Patents

Literature

753 results about "Single layer graphene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano graphene-modified lubricant

ActiveUS20110046027A1Modulate viscosityImprove the lubrication effectAdditivesBase-materialsCarbon nanotubeSingle layer graphene

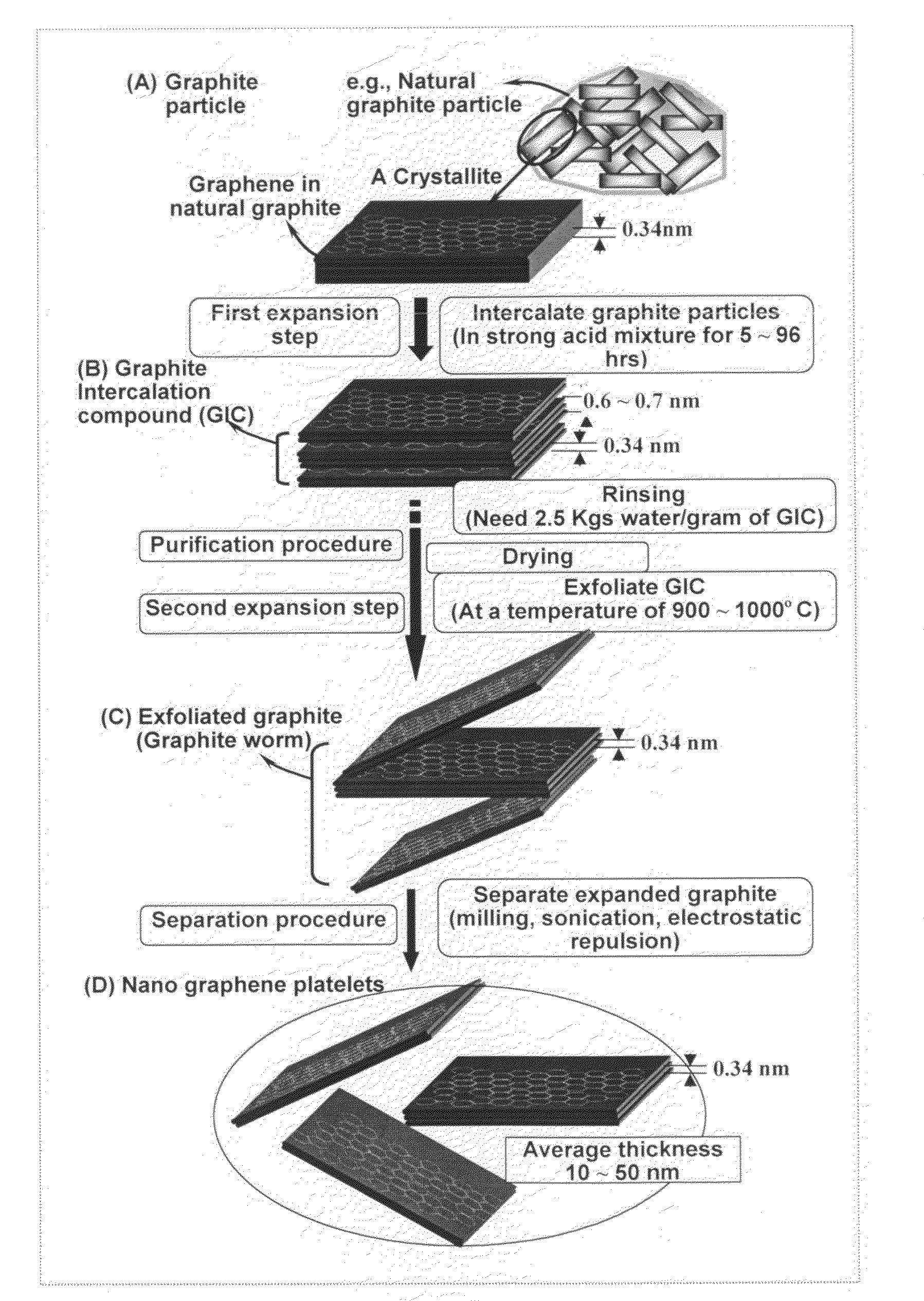

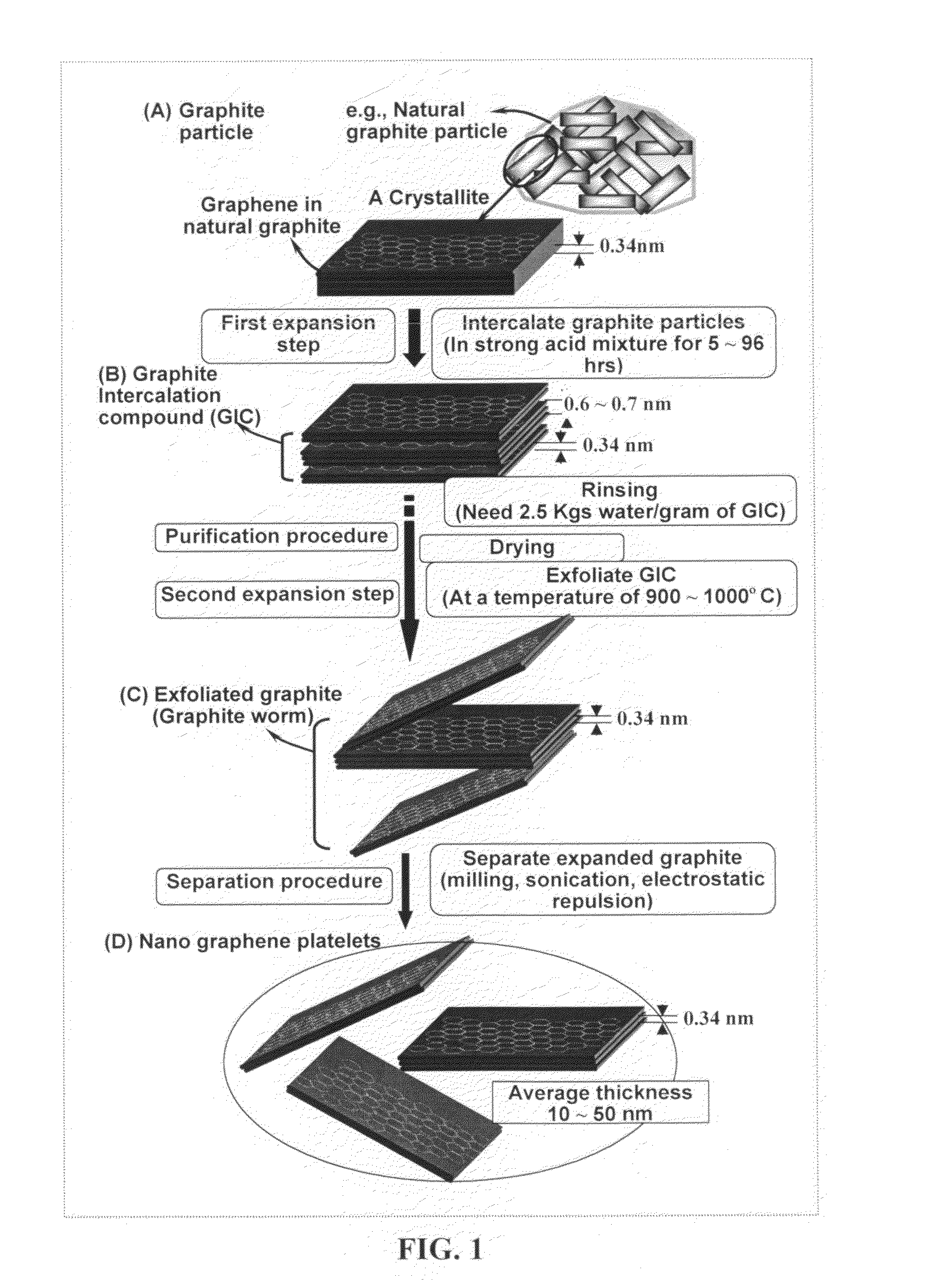

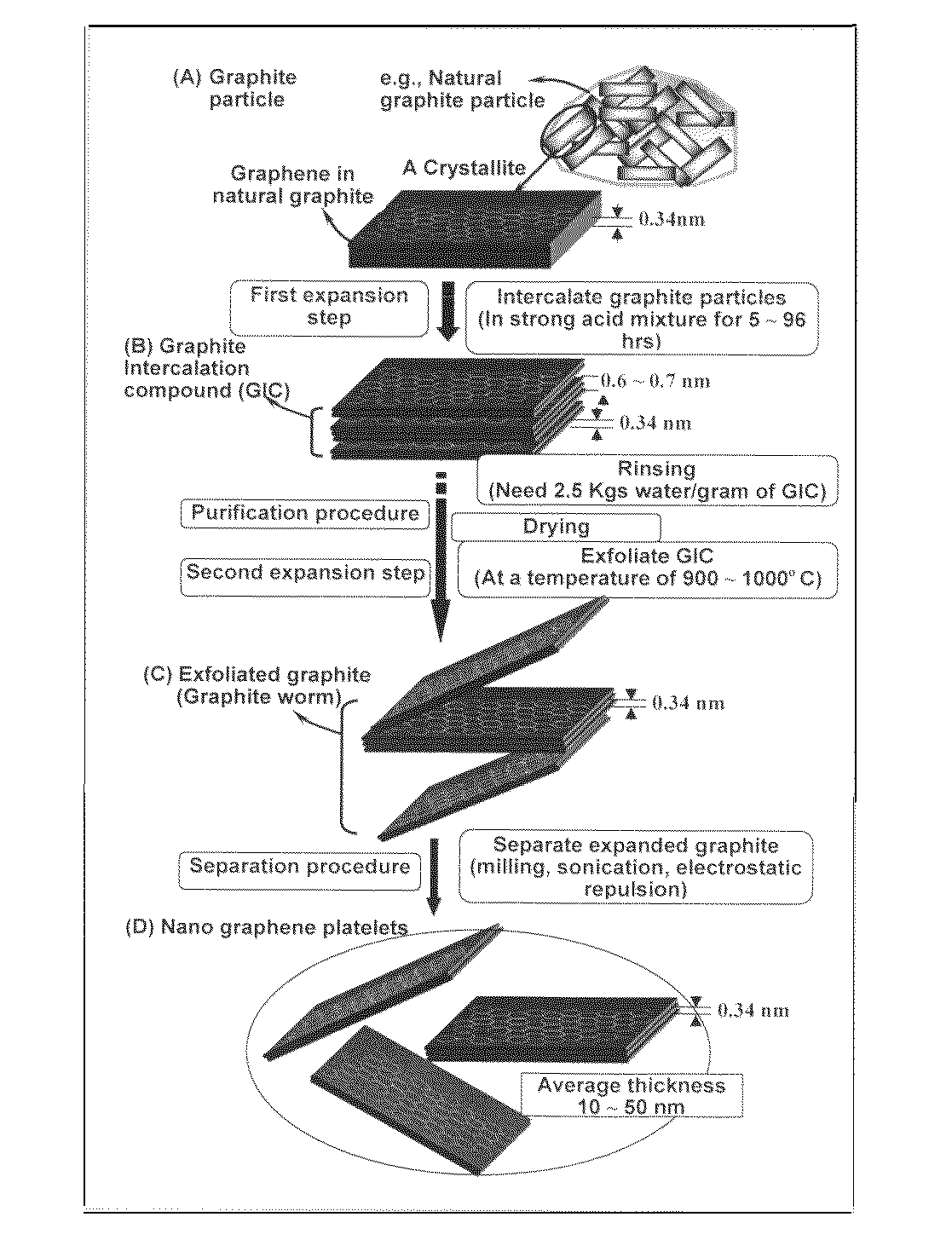

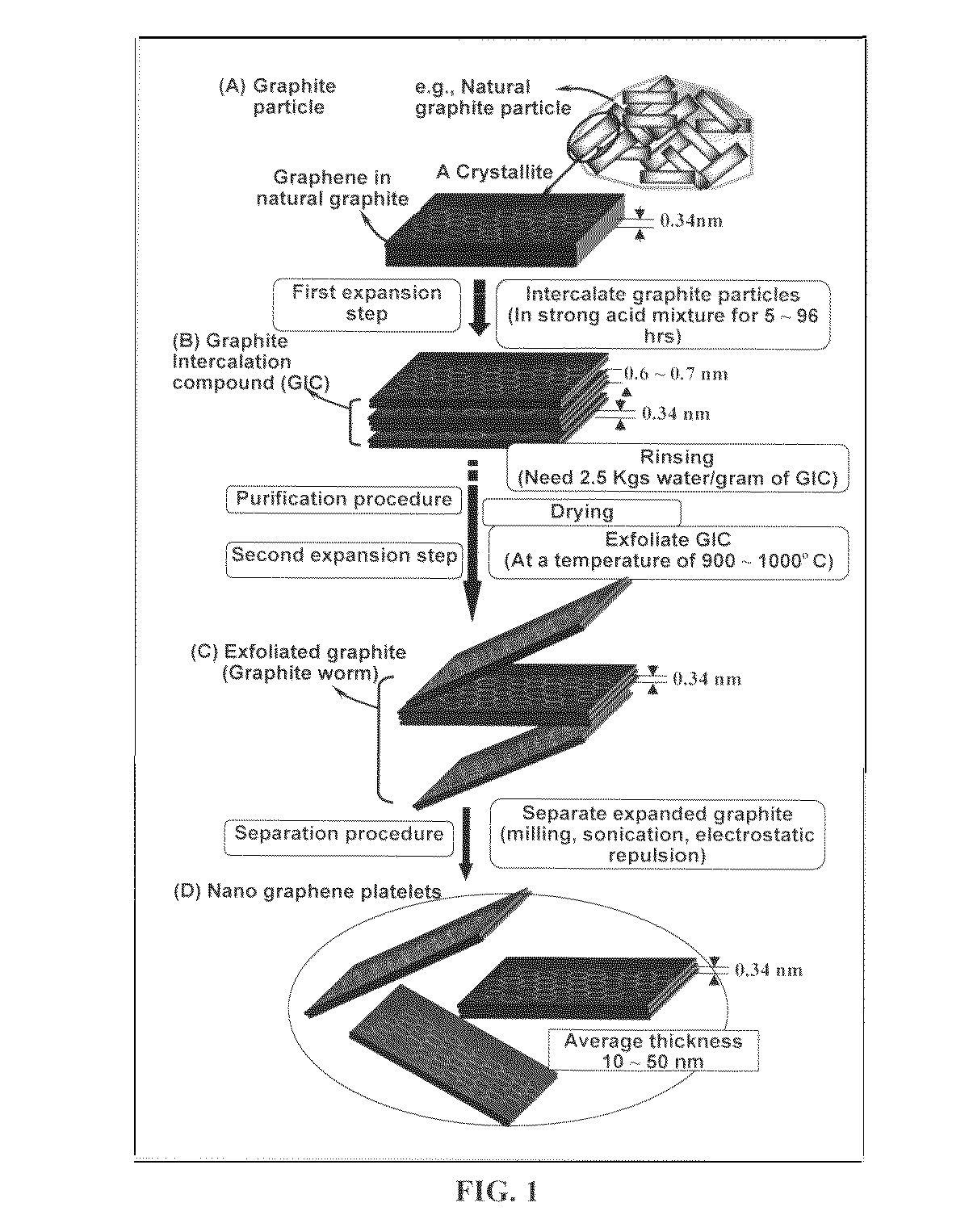

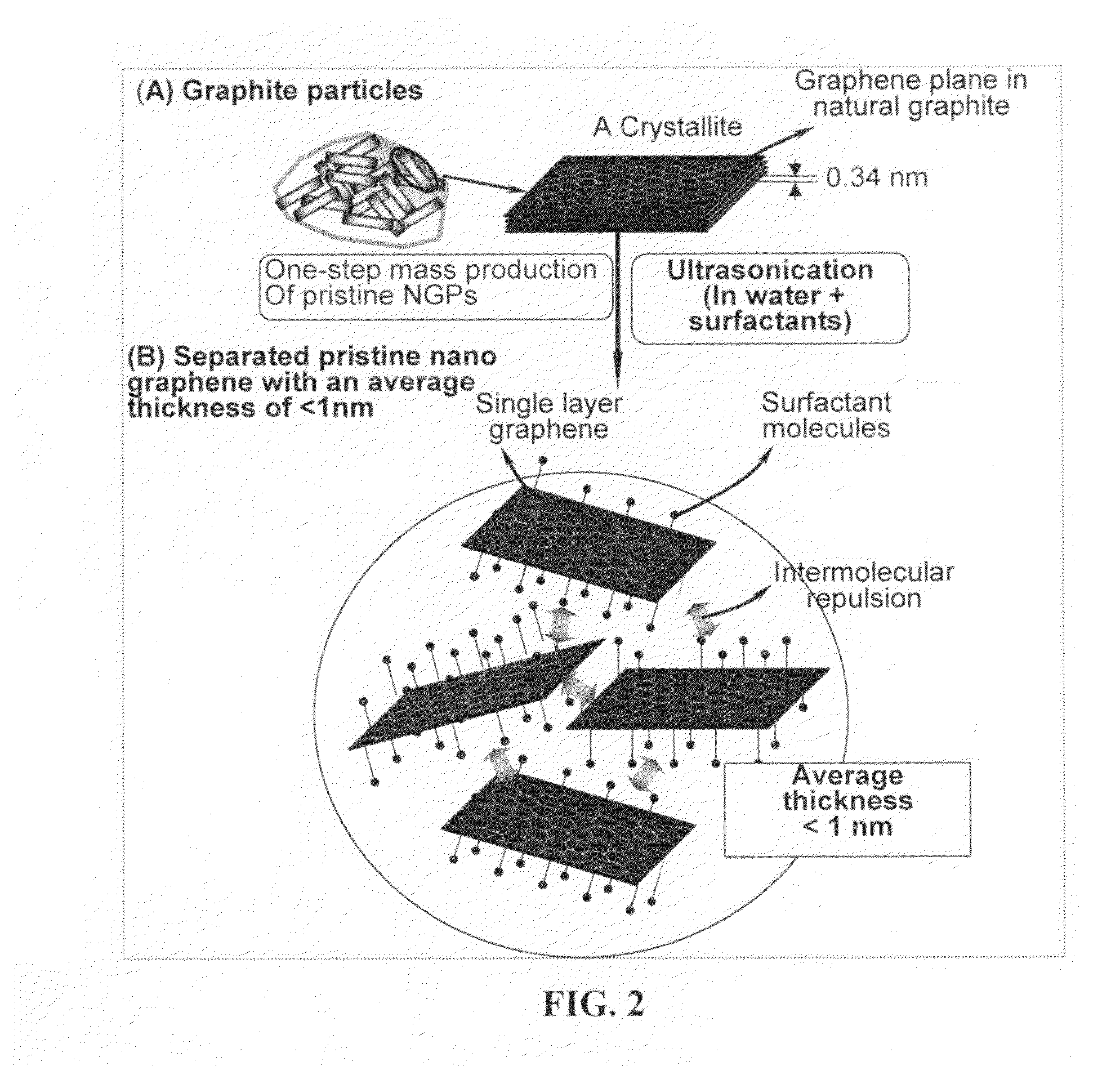

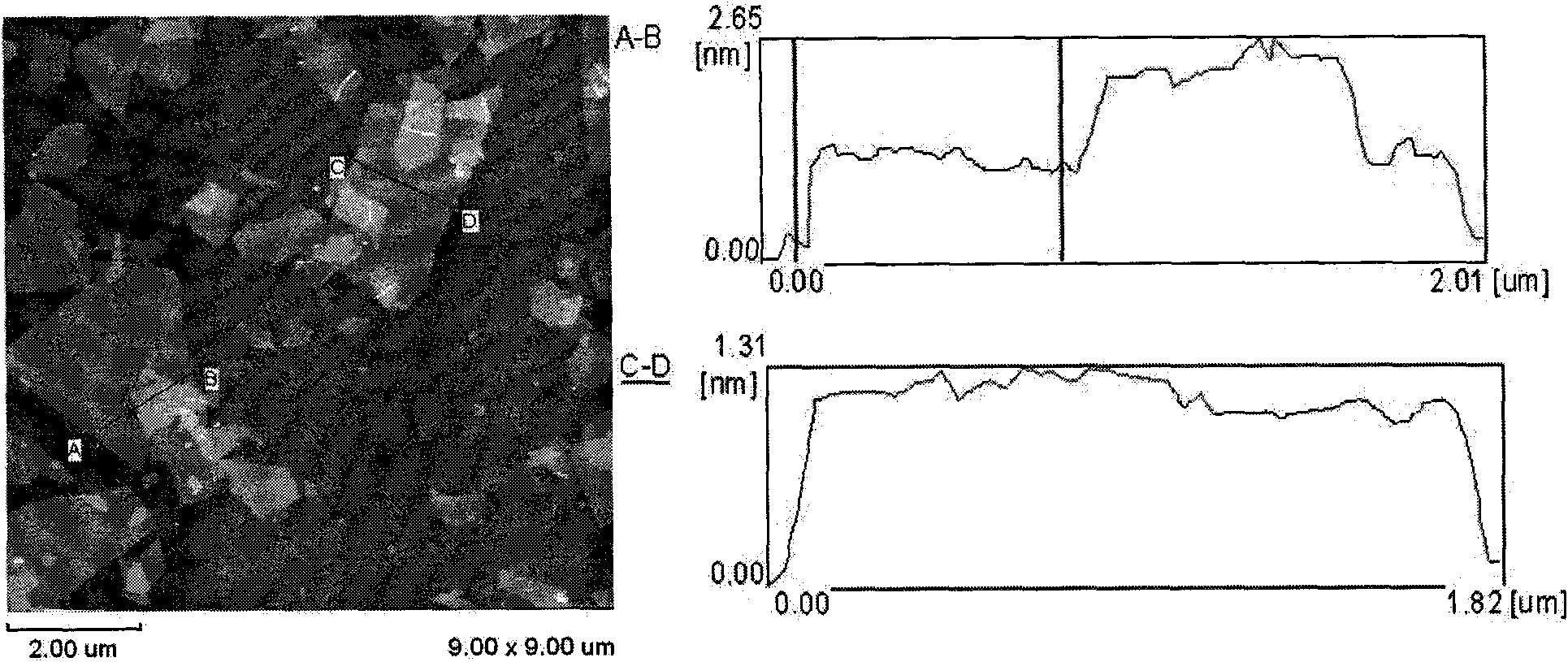

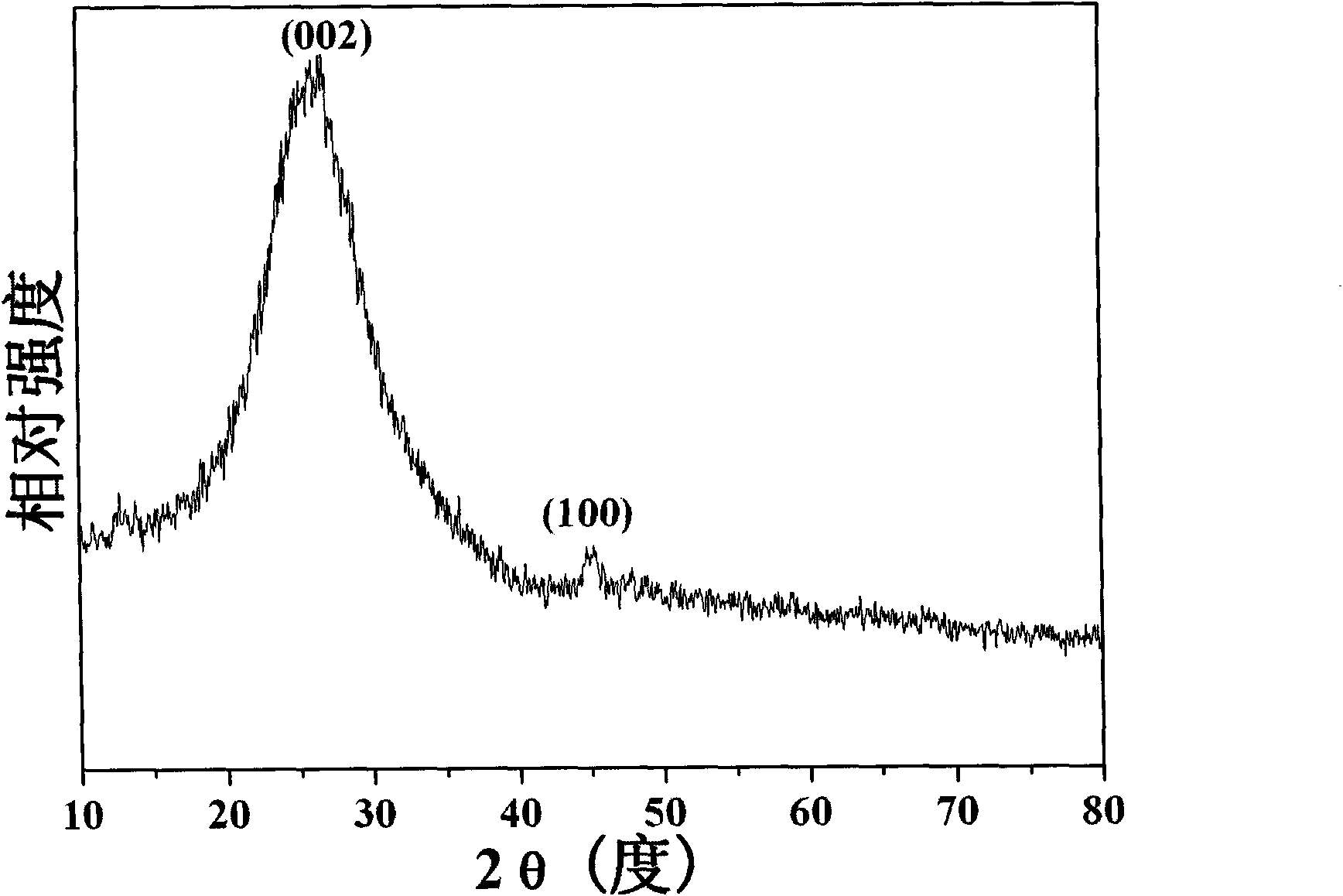

A lubricant composition having improved lubricant properties, comprising:(a) a lubricating fluid; and (b) nano graphene platelets (NGPs) dispersed in the fluid, wherein nano graphene platelets have a proportion of 0.001% to 60% by weight based on the total weight of the fluid and the graphene platelets combined. Preferably, the composition comprises at least a single-layer graphene sheet. Preferably, the lubricating fluid contains a petroleum oil or synthetic oil and a dispersant or surfactant. With the addition of a thickener or a desired amount of NGPs, the lubricant becomes a grease composition. Compared with graphite nano particle- or carbon nanotube-modified lubricants, NGP-modified lubricants have much better thermal conductivity, friction-reducing capability, anti-wear performance, and viscosity stability.

Owner:GLOBAL GRAPHENE GRP INC

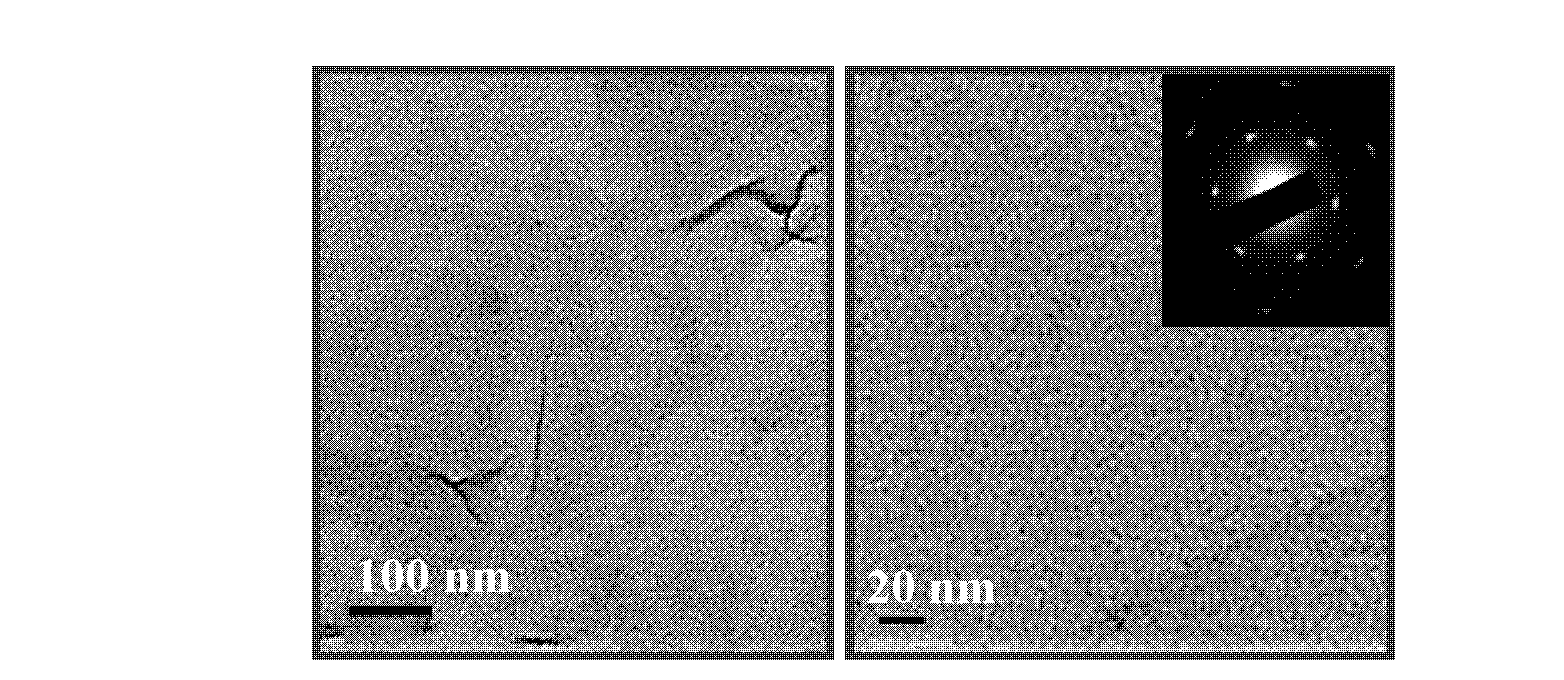

Method for preparing single-layer graphene

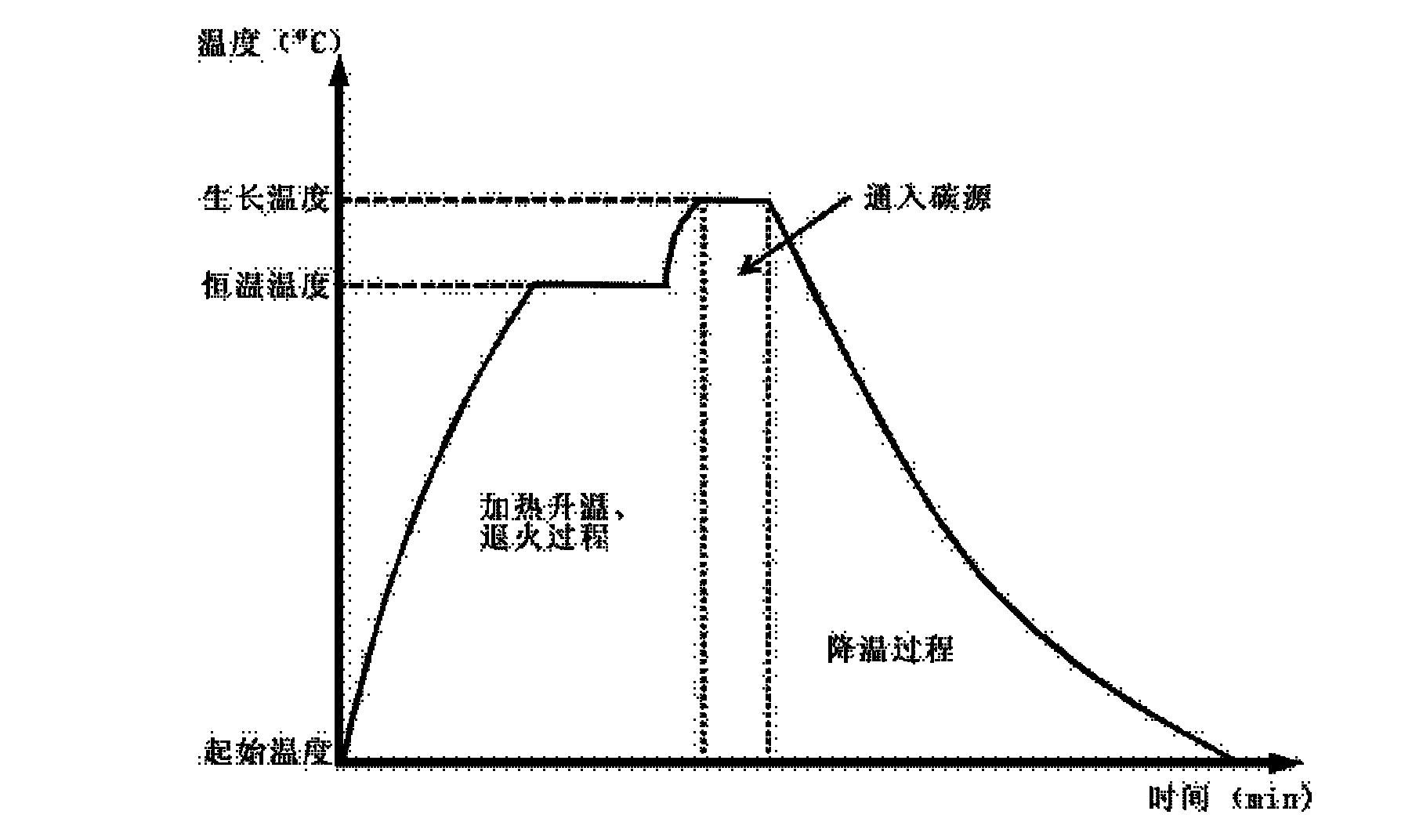

The invention discloses a method for preparing single-layer graphene. The method comprises the following steps of: 1) preparing an alloy substrate; and 2) in the hydrogen and inert atmosphere, catalyzing to grow graphene on the surface of the alloy substrate obtained in the step 1) by a chemical vapor deposition method, thereby finishing the preparation of the single-layer graphene. The method makes use of the characteristics of two or more alloy metals in the alloy substrate, realizes control on the decomposition, diffusion and precipitation processes of a carbon source, simply and efficiently restrains the precipitation process of carbon dissolved in the metal substrate to enable the graphene to be capable of growing in a surface catalytic manner to obtain the single-layer graphene withuniform layer distribution, and is suitable for industrial production and particularly for the controllable preparation of single-layer or few-layer graphene.

Owner:PEKING UNIV

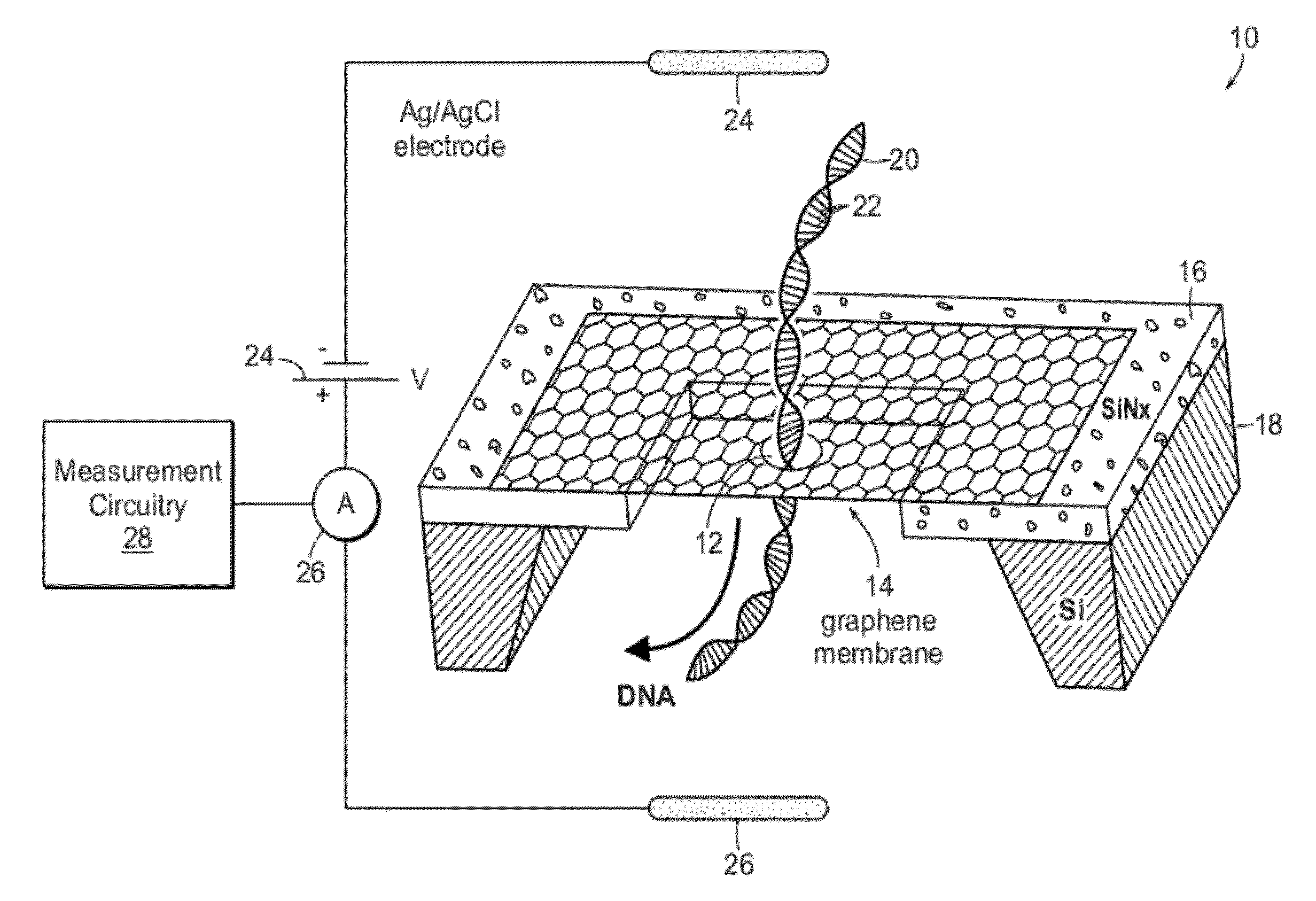

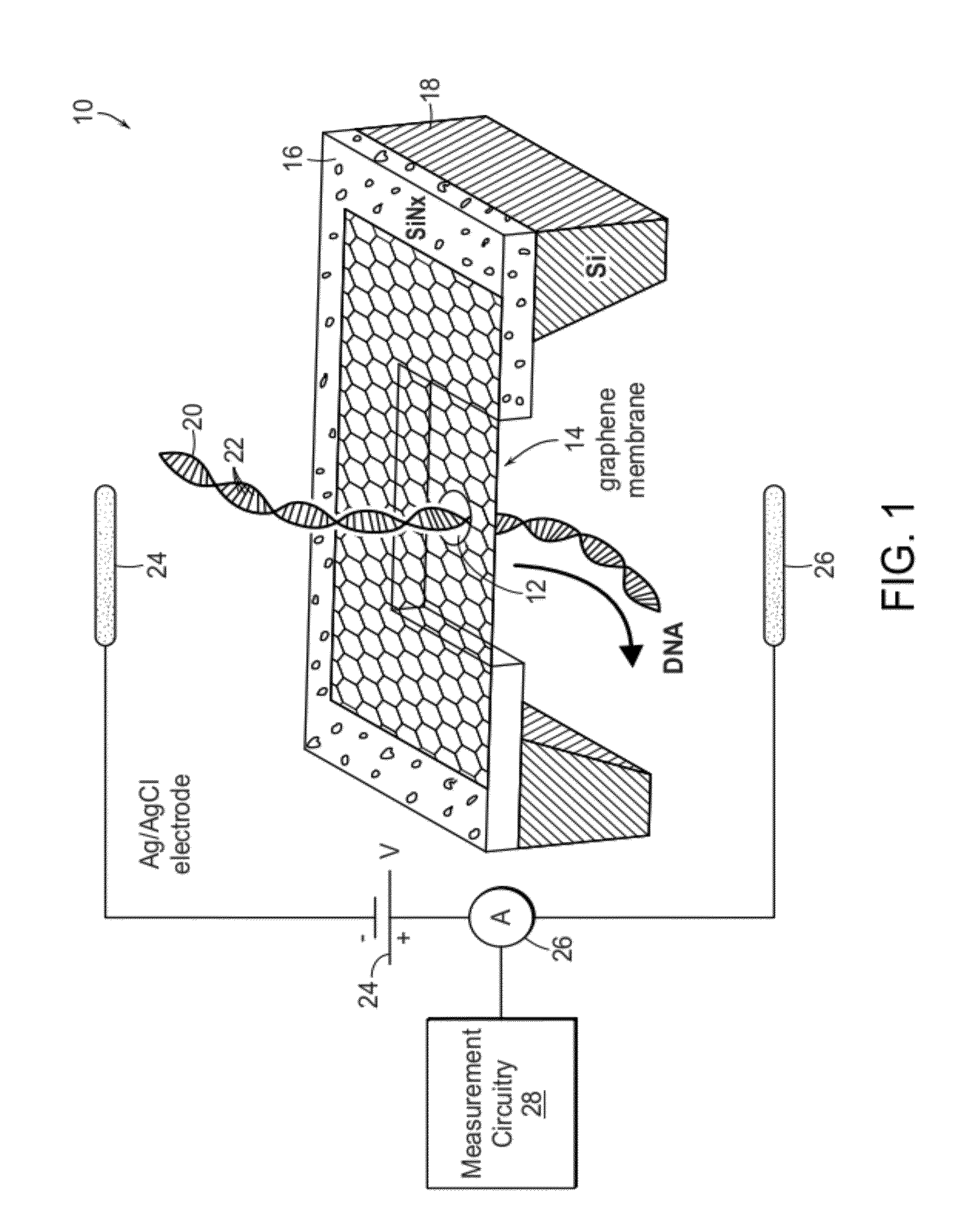

Nanometric Material Having a Nanopore Enabling High-Sensitivity Molecular Detection and Analysis

ActiveUS20120234679A1Sludge treatmentVolume/mass flow measurementSingle layer grapheneProtein translocation

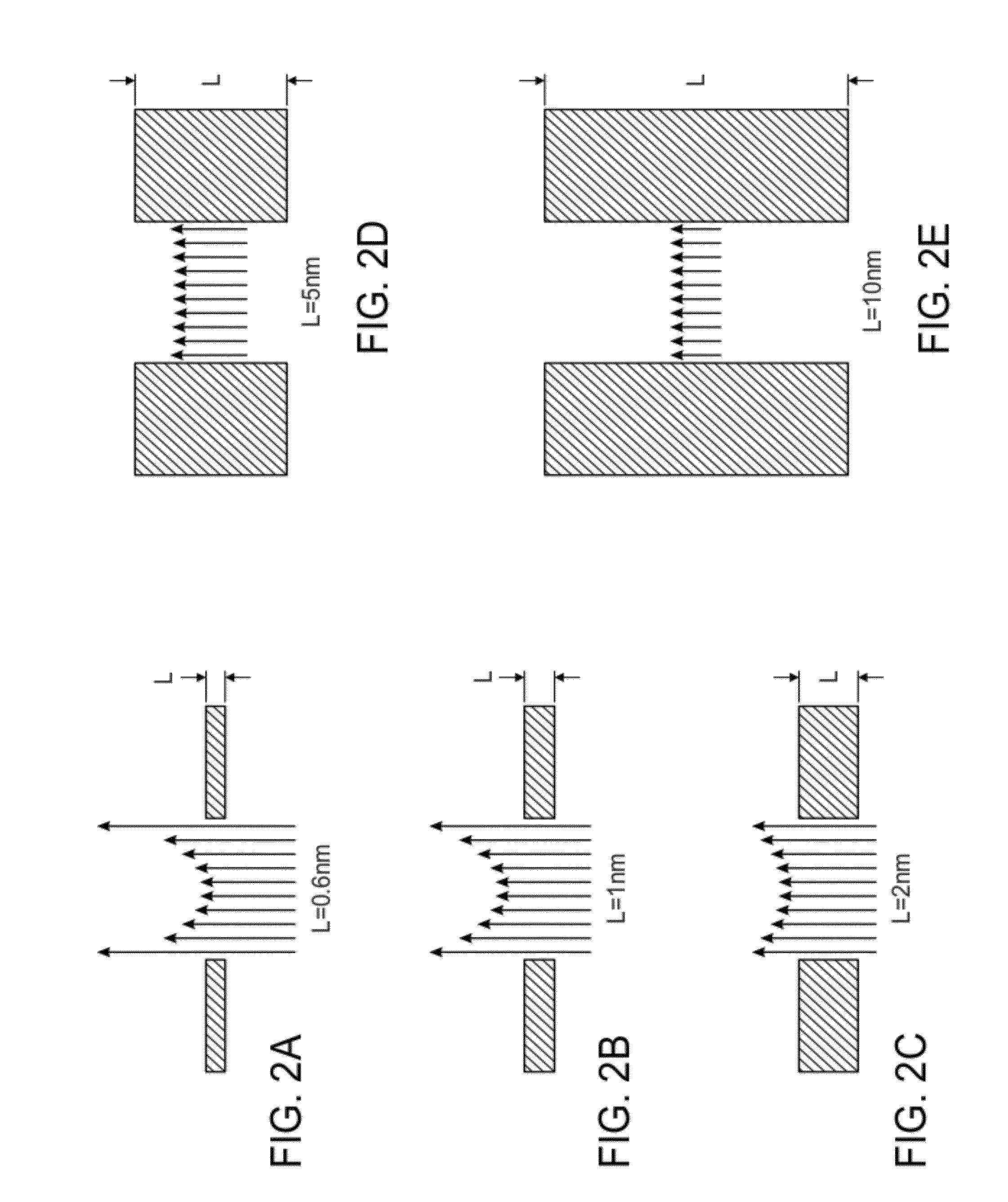

There is provided a substantially bare, self-supported single-layer graphene membrane including a nanopore extending through a thickness of the graphene membrane from a first to a second membrane surface opposite the first graphene membrane surface. A connection from the first graphene membrane surface to a first reservoir provides, at the first graphene membrane surface, a species in an ionic solution to the nanopore, and a connection from the second graphene membrane surface to a second reservoir is provided to collect the species and ionic solution after translocation of the species and ionic solution through the nanopore from the first graphene membrane surface to the second graphene membrane surface. An electrical circuit is connected on opposite sides of the nanopore to measure flow of ionic current through the nanopore in the graphene membrane.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

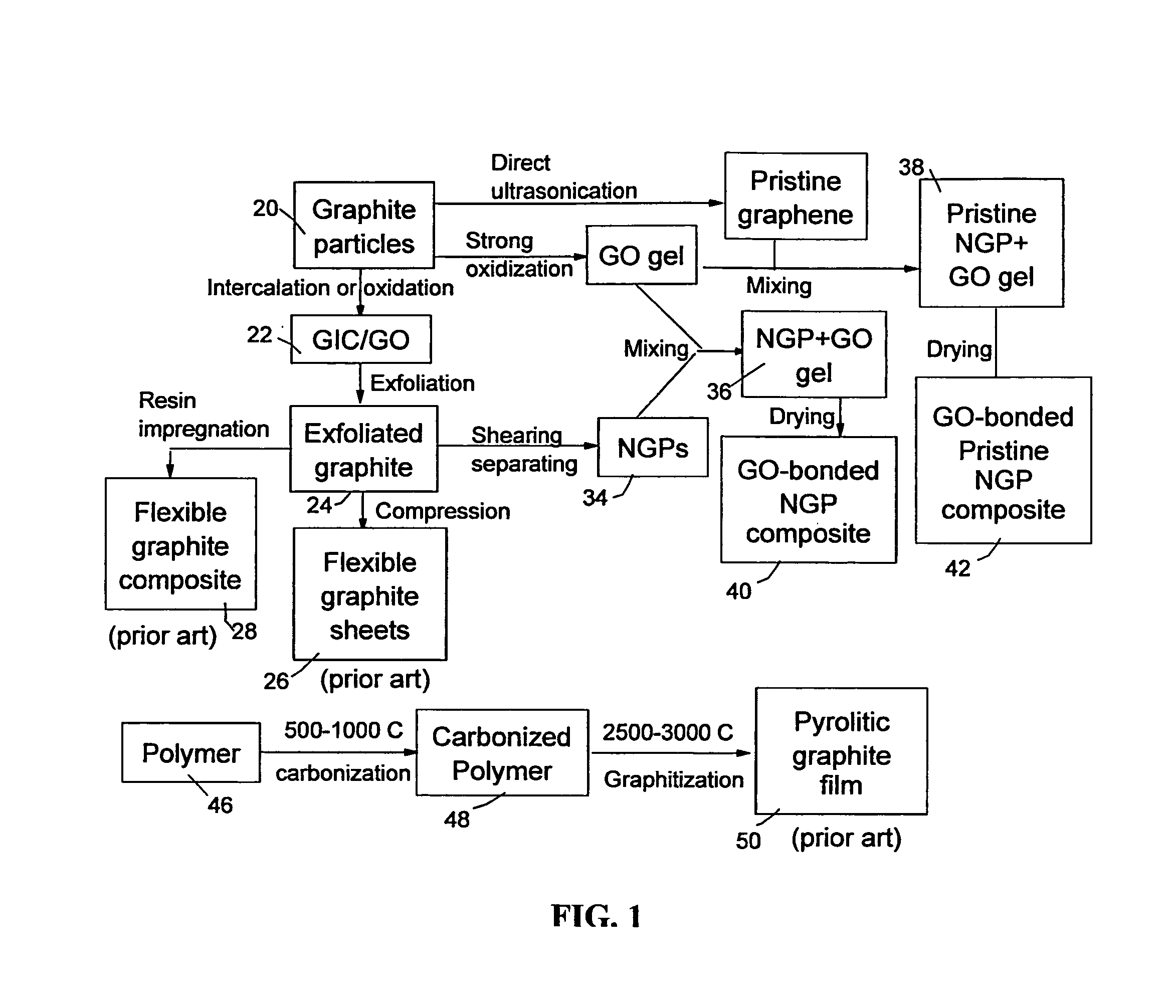

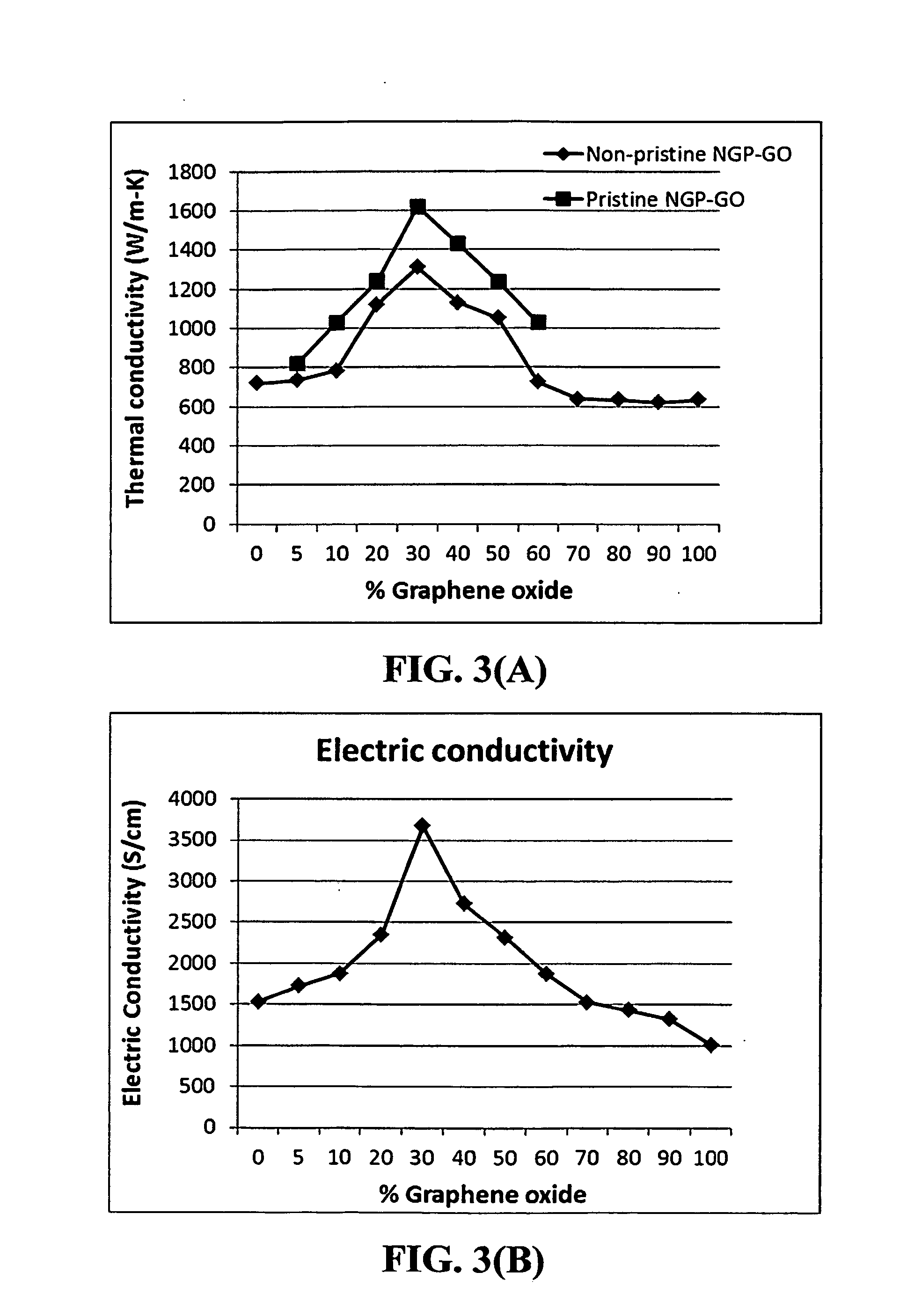

Graphene oxide gel bonded graphene composite films and processes for producing same

ActiveUS20130236715A1Low densityThermal conductivityMaterial nanotechnologyNon-metal conductorsPhysical chemistryThin membrane

Disclosed is a graphene composite thin film composition composed of nano graphene platelets (NGPs) bonded by a graphene oxide binder, wherein the NGPs contain single-layer graphene or multi-layer graphene sheets having a thickness from 0.335 nm to 100 nm. The NGPs occupy a weight fraction of 1% to 99.9% of the total composite weight. The graphene oxide binder, having an oxygen content of 1-40% (preferably <10%) by weight based on the total graphene oxide weight, is obtained from a graphene oxide gel. The composite forms a thin film with a thickness no greater than 1 mm, but preferably no greater than 100 μm and no less than 10 μm. This composition has a combination of exceptional thermal conductivity, electrical conductivity, and mechanical strength unmatched by any thin-film material of comparable thickness range.

Owner:GLOBAL GRAPHENE GRP INC

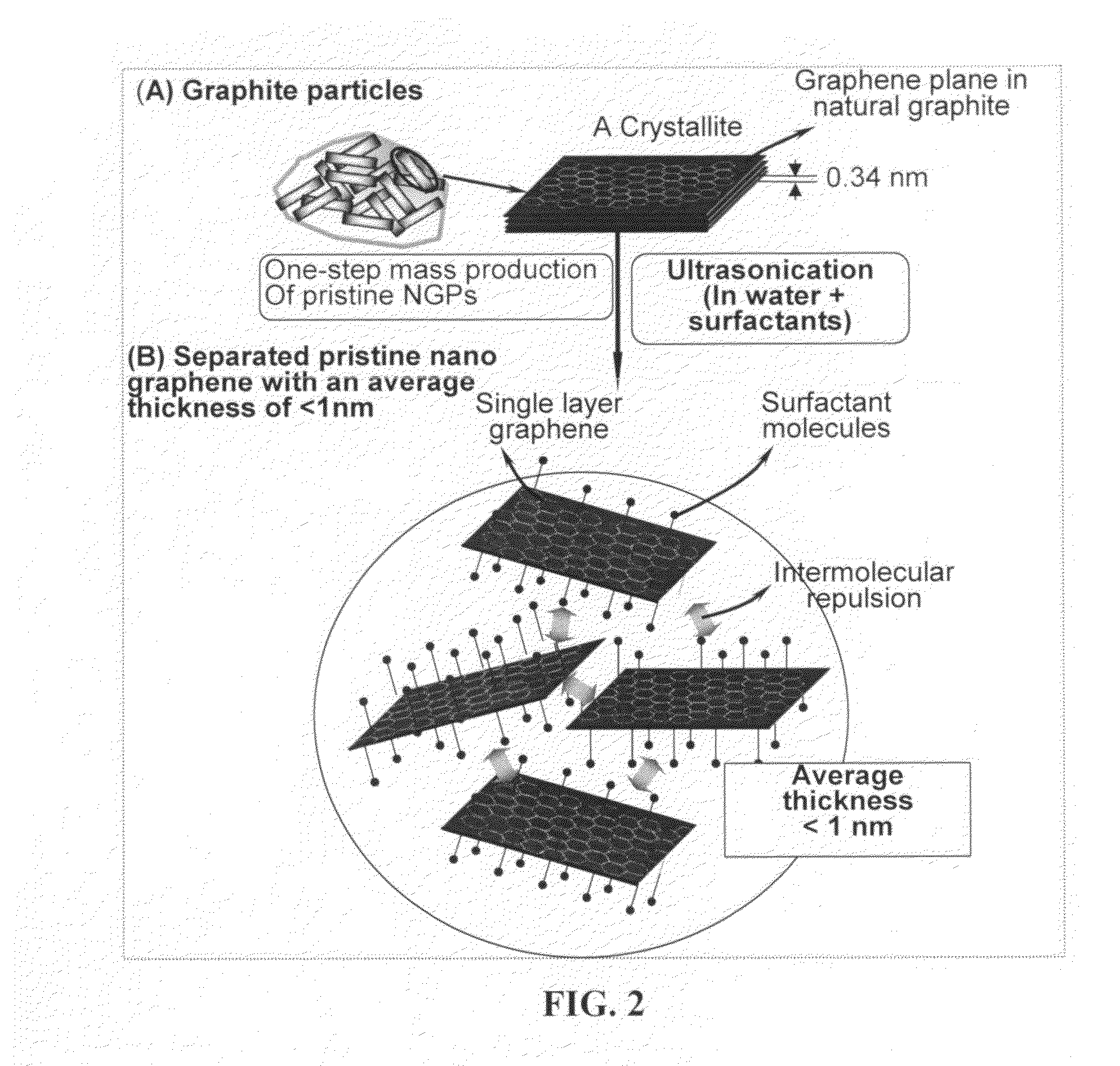

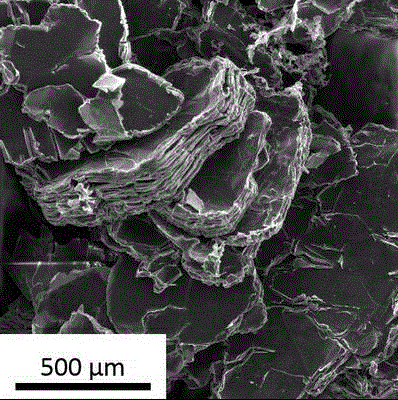

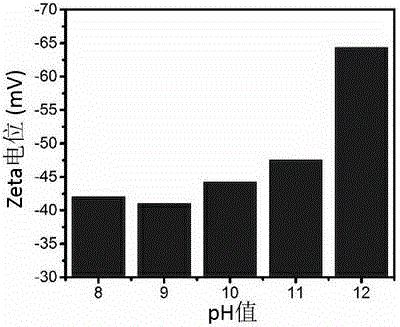

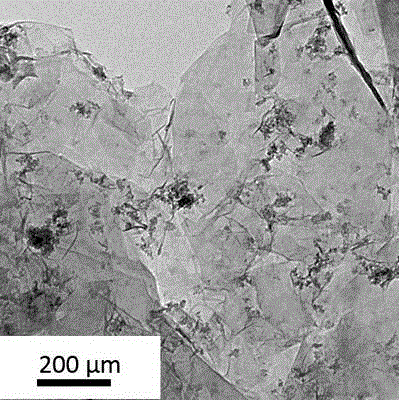

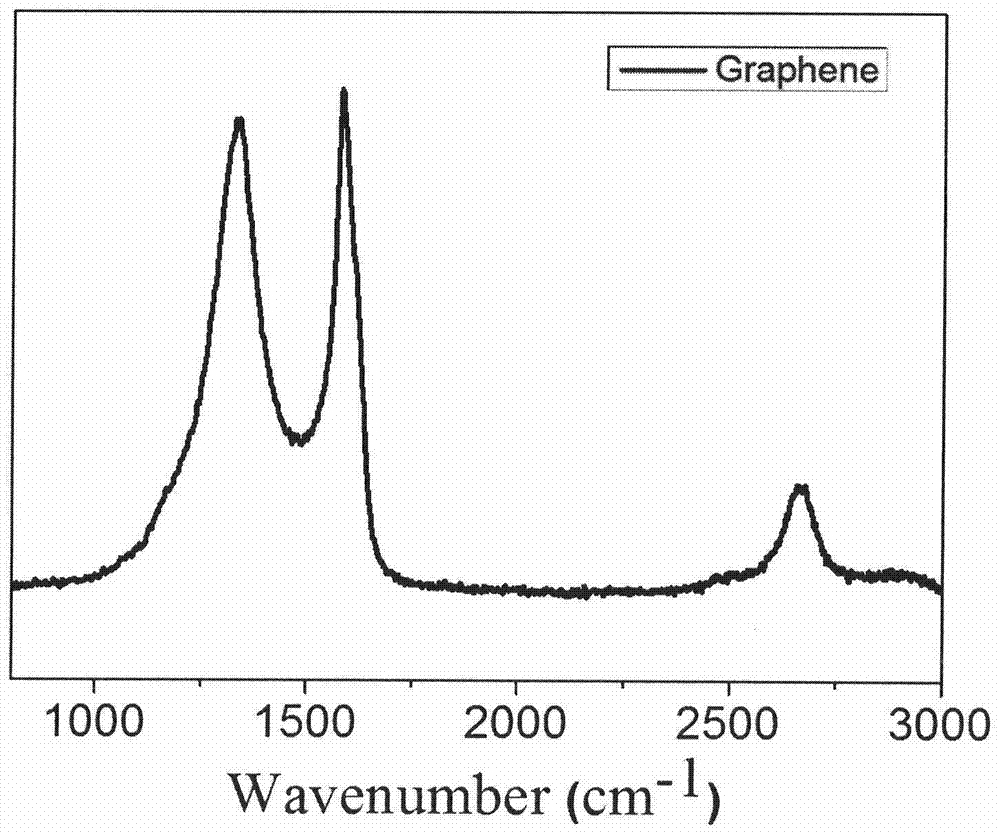

Method for preparing graphene through large-scale aqueous phase

The invention provides a method for preparing graphene through a large-scale aqueous phase. According to the method, graphite serves as a raw material. The method comprises the following steps: intercalating the graphite by adopting an intercalator, so that interlayer spacing between graphene sheet layers is enlarged, and the interaction force between the layers is weakened; and directly treating the intercalated graphite through ultrasonic waves, stripping and uniformly dispersing the graphite in an alkaline aqueous solution with the pH value of 10-14, wherein the content of graphene in the dispersion can be over 100mg / mL (about 10 weight percent of graphene), the content of single-layer graphene in the aqueous phase dispersion is more than 90 percent, the equivalent diameter of the graphene sheet layers can be over 1-10 microns, and a graphene film formed by filtering has a complete lattice structure and high electric conductivity. The prepared high-concentration aqueous phase graphene paste can be stored for a long time and is convenient to transport and use. The method is simple in process flow, high in production efficiency, low in energy consumption and low in cost, a commercially available low-cost reagent is adopted, the reagent is easy to recover, and the production process is environment-friendly and pollution-free.

Owner:安徽百特新材料科技有限公司

Nano graphene-modified lubricant

ActiveUS8222190B2Improve the lubrication effectWider surface areaBase-materialsCarbon nanotubeSingle layer graphene

A lubricant composition having improved lubricant properties, comprising: (a) a lubricating fluid; and (b) nano graphene platelets (NGPs) dispersed in the fluid, wherein nano graphene platelets have a proportion of 0.001% to 60% by weight based on the total weight of the fluid and the graphene platelets combined. Preferably, the composition comprises at least a single-layer graphene sheet. Preferably, the lubricating fluid contains a petroleum oil or synthetic oil and a dispersant or surfactant. With the addition of a thickener or a desired amount of NGPs, the lubricant becomes a grease composition. Compared with graphite nano particle- or carbon nanotube-modified lubricants, NGP-modified lubricants have much better thermal conductivity, friction-reducing capability, anti-wear performance, and viscosity stability.

Owner:GLOBAL GRAPHENE GRP INC

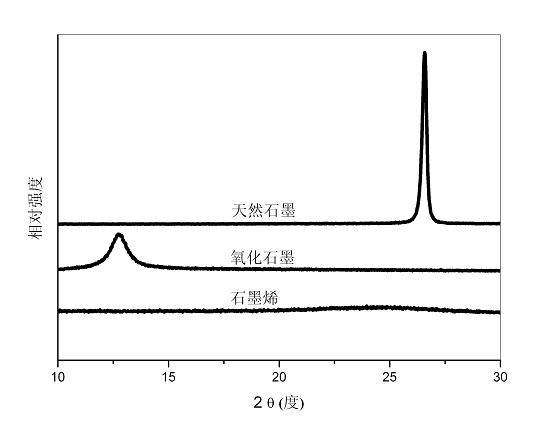

Method for simply and innoxiously preparing single-layer graphene

The invention relates to a method for simply and innoxiously preparing single-layer graphene, belonging to the chemical field of inorganic field. The technical processes of the invention are as follows: adopting a fixed amount of natural graphite powder; oxidizing the natural graphite powder in a strong oxidizing condition to obtain the graphite oxide; dispersing the obtained graphite oxide in the de-ionized water; then ultrasonically processing for a certain period in an ultrasonic machine to peel the graphite oxide off into single-layer graphite oxide sheet; then dispersing the graphite oxide sheet in the dimethylsulfoxide solution; transferring the mixture solution to a reaction kettle and reacting for 10 to 16 hours in 150 to 200 degrees centigrade; after filtered, obtaining the mass colour product, that is, single-layer grapheme. The invention adopts nontoxic reducing agent, dimethylsulfoxide, so it is good for environment protection. The invention has simple technique, operation convenience, and low manufacturing cost.

Owner:SHANGHAI UNIV

High-solubility multi-fold dry-state graphene oxide microsphere and preparation method thereof

The invention discloses a high-solubility multi-fold dry-state graphene oxide microsphere and a preparation method thereof. According to the dry-state graphene oxide microsphere, firstly graphene oxide dispersion liquid is prepared through an organic solvent dilution Hummers method, and then atomized drying is performed so that the dry-state graphene oxide microsphere can be obtained. The dry-state graphene oxide microsphere obtained through the preparation method is good in solubility, the solubility in water and common organic solvents is 20-30 mg / g, and the dry-state graphene oxide microsphere can be stably dispersed for a long time in the mode of a single-layer graphene oxide sheet; good solubility can still be kept after the dry-state graphene oxide microsphere is compressed into high-density blocks; the preparation method is simple, convenient and fast, low in energy consumption and suitable for large-scale industrial production. The problem that the solubility of graphene oxide obtained through an existing drying method is poor is solved, transportation, storage and use of the dry-state graphene oxide microsphere are facilitated because of high density, the dry-state graphene oxide microsphere can be used in the fields of graphene macroscopic assembly materials, functional graphene materials, graphene composite materials and the like.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

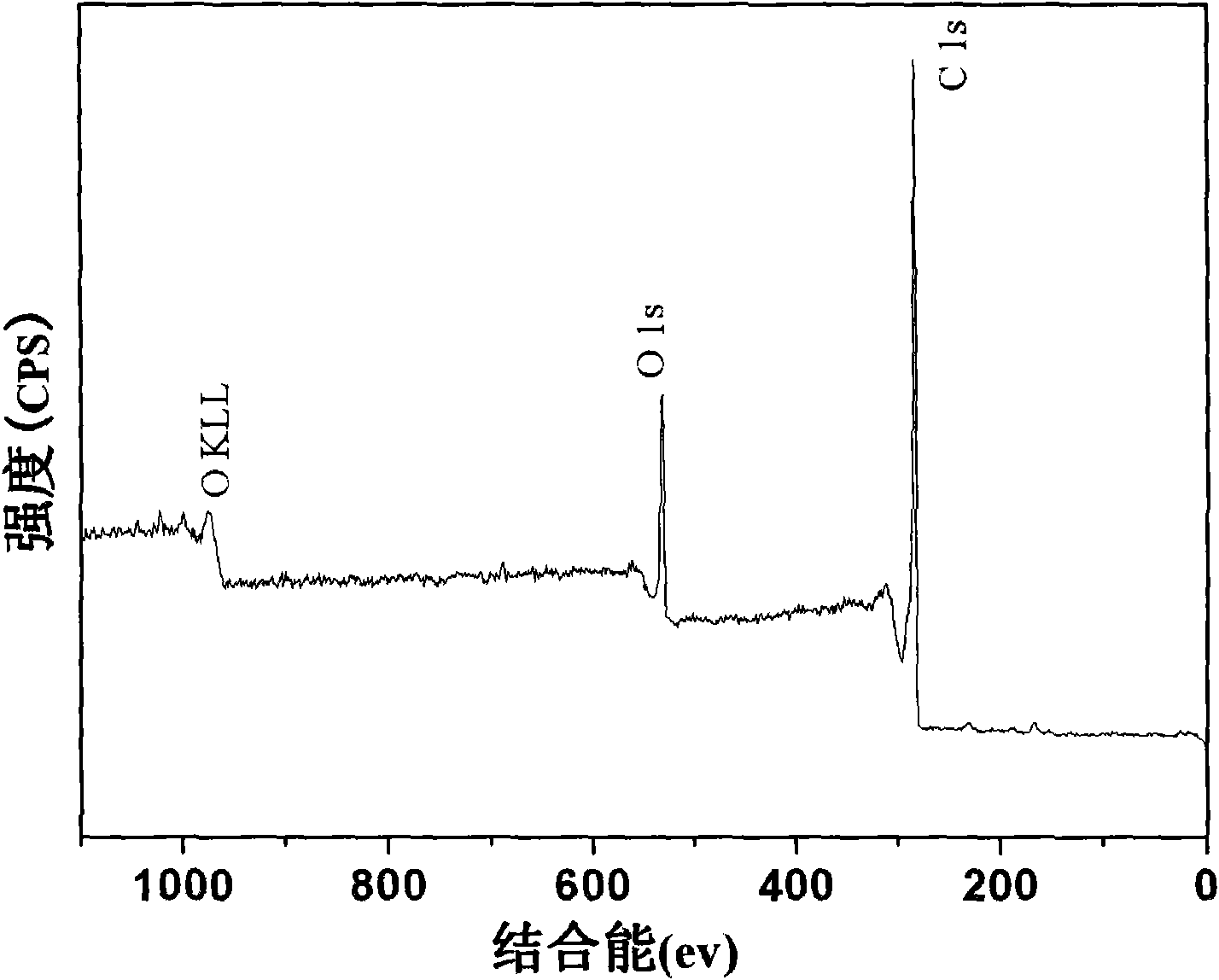

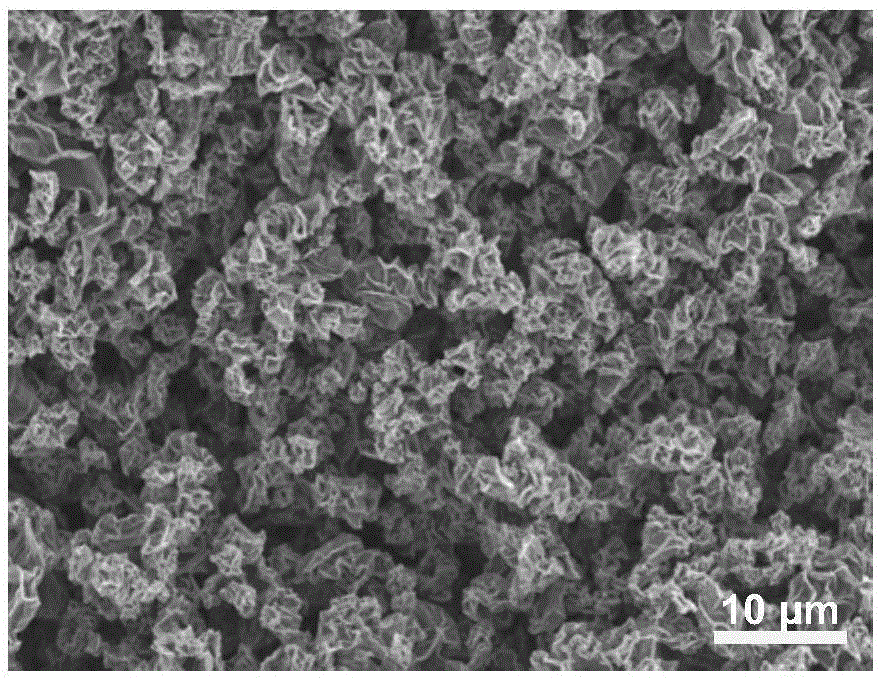

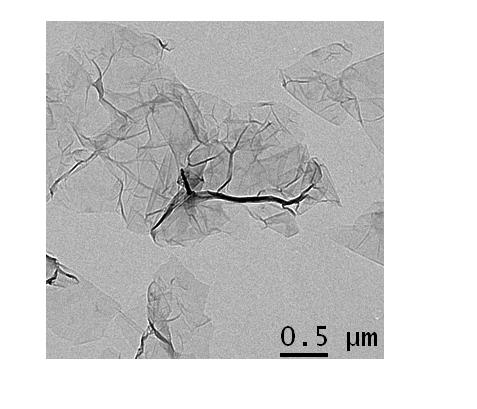

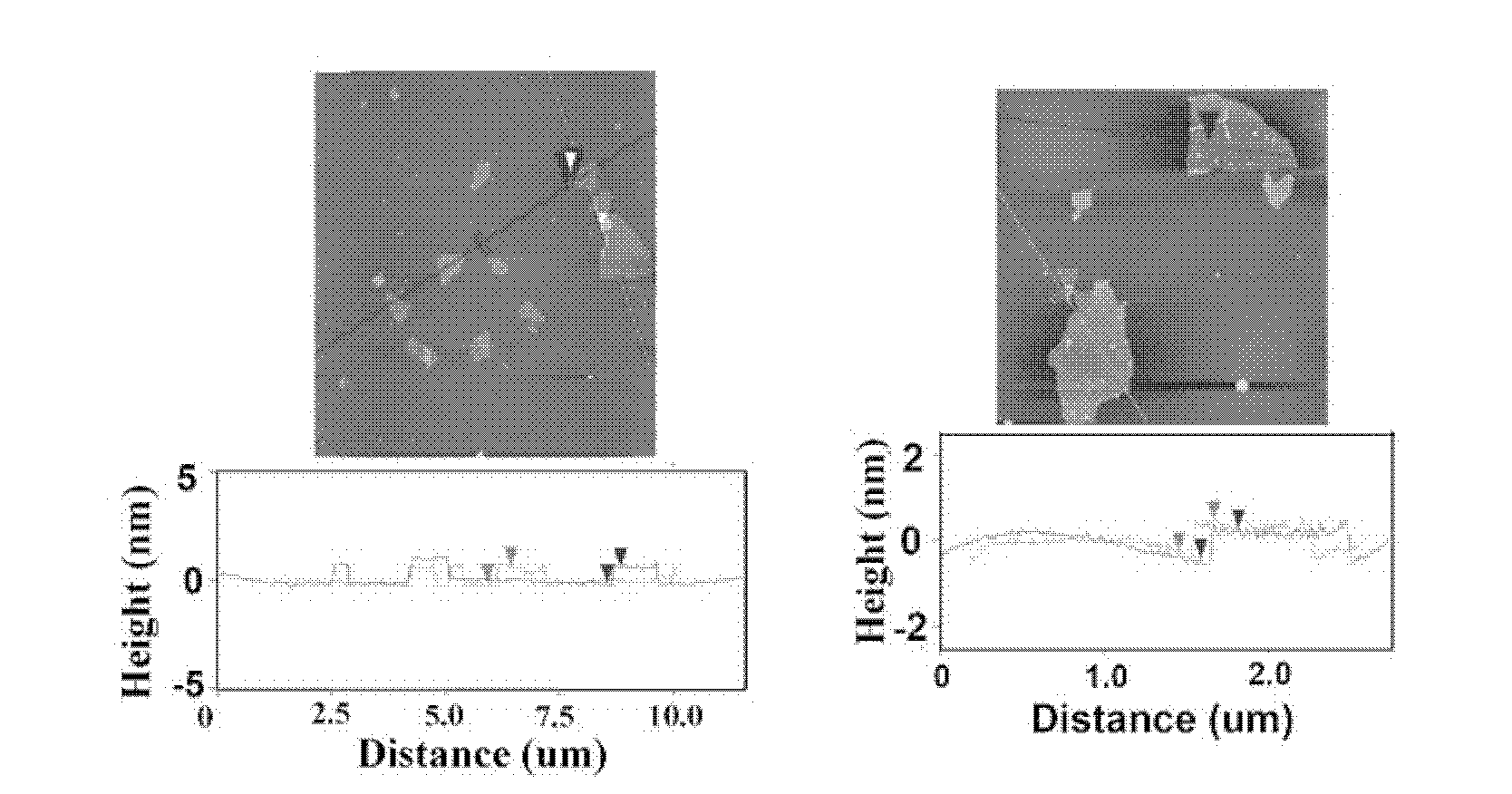

Single-layer graphene capable of dispersing stably and preparation method thereof

ActiveCN102398900AAvoid it happening againMethod environmentally friendlyOrganosolvConductive materials

The invention discloses a single-layer graphene capable of dispersing stably and a preparation method thereof, belonging to the field of nanometer graphite conductive materials. The single-layer graphene capable of dispersing stably in water or in an organic solvent is prepared through reduction of single-layer graphene oxide by phenolic aminated compounds. According to the method, the single-layer grapheme is prepared by employing a phenolic aminated green environment-friendly reducing agent, using graphite as a raw material and carrying out the three steps of oxidation, peeling and reduction. The method enables extreme toxicity of hydrazine reducing agents to be avoided, is green and environment-friendly and is applicable to mass production. The single-layer graphene prepared in the invention has the characteristics of stable dispersion in a water phase and / or an organic phase without addition of any stabilizing agents and good conductivity, and can be used in the fields of battery materials, energy storage materials, electronic devices, current-conducting and heat-conducting polymer composite materials, etc.

Owner:TORAY IND INC

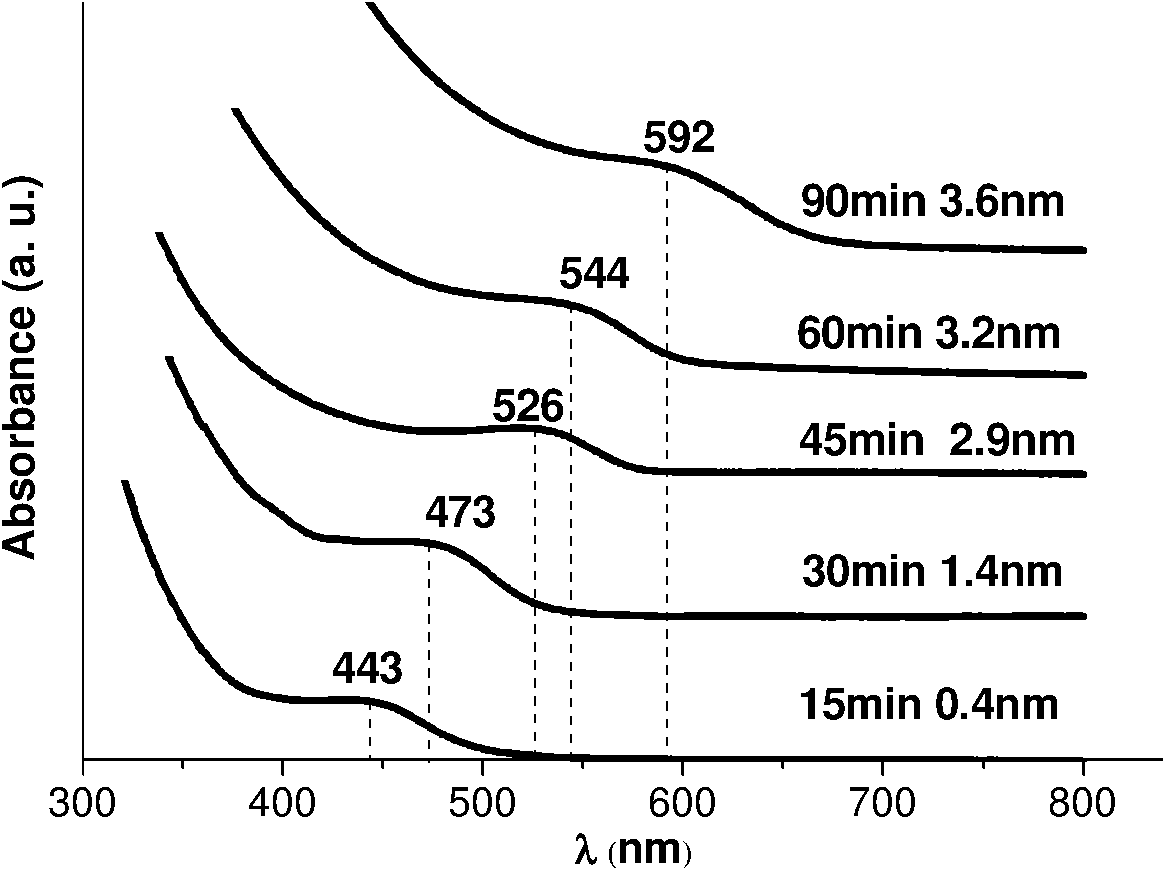

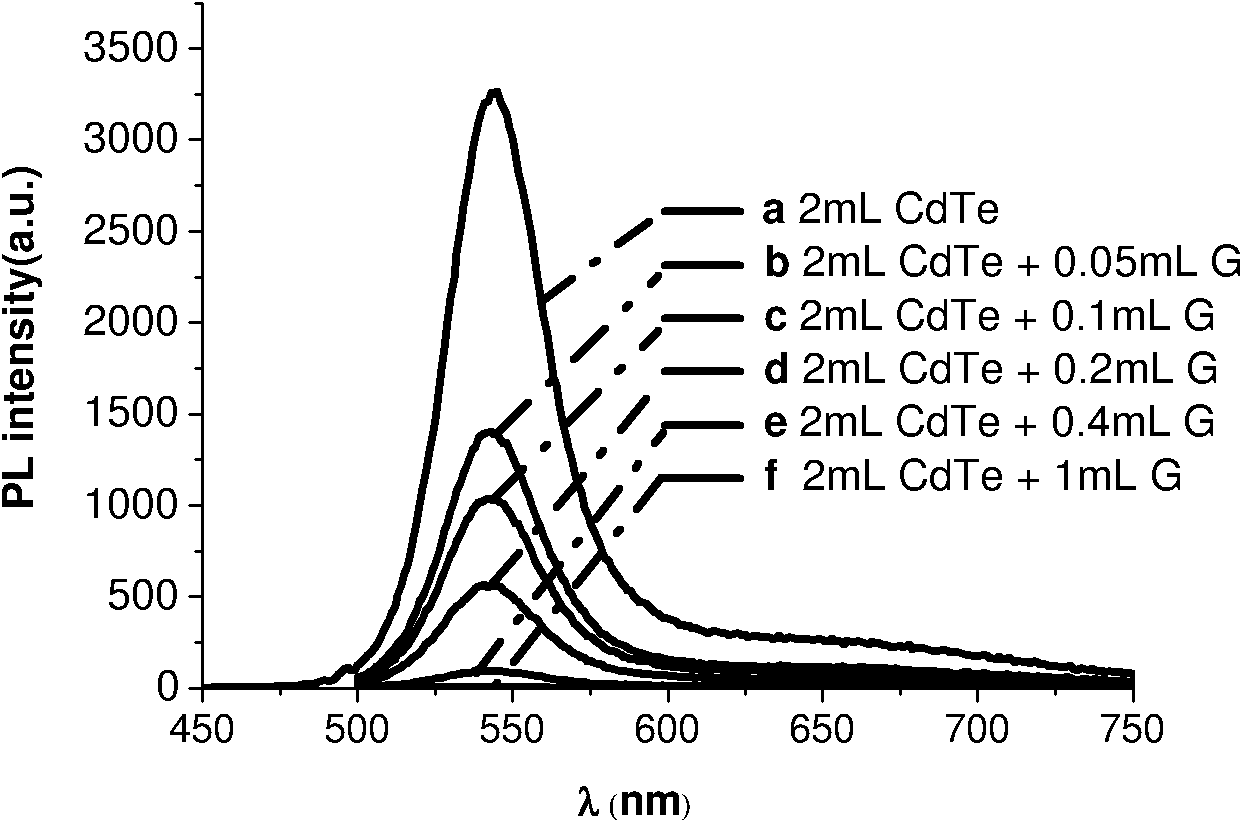

Method for preparing graphene/semiconductor quantum dot composite material

InactiveCN101913600ASimple preparation processSimple manufacturing processBinary selenium/tellurium compoundsWater solubleSingle layer graphene

The invention discloses a method for preparing a graphene / semiconductor quantum dot composite material, which belongs to the technical field of inorganic nano materials and prepares the graphene / semiconductor quantum dot composite material by preparing solution of single-layer graphene and solution of quantum dots and uniformly mixing the solution of graphene and the solution of quantum dots. The surfaces of the quantum dots synthesized by using mercaptan acid as a stabilizer of the invention have carboxyls, while the surfaces of graphene slices prepared by a chemical oxidation reduction process have hydroxys; therefore, the carboxyls can be bonded with the hydroxys by covalent bonds to form the graphene / quantum dot composite material. As the graphene and the quantum dots mutual soluble in water, ligand disreplacement or modification is avoided. Thus, the preparation process is simplified greatly and the cost is lowered.

Owner:SHANGHAI JIAO TONG UNIV

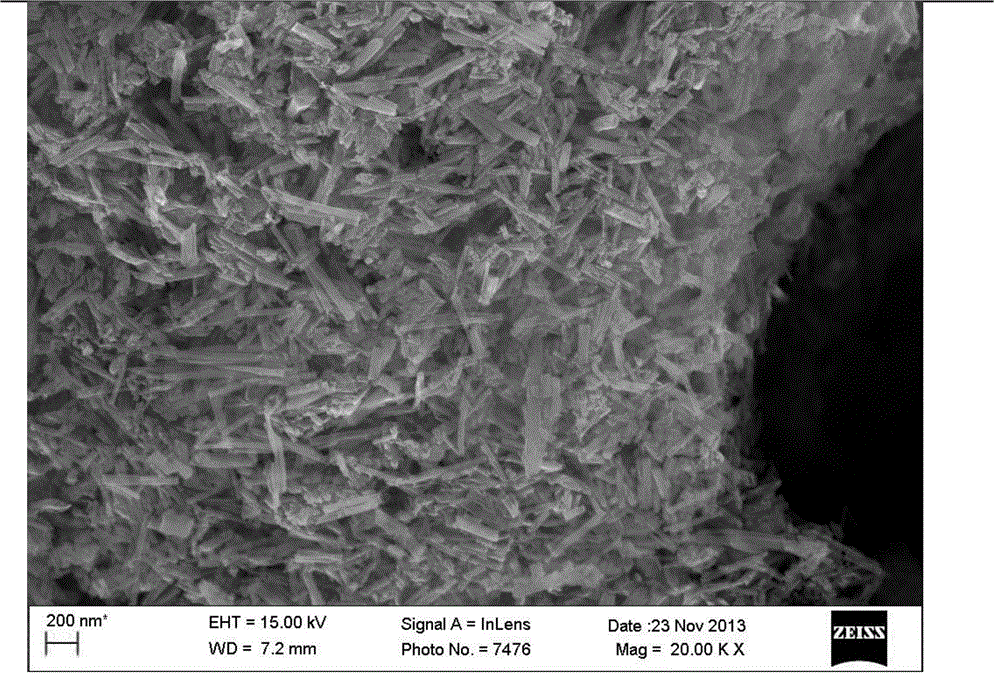

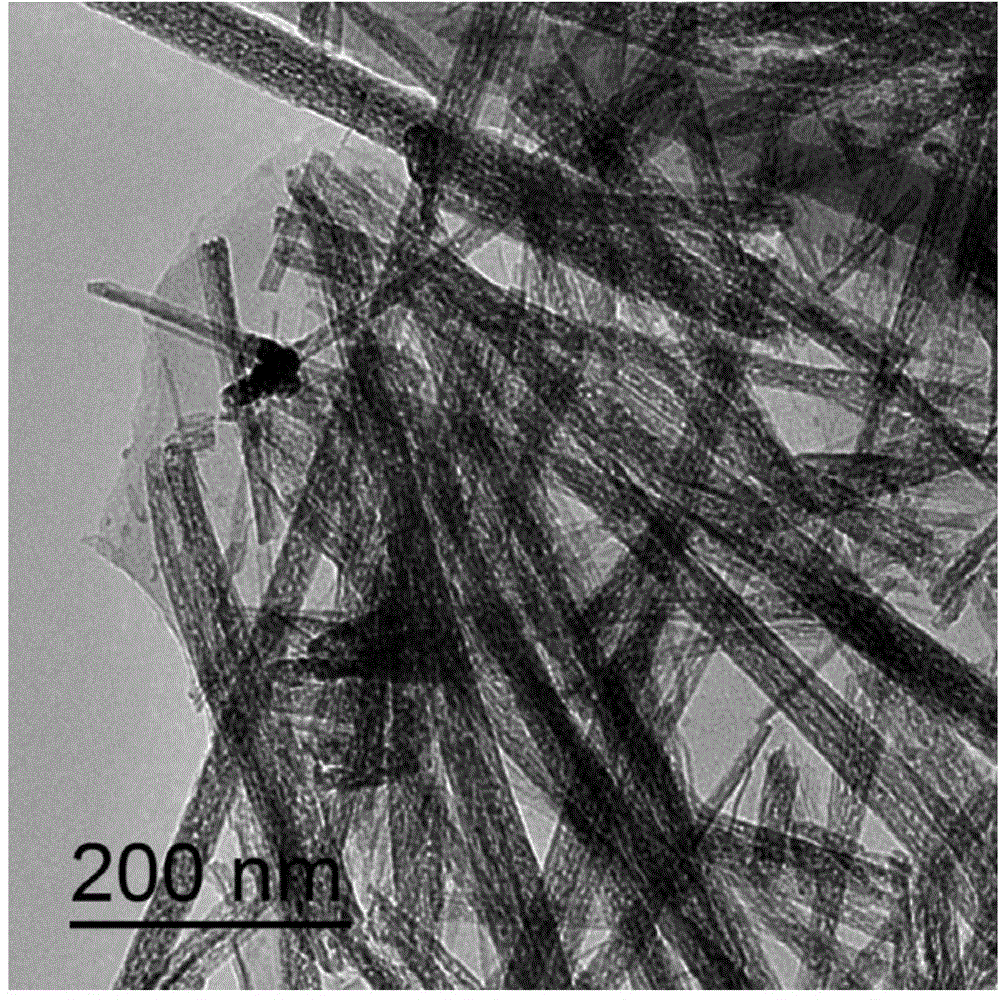

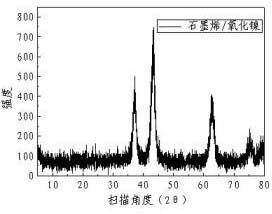

Graphene in-situ load needle-shaped Co3O4 composite electrode material and manufacturing method thereof

InactiveCN103985561AImprove conductivityOptimized areaHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNano structuring

The invention discloses a graphene in-situ load needle-shaped Co3O4 composite electrode material and a manufacturing method of the graphene in-situ load needle-shaped Co3O4 composite electrode material. Single-layer graphene with needle-shaped Co3O4 growing on the edge or two faces is adopted as a load frame of the composite electrode material, the plane size of a nanosheet layer is one micron to 50 microns, and the manufacturing method comprises the steps that graphite oxide is manufactured through a modified Hummers method, then ultrasonic treatment is carried out to obtain graphene oxide, a precursor of the composite electrode material is manufactured through the graphene oxide, and the precursor is annealed in inert atmosphere to obtain the composite electrode material. The manufacturing method of the composite electrode material is simple and environmentally friendly, according to the typical structure of the composite electrode material, the needle-shaped Co3O4 is combined with the surface or the side face of the graphene, a quasi two-dimensional nano structure is formed, the graphene sheet layer can be loaded with the needle-shaped Co3O4 in situ, the cycle life of the Co3O4 is prolonged, and the specific capacitance and other good electrochemical performance are improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

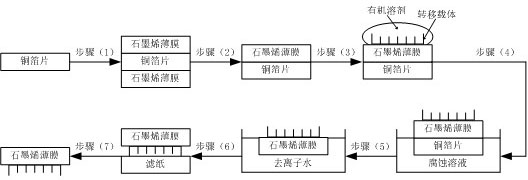

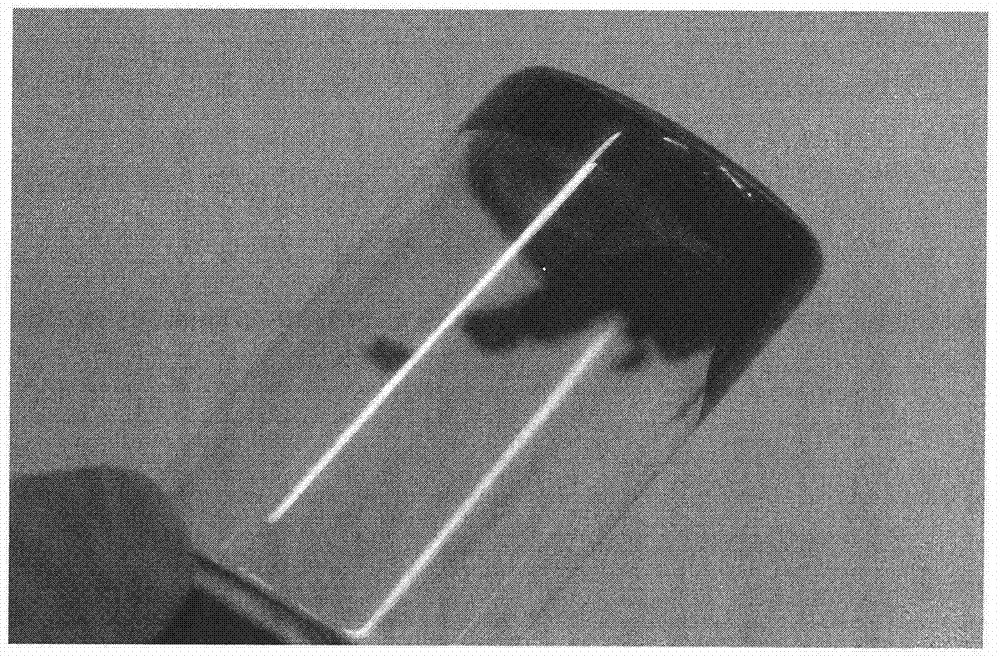

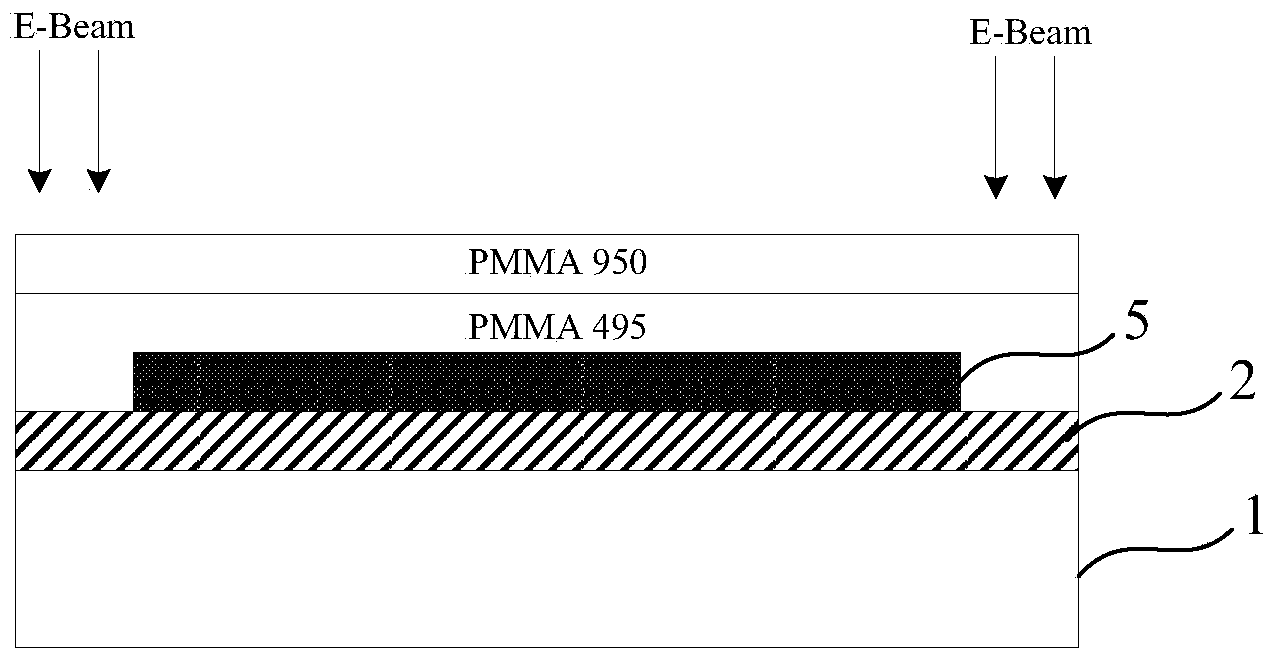

Direct graphene film transfer method

The invention relates to a direct graphene film transfer method. Currently, transferring graphene films from metal surfaces is quite inconvenient. The method includes: using the chemical vapor deposition method to grow a graphene film on a copper foil; using oxygen plasma cleaner to clear graphene on one side of the copper foil to obtain a combination of the single-layer graphene film with the copper foil; flatly attaching a transfer carrier onto the surface of the graphene film and drip adding an organic solvent of a proper quality to increase the interaction between the transfer carrier andthe graphene film; using etchant solution to clear the copper foil to obtain a combination of the single-layer graphene film with the transfer carrier; using deionized water to clean the graphene film for multiple times; and using a filter paper to clear the deionized water on the surface of the graphene film. Using the direct graphene film transfer method avoids the graphene films from being damaged by transfer media such as organic colloid and the like, single-layer graphene films of 100 micrometers or more can be obtained, simple equipment is required, product dimension is controllable, production safety is high, and industrial application is easy to implement.

Owner:ZHEJIANG UNIV

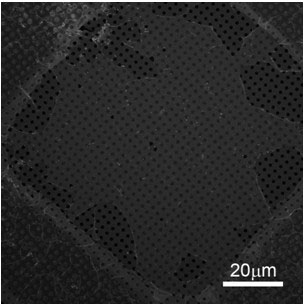

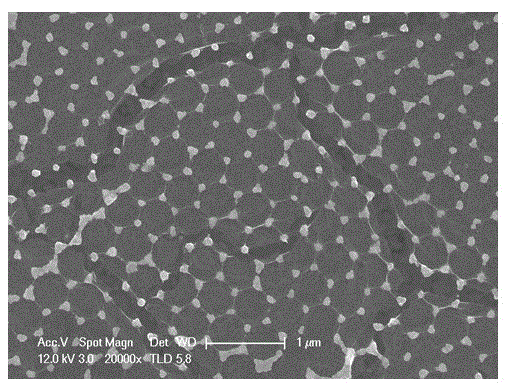

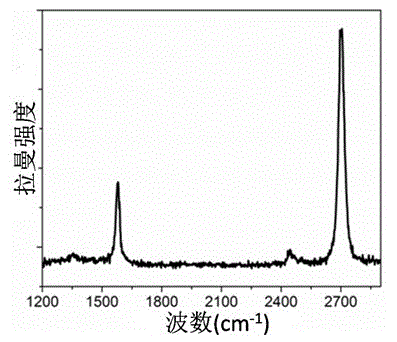

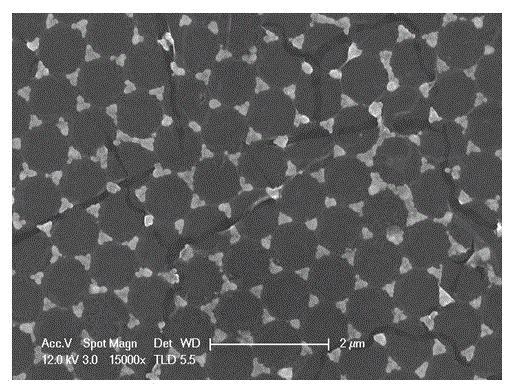

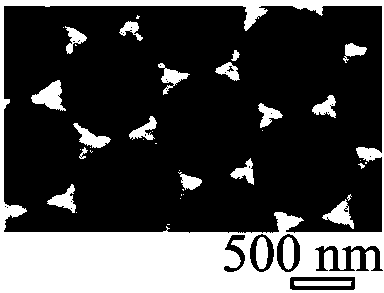

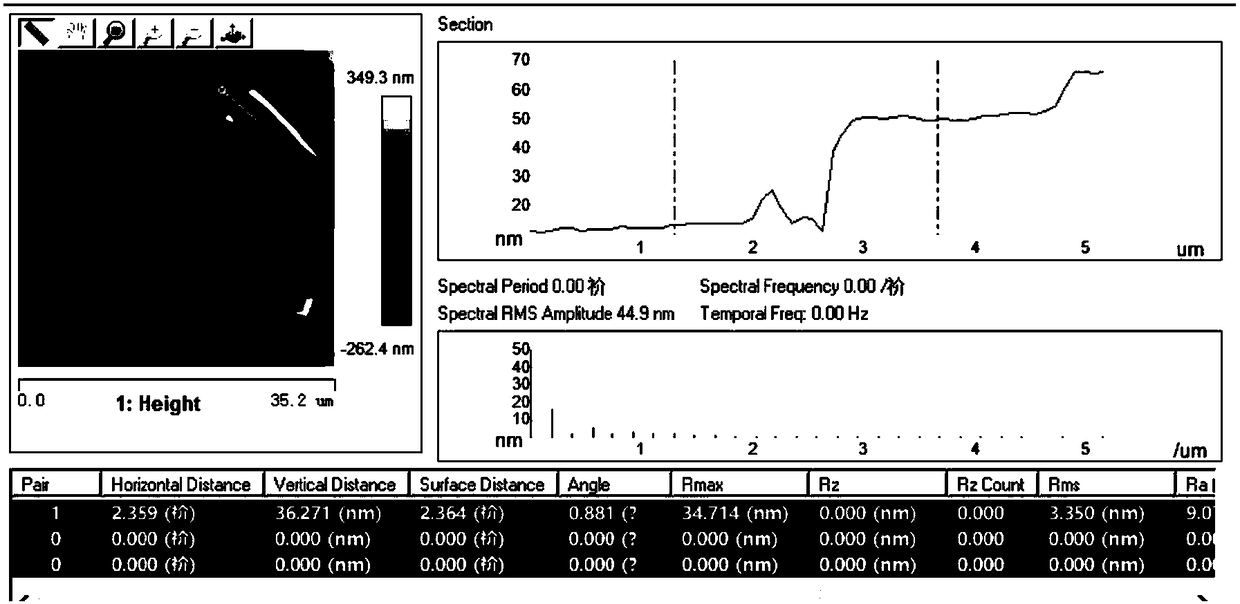

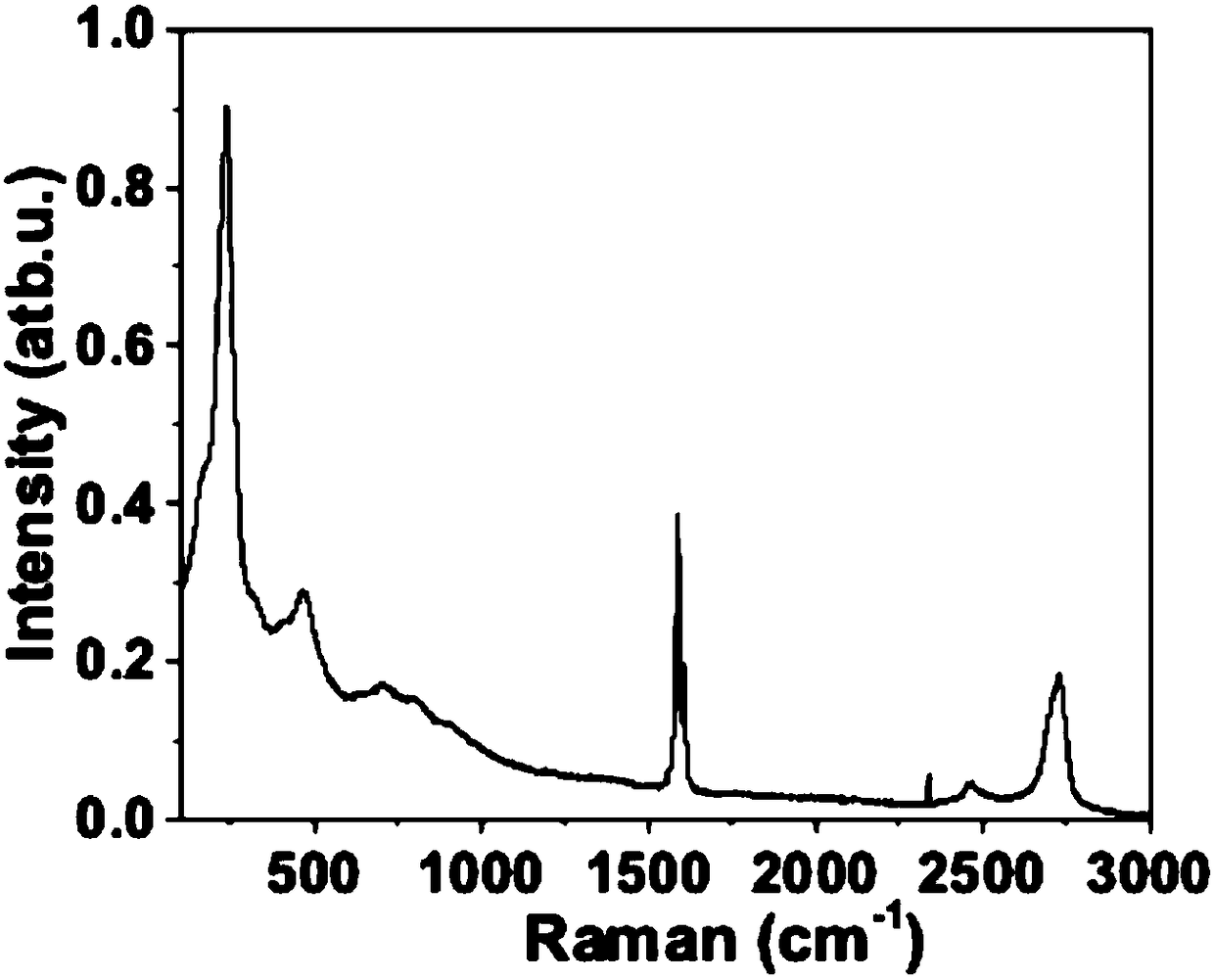

Compound base of precious metal nanometer array and single layer graphene and preparation method thereof

InactiveCN102942178ARaise the enhancement factorImprove uniformityMaterial nanotechnologyCarbon compoundsGraphiteSingle layer graphene

The invention discloses a compound base of a precious metal nanometer array and single layer graphene and a preparation method thereof. The invention includes transferring the single layer graphene prepared by a chemical vapor deposition method to the precious metal nanometer array, keeping warm for 30 minutes under the temperature of 50 DEG C, firmly combining the single layer graphene and the precious metal nanometer array to form the compound base of the precious metal nanometer array and the single layer graphene. The preparation method is simple and easy to operate and low in raw material price. The obtained compound base is order in large area. The compound base can be applied to photoelectron devices and the fields of surface enhanced raman chips, thin film solar batteries and the like.

Owner:WUHAN UNIV

Single-layer graphene dispersion liquid and preparation method thereof

The invention relates to the field of nanomaterial processing, and particularly relates to a single-layer graphene dispersion liquid and a preparation method thereof. The dispersion liquid comprises the following raw materials in percentage by weight: 1wt%-10wt% of graphene and 0.01wt%-5wt% of a dispersing agent, wherein the concentration of the graphene dispersion liquid is 10-60mg mL<-1>; the diameter of graphene is 200nm-10mn; and the preparation method comprises the following steps: preparing secondary expansion graphite from graphite; mixing secondary expansion graphite with the dispersing agent to obtain a mixed dispersing system; and carrying out mechanical shearing and peeling on the mixed dispersing system, so as to obtain the single-layer graphene dispersion liquid. According to the single-layer graphene dispersion liquid, flakes of secondary expansion graphite can be subjected to mechanical separating, so as to obtain single-layer graphene; and by virtue of the dispersion action of the dispersing agent, the obtained graphene dispersion liquid is relatively good in dispersity, and exists in a single layer.

Owner:BEIJING SCITECH GRAPHENE TECH CO LTD

Method for synthesizing graphene

ActiveCN102126720AImprove dispersion stabilityMild reaction conditionsNanotechnologyHydrogenSingle layer graphene

The invention discloses a method for synthesizing graphene, belonging to the technical field of materials and relating to synthesis for the graphene by photochemistry and hot chemistry solution methods based on an organic negative hydrogen donor as a reducing agent. The method comprises the following steps: pre-treating graphite; oxidizing the graphite; stripping the oxidized graphite to form graphene oxide; and reducing the grapheme oxide by the organic negative hydrogen donor under the conditions of heating or illuminating. In the method, the organic reducing agent such as organic negative hydrogen donor is used, and the illuminating or heating method is adopted under the condition of no any stabilizer, thus a large amount of single-layer graphene is obtained in a short reaction time, and simultaneously, the clean graphene can be obtained by using a simple extraction treatment method.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

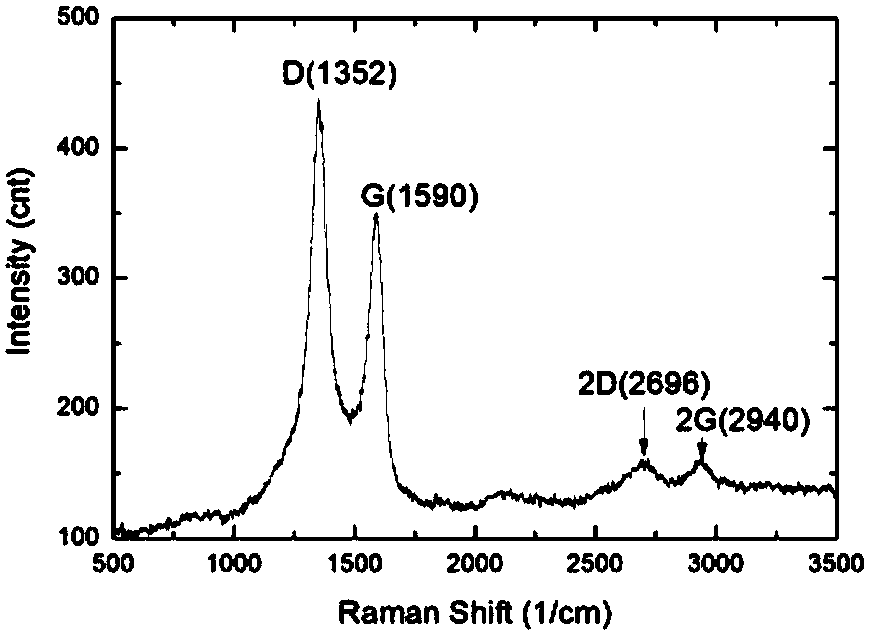

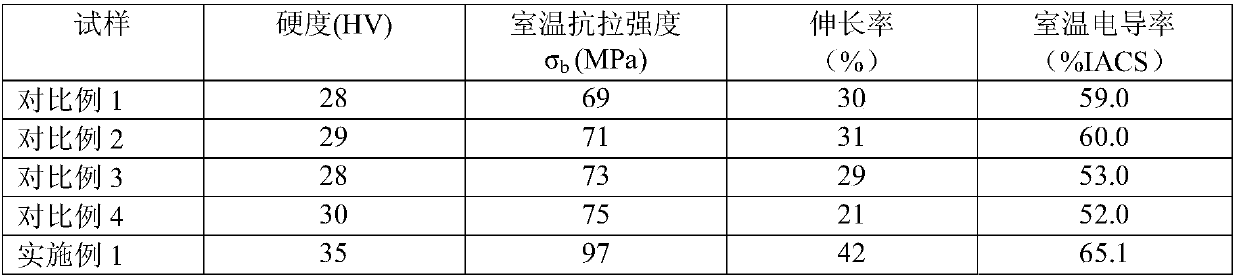

Single-layer graphene/aluminum composite material and preparation method thereof

InactiveCN107675028AHigh strengthImprove conductivityConductive materialMetal/alloy conductorsIngotSingle layer graphene

The invention relates to a single-layer graphene / aluminum composite material and a preparation method thereof. The preparation method comprises the following specific steps: (1) single-layer graphenepowder is added in anhydrous ethanol for ultrasonic dispersion to obtain single-layer graphene dispersion liquid; (2) aluminum powder is added in the single-layer graphene dispersion liquid for mixingball mill under argon protection, and is dried in vacuum to obtain single-layer graphene / aluminum composite powder; (3) the single-layer graphene / aluminum composite powder is prepared through a discharge plasma sintering method to obtain a single-layer graphene / aluminum prefabricated body; and (4) a pure aluminum block body or an aluminum alloy block body is smelted to obtain molten aluminum; then, heating is performed; and under the stirring condition, the single-layer graphene / aluminum prefabricated body is dispersed in the molten aluminum, is cast as a round ingot, and is thermally extruded to mold the single-layer graphene / aluminum composite material. The single-layer graphene / aluminum composite material is uniform in component, high in strength and electric conductivity, simple in production process and capable of realizing industrial production.

Owner:广州埃米石墨烯科技有限公司

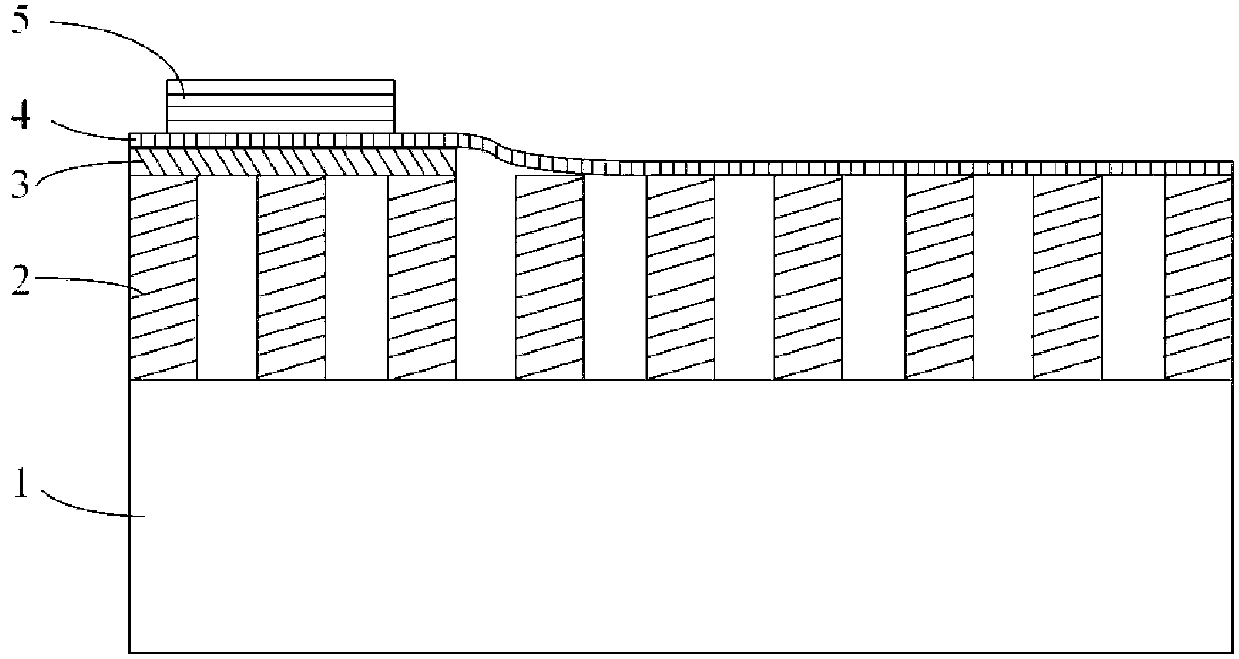

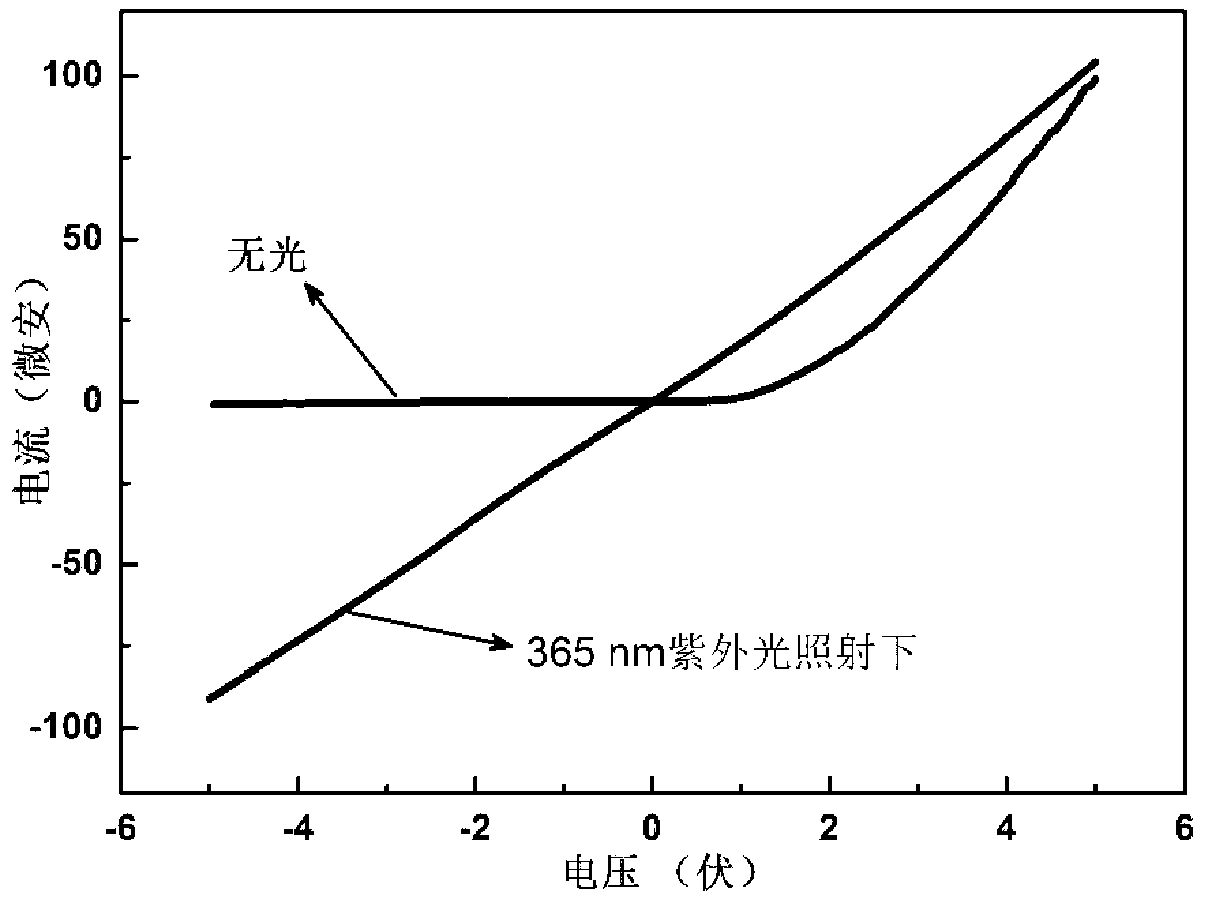

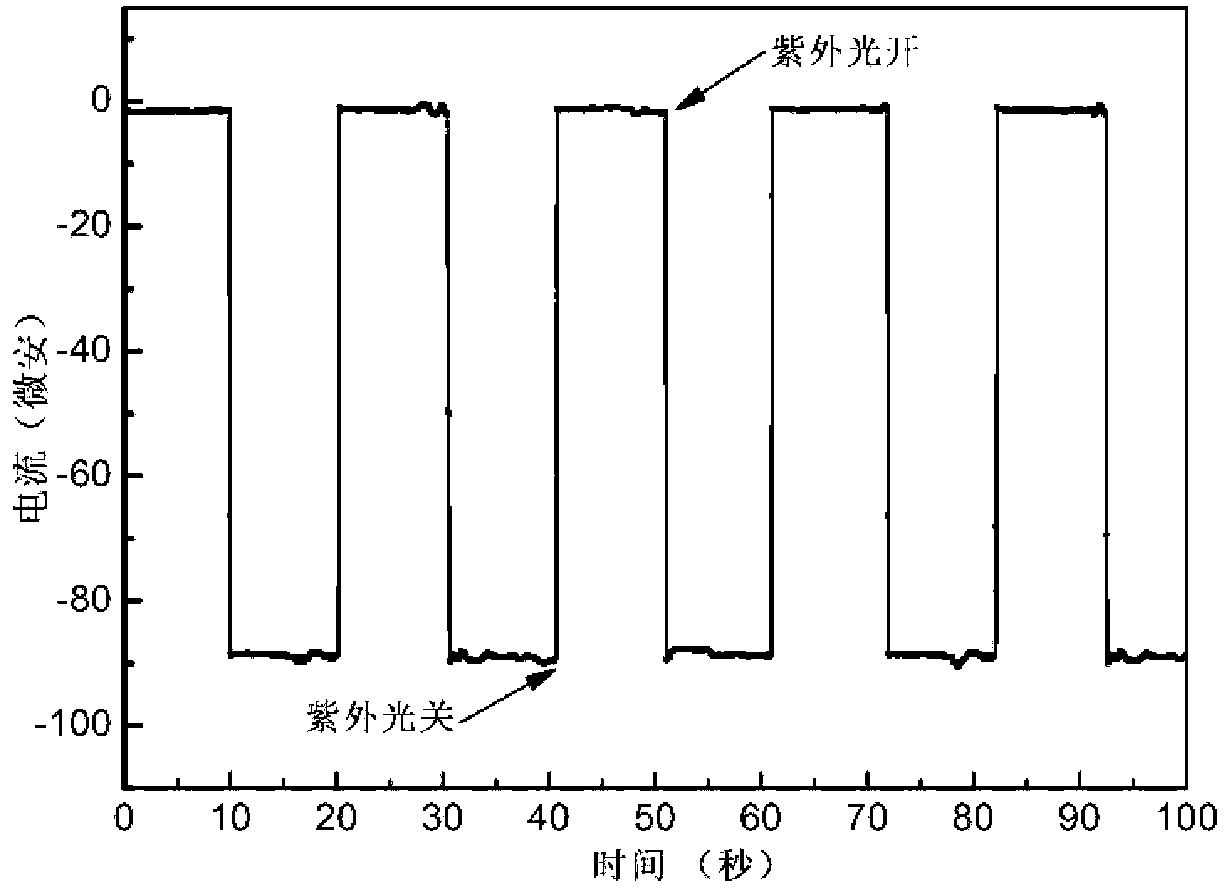

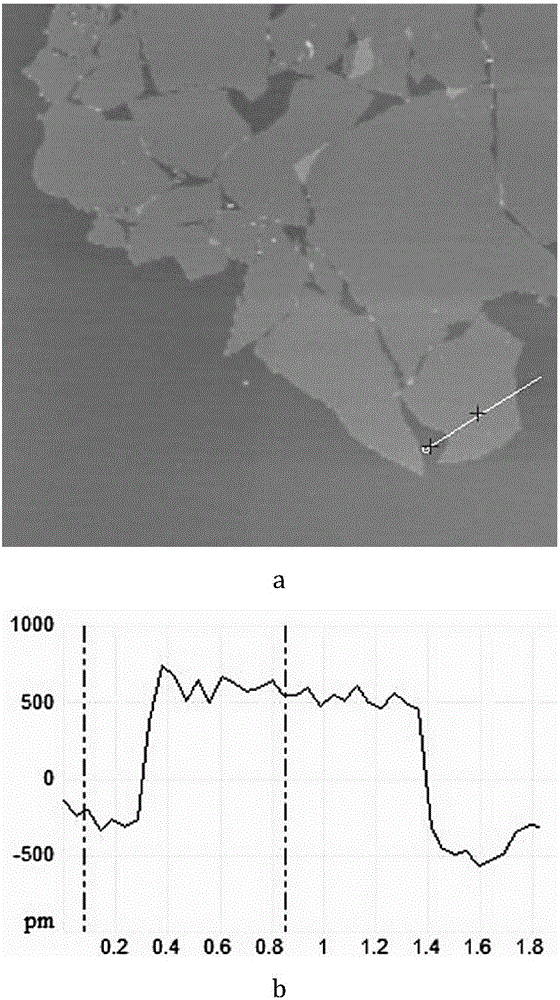

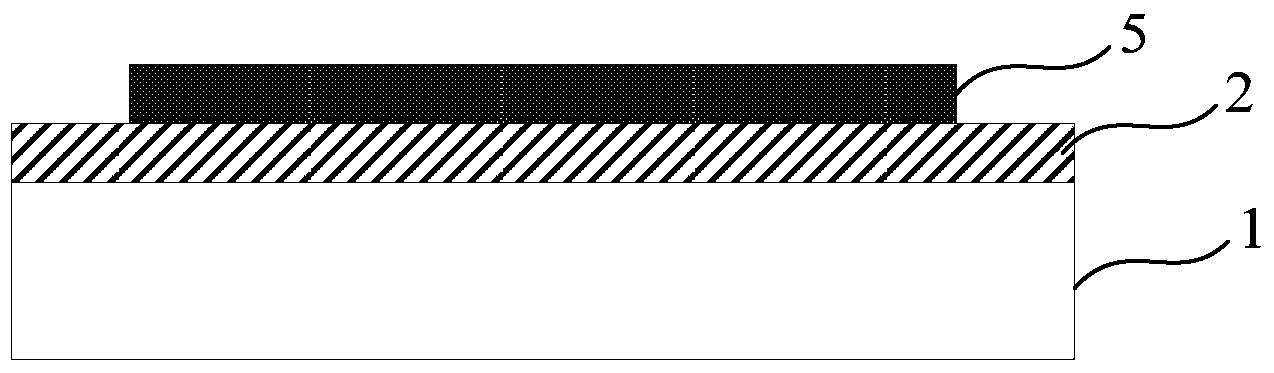

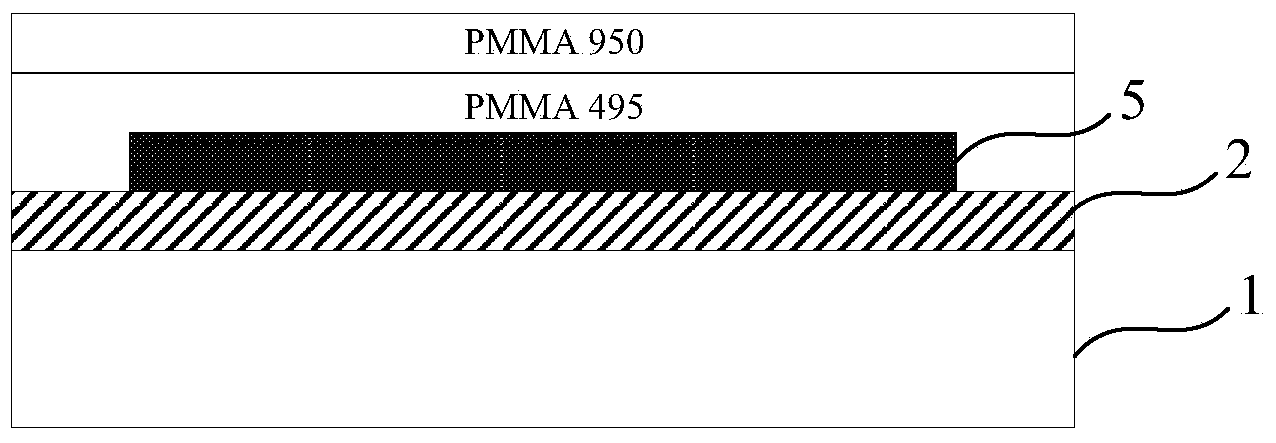

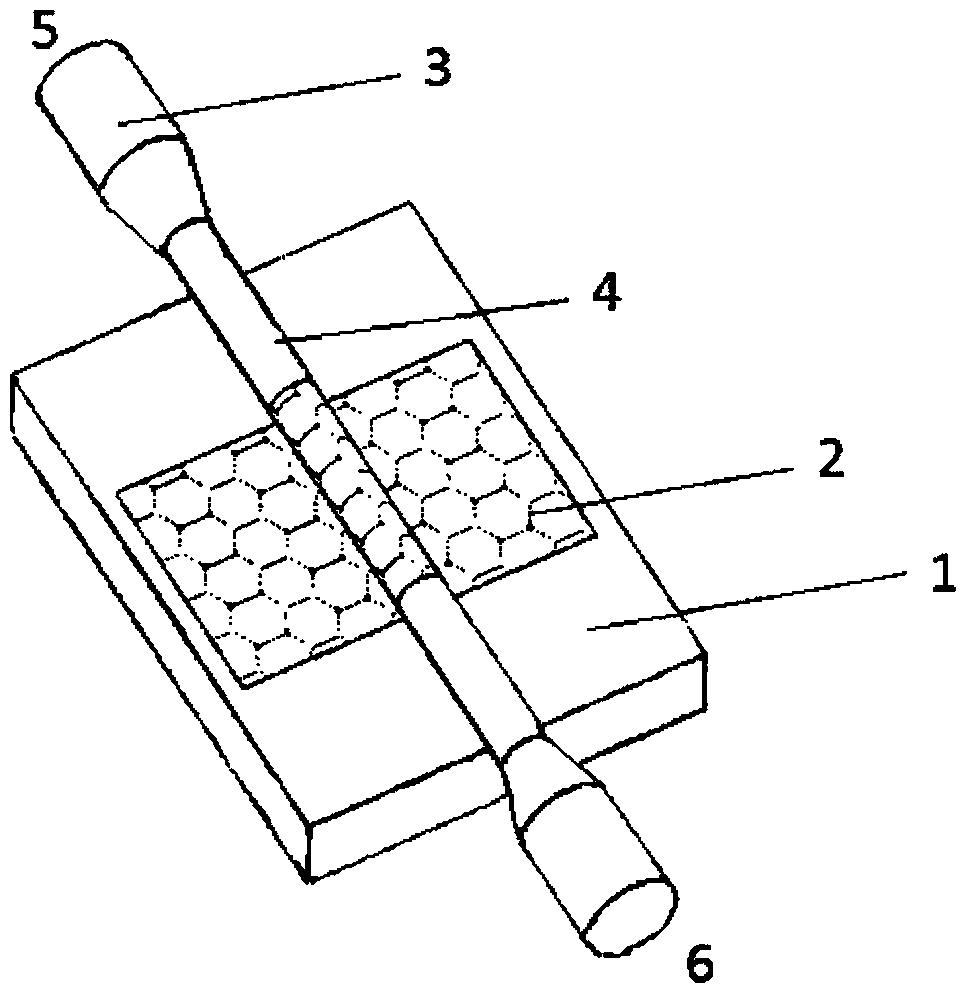

Ultraviolet photoelectric detector and preparation method thereof based on single-layer graphene/zinc oxide nano-rod array schottky junction

InactiveCN103346199ABoundary does not exceedLow costFinal product manufactureSemiconductor devicesInsulation layerUltraviolet

The invention discloses an ultraviolet photoelectric detector and a preparation method of the ultraviolet photoelectric detector based on a single-layer graphene / zinc oxide nano-rod array schottky junction. The ultraviolet photoelectric detector is characterized in that an N-type silicon substrate layer serves as a substrate, a zinc oxide nano-rod array is generated on the upper surface of the substrate in the perpendicular direction, an insulation layer covers the upper surface of the zinc oxide nano-rod array, and the area of the insulation layer is 1 / 4-1 / 3 of that of the zinc oxide nano-rod array; single-layer graphene covers the insulation layer, part of the single-layer graphene is in contact with the insulation layer, and the remaining part covers the zinc oxide nano-rod array; a metal electrode layer is arranged on the single-layer graphene. According to the ultraviolet photoelectric detector and the preparation method of the ultraviolet photoelectric detector based on the single-layer graphene / zinc oxide nano-rod array schottky junction, technology is simple, the ultraviolet photoelectric detector is suitable for large-scale production, and the preparation method of the ultraviolet photoelectric detector is capable of manufacturing the ultraviolet photoelectric detector which is low in manufacturing cost, free in pollution and strong in optical detecting capacity and laying a foundation for the application of a graphene and zinc oxide nanostructure in the ultraviolet photoelectric detector.

Owner:HEFEI UNIV OF TECH

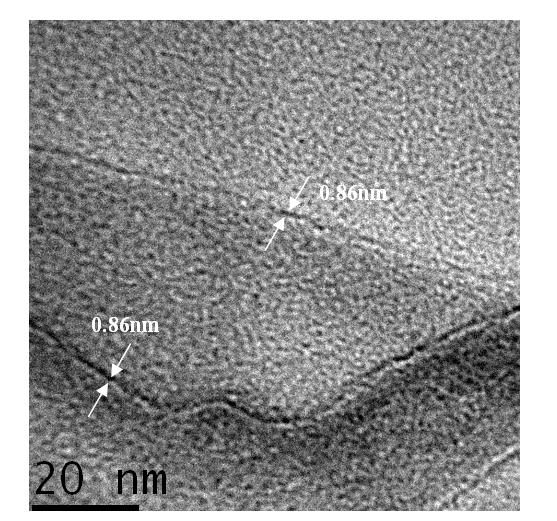

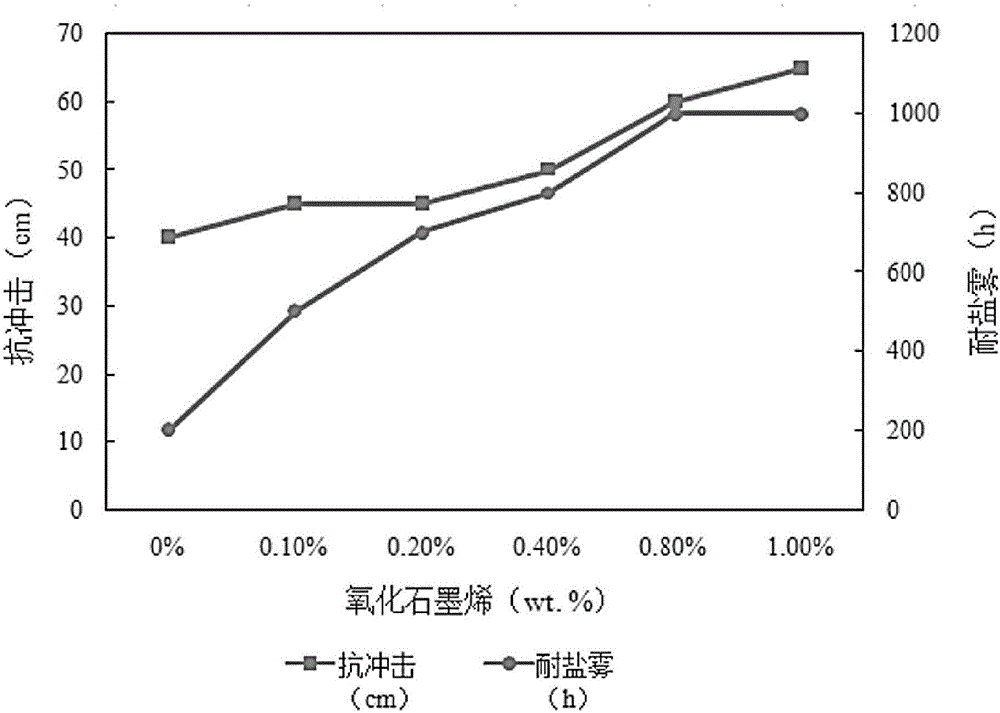

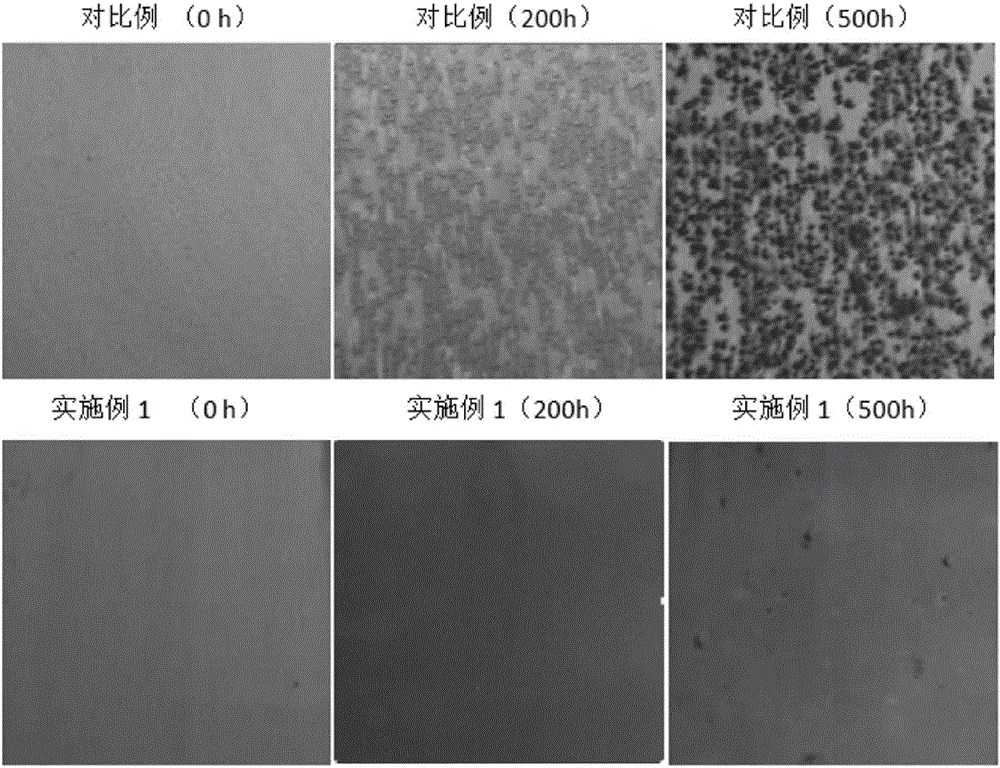

Graphene oxide modified water-based epoxy anticorrosive paint

InactiveCN106497338AAccelerated corrosionImprove impact resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyWater based

Disclosed is a graphene oxide modified water-based epoxy anticorrosive paint. The graphene oxide modified water-based epoxy anticorrosive paint is composed of paint modifying single-layer graphene oxide, water-based epoxy resin, rust-resisting pigment, filling, assistant water-based epoxy resin compound formula and water-based epoxy resin curing agent, wherein the single-layer graphene oxide is of a flake-shaped structure, which is 0.8-1.2 nm thick, and the inside of the layer is a hexagonal structure formed by carbon atom sp2 hybrid orbits. The graphene oxide modified water-based epoxy anticorrosive paint can significantly improve the shock-resisting performance and the anticorrosive performance, maintain optimal coating adhesion and reach up to a hardness level of 4H, thereby meeting the requirements on coating mechanical properties.

Owner:上海碳源汇谷新材料科技有限公司

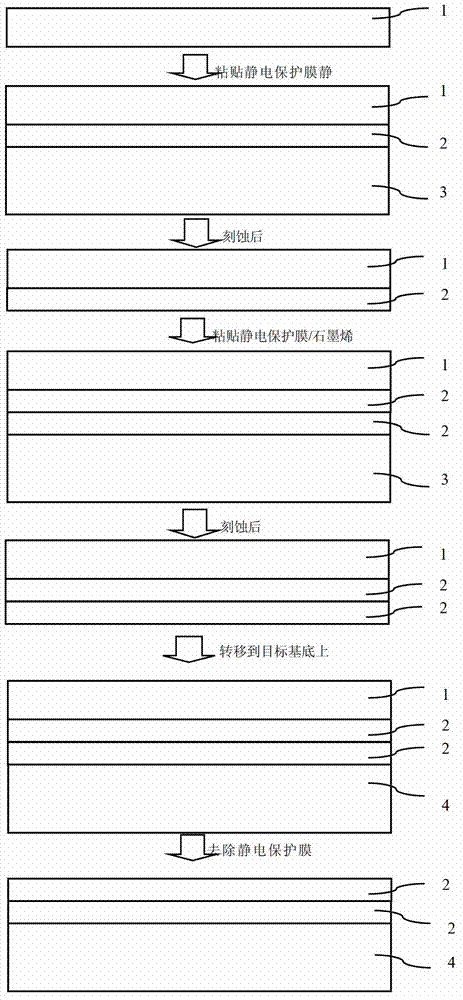

Method for transferring graphene film with static protective film as medium

ActiveCN102774118AEase of mass productionEasy to useLamination ancillary operationsLaminationOrganic solventEngineering

The invention relates to a method for transferring a graphene film with a static protective film as a medium. The method includes that the static protective film is attached to graphene containing a growing lining through an electrostatic adsorption effect, then the growing lining is removed, a graphene / static protective film combination is obtained, finally a single layer of the graphene / static protective film combination is attached to a target substrate, static is released, the static protective film is removed, and the single-layer graphene film is obtained; or after the single layer of the graphene / static protective film combination is obtained, the single-layer of the graphene / static protective film combination replaces the static protective film, attaching of the graphene / static protective film is conducted sequentially on the graphene containing the growing lining repeatedly, the growing lining is removed, and finally a plurality of layers of graphene films are obtained. The method is simple to operate and free of residual glue, and organic solvent for following washing is not required, and therefore process cost for transferring the graphene films is reduced.

Owner:WUXI GRAPHENE FILM +1

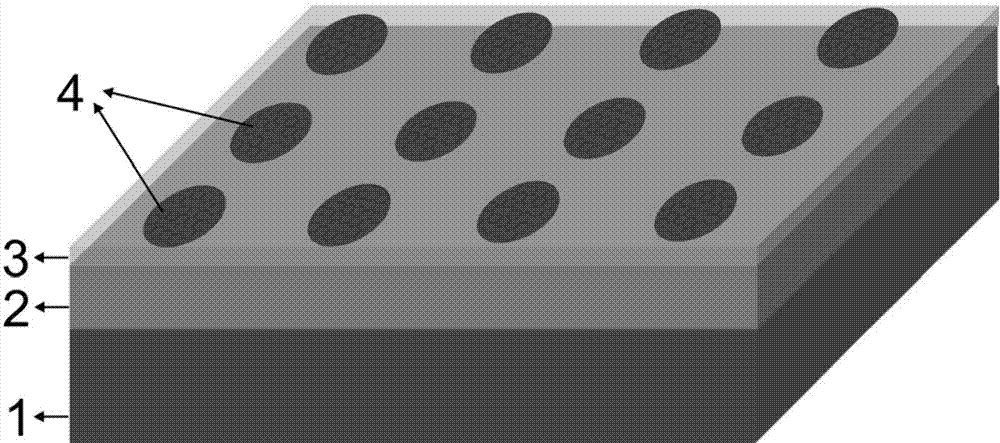

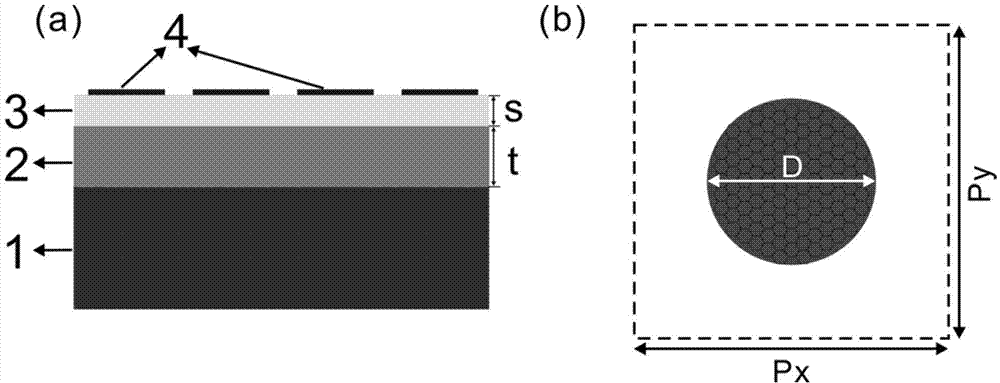

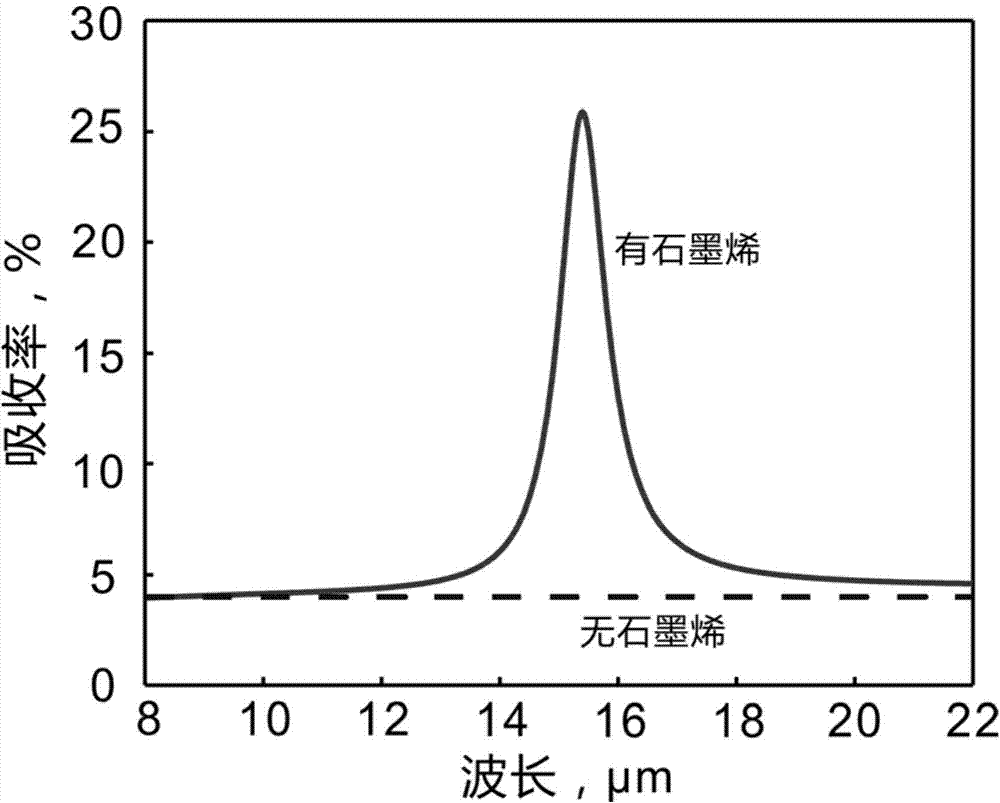

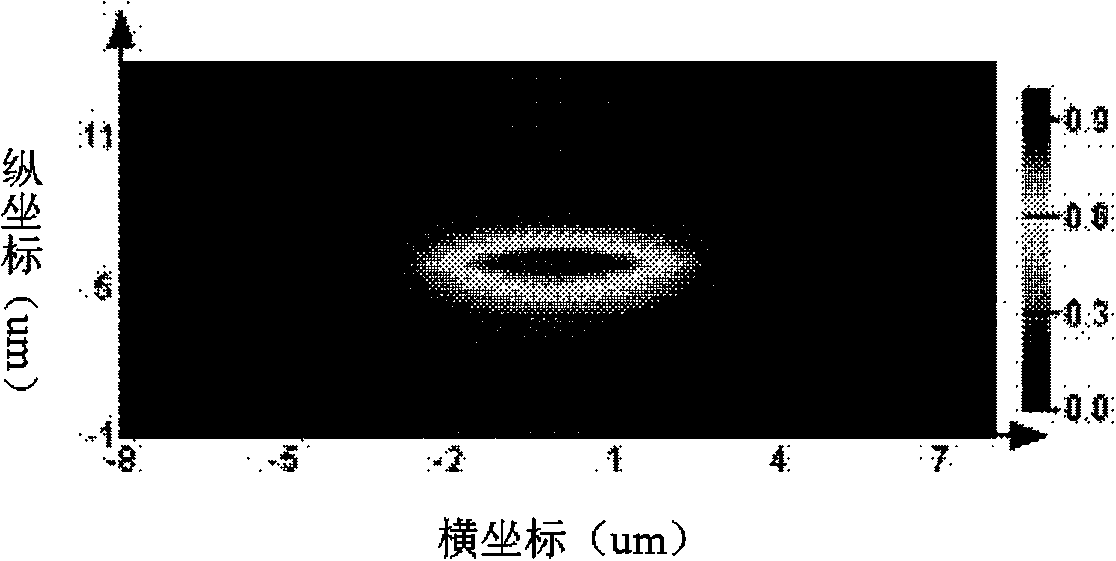

Photoelectric material adjustable absorption enhancing layer based on graphene surface plasmon

InactiveCN104851929ARich sourcesImprove optical absorptionSemiconductor devicesMicro nanoDoped graphene

The invention belongs to the field of photoelectric technology, and specifically relates to a photoelectric material adjustable absorption enhancing layer based on graphene surface plasmon. Graphene forming the enhancing layer is a thin film formed by single-layer graphene and having micro-nano scale structural features, graphene is doped to a certain concentration, and the Fermi level Ef of the graphene is larger than 0.1eV or smaller than -0.1eV, so that the graphene becomes a surface plasmon material; and the micro-nano structure is used for realizing wave-vector matching between incident light and a graphene surface plasmon mode, and under irradiation of the incident light, the doped graphene micro-nano structure generates surface plasmon, thereby realizing a local area of focusing. The absorption enhancing layer is applied to the upper side of photoelectric material used by photoelectric devices such as a solar cell and a photoelectric detector, can improve the absorption efficiency of the photoelectric material, and can realize active regulation and control of absorption characteristics of the photoelectric material, thereby expanding application of the photoelectric material in fields of spectrum-adjustable selective detection and the like.

Owner:NAT UNIV OF DEFENSE TECH

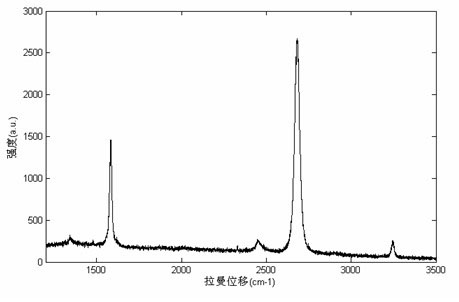

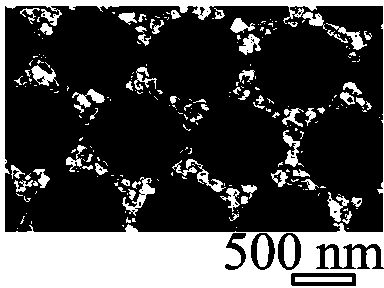

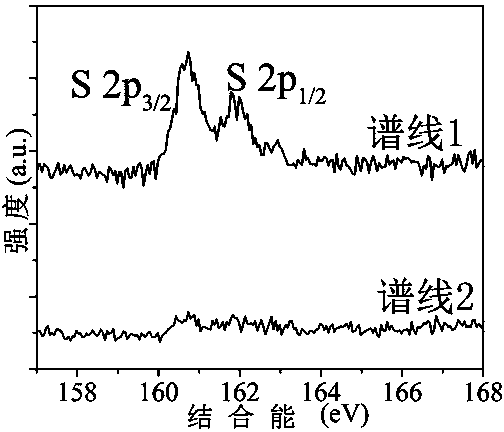

Preparation method for surface-enhanced Raman spectrum compound substrate

InactiveCN103512875ALarge area orderlyGood chemical stabilityRaman scatteringMicrosphereSurface-enhanced Raman spectroscopy

The invention discloses a preparation method for a surface-enhanced Raman spectrum compound substrate with stable chemical property. The preparation method comprises the following steps: transferring single-layer graphene which grows on a copper foil through the CVD (chemical vapor deposition) technology to a silver nano array prepared through a polystyrene microsphere template method, keeping warm at 50 DEG C for 30 min, and firmly binding the single-layer graphene and the noble metal nano array to form the surface-enhanced Raman spectrum compound substrate. The surface-enhanced Raman spectrum compound substrate prepared through the method has the advantages that the method is simple, the material is cheap, the substrate is large in area and ordered, the chemical property is stable, and the effects of sulfuration resistance and oxidation resistance are realized.

Owner:WUHAN UNIV

Terahertz photoelectric detector

ActiveCN103715291ARealize broadband detectionImplement detectionSemiconductor devicesSingle layer grapheneVoltage source

The invention provides a terahertz photoelectric detector. The terahertz photoelectric detector at least comprises a substrate with the surface covered with a medium layer, single-layer graphene formed on the surface of the medium layer, first metal electrodes arranged at the two ends of the single-layer graphene and a second metal electrode formed on the back face of the substrate. A current source for measuring the voltage change is arranged between the first metal electrodes, and a voltage source for providing the bias voltage is arranged between the second metal electrode and the first metal electrode at one end of the single-layer graphene. The photoconductive characteristic peak position of the single-layer graphene is modulated by adjusting the bias voltage, and therefore the terahertz frequency is detected.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

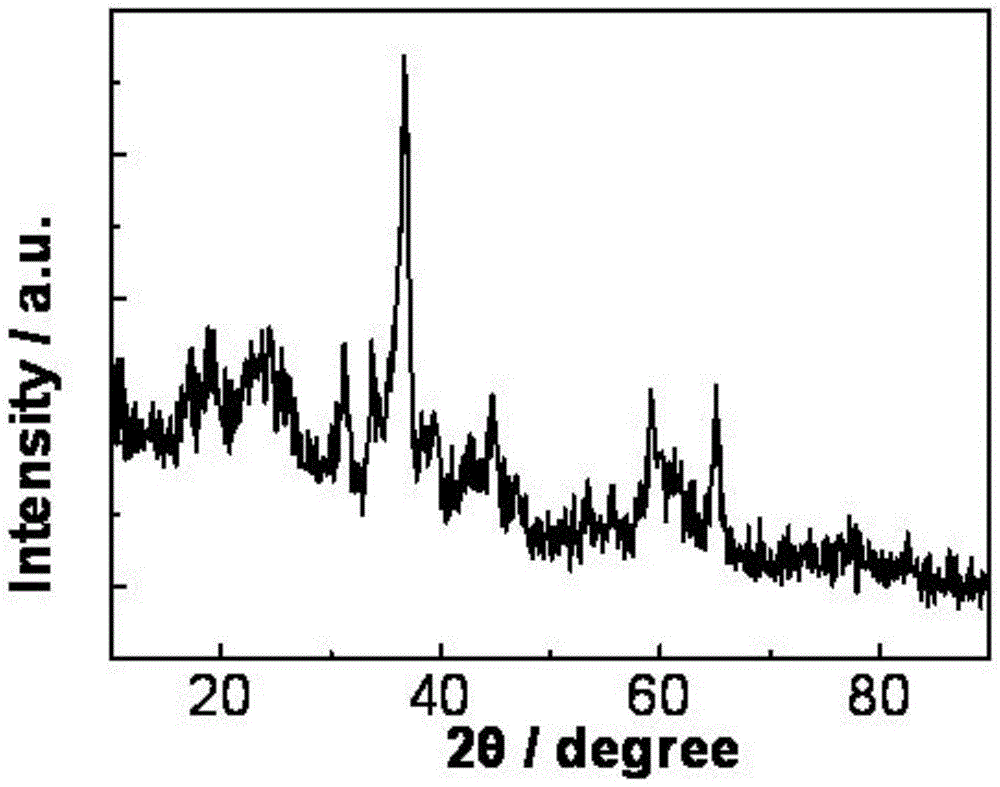

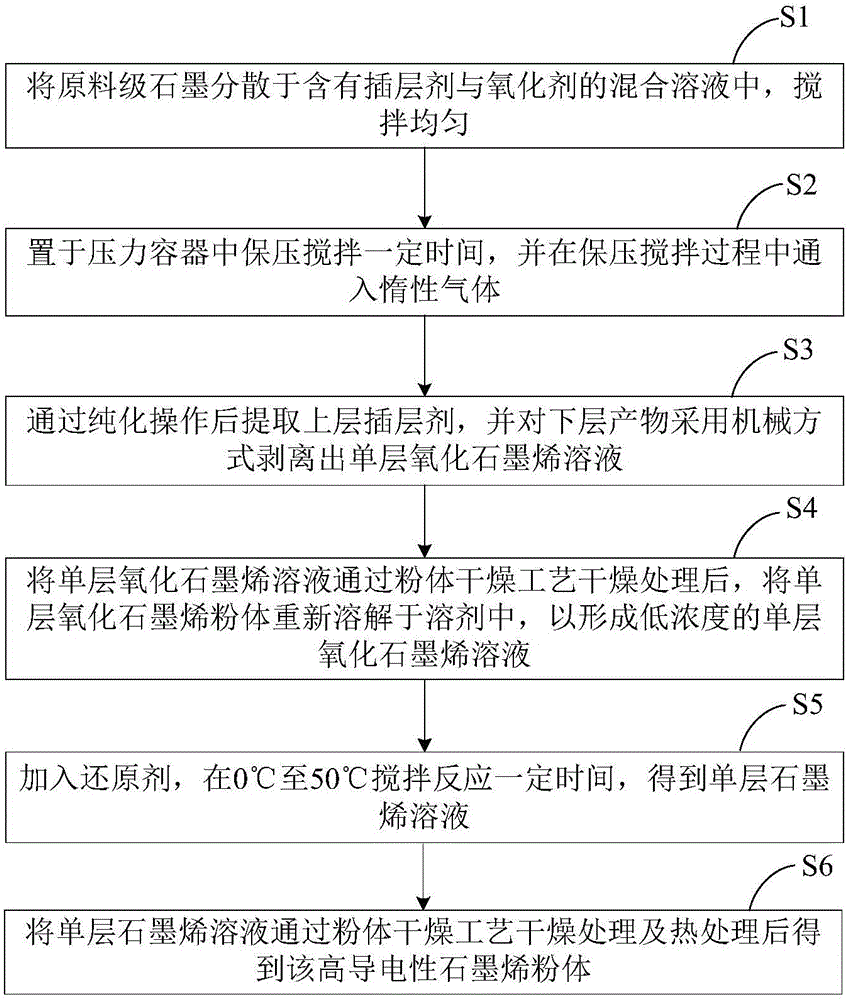

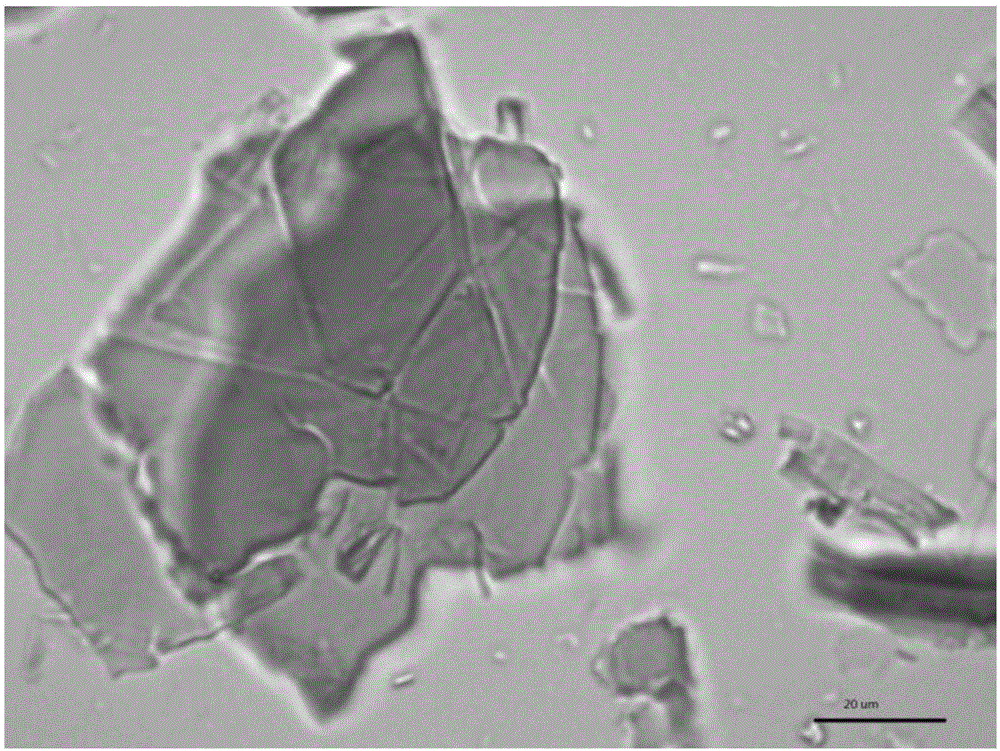

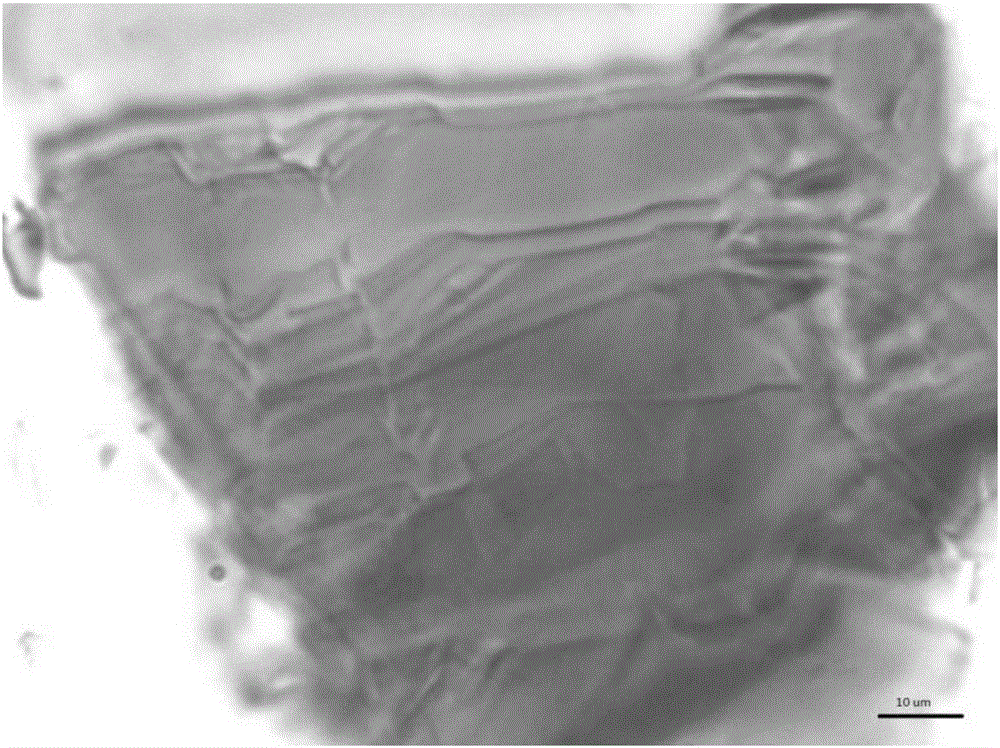

Preparation method of high-conductivity graphene powder

The invention provides a preparation method of high-conductivity graphene powder. The preparation method comprises the following steps: S1, dispersing raw material level graphite in a mixed solution containing an intercalator and an oxidizing agent, and performing uniform stirring so as to obtain a new solution; S2, placing the new solution in a pressure vessel, introducing inert gas, and performing pressure maintaining and stirring; S3, performing purification operation so as to extract an upper layer intercalator, and stripping out a single-layer oxidized graphene solution from lower-layer products in a mechanical manner; S4, performing drying treatment through a powder drying technology, and then dissolving the single-layer oxidized graphene powder in a solvent again so as to form a low-concentration single-layer oxidized graphene solution; S5, adding a reducing agent, and performing a stirring reaction at 0-50 DEG C for a certain time so as to obtain a single-layer graphene solution; S6, performing drying treatment and heat treatment on the single-layer graphene solution according to the powder drying technology so as to obtain the high-conductivity graphene powder. The preparation method disclosed by the invention has the advantages that the prepared graphene has few structural defects and is good in conductivity and high in yield; the preparation process is simple and convenient to operate, the cost is low, and the large-scale production is easy to realize.

Owner:江苏超电新能源科技发展有限公司

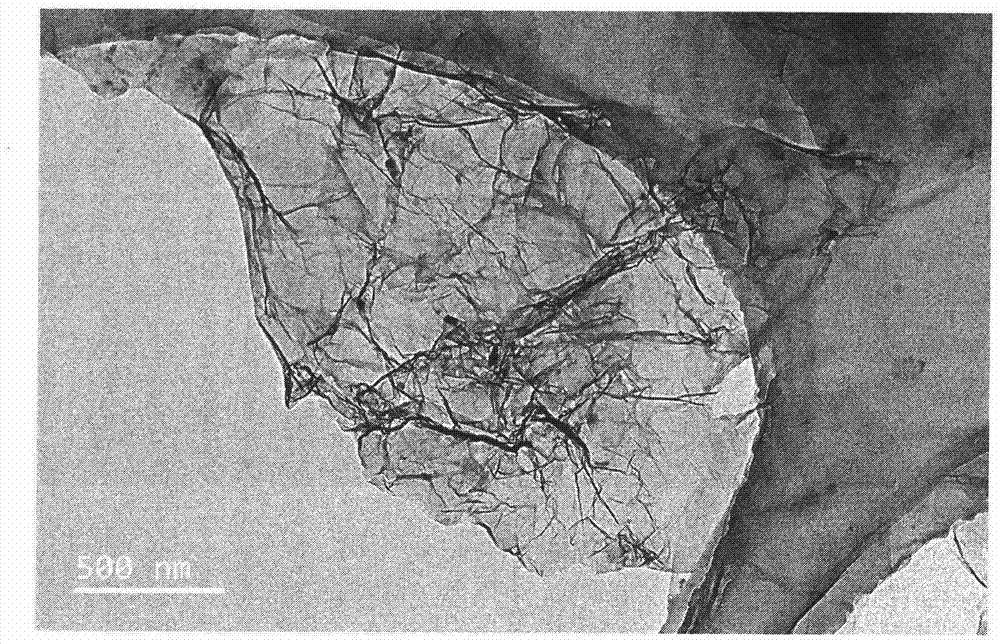

Independent self-support wrinkled graphene film in nano thickness and preparation method thereof

The invention discloses an independent self-support wrinkled graphene film in nano thickness and a preparation method thereof. The independent self-support wrinkled graphene film in nano thickness isobtained through film formation by suction filtration of oxidized graphene prior to chemical reduction and high-temperature treatment. The independent self-support wrinkled graphene film in nano thickness is formed by single-layer graphene through physical crosslinking, wherein the graphene is complete in base structure without obvious defects and rich in wrinkles, and the content of turbostraticstructures among lamellas exceed 30%. Since the independent self-support wrinkled graphene film in nano thickness is extremely thin in thickness (16-130 nm) with a great quantity of superficial wrinkles, thereby being highly flexible.

Owner:杭州德烯科技集团有限公司

Preparation method of bromine-doped high-conductivity ultrathin graphene film

The invention discloses a preparation method of a bromine-doped high-conductivity ultrathin graphene film. The graphene film is prepared from graphene oxide through the steps of filtration extractionfilm formation, chemical reduction, solid-liquid synchronous transfer, high-temperature graphitization, bromine doping and the like. The graphene film is prepared from single-layer graphene oxide / reduced graphene oxide through physical cross-linking. The thickness of the graphene film is 10 to 2,000 atomic layers; the graphene oxide film is quite small in thickness, moreover, has abundant defectsexisting inside, and therefore, has quite good transparency and extremely good flexibility. After the chemical reduction, most functional groups disappear; the graphene film starts to conduct; throughhigh-temperature reduction, a graphene structure is repaired; the electron mobility is promoted; after the bromine doping, the concentration of graphene charge carriers is promoted, and the graphenefilm can be used for a high-flexibility transparent conductive device.

Owner:杭州德烯科技集团有限公司

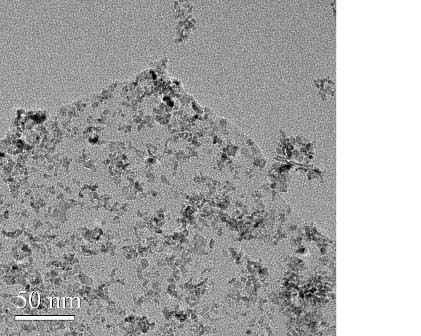

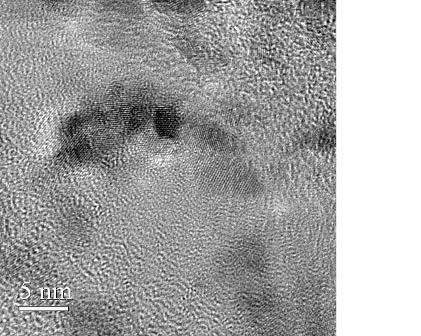

Nano-nickel oxide/graphene composite material and preparation method thereof

InactiveCN102184781ASimple preparation processShort preparation cycleElectrolytic capacitorsCapacitanceGraphane

The invention relates to a nano-nickel oxide / graphene composite material and a preparation method thereof. The composite material is characterized in that: nickel oxide nano-particles uniformly grow on two sides of single-layer graphene to form a novel quasi-two-dimensional composite nano-material. The graphene serving as a substrate frame has good conductivity, and excellent conductivity among the nickel oxide particles is realized through the graphene substrate, so that the apparent electric conductivity of the composite material is improved. The sizes of the nickel oxide nano-particles growing on the graphane flake are between 1 and 10 nanometers; the plane size of the composite graphene nano-flake is between 0.1 and 100 microns, and the thickness of the composite graphene nano-flake is between 1 and 20 nanometers; and the weight percentage of the nickel oxide in the composite material is between 60 and 95 percent. The preparation method comprises two typical steps of: preparing a nano-nickel oxide / graphene precursor material by adopting a chemical solution method; and sintering to form a phase at high temperature in protection of an inert gas. The nano-nickel oxide / graphene composite material prepared by the method has high single electrode capacitance and good circulating performance, and is suitable for electrode materials of super capacitors.

Owner:JIANGSU SUNETECH NEW ENERGY TECH CO LTD

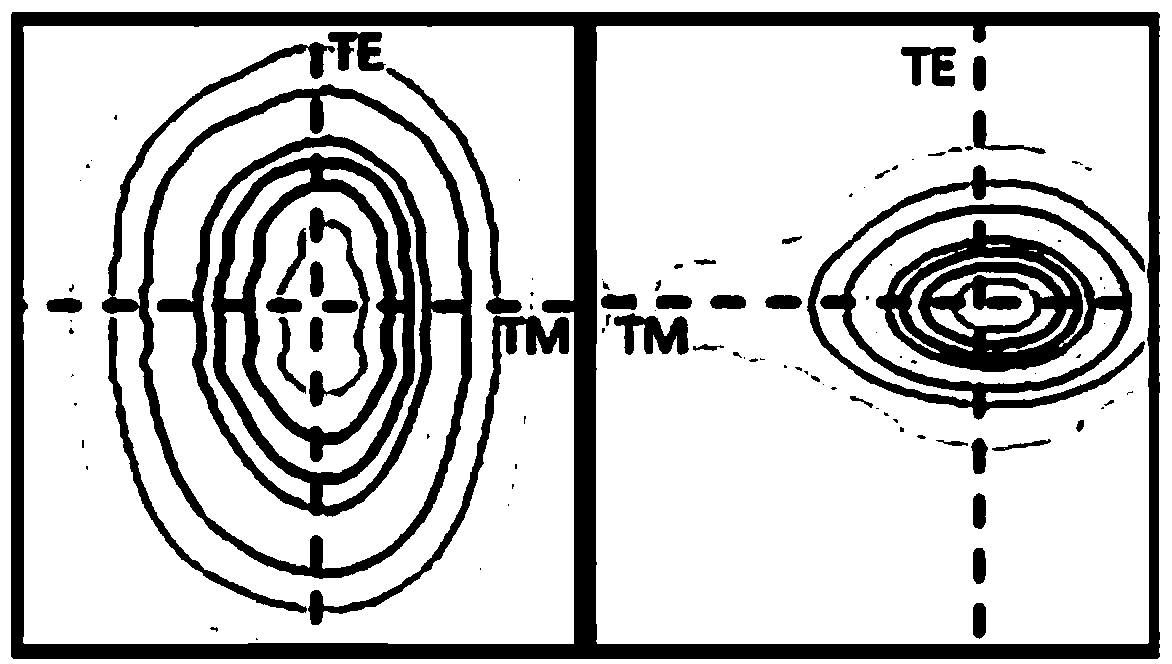

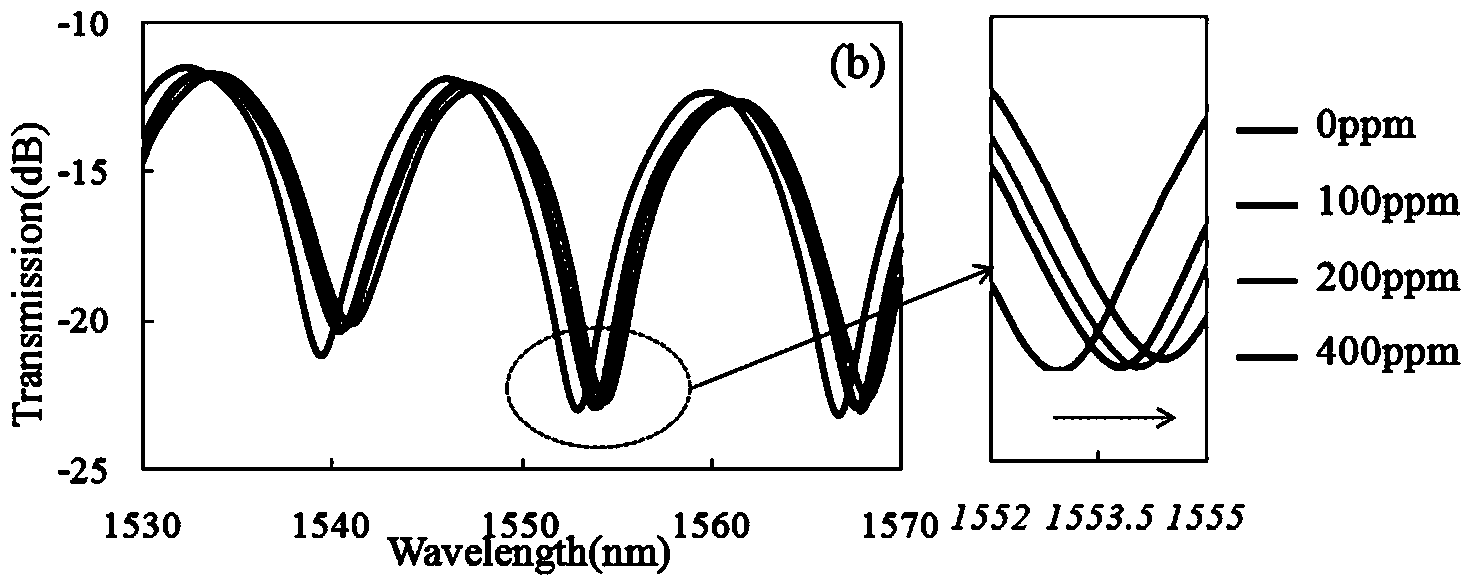

Micro optical fiber gas sensor covered by adopting graphene

InactiveCN103954590AReusableSmall sizePhase-affecting property measurementsRefractive indexMagnesium fluoride

The invention discloses a micro optical fiber gas sensor covered by adopting graphene and relates to the field of gas sensors, in particular relates to the field of an optical fiber intermodal interference sensor. A micro optical fiber which is drawn to have two thick ends and thin middle through a fused biconical taper method is arranged on a magnesium fluoride substrate, a single-layer graphene material covers the middle section of the micro optical fiber, and because the single-layer graphene material is extremely sensitive to chemical bonds between atoms and an extranuclear electron state is extremely sensitive to an ambient environment, distribution of a dielectric constant is changed due to contact between the material and trace gas molecule, so that the optical refractive index is changed, and finally the intermodal interference spectrum of light propagated in the optical fiber is changed, the gas types are identified by detecting the interference spectrum, and the aims of the gas sensor are achieved. Therefore, the micro optical fiber gas sensor has the advantages of small size, high precision, high sensitivity, stability in operation and repeated utilization effect.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

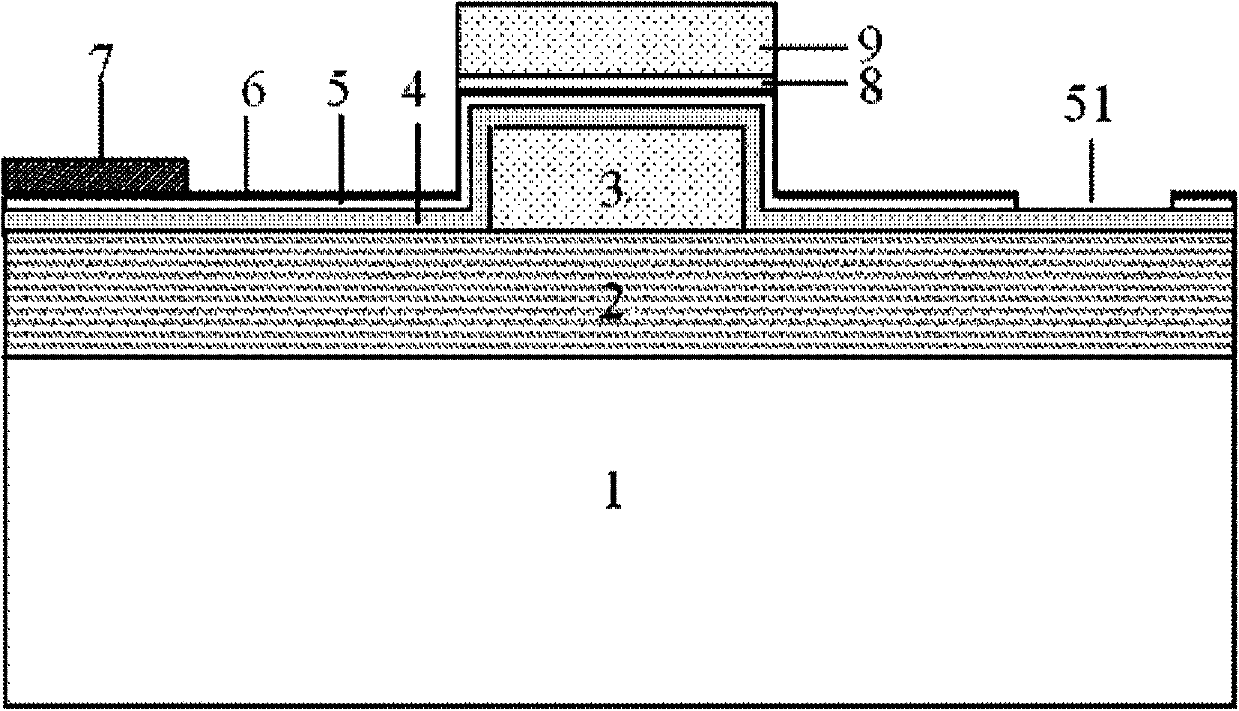

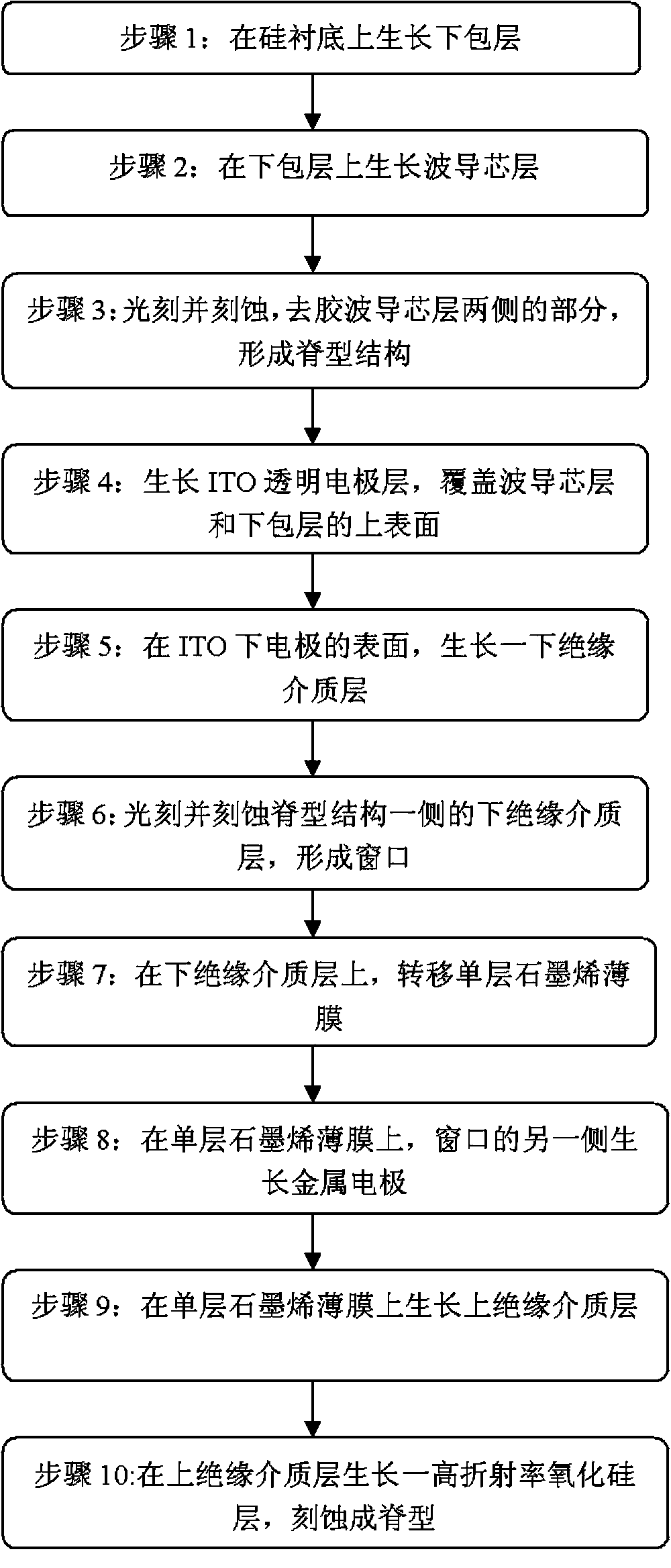

Low-refractivity waveguide modulator for graphene and preparing method

InactiveCN103439807AIncreased freedom in spectral designSmall sizeNon-linear opticsModulation bandwidthRefractive index

The invention provides a low-refractivity waveguide modulator for graphene. The low-refractivity waveguide modulator comprises a substrate, lower cladding, a waveguide core layer, an ITO transparent electrode, a lower insulating medium layer, a single-layer graphene film, a metal electrode, an upper insulating medium layer and a high refractive index silicon oxide layer, wherein the lower cladding is arranged on the substrate, the waveguide core layer is arranged in the middle of the lower cladding for forming a ridge-shaped structure, the ITO transparent electrode is arranged on the waveguide core layer and the two sides and covers the exposed upper surface of the lower cladding, the lower insulating medium layer is arranged on the surface of the ITO transparent electrode, the portion, on one side of the ridge-shaped structure, of the insulating medium layer is of a disconnection shape and forms a window, the single-layer graphene film is arranged on the lower insulating medium layer, the metal electrode is arranged on one side of the ridge-shaped structure and the single-layer graphene film of the other side far away from the window, the preset distance larger than 800nm is kept between the metal electrode and the ridge-shaped structure, the upper insulating layer is arranged on the single-layer graphene film on the ridge-shaped structure, and the high refractive index silicon oxide layer is arranged on the upper insulating medium layer. The low-refractivity waveguide modulator has the advantages of being small in size, wide in modulation bandwidth, low in insertion loss and simple in preparing process.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Graphene conductive ink

The invention discloses graphene conductive ink, which is composed of the following components in mass part: 20-50 parts of adhesive resin, 40-100 parts of alcohol solvent, 10-80 parts of graphene, 1-3 parts of dispersing agent, 1-3 parts of defoaming agent, and 1-3 parts of stabilizing agent, wherein the adhesive resin is one or two types from acrylic resin and polyurethane resin; the alcohol solvent is one or multiple types from ethyl alcohol, glycerin and isopropyl alcohol; the graphene is one or multiple types from single-layer graphene, double-layer graphene and three-layer graphene. The graphene conductive ink is simple in preparation procedure and low in cost; the graphene is selected as an electric conducting medium, so that the electric conducting performance is excellent, the stability is high and the mechanical property is good; the graphene conductive ink has excellent abrasive resistance and scratching resistance.

Owner:SUZHOU AITESI FURTHER MATERIALS CO LTD

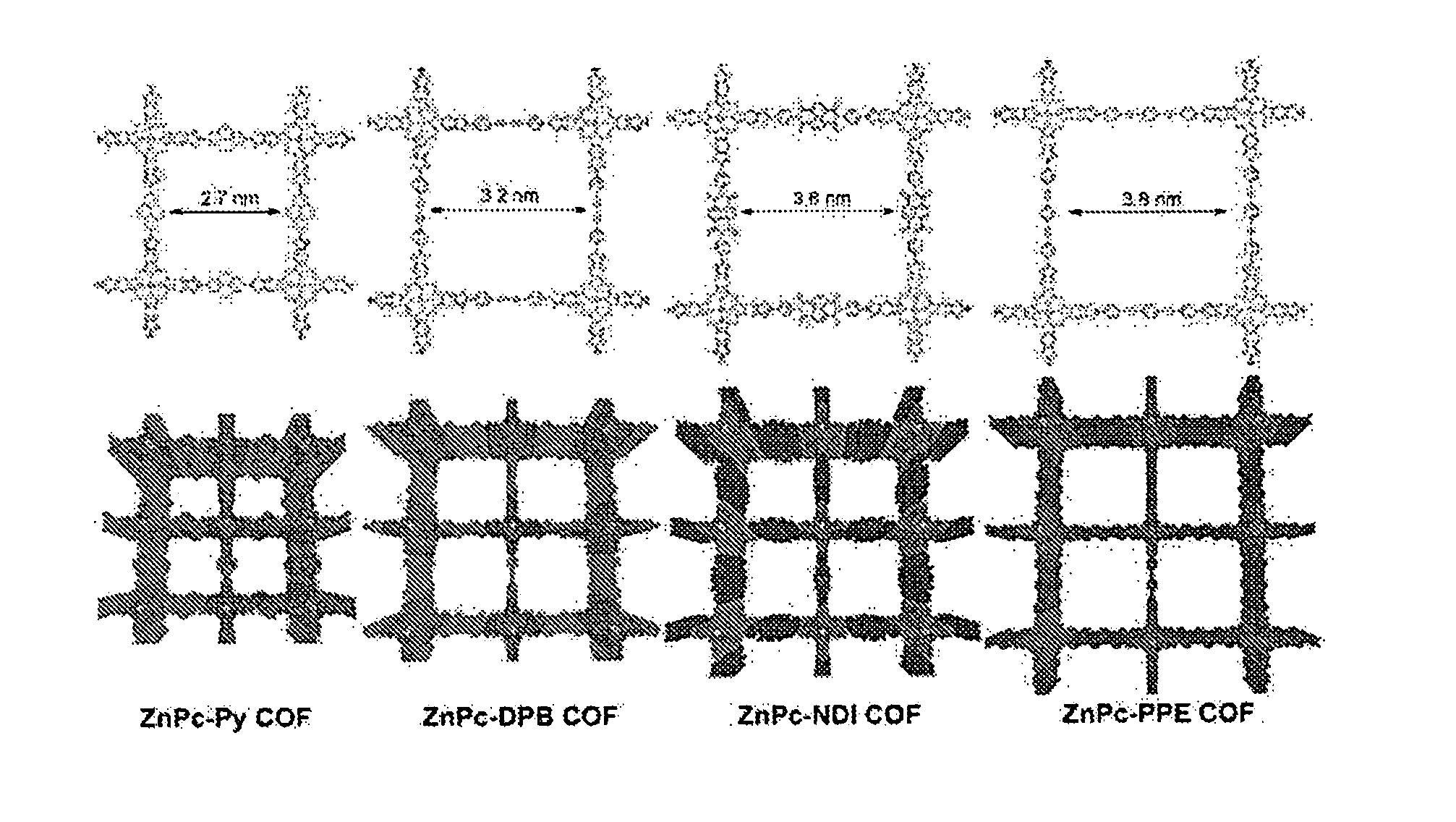

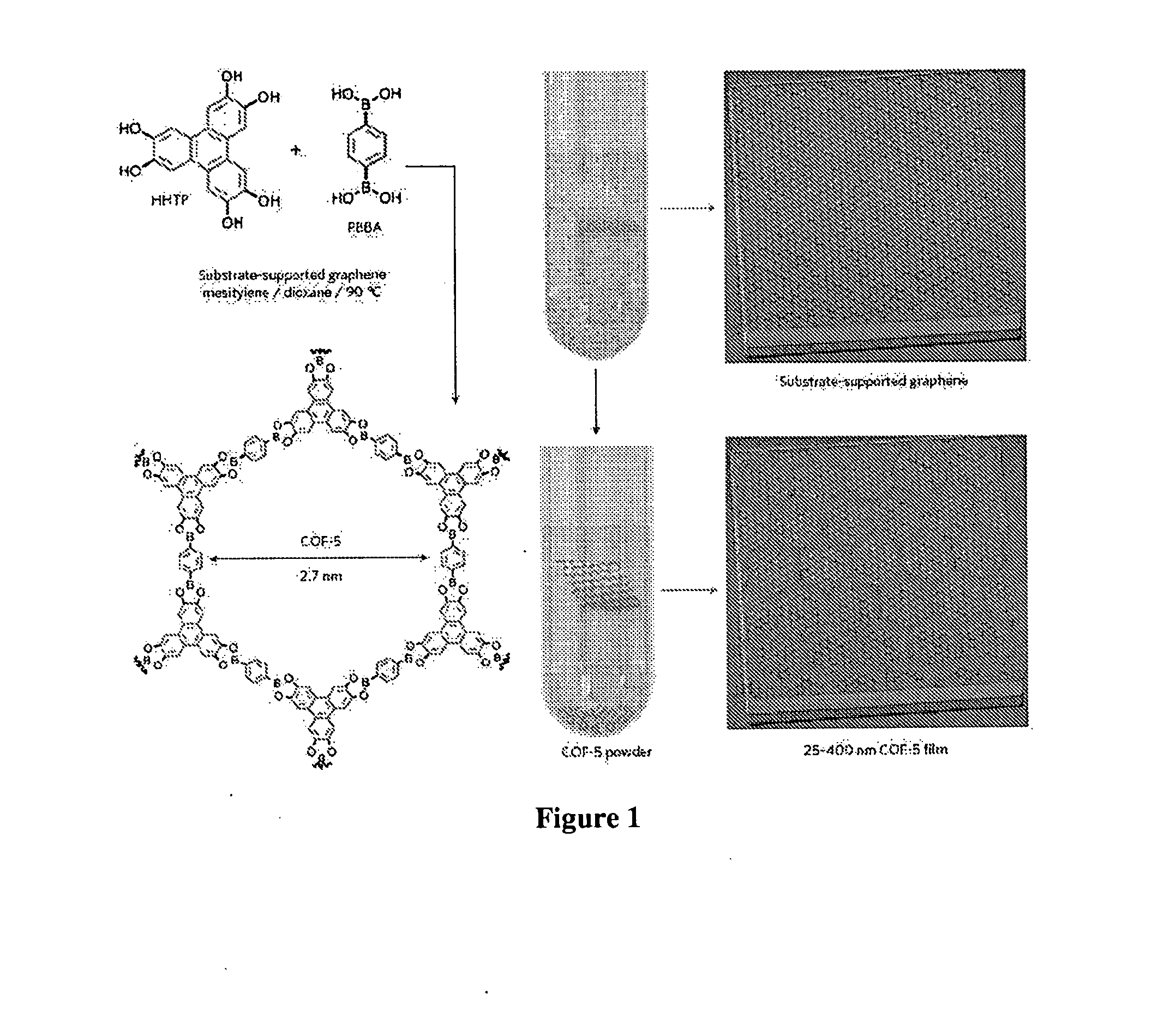

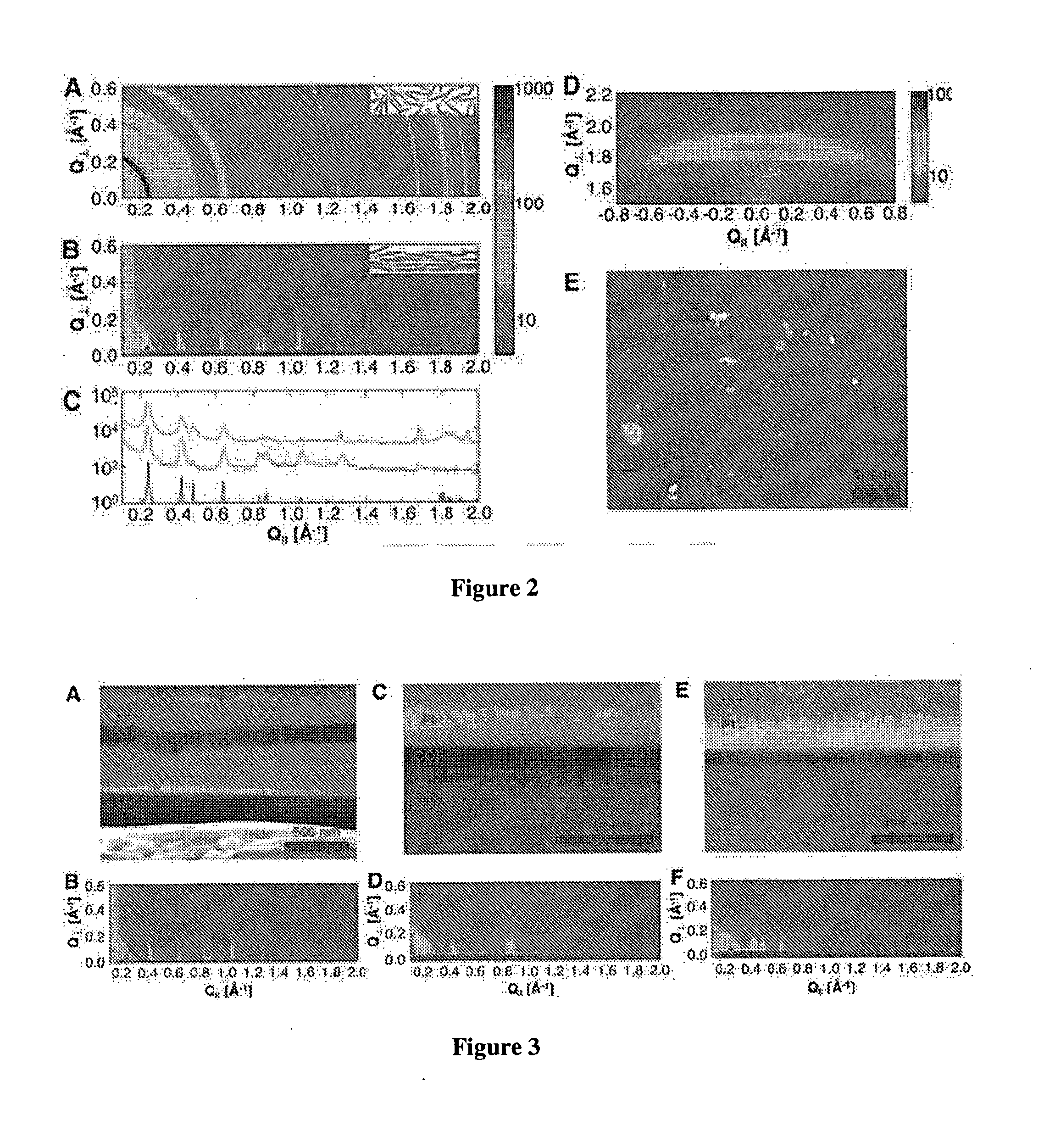

Covalent organic framework films, and methods of making and uses of same

ActiveUS20140037944A1High crystallinityMaterial nanotechnologyLiquid surface applicatorsSingle layer grapheneSolar cell

Multilayer structures comprising a covalent organic framework (COF) film in contact with a polyaromatic carbon (PAC) film. The multilayer structures can be made by combining precursor compounds in the presence of a PAC film. The PAC film can be for example, a single layer graphene film. The multilayer structures can be used in a variety of applications such as solar cells, flexible displays, lighting devices, RFID tags, sensors, photoreceptors, batteries, capacitors, gas-storage devices, and gas-separation devices.

Owner:CORNELL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com