Patents

Literature

51results about How to "Avoid hole plugging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

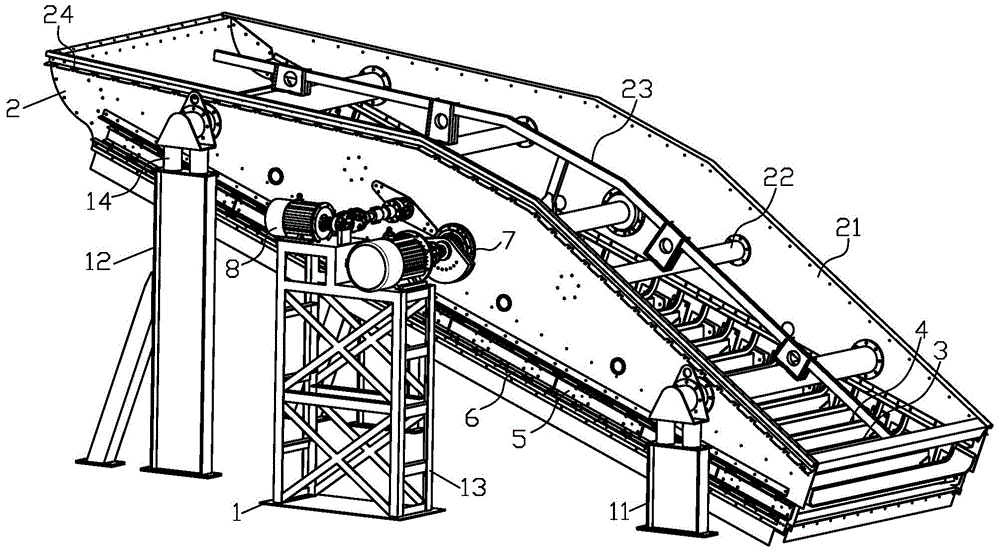

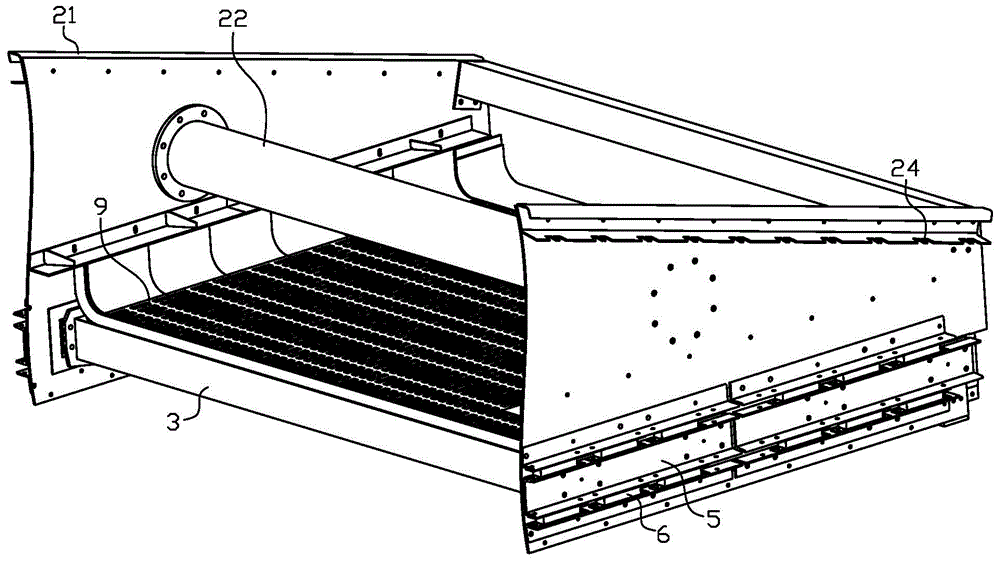

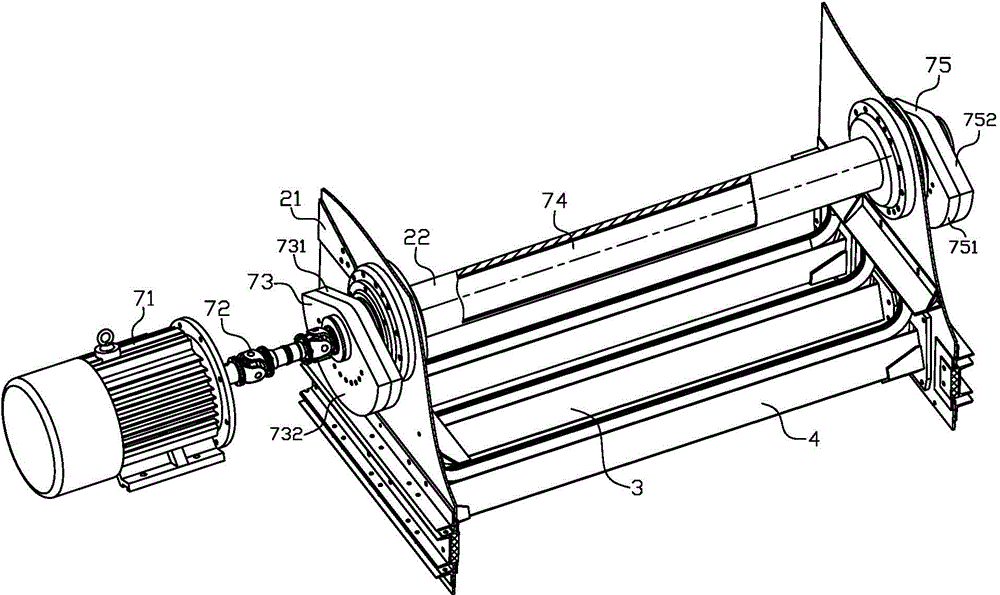

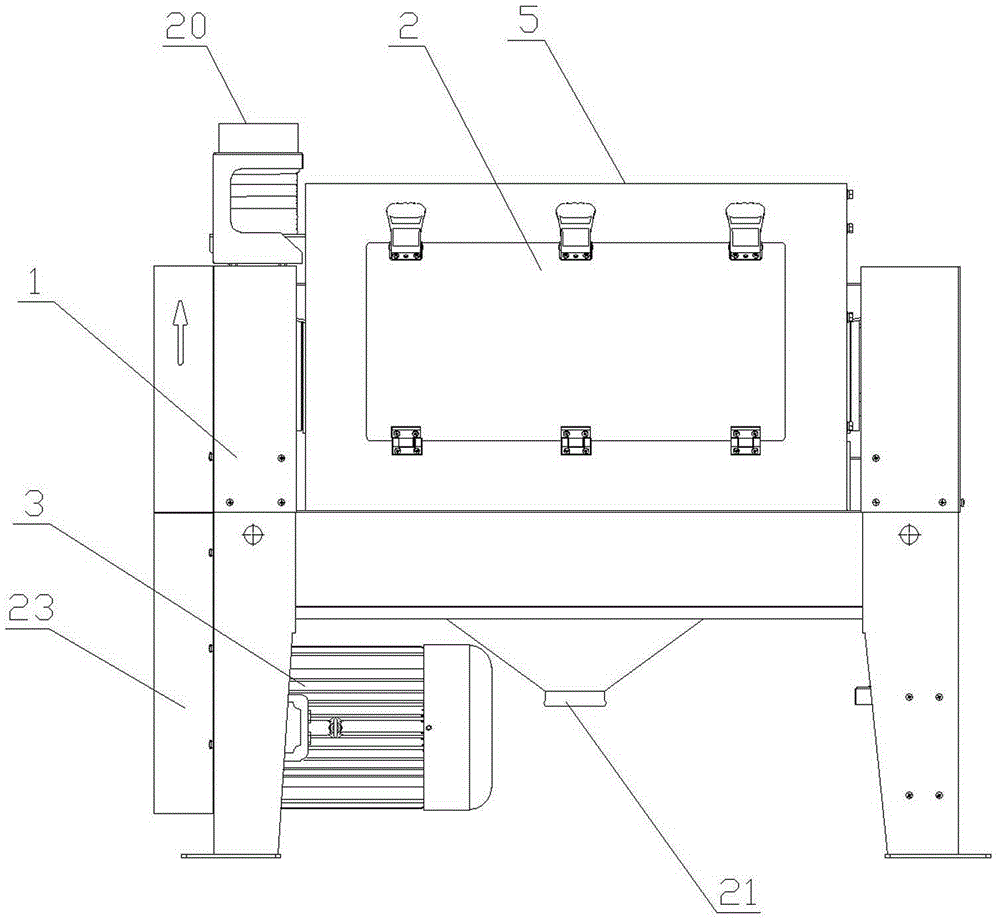

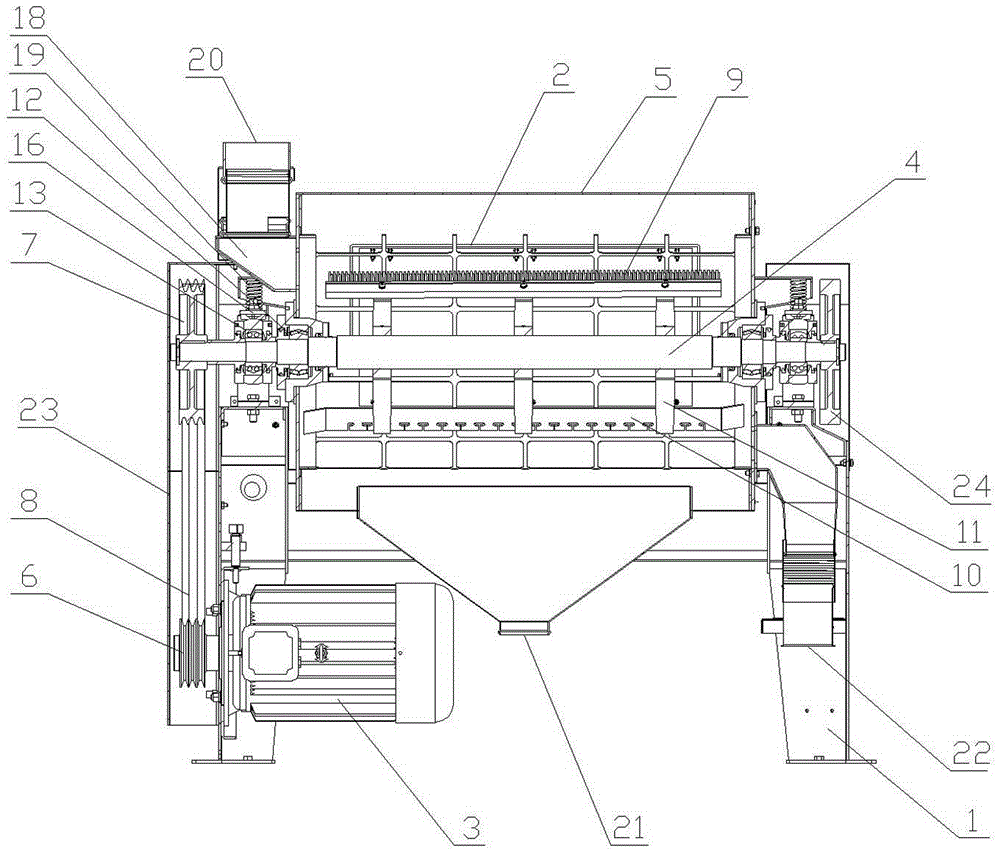

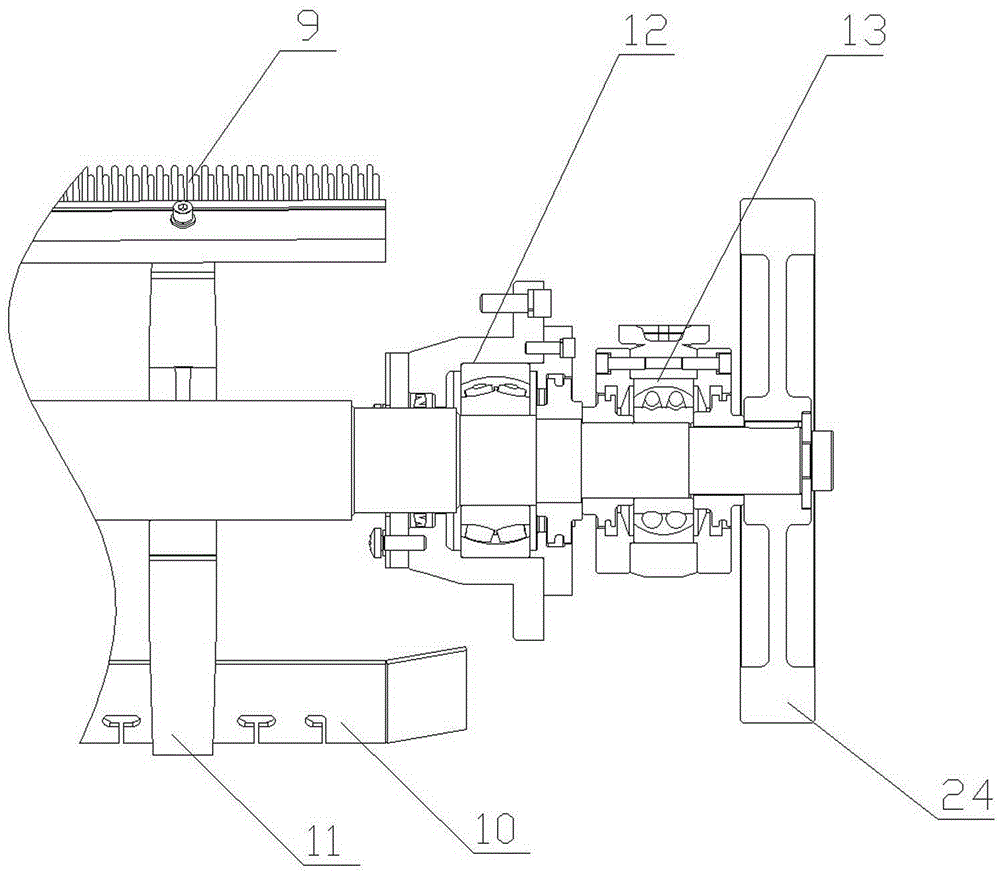

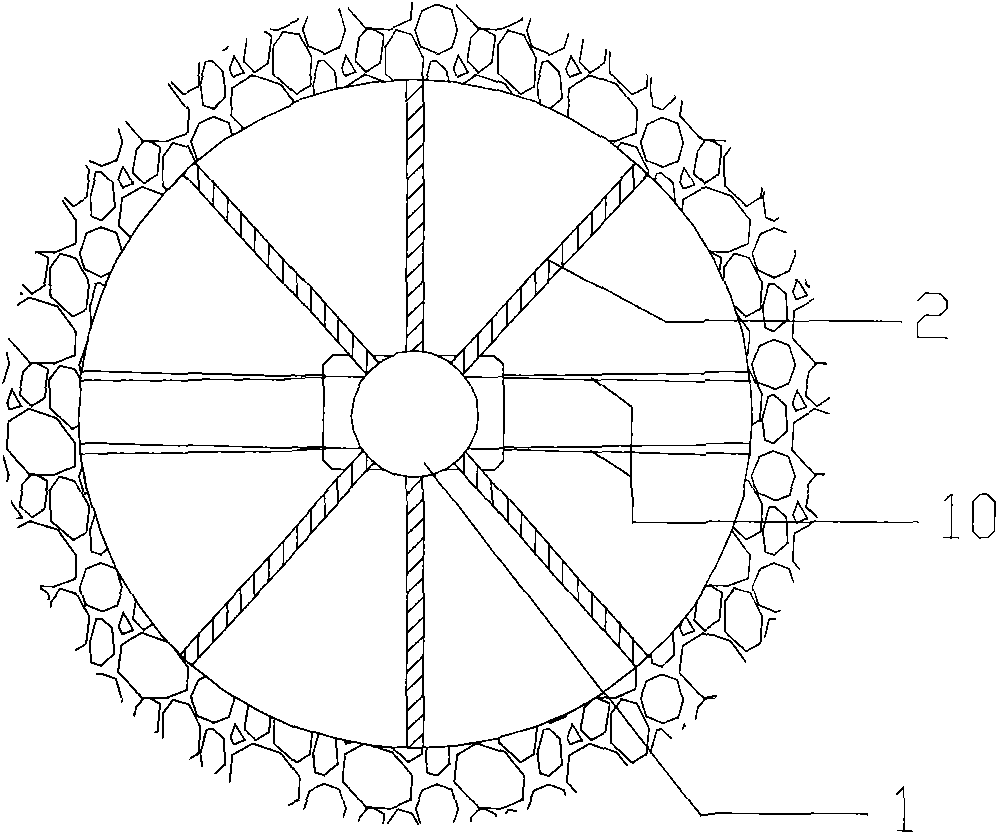

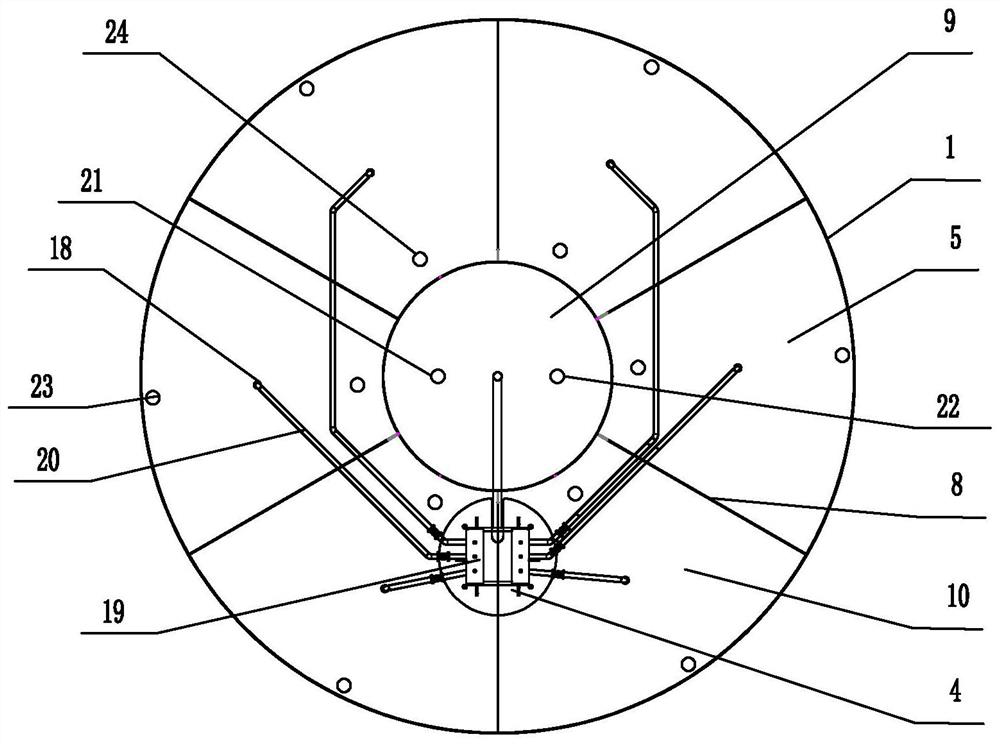

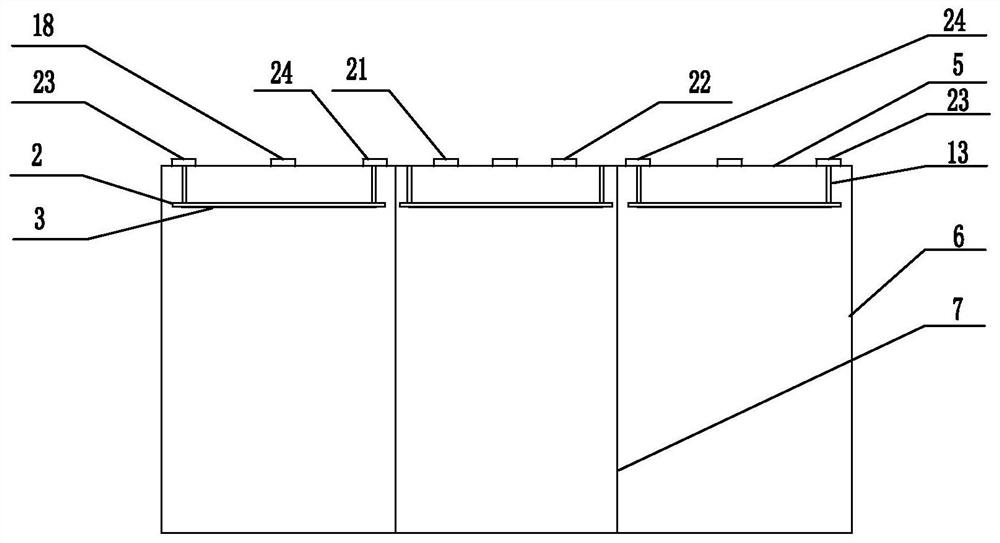

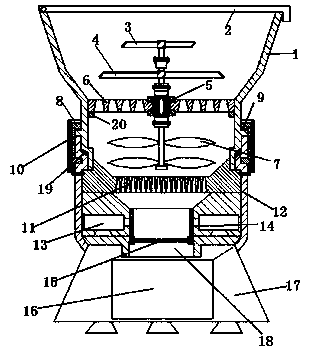

Three-degree-of-freedom flip-flow screen

InactiveCN104889057AOvercoming technical deficienciesGood dispersionSievingScreeningThree degrees of freedomGranularity

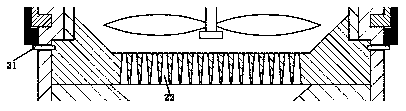

The invention discloses a three-degree-of-freedom flip-flow screen which comprises a support frame assembly, a screen box, a movable beam, a fixed beam, a rubber shearing spring, a movable beam connecting plate, an inertial exciting device, a transverse exciting device and a screen piece, wherein the support frame assembly is composed of a front support frame, a rear support frame and an exciter support frame. The screen box is supported on the front support frame and the rear support frame through a rubber damper spring. The fixed beam is fixedly connected with the screen box. The movable beam connecting plate with the movable beam is connected with the screen box through the rubber shearing spring. The two ends of the screen piece are respectively and fixedly connected with the movable beam and the fixed beam. The power end of the inertial exiting device and the power end of the transverse exciting device are fixedly installed on the top of the exciter support frame. The screen piece can obtain the vibrational excitation with three degrees of freedom, and the parameters of the inertial vibration and the transverse vibration can be adjusted separately. The three-degree-of-freedom flip-flow screen is particularly suitable for screening of humid materials with the fine granularity, and has the advantages of being compact in structure, long in service life, large in processing amount, high in efficiency and low in cost.

Owner:ANHUI UNIV OF SCI & TECH +1

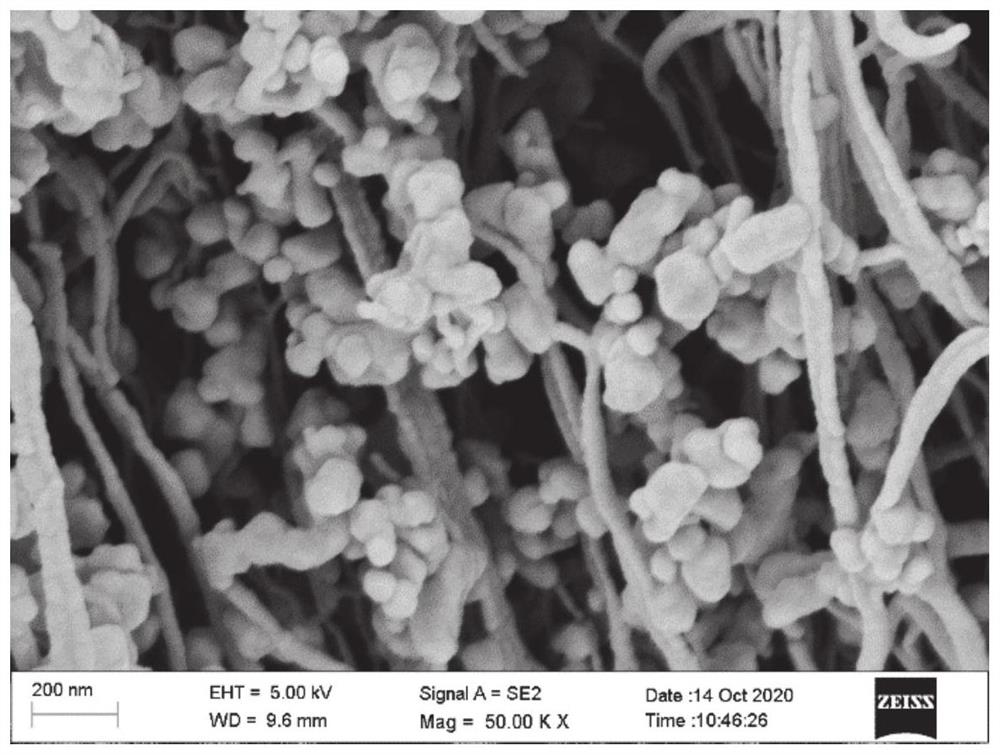

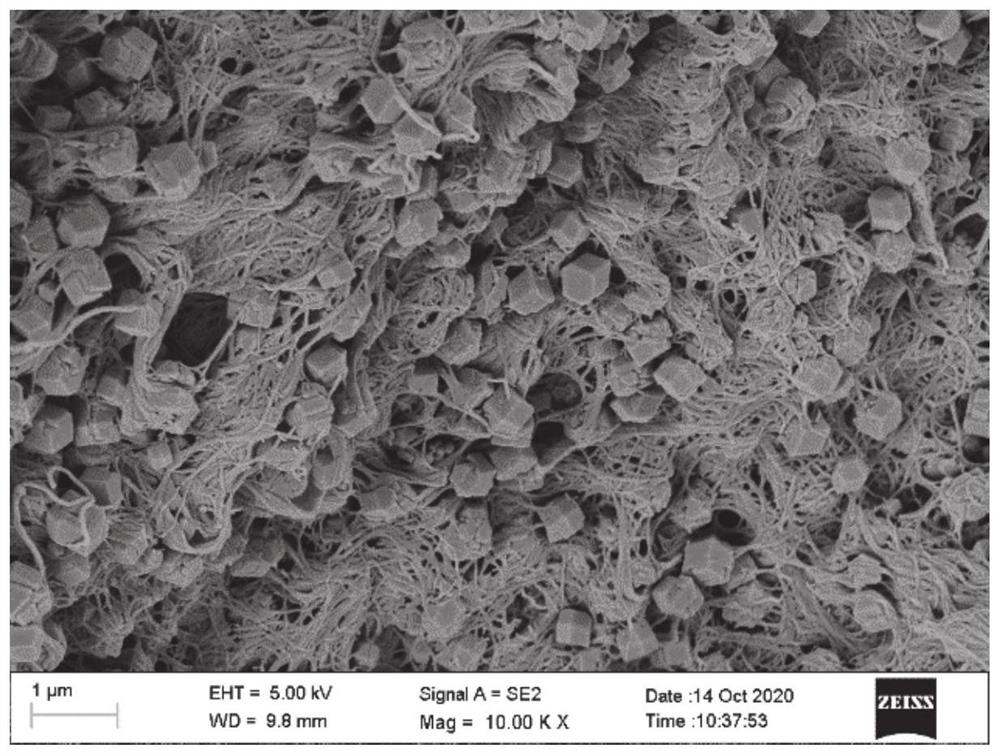

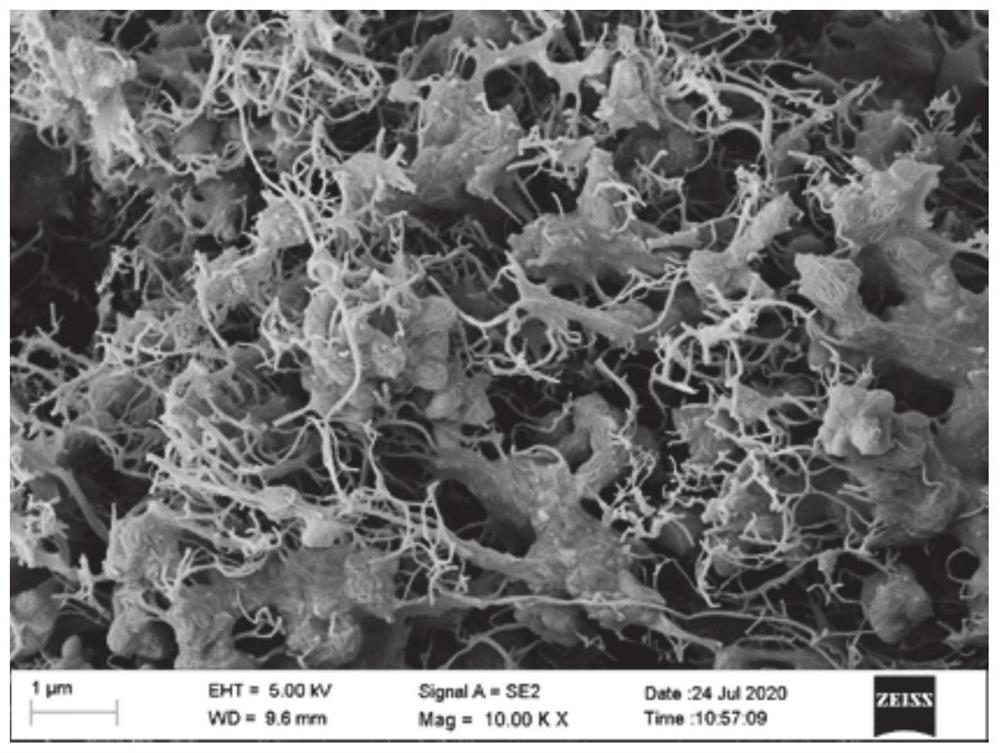

Carbon aerogel/metal organic framework composite material, preparation method and application thereof in gas storage

PendingCN112691645ALarge specific surface areaFast adsorption kineticsMethane captureOther chemical processesMetal-organic frameworkMethane gas

The invention provides a carbon aerogel / metal organic framework composite material, a preparation method and application thereof in gas storage, and belongs to the technical field of high polymer materials and gas storage. The composite material is composed of an MOFs material with good adsorption capacity and a carbon aerogel framework material, wherein the MOFs material is used as an object material to be directly assembled into an aerogel framework, a blocky composite adsorbent material without a binder is obtained after joint carbonization, and methane gas can be effectively adsorbed and stored, therefore, the carbon aerogel / metal organic framework composite material has good practical application value.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

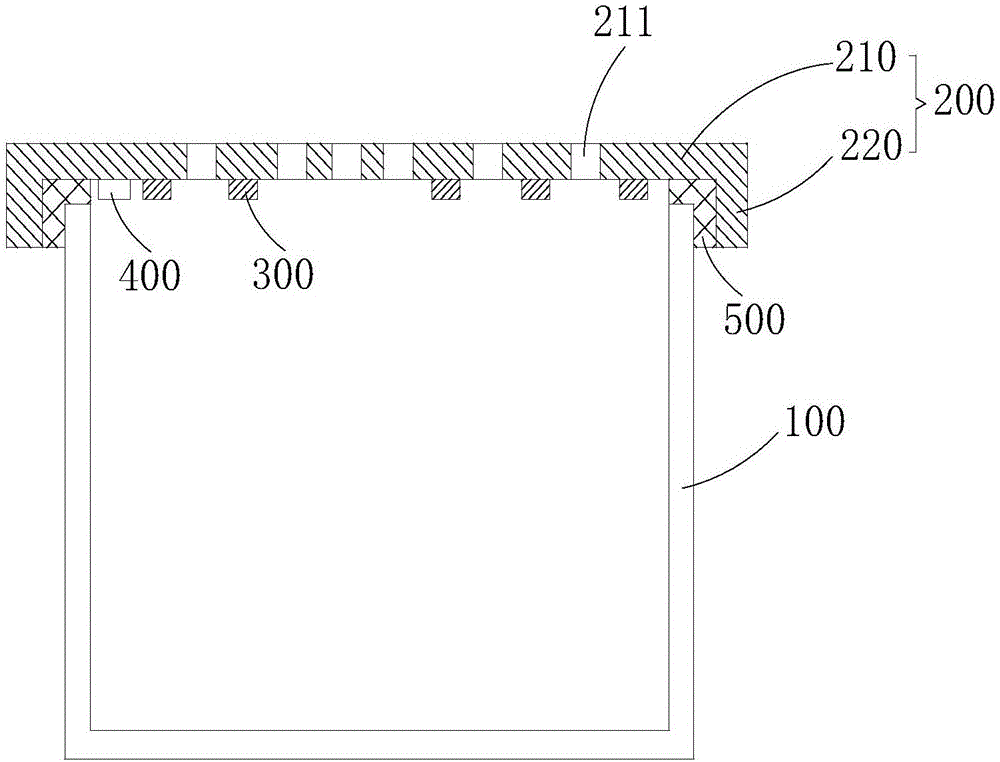

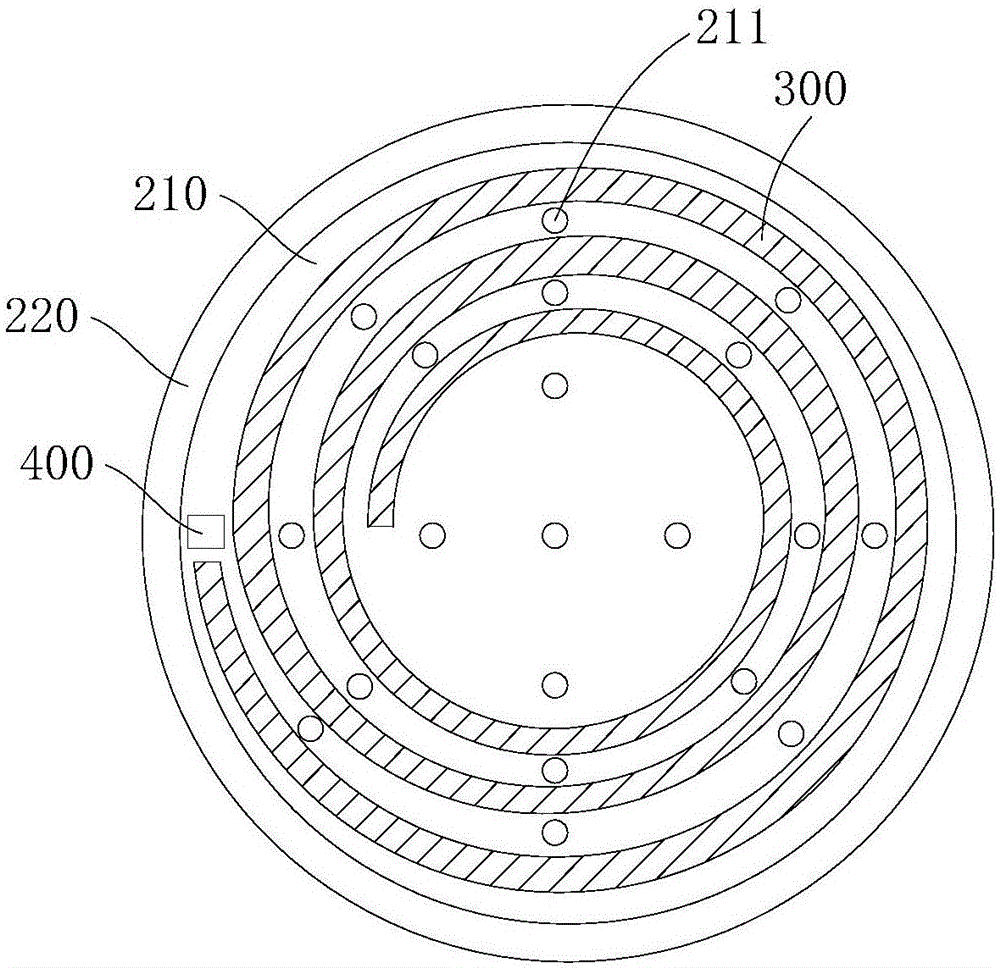

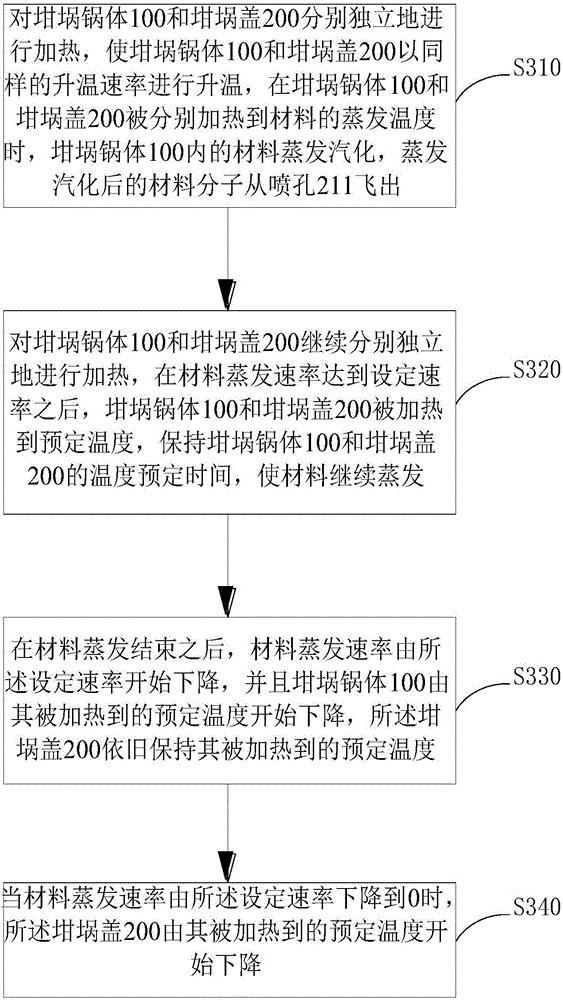

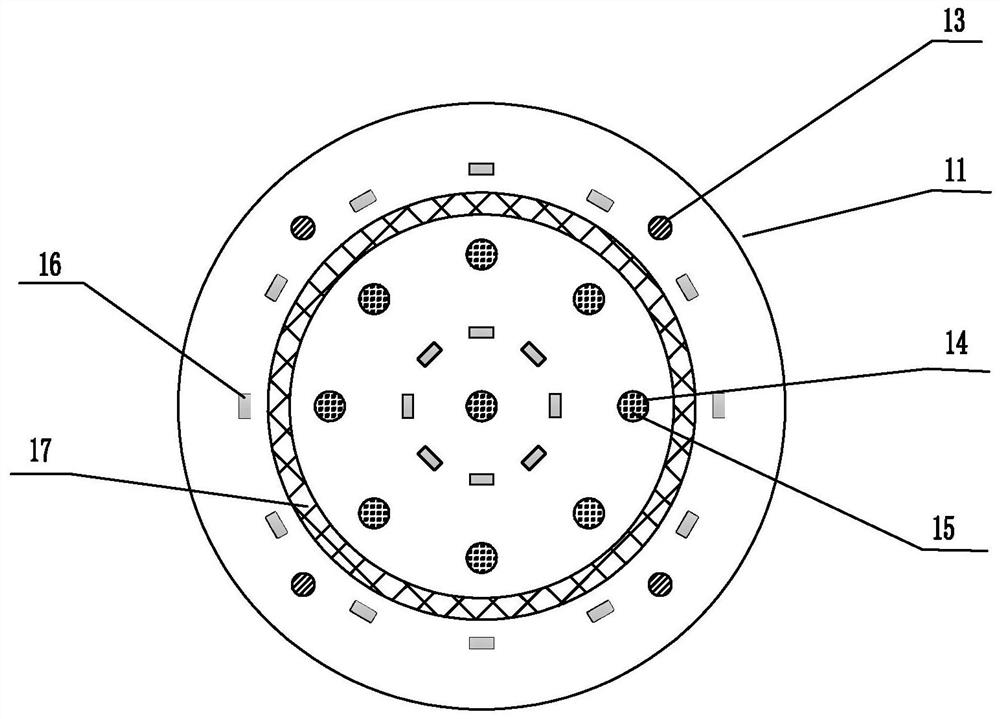

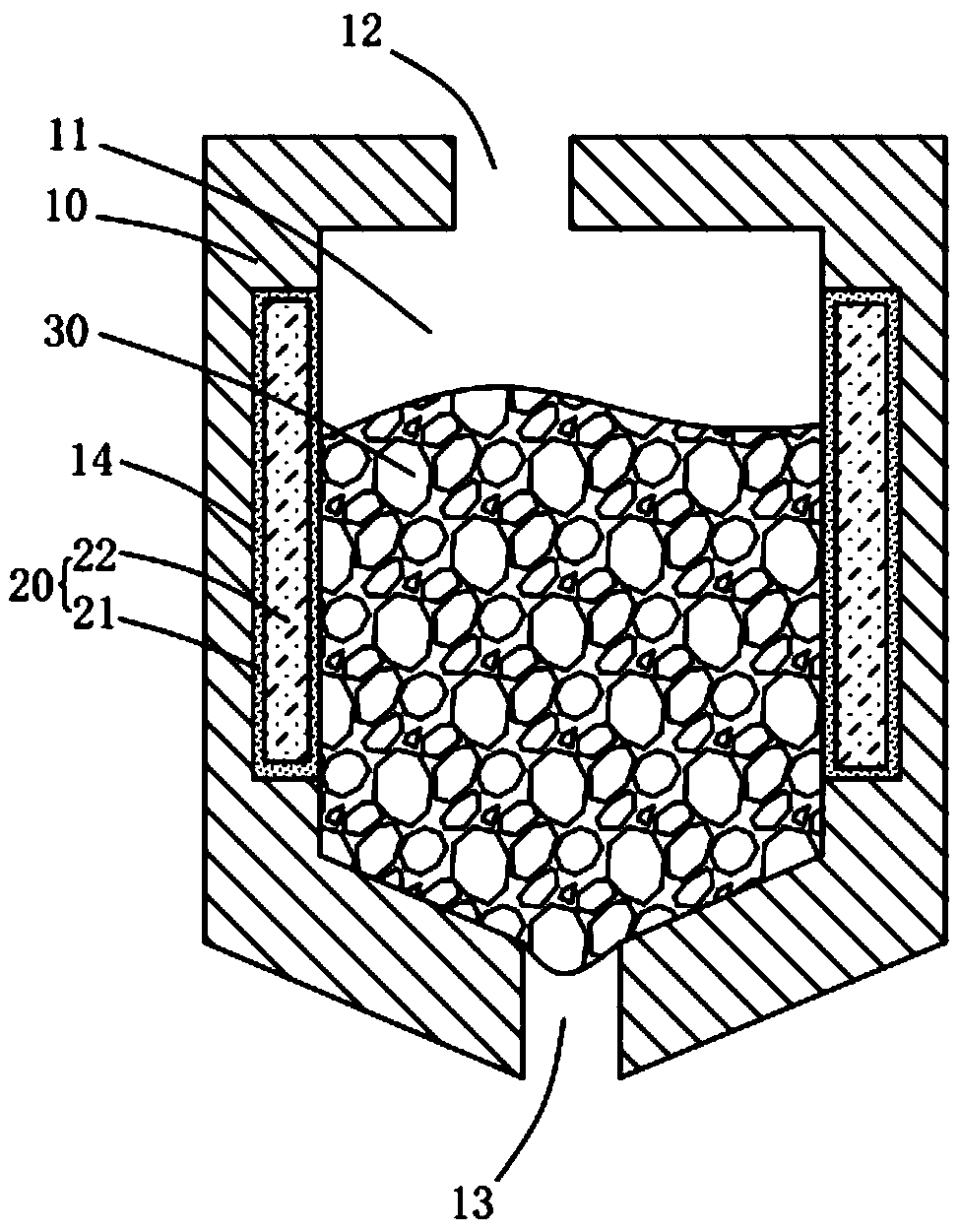

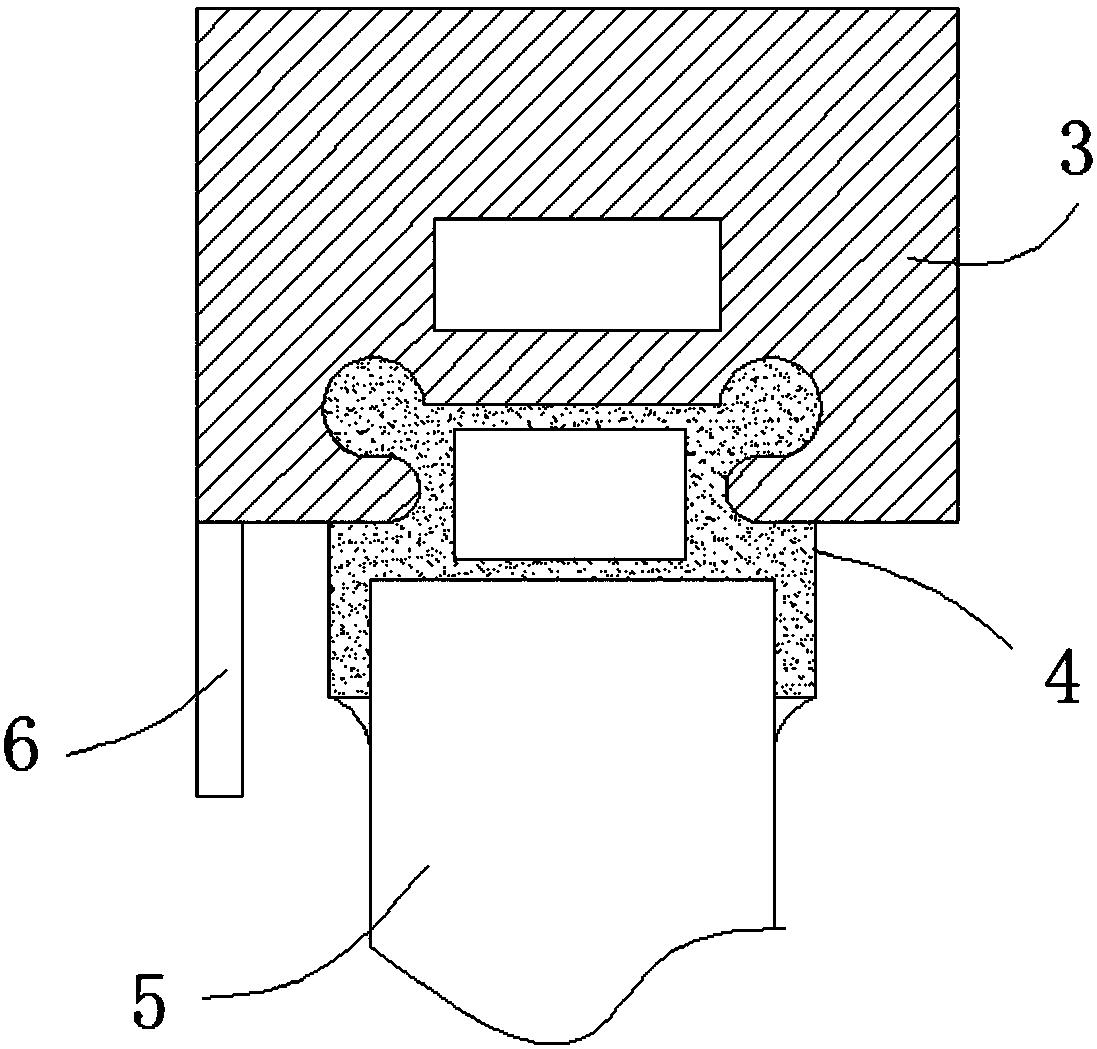

Evaporation crucible and evaporation method thereof

InactiveCN106756804AUniform temperatureAvoid hole pluggingVacuum evaporation coatingSputtering coatingCrucibleEvaporation

The invention discloses an evaporation crucible. The evaporation crucible comprises a crucible body, a crucible cover and a heating assembly. The crucible body is used for storing an evaporation material and covered with the crucible cover; the crucible cover is provided with a plurality of spray holes which are used for making vaporized evaporation material molecules fly off; and the heating assembly is arranged on the crucible cover, does not cover the spray holes and heats the crucible cover independently. The invention further discloses an evaporation method of the evaporation crucible. By means of the evaporation crucible and the evaporation method thereof, in the evaporation process and the evaporation finishing process, the temperature of the crucible cover is always kept at the material vaporization temperature, and the temperature of the whole crucible cover is uniform, so that the vaporized material molecules are not solidified at the spray holes when passing through the spray holes, and accordingly, the phenomenon of hole blocking is avoided.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

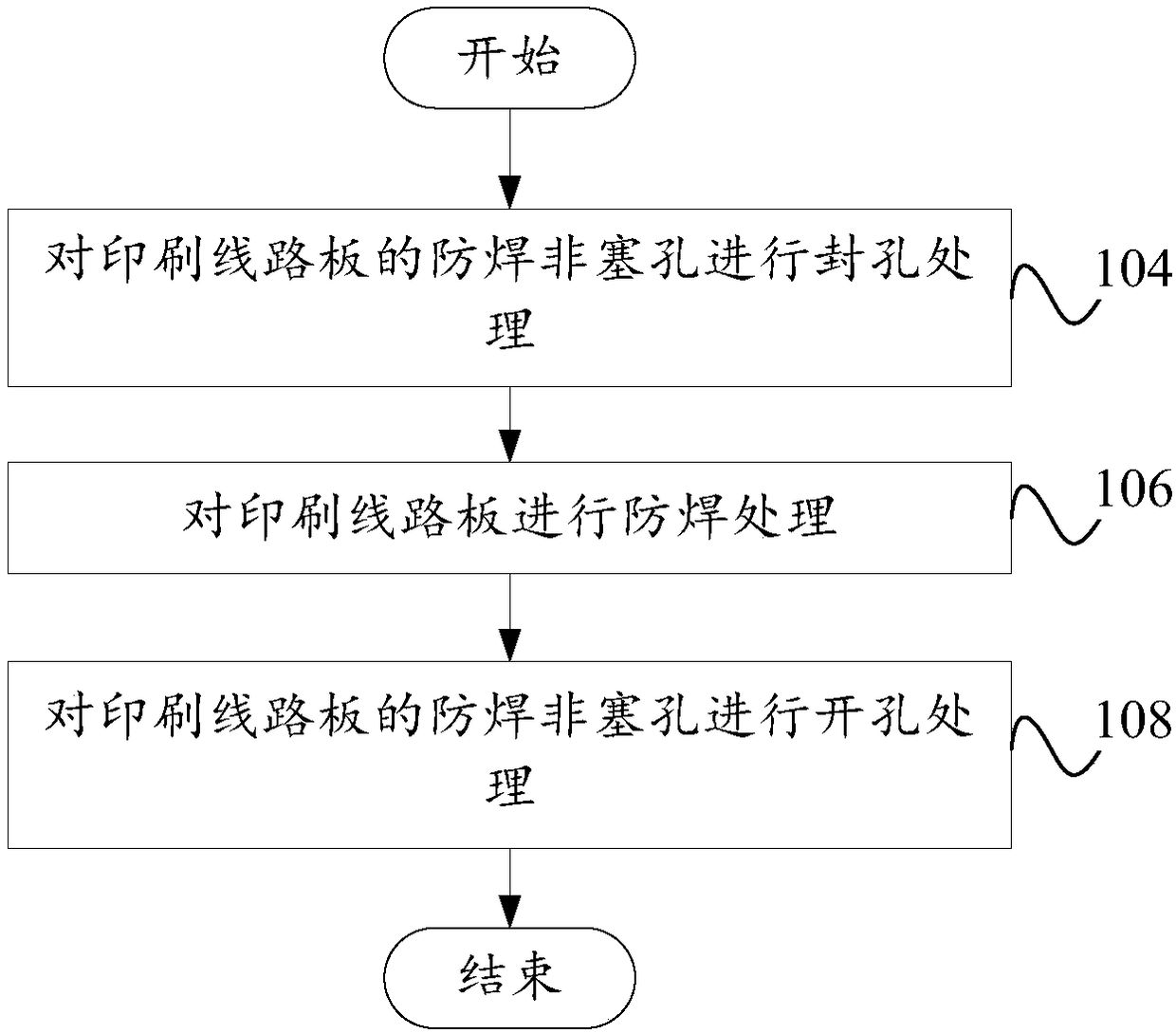

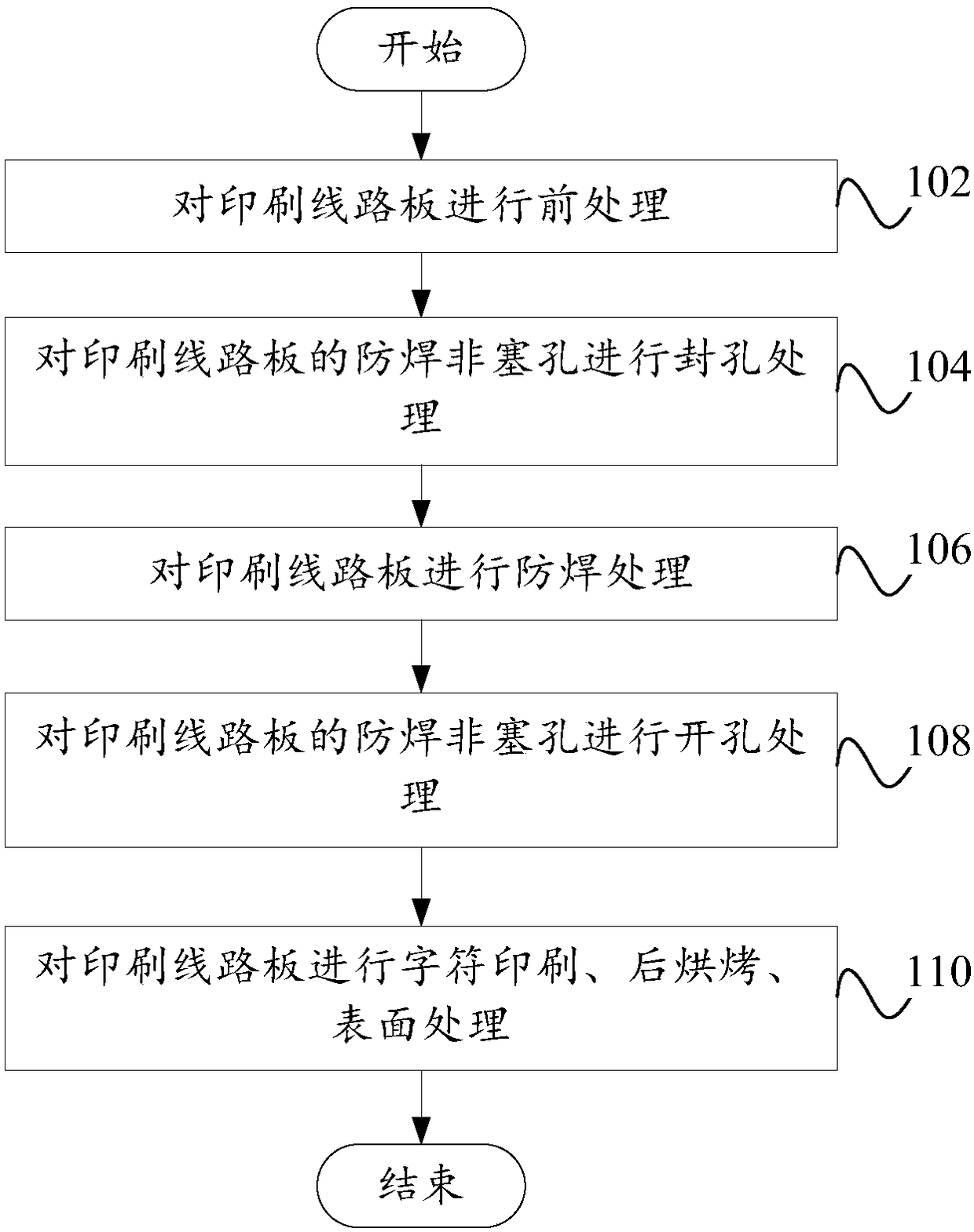

Method for preventing solder mask ink from plugging hole, printed circuit board and computer device

InactiveCN108934128AAvoid incomplete ink printingAvoid pluggingNon-metallic protective coating applicationSolder maskEngineering

The invention provides a method for preventing solder mask ink from plugging a hole, a printed circuit board, a computer device and a computer readable storage medium. The method for preventing the solder mask ink from plugging the hole comprises the following steps: a solder mask non-plugging hole of the printed circuit board is subjected to hole sealing operation; solder masking operation is performed on the printed circuit board; the solder mask non-plugging hole of the printed circuit board is subjected to hole opening operation. The method disclosed in the present invention can help prevent the non-plugging hole from being plugged by ink, the method can help prevent a problem of printed circuit board and blocking point net expansion and shrinkage that occurs when block point net ink is used and a problem of alignment precision, scrapping of the printed circuit board which is caused when the hole is plugged by ink can be reduced, and high reliability and high efficiency can be realized.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

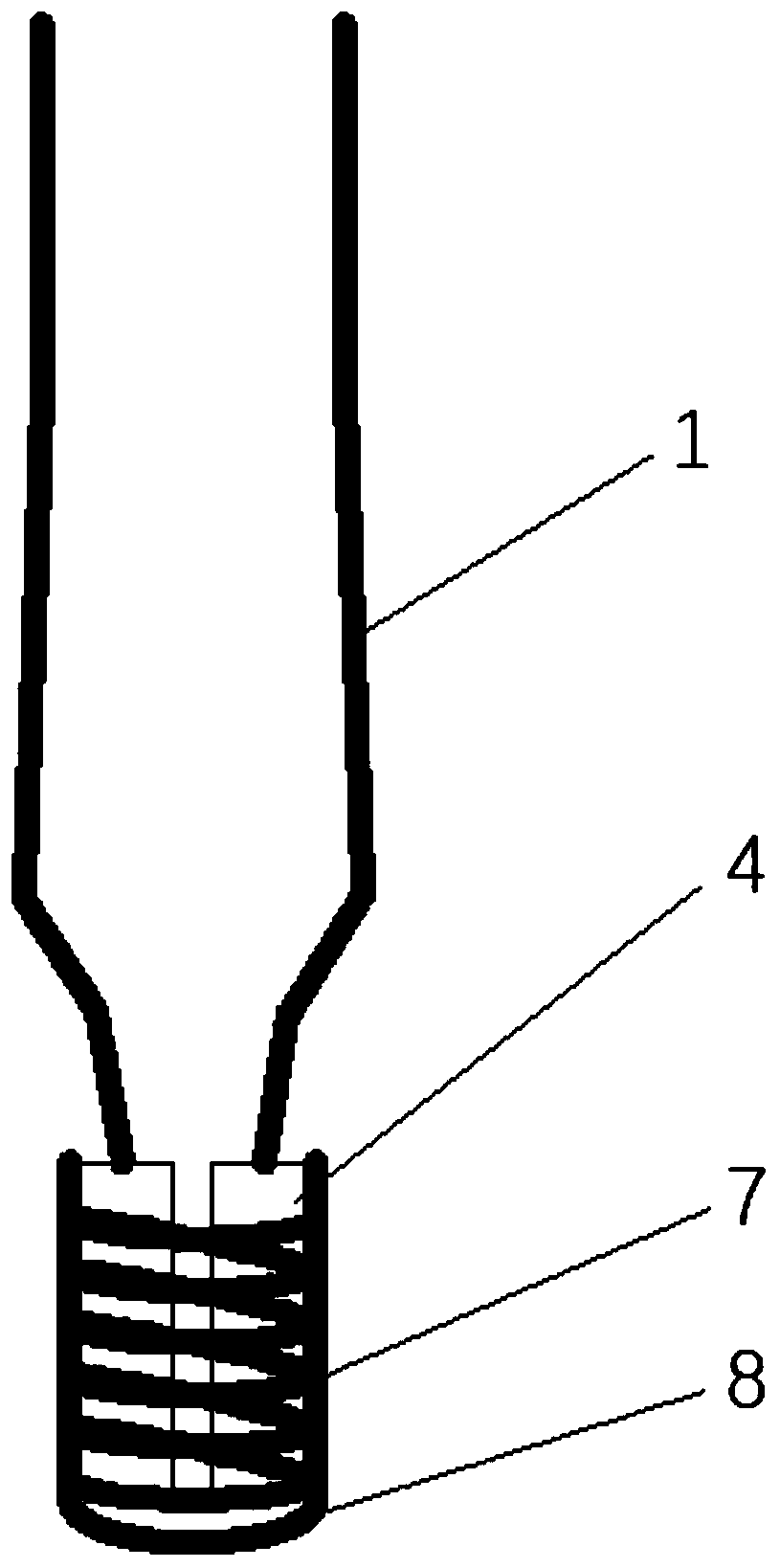

Novel dynamic separation sieve

ActiveCN105396776AAvoid destructionEasy to separateSievingScreeningDrive wheelPulp and paper industry

The invention discloses a novel dynamic separation sieve which comprises a rack, a sieve barrel arranged on the rack and a motor arranged on the rack. A sieve net which is tightened through a sieve net compression mechanism is arranged on the inner wall of the sieve barrel. The sieve barrel comprises a sieve barrel spindle connected to the rack through a supporting bearing and a sieve barrel housing arranged on the sieve barrel spindle. The sieve barrel spindle is an eccentric shaft, the sieve barrel housing is arranged on the sieve barrel spindle through a sieve barrel rotating shaft capable of achieving self-aligning, and a conveyor belt is connected between a driving wheel of the motor and a transmission wheel fixed to one end of the sieve barrel spindle. According to the novel dynamic separation sieve, the eccentric shaft is adopted as the sieve barrel spindle, the sieve barrel makes vibration motion on the rack to prevent materials which are similar to sieve net holes in boundary dimension from being blocked on the sieve net or prevent fine powder from being attached to sieve net wires, the phenomenon of hole blockage is avoided, and a high separation effect is achieved; strong springs are used for fixing the sieve barrel, and the working state that the sieve barrel vibrates instead of rotating is achieved. The equipment does not wholly rotate, so that normal operation of other equipment near the sieve is not affected.

Owner:HEBEI PINGLE FLOUR MACHINERY GROUP

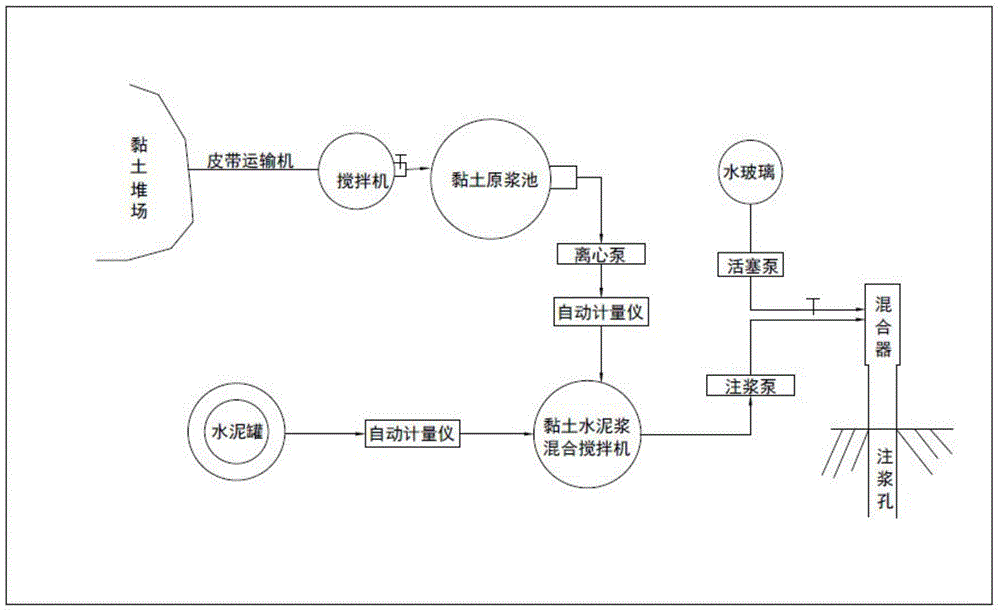

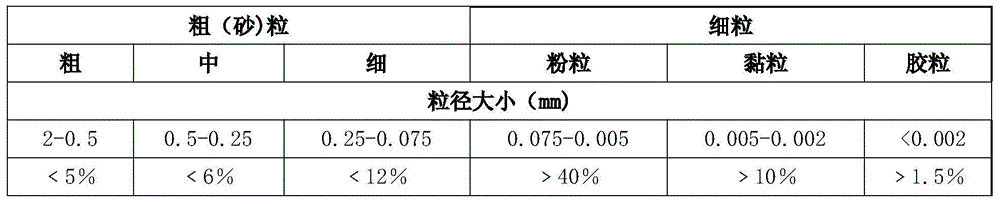

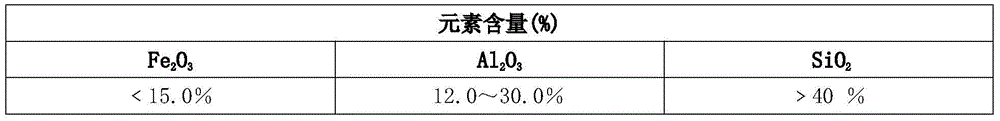

Modified clay double-fluid grout and grout-making and grouting process thereof

The invention relates to modified clay double-fluid grout. The modified clay double-fluid grout is formed by adding an adjuvant into modified clay grout and mixing, wherein the adjuvant is sodium silicate of which the baume degree is 39 degrees-42 degrees and the modified clay grout comprises the following components in parts by weight: 1 part of cement, 1 part of clay and 2 parts of water, wherein the addition of sodium silicate accounts for 10%-40% of volume of the modified clay grout; or 1 part of cement, 1 part of clay and 1.6 parts of water, wherein the addition of cement accounts for 10%-30% of volume of the modified clay grout. The invention also provides a grout-making and grouting process of the modified clay double-fluid grout.

Owner:深圳市中金岭南有色金属股份有限公司凡口铅锌矿 +1

Hydraulic cutting nozzle with residue filer device

InactiveCN101881150AImprove stabilityAffect the pumping effectLiquid/gas jet drillingFluid removalPunchingSteel ball

The invention discloses a hydraulic cutting nozzle with a residue filer device, and relates to the technology that high-pressure water jet is adopted for cutting in a coal bed, which solves the problem that the existing hydraulic cutting nozzle without the function of filtering residues is easy to block a hole so as to cause the failed construction of cutting. The invention comprises a punching nozzle positioned on a tip of a shell, and a cutting nozzle positioned on the side of the shell, and is characterized in that: the external part of the shell is provided with a two-segment filter tooththe front part of which is hinged, the front end of the two-segment filter tooth is hinged on the front end of the shell, the back end of the two-segment filter tooth is hinged with a reset spring arranged on the external part of the shell, a position of the two-segment filter tooth after folding, is provided with a disposable plastic hoop, the inner cavity of the shell is provided with a movablecore which is matched with the inner cavity in a sliding way, the front end of the movable core is provided with a positioning convex shoulder which can slide in the front cavity of the shell, and the back end of the movable core is in a spherical surface contacted with steel ball. The invention is beneficial to the popularization and application of the high-pressure water jet cutting technology in the coal-mine gas drainage under suction.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

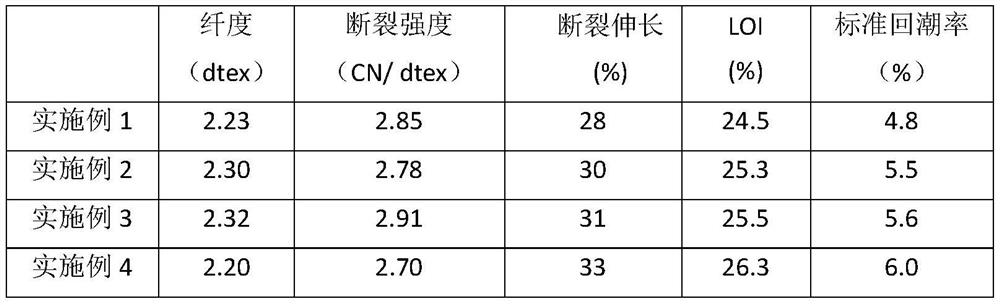

Preparation method of halogen-free flame-retardant polyacrylonitrile fiber

PendingCN112746347AAvoid churnHigh recycling costFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentPolymer scienceSpinning

The invention provides a preparation method of a halogen-free flame-retardant polyacrylonitrile fiber. The method mainly comprises the following steps: heating and melting a halogen-free flame retardant containing phosphorus and nitrogen, then stirring and blending with a polyacrylonitrile spinning solution, carrying out wet spinning, and then carrying out cross-linking hydrolysis to obtain the flame-retardant polyacrylonitrile fiber. According to the preparation method disclosed by the invention, the halogen-free organic phosphorus-nitrogen flame retardant can be uniformly and stably dispersed in the spinning solution, so that a hole blocking phenomenon is effectively avoided during spinning, and the period of replacing a nozzle during spinning is greatly prolonged. Meanwhile, chemical modification of crosslinking and alkaline hydrolysis is further carried out on the surface of the fiber after a hot drafting procedure in a spinning process of the flame-retardant acrylic fiber, the flame retardance LOI of the prepared acrylic fiber is larger than or equal to 26%, and the hygroscopicity of the acrylic fiber is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

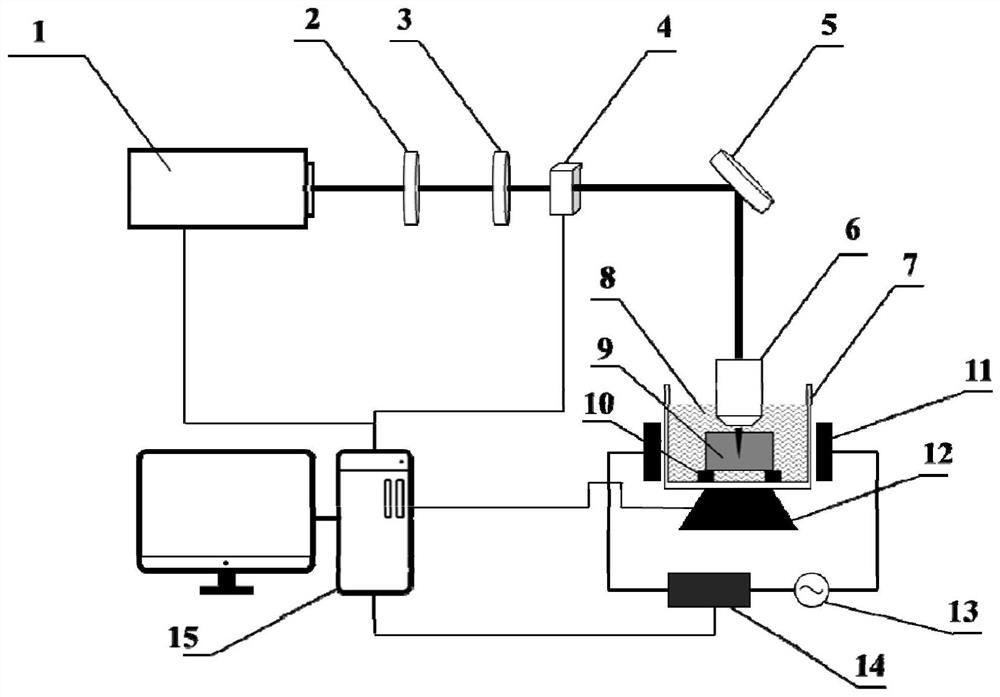

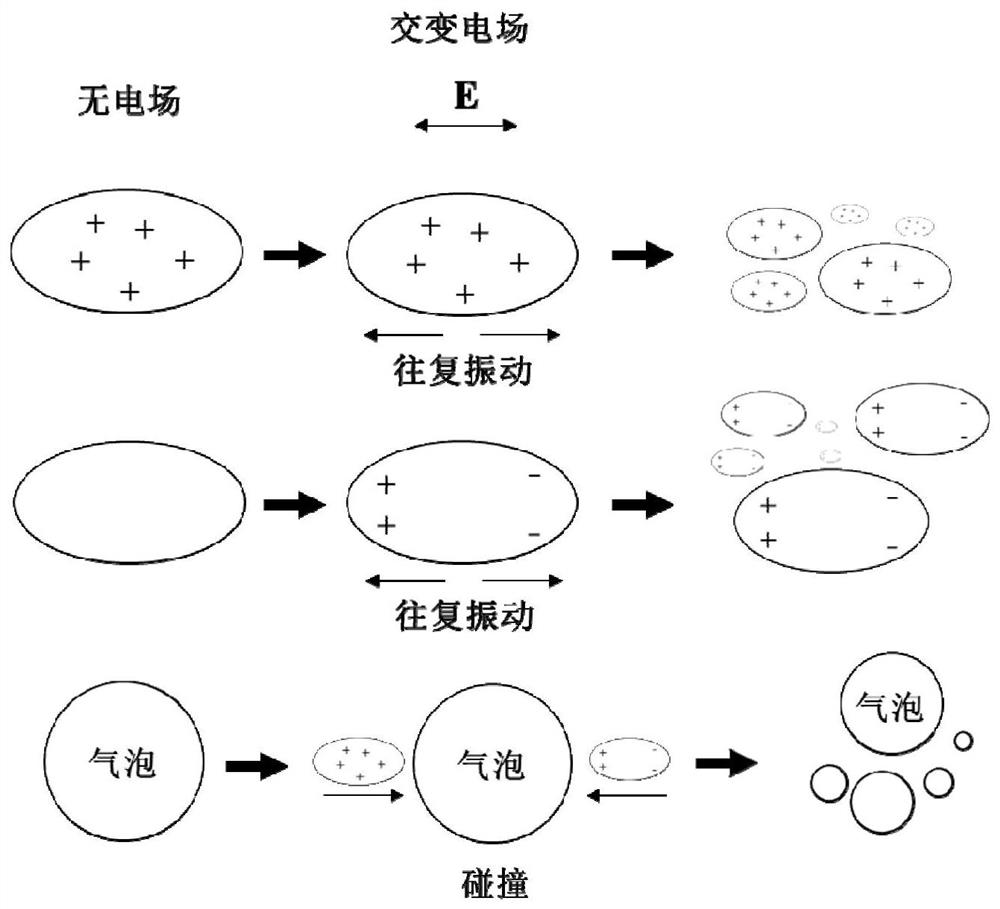

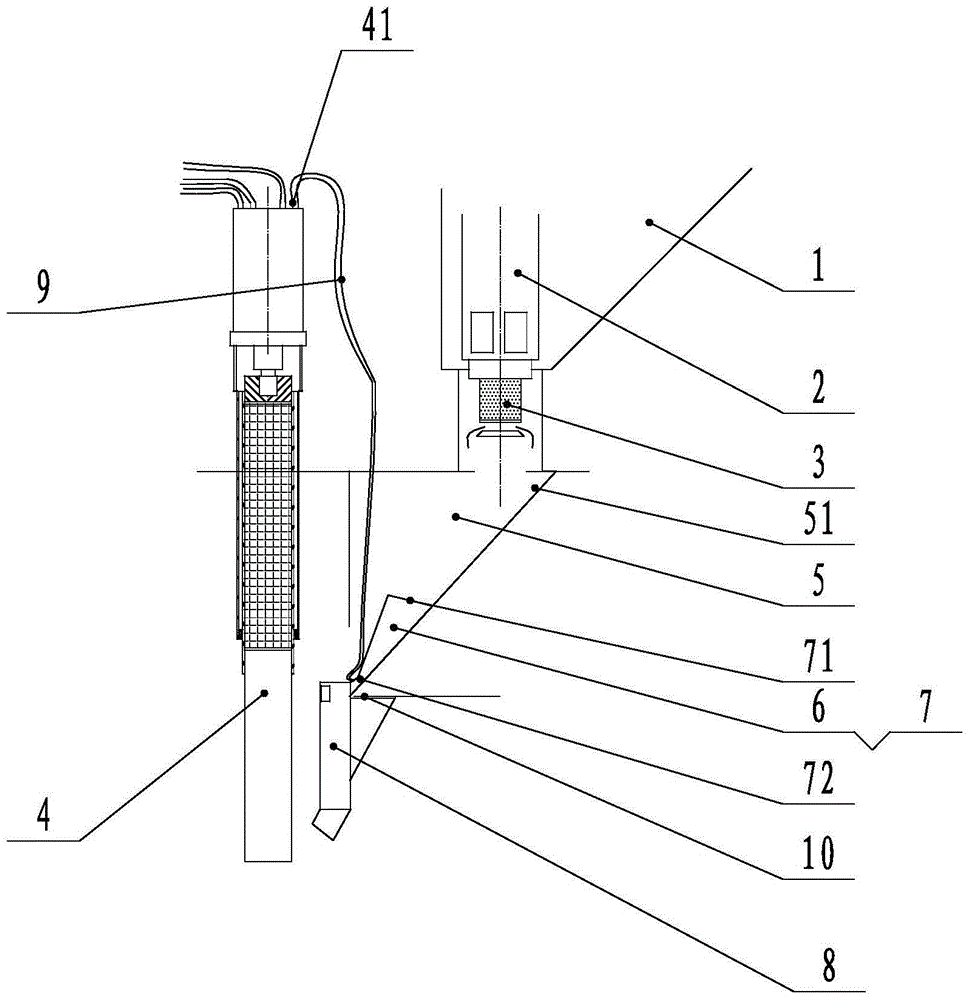

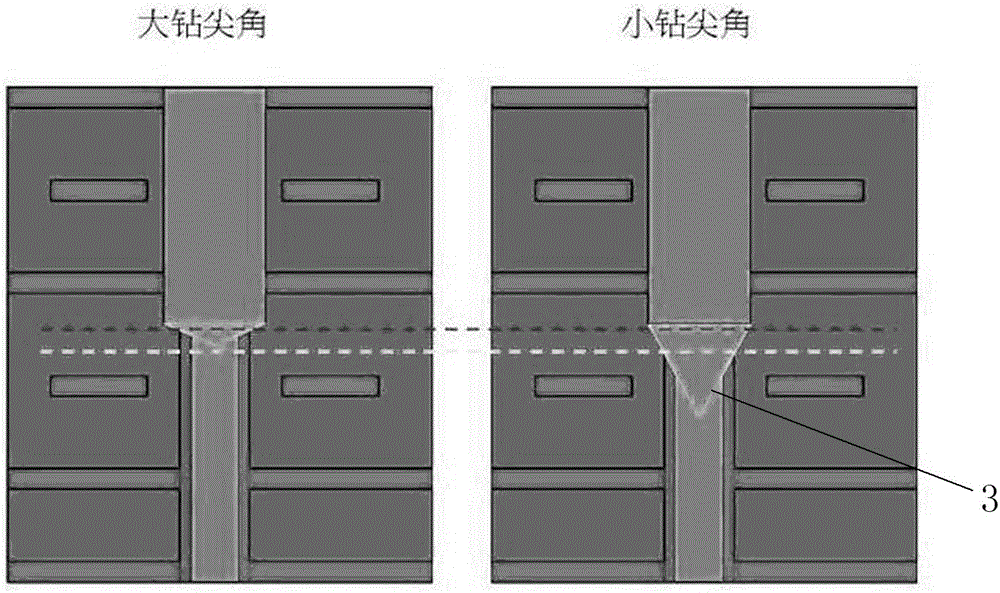

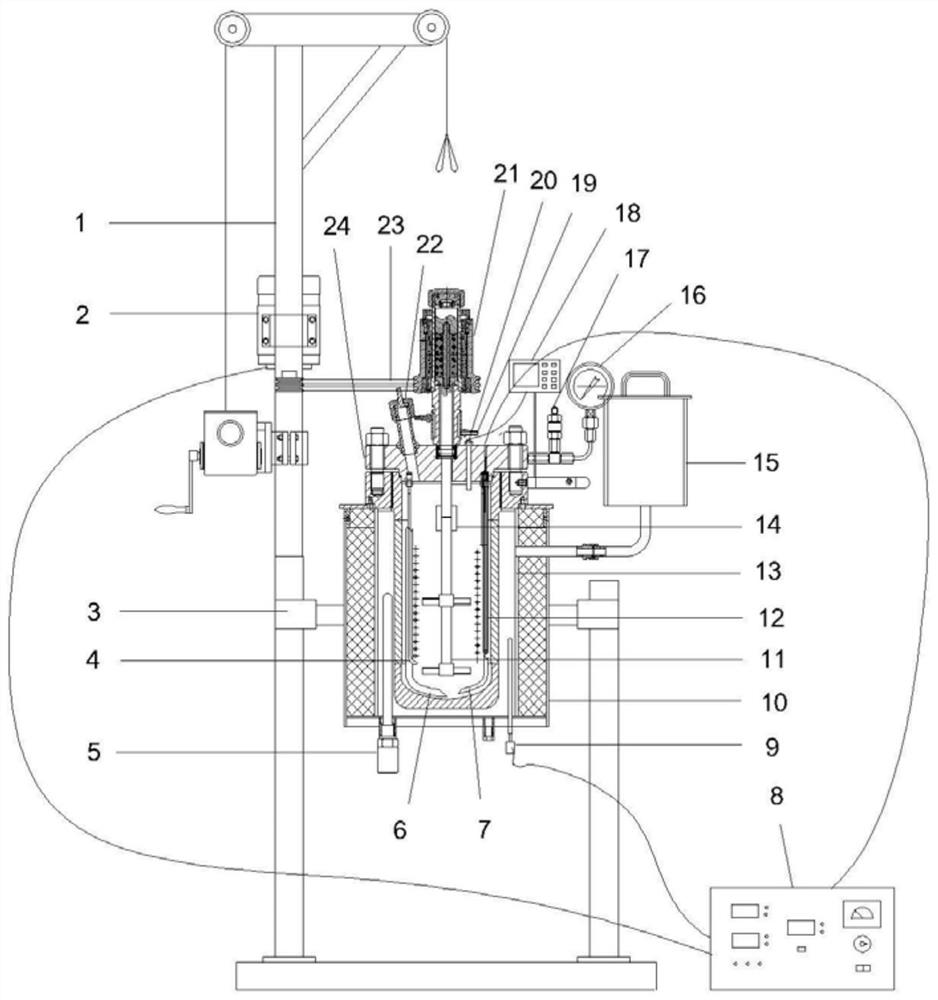

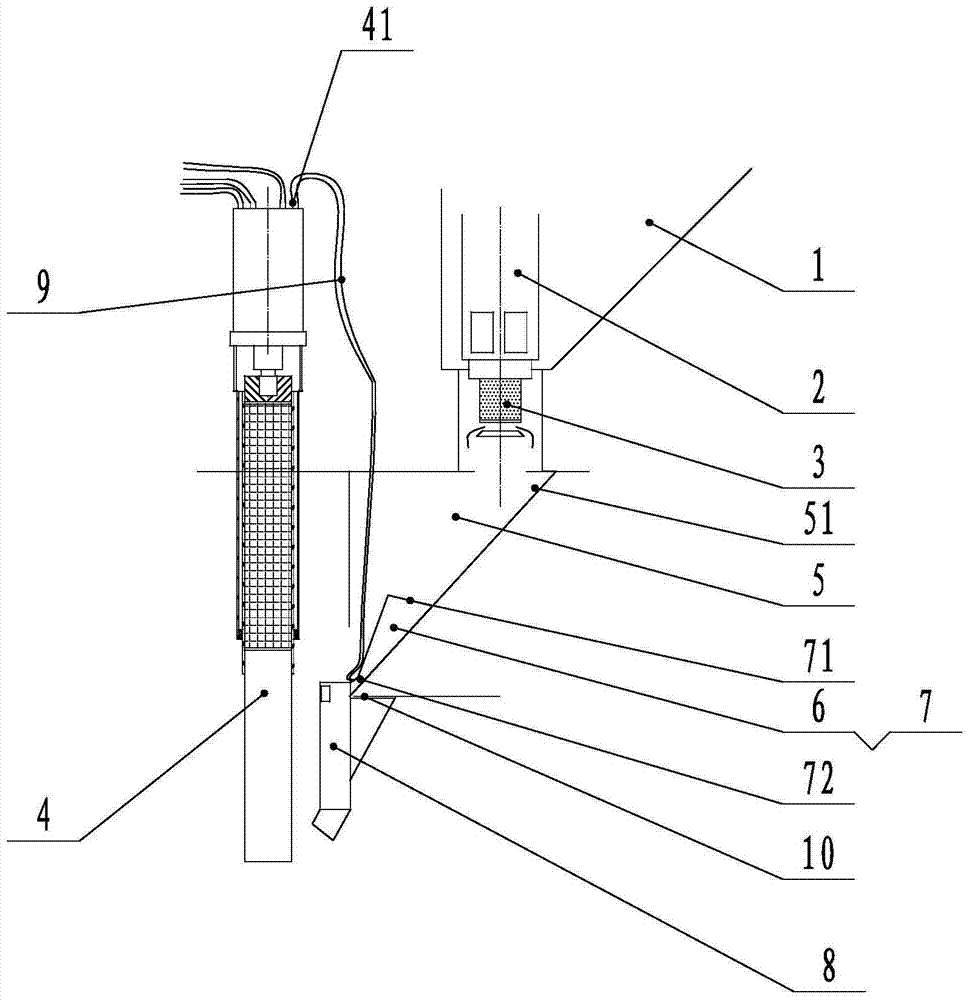

System and method for processing micro-channel through femtosecond laser assisted by alternating electric field

ActiveCN112756819AAspect ratioAvoid hole pluggingLaser beam welding apparatusFrequency changerFemto second laser

The invention belongs to the technical field of application of femtosecond laser, and relates to a system and method for processing a micro-channel through femtosecond laser assisted by an alternating electric field. The system is composed of an alternating electric field circuit system and a femtosecond laser ray-path system, and comprises a femtosecond laser, optical components, electric pressing boards, an alternating current power supply, a frequency converter, a nanometer translation stage and the like. According to the micro-channel processing method, the external electric field which periodically changes is achieved by means of high-frequency alternating current, thus charged ablation products in a femtosecond laser processing process conduct low-amplitude reciprocating vibration at a corresponding frequency under the action of the periodic high-frequency alternating electric field, or after the ablation products are polarized, force imbalance is caused by uneven charges, thus reciprocating oscillation occurs, and dissociation and fragmentization of the processing products are achieved, so that vibration dissociation processes of the electroneutral ablation products of bubbles and the like are driven; and by means of the method, the ablation products of debris, residues, the bubbles and the like can be effectively discharged, the quality problem brought by defects or light field fluctuation is solved, and meanwhile, sample vibration is avoided, so that the high-quality micro-channel structure with a high depth-diameter ratio is obtained.

Owner:TSINGHUA UNIV +1

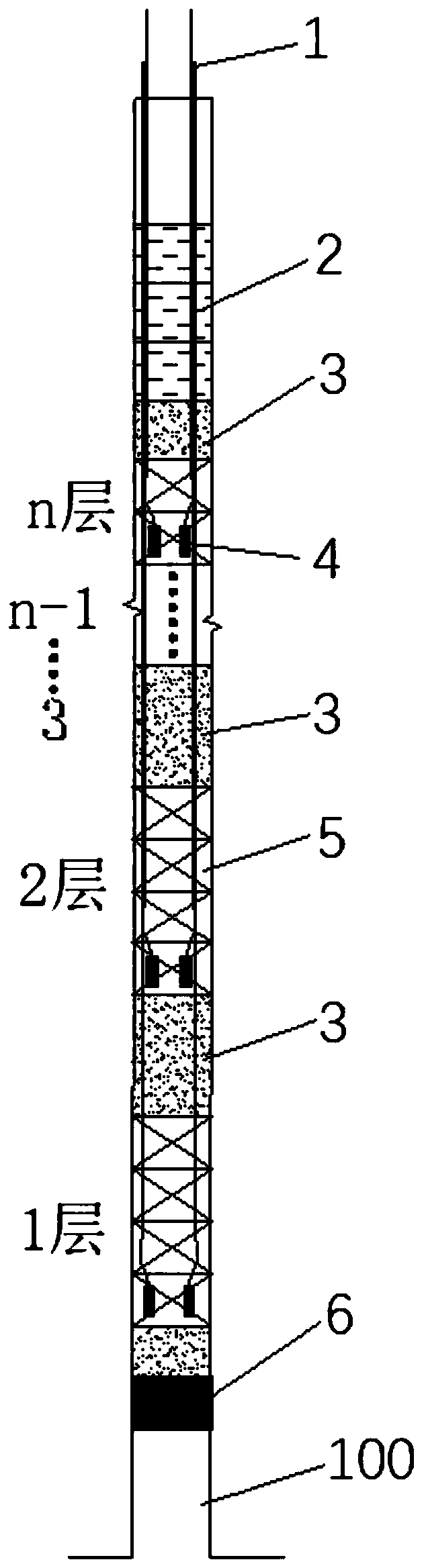

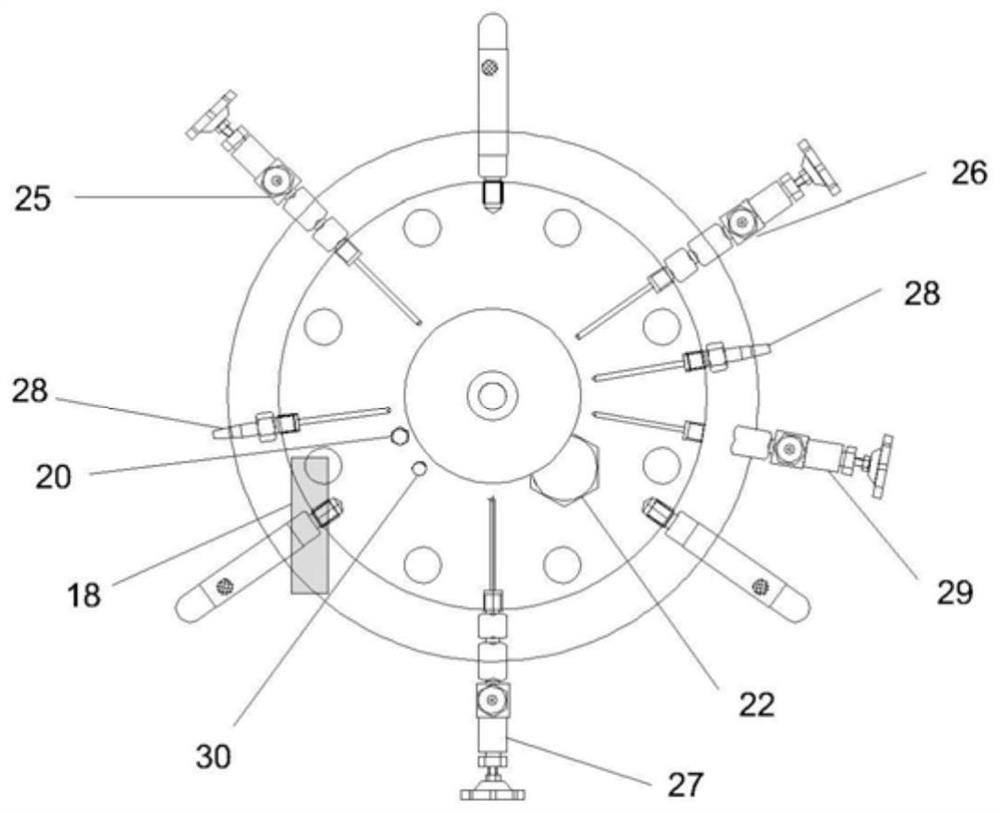

Subdivision suction bucket-shaped foundation for preventing hole blocking by soil plug and reverse grouting

ActiveCN112195958AGuaranteed contactGuaranteed carrying capacityFoundation engineeringSoil scienceSuction force

The invention discloses a subdivision suction bucket-shaped foundation for preventing hole blocking by soil plug and reverse grouting. The subdivision suction bucket-shaped foundation comprises a suction bucket and water pumping installation equipment. The suction bucket comprises a suction bucket top plate, an outer bucket wall, an inner bucket wall and compartment rib plates, wherein the suctionbucket top plate, the outer bucket wall, the inner bucket wall and the compartment rib plates are fixedly connected, and the inner bucket wall and the compartment rib plates divide the suction bucketinto an inner side compartment and a plurality of outer side compartments. The subdivision suction bucket-shaped foundation further comprises a soil plug baffle, a soil plug detection device, a waterthrough hole and a geotextile filter screen. A filter screen is arranged in the foundation, and the hole blocking phenomenon possibly occurring in the injection process is prevented. The soil plug baffle and the detection device are arranged in the foundation, whether the height of the soil plug in the bucket exceeds the limit or not can be monitored in real time, and when the whole height of thesoil plug reaches the soil plug baffle, constructors can stop further suction injection according to monitoring data and then perform reverse grouting to fill gaps. Slurry injected into the bucket can ensure that a top cover of the suction bucket is in complete contact with the soil body, so that the installation quality of the suction bucket is improved, and the bearing capacity of the suction bucket and the safety of the bucket top plate structure are further ensured.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Continuous aluminum oxide feeding equipment

ActiveCN105671594AReduce temperature and alumina concentration fluctuationsImprove current efficiencyComposite materialOxide

The invention discloses continuous aluminum oxide feeding equipment which comprises a material box, a feeding air cylinder, a fixed container, a crust breaking head, a material passing frame, an oblique plate, a buffer and a feeding pipe. The feeding pipe is led to the bottom of the crust breaking head. The continuous aluminum oxide feeding equipment further comprises an air pipe which is arranged at a buffer outlet and used for blowing air to the buffer outlet. Compared with the prior art, the continuous aluminum oxide feeding equipment has the beneficial effects that (1) aluminum oxide is made to enter an electrolyte slowly, and the temperature fluctuation of an electrolytic cell and the concentration fluctuation of the aluminum oxide are reduced, so that the current efficiency is improved, and energy consumption is reduced; (2) the aluminum oxide is made to have enough time to be melted into the electrolyte, so that sediment at the furnace bottom is reduced, the pressure drop at the furnace bottom is reduced, and energy consumption is reduced; (3) the aluminum oxide is made to enter the electrolyte slowly through a pipeline, and the crust breaking head is prevented from being impacted so that the aluminum oxide can be prevented from being dispersed, the actual amount of materials entering the electrolytic cell is increased, and the effect coefficient is decreased; and (4) large particles in the aluminum oxide are blown away through the gas reverse blowing principle, so that blockage is eliminated, and the hole blockage phenomenon can be effectively prevented.

Owner:SNTO TECH GRP

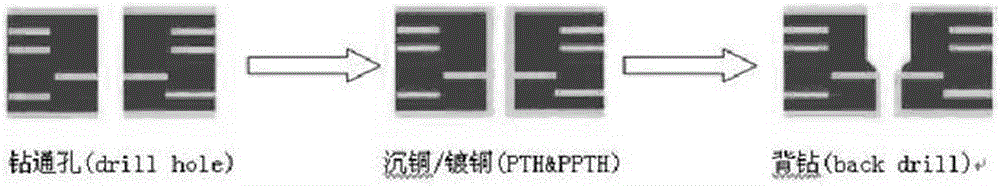

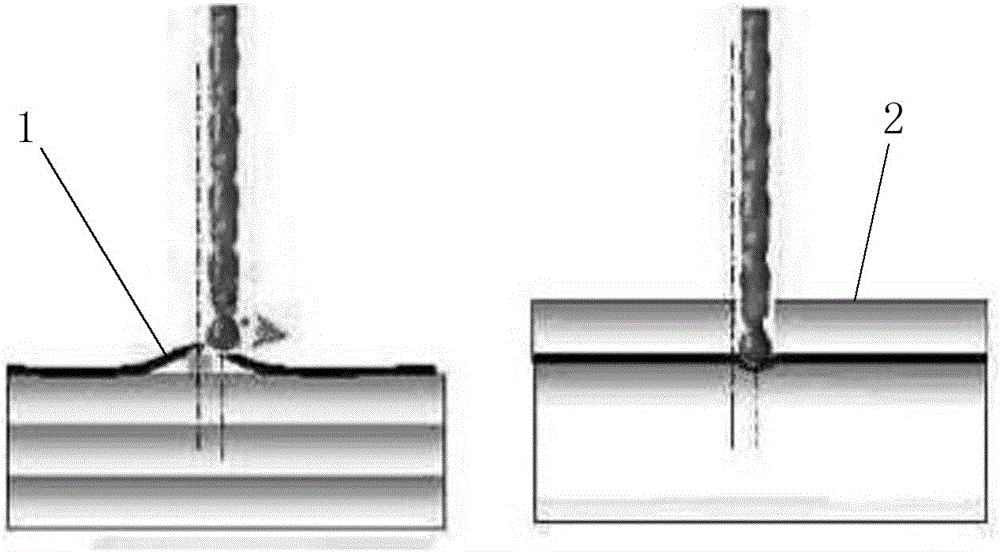

Machining method for drilling of backboard of PCB

InactiveCN106735433AHole feature guaranteeNot easy to break the drillBoring/drilling machinesCopperMachining

The invention discloses a machining method for drilling of a backboard of a PCB. During first time of drilling, drilling is conducted through a mode combining two micro drill bits of a long chip discharging groove UC-shaped (a long blade drill pin) micro drill bit and a short chip discharging groove ST-shaped (a short blade drill pin) micro drill bit; firstly, pre-drilling is conducted through the short chip discharging groove ST-shaped micro drill bit, the depth of a hole is 10-30% of the thickness of the board, and then the long chip discharging groove UC-shaped micro drill bit is used for drilling; during long chip discharging groove drilling, a mode of multi-step drilling is adopted, and if the depth the to-be-drilled hole is d, drilling is conduced according to the proportion of 1 / d:2 / d:3 / d:4 / d for each step in sequence; and during back drill drilling, a drill pin with the drill pit angle being 150-170 degrees is selected, a one-side copper-clad board is adopted, and the copper side is placed downwards and makes contact with the PCB. Compared with the prior art, a traditional back drill drilling mode adopting positive and negative drilling and using a traditional aluminum board to serve as a cover board is changed, drilling efficiency is effectively improved, positioning precision is good, and problems that machining, flashing, hole plugging, pin breaking and the like of back drill drilling are effectively solved.

Owner:新野鼎邦实业有限公司

Production process of aluminum sol and aluminum sol prepared by production process

ActiveCN112744847AProduction environmental protectionMild production conditionsPhysical/chemical process catalystsAluminium oxides/hydroxidesPhysical chemistryMaterials science

The invention discloses an aluminum sol production process and aluminum sol produced by the process, and the process comprises the following steps: carrying out first contact on an aluminum source and a first alkali source to obtain a first reaction solution with the pH value of 3-5, then carrying out first heating aging, carrying out second contact on the solution subjected to the first heating aging and a second alkali source to obtain a second reaction solution with the pH value of 3-4.5, then carrying out secondary heating aging, and carrying out common electrodialysis on the obtained salt-containing aluminum sol to obtain aluminum sol and recovered salt; and allowing the recovered salt to be subjected to bipolar membrane electrodialysis to respectively obtain a product acid and recovered alkali, and circularly using at least part of the recovered alkali in the step (1) and / or the step (2); The primary heating aging and the secondary heating aging are carried out at the temperature of not more than 100 DEG C. The production process provided by the invention has the advantages of low production cost, mild conditions in the whole production process, basically no waste emission, and good quality of the prepared alumina sol product.

Owner:CHINA PETROLEUM & CHEM CORP +1

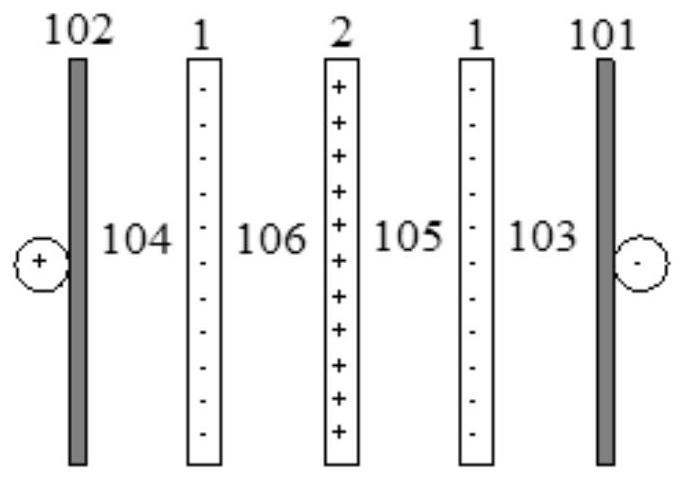

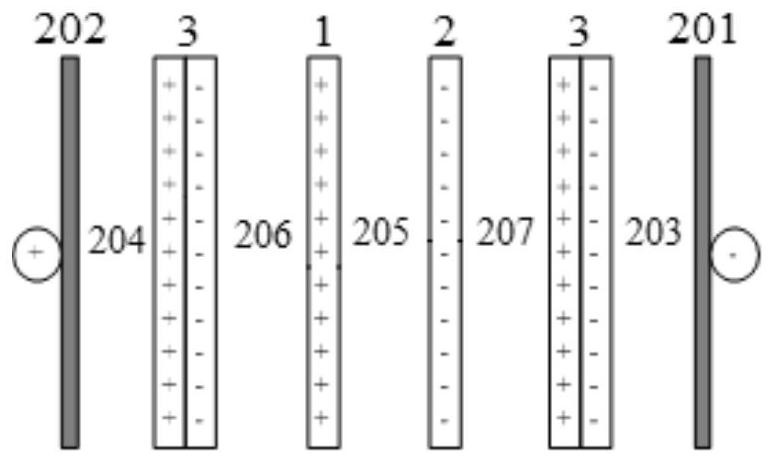

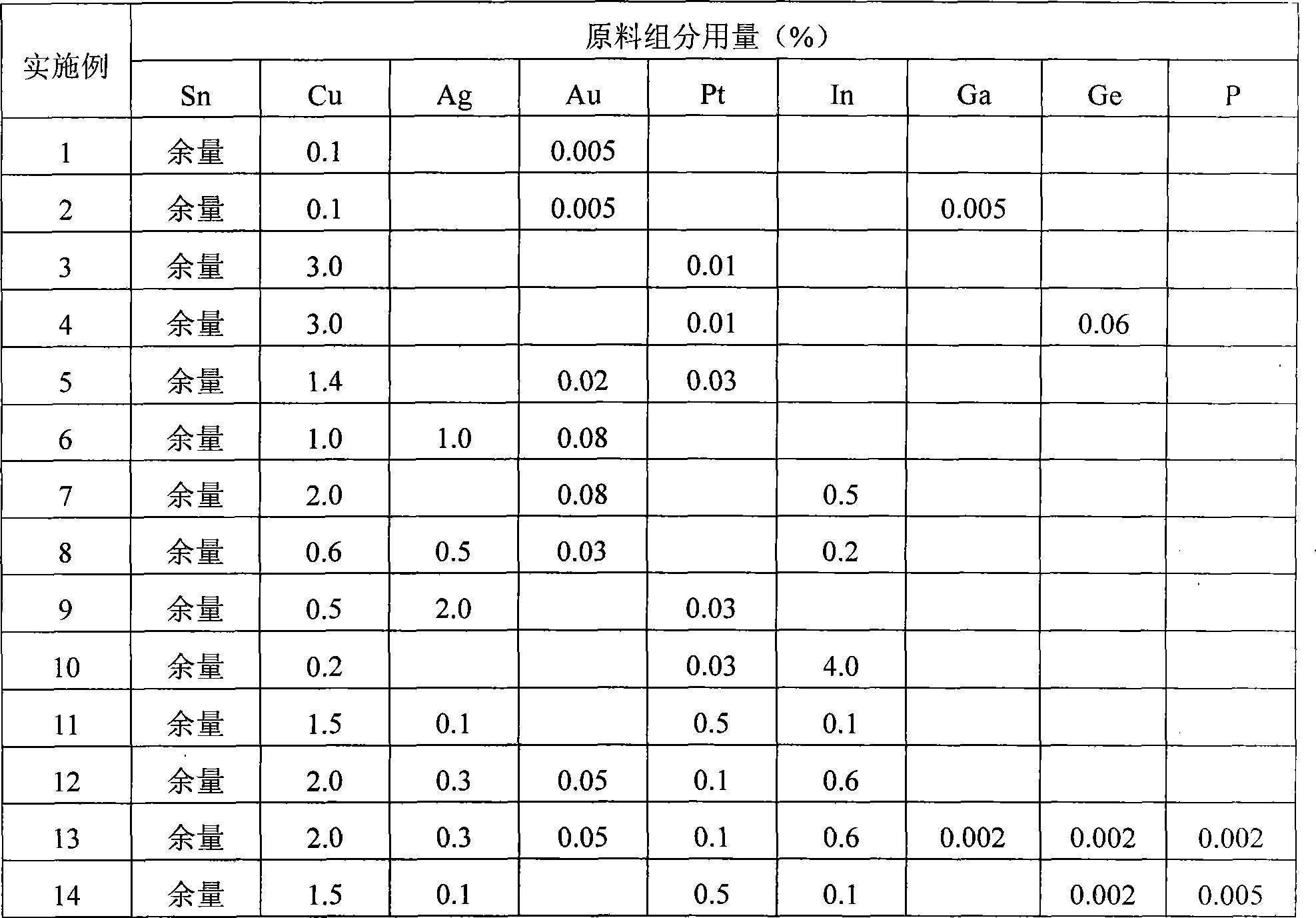

Leadless soft brazing material

ActiveCN101474728AEasy to prepareMeet lead-free soldering requirementsWelding/cutting media/materialsSoldering mediaPlatinumIndium

The invention discloses a lead-free soft soldering solder having three basic formations, namely that stannum is used as a base, and according to weight percentage, the solder also comprises 0.1 to 3.0 percent of copper and 0.01 to 0.5 percent of aurum, or also comprises 0.1 to 3 percent of copper and 0.01 to 0.5 percent of platinum, or comprises 0.1 to 3 percent of copper and aurum and platinum which totally occupy 0.01 to 0.5 percent. Argentum and (or) indium, of which the content is not higher than 4 percent according to weight percentage are added to the solder. The lead-free soft soldering solder has favorable antioxygenic property, and effectively avoid the phenomenon of hole blockage during secondary welding; and the production method is simple and is easy to be realized for industrial purposes.

Owner:惠州市成利工业有限公司

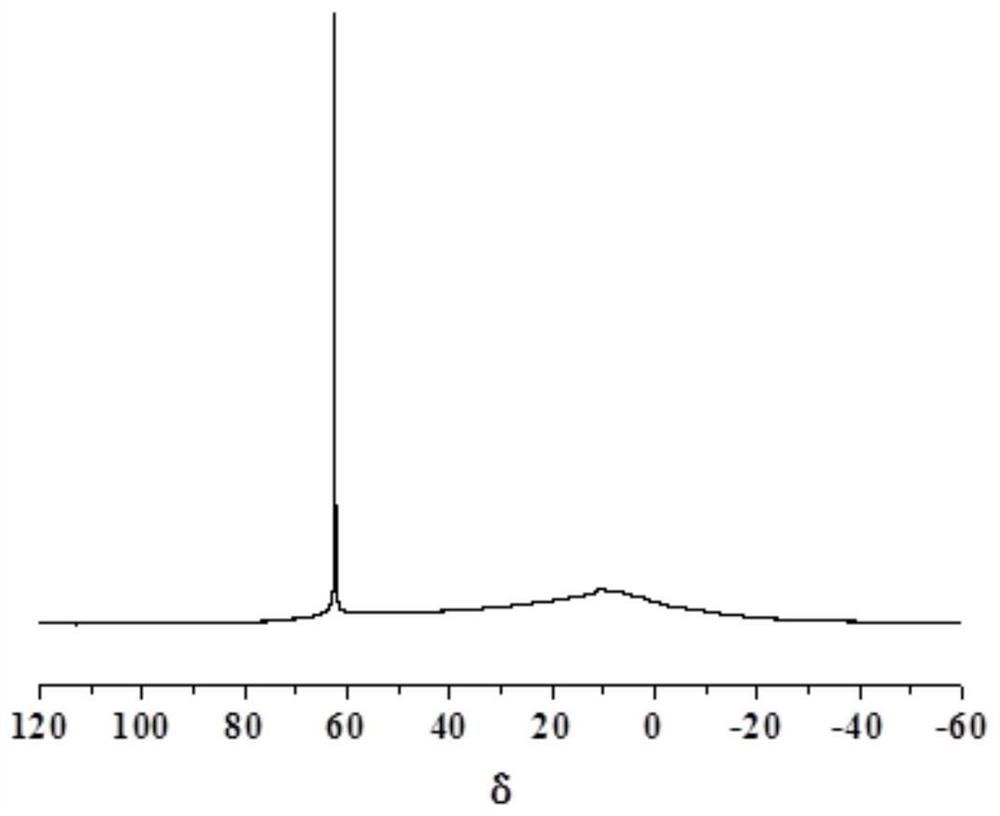

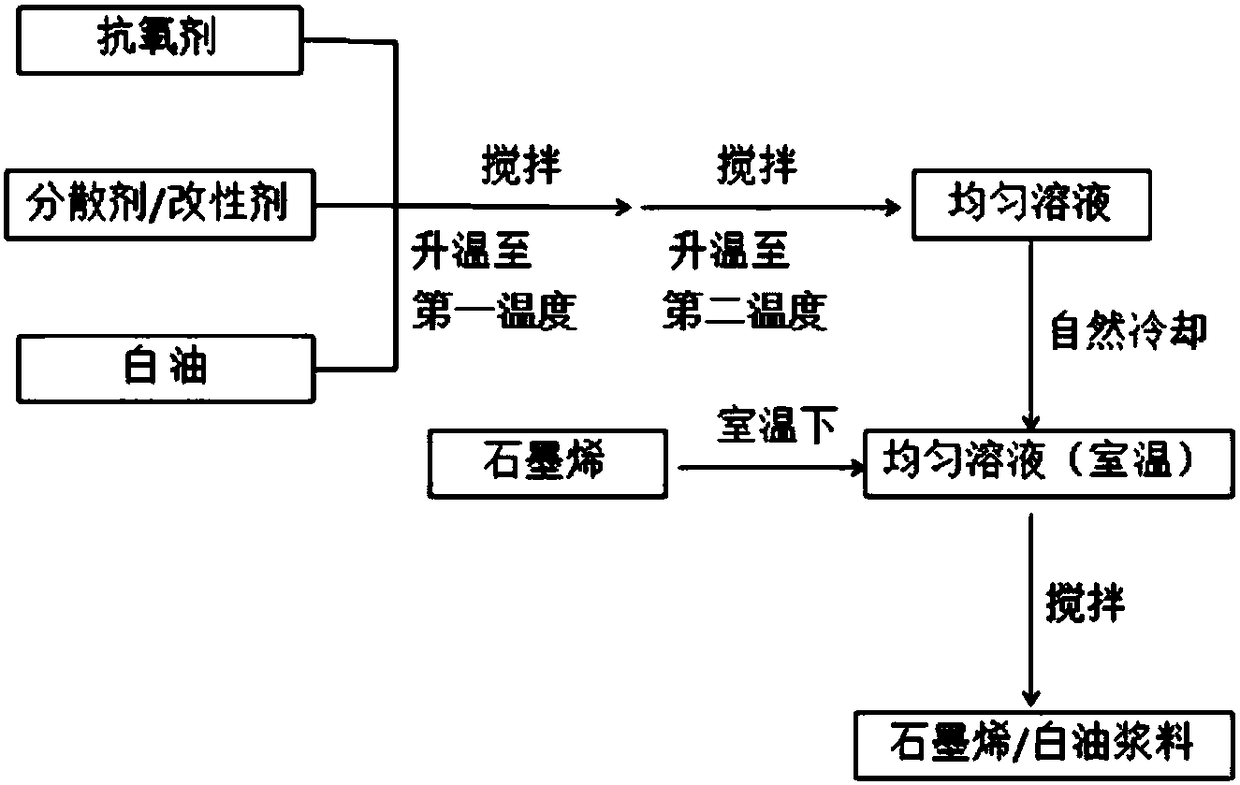

White oil sizing agent for composite graphene, preparation method thereof, as well as preparation method of composite fiber of graphene and UHMWPE (Ultrahigh Molecular Weight Polyethylene)

PendingCN109306537AAvoid hole pluggingEvenly dispersedArtificial filament heat treatmentMelt spinning methodsSizingAntioxidant

The invention discloses a preparation method of a white oil sizing agent of composite graphene. The preparation method comprises the following steps: 1) adding a component A and a component B into white oil, heating the mixture with stirring till the component A and the component B are fully dissolved to form a uniform solution, and naturally cooling the solution to room temperature, wherein the component A is an antioxidant, and the component B is a dispersing agent and / or a modifying agent; 2) stirring graphene powder at a high speed andat room temperature, adding the graphene powder into the solution prepared in the step 1), and continuously stirring till a uniformly-dispersed graphene / white oil sizing agent is formed.

Owner:南通恒尚新材料科技有限公司 +1

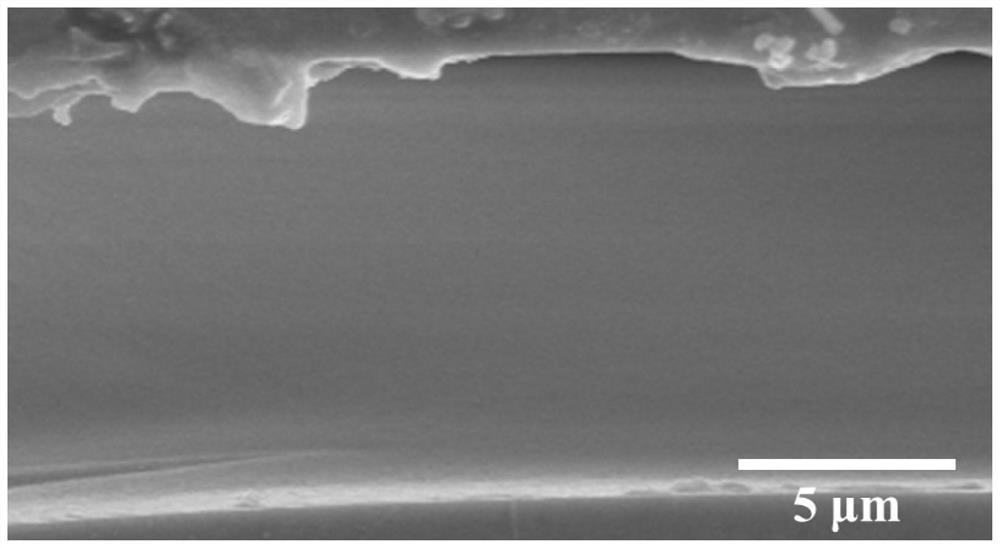

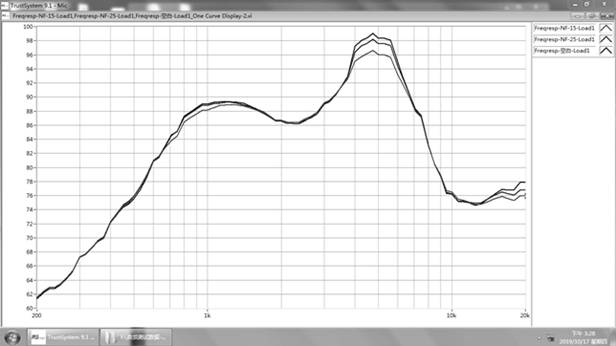

Audio super-amphiphobic gauze composite film

InactiveCN112714385AImprove acoustic propertiesEfficient protection featuresElectrical transducersSynthetic resin layered productsAudio frequencyElectronics

The invention provides an audio super-amphiphobic gauze composite film. The composite film is mainly applied to sound-transmitting and air-permeable hole channels of consumer electronics and intelligent household appliances. The audio super-amphiphobic gauze composite film is characterized in that the audio gauze is compounded with the fiber layer and the super-amphiphobic layer, so that the audio super-amphiphobic gauze composite film has excellent audio, efficient dustproof and super-amphiphobic properties.

Owner:TIANJIN RIJIN TECH

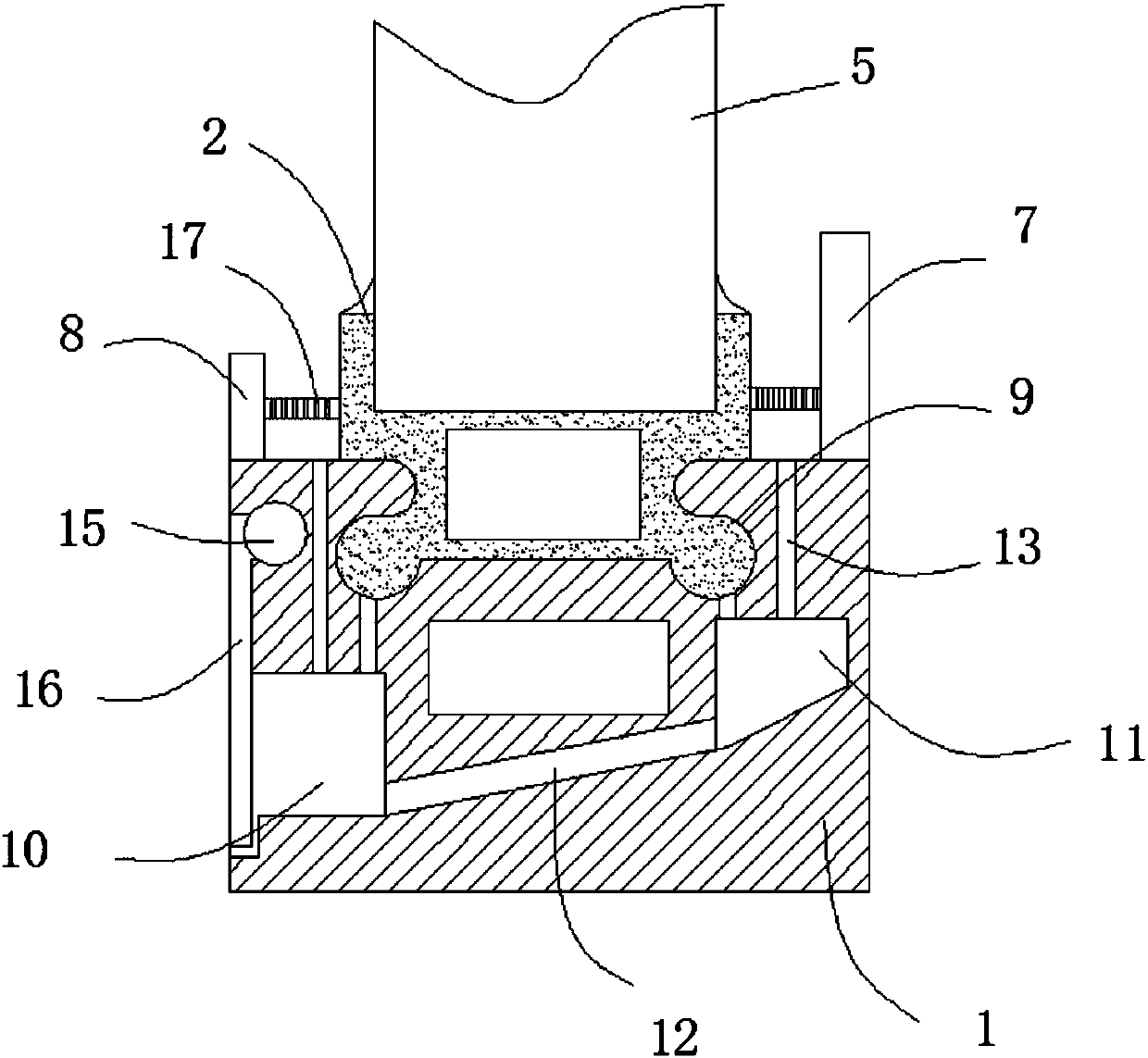

Fruit juicing machine

The invention discloses a fruit juicing machine. The juicing machine is provided with a rough crashing assembly and a fine crashing assembly, can crash fruits more rapidly and uniformly, increases therate of juice extrusion in the following process, and can greatly improve the juicing efficiency. Meanwhile, a filter net of the machine is of a big-end-down conical hole structure, so that hole blocking is effectively prevented during discharging, and the stability of juicing is improved; a double-end motor is adopted to improve the juicing efficiency and the stability of the juicing machine; ajuice receiving assembly can filter juice furthermore through a filtering plate according to needs, and therefore the taste of the juice is improved. In addition, a split structure convenient to splitis adopted, therefore, the fruit juicing machine is convenient to clean, and the practicability of the juicing machine is improved greatly.

Owner:府谷县清水村清泉开发有限责任公司

Treatment method of silicon powder for molten silicon infiltration

The invention relates to a treatment method of silicon powder for molten silicon infiltration. The treatment method can be used for preparing reactive sintering silicon carbide, a carbon fiber reinforced silicon carbide-based composite material and a silicon carbide fiber reinforced silicon carbide-based composite material. Traditional reactive siliconizing mostly adopts silicon powder as a siliconizing raw material, and the problems of hole blockage or non-uniform infiltration and the like are easy to occur in the siliconizing process. According to the invention, the silicon powder is pretreated, so a thin shell is formed on the surface of the silicon powder, and the silicon can be broken and quickly enter a porous body by utilizing the volume change effect of the silicon powder in melting and heating processes; and thus, the problems of hole blockage and the like in reaction are avoided, and infiltration efficiency is favorably improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Vibrating screen for wet sieving

The invention discloses a vibrating screen for wet sieving. The vibrating screen comprises a plurality of layers of screen cloths, a distributor and a material outlet, wherein the screen cloths are sequentially and vertically arranged; the distributor is arranged above the first layer of screen cloth; a stirring device is arranged above the distributor; the material outlet is arranged below the last layer of screen cloth; at least one layer of screen cloth in the screen cloths is provided with a flushing device in parallel; the flushing device is connected with a flushing pipeline; and flushing sprayers are arranged on the flushing device. The phenomenon that meshes of a vibrating screen are prone to being blocked in the use process can be avoided, the solid-liquid ratio of filtered powder is increased, and the production efficiency of the powder is improved.

Owner:青海万加环保新材料有限公司

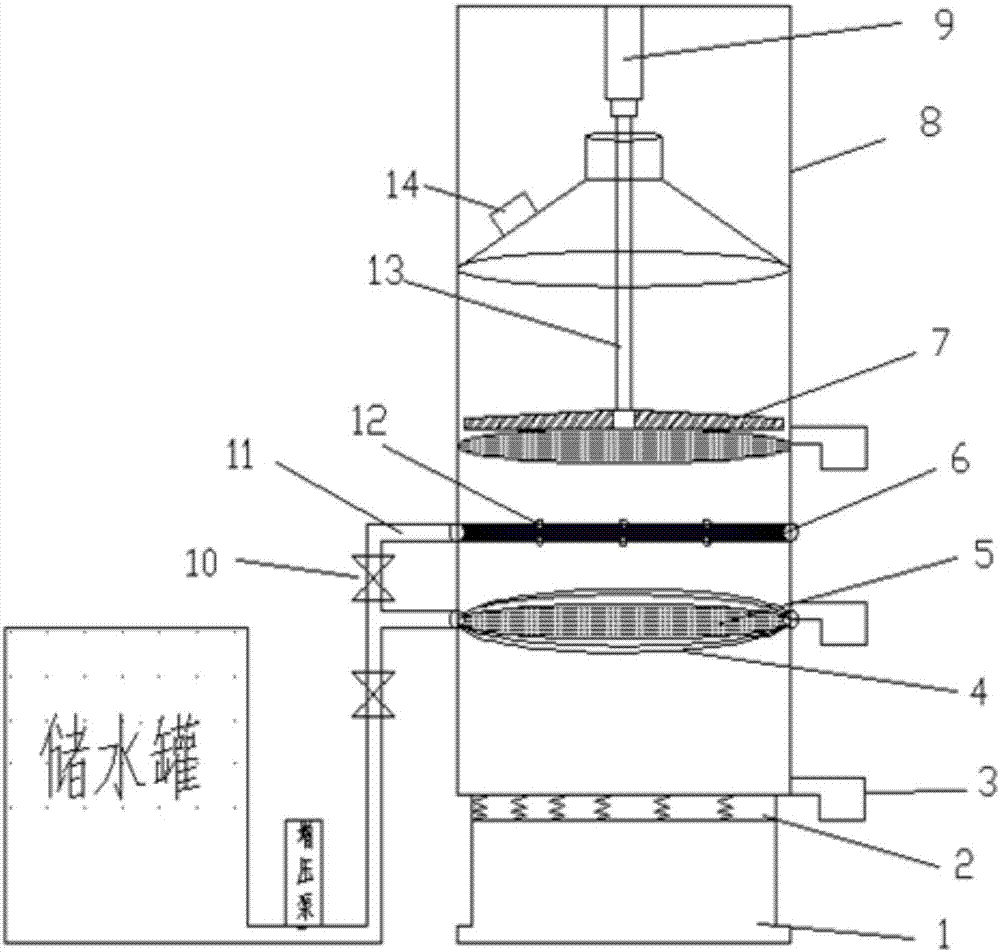

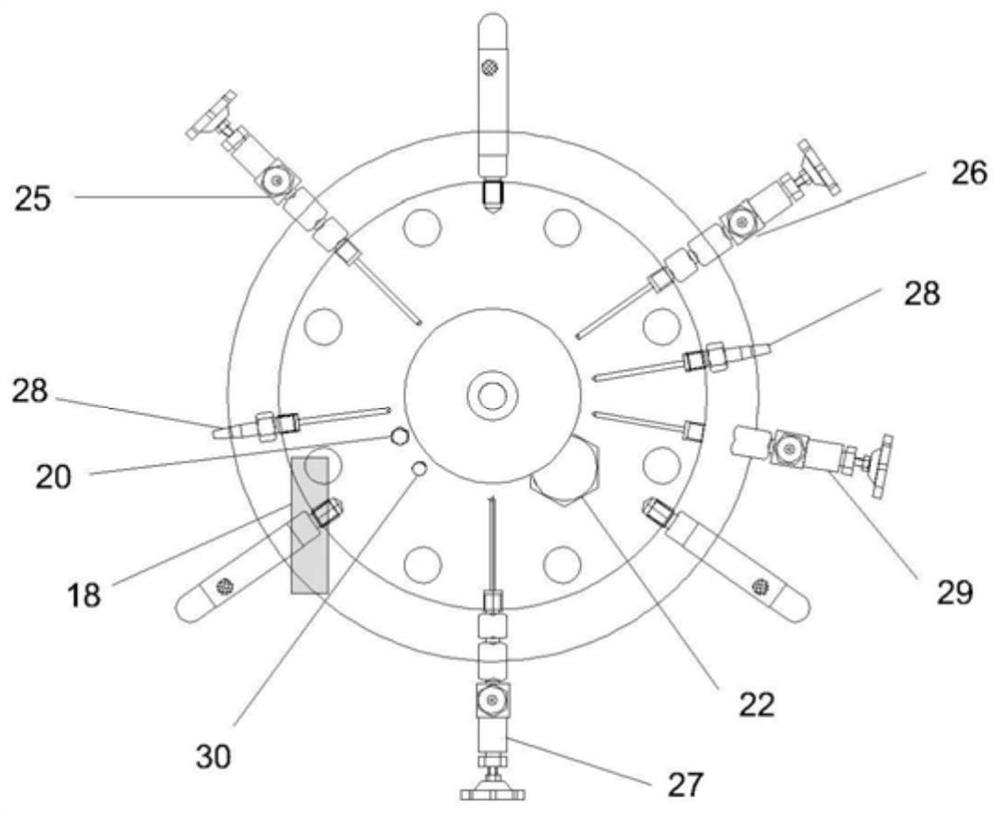

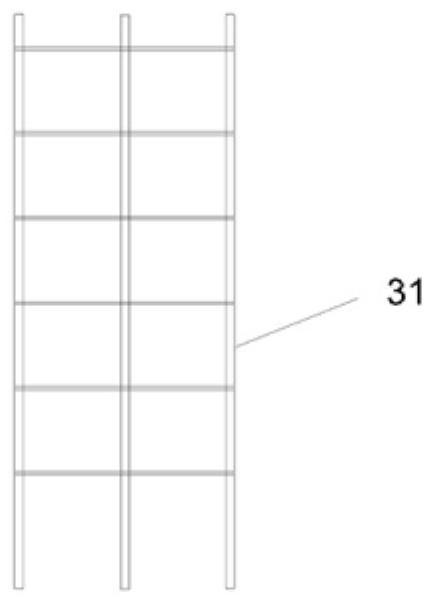

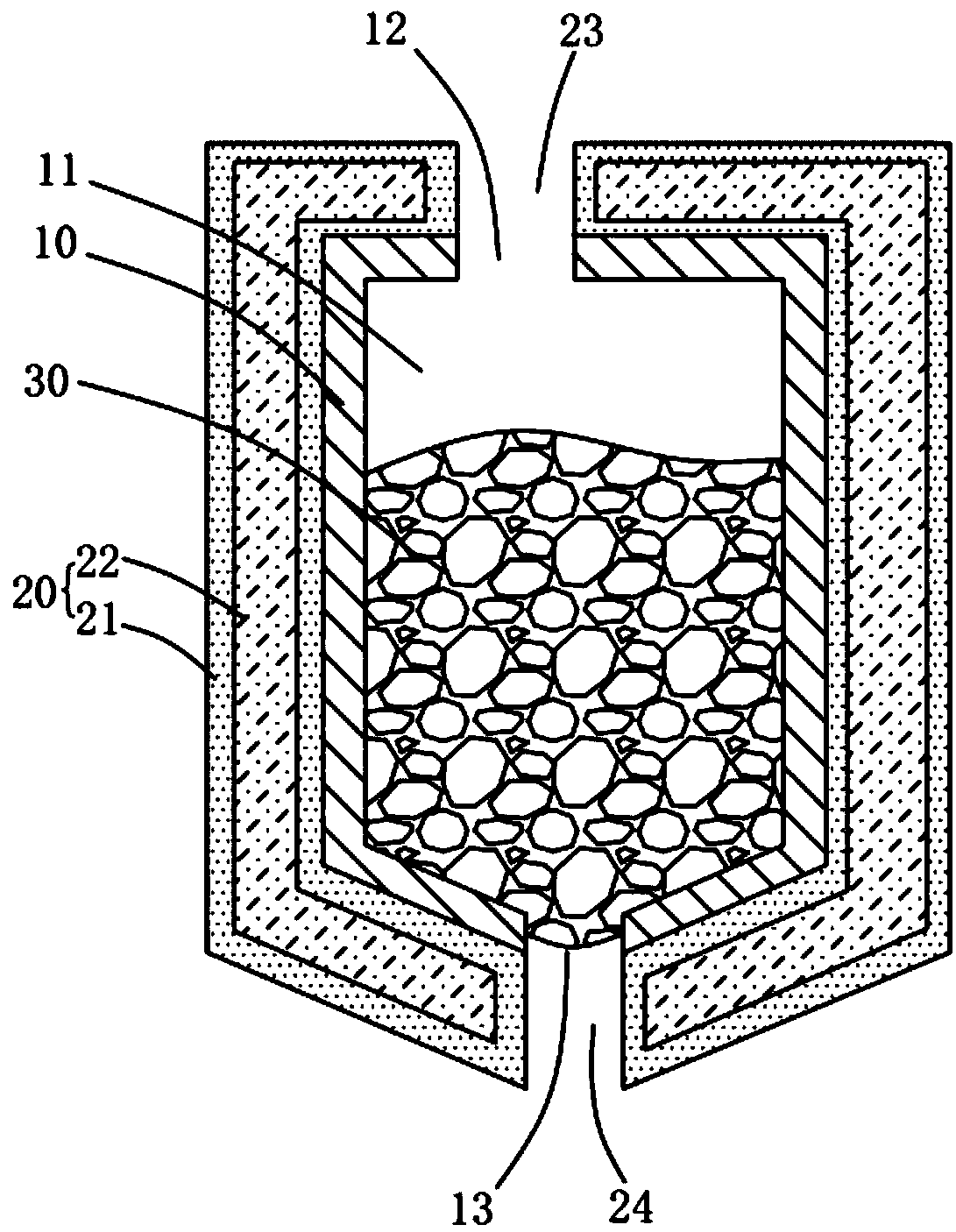

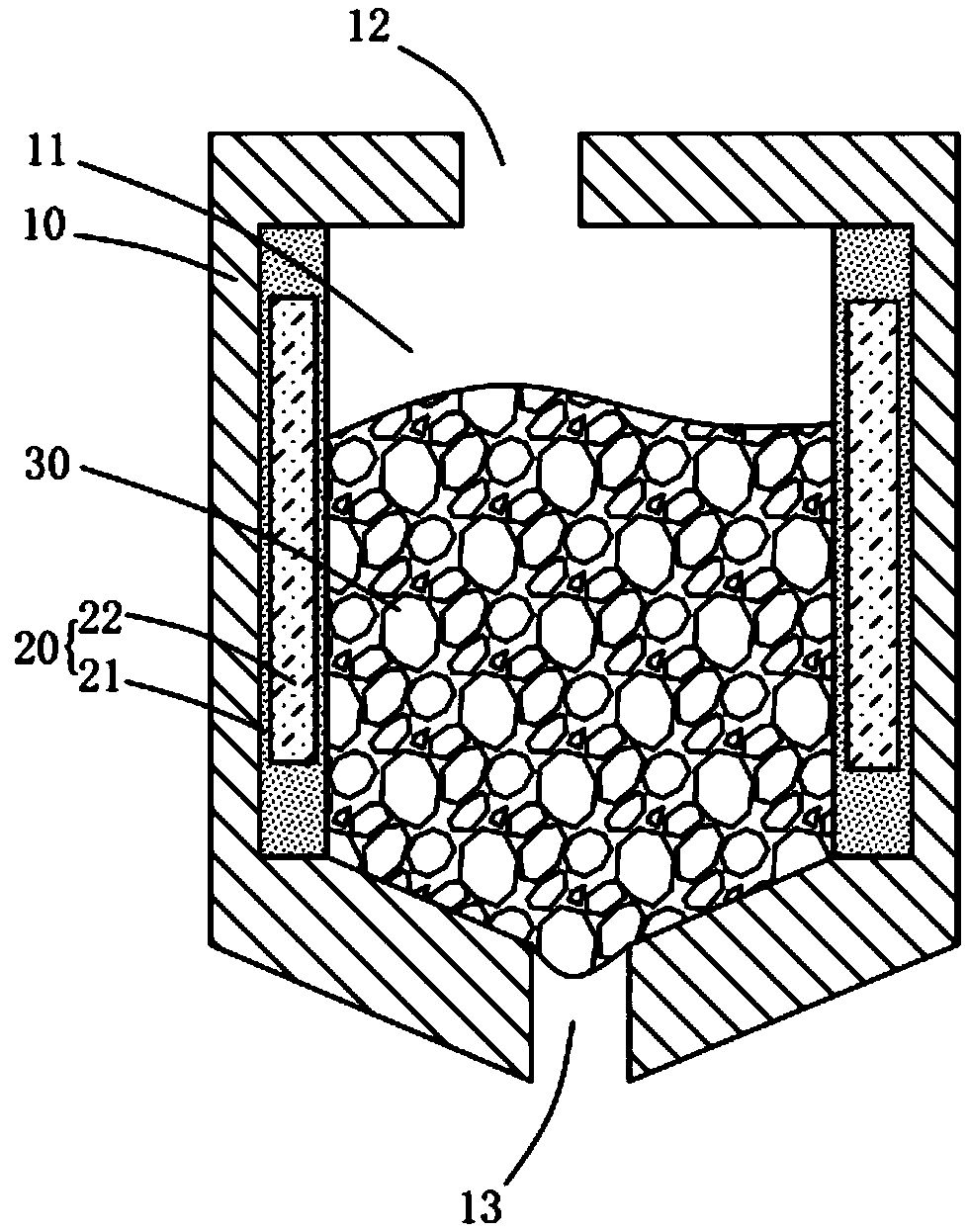

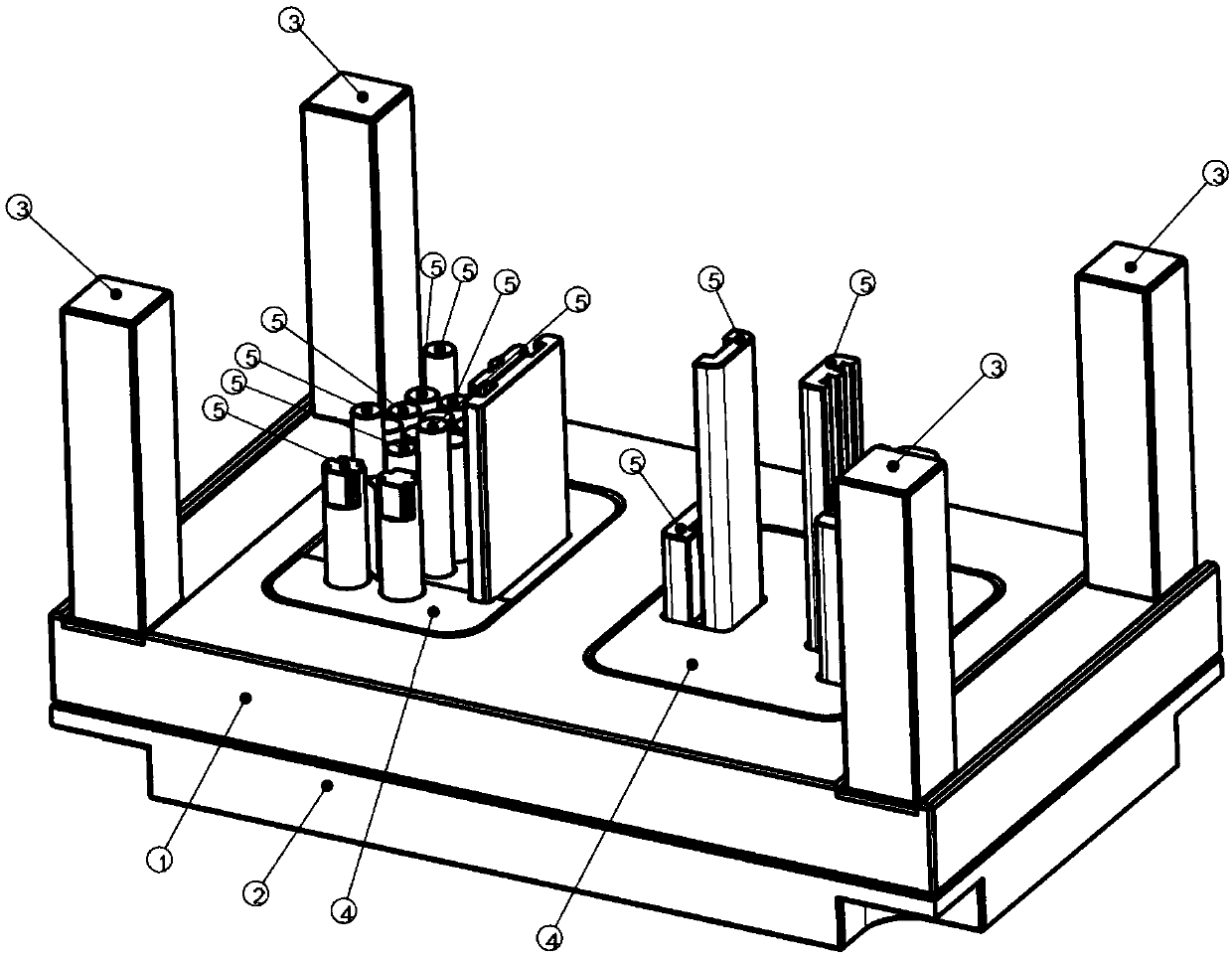

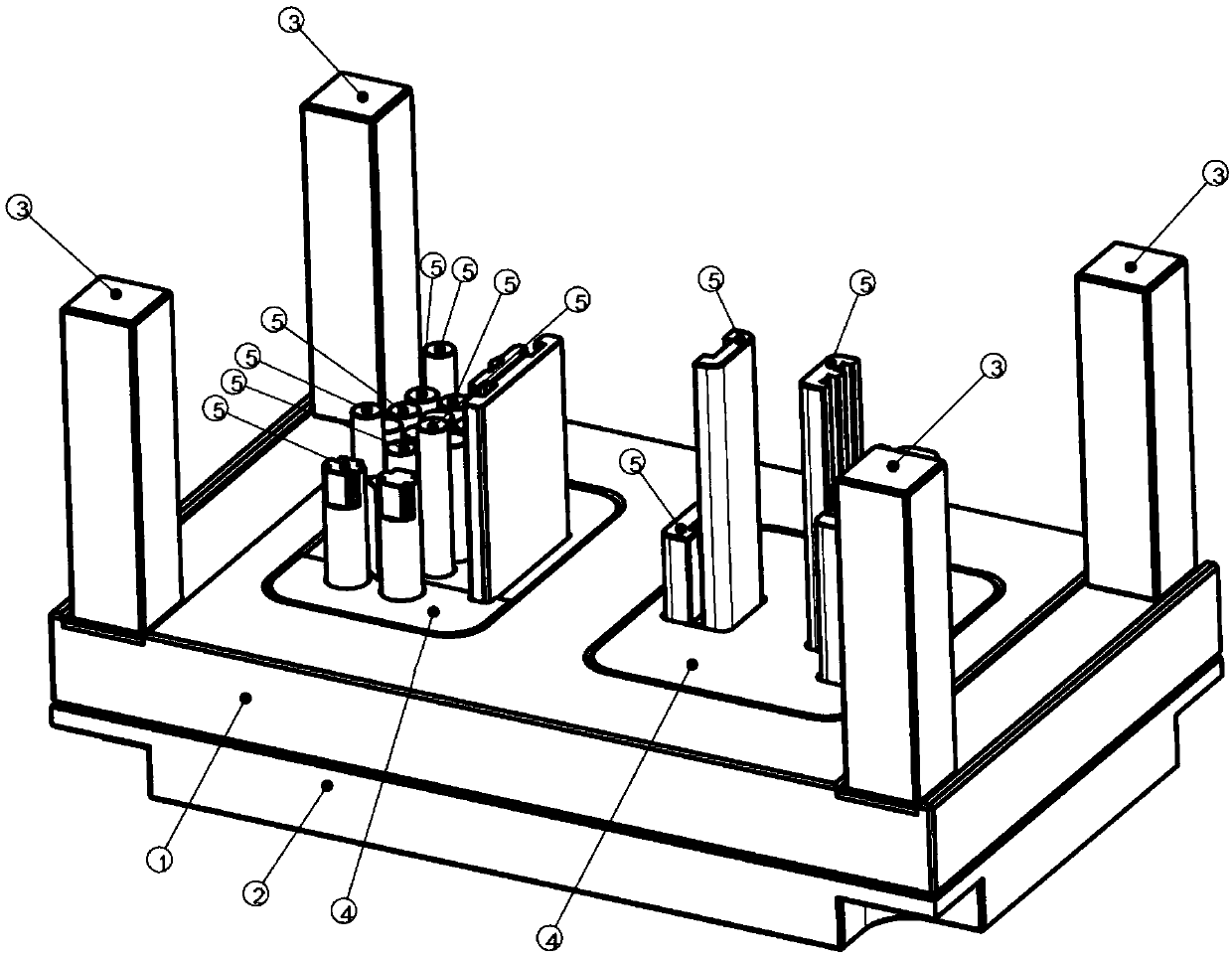

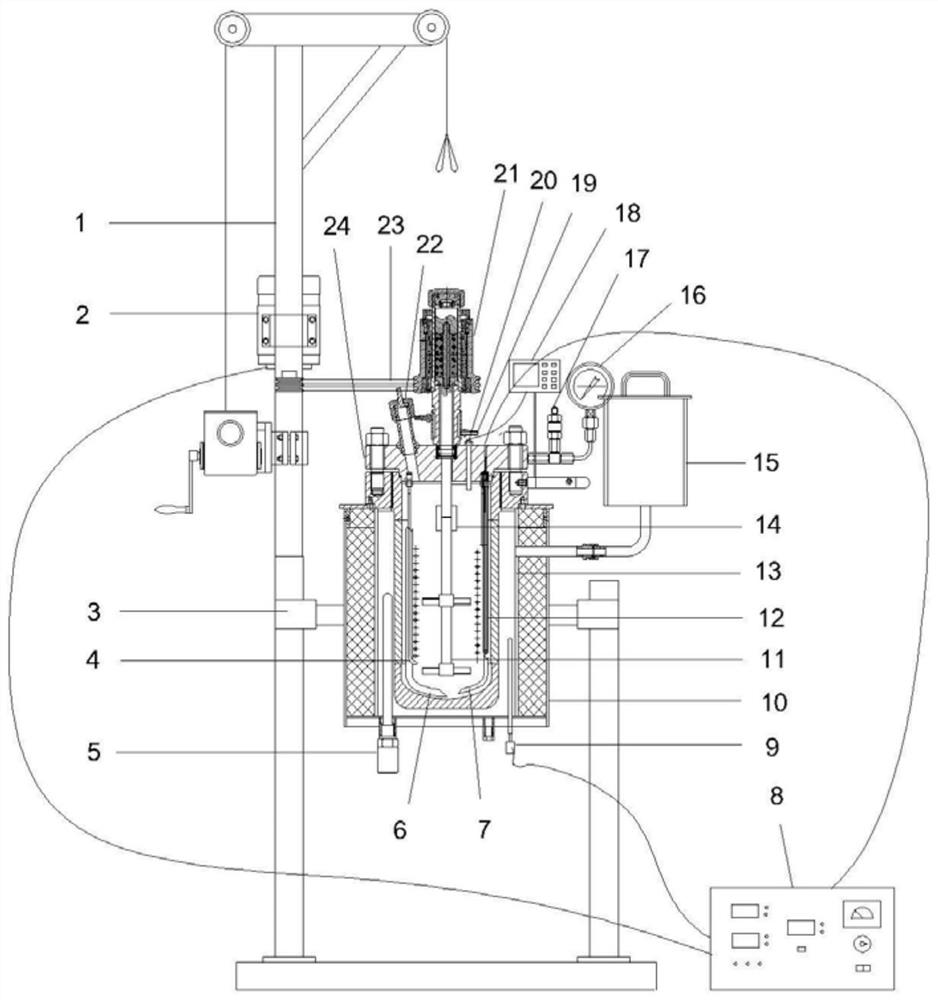

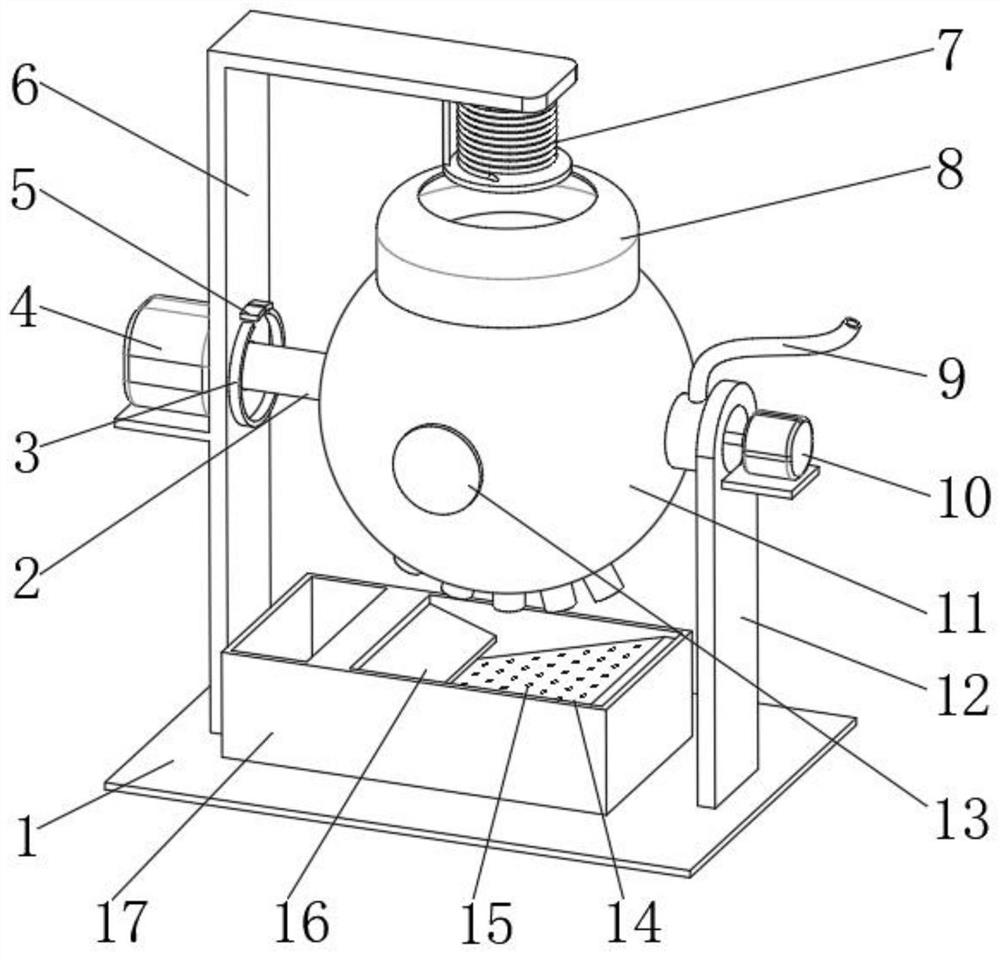

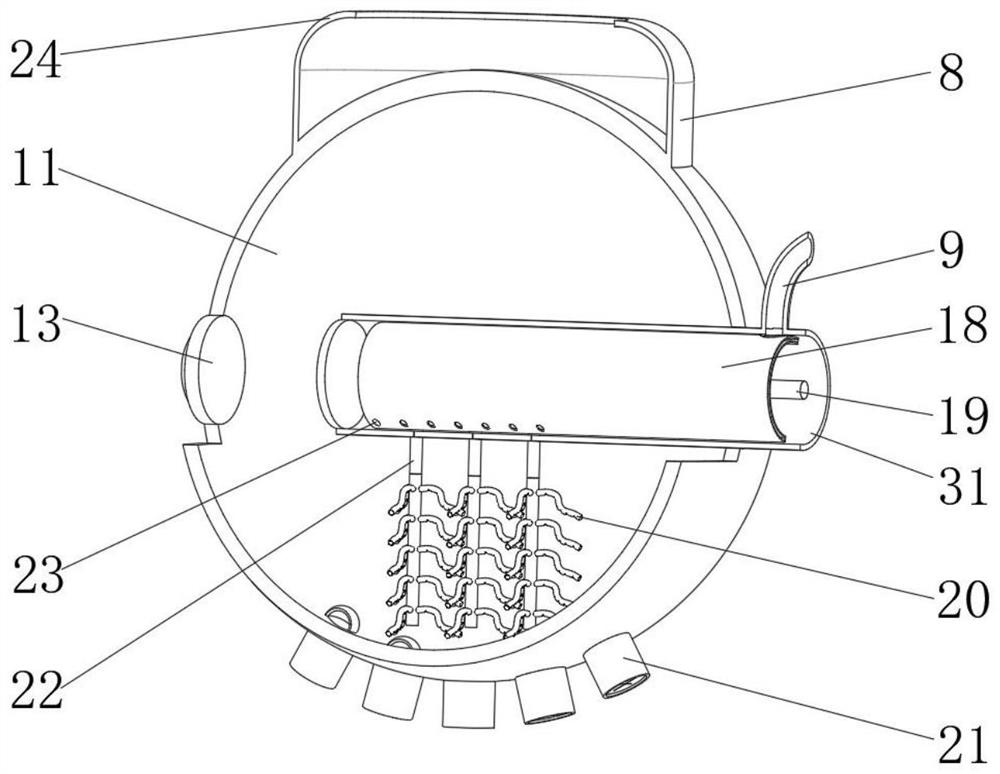

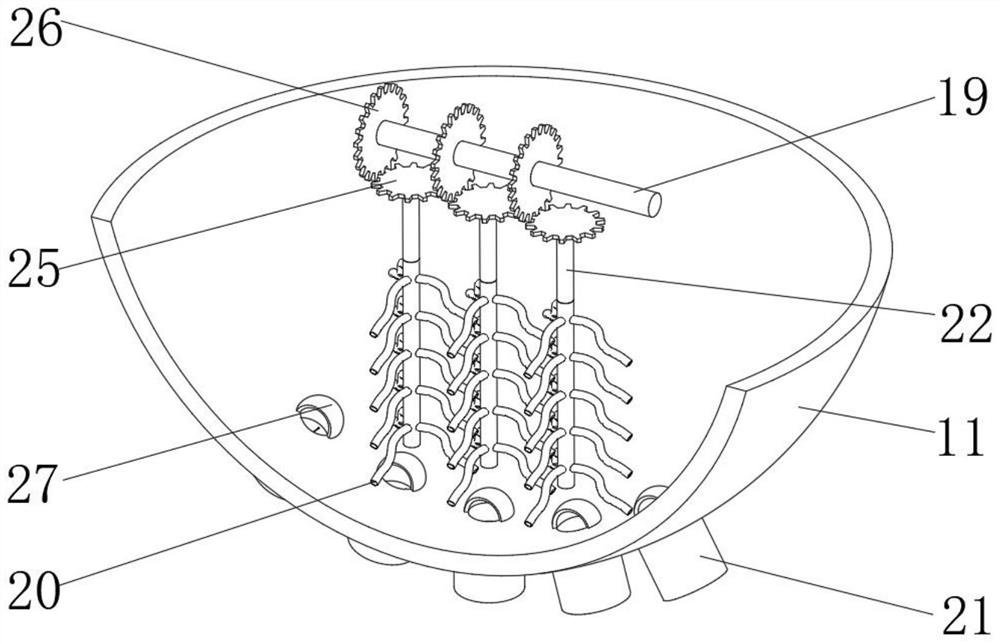

Solid-liquid dual-purpose high-temperature and high-pressure carbonization reaction kettle capable of indicating carbonization degree

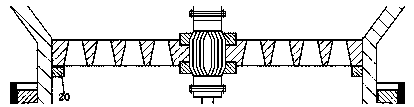

ActiveCN111715146AAchieve hybridAchieve dissolutionCalcium/strontium/barium carbonatesMagnesium carbonatesCarbonizationStress sensors

The invention relates to a solid-liquid dual-purpose high-temperature and high-pressure carbonization reaction kettle capable of indicating the carbonization degree. The reaction kettle comprises a support frame, a reaction kettle body, a kettle cover, a stirring piece, a heating piece, a test piece bracket and a carbonization degree indicator, wherein the reaction kettle body is fixedly arrangedon the support frame; the kettle cover covers the reaction kettle body; a closed reaction cavity can be formed by the reaction kettle cover and the reaction kettle body; the stirring piece extending into the reaction cavity is detachably mounted on the kettle cover; the heating piece is arranged in the reaction kettle body; a solid test piece to be reacted can be placed on the test piece bracket,a cooling water coil for cooling the reaction cavity is also arranged in the reaction kettle body, and the carbonization degree indicator is used for displaying the carbonization degree of the test piece in the reaction kettle and is connected with a pressure sensor extending into the reaction cavity of the reaction kettle body. Compared with the prior art, the carbonization reaction with multiplematerials, adaptation to multiple conditions and efficient regulation and control can be realized through the simple design, the utilization rate is high and the cost is low.

Owner:TONGJI UNIV

Printing nozzle with temperature adjusting function and printing device

InactiveCN108909184AReduce the temperatureAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingSpray nozzleEngineering

The invention discloses a printing nozzle with a temperature adjusting function and a printing device. The printing nozzle comprises a nozzle main body and a temperature adjusting layer, wherein the nozzle main body is provided with an accommodating cavity; the accommodating cavity is used for loading printing materials; the temperature adjusting layer is arranged on the nozzle main body; and thetemperature adjusting layer is used for adjusting the temperature of the nozzle main body. The printing device comprises an ink supply channel, a jet and the printing nozzle with the temperature adjusting function, wherein the ink supply channel and the jet communicate with the accommodating cavity. According to the printing nozzle with the temperature adjusting function and the printing device, the temperature adjusting layer is arranged on the nozzle main body, when the temperature of the nozzle main body rises too fast during the quick printing process, the temperature adjusting layer absorbs heat to decrease the temperature of the nozzle main body, printing equipment is prevented from being damaged due to high temperature, and the phenomenon that holes are blocked as the solid contentof the printing materials is relatively high is prevented.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

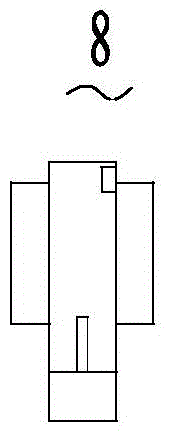

Device for detecting blockage of automobile connector pin hole

PendingCN111123392AEasy to put inEasy to detectGeological measurementsEngineeringStructural engineering

The invention relates to a device for detecting the blockage of an automobile connector pin hole. The device includes a fixed plate, a clamping groove is formed on the fixed plate, a pin fixing insertis embedded in the clamping groove, a pin for detection is arranged on the pin fixing insert, when the device is used, the pin for detection is inserted into a to-be-detected automobile connector pinhole, if the pin for detection can be inserted into the to-be-detected automobile connector, the to-be-detected automobile connector pin hole is not blocked, and if the pin for detection cannot be inserted into the to-be-detected automobile connector , the to-be-detected automobile connector pin hole is blocked. Compared with the prior art, the device is simple in structure, convenient to use andhigh in detection efficiency, outflow of defective products is effectively controlled, and the phenomenon of detecting whether a broken pin blocks the hole in a product only through visual inspectionis avoided. The device is convenient to operate, if a product cannot be inserted smoothly, a hole blockage phenomenon of the product can be found immediately, a defective product can be found, and outflow of the defective product is effectively avoided.

Owner:SHANGHAI CHIEF LAND ELECTRONICS CO LTD

Double-layer floating vibrating sieve

InactiveCN103272765AIncrease vibration intensityImprove screening efficiencySievingScreeningMarine engineeringResonance

The invention discloses a double-layer floating vibrating sieve. The double-layer floating vibrating sieve comprises a sieve box, an upper layer sieve plate and a lower layer sieve plate are installed inside the sieve box, a layer of resonators are installed below each layer sieve plate in a parallel mode, one end of each layer sieve plate is fixed on the sieve box, the other end of each layer sieve plate is fixed on the resonators, and elastic parts which are uniformly distributed are installed between the upper and lower layer sieve plates and the upper and lower layer resonators respectively. According to the double-layer floating vibrating sieve, the vibration strength of the upper and lower layer sieve plates is improved by resonance produced by the resonators between the upper and lower layer sieve plates and the sieve box, so that the screening efficiency can be effectively improved, energy can be saved, the hole blockage phenomena can be prevented, and the double-layer floating vibrating sieve is particularly applicable to treatment of materials which are much in moisture and high in viscidity.

Owner:新乡市华龙冶金设备有限公司

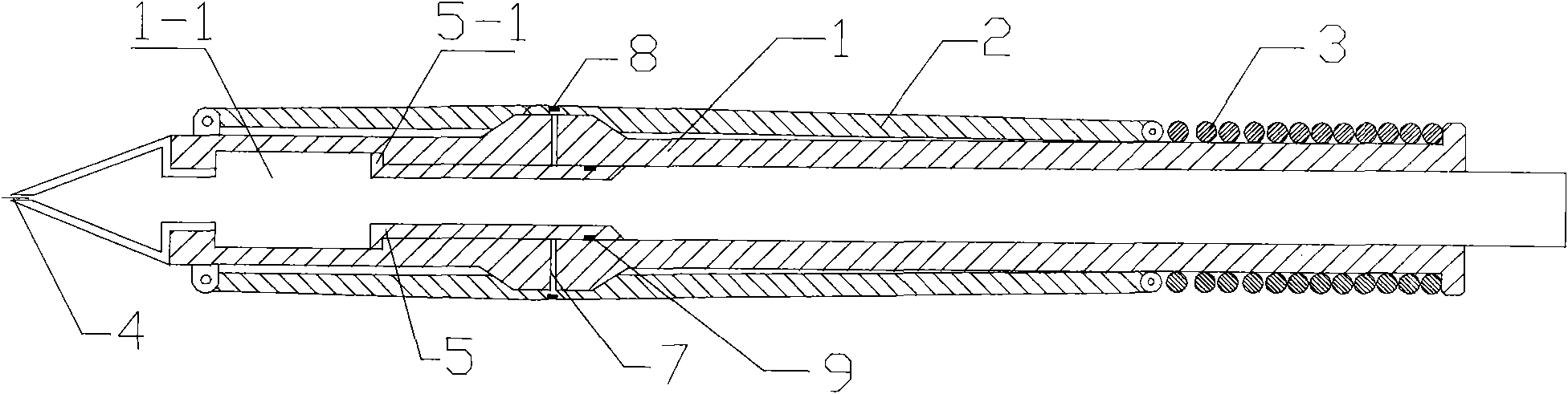

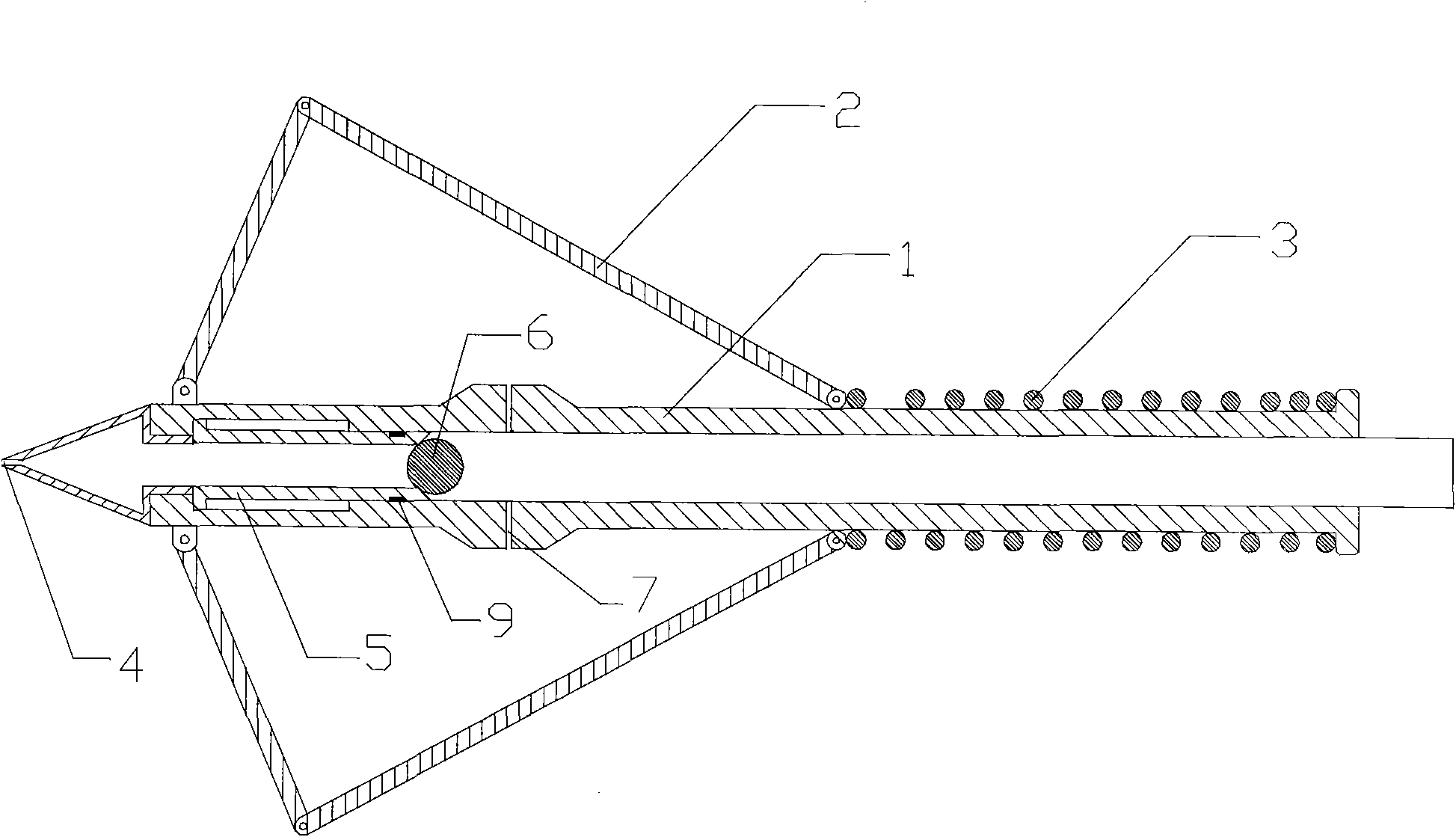

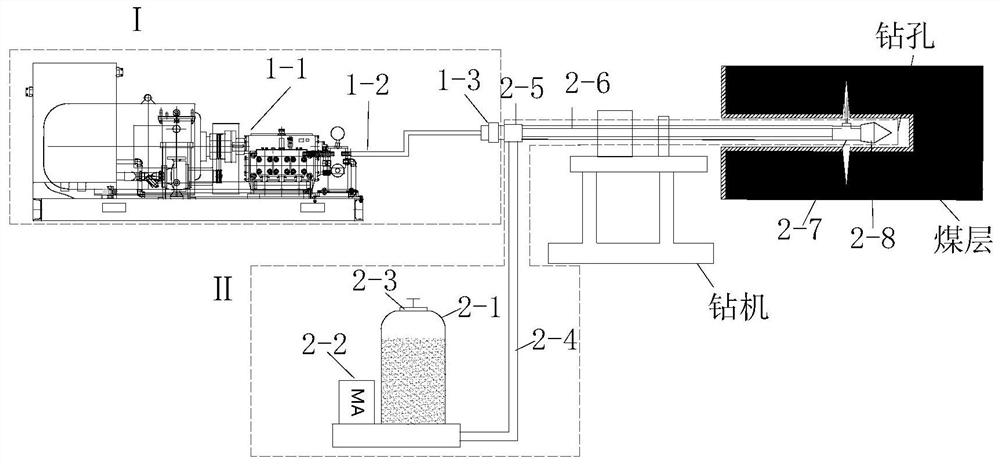

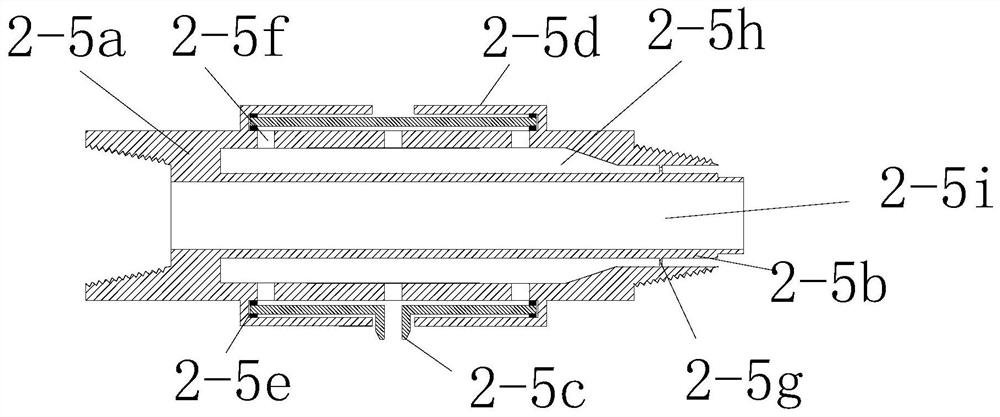

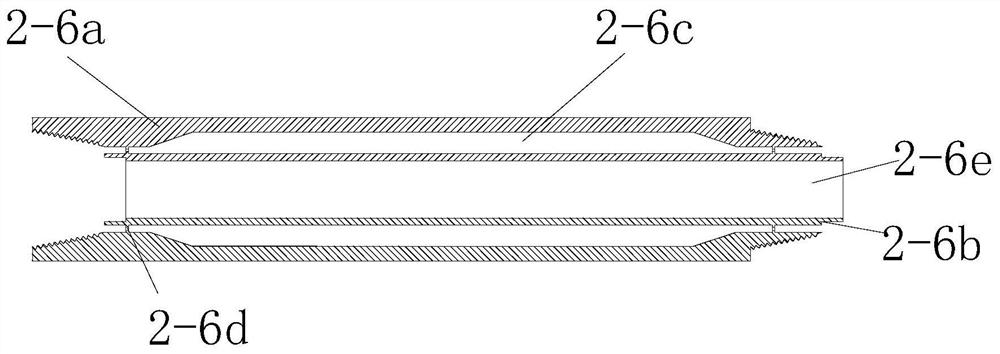

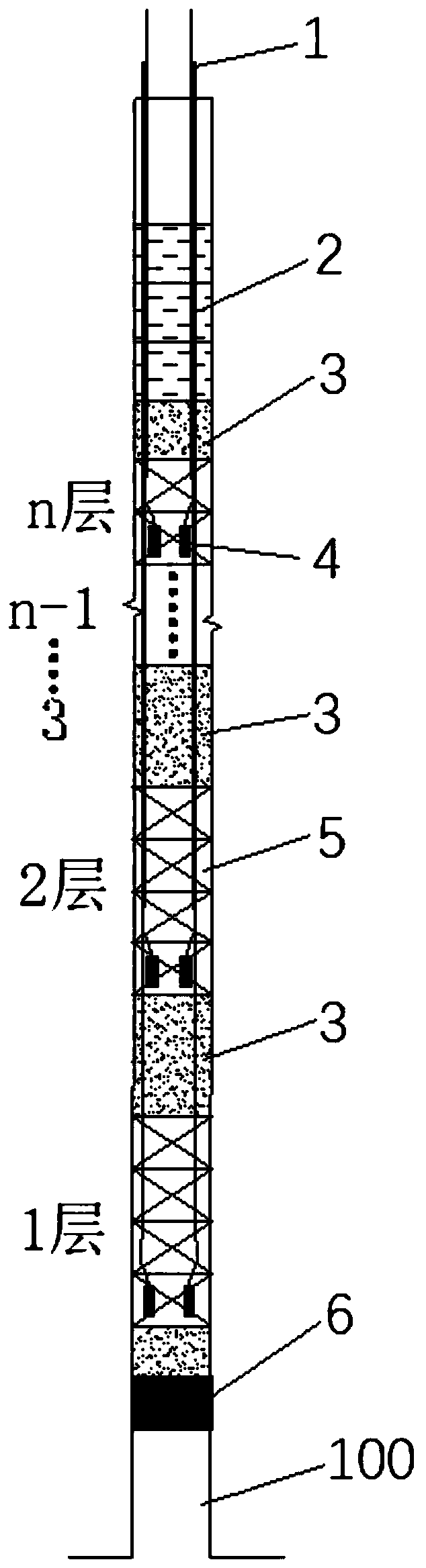

Rear-mounted double-channel abrasive jet slotting device

The invention relates to a rear-mounted double-channel abrasive jet slotting device, and belongs to the field of coal seam pressure relief and permeability improvement. The rear-mounted double-channel abrasive jet slotting device mainly comprises an ultrahigh-pressure clean water pump, an ultrahigh-pressure hose, an ultrahigh-pressure rotary water tail, an abrasive pumping device, an abrasive rotary sealing water tail, a double-channel sealing drill rod and a double-channel slotting device. The ultrahigh-pressure clean water pump provides a jet flow power source, and the ultrahigh-pressure hose, the ultrahigh-pressure rotary water tail and the double-channel sealing drill rod ensure safe transmission of high-pressure water. The abrasive pumping device, the abrasive rotary sealing water tail, the double-channel sealing drill rod and the double-channel slotting device form an abrasive sand adding channel, and double-channel supply of high-pressure water transmission and abrasive transmission separation is achieved. According to the rear-mounted double-channel abrasive jet slotting device, the double-channel abrasive jet slotting device is innovatively invented, and abrasion to a high-pressure hose and a drilling tool in the abrasive and high-pressure water mixed conveying process is avoided. Meanwhile, the on-way pressure loss of the high-pressure water is avoided, the high-pressure water jet slotting coal breaking capacity is greatly improved, and the service life of equipment is prolonged.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

Drilling method for mother board of circuit board

InactiveCN113141717AResolve the breakImprove cooling efficiencyInsulating layers/substrates workingCleaning processes and apparatusChemical reactionThermodynamics

The invention discloses a drilling method for a mother board of a circuit board. According to the method, after drilling is completed every time, drilling dirt can be more effectively discharged out of the hole, the hole blocking phenomenon caused by excessive accumulation of the drilling dirt is avoided, the heat dissipation efficiency of the inner-layer thick copper drill hole can be improved, the bad problems that the roughness in the hole is too large due to too large heat and the like are solved, and meanwhile the problem that a drill point is broken is solved; the tool retracting speed is correspondingly reduced to 320 mm / s, so that the smoothness of the wall of the drilled hole is improved; a segmented drilling method which is the same as a back drilling method is adopted, so that the heat dissipation efficiency of drilling is effectively improved; in the plasma chemical reaction, particles playing a chemical role are mainly positive ion and free radical particles, the effect on different materials is uniform, and the drilling dirt removing effect is good. Through testing, the working environment in the drilling process is clean and tidy, stains are reduced, and the tidiness in the mother board drilling process is improved.

Owner:丰顺县和生电子有限公司

A VCR mining method no-sweep hole blasting charge structure and its construction method

The invention discloses a drill-hole cleaning free blasting charge structure adopting a VCR mining method and a construction method of the drill-hole cleaning free blasting charge structure. A blasting segment of a blasthole is filled with multiple layers of explosives in a layered manner. The explosives are spaced by particle filler. The explosives are guided out of the blasthole through a detonation assembly to be connected with a detonation network. The length of the explosive at the topmost layer is smaller than the length of the rest of layers of explosives, the position, above the explosive at the topmost layer, of the blasthole is filled with particle filler, and the position, above the particle filler, of the blasthole is filled with a water column. The reasonable and scientific charge structure is adopted, the combined blocking structure of a small quantity of explosives, particle blockage and the water column is adopted on the upper portion of the explosive on the top layer,the phenomenon of hole blocking of the top non-blast segment is effectively eradicated fundamentally, the additional economic cost caused by the drill-hole cleaning workloads due to blasting hole blocking is saved, the production construction period is prevented from being delayed, and the negative effects caused by large-charge-mass blasting in the VCR mining method are greatly reduced.

Owner:CENT SOUTH UNIV +1

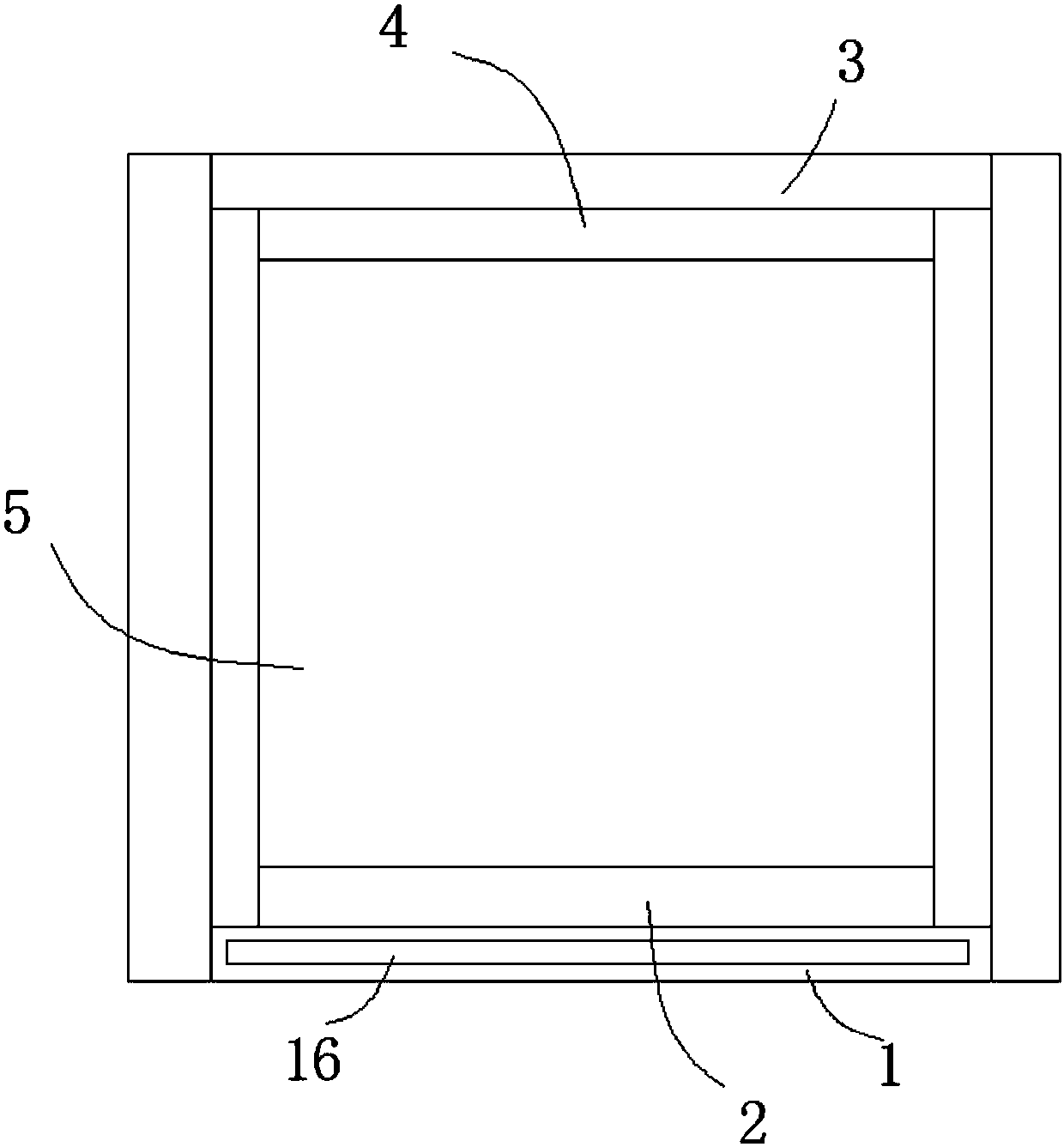

Aluminum alloy Door and window convenient for internal drainage

InactiveCN107842295AAvoid non-drainable situationsFlexible useCondensed water drain-offEngineeringAluminium alloy

The invention discloses an aluminum alloy door and window convenient for internal drainage. The aluminum alloy door and window includes an inner frame and an outer frame. The inner frame includes a second lower frame and a second upper frame. The outer frame includes a first lower frame and a first upper frame. Glass is arranged between the second lower frame and the second upper frame, and the second lower frame is connected with the first upper frame. An upper occulting bar is fixedly arranged on the side, close to the second upper frame, of the first upper frame. The upper occulting bar islocated on one side of the glass. An arranging groove is formed in the side, close to the second lower frame, of the first lower frame in the length direction. The second lower frame is slidably connected within the arranging groove in a sleeving mode. The interior of the first lower frame is provided with an outer water collecting slot and an inner water collecting slot. According to the aluminumalloy door and window convenient for internal drainage, through the match usage of structures such as a cover plate, a filter plate, the outer water collecting slot, the inner water collecting slot and a water guiding hole, the aluminum alloy door and window can drain internally and externally; the blocking phenomenon can be avoided; the service life of the aluminum alloy door and window can be prolonged; and the usage is flexible.

Owner:ZHEJIANG CHANGXING KECHUANG METAL PROD CO LTD

A solid-liquid dual-purpose high-temperature and high-pressure carbonization reaction kettle that can indicate the degree of carbonization

ActiveCN111715146BAchieve hybridAchieve dissolutionCalcium/strontium/barium carbonatesMagnesium carbonatesThermodynamicsPhysical chemistry

Owner:TONGJI UNIV

A bearing steel ball cleaning equipment with screening function

ActiveCN112536282BReliable screeningAvoid hole pluggingCleaning using toolsCleaning using liquidsCouplingElectric machinery

The invention discloses a bearing steel ball cleaning device with a screening function, and relates to the technical field of bearing steel ball cleaning equipment; in order to improve the screening effect; it specifically includes a base, and the outer wall of the top of the base is fixed with a first support frame and a second support frame by screws. A support frame, the outer wall of one side of the first support frame is fixed with a first motor by screws, the output end of the first motor is connected to a rotating main shaft through a coupling, and a cleaning chamber is welded on the outer wall of one end of the rotating main shaft, so The outer wall on one side of the second support frame is fixed with a support tube by screws, and the inner wall on one side of the cleaning chamber is sealed and rotatably connected to the outer wall of the support tube. The invention facilitates the screening of steel balls during the rotation of the cleaning chamber by setting the sieve material arc plate and other structures. Since the gap between the sieve material arc plate and the bottom inner wall of the cleaning chamber is smaller than the diameter of the bearing steel ball to be cleaned, the sieve The material arc plate can reliably screen out damaged or substandard steel balls.

Owner:唐山志威科技有限公司

Alumina continuous feeding equipment

Owner:SNTO TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com