Device and method for adsorbing, recycling and treating organic waste gases efficiently

An organic waste gas, adsorption and recovery technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of non-standard discharge, non-compliance discharge and recovery treatment, low removal rate, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment provides a device and treatment method for efficient adsorption recovery treatment of organic waste gas.

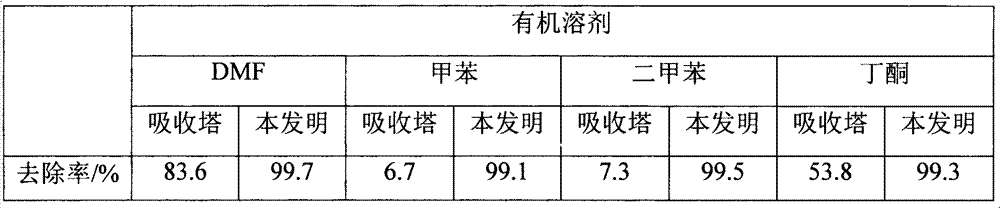

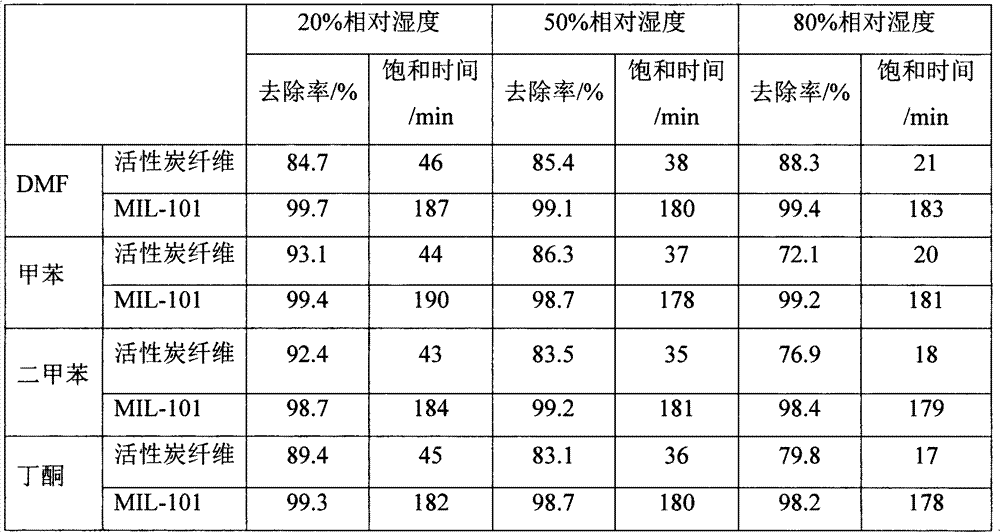

[0022] The tail gas discharged from a synthetic leather workshop is mainly composed of DMF, toluene, xylene, methyl ethyl ketone and air, and the air volume of the tail gas is 25000m 3 / h, DMF concentration is 2500mg / m 3 , the concentration of toluene is 1200mg / m 3 , the concentration of xylene is 1000mg / m 3 , butanone concentration is 600mg / m 3 .

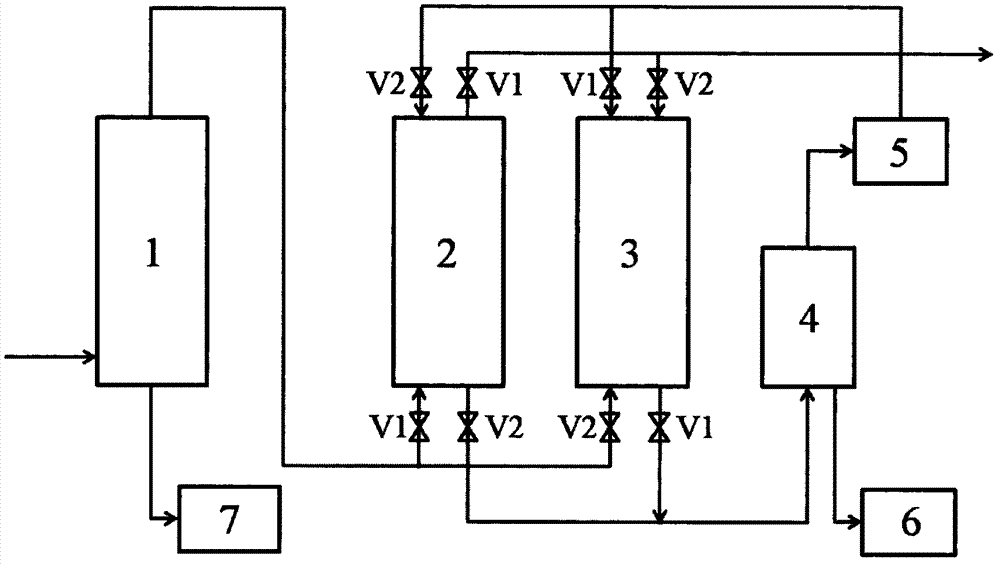

[0023] attached figure 1 It is the process flow diagram of embodiment 1. A device for efficient adsorption recovery treatment of organic waste gas, including organic waste gas transmission pipeline, steam transmission pipeline, water absorption tower, absorption and desorption tower with two or more adsorption tanks arranged in parallel, switching valve, condenser, organic solvent separation and recovery system, organic solvent recovery tank and steam generator.

[0024] The adsorption tank 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com