Preparation method of compound-type starch modification super absorbent resin

A superabsorbent resin and starch modification technology, which is applied in the field of water-retaining agent preparation, can solve the problems of high preparation cost, soil salt tolerance and low water retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

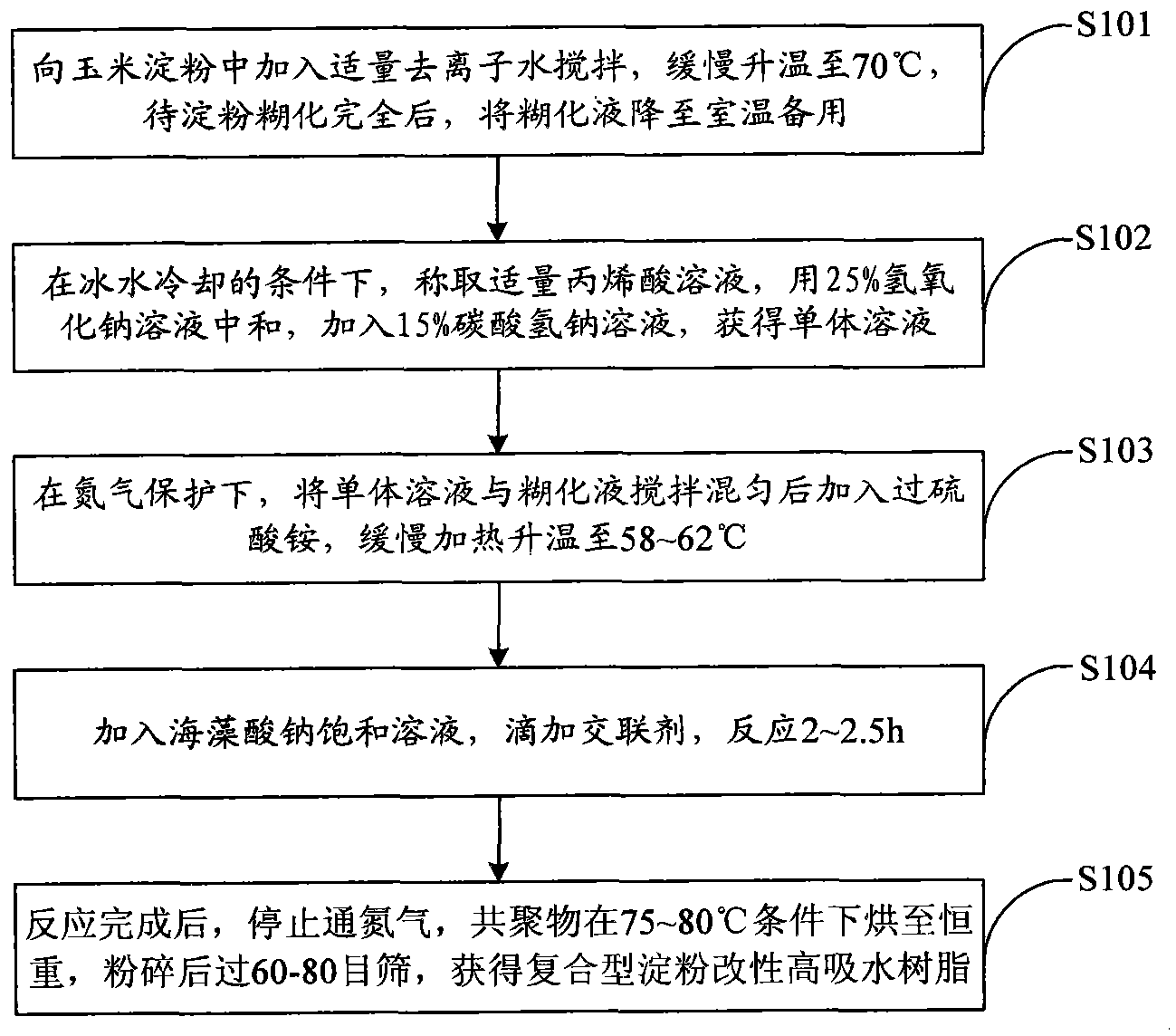

[0028] The preparation method comprises the following steps:

[0029] In step S101, add an appropriate amount of deionized water to the cornstarch and stir, slowly raise the temperature to 70°C, and after the starch is completely gelatinized, lower the gelatinized solution to room temperature for later use;

[0030] In step S102, under the condition of cooling with ice water, weigh an appropriate amount of acrylic acid solution, neutralize it with 25% sodium hydroxide solution, and add 15% sodium bicarbonate solution as a pH buffer to obtain a monomer solution;

[0031] In step S103, under the protection of nitrogen, the monomer solution and the gelatinized liquid are stirred and mixed, then ammonium persulfate is added, and the temperature is slowly heated to 58-62°C;

[0032] In step S104, add a saturated solution of sodium alginate, drop a cross-linking agent, and react for 2-2.5 hours;

[0033] In step S105, after the reaction is completed, the nitrogen flow is stopped, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com