A kind of hollow carbon sphere material and its preparation method and application

A hollow carbon and microsphere technology is applied in the field of preparation and application of porous materials to achieve the effects of high yield, easy large-scale industrial production, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In view of this, in a specific embodiment of the present invention, there is provided a method for preparing hollow carbon microspheres co-doped with nitrogen and phosphorus and the shell layer has a hierarchical macropore-mesoporous structure, including:

[0035] (1) Dispersing the silica nanospheres in distilled water and ultrasonically treating them to obtain a silica template dispersion;

[0036] (2) adding the silica template dispersion liquid obtained in step (1) into the melamine resin prepolymer system, and purifying by solvothermal method under the action of a catalyst to obtain a precursor-template complex, namely composite resin microspheres;

[0037] (3) The precursor-template composite obtained in step (2) is subjected to high-temperature carbonization and template removal to obtain hollow carbon microspheres co-doped with nitrogen and phosphorus, and the shell layer has a hierarchical macropore-mesoporous structure.

[0038] In yet another specific embodim...

Embodiment 1

[0050] 1) Disperse 0.7g of silicon dioxide in 30mL of water, and sonicate to obtain a silicon dioxide template dispersion;

[0051] 2) In another system, add 30mL of water, 10mL of formaldehyde, 0.024g of hexamethylenetetramine, dissolve and add 6.3g of melamine, after a period of prepolymerization, heat up to 65°C and stir until the solution is clear; Pour silicon dioxide into the system, add 0.175 mmol of hydroxyethylidene diphosphonic acid, stir at 65°C for 4 hours, filter with suction, and dry;

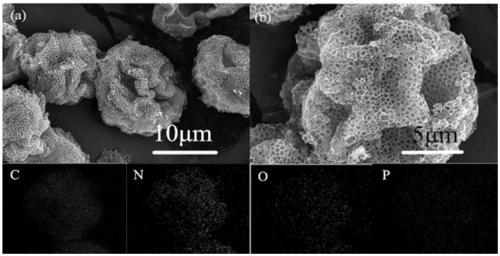

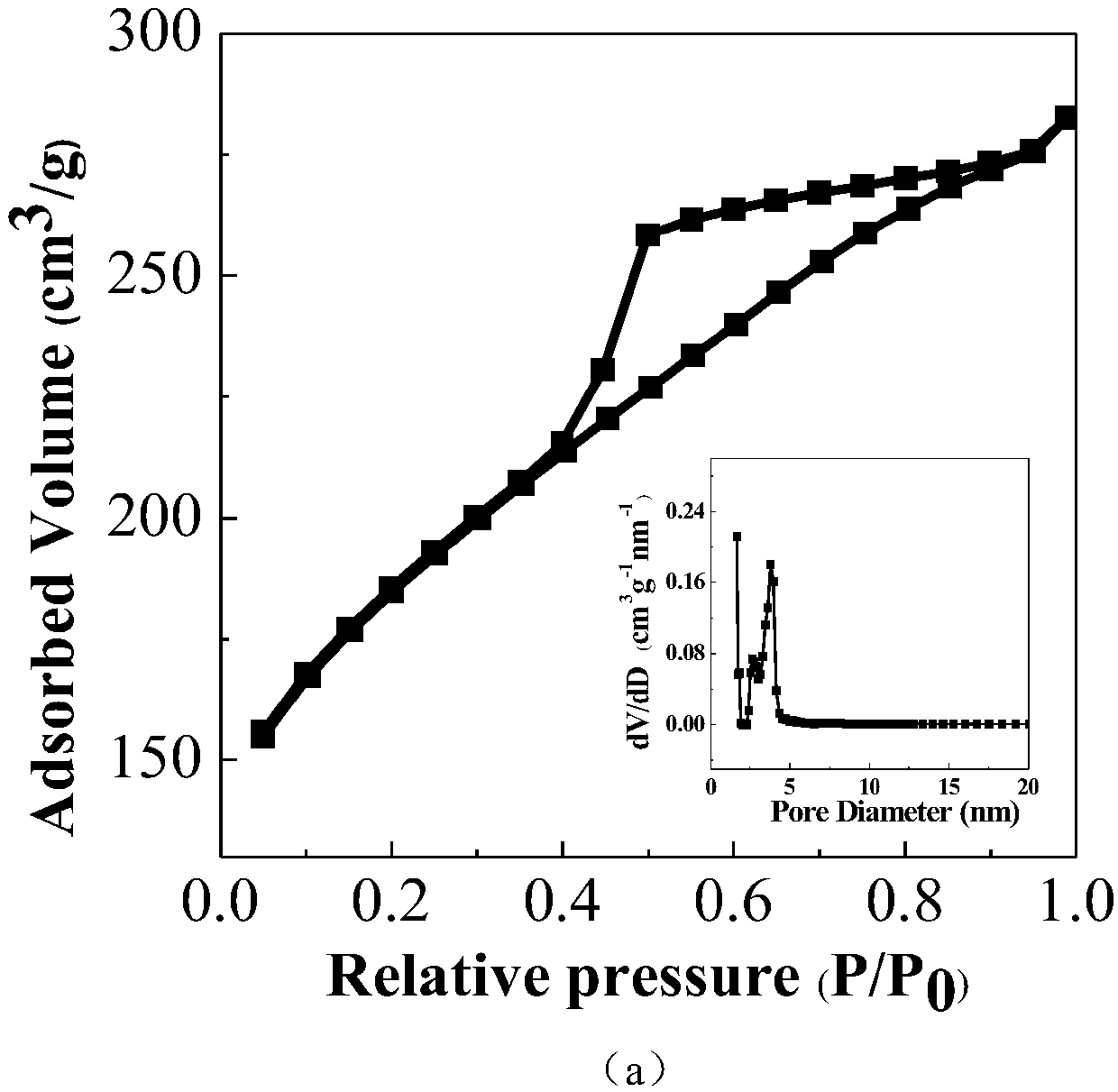

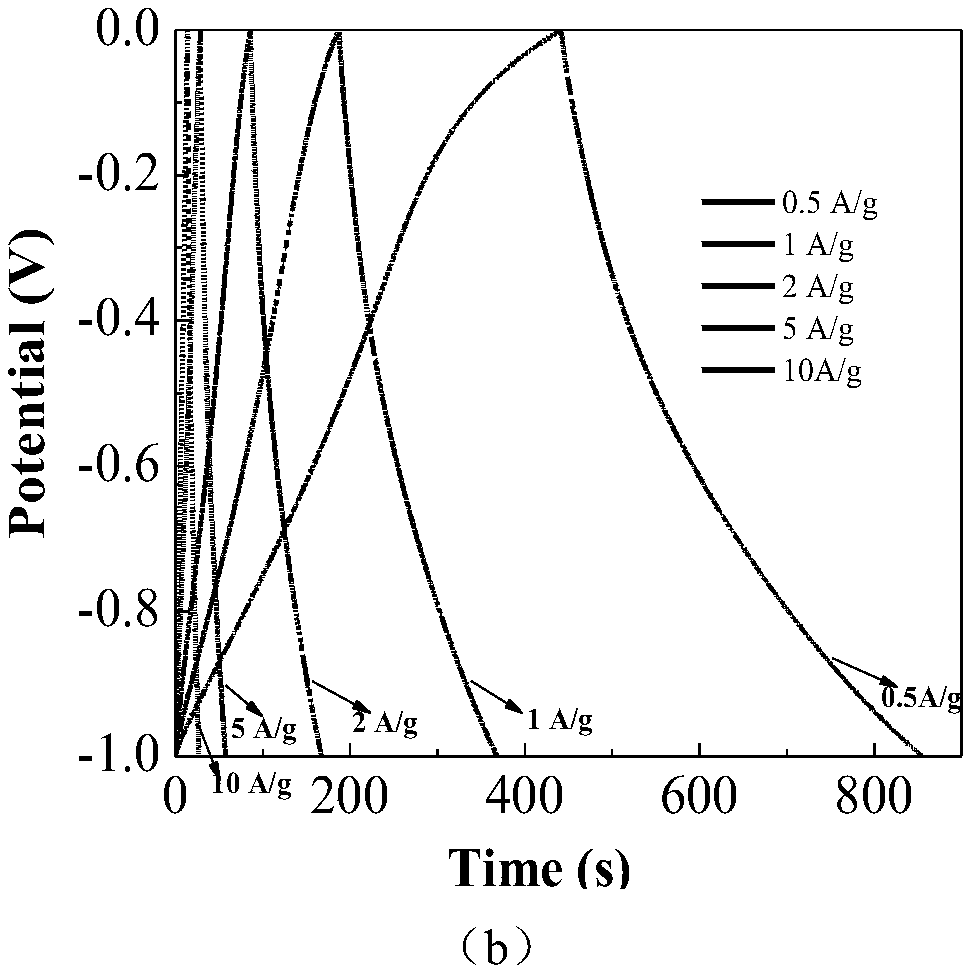

[0052] 3) After carbonization at 700°C for 2 hours, and then removing silicon dioxide with HF, carbon microspheres with a nitrogen-phosphorus co-doped shell layer and a hierarchical pore structure can be obtained, with a particle size of 15±0.7 μm and a nitrogen content of 15.35% , the phosphorus content is 0.2%. Nitrogen adsorption and desorption analysis showed that the most probable pore diameter was 3.8nm. The electrochemical test results show that when the current density i...

Embodiment 2

[0054] 1) Disperse 0.7g of silicon dioxide in 30mL of water, and sonicate to obtain a silicon dioxide template dispersion;

[0055] 2) In another system, add 30mL of water, 10mL of formaldehyde, 0.024g of hexamethylenetetramine, dissolve and add 6.3g of melamine, after a period of prepolymerization, heat up to 65°C and stir until the solution is clear; Pour silicon dioxide into the system, add 0.175 mmol of hydroxyethylidene diphosphonic acid, stir at 65°C for 4 hours, filter with suction, and dry;

[0056] 3) High temperature carbonization at 800°C for 2 hours, and then removing silicon dioxide with HF, then you can get hollow carbon microspheres with nitrogen-phosphorus co-doped shell layer and hierarchical pore structure, with a particle size of 12±1 μm and a nitrogen content of 8.03% , the phosphorus content is 0.24%. The hollow structure can be observed by transmission electron microscope.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com