Figured island superfine fiber, figured island superfine fiber synthetic leather base cloth, suede leather for clothes, smooth synthetic leather for clothes and production method of fiber, base cloth, suede leather and smooth synthetic leather

A technology of ultra-fine fiber and manufacturing method, applied in Dingdao ultra-fine fiber synthetic leather base cloth, synthetic leather and its manufacture, Dingdao ultra-fine fiber field, to achieve convenient cutting and product design, superior writing effect, and superior mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The island-fixed superfine fiber of this embodiment includes island components and sea components, and the weight percentage of the two is 60%: 40%, wherein the island components are polyamide PA6, and the sea components are PE;

[0050] The preparation method of fixed island superfine fiber, comprises the following steps:

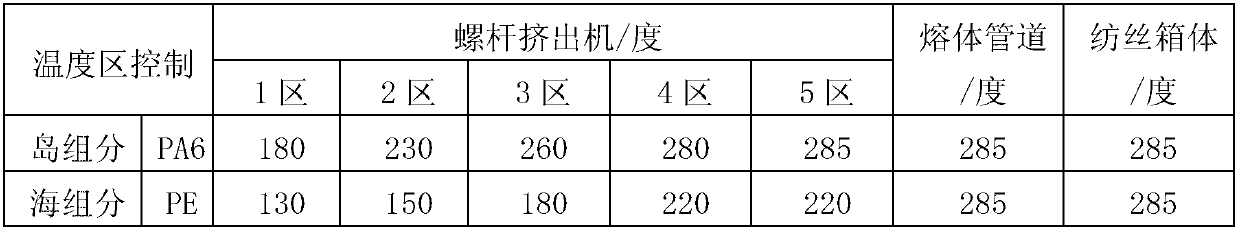

[0051] The island component is sliced and dried. After drying, the water content of the slice is controlled at 100PPM. The dried sea component and the island component are put into their respective spinning storage tanks, and enter their respective screw extrusion through the feeding system. The machine is heated and melted, filtered, and then transported to the spinning box through the melt pipeline. The temperature control of the island components in each area is as follows:

[0052]

[0053] The spinning melt entering the spinning box first enters the respective metering pumps for metering, ensuring that the weight percentage of the island c...

Embodiment 2

[0057] The island-fixed superfine fiber of this embodiment includes island components and sea components, and the weight percentage of the two is 50%:50%, wherein the island components are polyamide PET, and the sea components are PE;

[0058] The preparation method of fixed island superfine fiber, comprises the following steps:

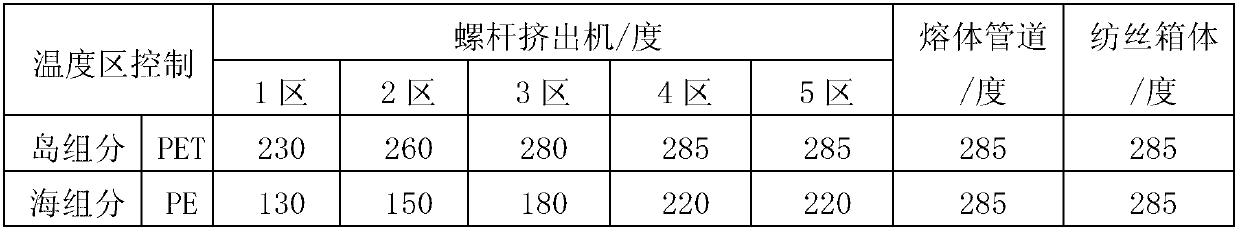

[0059] Dry the slices of the sea component and the island component. After drying, ensure that the water content of the slice is controlled at 30PPM. Put the dried sea component and the island component into their respective spinning storage tanks, and enter their respective spinning storage tanks through the feeding system. The advanced screw extruder is heated and melted, filtered, and then transported to the spinning box through the melt pipeline. The temperature control of the island components in each area is as follows:

[0060]

[0061] The spinning melt entering the spinning box is metered into the composite spinning assembly through its o...

Embodiment 3

[0064] The island-fixed superfine fiber of this embodiment includes island components and sea components, and the weight percentage of the two is 80%: 20%, wherein the island components are polyamide PA6, and the sea components are PS;

[0065] The preparation method of fixed island superfine fiber, comprises the following steps:

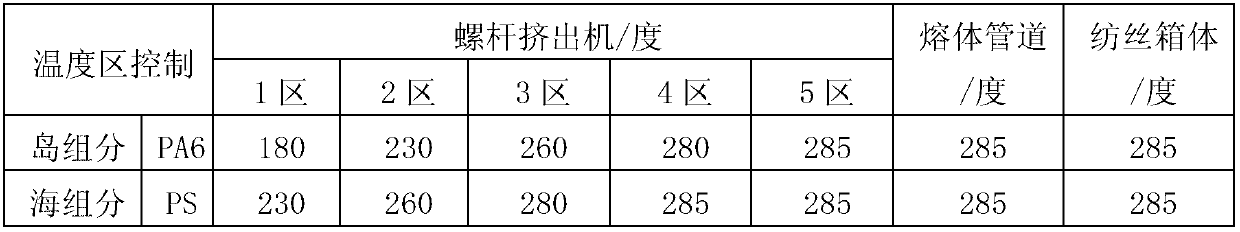

[0066] PA6 (polyamide) is used as the island component, and after drying to ensure that the water content of the slice is controlled at 80PPM, PS (polystyrene) is used as the sea component, which are respectively put into their respective storage tanks, and enter their respective screw extruders through the feeding system. The machine is heated and melted, filtered, and then transported to the spinning box through the melt pipeline. The temperature control of the island components in each area is as follows:

[0067]

[0068] The spinning melt entering the spinning box is metered into the composite spinning assembly through its own metering pump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com