Device and method for adsorbing, recovering and treating organic exhaust gas by aerogel

An organic waste gas, adsorption recovery technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve problems such as the decline of organic solvents, achieve the effect of improving efficiency, uniform pore size distribution, and overcoming technical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

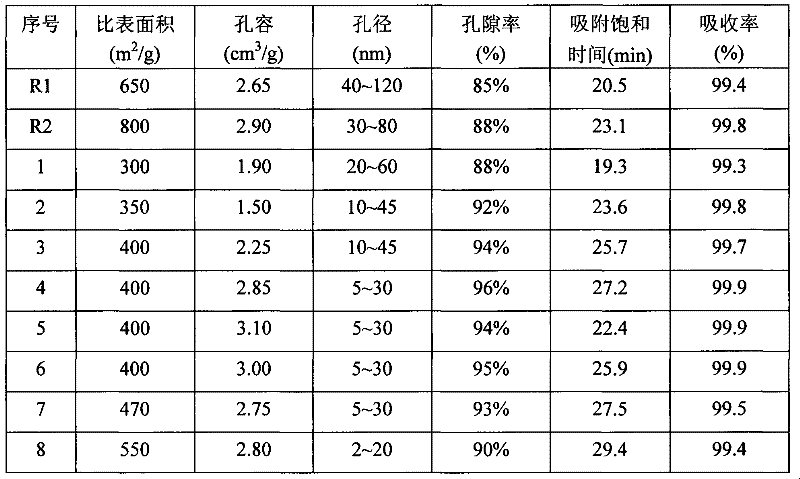

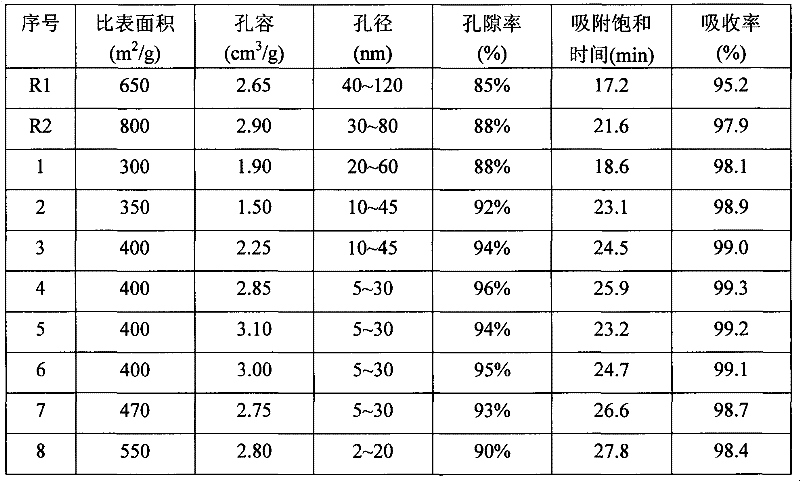

Examples

Embodiment 1

[0021] This embodiment provides an airgel adsorption recovery device and treatment method for organic waste gas.

[0022] The exhaust gas discharged from a tipping paper printing workshop is mainly composed of ethanol, ethyl acetate, hexanediol ethyl ether and air, etc. The exhaust air volume is 21000m 3 / h.

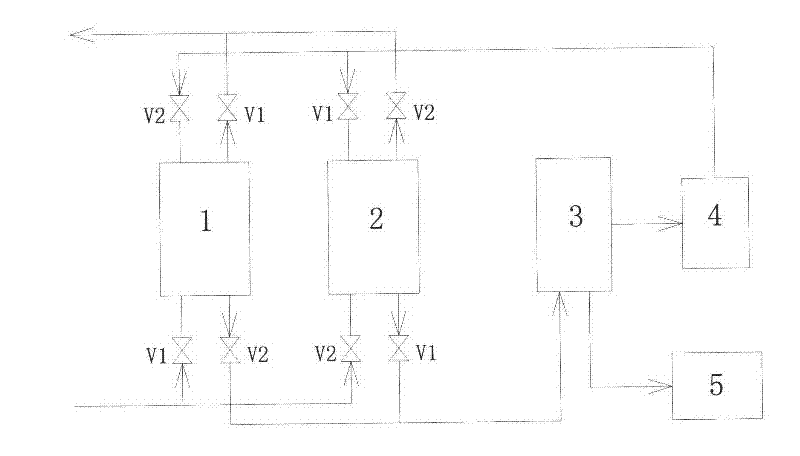

[0023] attached figure 1 It is the process flow diagram of embodiment 1. An airgel adsorption recycling device for treating organic waste gas comprises a waste gas delivery channel, a steam delivery channel, two adsorption tanks arranged in parallel, a switching valve, a condenser, a solvent recovery tank and a steam generator.

[0024] The adsorption tank 1 and the adsorption tank 2 are provided with an airgel adsorption layer.

[0025] The airgel used in this embodiment is silicon aerogel, which is chemically stable, resistant to acid and alkali, water, high temperature and high pressure. Silica airgel has the following advantages as an adsorbent: 1. Good flame ret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com