Patents

Literature

196 results about "Leather industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing synthetic leather and synthetic leather

InactiveCN101941321AAchieving water-basedRealize cleaner productionSynthetic resin layered productsTextiles and paperLeather industryPolymer science

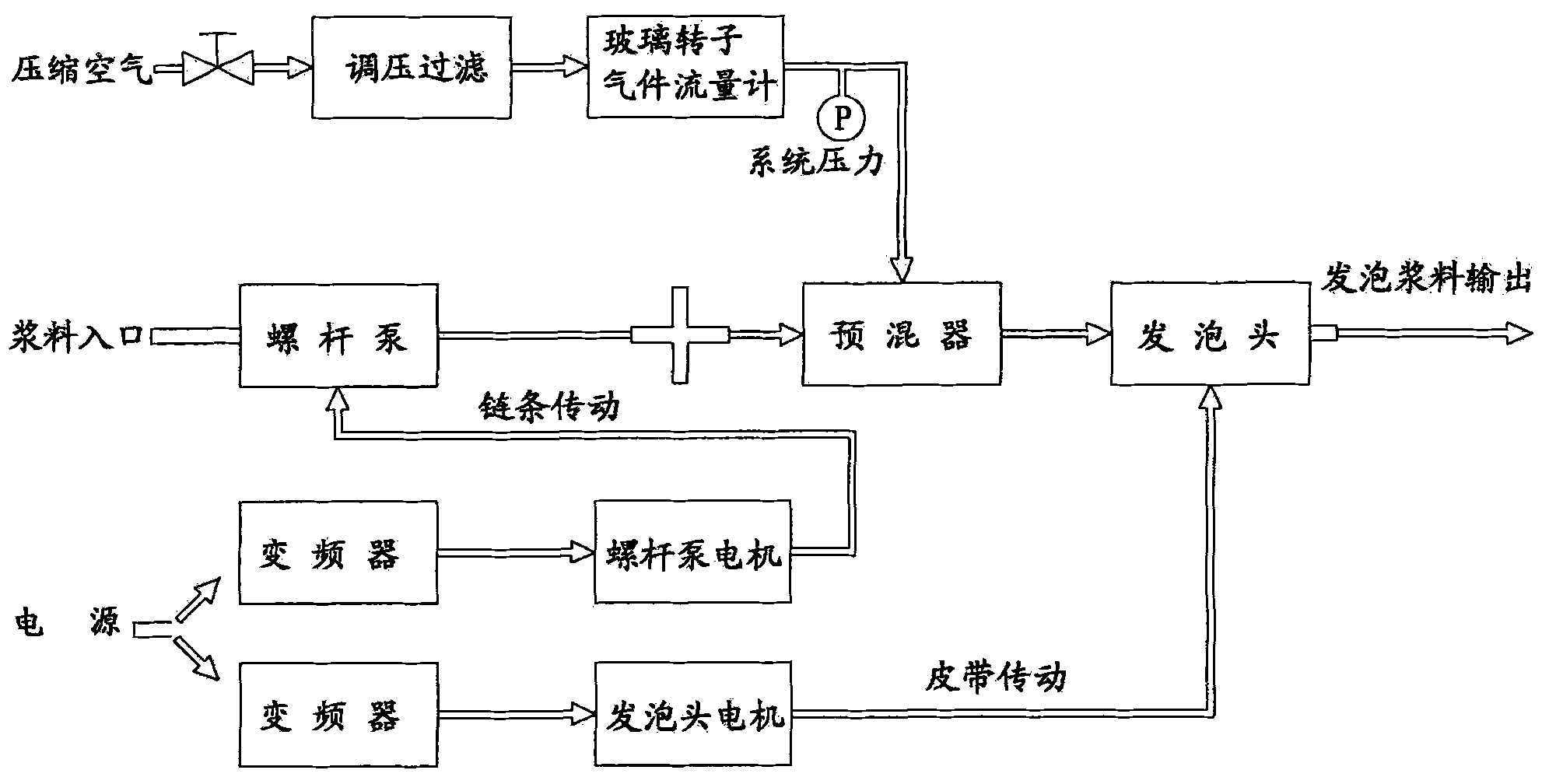

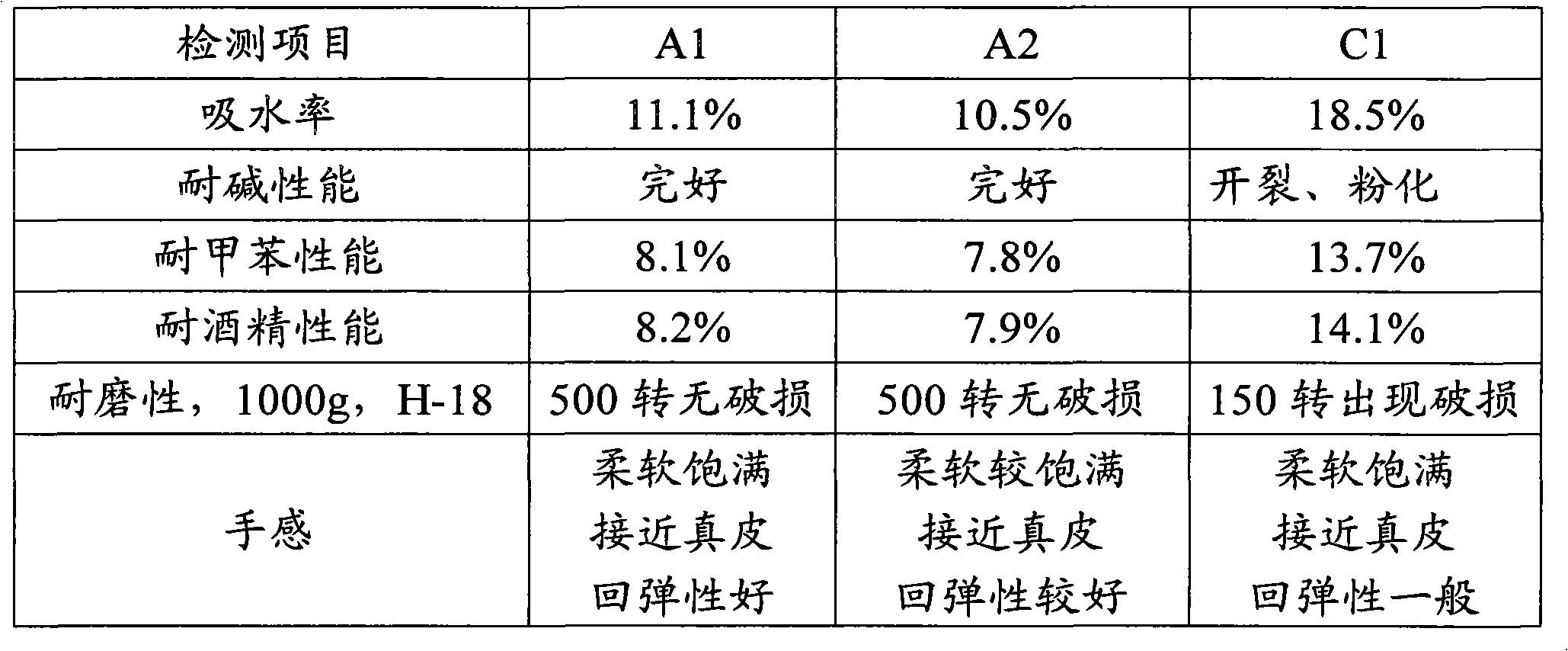

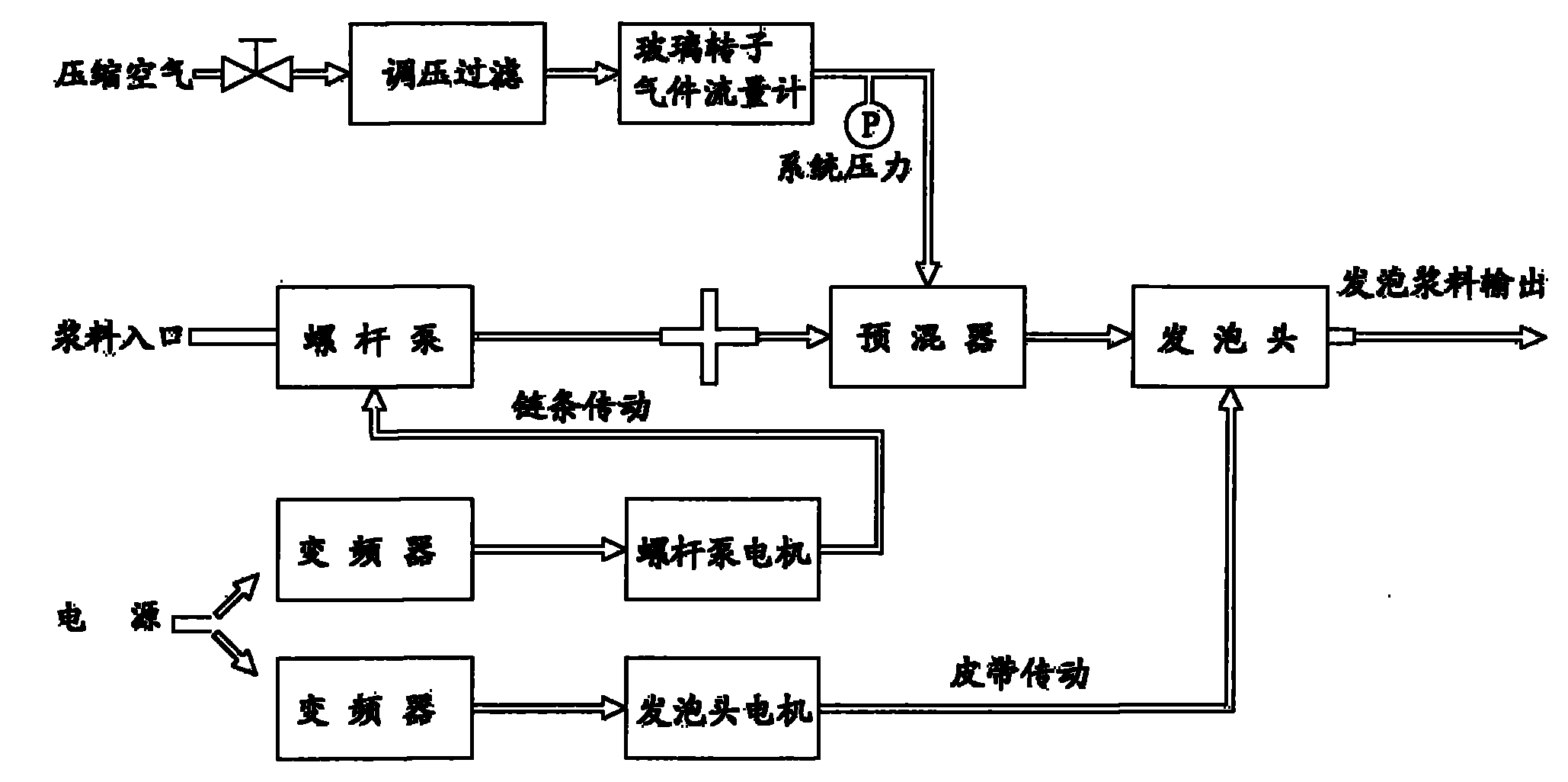

The invention provides a method for preparing synthetic leather and the synthetic leather prepared by the method. The method comprises the following steps: (1) coating slurry containing surface waterborne polyurethane resin on the surface of release paper, and drying to form a finishing coat; (2) mixing and foaming the slurry containing the foaming waterborne polyurethane resin with air by using a foaming machine, and coating the foamed slurry on the surface of the finishing layer, and drying to form a medium foaming layer; and (3) adhering the surface of the foaming layer and a basic fabric by using an adhesive containing waterborne polyurethane resin, and drying. The method uses the waterborne resin foaming layer to replace the Base leather manufacturing process, avoids using toxic and harmful organic solvents, such as dimetbyl formamide (DMF), toluene and the like, solves the pollution problem in the synthetic leather industry, and realizes clean manufacture of the synthetic leather.

Owner:丽水市优耐克水性树脂科技有限公司

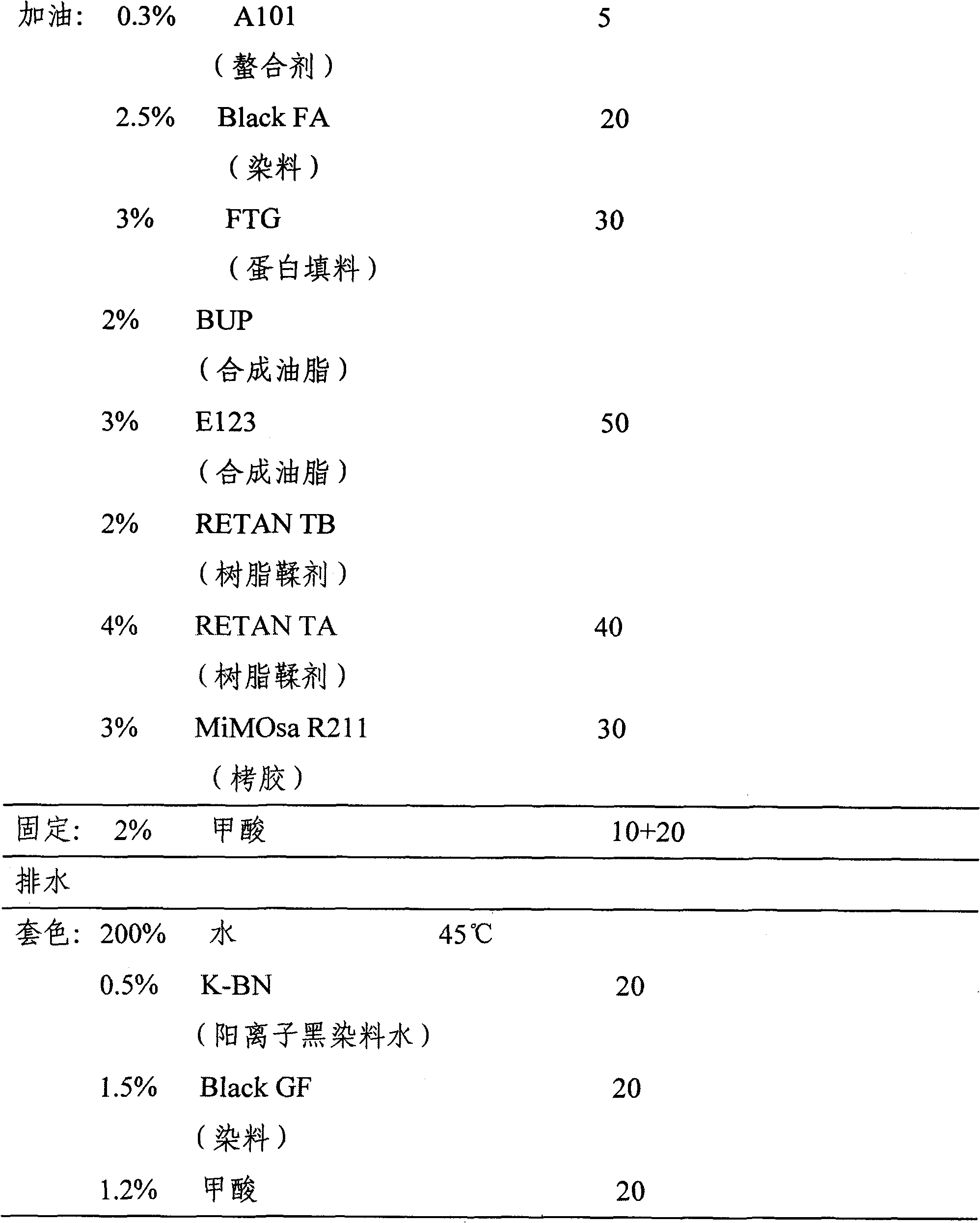

Circularly-tanning technology for chrome tanning liquor of sheep garment leather

InactiveCN102586505APure white coatFull coatTanning treatmentPre-tanning chemical treatmentLeather industryFlocculation

The invention discloses a circularly-tanning technology for chrome tanning liquor of sheep garment leather. The circularly-tanning technology comprises the following steps: conditioning, drying, shearing, main-soaking, fleshing, degreasing, pickling, softening, disacidifying, softening, pickling, tanning, wet grinding, retanning, neutralizing, adding grease, retanning, dyeing hair, and dyeing plates. According to the circularly-tanning technology for chrome tanning liquor of sheep garment leather, the formation of hexavalent chromium can be effectively reduced, and the chrome waste liquor flocculation is omitted. According to the test on the chrome content after the chrome tanning liquor is utilized, the chrome waste liquor can be recycled repeatedly by supplementing corresponding chrome powder during next-time recycling, thereby realizing the clean production of tanned leather industry. According to the circularly-tanning technology, the sealed no-emission utilization of a chrome resource can be guaranteed so as to greatly reduce environmental pollution, effectively lower waste water emission and save enterprise waste treatment and production cost. In addition, the quality of the produced leather is consistent with that of the common chrome tanned leather, the shrinkage temperature is above 100DEG C, and a leather body is soft, plump and flexible, is colorful, has pure white hair and has no effect on the dyed hair and the dyed plates.

Owner:ZHEJIANG ZHONGHUI FUR & LEATHER +2

Nano pulp for producing nano synthetic leather base by wet method and wet method process thereof

InactiveCN101407997AEvenly dispersedSolve the technical bottleneck problem that is easy to reuniteFibre treatmentLeather industryNano size

The invention relates to a nano sizing agent used for producing nano synthetic leather Bayes by adopting a wet method, and the wet processing thereof; the nano sizing agent is formed by the following components (part by weight): 100 to 300 parts by weight of polyurethane resin (the solid content of 30 percent is taken as an example), 1.0 to 9.0 parts by weight of nano precursor, 0.2 to 10.0 parts by weight of inhibitor, 20 to 90 parts by weight of filling material, 0.1 to 0.6 part by weight of leveling agent, and 100 to 600 parts by weight of thinner. The wet processing is: coating-solidification-water washing-drying-coiling. On the premise of not changing the current wet production technology and equipment of the synthetic leather industry, the invention adopts special in situ hybridization technique to uniformly lead nanoscale inorganic grains into a polyurethane coating, thus improving the performances of air permeability and moisture permeability, bacteriostasis and fungus resistance, ultraviolet resistance and the like of the synthetic leather Bayes.

Owner:WENZHOU UNIVERSITY

Reducing leather and preparation method thereof

ActiveCN101851828ARandom croppingNo location differenceNon-adhesive dressingsTanning treatmentFiberApparent density

The invention discloses reducing leather and a preparation method thereof. The leather is mainly and three-dimensionally weaved by collagenous fiber obtained by defibrination of leather materials, and the apparent density thereof is 0.35g / cm3-1.4g / cm3. The preparation method of the leather comprises the steps: carrying out defibrination on the leather materials to prepare the collagenous fiber, forming web, carrying out hydroentanglement and wet-hot shrinkage and forming. The leather is reducing leather, the weaving structure, the apparent density, all strength indexes and wear resistance of which are approximate to those of true leather. Compared with the true leather, the reducing leather has the advantages that the leather is large and tidy and can be cut randomly, the weaving apparent density is consistent without location difference; and simultaneously, the raw materials of the reducing leather mainly adopt corner wastes in the leather-working industry. The promotion of the method can enhance the circulation and reutilization of resources in the leather-working industry, and is beneficial to realizing transformation from the traditional leather-working industry to the energy-saving and environment-friendly industry.

Owner:GUANGZHOU WUYUAN NEW MATERIAL CO LTD

Comprehensive treatment method of H acid production wastewater

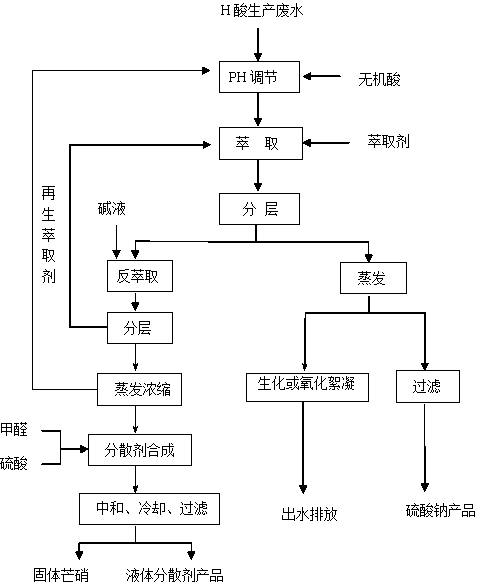

ActiveCN104326614AImprove extraction efficiencyHigh partition coefficientTransportation and packagingMixingLeather industryResource utilization

The invention discloses a comprehensive treatment method of H acid production wastewater. The method comprises the following steps: regulating the pH value of the H acid production wastewater, afterwards complexing and extracting a naphthalene sulfonic acid type substance in the wastewater, back-extracting an extract phase by using alkaline liquor, recycling an extracting agent after the extracting agent is regenerated, evaporating and concentrating back-extraction liquid to synthesize a liquid dispersant product; transferring a raffinate phase into an evaporation system, evaporating and separating to obtain a sodium sulfate byproduct, and discharging the desalted evaporation and condensation water after the water reaches the standards by means of biochemical or oxidization flocculation treatment. According to the method disclosed by the invention, the naphthalene sulfonic acid type substance in the wastewater is recycled by utilizing a complexation-extraction method, and the sodium sulfate salt product is recycled by utilizing an evaporation method. The liquid dispersant product (degree of polymerization is 1-3) synthesized by utilizing the recycled naphthalene sulfonate solution is used as a dispersing agent in textile dyeing and leather industries. The method disclosed by the invention is reasonable in process design and can be used for effectively realizing comprehensive treatment and resource utilization of the H acid production wastewater.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Ecological type water-based synthetic leather

InactiveCN103361988ANo change in physical propertiesGuaranteed cleanlinessLamination ancillary operationsSynthetic resin layered productsLeather industryWater based

The invention relates to ecological type water-based synthetic leather which comprises a dry layer, a foaming layer, a bonding layer and a base material, and is characterized in that the dry layer, the foaming layer, the bonding layer and the base material are sequentially compounded in a layered way; and the dry layer, the foaming layer and the bonding layer are made from water-based resin. The product does not change the physical properties of solvent type synthetic leather, the whole leather layer structure adopts the non-toxic, harmless, safe and environment-friendly water-based material, and all the links of the whole production process are maintained to be clean and environment-friendly, so that the ecological type water-based synthetic leather is completely environment-friendly. The ecological type water-based synthetic leather saves a great deal of organic solvent, reduces the production cost of the synthetic leather, and is in accordance with the development tendency of synthetic leather industry, thus having a wide application prospect.

Owner:广东宏裕智汇创新科技有限公司

Formula of environment-friendly type aqueous color paste for leather and coating as well as manufacturing method thereof

InactiveCN101531836ASolve pollutionNo change in propertiesInorganic pigment treatmentDyeing processLeather industryDiethylene glycol

The invention relates to a formula of environment-friendly type aqueous color paste for leather and coating as well as a manufacturing method thereof, wherein the environment-friendly type aqueous color paste for leather and coating belongs to a special coloring agent in the leather industry, the printing and dyeing industry and the like, and is widely used for coloring the base material such as various artificial leather, synthetic leather, coating cloth and the like. The formula comprises, based on the weight part, 20 to 50 parts of water, 30 to 45 parts of carbon black, 1 to 5 parts of dispersant, 1 to 5 parts of ammonium salt auxiliary agent, 20 to 30 parts of aqueous intermediate and 1 to 4 parts of diethylene glycol. The product in the invention has the advantages of good coloring effect, good permeability and wear resistance, no burning, no toxicity and no pollution.

Owner:嘉兴市博豪家纺有限公司

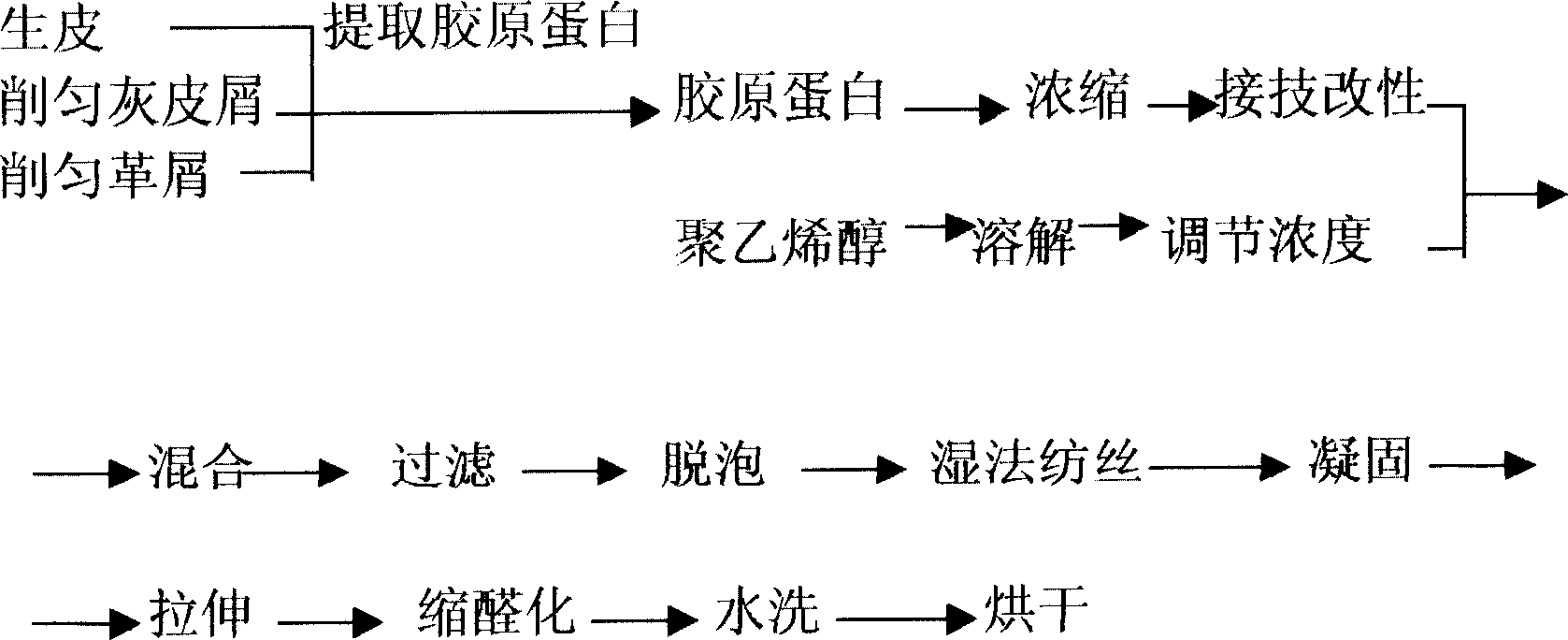

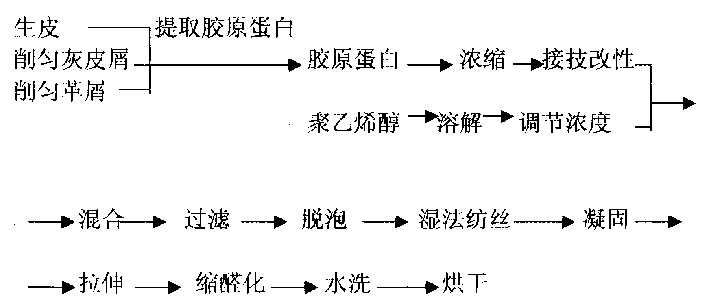

Collagen protein composite fiber and its producing method

InactiveCN1492087AComfortable to wearGood hygroscopicityConjugated artificial filamentsLeather industryPolyvinyl alcohol

The present invention relates to new material in textile industry. Collagen protein extracted from animal skin or leather industry leftover is grafting modified with olefin monomer and mixed with PVA to form spinning liquid with certain density and viscosity; and through further wet spinning, solidification, stretching and acetalization, the composite collagen protein fiber for textile industry is produced. The composite collagen protein fiber consists of collagen protein 10-45 wt%, olefin monomer modifier 5-20 wt% and PVA 50-85 wt%. The composite collagen protein fiber has excellent affinity to human skin, high hygroscopicity, wearing comfort and easy colorizing.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

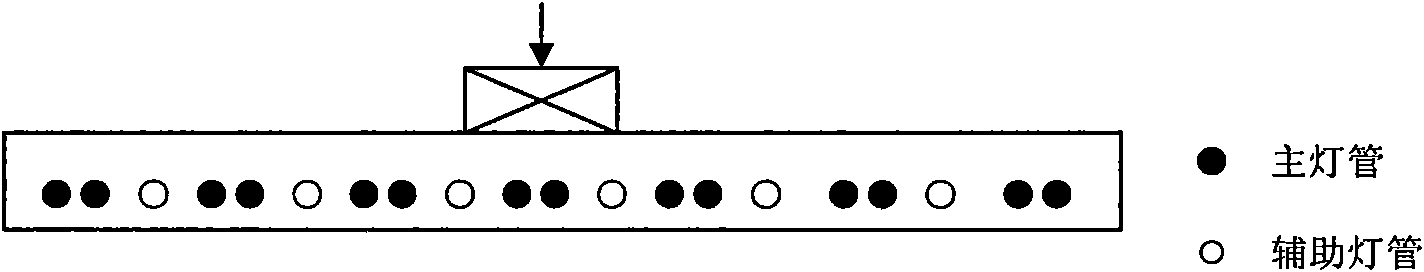

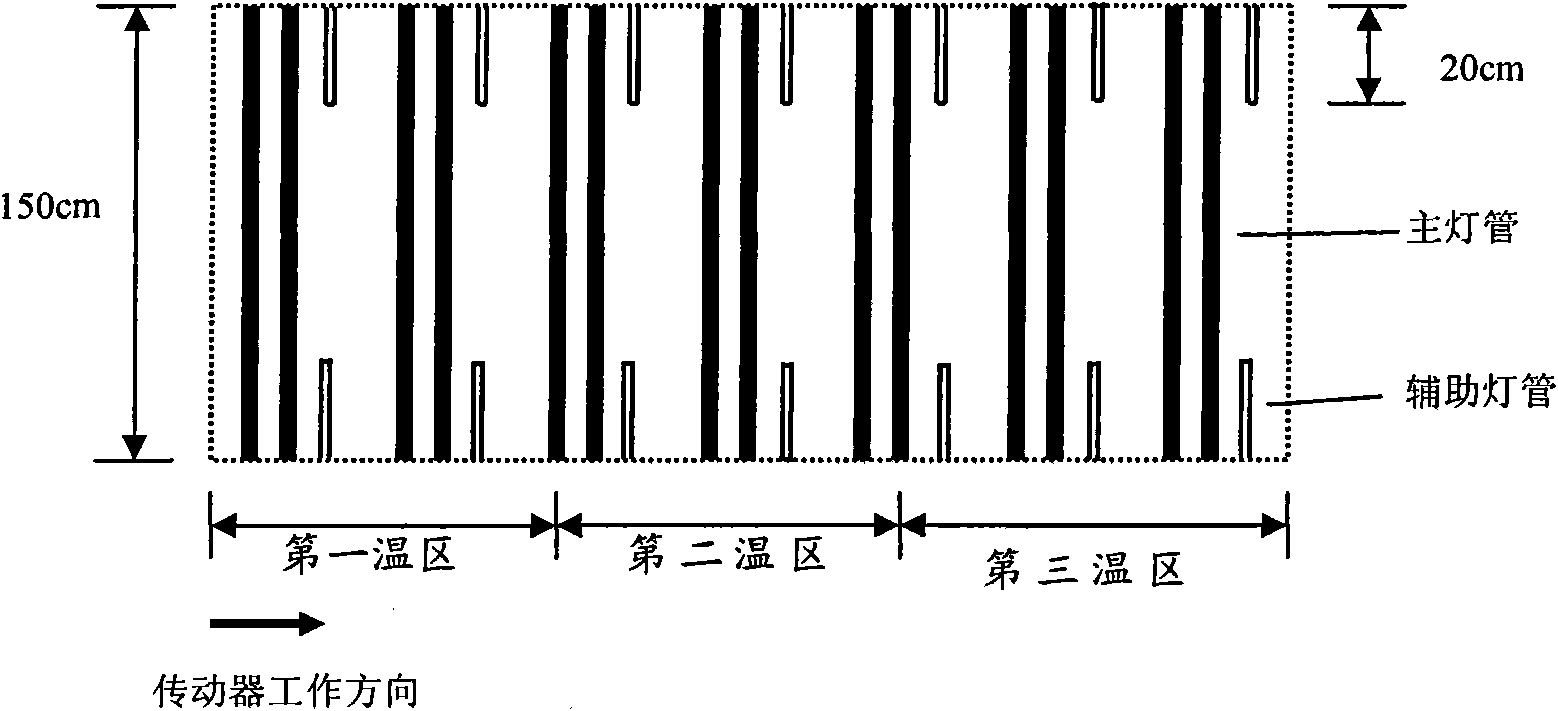

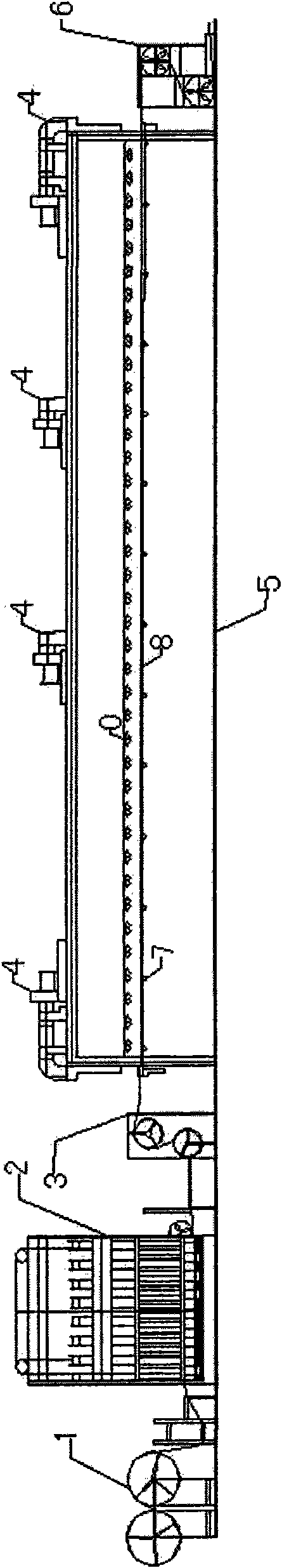

Dry method production line of water-based ecological synthetic leather

InactiveCN101942768AIncrease productivityRealize full environmental protectionSucessive textile treatmentsLiquid/gas/vapor removalProduction lineLeather industry

The invention provides a dry method production line of water-based ecological synthetic leather, which comprises a driver, a coating table and an oven, wherein the driver is used for conveying release paper or base clothes; the coating table is used for sizing on the release paper or the base clothes for one time or many times to form a single-layer or multi-layer water-based resin coating; the oven is used for drying the single-layer or multi-layer water-based resin coating; and medium wave infrared drying equipment is arranged in the oven. The production line of the invention has the advantages of safety, energy saving and high production efficiency, has double functions of production lines of the traditional dry method and the traditional wet method for producing leather, realizes the complete environment protection of the synthetic leather industry, and enables the quality of the processed water-based ecological synthetic leather to be more excellent.

Owner:丽水市优耐克水性树脂科技有限公司

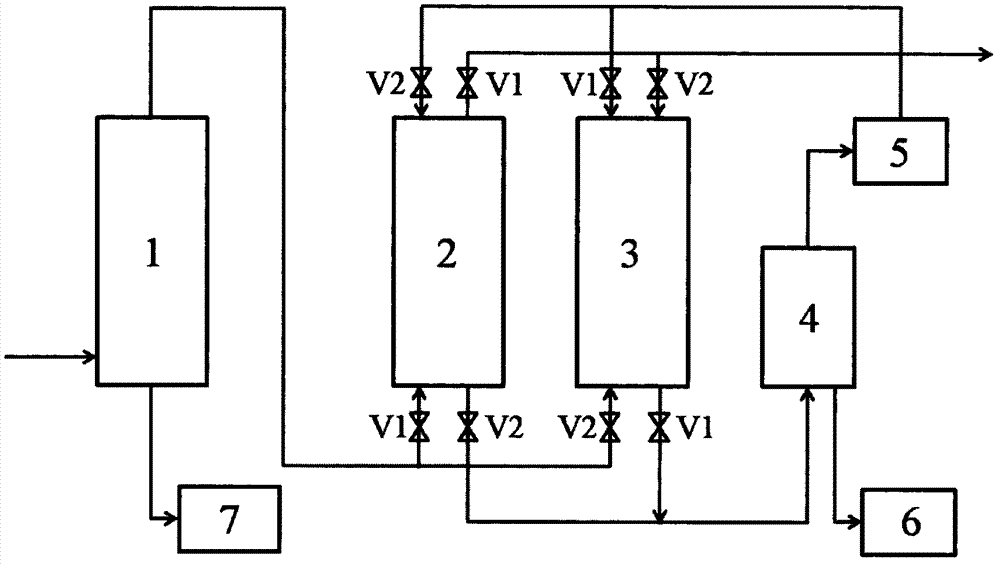

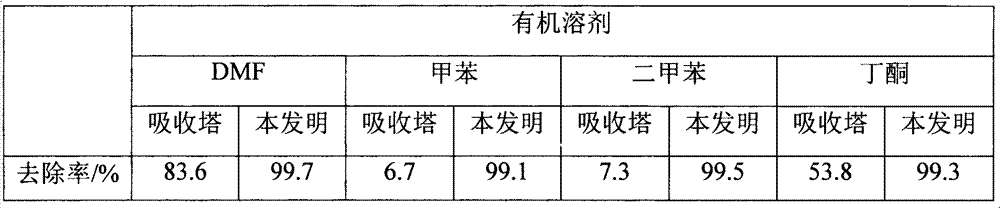

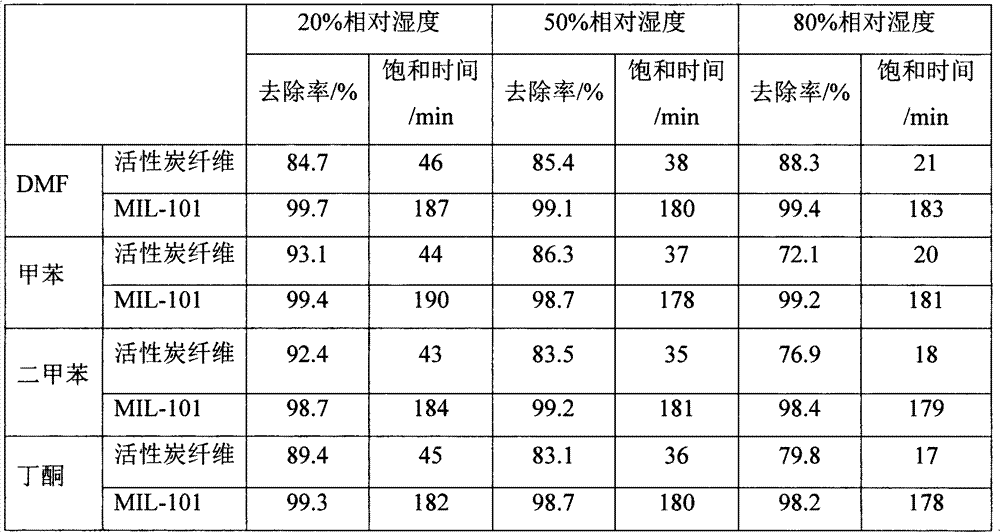

Device and method for adsorbing, recycling and treating organic waste gases efficiently

InactiveCN102698558AImprove the efficiency of adsorption recovery treatmentDispersed particle separationLeather industryRecovery method

The invention relates to a method for purifying, recycling and treating organic waste gases and provides a device for adsorbing, recycling and treating organic waste gases efficiently, which comprises an organic-waste-gas conveying pipe, a steam conveying pipe, a water absorption tower, an adsorption and desorption tower, an organic-solvent separating and recycling system, a switching valve, a condenser, an organic-solvent recycling tank and a steam generator, wherein two or more adsorption tanks are juxtaposedly arranged on the adsorption and desorption tower. Because the adsorption and desorption tower with two or more adsorption tanks arranged juxtaposedly are connected in series with the rear part of the water absorption tower, and the novel MIL-101 metal organic framework material are used as the adsorbent to replace the traditional adsorbents such as the granular activated carbon or activated carbon used for purifying and recycling organic waste gases in the synthetic leather industries and the like, the problems that the efficiency of removing the organic waste gases by using the single water absorption tower is low and the discharge of the organic waste gases does not reach the standard are solved, and the efficiency of adsorbing and recycling the organic waste gases is improved.

Owner:CHANGZHOU MINGCHENG XIANGRUI ENVIRONMENTAL PROTECTION TECH

Water-based polymer pigment dispersant and leather cationic pigment paste prepared from same

ActiveCN101845122ATo achieve the purpose of parcel dispersionGuaranteed storage stabilityTransportation and packagingMixingWater basedLeather industry

In the invention, acrylates, acrylate derivatives and functional unsaturated monomers are used for synthesizing and developing a new water-based cationic polymer dispersant; and the dispersant is used for preparing a series of water-based superfine cationic pigment paste with the same dispersion system for leathers, and the average particle diameter reaches 0.3-1.0 micrometer; The cationic pigment paste can be used for coating leathers to enable the leathers to have soft hand feeling, good covering power and bright color. The weight-average molecular weight of the polymer dispersant is about 5000-50000, and the polymer dispersant has cationic characteristics and is suitable for dispersing various common pigments in the leather industry.

Owner:成都达威化工科技有限公司

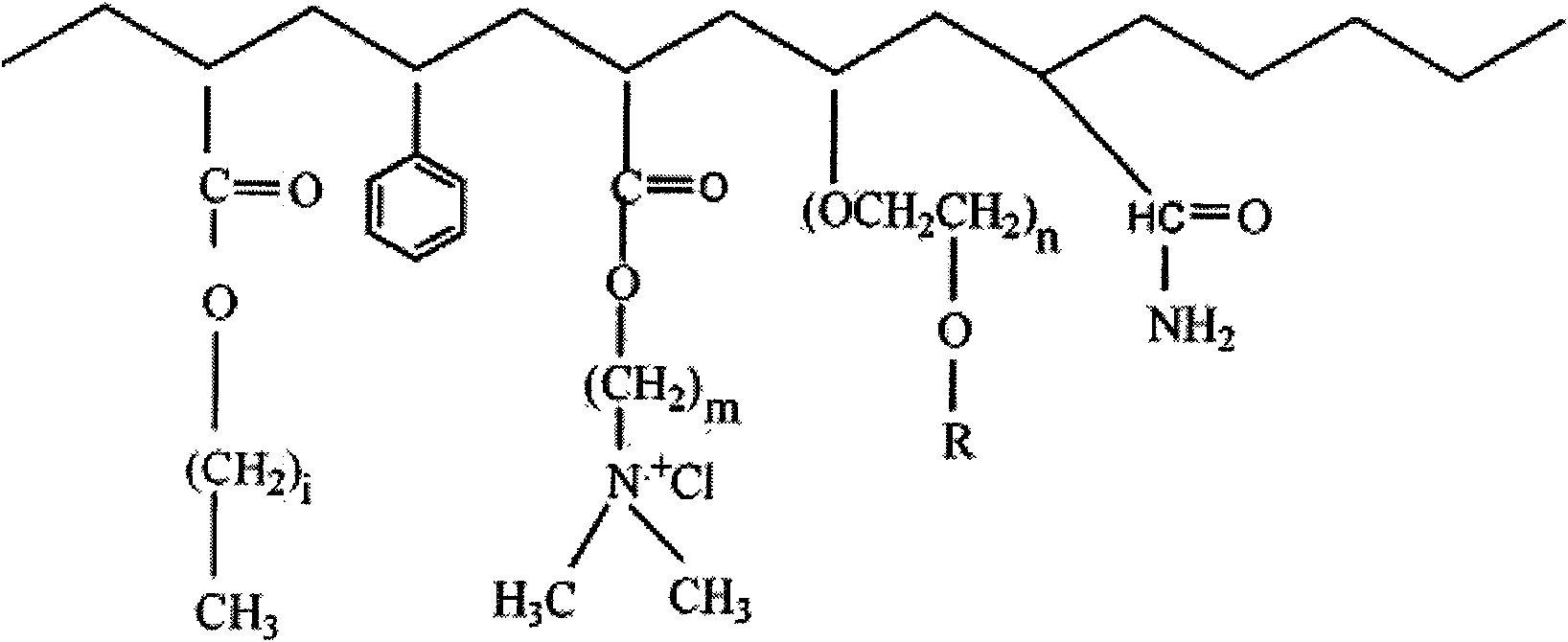

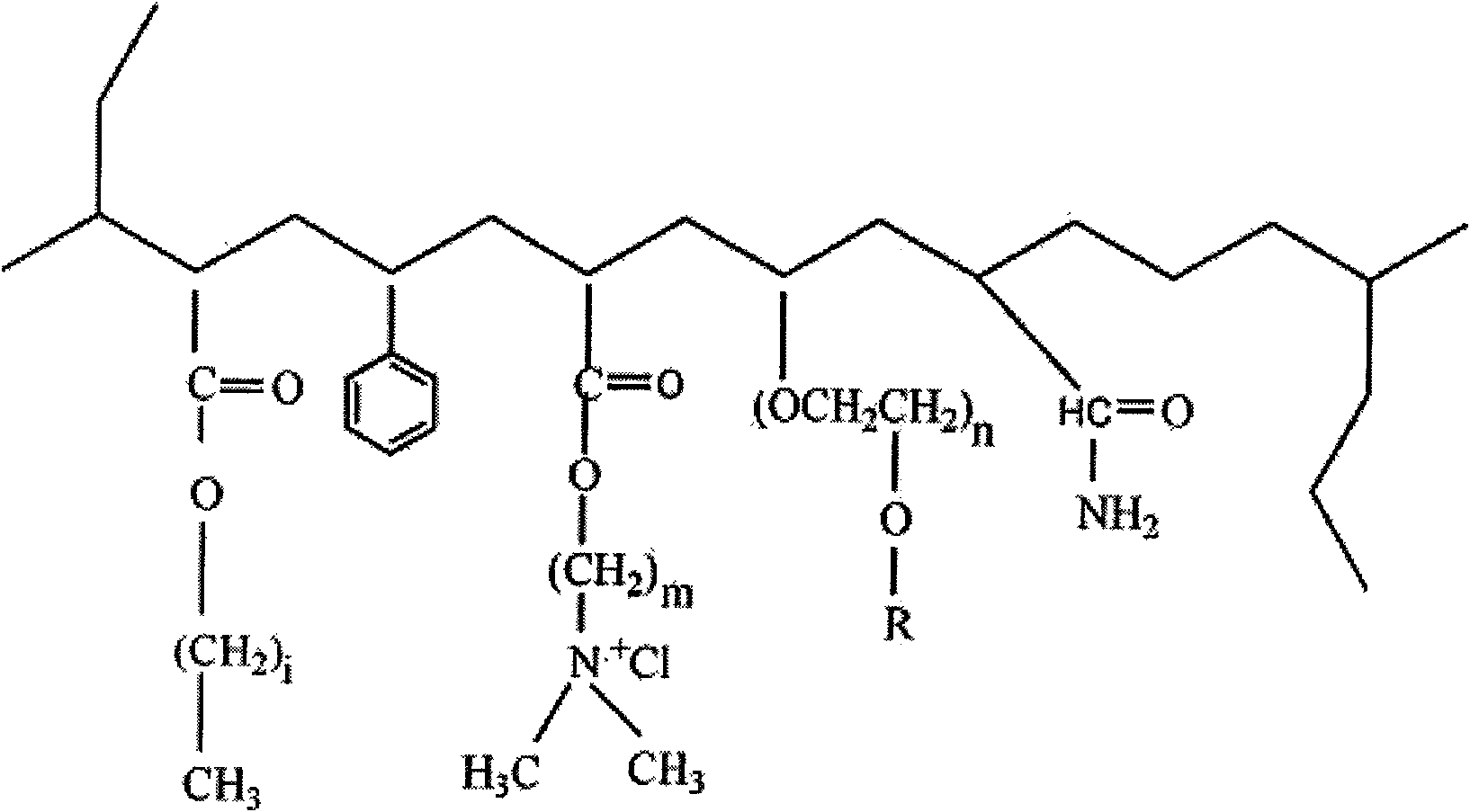

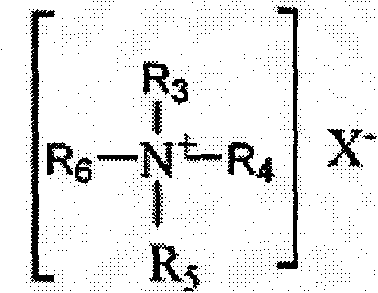

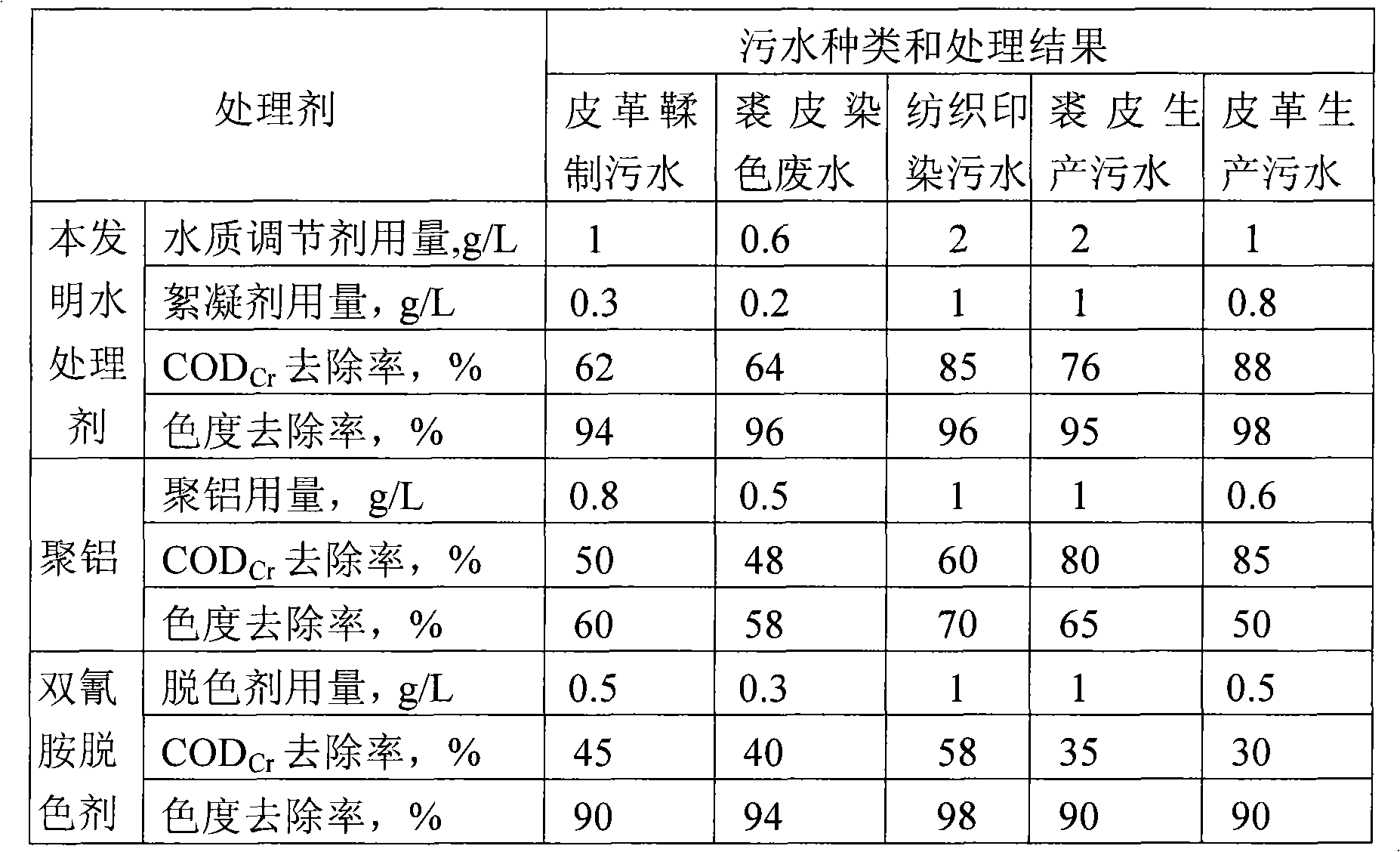

Water treatment agent and preparation method and application thereof

InactiveCN101781034AImprove settlement performanceSolve the problem of small and difficult subsidenceWaste water treatment from animal processingMultistage water/sewage treatmentLeather industryTextile printer

The invention discloses a novel water treatment agent and a preparation method and application thereof. The water treatment agent consists of a water quality conditioning agent and a magnesium-iron composite decoloring flocculating agent; the water quality conditioning agent is prepared by the following formula which comprises the components in parts by weight: 50-90 parts of calcium oxide, 10-40parts of aluminium potassium sulfate and 10-30 parts of magnesium sulfate heptahydrate; and the magnesium-iron composite decoloring flocculating agent is prepared by the following formula which comprises the components in parts by weight: 5-30 parts of ferrous sulphate, 60-90 parts of magnesium sulfate heptahydrate and 0.1-5 parts of flocculation increasing agent. The water treatment agent can beused for waste water treatment of industrial waste water, especially in the leather industry, the fur industry and the textile printing and dyeing industry with serious pollution. When being used forsewage treatment, the water treatment agent has little investment, fast effect, good treatment effect and no secondary pollution; and the water treatment agent has low cost, and the production methodis simple and convenient and has no pollution.

Owner:北京泛博科技有限责任公司

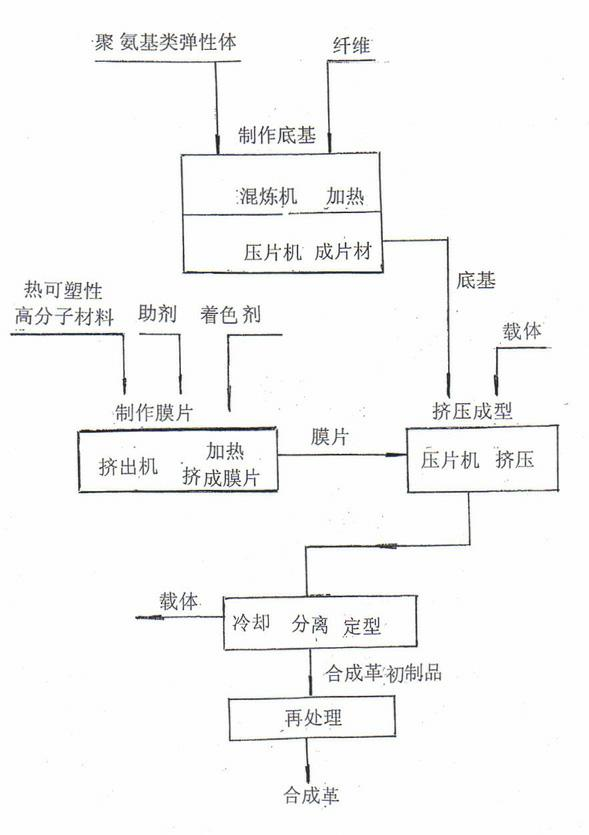

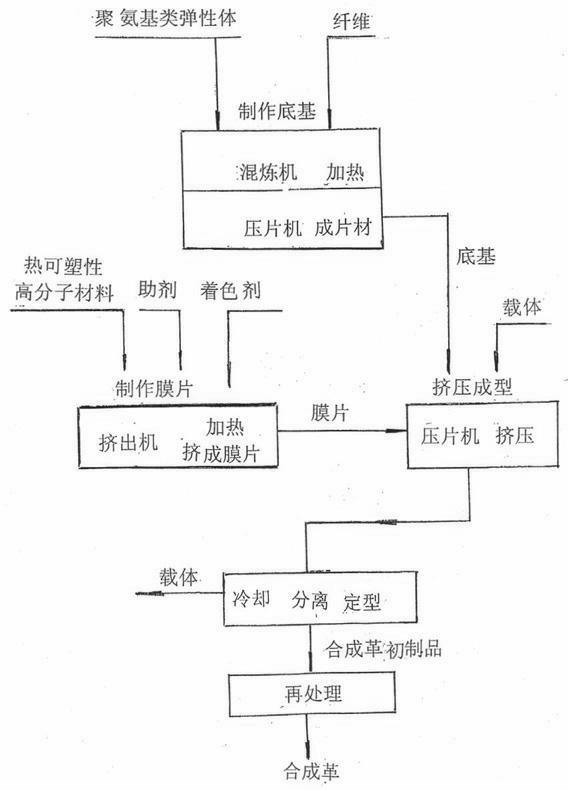

Manufacturing method of backer-free synthetic leather

ActiveCN102321979ANo pollutionMeet environmental protection requirementsLaminationLamination apparatusLeather industryFiber

The invention relates to a manufacturing method of backer-free synthetic leather and relates to a manufacturing method of synthetic leather. The manufacturing method comprises the following steps of: mixing and heating a thermoplastic high polymer polyamino elastomer and fibers, preparing substrates in different thicknesses by adopting a compression roller; then heating and melting a mixed material composed of the thermoplastic high polymer elastomer material, a dyeing agent and an auxiliary into a membrane by virtue of an extruding machine, wherein the membrane is tightly and uniformly distributed on the substrates, and a carrier provided with a decorative pattern is extruded onto the membrane; and after cooling, mutually separating the carrier and the membrane to obtain a primary product of the synthetic leather. The manufacturing method provided by the invention thoroughly changes the traditional process in the synthetic leather industry, no pollution is produced in the production process, and synthetic leather products are not polluted. The synthetic leather product has the advantages of unique and excellent visual effect, good abrasion performance and good high and low temperature resistance.

Owner:HUALUN LEATHER & PLASTIC SUZHOU

Graphite-enhanced ultrafine synthetic leather fiber

ActiveCN105463598AHigh breaking strengthAntistaticMelt spinning methodsArtifical filament manufactureLeather industryPolymer science

A graphite-enhanced ultrafine synthetic leather fiber is provided. Graphite nylon 6 master batch is prepared via a twin-screw extrusion way; the nylon 6 master material is added to nylon 6 granules via a metering device for sea-island melt spinning; and graphite-enhanced ultrafine fibers can be achieved after decrement and splitting. The graphite-enhanced ultrafine synthetic leather fiber is characterized by high breaking tenacity, static resistance, bacteria resistance, aging resistant and strong flexibility; ultrafine fiber synthetic leather quality and comprehensive performance can be improved when the graphite-enhanced ultrafine synthetic leather fiber is applied to synthetic leather industry; and traditional sea-island fiber spinning equipment can be employed for production.

Owner:SICHUAN UNIV

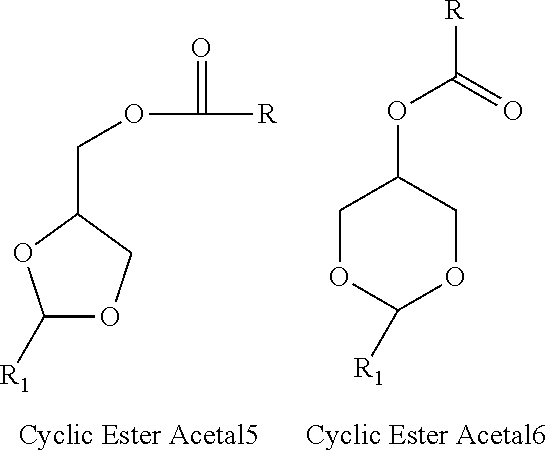

Acetals Esters Produced from Purified Glycerin for Use and Application as Emollients, Lubricants, Plasticizers, Solvents, Coalescents, Humectant, Polymerization Monomers, Additives to Biofuels

It refers to a new group of acetal monoesters and diesters which have in its structure the ester function and cyclic ethers that give these products excellent properties as solvency, plasticity in polymers, solubility in polar and nonpolar means, spreadability, wetting, low volatility, non-toxicity and biodegradability. These properties make these products excellent candidates as solvents in formulations of pesticides, agricultural herbicides, for the paint and leather industry in domestic or industrial hygiene formulations; as plasticizers for polymers such as polyvinyl chloride, nitrocellulose, cellulose, acrylics, polyvinyl vinyl and its copolymers; as lubricants in industrial formulations, textile industry; as emollients agents which donate oiliness for the cosmetic industry; as wetting agents that are commonly used, and as biodiesel additives to reduce the freezing point and to improve its combustion.

Owner:GLYCEROSOLUTION QUIMICA

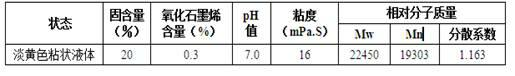

Method for preparing acrylic resin modified graphene oxide leather tanning agent

InactiveCN102586507AEquivalent tensile strengthEquivalent tear strengthTanning treatmentLeather industryAcrylic resin

The invention relates to a method for preparing an acrylic resin modified graphene oxide leather tanning agent. Pollution becomes a main problem that hampers the sustainable development of leather industry, wherein a chrome tanning agent is one of leading pollution sources. The method comprises the following steps of: adding concentrated sulfuric acid into a mixture of graphite powder and sodium nitrate, adding potassium permanganate, raising the temperature, reducing the temperature, washing, and dispersing by using ultrasonic waves to obtain an aqueous solution of graphene oxide; and adding methacrylic acid and acrylic acid into the aqueous solution of graphene oxide, treating by using ultrasonic waves, heating, dripping an initiator solution, keeping the temperature, reacting, and controlling the solid content to be 15 percent to obtain a product. The leather tanning agent can be used as a main tanning agent and is used for tanning leather; the tensile strength, the tearing strength and the breaking elongation of the tanned leather are equivalent to those of chrome tanned leather, and the tanned leather has soft and smooth handfeel; the leather tanning agent can substitute pollutional tanning agents such as a chrome tanning agent, an aldehyde tanning agent and the like, so that the pollution of the chrome tanning agent is reduced or eliminated from the source; and the leather tanning agent has a good application prospect.

Owner:SHAANXI UNIV OF SCI & TECH

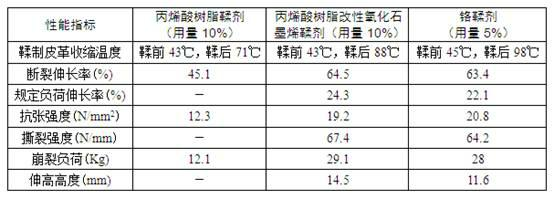

Bacterial strain capable of producing alkali protease and industrialized liquid fermentation method of bacterial strain

ActiveCN103409347AReduce manufacturing costOptimizing the fermentation mechanismBacteriaHydrolasesLeather industryAlkaline protease

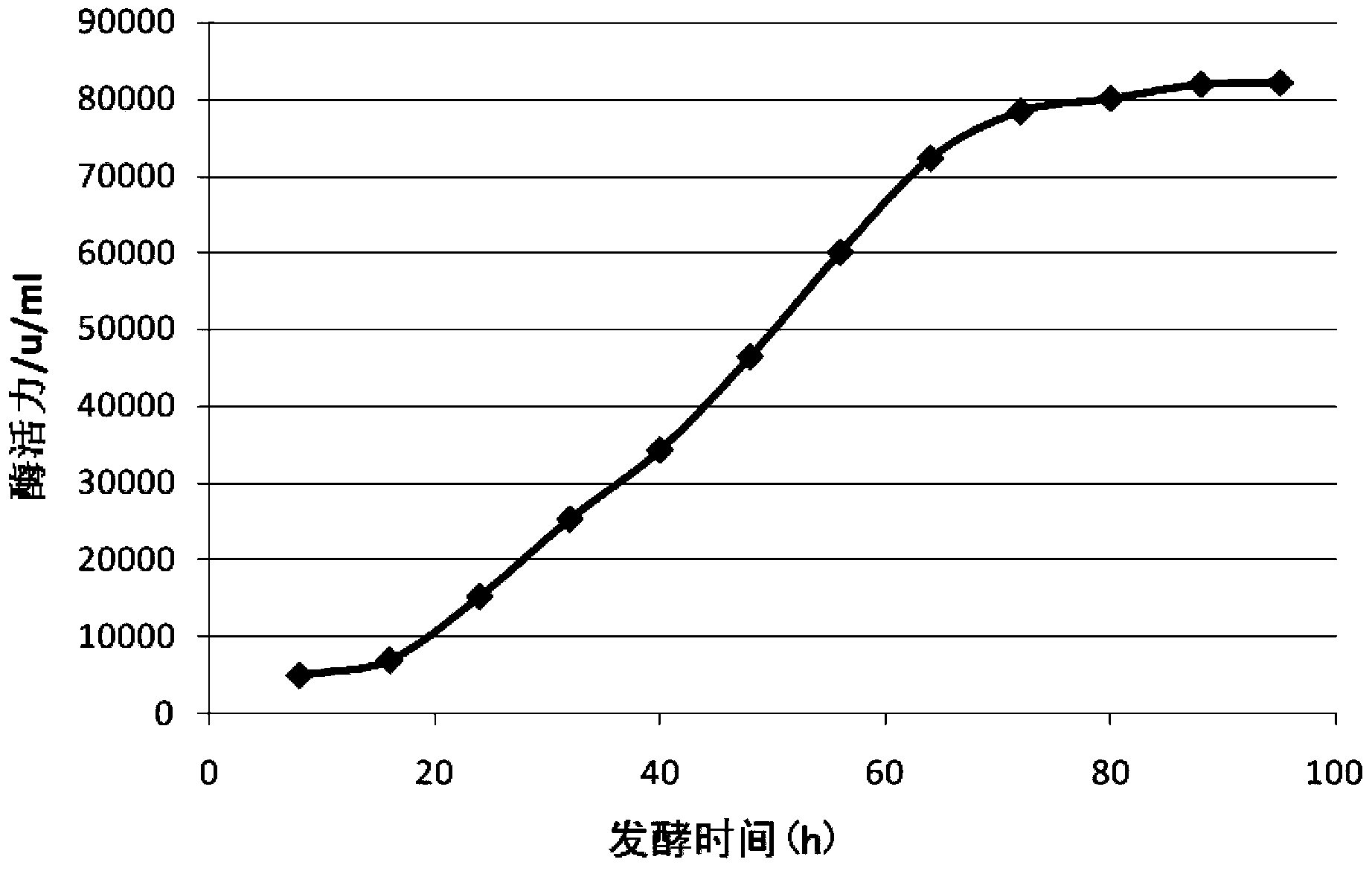

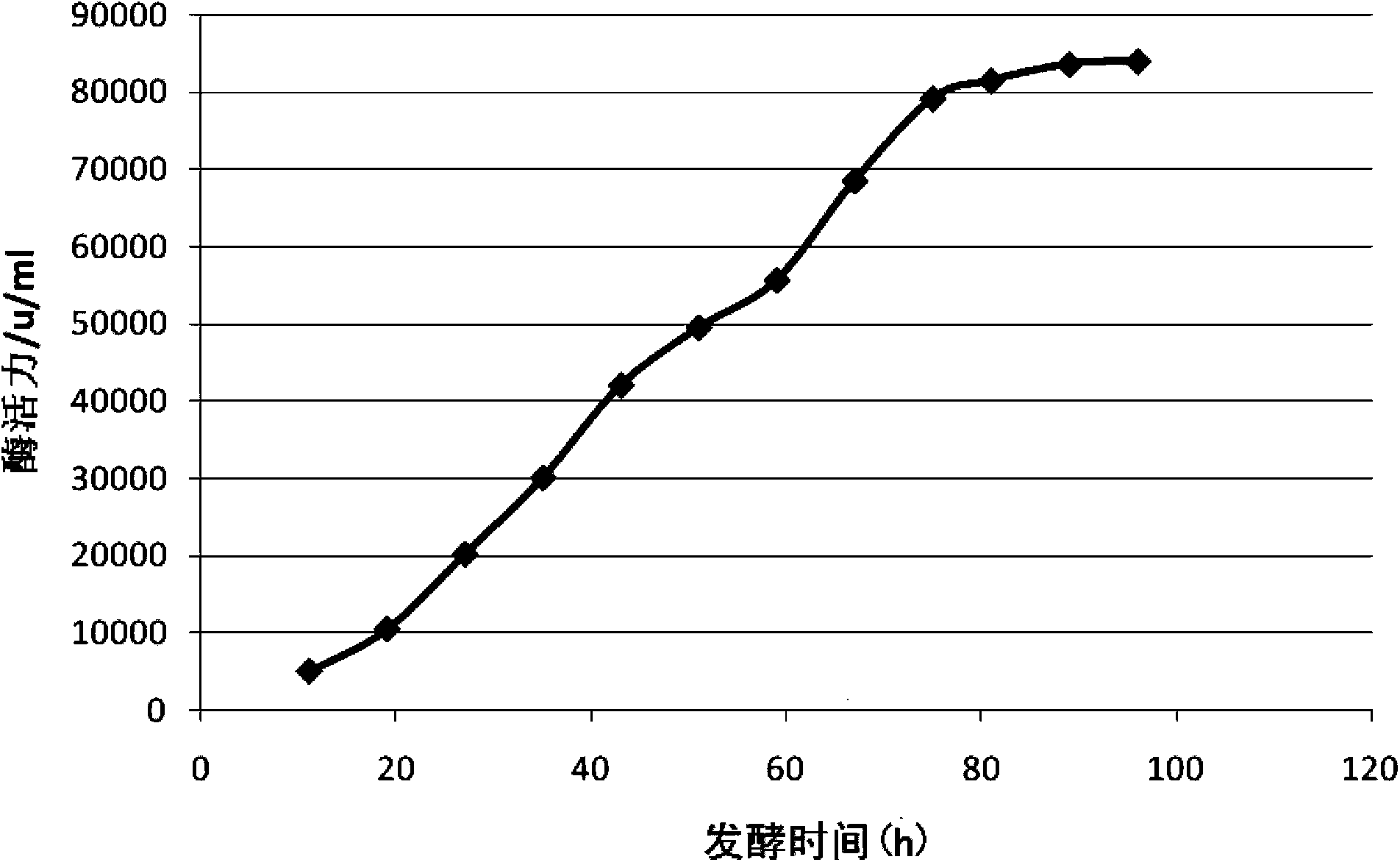

The invention discloses a bacterial strain capable of producing alkali protease and an industrialized liquid fermentation method of the bacterial strain, and belongs to the field of bioengineering technology. The bacterial strain is mutant strain Ap180 of Bacillus alcalophilus, and the preservation number is CGMCC No.7545. The bacterial strain is obtained by repeat UV-induced mutation, nitrosoguanidine-induced mutation and selection of a wild bacterial strain obtained from saline lands. Characteristics of the bacterial strain are that: efficiency of alkali protease production is high, and stability is excellent. The Bacillus alcalophilus strain, which is capable of producing alkali protease and is suitable for industrialized production , is provided in the invention, and related fermentation mechanism is optimized. According to the fermentation mechanism, operation processes are simple, cultivating conditions are mild, fermenting enzyme activity is more than 80000u / ml, production cost of enzyme activity per unit is reduced, and the requirements of market are met. Applications of the alkali protease in fields such as washing agent, forage, and leather industry are more extensive.

Owner:SHANDONG LONGKETE ENZYME PREPARATION

Manufacturing method of waterborne polyurethane nubuck leather

InactiveCN103397533AHigh color fastnessEven and fine cellsSynthetic resin layered productsTextiles and paperLeather industryColour fastness

The invention relates to a manufacturing method of waterborne polyurethane nubuck leather. The entire synthetic leather industry is built on the basis of solvent polyurethane as a main body at present, and causes great harm to the environment and a human body. The manufacturing method comprises the following steps: coating a prepared waterborne polyurethane foam slurry coating on base fabric; drying the coated base material, and carrying out surface polishing treatment; and finally carrying out dyeing and finishing, drying and surface modification on the polished semi-finished product to obtain the waterborne polyurethane nubuck leather. The waterborne polyurethane nubuck leather manufactured by the method has bright color, high color fastness, uniform and delicate abscess, soft handfeeling, good drapability, air and water vapor permeability and simple manufacturing process; the surface style has the effect similar to that of dermal frosted leather; the appearance and the handfeeling of the waterborne polyurethane nubuck leather are similar to those of natural leather; no organic solvent is used in the production process; no organic solvent is discharged; according to the manufacturing method, energy-saving and environment-friendly effects are achieved. Thus, the technology has positive significance in the aspects of increasing the varieties and designs of the waterborne polyurethane nubuck leather and improving the added value of products.

Owner:SHAANXI UNIV OF SCI & TECH

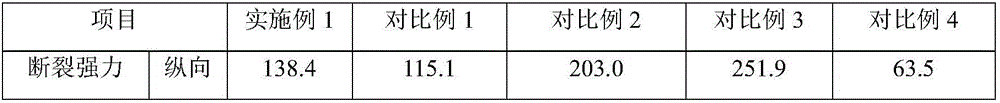

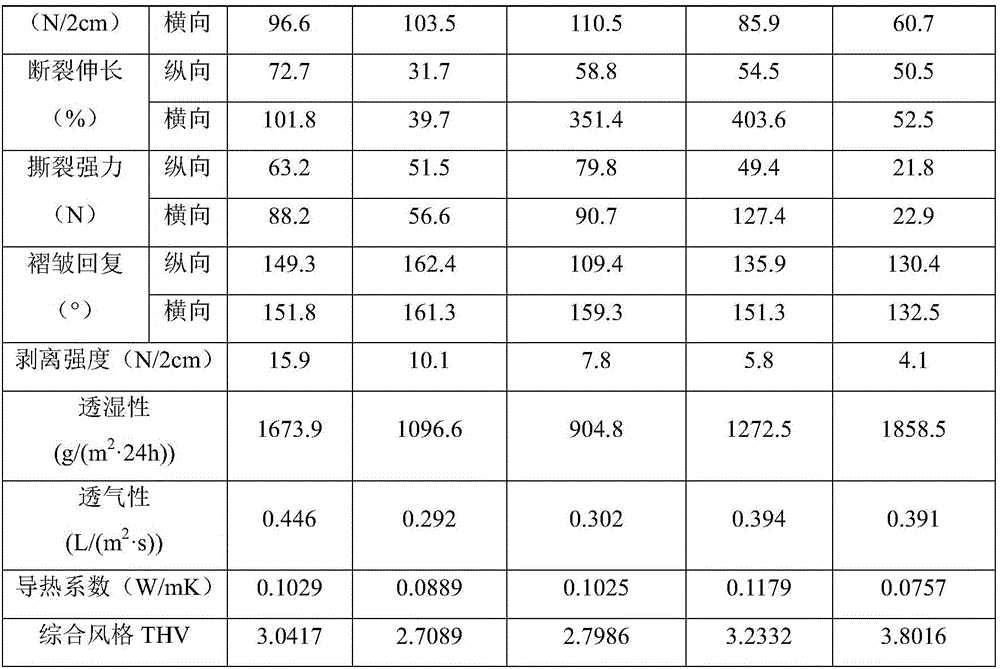

Preparation method for spun-bonded filament orange petal-type superfine leather

The invention discloses a preparation method for spun-bonded filament orange petal-type superfine leather. The preparation method comprises the following steps: first, preparing two-component orange petal-type composite filament fibres by adopting a spun-bonding method, paving a net on a net curtain, and strengthening through spunlace to obtain a base fabric of a non-woven fabric; then, preparing a water-based polyurethane surface layer and a foaming layer on release paper, and preparing a water-based polyurethane bonding layer on the base fabric; finally, adhering the surface layer and the foaming layer to the bonding layer of the base fabric to obtain the spun-bonded filament orange petal-type superfine leather. Compared with the prior art, the filament spunlace non-woven fabric is spun-bonded by adopting two-component superfine fibres, and water-based polyurethane resin is combined, so that the problems of organic wastewater caused by a methylbenzene reduction or alkaline reduction process and DMF (Dimethyl Formamide) solvent pollution caused by a solvent type production system in the existing superfine fibre synthesis leather industry are effectively solved; a superfine fibre synthesis leather production line which is simple in process, green, environment-friendly and pollution-free is formed.

Owner:TIANJIN POLYTECHNIC UNIV

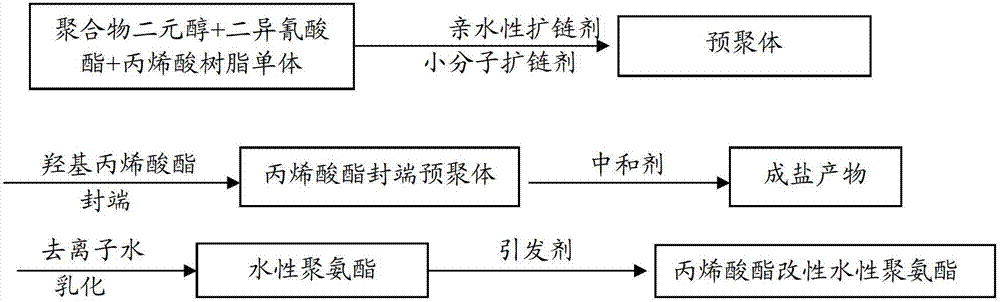

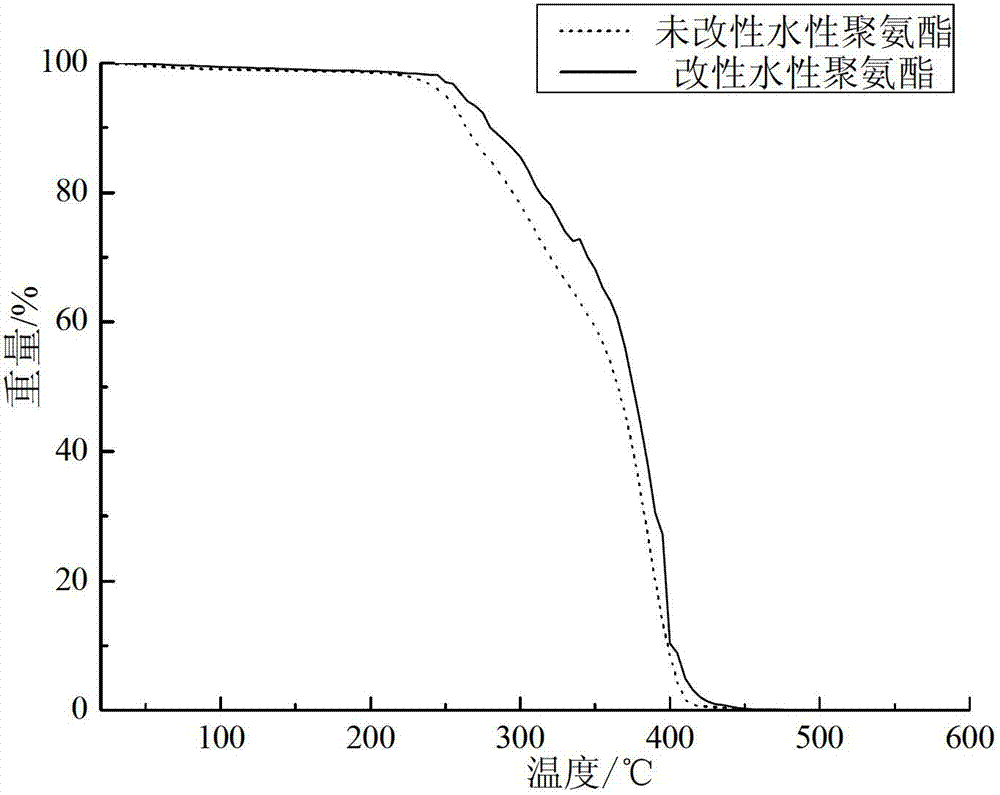

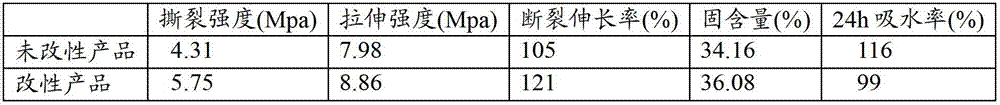

Preparation method of waterborne polyurethane for synthetic leather

The invention provides a preparation method of waterborne polyurethane for synthetic leather. By using a micromolecular acrylic monomer for replacing acetone to be used as a diluting agent, a hydrophilic chain extender is dissolved in the earlier stage of synthesis, so that the viscosity of a reaction solution is lowered; the micromolecular acrylic monomer is used as a reaction monomer in the later stage for modifying polyurethane, so that no solvent residues exist after the reaction is ended. According to the method, a VOC (Volatile Organic Compound) in the waterborne polyurethane is greatly reduced, and the performance of the waterborne polyurethane is improved. The preparation method has the advantages of simple process, high equipment utilization rate, cleanness without pollution, convenience for industrial production. The waterborne polyurethane has the advantages of high solid content, good durability, low cost, no pollution in production and use processes, and wide application prospect in the synthetic leather industry.

Owner:江西豪丰实业有限公司

One-component, high-solid-content and low-crystallinity polyurethane resin and preparation method thereof

The invention relates to a one-component, high-solid-content and low-crystallinity polyurethane resin and a preparation method thereof. The polyurethane resin comprises the following components by mass: 1 to 11% of isophorone diisocyanate, 9 to 34% of diphenylmethane-4, 4'-diisocyanate, 11 to 50% of polyadipate type polyester polyol, 1 to 31% of castor oil, 0.5 to 8% of chain extender, and 20 to 50% of solvent, wherein the solvent is the mixture of N, N-dimethylformamide and butanone or the mixture of the N, N-dimethylformamide and acetic ether. The polyurethane resin provided by the invention is high in solid content and low in crystallinity, and can be applied to the synthetic leather industry, such as the bags industry, the clothing industry and the furniture industry.

Owner:SHANGHAI HUIDE TECH CO LTD

Preparing process of composite sound absorbing paper

InactiveCN101285285AImprove sound absorptionImprove stabilityPaper/cardboardPaper-making machinesFiberLeather industry

The invention provides a technique for making composite sound-absorbing paper. The method comprises the following steps that: the leather waste materials generated in the leather industry are pre-processed to be washed by water, to remove oil and the fishy smell firstly; secondly, according to certain concentration, the pulping process is performed by the paper-making method in a PEI pulping machine to obtain scattered collagenous fibers; next, the collagenous fibers and bleached softwood pulp are mixed according to certain ratio, a retention and filtration aid and fillings are added, the paper is made in a paper sheet forming machine. The sound-absorbing paper has good function of absorbing sound and reducing noise; the average sound absorption is more than 0.5; moreover, the sound-absorbing material also has good flame retardant property and waterproof property. The technique ensures that the valuable resource of the leather excess material can be utilized reasonably and effectively, provides research train of thought and method for the deep exploitation and utilization of the leather excess material, the application of collagenous fibers and plant fibers to the composite material field, and the cross-over study of the paper-making industry, the leather industry and the acoustic material fields, and has important theoretical significance and particle application value.

Owner:SHAANXI UNIV OF SCI & TECH

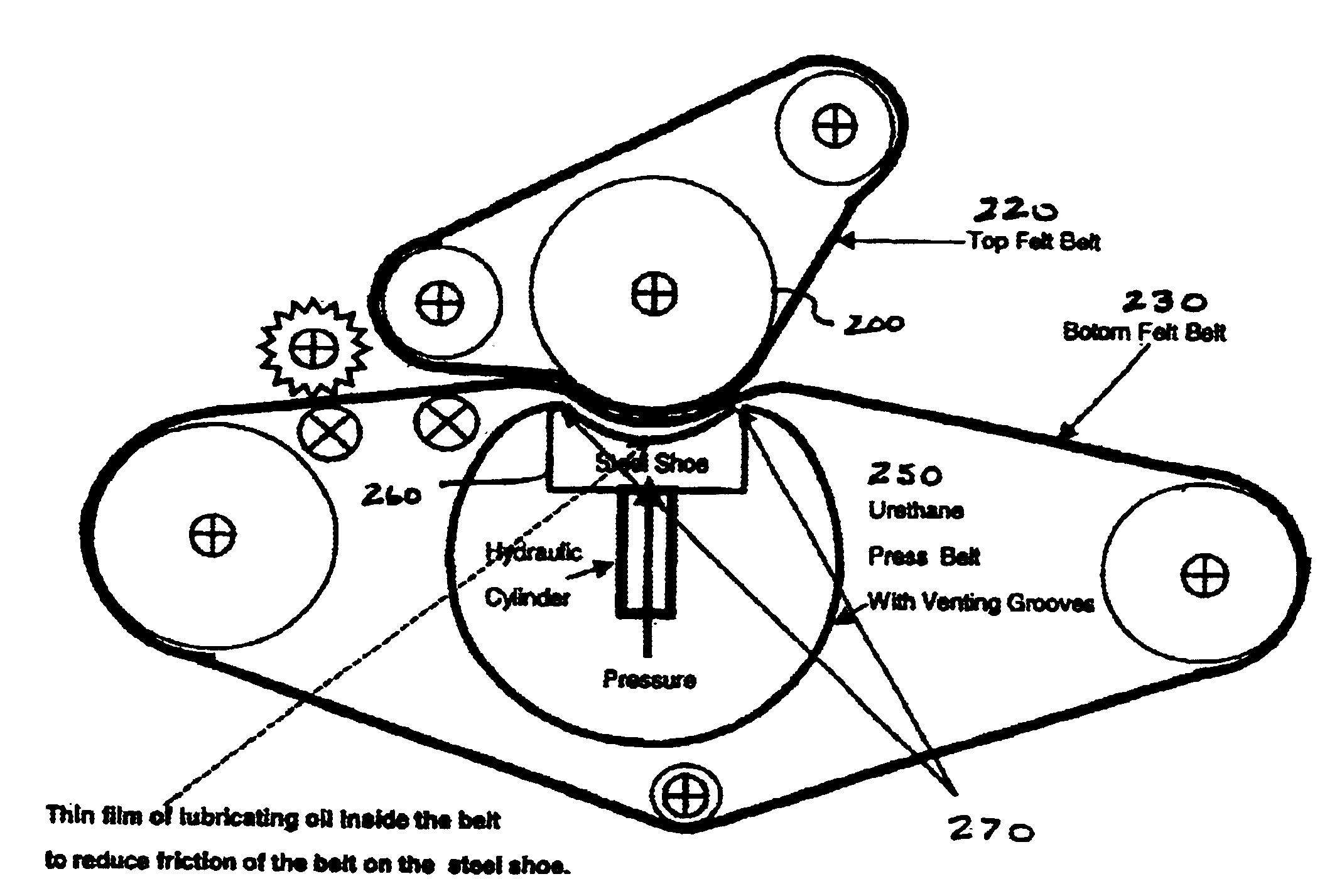

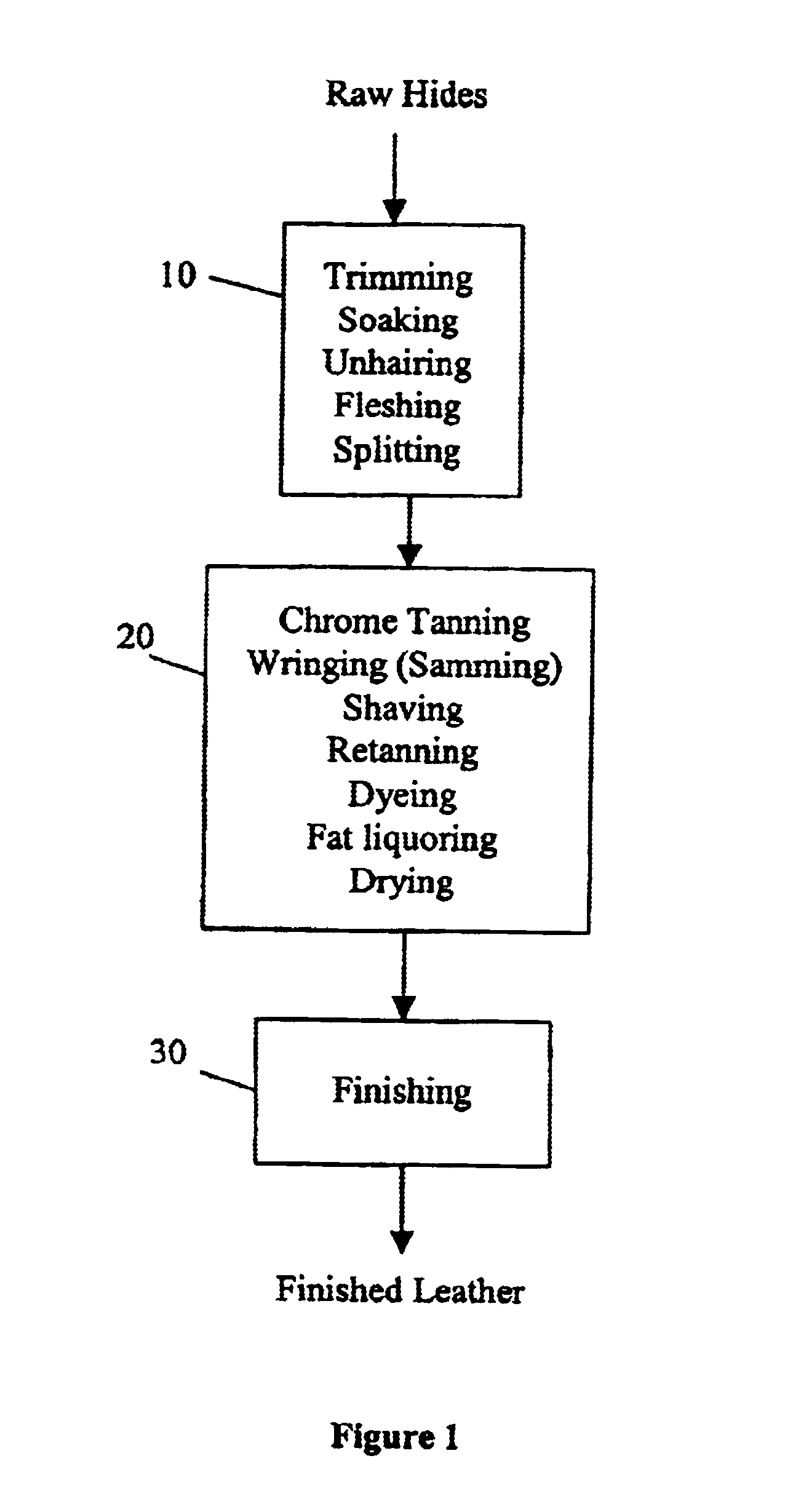

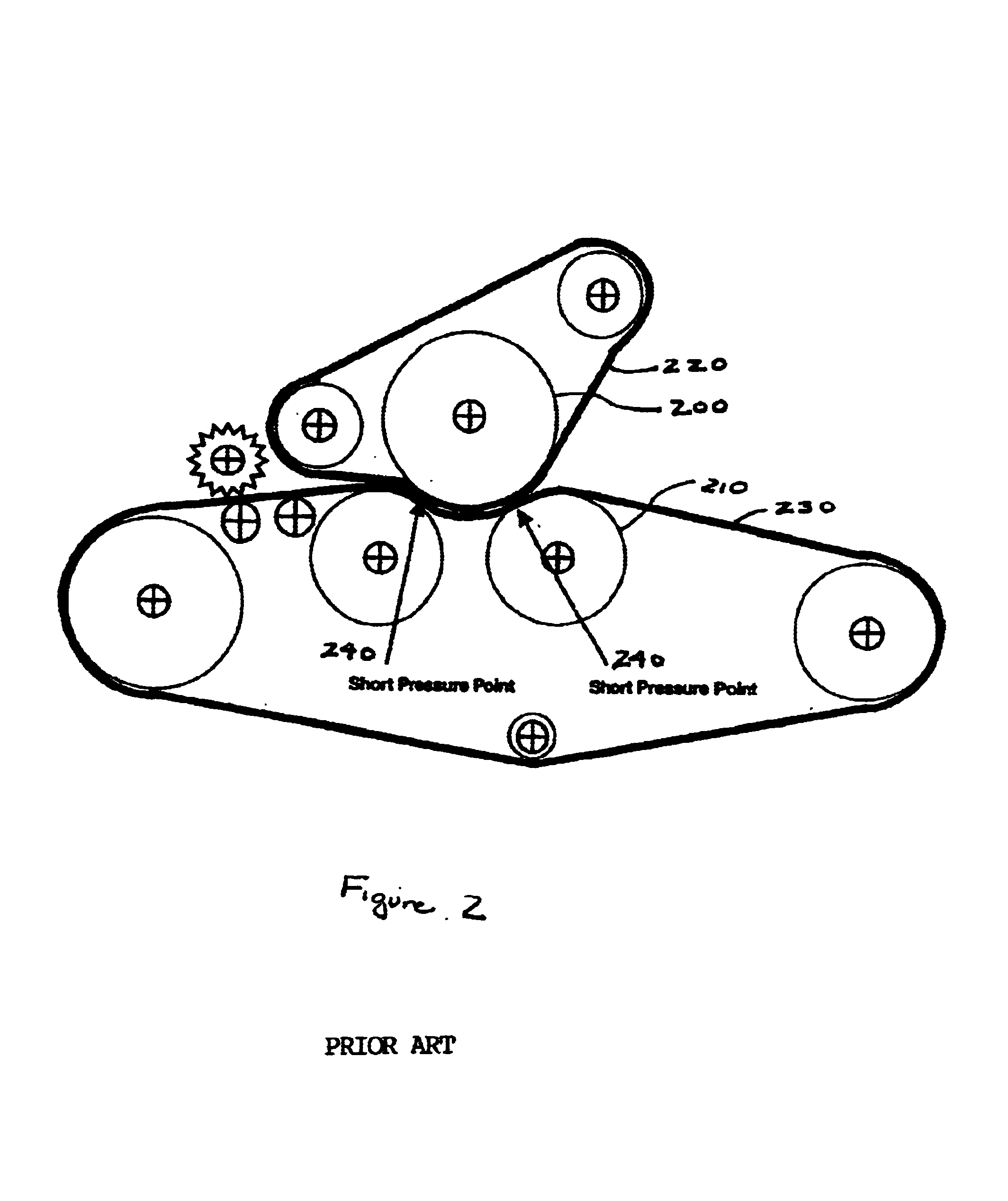

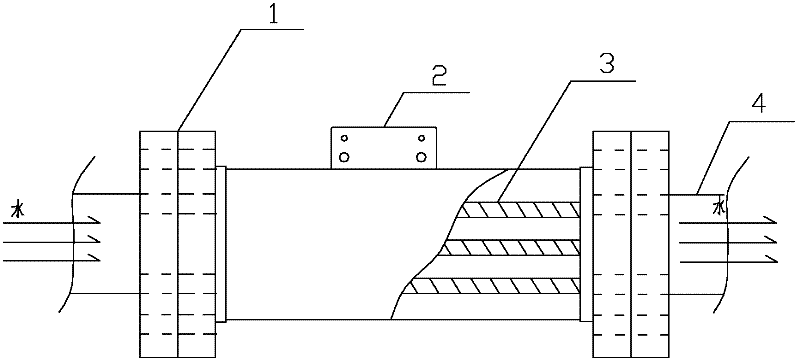

Extended nip press for the leather industry

InactiveUS6854301B1Efficiently expelledExtended stayLeather pressing/rollingPackaging toiletriesLeather industryMechanical engineering

An extended nip press machine, similar to those used in the paper industry, for use in the leather industry to remove water from hides after the tanning process. The leather press consists of a shoe whose surface substantially matches the radius of an opposing pressure roll. Moving across the shoe is an endless belt, which is lubricated by a thin film of oil. Between the belt and corresponding pressure roll pass two endless felt belts, which are the means of conveying the leather hides. The nip formed by the shoe press is dramatically longer than a conventional press nip, thereby increasing the dewatering efficiency of the leather press.

Owner:ALBANY INT CORP

Treatment method of waste water in leather industry

InactiveCN103043864ASmall footprintSolve the bloat problemMultistage water/sewage treatmentLeather industryIndustrial waste water

The invention discloses a treatment method of waste water in the leather industry. The method comprises the following sequential steps of filtering, homogenizing, floating, scraping slag, adding acid and a flocculating agent for precipitation, oxidizing, hydrolyzing, acidizing, precipitating, filtering, and discharging. The method adopts a hollow fiber membrane component to substitute a secondary precipitation tank in the traditional technology, so that the floor area of a treatment system is reduced; in addition, the method solves the problem of sludge bulking in the traditional suspended activated sludge technology; the effluent quality is stable and reliable; and the operation process is relatively simple and convenient.

Owner:CHANGZHOU UNIV

Method for improving dyeing property of superfine fiber synthetic leather base cloth

ActiveCN103603197AImprove dyeing effectAdd active groupsFibre treatmentDyeing processAlkaline proteaseLeather industry

The invention relates to a method for improving the dyeing property of superfine fiber synthetic leather base cloth. The method comprises the following steps: adding water into gelatin, stirring to enable the gelatin to expand to obtain a gelatin solution, and adding alkaline protease into the gelatin solution for hydrolysis; adding the superfine fiber synthetic leather base cloth into a rotating drum, and treating the superfine fiber synthetic leather base cloth by acid to obtain surface modified superfine fiber synthetic leather base cloth; adding collagen into the rotating drum, performing graft modification on the collagen with the surface modified superfine fiber synthetic leather base cloth, and reacting to obtain collagen modified superfine fiber synthetic leather base cloth; and adding a dye into the rotating drum to dye the collagen modified superfine fiber synthetic leather base cloth. According to the invention, the superfine fiber synthetic leather base cloth is modified by the collagen, so that the superfine fiber synthetic leather base cloth is covalently modified by the collagen, furthermore, the dyeing performance of the superfine fiber synthetic leather is effectively improved, the dye uptake is up to about 94.21%, and the superfine fiber synthetic leather industry can be favorably developed.

Owner:SHAANXI UNIV OF SCI & TECH

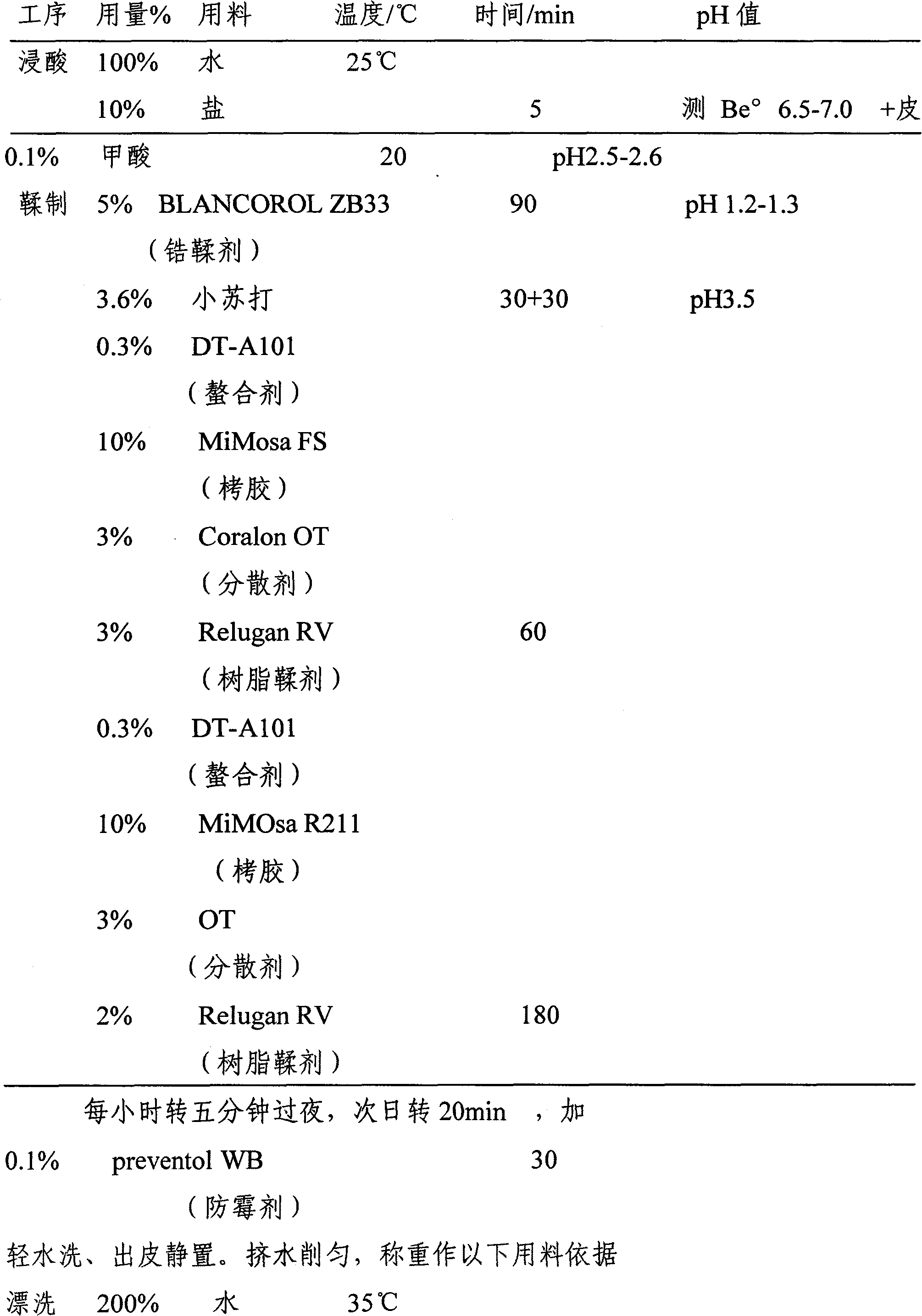

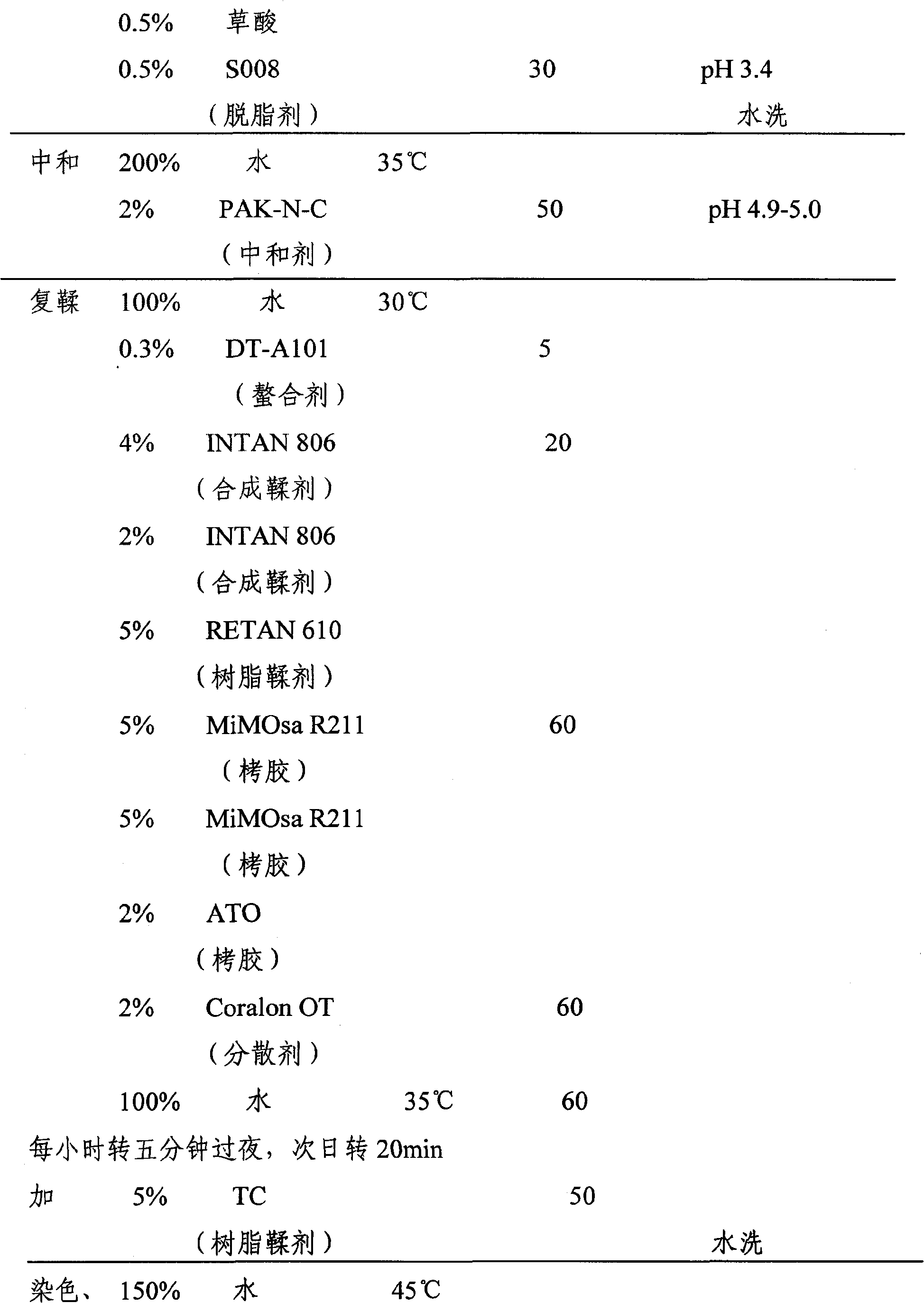

Technique for preparing goat chrome-free tanning upper leather

InactiveCN101358254ANo pollution in the processInelasticTanning treatmentLeather impregnationLeather industryEngineering

The invention discloses a production process of goat free-chrome vamp leather, which comprises the following steps: pickling, tanning, rinsing, neutralizating, retanning, dying and oiling, fixing, color registering, water washing, leather outputting, wringing on the next day, vacuuming 50 DEG C / 70 seconds, air-drying, collecting leather for quiescence, damping quiescence, vibration staking, bending repair, toggling and trimming, all the steps are carried out and a finished product is completed. The invention is characterized in that zirconium tanning agents, vegetable tanning agents, synthesized tanning agents replace the traditional chrome tanning agents during tanning and retanning, the production process has no pollution, and has safe operation process; thus the effect of completely controlling the chrome pollution of the leather industry is achieved. The shrinking temperature of the obtained crust leather can reach 95 DEG C, the leather body is full, soft and elastic, the grain surface is neat and fine, and the physical and the mechanical properties can completely reach the requirements for the property of the goat vamp leather.

Owner:JIANGSU XINGAINIAN LEATHER

Acidic proteinase and preparation method thereof

InactiveCN101948820AIncrease profitHigh extraction and purification yieldHydrolasesMicroorganism based processesLeather industryAspergillus niger

The invention relates to an acidic proteinase and a preparation method thereof and the acidic proteinase belongs to the microbial acidic proteinase. The invention is characterized in that 1) the enzymatic characteristics of the acidic proteinase are as follows: the optimum pH value is 2.5-3.5, the stable pH value is 2.5-6.0; the optimum temperature is 40-50 DEG C, the temperature stability range is 30-50 DEG C; and 2) the preparation method uses Aspergillus Niger which is stored in the China Center of Industrial Culture Collection (CICC) and has a preservation number of 2238, as the enzyme-producing strain and uses wheat bran as the raw material; the solid fermentation technology is adopted for preparation; the fermentation and enzyme-producing capability is not less than 47000u / g (dry yeast), the liquid enzyme yield is not less than 85% and the soid enzyme yield is not less than 80%, which all achieve the food grade sanitation standard. The invention provides the acidic proteinase and the preparation method thereof, wherein the utilization rate of the fermentation equipment is high, the byproduct of crop processing is used as the main raw material, the enzyme activity for fermentation is high, the extracting and purifying rate of enzyme is high and the production cost is low. The acidic proteinase of the invention is suitable to be used as the raw material or product additive of the products in the leather industry, the pharmaceutical industry, the brewing industry and the feed industry.

Owner:SHANDONG LONGKETE ENZYME PREPARATION

A process for the preparation of a synthetic tanning agent

A process for the p reparation of a synthetic tanning a gent is disclosed whereby multi functional polymer is polymerized with sulfonated aromatic compound, pretreated with organic ligand to form an organo-polymeric matrix, free from formaldehyde. The product has potential application in leather industry for not only ensuring an eco-friendly approach in chrome tanning by way of eliminating the conventional pickling process and the resulting problem of total dissolved solids (TDS) associated with the effluent, but also suggesting an exhaust aid for chrome because of its multiple carboxyl groups. The product can also be used as a retanning agent in leather processing.

Owner:印度科学工业研究所

Method for crosslinking collagen through oxidized oligosaccharide

The invention relates to a method for crosslinking collagen through an oxidized oligosaccharide. The method comprises the steps that the oxidized oligosaccharide with a certain quantity of aldehyde groups serves as a crosslinking agent, a crosslinking reaction occurs between the oxidized oligosaccharide and collagen molecules or an aggregate of the collagen molecules, then cleaning or dialyzing treatment is performed, and finally freeze drying is performed with a freeze drying machine to obtain crosslinked collagen molecules containing the oligosaccharide structure or an aggregate of the crosslinked collagen molecules. According to the crosslinked collagen obtained through the method, not only are the original performances of collagen kept, but also the oligosaccharide structure with the activity is introduced, the formed crosslinked structure can resist a certain degradation function of biological enzymes, all the basic performances are excellent, the biocompatibility is good, and the certain functionality is simultaneously achieved. The method can be applied to biological material and leather industries.

Owner:SICHUAN UNIV

Leather making method for magnetically processing leather making water and leather chemical water solution into nanometer small-molecule water to be combined with ultrasonic wave enhancement technology

InactiveCN102583665AImprove softeningIncrease water filling speedTanning treatmentPre-tanning chemical treatmentLeather industryIndustrial waste water

The invention discloses a leather making method for magnetically processing leather making water and a leather chemical water solution into nanometer small-molecule water to be combined with an ultrasonic wave enhancement technology. The leather making method is characterized in that the magnetized nanometer small-molecule water is combined with the ultrasonic wave enhancement technology to be applied to each leather making procedure, so that the efficiency of the physiochemical process of each leather making procedure can be improved, the consumption of chemical materials is reduced, environmental pollution caused by the emission of harmful drugs and industrial wastewater is reduced to the maximum extent, the use quantity of water is greatly saved, the waste of water is decreased in the leather making process, and the production cost is reduced, so that the leather making method is a reform of the traditional leather making method and provides a new effective path for the developmentof the leather industry.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com