Patents

Literature

34results about How to "Capacitive increase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

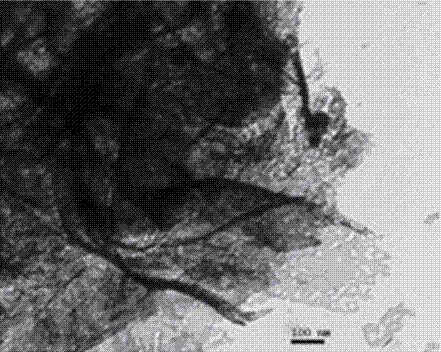

Nano-nickel oxide/graphene composite material and preparation method thereof

InactiveCN102184781ASimple preparation processShort preparation cycleElectrolytic capacitorsCapacitanceGraphane

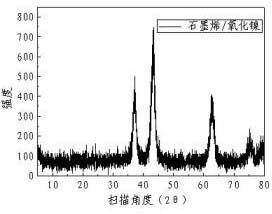

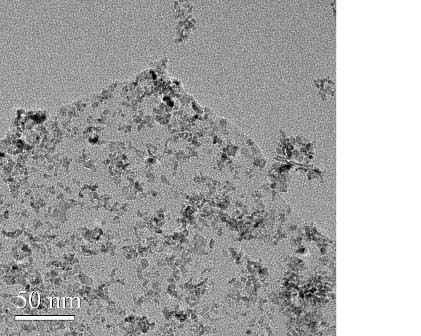

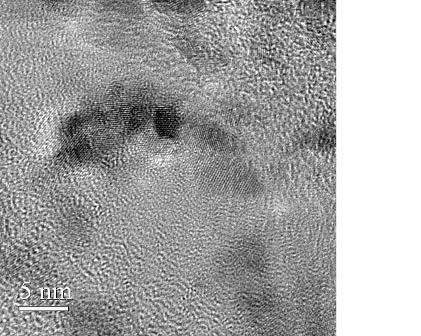

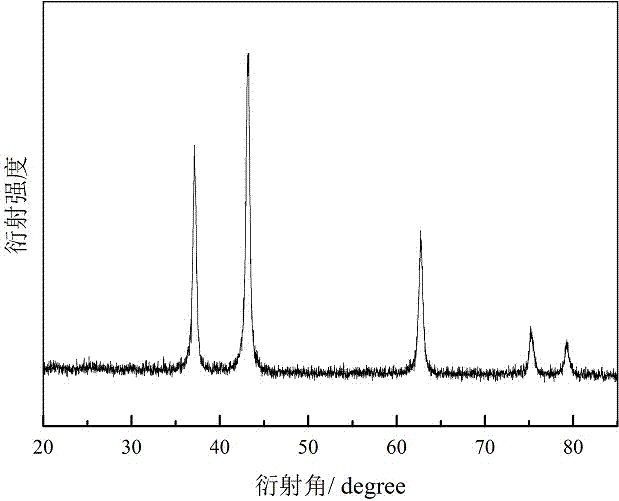

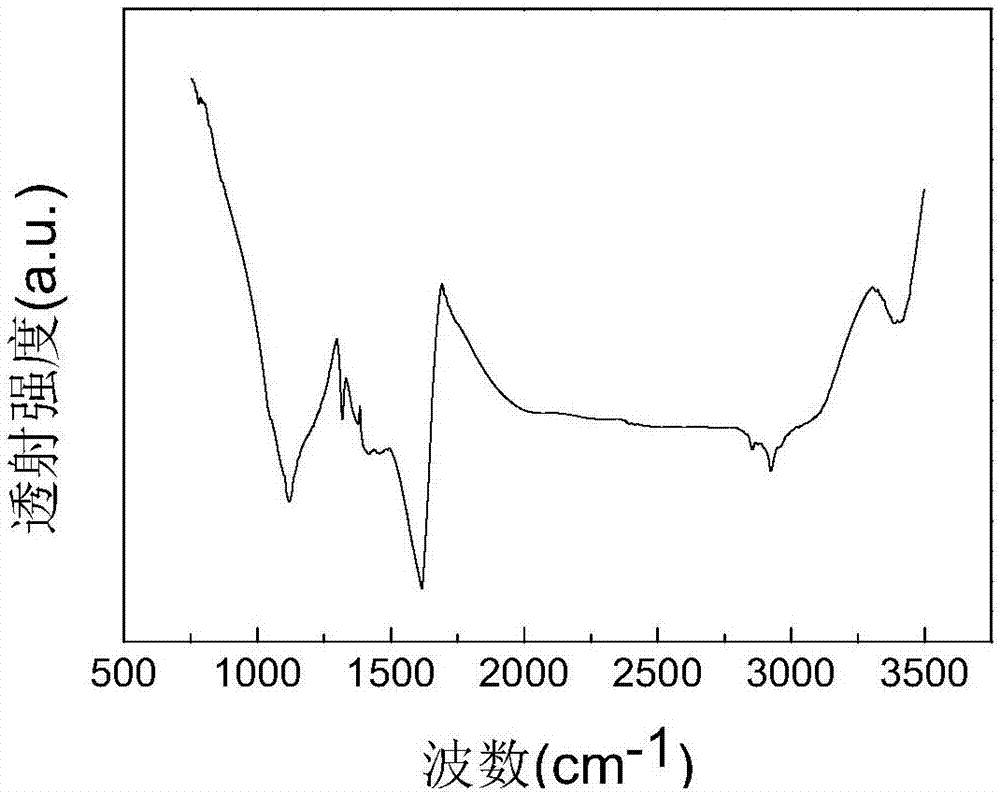

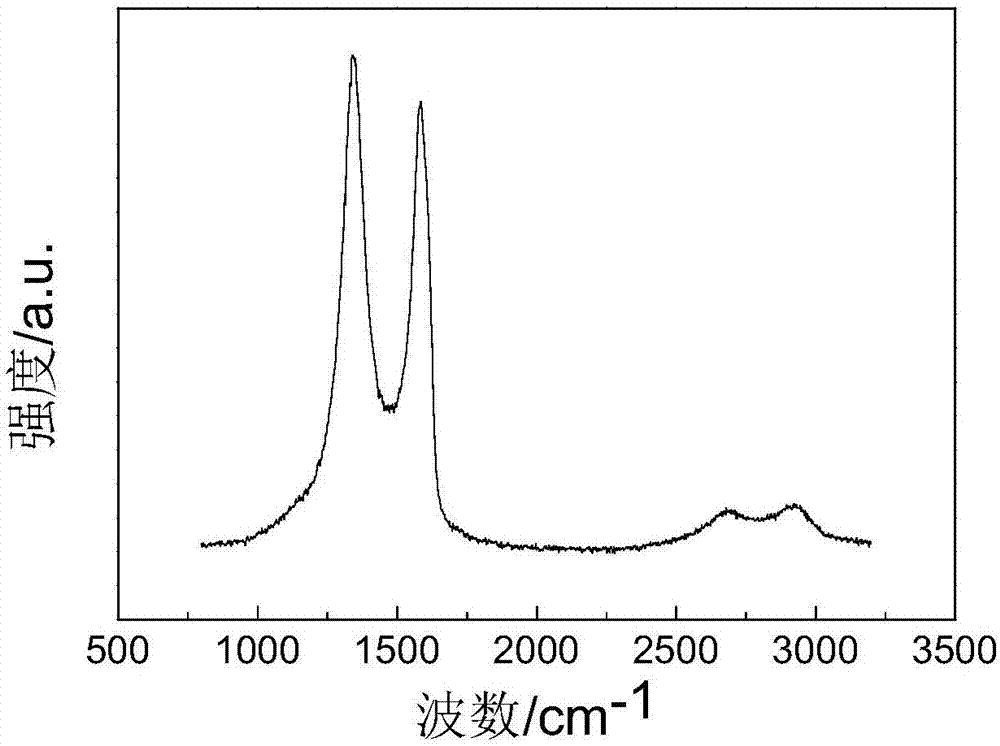

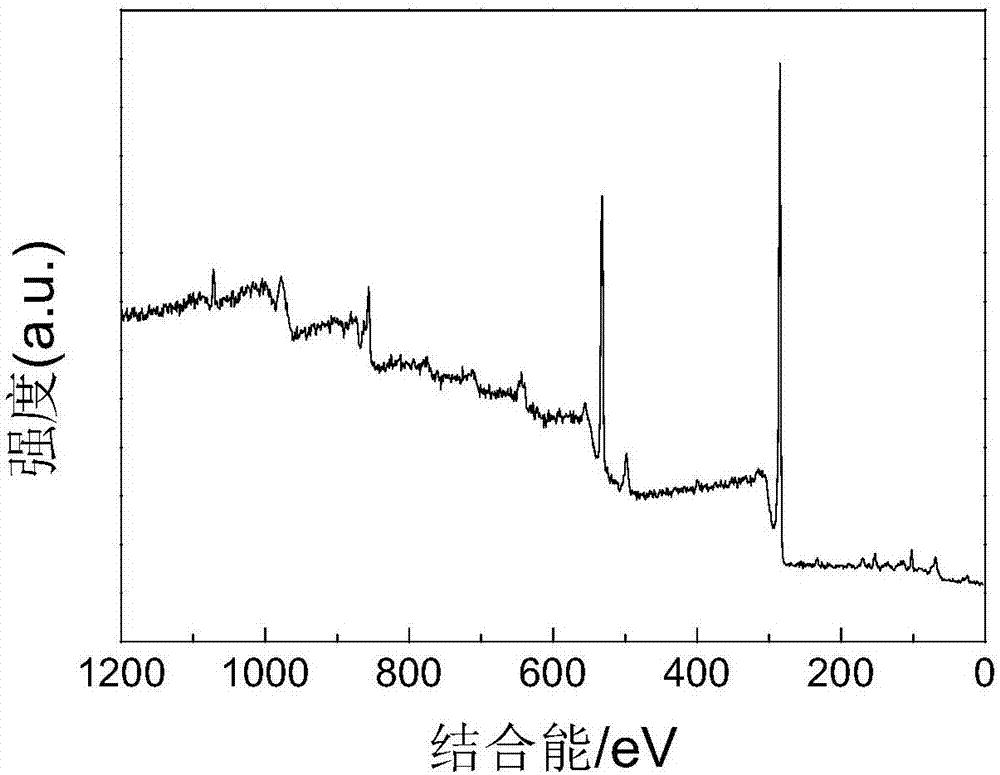

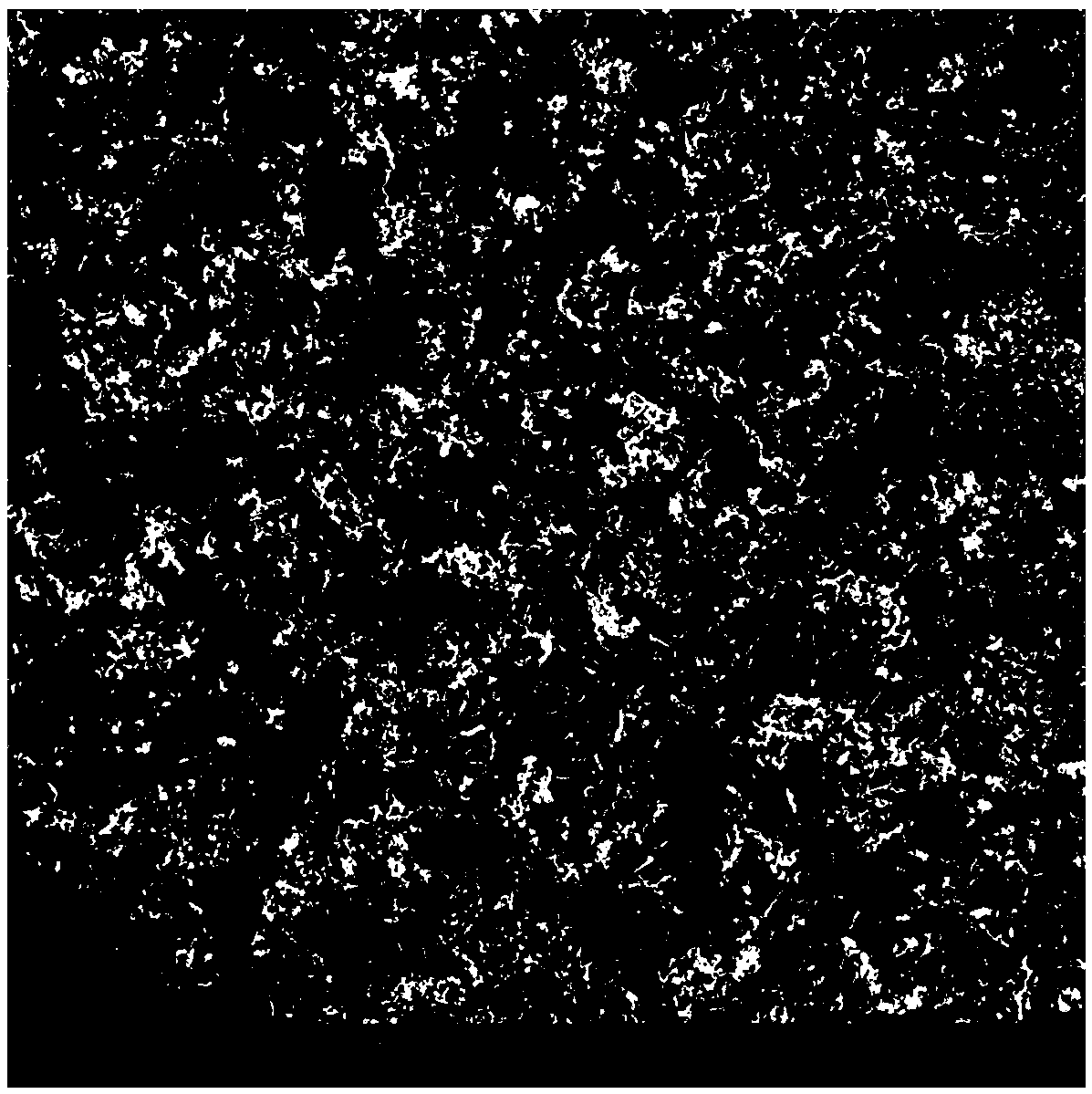

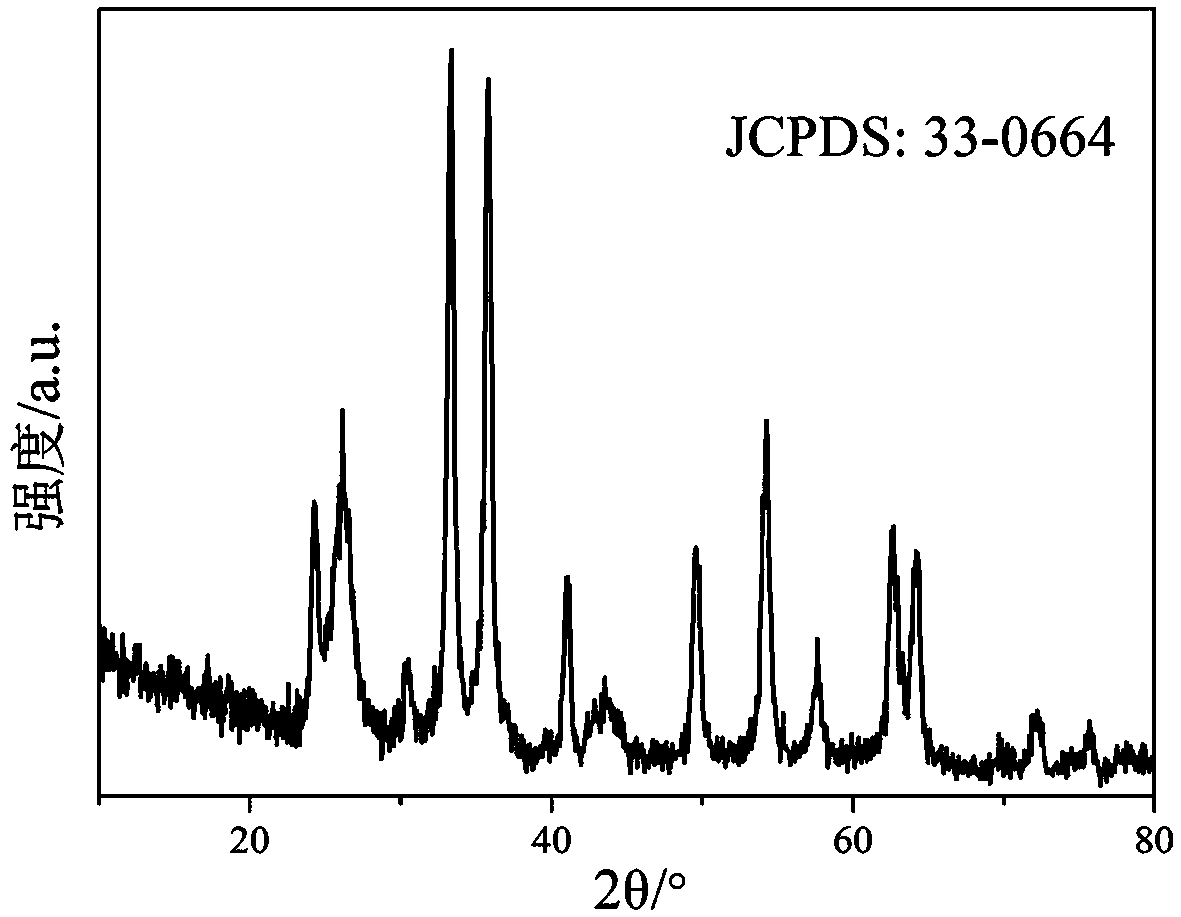

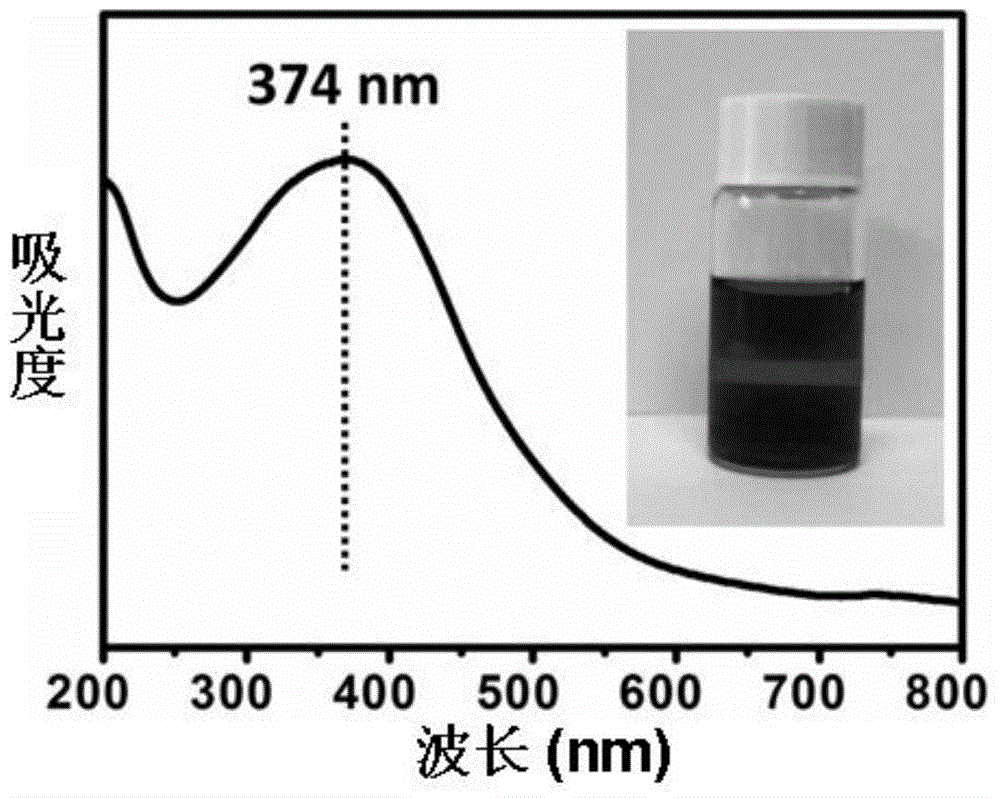

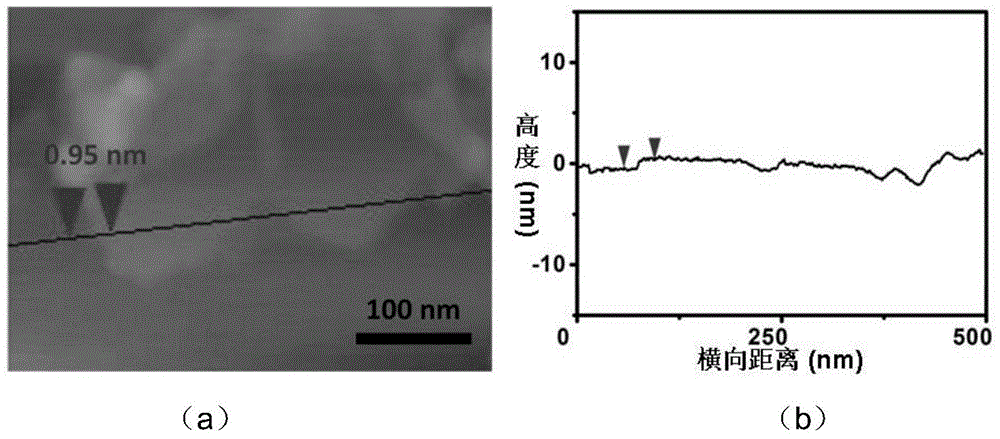

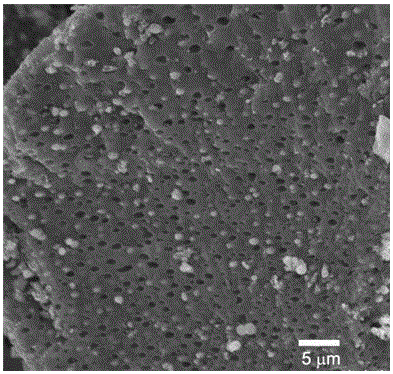

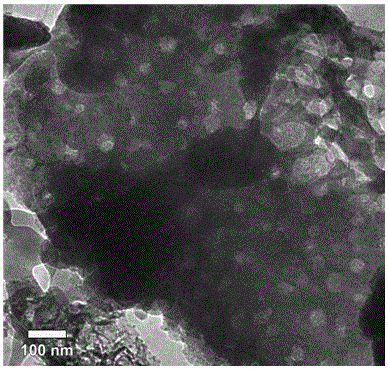

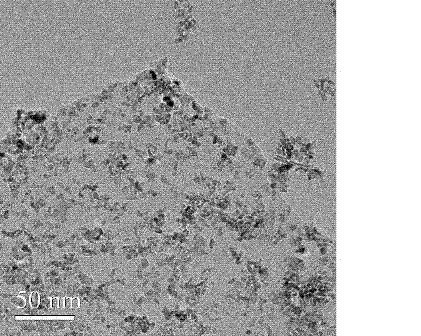

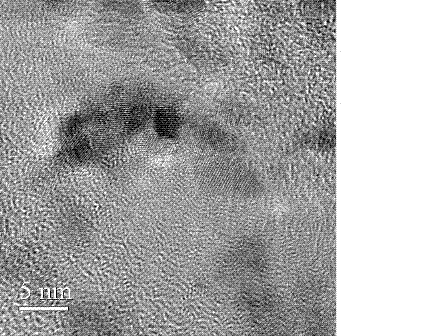

The invention relates to a nano-nickel oxide / graphene composite material and a preparation method thereof. The composite material is characterized in that: nickel oxide nano-particles uniformly grow on two sides of single-layer graphene to form a novel quasi-two-dimensional composite nano-material. The graphene serving as a substrate frame has good conductivity, and excellent conductivity among the nickel oxide particles is realized through the graphene substrate, so that the apparent electric conductivity of the composite material is improved. The sizes of the nickel oxide nano-particles growing on the graphane flake are between 1 and 10 nanometers; the plane size of the composite graphene nano-flake is between 0.1 and 100 microns, and the thickness of the composite graphene nano-flake is between 1 and 20 nanometers; and the weight percentage of the nickel oxide in the composite material is between 60 and 95 percent. The preparation method comprises two typical steps of: preparing a nano-nickel oxide / graphene precursor material by adopting a chemical solution method; and sintering to form a phase at high temperature in protection of an inert gas. The nano-nickel oxide / graphene composite material prepared by the method has high single electrode capacitance and good circulating performance, and is suitable for electrode materials of super capacitors.

Owner:JIANGSU SUNETECH NEW ENERGY TECH CO LTD

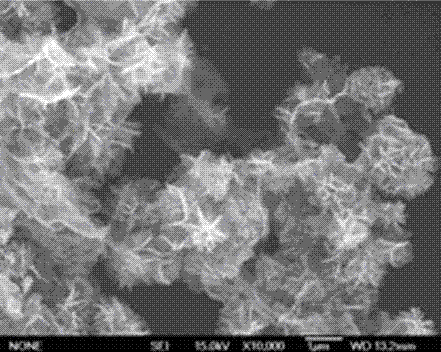

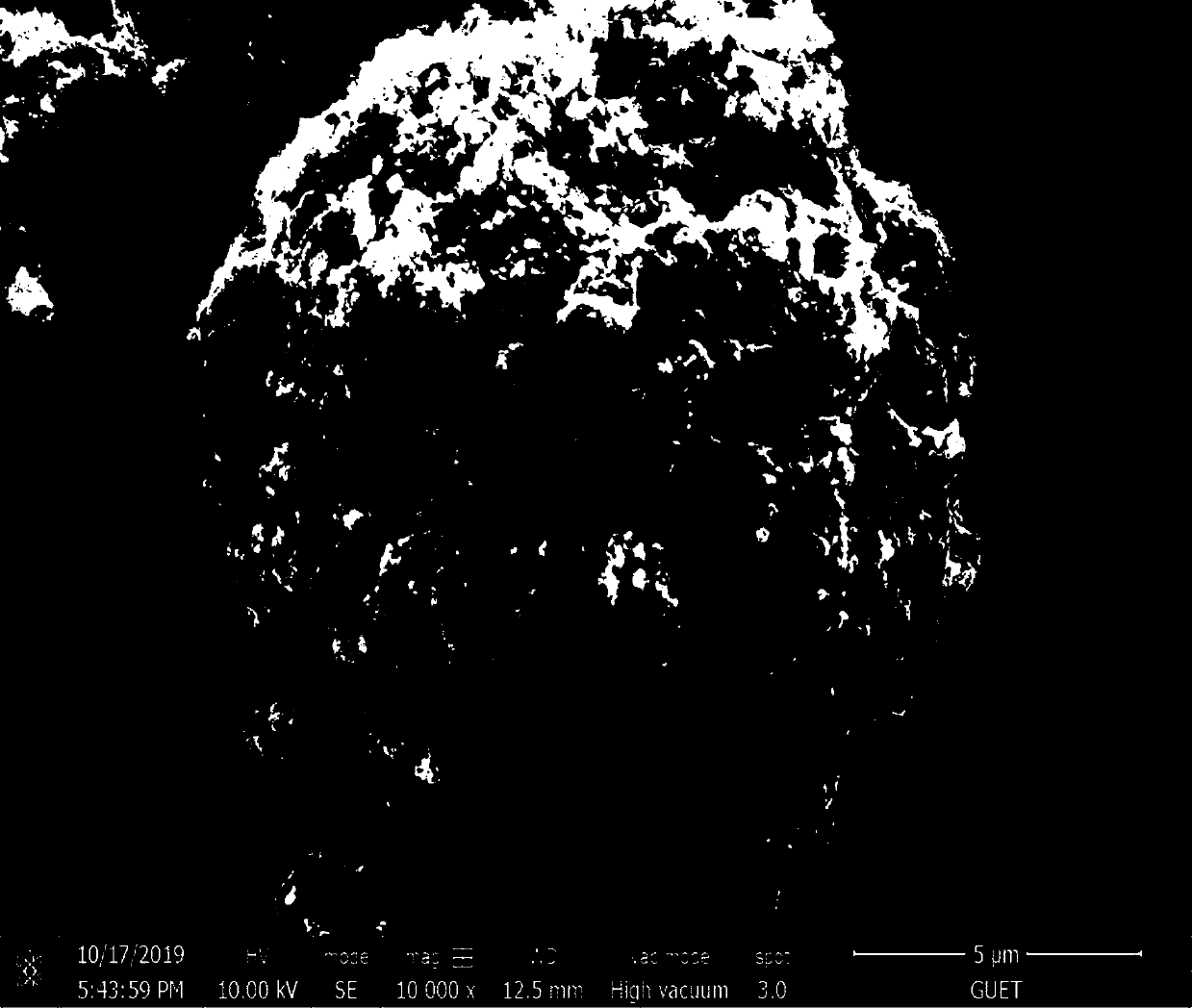

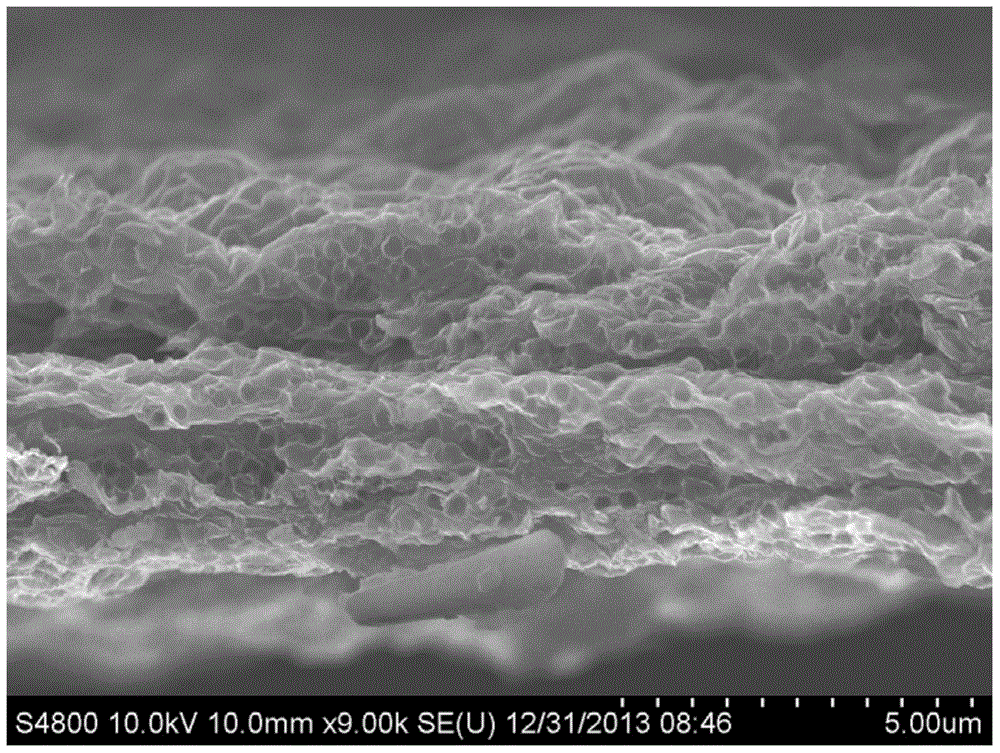

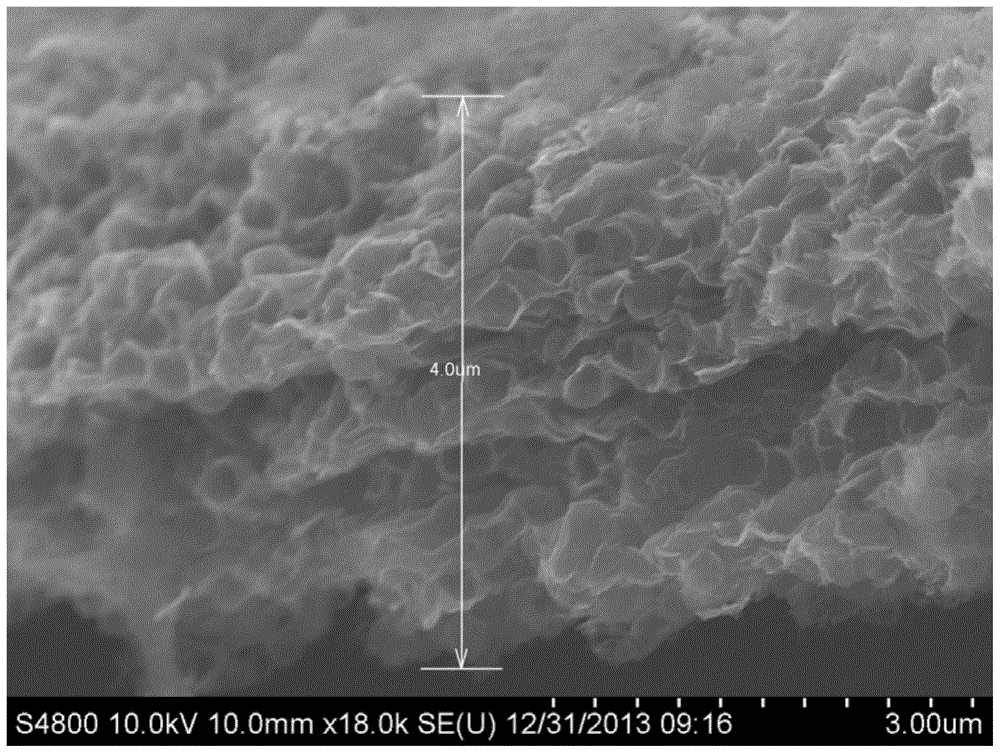

Preparation method for graphene load flower-shaped porous nickel oxide composite materials

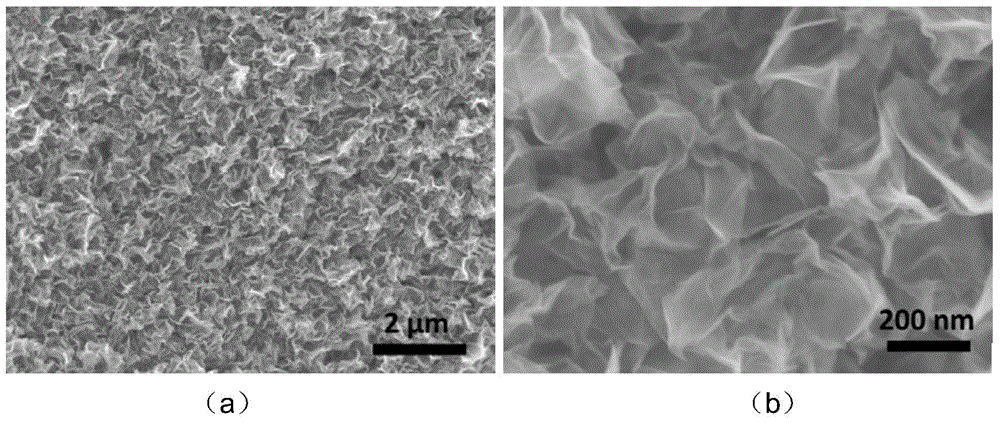

InactiveCN103943379AProminent structureOutstanding performanceHybrid/EDL manufactureCapacitanceSupercapacitor

The invention relates to a preparation method for graphene load flower-shaped porous nickel oxide composite materials. The preparation method is characterized in that graphene serves as a matrix, and flaky porous nickel oxide is assembled into flower-shaped nickel oxide balls and grows on the graphene matrix. The graphene serving as a matrix framework has good electric conductivity, the flower-shaped nickel oxide micro balls can achieve good electric conductivity through the graphene, and the appearance electric conductivity of the composite materials is improved. The width of a nickel oxide piece is 200-300 nm, the length of the nickel oxide piece is 400-600 nm, the thickness of the nickel oxide piece is 5-10 nm, mesopores of 2-10 nm are distributed in the flaky layer structure, and the diameter of the formed flower-shaped nickel oxide micro balls is 1-3 micrometers. The graphene load flower-shaped porous nickel oxide composite materials prepared through a hydrothermal method have the advantages of being large in specific surface area, high in single electrode capacity, good in cycle performance and the like, and suitable for supercapacitor electrode materials.

Owner:SHANGHAI UNIV

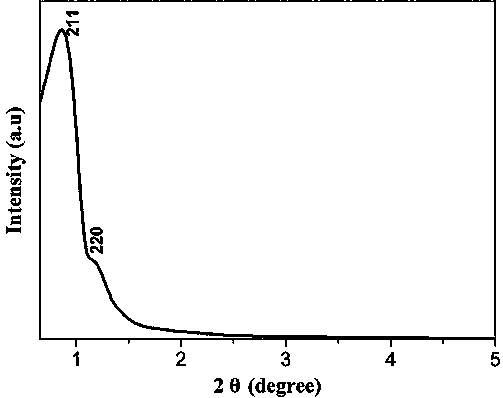

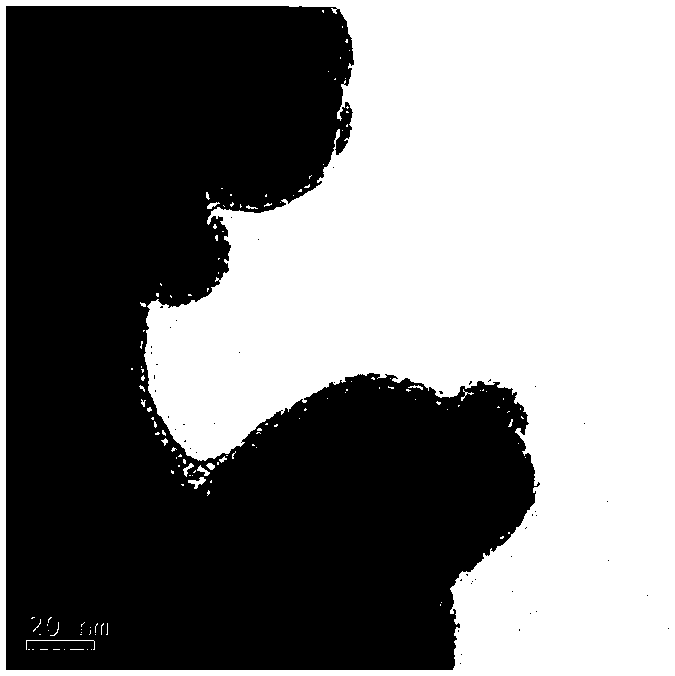

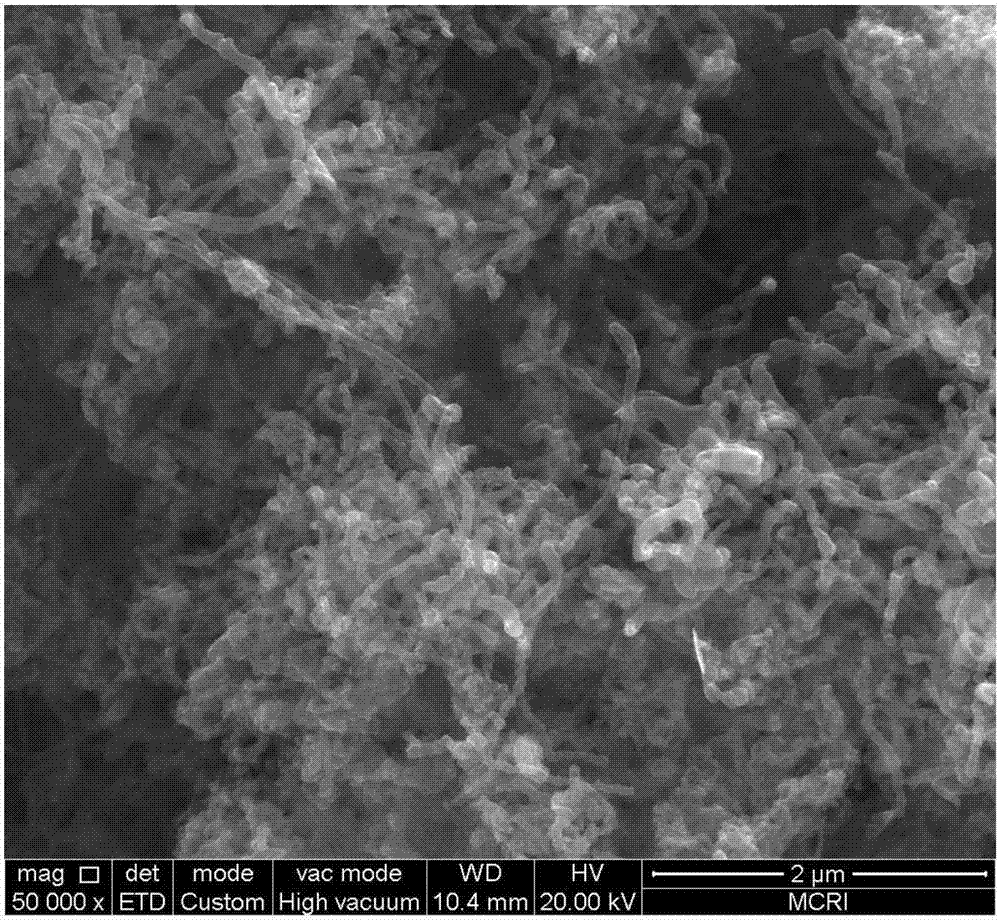

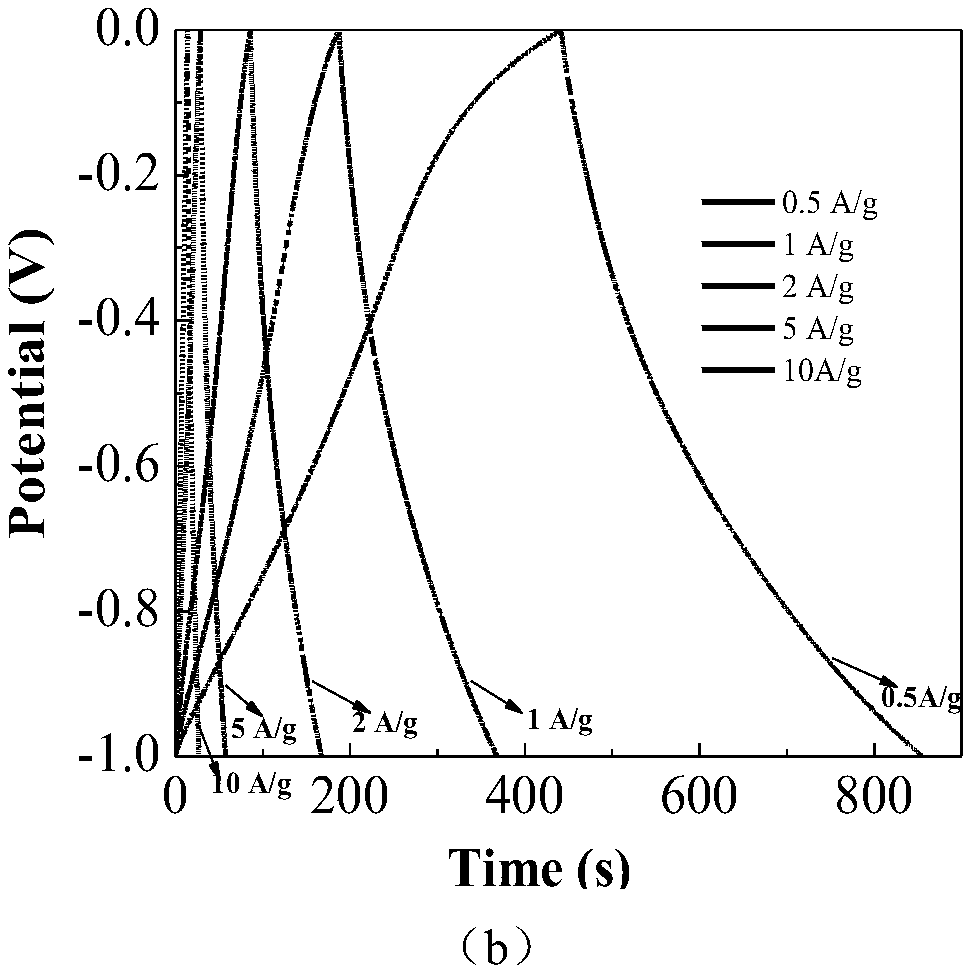

Preparation method and application of heteroatom-doped porous carbon nano-tube

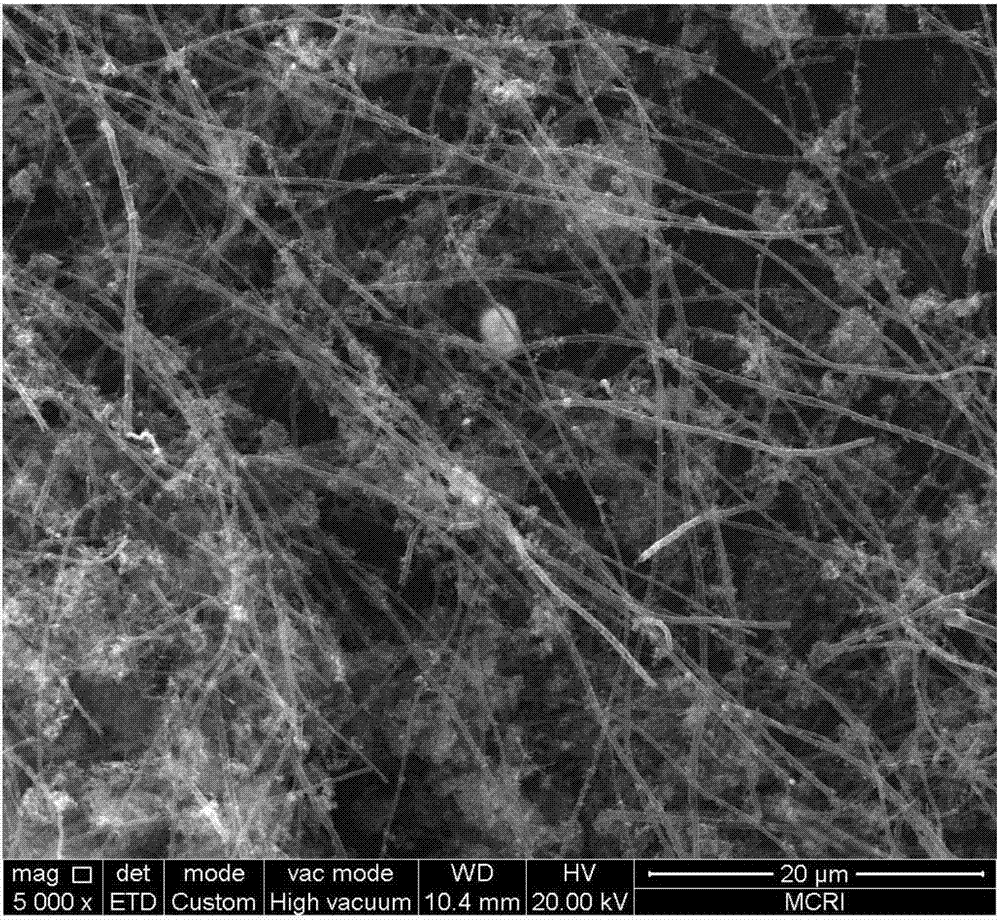

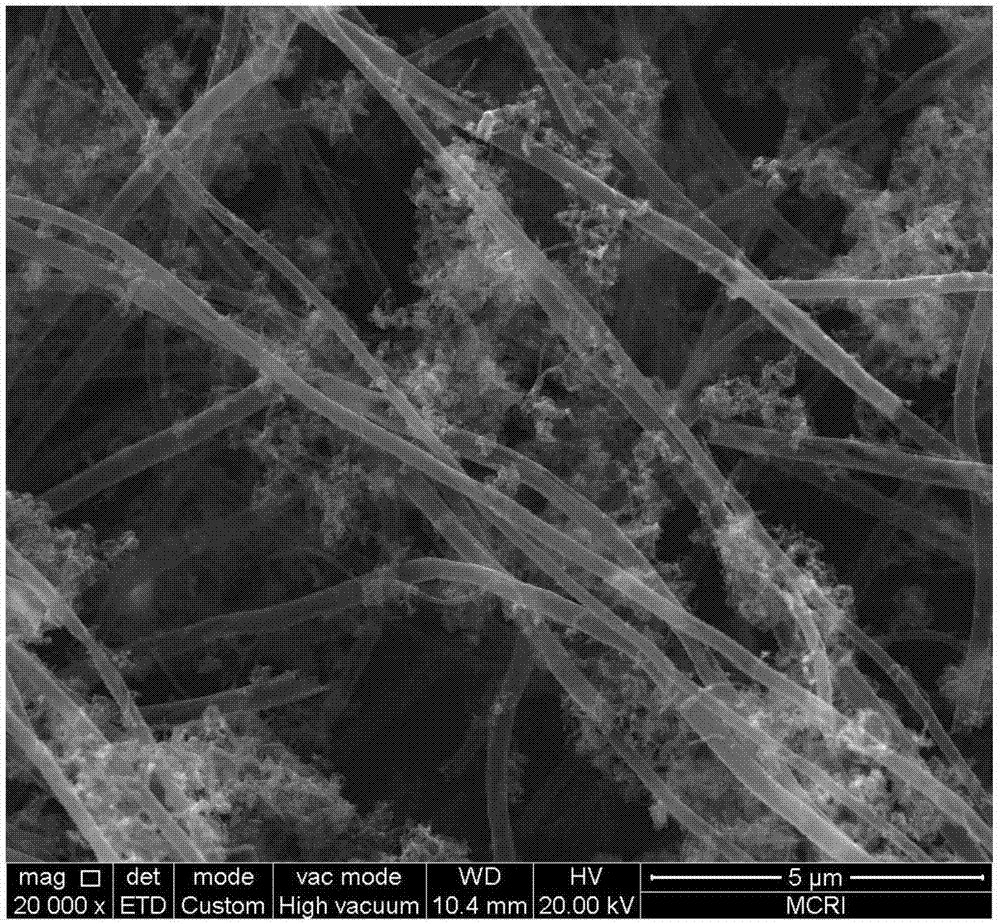

InactiveCN103896246ASimple processHigh yieldMaterial nanotechnologyHybrid capacitor electrodesCapacitancePolyphosphazene

The invention discloses a preparation method and application of a heteroatom-doped porous carbon nano-tube in the technical field of the inorganic carbon nano industry. The carbon nano-tube prepared by using a polyphosphazene nano-tube as a precursor has relatively large specific surface area, and abundant mesoporous structures are formed on the tube wall of the carbon nano-tube. According to the invention, the preparation process is simple in technology and high in yield; the prepared carbon nano-tube is regular in shape and appearance and high in heteroatom content, and has good capacitive performance when being used as an electrode material of a super-capacitor. Charge and discharge tests show that a sample subjected to carbonization at 900 DEG C has the specific capacity of 190F / g and excellent cycling stability.

Owner:SHANGHAI JIAO TONG UNIV

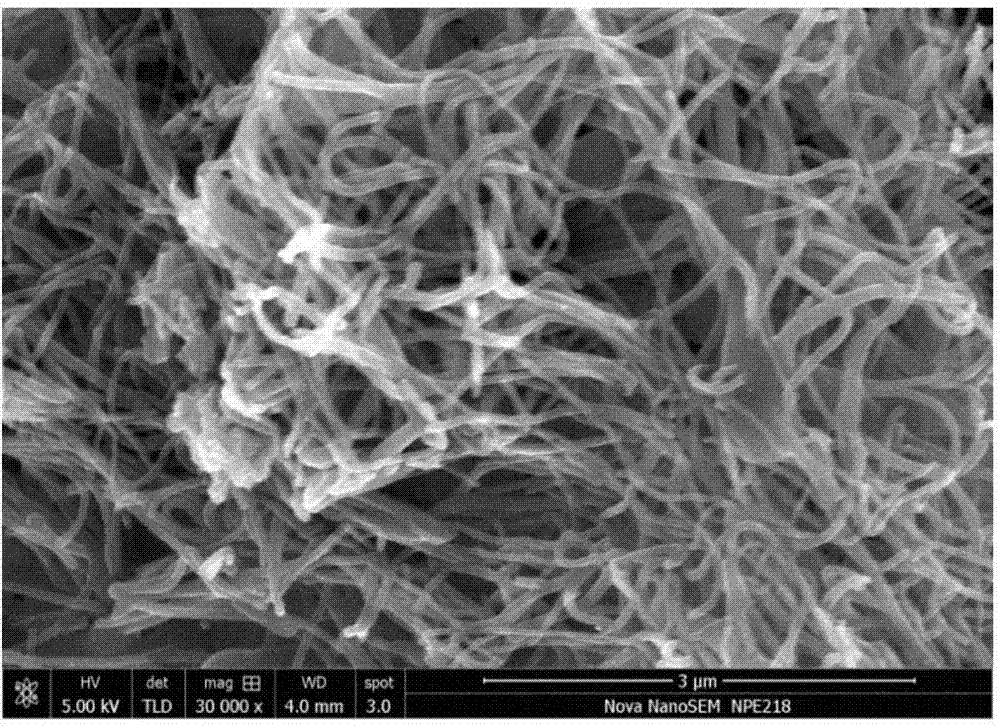

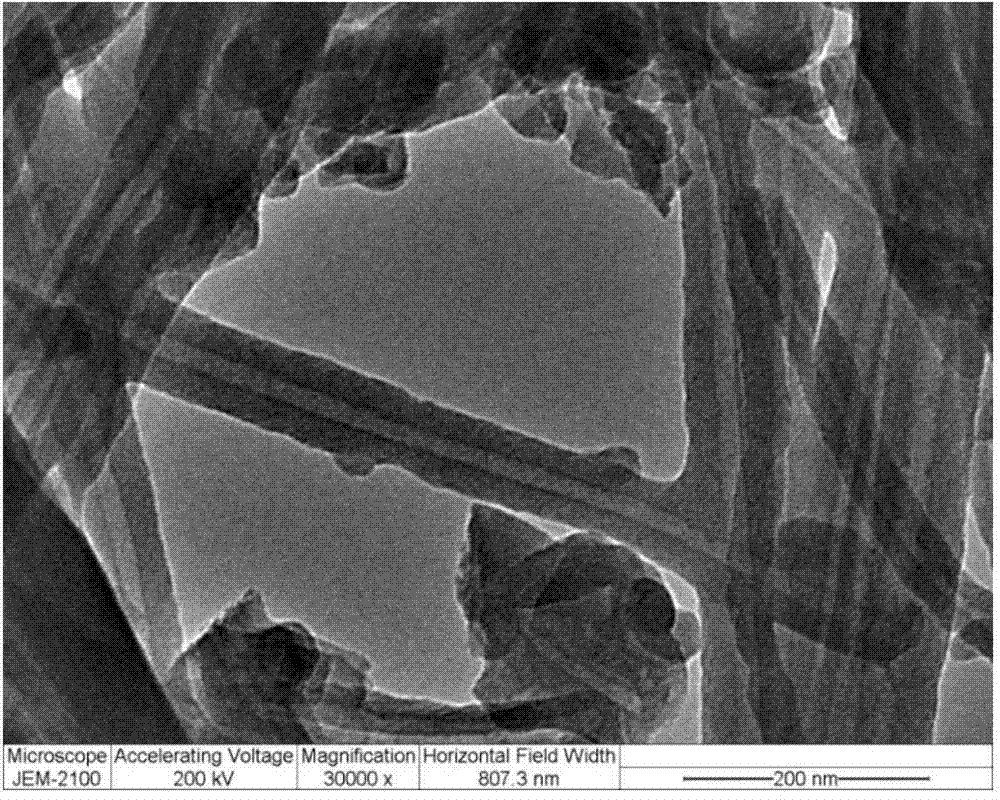

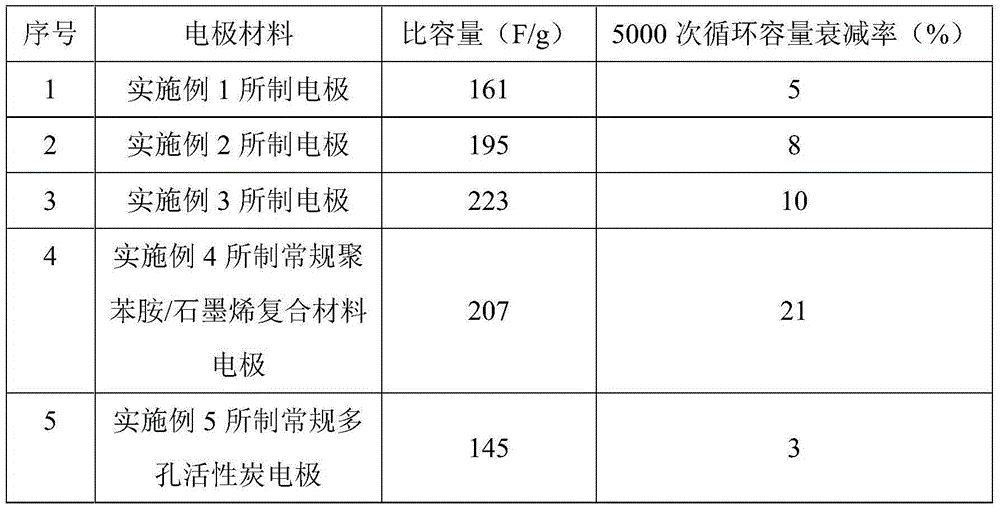

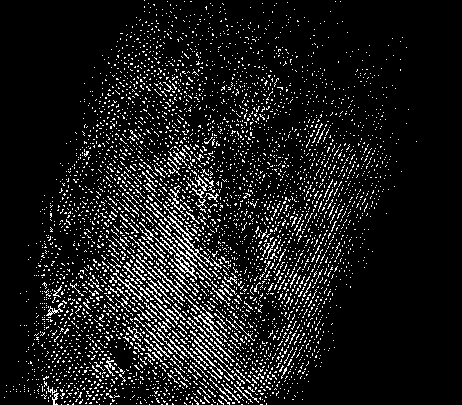

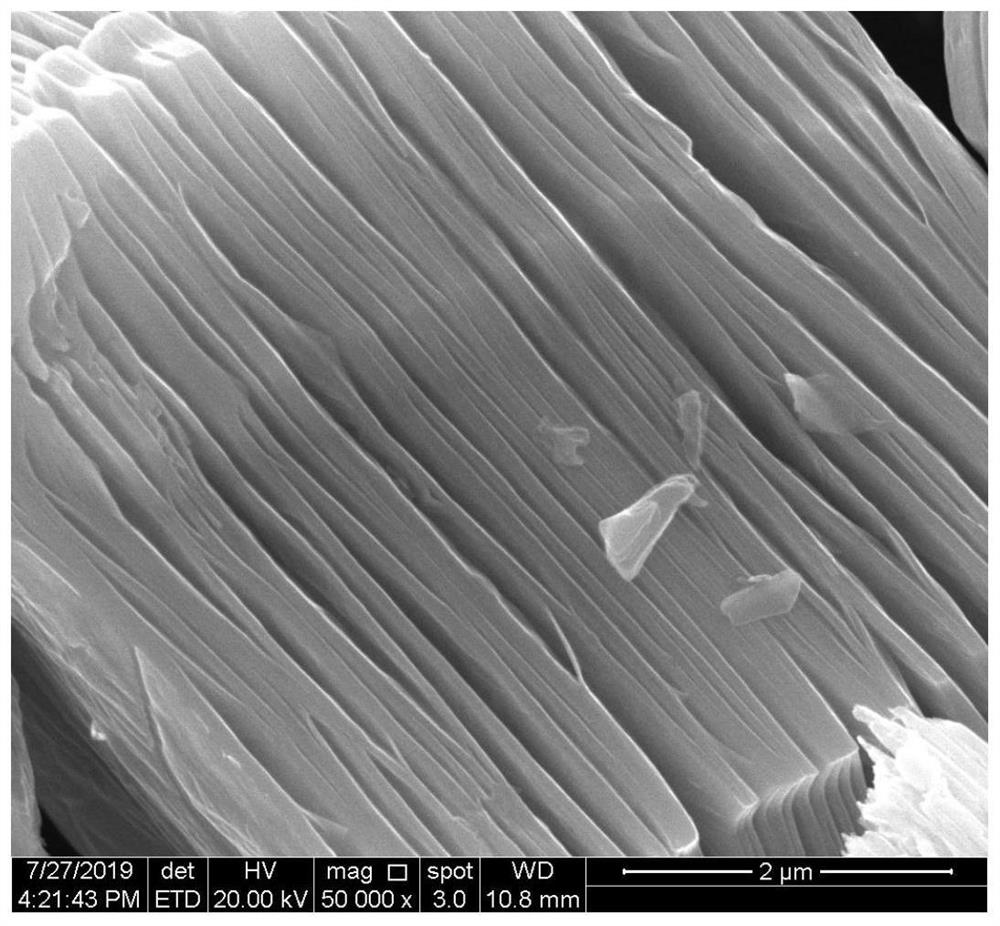

Polyaniline nanometer tube array/graphene composite material electrode and manufacturing method and application thereof

ActiveCN105206430AAchieve synergyImprove performanceHybrid capacitor electrolytesHybrid capacitor electrodesCapacitanceFiber

The invention provides a polyaniline nanometer tube array / graphene composite material electrode and a manufacturing method and application thereof, and belongs to the field of new energy products. The composite material electrode comprises a polyaniline nanometer tube array / graphene composite material and a conductive substrate. Graphene is doped in a polyaniline nanometer tube array to form a fiber-slice coexisting structure, the diameter of polyaniline nanometer tubes ranges from 150 nm to 300 nm, and the pipe spacing of the polyaniline nanometer tubes ranges from 300 nm to 400 nm. The conductive substrate is coated with the composite material to form the polyaniline nanometer tube array / graphene composite material electrode. The composite material electrode is high in conductivity and excellent in circulating performance and capacitance performance; the method for preparing the composite material electrode is easy to operate and friendly to the environment; a super capacitor with the composite material electrode is high in capacitance and good in circulating performance.

Owner:南京绿索电子科技有限公司

Activated graphene sheet and preparation method thereof

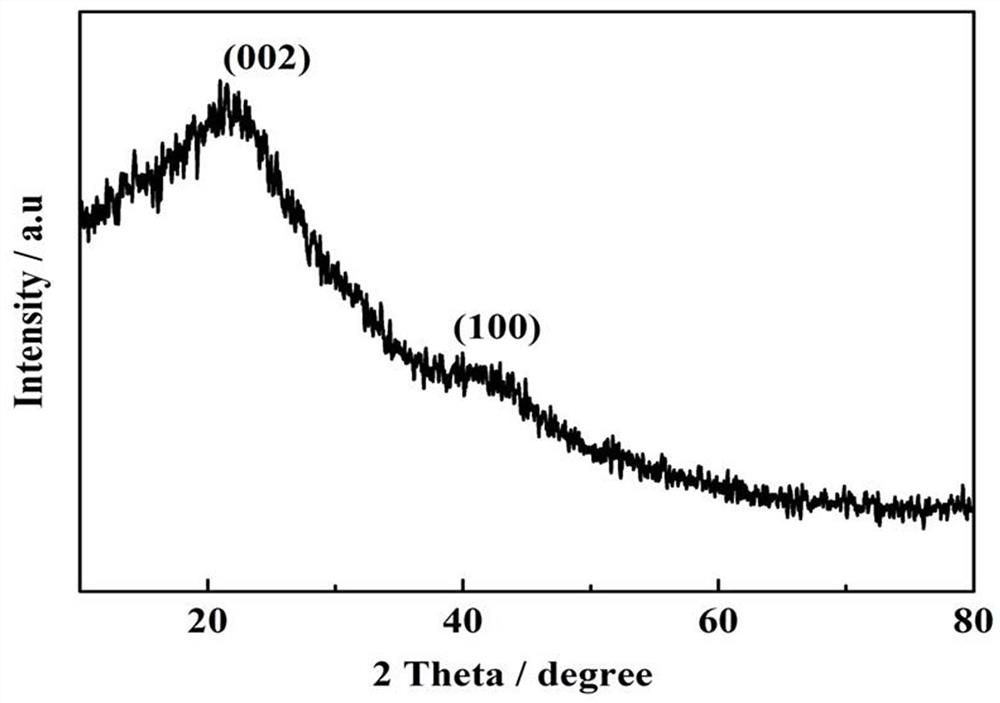

InactiveCN104045080AUniform pore size distributionImprove electrochemical performanceGraphene flakeGraphite

The invention provides an activated graphene sheet and a preparation method thereof. The preparation method of the activated graphene sheet comprises the steps of adding sulfuric acid, nitric acid and potassium permanganate to carry out intercalation treatment on a graphene sheet serving as a raw material and then carrying out KOH activation process. The activated graphene sheet disclosed by the invention has the advantages of good conductivity, large specific surface area, high mesopore content, less impurities, low production cost, low equipment investment, simple operation, excellent electrochemical properties and good physical and chemical stabilities and can be put into industrialization easily.

Owner:FUZHOU UNIV

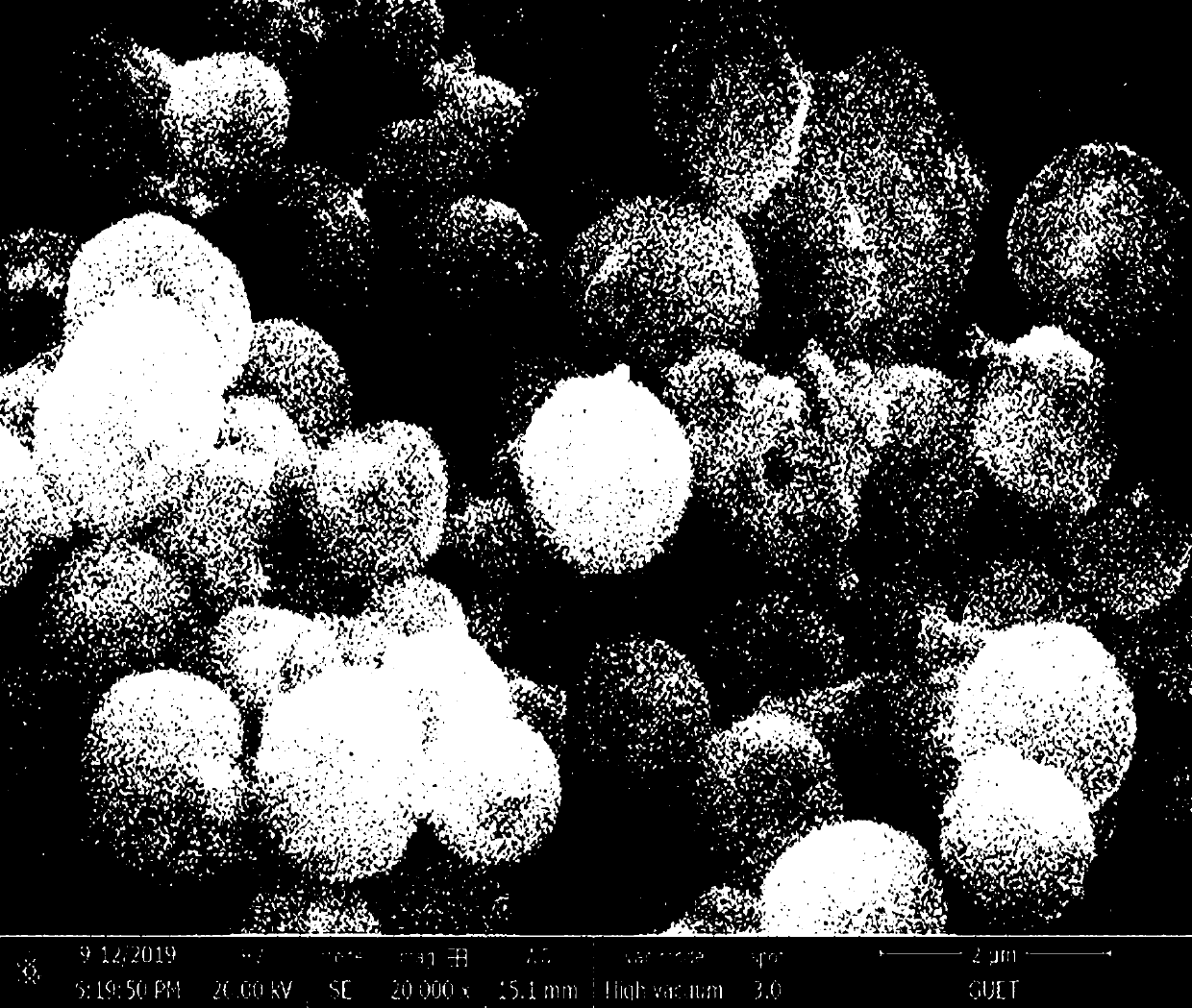

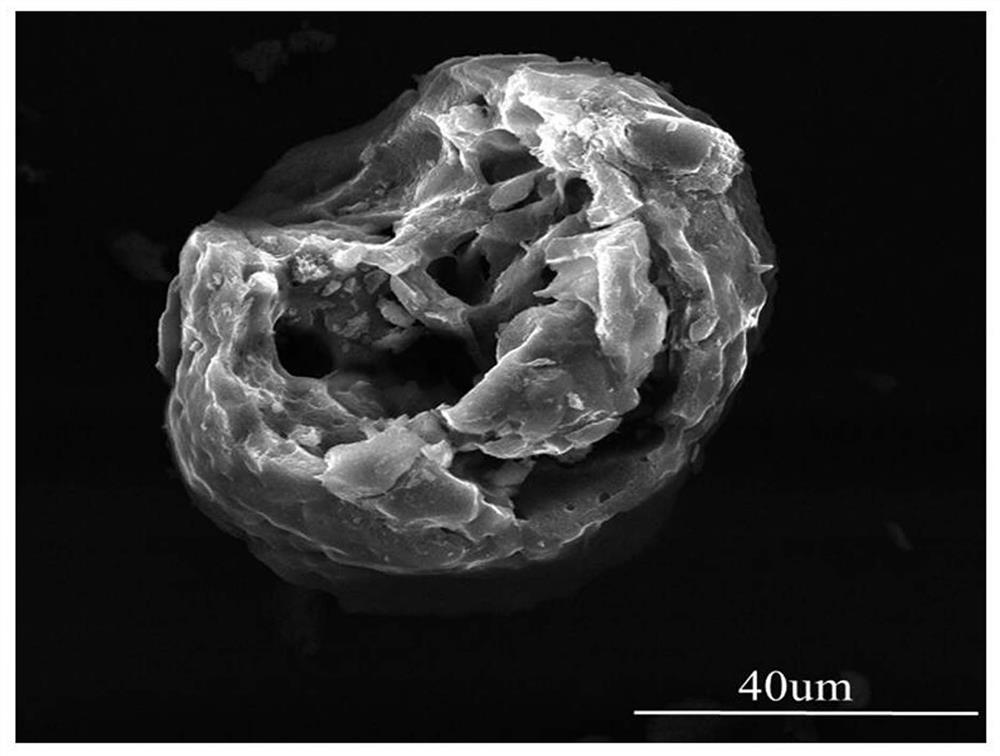

Yeast cell-based Ni-Co-S loaded porous carbon material as well as preparation method and application thereof

InactiveCN110942924AAvoid harmSolving Tolerance IssuesHybrid capacitor electrodesCarbon preparation/purificationPorous carbonCarbonization

The invention discloses a Ni-Co-S loaded porous carbon material based on yeast cells. The preparation method comprises the following steps: preparing carbonized yeast cell porous carbon, carrying outhydrothermal reaction on the carbonized yeast cell porous carbon, cobalt nitrate, nickel nitrate and urea, and oxidizing and vulcanizing to obtain the material, the obtained material is of a core-shell structure, and cobalt and nickel elements are uniformly loaded on the surface of the yeast cell porous carbon in the form of NiCo2S4; wherein the shell-core structure is formed by carbonizing ellipsoidal single-cell fungal yeast, and carbonized yeast cells are of a hollow carbon sphere structure. The preparation method comprises the following steps: 1) preparing yeast cell porous carbon; 2) adsorbing cobalt-nickel metal ions by yeast cell porous carbon; and 3) vulcanizing the yeast cell porous carbon adsorbing the cobalt-nickel metal ions. When the material is used as a supercapacitor, the material is charged and discharged in a range of-0.2 to 0.5, and when the discharge current density is 1 A / g, the specific capacitance is 700 to 800 F / g. The invention has the following advantages: noharm is caused to human body; and the tolerance problem of the yeast cell metal salt solution is solved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

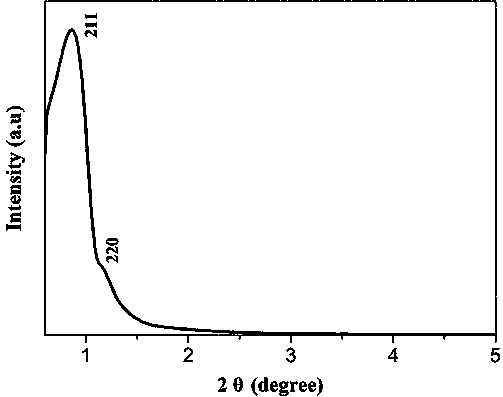

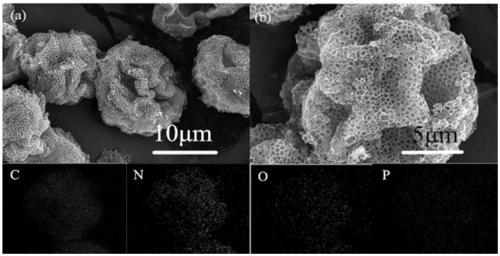

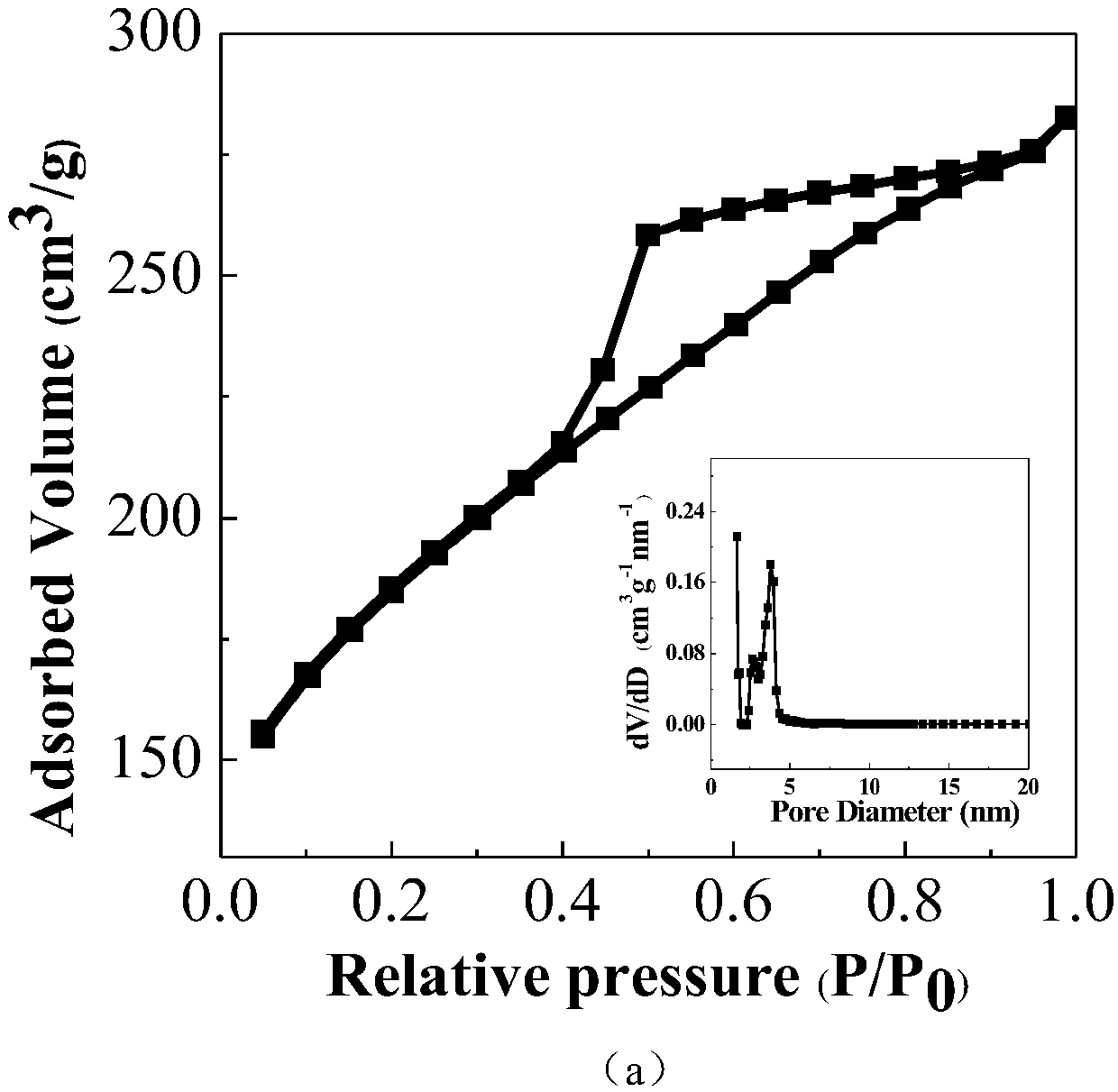

Preparation method of nitrogen, phosphorus, and sulfur ternary co-doped ordered mesoporous carbon material

InactiveCN108288547ACapacitive increasePromote wettingHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceSucrose

The invention relates to a preparation method of a nitrogen, phosphorus, and sulfur ternary co-doped ordered mesoporous carbon material and aims to solve the problem of limitation of existing single heteroatom doping on improvement of capacity of the mesoporous carbon material. The preparation method comprises the steps of preparing an ordered mesoporous silicon dioxide template (KIT-6); stirringand aging a sucrose, phosphoric acid and thiosemicarbazide mixed solution and a KIT-6 dispersion liquid for 10-14 hours under 40-60 DEG C; placing the obtained paste compound in a drying oven for drying for 10-14 hours under 70-90 DEG C; placing the product in a tubular furnace for pyrolysis for 1-3 hours under high-pure nitrogen (the nitrogen flowing rate is 50mL / s) at 700-900 DEG C, wherein theheating rate is 2 DEG C per minute; and immersing the carbonized composite material in an HF solution, performing stirring to remove the silicon dioxide template, performing filtering, washing with ultrapure water and ethyl alcohol, and obtaining the nitrogen, phosphorus, and sulfur ternary co-doped ordered mesoporous carbon material (NPS-OMC) after drying. The nitrogen, phosphorus, and sulfur ternary co-doped ordered mesoporous carbon material is prepared by the template and by nanometer pouring, and the specific capacity of the material electrode can reach 343F / g.

Owner:QIQIHAR UNIVERSITY

Preparation method of graphene nickel foam electrode

ActiveCN107967998ASave raw materialsEasy to operateHybrid capacitor electrodesCell electrodesCvd grapheneGraphene electrode

The invention relates to a preparation method and application of a graphene nickel foam electrode. The preparation method comprises the steps of cleaning and drying nickel foam as a working electrode,carrying out scanning in a graphene oxide dispersion liquid by using a cyclic voltammetry to prepare a graphene oxide nickel foam electrode; and drying and then carrying out constant-potential reduction in a glycine-hydrochloric acid buffer solution to obtain the graphene nickel foam electrode. Compared with the preparation methods of other graphene electrodes, the preparation method of the graphene nickel foam electrode has the advantages of being cheap in raw materials, free of pollution, green and environment-friendly, and mass production is facilitated. The graphene nickel foam electrodesupported through the nickel foam has good capacitive performance in a neutral electrolyte and can be applied to the field of energy storage.

Owner:NORTHEASTERN UNIV

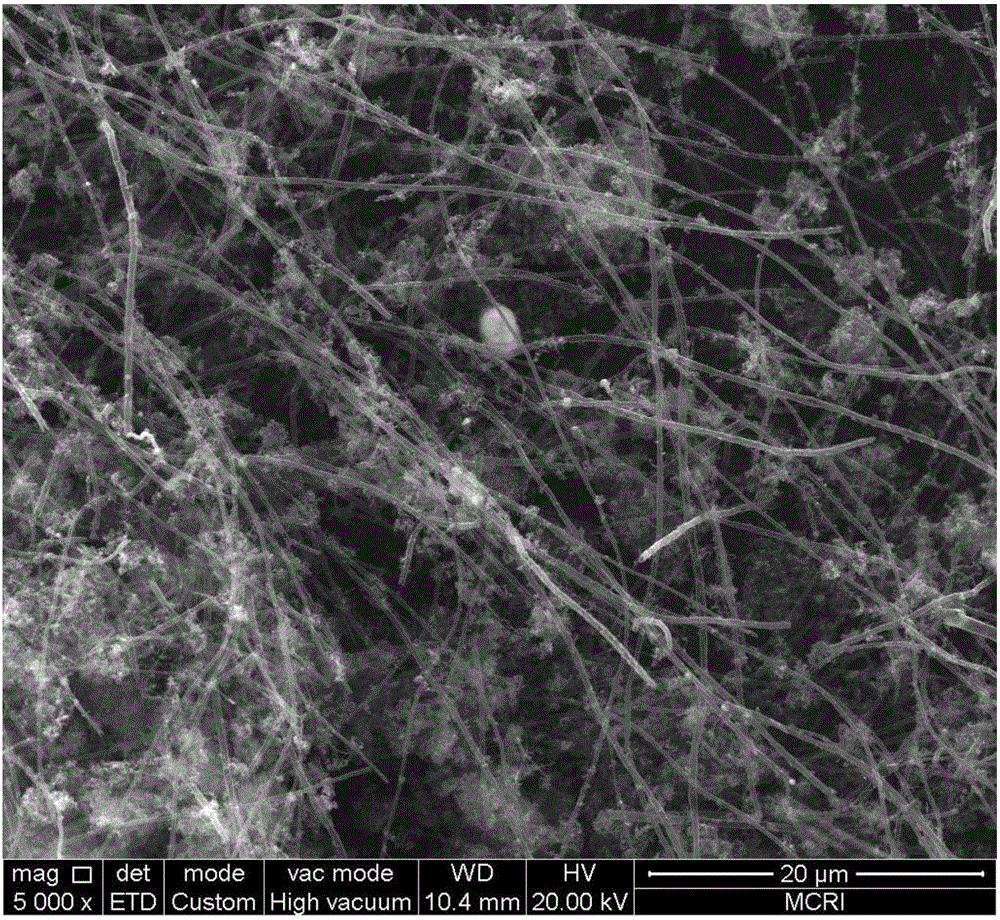

Preparation method of N-doped carbon nanotube/nickel cobalt oxide/N-doped porous carbon

ActiveCN108417402AImprove Capacitive PerformanceGood electrical conductivityMaterial nanotechnologyHybrid capacitor electrodesCobalt oxideCapacitance

The invention discloses a preparation method of N-doped carbon nanotube / nickel cobalt oxide / N-doped porous carbon. The method comprises the steps of (1) adding coal-based polyaniline to a nickel acetate solution to obtain paste A; (2) adding the coal-based polyaniline to a cobalt oxalate suspension to obtain paste B; (3) pyrolyzing the paste A; (4) pyrolyzing the paste B; (5) mixing products, which are collected through twice pyrolysis, on a quartz plate evenly and marking quartz plate products; (6) mixing a quartz boat product A, a quartz boat product B and the quartz plate products evenly toobtain mixed powder; (7) carrying out hydrothermal reaction to obtain a black sediment; and (8) washing, drying and burning to obtain N-doped carbon nanotube / nickel cobalt oxide / N-doped porous carboncomposite powder. The prepared N-doped carbon nanotube / nickel cobalt oxide / N-doped porous carbon composite powder has relatively low internal resistance and charge transfer resistance, relatively high specific capacitance and relatively good rate characteristics and cycling stability.

Owner:XIAN UNIV OF SCI & TECH

Preparation method for ferric oxide/carbon nanotube composite electrode material based on microwave irradiation

InactiveCN107910191AThe process steps are simpleReduce pollutionHybrid capacitor electrodesIron oxideCarbon nanotube

The invention discloses a preparation method for a ferric oxide / carbon nanotube composite electrode material based on microwave irradiation. Carbon nanotubes are ultrasonically dispersed into aqueoussolution of ferrous sulfate; excessive hydrogen peroxide is added drop by drop; reflux reaction is carried out under the microwave irradiation, thereby preparing a ferric oxide / carbon nanotube composite electrode material precursor; and the precursor is annealed under an inert atmosphere, thereby obtaining the ferric oxide / carbon nanotube composite electrode material. The preparation method provided by the invention is simple, rapid and environmentally friendly and is low in cost. The prepared composite electrode material has relatively high specific capacitance and rate performance.

Owner:TAIYUAN UNIV OF TECH

Combined preparation method of carbon micro-nanotubes and N-doped porous carbon/nickel manganese oxide

ActiveCN106348276AImprove Capacitive PerformanceSolve the emission problemMaterial nanotechnologyHybrid capacitor electrodesCapacitancePyrolysis

The invention discloses a combined preparation method of carbon micro-nanotubes and N-doped porous carbon / nickel manganese oxide. The method comprises the following steps: 1, preparing coal-based polyaniline; 2, putting nickel acetate and the coal-based polyaniline into anhydrous ethanol to obtain paste; 3, coating a quartz plate with a nickelocene solution in a spinning way; 4, putting the paste into a first temperature area of a horizontal tube type atmosphere furnace, and putting the quartz plate into a second temperature area; 5, introducing nitrogen into the furnace, heating up, collecting the product carbon micro-nanotubes on the quartz plate, and collecting the product in a quartz boat of the first temperature area; 6, treating the product in the quartz boat; 7, carrying out suction filtration and then washing, carrying out vacuum drying, and calcining to obtain the N-doped porous carbon / nickel manganese oxide. According to the method, hydrogen-containing gaseous hydrocarbon generated by cracking is effectively utilized in a pyrolysis process of the coal-based polyaniline, and is enabled to crack on the surface of nickel and deposit to form the carbon micro-nanotubes; furthermore, alpha-MnO2 and NiMn2O4 are also generated while the nickel is oxidized into NiO, so that the capacitance performance of a composite material is comprehensively improved.

Owner:XIAN UNIV OF SCI & TECH

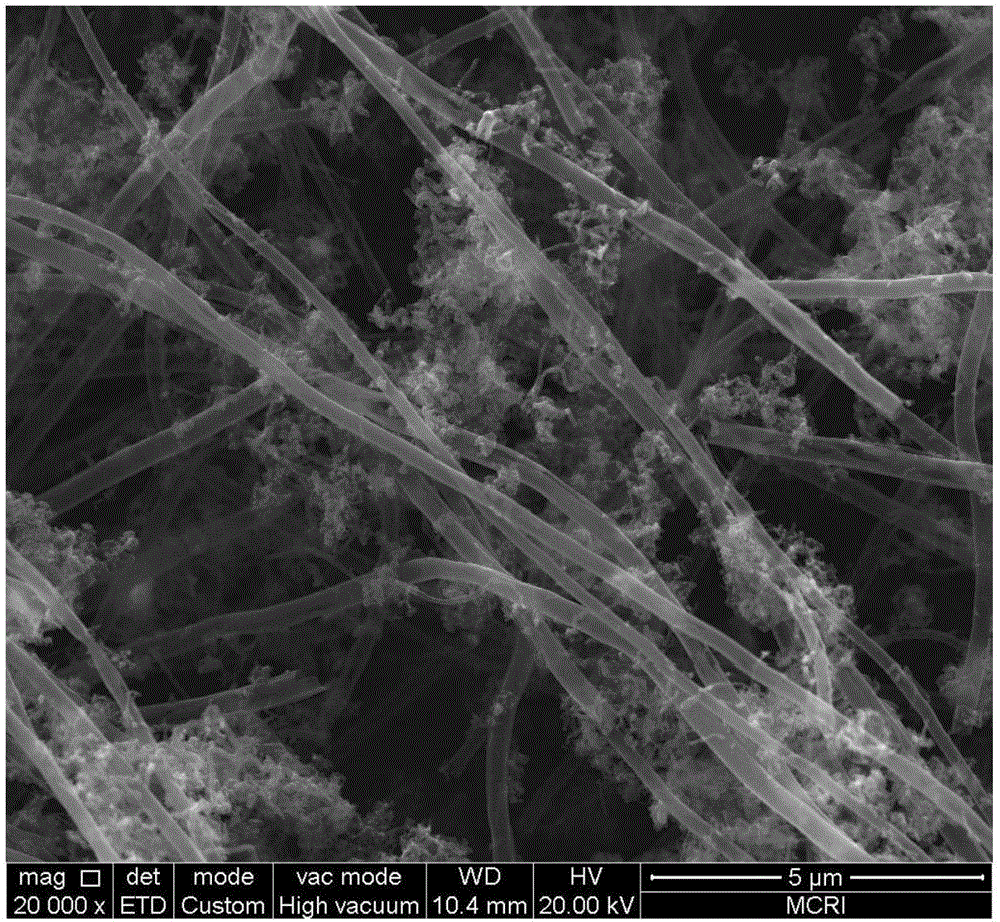

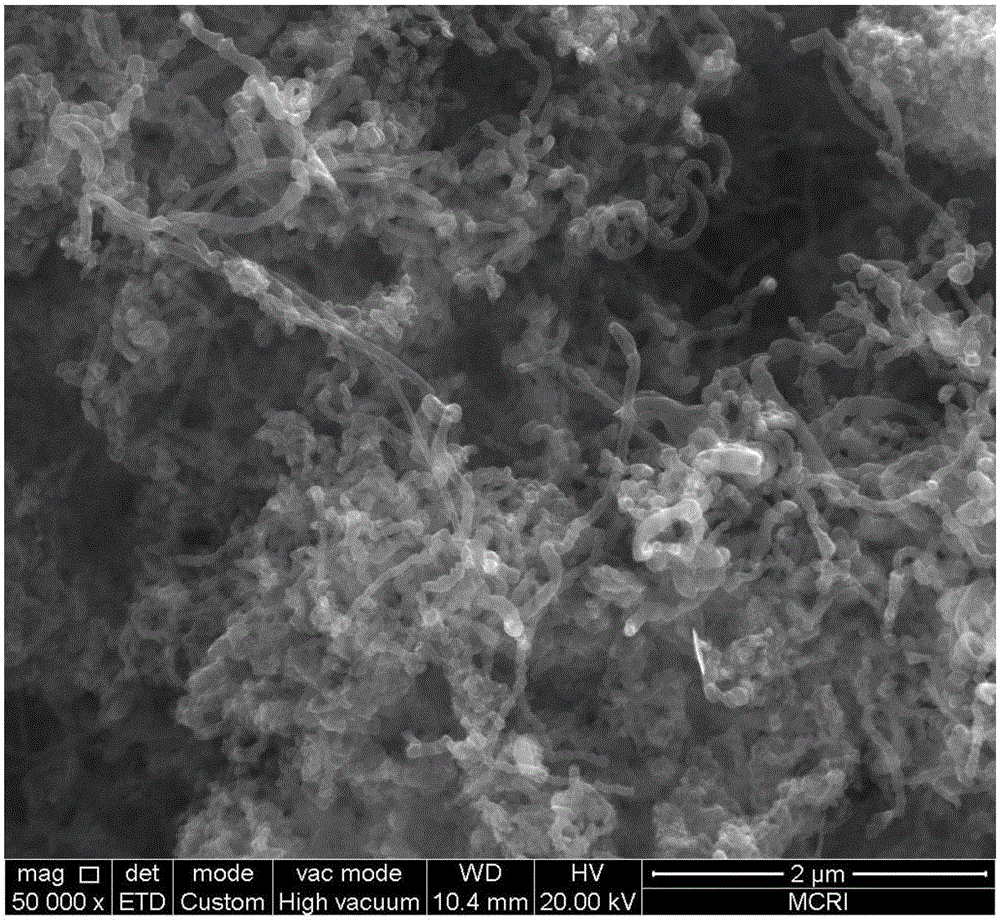

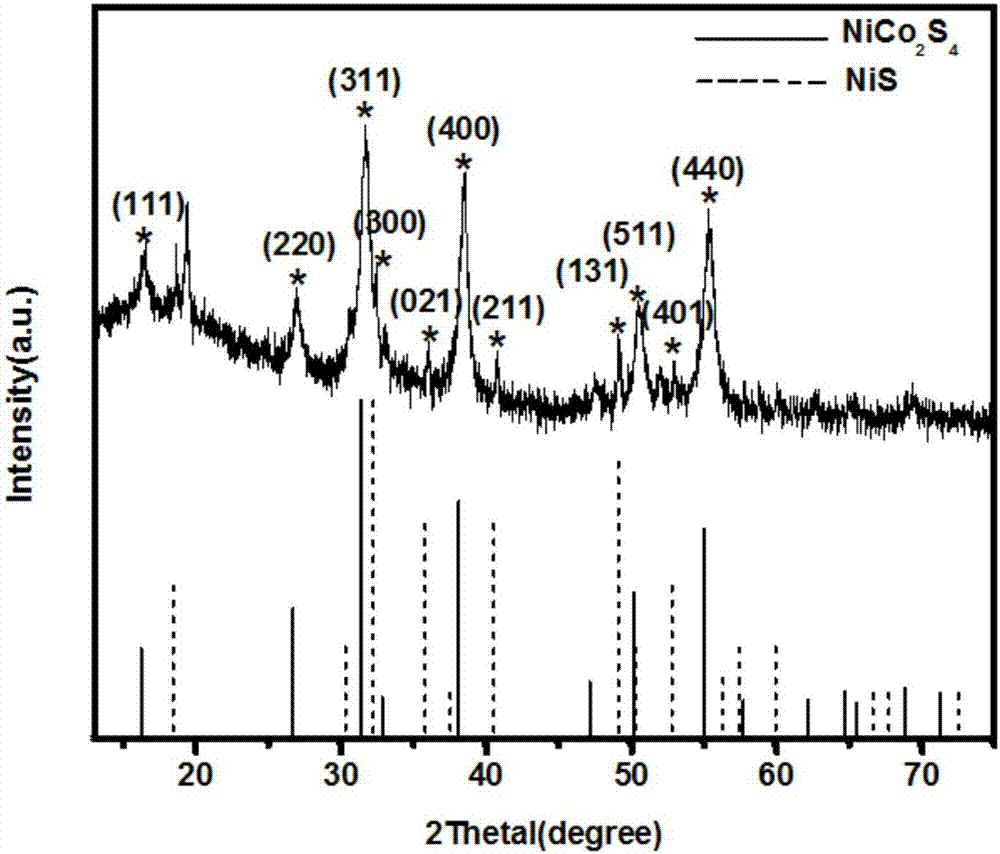

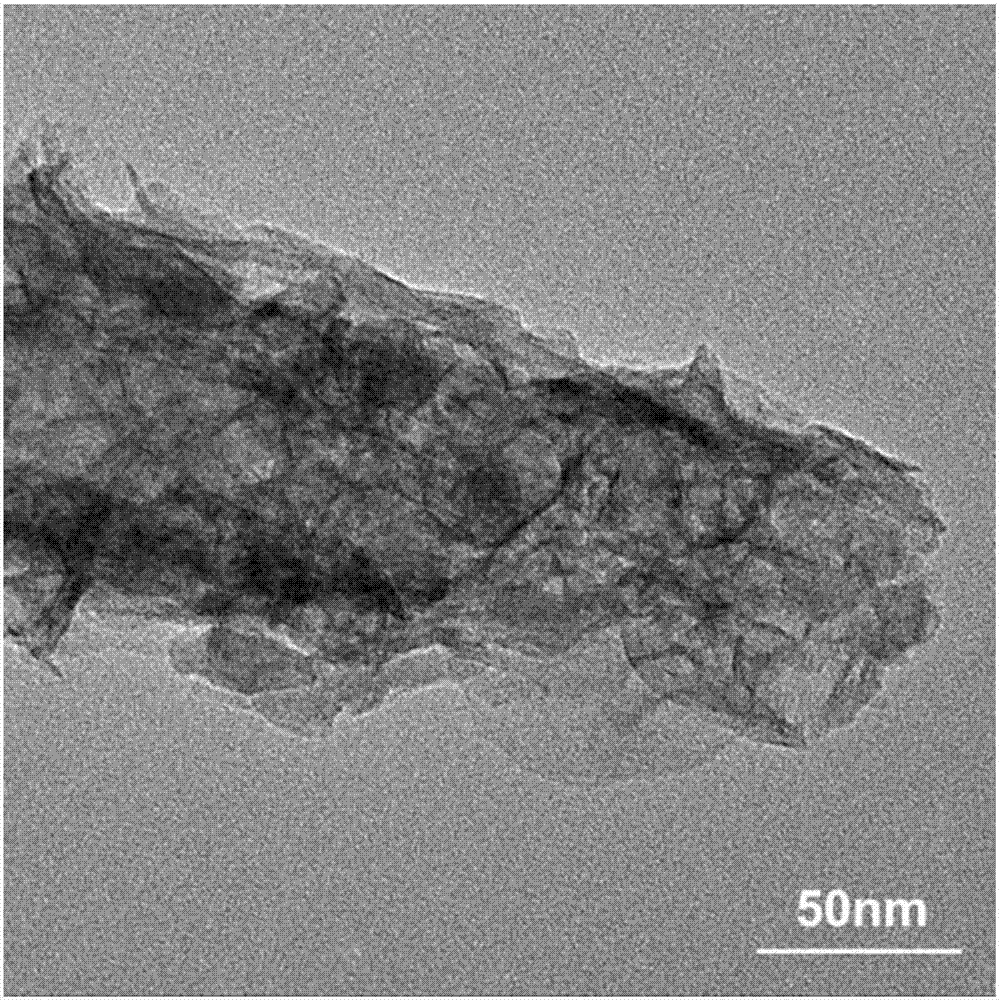

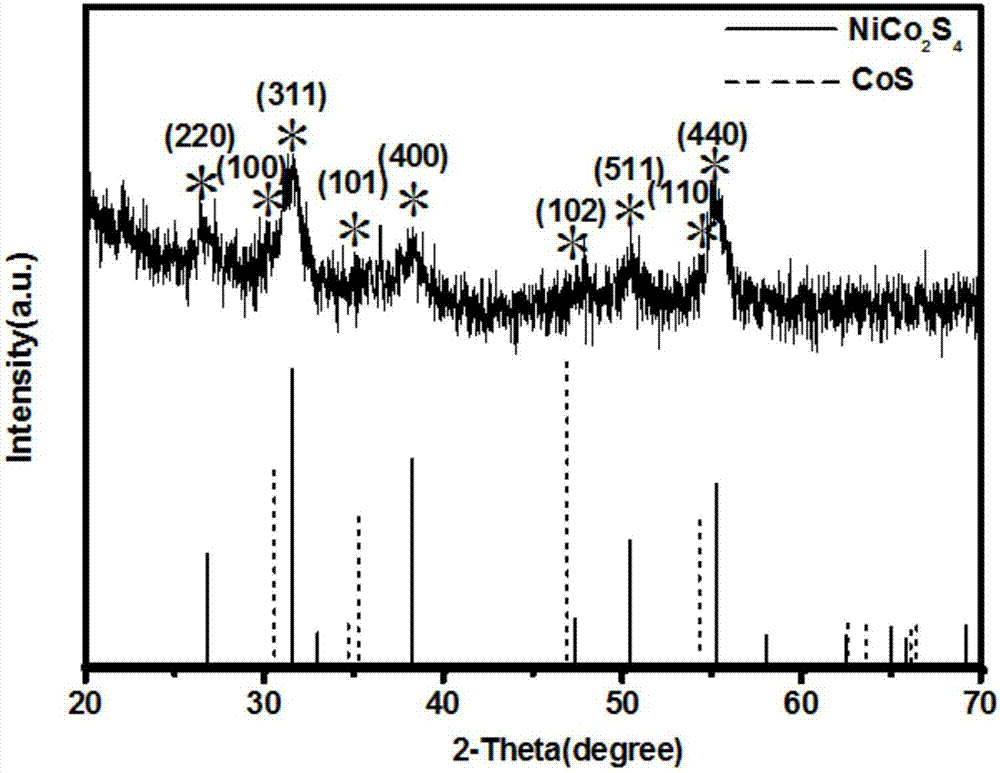

NiCo2S4/XS (X=Ni, Co) composite nanometer material and preparation method and application thereof

InactiveCN106898501AAvoid using influenceLow priceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceAdhesive

The invention discloses a NiCo 2 S 4 / XS (X=Ni, Co) composite nanomaterial and its preparation method, a composite nanomaterial NiCo was prepared on the foamed nickel substrate through two steps of hydrothermal and vulcanization. 2 S 4 / XS (X=Ni, Co) and use it as the electrode material of the supercapacitor. Compared with other materials, the doping of Ni and Co can improve the electrode surface roughness, conductivity, provide faster ion and electron transfer, and promote the Faradaic reversible reaction. As an electrode material without binder, the material exhibits excellent pseudocapacitive performance, and the preparation method is simple and novel.

Owner:HUAQIAO UNIVERSITY

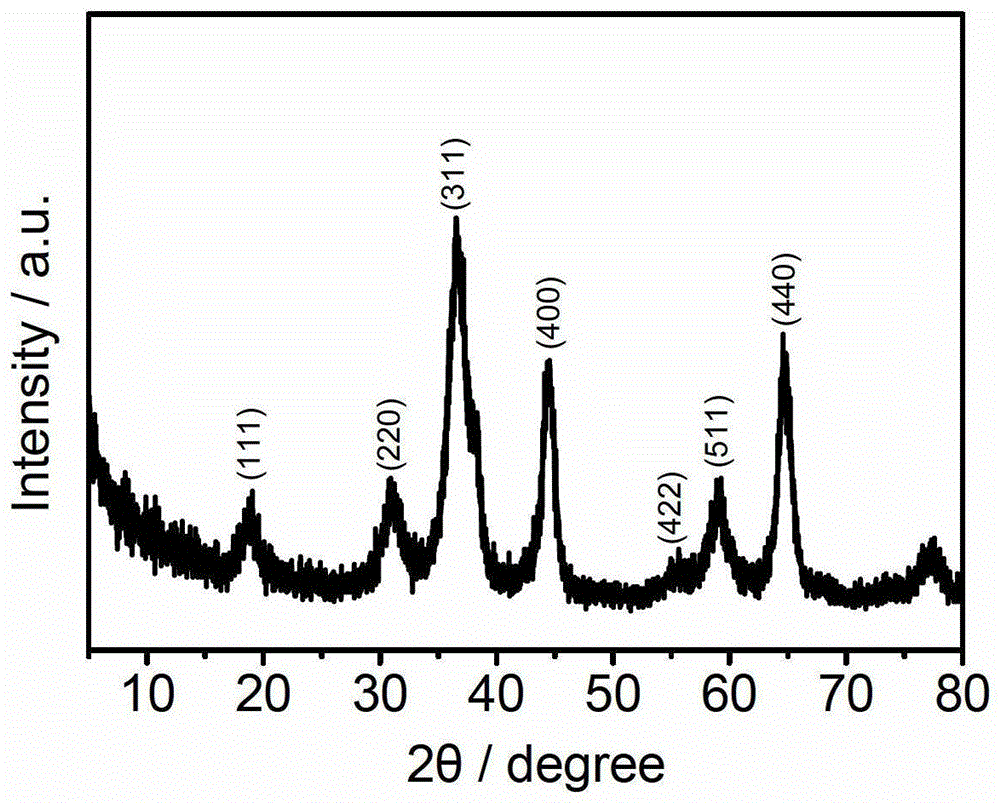

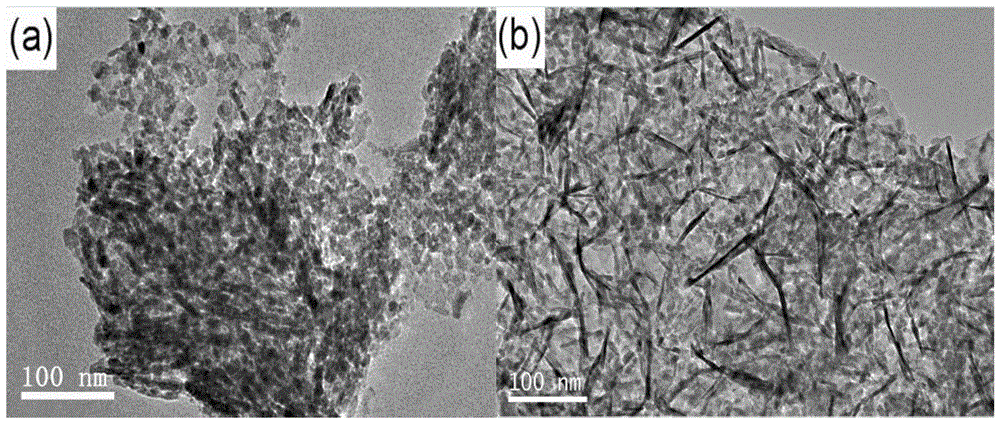

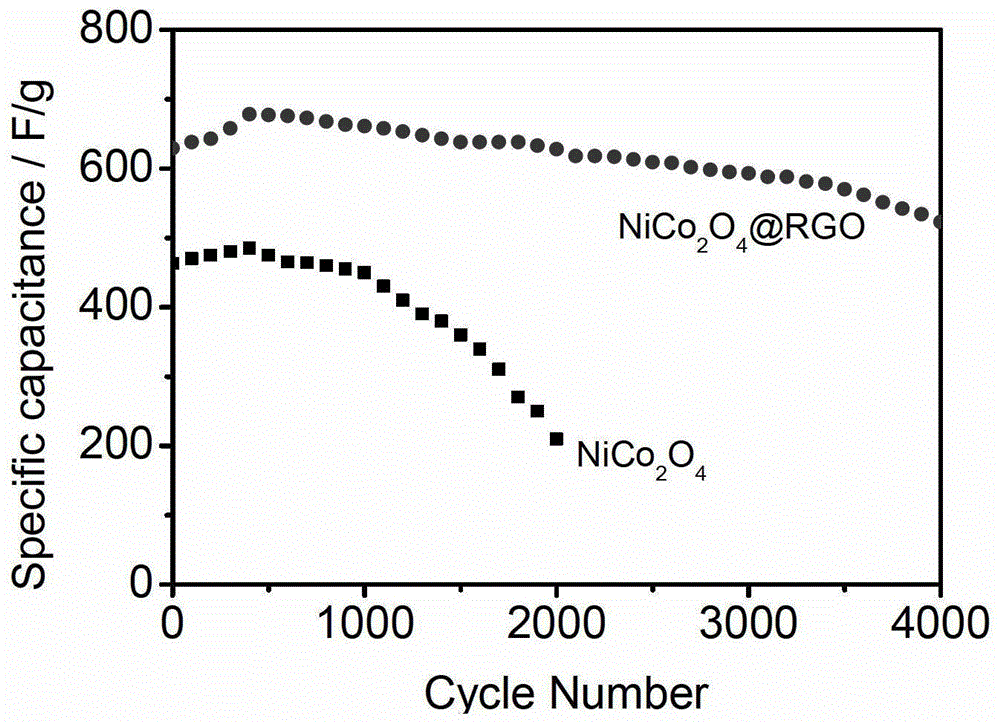

A kind of nickel cobalt oxide graphene composite material and its application and preparation method

The invention relates to a nickel cobaltate-graphene composite material and a preparation method thereof. The composite material comprises graphene and nickel cobaltate, wherein nickel cobaltate nanowires are uniformly grown on a graphene sheet, the wire length of the nickel cobaltate nanowires is 50-300nm, and the wire width is 5-30nm. The preparation method comprises the following steps of: taking a graphene oxide water solution and a cobalt salt and nickel salt water solution which are dispersed in an ultrasonic manner, mixing, further adding a precipitator, uniformly stirring and mixing, transferring into a high-temperature reaction kettle, performing hydro-thermal reaction for a certain period of time, filtering, washing and drying an obtained product, and further performing thermal treatment so as to obtain the nickel cobaltate nanowire-graphene composite material. The nickel cobaltate nanowire-graphene composite material prepared by the method disclosed by the invention has the advantages of high single-electrode capacitance and good cycle performance, and is suitable for being used as an electrode material of a super-capacitor.

Owner:CHANGZHOU UNIV

Cobalt sulfide/g-C3N4 composite electrode material with two-dimensional hollow nano sheet structure and preparation method thereof

ActiveCN110697794AImprove electrochemical performanceComplete structureCobalt sulfidesHybrid capacitor electrodesCapacitanceElectrolyte

The invention provides a cobalt sulfide / g-C3N4 composite electrode material with a two-dimensional hollow nano-sheet structure and a preparation method thereof. The invention provides the preparationmethod of the cobalt sulfide / g-C3N4 with the two-dimensional hollow nano-sheet structure. Specifically, g-C3N4 is added into a reaction solution containing a cobalt salt, C4H6N2 and a solvent, cobaltions react with C4H6N2 to form a two-dimensional nano-sheet precursor in situ on the g-C3N4, then a sulfur source is added, and the cobalt sulfide / g-C3N4 composite electrode material with the two-dimensional hollow nano-sheet structure is obtained through hydrothermal reaction. The preparation process of the material is simple, the cost is low, and no pollution is caused. The composite electrode material can increase the contact area between an electrolyte solution and an electrode material, shorten the ion transmission path, accelerate the ion transmission rate and increase the conductivity.As the electrode material of a supercapacitor, the material has excellent specific capacitance and cycle stability.

Owner:NINGBO UNIV

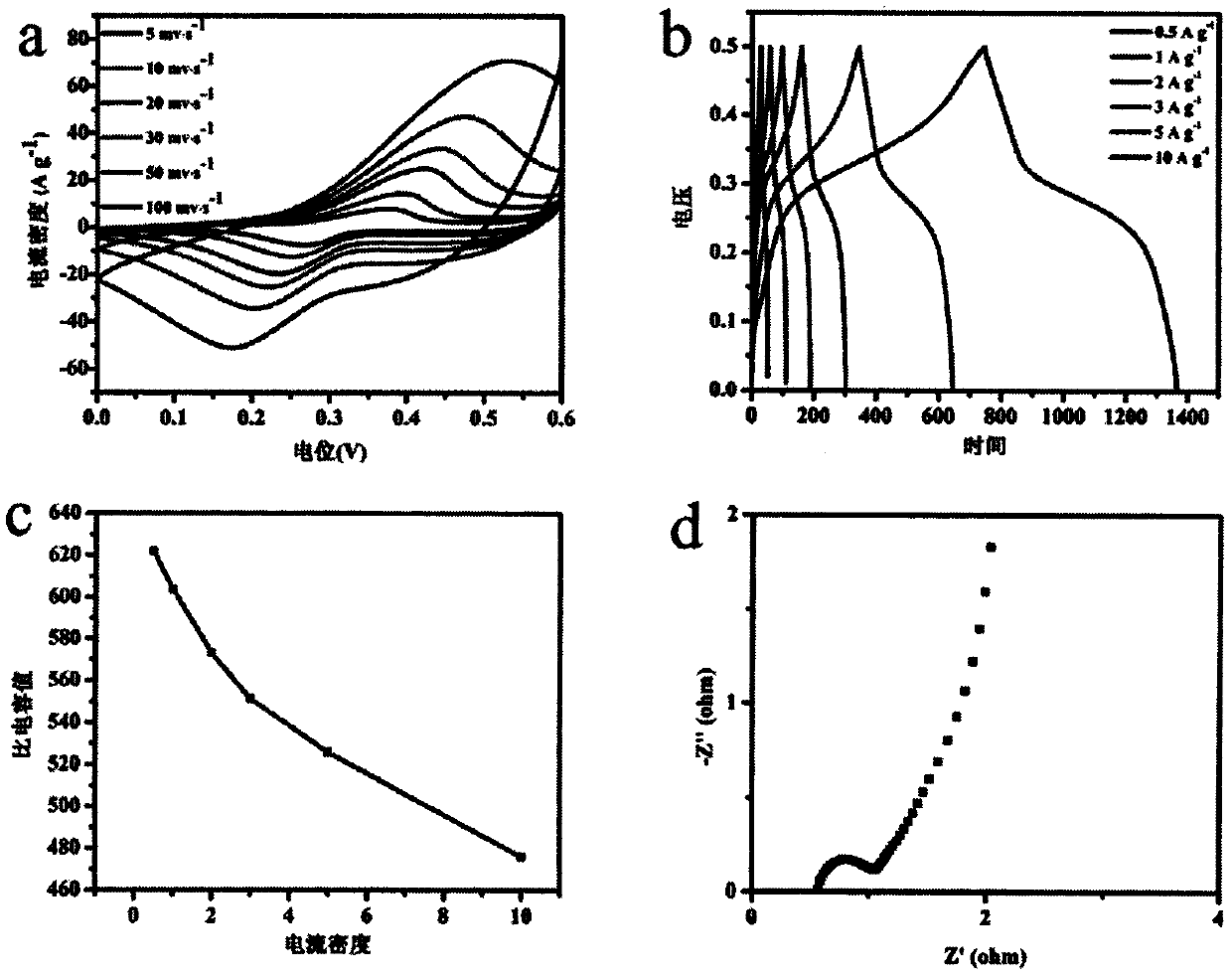

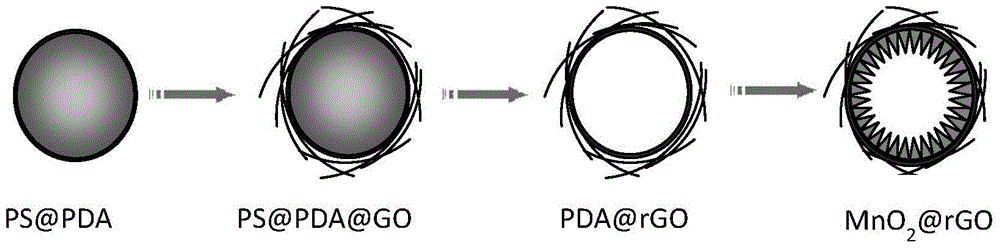

A kind of porous graphene/mno 2 Composite film and its preparation method and application

ActiveCN103903879BIncrease contact areaImprove mechanical propertiesHybrid capacitor electrodesHybrid/EDL manufacturePorous grapheneComposite film

The invention relates to a porous grapheme / MnO2 composite film and a preparation method and application thereof. The preparation method comprises the following steps of (1), providing a ball-shaped formwork and coating the surface of the ball-shaped formwork with a polymer layer; (2) providing graphene oxide solution, evenly mixing a small formwork ball coated with the polymer layer obtained in the step (1) with the graphene oxide solution, performing vacuum filtration, and stripping the composite film from a filter membrane after drying; (3) performing high temperature annealing on the composite film obtained in the step (2) to obtain a film of a porous structure; (4) putting the film obtained in the step (3) into potassium permanganate solution to perform hydrothermal reaction to obtain the porous grapheme / MnO2 composite film. No any binder or conductive agent is needed to be added to the porous composite film prepared by the method, and the porous composite film is good mechanical property and super capacitive performance, has the advantages of being good in high-rate charge and discharge performance, long in circle life and the like, and can be applied to preparing super-capacitors and improve performance of super-capacitors greatly.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Preparation method of nanoporous gold/manganese dioxide composite electrode material

ActiveCN107622878AGood specific capacitance characteristicsCapacitanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceComposite electrode

The invention discloses a preparation method of a nanoporous gold / manganese dioxide composite electrode material. The preparation method includes the following steps: (1) taking and de-alloying an Au35Ag65 alloy film, and preparing a nanoporous gold film; and (2) processing the nanoporous gold film through an atomic layer deposition method, taking Mn(thd)3 and ozone as a precursor, controlling thereaction temperature at 150-250 DEG C, carrying out Mn(thd)3 pulsing, N2 cleaning, O3 pulsing and N2 cleaning, repeating the deposition for 500-5000 cycles, and uniformly depositing manganese dioxideon the inner and outer surfaces of the nanoporous gold film to get a nanoporous gold / manganese dioxide composite electrode material. The composite electrode material of the invention has good specific capacitance characteristic, a controllable structure and stable performance.

Owner:NAT UNIV OF DEFENSE TECH

A One-step Synthesis Method of Monolayer Manganese Dioxide Nanosheets

InactiveCN104310486BPlay multiple rolesLow toxicityMaterial nanotechnologyManganese oxides/hydroxidesElectrochemistryHydrolysis

Owner:JILIN UNIV

Preparation method of Ni(OH)2/graphene composite material and preparation method of supercapacitor

ActiveCN113415831AReduce surface functional groupsAvoid reunionHybrid capacitor electrodesGraphenePorous grapheneGraphite oxide

The invention discloses a preparation method of a Ni(OH)2 / graphene composite material, which comprises the following steps of adding porous graphene oxide dispersion liquid into N, N-dimethylformamide, adding nickel acetate, reacting at constant temperature, centrifuging and washing, and dissolving the washed product in water, carrying out hydrothermal reaction, and after the reaction is finished, drying to obtain the Ni(OH)2 / graphene composite material. The invention also provides a method of the supercapacitor. The method comprises the following steps that Ni(OH)2 / HGO ink is prepared from the Ni(OH)2 / graphene composite material; and the silver paste and the Ni(OH)2 / HGO ink are sequentially overlaid and brushed on a PET plate through silk-screen printing to form a pattern, and drying is carried out to complete the preparation of the supercapacitor. According to the Ni(OH)2 / HGO composite nano material prepared by the invention, the voltage window of the supercapacitor can be improved to a great extent, so that the energy density of the supercapacitor is improved to a great extent.

Owner:HUNAN UNIV

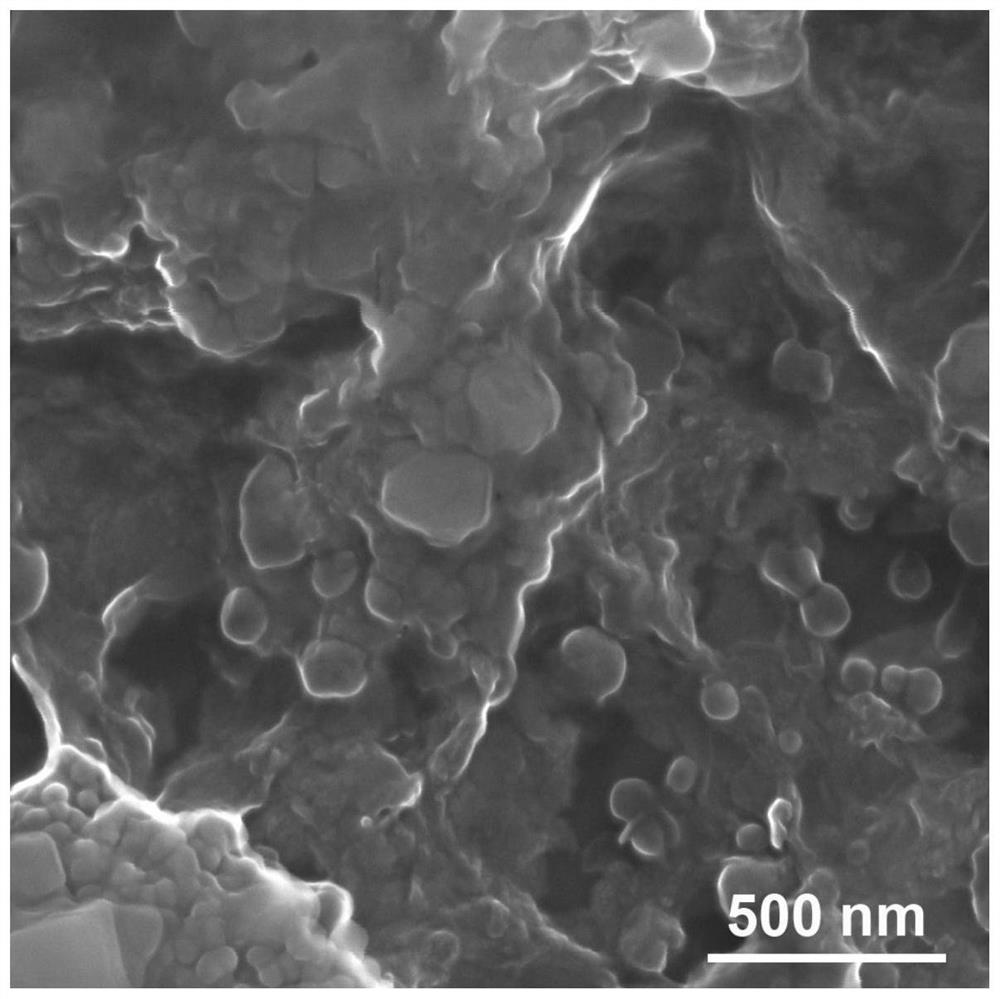

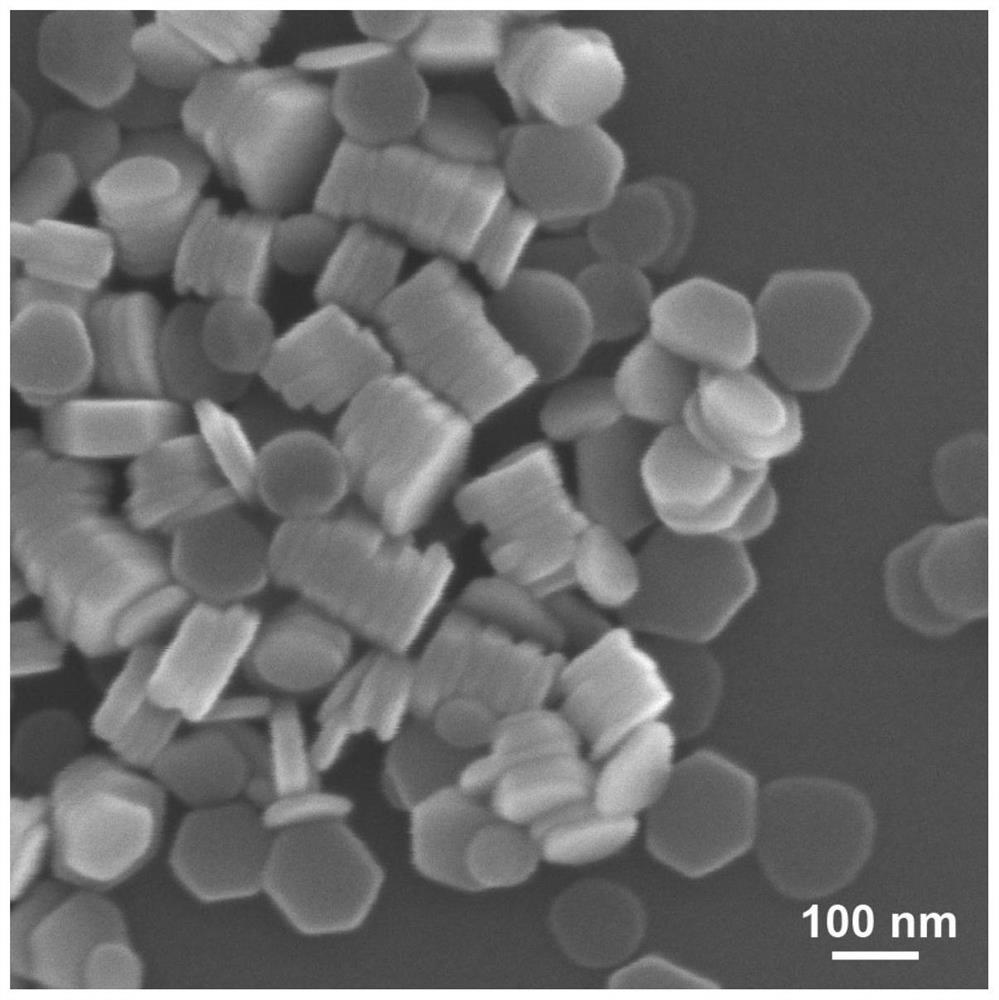

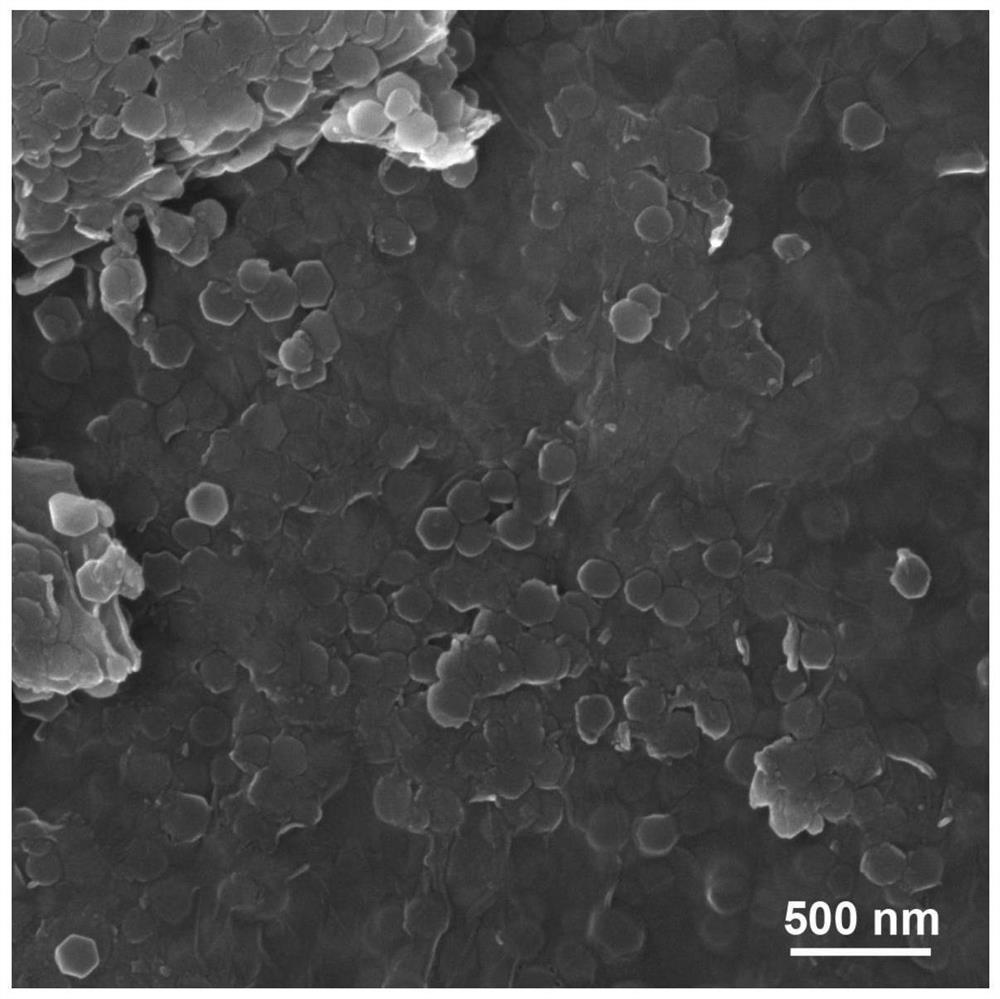

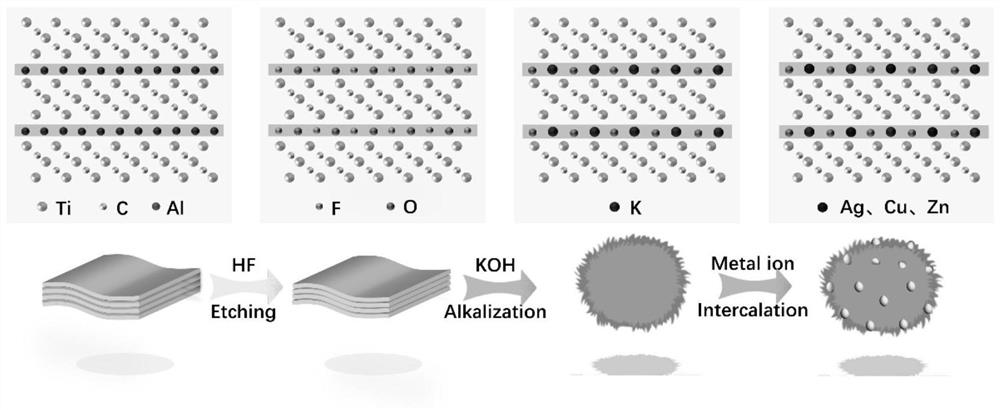

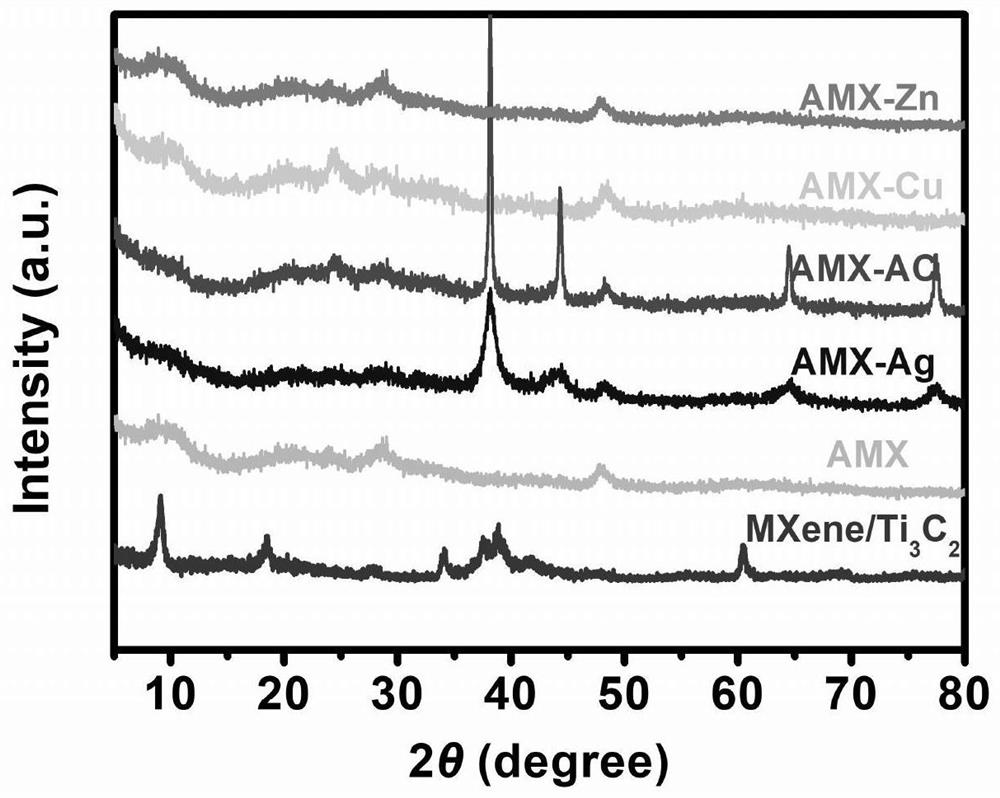

Preparation method and application of MXene derivative/metal nano composite material

ActiveCN112768259ALow conductivityImprove conductivityHybrid capacitor electrodesHybrid/EDL manufacturePyrrolidinonesGlycol synthesis

The invention discloses a preparation method and an application of an MXene derivative / metal nano composite material. The preparation method comprises the following steps: dispersing MXene Ti3C2 and H2O2 in a KOH solution, magnetically stirring, and transferring into a high-pressure kettle for a hydrothermal reaction at 140 DEG C for 12 hours; washing with deionized water, and carrying out vacuum drying to obtain a MXene derivative (AMX); mixing an AMX powder, metal salt M and polyvinylpyrrolidone k-30, dispersing in ethylene glycol, magnetically stirring, transferring into the high-pressure kettle, and carrying out hydrothermal treatment at 160 DEG C for 3 hours; and washing a product with deionized water, and carrying out vacuum drying to obtain the MXene derivative / metal nano composite material. The MXene derivative / metal composite material is synthesized in one step through a hydrothermal method and used as an electrode material of a supercapacitor, good electrochemical energy storage characteristics are achieved, and the preparation method is simple in process, low in cost, environmentally friendly, high in repeatability, capable of achieving large-scale preparation and the like.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

A kind of preparation method of n-doped carbon nanotube/cobalt-nickel oxide/n-doped porous carbon

ActiveCN108417402BSolve the emission problemGood electrolyte ion adsorption propertiesMaterial nanotechnologyHybrid capacitor electrodesCapacitancePorous carbon

The invention discloses a preparation method of N-doped carbon nanotube / nickel cobalt oxide / N-doped porous carbon. The method comprises the steps of (1) adding coal-based polyaniline to a nickel acetate solution to obtain paste A; (2) adding the coal-based polyaniline to a cobalt oxalate suspension to obtain paste B; (3) pyrolyzing the paste A; (4) pyrolyzing the paste B; (5) mixing products, which are collected through twice pyrolysis, on a quartz plate evenly and marking quartz plate products; (6) mixing a quartz boat product A, a quartz boat product B and the quartz plate products evenly toobtain mixed powder; (7) carrying out hydrothermal reaction to obtain a black sediment; and (8) washing, drying and burning to obtain N-doped carbon nanotube / nickel cobalt oxide / N-doped porous carboncomposite powder. The prepared N-doped carbon nanotube / nickel cobalt oxide / N-doped porous carbon composite powder has relatively low internal resistance and charge transfer resistance, relatively high specific capacitance and relatively good rate characteristics and cycling stability.

Owner:XIAN UNIV OF SCI & TECH

Preparation method of graphene foamed nickel electrode

ActiveCN107967998BImprove Capacitive PerformanceCapacitive increaseHybrid capacitor electrodesCell electrodesElectrolytic agentCapacitance

The invention relates to a preparation method and application of a graphene nickel foam electrode. The preparation method is to wash and dry the nickel foam and use it as a working electrode. In the graphene oxide dispersion, use cyclic voltammetry to scan to prepare the graphene oxide nickel foam electrode. After drying, it is maintained in a glycine-hydrochloric acid buffer solution. Potential reduction was performed to obtain a graphene nickel foam electrode. Compared with other graphene electrode preparation methods, the preparation method of the graphene foam nickel electrode of the present invention has cheap raw materials, no pollution, is green and environmentally friendly, and is convenient for mass production. Graphene nickel foam electrodes supported by nickel foam show good capacitive properties in neutral electrolytes and can be used in the field of energy storage.

Owner:NORTHEASTERN UNIV LIAONING

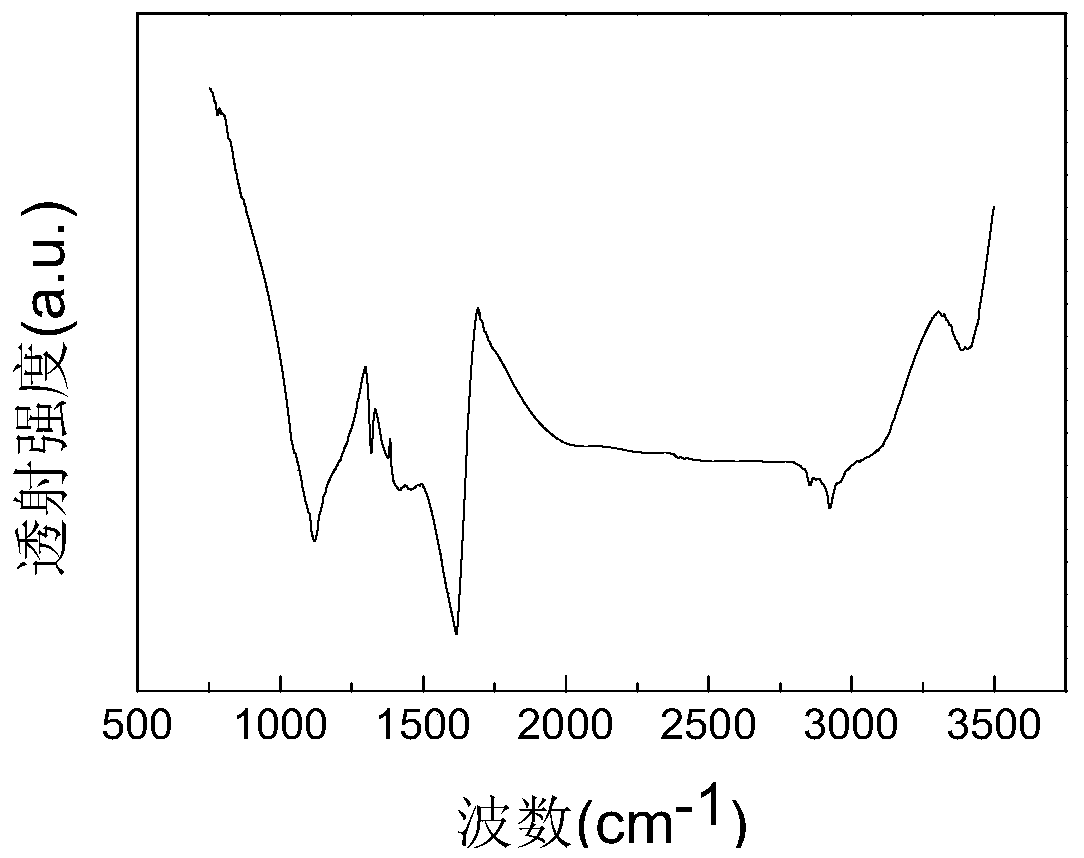

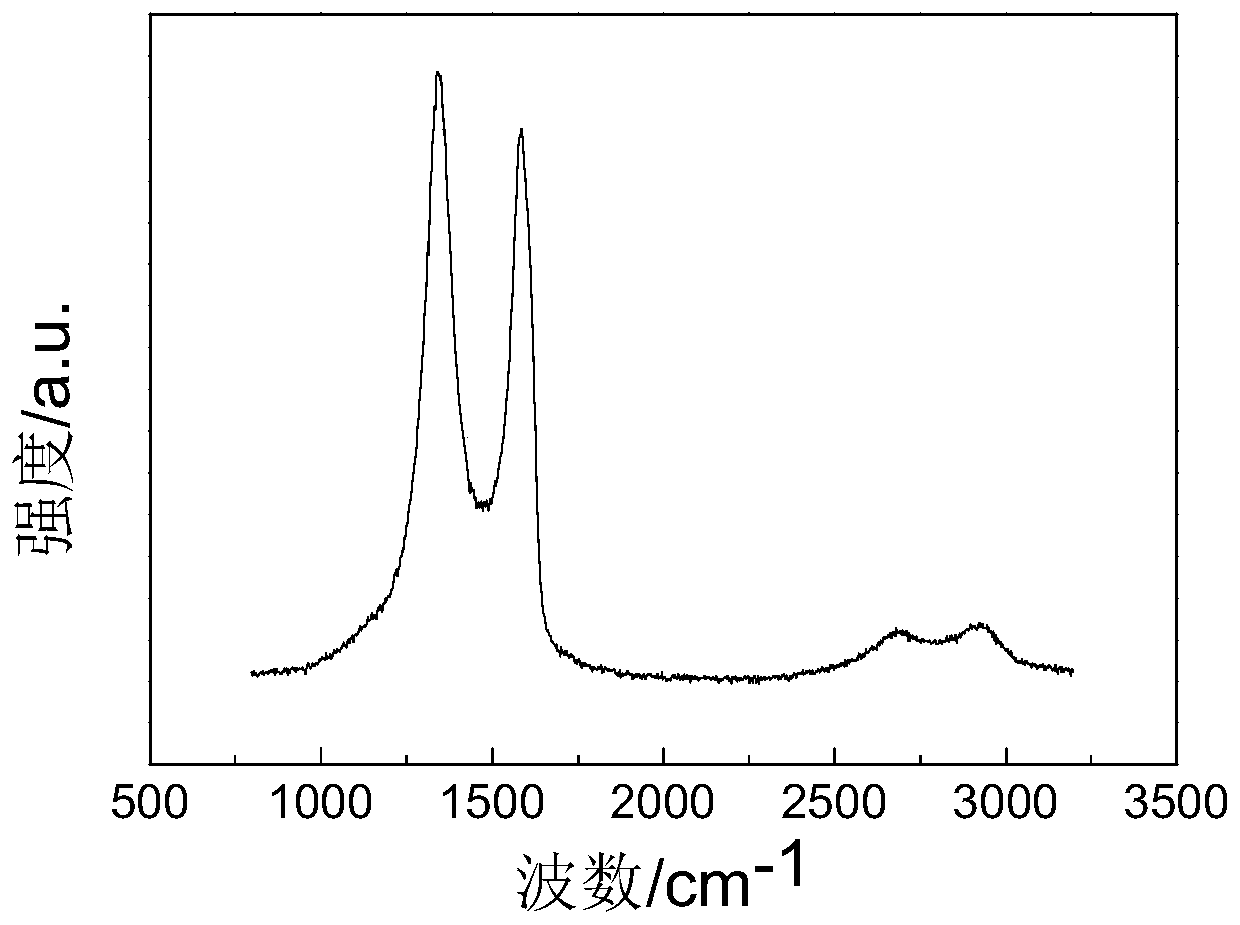

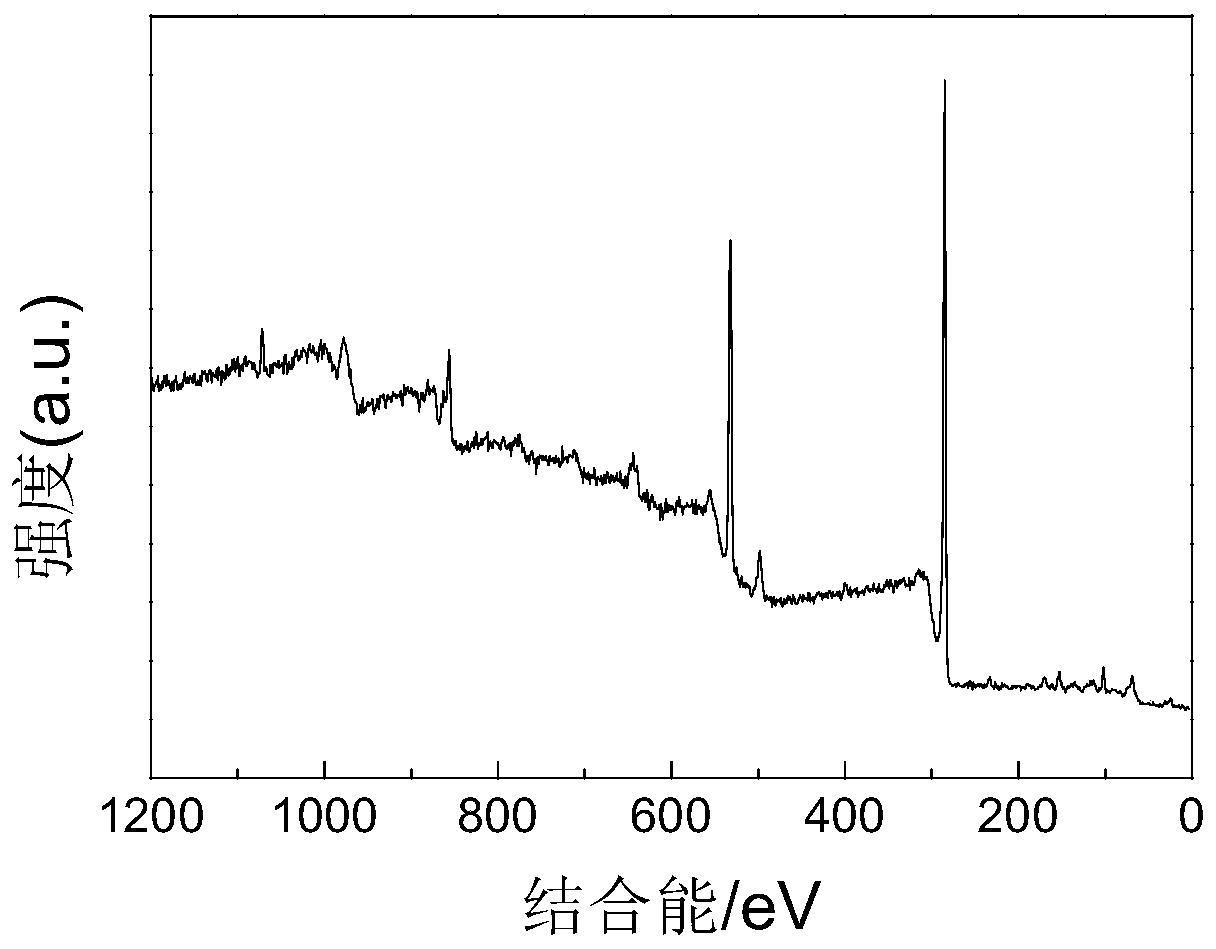

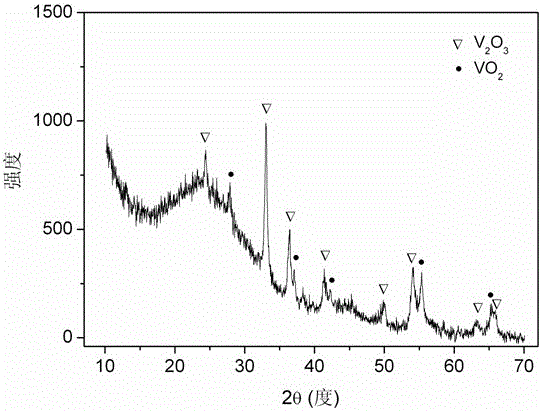

Vanadium oxide and carbon composite material with hierarchical pore structure and preparation method thereof

ActiveCN103258653BFast transferGuaranteed normal transmissionHybrid capacitor electrodesHybrid/EDL manufactureCarbon compositesCarbonization

The invention relates to vanadium oxide and carbon composite material with a hierarchical pore structure and a preparation method of the vanadium oxide and carbon composite material with the hierarchical pore structure. The vanadium-carbon ratio of the material is 0.4-1.5, the material is of the hierarchical pore structure and provided with macropores and mesopores, the diameters of the macropores are 0.2-1.5 micrometers, the diameters of the mesoporous are 15-50 nanometers and 2.6-5.4 nanometers, and the specific surface areas of the material are 105.0-413.8 square meter per gram. The preparation method includes the following steps: mixing hydrochloric acid, segmented copolymers, ethanol, phenolic resin and ammonium metavanadate, and obtaining the material through thermal polymerization and carbonization after volatilization induced self-assembly. The composite material can be used as supercapacitor electrode material. Researches in cyclic voltammetry and continuous current charge and discharge of a three-electrode system show that capacitive performance of a vanadium oxide and carbon composite material electrode is improved obviously compared with capacitive performance of an electrode made of mesoporous carbon. The preparation method is simple, low in requirement for devices, good in operability, and low in cost.

Owner:WUHAN UNIV OF TECH

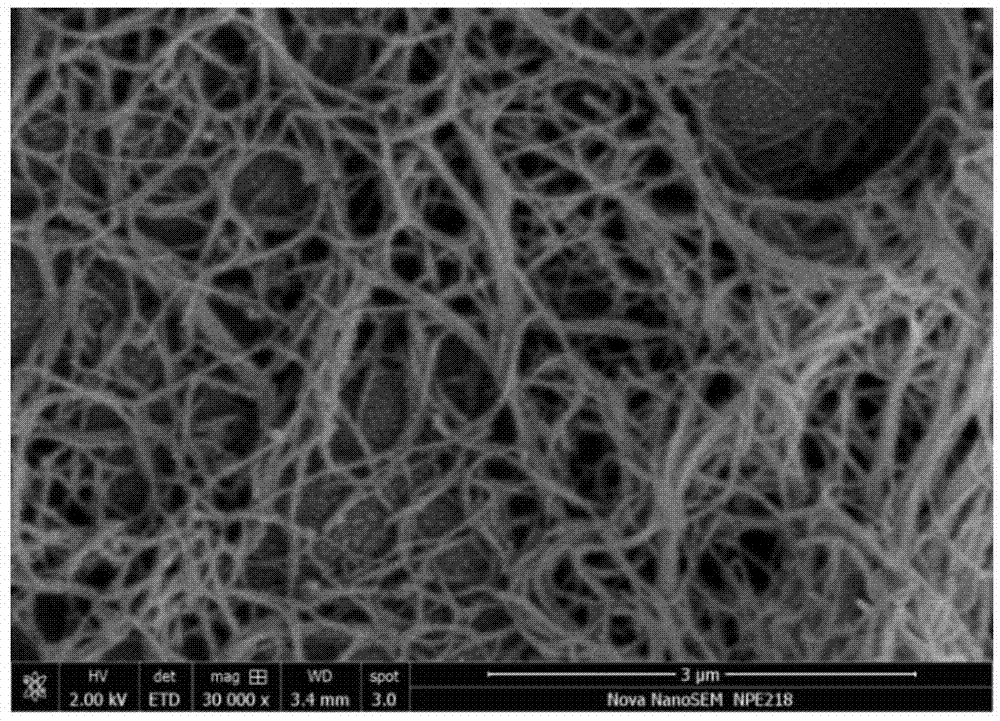

Ionic liquid coated paper of thin-walled carbon nanotube and preparation method of ionic liquid coated paper

ActiveCN102677546BStrong dielectricOvercome van der Waals forcesSurface covering paperMaterial nanotechnologyAdhesiveSupercapacitor

The invention belongs to the technical field of conducting materials and discloses an ionic liquid coated paper of a thin-walled carbon nanotube and a preparation method of the ionic liquid coated paper. An ionic liquid in the paper of carbon nanotubes is evenly coated on the outer surfaces of the carbon nanotubes to form a coaxial structure, and then the carbon nanotubes are mutually lapped to form a net structure. The paper of the carbon nanotubes is prepared by the steps that firstly 15wt% to 30wt% of ionic liquid and the thin-walled carbon nanotube are subjected to dispersion mill, and then are compacted. The ionic liquid can have functions of dispersing the thin-walled carbon nanotube, opening tube bundles of the thin-walled carbon nanotube and serving as an adhesive. Compared with resistance of papers of thin-walled carbon nanotubes, which are directly compacted without using the ionic liquid, the resistance of the prepared paper of the thin-walled carbon nanotube is reduced by 20-40%, when the paper is used as an electrode material of a supercapacitor at a voltage of 4-6.5 volts, the performances of the supercapacitor are improved by 20-100%, and when the paper is used as a strength material, the tensile strength is improved by 20-100%. Besides, the preparation method has the advantages of being low in cost and easy to repeat and amplify.

Owner:TSINGHUA UNIV

A method for jointly preparing carbon micronanotubes and n-doped porous carbon/nickel-manganese oxide

ActiveCN106348276BSolve the emission problemExcellent pseudocapacitive performanceMaterial nanotechnologyHybrid capacitor electrodesCapacitancePorous carbon

The invention discloses a method for jointly preparing carbon micro-nanotubes and N-doped porous carbon / nickel-manganese oxide, comprising: 1. preparing coal-based polyaniline; 2. placing nickel acetate and coal-based polyaniline in absolute ethanol , to obtain a paste; 3. spin-coat the nickelocene solution on the quartz sheet; 4. place the paste in the first temperature zone of the horizontal tubular atmosphere furnace, and place the quartz sheet in the second temperature zone; 5. Introduce nitrogen, heat up, collect the product carbon micronanotubes on the quartz sheet, and collect the product in the quartz boat in the first temperature zone; 6. Process the product in the quartz boat; 7. Wash after suction filtration, vacuum dry, and calcine. N-doped porous carbon / nickel-manganese oxide is obtained. In the pyrolysis of coal-based polyaniline, the present invention effectively utilizes the hydrogen-containing gaseous hydrocarbons produced by cracking to crack and deposit carbon micronanotubes on the surface of nickel; α‑MnO2 and NiMn2O4 comprehensively improve the capacitive performance of the composite.

Owner:XIAN UNIV OF SCI & TECH

A kind of hollow carbon sphere material and its preparation method and application

ActiveCN107032321BCapacitive increaseImprove electrochemical performanceHybrid capacitor electrodesCarbon preparation/purificationMicrosphereMelamine formaldehyde resin

Owner:SHANDONG UNIV OF SCI & TECH

A preparation method for printing supercapacitors based on ag/ppy composite nanomaterials

ActiveCN107799325BImprove conductivityImprove Capacitive PerformanceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceSolid state electrolyte

The invention relates to a fabrication method of an Ag / PPy composite nanometer material-based printed supercapacitor. Acetate is introduced to the fabrication process of an Ag / PPy composite nanometermaterial, so that the obtained Ag / PPy composite nanometer material has a legume-shaped core-shell structure, the capacitance performance of the material is favorably improved, and a flexible and solid-state supercapacitor is fabricated by selecting different flexible substrates and printing silver paste, the synthesized Ag / PPy composite nanometer material and a PVA-H3PO4 solid-state electrolyte byemploying silk-screen printing mode. The energy density of the supercapacitor manufactured by the method can reach 4.33 micro watt hour per square meter, 77.6% of unit specific capacitance is still maintained after the supercapacitor is bent for 1,000 times, 82.6 of unit specific capacitance is still maintained after the supercapacitor is bent for 10,000 times, the supercapacitor is low in cost,and substitution and supplement of a traditional high-cost energy storage device are achieved; and moreover, the supercapacitor has the advantages of simple reaction step, short reaction time and thelike, is simple and convenient to operate, can be used for industrial mass fabrication and production and can be applied to the field of flexible energy storage, and the synthesis method is clean andenvironmental-friendly and is suitable for promotion and application.

Owner:WUHAN UNIV

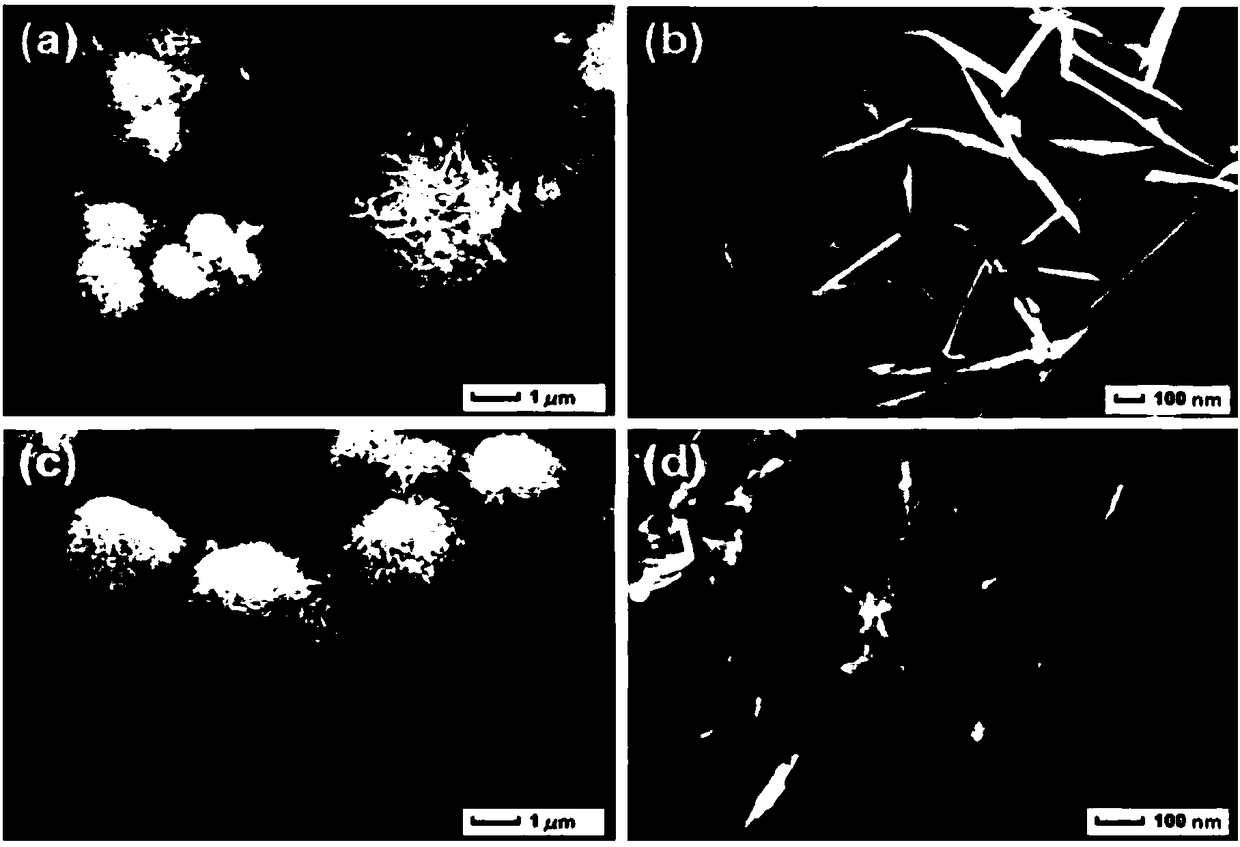

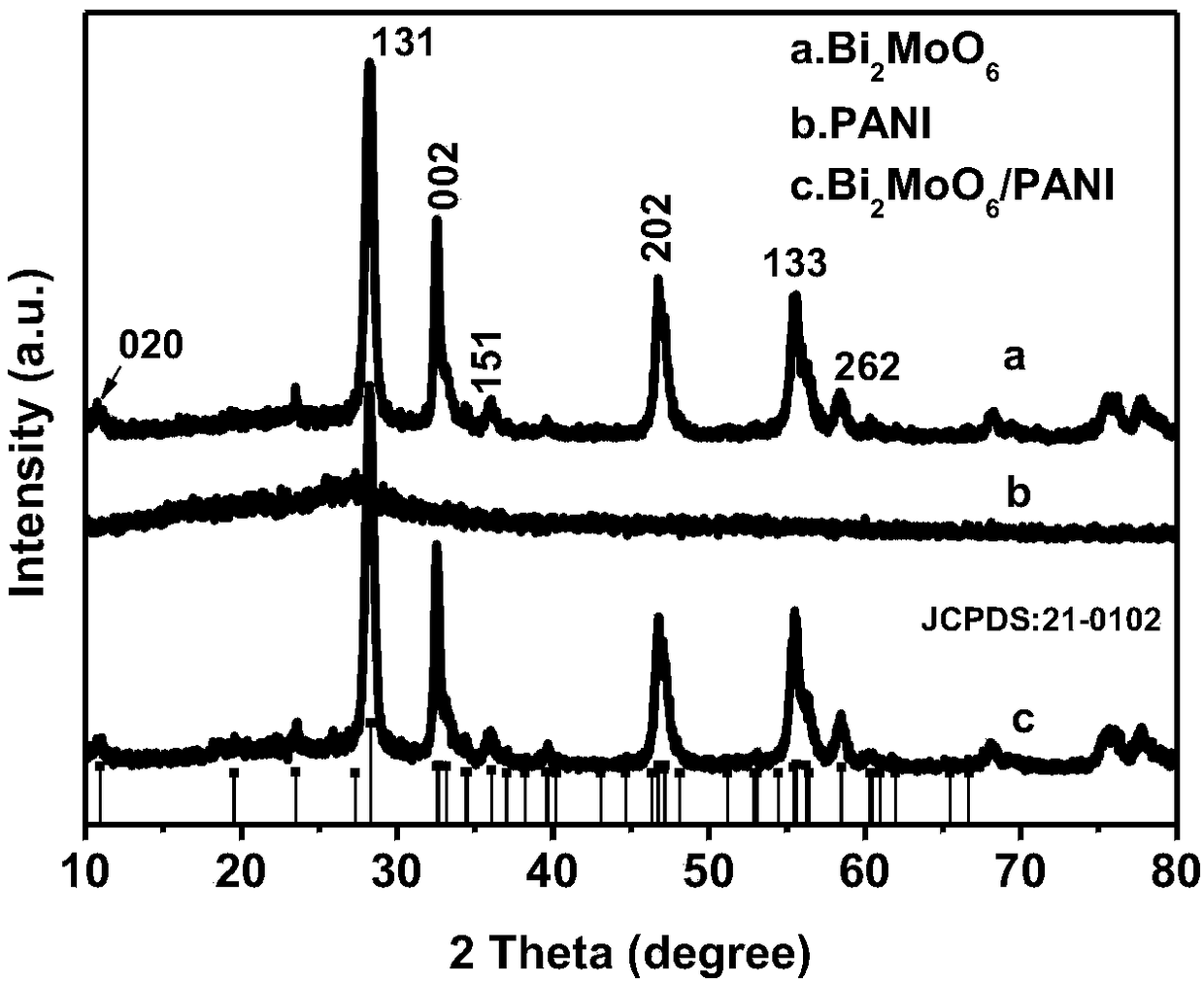

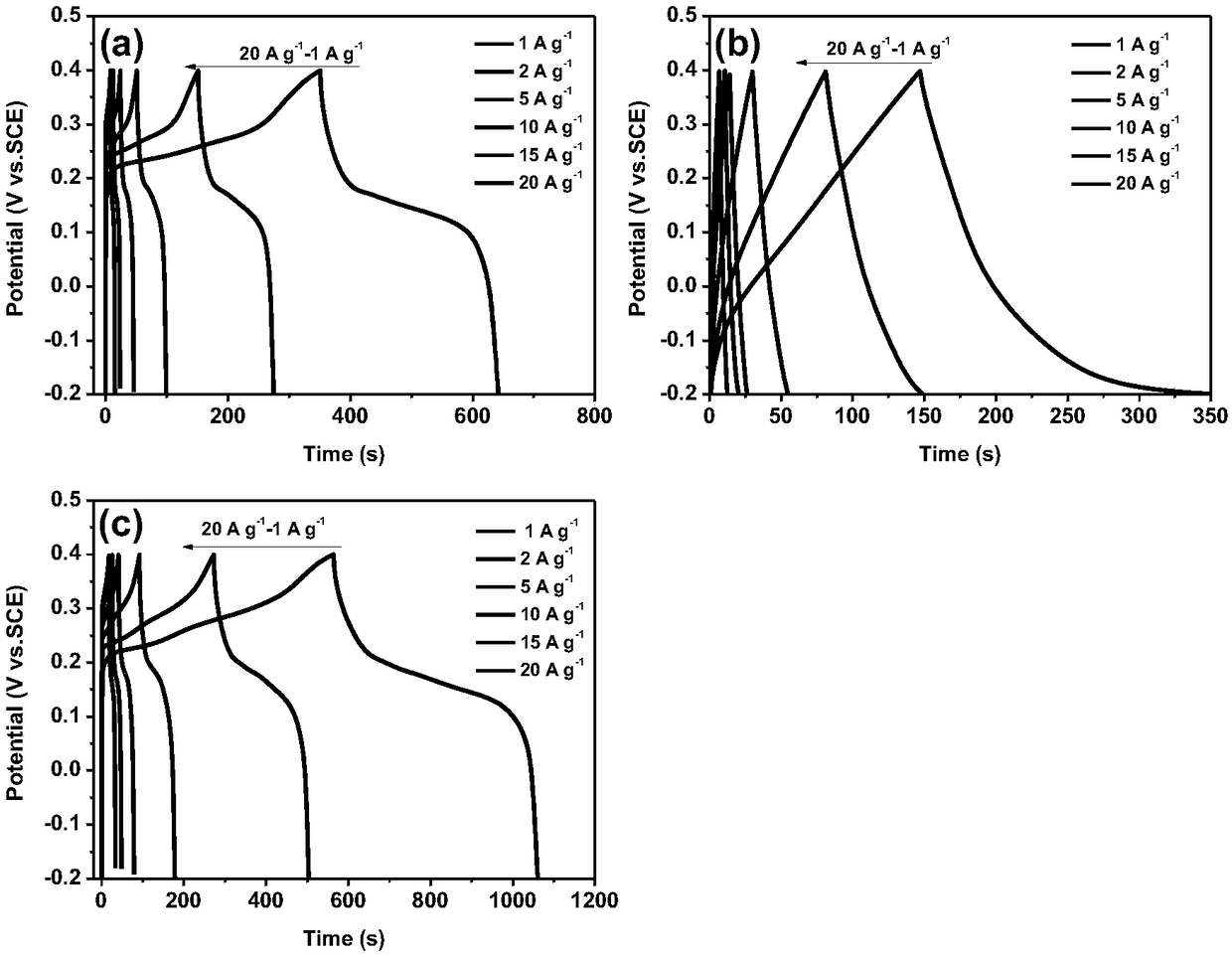

Preparation method of bismuth molybdate/polyaniline composite supercapacitor electrode material

InactiveCN106981369BDoes not affect shapeSimple preparation processHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceSolvent

The invention provides a preparation method for a bismuth molybdate / polyaniline composite supercapacitor electrode material. The preparation method comprises the following steps of dissolving bismuth nitrate and sodium molybdate into ethylene glycol at a molar ratio at a room temperature to obtain a mixed solution A, and performing ultrasonic uniformity and adding a mixed solution of urea and absolute ethyl alcohol; stirring continuously and uniformly and then pouring the mixed solution into a polytetrafluoroethylene stainless steel hydrothermal reaction kettle, sealing and performing a solvothermal reaction; after naturally cooling, performing washing and drying to obtain bismuth molybdate; performing ultrasonic dispersion of bismuth molybdate and lignin sodium sulfonate into deionized water to obtain a mixed solution, then adding an aniline monomer and p-toluenesulfonic acid, and then changing into ice- bath stirring, after the aniline is dispersed, obtaining a mixed solution B; and slowly dropwise adding an ammonium persulfate solution to the mixed solution B, and after the ice-bath reaction is completed, performing washing and drying to obtain the bismuth molybdate / polyaniline composite material. The method is simple, and the capacitance performance of the prepared bismuth molybdate / polyaniline composite material is greatly improved.

Owner:JIANGSU UNIV

Preparation method and application of eggshell membrane derived carbon/MXene/manganese dioxide composite material

ActiveCN110817876ARetain self-supportIncrease capacitanceHybrid capacitor electrodesTitanium carbideCapacitanceEggshell membrane

The invention discloses a preparation method and application of an eggshell membrane derived carbon / MXene / manganese dioxide composite material. The preparation method comprises the following steps: 1)treating eggshell membranes with an acid, and cleaning the eggshell membranes with water and isopropanol; 2) loading MXene on the eggshell membrane treated in the step 1); 3) calcining and carbonizing the eggshell membrane loaded with MXene in an inert gas atmosphere; and 4) adding an obtained calcined eggshell membrane derived carbon / MXene compound into a hydrochloric acid solution containing potassium permanganate, and carrying out hydrothermal reaction to obtain the eggshell membrane derived carbon / MXene / manganese dioxide composite material. According to the invention, the eggshell membrane with a three-dimensional porous structure is used for effectively loading MXene and manganese dioxide, and aggregation of MXene and manganese dioxide is reduced; the obtained composite material canbe cut into any shape and can be directly used as an electrode material of a supercapacitor, the capacitance performance is good, the preparation process is simple, large-scale production is easy to realize, and the application prospect in the field of new energy devices is promising.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Nano-nickel oxide/graphene composite material and preparation method thereof

InactiveCN102184781BSimple preparation processShort preparation cycleElectrolytic capacitorsGraphaneCapacitance

The invention relates to a nano-nickel oxide / graphene composite material and a preparation method thereof. The composite material is characterized in that: nickel oxide nano-particles uniformly grow on two sides of single-layer graphene to form a novel quasi-two-dimensional composite nano-material. The graphene serving as a substrate frame has good conductivity, and excellent conductivity among the nickel oxide particles is realized through the graphene substrate, so that the apparent electric conductivity of the composite material is improved. The sizes of the nickel oxide nano-particles growing on the graphane flake are between 1 and 10 nanometers; the plane size of the composite graphene nano-flake is between 0.1 and 100 microns, and the thickness of the composite graphene nano-flake is between 1 and 20 nanometers; and the weight percentage of the nickel oxide in the composite material is between 60 and 95 percent. The preparation method comprises two typical steps of: preparing a nano-nickel oxide / graphene precursor material by adopting a chemical solution method; and sintering to form a phase at high temperature in protection of an inert gas. The nano-nickel oxide / graphene composite material prepared by the method has high single electrode capacitance and good circulating performance, and is suitable for electrode materials of super capacitors.

Owner:JIANGSU SUNETECH NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com