Method for synthesizing graphene

A technology for synthesizing graphite and graphene oxide, which is applied in the field of nanomaterials, can solve problems affecting graphene electron transport and graphene device processing difficulties, and achieve mild reaction conditions, good dispersion stability, and significant application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

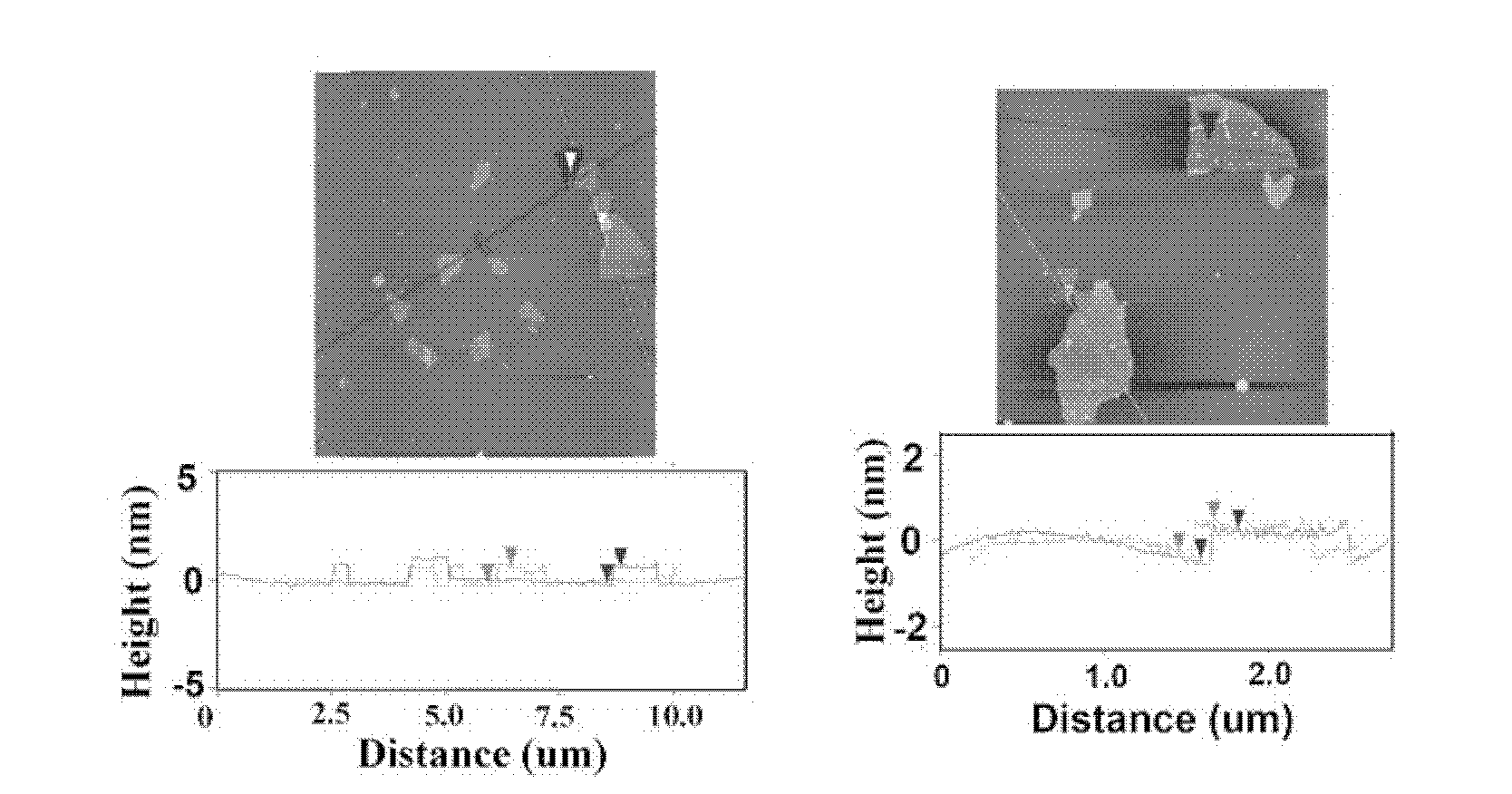

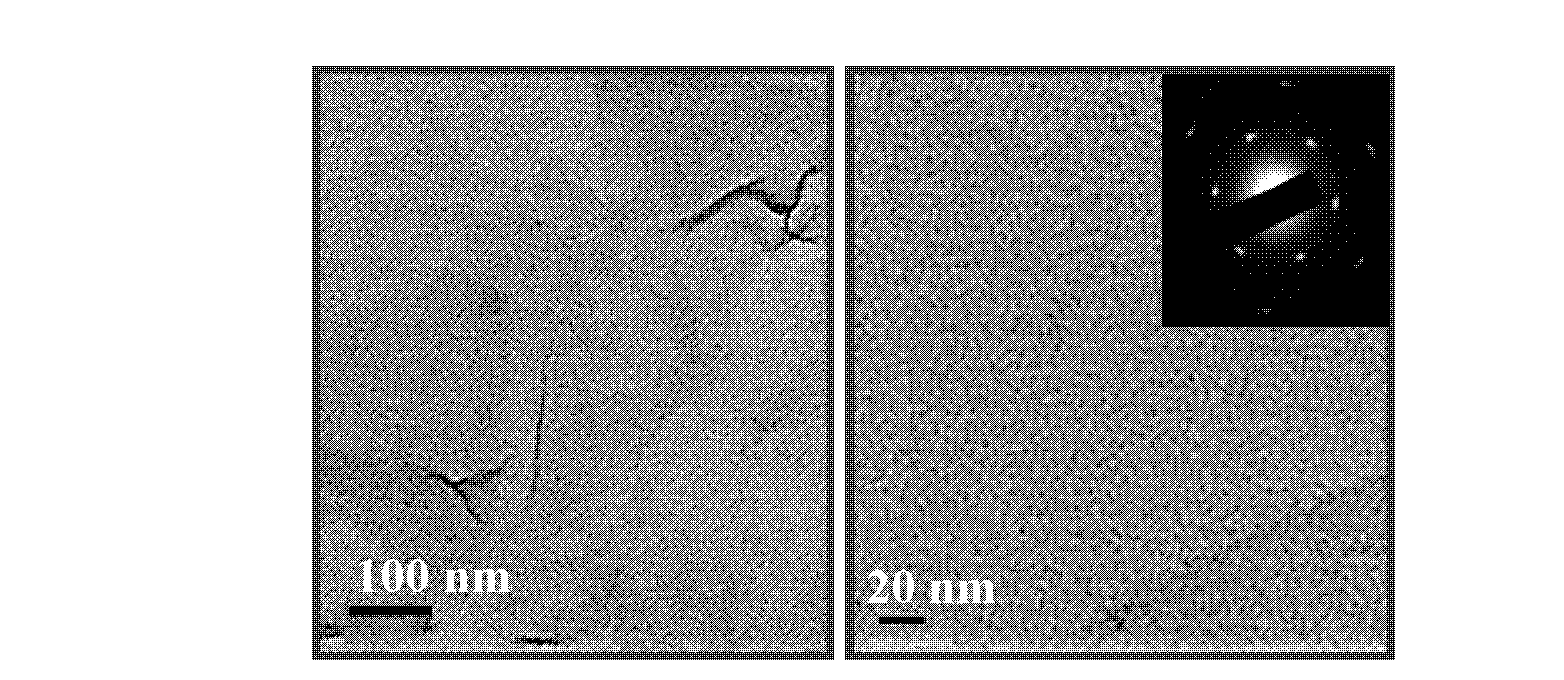

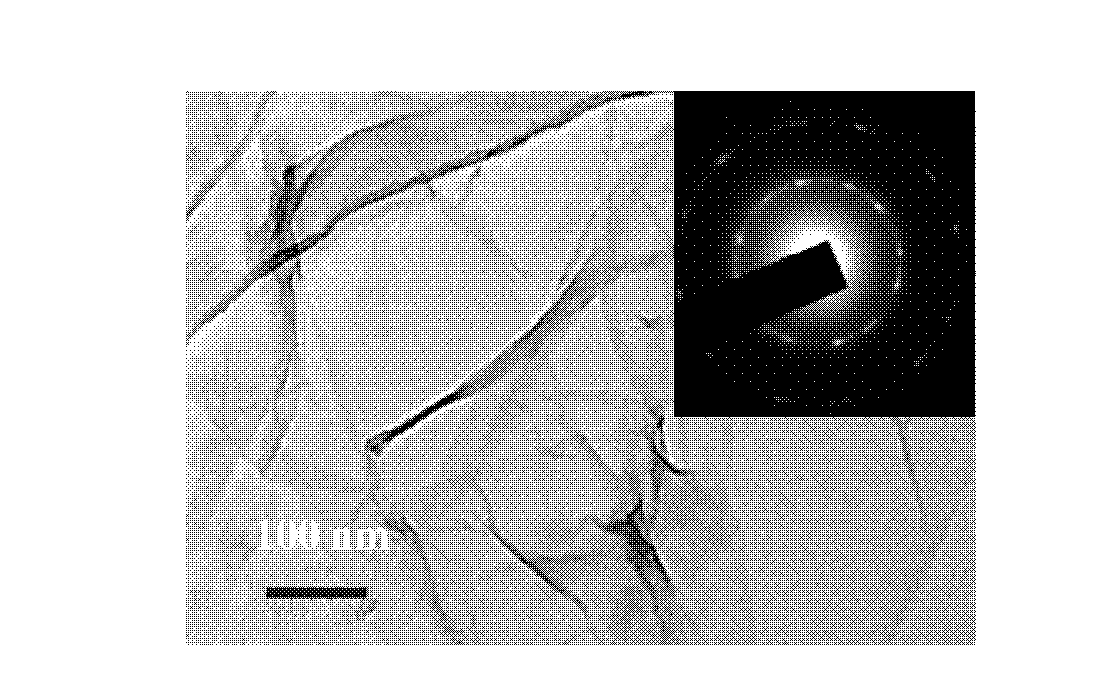

Image

Examples

Embodiment 1

[0032] The method for synthesizing graphene based on an organic negative hydrogen donor under light or heating conditions comprises the following steps:

[0033] 1) Expansion treatment of graphite.

[0034] Heat 9mL of concentrated sulfuric acid to 80°C, add 1.6g of potassium peroxodisulfate and 1.6g of phosphorus pentoxide, stir at this temperature to completely dissolve the solid, then slowly add 2g of 325 mesh flake graphite, and finish adding within 5 minutes; The mixed solution was reacted at 80°C for 4.5h, cooled to room temperature after the reaction was completed, then added 350mL deionized water, left for 12 hours, filtered the mixture through a 0.2um filter membrane, and washed away the residual acid with a large amount of water; the solid Let stand at room temperature for 12 hours.

[0035] 2) Oxidation of expanded graphite

[0036] Take 80mL of concentrated sulfuric acid and place it in an ice bath at 0°C, add the expanded graphite obtained in step 1) to the sulf...

Embodiment 2

[0042]Repeat Example 1, its difference is only: in step 3), the concentration of described graphene oxide is 0.3mg / mL; In step 4), described 1,4-dihydropyridine is 30mg, The light wavelength λ>400nm, the light reaction time is 3h, and the light-proof heating reaction time is 5h.

Embodiment 3

[0044] Repeat Example 1, its difference is only: in step 3) in, the concentration of described graphene oxide is 0.6mg / mL, in step 4) in described 1,4-dihydropyridine is 30mg, light The wavelength λ>400nm, the light reaction time is 3h, and the light-proof heating reaction time is 5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com