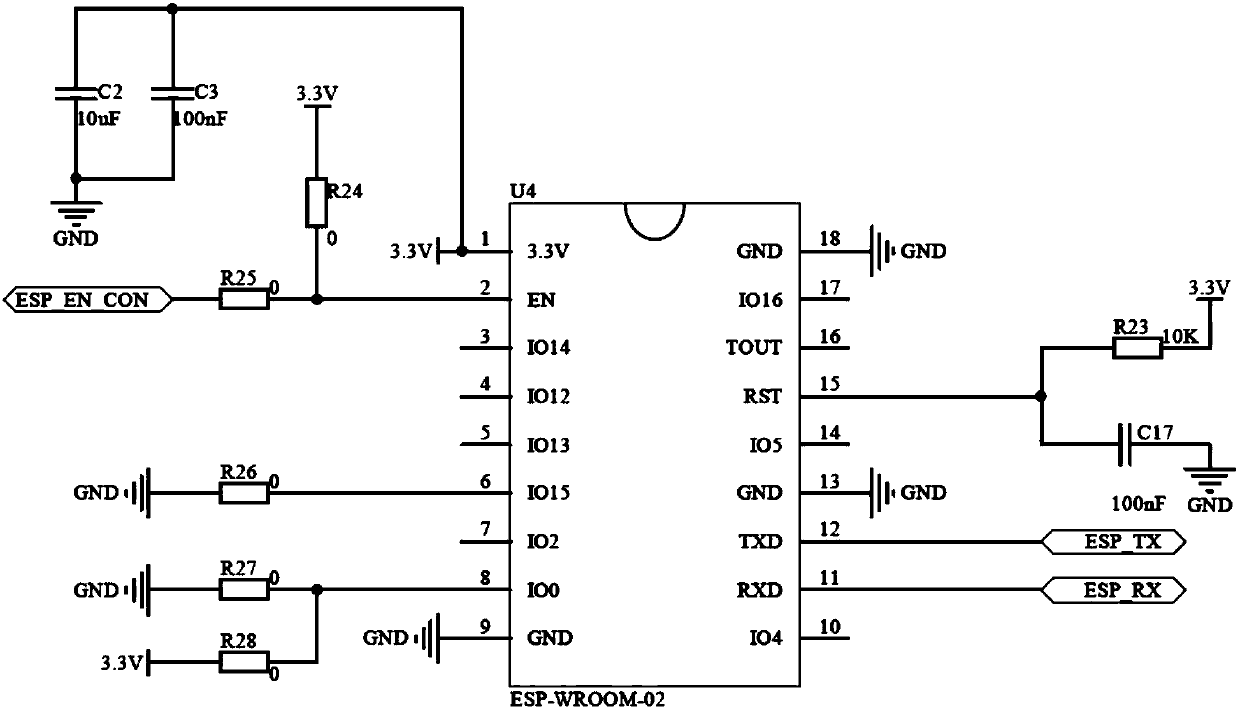

Storage battery charger, mobile terminal for storage charge management, and cloud platform based storage battery charge management system and method

PendingCN107809130AEasy to useEasy to manageBatteries circuit arrangementsCells structural combinationWi-FiBattery charge

The invention discloses a storage battery charger, a mobile terminal for storage charge management, and a cloud platform based storage battery charge management system and method, and relates to the field of IoT application related to storage battery charge management. The system provided by the invention includes the storage battery charger, the mobile terminal for storage battery charge management and a cloud server. The storage battery charger is in communication with the mobile terminal and the cloud server via a WI-FI module and uploads storage state data and charge data to the cloud server and downloads control commands from the mobile terminal. By adopting the technical scheme provided by the invention, IoT management on the storage battery charger is realized, a mode of storage battery charge management is optimized and big data support and product optimization direction are provided for storage battery manufacturers.

Owner:NINGBO CARSTEL MFG CO LTD

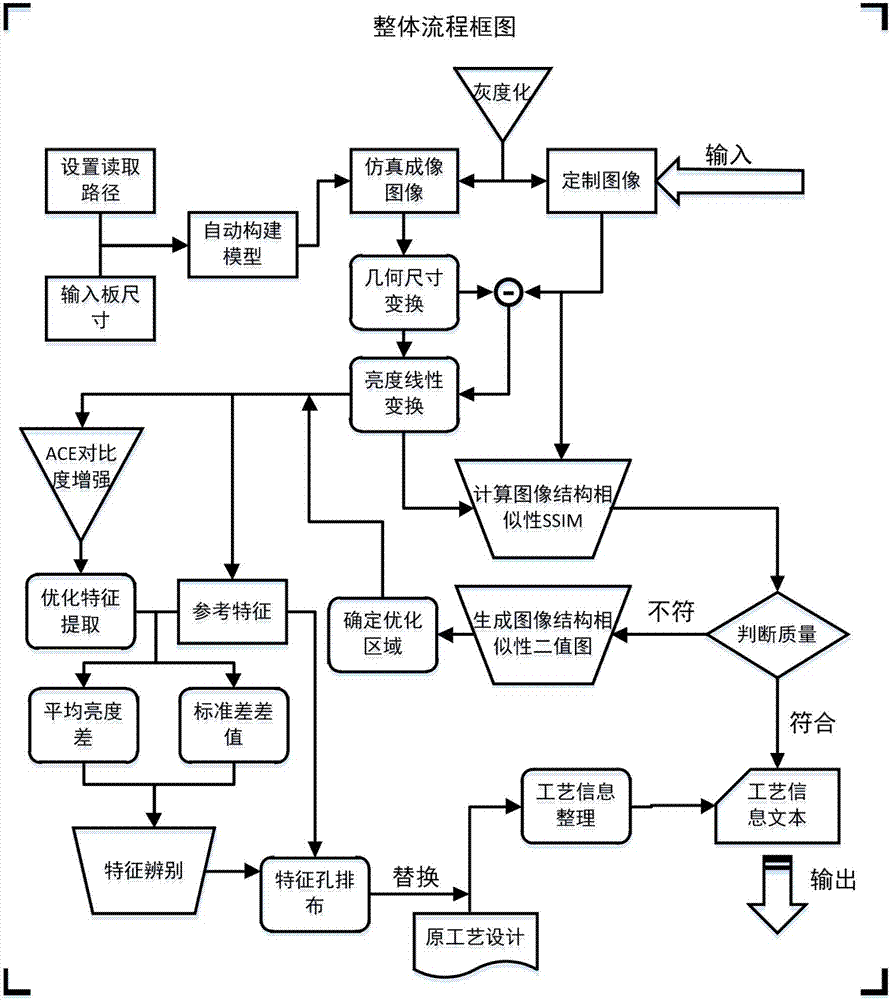

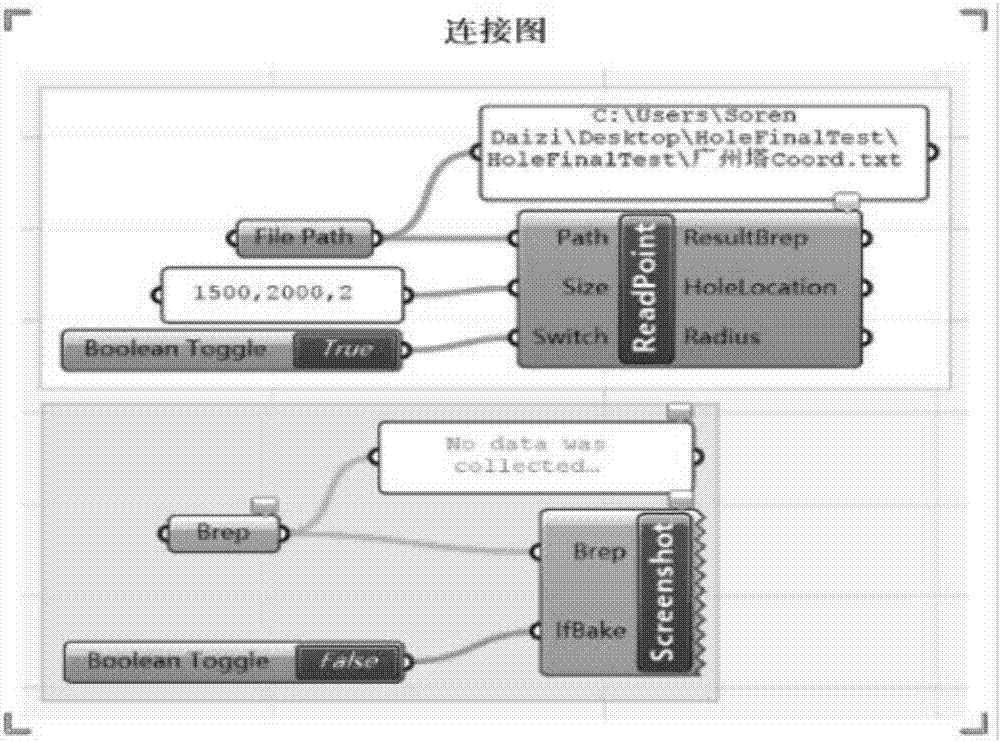

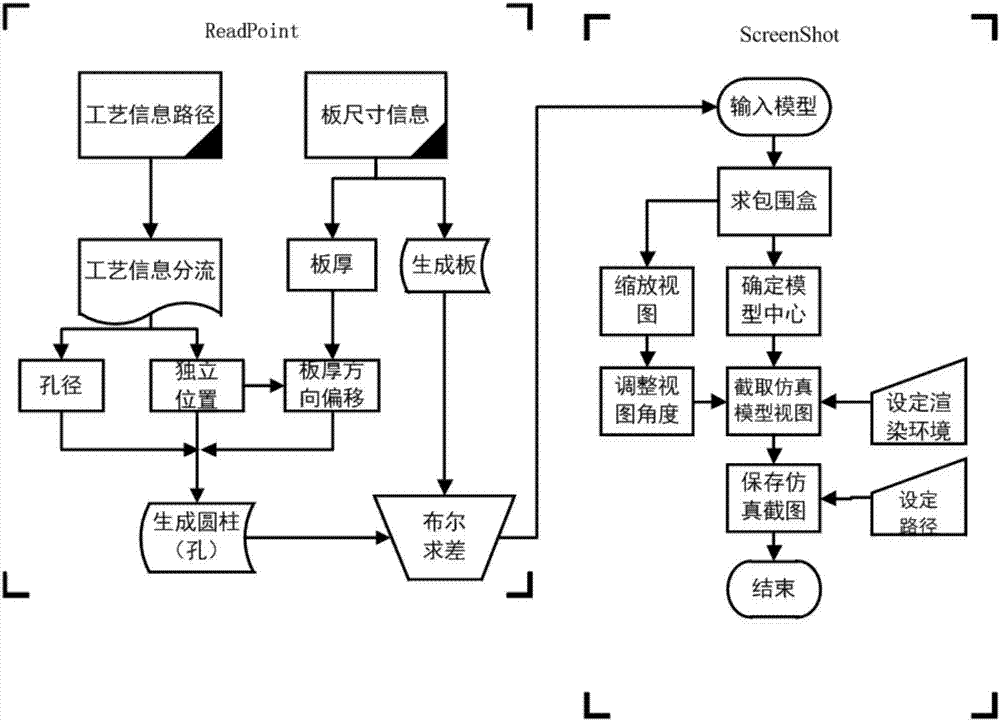

Manufacturing method for evaluating and optimizing decorative sheet on basis of image structure similarity

InactiveCN107480379AFast modeling and simulationRapid human quality assessmentGeometric CADSpecial data processing applicationsNumerical controlProduct optimization

A manufacturing method for evaluating and optimizing a decorative sheet on the basis of image structure similarity comprises the following steps that firstly, a special automatic modeling and simulating function battery combination is built in a Rhinoceros+Grasshopper simulation platform, a simulation three-dimensional model of the artistic punched decorative sheet is constructed, rendering is conducted, a simulation effect graph is obtained, and a simulation imaging image is extracted; secondly, the simulation imaging image and an original customized image are converted into gray images; thirdly, geometric transformation and brightness linear transformation are carried out; fourthly, image structure similarity is calculated; fifthly, a structure similarity graph is generated; sixthly, an optimization region is determined; seventhly, contrast enhancement and feature extraction are carried out; eighthly, the feature difference is calculated; ninthly, process information is replaced; tenthly, new machining process information is imported into numerical control machining equipment, and a numerical control punching process is carried out on the decorative sheet. According to the manufacturing method, quality prediction and design optimization of products are effectively achieved, the product optimization efficiency is improved, and the product quality is ensured.

Owner:GUANGDONG UNIV OF TECH

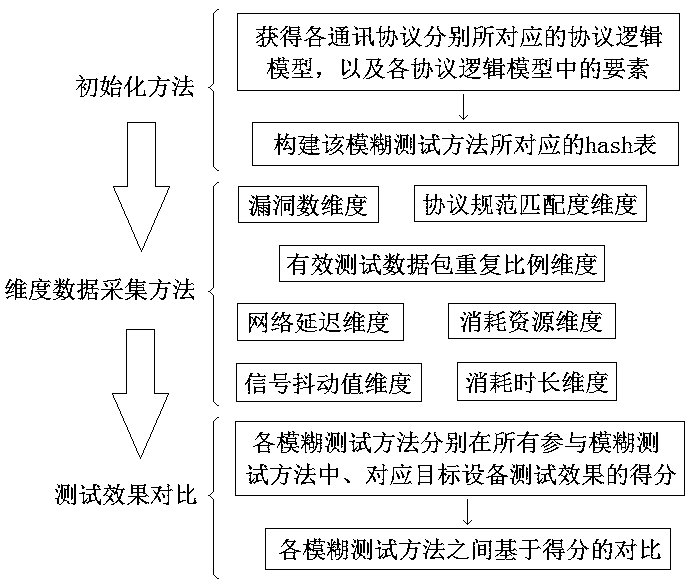

Fuzzy test application effect comparison method

ActiveCN110995770AThe test effect is goodContrast and contrast effect displayTransmissionAlgorithmProduct optimization

The invention relates to a fuzzy test application effect comparison method. Multi-dimensional cooperative participation is adopted; a hash table structure and a statistical algorithm are applied; calculation is carried out according to dimensions of target equipment tests corresponding to different fuzzy test methods; finally, each fuzzy test method corresponds to the score of the test effect of the target equipment in all the methods participating in the fuzzy test. The test effect comparison of different fuzzy test methods is realized, objective, accurate and efficient fuzzy test method comparison effect display is realized, the design method is used for benchmarking test, test effects of different test products can be conveniently compared, and product optimization is realized.

Owner:信联科技(南京)有限公司 +1

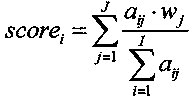

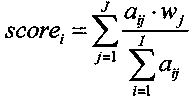

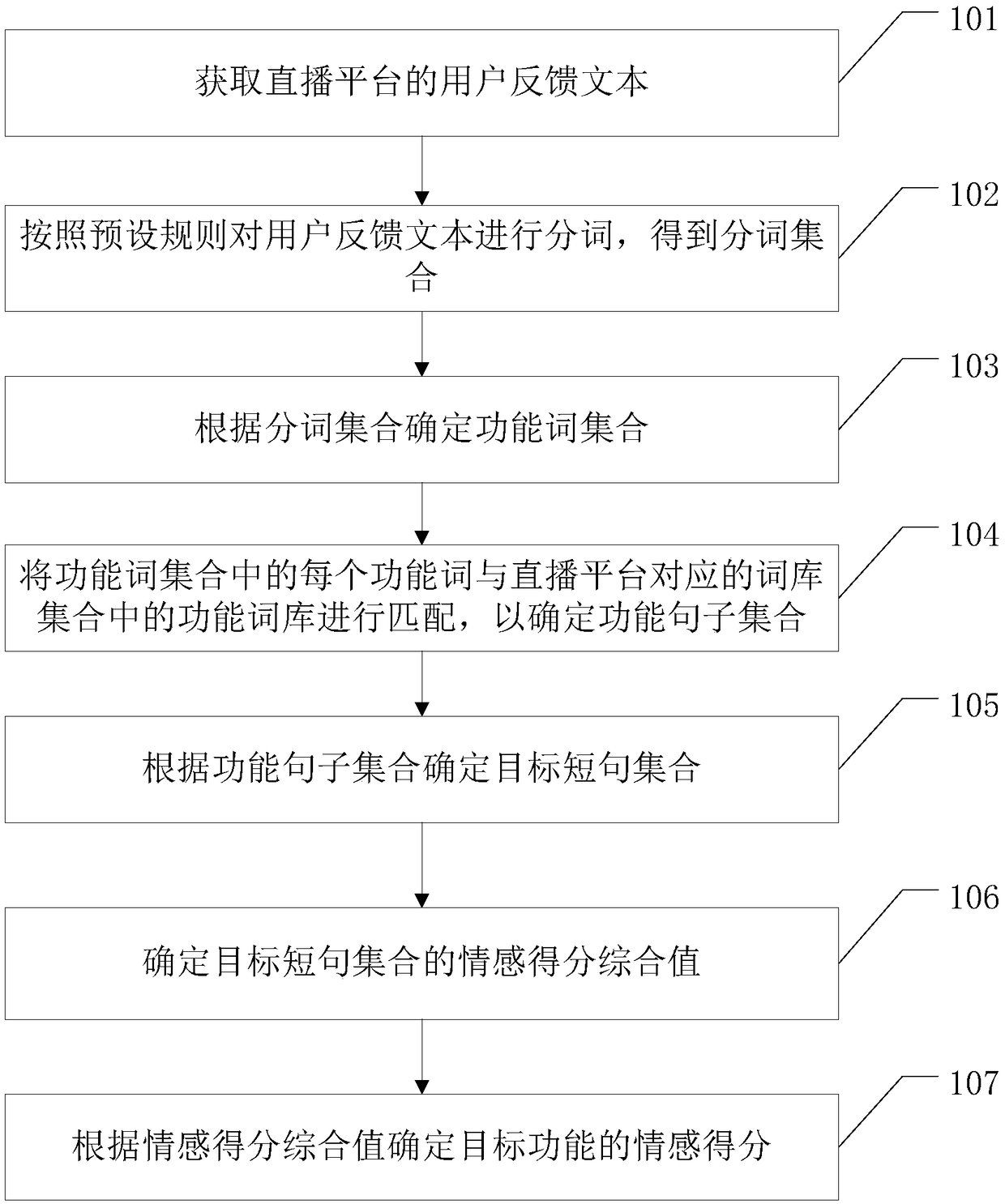

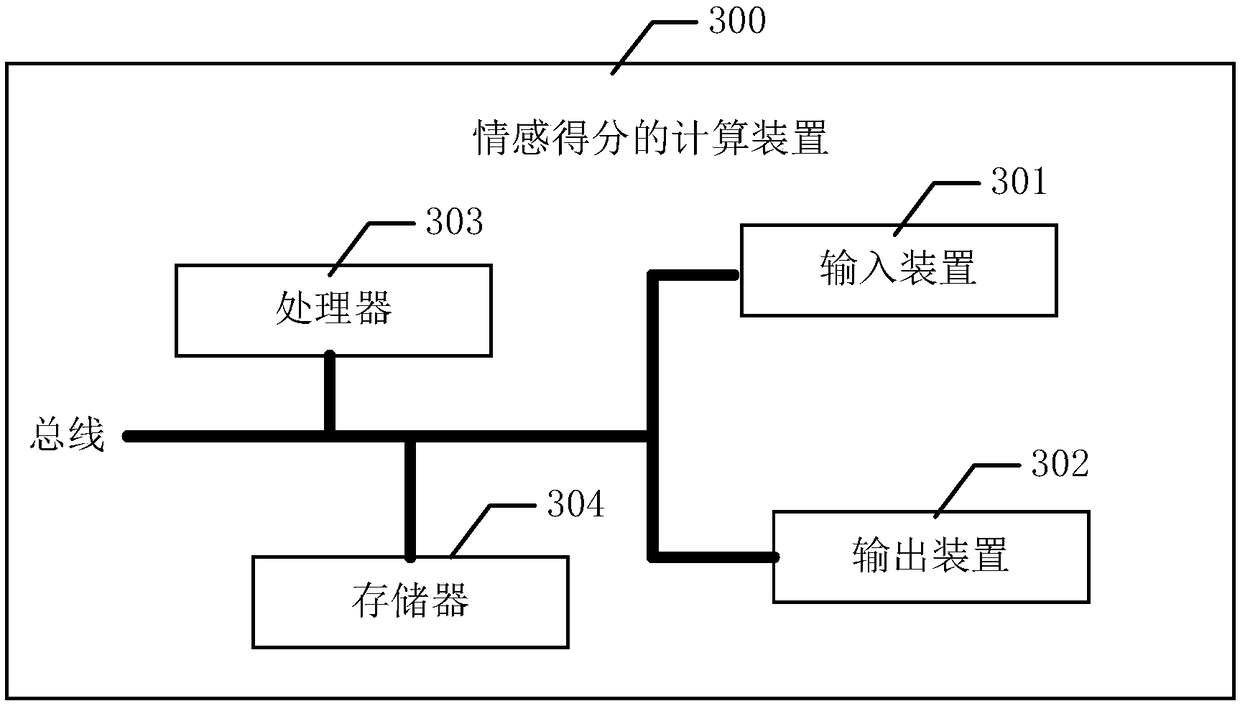

A method for calculating an emotion score and a related device

ActiveCN109299463ASolve Collection InductionAutomated identification of functional issuesSemantic analysisUnstructured textual data retrievalEmotional biasProduct optimization

The embodiment of the invention provides a method for calculating the emotional score and related equipment, which is used for solving the problem of collecting and summarizing the functional feedbackmanually collected by the user in the existing live broadcast platform, realizing automatic identification of the functional problem and giving the emotional bias score of each function, and facilitating the product optimization judgment. The method comprises the following steps: obtaining user feedback text of the live broadcast platform; Segmentation of the user feedback text according to a preset rule to obtain a segmentation set; Determining a functional word set according to the word segmentation word set; Matching each functional word in the functional word set with a functional word set in a vocabulary set corresponding to the live broadcast platform to determine a functional sentence set; Determining a target short sentence set according to the functional sentence set; Determiningan emotion score synthesis value of the target short sentence set; Determining an emotion score of the target function according to the emotion score composite value.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

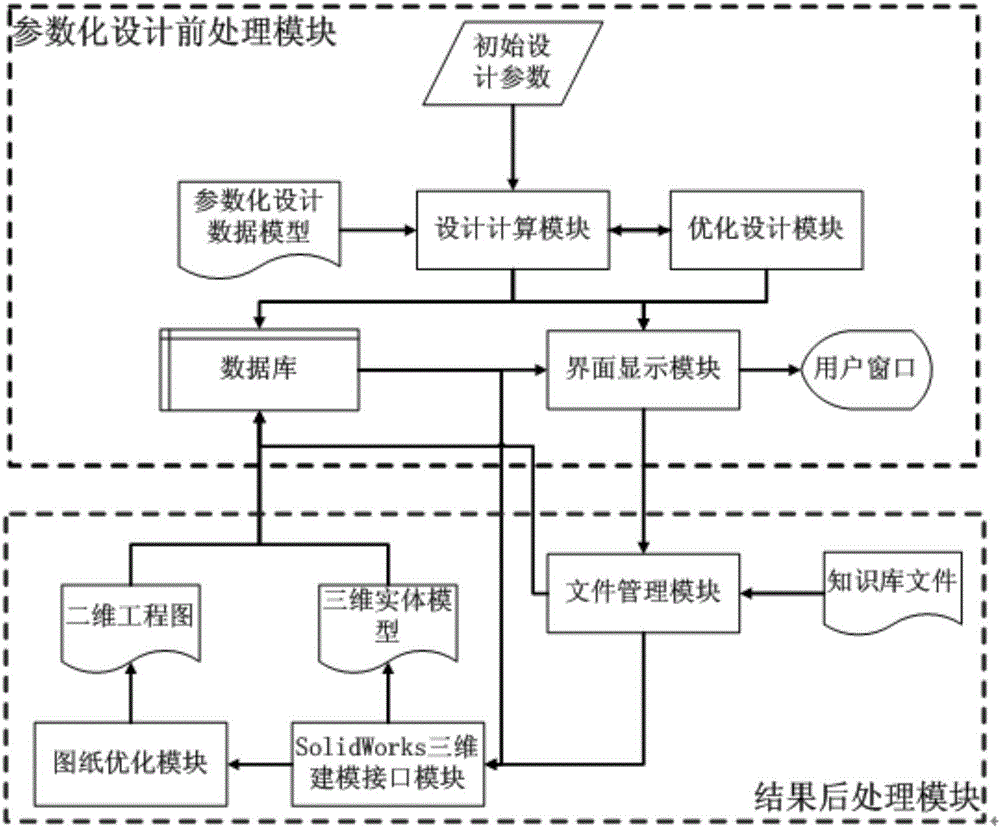

An RV reducer parametrization design modeling method

InactiveCN106407567ABe data-drivenEasy to serializeGeometric CADDesign optimisation/simulationReducerProduct optimization

The invention provides an RV reducer parametrization design modeling method comprising a first step of establishing a parametrization data flow model and a second step of establishing a parametrization design system. The first step comprises the sub-steps of: performing module division and series division on a product structure; dividing parts into a first-stage speed reduction part, a second-stage speed reduction part and an output part according to the working principles of the product; dividing parameters into different levels according to structural characteristics, and analyzing various feature sizes to determine the drive size and the driven size, wherein the drive size is the design target size; then optimizing the design flow of the reducer and dividing the whole design flow into four stages, which are an initial parameter input stage, a product initial design stage, a product optimization design stage and a product detail design stage; finally realizing the delivery of input and output information of design feature parameters of each part through design and cooperation relationships. The parametrization design system comprises a parametrization design preprocessing module and a result postprocessing module.

Owner:天津百利机械装备研究院有限公司

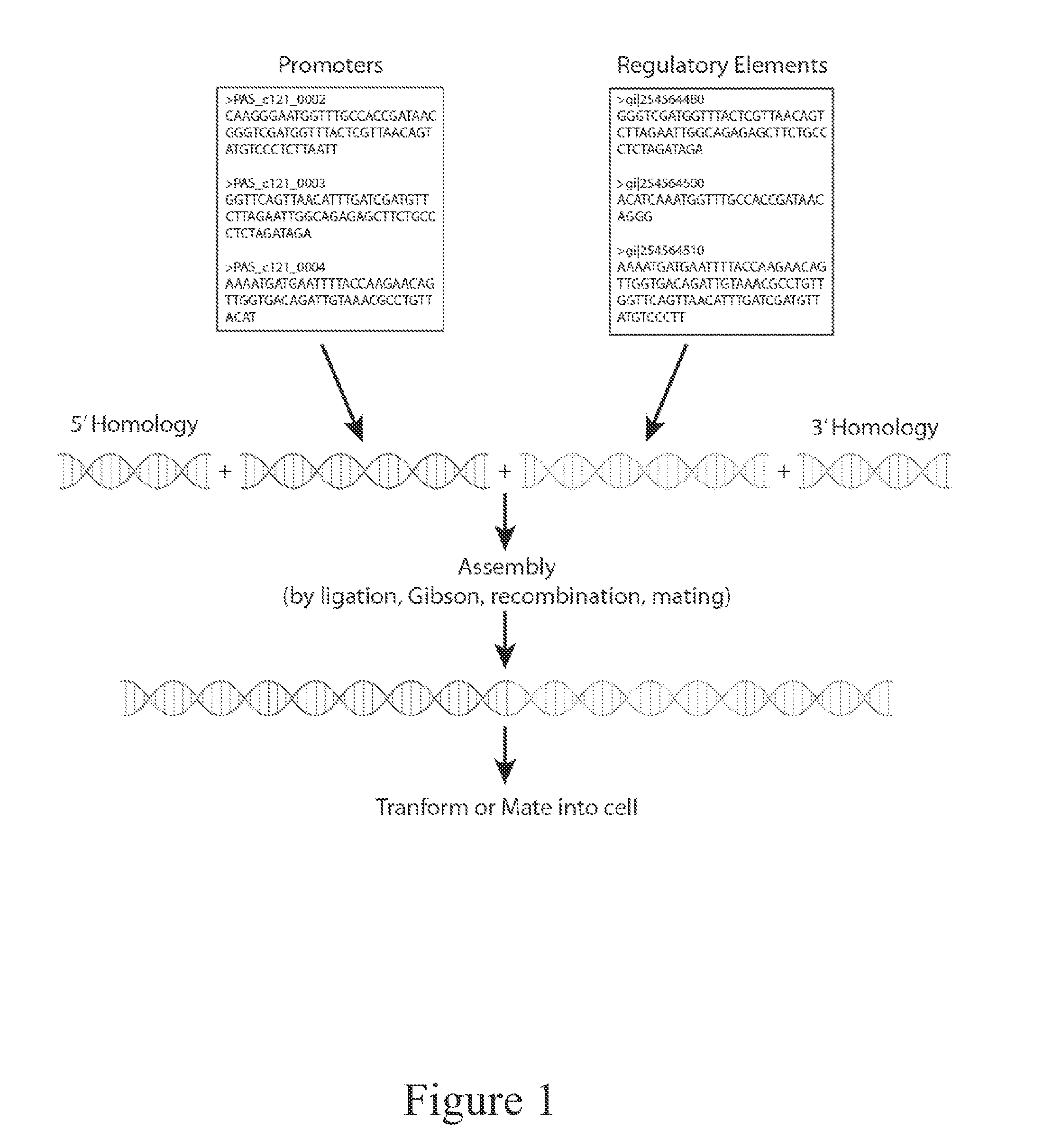

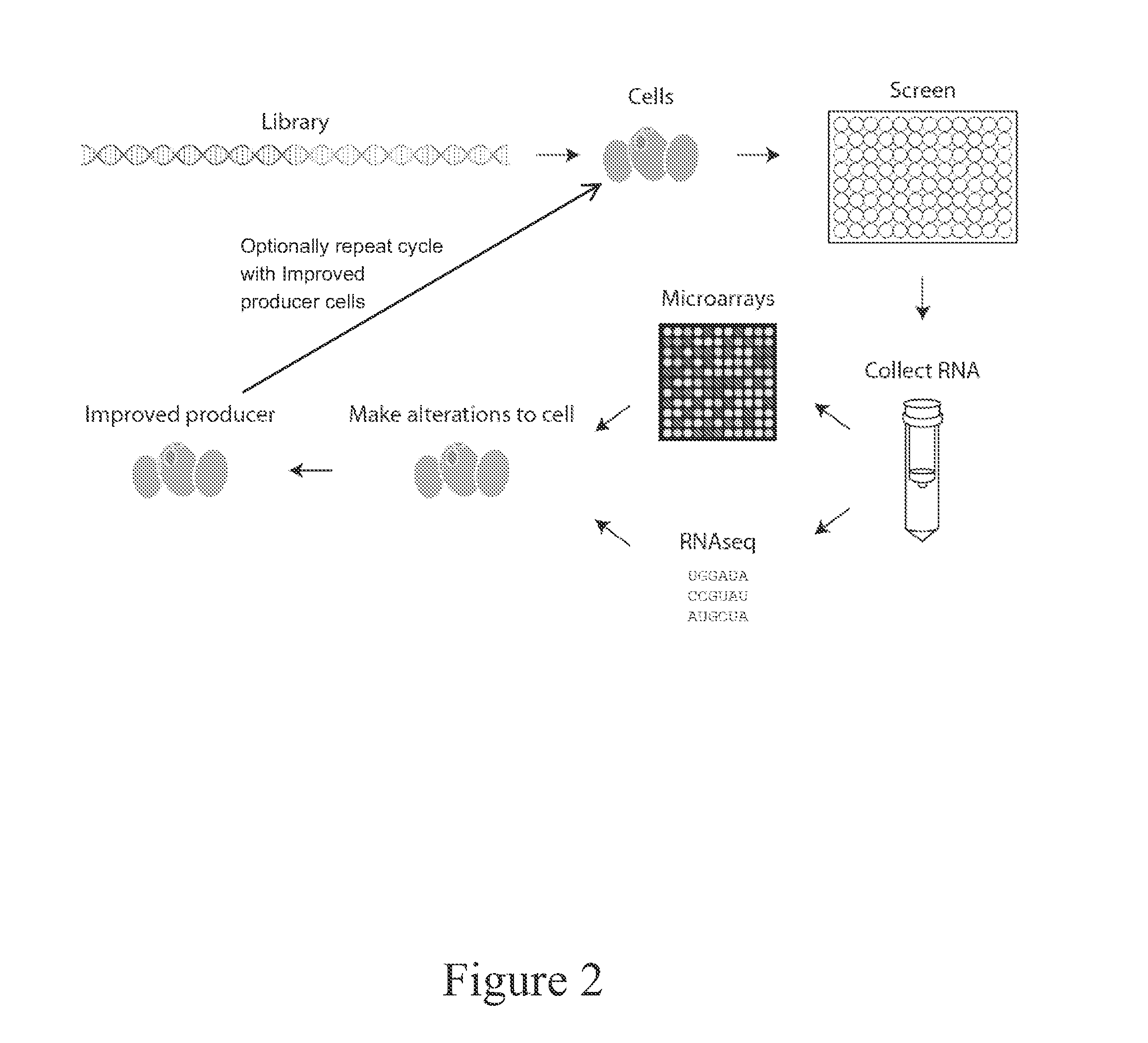

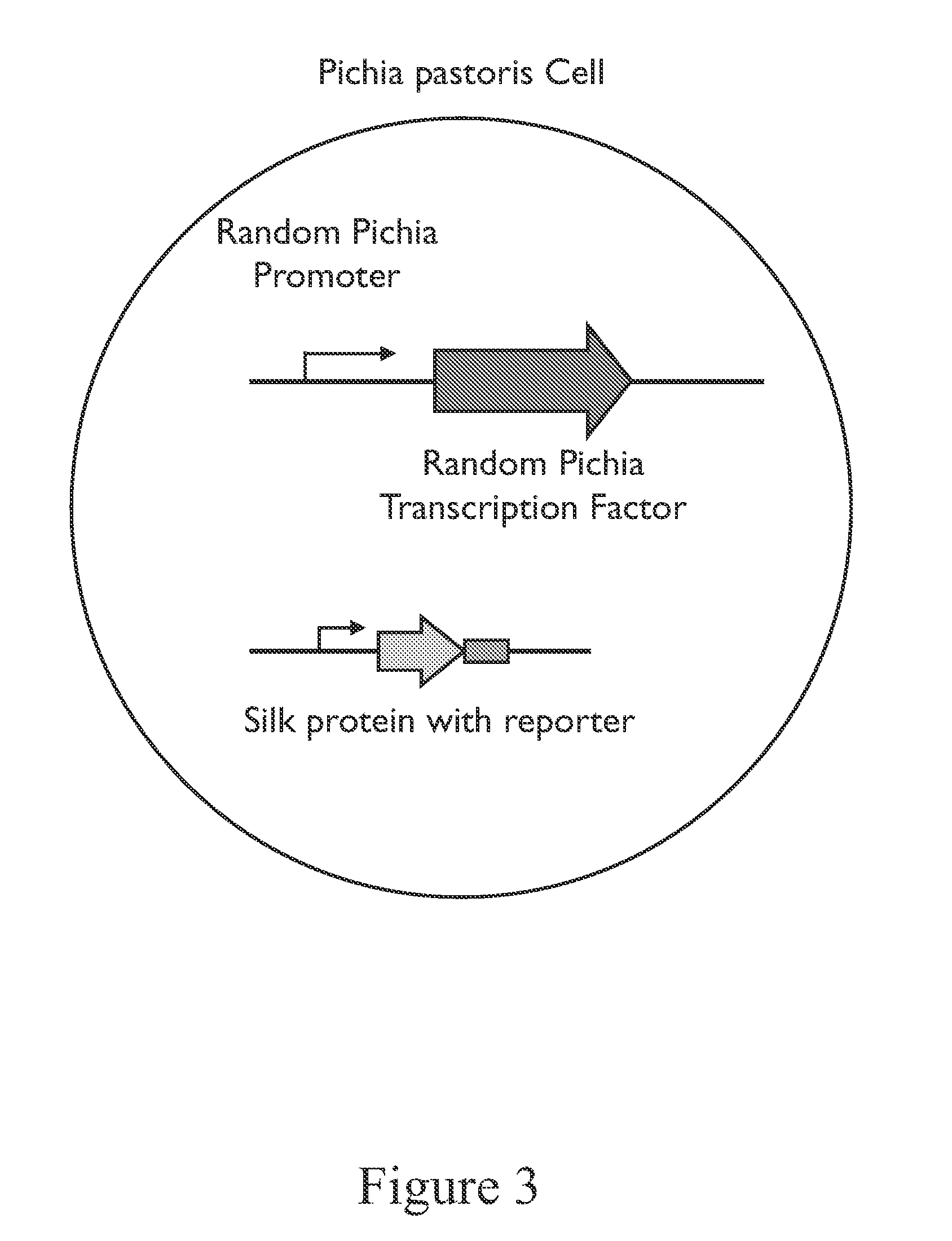

Cellular Reprogramming for Product Optimization

InactiveUS20150293076A1Significant perturbationLarge search spacePeptide-nucleic acidsLibrary screeningBiotechnologyMetabolite

Owner:BOLT THREADS

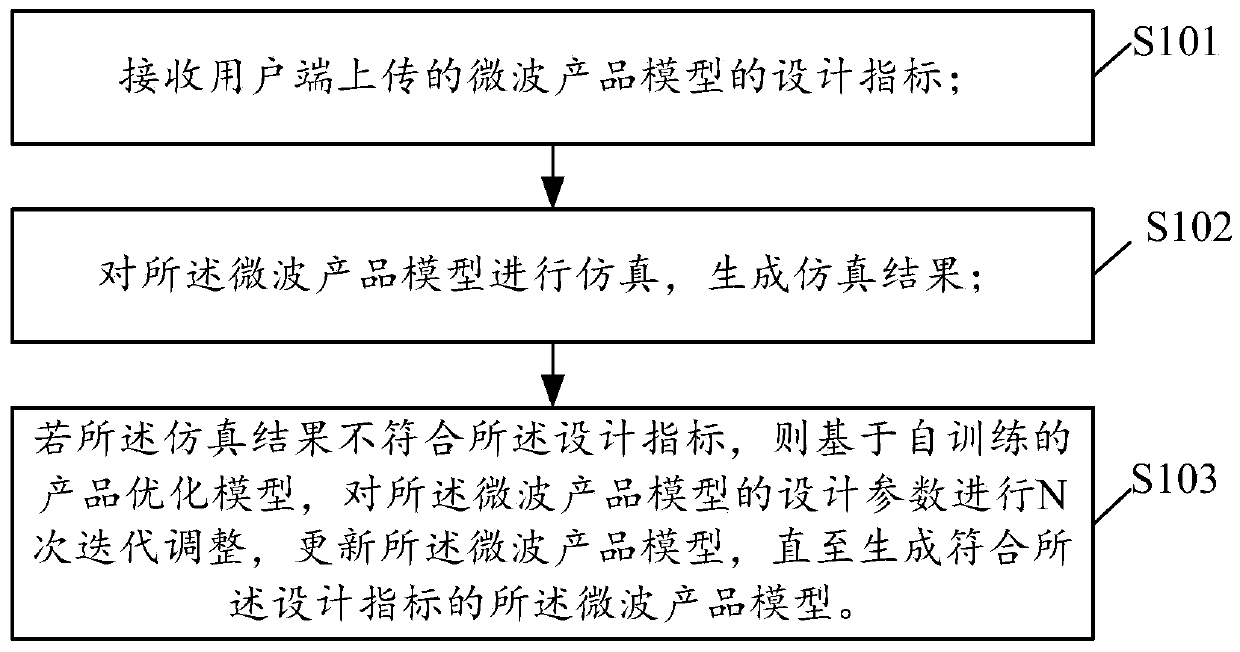

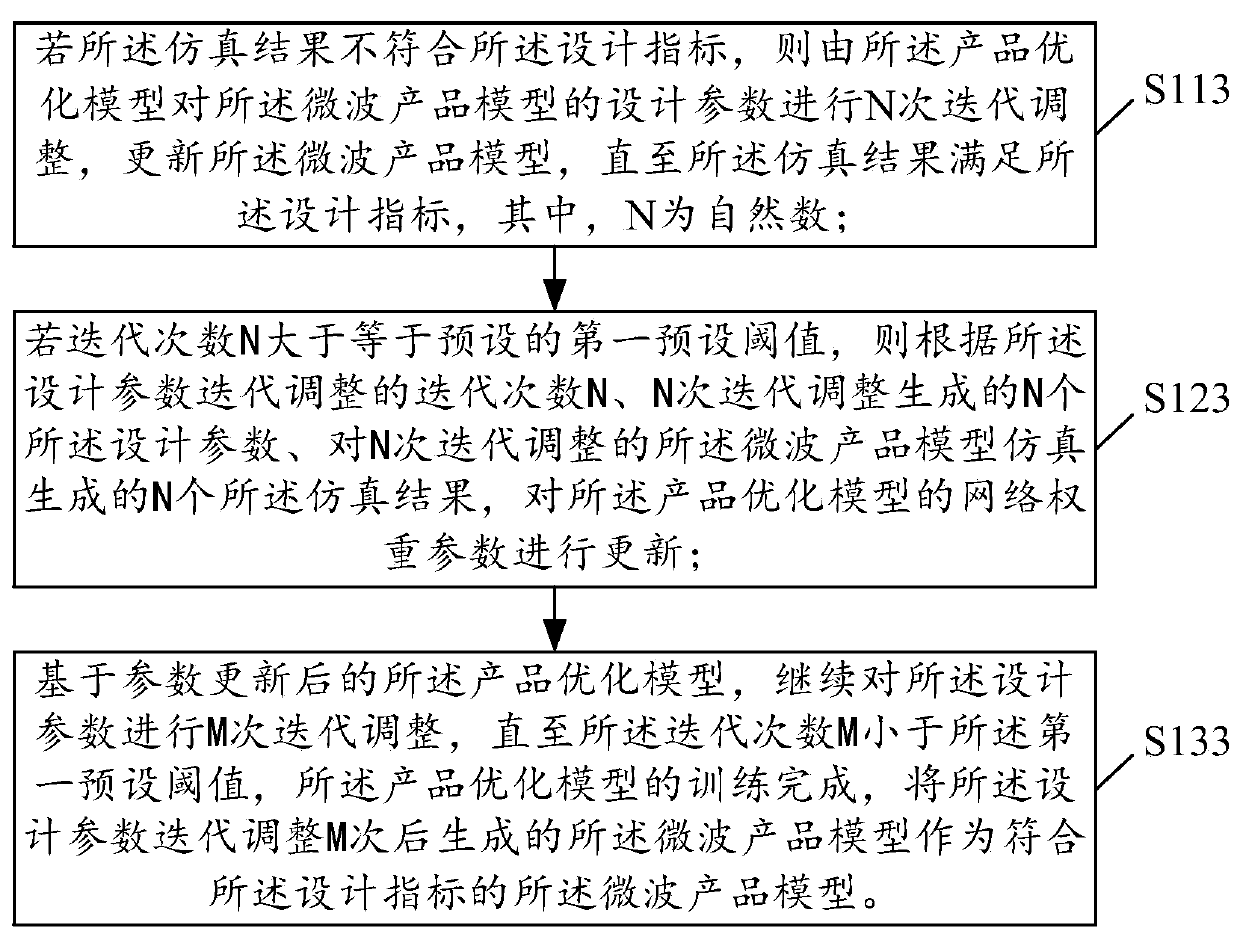

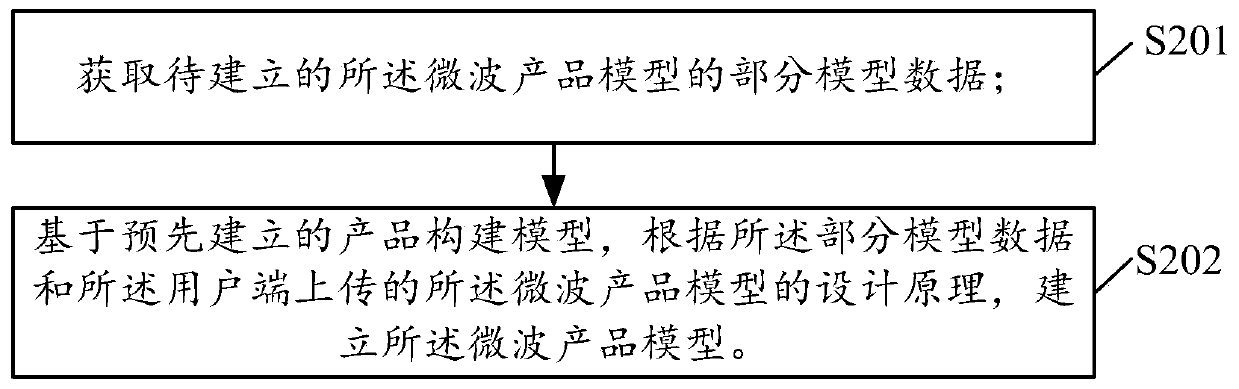

Electronic device, microwave product model design device, and computer-readable medium

ActiveCN111274727AReduce consumptionRelieve pressureDesign optimisation/simulationMachine learningProcess engineeringProduct optimization

The invention discloses electronic equipment, a microwave product model design device and a computer readable medium. The electronic equipment comprises a memory, a processor and a computer program which is stored in the memory and can run on the processor. When the processor executes the computer program, the following steps are realized: receiving a design index of a microwave product model uploaded by a user side; simulating the microwave product model to generate a simulation result; and if the simulation result does not accord with the design index, performing iterative adjustment on thedesign parameters of the microwave product model for N times based on a self-trained product optimization model, and updating the microwave product model until the microwave product model accordant with the design index is generated. Through the equipment, in the product development process, the microwave product model is updated through the self-trained product optimization model, the microwave product model meeting the design indexes is output and can be directly used for product development, and the product development period is greatly shortened.

Owner:南京星火技术有限公司

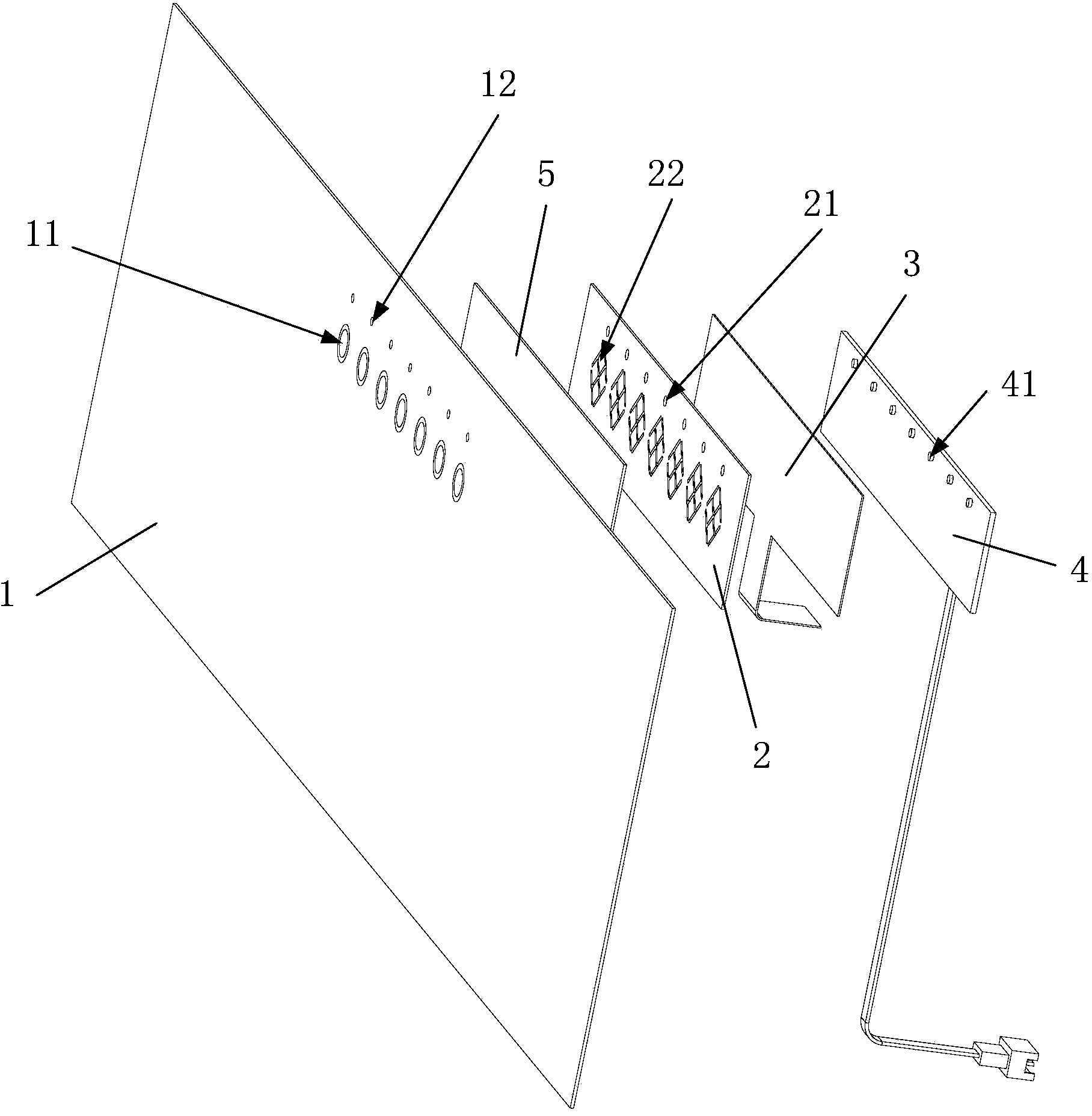

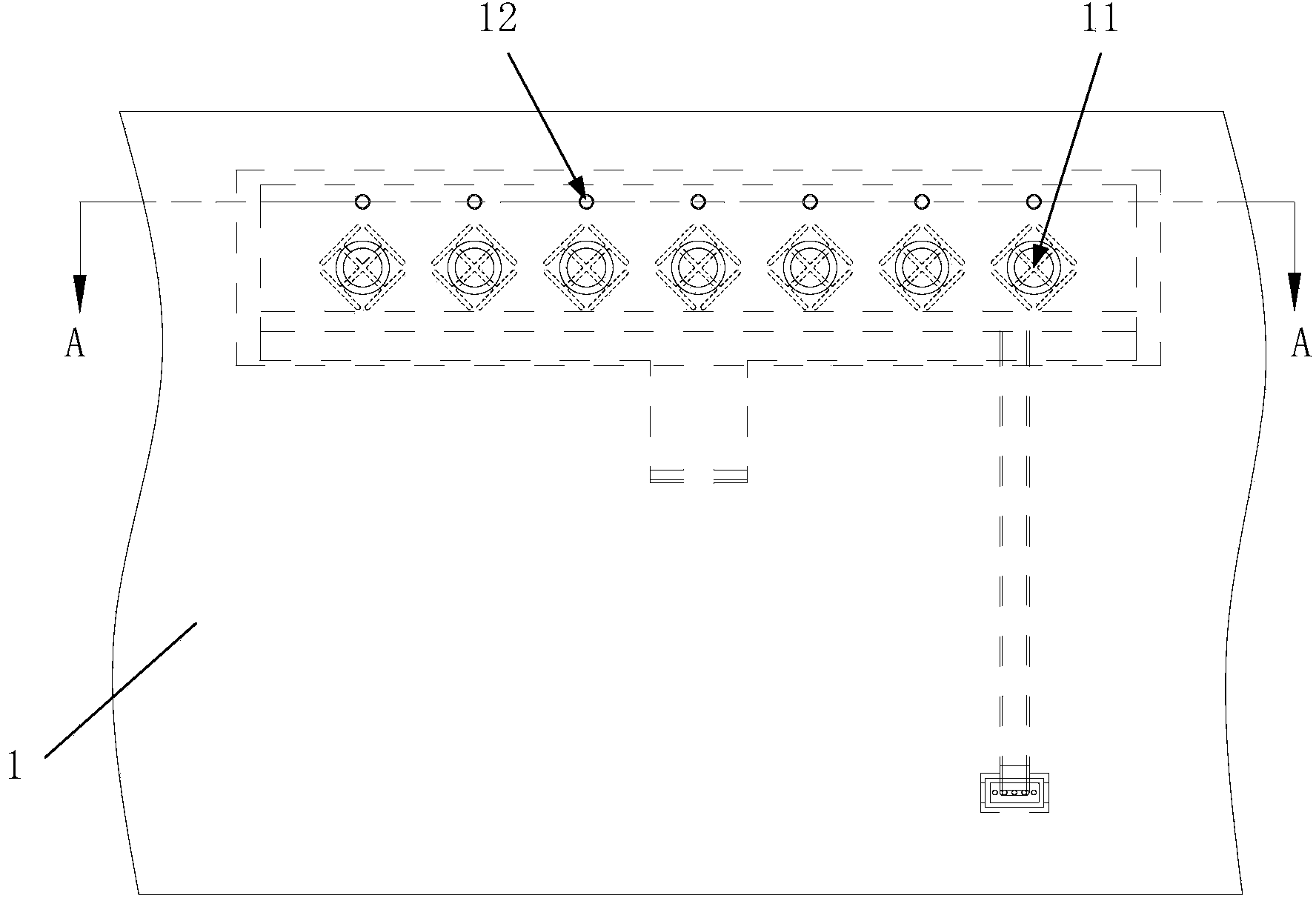

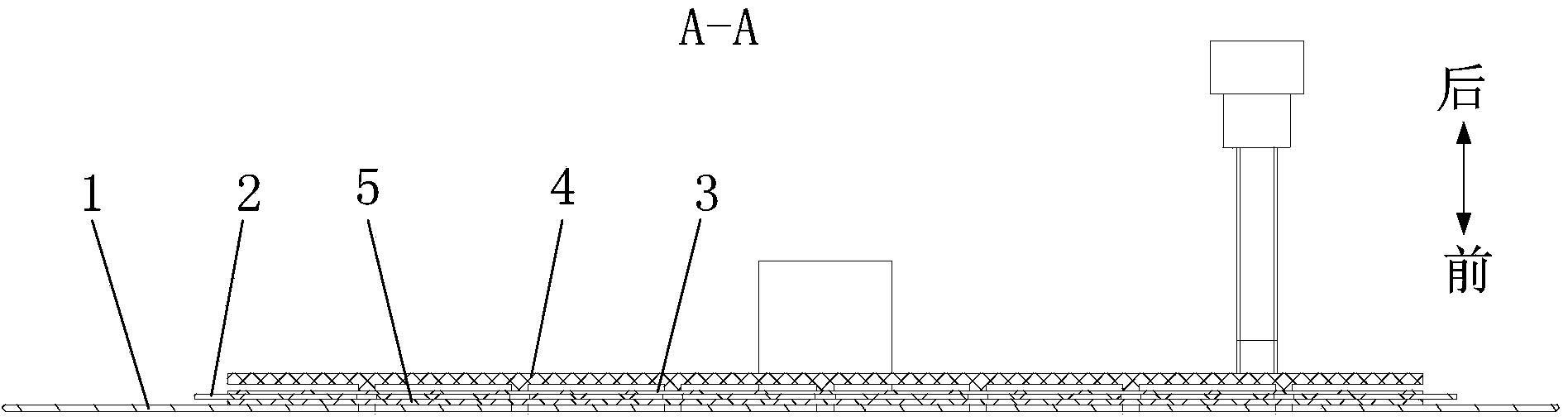

Touch key assembly and method for producing touch key assembly

InactiveCN104319141ASimple structureEasy to assembleElectric switchesDomestic articlesKey pressingProduct optimization

The invention provides a touch key assembly and a method for producing the touch key assembly. The touch key assembly comprises a panel, a supporting plate, a sensor and a PCB, wherein the supporting plate is located behind the panel and is installed on the panel, the rear surface of the panel corresponds to the front surface of the supporting plate, the sensor is located behind the supporting plate and is installed on the supporting plate, the front surface of the sensor corresponds to the rear surface of the supporting plate, the PCB is located behind the sensor, and the PCB and the sensor are installed together. The touch key assembly is simple in structure and convenient to assemble, the manufacturing difficulty of the panel is converted into the manufacturing difficulty of the supporting plate and the sensor through the arrangement of the supporting plate, the manufacturing difficulty of the panel is effectively lowered, the manufacturing difficulty of the panel, the manufacturing difficulty of the supporting plate and the manufacturing difficulty of the sensor are all quite low, in this way, the purpose of reducing the production cost of the touch key assembly is achieved, and the design concept of product optimization of enterprises is better reflected.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

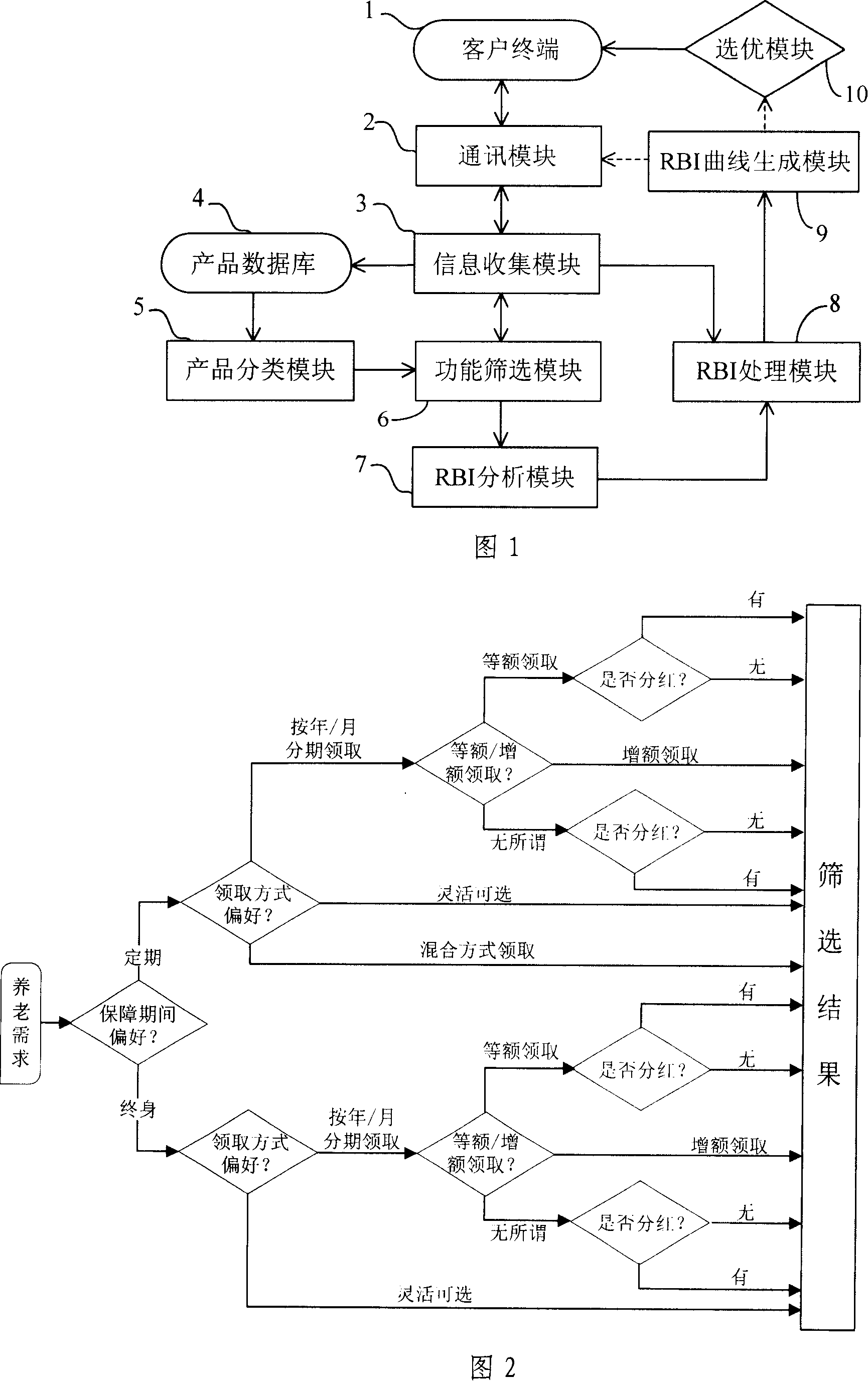

System and method for selecting excellence of finance product based on requirement of client

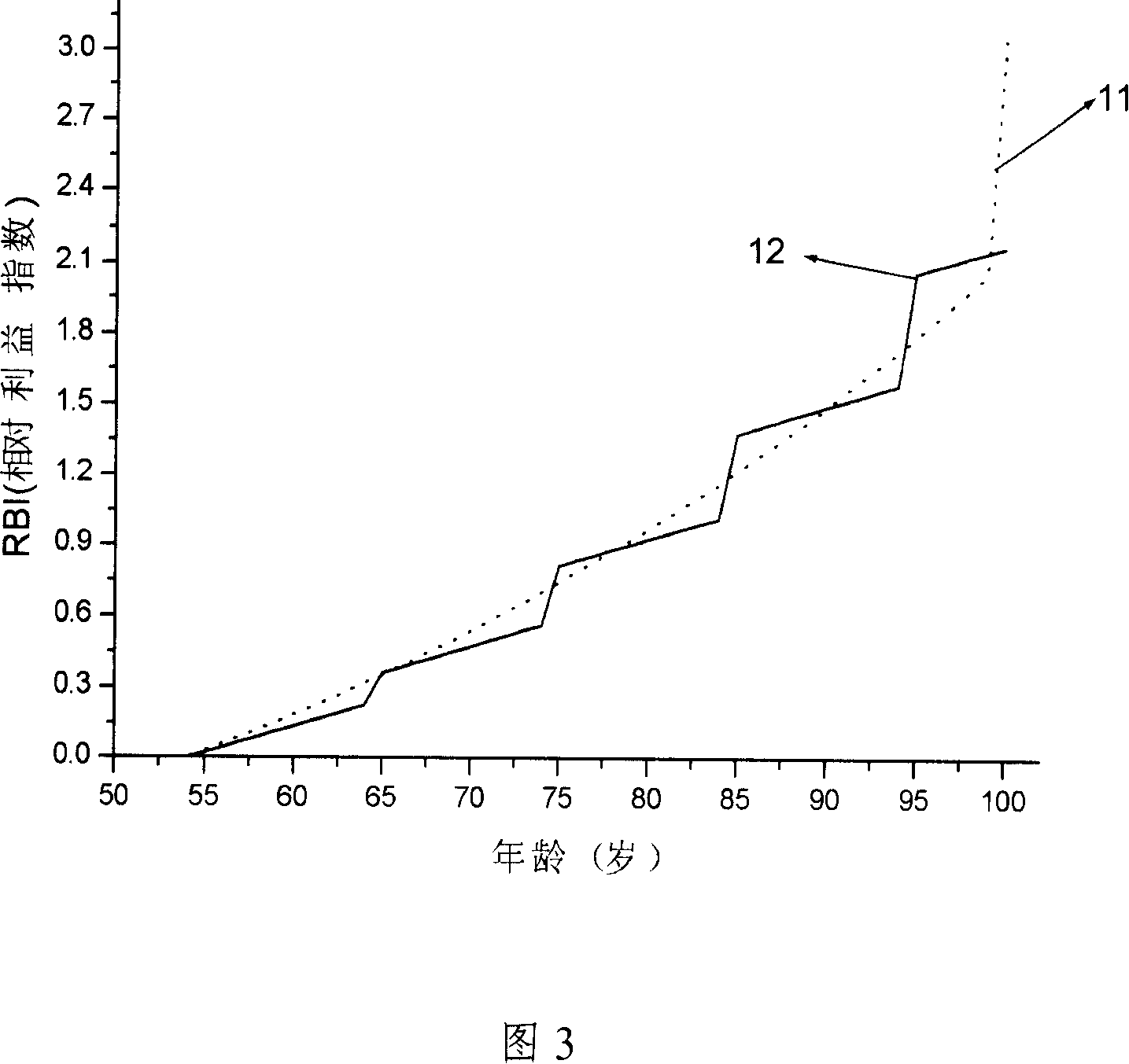

This invention provides one finance product optimization system and method based on customer end, which comprises the following steps: firstly processing single function sort division on product database relative products to determine each sort product difference function and filter process; according to product function different selection menu to get customer function demands information; then processing quantification to meet customer function demands to determine RBI parameter and its value range; further to get customer demands information and each RBI parameter value range for matching or filtering to get RBI parameter matching; finally according to the RBI parameter matching to draw RBI curve to feed back results to customer end.

Owner:BEIJING MINGYA INSURANCE BROKERS

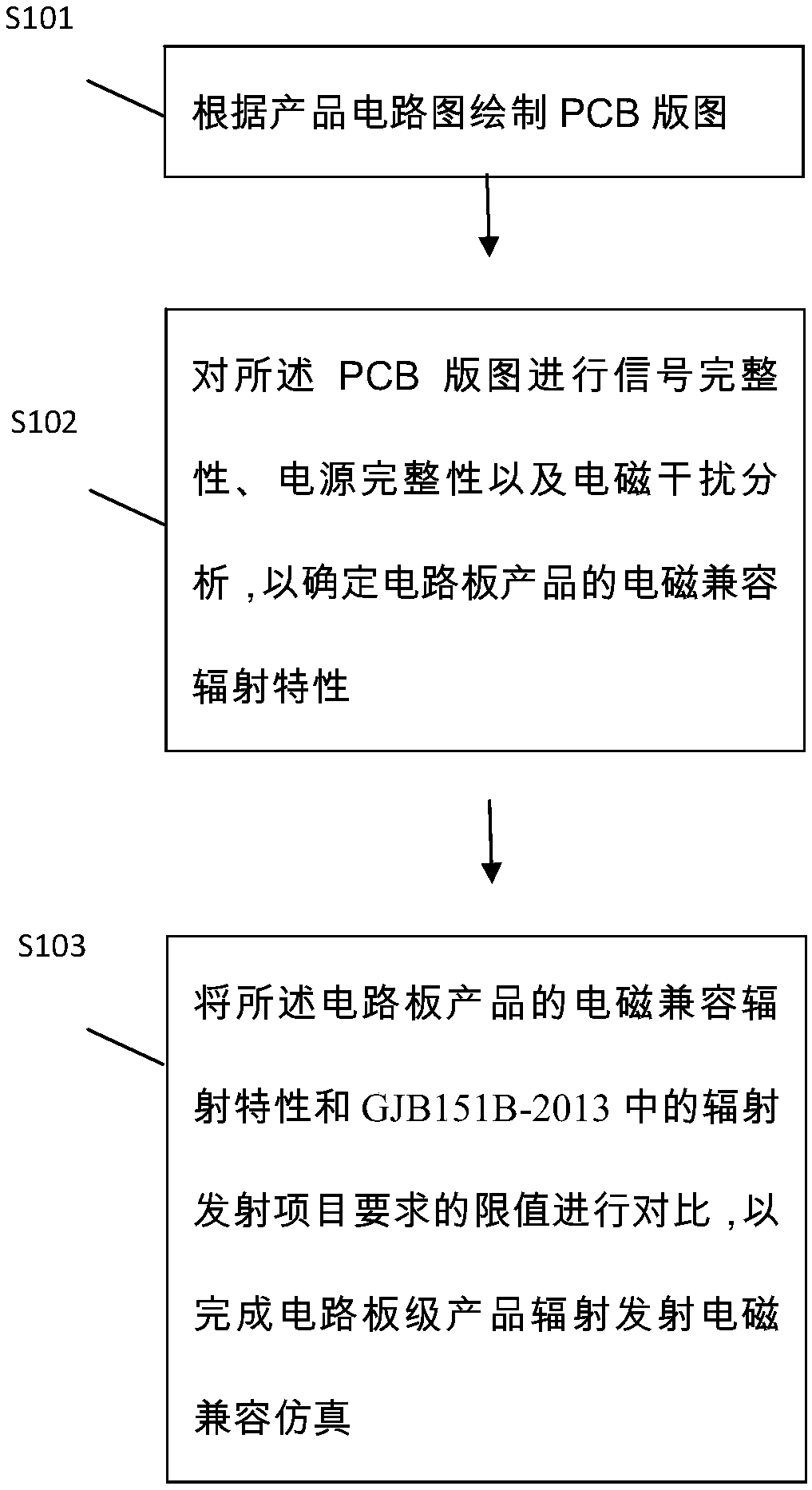

A circuit board level product radiation emission electromagnetic compatibility simulation method

PendingCN109598060ADetermining EMC Radiation CharacteristicsEasy to implementCAD circuit designSpecial data processing applicationsElectromagnetic interferenceEngineering

The invention discloses a circuit board level product radiation emission electromagnetic compatibility simulation method. The method comprises the steps: drawing a PCB layout according to a product circuit diagram; Analyzing the signal integrity, the power supply integrity and the electromagnetic interference of the PCB layout to determine the electromagnetic compatibility radiation characteristics of the circuit board product; And comparing the electromagnetic compatibility radiation characteristic of the circuit board product with a limit value required by a radiation emission project in GJB151B to complete the radiation emission electromagnetic compatibility simulation of the circuit board product. Through the steps of PCB layout introduction, PCB lamination parameter modification, excitation source addition, simulation setting, result post-processing and the like, the electromagnetic compatibility radiation characteristic of a circuit board product is determined, and the electromagnetic compatibility radiation characteristic of the circuit board product are determined and compared with The limits required by the radiation emission items in the national military standard GJB151B-2013. The method can effectively realize the emission level of electromagnetic radiation of products through the national military standard GJB151B-2013 certification, and provide an important theoretical basis for the subsequent product optimization design..

Owner:BEIJING INST OF REMOTE SENSING EQUIP

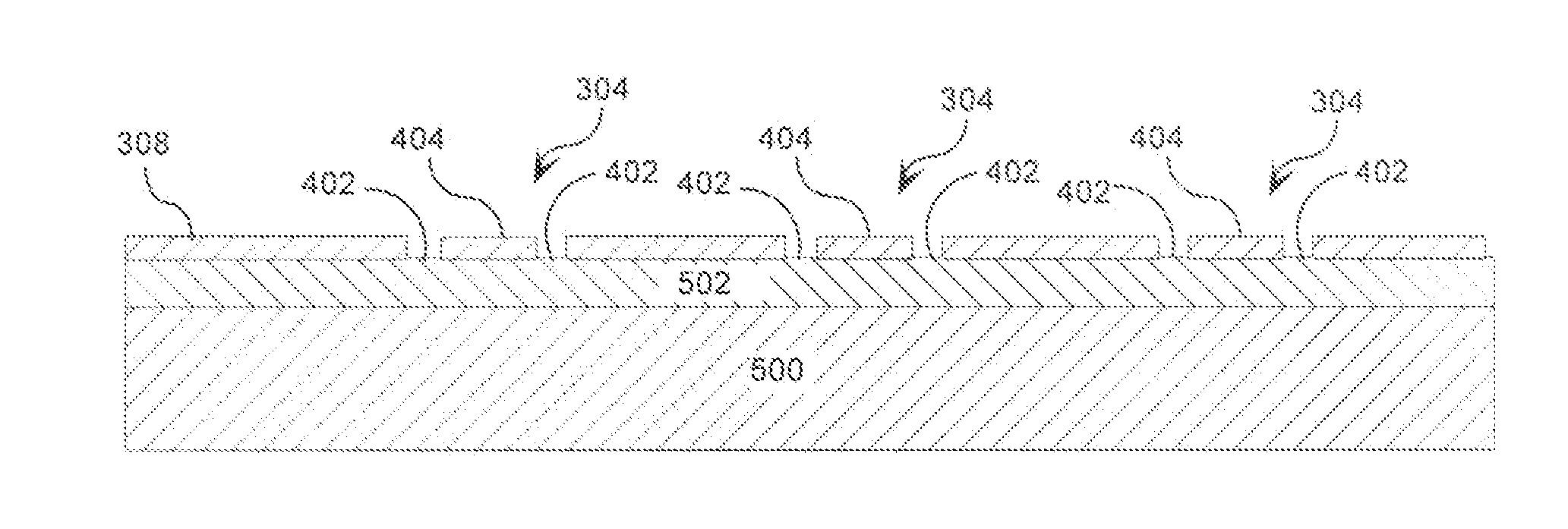

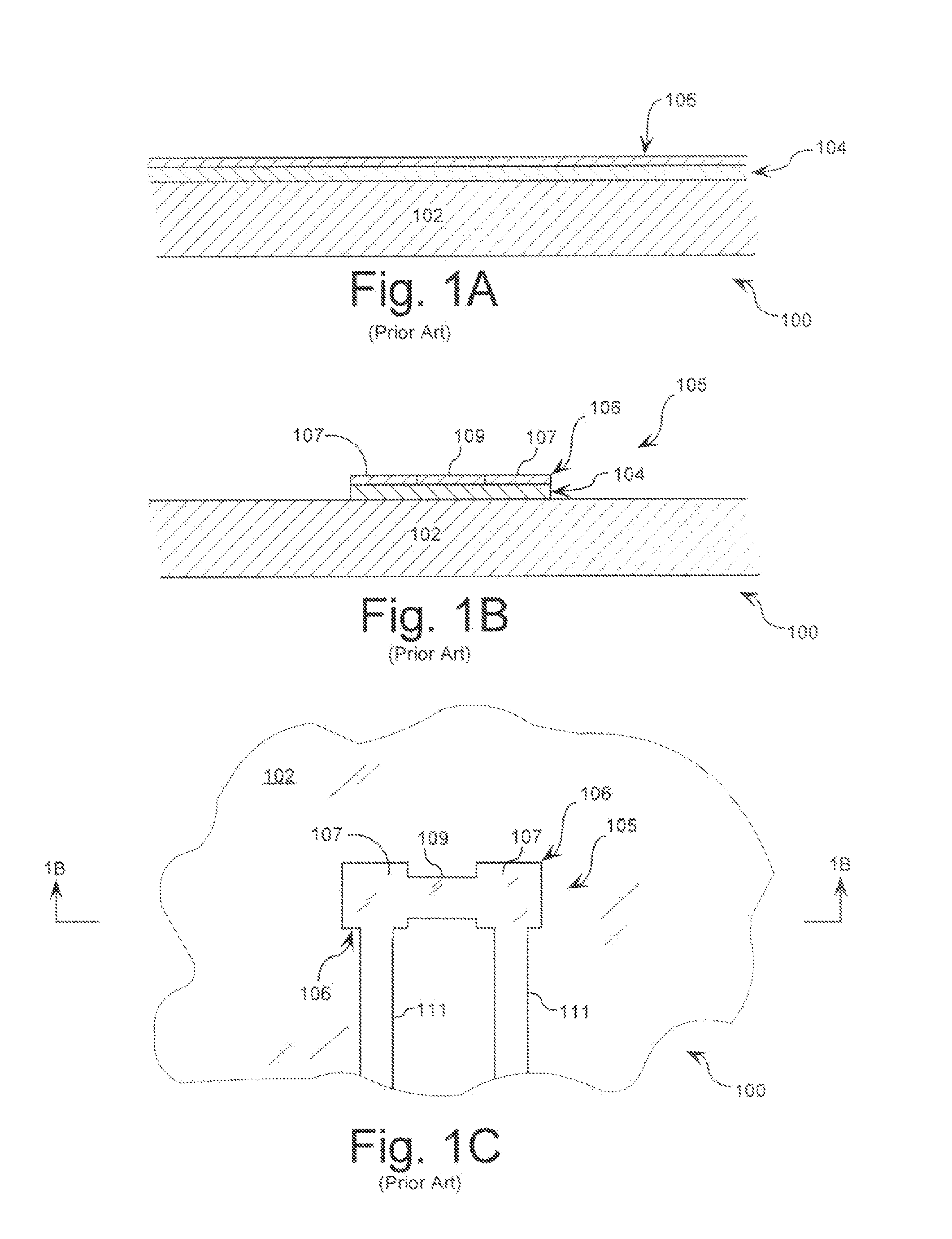

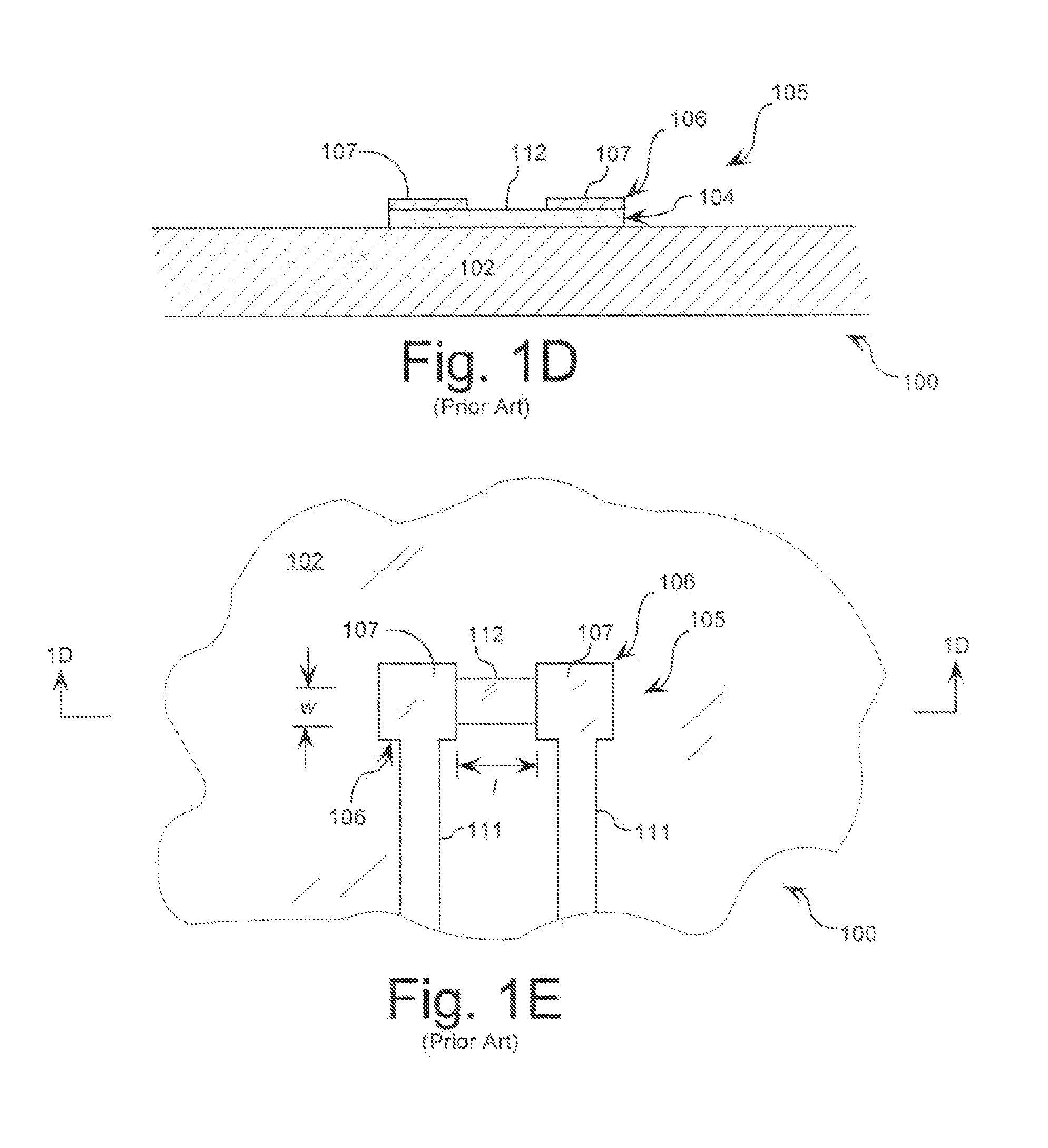

Product Optimization Process for Embedded Passives

InactiveUS20100024210A1Improve analysis accuracyPrinted circuit assemblingInspection/indentification of circuitsProduct optimizationElectrical and Electronics engineering

Owner:HARRIS CORP

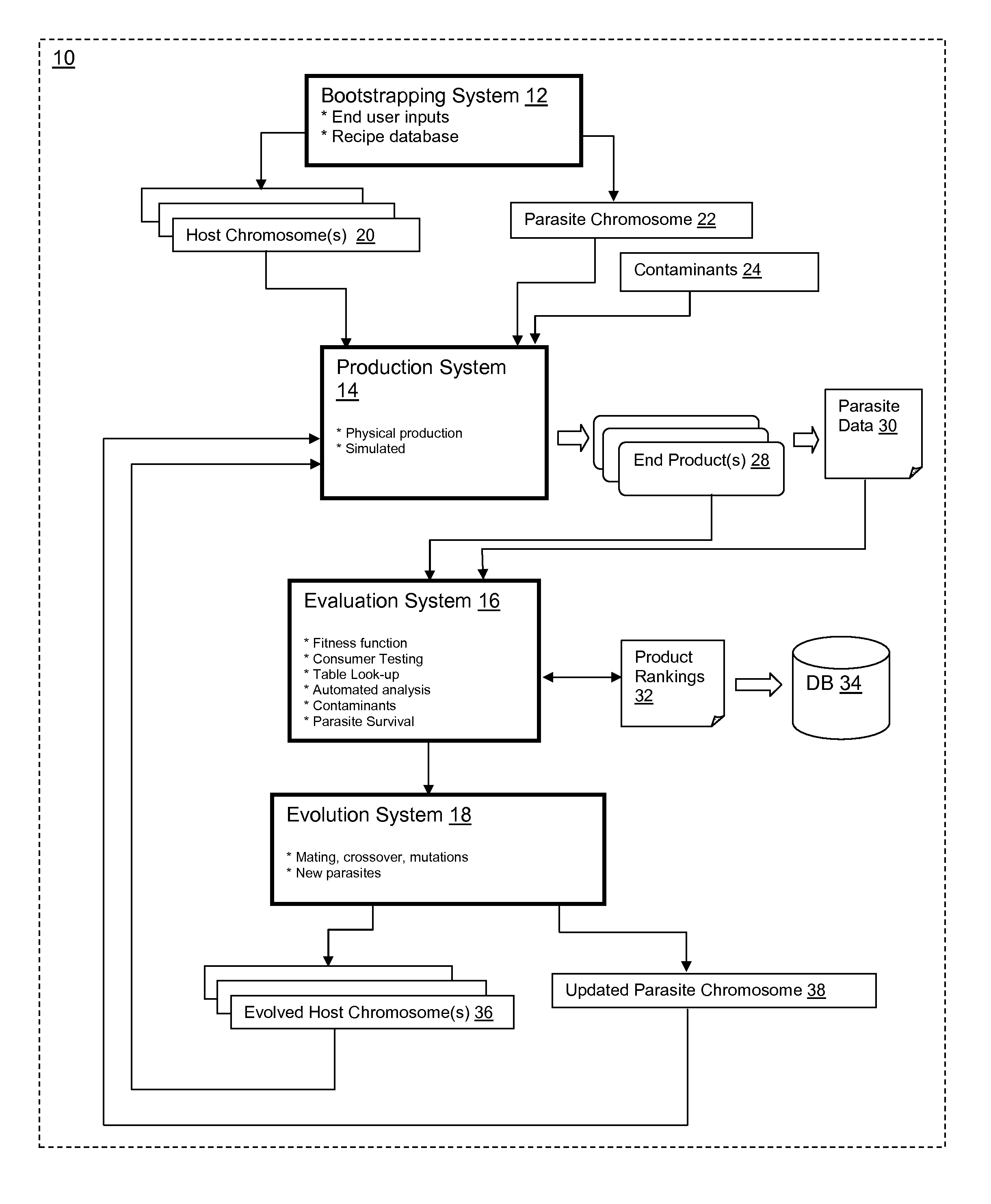

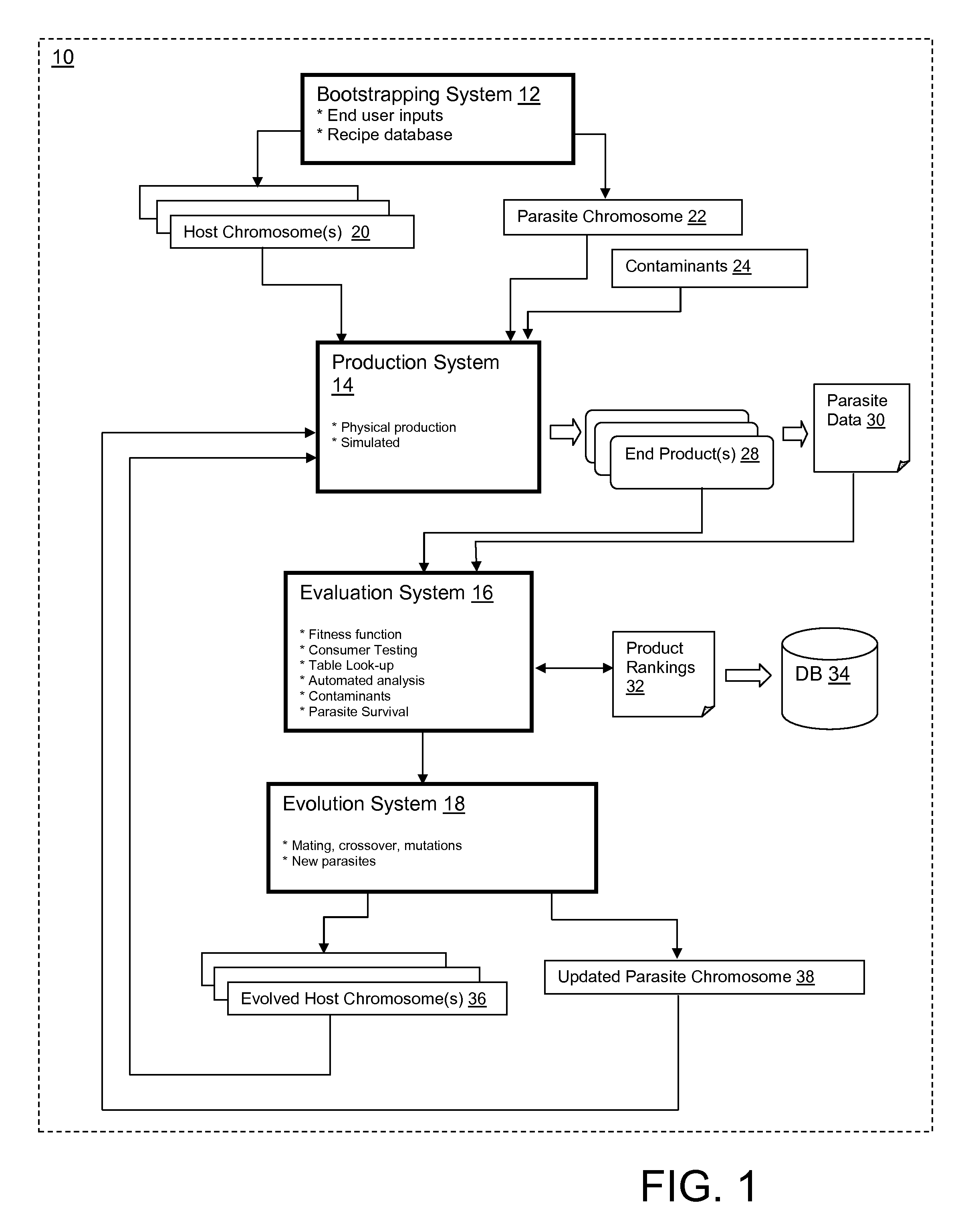

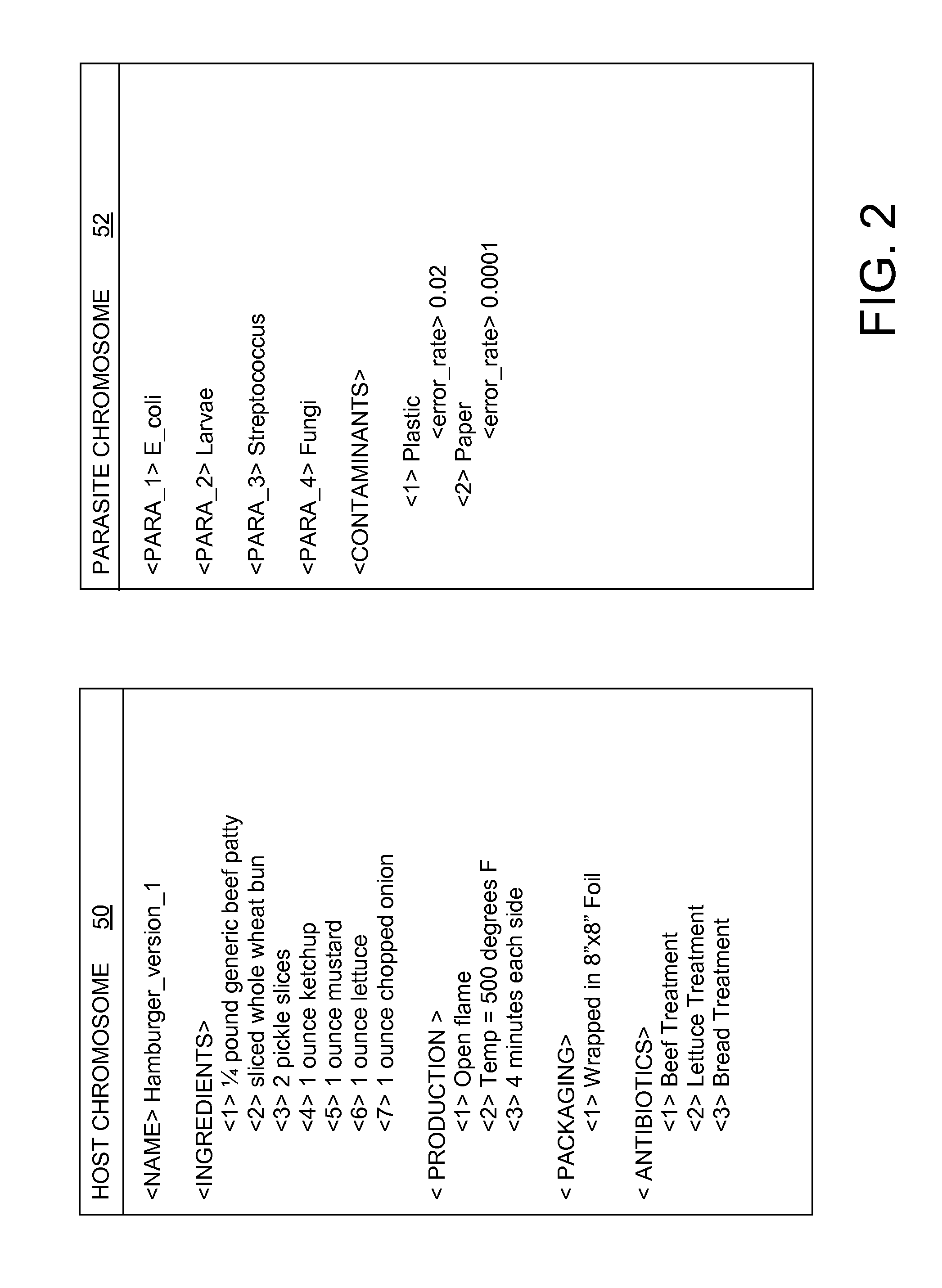

Co-evolutionary product optimization

ActiveUS8718824B2Increase food productionBioreactor/fermenter combinationsBiological substance pretreatmentsPersonalizationEvolutionary systems

A system, method and program product for enhancing individualized and safe food production using an iterative co-evolutionary approach. A system is disclosed that includes a production system for generating a set of end products based on an inputted set of host chromosomes and a parasite chromosome (which may include machine / human contaminants); an evaluation system for evaluating each end product; an evolution system for generating a set of evolved host chromosomes and an updated parasite chromosome; and a mechanism for generating a further set of end products based on the evolved host chromosomes and the updated parasite chromosome.

Owner:IBM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com