Patents

Literature

125results about How to "Inhibition of capacity fading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

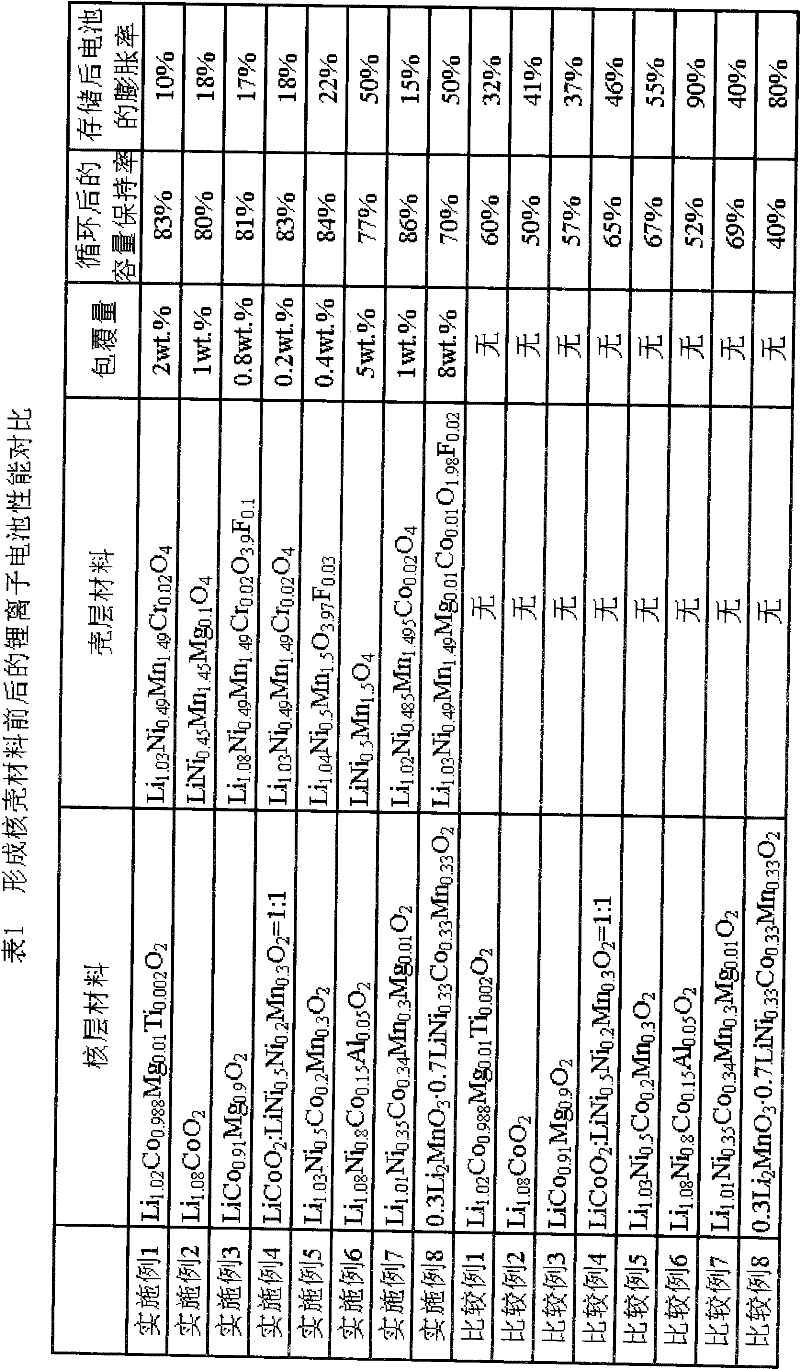

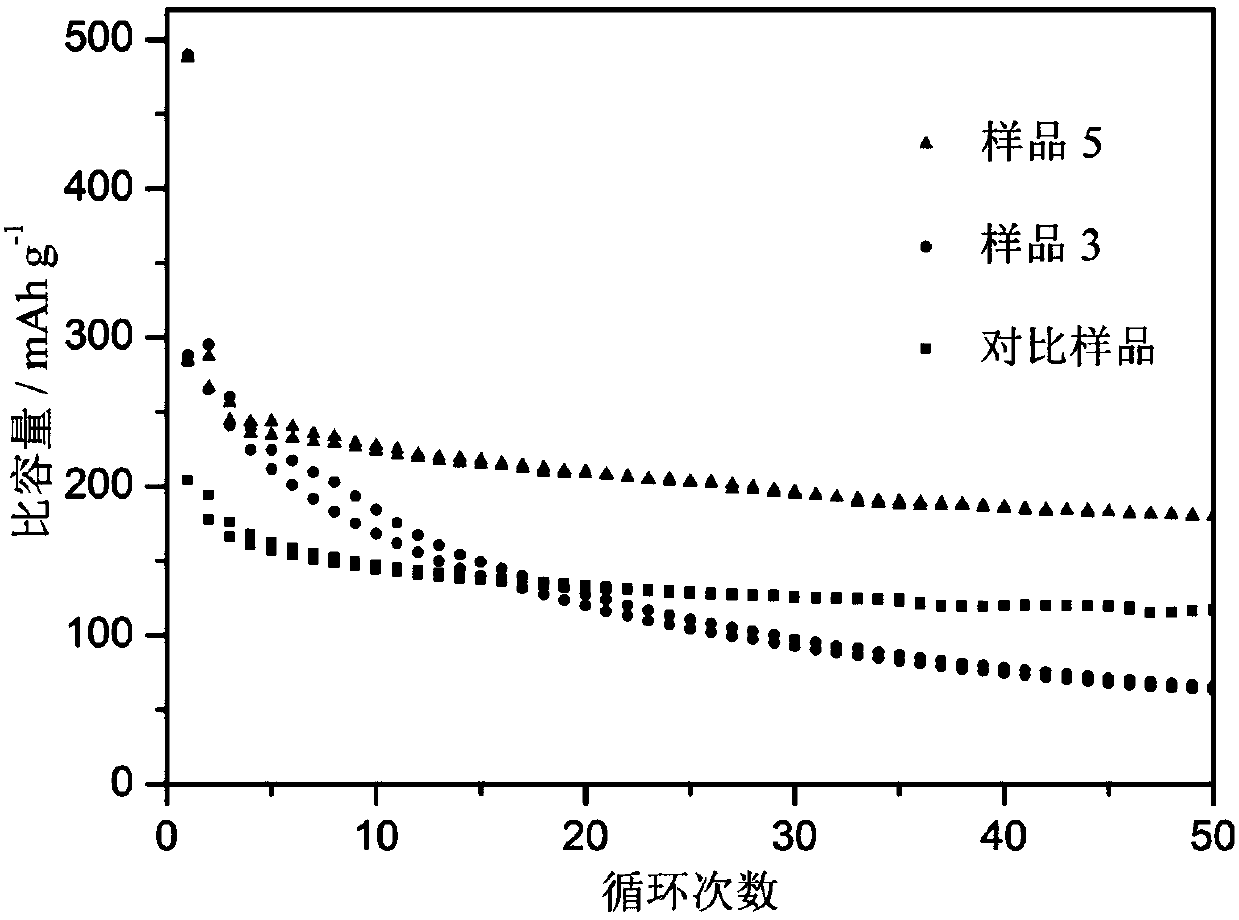

Lithium ion battery and its positive material

ActiveCN102394295AImprove cycle performanceIncrease storage capacityCell electrodesSecondary cellsHigh temperature storageManganese

The invention discloses a lithium ion battery and a positive material, the positive material possesses a core-shell structure, the material of a core layer is at least one of lithium cobaltate, a ternary material and a lithium manganese material, the material of a shell layer is lithium nickel manganese spinel. The preparation method comprises the following steps: preparing the sol shell layer material, then adding the core layer material in the sol, stirring, drying and calcining to prepare the lithium ion battery positive material with the core-shell structure. In addition, the invention also discloses the lithium ion battery prepared by the positive material with the core-shell structure, the end of charge voltage is 4.3-4.7V(vs. Li), the lithium ion battery has excellent charge and discharge cycling performance and high temperature storage performance under high voltage.

Owner:DONGGUAN AMPEREX TECH +1

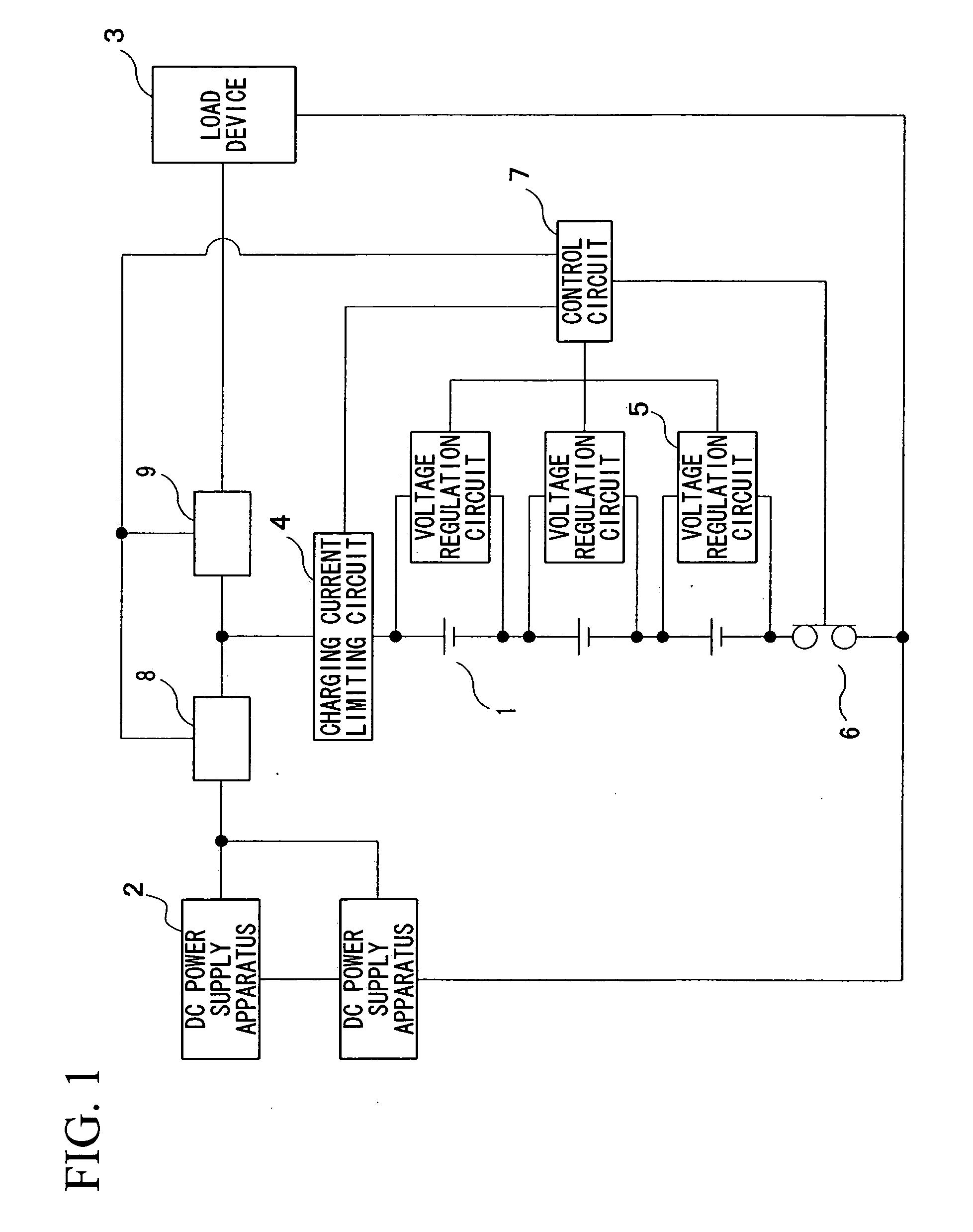

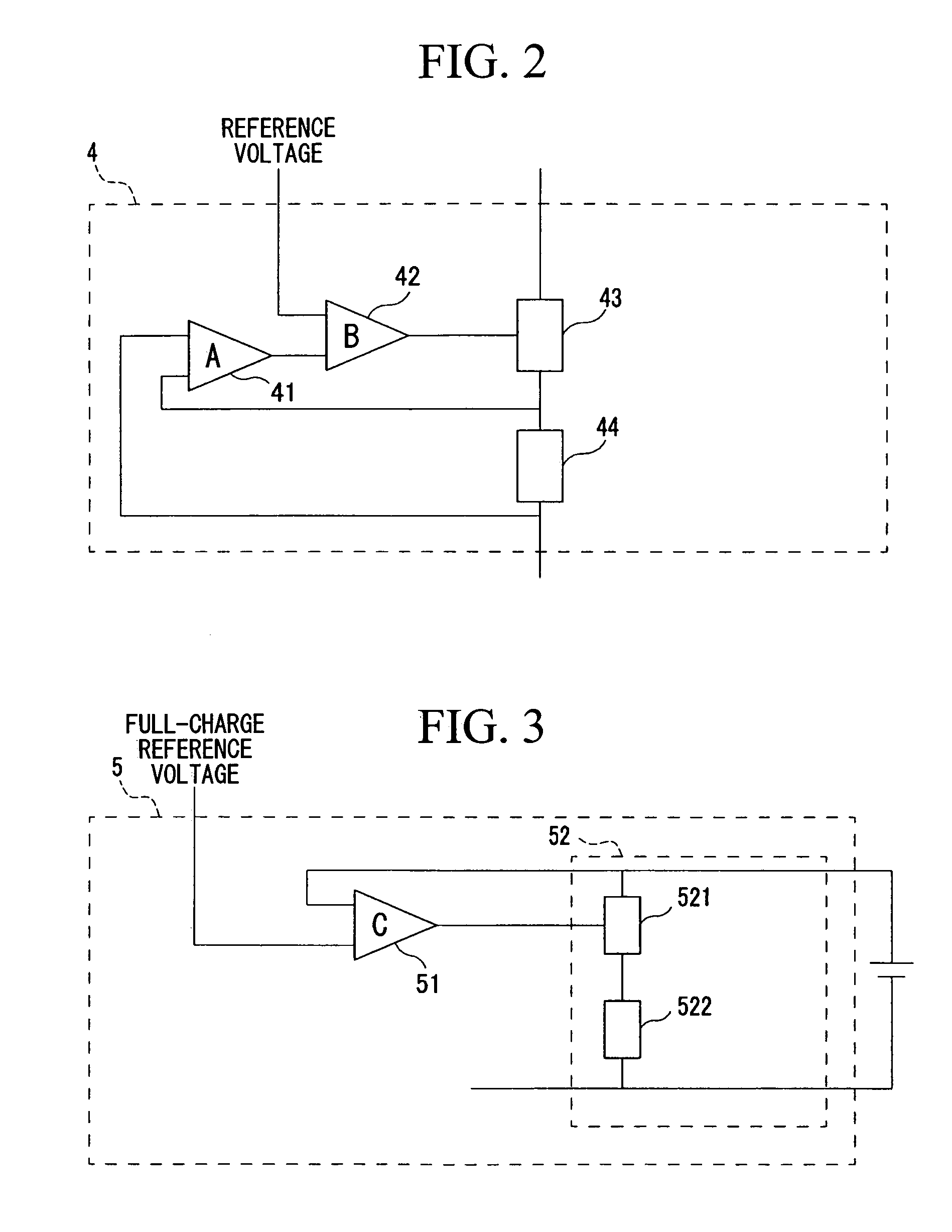

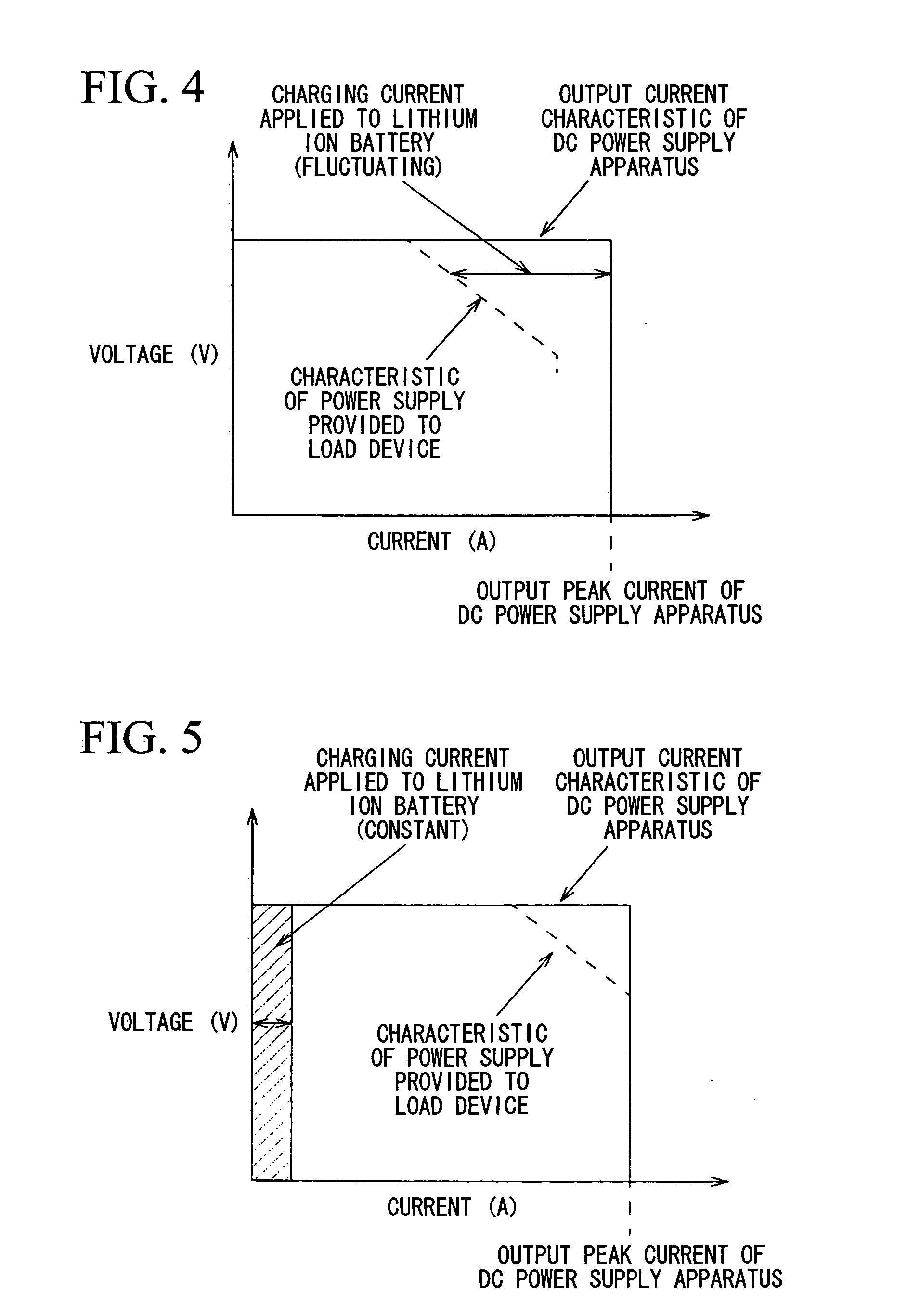

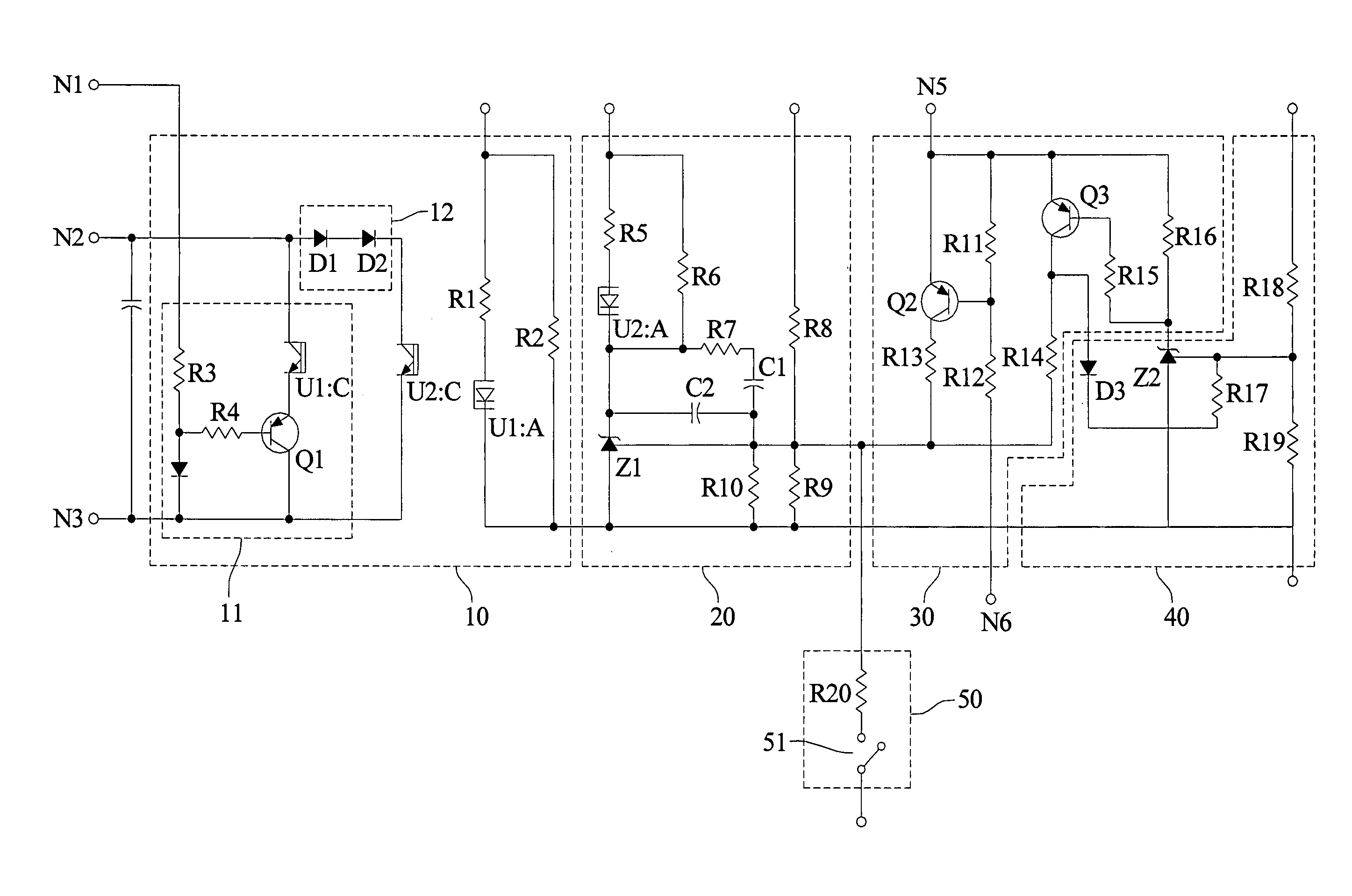

Power supply system

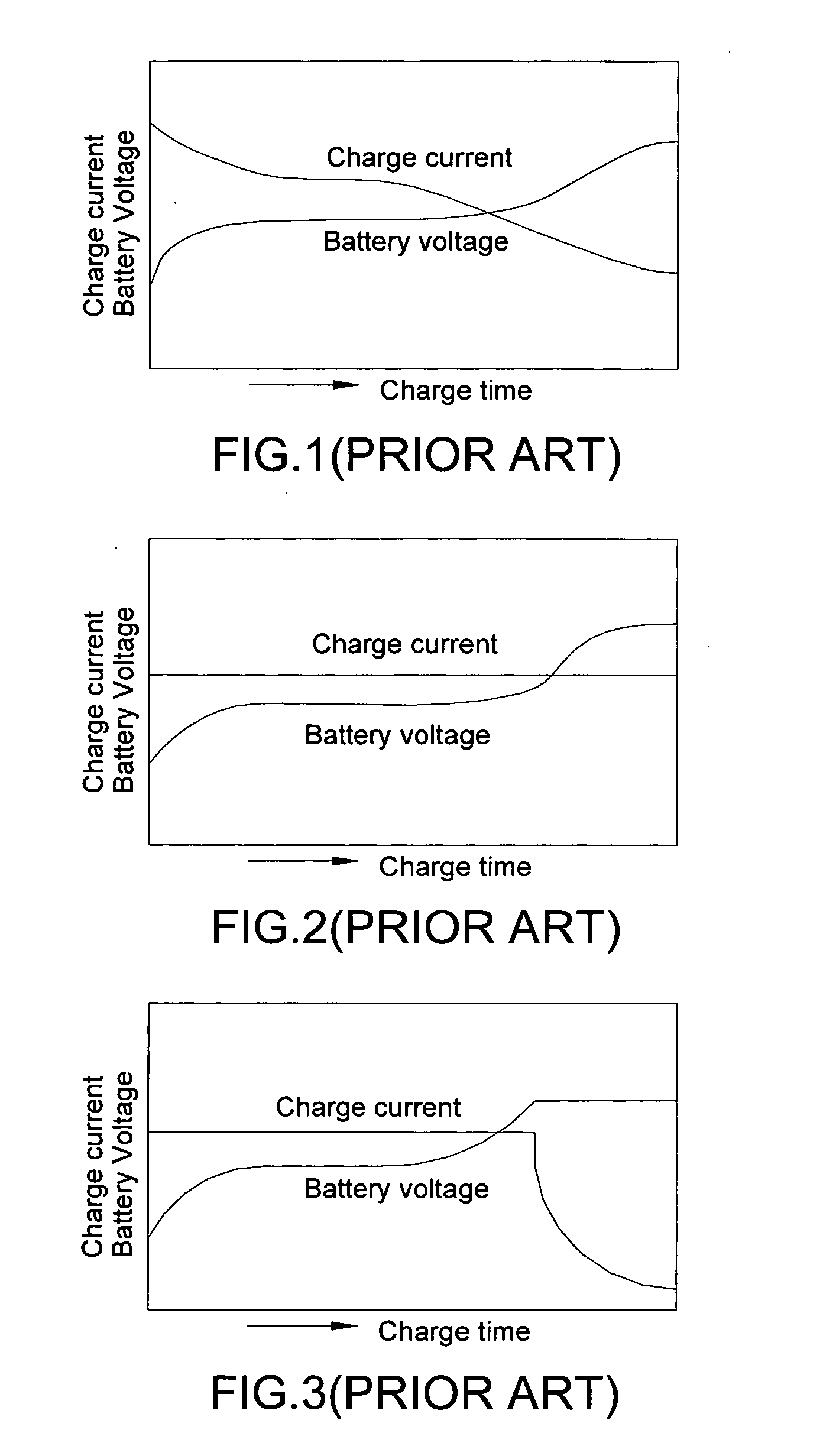

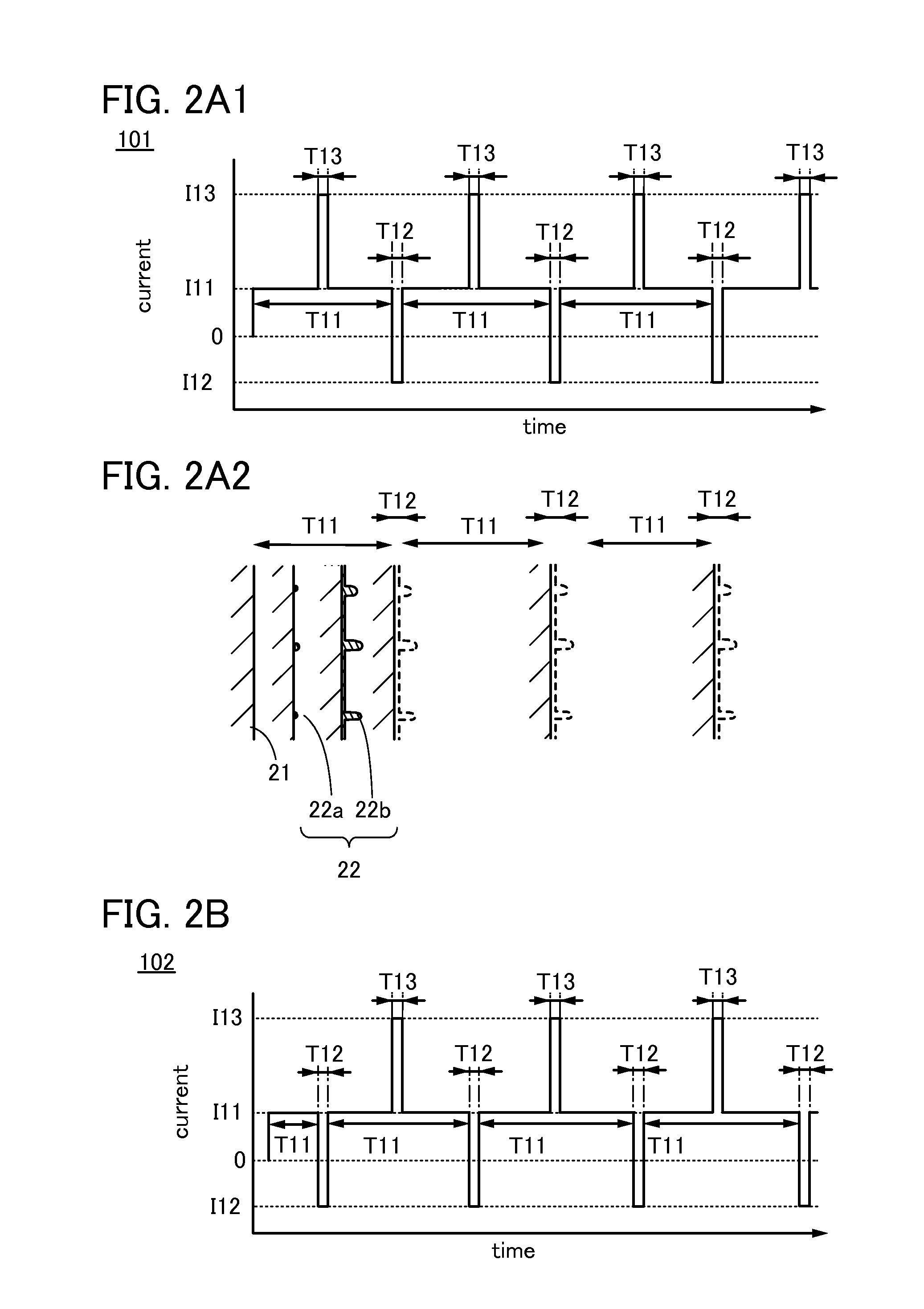

InactiveUS20070103118A1Inhibition of capacity fadingEliminate needSecondary cells charging/dischargingElectric powerCurrent limitingCharge current

A power supply system comprising: a DC power supply apparatus; a load device; a lithium ion battery for backup that is connected in parallel with said DC power supply apparatus and said load device; a charging current limiting circuit that is connected in series with said lithium ion battery and supplies a charging current of an arbitrary value independent of load fluctuations in the charging path of the lithium ion battery; a switch that disconnects said lithium ion battery from said DC power supply apparatus or said load device, or connects said lithium ion battery to said DC power supply apparatus or said load device; and a control circuit that monitors the voltage value of said charging path, sets a reference voltage setting used for setting the charging current of an arbitrary value in said charging current limiting circuit, and controls said switch when said voltage of said charging path exceeds a specified voltage value during charging.

Owner:NTT FACILITIES INC

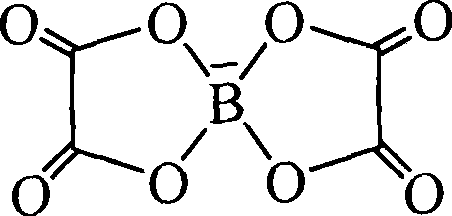

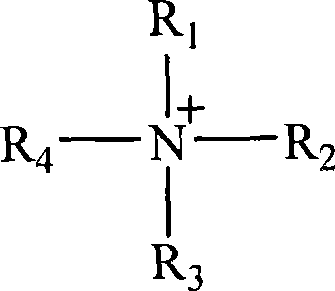

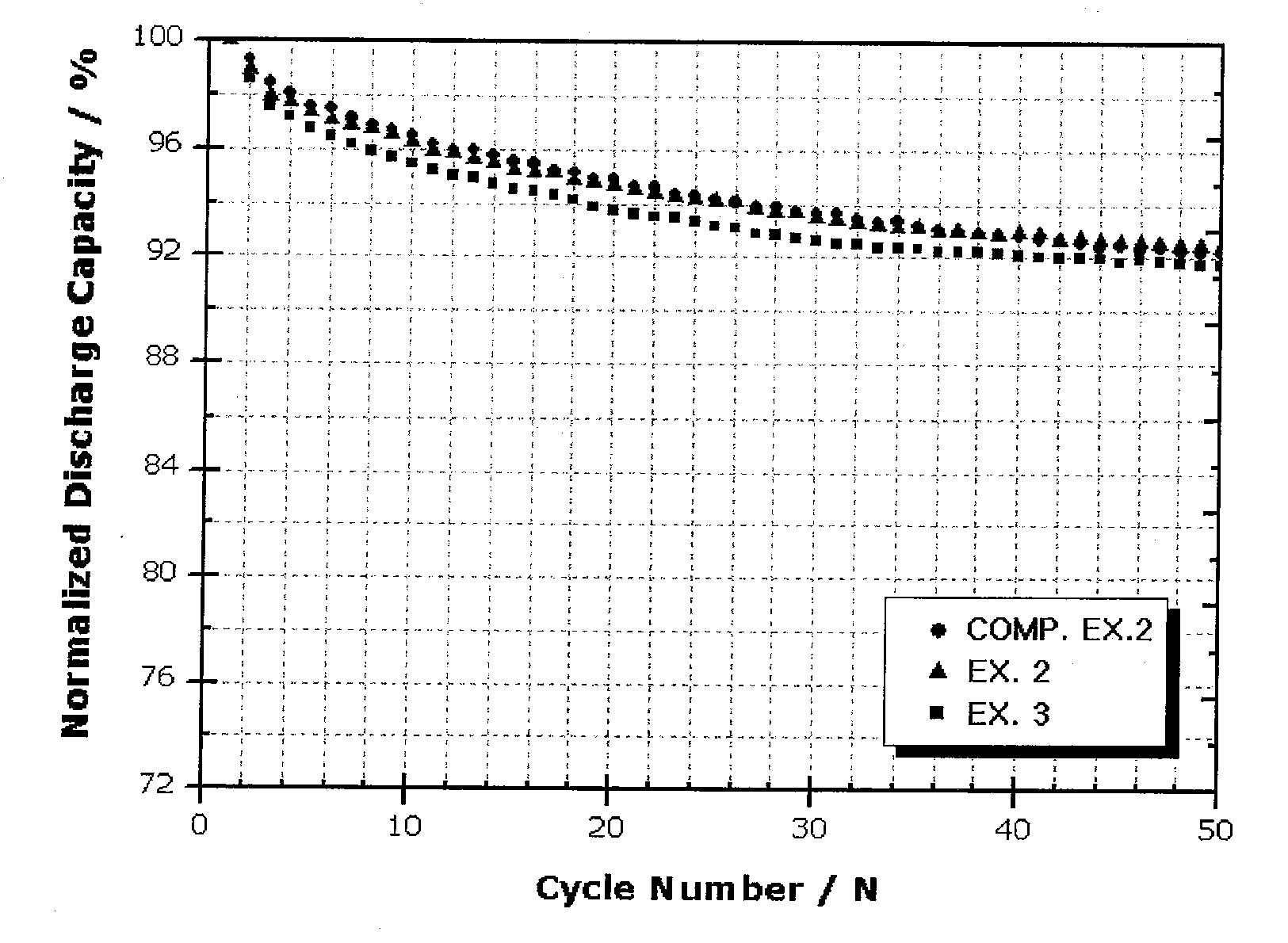

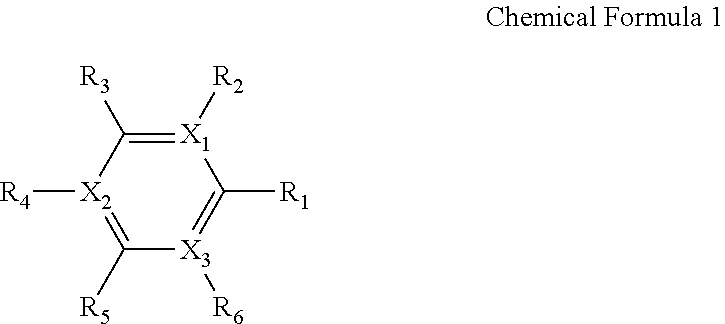

Lithium ion battery electrolyte and lithium ion battery containing the same

ActiveCN101471454AWide liquid temperature rangeFlame retardantSecondary cellsElectrolytic agentCombustion

A Li-ion battery electrolyte contains lithium salt, ionic liquid and a non-aqueous solvent, wherein the anion contained in the ionic liquid is showed by formula (1). A Li-ion battery comprises an electrical core and the above electrolyte, which can retard combustion of organic solvents. The Li-ion battery using the electrolyte can suppress capacity fade at low temperature, and can reduce the amount of gas generated by the electrolyte at high temperature, thereby effectively preventing battery expansion and improving the high-temperature performance of the battery.

Owner:BYD CO LTD

Preparation method of high-safety metal composite negative electrode

ActiveCN108461724AAvoid erosionAvoid reactionCell electrodesSecondary cells servicing/maintenanceProtection layerMaterials science

The invention relates to a preparation method of a high-safety metal composite negative electrode. The preparation method comprises the following steps: (a) heating metal lithium to a fused state under the protection of inert gas; (b) adding an inorganic non-metal compound into the metal lithium with the fused state; after stirring and reacting, cooling, wherein the inorganic non-metal compound isselected from one or a mixture of more of sulfide, phosphide, nitride and fluoride, and the mass ratio of the metal lithium to the inorganic non-metal compound is (10 to 3) to 1. According to the preparation method, a compound protection layer can be formed on a lithium negative electrode so that electrolyte and a lithium sheet are effectively isolated and the lithium sheet is prevented from corrosion and reaction; uniform distribution of lithium ions is realized and lithium dendrites are prevented from being generated; a framework supporting effect is provided.

Owner:苏州德加能源科技有限公司

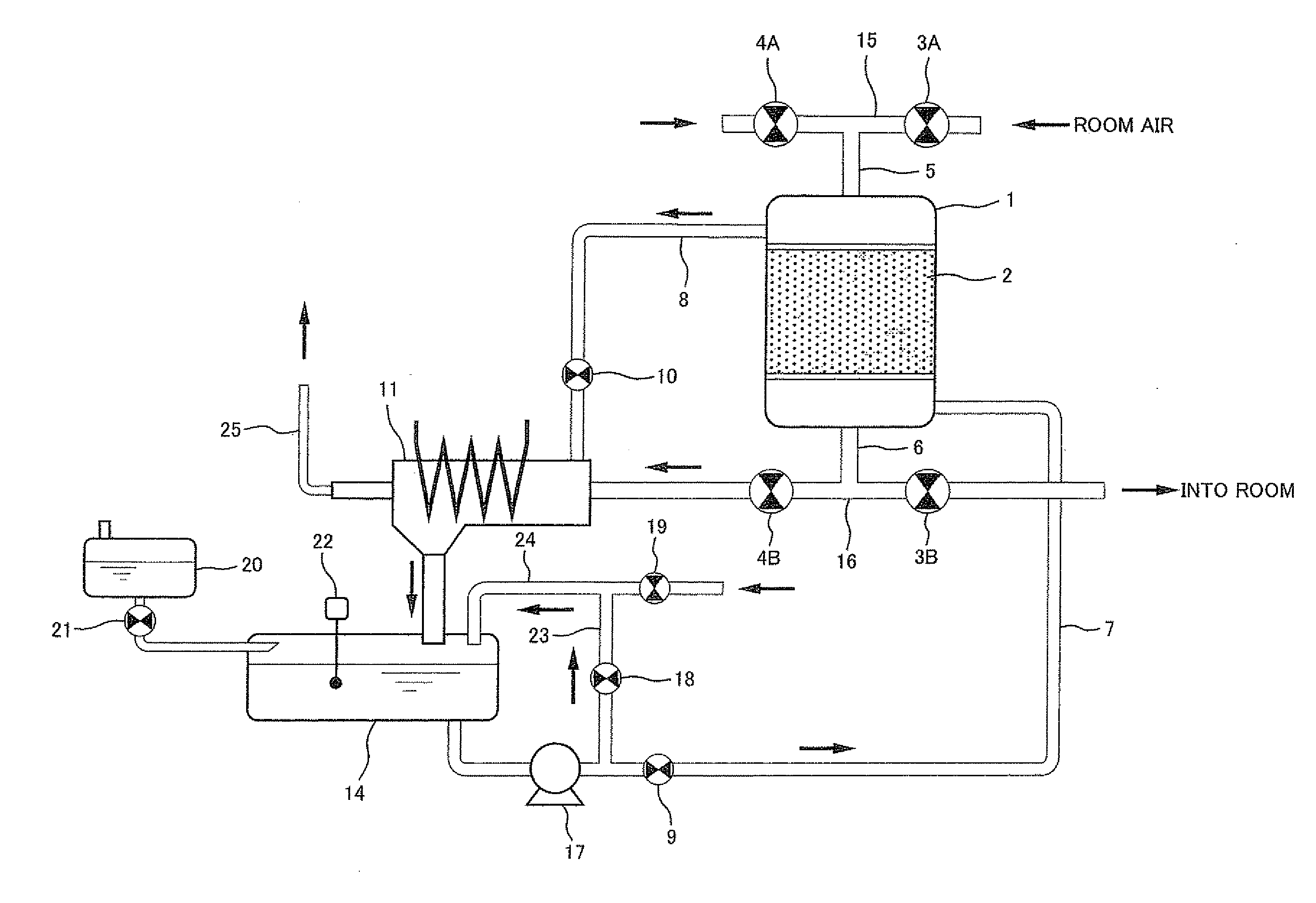

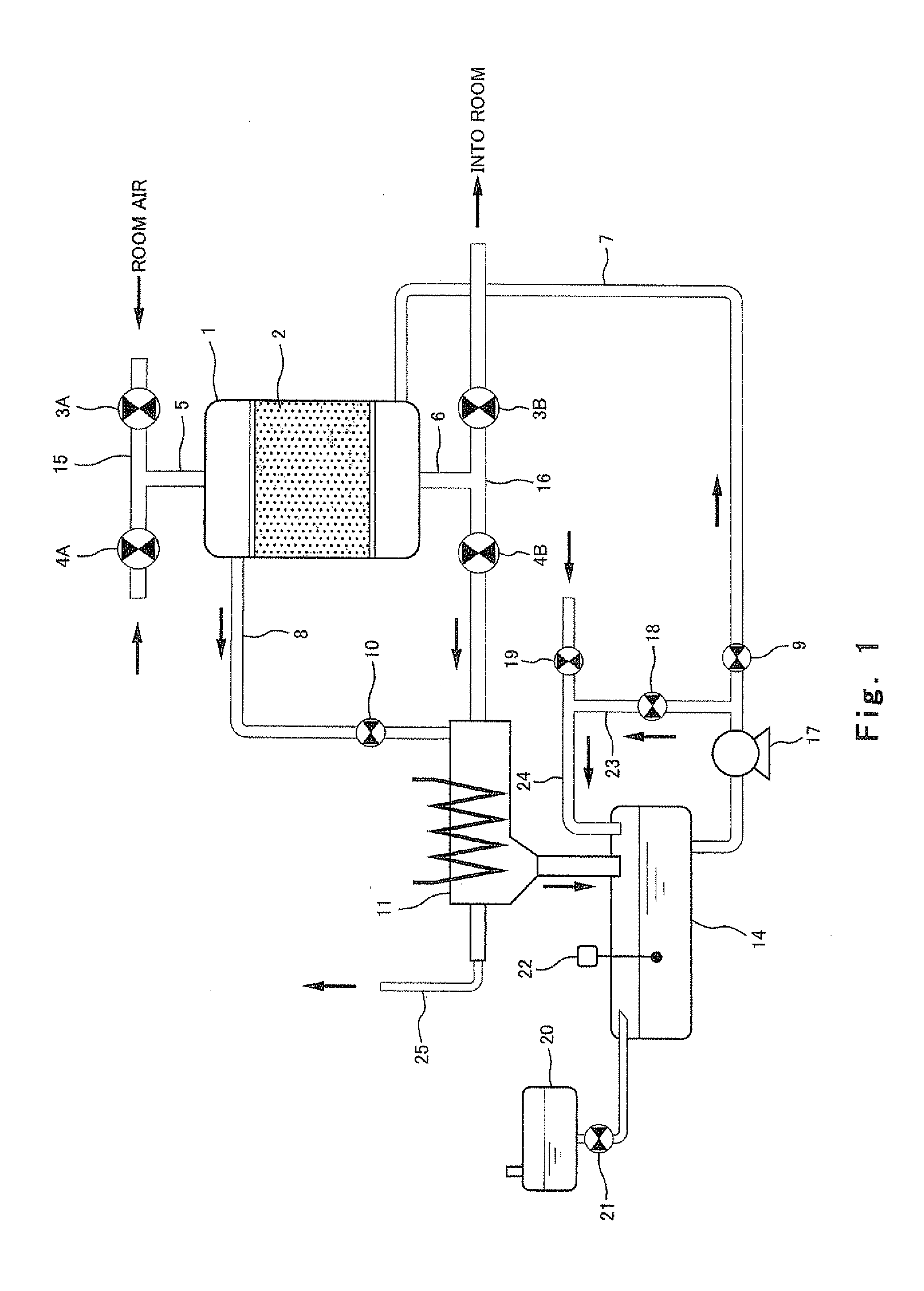

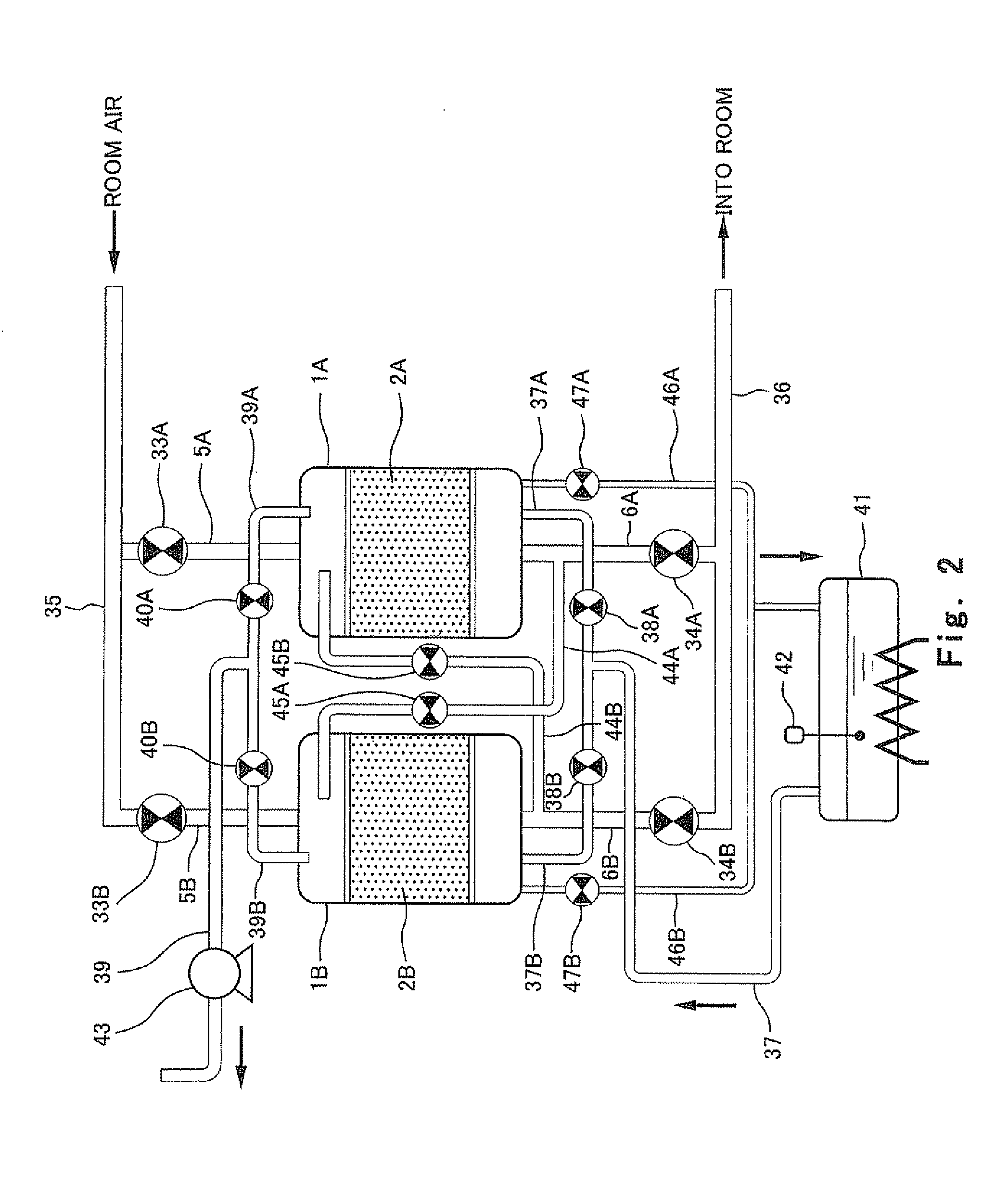

Carbon dioxide separation method and apparatus

ActiveUS20120160099A1Inhibition of capacity fadingReduce the amount requiredGas treatmentCarbon compoundsSorbentAqueous solution

A carbon dioxide separation method and a carbon dioxide separation apparatus capable of maintaining a carbon dioxide adsorption capacity for a long term by collecting an amine compound that evaporates during an operation of the apparatus and reloading the amine compound onto a carbon dioxide adsorbent. An amine collector and an amine aqueous solution preparation device are connected to an adsorbent-packed tank packed with a carbon dioxide adsorbent. An amine compound that evaporates from the carbon dioxide adsorbent during an operation of the apparatus is collected by the amine collector into the amine aqueous solution preparation device. The collected amine compound is reloaded onto the carbon dioxide adsorbent via a supply line.

Owner:KAWASAKI HEAVY IND LTD

Redox flow battery and method for operating the battery continuously in a long period of time

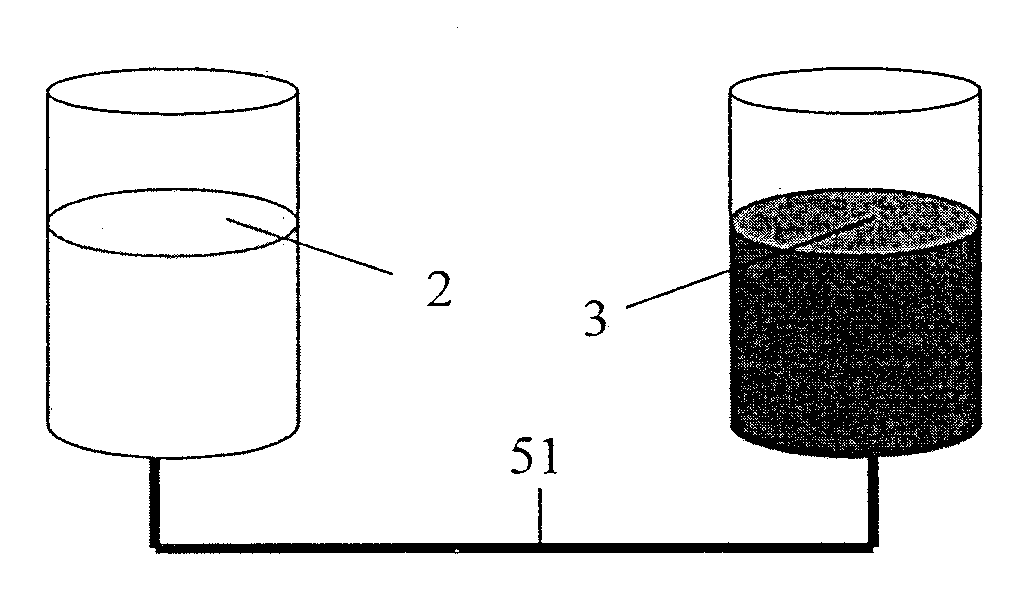

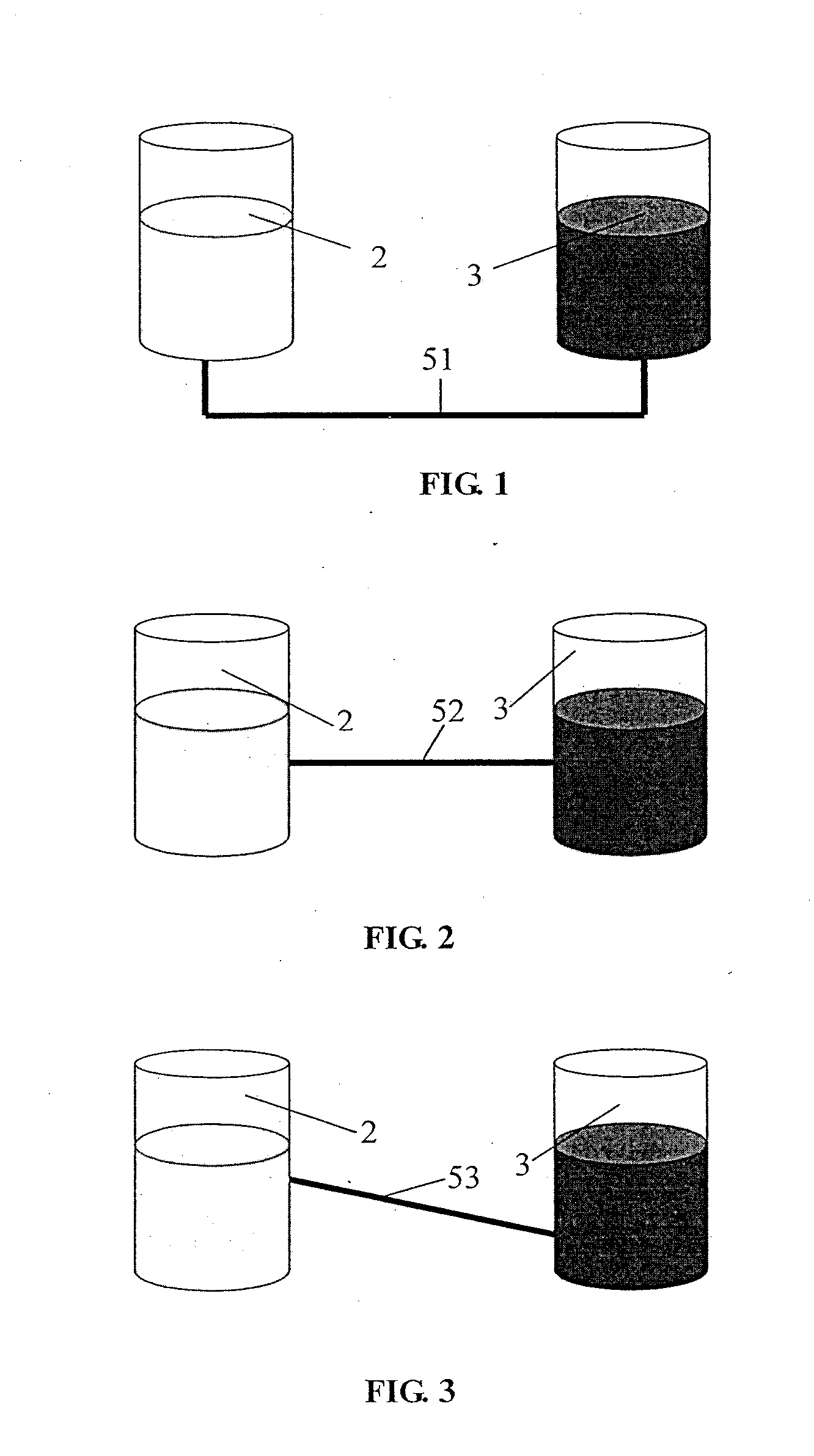

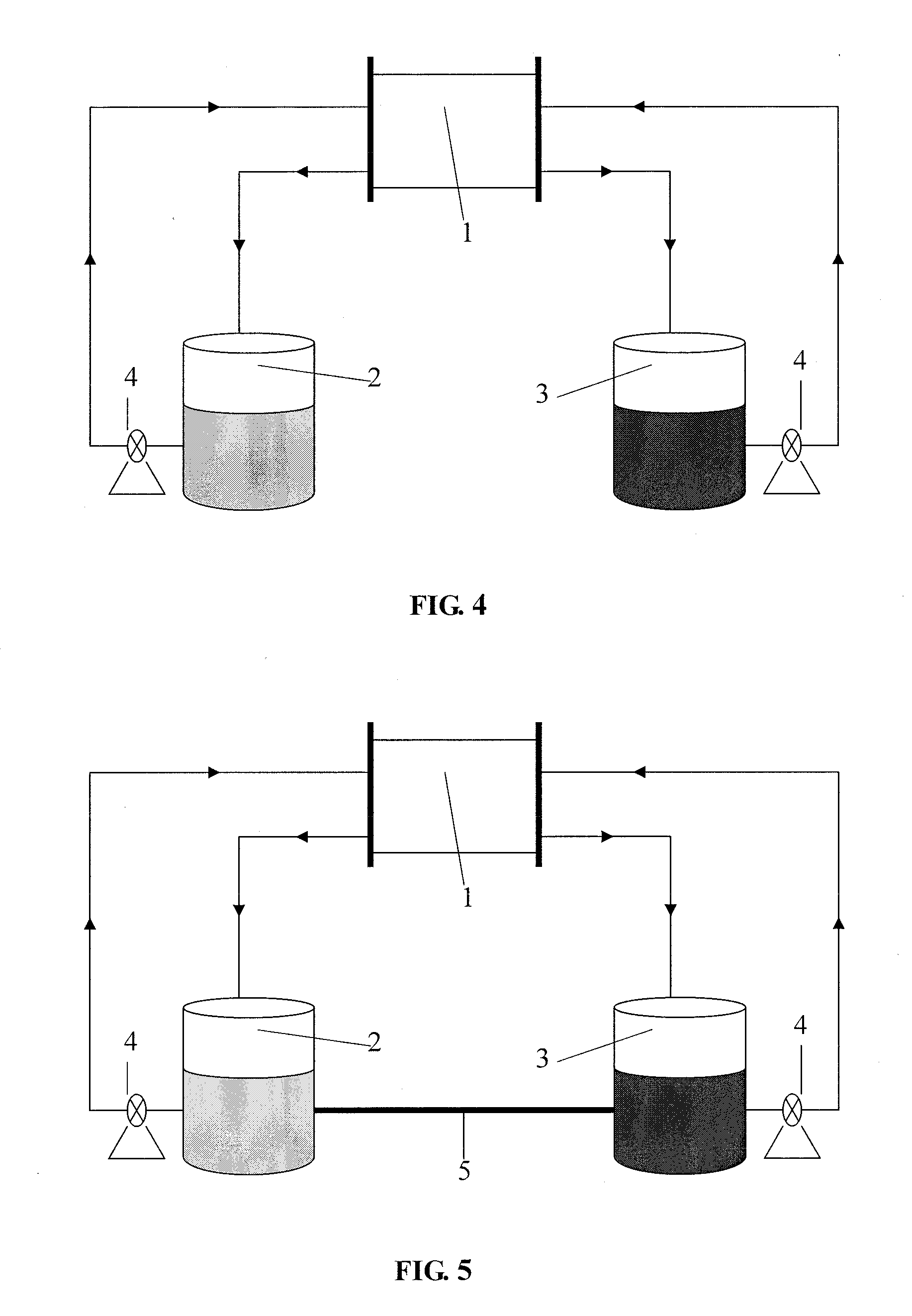

ActiveUS20110300417A1Inhibition of capacity fadingReduce frequencyReactant parameters controlElectrolyte stream managementElectrical batteryDiameter ratio

The present invention provides a redox flow battery comprising a positive electrolyte storage tank and a negative electrolyte storage tank, wherein the positive electrolyte storage tank and the negative electrolyte storage tank is kept to be in liquid communication through a pipe, wherein the length-to-diameter ratio of the pipe for the liquid communication is not less than about 10. The present invention also provides a method for operating the redox flow battery continuously in a long period of time.

Owner:BEIJING PRUDENT CENTURY TECH CO LTD

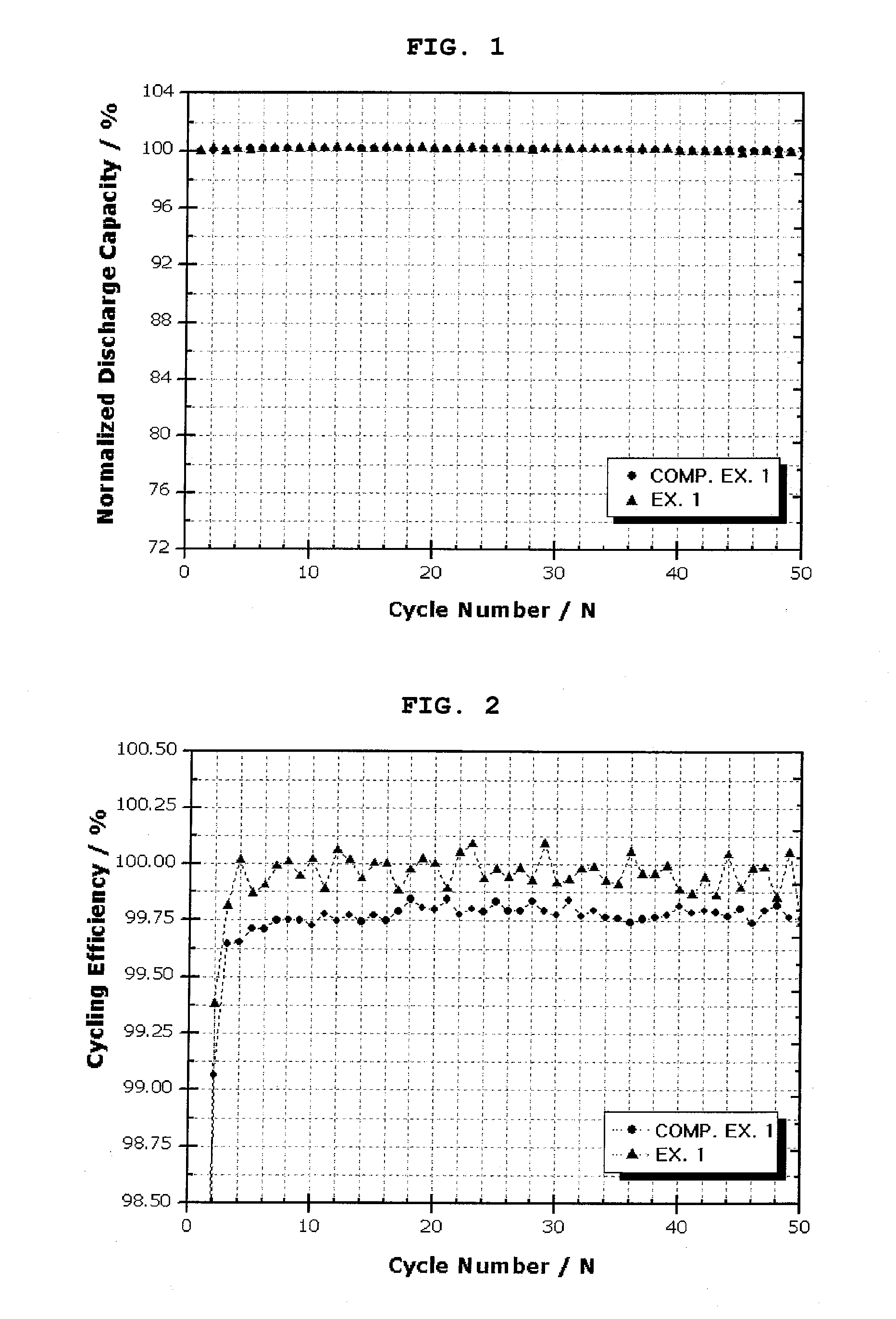

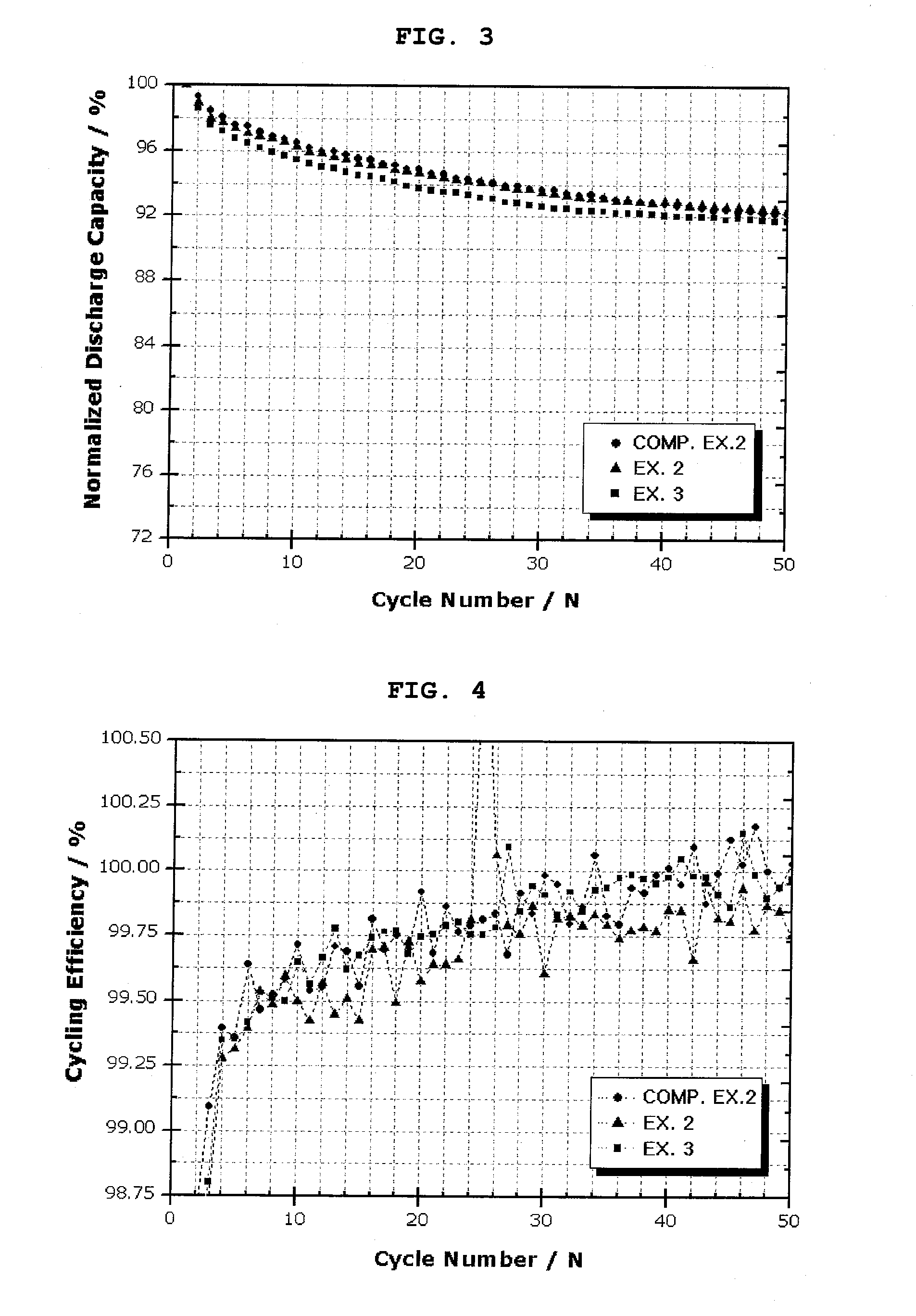

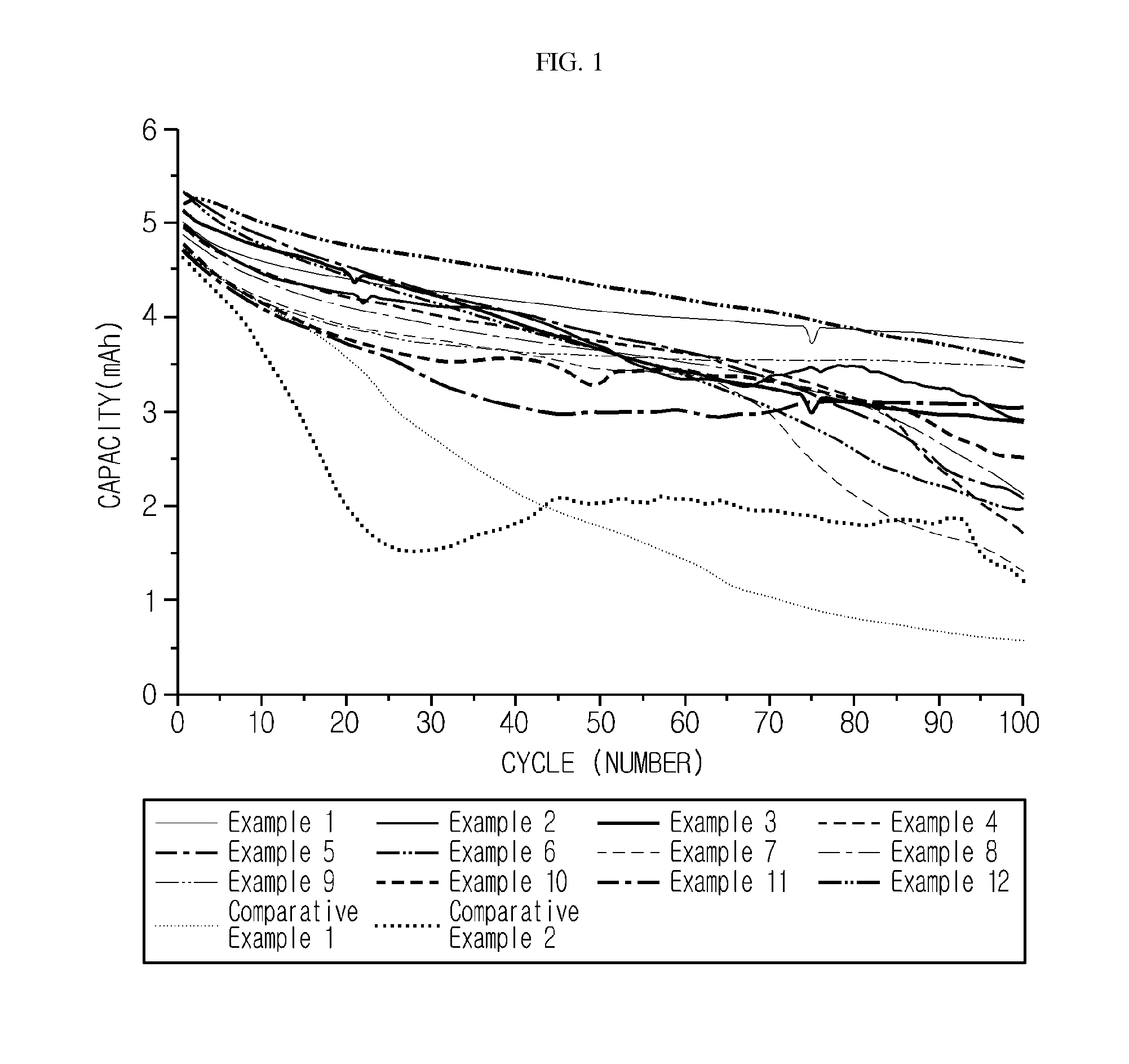

Electrode active material having core-shell structure

ActiveUS20110129729A1Maximize capacityInhibition of capacity fadingActive material electrodesNon-conductive material with dispersed conductive materialOligomerElectric capacity

Disclosed is an electrode active material having a core-shell structure, which includes: (a) a core capable of intercalating and deintercalating lithium ions; and (b) a shell including a polymer or an oligomer having a glass transition temperature of 25° C. or less when impregnated with an electrolyte, wherein a surface of the core is coated with the shell. Also, an electrode manufactured by using the electrode active material and a secondary battery including the electrode are disclosed. The shell (b) suppresses the formation of an SEI layer during initial charge of a battery, and prevents initial capacity reduction. Accordingly, it is possible to achieve a high capacity battery. The electrode active material having a core-shell structure, specially a metal (loid) based electrode active material having a core-shell structure can have a slightly higher electric capacity, compared to a conventional electrode active material, specially a conventional metal (loid) based electrode active material, and can minimize gas generation during charge / discharge.

Owner:LG ENERGY SOLUTION LTD

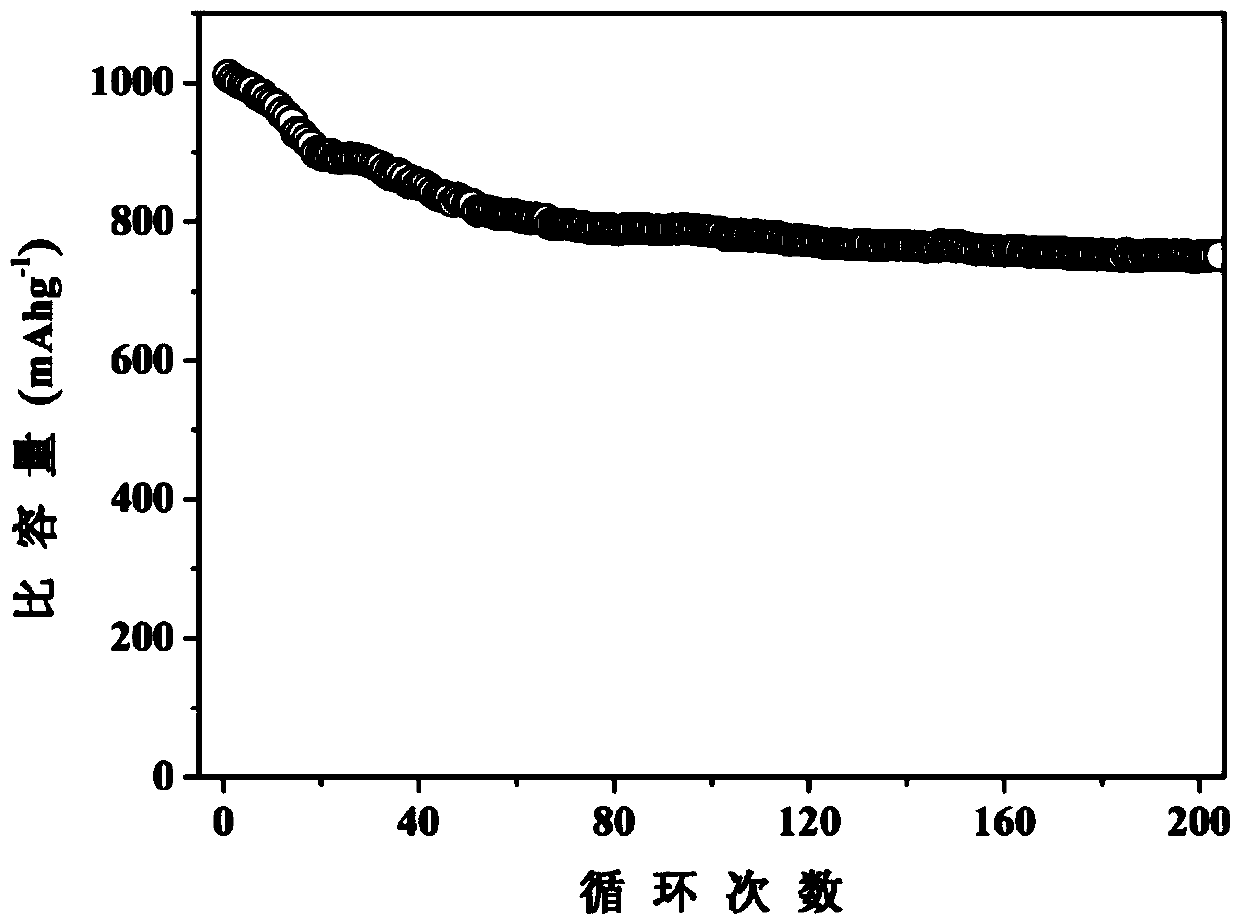

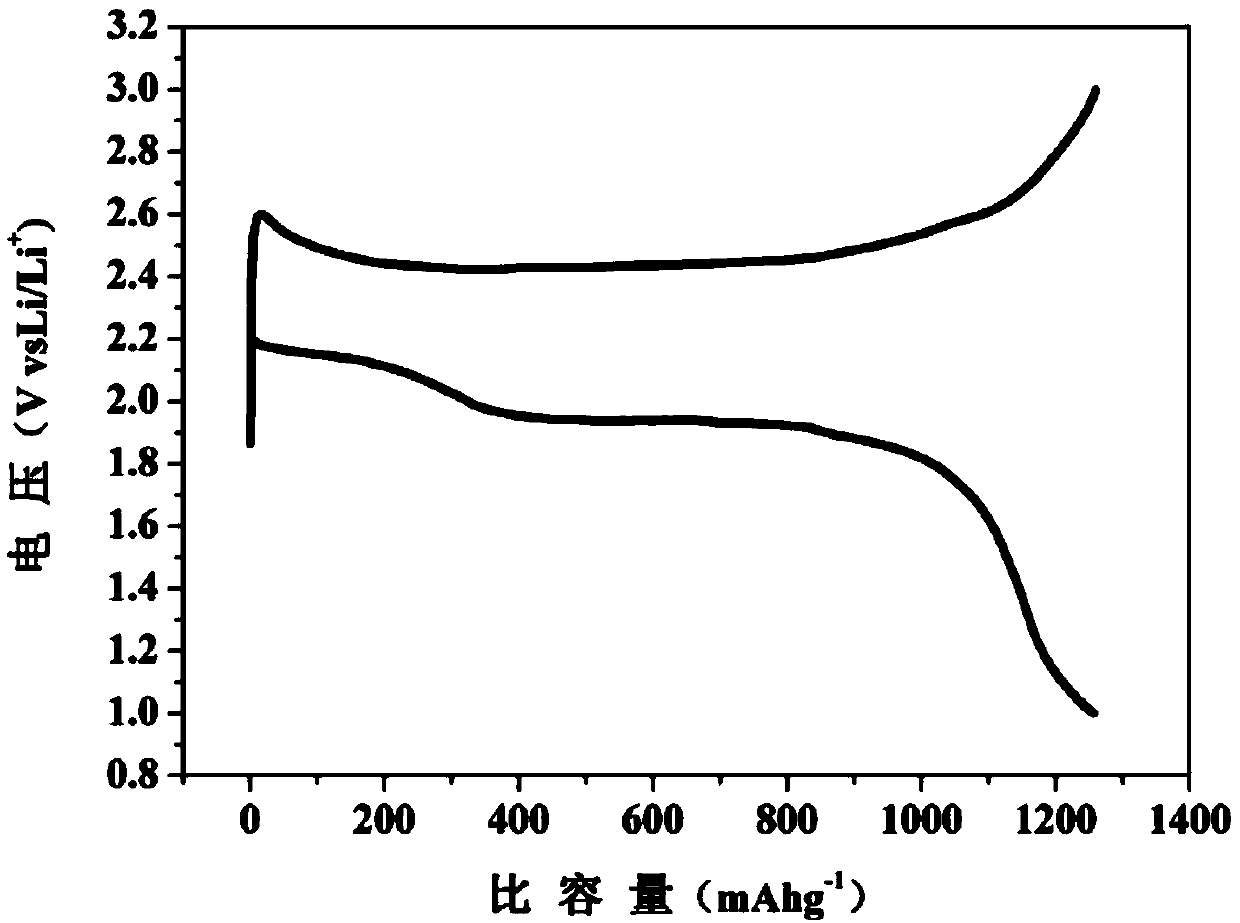

Bergmeal-based lithium sulphur battery cathode material as well as preparation and application methods thereof

InactiveCN103730632AInhibition of volume expansionReduce solubilityPositive electrodesLi-accumulatorsLithium–sulfur batteryCharge discharge

The invention discloses a bergmeal-based lithium sulphur battery cathode material as well as preparation and application methods thereof. The cathode material uses bergmeal as the skeleton, and elemental sulfur is injected into the bergmeal, so as to obtain sulfur-bearing composite material, and then the sulfur-bearing composite material is coated with a conductive material. By adopting the bergmeal, the dissolution of polysulfide can be reduced and the volume expansion of sulphur during charge-discharge process is restrained, and the cycling performance of lithium sulphur batteries is improved. Conductive material is used for coating, so that the electrical conductivity of material is improved and the capacity of the lithium sulphur batteries is increased. The lithium sulphur battery cathode material is simple in preparation technology, and the bergmeal belongs to natural environmentally-friendly material, and is low in cost and benificla to the industrialization of the lithium sulphur batteries. Meanwhile, the introduction of the bergmeal also promotes the industrial transformation and upgrading of the nonmetallic minerals.

Owner:XIANGTAN UNIV

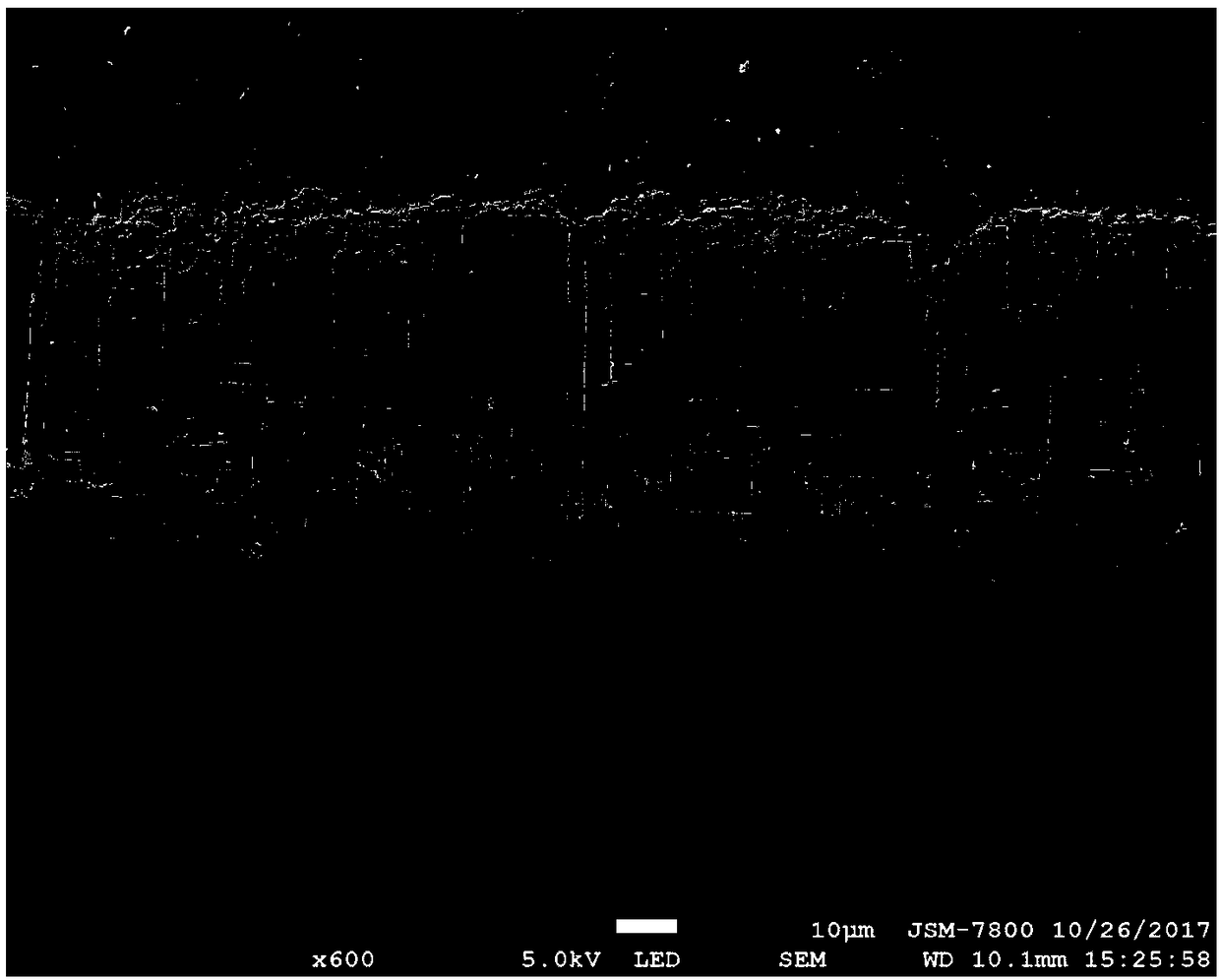

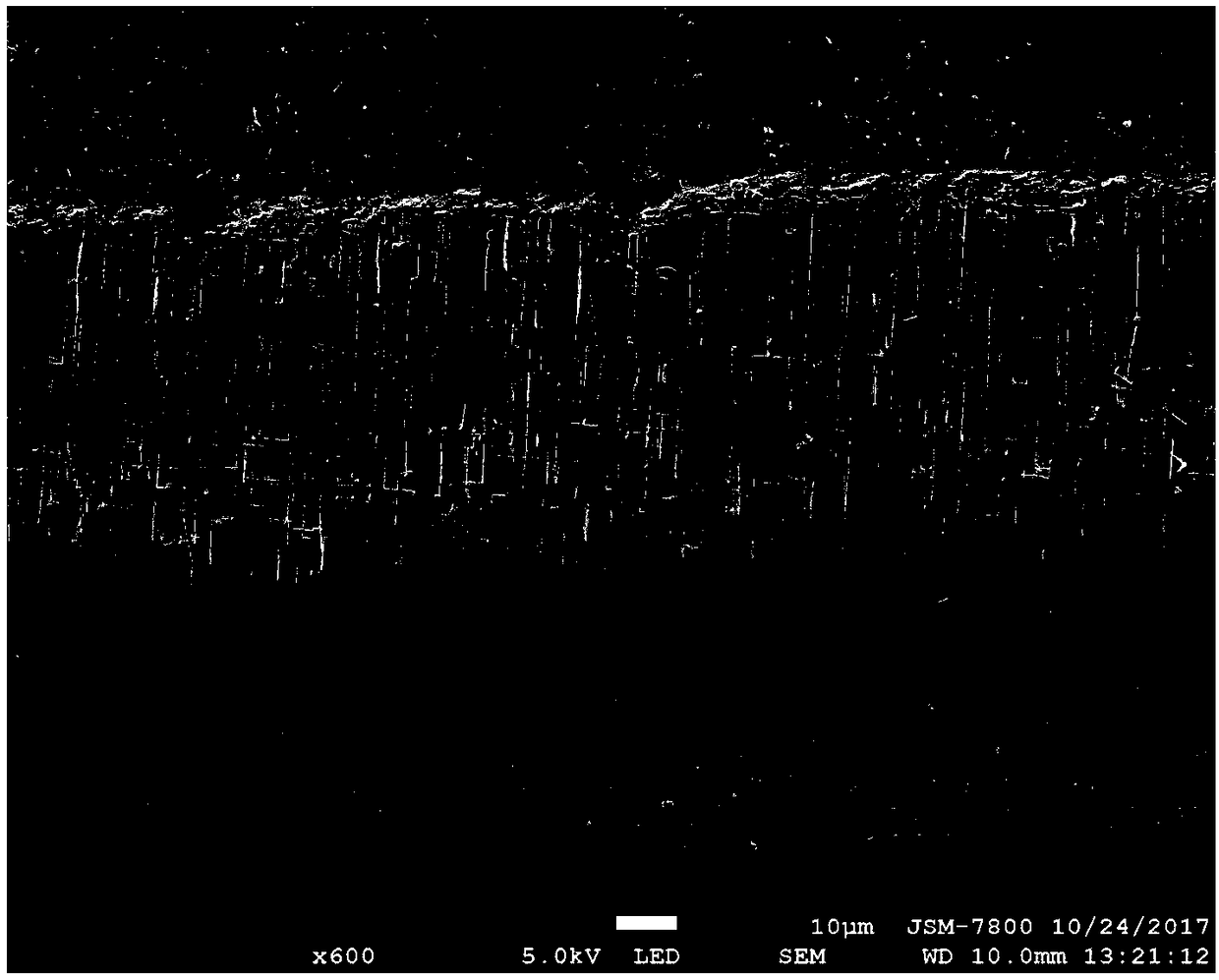

Lithium ion battery film cathode containing porous polymer elastomer and preparation method thereof

ActiveCN102130323AIncrease capacityReduce capacityElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesElastomerPorosity

The invention discloses a lithium ion battery film cathode containing a porous polymer elastomer, which comprises a copper foil current collector and a surface coating, wherein the surface coating is uniformly coated on the surface of the copper foil current collector; and the surface coating is formed in a way that a high-capacity nano particle is compounded in a directional porous polymer elastomer. The high-capacity nano particle is loaded in a hole of the porous polymer elastomer through suction filtration, rolling and electrophoresis and coated on the copper foil current collector. The porous polymer elastomer is one of porous polythiophene, porous polypyrrole or porous polyaniline. The film cathode prepared in the invention can effectively prevent the high-capacity nano particle from causing pulverization due to volumetric expansion and causing capacity attenuation due to secondary agglomeration in charge and discharge processes, and improves the circulation property of the nanoparticle. Meanwhile, the porosity of the polymer can ensure rapid transmission of lithium ions in the cathode, thereby achieving the purpose of being rapidly charged and discharged. The cathode prepared in the invention can be directly used in battery assembly without tabletting or filming, and is suitable for industrialized production.

Owner:湖南宸宇富基新能源科技有限公司

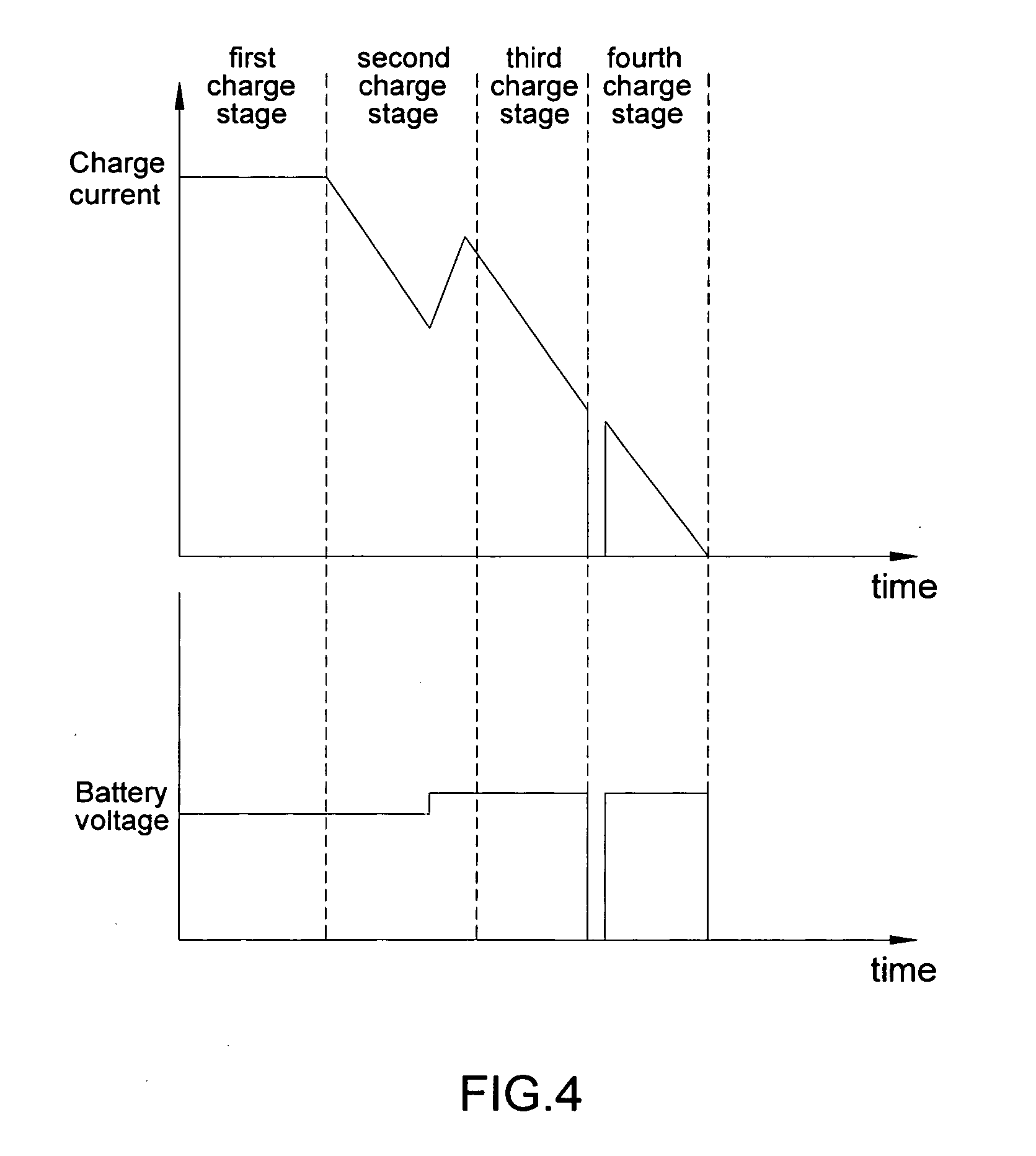

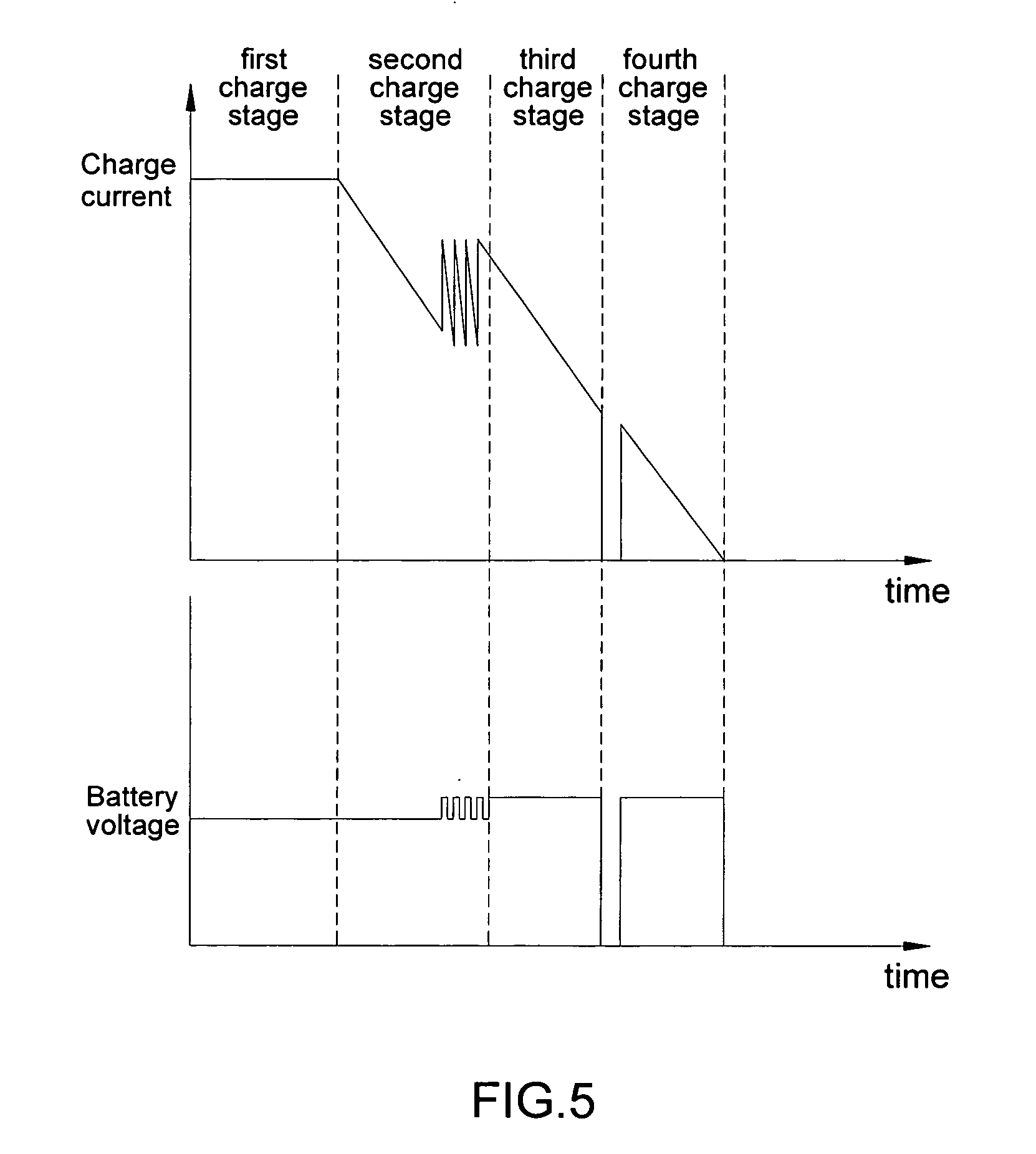

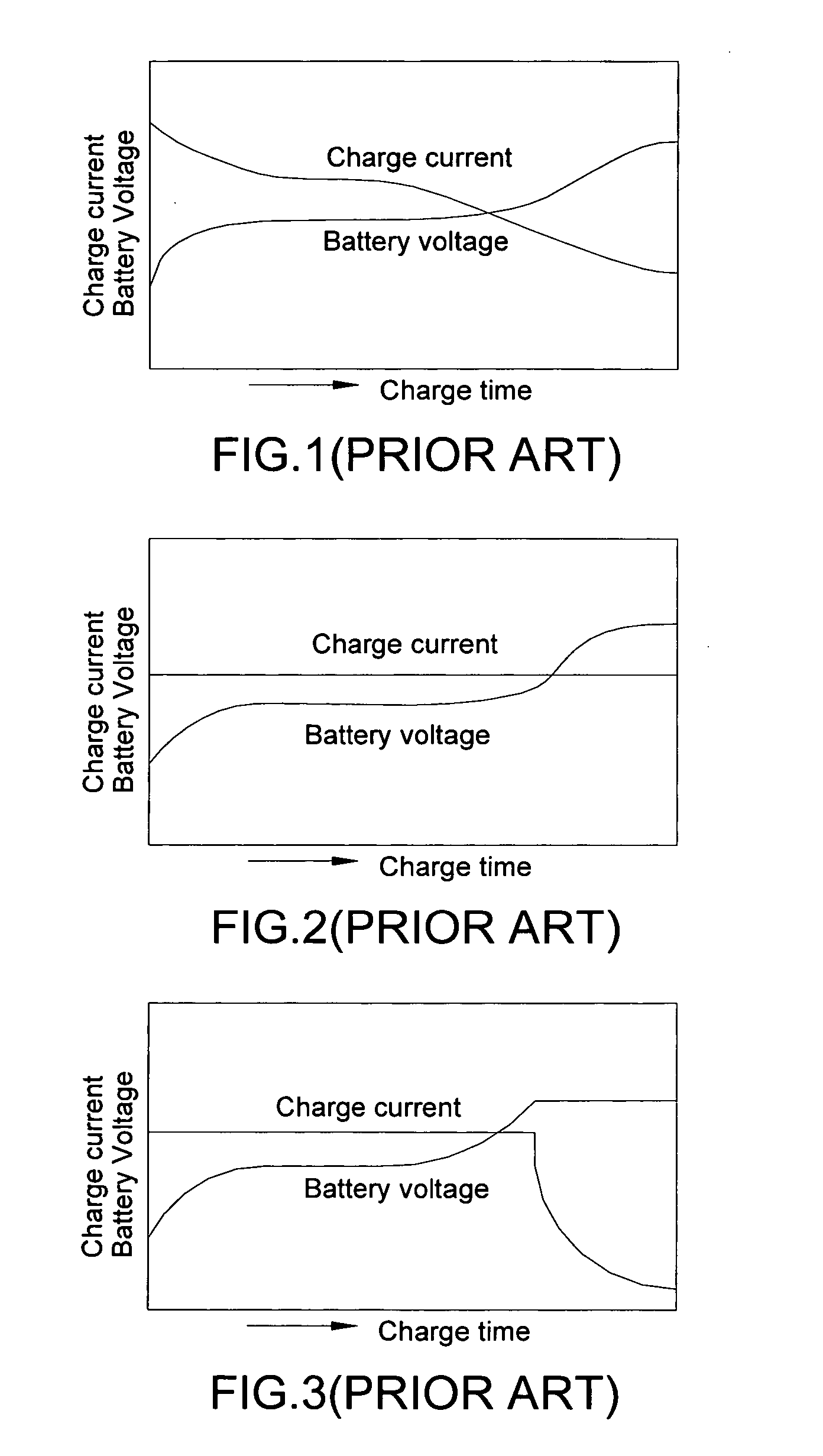

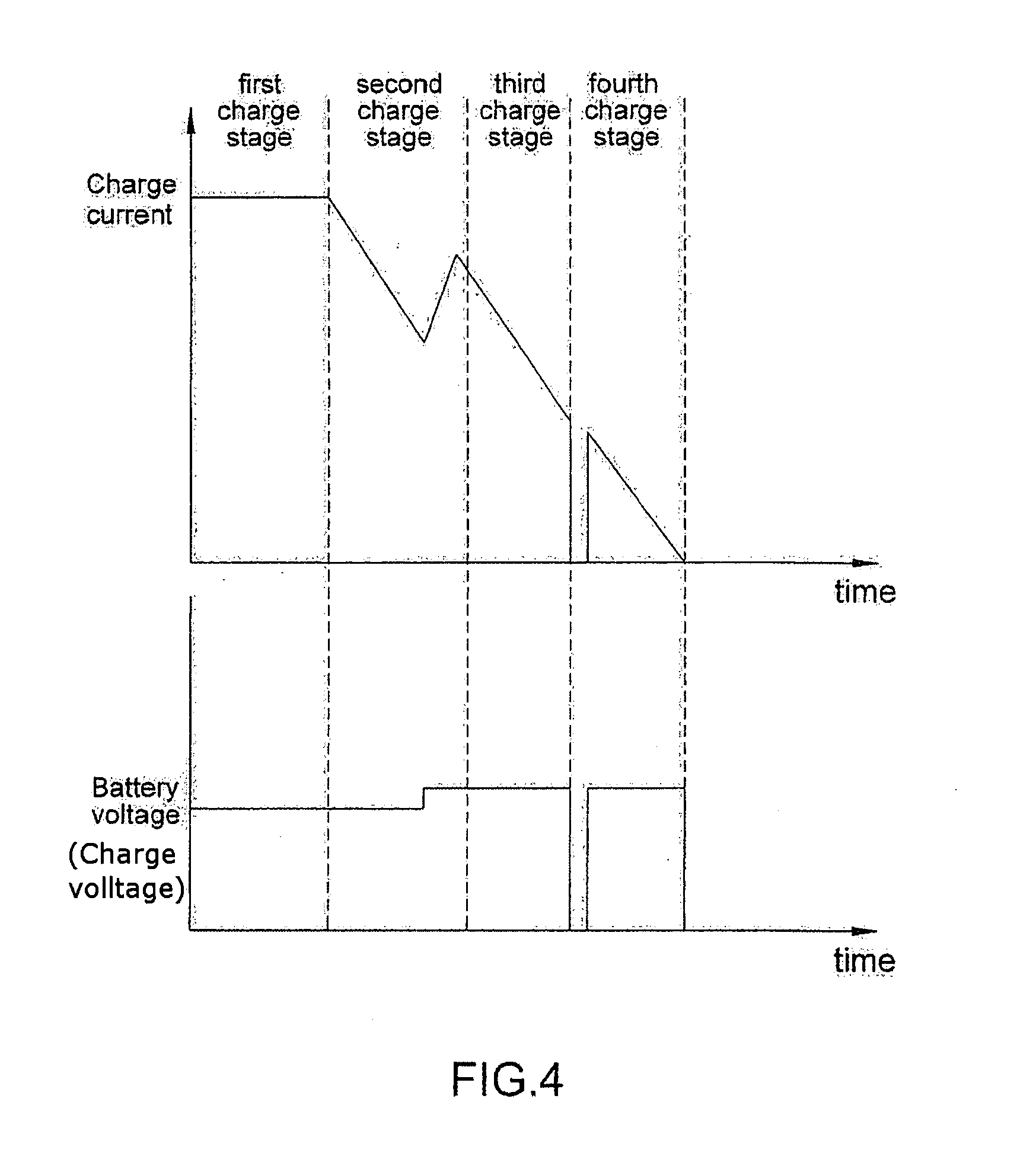

Battery charge circuit with multi-charge stage and method thereof

InactiveUS7375491B2Reduce generationExtend your lifeBatteries circuit arrangementsElectric powerCharge currentBattery charge

A charge circuit having multi charge stages for charging at least one battery includes: a first current generating circuit for generating a first charge power having a first charge current in pulse form with a first frequency and a first charge voltage to charge the at least one battery; a voltage generating circuit connected to the first current generating circuit for controlling the first charge power having a first charge current in pulse form with a first frequency and a first charge voltage; a voltage control circuit connected to the voltage generating circuit for generating a first constant voltage and / or a second constant voltage; and a second current generating circuit connected to the voltage generating circuit for generating a variant power comprising a variant current in pulse form with a second frequency wherein a charge voltage included in the variant power varies with the second frequency.

Owner:SUNJETT CORP

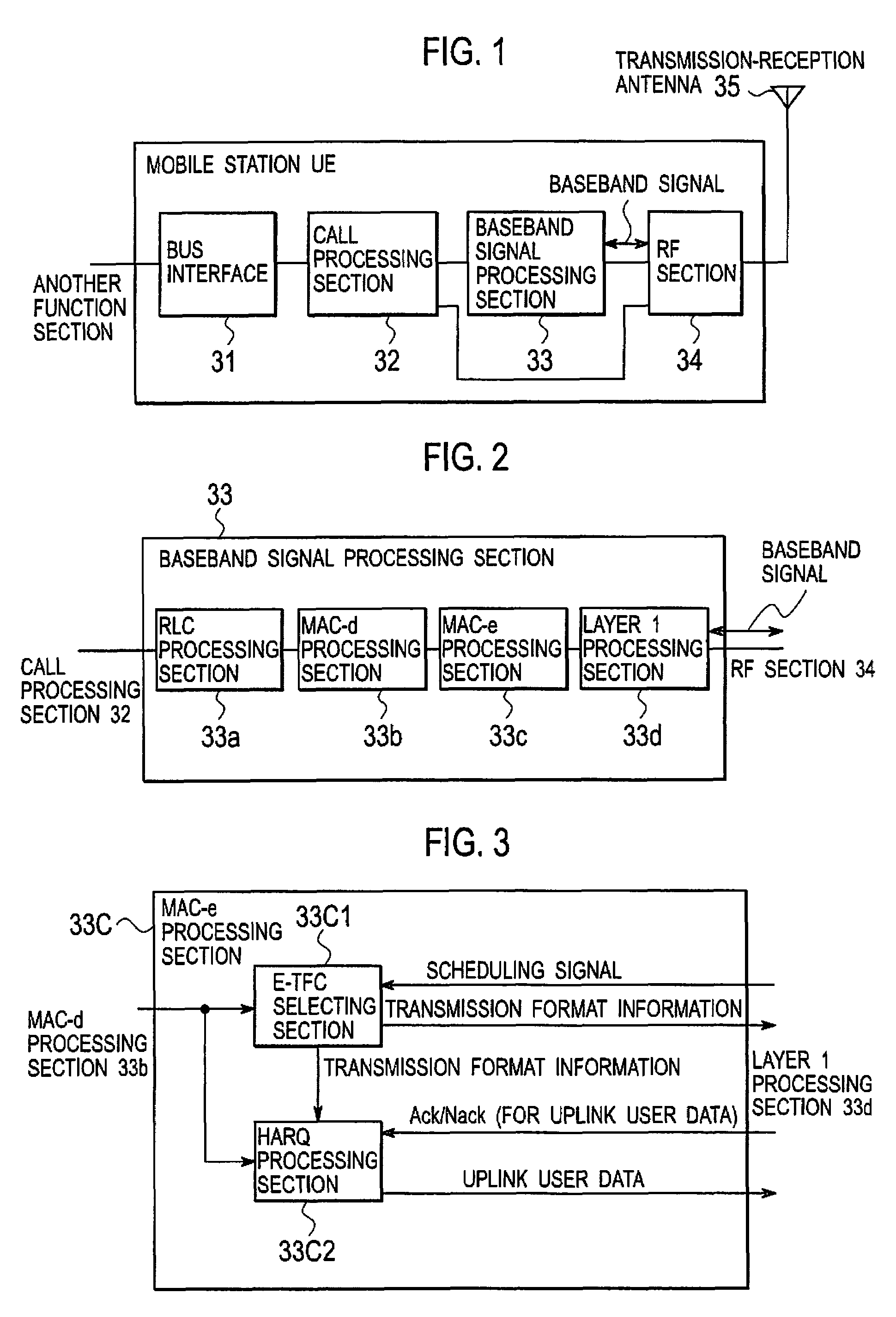

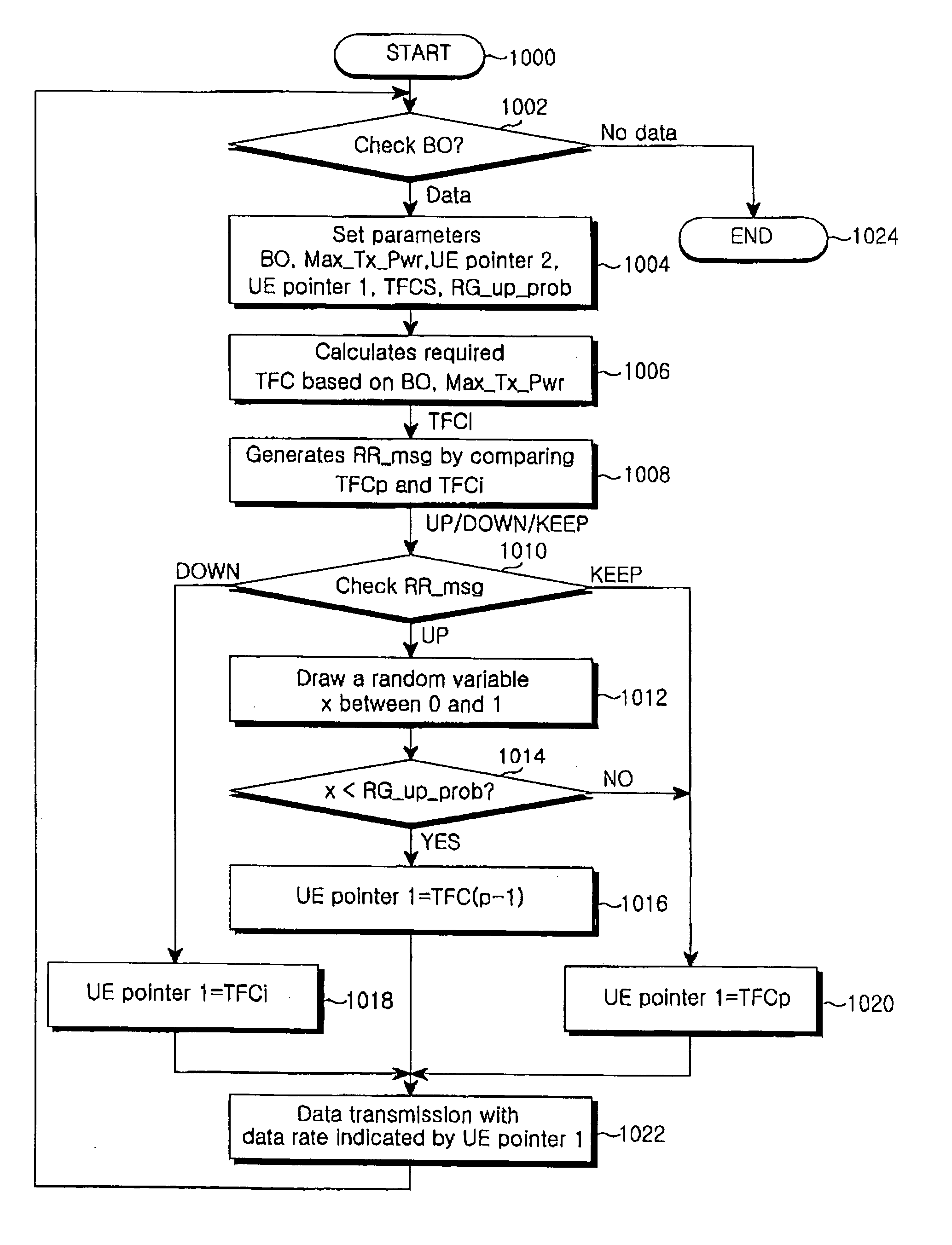

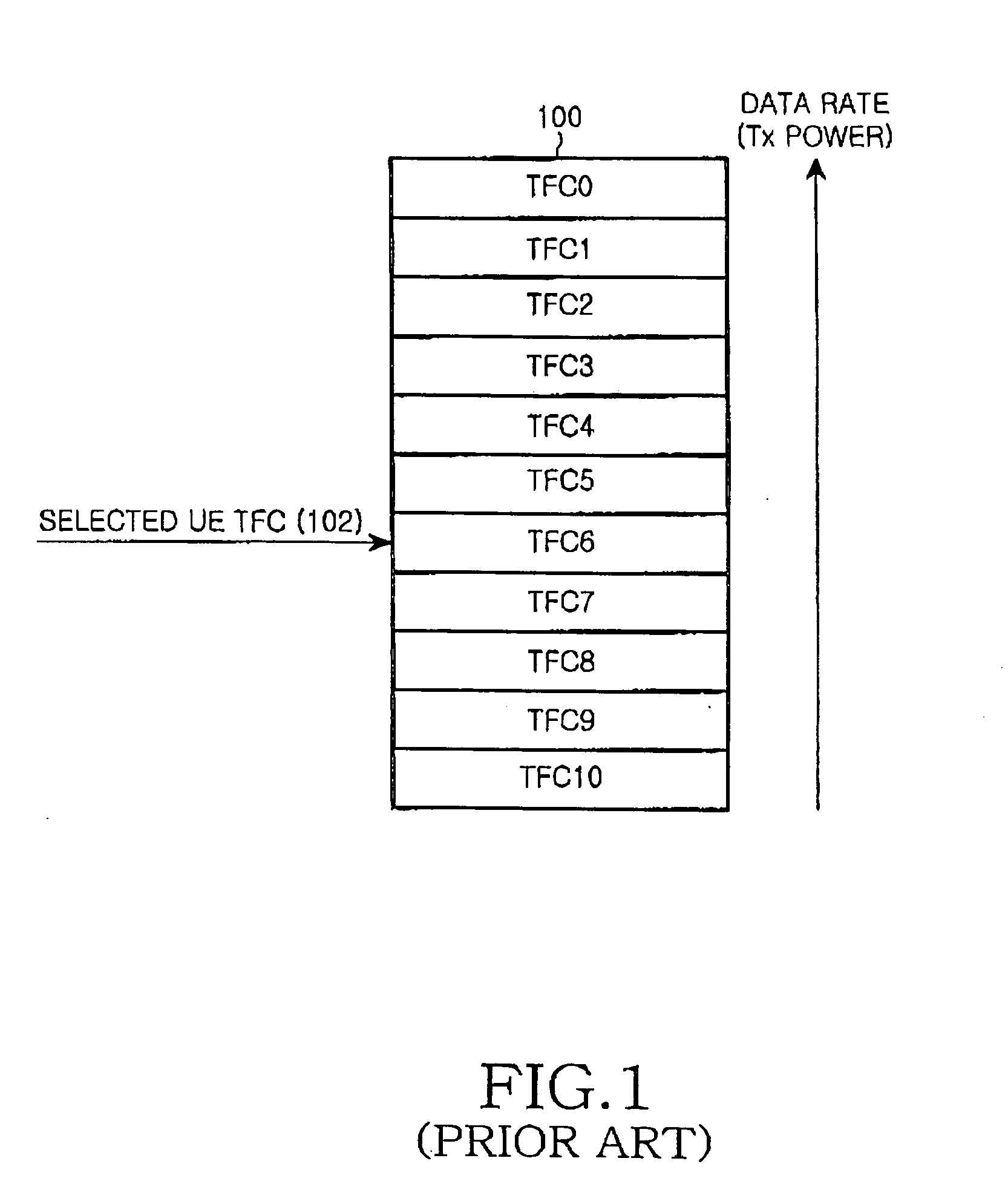

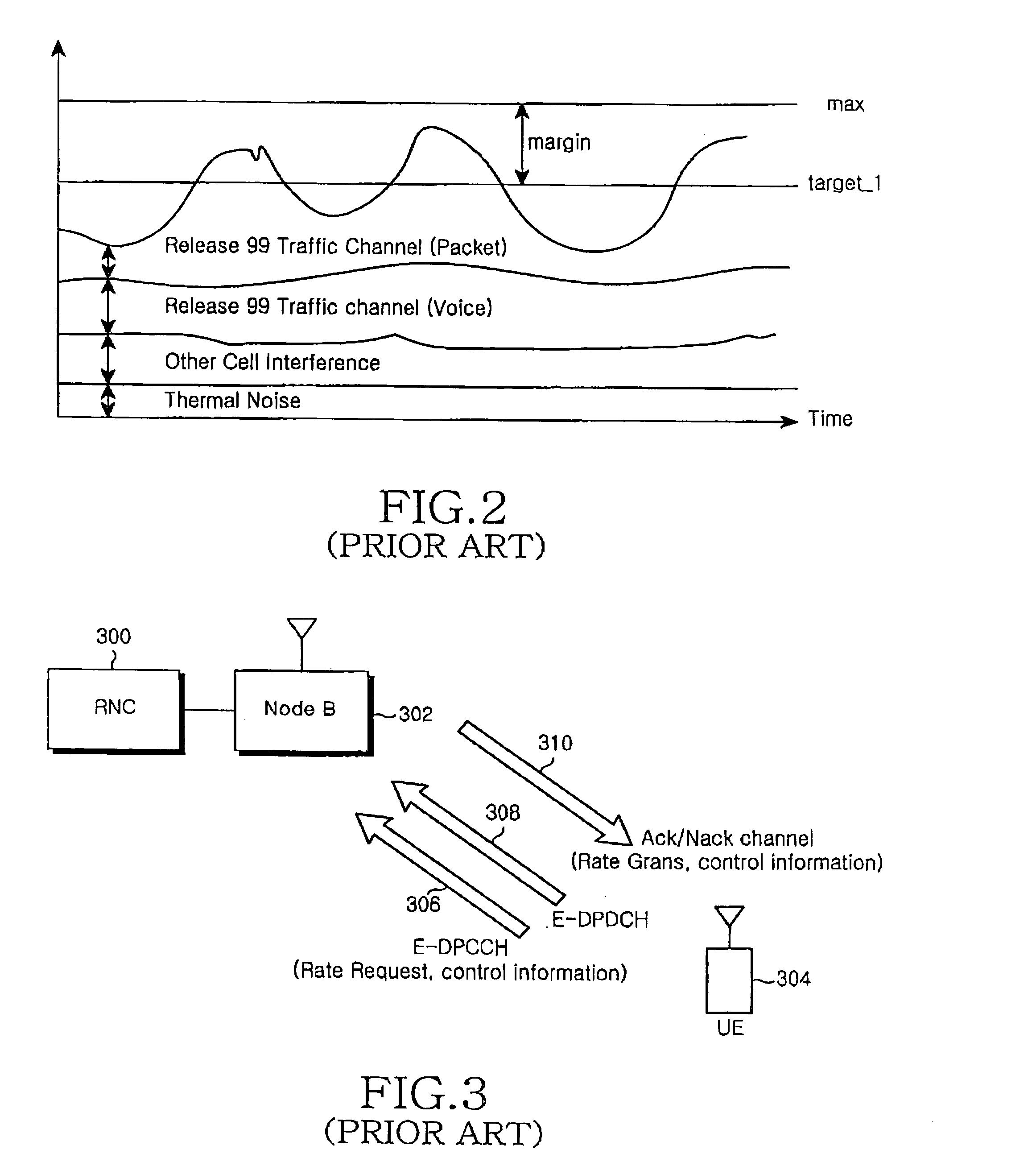

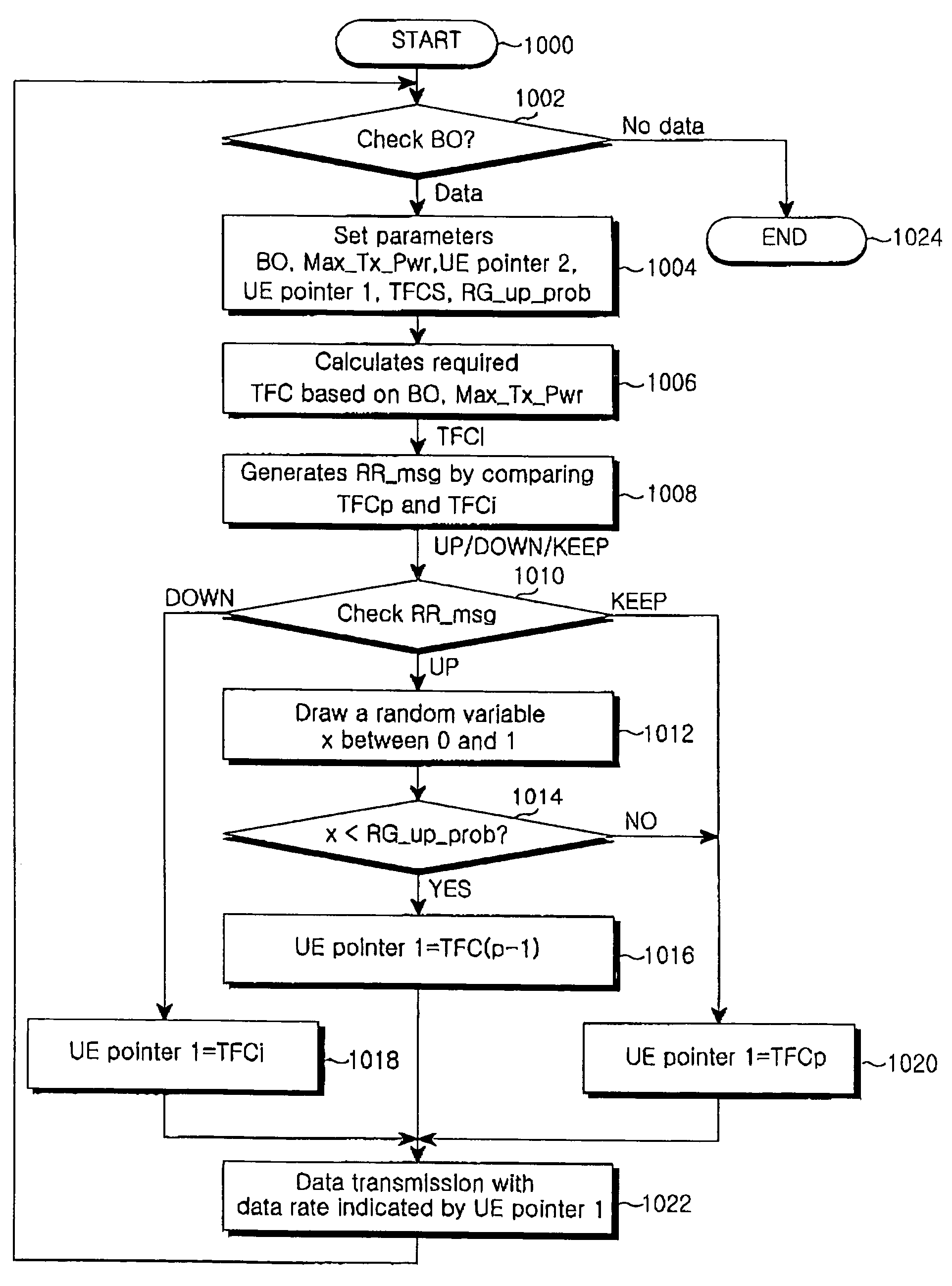

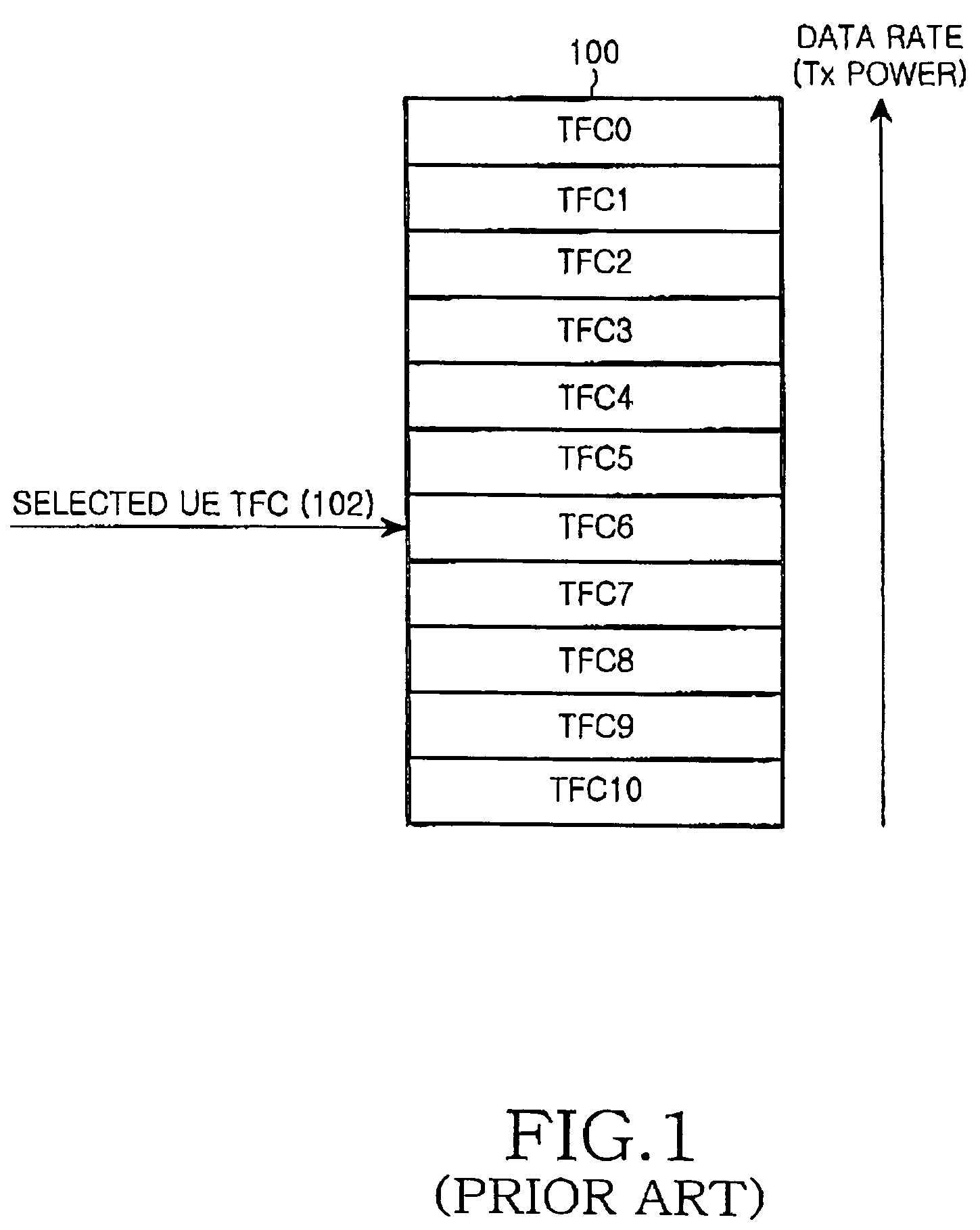

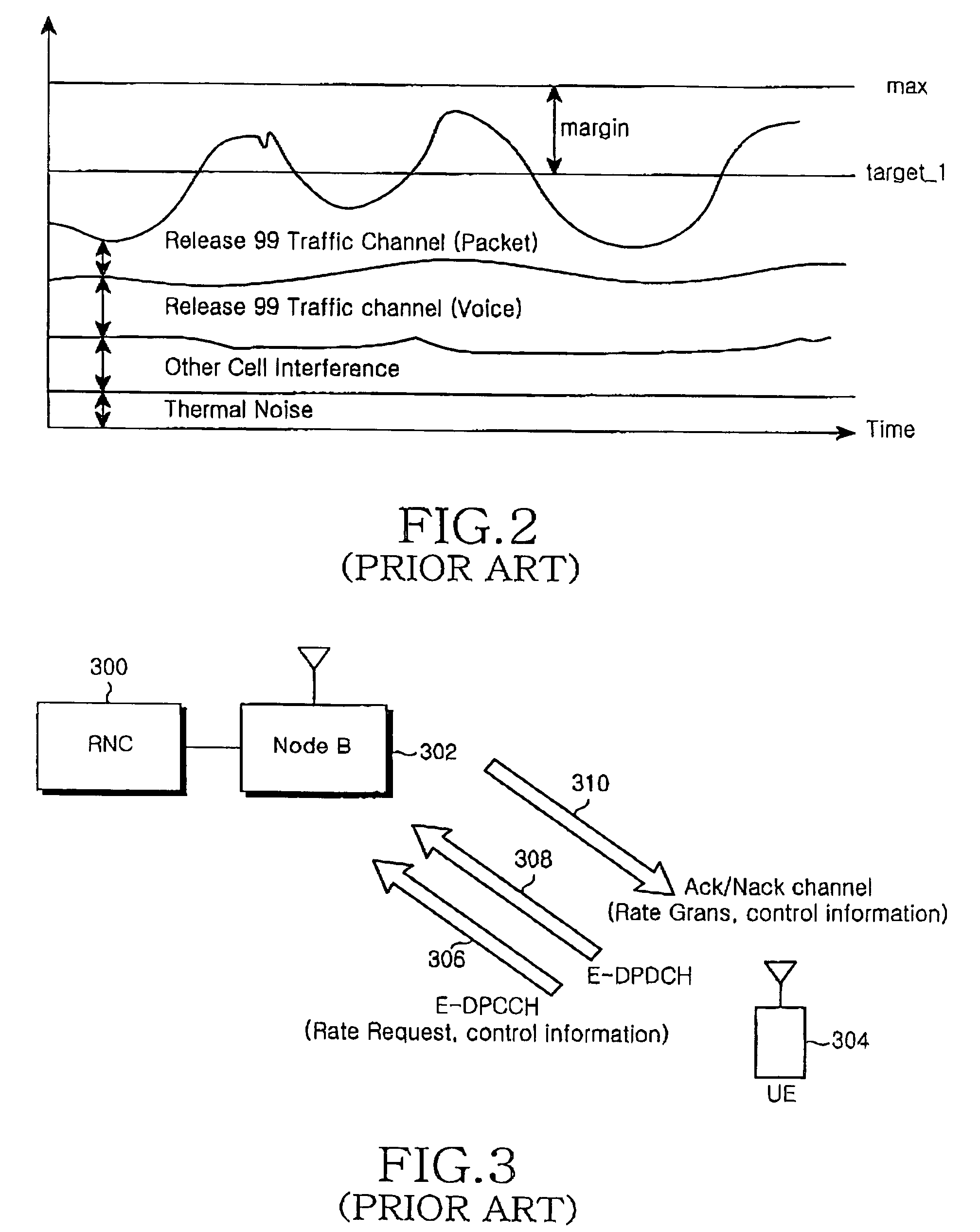

Apparatus and method for data rate scheduling of user equipment in a mobile communication system

ActiveUS20050117551A1Effective distributionInhibition of capacity fadingNetwork traffic/resource managementFrequency-division multiplex detailsData rateMobile communication systems

An apparatus and method are provided for determining a data rate by means of control information in a mobile communication system which includes a User Equipment (UE) and a Node B. The UE transmits data to the Node B, and the Node B transmits the control information to the UE. The data rate is determined by means of the control information and is used for transmission of the data by the UE. The apparatus and method comprise determining a preliminary data rate in consideration of a quantity of data waiting for transmission; comparing the preliminary data rate with a previous data rate used for previous data transmission; and determining the data rate according to a result of comparison so that the UE can transmit the data at the data rate.

Owner:SAMSUNG ELECTRONICS CO LTD

Nonaqueous electrolyte and lithium secondary battery using the same

ActiveUS20130004859A1Inhibit deteriorationImproved high temperature life characteristicsCell electrodesOrganic electrolyte cellsPolycyclic compoundElectrical battery

Disclosed are a nonaqueous electrolyte for a lithium secondary battery containing a hetero polycyclic compound and a lithium secondary battery using the same.

Owner:LG ENERGY SOLUTION LTD

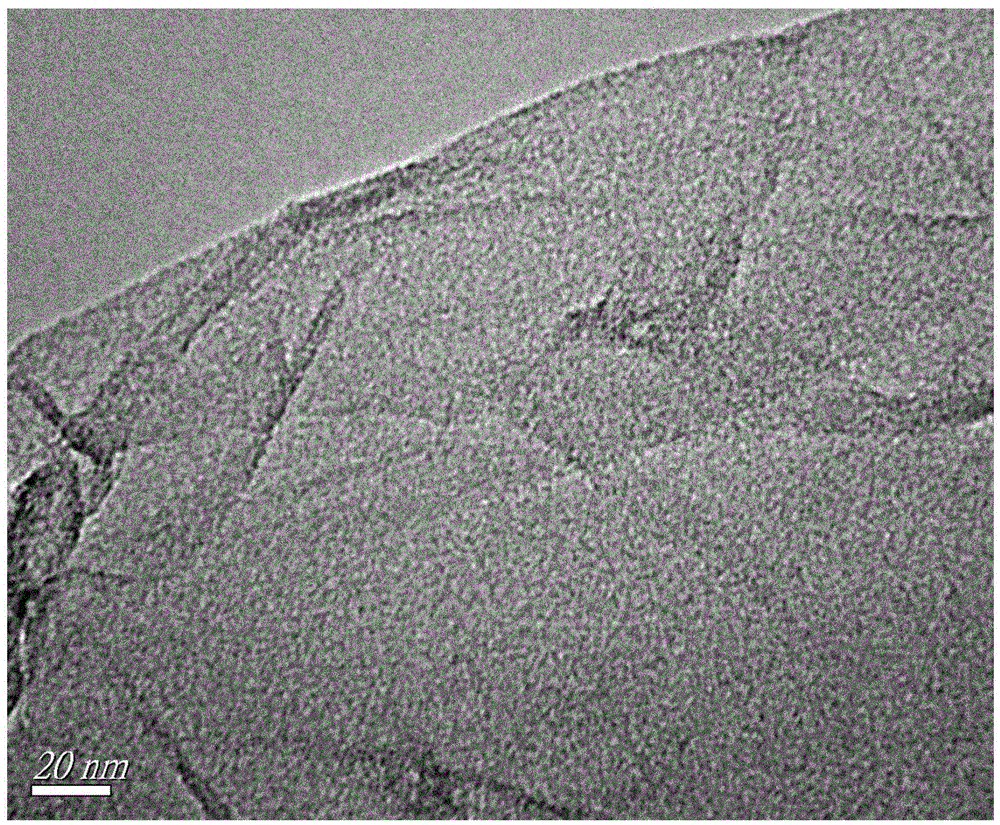

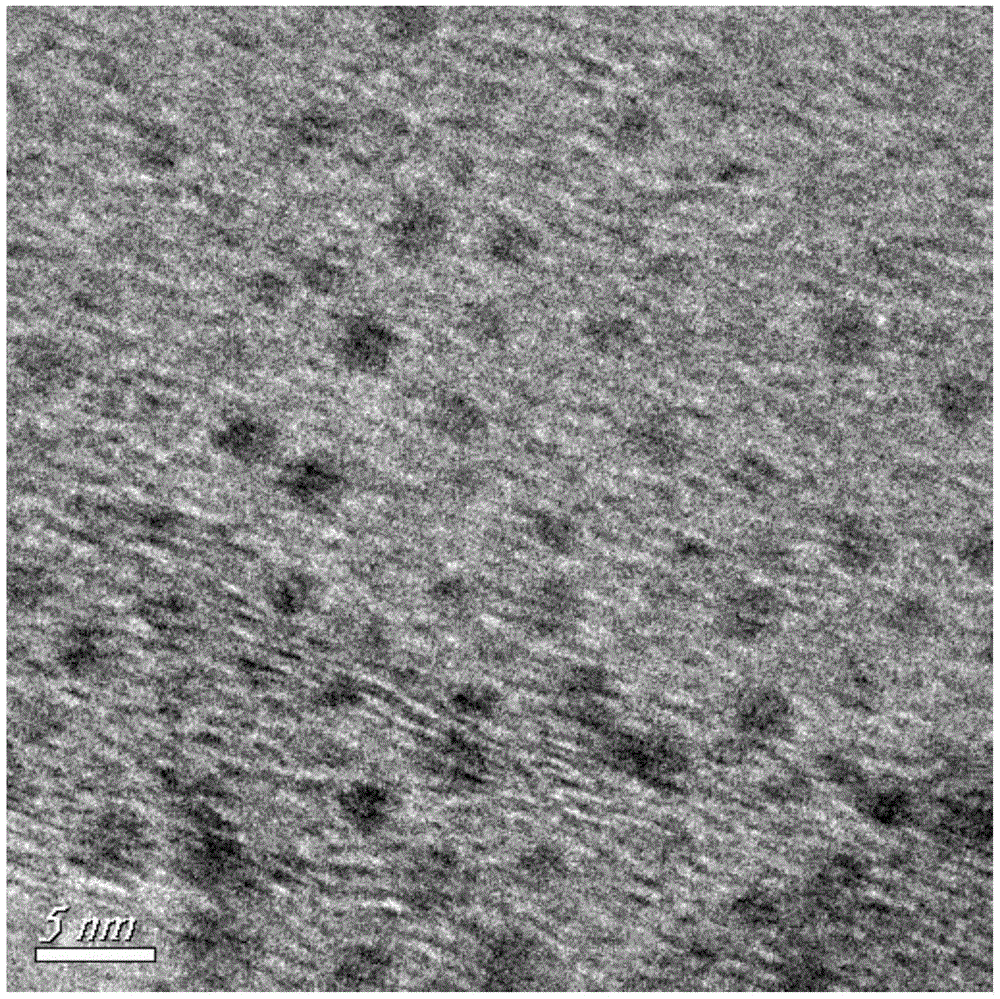

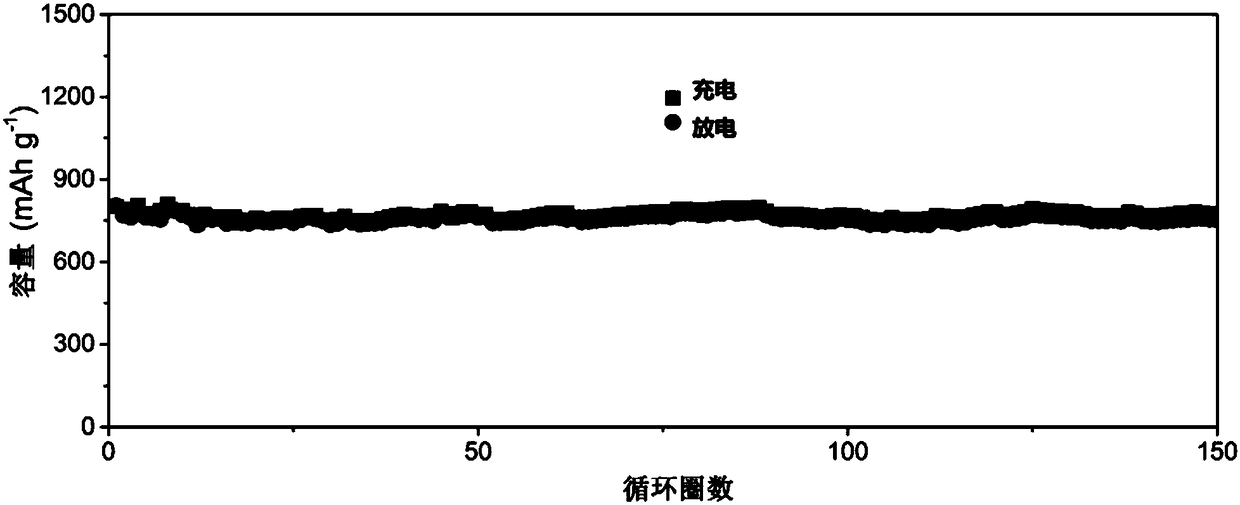

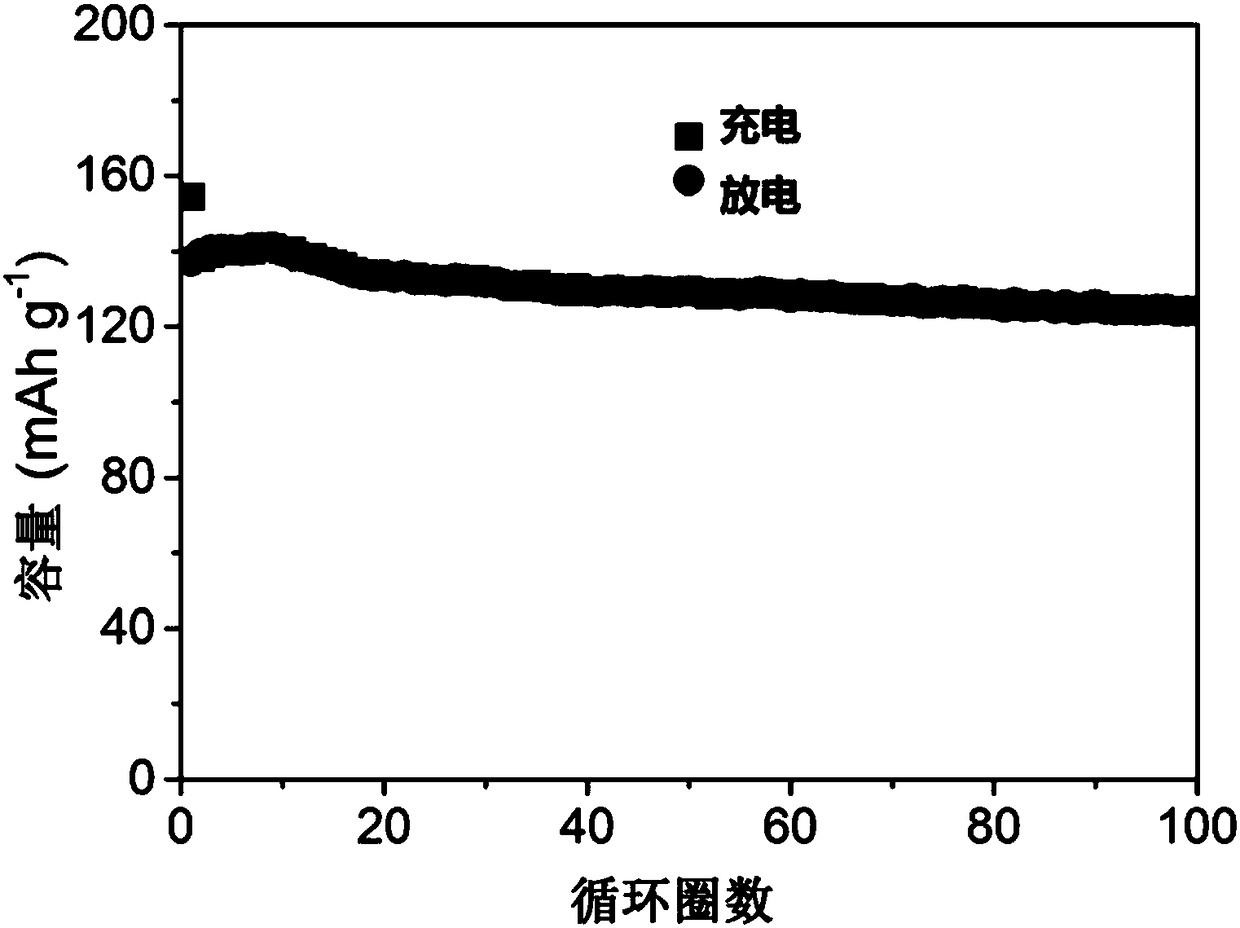

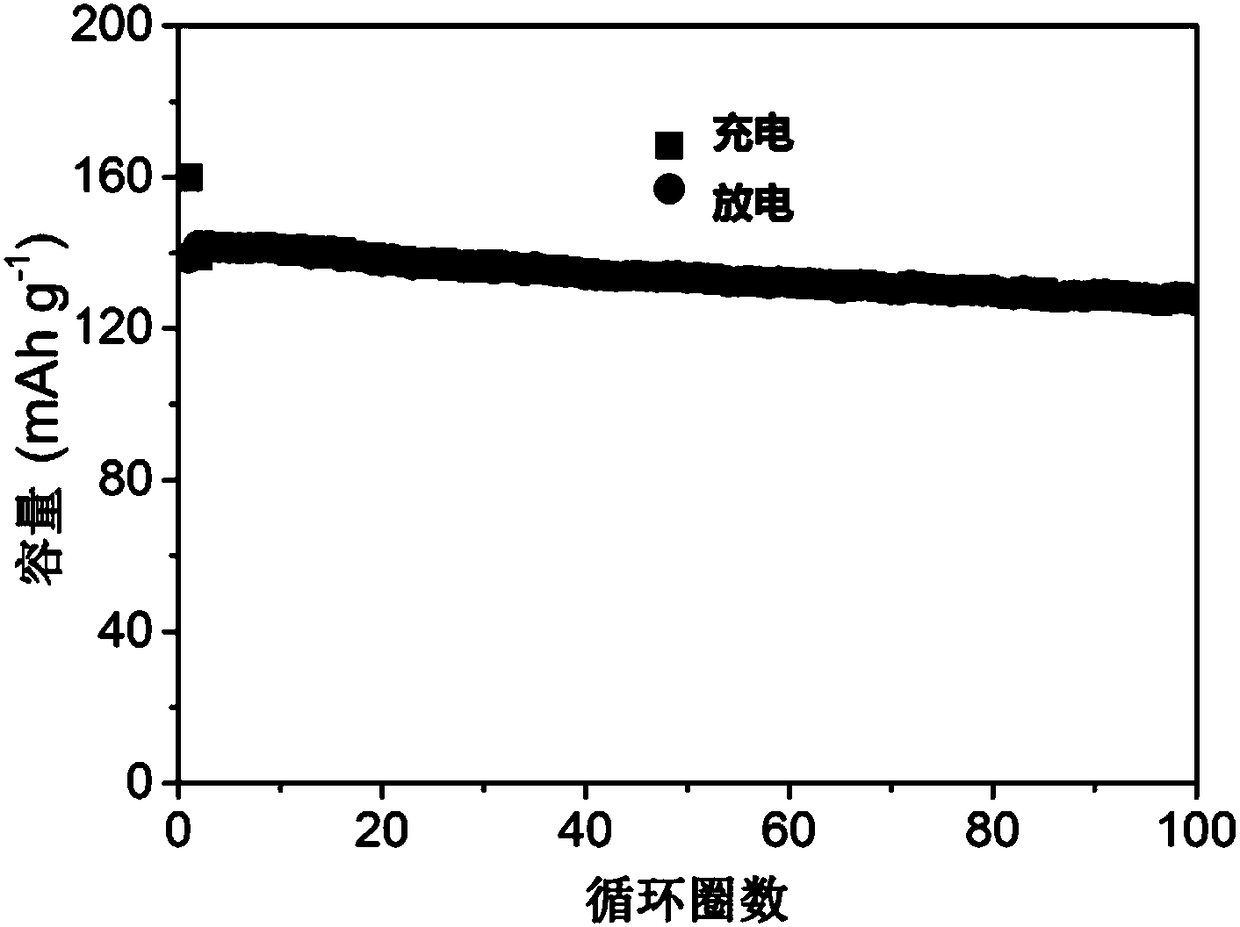

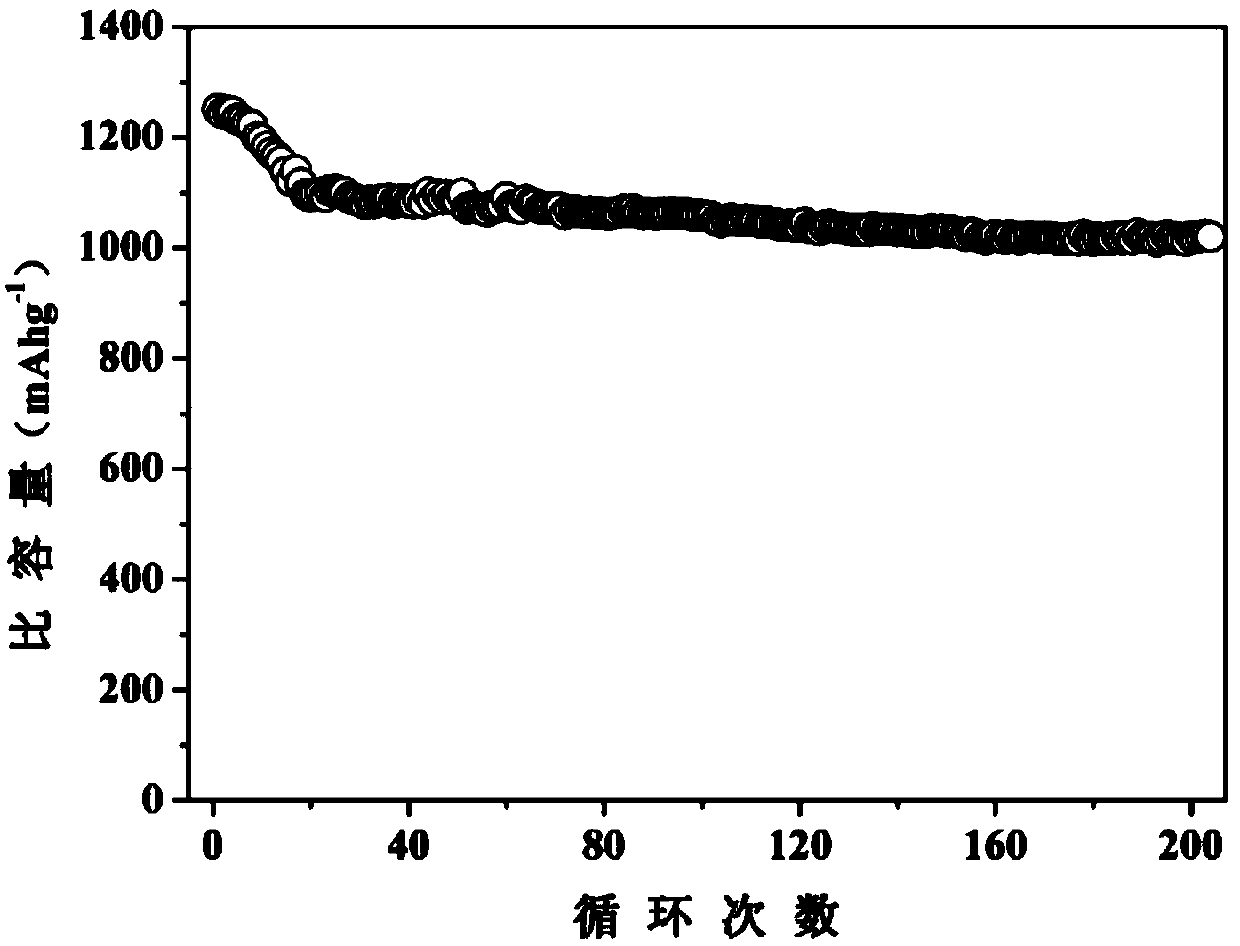

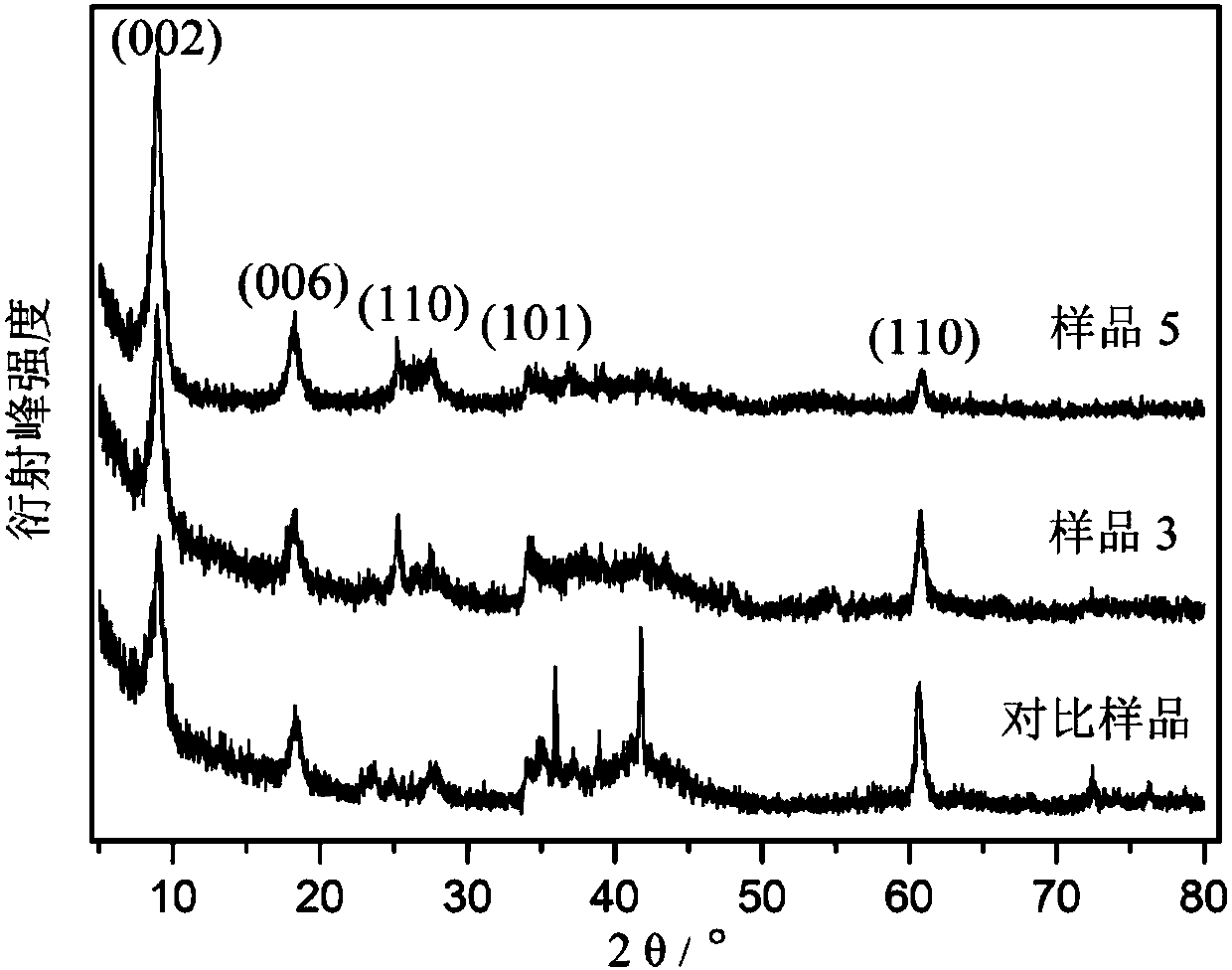

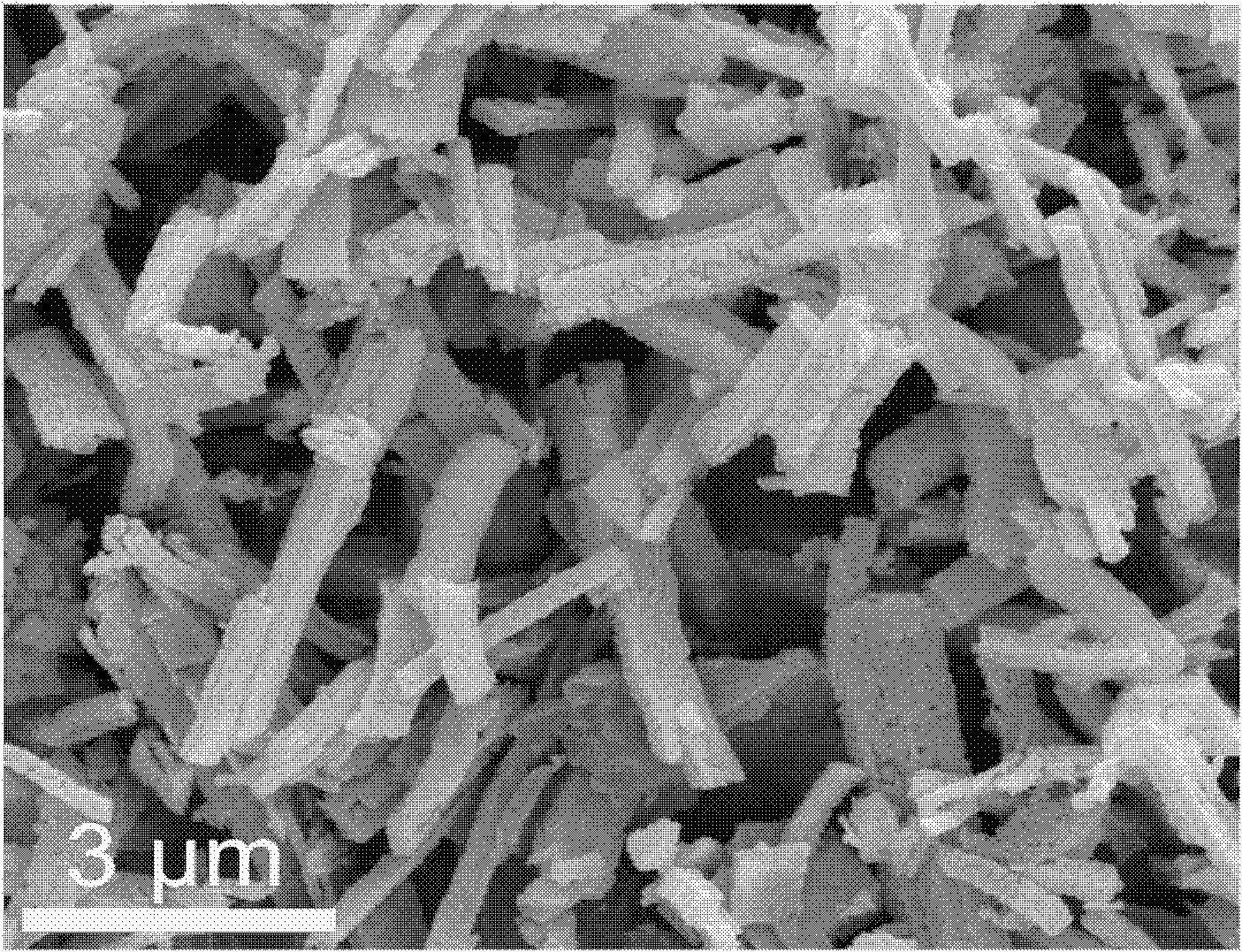

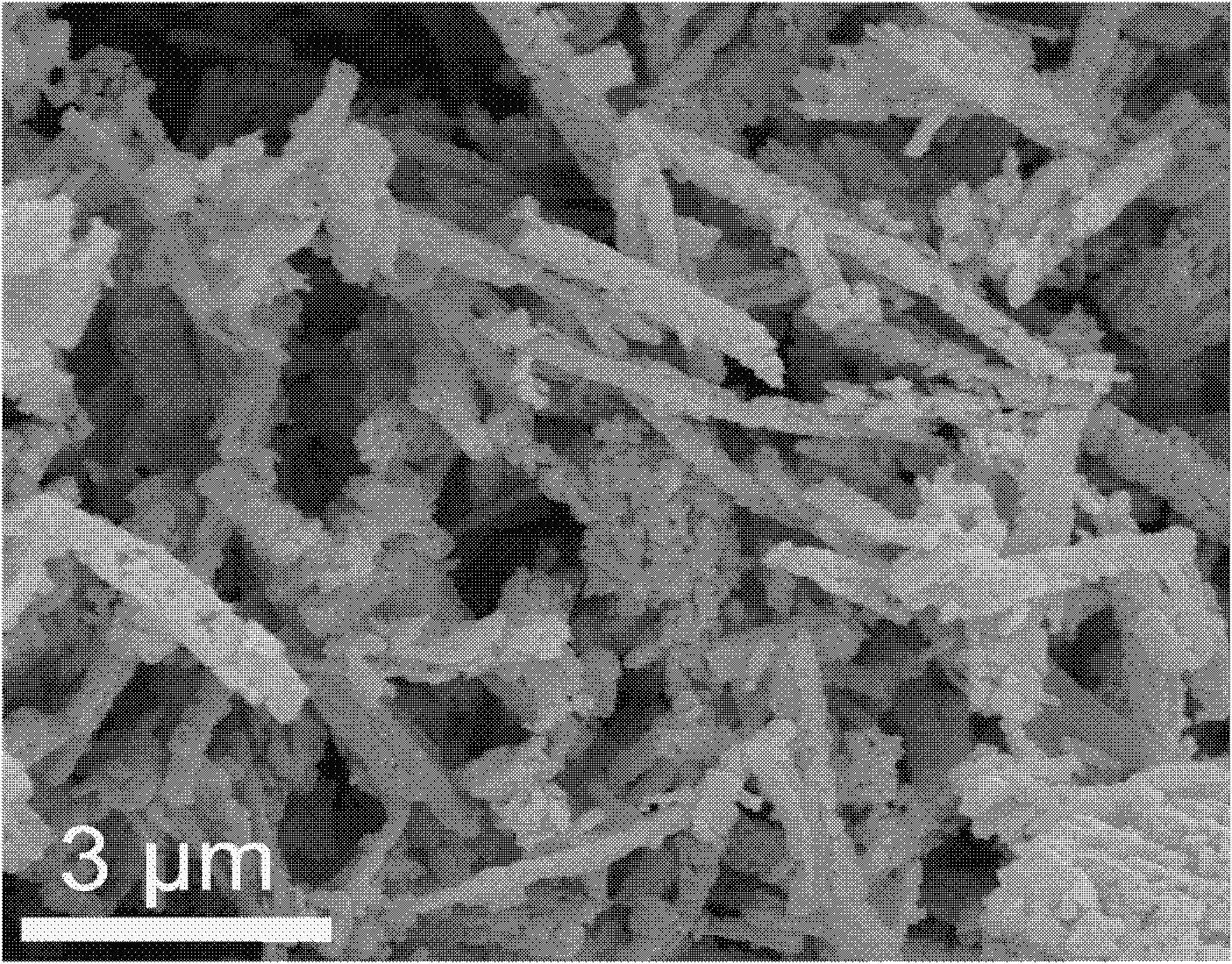

Carbon nanotube and tin dioxide modified titanium carbide lithium ion battery negative electrode material with three-dimensional 'plane-line-plane' structure and preparation method thereof

InactiveCN107742702AInhibition of capacity fadingImprove face-to-face contactCell electrodesSecondary cellsLayered structureContact condition

The invention discloses a carbon nanotube and tin dioxide modified titanium carbide lithium ion battery negative electrode material with three-dimensional 'plane-line-plane' structure and a preparation method thereof. Titanium aluminide carbide, stannous chloride, CNT (carbon nanotube) and the like are used as raw materials, the concentration of a SnCl2 solution is controlled to be 0.02-0.5mol / l,the mass percentage in a composite material is 10%, and a hydrothermal reaction condition is carrying out heat preservation at 130 DEG C or 190 DEG C for 5 hours. The high capacity of SnO2 increases the lithium ion intercalation capacity of Ti3C2Tx, the CNT not only inhibits the capacity attenuation of SnO2 in charging and discharging, but also bridges a discontinuous two-dimensional layered structure of Ti3C2Tx into a complete three-dimensional 'plane-line-plane' structure to form a continuous conductive network, and a surface-to-surface contact condition of the Ti3C2Tx interlayer structure is improved to obtain a lithium ion battery negative electrode material with excellent electrochemical performance. The method provided by the invention is a modification method with a simple process and a low cost, and is suitable for industrial production.

Owner:TIANJIN UNIV

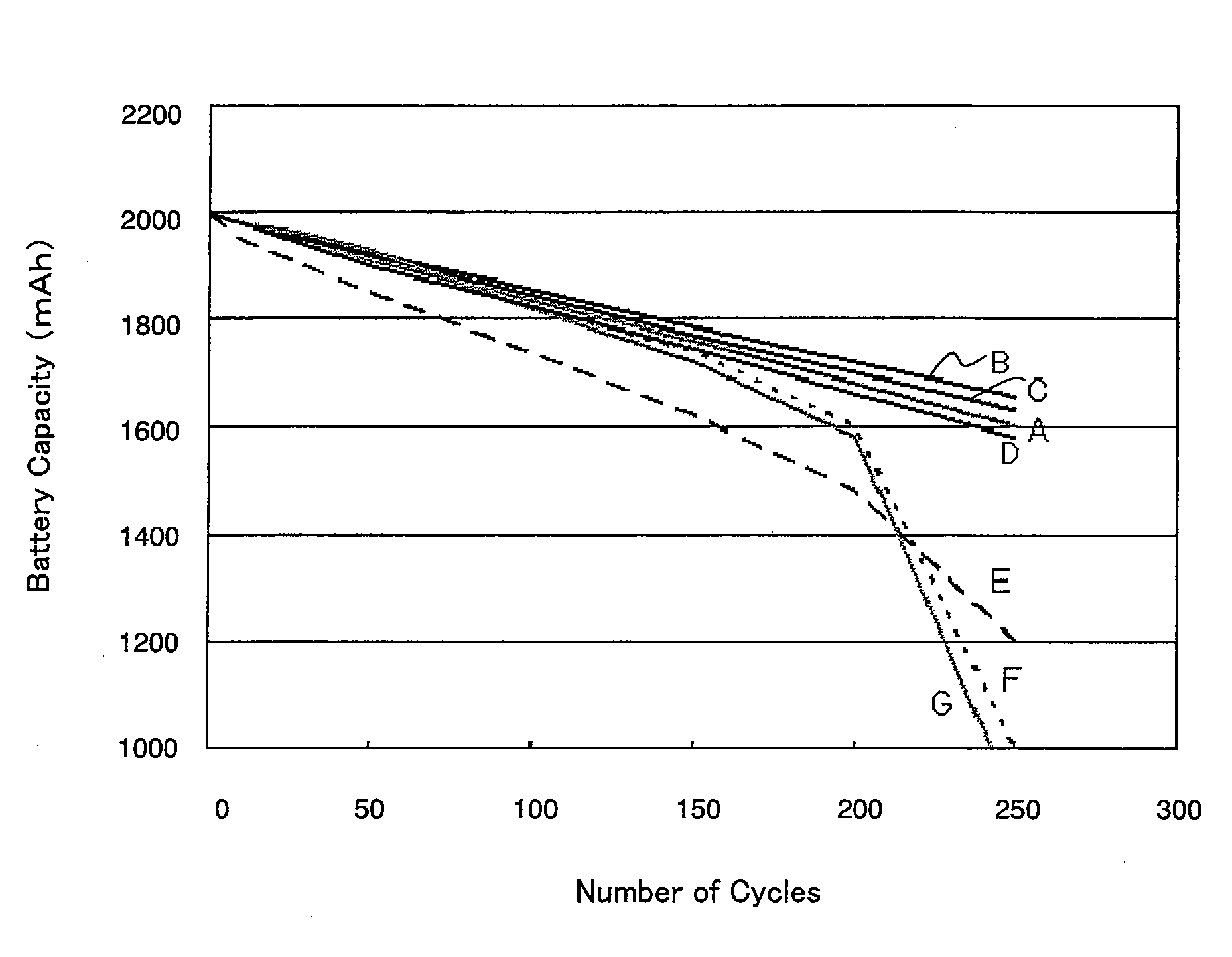

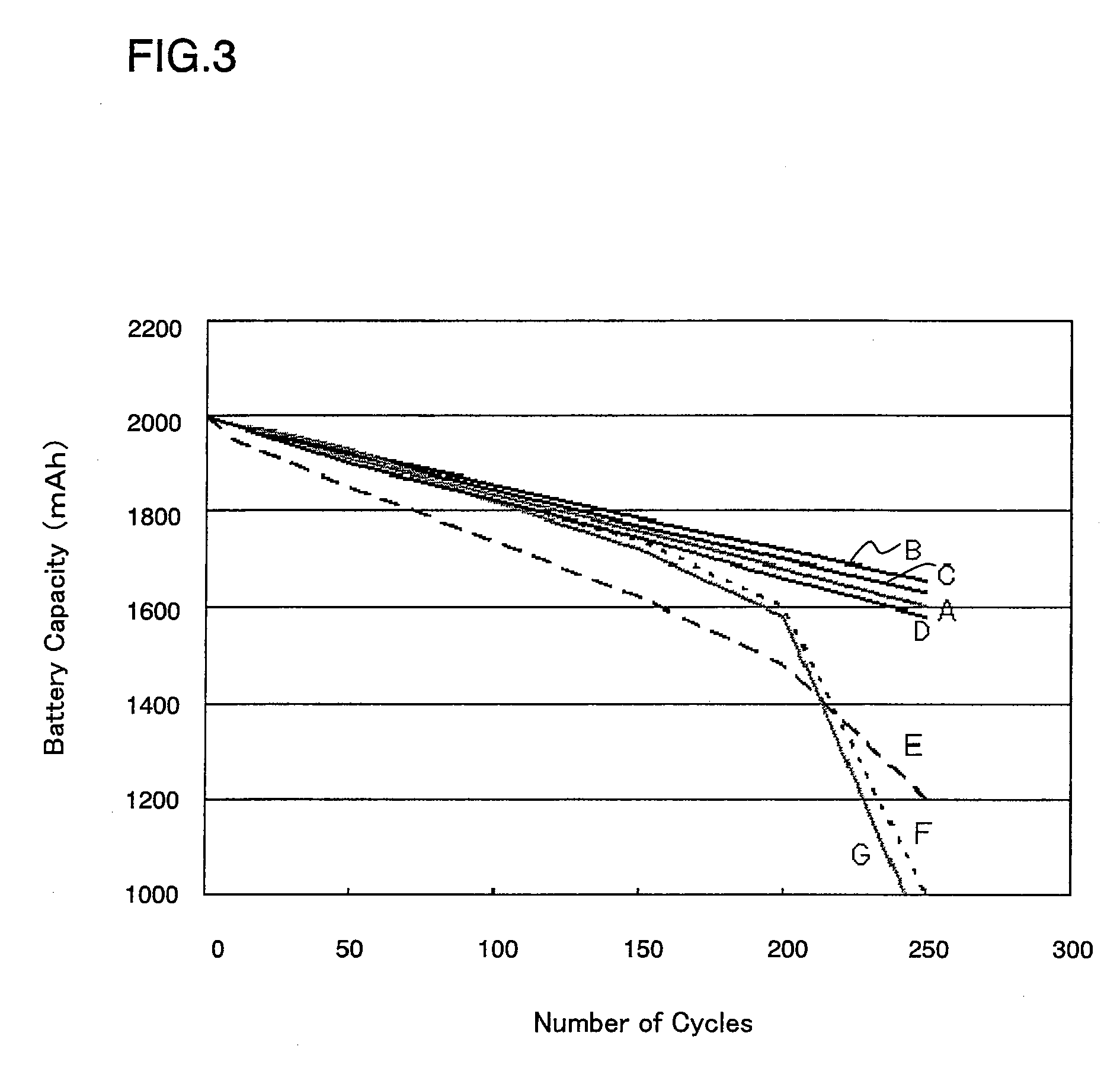

Non-aqueous electrolyte secondary battery

InactiveUS20080213670A1Easy dischargeInhibition of capacity fadingActive material electrodesSecondary cellsBattery capacityCharge and discharge

In a non-aqueous electrolyte secondary battery including an electrode assembly including a positive electrode containing a positive electrode active material, a negative electrode containing a negative electrode active material, and a separator interposed therebetween; and a non-aqueous electrolyte, 80 wt % or more of the positive electrode active material is primary particles, and the separator is formed by a porous film, or the porous film is formed at at least one position from the following: between the positive electrode and the separator main body, between the negative electrode and the separator main body, and inside the separator main body, to capture the metal ions leached from the positive electrode active material. Such an arrangement enables a non-aqueous electrolyte secondary battery with significantly less decline in battery capacity, excellent charge and discharge cycle life performance, and capable of stable output for a longer period of time.

Owner:PANASONIC CORP

Apparatus and method for data rate scheduling of user equipment in a mobile communication system

ActiveUS7596122B2Effective distributionInhibition of capacity fadingFrequency-division multiplex detailsNetwork traffic/resource managementData rateMobile communication systems

An apparatus and method are provided for determining a data rate by means of control information in a mobile communication system which includes a User Equipment (UE) and a Node B. The UE transmits data to the Node B, and the Node B transmits the control information to the UE. The data rate is determined by means of the control information and is used for transmission of the data by the UE. The apparatus and method comprise determining a preliminary data rate in consideration of a quantity of data waiting for transmission; comparing the preliminary data rate with a previous data rate used for previous data transmission; and determining the data rate according to a result of comparison so that the UE can transmit the data at the data rate.

Owner:SAMSUNG ELECTRONICS CO LTD

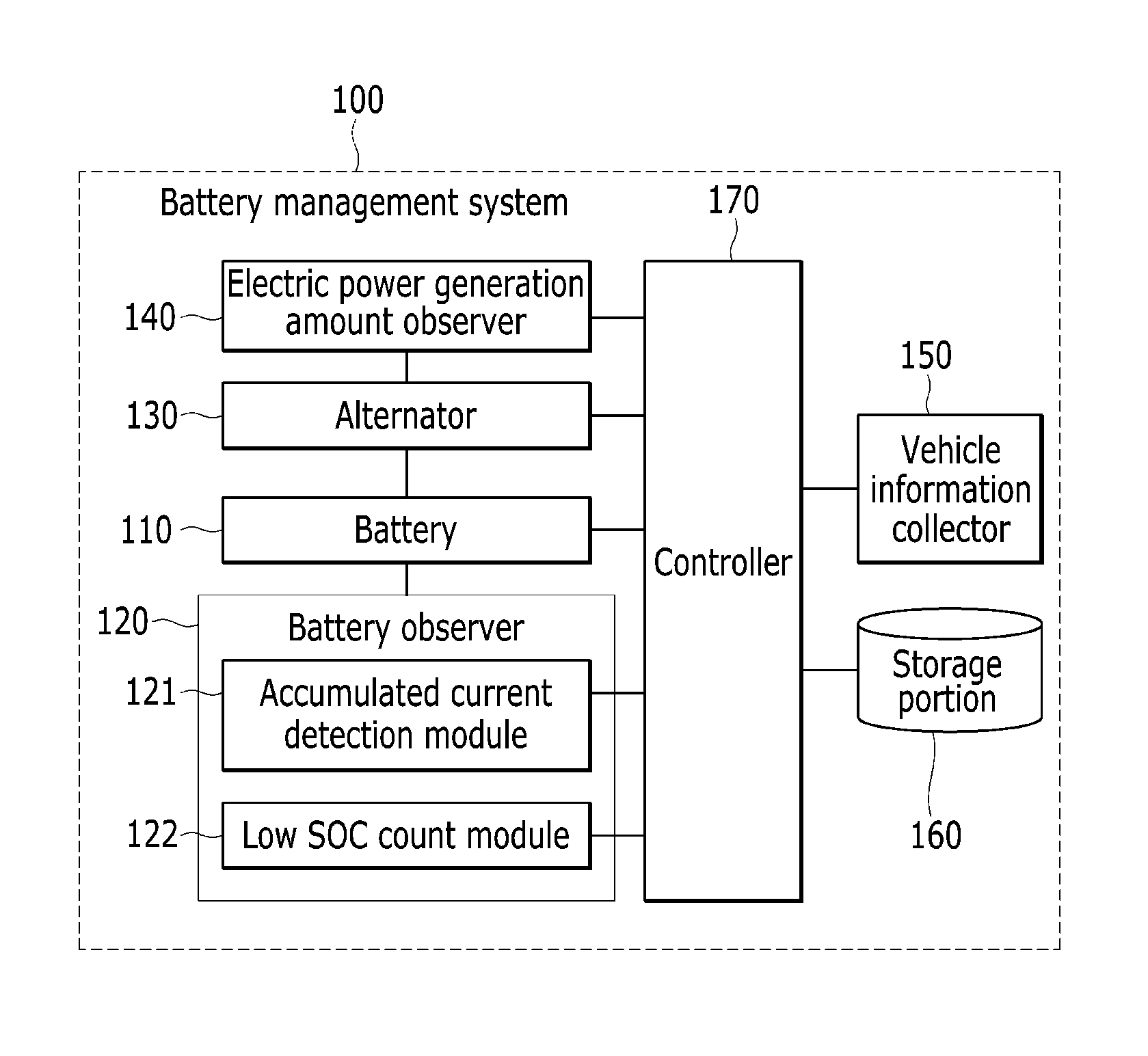

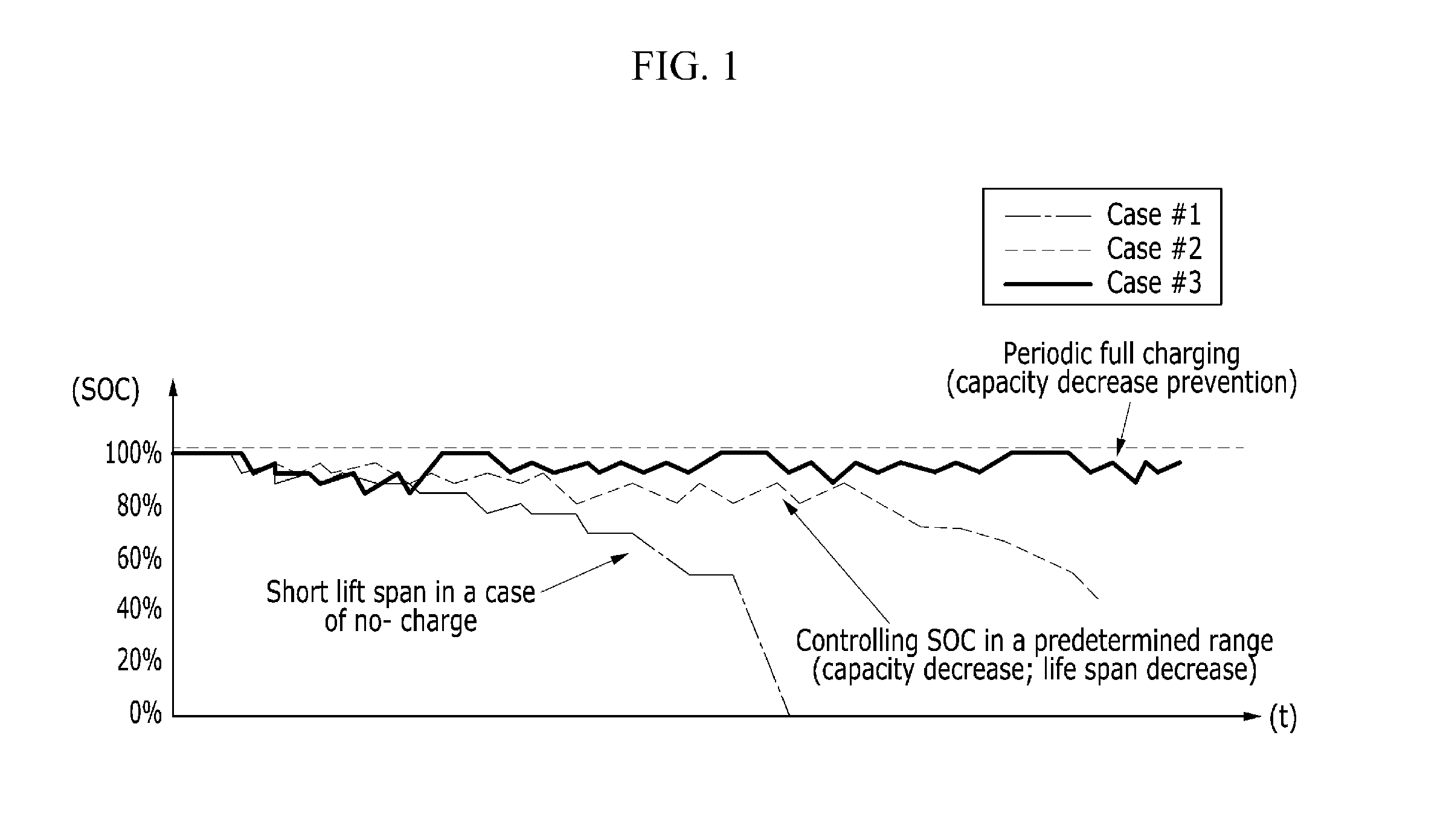

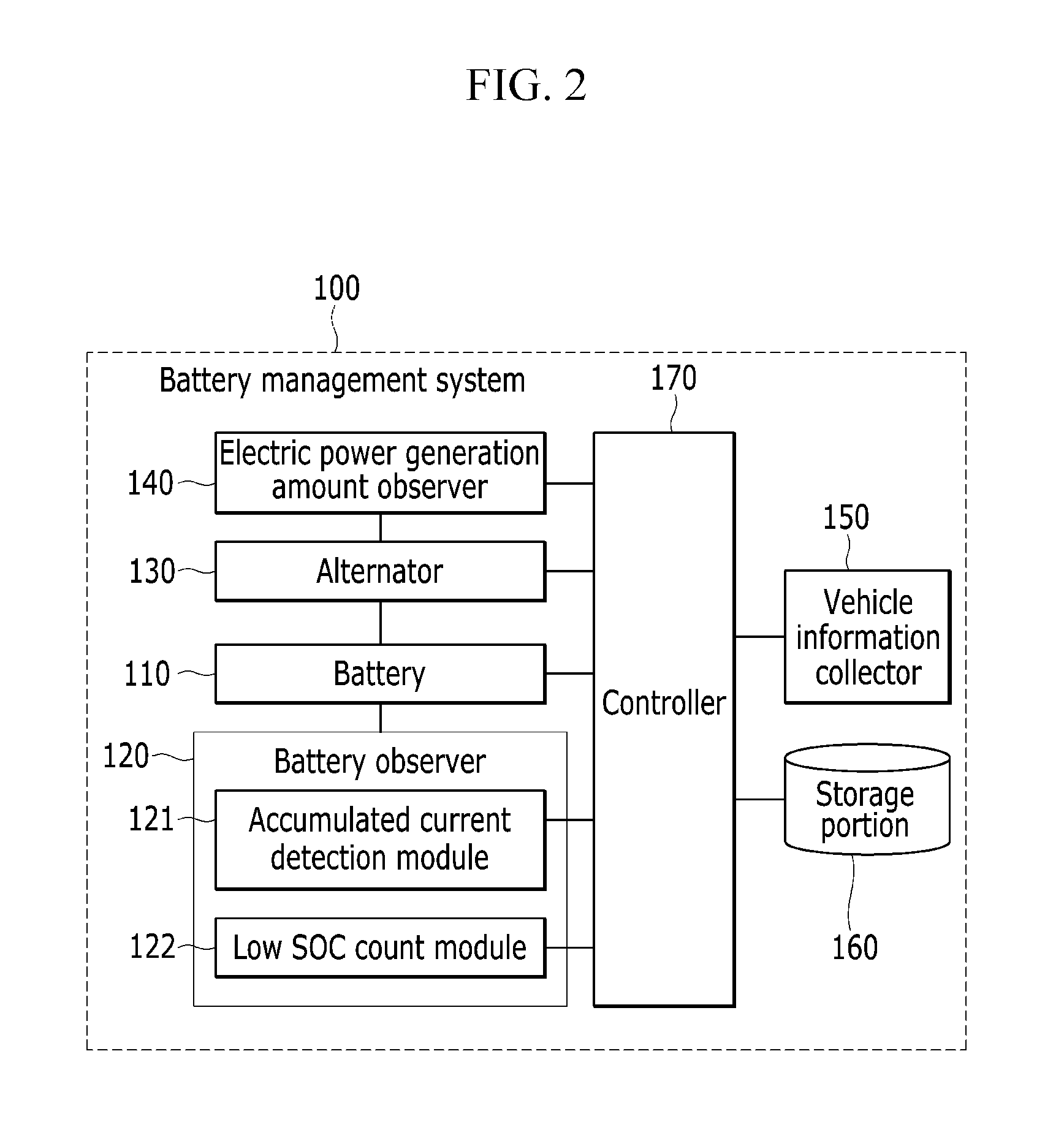

Battery management system and method of vehicle

InactiveUS20130113277A1Inhibition of capacity fadingIncreased durabilityBatteries circuit arrangementsElectric devicesElectricityAlternator

Disclosed is a battery management system. More specifically, the battery management system includes an alternator that supplies a battery and electronic equipment of a vehicle with electricity that is generated by a driving torque of the vehicle, a battery that supplies the electronic equipment with power that is charged by the alternator, a battery observer that observes a condition of the battery, a vehicle information collection portion that collects vehicle condition information according to driving of the vehicle, and a control portion that performs charging recovery of the battery by activating a battery refresh operation when at least one condition of a current accumulation value of the battery, a low SCO entry frequency, and a vehicle starting frequency satisfies a predetermined battery refresh condition.

Owner:HYUNDAI MOTOR CO LTD +1

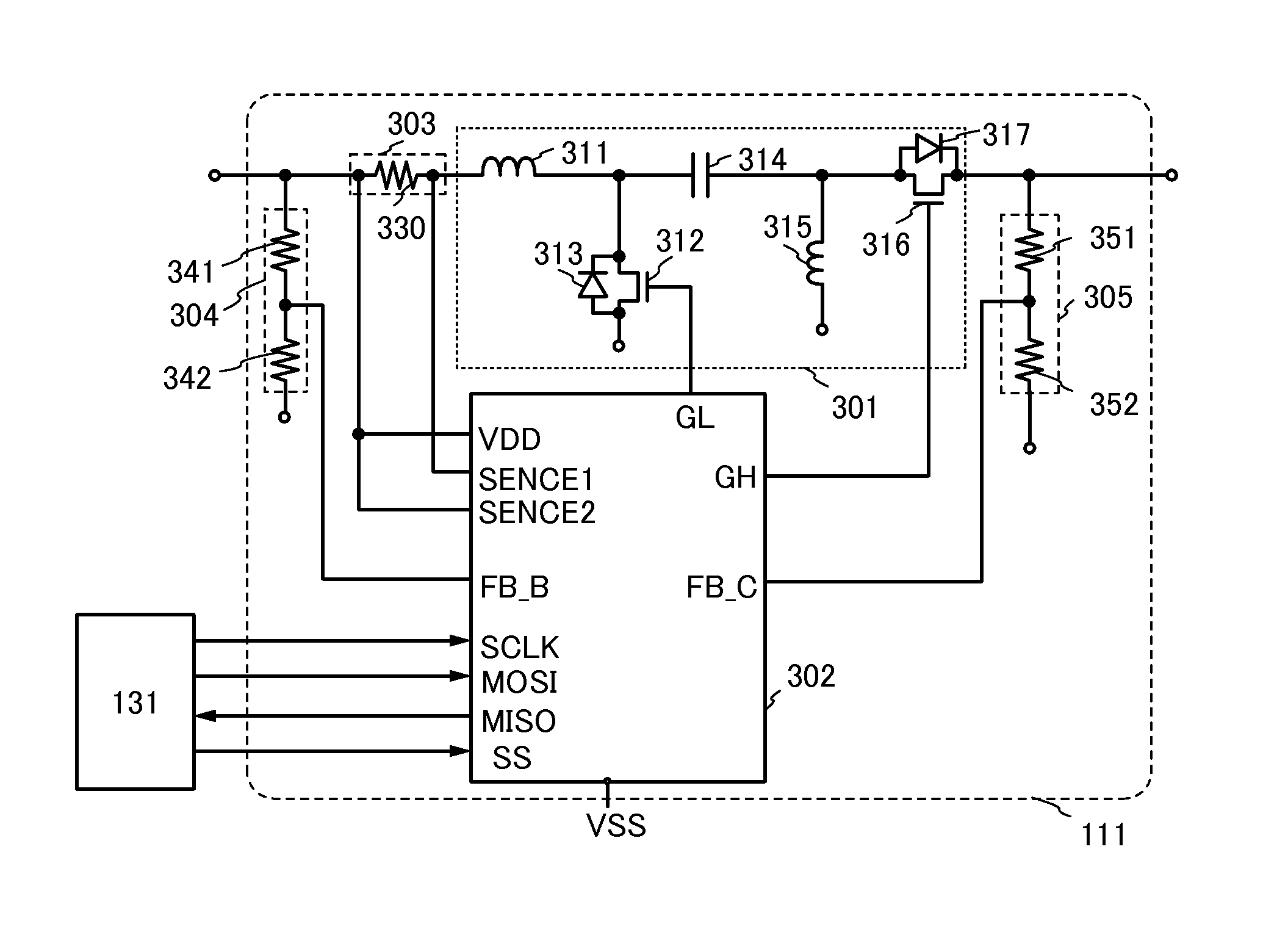

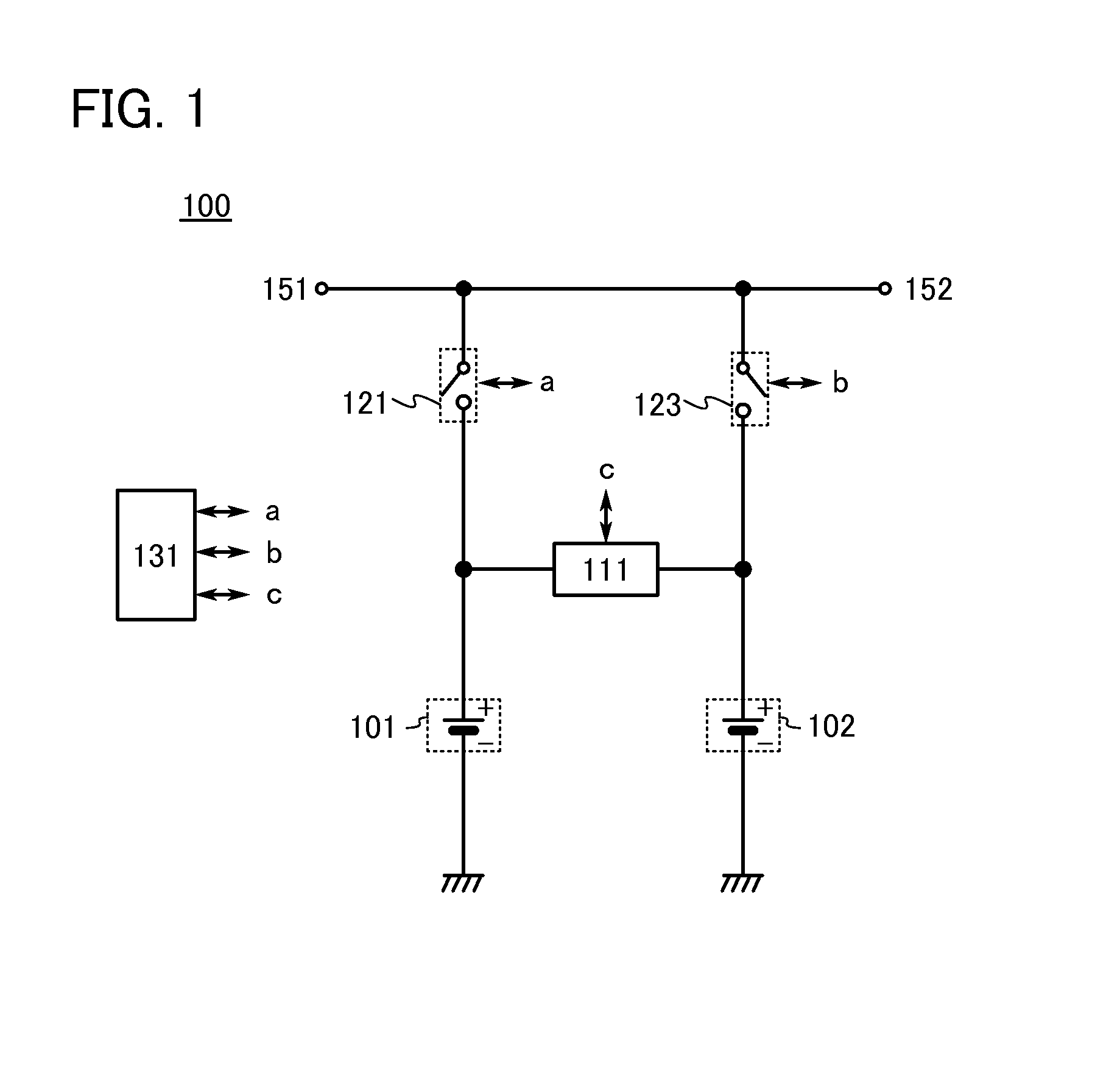

Secondary battery, secondary battery module, method for charging the secondary battery and the secondary battery module, method for discharging the secondary battery and the secondary battery module, method for operating the secondary battery and the secondary battery module, power storage system, and method for operating the power storage system

InactiveUS20140203654A1Prevent degradationReduce power consumptionCharge equalisation circuitSecondary cellsEngineeringControl circuit

Degradation of a secondary battery or the like is prevented. A reduction in the capacity of a secondary battery or the like due to charging or discharging is prevented. A secondary battery module in which a secondary battery can be charged in a charging period into which short discharging periods are inserted is provided. A secondary battery module in which a plurality of secondary batteries are connected in parallel, and in a charging period of the secondary batteries, current due to short-time discharging of one secondary battery can be used for charging another secondary battery is provided. To carry out such operation, a secondary battery module includes a plurality of secondary batteries, a DC / DC converter, a switch, and a control circuit.

Owner:SEMICON ENERGY LAB CO LTD

Method for synthesizing ethylene sulfate

The invention relates to a method for synthesizing ethylene sulfate, and belongs to the technical field of chemical power supplies. The method comprises the following steps: A, carrying out a contactreaction on sulfur dioxide with ethylene oxide in the presence of a composite catalyst, controlling the reaction temperature to be 120-160 DEG C, introducing sulfur dioxide gas to keep the pressure ofthe reaction system at 5-12 MPa, and controlling the reaction time at 1-2.5 hours to obtain ethylene sulfite for standby use; B, adding an aqueous solution of sodium hydrogen carbonate into the ethylene sulfite obtained in the step A, carrying out cooling to a temperature ranging from -5 DEG C to 5 DEG C, dropwise adding a mixed solution of sodium periodate and ruthenium trichloride under a condition with a temperature ranging from -5 DEG C to 5 DEG C, keeping the temperature for 1-1.5 hours after the adding is completed so as to obtain a reaction solution with co-existed water phase and organic phase, carrying out standing for layering, and separating out the water phase to obtain the organic phase, namely a crude product of the ethylene sulfate; and C, carrying out molecular distillation on the crude product of the ethylene sulfate obtained in the step B under the condition with a temperature of 70-80 DEG C to obtain the ethylene sulfate. The ethylene sulfate prepared by the methodhas high purity and high yield, and when the ethylene sulfate is added into a battery, the performance of the battery is better.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

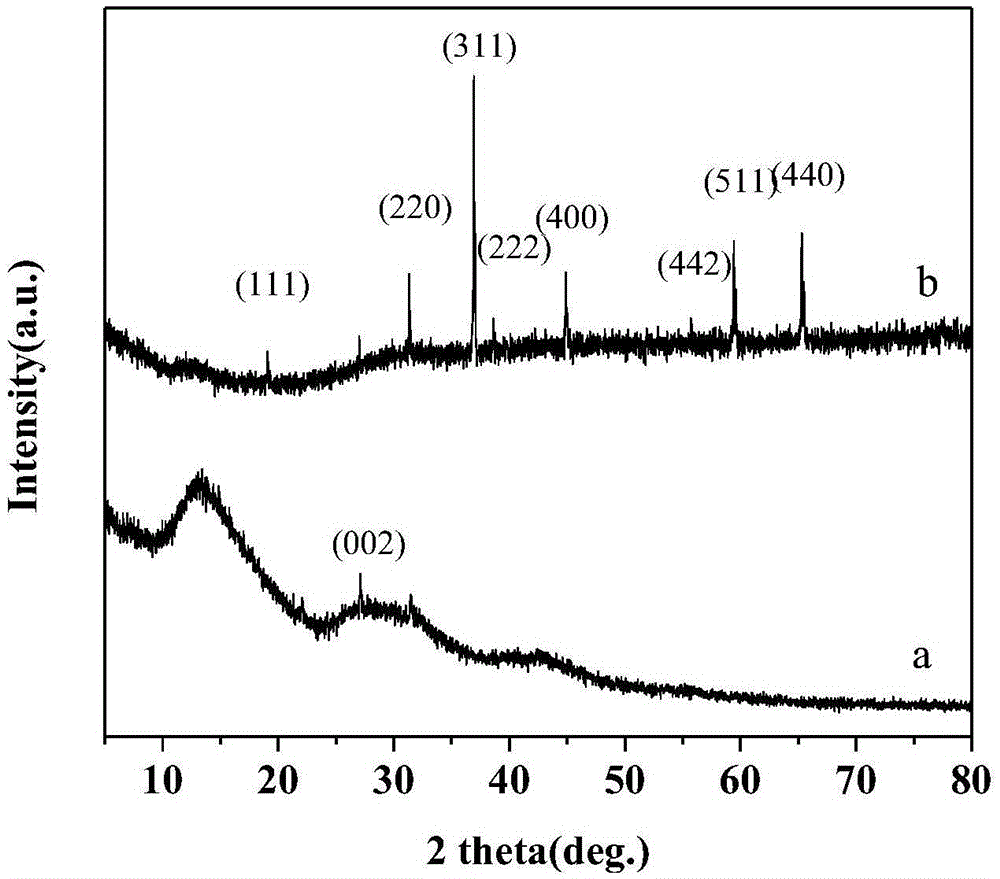

Method for synthesizing ferric phosphate material

The invention relates to a method for synthesizing a ferric phosphate material, belonging to the technical field of lithium ion cathode materials. The method for synthesizing the ferric phosphate material comprises the following steps of: (1) manufacturing a hollow spherical template: stirring oil with carbon hydrogen bonds and a water-soluble surfactant free of metal ions for 0.1-10 h in a water solution to form an emulsion, wherein the weight ratio of the oil to the surfactant is 1:(1-9), and the total weight of the oil and the surfactant accounts for 0.1-5% of the solution; (2) precipitating ferric phosphate: adjusting the pH value of an acid solution containing phosphates and ferric salts by using the emulsion to form ferric phosphate precipitate, wherein the precipitate is adhered to an emulsion microsphere to form a structure of which the exterior is ferric phosphate and the kernel is the emulsion microsphere; and (3) processing the ferric phosphate microsphere: filtering and drying the ferric phosphate microsphere, calcining the ferric phosphate microsphere at high temperature to form a hollow / shell structure microsphere ferric phosphate material. The method provided by the invention has the advantages of simple process, operation convenience, stable ferric phosphate microsphere, large rate discharge capacity and low temperature capacity and the like.

Owner:天津恒普科技发展有限公司

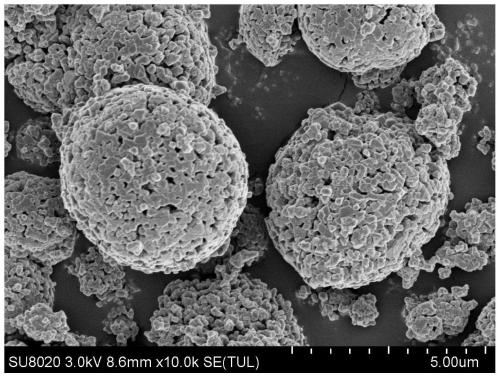

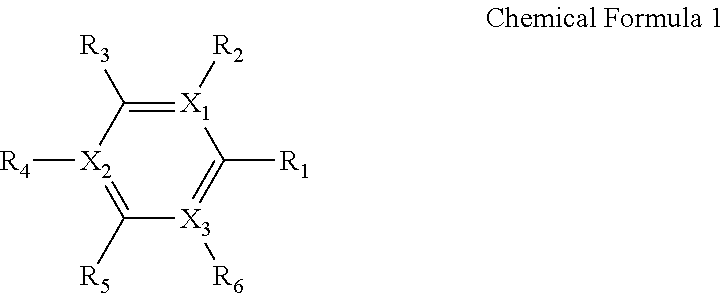

A kind of porous structure lithium manganate electrode material and preparation method and application

ActiveCN102280634AImprove electrochemical performanceIncrease contact areaCell electrodesManganateManganese

The invention provides a lithium manganese oxide electrode material with a porous structure. The material has a one-dimensional porous structure and comprises lithium manganese oxide porous nanorods, lithium manganese oxide porous submicron rods and lithium manganese oxide porous micron rods. A manufacturing method of the material comprises the following steps: adding oxalate into an organic mixed solution and then adding a manganese salt solution for reaction; carrying out centrifugation, separation and washing on a white product and then heating to decompose the processed white product to obtain a black product; and adding lithium to the black product for mixing and roasting to obtain a target product, namely, the lithium manganese oxide electrode material, wherein the lithium manganeseoxide electrode material can be used for manufacturing the lithium manganese oxide anode of a lithium ion battery. According to the invention, the lithium manganese oxide electrode material can form a spinel phase with rich lithium, has the larger specific area, and can increase the contact area of active substances and an electrolyte; the lithium manganese oxide electrode material has smaller internal grains which can form a dispersion channel capable of shortening ions, thus improving the electrochemical performance; and the lithium manganese oxide electrode material has good high multiplying power performance and cycle performance, thus being possible to apply to the new-generation power batteries massively. The manufacturing method is simple in process, easy to implement and beneficial to popularization and application.

Owner:NANKAI UNIV

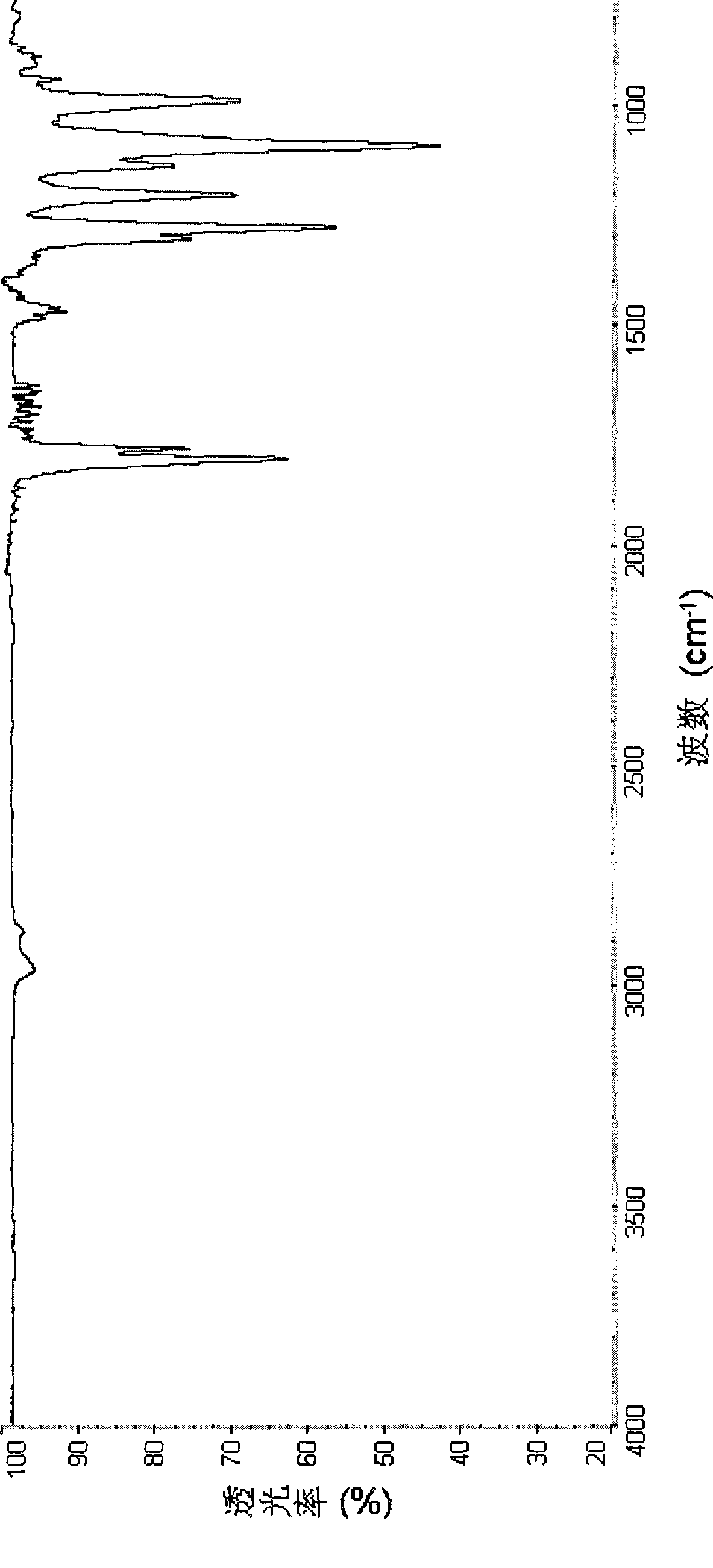

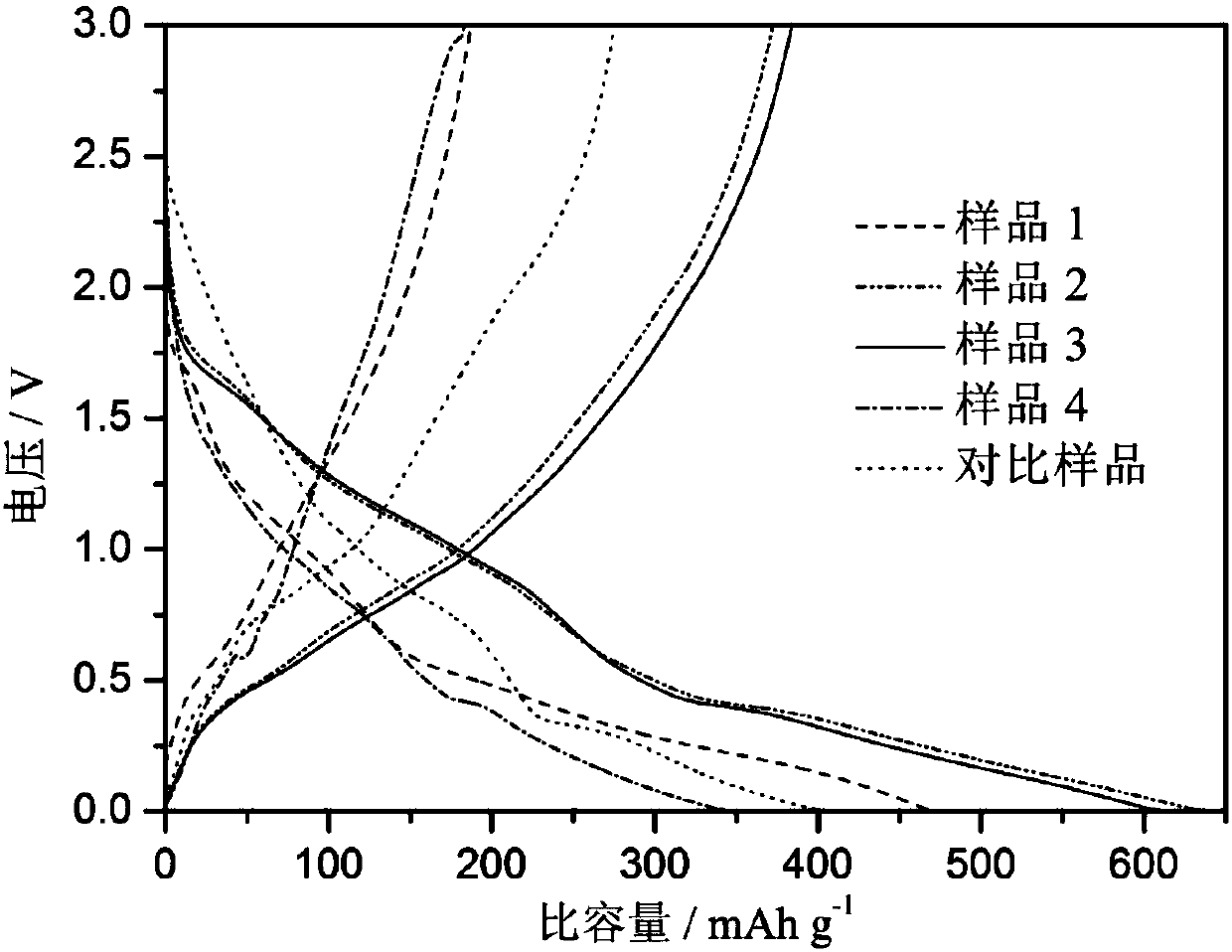

Method for producing 4-propyl-[1,3,2]dioxathiolane-2,2-dioxide

A method for producing 4-propyl-[1,3,2]dioxathiolane-2,2-dioxide comprises an addition reaction, an oxidation reaction and a purifying process. The method concretely comprises the following steps: 1, carrying out the addition reaction: carrying out addition reaction on thionyl chloride and 1,2-pentanediol as reaction raw materials; 2, carrying out the oxidation reaction: adding a sodium hypochlorite and catalyst mixed solution, carrying out the oxidation reaction to obtain a water phase and organic phase co-existence reaction solution, standing the water phase and organic phase co-existence reaction solution for layering, and separating the obtained water phase to obtain the organic phase which is crude 4-propyl-[1,3,2]dioxathiolane-2,2-dioxide; and 3, purifying: carrying out molecular distillation to obtain 4-propyl-[1,3,2]dioxathiolane-2,2-dioxide. The purity of the prepared 4-propyl-[1,3,2]dioxathiolane-2,2-dioxide can be greater than 99.5%, the water content is not greater than 100PPM, the acid value is not greater than 100PPM, and 4-propyl-[1,3,2]dioxathiolane-2,2-dioxide can be added to a battery in order to improve the performances of the battery and prolong the life of the battery.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

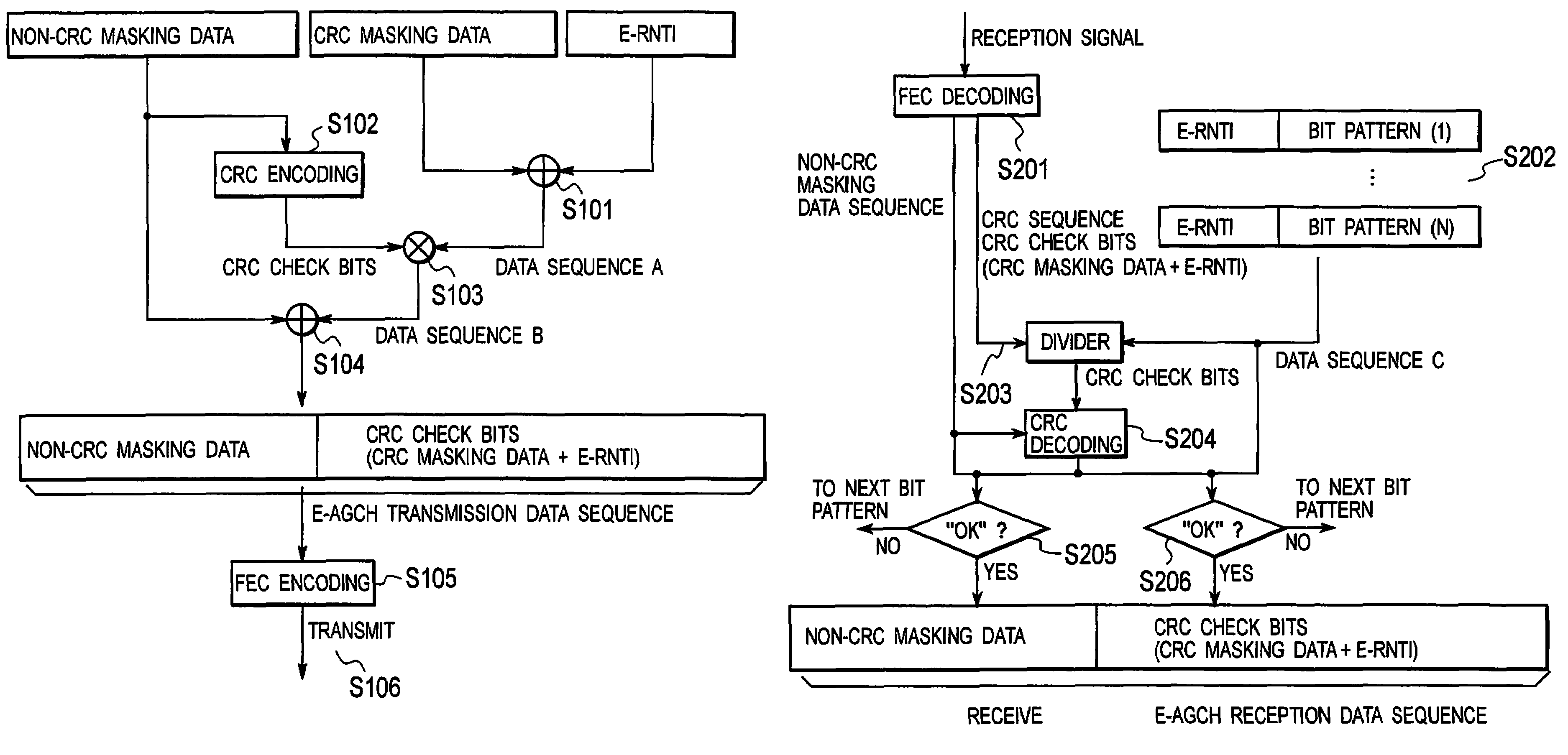

Transmitting method, receiving method, radio base station, and mobile station

InactiveUS7697483B2Inhibition of capacity fadingReduce data sizeCode conversionCoding detailsComputer hardwareMobile station

A transmission method according to the present invention includes: concatenating CRC masking data and receiver identification information for identifying the receiver; generating CRC check bits by performing a CRC encoding processing against non-CRC masking data; masking the CRC check bits by the concatenated receiver identification information and CRC masking data; concatenating the masking result and the non-CRC masking data; generating a transmission signal by performing an FEC encoding processing against the concatenated masking result and the non-CRC masking data, which are added; and transmitting the transmission signal to the receiver.

Owner:NTT DOCOMO INC

Preparation method of Co3O4/nitrogen doped graphene composite electrode material

InactiveCN105489399AEasy to operateStable structureHybrid capacitor electrodesHybrid/EDL manufactureFiltrationNitrogen doped graphene

The invention provides a preparation method of Co3O4 / nitrogen doped graphene composite electrode material. The preparation method comprises the following steps that step 1. nitrogen doped graphene is prepared; step 2. a soluble alkaline solution is prepared; step 3. polyacrylamide (PAM), heptahydrated cobalt sulfate and nitrogen doped graphene prepared in the step 1 are ultrasonic-dispersed in deionized water so that mixed liquid A is obtained; step 4. the soluble alkaline solution prepared in the step 2 is dropped in the mixed liquid A to react, and pH=8.5-10 is obtained through adjustment so that mixed liquid B is obtained; and step 5. the mixed liquid B is transferred to a microwave reactor to perform heating reaction, and suction filtration, washing and drying are performed on the product after the end of reactor so that the Co3O4 / nitrogen doped graphene composite electrode material is obtained finally. The prepared composite material is stable in structure, and the method has advantages that the method is simple and environment-friendly, the reaction conditions are moderate, reaction is easy to control, cost is low and the technology and the process are simple and convenient.

Owner:JIANGSU UNIV

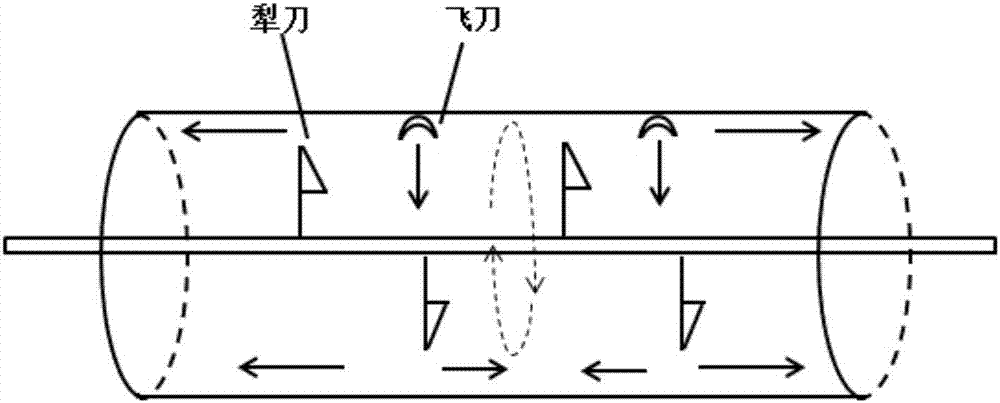

Anode foil etching process for aluminum electrolytic capacitor

ActiveCN108183033AImprove pit appearanceEnhanced mass transferElectrolytic capacitor manufactureCarboxylic acidMaterials science

The invention provides an anode foil etching process for an aluminum electrolytic capacitor. The process comprises a pre-processing, a primary pitting corrosion, a secondary expanding corrosion and apost-processing. For the primary pitting corrosion, a complexing agent is added in an etching solution, and the complexing agent is a carboxylic-acid-containing compound or a salt thereof. The carboxylic-acid-containing compound or a salt complexing agent can combine with free Al3+ in the etching solution, the mass transfer of Al3+ in a tunnel hole is improved, a condition that AL3+ is enriched and hydrolyzed in the tunnel hole to form a passivation film is prevented, the hole depth consistency of etched foil holes is improved obviously, lateral branch holes are reduced, and the capacity and bending performance of an electrode foil are improved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD +1

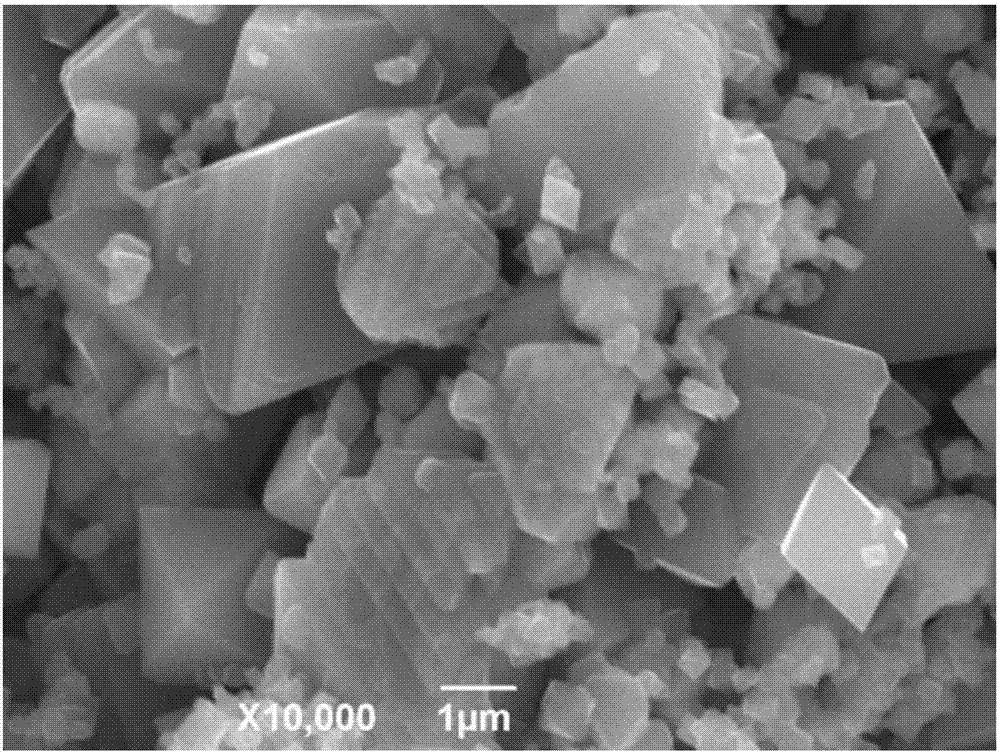

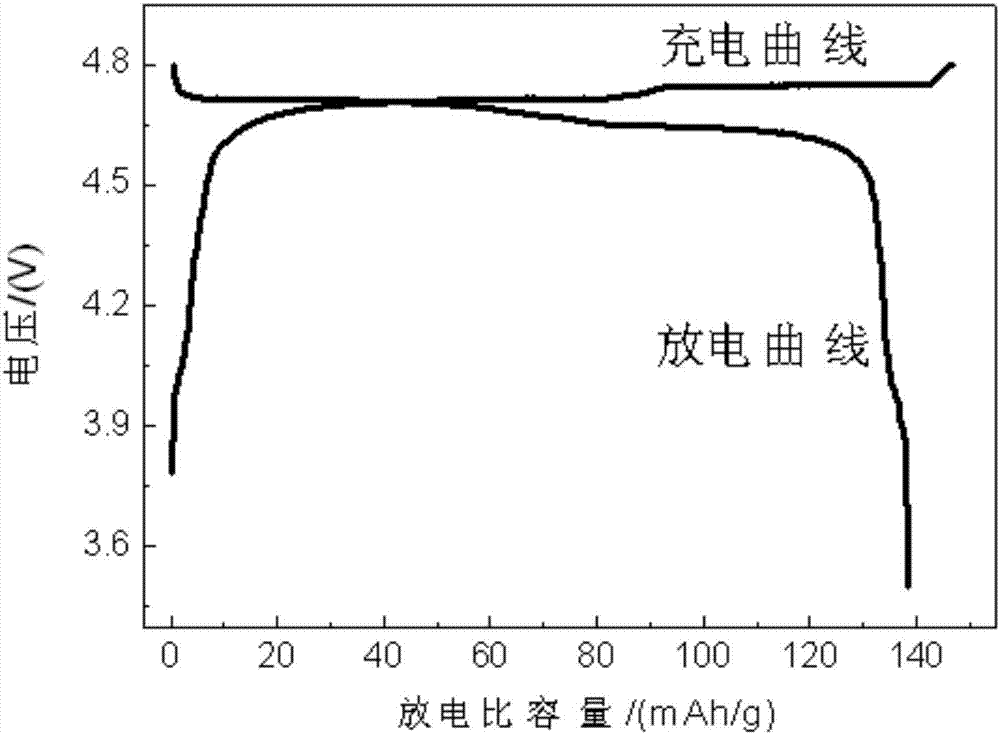

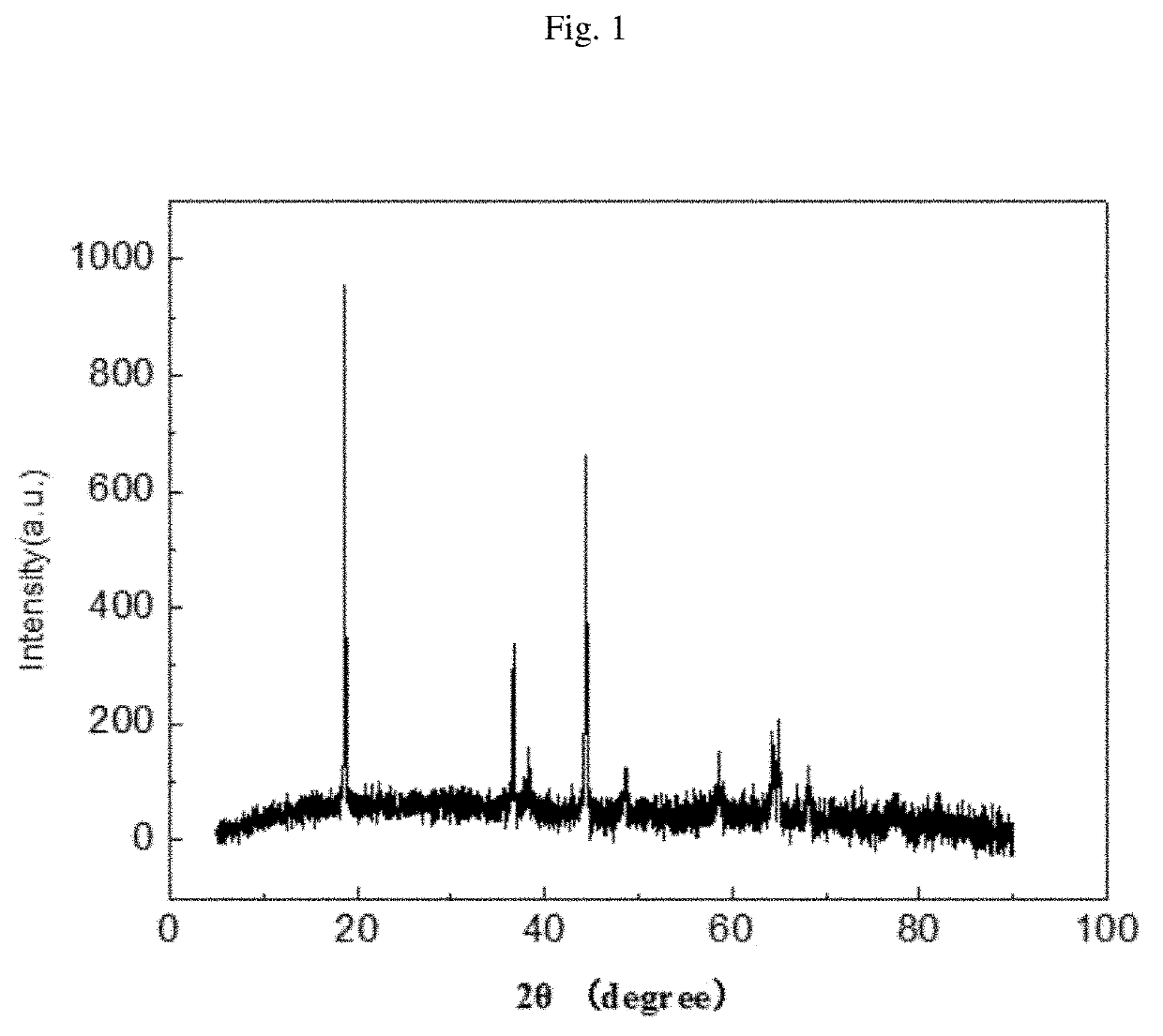

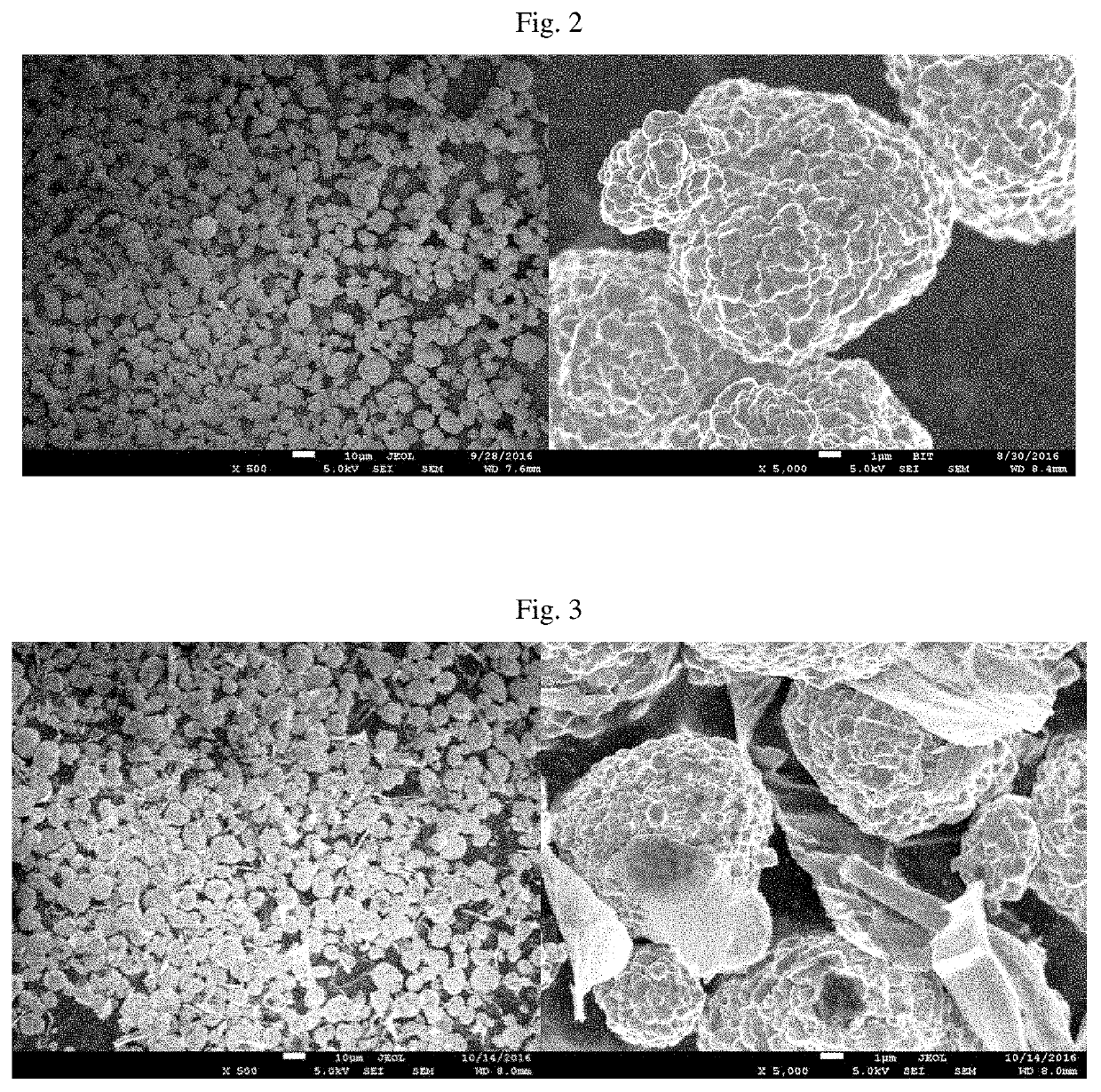

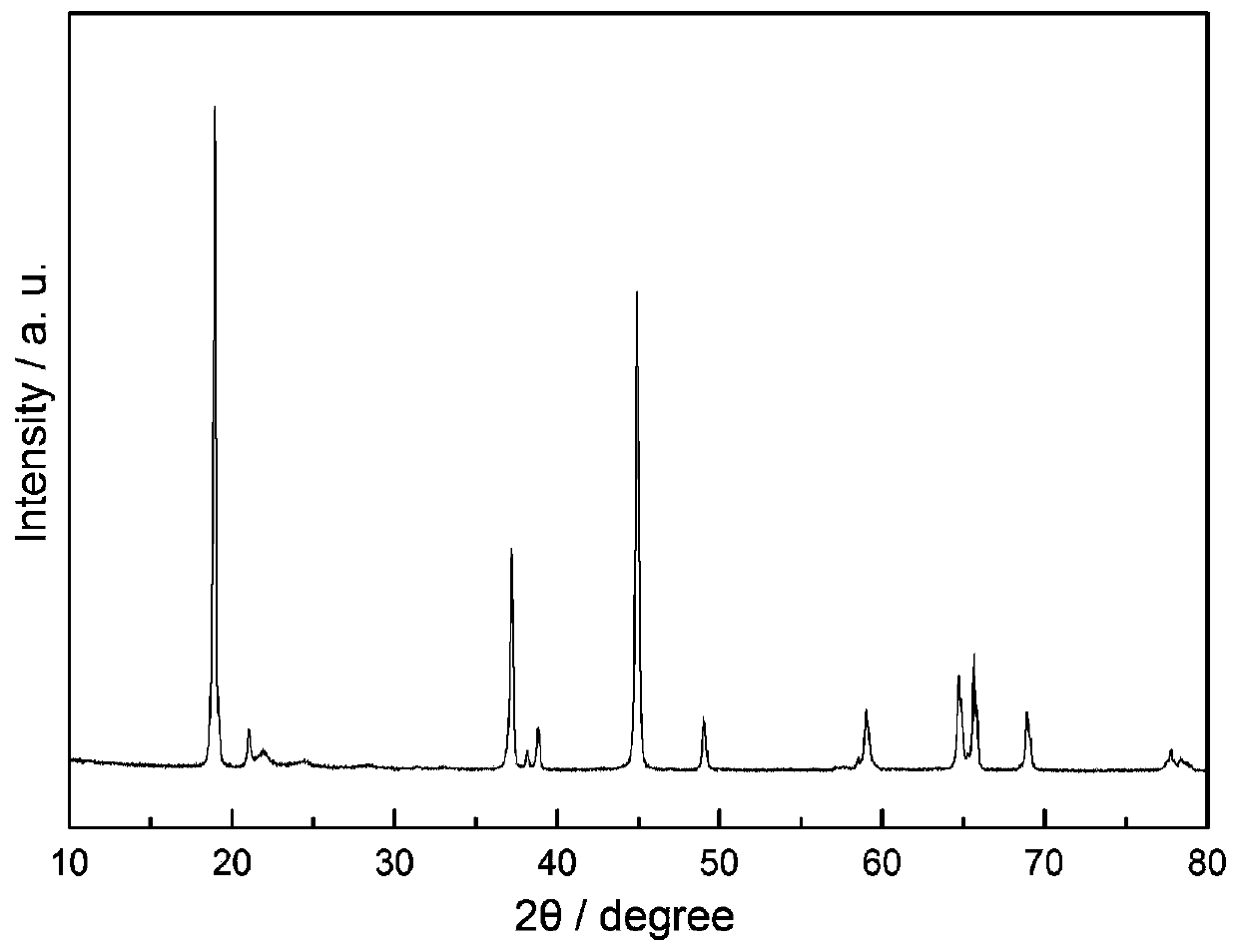

High-voltage spinel and lithium nickel manganese oxide anode material and method for preparing same

ActiveCN107364901AEvenly distributedIncrease product capacityCell electrodesSecondary cellsMicrometerSingle crystal

The invention provides a high-voltage spinel and lithium nickel manganese oxide anode material and a method for preparing the same. Spinel type nickel and aluminum co-doped trimanganese tetroxide prepared by the aid of wet processes is used as an important material for the high-voltage spinel and lithium nickel manganese oxide anode material prepared by the aid of the method. The method includes steps of (1), uniformly mixing lithium sources and the nickel and aluminum co-doped trimanganese tetroxide with one another to obtain mixed materials; (2), sintering the mixed materials to obtain the high-voltage spinel and lithium nickel manganese oxide anode material. The high-voltage spinel and lithium nickel manganese oxide anode material and the method have the advantages that the method includes simple procedures, and organic solvents can be omitted; the D50 of a product which is the high-voltage spinel and lithium nickel manganese oxide anode material prepared by the aid of the method is 8.932-9.466 micrometers, the specific surface area of the high-voltage spinel and lithium nickel manganese oxide anode material is 2.185-2.434 m<2> / g, component particles of the high-voltage spinel and lithium nickel manganese oxide anode material are single crystals, manganese elements, nickel elements and aluminum elements are uniformly distributed in the high-voltage spinel and lithium nickel manganese oxide anode material, the large and small component particles are the single crystals, and accordingly the high-voltage spinel and lithium nickel manganese oxide anode material is stable in structure, high in discharge capacity, good in rate capability and excellent in cycle performance.

Owner:HUNAN CHANGYUAN LICO CO LTD

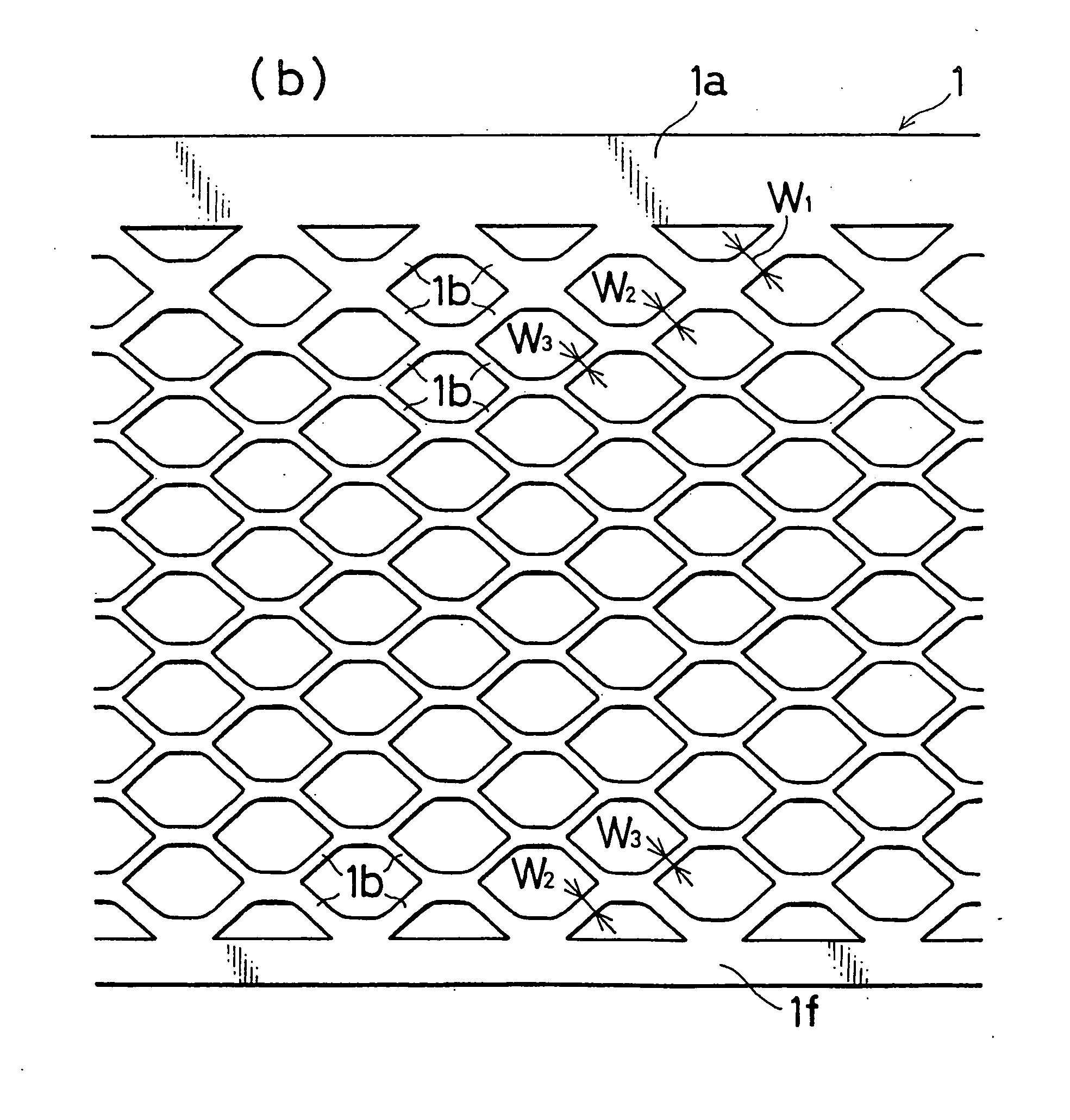

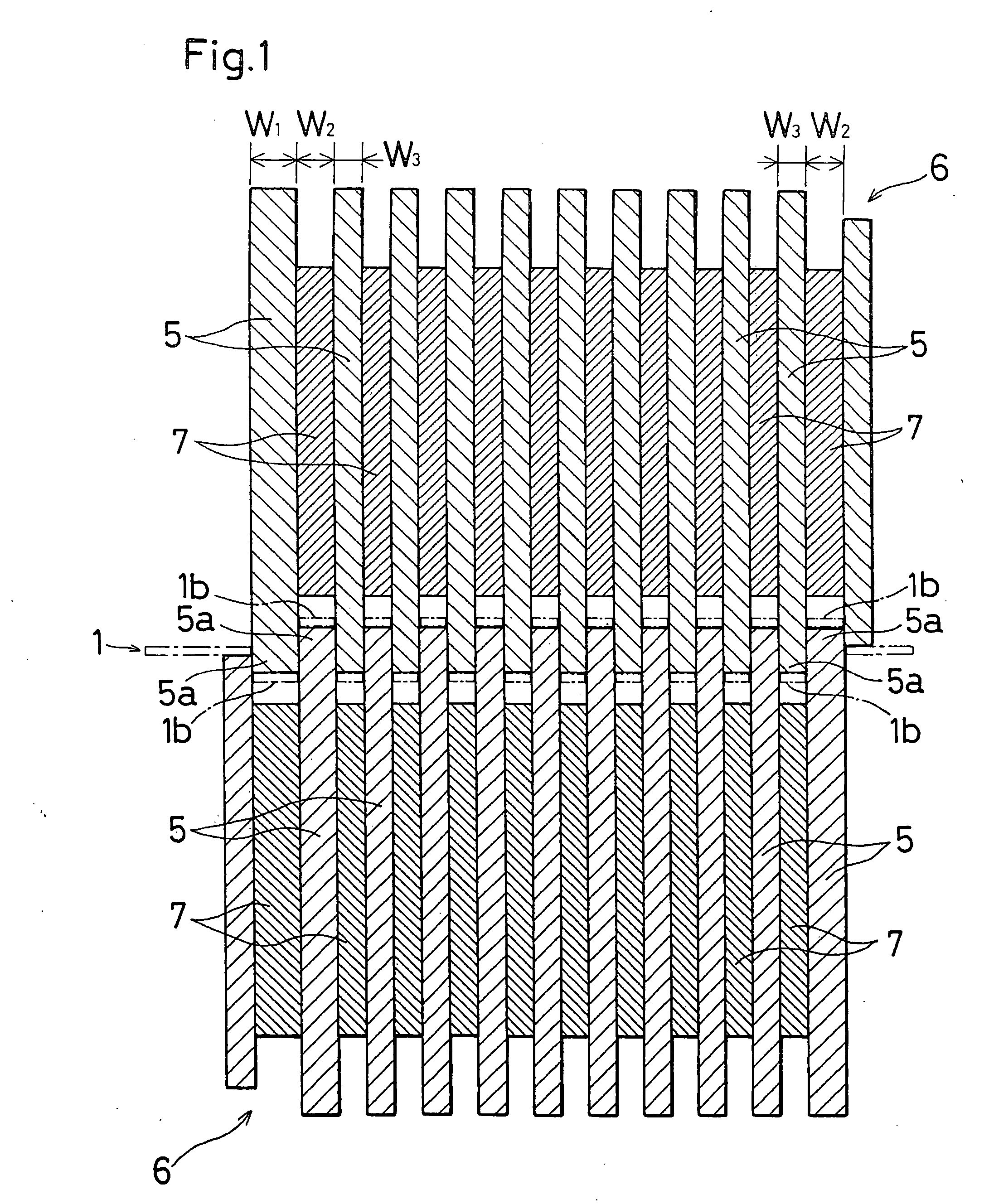

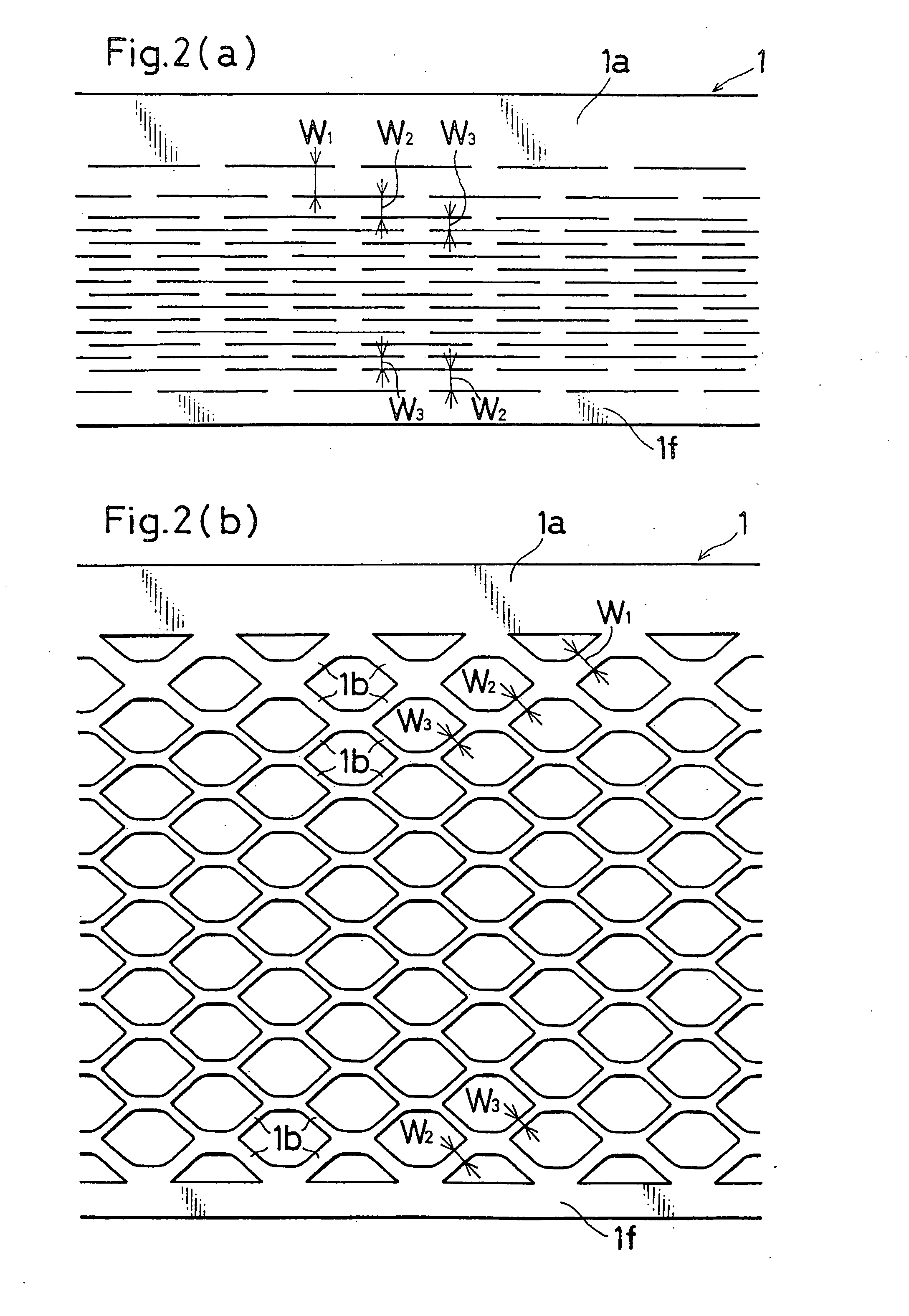

Storage battery

ActiveUS20060213055A1High tensionReduce tensionElectrode manufacturing processesPrimary cellsProduction rateEngineering

A storage battery is provided in which an expand grid is improved with respect to the widths of grid wires 1b, the sectional areas of nodes 1e, and the shapes of meshes 1c, whereby the productivity of the expand grid can be enhanced and the life performance can be improved. As means for attaining the object, a storage battery in which an expand grid is used as a battery plate, the expand grid being a grid member which is formed by expanding a side portion of a collector frame portion 1a of a metal sheet 1 to connect a large number of grid wires 1b to one another in a net-like shape, is configured so that widths of grid wires 1b of a row which is directly connected to the collector frame portion 1a of the expand grid, and a lateral end row are larger than widths of grid wires 1b of at least one of intermediate rows.

Owner:GS YUASA INT LTD

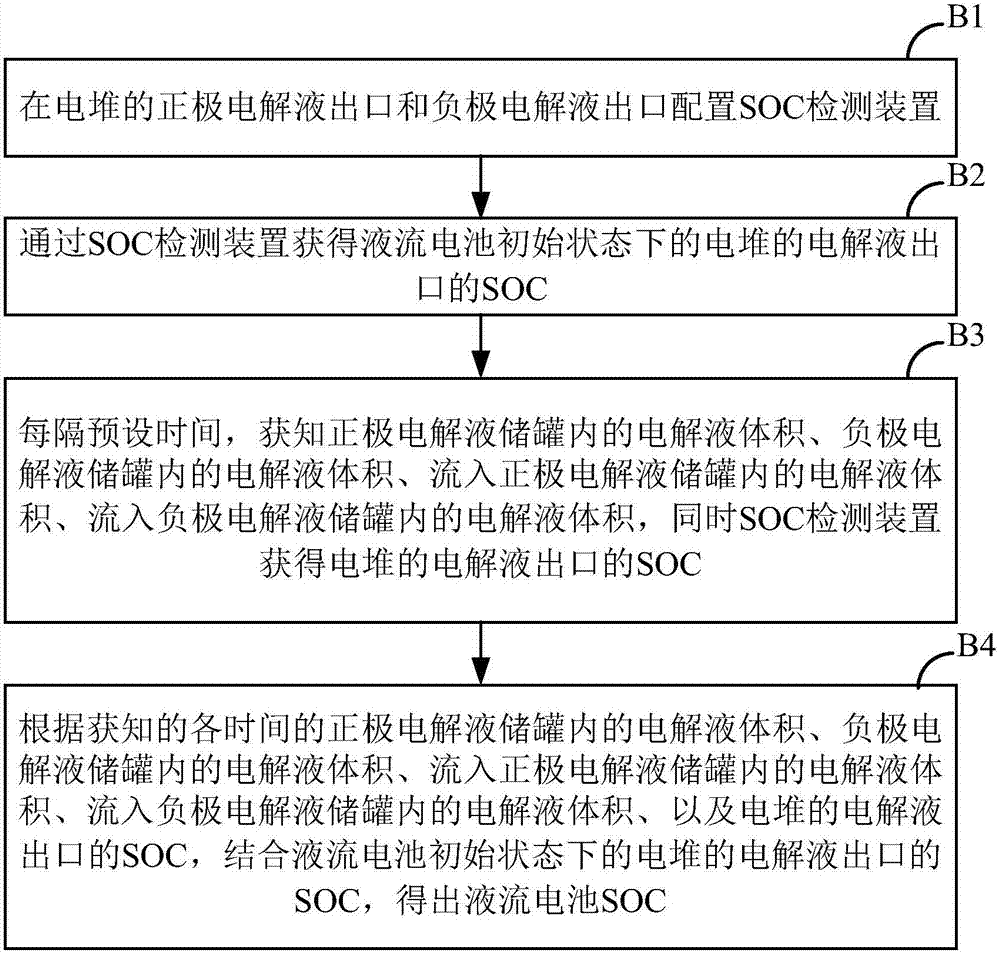

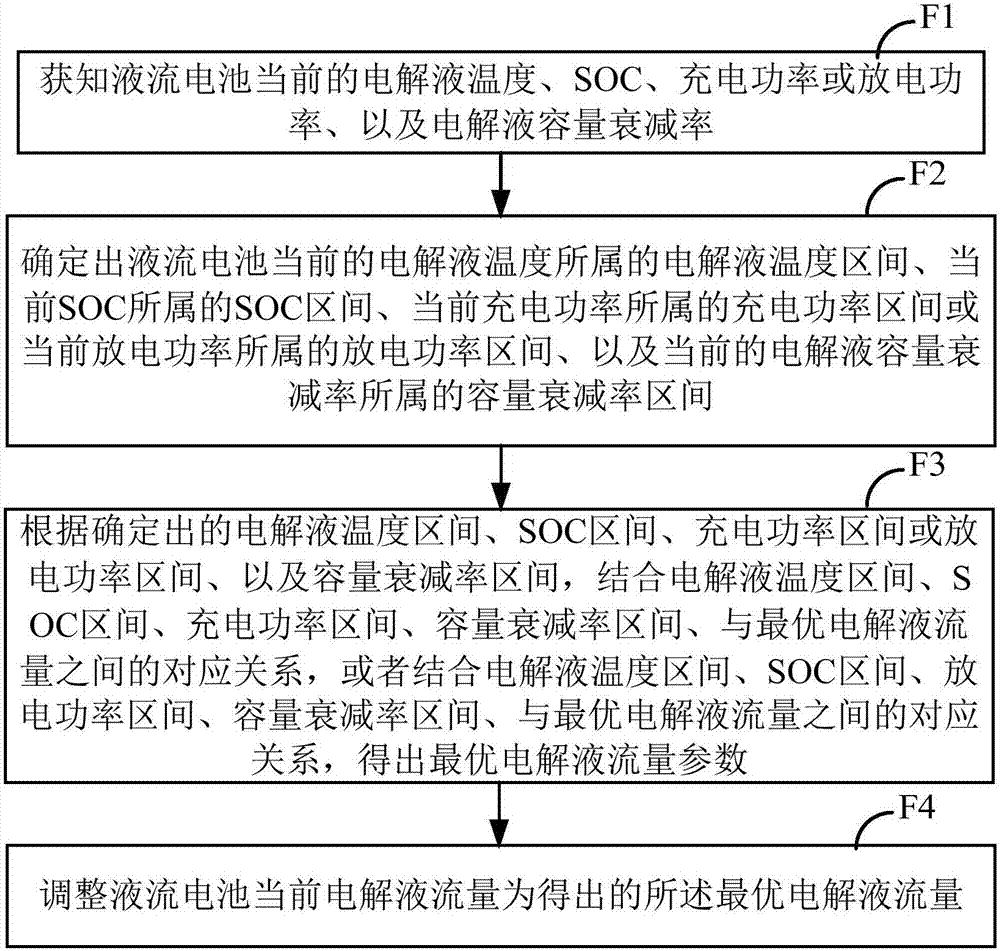

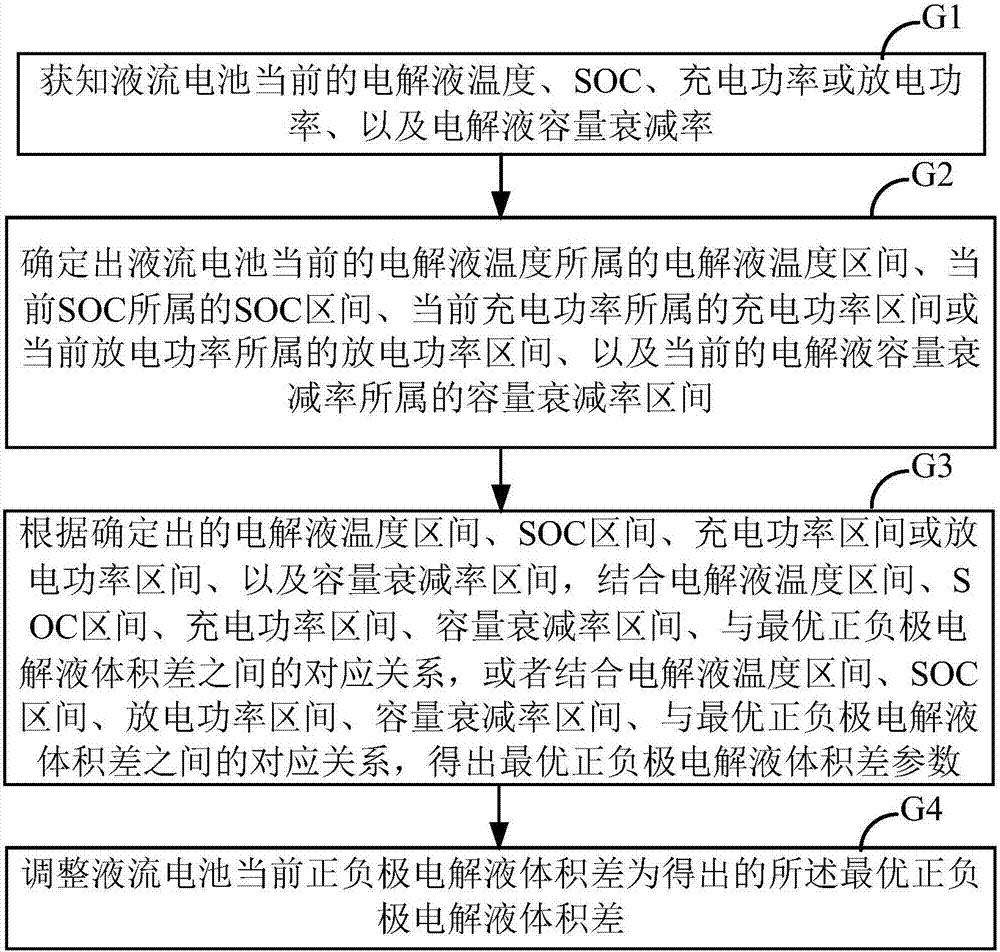

Control method and control system of redox flow battery and redox flow battery

ActiveCN107195944AThe test result is accurateSatisfy traffic demandRegenerative fuel cellsControl systemRedox

The invention discloses a control method and control system of a redox flow battery and the redox flow battery. The control method comprises the following steps of configuring SOC detection devices at a positive electrolyte outlet and a negative electrolyte outlet of an electric stack; acquiring SOC of the electrolyte outlets of the electric stack under an initial state of the redox flow battery by the SOC detection devices; acquiring electrolyte volume in a positive electrolyte storage tank, electrolyte volume in a negative electrolyte storage tank, electrolyte volume flowing into the positive electrolyte storage tank and electrolyte volume flowing into the negative electrolyte storage tank per preset time, and simultaneously acquiring the SOC of the electrolyte outlets of the electric stack by the SOC detection devices; and obtaining SOC of the redox flow battery. SOC detection results in the positive electrolyte storage tank and the negative electrolyte storage tank within a certain time are accumulated and averaged, so that the SOC detection results are more accurate.

Owner:DALIAN RONGKE POWER

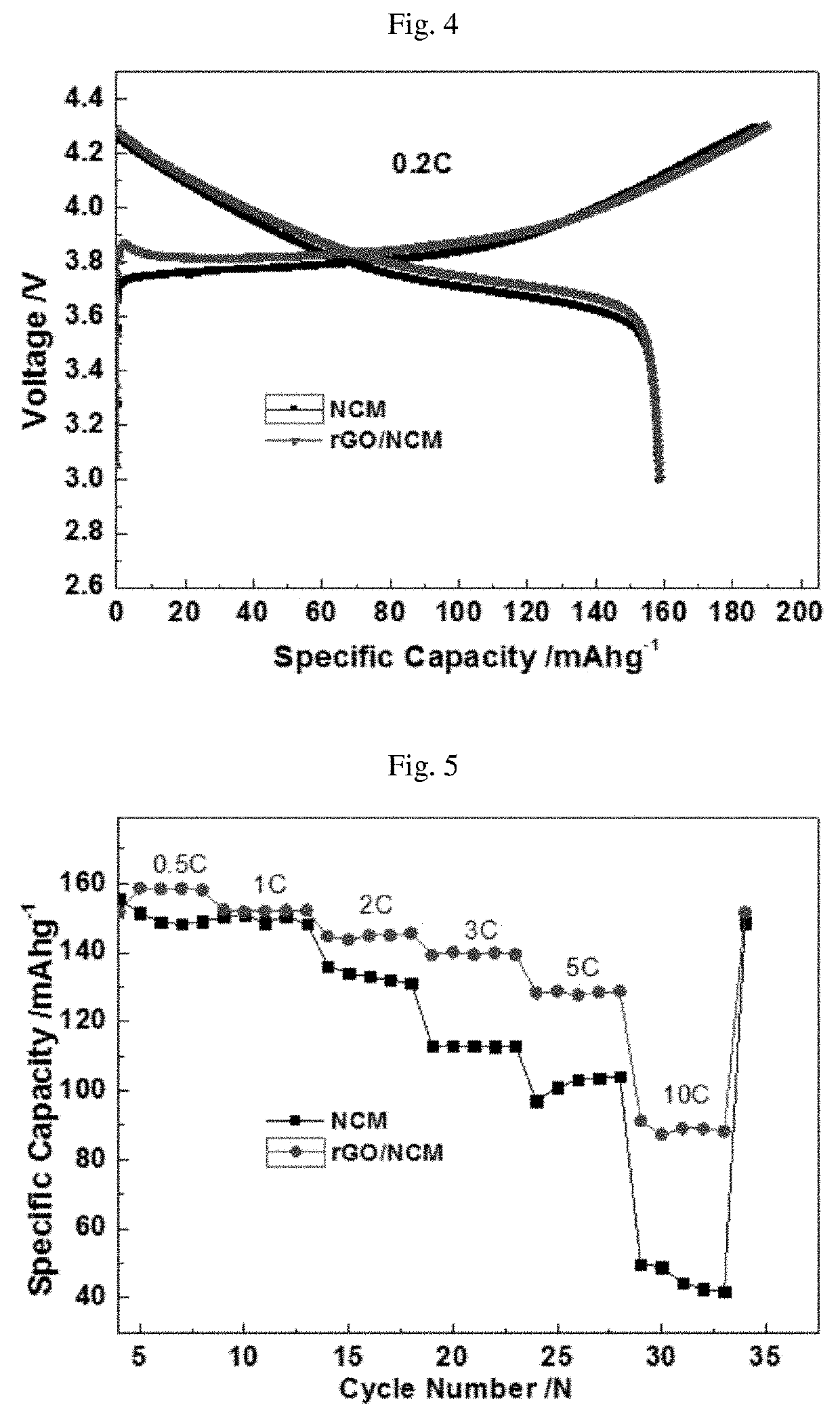

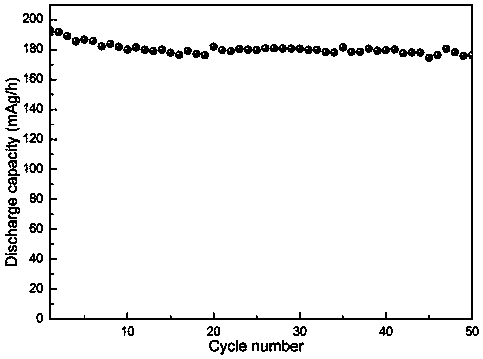

Method for preparing graphene/ternary material composite for use in lithium ion batteries and product thereof

ActiveUS20190355978A1Increased mechanical flexibilityIncrease compaction densityCell electrodesSecondary cellsOrganic solventNetwork structure

Provided is a method for preparing a graphene / ternary material composite for use in lithium ion batteries, comprising the following preparation steps: (a) mixing a ternary material and a graphene oxide powder in an organic solvent to form a mixed dispersion; (b) adding a reducing agent to the mixed dispersion from step (a), and carrying out a reduction reaction at a reduction temperature of 80-160° C. while stirring, to obtain a reduction reaction mixture after a reduction time of 60-240 min; and (c) evaporating the solvent from the reduction reaction mixture from step (b) while stirring, and drying and then annealing the mixture at a low temperature in an inert atmosphere to obtain a graphene / ternary material composite having a three-dimensional network structure. Also provided is a graphene / ternary material composite prepared by using this method.

Owner:BEIJING TUNGHSU CARBON ADVANCED MATERIALS TECH CO LTD +1

Carbon nanotube modified lithium-rich manganese-based positive electrode material and preparation method thereof

ActiveCN111106337ASolve the uniform dispersionIncrease adsorption sitesCell electrodesSecondary cellsManganeseLithium-ion battery

The invention belongs to the field of lithium ion battery material preparation, and in particular relates to a preparation method of a carbon nanotube modified lithium-rich manganese-based positive electrode material xLi2MnO3. (1-x) LiMO2. According to the preparation method, a precursor and a carbon nanotube are modified at the same time in a pre-oxidation mode; a conductive network combination of the carbon nanotube and the positive electrode material can be formed; and the conductivity of the prepared material is improved. The preparation method comprises the steps of uniformly mixing a transition metal salt solution according to a stoichiometric ratio, dropwise adding a precipitant and a complexing agent, washing and drying to obtain a precursor, stirring, dispersing and drying the precursor and a carbon nanotube aqueous dispersion, adding into an oxidant solution for pre-oxidation, drying, mixing with a lithium source, calcining and cooling to obtain a final product. The lithium-rich manganese-based material disclosed by the invention not only has high specific capacity, but also has excellent rate capability and cycle performance. A lithium ion battery adopting the positive electrode material has huge application potential in the aspect of power batteries.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Battery charge circuit with multi-charge stage and method thereof

InactiveUS20070139011A1Reduce generationExtend your lifeBatteries circuit arrangementsElectric powerCharge currentBattery charge

A charge circuit having multi charge stages for charging at least one battery includes: a first current generating circuit for generating a first charge power having a first charge current in pulse form with a first frequency and a first charge voltage to charge the at least one battery; a voltage generating circuit connected to the first current generating circuit for controlling the first charge power having a first charge current in pulse form with a first frequency and a first charge voltage; a voltage control circuit connected to the voltage generating circuit for generating a first constant voltage and / or a second constant voltage; and a second current generating circuit connected to the voltage generating circuit for generating a variant power comprising a variant current in pulse form with a second frequency wherein a charge voltage included in the variant power varies with the second frequency.

Owner:SUNJETT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for producing 4-propyl-[1,3,2]dioxathiolane-2,2-dioxide Method for producing 4-propyl-[1,3,2]dioxathiolane-2,2-dioxide](https://images-eureka.patsnap.com/patent_img/93bc29aa-fe83-41af-a96c-e8d9f68ba748/HDA0000728080960000011.PNG)