Patents

Literature

2641 results about "Product design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Product design as a verb is to create a new product to be sold by a business to its customers. A very broad coefficient and effective generation and development of ideas through a process that leads to new products. Thus, it is a major aspect of new product development.

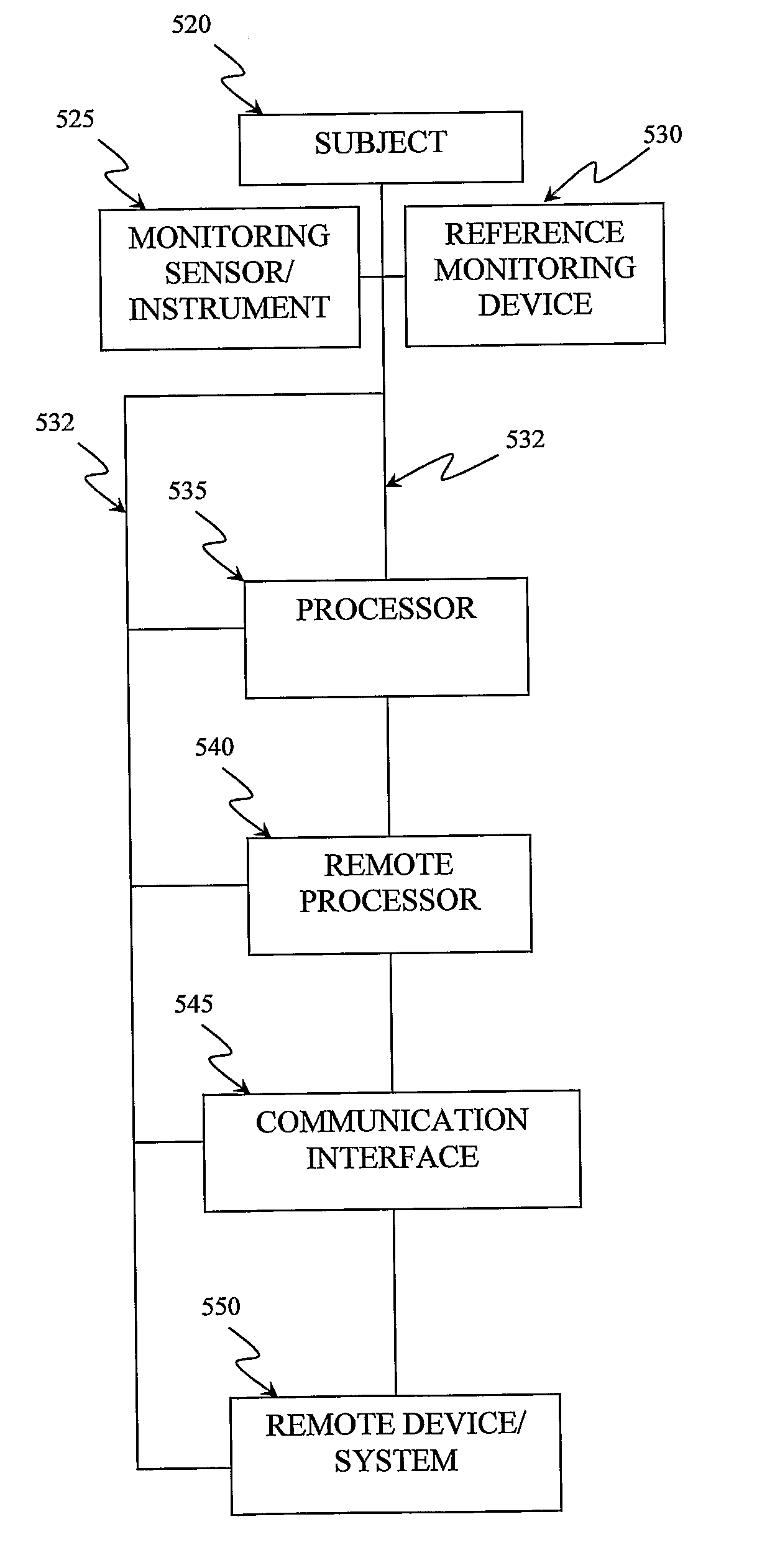

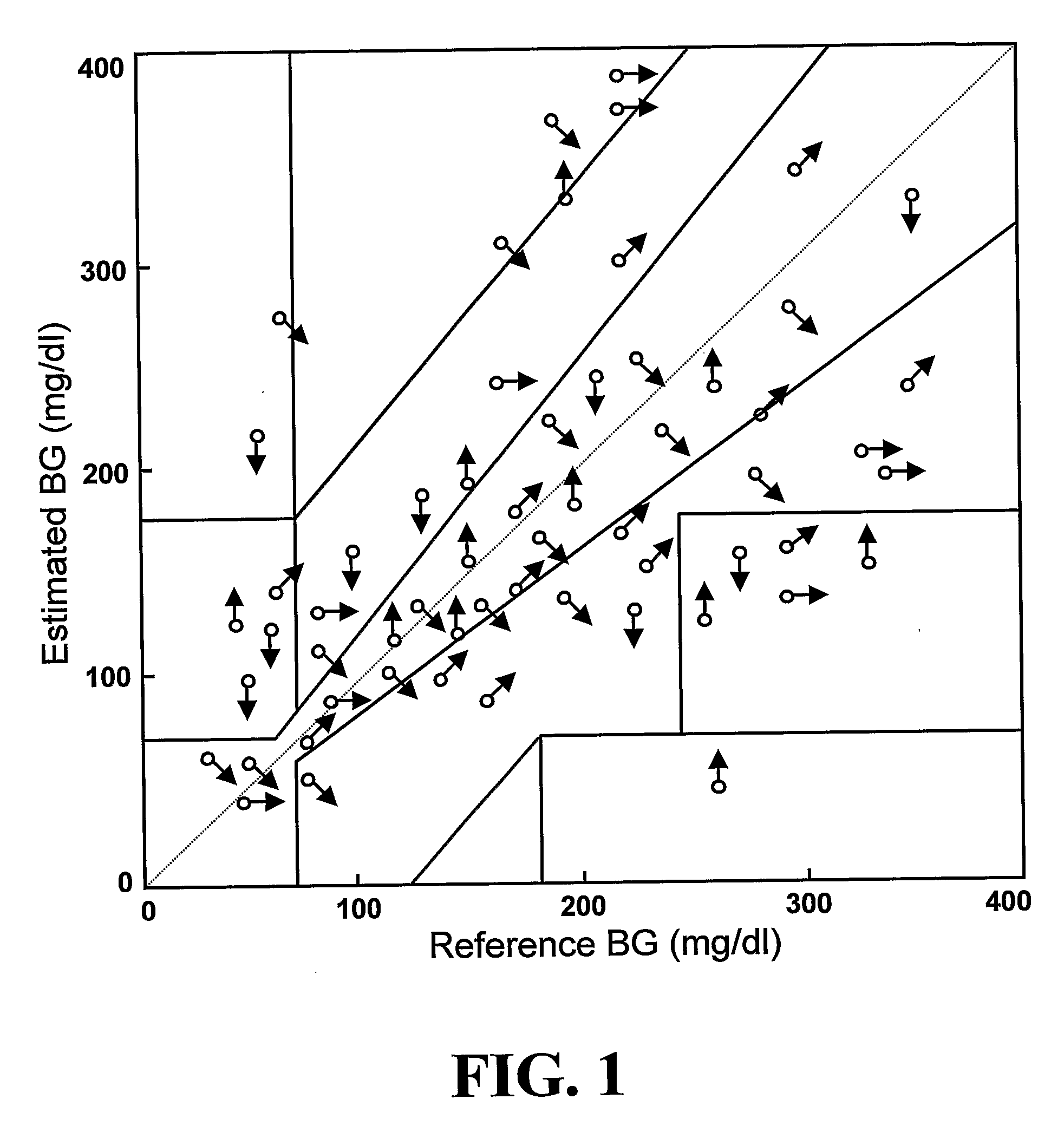

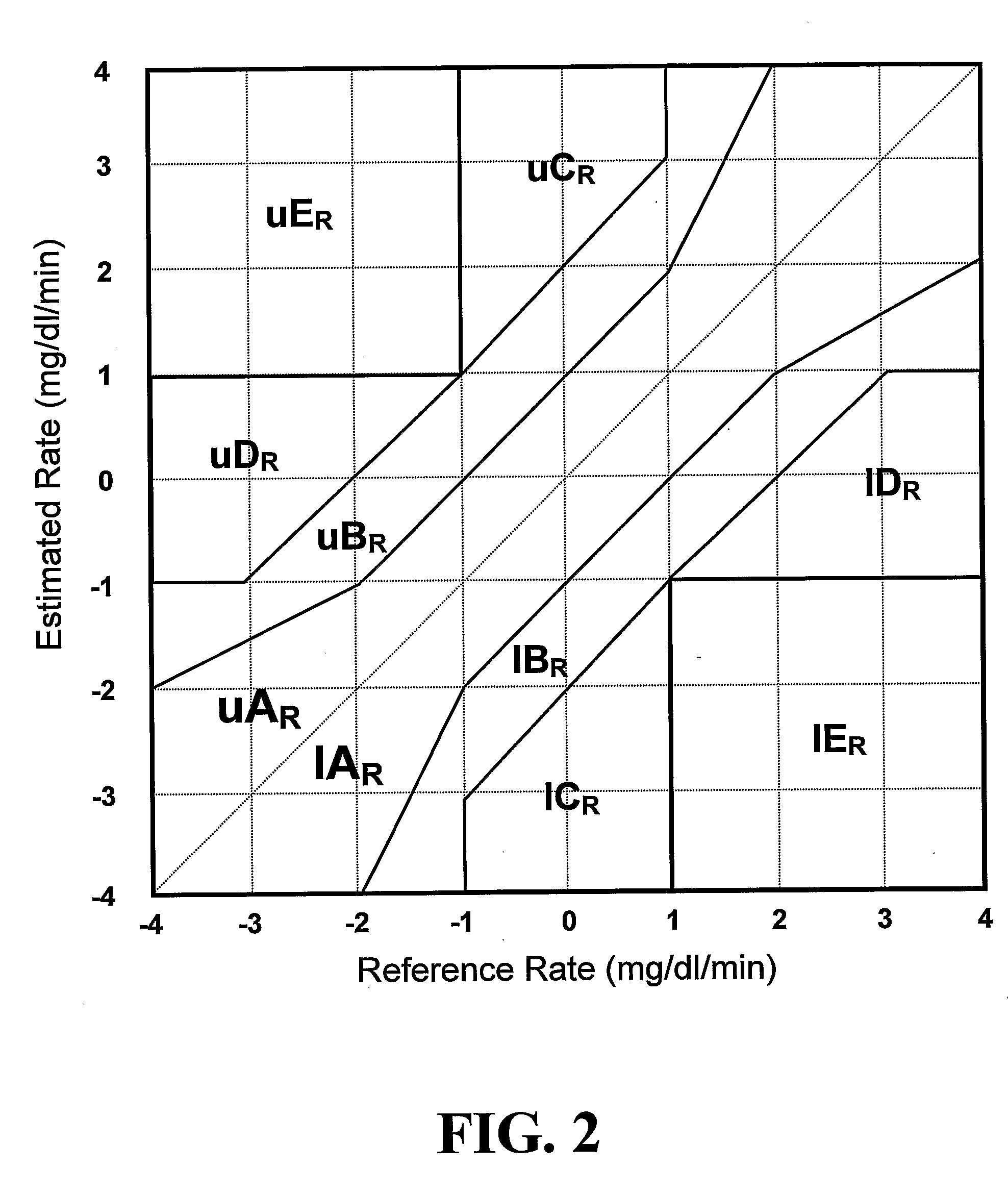

Method, System and Computer Program Product for Evaluating the Accuracy of Blood Glucose Monitoring Sensors/Devices

ActiveUS20070232878A1Microbiological testing/measurementDiagnostic recording/measuringTime lagGlucose sensors

Continuous Glucose Error-Grid Analysis (CG-EGA) method, system or computer program product designed for evaluation of continuous glucose sensors providing frequent BG readings. The CG-EGA estimates the precision of such sensors / devices in terms of both BG values and temporal characteristics of BG fluctuation. The CG-EPA may account for, among other things, specifics of process characterization (location, speed and direction), and for biological limitations of the observed processes (time lags associated with interstitial sensors).

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

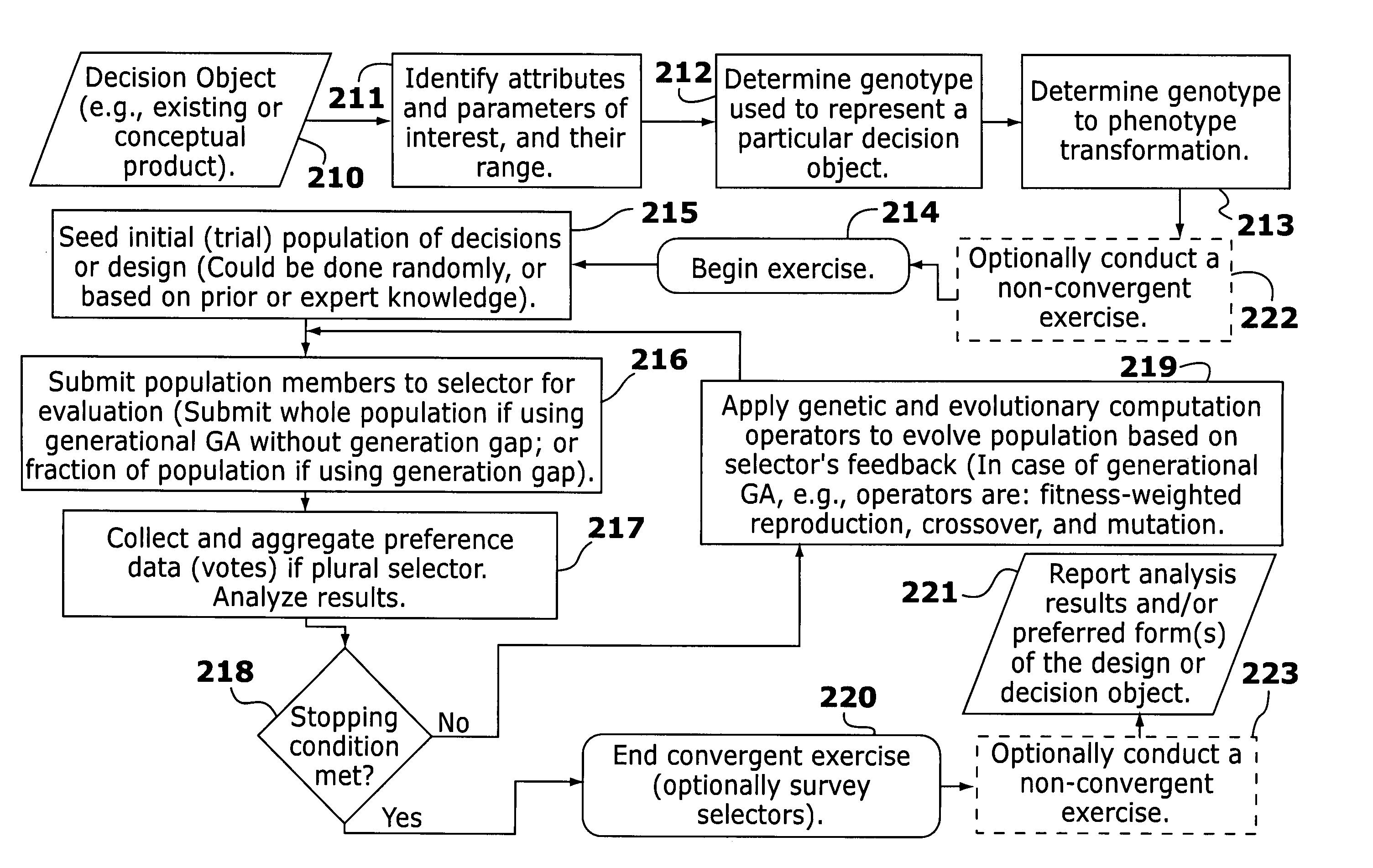

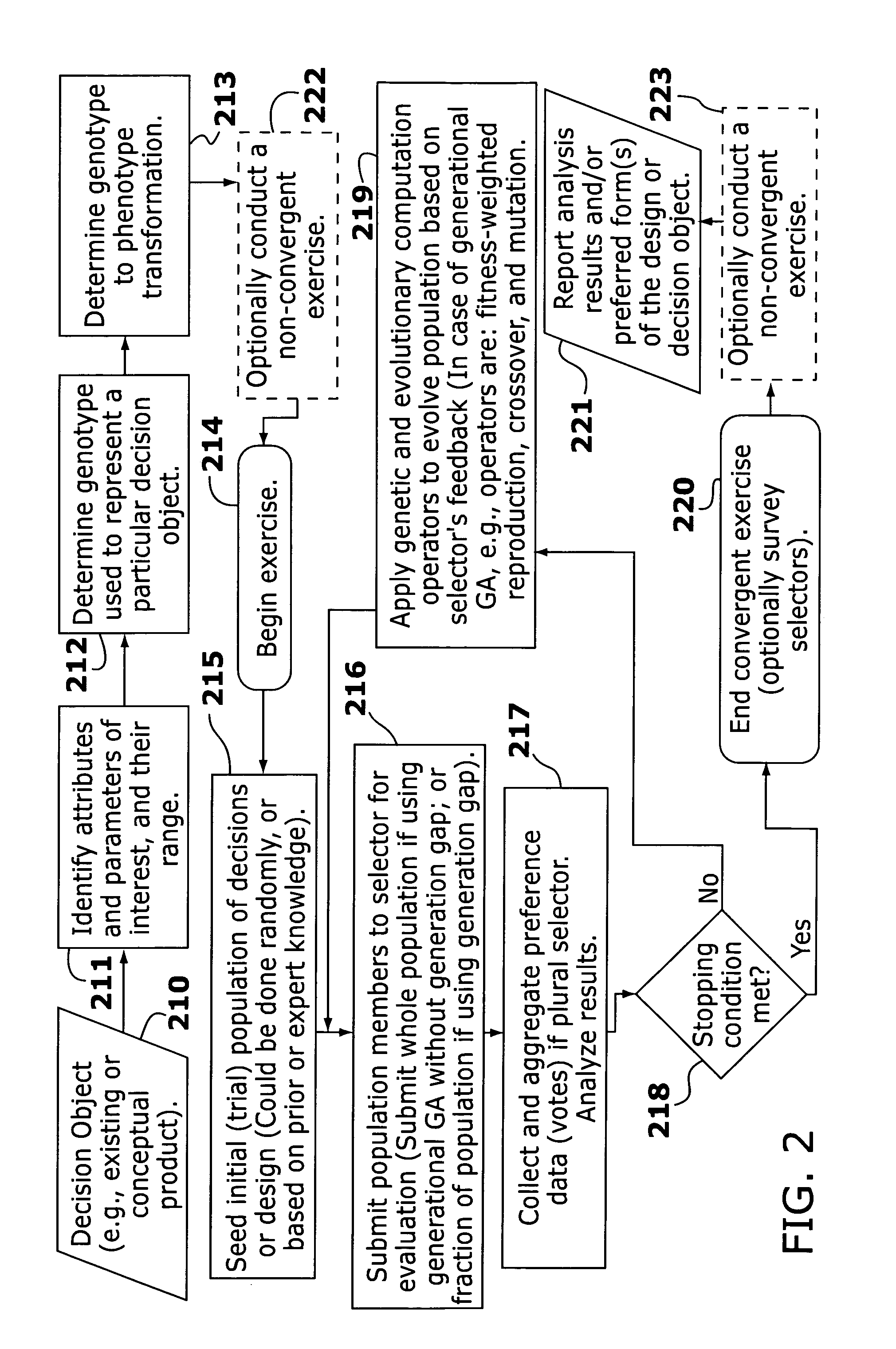

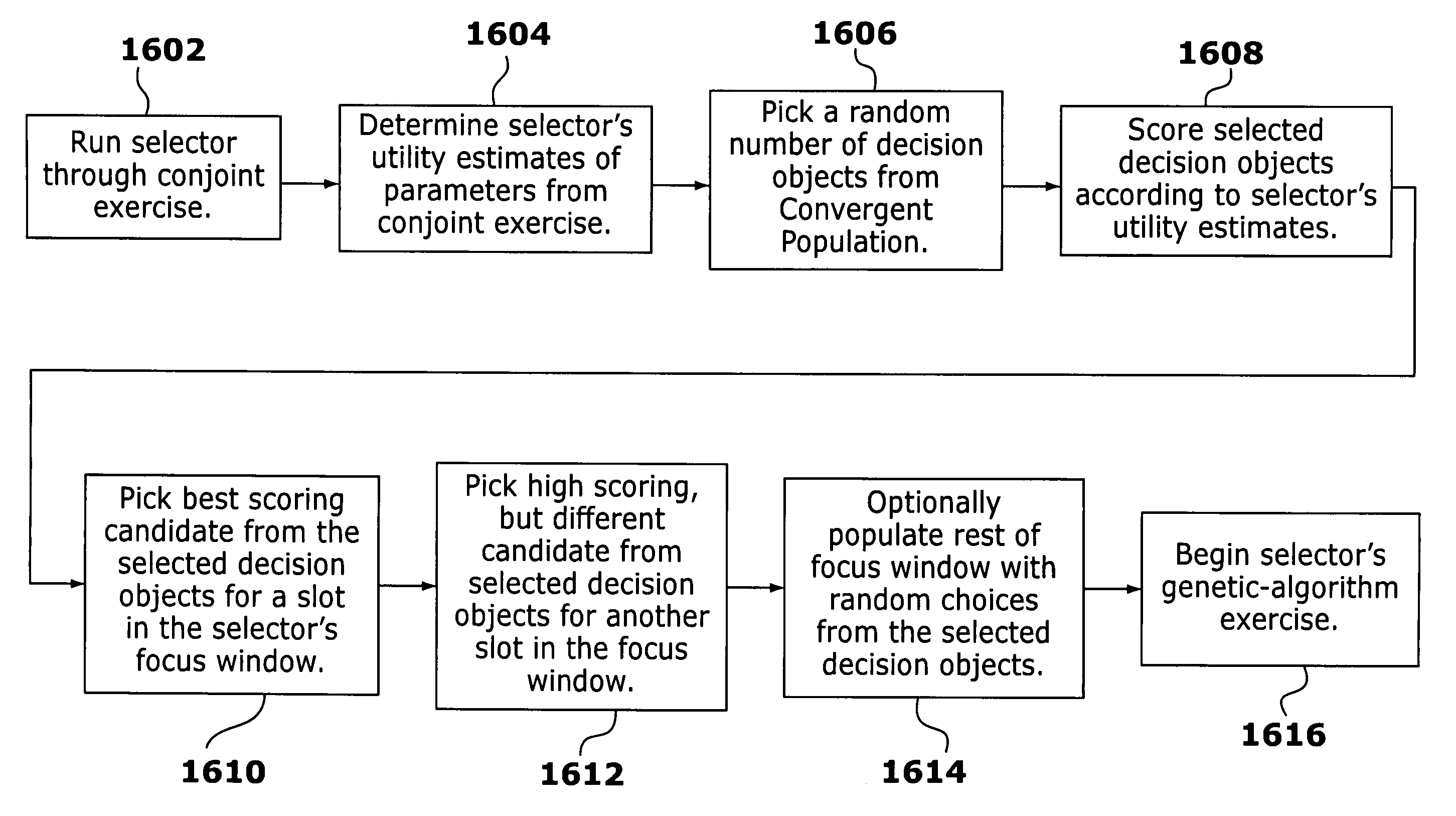

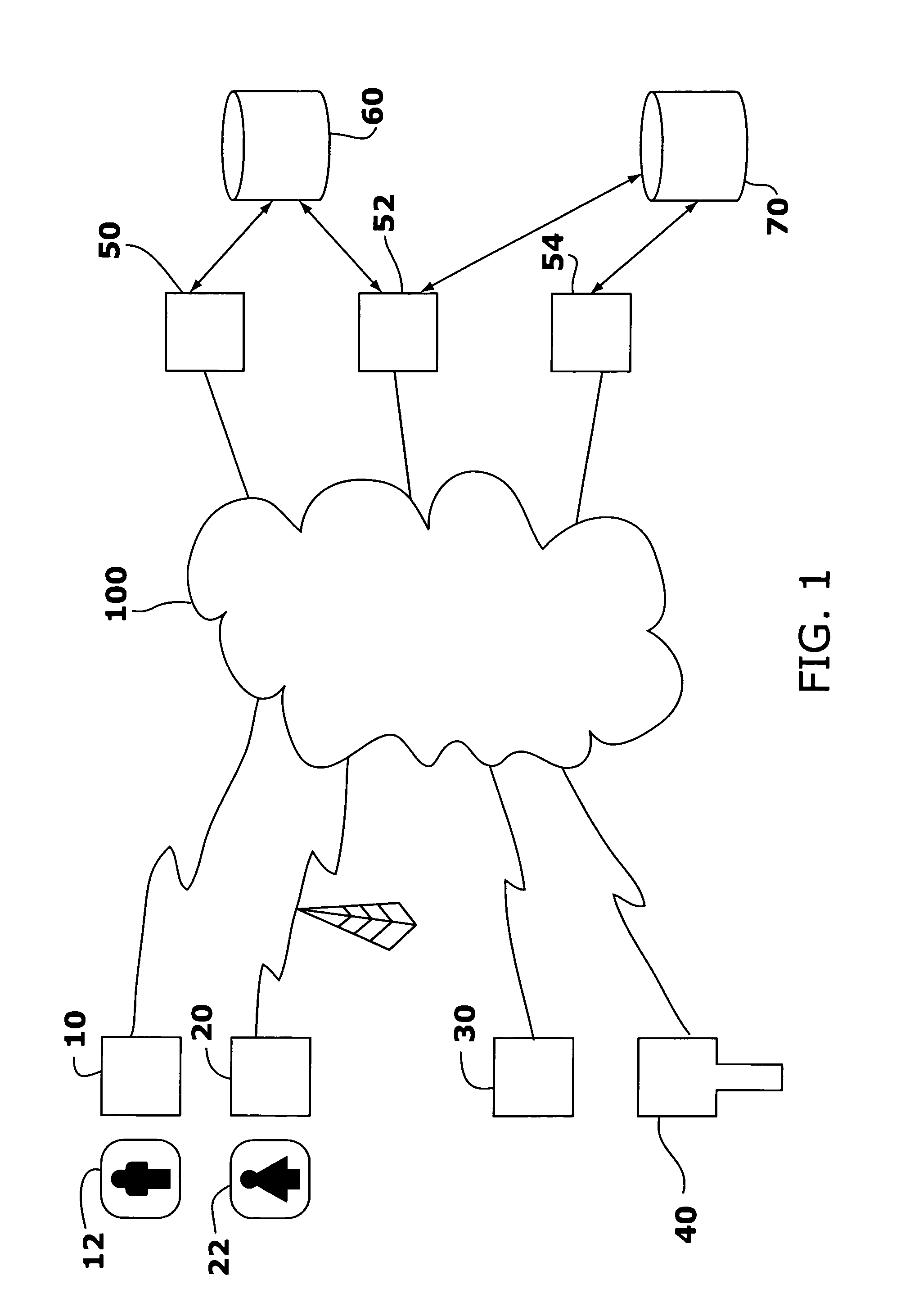

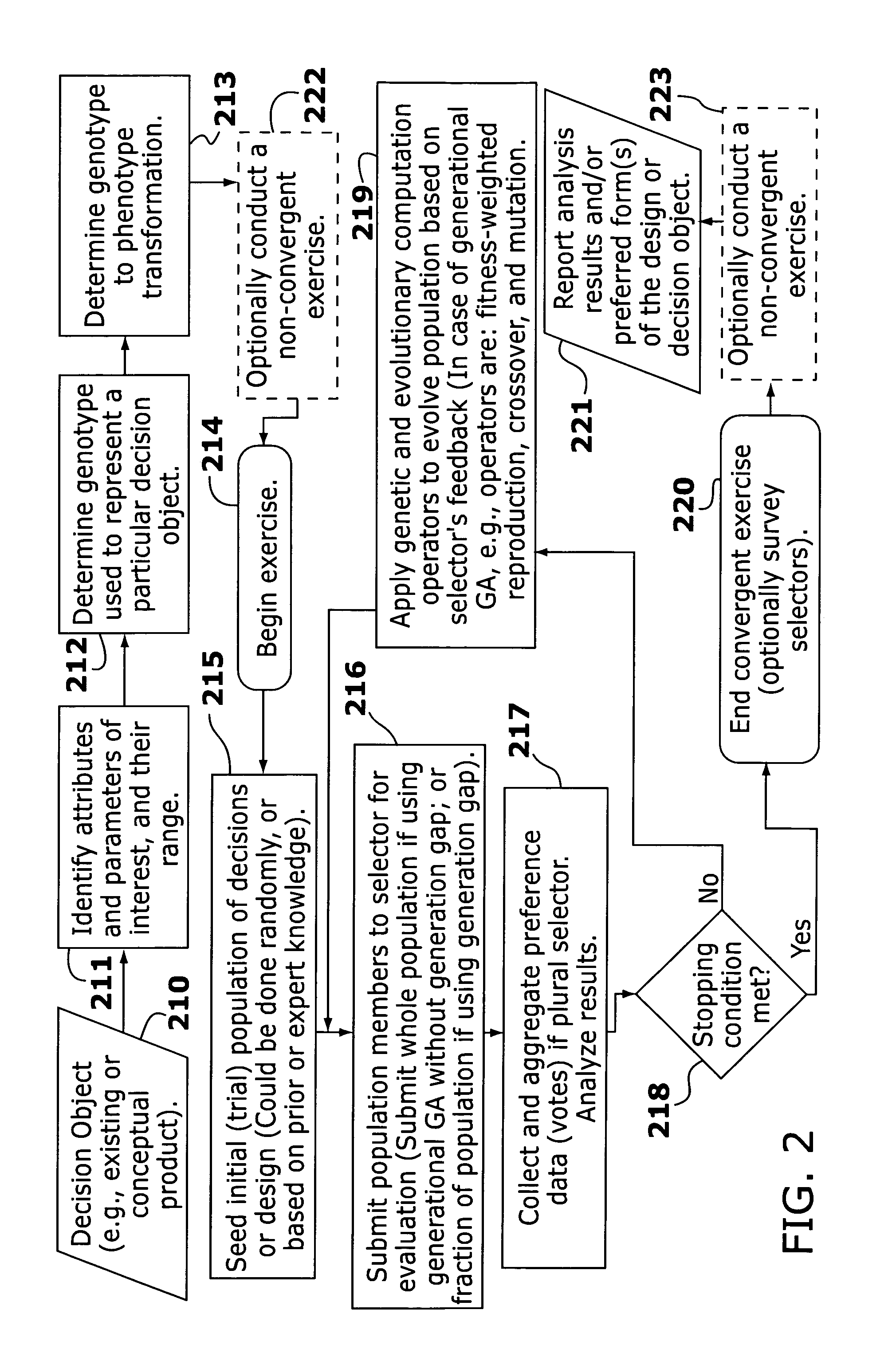

Determining design preferences of a group

ActiveUS20050261953A1Efficient analysisEasy to recruitMarket predictionsDigital computer detailsKnowledge managementTest group

Disclosed are methods and apparatus for conducting market research and developing product designs. The methods involve generating and presenting, typically electronically, generations of design alternatives to persons participating in the design, selection, or market research exercise. The participants transmit data indicative of their preferences among or between the presented design alternatives. Some of the data is used to conduct a conjoint analysis or non-convergent exercise to investigate the drivers of the preferences of the group or its members, and at least a portion are used to derive follow-on generations of design alternatives or proposals. The follow-on designs are preferably generated through the use of an evolutionary or genetic computer program, influenced by the participants' preferences. The process results in the generation of one or more preferred product forms and information permitting a better understanding of what attributes of the product influence the preferences of the test group members.

Owner:NIELSEN CONSUMER LLC

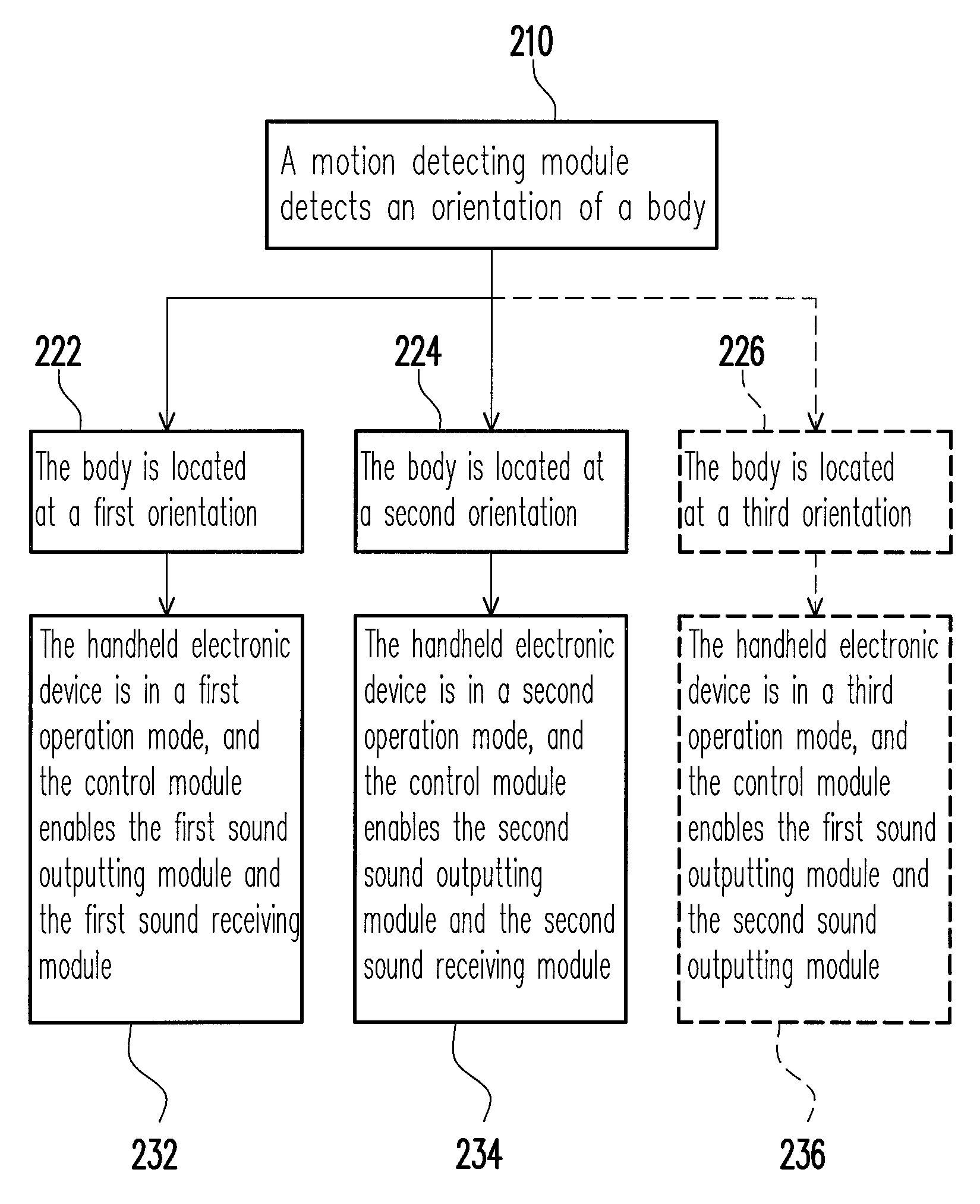

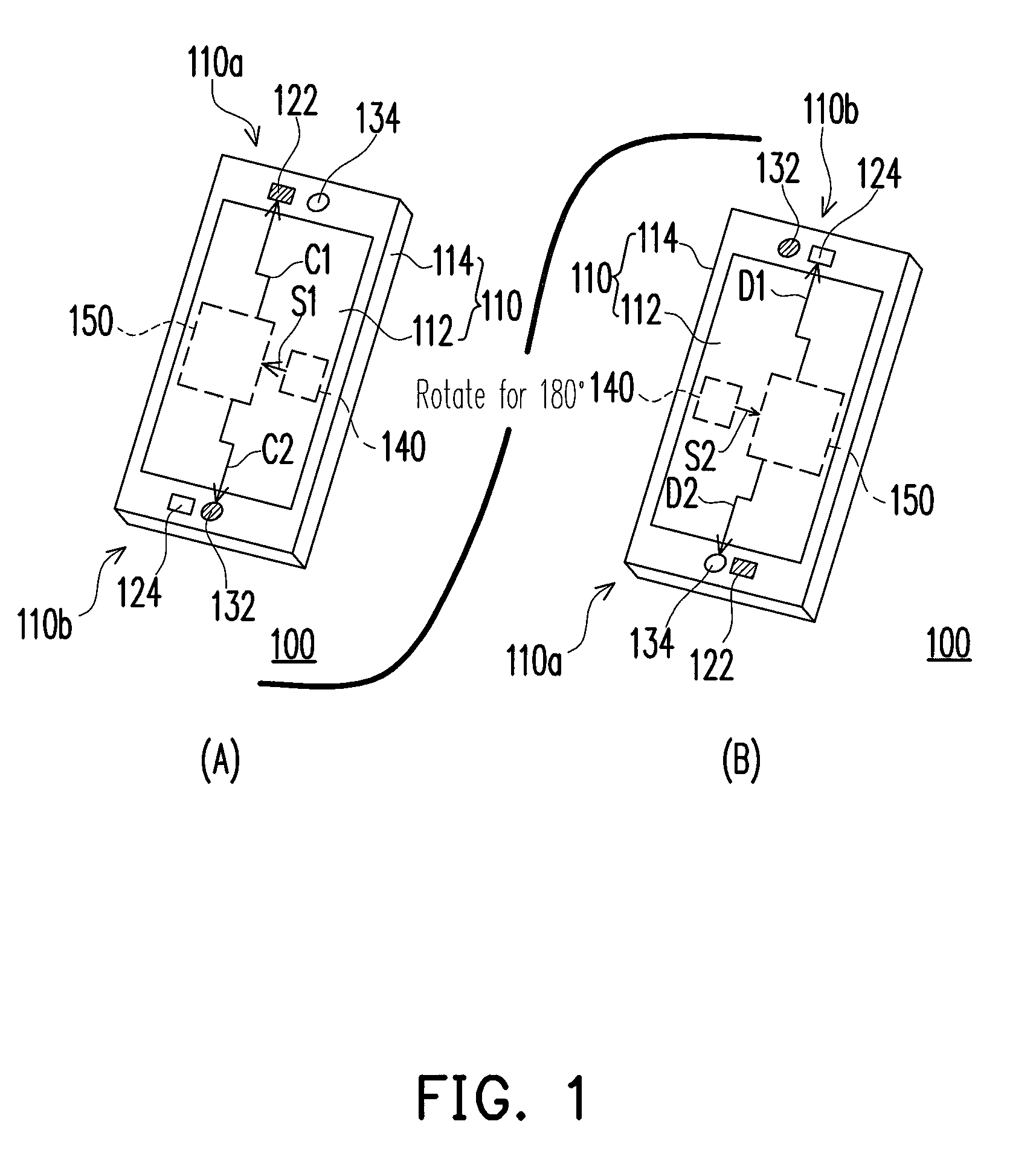

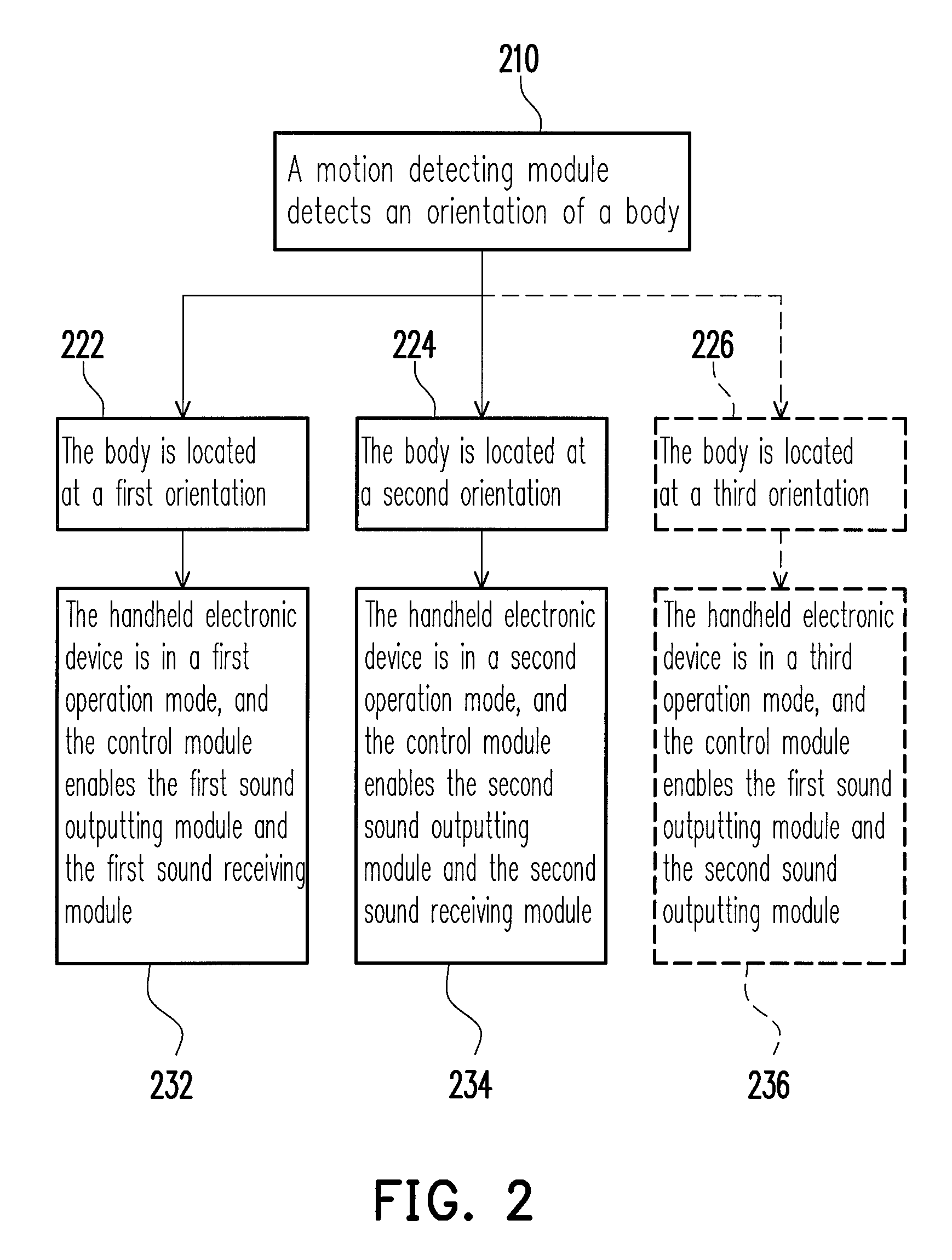

Handheld electronic device and operating method thereof

ActiveUS8374595B2Interconnection arrangementsDigital data processing detailsComputer moduleElectric equipment

A handheld electronic device and an operating method thereof are provided, in which at least two sets of sound outputting modules and sound receiving modules are disposed in the handheld electronic device. The operating method detects an orientation of the handheld electronic device by a motion detecting module and enables different sets of the sound outputting modules and the sound receiving modules according to a variation of the orientation of the handheld electronic device, so as to change a direction of a call operation, and thus a user can successfully make a phone call, even if the handheld electronic device is held upside down. Furthermore, the operating method can control the sound outputting modules and the sound receiving modules individually or collectively according to actual demands to achieve a multifunctional product design.

Owner:HTC CORP

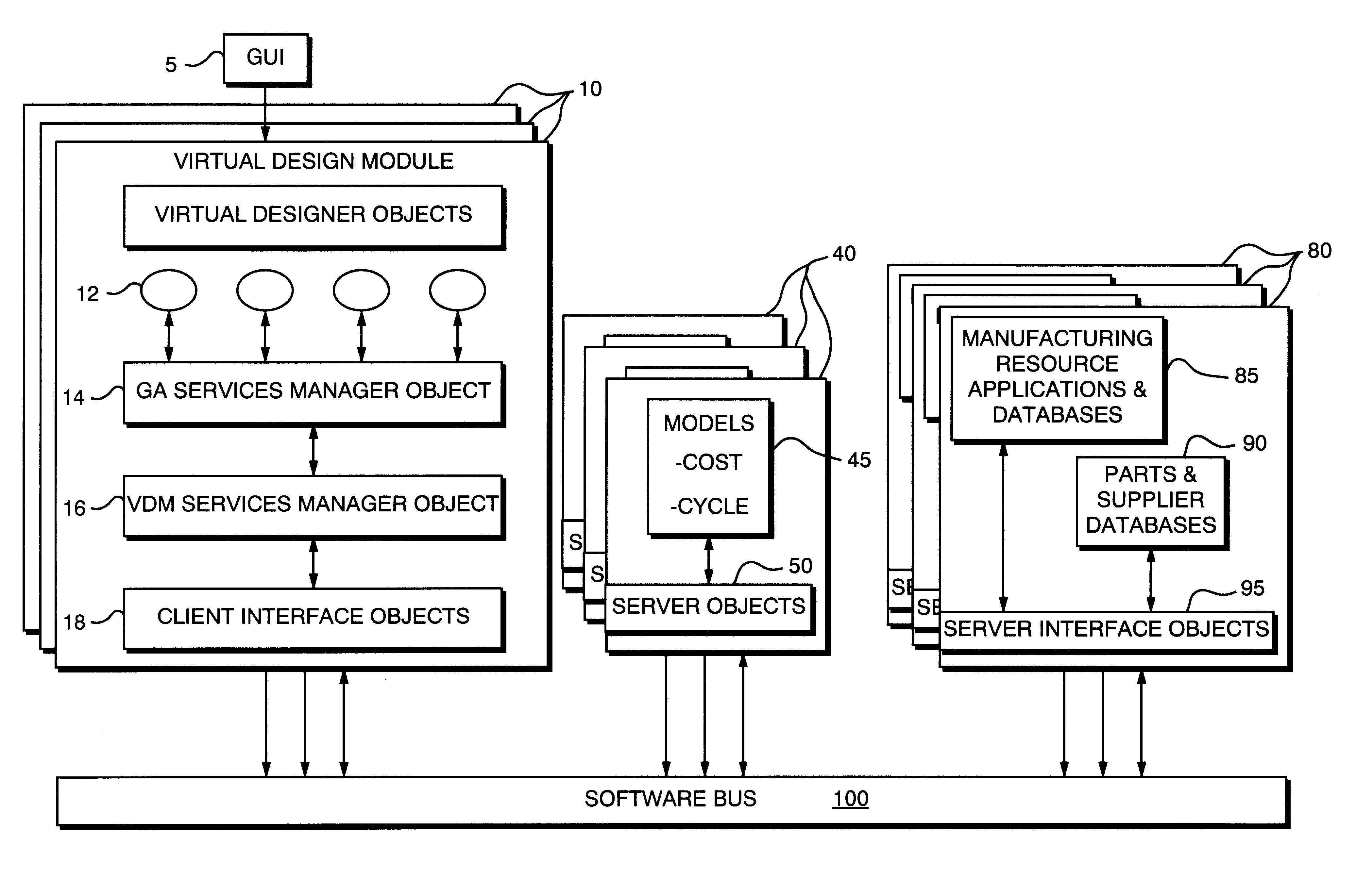

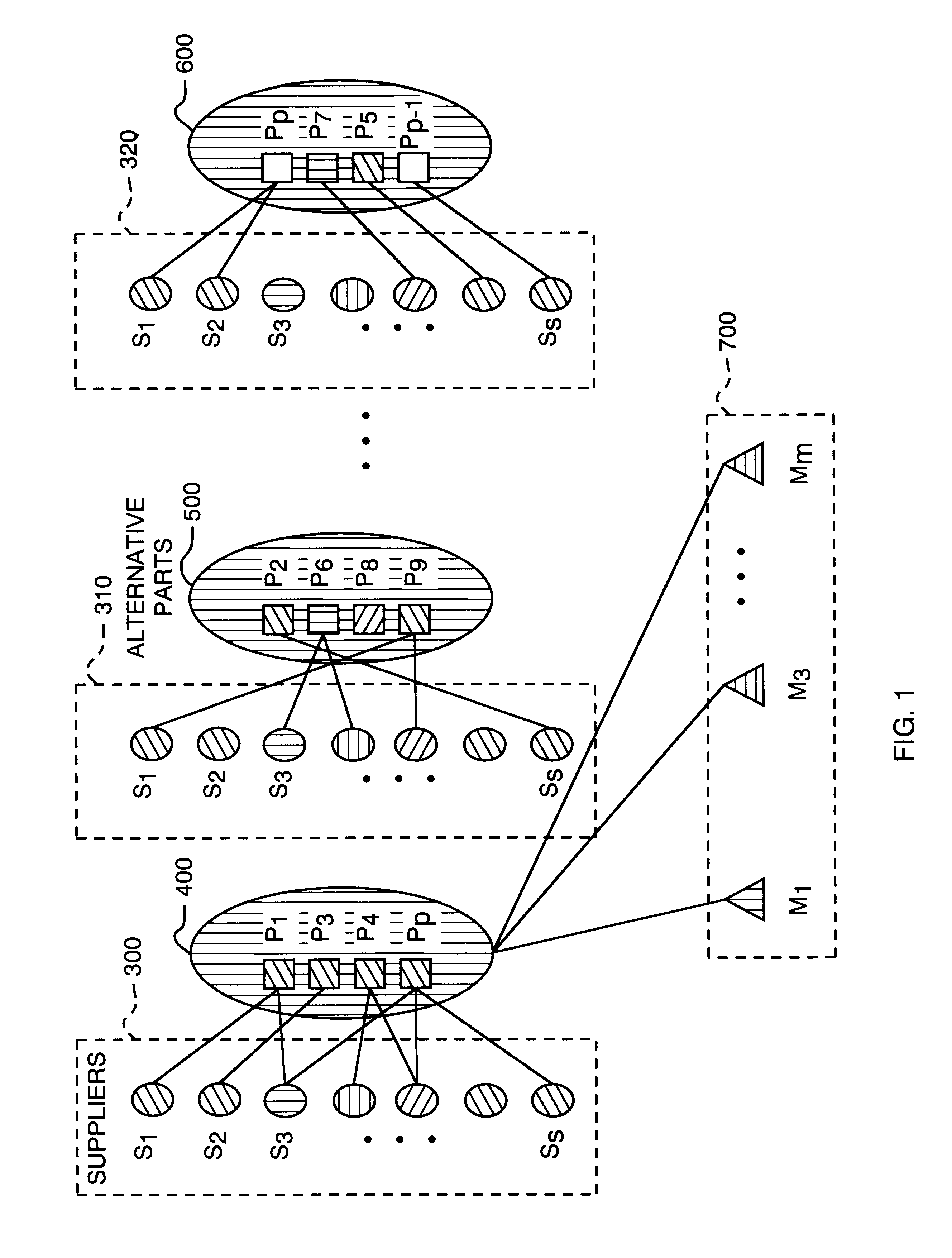

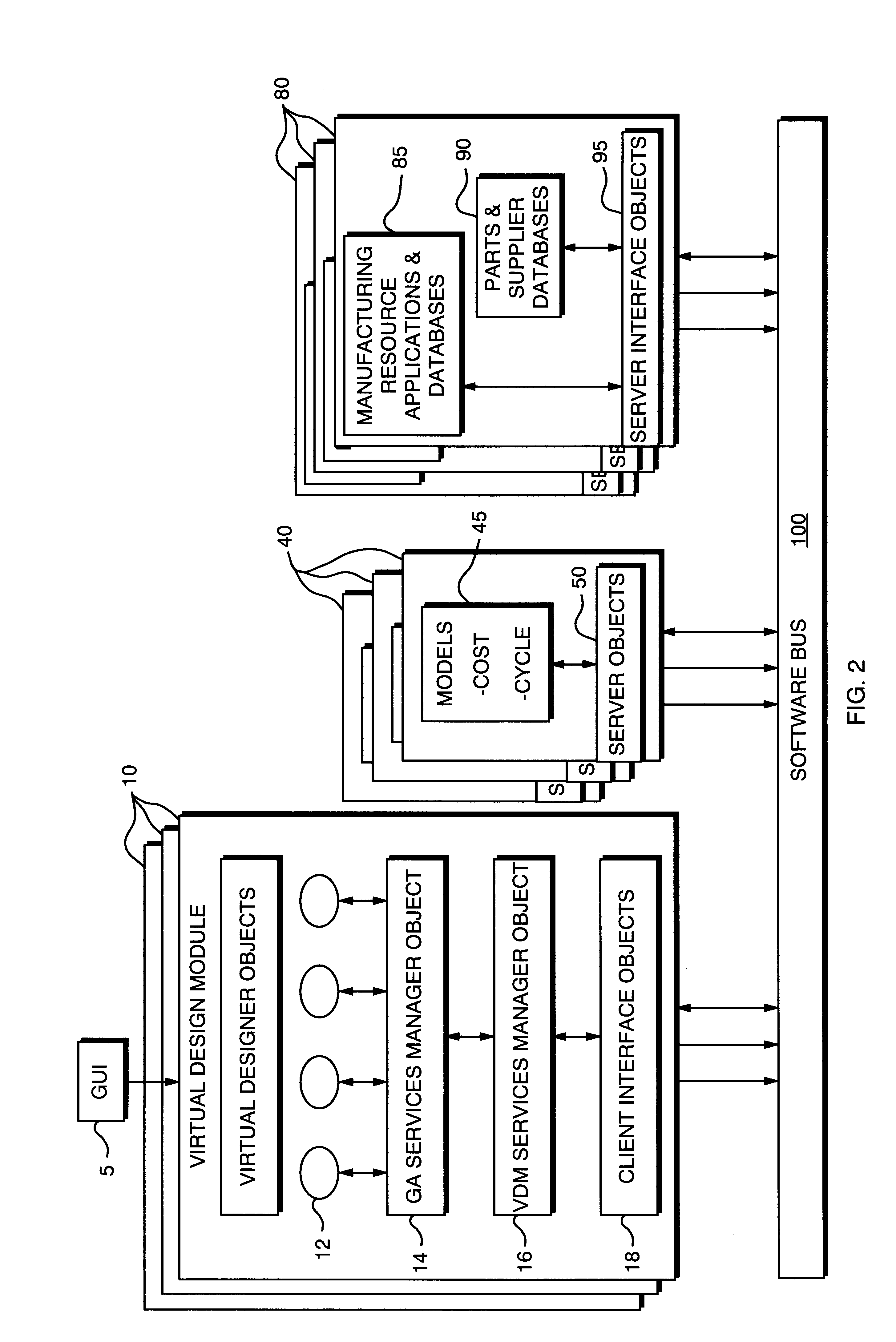

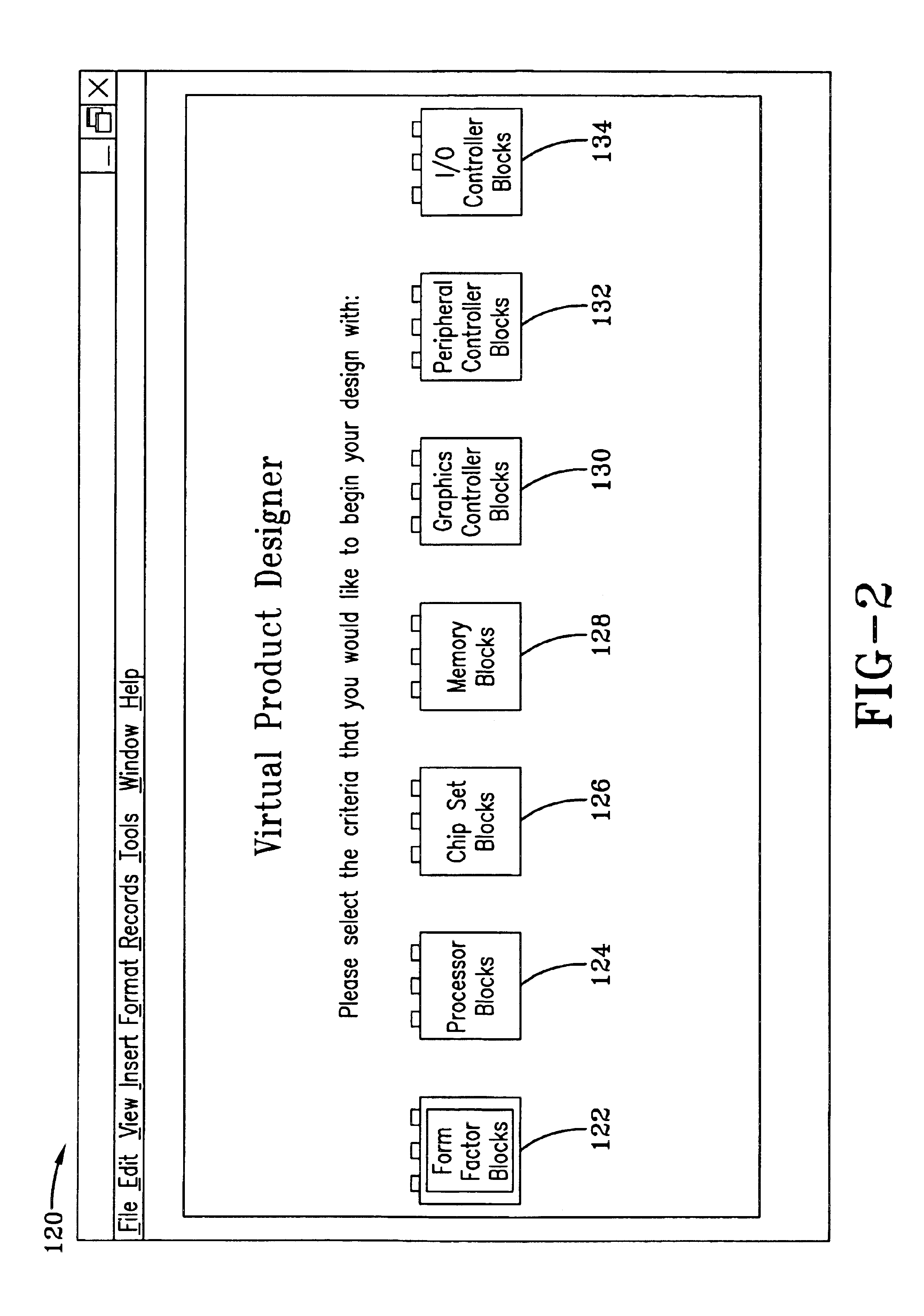

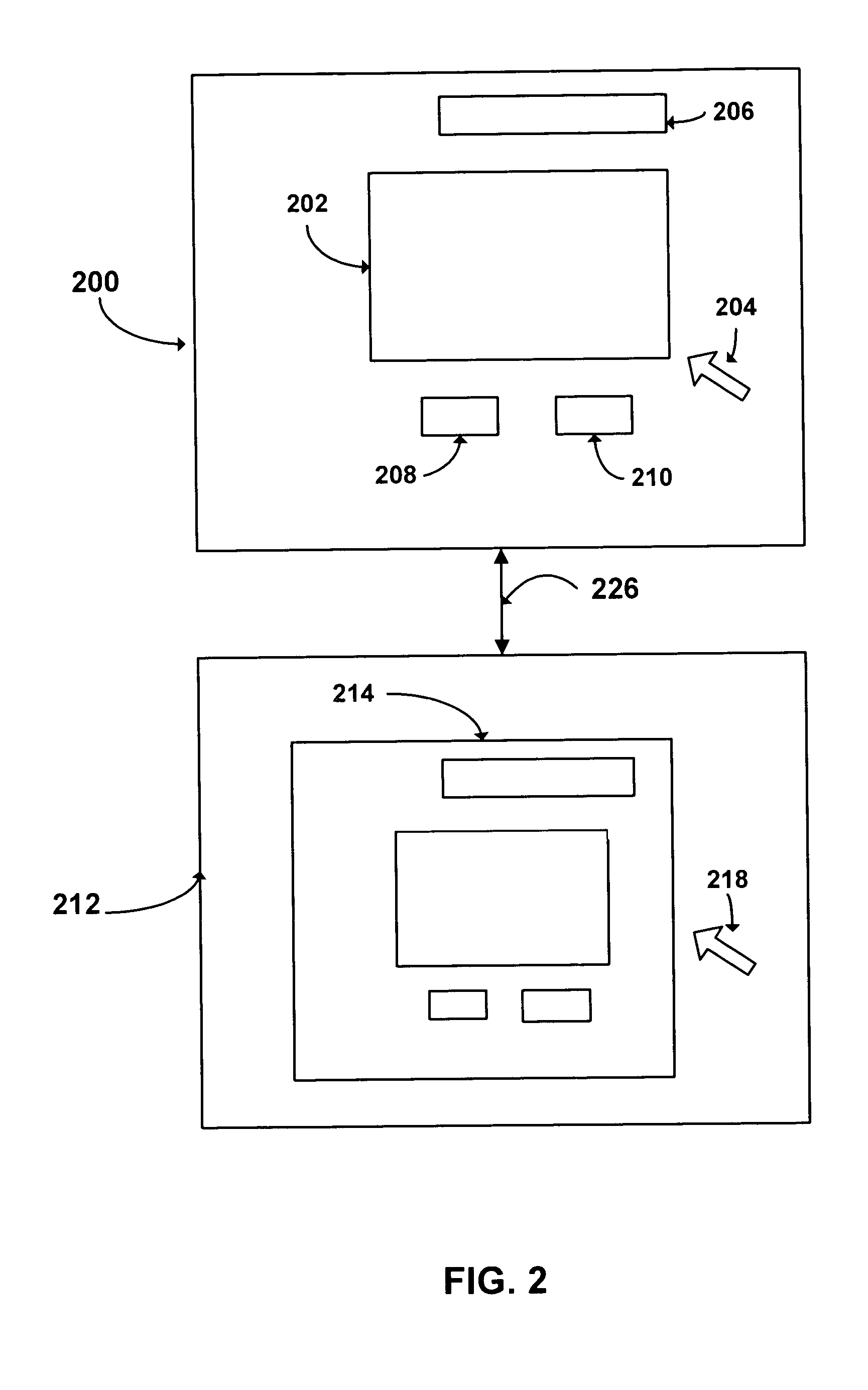

Virtual design module

A Virtual Design Module (VDM) used in a networked design environment generates manufactured product designs that are near optimal in terms of cost and production cycle time by using design data files containing alternative parts and manufacturers information. Numerous product design alternatives are considered and evaluated in terms of design-manufacturing-parts-supplier feasibility and real-time information on cost and production cycle time for realization. The VDM generates a population of new designs with appropriate board design information to allow for design-manufacturer-supplier decision making and determines the feasibility of each member of the current generation of designs and rejects designs that are not feasible. The VDM triggers Mobile Software Agents (MSA) that obtain data for parts availability, cost, lead time and manufacturer data for manufacturing availability, cost and lead time for each feasible member of the current generation of designs and return the data. In one application for printed circuit board design, the VDM evaluates each member of the current generation of designs by calculating cost, lead-time and value using a J function. The VDM then improves board designs through selection and use of board design modifiers. The process continues until optimized designs are obtained. Optimized board designs are output as results to an operator.

Owner:RENESSELAER POLYTECHNIC INST

Determining design preferences of a group

ActiveUS7308418B2Efficient analysisEasy to recruitMarket predictionsDigital computer detailsMarket placeConjoint analysis

Disclosed are methods and apparatus for conducting market research and developing product designs. The methods involve generating and presenting, typically electronically, generations of design alternatives to persons participating in the design, selection, or market research exercise. The participants transmit data indicative of their preferences among or between the presented design alternatives. Some of the data is used to conduct a conjoint analysis or non-convergent exercise to investigate the drivers of the preferences of the group or its members, and at least a portion are used to derive follow-on generations of design alternatives or proposals. The follow-on designs are preferably generated through the use of an evolutionary or genetic computer program, influenced by the participants' preferences. The process results in the generation of one or more preferred product forms and information permitting a better understanding of what attributes of the product influence the preferences of the test group members.

Owner:NIELSEN CONSUMER LLC

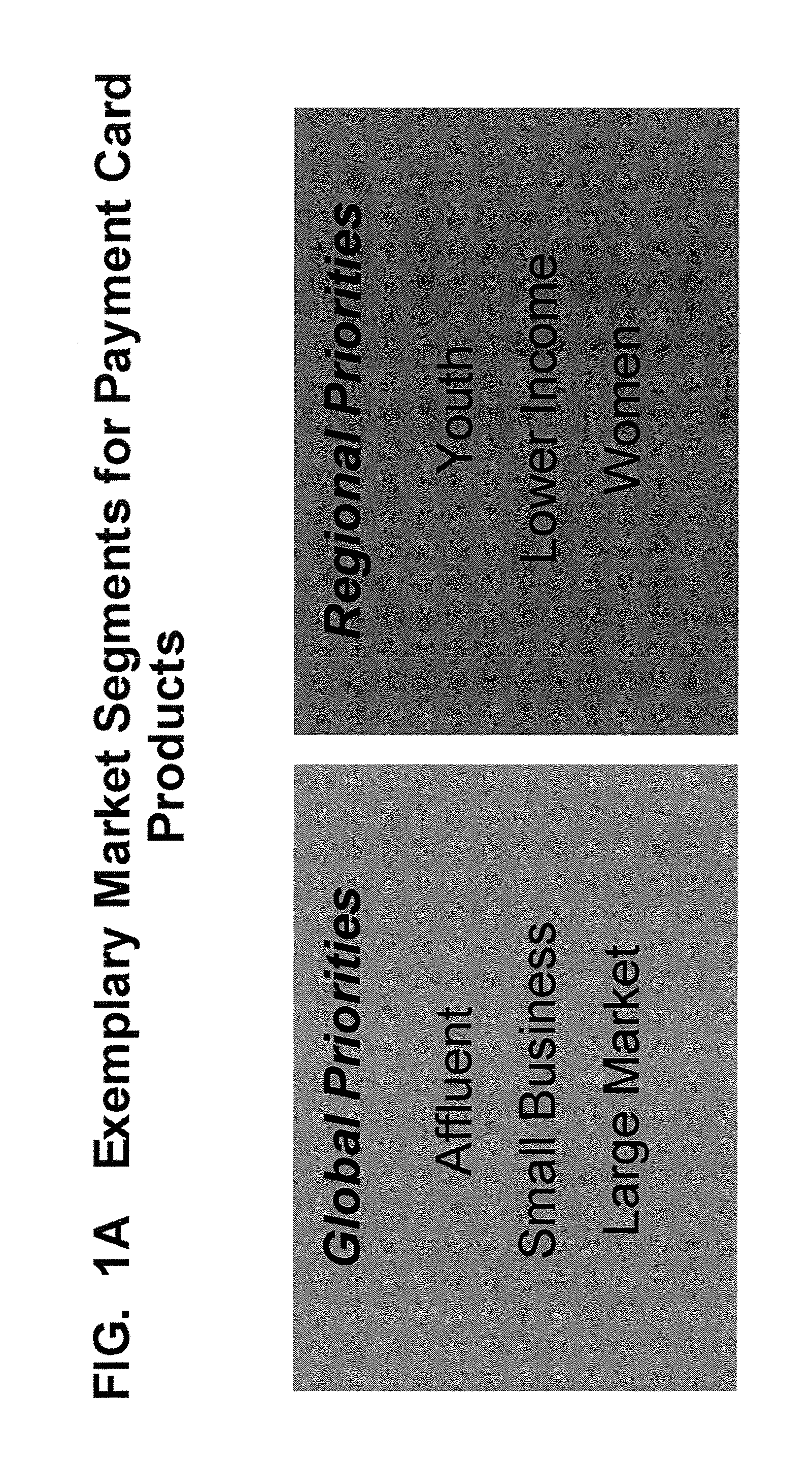

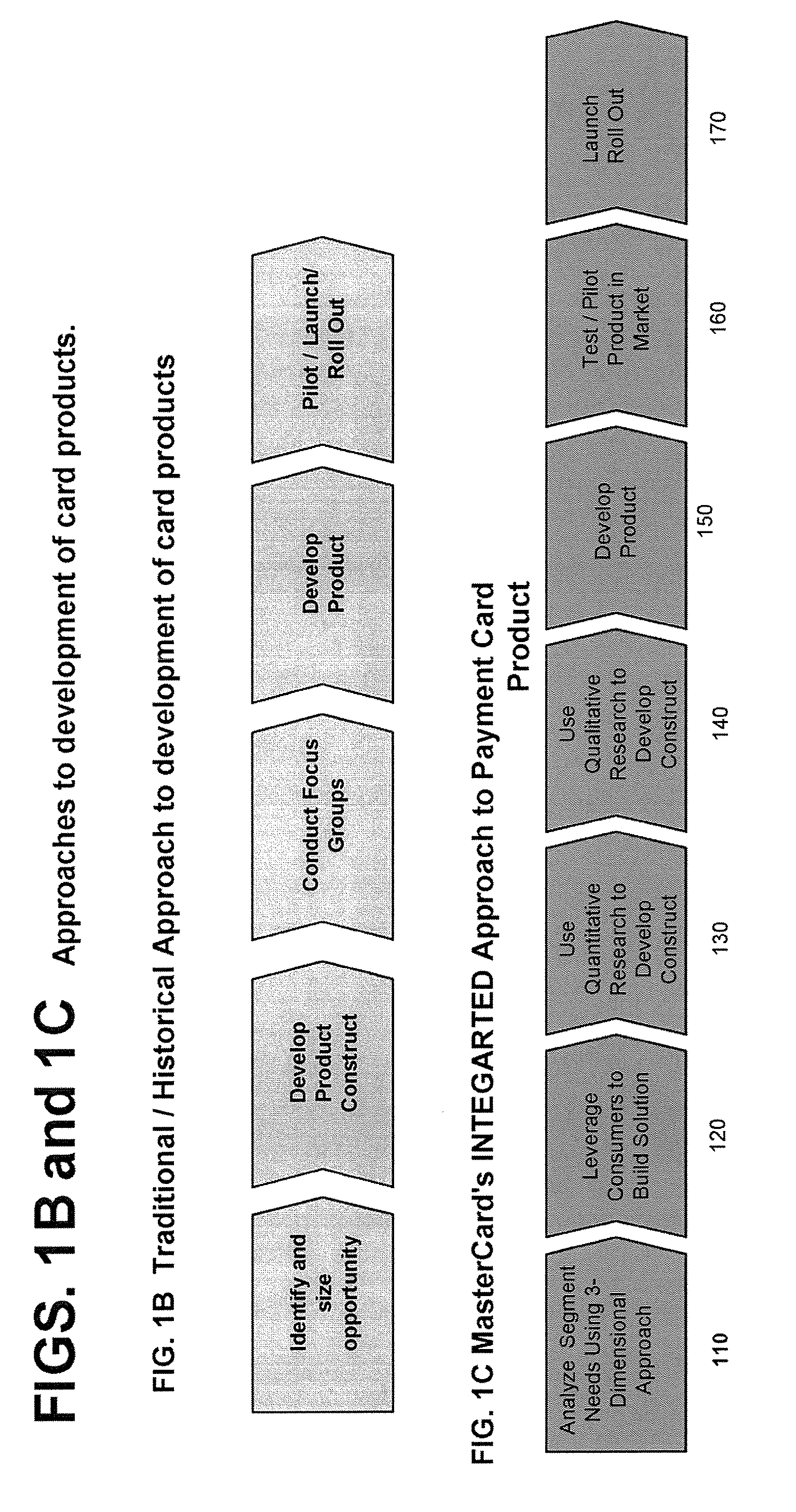

Systems And Methods For Segment-Based Payment Card Solutions

A payment card product targeted to specific consumer market segments is provided. The payment card product has features, benefits and functions that are responsive to consumer needs, aspirations and habits, which evolve over time and across consumer market segments. The consumer market segments are comprehensively characterized using a combination of demographic, attitudinal and behavioral analyses and research. Consumer ideation processes used in product design ensure that the card features, benefits and functions are relevant to consumers. Quantitative methods are used to optimize the product design with respect to consumer market segment characteristics.

Owner:MASTERCARD INT INC

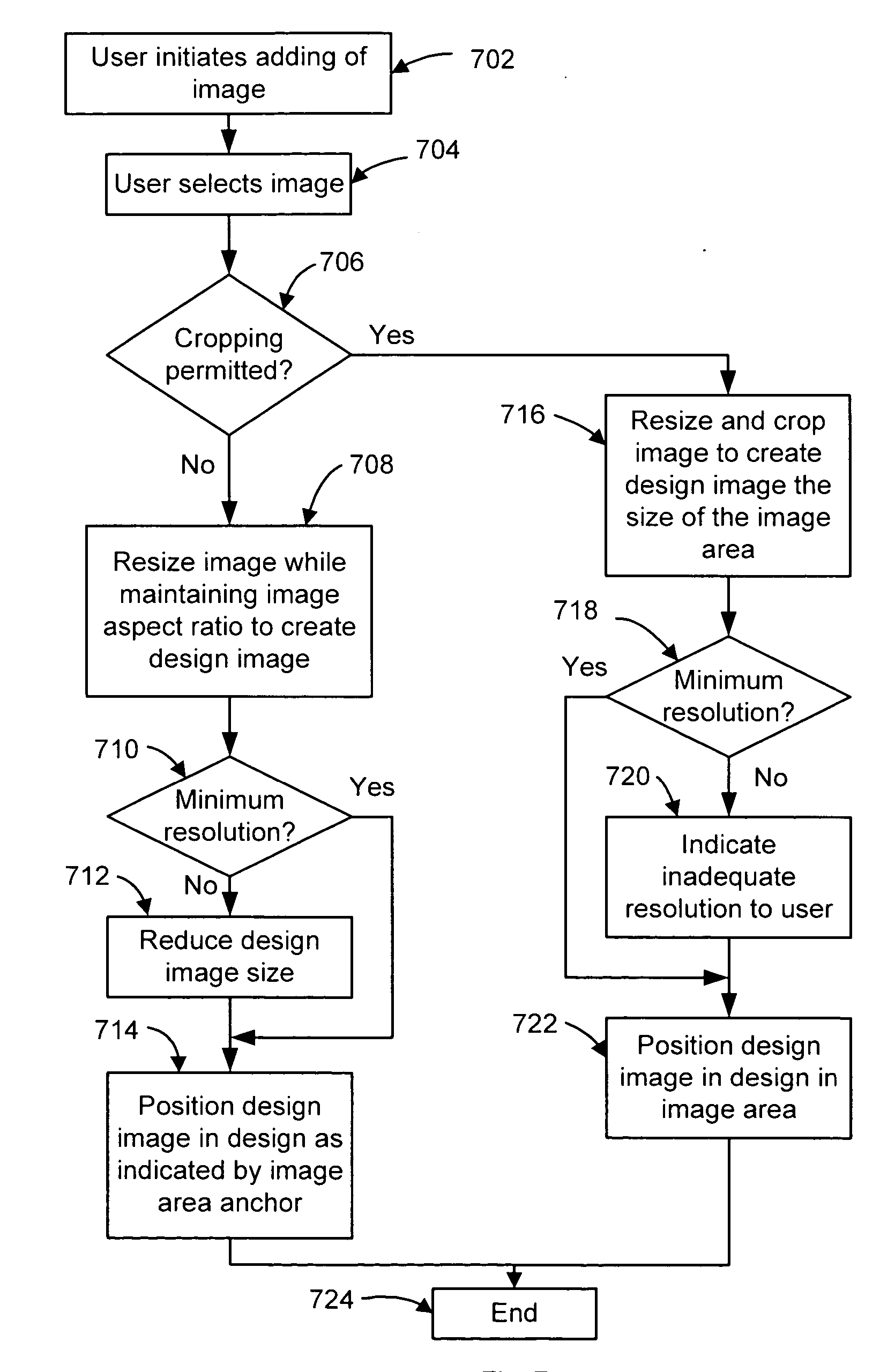

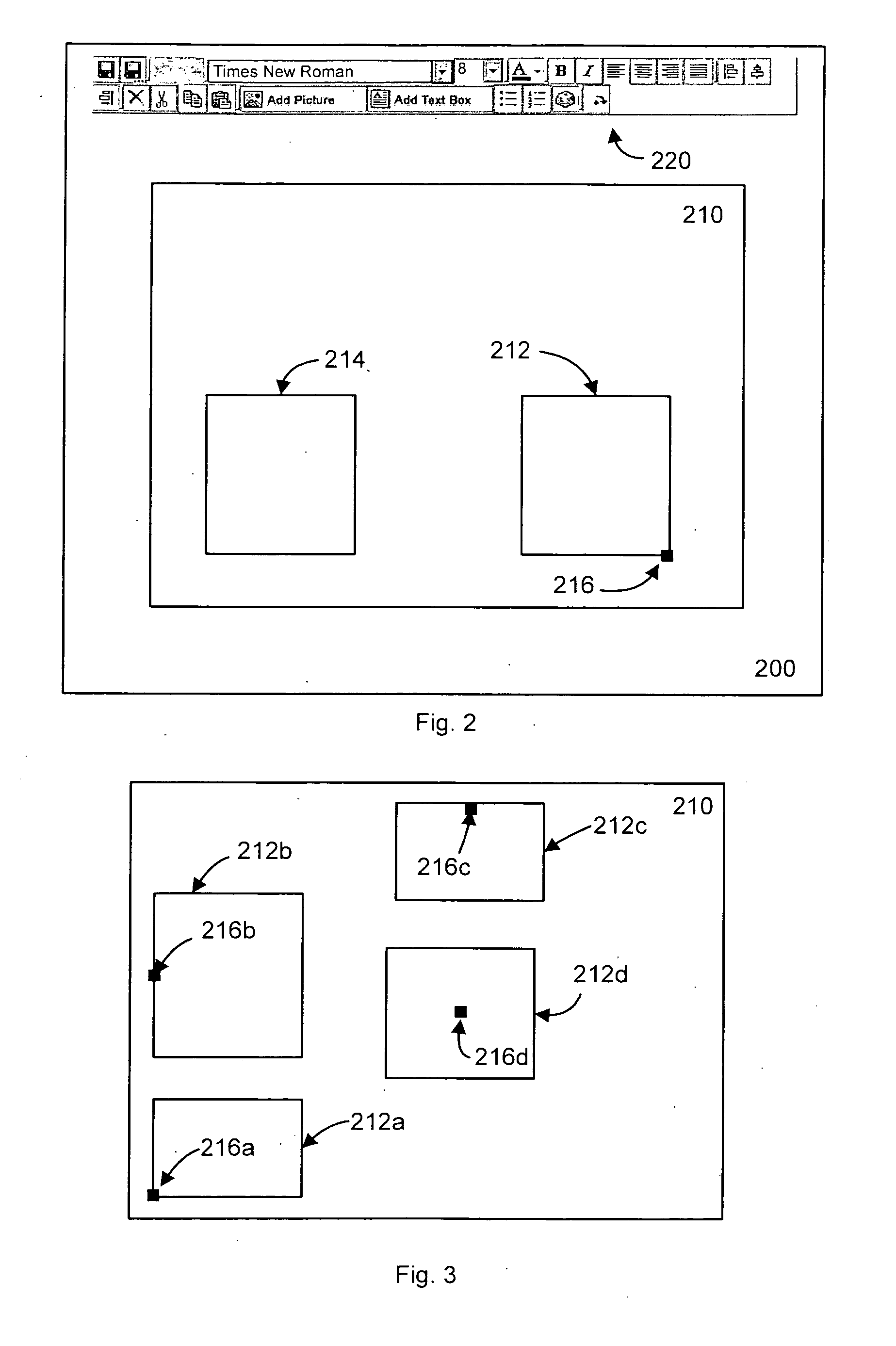

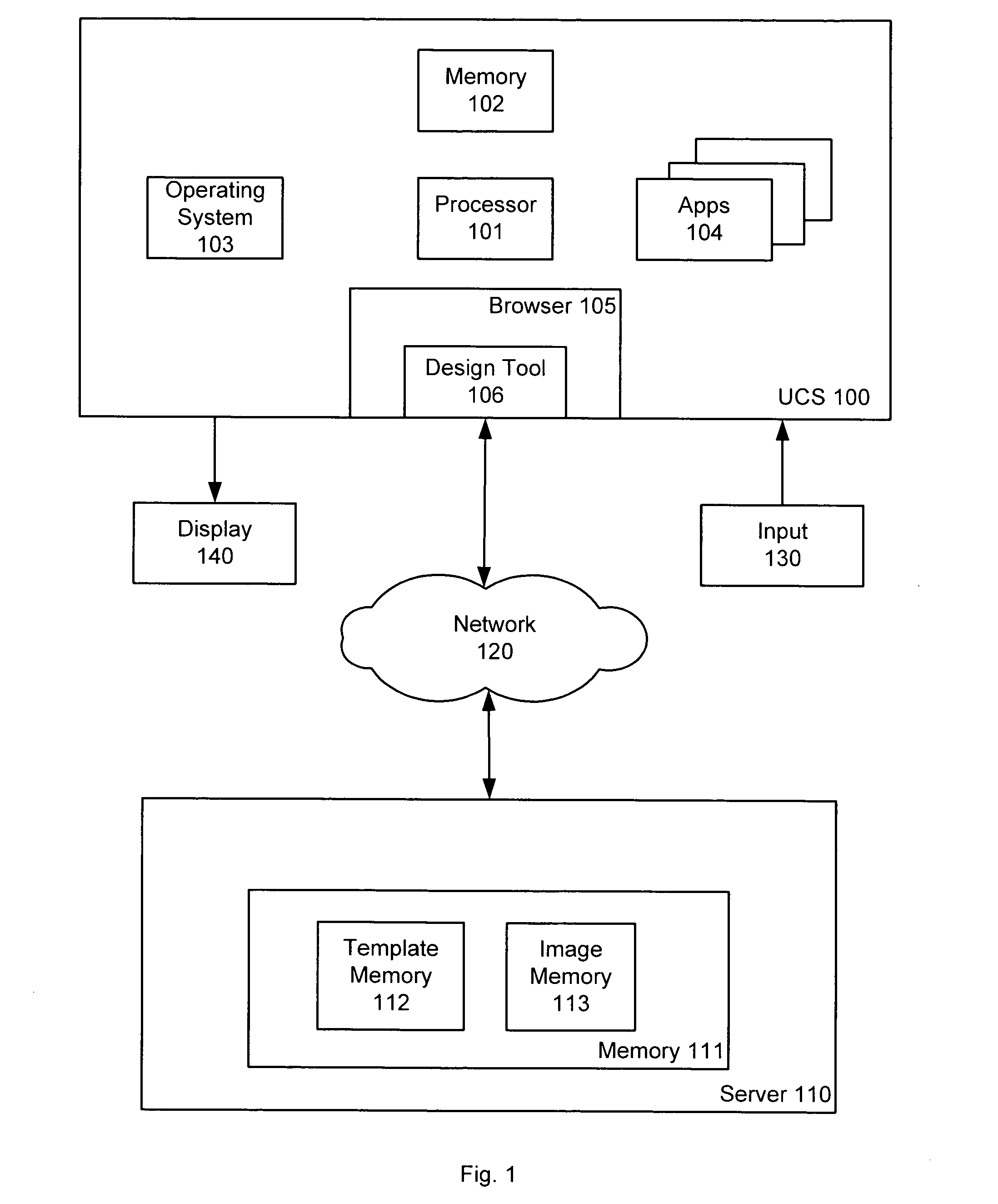

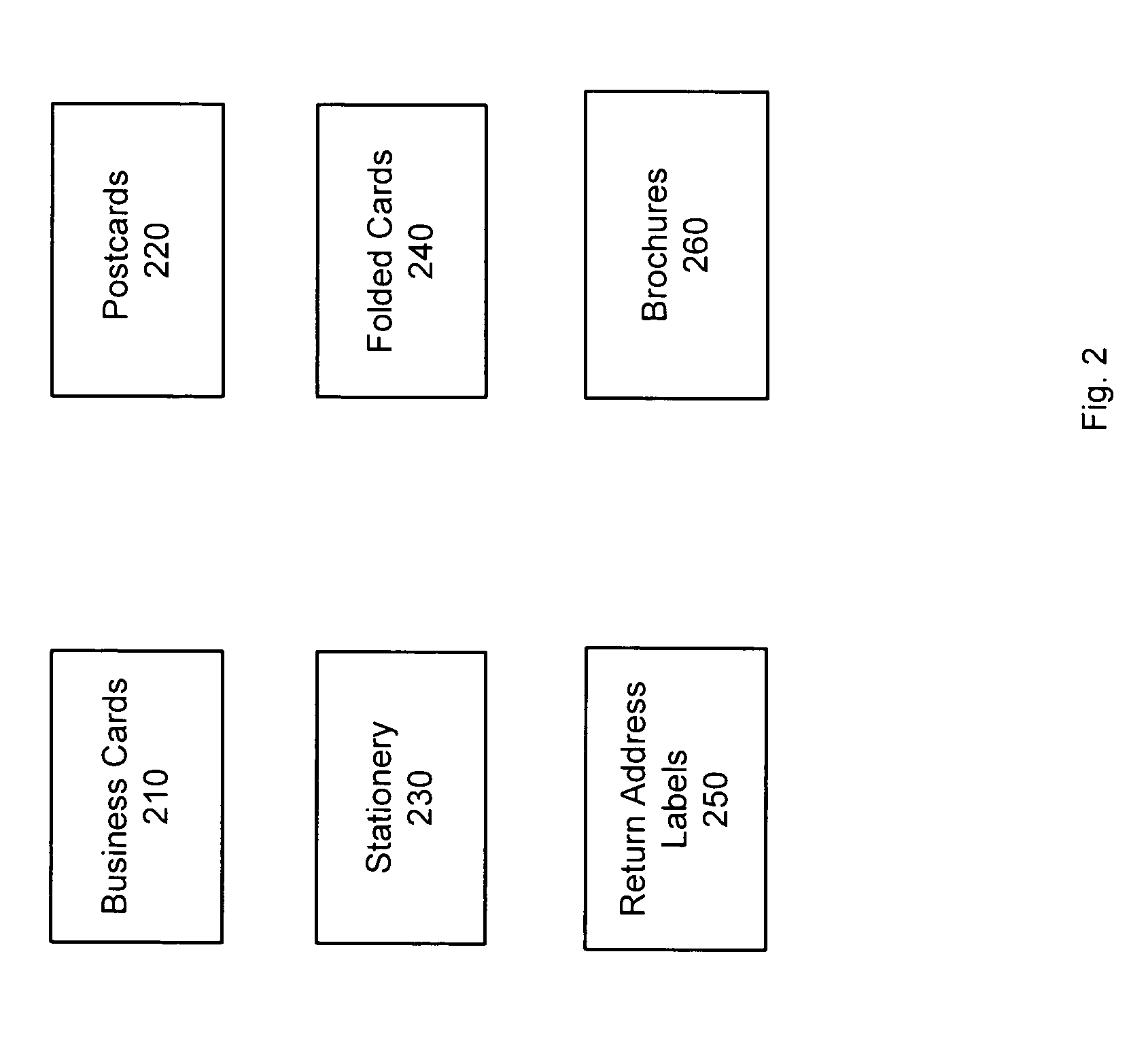

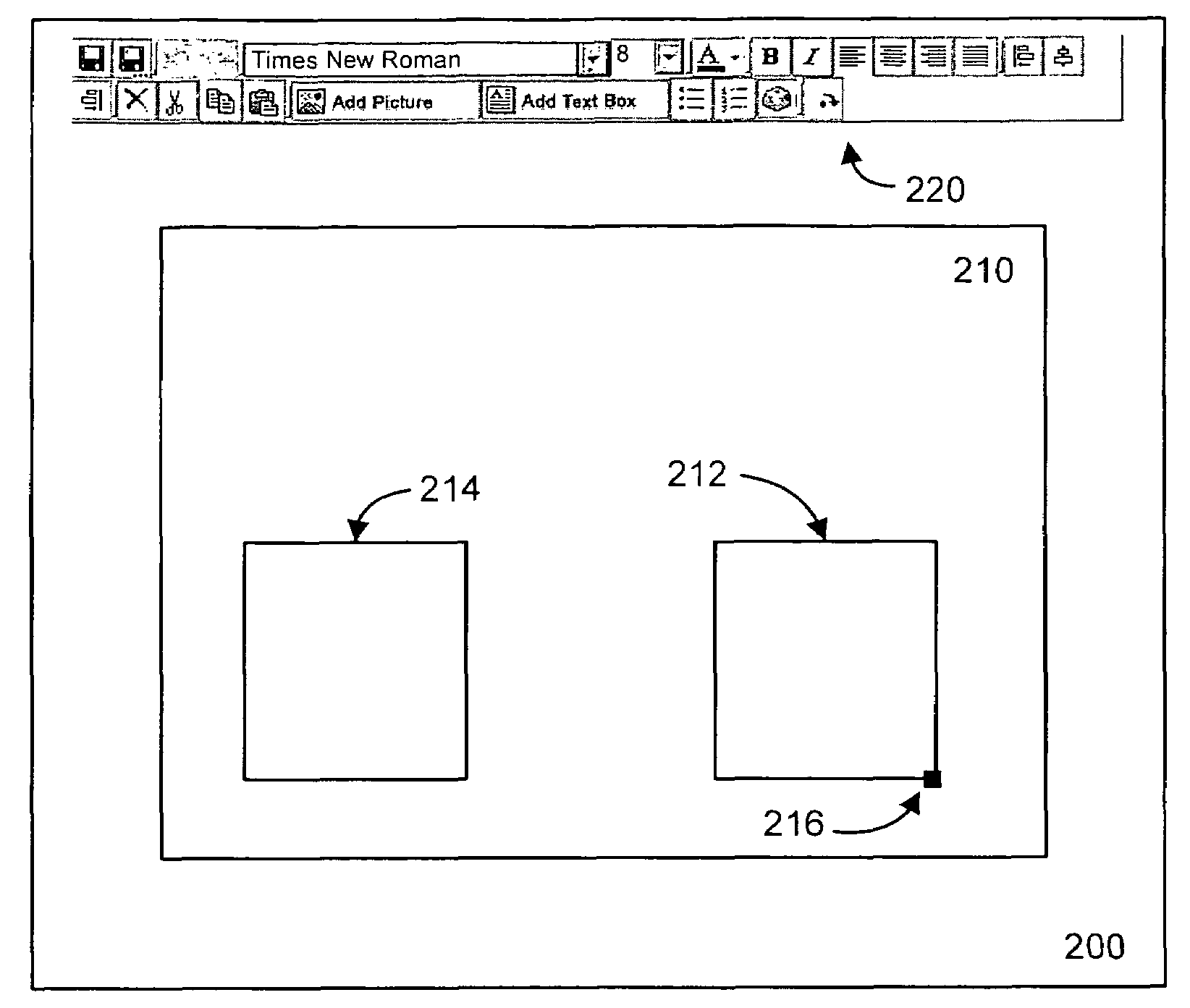

Automated image processing

ActiveUS20060197963A1Increase speedImprove reliabilityDigitally marking record carriersVisual presentation using printersElectronic documentImaging processing

Automated electronic document design systems and methods for appropriately sizing and positioning uploaded user images into predefined image areas in a product design being created in a Web environment. For an image that is not to be cropped when incorporated into the design, the image is sized to fit within the selected image area and positioned in the image area according to a predefined anchor location. The aspect ratio of the original image is maintained. For an image that is available for cropping when incorporated into the design, the image is sized and cropped to create a version of the image that fills the image container.

Owner:CIMPRESS SCHWEIZ

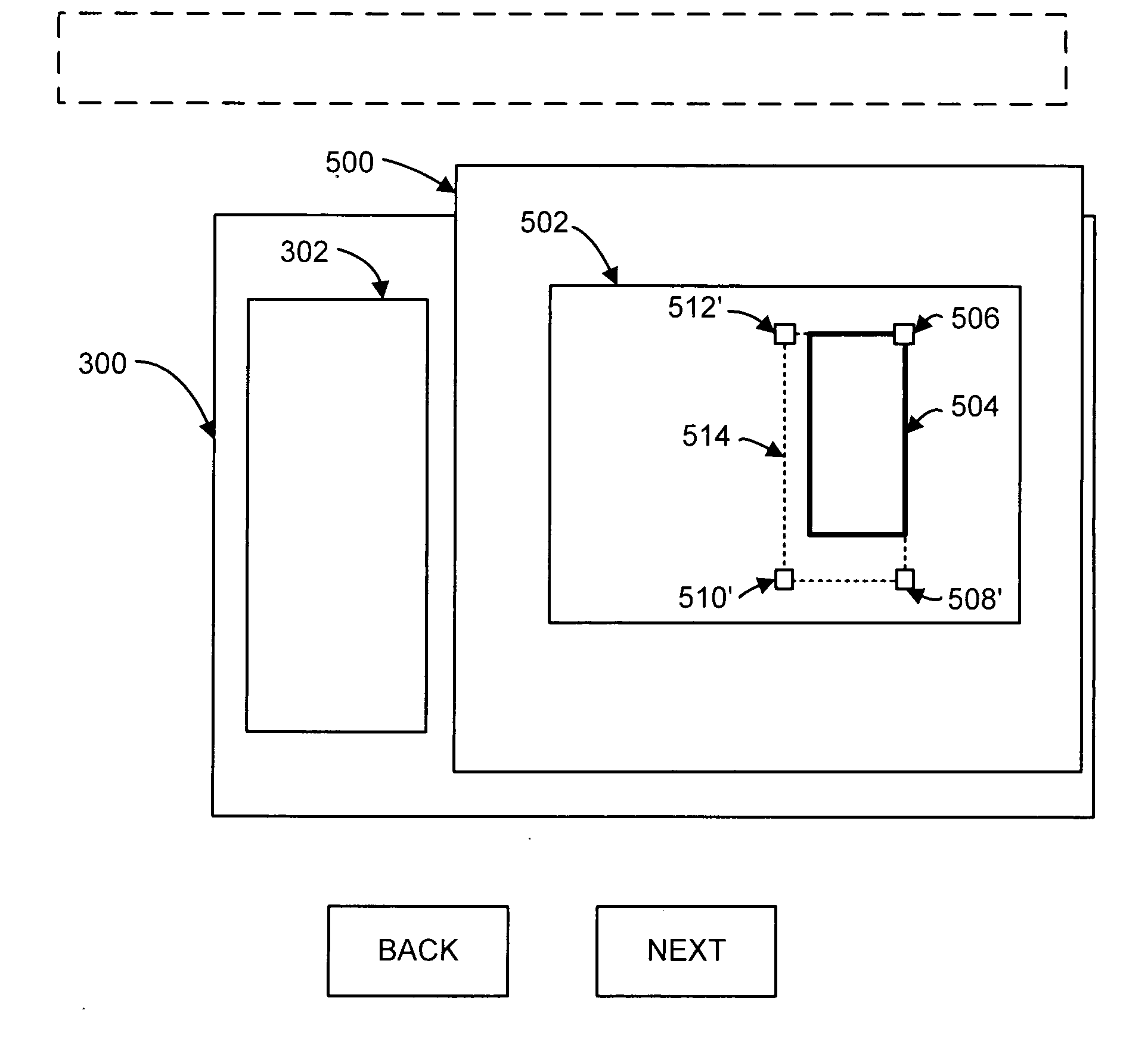

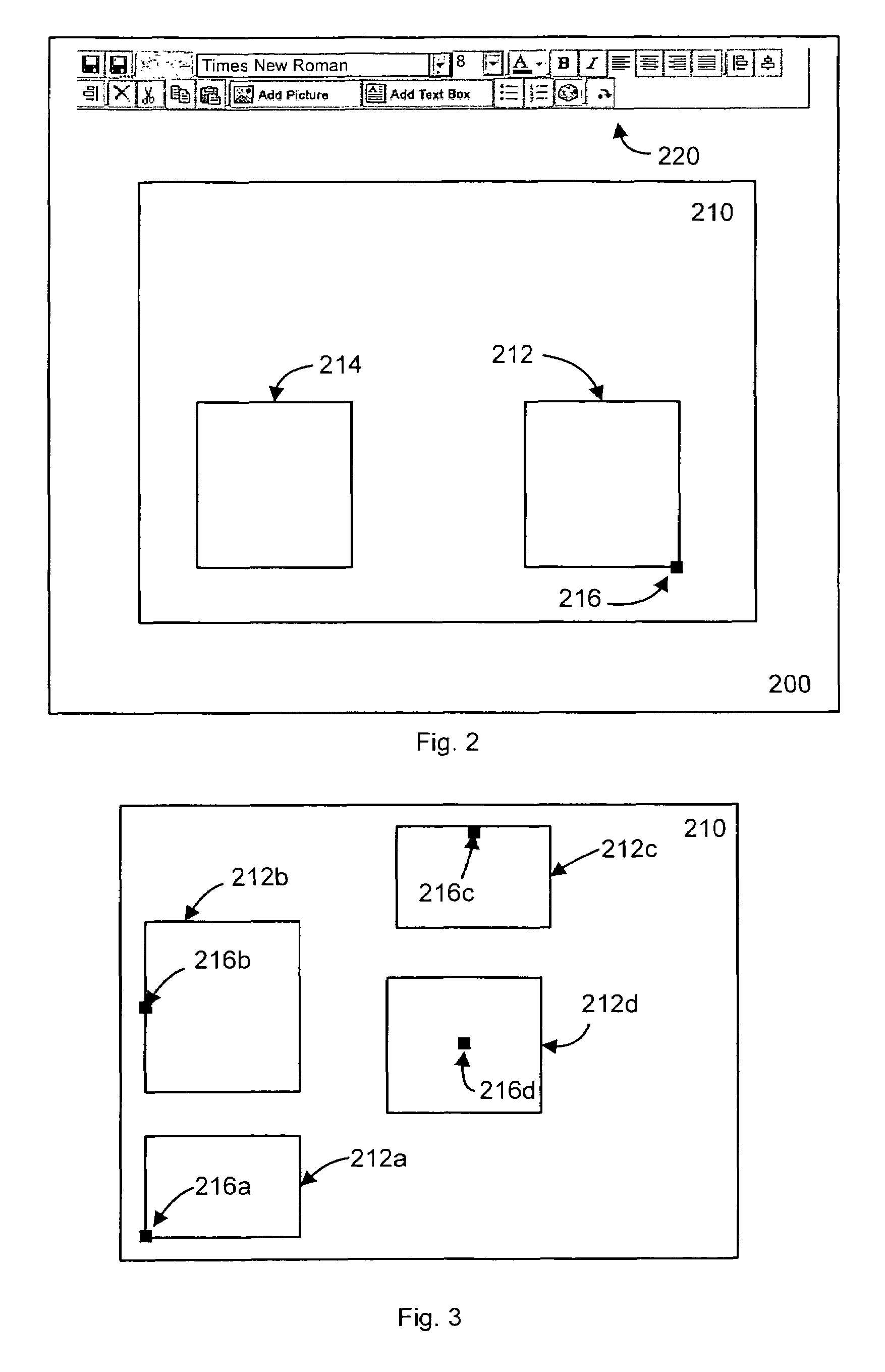

Image cropping system and method

ActiveUS20050104897A1Height to width ratio is constantCathode-ray tube indicatorsExecution for user interfacesElectronic documentCropping system

Electronic document design systems and methods allowing a user engaged in customizing an electronic product to re-crop product images in a manner that is compatible with the product layout. Upon selection of an image area in the product design, the user can choose to re-crop the image currently displayed in the image area or to select and crop a different image to be used in the selected image area. A cropping indicator that can be resized and repositioned is provided to the user. The cropping indicator is automatically sized to have and retain the same height to width ratio as the selected image area. Upon completion of any resizing or repositioning operation, the selected image area of the electronic product is updated to reflect the cropping changes made by the user.

Owner:CIMPRESS SCHWEIZ

Process for formulating a customized skin care product

InactiveUS7349857B2Performance advantageStability of product can be controlledPigmenting treatmentVacuum evaporation coatingBiometric dataAdditive ingredient

The invention relates to a method and a process of determining individual skin structure and function at a point in time for the purpose of determining and formulating skin care products that remedy the deficiencies observed in the skin. Objective and repeatable dermal biometric instrumentation techniques can be used to measure skin moisture content, sebum content, firmness and elasticity properties, skin thickness, transepidermal water loss, skin pH and to perform a photo analysis of the face with UV and visible light. By customizing the skin care products, the individually added active ingredients can be controlled, the diluents can be modified, dermal penetration rates can be controlled, the surfactant systems can be adjusted, and the stability of the product can be controlled. To prevent the loss of active materials in the product, the skin care product is manufactured for an individual consumer and is only sold in a quantity of a three months supply. Additionally, a variety of ingredients can be combined that a mass produced product cannot contain due to stability / compatibility issues. This invention overcomes the limitations in formulating skin products for the mass market by providing a product designed with objective biometric data and created for the specific clinical condition of an individual's skin.

Owner:MANZO ROBERT P

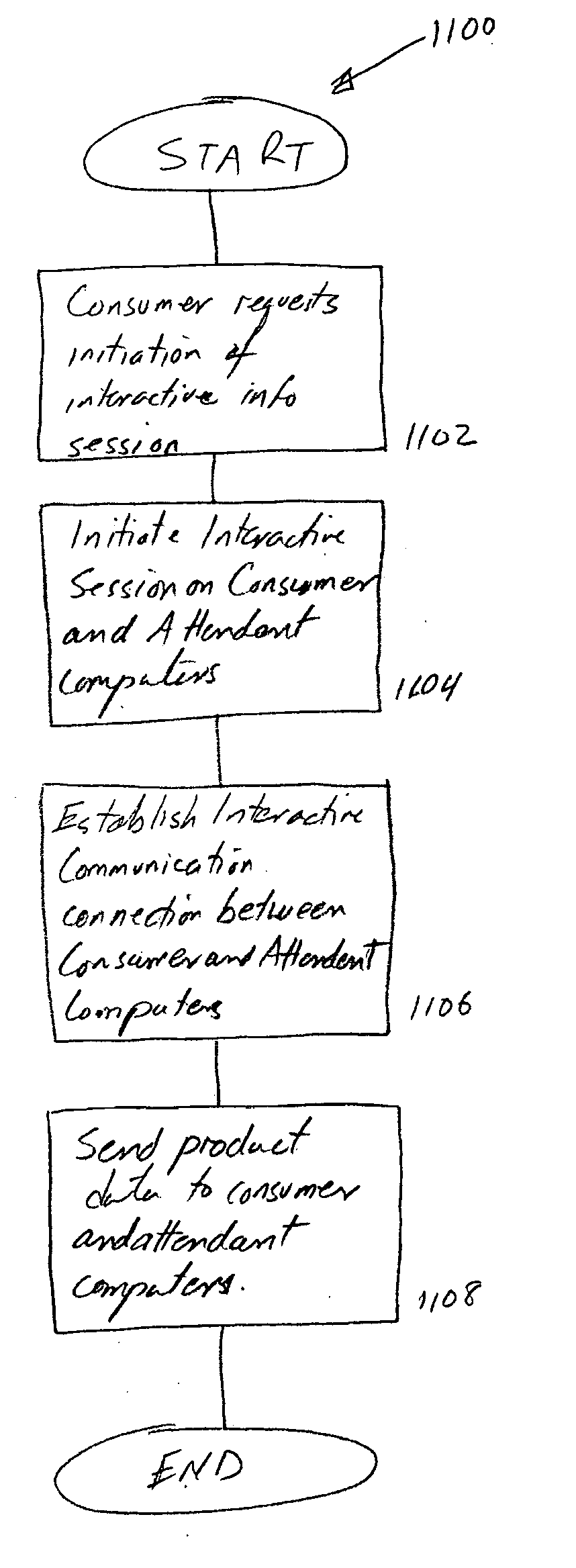

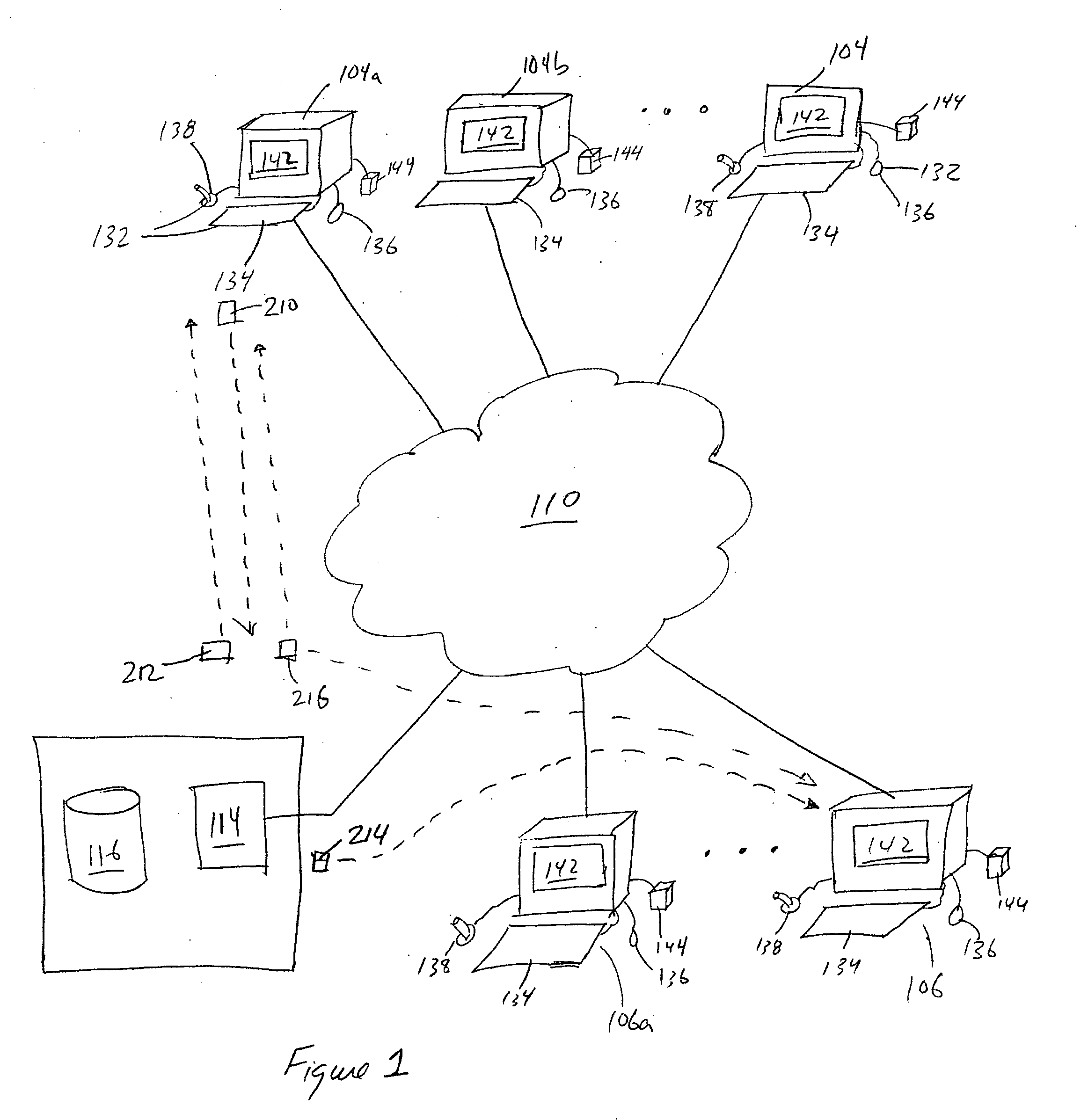

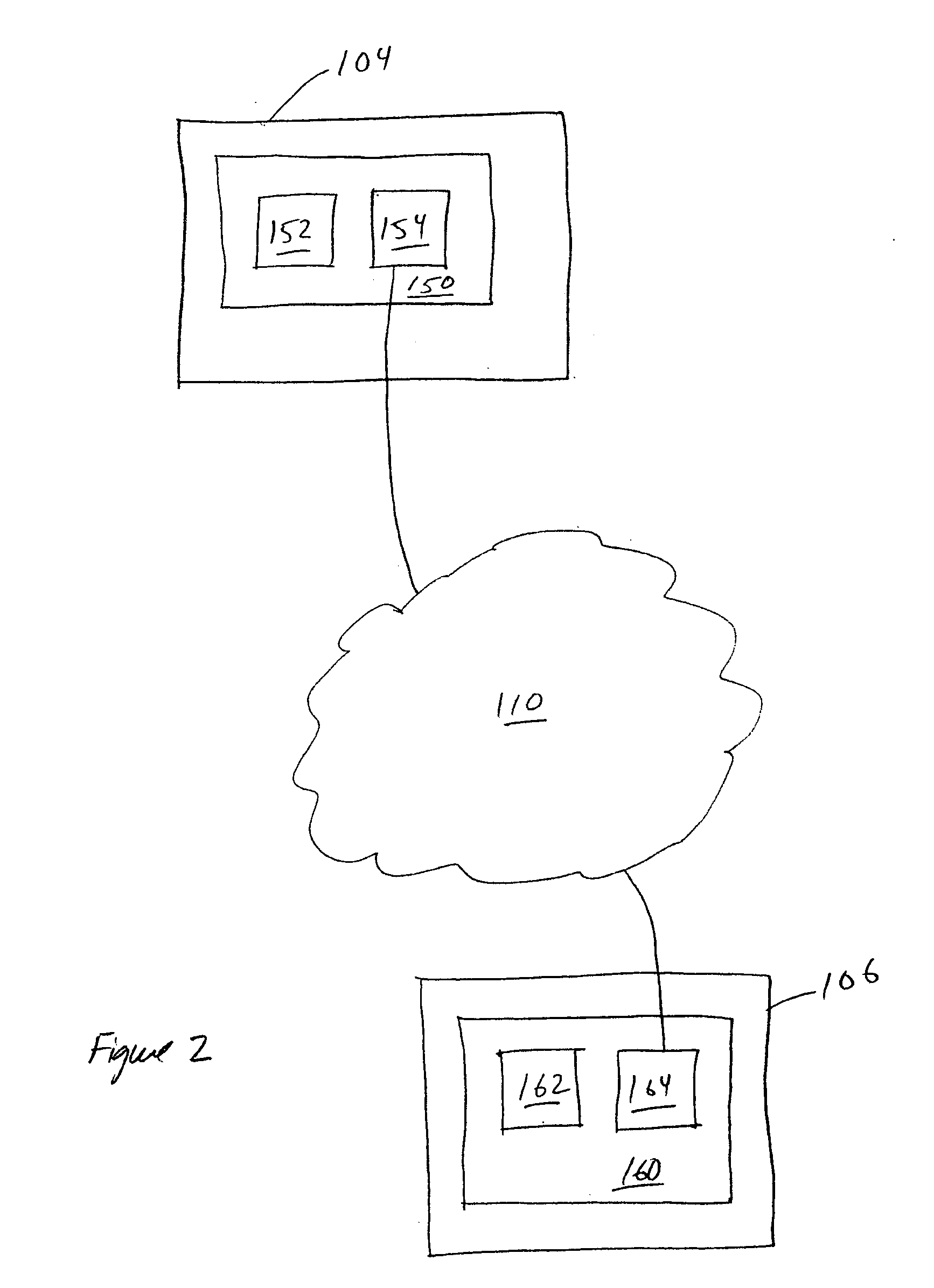

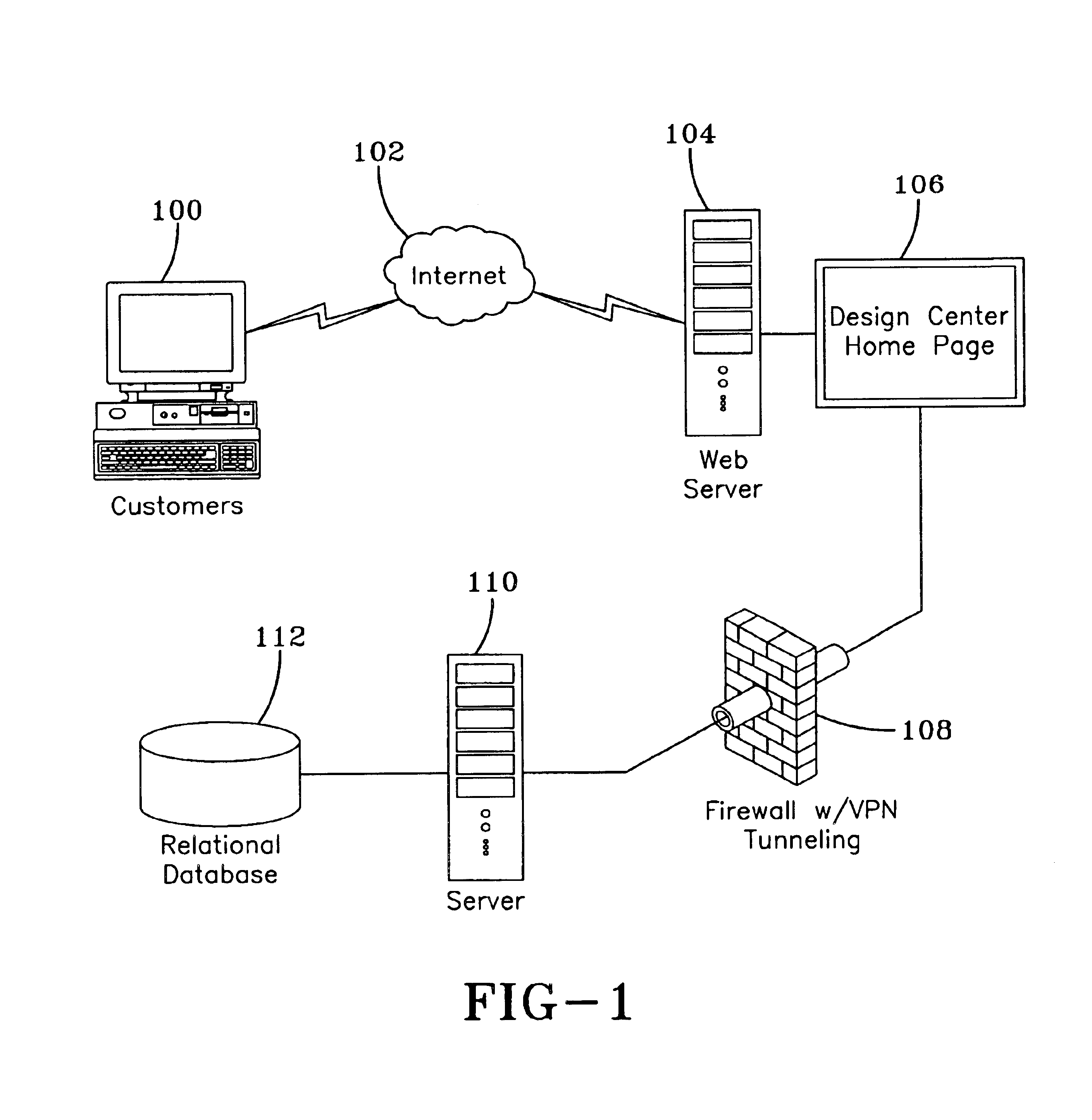

Systems and methods for interactively displaying product information and for collaborative product design

ActiveUS20050251462A1View effectivelySpecial service provision for substationOffice automationGraphicsPlanogram

A system for interactively displaying and distributing information. The information may relate to consumer products, any type of article of commerce, marketing and advertising layouts, floor plans, planograms or any other type of information that is capable of being illustrated graphically. A consumer engages in an Interactive Information Session with an attendant, such a help desk attendant. During the Interactive Information Session, the attendant and consumer see synchronized displays of images or animations of the information, which may be manipulated by either one of them. The attendant and the user can communicate interactively by voice or text during at least part of the Interactive Information Session. In another embodiment, two or more users of a system according to the invention can collaboratively design a product, marketing or advertising layouts, planograms, floor plans or other graphical information in an Interactive Design Session. During the session one of the users controls the design at any time. Different users may have control at different times. The users can engage in interactive voice or text communications during at least part of the Interactive Design Session.

Owner:XENOGENIC DEV LLC

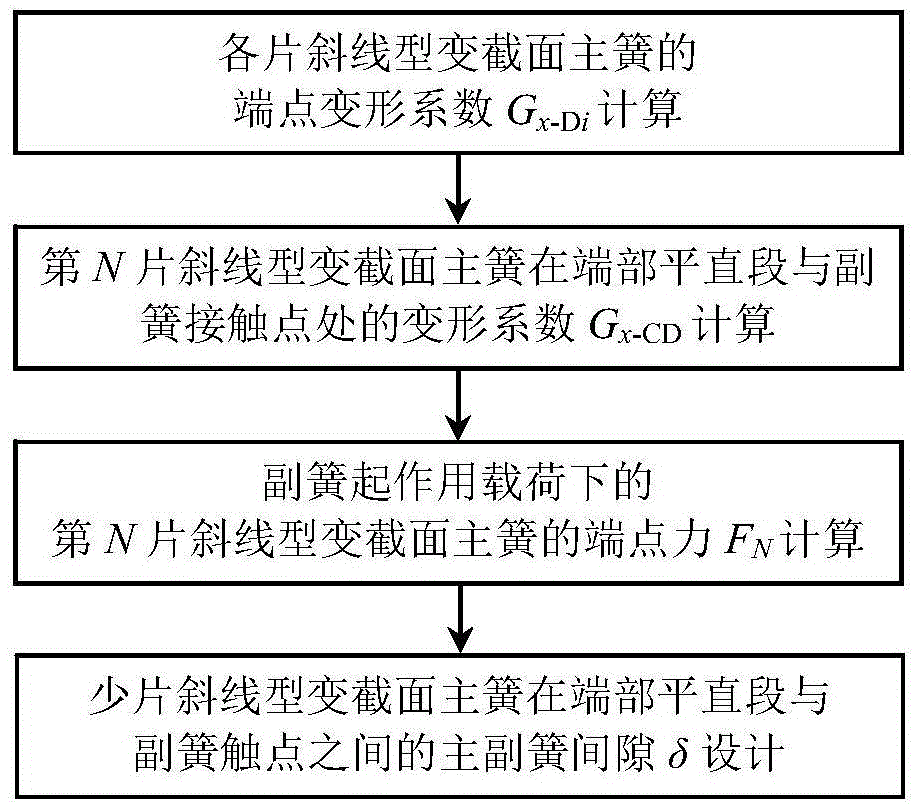

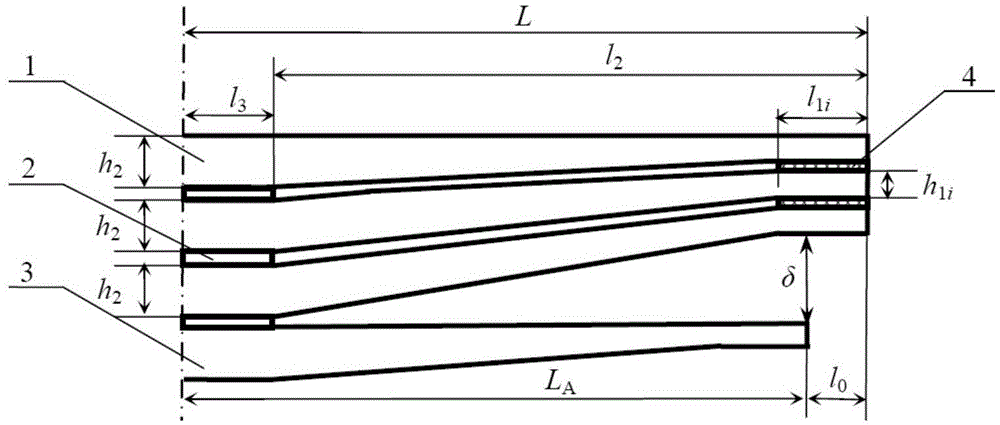

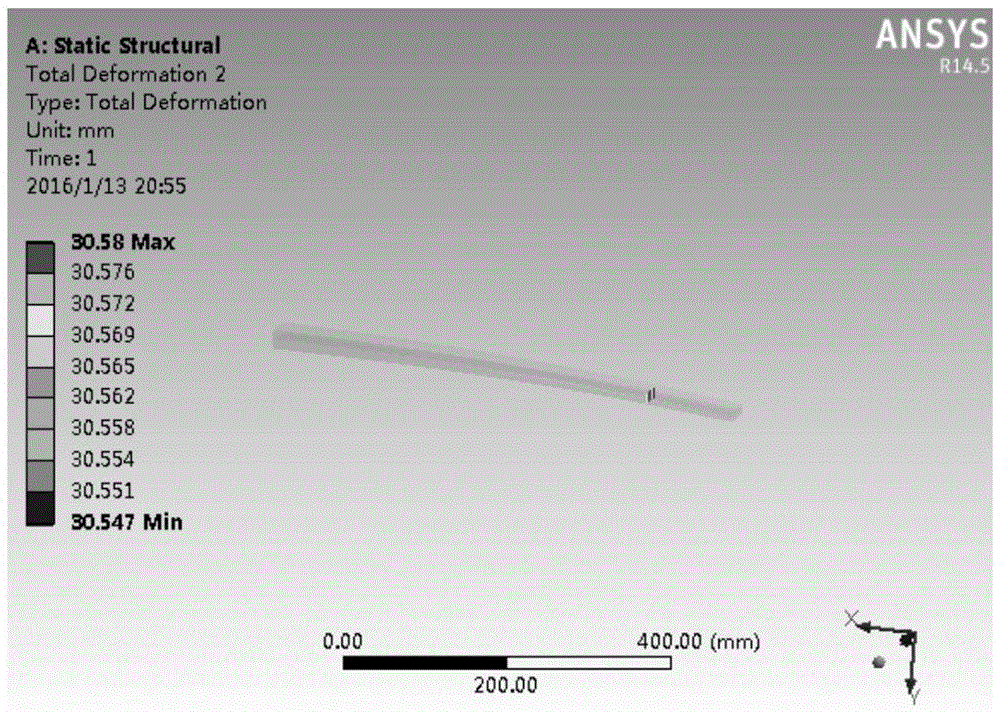

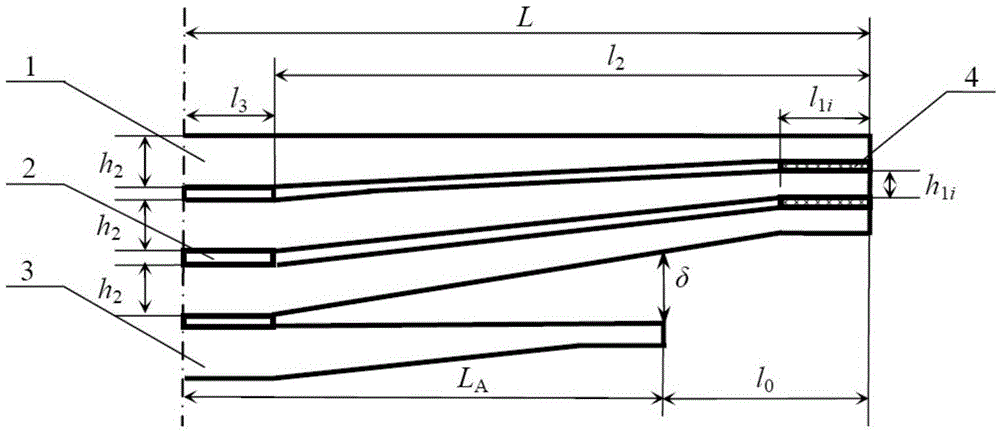

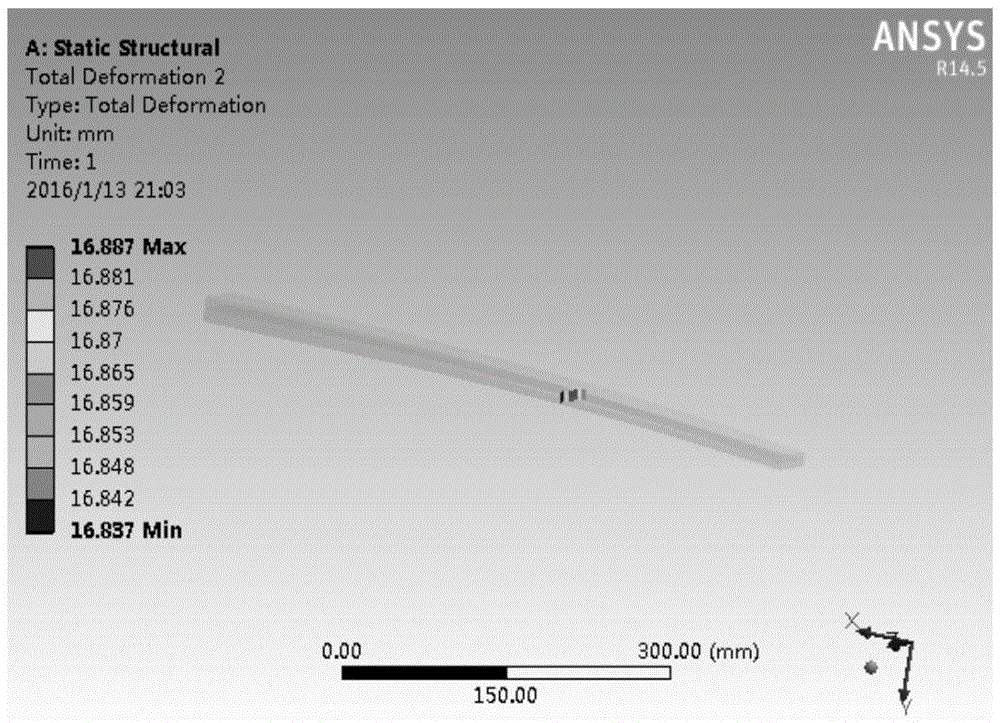

Method for designing gaps of end straight sections of diagonal few-leaf main springs and auxiliary springs

ActiveCN105526290AExact design valueReliable design valueGeometric CADLeaf springsEngineeringDesign values

The invention relates to a method for designing gaps of end straight sections of diagonal few-leaf main springs and auxiliary springs, and belongs to the technical field of suspension steel plate springs. The method includes determining endpoint deformation coefficients of the various main springs and deformation coefficients G<x-CD> of contact points of the end straight sections of the N main springs and the auxiliary springs according to structure sizes and elastic modulus of the various diagonal variable-section main springs; acquiring endpoint force F<N> of the N main springs according to acting load of the auxiliary springs and the endpoint deformation coefficients of the various main springs; designing the main and auxiliary spring gaps between contact points of the end straight sections of the main springs and the auxiliary springs according to the thicknesses h<2> of roots of the N main springs, the endpoint force F<N> and the deformation coefficients G<x-CD>. The method has the advantages that as known from simulation verification, design values of the gaps of the end straight sections of the diagonal few-leaf variable-section main springs and the auxiliary springs can be accurately and reliably obtained by the aid of the method, and accordingly the product design level and performance and the vehicle ride comfort can be improved; the design and experiment costs can be reduced, and the product development speeds can be increased.

Owner:山东恒日悬架弹簧股份有限公司

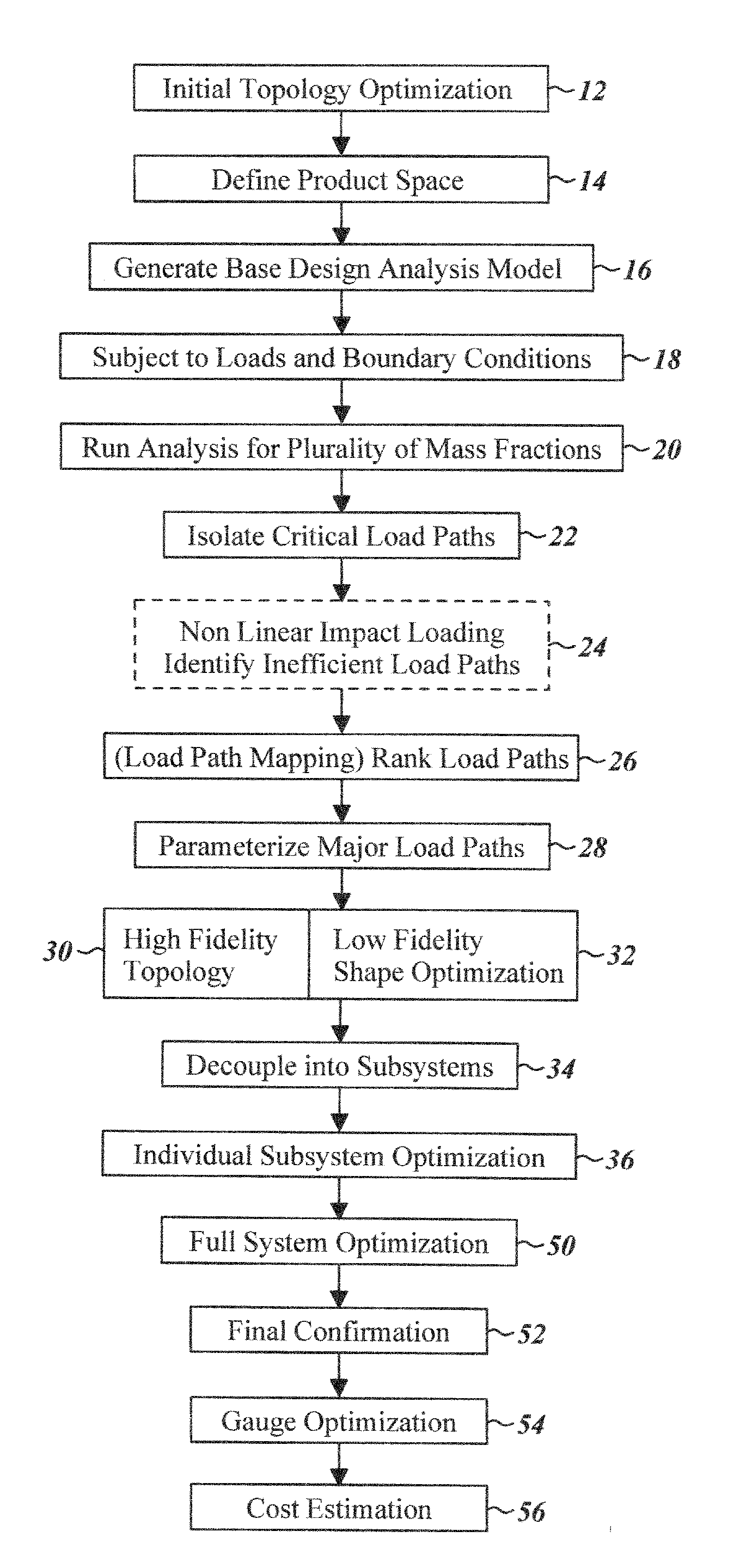

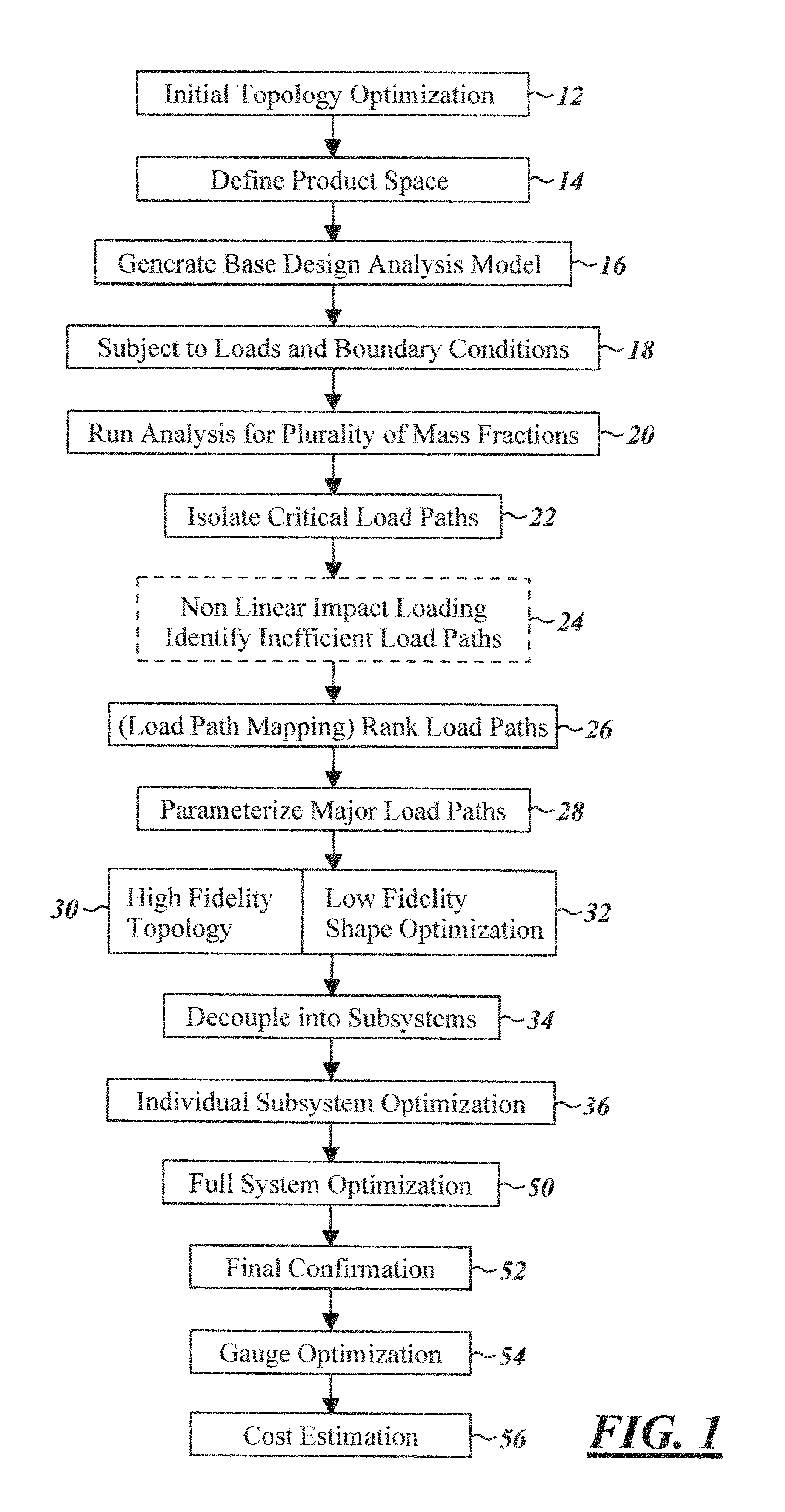

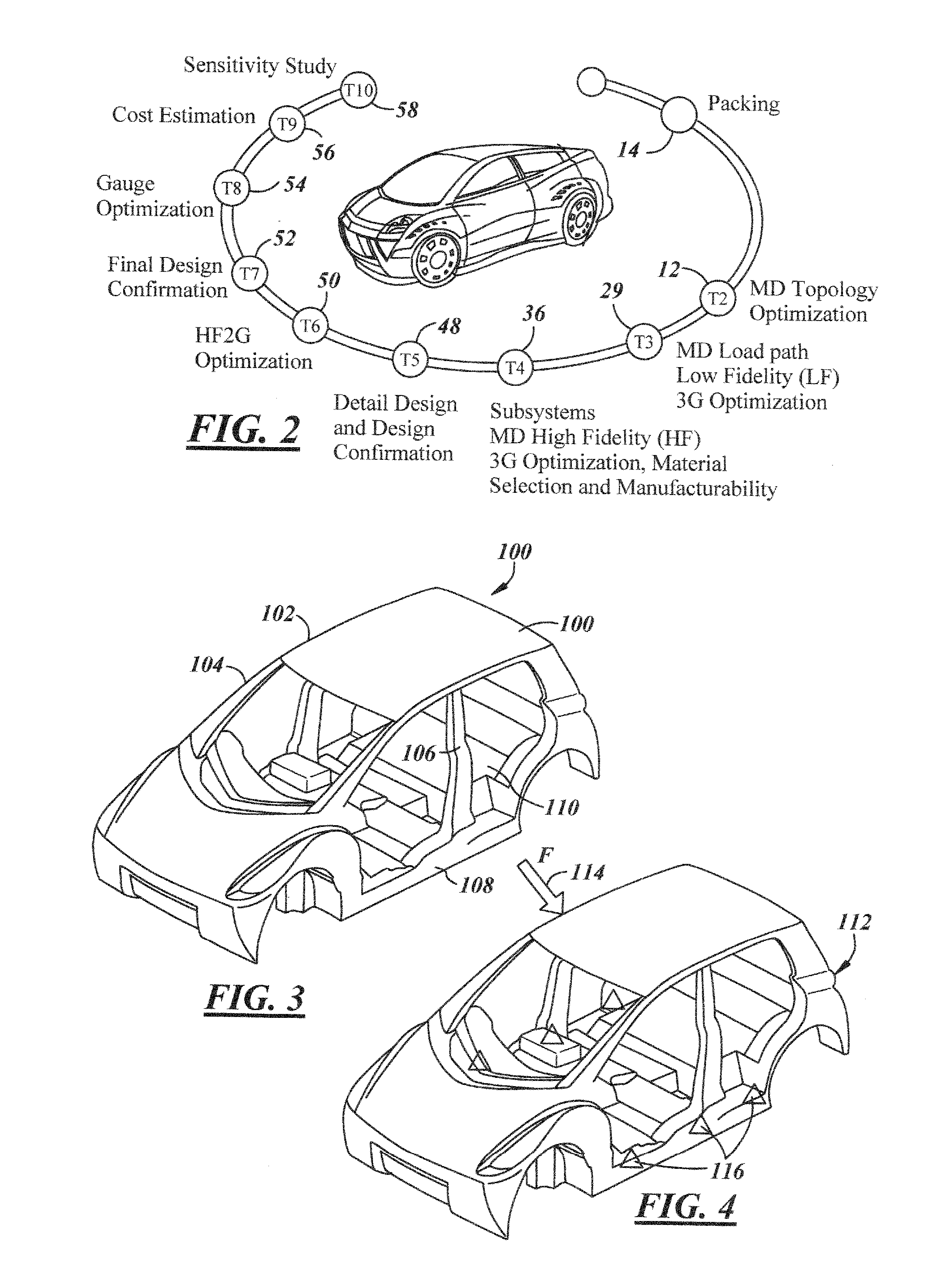

Design Optimization System

ActiveUS20110137443A1Geometric CADDesign optimisation/simulationCritical structureTopology optimization

In accordance with the objects of the present invention, a method of complex product design is provided. The method defines a product design space a base design analysis model is then automatically generated within the product design space. A topology optimization of the base design analysis model is performed including solving the topology optimization for multiple mass fractions to identify critical structure areas. The results of the topology optimizations are utilized to identify a plurality of load paths. An optimization of said plurality of load paths is performed to find the optimized load paths. Critical structure areas along the plurality of optimized load paths are then parameterized. An optimization is performed utilizing a multi-disciplinary optimization to optimize geometry, material and thickness along the optimized load paths. A manufacturing analysis of the shape optimized structure is performed and the shape optimized structure is modified to comply with manufacture requirements. An optimization is then performed using multi-disciplinary optimization comprising a gauge and grade optimization.

Owner:NITED STATES STEEL CORP +1

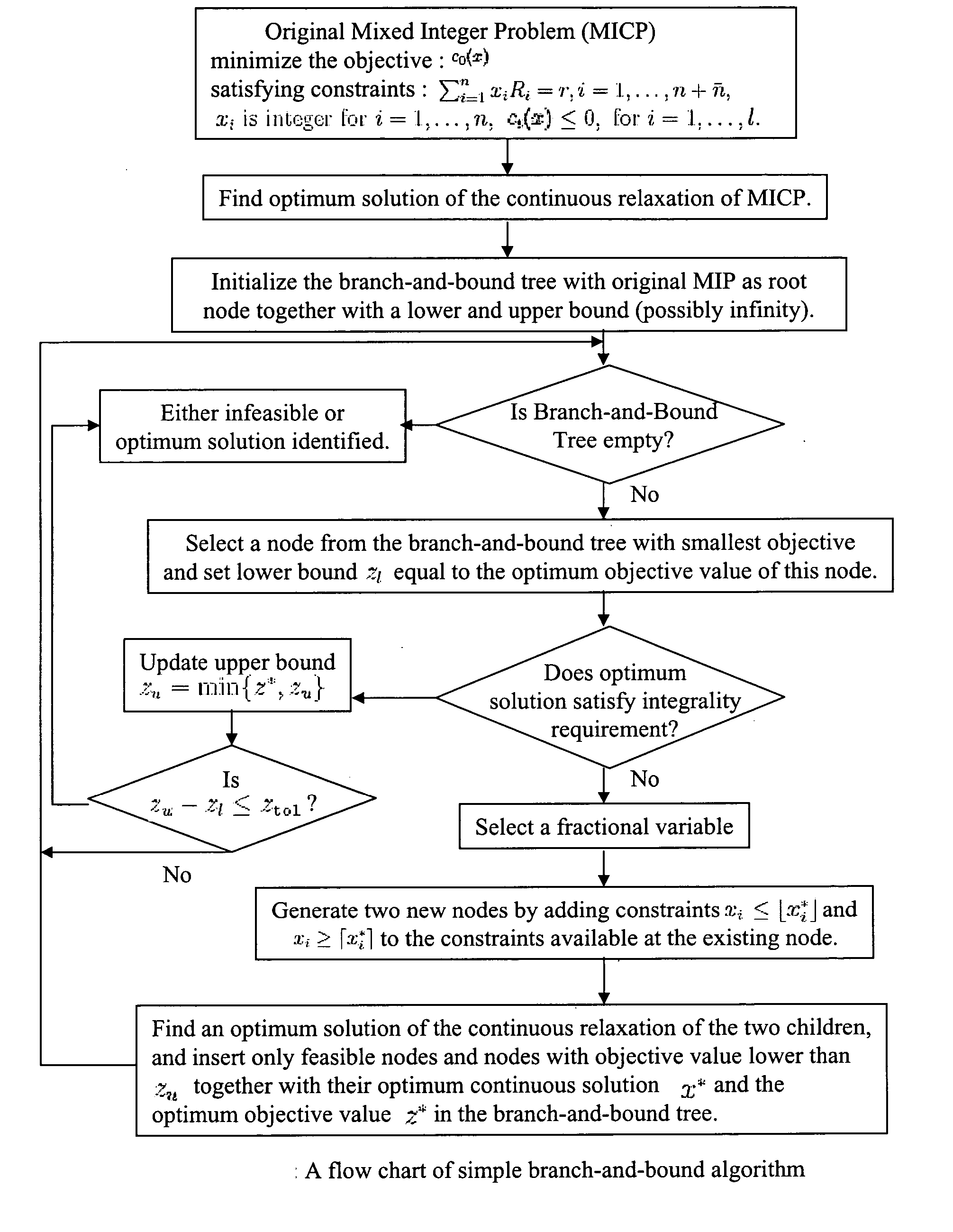

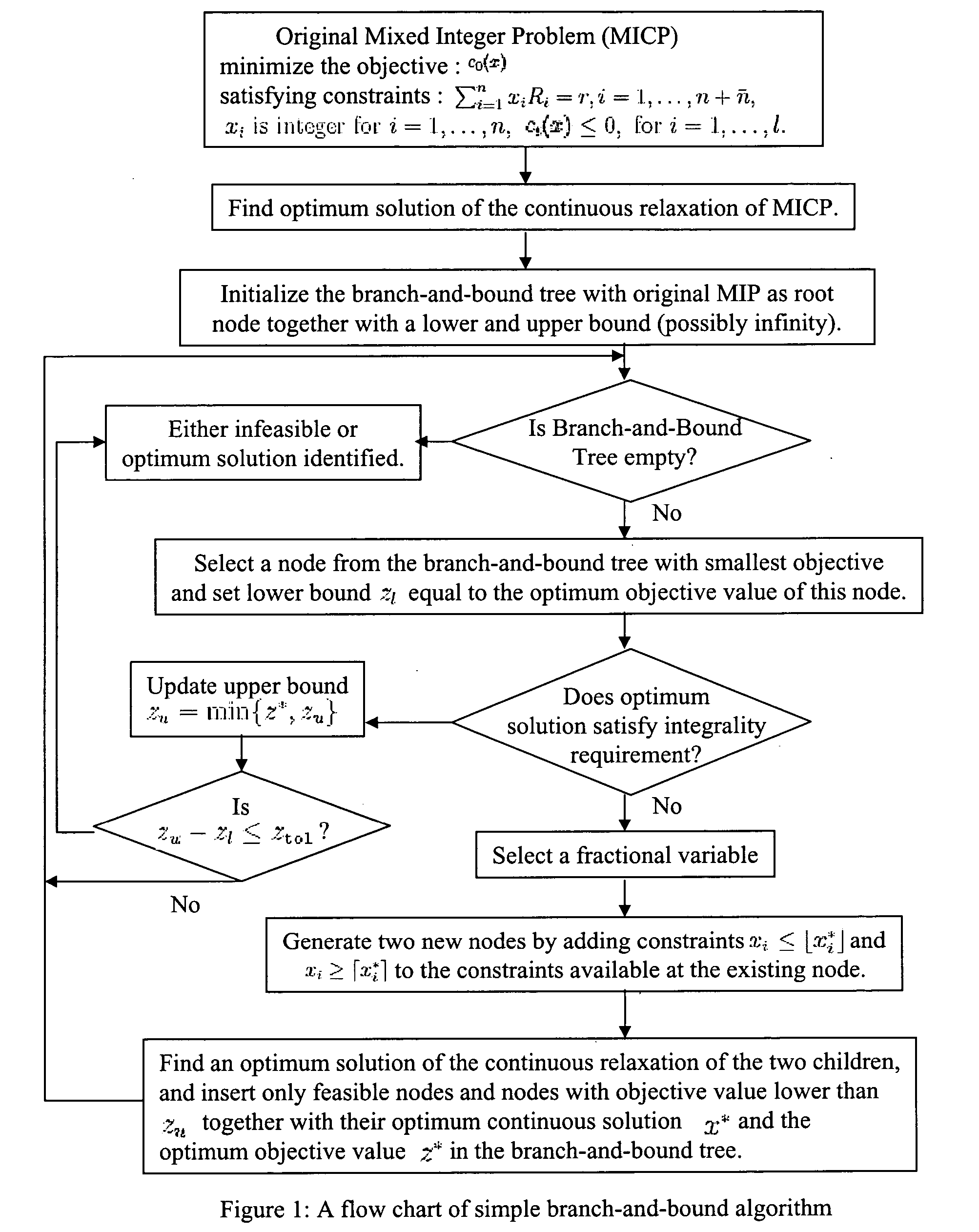

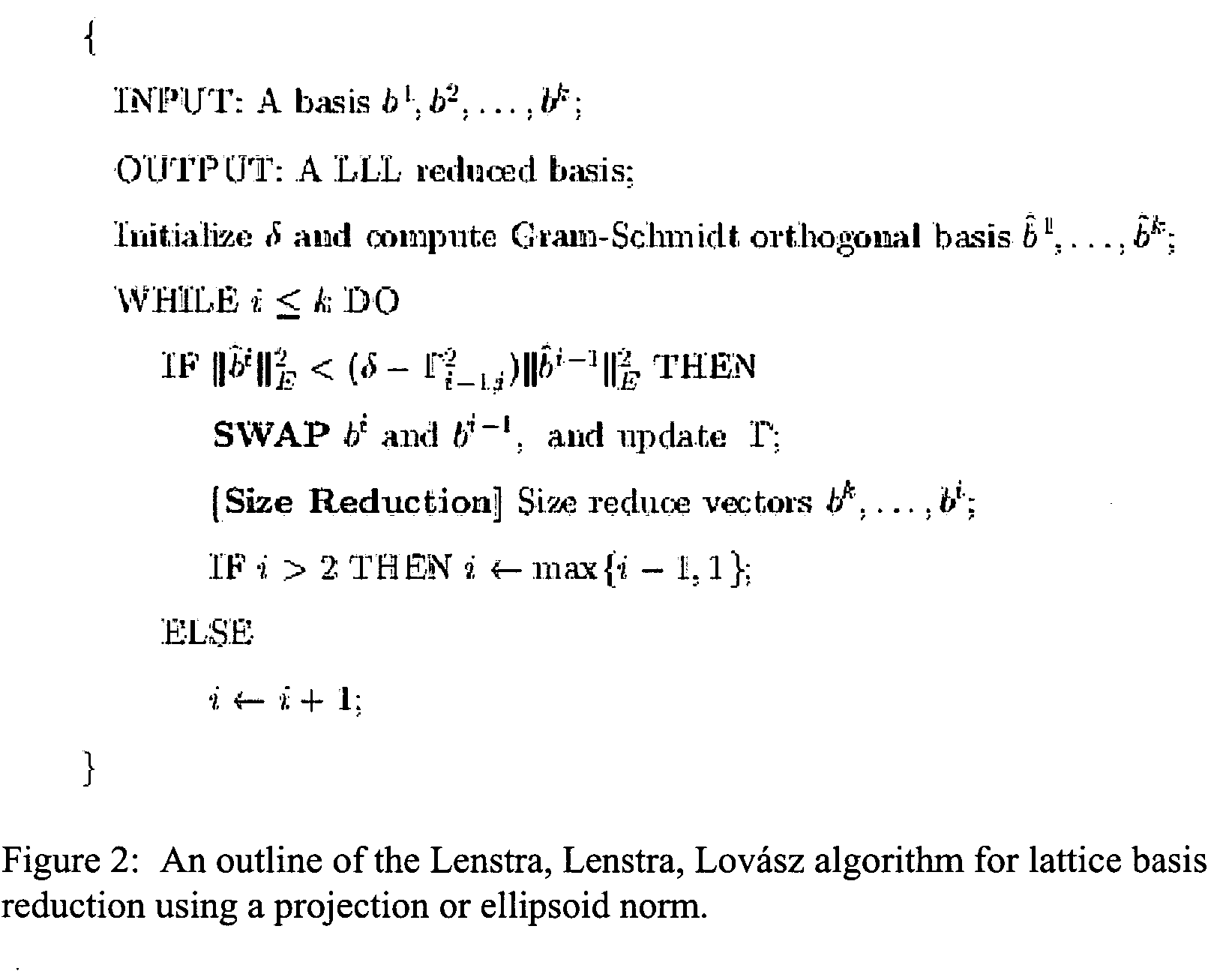

Generalized branching methods for mixed integer programming

InactiveUS20060112049A1Simple methodKnowledge representationComplex mathematical operationsLattice basisTheoretical computer science

A method and system using branching on hyperplanes and half-spaces computed from integral adjoint and / or kernel or dual lattice basis for solving mixed integer programs within specified tolerance. It comprises steps of: (1) preprocessing to ensure feasibility and linear objective; (2) computing adjoint and / or kernel lattice basis of the equality constraint coefficient matrix, or its transformed sub-matrix; (3) generating a generalized-branch-and-cut tree; (4) selecting a node and adding new constraints or approximating existing constraints; (5) processing a node to update lower and upper bounds, deleting nodes, or removing variables; (6 optional) computing an ellipsoidal approximation of continuous relaxation of (5); (7 optional) computing new lattice basis; (8) partitioning the set in (4) generating two or more nodes; (9) repeating (5-8) till termination. Such can be applied to problems in marketing management, data mining, financial portfolio determination, product design optimization, and other complex systems where optimization of system is desired.

Owner:NORTHWESTERN UNIV

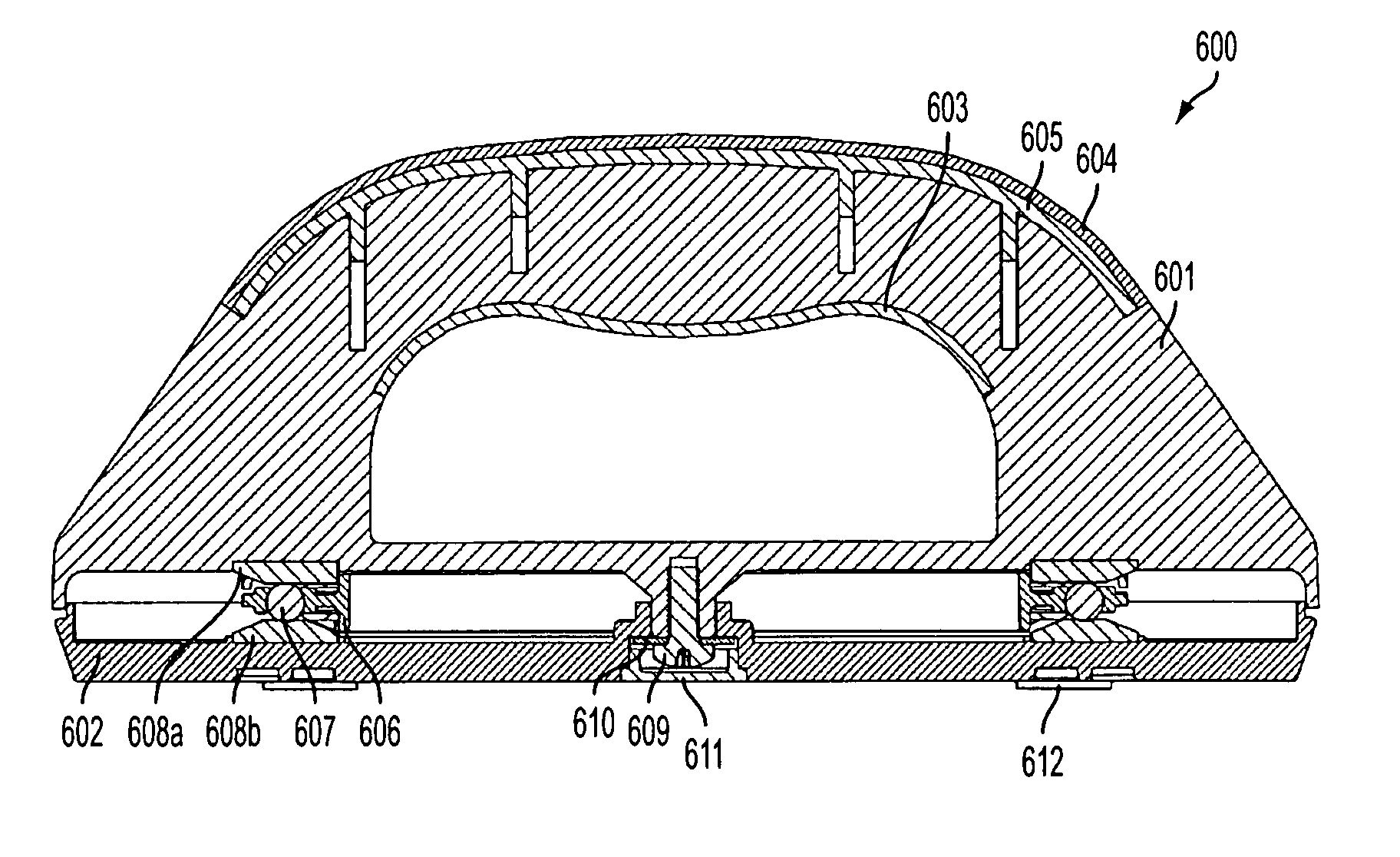

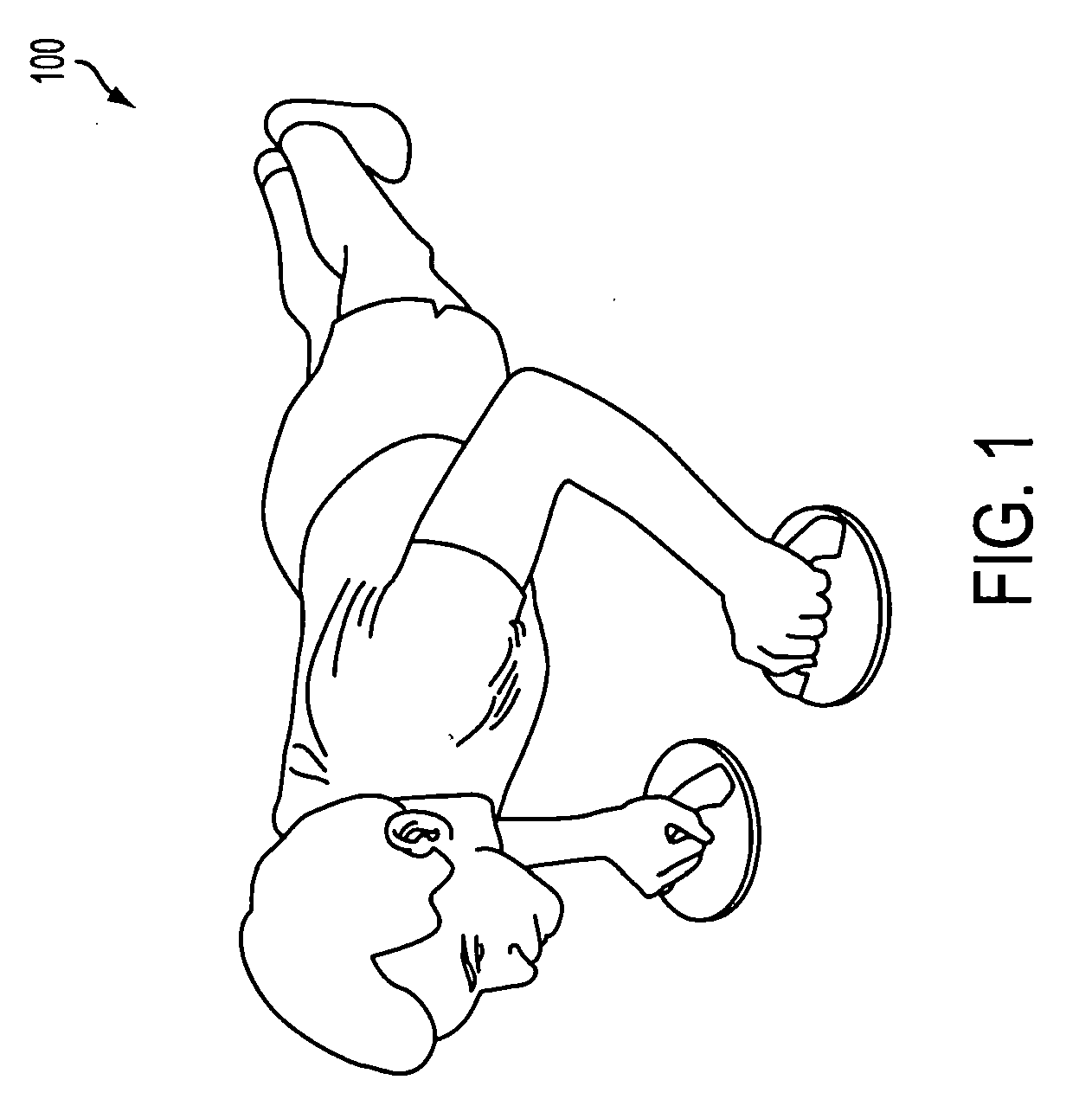

Push-up exercise apparatus

InactiveUS20060035771A1Increase exerciseIncrease relative motionStiltsMuscle exercising devicesCircular discMuscle group

An improved exercise apparatus for use in performing exercises may include: an upper portion which may have a handle coupled to an upper surface, and a lower surface; and a lower portion having a lower surface including a slip resistant material, and having an upper surface rotatably coupled to the lower surface of the upper portion. The exercise apparatus, is a fitness product designed to allow the exerciser to do push-ups without strain on the wrists and / or to increase the number of major muscle groups used, as compared to an unassisted push-up. The exercise may be used by assuming a push-up position on the floor, while engaging the apparatus in the exerciser's hands with the handle in a starting position, about parallel to the body. One disc of the exercise apparatus device may be placed in the left hand, and the other disc may be placed in the right hand. As the exerciser pushes his body up, the handle may rotate and / or swivel about 90 degrees so that the handle may then be substantially perpendicular to the exerciser's body at the height of the push-up. As the exerciser exercises, the handle may swivel back to the starting position, parallel to the body.

Owner:ULTIMATE PUSH UP

Automated image processing

ActiveUS7489324B2Increase speed and reliability and easeReduce riskDigitally marking record carriersDigital computer detailsElectronic documentImaging processing

Automated electronic document design systems and methods for appropriately sizing and positioning uploaded user images into predefined image areas in a product design being created in a Web environment. For an image that is not to be cropped when incorporated into the design, the image is sized to fit within the selected image area and positioned in the image area according to a predefined anchor location. The aspect ratio of the original image is maintained. For an image that is available for cropping when incorporated into the design, the image is sized and cropped to create a version of the image that fills the image container.

Owner:CIMPRESS SCHWEIZ

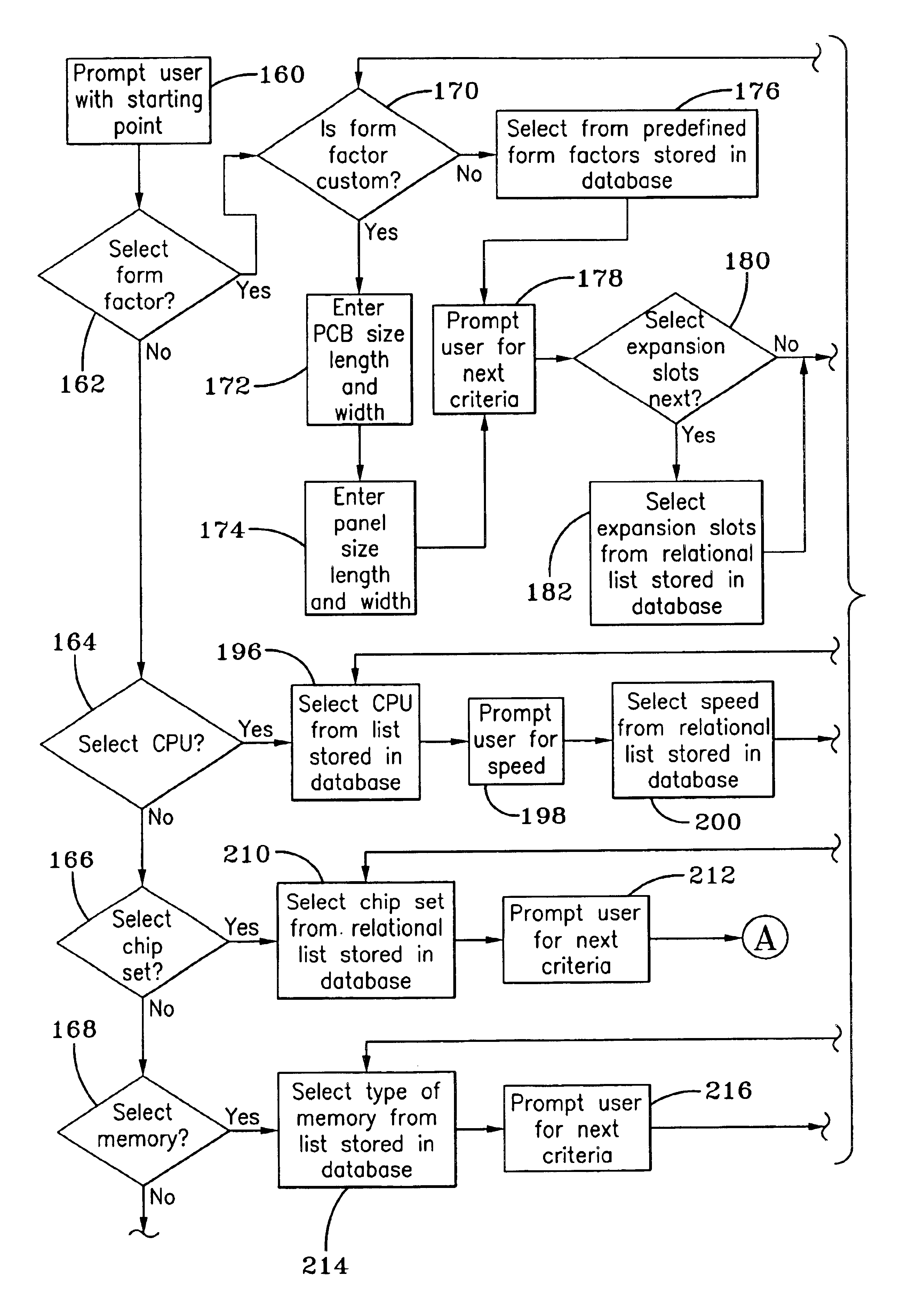

Single board computer quotation and design system and method

InactiveUS6898580B1Simplify the manufacturing processReduce manufacturing costCAD network environmentComputer programmed simultaneously with data introductionThe InternetSingle-board computer

The present invention is a virtual product designer that allows a user to provide specifications for a custom board level product and receive an instantaneous cost quotation and feasibility assessment of the product. The user may connect through the Internet to a virtual product designer to obtain a cost quotation and design feasibility assessment for a specified product. Functional modules that serve as building blocks for a custom design are defined and stored in a library. Attributes and design parameters associated with the functional modules are used to calculate a cost quotation and evaluate design feasibility. As the user changes design requirements while interacting with the virtual product designer, the user is continually updated on the relevant functional, electrical, mechanical and cost parameters.

Owner:MICRO INDS CORP

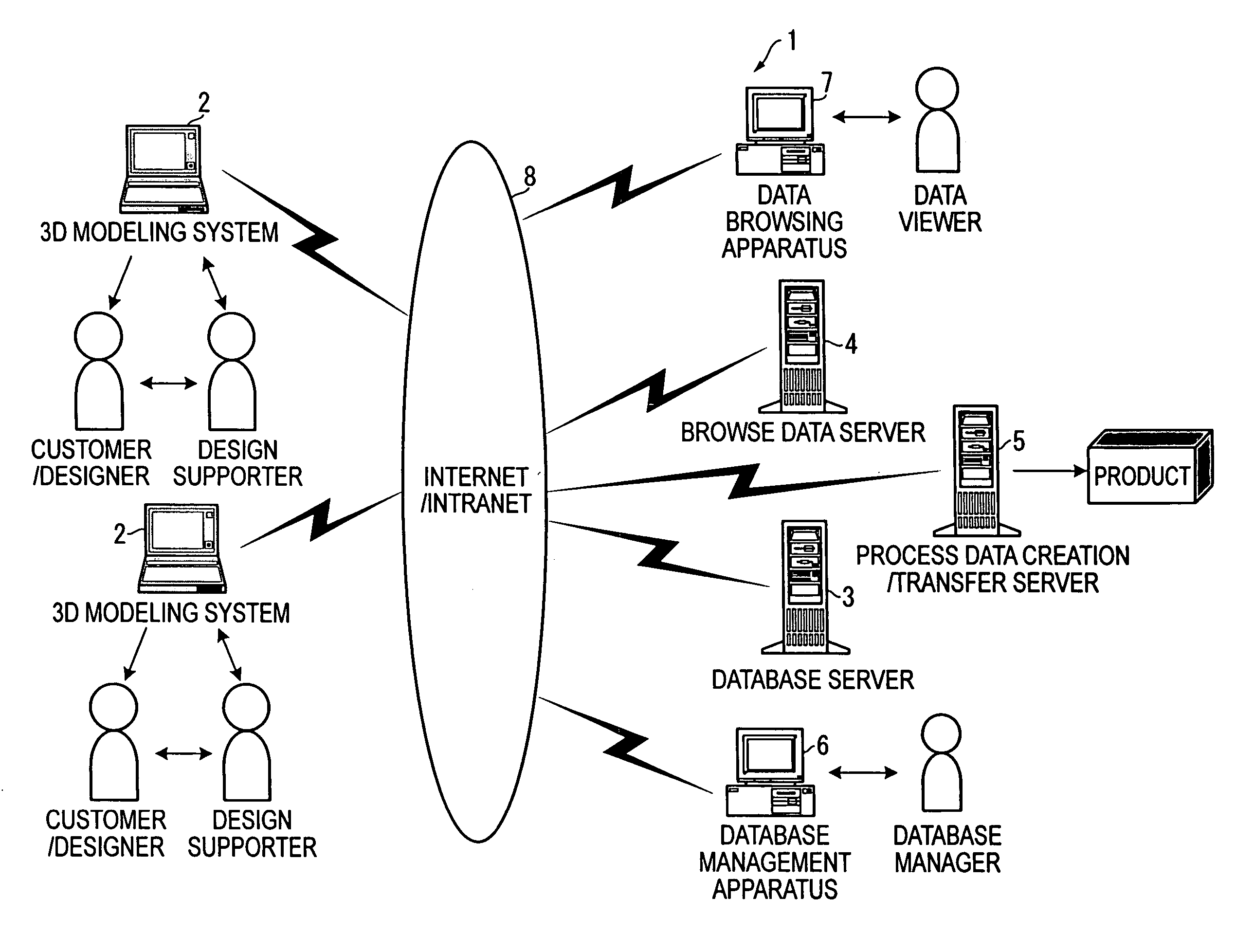

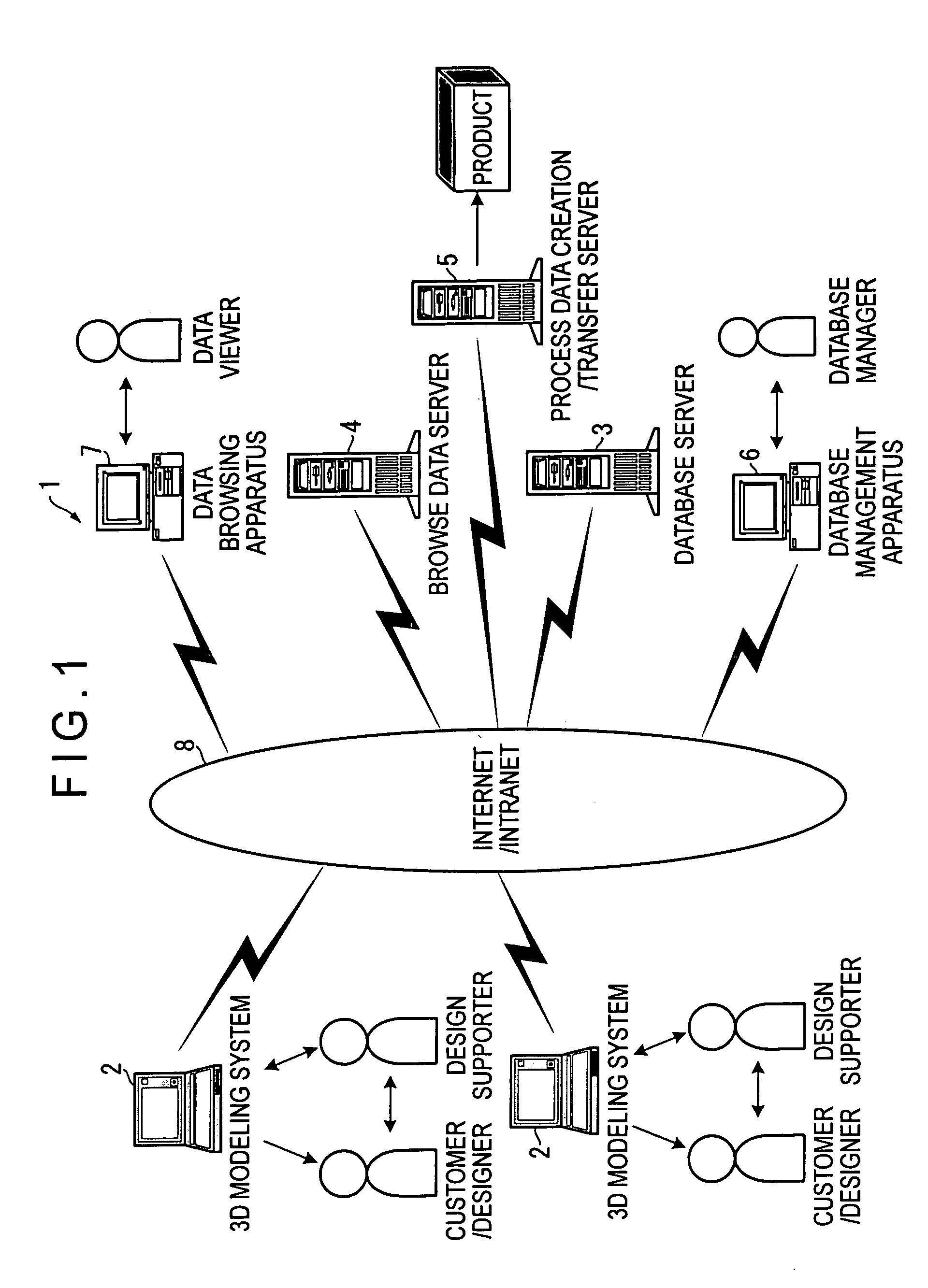

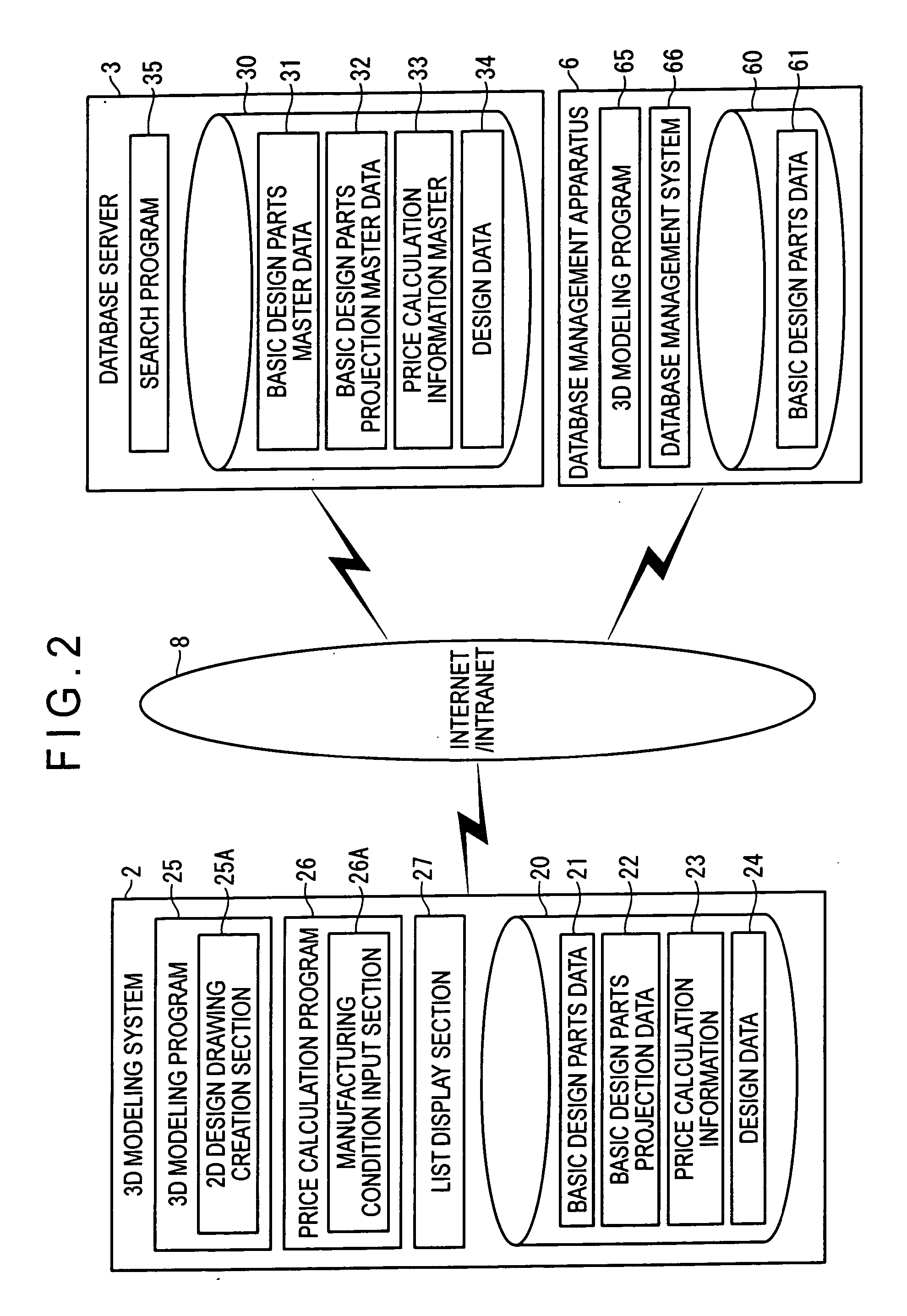

Product design method, product design apparatus, product design system, and product design program

InactiveUS20060052892A1Time requiredShorten the timeData processing applicationsCAD network environment3D modelingStorage cell

A product design apparatus (2) includes: a storage unit (20) for storing 3D CAD-based model data (21) of a plurality of products different from one another in terms of design and 2D product projection data (22) corresponding to the 3D CAD-based model data; a list display section (27) for displaying a list of the product projection data (22) on a screen; a 3D modeling program (25) for displaying the 3D CAD-based model data corresponding to the specified product projection data on the screen and for performing a shape modification through an operator's operation; and the storage unit (20) for storing designed data (24). Since a design can be performed based on the data that has been selected from the displayed data list, a product close to the customer's image can be designed in a short time, thereby shortening the time for determination of the design.

Owner:YKK CORP

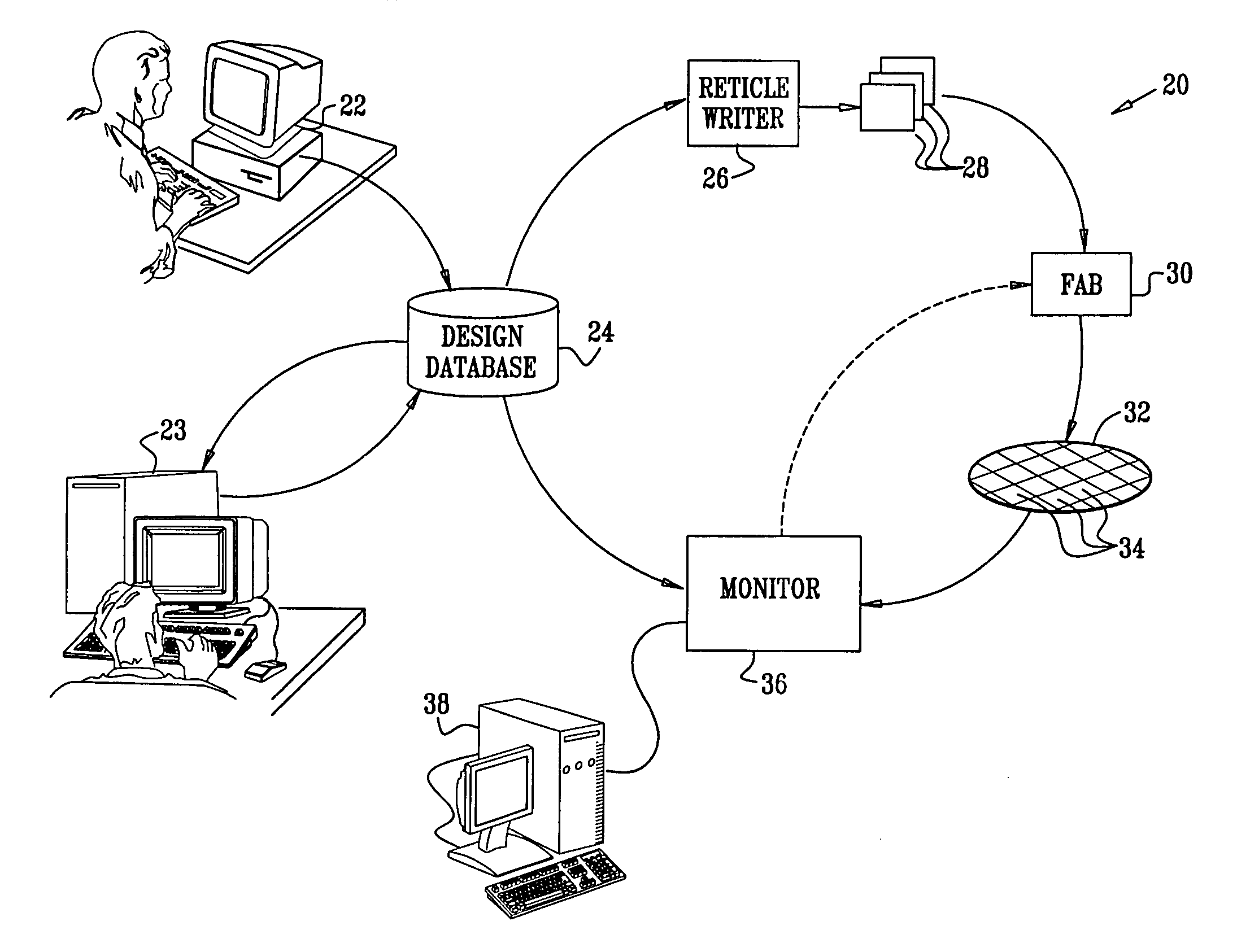

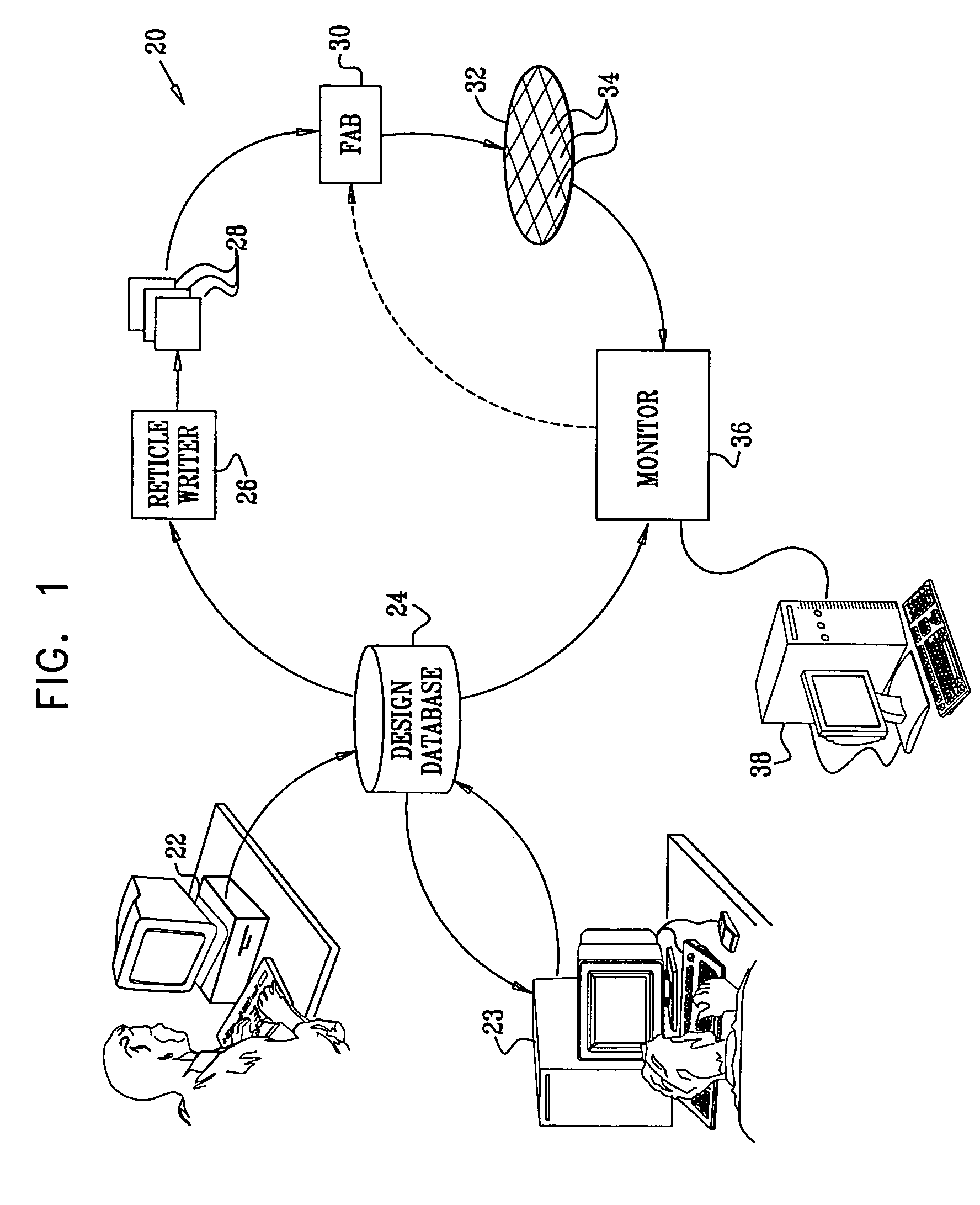

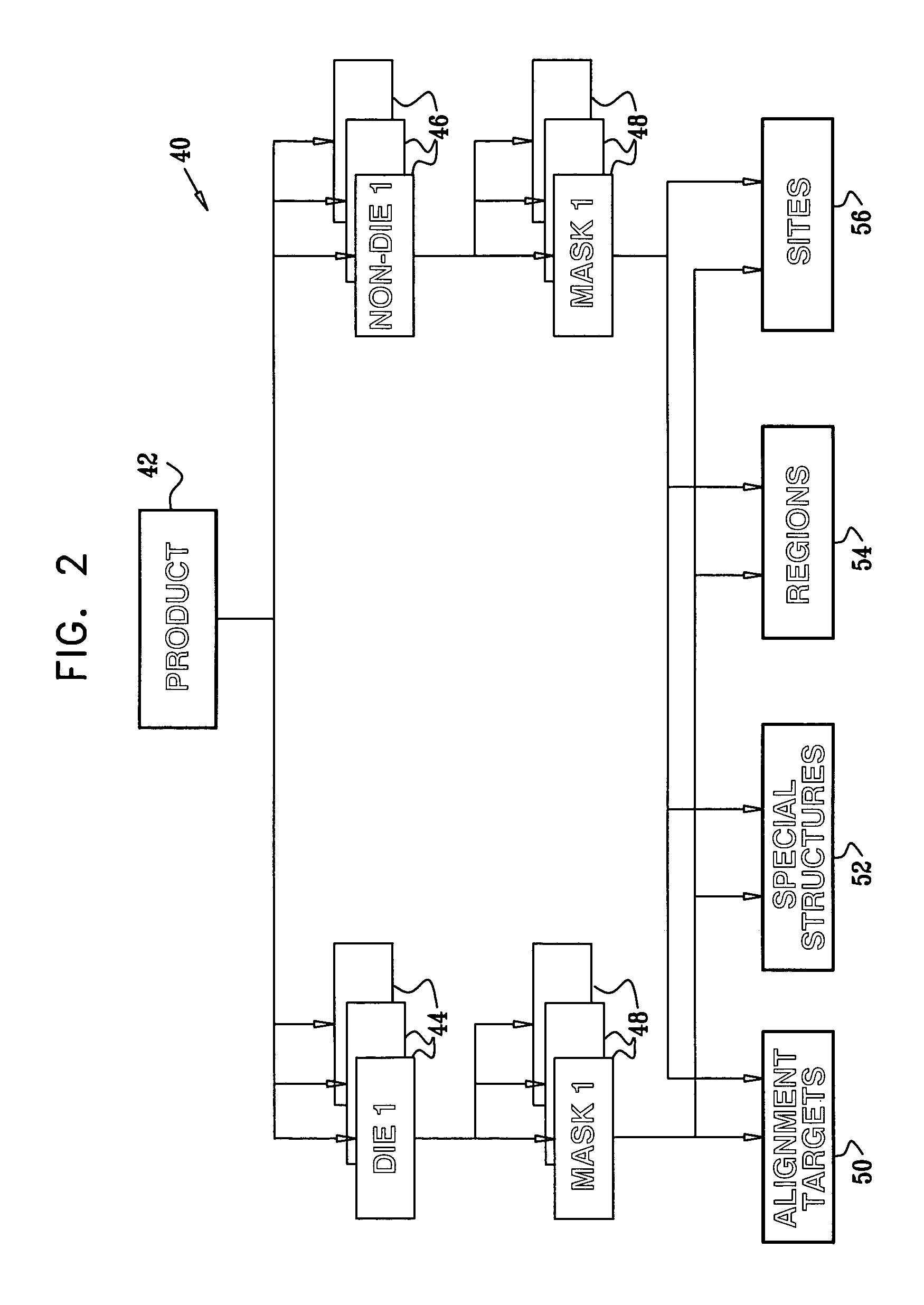

Design-based monitoring

ActiveUS7135344B2Maximize sensitivityMinimize impactSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A method for monitoring fabrication of an integrated circuit (IC) on a semiconductor wafer includes generating a product design profile (PDP) using an electronic design automation (EDA) tool, the PDP comprising an indication of a site in at least one layer of the IC that is susceptible to a process fault. Upon fabricating at least one layer of the IC on the wafer, a process monitoring tool is applied to perform a measurement at the site in at least one layer responsively to the PDP.

Owner:APPL MATERIALS ISRAEL LTD

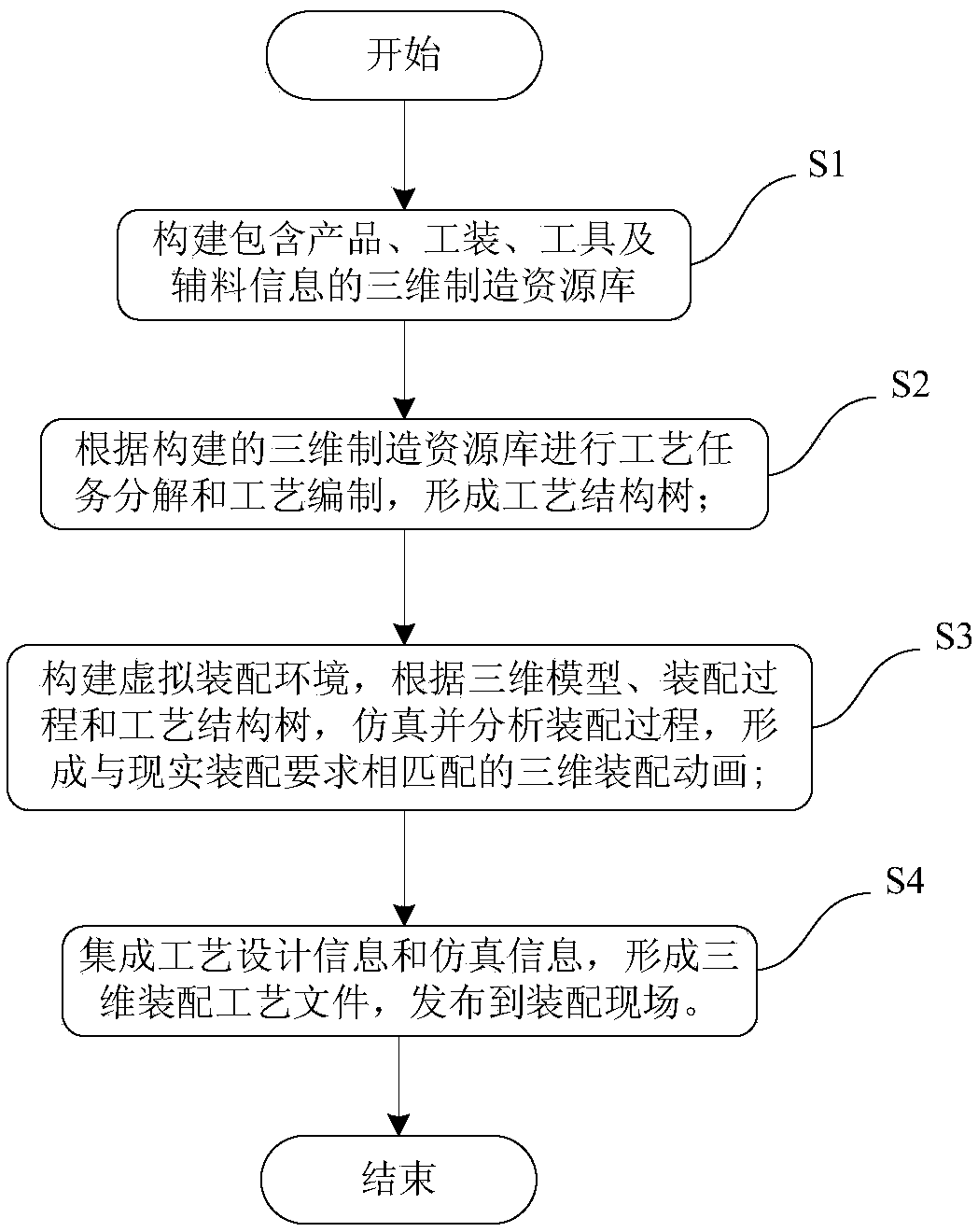

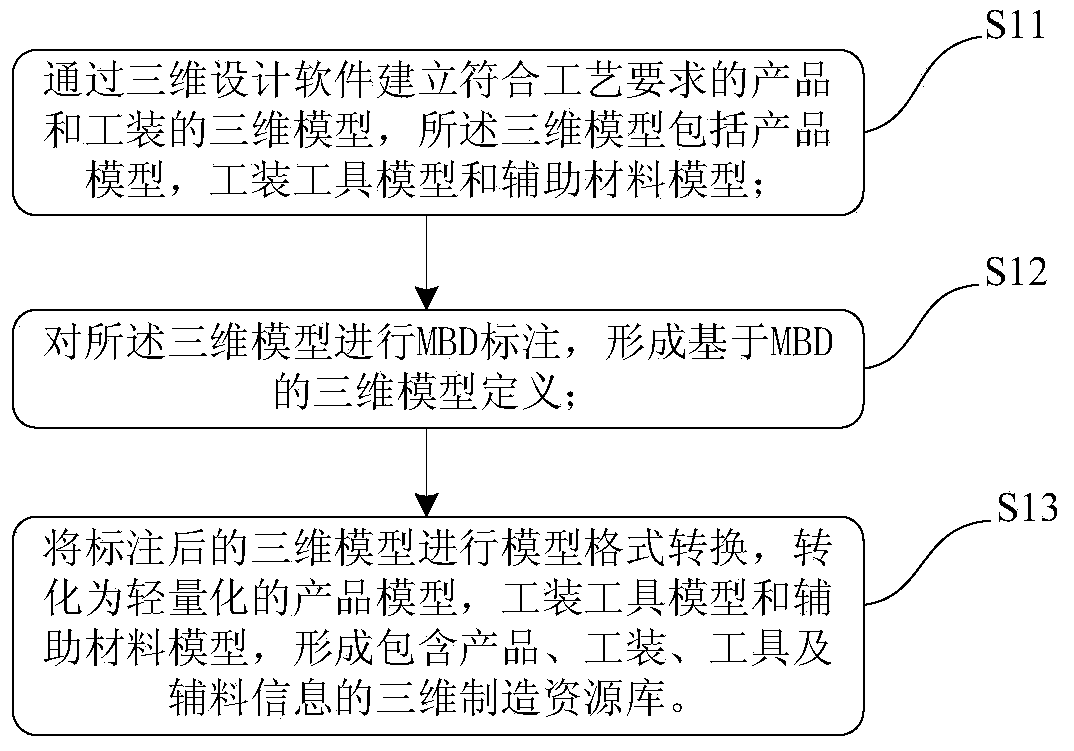

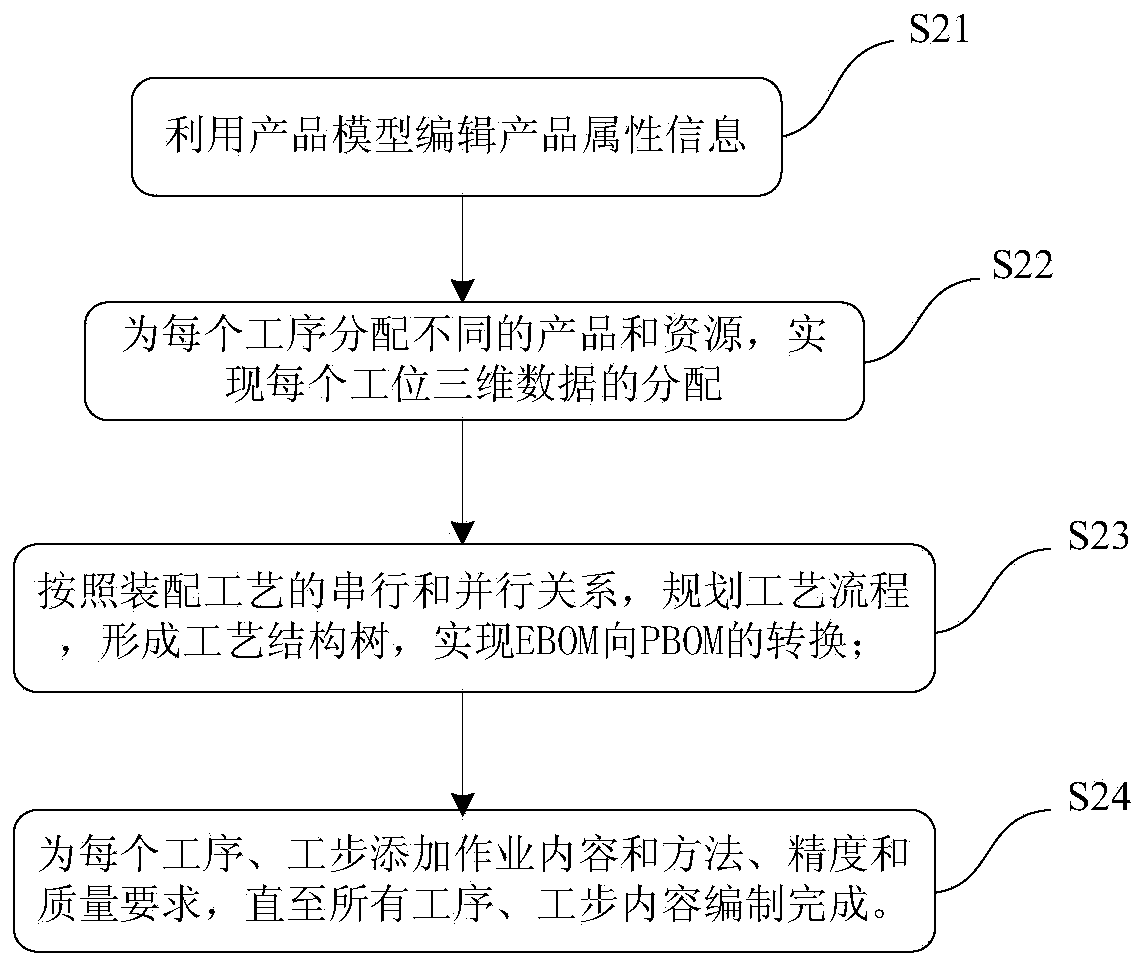

Three-dimensional assembly process generation method and system for aerospace product

InactiveCN103413004AAddressing the information gapAccurate visualizationAnimationSpecial data processing applicationsAnimationInformation gap

The invention provides a three-dimensional assembly process generation method and system for an aerospace product. The system comprises a three-dimensional manufacturing resource library building module, a three-dimensional assembly process design module, a three-dimensional assembly process simulation module and a three-dimensional assembly process release module, the three-dimensional manufacturing resource library building module is used for building a three-dimensional manufacturing resource library containing product, fixture, tool and auxiliary material information, the three-dimensional assembly process design module is used for decomposing process tasks and planning a process according to the built three-dimensional manufacturing resource library to form a process structure tree, the three-dimensional assembly process simulation module is used for building a virtual assembly environment and simulating and analyzing the assembly process according to a three-dimensional model, the assembly process and the process structure tree to form a three-dimensional assembly animation meeting actual assembly requirements, and the three-dimensional assembly process release module is used for integrating process design information and simulation information, forming a three-dimensional assembly process file and releasing the three-dimensional assembly process file to an assembly site. Accurate and visual three-dimensional visual means are provided for aerospace product assembly, so that the problem of information gaps among three-dimensional product design, three-dimensional process design and three-dimensional assembly site implementation in the prior art can be solved.

Owner:SHANGHAI JIAO TONG UNIV

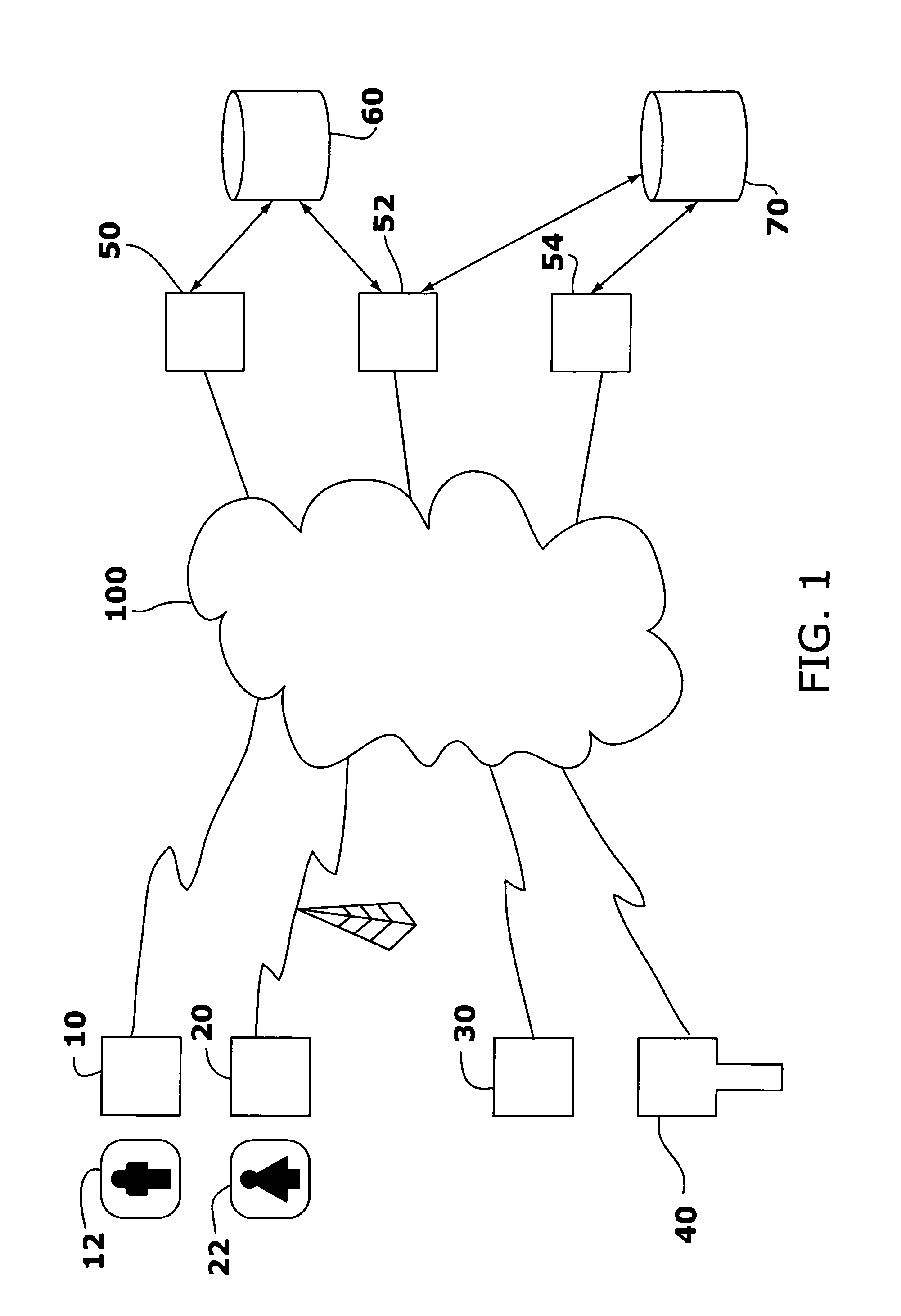

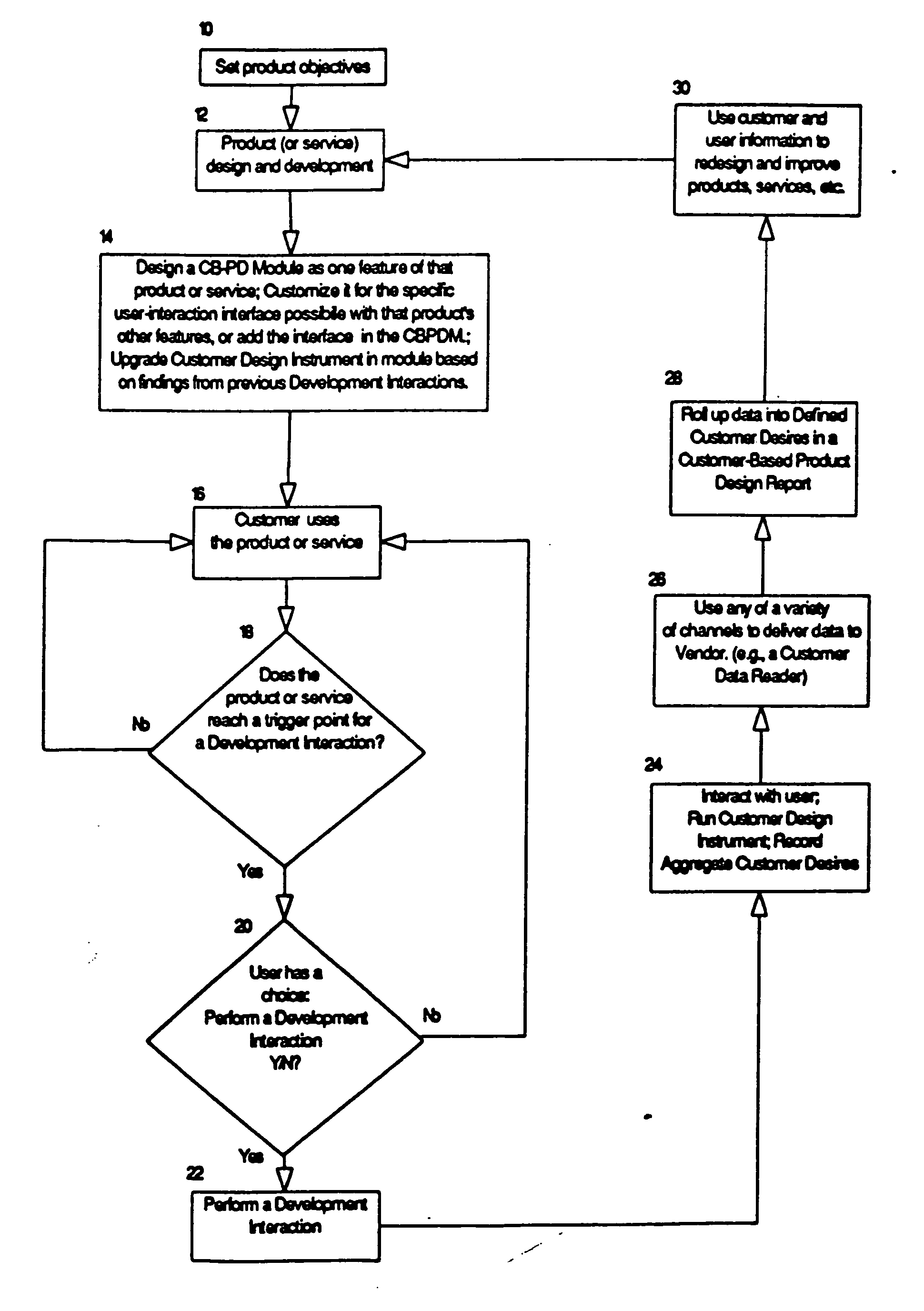

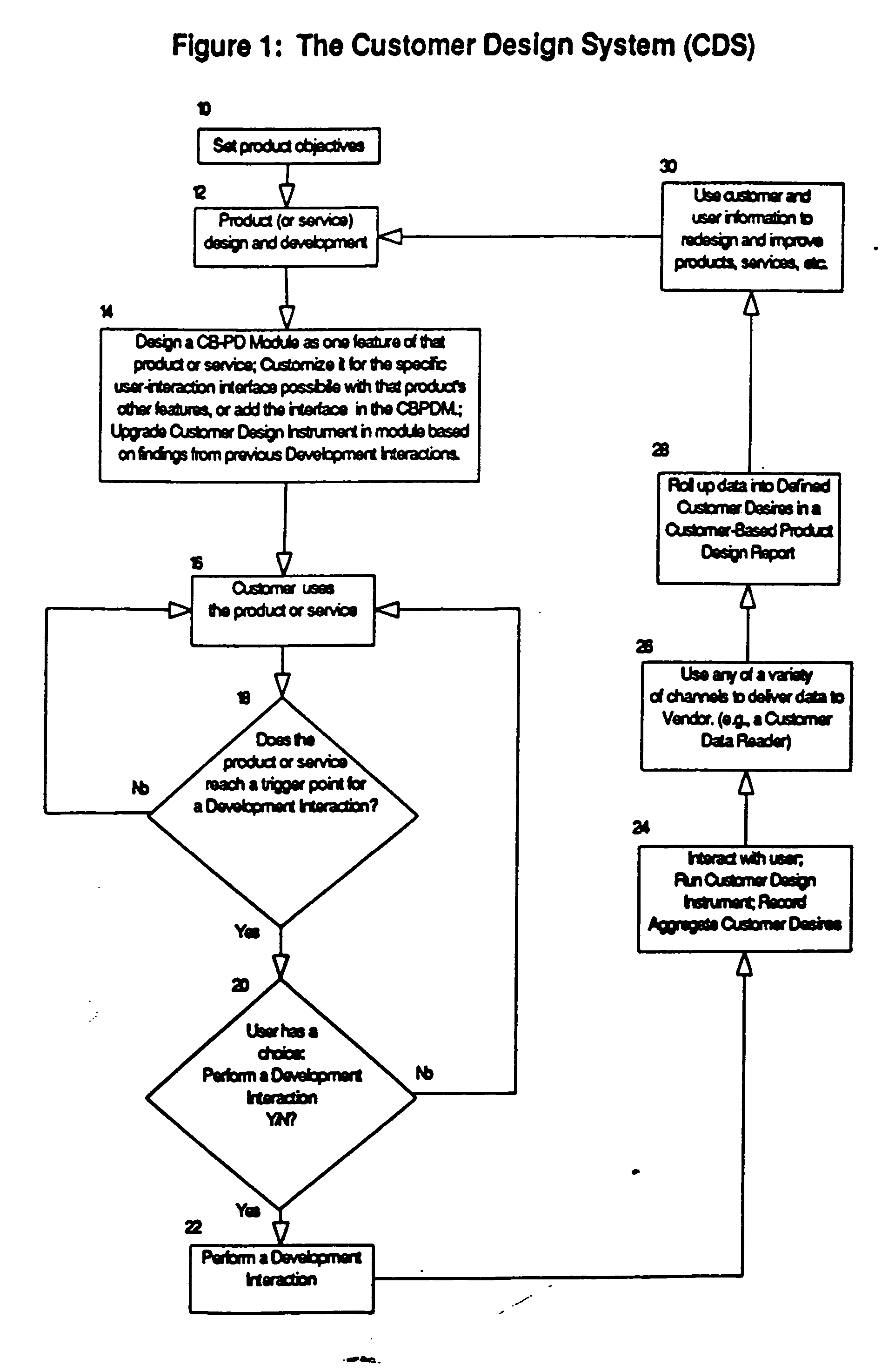

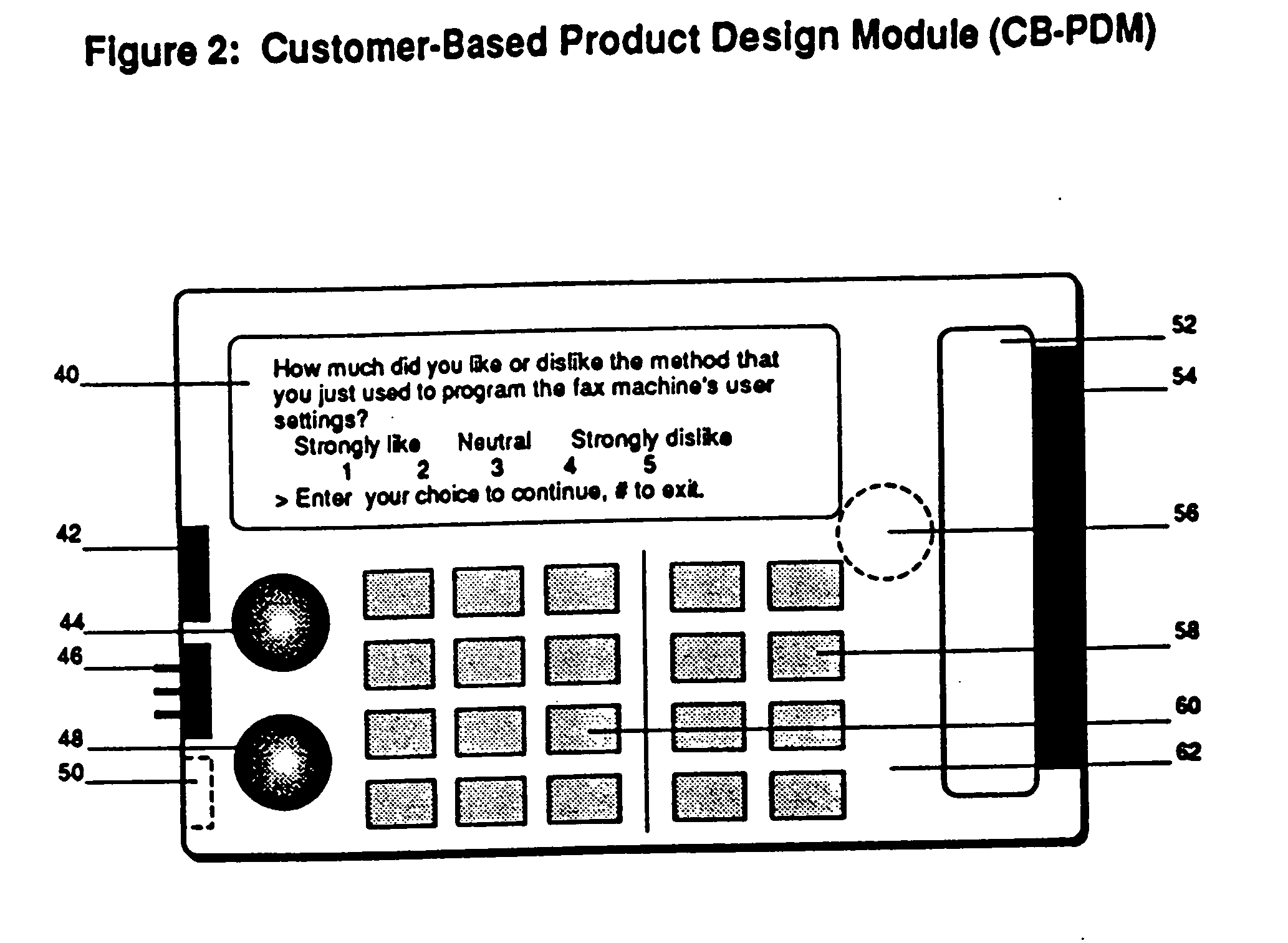

Customer-based product design module

InactiveUS20070043632A1Faster and accurate and profitable working relationshipImprove efficiency and benefitAcutation objectsMarket predictionsData processing systemDecision maker

A network of data processing-based and telecommunications-based apparatuses and systems are disclosed, including a product sub-system that interacts with a user, gathers information from the user, communicates the information to the product's vendor, and receives new pre-programmed interactions from the vendor for future interactions with the user. In addition to this computing / networking apparatus which is a sub-system in or attached to a product or service, other components of this invention include a data processing system for constructing and downloading pre-programmed interactions to the product sub-system; a communications sub-system for transmitting the data directly from the product sub-system to the vendor's computer; a communications apparatus for reading the product sub-system's data, transmitting it to the vendor's computer, and downloading new pre-programmed interactions to the product sub-system; a data processing system that resides in the product sub-system and conducts numerous types of interactions with a user; and a data processing system that resides in the vendor's computer and analyzes and reports the information gathered from product users. This invention may be built into a variety of products and services to establish networks of customer-vendor interactions and communications. It makes possible new customer roles and contributions to the design and development of products and services, and the nature of customer-vendor relationships. A variety of functions are enabled by this invention, which include (depending on the configuration of a particular product sub-system) inquiries, reports, suggestions, help, interactive services, transactions and two-way real-time communications. As a complete system, this invention may be viewed as a new medium through which customers interact directly with products and services at the time they are using them, to describe their conception of what the product or service should be and how the vendor should work with them to satisfy their needs better. The customer data, suggestions and other information are transmitted to the product vendor's computer where they are collected, analyzed by automated means and presented in automated reports to product managers, product designers and other decision makers. This source of continuous customer-based information may assist in improving products, services and customer relationships both sooner and more accurately, thereby producing strategic business advantages over competitors who do not engage in a similar improvement dialog with their customers. Over time, the cost of incorporating such sub-systems may fall and the impact from using them may rise, producing a greater reliance on customer involvement and customer input into a growing range of business decisions. This may produce a gradual transfer, from vendors to customers, of conceptual commercial guidance, both in individual cases and in aggregate. This invention suggests the emergence of a “partnership capitalist” economy in which a variety of interactive products and services link customers and vendors with networks that are built into those products and services, producing greater understanding, efficiency and accuracy in designing, manufacturing and selling the products, services and lifestyles that customers truly want.

Owner:LODSYS GRP

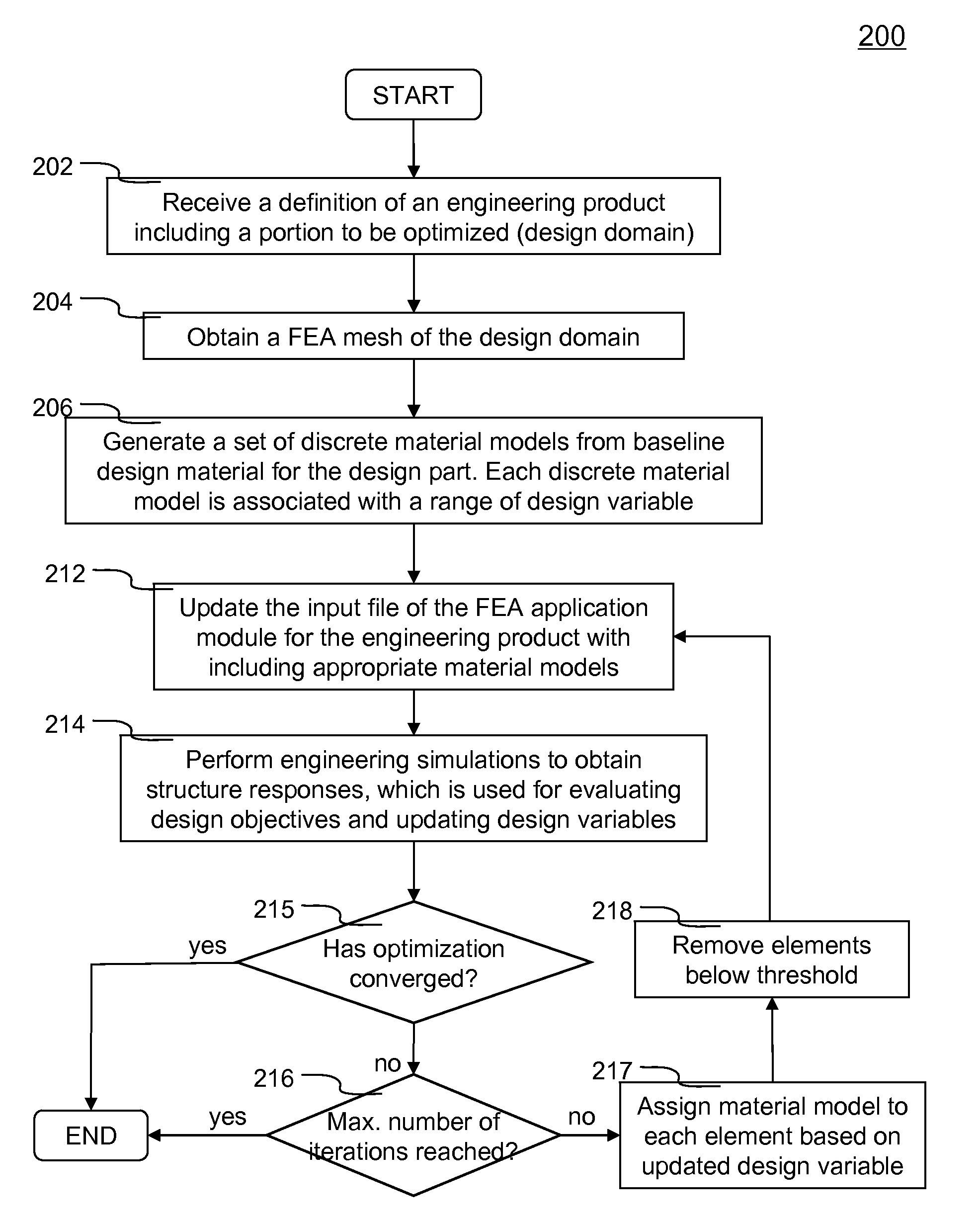

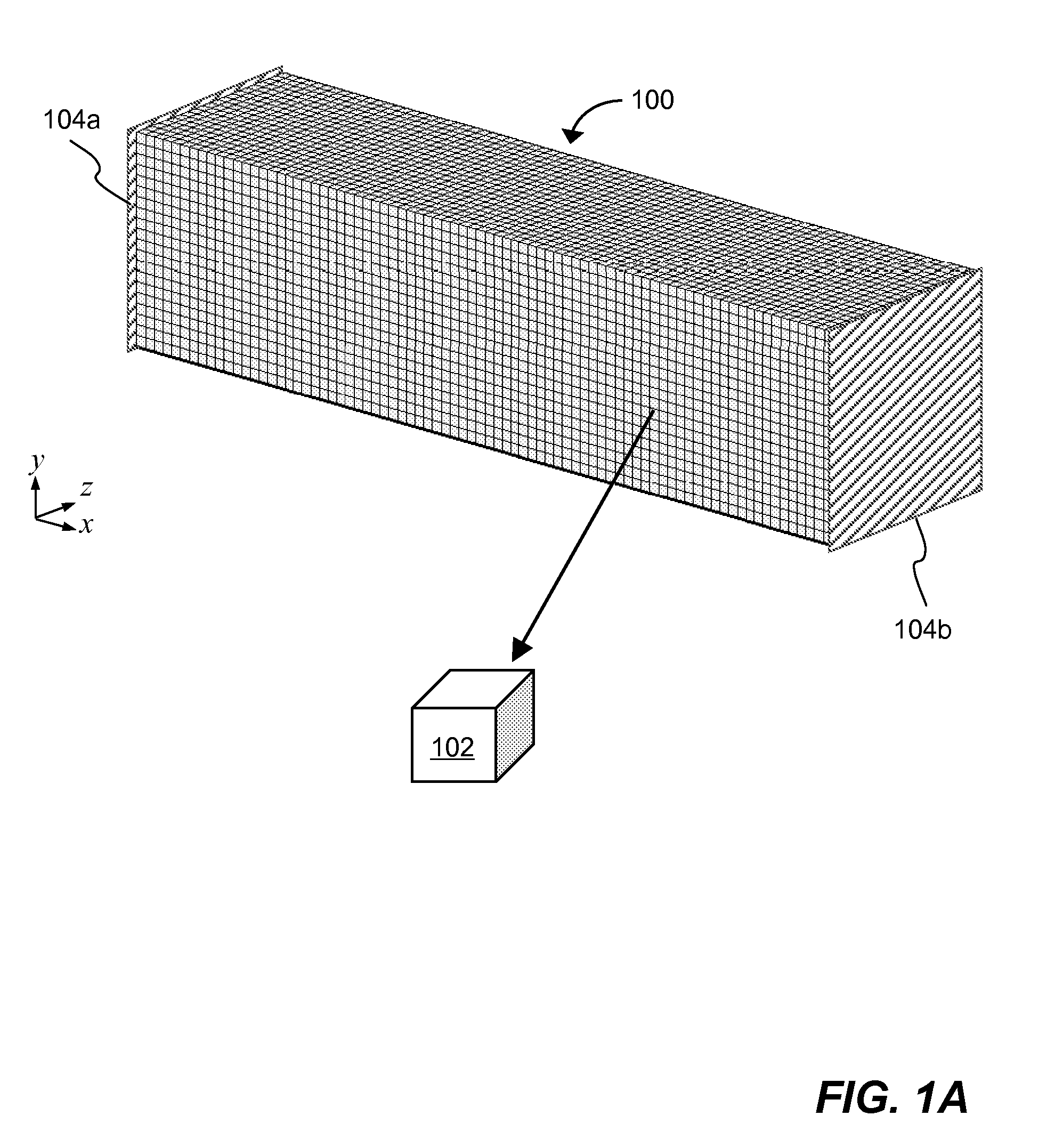

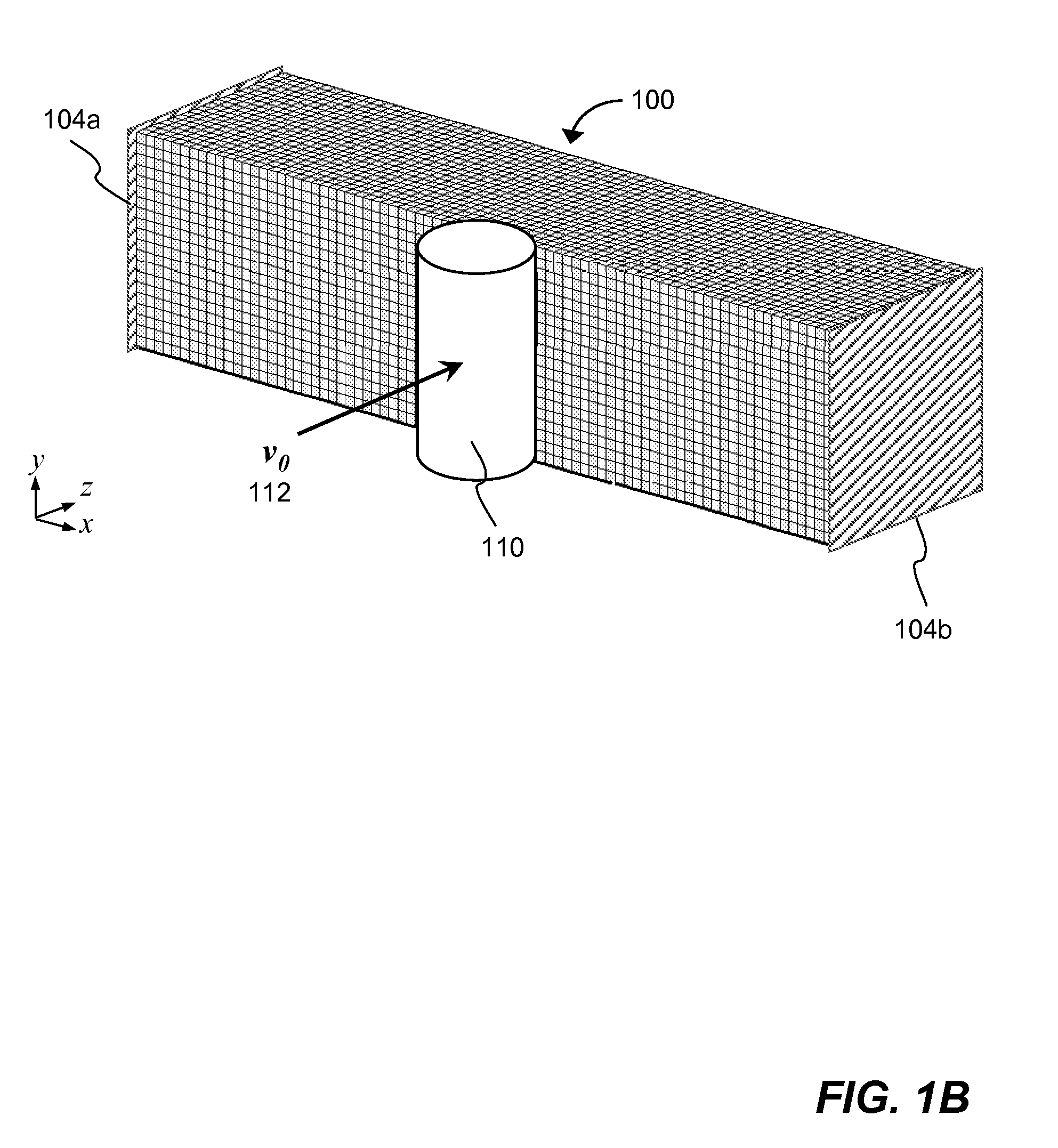

Topology optimization for designing engineering product

ActiveUS20100262406A1Geometric CADComputation using non-denominational number representationElement analysisDesign objective

Improved topology optimization for engineering product design is disclosed. An engineering product including a design domain to be optimized is defined. Design domain can be a portion of or the entire engineering product. Design objective and optional constraint are also defined such that optimization goal can be achieved. Additionally, initial configuration of the design domain is represented by a finite element analysis (FEA) mesh. Each element or element group is associated with a design variable. A set of discrete material models is created from the baseline material used for the design domain. The set of discrete material models is configured to cover entire range of the design variable and each discrete material model represents a non-overlapping portion. Each element representing the design domain is associated with an appropriate discrete material model according to the design variable. Structure response of entire engineering product is obtained via FEA to evaluate design objective and update design variable.

Owner:ANSYS

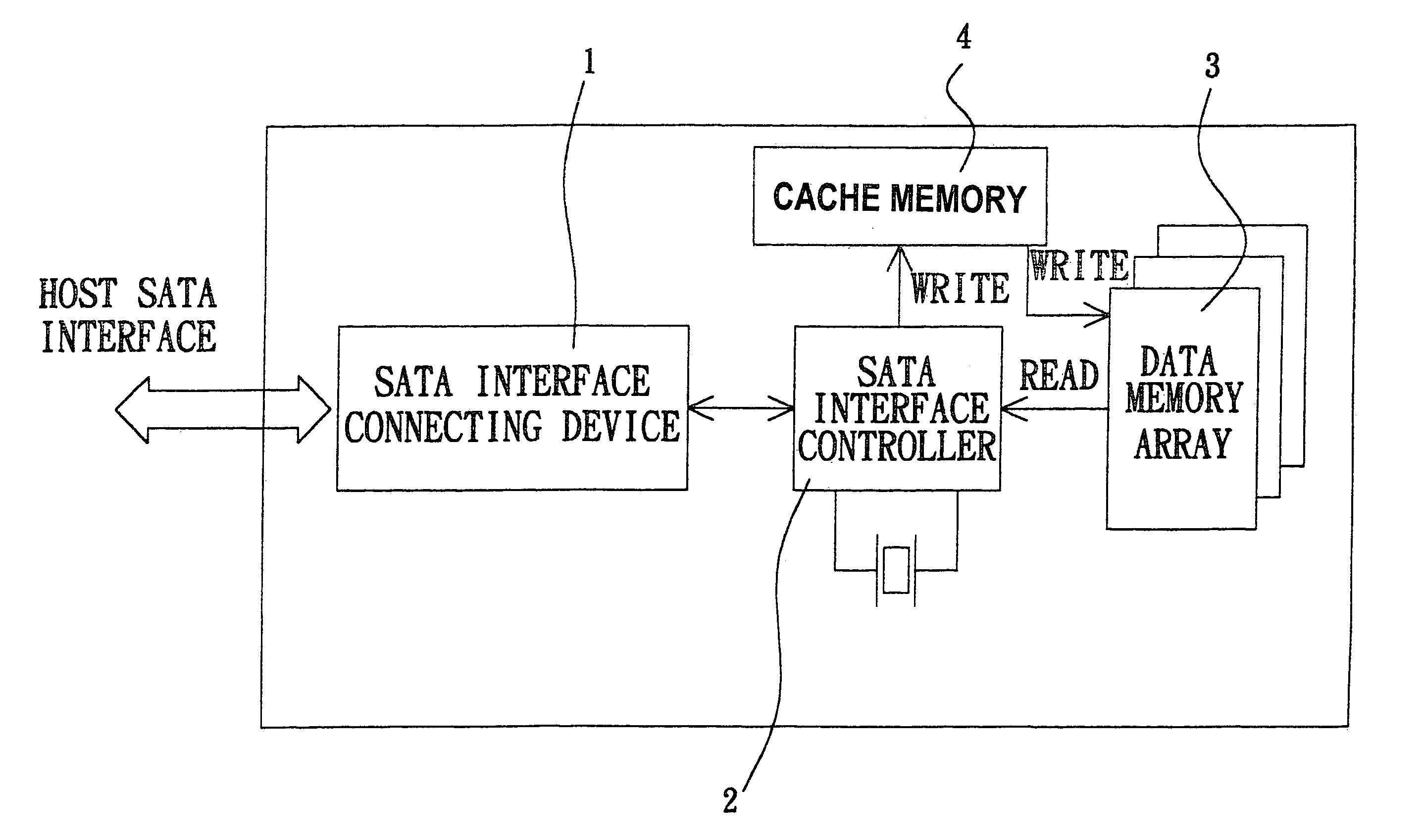

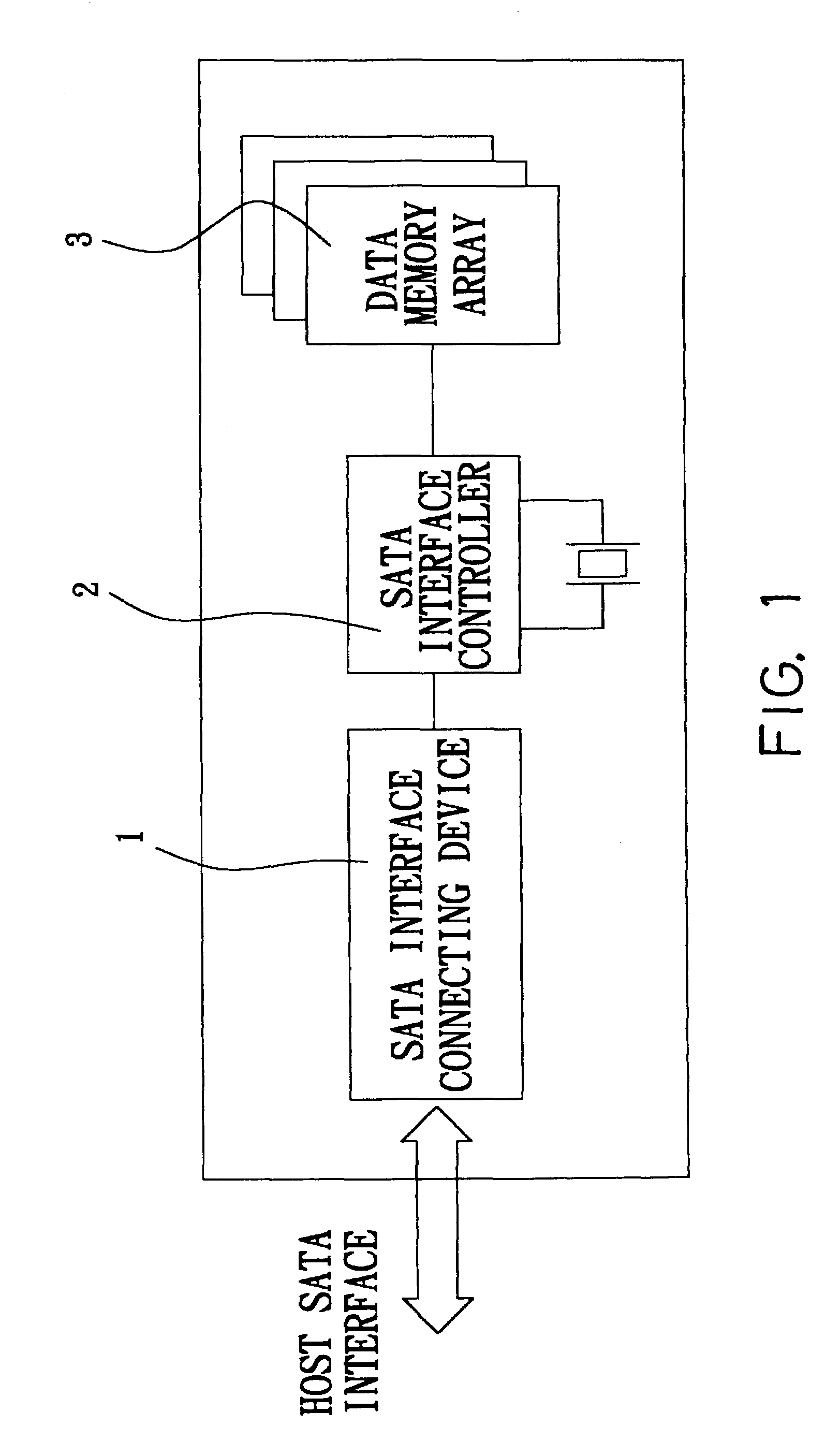

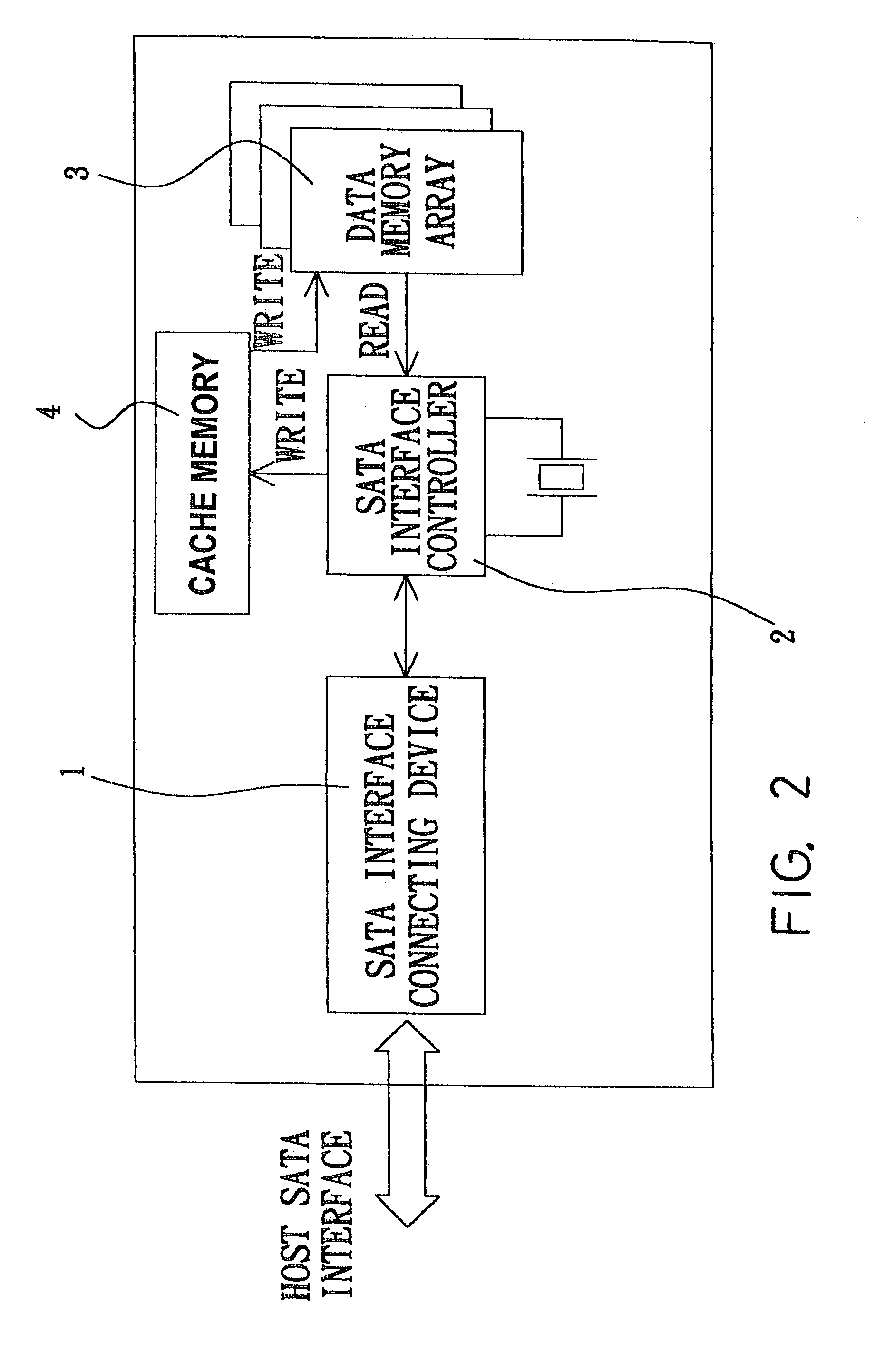

Solid state disk on module with high speed data transmission

InactiveUS7003623B2Input/output to record carriersError detection/correctionSolid-state driveData transmission

IDE interface used in the conventional solid state disk on module is an interface for data transmission. However, the speed of date transmission with the IDE interface becomes slower since the standard of a faster SATA interface has been created. Therefore, how to design a solid state disk on module with high speed transmission by means of the developed SATA interface is a latest trend of the new product design. The present invention discloses a circuit structure, which can enhance the data transmission speed of the solid state disk on module with the SATA interface.

Owner:SAMSUNG ELECTRONICS CO LTD

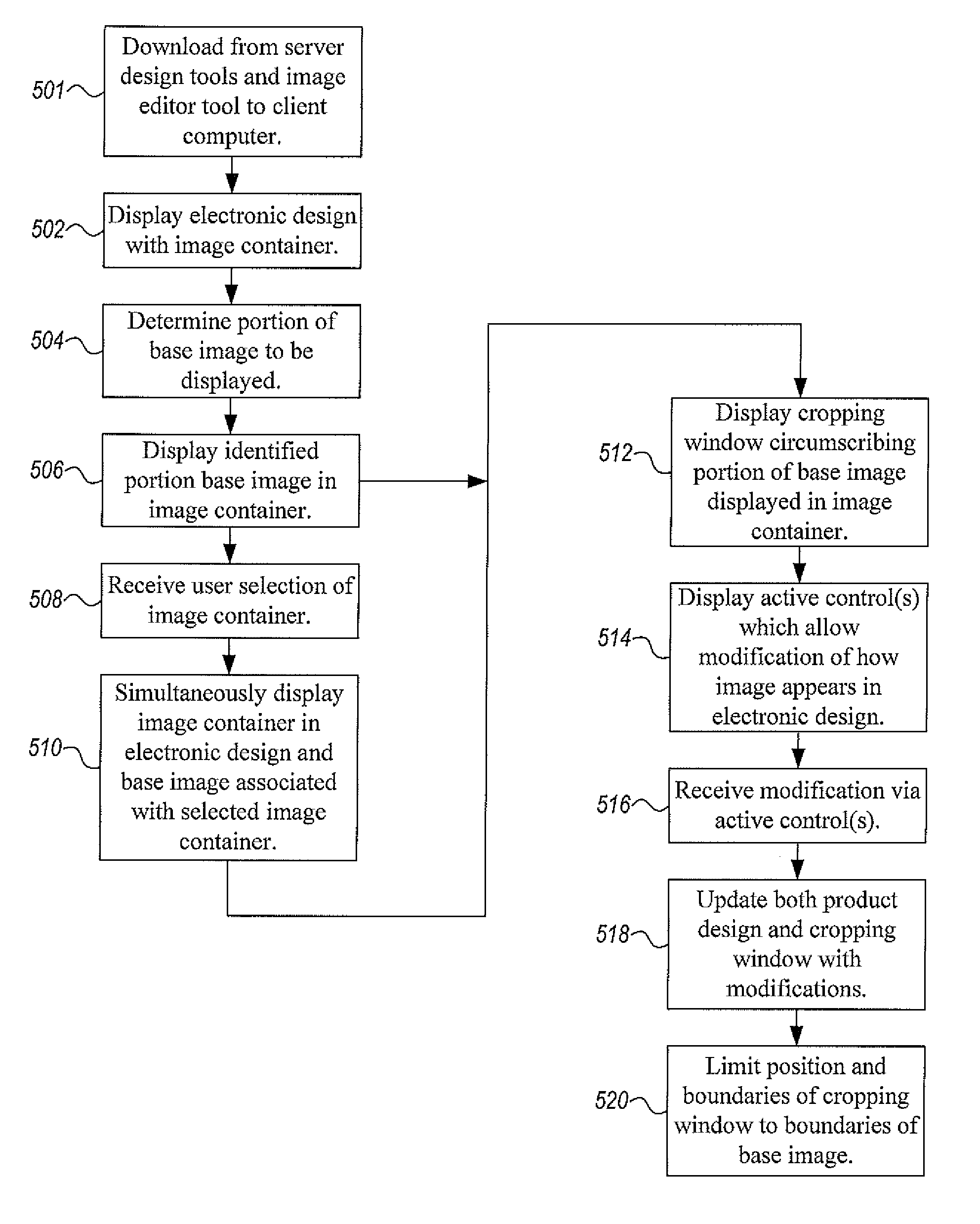

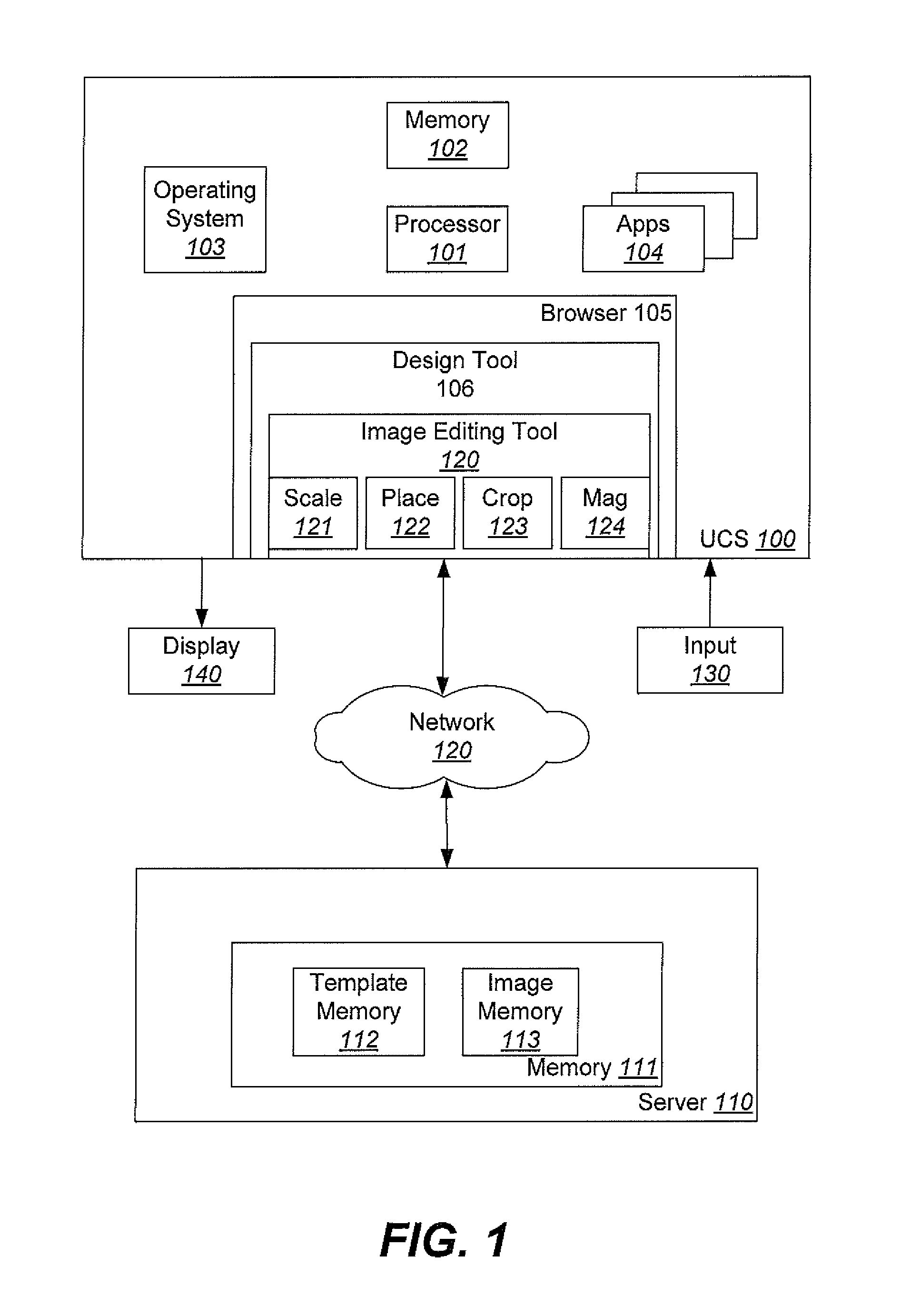

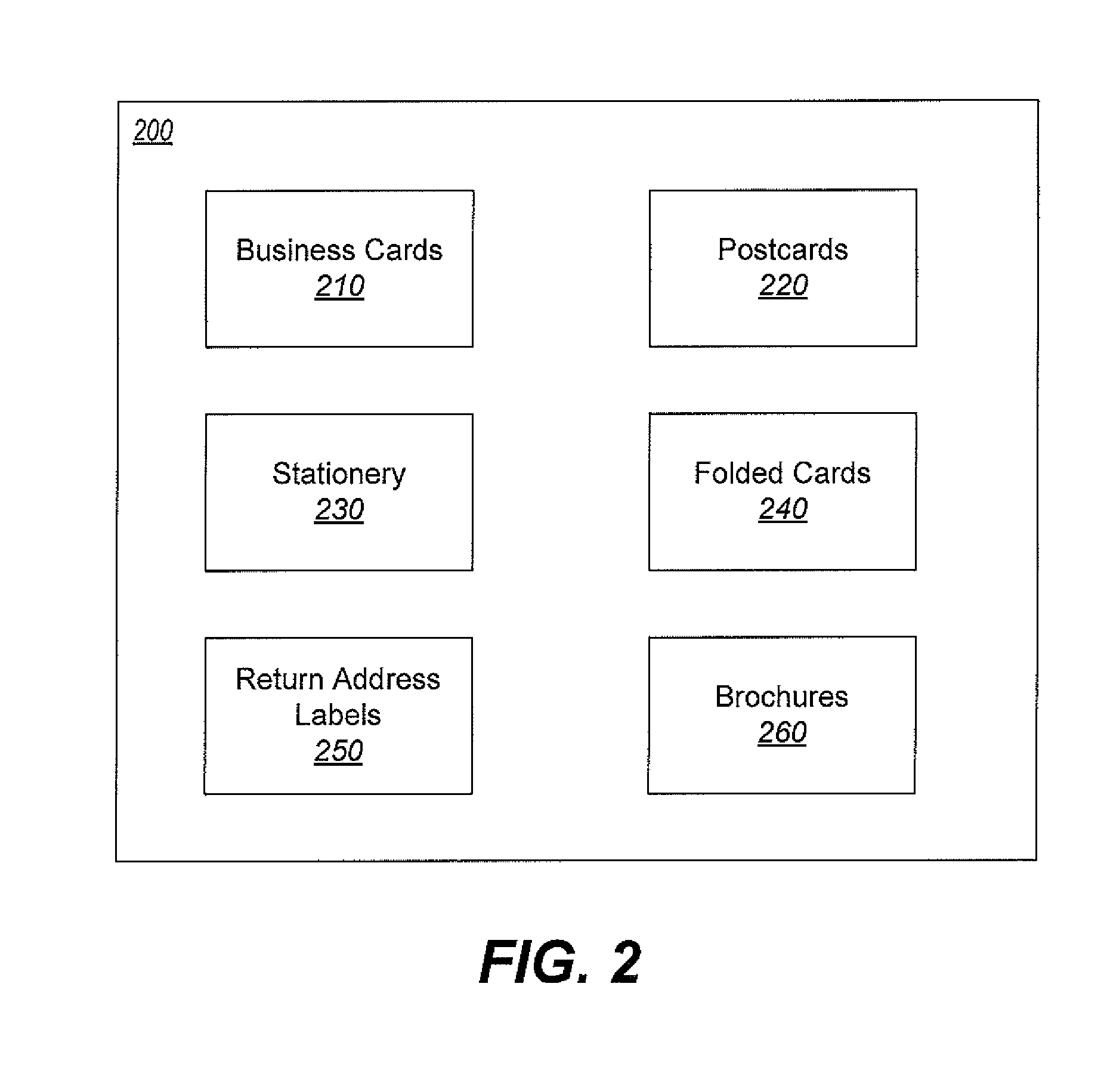

System and method for image editing of electronic product design

ActiveUS20090147297A1Facilitating user customizationEasy to customizeDigital computer detailsCathode-ray tube indicatorsElectronic documentMagnification

Electronic document design systems and methods allowing a user engaged in customizing an electronic product to select an image container and modify the placement, scaling, and displayed portion of an image associated with the image container. Upon user selection of an image container from the product design, an image pane is presented to the user which displays the base image associated with the selected image container and at least one active control on either or both of the image container and the image pane which allow the user to modify which portion of, and how the portion of, the base image appears in the electronic product design. The image editor tool is displayed simultaneously with the product design to allow the user to immediately see the resulting changes in the product design due to modifications, using the active control(s), of the placement or scaling of the selected image container or of the cropping of the base image or magnification of the portion of the base image appearing within the image container.

Owner:CIMPRESS SCHWEIZ

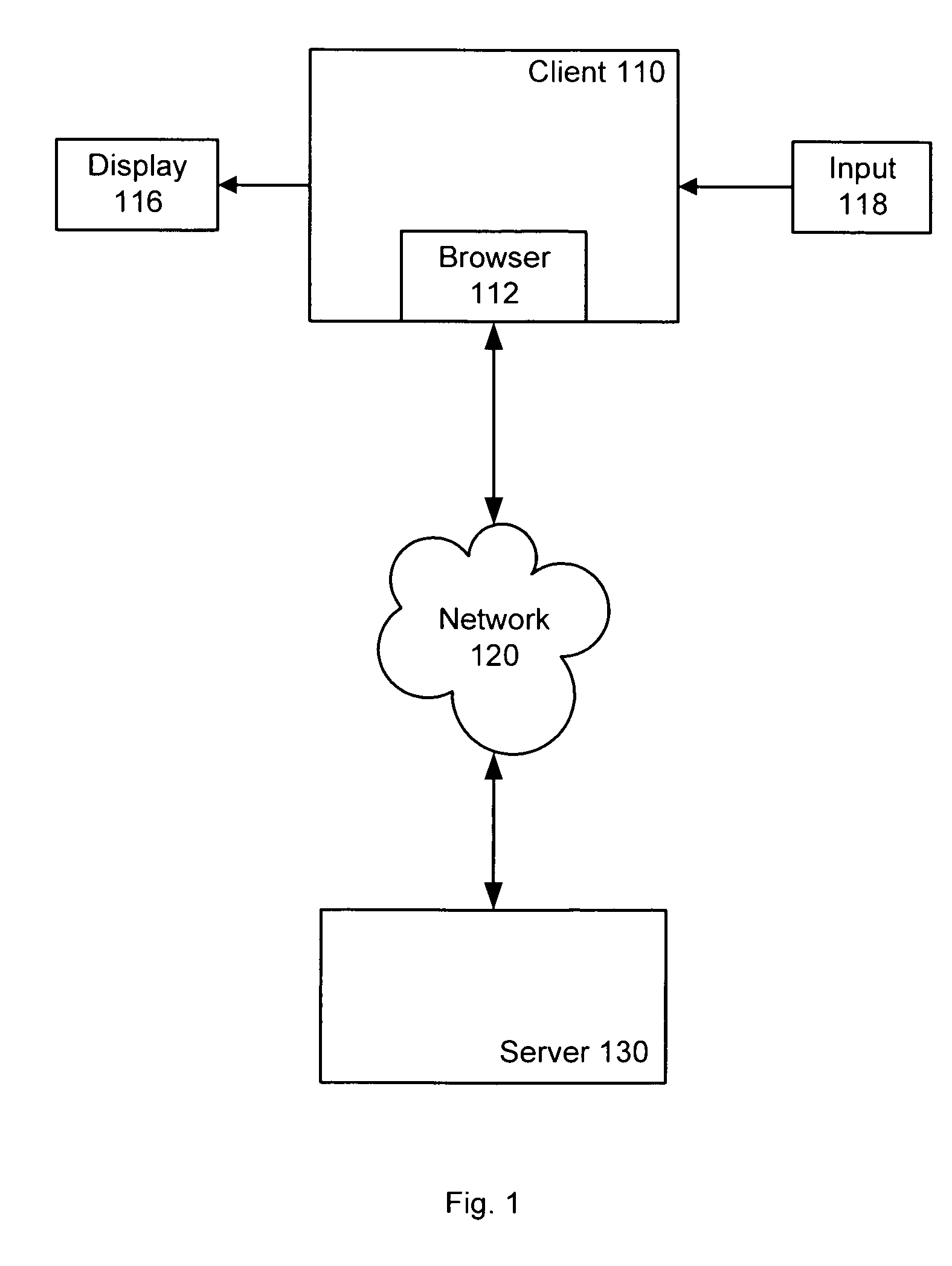

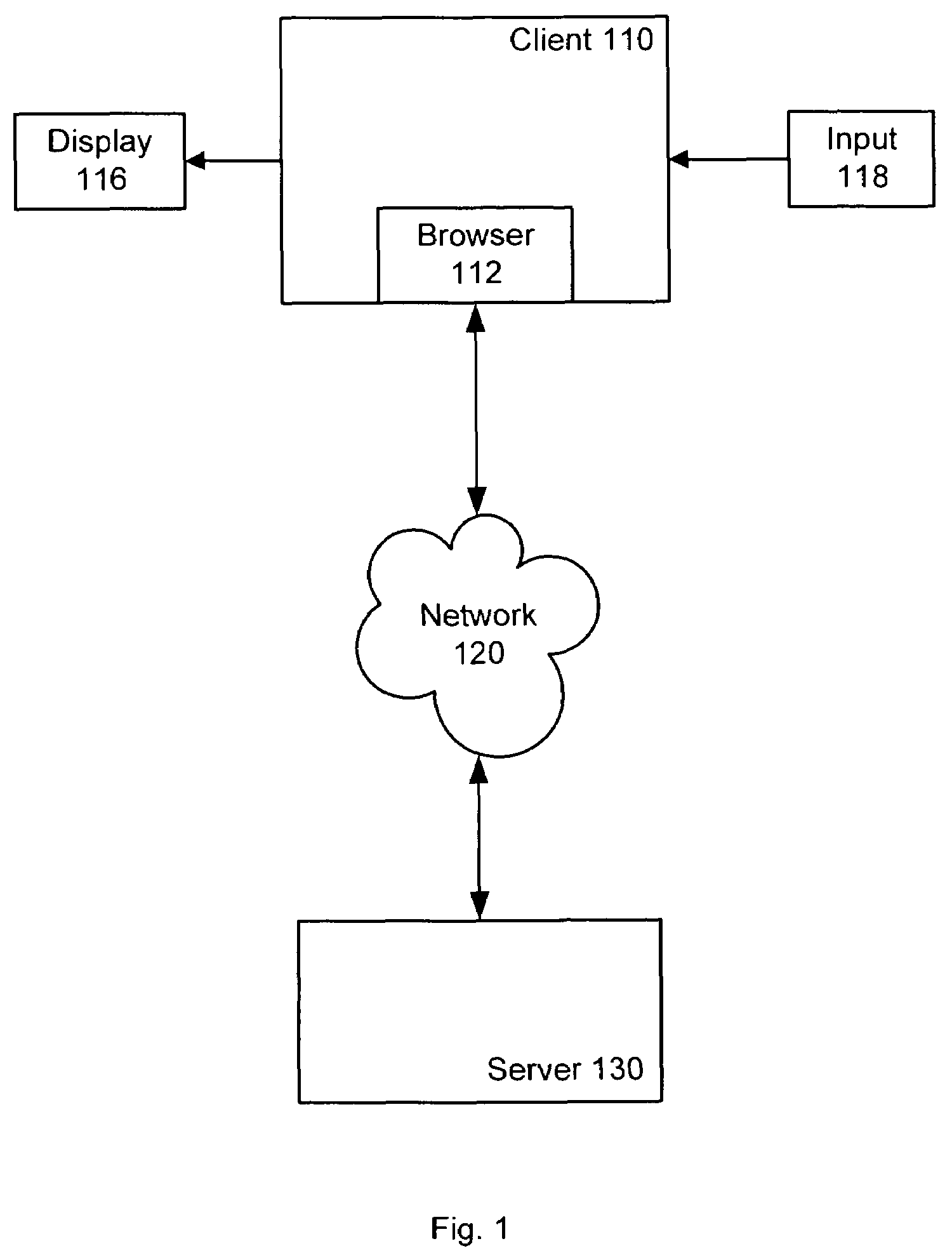

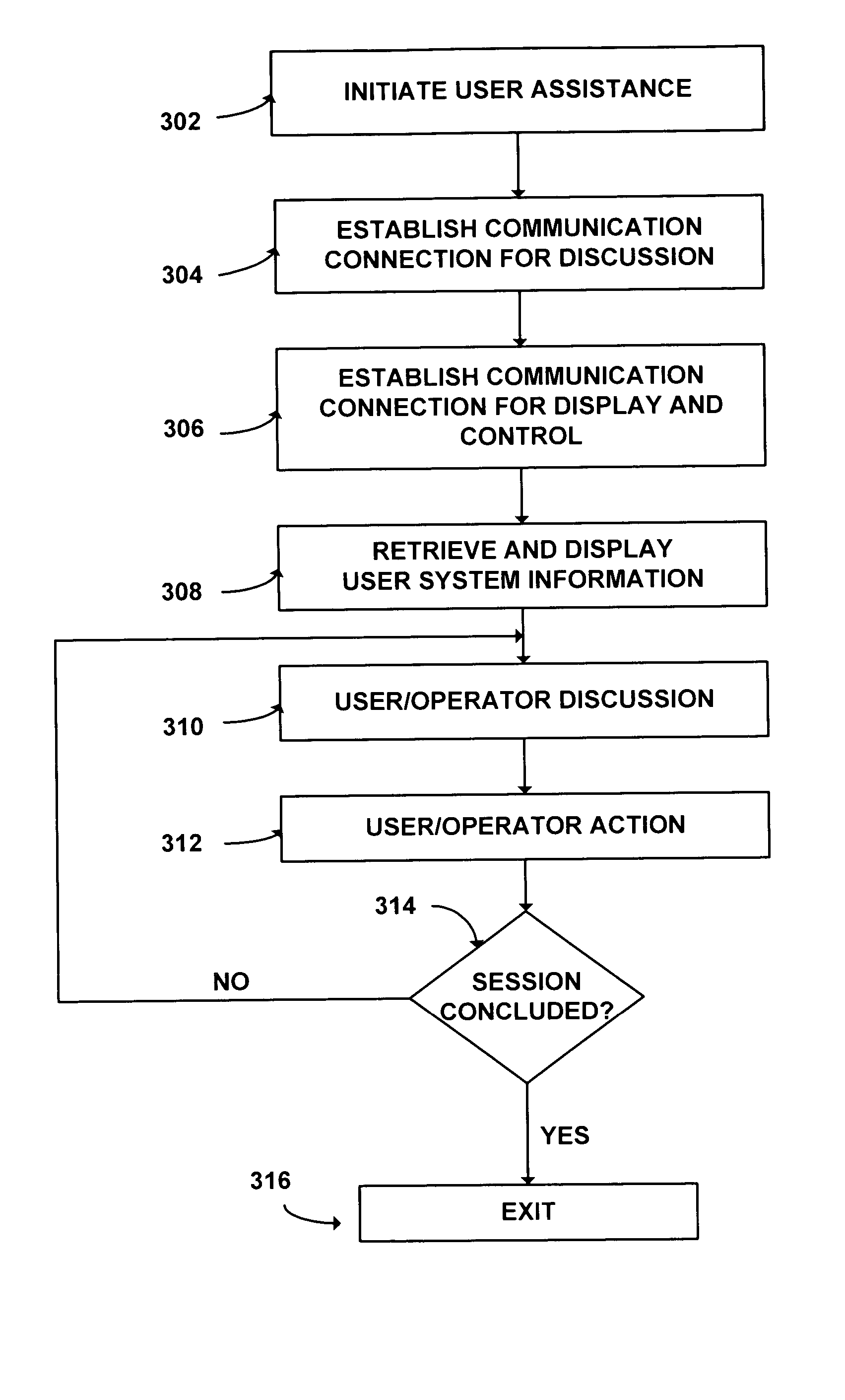

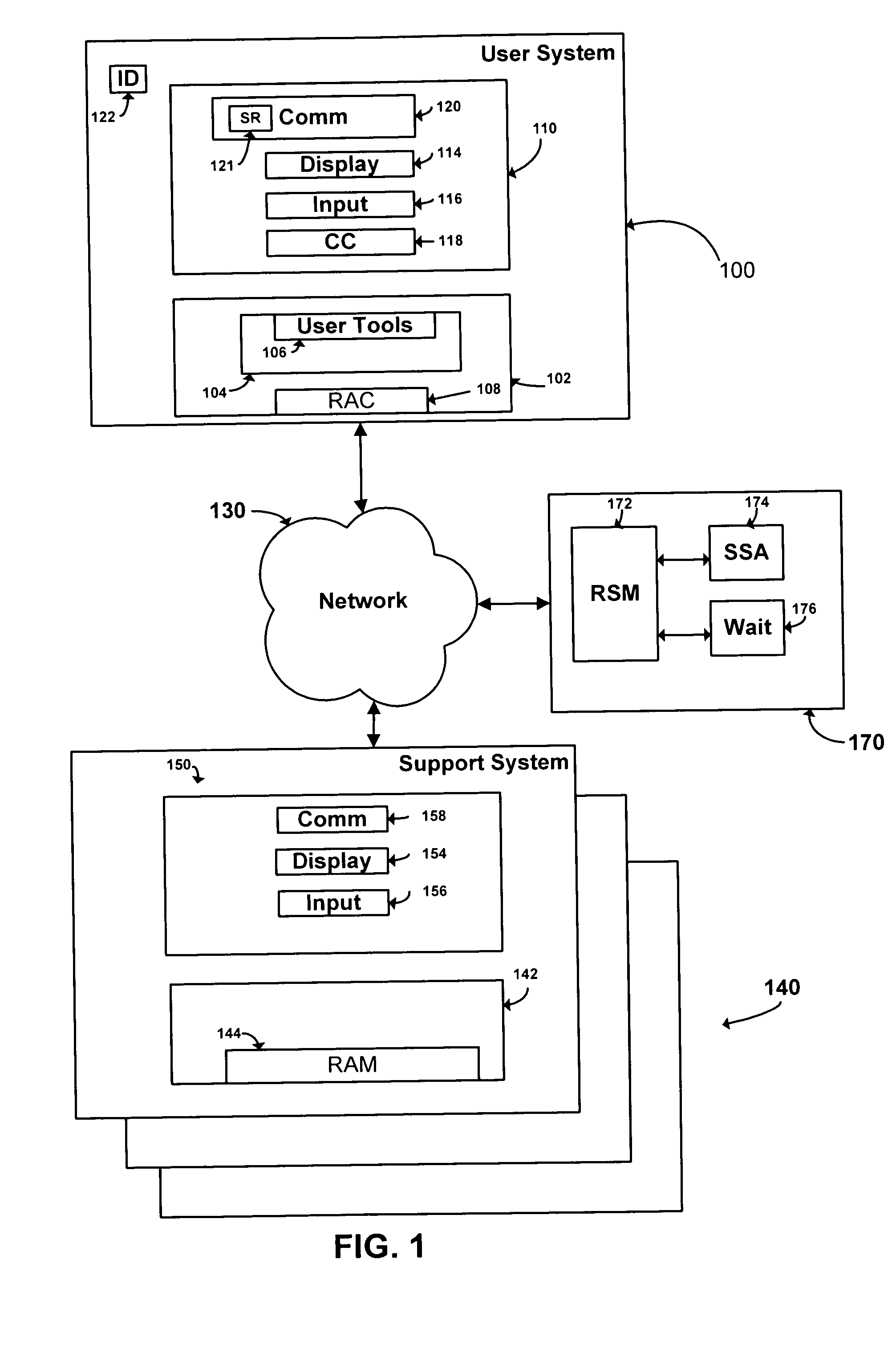

System and method for remote assistance

ActiveUS20050044232A1Multiple digital computer combinationsApparatus for meter-controlled dispensingSupporting systemComputer science

A number of geographically dispersed automated product design systems and support systems are connected to a network. A user of a design system requesting assistance in using the design system is connected to an operator of one of the support systems. A display and control connection is established between the user system and the support system such that the operator of the support system can monitor and control the user system. A discussion connection is established between the user of the user system and the operator of the support system such that the user can submit inquiries to and receive responses from the operator while the operator is viewing the information being displayed to the user at the user system.

Owner:CIMPRESS SCHWEIZ

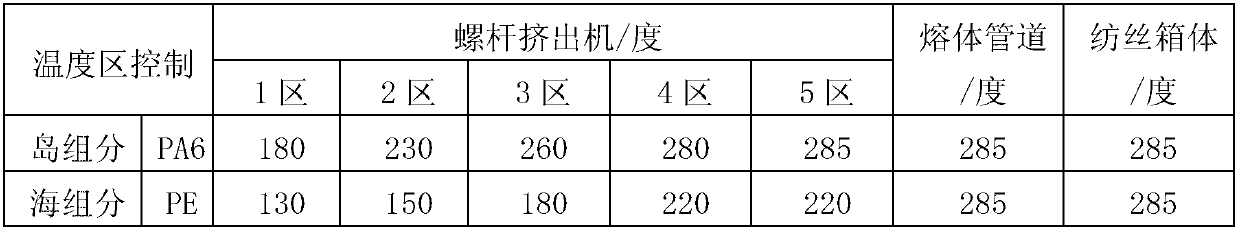

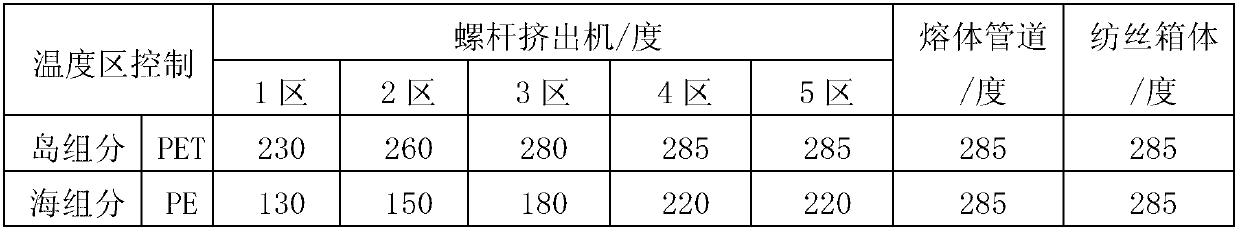

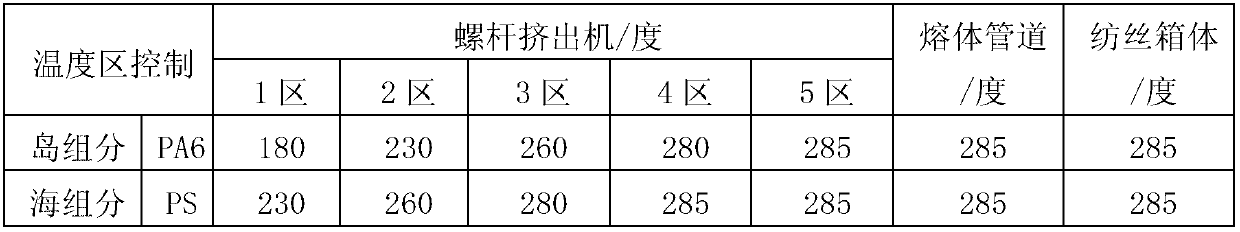

Figured island superfine fiber, figured island superfine fiber synthetic leather base cloth, suede leather for clothes, smooth synthetic leather for clothes and production method of fiber, base cloth, suede leather and smooth synthetic leather

The invention relates to figured island superfine fiber, figured island superfine fiber synthetic leather base cloth, suede leather for clothes, smooth synthetic leather for clothes and a production method of the fiber, the base cloth, the suede leather and the smooth synthetic leather and belongs to the technical field of synthetic leather and production method of the synthetic leather. The production method of the figured island superfine fiber mainly comprises the steps of 1), performing slice drying and fusion; 2), conducting composite spinning; 3), applying oil and dropping a bucket; 4), performing drafting and crimping; and 5) drying and cutting off the fiber. The figured island superfine fiber synthetic leather base cloth, the suede leather for clothes and the smooth synthetic leather for clothes can be produced through the follow-up processing of the figured island superfine fiber. A prepared synthetic leather product has excellent mechanical property, dyeing property and color fastness, is more suitable for synthetic leather of suede or synthetic leather for clothes, which is prepared by surface making, roller coating and surface printing deep processing based on the suede leather, and product application of the leather, and the product is high in durability, strong in color fastness, convenient to cut, fashionable in product design, moisture permeable, vapor permeable, fine and smooth in sensing of suede, and good in writing effect.

Owner:烟台万华超纤股份有限公司

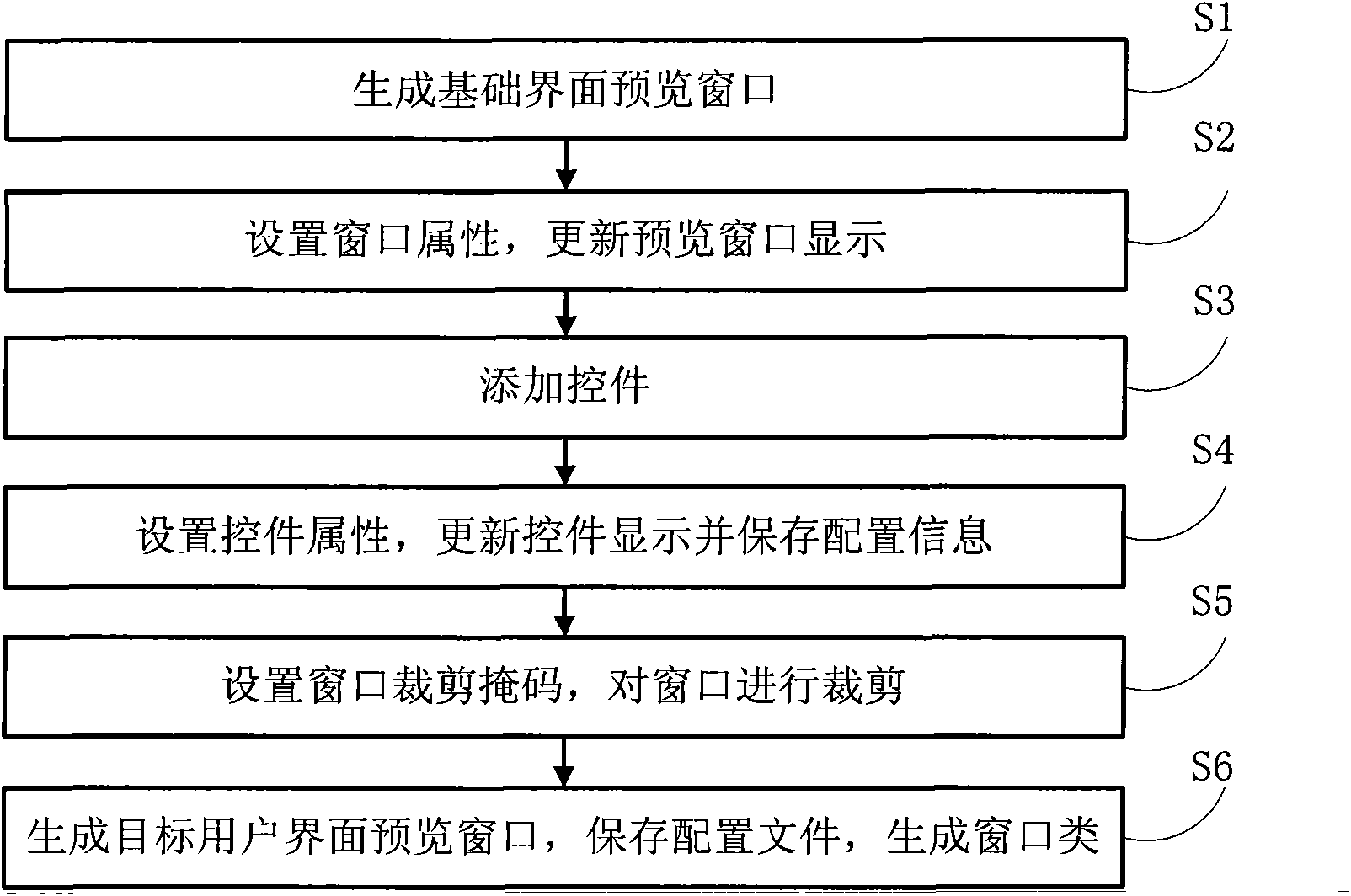

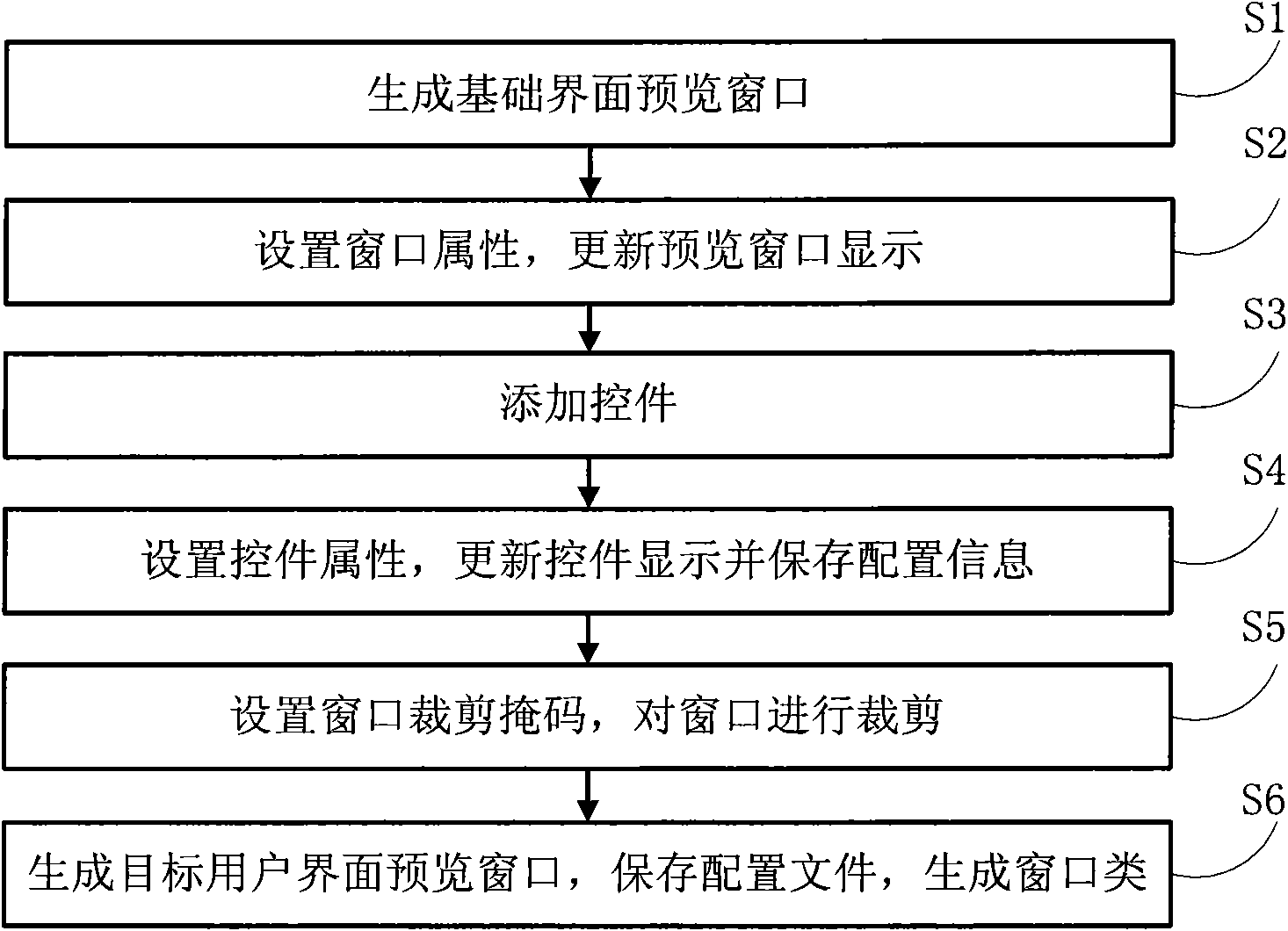

User interface generation method

InactiveCN101944027AFacilitate relationship managementSpecific program execution arrangementsGeneration processSoftware engineering

The invention discloses a user interface generation method, which comprises the following steps of: 1, generating a base interface preview window; 2, setting window attribute, and updating preview window display according to the set window attribute; 3, adding controls on the updated base interface preview window in a control tree mode; 4, setting control attribute, dynamically updating the control display according to the set control attribute, and saving configuration information; 5, setting a window clipping mask, and clipping the window according to the set window clipping mask; and 6, generating a preview window of a target user interface, saving a configuration file of the target user interface, generating a window class according to the configuration file, and adding the service logic of a window interface. In the method, an executable software interface can be generated through control drag, attribute setting and other operation by a product designer or an interface developer without direct encoding, the controls contained in the interface generation process are layered according to a tree structure so as to facilitate relationship management among the controls.

Owner:ULTRAPOWER SOFTWARE

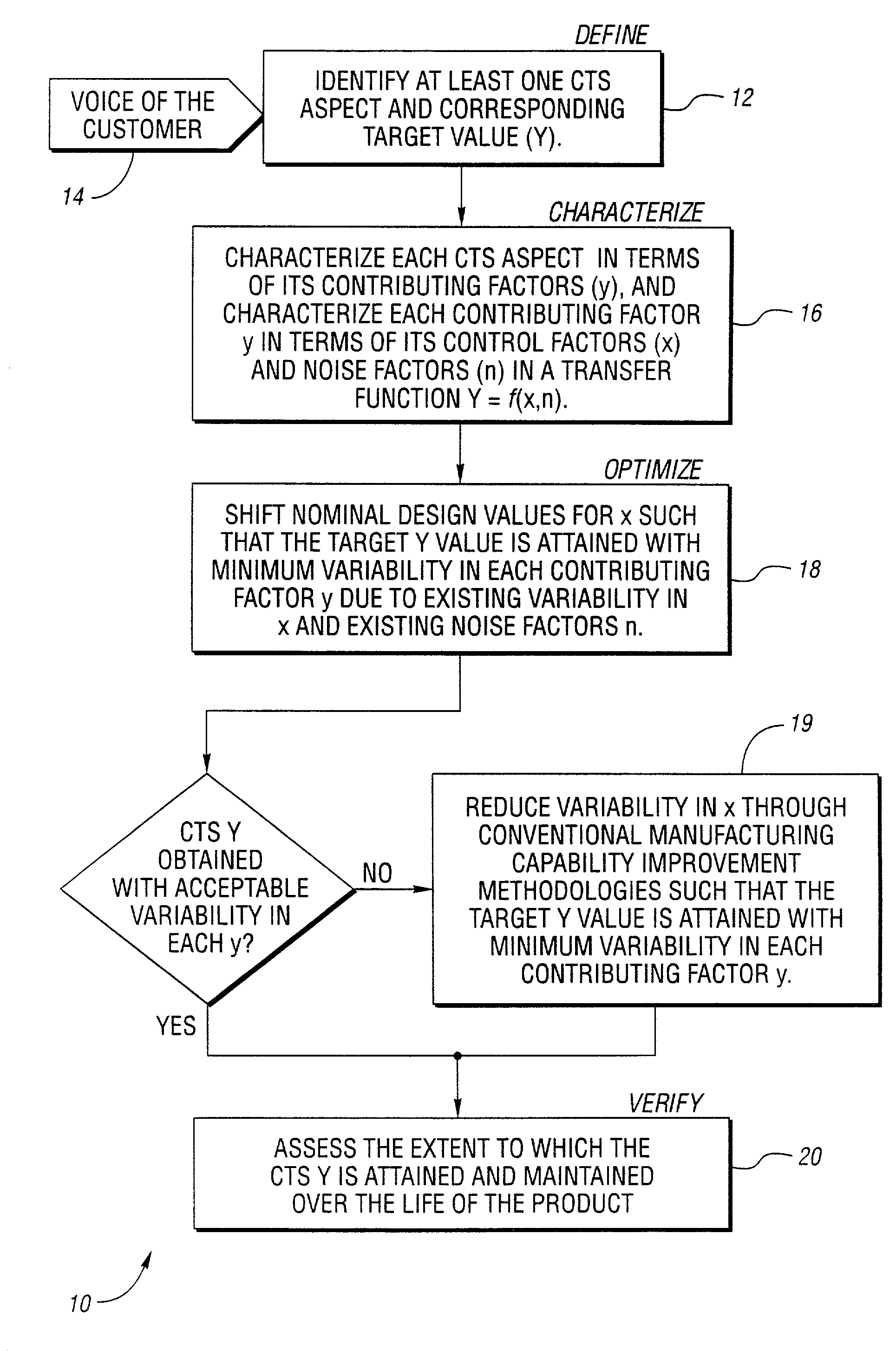

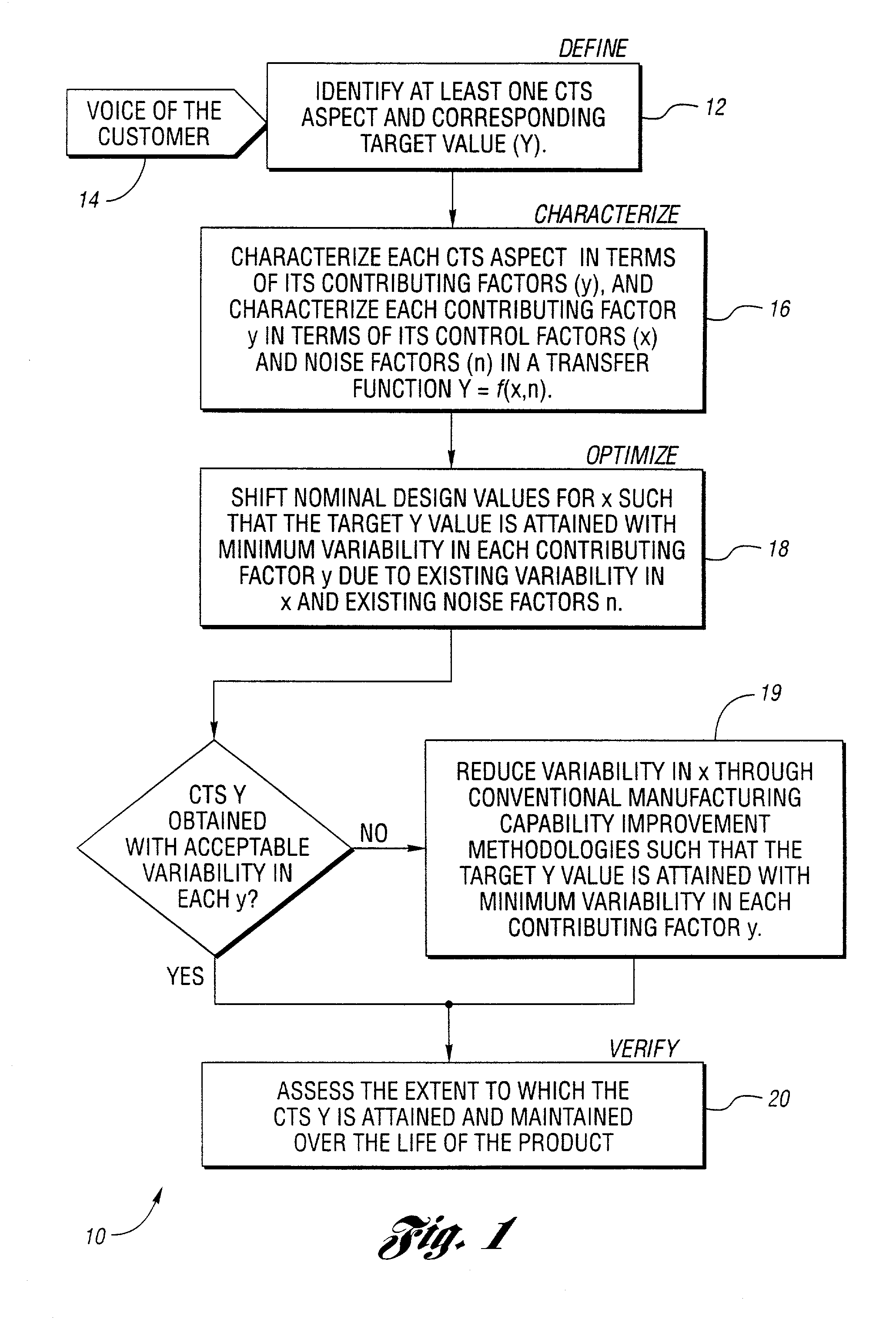

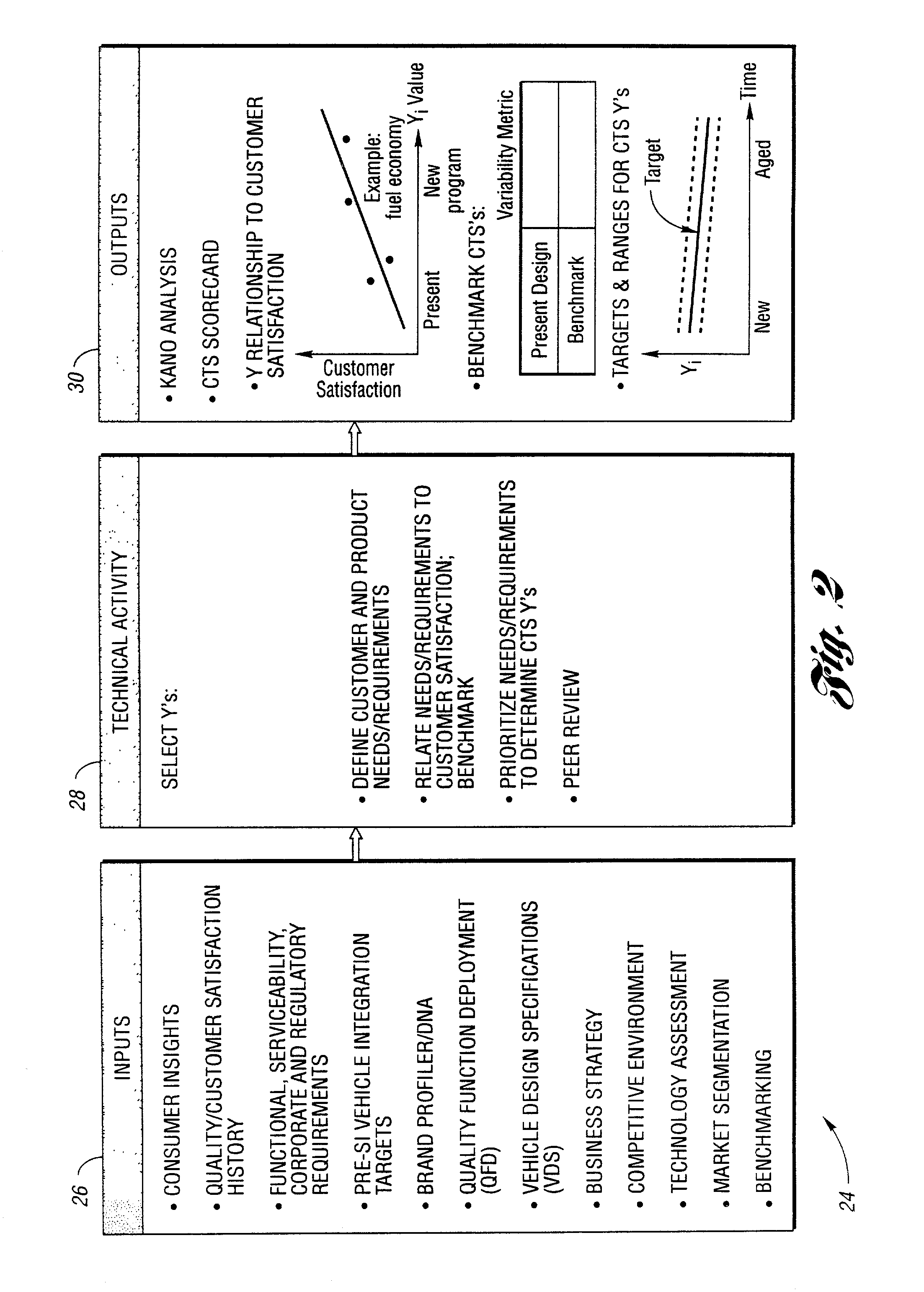

Method and system for product optimization

ActiveUS7219068B2Improve the level ofFacilitate the processForecastingSpecial data processing applicationsProduct optimizationLife time

A method and computer-implemented system for optimizing a product. Based on the “voice of the customer”, aspects of the product that are critical to the customer satisfaction, and target values, therefore, are identified. Aspects are characterized in terms of their contributing factors. Each contributing factor is characterized in a transfer function in terms of control and noise factors impacting the contributing factors. Contributing factors are optimized during product design by shifting nominal design values for control factors with respect to the transfer function such that target contributing factors are attained with minimum variability due to existing noises and variability in control. Where target values cannot be obtained through design optimization, conventional methods of manufacturing optimization are implemented. The extent to which the target values are attained and maintained over the life of the product are assessed.

Owner:FORD MOTOR CO

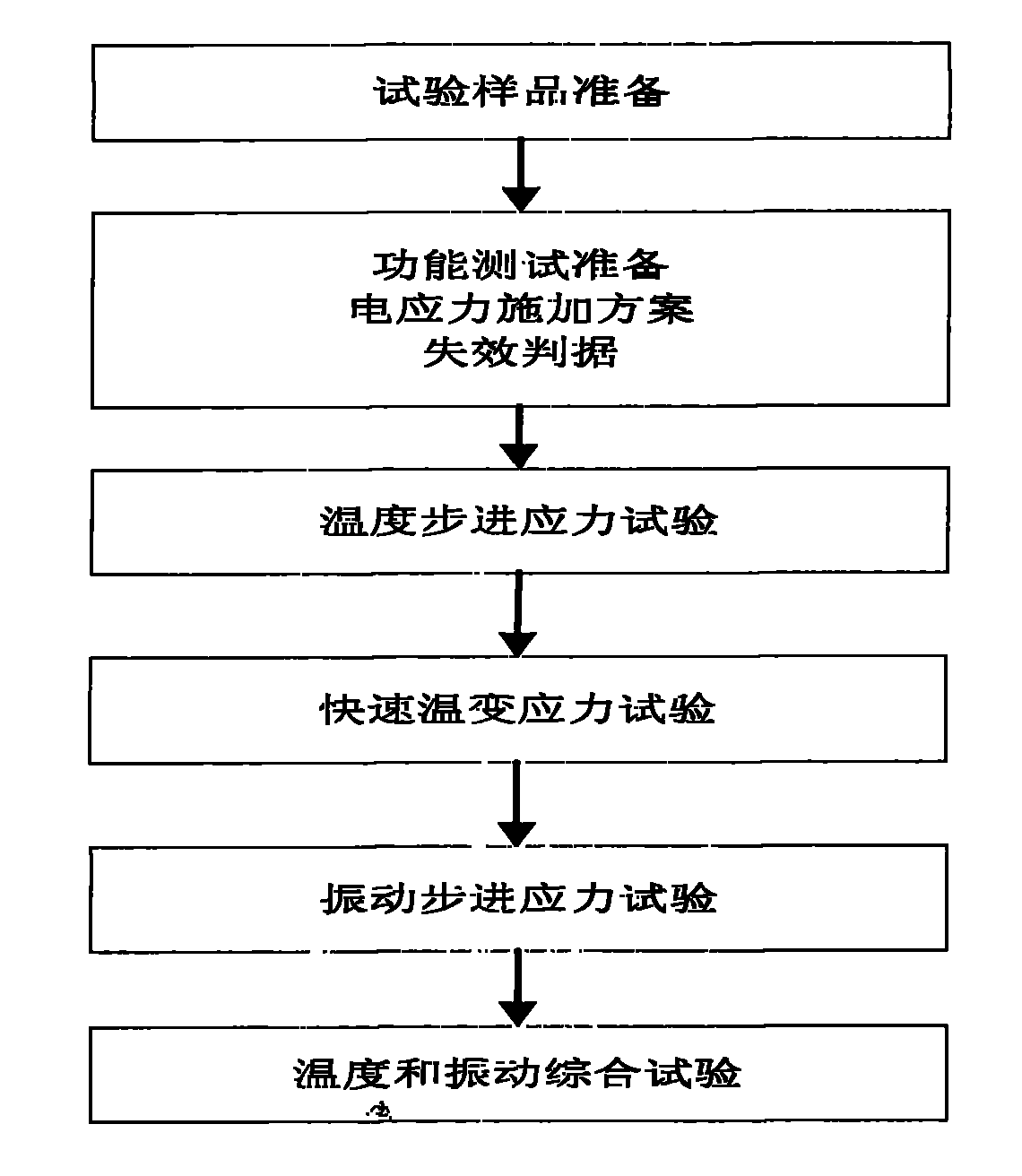

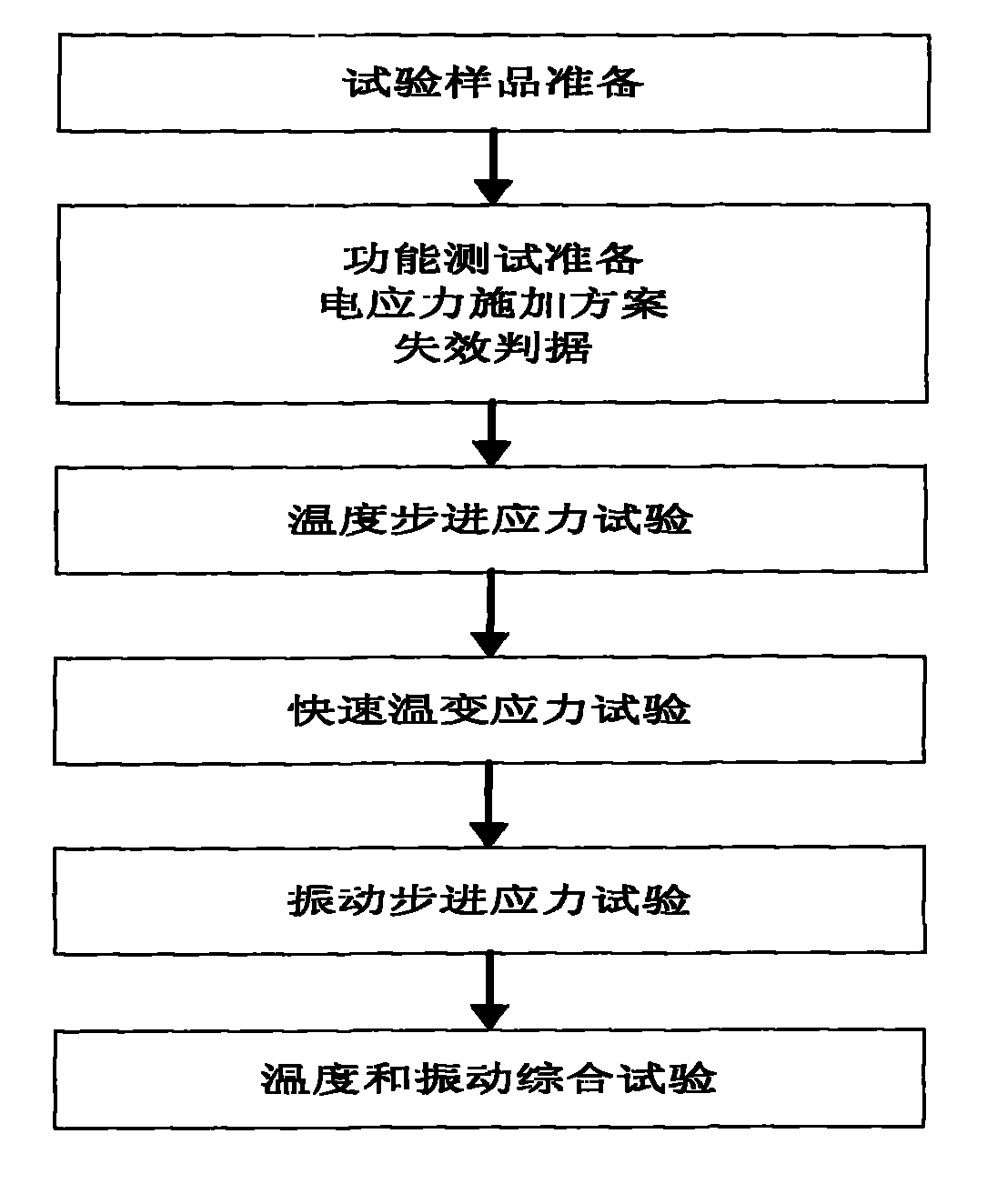

Test method for detecting reliability of product

ActiveCN101900788AImprove sturdinessImprove reliabilityElectrical testingDependabilityProduct design

Owner:BEIJING SHENGTAOPING TEST ENG TECH RES INST

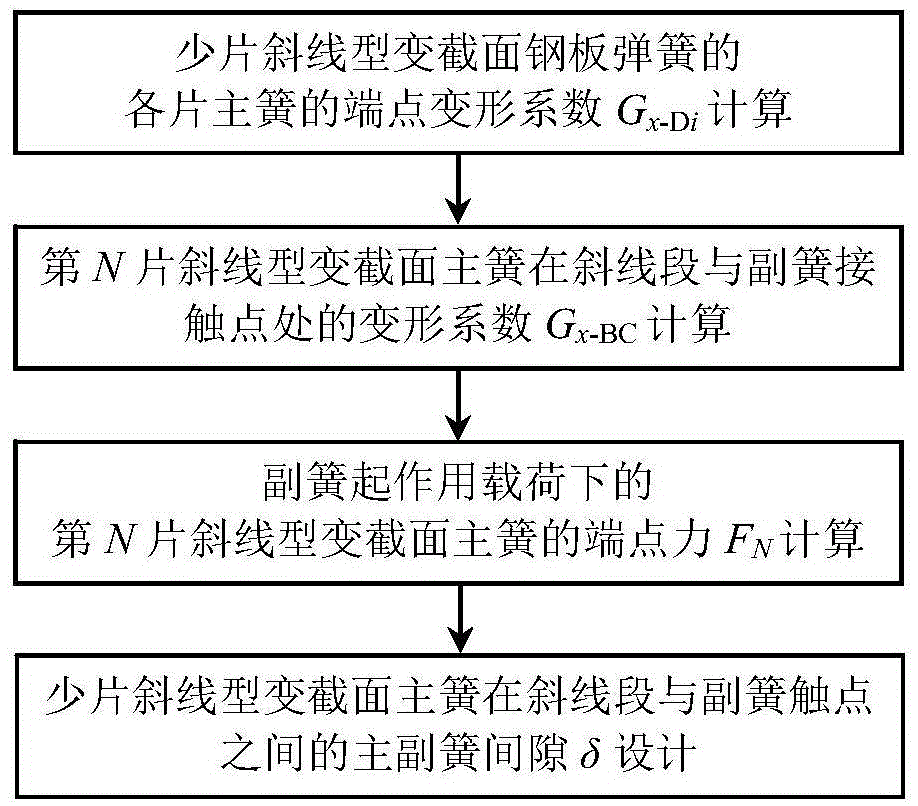

Method for designing few-leaf oblique line type variable-section main springs in gaps between oblique line segments and auxiliary spring

ActiveCN105550487AImprove the design levelQuality improvementGeometric CADDesign optimisation/simulationLine segmentOblique line

The invention relates to a method for designing few-leaf oblique line type variable-section main springs in the gaps between oblique line segments and an auxiliary spring, and belongs to the technical field of suspension steel plate springs. According to the structural sizes and the elasticity moduli of the oblique line type variable-section main springs, the endpoint deformation coefficient Gx-Di of each main spring and the deformation coefficient Gx-BC of the Nth main spring at the contact point of the corresponding oblique line segment and the auxiliary spring are determined first; then, according to the required auxiliary spring acting load design value and the endpoint deformation coefficient Gx-Di of each main spring, endpoint force FN of the Nth main spring is obtained; then, according to the thickness h of the root straight section of the Nth main spring, the Gx-BC and the FN, main spring and auxiliary spring gaps between the oblique line segment of the main springs and the contact point of the auxiliary spring are designed. Through simulation verification, it can be known that the main and auxiliary spring gap design value meeting the auxiliary spring acting load requirement can be obtained by means of the method, and the product design level, product performance and vehicle smoothness are improved. Meanwhile, design and testing cost is reduced, and product development speed is increased.

Owner:JIANGSU HAIHONG MACHINERY MFG

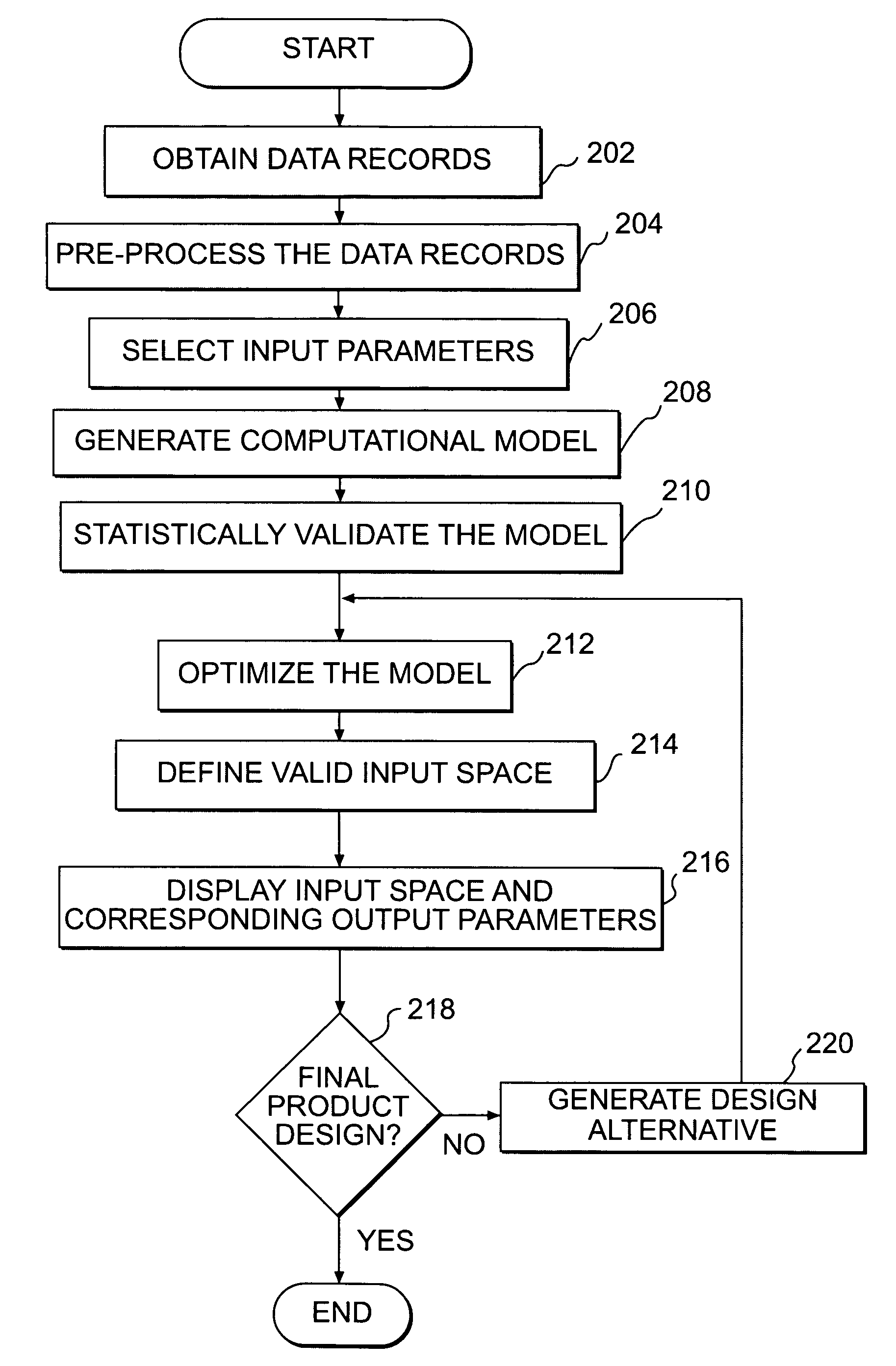

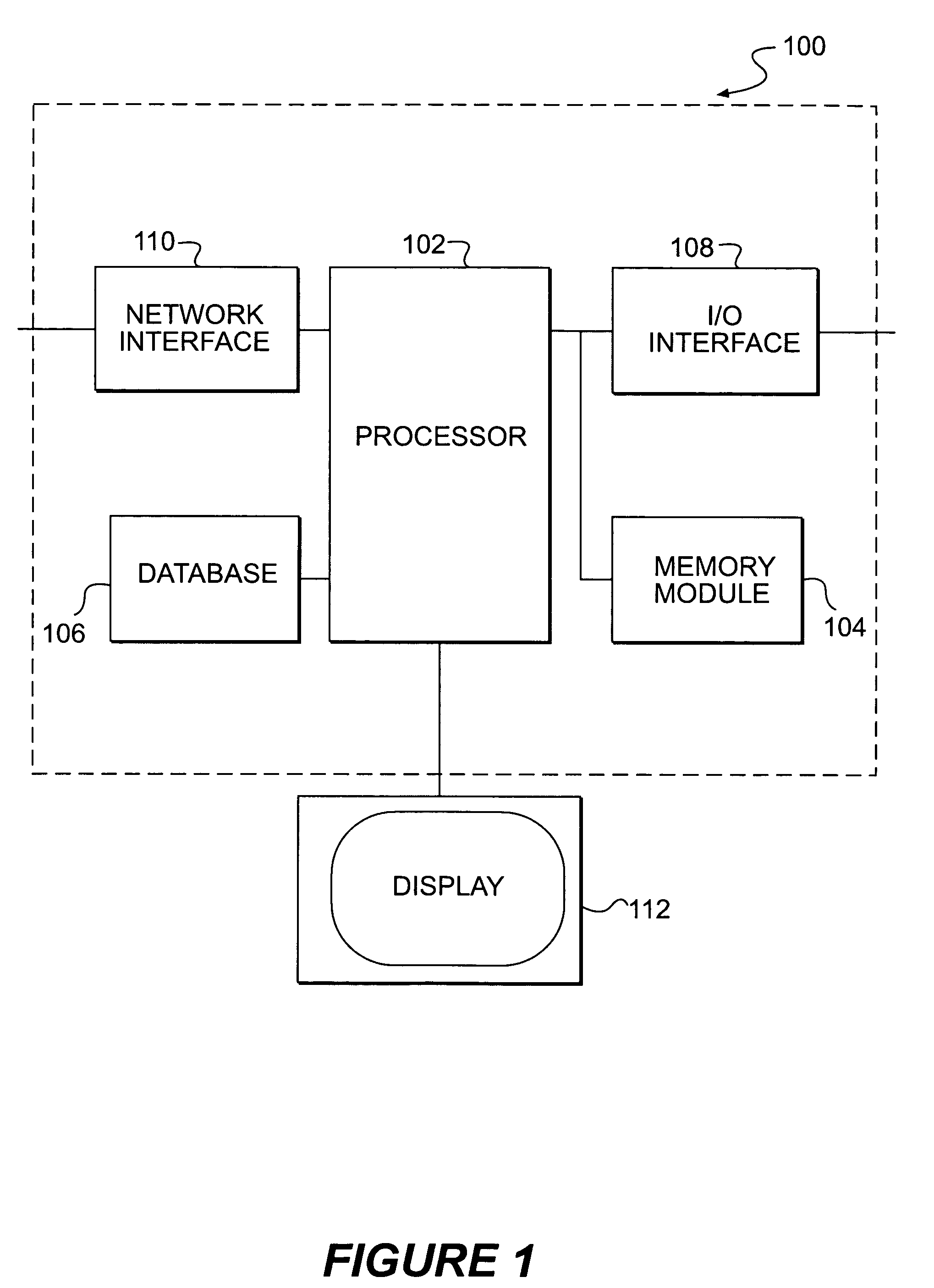

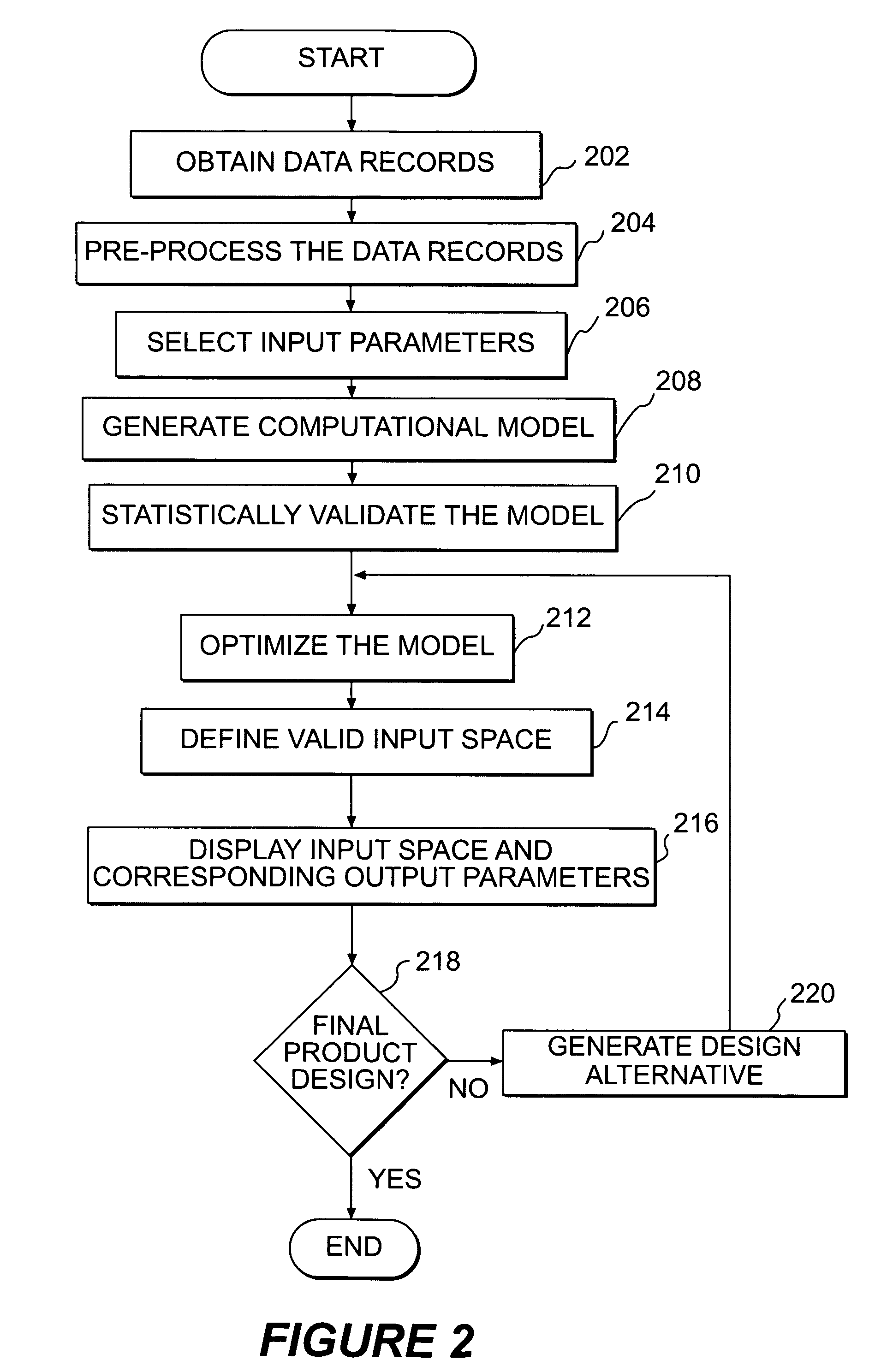

Probabilistic modeling system for product design

InactiveUS20060229753A1Design optimisation/simulationProbabilistic CADComputational modelData recording

A method for designing a product includes obtaining data records relating to one or more input variables and one or more output parameters associated with the product. One or more input parameters may be selected from the one or more input variables, and a computational model indicative of interrelationships between the one or more input parameters and the one or more output parameters based on the data records may be generated. The method further includes providing a set of constraints to the computational model representative of a compliance state for the product and using the computational model to generate statistical distributions for the one or more input parameters and the one or more output parameters, based on the set of constraints, that represent a design for the product.

Owner:CATERPILLAR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com