Patents

Literature

168results about How to "Increase vibration intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

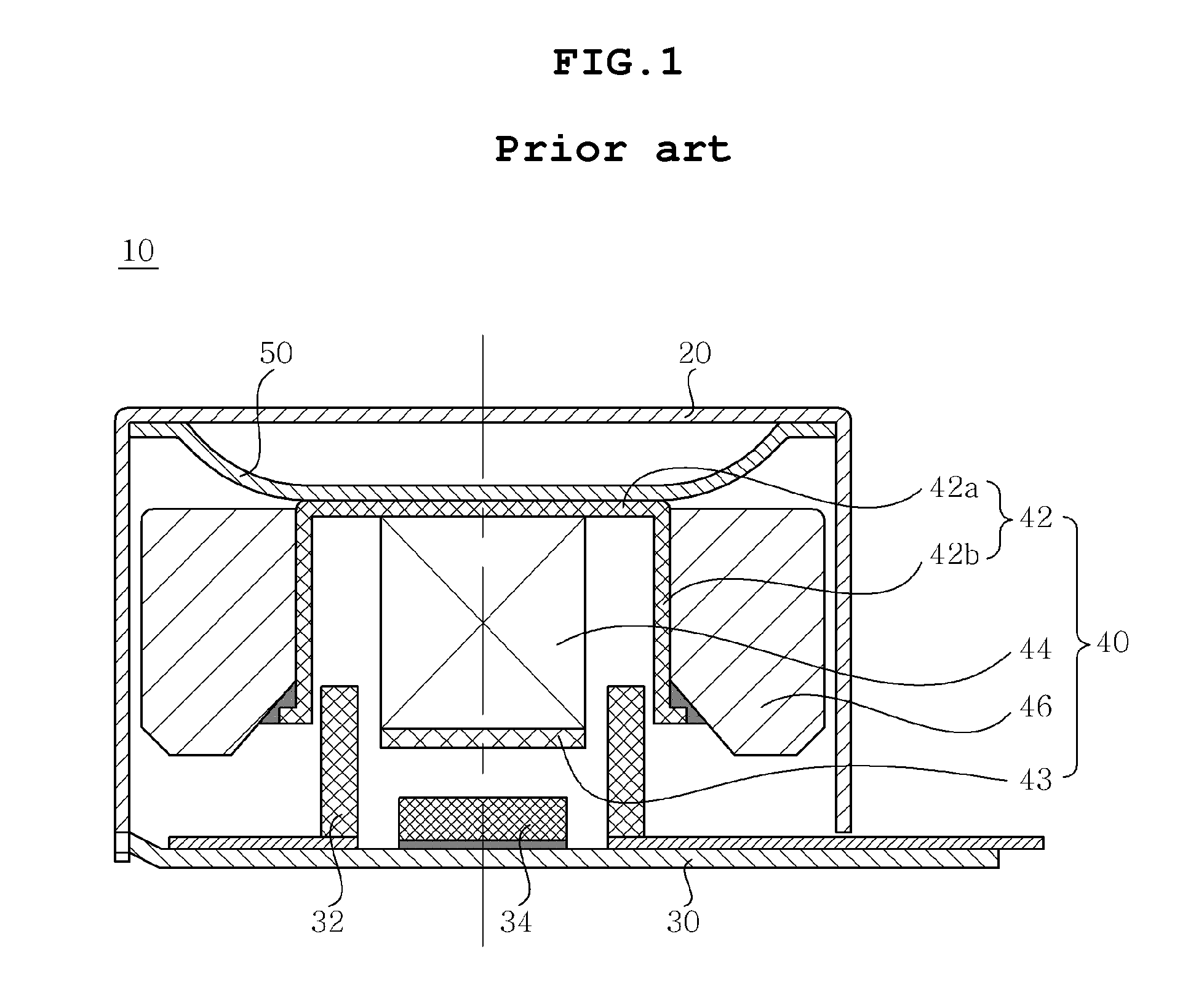

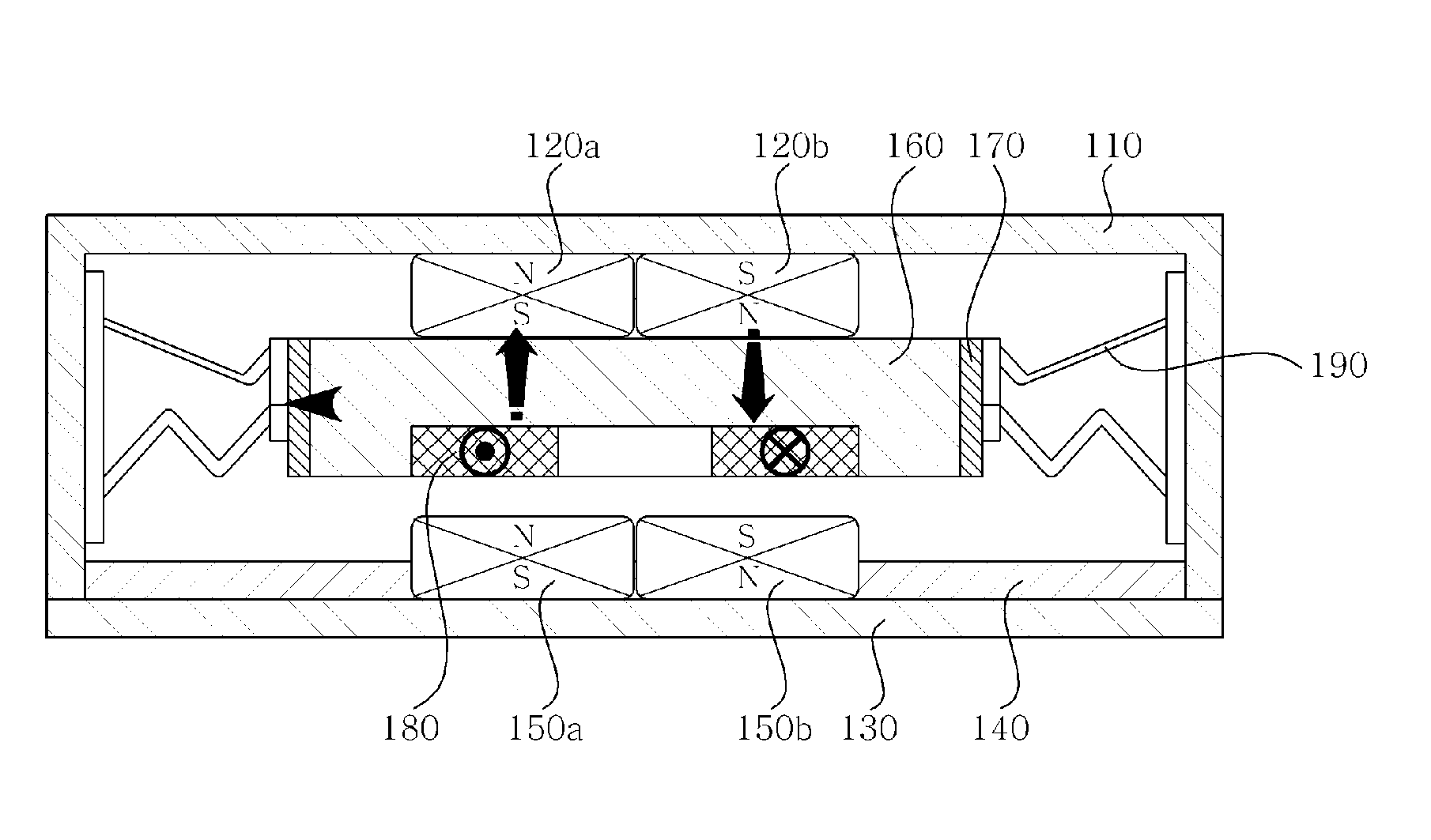

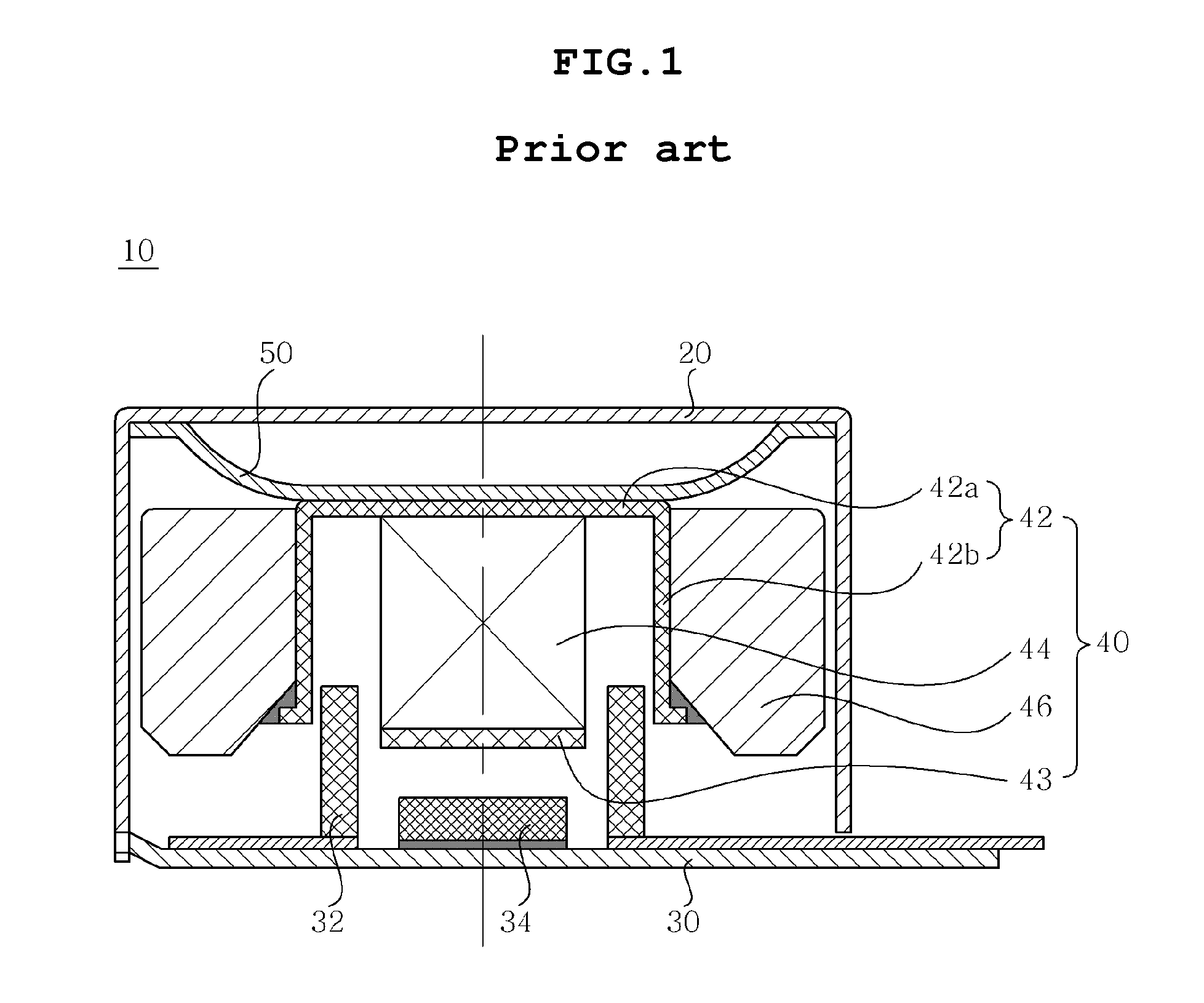

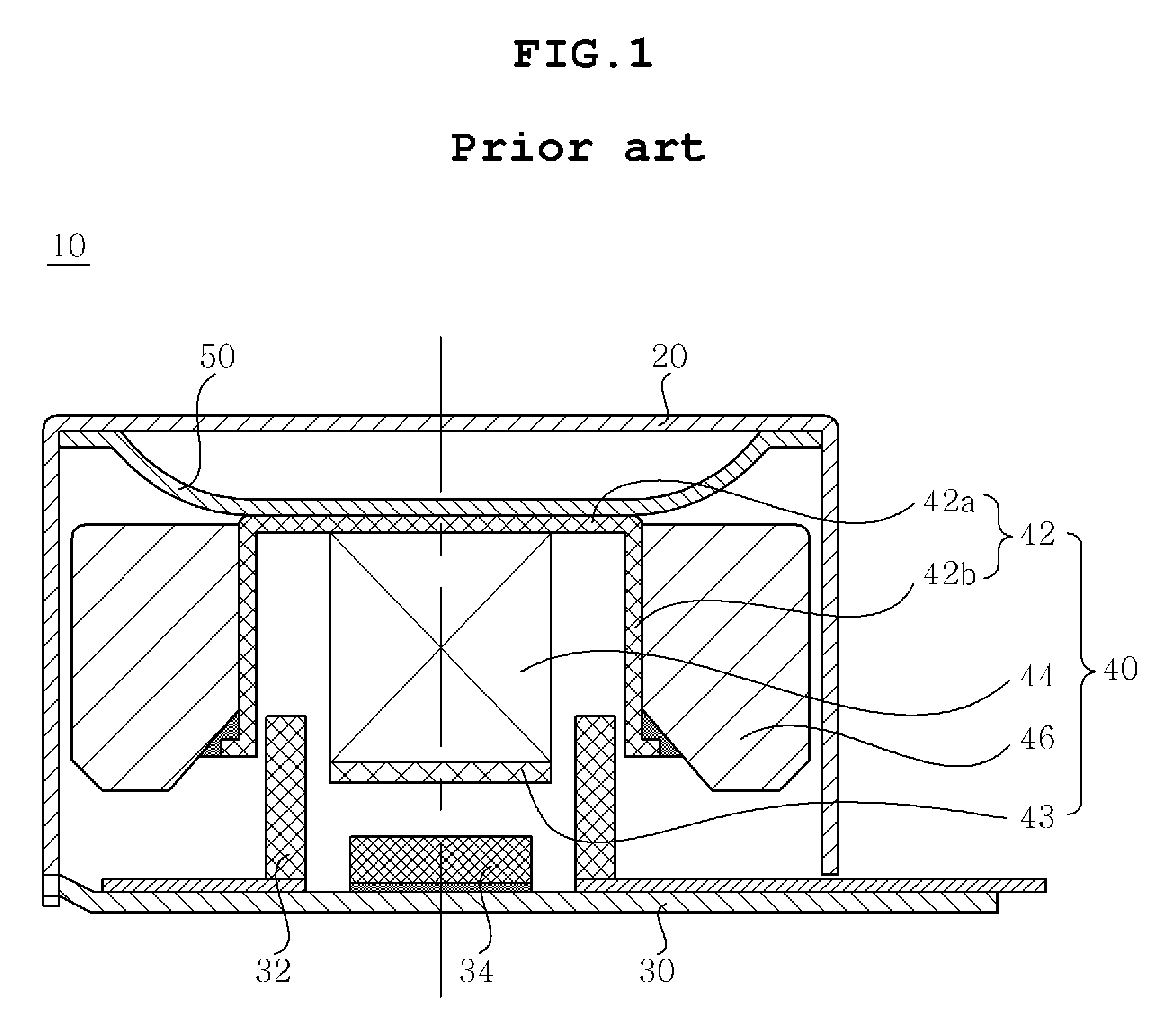

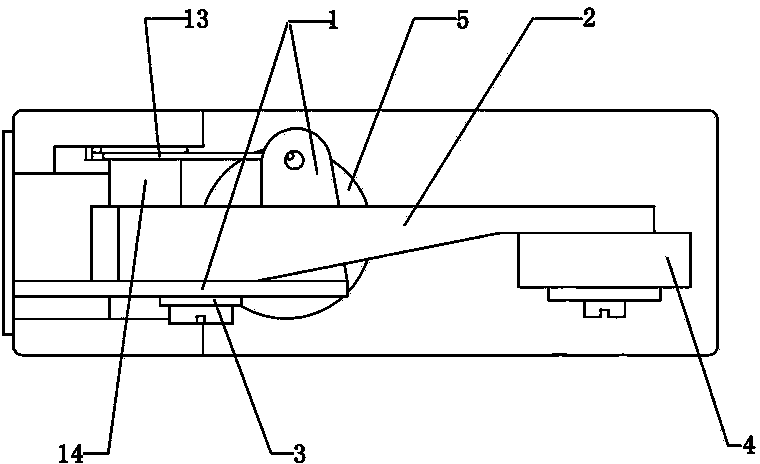

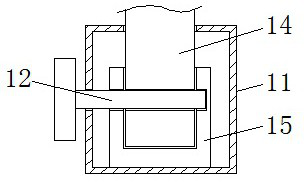

Horizontal linear vibrator

ActiveUS20110018364A1Reduce thicknessIncrease vibration intensityMagnetic circuitMechanical energy handlingInterior spaceResponsivity

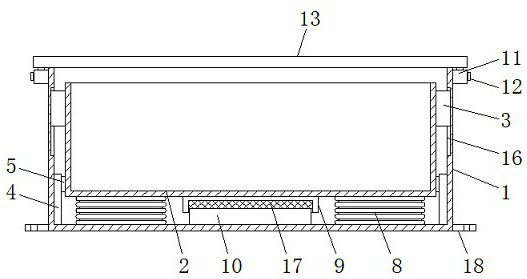

The present invention provides a horizontal linear vibrator which can reduce the thickness but increase the strength of vibrations while at the same time guaranteeing a sufficiently long lifetime and satisfactory responsivity. The horizontal linear vibrator includes a casing, a bracket, a vibration unit and springs. The casing defines an internal space therein. A first magnet is attached to an upper plate of the casing. The bracket is coupled to the lower end of the casing. The second magnet is attached to the bracket such that different poles of the first and second magnets face each other. The vibration unit has a weight, and a cylindrical coil which is provided in or under the weight. The springs are coupled to the sidewall plates of the casing or the bracket. The springs elastically support the vibration unit to allow the vibration unit to vibrate in the horizontal direction.

Owner:PARTRON

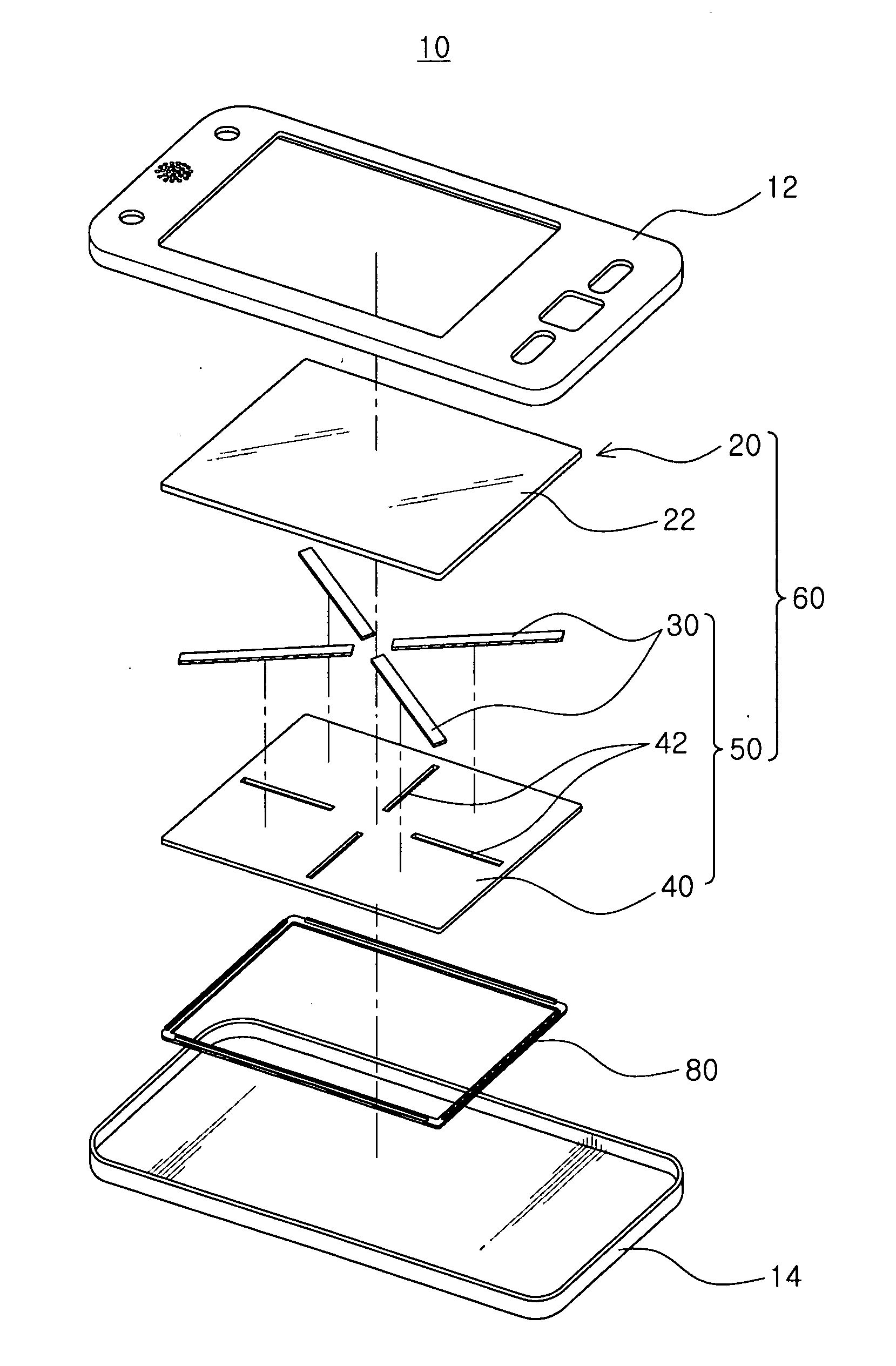

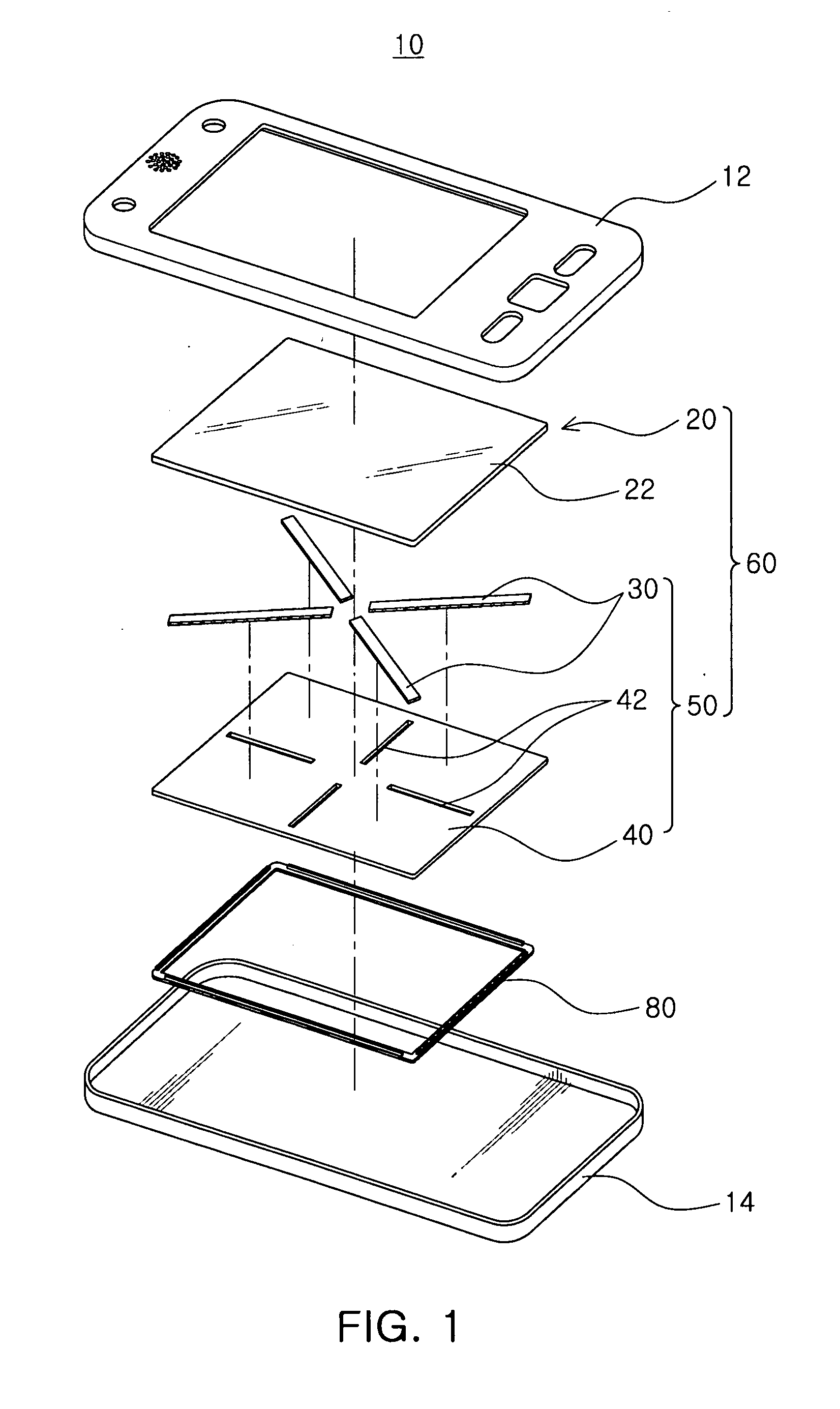

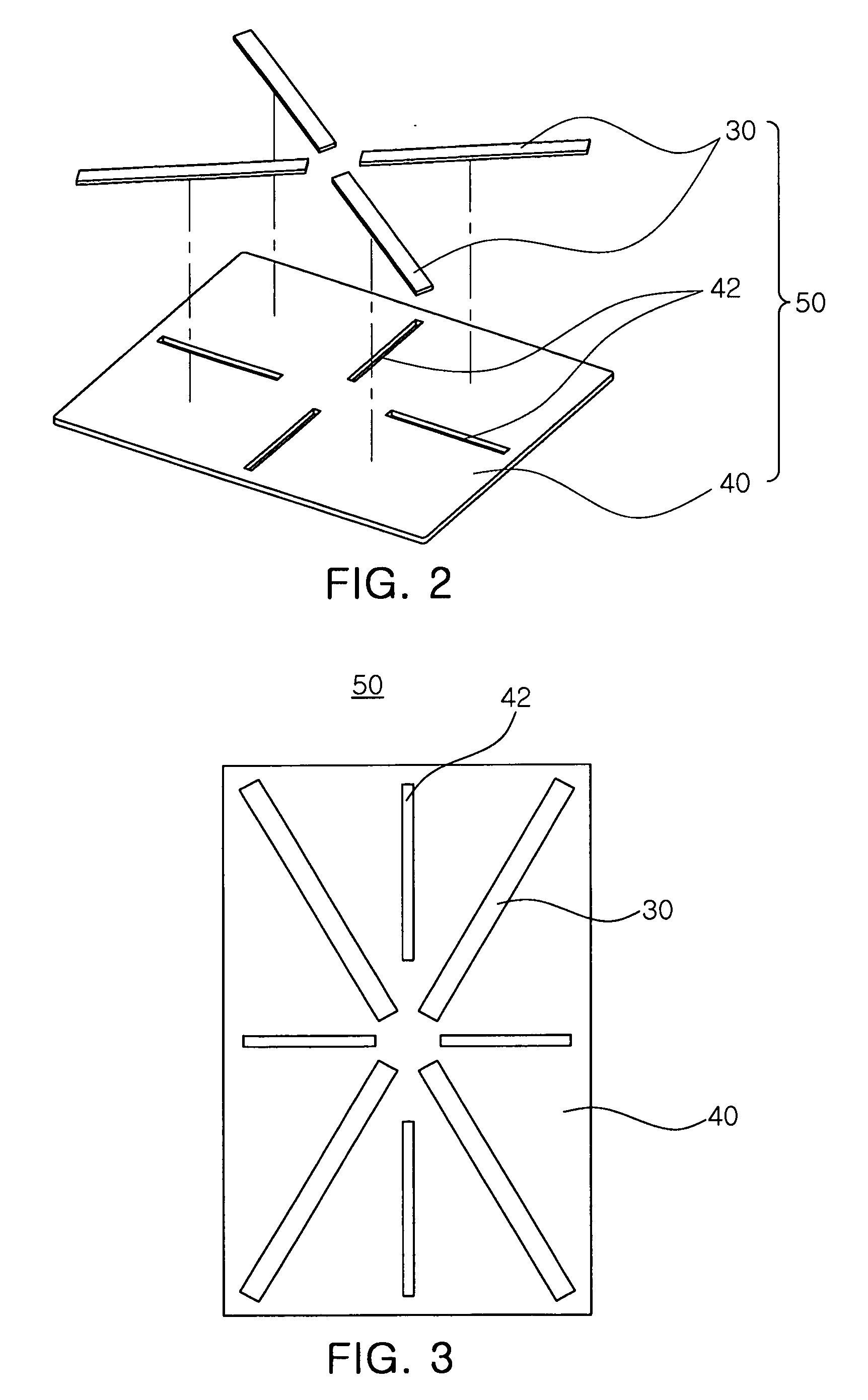

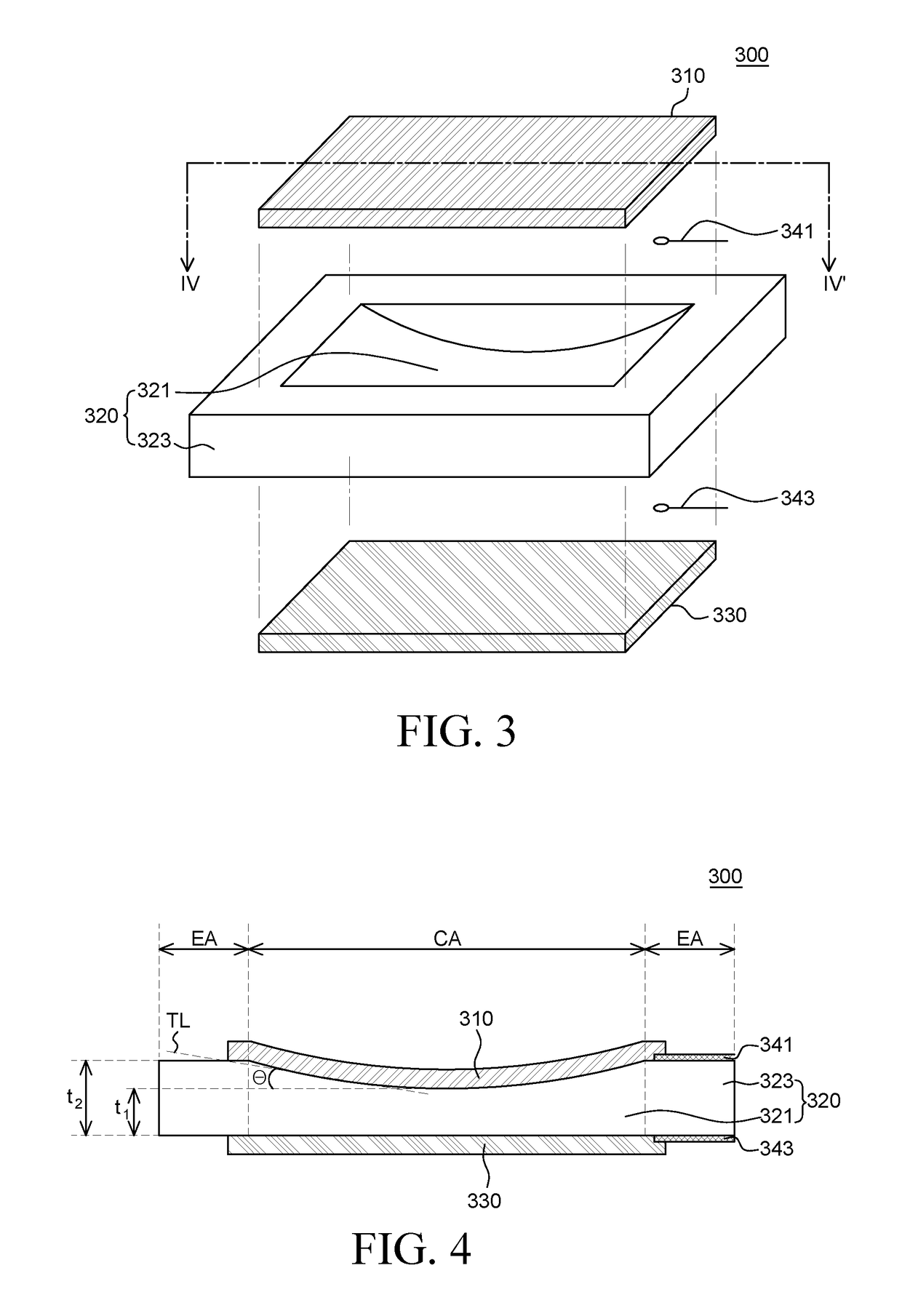

Haptic feedback actuator, haptic feedback device and electronic device

InactiveUS20120038471A1Increase vibration intensityUniform haptic feedbackDigital data processing detailsRepeater circuitsContact pressureTactile device

There is provided a haptic feedback actuator, a haptic feedback device and an electronic device. The haptic feedback actuator includes a support plate disposed in a lower portion of a haptic device; one or more actuators disposed on the support plate, each having one end towards a central portion of the support plate and the other end towards a corner of the support plate, and generating vibrations so as to give different types of haptic feedback according to a change in contact pressure applied to the haptic device; and one or more dividing portions, each penetrating the support plate in a thickness direction thereof and dividing the support plate into vibration areas corresponding to the respective actuators.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

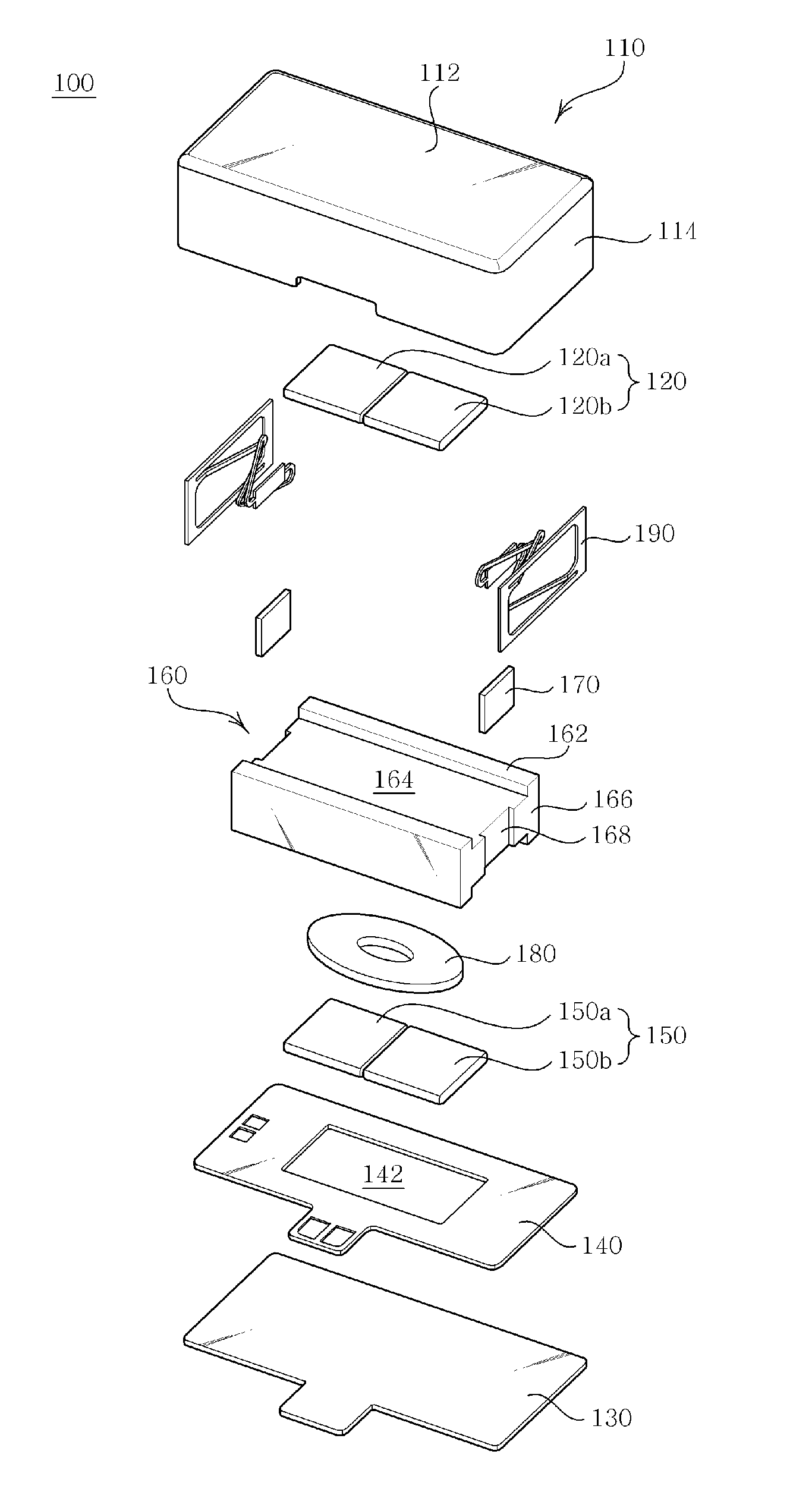

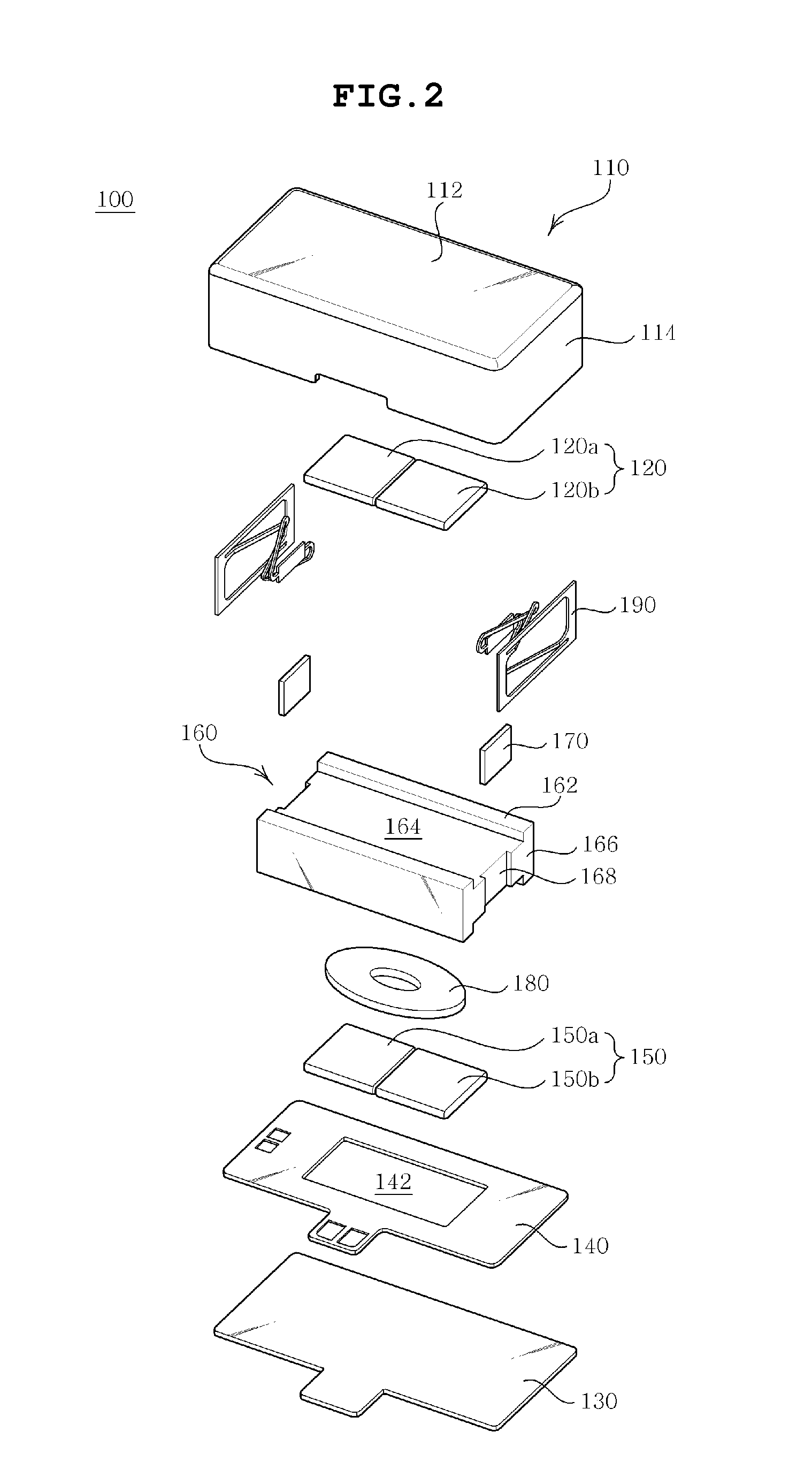

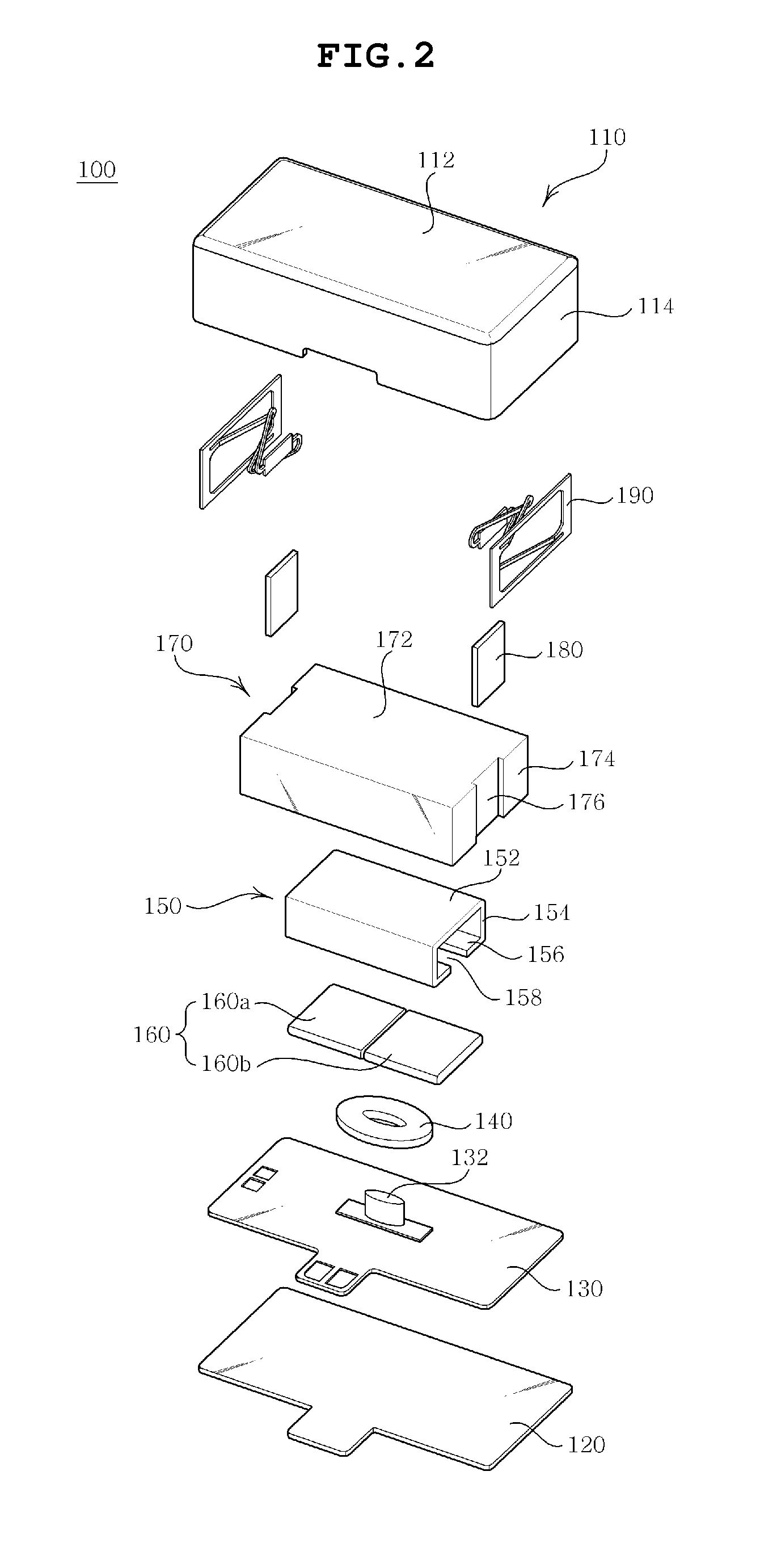

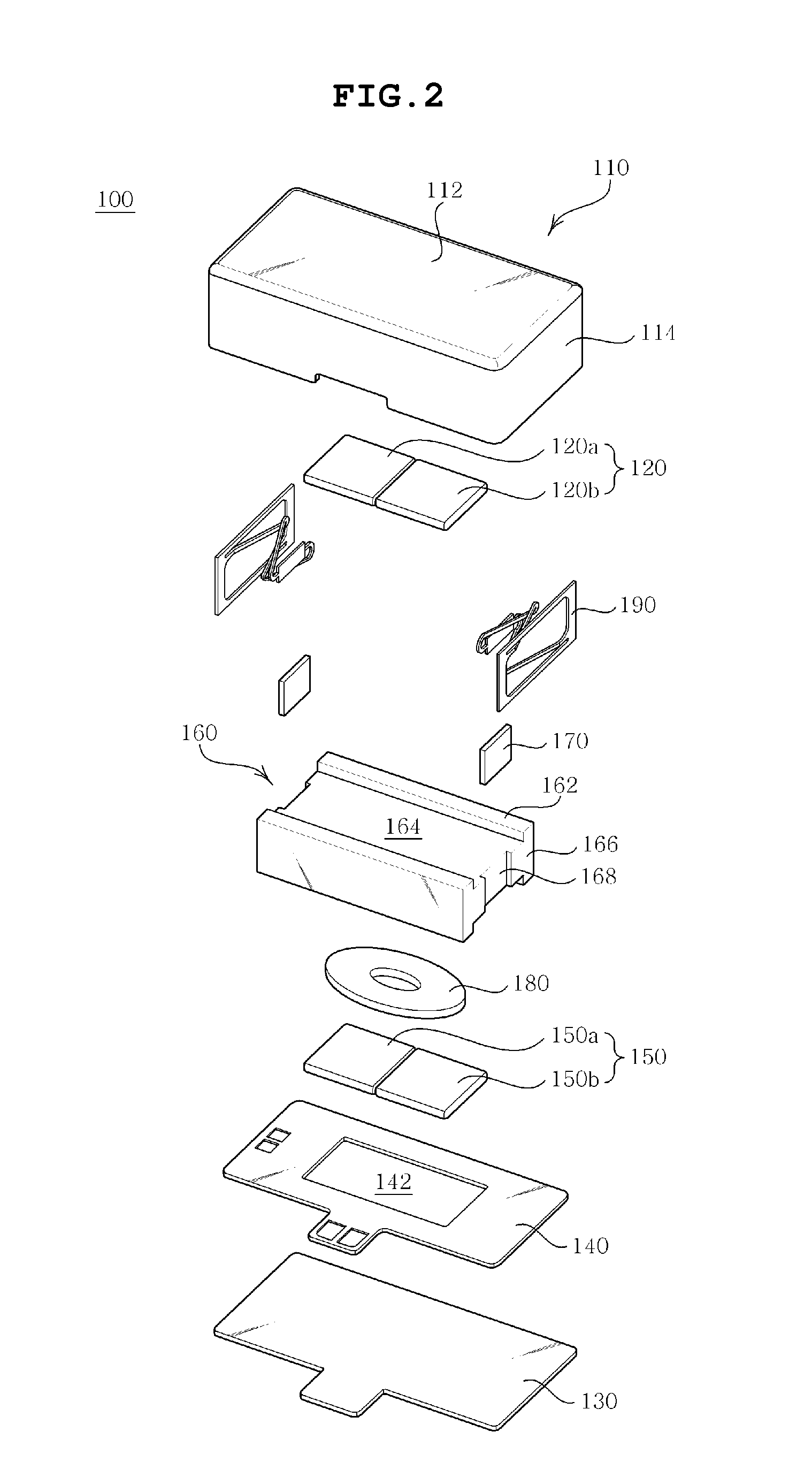

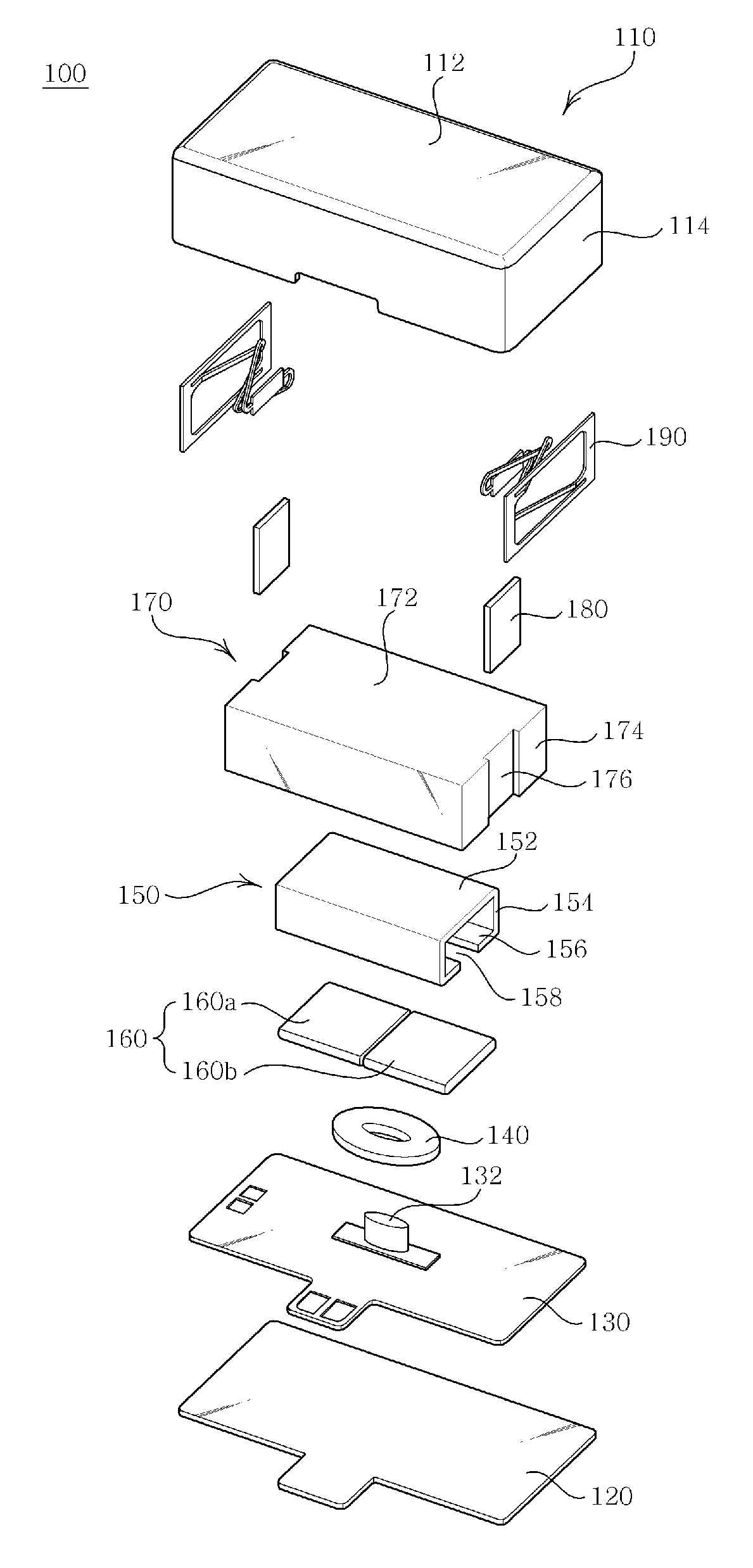

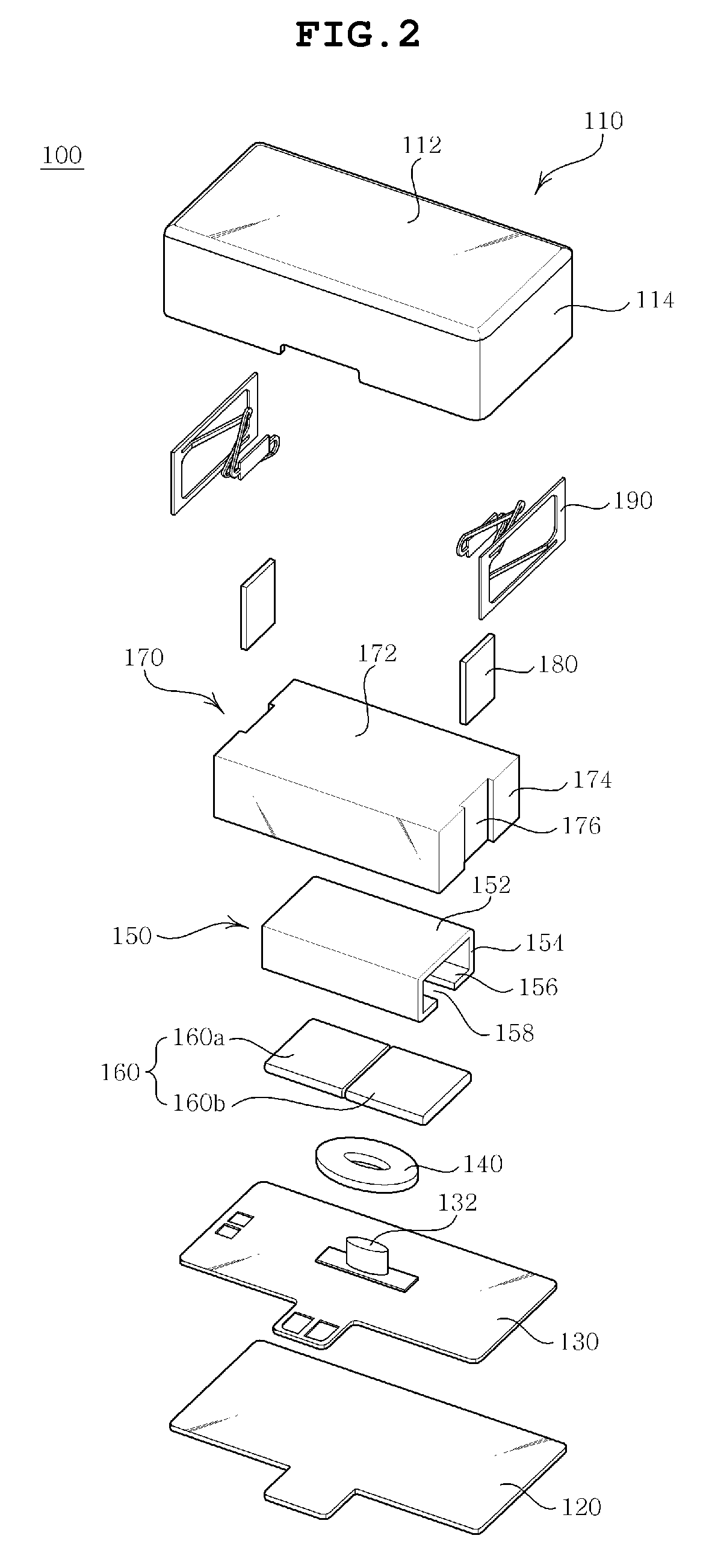

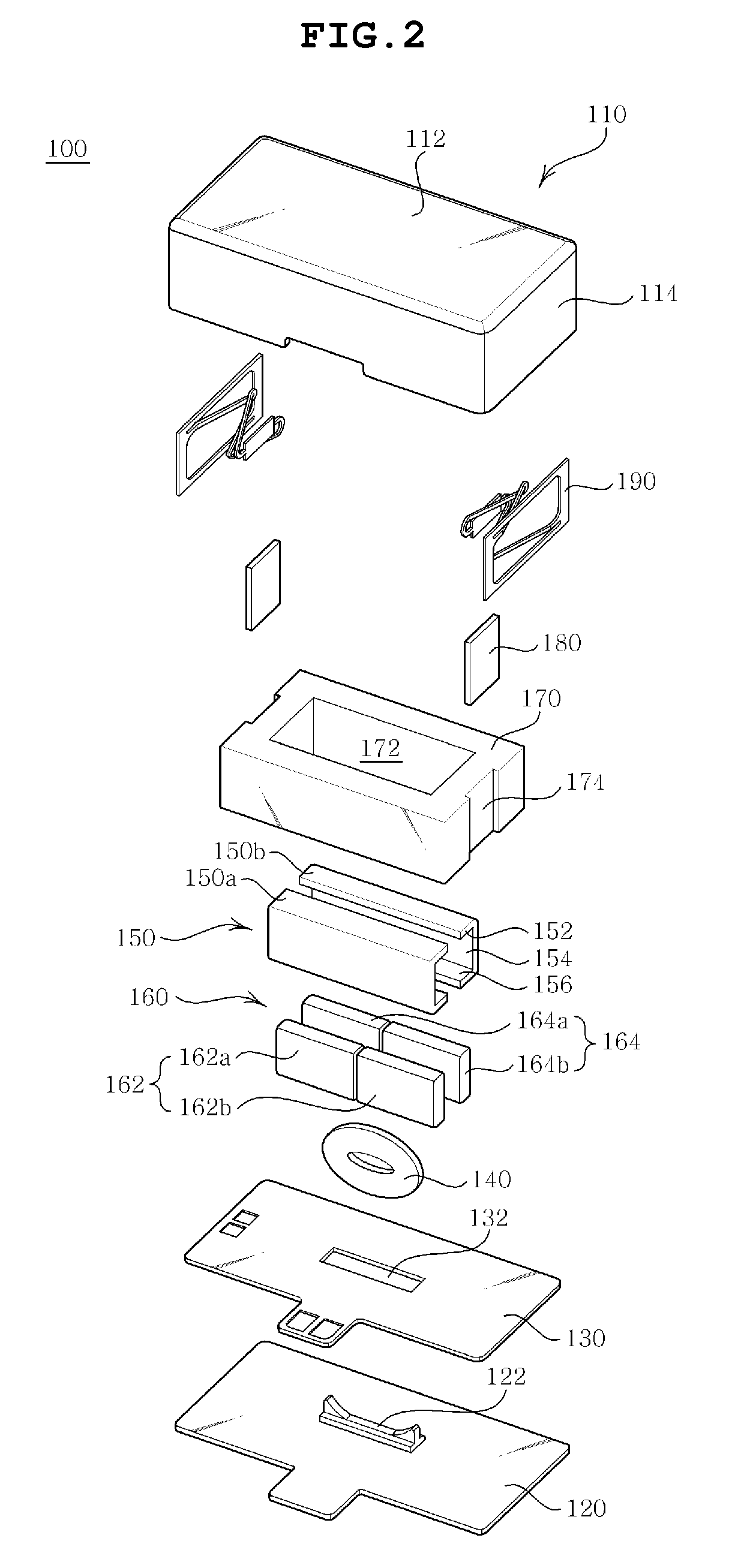

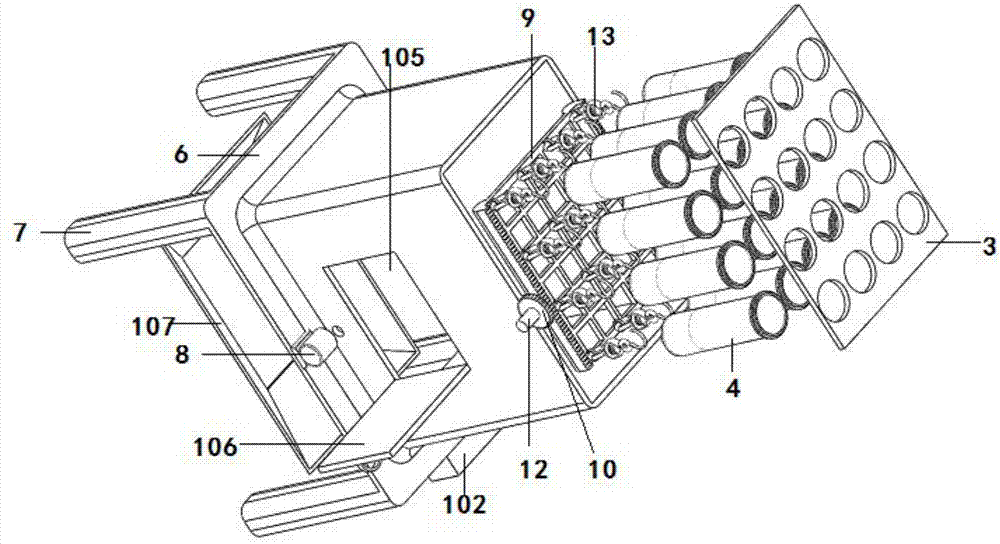

Horizontal linear vibrator

InactiveUS20140152126A1Reduce thicknessIncrease vibration intensityMechanical vibrations separationDynamo-electric machinesResponsivityEngineering

The present invention provides a horizontal linear vibrator which can reduce the thickness but increase vibration strength while at the same time guaranteeing a sufficiently long lifetime and satisfactory responsivity. The horizontal linear vibrator includes a casing, a bracket, a vibration unit and springs. The casing defines an internal space therein. The bracket is disposed under the casing. A cylindrical coil is provided on the bracket. The vibration unit has a magnet, a yoke and a weight. The yoke contains the magnet therein and is open on the lower end thereof. The weight is coupled to the outer surface of the yoke. The springs are coupled to sidewall plates of the casing or the bracket. The springs elastically support the vibration unit to allow the vibration unit to vibrate in the horizontal direction.

Owner:MPLUS

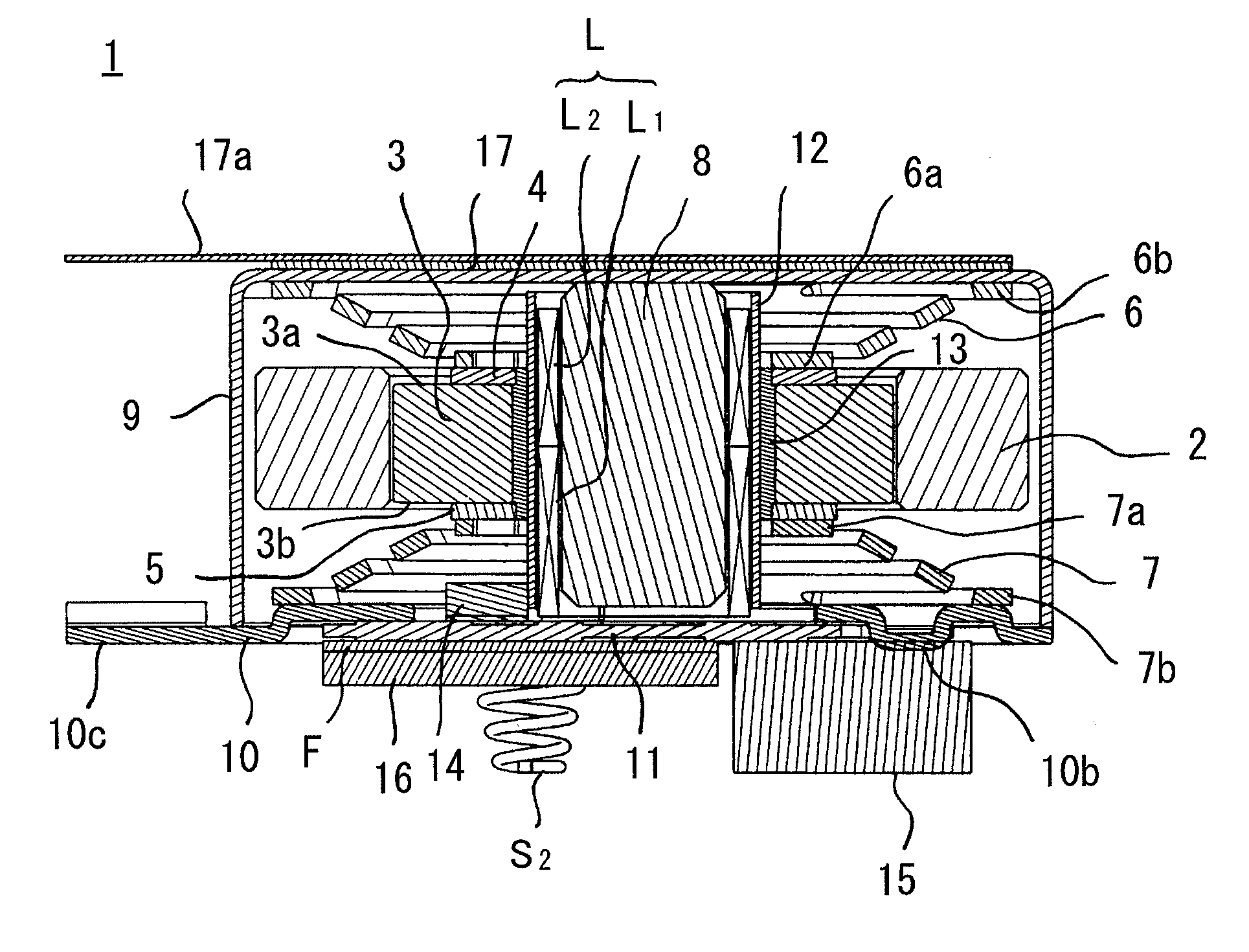

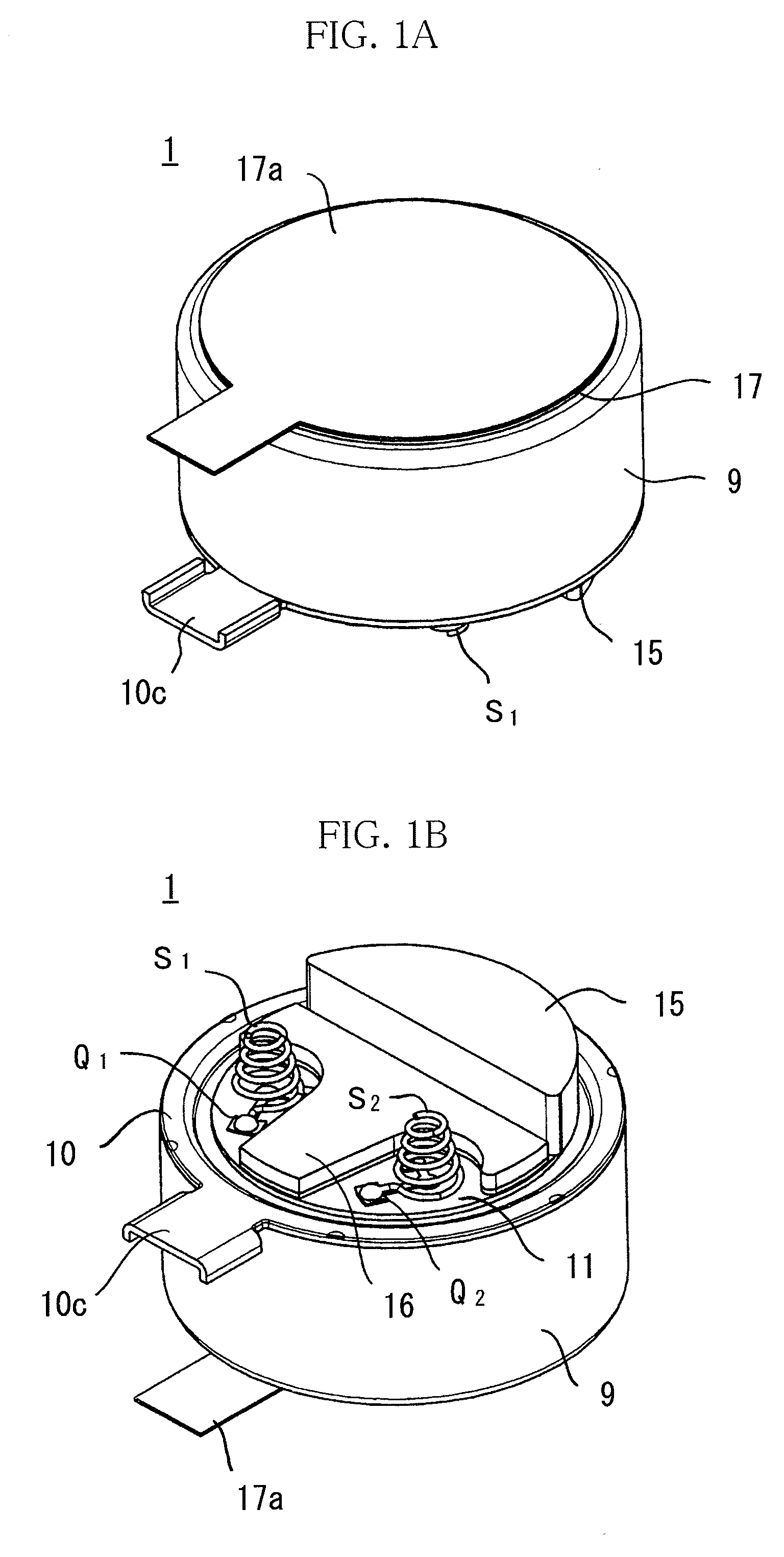

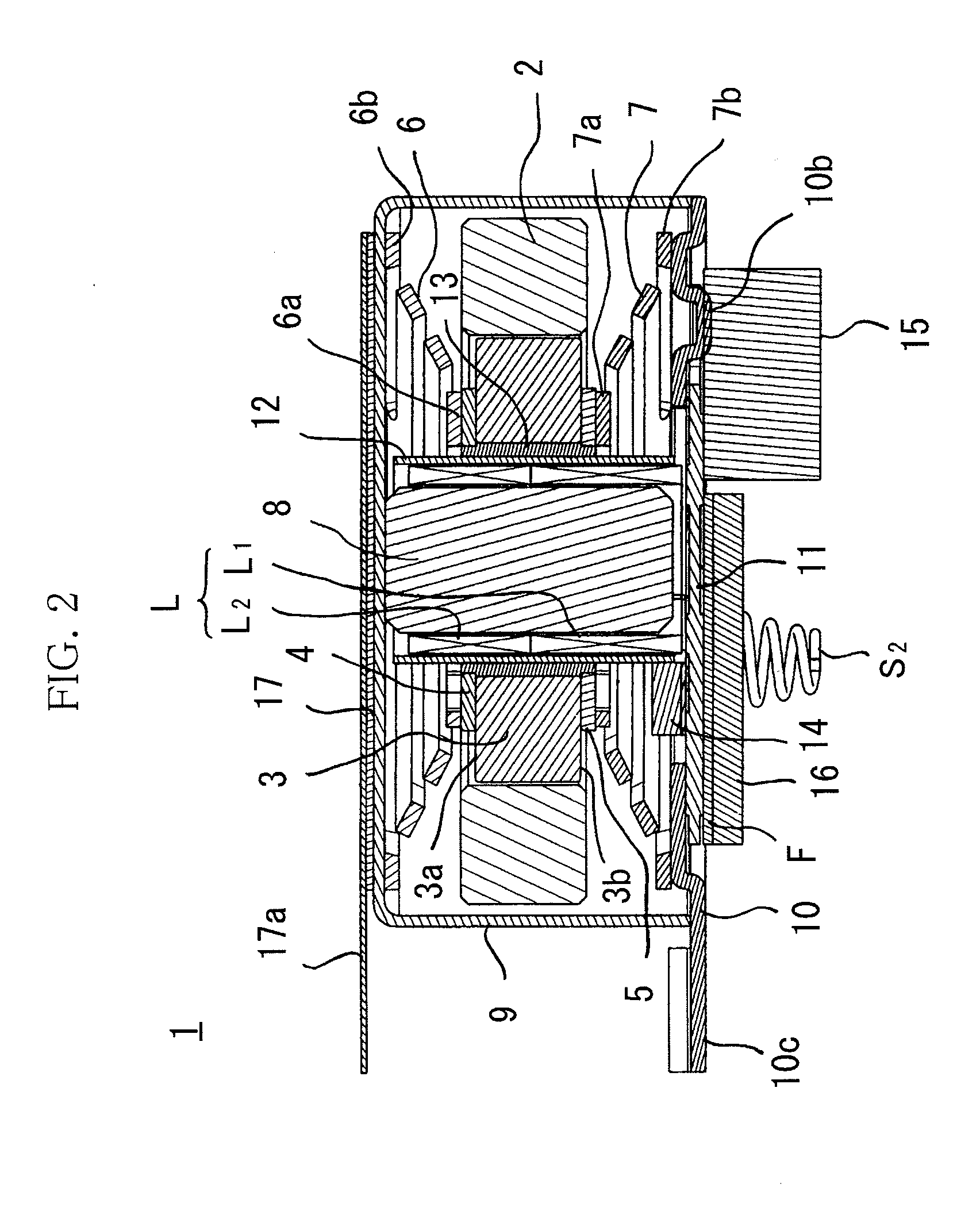

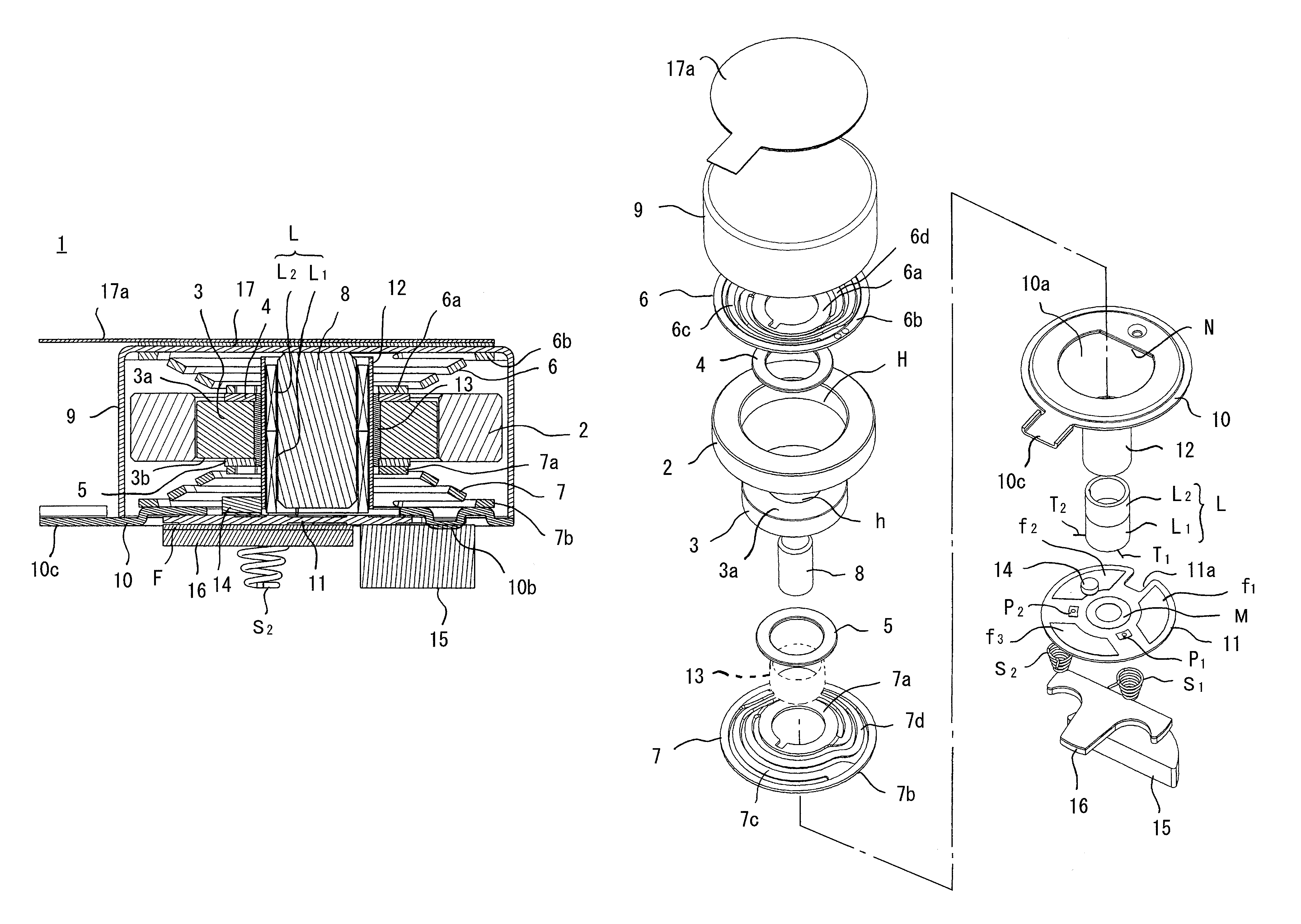

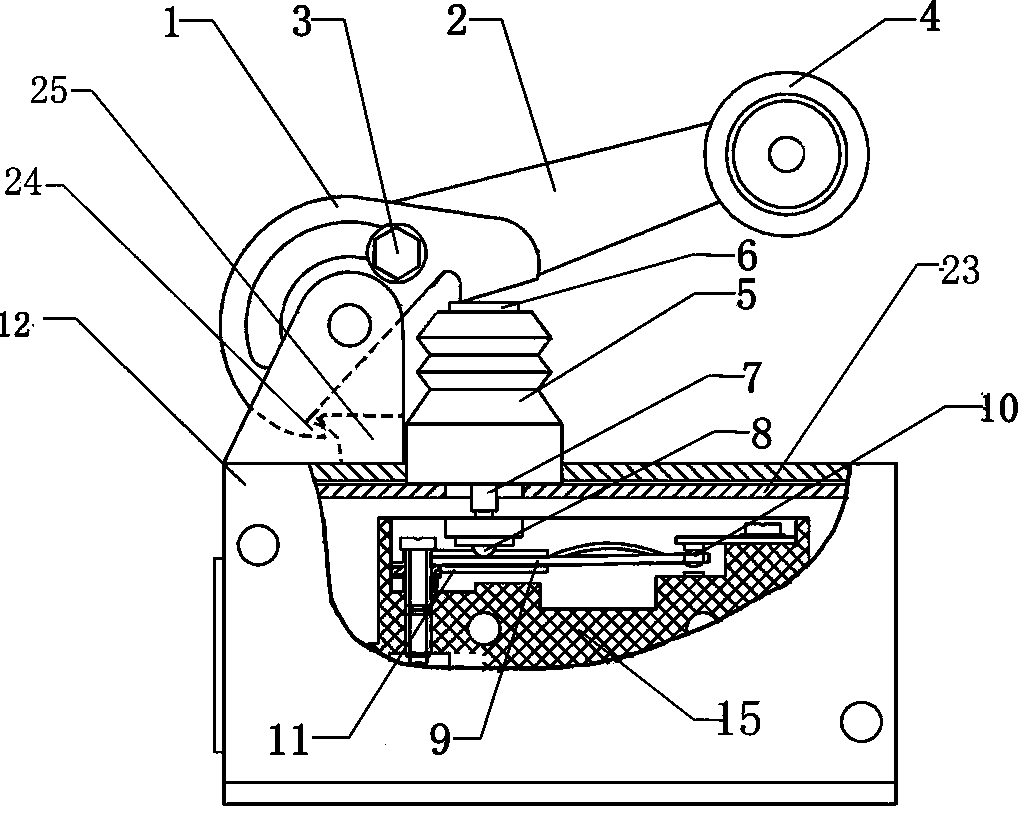

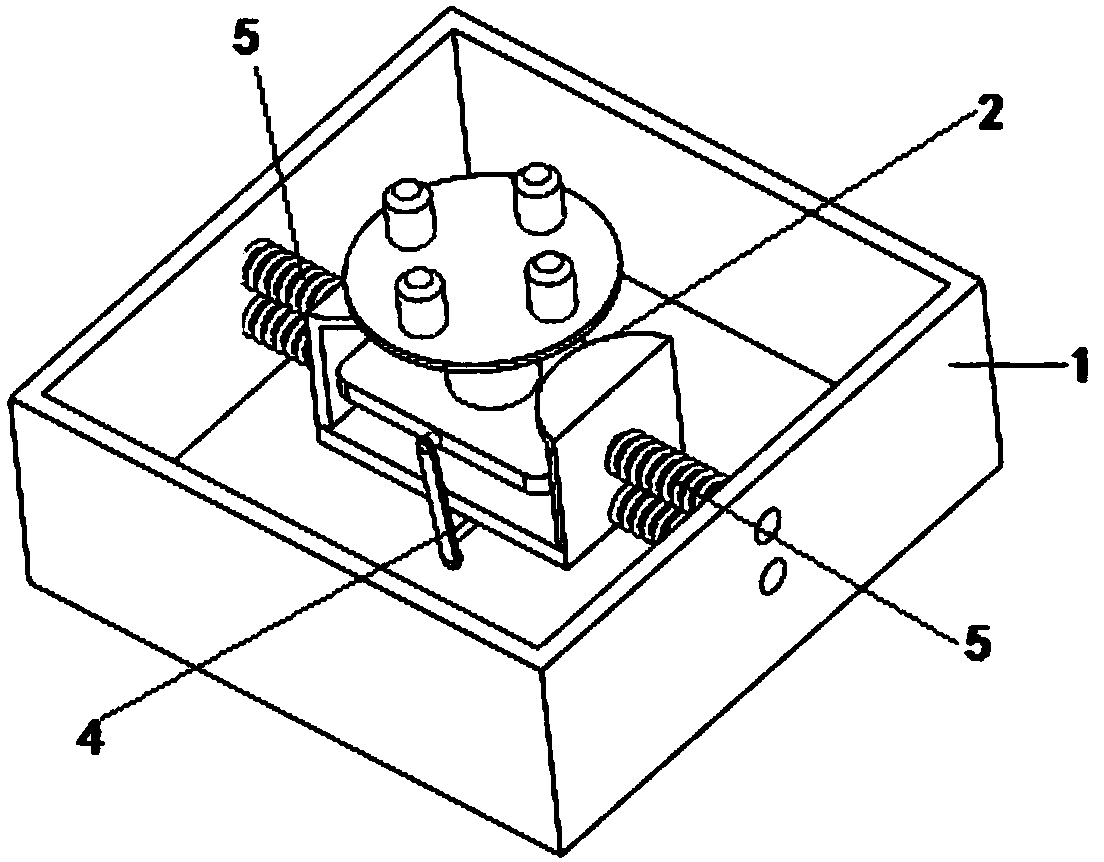

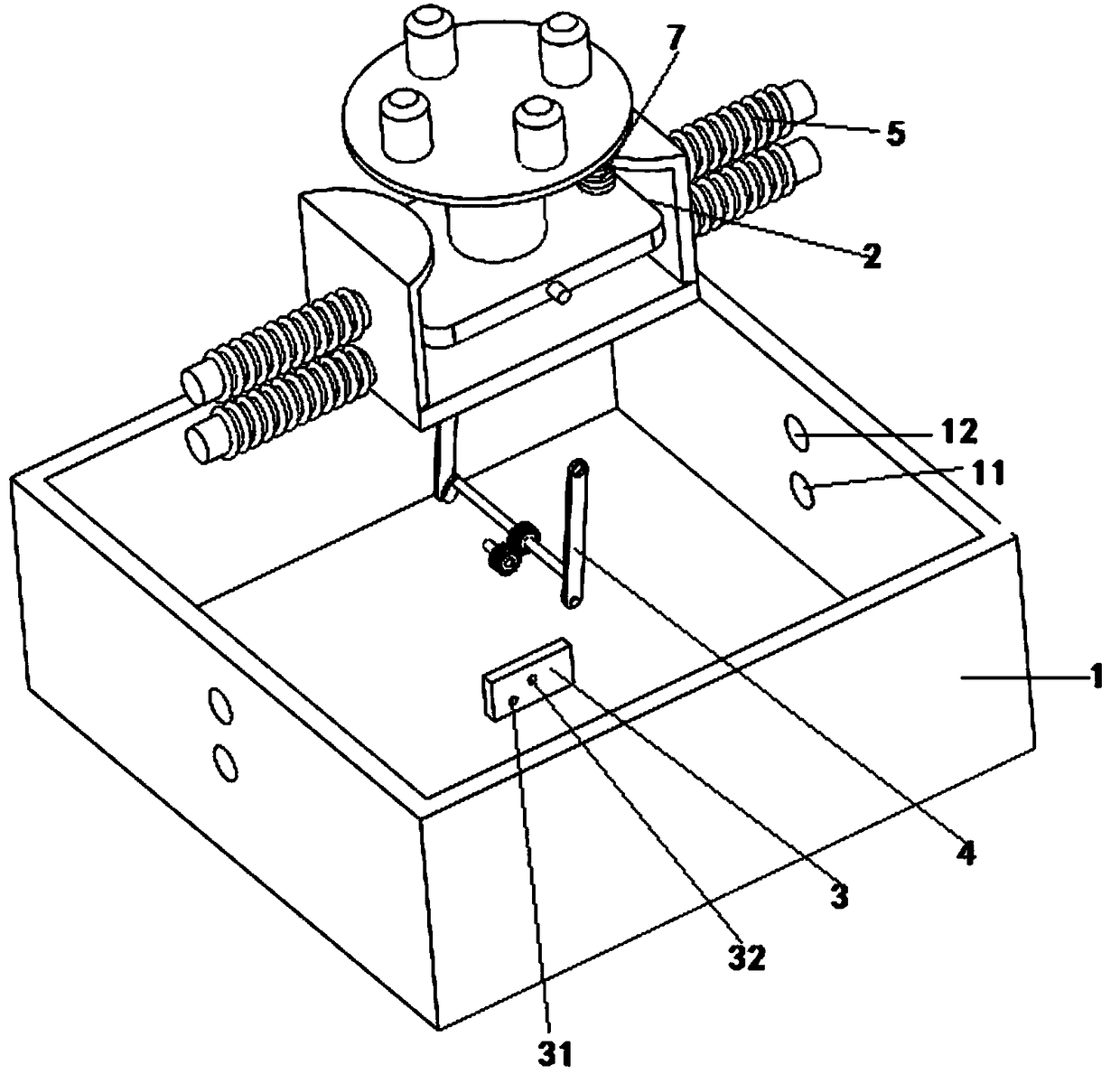

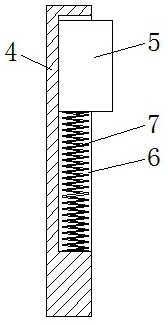

Recirocating vibration generator

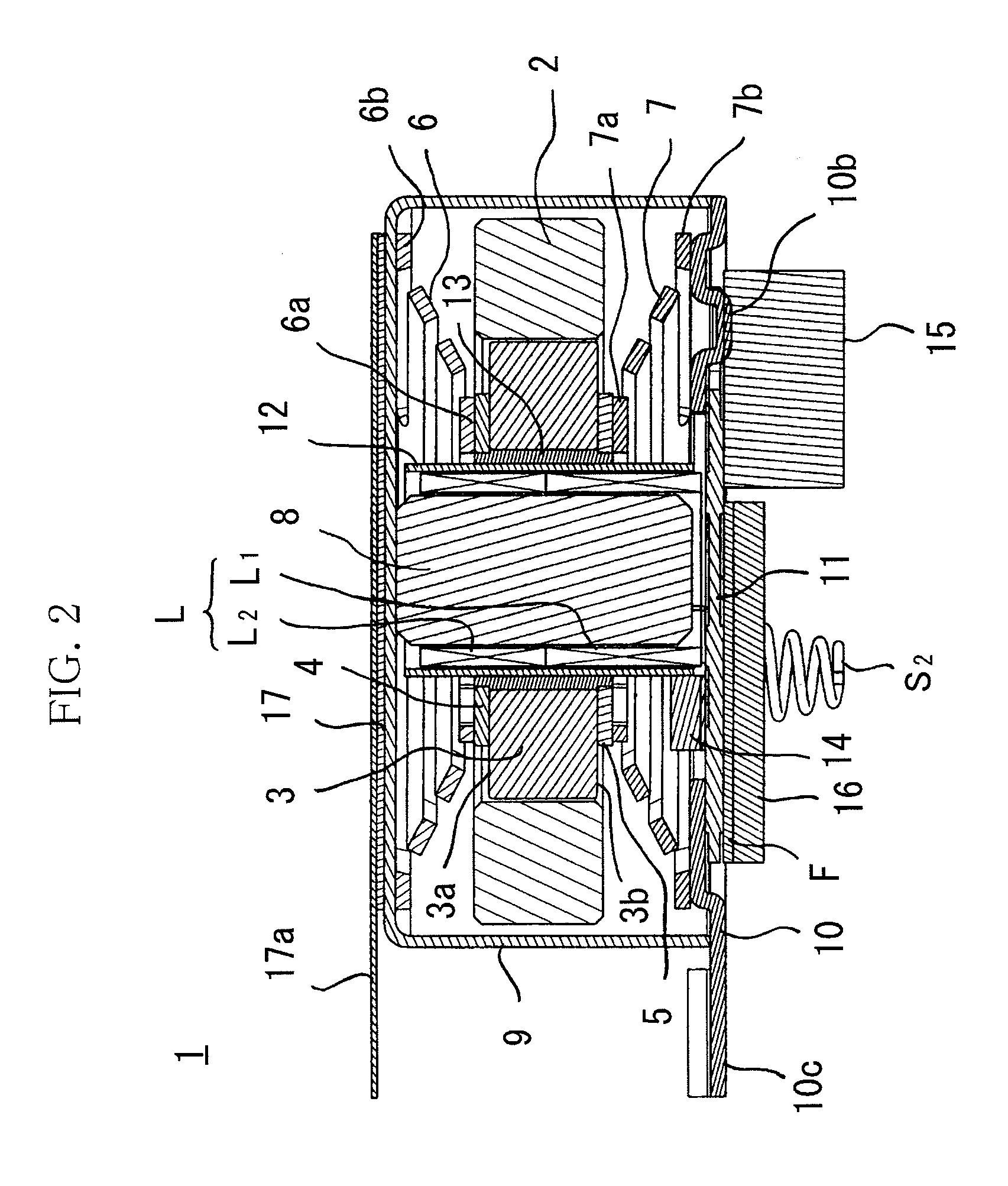

InactiveUS20110198948A1Increase vibration intensityReduce power consumptionMechanical vibrations separationSupports/enclosures/casingsReciprocating motionClosed loop

A reciprocating vibration generator making the magnetic circuit of a permanent magnet a closed loop so as to obtain a high vibration force, specifically a vibration linear actuator having a ring-shaped weight, a reciprocating vibrator having a ring-shaped permanent magnet in a center hole of the weight, a first plate spring and a second plate spring supporting this reciprocating vibrator with respect to a recessed case and an end plate to be able to elastically displace in a thickness direction between a first end face and a second end face, a tube-shaped toroidal coil running through a center hole of the ring-shaped permanent magnet and generating a reciprocating vibration magnetic field for driving the ring-shaped permanent magnet to reciprocate in the thickness direction, and a columnar core running through the inside of this toroidal coil, wherein the ring-shaped permanent magnet is magnetized in the thickness direction, and the toroidal coil has a lower stage toroidal coil and an upper stage toroidal coil coaxial with and adjacent to the same, wound in the opposite direction, and connected in series with the same.

Owner:SANYO SEIMITSU

Ultrasonic fingerprint identification region marking system with no need to carry out extra processing on mobile phone panel

InactiveCN106535310AFamiliar with implementationIncrease vibration intensityInput/output for user-computer interactionPower managementComputer moduleOn-screen display

The invention provides an ultrasonic fingerprint identification region marking system with no need to carry out extra processing on a mobile phone panel. A fingerprint sensor can be hidden under the mobile phone panel without damaging the completeness of the panel. According to an existing scheme, in order to enable a user to find an ultrasonic fingerprint identification region, some extra processing is carried out on the mobile phone panel, for example, a sunken region is processed on the mobile phone panel, thereby enabling the user to identify. The invention provides the ultrasonic fingerprint identification region marking scheme with no need to carry out extra processing on the mobile phone panel. Through adoption of the scheme, a mobile phone display screen is an OLED screen; the whole screen stretches to the bottom of the mobile phone panel; through utilization of a micro power consumption feature when the OLED mobile phone screen displays black, the fingerprint identification region is marked by setting one part of the screen above a hidden fingerprint identification module to be constant bright; and the other part of the screen displays the black, thereby saving power; a user is guided through a mobile phone vibration unit, thereby informing the user of a fingerprint identification region range; and the completeness of the display panel does not need to be damaged for extra processing.

Owner:段赟

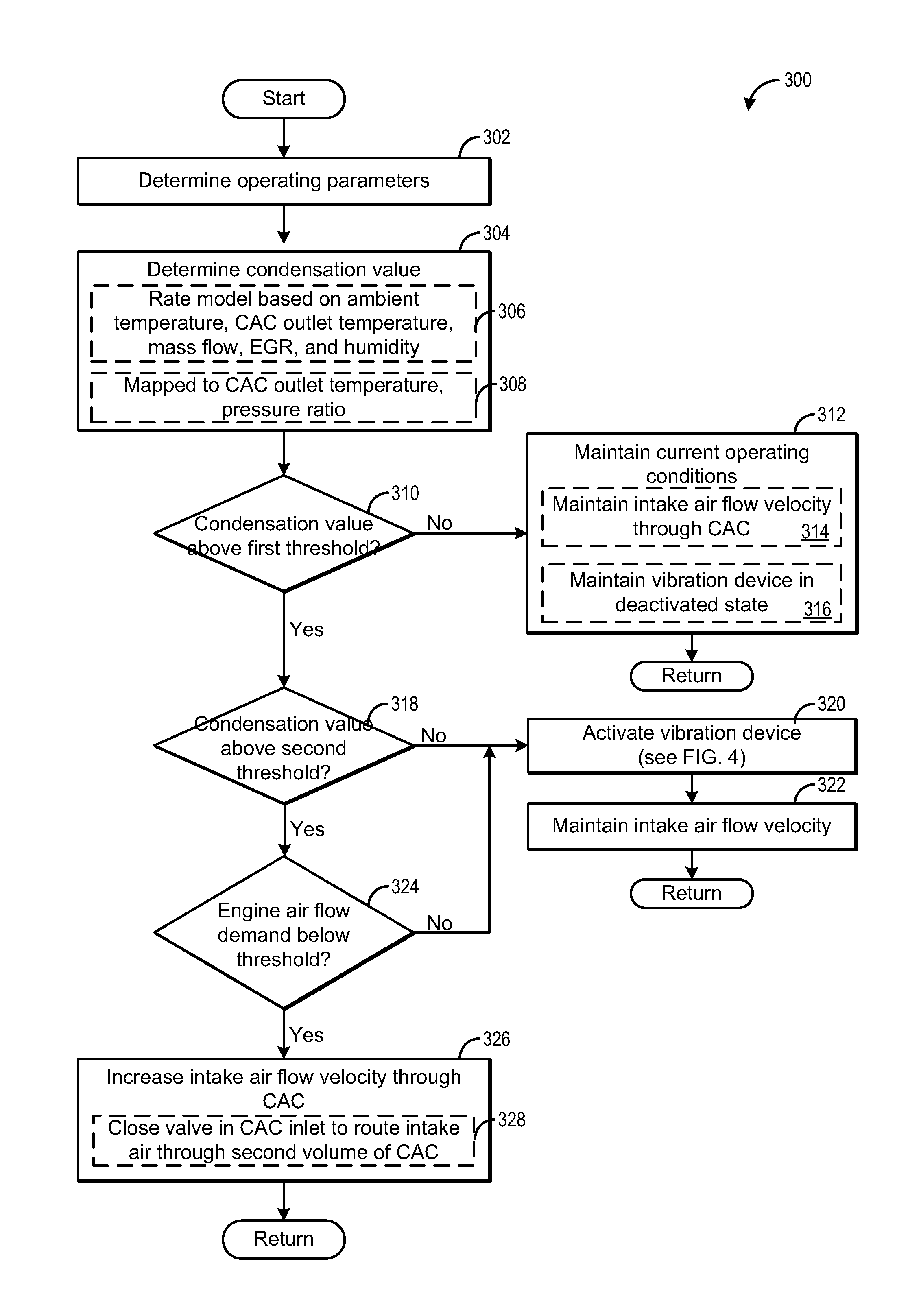

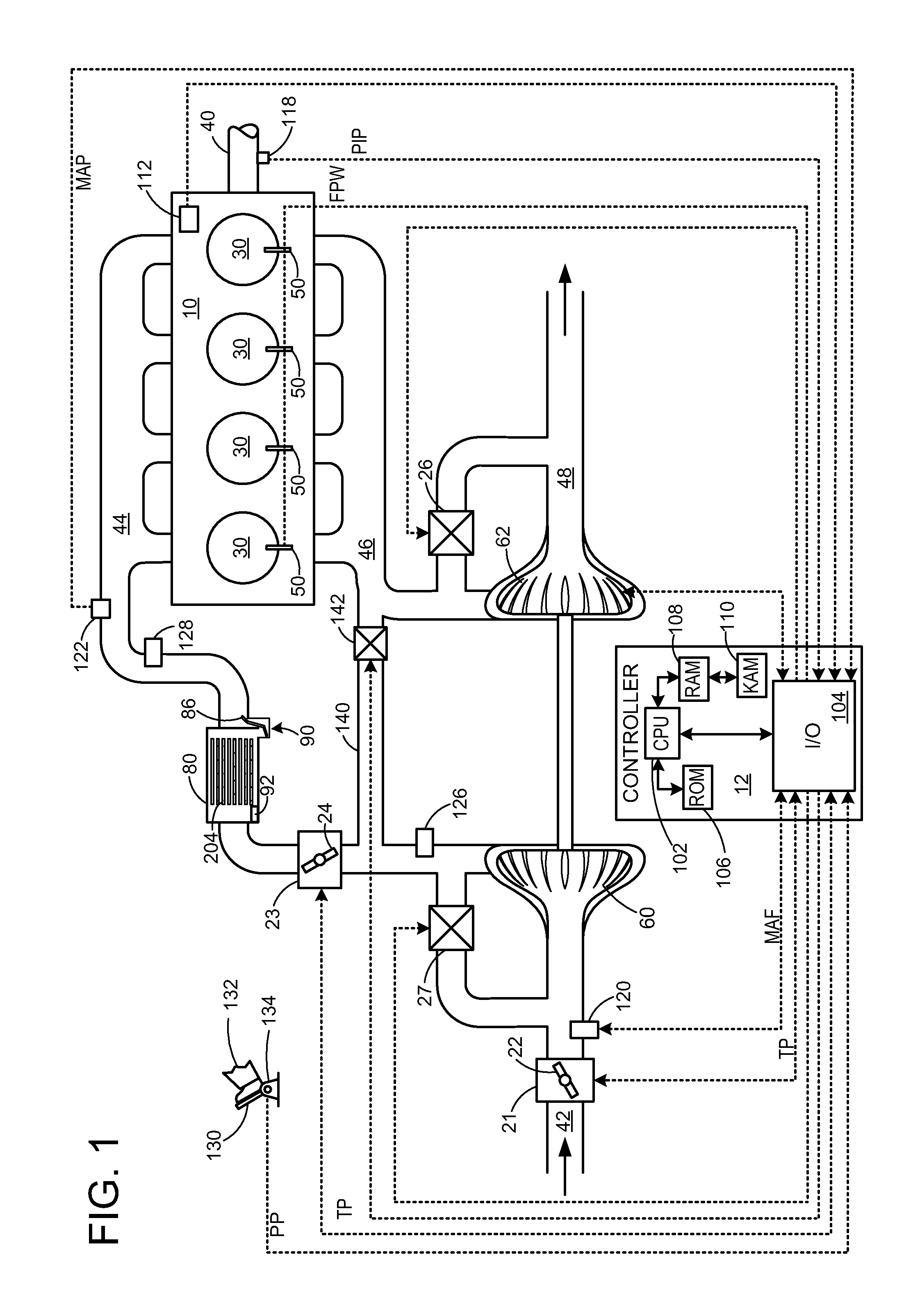

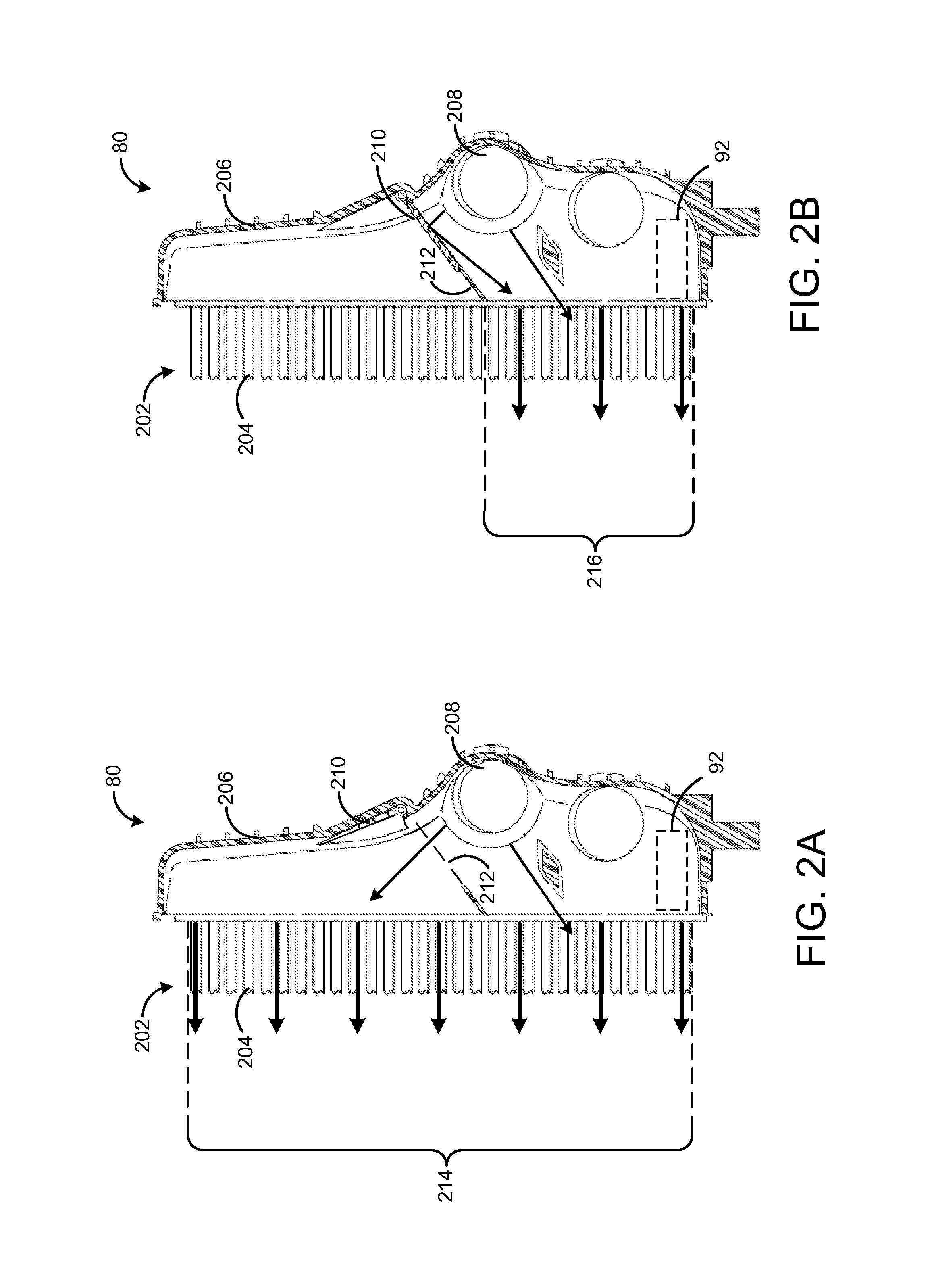

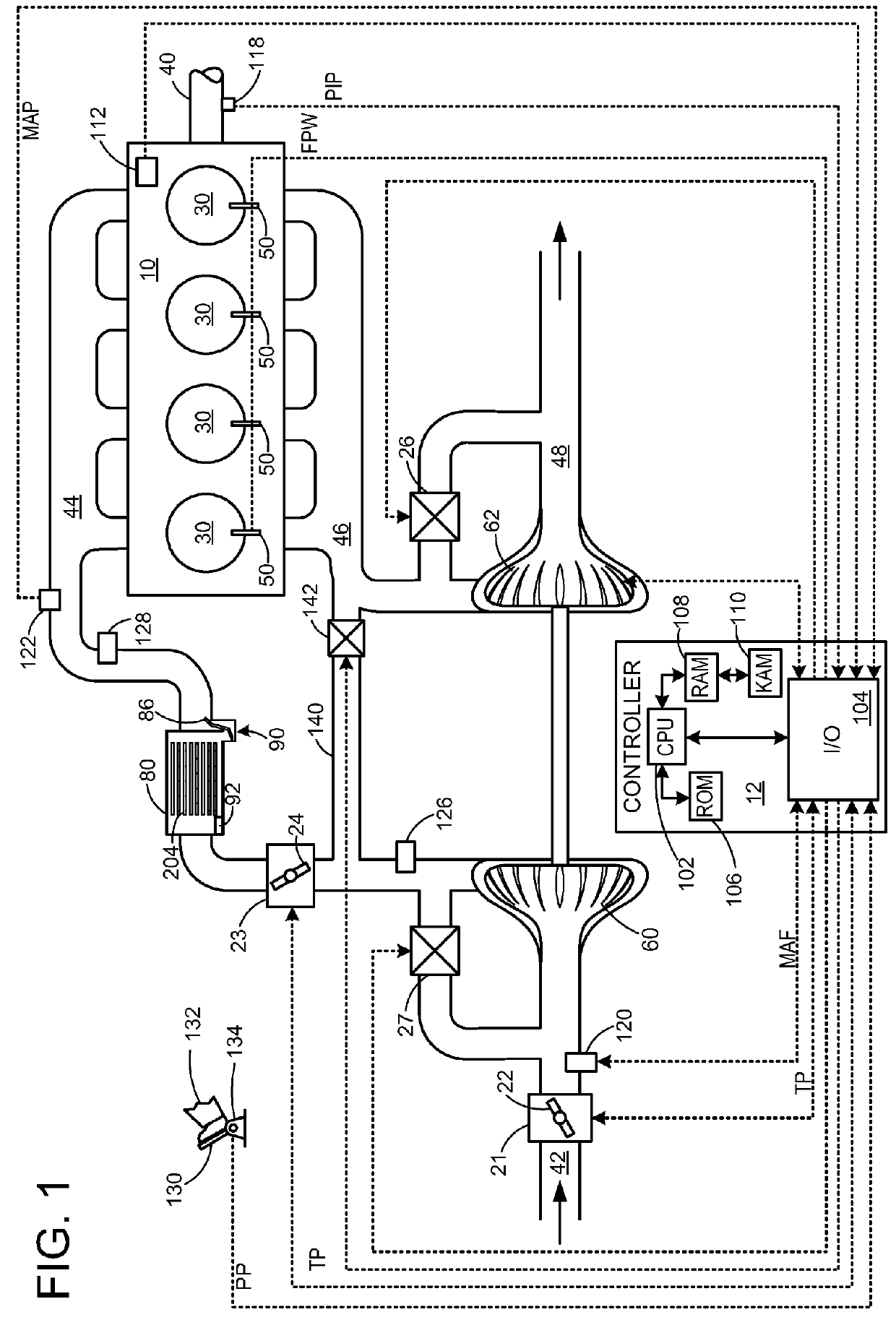

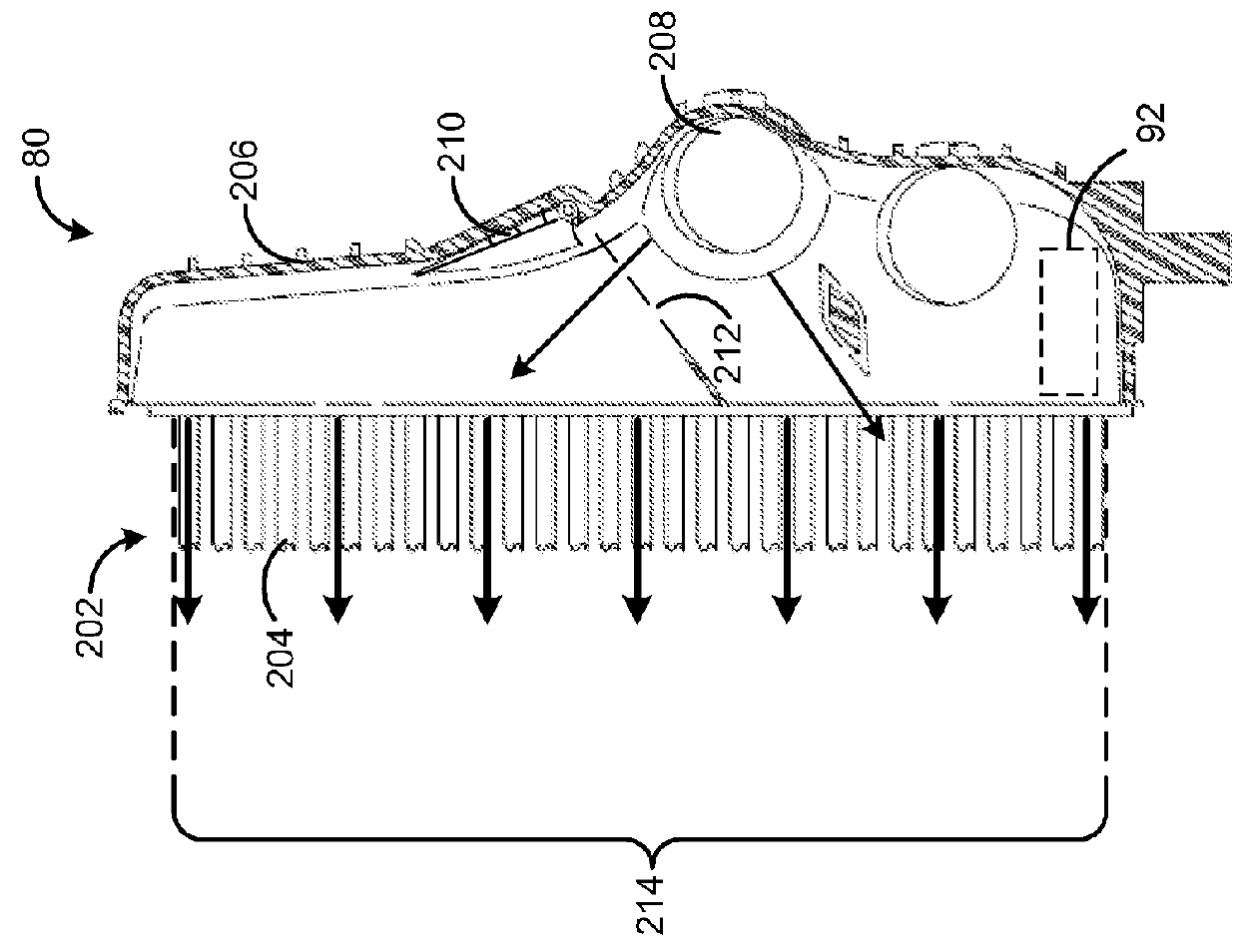

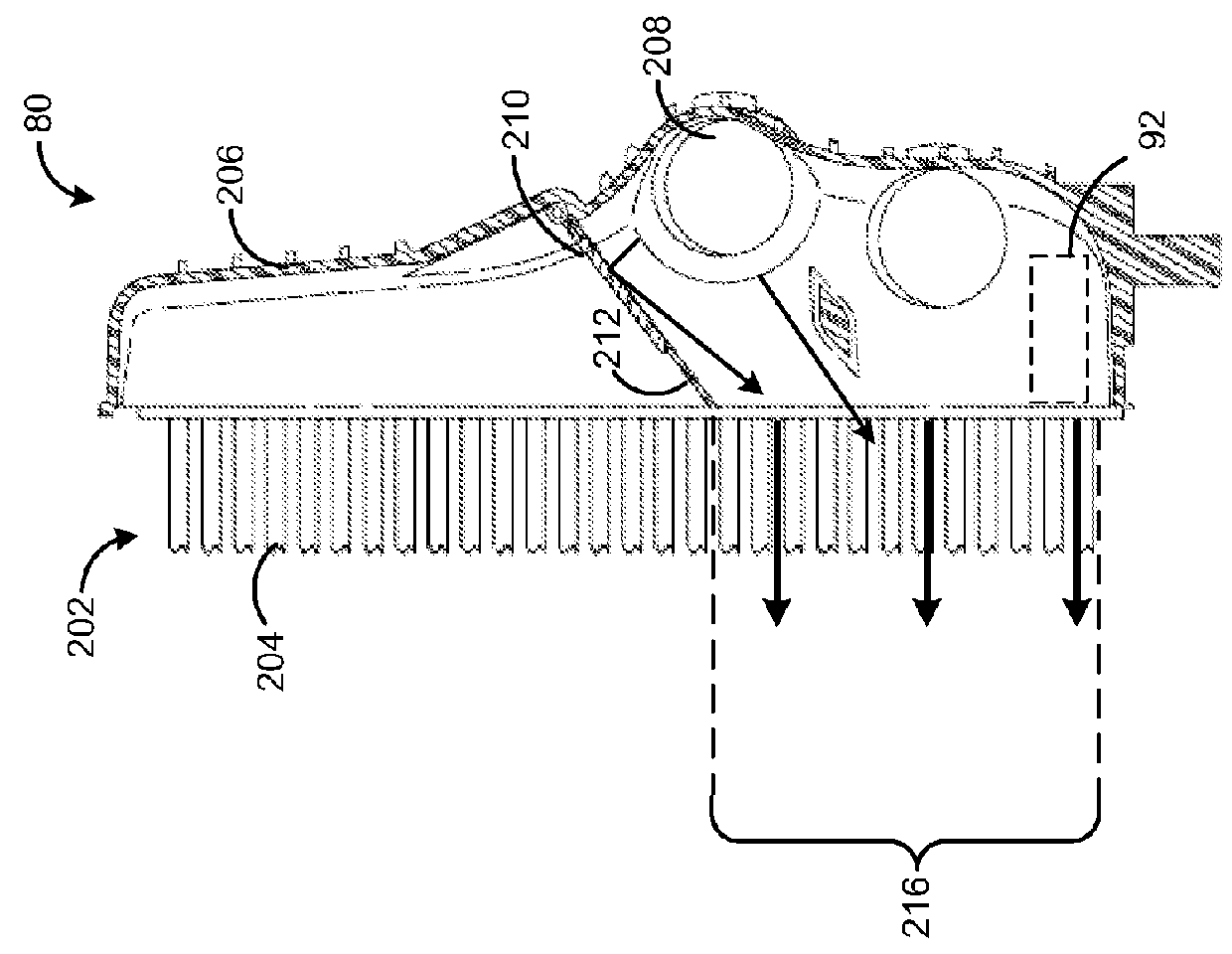

Charge air cooler condensation control

ActiveUS20140075976A1Reduce energyReduce accumulation of condensateInternal combustion piston enginesExhaust gas recirculationChillerAerospace engineering

Owner:FORD GLOBAL TECH LLC

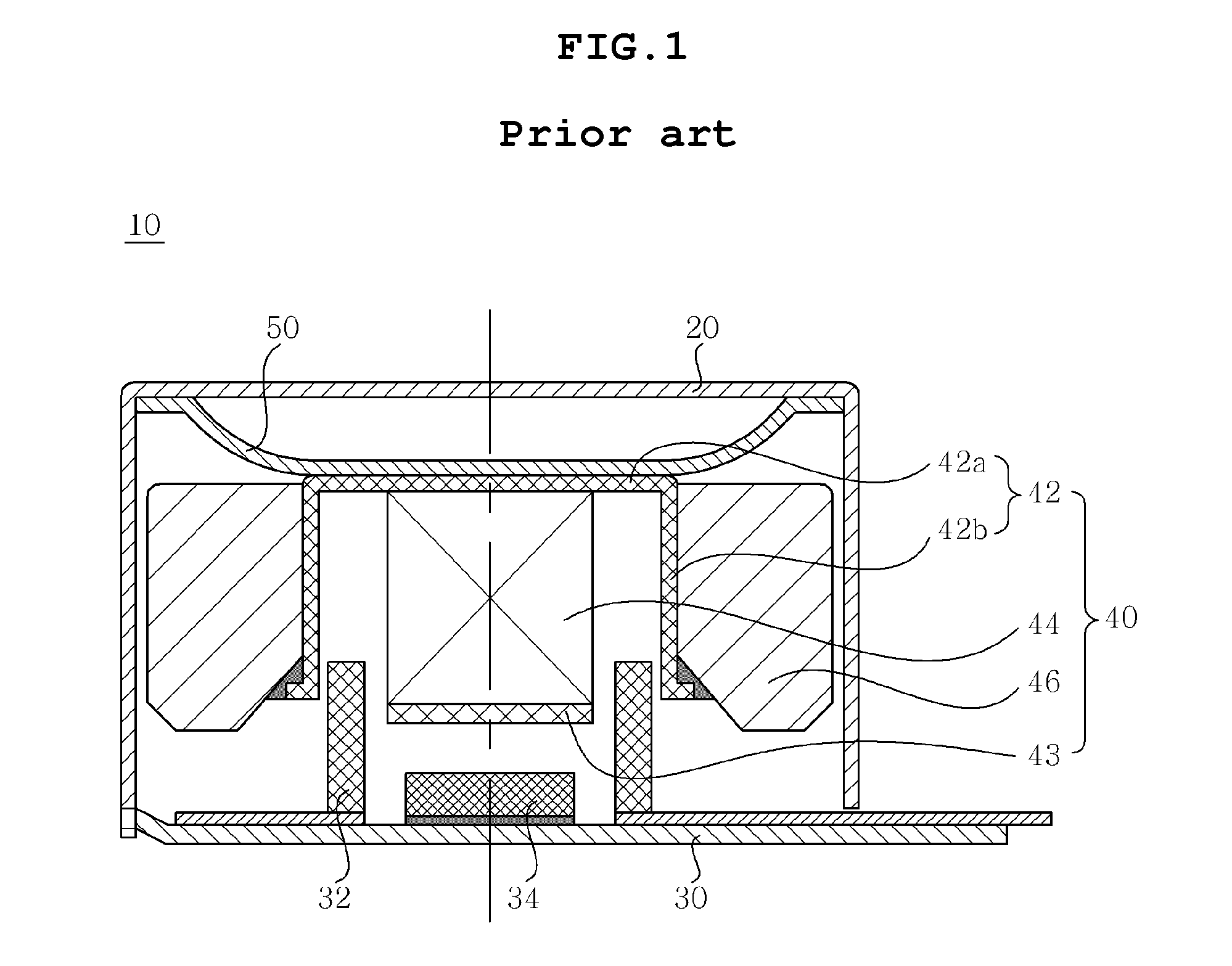

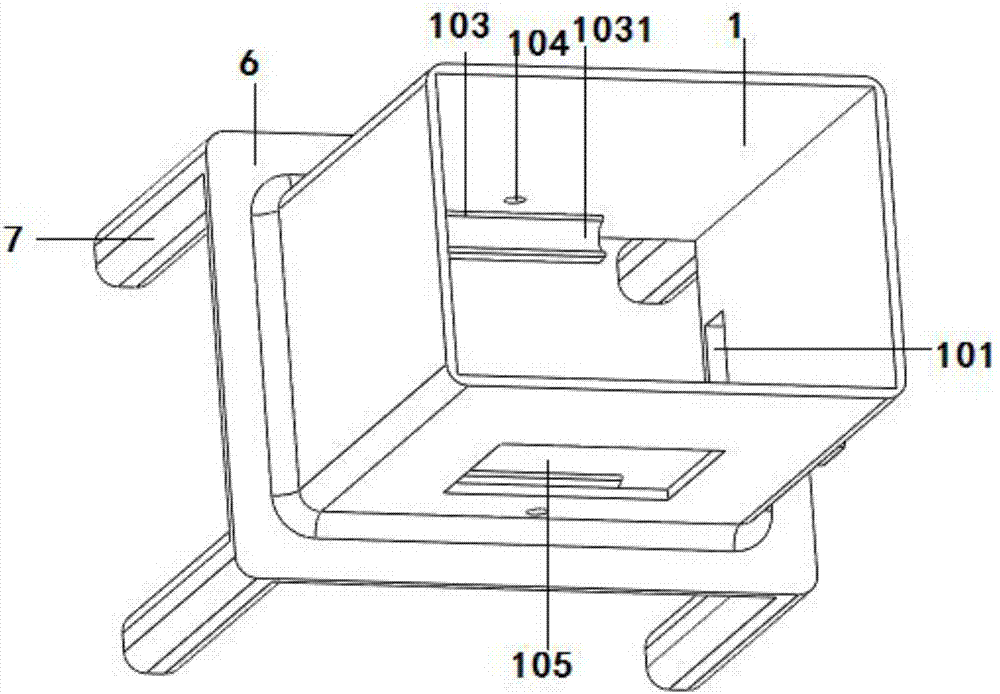

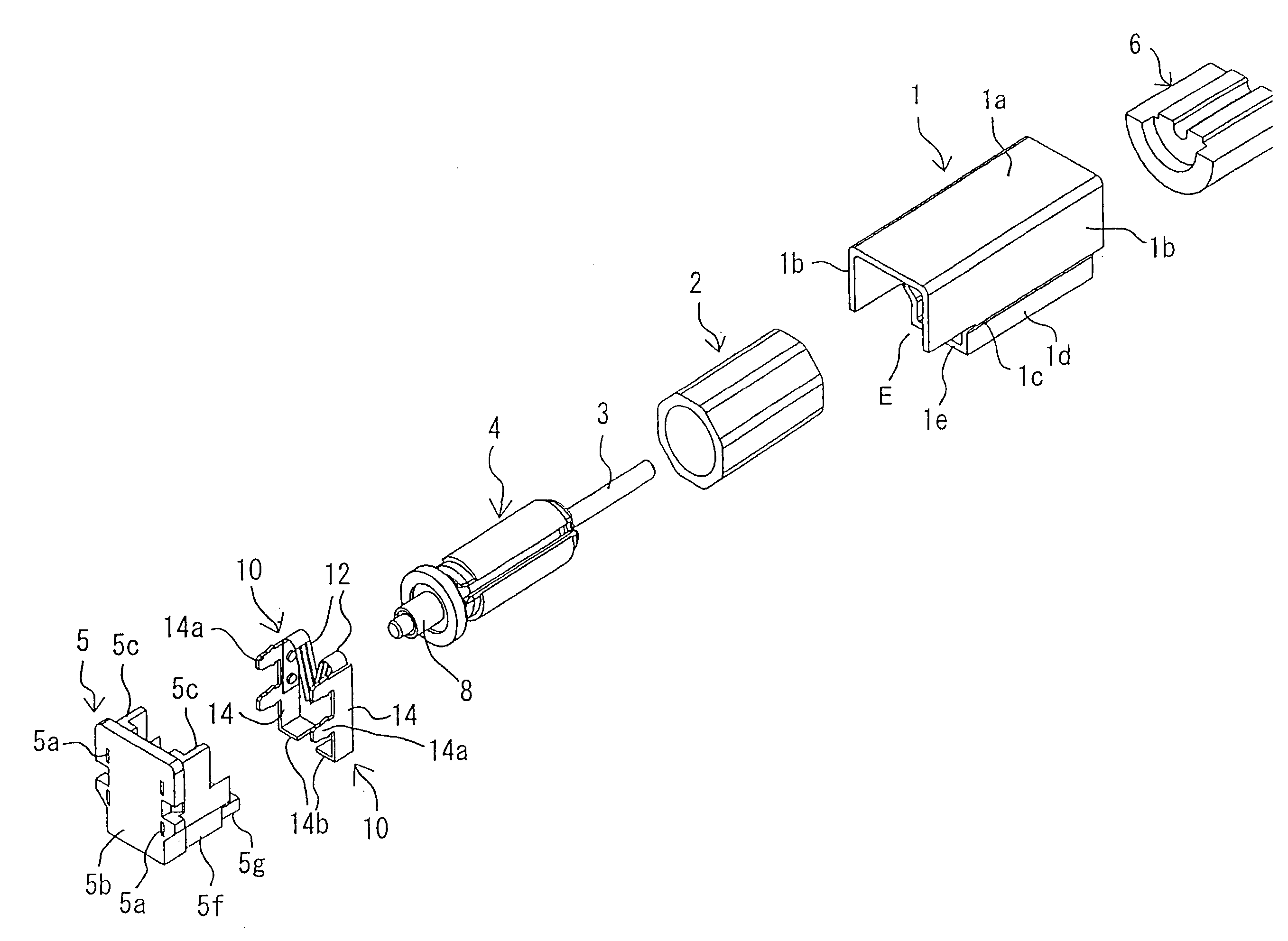

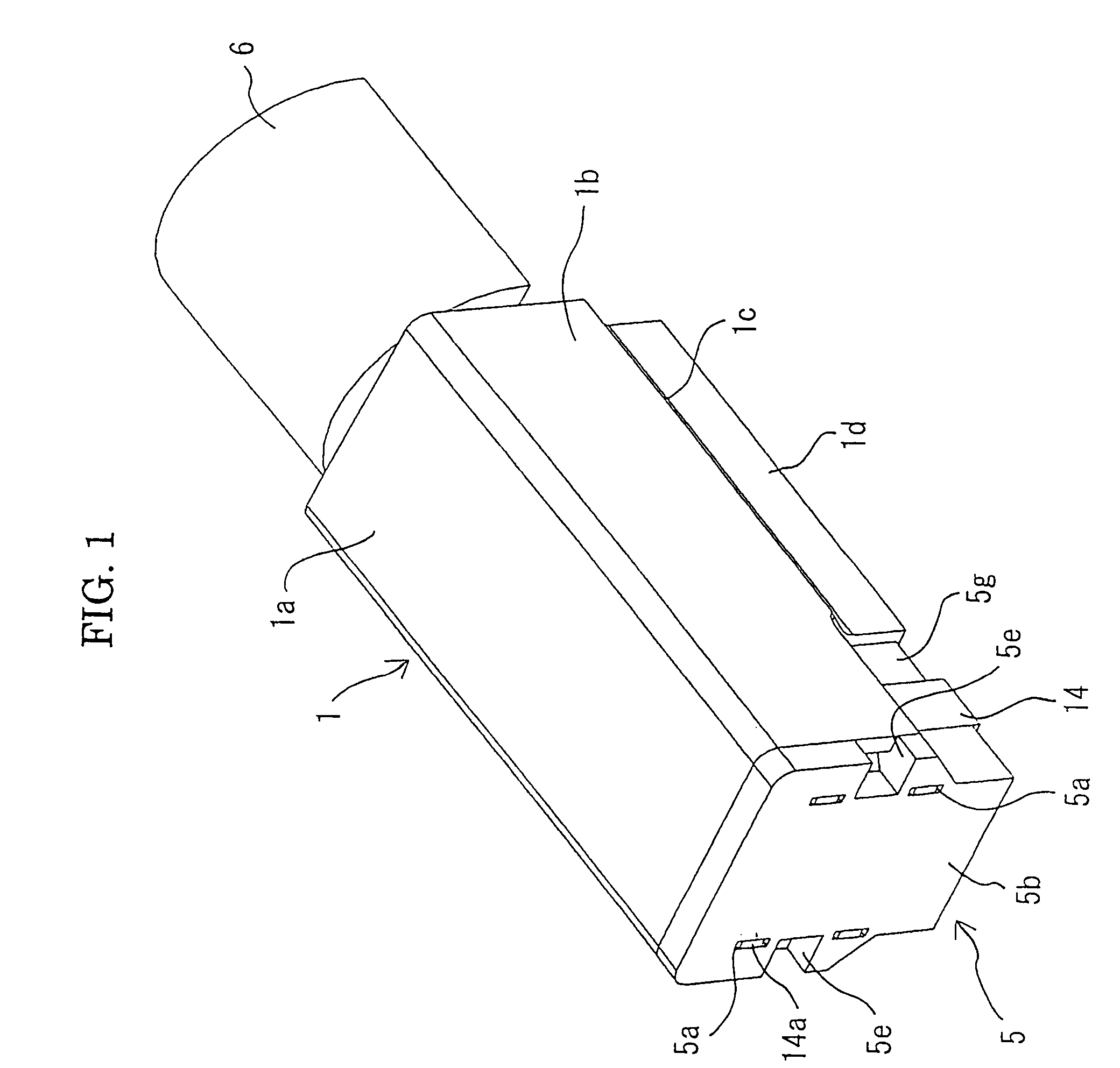

Horizontal linear vibrator

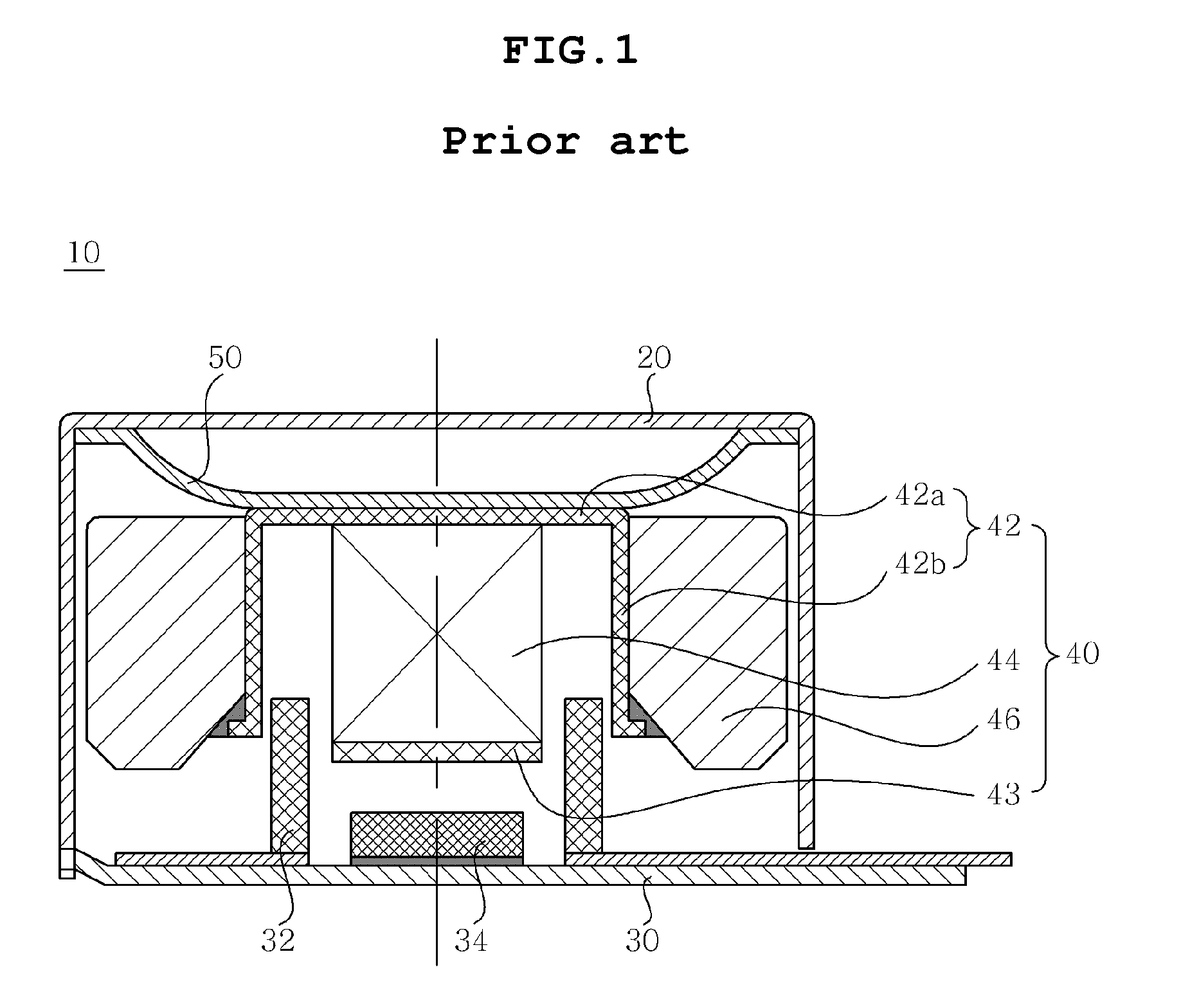

ActiveUS7999421B2Reduce thicknessLong lastingMagnetic circuitMechanical energy handlingResponsivityUltimate tensile strength

The present invention provides a horizontal linear vibrator which can reduce the thickness but increase the strength of vibrations while at the same time guaranteeing a sufficiently long lifetime and satisfactory responsivity. The horizontal linear vibrator includes a casing, a bracket, a vibration unit and springs. The casing defines an internal space therein. A first magnet is attached to an upper plate of the casing. The bracket is coupled to the lower end of the casing. The second magnet is attached to the bracket such that different poles of the first and second magnets face each other. The vibration unit has a weight, and a cylindrical coil which is provided in or under the weight. The springs are coupled to the sidewall plates of the casing or the bracket. The springs elastically support the vibration unit to allow the vibration unit to vibrate in the horizontal direction.

Owner:PARTRON

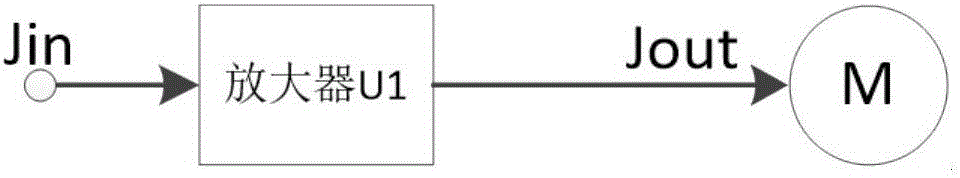

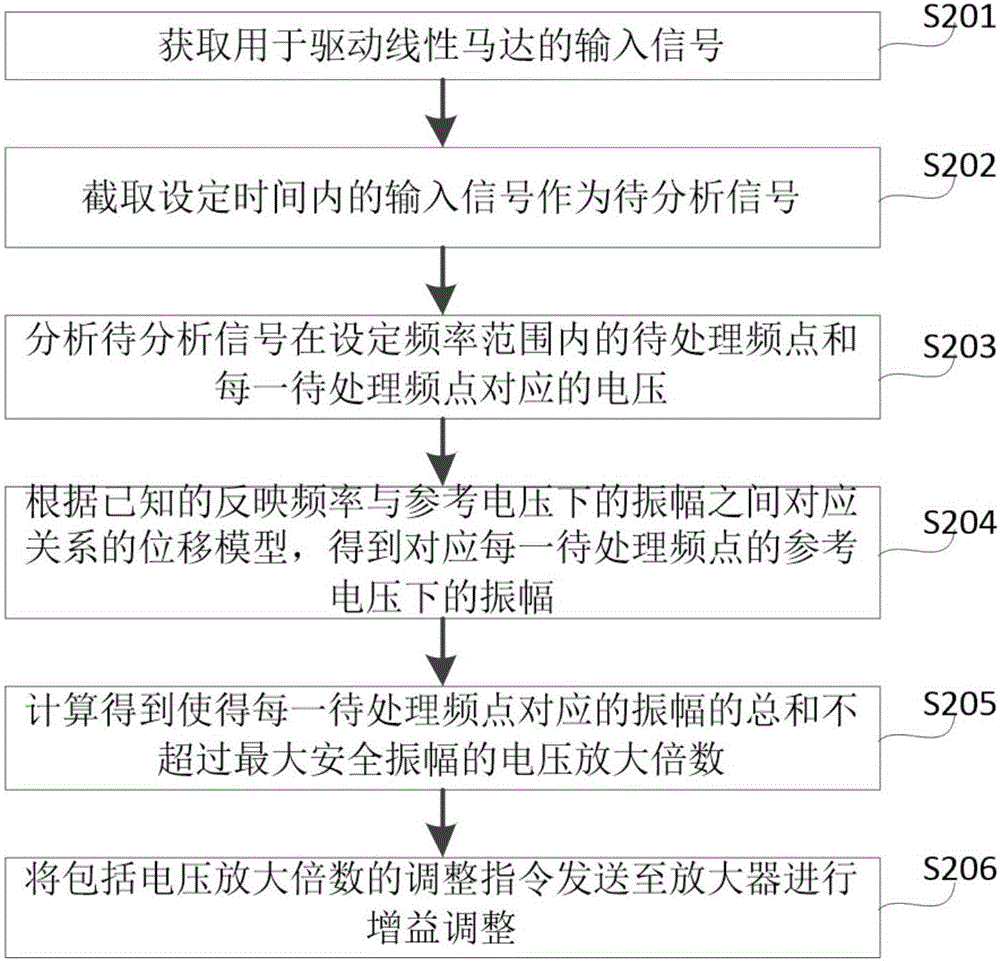

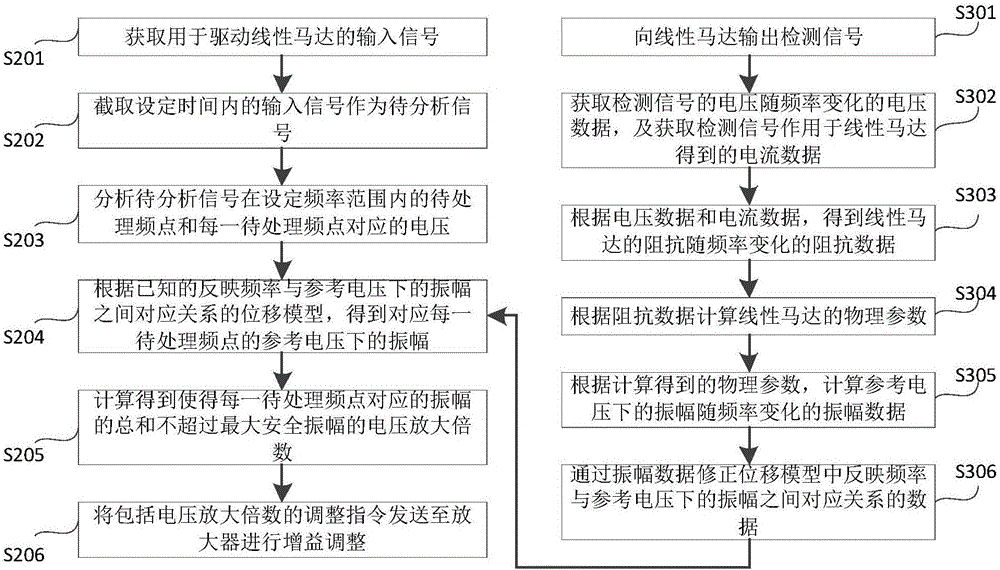

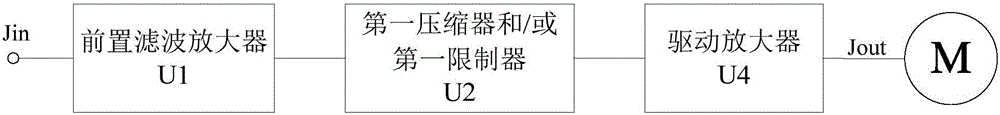

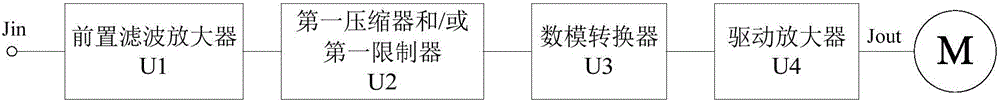

Method, device and system for actively controlling vibration of linear motor and electronic equipment

ActiveCN106301137AEnsure safetyIncrease vibration intensityAC motor controlAudio power amplifierVoltage reference

The invention discloses a method, device and system for actively controlling vibration of a linear motor and electronic equipment. The method comprises the following steps of acquiring an input signal for driving the linear motor; capturing the input signal within a set time as a signal to be analyzed; analyzing frequency points to be processed of the signal to be analyzed within a set frequency range and a voltage corresponding to each frequency point to be processed; obtaining an amplitude under a reference voltage corresponding to each frequency point to be processed according to a displacement model of a corresponding relation between the known reflection frequency and the amplitude under the reference voltage; calculating to obtain that the sum of the amplitude corresponding to each frequency point to be processed does not exceed a voltage amplification factor of maximum safety amplitude according to the maximum safety amplitude of the linear motor, the voltage corresponding to each frequency point to be processed and the amplitude under the reference voltage; sending an adjustment instruction comprising the voltage amplification factor to an amplifier for gain adjustment. Therefore, the highest vibration strength can be output possibly on the premise that the motor safety can be ensured.

Owner:GOERTEK INC

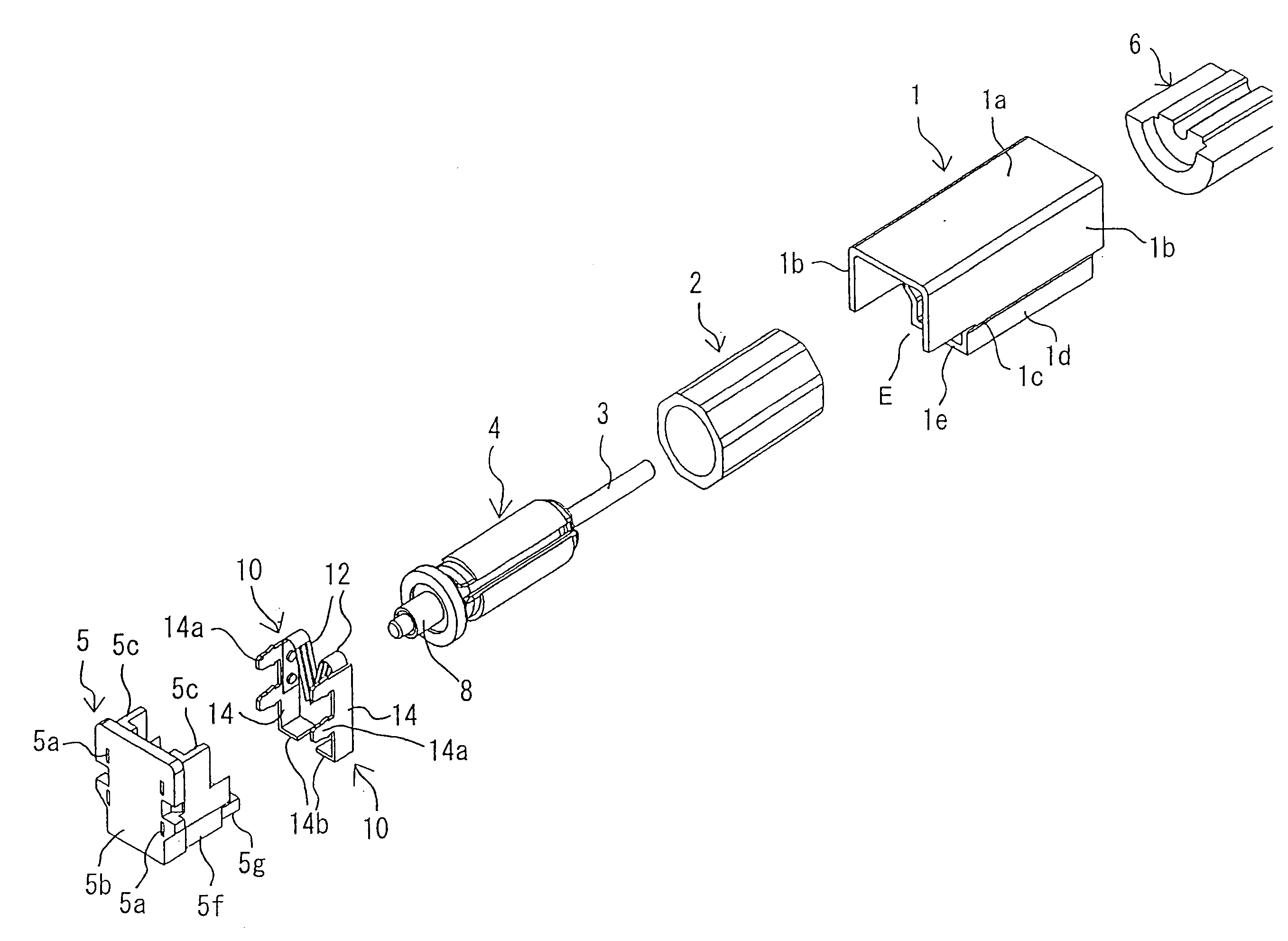

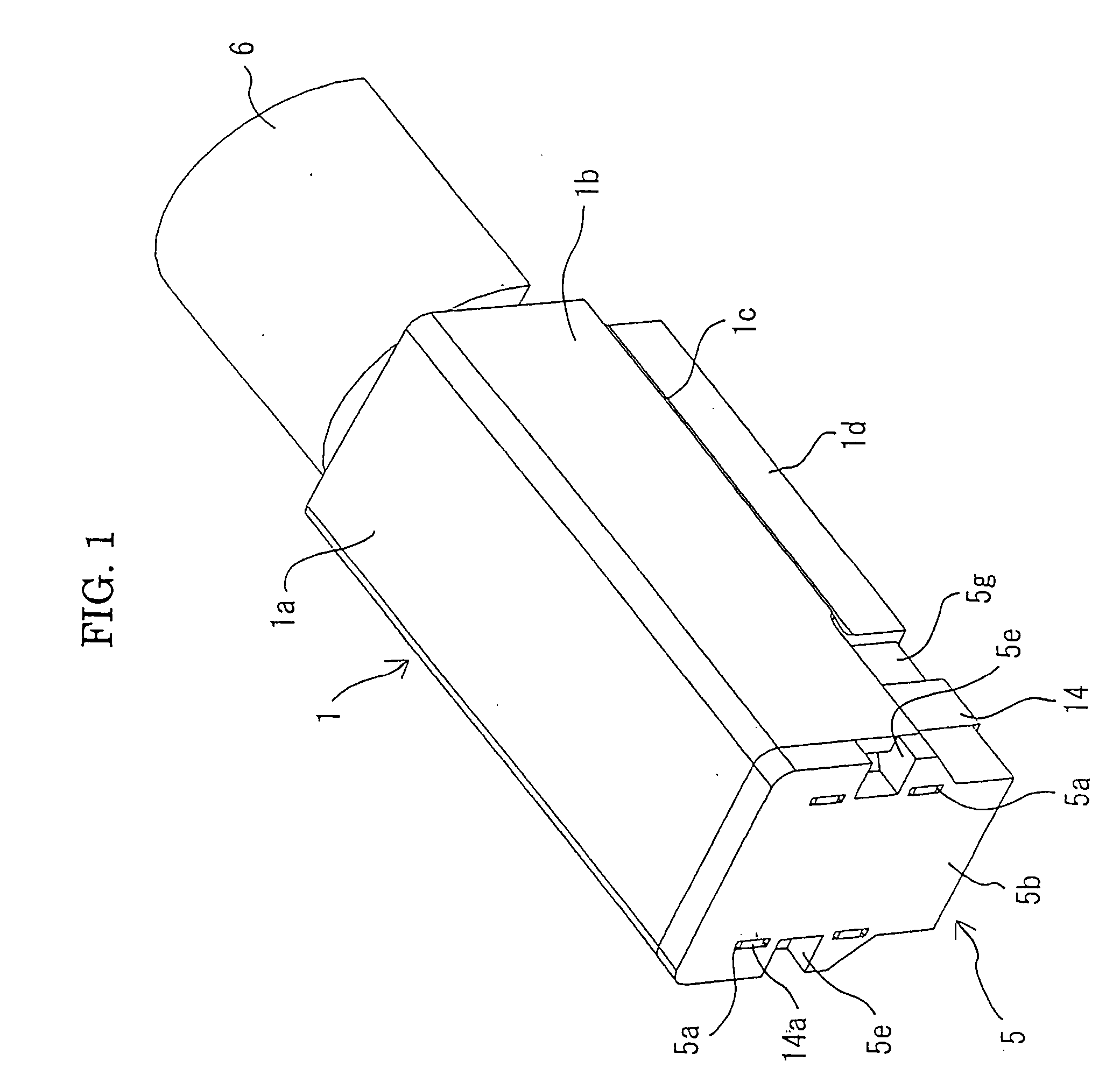

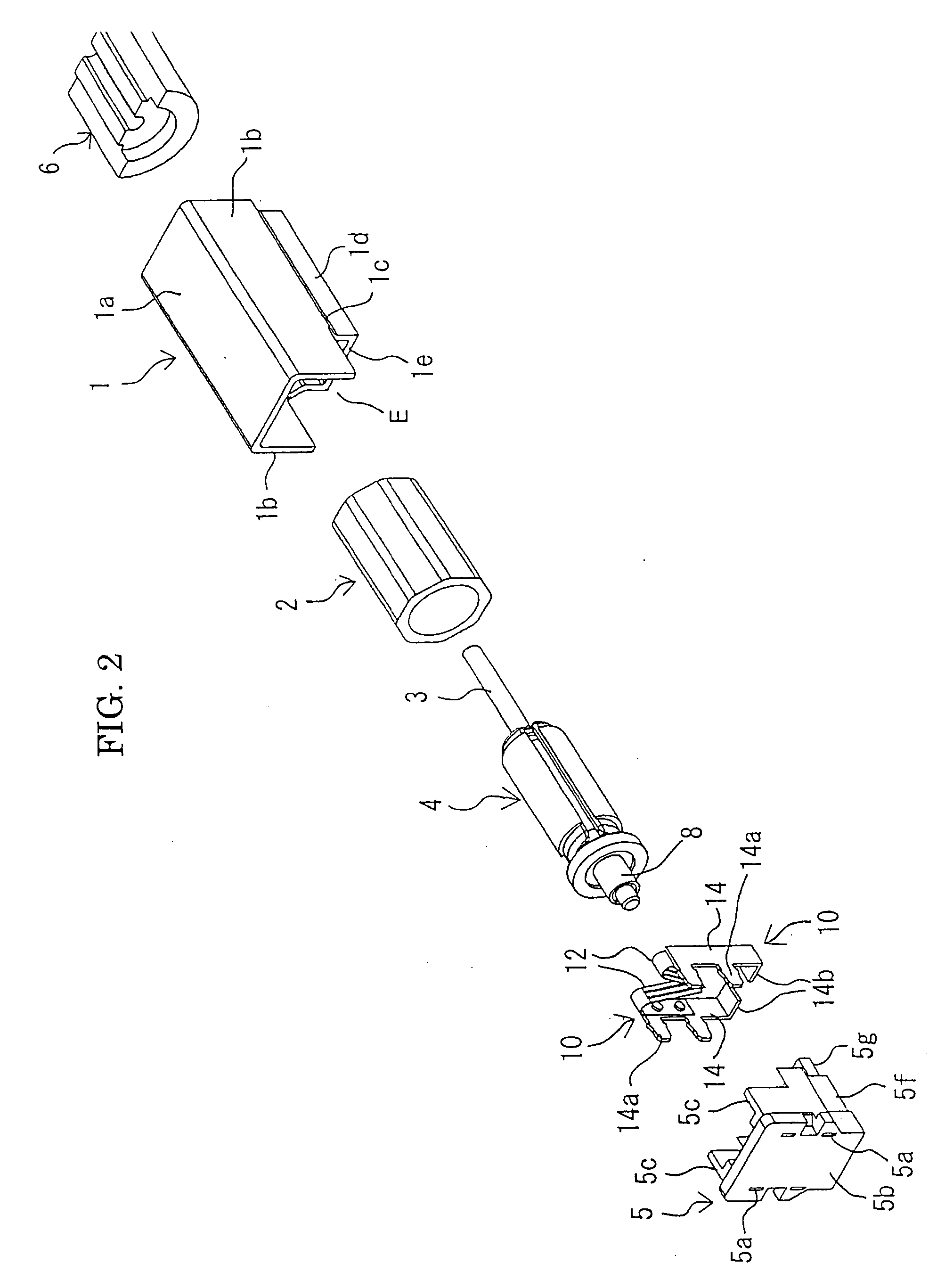

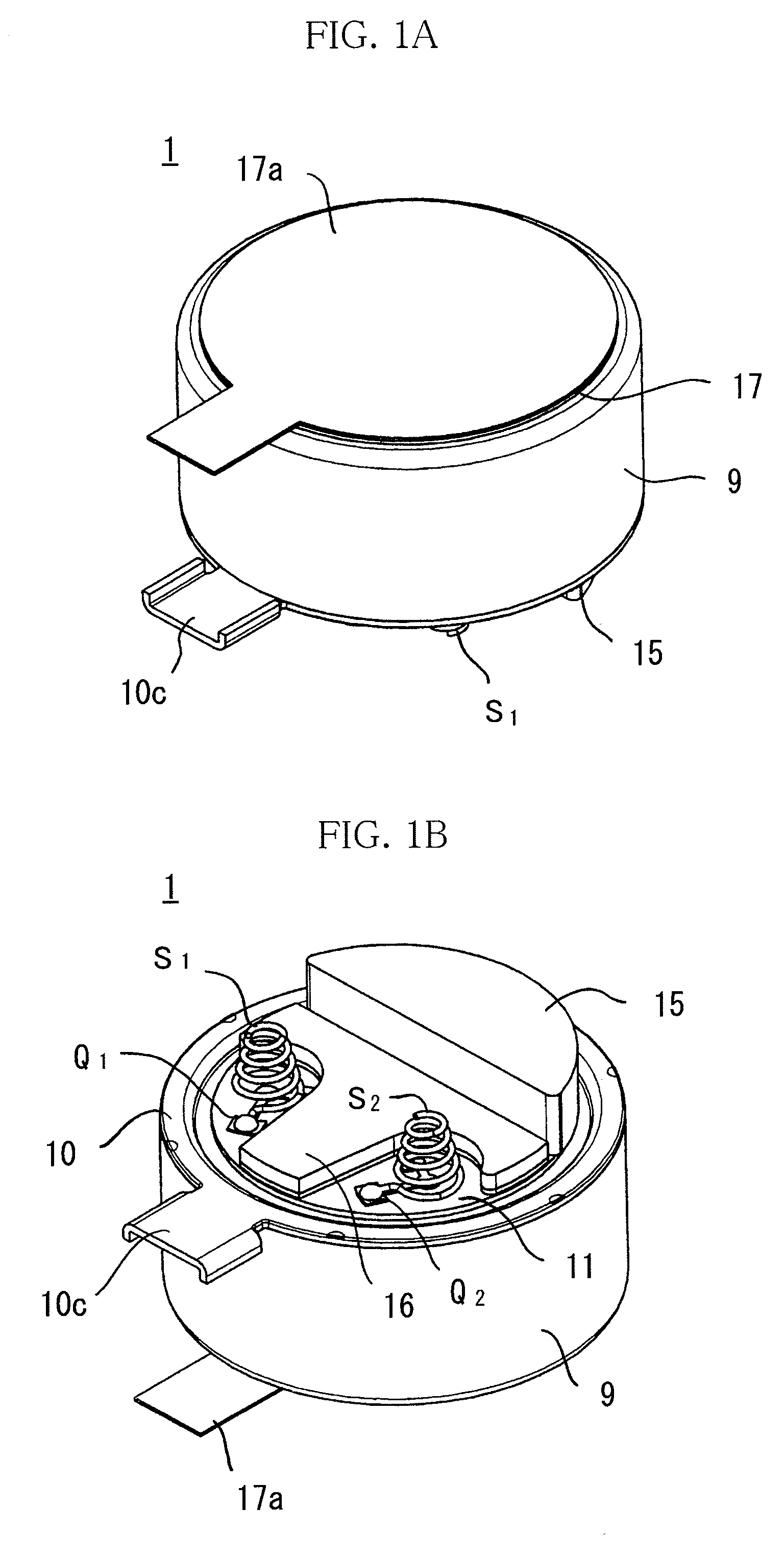

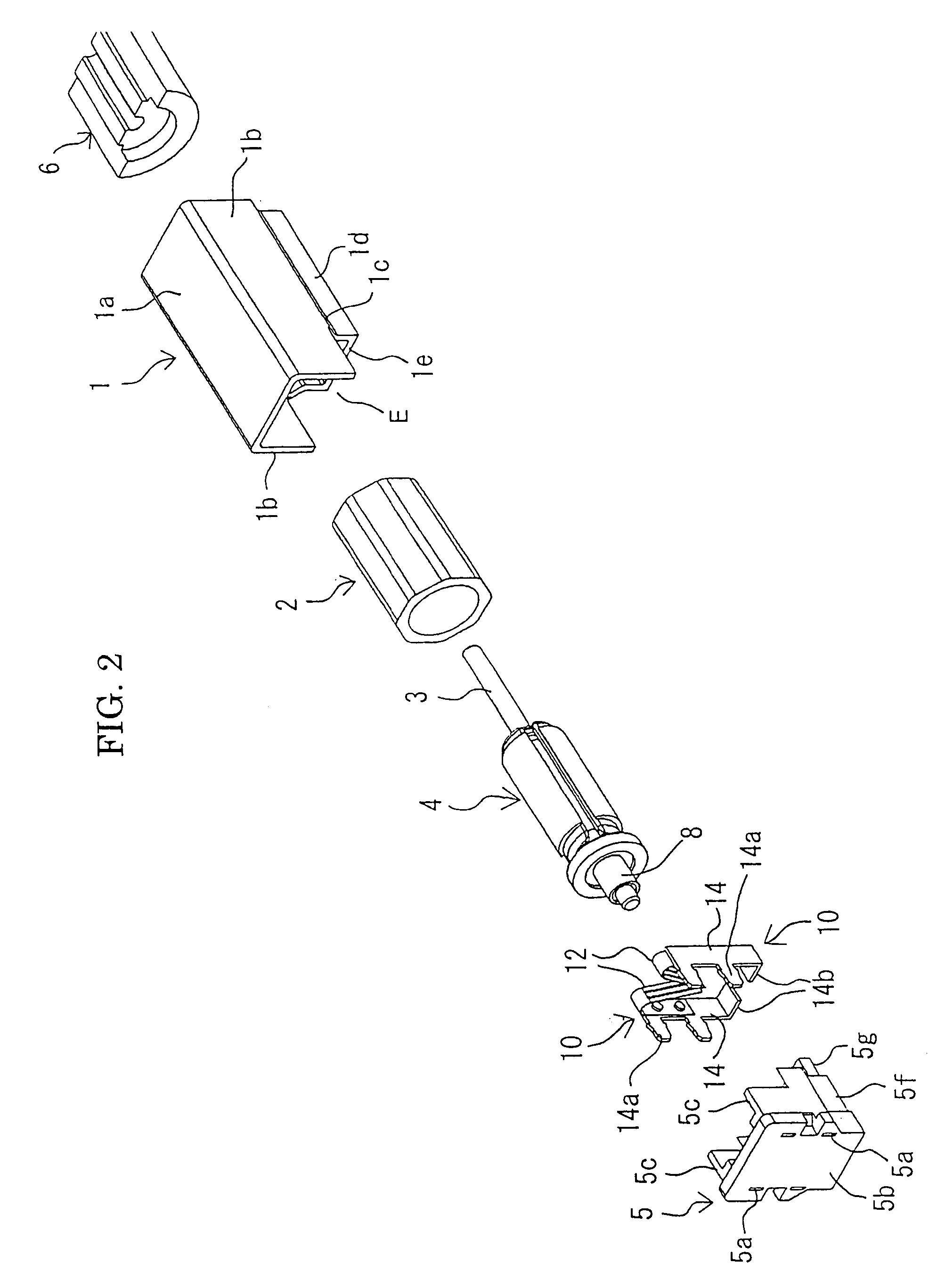

Small-sized motor

ActiveUS20050073205A1Improve efficiencyIncrease vibration intensityMechanical energy handlingSupports/enclosures/casingsSurface mountingEngineering

A small-sized motor of a structure not requiring any metal holder frame in a surface mounting process to a printed circuit board by reflow soldering, wherein the motor case is provided with a level flat part, a pair of left and right first side parts bent downward from this substantially perpendicularly and parallel to each other, a pair of left and right second side parts bent inward from these at an inclination of about 45°, and a pair of left and right third side parts bent down from these and parallel to each other, and a level bottom part connecting these bottom ends and extending substantially parallel to the level flat part.

Owner:SANYO SEIMITSU

Horizontal linear vibrator

InactiveUS9553497B2Reduce thicknessLong lastingMechanical vibrations separationDynamo-electric machinesResponsivityEngineering

Owner:MPLUS

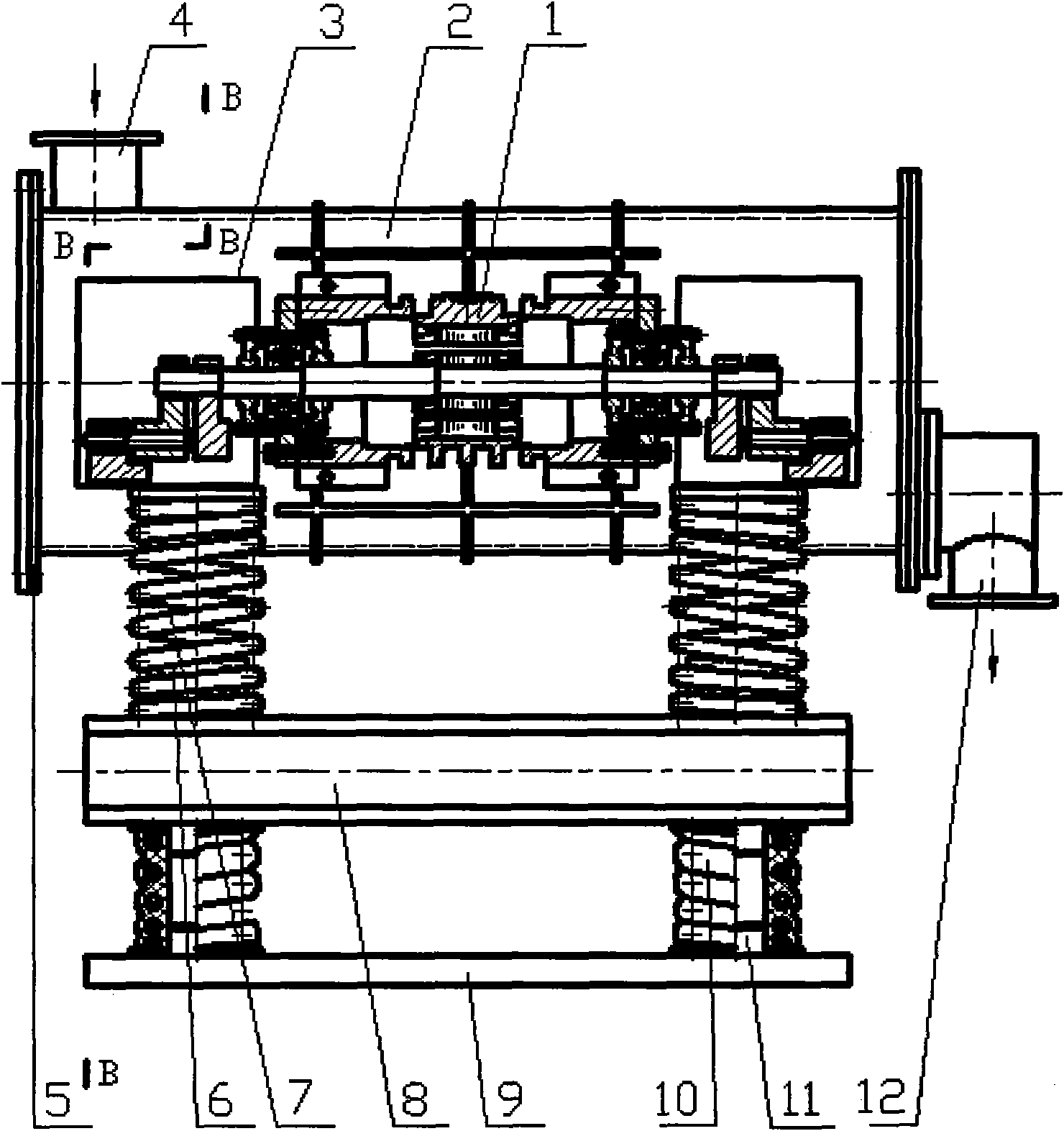

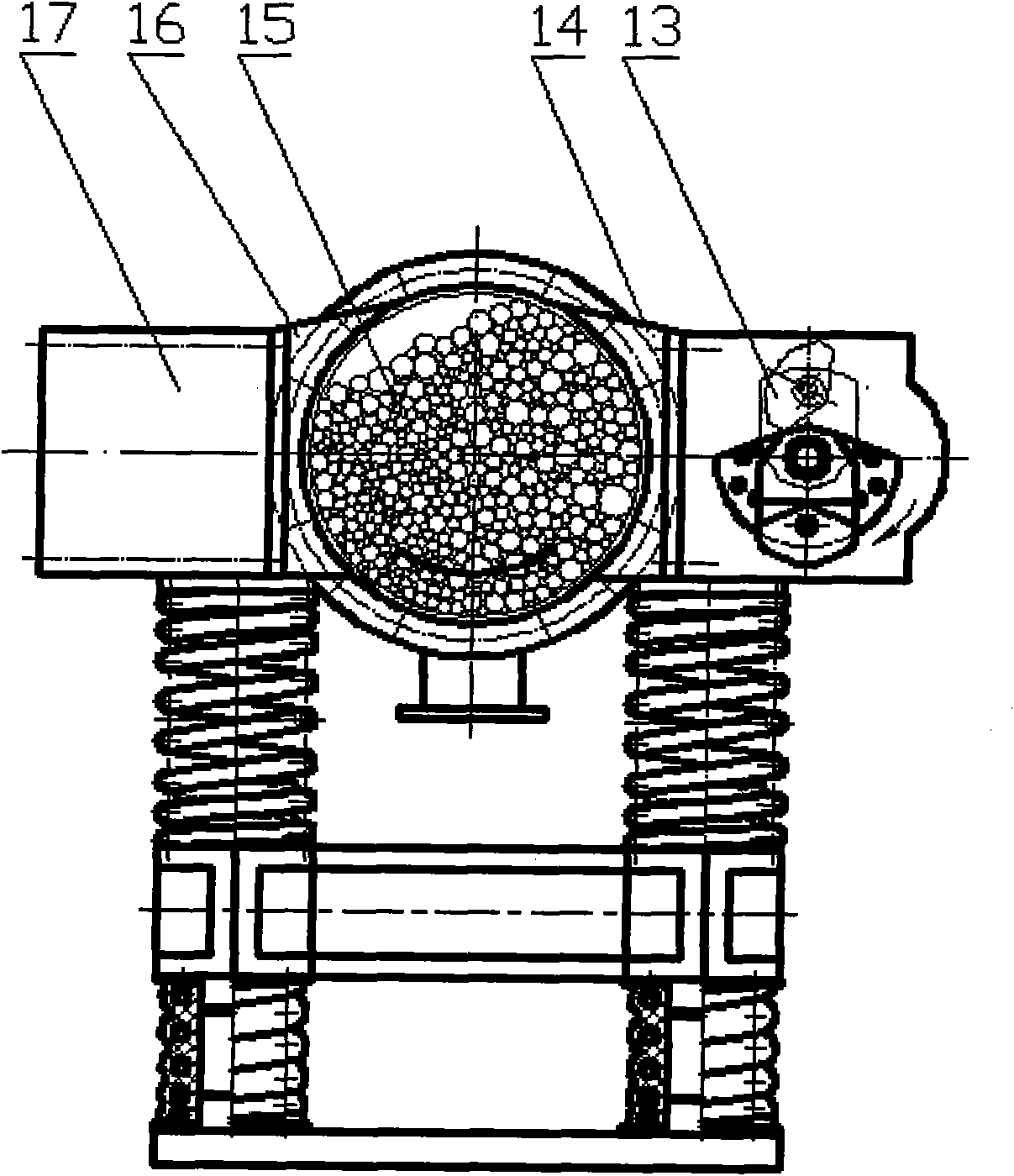

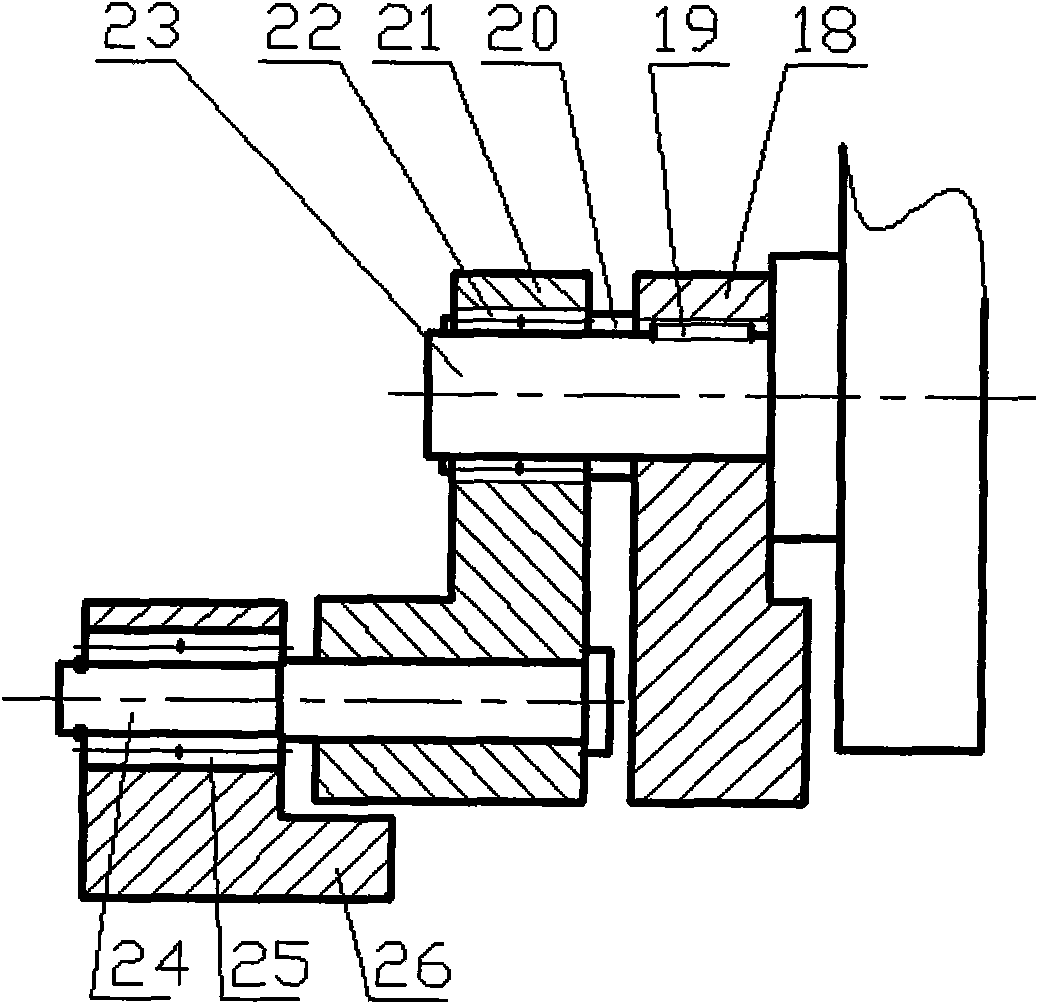

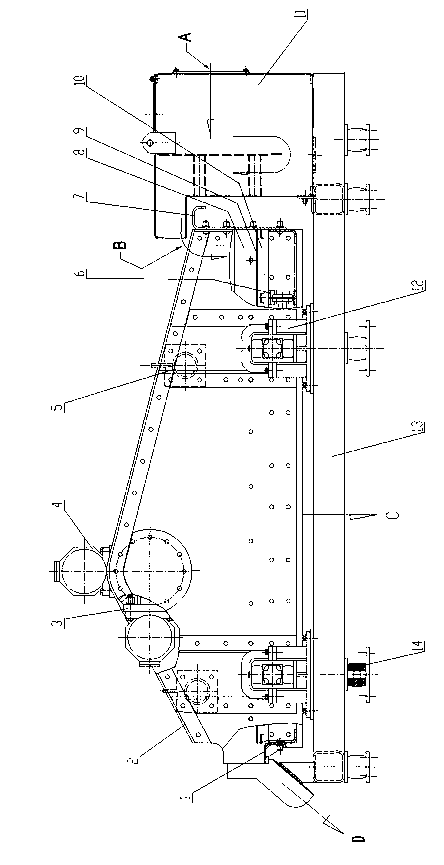

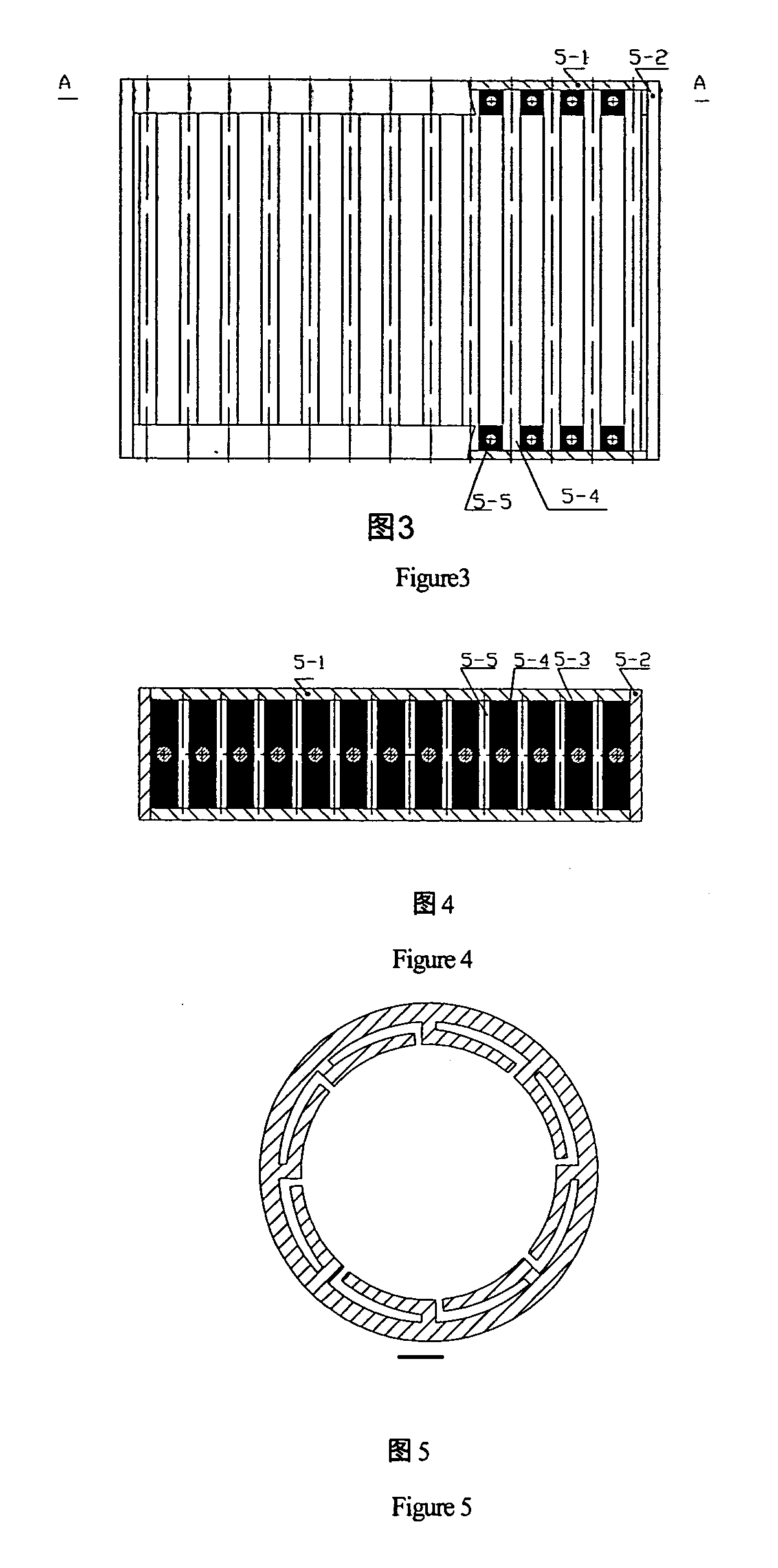

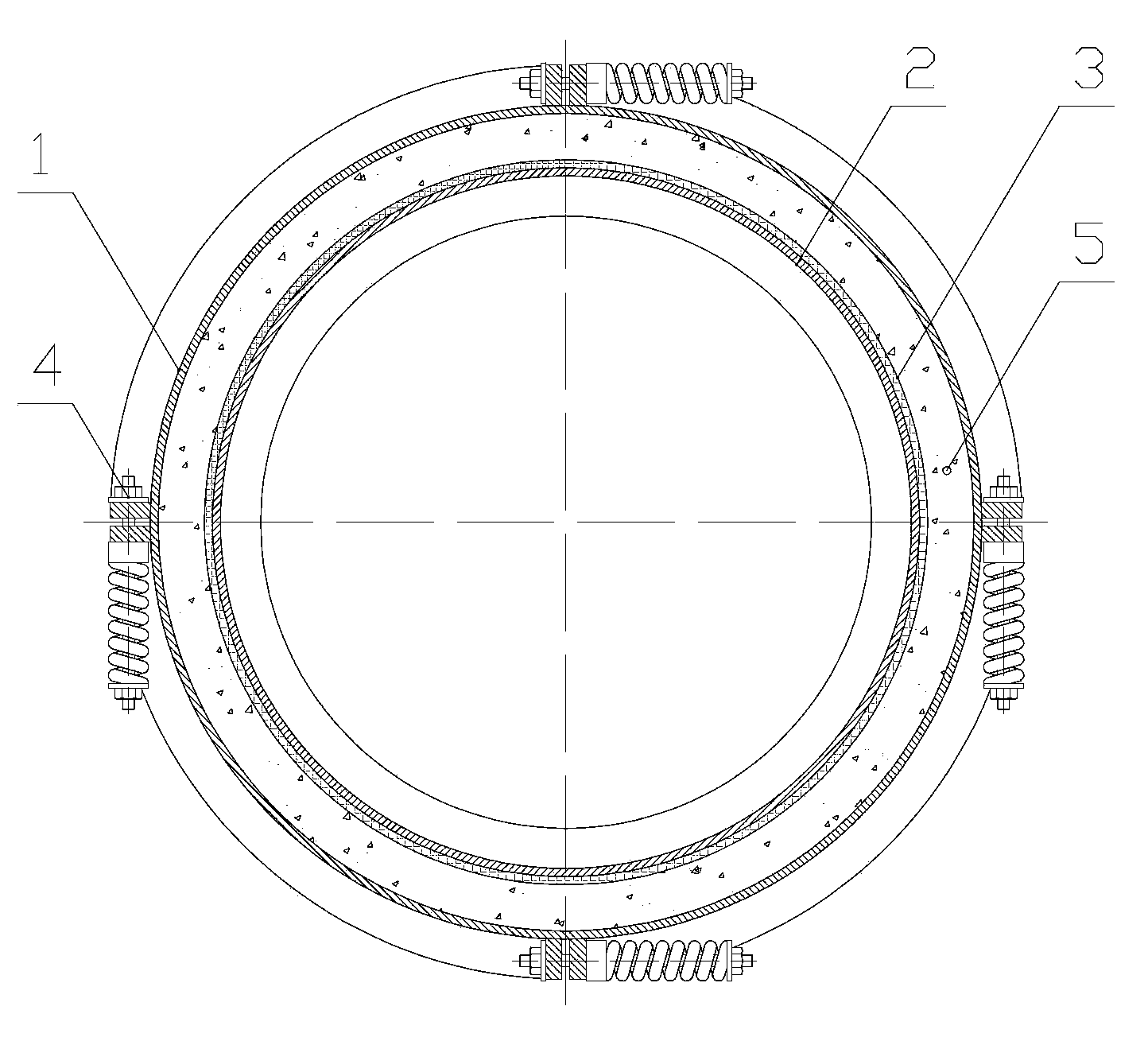

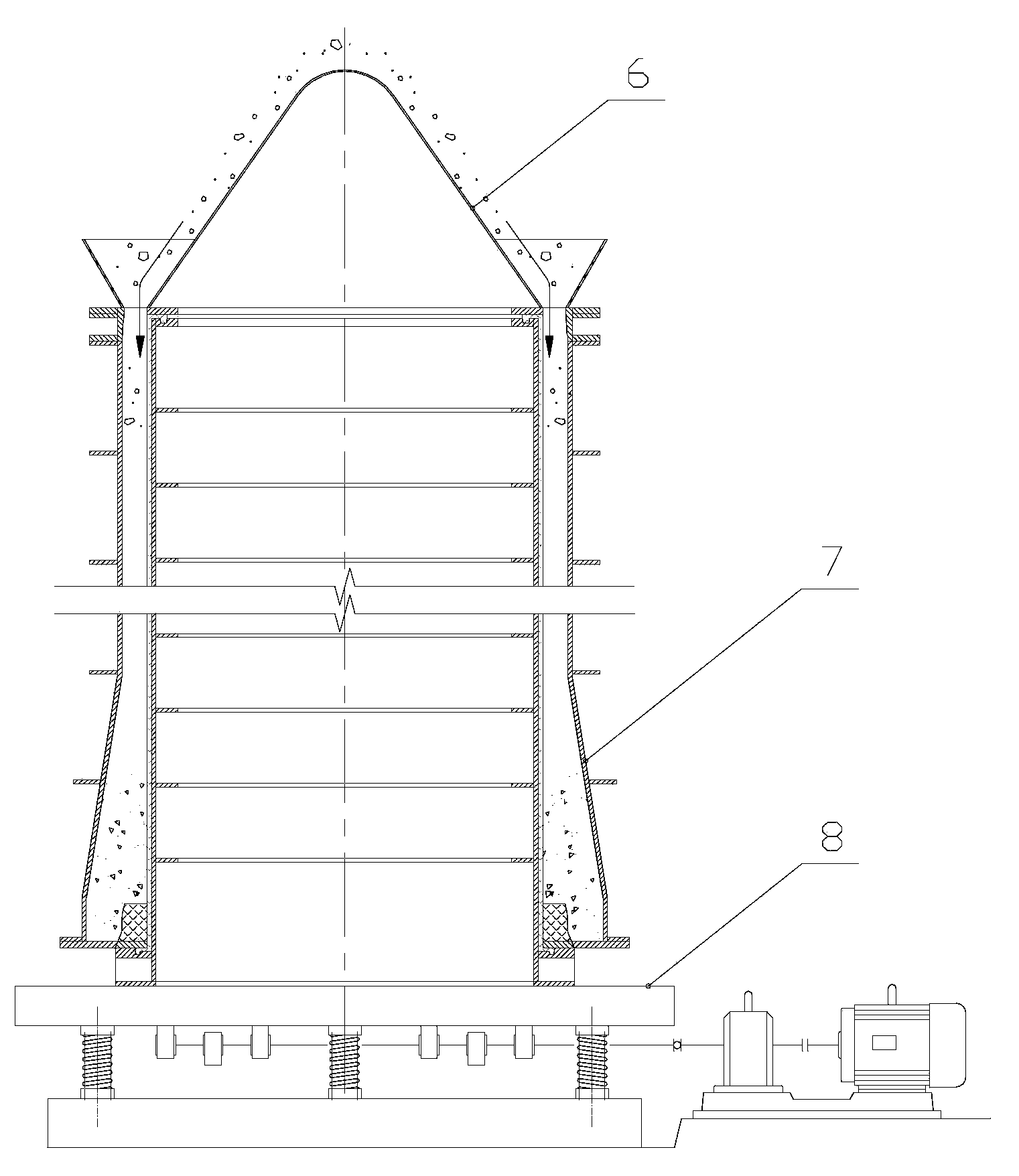

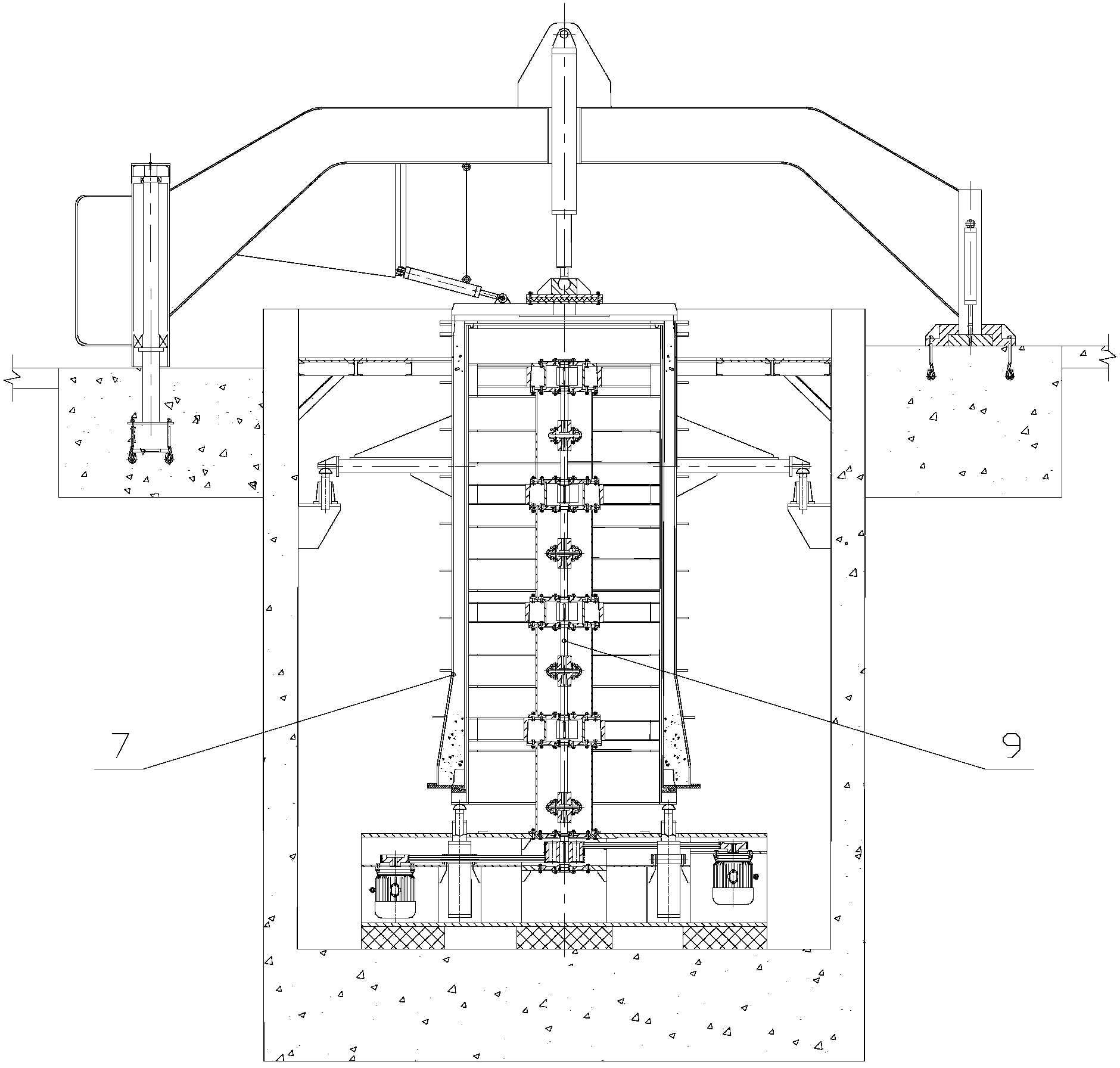

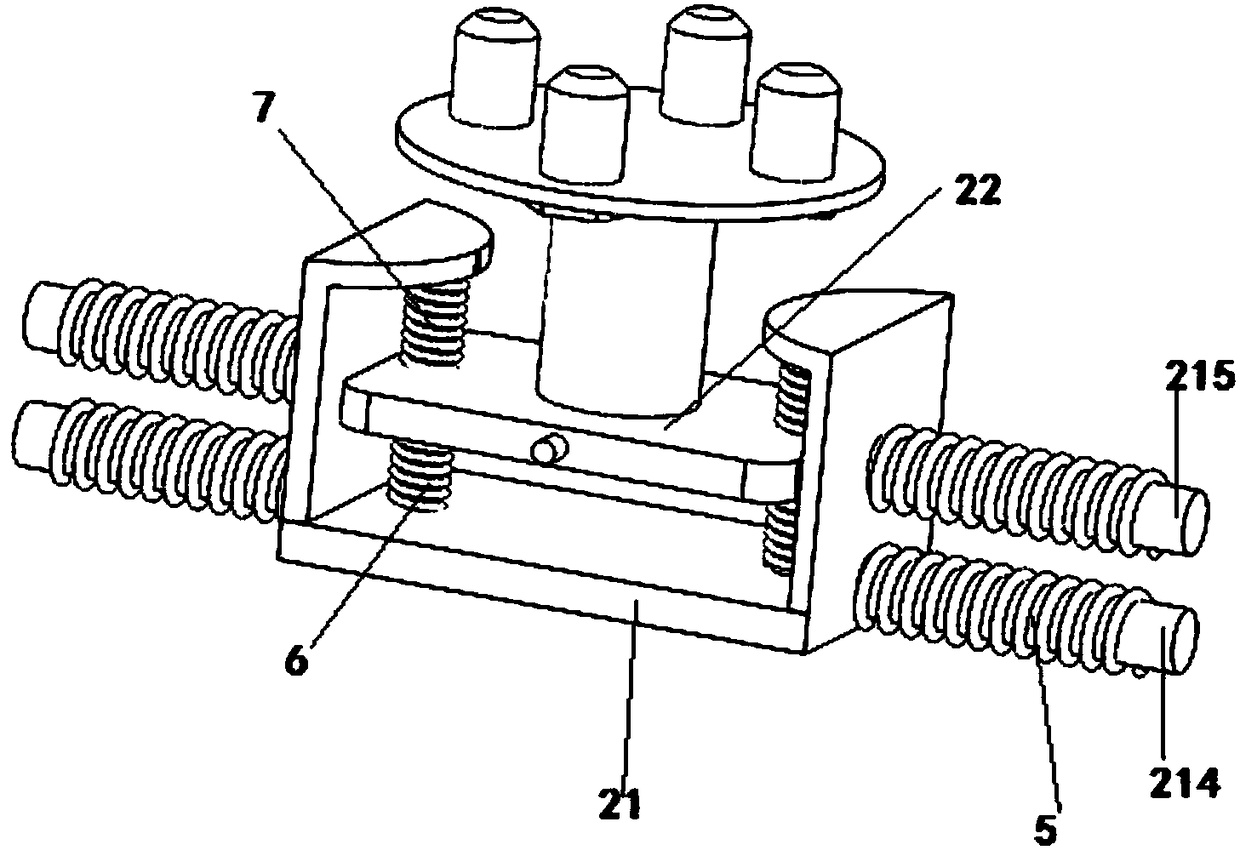

Variable stiffness double-mass two-stage pendulum chaotic vibromill

The invention discloses a variable stiffness double-mass secondary pendulum chaotic vibromill and relates to a vibromill, and in particular relates to a variable stiffness double-mass two-stage pendulum chaotic vibromill. The chaotic vibromill comprises an upper mass, a lower mass, a main vibration spring, a vibration isolation spring, a base, and the like, wherein the upper mass mainly comprises a vibration motor, a cylinder body, a right connecting frame, a left connecting frame and a counter weight; the cylinder body mainly comprises a feed inlet, an end cover, a discharge hole and a mill medium; the upper mass and the lower mass are connected through the main vibration spring, and the inner diameter of the main vibration spring is matched with the outer diameters of spring guide posts on the upper mass and the lower mass; the lower mass is supported on the base through the vibration isolation spring; the vibration motor comprises pendulum assemblies, and the pendulum assemblies are symmetrically distributed at the left end and the right end of a vibration motor shaft; and each pendulum assembly comprises a fixed pendulum, a flat key, a shaft sleeve, a primary movable pendulum, a bearing 1, a vibration motor shaft, a secondary movable pendulum shaft, a bearing 2 and a secondary movable pendulum.

Owner:江华瑶族自治县金牛开发建设有限公司

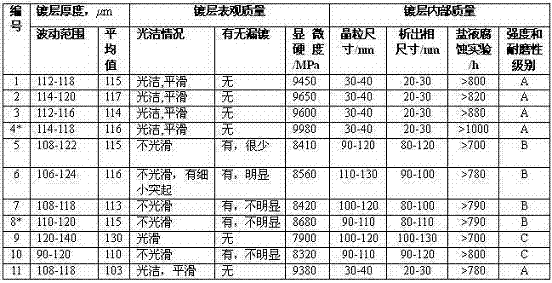

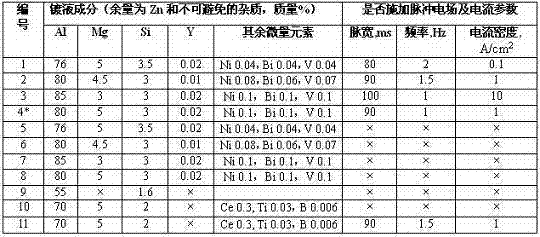

A method for hot-dip aluminum plating of steel structure parts

InactiveCN102268625AImprove corrosion resistanceExcellent immersion performanceHot-dipping/immersion processesMelting tankRare earth

The invention relates to the technical field of metal surface coatings, in particular to a hot dipping method for a steel structure. A hot dipping alloy consists of the following components in percentage by mass: 75 to 85 percent of Al, 3 to 5 percent of Mg, 3 to 5 percent of Si, 0.01 to 0.02 percent of rare earth Y, 0.04 to 0.10 percent of Ni, 0.04 to 0.10 percent of Bi, 0.04 to 0.10 percent of V, and the balance of Zn and inevitable impurities; and in the hot dipping process, a pulsed electric field is applied to a weld pool, and the parameter ranges of the pulsed electric field are that: the pulse width is 80 to 100ms, the acting frequency is 1 to 2Hz and the peak density of pulse current introduced into the weld pool is 0.1 to 10A / cm<2>. By the synergism of the rare earth Y, Ni, Bi and V, the fluidity and wettability of aluminum are improved; the strength and corrosion resistance of a coating are improved by nano Si and Mg2Si phases separated under the action of the pulsed electric field; and the pulsed electric field also has effects of refining grains and improving the compactness of the coating. By the invention, the coating quality is improved, metal consumption is reduced, a process is simple, the conventional process and equipment are mature, the cost is low and the method is worth promoting.

Owner:JIANGSU UNIV

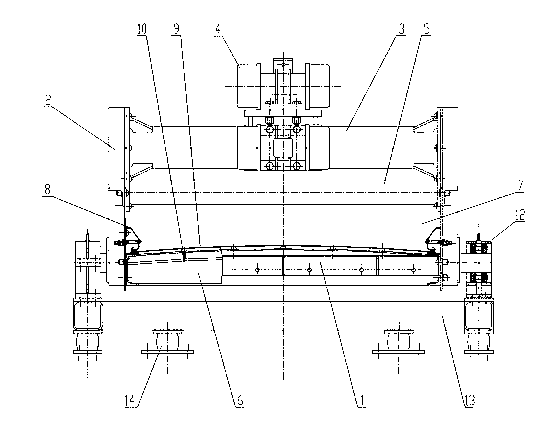

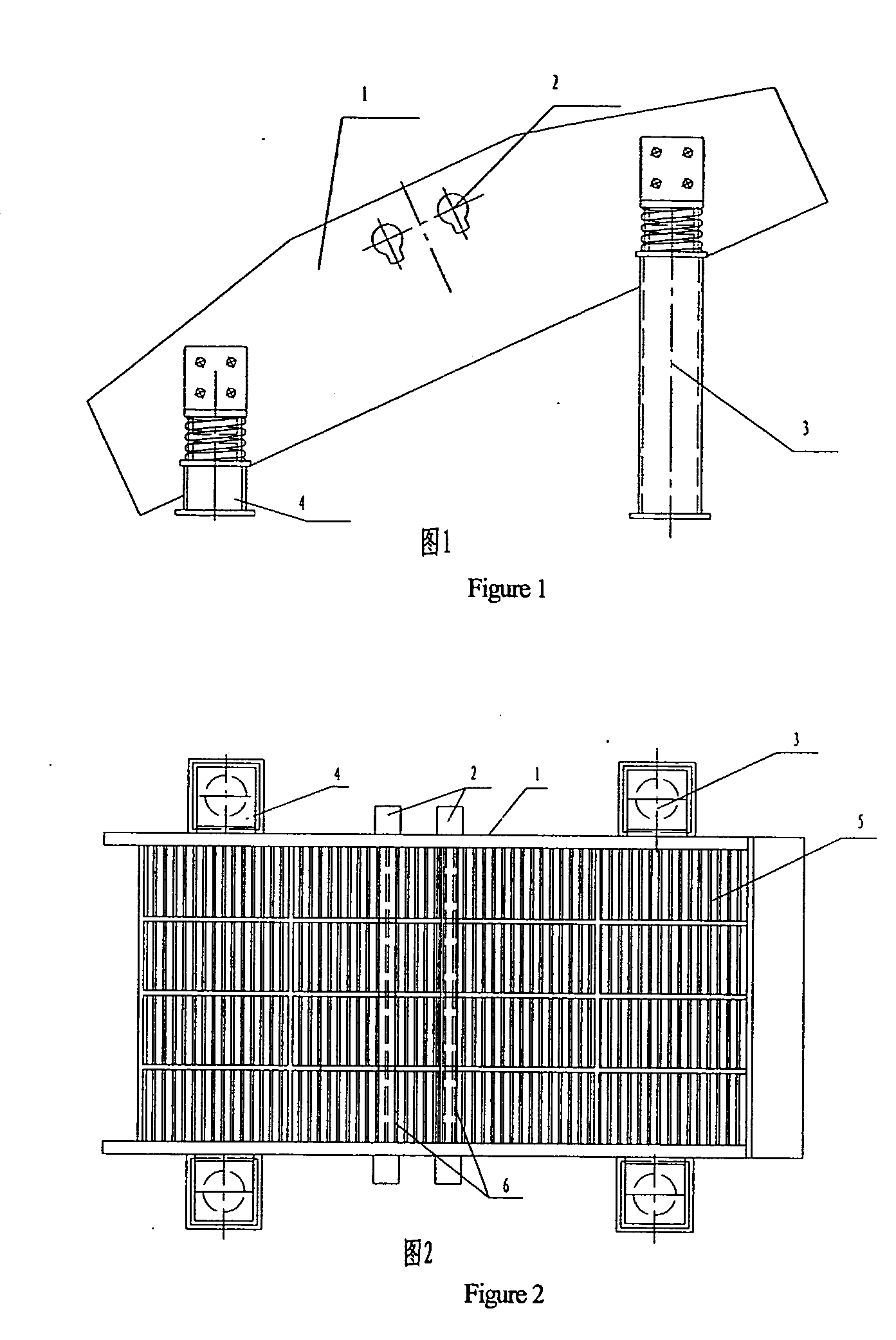

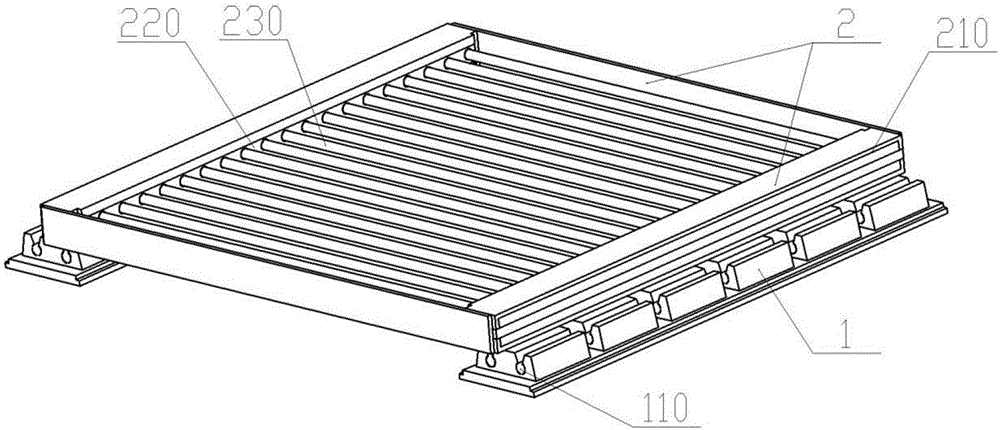

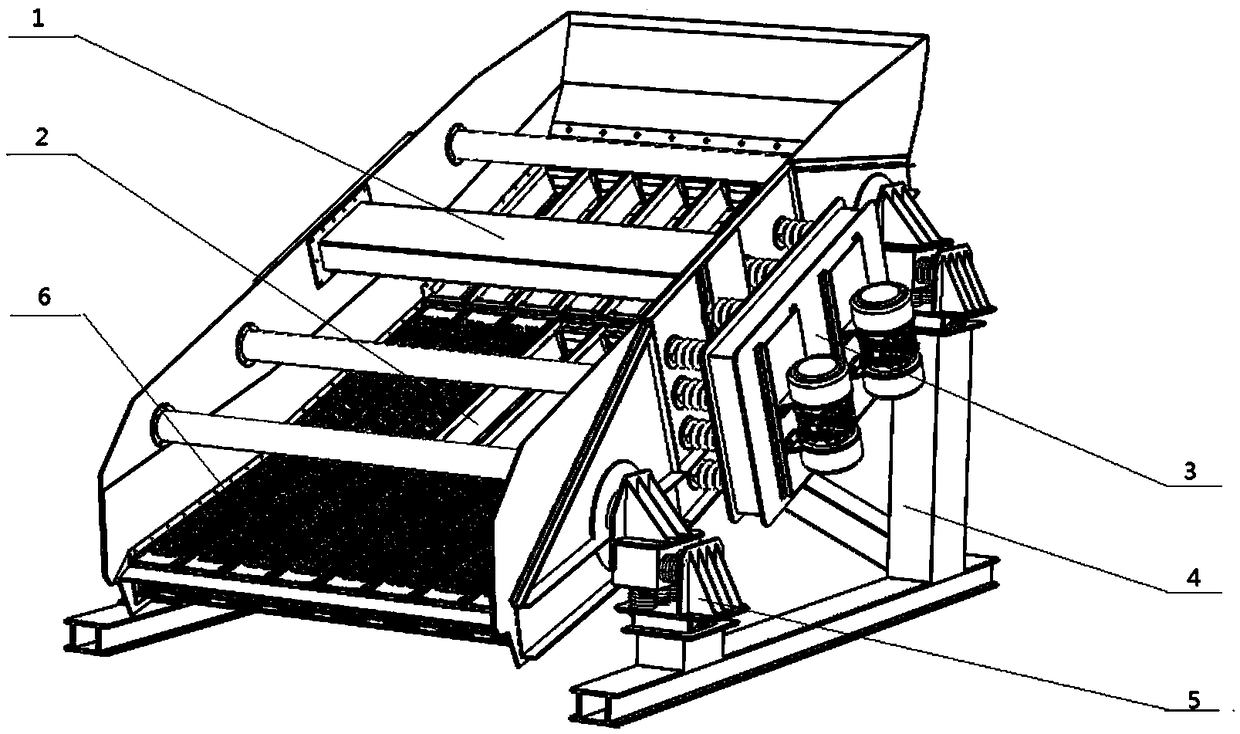

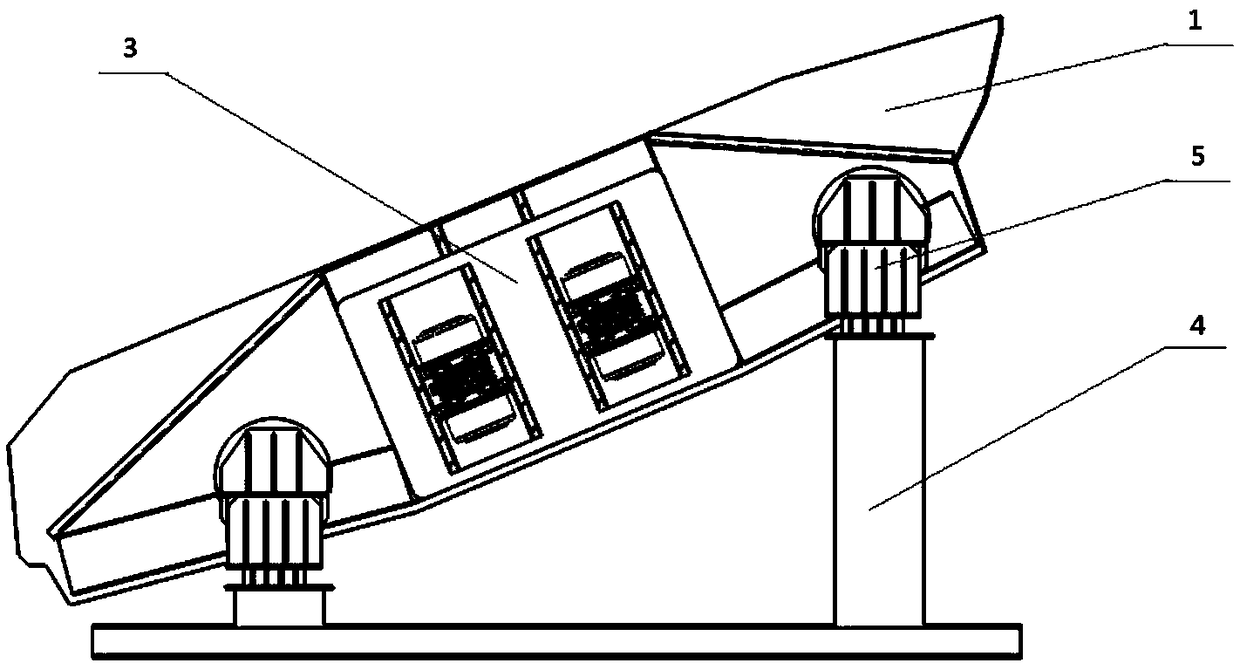

Total amplitude supporting high-frequency linear vibrating screen

ActiveCN103272763AHigh anti-vibration index performanceReduce shockSievingScreeningSlurryGravity center

A total amplitude supporting high-frequency linear vibrating screen belongs to the field of vibrating screening machinery and mainly solves the problem that the existing high-frequency vibrating screen is insufficient in vibration frequency and can not meet production requirements. A plurality of sections of screen cloth are arranged on a screen cloth bracket transversely in a tightening mode in an arc shape, two vibrating devices or vibrating motors are arranged on horizontal and vertical vibrating device base plates in the middle of a vibrating beam, and a vibrating resultant action line passes through the gravity center of a screen box. The screen box is connected with a total amplitude elastic supporting base on a base support through four square trunnions. The total amplitude elastic supporting base is composed of an upper support, a lower support and rubber springs, and the square trunnions are arranged between an upper rubber spring and a lower rubber spring. The base support is connected with a base through a secondary damping device. A sealed slurry material box is arranged at the feeding end of the screen box on the base support. The total amplitude supporting high-frequency linear vibrating screen has the advantages of being high in vibrating frequency and large in vibrating strength and material screening productivity and the like, can be widely applied to precise screening of milled powder of an iron mine ball mill, fine-mesh-level wet materials like petroleum drilling slurry, coal and chemical-mesh-level materials.

Owner:王海生

Horizontal linear vibrator

ActiveUS8097988B2Reduce thicknessLong lastingMechanical vibrations separationMechanical energy handlingResponsivityEngineering

The present invention provides a horizontal linear vibrator which can reduce the thickness but increase the strength of vibrations while at the same time guaranteeing a sufficiently long lifetime and satisfactory responsivity. The horizontal linear vibrator includes a casing, a bracket, a vibration unit, a cylindrical coil and springs. The bracket is coupled to the casing to form an internal space. The vibration unit includes a weight, a pair of yokes and magnets. The weight has an opening therein. The yokes are disposed on the inner surfaces of the weight. The magnets are provided in the yokes such that different poles of the magnets face each other. The cylindrical coil is perpendicularly mounted to the bracket and disposed in space between the pair of yoke. The springs are coupled to both ends of the casing or the bracket. The springs elastically support the vibration unit to allow the vibration unit to vibrate in the horizontal direction.

Owner:PARTRON

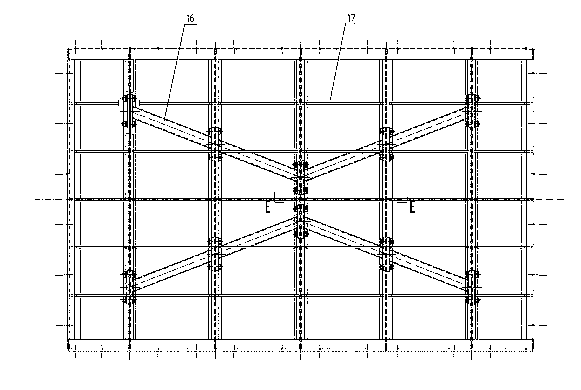

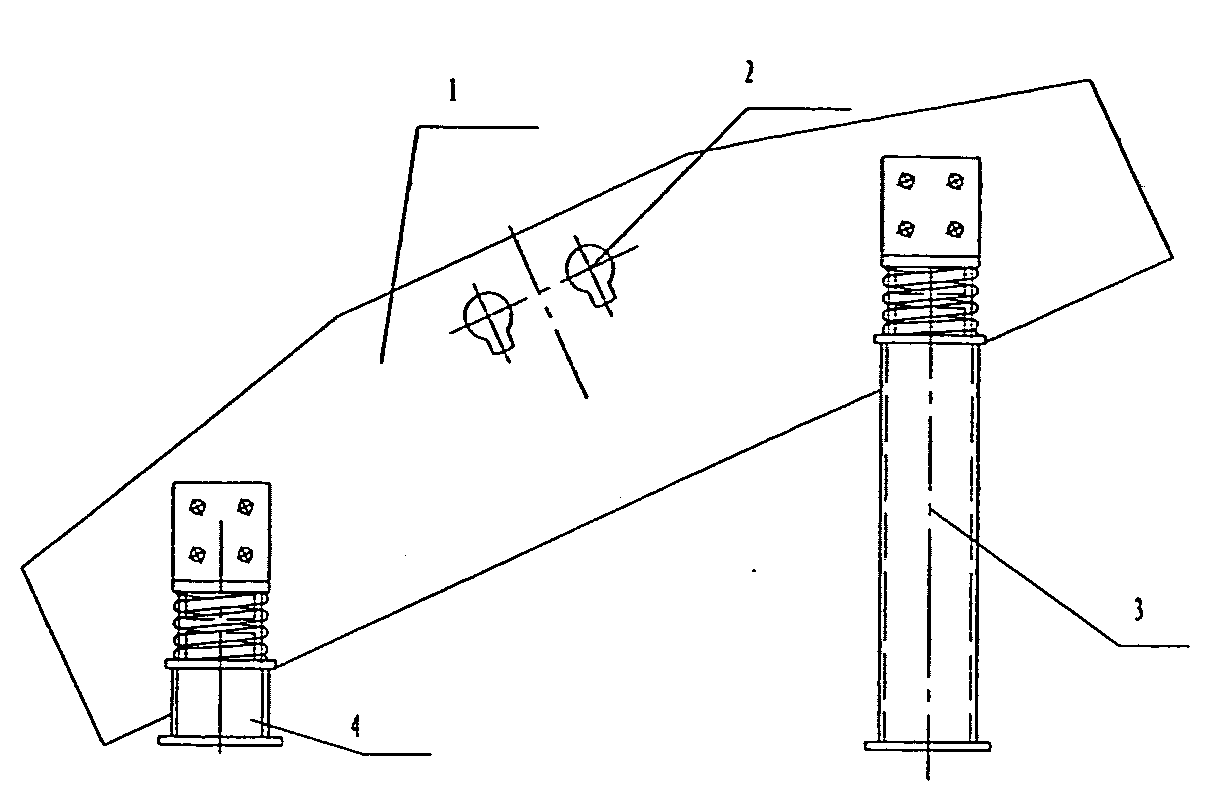

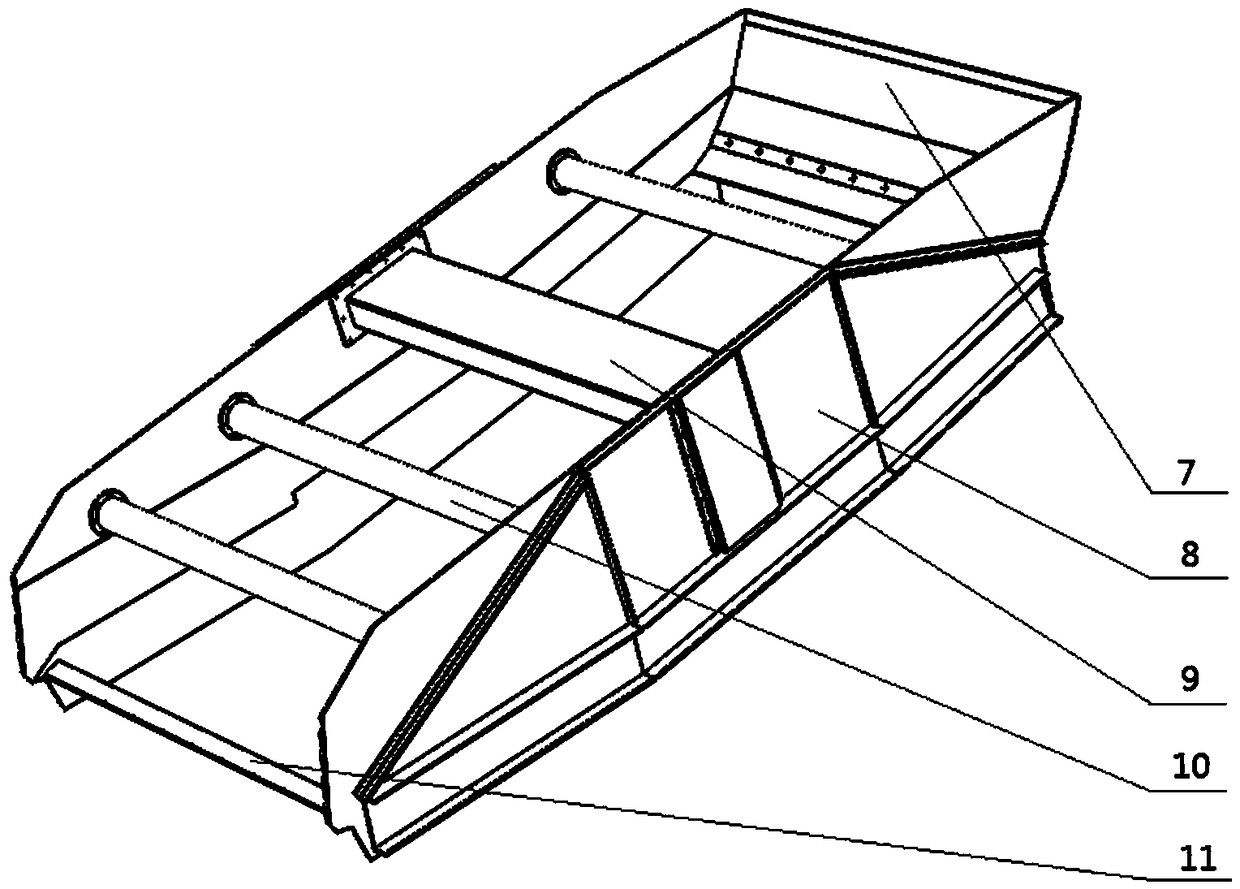

Elastic sieving technique and corresponding large-sized elastic vibration screen

InactiveUS20070261999A1Reduce power consumptionSimple and easy to and maintainSievingScreeningResonanceElastic vibration

An elastic sieving method and corresponding large-sized elastic vibration screen The present invention utilizes a screening surface and a separate sieving machine. A screen mat located on the sieve box is connected to multiple small rectangular screens. While the machine is vibrating, the resonation of screen rods located on the screen mat connected by small rectangular screens are initiated to screen the material and to cause the vibration of the whole vibration screen and realize the conveyance and lamination of materials. Because the screening surface is in a state of resonance, the vibration strength is strong enough to prevent the screen meshes from becoming plugged, allowing for high sieving efficiency. A bearing in the sieving mechanism is installed with a vibration damping ring, placing the bearing in a resonant state, allowing for a low dynamic stress level, which satisfies the process requirement for large-sized vibration screen excitation units with a screening surface as wide as 4800 mm. Thus, the production efficiency of vibration screen is high, the structure of the machine is simple and easy to repair and maintain, and energy consumption is reduced. Furthermore, the dynamic stress level of the sieving machine is low, the reliability is high, and the vibrations are stable. These properties allow the present invention to have a wide range of practical applications, including uses in the coal, metallurgic, chemical and environmental protection fields.

Owner:CHINA UNIV OF MINING & TECH

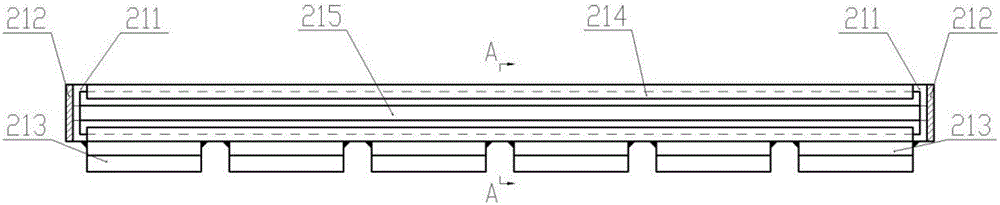

Standard rail chair type elastic rod sieve plate

InactiveCN105127092AAvoid corrosionIncrease vibration intensitySievingScreeningModular designEngineering

The invention discloses a standard rail chair type elastic rod sieve plate which comprises rail chairs and an elastic sieve surface. The elastic sieve surface comprises a sieve frame, an elastic support body and sieve rods, the elastic support body is fixed in a containing body of the sieve frame, the two ends of each sieve rod are fixed in the elastic support body, and the elastic sieve surface is connected with the rail chairs through buckle devices. According to the standard rail chair type elastic rod sieve plate, the elastic support body can enable the sieve rods to be located in a resonant state in the working process of a vibrating sieve, the vibration intensity of the sieve surface is improved, and by means of the autoroatation and movement in the axial direction of the sieve rods, the problems of material stacking, bonding and mesh blocking are well solved, and the screening efficiency of the vibrating sieve is improved; due to the fact that the rail chairs are connected with the elastic sieve surface through the buckle devices, the structure is compact, assembly and disassembly are convenient, the practicability is strong, and the labor intensity of workers is reduced; according to the standard rail chair type elastic rod sieve plate, the modular design is adopted, and scale production and market promotion are facilitated.

Owner:CHINA UNIV OF MINING & TECH

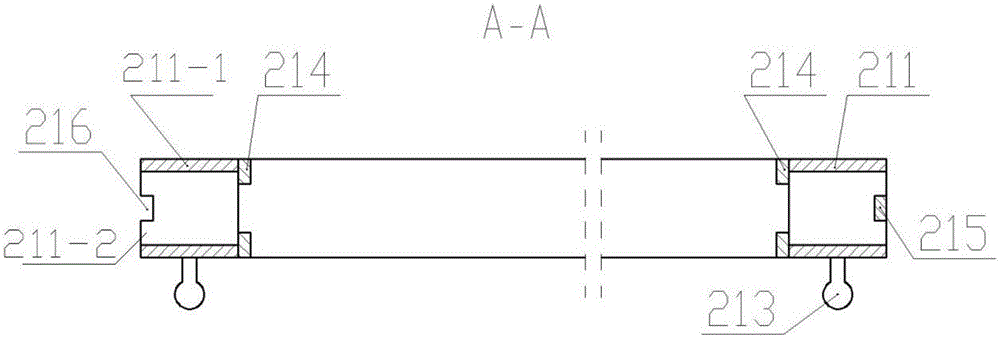

Process for forming vibration and extrusion process prestressed concrete pipe through core mold vibration method

InactiveCN103895098AUniform qualityOvercome a series of defects caused by vibration-forming plastic concrete mixturesCeramic shaping apparatusPre stressUltimate tensile strength

The invention provides a process for forming a vibration and extrusion process prestressed concrete pipe through a core mold vibrator. An inner mode and an outer mold which are completely installed are hoisted to be arranged on the core mold vibrator in a sleeved mode together so that a model and the core mold vibrator can be tightly attached to each other through locking devices. A feed hopper is arranged above the model, the core mold vibrator is started and conducts feeding while vibrating till the model is filled with concrete mixtures, and then other procedures are completed. According to the process, the vibration and extrusion process prestressed concrete pipe is formed by the core mold vibrator which is high in vibration intensity and good in vibration effect, quality of the prestressed concrete pipe can be improved, production cost can be reduced, the environment can be protected, and the waste residue discharge can be reduced.

Owner:TIANJIN ZEBAO CEMENT PROD

Self-cleaning vibrating bag-type dust remover

PendingCN107335300AAvoid damageAchieve elastic deformationDispersed particle filtrationFixed bearingVibration amplitude

The invention discloses a self-cleaning vibrating cloth bag dust collector, which comprises a dust removal box body, a cleaning box body is fixed on the top of the dust removal box body, horizontally distributed cloth bag fixing frames are vertically fixed on the side wall of the dust removal box body, the dust removal box body and cleaning The boxes are separated by a cloth bag fixing frame. The bag fixing frame is sealed and fixed with a dust removal bag. The bag support frame is set in the dust removal bag. The air inlet channel is fixed at the entrance of the flue gas, the bottom of the dust bag is fixed with a first snap ring, the outer surface of the side wall of the dust removal box is covered with a fixed bearing ring, and the bottom of the bearing ring is vertically and evenly distributed with four supporting columns , a motor is fixed on the surface of the bearing ring. The present invention is provided with a vibrating frame, which is connected to the dust-removing cloth bag through a buffering and pulling mechanism, and the reciprocating motion of the vibrating frame drives the reciprocating vibration of the dust-removing cloth bag, and the vibration amplitude is relatively large, which can safely realize the self-cleaning ability of the dust-removing cloth bag.

Owner:ANHUI SHENGYUN ENVIRONMENT PROTECTION GRP CO LTD

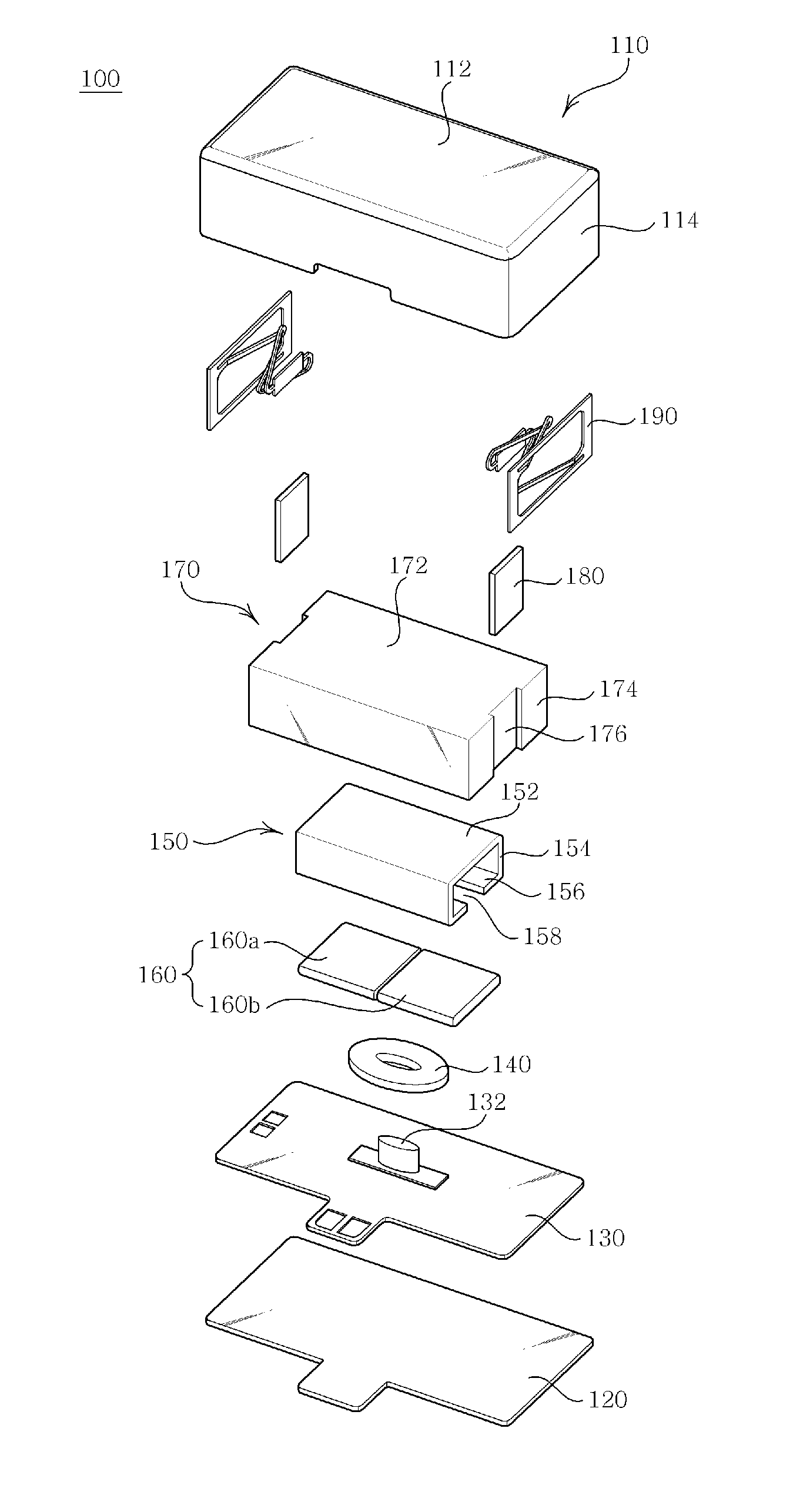

Reciprocating vibration generator

InactiveUS8519573B2Increase vibration intensityReduce power consumptionMechanical vibrations separationSupports/enclosures/casingsReciprocating motionClosed loop

A reciprocating vibration generator making the magnetic circuit of a permanent magnet a closed loop so as to obtain a high vibration force, specifically a vibration linear actuator having a ring-shaped weight, a reciprocating vibrator having a ring-shaped permanent magnet in a center hole of the weight, a first plate spring and a second plate spring supporting this reciprocating vibrator with respect to a recessed case and an end plate to be able to elastically displace in a thickness direction between a first end face and a second end face, a tube-shaped toroidal coil running through a center hole of the ring-shaped permanent magnet and generating a reciprocating vibration magnetic field for driving the ring-shaped permanent magnet to reciprocate in the thickness direction, and a columnar core running through the inside of this toroidal coil, wherein the ring-shaped permanent magnet is magnetized in the thickness direction, and the toroidal coil has a lower stage toroidal coil and an upper stage toroidal coil coaxial with and adjacent to the same, wound in the opposite direction, and connected in series with the same.

Owner:SANYO SEIMITSU

Method, device and system for actively controlling linear motor vibration, and electronic device

ActiveCN106160622AEnsure safetyIncrease vibration intensityAC motor controlAudio power amplifierEngineering

The invention discloses a method, a device and a system for actively controlling linear motor vibration, and electronic device. The method comprises the steps: an input signal for driving a linear motor or a signal generated according to the input signal is acquired for serving as a to-be-processed signal; the frequency and the voltage of the to-be-processed signal are analyzed; according to data for reflecting output voltage, vibration frequency and maximum safe amplitude correspondence, the output voltage for making the analyzed frequency to reach the maximum safe amplitude serves as maximum safe output voltage; according to the maximum safe output voltage and the amplification times of a power amplifier, maximum safe input voltage can be obtained through calculation; an adjusting instruction containing a ratio of the maximum safe input voltage to analyzed voltage is transmitted to a pre-filtering amplifier, and the adjustment of gain is performed; the adjusting instruction containing the maximum safe input voltage is outputted to a compressor and / or limiter, and the parameter adjustment is performed. According to the invention, the maximum vibration strength can be outputted under a premise of ensuring the safety of the linear motor.

Owner:GOERTEK INC

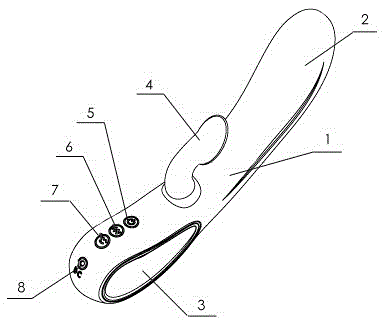

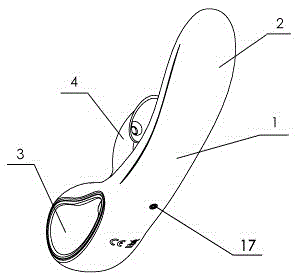

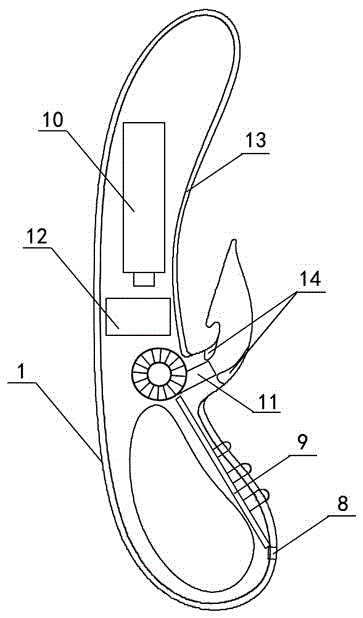

Air-suction vibration massager and using method thereof

InactiveCN105616124AEasy to useExquisite appearanceVibration massageGenitals massageKey pressingFrequency conversion

The invention relates to an air-suction vibration massager which comprises a massager body, wherein the outer side of the massager body is prepared by using a soft silica gel material; the upper part of the massager body is a massaging part; the lower part of the massager body is a handle; the massager body is in an arc-shaped structure; an air-suction vibration head is arranged on the inner side of the arc shape the massager body; a power supply switch, an air-suction frequency adjustment key, a vibration frequency adjustment key, a charging port and an air outlet are arranged on the surface of the lower part of the massager body. Compared with the prior art, the air-suction vibration massager disclosed by the invention is attractive in appearance, simple in structure, reasonable in structure and the like. The invention also discloses an air-suction massaging method which supplies convenience to users and has a quite high massaging effect; the different massaging method is experienced. A silencing device of the air-suction vibration massager reduces noises caused by the massager, and the massaging efficiency is improved. A vibration motor of the air-suction vibration massager is a frequency conversion motor; vibration intensity is effectively increased by different vibration modes.

Owner:LIAOYANG BAILE HEALTH CARE PROD CO LTD

Vibrating equal-thickness flip-flow screen for multi-plastid activation

ActiveCN109453989AAvoid damageWith horizontal activationSievingScreeningEngineeringBiological activation

The invention discloses a vibrating equal-thickness flip-flow screen for multi-plastid activation. The flip-flow screen comprises an outer screen frame, a flip-flow body, an excitation device, a supporting frame, a T-shaped vibration isolation spring device and a screen plate, and the flip-flow body is fixedly arranged between two side plates of the outer screen frame to form a screen box; the excitation device is connected to the side face of the screen box through a main vibration spring; and the supporting frame and the outer screen frame are connected through the T-shaped vibration isolation spring device. The vibrating equal-thickness flip-flow screen for multi-plastid activation has the advantage that multi-plastid transverse vibration (which is beneficial to activating materials), equal-thickness screening and screen surface relaxation are achieved. The flip-flow screen only has transverse shearing dynamic load to the ground, a special vibration mode has a transverse activationeffect on materials, and the screening efficiency is high. The flip-flow screen surface makes the materials jump, and the hole blocking phenomenon is effectively eliminated. A motor is connected witha vibrating plastid small in amplitude, and the function of protecting the motor is achieved. The vibrating plastid and the screen box are flexibly connected through a plurality of sets of springs, sothat the stress of the whole structure is more reasonable.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

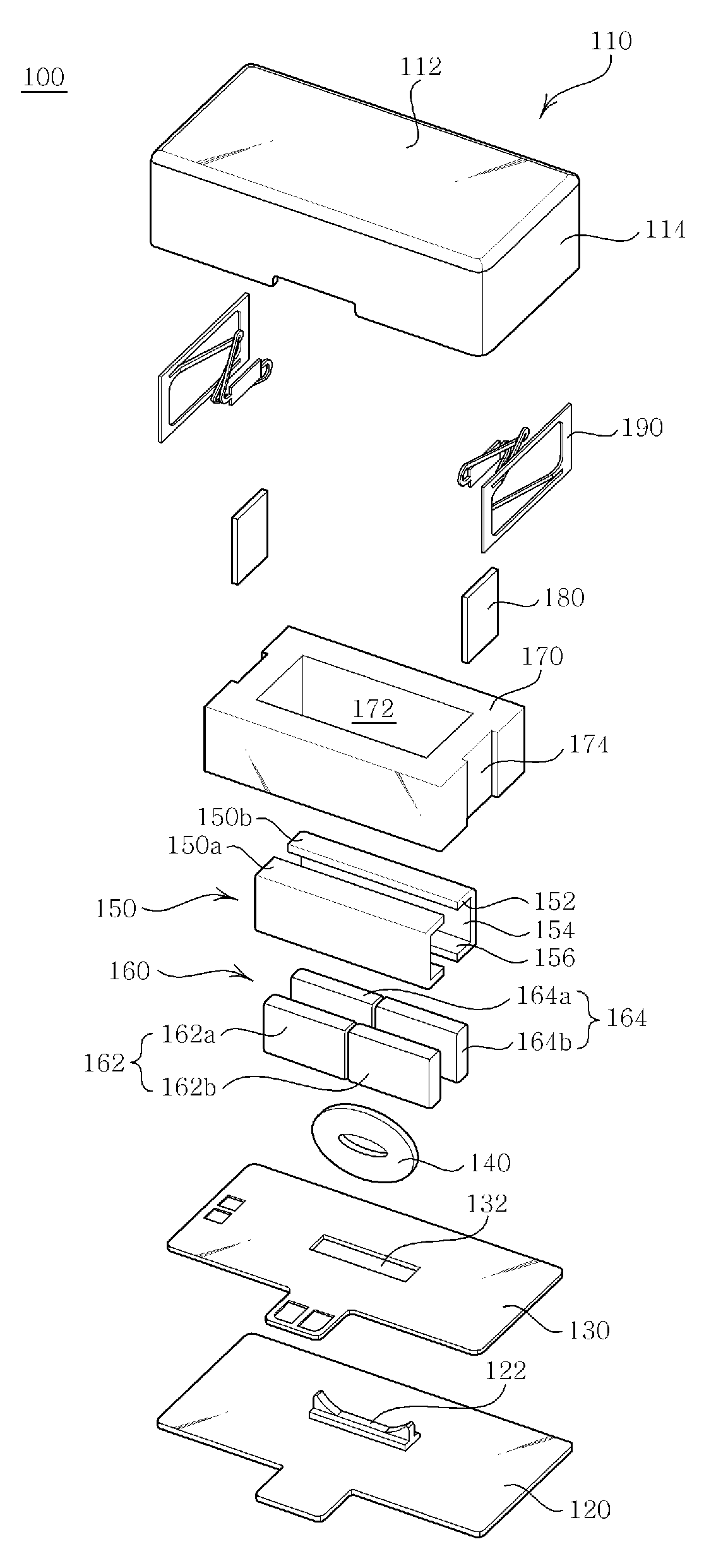

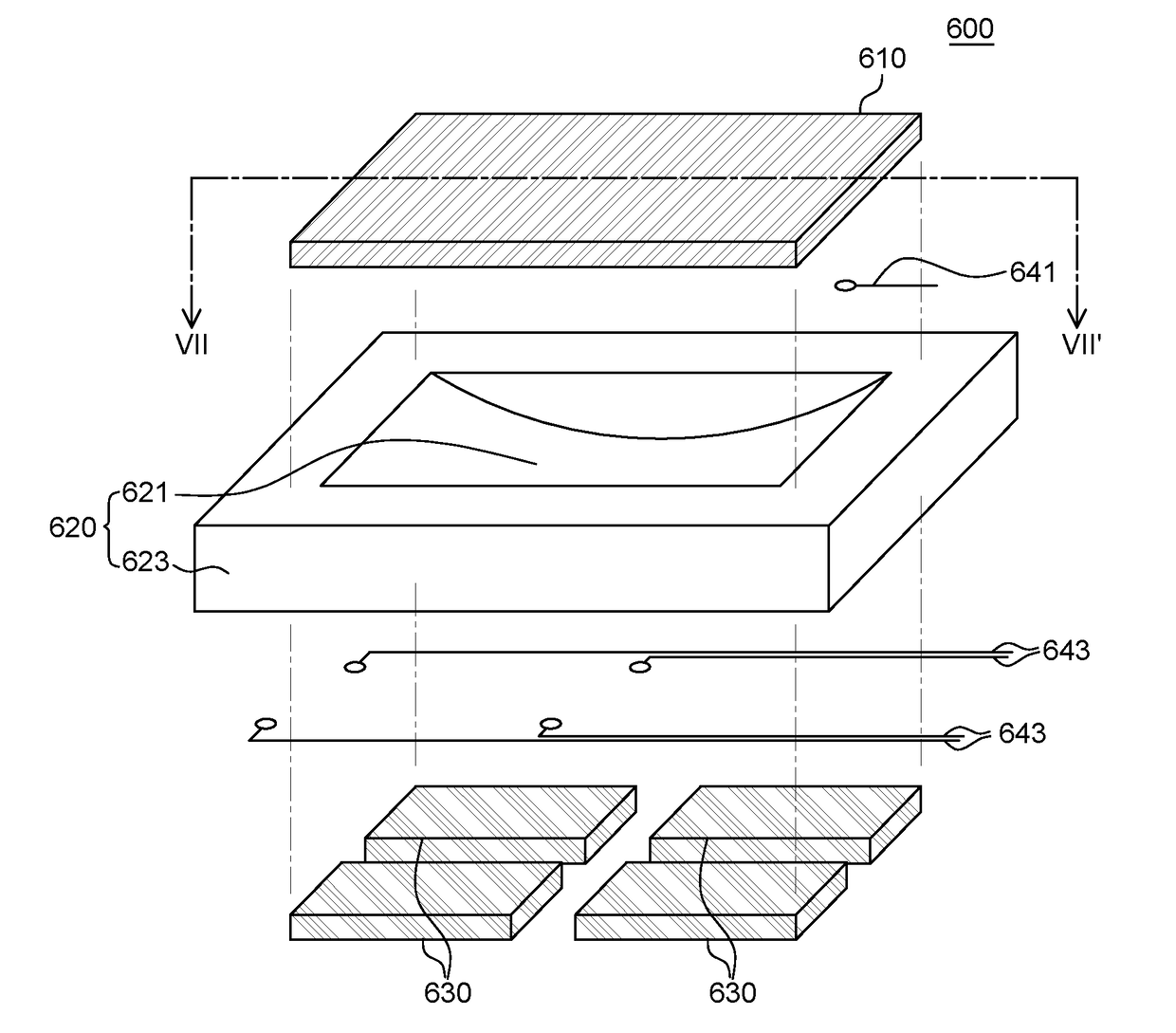

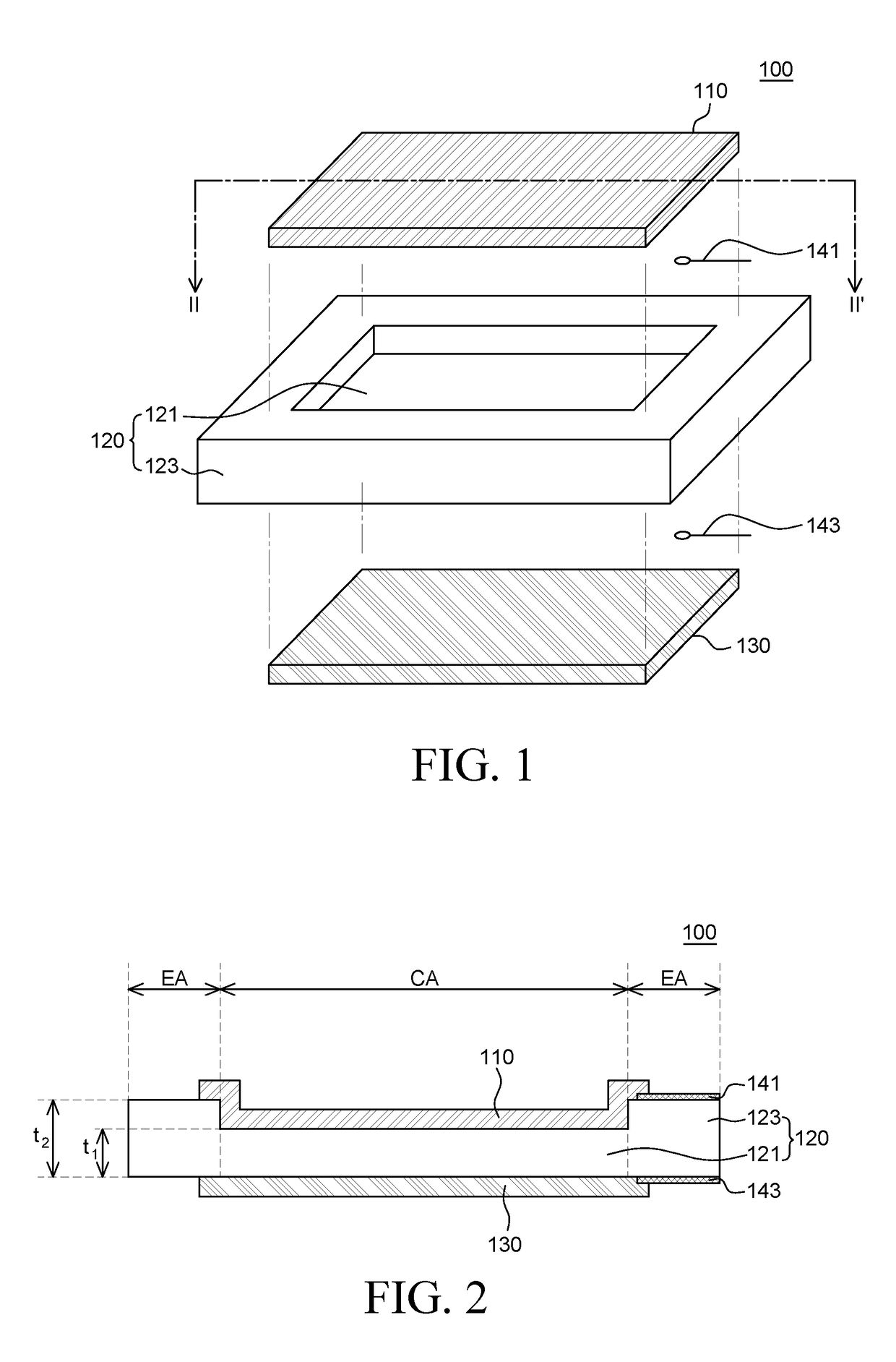

Touch Sensitive Element and Display Device Including the Same

ActiveUS20180120942A1Small thicknessIncrease vibration intensityInput/output for user-computer interactionSolid-state devicesDisplay deviceBiomedical engineering

There is provided a touch sensitive element including an electroactive layer, and an electrode disposed on at least one surface of the electroactive layer. The electroactive layer has a first portion having a first thickness and a second portion which has a second thickness different from the first thickness and is in contact with the first portion at an outside of the first portion.

Owner:LG DISPLAY CO LTD

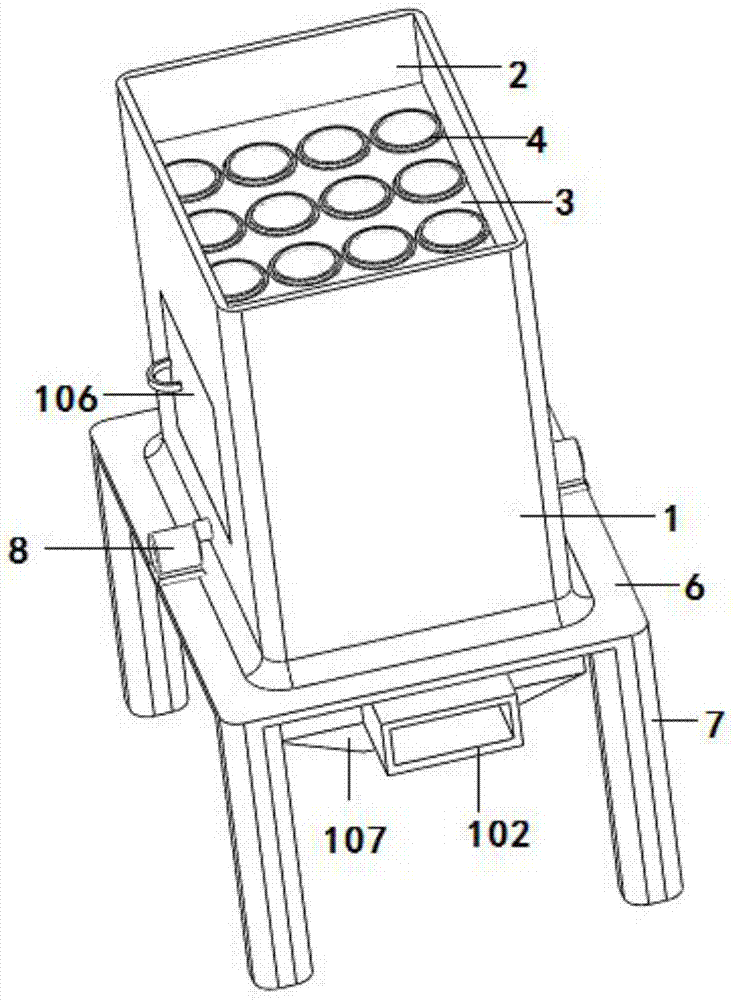

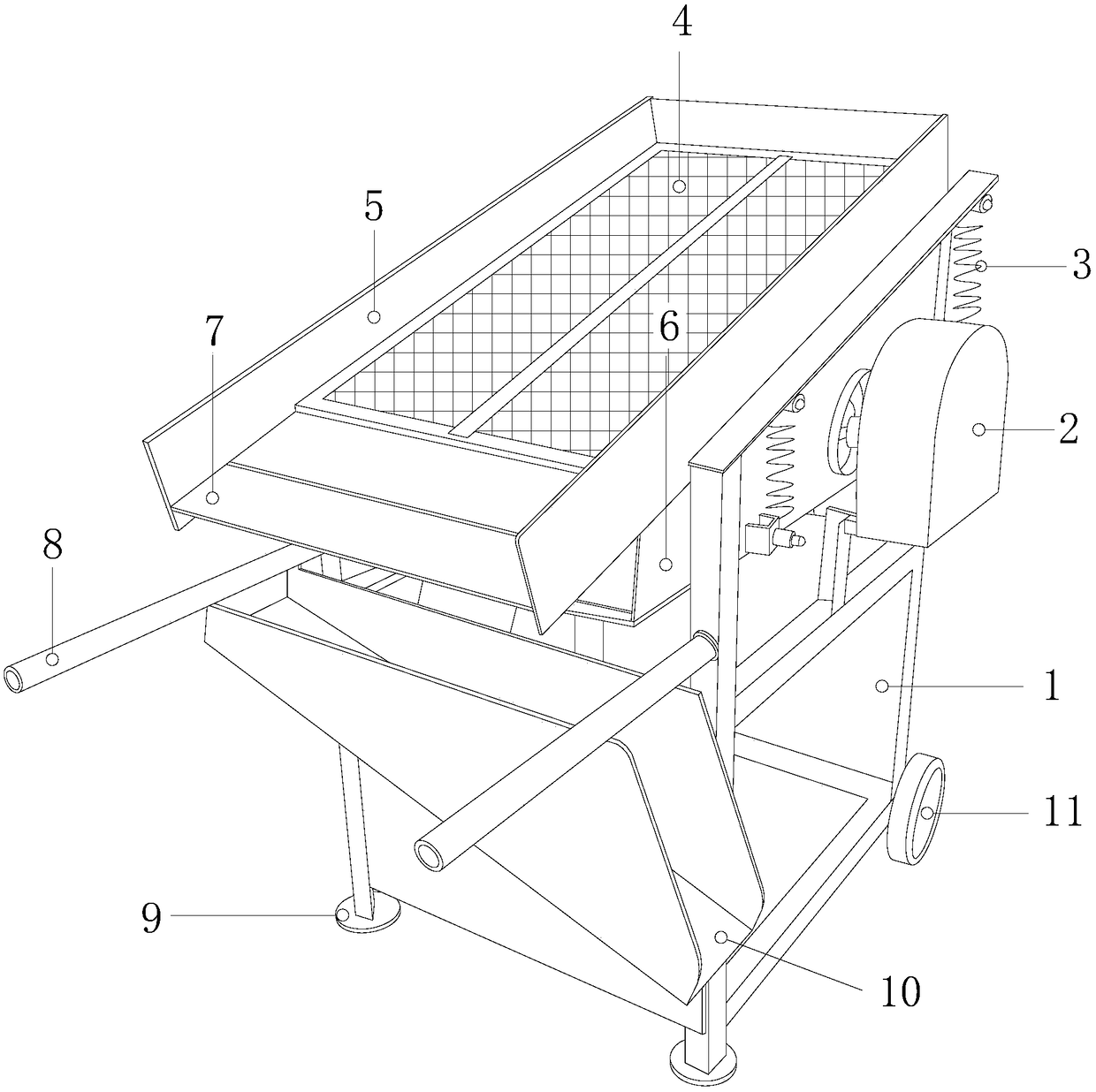

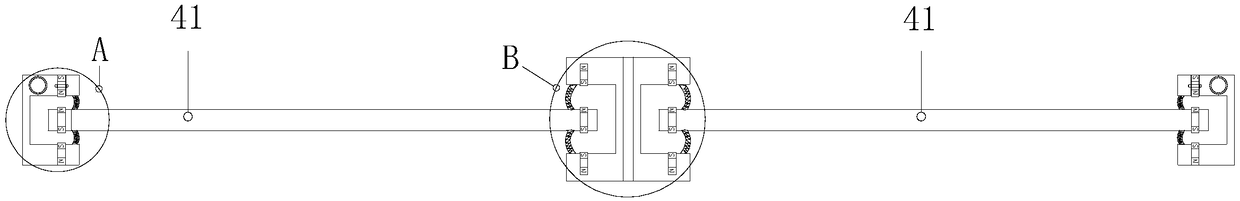

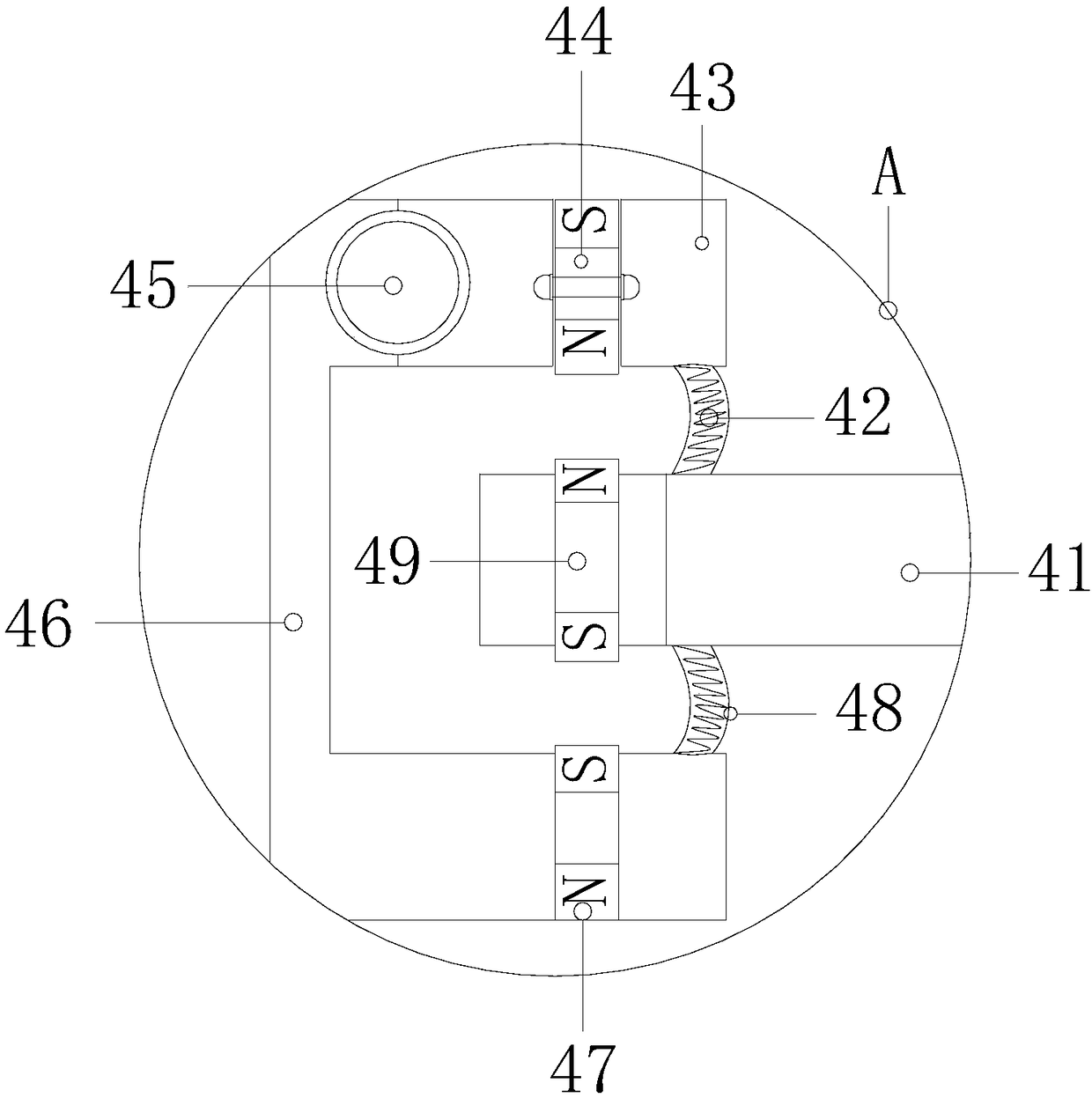

Sand screening machine for reducing viscosity of wet mud

The invention provides a sand screening machine for reducing the viscosity of a wet mud, relates to the field of interior decoration machinery equipment, and solves the problems that the wet mud is easy to adhere to a screen mesh or screen holes and the screen mesh is not easy to disassemble and clean. The sand screening machine for reducing the viscosity of the wet mud comprises a servo electriccabinet, a coarse sand screen mesh, an installation plate and the like. By utilizing the principle of homopolar repulsion of magnets, same poles of a No.1 permanent magnet, a No.2 permanent magnet anda No.3 permanent magnet are opposite, so that the vibration strength of a screen mesh body can be improved; a quick lime coating layer and moisture in the wet mud are matched to produce chemical reaction and radiate heat, and a lug and sand generate heat by friction, so that the surface temperature of a mesh surface of the screen mesh rises, the moisture in the wet mud is absorbed, and the wet mud is not easy to adhere sand or block the filtration screen holes; and then by utilizing the principle of opposites attraction of the magnets, the No.3 permanent magnet is turned over at 180 degrees,a movable plate rotates upwards, and the screen mesh body further moves upwards, so that the screen mesh body can be easily taken down and cleaned so as to be conveniently used for the next time.

Owner:刘培珠

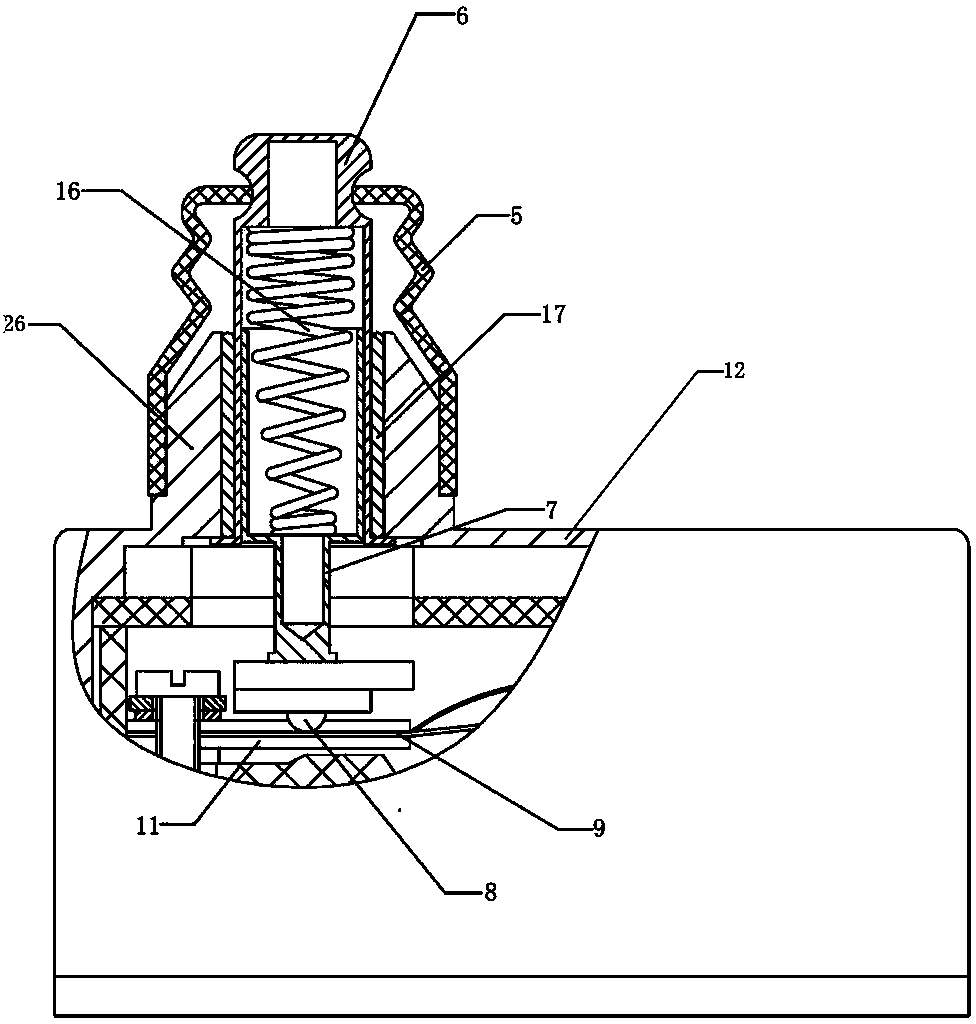

Power type microswitch

ActiveCN103441016AHigh mechanical strengthImprove electrical performanceSnap-action arrangementsTorsion springContactor

The invention discloses a power type microswitch. The power type microswitch comprises a contact spring assembly, a rolling touch assembly and a button actuating assembly, wherein the contact spring assembly is arranged on a base, the rolling touch assembly is arranged on an outer shell, and the button actuating assembly is arranged between the contact spring assembly and the rolling touch assembly. The contact spring assembly comprises an upper spring leaf with an upper stationary contact, a lower spring leaf with a lower stationary contact, a movable spring leaf with a movable contact and a spring lifting locating and supporting chip. The rolling touch assembly comprises a folded edge touch plate with a circular arc adjusting groove, a rocking bar, a rolling wheel, a torsion spring and a limiting boss. The button actuating assembly comprises a button, a push rod, a touch button, a conical spring and a protecting bush. The power type microswitch has the advantages of being high in protection (dustproof, waterproof) level, good in environment resistance, small in movement clearance, large in working current and the like. The special structure of the button actuating assembly enables the microswitch to be straightforward in power connection when electrification switching is carried out, reduces and even avoids the phenomena such as contactor adhesion and arc discharge, prolongs the service life of the microswitch and improves the working reliability of the microswitch.

Owner:中壹发展八五零电子有限公司

Charge air cooler condensation control

ActiveUS9334791B2Lower energy requirementsIncrease vibration intensityInternal combustion piston enginesExhaust gas recirculationChillerAerospace engineering

Owner:FORD GLOBAL TECH LLC

Collision-type uniform seed dressing device

ActiveCN108476659ACause some damagesDoes not affect later growthSeed coating/dressingHuman bodyEngineering

The invention discloses a collision-type uniform seed dressing device. The device comprises an elastic force shocking fixing device which comprises a base case, wherein an elastic force vibration seatis installed and fixed between two opposite side walls of the base box, a transmission fixing plate is vertically fixed in the middle of the surface of the box bottom of the base box, an elastic force transmission mechanism is installed and fixed on the transmission fixing plate, and the elastic force transmission mechanism is connected with an elastic force vibration seat. According to the collision-type uniform seed dressing device, seeds can be directly placed in a mixing drum, then the mixing drum can perform irregular vibration action upwards, downwards, leftwards and rightwards throughthe action of the elastic force shocking fixing mechanism, materials in the mixing drum can mutually collide to be mixed, not only is the seed dressing efficiency improved, but also the seeds cannot be damaged in the seed dressing process to influence later-stage growth, meanwhile, the harm to a human body due to direct contact between a person and a pesticide is avoided, and the human cost is reduced as well.

Owner:合肥俊刚机械科技有限公司

Connecting method of variable cross-section phononic crystal elastic material

InactiveCN101976559AHigh bonding strengthIncrease vibration intensitySound producing devicesEngineeringCopper

The invention belongs to the field of functional materials and particularly provides a connecting method of a variable cross-section phononic crystal elastic material. The connecting method is characterized in that the variable cross-section phononic crystal elastic material consists of a copper block and a rubber column, the copper block and the rubber column are firstly bonded by using glue, then a copper pressure piece is added, and a bolt is further used for fixation, wherein the thickness of the copper pressure piece is 0.5mm-1mm, the outer diameter is 0.2mm smaller than a groove of the copper block, and the inner diameter is 0.2mm bigger than the rubber column. The connecting method adopts the glue bonding and simultaneously utilizes the pressure piece and the bolt to strengthen the bonding strength. Therefore, the bonding strength in the material is far larger than that of the traditional glue bonding method, thereby leading a phononic crystal to be capable of being applied in a plurality of vibration damping environments with high vibration strength.

Owner:UNIV OF SCI & TECH BEIJING

Small-sized motor

ActiveUS7045921B2Improve efficiencyIncrease vibration intensityMechanical energy handlingSupports/enclosures/casingsSurface mountingEngineering

A small-sized motor of a structure not requiring any metal holder frame in a surface mounting process to a printed circuit board by reflow soldering, wherein the motor case is provided with a level flat part, a pair of left and right first side parts bent downward from this substantially perpendicularly and parallel to each other, a pair of left and right second side parts bent inward from these at an inclination of about 45°, and a pair of left and right third side parts bent down from these and parallel to each other, and a level bottom part connecting these bottom ends and extending substantially parallel to the level flat part.

Owner:SANYO SEIMITSU

New energy automobile vehicle-mounted storage battery shock-resistant mounting box

The invention discloses a new energy automobile vehicle-mounted storage battery anti-vibration mounting box which comprises a box body, a placement box is arranged in the box body, limiting blocks arefixedly mounted at the tops of the two sides of the placement box, fixing blocks are fixedly mounted at the bottoms of the two sides of an inner cavity of the box body, and sliding grooves are formedin the fixing blocks. Sliding blocks are slidably connected into the sliding grooves. The limiting blocks are additionally arranged on the side face of the containing box, stability during downward movement can be guaranteed, inclination in the box body during vibration is avoided, the buffering air bag is additionally arranged at the bottom to buffer downward vibration force, and meanwhile the rubber pad is additionally arranged between the upper pressing block and the lower pressing block to enhance the buffering force between the upper pressing block and the lower pressing block and damagecaused by direct collision is avoided; and through a series of structures, buffer protection with the bottom of the placement box is facilitated, the safety of the internal storage battery during useis enhanced, the storage battery is prevented from being damaged by excessive vibration during running of the automobile, and the use quality is effectively guaranteed.

Owner:赵全民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com