White oil sizing agent carrying dispersed graphene and preparation method thereof, as well as preparation method of UHMWPE (Ultrahigh Molecular Weight Polyethylene) fiber

A graphene and white oil technology, applied in the direction of fiber chemical characteristics, single-component polyolefin rayon, rayon manufacturing, etc., can solve the problem of spinneret plugging, difficulty in stable and uniform dispersion, and inconformity with superfiber technology Questions such as requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

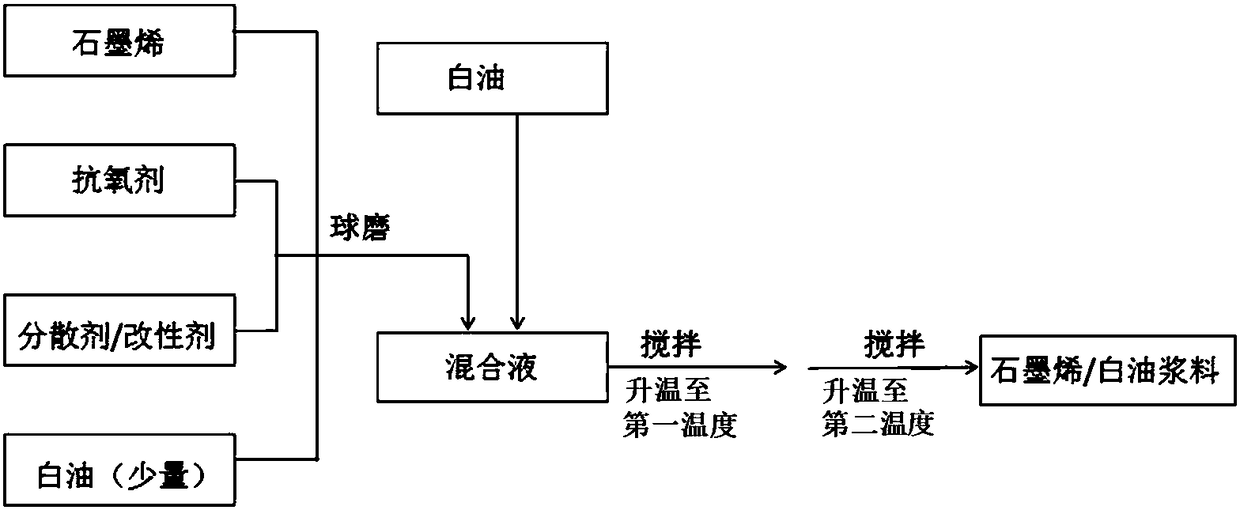

[0101] (2) Adjust the formula and improve the process parameters for the preparation of the graphene / white oil slurry, that is: add the mixed material after ball milling into the white oil solvent, heat it to 8-130°C for 0.2-3h while stirring, Then gradually raise the temperature to 130-160° C., and keep it warm for 2-15 hours until a uniform solution is formed, that is, a uniformly dispersed graphene / white oil slurry.

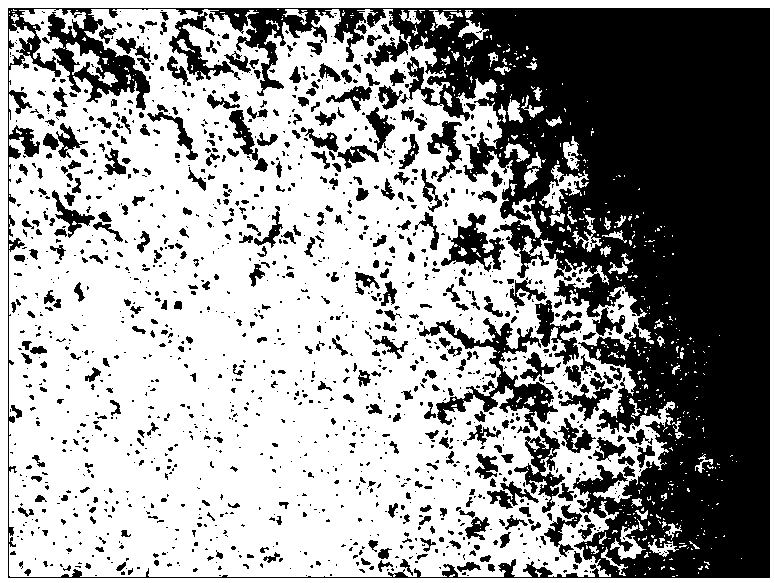

[0102] The graphene / white oil slurry dispersion stability that the present invention adopts new technology to prepare has obvious improvement effect (see attached figure 2 ), can quickly pass through a 650-mesh screen at room temperature, and there is basically no sieve residue on the screen, which lays the foundation for the subsequent preparation of high-strength graphene / UHMWPE composite fibers, thus solving the problem of spinneret blockage in the continuous production of superfibers To solve the hole problem, the tensile strength of the prepared composite...

Embodiment 1

[0105] For slurry preparation, see figure 1 :

[0106] Mix the antioxidant 1010 (0.01kg), PSS (0.01kg), graphene powder (0.01kg) and 9.997kg white oil to completely infiltrate the antioxidant 1010, PSS, and graphene powder, and then The above-mentioned mixed material is ball milled so that the components are fully mixed. The speed of the ball mill is 500rpm, the mass ratio of the ball to material is 10:1, and the balls are mixed with balls with diameters of 5mm, 12mm and 15mm. The three The volume ratio of 3:1:1, ball milling 1h;

[0107] Add the above-mentioned mixed material into 89.973kg of white oil, heat it to 80°C for 0.5h while stirring, then gradually raise the temperature to 120°C and keep it for 4h to form a uniform solution, that is, a uniformly dispersed graphene / white oil slurry (dispersion See figure 2 ).

[0108] Application of slurry in UHMWPE fiber:

[0109] Add 10kg of UHMWPE powder (graphene accounts for 0.1% of UHMWPE) and 1.14kg of white oil to the o...

Embodiment 2

[0111] Preparation of composite paste, see figure 1 :

[0112] Mix antioxidant 1010 (1kg), SDS (1kg), graphene powder (0.01kg) and 9.799kg white oil, carry out ball milling above-mentioned mixed material, make each component fully mix, and the rotating speed of described ball milling is 1000rpm 1. The mass ratio of the ball to the material is 10:1, and the grinding ball is made of a mixture of grinding balls with diameters of 5mm, 12mm and 15mm. The volume ratio of the three is 3:1:1, and the ball is milled for 10 minutes;

[0113]The above-mentioned mixed material was added to 88.191kg white oil, heated to 110°C for 0.6h while stirring, and then gradually heated to 138°C for 5h to form a uniform solution, i.e. a uniformly dispersed graphene / white oil slurry.

[0114] Further preparation of composite fibers of UHMWPE:

[0115] Add 10kg of UHMWPE powder (graphene accounts for 0.1% of UHMWPE) and 3.12kg of white oil to the obtained slurry to make a pre-spinning solution, ente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com