Top cover collinear manufacturing process of common and panoramic sunroofs

A panoramic sunroof, sunroof technology, applied in the direction of process efficiency improvement, transportation and packaging, vehicle parts, etc., can solve the problems of high cost, mold development, high maintenance cost, increase mold conversion time, etc., to improve production capacity and shorten molds. The effect of low changeover time and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The traditional compensation scheme for the outer panel of the roof is single-line compensation. In order to take into account common and panoramic sunroof roofs to achieve the same extension sequence, six control lines are used for compensation, such as Figure 8 As shown, 8.1 is a small skylight, 8.2 is a large skylight, and 8.3 is a control line.

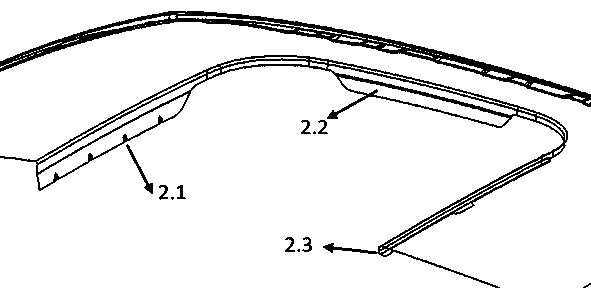

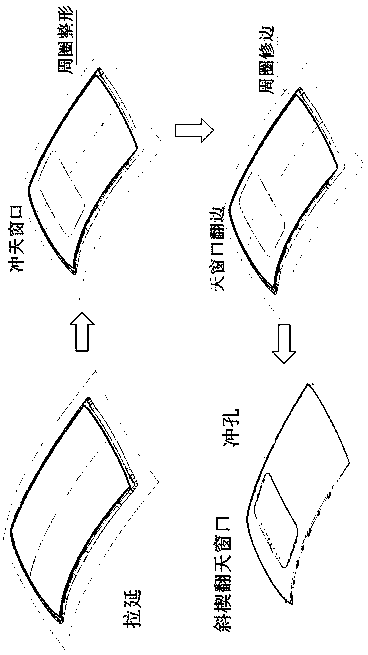

[0039] Through the research and analysis of the mold structure, the sunroof part adopts the design structure of the repaired integrated mold, such as Figure 5 shown. Realize one-step molding of trimming and shaping, and overcome the problems of weak mold strength, lateral force of flanging, easy pulling, difficulty in waste collection, accumulation of waste, and difficulty in picking up parts. Mold structure such as Figure 9 shown.

[0040] Product optimization: increase the strength of the insert, and ensure that the thickness of the convex and concave mold inserts is not less than 8mm through product optimization, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com