Patents

Literature

57results about How to "Solve the plugging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

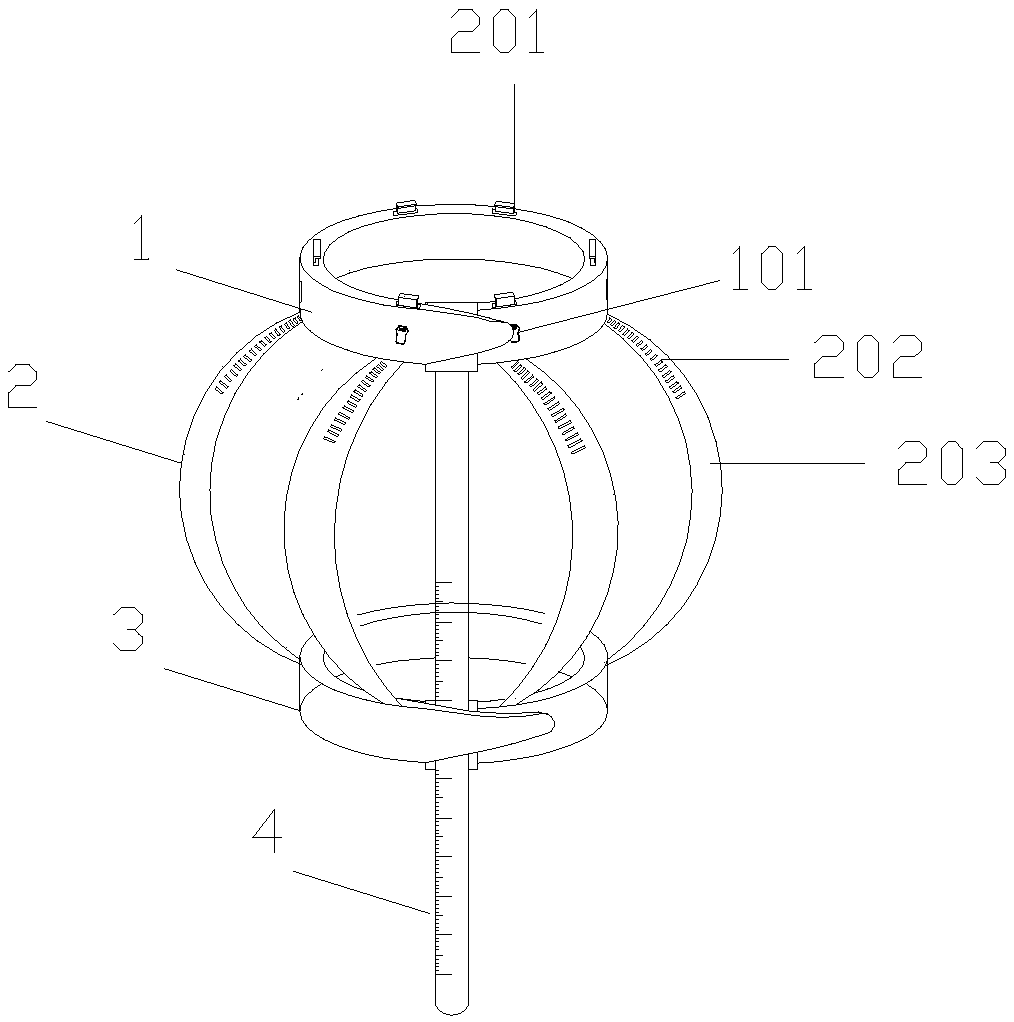

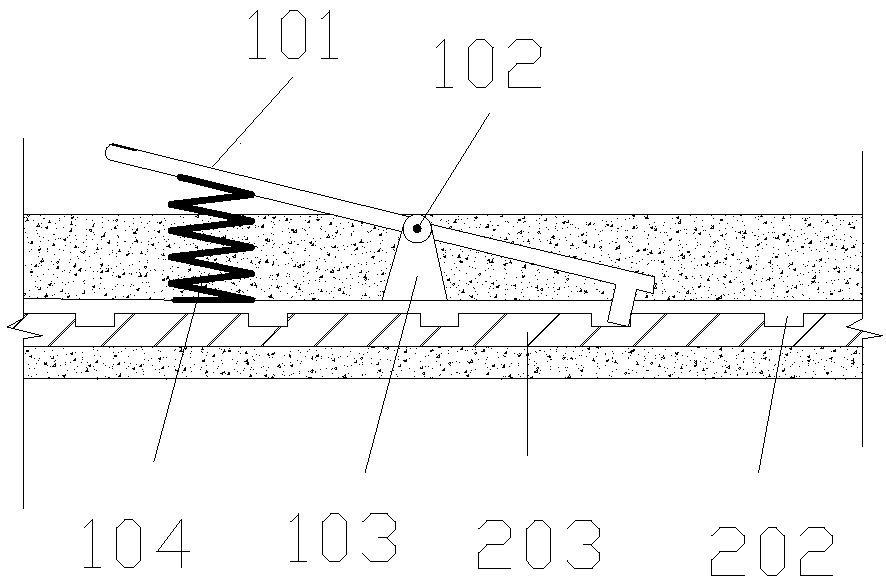

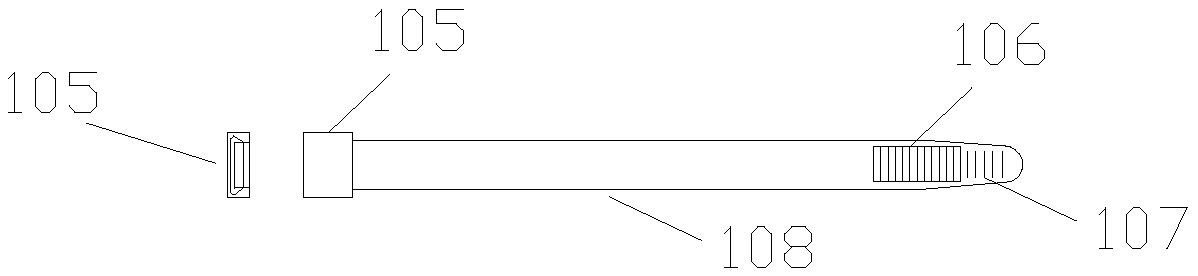

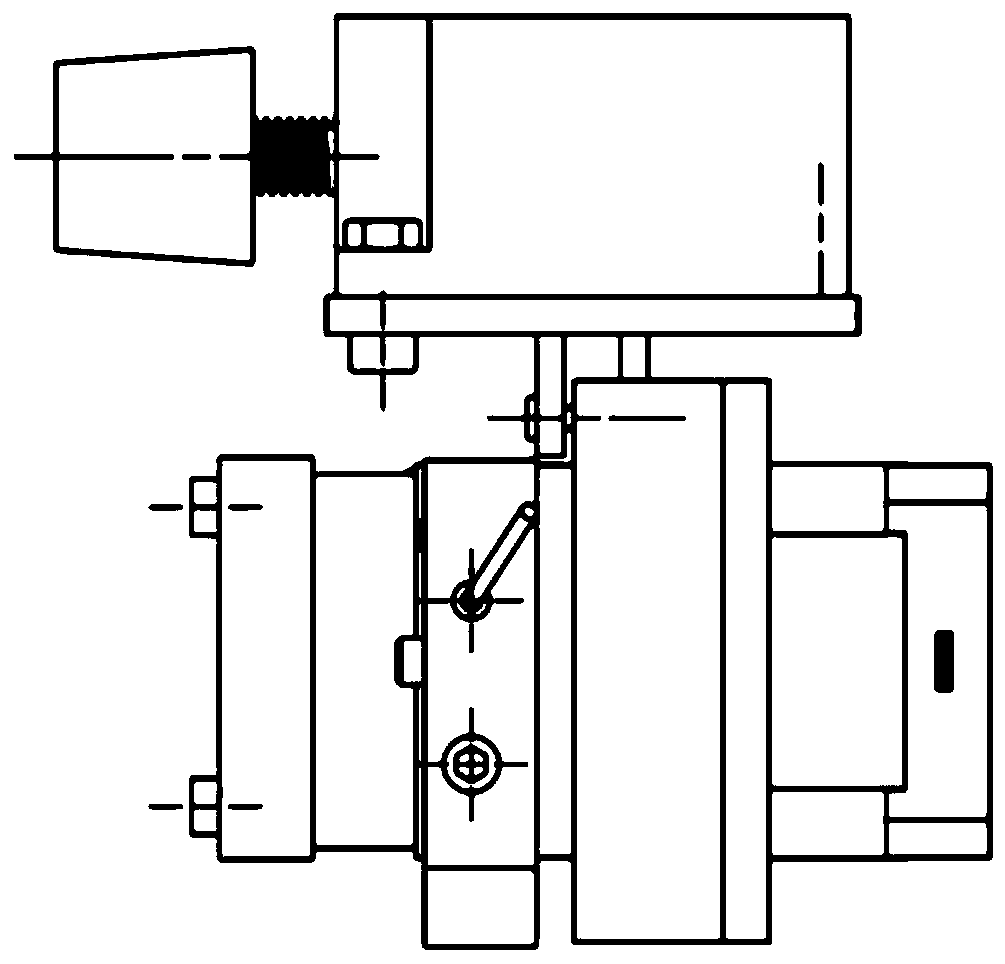

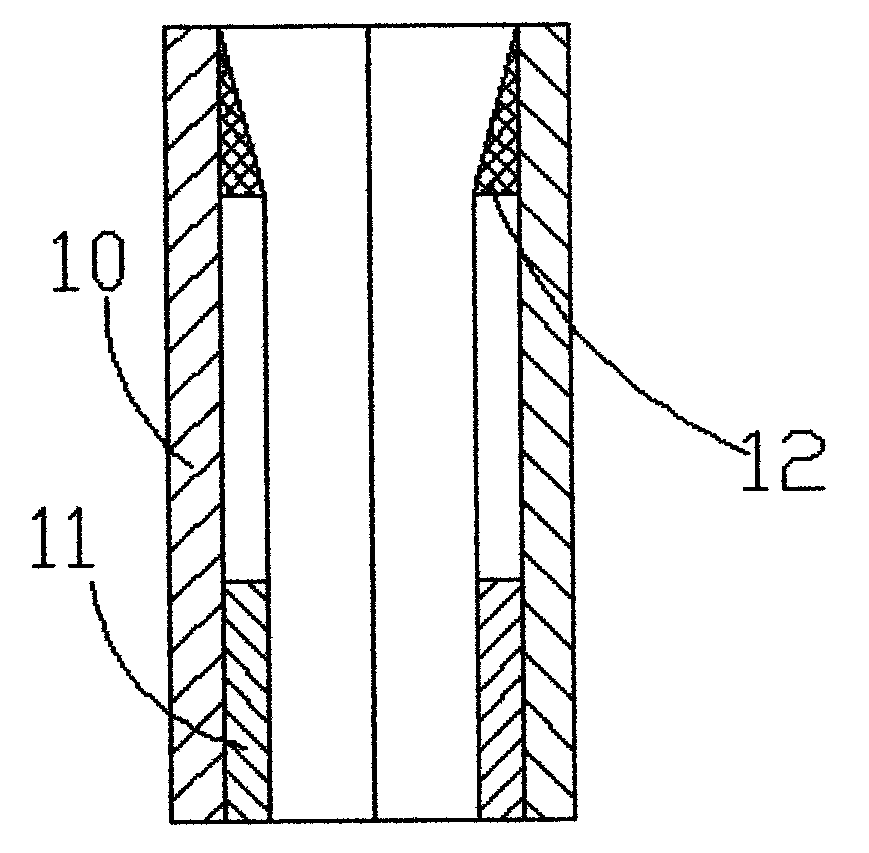

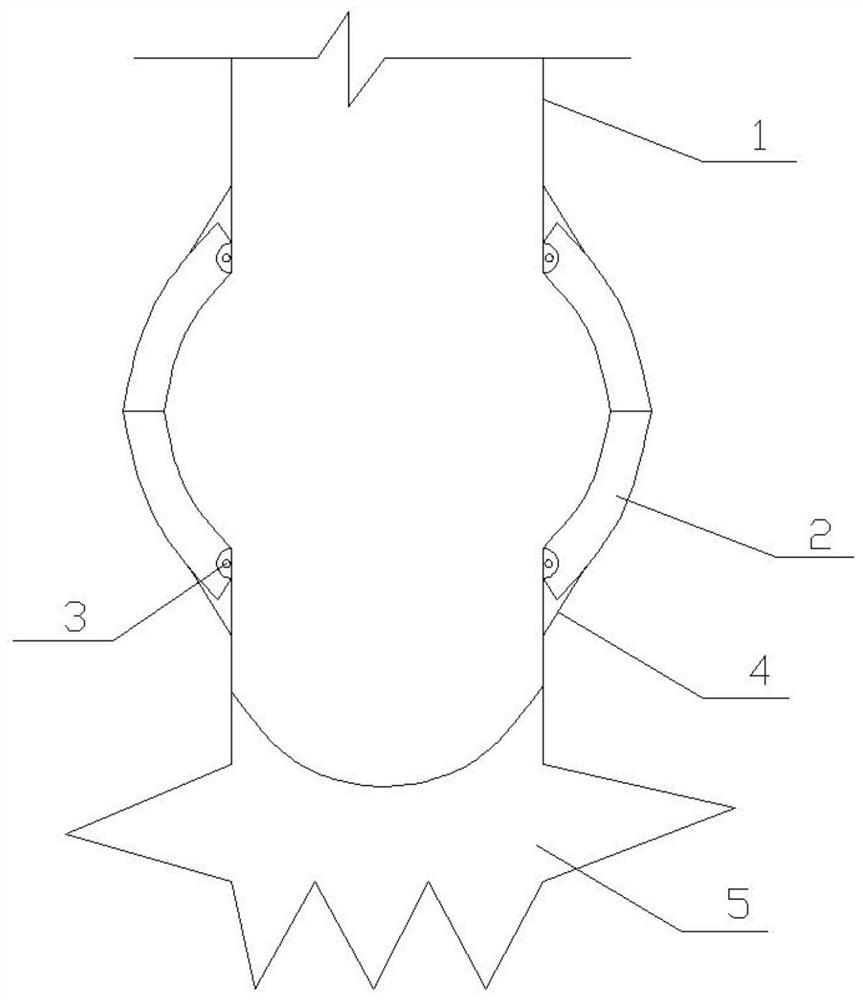

Uncoupled charging positioning device and methods

The invention discloses an uncoupled charging positioning device. The uncoupled charging positioning device mainly comprises an upper ring unit, an elastic support piece unit, a lower ring unit and ascaleplate. The upper end of the elastic support unit is movably connected with the upper ring unit, and the lower end of the elastic support piece unit is fixedly connected to the lower ring unit. The scaleplate is in a straight strip shape, and the scaleplate is provided with scales matched with the expansion radius of the elastic support unit. The upper end of the scaleplate is fixedly connected with the upper ring unit, and the lower end of the scaleplate is movably connected with the lower ring unit. The invention further discloses a concentric uncoupled charging method and an eccentric uncoupled charging method. The positioning device and the methods have the beneficial effects that an upper ring, a lower ring and elastic support pieces are used, the upper ring and the lower ring arefixed by an explosive roll, the explosive roll is separated from a blasthole wall by using the elastic support pieces, the centering problem of the uncoupled charging and the positioning problem in the eccentric uncoupled charging process in the prior art are solved, and meanwhile the breakage of the explosive roll and the hole blockage caused by the rough hole wall during the charging process are avoided as well.

Owner:WUHAN UNIV OF TECH

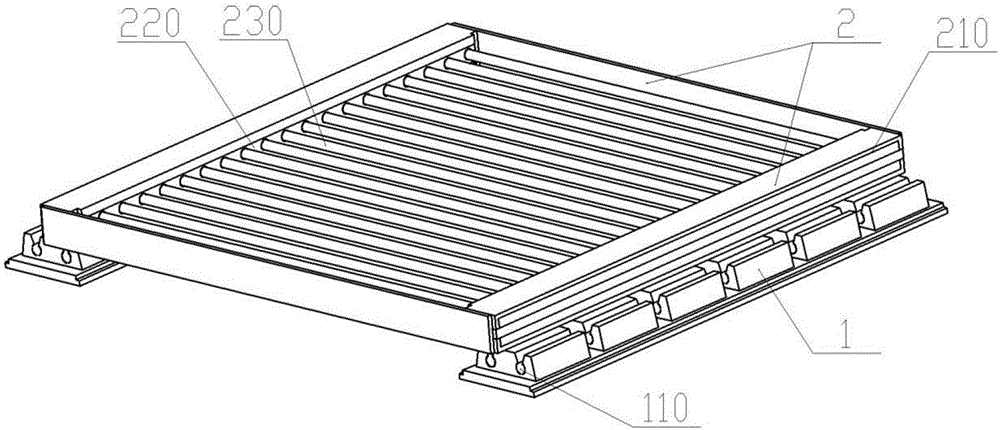

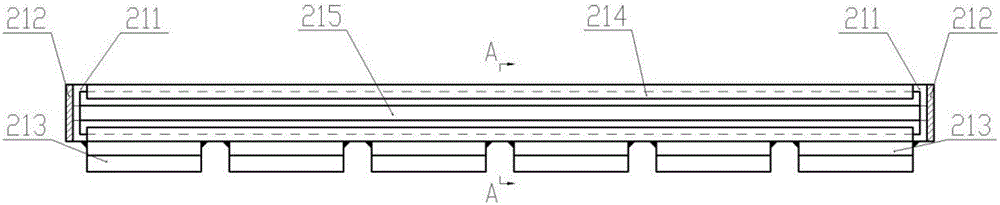

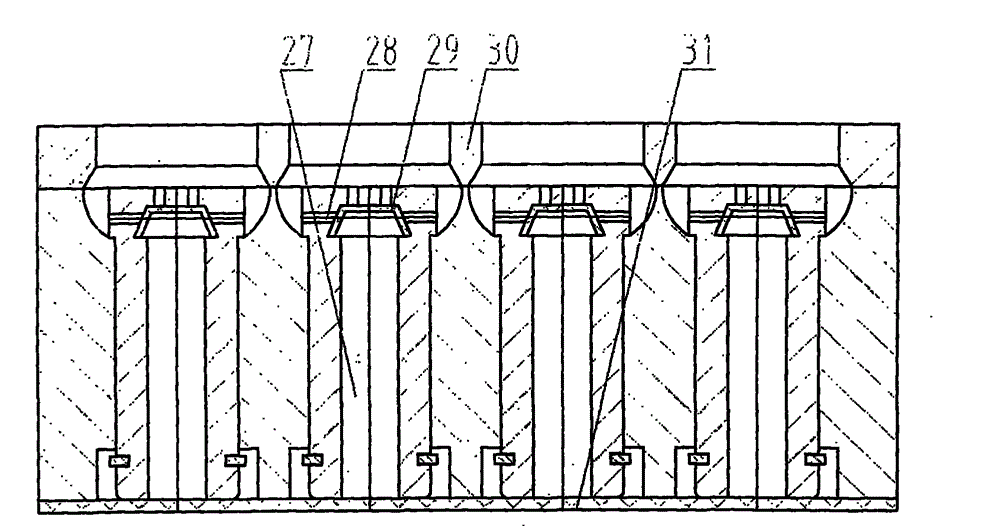

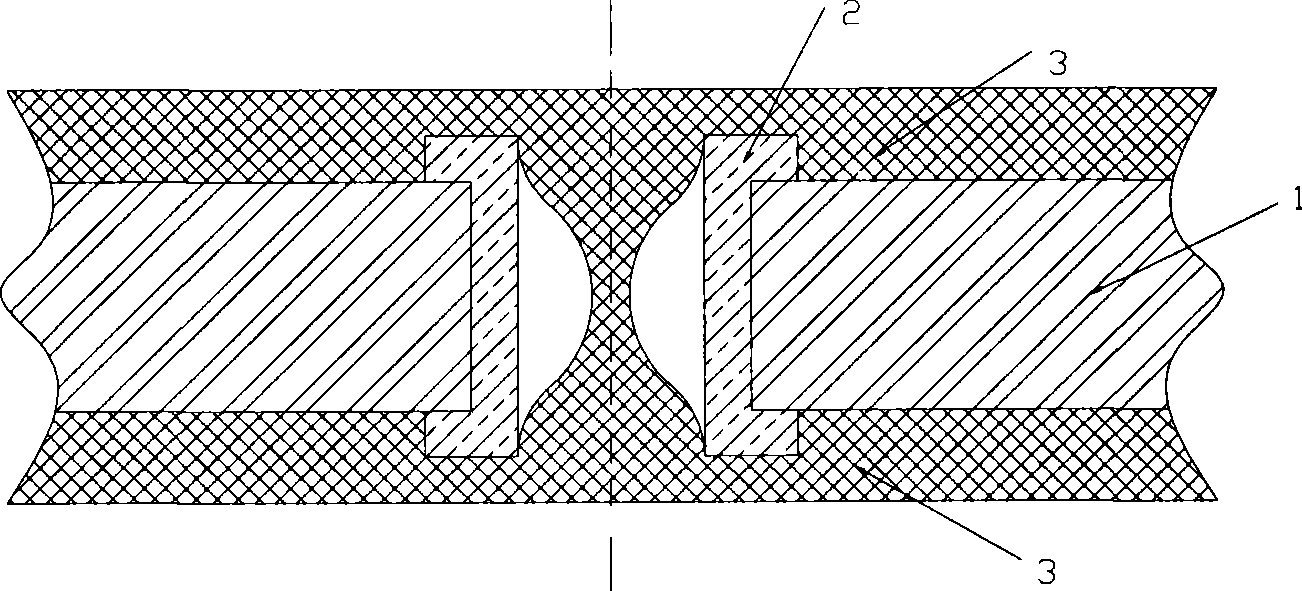

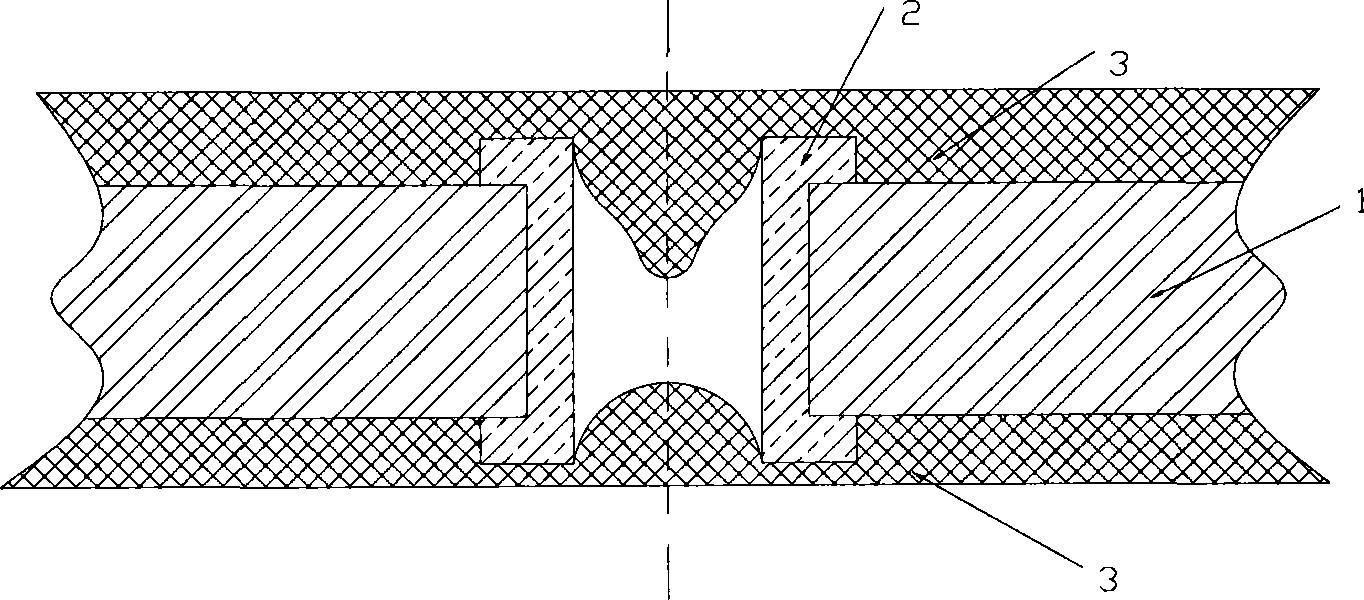

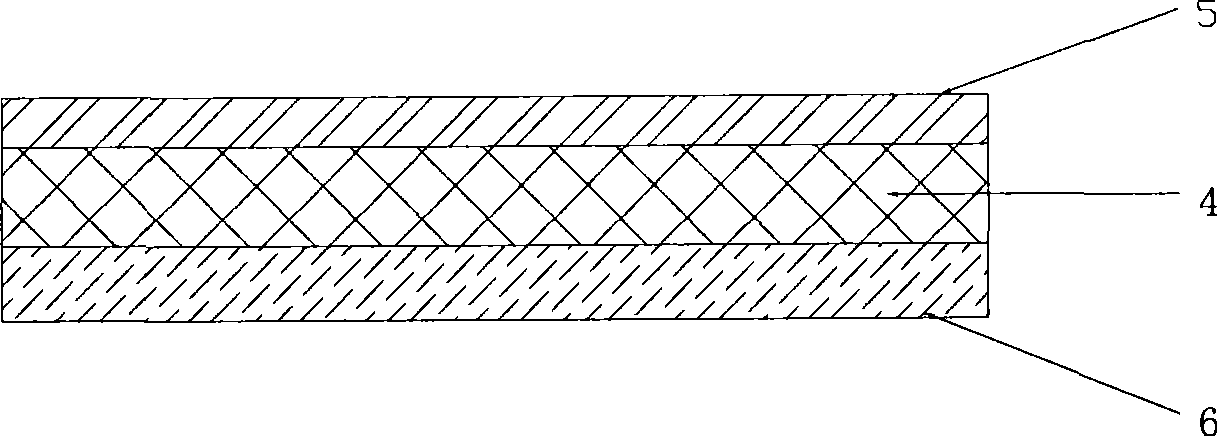

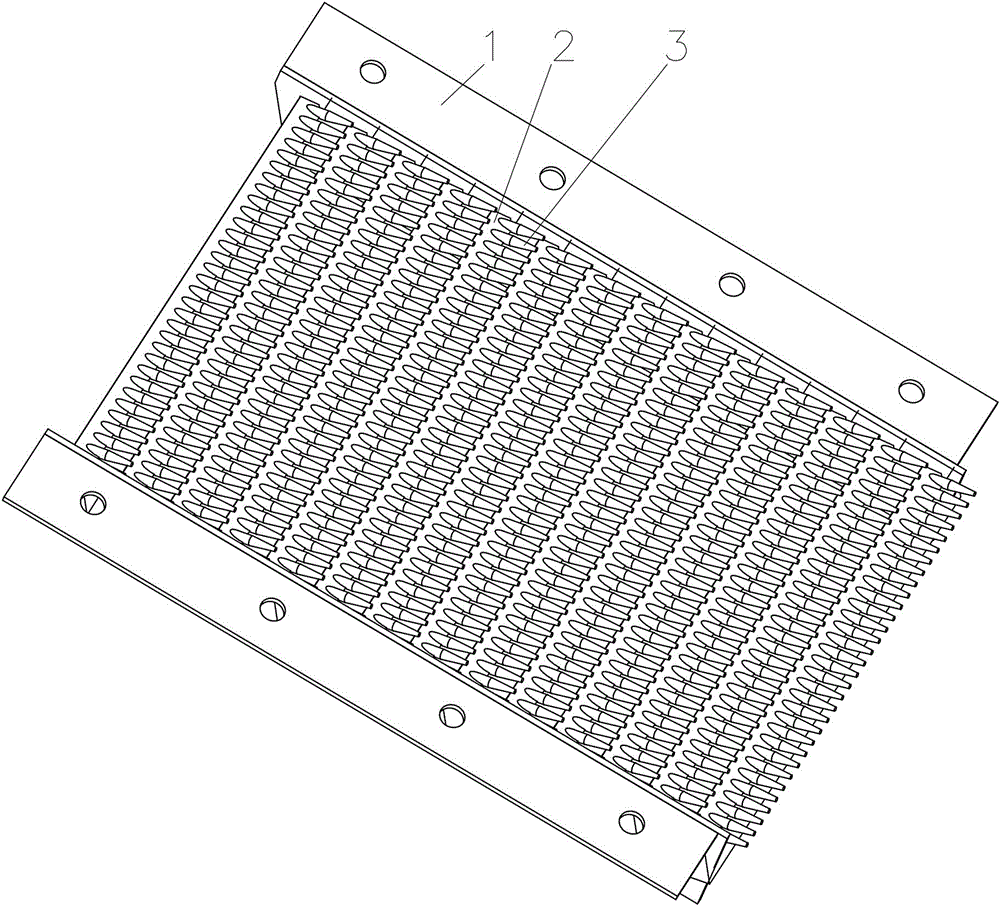

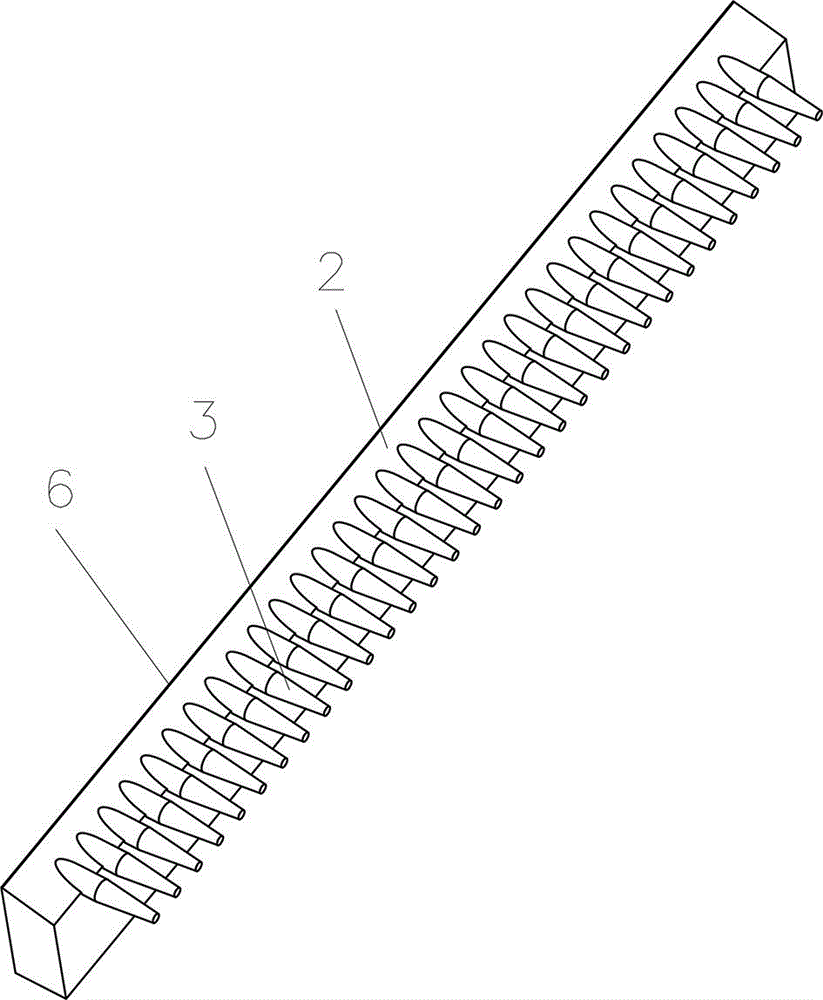

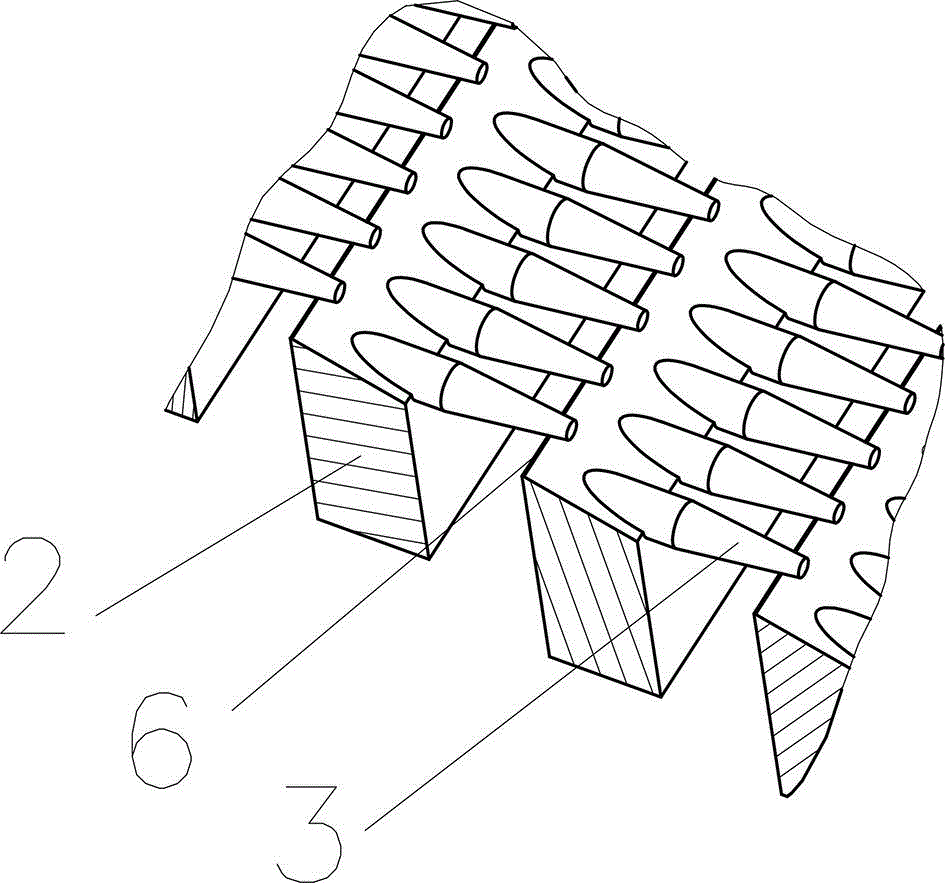

Standard rail chair type elastic rod sieve plate

InactiveCN105127092AAvoid corrosionIncrease vibration intensitySievingScreeningModular designEngineering

The invention discloses a standard rail chair type elastic rod sieve plate which comprises rail chairs and an elastic sieve surface. The elastic sieve surface comprises a sieve frame, an elastic support body and sieve rods, the elastic support body is fixed in a containing body of the sieve frame, the two ends of each sieve rod are fixed in the elastic support body, and the elastic sieve surface is connected with the rail chairs through buckle devices. According to the standard rail chair type elastic rod sieve plate, the elastic support body can enable the sieve rods to be located in a resonant state in the working process of a vibrating sieve, the vibration intensity of the sieve surface is improved, and by means of the autoroatation and movement in the axial direction of the sieve rods, the problems of material stacking, bonding and mesh blocking are well solved, and the screening efficiency of the vibrating sieve is improved; due to the fact that the rail chairs are connected with the elastic sieve surface through the buckle devices, the structure is compact, assembly and disassembly are convenient, the practicability is strong, and the labor intensity of workers is reduced; according to the standard rail chair type elastic rod sieve plate, the modular design is adopted, and scale production and market promotion are facilitated.

Owner:CHINA UNIV OF MINING & TECH

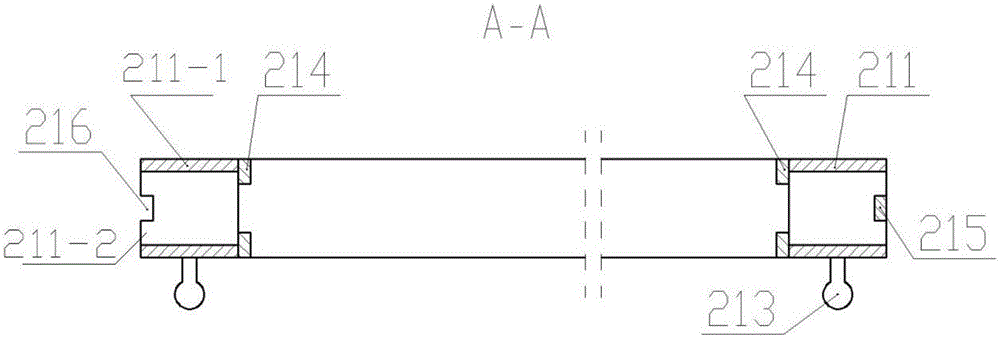

Dense-medium dry separation equipment

ActiveCN102974543AImprove stabilityMaintain stabilityGas current separationFluidized bedProcess engineering

The invention discloses a dense-medium dry separation equipment, which comprises a fluidized bed, a tank body, a material guiding and propelling device, an air distribution device, a scraper conveying device and a material taking and screening device, wherein the fluidized bed is used for separating materials; the tank body is used for providing a space and installation equipment for forming of the fluidized bed; the material guiding and propelling device is used for guiding the materials into the fluidized bed along the side end of the fluidized bed to be loosened and layered and propelling the materials to move forwards; according to the air distribution device, compressed air passes through an air distribution plate to acquire pressure difference and is then conveyed into the fluidized bed to be sufficiently, evenly and stably fluidized, and clean coal, middings coal and gangue are separated in an optimal manner; the scraper conveying device is a large-scale scraper conveying device for the dry separation equipment, an anti-deformation measure is adopted by scrapers in order to prevent wider scraper components from deforming, and the separated gangue and middings coal are discharged from the scrapers; and after the materials pass through the separating fluidized bed, the clean coal is taken out from the material taking and screening device at the fluidized bed side, and dense media are screened out and return to the fluidized bed in the material taking process. The dense-medium dry separation equipment disclosed by the invention can overcome the defect of incapability of fluidizing and separating caused by blockage of an air outlet.

Owner:孙刚 +3

Manufacturing method of flexible circuit board

InactiveCN101534608AThe phenomenon of disassociationSolve the pluggingPhotomechanical apparatusConductive material chemical/electrolytical removalHigh densityFlexible circuits

The invention provides a manufacturing method of flexible circuit board, which changes the double-sided thick photosensitive layer in the prior art into the layer with a thick photosensitive layer on one side and a thin photosensitive layer on the other side. Moreover, the method of respectively forming the two sides is adopted, thereby completely preventing the linkage of the photosensitive layers in the through hole and solving the problem that the dry membrane blocks the hole during the manufacturing process of the high-density flexible printed circuit board.

Owner:苏州相城埭辰科技产业发展有限公司

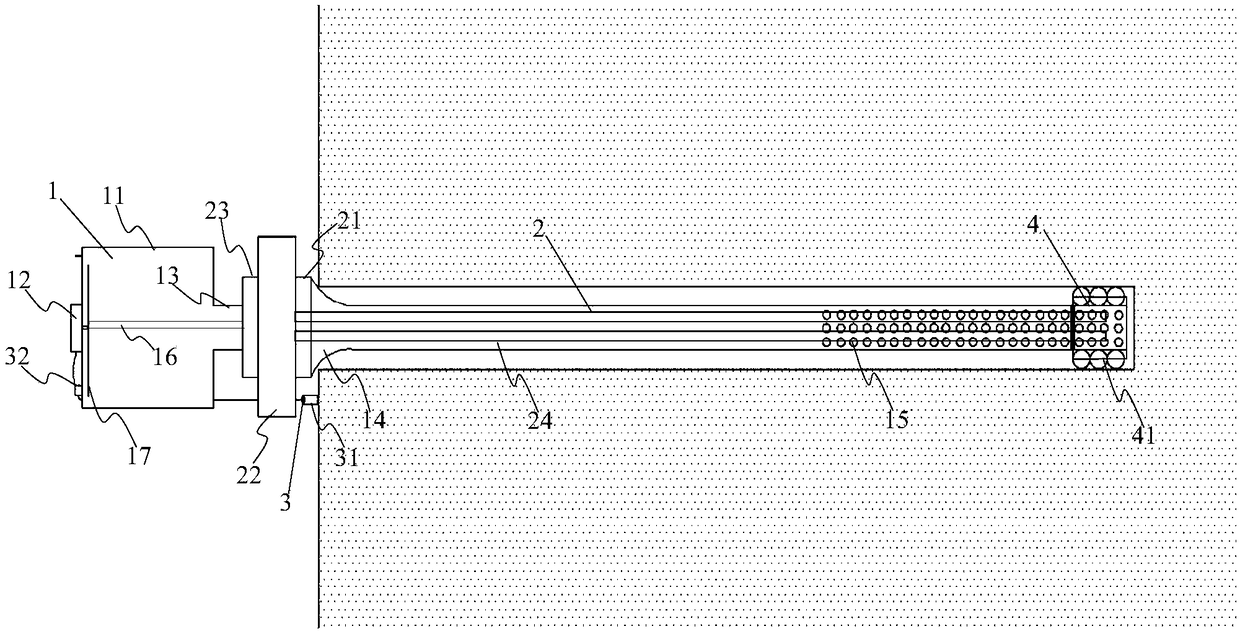

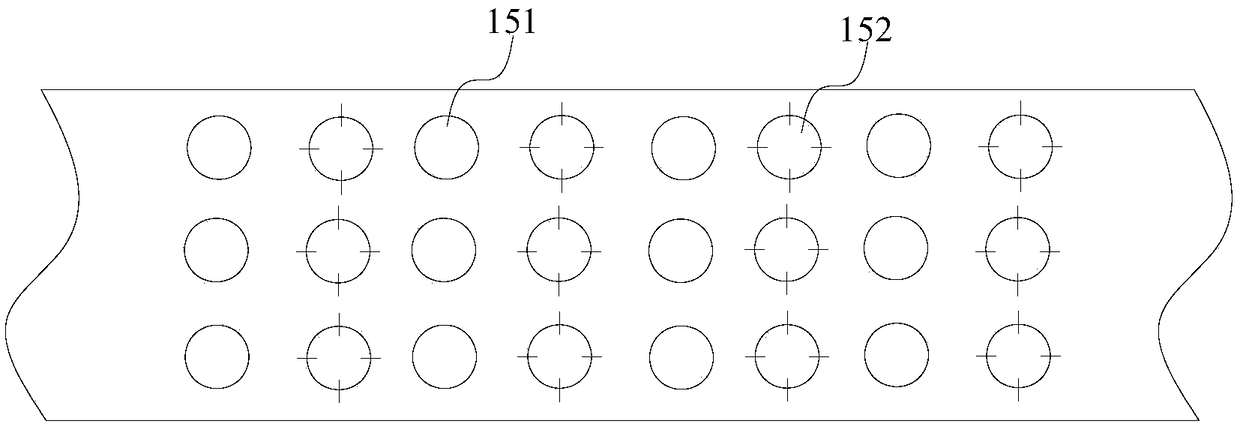

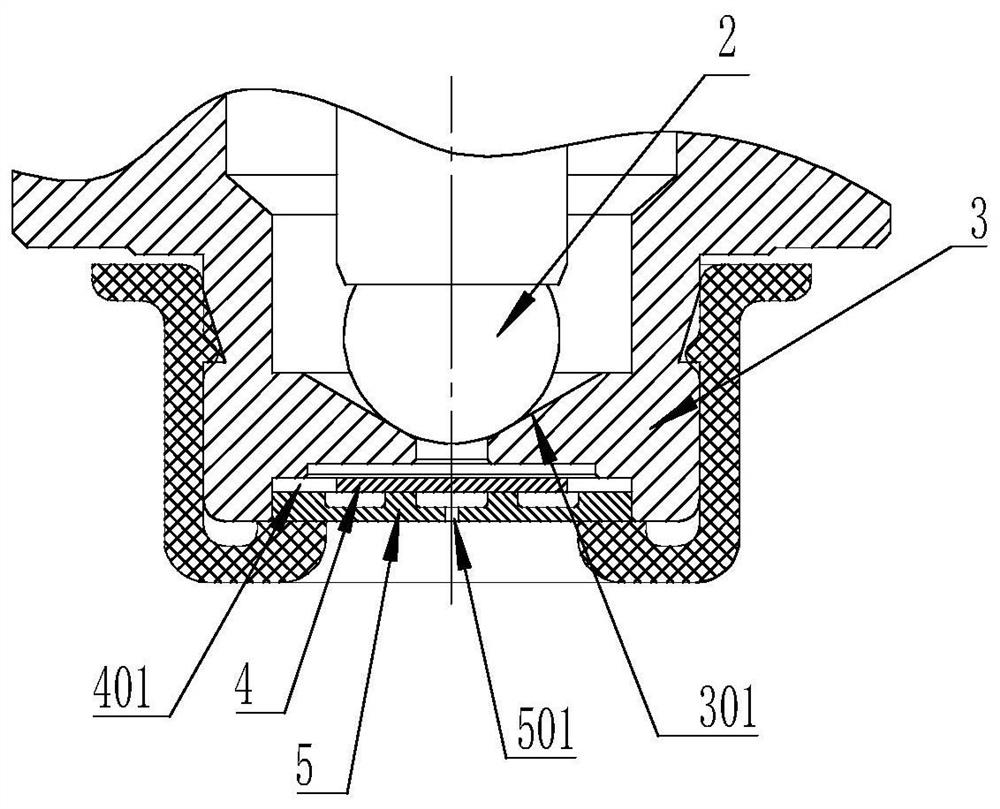

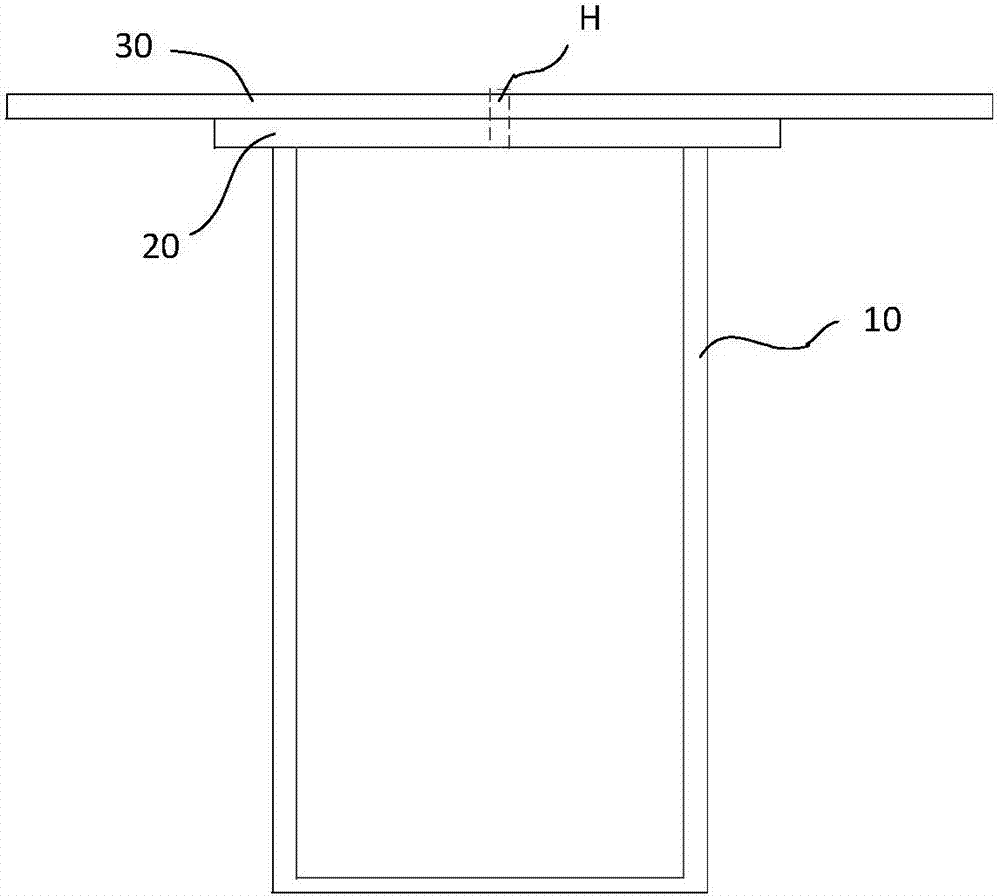

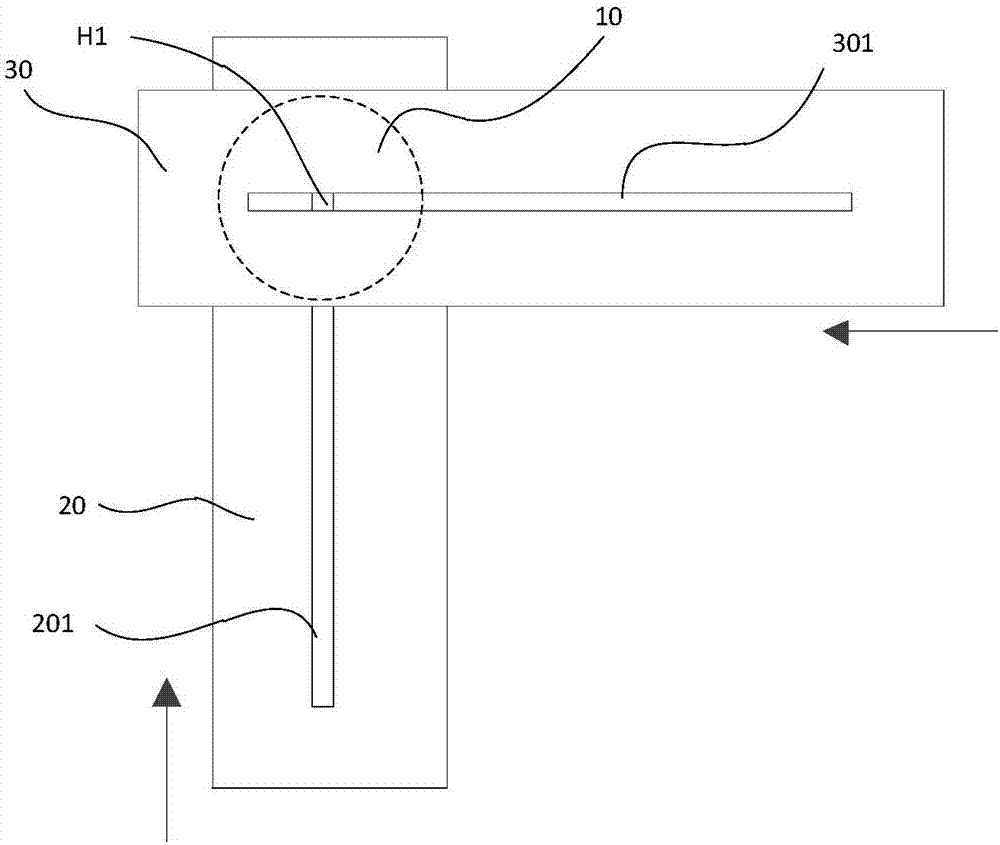

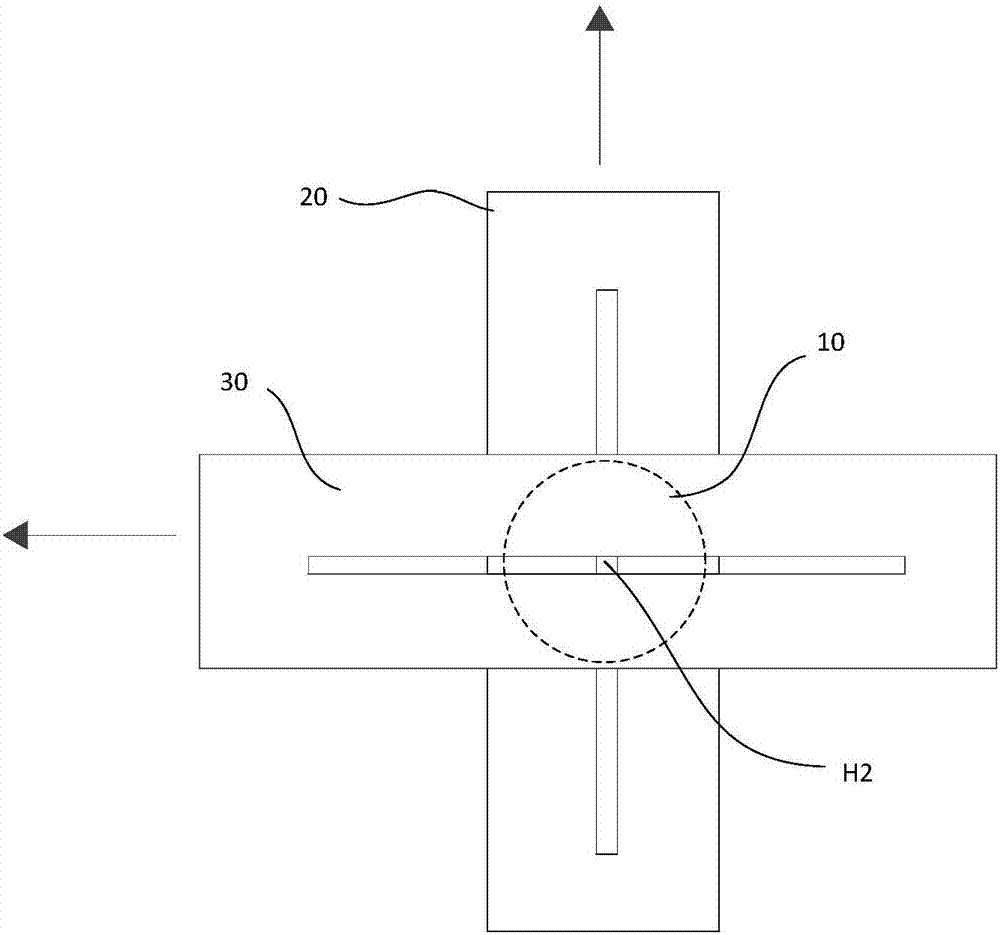

Secondary support grouting anchor rod with self-adaptive function

The invention discloses a self-adaptive secondary support grouting anchor rod, and relates to the technical field of support equipment. The technical problem that secondary grouting reinforced supporting is carried out by automatically adapting to mine pressure change is solved. The self-adaptive secondary support grouting anchor rod comprises a grouting mechanism, an anchoring mechanism, a monitoring mechanism and a positioning mechanism, wherein the grouting mechanism comprises a grouting box, a grouting motor, a one-way valve, a grouting stopping plug and a grouting hole. The grouting box is internally provided with a lead screw structure and a push plate, and the one-way valve is arranged at an outlet of the grouting box. The grouting hole is formed in the front section of a rod body,and the grouting stopping plug is arranged at the rear end of the rod body. The anchoring mechanism comprises an inner nut, a pad plate, an outer nut and the rod body. The monitoring mechanism includes a pressure sensor and a threshold starting switch, and the pressure sensor is arranged between the pad plate and a drilling hole. The positioning mechanism includes a sliding positioning device, andthe sliding positioning device is provided with a ball. The self-adaptive secondary support grouting anchor rod has the advantages that by using the anchor rod for supporting, the anchor rod can be fixed in the middle axis position of the drilling hole, automatic grouting can be achieved according to the change of the mine pressure, the construction is convenient, and the degree of automation ishigh.

Owner:SHANDONG UNIV OF SCI & TECH

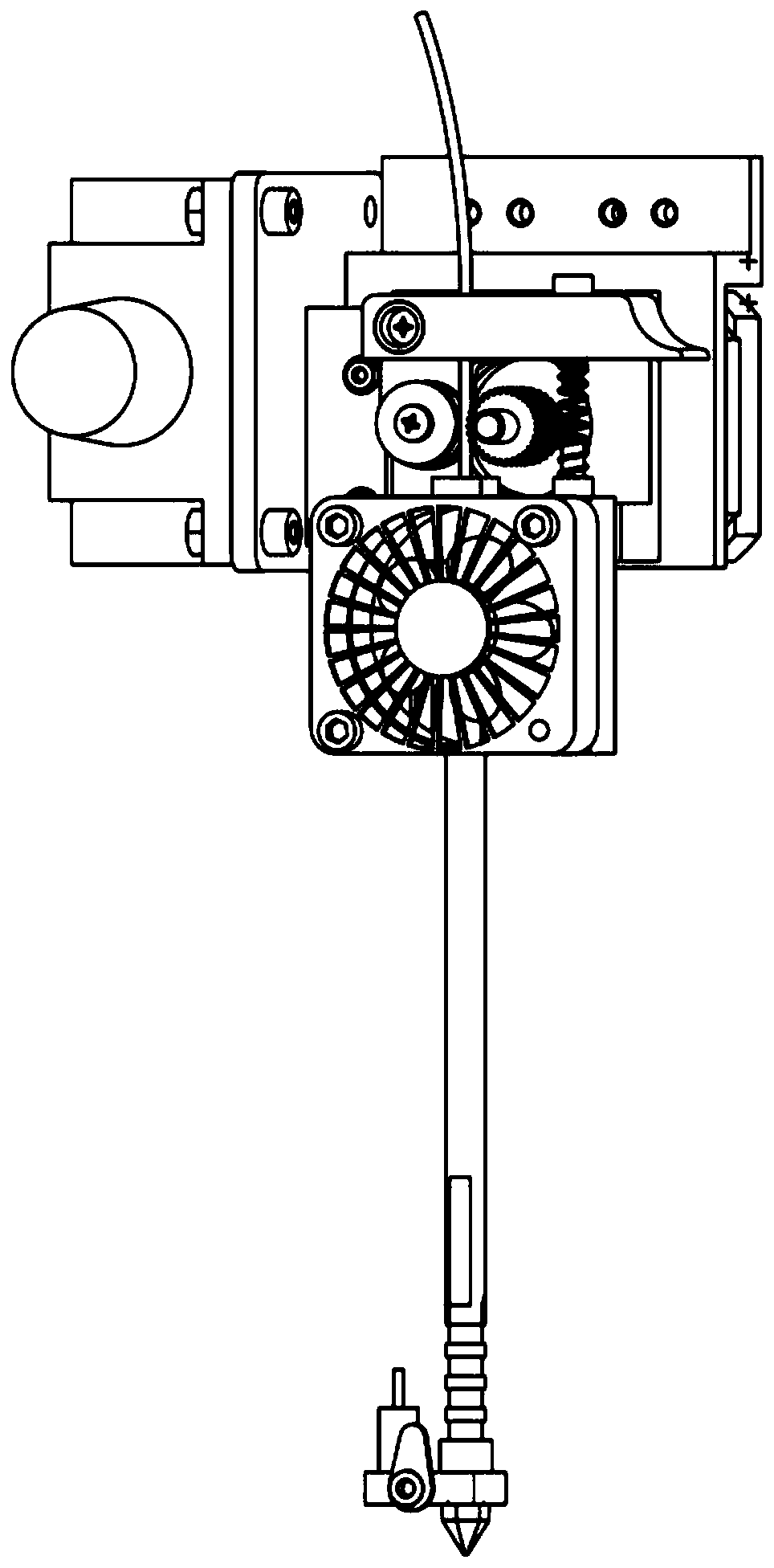

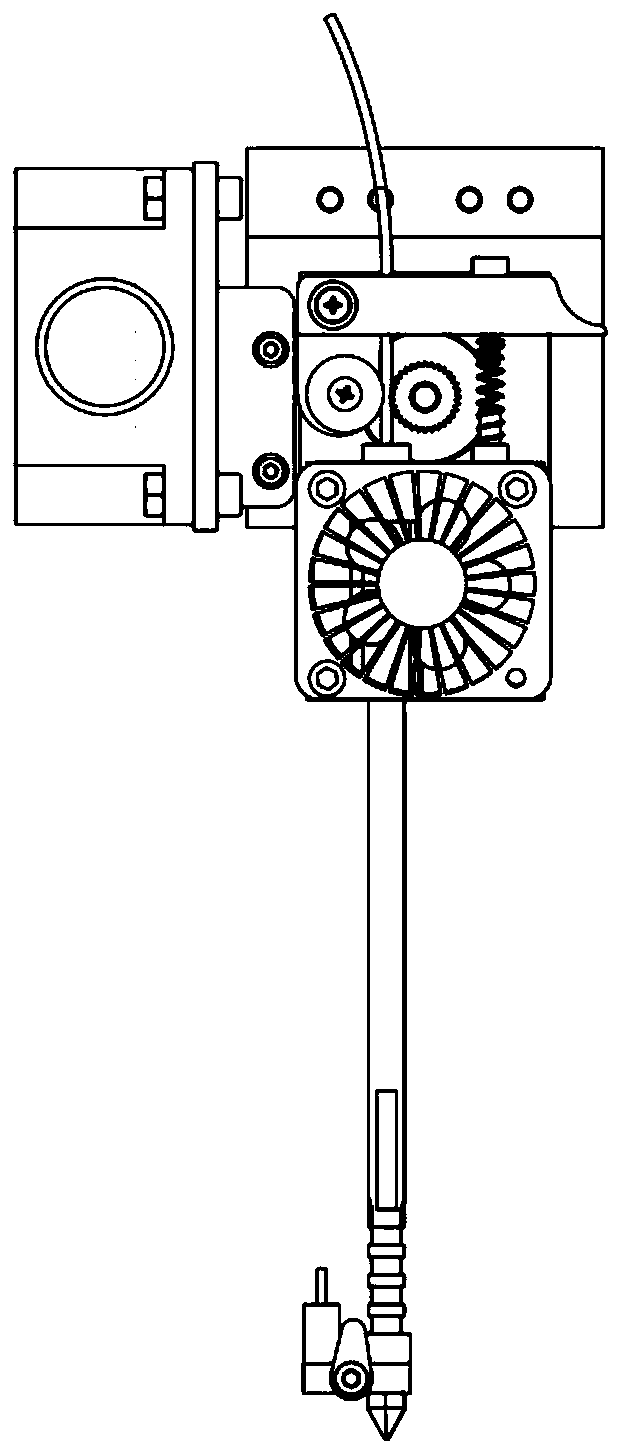

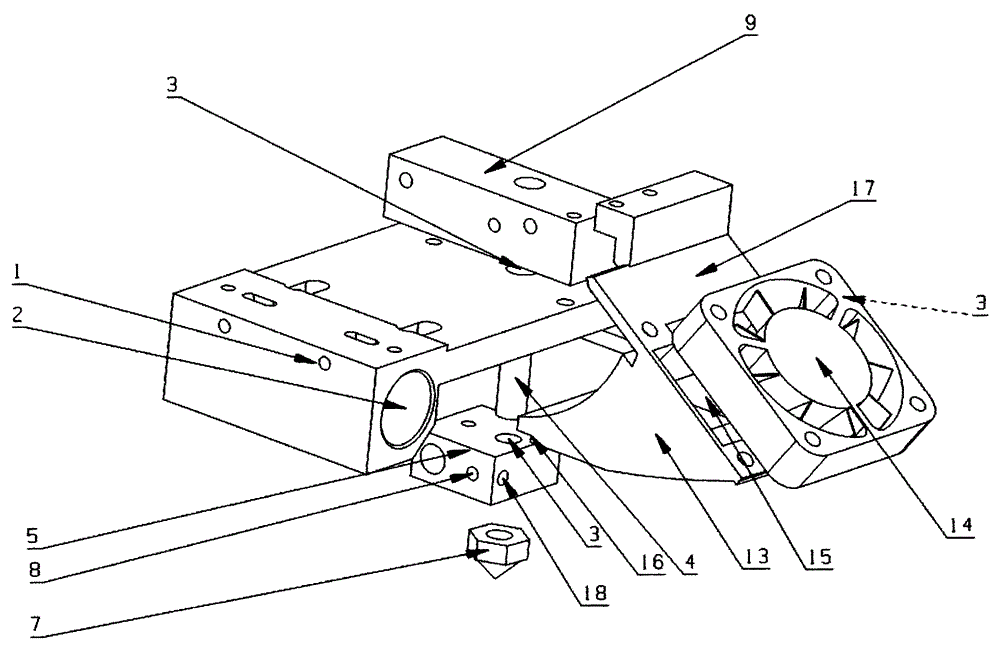

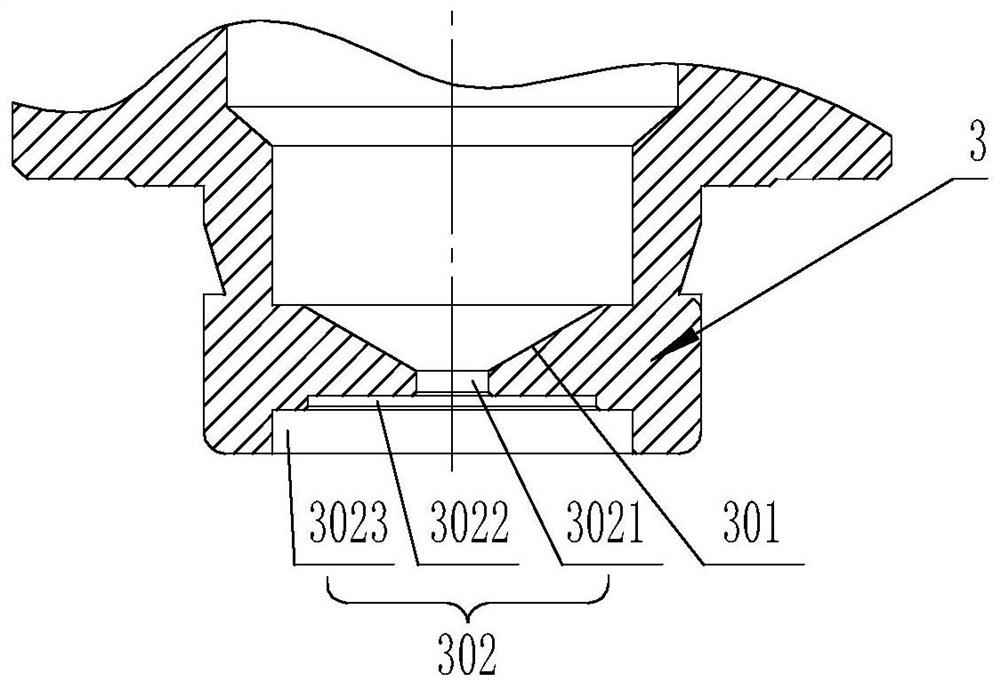

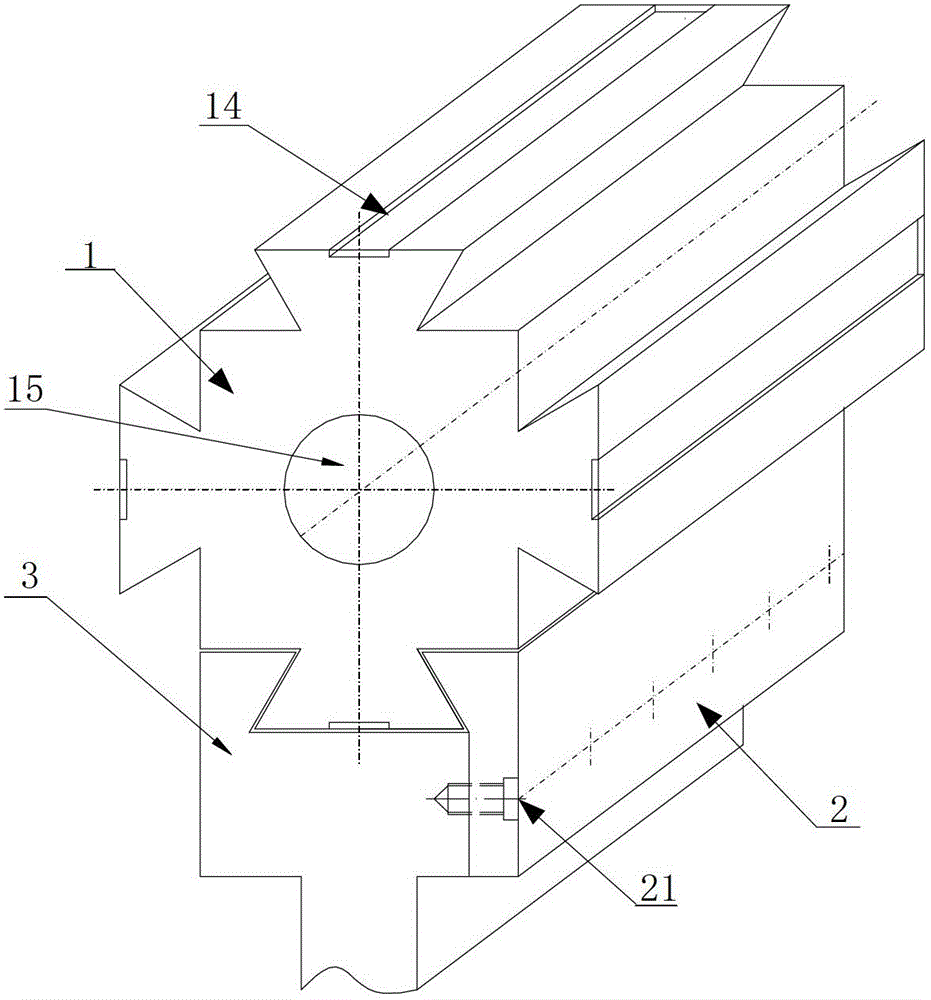

FDM spinneret mechanism for 3D printing of complex workpiece

PendingCN110682533AImprove manufacturing precisionSolve complexityManufacturing heating elements3D object support structuresThermal dilatationComputer printing

The invention discloses an FDM spinneret mechanism for 3D printing of a complex workpiece. The FDM spinneret mechanism comprises a wire feeding system mounted above and a wire outlet system fixed below the wire feeding system; in the wire feeding system, an L-shaped connecting piece connected with a throat pipe is optimized, a fan speed governor is installed on the side of the connecting frame, and a lengthened throat pipe is designed in the wire outlet system to print the complex workpiece. The spinneret mechanism can effectively solve the problem that an FDM three-dimensional printer printsthe complex workpiece as well as the problem existing in a current three-dimensional printing that a nozzle is blocked due to the fact that wire materials are prone to thermal expansion. According tothe FDM spinneret mechanism for 3D printing of the complex workpiece, the application range of FDM three-dimensional printing is expanded while the printing efficiency and the printing product precision are improved, and higher economic benefits are achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for manufacturing solder mask layer for improving hole plugging caused by solder resist ink

InactiveCN110337192AEfficient removalAvoid pluggingPhotosensitive material processingNon-metallic protective coating applicationResistSolder mask

The invention relates to the technical field of printed circuit boards, in particular to a method for manufacturing a solder mask layer for improving hole plugging caused by solder resist ink. According to the method, the developing effect is improved by optimizing a developing speed, a developing pressure and a washing pressure, the solder resist ink leaked into a hole can be effectively removedin the optimized developing process, and the exposed and cured solder resist ink on a plate surface cannot be affected, so that the solder resist ink going deep into the hole after the post-baking process is prevented from being thermally cured to block the hole. In addition, laser hole burning treatment is added after the post-baking process, so that solder resist ink possibly remained in the hole can be removed, the solder resist ink in the hole can be completely removed, and the hole forming quality is guaranteed. The solder mask layer manufactured by the method can solve the problem of hole plugging caused by solder resist ink, avoids the process of repairing a production plate additionally due to the hole plugging caused by solder resist ink, improves the production efficiency, and reduces the production cost.

Owner:珠海崇达电路技术有限公司 +1

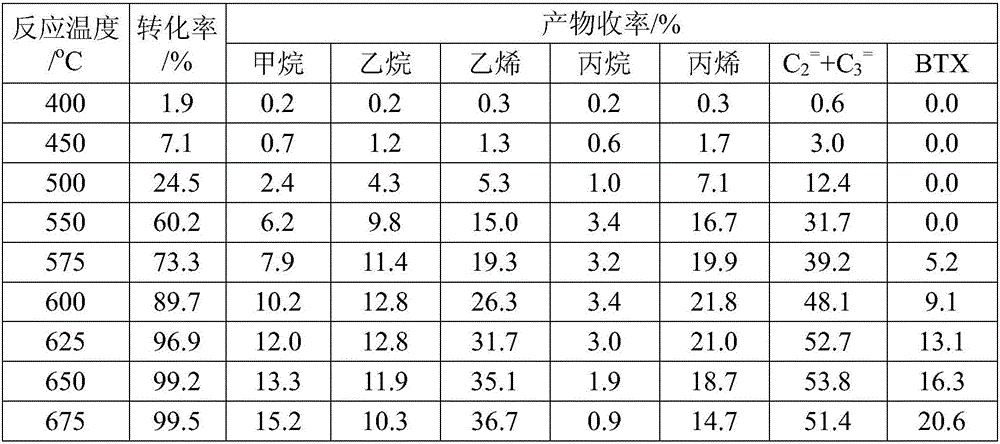

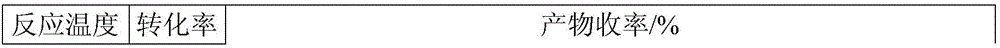

Method for preparing low carbon olefins by catalytically pyrolyzing n-butane through metal chromium framework doped molecular sieve

InactiveCN106083509ALow added valueSolve the pluggingMolecular sieve catalystsHydrocarbonsReaction temperatureAdditional values

The invention provides a method for preparing low carbon olefins by catalytically pyrolyzing n-butane through a metal chromium framework doped molecular sieve. The method comprises the following steps that n-butane makes contact with a metal chromium framework doped ZSM-5 molecular sieve catalyst for a reaction at reaction temperature and under the reaction pressure and in a carrier gas atmosphere, and ethylene and propylene are obtained; the metal chromium framework doped ZSM-5 molecular sieve catalyst is prepared and obtained by means of an in-situ synthesis principle, wherein the molar ratio of SiO2 to (Al2O3 and Cr2O3) is 80:160, and the molar ratio of Cr2O3 to Al2O3 is 0.005:1.0. According to the method for preparing low carbon olefins by catalytically pyrolyzing n-butane through the metal chromium framework doped molecular sieve, n-butane which is low in price, easy to obtain, low in additional value, relatively stable in chemical property and difficult to pyrolyze is utilized as the raw material, the metal chromium framework doped ZSM-5 molecular sieve serves as the bifunctional catalyst, and then ethylene and propylene are produced; therefore, n-butane can be utilized efficiently, the yield of ethylene and propylene is high, and a good industrial application prospect is achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Manufacturing method of HDI plate back drilling hole

InactiveCN111107715AOptimize the production processReduce the problem of draped copper wireConductive material chemical/electrolytical removalCircuit precursor manufactureElectroless platingCopper wire

The invention discloses a manufacturing method of an HDI plate back drilling hole. The method comprises the steps that a production board is drilled, drilled holes comprise a through hole needing backdrilling, and the through hole is metalized through electroless plating copper; a layer of thin copper is flash-plated on the production board through full-board electroplating, wherein the thicknessof a thin copper layer formed during flash-plating is 5 to 8 microns; tin is electroplated on the production board to enable the board surface copper layer and the hole copper to be covered by the tin layer; depth-controlled back drilling is carried out on the through hole needing back drilling according to the design requirement, so that the copper layer at the back drilling part in the throughhole is removed, and a stepped back drilling hole is formed; acid etching treatment is carried out on the production board, and tin is removed; and full-board electroplating treatment is carried out on the production board, and the board surface copper layer and the hole copper are plated to the thickness required by the design. According to the method, by optimizing the production technological process, the problem that a conventional etching process cannot solve the problem of hole blocking of a back drilling burr copper wire is effectively solved; back drilling manufacturing of the HDI plate is achieved; and the percent of pass is high.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

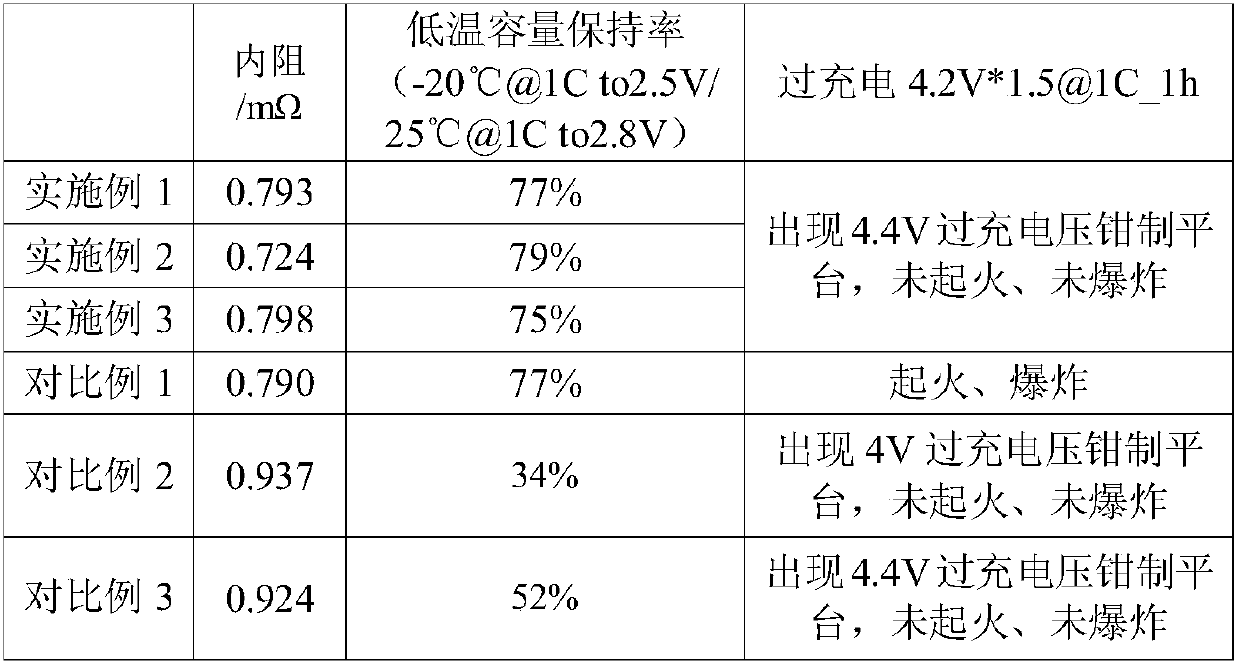

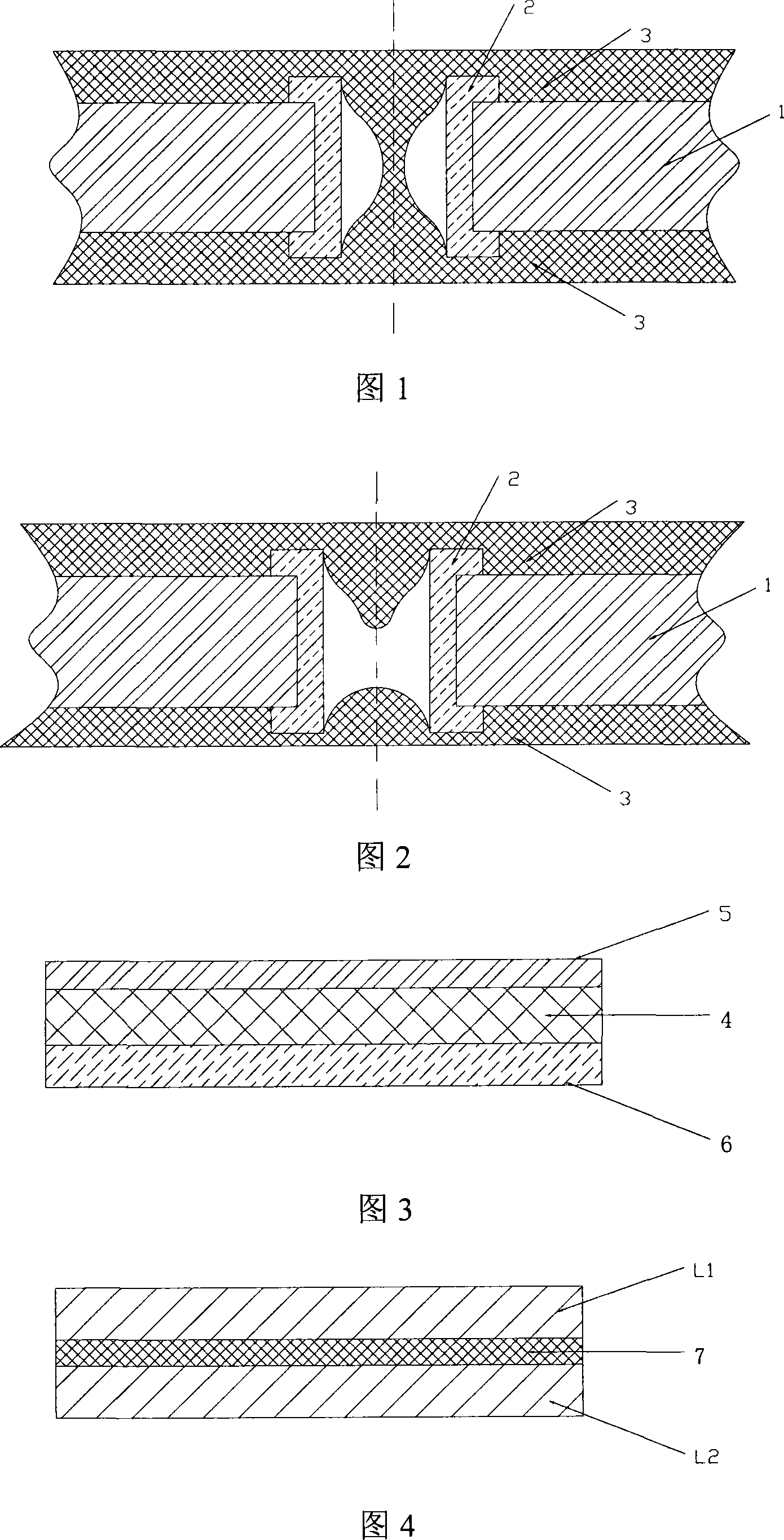

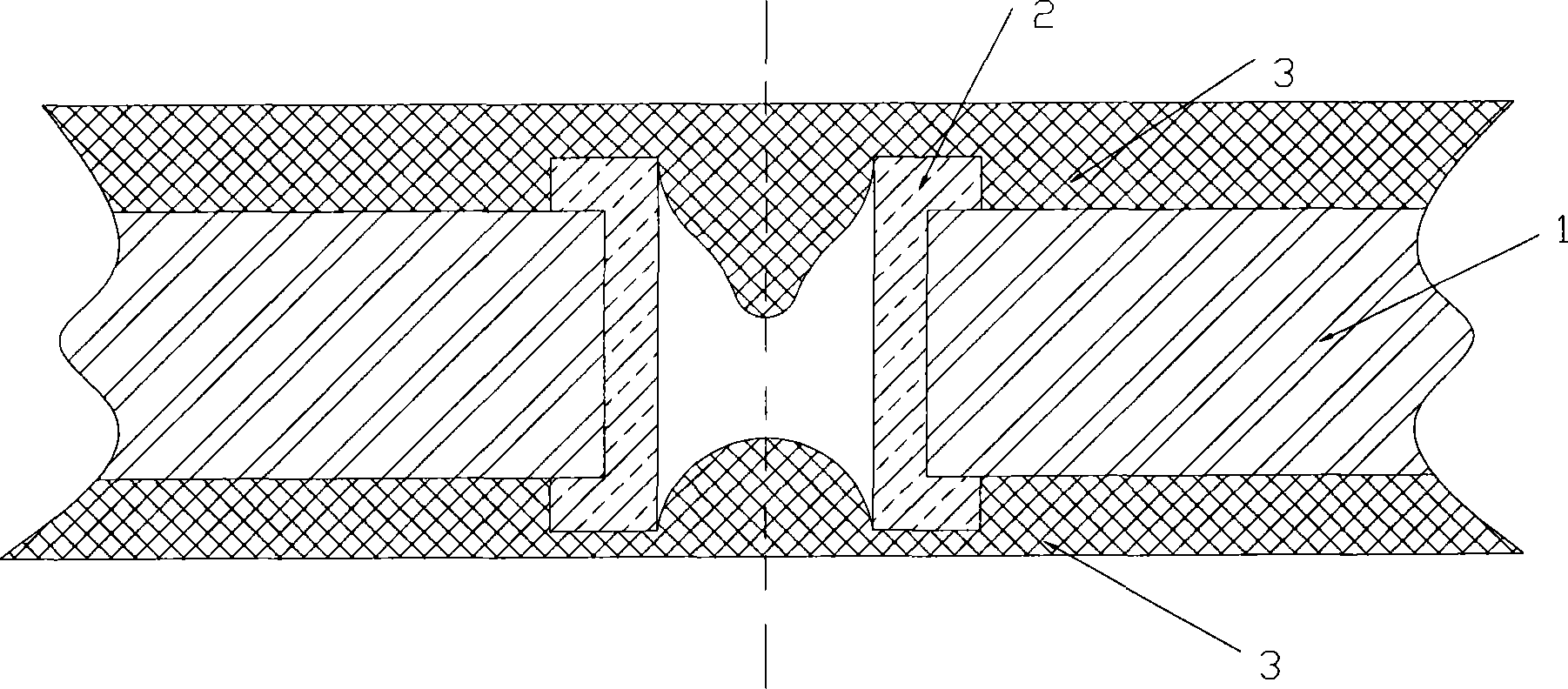

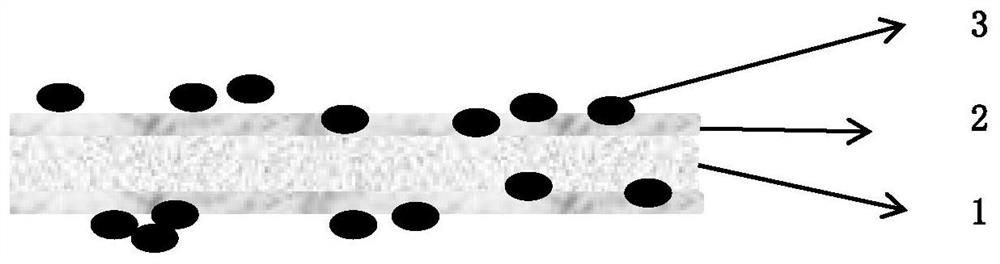

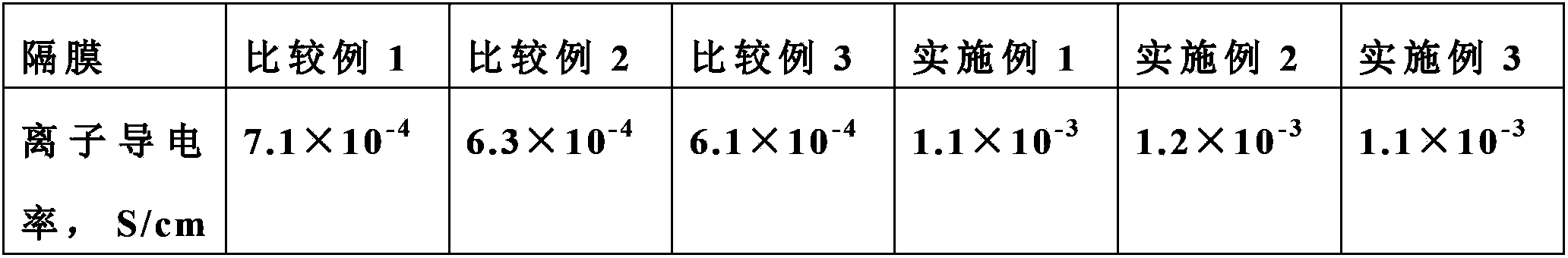

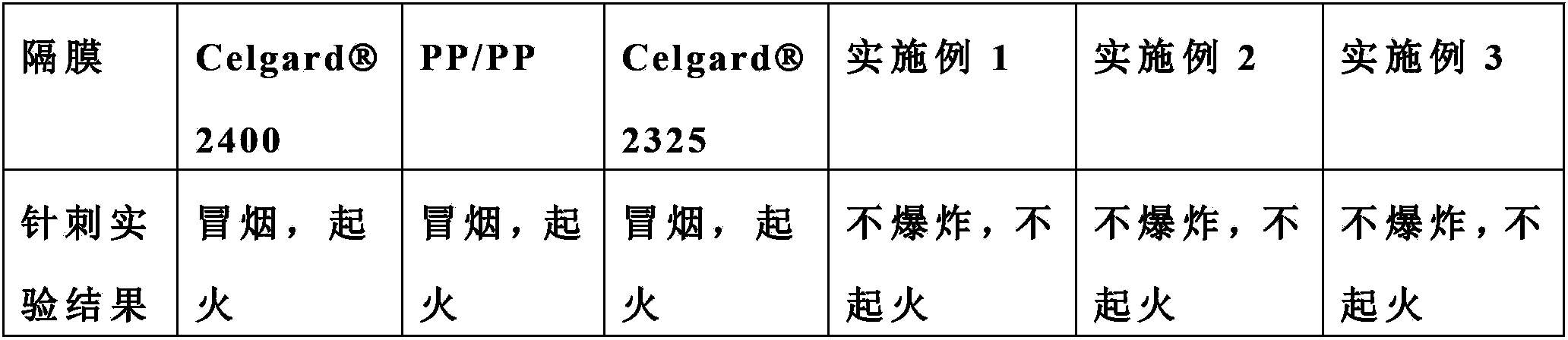

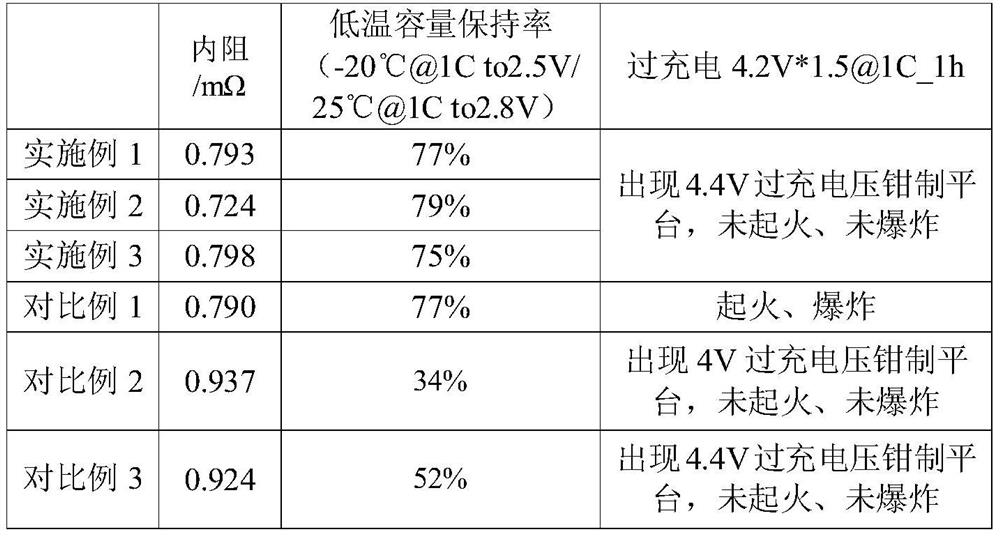

Membrane as well as preparation method thereof and lithium battery

ActiveCN108682774AImprove low temperature capacity retentionPlay the role of overcharge protectionMaterial nanotechnologySecondary cellsFiberPolypyrrole

The invention provides a membrane as well as preparation method thereof and a lithium battery. The membrane comprises a basal membrane layer and a nano-fiber layer coated on the surface of the basal memrane layer, wherein the basal membrane layer contains a basal membrane and a first electroactive polymer dispersed in the basal membrane; the nano-fiber layer contains nano-fibers and a second electroactive polymer coated with the nano-fibers, wherein the first electroactive polymer is prepared from at least one of the following components: polyhenylene, polynaphthalenophane and a derivative thereof; and / or the second electroactive polymer is prepared from at least one of the following components: polyaniline, polypyrrole, polyacetylene and a derivative thereof. According to the membrane, onone hand, because the nano-fibers are adopted, the pore diameter distribution of the membrane is uniform because of the shape structure of the nano-fibers; on the other hand, because the nano-fibershave the excellent liquid absorption liquid-retaining performance, so that the ionic conductivity of the membrane is improved; meanwhile, because the basal membrane layer contains the first electroactive polymer and the second electroactive polymer, the membrane has the effect of preventing over-charging.

Owner:桑德新能源技术开发有限公司 +1

Manufacturing method for circuit board back hole drilling

InactiveCN111050494ASolve the pluggingEasy to exportMultilayer circuit manufacturePrinted element electric connection formationSlagEngineering

The invention relates to the technical field of printed circuit boards, in particular to a manufacturing method for circuit board back hole drilling. According to the method of the invention, a copperlayer with a thickness smaller than or equal to 10 micrometers is electroplated in a whole-plate electroplating process; compared with a method which electroplates a copper layer at one time to meetthe design requirement of a final product, the method of the invention enables the hole diameter of a first through hole is relatively large during back drilling, and therefore, drilling slag can be guided out from the first through hole, and the amount of drilling slag formed during the back drilling can be reduced, especially, the amount of copper drilling slag can be decreased; the granularityof the copper drilling slag is small, hole blocking caused by large-particle copper drilling slag can be avoided; the copper drilling slag remaining in the hole can be completely removed during alkaline etching, and therefore, a hole blocking risk is reduced, and a reliability hidden danger in the aspect of circuit conduction caused by the fact that the copper drilling slag remains in the hole canbe eliminated. Especially for a first through hole with the hole diameter of 0.15 mm, the thickness of the hole wall copper of the through hole, which is formed by electroless plating copper and whole-board electroplating is controlled to be 5 microns, and a hole blocking phenomenon is avoided, and the problem of hole blocking during the back drilling is completely solved.

Owner:大连崇达电子有限公司 +1

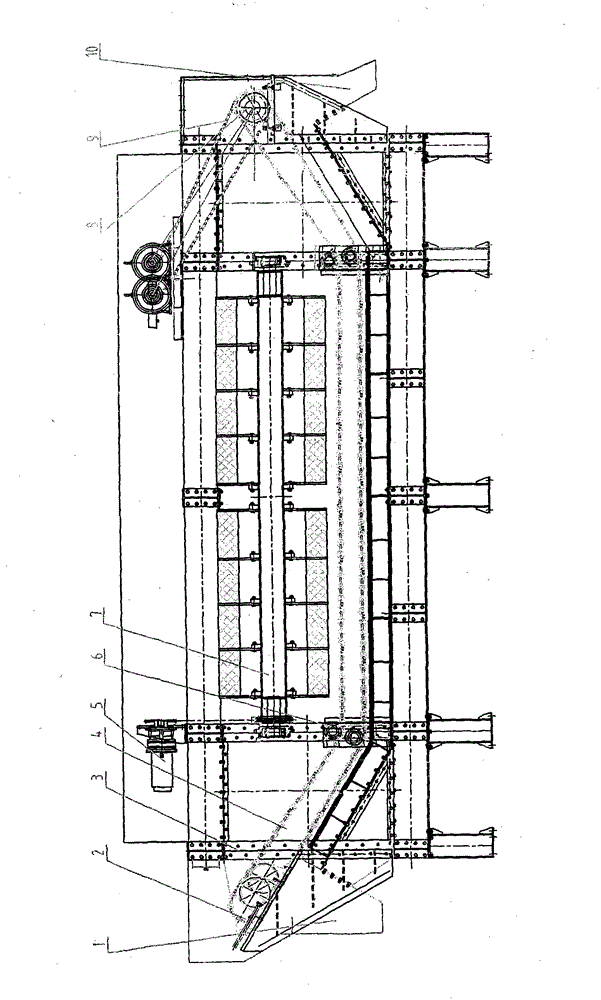

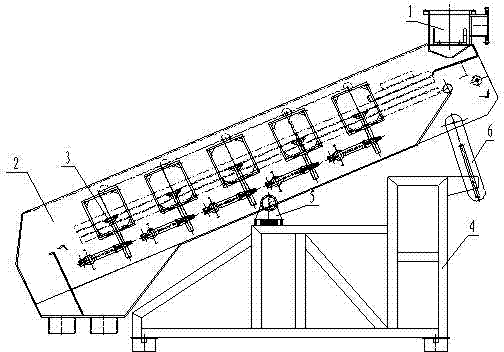

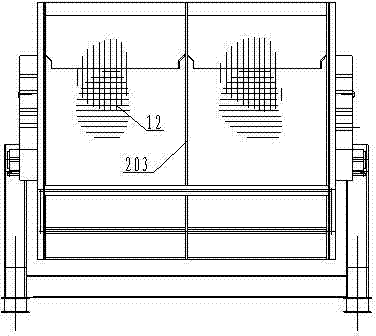

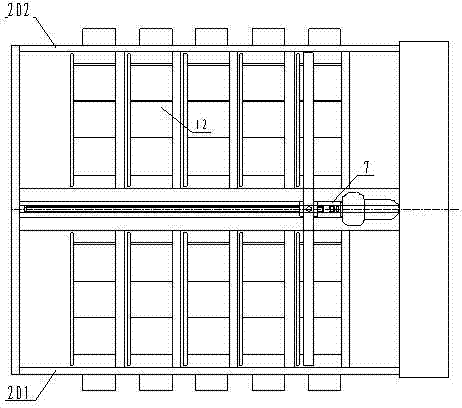

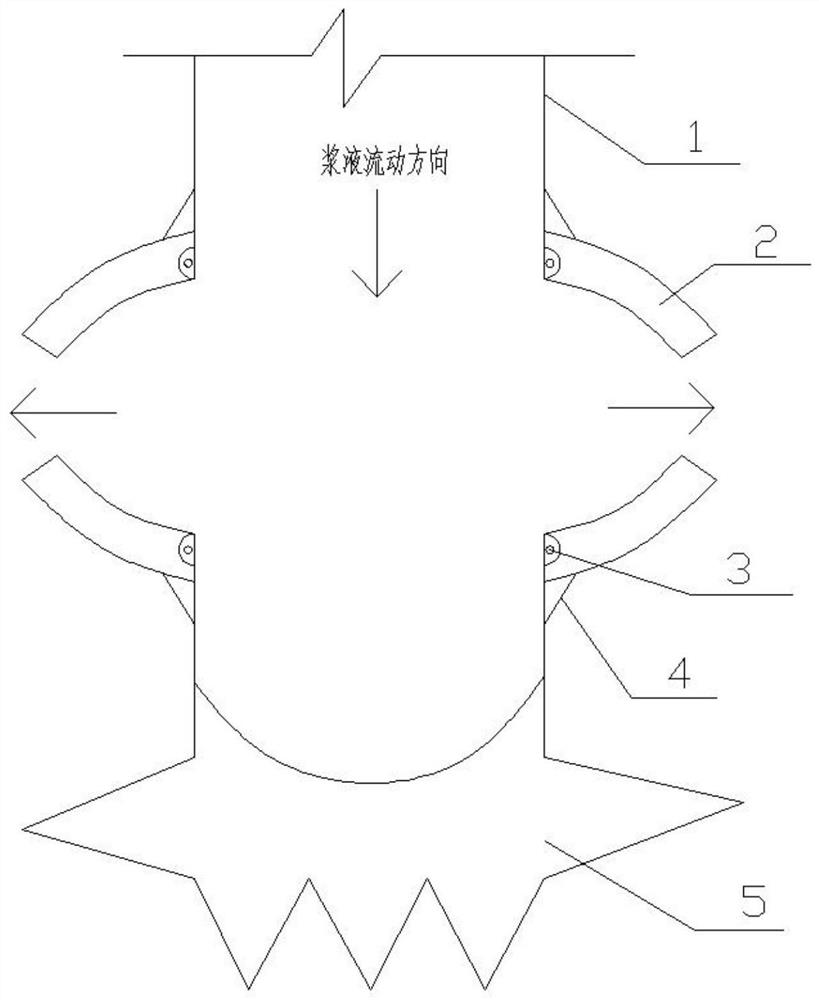

Full automatic vibrating fine screen allowing water spraying

The invention relates to a full automatic vibrating fine screen allowing water spraying. A screen body is formed by a left end plate, a right end plate and a middle plate; the screen body is fixed on a supporting frame through a support and a drawing arm; an upper hopper is fixed on the screen body; a screen mesh is fixed on an excitation system which is installed on bilateral sides of the screen body; a transmission device is fixed on the middle plate which is arranged at a middle position of the screen body; the transmission device is formed by a cycloidal pin gear speed reducer, a sliding plate, a screw rod, a nut, a sliding bar, a bearing base and a coupler; the cycloidal pin gear speed reducer drives the screw rod to rotate through the coupler; two ends of the screw rod are fixed through the bearing seat to drive the nut to horizontally move; the sliding plate is installed at the lower end of the screw rod; the bearing seat is fixed on the sliding plate; the sliding bar is installed at the bottom of the nut; a water spraying pipe is connected with the nut; a protective cover is installed at a position from the water spraying pipe bottom to the nut upper portion. The full automatic vibrating fine screen allowing water spraying has the advantages of enabling a screen to vibrate due to the excitation system, enabling the water spraying pipe to perform circulating or discontinuous linear water spraying motions due to the transmission device, being convenient to operate, low in cost and water saving, enabling materials not to block holes and being applied to mine material fine screen industries.

Owner:魏国帅

Wire-extruding assembly of 3D printer

InactiveCN105313329AImprove cooling effectThe surface of the product is delicate3d printerScrew thread

The invention discloses a wire-extruding assembly of a 3D printer. The wire-extruding assembly of the 3D printer comprises an extruding machine base, an extruding head assembly and a wind-leading structure. The extruding head assembly comprises a square extruding base fixed to a base body. A screw hole penetrating vertically and a heating pipe hole penetrating horizontally are formed in the extruding base. A thermistor hole is formed in one side of the heating pipe hole. An extruding head and an extruding throat pipe are arranged at the two ends of the screw hole in the extruding base respectively. The end opening of the extruding head abuts against the end opening of the extruding throat pipe in a contacting mode in the screw hole. The other end of the extruding throat pipe is connected with a fixed aluminum piece which is fixed on the base body. The extruding throat pipe comprises a pipe body with outer threads. One end of the pipe body is provided with a heat isolation part of which the inner portion is through, and a cone-shaped opening is formed in the other end of the pipe body. The wind-leading structure comprises a wind-leading nozzle and a cooling fan. The wind-leading nozzle comprises a cone-shaped nozzle body. The cooling fan is arranged at the inlet end of the cone-shaped nozzle body, and a flat wind nozzle is arranged at the outlet end of the cone-shaped nozzle body. A fixing part is arranged on one side of the inlet end, and the fixing part and the fixed base are fixedly connected. According to the wire-extruding assembly of the 3D printer, the wire plugging problem is solved, meanwhile, cooling is achieved, and the quality of a printed product is improved.

Owner:SUNHOO HANGZHOU IND DESIGN CREATIVE COMPANY

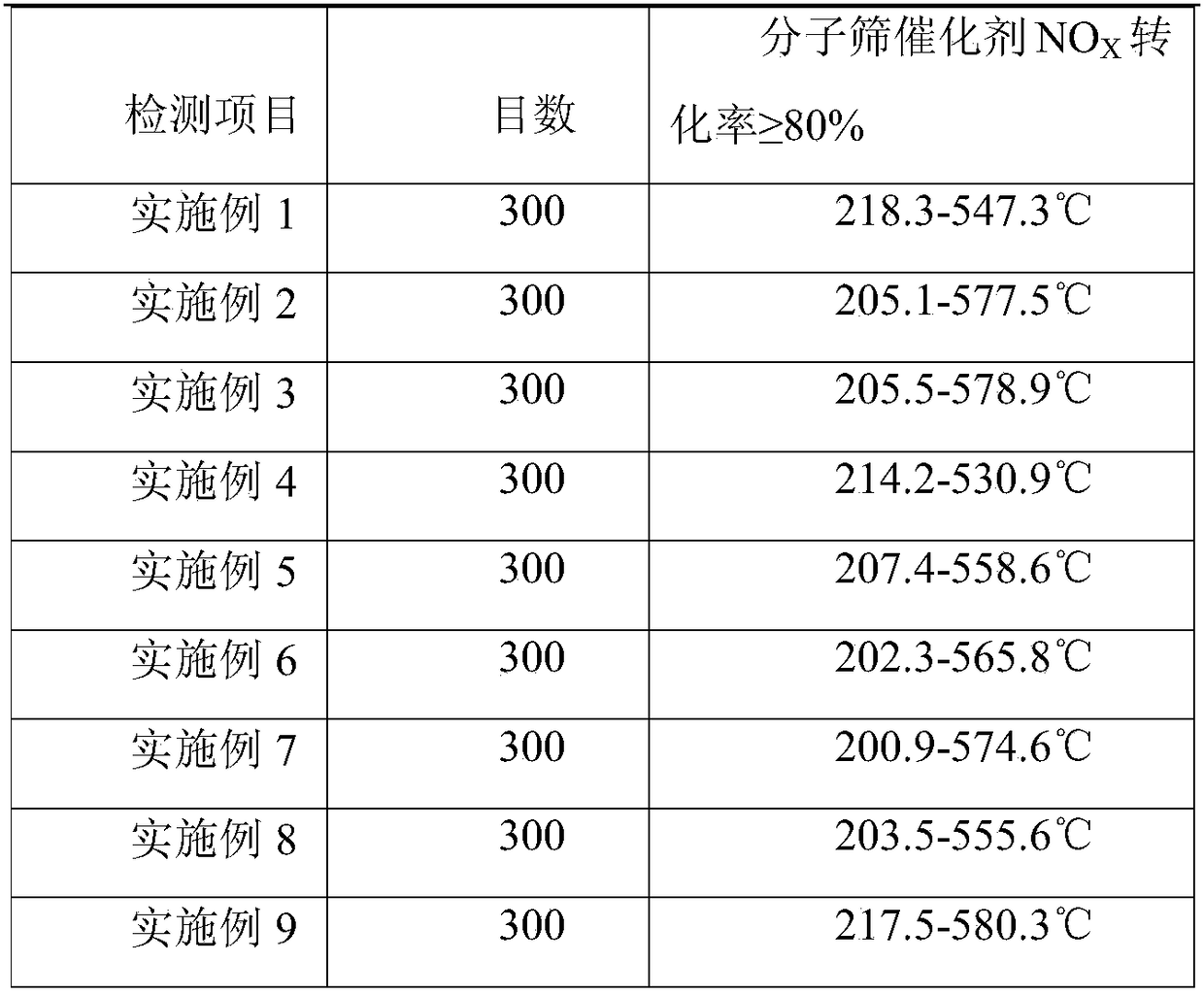

Extrusion-type molecular-sieve denitration catalyst based on copper-iron mixing and preparation method of molecular-sieve denitration catalyst

InactiveCN108273544ASimple processGood low temperatureMolecular sieve catalystsDispersed particle separationPolyethylene glycolStearic acid

The invention discloses an extrusion-type molecular-sieve denitration catalyst based on copper-iron mixing and a preparation method of the molecular-sieve denitration catalyst. The preparation methodcomprises the following steps: (1) uniformly mixing a molecular sieve, talc, water-washed kaolin and calcined kaolin, then adding hydroxypropyl methyl cellulose, polyoxyethylene, stearic acid and glass fibers, and carrying out uniform mixing to obtain mixed powder; and (2) adding polyethylene glycol, lactic acid, a copper source, an iron source and deionized water into the mixed powder obtained inthe step (1), carrying out mixing, and sequentially carrying out kneading, aging, pugging, extruding, drying and calcining to obtain the extrusion-type molecular-sieve denitration catalyst based on copper-iron mixing. The preparation method provided by the invention has simple process and low production cost, and the prepared extrusion-type catalyst based on copper-iron mixing has the characteristics that the low-temperature activity and the high-temperature activity of the catalyst are improved simultaneously.

Owner:凯龙蓝烽新材料科技有限公司

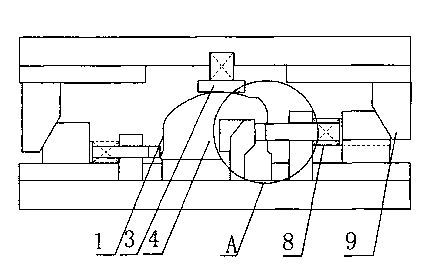

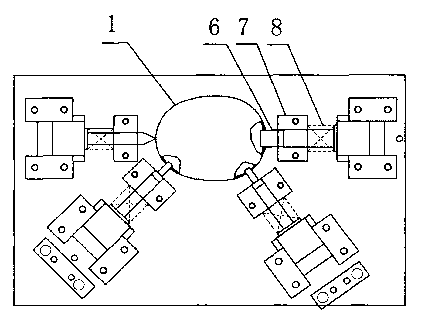

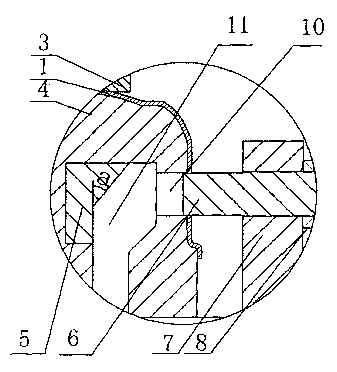

Shell lateral punching mold

A shell lateral punching mold is characterized in that a female mold is provided with a female mold hole which is right opposite to a punch, an outlet of the female mold hole is connected with a vertically-downward discharging hole, the position of the discharging hole, which is right opposite to the punch, is provided with an oblique surface guide forcedly-returning structural member with an oblique surface, the punch and the female mold are installed on a lower mold, the lower mold is also provided with a punch guide block which is installed in the middle part of the punch, and a pressure plate is used for pressing an oblique surface of a shell skew mold which is sleeved on the female mold to be contacted with an oblique surface on the tail part of the punch. The shell side punching mold adopts an oblique surface guide forcedly returning way, the forwarding direction of punched waste is forcedly changed from the horizontal direction to the vertically downward direction under the effect of the oblique surface guide forcedly-returning structural member while the punching action is completed, so that the waste is successfully dropped one by one, the problem that the hole is blocked by the waste can be solved, success in production is guaranteed, the generation of rejects can be reduced, the production efficiency is improved, the service life of the mold is prolonged, the product quality is improved, and a purpose for reducing the cost is realized.

Owner:DALIAN GAOHONG PRECISION MOLD

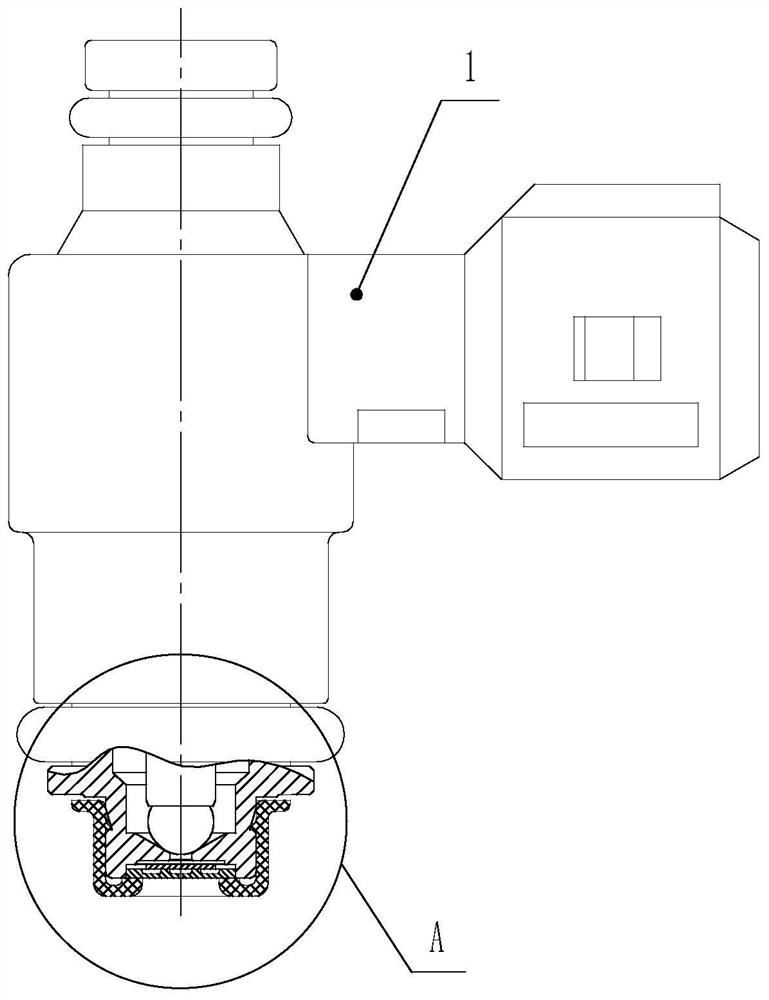

Fluid electromagnetic valve type metering ejector

PendingCN111794835ABoost atomized particlesEnhanced turbulence effectExhaust apparatusSilencing apparatusEngineeringSteel ball

The invention relates to an ejector, in particular to a fluid electromagnetic valve type metering ejector. The fluid electromagnetic valve type metering ejector comprises an electromagnetic valve typeejector body with a fluid input port and a nozzle with an atomizing hole; the nozzle comprises a valve seat with a valve hole and a sealing steel ball installed at the valve hole; a splitter and a turbulent flow orifice plate are sequentially installed in a valve seat middle hole located at the front end of the valve hole from inside to outside; the splitter is provided with a splitter groove inthe radial direction, a turbulent flow cavity and a spraying hole which are in communication with each other are coaxially formed in the center of the turbulent flow orifice plate, and at least two centrifugal turbulent flow grooves are evenly distributed in the circumference of the turbulent flow cavity; one end of each centrifugal turbulence groove is tangentially connected with the turbulence cavity to form a centrifugal structure; and the other end of each centrifugal turbulence groove is in communication with the splitter groove of the splitter sheet. According to the fluid electromagnetic valve type metering ejector, fluid atomization particles can be increased, the atomization effect of gasoline fluid can be guaranteed, exhaust emission of a gasoline engine meets the requirements oflaws and regulations, the problem of hole blockage caused by oil product quality difference can be solved, and the maintenance time of products is shortened.

Owner:LIUZHOU YUANCHUANG EFI TECH

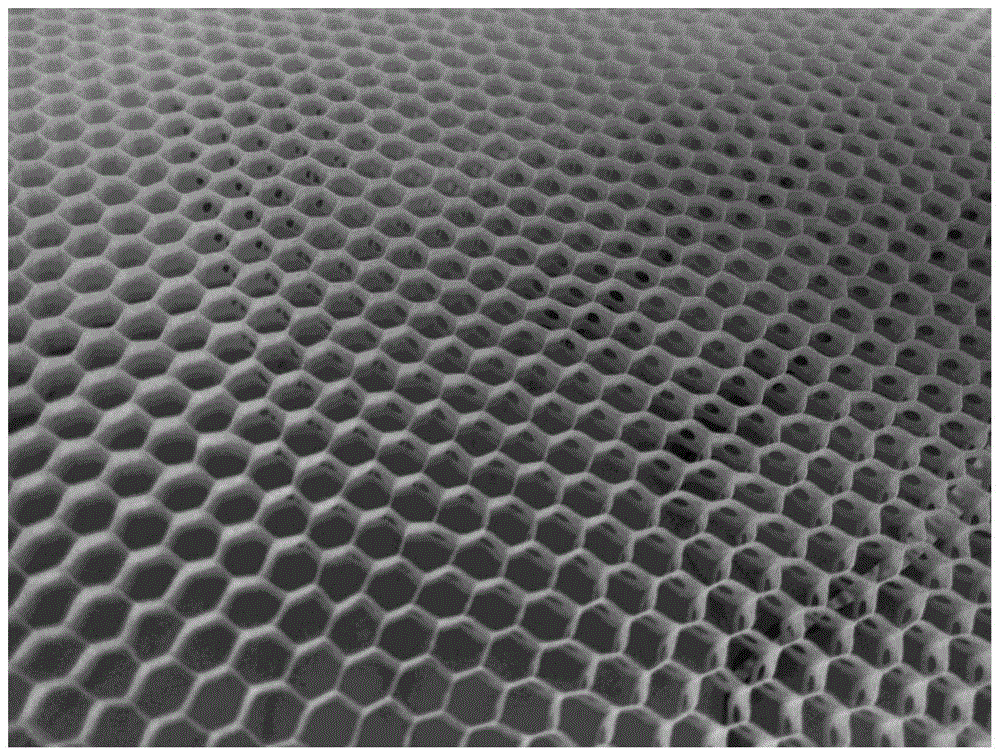

Impregnation formula for punched Nomex paper honeycomb and use method thereof

ActiveCN105672036AImproving the quality of impregnationReduce surface tensionDefoamers additionSurfactants additionNomexHoneycomb

The application belongs to the field of materials and particularly relates to an impregnation formula for punched Nomex paper honeycomb and a use method thereof. A defoamer or a surface additive is added to impregnation glue liquid to reduce surface tension of the glue liquid, so that when a honeycomb core plate is moved out from a glue trough, the holes on walls of the honeycomb lattices are unobstructed. The impregnation formula not only improves impregnation quality of punched honeycomb but also increases efficiency of impregnation of the punched honeycomb.

Owner:THE RES INST FOR SPECIAL STRUCTURES OF AERONAUTICAL COMPOSITE AVIC

Method for manufacturing depth-controlled metallized micropores in circuit board

InactiveCN111163591ASolve the pluggingShort processConductive material chemical/electrolytical removalMultilayer circuit manufactureTinningSlag

The invention relates to the technical field of printed circuit boards, in particular to a method for manufacturing depth-controlled metallized micropores in a circuit board. According to the invention, the back drilling processing is carried out after the electroless plating copper processing; the copper deposited on the first through hole in the copper deposition processing is very thin; the thickness of the copper layer is electroplated at one time to meet the design requirement of a final product; during back drilling, the hole diameter of the first through hole is relatively large; drilling slag can be guided out of the first through hole easily, the amount of the drilling slag, especially the amount of copper drilling slag, formed during back drilling can be reduced, meanwhile, the granularity of the copper drilling slag is small, large-particle copper drilling slag can be prevented from blocking the hole, the risk of hole blocking is reduced, and the reliability hidden danger inthe aspect of line conduction due to the fact that the copper drilling slag remains in the hole can be eliminated. According to the method, the processes of tinning and alkaline etching for removingthe copper drilling slag in the hole are reduced, the production process is shortened and simplified, the production efficiency is improved, and the production cost is reduced.

Owner:SHENZHEN SUNTAK MULTILAYER PCB +1

Manufacturing method of flexible circuit board

InactiveCN101534608BThe phenomenon of disassociationSolve the pluggingConductive material chemical/electrolytical removalHigh densityFlexible circuits

The invention provides a manufacturing method of flexible circuit board, which changes the double-sided thick photosensitive layer in the prior art into the layer with a thick photosensitive layer on one side and a thin photosensitive layer on the other side. Moreover, the method of respectively forming the two sides is adopted, thereby completely preventing the linkage of the photosensitive layers in the through hole and solving the problem that the dry membrane blocks the hole during the manufacturing process of the high-density flexible printed circuit board.

Owner:苏州相城埭辰科技产业发展有限公司

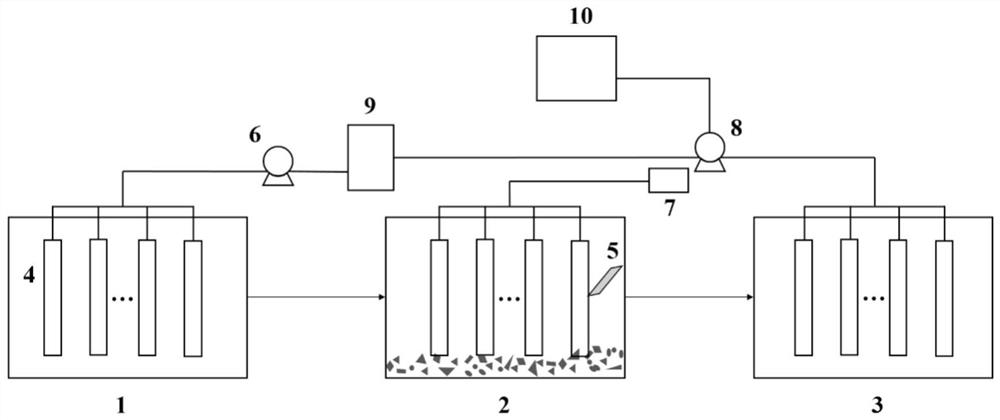

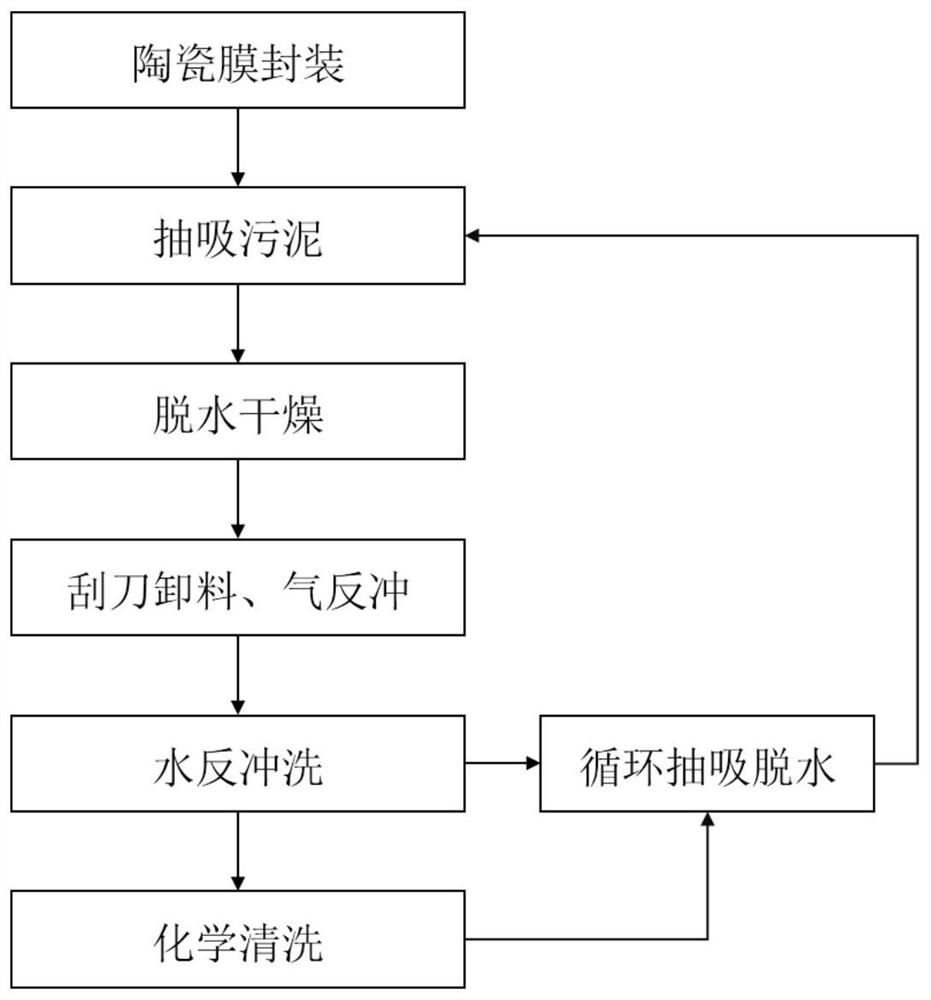

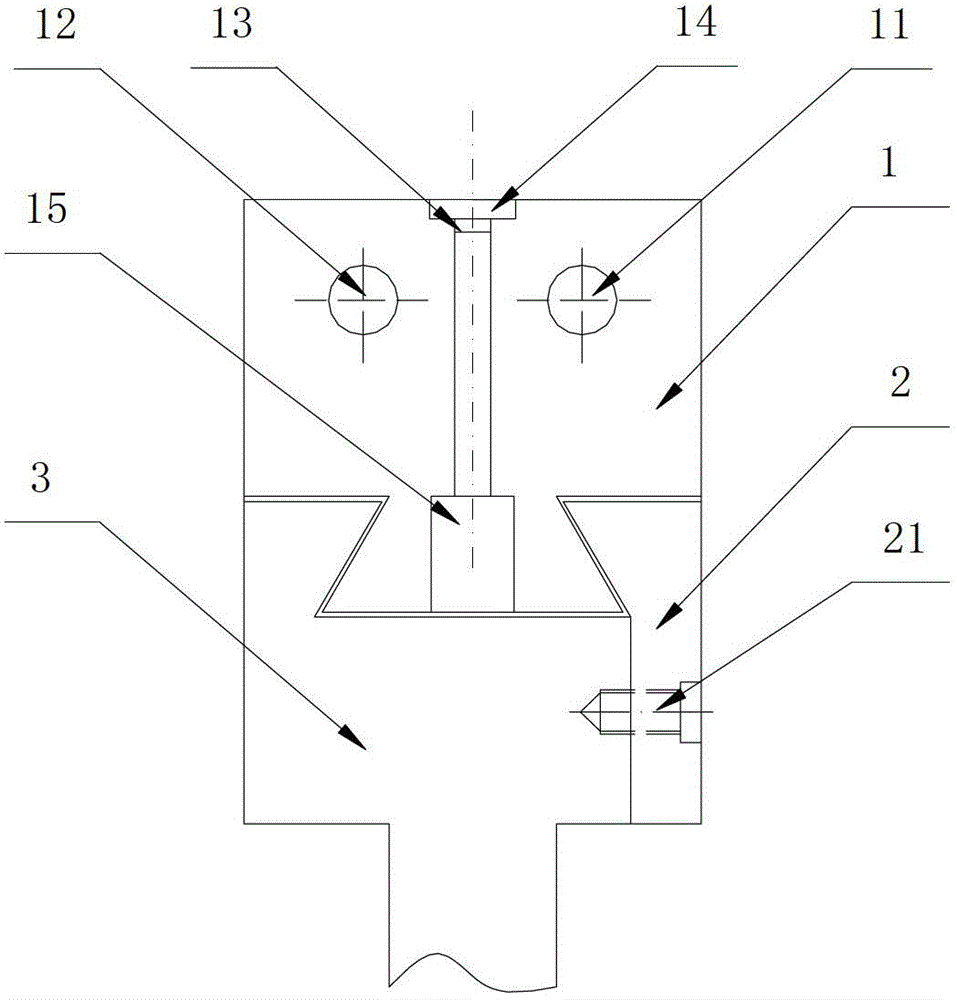

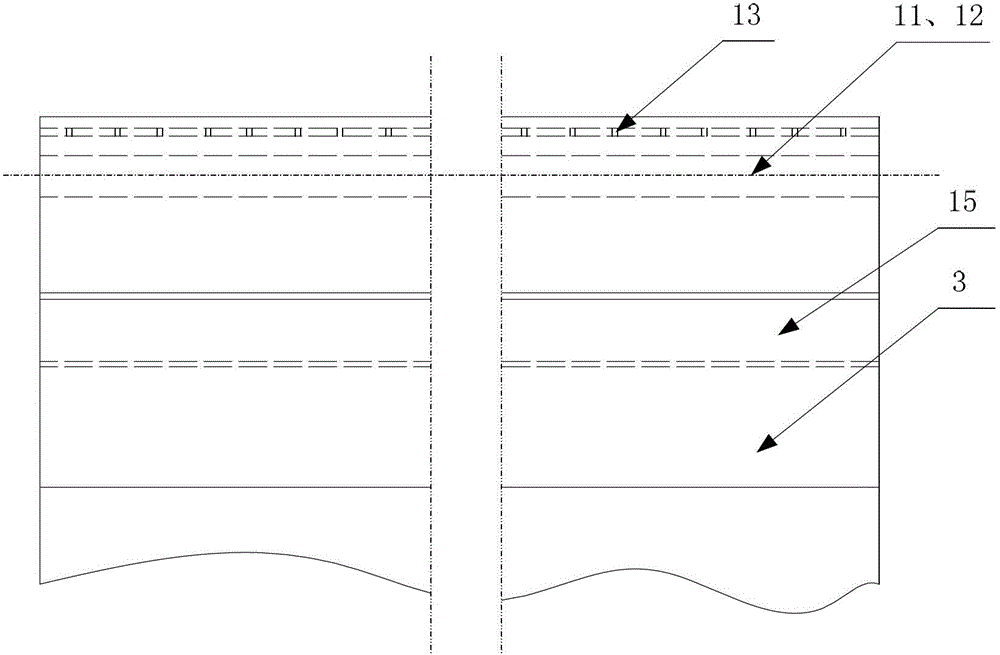

Physicochemical sludge dewatering method

PendingCN112194334AReduce turbidityEasy to interceptSludge treatmentUltrafiltrationAir pumpCleansing Agents

The invention provides a physicochemical sludge dewatering method, which comprises the following steps of: firstly, immersing a ceramic membrane component in physicochemical sludge feed liquid, connecting one end of the ceramic membrane component with a vacuum pump for suction, lifting the membrane component out of the sludge feed liquid after a period of time, further performing sucking and dewatering, then lifting the ceramic membrane component to a filter cake tank, and conducting backflushing by adopting a scraper and an air pump; and after the filter cake is removed, lifting the flat plate membrane component to a cleaning pool, carrying out back washing by using the collected dehydration filtrate, and then repeating the steps to carry out suction dehydration; and cleaning the ceramicmembrane by using a chemical cleaning agent to recover the flux of the ceramic membrane after circulating for multiple times. The method provided by the invention is low in energy consumption, simpleand feasible, not only can reduce the moisture content of physicochemical sludge, but also can greatly reduce the turbidity of sludge dewatering filtrate by adopting a ceramic microfiltration membraneas a filtering medium, reduces the cost in the operation process by recycling the filtrate, and avoids the defect that a tubular membrane is not easy to discharge by using a flat plate ceramic membrane; and the practical application value of the ceramic membrane in the aspect of sludge dewatering is improved.

Owner:NANJING UNIV OF TECH

Argon arc welding machine lower electrode

InactiveCN103934555ALow running costHigh material utilizationWelding/cutting media/materialsWelding electrode featuresSlagAssurance quality

The invention relates to a lower electrode structure of electrical arc welding, in particular to an argon arc welding machine lower electrode which is provided with a plurality of working faces. A molten pool groove is formed in the plane of each working face. The molten pool grooves of the upper working faces are used for carrying out welding operation, and the argon arc welding machine lower electrode is fixed on a lifting base through the lower working faces. When a molten pool groove of a working face is broken, the lower electrode rotates to another working face for welding operation. The molten pool grooves are of a non-nozzle integrated shallow groove structure, the lower electrode is provided with a protecting cooling gas channel which is a large-flow thin-wall through hole, a cooling structure of a lower electrode body is formed, and the section contour of the lower electrode is a square with four working faces or a multi-side wedge shape or a regular hexagon with six working faces. According to the lower electrode, material using rate is improved, operation cost is lowered, under the premise that quality is guaranteed, slag planing processing is removed, arranging and maintaining cost of a slag planing machine is saved, slag planing secondary quality pollution is avoided, the problem of welding nozzle wire blocking is solved, and welding nozzle replacing cost is lowered.

Owner:BAOSTEEL STAINLESS STEEL

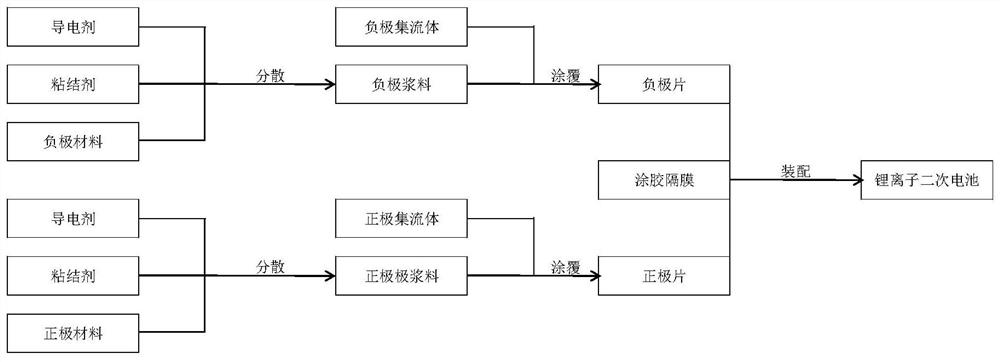

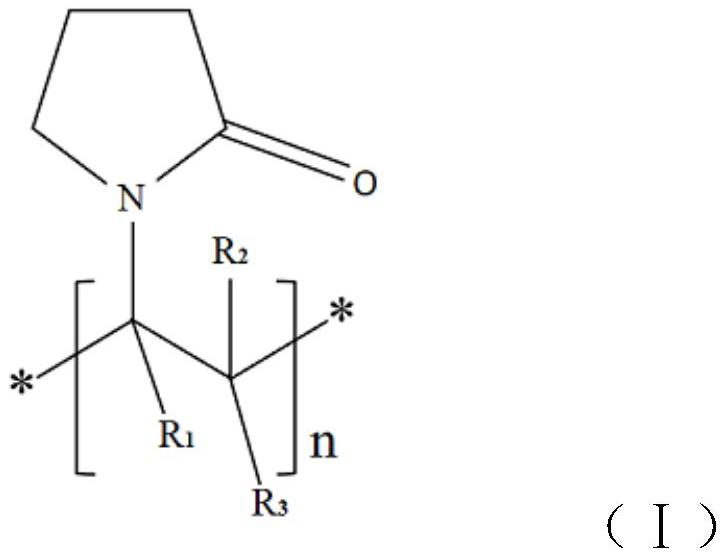

Aqueous binder and preparation method thereof, glued diaphragm and preparation method thereof, and lithium ion secondary battery

ActiveCN112226182AImprove Coulombic efficiencyAvoid destructionFilm/foil adhesivesNitrile polymer adhesivesWater soluble polymersHot pressing

The invention discloses a water-based binder and a preparation method thereof, a glued diaphragm and a preparation method thereof, and a lithium ion secondary battery. The water-based binder comprisesthe following raw materials: a point-bonded polymer, a surface-bonded polymer and a polymer lithium salt, wherein the point-bonded polymer is a granular polymer; and the surface-bonded polymer is a water-soluble polymer, and has a molecular mass of 100,000-1,000,000 and a glass-transition temperature of higher than 60 DEG C. The problems of hole blockage, coulombic efficiency reduction and the like after hot pressing of the glued diaphragm are solved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

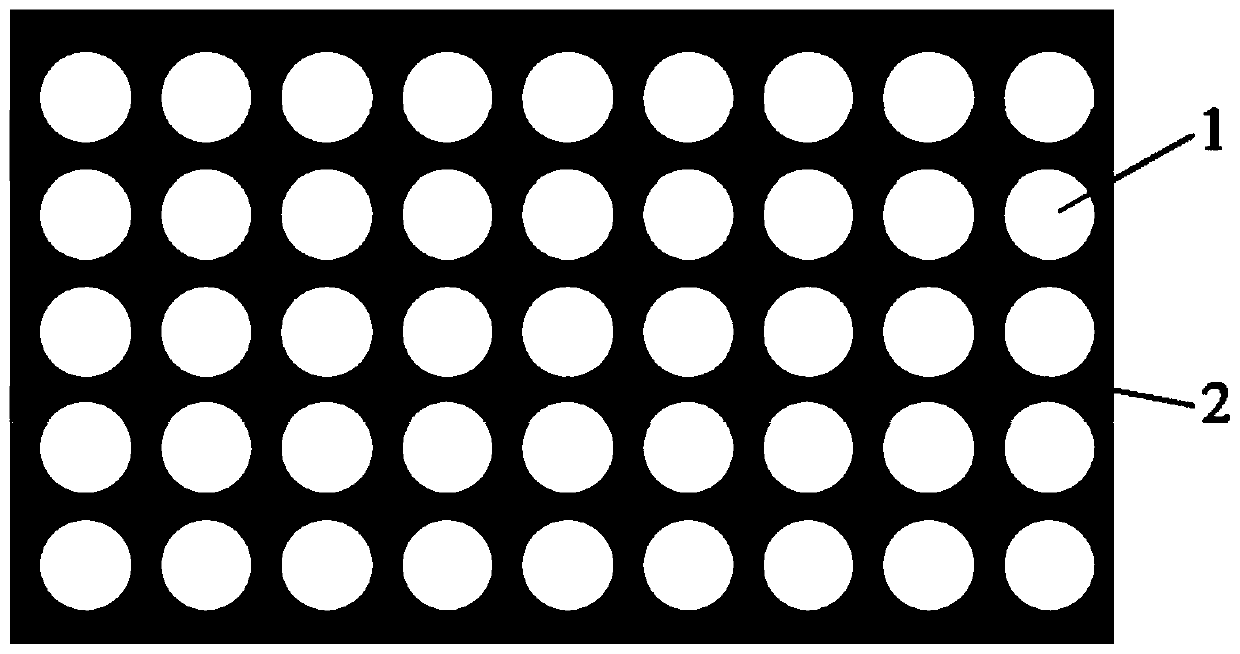

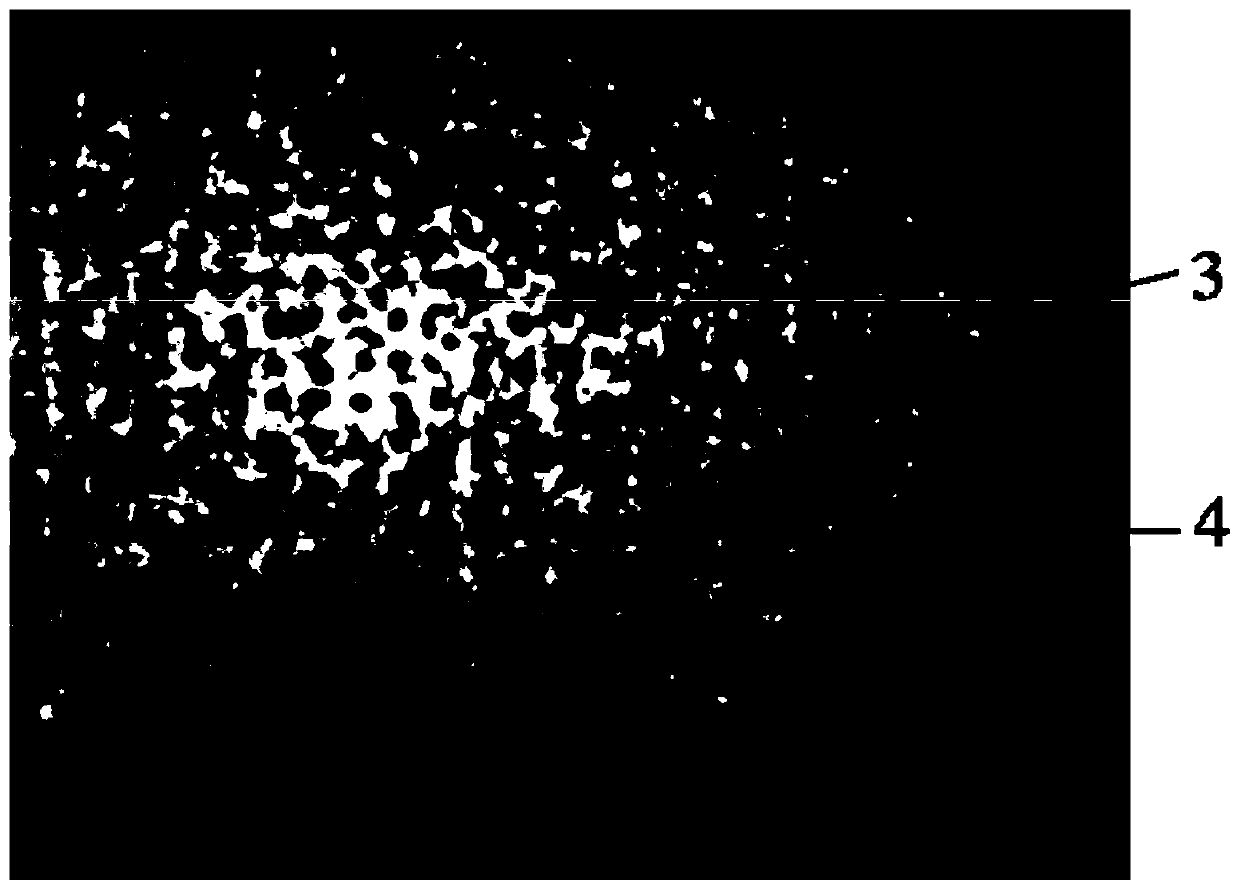

Method for preparing multilayer composite membrane for secondary battery by using electrostatic spinning coating method

ActiveCN102779964BImprove securityEnsure safetySynthetic resin layered productsCell component detailsComposite filmElectrospinning

The invention discloses preparation of a multilayer composite membrane for a secondary battery by using an electrostatic spinning coating technology combined with a pore-forming technology, a manufacturing method of the multilayer composite membrane and the secondary battery prepared by using the membrane. The method is characterized by comprising the following steps of: (1) dissolving a high-molecular organic matter into a solvent to form a high-molecular solution; (2) adding a small-molecular organic matter and / or an inorganic nanometer material into the high-molecular solution to ensure that the small-molecular organic matter is dissolved into the high-molecular solution; dispersing an inorganic nanometer material into the high-molecular solution to form an organic / inorganic mixed solution; (3) uniformly coating the formed organic / inorganic mixed solution on at least one side of a film matrix by using the electrostatic spinning coating technology to form a composite film, and drying the composite film; and (4) extracting the small-molecular organic matter from the dried composite film to continuously dry and form the multilayer composite membrane for the secondary battery. By using the method, an inorganic complex of inorganic membranes is realized quickly and conveniently, the ionic conductivity of the lithium ion battery membrane can be improved, and the heat stability and the security of the battery are guaranteed; and the method has the advantages of being simple in operation and convenient for industrialization.

Owner:LONG POWER SYST SUZHOU

Preparation method of battery diaphragm

ActiveCN110148695AEvenly distributedGood spraying stabilitySecondary cellsCell component detailsPolyvinylidene fluorideCeramic coating

The invention provides a preparation method of a battery diaphragm. The preparation method comprises the following steps: S1, coating a ceramic coating solution containing a hydrophobic substance on abase membrane under a light shielding condition to obtain a ceramic diaphragm; S2, covering the ceramic diaphragm obtained in the step S1 with a mask with a pattern, and carrying out ultraviolet irradiation to obtain a ceramic diaphragm with a hydrophilic part and a hydrophobic part; and S3, coating the ceramic diaphragm obtained in the step S2 with the polyvinylidene fluoride dispersion liquid.By adding a hydrophobic substance into a ceramic formula, the problems of hole blockage and needle blockage during spraying are solved. PVDF dot matrix coating can be achieved only through a traditional coating mode, so high-price equipment is not used, and cost is reduced. The performance of the product is equivalent to or better than that of the existing dot matrix PVDF diaphragm, so that the market requirement is met. The method is simple and easy to implement, and the dot matrix PVDF coated diaphragm can be produced on a large scale.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Vibrating screen

The invention discloses a vibrating screen comprising a screen frame. More than one screen teeth are arranged on the frontal surface of a cross beam side by side in the same direction to form a screen strip unit. The back parts of the screen teeth are fixedly connected with the cross beam; and the ends are suspended. The structure adopts a whole single material; the front part at least has one section as a rotating curved surface structure; the cross section thereof is gradually decreased from the back end to the front end; an included angle between the tangent line of at least one point of the generatrix, coplanar with a rotating shaft, of the rotating curved surfaces of the screen teeth and a revolving shaft is greater than 5.5 degrees and smaller than 45 degrees; multiple screen strip units are arranged in a front-back manner, and the screen teeth are fixedly connected to the screen frame in the same direction; the screen teeth of the screen strip units at the back part are positioned above the cross beams of the previous screen strip units; and the front ends of the screen teeth are beyond of the back surfaces of the cross beams of the previous screen strip units. The screen teeth are rigid, and the surfaces are smooth curved surfaces, so that the vibrating screen has the advantages of high screening precision and low hole blockage rate, and totally solves the defects in the prior art.

Owner:WUHAN MOLINHAN ELECTROMECHANICAL EQUIP +1

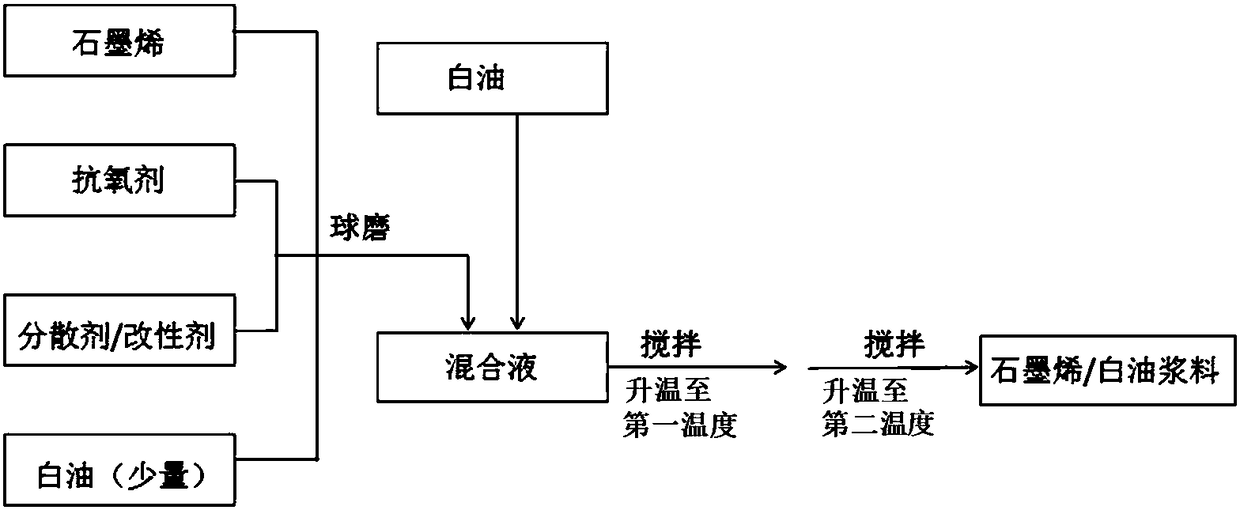

White oil sizing agent carrying dispersed graphene and preparation method thereof, as well as preparation method of UHMWPE (Ultrahigh Molecular Weight Polyethylene) fiber

ActiveCN109306536AConducive to subsequent spinningImprove dispersion stabilityMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberAntioxidant

The invention discloses a preparation method of white oil sizing agent carrying dispersed graphene. The preparation method comprises the following steps: 1) mixing a component A, a component B, graphene powder and white oil, and performing ball milling on the mixture in order that the components are mixed fully, wherein the component A is an antioxidant, and the component B is a dispersing agent and / or modifying agent; 2) adding the mixture obtained in the step 1) into the white oil, heating the mixture to a first temperature with stirring, keeping the temperature for 0.2 to 3 hours, then heating the mixture to a second temperature, and keeping the temperature while continually stirring for 2 to 15 hours to form a uniform solution, wherein the second temperature is 30 to 62 DEG C higher than the first temperature.

Owner:南通恒尚新材料科技有限公司 +1

Evaporation source device used for evaporation

ActiveCN107267919ASolve the pluggingIncrease production capacityVacuum evaporation coatingSputtering coatingEvaporationEngineering

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

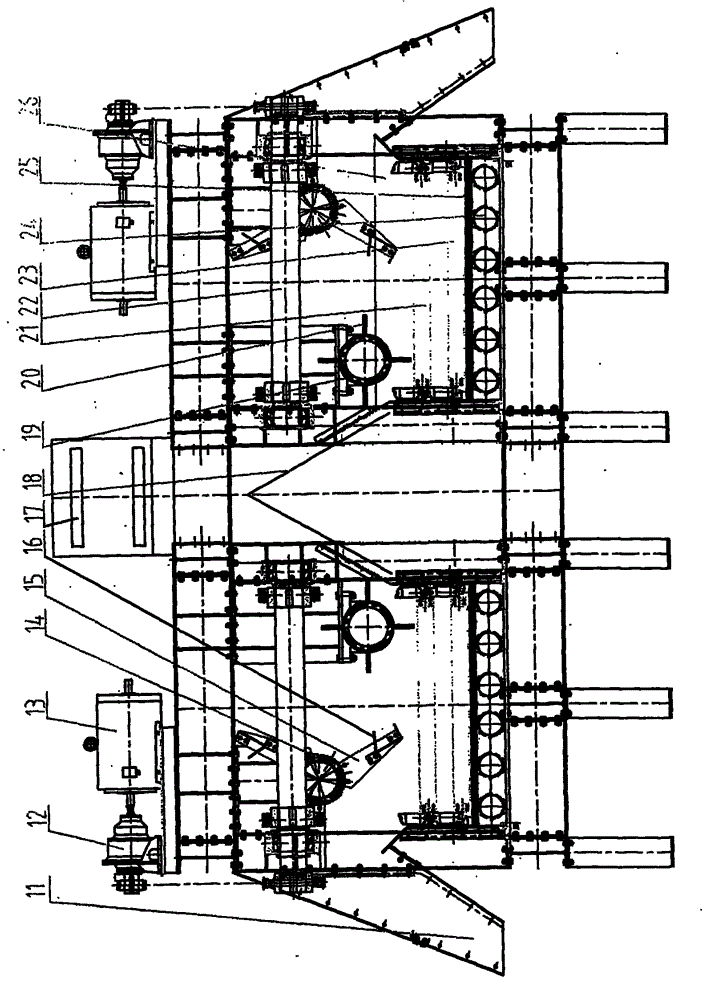

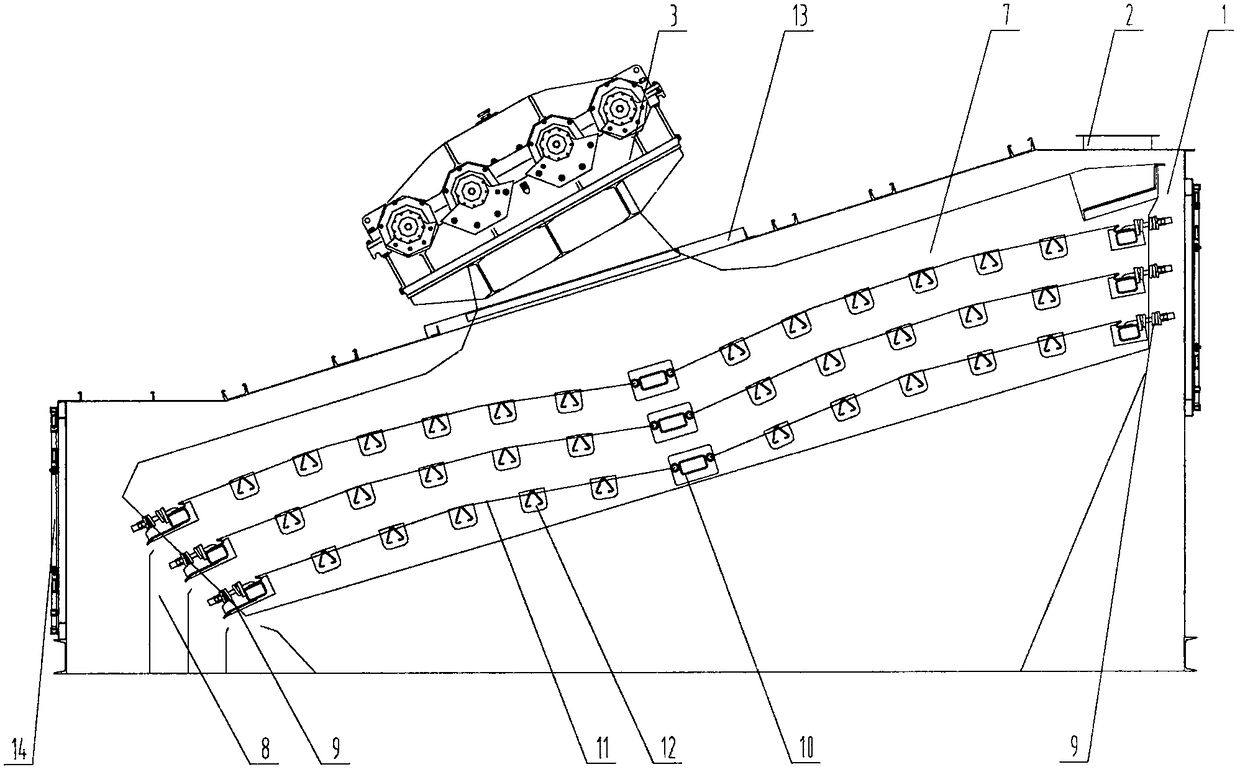

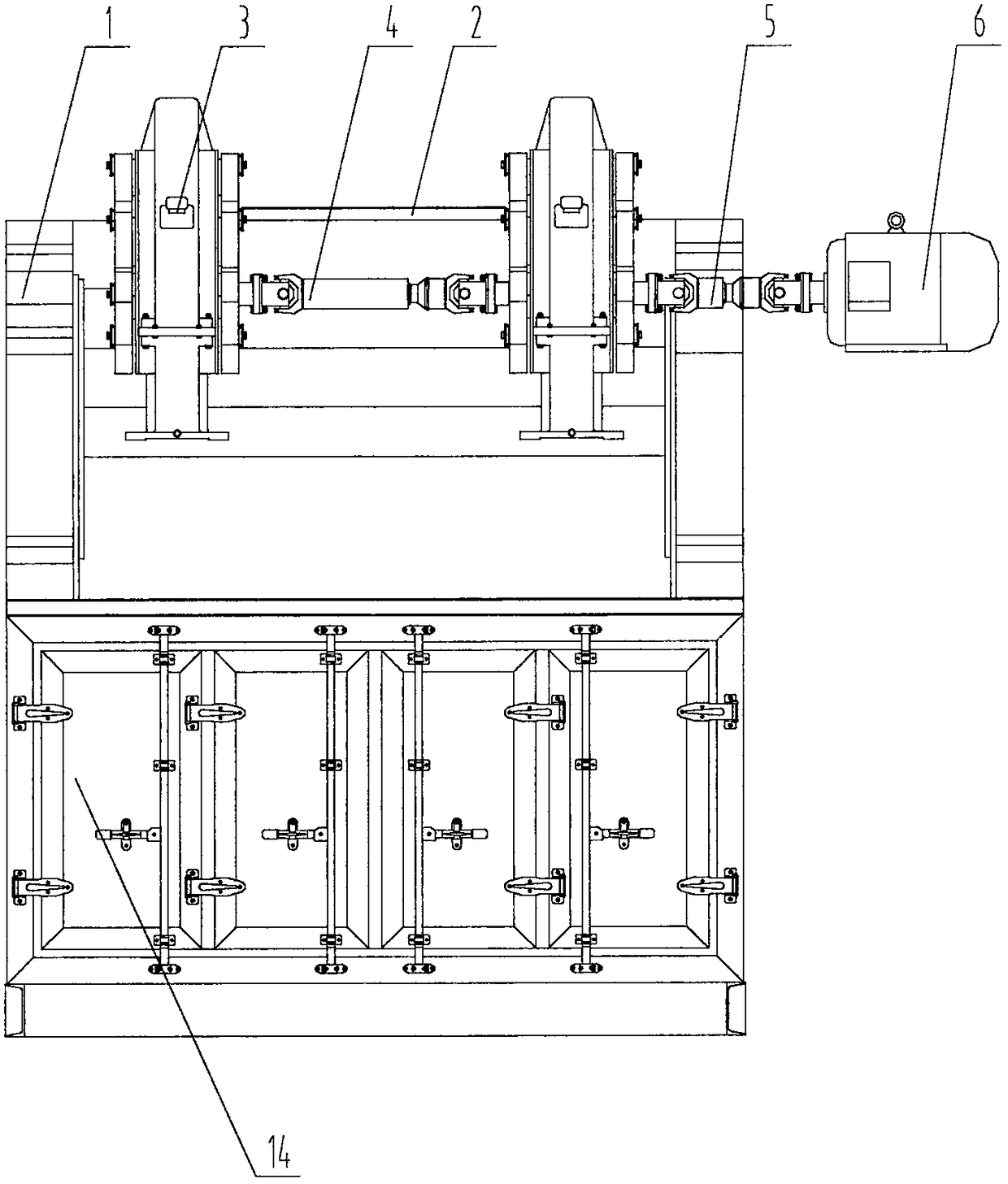

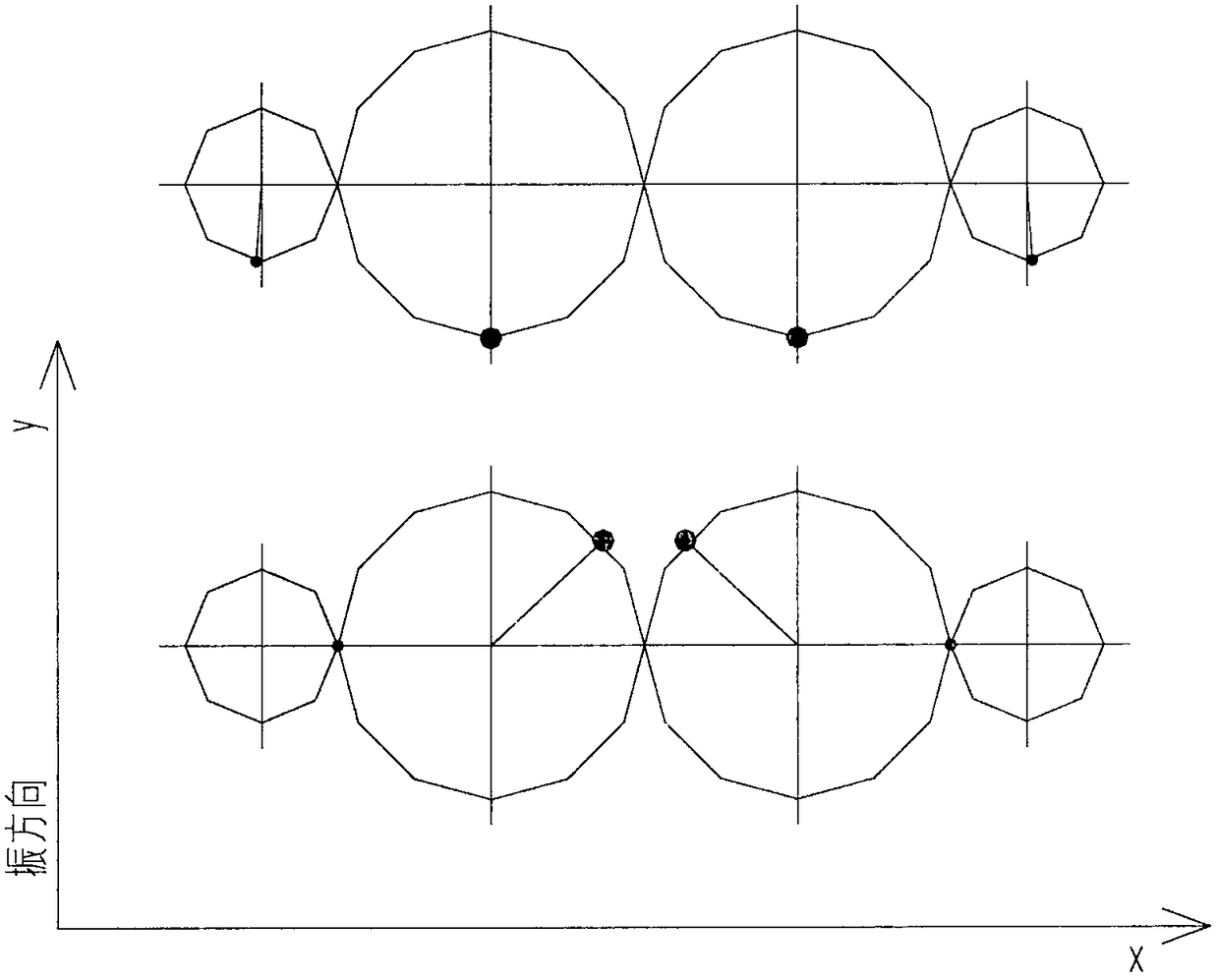

Four-shaft non-anharmonic vibrating screen and screening method thereof

The invention belongs to a four-shaft non-anharmonic vibrating screen and a screening method thereof. The vibrating screen comprises a box, a feeding inlet is formed in the top of one end of the box,a screen body is arranged on the box, the screen body is of a trapezoid frame structure with the inclination, large top and small bottom, the two ends of the screen body are each fixedly provided witha plurality of sets of screen net tensioning devices from top to bottom, a middle beam is arranged between the screen net tensioning devices, a screen net is arranged between the middle beam and thescreen net tensioning devices, a plurality of supporting beams are arranged at the bottom of the screen net, a plurality of discharging outlets are formed in the bottom of the box, a screen cover is arranged between the box and the upper middle portion of the screen body, two four-shaft thin oil vibration exciters are arranged at the top of the screen body, a middle shaft is arranged between driving shafts of the two four-shaft thin oil vibration exciters, and the outer side of the driving shaft of one four-shaft thin oil vibration exciter is connected with a motor through a drive shaft. The vibrating screen has the advantages of being simple in structure, reasonable in design, low in cost and high in screening efficiency, facilitating material layering and through screening and avoiding material blockage.

Owner:XINXIANG GELIN IND DEV

Coal mine underground grouting drill rod and using method

InactiveCN113187542AInnovativeRealistically feasibleDrilling rodsMaterial fill-upMining engineeringNatural state

The invention discloses a coal mine underground grouting drill rod and a using method in order to reduce the disturbance to broken rock and gangue in the process of pulling out a drill rod in the grouting and filling work of a drill rod first and a grouting pipe later, effectively solve the problem of hole blockage, facilitate underground grouting operation, and reduce grouting and filling procedures. The drill rod is mainly composed of a drill rod body, a one-way opening and closing device, a rotary connector, a protective cover, a drill bit and other members. The rotary connector is connected with the one-way opening and closing device and the drill rod body so that the one-way opening and closing device can be opened and closed; a small spring is arranged in the rotary connector so that the one-way opening and closing device can be always in a closed state in a natural state and a drilling process; and meanwhile the protective cover guarantees a movable space for rotary opening and closing of the one-way opening and closing device. The coal mine underground grouting drill rod is simple in structure and convenient to operate, drilling and grouting filling can be carried out while drilling is carried out in a broken top plate or caving the gangue, the tedious working procedures of two-time operation of arranging the drill rod and a grouting pipe are reduced, the hole blocking problem is effectively solved, and underground grouting operation is facilitated.

Owner:ANHUI UNIV OF SCI & TECH

Diaphragm and preparation method thereof, lithium battery

ActiveCN108682774BImprove low temperature capacity retentionPlay the role of overcharge protectionMaterial nanotechnologySecondary cellsActive polymerPolymer science

The invention provides a diaphragm, a preparation method thereof, and a lithium battery. The diaphragm includes a base film layer and a nanofiber layer coated on the surface of the base film layer; wherein the base film layer contains a base film and the first electroactive polymer dispersed in the base film; the nanofiber layer contains nanofibers and coating A second electroactive polymer based on nanofibers; wherein the first electroactive polymer includes at least one of the following: polyphenylene, polynaphthine, and derivatives thereof; and / or the second electroactive polymer Including at least one of the following: polyaniline, polypyrrole, polyacetylene, and derivatives thereof. On the one hand, because of the use of nanofibers, the pore size distribution of the diaphragm is uniform due to the shape and structure of the nanofibers; on the other hand, the ionic conductivity of the diaphragm is improved because the nanofibers have excellent liquid absorption and liquid retention properties; At the same time, due to the first electroactive polymer and the second electroactive polymer, the diaphragm has the function of preventing overcharging.

Owner:桑德新能源技术开发有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com