Patents

Literature

441 results about "Starch gelatinization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

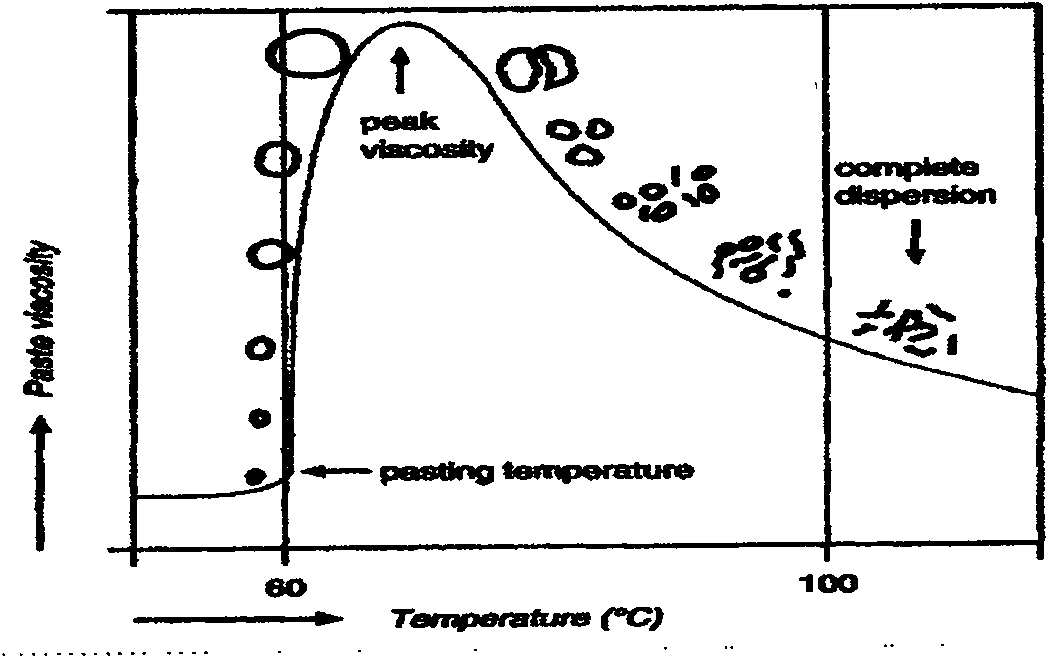

Starch gelatinization is a process of breaking down the intermolecular bonds of starch molecules in the presence of water and heat, allowing the hydrogen bonding sites (the hydroxyl hydrogen and oxygen) to engage more water. This irreversibly dissolves the starch granule in water. Water acts as a plasticizer. Three main processes happen to the starch granule: granule swelling, crystal or double helical melting, and amylose leaching.

Whole grain non-dairy milk production, products and use

ActiveUS20070014892A1Increase coverageReserved functionDough treatmentWort preparationSlurryWhole milk

A method comprising selection of unbroken whole grain rice that are first washed, or whole grain corn that is first reduced in size, and then making an aqueous slurry that is subsequently wet milled to release all the protein, fat, fiber, and starch components normally held in the structure of the grain. The resulting slurry can be reacted with heat to gelatinize the starch and the subsequent product dried. Also, the heated slurry containing the liberated components can be treated to enzymatic hydrolysis via the process of liquefaction and optionally saccharification, producing whole grain rice milk products having diverse carbohydrate compositions. The whole grain milk products are characterized by a nutritional composition containing substantially all the nutritional components of the whole grain, being an opaque whole milk colloid, having smooth texture versus pulpiness, lacking in all bitterness normally associated with whole grain products, and having a variety of sweetness levels from non-sweet to very sweet.

Owner:STEUBEN FOODS

High fiber and high protein baked goods production

InactiveUS20100303991A1Pleasant tastePotential healthDough/pre-mixesConfectioneryStarch gelatinizationHigh protein food

Substantially uniform hydration and dispersion of high amounts of protein and fiber are achieved while avoiding lump formation, hard textures, and off-tastes in the continuous, mass production of high protein and high fiber content sheetable doughs, and baked goods such as crackers, snacks, and cookies made from the sheeted doughs, by hydrating the protein and fiber with water at a temperature below the denaturization temperature of the proteins, and steaming the hydrated mixture without substantial gelatinization of starch during dough production. The steamed, hydrated mass may be admixed with ingredients comprising at least one flour comprising starch to obtain a dough while avoiding substantial gelatinization of starch of the at least one flour during mixing. The baked goods may have a protein content of at least about 4 g, a fiber content of at least about 4 g, and a whole grain flour content of at least about 4 g per 30 g serving.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Acid fungal protease in fermentation of insoluble starch substrates

The invention is directed to methods of producing ethanol and decreasing residual starch production in a no cook fermentation comprising contacting granular starch containing substrates with a granular starch hydrolyzing enzyme, a protease, and a fermenting microorganism under suitable fermentation conditions at a temperature below the starch gelatinization temperature of the starch substrate to produce ethanol, wherein the ethanol production is increased and the amount of residual starch is decreased compared to a substantially similar method conducted without the protease.

Owner:GENENCOR INT INC

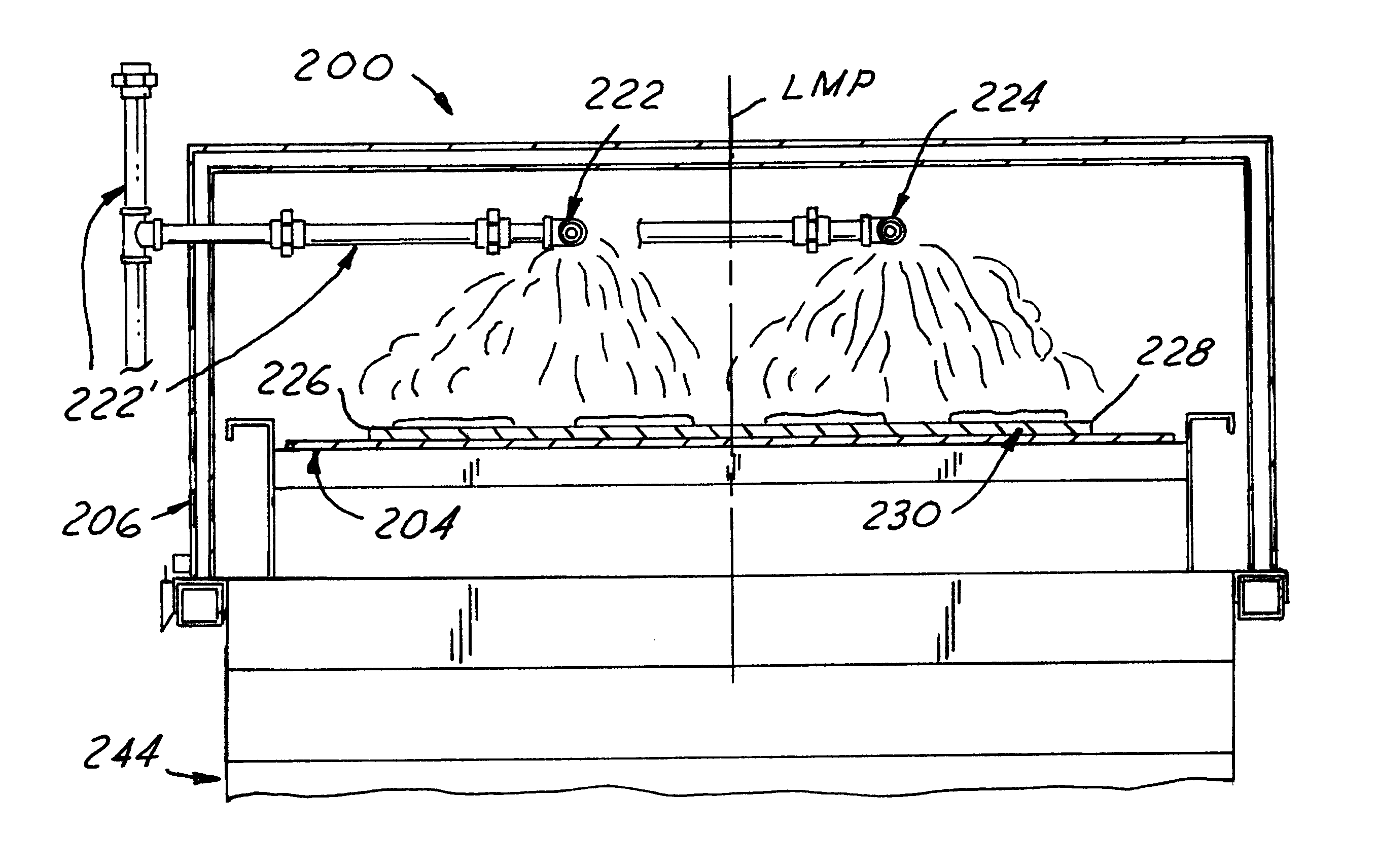

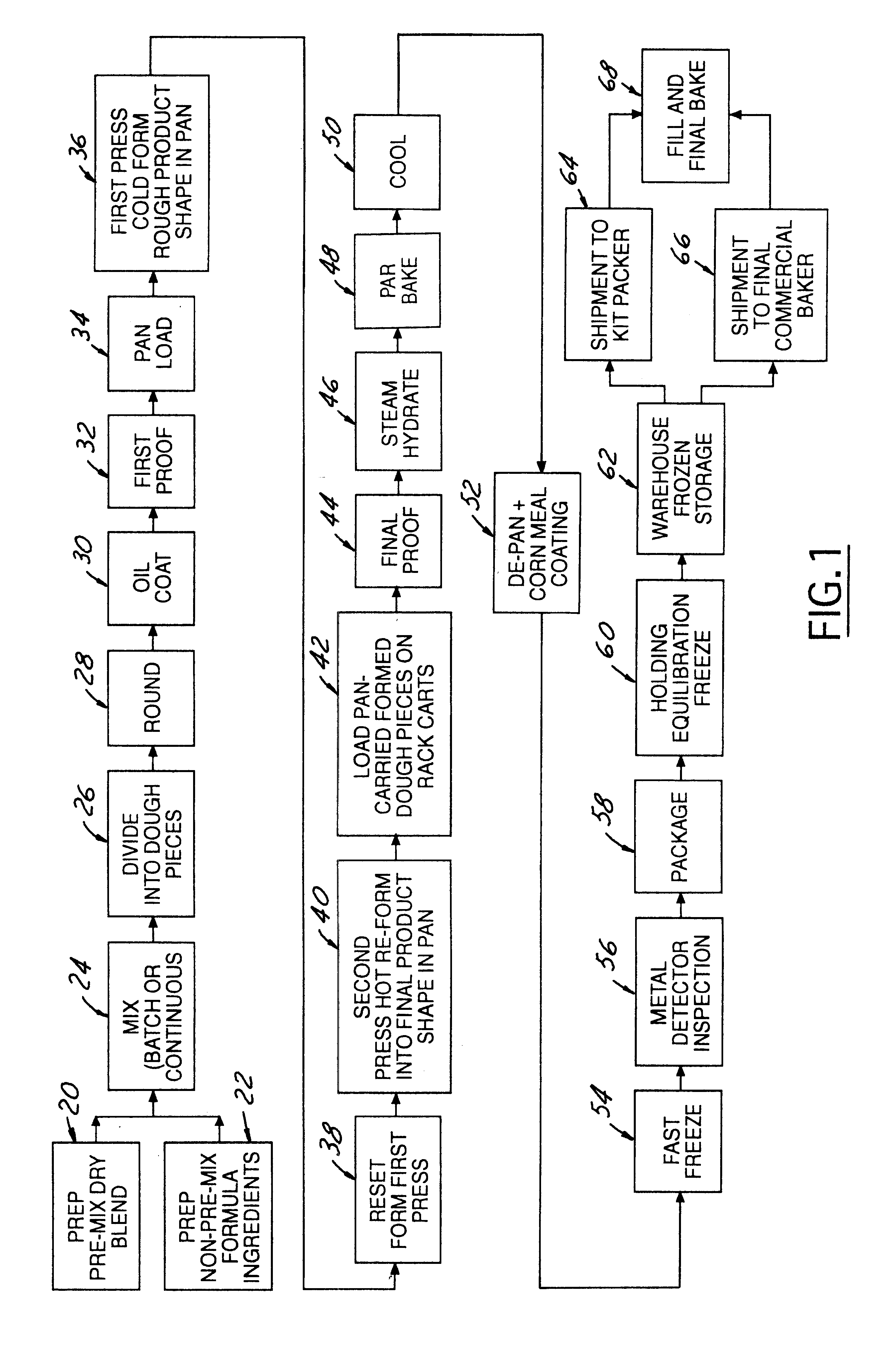

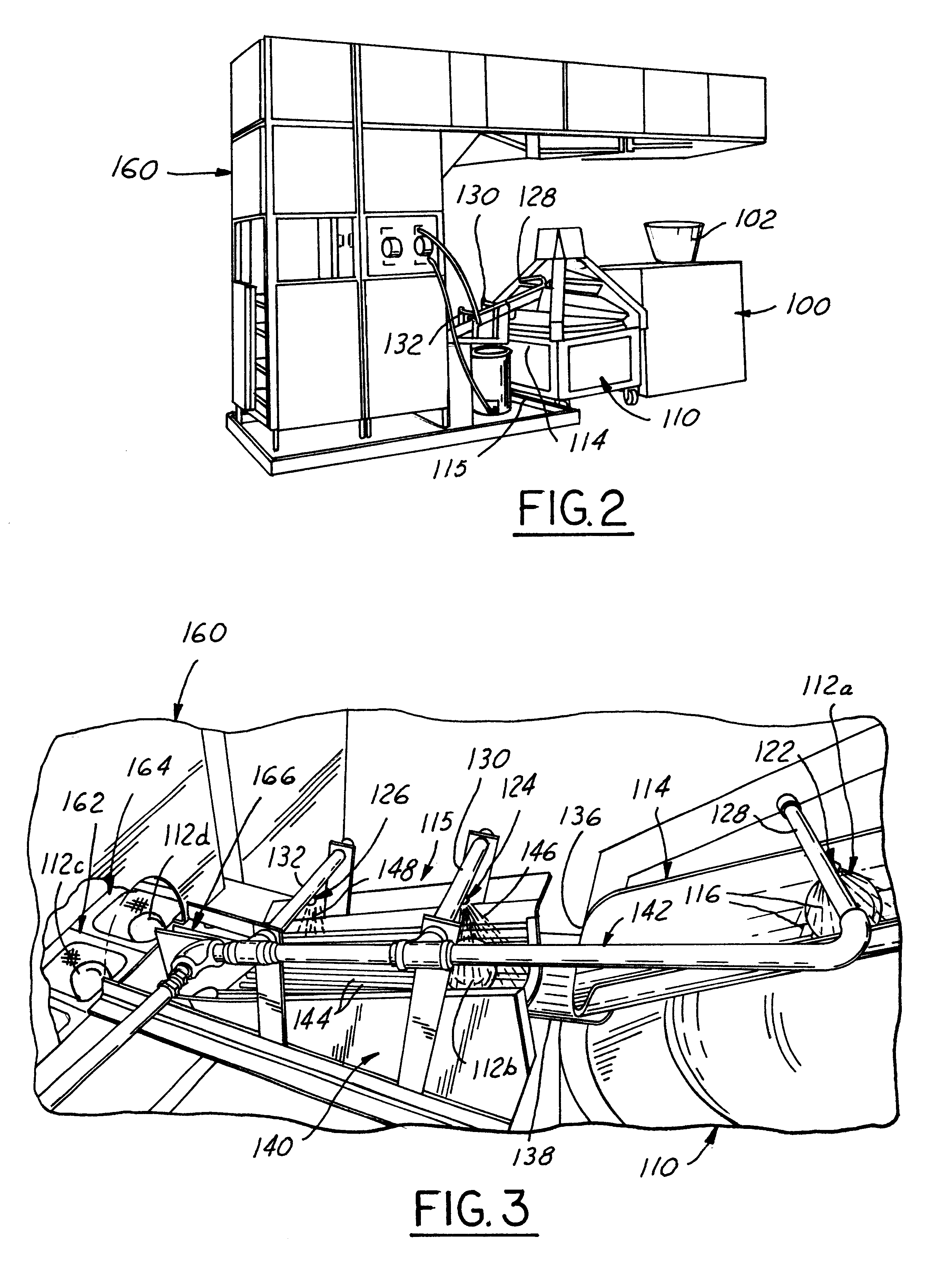

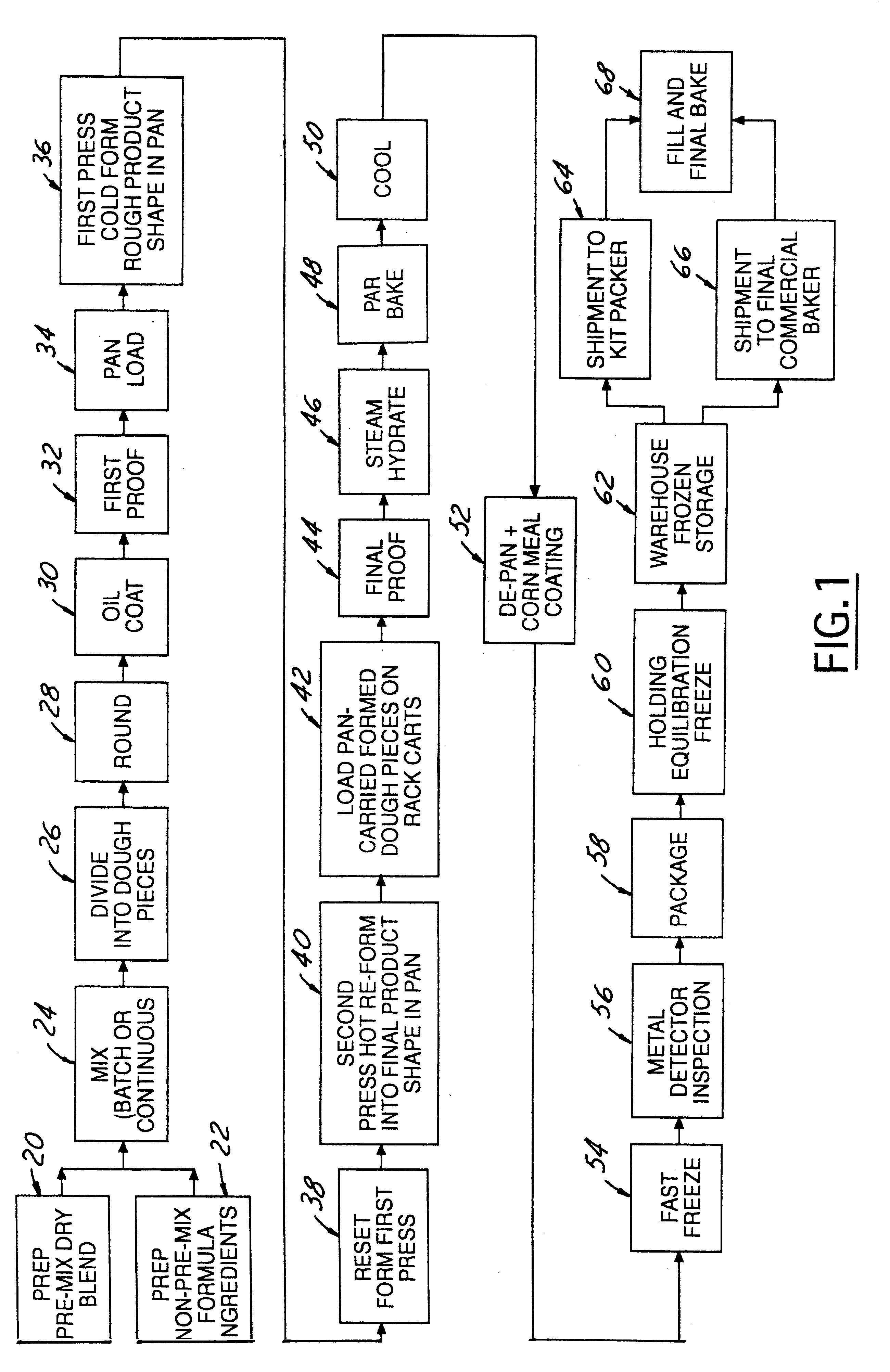

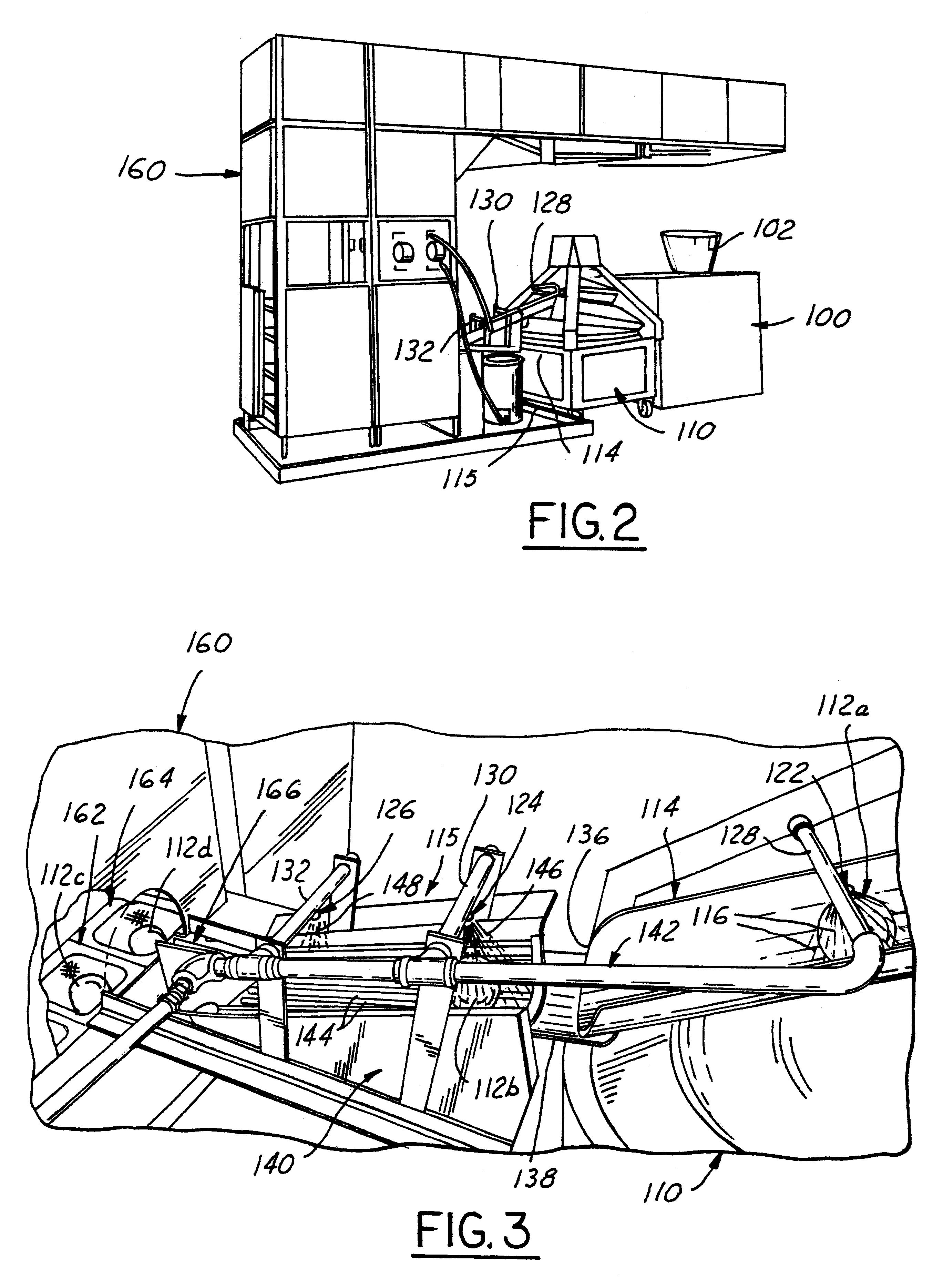

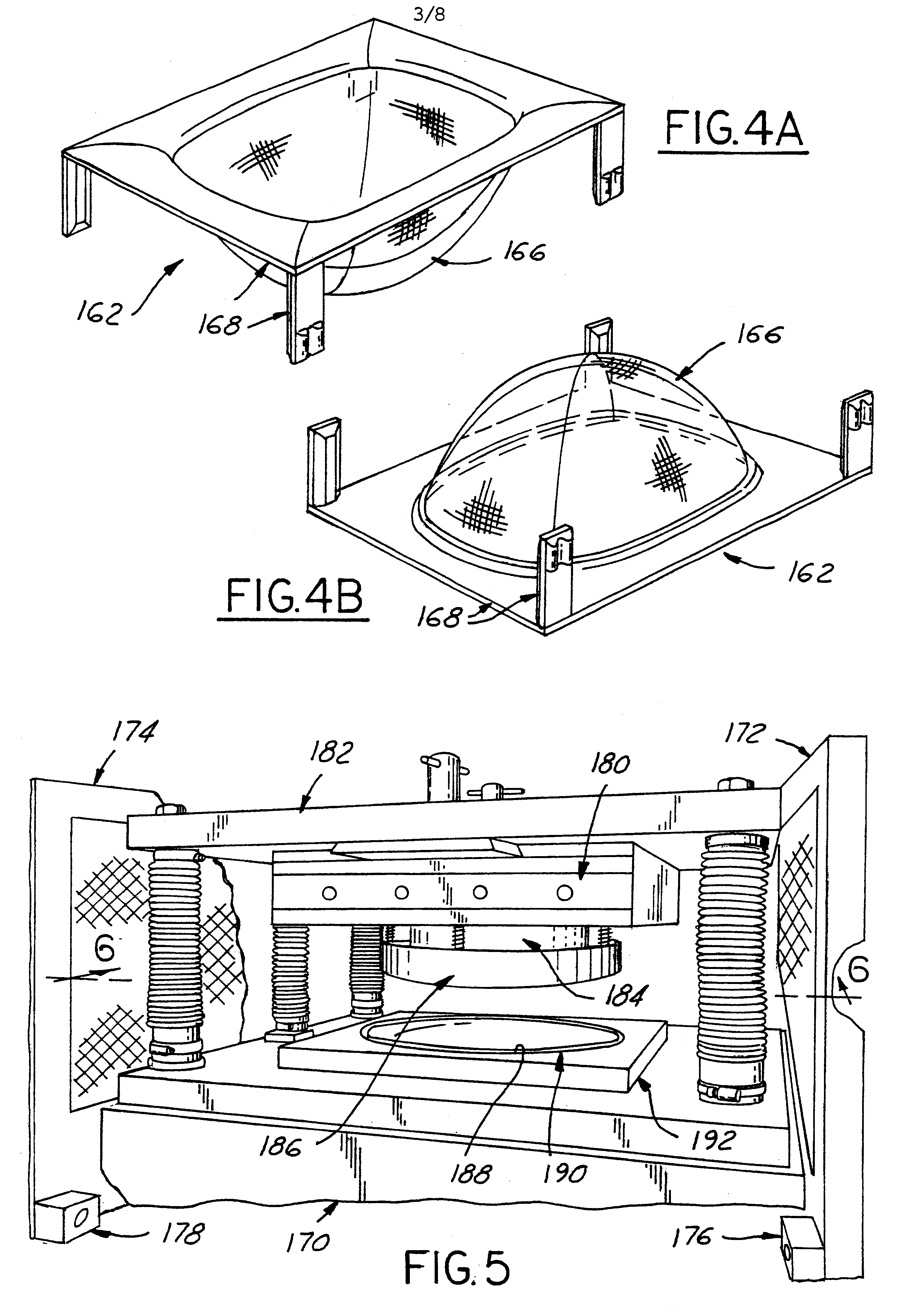

Pizza crust and process and apparatus for making same

InactiveUS6629493B1Speed up the processEasy to adjustAir-treating devicesBakery productsStarch gelatinizationMoisture absorption

Apparatus for preparing parbaked food products, such as pizza crust shells, and dough formulation used therein, and the product produced thereby and / or therefrom. The apparatus operates on a starting material dough including flour, sugar and water, and preferably also a leavening agent such as instant yeast. The dough is rounded, first proofed, panned, pressed and second proofed in the apparatus. The prepared dough piece is then steam hydrated in the apparatus under conditions sufficient to cause moisture absorption and a resultant increase in moisture content throughout the dough. Then the hydrated dough piece is immediately sequentially parbaked until gelatinization of the starch is complete. At least one parbaking condition of the apparatus is adjusted as selected from the group consisting of initial dough temperature, oven temperature, parbaking time, dough absorption and dough thickness and coordinated with the moisture content condition of the dough upon completion of the steam hydration for thereby delaying external browning of the dough until the starch gelatinization is complete, and for thereby discontinuing the parbaking before substantial caramelization of the sugar in the crust takes place.

Owner:M & M HLDG

Pizza crust and process and apparatus for making same

InactiveUS6365210B1Increase moistureImprove the finishMilk preservationDough treatmentMoisture absorptionSugar

A method of preparing parbaked food products, such as pizza crust shells, apparatus and dough formulation used therein, and the product produced by the process. The process comprises the steps of providing a dough including flour, sugar and water, and preferably also a leavening agent such as instant yeast. The dough is rounded, first proofed, panned, pressed and second proofed. The prepared dough piece is then steam hydrated under conditions sufficient to cause moisture absorption and a resultant increase in moisture content throughout the dough. Then the hydrated dough piece is immediately sequentially parbaked until gelatinization of the starch is complete. At least one parbaking condition is adjusted selected from the group consisting of initial dough temperature, oven temperature, parbaking time, dough absorption and dough thickness and coordinated with the moisture content condition of the dough upon completion of the steam hydration for thereby delaying external browning of the dough.

Owner:M & M HLDG

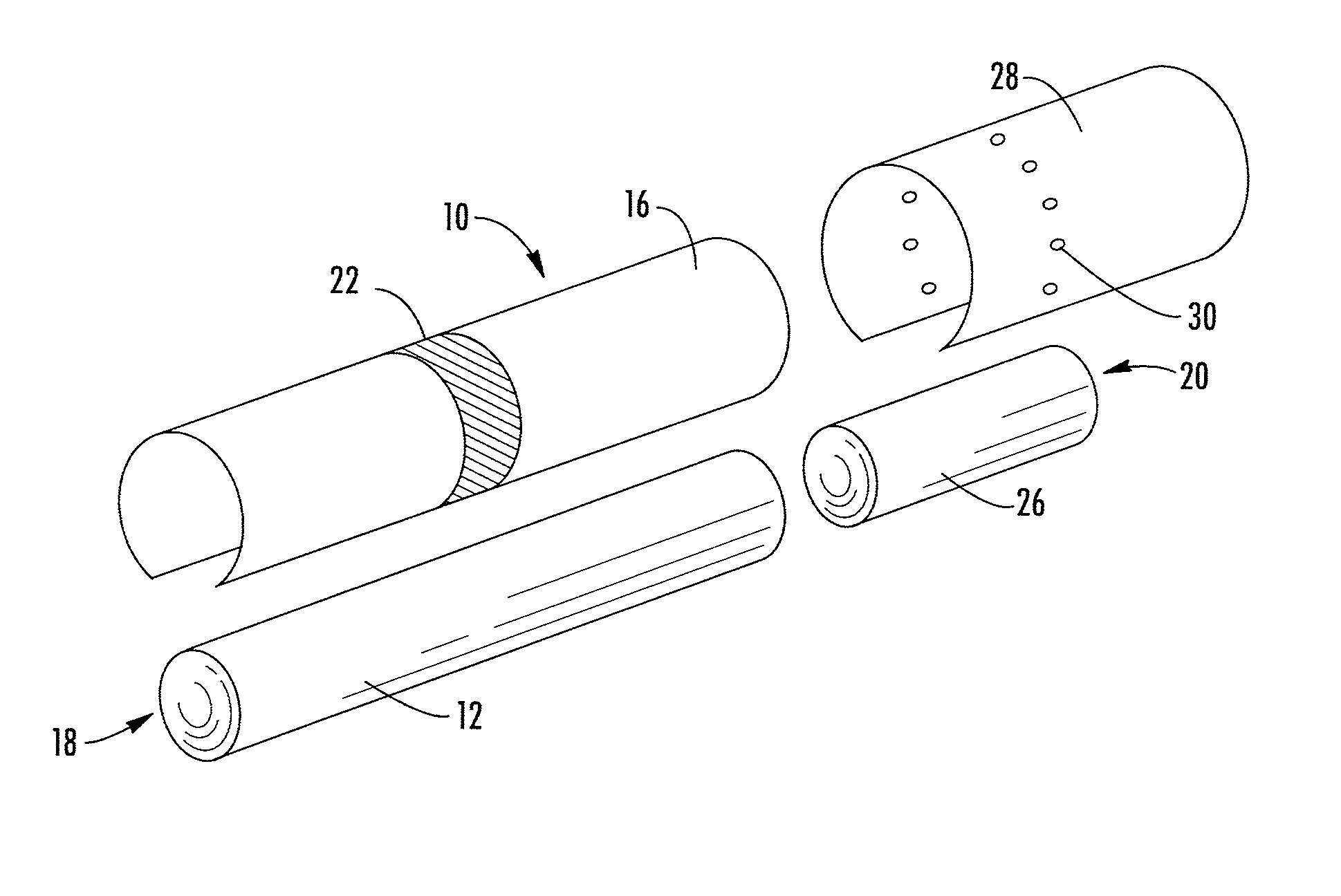

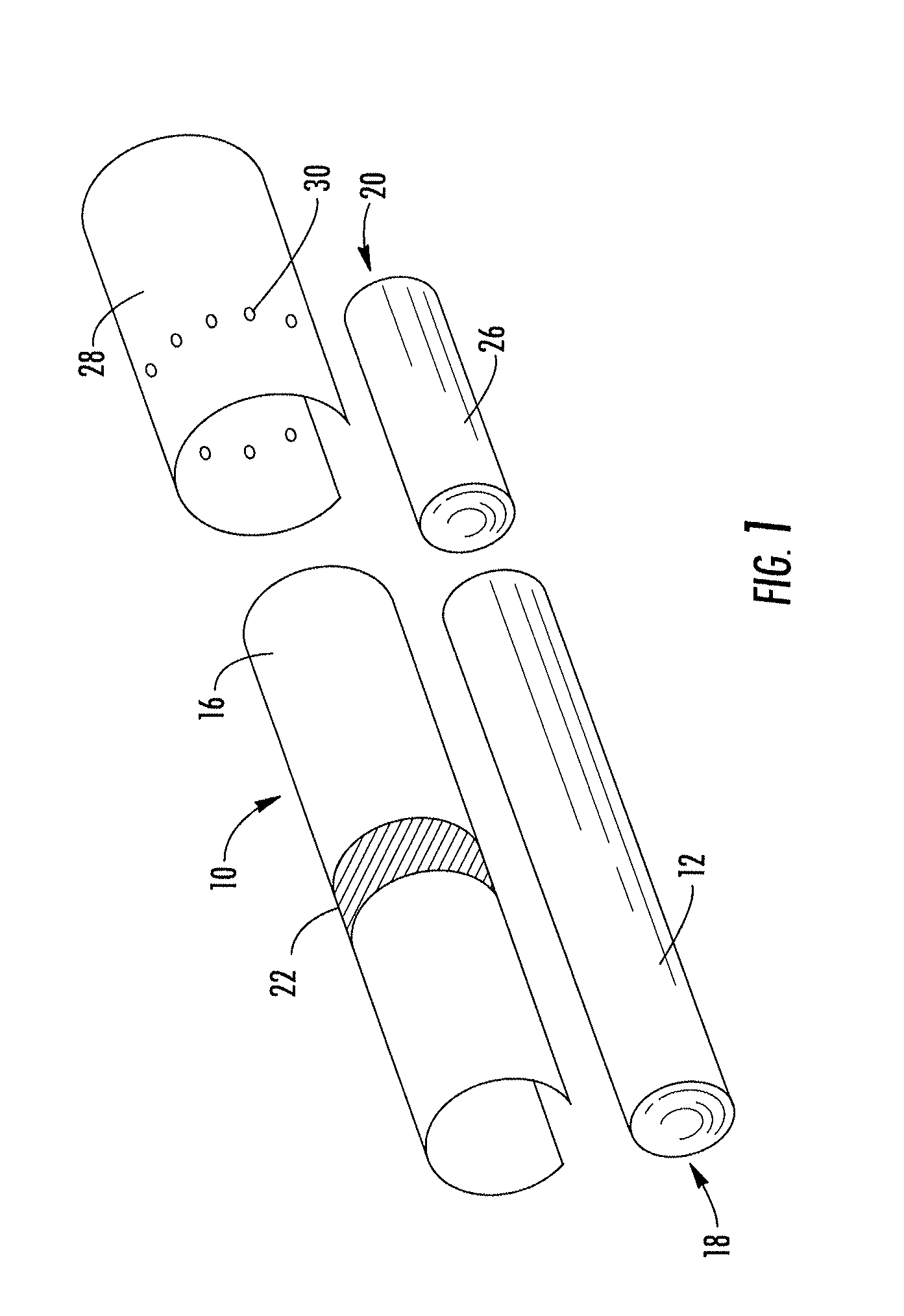

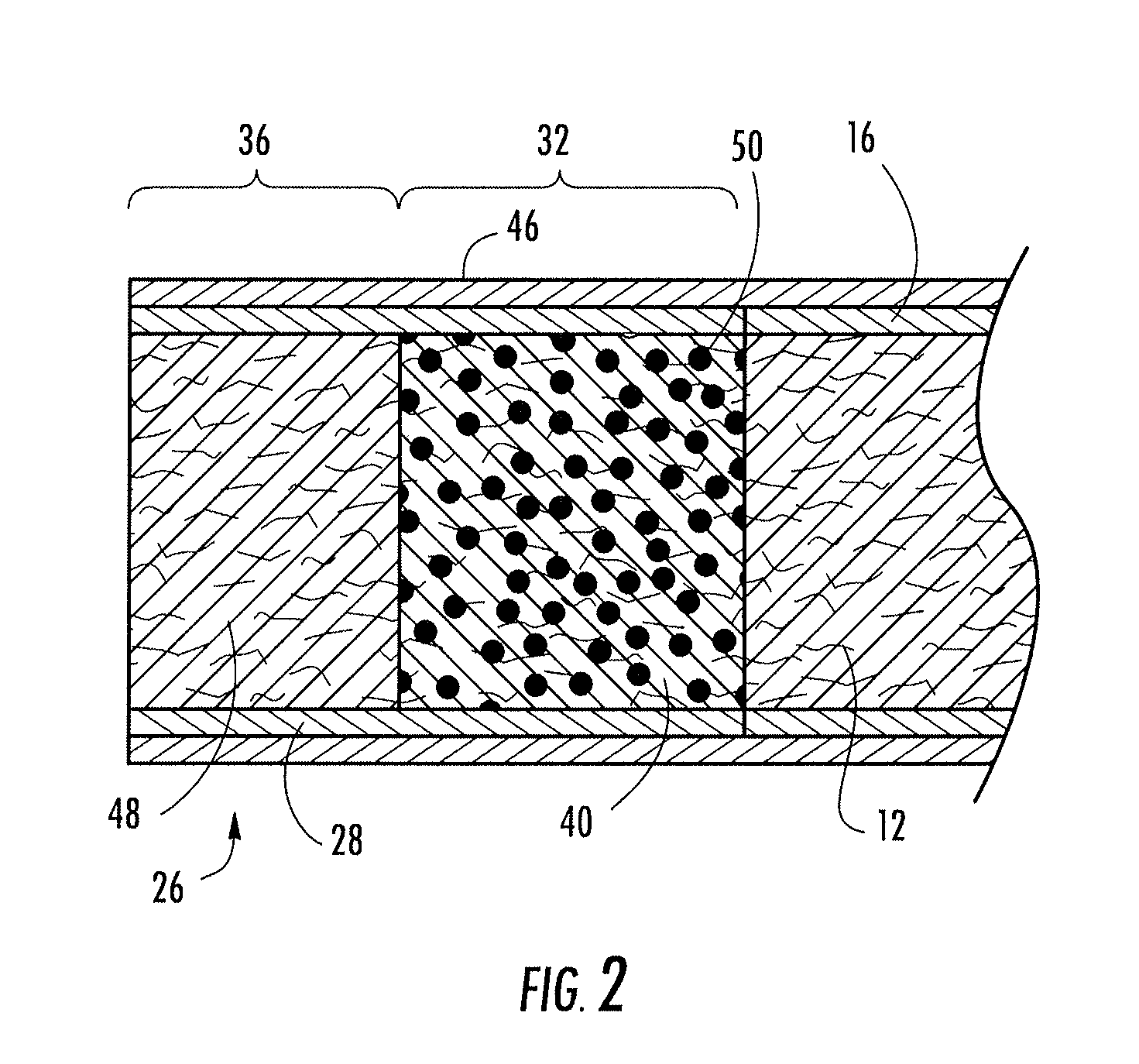

Degradable filter element

ActiveUS20110036366A1Improve degradation ratePromote degradationTobacco treatmentTobacco smoke filtersFiberPolymer science

A filter material adapted for use as a filter element of a smoking article is provided, the filter material including at least one segment of fibrous tow having a plurality of degradable particles dispersed therein, the degradable particles comprising a starch material. Exemplary starch materials include naturally-occurring starch, hydroxyalkylated starch, starch esters, ionically modified starch, oxidized starch, hydrolyzed starch, plasticized starch, gelatinized starch, grafted starch, crosslinked starch, transglycosylated starch, starch ethers, and mixtures thereof, as well as blends of starch with other polymers. Filter elements and smoking articles, such as cigarettes, that contain the filter material are also provided. A method of preparing polymer fibers for use in filter elements is also provided, the method including adding the starch material to a fiber precursor solution prior to fiber extrusion or dry-blending the starch material with the polymer material to be formed into fibers.

Owner:R J REYNOLDS TOBACCO COMPANY

Barley with reduced SSII activity and starch containing products with a reduced amylopectin content

ActiveUS7888499B2Improve the level ofReduce the temperatureBiocideTransferasesLipid formationStarch gelatinization

Owner:THE HEALTHY GRAIN PTY LTD

Method for preparing starch microspheres

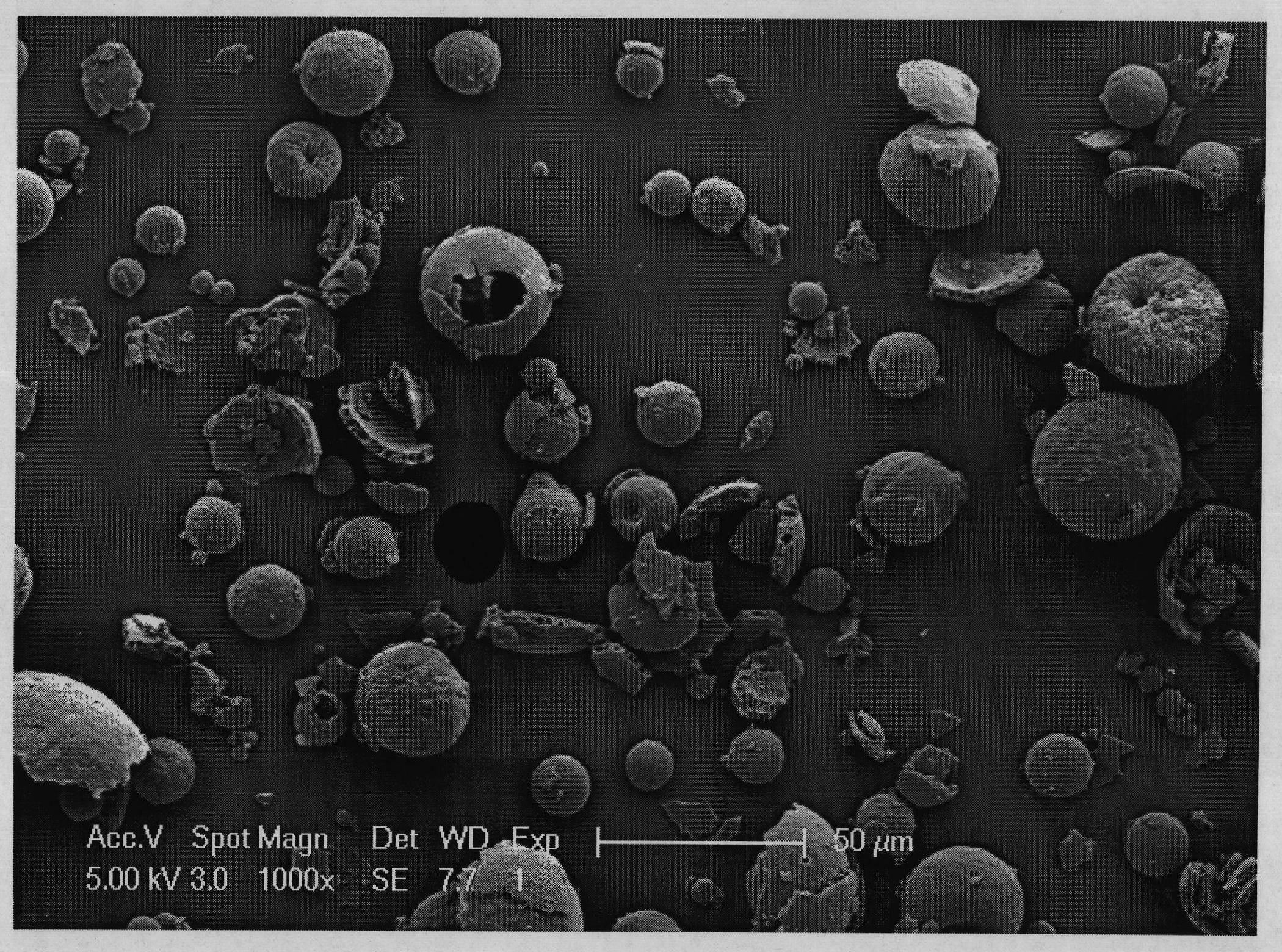

ActiveCN102008926AUnique structural featuresGood slow releasePharmaceutical non-active ingredientsGranular deliveryEmulsionStarch gelatinization

The invention discloses a method for preparing starch microspheres, which comprises the following steps of: stirring 20 to 70 percent of plant starch emulsion at the constant temperature in the critical temperature of starch gelatinization for 10 to 30 minutes under the action of 2 to 15 percent of water-soluble thickening agent, standing, cooling naturally, removing supernate, washing, and drying to prepare the starch microspheres. The surfaces of the prepared starch microspheres are smooth, the inner part is hollow, one or more nano-scale micropores are distributed on the surface, the wall thickness is uniform, the grain diameter is between 10 and 100 micrometers, and the wall thickness is between 1 and 10 micrometers. The prepared starch microspheres have a simple preparation process and readily available materials, and are widely applied to fields of medicines, cosmetics, food modifiers, printing ink, papermaking and the like.

Owner:合肥市君科合成材料有限公司

Production method of starch empty capsule

ActiveCN103830736AMeet the requirementsSimple processPharmaceutical non-active ingredientsCapsule deliveryStarch gelatinizationPlasticizer

The invention relates to a production method of a starch empty capsule. The raw material used is a low viscosity starch gel liquid. A preparation method of the low viscosity starch gel liquid comprises the following steps: mixing gel, a plasticizer and water; stirring and dissolving; then, adding starch or modified starch; and heating to gelatinize the starch. The preparation method is characterized by further comprising the step of adding amylase for enzyme reaction to obtain the gel liquid with the viscosity of 1000-7000cps. Production conditions such as dipping temperature, temperature of a gel disc and temperature of a drying tunnel which are strictly controlled are obtained when the hollow capsule is prepared by using the low viscosity starch gel liquid by means of repeatedly researching and testing the technological parameters of each step in production of the hollow capsule. By taking the starch as the raw material, a hollow plant capsule product which satisfies the requirements of pharmacopeia can be produced. The production method disclosed by the invention is simple in process and convenient to operate. Existing capsule production equipment can be directly utilized, so that the production method is suitable for industrialized production.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

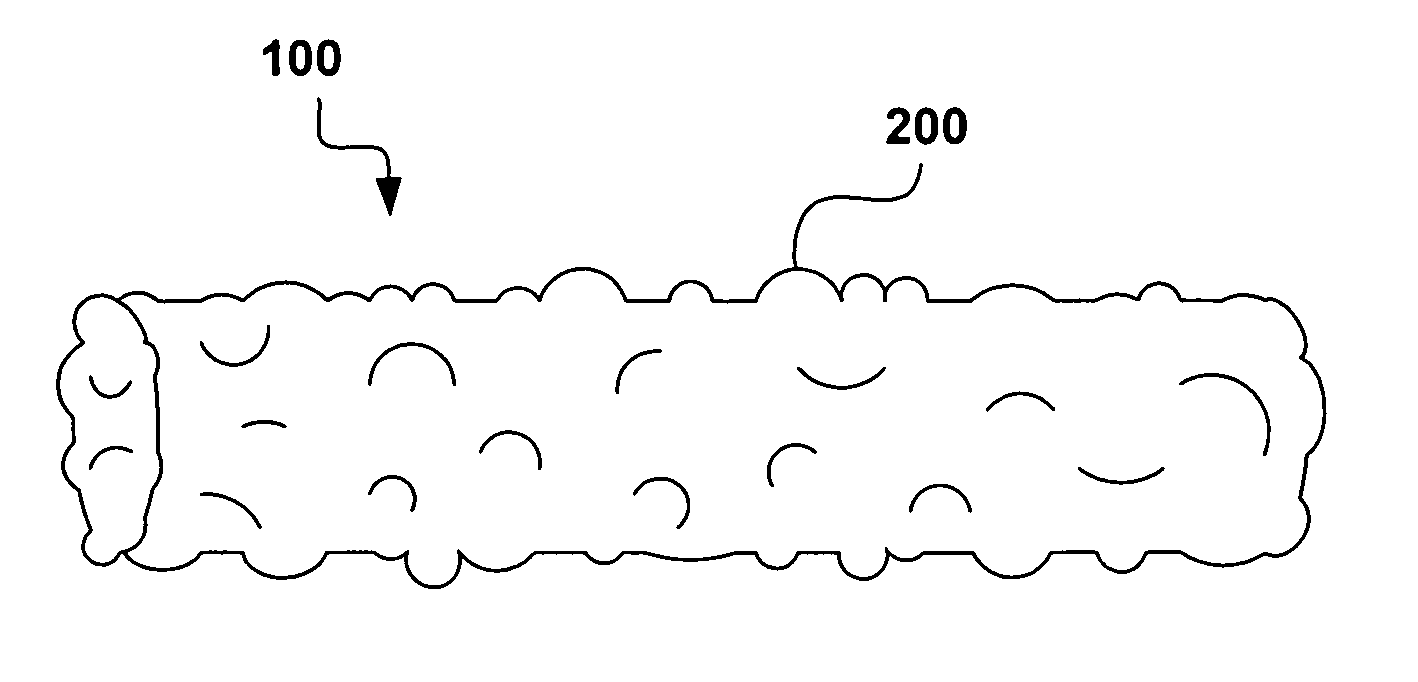

Pet treats with rough surface texture

A pet treat with a rough surface texture and appearance is produced from a matrix binder and at least one granular filler having a particle size between 0.1 mm to 6 mm. The matrix binder may be selected from gelatinized starches, gelatinized flours, wheat gluten, soy protein, casein, caseinates, gelatin, hydrocolloids, gums and mixtures thereof. The granular filler may be selected from mill feeds, whole grains, distillers dried grains, pork grind, bird seed and mixtures thereof.

Owner:MGP INGREDIENTS

Process for preparing starch grafting acrylamide paper reinforcing agent

InactiveCN102617799AGood storage stabilitySmall molecular weightReinforcing agents additionPaper/cardboardBursting strengthEmulsion

The invention relates to a process for preparing a starch grafting acrylamide paper reinforcing agent, which includes the following steps of adding an oxidant and sodium hydroxidein into a starch emulsion for an oxidizing reaction at the temperature between 30 DEG C and 80 DEG C; adding a cationization reagent for a cationization reaction at the temperature between 30 DEG C and 90 DEG C; gelatinizing and cooling the obtained starches, utilizing acrylamide and cation monomers as mixed grafting monomers, adding initiating agents, performing a graft copolymerization reaction in the aqueous phase at the temperature between 40 DEG C and 80 DEG C, and obtaining a starch grafting copolymer. The starch grafting copolymer is a reinforcing agent capable of being used in improving the ring crush strength, the bursting strength, the stiffness and the like of papers.

Owner:GUANGDONG PAPER IND RES INST

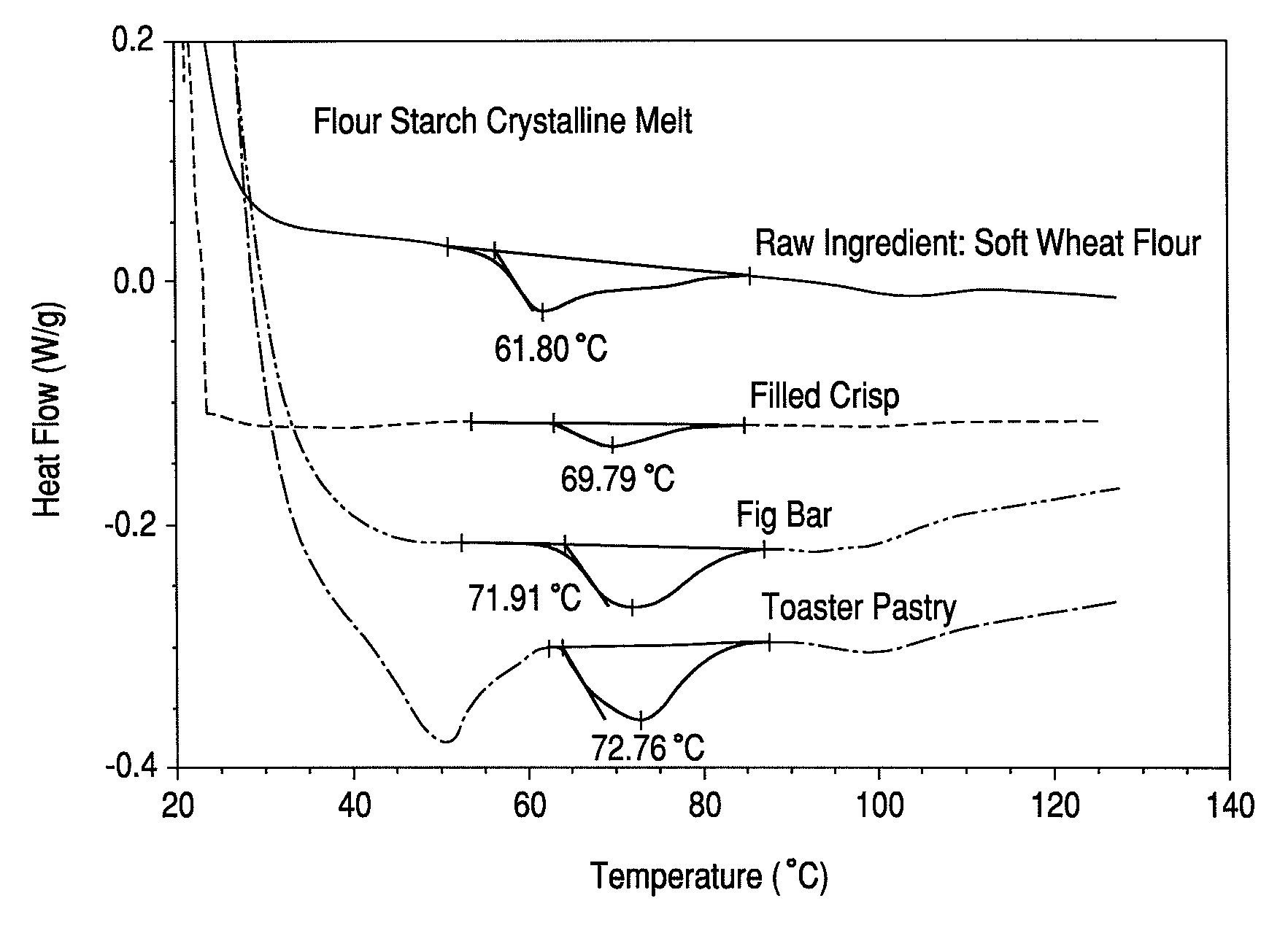

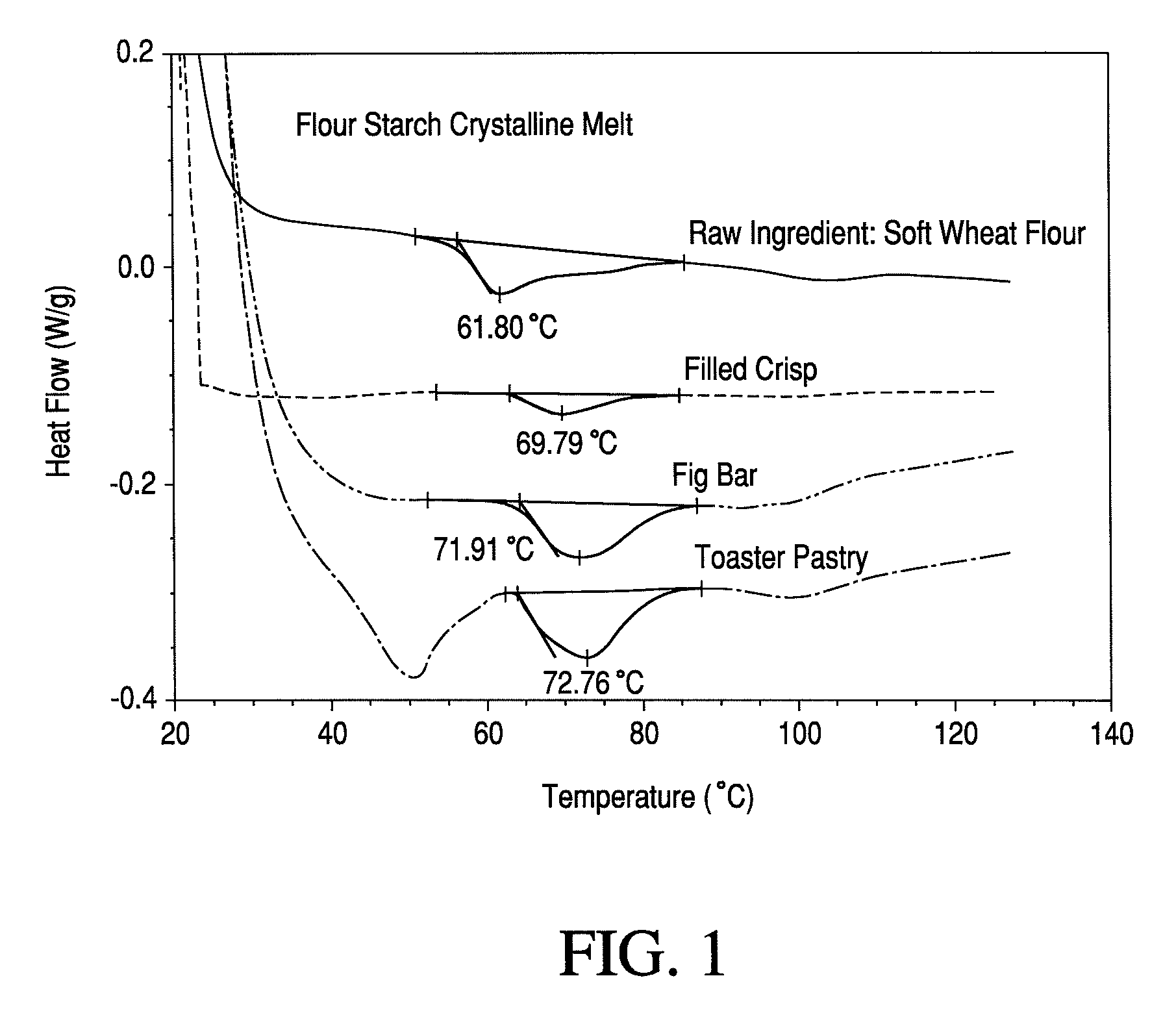

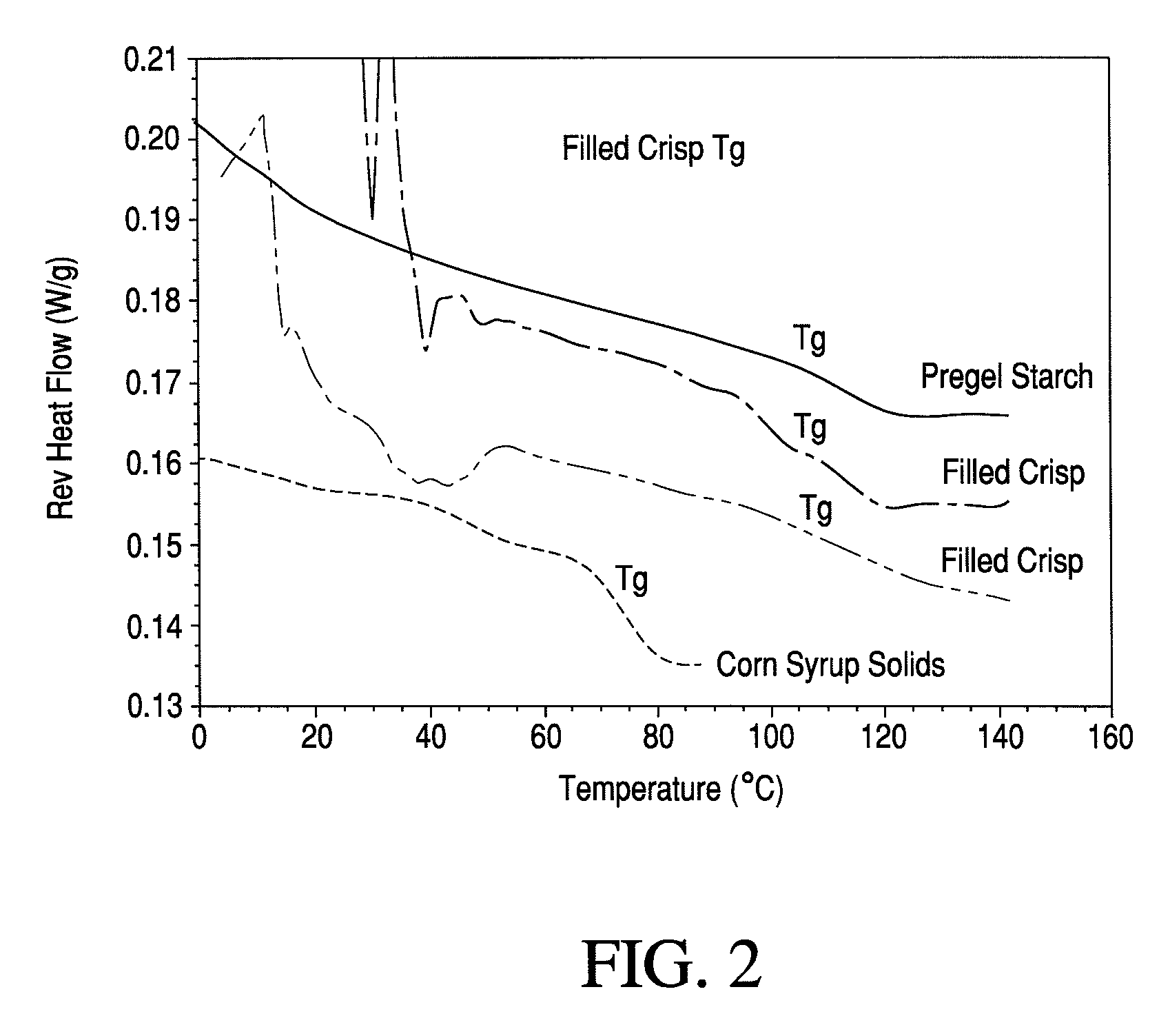

Filled, baked crispy snack having a high moisture content

ActiveUS20090220654A1Improve gelatinizationIncreased TgDough treatmentConfectioneryHigh resistanceReady to eat

A shelf-stable, filled, baked crispy snack which possesses a crispy textured casing and a moist, soft textured filling over a prolonged period of time is obtained by formulating a casing which when baked has a high glass temperature (Tg) at a high moisture content. Increasing the degree of starch gelatinization to increase the Tg may be achieved during baking and by the addition of a pregelatinized starch. The high Tg baked casing permits the use of a high moisture content filler in high amounts to provide a shelf-stable substantial textural dichotomy in the filled, baked, crispy snack. The filled, baked snack exhibits an unexpectedly high resistance to deformation or peak force at high baked casing moisture contents. The baked snack is ready-to-eat out of the packaging and does not have to be toasted, microwaved or further baked, cooked, or heated for consumption, or to achieve a crisp textured casing.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

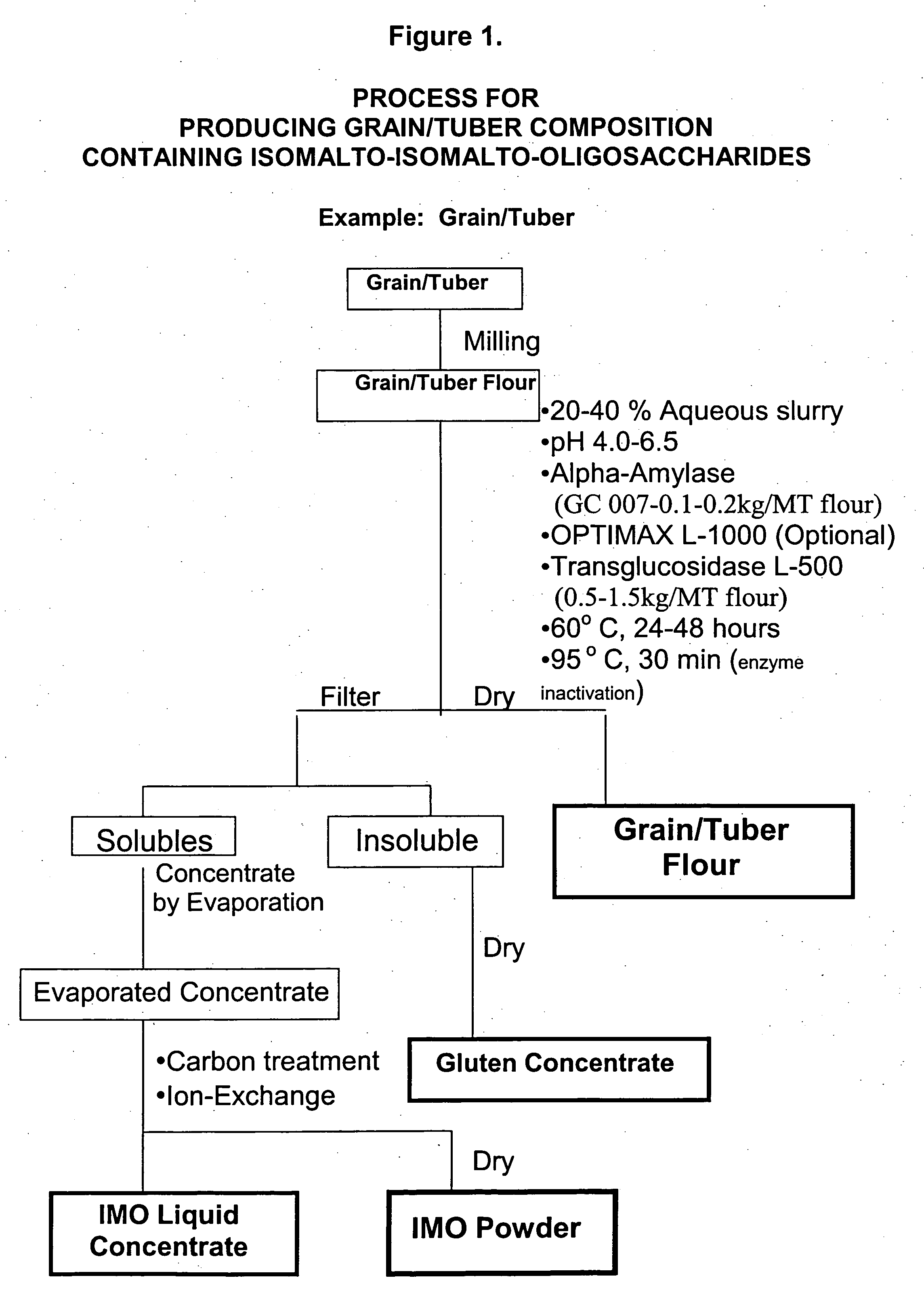

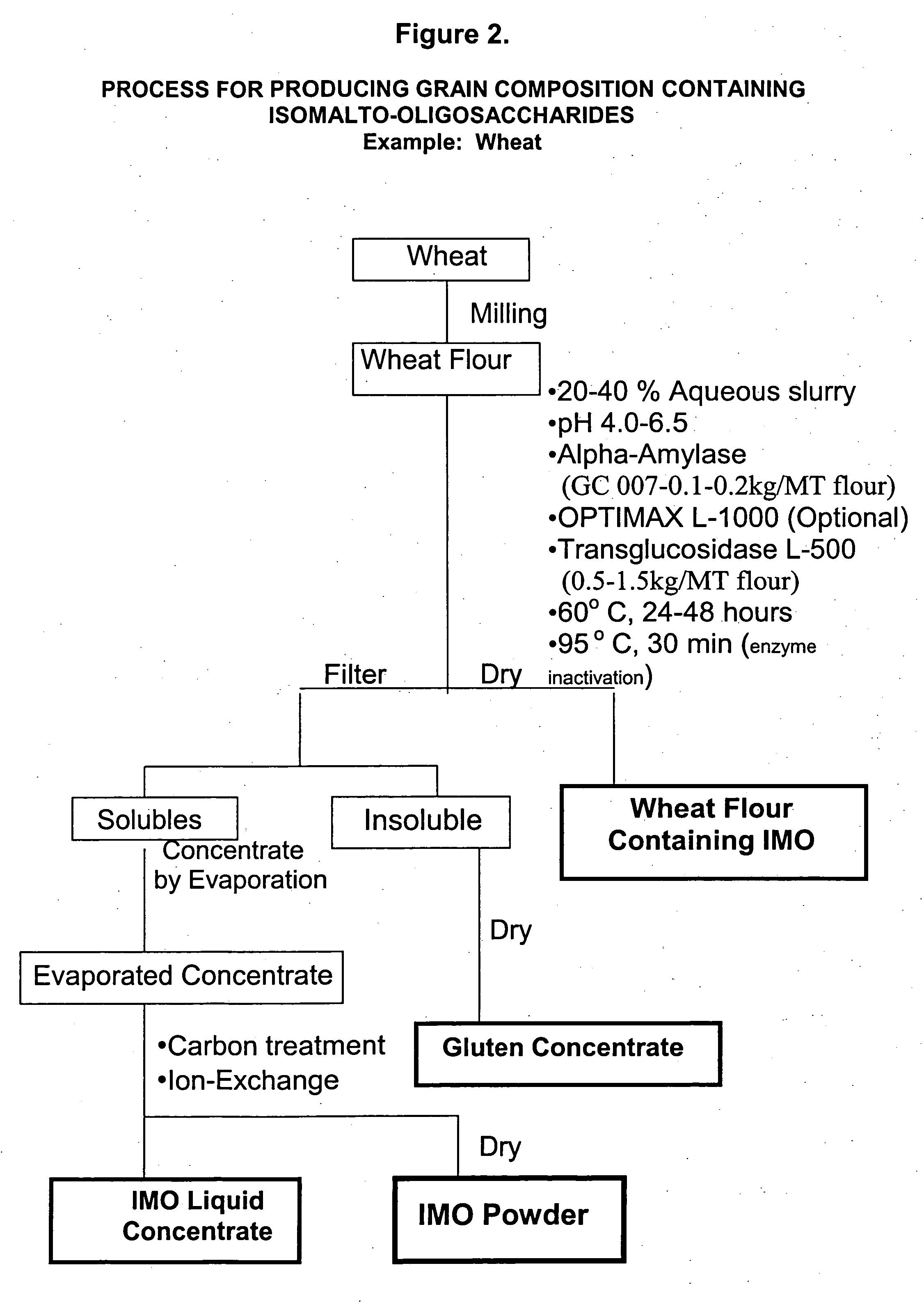

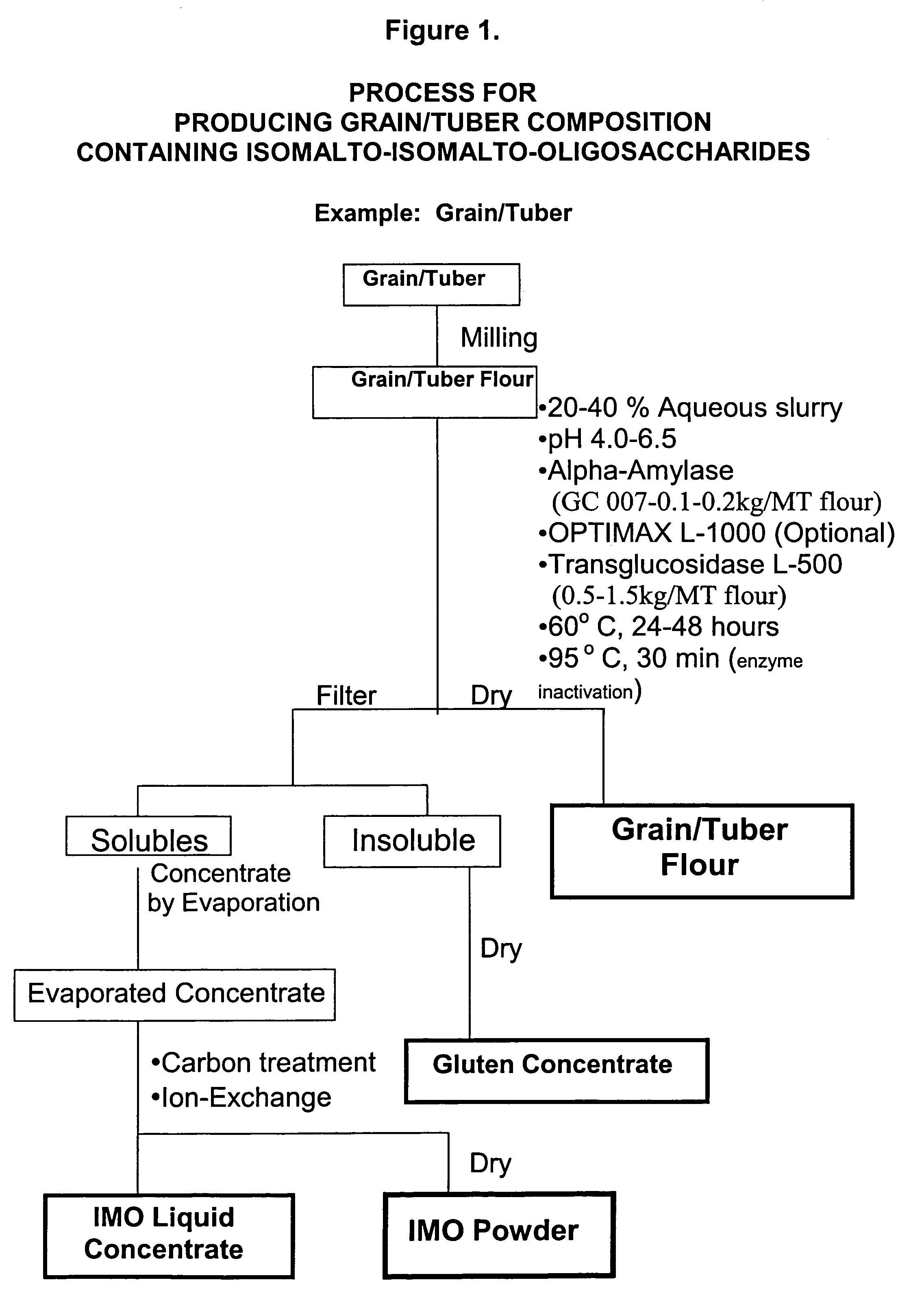

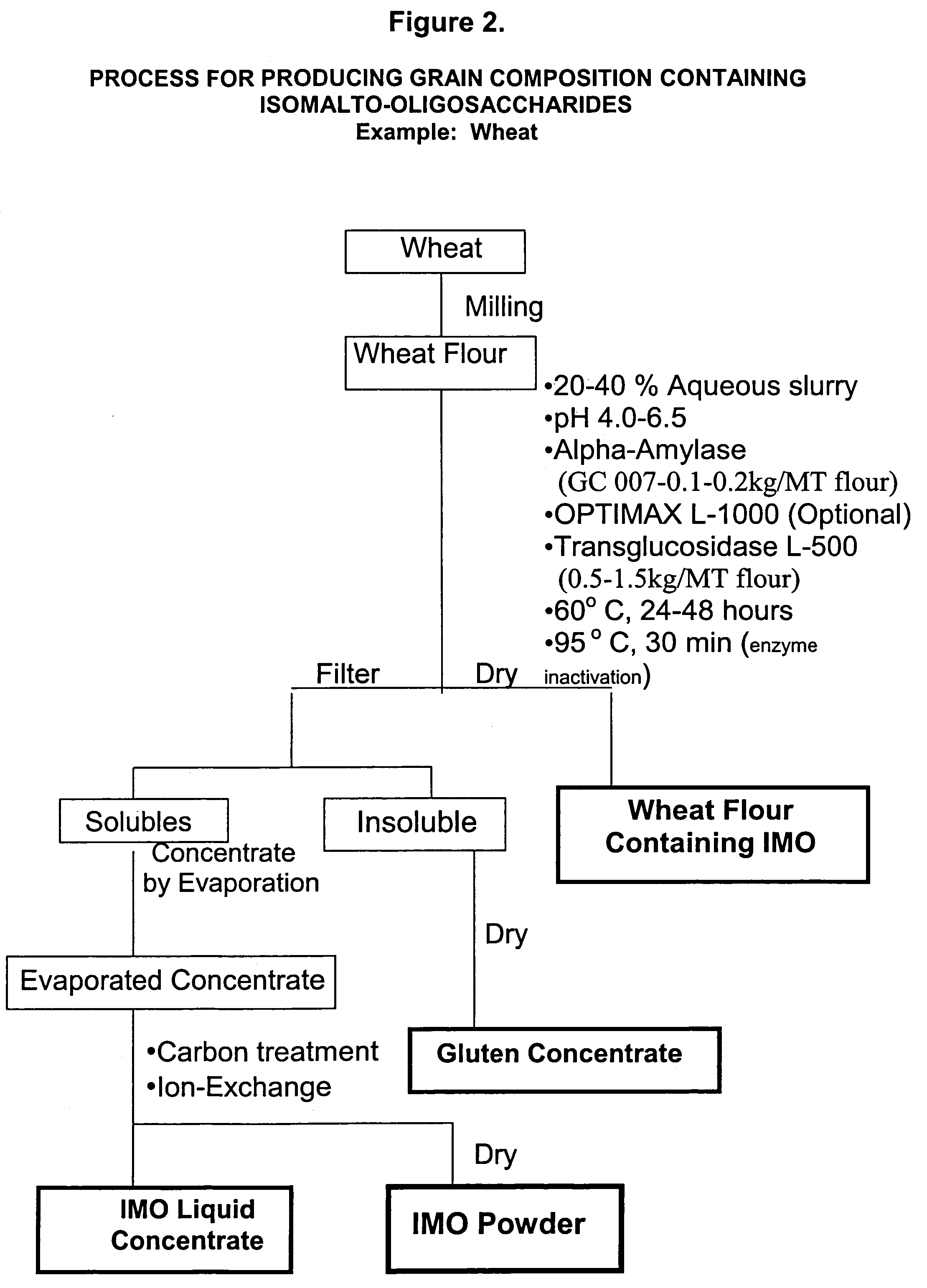

Grain compositions containing pre-biotic isomalto-oligosaccharides and methods of making and using same

Methods for the production of substrate, tuber, and grain compositions containing isomalto-oligosaccharides are described. The methods comprise (a) contacting a substrate, tuber or grain containing ungelatinized starch with a maltogenic enzyme and a starch liquefying enzyme to produce maltose; (b) contacting said maltose with a transglucosidic enzyme, wherein said steps (a) and step (b) occur at a temperature less than or at a starch gelatinization temperature; and (c) obtaining a substrate, grain or tuber composition having an enzymatically produced isomalto-oligosaccharide, wherein the oligosaccharide is derived from the grain. The maltogenic enzyme can be either exogenous or endogenous to the grain. The contacting steps can be sequential or concurrent. The present invention also describes flour, oral rehydrating solutions, beer adjuncts, food, feed, beverage additives incorporating the grain compositions made as described.

Owner:DANISCO US INC

Cation surface sizing agent and preparation method thereof

InactiveCN101649583AReduce manufacturing costPrevent penetrationWater-repelling agents additionPaper/cardboardAmylaseSizing

The invention provides a cation surface sizing agent and preparation method thereof. Raw materials are as follows by weight percent: 8-17% of styrene, 5-15% of butyl acrylate, 0.5-5% of acrylamide, 0.5-5% of N-hydroxymethyl acrylamide, 1-5% of methyl acryloyl ethyl trimethylammonium chloride, 2-8% of starch, 0.001-0.003% of amylase, 0.2-0.7% of organic acid, 0.2-0.8% of emulsifier, 1-5% of 27% hydrogen peroxide, 0.01-0.05% of iron dichloride, the balance water. The cation surface sizing agent is prepared by starch pasting, monomer pre-emulsion and emulsion polymerization. The invention is usedfor surface sizing of paper and achieves the aim of improving physical performances of paper such as water-resistance, ring crush compression resistance, surface strength and the like.

Owner:东莞市清正合成高新材料有限公司 +1

Edible potato starch powder composite food packaging film and its preparation method

InactiveCN1410481AWide range of sources and cheapWith physiological health functionStarch gelatinizationPlasticizer

An edible potato starch composite film as a packaging material of food is prepared from potato starch, thickening agent, and plasticizer through mixing potato starch with water for gelatinizing, adding thickening agent and plasticizer in sequence, stirring, filtering, vacuum defoaming, and filming by the doctor blading method. Its advantages are low cost, high transparency and strength, and full degradation.

Owner:WUHAN UNIV

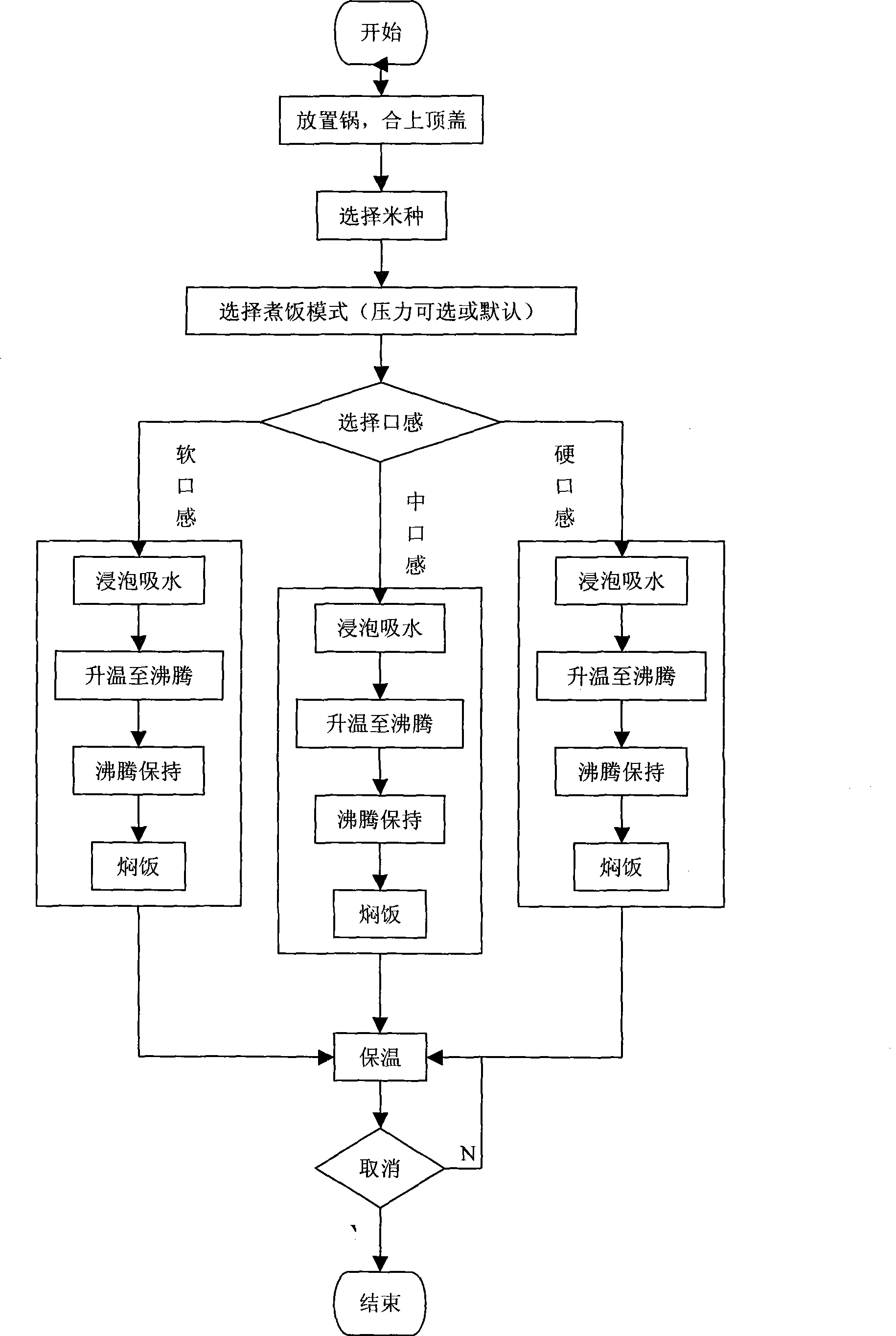

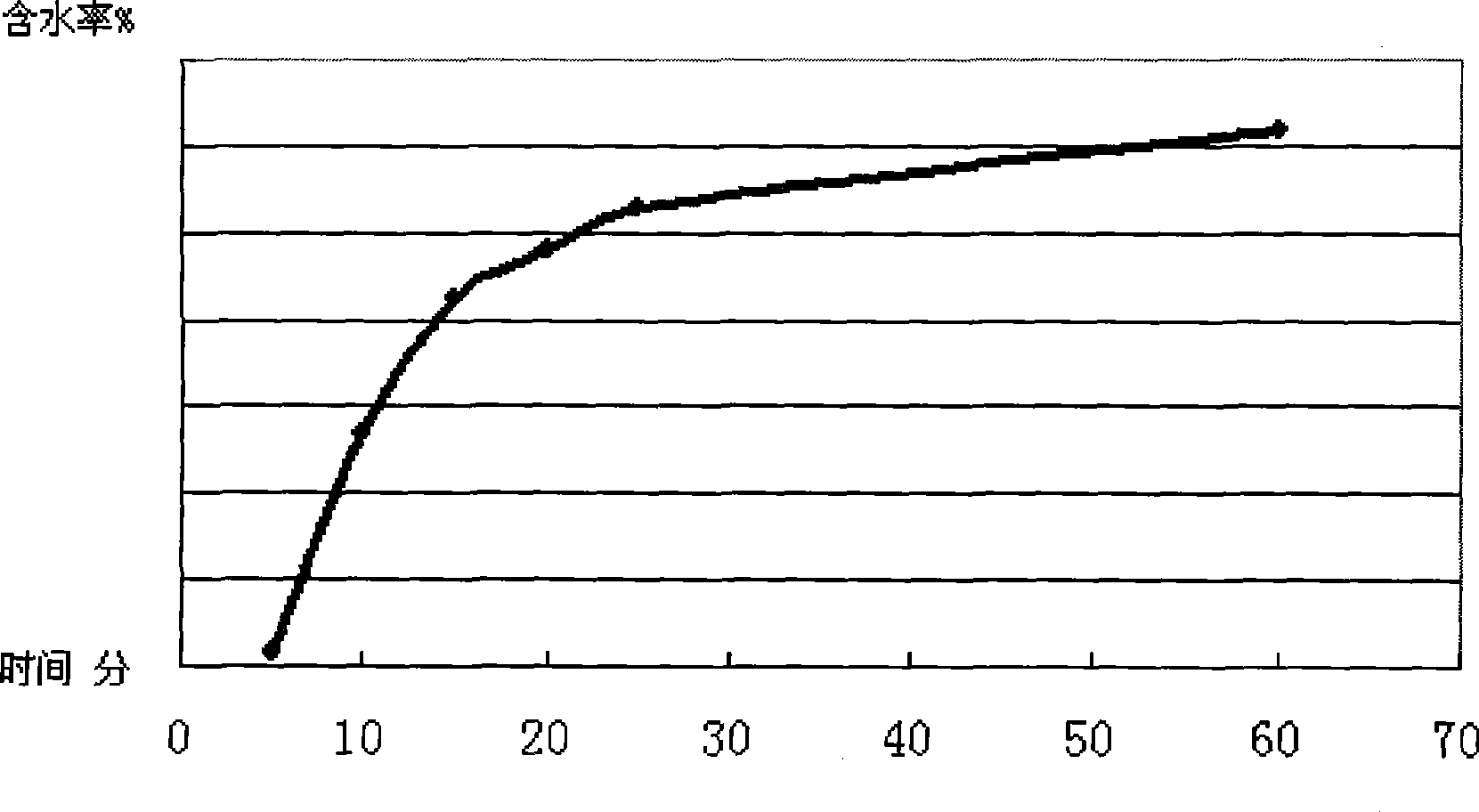

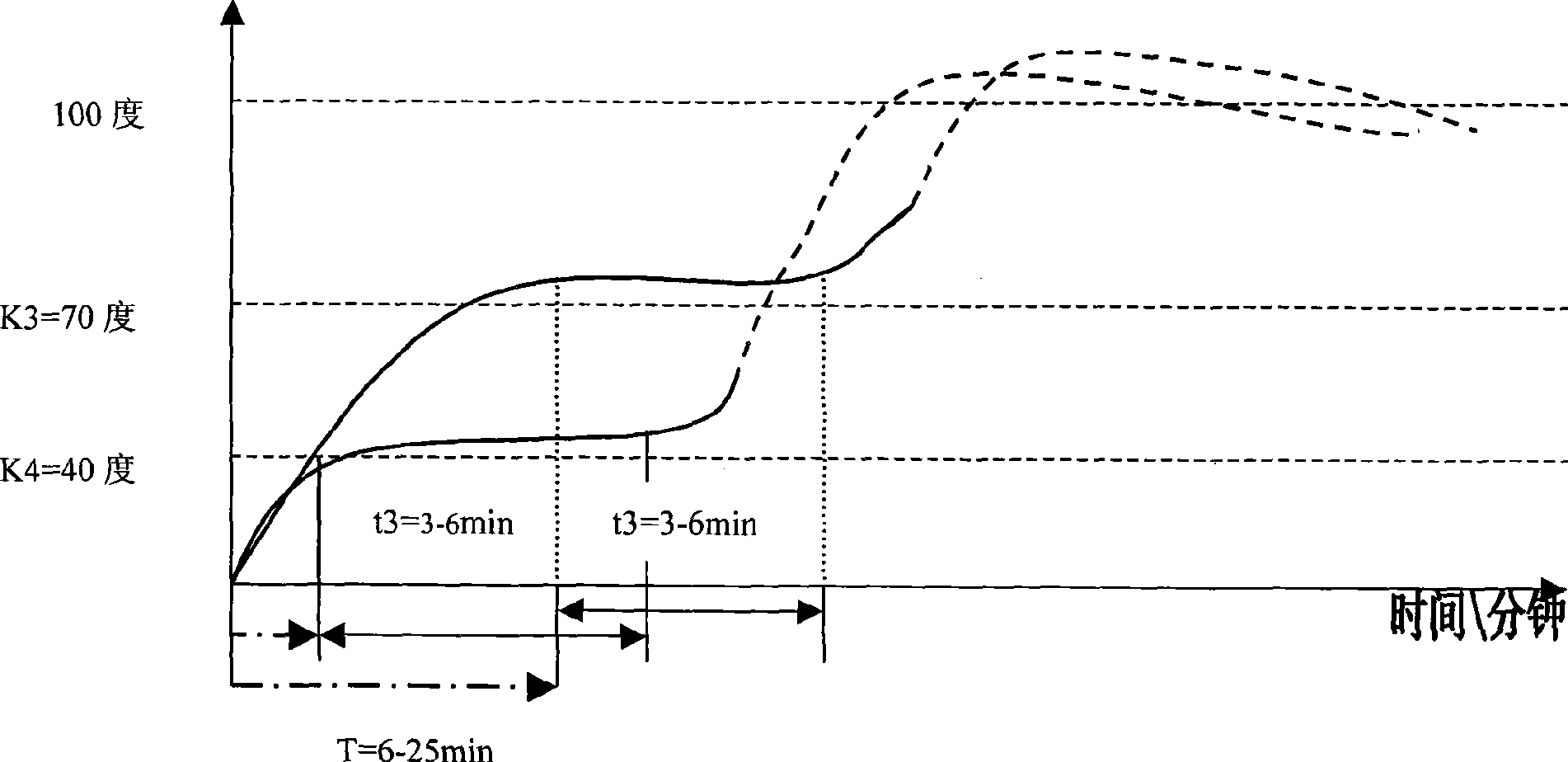

Rice cooking control method for pressure electric cooker

InactiveCN101364094AGood appearance and textureMeet the needs of gelatinizationCooking vesselsProgramme control in sequence/logic controllersStarch gelatinizationCooker

The invention relates to a rice-cooking control method for an electric rice cooker. The method comprises the following steps: (1) setting an immersion time (t) and an immersion temperature (K) according to different rice types, mouthfeel and pressures, wherein the immersion time (t) is in the range from 3 min to 8 min and the immersion temperature (K) is in the range from 50 DEG C to 80 DEG C; (2) starting a heater until a measured immersion temperature reaches the preset immersion temperature (K) after a time period (T), wherein the time period (T) is in the range from 5 min to 20 min, and defining the time period as t after reaching the preset immersion temperature (K); and (3) after reaching the preset immersion time (t), according to the preset program, heating to boil, keeping boiling under the preset pressure (P) inside the rick cooker, and simmering and exhausting after boiling. The rice-cooking control method can control the temperature and the time of the immersion and swelling process of different types of rice under different pressures to meet the requirement for starch gelatinization, and ensure good quality of the cooked rice.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

Grain compositions containing pre-biotic isomalto-oligosaccharides and methods of making and using same

Methods for the production of substrate, tuber, and grain compositions containing isomalto-oligosaccharides are described. The methods comprise (a) contacting a substrate, tuber or grain containing ungelatinized starch with a maltogenic enzyme and a starch liquefying enzyme to produce maltose; (b) contacting said maltose with a transglucosidic enzyme, wherein said steps (a) and step (b) occur at a temperature less than or at a starch gelatinization temperature; and (c) obtaining a substrate, grain or tuber composition having an enzymatically produced isomalto-oligosaccharide, wherein the oligosaccharide is derived from the grain. The maltogenic enzyme can be either exogenous or endogenous to the grain. The contacting steps can be sequential or concurrent. The present invention also describes flour, oral rehydrating solutions, beer adjuncts, food, feed, beverage additives incorporating the grain compositions made as described.

Owner:DANISCO US INC

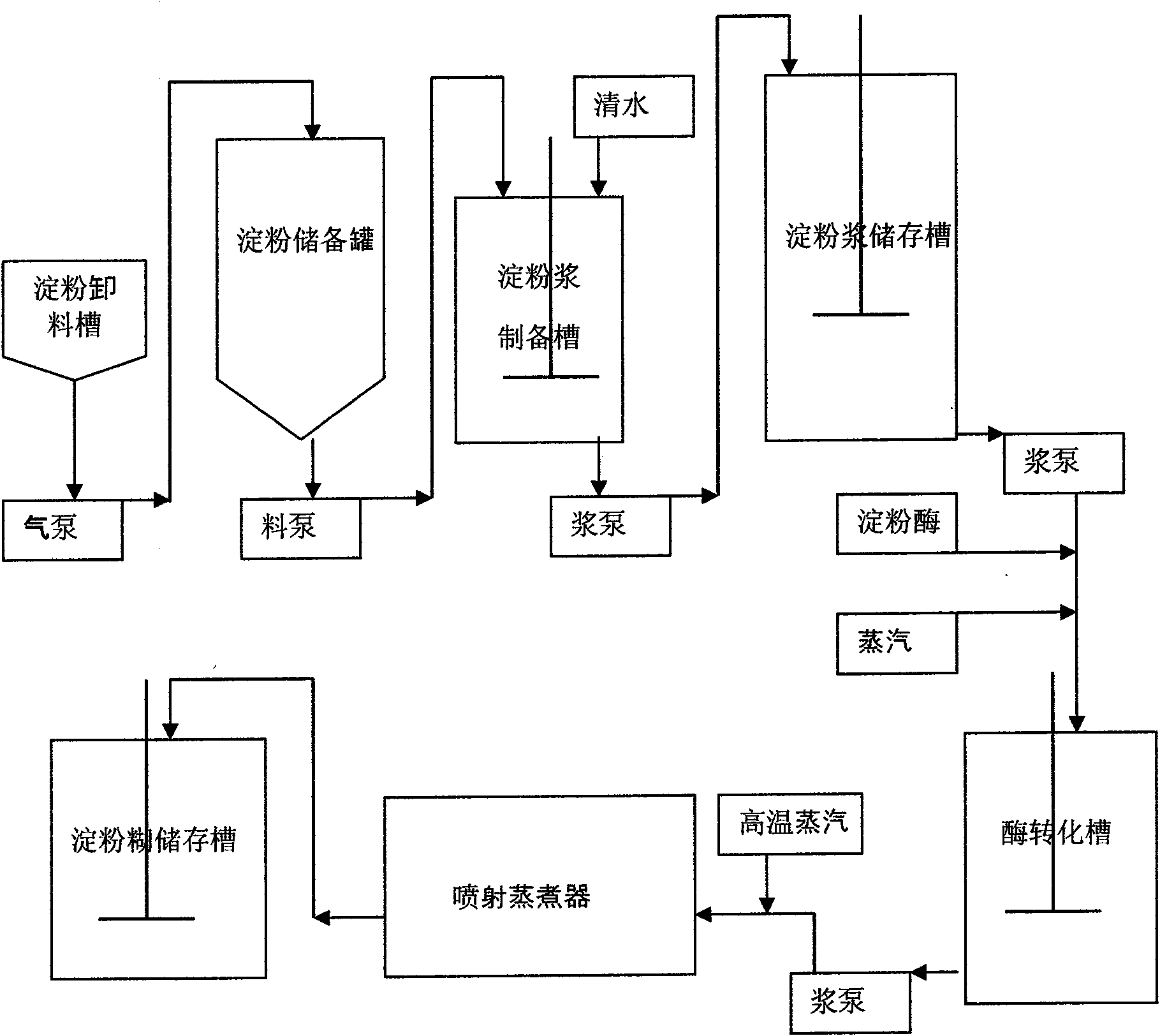

Method for producing starch glue by low-temperature fast enzymatic conversion

InactiveCN101649582AReduce consumptionReduce dosageWater-repelling agents additionPaper/cardboardStarch gelatinizationAlpha-amylase

The invention discloses a method for producing starch glue by low-temperature fast enzymatic conversion, which comprises the following process steps: 1) starch size mixing: adding clear water in the starch, adjusting the concentration of the starch to 20% to 30% by weight; 2) carrying out enzymolysis on the adjusted starch size, adding 0.003%-0.015% of alpha-amylase of dry basis weight of the starch into the starch size for enzymolysis; 3) carrying out high-temperature enzyme inactivation on the starch after enzymolysis, and simultaneously carrying out gelatinization; and 4) placing the starchafter gelatinization into a starch paste storage tank for standby. The process of the invention shortens production time, reduces energy consumption, greatly improves the viscosity of the product; the product is used in surface sizing of paper, which improves the stiffness of the paper, enhances the ability of compression resistance and tension resistance and reduces the dosage of the starch glue, thus reducing manufacturing cost, and ensuring the competitiveness of enterprises.

Owner:DONGGUAN NINE DRAGONS PAPER IND

Expanded sinking formula feed suitable for sea crabs to ingest and method for preparing same

InactiveCN101569376AReduce lossImprove starch gelatinizationFood processingClimate change adaptationStarch gelatinizationWater quality

The invention discloses expanded sinking formula feed suitable for sea crabs to ingest and a method for preparing same. The method comprises the following steps: coarse-grinding a large amount of materials, evenly mixing the materials for the first time, ultra-fine grinding, evenly mixing the materials for the second time, conditioning, drying, cooling and the like. The expanded sinking formula feed has the advantages of high stability in water, long stabilization time in water, and low water and environmental pollution; the starch gelatinization of the product is as high as 90% to 95%, thereby improving the digestive utilization ratio of the product; and the expanded sinking formula feed turns soft and flexible through water absorption and is preferable for the digestion of sea crabs, therefore, the expanded sinking formula feed can be substituted totally for the existing formula feed of fresh trash fish and hard granules and applied to the artificial breeding of the sea crabs.

Owner:ZHEJIANG JINDADI FEED

Starch adhesive agent and preparation method thereof

The invention discloses a starch adhesive and a preparation method thereof. The starch adhesive is primarily prepared with 100 portions of starch, 350 to 450 portions of water, 50 to 100 portions of acroleic acid and 0.01 to 0.1 portion of lauryl mercaptan through radiation grafting polymerization. The preparation method comprises the following steps: the starch is added to a reactor; water is added to the starch and is uniformly stirred; subsequently, the acroleic acid and the lauryl mercaptan are added; the mixture is heated to be 60 to 85 DEG C so that the starch is gelatinized; subsequently, the mixture is arranged in a <60>Co-Gamma ray radiation field for irradiation grafting polymerization with the received dosage of 0.2 to 2KGy; after the polymerization, sodium benzoate, sodium borate and bentonite are added and are stirred uniformly. The starch adhesive has the advantages of small product density, great cohesive force, no free alkali, quickly drying, low cost, high storage stability, long flatting and storage period and so on. The preparation method has the advantages that the reaction condition is gentle, the energy consumption is lower, the increase production and the expansion are easy, the preparation process is simplified, manufacturing cost is low and so on.

Owner:湖南葆华环保科技有限公司

Method for preparing hydroxyethyl starch

InactiveCN101775076AAvoid destructionSolve problems such as removal difficultiesBlood disorderExtracellular fluid disorderHydroxyethyl starchStarch gelatinization

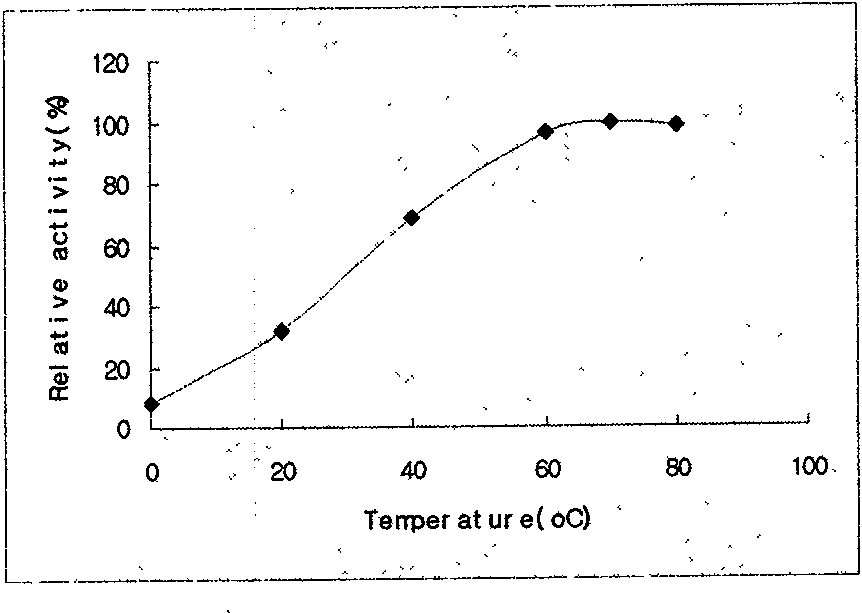

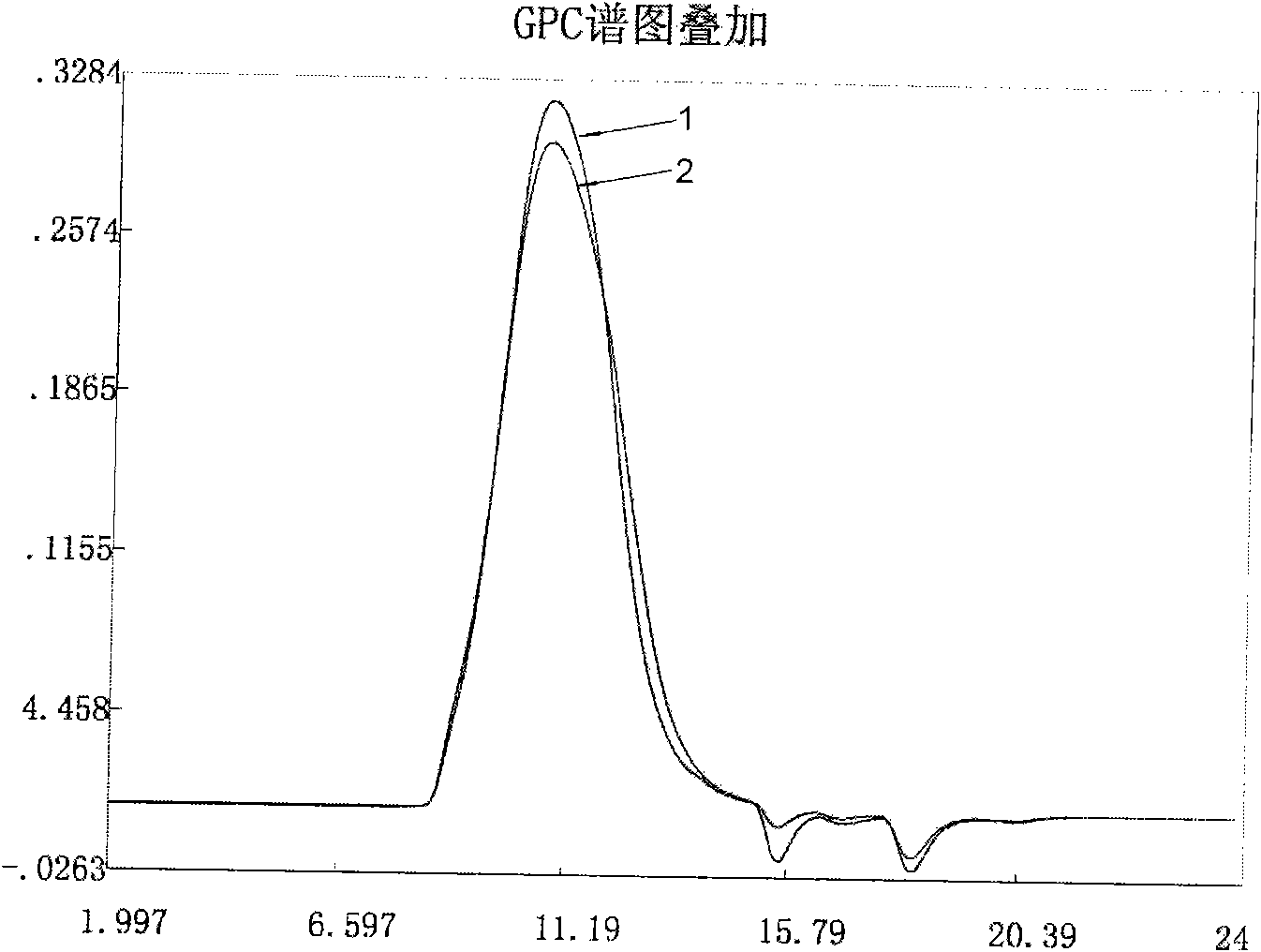

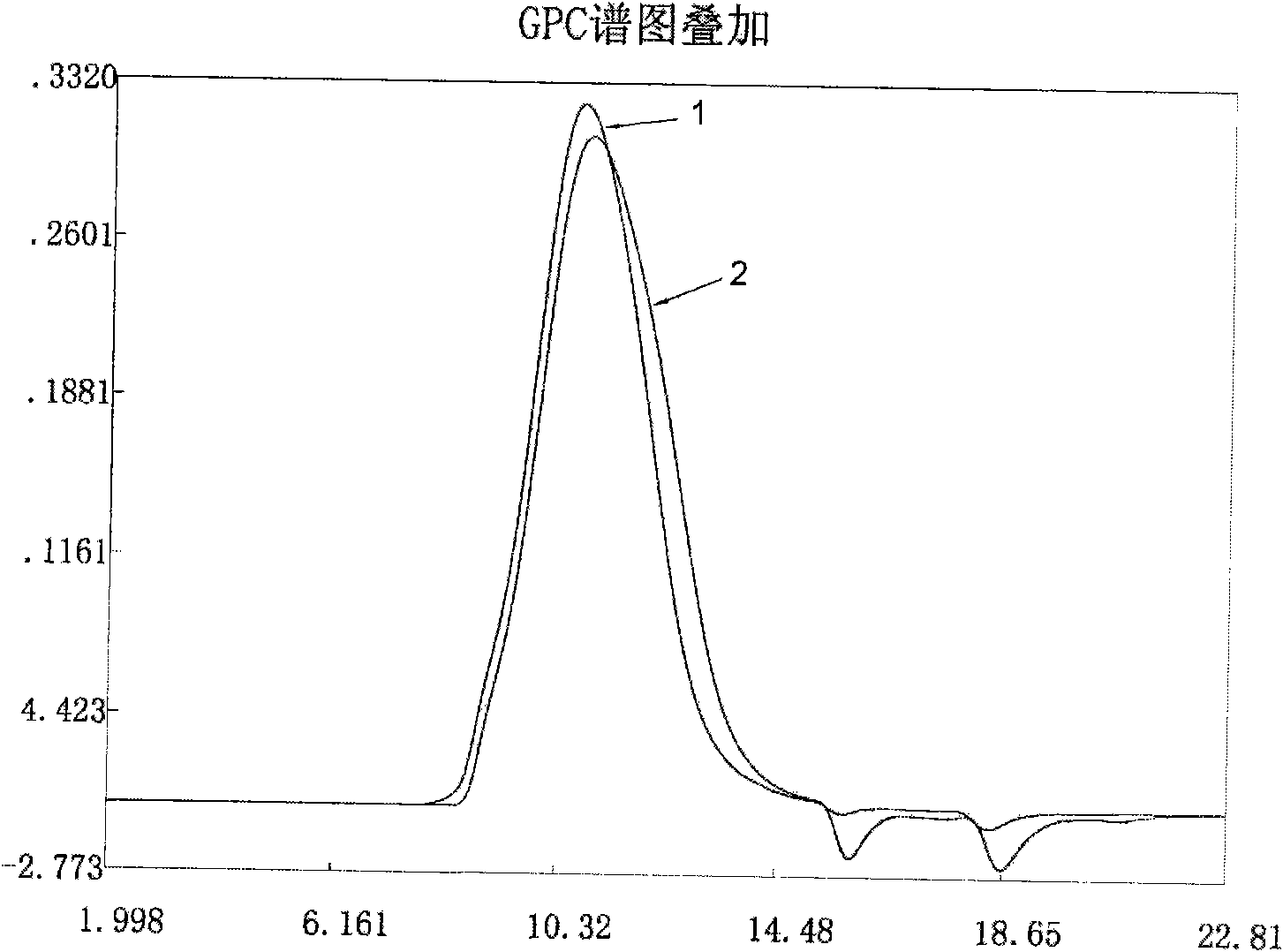

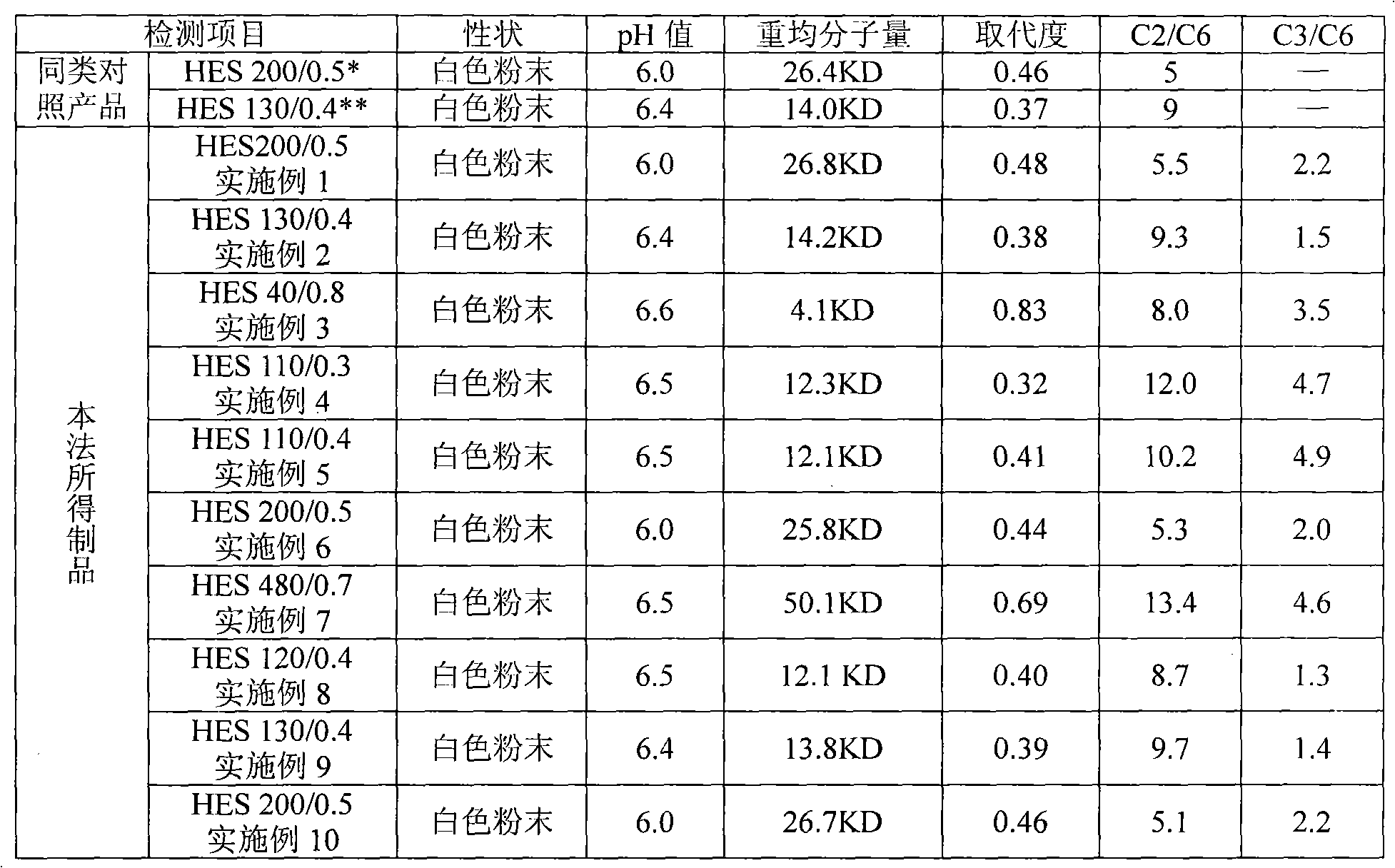

The invention discloses a method for preparing hydroxyethyl starch. The starch raw materials are subjected to hydroxyethylation and acid hydrolysis treatment in a solvent medium respectively. The method for preparing the hydroxyethyl starch comprises the following steps: firstly, under the alkaline condition that the pH is 13-14, carrying out hydroxyethylation reaction by using ethylene oxide or chlorethanol in an amount which is 0.2 to 1.8 times mol of the starch as a hydroxyethylation reagent; secondly, hydrolyzing the starch raw materials which are subjected to the hydroxyethylation under the acidic condition that the pH is 1-3 to obtain the hydroxyethylation starch, wherein the weight-average molecular weight is 20 to 500kD; the molar degree of substitution is 0.1 to 0.9, and the substituted ratio at the C2 / C6 position is 3 to 20 and the substituted ratio at the C3 / C6 position is 0.1 to 8. The method for preparing the hydroxyethyl starch can prevent the starch structure from being damaged without pasting the starch, solve the problems that the control of the molecular weight of the products is inaccurate during acid hydrolysis, an organic residual solvent which is subjected to the hydroxyethylation is hardly removed and the like, and is favorable for industrialized production. Therefore, hydroxyethylation starch products with different molecular weights and / or degrees of substitution can be obtained.

Owner:CHENGDU QINGSHAN LIKANG PHARMA CO LTD

Starch grafting acrylic acid compound water-retaining agent and production method thereof

ActiveCN102372892ALow costFast water absorptionOrganic fertilisersSoil conditioning compositionsPolymer scienceStarch gelatinization

The invention discloses a starch grafting acrylic acid kieselguhr compound water-retaining agent and a production method thereof. The technology is completed by adopting the acrylic acid neutralization and starch pasting in one step, so the production technology is simplified. The monomer concentration is improved, so the polymer is applicable to being processed by a granulator, and the drying energy consumption is reduced at the same time. First, an adherent / surface active agent is added, so the product water absorbing rate is improved, and the granulation is smoother. The water absorbing rate of the product is 270g / h and 290g / 2h, and the repeated water absorbing rate is not less than 95%. The color is white, and the strength is good.

Owner:SHANGHAI ZHONGWEI BIOCHEM

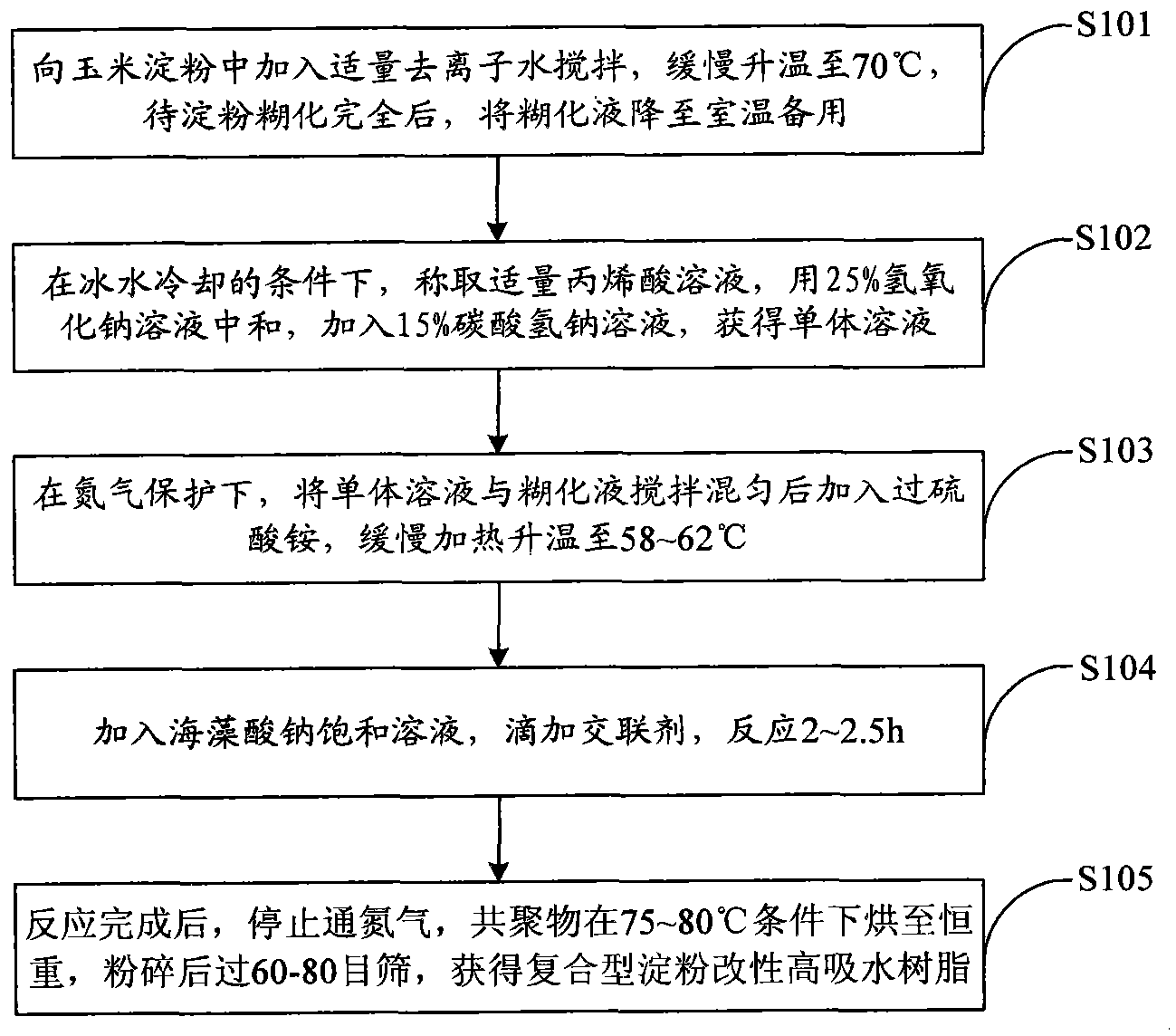

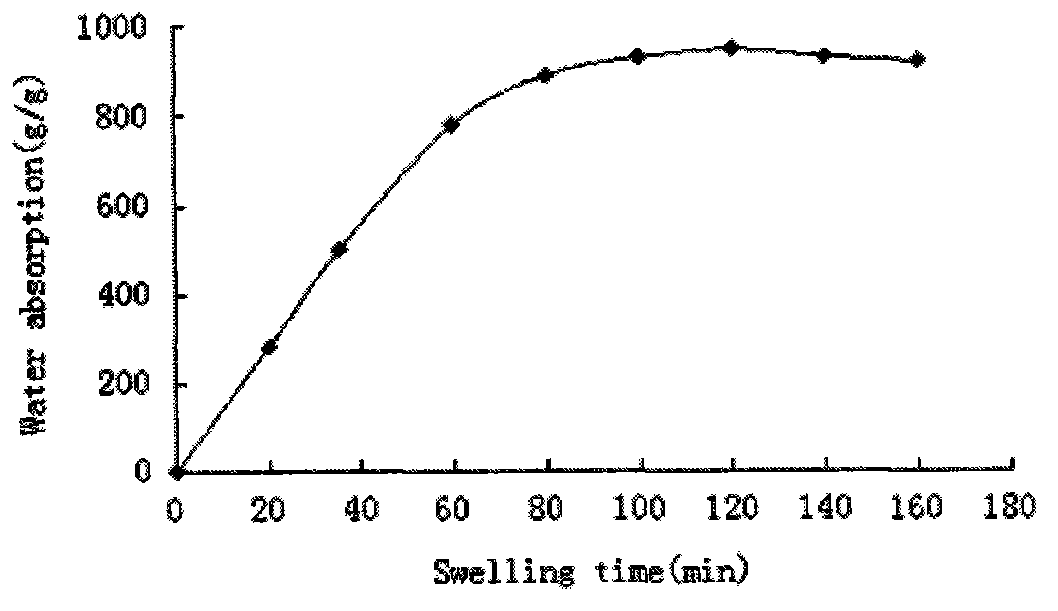

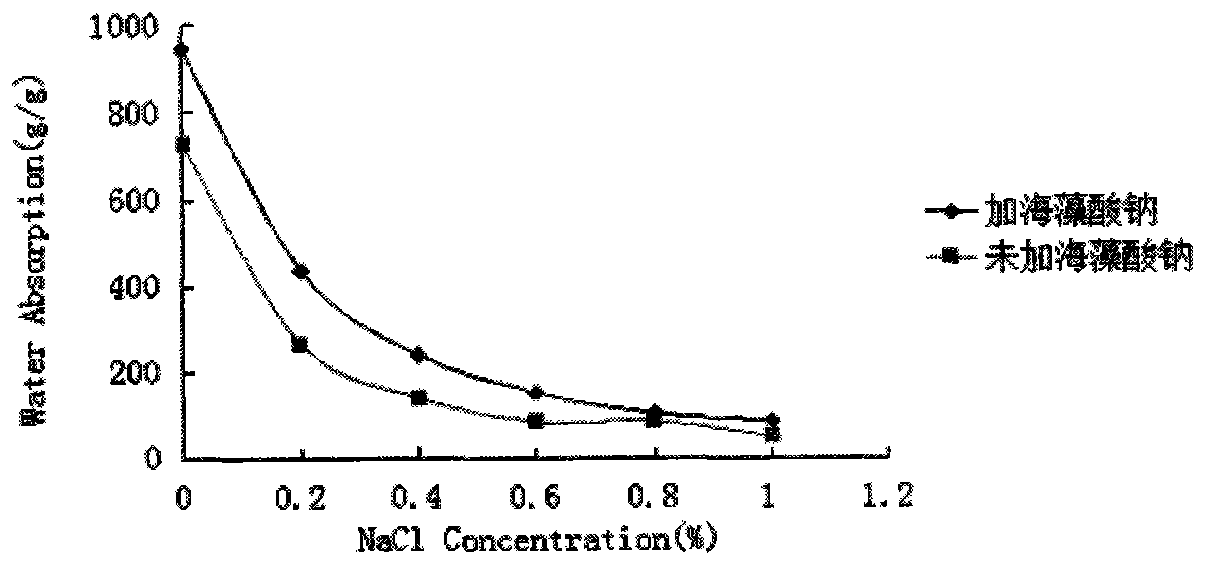

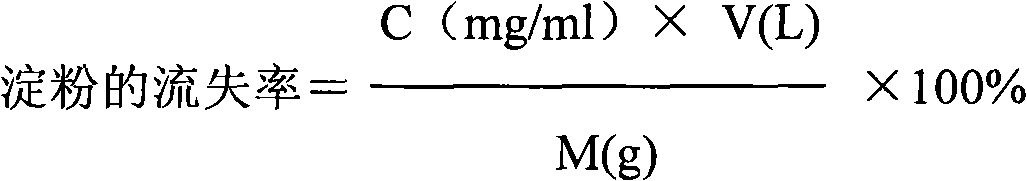

Preparation method of compound-type starch modification super absorbent resin

The invention discloses a preparation method of a compound-type starch modification super absorbent resin. The preparation method comprises the following steps of: adding deionized water to corn starch, stirring, slowly heating to 70 DEG C, and after completely dextrinizing the starch, reducing pasting liquid to a room temperature for standby application; weighting a right amount of acrylic acid solution under the action of ice water cooling, neutralizing by a 25% sodium hydroxide solution, adding 15% sodium bicarbonate as a pH buffering agent, and obtaining a monomer solution; after uniformly mixing the monomer solution and the pasting liquid in the presence of nitrogen, adding ammonium persulfate, and slowly heating to 58 DEG C to 62 DEG C; adding a sodium alginate saturated solution, dropwise adding a cross-linking agent, and reacting for 2-2.5 hours; after reaction is ended, stopping the feeding of nitrogen, drying copolymers to constant weight at 75-80 DEG C, smashing, screening by a 60-80 screen and obtaining the compound-type starch modification super absorbent resin. The environment-friendly water-absorbent resin with high salt tolerance and high water retention rate is prepared by starch graft copolymerization and alginate crosslinking.

Owner:NANJING FORESTRY UNIV

Anti-browning method of milky lotus root juice

InactiveCN101703301AImprove securityEliminate enzymatic browning reactionsFood scienceFiltrationUltrafiltration

The invention discloses an anti-browning method of milky lotus root juice and belongs to the technical field of fruit and vegetable food processing. The method comprises: cleaning lotus roots, peeling the lotus roots, removing the stem nodes of the lotus roots and slicing; adding a compound color fixative, blanching the sliced lotus roots for inactivating enzymes and adding water into the sliced lotus roots for pulping, wherein the compound color fixative added in the processing process can inhibit the complex browning reactions of the lotus roots in a high-temperature blanching process, the blanching can inactivate endogenous polyphenol oxidase in the lotus roots and inhibit enzymatic browning (the major cause of the browning of lotus root juice) of the lotus root juice in post-processing, storage and transport processes, and blanching can gelatinize the starch in the lotus roots to facilitate a follow-up enzymolysis process, destruct cell tissues and promote the dissolution of flavor substances; and adding fungalamylase for decomposing starch in the lotus root juice, obtaining mother lotus root juice for use in subsequent processing by rough filtration and ultrafiltration, and subjecting the lotus root mother juice to sugar and acid adjustment, sterilization and vacuum filling to obtain a lotus root juice drink. The lotus root juice drink keeps a desirable white index.

Owner:杭州天堂食品有限公司 +1

New technique for improving paper strength by joint gelatinization of starch and pulp

InactiveCN101597875APrevent reversalAvoid polyelectrolyte reversalSpecial paperPulp de-wateringFiberStarch gelatinization

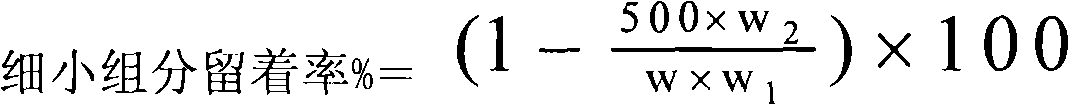

The invention belongs to the technical field of paper strengthening, in particular to a method using starch as a paper dry strengthen agent. The method comprises the following steps: uniformly mixing starch accounting for 0.5-25% of oven dry mass of pulp with pulp, carrying out extrusion and concentration, heating for 8-150min at 70-100 DEG C to gelatinize starch, carrying out defibering and dispersion on the heated pulp, and manufacturing paper with pulp. The invention has simple process, low production cost and less pollution, improves the strength of paper by 30-110%, has above 80% of starch retention ratio, and can improve the retention ratios of fillers and fiber fines.

Owner:NANJING FORESTRY UNIV

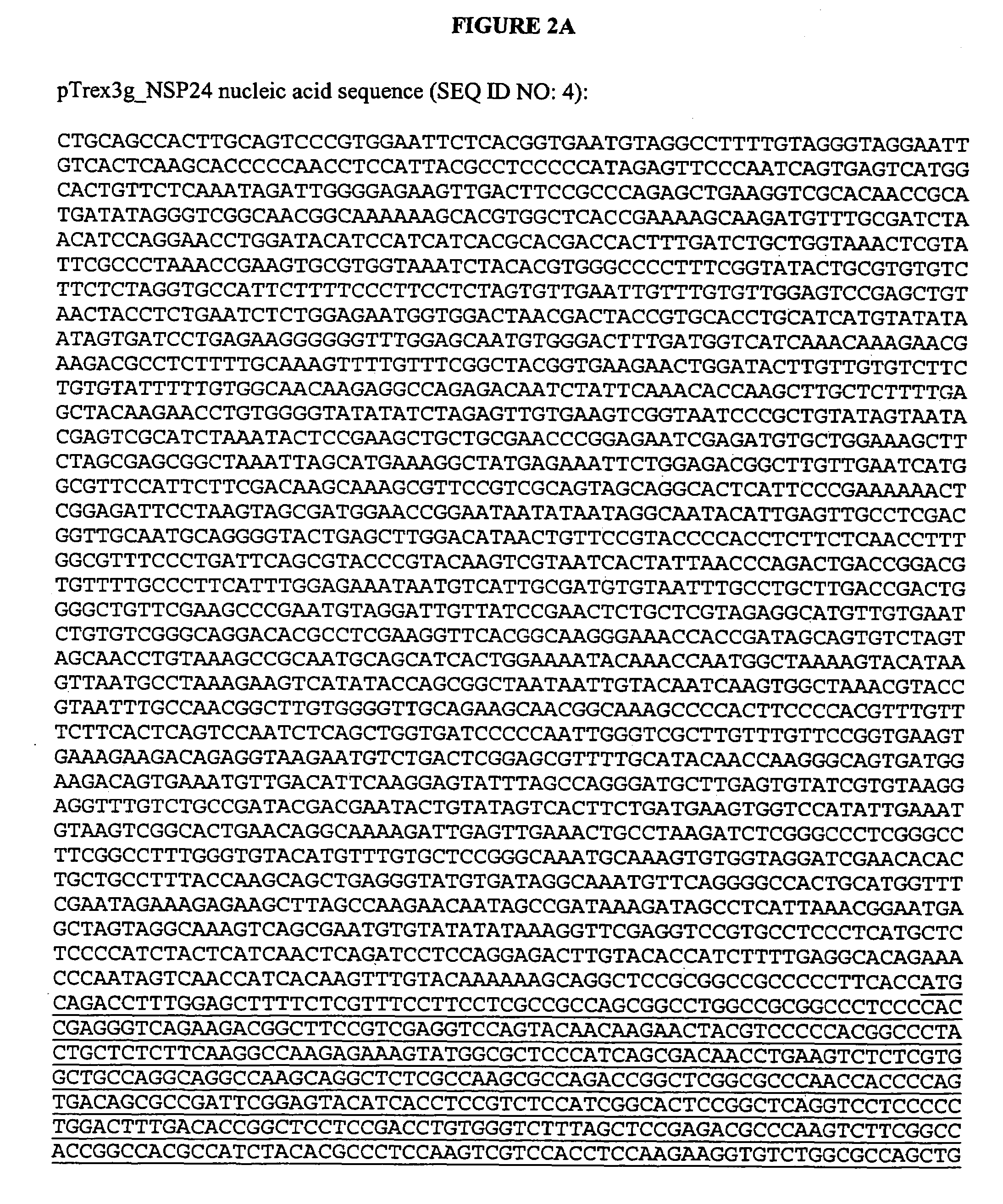

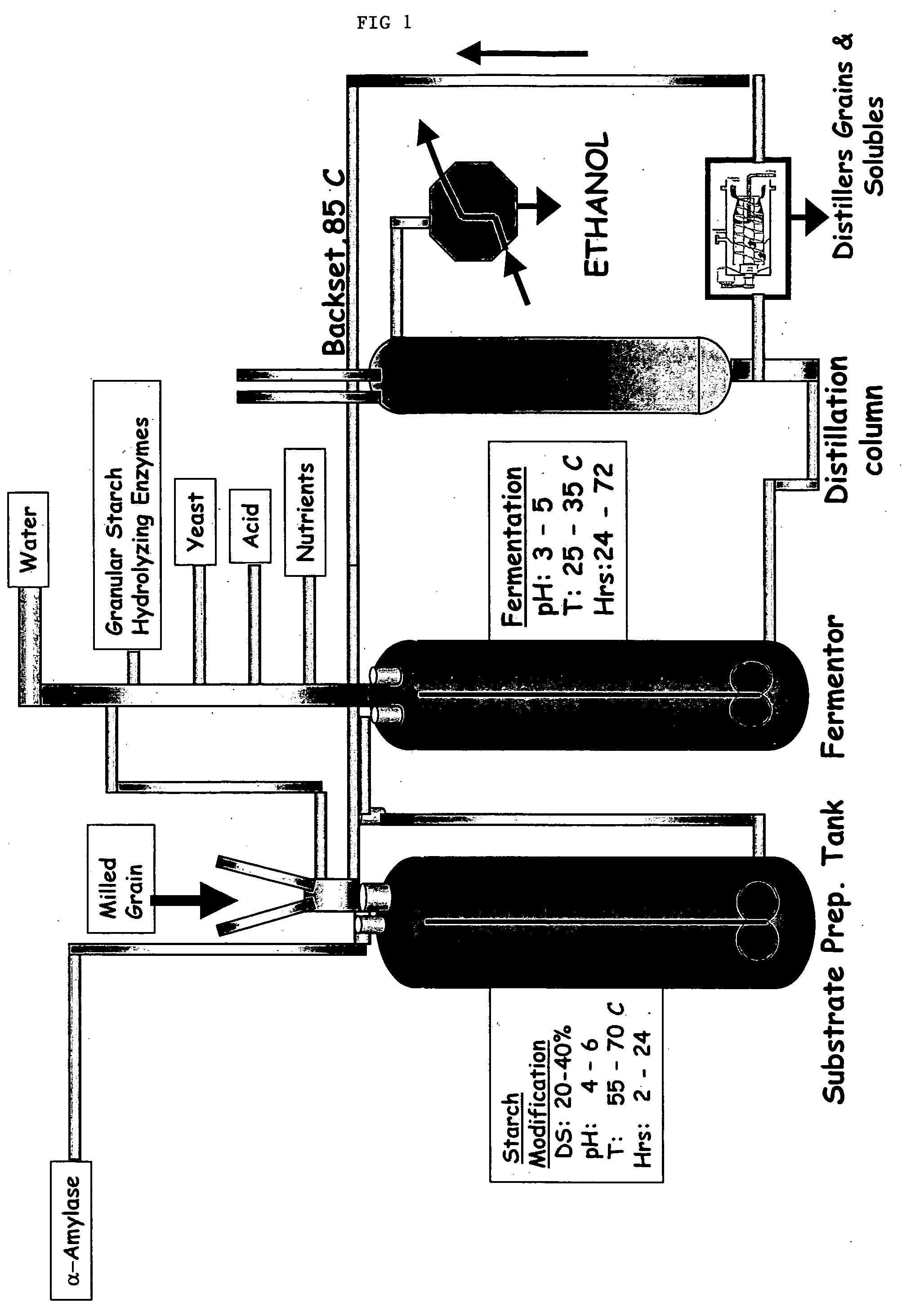

Acid fungal protease in fermentation of insoluble starch substrates

The invention is directed to methods of producing ethanol and decreasing residual starch production in a no cook fermentation comprising contacting granular starch containing substrates with a granular starch hydrolyzing enzyme, a protease, and a fermenting microorganism under suitable fermentation conditions at a temperature below the starch gelatinization temperature of the starch substrate to produce ethanol, wherein the ethanol production is increased and the amount of residual starch is decreased compared to a substantially similar method conducted without the protease.

Owner:GENENCOR INT INC

Process for conversion of granular starch to ethanol

InactiveUS20070281344A1Microbiological testing/measurementBiofuelsStarch gelatinizationAlpha-amylase

The present invention concerns a method of producing glucose from a granular starch substrate comprising, contacting a slurry comprising granular starch obtained from plant material with an alpha-amylase at a temperature below the starch gelatinization temperature of the granular starch to produce oligosaccharides and hydrolyzing the oligosaccharides to produce a mash comprising at least 20% glucose and further comprising fermenting the mash to obtain ethanol.

Owner:GENENCOR INT INC

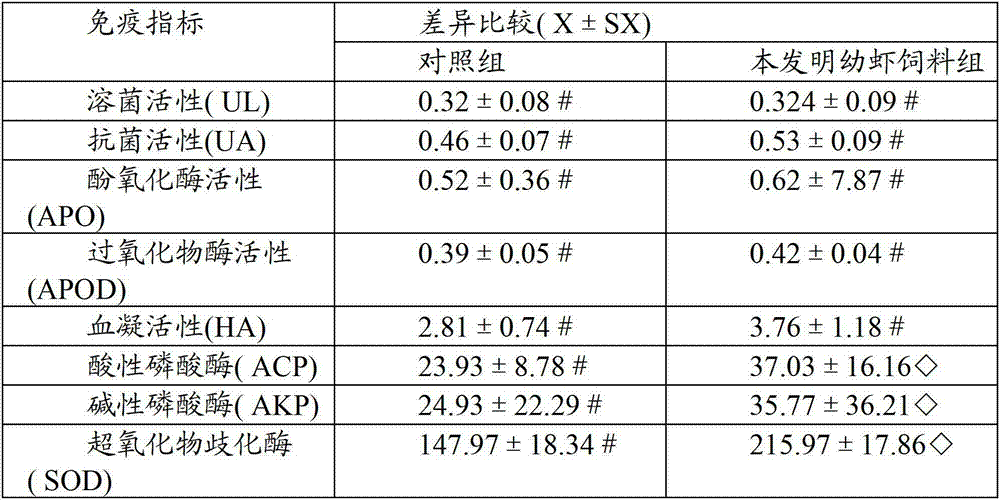

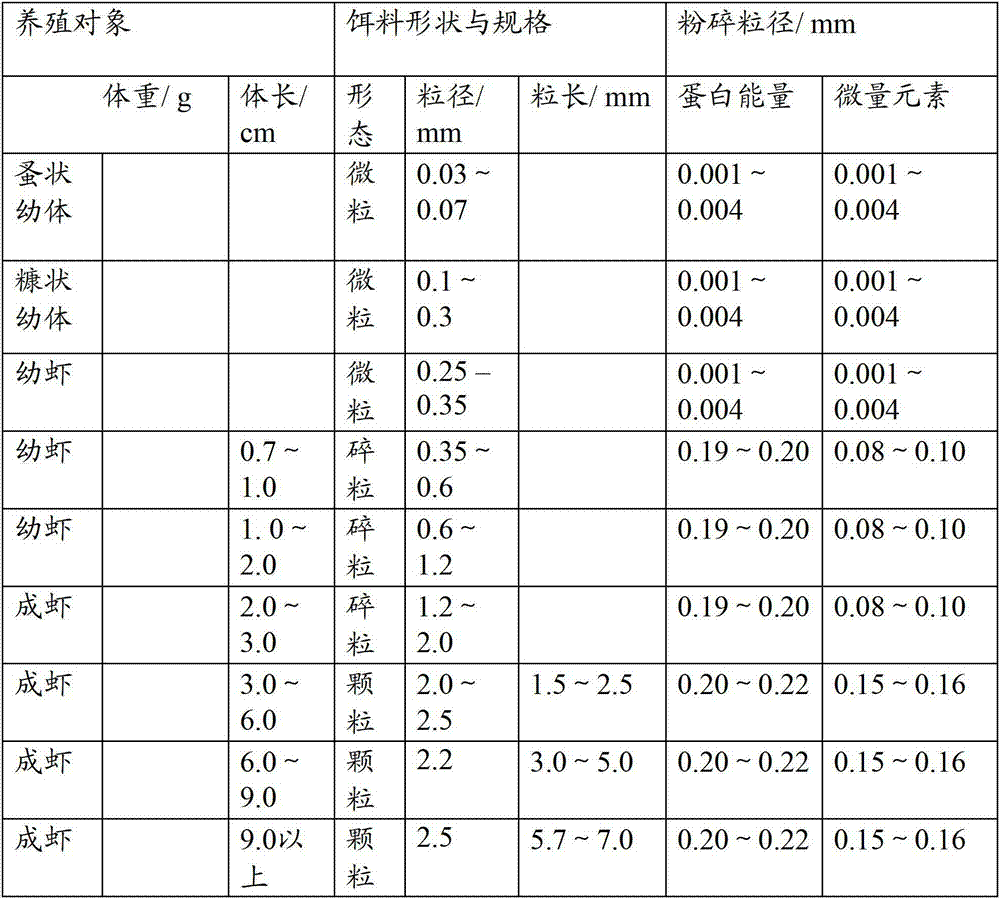

Feed for juvenile prawns and preparation method thereof

InactiveCN102845589AImprove submergenceImprove adhesionAnimal feeding stuffAquaculture industryDisease

The invention discloses a feed for juvenile prawns. The feed comprises one or more selected from the following components: fish meal, wheat bran, bean cake, vinasse, yeast, a composite vitamin premix, a traditional Chinese medicinal composite additive, a mineral matter premix and a feed adhesive. Weight parts of the above mentioned components are as follows: 10 to 40 parts of fish meal, 10 to 20 parts of wheat bran, 10 to 15 parts of bean cake, 1 to 2 parts of vinasse, 1 to 2 parts of yeast, 1 to 2 parts of the composite vitamin premix, 1 to 2 parts of the traditional Chinese medicinal composite additive, 1 to 2 parts of the mineral matter premix and 10 to 15 parts of the feed adhesive. According to the invention, Chinese herbal medicines are applied to prevent and treat fish and prawn diseases, which is in accordance with disease controlling criteria for development of nuisanceless aquaculture and production of green aquatic products, especially in accordance with demands for intensive and large-scale production in the current aquaculture industry; the Chinese herbal medicines compose a compound preparation in proportion, which enables synergistic effects of the medicines to be better performed; a steaming process is utilized to allow starch in the feed adhesive to agglutinate at different temperatures, so the degree of expansion is increased, the degree of gelatinization of the starch is substantially improved, the effects of a chemical adhesive in feed processing can be totally replaced, and sinking performance and binding performance of the feed are enhanced, which is beneficial for growth and culture of juvenile prawns.

Owner:杨高林

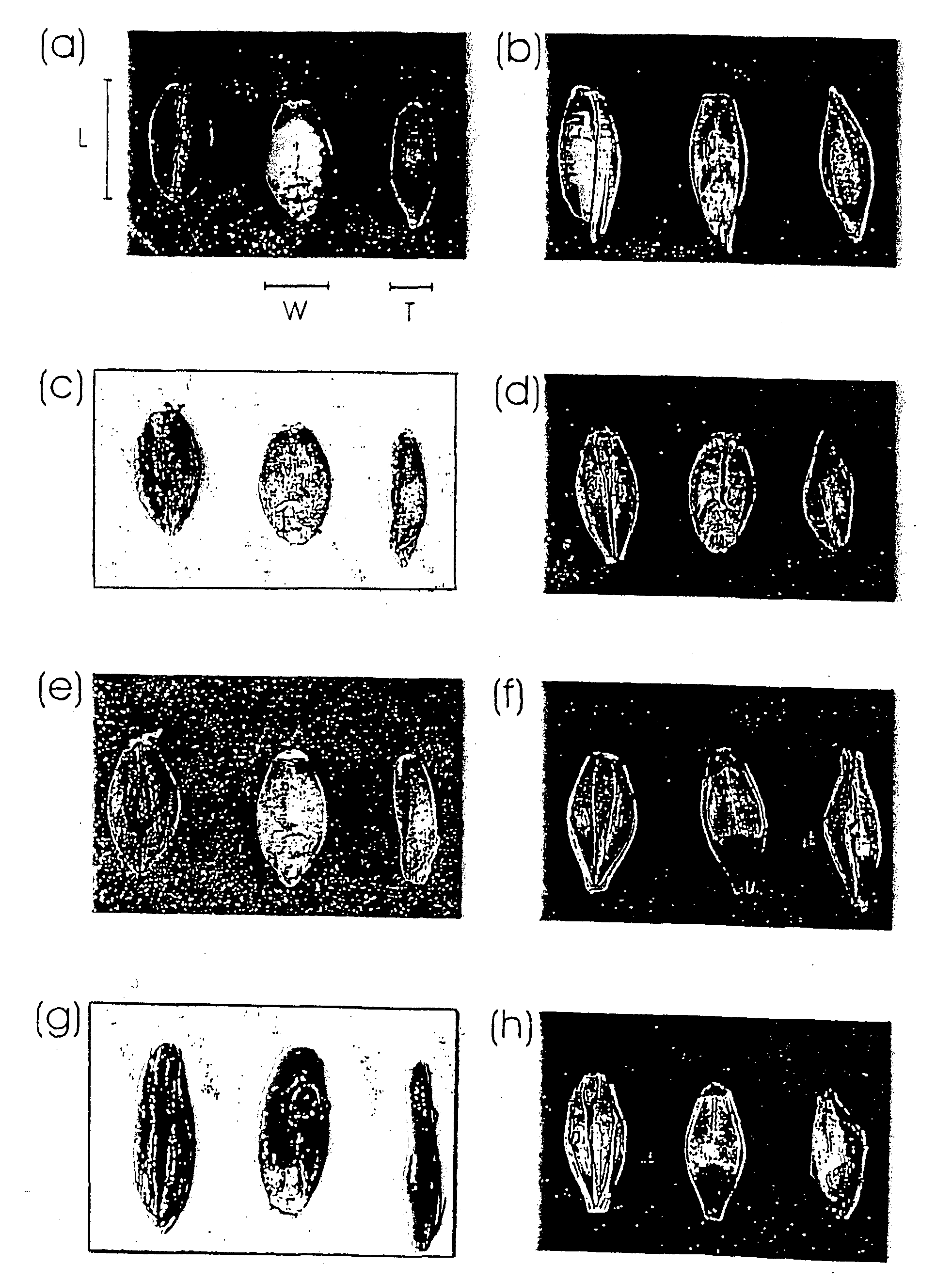

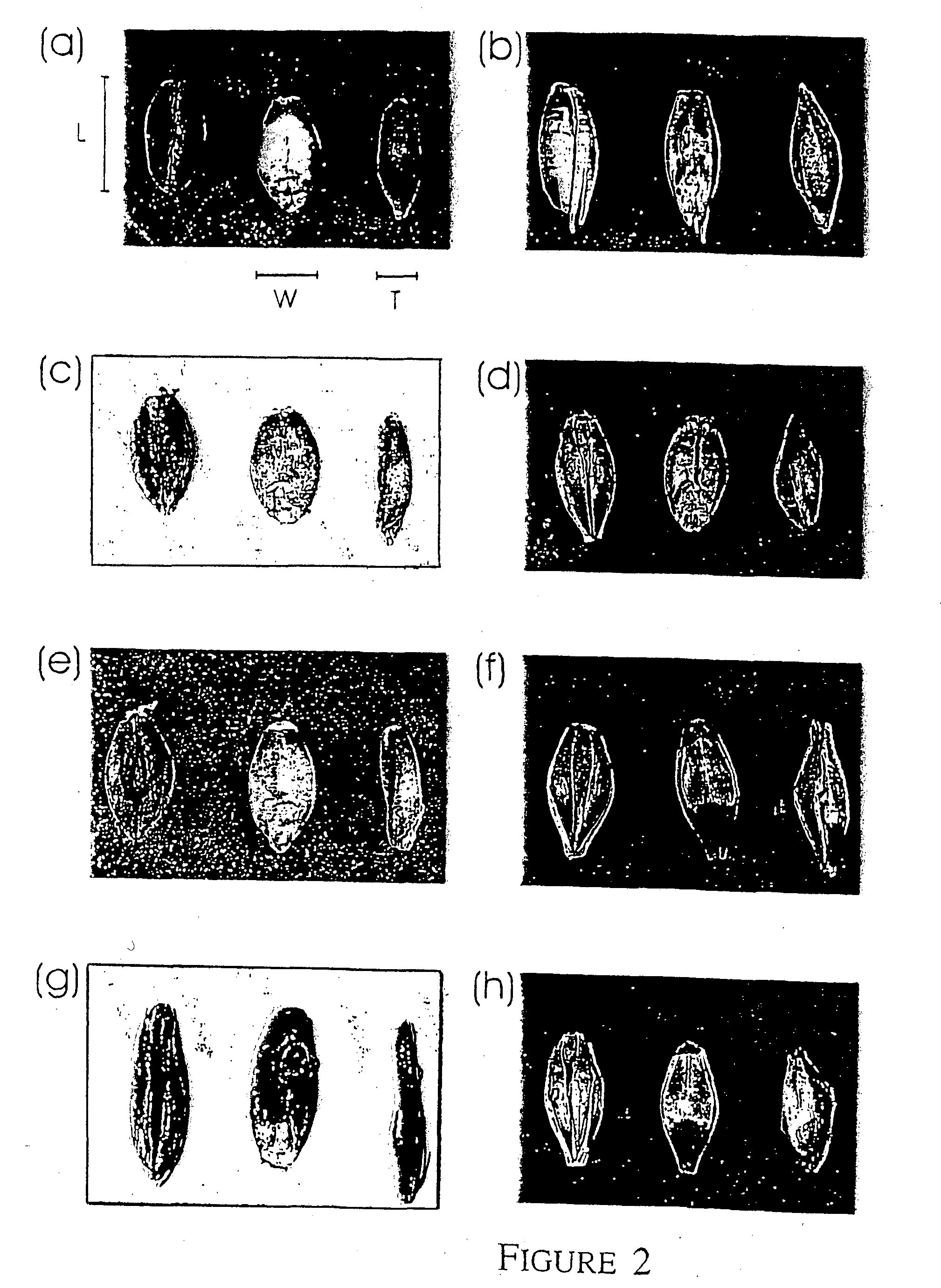

Barely with reduced SSII activity and starch and starch containing products with a reduced amylopectin content

InactiveUS20100330253A1Reduced amylopectin contentImprove the level ofBryophytesDough treatmentLipid formationStarch gelatinization

Barley with reduced SSII activity has a starch structure with reduced amylopectin content and a consequent high relative amylose content. Additionally the grain can have a relatively high β glucan content. The structure of the starch may also be altered in a number of ways which can be characterised by having a low gelatinsation temperature but with reduced swelling. The viscosity of gelatinised starch of the starch is also reduced. There is a chain length distribution of the amylopectin content and a low crystallinity of the starch. The starch is also characterised by having high levels of lipid associated starch exhibiting very high levels of V form starch crystallinity. The dietary fibre content of the starch is high. This has desirable dietary and food processing characteristics.

Owner:THE HEALTHY GRAIN PTY LTD

CMC starch glue

InactiveCN104559832AImprove adhesionImprove quick-dry performanceNon-macromolecular adhesive additivesStarch derivtive adhesivesEpoxyNuclear chemistry

The embodiment of the invention discloses a CMC starch glue which comprises the following components in percentage by mass: 6-8% of corn starch, 5-8% of sodium hydroxide (30% of solution), 0.5-2% of hydrogen peroxide (30% of solution), 0.3-1% of borax, 6-12% of epoxy chloropropane, 0.05-0.2% of sodium carboxymethylcellulose and the balance of water, totaling 100%. By adding sodium carboxymethylcellulose to consume redundant water and forming high polymers by virtue of hydroxylation reaction during starch dextrinization, the initial adhesive force and quick dryness of the starch glue are improved.

Owner:林贤文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com