Lithium ion battery and its positive material

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of capacity retention rate attenuation, attenuation, lattice distortion, etc., and achieve the effect of improving cycle performance and storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

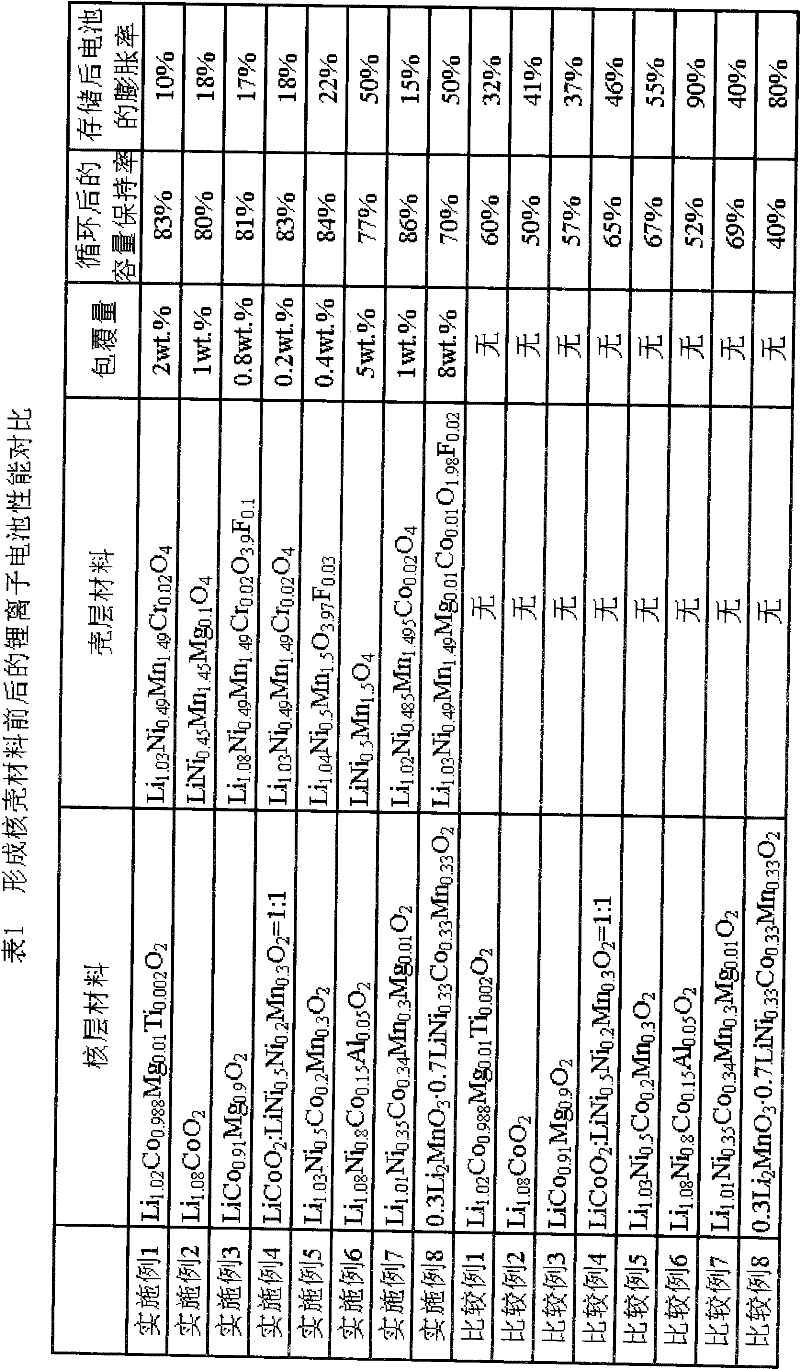

Examples

Embodiment 1

[0034] At 25°C, weigh 2.93g of lithium acetate, 10.19g of manganese acetate, 3.40g of nickel acetate, and 0.22g of chromium nitrate into 400ml of water, and stir to dissolve them to form a lithium-nickel-manganese-chromium mixed solution; weigh 17.98g of lemon Add the acid to 400mL of water, stir to dissolve it; add the mixed solution of lithium nickel manganese chromium to the citric acid solution, adjust the pH of the solution to 6; stir at 60°C to form a sol; add 250g Li 1.02 co 0.988 Mg 0.01 Ti 0.002 o 2 powder, stirred evenly, and reacted at 60°C to obtain a deposit; after drying the obtained deposit at 100°C, it was first calcined at 950°C in an air atmosphere for 8 hours, and then at 650°C in an air atmosphere for 4 hours to obtain a coated 2wt% Li 1.02 co 0.988 Mg 0.01 Ti 0.002 o 2 / Li 1.03 Ni 0.49 mn 1.49 Cr 0.02 o 4 Cathode material with core-shell structure.

[0035] The lithium ion battery positive electrode material Li with core-shell structure prepa...

Embodiment 2

[0037] At 25°C, weigh 0.96g of lithium nitrate, 5.00g of manganese nitrate, 1.81g of nickel nitrate, and 0.35g of magnesium nitrate, add them to 200ml of ethanol, stir to dissolve them, and form a mixed solution of lithium, nickel, manganese and magnesium; weigh 1.86g of lemon Add the acid to 200mL ethanol, stir to dissolve it; add the mixed solution of lithium, nickel, manganese and magnesium to the citric acid solution, and adjust the pH of the solution to 5; stir at 45°C to form a sol; add 250g Li 1.08 CoO 2 Powder, stirred evenly, reacted at 50°C to obtain a deposit; after drying the obtained deposit at 100°C, first roasted at 800°C under an oxygen atmosphere for 6 hours, and then at 600°C for 4 hours under an oxygen atmosphere to obtain a coated 1wt% Li 1.08 CoO 2 / LiNi 0.45 mn 1.45 Mg 0.1 o 4 Cathode material with core-shell structure.

[0038] The lithium ion battery positive electrode material Li with core-shell structure prepared according to the above method ...

Embodiment 3

[0040] At 25°C, weigh 0.821g of lithium nitrate, 4.107g of manganese nitrate, 1.571g of nickel nitrate, 0.088g of chromium nitrate, and 0.006g of lithium fluoride into 200ml of ethanol, stir to dissolve them, and form a lithium-nickel-manganese-chromium mixed solution; Weigh 1.75g of citric acid and add it to 200mL ethanol, stir to dissolve it; add lithium nickel manganese chromium mixed solution to the citric acid solution, adjust the pH of the solution to 6; stir at 45°C to form a sol; add 250g LiCo 0.91 Mg 0.9 o 2 powder, stirred evenly, and reacted at 50°C to obtain a deposit; after drying the obtained deposit at 100°C, it was first calcined at 800°C for 6 hours in an oxygen atmosphere, and then at 600°C for 6 hours in an oxygen atmosphere to obtain a clad 0.8wt% LiCo 0.91 Mg 0.9 o 2 / Li 1.08 Ni 0.49 mn 1.49 Cr 0.02 o 3.9 f 0.1 Cathode material with core-shell structure.

[0041] The lithium-ion battery cathode material LiCo with core-shell structure prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com