Patents

Literature

119results about How to "Act as a "dispersant"" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Perfluorinated ion exchange resin as well as preparation method and application thereof

ActiveCN101768236ASolve the problem of insufficient molecular weightAct as a dispersantSemi-permeable membranesCell electrodesTetrafluoroethylenePolymer science

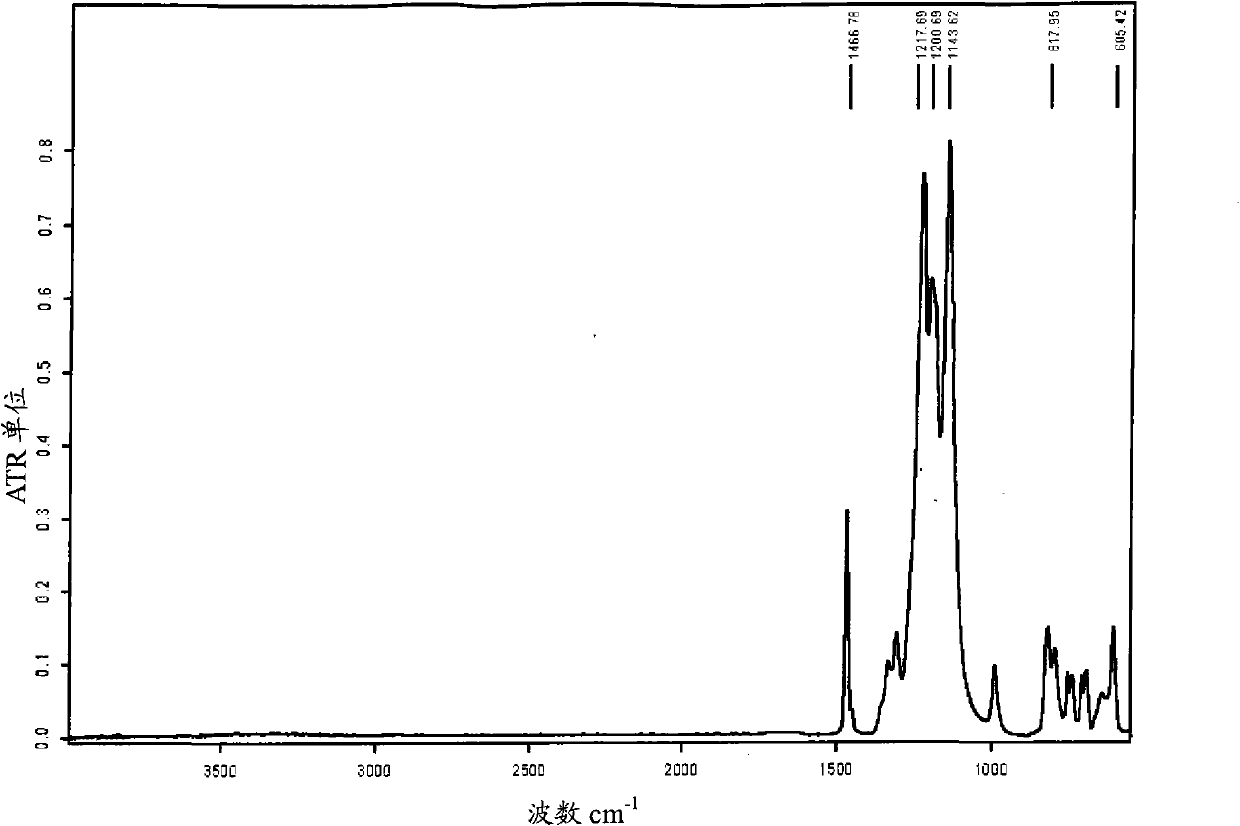

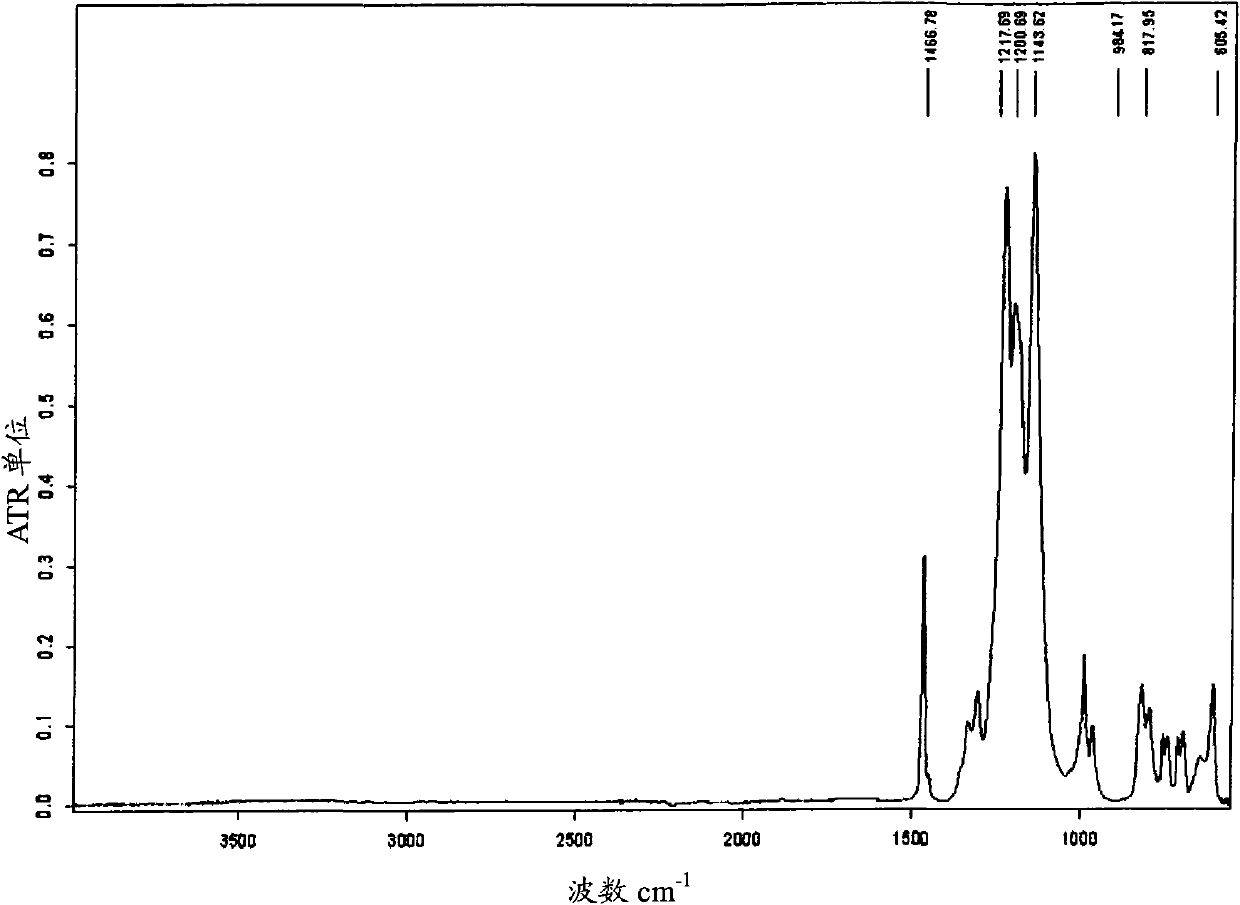

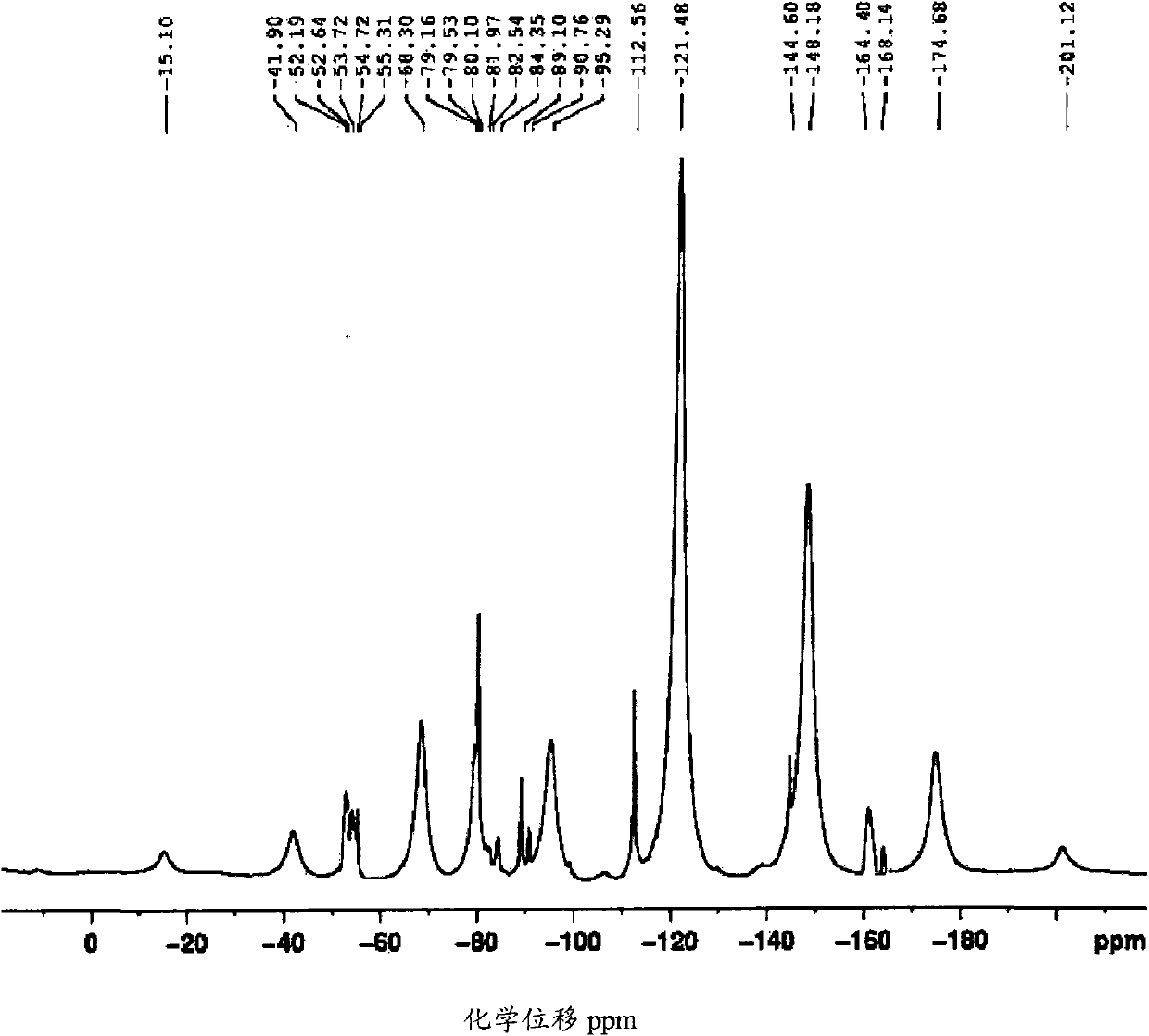

The invention provides a perfluorinated ion exchange resin as well as a preparation method and application thereof, wherein the perfluorinated ion exchange resin is provided with a phosphonate side group and sulfonyl fluoride short side groups with two different structures and has the function of high exchange capacity. The perfluorinated ion exchange resin is formed by tetrafluoroethylene, sulfonyl fluoride alkene ether monomers with the short side groups in two different structures, and a phosphonate side group alkene ether monomer through multi-copolymerization, and the repeated unit is represented by the following formula. An ion exchange membrane made of the resin can not only have various chemical media resistance, but also have high iron exchange capacity, high conductivity, high mechanical strength, high dimensional stability, low membrane resistance and long service life and is applicable for a fuel cell and a high-temperature fuel cell.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

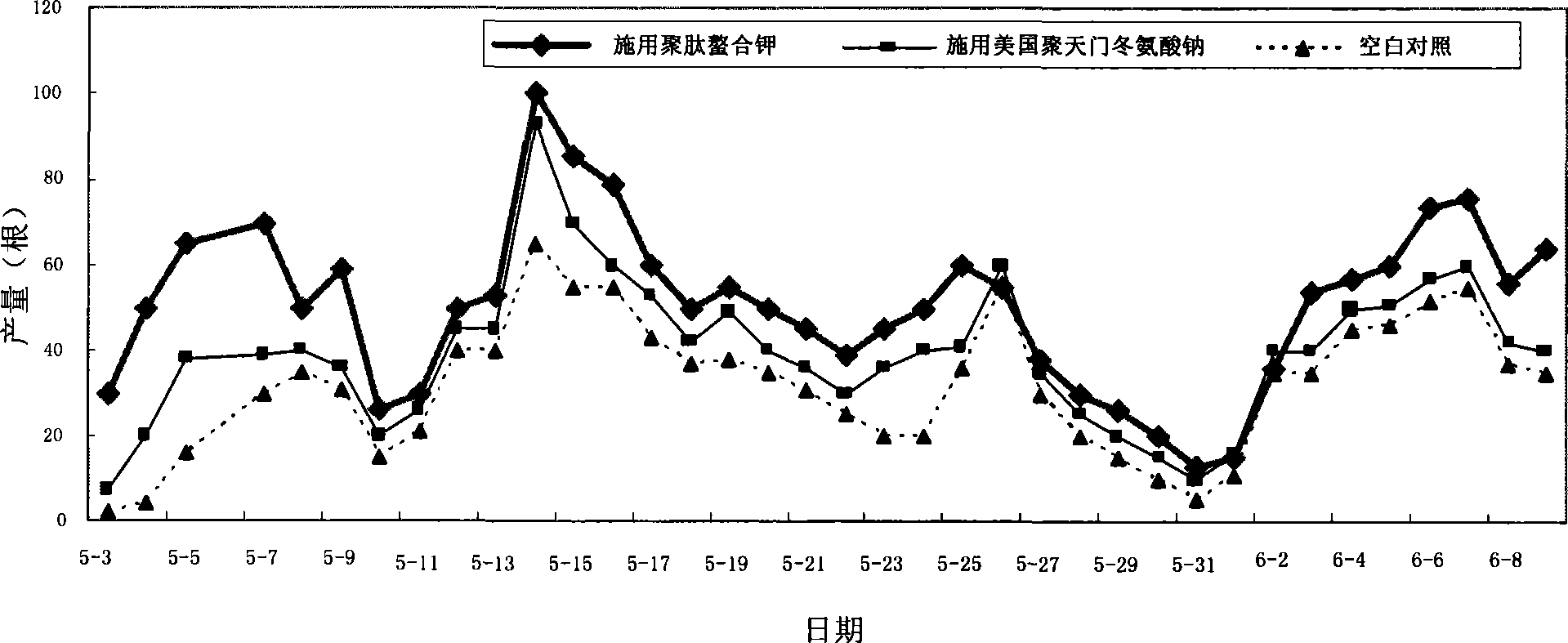

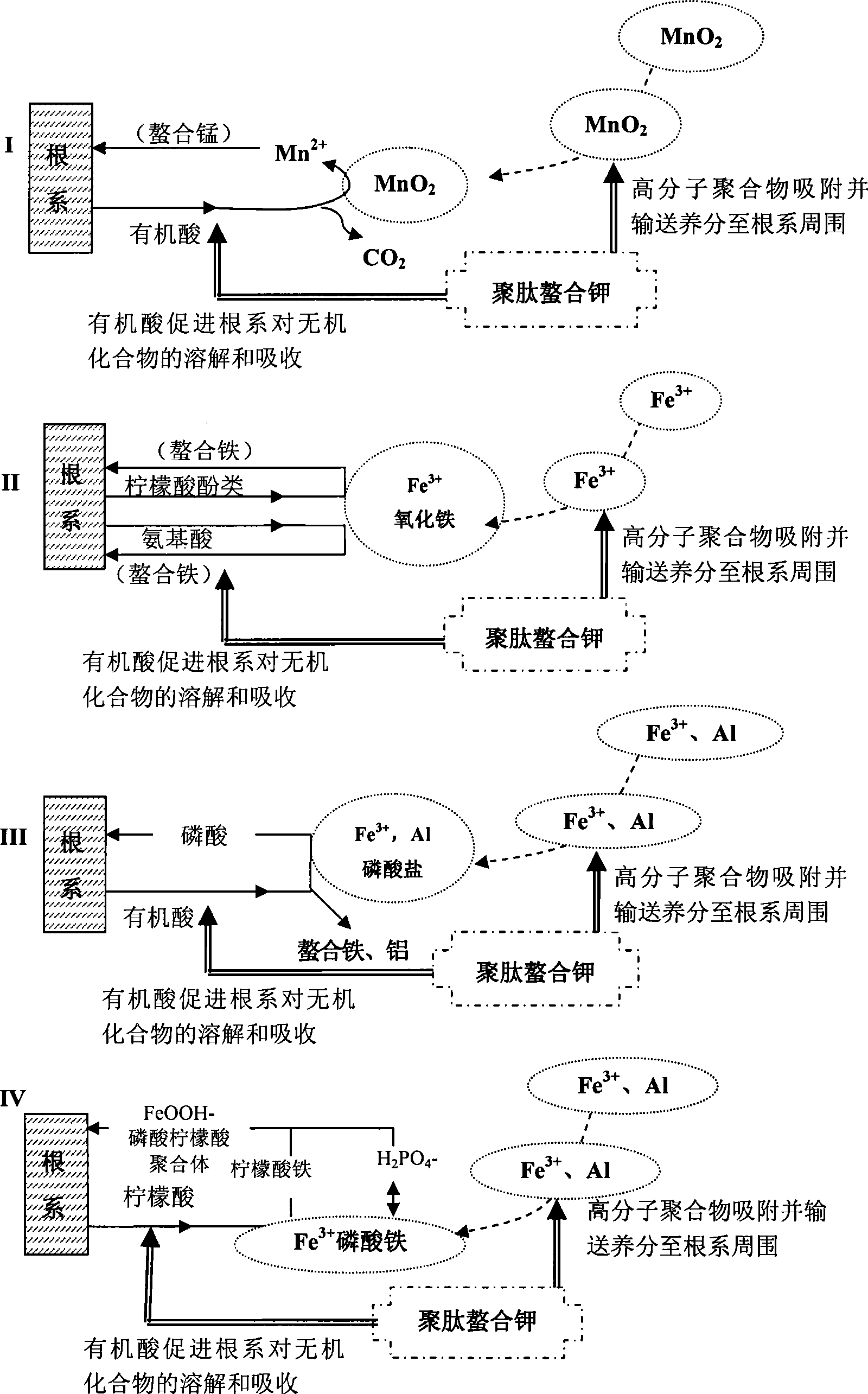

Plant nutrient absorption enhancer and preparation method and use thereof

ActiveCN101379977APromotes Balanced and Effective AbsorptionPromotes Nutrient AbsorptionBiocidePlant growth regulatorsChemistryAgriculture

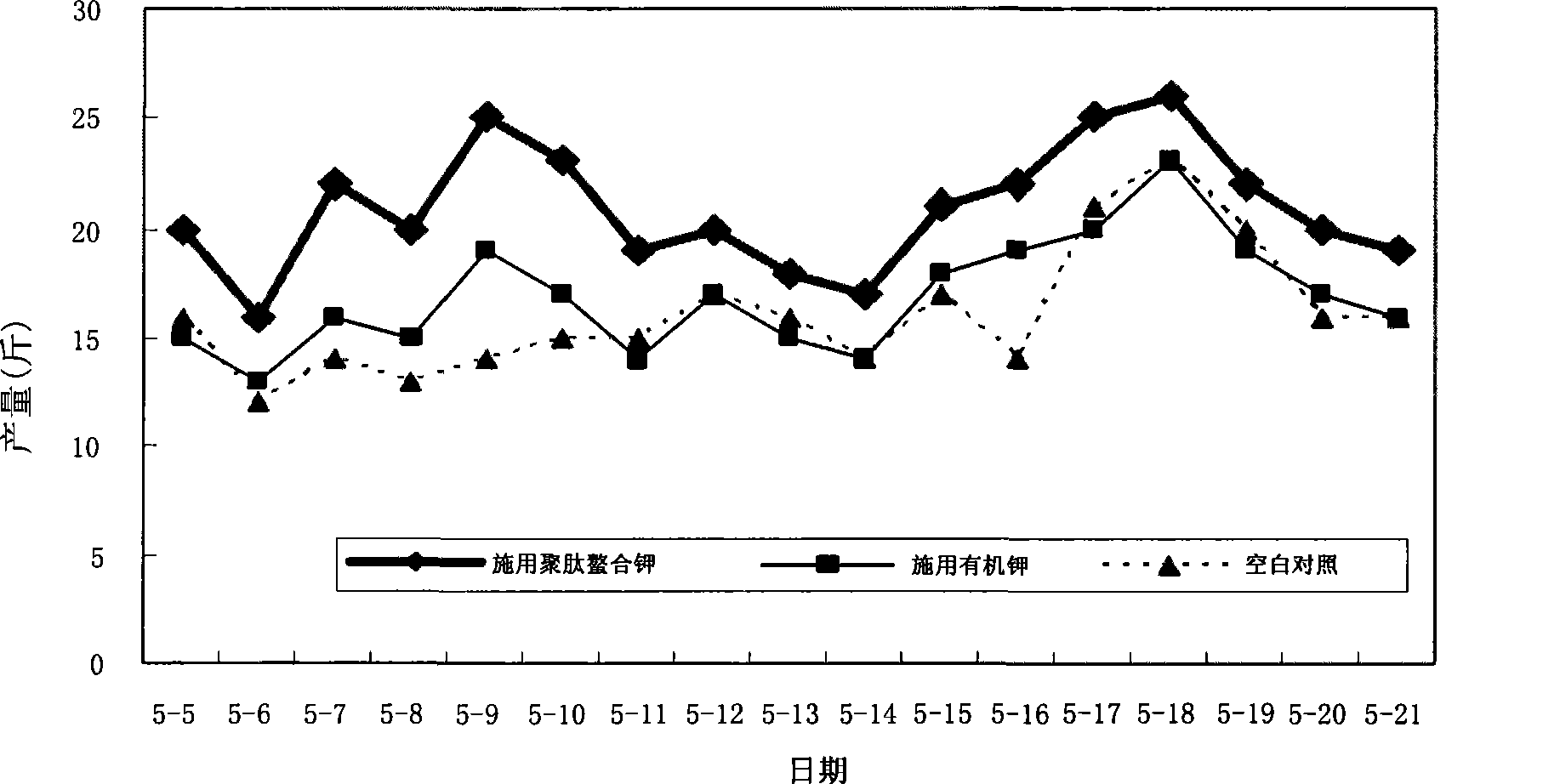

The invention provides a novel product of plant nutrient sorbefacient which takes the reaction products of succinimide, organic acid, potassium hydroxide as the aqueous solution of active components, and the aqueous solution has 25-60% of active components with the pH value ranging from 7 to 8; the organic acid can be caused to have complexation with metallic ion to form dicarboxylic acid or tribasic carboxylic acid of soluble metal complex. The invention also provides a method for preparing the plant nutrient sorbefacient and the application of the method in the agricultural industry. The plant nutrient sorbefacient can chelate nitrogen, phosphorus, potassium and micronutrient elements which are needed by growing plant, and convey the nutrient elements to the surrounding of plant root system, thereby promoting the plant to absorb the nutrient, increasing the utilization rate of fertilizer and crop yield, and improving the quality of crops. The invention also provides multiple application modes of the plant nutrient sorbefacient in the agricultural industry on the basis of agricultural productive practice, so as to have flexible and wide application scope.

Owner:BEIJING JUTAI TECH

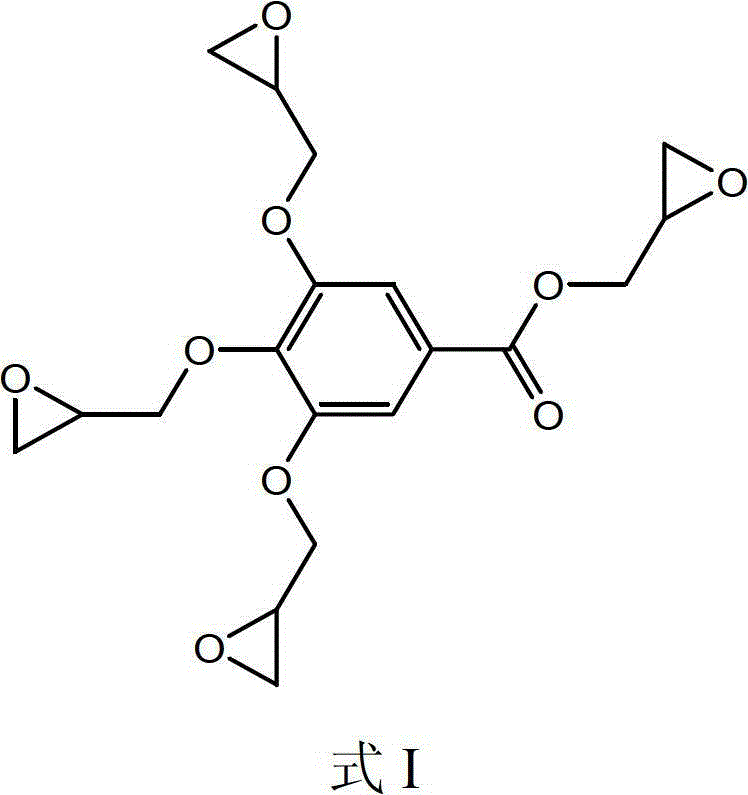

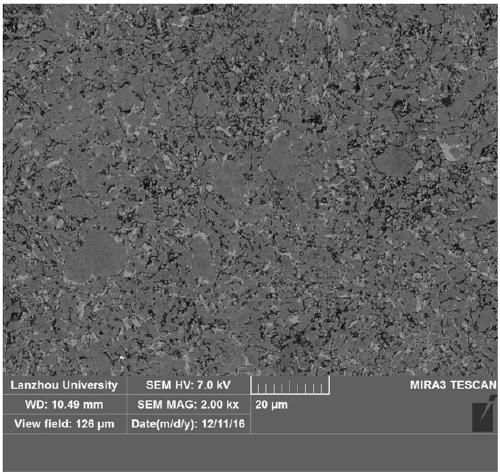

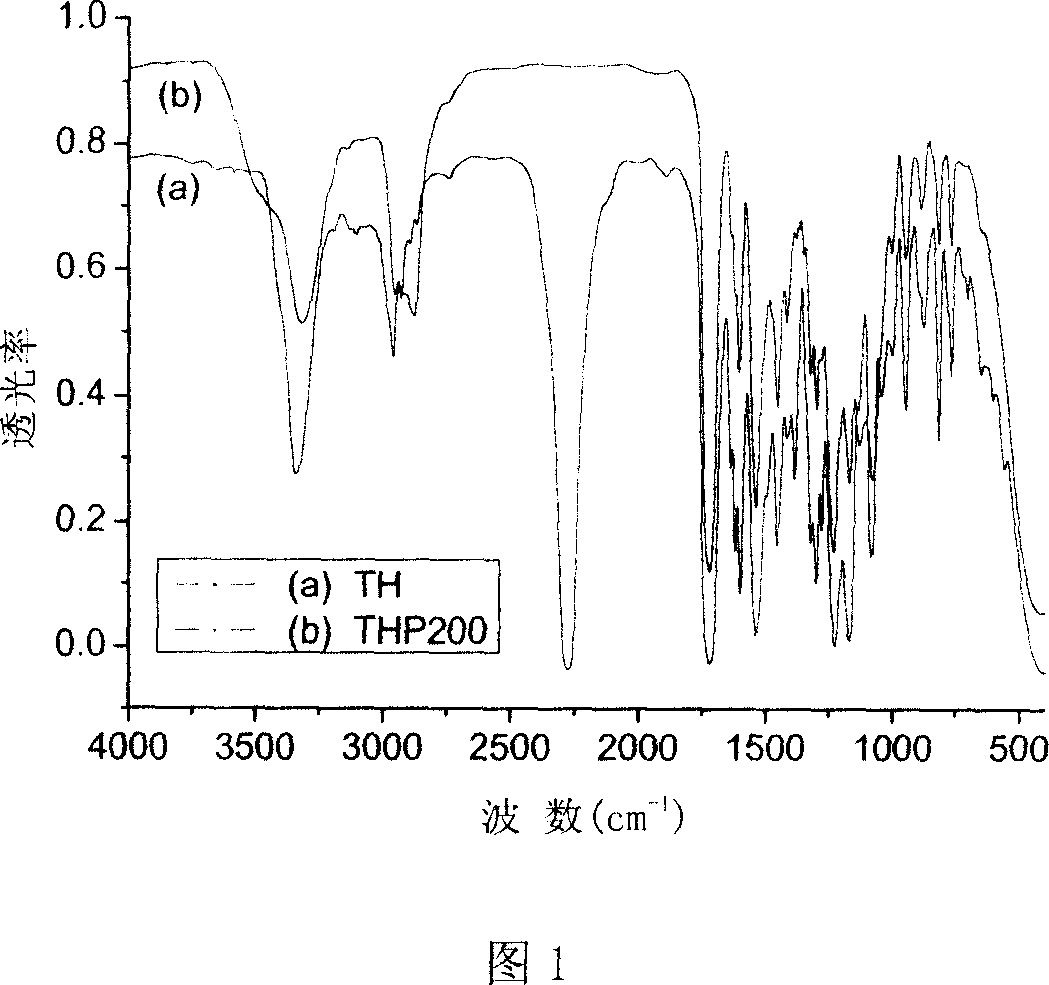

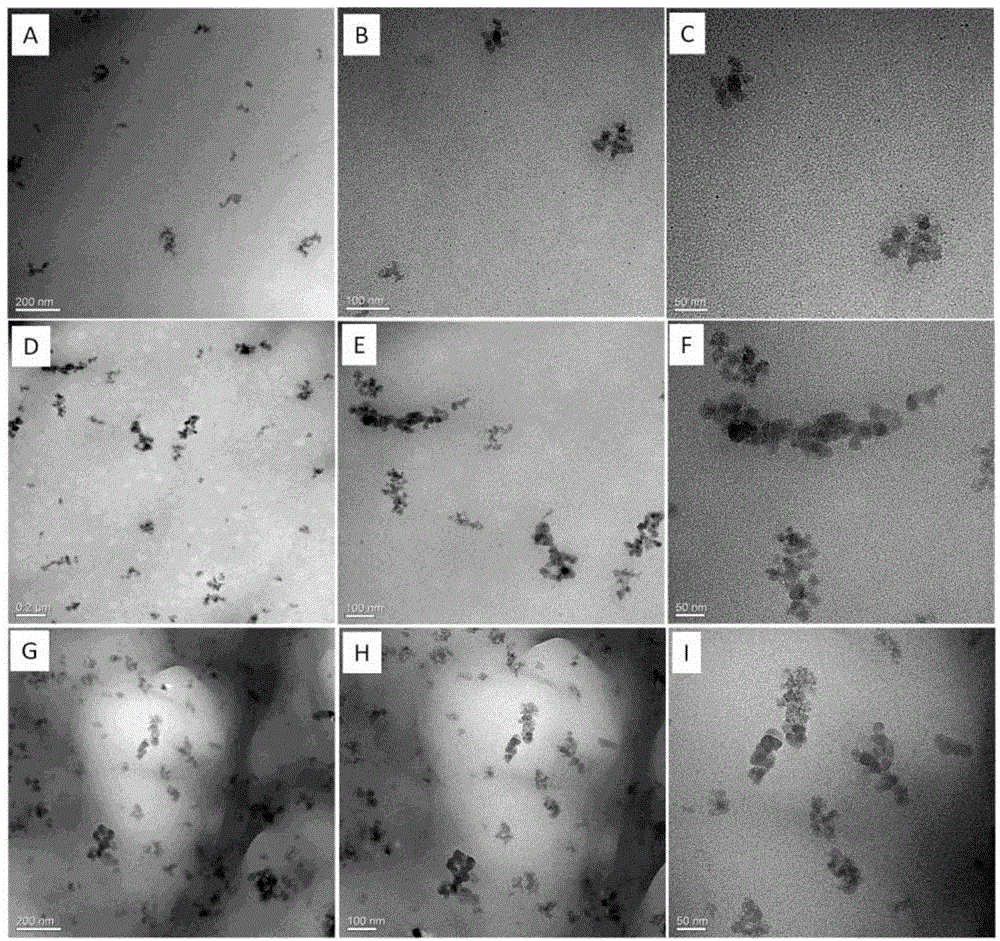

Method for stably dispersing graphene or/and carbon nanotubes in organic solvent

ActiveCN102911531AGood dispersionPlay the role of non-chemical bond modificationPigment treatment with non-polymer organic compoundsEpoxyOrganic solvent

The invention discloses a method for stably dispersing graphene or / and carbon nanotubes in organic solvent. The method includes steps of dispersing graphene or / and carbon nanotubes and bio-based gallic acid epoxy resin into the organic solvent under action of ultrasonic to obtain uniform and stable graphene or / and carbon nanotube dispersing liquid. The method is simple, requires simple equipment, and is low in production cost. The graphene or / and carbon nanotube dispersing liquid prepared by the method is high in stability and good in dispersibility, and accordingly provides necessary technical preparation for producing high-performance graphene or / and carbon nanotube composite materials. During parathion of the graphene or / and carbon nanotube composite material, the bio-based gallic acid epoxy resin can not only serve as a dispersing agent but serve as an interference compatilizer for improving interference interaction of the graphene or / and carbon nanotubes and the epoxy resin matrix.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

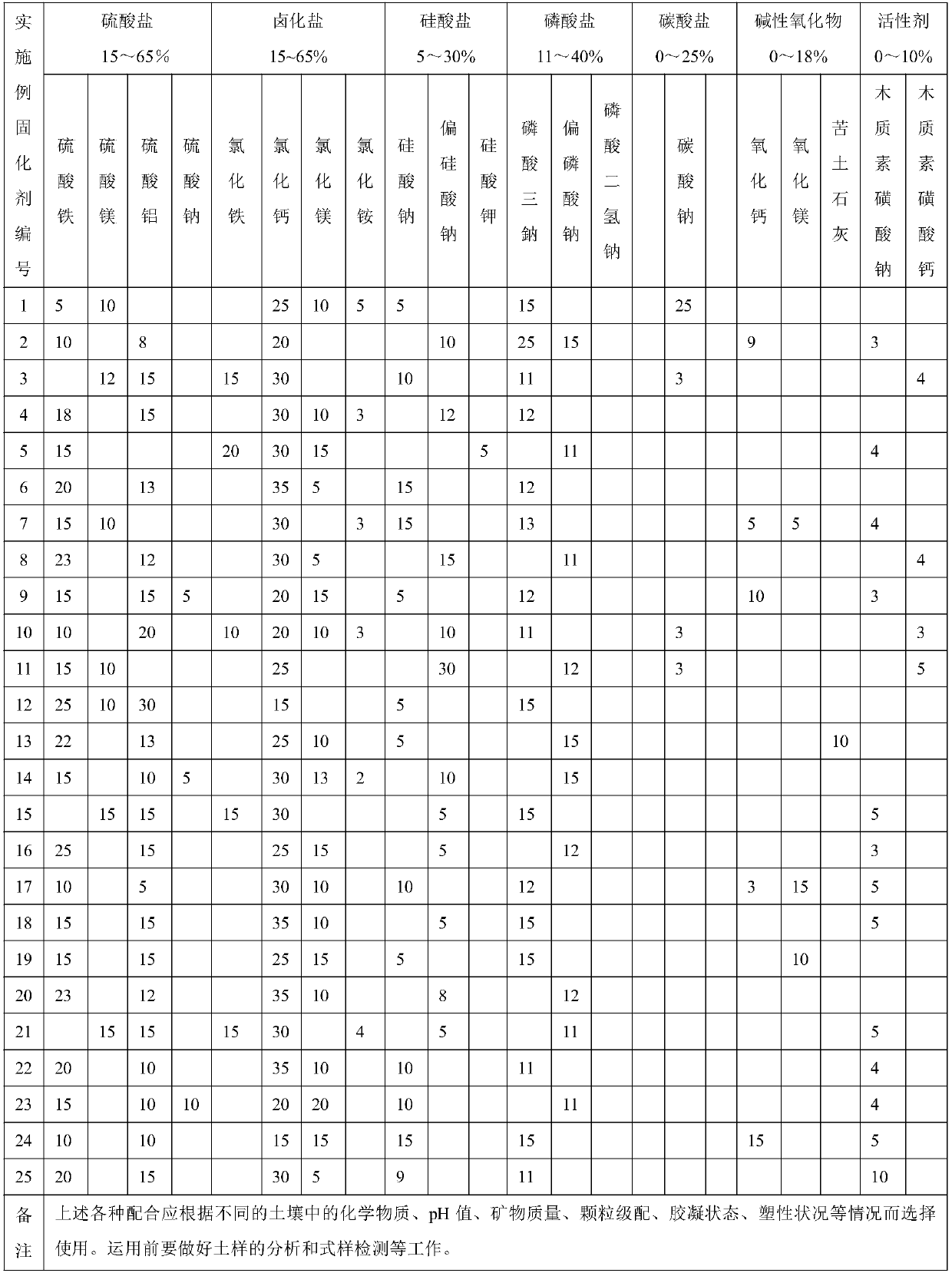

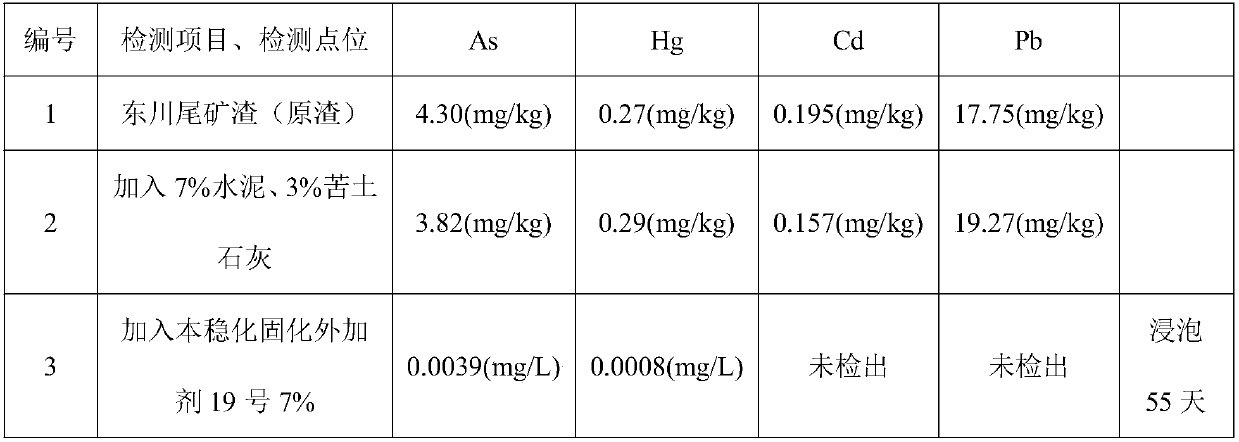

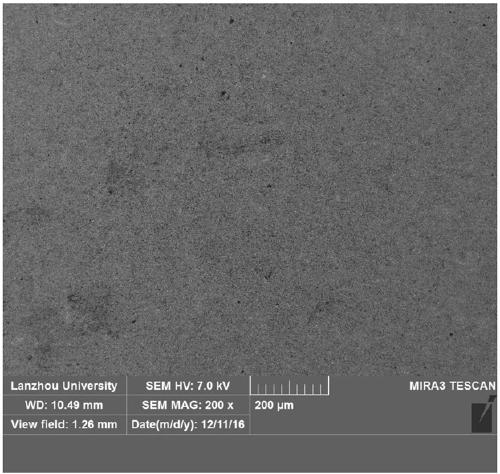

Environment-friendly inorganic soil solidification additive

InactiveCN105950157AImprove compatibilityFull effectOther chemical processesBuilding constructionsSoil propertiesHazardous substance

The invention provides an environment-friendly inorganic soil solidification additive which comprises, by mass, 15-65% of sulfate, 15-65% of halide salt, 11-40% of phosphate, 5-30% of silicate, 0-25% of carbonate, 0-18% of basic oxide and 0-10% of lignosulfonate. The environment-friendly inorganic soil solidification additive is characterized in that all components in soil directly or indirectly undergo soil particle surface chemical modification and modification of substances among soil particles, and generation of colloidal gel materials and generation of various materials of crystal structures are promoted. As time goes, hardened skeletons such as ettringite needle-shaped crystals and apatite crystals appear gradually in solidified soil, soil solidification compressive strength, hydrophobicity, water permeability, stability of heavy metal and other harmful materials and other physical and chemical solidification effects are good, and the environment-friendly inorganic soil solidification additive can adapt to various climates, geographies and soil properties and is high in compatibility and obvious in stabilization and solidification effect on heavy metal and other harmful materials.

Owner:松田勤

Preparation method and application of MAX-phase enhanced nickel-based high-temperature lubricating composite material

ActiveCN109666815AHigh bonding strengthGood self-lubricating performanceCylinder headsGas turbine plantsAlloyGraphite

The invention discloses a preparation method and application of a MAX-phase enhanced nickel-based high-temperature lubricating composite material. The preparation method comprises the following steps:carrying out mechanical mixing on Ti powder, Si powder and TiC powder; preparing loose block-shaped Ti3SiC2 ceramic through a powder metallurgy method; then carrying out crushing and ball-milling treatment on the prepared loose block-shaped Ti3SiC2 ceramic, so as to obtain Ti3SiC2 ceramic powder; then carrying out mechanical mixing on the sieved Ti3SiC2 powder and NiAl powder; compacting and molding; and finally, preparing a block-shaped NiAl-Ti3SiC2 composite material through hot-pressing sintering, wherein the phase content of NiAl and Ti3SiC2 in the block-shaped NiAl-Ti3SiC2 composite material is 60 to 90 percent and 10 to 40 percent respectively. The NiAl composite high-temperature lubricating material is prepared by adopting the powder metallurgy method and the self-lubricating performance of hot-pressing sintering and synthesis in the composite material is better than that of Ti3SiC2-phase ceramic of graphite and MoS2; and meanwhile, an NiAl alloy has excellent corrosion resistance and abrasion resistance, and has good sintering performance, so that NiAl alloy powder is selected as a matrix of the composite material.

Owner:咸阳瞪羚谷新材料科技有限公司

Composite nano material modified emulsion and its preparation method

A composite nano material modified acrylate emulsion is prepared through proportionally mixing aluminium oxide nanoparticles with nano-class silica gel, ultrasonic dispersing, and proportionally mixing the composite nano material with acrylate emulsion for modifying it. It has the greatly improved stability, and resistance to water and alkali.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

Tipping paper anti-bacterial aqueous printing ink

ActiveCN104725935AImprove hydrophilicityImprove antibacterial propertiesInksAcrylic resinPolyethylene glycol

The invention relates to the technical field of aqueous printing ink and discloses tipping paper anti-bacterial aqueous printing ink which is non-toxic and harmless, good in dispersibility and strong in anti-bacterial effect. The tipping paper anti-bacterial aqueous printing ink comprises the following components: a nano titanium dioxide modified waterborne acrylic resin solution, a waterborne resin solution B, deionized water, ethanol, organic pigments, a defoamer, a flatting agent and a buffer agent. The preparation process comprises the following steps: firstly preparing silane coupling agent modified inorganic nanoparticles from nano titanium dioxide, ethanol, deionized water and a silane coupling agent; then, preparing the nano titanium dioxide modified waterborne acrylic resin solution from an alkanyl acrylate monomer, a hydroxyalkyl acrylate monomer, a silane coupling agent modified inorganic nanoparticles, polyethylene glycol, a water soluble initiator, an emulsifier, ammonia water and deionized water; and finally preparing the tipping paper anti-bacterial aqueous printing ink from the nano titanium dioxide modified waterborne acrylic resin solution, the waterborne resin solution B, tea saponin, deionized water, ethanol, the organic pigments, the defoamer, the flatting agent and the buffer agent.

Owner:长兴艾飞特科技股份有限公司

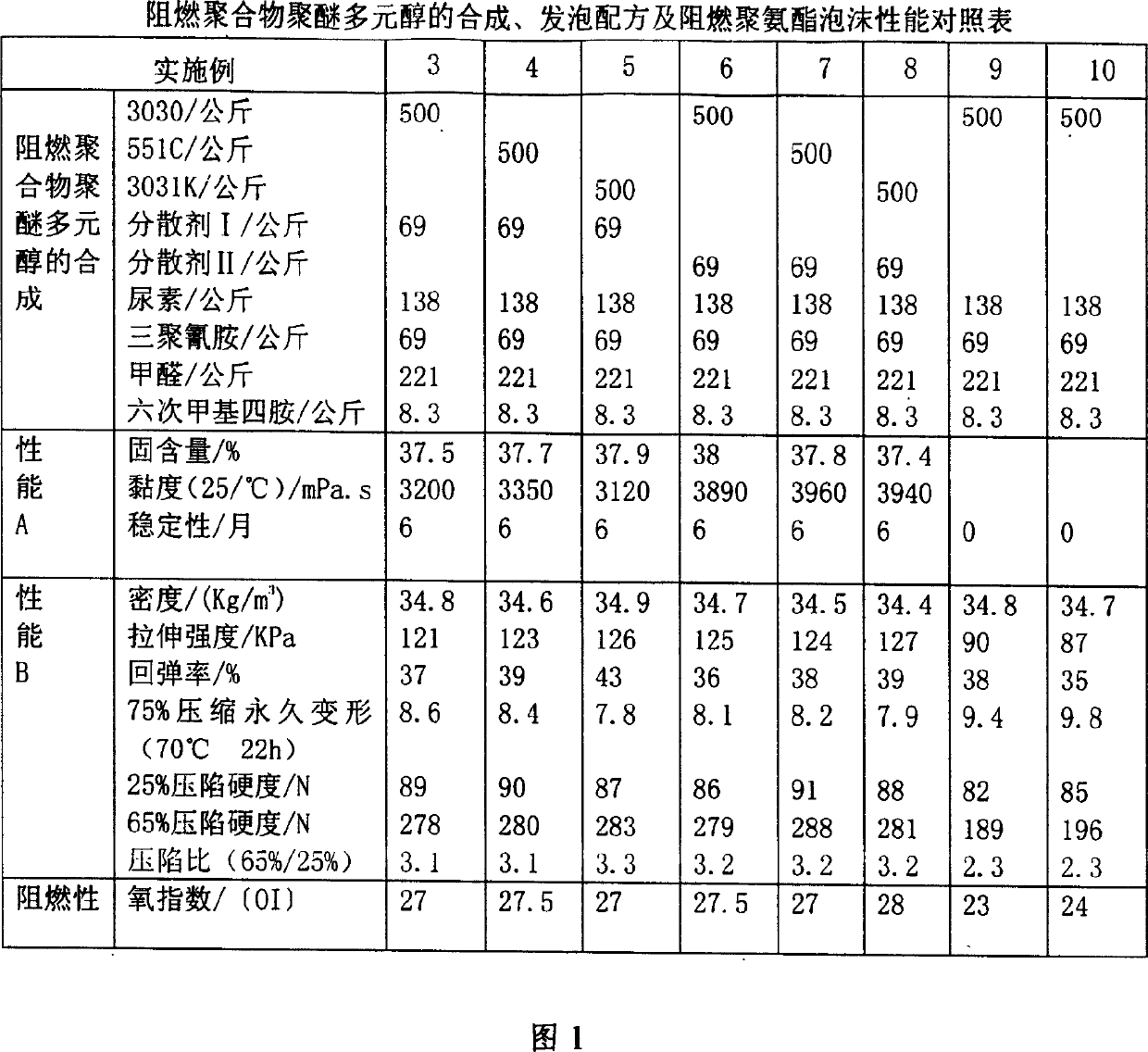

Preparation method of fire retardant polymer polyether polyol and method for preparing block fire retardant polyurethane foam mateial therefrom

A flame-retarding polyether polyol is a stable polymer colloid dispersed system composed of the continuous phase (universal polyether polyol) and the dispersed phase (surface grafted partially aminated diisocyanate modified polyether polyol nanoparticles). It is prepared through the reaction of formaldehyde-urea-cyanuramide-hexamethine tetramine in polyether polyol under existance of said dispersed system, and drying. A flame-retarding polyurethane foam is prepared from said flame-retarding polyether polyol, universal polyetherpolyol and diisocyanate through block foaming under existance of catalyst and foaming agent.

Owner:QINGDAO UNIV OF SCI & TECH +1

Preparation method of polycarboxylate water reducer with intensively-distributed carboxyl groups and high water reduction performance, product thereof, and application of product

The invention provides a preparation method of a polycarboxylate water reducer with intensively-distributed carboxyl groups and high water reduction performance. The preparation method comprises the following steps: adding a low molecular weight unsaturated carboxylic acid compound, adding a catalyst, and reacting to obtain an unsaturated carboxylic acid polymer; adding the unsaturated carboxylic acid polymer, an unsaturated polyether monomer and an unsaturated sulfonate or polyether monomer unsaturated carboxylate, adding distilled water, mechanically stirring for fully dissolving to form a clarified solution, adding an initiator, adding an aqueous solution of a chain transferring agent in a dropwise manner at a constant speed, continuously reacting after the dropwise addition ends, and stopping the reaction to obtain polycarboxylic acid with intensively-distributed carboxyl groups; and adding an alkali solution to the polycarboxylic acid with intensively-distributed carboxyl groups, neutralizing to the pH value of 5-7, and adding water to dilute in order to obtain the product. The invention also provides the polycarboxylate water reducer prepared through the method, and an application of the polycarboxylate water reducer in concrete. The polycarboxylate water reducer has better initial fluidity and ageing fluidity than common polycarboxylate water reducers, and has very good application prospect.

Owner:SHANGHAI TAIJIE CHEM

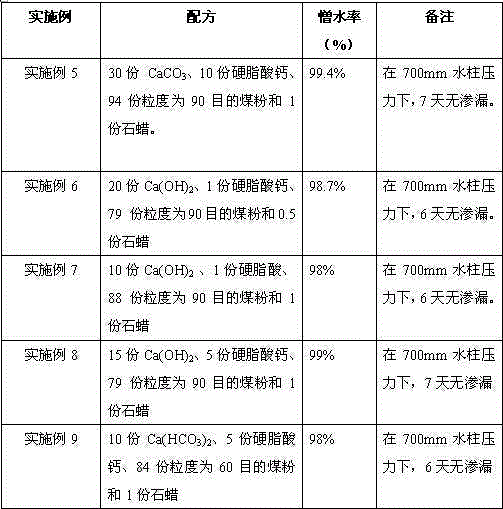

Waterproof pulverized coal and preparation method thereof

The invention discloses a waterproof pulverized coal and a preparation method thereof, wherein the waterproof pulverized coal comprises components with parts by weight: calcium salt or calcium hydroxide (Ca(OH)2) 5-30 parts, stearic acid or stearate 1-10 parts or pulverized coal 60-94 parts. The method for preparing the waterproof pulverized coal comprises steps: firstly, the components with parts by weight are weighted, are added into a roller type reaction kettle to be kept to heat for 20-60 min after being heated to 110-140 DEG C, thereby obtaining the waterproof pulverized coal. The method for preparing the waterproof pulverized coal can convert pulverized coal to be a hydrophobic substance from a hydrotropic substance, greatly reduces hydrophilic performance of the pulverized coal, and can prevent volatile components in the pulverized coal from volatilizing, thereby preventing the autoignition problem of the pulverized coal during storing, prolonging service life, improving safety during storage and transportation, and having excellent application prospect.

Owner:重庆四季金标科技有限公司

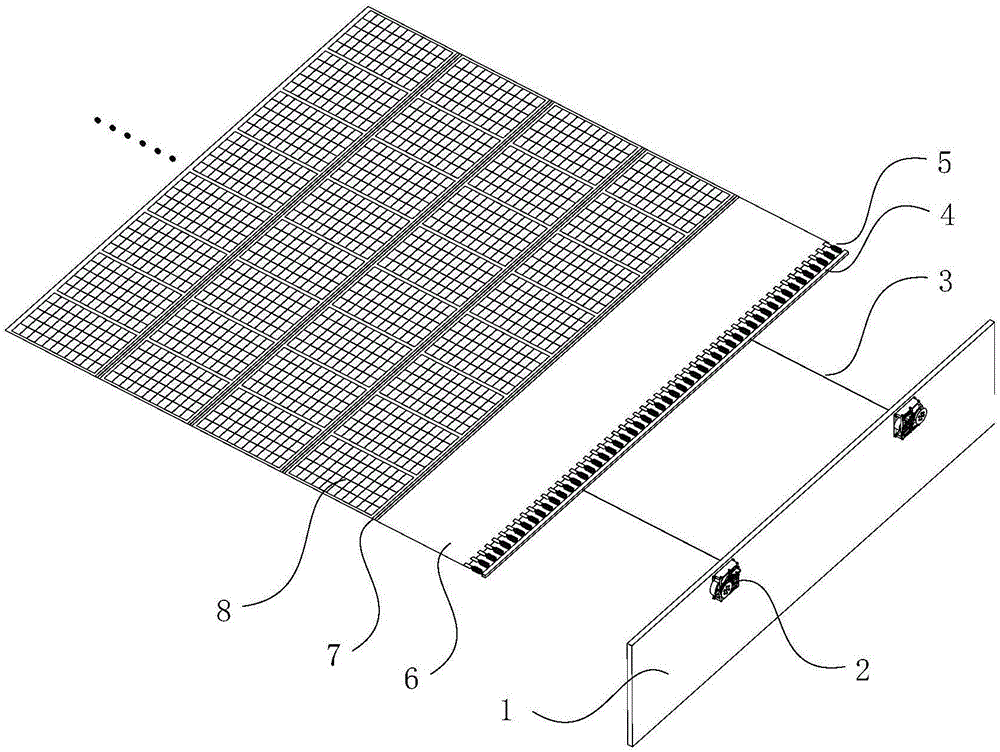

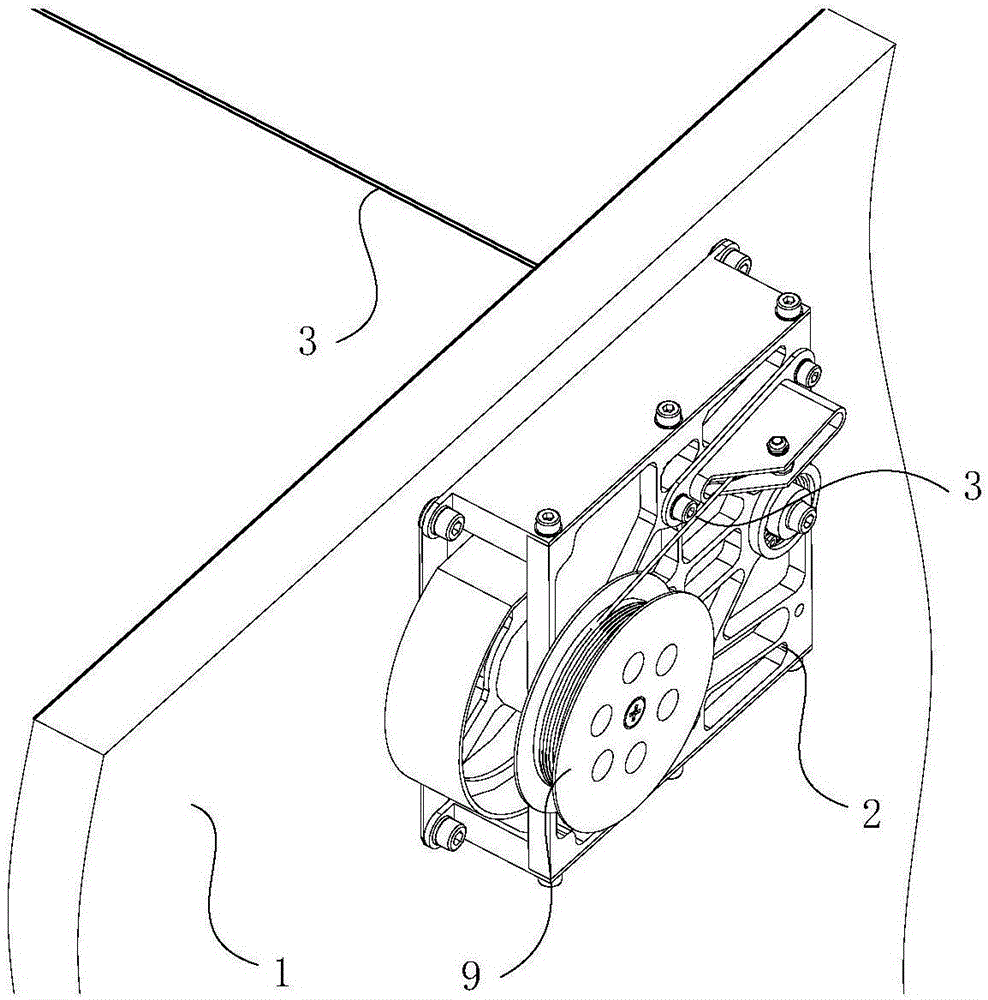

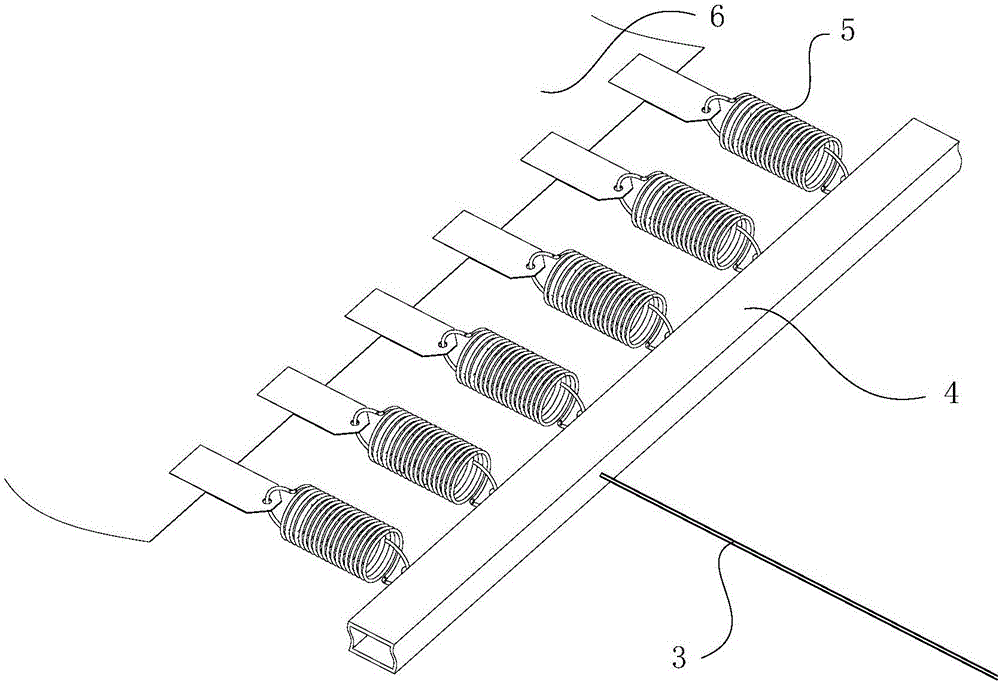

Solar carpet uniform loading, tensioning and displacement compensating mechanism

ActiveCN106240847ARealize the displacement compensation functionSolving Tension ProblemsCosmonautic vehiclesCosmonautic power supply systemsIn planeInterference resistance

The invention discloses a solar carpet uniform loading, tensioning and displacement compensation mechanism. By applying the solar carpet uniform loading, tensioning and displacement compensating mechanism, when expansion displacement of a solar wing is generated due to spatial high-low temperature alternation, uniform and constant tensioning force can be provided, the effect that the solar wing has stable rigidity property is guaranteed, the displacement compensation dimension is large, and the interference resistance is high. The solar carpet uniform loading, tensioning and displacement compensating mechanism is composed of a constant torque spring taking-up mechanism, tensioning steel wire ropes, a uniform loading beam, uniform loading springs, a flexible transitional carpet and piano wire hinges. By changing the lengths of the tensioning steel wire ropes, the displacement, generated by shrinkage and expansion, of a flexible solar carpet is compensated, and the effect that the tensile force of the tensioning steel wire ropes is constant all the time is guaranteed. Through the uniform loading beam, the uniform loading springs and the flexible transitional carpet, the concentrated tensile force transferred from the tensioning steel wire ropes is dispersed into the in-plane acting force uniformly, and the purpose of uniform loading is achieved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

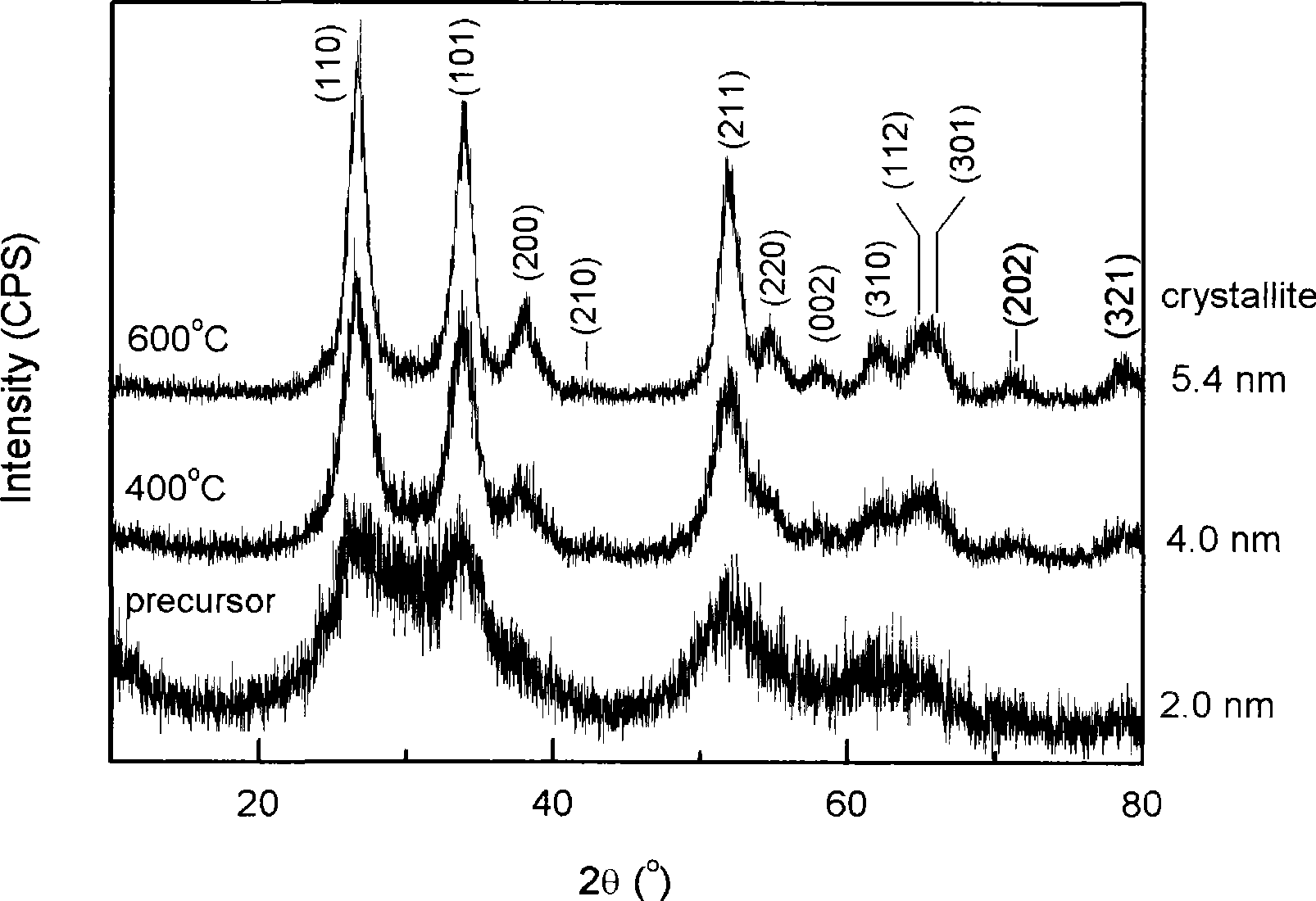

Process for producing tin-stibium oxide ultra-fine nano-powder

InactiveCN101428848AAvoid stickingAct as a dispersantGallium/indium/thallium compoundsTin oxidesDispersion stabilityUltra fine

The invention relates to a preparation method of tin-antimony oxide superfine nanometer powder, which is characterized in that the method comprises the following steps: firstly, dissolving tin inorganic salt, antimony inorganic salt and sodium hydroxide in an ethylene glycol solvent; heating up till the color of the solution is changed into yellow and deposition occurs; secondly, cooling mixed liquor and adding distilled water, stirring for one hour, and fully separating out the deposition; thirdly, cleaning the deposition after being centrifuged with ethanol for more times, and obtaining the tin-antimony oxide superfine nanometer powder after the deposition is dried; and fourthly, calcining the precursor powder in air, cleaning the powder with the distilled water, and obtaining the tin-antimony oxide superfine nanometer powder. The grain size of the tin-antimony oxide superfine nanometer powder prepared in the invention is 5.4 nm; and the powder has the advantages of superfine crystal grain, uniform grain size, good dispersion stability in the solvent, and the like, and is applicable to transparent conductive coating layers, shading coating layers, and electrostatic prevention, electromagnetic radiation prevention and dazzle prevention coating layers.

Owner:NANCHANG HANGKONG UNIVERSITY

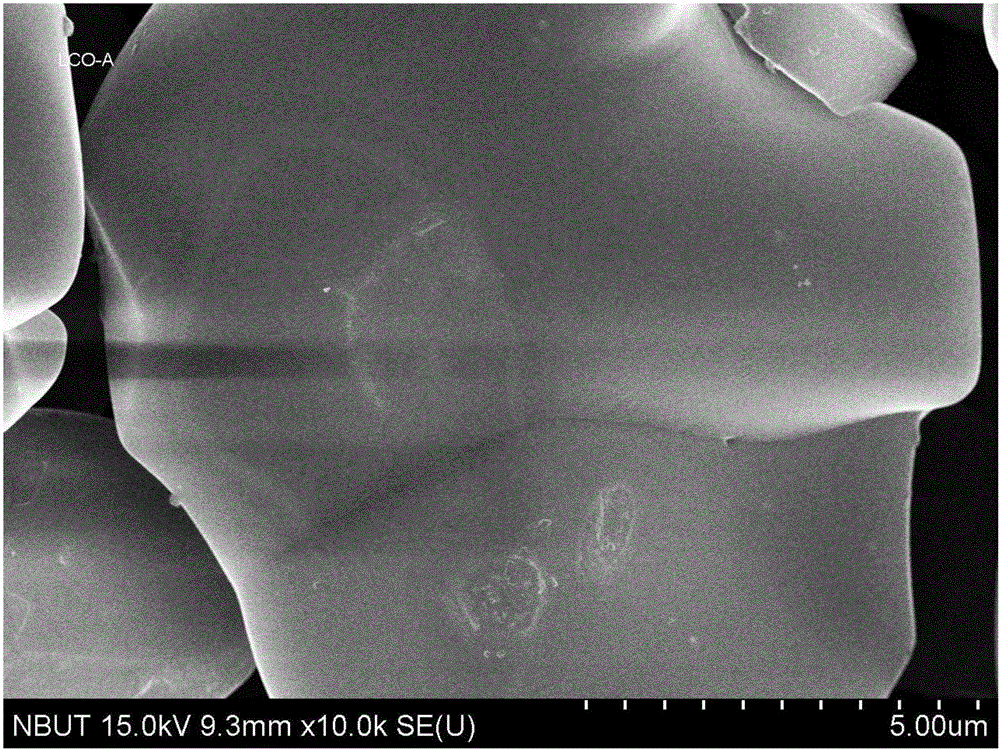

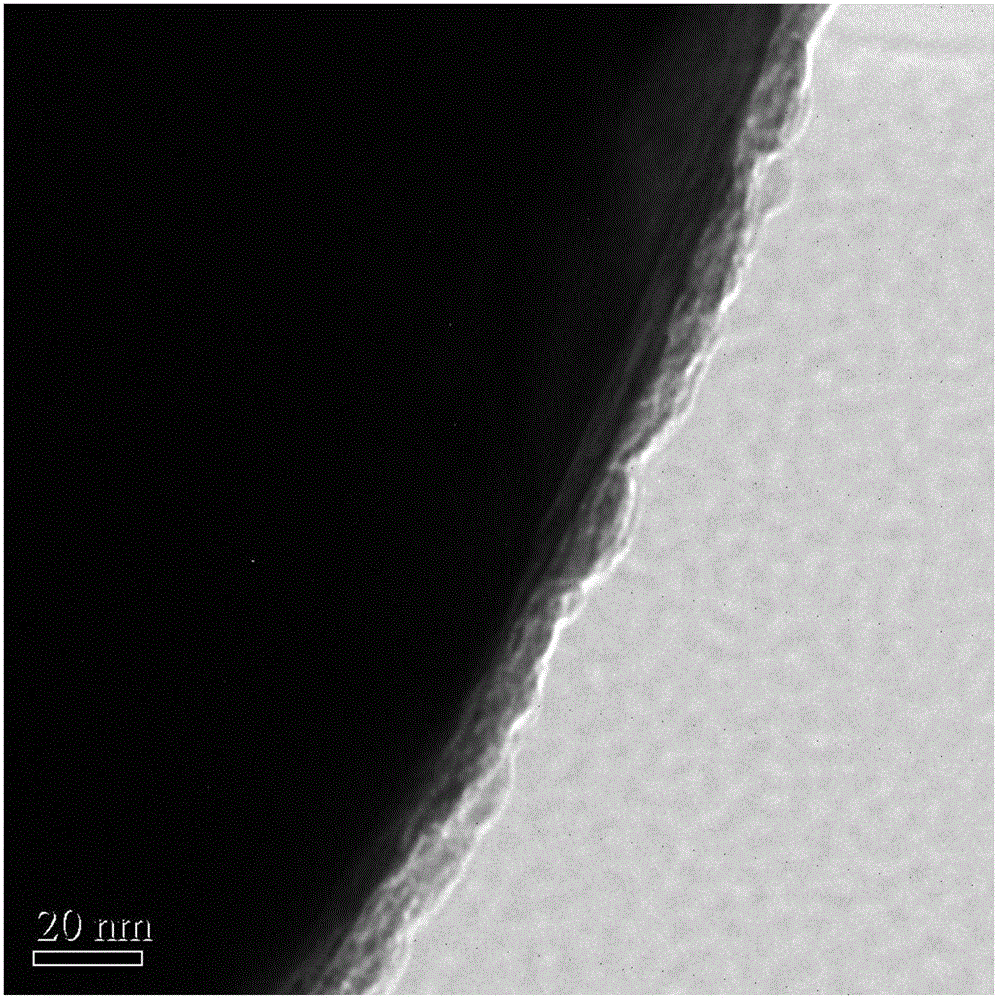

Method for preparing coated layered positive electrode material from sodium metaaluminate

ActiveCN106067545AImprove uniformity and integrityEasy to operateCell electrodesSecondary cellsIonChemistry

The invention discloses a method for preparing a coated layered positive electrode material from sodium metaaluminate. The method comprises 1, weighing polyvinylpyrrolidone (PVP) and a layered positive electrode material according to a mass ratio of 1: 75, dissolving the PVP in deionized water, and dispersing the layered positive electrode material in the solution to obtain a solution A, 2, weighing a complexing agent and sodium metaaluminate according to a mole ratio of 5: 100 to 30: 100, 3, dissolving the weighed sodium metaaluminate in deionized water to obtain a sodium metaaluminate solution with a concentration of 0.01-0.09mol / L, 4, dissolving the weighed complexing agent in an acid solution with a concentration of 0.01mol / L to obtain a solution C, 5, under conditions of a constant temperature water bath and vigorous stirring, simultaneously pumping the solution B and the solution C into the solution A, wherein reaction pH is kept in a range of 9-10 through control of a solution C pumping rate, 6, after the solution B is pumped into the solution A, carrying out vigorous stirring for 1h under the condition of a constant temperature water bath, and 7, carrying out pumping filtration, washing, drying and calcining on the reaction product solution to obtain the alumina membrane-coated layered positive electrode material.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

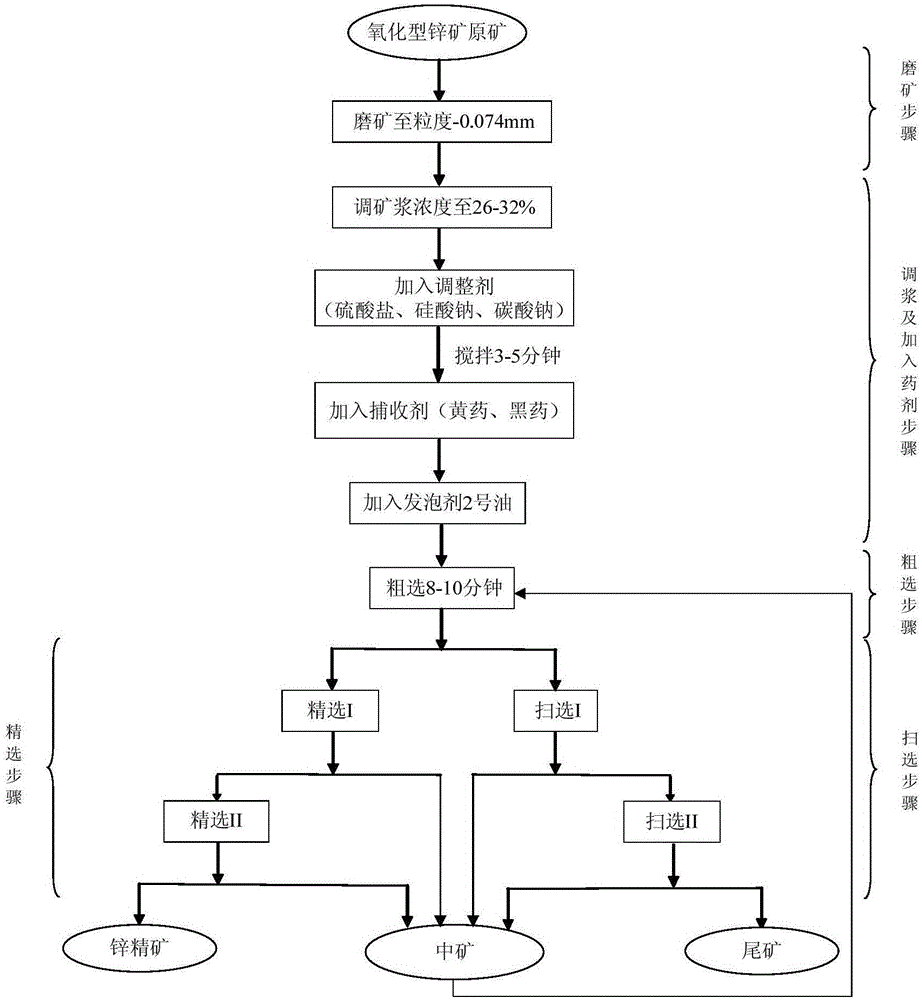

Oxidized zinc ore flotation reagent and method

ActiveCN105013621AFacilitate or inhibit buoyancyGood water solubilityFlotationSodium carbonateSodium silicate

The invention relates to an oxidized zinc ore flotation reagent. The oxidized zinc ore flotation reagent comprises the following ingredients by weight: a regulator consisting of a 180-800 g / t sulfate, 200-500 g / t sodium silicate and 50-200 g / t sodium carbonate, a collector consisting of 130-800 g / t xanthate and a 60-800 g / t black catching agent, and a foaming agent consisting of 100-180 g / t 2# oil. The flotation reagent can achieve the purpose of effective zinc ore enrichment, and different combinations by weight and different ingredient adding sequences of the flotation reagent can be adopted for oxidized zinc ores at different geographical positions, so that the zinc ore utilization ratio, the zinc recovery rate and the zinc finished ore grade are all improved, the zinc recovery rate can be up to 87-90%, and the obtained zinc finished ore grade can be 52-60%. The invention also relates to an oxidized zinc ore flotation method.

Owner:INST OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Process for preparing acrylate resin for powder paint

InactiveCN1944481AHealth hazardEliminate the removal processPowdery paintsFunctional monomerPolymer science

The preparation process of acrylate resin for powder paint is one high molecular compound polymerizing process with only C-C unsaturated bond reaction. The materials includes dispersing medium in 333.3-1000.0 weight portions, monomer mixture in 100.0 weight portions, free radical initiator in 0.5-8.0 weight portions, chain transferring agent in 0-1.0 weight portions and dispersant in 5.0-30.0 weight portions. The dispersing medium is mixture of alcohol or ethylene glycol monomethyl ether and deionized water; and the monomer mixture consists of soft monomer, hard monomer and functional monomer. The polymerizing process includes compounding mixed reactant liquid, preparing dispersing medium and reaction condition, and reaction and stilling to separate out product. The present invention is superior to available technology, and the obtained acrylate resin has high storage stability and can prepare powder paint with high mechanical performance and high outdoor endurance.

Owner:HEBEI UNIV OF TECH

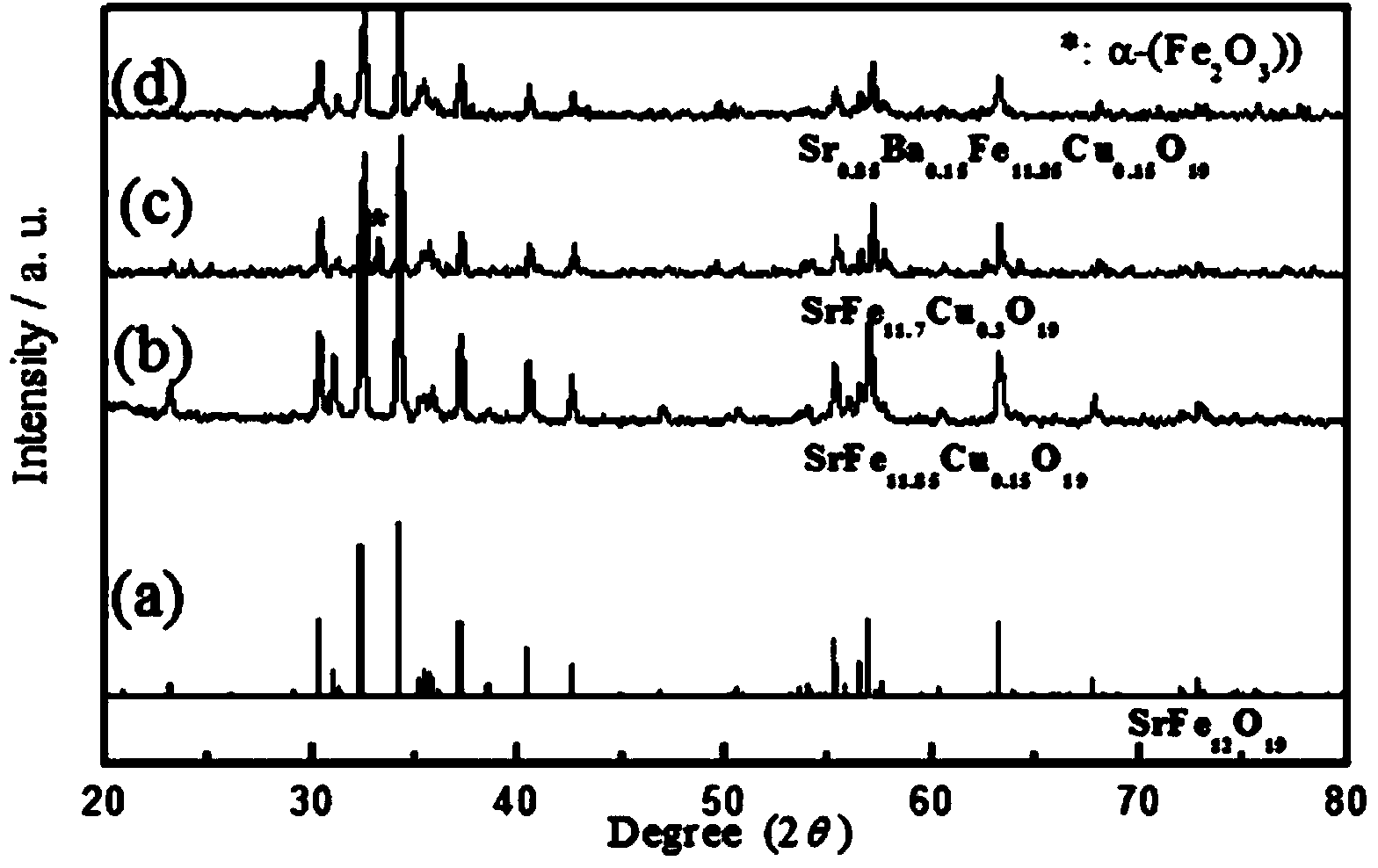

Preparation and sintering of single-aperture blank of oxygen self-supported permanent magnetic ferrite pre-sintering material

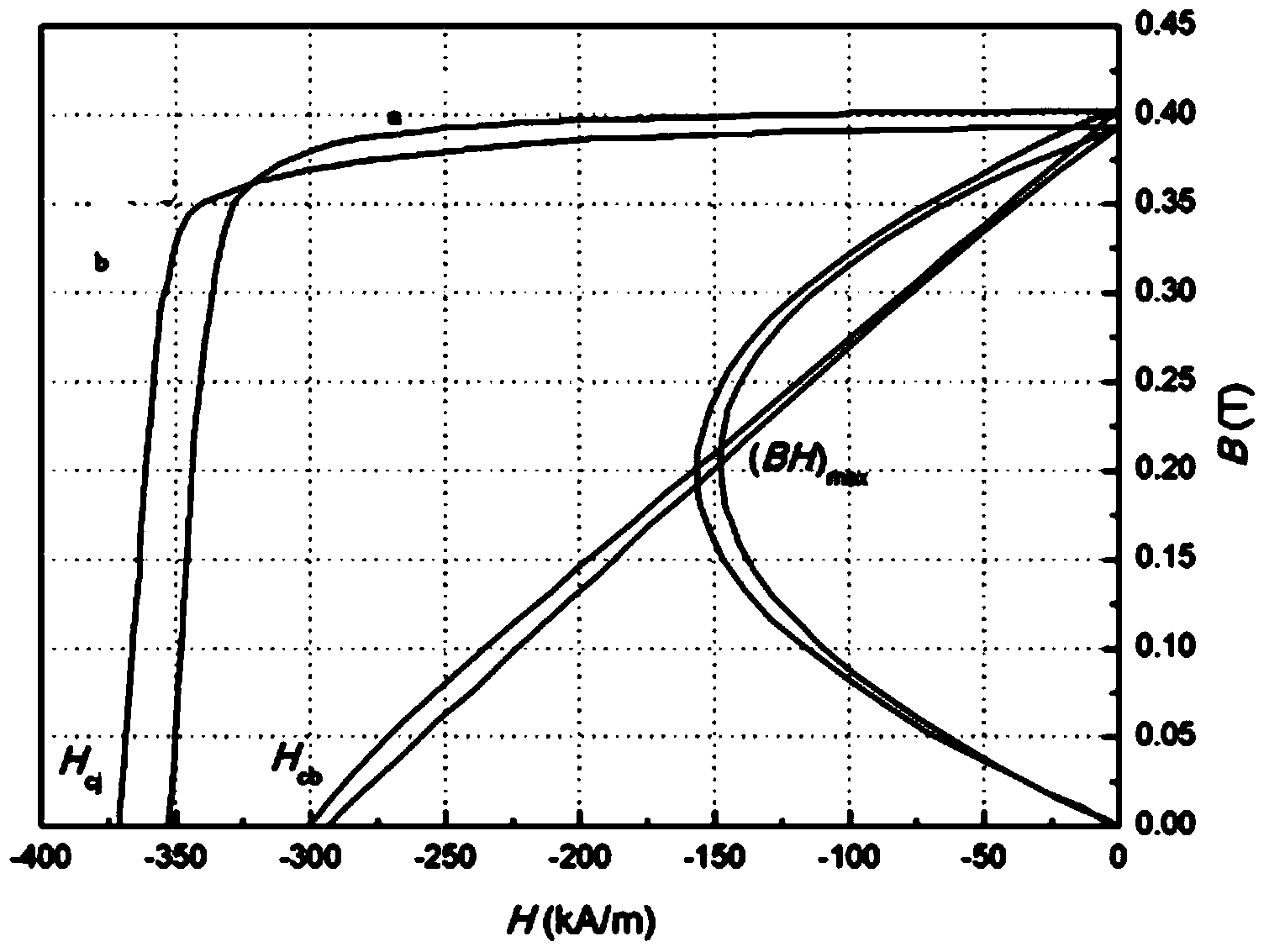

The invention relates to preparation and sintering of a single-aperture blank of an oxygen self-supported permanent magnetic ferrite pre-sintering material and belongs to the technical field of preparation of magnetic functional materials. The technical scheme is carried out according to a main-phase molecular formula: Srl-xBaxO.nFe (12-y) / nRy / nO3, wherein x is not less than 0 and is not greater than 0.998, and n is not less than 5.75 and not greater than 6.15, 0 & 1t; y is not greater than 0.6, and R is Mn and is secondarily added with one or more than two of industrial pure oxides CeO2, GeO2 and MnO2. To the prepared pre-sintering material and a high-performance permanent magnetic ferrite material prepared from auxiliary secondary adding, the residual magnetism Br value is at least 392 mT, the Hcj value is at least 343.1 kA / m, and the BHmax value is at least 27.9 kJ / m<3>. The preparation and sintering have the advantages that a certain amount of K2MnO4 is added to a raw material of the ferrite pre-sintering material prepared by one-time sintering and meanwhile MnO2 is added into a secondary adding auxiliary material, so that the uniformity of performance of the same batch of products is improved, and the grain refinement is facilitated at the same time; the problem of the restriction of residual magnetic flux density Br and Hcj is effectively solved, and the prepared permanent magnetic ferrite has high Br and Hcj.

Owner:宿州学院

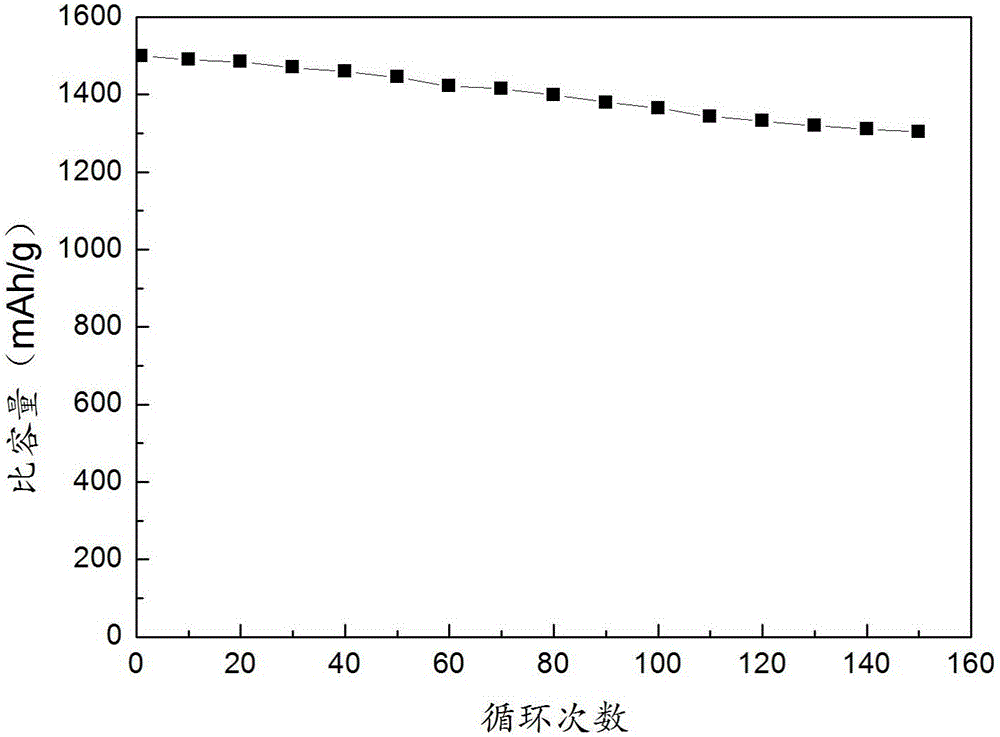

Graphene-doped stannic-oxide-based lithium nano battery cathode material and preparation method

ActiveCN105826541AHigh specific capacityImprove conductivityCell electrodesSecondary cellsHigh pressureAqueous solution

The invention relates to a preparation method of a graphene-doped stannic-oxide-based lithium nano battery cathode material. The method includes the steps that firstly, SnCl4.5H2O is added to a graphene oxide aqueous solution, and a gel-shaped substance is prepared by regulating the PH value through a regulator; then a reaction is conducted in a high-temperature and high-pressure environment, after drying is conducted, calcination is conducted under the inert atmosphere, and an electrode material is obtained. According to the electrode material, a covalent bond is formed between graphene and SnCl4, the cooperative function between the graphene material and the stannic-oxide-based material is fully played, a graphene-doped stannic-oxide-based lithium battery can have high specific capacity and conductive performance, and the multiplying power charging and recycling performance of the material is greatly improved.

Owner:江苏引潮蕴飞新材料有限公司

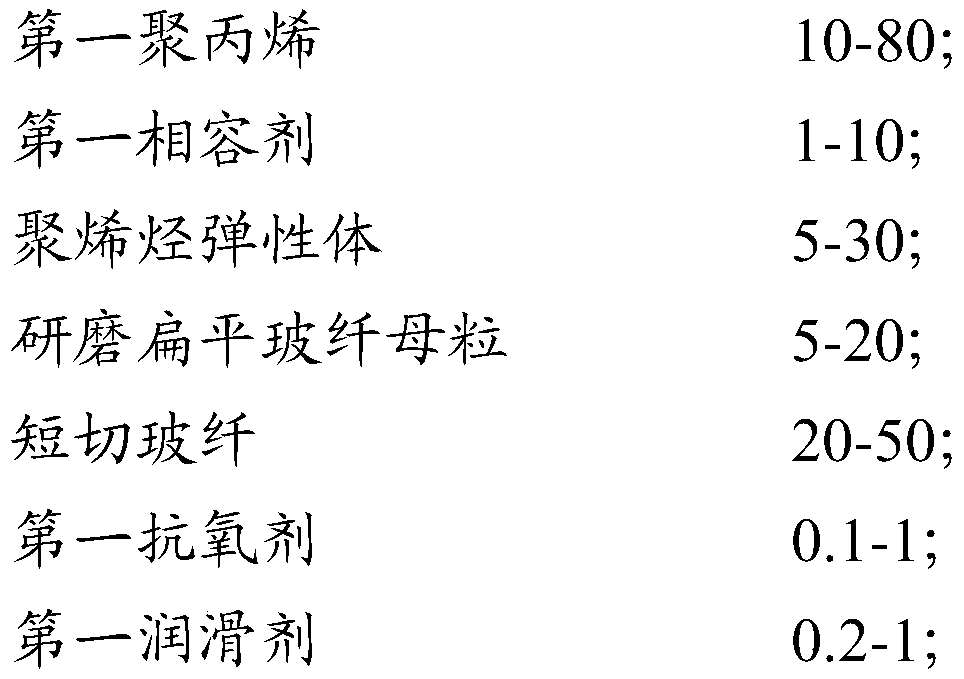

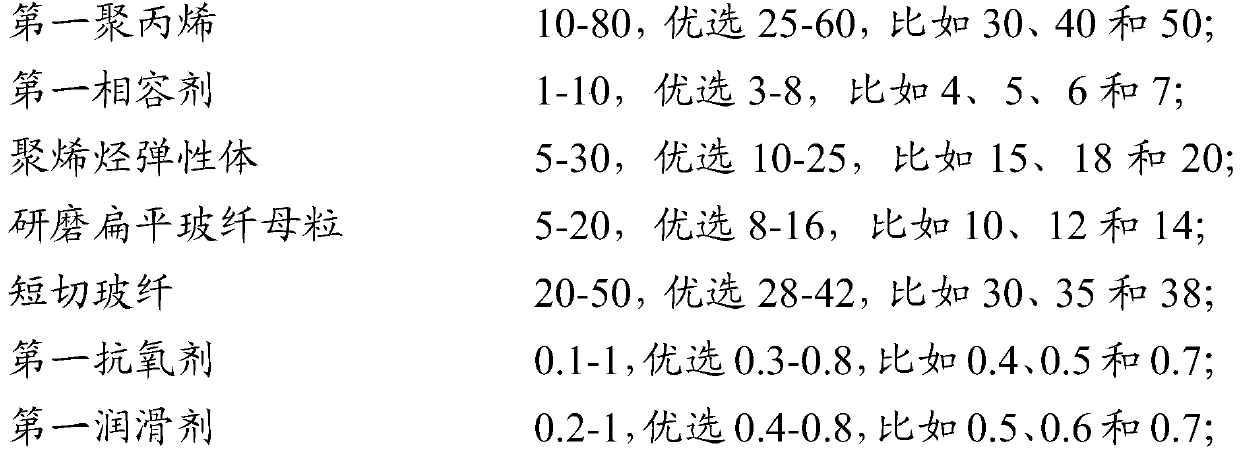

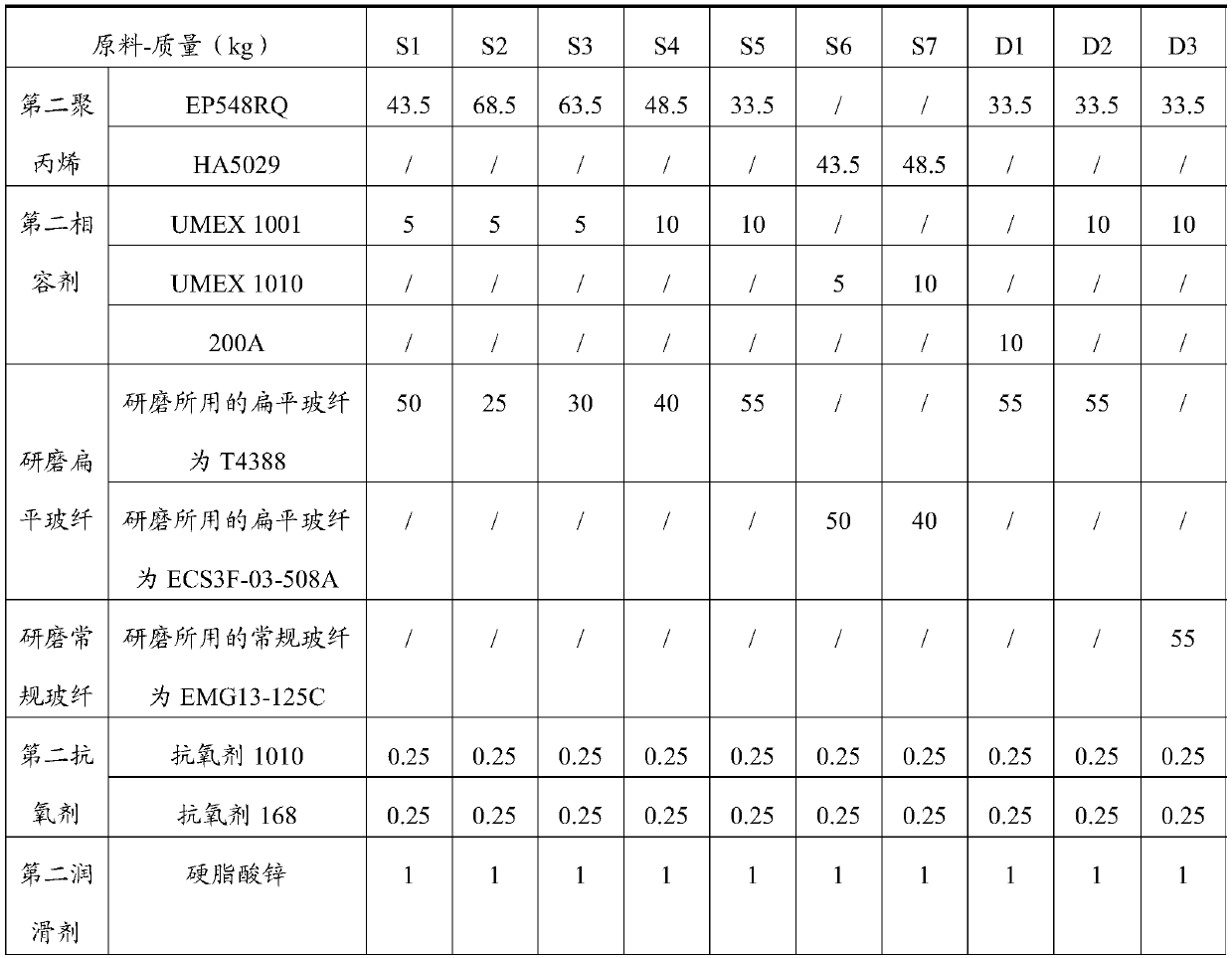

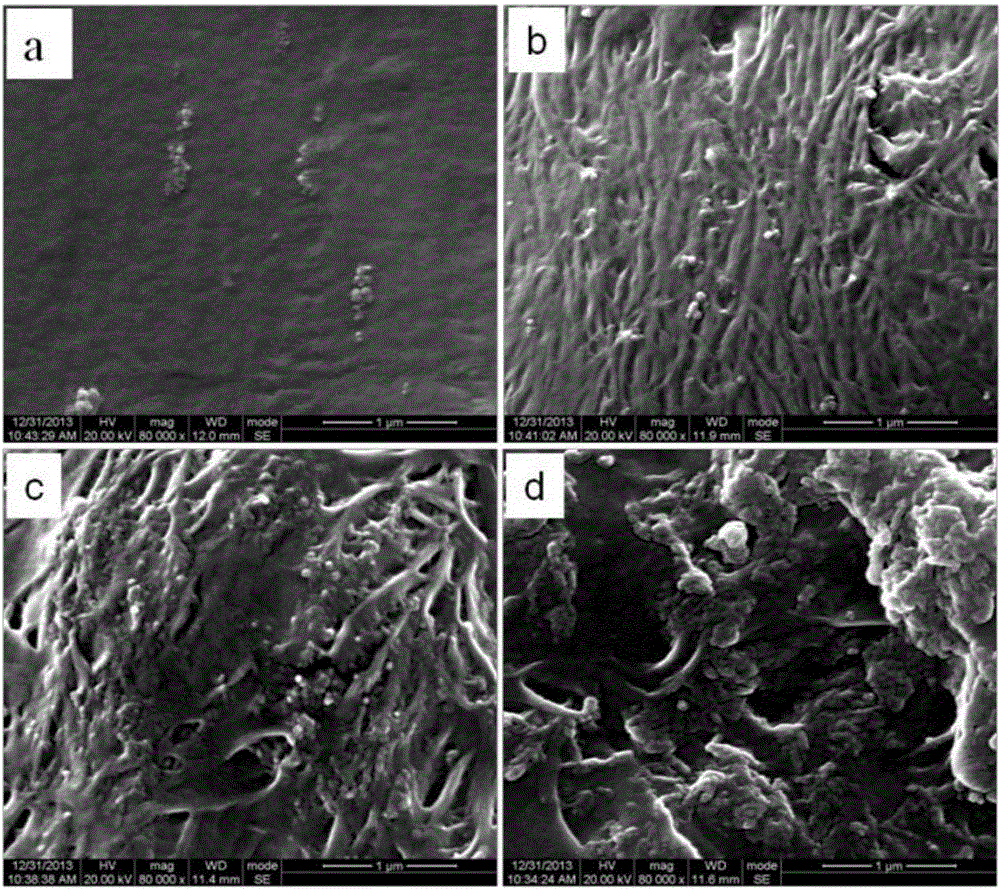

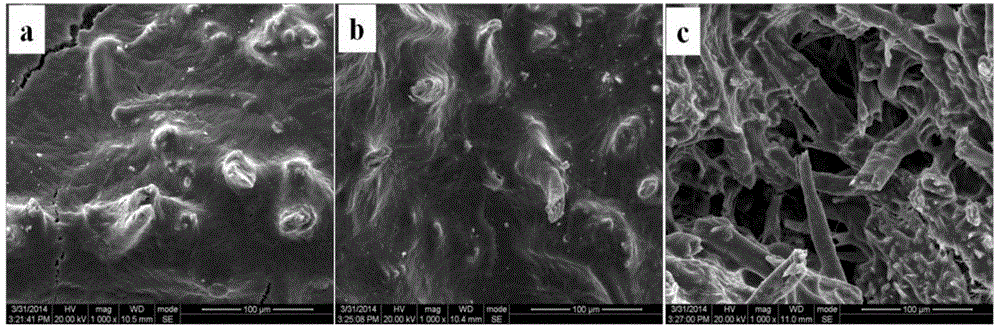

Short glass fiber reinforced polypropylene composite material and preparation method thereof

The invention provides a short glass fiber reinforced polypropylene composite material and a preparation method thereof. The composite material is prepared from the following raw materials in parts byweight: 10-80 parts of first polypropylene, 1-10 parts of a first compatibilizer, 5-30 parts of a polyolefin elastomer, 5-20 parts of grinded flat glass fiber master batch, 20-50 parts of chopped glass fiber, 0.1-1 part of a first antioxidant, and 0.2-1 part of a first lubricant, wherein the grinded flat glass fiber master batch is obtained by mixing raw materials including second polypropylene,a second compatilizer, grinded flat glass fibers, a second antioxidant and a second lubricant and then extruding and granulating. The preparation method comprises the following steps: (1) mixing raw materials for preparing grinded flat glass fiber master batch, and extruding and granulating to obtain grinded flat glass fiber master batch; and (2) feeding chopped glass fibers into a double-screw extruder through a side feeding port, feeding other raw materials into the double-screw extruder through a main feeding port, and extruding and granulating. The composite material has the advantages oflow floating fiber, excellent appearance, high strength and high toughness. The preparation method is simple.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +2

Regenerated cellulose nano-particles and preparation method thereof

The invention discloses regenerated cellulose nano-particles and a preparation method thereof. The method comprises the following steps: thermally gelating a cellulose solution, soaking to prepare cellulose hydrogel, soaking the cellulose hydrogel a PEO water solution to obtain a cellulose gel / PEO / water mixture, dewatering the cellulose gel / PEO / water mixture obtain a PEO / cellulose primary mixture, and finally further mixing the PEO / cellulose primary mixture by a fusion mixing method to obtain the cellulose nano-particles which are uniformly dispersed in PEO. The method provided by the invention is green and environment-friendly, consumes low energy and employs simple equipment; the end products are in stable solid state, that is, the cellulose nano-particles are uniformly dispersed in PEO, are convenient and stable to store and transport, and are free of a drying process during further application. PEO in the mixture can take the functions of a dispersing agent, a surface modification agent and the like at the same time. Different from the conventional fibrous nano fiber material, the regenerated cellulose nano-particles prepared according to the method are spherical particles and aggregates thereof.

Owner:SICHUAN UNIV

Water soluble fullerene clathrate for chemicals for daily use and preparation method thereof

PendingCN109381368AStrong antioxidant activityStrong physiological activityInorganic/elemental detergent compounding agentsCosmetic preparationsWater solubleBiological body

The invention discloses a water soluble fullerene clathrate for chemicals for daily use and a preparation method thereof, and relates to the field of chemicals for daily use. According to the preparation method, fullerene powder and an anionic surfactant are grinded in ethanol and then dried in vacuum, then the mixture is ball-milled with a water soluble inclusion material, the powder is dissolvedin water, then vacuum suction filtration is performed to remove undissolved substances, and finally rotary evaporation and freeze drying are carried out to obtain the water soluble fullerene clathrate solid powder. Through physical wrapping, the water soluble fullerene clathrate is prepared, the molecular structure of fullerene is not changed, the fullerene still has good anti-oxidation activity,excellent physiological activity is guaranteed, and the fullerene also has good stability. The preparation method does not use any organic solvent that is harmful to organisms and environment, is green and safe, and can be industrialized.

Owner:苏州大德碳纳米科技有限公司

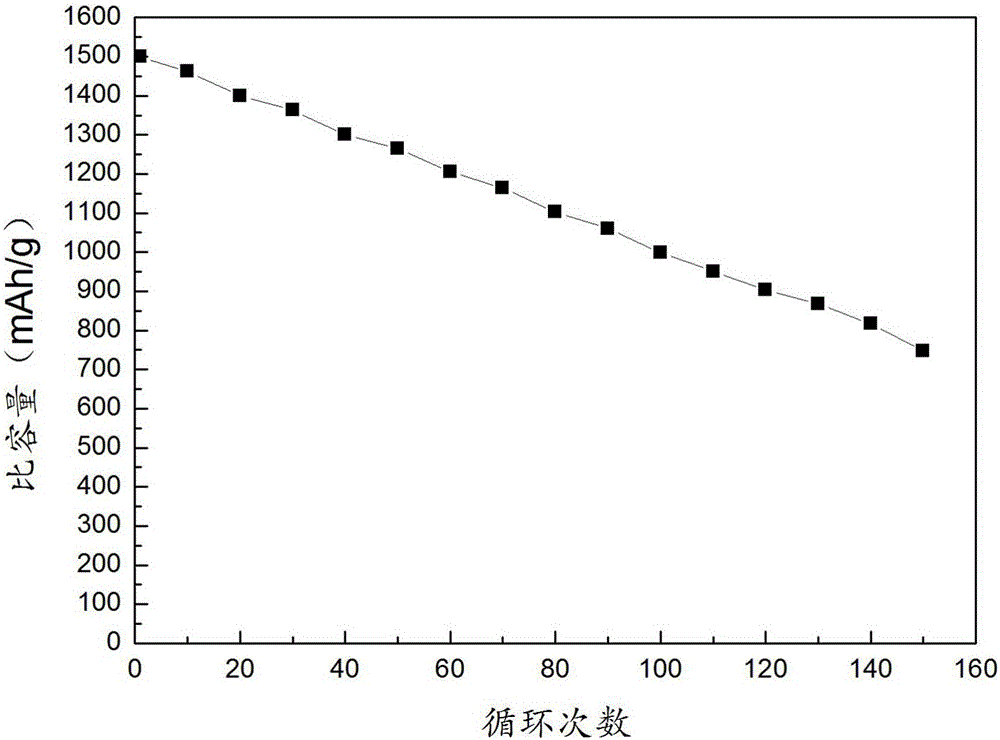

Negative electrode material of lithium battery and preparation method and application thereof

InactiveCN109360976AHigh specific capacityIncrease total decentralized controlCell electrodesLi-accumulatorsGraphiteButadiene-styrene rubber

The invention provides a negative electrode material of a lithium battery. The material comprises 80-90 wt% of graphite, 0.5-6 wt% of a conductive agent, 0.5-6 wt% of carboxymethylcellulose lithium and 1-10 wt% of styrene-butadiene latex. When the negative electrode material is used as a negative electrode of the lithium battery, Li ions can be additionally provided for the lithium battery, the dispersing control efficiency of the lithium ions is improved, the embedding and releasing number of the lithium ions between a positive electrode and the negative electrode is improved, the lithium ionmoving route between the positive and negative electrodes is shortened, so that the conductive rate and transmission rate between the positive and negative electrodes are effectively improved, and the lithium battery which adopts the negative electrode material as the negative electrode has higher specific capacity and circulation efficiency.

Owner:CHONGQING LIHONG FINE CHEM

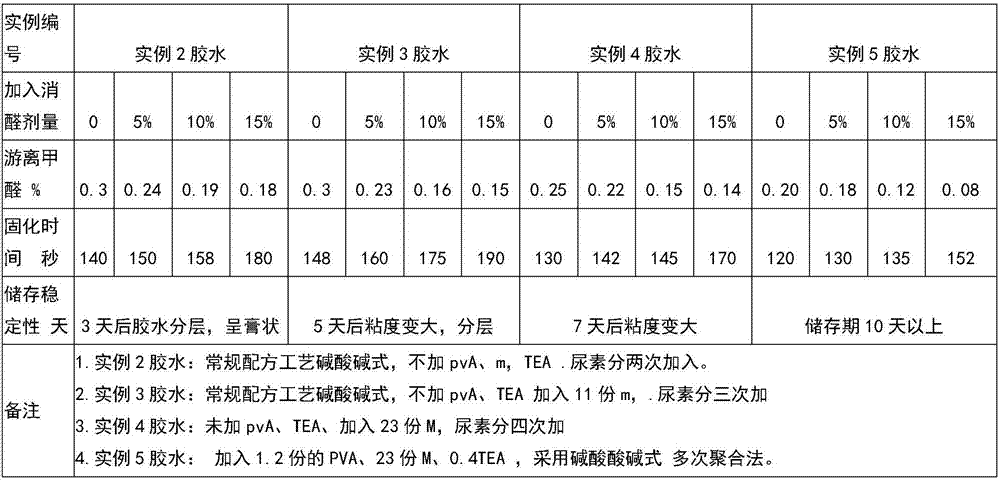

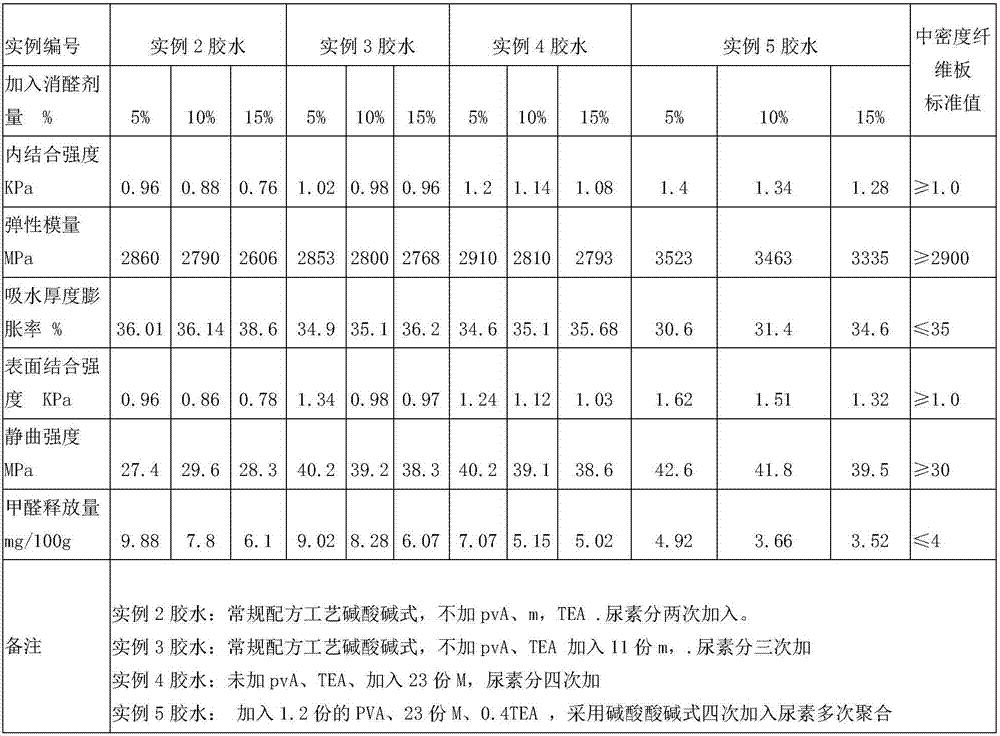

Modified urea-formaldehyde adhesive for applewood level E0 medium-density fiberboards and preparation method thereof

InactiveCN107151298AReasonably adjust the HP valueReduce free aldehydesAldehyde/ketone condensation polymer adhesivesCondensation processMedium density

The invention discloses modified urea-formaldehyde adhesive for applewood level E0 medium-density fiberboards, prepared from formaldehyde, urea, polyvinyl alcohol, melamine, triethanolamine, formic acid and sodium hydroxide by means of alkali-acid-acid-alkali multiple condensation process. The modified urea-formaldehyde adhesive has the advantages that a modified synthetic process of urea-formaldehyde adhesive is utilized, the molar ratio and reaction time are adjusted, low-temperature multiple condensation is employed, initial adhesion and interweaving of the adhesive are increased, preparation of self-made formaldehyde removers and other techniques are utilized during use, the modified urea-formaldehyde adhesive fully meets the requirements for the production of level E0 fiberboards, the content of harmful substances is decreased, and product quality and benefit are increased.

Owner:SHAANXI ZHONGXING FOREST PROD TECH CO LTD

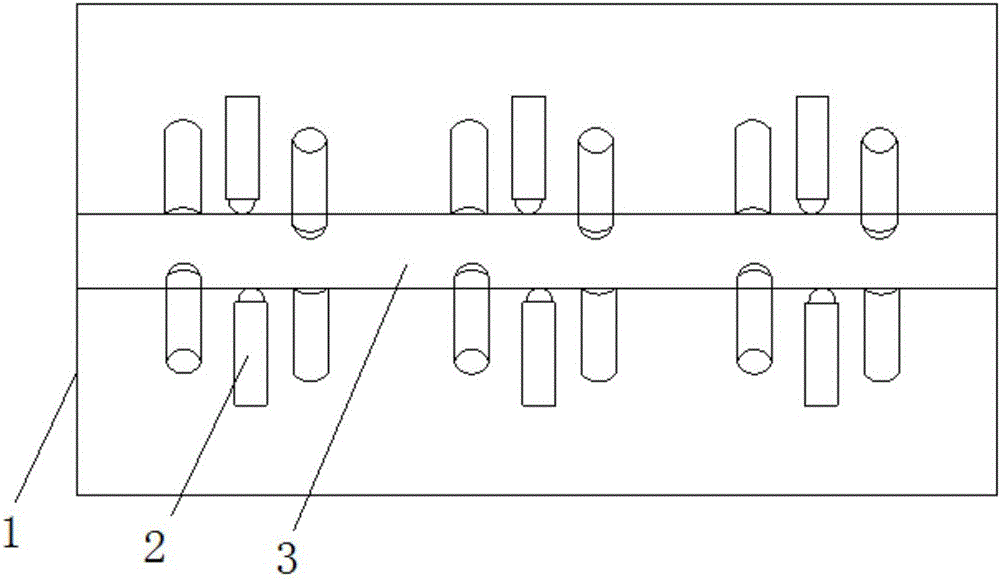

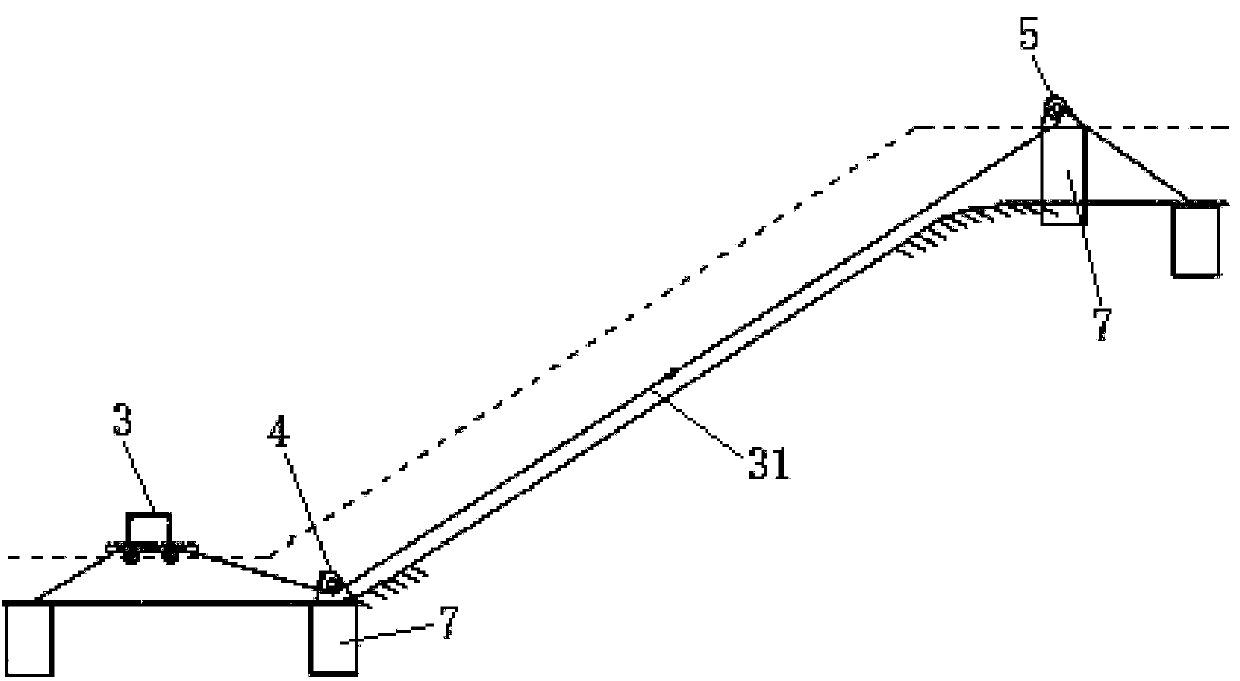

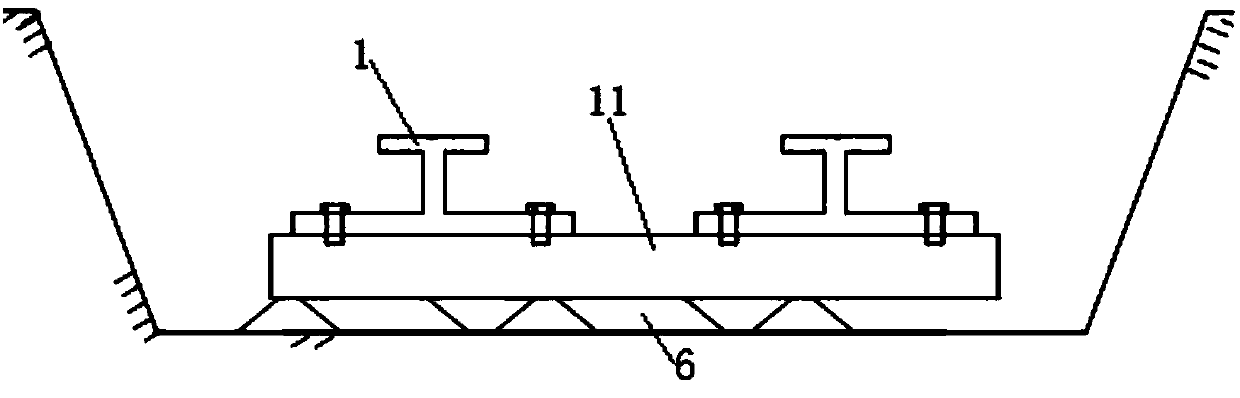

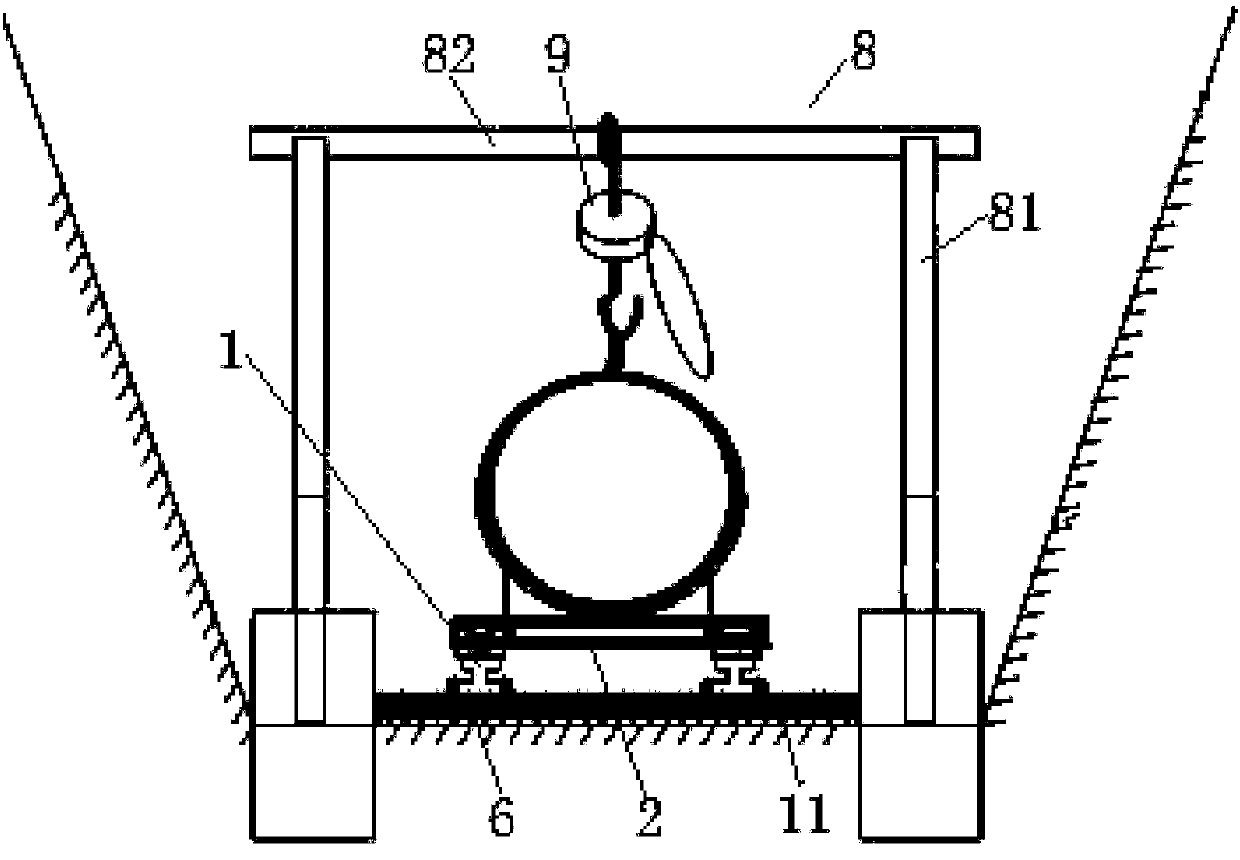

Long-distance pipeline steep slope region pipe arranging mechanism

The invention relates to a long-distance pipeline steep slope region pipe arranging mechanism. The long-distance pipeline steep slope region pipe arranging mechanism is used for mounting the pipelinein a pipe ditch, in the length direction of a steep slope, dug in a foundation and comprises a rail, a moving trolley and a winch; the rail is laid on the bottom of the pipe ditch in the length direction of the pipe ditch, the moving trolley is located in the pipe ditch and is mounted on the rail in a sliding manner, when the pipeline is arranged, the pipeline is arranged on the moving trolley, the winch is erected at the position, corresponding to the bottom of the steep slope, above the foundation, first pulleys are arranged at the two sides, corresponding to the feet of the steep slope, ofthe bottom of the pipe ditch, second pulleys are arranged on the two sides, corresponding to the top of the steep slope, of the bottom of the pipe ditch, and two traction ropes are arranged on the winch, sequentially wind around the first pulleys and the second pulleys, on the same side, of the bottom of the pipe ditch, and are connected with the traction trolley. The mechanism has the beneficialeffects that design is reasonable, the problems of pipe arranging, pipe stabilizing and welding difficulty in the pipeline steep slope construction process can be solved, various safety steps in the construction are reduced, and the whole construction process is safer, stable and portable.

Owner:天圜工程有限公司

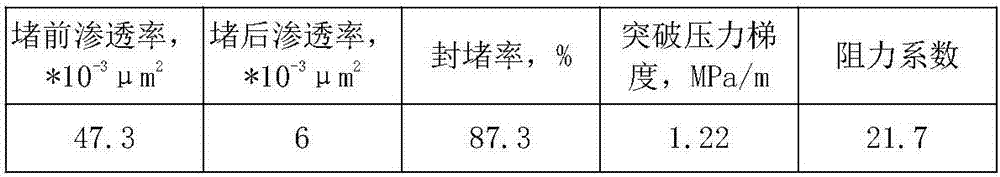

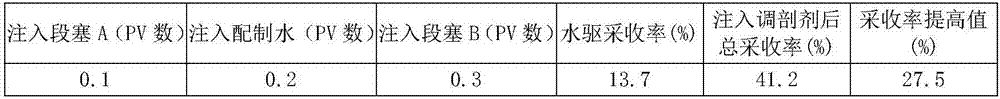

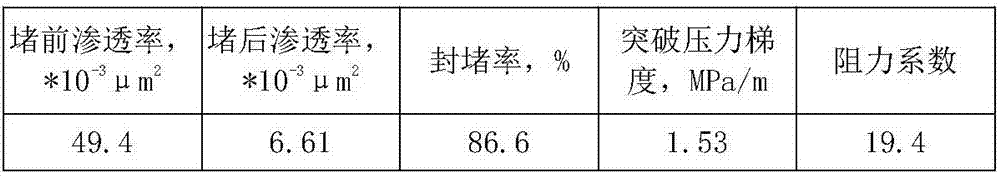

Low-permeability fracture reservoir in-depth profile controlling agent and using method thereof

InactiveCN107254302ADelayed gelationLow viscosityFluid removalDrilling compositionAluminum IonSweep efficiency

A deep profile control agent for low-permeability fractured reservoirs and its application method relate to the field of oilfield applied chemistry. The present invention injects into low-permeability fractured reservoirs in the form of double slugs. The front slugs have delayed gelation, and the viscosity is low when initially injected into the reservoirs, and can enter the near-well zone, middle and deep fractures of the reservoir, and form after gelling Stable plugging; the rear slug is mixed with low molecular weight compound polymer and chromium-aluminum ion cross-linking agent, which has the characteristics of low viscosity and strong fluidity. Implement control and flooding to reduce the remaining oil content in the reservoir and increase the water absorption index; improve the heterogeneity of the reservoir through the combination of double slugs, increase the follow-up water flooding sweep coefficient, and inhibit the formation of dead oil areas in low-permeability fractured reservoirs. In order to improve the disadvantages of traditional oil recovery methods such as low recovery rate and poor economic benefits of low permeability fractured reservoirs.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Water-based polishing oil with antibacterial function

ActiveCN104725966AImprove hydrophilicityEasy to modifyWax coatingsAntifouling/underwater paintsWater basedAcrylic resin

The invention relates to the technical field of water-based polishing oil and discloses water-based polishing oil with an antibacterial function. The water-based polishing oil is prepared from nano-titanium dioxide modified water-based acrylic resin liquid, water-based resin liquid B, water-based wax emulsion, deionized water, ethanol, a defoaming agent, a flatting agent and a buffer agent. The process for preparing the water-based polishing oil comprises the following steps: preparing silane coupling agent modified inorganic nanoparticles by using nano-titanium dioxide, ethanol, deionized water and a silane coupling agent; preparing the nano-titanium dioxide modified water-based acrylic resin liquid by using an acrylic monomer, the silane coupling agent modified inorganic nanoparticles, polyethylene glycol, a water-soluble initiator, an emulsifier, ammonium hydroxide and deionized water; and preparing the water-based polishing oil from the nano-titanium dioxide modified water-based acrylic resin liquid, water-based resin liquid B, water-based wax emulsion, tea saponin, deionized water, ethanol, a defoaming agent, a flatting agent and a buffer agent. The water-based polishing oil has the advantages of no toxicity, no hazard, good dispersion and strong antibacterial effect.

Owner:长兴艾飞特科技股份有限公司

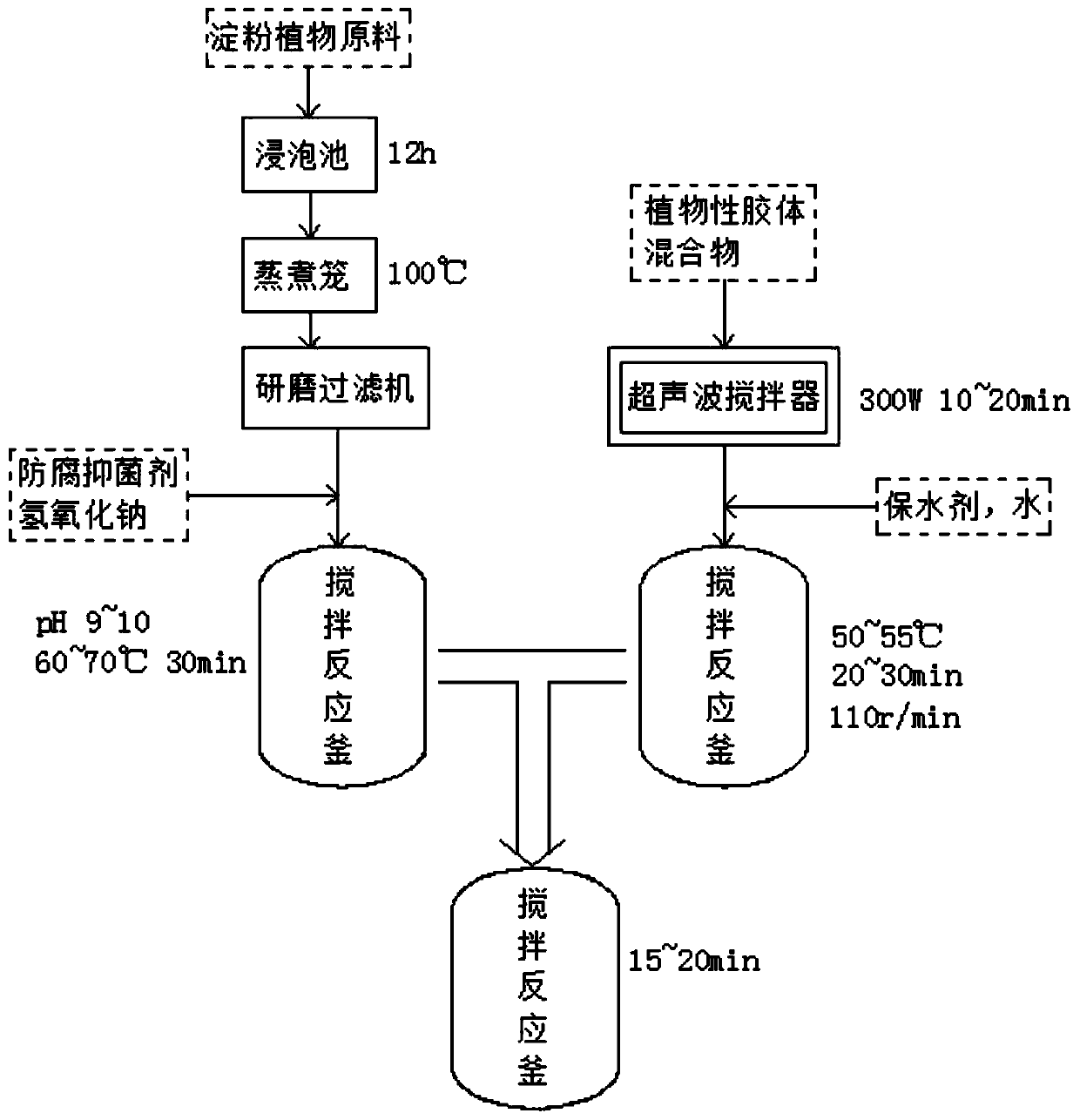

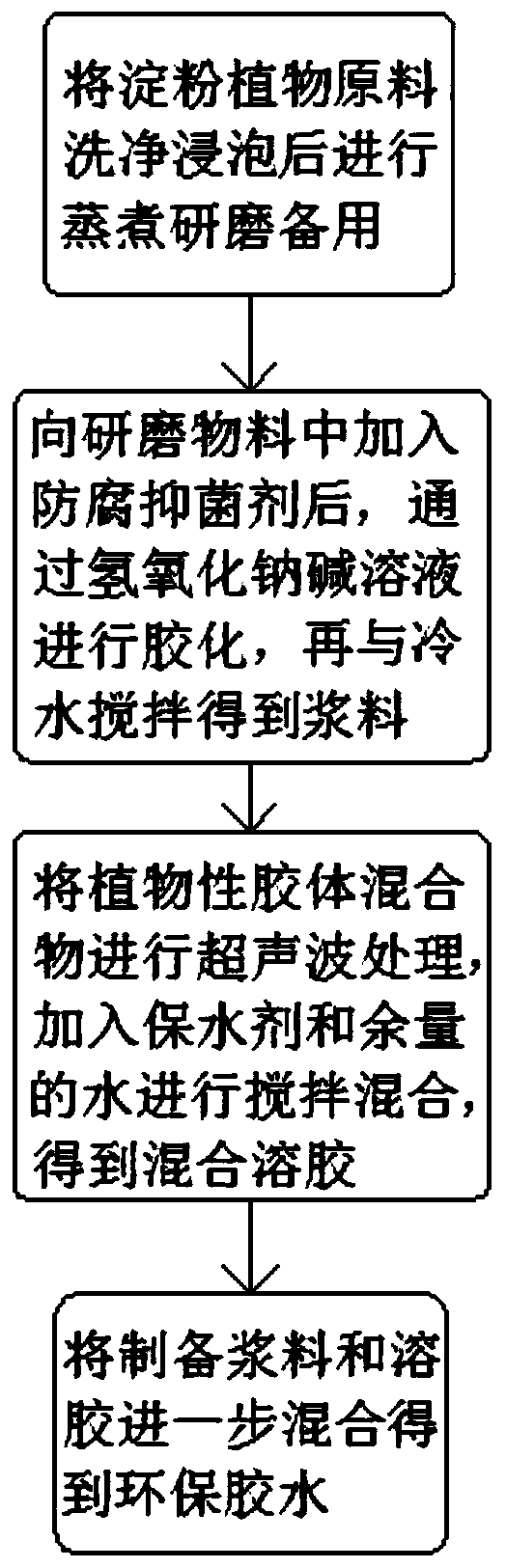

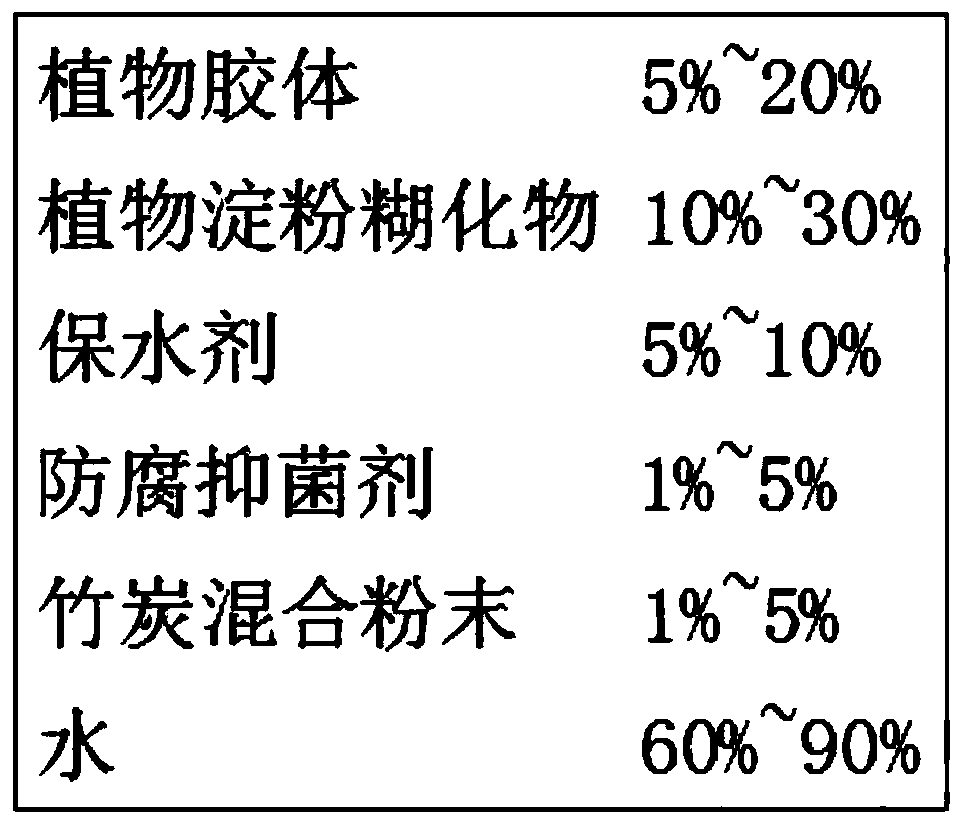

Environment-friendly glue and production process thereof

InactiveCN110903781ACause harmGood adhesionNon-macromolecular adhesive additivesStarch adhesivesBiotechnologyStarch gelatinization

The invention discloses an environment-friendly glue and a production process thereof. The liquid fuel comprises the following components by the weight percentage: 5%-20% of plant colloid, 10%-30% ofa plant starch gelatinization product, 2%-8% of a water-retaining agent, 1%-5% of an antiseptic bacteriostatic agent, 1%-5% of bamboo charcoal mixed powder, and 50%-80% of water. According to the environment-friendly glue and the production process thereof, the environment-friendly glue is prepared from green plant materials such as plant colloid, plant starch gelatinization product and the like,and is green, environment-friendly, non-toxic and harmless; with cooperation of the antiseptic bacteriostatic agent and the bamboo charcoal mixed powder, the hardness of the adhesive surface is increased, and the environment-friendly glue is not easy to fall off, convenient to use for a long time, not easy to mildew and breed bacteria, simple in processing flow, energy-saving, convenient to produce, green and environment-friendly in processing and use, and suitable for object processing and life.

Owner:南京格润包装材料有限公司

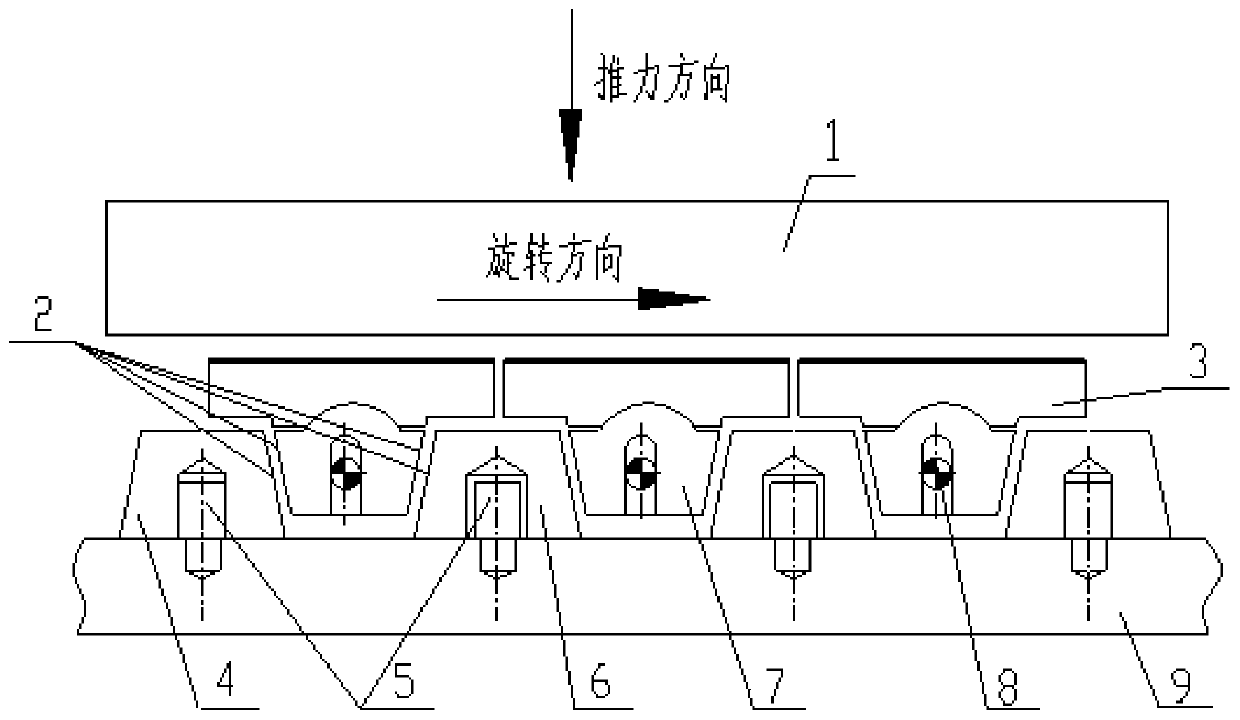

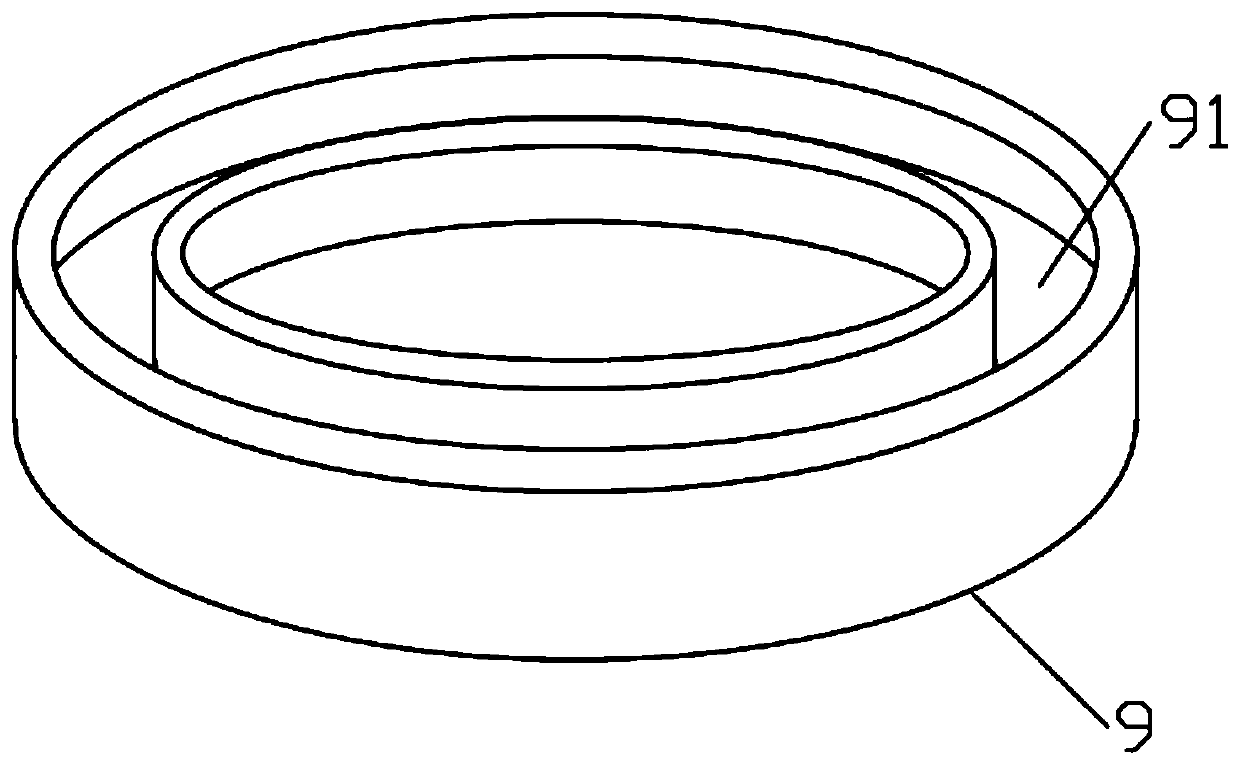

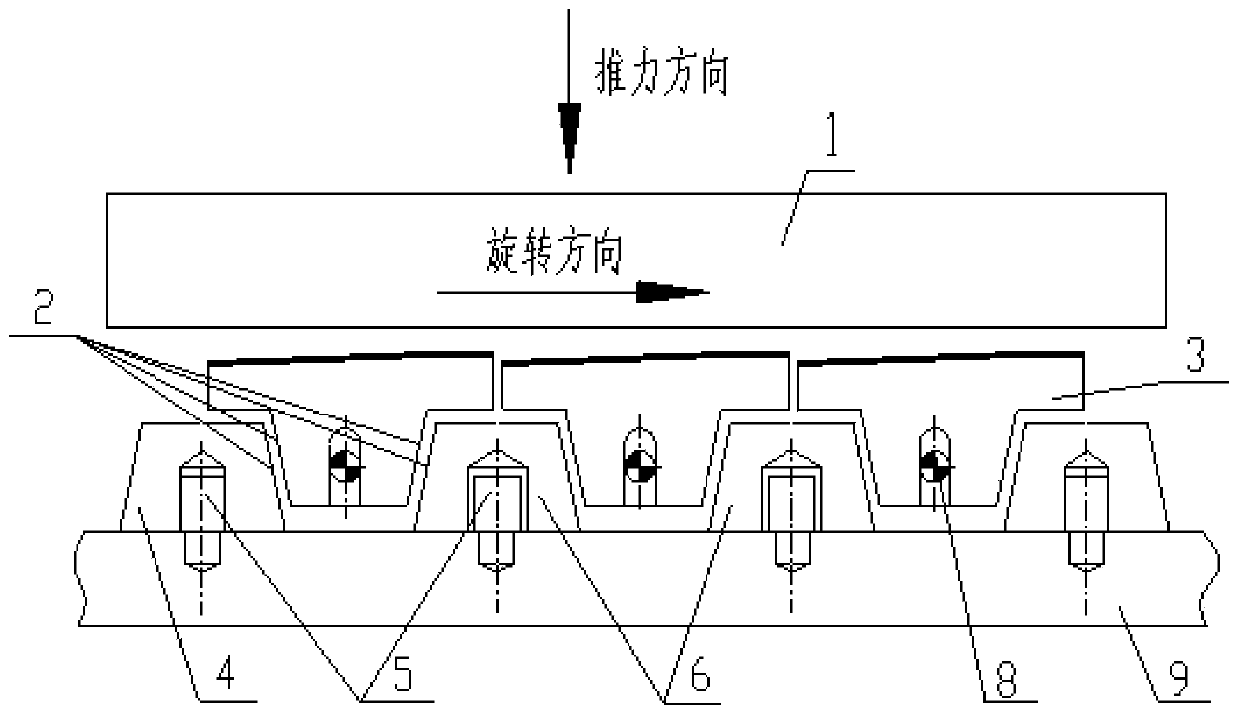

Uniform-load thrust bearing

InactiveCN110529493AEasy to reflect uneven forcePrevent overload failureBearing componentsSliding contact bearingsStress conditionsThrust bearing

The invention discloses a uniform-load thrust bearing. The thrust bearing comprises a thrust base ring, an annular groove formed in the thrust base ring and coaxial with the thrust base ring, a plurality of uniform loading blocks arranged in the annular groove, and a plurality of supporting blocks arranged in the annular groove, distributed at intervals with the uniform loading blocks and in transmission connection with the uniform loading blocks through wedge surfaces. The load balancing blocks comprise at least one static load balancing block fixedly connected with the thrust base ring and aplurality of movable load balancing blocks arranged in the annular groove in a sliding mode, the wedge faces on the supporting blocks face opposite directions, and the supporting blocks are connectedwith thrust pads. The beneficial effects of the invention are that: according to the scheme, uneven stress of the thrust pads can be reflected to axial sliding of the supporting blocks; therefore, the transmission of the inclined wedge surface is converted into the circumferential sliding of the uniform loading blocks, and the gap between the thrust pads and the thrust disc is adaptively adjustedaccording to the stress condition of the thrust pads through the coordination action of the whole circle of uniform loading blocks and the supporting blocks to realize uniform loading, so that the overload failure of the thrust pads is avoided, and the service life of the bearing is prolonged.

Owner:DONGFANG TURBINE CO LTD

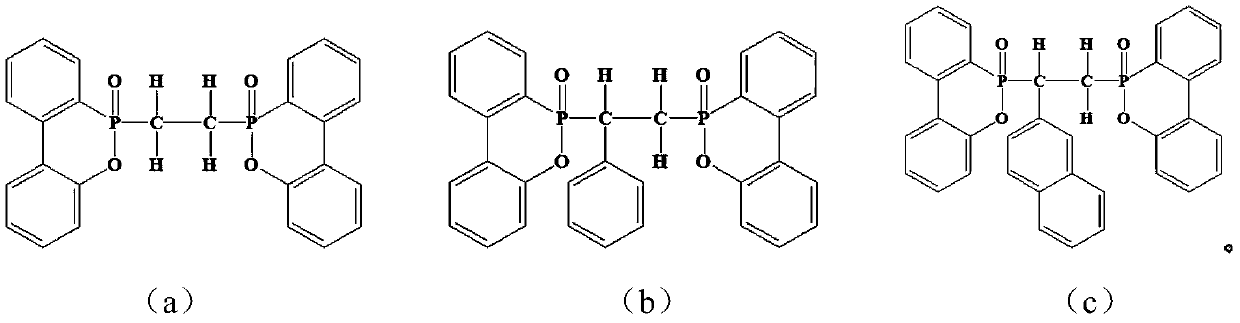

Flame-retardant polyamide fiber and preparation method thereof

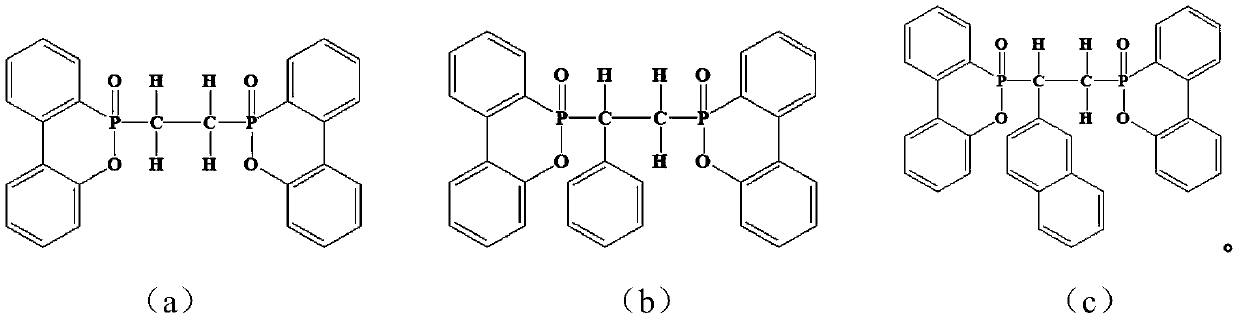

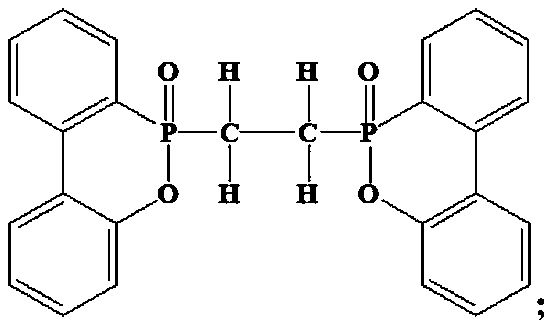

ActiveCN110923841AImprove spinnabilityImprove mechanical propertiesFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolymer scienceZinc compounds

The invention relates to a flame-retardant polyamide fiber and a preparation method thereof. The preparation method comprises the steps of performing melt blending on polyamide, melamine cyanurate, graphite-like carbon nitride, a zinc compound and a 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) derivative to prepare a flame-retardant polyamide slice, performing melt spinning and drafting winding, or performing melt blending on the substances to prepare flame-retardant masterbatch, adding 8.25-25wt% of the flame-retardant masterbatch in a direct spinning process of the polyester slice or a melt to perform melt spinning and drafting winding, wherein the prepared flame-retardant polyamide fiber is made from the flame-retardant polyamide, and in parts by mass, the flame-retardant polyamide is mainly composed of 92-95.8 parts of the polyamide, 1-2 parts of the melamine cyanurate, 0.1-0.5 parts of the graphite-like carbon nitride, 0.1-0.5 parts of the zinc compound and 3-5 partsof the DOPO derivative. The preparation process is simple, and the prepared flame-retardant polyamide fiber has the relatively good mechanical property and flame retardant property.

Owner:上海力道新材料科技股份有限公司

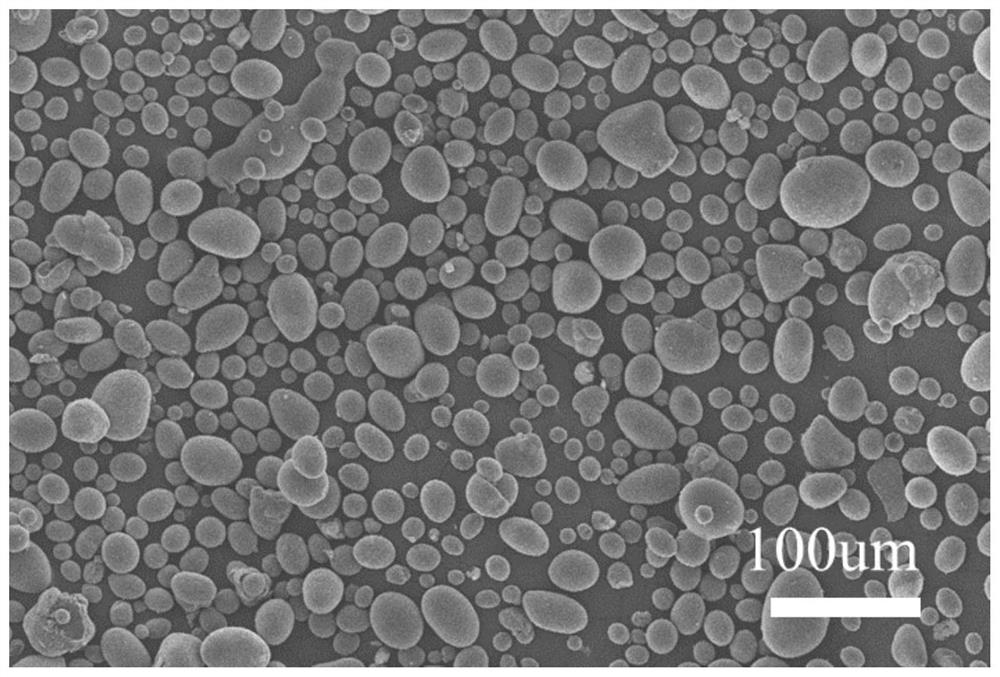

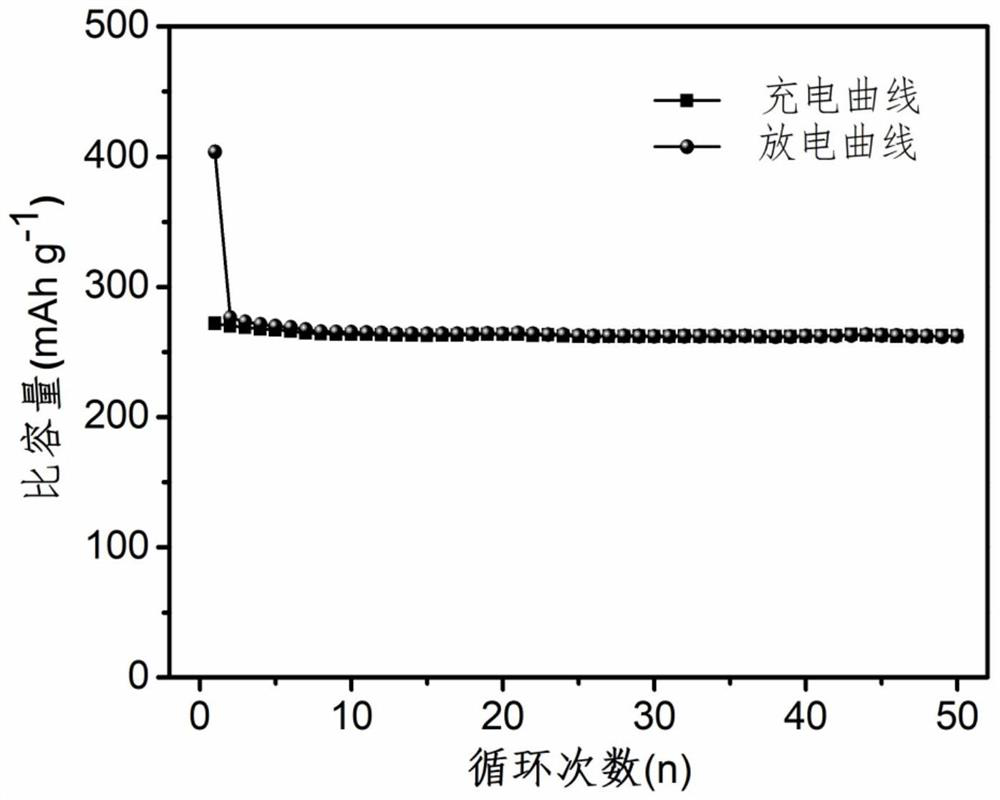

Preparation method of sodium ion battery negative electrode material

PendingCN113620272AAvoid foamingAvoid Merging ProblemsCell electrodesSecondary cellsElectrical batteryMicrosphere

The invention discloses a preparation method of a sodium ion battery negative electrode material, and belongs to the technical field of sodium ion batteries. The preparation method comprises the following steps: mechanically and uniformly mixing starch and carbon black according to a certain proportion, then performing stabilization treatment in a muffle furnace at 200-260 DEG C, and finally performing high-temperature carbonization at 800-1600 DEG C in a nitrogen atmosphere to obtain starch-based carbon microspheres. The added carbon black particles are uniformly dispersed on the surfaces of the starch particles, and the starch particles are separated from one another, so that the starch particles are uniformly heated in the stabilization process, the dehydration reaction of starch molecules and the breakage of molecular chains are facilitated, the problems of foaming and melting in the high-temperature carbonization process are avoided, and the integrity of the spherical morphology of the starch particles is maintained. The raw materials are green, environment-friendly and renewable, the preparation process is simple, and the material shows high reversible capacity and cycling stability when being used as a sodium-ion battery negative electrode material.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH +1

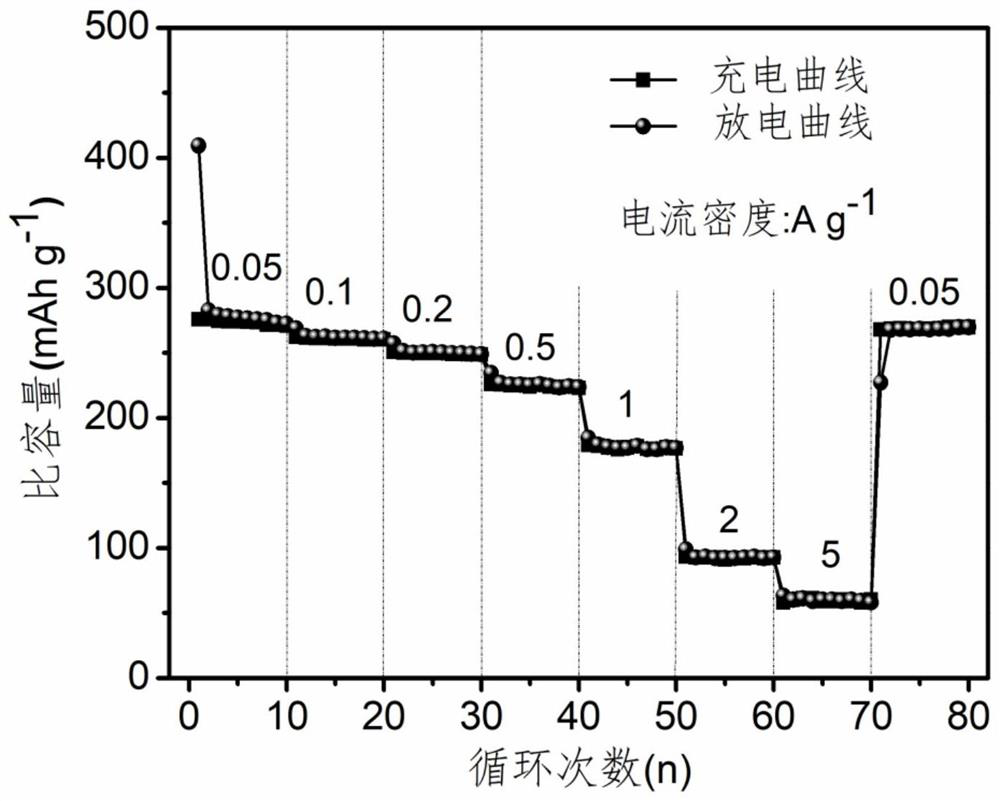

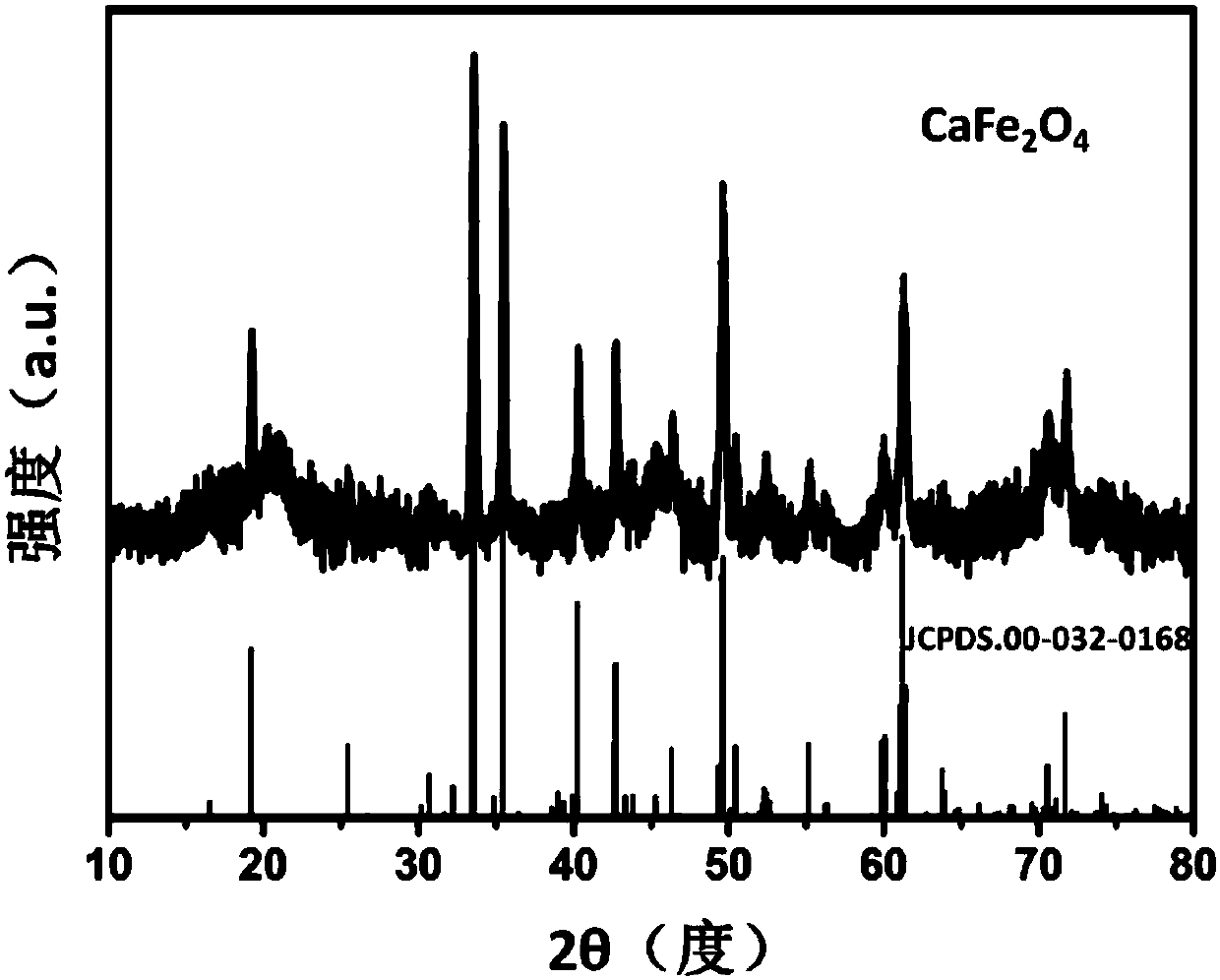

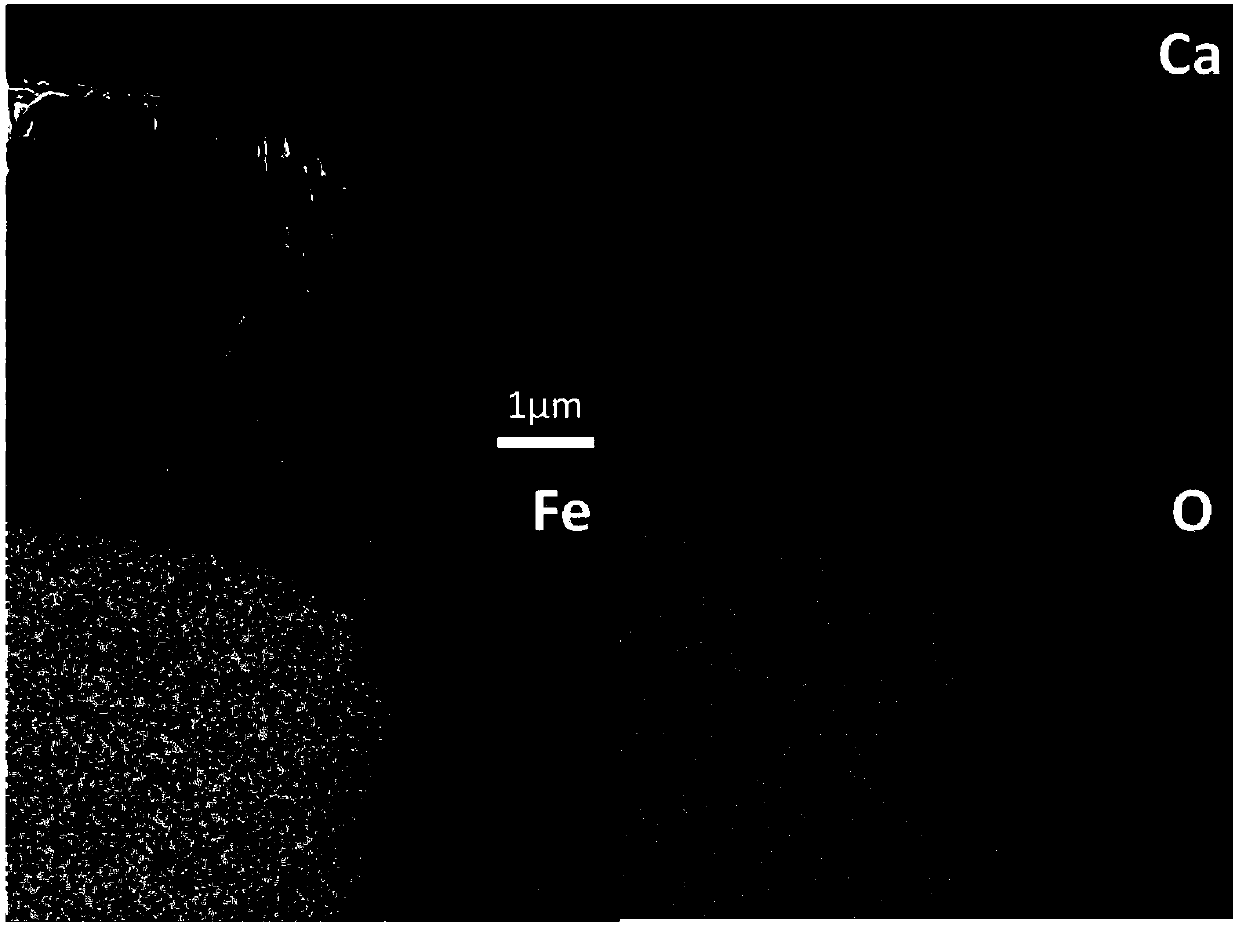

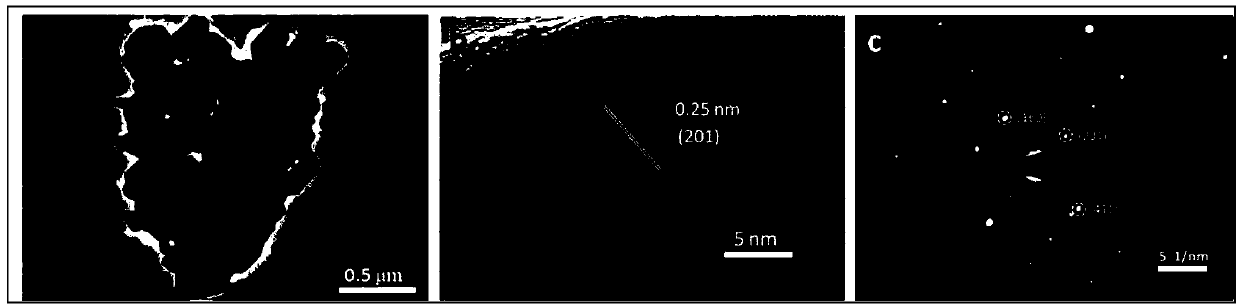

Alkaline earth metal ferrite electrode material and preparation method and application thereof

InactiveCN107611419AImprove electrochemical performanceHigh specific capacityCell electrodesSecondary cellsAlkaline earth metalN dimethylformamide

The invention relates to a preparation method and an application of alkaline earth metal ferrite. The preparation method comprises the following steps of 1) weighing polyvinylpyrrolidone and adding toN, N-dimethylformamide, and performing stirring to obtain a clear and transparent solution; 2) weighing an iron source and a calcium source or a magnesium source based on proportion and adding to thesolution obtained in the step 1), and performing continuous stirring; 3) drying the solution obtained in the step 2) to obtain a red glass-shaped product; and 4) performing sintering heat treatment on the dried product obtained in the step 3), firstly performing low-temperature heat treatment and then performing high-temperature heat treatment, and finally performing natural cooling to obtain a CaFe<2>O<4> sample or a MgFe<2>O<4> sample. The preparation method has the beneficial effects as follows: the alkaline earth metal ferrite, used as a novel negative electrode active material of the lithium ion battery, has excellent electrochemical performance, relatively high specific capacity, ultra high cycle stability and excellent rate capability; and meanwhile, the process is simple, the rawmaterials are low in cost, the synthesis process is green and environment friendly, the output is high, and large-scale production can be realized.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com