Standard rail chair type elastic rod sieve plate

A technology of elastic rod and standard rail, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems such as rapid stratification of materials, high production cost of screening equipment, uneven material humidity, etc. Compact, good mechanical properties, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the drawings.

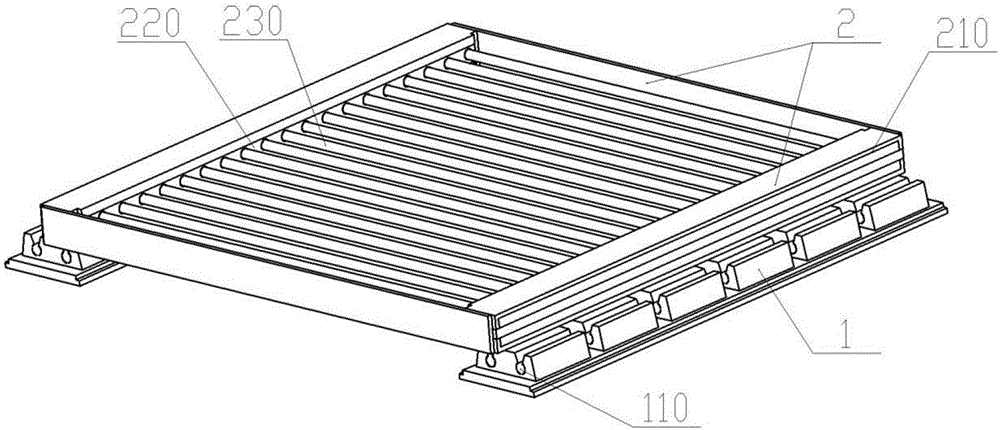

[0023] Such as figure 1 As shown, the outer dimension of the standard rail seat type elastic rod screen plate of the present invention is 610x610mm, which is suitable for large-scale production and market promotion. It includes a rail seat 1 and an elastic screen surface 2. The elastic screen surface 2 includes a screen frame 210 , The elastic support 220 and the screen rod 230, the elastic support 220 is fixed in the containment body 211 of the screen frame 210, the two ends of the screen rod 230 are fixed in the elastic support 220, the elastic screen surface 2 and the rail seat 1 pass Snap device connection.

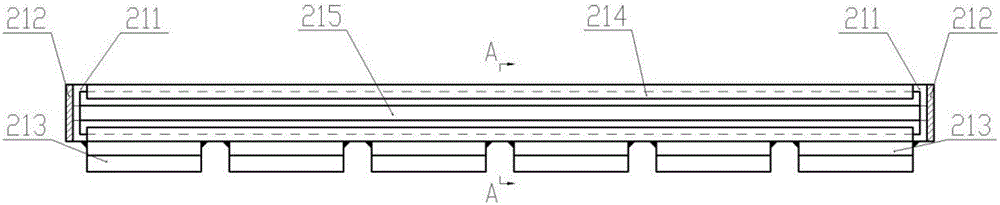

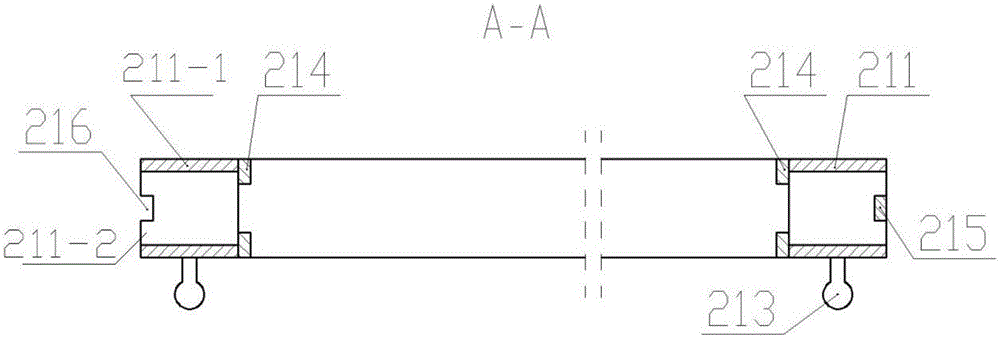

[0024] Such as Figure 2 to 6 As shown, the screen frame 210 includes a containment body 211, a first baffle 215, a second baffle 214, a connecting plate 212, and a buckle 213. The containment body 211 is provided at both ends of the connecting plate 212, and the containment b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com