Environment-friendly glue and production process thereof

A production process and environmentally friendly technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of poor environmental protection of adhesive glue, glutinous rice glue and other colloids that are easily deteriorated, so as to prevent mildew and deteriorate, reduce Mildew and deterioration, the effect of improving the bonding hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

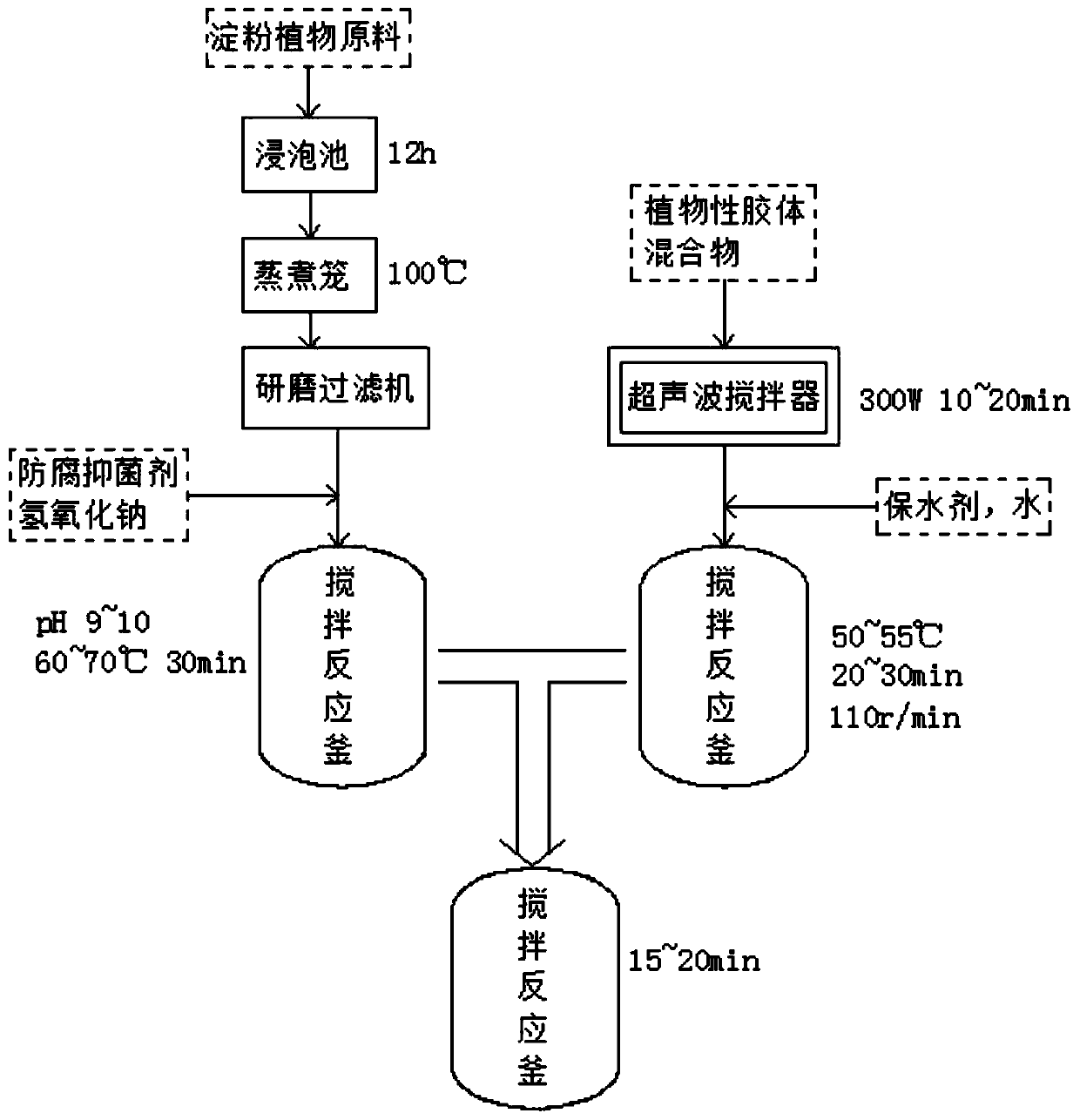

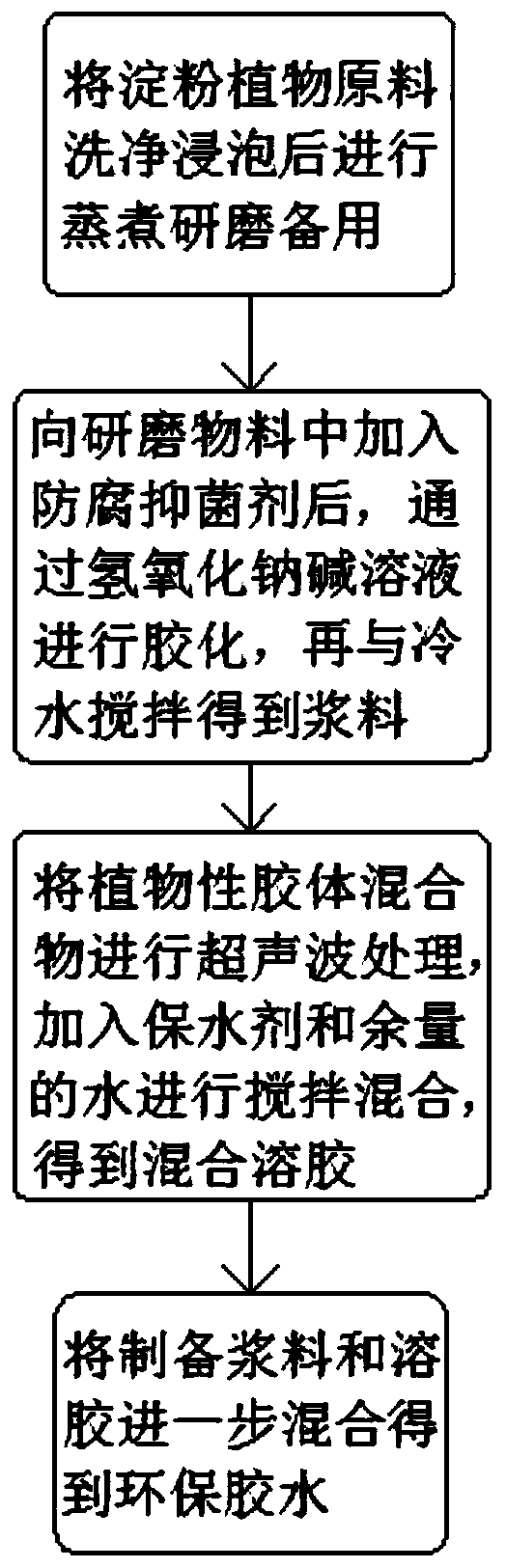

Method used

Image

Examples

Embodiment 1

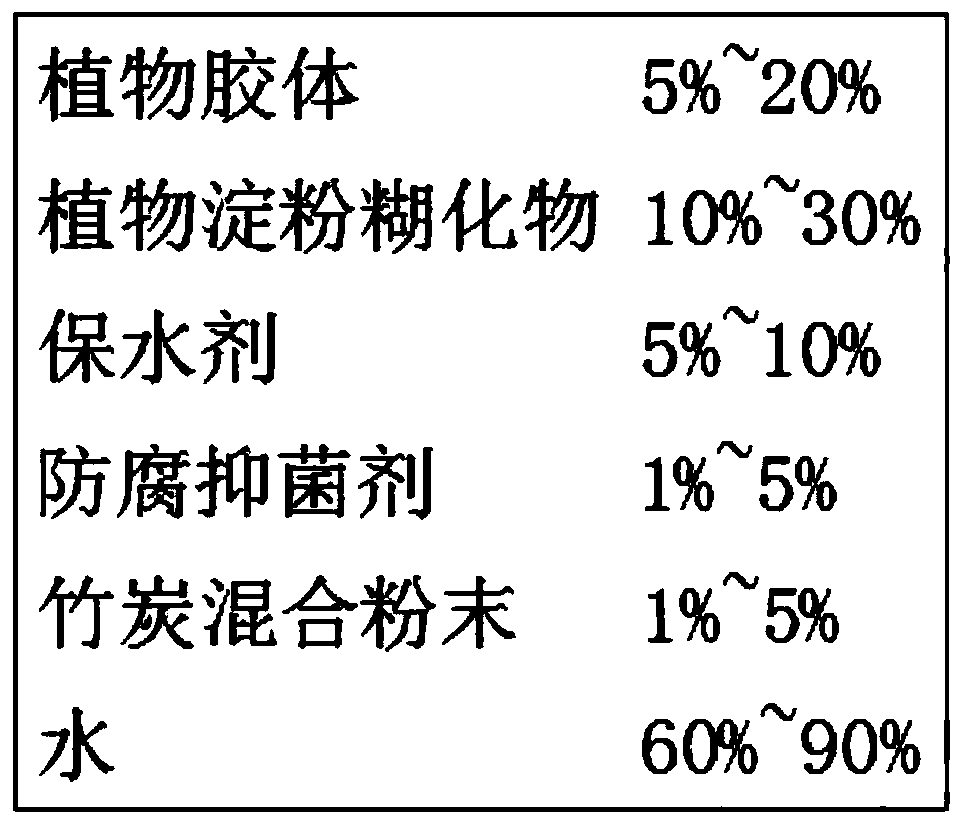

[0040] A kind of environment-friendly glue, liquid fuel composition is by weight percentage:

[0041] Vegetable colloid 10%;

[0042] Vegetable starch gelatin 10%;

[0043] Water retaining agent 5%;

[0044] Antiseptic bacteriostatic agent 4%;

[0045] Bamboo charcoal mixed powder 1%;

[0046] Water 70%.

[0047] Plant colloids include stone flower gum, guar gum, gum arabic, carrageenan and xanthan gum. The fusion process of plant colloid mixtures adopts ultrasonic treatment. The ultrasonic power is 300W and the ultrasonic time is 10-20min. Pre-mixing treatment between the auxiliary plant colloids.

[0048] Plant starch gelatinization is a mixture of various plant starches such as glutinous rice flour, soybean flour, corn flour and sweet potato flour. It is prepared by heating and gelatinizing with an aqueous solution of sodium hydroxide alkali and then mixing it with cold water. The raw material of plant starch is subjected to alkaline gelatinization treatment, which is ...

Embodiment 2

[0068] A kind of environment-friendly glue, liquid fuel composition is by weight percentage:

[0069] Vegetable colloid 10%;

[0070] Vegetable starch gelatin 20%;

[0071] Water retaining agent 3%;

[0072] Antiseptic and antibacterial agent 2%;

[0073] Bamboo charcoal mixed powder 5%;

[0074] Water 60%.

[0075] Plant colloids include stone flower gum, guar gum, gum arabic, carrageenan and xanthan gum. The fusion process of plant colloid mixtures adopts ultrasonic treatment. The ultrasonic power is 300W and the ultrasonic time is 10-20min. Pre-mixing treatment between the auxiliary plant colloids.

[0076] Plant starch gelatinization is a mixture of various plant starches such as glutinous rice flour, soybean flour, corn flour and sweet potato flour. It is prepared by heating and gelatinizing with an aqueous solution of sodium hydroxide alkali and then mixing it with cold water. The raw material of plant starch is subjected to alkaline gelatinization treatment, which ...

Embodiment 3

[0096] A kind of environment-friendly glue, liquid fuel composition is by weight percentage:

[0097] Vegetable colloid 17%;

[0098] Vegetable starch gelatin 17%;

[0099] Water retaining agent 3%;

[0100] Antiseptic and antibacterial agent 2%;

[0101] Bamboo charcoal mixed powder 1%;

[0102] Water 60%.

[0103] Plant colloids include stone flower gum, guar gum, gum arabic, carrageenan and xanthan gum. The fusion process of plant colloid mixtures adopts ultrasonic treatment. The ultrasonic power is 300W and the ultrasonic time is 10-20min. Pre-mixing treatment between the auxiliary plant colloids.

[0104] Plant starch gelatinization is a mixture of various plant starches such as glutinous rice flour, soybean flour, corn flour and sweet potato flour. It is prepared by heating and gelatinizing with an aqueous solution of sodium hydroxide alkali and then mixing it with cold water. The raw material of plant starch is subjected to alkaline gelatinization treatment, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com