Method for preparing high-expansion nano silica composite microspheres

A technology of nano-silica and composite microspheres, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of decreased blocking ability, unstable structure, and inability to block, and achieve improved expansion performance, good structural stability, etc. The effect of stable and reliable blocking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

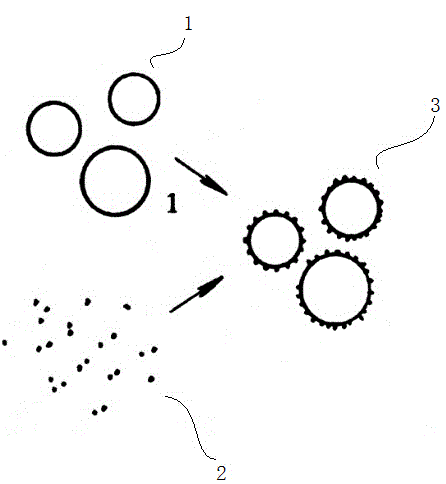

[0026] A method for preparing high-expansion nano-silica composite microspheres, first selecting nano-scale SiO 2 Powder as raw material, nano-scale SiO 2 The powder comes from FQ140121 of Shanghai Guanqi Electronic New Material Co., Ltd., and the particles within the particle size range of 20-50nm are larger than 80%, including the following steps:

[0027] S1: SiO with surface modifier 2 The nanoparticles are surface grafted and modified; the surface modifier is 3-(methacryloyloxy)propyltrimethoxysilane;

[0028] S2: the modified SiO 2 Put the nanoparticles into the organic solvent, and add dispersant, monomer acrylamide, acrylic acid, crosslinking agent, initiator at the same time, and disperse evenly with ultrasound; in the present invention, the mass percentage of each substance is SiO 2 Nanoparticles: dispersant: monomer acrylamide: acrylic acid: crosslinking agent: initiator is 1:4:10:11:2:0.1, the quality of the solvent used is SiO 2 100 to 300 times that of nanopa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com