Three-degree-of-freedom flip-flow screen

A degree of freedom, relaxation screen technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the large difference between the excitation center and the center of mass position, can not effectively improve the screening efficiency, and adversely affect the service life of the relaxation screen. and other problems, to achieve the effect of simple control, low equipment cost and operating power consumption, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

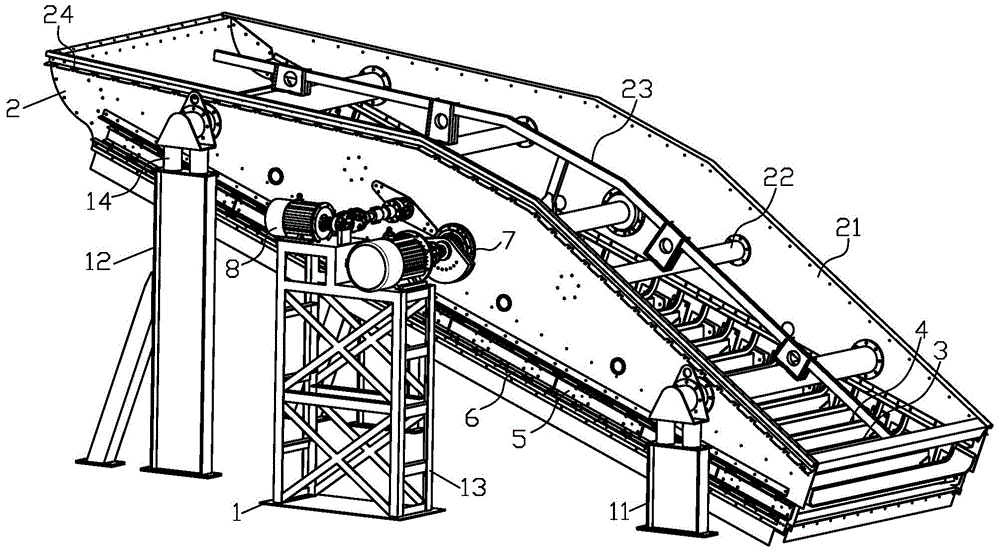

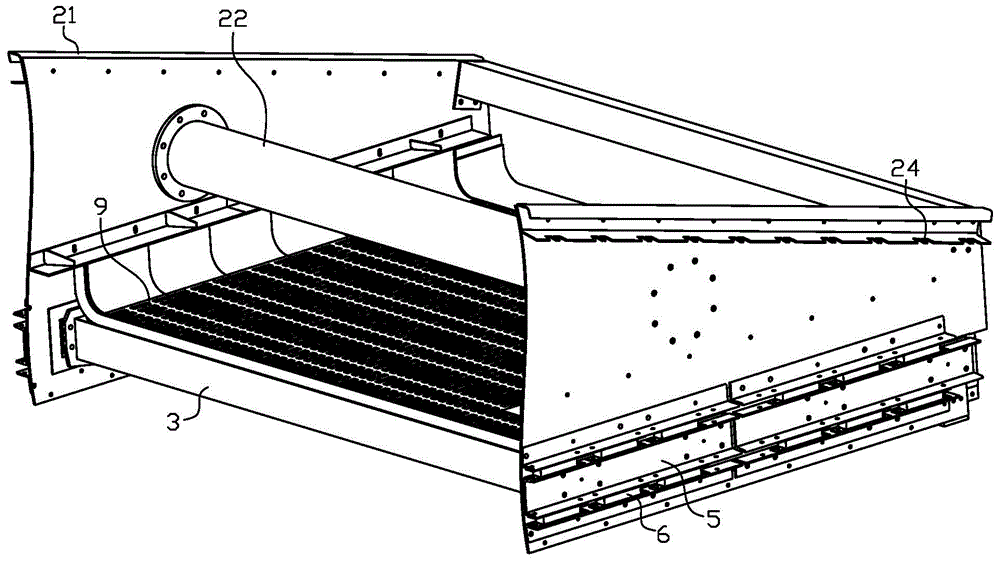

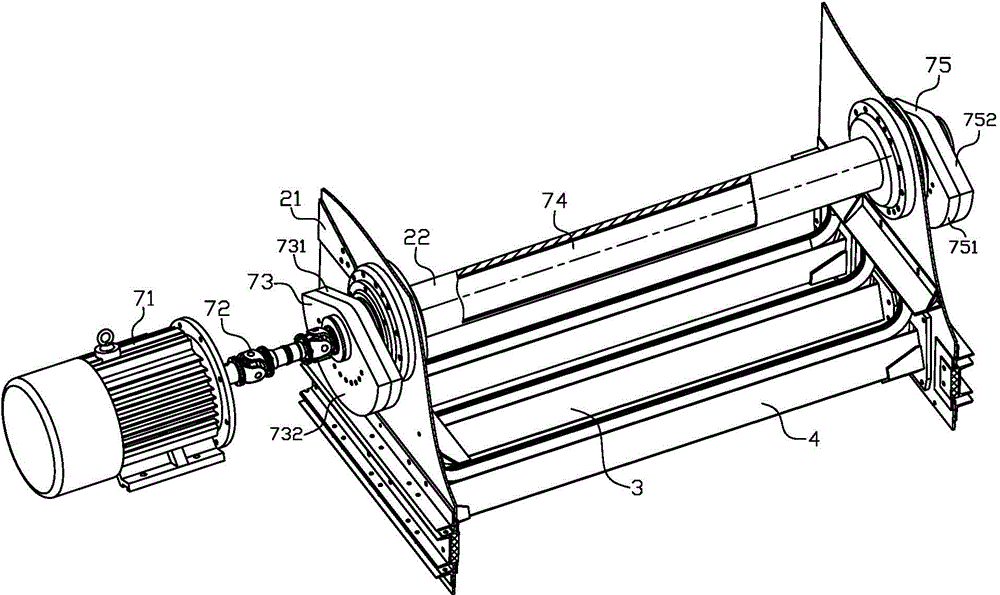

[0023] Such as figure 1 and figure 2 As shown, a three-degree-of-freedom relaxation screen includes a support frame assembly 1, a screen box 2, a movable beam 3, a fixed beam 4, a movable beam connecting plate 5, a rubber shear spring 6, an inertial vibration device 7, a transverse excitation Vibration device 8 and sieve sheet 9. Wherein, the support frame assembly 1 is composed of a front support frame 11, a rear support frame 12 and an exciter support frame 13, the number of the front support frame 11 and the rear support frame 12 is two, and they are symmetrically arranged in Both sides of the screen box 2 are used to support the screen box 2; the vibrator support frame 13 is located in the middle of one side of the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com