Nano-nickel oxide/graphene composite material and preparation method thereof

A technology of nano-nickel oxide and composite materials, which is applied in the field of electrochemistry and material synthesis, can solve the problems of easy agglomeration of NiO nano-materials, long charging time, and low power density, and achieve short preparation cycle, improved capacitance performance, and large output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

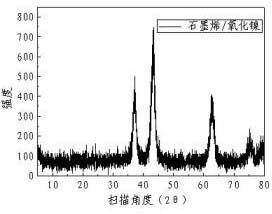

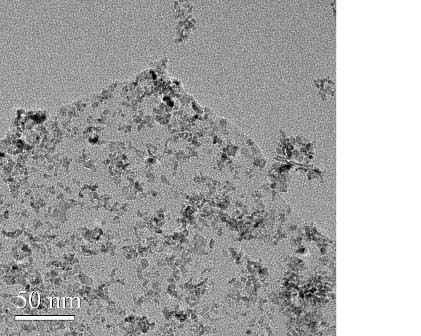

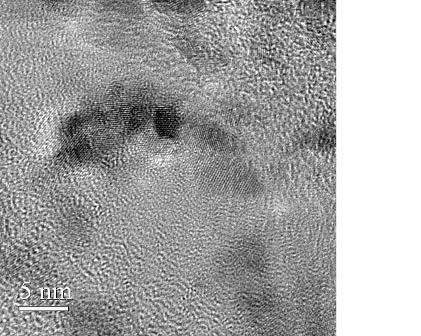

[0027] Embodiment one: adopt Ni (NO 3 ) 2 Preparation of graphene / nickel oxide composites as nickel source

[0028] First, weigh 2.5g of potassium persulfate and 2.5g of phosphorus pentoxide, dissolve in 20ml of concentrated sulfuric acid, heat to 80°C and keep it warm, then add 3g of natural graphite, keep the temperature for 4.5h, cool to room temperature, and dilute with 500ml of deionized water After standing still for 20 hours, it was filtered and vacuum-dried at 60°C. Dissolve the above product in 120ml of concentrated sulfuric acid, and slowly add 15g of potassium permanganate into the above solution under ice bath conditions; stir at a constant temperature of 35°C for 2h, then slowly dilute with 250ml of water, and let it stand for 2h; add 700ml of deionized water Dilute, add 20ml (30%) to the above solution; then wash with 1L of 1:10 HCl solution; then filter and wash with 1L deionized water to obtain graphite oxide solution.

[0029] Take 50ml graphite oxide solut...

Embodiment 2

[0033] Embodiment two: adopt NiCl 2 ·6H 2 Preparation of graphene / nickel oxide composites with O as nickel source

[0034] Take 50ml of prepared 2.5mg / ml graphite oxide solution, add the same volume of deionized water to dilute and stir for 0.5h, then weigh 0.01mol nickel chloride hexahydrate (NiCl 2 ·6H 2 O) Prepare a 1M solution with deionized water, take 10ml nickel chloride solution and slowly add it dropwise to 50ml graphite oxide solution, stir for 0.5h, then take 1M NH prepared in advance 4 HCO 3 Add 15ml of the solution dropwise to the above solution, adjust the pH of the solution to 7.5 under the detection of a pH meter, then stir for 1 hour, filter with a suction filter bottle, then wash with absolute ethanol for 3 times, and then wash with deionized water for 3 times . The precursor of the graphene / nickel oxide composite material was obtained, and the precursor was vacuum-dried at 80°C for 12h, and then the prepared dry precursor sample was heated to 400°C for ...

Embodiment 3

[0035] Embodiment three: adopt NiSO 4 Preparation of graphene / nickel oxide composites as nickel source

[0036] Take 50ml of the prepared 2.5mg / ml graphite oxide solution, add the same volume of deionized water to dilute and stir for 1h, then weigh 2.62g of nickel sulfate to make a 1M solution, take 10ml of the prepared nickel sulfate solution and slowly add it dropwise to 50ml In the graphite oxide solution, stir for 1h, then take 15ml of 1M ammonium bicarbonate solution and add it dropwise to the above solution, use a pH meter to monitor the pH of the solution system in real time, when the pH is adjusted to 7.5, stop adding the ammonium bicarbonate solution dropwise, and then Stir for 1 hour. After the reaction is over, filter with a suction filter bottle, then wash with absolute ethanol for 3 times, and then repeat the same steps with deionized water for 3 times. The precursor of the graphene / nickel oxide material prepared in this way, the precursor is vacuum-dried at 80°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com