Preparation method of bismuth molybdate/polyaniline composite supercapacitor electrode material

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc. It can solve the problems of poor cycle stability, low working voltage and energy storage density, poor mechanical properties, etc., and achieve capacitive performance Improvement, the effect that the method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

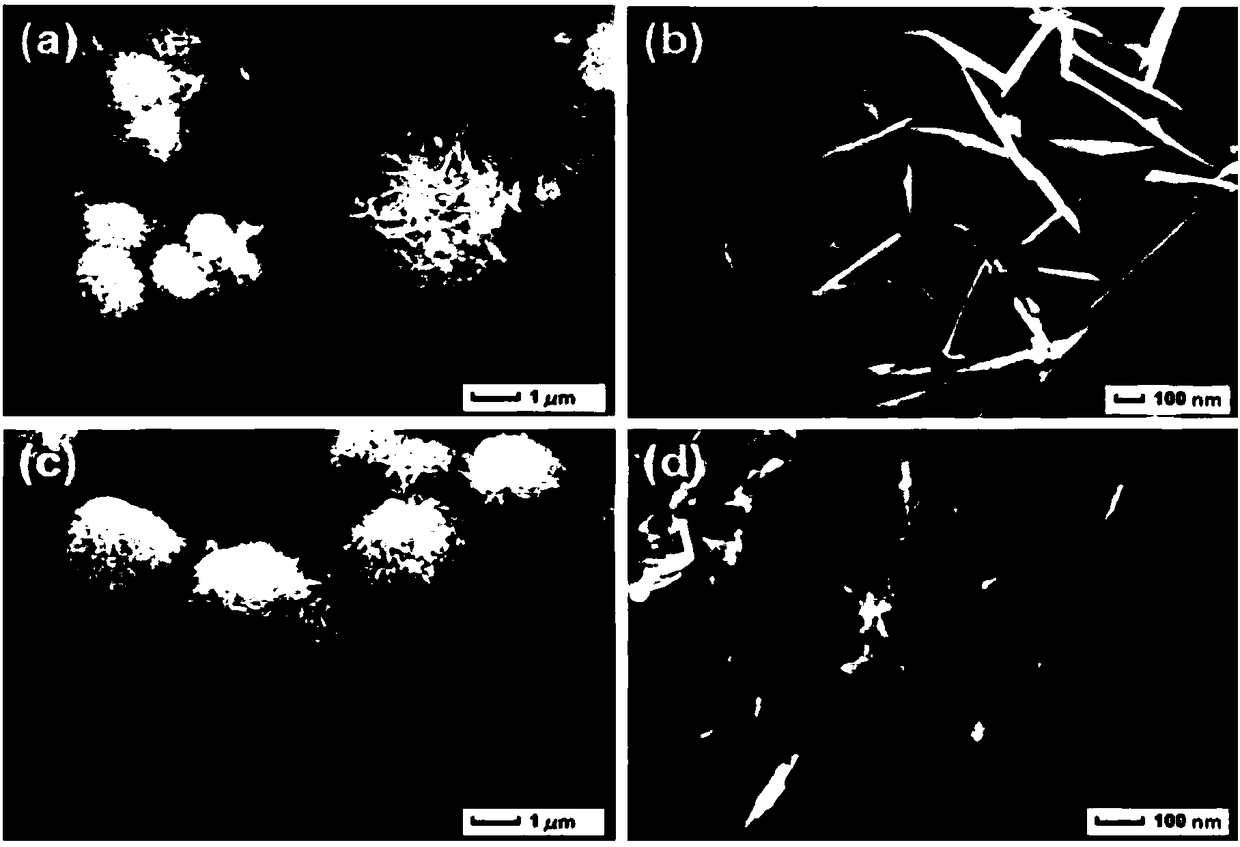

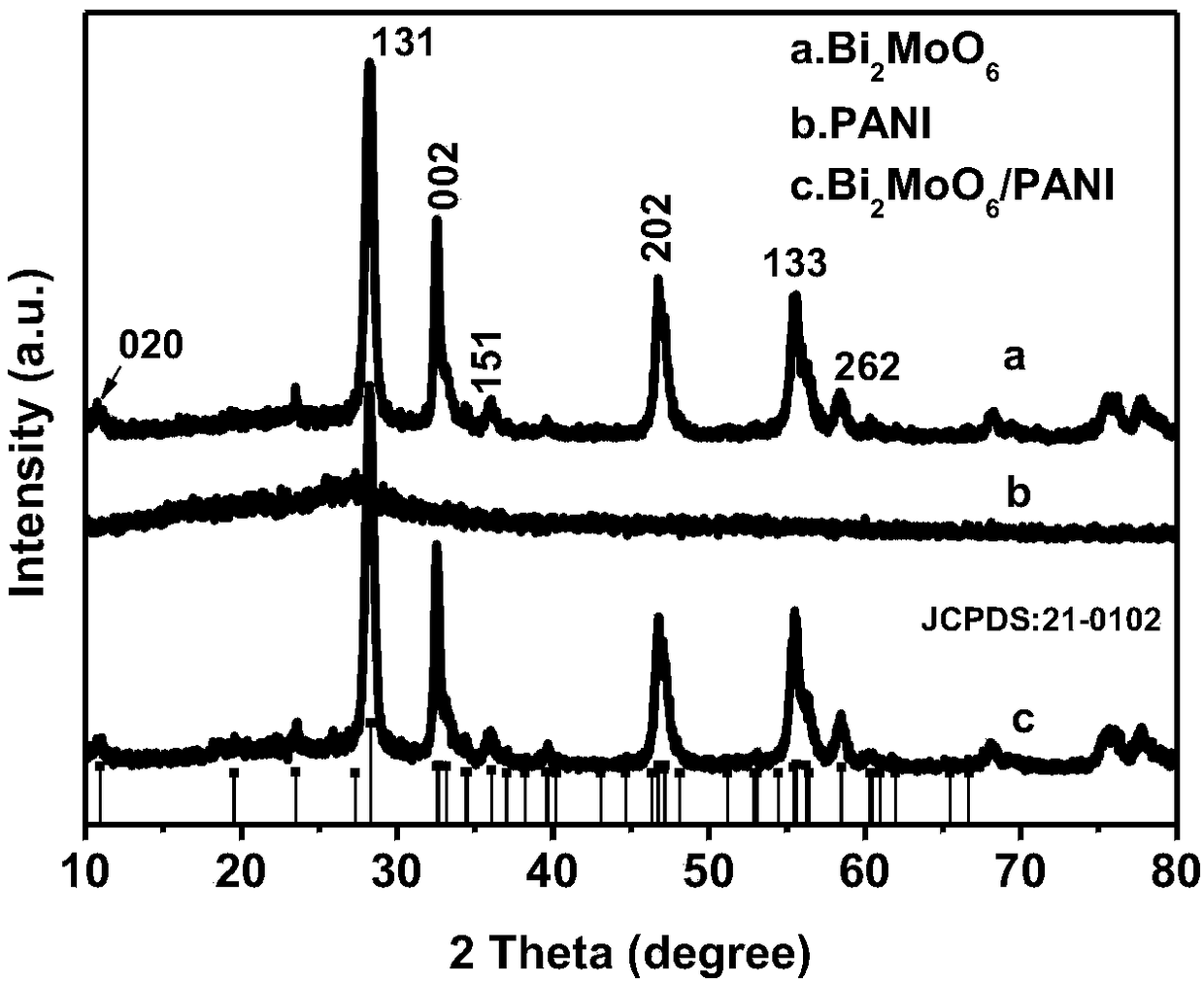

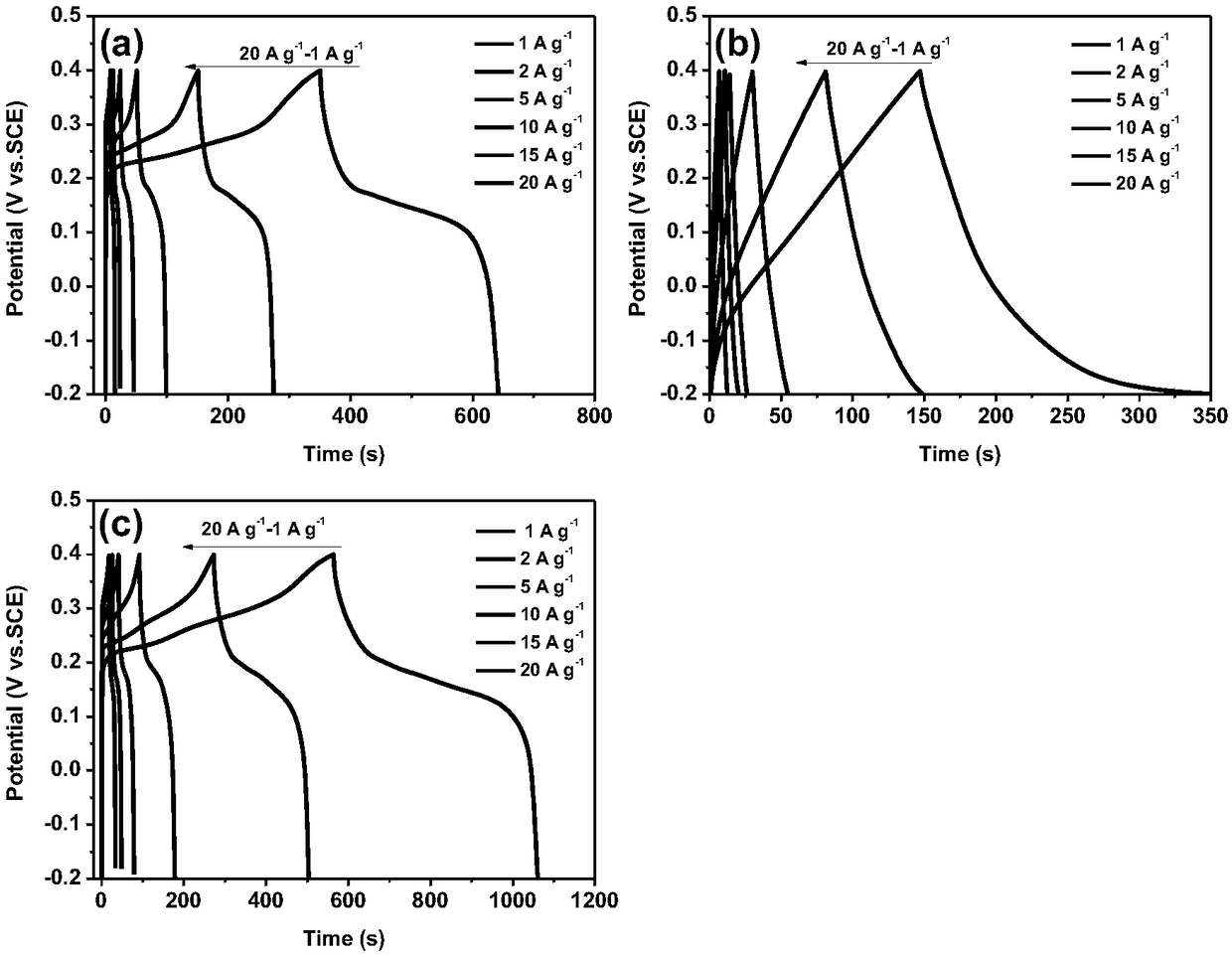

[0022] At room temperature, dissolve 2 mmol of bismuth nitrate and 1 mmol of sodium molybdate in 5 mL of ethylene glycol, add urea solution (3 mmol of urea dissolved in 15 mL of absolute ethanol) after ultrasonication for 0.5 h, continue stirring for 15 min, and dissolve the mixed solution Pour it into a 50mL polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, seal it, and heat it at 140°C for 8 hours. After cooling naturally, wash it three times with deionized water and absolute ethanol alternately. Vacuum drying for 12 hours to obtain bismuth molybdate.

[0023] Ultrasonic disperse 0.10g of bismuth molybdate and 0.30g of sodium lignosulfonate in 50mL of deionized water to obtain a mixed solution, add 0.20mL of aniline monomer and 0.39g of p-toluenesulfonic acid, then change to ice bath stirring, and slowly Ammonium persulfate solution (0.43 g of ammonium persulfate dissolved in 20 mL of deionized water) was added dropwise, and after reacting in an ice...

Embodiment 2

[0025] At room temperature, dissolve 2 mmol of bismuth nitrate and 1 mmol of sodium molybdate in 10 mL of ethylene glycol, add urea solution (4 mmol of urea dissolved in 20 mL of absolute ethanol) after ultrasonication for 0.5 h, continue stirring for 15 min, and dissolve the mixed solution Pour it into a 50mL polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, seal it, and heat it at 160°C for 10 hours. After cooling naturally, wash it alternately with deionized water and absolute ethanol for 3 times. Vacuum drying for 12 hours to obtain bismuth molybdate.

[0026] Ultrasonic disperse 0.10g of bismuth molybdate and 0.40g of sodium lignosulfonate in 50mL of deionized water to obtain a mixed solution, add 0.30mL of aniline monomer and 0.39g of p-toluenesulfonic acid, then change to ice bath stirring, wait for the aniline to disperse slowly Ammonium persulfate solution (0.43 g of ammonium persulfate dissolved in 20 mL of deionized water) was added dropwis...

Embodiment 3

[0028] At room temperature, dissolve 2 mmol of bismuth nitrate and 1 mmol of sodium molybdate in 10 mL of ethylene glycol, add urea solution (5 mmol of urea dissolved in 25 mL of absolute ethanol) after ultrasonication for 0.5 h, continue stirring for 15 min, and dissolve the mixed solution Pour it into a 50mL polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, seal it and heat it at 160°C for 12 hours. After cooling naturally, wash it three times with deionized water and absolute ethanol alternately. Vacuum drying for 12 hours to obtain bismuth molybdate.

[0029] Ultrasonic disperse 0.10g of bismuth molybdate and 0.50g of sodium lignosulfonate in 50mL of deionized water to obtain a mixed solution, add 0.40mL of aniline monomer and 0.39g of p-toluenesulfonic acid, then change to ice bath stirring, wait for the aniline to disperse slowly Add ammonium persulfate solution (0.43 g of ammonium persulfate dissolved in 20 mL of deionized water) dropwise, reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com